Page 1

QT-80W

SERVICE MANUAL

No. S4129QT80W///

STEREO RADIO CASSETTE RECORDER

MODEL

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified should

be used.

QT-80W

CONTENTS

Page

SPECIFICATIONS ............................................................................................................................................................. 2

VOLTAGE SELECTION..................................................................................................................................................... 2

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR ................................................................................................. 2

NAMES OF PARTS ........................................................................................................................................................... 3

HOW TO SET THE POINT "0" ON TUNER DIAL MEMORY............................................................................................. 3

DISASSEMBLY.................................................................................................................................................................. 4

REMOVING AND REINSTALLING THE MAIN PARTS..................................................................................................... 5

ADJUSTMENT ................................................................................................................................................................... 7

SCHEMATIC DIAGRAM .................................................................................................................................................. 10

WIRING SIDE OF P.W.BOARD....................................................................................................................................... 12

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. 14

TYPES OF TRANSISTOR ............................................................................................................................................... 14

VOLTAGE ........................................................................................................................................................................ 14

PARTS GUIDE/EXPLODED VIEW

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

QT-80W

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

General

Power source

Power consumption

Output power

Speakers

Output terminal

Input terminals

Dimensions

Weight

Radio

Frequency range

Tape recorder

Frequency response

Signal/noise ratio

Wow and flutter

Motor

Bias system

Erase system

SPECIFICATIONS

AC 110-127/220-240 V, 50/60 Hz

DC 12 V [“D” size (UM/SUM-1, R20 or HP-2) battery x 8]

20 W

MPO: 18 W (9 W + 9 W) (AC operation, 10 % T.H.D)

RMS: 10 W (5 W + 5 W) (DC operation, 10 % T.H.D)

8 cm (3-1/8”) full range speaker x 4

Headphones: 16-50 ohms (recommended: 32 ohms)

Mixing microphone: 600 ohms

Line input: 350 mV/47 kohms

Width: 520 mm (20-1/2”)

Height: 191 mm (7-1/2”)

Depth: 216 mm (8-1/2”)

4.2 kg (9.3 lbs.) without batteries

FM: 88 - 108 MHz

SW1: 2.3 - 7.3 MHz

SW2: 7.3 - 22 MHz

MW: 526.5 - 1,606.5 kHz

60 - 12,000 Hz (Normal tape)

40 dB

0.3 % (WRMS)

DC 9 V electric governor

AC bias

Magnet erase

Specifications for this model are subject to change without prior notice.

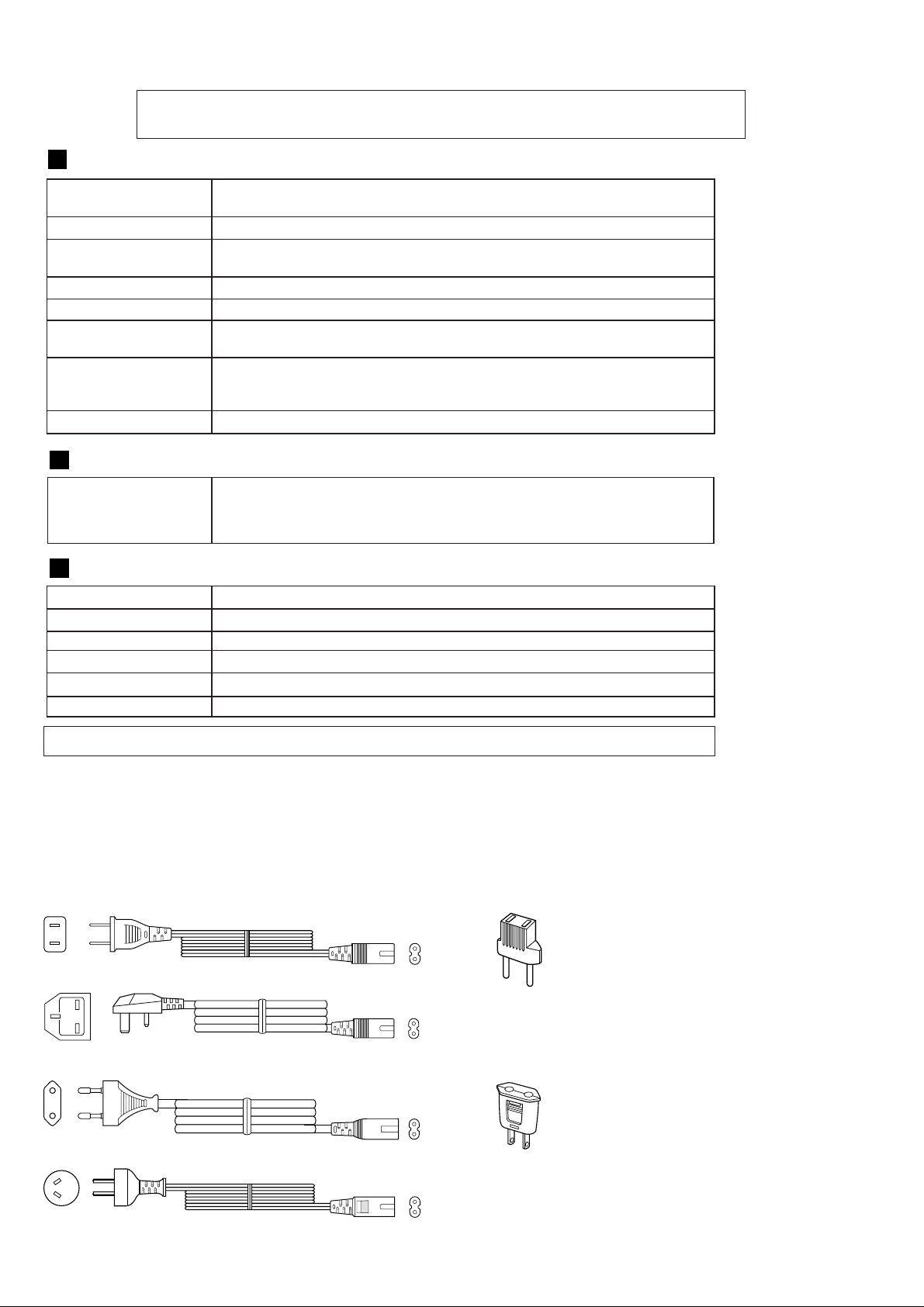

VOLTAGE SELECTION

Before operating the unit on mains, check the preset voltage. If the voltage is different from your local voltage, adjust the voltage

as follows. Slide the selector with a screwdriver to the appropriate voltage number. (AC 110 - 127 V or AC 220 - 240 V)

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR

92L3404-074001

QACCB0012AW00

QACCE0007AW00

QACCL0002AW00/QACCL0008AW00

QPLGA0003AWZZ

QPLGA0004AWZZ

– 2 –

Page 3

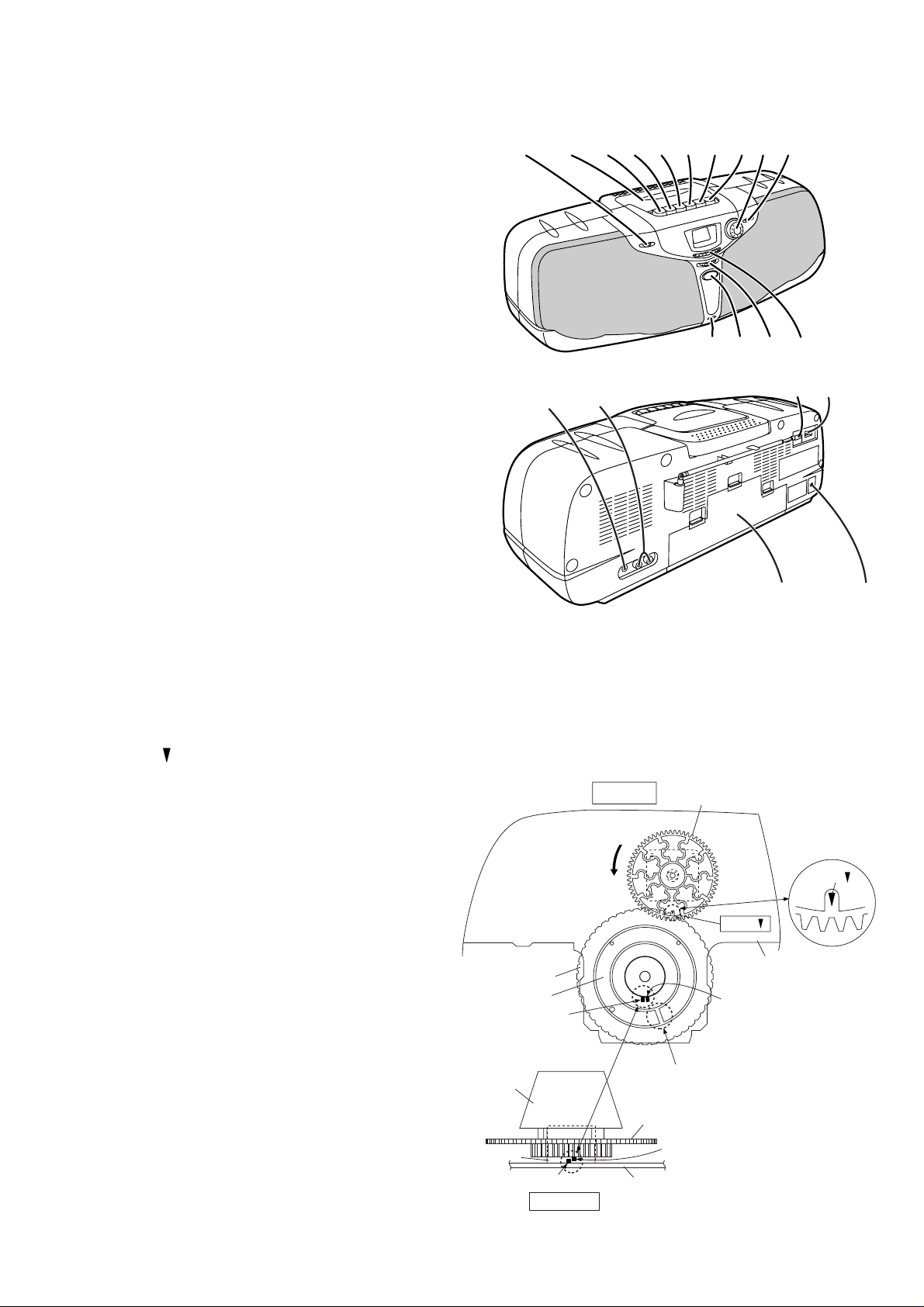

NAMES OF PARTS

QT-80W

01. Function/Beat Cancel Switch

02. Cassette Compartment

03. Record Button

04. Play Button

05. Rewind Button

06. Fast Forward Button

07. Stop/Eject Button

08. Pause Button

09. Volume Control

10. Band Selector

11. Built-in Microphone

12. Extra Bass Button

13. Fine Tuning Control

14. Tuning Control

15. Mixing Microphone Socket

16. Line Input Sockets

17. AC Voltage Selector

18. AC Input Socket

19. Battery Compartment

20. Headphone Socket

12345678910

15

11 12 13

16

14

17

18

HOW TO SET THE POINT "0" ON TUNER DIAL MEMORY

1. Remove the front cabinet and main PWB. (Refer to page 4,

of disassembly section.)

