Page 1

TENTATIVE

SERVICE MANUAL

SERVICE-ANLEITUNG

DIGITAL MULTIMEDIA PROJECTOR

DIGITALER MULTIMEDIA PROJEKTOR

MODEL

PG-M20X

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

CONTENTS

Page

» SPECIFICATIONS ............................................. 2

» IMPORTANT SERVICE SAFETY

NOTES (for USA)............................................... 3

» NOTE TO SERVICE PERSONNEL ................... 4

» OPERATION MANUAL ...................................... 7

» REMOVING OF MAJOR PARTS ..................... 13

» RESETTING THE TO TAL LAMP TIMER ......... 16

» ELECTRICAL ADJUSTMENT........................... 19

» TROUBLE SHOOTING TABLE ........................ 25

» CHASSIS LAYOUT .......................................... 46

» BLOCK DIAGRAM........................................... 48

» OVERALL WIRING DIAGRAM ........................ 50

» SCHEMATIC DIAGRAM .................................. 52

» PRINTED WIRING BOARD ASSEMBLIES..... 98

» PARTS LIST

Ë

ELECTRICAL PARTS ................................ 103

Ë

CABINET AND MECHANICAL PARTS ..... 116

Ë

ACCESSORIES PARTS ............................ 120

Ë

PACKING PARTS....................................... 120

» PACKING OF THE SET ................................. 121

PG-M20X

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

PG-M20X

Specifications

Product type

Model

Video system

Display method

DMD panel

Lens

Projection lamp

Component input signal

(INPUT1)

Horizontal resolution

Computer RGB input signal

(INPUT 1)

S-video input signal

(INPUT 2)

Video input signal

(INPUT 3)

Pixel clock

Vertical frequency

Horizontal frequency

Audio input signal

Audio output

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Power dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Supplied accessories

Replacement parts

Digital Multimedia Projector

PG-M20X

NTSC 3.58/NTSC 4.43/PAL/PAL-M/PAL-N/PAL 60/SECAM/

DTV480I/DTV480P/DTV720P/DTV1080I

Single Chip Digital Micromirror Device™ (DMD™) by Texas Instruments

Panel size: 0.7" (17.8 mm), 1 chip XGA DMD

No. of dots: 786,432 dots (1,024 [H] × 768 [V])

1–1.2 × zoom lens, F1.75–2.04, f = 28.0–33.5 mm

High Intensity Discharge Lamp (HID Lamp), DC 210 W

29-pin connector

DVI input signal:Digital 250–1,000 mV 50 Ω

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

: 0.7 Vp-p, 75 Ω terminated

P

B

: 0.7 Vp-p, 75 Ω terminated

P

R

700 TV lines (DTV720P)

29-pin connector

RGB separate/sync on green type analog input: 0–0.7 Vp-p, positive, 75 Ω terminated

HORIZONTAL SYNC. SIGNAL: TTL level (positive/negative)

VERTICAL SYNC. SIGNAL: Same as above

4-pin Mini DIN connector

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

RCA connector: VIDEO, composite video, 1.0 Vp-p, sync negative, 75 Ω

terminated

12–230 MHz

43–100 Hz

15–126 kHz

ø3.5 mm M

2.0 W (monaural)

4 cm × 3 cm

AC 100–240 V

3.2 A

50/60 Hz

290 W

<1,090 BTU/hour

41°F to 95°F (+5°C to +35°C)

–4°F to 140°F (–20°C to +60°C)

Plastic

38 kHz

5

⁄8" × 3" × 11 15⁄16" (219 (W) × 76 (H) × 303 (D) mm) (main body only)

8

3

8

⁄4" × 3 1⁄4" × 12 1⁄2" (223 (W) × 83 (H) × 318 (D) mm) (including adjustment feet

and projecting parts)

5.8 lbs. (2.6 kg)

Remote control, Two R-03 batteries, Power cord for U.S., Canada etc. (6', 1.8 m), Power

cord for Europe, except U.K. (6', 1.8 m), Power cord for U.K., Hong Kong and Singapore (6',

1.8 m), Power cord for Australia, New Zealand and Oceania (6', 1.8 m), DVI to 15-pin D-sub

cable (6', 1.8 m), USB cable (6', 1.8 m), Carrying case, Lens cap (attached), Lens cap

strap, Terminal cover (attached), CD-ROM, Operation manual, Quick reference guides

Lamp unit (Lamp/cage module) (BQC-PGM20X//1), Remote control (RRMCGA013WJSA),

Two R-03 batteries (“AAA” size, UM/SUM-4, HP-16, or similar), Power cord for U.S., Canada

etc. (QACCDA007WJPZ), Power cord for Europe, except U.K. (QACCV4002CEZZ), Power

cord for U.K., Hong Kong and Singapore (QACCB5024CENA), Power cord for Australia,

New Zealand and Oceania (QACCL3022CEZZ), DVI to 15-pin D-sub cable

(QCNWGA010WJZZ), USB cable (QCNWG0001WJPZ), Carrying case

(GCASN0005CESA), Lens cap (CCAPHA001WJ01), Lens cap strap (UBNDT0013CEZZ),

Terminal cover (GCOVD0103CESA), CD-ROM (UDSKA0058CEN1), Operation manual

(TINS-7609CEZZ), Quick reference guides

Analog 0.7 Vp-p 75 Ω

INIJACK

: AUDIO, 0.5 Vrms, more than 47 kΩ (stereo)

This SHARP projector uses a DMD panel. This very sophisticated panel contains 786,432 pixels. As with any high technology electronic equipment such as large screen TVs, video

systems and video cameras, there are certain acceptable

tolerances that the equipment must conform to.

Specifications are subject to change without notice.

This unit has some inactive pixels within acceptable tolerances which may result in inactive dots on the picture screen.

This will not affect the picture quality or the life expectancy

of the unit.

2

Page 3

PG-M20X

2

2

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

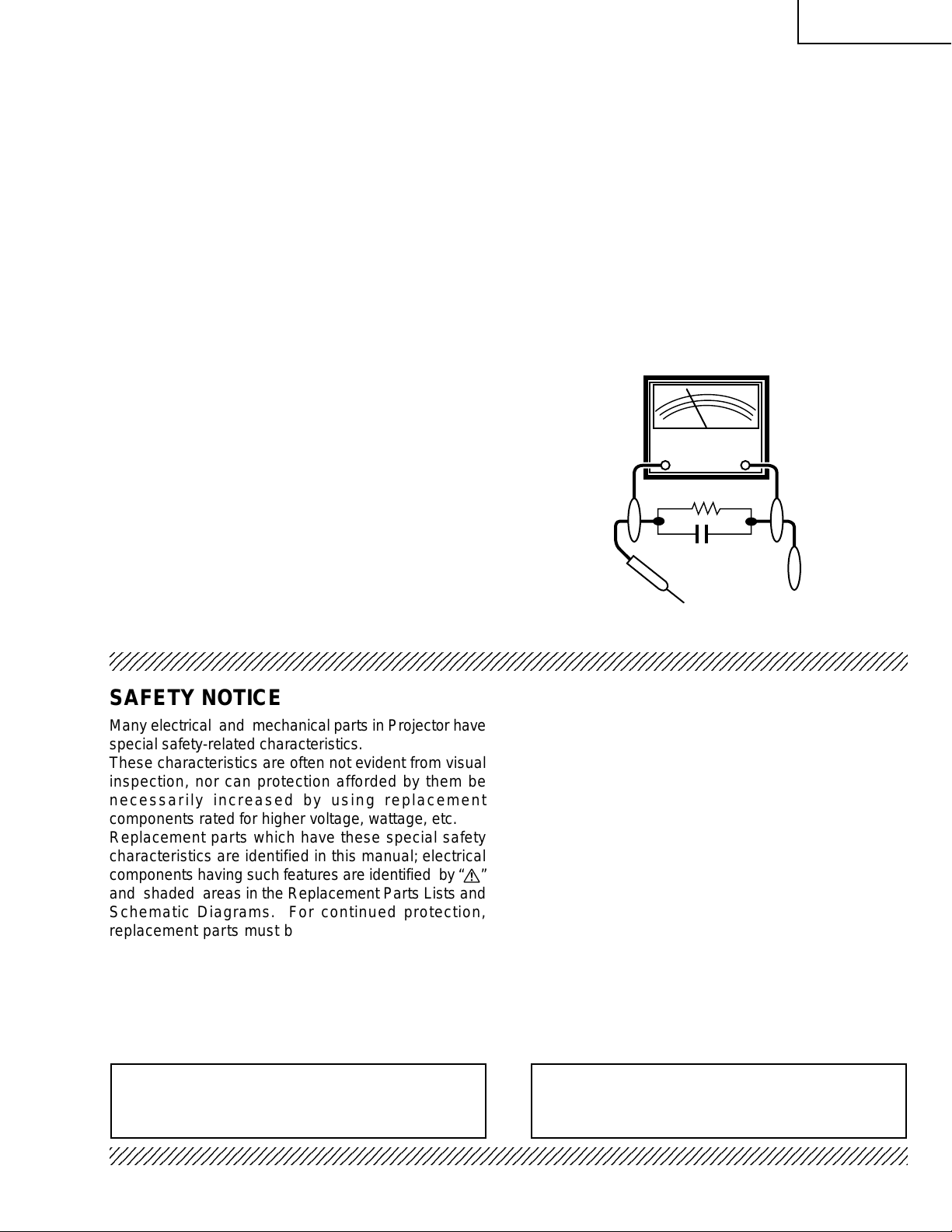

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm

per volt., or higher, sensitivity to measure the AC

voltage drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. A C .) or more is e xcessiv e and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in Projector have

special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans

la liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT:La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

3

Page 4

PG-M20X

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the pr ojector

emits small amounts of UV-Radiation.

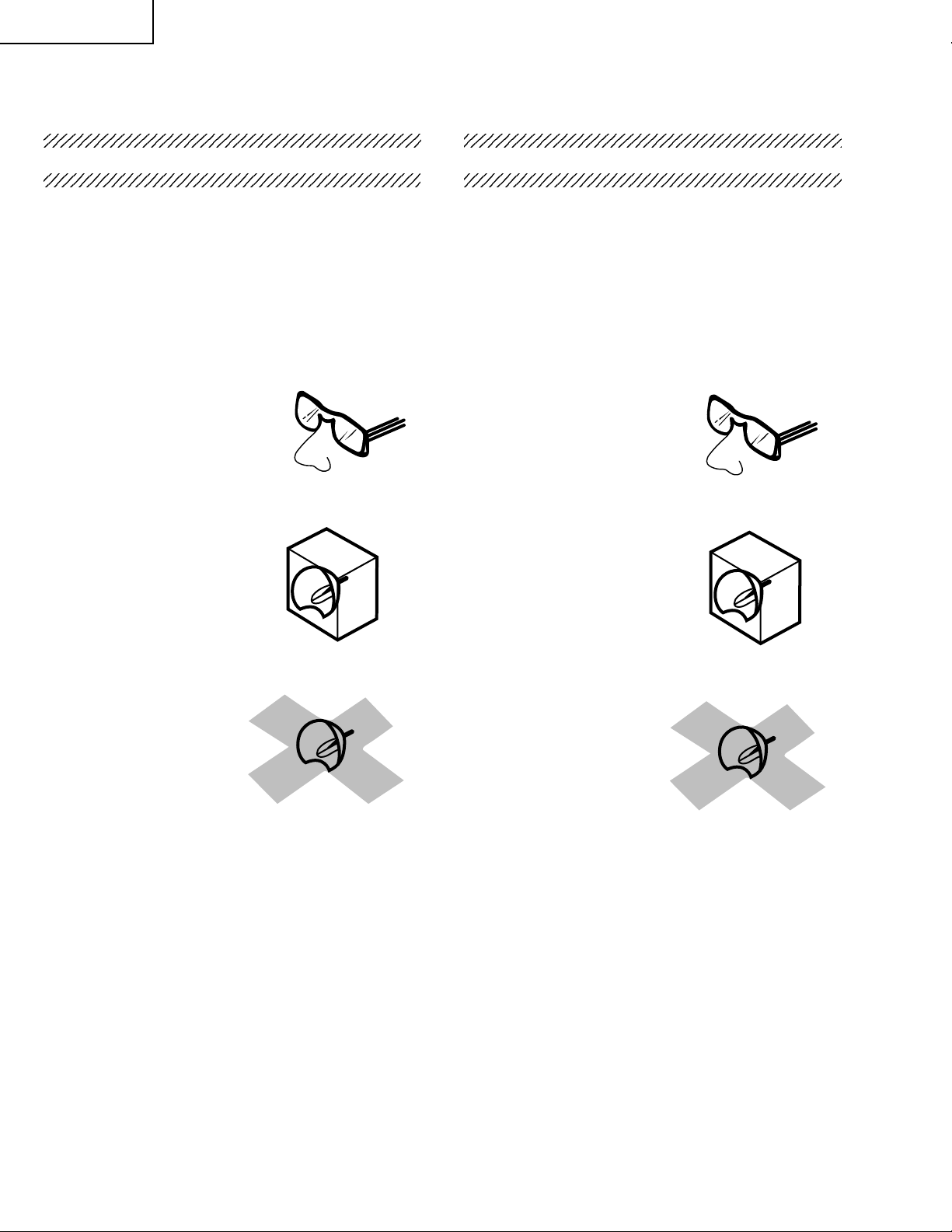

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NO TE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe métal halide,

dans le projecteur émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour v otre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours por ter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type BQCPGM20X//1 rated 85V/210W.

4. The lamp emits small amounts of UV-Radiation,

avoid direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type BQC-PGM20X//1 caractéristique 85V/210W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

4

Page 5

PG-M20X

4

5

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

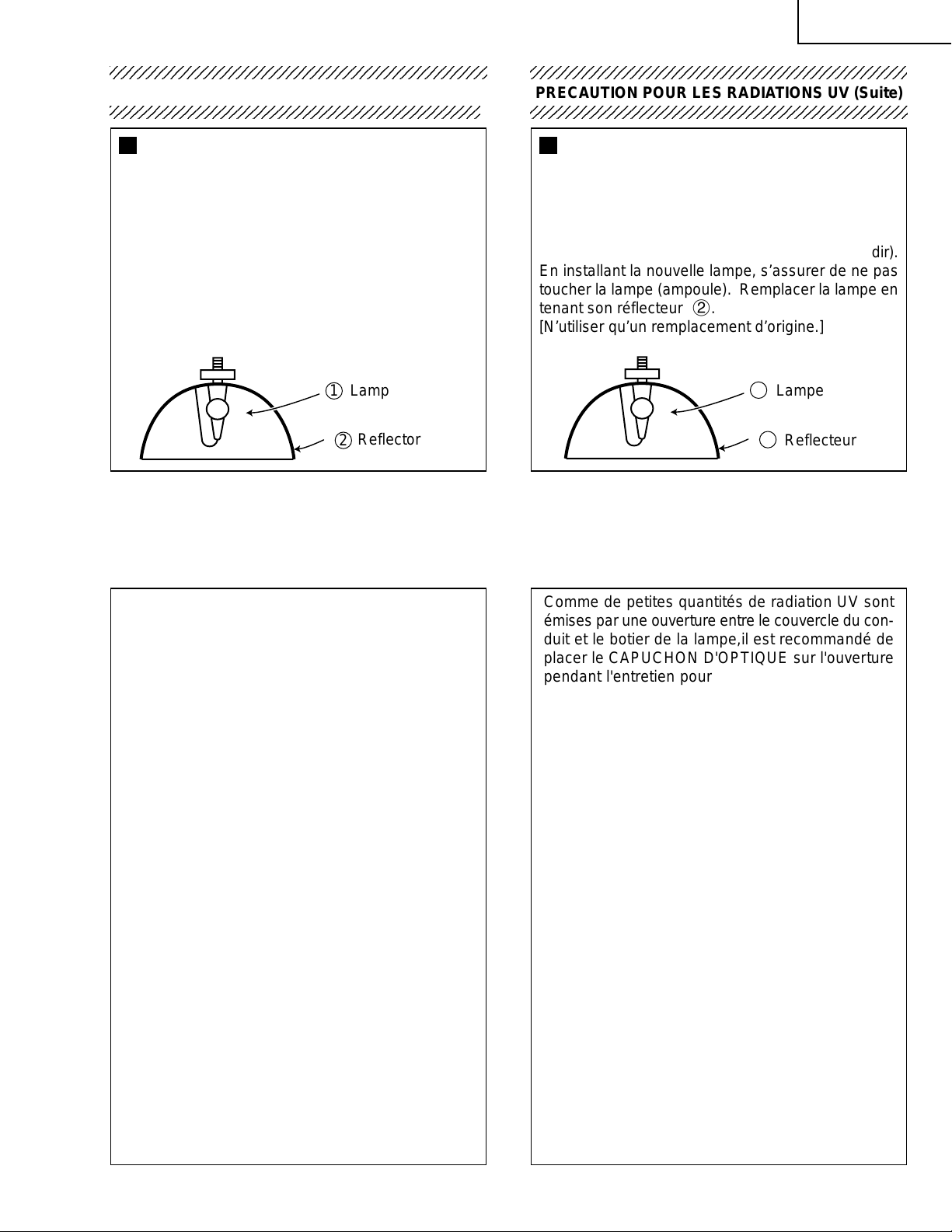

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Ne ver turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high v oltages

at its start.

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure (Fig. 1).

Note: Please obtain a lens cap before servicing a

models PG-M20X that is received without

one.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre le couvercle du conduit et le botier de la lampe,il est recommandé de

placer le CAPUCHON D'OPTIQUE sur l'ouverture

pendant l'entretien pour éviter une exposition des

yeux et la peau (Fig. 1).

Remarque: Priére de se procurer un capuchon

d'optique acant d'entretien un modéle

PG-M20X qui est livré sans.

Figure 1.

Figure 1.

5

Page 6

PG-M20X

WARNING: High brightness light source, do not stare into the beam of light, or view directl y . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMO VE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREWS

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMO VE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING T O QU ALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within

a triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are

in the manual with the projector.

