Page 1

Illustration: QT-CD161

QT-CD161/141

SERVICE MANUAL

No. S5929QTCD161/

QT-CD161(S)

QT-CD141(BK)

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified should

be used.

CONTENTS

Page

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)....................................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................. 2

NAMES OF PARTS ........................................................................................................................................................... 3

REMOTE CONTROL ..........................................................................................................................................................3

DISASSEMBLY.................................................................................................................................................................. 4

REMOVING AND REINSTALLING THE MAIN PARTS..................................................................................................... 5

ADJUSTMENT ................................................................................................................................................................... 6

NOTES ON SCHEMATIC DIAGRAM ................................................................................................................................ 9

TYPES OF TRANSISTOR ................................................................................................................................................. 9

WAVEFORMS OF CD CIRCUIT...................................................................................................................................... 10

BLOCK DIAGRAM ........................................................................................................................................................... 11

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD............................................................................................. 14

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... 23

FUNCTION TABLE OF IC................................................................................................................................................ 27

PARTS GUIDE/EXPLODED VIEW

PACKING OF THE SET (FOR U.S.A. ONLY)

DIFFERENCE BETWEEN QT-CD161 AND QT-CD141

SECTION

REMOTE CONTROL

HEADPHONE SOCKET

QT-CD161

QT-CD141

SHARP CORPORATION

– 1 –

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

QT-CD161/141

g

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the chassis

and other metal parts in the audio product.

2. Inspect all protective devices such as insulating materials,

cabinet, terminal board, adjustment and compartment covers

or shields, mechanical insulators etc.

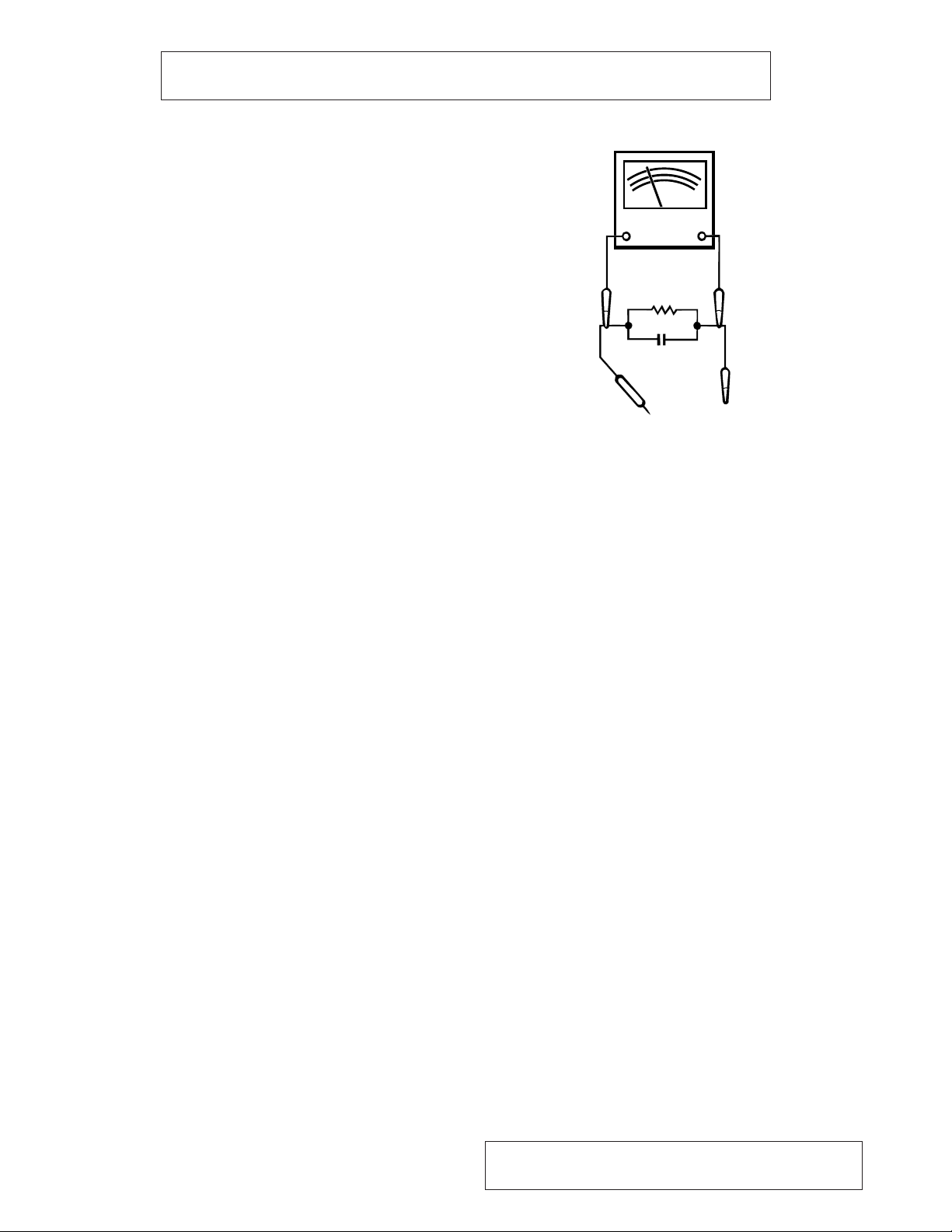

3. To be sure that no shock hazard exists, check for leakage

current in the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all exposed

metal cabinet parts and a known earth ground, such as

conduit or electrical ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher,

sensitivity to measure the AC voltage drop across the

resistor (See diagram).

* Connect the resistor connection to all exposed metal parts

having a return path to the chassis (antenna, metal cabinet,

screw heads, knobs and control shafts, escutcheon, etc.)

and measure the AC voltage drop across the resistor.

VTVM

AC SCALE

1.5k ohms

10W

0.15 µ F

TO EXPOSED

METAL PARTS

All check must be repeated with the AC line cord plug connection

reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp.

AC.) or more is excessive and indicates a potential shock

hazard which must be corrected before returning the audio

product to the owner.

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SPECIFICATIONS

● General

Power source: AC 120 V, 60 Hz

DC 12 V [ "D" size (UM/SUM-1,

R20 or HP-2) battery × 8]

DC 3 V [ "AA" size (UM/SUM-3,

R6 or HP-7) battery × 2 for tuner

memory]

Power

consumption:

Output power: FTC; 2.0 W min. RMS per channel

Speakers: 4" (10 cm) full-range speaker x 2

Output

terminals:

Dimensions: Width; 18-15/16" (480 mm)

Weight: 7.1 lbs. (3.2 kg) without batteries

● Radio

Frequency

e:

ran

Stand-by; 1.5 W

Power on; 20 W

into 8 ohms from 150 Hz to 20

kHz, with no more than 10 % total

harmonic distortion.

RMS; 2.3 W/CH

(DC operation, 10 % T.H.D.)

Headphones; 16-50 ohms

(recommended; 32 ohms)

Height; 6-1/16" (153 mm)

Depth; 10" (254 mm)

FM; 87.5 - 108 MHz

AM; 530 - 1,720 kHz

● Tape recorder

Frequency

response: 50 - 14,000 Hz (Normal tape)

Signal/noise

ratio: 50 dB

Wow and

flutter: 0.25 % (WRMS)

Motor: DC 12 V electric governor

Bias system: AC bias

Erase

system: Magnet erase

● Compact disc player

Type: Compact disc

Signal

readout:

Non-contact, 3-beam semi-conductor laser pickup

Audio

channels: 2

Quantization: 16-bit linear quantization

Filter: 4-times oversampling digital filter

D/A

converter: 1-bit D/A converter

Wow and

flutter:

Specifications for this model are subject to change without

prior notice.

Unmeasurable

(less than 0.001% W. peak)

– 2 –

Page 3

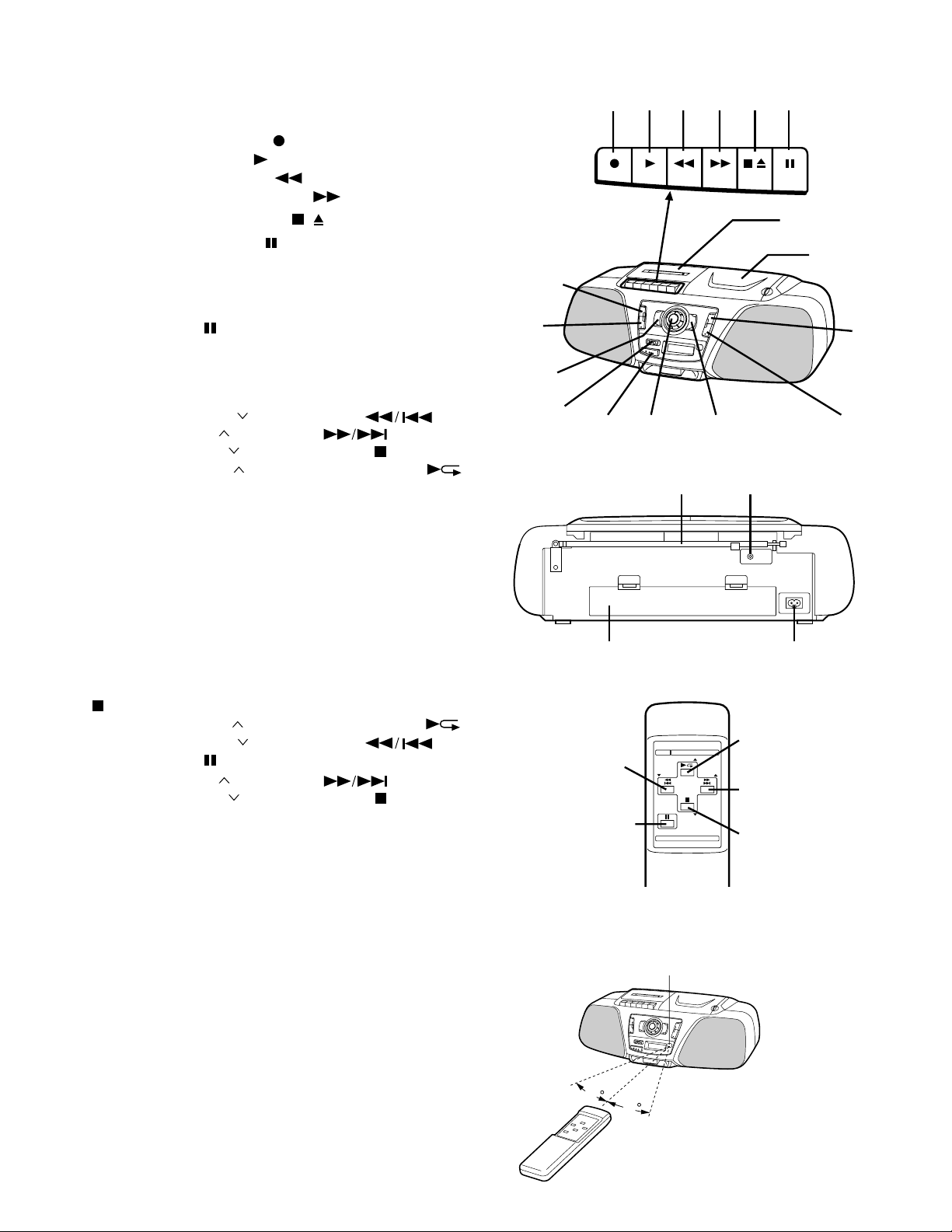

NAMES OF PARTS

QT-CD161/141

1. Cassette Compartment

2. CD Compartment

3. (TAPE) Record Button:

4. (TAPE) Play Button:

5. (TAPE) Rewind Button:

6. (TAPE) Fast Forward Button:

7. (TAPE) Stop/Eject Button:

8. (TAPE) Pause Button:

9. Band/Pause:

10. Tuner Memory

11. Volume

12. Power, On/Function Switch

13. Extra Bass Button: X-BASS

14. (CD) Track Down: /Review Button:

15. (CD) Track Up: /Cue Button:

16. (TUNER)Tuning: /(CD) Stop Button:

17. (TUNER) Tuning: /(CD) Play/Repeat Button:

18. FM Telescopic Rod Aerial

19. Headphone Socket (QT-CD161 Only)

20. Battery Compartment

21. AC Power Input Socket

/

10

16

12

334455678

1

2

9

15

171113

14

1918

Remote control (QT-CD161 ONLY)

1. (TUNER) Tuning: /(CD) Play/Repeat Button:

2. (CD) Track Down: /Review Button:

3. Band/Pause:

4. (CD) Track Up: /Cue Button:

5. (TUNER)Tuning: /(CD) Stop Button:

REMOTE CONTROL (QT-CD161 ONLY)

Notes concerning use:

● Replace the batteries if the operating distance is

reduced or if the operation becomes erratic.

