Page 1

INSTALLATION INSTRUCTIONS

For Sharp Carousel® Built-in Kit

Models RK94S27F or RK94S30F

S = STAINLESS

THIS KIT IS UL APPROVED TO ALLOW CERTAIN MICROWAVE

OVENS TO BE INSTALLED ABOVE ANY ELECTRIC WALL OVEN.

PLEASE SEE THE OPERATION MANUAL REGARDING APPROVED

BUILT-IN APPLICATIONS.

IMPORTANT:

This Built-in Kit is designed for and approved only for those

Sharp Microwave Ovens specifying Built-In Kit RK94S27F or

RK94S30F. Refer to Operation Manual for approved models.

IMPORTANT NOTES TO THE INSTALLER

• PLEASE READ THESE INSTRUCTIONS THOROUGHLY

BEFORE BEGINNING INSTALLATION.

• Observe all governing codes, ordinances, and safety

instructions.

• Be sure to leave these instructions with the consumer.

• Be sure to DISCONNECT THE PLUG of the microwave

oven from the electrical outlet before installing the Built-in

Kit. Remove the Carousel turntable from the oven cavity.

• Because the kit includes metal parts, due caution should

be used in handling and installation to avoid the possibility

of injury.

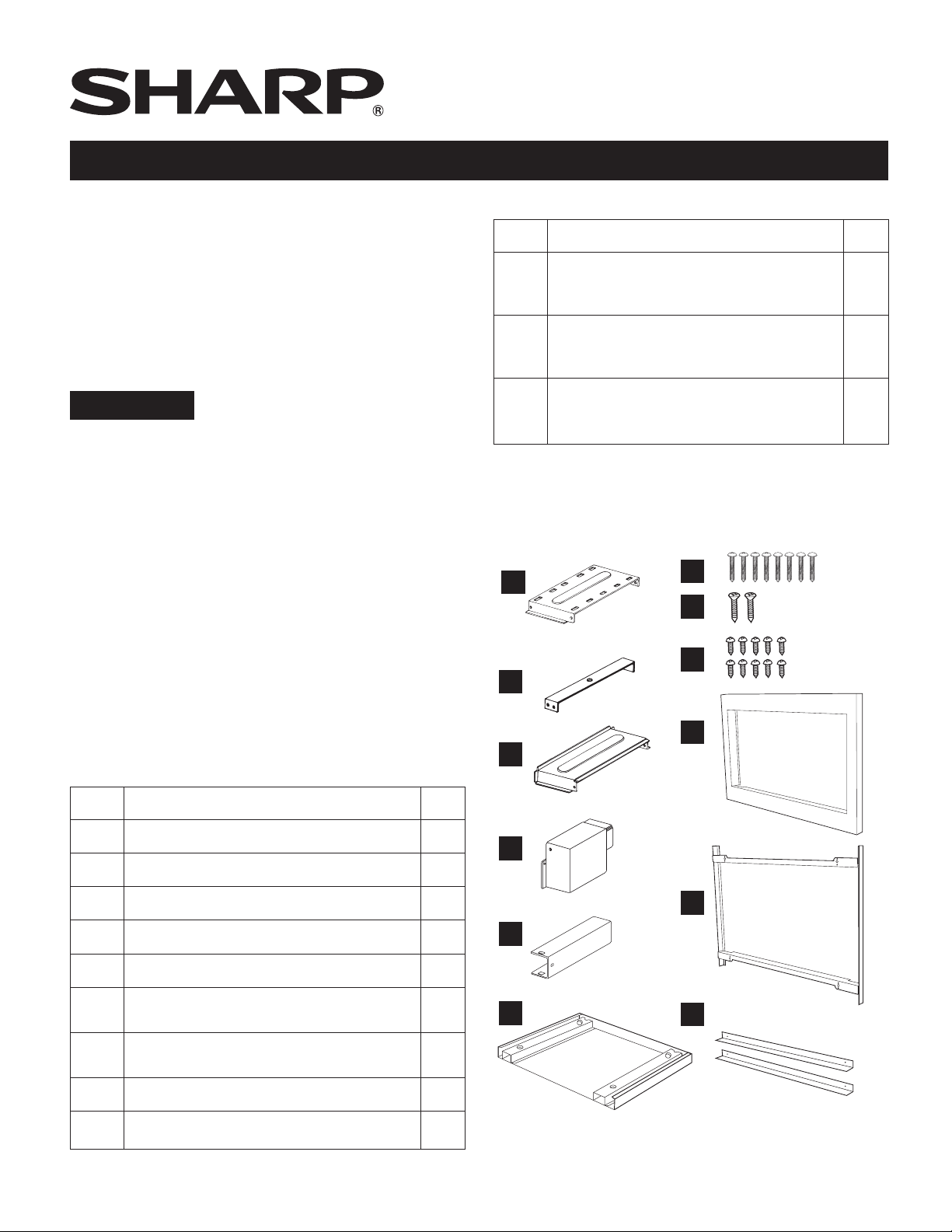

ITEM PART NAME QTY

ITEM PART NAME QTY

FRONT FRAME

J

RK94S27F: FDECAB229MRK0

RK94S30F: FDECAB227MRK0

BACK FRAME

K

RK94S27F: FDECAB255MRK0

RK94S30F: FDECAB226MRK0

AIR DEFLECTOR

L

RK94S27F: PREF-B038MRP0

RK94S30F: PREF-B039MRP0

Check list for parts when unpacking.

NOTE: (J) FRONT FRAME and (K) BACK FRAME are shipped

attached. Snap apart before installation.

A

DUCT (A)-1

G

H

1

1

2

I

B

DUCT (A)-2

J

C

DUCT (A)-3

A DUCT (A)-1: PDUC-0259WRW0 1

B DUCT (A)-2: PDUC-B127MRP0 1

C DUCT (A)-3: PDUC-A734WRW0 1

D DUCT (B): PDUC-0260WRW0 1

E DUCT (C): PDUC-A274WRW0 1

BOTTOM DUCT ASSEMBLY:

F

FDUC-B099MRK1A

M3.9-16MM PAN HEAD TAPPING

G

SCREW, ZINC: XOPS740P16000

H WOOD SCREW: XTSS740P20000 2

I CABINET SCREW: XOTS740P12000 10

D

DUCT (B)

K

E

DUCT (C)

