Page 1

R-820BC

SUPPLEMENTAL SERVICE MANUAL

S2401R820BPW/

DOUBLE GRILL

CONVECTION

MICROWAVE OVEN

MODEL

In the interest of user-safety the oven should be restored to its original

condition and only parts identical to those specified should be used.

GRILL

2

CONVECTION

This is a supplemental Service Manual for Model R-820BC. This model is quite similar to base model R-820BW. Use

this supplemental manual together with the Base Model Service Manual (Refer No. is S5812R820BPW/) for complete

operation, service information, etc..

TABLE OF CONTENTS

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY ................... INSIDE FRONT COVER

BEFORE SERVICING ......................................................................................................INSIDE FRONT COVER

WARNING TO SERVICE PERSONNEL ................................................................................................................ 1

MICROWAVE MEASUREMENT PROCEDURE ................................................................................................... 2

FOREWORD AND WARNING ............................................................................................................................... 3

PICTORIAL DIAGRAM .......................................................................................................................................... 4

POWER UNIT CIRCUIT ........................................................................................................................................ 5

PARTS LIST .......................................................................................................................................................... 6

PACKING AND ACCESSORIES ........................................................................................................................... 8

WARNING TO SERVICE PERSONNEL: Microwave ovens contain circuitry capable of producing very high voltage and

current, contact with following parts may result in a severe,

possibly fatal, electrical shock. (High Voltage Capacitor, High

Voltage Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc..)

R-820BC

Page

SHARP CORPORATION

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

Page 2

R-820BC

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(a) Do not operate or allow the oven to be operated with the door open.

(b) Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary: (1) interlock operation, (2) proper door closing, (3)

seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and

latches, (5) evidence of dropping or abuse.

(c) Before turning on microwave power for any service test or inspection within the microwave generating

compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment,

integrity, and connections.

(d) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave

generation and transmission systems shall be repaired, replaced, or adjusted by procedures described

in this manual before the oven is released to the owner.

(e) A microwave leakage check to verify compliance with the Federal Performance Standard should be

performed on each oven prior to release to the owner.

BEFORE SERVICING

Before servicing an operative unit, perform a microwave emission check as per the Microwave

Measurement Procedure outlined in this service manual.

If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS

CORPORATION immediately @1-800-237-4277.

If the unit operates with the door open, service person should 1) tell the user not to operate the oven

and 2) contact SHARP ELECTRONICS CORPORATION and Food and Drug Administration's

Center for Devices and Radiological Health immediately.

Service personnel should inform SHARP ELECTRONICS CORPORATION of any certified unit found

with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit

until the oven has been brought into compliance.