AVERTISSEMENT: Sour ce lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regar der

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

A VERTISSEMENT : AFIN D’EVITER T OUT RISQ UE D’INCENDIE OU D’ELECTR OCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ELECTR OCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQ UE

D’ELECTR OCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L ’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR T OUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

6

Page 7

PG-M20X

Precautions for using lead-free solder

1 Employing lead-free solder

"Main PWB" of this model employs lead-free solder . The LF symbol indicates lead-free solder, and is attached on the

PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40ºC, we recommend y ou

to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldening bit,

contact our service station or service ranch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220ºC which is higher than the conventional lead solder

by 40ºC, and as it has poor solder wettabillty, you may be apt to keep the soldering bit in contact with the PWB for

extended period of time. However, Since the land ma y be peeled off or the maxim um heat-resistance temperature of

parts may be excoeded, remove the bit from the PWB as soon as you conurm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tum on and

off the power of the bit as required.

if a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Becareful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

7

Page 8

PG-M20X

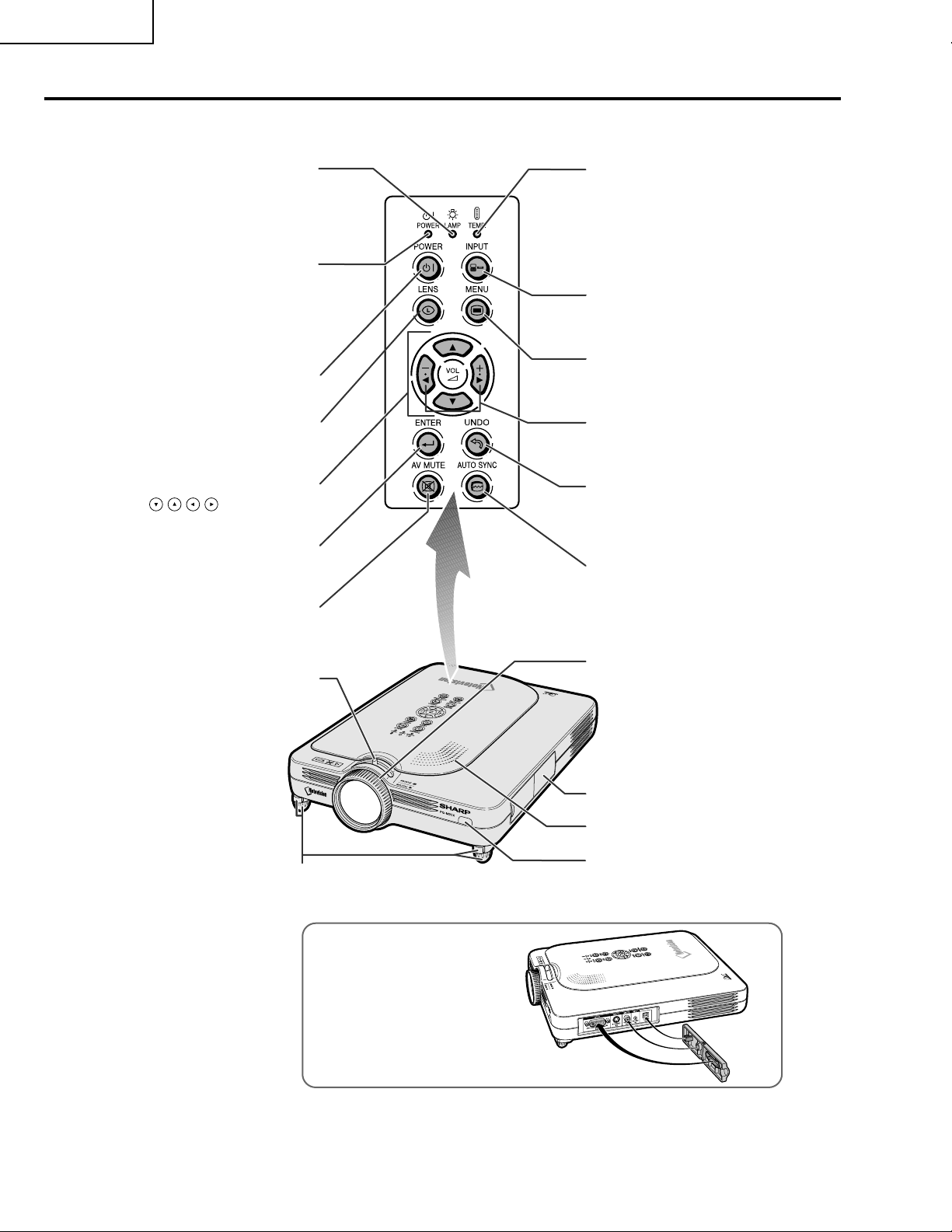

Location of Controls

Projector (Front and Top View)

LAMP REPLACEMENT

indicator

Illuminates in green normally.

Replace the lamp when the

indicator illuminates in red.

POWER indicator

Illuminates in red, when the

projector is in standby.

When the power is turned

on, this indicator will

illuminate in green.

POWER button

Turns the power on or off.

LENS button

For adjusting Keystone or

Digital Shift setting.

Adjustment buttons

(

For selecting menu items.

)

ENTER button

For setting items selected

or adjusted on the menu.

AV MUTE button

For temporarily turning off the

sound and picture.

Zoom knob

TEMPERATURE

WARNING indicator

Illuminates in green

normally. When the

internal temperature

rises, this indicator will

illuminate in red.

INPUT button

For switching input mode

1, 2 or 3.

MENU button

For displaying adjustment

and setting screens.

VOLUME buttons

For adjusting the

speaker sound level.

UNDO button

For undoing an operation

or returning to the default

settings.

AUTO SYNC button

For automatically

adjusting images when

connected to a computer.

Focus ring

Foot releases/Adjustment

feet

For adjusting the projector’s

height.

Terminal cover

Speaker

Remote control

sensor

Attaching the terminal cover

Attach the terminal cover by

placing it on the side panel of the

projector and pressing it into

place, as shown in the illustration.

8

Page 9

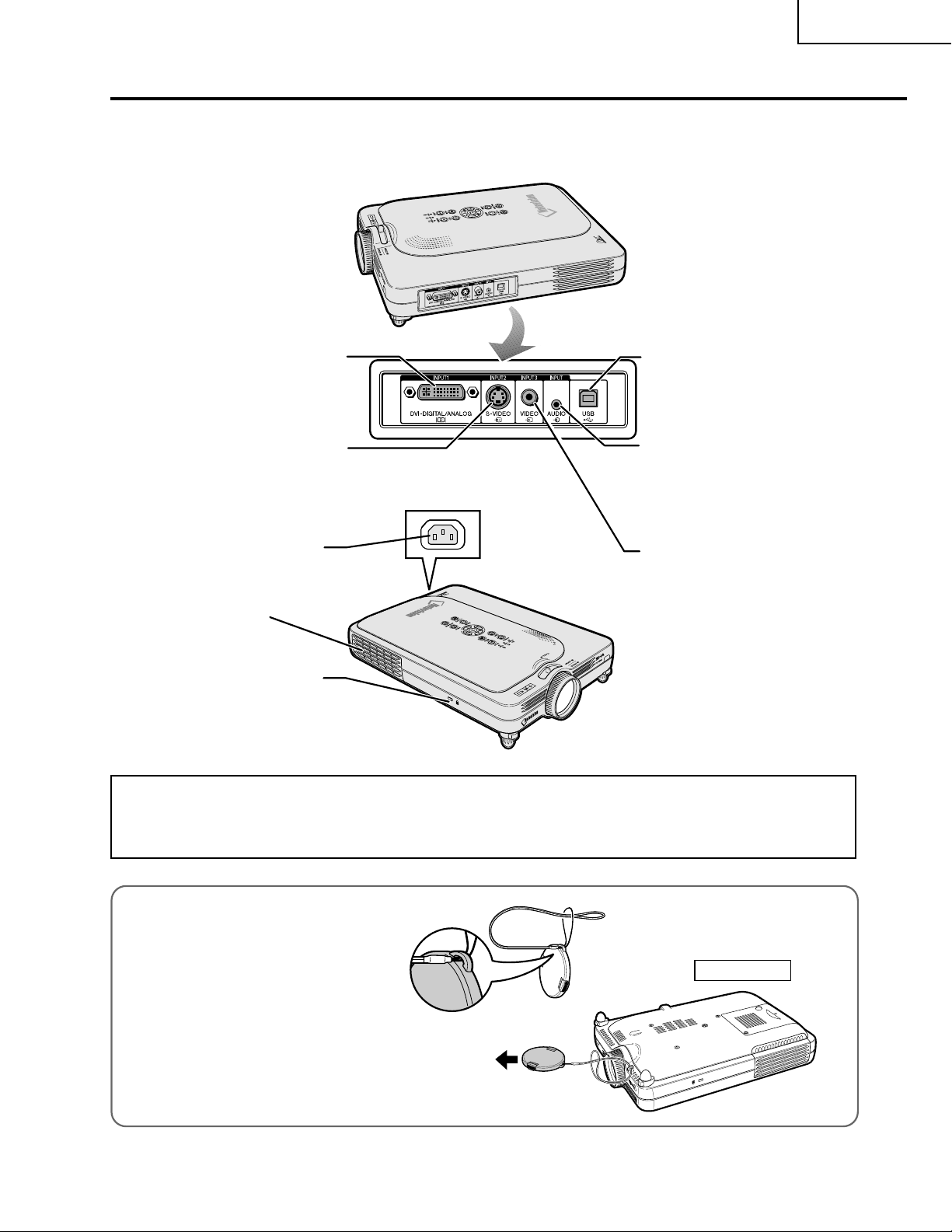

Projector (Side View)

PG-M20X

INPUT 1 terminal

Port for DVI digital, computer

RGB, and COMPONENT

signals.

INPUT 2 terminal

Terminal for connecting video

equipment with an S-VIDEO

terminal.

AC socket

USB terminal

For connecting a computer using a USB cable.

INPUT AUDIO terminal

Shared audio terminal for

INPUT 1, INPUT 2, and

INPUT 3.

INPUT 3 terminal

For connecting video

equipment.

Exhaust vent

Kensington Security

Standard connector

Using the Kensington Lock

•

This projector has a Kensington Security Standard connector for use with a Kensington MicroSaver Security

System. Refer to the information that came with the system for instructions on how to use it to secure the

projector.

Attaching the lens cap

After putting the lens cap strap on the

lens cap, pass the other end of the strap

through the hole under the projector, next

to the lens, as shown in the illustration.

Bottom View

9

Page 10

PG-M20X

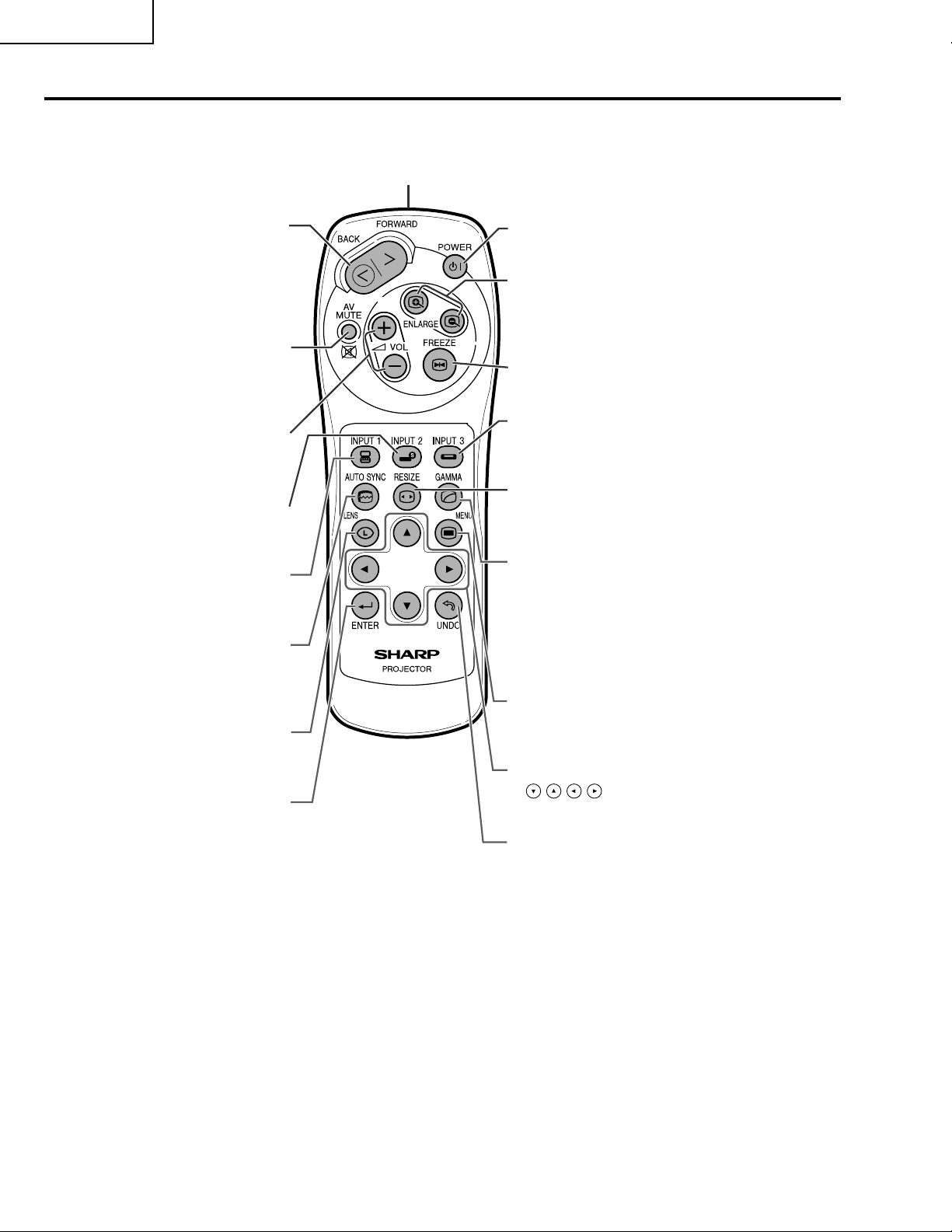

Remote Control

Remote control signal transmitter

FORWARD/BACK button

Moves forward or backwards

when connected to a computer

using a USB cable. Same as the

[Page Down] and [Page Up]

keys on a computer keyboard.

AV MUTE button

For temporarily turning off the

sound and picture.

VOLUME buttons

For adjusting the speaker

sound level.

INPUT 2 button

For switching the input mode to

INPUT 2.

INPUT 1 button

For switching the input mode to

INPUT 1.

AUTO SYNC button

For automatically adjusting

images when connected to a

computer.

LENS button

For adjusting Keystone or

Digital Shift setting.

ENTER button

For setting items selected or

adjusted on the menu.

POWER button

Turns the power on or off.

ENLARGE (Enlarge/Reduce)

buttons

For enlarging or reducing part of the

image.

FREEZE button

For freezing images.

INPUT 3 button

For switching the input mode to

INPUT 3.

RESIZE button

For switching the screen size

(NORMAL, BORDER, etc).

GAMMA button

For correcting the brightness of an

image, when the images displayed

are hard to see because of the

brightness of the room. Four

gamma modes are available to

choose from.

MENU button

For displaying adjustment and

setting screens.

Adjustment buttons

(

For selecting menu items.

)

UNDO button

For undoing an operation or

returning to the default settings.