2. Turn the gear dial in the arrowed direction until it stops so

that the " " mark comes to the front of main PWB.

3. When the tuning knob is set at 2, adjust it from above so that

its "0" point rib comes to the right of "0" point rib of the dial

drum when you face the unit.

4. Check the tuning display label by turning the tuning knob.

The frequency band will be FM 88 - 108 MHz when the dial

is turned counter-clockwise.

5. Reassemble the front cabinet.

Tuning Knob

Dial Drum

Dial Drum “0”

Point Rib

Top Side

2

19

Gear Dial

Mark “ ”

Main PWB Front Side

Tuning Knob “ 0 ” Point Rib

20

Mark “ ”

Dial Drum

Tuning Knob

Bracket

Dial Drum “0” Point Rib

– 3 –

Front Side

“0” Point of Tuning Display

3

Tuning Knob

Tuning Knob “0” Point Rib

Main PWB

Figure 3

Page 4

QT-80W

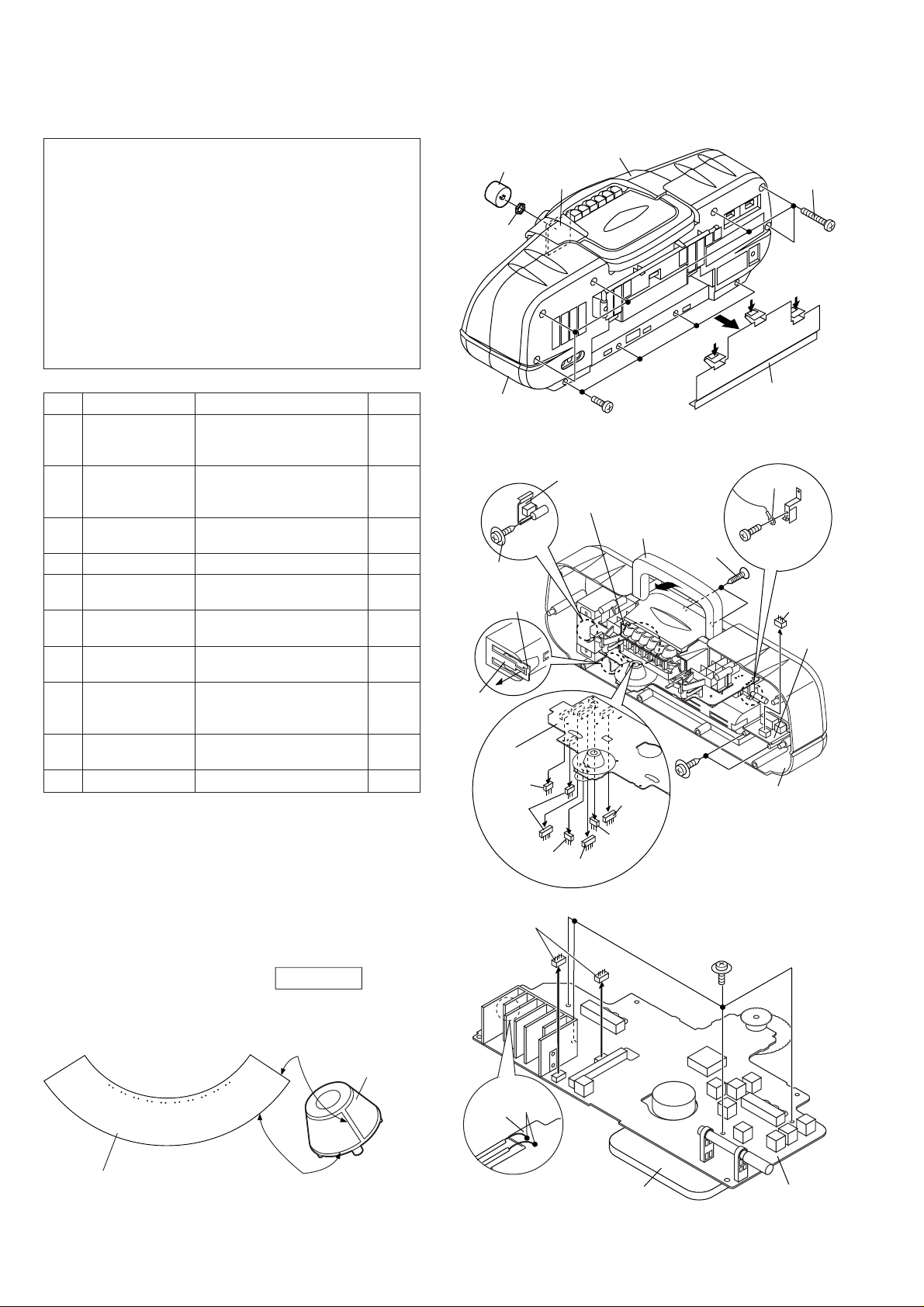

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep it safe and ensure excellent

performance:

1. Take cassette tape out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

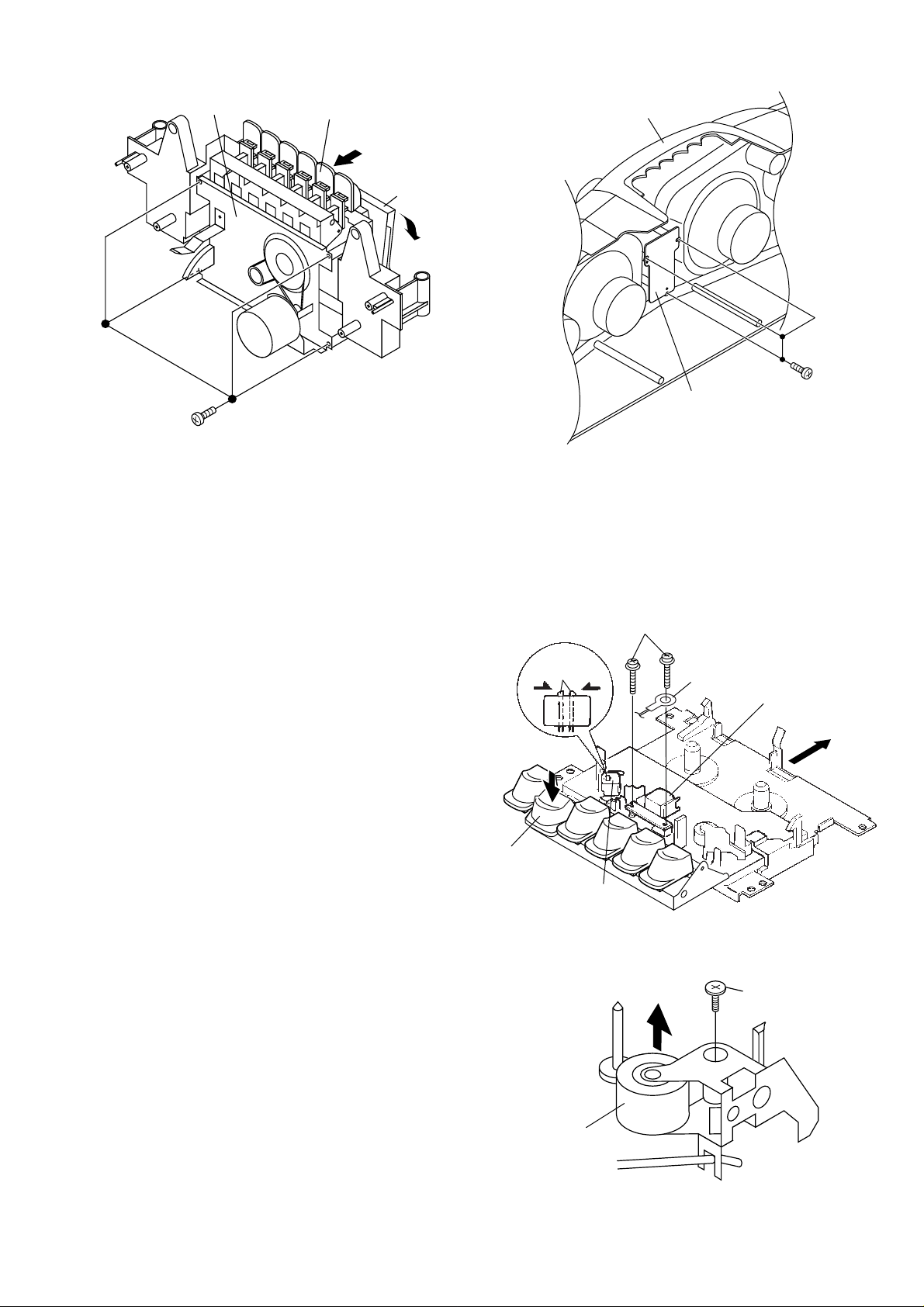

STEP REMOVAL PROCEDURE FIGURE

1 Rear Cabinet 1. Battery Lid............ (A1) x1 4-1

2. Screw ................... (A2) x6

3. Screw ................... (A3) x4

2 Front Cabinet 1. Knob..................... (B1) x1 4-1

2. Nut........................ (B2) x1

3. Socket .................. (B3) x3 4-2

3 Jack PWB 1. Socket ..................(C1) x2 4-2

2. Screw ...................(C2) x2

4 Volume PWB 1. Socket ..................(D1) x1 4-2

5 Battery PWB 1. Socket .................. (E1) x1 4-2

2. Hook..................... (E2) x1

6 Headphones PWB 1. Socket .................. (F1) x1 4-2

2. Screw ................... (F2) x1

7 Main PWB with 1. Screw ...................(G1) x2 4-2

Tape Mechanism 2. Screw ...................(G2) x1

8 Main PWB 1. Socket ..................(H1) x2 4-3

2. Screw ...................(H2) x4

3. Solder................... (H3) x2

9 Tape Mechanism 1. Open the cassette holder. 5-1

2. Screw ....................(J1) x4

10 X-BASS PWB 1. Screw ................... (K1) x3 5-2

(B1)x1

(B2)x1

Rear Cabinet

(F2)x1

ø4x10mm

Battery PWB

(E2)x1

Main PWB

(C1)x1

(B3)x2

Front Cabinet

Volume

PWB

(A3)x4

ø3x12mm

Figure 4-1

Headphones PWB

Tape Mechanism

Handle

(D1)x1

(G1)x2

ø3x12mm

(C2)x2

ø4x14mm

(A2)x6

ø3x30mm

(A1)x1

Lug Wire

(G2)x1

ø3x8mm

(B3)x1

Jack

PWB

Rear

Cabinet

How to attach the tuning display label

(See Fig. 4-4.)

