Page 1

SERVICE MANUAL

SERVICE-ANLEITUNG

S91A5PG-M15S/

DIGITAL MULTIMEDIA PROJECTOR

DIGITALER MULTIMEDIA PROJEKTOR

PG-M15X

PG-M15X

PG-M15S

AN-M15T

MODELS

PG-M15S

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

AN-M15T

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

PG-M15X

PG-M15S

AN-M15T

CONTENTS

Page Page

» SPECIFICATIONS ............................................. 3

» IMPORTANT SERVICE SAFETY

NOTES (for USA)............................................... 4

» NOTE TO SERVICE PERSONNEL ................... 5

» OPERATION MANUAL ...................................... 8

» REMOVING OF MAJOR PARTS ..................... 13

» RESETTING THE TO TAL LAMP TIMER ......... 23

» OPTICAL ADJUSTMENT AND MEASURING... 25

» THE OPTICAL UNIT OUTLINE ....................... 28

» TROUBLE SHOOTING TABLE ........................ 30

» OVERALL WIRING DIAGRAM ........................ 70

Seite Seite

» TECHNISCHE DATEN..................................... 38

» HINWEISE FÜR DAS

WARTUNGSPERSONAL ................................ 39

» BEDIENUNGSANLEITUNG ............................ 40

» ENTFERNEN DER HAUPTTEILE..................45

» RÜCKSTELLEN DES

LAMPENBETRIEBSZEIT-TIMERS .................55

» OPTISCHE EINSTELLUNG UND

MESSUNG......................................................57

» ÜBERSICHT DER OPTIK-EINHEIT ............... 60

» FEHLERSUCHTABELLE ................................62

» GESAMTSCHALTPLAN .................................70

» BLOCK DIAGRAM........................................... 71

» SCHEMATIC DIAGRAM .................................. 74

» PRINTED WIRING BOARD ASSEMBLIES..... 99

» PARTS LIST

» PACKING OF THE SET ................................. 113

» AN-M15T........................................................ 114

INHALT

» BLOCKSCHALTBILD ......................................71

» SCHEMATISCHER SCHALTPLAN.................74

» LEITERPLATTENEINHEITEN ........................99

» ERSATZTEILLISTE

» VERPACKEN DES GERÄTS......................... 113

» AN-M15T........................................................ 114

Ë

ELECTRICAL PARTS ................................ 101

Ë

CABINET AND MECHANICAL PARTS ..... 108

Ë

ACCESSORIES PARTS ............................ 112

Ë

PACKING PARTS....................................... 112

Ë

ELEKTRISCHE BAUTEILE ....................... 101

Ë

GEHÄUSE UND MECHANISCHE

BAUTEILE.................................................. 108

Ë

ZUBEHÖRTEILE ....................................... 112

Ë

VERPACKUNGSTEILE.............................. 112

2

Page 3

Specifications

Product type

Model

Video system

Display method

DMD panel

Lens

Projection lamp

Contrast ratio

Video input signal

S-video input signal

Component input signal

Horizontal resolution

Computer RGB input signal

Pixel clock

Vertical frequency

Horizontal frequency

Audio input signal

Audio output

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Power dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Supplied accessories

Replacement parts

Digital Multimedia Projector

PG-M15X/PG-M15S

NTSC/NTSC 4.43/PAL/PAL-M/PAL-N/PAL 60/SECAM/DTV480i

Single Chip Digital Micromirror Device™ (DMD™) by Texas Instruments

Panel size: 0.7 (17.8 mm), 1 chip XGA DMD/SVGA DMD

No. of dots: 786,432 dots (1,024 [H] 768 [V])/PG-M15X

480,000 dots (800 [H] 600 [V])/PG-M15S

1-1.2 X zoom lens, F2.2–2.4, f 28.5–34.2 mm

High Intensity Discharge Lamp (HID Lamp), AC 130 W

500:1

RCA Connector (INPUT 3): VIDEO, composite video, 1.0 Vp-p, sync negative, 75 Ω

terminated

4-pin Mini DIN connector (INPUT 2)

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

29-pin Connector (INPUT 1)

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

P

B

: 0.7 Vp-p, 75 Ω terminated

P

R

: 0.7 Vp-p, 75 Ω terminated

580 TV lines (video input)

29-pin

CONNECTOR

(INPUT 1)

RGB separate/sync on green type analog input: 0–0.7 Vp-p, positive, 75 Ω terminated

H

ORIZONTAL SYNC.SIGNAL

: TTL level (positive/negative)

V

ERTICAL SYNC.SIGNAL

: Same as above

25–135 MHz

56–85 Hz

31.5–80 kHz

3.5 ø M

INIJACK

: AUDIO, 0.4 Vrms, more than 47 kΩ (stereo)

2.0 W (monaural)

4 2.8 cm

AC 100–240 V

2.0 A

50/60 Hz

180 W

<680 BTU/hour

41°F to 95°F (5°C to 35°C)

4°F to 140°F (20°C to 60°C)

Magnesium alloy (Terminal panel, Lamp cover and Side vent cover constructed of plastic)

38 kHz

8

55

⁄64 1 31⁄32 6 59⁄64 (225 (W) 50 (H) 176 (D) mm) (main body only)

8

55

⁄64 2 19⁄32 6 31⁄32 (225 (W) 66 (H) 177 (D) mm) (including adjustment feet

and projecting parts)

3.5 lbs (1.6 kg)

Remote control, Two AAA size batteries, Power cord for U.S., Canada etc. (5 11, 1.8 m),

Power cord for Europe, except U.K. (5 11, 1.8 m), Power cord for U.K., Hong Kong and

Singapore (5 11, 1.8 m), Power cord for Australia, New Zealand and Oceania (5 11, 1.8

m), DVI-Analog to VGA cable (5 11, 1.8 m), DVI-Analog to VGA adaptor, PC audio cable

(6 7, 2.0 m), DIN-D-sub RS-232C cable (6

1

/2, 16.5 cm), Computer RGB cable (5 11,

1.8 cm), USB mouse control cable (5 11, 1.8 m), Video cable (5 11, 1.8 m), S-video

cable (5 11, 1.8 m), AV audio cable (5 11, 1.8 m), Soft carrying pouch, Lenscap with

strap, CD-ROM, Projector operation manual, Projector quick reference guide

Remote control (9HJ7583104001), AAA size battery (9HJ4683101001), Power cord for

U.S., Canada etc. (9HJ4283114001), Power cord for Europe, except U.K.

(9HJ4283116001), Power cord for U.K., Hong Kong and Singapore (9HJ4283117001),

Power cord for Australia, New Zealand and Oceania (9HJ4283118001), DVI-Analog to

VGA cable (9HJ4283119001), DVI-Analog to VGA adaptor (9HJ4283124001), PC audio

cable (9HJ4283120001), DIN-D-sub RS-232C cable (9HJ4283123001), Computer RGB

cable (9HJ4283111001), USB mouse control cable (9HJ4283122001), Video cable

(9HJ4283112001), S-video cable (9HJ4283113001), AV audio cable (9HJ4283121001),

Soft carrying pouch (9HJ5383101001), Lens cap with strap (9HJ7083117001), CD-ROM

(9HJ3683104001), Projector operation manual (9HJ3683107001), Projector quick

reference guide (9HJ3683110001)

This unit has some inactive pixels within acceptable tolerances which

may result in inactive dots on the picture screen. This will not affect

the picture quality or the life expectancy of the unit.

This SHARP projector uses a DMD panel. This very sophisticated

panel contains 786,432 (PG-M15X)/480,000 (PG-M15S) pixels. As

with any high technology electronic equipment such as large screen

TVs, video systems and video cameras, there are certain acceptable

tolerances that the equipment must conform to.

Specifications are subject to change without notice.

PG-M15X

PG-M15S

AN-M15T

3

Page 4

PG-M15X

2

2

PG-M15S

AN-M15T

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

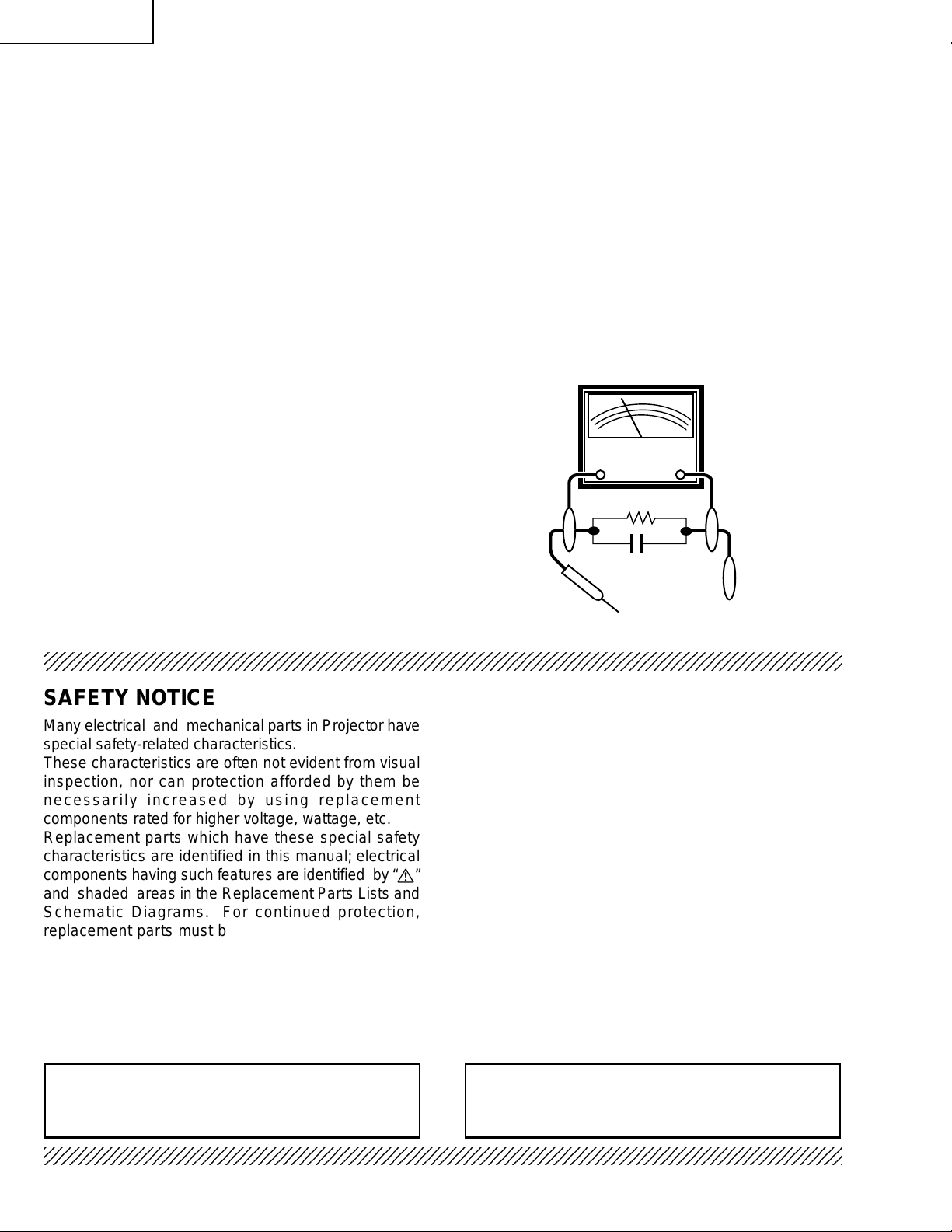

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm

per volt., or higher, sensitivity to measure the AC

voltage drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. A C .) or more is e xcessiv e and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in Projector have

special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified b y “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans

la liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT:La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