10

Page 11

Connection Pin Assignments

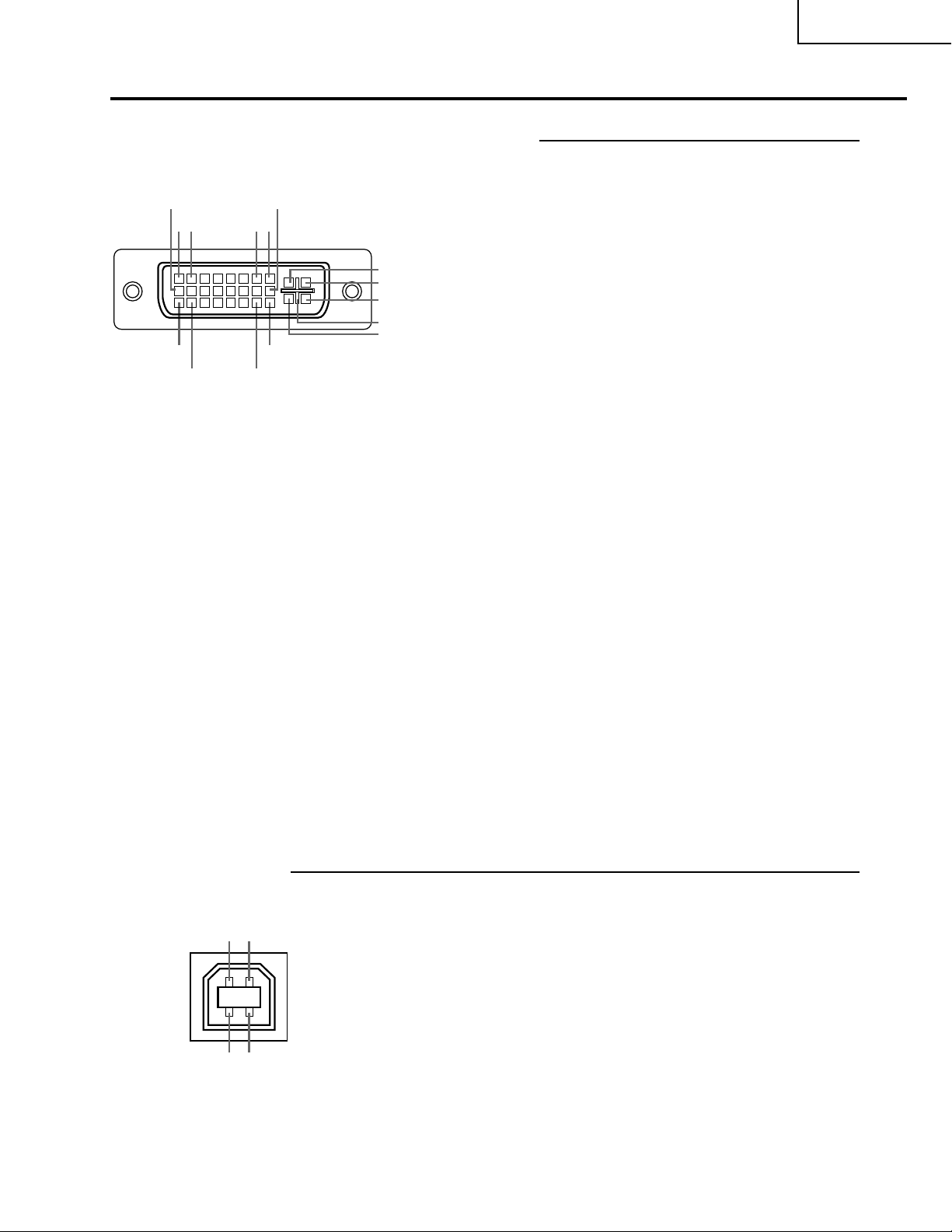

DVI Digital / Analog INPUT 1 port : 29 pin connector

• DVI Digital INPUT

•••••••••

9

••••

21

17

••••

18 23

~

~

~

•••••••••

••••

••••

16

87

C1

C2

C4

C5

C3

24

Pin No. Signal Pin No. Signal

10 T.M.D.S data 1+ C1 Not connected

11 T.M.D.S data 1 shield C2 Not connected

12 Not connected C3 Not connected

13 Not connected C4 Not connected

14 +5V current C5 Ground

15 Ground

PG-M20X

1 T.M.D.S data 2– 16 Hot plug detection

2 T.M.D.S data 2+ 17 T.M.D.S data 0–

3 T.M.D.S data 2 shield 18 T.M.D.S data 0+

4 Not connected 19 T.M.D.S data 0 shield

5 Not connected 20 Not connected

6 DDC clock 21 Not connected

7 DDC data 22 T.M.D.S clock shield

8 Not connected 23 T.M.D.S clock+

9 T.M.D.S data 1– 24 T.M.D.S clock–

• DVI Analog RGB Input

Pin No. Signal Pin No. Signal

1 Not connected 16 Hot plug detection

2 Not connected 17 Not connected

3 Not connected 18 Not connected

4 Not connected 19 Not connected

5 Not connected 20 Not connected

6 DDC clock 21 Not connected

7 DDC data 22 Not connected

8 Vertical sync 23 Not connected

9 Not connected 24 Not connected

10 Not connected C1 Analog input Red

11 Not connected C2 Analog input Green

12 Not connected C3 Analog input Blue

13 Not connected C4 Horizontal sync

14 +5V current C5 Ground

15 Ground

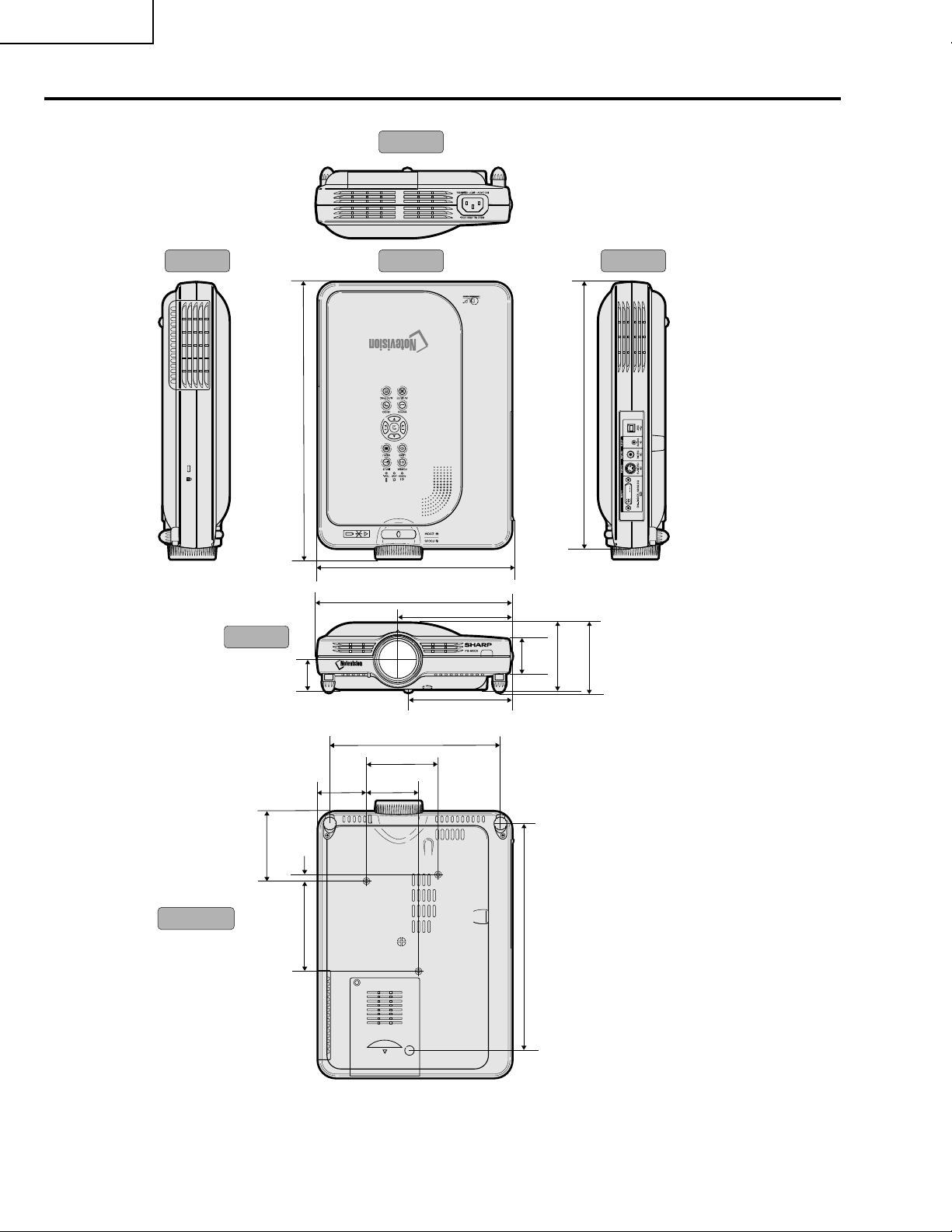

4-pin USB connector

12

• USB connector: 4 pin B-type USB connector

Pin no. Signal Name

1 VCC USB current

2 USB– USB data–

3 USB+ USB data+

4 SG Signal Ground

• DVI Analog Component Input

Pin No. Signal Pin No. Signal

1 Not connected 16 Not connected

2 Not connected 17 Not connected

3 Not connected 18 Not connected

4 Not connected 19 Not connected

5 Not connected 20 Not connected

6 Not connected 21 Not connected

7 Not connected 22 Not connected

8 Not connected 23 Not connected

9 Not connected 24 Not connected

10 Not connected C1 Analog input Pr/Cr

11 Not connected C2 Analog input Y

12 Not connected C3 Analog input Pb/Cb

13 Not connected C4 Not connected

14 Not connected C5 Ground

15 Ground

43

11

Page 12

PG-M20X

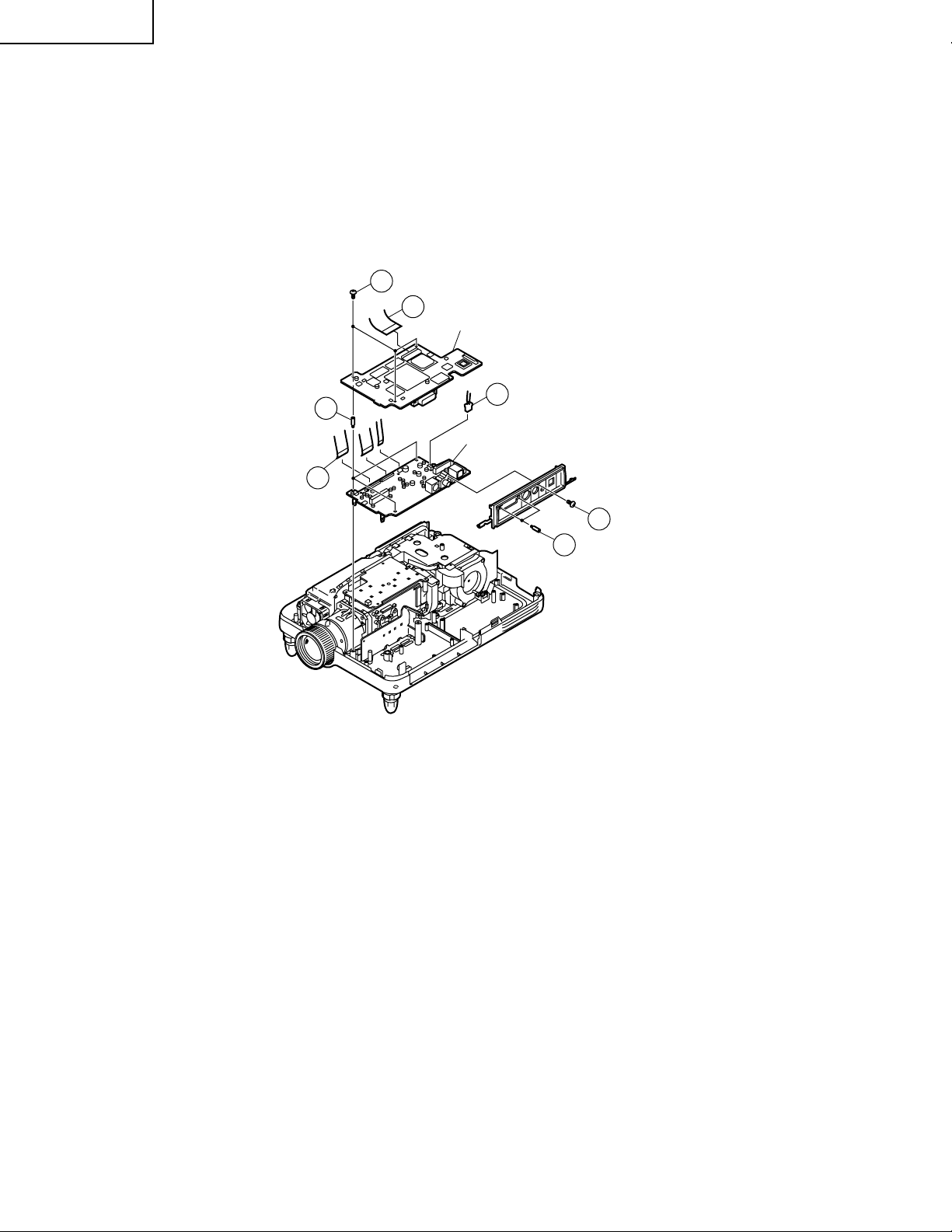

Dimensions

Side View Side ViewTop View

Rear View

12

(318.3)

Front View

1

/

8

3

(80)

9

/

16

3

1

(34.2)

5

/

16

(7.5)

1115/

16

(302.5)

3

/4 (223)

8

5

8

/8 (219)

1

5

/16 (128)

1

1

/

2

/

8

9

4

/16 (115.5)

11

7

/16 (195)

1

3

/4 (82.5)

3

2

(55.5)

3

2

/

(60)

8

/

16

(38.7)

3

(76.1)

1

3

(82.9)

/

4

Bottom View

1

4

(104)

/

8

5

10

/

(261.5)

16

Units: inches (mm)

12

Page 13

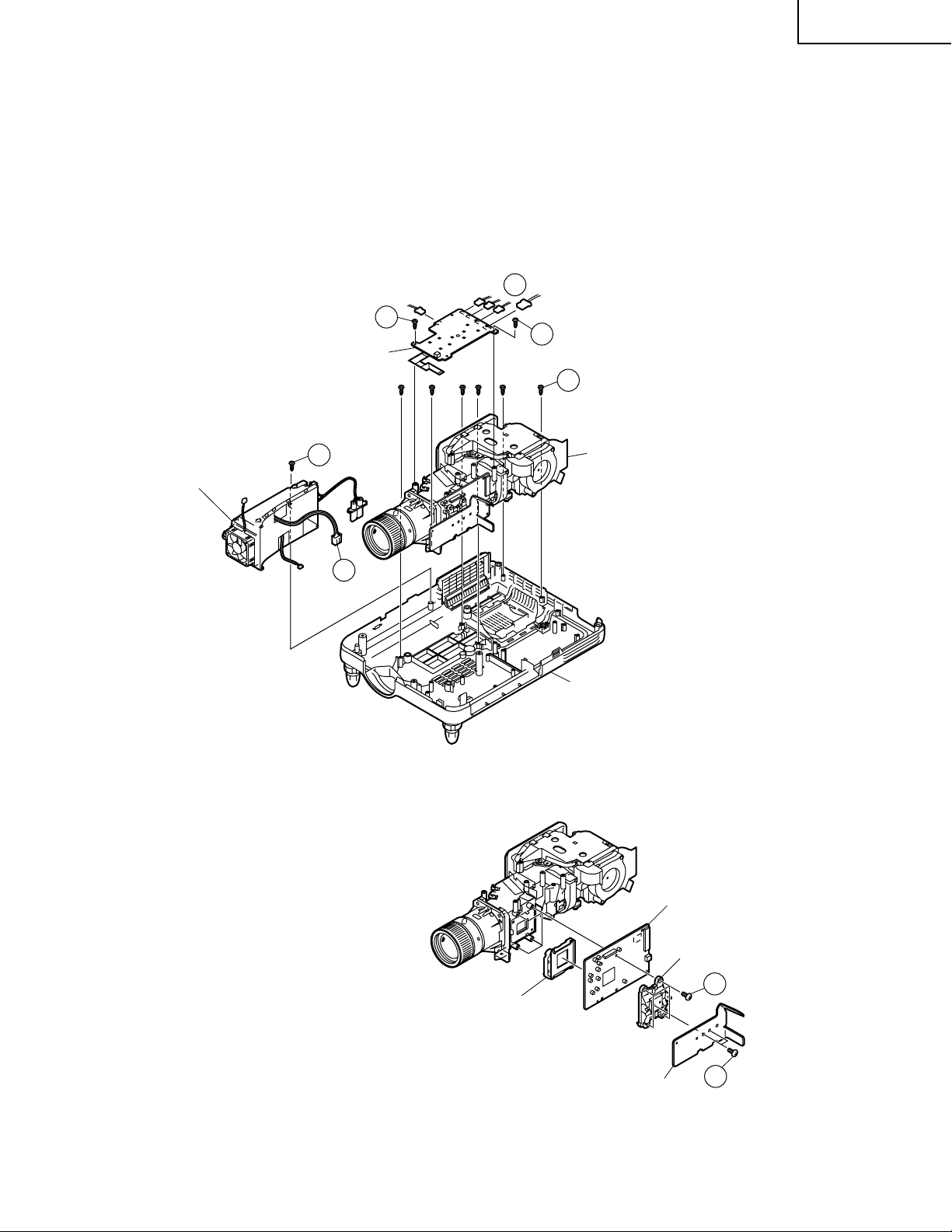

REMOVING OF MAJOR PARTS

1. Removal of the top body

1-1. Detach the terminal block cover.

1-2. Remove the five lock screws from the top body.

1-3. Slightly lift the front of the top body and disconnect the speaker connector.

2. Removal of the power PWB unit and cooling fan

2-1. Disconnect the specified connectors.

2-2. Detach the cooling fan.

2-3. Remove the four lock screws from the power unit.

2-4. Remove the three lock screws from the PFC PWB.

Top body

1-2

PG-M20X

1-3

1-2

1-2

1-2

1-1

Terminal cover

1-2

2-3

Power Unit

2-1

2-4

PFC Unit

13

2-1

2-2

Cooling fan

Page 14

PG-M20X

3. Removal of the PC I/F PWB and input PWB

3-1. Disconnect the specified connectors.

3-2. Remove the three lock screws and two hex screws from the PC I/F PWB.

3-3. Disconnect the connector from the input PWB.

3-4. Remove the three lock screws from the input PWB.

3-5. Remove the lock screw from the terminal block cover.

3-2

3-1

PC I/F Unit

3-3

3-4

3-3

Input Unit

3-5

3-2

14

Page 15

4. Removal of the operation PWB, optical unit and ballast unit

4-1. Disconnect the specified connectors from each PWB.

4-2. Remove the two lock screws from the operation PWB.

4-3. Remove the six lock screws from the optical unit.

4-4. Remove the lock screw from the ballast unit.

5. Removal of the formatter PWB

5-1. Remove the two lock screws from the heat sink.

5-2. Remove the four lock screws from the backer plate assembly, and detach the formatter PWB.

4-1

4-2

4-2

KEY Unit

4-3

PG-M20X

Ballast Unit

4-4

Optical mechanism Unit

4-1

Bottom body

Formatter Unit

DMD Unit

15

Backer plate Assy

Heat sink

5-1

5-1

Page 16

PG-M20X

RESETTING THE TOT AL LAMP TIMER

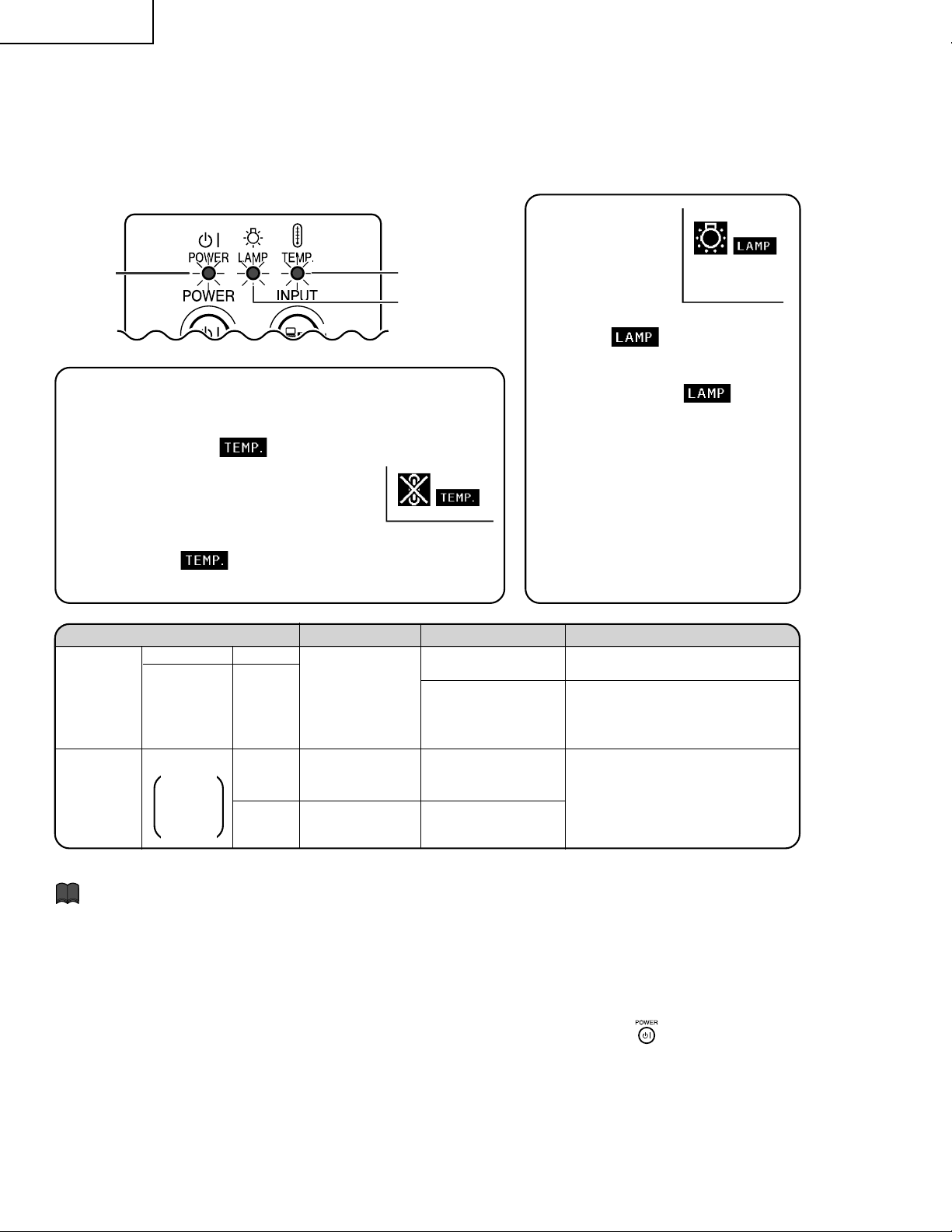

■ The warning lights on the projector indicate problems inside the projector.