Reference

1. Start Stick Label Matching

With Base Line

Base Line

10

108

1600

9

22.0

7.3

19.0

1400

6.0

104

1200

5.0

15.0

8

7

6

5

100

1000

800

4.0

12.0

Tuning Display Label

96

4

3.2

10.0

700

0

1

88

2

3

540

92

2.3

7.3

600

2.6

8.5

2. This Line Must Be

Stick Matching

Figure 4-4

Dial Drum

– 4 –

Main

PWB

(C1)x1

(F1)x1

(H1)x2

(H3)x2

Tape Mechanism

(E1)x1

Figure 4-2

(H2)x4

ø3x10mm

Main PWB

Figure 4-3

Page 5

QT-80W

Tape Mechanism

Stop/Eject Button

Push

Cassette

Holder

Open

(J1)x4

ø3x10mm

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1 to 9 of the disassembly method to remove the

tape mechanism. (See page 4.)

Front Cabinet

X-BASS

Figure 5-2Figure 5-1

(K1)x3

ø2.6x8mm

PWB

How to remove the record / playback and erase

heads (See Fig. 5-3.)

1. Remove the screws (A1) x 2 pcs., to remove the record/

playback head.

2. Remove the hooks (A2) x 2 pcs., toward the center position

as shown in Fig. 5-3. and then extract the erase head

upward.

Note:

After replacing the heads and performing the azimuth

adjustment, be sure to apply screwlock.

How to remove the pinch roller (See Fig. 5-4.)

1. Remove the screw (B1) x 1 pc., and remove the pinch roller

upwards.

Push

PLAY

Button

Hook

(A2)x2

Erase Head

(A1)x2

ø2x7mm

Lug Wire

Record/Playback

Head

Figure 5-3

(B1)x1

ø1.5x2.5mm

– 5 –

Pinch Roller

Figure 5-4

Page 6

QT-80W

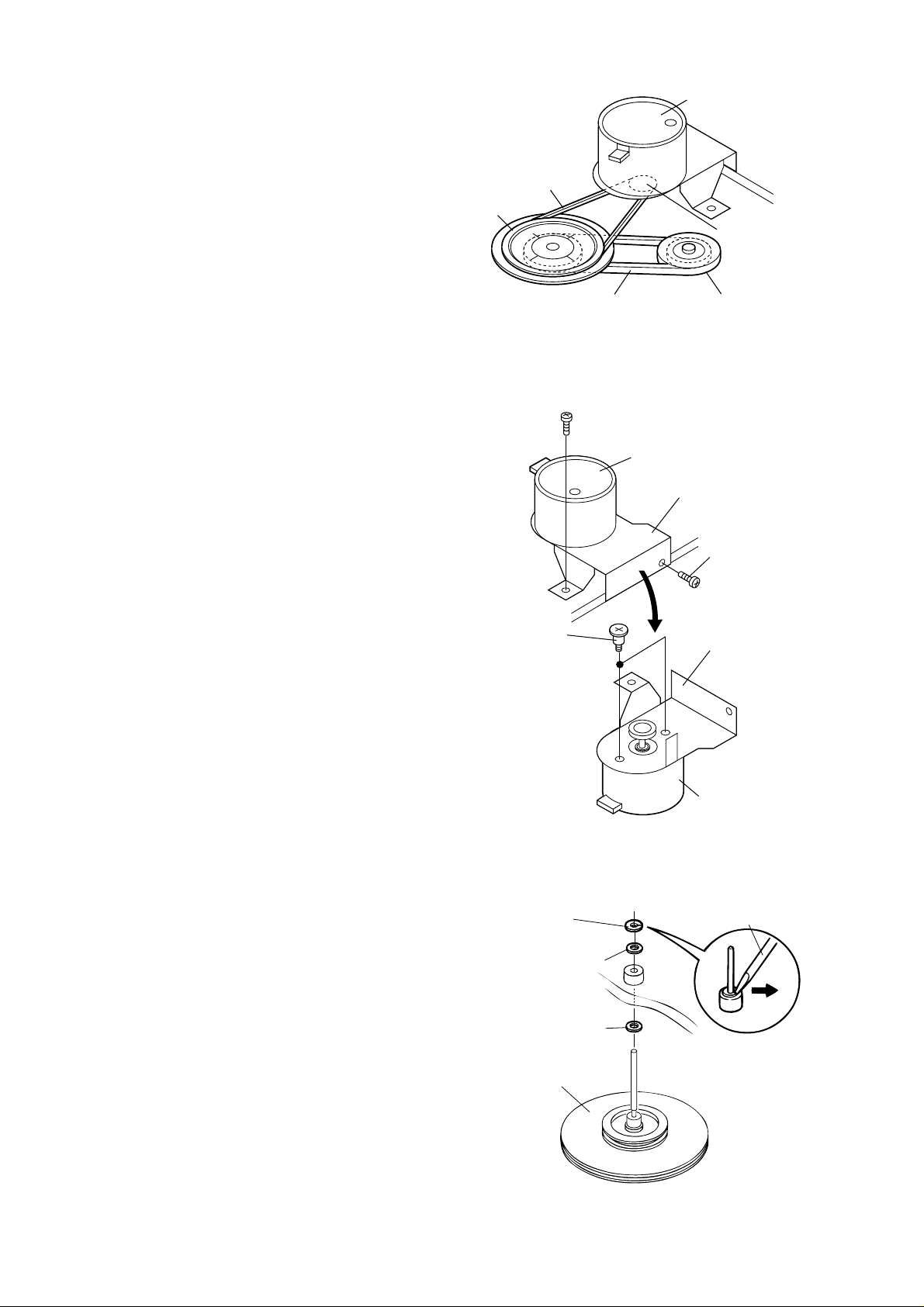

How to remove the belts (See Fig. 6-1.)

1. Remove the main belt (C1) x 1 pc., from the motor pulley.

2. Remove the FF/REW belt (C2) x 1 pc., from the REW/FF

roller.

3. Put on the belts in the reverse order of removal.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

How to remove the motor

(See Fig. 6-2.)

1. Remove the main belt. (See Fig. 6-1.)

2. Remove the screws (D1) x 2 pcs., to remove the motor

bracket.

3. Remove the screws (D2) x 2 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor bracket

angle.

Main Belt

(C1)x1

Flywheel

FF/REW Belt

(C2)x1

Figure 6-1

(D1)x1

ø2x4mm

Motor

Motor

Motor Pulley

REW/FF

Roller

Motor Bracket

(D1)x1

ø2x4mm

How to remove the flywheel (See Fig. 6-3.)

1. Remove the belt. (See Fig. 6-1.)

2. Remove the stop washer (E1) x 1 pc., with a small precision

screwdriver to extract the flywheel from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

(D2)x2

ø2.6x1.6mm

Special Screw

(E1)x 1

Stop Washer

Washer

Washer

Flywheel

Motor Bracket

Motor

Figure 6-2

Driver

How to reinstall the parts

Install each part in the reverse order of the removal with care.

Figure 6-3

– 6 –

Page 7

ADJUSTMENT

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

FM Section

Step

1 FM IF: (1) FM IF sweep Inject the IF Signal are taken Adjust T106, T108 (1) Band SW in FM.

2 FM BAND (1) FM RF sweep Inject the RF Same as step 1 Adjust P.V.C. (TC1) Same as step 1

3 FM BAND Same as step 2 Same as step 2 Same as step 1 Adjust L103 to get Tune P.V.C. to low

4 Repeat step 2, 3 until no further improvement can be made.

5 FM TRACKING Same as step 2 Same as step 2 Same as step 1 Adjust P.V.C. (TC2) to Tune P.V.C. to

6 FM TRACKING Same as step 2 Same as step 2 Same as step 1 Adjust L102 to get MAX. Tune P.V.C. to

7 Repeat step 5, 6 and then step 2, 3, 5, 6 until no further improvement can be made.

Alignment

Frequency

10.7 MHz generator sweep signal out from point TP3 and repeat to get (2) VOL. & TONE

(T108) (2) Alignment through 300 pF best "S" curve with control in MIN.

FM oscilloscope capacitor to point center at 10.7 MHz position

DETECTION: (3) Power supply TP2 (3) Tune P.V.C. to

(T106) high end

COVERAGE fH: generator signal directly to get MAX. output

108.2 MHz (2) Alignment point TP1

COVERAGE fL: MAX. output end

87.4 MHz

fH: 106 MHz get MAX. output 106 MHz

fL: 90 MHz output 90 MHz

Test Equipment

oscilloscope

(3) Power supply

Signal-in

Signal-out

Adjust

QT-80W

Remark

FM Stereo Section

Step

1 VCO: 75 kHz (1) Frequency counter Inject MONO Through test Adjust VR102 let (1) FM and stereo

Alignment

Frequency

Test Equipment

(2) Power supply signal at 98 MHz circuit as Fig 7. Frequency counter position

(3) FM Signal directly to point value: 76 K ± 200 Hz. (2) Tune radio to

generator TP1 and ground 98 MHz

Pin 13 of IC102

Signal-in Signal-out

Pin 21 of IC102

Adjust

Remark

D

G

FET 2SK212

(or other 2SK type FET)

10pF

S

1M ohm

0.1

F

To frequency

counter

10K ohm

Figure 7

– 7 –

Page 8

QT-80W

MW Section

Step

1 MW IF: 455 kHz (1) AM IF sweep Let the MW ANT Take out the signal Adjust T107 get MAX. (1) Band SW in MW

2 MW (1) MW sweep Same as step 1 Same as step 1 Adjust P.V.C. (TC3) Same as step 1

3 MW BAND Same as step 2 Same as step 1 Same as step 1 Adjust T103 to get Tune P.V.C. to low

4 Repeat step 2, 3 until no further improvement can be made.

5 MW BAND Same as step 2 Same as step 1 Same as step 1 Adjust P.V.C. (TC4) Tune P.V.C. to

6 MW TRACKING Same as step 2 Same as step 1 Same as step 1 Adjust L109 get MAX. Tune P.V.C. to

7 Repeat step 5, 6 and then step 2, 3, 5,6 until no further improvement can be made.

Alignment

Test Equipment

Signal-in

Signal-out Adjust

Frequency

generator with coil close to the from point TP4 output at 455 kHz position

loop antenna generator ANT. (2) VOL. control in MIN.