Page 3

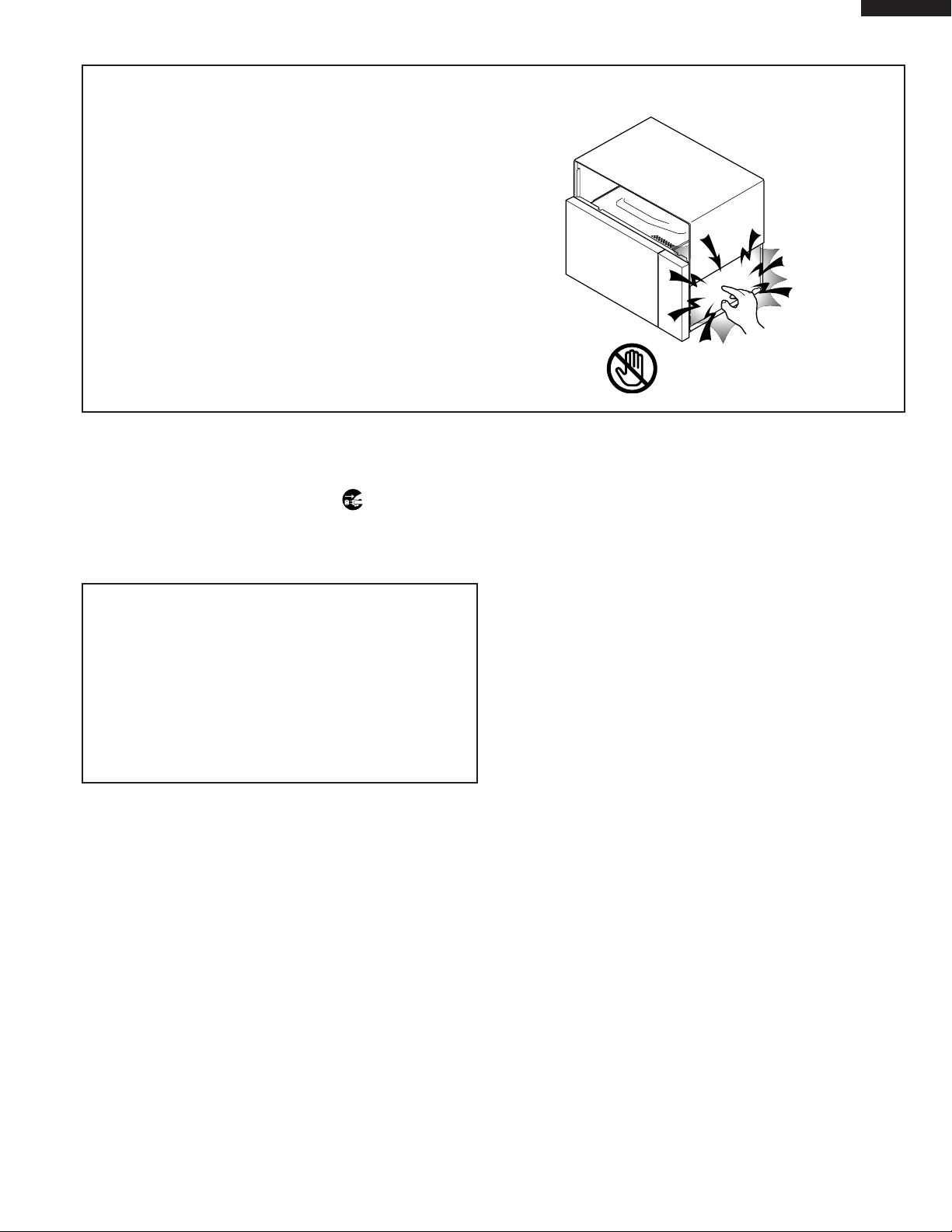

WARNING TO SERVICE PERSONNEL

Don't Touch !

Danger High Voltage

Microwave ovens contain circuitry capable of producing very high voltage and current, contact with

following parts

fatal, electrical shock.

(Example)

High Voltage Capacitor, High Voltage Power Trans-

former, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc..

Read the Service Manual carefully and follow all

instructions.

may result in a severe, possibly

R-820BC

Before Servicing

1. Disconnect the power supply cord, and then remove

outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

WARNING:RISK OF ELECTRIC SHOCK.

DISCHARGE THE HIGH-VOLTAGE

CAPACITOR BEFORE SERVICING.

The high-voltage capacitor remains charged about 60

seconds after the oven has been switched off. Wait for 60

seconds and then short-circuit the connection of the highvoltage capacitor (that is the connecting lead of the highvoltage rectifier) against the chassis with the use of an

insulated screwdriver.

Whenever troubleshooting is performed the power supply

must be disconnected. It may in, some cases, be necessary

to connect the power supply after the outer case has been

removed, in this event,

1. Disconnect the power supply cord, and then remove

outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Disconnect the leads to the primary of the power

transformer.

5. Ensure that the leads remain isolated from other

components and oven chassis by using insulation tape.

6. After that procedure, reconnect the power supply cord.

When the testing is completed,

1. Disconnect the power supply cord, and then remove

outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Reconnect the leads to the primary of the power

transformer.

5. Reinstall the outer case (cabinet).

6. Reconnect the power supply cord after the outer case is

installed.

7. Run the oven and check all functions.

After repairing

1. Reconnect all leads removed from components during

testing.