■ If a problem occurs, either the TEMPERATURE WARNING indicator or the LAMP REPLACEMENT

indicator will illuminate red, and the power will turn off. After the power has been turned off, follow

the procedures given below.

About the

POWER

indicator

About the TEMPERATURE WARNING indicator

If the temperature inside the projector increases, due to blockage of the air vents, or

the setting location, “

lower left corner of the picture. If the temperature keeps on rising, the lamp will turn

off and the TEMPERATURE WARNING indicator will blink, the cooling fan will run for

further 90 seconds, then the power will be

shut off. After “

perform the following measures.

” will blink in the

” appears, be sure to

TEMPERATURE

WARNING

indicator

LAMP

REPLACEMENT

indicator

LAMP

REPLACEMENT

indicator

■When the lamp

exceeds 1,900 cumulative hours

of use, “

on the screen in yellow. When

the cumulative hours of use

reach 2,000, “

change to red, the lamp will automatically turn off and then the

projector as well. At this time , the

LAMP REPLACEMENT indicator will illuminate in red.

■If you try to turn on the projector

a fourth time without replacing

the lamp, the projector will not

turn on.

” will be displa yed

” will

Maintenance indicator Condition Problem Possible Solution

Abnormal

Red on/

Power off

Red

blinks

Red on/

Power off

The internal

temperature is

abnormally high.

Time to change

the lamp

The lamp does

not illuminate.

• Blocked air intake

• Cooling fan break-

down

• Internal circuit failure

• Clogged air intake

• Lamp usage time

exceeded 1,900

hours

• Burnt-out lamp

• Lamp circuit failure

• Relocate the projector to an area

with proper ventilation.

• Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center for repair.

• Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center for repair or

lamp replacement.

• Please exercise care when

replacing the lamp.

TEMPERA-

TURE

WARNING

indicator

LAMP

REPLACE-

MENT

indicator

Normal Abnormal

Off

Green on

Green

blinks

when the

lamp is

active.

Info

•If the LAMP REPLACEMENT indicator illuminates, and the power turns off, follow the above possible solutions and then wait until the projector has cooled down completely before plugging in the power cord and

turning the power back on. (At least 5 minutes.)

•If the power is turned off and then turned on again, as during a brief test, the LAMP REPLACEMENT indicator may be triggered, preventing the power from going on. Should this occur, take the power cord out of the

wall outlet and plug it back in again.

•If you want to clean the air vents during projector operation, be sure to first press

and after the power

has turned off and the cooling fan has stopped, then clean the vents.

•Do not unplug the power cord after the power has been turned off and while the cooling fan is running. The

cooling fan runs for about 90 seconds.

16

Page 17

PG-M20X

Lamp

■ It is recommended that the lamp (sold separately) be replaced after approximately 1,900 cumulative

hours of use or when you notice a significant deterioration of the picture and color quality. The

lamp usage time can be checked with the on-screen display. See page 58.

■ For lamp replacement, please consult your nearest Sharp Authorized Projector Dealer or Service

Center.

IMPORTANT NOTE TO U.S. CUSTOMERS:

The lamp included with this projector is backed by a 90-day parts and labor limited warranty. All service

of this projector under warranty, including lamp replacement, must be obtained through a Sharp Authorized Projector Dealer or Service Center. For the name of the nearest Sharp Authorized Projector Dealer

or Service Center, please call toll-free: 1-888-GO-SHARP (1-888-467-4277).

U.S.A. ONLY

Caution Concerning the Lamp

■ This projector utilizes a pressurized mercury lamp. A loud sound may indicate lamp failure. Lamp

failure can be attributed to numerous sour ces such as: excessive shock, improper cooling, surface

scratches or deterioration of the lamp due to a lapse of usage time. The period of time up to failure

largely varies depending on the individual lamp and/or the condition and the frequency of use. It is

important to note that failure can often result in the bulb cracking.

■ When the LAMP REPLACEMENT indicator and on-screen display icon are illuminated or flash, it is

recommended that the lamp be replaced with a new one immediately, even if the lamp appears to be

operating normally.

■ Should the lamp break, the glass particles may spread inside the lamp ca ge or gas contained in the

lamp may be vented into the room from the exhaust vent. Because the gas in this lamp includes

mercury, ventilate the room well if the lamp breaks and avoid all exposure to the released gas. In

case of exposure to the gas, consult with a doctor as soon as possible.

■ Should the lamp break, there is also a possibility that glass particles may spread inside of the

projector. In such a case, it is recommended you contact your nearest Sharp Authorized Projector

Dealer or Service Center to remove the damaged lamp and assure safe operation.

Replacing the Lamp

Caution

•Do not remove the lamp unit immediately after operation of the projector. The lamp will be hot and touching

it can lead to burn or injury.

•Wait at least one hour after the power cord is disconnected to allow the surface of the lamp unit to fully cool

before removing the lamp unit.

■ If the new lamp does not light after replacement, take your projector to the nearest Sharp Autho-

rized Projector Dealer or Service Center for repair. Purchase a replacement lamp unit of type BQCPGM20X//1 from your nearest Sharp Authorized Projector Dealer or Service Center. Then carefully

change the lamp by following the instructions described in this section. If you wish, you may have

the lamp replaced at your nearest Sharp Authorized Projector Dealer or Service Center.

17

Page 18

PG-M20X

How to Release the System Lock

Turn on the power. If the system lock is applied, the system-resetting screen appears. Press the following keys in this

order.

MENU → ENTER → ENTER → MENU → UNDO → UNDO → MENU

After pressing the MENU key first, press the remaining six keys within 10 seconds.

18

Page 19

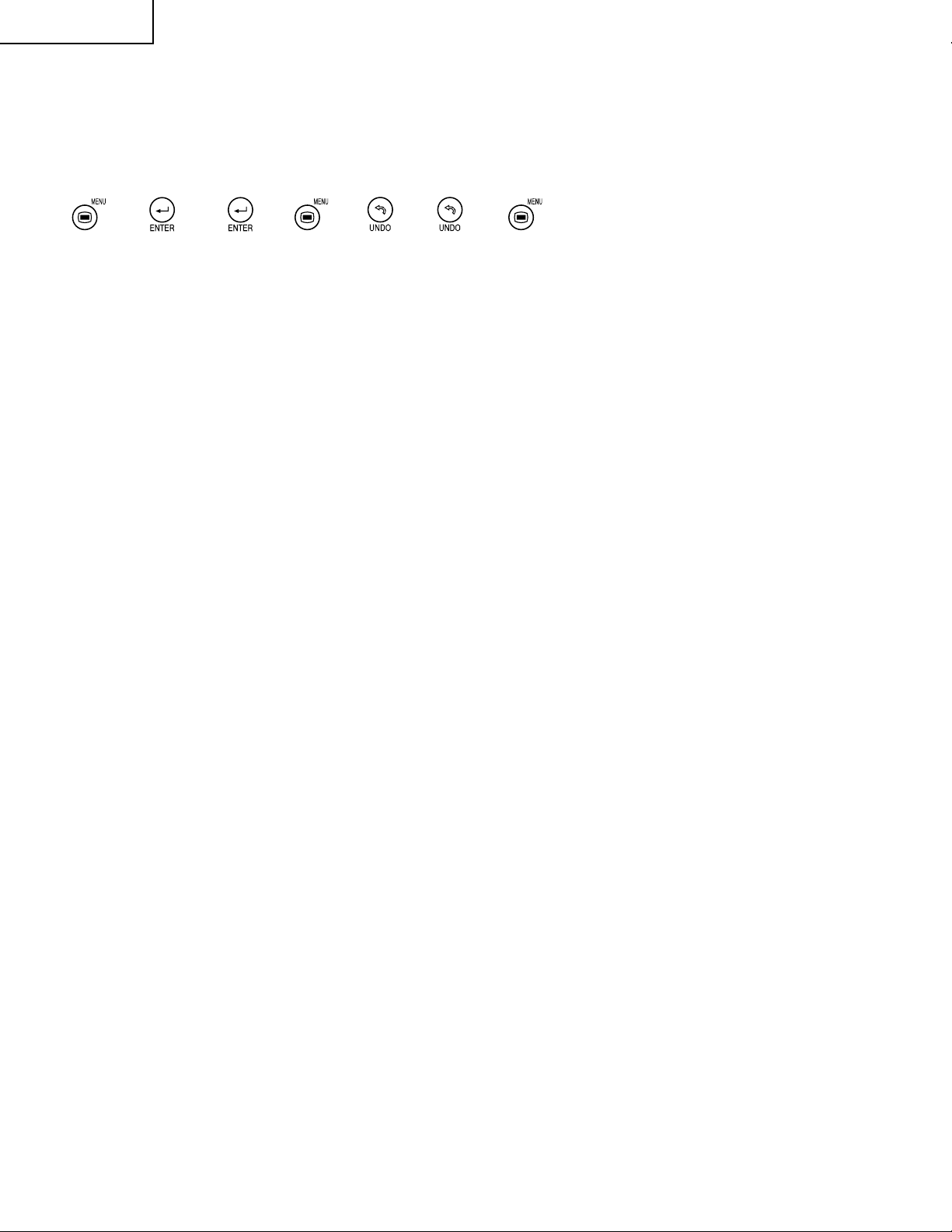

ELECTRICAL ADJUSTMENT

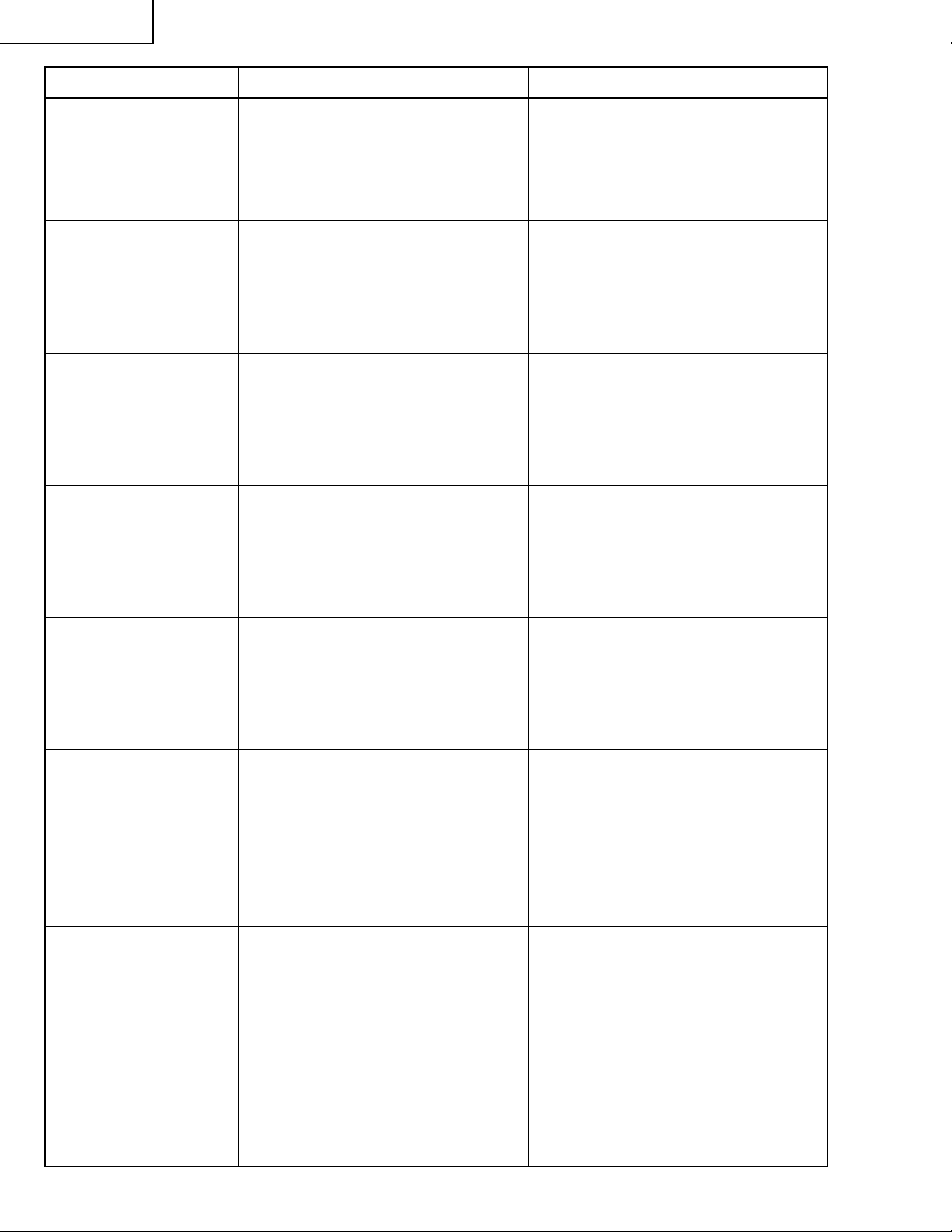

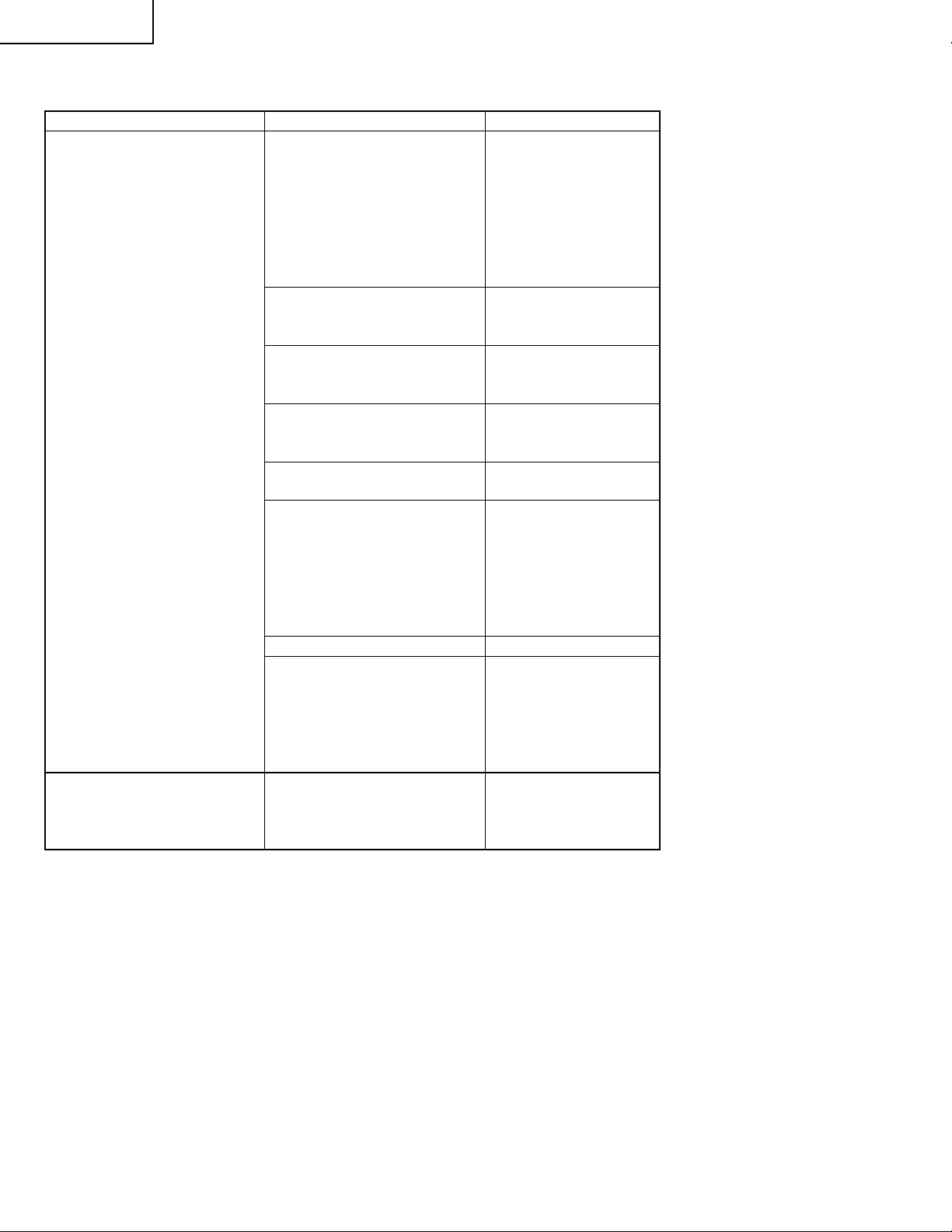

No. Adjustment Items Adjustment Conditions Adjustment Procedures

PG-M20X

1 Initialization of

EEPROM

2 Adjustment of CW

index

3 Adjustment of

RGB gradation

reproduction

1. Tur n on the power (the lamp lights

up) and warm up the system for 15

minutes.