(2) Alignment position

oscilloscope (3) Tune P.V.C. to

(3) Power supply high end

TRACKING fH: generator with get MAX. output at

1,650 kHz antenna 1,650 kHz

(2) Alignment

oscilloscope

(3) Power supply

COVERAGE fL: MAX. output at 515 kHz end

515 kHz

COVERAGE fH: get MAX. output at 1.400 kHz

1,400 kHz 1,400 kHz

fL: 600 kHz output at 600 kHz 600 kHz

Remark

SW1 Section

Step

1 SW1 BAND (1) SW1 sweep Let the MW ANT Take out the signal Adjust CT102 get MAX. (1) Band SW in SW1

2 SW1 BAND Same as step 1 Same as step 1 Same as step 1 Adjust T104 get MAX. Tune P.V.C. to low

3 Repeat step 1, 2 until no further improvement can be made.

4 SW1 Same as step 1 Same as step 1 Same as step 1 Adjust CT104 get MAX. Tune P.V.C. to 6 MHz

5 SW1 Same as step 1 Same as step 1 Same as step 1 Adjust T101 get MAX. Tune P.V.C. to

6 Repeat step 4, 5 and then step 1, 2, 4, 5 until no further improvement can be made.

Alignment

Test Equipment

Signal-in Signal-out Adjust Remark

Frequency

COVERAGE fH: generator with coil close to the from point TP4 output at 7.4 MHz position

7.4 MHz antenna generator ANT. (2) VOL. control in MIN.

(2) Alignment point TP1 position

oscilloscope (3) Tune P.V.C. to

(3) Power supply high end

COVERAGE fL: output at 2.25 MHz end

2.25MHz

TRACKING fH: output at 6 MHz

6 MHz

TRACKING fL: output at 2.6 MHz 2.6 MHz

2.6 MHz

SW2 Section

Step

1 SW2 BAND (1) SW2 sweep Inject the RF Take out the signal Adjust CT101 get MAX. (1) Band SW in SW2

2 SW2 BAND Same as step 1 Same as step 1 Same as step 1 Adjust T105 get MAX. Tune P.V.C. to low

3 Repeat step 1, 2 until no further improvement can be made.

4 SW2 Same as step 1 Same as step 1 Same as step 1 Adjust CT103 get MAX. Tune P.V.C. to

5 SW2 Same as step 1 Same as step 1 Same as step 1 Adjust T102 get MAX. Tune P.V.C. to

6 Repeat step 4, 5 and then step 1, 2, 4, 5 until no further improvement can be made.

Alignment

Frequency

COVERAGE fH: generator signal directly to from point TP4 output at 22.5 MHz position

22.5 MHz (2) Alignment point TP1 (2) VOL. control in MIN.

Test Equipment Signal-in

Signal-out

Adjust

Remark

oscilloscope position

(3) Power supply (3) Tune P.V.C. to

high end

COVERAGE fL: output at 7.2 MHz end

7.2 MHz

TRACKING fH: output at 19 MHz 19 MHz

19 MHz

TRACKING fL: output at 8.5 MHz 8.5 MHz

8.5 MHz

– 8 –

Page 9

Erase Head

Head fixing

screw

Record/

Playback

Head

Tape Mechanism

MAIN PWB

QT-80W

MW BAR ANTENNA

MW

TRACKING fL

ROD

ANTENNA

L109

FM

DETECTION

T103

CT102

T104

T105

VCO

VR102

T106

MW BAND

COVERAGE fL

fH

SW1 BAND

COVERAGE

fL

fL

CT101

fH

TP3

13

17

18

21

24

TP4

SW1

TRACKING

SW2 BAND

COVERAGE

12

IC102

1

TP1

fH

fL

MW IF

T107

CT104

T102

T108

FM IF

T101

CT103

fH

SW2

TRACKING

fL

TP2

IC101

9

8

L103

TC1

TC3

MW

TRACKING fH

fL

FM BAND

COVERAGE

fH

1

TC2

TC4

TUNER P.V.C.

BIAS

OSCILLATION

TP5

IC201

L102

fL

fH

MW BAND

COVERAGE fH

T201

C216

FM

TRACKING

S201

RECORD/PLAYBACK

MECHANISM SECTION

Step

1 Head Playback test tape Connect VTVM and oscilloscope to Head fixing screw Adjust to get MAX.

2 Bias Frequency Record position Connect frequency counter to TP5 and Adjust T201 80 kHz ± 1 kHz

3 Beat cancel Record position Same as step 3 S201 from playback 75 kHz ± 0.5 kHz

BIAS

OSCILLATION

TP5

Item

adjustment MTT-113 6.3 kHz speaker output (see Fig 9-3.) audio output

adjustment ground (Bias Oscillation)

T201

C216

IC201

S201

REC

Condition

1

2

3

4

CON504

M601

TAPE

MOTOR

CON201

1

2

3

4

RECORD/PLAYBACK

PLAY

BACK

CN201

Figure 9-1 ADJUSTMENT POINTS

TAPE Section

Connection Adjust

SW601

TAPE MAIN

4

3

2

1

CN504

1

2

3

4

RECORD/

PLAYBACK HEAD

TAPE

Output

to record

MAIN PWB

ERASE HEAD

Figure 9-2 ADJUSTMENT POINTS

Figure 9-3

– 9 –

Page 10

QT-80W

A

B

C

D

E

F

G

H

ROD

ANTENNA

JK201

MIXING

MICROPHONE

MIC

BUILT-IN

MICROPHONE

JK301

LINE INPUT

RECORD/

PLAYBACK

HEAD

L-CH

TAPE

R-CH

ERASE HEAD

SELECTOR

TP1

S101-C

VD101

1S2638

C116

0.02

C117

0.02

R108

22K

VR101

100K(B)

FINE TUNING

CON203

CN203

2

L-CH

R-CH

S101

BAND

FM

MW

SW1

SW2

R106

100K

R107

100K

C115

R109

22K

JACK

PWB-A2

R240

1K

R234

4.7K

2

C227

11

10/16

GND

4

4

3

3

2

2

1

1

CN201

CON201

RECORD/PLAYBACK

BP101

BAND PASS

FILTER

88-108MHz

1

S101

BAND

SELECTOR

S101-F

VC4

S101-D

5P

VC3

SELECTOR

R

S201-C

P

R

S201-H

P

S201

2

5

1

3

1

S101

BAND

C101

0.001

3

FM

MW

SW1

SW2

FM

MW

SW1

SW2

CN202

5

4

3

2

1

3

2

1

CN301

0.0022(ML)

R212

18K

C212

0.0022(ML)

C223

100P

22P(CH)

L102

FM RF

C102

0.001

C111

300P

C113

1500P

C114

0.0047

CON202

5

4

3

2

1

3

GND

2

1

CON301

C211

R211

18K

R250

18K

TP5

Q208

2SC945

1

C106

C141

10P

CT104

10P

CT103

10P

C112

5P

CT102

10P

CT101

10P

C118

0.22

SWITCHING

R242

10K

R301

R303

10K

C216

0.0027

2

C104

R122

10

R124

Q204

SS8550

10K

RPR

RECORD/

PLAYBACK

RPR

OSCILLATION

R254

10K

3

0.001

TC4

33K

S201

R253

10K

IC101

FM FRONT END

LA1186N

4

5

C143

0.1

D103

TC2

VC2

1N4148

C103

10/16

L109

MW BAR ANTENNA

T101

SW1 ANTENNA

T102

SW2 ANTENNA

TC3

T103

MW OSCILLATION

T104

SW1 OSCILLATION

T105

SW2 OSCILLATION

C235

47/16

C270

10/16

C231

1/50

C230

1.8K

R233

0.01(ML)

R302

2.2K

R304

2.2K

S201-E

S201-D

P

C201

0.0015(ML)

S201-A

S201-B

P

T201

C251

0.018

(ML)

BIAS

0.0068(ML)

FM(MONO)/BEAT

TAPE(STAND-BY)

6789

TP2

T108

FM IF

C139

0.02

R110

100

R111

47

R112

47

C119

0.22

R237

4.7K

R256

680K

Q207

2SC945

MIXING MIC

PRE AMP.

C209

0.001(ML)

IC201

BA3313L

R202

3.9K

C204

C202

47/16

0.0015(ML)

150

R204

R201

3.9K

120K

R231

BIAS OSC.

R225

3DA8050

22K

C220

C219

0.022

LINE

S301-E

FM(ST)

BEAT CANCEL

L103

TC1

L102

TC2

R102

33

S101

BAND

SELECTOR

FM

MW

SW1

SW2

C121

0.22

FM

MW

SW1

SW2

SELECTOR

R241

330

C233

39K

R215

OUT1

2 3 4

1

5.6K

R208

C206

0.022(ML)

Q201

(ML)

S301

FUNCTION/

C107

15P

(CH)

R101

47

S101-E

S101-A

S101

BAND

1/50

R222

C210

0.001

ALC

C213

L103

10/16

22K

+B

fH

C120

(ML)

NF1

47/16

C218

47/16

R247

fL

fH

fL

FM OSC.

C258

330P

C208

0.47/50

220

FM BAND

COVERAGE

FM

TRACKING

C108

20P

(CH)

C138

220/16

CF101

10.7MHz

FM IF

22K

R223

R217

330K

R218

330K

39K

R216

IN1

N.C.

5

C259

0.0027

470K

R213

C207

0.47/50

R105

fL

T103

MW BAND

COVERAGE

fH

TC4

fL

L100

MW

TRACKING

fH

TC3

C109

R103

5P

220K

C142

0.02

TC1

VC1

0.22

C137

T106

FM

100

DETECTION

C145

100/16

24

AM

FM IF

1

1

2

PLAYBACK/RECORD

PRE AMP. & CONTROL

GND

6 7

C214

220/16

P

S201-G

R

R224

10

21

23

22

STB

OSC

AM RF

AM MIX

2 3 4 5 6

3

0.02

C123

T107

MW IF

CF102

AM IF

C122

0.02

+B

22K

22K

R243

R244

IC201

BA3313L

FILTER

VCC

IN2

GND

8

9

R214

100

1/50

C257

C260

0.0027

C215

0.022(ML)

R232

120K

R209

1K

P

S201-I

R

S201

RECORD/

PLAYBACK

+VCC

AGC

10

C261

330P

R210

C110

0.02

R121

AM IF

C124

1

S301-B

+B

R207

R219

27K

1K

3.9K

22/16

CT102

T104

T101

CT104

R104

820K

C136

0.0047

(ML)

2.7K

R120

TP4

IC102

FM DET

LA1805

7

C125

0.015(ML)

C126

0.015

3

2

TAPE(STAND-BY)

FM(ST)

FM(MONO)/BEAT

LINE

S301

FUNCTION/

BEAT CANCEL

NF2

OUT2

12

11

D201

1N4148-T72

C203

R251

47/16

5.6K

R203

150

R220

27K

C518

fL

fH

fL

fH

C135

TP3

0.0082(ML)

17181920

DET

OUT

AM IN

GNDGND

8 9 10 11

(ML)

1/50

C127

R113

R114

2.2K

R116

2.2K

18K

S201-F

3DA8050

+B

0.1

C516

220/16

SW1 BAND

COVERAGE

SW1

TRACKING

S301

FUNCTION/

BEAT CANCEL

R118

100K

470P

C134

C133

3.3/50

C132

15

16

IN

MPX

IF AD

L-CH

R-CH

1/50

C128

10K

R115

R

S201

P

RECORD/PLAYBACK

Q501

T105

CT101

T102

CT103

S301-F

R119

C131

1500P

3.3/50

13

14

FM IF DET./

VCO

MO/ST

MW/SW MIXER

N.C.