4

Page 5

PG-M15X

PG-M15S

AN-M15T

NOTE TO SERVICE

PERSONNEL

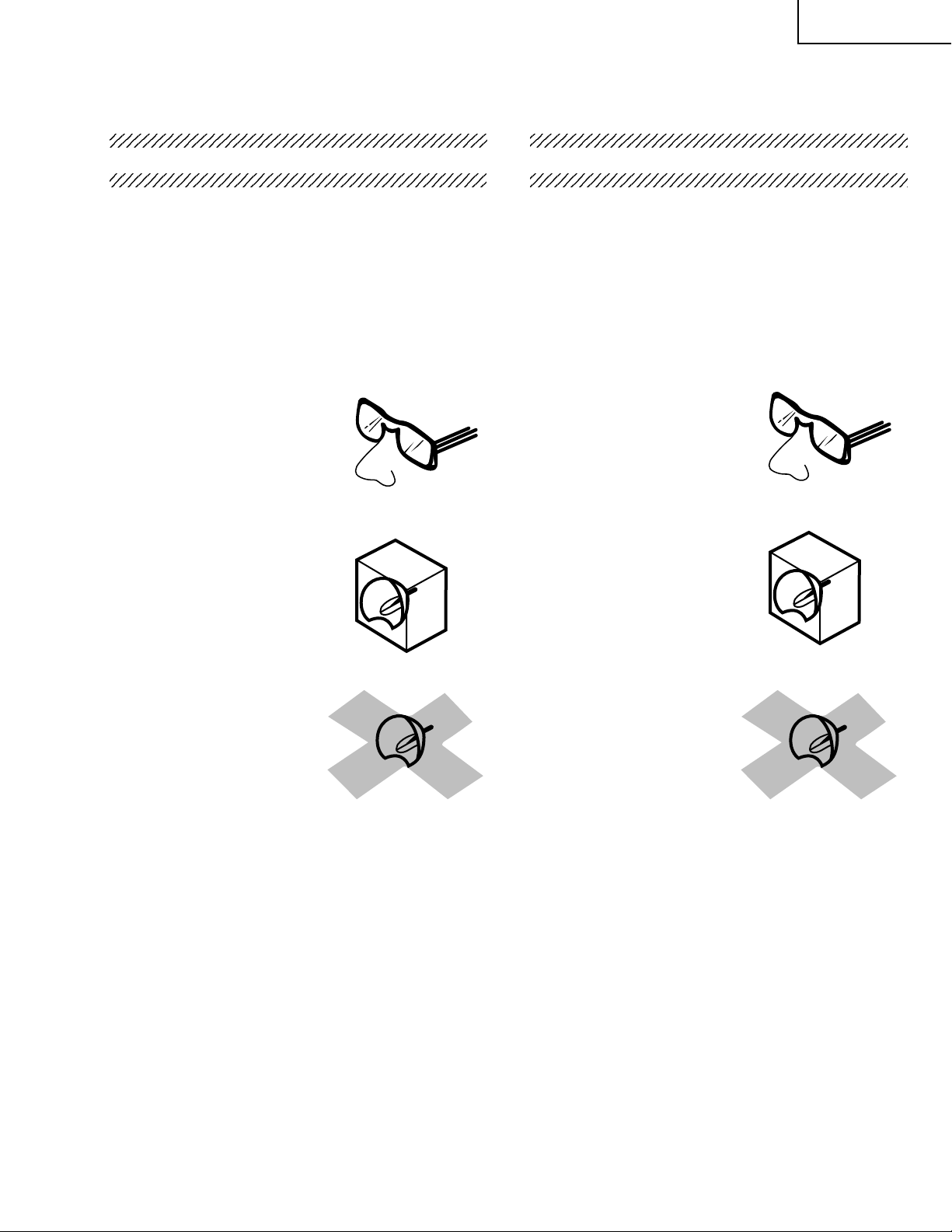

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the pr ojector

emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NO TE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe métal halide,

dans le projecteur émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour v otre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours por ter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

9HJ7083119001 or BQC-PGM15X//1 rated 85V/

130W.

4. The lamp emits small amounts of UV-Radiation,

avoid direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type 9HJ7083119001 ou BQC-PGM15X//1

caractéristique 85V/130W.

4. La lampe émet de petites quantités de radiation UV éviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

5

Page 6

PG-M15X

4

5

PG-M15S

AN-M15T

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

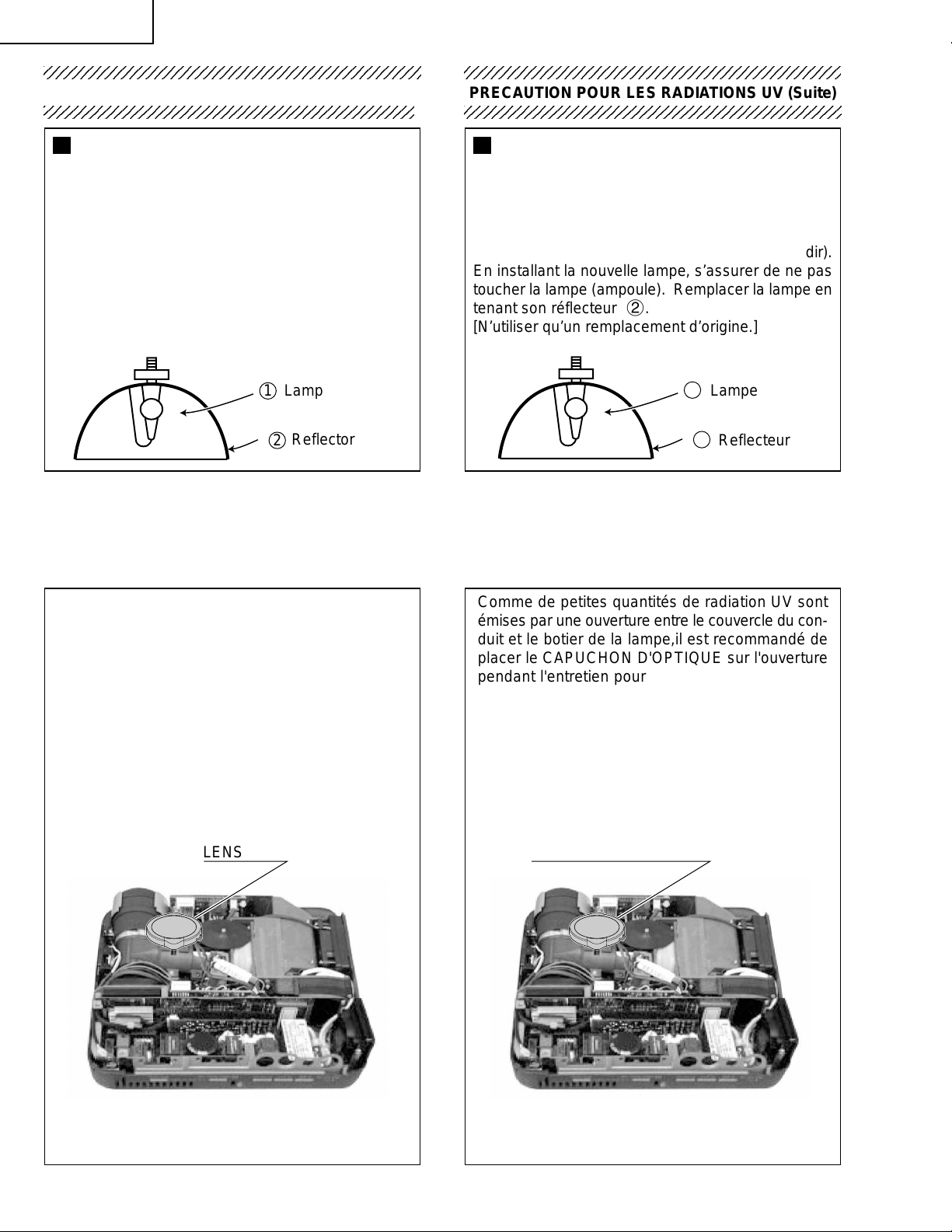

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Ne ver turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high v oltages

at its start.

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

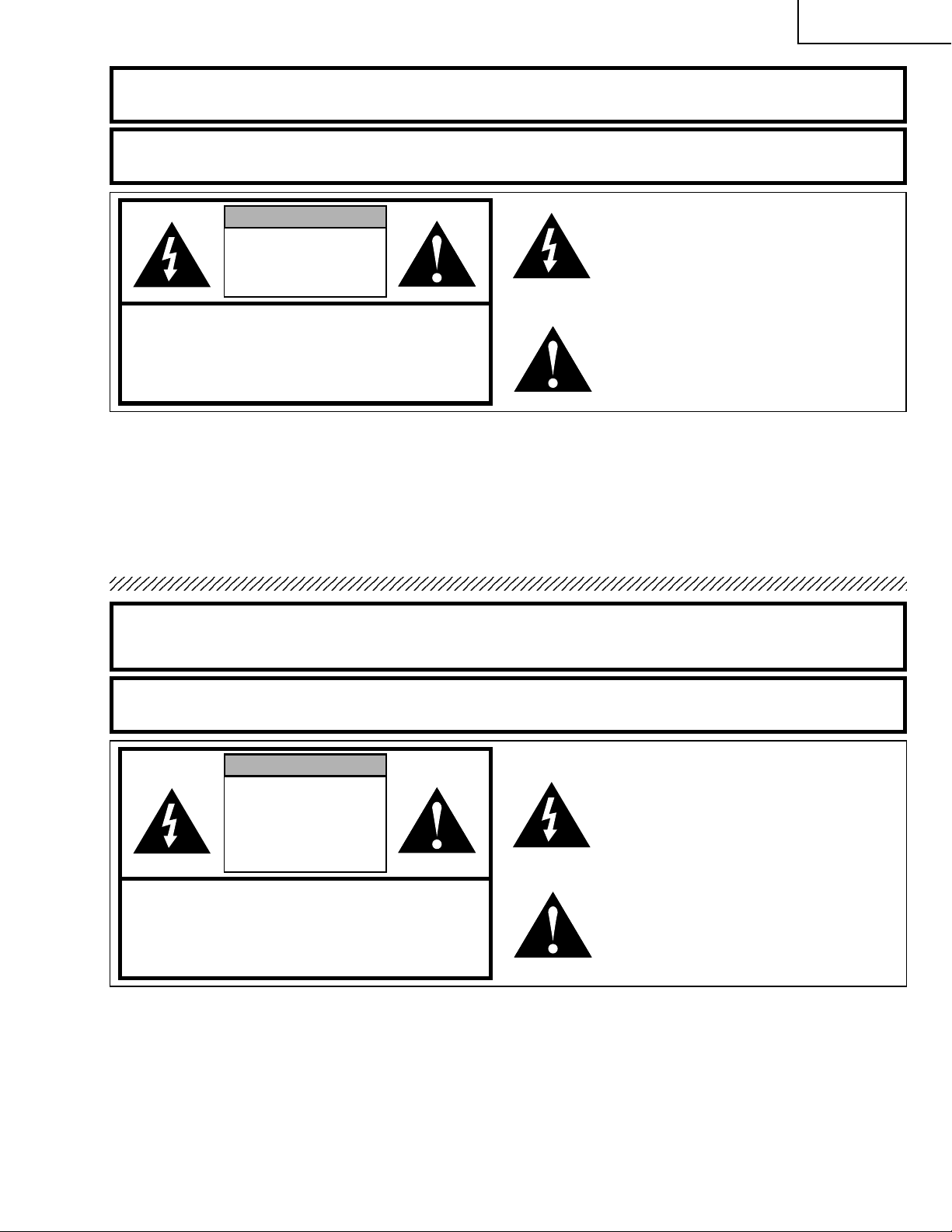

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the lamp

housing, it is recommended to place the LENS CAP

on the opening during servicing to avoid eye and

skin exposure (Fig. 1).

Note: Please obtai n a l ens cap be fore servicing a

models PG-M15X/M15S that is received without one.

LENS CAP CAPUCHON D'OPTIQUE

Comme de petites quantités de radiation UV sont

émises par une ouverture entre le couvercle du conduit et le botier de la lampe,il est recommandé de

placer le CAPUCHON D'OPTIQUE sur l'ouverture

pendant l'entretien pour éviter une exposition des

yeux et la peau (Fig. 1).

Remarque: Priére de se procurer un capuchon

d'optique acant d'entretien un modéle

PG-M15X/M15S qui est livré sans.

Figure 1.

Figure 1.