2. Reinstall the outer case (cabinet).

3. Reconnect the power supply cord after the outer case is

installed.

4. Run the oven and check all functions.

Microwave ovens should not be run empty. To test for the

presence of microwave energy within a cavity, place a cup

of cold water on the oven turntable, close the door and set

the power to HIGH and set the microwave timer for two (2)

minutes. When the two minutes has elapsed (timer at zero)

carefully check that the water is now hot. If the water

remains cold carry out Before Servicing procedure and reexamine the connections to the component being tested.

When all service work is completed and the oven is fully

assembled, the microwave power output should be checked

and microwave leakage test should be carried out.

1

Page 4

R-820BC

MICROWAVE MEASUREMENT PROCEDURE

A. Requirements:

1) Microwave leakage limit (Power density limit): The power density of microwave radiation emitted by a microwave oven

should not exceed 1mW/cm2 at any point 5cm or more from the external surface of the oven, measured prior to acquisition

by a purchaser, and thereafter (through the useful life of the oven), 5 mW/cm2 at any point 5cm or more from the external

surface of the oven.

2) Safety interlock switches Primary interlock relay and door sensing switch shall prevent microwave radiation emission in

excess of the requirement as above mentioned, secondary interlock switch shall prevent microwave radiation emission

in excess of 5 mW/cm

B. Preparation for testing:

Before beginning the actual measurement of leakage, proceed as follows:

1) Make sure that the actual instrument is operating normally as specified in its instruction booklet.

Important:

Survey instruments that comply with the requirement for instrumentation as prescribed by the performance standard

for microwave ovens, 21 CFR 1030.10(c)(3)(i), must be used for testing.

2) Place the oven tray in the oven cavity.

3) Place the load of 275±15 ml (9.8 oz) of tap water initially at 20±5˚C (68˚F) in the center of the oven cavity.

The water container shall be a low form of 600 ml (20 oz) beaker with an inside diameter of approx. 8.5 cm (3-1/2 in.)

and made of an electrically nonconductive material such as glass or plastic.

The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage

is measured accurately.

4) Set the cooking control on Full Power Cooking Mode

5) Close the door and select a cook cycle of several minutes. If the water begins to boil before the survey is completed,

replace it with 275 ml of cool water.

2

at any point 5cm or more from the external surface of the oven.

C. Leakage test:

Closed-door leakage test (microwave measurement)

1) Grasp the probe of the survey instrument and hold it perpendicular to the gap between the door and the body of the oven.

2) Move the probe slowly, not faster than 1 in./sec. (2.5 cm/sec.) along the gap, watching for the maximum indication on

the meter.

3) Check for leakage at the door screen, sheet metal seams and other accessible positions where the continuity of the metal

has been breached (eg., around the switches, indicator, and vents).

While testing for leakage around the door pull the door away from the front of the oven as far as is permitted by the closed

latch assembly.

4) Measure carefully at the point of highest leakage and make sure that the highest leakage is no greater than 4mW/cm2,

and that the secondary interlock switch does turn the oven OFF before any door movement.

NOTE: After servicing, record data on service invoice and microwave leakage report.

2

Page 5

R-820BC

SERVICE MANUAL

DOUBLE GRILL

CONVECTION

MICROWAVE OVEN

R-820BC

FOREWORD

This Manual has been prepared to provide Sharp Electronics Corp. Service Personnel with Operation and Service

Information for the SHARP MICROWAVE OVEN, R-820BC.

The model R-820BC is quite similar to base model R-820BW (Refer No. is S5812R820BPW/).

It is recommended that service personnel carefully study the entire text of this manual and the based model's manual so that

they will be qualified to render satisfactory customer service.

Check the interlock switches and the door seal carefully. Special attention should be given to avoid electrical shock and

microwave radiation hazard.

WARNING

Never operate the oven until the following points are ensured.

(A) The door is tightly closed.

(B) The door brackets and hinges are not defective.

(C) The door packing is not damaged.

(D) The door is not deformed or warped.

(E) There is no other visible damage with the oven.

Servicing and repair work must be carried out only by trained service personnel.