● Periodically clean the transmitter LED on the

remote control and the sensor on the main unit

with a soft cloth.

● Exposing the sensor on the main unit to strong

light may interfere with operation. Change the

lighting or the direction of the unit.

● Keep the remote control away from moisture,

excessive heat, shock, and vibrations.

20 21

1

2

Sensor Remote

15

15

8" - 20'

(0.2 m - 6 m)

0,2 m - 6 m

– 3 –

Page 4

QT-CD161/141

(B2)x2

ø3x10mm

(A2)x1

(B3)x1

Front Cabinet

Top Cabinet

(B1)x1

Main PWB

(B2)x1

ø3x10mm

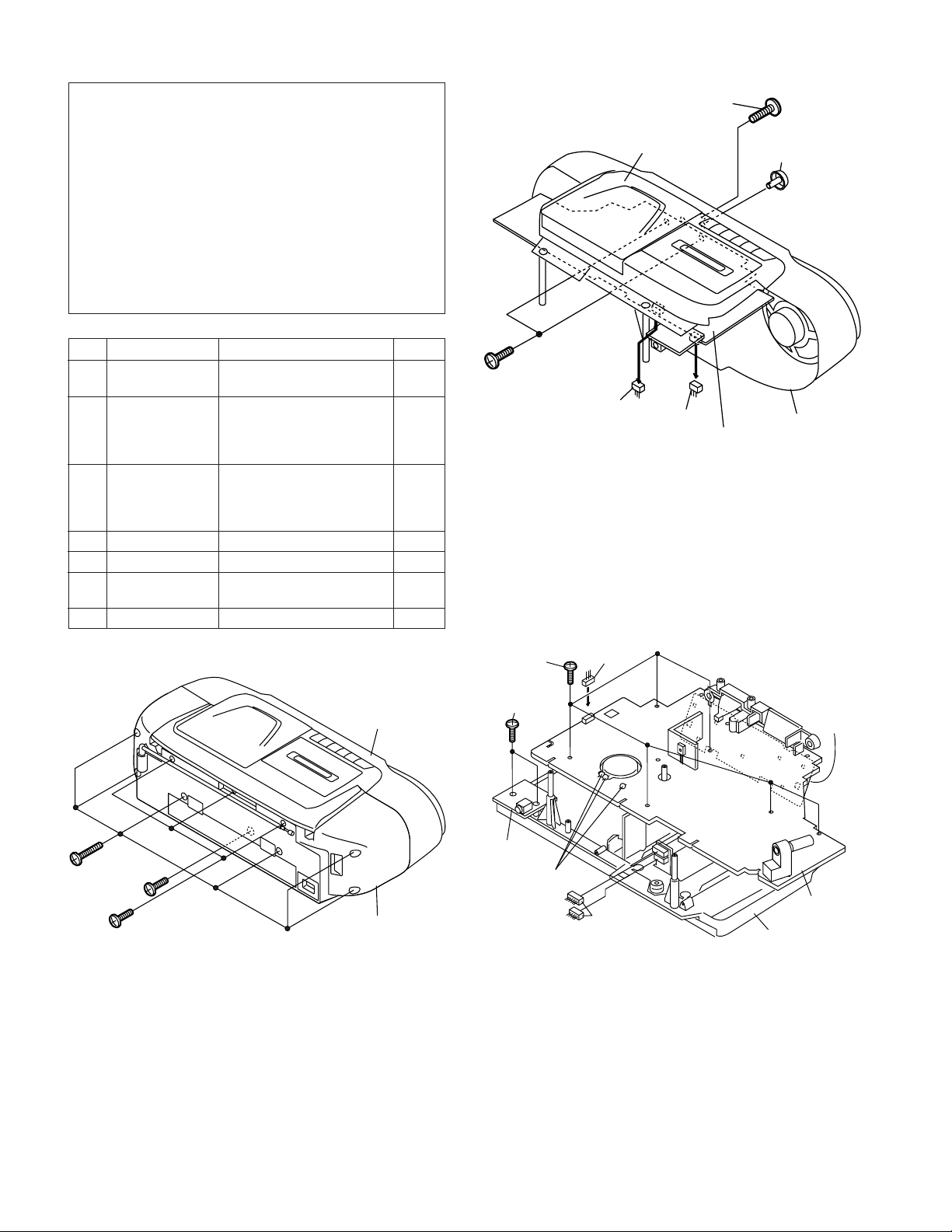

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep it safe and ensure excellent

performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

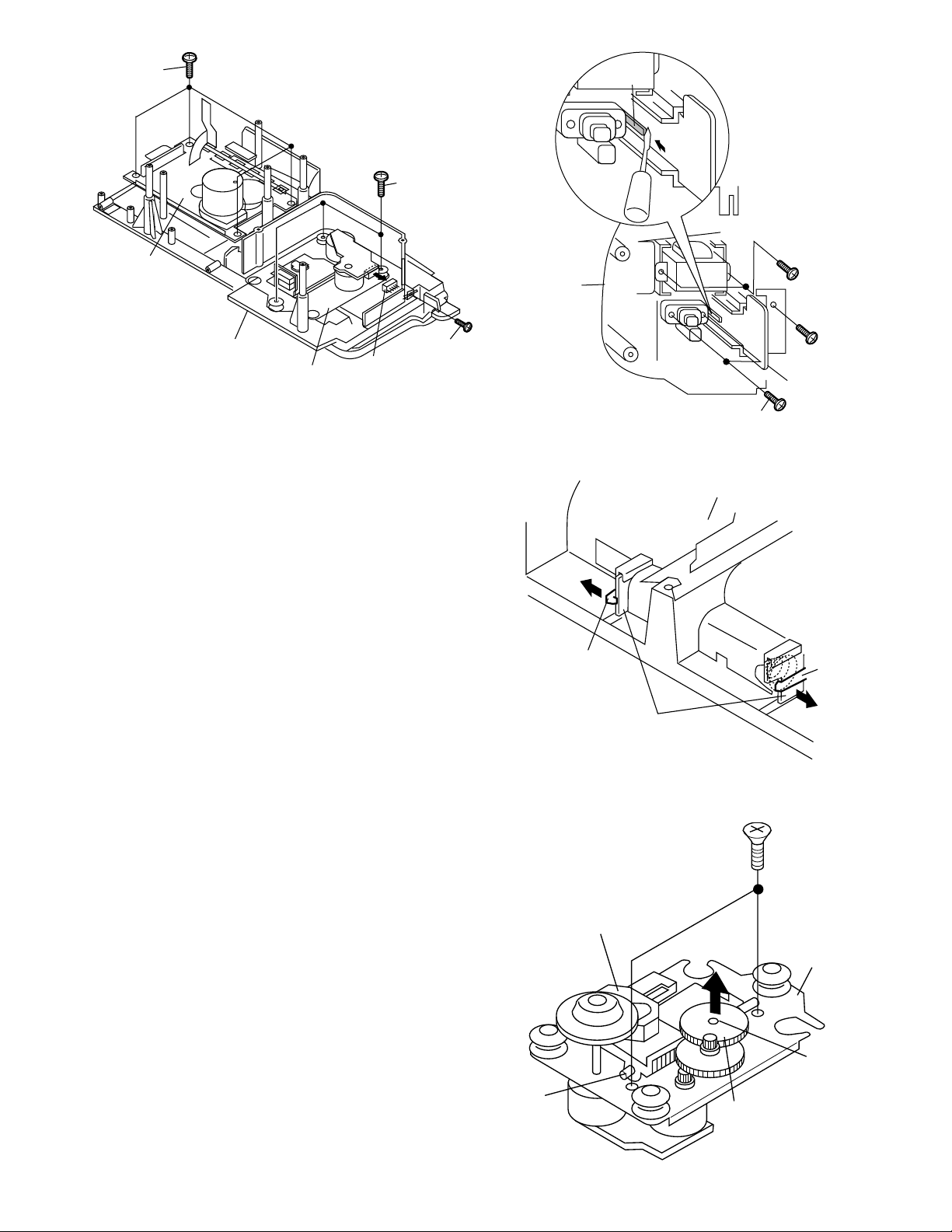

STEP REMOVAL PROCEDURE FIGURE

1 Rear Cabinet 1. Screw ................. (A1) x10 4-1

2. Socket .................. (A2) x1 4-2

2 Top Cabinet 1. Knob..................... (B1) x1 4-2

(with CD Mechanism/

Tape Mechanism/ 3. Socket .................. (B3) x1

Main PWB)

3 Main PWB/ 1. Screw ................... (C1) x9 4-3,5-1

Switch PWB/ 2. Socket .................. (C2) x4 4-3,5-1

Headphones PWB 3. Soldering .............. (C3) x3 4-3

(QT-CD161 Only)

4 Tape Mechanism 1. Screw ................... (E1) x4 5-1

5 CD Mechanism 1. Screw ................... (F1) x3 5-1

6 Terminal PWB 1. Screw ...................(G1) x5 5-2

7 Battery PWB 1. Hook.....................(H1) x2 5-3

2. Screw ................... (B2) x3

2. Hook.....................(G2) x1

Figure 4-2

(A1)x6

ø3x20mm

(A1)x1

ø3x12mm

(A1)x3

ø3x12mm

Figure 4-1

Front Cabinet

Rear Cabinet

(C1)x6

ø3x10mm

(C1)x2

ø3x10mm

Headphones

PWB

(C3)x3

(C2)x1

Switch

PWB

Main PWB

(C2)x2

Top Cabinet

Figure 4-3

– 4 –

Page 5

(E1)x4

Driver

Push

(G2)x1

ø3x10mm

QT-CD161/141

(F1)x3

ø2.5x10mm

Tape

Mechanism

Top Cabinet

Figure 5-1

CD Mechanism

(C2)x1

(C1)x1

ø2.5x8mm

Rear Cabinet

Pull

(H1)x1

(G1)x2

ø3x10mm

(G1)x1

ø3x10mm

Terminal PWB

(G1)x2

ø3x10mm

Figure 5-2

Rear Cabinet

(H1)x1

REMOVING AND REINSTALLING THE MAIN PARTS

CD MECHANISM SECTION

Perform steps 1, 2, 3 and 5 of the disassembly method to

remove the CD mechanism.

How to remove the pickup (See Fig. 5-4.)

1. Remove the screws (A1) x 2 pcs., to remove the shaft (A2)

x1 pcs.

2. Remove the stop washer (A3) x1 pcs., to remove the gear

(A4) x 1 pcs.