AM/

FM

12

SW2

SW1

R117

10

MW

FM

1/50

C129

10K

LINE

FM(MONO)/

BEAT

FM(ST)

TAPE

(STAND-BY)

FM(MONO)/BEAT

FM(ST)

TAPE(STAND-BY)

+B

R501

560

ZD501

TZX8V2 C

fL

SW2 BAND

COVERAGE

fH

fL

SW2

TRACKING

fH

LINE

FM(MONO)/BEAT

FM(ST)

TAPE(STAND-BY)

VR102

10K(B)

VCO

15K

IC102

LA1805

S101-B

S101

BAND

SELECTOR

R123

100

S301-C

S301

FUNCTION/

BEAT CANCEL

C303

0.047(ML)

C304

0.047(ML)

LINE

S301-D

S301

FUNCTION/

BEAT CANCEL

SW601

TAPE MAIN

PLAY

M

M601

TAPE

MOTOR

+9V

+B

3

2

1

4

3

2

1

CON302

CN504

• NOTES ON SCHEMATIC DIAGRAM can be found on page 14.

1

2

34 5

Figure 10 SCHEMATIC DIAGRAM (1/2)

– 10 –

6

Page 11

78 9101112

1

5

3

FM IF

MIX

RF AMP

22

RNG.

23

OSC

24

LEVEL DET

AM IF

GND

6

IC BLOCK DIAGRAM

12

17

POST

AMP.

MUTING

TUNING

INDIC.

DRIVE

16

19

8

20

2

DCT

DET

AGC

4

IC101: LA1186N

VRE1

RF

1 2

MIX

3

4

QT-80W

Vcc

OUT 1

33K

47µ

47µ

NF 1

IN 1

GND

IN 2

NF 2

1

150K

3

5

7

9

11

IC201: BA3313L

ST. BY

6

5

240

4

7

100µ

9

240

8

33K

44K

ALC

150K

0.1µ

1

3

2

44K

11

10

12

IC401: BA5415A

GND

1000µ

1000µ

47µ

47µ

0.1µ

ALC

2

4

N.C.

6

GND(SUB)

8

VCC

10

FILTER

12

OUT 2

VCC

1000µ

RL

RL

FM

AM

15 14

11

13

PILOT DET

PHASE DET

DECODER

18

9

TNG.

VCO

IC102: LA1805

10

7

STEREO

INDIC.

DRIVE

FF

STEREO

SW

21

Vcc

FF

FF

BUTTER

REG

5

7

6

OSC

8

9

R221

220

R305

4.7K

R307

3.9K

S302-A

ON

OFF

3

1

S302

X-BASS

OFF

ON

S302-B

3

2

1

CN302

X-BASS PWB-A5

3.9K

R310

R308

4.7K

4

3

2

1

CON504

X-BASS

CONTROL

Q303

2SC945

C256

1000/16

R306

6.8K

R309

6.8K

R326

22K

X-BASS

CONTROL

D401

1N4148-T72

MOTOR

CONTROL

3DA8050

C514

100/16

R325

22K

R322

C310

Q401

4.7K

0.15(ML)

C312

0.15(ML)

4.7K

R321

Q304

2SC945

+B

R410

560

ZD401

TZX10V C

R317

10K

C305

1/50

C309

0.0015(ML)

C311

0.0015

(ML)

C306

1/50

C415

FM SIGNAL

MW/SW1/SW2 SIGNAL

R314

2.2K

C308

R311

1/50

330K

Q301

R318

10K

100/16

C301

220P

6

2

4

5

7

1

3

Q404

SS8550

R432

D403

6

2

4

CON303

5

7

1

3

CN303

C302

220P

R431

1K

D404

1N4148

2SC945

6

R312

330K

22K

1N4148

R313

470

VOLUME

CONTROL

VR301-A

VR301

50K(B)

VOLUME

VR301-B

3

VOLUME PWB-A4

C307

1/50

R315

2.2K

Q302

VOLUME

2SC945

CONTROL

R316

470

R409

REGULATOR

2.2

Q405

SS8550

R433

FUNCTION/

1K

BEAT CANCEL

FM(MONO)/BEAT

FM(ST)

TAPE(STAND-BY)

R434

S301

LINE

22K

+B

+B

S301-A

PLAYBACK SIGNAL

RECORD SIGNAL

MAIN PWB-A1

R423

47K

STAND-BY

C401

R401

1K

R402

1K

+B

C512

3300/16

1/50

C403

47/16

C416

100/16

C402

1/50

C404

47/16

+12V DC

0.1

C511

R403

R405

220

R406

220

R404

33K

+B

C417

6

33K

C420

1000P

5

4

7

IC401

9

8

C419

1000P

IC401

BA5415A

POWER AMP.

+B

0.02

C501

D501

1N4004S

0.02

C502

D502

1N4004S

0.1

12

D503

D504

1

11

10

1N4004S

1N4004S

3

2

C503

C504

0.02

0.02

C405

0.1

R413

R414

C407

47/16

3.3

3.3

C408

47/16

C406

0.1(ML)

0.1

F501

T2A L 250V

C413

470/16

C409

1000/16

C411

C412

0.1(ML)

C410

1000/16

+B

+B

+B

CON503

4

4

3

3

2

2

1

1

CON501

55

4

4

3

3

2

2

1

1

CON502

22

+B

1

1

T501

POWER

TRANSFORMER

CN503

HEADPHONES

PWB-A3

CN501

5

R408

150

1

BATTERY

PWB-A6

BATTERIES

DC 12 V [ "D" SIZE

(UM/SUM-1, R20 or

HP-2)BATTERY x 8 ]

CON601

BATTERY (+12V)

SW501

VOLTAGE

SELECTOR

AC 220-240 V

AC 110-127 V

0V

AC INPUT SOCKET

AC 110-127 V/220-240 V,

R407

150

50/60 Hz

SO501

SP503

6 OHM

R-CH

SPEAKERS

SP504

6 OHM

SP501

6 OHM

L-CH

SPEAKERS

SP502

6 OHM

AC POWER

SUPPLY CORD

AC 110-127 V/

220-240 V,

50/60 Hz

JK401

HEADPHONES

Figure 11 SCHEMATIC DIAGRAM (2/2)

– 11 –

Page 12

QT-80W

A

B

C

D

E

F

G

H

L109

MW BAR ANTENNA

ROD

ANTENNA(228)

M601

TAPE MOTOR

(241-5)

BK

RD

OR

BL

SW601

TAPE MAIN

(241-6)

GY

ERASE

HEAD

(241-4)

RECORD/

PLAYBACK

HEAD(241-3)

RD

WH

GY

TAPE

BK

PLAYBACK

BK

RD

OR

BL

BK

WH

BK

RD

BK

(233)

(239)

S201

RECORD/

CN504

1

2

3

4

CN201

1

2

3

4

GND

C218

C219

C251

C514

1

CON504

R254

R214

D201

R203

T201

234

R247

R225

E

Q401

B

R253

B

Q208

C220

C

EC

C216

R410

ZD401

C134

C129

C126

C125

C203

Q201

TP5

GHI

C415

C518

R116

R114

C

B

E

C223

R207

R224

VR102

C133

C207

R251

R232

F

VCO

C128

C260

C205

R211

C211

S201

C516

ZD501

C416

C261

E

R120

C135

R119

R118

R104

R115

C257

12

11

C259

R213

D

R501

R405

C402

1

2

3

4

5

6

7

8

IC401

9

10

11

12

C408

C119

C120

C121

R201

C201

C417

C406

R113

C214

R250

1

E

Q501

D502

C136

C137

C131

C132

C127

3579

R202

C213

234

CON201

C

B

C405

C407

C419

R406

C412

D504

CON502

T106

IC102

C124

R123

C258

246810

1

C202

C212

C403

C511

C504

C145

TP4

TP3

CF102

R103

IC201

C208

R204

C311

C312

D401

C401

R403

C420

C502

12

C503

T2A L 250V

T103

51012

3

2

1

C110

R212

ABC

C413

R414

F501

R208

R404

R402

R110

R121

R219

C206

C411

C112

C111

R105

C138

24201513

1

C122

TP2

R209

R210

R231

R216

REC.