1

8

E 1

F

L

Page 2

STANDARD INSTALLATION INSTRUCTIONS

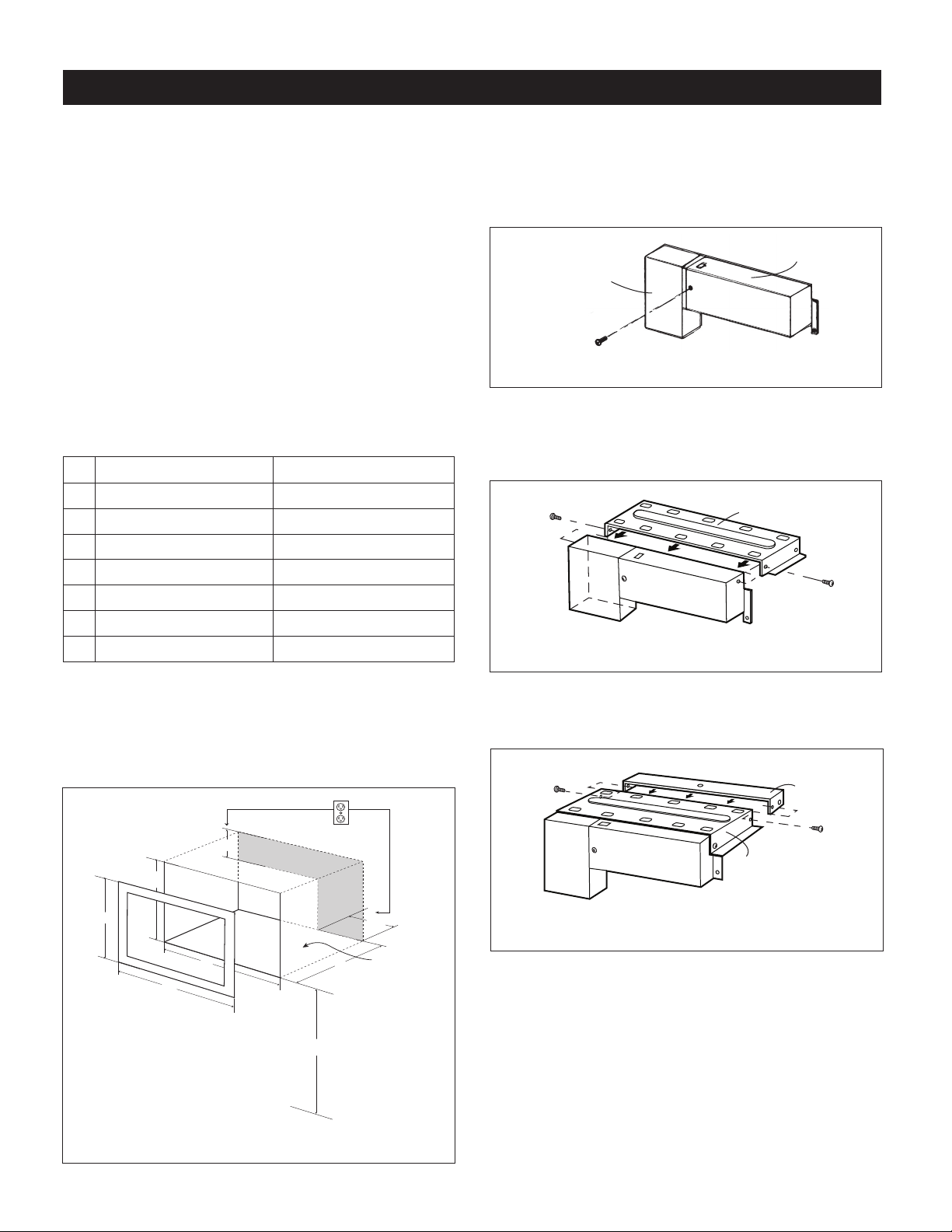

STEP 1 - CABINET OR WALL OPENING

Provide an opening in the wall or cabinet as indicated

in Figure 1. The depth should be a minimum of 20 1/8"

(511.2 mm). If the Depth (E) dimension is greater than 21"

(533.4 mm), the outlet location may be in any area on the

rear wall. The oor of the opening should be constructed of

plywood strong enough to support the weight of the oven

(approximately 100 lbs/45 kg) and should be level for proper

operation of the oven.

NOTE: While the proper function of the oven does not

require that the opening be enclosed (with sides, ceiling and

rear partition), this may be required by local code, and it

is suggested that the local code be checked for any such

requirement.

The opening in the wall or cabinet must be within the

following dimensions, centered horizontal to the cabinet.

RK94S27F RK94S30F

A 20" (508 mm) 20" (508 mm)

7

B 26

C 18

D 25

E Min. 20

F 5" (127 mm) 5" (127 mm)

G 10" (254 mm) 10" (254 mm)

/8" (682.6 mm) 29 7/8" (758.8 mm)

1

/2" (470 mm) 18 1/2" (470 mm)

1

/4" (641.3 mm) 25 1/4" (641.3 mm)

1

/8" (511.2 mm) Min. 20 1/8" (511.2 mm)

STEP 2 - EXHAUST DUCT ASSEMBLY INSTALLATION

A. Insert the edge of DUCT (B) into the hold lip of DUCT (C).

Secure together by using a SCREW (I) provided in the kit.

See Figure 2.

DUCT (B)

SCREW (I)

FIGURE 2

B. Position DUCT (A)-1 on the top of the oven inserting

edge of DUCT (BC) assembly into hole lip of DUCT (A)-

1. Tighten 2 SCREWS (I), securing DUCT (A)-1 to DUCT

(BC) assembly. See Figure 3.

SCREW (I)

DUCT (BC)

FIGURE 3

DUCT (C)

DUCT (A)-1

SCREW (I)

Outlet should NOT be in the shaded area as indicated on

Figure 1.

NOTE:

• If the dimension of DEPTH (E) is more than 21" (533.4 mm),

the outlet location may be any area on the rear wall.

F

C

A

D

B

NOTE: Floor of opening

should be 90˚ to front

34-1/2” MIN.

G

FLOOR

E

cabinet frame.

FLOOR

C. Position DUCT (A)-2 on the top of the oven and insert it

into the hold lip of DUCT (A)-1. Secure DUCT (A)-2 to

DUCT (A)-1 using 2 SCREWS (I) provided. See Figure 4.

SCREW (I)

DUCT (A)-1

DUCT (A)-2

SCREW (I)