3. Remove the pickup.

Shaft

(A2) x1

Pickup

Battery PWB

Figure 5-3

Pull

(A1) x2

ø2.6 x6mm

CD

Mechanism

Stop

Washer

(A3) x1

Gear

(A4) x1

Figure 5-4

– 5 –

Page 6

QT-CD161/141

Pin 13 of IC2 Pin 21 of IC2

D

G

S

10 kohm

TO FREQUENCY

COUNTER

FET : 2SK19 or 2SK54

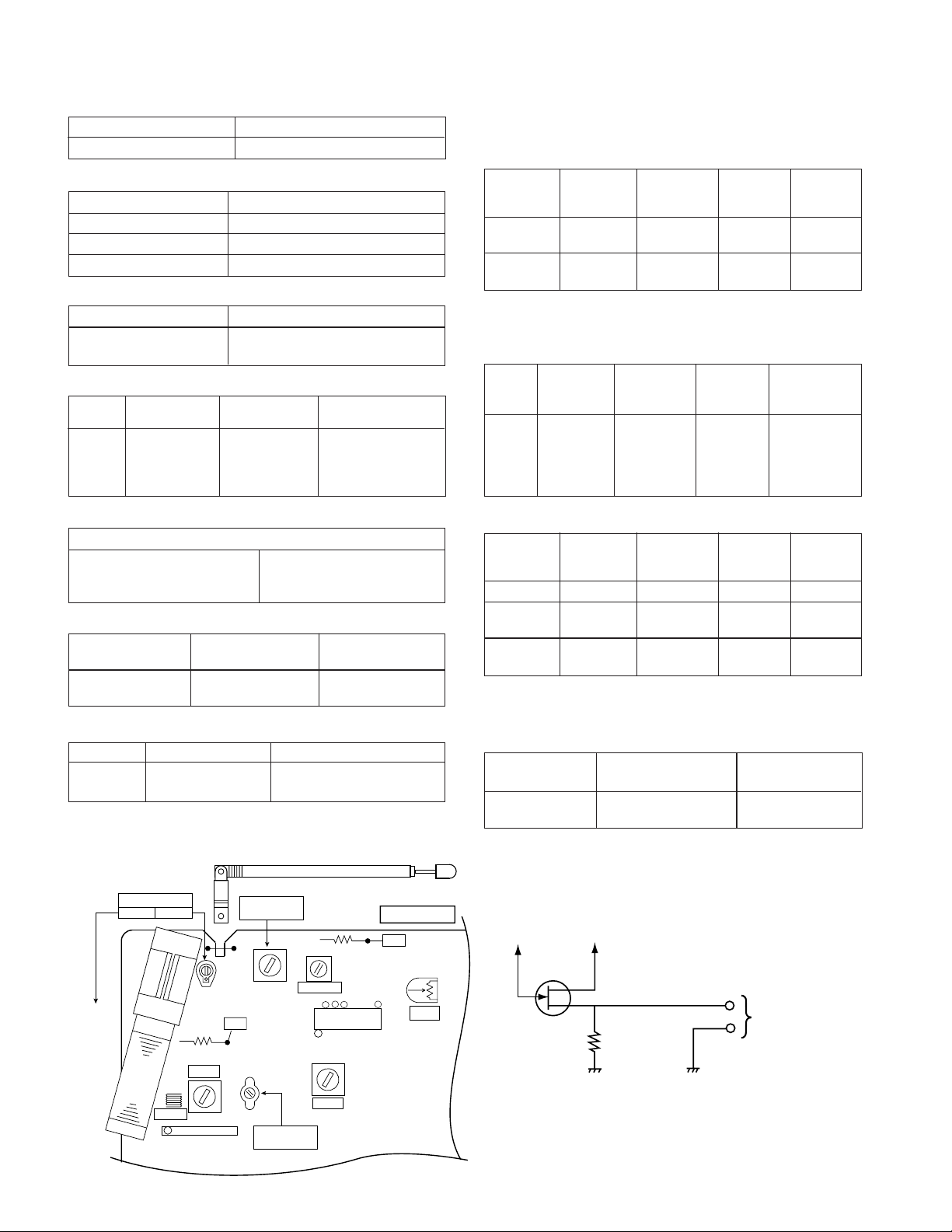

MECHANISM SECTION

• Driving Force Check

Torque Meter

PLAY: TW-2412 Over 120 g

• Torque Check

Torque Meter

Play: TW-2111 25 to 65 g.cm

Fast Forward: TW-2231 60 to 130 g.cm

Rewind: TW-2231 60 to 130 g.cm

• Head Azimuth

Torque Meter

MTT-114 Output: Speaker Terminal

• Tape Speed

Test

Tape

MTT-111 In motor 3,000 ± 90 Hz Output: Speaker

Adjusting

Point

TAPE SECTION

Position of each switch or control

Volume control Max

Function switch Tape/Power Off

X-BASS On

• Bias Oscillation

Adjustment Point

L301 82 kHz ± 6 kHz Pin 2 of CNP201

• Playback Amplifier Sensitivity Check

Test Tape

MTT-118 1.8 V ± 3 dB Speaker Terminal

AM TRACKING

fL fH

L3

AM BAR

ANTENNA

FM RF

Specified Value

Specified Value

Specified Value

(CNP201 Load resistance: 8 ohms)

Specified

Specified Value

– 6 kHz

Specified Value

TC1

TP1

R7

FM IF

L1

T1

1

IC1

Value

Instrument Connection

(Load resistance: 8 ohms)

FM ROD ANTENNA

AM BAND

COVERAGE

L4

FM DET.

L2

FM BAND

COVERAGE

Instrument

Connection

Teaminal

(CNP201 Load

resistance: 8 ohms)

Instrument

Connection

R26

T2

19

17

21

IC2

1

T3

AM IF

Figure 6-2 ADJUSTMENT POINTS

ADJUSTMENT

TUNER SECTION

fL: Low-range frequency

fH: High-renge frequency

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test Stage

Band — 87.5 MHz (fL): L2 *1

Coverage 2.0 ± 0.1 V

RF 90.0 MHz 90.0 MHz L1 *2

*1. Input: Antenna, Output: TP1

*2. Input: Antenna, Output: Speaker Terminal

• Detection

Signal generator: 10.7 MHz, FM sweep generator

IF 10.7 MHz 98.00 MHz T1(Turn Input: Pin 1 of

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage

IF 450 kHz 1,720 kHz T3 *1

Band — 530 kHz (fL): L4 *3

Coverage

Tracking 600 kHz 600 kHz (fL): L3 *2

*1. Input: Antenna, Output: Pin19 of IC2

*2. Input: Antenna, Output: Speaker Terminal

*3. Input: Input is not connected, Output: TP1

• VCO Frequency

VR1 76 kHz ± 200 Hz Pin 13, pin 21 and

Note:

After preparing the test circuit shown in Fig. 6-1, connect the

Pin 13, Pin 21 and ground of the IC2 with the test circuit, and

measure the value. At this time, apply a standard unmodulated

MAIN PWB

TP2

VR1

13

VCO

signal input and adjust the VCO.

– 6 –

Frequency

(10~30 dB)

Test

Stage

Adjusting Point

Frequency

Frequency Frequency

1,400 kHz 1,400 kHz (fH):TC1

Frequency

Display

Frequency

Display

Display

Specified

Value

Setting/

Adjusting

Parts

Setting/

Adjusting

Parts

the core of IC1

T1 fully Output: TP2

counterclockwise.

Setting/

Adjusting

Parts

1.4 ± 0.05 V

ground of IC2

Figure 6-1 VCO FREQUENCY TEST CIRCUIT

Instrument

Connection

Instrument

Connection

Instrument

Connection

Instrument

Connection

Page 7

QT-CD161/141

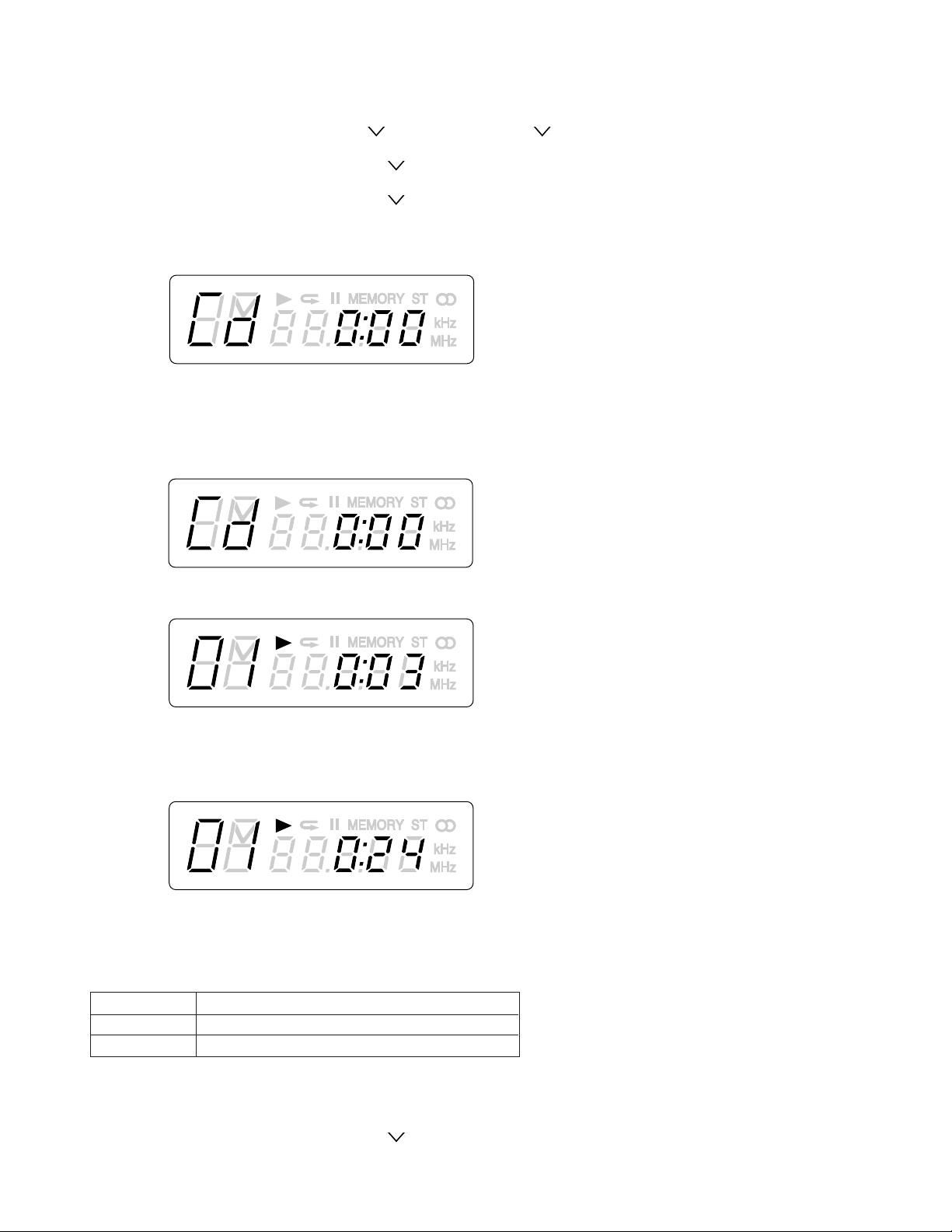

TURNING ON THE TEST MODE

The types of test mode for this microcomputer and specific test mode turning-on procedure are as follows. Only the unit key is used.

The remote control key is not valid. The power must be turned on while two keys are held down.

(1) CD test mode function

The power is turned while the (PRESET ) and STOP (TUNING ) keys are held down.

(2) Tuner test mode function

The power is turned on while the (PRESET ) and PAUSE (BAND) keys are held down.

(3) LCD test mode function

The power is turned on while the (PRESET ) and MEMORY keys are held down.

CD TEST MODE

When the CD test mode is turned on, the CD pickup is moved to the innermost periphery, and the following indication appears.

The operation of CD test mode is as follows.

Indication

(1) The CD pickup is moved with the unit UP key and DOWN key.

UP key: The pickup is slid to the outer periphery.

DOWN key: The pickup is slid to the inner periphery. However, when it reaches the innermost periphery, it does not move further

inward.

(2) When the PLAY key is pressed in stop state, the laser diode turns on if CD lid is closed.

Indication

(3) When the PLAY key is pressed in laser ON state, playback is started from the current position of pickup.

Indication

The current playback track No. and time are indicated.

(4) When the STOP key is pressed during playback, the laser goes out and playback is stopped, and the process returns to step

(1). (The pickup position does not change.)