CON303

R321

R401

R322

R423

R413

D503

CF101

C123

C204

C210

PLAY

BACK

C404

C409

CON501

T104

R124

R111

R117

23

1

T107

C142

D103

9

8

7

6

5

4

IC101

3

2

1

C101

C256

R220

1234567

D404

R433

C410

C512

CON503

Q405

D501

E

B

C

C501

CT102

R101

TP1

T108

R102

C104

C209

12345

R434

R112

C143

R221

R215

C309

C310

C113

S101

AD

B

C

C109

L103

C102

R122

L102

S301

A

B

C

D403

4321

C

B

E

Q404

E

F

T101

C139

R241

R242

D

E

F

R432

C106

C114

C107

R314

R315

T105

C118

CT101

S101

BAND SELECTOR

CT104

CT103

C103

C108

TC1

VC1

VC3

VC4

TC2

VC2

BP101

132

C235

R237

C270

B

C

E

Q204

R222

Q303

C308

R313

C307

R312

S301

FUNCTION/

BEAT CANCEL

R302

R304

R303

R301

123

CON301

R435

R256

C301

Q302

C306

R310

C141

TC3

TC4

Q207

E

C

B

B

C

E

Q301

E

C

B

C

B

R308

C304

CON302

T102

C233

R318

R317

Q304

B

C

E

R223

E

R316

C302

C303

321

STAND-BY

A

B

BEAT

CANCEL

C231

C305

R311

R307

R309

ON

C230

R218

R306

FM

MW

SW1

SW2

MAIN PWB-A1

R109

C115

R233

CON202

1

2

3

4

5

R217

R243

R244

R326

R325

R305

TAPE

FM(ST)

FM(MONO)

LINE

S101

BAND

SELECTOR

R107

R106

S301

FUNCTION/

BEAT CANCEL

C117

C116

VR101

FINE

TUNING

R108

VD101

1

2

34 5

6

Figure 12 WIRING OF P.W.BOARD (1/2)

– 12 –

Page 13

MIC

BUILT-IN

MICROPHONE

QT-80W

COLOR TABLE

BROWN

BR

RED

JK201

CN202

RD

5

BK

4

WH

3

WH

2

WH

1

CN203

CN301

BK

1

WH

2

WH

3

PK

2

WH

1

BK

WH

5

1

CON203

1

2

3

1

R234

C227

R240

JK201

MIXING

MICROPHONE

L-CH

JK301

LINE INPUT

R-CH

RD(R)

OR

YL

GR

BL

VL

GY

WH(W)

BK

PK

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

SP502

RD

BK

SP501

L-CH

SPEAKERS

CN302

CN303

BK

7

RD

6

BK

5

BR

4

WH

3

YL

2

BL

1

X-BASS PWB-A5

WH

1

PK

2

WH

3

JACK PWB-A2

VOLUME PWB-A4

VR301

7

VOLUME

VR301-A

1

VR301-B

1

S302

3

X-BASS

OFF

AB

ON

AC POWER

SUPPLY CORD

AC 110-127 V/

AC 220-240 V,

50/60 Hz

CN503

1

2

3

4

SO501

AC INPUT

SOCKET

AC 110-127 V/

AC 220-240 V,

50/60 Hz

RD

RD

RD

BK

RD

BK

BK

RD

BK

RD

VOLTAGE SELECTOR

AC 220 V-240 V AC 110 V-127 V

BK

RD

RD

WH

BL

T501

POWER

TRANSFORMER

YL

YL

BK

RD

BL

SW501

BK

SP504

SP503

WH

R-CH

SPEAKERS

(231)

(230)

CN501

HEADPHONES

PWB-A3

BK

RD

BATTERY PWB-A6

WH

1

1

WH

2

WH

3

WH

4

WH

5

5

R408

JK401

R407

JK401

HEADPHONES

CON601

1

2

RD

BK

BATTERIES

DC 12 V [ "D" size

(UM/SUM-1,R20 or HP2)

battery x 8 ]

78 9101112

Figure 13 WIRING OF P.W.BOARD (2/2)

– 13 –

Page 14

QT-80W

NOTES ON SCHEMATIC DIAGRAM

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means pico-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic

capacitor, the expression “capacitance/withstand voltage”

is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

• The indicated voltage in each section is the one measured by

Digital Multimeter between such a section and the chassis

with no signal given.

REF. NO

S101 BAND SELECTOR FM—MW—SW1—SW2

S201 RECORD/PLAYBACK REC—P.B.

S301 FUNCTION/ LINE

S302 X-BASS OFF—ON

SW501 VOLTAGE SELECTOR AC 220-240 V—

SW601 TAPE MAIN OFF—ON

DESCRIPTION

BEAT CANCEL

POSITION

AC 110-127 V

TYPES OF TRANSISTOR

FRONT

VIEW

ECB

2SC945

3DA8550

SS8550

FRONT

VIEW

EBC

3DA8050

IC101: LA1186N [FM]

Pin No.

Voltage

IC102: LA1805 [FM]

Pin No.

Voltage

Pin No.

Voltage

IC102: LA1805 [MW/SW1/SW2]

Pin No.

Voltage

Pin No

Voltage

IC201: BA3313L [PLAYBACK]

Pin No.

Voltage

IC201: BA3313L [RECORD]

Pin No.

Voltage

1 2 3 4 5 6 7 8 9

0.9V 1.5V 5.3V 0V 0V 5.3V 0V 4.7V 5.3V

1 2 3 4 5 6 7 8 9 10 11 12

1.5V 1.5V 5.5V 2.2V 1.5V 0V 0V 0V 2V 2V 4.8V 0.8V

13 14 15 16 17 18 19 20 21 22 23 24

1.1V 1.5V 1.5V 1.2V 2.3V 0.22V 0.12V 5.5V 5.5V 0V 1.6V 0.8V

1 2 3 4 5 6 7 8 9 10 11 12

1.55V 1.55V 6.7V 0.8V 1.55V 0V 0V 0V 2V 2V 6.5V 0.8V

13 14 15 16 17 18 19 20 21 22 23 24

0V 1.65V 1.1V 1.2V 1.65V 0.8V 0.55V 6.7V 6.5V 1.6V 1.6V 1.6V

1 2 3 4 5 6 7 8 9 10 11 12

2.7V 0.25V 6.6V 0V 6.9V 0V 0V 0V 0V 5.2V 0V 3V

1 2 3 4 5 6 7 8 9 10 11 12

2.8V 0.26V 6.4V 0V 6.8V 0V 0V 0V 0V 0.265V 0V 3V

VOLTAGE

Q201: 3DA8050

Pin No.

Voltage

Q204: SS8550

Pin No.

Voltage

Q207: 2SC945

Pin No.

Voltage

Q301: 2SC945

Pin No.

Voltage

Q302: 2SC945

Pin No.

Voltage

Q303: 2SC945

Pin No.

Voltage

1 2 3

E: 7V B: 6.7V C:7.6V

1 2 3

E:7.5V C:7.5V B: 0V

1 2 3

E: 0V C:3.5V B:0.5V

1 2 3

E: 0V C:4V B:0.7V

1 2 3

E: 0V C:4V B:0.7V

1 2 3

E: 0V C: 0V B: 5V

IC401: BA5415A [FULL POWER]

Pin No.

Voltage

Q404: SS8550

Pin No.

Voltage

1 2 3 4 5 6 7 8 9 10 11 12

13V 7.7V 13V 0.6V 5V 5.2V 13V 0V 0.6V 13V 7.8V 0V

1 2 3

E: 15V C: 15V B: 0V

Q405: SS8550

Pin No.

Voltage

1 2 3

E: 15V C: 15V B: 15V

– 14 –

Q501: 3DA8050

Pin No.

Voltage

1 2 3

E:7.5V C: 15V B:8.2V

Q304: 2SC945

Pin No.

Voltage

1 2 3

E: 0V C: 0V B: 5V

Page 15

PARTS GUIDE

STEREO RADIO CASSETTE RECORDER

QT-80W

“HOW TO ORDER REPLACEMENT PARTS”

To have your order filled promptly and correctly, please furnish the

following information.

1. MODEL NUMBER 2. REF. No.

3. PART NO. 4. DESCRIPTION

MARK: SPARE PARTS-DELIVERY SECTION

MODEL

For U.S.A. only

Contact your nearest SHARP Parts Distributor to order.

For location of SHARP Parts Distributor,

Please call Toll-Free;

1-800-BE-SHARP

QT-80W

Explanation of capacitors/resistors parts codes

Capacitors

VCC ....................... Ceramic type

VCK........................ Ceramic type

VCT........................ Semiconductor type

VC • • MF ............... Cylindrical type (without lead wire)

VC • • MN............... Cylindrical type (without lead wire)

VC • • TV................ Square type (without lead wire)

VC • • TQ ............... Square type (without lead wire)

VC • • CY ............... Square type (without lead wire)

VC • • CZ ............... Square type (without lead wire)

VC • • • • • • • • • J .. The 13th character represents capacity difference.

("J" ±5%, "K" ±10%, "M" ±20%, "N" ±30%,

"C" ±0.25 pF, "D" ±0.5 pF, "Z" +80-20%.)

If there are no indications for the electrolytic capacitors, error is ±20%.

NOTE:

Parts marked with “ ” are important for maintaining the safety of the set.

Be sure to replace parts with specified ones for maintaining the safety and performance of the set.

Resistors

VRD ....................... Carbon-film type

VRS........................ Carbon-film type

VRN ....................... Metal-film type

VR • • MF ............... Cylindrical type (without lead wire)

VR • • MN............... Cylindrical type (without lead wire)

VR • • TV................ Square type (without lead wire)

VR • • TQ ............... Square type (without lead wire)

VR • • CY ............... Square type (without lead wire)

VR • • CZ ............... Square type (without lead wire)

VR • • • • • • • • • J .. The 13th character represents error.

("J" ±5%, "F" ±1%, "D" ±0.5%.)

If there are no indications for other parts, the resistors are ±5%

carbon-film type.

Page 16

QT-80W

NO.

PARTS CODE

PRICE

RANK

DESCRIPTION

INTEGRATED CIRCUITS

IC101 VHILA1186N/-1 J AE FM Front End,LA1186N

IC102 VHILA1805//-1 J AM

IC201 92L2301-461001 J Playback/Record Pre Amp.&

IC401 92L2301-455001 J Power Amp.,BA5415A

FM IF Det./MW/SW Mixer,LA1805

Control,BA3313L

TRANSISTORS

Q201 92L2103-109001 J Silicon,NPN,3DA8050

Q204 92L2101-025001 J Silicon,PNP,SS8550

Q207,208 92L2103-032001 J Silicon,NPN,2SC945

Q301~304 92L2103-032001 J Silicon,NPN,2SC945

Q401 92L2103-109001 J Silicon,NPN,3DA8050

Q404 92L2101-025001 J Silicon,PNP,SS8550

Q405 92L2101-025001 J Silicon,PNP,SS8550

Q501 92L2103-109001 J Silicon,NPN,3DA8050

DIODES

D103 VHD1N4148//-1 J AA Silicon,1N4148

D201 92L2501-010001 J Silicon,1N4148-T72

D401 92L2501-010001 J Silicon,1N4148-T72

D403,404 VHD1N4148//-1 J AA Silicon,1N4148

D501~504 VHD1N4004S/-1 J AB Silicon,1N4004S

VD101 92L2507-001001 J Silicon,1S2658

ZD401 92L2504-003001 J Zener,10V,TZX10V C

ZD501 92L2504-003019 J Zener,8.2V,TZX8V2 C

FILTERS

BP101 92L4401-008001 J Band Pass Filter

CF101 RFILF0072AFZZ J AG FM IF,10.7 MHz

CF102 92L4403-011001 J AM IF

TRANSFORMER

1 T501 92L5102-109001 J Power

COILS

L102 92L1107-009001 J FM RF

L103 92L1107-007001 J FM Oscillation

L109 92L7602-001001 J MW Bar Antenna

T101 92L1111-025001 J SW1 Antenna

T102 92L1104-092001 J SW2 Antenna

T103 92L1104-091001 J MW Oscillation

T104 92L1104-090001 J SW1 Oscillation

T105 92L1104-089001 J SW2 Oscillation

T106 92L1104-024001 J FM Detection

T107 92L1104-094001 J MW IF

T108 92L1104-038001 J FM IF,10.70 MHz

T201 92L1104-093001 J Bias Oscillation

VARIABLE RESISTORS

VR101 92L1701-052001 J 100 kohm (B),Semi-VR

VR102 92L1601-001001 J 10 kohm (B),Semi-VR [VCO]