1. Signal input: 64-step color bar

2. Select the following group and subject.

Group: DLP

Subject: Select CW-INDEX.

1. Feed the SMPTE pattern signal.

2. Select the following group and subject.

Group: DLP

Subject: G1-GAIN

1. Carry out the following setting.

Press SW2001 to enter the process

mode, and ex ecute S2 on SSS menu.

1. Feed the signal to INPUT 1.

2. Select subject and make adjustment

so that the lamp gradation patterns

of R, G and B should be smooth without noise.

R

G

B

1. Confirm that 100% and 95% white

gradation, and 0% and 5% black g r adation are discernible.

2. If the white gradation looks differently,

do fine adjustment by G1-GAIN.

4 Adjustment of

video brightness/

contrast

5 Adjustment of

video tint

1. Feed the NTSC100% window patter signal. (Burst signal)

2. Select the following group and subject.

Group: VIDEO

Subject: AUTO

1. Feed the split color bar signal.

2. Select the following group and subject.

Group: VIDEO

Subject: TINT

19

1. After signal input, select AUTO using the set's switch or the remote

controller's button for automatic adjustment.

1. Confirm the fixed value.

Fixed value: 128

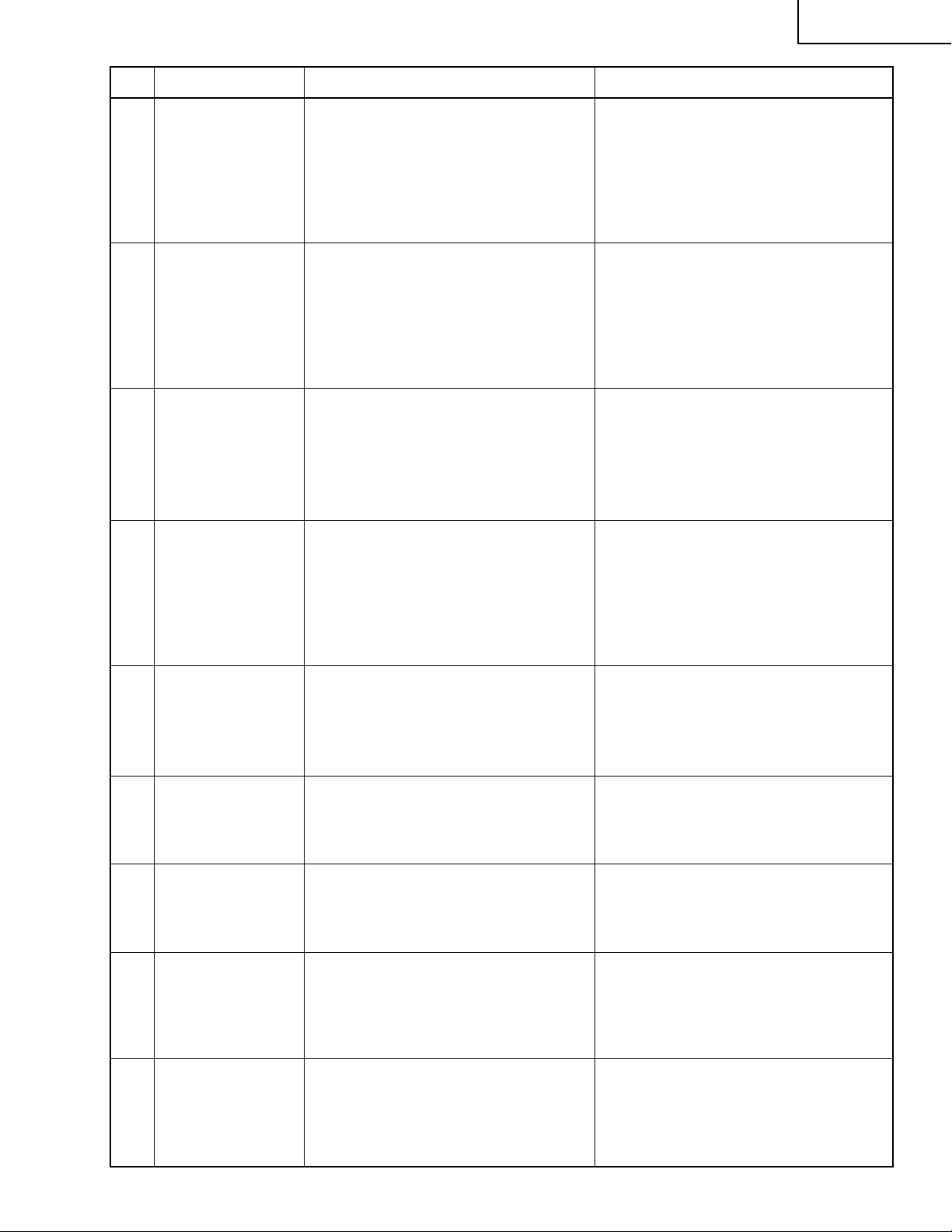

Page 20

PG-M20X

No. Adjustment Items Adjustment Conditions Adjustment Procedures

6 Adjustment of

NTSC color

saturation

7 Adjustment of PAL

color saturation

8 Adjustment of

SECAM color

saturation

9 Adjustment of

COMPO G brightness

1. Feed the internal 8ch (split color bar)

signal.

2. Select the following group and subject.

Group: VIDEO

Subject: N-COLOR

1. Feed the PAL color bar signal.

2. Select the following group and subject.

Group: VIDEO

Subject: P-COLOR

1. Feed the SECAM color bar signal.

2. Select the following group and subject.

Group: VIDEO

Subject: S-COLOR

1. Input signal: 0% gray pattern signal (480I)

2. Select the following group and subject.

Group: COMPO

Subject: G-BRIGHT

1. Confirm the fixed value.

Fixed value: 59

1. Confirm the fixed value.

Fixed value: 59

1. Confirm the fixed value.

Fixed value: 59

1. Feed the signal to INPUT 1.

Make adjustment so that some bits

should be missing in the picture.

10 Adjustment of

COMP CR-Offset

11 Automatic Adjust-

ment of RGB

white balance

12 Automatic Adjust-

ment of SRGB

white balance

1. Feed the color difference signal

(480I): Y 0% brightness, Cb and Cr

0% white patterns.

Group: COMPO

Subject: AUTO

1. Feed the 50% gray pattern signal

(XGA, 60 Hz).

2. Select the following group and subject.

Group: DLP

Subjects: R1-GAIN (Red)

B1-GAIN (Blue)

1. Feed the 50% gray pattern signal

(XGA, 60 Hz).

2. Select the following group and subject.

Group: DLP

Subjects: S-R1-GAIN (Red)

S-G1-GAIN (Green)

S-B1-GAIN (Blue)

1. After signal input, select AUTO using the set's switch or the remote

controller's button for automatic adjustment.

1. Adjust R-1 GAIN and B1-GAIN so that

x-value should be 266±3 and y-value

320±3.

1. Set the value of S-R1-GAIN to 34.

2. Adjust S-G1-GAIN and S-B1-GAIN

so that x-value should be 310±3 and

y-value 335±3.

20

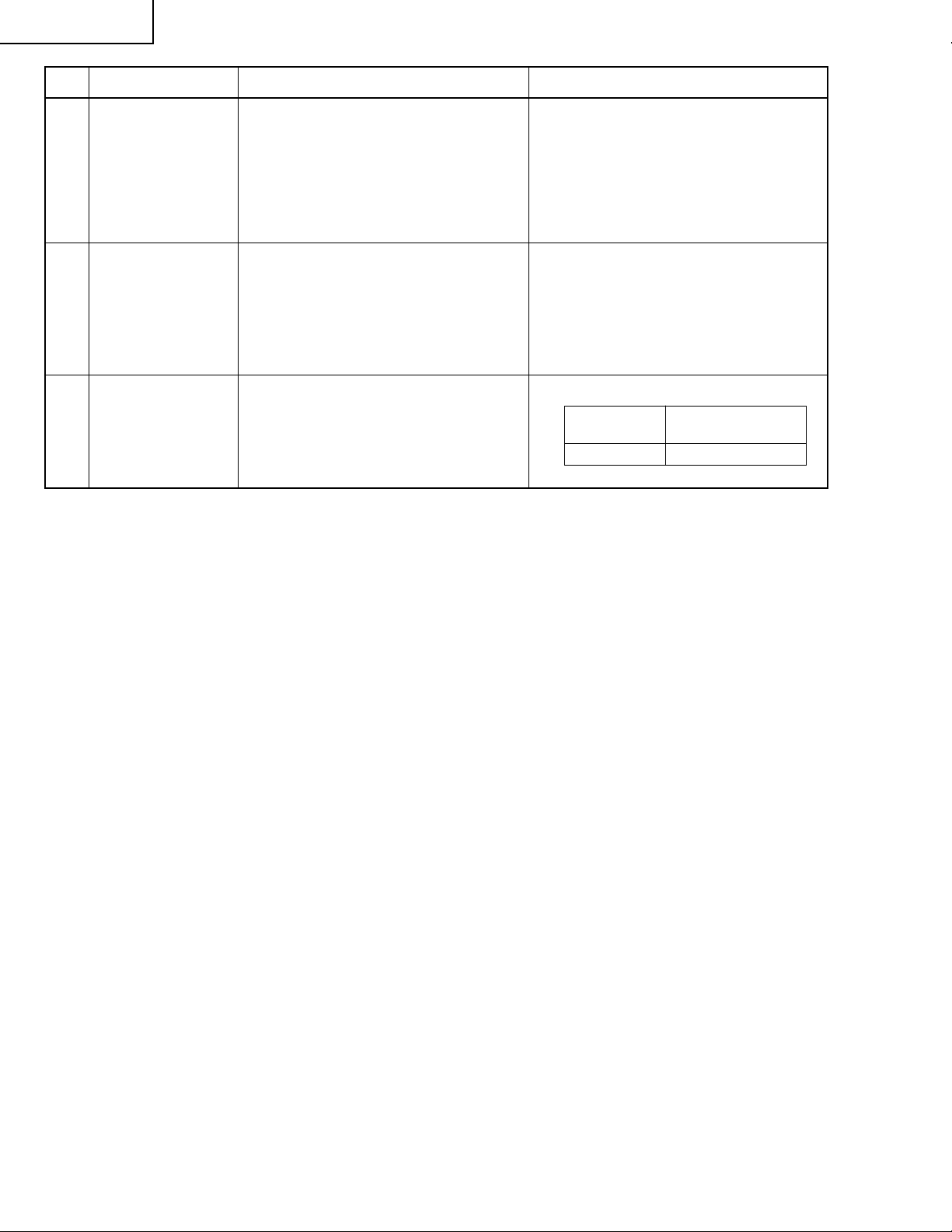

Page 21

No. Adjustment Items Adjustment Conditions Adjustment Procedures

PG-M20X

13 Automatic adjust-

ment of video

white balance

14 Automatic adjust-

ment of DTV white

balance

15 Adjustment of

DLP voltage (For

reference)

16 Confirmation and

re-adjustment of

white balance

1. Feed the 50% gray pattern signal

(NTSC, burst signal).

2. Select the following group and subject.

Group: DLP

Subjects: V-R1-GAIN (Red)

V-B1-GAIN (Blue)

1. Feed the 50% gray pattern signal

(480I, color difference signal).

2. Select the following group and subject.

Group: DLP

Subjects: C-R1-GAIN

C-B1-GAIN

1. Read voltage rank of DLP description.

2. Set the switch corresponding to the

rank which has been read. (on the

formatter PWB)

1. The adjusting conditions for each

item are as follows:

For RGB input, see Item 11

For SRGB input, see Item 13

For video input, see Item 14

For DVT input, see Item 12

1. Adjust V -R1-GAIN and V-B1-GAIN so

that x-value should be 265±3 and yvalue should be 298±3.

1. Adjust C-R1-GAIN and C-B1-GAIN

so that x-value should be 263±3 and

y-value should be 295±3.

1. Carry out adjustment when DLP chip

has been replaced or combination of

chip and formatter has been changed.

2. Rank: BCDE

Setting value: 1234

Confirm that there is no deviation in white

balance from that of the monitoring

equipment.

For readjustment, proceed in the order

of RGB input, video input and DTV input.

17 Confirmation of

color-related

operation

18 Confirmation of

picture-related

operation

19 Confirmation of

RGB

20 Confirmation of

off-timer operation

21 Confirmation of

thermistor operation

1. Receive the color bar signal. 1. Select L1 in the process mode.

Check the performance of color and

tint.

1. Receive monoscope pattern signal. 1. Se lec t L2 i n th e pr ocess mode.

Check Picture, Brightness and Sharpness.

1. Receive the RGB signal. 1. Select L4 on the process mode.

Check Picture, Brightness, Red, Blue,

Clock, Phase, H-POS and V-POS.

1. Select OFF in the process mode.

Confirm that the off-timer starts with

5-minute display, counts 1 minute for

1 second, and turns off when 0 minute

is displayed.

1. Heat the thermistor by dryer. 1. Confir m that the temperature is displayed.

21

Page 22

PG-M20X

No. Adjustment Items Adjustment Conditions Adjustment Procedures

22 Automatic sync

operation

23 Confirmation of

USB operation

24 Factory settings 1. Make the following settings.

1. Receive the phase checking pattern

signal.

Connect the set to a personal computer

by USB cable.

1. Confirm that Clock, Phase, H-POS

and V-POS can be automatically

adjusted in the VGA/S-VGA/XGA

mode.

Using the remote controller, make sure

that feed and return operations are effective on the display of the personal

computer.

Process Remote controller

adjustment settings

S4 "Factory Setting 4"

How to Adjust the PC I/F unit

1. Initialization of EEPROM

1) Press SW2002 to enter the process mode.

2) Execute S1 on the SSS menu. (By S1, all the contents of EEPROM are initialized.)

3) Confirm that the program version "Ver. XXX" has become the latest one

2. Adjusting items

1) Adjustment of RGB drive/gain

(1) feed the window pattern signal that has 100% and 0% signals.

(2) Select AUTO among the A/D items in the process mode and carry out adjustment.

22

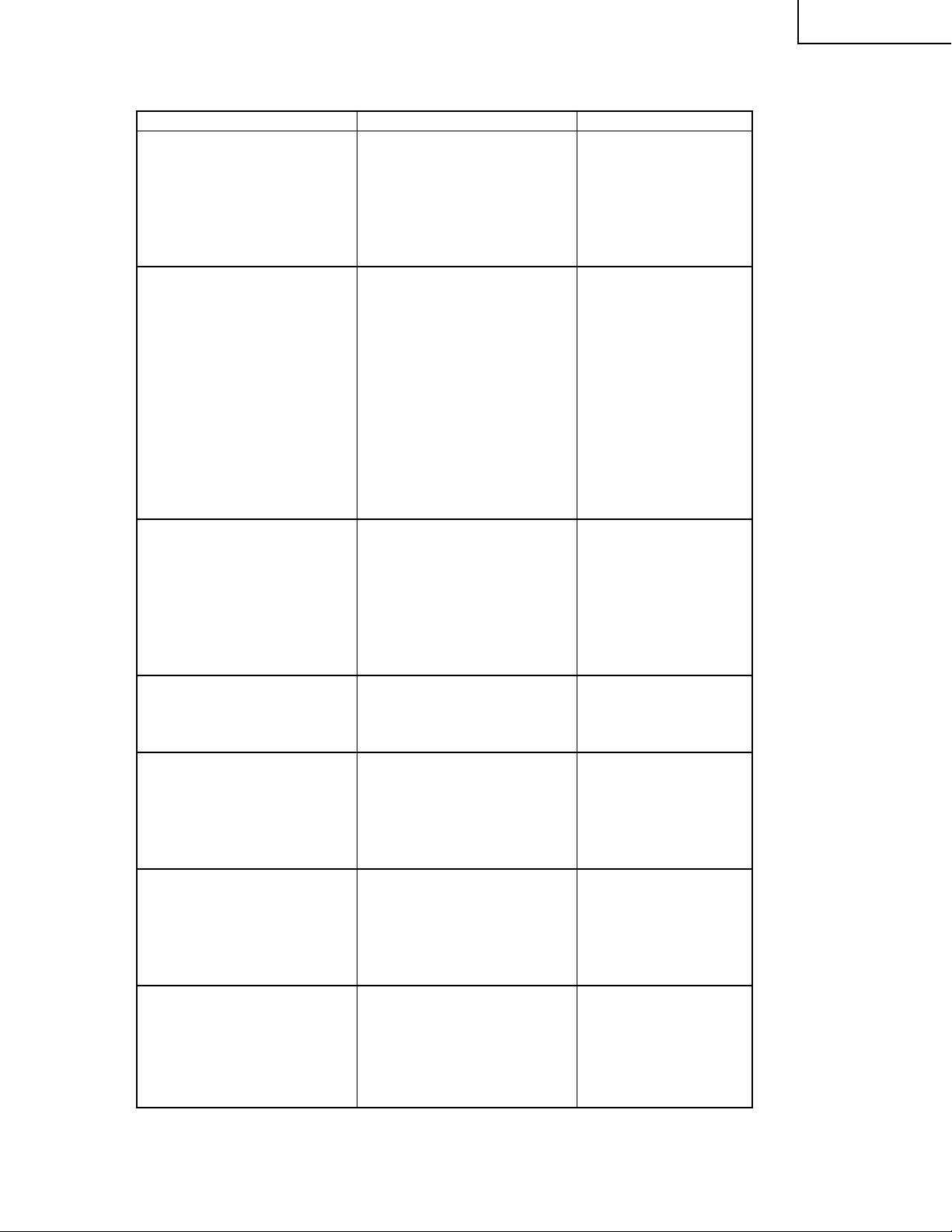

Page 23

» Adjustment mode process menu

Group Sub Group Subject

Adjust PC Image A/D R-BRIGHT

Adjust DLP Image DLP R1-BLK

Adjust VIDEO Image VIDEO PICTURE

Adjust Component Image DTV G-BRIGHT

Process mode LINE L1

INTIAL SETTING SSS TIME

Sample Pattern PATTERN RGB

PG-M20X

G-BRIGHT

B-BRIGHT

R-D

B-D

G-D

AD-AUTO

R1-GAIN

G1-BLK

G1-GAIN

B1-GAIN

CW-INDEX

S-R1-GAIN

S-G1-GAIN

S-B1-GAIN

C-R1-GAIN

C-B1-GAIN

V-R1-GAIN

V-B1-GAIN

BRIGHT

TINT

N-COLOR

P-COLOR

S-COLOR

STAT-GAIN

VIDEO-AUTO

CB-OFFSET

CR-OFFSET

COMPO-AUTO

L2

L3

OFF

TEMP OFF

SENSOR CHECK

S1

S2

S3

S4

S5

RGB(50)