FIGURE 4

FIGURE 1

E 2

Page 3

STANDARD INSTALLATION INSTRUCTIONS

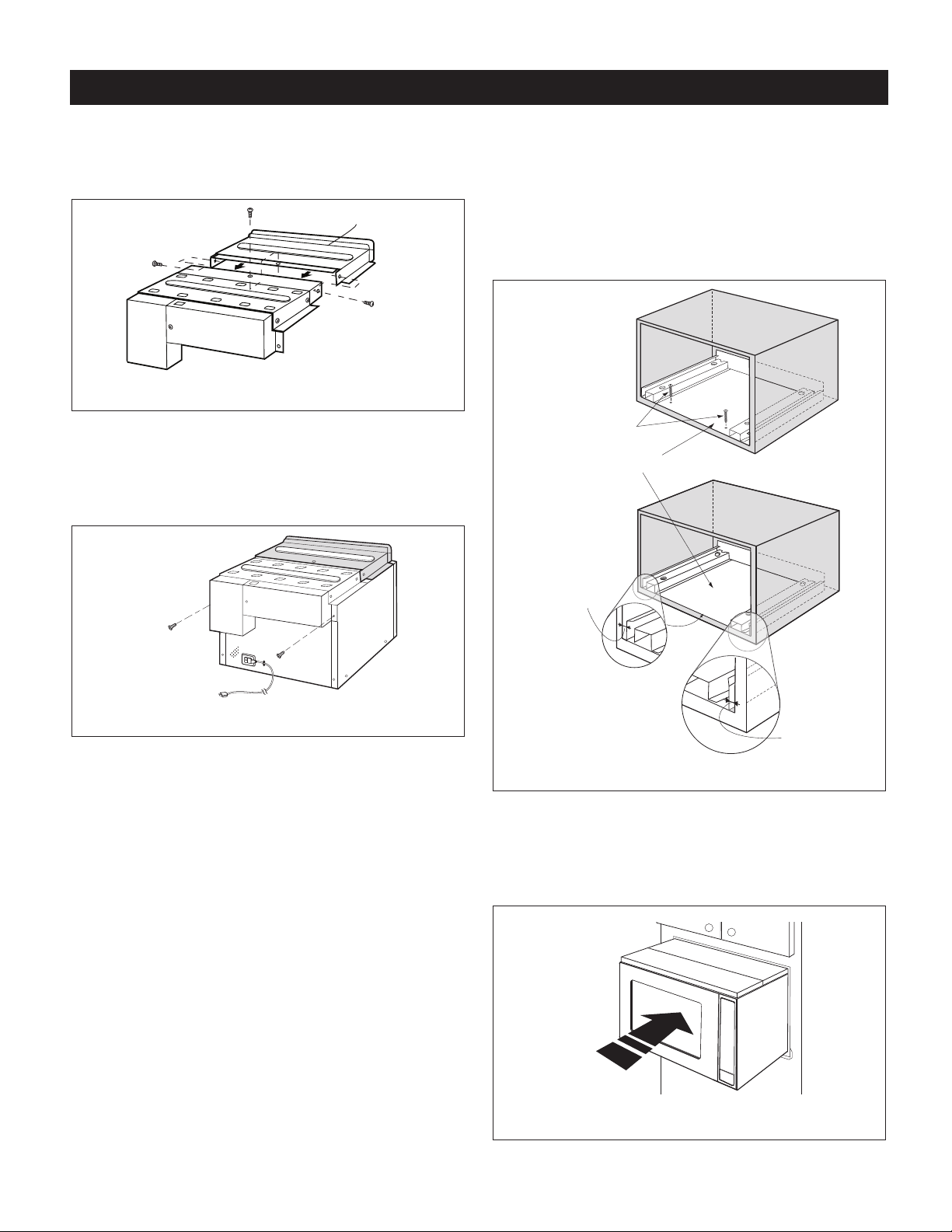

D. Position DUCT (A)-3 on top of the oven and insert it into

DUCT (A)-2. Secure DUCT (A)-3 using 3 SCREWS (I)

provided. See Figure 5.

SCREW (I)

SCREW (I)

DUCT (A)-3

SCREW (I)

DUCT (A)-2

FIGURE 5

E. Remove SCREWS from the upper right and left corners

at the rear of the oven. Place duct assembly on the top

of the unit as shown and secure the duct assembly to the

oven using the 2 SCREWS just removed from the oven.

See Figure 5A.

STEP 3 - SURFACE INSTALLATION

A. BOTTOM DUCT ASSEMBLY: Place the Bottom duct in

the center of the opening so that gap "A" is equal to gap

"B". When the BOTTOM DUCT ASSEMBLY is positioned

properly, the front edge of the duct will be ush with the

front of the cabinet. Secure with 2 SCREWS (H) See

Figure 6.

SCREW (H)

BOTTOM DUCT ASSEMBLY

SCREW

SCREW

FIGURE 5A

GA P "A"

NOTE:

CENTER BOTTOM

DUCT ASSEMBLY IN

THE OPENING

DETAIL A

GAP "B"

FIGURE 6

B. CABINET INSTALLATION: Place the oven adjacent to

the wall or cabinet opening. Plug the power cord into the

electrical outlet. Carefully guide the assembled oven into

the prepared opening. Slide the oven on the BOTTOM

DUCT ASSEMBLY. See Figure 7.