6

Page 7

PG-M15X

PG-M15S

AN-M15T

WARNING: High brightness light source, do not stare into the beam of light, or view directl y . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREWS

CAUTION: T O REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMO VE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING T O Q U ALIFIED SER VICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are

in the manual with the projector.

AVERTISSEMENT: Sour ce lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

A VERTISSEMENT: AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ELECTR OCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REP ARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQ UE

D’ELECTR OCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REP ARABLE

PAR L ’UTILISA TEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR T OUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QU ALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

7

Page 8

PG-M15X

PG-M15S

AN-M15T

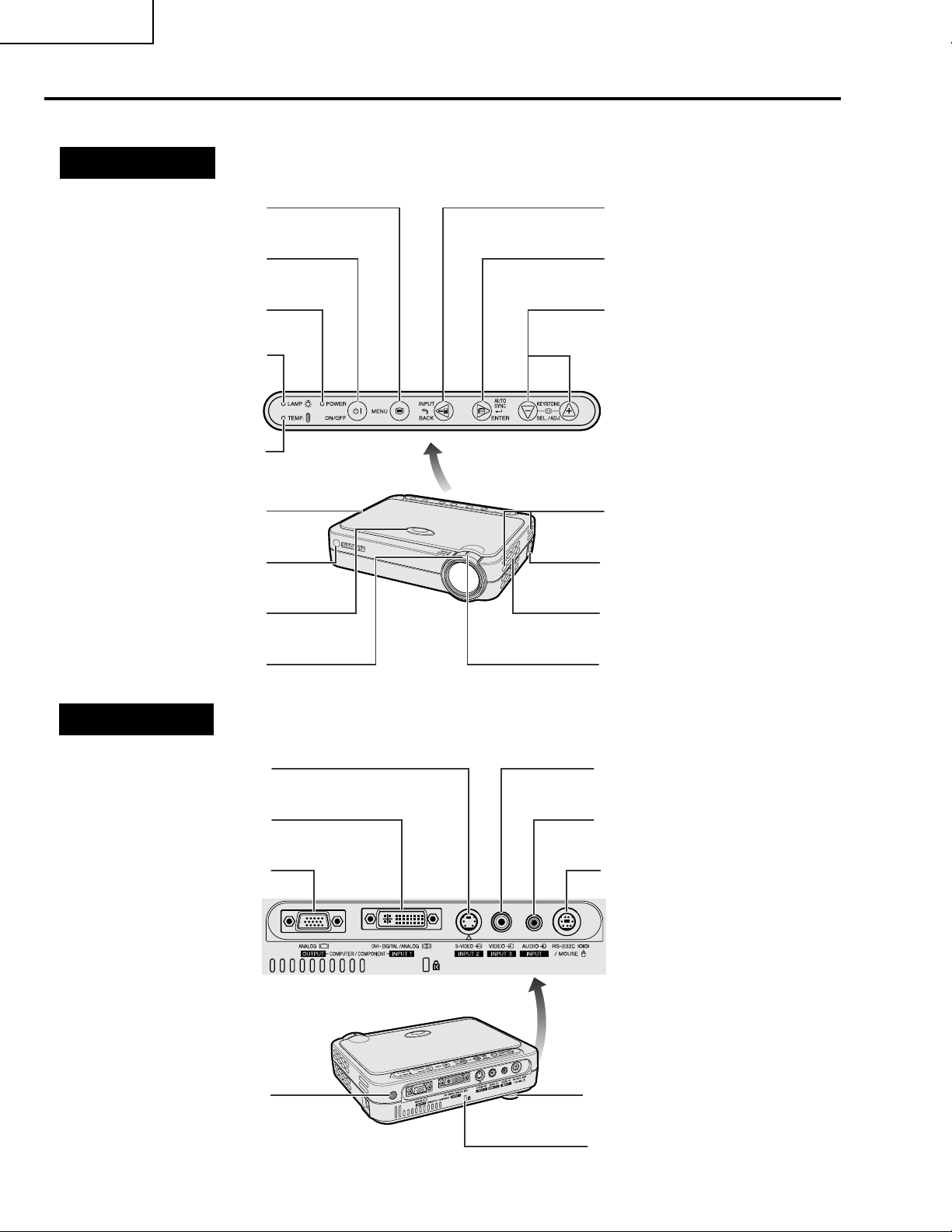

Location of Controls

Projector

Front and Top View

MENU button

ON/OFF button

POWER indicator

LAMP REPLACEMENT

indicator

TEMPERATURE WARNING

indicator

Cooling fan (Exhaust vent)

Remote control sensor

HEIGHT ADJUST button

INPUT/BACK button

AUTO SYNC/ENTER button

KEYSTONE (/)/

SELECT/ADJUST ('/") buttons

Intake vent

AC socket

Speaker

+–

FOCUS ring

Side and Rear View

S-VIDEO INPUT 2 terminal

(4-pin Mini DIN)

DVI-DIGITAL/ANALOG

INPUT 1 port (29-pin)

ANALOG OUTPUT port for

INPUT 1 (HD 15)

Remote control sensor

ZOOM knob

VIDEO INPUT 3 terminal

(RCA)

AUDIO INPUT terminal

(3.5 mm stereo Minijack)

RS-232C/MOUSE port

(7-pin Mini DIN)

Adjuster

Kensington Security Standard

connector

8

Page 9

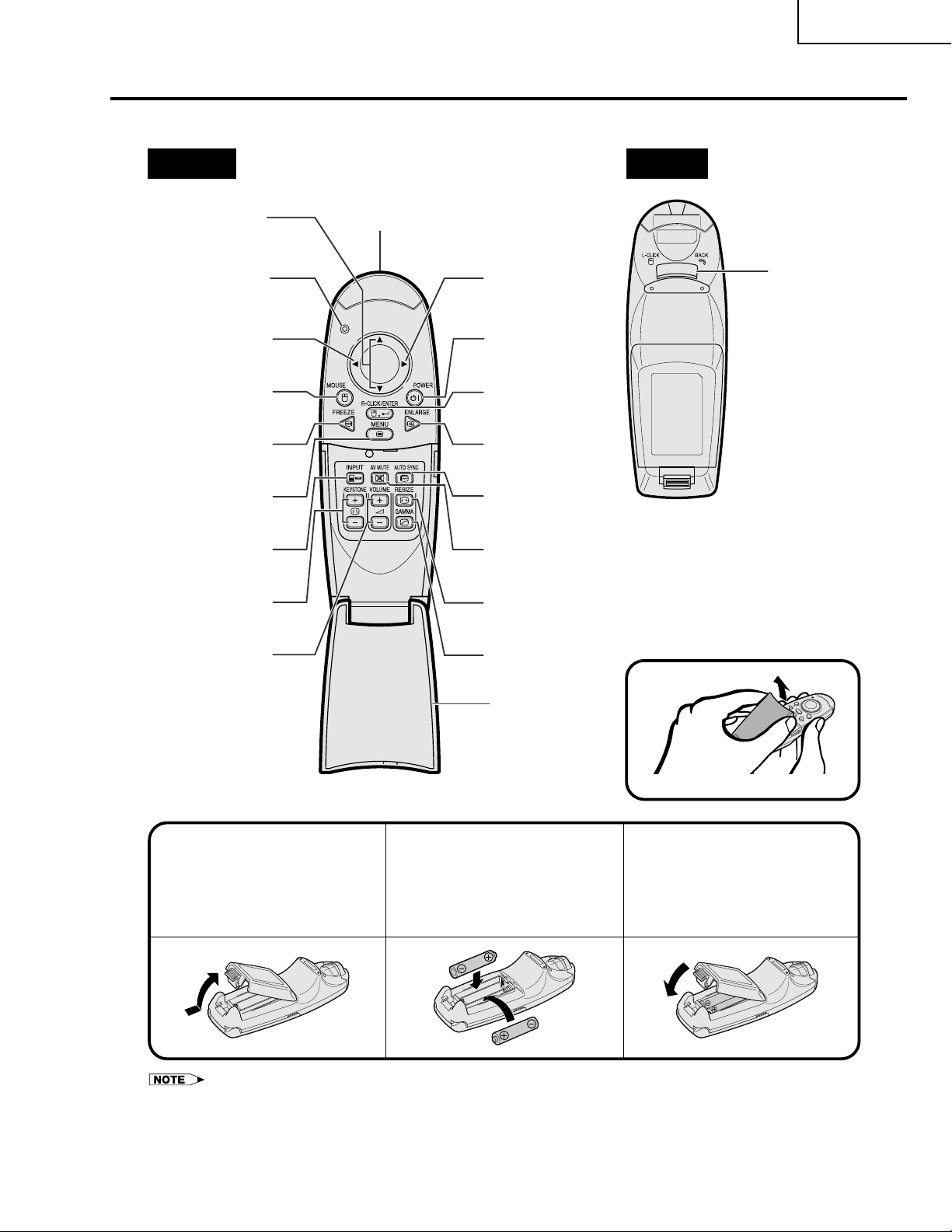

Operating the Wireless Mouse Remote Control

Remote Control

Front View Rear View

PG-M15X

PG-M15S

AN-M15T

Mouse ('/")/

Adjustment ('/")

buttons

Remote control signal

transmitter indicator

(Flashes when remote

control sends a signal)

Mouse (\ ) button

MOUSE button

FREEZE button

MENU button

INPUT button

KEYSTONE (+/– )

buttons

VOLUME buttons

Remote control signal

transmitting window

Mouse (|) button

POWER button

RIGHT-CLICK/

ENTER button

ENLARGE button

AUTO SYNC button

AV MUTE button

RESIZE button

GAMMA button

LEFT-CLICK/

BACK button

Opening the Flip Cover

Flip cover

Inserting the Batteries

Press the tab and lift open

13

the battery cover in the

direction of the arrow.

• If the remote control gets wet, wipe it dry immediately.

• Avoid excessive heat and humidity.

• If you will not be using the remote control for a long time, remove the batteries.

• Do not mix new and old or different types of batteries.

• There are operations that can only be carried out by remote control. Handle the remote control carefully.

Insert two AAA size

2

batteries, making sure

their polarities match the

and marks inside

–+

the battery compartment.

Insert the tabs on the

end of the battery cover

into their slots and press

the cover into position.