CROSS

SETP

COLOR

CHR

23

Page 24

PG-M20X

Group Sub Group Subject

Adjust CVIC CVIC-PROGRSSIVE MODE

IP

MDSW

PTGSW

C-TESTSW

C-ILG-LY

C-MOD-LY

C-VE-LV

CVIC-ENHANCE-VIDE ENH-PLUS

ENH-MINUS

DFC

CVIC-ENHANCE-HTTV ENH-PLUS

ENH-MINUS

DFC

CVIC-ENHANCE-RGB ENH-PLUS

ENH-MINUS

DFC

CVIC-SCREEN CUBIC-RGB

CUBIC-VEDEO

CVIC-NR YNR-LEVEL

YNR-K

YNR-FSEL

CNR-LEVEL

CNR-K

CNR-FSEL

CNR-FILSW

CVIC-PTG TBL-NO

CVIC-CMS RED

YELLOW

GREEN

VYAN

BLUE

MAGENTA

Version Check etc Special IPL

IPL2

E2PROM

ADR RD/WR

24

Page 25

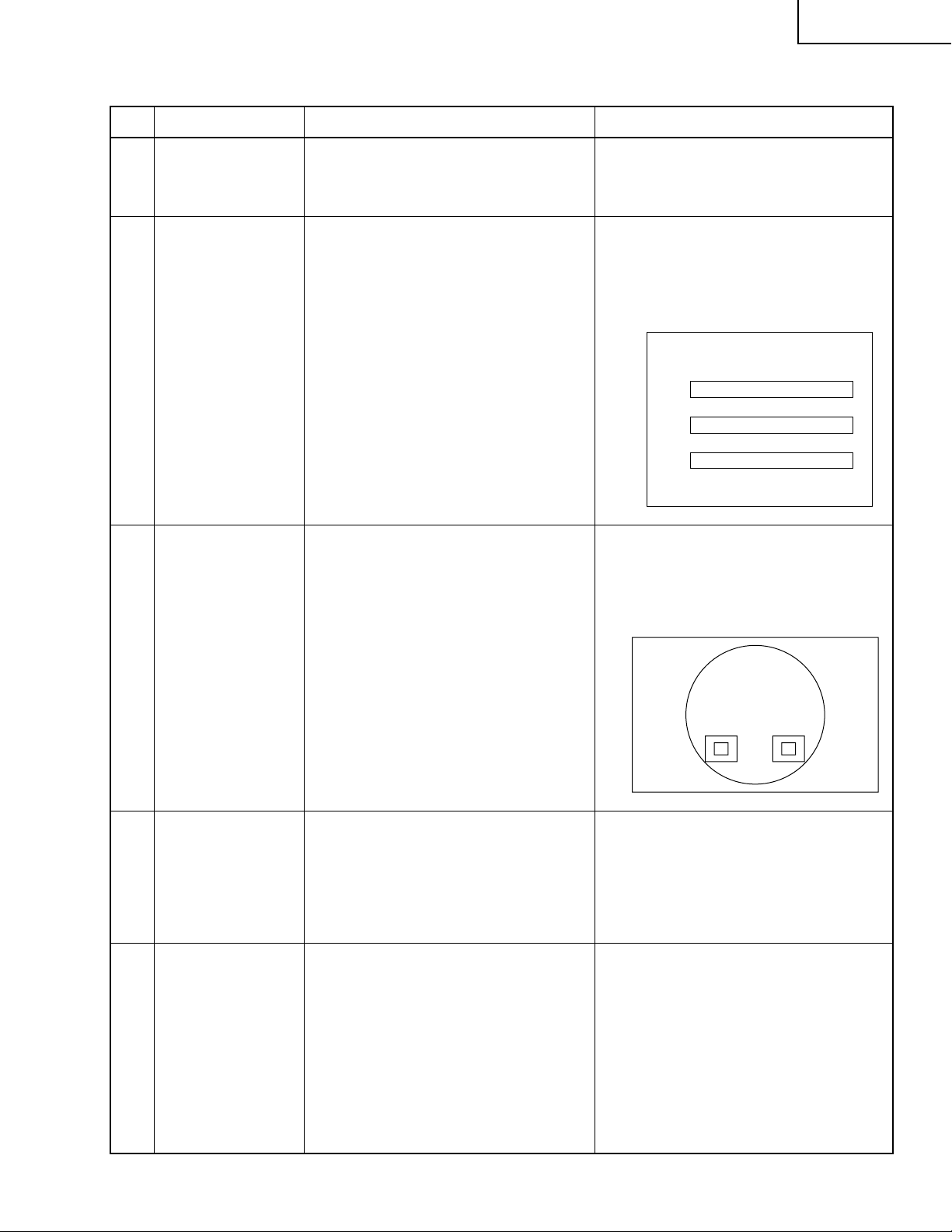

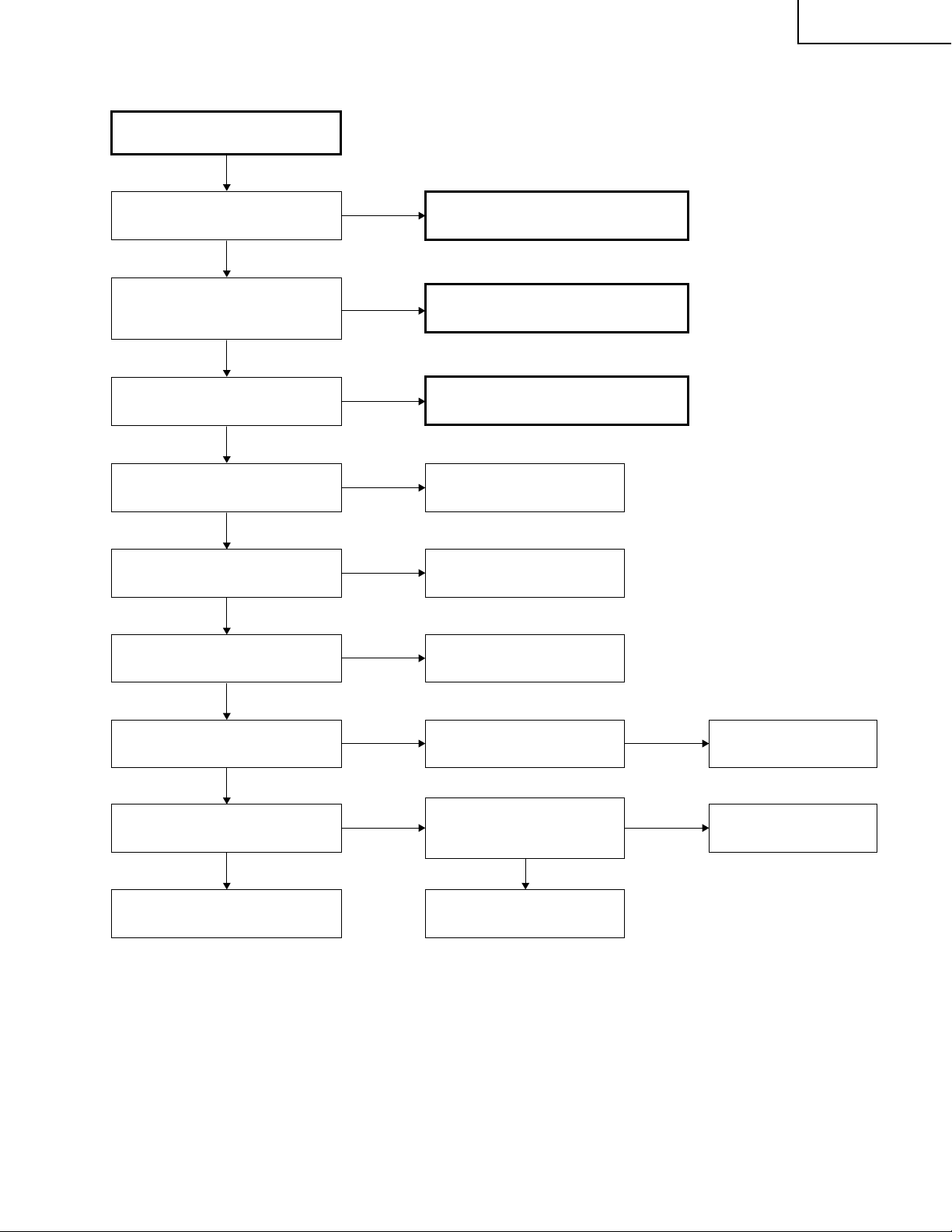

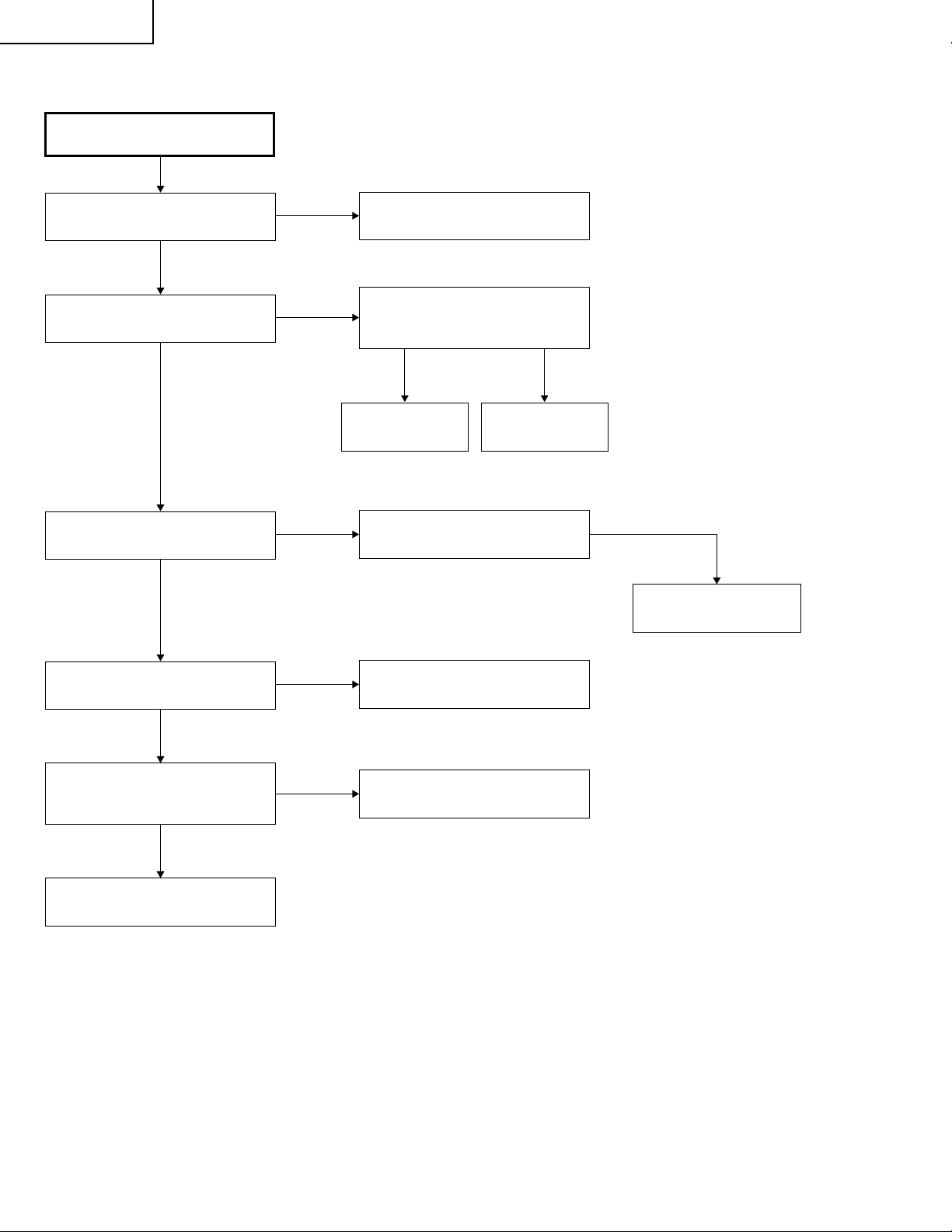

Checking of Basic Operation

PG-M20X

TROUBLE SHOOTING TABLE

Does the POWER LED light up or

flicker in red or green?

Yes

Does the set operate by the set's

key or the remote controller's

power key?

Yes

Does the cooling fan rotate and

does the lamp light up?

Yes

Is the user menu displayed?

Yes

Does the RGB input operate

normally?

Yes

Does the video input operate

normally?

Yes

No

No

No

No

No

No

Go to "Checking of Power Unit".

Go to "Checking of Sub-microcomputer

and Its Periphery"

Go to "Checking of Lamp Lighting-up"

Check the formatter circuit and

its periphery.

Check IC8013 (AD) and go to

"Checking of RGB Input".

Check IC8015 and peripheral

circuit.

Do the component input/DVI input

operate normally?

Yes

Does the DVI input operate

normally?

Yes

End

No

No

Is there input signal at pins

(8), (17) and (23) of IC8013?

Go to "Checking of Video

Input". Is there input signal at

the emitter of Q8002?

Yes

Check IC8015 and its

peripheral circuit.

No

No

Check IC3851 and its

peripheral circuit.

Check IC3502 and its

peripheral circuit.

25

Page 26

PG-M20X

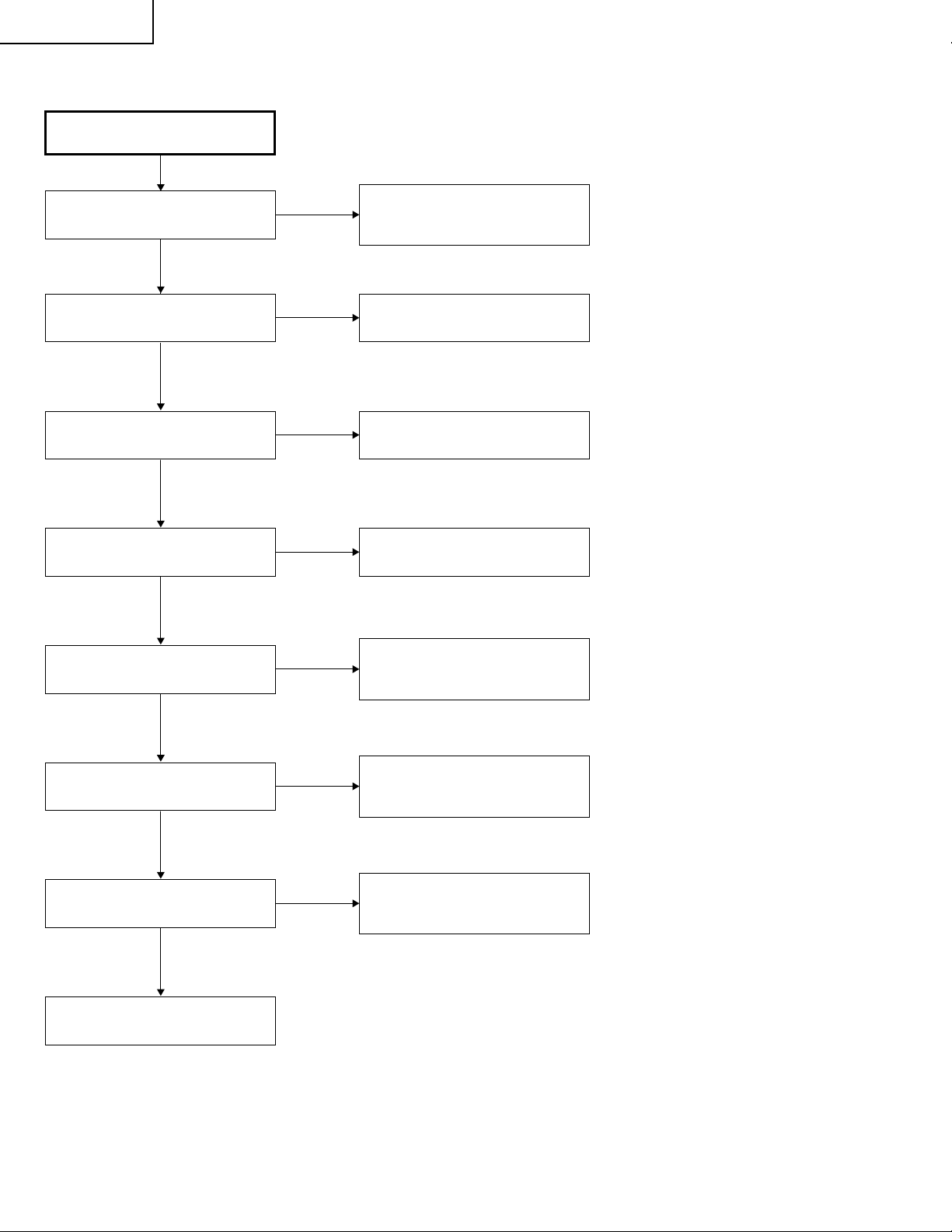

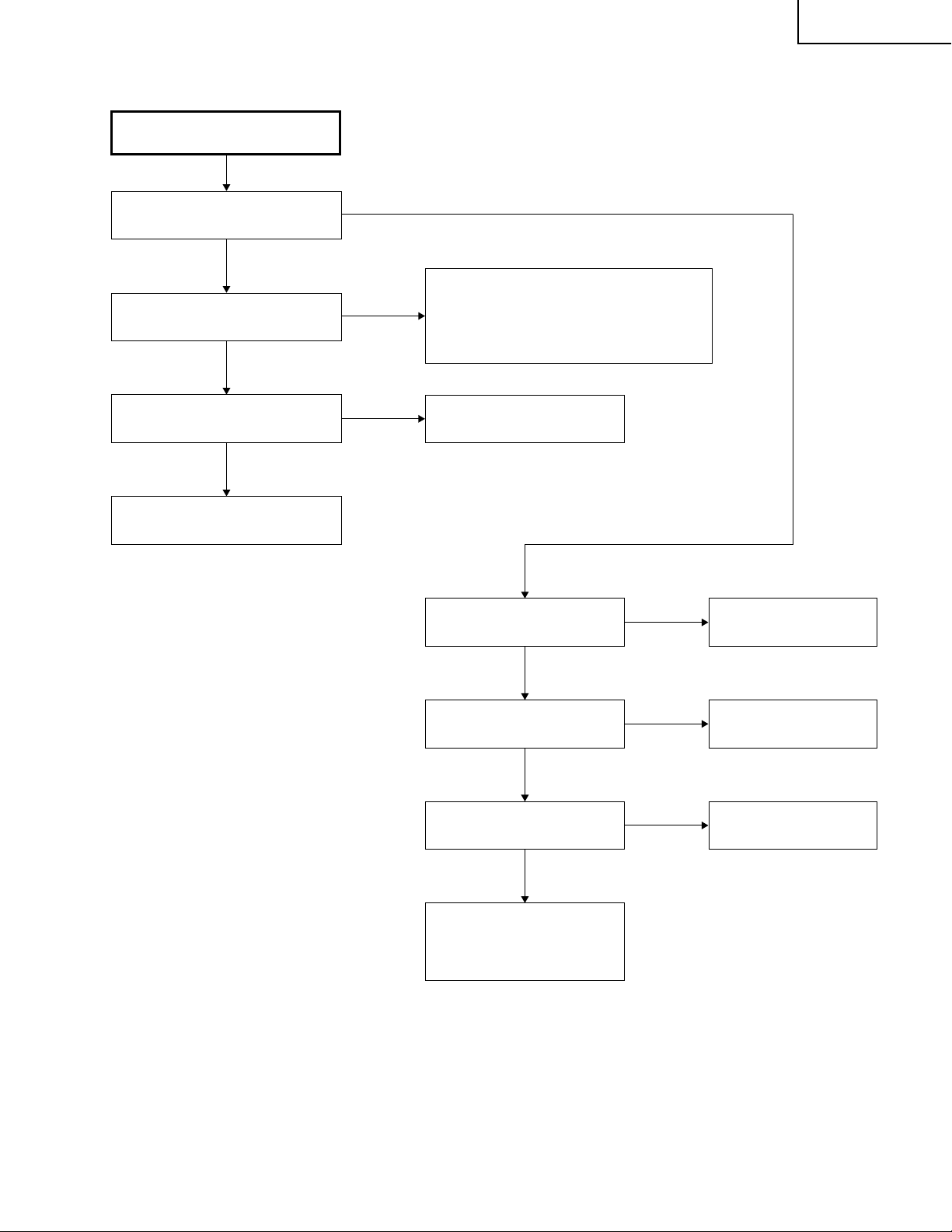

Checking of Power Unit

Are connectors in the power unit

completely inserted?