(5) When the MEMORY key is pressed during playback, tracking servo ON/OFF is performed. (Even if the playback is stopped

in servo OFF state, the servo is turned on when the playback is restored.)

Indication

Others

While the CD lid is open (LID-SW = "H"), the test mode is turned on but the operations of step (2) and subsequent steps are not

performed. The operation of step (1) is performed.

The current pickup position and time are indicated. (When the

pickup is moved with the UP/DOWN key, the time at that point

is indicated.)

Contents of error display

Error display

Er 01

Er 02

when TOC information cannot be read normally.

When a PU-IN SW detection error occurs.

Contents of an error

TUNER TEST MODE

The tuner test mode is intended to store the measurement frequency for adjustment and inspection in the preset memory CH

without frequency adjustment in the case of tuner adjustment in the production line.

When the power is turned on while the PRESET (DOWN) key and BAND (PAUSE) key are held down together, the frequency

for adjustment measurement of destination (specified according to AREA terminal) is preset-stored in the preset memory CH. (The

frequency to be preset-stored for specific destination is as shown in the next page.)

– 7 –

Page 8

QT-CD161/141

In the tuner test mode the band is FM, and the mode is FM STEREO in case of start-up.

As with the ordinary mode, when the PRESET key is pressed for 1ch of preset memory CH, maximum CH is set. When the

PRESET key is pressed for maximum CH of preset memory CH, 1ch is set.

The BAND key is valid. As in the ordinary mode, the band/FM MONO/STEREO mode can be switched.

To exit from the tuner test mode, turn off the power to the microcomputer.

Indication

Preset frequencies for various destinations (random preset memory)

BAND (CH) U.S.A. EUROPE GENERAL 1 GENERAL 2

1 FM 87.5M FM 87.50M FM 87.50M FM 87.5M

2 FM 108.0M FM 108.00M FM 108.00M FM 108.0M

3 FM 98.0M FM 98.00M FM 98.00M FM 98.0M

4 FM 90.0M FM 90.00M FM 90.00M FM 90.0M

5 FM 106.0M FM 106.00M FM 106.00M FM 106.0M

6 AM 530K AM 522K AM 531K AM530K

7 AM1720K AM1620K AM1602K AM1620K

8 AM 990K AM 990K AM 990K AM 990K

9 AM600K AM 603K AM 603K AM 600K

10 AM 1400K AM 1404K AM 1404K AM 1404K

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Note:

The unit shown in table is Hz. K is x1000. M is x1,000,000.

The slash indicates that data are not stored in the memory.

FM is stereo mode.

The indication is the same as that of ordinary operation. However,

when the test mode is turned on, the indication shown left lights

for one second.

LCD TEST MODE

When the LCD test mode is turned on, all the segments of LCD light.

Indication

– 8 –

Page 9

NOTES ON SCHEMATIC DIAGRAM

QT-CD161/141

• Resistor:

To differentiate the units of resistors, the symbol as K and M

are used: the symbol K means 1000 ohm and the symbol M

means 1000 kohm and the resistor without any symbol is an

ohm resistor. The resistor designated "Fusible" is a fuse type

resistor

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means micro-micro-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic capacitor,

the expression “capacitance/withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• The indicated voltage in each section is the one measured by

Digital Multimeter between such a section and the chassis

with no signal given.

REF. NO DESCRIPTION POSITION

SW102 RECORD/PLAYBACK PLAYBACK

SW201 FUNCTION/POWER TAPE—TUNER— CD/

OFF—ON

SW202 X-BASS OFF—ON

SW501 TUNER UP OFF—ON

SW502 TUNER DOWN OFF—ON

SW503 BAND OFF—ON

1. Tuner

( ): AM mode

Marking except for ( ): FM mode

2. CD

( ): Play mode

Marking except for ( ): Stop state

3. Deck section

( ): Record mode

Marking except for ( ): Playback mode

Display / Control section:

( ): Active state

Marking except for ( ): CD Function mode at stop state

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

REF. NO DESCRIPTION POSITION

SW504 MEMORY OFF—ON

SW505 PRESET DOWN OFF—ON

SW506 PRESET UP OFF—ON

SW507 CD LID OPEN/CLOSE OFF—ON

SW601 TAPE MAIN OFF—ON

SW702 PICKUP IN OFF—ON

FRONT

VIEW

E C B

(S)(G)(D)

(1) (2) (3)

KTA1266 GR

KTA1273 Y

KTC3194 Y

KTC3199 GR

KTC8050 D

KRA102 M

KRA109 M

KRC104 M

KRC107 M

Figure 9 TYPES OF TRANSISTOR

– 9 –

Page 10

QT-CD161/141

PLAY

20ms

1.00 V

SPO

NORMAL DISC

TN0=01

20ms

2.00 V

CLV+

PLAY

TCD-712 (140mm)

TN0=01

50ms

1.00 V

SPO

50ms

2.00 V

CLV+

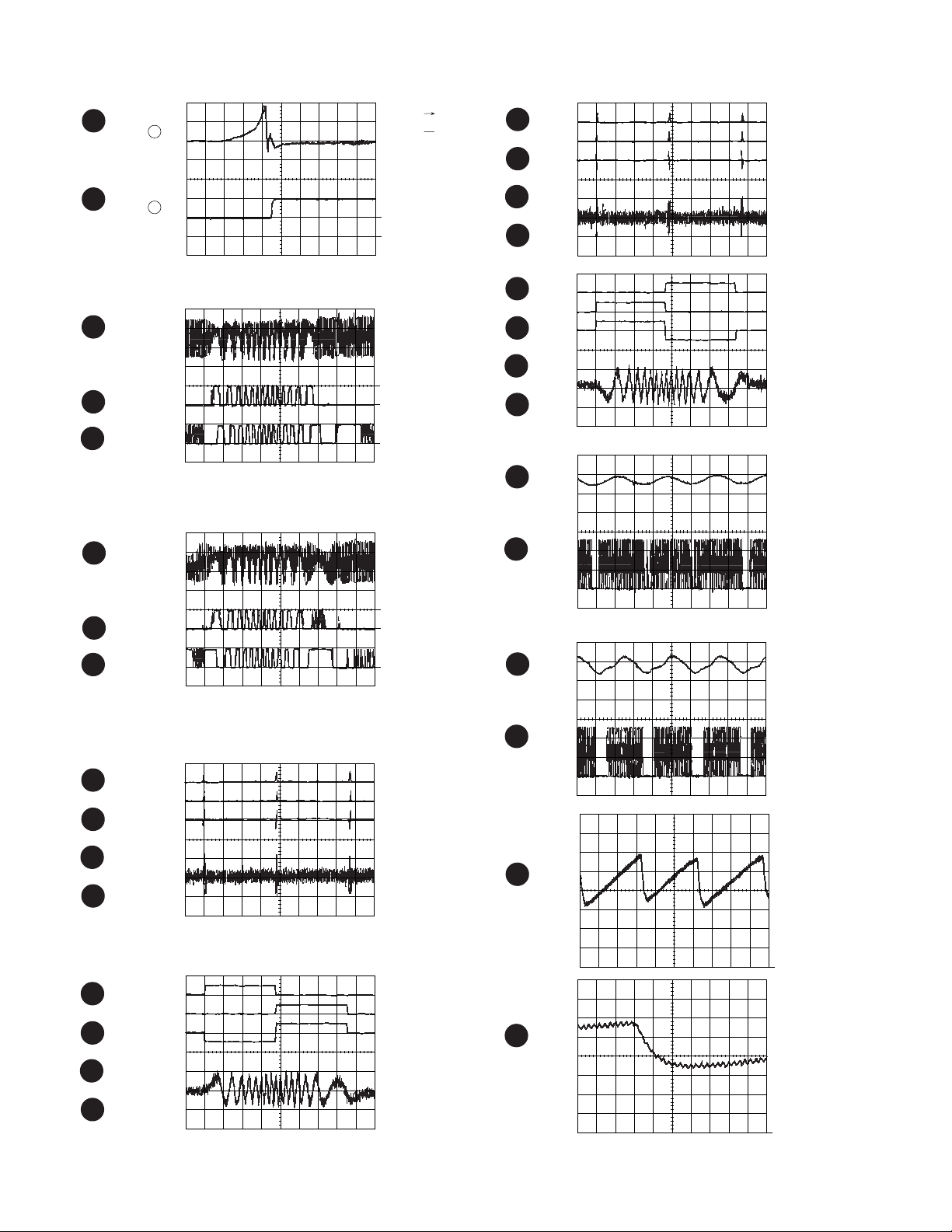

WAVEFORMS OF CD CIRCUIT

1

1

2

3

4

5

3

5ms

0.50 V

IC801 20 F.E

5ms

5.0 V

IC801 54 DRF

0.5ms

1.00 V

HF

0.5ms

5.0 V

HFL

0.5ms

5.0 V

TES

0.5ms

1.00 V

H.F

STOP PLAY

FOCUS SERCH

3

1

CUE

1

2

3

REVIEW

6

7

8

9

6

7

8

9

10

11

50ms

10.0 V

JP+

50ms

10.0 V

JP-

50ms

0.50 V

JP

50ms

1.00 V

TE

0.5ms

10.0 V

JP+

0.5ms

10.0 V

JP-

0.5ms

0.50 V

JP

0.5ms

1.00 V

TE

REVIEW

0.5ms

4

5

5.0 V

HFL

0.5ms

5.0 V

TES

1

2

3

10

11

50ms

6

7

8

9

6

7

8

9

10.0 V

JP+

50ms

10.0 V

JP-

50ms

0.50 V

JP

50ms

1.00 V

TE

0.5ms

10.0 V

JP+

0.5ms

10.0 V

JP-

0.5ms

0.50 V

JP

0.5ms

1.00 V

TE

CUE

12

12

5s

100mV

SLD

0.5s

100mV

SLD

PLAY

TCD-712

1

1

– 10 –

Page 11

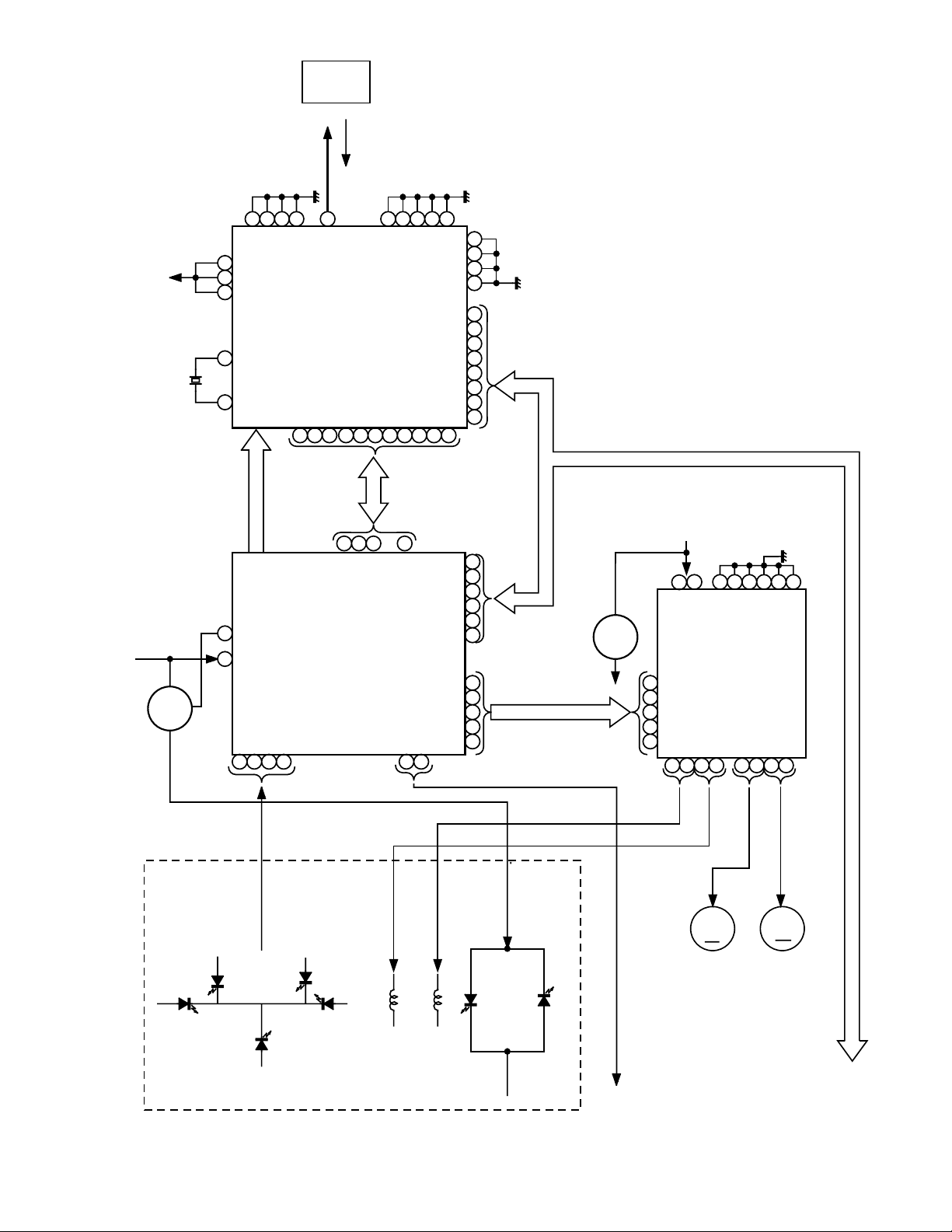

TO

MAIN

SECTION

+7.4V

(CD)