E 3

FIGURE 7

Page 4

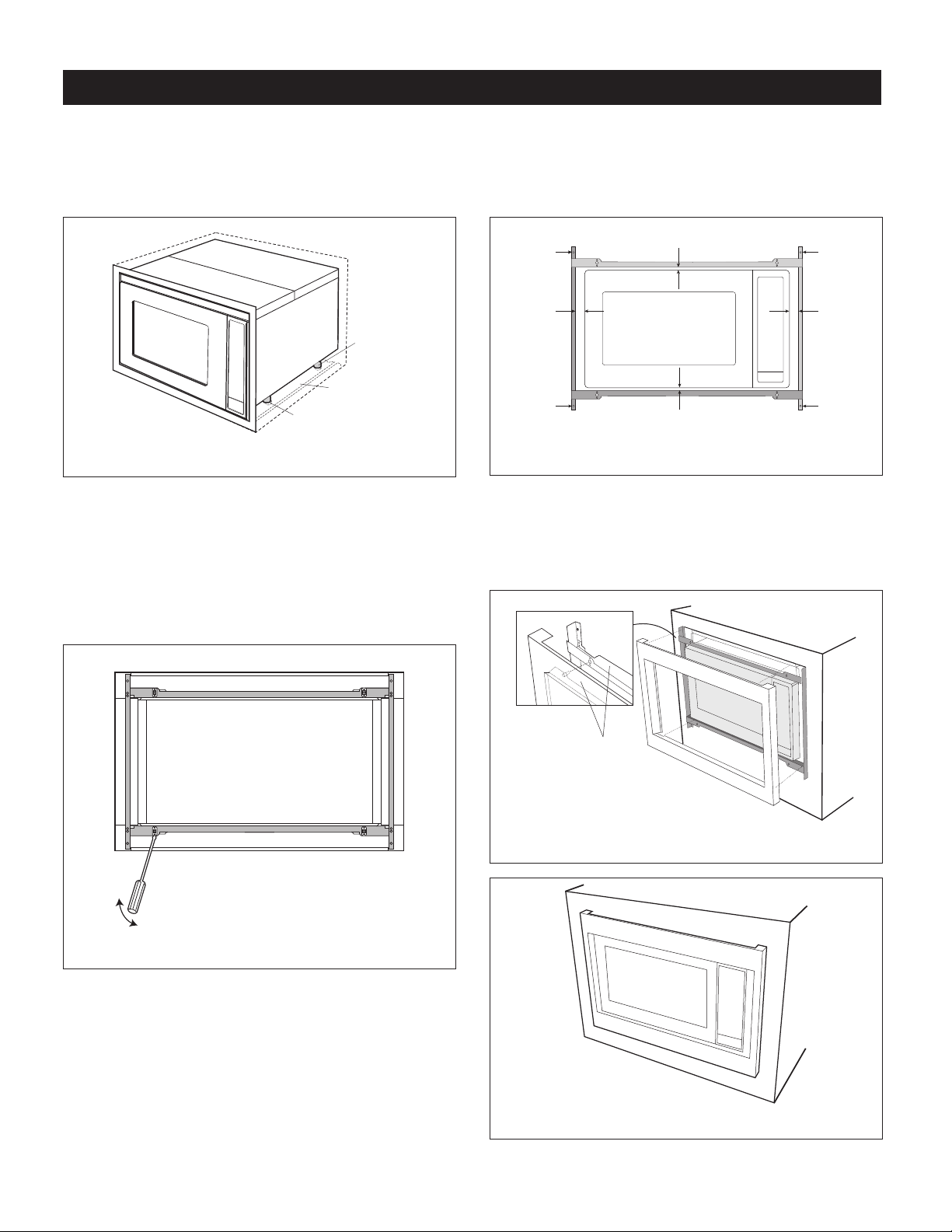

STANDARD INSTALLATION INSTRUCTIONS

C. CABINET INSTALLATION: Avoid pinching the cord

between the oven and the wall. Adjust the position of the

oven so that the feet of the oven are tted into the holes

of the BOTTOM DUCT ASSEMBLY. See Figure 8.

FOOT

BOTTOM DUCT

ASSEMBLY

DUCT RECESS

FIGURE 8

D. DISASSEMBLY: The FRONT FRAME and BACK FRAME

come pre-assembled with ball studs engaged in the

receivers. Separate the FRONT FRAME from the BACK

FRAME. Place the assembly facedown on a protected

surface. At the location of the ball stud, insert a athead

screwdriver between the FRONT FRAME and the BACK

FRAME and gently pry up to disengage the ball stud from

the receiver. Repeat for each corner. See Figure 9.

E. BACK FRAME INSTALLATION: Position BACK FRAME

equal space top to bottom, side to side. Mark for 4 holes,

1

center punch and pre-drill with

/16" drill bit. Secure

frame with 4 SCREWS (G). See Figure 10.

MOUNTING HOLES

EQUAL GAP

SIDE TO SIDE

MOUNTING HOLES

EQUAL GAP TOP, BOTTOM

MOUNTING HOLES

MOUNTING HOLES

FIGURE 10

F. FRONT FRAME INSTALLATION: Place the FRONT FRAME

onto the BACK FRAME and align ball studs and receivers.

Secure the FRONT FRAME to the BACK FRAME by rmly

pushing the FRONT FRAME onto the BACK FRAME,

engaging the 4 snap attachments. See Figures 11-12.

FIGURE 9

SNAP

ATTACHMENT

FIGURE 11

FIGURE 12

E 4

Page 5

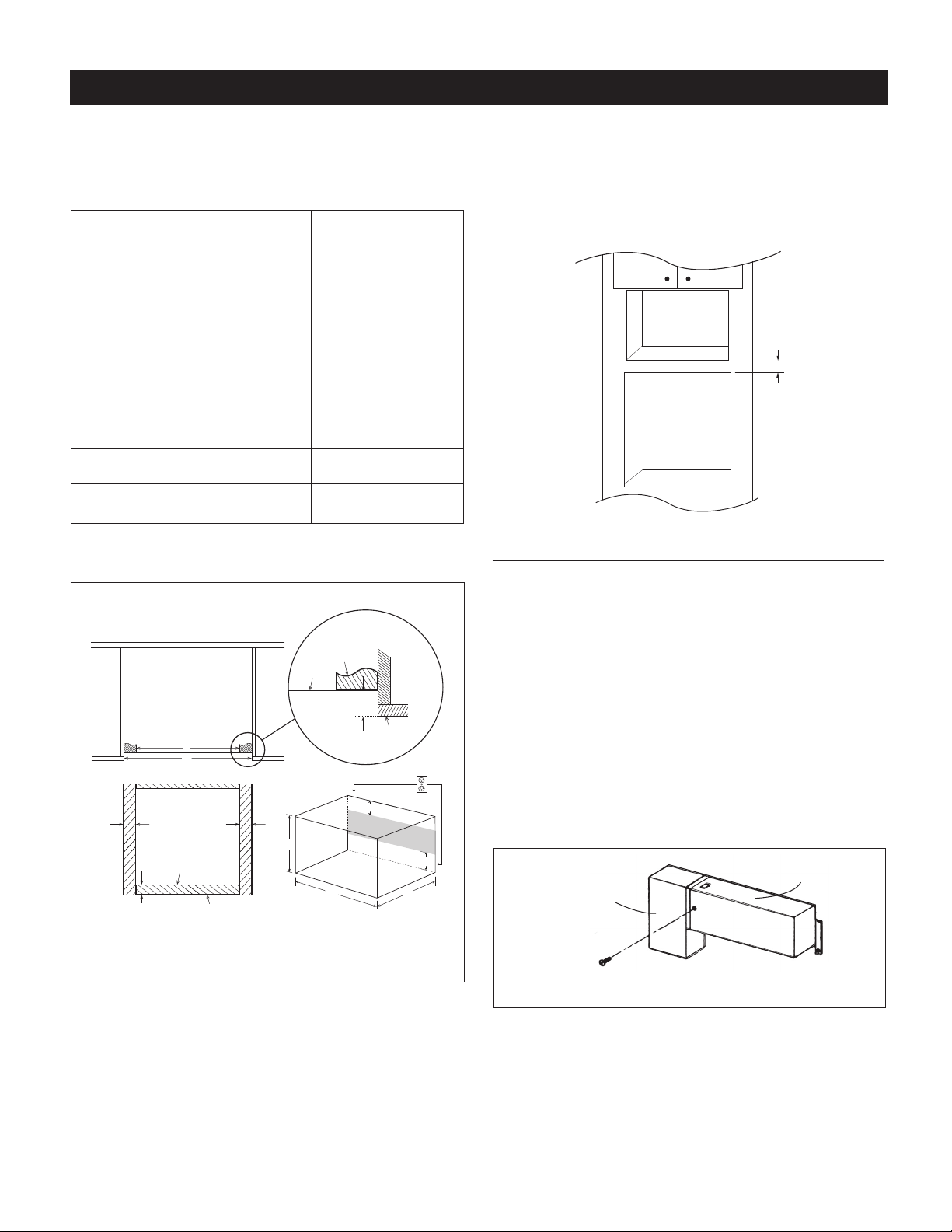

FLUSH INSTALLATION INSTRUCTIONS

(76 MM)

STEP 1 - CABINET OR WALL OPENING

The opening in the wall or cabinet must be within the

following dimensions:

OPENING RK94S27F RK94S30F

1

A 25

Width (B) 27

Height (C) 22

D 1" (25.4 mm) 2

E 2

F 1

G 5" (127 mm) 5" (127 mm)

Minimum

Depth (I)

Outlet should NOT be in the shaded area H as indicated in

Figure 1.