9

Page 10

PG-M15X

PG-M15S

AN-M15T

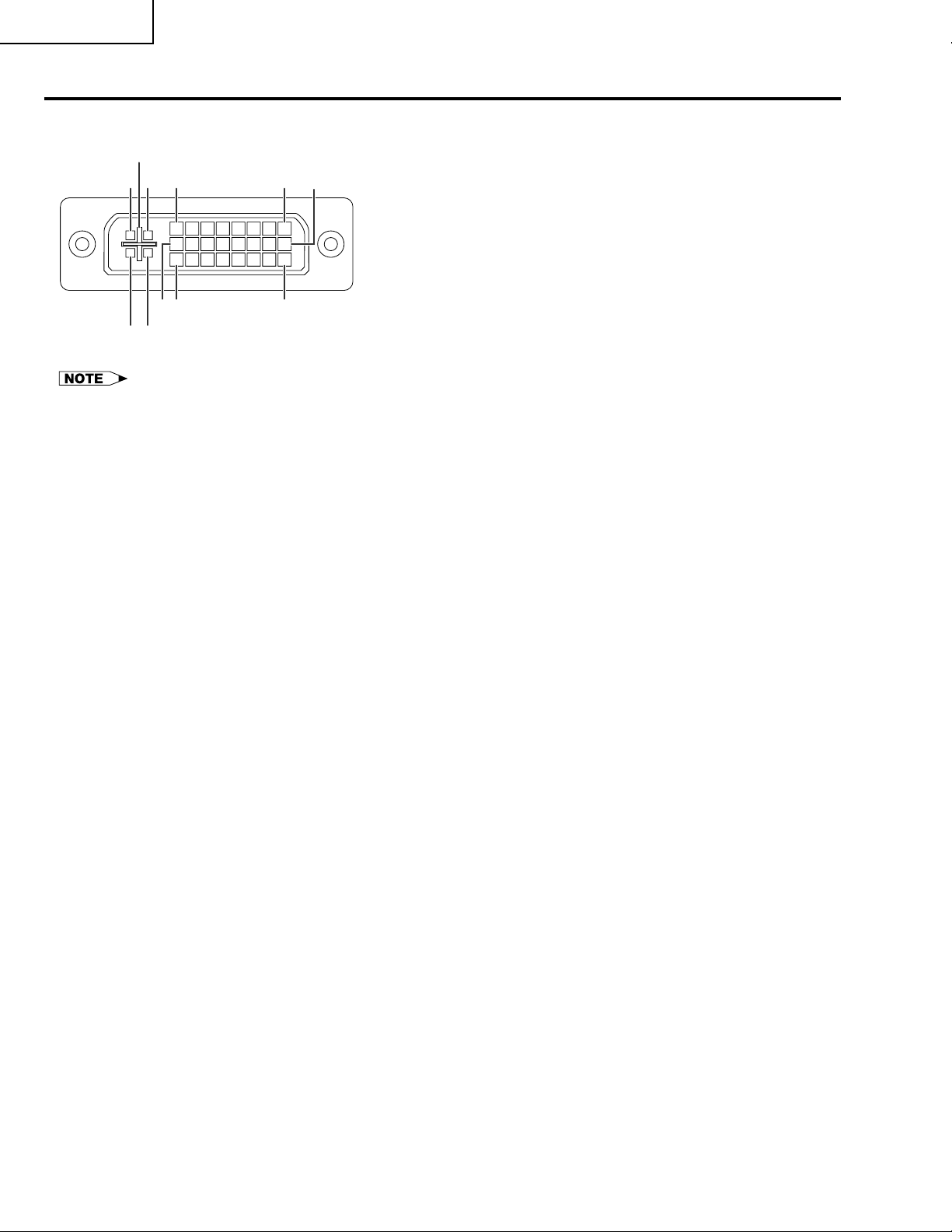

Connection Pin Assignments

DVI INPUT 1 Port: 29-pin

C5

C4 C3

24 17

9

816 1

C2 C1

•*1 Return for Ⳮ5 V, Hsync. and Vsync.

•*2 These pins are not used on this equipment.

DVI input

Pin No. Name

1 T.M.D.S. Data 2ⴑ

2 T.M.D.S. Data 2Ⳮ

3 T.M.D.S. Data 2/4 Shield

4 T.M.D.S. Data 4ⴑ*

5 T.M.D.S. Data 4Ⳮ*

6 DDC Clock

7 DDC Data

8 Vertical Sync

9 T.M.D.S. Data 1ⴑ

10 T.M.D.S. Data 1Ⳮ

11 T.M.D.S. Data 1/3 Shield

12 T.M.D.S. Data 3ⴑ*

13 T.M.D.S. Data 3Ⳮ*

14 Ⳮ5 V Power

15 Ground*

16 Hot Plug Detect

17 T.M.D.S. Data 0ⴑ

18 T.M.D.S. Data 0Ⳮ

19 T.M.D.S. Data 0/5 Shield

20 T.M.D.S. Data 5ⴑ*

21 T.M.D.S. Data 5Ⳮ*

22 T.M.D.S. Clock Shield

23 T.M.D.S. ClockⳭ

24 T.M.D.S. Clockⴑ

C1 Analog input Red

C2 Analog input Green

C3 Analog input Blue

C4 Horizontal Sync

C5 Ground

RGB input

Pin No. Name

1 Not connected

2 Not connected

2

2

2

2

1

2

2

3 Not connected

4 Not connected

5 Not connected

6 DDC Clock

7 DDC Data

8 Vertical Sync

9 Not connected

10 Not connected

11 Not connected

12 Not connected

13 Not connected

14 Ⳮ5 V Power

15 Ground

16 Not connected

17 Not connected

18 Not connected

19 Not connected

20 Not connected

21 Not connected

22 Not connected

23 Not connected

24 Not connected

C1 Analog input Red

C2 Analog input Green

C3 Analog input Blue

C4 Horizontal sync

C5 Ground

COMPONENT input

Pin No. Name

1 Not connected

2 Not connected

3 Not connected

4 Not connected

5 Not connected

6 Not connected

7 Not connected

8 Not connected

9 Not connected

10 Not connected

11 Not connected

12 Not connected

13 Not connected

14 Not connected

15 Ground

16 Not connected

17 Not connected

18 Not connected

19 Not connected

20 Not connected

21 Not connected

22 Not connected

23 Not connected

24 Not connected

C1 Analog input Pr

C2 Analog input Y

C3 Analog input Pb

C4 Not connected

C5 Ground

10

Page 11

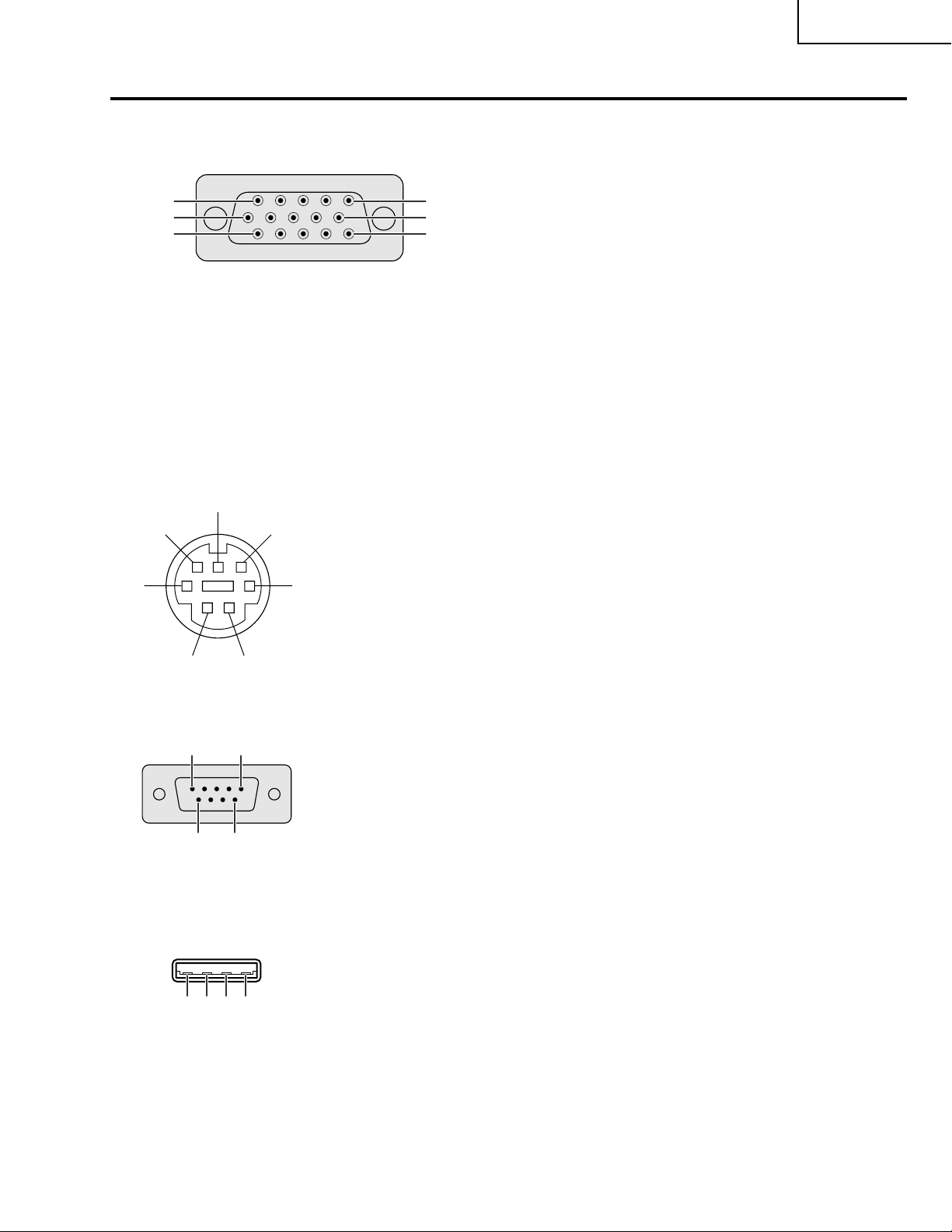

OUTPUT (INPUT 1) Signal Port: 15-pin Mini D-sub female connector

RGB output

Analog

1 Video output (red)

11

15

6

1

10

5

2 Video output

(green/sync on green)

3 Video output (blue)

4 Not connected

5 Not connected

6 Earth (red)

7 Earth (green/sync on green)

8 Earth (blue)

9 Not connected

10 GND

11 GND

12 Not connected

13 Horizontal sync signal

14 Vertical sync signal

15 Not connected

PG-M15X

PG-M15S

AN-M15T

COMPONENT output

Analog

R

(CR)

1P

2Y

B

(CB)

3P

4 Not connected

5 Not connected

6 Earth (P

7 Earth (Y)

8 Earth (P

9 Not connected

10 Not connected

11 Not connected

12 Not connected

13 Not connected

14 Not connected

15 Not connected

R

)

B

)

RS-232C T erminal: 7-pin Mini DIN female connector

6

7

5

4

21

Pin No. Signal Name

1 VCC (USB) USB Power

2 RD Receive Data

3 SD Send Data

4 USB (ⳮ) USB Data (ⳮ)

3

5 GND Signal Ground

6 USB (Ⳮ) USB Data (Ⳮ)

7 NC (Reserved)

RS-232C Port: 9-pin D-sub male connector of the DIN-D-sub RS-232C cable

15

69

Pin No. Signal Name

1CD

2 RD Receive Data

3 SD Send Data

4ER

5 SG Signal Ground

6 DR Data Set Ready

7 RS Request to Send

8 CS Clear to Send

9 CI

USB connector: 4-pin USB connector of the USB mouse control cable

Pin No. Signal Name

1 VCC USB Power

4321

2 USBⳮ USB Dataⳮ

3 USBⳭ USB DataⳭ

4 SG Signal Ground

11

Page 12

PG-M15X

PG-M15S

AN-M15T

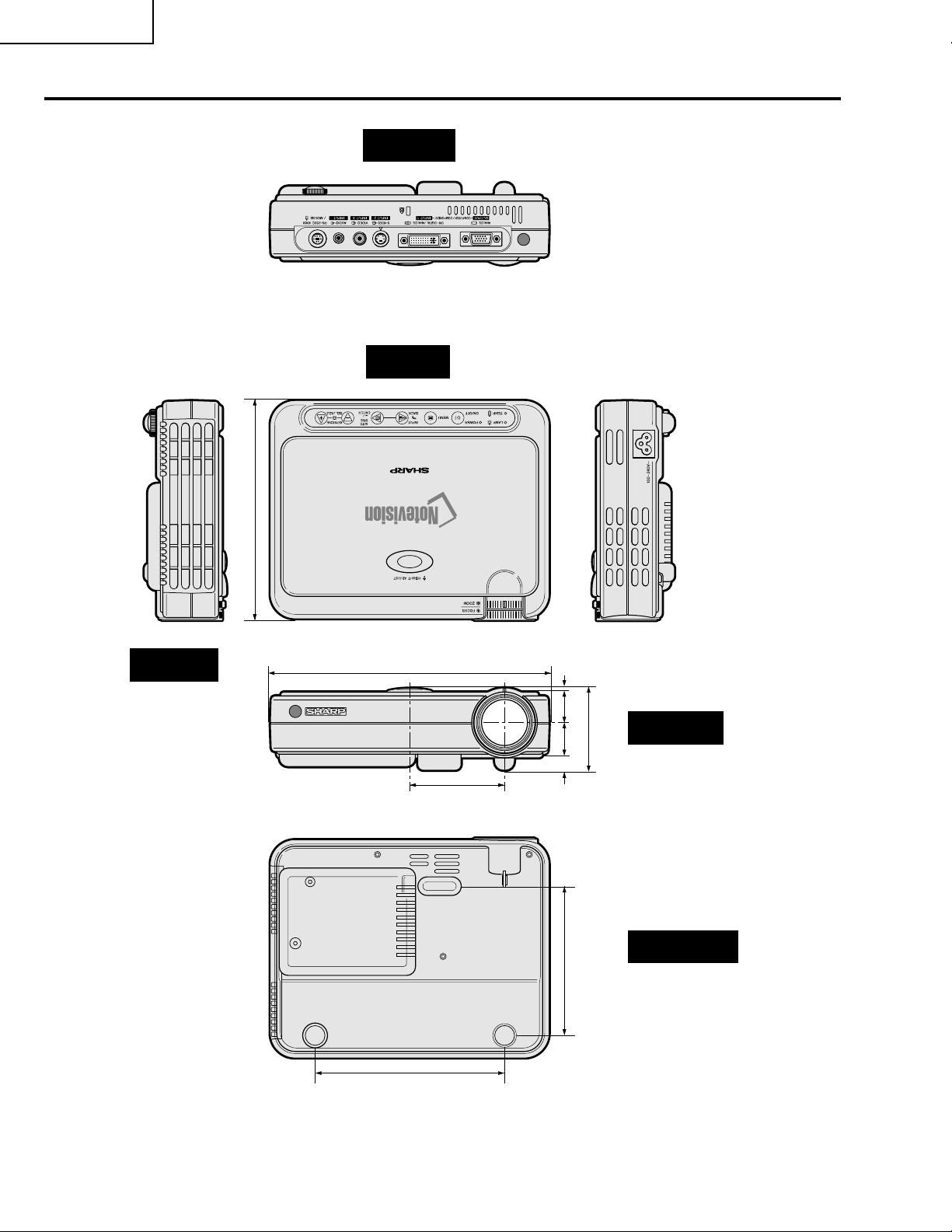

Dimensions

Rear View

T op View

Side View

(176)