QT-CD161/141

+5V

LASER

DRIVER

+5V

Q801

XL801

16.93MHz

23

6

45

62

64

51 37

62

634364

XVDD

VDD

VVDD

LC78622E

SERVO/SIGNAL

FIN1

E

4

CONTROL

EFMO

104412

9

F

XIN

XOUT

LDD

VCC1

FIN2

123

LCHO

IC802

CLV+

CLV–

13

43

44

SLI

14

V/P

15

SLC

EFMIN

IC801

LA9240M

SERVO AMP.

46

HFL

16

CV+

3955385433

TES

TOFF

18 19

17

~

3240

JP–

SL–

31

30

32

11

8

4

2

53

56

57

58

RES. CQCK. COIN

SQOUT. RWC. WRQ

61

1

JP–

JP+

TGL

20

54

DRF

53

CE

52

DAT

51

CL

50

CLK

49

DEF

29

SLD

SLEQ

28

27

SPO

FD

16

TO

SL+

15

CL, DAT, SELIAL CONTROL

CONSTANT

VOLTAGE

Q804

REGULATOR

+5V

+7.4V

30

1

978

IC803

LA6541

FOCUS/TRACKING

3

/SPIN/SLIDE

13

29

28

18

25

DRIVER

20

26

5

21

6

22

24

102511

PICKUP UNIT

FOCUS COIL

TRACKING COIL

Figure 11 BLOCK DIAGRAM (1/3)

– 11 –

TO MAIN

SECTION

M

M701

SPIN

MOTOR

M

M702

SLIDE

MOTOR

TO MAIN

SECTION

Page 12

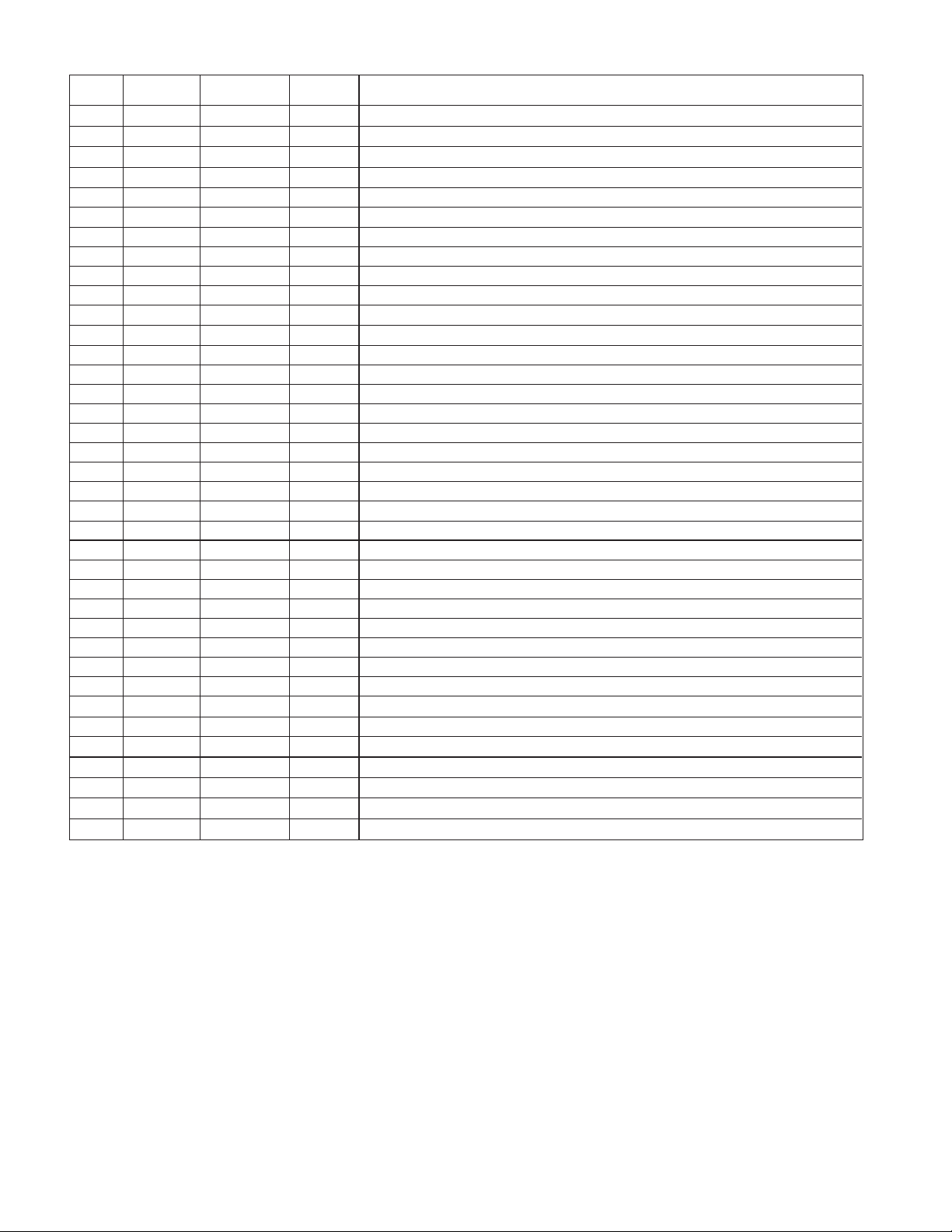

QT-CD161/141

SPEAKERS

SP501

L-CH

SP502

R-CH

SO601

AC INPUT

AC 120V

60Hz

IC202

LA4597

POWER AMP.

VOLUME

X-BASS

12

L

2

VR201

A,B

SW202

A,B

DC12V

10

8

11

5

R

6

Q201

Q202

Q251

+B

AM / FM

SELECT

FUNCTION

+B2

SW201-D

POWER /

FUNCTION

STANBY

VOLTAGE

REGULATOR

+B1

SW201-C

3

IC203

KIA7808P

1

POWER/

2

FM +B

T601

POWER

TRANSFORMER

BATTERY

TUNER

+B

RECTIFIER

D651~D654

SW601

MAIN

["D" SIZE (UM/SUM-1,

R20 or HP-2)BATTERYx8]

BACK UP

+B

DC3V

BATTERY

["AA" SIZE (UM/SUM-3,

FOR TUNER MEMORY]

R6 or HP-7)BATTERYx2

FROM TUNER

SECTION

IC2-9,10PIN

RADIO

POWER/

FUNCTION

SW201-A,B

CD/DISPLAY

SECTION

CD

FROM

TAPE

REC

REC / PB

SW102

A,F

REC

P. B

12

6

1

L

R

L

R

9

5

REC

P.B

8

AMP.

IC101

EQULIZER

REC / PB

SW102

C,E

BA331IL

P.B

L-CH

REC

SW102

REC / PB

B.D

P.B

REC / PB

HEAD

Figure 12 BLOCK DIAGRAM (2/3)

– 12 –

R-CH

MOTOR

+B1

Q351

L301

SW102-H

REC / PB

ERASE

HEAD

M601

TAPE

SW201-G

REC / PB

BIAS

OSC.

Page 13

LCD501

LCD DISPLAY

QT-CD161/141

TUNER

+B

Q501

Q502

IC502

RESET

21

20

19

18

17

16

15

14

1213

11

10

9

8

7

6

5

4 3 2 1

RESET

79

76

,

72

~~

56

13

20

19

13

X501

27

24

32

23

31

IC501

CD/TUNER CONTROL

MICROCOMPUTER

6

17

16

22

7

10

23

MONO/ST

12

13

11

14

6

5

4

3

24

RX501

SW702

PICKUP IN

TO CD

SECTION

+B

FM DET

TO MAIN

SECTION

VR1

VCO

T2

AM OSC OUT

15

9

10

16

13

18

20

22

24

MO/ST

L-CH OUT

R-CH OUT

MPX IN

MPX VCO

DET OUT

FM DET

AM RF IN

AM OSC

SW504

MEMORY

SW503

BAND

SW502

TUNER DOWN

SW501

TUNER UP

SW505

PRESET DOWN

SW506

PRESET UP

+B

TUNER

STEREO

GND

AM IF IN

AM MIX OUT

FM IF IN

SW601

MAIN

IC2

LA1805

FM /AM/IF APX.

+B

21

8

7

6

5

AM IF IN

AM IF

AM MIX OUT

2

1

CF2

AUDIO

+12V

VOLTAGE

REGULATOR

ZD1

T3

+5V

CF1

A-GND

VT

Q3

Q4

VT CONTROL

IC3

TC9216P

PLL

D GND

VT

TUNER +B

Q5

Q6

FM+B

FM RIPPLE

FILTER

IF IN

10

AM IN

11

FM IN

12

PERIDO

CLOCK

DOUT

14

VSS

13

X OUT

1

4.5MHz

FM+B

6

OF1

5

4

DATA

3

2

X IN

X1

9

L3

AM ANT.

TC1

VD3-1

RF AMP.

Q1

VD3-2

L4

AM OSC.

FM ROD

ANTENA

Figure 13 BLOCK DIAGRAM (3/3)

– 13 –

VD2

FM OSC

L2

VT

VD1

FM RF

L1

T1

FM IF

8

7

IC1

6

5

4

3

1

F1

B.P.F

TA7358AP

FM FRONT END

Page 14

QT-CD161/141

5

0

C846

2

B

MAIN PWB-A1(1/4)

A

B

C

0.1/50

D

E

C811

0.1

CD SIGNAL

C803

0.1/50

C804

0.001

R804

2.2K

R805

C807

6.8K

R806

100

R807

1K

R809

27K

R811

3.3K

R839

GND

22K

R840

22K

R802

100K

C805

0.033

C806

0.033

C809

0.047

R808

12K

R828

1K

R829

1K

C808

0.068

R803

15K

C810

180P

R813

33K

15K

R812

VREF

R842

22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

C813

E

F

TB

TE–

TE

TESI

SCI

TH

TA

TD–

TD

JP

17

0.1

R815

64

FD–

47K

18

LASER

DRIVE

Q801

KTA1266 GR

C849

0.022

C848

1/50

C840 0.33/50

61

63 62

BH1

LDS

LDD

VCC1

FIN2

1

2

FIN1

LA9241M

SERVO AMP.