E

/8" (638.2 mm) 25 1/8" (638.2 mm)

1

/8" (689 mm) 30 1/8" (765.2 mm)

7

/16" (569.9 mm) 22 7/16" (569.9 mm)

1

/2" (63.5 mm)

1

/8" (54 mm) 2 1/8" (54 mm)

1

/2" (38.8 mm) 1 1/2" (38.8 mm)

20" (508 mm) 20" (508 mm)

Top View

A

B

Front View

D D

Shelf

Bottom of flush cutout

Mounting

cleat

Shelf

F

G

C

B

Cabinet

face

H

G

I

NOTE:

• Please allow minimum 3" (76 mm) wood gap between the

microwave oven cutout and the appliance cutout below

the microwave oven. See Figure 2.

Microwave cutout

3"

Wall oven cutout

Min.

FIGURE 2

• The oor of the opening should be constructed of

plywood strong enough to support the weight of the oven

and oor load (approximately 100 pounds/45 kg). The

oor should be level and 90˚ with the face of the cabinet

for proper installation and operation of the oven. Be sure

to check the local building code as it may require that the

opening be enclosed with sides, ceiling and rear partition.

The proper functioning of the oven does not require the

enclosure.

STEP 2 - EXHAUST DUCT ASSEMBLY INSTALLATION

A. Insert the edge of DUCT (B) into the hold lip of DUCT (C).

Secure together by using a SCREW (I) provided in the kit.

See Figure 3.

DUCT (B)

DUCT (C)

FIGURE 1

NOTE:

Dimension C above will result in 1

1

⁄4" (31.8 mm) spaces

above and below the trim to allow for necessary intake and

exhaust air ow to ensure appliance does not overheat. Do

not reduce this spacing as doing so will void the warranty

for any issues resulting from a lack of airow.

SCREW (I)

FIGURE 3

E 5

Page 6

FLUSH INSTALLATION INSTRUCTIONS

B. Position DUCT (A)-1 on the top of the oven inserting

edge of DUCT (BC) assembly into hole lip of DUCT (A)-

1. Tighten 2 SCREWS (I), securing DUCT (A)-1 to DUCT

(BC) assembly. See Figure 4.

SCREW (I)

DUCT (BC)

DUCT (A)-1

SCREW (I)

FIGURE 4

C. Position DUCT (A)-2 on the top of the oven and insert it

into the hold lip of DUCT (A)-1. Secure DUCT (A)-2 to

DUCT (A)-1 using 2 SCREWS (I) provided. See Figure 5.

SCREW (I)

DUCT (A)-1

DUCT (A)-2

SCREW (I)

E. Remove SCREWS from the upper right and left corners

at the rear of the oven. Place duct assembly on the top

of the unit as shown and secure the duct assembly to the

oven using the 2 SCREWS just removed from the oven.

See Figure 6B.

SCREW

SCREW

FIGURE 6B

STEP 3 - EXHAUST DUCT ASSEMBLY INSTALLATION

A. Place the Exhaust Duct Assembly in the center of the

opening. Align the front edge of the duct with the front of

the cabinet. Align the front edge of the right side of the

duct with the front of the shelf. See Figure 7.

B. Secure the Exhaust Duct Assembly with 2 SCREWS (H).

See Figure 7.

FIGURE 5

D. Position DUCT (A)-3 on top of the oven and insert it into

DUCT (A)-2. Secure DUCT (A)-3 using 3 SCREWS (I)

provided. See Figure 6.

SCREW (I)

SCREW (I)

DUCT (A)-3

SCREW (I)

DUCT (A)-2

FIGURE 6

Screw H

Screw H

FIGURE 7

Exhaust duct assembly

right side aligns to front

edge of shelf

E 6

Page 7

FLUSH INSTALLATION INSTRUCTIONS

STEP 4 - FRAME INSTALLATION

A. Place the oven adjacent to the wall or cabinet opening.

Plug the power cord into the electrical outlet.

B. Carefully guide the assembled oven into the prepared

opening. Slide the oven onto the Exhaust Duct Assembly.

See Figure 8. Avoid pinching the cord between the oven

and the wall. Adjust the position of the oven so that the

feet of the oven are tted into the recesses of the Exhaust

Duct Assembly and the door opens properly. See Figure 9.

Screw D

Screw D

FIGURE 8

C. DISASSEMBLY: The FRONT FRAME and BACK FRAME

come pre-assembled with ball studs engaged in the

receivers. Separate the FRONT FRAME from the BACK

FRAME. Place the assembly facedown onto a protected

surface. At the location of the ball stud, insert a athead

screwdriver between the FRONT FRAME and the BACK

FRAME and gently pry up to disengage the ball stud from

the receiver. Repeat for each corner. See Figure 10.

FIGURE 10

D. BACK FRAME INSTALLATION: Position BACK FRAME

equal space top to bottom, side to side. Mark for 4 holes

on the installed wood cleats, center punch and pre-drill

1

⁄16” drill bit. Secure frame with 4 SCREWS (G). See

with

Figure 11.

FIGURE 9

Duct recess

Foot

Exhaust

duct

assembly

Screw G

Screw G

Mounting holes

Equal gap

side to side

Mounting holes

Mounting holes

Screw G

Equal gap top, bottom

Screw G

Mounting holes

FIGURE 11

E 7

Page 8

E. Install Air Deectors top and bottom. Center (left and

right) the Air Deectors above and below the installed

BACK FRAME. Secure Air Deectors with 4 SCREWS (G).

See Figure 12. Mark holes and pre-drill the wood cleats

1

with

⁄16” drill bit.

FIGURE 12

F. FRONT FRAME INSTALLATION: Place the FRONT

FRAME onto the BACK FRAME and align ball studs

and receivers. Secure the FRONT FRAME to the BACK

FRAME by rmly pushing the FRONT FRAME onto the

BACK FRAME, engaging the 4 snap attachments. See

Figures 13-14.

Snap

Attachment

FIGURE 13

SHARP ELECTRONICS CORPORATION

100 Paragon Drive • Montvale, New Jersey 07645 • U.S.A.

SHARP ELECTRONICS OF CANADA LTD.