64

/

59

6

855/64 (225)

1

3

/64 (76.5)

(3)

3

/

1

(13)

64

/

33

(24.5)

32

/

31

1 (25.5)

(120.5)

4

/

3

4

(66)

Front View

32

/

19

2

Bottom View

61/32 (153)

Units: inches (mm)

12

Page 13

PG-M15X

PG-M15S

AN-M15T

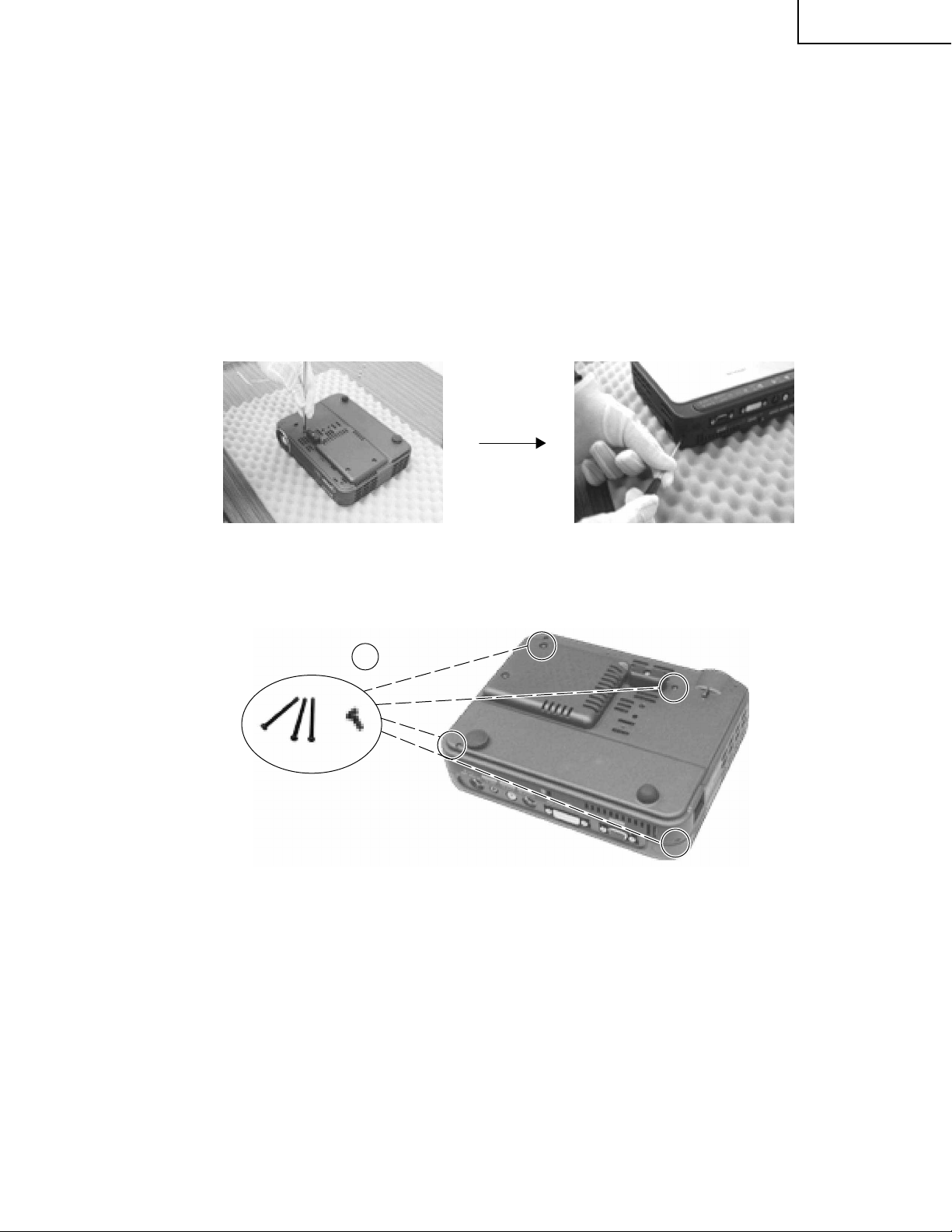

REMOVING OF MAJOR PARTS

Tools required

1. Philips screw driver (Size : 1, 2)

2. Nut driver (2.5mm)

3. Ball end hexagonal driver (5.0mm)

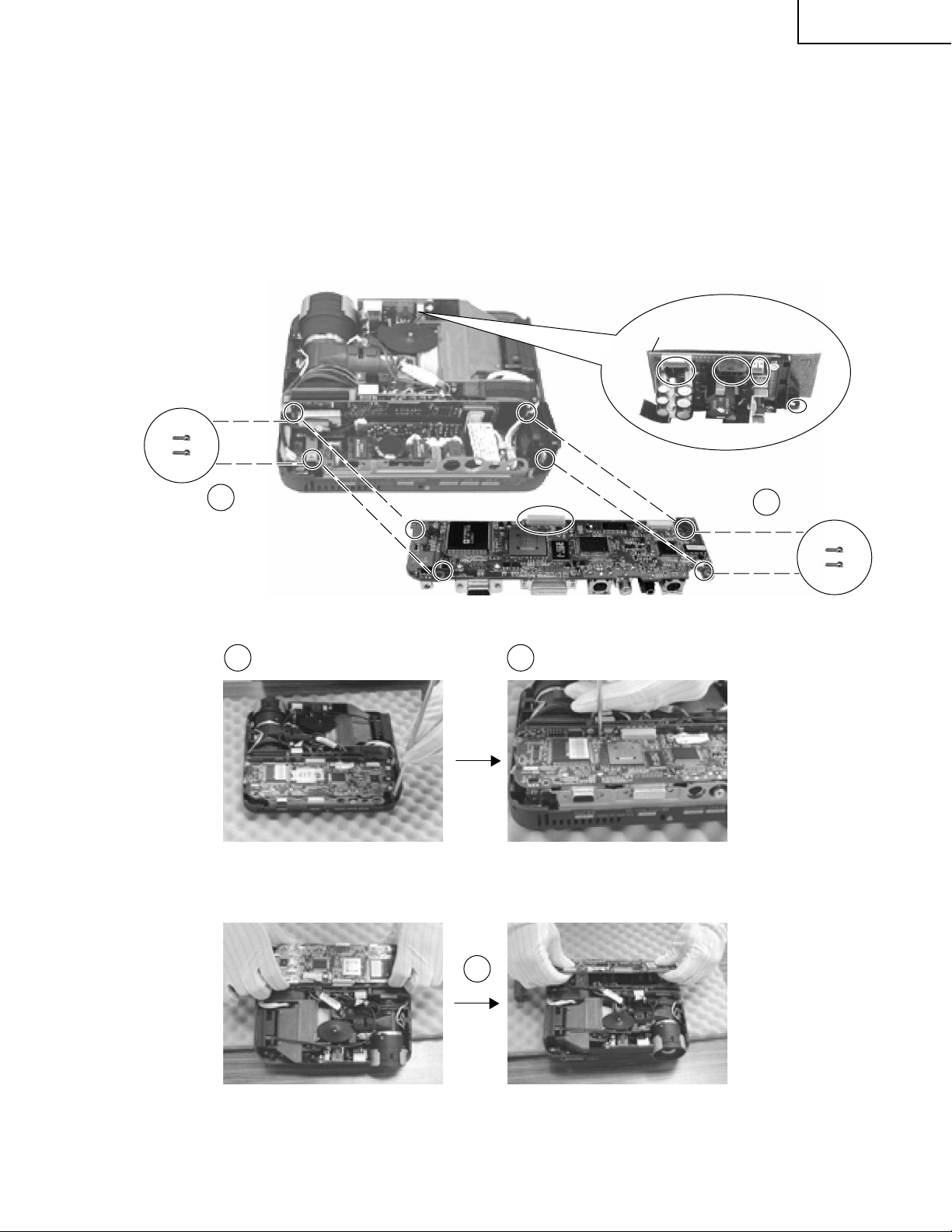

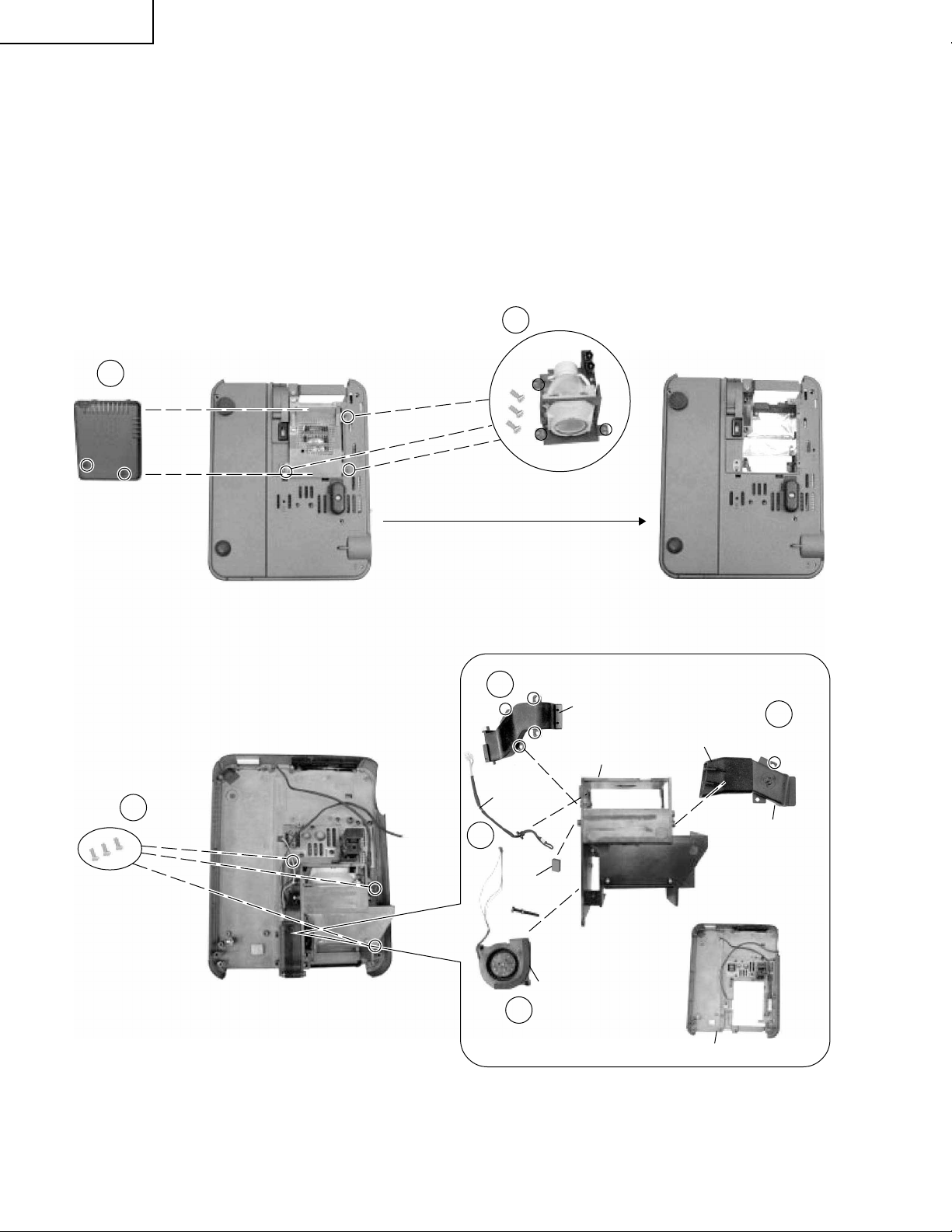

1.Disassemble Top Cover Module, Main PWB Unit and DC to DC PWB Unit

1-1. Remove four screws on Bottom Cover. (Refer to Step 1, 2.)