15

TO

16

FD

FE–

FE

FA–

FA

19

20

22

21

C812

330P

R817

R814

10K

82K

R816

C814

1.5K

0.01

C838 0.01

C839 0.1

59

60

LF2

PH1

IC801

A GND

SP

NC

24

23

C815

0.0047

R819

39K

C835 0.1/50

C837 10/16

56

57

58

VR

REFI

SP–

SPG

26

25

C816

0.001

R820

10K

R821

R822

6.8K

1.2K

R823

55

VCC2

34

33

27

56K

C817

0.47/50

FSS

TGL

JP+

SPD

28

R824

R830

54 53

DRF

SLEQ

10K

1K

C818

48

47

52

CE

1/50

DAT

NC

TBC

29

C819

R825

51

SLD

47/16

1.2K

R831

50

CL

RFS–

RFSM

TOFF

30

C820

0.0033

1K

49

CLK

FSC

GND

SLI

SLC

CV+

CV–

SLOF

HFL

TES

SL+

SL–

31

R826

DEF

JP–

32

R827

220K

220K

R871

4.7K

48

47

46

45

44

43

42

C830

41

40

39

38

37

36

35

34

33

2.0P

C845

4.7/50

C834

0.033

C833

0.001

R833

5.6K

R832

56K

C850

0.1

R836

47K

R835

C822

220P

R810

82K

C832

27P

470

C821

1/50

R838

33K

R837

47K

C831

0.0027

D802

1N4148

R834

1K

C851

0.022

100K

R849

R8

68

R8

1.

PIN

VOLTAGE

NO.

0V

1

F

G

0V

2

1.5V

3

0V

4

2V

5

5V

6

0.3V

7

0V

8

2.5V

9

2.5V

10

0V

11

0V

12

0V

13

5V

14

0V

15

4.8V

16

5V

17

5V

18

0V

19

0V

20

2.5V

21

22

0V

PIN

NO.

IC802

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

VOLTAGE

5V

0V

0V

0V

0V

0V

0V

5V

2.5V

0V

0V

0V

5V

4.7V

2V

0V

0V

2V

4.7V

0V

5V

2.3V

PIN

NO.

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

VOLTAGE

2V

0V

0.1V

2.2V

0V

2.5V

0V

2.5V

0V

0V

0V

4.1V

4.1V

5V

0V

2.7V

2.4V

0V

0V

0V

P16 1-F

PU IN

WRQ

SQOUT

DRF

SL–

SL+

P19 8-H

RWC

CO IN

CQCK

RES

D-GND

+B 7.4V

POWER GND

L-CH

AUDIO GND

R-CH

2

3

4

5

6

7

8

9

10

11

1

+B

45

13

14

15

16

H

• The numbers 1 to 12 are waveform numbers shown in page 10.

1

2

34 5

Figure 14 SCHEMATIC DIAGRAM (1/6)

– 14 –

C887

0.022

6

+

Page 15

QT-CD161/141

R858

680

R856

1.2K

C841

0.047

C842

0.047

R857

27K

C847

0.01

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

4

6

TEST1

PDO

VVss

ISET

VVDD

FR

Vss

EMFO

EMFIN

TEST2

CLV+

CLV–

V/P

TOFF

17

R860

1K

5 9

8

0

1

2

6

6 3 6

CS

6

4.2M

TEST5

1

2

16M

DEFI

TAI

5

RES

TST11

IC802

LA78623D

SERVO/SIGNAL

CONTROL

15

HFL

16

TES

FSEQ

PCK

JP-

JP+

18

TGL

19

VDD

20

23

22

21

5

7 6 5

24

COIN

CQCK

CONT2

CONT1

25

5

5

SQOUT

48

47

NC

34

TEST4

33

CONT3

26

5 4 5

RWC

EFLG

SBSY

CONT4

27

28

C802

2

3 5

FSX

WRQ

EMPH

CONT5

29

R801

47/16

1

5

SBCK

XVSS

XOUT

XVDD

MUTER

RVDD

RCHO

RVSS

LVSS

LCHO

LVDD

MUTEL

C2F

31

30

1K

0

5

SFSY

XIN

DOUT

32

9

4

48

PW

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

TEST3

C801

0.01

LD

PD

BI802

CNS802

5

5

4

4

3

3

2

F

E

B

A

K

TR+

TR–

FO–

FO+

XL801

16.93MHz

C868

R874

100

0.0022

10K

R876

10K

R875

0.0022

C870

C869

100/10

R880

100

C890

10/16

C867

10/16

R873

100

1

1

2

3

4

5

6

7

8

BI801

2

1

1

2

3

4

5

6

7

8

CNS801

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

VR

K

5

E

4

A

3

B

2

F

1

TR–

1

TR+

2

FO+

3

FO–

4

GND

5

PD

6

VR

7

LD

8

TR–

PICKUP UNIT

IC801

PIN

NO.

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

VOLTAGE

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.2V

2.2V

0V

0V

5V

5V

4.8V

0V

5V

0V

0V

1.5V

2.4V

2.5V

2.5V

VOLTAGE

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

0V

M0N

PIN

NO.

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

LD

K

E

A

B

F

C

TR+

FO+

FO–

TR–

VOLTAGE

0V

2.5V

2.5V

0V

0V

2.4V

4.1V

4.7V

0V

0V

5V

5V

2.5V

2.5V

0.9V

0.9V

2.1V

4.2V

0V

5V

L801

0.82µH

+B +B

30

BIAS IN

IC803

LA6541

RESET

VCC

VIN4

VIN4G

VO4+

VO4–

GND

GND

GND

VO3–

VO3+

VG3

VIN3

29

28

27

26

25

24

23

22

21

20

19

18

CD

17

16

C846

330/10

Q802

KTA1273 Y

C844

330/10

L802

0.68µH

1

VCC

MUTE

2

3

VIN1

4

VG1

VO1+

5

6

VO1–

7

GND

8

GND

9

GND

10

VO2–

11

VO2+

12

VG2

13

VIN2

14

REG OUT

REG-B

15

C843

100/10

C873

0.01

TR+

TR–

FO–

FO+

SP+

SP–

SL+

SL–

PU-IN

C888

0.022

TUNER GND

6

5

4

3

2

1

BI803

CD MOTOR PWB-B

6

6

5

5

4

4

3

3

2

2

1

1

CNS803

CNP803

VOLTAGE

1

2

3

4

5

6

7

8

9

7.2V

0V

2.8V

0V

3.6V

0V

GND

GND

GND

3.2V

3.2V

0V

2.6V

5.1V

6.6V

IC803

PIN

NO.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

VOLTAGE

0V

0V

2.5V

2.6V

3.5V

2.9V

GND

GND

GND

3.2V

3.2V

0V

2.6V

0.4V

7.2V

PIN

NO.

10

11

12

13

14

15

M

M

M701

SPINDLE

MOTOR

M702

SLED

MOTOR

SW702

PICKUP IN

• NOTES ON SCHEMATIC DIAGRAM can be found on page 9.

78 9101112

Figure 15 SCHEMATIC DIAGRAM (2/6)

– 15 –

Page 16

QT-CD161/141

R

R

A

FM SIGNAL

CD SIGNAL

PLAYBACK SIGNAL

RECORD SIGNAL

B

L-CH

C

D

E

R-CH

ERASE HEAD

TUNER +B

P18 3-A,4-A

CNS101 CNP101

1 1

2 2

3 3

4 4

R P

SW102-H

R-CH

23

GND(A)

22

L-CH

21

32

D GND

28

R104

12K

R102

330

SW102-C

R

PP

R

P

SW102-E

+B

SW102-B

R

C107

(B)820P

C108

820P(B)

R

SW102-D

0.0018(B)

15K(1/4W)

R101

330

0.0018(B)

R109

270P(B)

R110

C351

0.0022

(ML)

120

C109

270P(B)

C111

330P(B)

C110

120

R103

12K

5

9

C105

R105

R107

1K

C112

330P(B)

P

R108

1K

C106

R106

15K

C115

0.018(ML)

R113

8.2K

R115

R117

3.9K

3.9K

C119

8

2.2/50

10

2

C120

47/16

C118

10/16

R118

3.9K

R353

47K(1/4W)

0.0056

R120

3.3K

C353

(ML)

R119

C113

47/16

3 1

NF1

IN1

BA3311L

REC./P.B.

EQUALIZER

IN2

NF2

11

4

C114

47/16

C116

0.018

(ML)

BIAS OSC

L301

C117

10/16

PRE AMP

IC101

OUT1

FILTER

ALC T

GND

OUT2

6

7

R116

3.9K

R114

8.2K

SW102-G

P R

R351

330

(1/4W)

C354

0.022(ML)

R352

150

(1/4W)

C352

220/10

VCC

12

R121

2.7K

C121

SW102-A

3.3K

0.01

D101

1N4148

D102

1N4148

C122

0.01(Z)

P R

D103

1N4148

C123

220/10

R125

680K

SW102-F

R P

R122

2.7K

R124

3.3K

Q351

KTC8050 D

R354

10(1/4W)

R123

3.3K

TAPE

TUNER

CD

SW201-A

TAPE

TUNER

CD

SW201-B

+B

C152

0.039

(ML)

R153

2.2K

C151

0.039(ML)

SW202-A

X-BASS

SW202-B

X-BASS

R154

2.2K

D303

1N4004

OFF ON

OFF ON

2

2

R457

R458

1.2K

1.2K

+B

C252

0.022

F

P14 2-H,P19 11-HION

R-CH

AUDIO GND

L-CH

CD +7.4V

DIGITAL GND

POWER GND

+7.4V

MUTE

FUNC(CD)

BACK UP

P19 7-A,11-H

R456

15K

16

15

14

R455

42

15K

1

13

+B

12

43

44

40

G

MAIN PWB-A1(2/4)

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 9.

1

2

34 5

Figure 16 SCHEMATIC DIAGRAM (3/6)

6

– 16 –

Page 17

QT-CD161/141

R151

22K

R152

22K

C217

0.0027

(B)

C215

0.027(ML)

R219

3.3K

R220

3.3K

C216

0.027(ML)

C218

0.0027(B)

IC101

PIN

VOLTAGE

NO.

<0V> [3.23V]

1

<0V> [0V]

2

<0.6V> [0.6V]

3

<0V> [0V]

4

<0V> [0V]

5

<0V> [0V]

6

<0V> [0V]

7

<7.43V> [7.43V]

8

<0V> [0V]

9

<7.37V> [7.37V]

10

<0.6V> [0.6V]

11

<3.3V> [3.3V]

12

< >: Recording

[ ]: Play

C228

VR201-B

20K(B)

VR201-A

20K(B)

1/50

C219

R221

0.068

1K

(ML)

R223

4.7K

R225

100K

Q202

KTC3199 GR

R224

4.7K

C220

R222

0.068

1K

IC202

PIN

VOLTAGE

NO.

0.1V

1

0V

2

11.2V

3

0V

4

11.3V

5

0V

6

0.1V

7

12V

8

10.4V

9

5.8V

10

0V

11

5.8V

12

10.4V

13

0.001(B)

Q201

KTC3199 GR

C225

220/25

C222

0.001(B)

C221

C223

100/10

C224

100/10

2

1

4

7

3

6

D201

1SS133

+

–

IC202

LA4597

POWER

AMP.