335 Britannia Road East • Mississauga, Ontario L4Z 1W9 • Canada

FIGURE 14

For any other assistance or information about this kit,

in USA please call Sharp’s Customer Assistance Center at

1-800-BE-SHARP (1-800-237-4277)

In Canada, call 905-568-7140

E 8

Page 9

INSTRUCTIONS D’INSTALLATION

Pour l’ensemble d’encastrement du

Sharp Carousel®

Modèles RK94S27F ou RK94S30F

S = INOXYDABLE

CET ENSEMBLE EST APPROUVÉ POUR PERMETTRE À CERTAINS

FOURS À MICRO-ONDES D’ÊTRE INSTALLÉS AU-DESSUS

D’UN FOUR ENCASTRÉ ÉLECTRIQUE. REPORTEZ-VOUS AU

MANUEL D’UTILISATION POUR CONNAÎTRE LES APPLICATIONS

D’ENCASTRATION APPROUVÉES.

IMPORTANT:

Cet ensemble d’encastrement est conçu pour et approuvé

uniquement pour les fours micro-ondes Sharp spéciant

l’ensemble d’encastrement RK94S27F ou RK94S30F.

Reportez-vous au Manuel d’utilisation pour connaître les

modèles approuvés.

NOTES IMPORTANTES POUR L’INSTALLATEUR

• VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS

AVANT DE COMMENCER L’INSTALLATION.

• Observez tous les codes et ordonnances applicables

ainsi que les instructions de sécurité.

• Assurez-vous de laisser ces instructions au client.

• Assurez-vous de DÉBRANCHER LA FICHE du four à

micro-ondes de la prise électrique avant l’installation de

l’ensemble d’encastrement. Retirez le plateau rotatif de la

cavité du four.

• Une précaution particulière devrait être prise lors de la

manipulation et de l’installation de cet ensemble afin

d’éviter toute blessure, puisque celui-ci contient des

pièces de métal.

ARTICLE NOMS DES PIÈCES QTÉ

H VIS À BOIS : XTSS740P20000 2

I VIS D’ARMOIRE : XOTS740P12000 10

CADRE AVANT

J

RK94S27F : FDECAB229MRK0

1

RK94S30F : FDECAB227MRK0

CADRE ARRIÈRE

K

RK94S27F : FDECAB255MRK0

1

RK94S30F : FDECAB226MRK0

DÉFLECTEUR D'AIR

L

RK94S27F : PREF-B038MRP0

2

RK94S30F : PREF-B039MRP0

Vériez la liste de pièces lors du déballage.

REMARQUE : Le (J) CADRE AVANT et le (K) CADRE ARRIÈRE

sont expédiés en étant attachés ensemble. Détachez-les

avant l’installation.

A

DUCT (A)-1

CONDUIT (A)-1

G

H

I

B

DUCT (A)-2

CONDUIT (A)-2

J

C

DUCT (A)-3

CONDUIT (A)-3

ARTICLE NOMS DES PIÈCES QTÉ

A CONDUIT (A)-1 : PDUC-0259WRW0 1

B CONDUIT (A)-2 : PDUC-B127MRP0 1

C CONDUIT (A)-3 : PDUC-A734WRW0 1

D CONDUIT (B) : PDUC-0260WRW0 1

E CONDUIT (C ): PDUC-A274WRW0 1

F

G

ASSEMBLAGE DU CONDUIT

INFÉRIEUR : FDUC-B099MRK1A

VIS À TÔLE À TÊTE CYLINDRIQUE

M3,9-16MM, ZINC : XOPS740P16000

1

8

F 1

D

DUCT (B)

CONDUIT (B)

K

E

CONDUIT (C)

DUCT (C)

F

L

Page 10

INSTRUCTIONS D'INSTALLATION STANDARD

ÉTAPE 1 - OUVERTURE DE L'ARMOIRE OU DU MUR

Faire une ouverture dans le mur ou l'armoire comme illustré

à la Figure 1. La profondeur doit être d'une longueur minimum

de 511,2 mm (20 1/8 po). Si la profondeur (E) dépasse 533,4

mm (21 po), l'emplacement de la prise peut être situé

n'importe où sur le mur arrière. Le plancher de l'ouverture doit

être construit dans un contreplaqué assez fort pour supporter

le poids du four et sa propre charge (environ 45 kg/100 lbs)

et doit être situé à un niveau convenable pour l'utilisation

du four.

REMARQUE : Bien que le bon fonctionnement du four

n'exige pas que l'ouverture soit close (avec cloisons

latérales, arrière et plafond), le code local pourrait l'exiger; il

est donc suggéré de vérier ce point.

L'ouverture du mur ou de l'armoire doit respecter les

dimensions suivantes et être centrée horizontalement dans

l'armoire.

RK94S27F RK94S30F

A 508 mm (20 po) 508 mm (20 po)

7

B 682,6 mm (26

C 470 mm (18

D 641,3 mm (25

E Min. 511,2 mm (20

F 127 mm (5 po) 127 mm (5 po)

G 254 mm (10 po) 254 mm (10 po)

La prise NE doit PAS se trouver dans l'aire ombrée comme

illustré à la schéma 1.

REMARQUE

• Si la profondeur (E) dépasse 533,4 mm (21 po),

l'emplacement de la prise peut être situé n'importe où

sur le mur arrière.

/8 po) 758,8 mm (29 7/8 po)

1

/2 po) 470 mm (18 1/2 po)

1

/4 po) 641,3 mm (25 1/4 po)

1

/8 po) Min. 511,2 mm (20 1/8 po)

ÉTAPE 2 - ENSEMBLE DU CONDUIT D’ÉVACUATION

A. Insérer le bord du CONDUIT (B) dans le joint à lèvre du

CONDUIT (C). Les xer ensemble à l’aide d’une VIS (I)

fournis dans le kit. Voir schéma 2.

CONDUIT

(B)

VIS (1)

SCHÉMA 2

B. Placer le CONDUIT (A)-1 au dessus du four en insérant

le bord de l’ensemble du CONDUIT (BC) dans la lèvre du

CONDUIT (A)-1. Serrer deux VIS (I) pour xer le CONDUIT

(A)-1 à l’ensemble du CONDUIT (BC). Voir schéma 3.

VIS (I)

CONDUIT (BC)

SCHÉMA 3

C. Placer le CONDUIT (A)-2 au dessus du four et l’insérer

dans le joint à lèvre du CONDUIT (A)-1. Fixer le CONDUIT

(A)-2 au CONDUIT (A)-1 à l’aide de deux VIS (I) fournies.

Voir schéma 4.

VIS (I)

CONDUIT (C)

CONDUIT (A)-1

VIS (I)

CONDUIT

(A)-2

F

C

A

D

B

REMARQUE : Le

plancher de l'ouverture

doit former un angle

90o avec le cadre de

façade de l'armoire.

MIN. 87,6 CM

34-1/2” MIN.

(34 1/2 PO)

SCHÉMA 1

E

PLANCHER

FLOOR

G

FLOOR

PLANCHER

VIS (I)

CONDUIT (A)-1

SCHÉMA 4

F 2

Page 11

INSTRUCTIONS D'INSTALLATION STANDARD

D. Placer le CONDUIT (A)-3 au dessus du four et l’insérer

dans le CONDUIT (A)-2. F ixer le CONDUIT (A)-3 à l’aide

de trois VIS (I) fournies. Voir schéma 5.