Yes

Is the lamp door closed

completely?

Yes

Is the bimetal switch turned off?

Yes

Is AC voltage applied across relay

RL7001?

Yes

No

No

No

No

Insert the connectors CN702,

CN704, CN7003, CN7001,

CN7004 and CN7101 completely.

Close the lamp door completely by

screws.

Replace the bimetal switch, or rest

it by pressing the red button.

Replace F701.

Is there DC voltage of about 6V at

pin (1) of CN7002?

Yes

Is there DC voltage of about 370V

across CN702?

Yes

Is there rated voltage at the output

terminals of CN7001 and CN7102?

Yes

Check the PWB circuits of relevant

output sides.

No

No

No

Check Q7501, Q7502 and Q7503

and their peripheral circuits. If any

circuit is damaged, replace it.

Check the circuits connected to the

primary side of T701. If any circuit

is damaged, replace it.

Check the circuits connected to the

secondary side of T701. If any

circuit is damaged, replace it.

26

Page 27

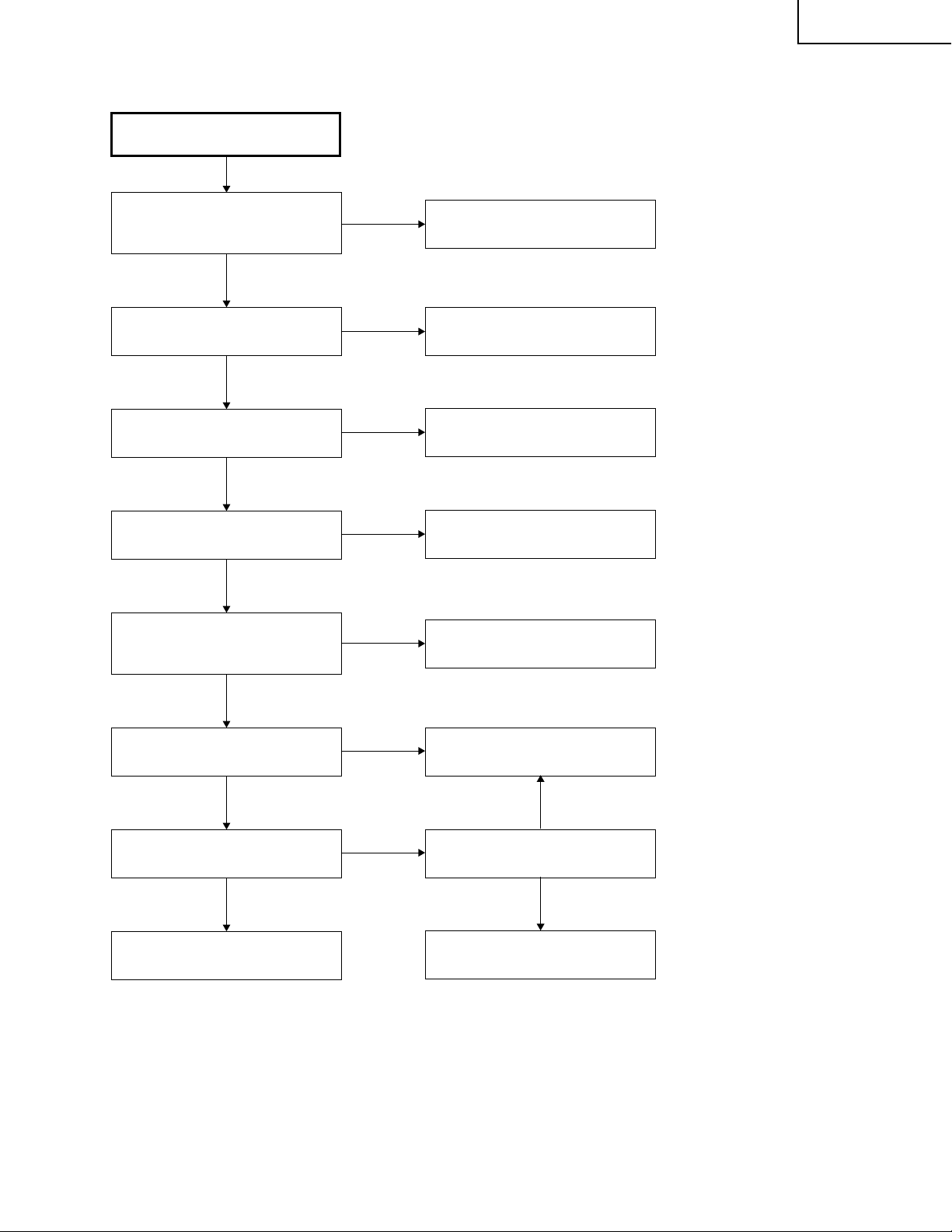

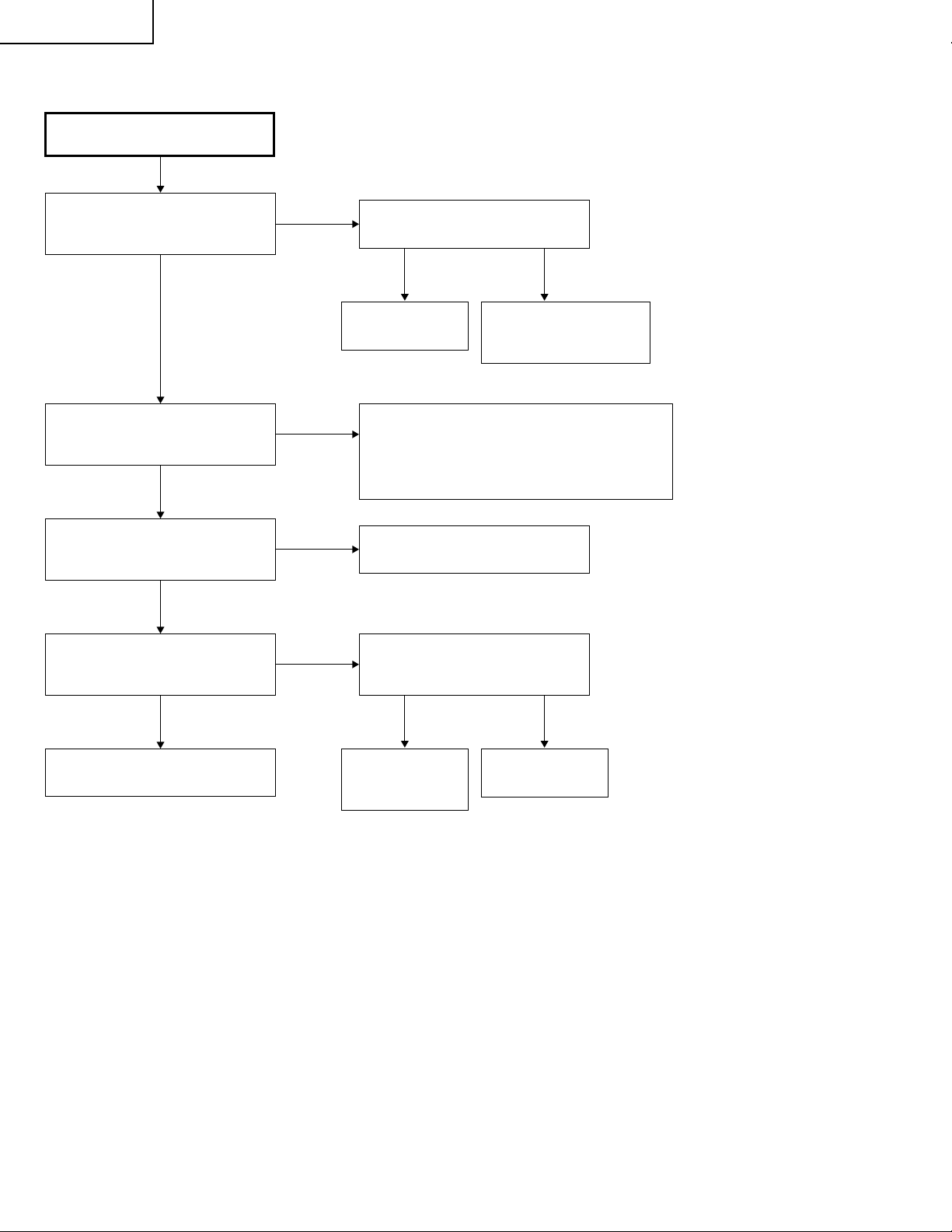

Lamp Does Not Light Up.

PG-M20X

Is any of SC9001, SC9002, P9002

and P9003 connectors

disconnected or in poor contact?

No

Is an appropriate voltage supplied

to SC9002?

Yes

Is there the 180-Hz pulse signal at

pin (1) of P9002?

No

Is the color wheel rotating?

Yes

Is there the 180-Hz pulse signal at

pin (2) of P9003 when no input

signal is given?

Yes

Yes

No

Yes

No

No

Insert the connectors completely.

Go to "Checking of Input PWB"

Go to "Checking of Lamp" and

"Checking of Ballast"

Go to "Color Wheel Does Not

Rotate."

Go to "Checking of Input PWB"

Is the signal at pin (10) of IC9101

at High level?

Yes

Is the signal at pin (9) of IC9101

at High level?

Yes

Trouble with 1C9101 or its

peripheral part.

No

No

Go to "Checking of PC I/F unit"

No

Are the signals at pins (69) and

(70) at High level?

Yes

Trouble with IC9003

27

Page 28

PG-M20X

Lamp does not light up.

Yes

Is the cooling fan rotating?

Yes

Is the color wheel rotating sound

heard?

Yes

Is the lamp discharging sound

heard?

No

No

No

Yes

Check the power circuit or the fan

circuit on the key/input PWB.

Check IC3101, the motor driver

circuit and their periphery.

Check the waveform of SC3101.

Normal Abnormal

Replace the color

wheel.

Check the socket

Check the

formatter PWB.

No

Replace the lamp.

Is DC 34V voltage applied across

the ballast power?

Yes

Is voltage higher than 3.5V applied

to pin (19) of P9002 on the

formatter PWB?

Yes

Check the ballast power.

No

No

Check the power circuit.

Check IC9101 and its periphery

on the formatter PWB.

28

Page 29

No

Yes

Does POWER LED flicker in red

(for 2 seconds)?

No

Is there B+3.3V output at pins (12)

and (13) of CN3701?

Is there 6V output at pins (5) and

(6) of P2003?

Yes

Go to "Checking of PC I/F Unit", and check

the flexible connector.

Communication error of sub-microprocessor

(KEY) and SH microprocessor (PC I/F unit)

Pins (20) and (21) of P2001.

Yes

Go to "Checking of Power Unit"

Check Q2001 thru Q2004 of

IC2001.

No

No

Yes

Is Bu+6.2V signal outputted?"

Go to "Checking of

Power Unit"

Yes

No

Is Bu+3.3V signal outputted?

Check IC2010 and its

periphery.

Check IC2002 and its

periphery.

Yes

No

Is 3.3V signal output at pin

(19) of IC2001?

Check IC2001 and its

periphery and go to

"Checking of Remote Control

Communication".

Checking of Sub-microprocessor

and Its Periphery

PG-M20X

29

Page 30

PG-M20X

Checking of Low-pass Filter Circuit

Is video signal is inputted to pins

(4), (8) and (12) of IC3851?

Yes

Is video signal inputted to pins

(24), (21) and (17) of IC3851?

Yes

Is video signal is inputted to pins

(16), (20) and (24) of SC3001?

Yes

The low-pass filter circuit on the

input PWB is normal. Does the

picture appear?

Yes

No

No

No

No

Check pins (4), (8) and (12) of

SC3001.

Normal Abnormal

Check Q3854 and

Q3855.

IC3851 is defective.

If the picture quality is abnormal, check whether

or not the following voltages are outputted to

pin (28) of IC3851.

0.3 V for 480i, 1 V for 720p, 1080i, Check IC301.

Check Q3851, Q3852 and Q3853

and their periphery.

Is the video signal inputted to pins

(8), (17) and (23) of IC8013

(AD9888) of the PC I/F unit?

Yes No

Check the PC I/F unit.

Check DVI (analog)

input.

End

Check the SOG

circuit or IC8013

and its periphery.

30

Check IC8013

and its periphery.

Page 31

Feed the 480i component signal in INPUT 1.

Select INPUT 1 using the set's key or the remote controller.

Select 480i among the special modes on the user

menu screen.

Is 480i selected among the special

modes?

Does the contour of picture

appear clear.

Confirmation of synchronization.

Is Y signal including sync signal

inputted to pin (3) of IC2502?

Is picture outputted?

Is the color normal?

No

Is the signal type set to the

component?

In case of monitor output,

disconnect the monitor output

cable.

Set the monitor output.

Check the monitor output

equipment and cable.

No

Yes

Yes

No

Yes

Yes No

Yes

Abnormal

No

Set the signal type.

IC8025 is defective. Select 480i.

Restored to normal condition

Yes

End

Checking of DTV

(480i Component Input)

Check IC8016

(Video decoder).

Go to "Checking of

Low-pass Filter Circuit"

Check IC3501 and its

periphery.

Yes

No

PG-M20X

31

Page 32

PG-M20X

Checking of Video Input

Feed the composite video signal to

INPUT 3. Select INPUT 3 using the

set's key or the remote controller.

Does the picture appear?

No No

Is the video signal including sync

signal inputted to pin (3) of SC3001

on the input PWB?

No

Is the video signal including sync

signal inputted to pin (7) of SC3502

on the input PWB?

No

Yes Yes

Yes

Yes

Is the picture disturbed?

1

Check IC8016 (video decoder)

of PC board and its periphery.

Check Q8002.

Check Q3512 and Q3513 on

the input PWB.

Are pin(5) (horizontal) and

pin(10) (vertical) signals

inputted to IC8363 on the

PC I/F unit?

No

Check IC8363 and

IC8025 (CVIC2) and

their periphery.

1

Yes

Check IC3502 and its peripheral

circuit.

No

Feed the S-video signal to INPUT 2.

Select INPUT 2 using the set's key

or the remote controller. Does the

picture appear?

Yes

Is the color normal?

Yes

End

No

32

Yes

Is the C signal inputted

to pin (11) of SC3001?

No

Check Q3502 on the

input PWB.

Page 33

» FORMATTER Unit

PG-M20X

Abnormal picture

Rainbow-like picture

Go to "Lamp Does Not

Light Up."

Is signal outputted at

pins (3), (5) and (7) of

SC9001?

Yes

Trouble with IC9003,

IC9006 or their periphery

Is any of SC9001, SC9002, P9002

and P9003 connectors

disconnected or in poor contact?

Is an appropriate voltage supplied

to SC9002?

No

No

Yes

Blackout

No

No Yes

Yes

No

Is the lamp on?

Go to "Checking of PC I/F nunit"

Insert the connectors

completely.

Go to "Checking of Input PWB"

Others

Reassemble the DMD, optical

mechanism and formatter unit.

Is the symptom improved?

No

Is the voltage at the positive-polarity

pin of C9066 appropriate (+7V)?

Yes

Is the voltage at the positive-polarity

pin of C9068 appropriate (+23 to +26V)?

Yes

Is the voltage at the negative-polarity

pin of C9562 appropriate (-26V)?

Yes

Trouble with the DMD

Yes

No

No

No

End

Trouble with peripheral circuit

of C9066 or trouble with IC9003

Trouble with peripheral circuit

of C9068 or trouble with IC9003

Trouble with peripheral circuit

of C9562 or trouble with IC9003

33

Page 34

PG-M20X

» PC I/F Unit-1/12

Checking of PC PWB

0

Is the user menu displayed?

No

Check the onscreen display.

Check the RGB input.

Check the component input.

Check the video input.

Yes

Check the DVI digital input.

PCカードのチェック

Check the PC card.

End

34

Page 35

» PC I/F Unit-2/12

Checking of Onscreen Display

PG-M20X

Is the user menu displayed

normally by the MENU key?

No

Enter the process menu and select

PATTERN. Then select the

COLOR pattern.

Is the onscreen display color

normal?

Yes

Make STEP signal selection.

Is the STEP signal normal?