Step 1 Step 2

1-1

13

Page 14

PG-M15X

Terminal sheet

1-5

PG-M15S

AN-M15T

1-2. Lift up Top Cover and unplug two wires connected to IR PWB Unit and Main Unit. (Refer to Step 3~5.)

1-3. Remove Top Cover .

1-4. Remove one screw to take off IR PWB Unit and IR PWB Unit Cover.

1-5. Remove four D-SUB shafts from the D-SUB Terminals to take off Terminal Sheet. (Refer to Step 6~7.)

1-21-2

Step 3 Step 4 Step 5

1-3

IR PWB Unit Cover

Step 6

1-4

IR PWB Unit

Step 7

14

Page 15

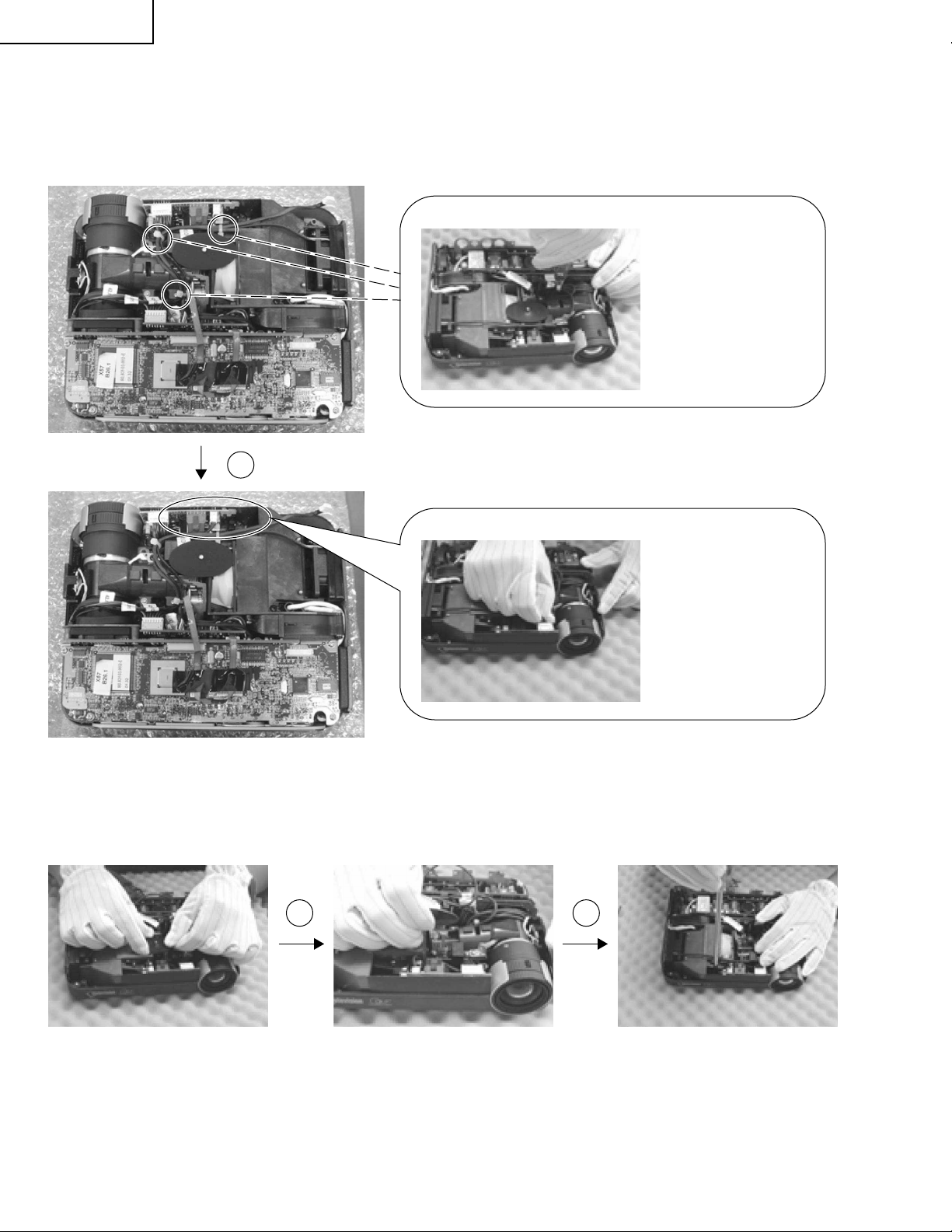

2.Disassemble Optical Engine Module

2-1. Remove 4 screws from main PWB unit.

2-2. Using a ball end hexagonal driver, loosen 2 screws holding terminal sheet holder.

(approx. 4 rotation)(Step 8.)

2-3. Place a tool in between main PWB unit and formatter PWB unit and disconnect the connector. (Step 9.)

2-4. Pull the main unit outwards and remove main PWB unit. (Step 10,11.)

DC to DC PWB Unit

PG-M15X

PG-M15S

AN-M15T

2-1

2-2 2-3

Step 8 Step 9

2-1

2-4

Step 10 Step 11

15

Page 16

PG-M15X

PG-M15S

AN-M15T

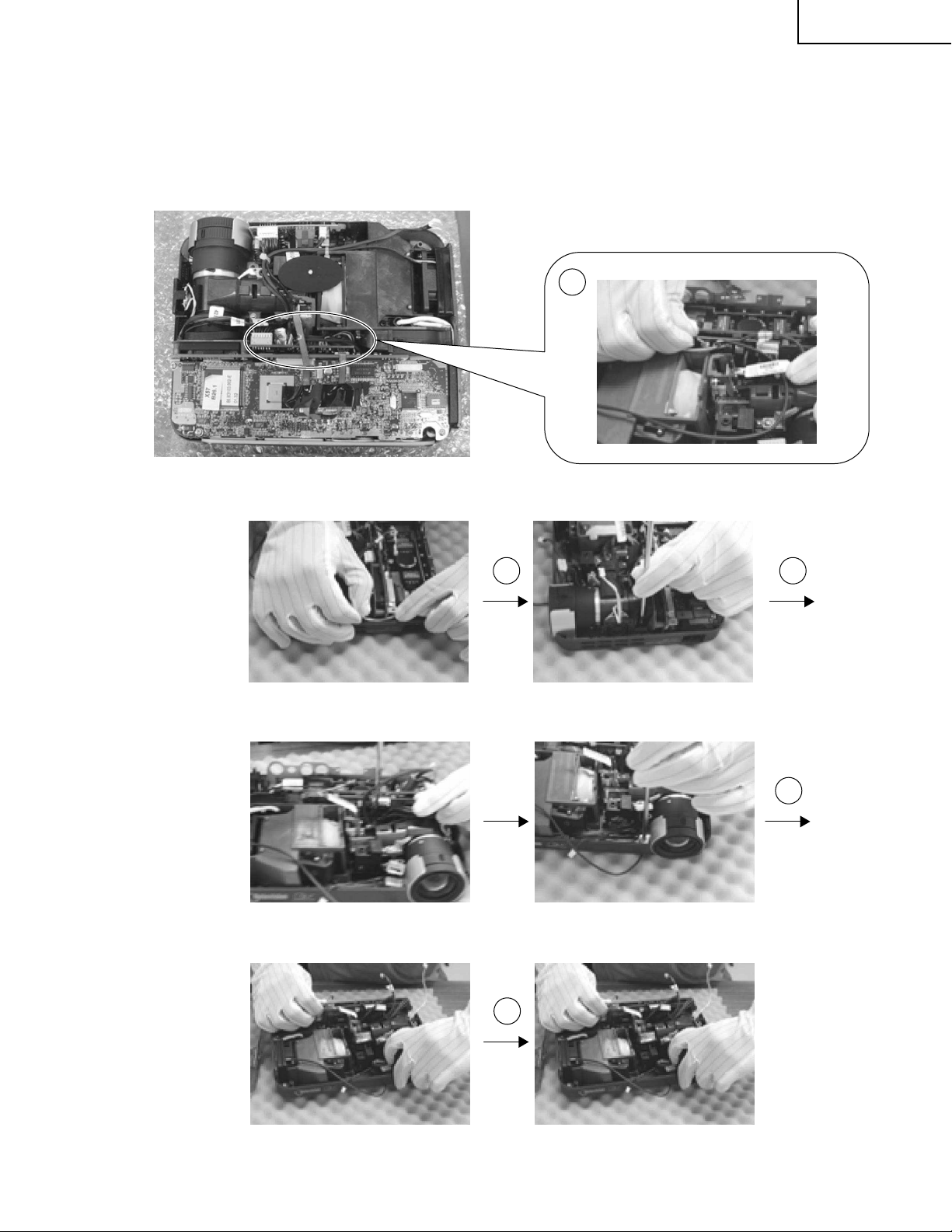

2-5. Remove one screw of DC to DC PWB Unit Holder, unplug three Connecting Cords, and then detach DC to

DC PWB Unit.

(Step 12,13.)

2-6. Remove push bar, push bar spring, and rubber. (refer to step 14~16.)

Cut three cable tie

from Optical Engine

Module.

Step 12

2-5

Step 13

Unplug three

Connecting Cords

of DC to DC PWB Unit

2-6 2-6

Step 14 Step 15 Step 16

16

Page 17

2-7. Unplug six wires of Thermal PWB Unit. (Step 17.)

2-8. Remove 5 screws from optical engine module (Step 18~20.)

2-9. Remove 2 screws from projection lens cover. (Step 21.)

2-10

. Remove optical engine module, projection lens cover, and Thermal Unit. (Step 22, 23.)