VIS (I)

VIS (I)

CONDUIT (A)-3

VIS (I)

CONDUIT (A)-2

SCHÉMA 5

E. Retirer la VIS des coins supérieurs droit et gauche à

l'arrière du four. Placer l'ensemble conduit au-dessus de

l'appareil comme illustré et xer l'ensemble conduit sur le

four à l'aide des deux vis qui viennent d'être retirées. Voir

schéma 5A.

ÉTAPE 3 - INSTALLATION DE LA SURFACE

A. ASSEMBLAGE DU CONDUIT INFÉRIEUR Placer le

conduit inférieur au centre de l'ouverture de sorte que

l'écart « A » soit égal à l'écart « B ». Lorsque l'assemblage

du conduit inférieur est placé correctement, le rebord

avant du conduit sera aligné avec le devant de l'armoire.

Fixer à l'aide des 2 VIS (H). Voir schéma 6.

VIS (H)

ASSEMBLAGE DU CONDUIT INFÉRIEUR

VIS

VIS

SCHÉMA 5A

ÉCART « A »

REMARQUE :

CENTRER

L'ASSEMBLAGE

DU CONDUIT

INFÉRIEUR DANS

L'OUVERTURE

DÉTAIL A

ÉCART « B »

SCHÉMA 6

B. INSTALLATION DANS L'ARMOIRE : Placer le four près

de l'ouverture du mur ou de l'armoire. Brancher le cordon

d'alimentation dans la prise électrique. Guider avec

précaution le four assemblé dans l'ouverture préparée.

Faire glisser le four sur l'assemblage du conduit inférieur.

Voir schéma 7.

F 3

SCHÉMA 7

Page 12

INSTRUCTIONS D'INSTALLATION STANDARD

C. INSTALLATION DANS L'ARMOIRE : Éviter de pincer le

cordon entre le four et le mur. Ajuster la position du four

de façon à ce que ses pattes entrent dans les trous de

l'assemblage de conduit inférieur. Voir schéma 8.

PATTE

ASSEMBLAGE

DU CONDUIT

INFÉRIEUR

RENFONCEMENT

DU CONDUIT

SCHÉMA 8

D. DÉMONTAGE : le CADRE AVANT et le CADRE ARRIÈRE

sont pré-assemblés avec des pions à rotule engagés

dans les récepteurs. Séparez le FRONT FRAME de

BACK FRAME. Placez l'ensemble face vers le bas sur

une surface protégée. À l'emplacement du goujon à bille,

insérez un tournevis à tête plate entre le FRONT FRAME

et le BACK FRAME et tirez doucement pour dégager le

goujon à bille du récepteur. Répétez pour chaque coin.

Voir Sketch 9.

E. INSTALLATION DU CADRE ARRIÈRE : Placer le cadre

arrière à distances égales de haut en bas et de chaque

côté. Tracer l'emplacement de quatre (4) trous au centre

à l'aide d'un poinçon et prépercer à l'aide d'une mèche

1

de 1,45 mm (

/16 po). Fixer le cadre à l'aide de quatre (4)

VIS (G). Voir schéma 10.

TROUS DE FIXATION

MOUNTING HOLES

ÉCART ÉGAL DE

EQUAL GAP

SIDE TO SIDE

CHAQUE CÔTÉ

ÉCART ÉGAL DE HAUT EN BAS

EQUAL GAP TOP, BOTTOM

MOUNTING HOLES

TROUS DE FIXATION

TROUS DE FIXATION

MOUNTING HOLES

MOUNTING HOLES

TROUS DE FIXATION

SCHÉMA 10

F. INSTALLATION DU CADRE DE FAÇADE : Poser le CADRE

DE FAÇADE sur le CADRE ARRIÈRE et aligner les pivots

à rotule avec les agrafes. Fixer le CADRE DE FAÇADE

en le poussant fermement contre le CADRE ARRIÈRE et

en engageant les quatre (4) xations encliquetables. Voir

schémas 11-12.

SCHÉMA 9

F 4

FIXATION

ENCLIQUETABLE

SCHÉMA 11

SCHÉMA 12

Page 13

INSTRUCTIONS D’INSTALLATION POUR L’ENCASTREMENT

(76 MM)

ÉTAPE 1 – OUVERTURE DANS UNE ARMOIRE OU DANS

LE MUR

L’ouverture dans le mur ou l’armoire doit avoir les dimensions

suivantes :

OUVERTURE RK94S27F RK94S30F

C

Tablette

Shelf

638,2 mm

(25 1/8 po)

569,9 mm

(22 7/16 po)

Taquet

Mounting

d’installation

cleat

Devant de

Cabinet

F

l’armoire

G

H

B

face

1

/2 po)

I

G

A

Largeur (B) 689 mm (27

Hauteur (C)

638,2 mm

1

/8 po)

(25

569,9 mm

7

(22

/16 po)

1

/8 po) 765,2 mm (30 1/8 po)

D 25,4 mm (1 po) 63,5 mm (2

E 54 mm (2

F 38,8 mm (1

1

/8 po) 54 mm (2 1/8 po)

1

/2 po) 38,8 mm (1 1/2 po)

G 127 mm (5 po) 127 mm (5 po)

Profondeur

Minimum (I)

508 mm (20 po) 508 mm (20 po)

La prise ne doit PAS être dans la zone ombragée H comme

indiqué à la schéma 1.

Top View

Vue du haut

A

B

Front View

Vue de l’avant

D D

Shelf

Tablette

Bottom of flush cutout

E

Bas du gabarit d’encastrement

REMARQUE :

• Laissez un dégagement minimum de 76 mm (3 po) entre

le gabarit du four à micro-ondes et le gabarit de l’appareil

sous le four micro-ondes. Consultez la schéma 2.

Gabarit du

Microwave cutout

micro-ondes

Minimum

3"

Gabarit du four

Wall oven cutout

encastré

de 76 mm

(3 po)

Min.

SCHÉMA 2

• Le fond de l’ouverture doit être fabriqué à l’aide d’un

contreplaqué assez résistant pour soutenir le poids du

four et la charge appliquée sur celui-ci (environ 45 kg/100

lb). Le fond doit être au niveau et à 90 degrés par rapport

à la devanture de l’armoire pour permettre l’installation

et le fonctionnement approprié du four. Assurez-vous de

consulter les codes locaux du bâtiment, car ces derniers

peuvent exiger que l’ouverture comprenne des partitions

latérales, une partition supérieure et une partition

arrière. Le fonctionnement adéquat du four n’exige pas

l’encastrement.

ÉTAPE 2 - ENSEMBLE DU CONDUIT D’ÉVACUATION

A. Insérer le bord du CONDUIT (B) dans le joint à lèvre du

CONDUIT (C). Les xer ensemble à l’aide d’une VIS (I)

fournis dans le kit. Voir schéma 3.