Yes

No

Yes

The onscreen display is normal.

Adjust the DLP system in the

process adjustment mode.

0

Rewrite the onscreen display data.

No

Is the signal compatible with the

STEP signal outputted at TL106

thru TL111?

Yes

Go to "Checking of GA4 and Its

Periphery".

Rewrite the onscreen display data.

No

0

IC8025 is defective.

35

Page 36

PG-M20X

» PC I/F Unit-3/12

Checking of RGB Input

Feed the sync separation type

analog RGB signal to INPUT 1.

1

Select INPUT 1 using the set's

key or the remote controller.

2

Does the picture appear?

Is the picture disturbed?

3

Do the three colors R, G and B

appear?

Carry out the AUTOSYNC process.

Is the contour of picture clear?

Yes

No

Yes

No

Yes

No

No

Go to "Confirmation of

Video Input".

Go to "Checking of Sync Signal".

Go to "Checking of RGB Signal".

Yes

Is there any disturbance in the

vertical stripe pattern?

No

End

Yes

IC8013, 8025 or its periphery is

defective.

36

Page 37

» PC I/F Unit-4/12

Confirmation of Video Input

Make "Confirmation of Input

Signal Setting".

PG-M20X

Is there video signal at the land

of C8070?

Yes

Go to "Checking of Sync Signal".

IC8025 or IC8013 is defective.

Confirmation of Input Signal Setting

Is the input menu selected

correctly?

Yes

No

No

Is there signal at the terminal C2 of

P8001 (DVI connector)?

Yes

Somewhere in the signal route is

defective. Check the capacitors and

resistors between the connector

and IC8013.

The signal source or connector

is defective.

Select the input menu correctly.

No

Are the connectors connected

correctly?

Yes

End

No

2

Connect the connectors correctly.

1

37

Page 38

PG-M20X

» PC I/F Unit-5/12

Checking of Sync Signal

Is there the vertical sync signal at

pin (11) of IC8363?

Yes

Is there the horizontal sync signal

at pin (5) of IC8363?

Yes

Is there the vertical sync signal at

TL8131?

Yes

Is there the horizontal sync signal

at TL8130?

Yes

No

No

No

No

Make confirmation of input signal

setting.

IC8330, IC8331 or its periphery

is defective.

IC8363 is defective.

Are both the vertical and horizontal

signals in appropriate timing?

No

Is the signal generator

(input source) appropriate?

Yes

IC8330, IC8331 or its periphery

is defective.

Yes

No

The sync signal is normal.

End of checking.

Set the signal source appropriately.

2

38

Page 39

» PC I/F Unit-6/12

Checking of R, G and B Signals

PG-M20X

Is the signal type set to RGB?

Yes

Set the process mode.

Select R, G and B individually on

the pattern menu.

Go to "Checking of GA4 and Its

Periphery".

For checking the input signal,

set the signal generator to

gradation signal.

No

Set the signal type to RGB.

Check TL8169, TL8170 and

TL8180 by oscilloscope.

(MSB bit after A/D conversion)

Are there the specified signals at

TL8169, TL8170 and TL8180?

Yes

IC8025 and its periphery are

defective.

No

Does the signal come to C8062,

C8070 and C8078?

Yes

IC8013 and its periphery are

defective.

No

Go to "Confirmation of

Video Input".

39

Page 40

PG-M20X

» PC I/F Unit-7/12

Checking of GA4 and Its Periphery

Select R, G and B individually on

the pattern menu in process mode.

Is picture outputted appropriately

in R, G and B?

No

Check pins (72), (52) and (32) of

SC8001 by oscilloscope.

These signals are MSB of B/G/R.

Do the signals selected on the

pattern menu match with those

checked by oscilloscope?

No

Does the clock signal come to pin

(78) of SC8001?

Yes

Yes

Yes

No

Checking of GA4 and its periphery

ends.

The DLP PWB is defective.

Is there the clock (32.5 MHz)

signal at TL8114?

No

Is there the clock (32.5 MHz)

signal at TL8110?

Yes

Yes

IC8029 is defective.

No

X8005 is defective.

Check TL8106, TL8107, TL8108,

TL8109, TL81010 and TL81011

by oscilloscope.

Do the signals selected on the

pattern menu match with those

checked by oscilloscope?

Yes

IC8029 is defective.

IC8025 is defective.

No

IC8025 is defective.

40

Page 41

» PC I/F Unit-8/12

Checking of Component Input

Feed the component signal to

INPUT 1.

Select INPUT 1 using the set's

key or the remote controller.

PG-M20X

(except 480I)

Is the picture appear?

Yes

4

Is the color normal?

No

Is the signal type set at component?

Yes

Carry out the process adjustment.

4

No

No

Go to "Checking of SOG Circuit".

Set the signal type to component.

Is the contour of picture clear?

Yes

The component is normal. End.

No

IC8013 or IC8025 is defective.

41

Page 42

PG-M20X

» PC I/F Unit-9/12

Checking of SOG Circuit

Check pin (2) of IC8365 by

oscilloscope.

Is the composite sync signal

reproduced in correct timing?

No

Check the land of C8070 by

oscilloscope.

Is there the Y signal including sync

signal?

Yes

The SOG sync separation circuit

(input PWB) is defective.

Yes

No

The SOG circuit is normal.

End.

Go to "Confirmation of Input

Signal Setting".

42

Page 43

Feed the composite video signal to

INPUT 3.

Select INPUT 3 using the set's key

or the remote controller.

Is there any disturbance in the

picture?

The video input is normal. End.

Is the color normal?

Is the picture appear?

Go to "Checking of Video

Sync Signal".

No

Yes

Input PWB is defective.

Q8003 and its periphery are

defective.

IC8015 is defective.

No

Is there the specified signal

at R114?

No

5

5

No

Checking of Video Input

Go to "Checking of Video

Sync Signal".

Carry out the process

adjustment.

Yes

No

Yes

Check the clock signal of IC8015

by FL8114.

Is the clock signal normal?

Yes

IC8025 and its periphery are

defective.

Yes

Yes

Is the video signal inputted to

C8141?

No

Go to "Checking of Video Sync

Signal".

» PC I/F Unit-10/12

PG-M20X

43

Page 44

PG-M20X

» PC I/F Unit-11/12

Checking of Video Sync Signal

Check pin (10) of IC8363 by

oscilloscope.

(Checking of vertical sync signal)

Is the vertical sync signal normal?

Yes

Check pin (6) of IC8363 by

oscilloscope.

(Checking of horizontal sync signal)

Is the horizontal sync signal

normal?

Yes

Are the horizontal sync signal and

vertical sync signal outputted at

TL8130 and TL8131?

Yes

Is there the specified clock

(13.5 MHz) signal at FL114?

Yes

No

No

No

No

Go to "Confirmation of Input Signal

Setting".

IC8015 and its periphery are

defective.

IC8015 and its periphery are

defective.

End

44

Page 45

» PC I/F Unit-12/12

Checking of DVI Digital Input

Feed the DVI digital signal to

INPUT 1.

Select INPUT 1 for input.

PG-M20X

Is the picture appear?

Yes

Is there any disturbance in the

picture?

Yes

Is the color normal?

Yes

The DVI digital input is normal.

Check pin (13) of IC8363 for vertical

sync signal, and check pin (3) of

IC8363 for horizontal sync signal.

No

No

No

IC8298 and its periphery are

defective.

Are the sync signals normal?

Yes

Check R8685 for clock signal.

Is the clock signal normal?

Yes

IC8025 and its periphery are

defective.

No

No

IC8298 and its periphery are

defective.

45

Page 46

CHASSIS LAYOUT

H

G

F

PG-M20X

E

D

C

B

A

121110987654321

46

47

Page 47

BLOCK DIAGRAM

PG-M20X

H

G

F

E

D

C

B

A

Rod Antenna

Filter

WIRED R/C

AUDIO-IN

S-Video

PCMCIA TYPE II Card

802.11b SS W-LAN

FLASH ATA

MEMORY

IC 5801

FM Receiver

RF-DATA

GYRO UNIT

USB

Video

VIDEO

INPUT UNIT

DVI

DVI

or

Filter

455kHz

IC 5803

Packet Flaming

PIC

A

UDIO

IC 3502

SW

S-C

S-Y

R/C

PC-BOARD

R,G,B

IC8330~IC8331

Comparator

IC8011

2

PROM

E

RX2+,RX2RX1+,RX1RX0+,RX0RXC+,RXC-

PC

Card

Slot

IC8298

3.3VC

Panel

Link

Reg.

G

H,V

Reg.

Reg.

D+,D-

IC 3851

LPF

R,G,B

SI_H,V

IC 3301

Audio AMP

LPF720P

G

DTVR,G,B

CN2

CARDVCC

RF_ON

ANT_49

GY

PLUGGED

BU+5V

USB_5V

S/VIDEO

S/COMP

IC 3901~3

SOG

Sync sep.

IC 8363

CD[15:0]

CA[25:0]

CONTROL

VCC3VEN

GY

GSYNC

SW

DTVR,G,B

PODCK

IN1IN2/RGBSEL

CN2

SYN_ENE,DATA,CLK

STREAM_A_CLK,DATA

STATUS,USB_PWR

B+CYPRESS

VOL

S+,S-

S-Y

S-C

VIDEO

VIDEO

S-C

VH,VV

IC 8013

A/D

Amp

D[15:0]

IC8002

Card Slot

Interface

A[23:0]

PLL

CPU BUS(65.5MHz)

CTL

R,G,B

PDE

IC 8015

Digital

Video

Decoder

24.576MHz

GSYNC

PCH,PCV

AD_SCL

AD_SDA

MEMR

MEMW

SYSCK

WAIT_CARD

IC 3201

USB-Controller

(CYPRESS)

6MHz

LEARN

AG_MENU

VOL

S/VIDEO

S/COMP

LPF720P

SOGSEL

AGCLK,AGDATA

CN

1

CN

1

VY[8]

VUV[8]

ITLC

VAO

VCLK

VH,VV

S

W

G

GPEN,GCLP,GCOAST

GHS2

GCLK

GRO[7:0],GRE[7:0]

GGO[7:0],GGE[7:0]

BE[7:0]

[7:0],G

BO

G

SH3-Bus Bridge

PDE

IC8028 IC8030

SDRAM

4M×(16+16)

D[31:0]

RD,WE1

IC8367

SCLI,SCLO,SDAI,SDAO

IRQ5,10,14

CTL

A[23:0]

CKIO

DDP_SCL,DDP_SCL

SCL

SDA

IC3002

DAC

PCON1

Reg. 1.9V,1.8V

32.5MHz

25MHz

IC 8025

OE

WE

WAIT

CVIC 2

IC 8005

FLASH

4M×16bit

SYNR

H

AD_SCL,AD_SDA

IC 3202

2

PROM

E

D[15:0]

A[23:0]

A[23:0]

D[15:0]

FANCONT1

PCON1

TXD1,RXD1

PLUGGED

CTL

CTL

POWER UNIT

EA

2.5V6V3.3V

13V

PFCCON

CONT4

FAN

OW

FANP

RS232C/RF ,L_CLICK,R_CLICK

S+,S-

RST_SYS

CLK

CS,RAS,

CAS,WE

BA1,BA1

A[0:10]

DQM[0:3]

DQ[0:31]

DCLK

DVS

DHS

DRO[9:0]

DRE[9:0]

DGO[9:0]

DGE[9:0]

DBO[9:0]

DBE[9:0]

RESET

1.8V,3.3V

A[23:0]

D[15:0]

16.58MHz

32.768KHz

CTL

IN1IN2/RGBSEL

132.7MHz(Core)

IC8319~

SDRAM

Controler

Main-MCU(SH3)

Reg.

2.5V,3.3V

5V,12VM

BU5V

IC8322

IC 8029

GA4

Panel

IC 8003

E

GA4_RST

RESET

IC 8007

2.5V5V3.3V

2

PROM

1.9V

6V

RST_SYS

FAN4

F4

Reg.

R/C

SCL,SDA

SCL,SDA

TXD1,RXD1

TEMP2

TXD2,RXD2

RST_SYS

TXD2,RXD2

TXD1,RXD1

TEMP2

13V

BU6V

PCON 0

PCON 1

VSYNCZ

HSYNCZ

ACTDATA

BU[9:0]

GY[9:0]

RV[9:0]

DDP_SDA

FA

DDP_SCL

PWRGOOD

RESETZ

DDP_LIGHT

LAMP_POW

N_LIGHT

CLKIN

ECO

TEMP1

KY

TH3001

Temp.

12VM

FAN 1 VCC

FANERR

FANPOW

AG_CLK

AG_DATA

RS232C/RF

L_CLICK

R_CLICK

PLUGGED

R/C

TXD2,RXD2

FANCONT1

BU5V

S+,S-

FAN_1_VCC

FA

EB

KY

FB

12VM

5V

2.5V

3.3V

MTRSIDO

FB

IC 9003

Data Processor

DDP1000

TH 9003 Temp.

IC2005

SW

Motor Controller

MTRSIDI

MTRSICLK

100MHz

SYSTEM

60MHz

OUTPUT

TM

DLP

ASIC

Reg.

BU5V

IC 3101

MTRCLK

MTRRSTZ

MTRSICSZ

IC 2002

Reset

FANERROR

FANPOW

FAN

CONT2

IC2001

Sub-MCU

7.38MHz

M

CWY[3..1]

CWCTR

FAN

CONT3

KEY3,2,1,0 (Analog)

LED(STBY,POW,

LAMPG,LAMPR.TEMP)

DMD FORMAT UNIT

CWINDEX

DQA[8:0]

RQ[7:0],RQB[7:0]

PCLKM

SCLKM

50MHz

FLAD[19:0]

FLD[15:0]

Control(5 wired)

VRSTEN

VBIASEN

VCC2EN

IC 9001

Clock Generator

IC 9004

FLASH

CONTROL(10)

IC 9005

Voltage

Generator

12V

5V

LAMPEN

LAMPLIT

KEY UNIT

Reg.

Reg.

Reg.

Reg.

POW

Color Wheel

DD[63:0]

DCLK (60MHz)

LOADB_LZ,TRC_L

Serial Bus(4 wired)

CTM

CTMN

400MHz

5V

VRST -26V

VBIAS +23~+26V

VCC2+7.5V

D

KEY

LED

5V

CW

IC 9006

RDRAM

128Mbit

IC9507

BALLAST

CW

Phase

Reset

Driver

ASIC

F1

F2

F3

F5

S

SENSOR

UNIT

Photo

Sensor

Comparator

MBSRT

[15:0]

FAN1

FAN2

FAN3

FAN5

3.3V

+7.5V

DMD

48

121110987654321

49

Page 48

O VERALL WIRING DIAGRAM

H

G

F

PG-M20X

E

D

C

B

A

121110987654321

50

51

Page 49

PG-M20X

DESCRIPTION OF SCHEMATIC

DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. Voltages at test points are measured at the supply

voltage of AC 230V. Signals are fed by a colour bar

signal generator for servicing purpose and the above

voltages are measured with a 20k ohm/V tester.

WAVEFORM MEASUREMENT CONDITION:

1. Wavef orms at test points are observed at the supply

voltage of AC 230V. Signals are fed by a colour bar

signal generator for servicing purpose.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise

noted.

C : Solid

S : Oxide Film T : Special

N : Metal Coating

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC

OUTLET BEFORE REPLACEING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE

REGARDED AS POTENTIAL SHOCK HAZARDS

WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “ å ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

W

: Cement

BESCHREIBUNG DES

SCHEMATISCHEN SCHALTPLANS

SPANNUNGSMESSUNGEN:

1. Spannungen an den Prüfpunkten werden bei einer

Netzspannung von 230V gemessen, Signale werden

für die Wartung mit einem Farbbalken-Signal

generator zugeführt, und Spannungen werden mit

einem Meßinstrument (20 kΩ/V) ermittelt.

SIGNALFORMMESSUNGEN:

1. Die Wellenformen an den Testpunkten werden bei

einer Netzspannung von 230V verfolgt. Signale

werden für die W artung mit einem Farbbalk en-Signal

generator zugeführt.

BEZEICHNUNG DES WIDERSTANDS UND

KONDENSATORS:

WIDERSTAND

1. Die Widerstandseinheit “Ω” wird weggelassen.

(K=kΩ=1000 Ω, M=MΩ).

2. Alle Widerstände haben ± 5%, sofern nicht anders

angegeben.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. Alle Widerstände haben 1/16W, sofern nicht anders

angegeben.

4. Alle Widerstände sind Kohletyp, sofern nicht anders

angegeben.

C : Fest

S : Oxidefilm T : Spezial

N : Metallüberzug

KONDENSATOR

1. Die Kapazitätseinheit ist µF, sofern nicht anders

angegeben.

(P=pF=µµF).

2. Alle Kondensatoren haben 50V, sofern nicht anders

angegeben.

3. Alle Kondensatoren sind Keramiktyp, sofer n nicht

anders angegeben.

(ML): Mylar (TA): Tantal

(PF): Polyprofilm (ST): Styrol

ACHTUNG:

bei diesem Schaltplan handelt es sich um den ursprünglichen.

Esönnen daher geringfügige Unterschiede zu dem lhrem bestehen.

SICHERHEITSANMERKUNGEN:

1. VOR DEM AUSWECHSELN VON TEILEN MUSS

UNBEDINGT NETZSTECKER AUS DER

NETZSTECKDOSE GEZOGEN WERDEN.

2. DIE WARMEABLEITER DER HALBLEITER SOLLTEN

BEIM BETRIEB DES CHASSIS ALS MÖGLICHE

URSACHEN VON GEFÄHRLICHEN ELEKTRISCHEN

SCHLÄGEN BETRACHTET WERDEN.

WICHTIGE SICHERHEITSANMERKUNGEN:

MIT “å ( )BEZEICHNETEN TEILE SIND

BESONDERS WICHTIG FÜR DIE A UFRECHTERHALTUNG

DER SICHERHEIT . BEIM WECHDIESER TEILE SOLLTEN

DIE VORGESCHRIEBENEN TEILE IMMER VERWENDET

WERDEN, UM SO W OHL DIE SICHERHEIT ALS AUCH DIE

LEISTUNG DES GERÄTES AUFRECHTZUERHALTEN.

W

: Zement

52

Page 50

WAVEFORMS

PG-M20X

1 SC3101 1-pin

(INPUT CWCTR)

H : 200µ sec/div

V : 6.90V/div

5 SC9001 3-pin

(FORMAT CLKIN)