DANGER

Certain initial parts are intentionally not grounded and present a risk of electrical shock only during servicing.

Service personnel - Do not contact the following parts while the appliance is energized;

High Voltage Capacitor, Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage

Harness;

If provided, Vent Hood, Fan assembly, Cooling Fan Motor.

All the parts marked “*” on parts list are used at voltages more than 250V.

Removal of the outer wrap gives access to voltage above 250V.

All the parts marked “∆” on parts list may cause undue microwave exposure, by themselves, or when they are damaged,

loosened or removed.

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH,

NEW JERSEY 07430-2135

3

Page 6

H

1

2

CN-G

CN-C

CN-C

3

4

CONTROL PANEL

BLK

RY3

SP1

2

RY6

ORG

BRN

45

RED

RY4

RED

ORG

PRIMARY

RY2

INTERLOCK

RELAY

T1

CN-A

15

ORG

ORG

BRN

6

G

CN-D

3

1

CN-B

RY1

RY5

CN-D

3

2

1 BLK

CN-B

2

GRY

1

GRN

BRN

BLK

ORG

CN-A

1

GRY

2

3

ORG

4

5

RED

BLK

F

GRILL HEATER

DOOR SENSING SWITCH

N.O.

GRY

GRN

COM.

MONITOR

SWITCH

N.C.

RED

WHT

WHT

COM

SECONDARY

INTERLOCK

SWITCH

COM.

N.O.

GRY

WHT

WHT

WHT

E

FUSE &

HOLDER

BLK

BLK

GRY

WHT

BLK

D

THERMISTOR

NOTE:

Hot (RED) wire must be

connected to the terminal

with blue mark on the

oven light socket.

BOTTOM HEATER

WHT

TURNTABLE

MOTOR

BLK

THERMAL

CUT-OUT

(OVEN)

OVEN LAMP

& SOCKET

WHT

WHT

BLK

BLUE MARK

RED

WHT

RED

C

ORG

EARTH

BLK

WHT

GRY

RED

BRN

GRN

HOT

BLK

WHT

WHT

CONVECTION

MOTOR

POWER

TRANSFORMER

B

NOTE:

The neutral (WHT) wire must be

connected to the terminal with "N"

mark on the power supply cord.

POWER SUPPLY

CORD

A

NEUTRAL

WHT

WHT

WHT

THERMAL

CUT-OUT

125

°C(MAG.)

WHT

WHT

ORG

FAN MOTOR

RED

WHT

HIGH VOLTAGE COMPONENTS

MAGNETRON

H.V.WIRE A

H.V.

RECTIFIER

H.V. WIRE B

H.V.

CAPACITOR

R-820BC

1

2

3

45

6

Figure S-1. Pictorial Diagram

H

G

F

E

D

C

B

A

Page 7

R-820BC

1

A

2

3

R4 27

AC120V

B

60Hz

A 1

VRS1

4

10G471K

1

d

ab

T1

D1-4

1N4002

8

D3

6

D4

D1

D2

D5

+

–

C1 0.1µ/50v

(J1)

C

c

45

Q2 2SB1238

C10

D6

R5 4.7k

C 2

+

–

C2 470µ/50v

R2 510 1/2w

C3 0.1µ/50v

C4 10µ/35v

R3 510 1/2w

SP1

C 3

C 1

C 9

C 4

LED

GND

VC

VA

VR

INT

6

A

B

C

RY5

BUZZER

C 5

C15

FAN MOTOR

FAN MOTOR

A 3

D12D11

R6 3.3k

RY1

D

CONVECTION

MOTOR

OVEN LAMP

TURNTABLE

MOTOR

E

F

BOTTOM

HEATER

TOP

HEATER

A 5

N.O.

COM

N.O.

COM

N.O.

COM

N.O.

RY6

RY4

RY3

RY2

MICRO

COM

D7D10D9D8

Q3

KRC243M

+

–

C5

10µ/35v

C16

C 6

C14

C 8

C11

C 7

C17

C13

C12

CONVECTION

MOTOR

OVEN LAMP

TURNTABLE

MOTOR

BOTTOM

HEATER

TOP

HEATER

N.C.