CONDUIT

(B)

VIS (1)

CONDUIT (C)

SCHÉMA 1

REMARQUE :

La dimension C ci-dessous laissera des espaces de 31,8 mm

1

⁄4 po) au-dessus et sous la garniture pour permettre

(1

la circulation d’air entrante et sortante nécessaire pour

empêcher la surchauffe de l’appareil. Ne réduisez pas cet

espace, car ceci annulerait la garantie pour tout problème

associé à un manque de circulation d’air.

SCHÉMA 3

F 5

Page 14

INSTRUCTIONS D’INSTALLATION POUR L’ENCASTREMENT

B. Placer le CONDUIT (A)-1 au dessus du four en insérant

le bord de l’ensemble du CONDUIT (BC) dans la lèvre du

CONDUIT (A)-1. Serrer deux VIS (I) pour xer le CONDUIT

(A)-1 à l’ensemble du CONDUIT (BC). Voir schéma 4.

VIS (I)

CONDUIT (BC)

CONDUIT (A)-1

VIS (I)

SCHÉMA 4

C. Placer le CONDUIT (A)-2 au dessus du four et l’insérer

dans le joint à lèvre du CONDUIT (A)-1. Fixer le CONDUIT

(A)-2 au CONDUIT (A)-1 à l’aide de deux VIS (I) fournies.

Voir schéma 5.

VIS (I)

CONDUIT (A)-1

CONDUIT

(A)-2

VIS (I)

E. Retirer la VIS des coins supérieurs droit et gauche à

l'arrière du four. Placer l'ensemble conduit au-dessus de

l'appareil comme illustré et xer l'ensemble conduit sur

le four à l'aide des deux vis qui viennent d'être retirées.

Voir schéma 6A.

VIS

VIS

SCHÉMA 6A

ÉTAPE 3 – INSTALLATION DE L’ASSEMBLAGE DU

CONDUIT D’ÉCHAPPEMENT

A. Positionnez l’assemblage du conduit d’échappement au

centre de l’ouverture. Alignez le rebord avant du conduit

avec le devant de l’armoire. Alignez le rebord avant

du côté droit du conduit avec le devant de la tablette.

Consultez la schéma 7.

B. Fixez l’assemblage du conduit d’échappement à l’aide

de 2 VIS (H). Consultez la schéma 7.

SCHÉMA 5

D. Placer le CONDUIT (A)-3 au dessus du four et l’insérer

dans le CONDUIT (A)-2. F ixer le CONDUIT (A)-3 à l’aide

de trois VIS (I) fournies. Voir schéma 6.

VIS (I)

VIS (I)

CONDUIT (A)-3

VIS (I)

CONDUIT (A)-2

SCHÉMA 6

Vis H

Screw H

Screw H

Vis H

SCHÉMA 7

Le côté droit de

Exhaust duct assembly

l’assemblage du conduit

right side aligns to front

d’échappement s’aligne

edge of shelf

avec le rebord avant de

la tablette.

F 6

Page 15

INSTRUCTIONS D’INSTALLATION POUR L’ENCASTREMENT

Screw G

Screw G

ÉTAPE 4 – INSTALLATION DU CADRE

A. Placez le four adjacent au mur ou à l’ouverture de

l’armoire. Branchez le cordon d’alimentation dans la prise

de courant électrique.

B. Glissez soigneusement le four assemblé dans l’ouverture

préparée. Glissez le four sur l’assemblage du conduit

d’échappement. Consultez la Figure 8. Évitez de pincer

le cordon entre le four et le mur. Ajustez la position du

four an que la patte du four entre dans les cavités de

l’assemblage du conduit d’échappement et que la porte

s’ouvre adéquatement. Consultez la schéma 9.

Screw D

Screw D

SCHÉMA 8

C. DÉSASSEMBLAGE : Le CADRE AVANT et le CADRE

ARRIÈRE sont déjà assemblés avec des pivots à rotule

insérés dans les récepteurs. Séparez le CADRE AVANT

du CADRE ARRIÈRE. Placez l’assemblage vers le bas sur

une surface protégée. À l’emplacement du pivot à rotule,

insérez le tournevis à tête plate entre le CADRE AVANT et

le CADRE ARRIÈRE et effectuez un mouvement de levier

pour désengager le pivot à rotule du récepteur. Répétez à

chaque coin. Consultez la schéma 10.

SCHÉMA 10

D. INSTALLATION DU CADRE ARRIÈRE : Positionnez le

CADRE ARRIÈRE à un espace égal entre le bas et les

côtés. Marquez les 4 trous des taquets d’installation en

bois, marquez à l’aide d’un poinçon et prépercez à l’aide

1

d’une mèche de

⁄16 po. Fixez le cadre à l’aide des 4 VIS

(G). Consultez la schéma 11.

SCHÉMA 9

Cavité du conduit

Duct recess

Patte

Foot

Assemblage

Exhaust

du conduit

duct

d’échappement

assembly

Screw G

Vis G

Vis G

Screw G

Trous de xation

Mounting holes

Dégagement égal

Equal gap

side to side

des deux côtés

Trous de xation

Mounting holes

Dégagement égal sur le

Equal gap top, bottom

haut et le bas

SCHÉMA 11

Trous de xation

Mounting holes

Mounting holes

Trous de xation

Vis G

Vis G

F 7

Page 16

INSTRUCTIONS D’INSTALLATION POUR L’ENCASTREMENT

E. Installez les déecteurs d’air supérieur et inférieur. Centrez

les déecteurs d’air (gauche et droit) au-dessus et sous

le CADRE ARRIÈRE installé. Déecteurs d’air sécurisés

avec 4 VIS (G). Consultez la schéma 12. Marquez des

trous et prépercez les taquets d’installation en bois avec

une mèche de 1⁄16 po.

SCHÉMA 14

SCHÉMA 12

F. INSTALLATION DU CADRE AVANT : Placez le CADRE

AVANT sur le CADRE ARRIÈRE et alignez les pivots

à rotule et les récepteurs. Fixez le CADRE AVANT au

CADRE ARRIÈRE en appuyant fermement sur le CADRE

AVANT sur le CADRE ARRIÈRE en enclenchant les 4

xations à pression. Consultez les schéma 13-14.

Fixation à

Snap

pression

Attachment

SCHÉMA 13

SHARP ÉLECTRONIQUE DU CANADA LTÉE,

335, rue Britannia Est • Mississauga, Ontario L4Z 1W9 • Canada

Pour tout autre type d'aide ou de renseignements concernant cette

trousse, aux États-Unis, veuillez communiquer au service

d'assistance à la clientèle de Sharp en composant le

905-568-7140 (Canada)

F 8

TINSKB288MRR1

Dec 10, 2019

Loading...

Loading...