–

+

8

5

12

13

11

9

1

0

C226

0.022(Z)

C233

470/10

C229

100/10

C231

0.1

(ML)

C232

0.1

(ML)

C230

100/10

C234

470/10

C227

4700/25

HEADPHONES PWB-A2

R227

120(1/4W)

R228

120(1/4W)

CNP201

3

1

FW202

1

3

CNS201

1

1

2

2

3

3

CNP201

QT-CD141

QT-CD161

CNS201

1

1

2

2

3

3

SPEAKER

WOOFER

8OHMS

SP501

L-CH

SP502

R-CH

WOOFER

8OHMS

SPEAKER

WOOFER

8OHMS

WOOFER

8OHMS

SP501

L-CH

SP502

R-CH

D251

1N4148

D252

R252

1N4148

22K

R254

10K

R256

4.7K

+B

TAPE

TUNER

CD

SW201-C

0.047(Z)

D301

1N4148

+B

D302

1N4148

R251

10K

C302

Q251

KTA1266 GR

R255

2.2K

1.8K

R253

VOLTAGE

REGULATOR

OUT

IC203

3

KIA7808P

2

SW201-D

CD

TUNER

TAPE

IN

1

C301

1/50

R230

2.7(1/4W)

CNP602

1

2

3

TERMINAL PWB-A3

D652

1N4004

CNS602

1

2

3

C652

0.022(Z)

C653

D653

0.022(Z)

1N4004

DC12V [ ''D'' SIZE(UM/SUM-1,

R20 OR HP-2)BATTERY x 8]

DC 3V [ ''AA'' SIZE(UM/SUM-3

R6 OR HP-7)BATTERY x 2

FOR TUNER MEMORY]

BATTERY PWB-A4,5

SW601

TAPE

MAIN SW

+

M

–

M601

TAPE MOTOR

D651

D654

1N4004

IN4004

C651

0.022(Z)

C654

0.022(Z)

T601

POWER TRANSFORMER

ACSO

AC INPUT

AC120V,60Hz

SO601

78 9101112

Figure 17 SCHEMATIC DIAGRAM (4/6)

– 17 –

Page 18

QT-CD161/141

P19 8-A,P16 1-E

P16 1-E

A

B

+B

C

R37

6.8K

D

CF2

3

1

T3

+B

E

C12

0.022

F

IC1

TA7358AP

FM FRONTEND

G

F1

FB

B.P.F

C49

1/50

R38

6.8K

R36

2.2K

R35

2.2K

C32

0.022

C13

47/16

9

C9

33P(CH)

8

R4

10

7

C8

15P(CH)

6

5

4

3

2

C2

1

0.01

3

2

1

1SS133

2

AMIF

C3

4.7P(CH)

D1

10K

R39

1

C48

1/50

C45

0.022(M)

R56

47

VD1

KV1360NT

C7

0.001

FM RF

3

2

C47

1/50

C33

22/16

C31

0.022

3

1

R5

10K

FM OSC

L2

T1

22K

R70

100K

L1

D2

1SS133

Q9

KRA109 M

12

NC

11

AM/FM

R CH

10

C46

0.022(M)

L CH

9

8

TUN IND

7

DTE OUT

ST IND

6

GND

5

AM IF

4

AM

3

MIX

2

IN

FM IF

1

CF1

2

C11

22P(CH)

VD2

KV1360NT

R71

C10

FM IF

R3

33K

R2

C4

27P(CH)

TP2

VCO

FM

–M/ST

MPZ

–IN

FM DET

FM

AM RF

AM

AM

OSC

6.8K

24P

(UJ)

22(1/4W)

C6

0.01(M)

C5

0.01(M)

13

C42

3.3/50

14

15

16

C41

3.3/50

17

18

C38

0.018

(M)

19

20

+B

21

22

+B

23

24

R7

4.7K

R13

390

FM BAND

COVERAGE

C14

0.022

C16

0.022(M)

R1

(STYROL)

R29

1.2K

IC2

T2

0.0015

6.8K(B)

R25

33K

R24

R-CH

GND(A)

L-CH

21

23

22

+B

C43

R30

D3

15K

VR1

VCO

D4

1SS133

LA1805

FM/AM/IF MPX.

C40

C72

470P

0.001

C36

C34

220/10

C37

C35

0.022

+B

TP1

AM TRACKING

0.0022

3.9K

FM DET

+B

R44

180(1/4W)

1SS133

R42

4.7K

+B

0.022

R12

4.7K

R9

100K

VD3-1

KV1591A-2

fL fH

AM ANT

R43

47K

0.022

R17

10K

C17

0.047

R48

56K

C26

R45

L5

C18

0.022

TC1

R72

1K

ZD1

DZ5.1BSB

220(1/4W)

C50

0.022

R47

56K

C57

100/10

C21

0.022

CH 470µH

C27

0.022

R15

1.2K

C24

2.2/50

5P

L3

0.022

10/16

C29

KTC3199 GR

CONTROL

R11

56K

C52

C51

GND(D)

MONO/STEREO

STEREO

TUNED

24

R46

56K

29

26

25

28

X1

4.5MHz

12P(CH)

1 2 3 4

X IN

X OUT

VDD

DO 1

DO 2

16

14

15

R16

2.2K

560

C25

0.001

Q4

KTC3199 GR

Q3

Q3,Q4:VT

C20

470P

C19

VD3-2

12P(UJ)

KV1591A-2

R10

L4

68K

AM OSC

PLL(DATA)

PLL(CLOCK)

PLL(PERIOD)

32

31

30

1K

R50

1K

R52

R51

1K

C30

15P(CH)

5

6

DATA

CLOCK

PERIOD

GND

FM-IN

11

12

13

C60

100P

R6

R8

47K

Q1

KTC3194 Y

RE AMP.

0.022

C58

0.01

0.022

AM BAND

COVERAGE fL

TUNER +B

+B

PIN

NO.

+B

C56

0.01

PPL

@

IC3

Q5

2

KRA102 M

3

1

2

R20

6.8K

TC9216P

1

3

C28

2.2/50

R18

47K

PIN

VOLTAGE

NO.

1.6V

1

1.6V

2

6V (6.3V)

3

0.2V (0.7V)

4

1.6V

5

0V

6

0V

7

0V

8

2.5V

9

2.5V

10

5.1V (6.6V)

11

0.8V (1V)

12

Q6

IC2

PIN

NO.

13

14

15

16

17

18

19

20

21

22

23

24

7

OT-1

OT-2

IF-IN

AM-IN

10

C22

0.01(M)

8

OT-3

I/O5(ST)

9

C71

IC3

PIN

VOLTAGE VOLTAGE

NO.

2.4V

1

2.3V

2

6.8V

3

0.1V

4

4.9V

5

3.0V

6

––

7

––

8

––

9

C59

C70

0.001

PIN

NO.

FM SIGNAL

AM SIGNAL

MAIN PWB-A1(3/4)

IC1

VOLTAGE

0.9V

1

1.6V

2

6.8V

3

0V

4

0V

5

6.8V

6

1.4V

7

6.2V

8

6.8V

9

KRC104 M

Q5,Q6:FM RIPPLE FILTER

VOLTAGE

1.2V (0V)

1.9V (1.6V)

1V (1.3V)

1.7V

1.5V (1.7V)

1.5V (1.5V)

0.4V (0.4V)

6.1V (6.4V)

6.1V (6.4V)

1.6V

1.6V

1.6V

( ): AM

10

––

11

0V

12

2.3V

13

GND

14

0V

15

––

16

0.5V

H

FM

ROD ANTENA

• NOTES ON SCHEMATIC DIAGRAM can be found on page 9.

1

2

34 5

Figure 18 SCHEMATIC DIAGRAM (5/6)

6

– 18 –

Page 19

QT-CD161/141

IC202

PIN

VOLTAGE

NO.

0.1V

1

0V

2

11.2V

3

0V

4

11.3V

5

0V

6

0.1V

7

12V

8

10.4V

9

5.8V

10

0V

11

5.8V

12

10.4V

13

P16 1-F,P14 2-H

BACK UP +B

GND(D)

40

1

+B +B

C501

100/10

1SS133

D502

C502

0.022

C503

10/16

C506

2.2/50

R502

2.7K

C505

0.022

3

C508

0.022

C509

0.1/50

KTC3199 GR

RESET

Q501

C521

0.0047

+7.4V

12

1SS133

C504

0.022

1SS133

2

PST9142

RESET

IC502

1

R504

100K

R505

5.6K

1

2

C516

150 (1/4W)

100P

R501

ZD501

DZ5.6BSB

D501

+B

D504

D503

1SS133

R503

1.8K

D505

1SS133

D506

1SS133

Q502

3

KRC107M

RESET

MONO/STEREO

TUNED

24

25

+B

R523

15K

R552

1K

R530

15K

P18 5-A

R550

15K

R549

15K

L501

100µH

56K

10K

R518

10K

R524

56K

R531

15K

STEREO

26

R508

R517

PLL(PERIOD)

PLL(CLOCK)

PLL(DATA)

31

30

29

R512 560

R513 560

R511 560

R519 560

R520 1K

R521 1K

R522 1K

R536 1K

R537 1K

R538 1K

1K

R510 1K

R509 1K

0.022

R534 1K

R535 1K

R533 1K

PIN

VOLTAGE

NO.

3.0V

1

1.5V

2

––

3

––

4

––

5

––

6

––

7

––

8

5.0V

9

5.0V

10

5.0V

11

––

12

2.1V

13

5.0V

14

4.6V

15

4.9V

16

4.9V

17

3.9V

18

––

19

––

20

––

21

22

––

3

1

2

1

3

RX501

REMOTE

SENSOR

C510

0.1(M)

R507

C512

0.022

C513

R528

10K

QT-CD161

ONLY

PIN

VOLTAGE

NO.

––

23

4.0V

24

0.5V

25

––V

26

5.0V

27

––

28

––

29

2.0V

30

2.3V

31

GND

32

––

33

5.0V

34

5.4V

35

––

36

––

37

––

38

––

39

––

40

––

41

––

42

––

43

––

44

SWITCH PWB-A5

FW501

3

1

OPEN/CLOS

C519

1

10/16

2

R548

47

C511

0.022

R526

10K

R527

10K

R532

1K

R539

1K

80

VL3

123456789

VL1

LID SW

CLOCK

DATA

PERIOD

T-MUTE

AREA

KEY1

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

KEY0

STEREO

MONO/ST

WRQ

SD

PU IN

DRF

RESET

CQCK

COIN

RWC

SL+

SL–

REMOCON

SYS

STOP

25

IC501

SW507

CD LID

2.7K

79

COM0

COM1

26

27

XL501

4.19MHz

VOLTAGE

––

––

––

––

––

––

––

––

––

––

––

2.2V

2.2V

2.2V

2.2V

2.2V

2.2V

2.2V

2.2V

2.2V

2.2V

2.2V

SW505

DOWN

PREST

R547

3.3K

SW501

TUNER

UP

R544

3.3K

PIN

VOLTAGE

NO.

2.2V

65

2.2V

66

2.2V

67

2.2V

68

2.2V

69

2.2V

70

2.2V

71

2.2V

72

5.0V

73

––

74

––

75

––

76

––

77

––

78

––

79

––

80

SW506

PREST UP

TUNER

DOWN

R545

5.6K

SW502

PIN

NO.

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

63

64

QT-CD161 ONLY

R506

COM2

COM3

AVSS

VREF

VCC

SEG0

SEG3

SEG2

SEG1

CD/TUNER CONTROL

MICROCOMPUTER

IX0016SJ

25

27

SQ OUT

RESET

P-MUTE1

P-MUTE2

VSS

32

R540

1K

SYNC IN

FUNC

33

36

35

34

R541

1K

XOUT

XIN

30

31

29

28

BAND

R546

15K

66676869707172737475767778

SEG6

SEG5

SEG4

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

IC501

38

39

37

SW503

65

SEG7

SEG9

40

SEG8

MEMORY

SW504

4142434445464748495051525354555657585960616263

IC101

PIN

VOLTAGE

NO.