MICRO

OVEN

THERMISTOR

N.C.

DOOR

SWITCH

D

E

F

B 2 B 1D 3 D 1

G

OVEN THERMISTOR

DOOR SWITCH

G

NOTE : IF NOT SPECIFIED, 1/4w ± 5%

: IF NOT SPECIFIED, 1SS270A

H

H

Figure S-2. Power Unit Circuit

1

2

3

45

6

5

Page 8

R-820BC

PARTS LIST

Note: The parts marked “∆” may cause undue microwave exposure.

The parts marked “*” are used in voltage more than 250V.

REF. NO. PART NO. DESCRIPTION Q'TY CODE

ELECTRIC PARTS

1- 1 QSW-MA110WRE0 Secondary interlock switch / door sensing switch 2 AH

1- 1 QSW-MA131WRE0

1- 2 FFS-BA021WRK0

1- 3 RMOTDA140WRE0 Turntable motor 1 AV

1- 3 RMOTDA231WRE0 Turntable motor (Interchangeable) 1 AR

1- 3 RMOTDA188WRE0 Turntable motor (Interchangeable) 1 AS

1- 4 FH-DZA025WRK0 High voltage rectifier assembly 1 AN

*

1- 5 RC-QZA173WRE0 High voltage capacitor (Interchangeable) 1 AX

*

1- 5 RC-QZA211WRE0 High voltage capacitor 1 AV

*

1- 6 RMOTEA370WRE0 Fan motor 1 AX

1- 7 QFSHDA009WRE0 Fuse holder 1 AG

1- 7 QFSHDA010WRE0 Fuse holder (Interchangeable) 1 AD

1- 8 FACCDA074WRE0 Power supply cord 1 AW

1- 9 FH-HZA063WRE0 Thremistor 1 AP

1-10 RMOTEA372WRE0 Convection motor 1 AX

1-11 QTANNA017WRW0 Short terminal 1 AD

1-12 RHET-A223WRE0 Grill heater (Top heater) 2 AV

1-13 RHET-A209WRE0 Bottom heater 1 BA

1-14 RLMPTA030WRE0 Oven lamp 1 AE

1-15 QSOCLA021WRE0 Oven lamp socket 1 AG

1-16 RTHM-A109WRE0 Thermal cut-out 170 deg. 1 AM

1-17 RTHM-A078WRE0 Thermal cut-out 125 deg. 1 AK

1-18 RTRN-A568WRE0 Power transformer 1 BP

*

∆

1-19 RV-MZA222WRE0 Magnetron 1 BN

*

∆

1-19 RV-MZA267WRE0 Magnetron (Interchangeable) 1 BL

*

2- 1 GCABDA097WRW0 Back plate 1 AW

2- 2 GCABUA886WRPZ Outer case cabinet 1 BE

2- 3 GDAI-A305WRW0 Base plate 1 AX

2- 4 GLEGPA074WRE0 Leg 2 AC

3- 1 DPWBFB795WRK0 Power unit 1 BD

3- 1A QCNCMA234DRE0 3-pin connector (CN-A) 1 AC

3- 1B QCNCMA275DRE0 2-pin connector (CN-B) 1 AB

3- 1C FW-VZA238DRE0 9pin wire harness (WH-1, WH-2) 2 AK

3- 1D QCNCMA410DRE0 2-pin connector (CN-D) 1 AB

C1 RC-KZA087DRE0 Capacitor 0.1 uF 50V 1 AA

C2 VCEAB31HW477M Capacitor 470 uF 50V 1 AE

C3 RC-KZA087DRE0 Capacitor 0.1 uF 50V 1 AA

C4-5 VCEAB31VW106M Capacitor 10 uF 35V 2 AA

D1-4 RH-DZA006PRE0 Diode (1N4002) 4 AD

D5-7 VHD1SS270A/-1 Diode (1SS270A) 3 AA

D8-12 VHD1SS270A/-1 Diode (1SS270A) 5 AA

Q2 VS2SB1238//-3 Transistor (2SB1238) 1 AA

Q3 VSKRC243M//-3 Transistor (KRC243M) 1 AB

R2-3 VRD-B12HF511J Resistor 510 ohm 1/2W 2 AB

R4 VRD-B12EF270J Resistor 27 ohm 1/4W 1 AB

R5 VRD-B12EF472J Resistor 4.7k ohm 1/4W 1 AA

R6 VRD-B12EF332J Resistor 3.3k ohm 1/4W 1 AA

RY1 RRLY-A080DRE0 Relay (OJ-SH-124LM) 1 AG

RY2-4 RRLY-A076DRE0 Relay (OMIF-S-124LM) 3 AK

RY5 RRLY-A080DRE0 Relay (OJ-SH-124LM) 1 AG

RY6 RRLY-A076DRE0 Relay (OMIF-S-124LM) 1 AK

SP1 RALM-A014DRE0 Buzzer (PKM22EPT-THAI) 1 AG

T1 RTRNPA124DRE0 Transformer 1 AQ

VRS1 RH-VZA032DRE0 Varistor (10G471K) 1 AE

3- 2 DPWBFB794WRK0 CPU unit 1 BC

3- 3 DPNLCB893WRKZ Control panel frame with key unit 1 BB

3- 3-1 JBTN-B267WRTZ Open button 1 AN

3- 3-2 MSPRCA050WRE0 Open button spring 1 AB

3- 3-3 FUNTKB149WREZ Key unit 1 AX

3- 3-4 TCAUAA076WRR0 User caution label 1 AB

3- 4 LHLD-A185WRF0 LCD holder 1 AL

3- 5 PSHEPA626WRE0 LED sheet 1 AF

3- 6 ************* This user caution label has been changed to 3-3-4.

Secondary interlock switch / door sensing switch (Interchangeable)