VR301 92L1701-049001 J 50 kohms (B)×2 [Volume]

[Fine Tuning]

VARIABLE CAPACITORS

CT101~104 92L1341-007001 J Trimmer,10 pF

VC1~4 92L1340-003001 J Variable Capacitor with Trimmer

(TC1~4)

CAPACITORS

C101,102 VCCSPA1HL102J J AA 0.001 µF,50V

C103 VCEAZA1CW106M J AC 10 µF,16V,Electrolytic

C104 VCCSPA1HL102J J AA 0.001 µF,50V

C106 VCCCPA1HH220J J AA 22 pF (CH),50V

C107 VCCCPA1HH150J J AA 15 pF (CH),50V

C108 VCCCPA1HH200J J AA 20 pF (CH),50V

C109 VCCSPA1HL5R0D J AA 5 pF,50V

C110 VCKYPA1HF203Z J 0.02 µF,50V

NO. PARTS CODE

C111 VCCSPA1HL301K J 300 pF,50V

C112 VCCSPA1HL5R0D J AA 5 pF,50V

C113 VCTYPA1HB152K J 1500 pF,50V

C114 VCKYPA1HF472Z J 0.0047 µF,50V

C115 VCCSPA1HL5R0D J AA 5 pF,50V

C116,117 VCKYPA1HF203Z J 0.02 µF,50V

C118,119 VCKYPA1CF224Z J 0.22 µF,16V

C120 VCEAZA1CW106M J AC 10 µF,16V,Electrolytic

C121 VCKYPA1CF224Z J 0.22 µF,16V

C122 92L1321-002005 J 0.02 µF,50V

C123 VCKYPA1HF203Z J 0.02 µF,50V

C124 VCEAZA1CW226M J AC 22 µF,16V,Electrolytic

C125,126 VCQYKA1HM153K J AB 0.015 µF,50V,Mylar

C127~129 VCEAZA1HW105M J AB 1 µF,50V,Electrolytic

C131 VCTYPA1HB152K J 1500 pF,50V

C132,133 VCEAZA1HW335M J AB 3.3 µF,50V,Electrolytic

C134 VCTYPA1HB471K J 470 pF,50V

C135 VCQYKA1HM822K J AA 0.0082 µF,50V,Mylar

C136 VCTYPA1HM472K J 4700 pF,50V

C137 VCKYPA1CF224Z J 0.22 µF,16V

C138 VCEAZA1CW227M J AC 220 µF,16V,Electrolytic

C139 VCKYPA1HF203Z J 0.02 µF,50V

C141 VCCCPA1HH100J J AA 10 pF (CH),50V

C142 VCKYPA1HF203Z J 0.02 µF,50V

C143 VCKYPA1HF104Z J 0.1 µF,50V

C145 VCEAZA1CW107M J AC 100 µF,16V,Electrolytic

C201,202 VCQYKA1HM152K J AB 0.0015 µF,50V,Mylar

C203,204 VCEAZA1CW476M J AB 47 µF,16V,Electrolytic

C205,206 VCQYKA1HM223K J AB 0.022 µF,50V,Mylar

C207,208 VCEAZA1HW474M J AB 0.47 µF,50V,Electrolytic

C209,210 VCQYKA1HM102K J AA 0.001 µF,50V,Mylar

C211,212 VCQYKA1HM222K J AA 0.0022 µF,50V,Mylar

C213 VCEAZA1CW476M J AB 47 µF,16V,Electrolytic

C214 VCEAZA1CW227M J AC 220 µF,16V,Electrolytic

C216 92L1331-005013 J 0.0027 µF,100V

C218 VCEAZA1CW476M J AB 47 µF,16V,Electrolytic

C219 VCQYKA1HM223K J AB 0.022 µF,50V,Mylar

C220 VCQYKA1HM682K J AA 0.0068 µF,50V,Mylar

C223 VCCCPA1HH101J J AA 100 pF (CH),50V

C227 VCEAZA1CW106M J AC 10 µF,16V,Electrolytic

C230 VCQYKA1HM103K J AA 0.01 µF,50V,Mylar

C231 VCEAZA1HW105M J AB 1 µF,50V,Electrolytic

C233 VCEAZA1HW105M J AB 1 µF,50V,Electrolytic

C235 VCEAZA1CW476M J AB 47 µF,16V,Electrolytic

C251 VCQYKA1HM183K J AB 0.018 µF,50V,Mylar

C256 VCEAZA1CW108M J 1000 µF,16V,Electrolytic

C257 VCEAZA1HW105M J AB 1 µF,50V,Electrolytic

C258 92L1321-001096 J 330 pF,50V

C259,260 92L1331-001023 J 0.0027 µF,100V

C261 92L1321-001096 J 330 pF,50V

C270 VCEAZA1CW106M J AC 10 µF,16V,Electrolytic

C301,302 92L1321-001016 J 220 pF,50V

C303,304 VCQYKA1HM473K J AB 0.047 µF,50V,Mylar

C305~308 VCEAZA1HW105M J AB 1 µF,50V,Electrolytic

C309 VCQYKA1HM152K J AB 0.0015 µF,100V,Mylar

C310 VCQYKA1HM154K J AB 0.15 µF,100V,Mylar

C311 VCQYKA1HM152K J AB 0.0015 µF,50V,Mylar

C312 VCQYKA1HM154K J AB 0.15 µF,100V,Mylar

C401,402 VCEAZA1HW105M J AB 1 µF,50V,Electrolytic

C403,404 VCEAZA1CW476M J AB 47 µF,16V,Electrolytic

C405,406 VCKYPA1HF104Z J 0.1 µF,50V

C407,408 VCEAZA1CW476M J AB 47 µF,16V,Electrolytic

C409,410 92L1301-041012 J 1000 µF,16V,Electrolytic

C411,412 VCQYKA1HM104K J AB 0.1 µF,50V,Mylar

C413 VCEAZA1CW477M J AC 470 µF,16V,Electrolytic

C415,416 VCEAZA1CW107M J AC 100 µF,16V,Electrolytic

C417 VCKYPA1HF104Z J 0.1 µF,50V

C419,420 VCTYPA1HB102K J AA 1000 pF,50V

C501~504 VCKYPA1HF203Z J 0.02 µF,50V

C511 VCKYPA1HF104Z J 0.1 µF,50V

C512 92L1301-041025 J 3300 µF,16V,Electrolytic

C514 VCEAZA1CW107M J AC 100 µF,16V,Electrolytic

C516 VCEAZA1CW227M J AC 220 µF,16V,Electrolytic

C518 VCKYPA1HF104Z J 0.1 µF,50V

PRICE

RANK

DESCRIPTION

RESISTORS

R101 VRD-ST2CD470J J AA 47 ohms,1/6W

R102 VRD-ST2CD330J J AA 33 ohms,1/6W

R103 VRD-ST2CD224J J AA 220 kohms,1/6W

R104 VRD-ST2CD824J J AA 820 kohms,1/6W

R105 VRD-ST2CD101J J AA 100 ohm,1/6W

– 1 –

Page 17

QT-80W

NO. PARTS CODE

R106,107 VRD-ST2CD104J J AA 100 kohm,1/6W

R108,109 VRD-ST2CD223J J AA 22 kohms,1/6W

R110 VRD-ST2CD101J J AA 100 ohm,1/6W

R111,112 VRD-ST2CD470J J AA 47 ohms,1/6W

R113 VRD-ST2CD103J J AA 10 kohm,1/6W

R114 VRD-ST2CD223J J AA 22 kohms,1/6W

R115 VRD-ST2CD103J J AA 10 kohm,1/6W

R116 VRD-ST2CD223J J AA 22 kohms,1/6W

R117 VRD-ST2CD100J J AA 10 ohm,1/6W

R118 VRD-ST2CD104J J AA 100 kohm,1/6W

R119 VRD-ST2CD153J J AA 15 kohms,1/6W

R120 VRD-ST2CD272J J AA 2.7 kohms,1/6W

R121 VRD-ST2CD392J J AA 3.9 kohms,1/6W

R122 VRD-ST2CD100J J AA 10 ohm,1/6W

R123 VRD-ST2CD101J J AA 100 ohm,1/6W

R124 VRD-ST2CD333J J AA 33 kohms,1/6W

R201,202 VRD-ST2CD392J J AA 3.9 kohms,1/6W

R203,204 VRD-ST2CD151J J AA 150 ohms,1/6W

R207,208 VRD-ST2CD562J J AA 5.6 kohms,1/6W

R209,210 VRD-ST2CD102J J AA 1 kohm,1/6W

R211,212 VRD-ST2CD183J J AA 18 kohms,1/6W

R213 VRD-ST2CD474J J AA 470 kohms,1/6W

R214 VRD-ST2CD331J J AA 330 ohms,1/6W

R215,216 VRD-ST2CD393J J AA 39 kohms,1/6W

R217,218 VRD-ST2CD334J J AA 330 kohms,1/6W

R219,220 VRD-ST2CD273J J AA 27 kohms,1/6W

R221 VRD-ST2CD221J J AA 220 ohms,1/6W

R222,223 VRD-ST2CD223J J AA 22 kohms,1/6W

R224 VRD-ST2CD100J J AA 10 ohm,1/6W

R225 VRD-ST2CD223J J AA 22 kohms,1/6W

R231,232 VRD-ST2CD124J J AA 120 kohms,1/6W

R233 VRD-ST2CD182J J AA 1.8 kohms,1/6W

R234 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R237 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R240 VRD-ST2CD102J J AA 1 kohm,1/6W

R241 VRD-ST2CD331J J AA 330 ohms,1/6W

R242 VRD-ST2CD103J J AA 10 kohm,1/6W

R243,244 VRD-ST2CD223J J AA 22 kohms,1/6W

R247 VRD-ST2CD221J J AA 220 ohms,1/6W

R250,251 VRD-ST2CD183J J AA 18 kohms,1/6W

R253,254 VRD-ST2CD103J J AA 10 kohm,1/6W

R256 VRD-ST2CD684J J AA 680 kohms,1/6W

R301 VRD-ST2CD103J J AA 10 kohm,1/6W

R302 VRD-ST2CD222J J AA 2.2 kohms,1/6W

R303 VRD-ST2CD103J J AA 10 kohm,1/6W

R304 VRD-ST2CD222J J AA 2.2 kohms,1/6W

R305 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R306 VRD-ST2CD682J J AA 6.8 kohms,1/6W