2-7

PG-M15X

PG-M15S

AN-M15T

Step 17

2-8 2-8

Step 18 Step 19

2-9

Step 20 Step 21

2-10

Step 22 Step 23

17

Page 18

PG-M15X

PG-M15S

AN-M15T

Projection Lens Cover

2-9

2-7

Speaker

DMD Off-Light Vent

Thermal PWB Unit

Optical Engine Module

2-8

2-6

Push Bar Spring

18

Pudh Bar

Leakage Rubber

Page 19

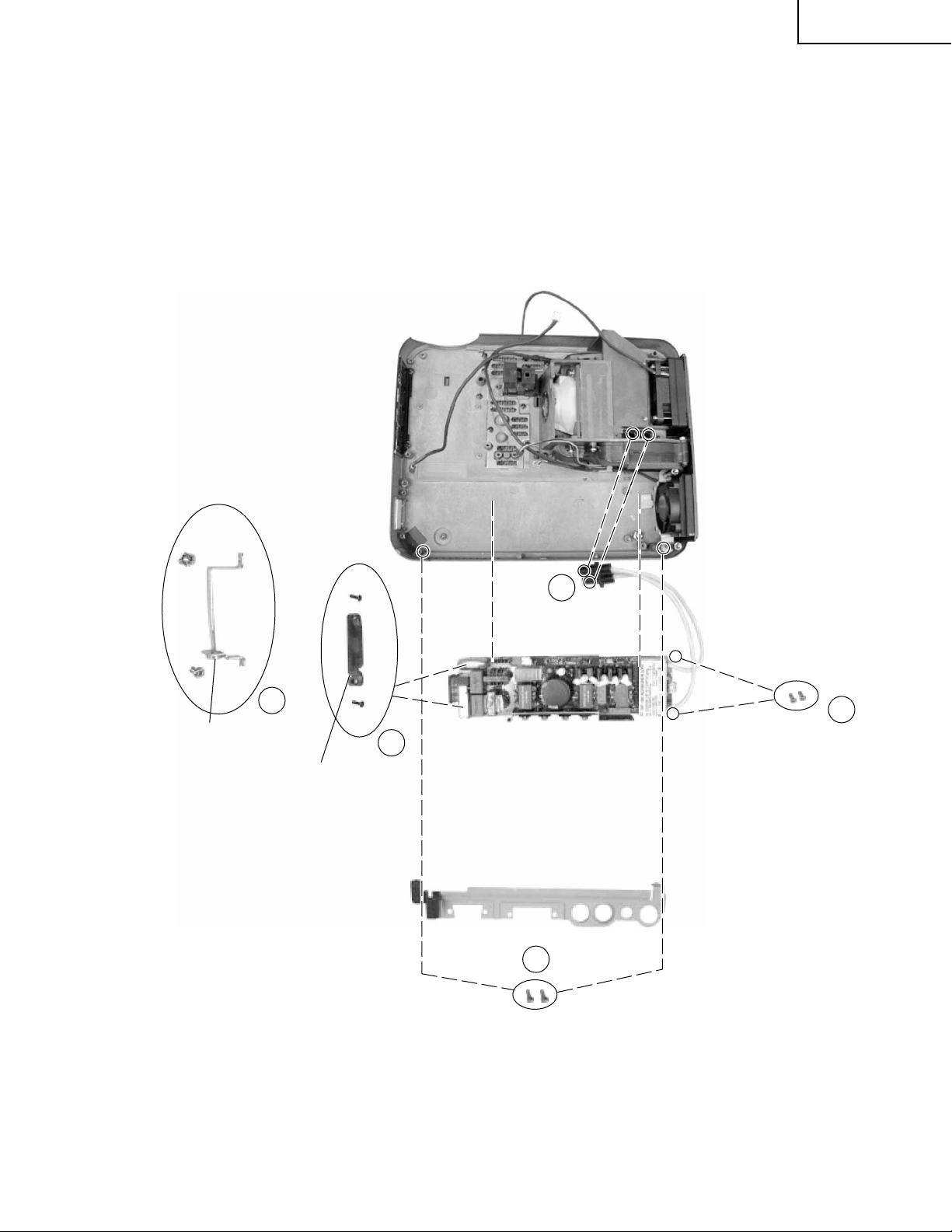

3.Disassemble Ballast PWB unit

3-1. Remove two screws and detach Terminal Sheet Holder.

3-2. Remove two screws and detach Grounding Sheet.

3-3. Remove two screws and detach AC Code Fix.

3-4. Remove two screws and detach ignitor cable from Lamp Housing.

3-5. Remove two screws and detach Ballast PWB unit.

PG-M15X

PG-M15S

AN-M15T

Grounding Sheet

3-2

3-3

AC Code Fix

3-4

3-5

Ballast PWB unit

Terminal Sheet Holder

3-1

19

Page 20

PG-M15X

PG-M15S

AN-M15T

4.Disassemble Lamp Housing

4-1. Loosen two screws and remove Lamp Cover.

4-2. Loosen three screws and lift Lamp.

4-3. Remove screw and detach Output Air Guide and Output Rubber duct.

4-4. Remove three screws and detach Lamp Housing.

4-5. Remove screw and nut then detach Fan from Lamp Housing.

4-6. Remove four screws and detach Blower Wind Guide from Lamp Housing.

4-7. Remove thermal Fuse from lamp Housing.

Lamp

4-2

4-1

Lamp Cover

4-4

4-6

4-7

Thermal

Fuse

Spacer

Blower Wind

Guide

Lamp Housing

Output

Rubber duct

4-3

Output

Air Guide

20

Fan

4-5

Bottom Cover

Page 21

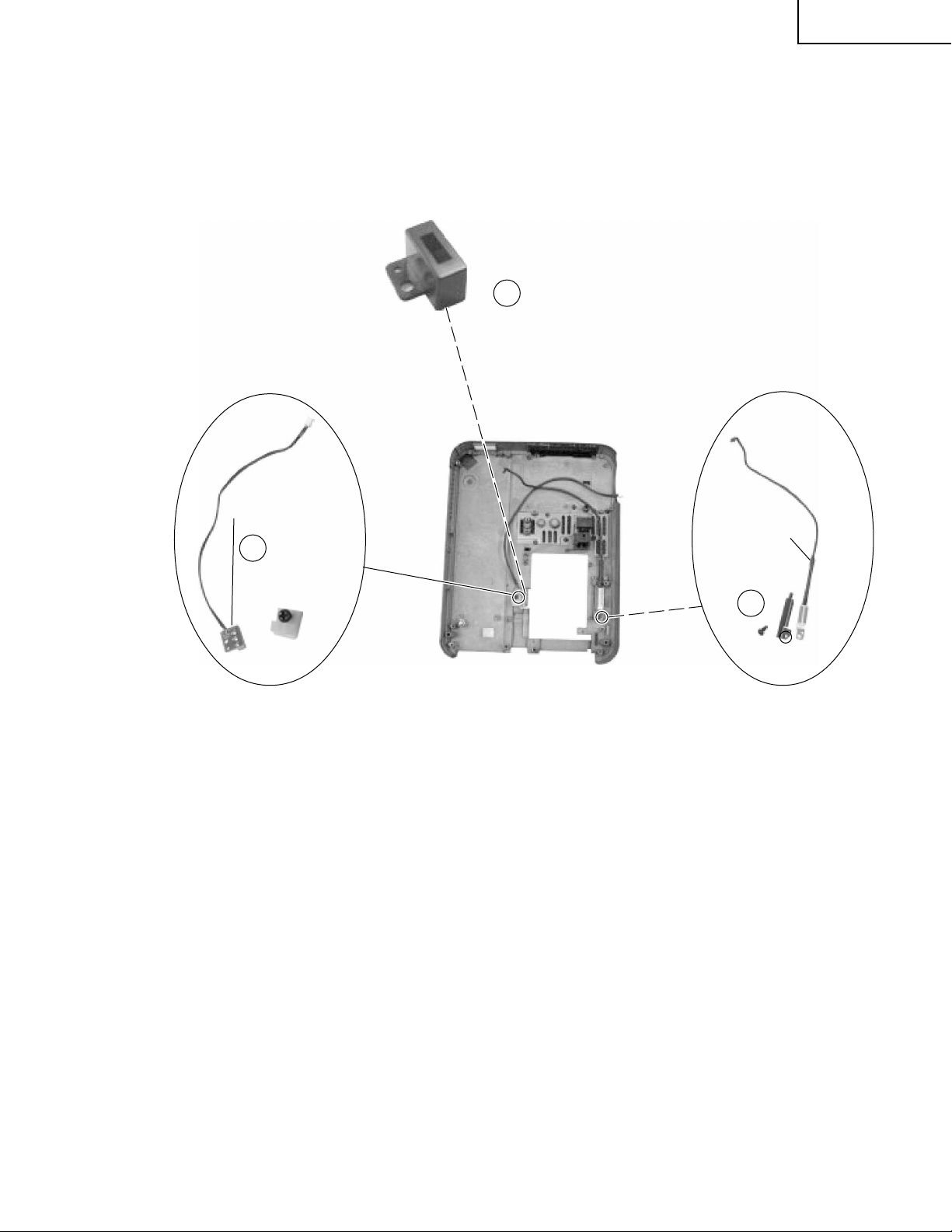

4-8. Remove screw and detach SW PWB unit and Interlock Protection Cover.

4-9. Remove screw and detach Thermal Switch.

4-8

Interlock Protection Cover

PG-M15X

PG-M15S

AN-M15T

SW PWB unit

4-8

Thermal

Switch 70°

4-9

Bottom Cover

21

Page 22

PG-M15X

PG-M15S

AN-M15T

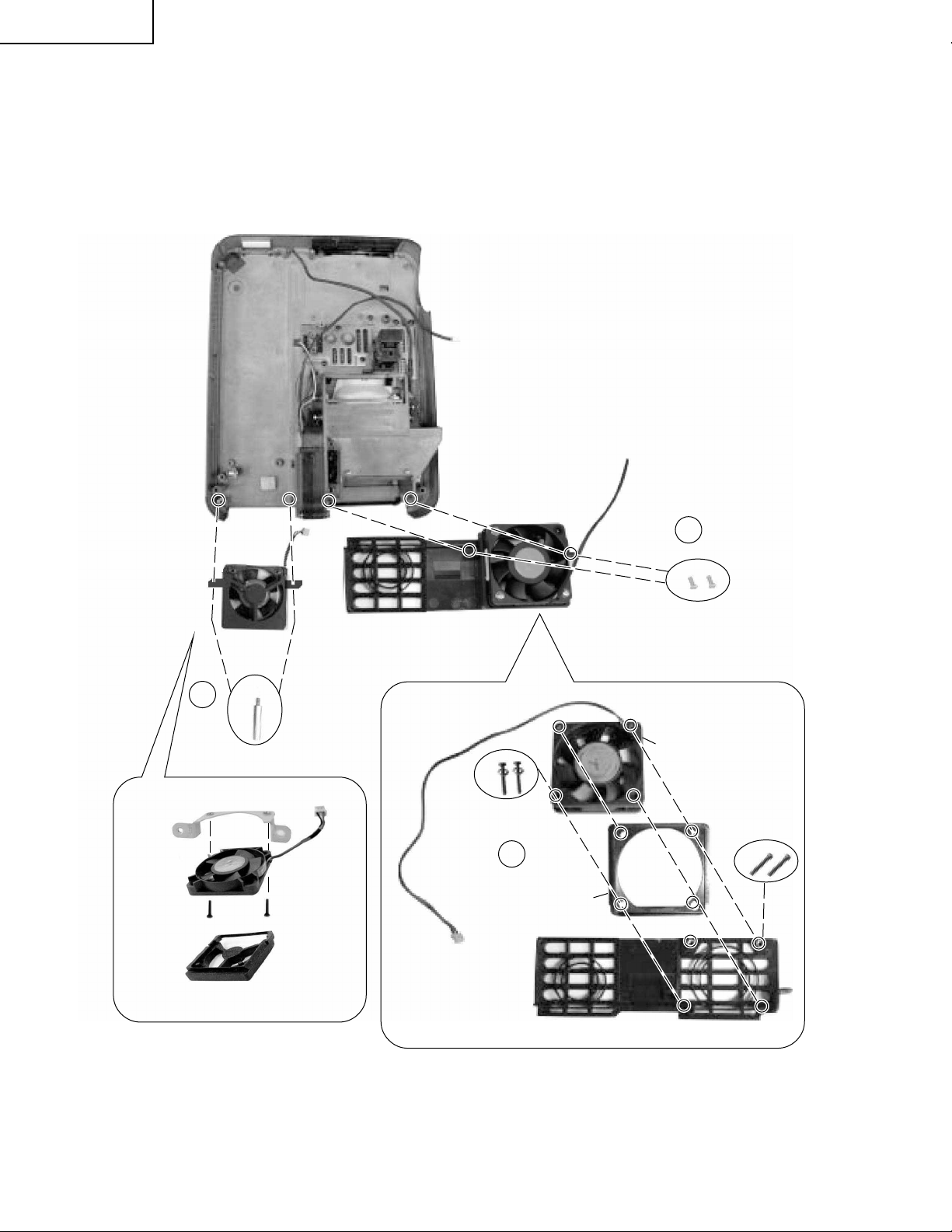

5.Disassemble Fan Module

5-1. Remove two Hexagon Copper Sticker and detach Assy Fan.