Monitor fuse and monitor switch (V-16G-2C25(R)) assembly

CABINET PARTS

CONTROL PANEL PARTS

2AG

1AL

6

Page 9

REF. NO. PART NO. DESCRIPTION Q'TY CODE

3- 7 XEPSD30P08XS0 Screw; 3mm x 8mm 4 AA

OVEN PARTS

4- 1 ************* Oven cavity (Not a replaceable part) 1 --

∆

4- 2 PHOK-A106WRF0 Latch hook 1 AL

∆

4- 3 FDUC-A337WRK0 Air duct assembly 1 BH

4- 4 PCOVPA340WRW0 Sub back plate 1 AQ

4- 5 LANGQA478WRP0 Turntable motor angle 1 AP

4- 6 MSPRTA186WRE0 Plate spring 1 AE

4- 7 NCPL-A051WRE0 Turntable motor shaft 1 AN

4- 8 PSPA-A109WRE0 Spacer 1 AB

4- 9 LBNDKA136WRP0 HV capacitor holder 1 AQ

4-10 NFANJA041WRE0 Fan blade 1 AF

4-11 PDUC-A697WRF0 Fan duct 1 AM

4-12 GCOVHA388WRW0 Bottom heater cover 1 AF

4-13 GLEGPA071WRF0 Leg 1 AG

4-14 LANGFA191WRW0 Chassis support 1 AN

4-15 LANGQA489WRP0 Thermistor angle 1 AW

4-16 LFLG-A030WREZ Bearing 1 AM

4-17 MLEVPA226WRF0 Switch lever 1 AF

4-18 MSPR-A004WRE0 Heat seal spring 2 AF

4-19 PCOV-A011WRP0 Bottom heater angle 2 AM

4-20 PCOVPA339WRE0 Waveguide cover 1 AF

4-21 PCUSGA385WRP0 Cushion 1 AH

4-22 PCUSUA190WRP0 Cushion 1 AC

4-23 PCUSUA191WRP0 Cushion 1 AC

4-24 PDUC-A691WRF0 Air intake duct 1 AG

4-25 PDUC-A692WRP0 Exhaust duct 1 AS

4-26 PDUC-A784WRWZ Air guide 1 AP

4-27 PGLSPA518WRE0 Light glass 1 AZ

4-28 PPACGA050WRE0 Cushion 1 AE

4-29 PREFHA061WRW0 Reflector 1 BE

4-30 PSHEPA487WRE0 Heater film 1 AA

4-31 PSKR-A331WRP0 Air separate angle 1 AY

4-32 MSPRCA113WRE0 H-spring 2 AC

4-33 PCUSGA420WRP0 Cushion 1 AE

4-34 NFANMA047WRP0 Convection fan 1 AX

4-35 NFANMA048WRP0 Cooling fan 1 AX

4-36 PCUSUA499WRP0 Cushion 1 AC

4-37 PDUC-A707WRW0 Convection duct 1 AR

4-38 PFPF-A210WRE0 Thermal insulation 1 AM

4-39 PPIPFA030WRE0 Pipe 1 AK

4-40 PSKR-A339WRP0 Convection air angle 2 AX