R307 VRD-ST2CD392J J AA 3.9 kohms,1/6W

R308 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R309 VRD-ST2CD682J J AA 6.8 kohms,1/6W

R310 VRD-ST2CD392J J AA 3.9 kohms,1/6W

R311,312 VRD-ST2CD334J J AA 330 kohms,1/6W

R313 VRD-ST2CD471J J AA 470 ohms,1/6W

R314,315 VRD-ST2CD222J J AA 2.2 kohms,1/6W

R316 VRD-ST2CD471J J AA 470 ohms,1/6W

R317,318 VRD-ST2CD103J J AA 10 kohm,1/6W

R321,322 VRD-ST2CD472J J AA 4.7 kohms,1/6W

R325,326 VRD-ST2CD223J J AA 22 kohms,1/6W

R401,402 VRD-ST2CD183J J AA 18 kohms,1/6W

R403,404 VRD-ST2CD333J J AA 33 kohms,1/6W

R405,406 VRD-ST2CD221J J AA 220 ohms,1/6W

R407,408 VRD-ST2EE151J J AA 150 ohms,1/4W

R409 VRD-ST2CD2R2J J AA 2.2 ohms,1/4W

R410 VRD-ST2CD561J J AA 560 ohms,1/6W

R413,414 VRD-ST2EE3R3J J AA 3.3 ohms,1/4W

R423 VRD-ST2CD473J J AA 47 kohms,1/6W

R432,433 VRD-ST2CD102J J AA 1 kohm,1/6W

R434 VRD-ST2CD223J J AA 22 kohms,1/6W

R501 VRD-ST2CD561J J AA 560 ohms,1/6W

PRICE

RANK

DESCRIPTION

OTHER CIRCUITRY PARTS

CN201 92L3421-773001 J Connector Ass’y,4Pin

CN202 92L3421-776001 J Connector Ass’y,5Pin

CN203 92L3421-775001 J Connector Ass’y,2Pin

CN301 92L3421-799001 J Connector Ass’y,3Pin

CN302 92L3421-777001 J Connector Ass’y,3Pin

CN303 92L3421-780001 J Connector Ass’y,7Pin

CN501 92L3421-778001 J Connector Ass’y,5Pin

CN503 92L3421-783001 J Connector Ass’y,4Pin

CN504 92L3421-774001 J Connector Ass’y,4Pin

NO.

CON201,202 92L3101-054003 J Plug,4Pin

CON203 92L3101-054001 J Plug,2Pin

CON301,302 92L3101-054002 J Plug,3Pin

CON303 92L3101-054006 J Plug,7Pin

CON501 92L3101-094004 J Plug,5Pin

CON502 92L3101-094001 J Plug,2Pin

CON503,504 92L3101-094003 J Plug,4Pin

CON601 92L3421-782001 J Connector Ass’y,2Pin

1 F501 92L5301-021001 J Fuse,T2A L 250V

JK201 92L3202-013001 J Jack,Mixing Microphone

JK301 92L3201-073001 J Jack,Line Input

JK401 92L3202-024001 J Jack,Headphones

M601(241-5) 92L02103007B-0 J Motor with Pulley [Tape]

MIC 92L7201-002001 J Built-in Microphone

S101 92L4103-022001 J Switch,Slide Type[Band Selector]

S201 92L4104-013001 J Switch,Push Type

S301 92L4103-022001 J Switch,Slide Type

S302 92L4104-002001 J Switch,Push Type [X-BASS]

1 SO501 92L3204-016001 J AC Input Socket

SP501~504 92L4801-083001 J Speaker

1 SW501 92L4106-011001 J Switch,Slide Type

SW601(241-6) 92L4110-007001 J Switch,Leaf Type [Tape Main]

PRICE

RANK

[Record/Playback]

[Function/Beat Cancel]

[Voltage Selector]

DESCRIPTIONPARTS CODE

CABINET PARTS

201 92L799QT800101 J Front Cabinet Ass’y

202 92L799QT800301 J Rear Cabinet Ass’y

202- 1 92L202QT800101 J Rear Cabinet

202- 2 92L236QT800101 J Plate,Battery Cover

203 92L799QT800501 J Top Panel Ass’y

203- 1 92L201QT800101 J Top Panel

203- 2 92L286QT800101 J Name Plate,SHARP

204 92L799QT800601 J Dial Drum Ass’y

204- 1 92L242QT800101 J Dial Drum

204- 2 92L579QT800101 J Label,Frequency Range

205 92L210QT800101 J Cover,Battery

206 92L211QT800101 J Cover,Cassette Holder

207 92L220QT800101 J Bracket,

208 92L226QT800101 J Bracket,Tuning Knob

209 92L227QT800101 J Bracket,Cassette Holder Cover

210 92L248QT800101 J Handle

211 92L251QT800101 J Holder,Bar Antenna

212 92L260QT800101 J Lens,Dial Tuning

213 92L270QT800101 J Knob,Tuning

214 92L270QT800201 J Knob,Fine Tuning

215 92L272QT800101 J Button,Record

216 92L272QT800201 J Button,Play

217 92L272QT800301 J Button,Rewind

218 92L272QT800401 J Button,Fast Forward

219 92L272QT800501 J Button,Stop/Eject

220 92L272QT800601 J Button,Pause

221 92L273QT800101 J Knob,Volume

222 92L273QT800201 J Button,X-BASS

223 92L278QT800101 J Knob,Band Selector

224 92L278QT800101 J Knob,Function

225 92L289QT800101 J Ring,Volume Knob

226 92L290QT800101 J Gear,Dial

227 92L430QT800101 J Heat Sink

228 92L43330616501 J Rod Antenna

229 92L471QT800101 J Spring,Cassette Holder

230 92L47423010101 J Spring,Battery,231 92L47470120101 J Spring,Battery,+

232 92L476QT800101 J Spring,Record

233 92L489QT800101 J Bracket,Rod Antenna

234 92L579QT800103 J Label,Specifications

235 92L250QT800101 J Bracket,X-BASS PWB

236 92L70338050101 J Damper Gear Ass’y

237 92L42838560501 J Bracket,Tape Mechanism

238 92L7603-002001 J Ferrite Bar

239 92L3451-000127 J Lead Wire with Lug

1 240 92L45670120101 J Holder,Fuse

241 92L7702-003001 J Tape Mechanism Ass’y

241- 1 92L02104003A-0 J Belt,REW/FF

241- 2 92L02104007A-0 J Belt,Main

241- 3 92L155-2AM J Head,Record/Playback

241- 4 92L6PA J Head,Erase

241- 5(M601) 92L02103007B-0 J Motor with Pulley [Tape]

241- 6(SW601) 92L4110-007001 J Switch,Leaf Type [Tape Main]

Tape Mechanism/Main PWB

– 2 –

Page 18

QT-80W

NO.

601 92L60026450800 J Screw,ø2.6×8mm

602 92L60030500610 J Screw,ø3×6mm

603 92L60220500410 J Screw,ø2×4mm

604 92L60620400410 J Screw,ø2×4mm

605 92L61030010810 J Screw,ø3×8mm

606 92L61030011010 J Screw,ø3×10mm

607 92L61030011210 J Screw,ø3×12mm

608 92L61030023010 J Screw,ø3×30mm

609 92L61126010800 J Screw,ø2.6×8mm

610 92L61130011210 J Screw,ø3×12mm

611 92L61226010810 J Screw,ø2.6×8mm

612 92L61230010810 J Screw,ø3×8mm

613 92L61430011010 J Screw,ø3×10mm

614 92L61530041010 J Screw,ø3×10mm

615 92L61540021410 J Screw,ø4×14mm

616 92L61540041410 J Screw,ø4×14mm

617 92L62030061070 J Screw,ø3×10mm

618 92L66090752012 J Nut,ø9×ø12×2mm

619 92L62030061070 J Screw,ø3×10mm

620 92L61440041010 J Screw,ø4×10mm

621 92L53008003008 J Washer,ø3×ø8×0.8mm

PARTS CODE

PRICE

RANK

DESCRIPTION

ACCESSORIES/PACKING PARTS

1 QACCB0012AW00 J AS AC Power Supply Cord

1 QACCE0007AW00 J AH AC Power Supply Cord

1 QACCL0002AW00 J AN AC Power Supply Cord

1 QACCL0008AW00 J AC Power Supply Cord

1 QPLGA0003AWZZ J AF Adaptor,AC Plug

1 QPLGA0004AWZZ J AF Adaptor,AC Plug

1 92L3404-074001 J AC Power Supply Cord

92L300QT800102 J Packing Add.,Left/Right

92L31020300401 J Polyethylene Bag,Accessories

92L31069420401 J Polyethylene Bag,Unit

92L510QT800101 J Packing Case

92L563184- J Label,Serial No.

92L579QT800201 J Label,Feature

92L580QT800101 J Operation Manual

92L593QT800101 J Schematic Diagram

P.W.B. ASSEMBLY (Not Replacement Item)

PWB-A1~6 92L771QT800101 J — Main/Jack/Headphones/Volume/

X-BASS/Battery

(Combined Ass’y)

– 3 –

Page 19

QT-80W

202-1

210

202-2

228

608x3

234

607

610x2

205

608x3

607

206

A

209

SO501

207

605x2

SW501

202

B

605x2

215

223

216

236

217

218

232

219

220

PWB-A3

620

229

616x2

TAPE

MECHANISM

241(241-1, 241-2,

241-3, 241-4,

241-5 (M601),

241-6 (SW601))

606x3

T501

PWB-A6

230

239

612

203

233

PWB-A2

240x2

615x2

601

621

224

C

237

D

606

602

607

231

607

614

204

204-2

204-1

226

213

604

E

613x4

203-2

SP501

SP502

F

PWB-A4

G

212

618

225

221

H

613x4

203-1

222

235

MIC

PWB-A5

611x3

SP503

201

PWB-A1

606

613x4

214

603

606x2

SP504

617x2

Silicon

Grease

613x4

609

211

606x2

IC401

227

BELT CONNECTION

Main Belt

Flywheel

FF/REW Belt

208

619x2

238

Motor

M601

REW/FF

Clutch

Note: Only the unit and consumale parts are supplied as parts supply for the Tape mechanism.

1

23456

Figure 4 CABINET EXPLODED VIEW

– 4 –

Page 20

QT-80W

COPYRIGHT © 2001 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

SHARP CORPORATION

AV Systems Group

Audio Systems Division

Higashihiroshima, Hiroshima 739-0192, Japan

Printed in Japan

A0105-1213DS•HA•C

EX

Loading...

Loading...