<0V> [3.23V]

1

<0V> [0V]

2

<0.6V> [0.6V]

3

<0V> [0V]

4

<0V> [0V]

5

<0V> [0V]

6

<0V> [0V]

7

<7.43V> [7.43V]

8

<0V> [0V]

9

<7.37V> [7.37V]

10

<0.6V> [0.6V]

11

<3.3V> [3.3V]

12

< >: Recording

[ ]: Play

1

2

3

4

5

6

7

8

9

10

11

1312

14

15

16

17

18

19

20

21

LCD501

R543

R542

6.8K

MAIN PWB-A1(4/4)

32

PU IN

WRQ

5

DRF

11

10

CQCK

RESET

P14 3-F

9

COIN

8

7

SL+

RWC

6

SL–

4

SQ OUT

42

43

FUNC(CD)

P-MUTE

P16 1-F

3.3K

78 9101112

Figure 19 SCHEMATIC DIAGRAM (6/6)

– 19 –

Page 20

QT-CD161/141

S

B

CD-C161 ONLY QT-CD141

3

J201

HEADPHONES

A

CNS201

P21 10-B

FROM

SPEAKER

R227

R228

CNP201

FW202

1

1

2

3

HEADPHONES PWB-A2

B

P22 3-E

TO SWITCH PWB

C

D

E

F

G

H

1

FW201

4

SW201

FUNCTION

OFF

ON

QT-CD161

ONLY

FW501

P22 6-E

TO SENSOR PWB

TAPE

CD

TUNER

5

1

4

L-CH

A

CD-TUNER-TAPE

C

21

(CD + 2-BAND)

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

RX501

REMOTE

1

SENSOR

2

R532

3

R548

C519

R501

ZD501

SW507

CD LID

OPEN/CLOSE

COLOR TABLE

BR

RD(R)

OR

YL

GR

BL

VL

GY

WH(W)

BK

PK

4

C252

LCD501

C501

C502

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

FW201

R-CH

B

SW201

D

R254

D252

C510

C503

FW501

C504

1

50

IC501

80

C511

W601

D505

1

2

1

C152

R152

R151

R255

R251

ECB

R541

41

45

5

1

R526

R504

IC502

C509

C151

B

A

R542

R543

R540

40

35

30

25

20

24

15

10

R527

C512

C513

R507

R528

R508

R530

D506

R505

B

3

C521

C

2

E

1

Q501

Q502

R511

R154

R153

SW202

X-BASS

D301

D302

R256

R252

Q251

R253

D251

55

64

60

70

65

75

R506

L501

J48

D501

D502

C506

R502

D503

D504

4

C508

C505

R503

1

4

BK

BK

XL501

R512

R518

R517

R513

R552

ONLY

P21 10-B

FROM

SPEAKER

CNS201

2

3

1

CNP201

C105

R105

R103

R104

C115

R113

R121

R115

R117

FW202

C221

C851

R45

R849

C219

R119

D201

R874

C117

R123

D101

R125

C121

C233

R225

C228

C224

C220

C222

101112

C868

XL801

33

R880

40

48

45

50

55

49

R860

64

C842

C847

R858

C841

C834

C833

R836

D802

C821

ZD1

C50

C57

R509

R457

R510

R455

R458

R456

C869

R875

R519

R221

C870

R523

R520

R521

C516

R876

R222

R224

R522

R223

R533

R534

R535

R536

R537

R538

C887

Q202

Q201

R539

R531

1

3

E C B E C B

C223

123456789

C225

R873

R524

R43

R549

R72

R550

3

2

R48

R47

R46

78

6

R50

R51

R52

345

C30

2

1

X1

C29

C71

C70

CNP101

1 2 3 4

CEHG

ABDF

R101

R108

C107

C108

R107

R109

C110

C109

C111

C112

C113

11

1 3579

10

12

246

8

D102

C119

C123

C120

C234

C227

C226

C229

C231

13

C232

IC202

C230

IC203

1

C301

2

3

C302

L802

C867

D303

C873

C843

C890

32

L801

35

30

25

17

20

IC802

15

16

10

60

5

R832

1

R856

R857

C831

R835

R838

C850

R871

C845

C835

C837

C838

Q6

123

C56

9

C21

10

11

L5

IC3

C27

C60

141312

15

16

R6

R8

C58

BCE

Q1

IC1

C8

C3

C2

D1

R102

R110

C114

C118

IC101

R120

D103

R833

C832

R837

C839

C840

R18

C28

R20

C72

Q5

C22

R16

C12

89

7

6

5

4

3

2

1

3

F1

2

1

C351

R352

R353

Q351

R354

C352

L301

ECB

CNP602

123

TO TERMINAL PW

C122

SW102

C116

R118

R124

C106

R116

R122

R114

R106

R351

C354

C353

CNS602

R230

Q802

C846

R831

R834

48

49

C830

C819

B C E

15

R824

R825

C818

10

C844

R830

C817

R822

40

45

IC801

50

55

64

C802

15

R823

C820

33

35

60

R801

C822

32

C801

R820

C815

R821

C816

R826

R827

R816

C812

R817

30

25

17

20

15

16

10

5

C810

1

C803

R803

R804

R802

IC803

R819

R815

C814

R813

C813

R811

R808

C805

C811

C804

R840

R814

R812

R809

R842

16

R839

C849

C848

BCE

1

BI801

20

25

30

8

R810

R829

R828

C809

C807

R806

R807

C808

1

BI802

R805

C806

5

R44

C888

6

1

BI803

R38

R36

C48

R42

C45

C47

R35

D3

R37

AM IF

T3

321

C32

R17

C26

C24

R15

C25

R13

C10

L2

C9

R71

R4

FM IF

R1

L1

D2

FM RF

C4

VD1

C7

C5

R2

CF2

1 2 3

C33

Q4

ECB

BCE

Q3

VD2

C11

R5

R70

R7

C14

T1

C13

R56

C6

R3

C16

C59

Q9

3 2 1

C49

C46

C37

12

10

IC2

5

1

C31

3

CF1

2

1

C18

R10

C20

R12

R11

C17

R9

AM BAR ANTENNA

R39

C51

MPX VCO CK

76kHz

R29

C43

13

C41

15

C38

R25

C36

20

R24

24

C34

VD3

-2 -1

L3

TC1

VR1

C35

AM OSC

L4

C19

R30

C42

C40

C52

Q801

W601

D4

12

10

1

FM DET

T2

11

CNS

6

BK

1

WH

2

WH

3

WH

4

WH

5

WH

6

WH

7

WH

8

7

CN

BK

1

WH

2

WH

3

WH

4

WH

5

8

9

CNS803

BR

1

GY

2

GY

3

GY

4

GY

5

GY

6

• The numbers 1 to 12 are waveform numbers shown in page 10.

1

2

34 5

Figure 20 WIRING OF P.W.BOARD (1/3)

– 20 –

MAIN PWB-A1

6

Page 21

QT-CD161/141

8

SP502 SP501

P20 1-A

TO

HEADPHONES PWB

CNP602

123

TO TERMINAL PWB

SW601

TAPE MAIN

(233-7)

M601

TAPE MOTOR

(233-6)

CNS602

BR

YL

11

W601

R

42

C848

BCE

Q801

1

R810

BI801

12

CNS801

6

BK

1

WH

2

WH

3

WH

4

WH

5

WH

6

WH

7

WH

8

7

(QT-CD161)

CNP201

P20 3-A

TO

MAIN PWB

(QT-CD141)

CNS201

CNS101

WH

1

BK

2

RD

3

BK

4

3

2

1

BK

WH

RD

BK

SPEKERS

ERASE HEAD

TAPE

(233-5)

PICK UP UNIT

54321

78 654321

L-CHR-CH

RECORD/PLAYBACK

HEAD(233-4)

BKRDWH

BK

9

C807

1

BI802

5

PX VCO CK

76kHz

C43

C41

38

25

C36

R24

C34

-

TC1

TENNA

VR1

C35

AM OSC

C19

10

1

R30

D4

C42

C40

FM DET

T2

L4

C52

8

9

BR

GY

GY

GY

GY

GY

BK

WH

WH

WH

WH

CNS803

1

2

3

4

5

6

CNS802

1

2

3

4

5

FM ROD ANTENNA( )

210

CD MOTOR PWB-B

-

+

PICKUP IN

SPENDLE MOTOR

M701

SLED MOTOR

M702

SW702

+

6

5

4

3

2

CNP803

1

F3895AF

-

B-A1

78 9101112

Figure 21 WIRING OF P.W.BOARD (2/3)

– 21 –

Page 22

QT-CD161/141

(208)

A

B

(230)

C

DC3V["AA" size (UM/SUM-3,R6 or HP-7)

D

BATTERIES

battery x 2 for tuner memory]

BATTERY PWB-A4

BATTERIES

DC12V["D" size (UM/SUM-1,

R20 or HP2) battery x 8]

C653

D653

D652

C652

C654

D654

D651

C651

TERMINAL PWB-A3

(237)

CNS602

PT

PT

ACSO

+B

GND

G

ACSO

OR

YL

YL

OR

RD

BK

BK

T601

POWER

TRANSFORMER

OR

OR

CNS602

3

2

1

RD

RD

P20 6-B

TO MAIN PWB

CNP602

SO601

AC SOCKET

AC 120V

60Hz

BACK-UP

BATTERY PWB-A5

E

P20 1-E

SW505

PRESET

DOWN

SW506

PRESET

UP

TO MAIN PWB

FW501

1

4

FW501

P20 1-B

TO MAIN PWB

FW201

F

G

SWITCH PWB-A6

SW504

MEMORY

SW503

R546

BAND

SW502

TUNER

DOWN

R545

FW201

4

C217

R219

C215

R220

VR201

1

C520

C216

C218

R544

SW501

TUNER

UP

R547

H

1

2

34 5

6

Figure 22 WIRING OF P.W.BOARD (3/3)

– 22 –

Page 23

QT-CD161/141

TROUBLESHOOTING (CD SECTION)

When the CD does not function

When the CD section does not operate when the objective lens of the optical pickup is dirty, this section may not operate. Clean

the objective lens, and check the playback operation. When this section does not operate even after the above step is taken, check

the following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC (Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup

lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Dust gradually accumulates on the objective lens during use, and it may degrade performance.

To avoid this problem, use a cleaning disc designed for CD optical pickup lenses.

HOW TO USE

1. Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the brush on the CD cleaner disc which has

the mark next to it.

2. Place the CD cleaner disc onto the CD disc tray with the brush side down, then press the play button.

3. You will hear music for about 20 seconds and the CD player will automatically stop. If it continues to turn, press the stop button.

CAUTION

The CD lens cleaner should be effective for 30 - 50 operations, however if the brushes become worn out earlier then please

replace the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft cloth.

Do not drink the cleaner fluid or allow it to come in contact with the eyes. In the event of this happening then drink and / or

rinse with clean water and seek medical advice.

The CD cleaner disc must not be used on car CD player or on computer CD ROM drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting product is prohibited by law.

Cleaner Liquid

Cleaning Disc

PARTS CODE:

UDSKA0004AFZZ

Figure 23

– 23 –

Page 24

QT-CD161/141

When the CD does not function

When the CD section does not operate When the objective lens of the optical pickup is dirty,this section may not operate.Clean

the objective lens,and check the playback operation.When this section does not operate even after the above step is taken,check

the following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC(Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup lens.

Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

• The CD function will not work.

The CD operating keys don't work.

Yes

Check the CD, DPS microcomputer (IC501), power supply, 4.19

MHz and 16.93 MHz clock, and reset terminal.

Yes

Check the waveform of SCK, SO (DATA) and SI (COMM).

Yes

See if the pick-up is in the pick-up in SW702(pu-in switch) position.

Yes

If the items mentioned above are OK, check the main

microcomputer IC501.

• The CD operating keys work.

Check the Focus - HF system.

Playback can be performed without a disc.

Yes

Does the pick-up move up and down twice?

No

Does the output waveform of IC801(16)(FD) match that shown in

Fig. 24?

No

Check the IC801(50)(CLK) line, 4MHz.

Check the microcomputer data on pins (51)(CL), (52)(DAT) and

(53)CE.

Yes

Yes

0.5s

0.50 V

IC801 16 FD

0.5s

0.50 V

IC801 15 TD

Focus search OK.

Check the area around IC803-BI801/CNS801.

Focus search

is performed

two times

when play

operation is

done without

disc.

– 24 –

1

2

Figure 24

Page 25

• Playback can only be performed when a disc

is loaded.

QT-CD161/141