4-41 PSKR-A345WRW0 Convection motor angle A 1 AU

4-42 PSKR-A346WRW0 Convection motor angle B 1 AR

4-43 PSLDHA140WRW0 Convection thermal cover 1 AQ

4-44 PCUSGA389WRP0 Cushion 1 AG

DOOR PARTS

∆

5- 1 DDORFA857WRK0 Door panel assembly 1 BB

∆

5- 2 GWAKPA948WRRZ Door frame 1 AZ

∆

5- 3 LSTPPA176WRF0 Latch head 1 AN

5- 4 LSTPPA177WRF0 Glass stopper 1 AF

5- 5 MSPRTA187WRE0 Latch spring 1 AC

5- 6 PGLSPA513WRE0 Front door glass 1 AV

5- 7 ************* These screws have been changed to 5-8. 0

5- 8 XCPSD40P08000 Screw : 4mm x 8mm 6 AA

5- 9 GCOVHA387WRF0 Choke cover 1 AS

MISCELLANEOUS

6- 1 FAMI-A104WRM0 Rack 1 AQ

6- 2 TCAUAA145WRR0 Earth caution 2 AG

6- 3 FSRAHA063WRYZ Turntable support 1 AK

6- 4 NTNT-A097WRE0 Turntable 1 BB

6- 5 TCAUAA200WRR0 Monitor caution 1 AB

6- 6 TINSEB034WRRZ Instruction book 1 AM

6- 7 FW-VZB045WRE0 Switch harness 1 AG

6- 8 FW-VZB872WREZ Main wire harness 1 BB

6- 9 QW-QZA213WRE0 High voltage wire B 1 AF

*

6-10 LHLDWA011WRE0 Purse lock M 1 AB

6-11 TCAUAA201WRR0 DHHS caution label 1 AC

6-12 TCAUAA240WRR0 Screw caution 1 AC

6-13 TLABMA978WRRZ Menu label 1 AL

R-820BC

7

Page 10

R-820BC

REF. NO. PART NO. DESCRIPTION Q'TY CODE

6-14 TLABNB032WRRZ Touch guide 1 AK

SCREWS,NUTS AND WASHERS

7- 1 XFPSD40P08K00 Screw : 4mm x 8mm 13 AA

7- 2 XEPSD40P25000 Screw : 4mm x 25mm 2 AA

7- 3 LX-EZA042WRE0 Special screw 2 AB

7- 4 LX-NZ0061WRE0 Flange nut 4 AA

7- 5 XBPWW30P05K00 Screw : 3mm x 5mm 2 AA

7- 6 XCTWW40P08000 Screw : 4mm x 8mm 8 AB

7- 7 XHPSD30P06000 Screw : 3mm x 6mm 1 AA

7- 8 XHTSD40P08RV0 Screw : 4mm x 8mm 3 AA

7- 9 XOTSD40P12RV0 Screw : 4mm x 12mm 13 AA

7-10 XOTSD40P12000 Screw : 4mm x 12mm 10 AA

7-11 ************* These line head screws have been changed to 7-9. 0 -7-12 XOTSF40P08000 Screw : 4mm x 8mm 1 AA

7-13 XBTSD40P05000 Screw : 4mm x 5mm 2 AA

7-14 XNEUW40-32000 Nut : 4mm x 3.2mm 1 AA

7-15 XRESE40-06000 Ring : 4mm x 0.6mm 1 AA

7-16 XWHUW40-08000 Washer : 4mm x 0.8mm 1 AA

7-17 XWHUW48-08120 Washer : 4.8mm x 0.8mm 1 AA

7-18 XWSUW40-10000 Washer : 4mm x 1.0mm 1 AA

7-19 LX-CZA070WRE0 Special screw (Torx tamper proof screw) 2 AC

7-20 XCPSD40P08000 Screw : 4mm x 8mm 1 AA

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO. 3. PART NO. 4. DESCRIPTION

Order Parts from the authorized SHARP parts Distributor for your area.

Defective parts requiring return should be returned as indicated in the Service Policy.

PACKING AND ACCESSORIES

TRAY HOLDER

(SPADFA424WRE0)

TURNTABLE TRAY

RACK

LAMP CAUTION

DOOR PROTECTION SHEET

(SPADPA204WRE0)

TOP PAD ASSEMBLY

(FPADBA381WRK0)

WRAP COVER

(SSAKHA034WRE0)

PLASTIC SHEET

(SPADPA616WREZ)

CABINET COVER

(SPAKHA009WRE0)

TOUCH GUIDE

INSTRUCTION BOOK

TURNTABLE SUPPORT

TRAY PAD

(SPADPA577WRE0)

FOAM SHEET

(SPAKHA012WREZ)

Not Replaceable Items.

8

BOTTOM PAD ASSEMBLY

(FPADBA382WRK0)

PACKING CASE

FPAK-A505WRKZ

Page 11

R-820BC

7-9

7-8

4-4

7-9

7-19

7-19

7-5

4-1

4-30

7-10

7-10

2-1

6-2

1-10

7-15

4-25

4-33

4-29

7-10

7-12

4-32

4-19

4-18

1-11

2-2

4-23

4-26

7-4

4-3

4-39

7-13

4-36

4-41

7-13

7-10

7-10

7-2

1-6

4-11

6-12

4-10

7-1

2-4

2-4

1-19

7-1

4-9

7-9

7-9

7-1

7-9

2-3

1-5

1-13

6-13

1-4

6-4

6-3

1-1

1-7

1-1

4-17

4-28

1-18

4-12

4-13

6-2

4-19

4-18

4-32

4-16

7-4

7-9

7-1

4-6

7-1

6-7

4-2

1-2

7-3

7-10

4-24

4-21

4-14

7-14

7-18

1-17

7-8

7-6

x3

7-16

4-34

4-40

7-10

6-5

7-10

7-7

4-40

4-37

4-35

4-42

4-38

4-43

7-17

4-31

7-10

4-15

7-1

1-9

1-8

1-12

1-16

1-15

1-14

7-20

4-22

7-1

7-1

4-7

1-3

4-5

4-8

4-20

7-6

7-6

7-6

7-8

6-11

A

A

4-27

7-9

7-9

4-44

1

OVEN AND CABINET PARTS

A

B

C

D

E

F

2

3

45

6

A

B

C

D

E

F

G

G

H

H

1

2

3

9

45

6

Page 12

R-820BC

1

2

3

45

6

3-7

A

CONTROL PANEL PARTS

3-2

3-5

3-4

A

3-3

B

3-7

B

3-3-3

3-3-4

3-1

C

C

DOOR PARTS

D

3-3-2

5-8

D

5-9

3-3-1

E

5-1

E

5-6

F

G

5-2

5-4

5-8

5-3

MISCELLANEOUS

6-7

6-1

F

G

5-5

6-8

H

6-10

H

6-9

Actual wire harness may be different from illustration.

1

2

3

45

2004 SHARP CORP. (2S1.700E) Printed in U.S.A

6

10

Loading...

Loading...