5-2. Remove two screws and detach Exhaust Window Assy.

5-3. Remove two screws and detach Fan and Rubber.

Fan Ass'y

5-1

Hexagon Copper Sticker

Fan

Rubber

5-2

Exhaust Window

Fan

5-3

Rubber

22

Page 23

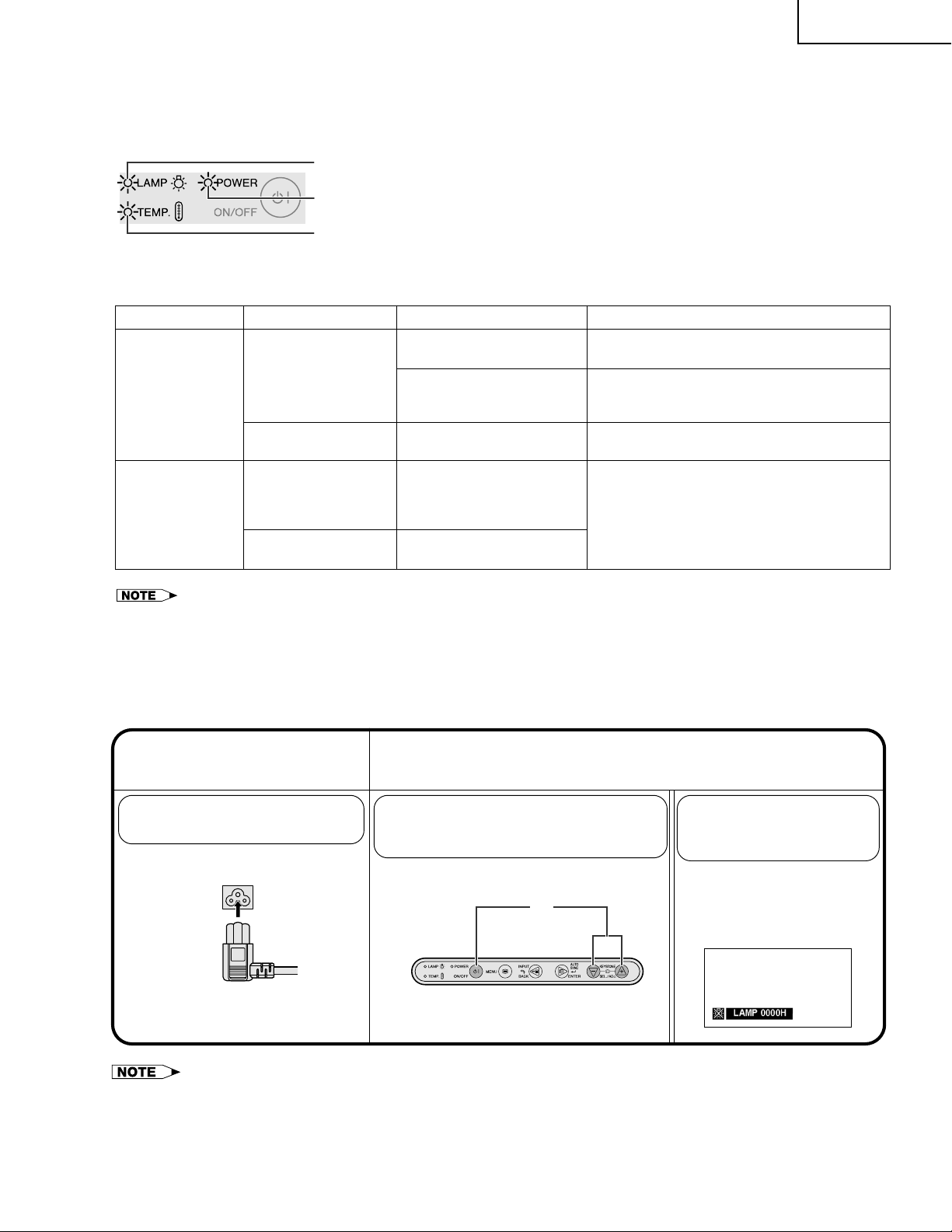

RESETTING THE TOT AL LAMP TIMER

PG-M15X

PG-M15S

AN-M15T

Maintenance Indicators

LAMP REPLACEMENT

indicator

POWER indicator

TEMPERATURE WARNING

indicator

Maintenance Indicator

TEMPERATURE

WARNING

indicator

LAMP

REPLACEMENT

indicator

Condition Possible Solution

The internal

temperature is

abnormally high.

The indicator flashes in

red.

The lamp does not

illuminate.

The lamp requires

replacement.

• The warning lights on the projector indicate problems

inside the projector.

• There are two warning lights: a TEMPERATURE

WARNING indicator which warns that the projector is too

hot, and a LAMP REPLACEMENT indicator which lets

you know when to change the lamp.

• If a problem occurs, either the TEMPERATURE WARNING

indicator or the LAMP REPLACEMENT indicator will

illuminate red. After turning off the power, follow the

procedures given below.

Problem

• Blocked air intake.

• Cooling fan breakdown.

• Internal circuit failure.

• Cooling down. • Wait until the indicator stops flashing and

• Burnt-out lamp.

• Lamp circuit failure.

• The lamp caga cover is

not securely installed.

• Lamp has been used for

over 1,400 hours.

• Relocate the projector to an area with proper

ventilation.

• Take the projector to your nearest Sharp

Authorized Projector Dealer or Service

Center for repair.

turns off.

• Carefully replace the lamp.

• Take the projector to your nearest Sharp

Authorized Projector Dealer or Service

Center for repair.

• If the TEMPERATURE WARNING indicator illuminates, follow the above possible solutions and then wait until the projector has cooled down

completely before turning the power back on. (At least 5 minutes.)

• If the power is turned off and then turned on again, as during a brief rest, the LAMP REPLACEMENT indicator may be triggered, preventing

the power from going on. Should this occur, take the power cord out of the wall outlet and put it back in again.

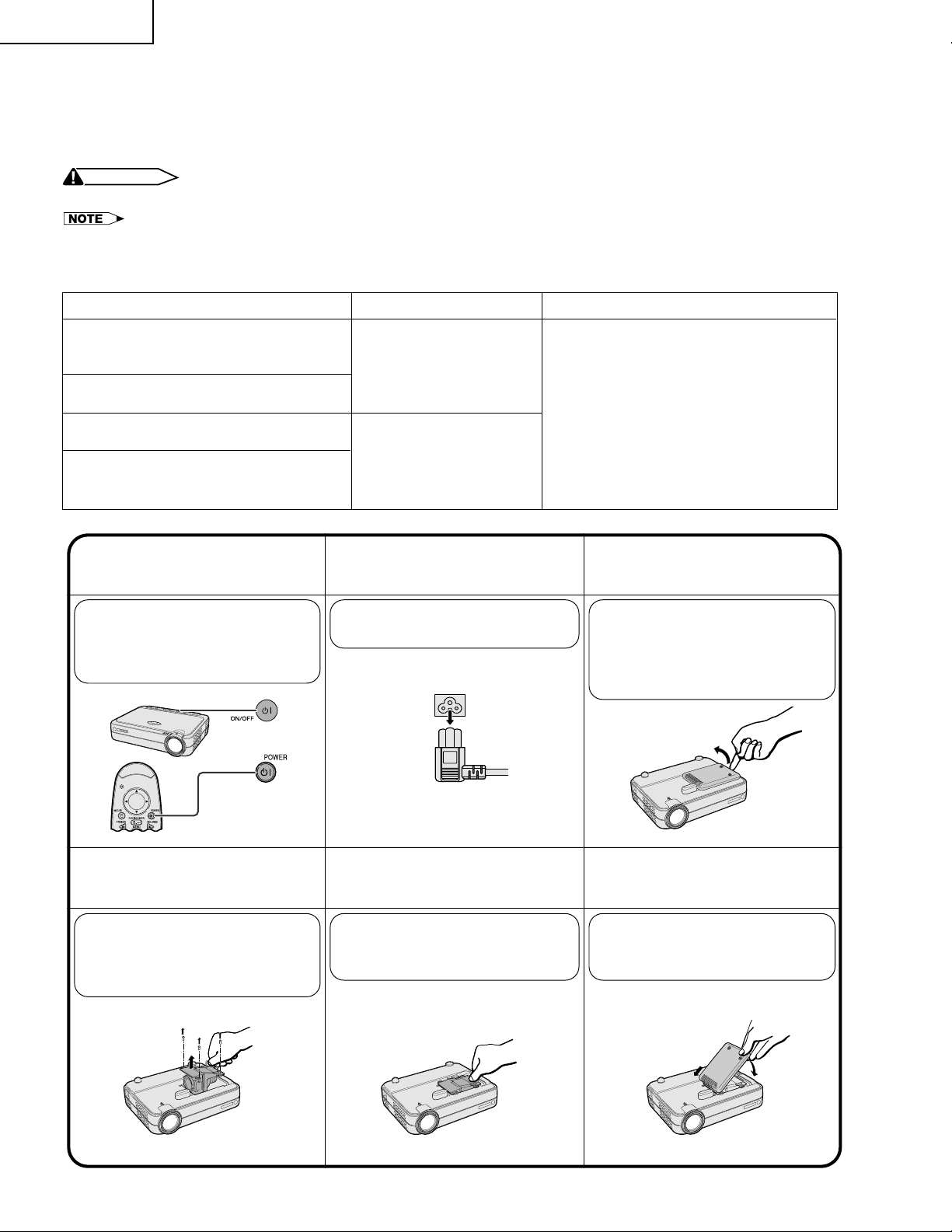

Resetting the lamp timer

Connect the power

1

cord.

Plug the power cord into the AC

socket of the projector.

Reset the lamp timer.

2

1 Press KEYSTONE (+) and

KEYSTONE (–) simultaneously and

ON/OFF at the same time.

1

“LAMP 0000H” is

displayed, indicating that

the lamp timer is reset.

Reset the lamp timer only after replacing the lamp.»

23

Page 24

PG-M15X

PG-M15S

AN-M15T

Lamp

The lamp in this projector operates for approximately 1,500 cumulative hours, depending on the usage environment. It is recommended that the lamp be replaced after 1,400 cumulative hours of use or when you notice a

significant deterioration of the picture and color quality. The lamp usage time can be checked with the On-screen

Display.

CAUTION

• Intense light hazard. Do not attempt to look into the aperture and lens while the projector is operating.

• As the usage environment can vary significantly, the projector lamp may not operate for 1,500 hours.

•“1,500 hours” above indicates average life span and should be used for reference only. This is different than the warranty period.

• For safety, the power will not be turned on from the fourth time when turning on the power without changing the lamp after use for 1,500

hours.

Condition

The LAMP REPLACEMENT indicator

illuminates red, and “LAMP” will appear in

yellow in the lower-left corner of the picture.

A significant deterioration of the picture and

color quality occurs.

The power will automatically turn off and

the projector will enter standby mode.

“LAMP” will appear in red in the lower-left

corner of the picture, and the power will

turn off.

Turn off the power.

1 3

Press ON/OFF on the projector

or POWER on the remote

control. Wait until the cooling

fan stops.

or

• Lamp has been used for

over 1,400 hours.

• Lamp has been used for

over 1,500 hours.

Disconnect the power

2

cord.

Unplug the power cord from the

AC socket.

Problem

• Purchase a replacement lamp unit (lamp

cage/module) of the current type BQCPGM15X//1 from your nearest Sharp

Authorized Projector Dealer or Service

Center.

• Replace the lamp.

If you wish, you may have the lamp

replaced at your nearest Sharp Authorized

Projector Dealer or Service Center.

Possible Solution

Remove the lamp cage

cover.

Turn over the projector and

loosen the user service screws

that secure the lamp cage cover.

Then lift open the cover in the

direction of the arrow.

Remove the lamp

46

cage.

Loosen the securing screws on

the lamp cage. Hold the lamp

cage by the handle and pull it

towards you.

Insert the new lamp cage.

5

Press the lamp cage firmly into

the lamp cage compartment.

Fasten the securing screws.

Attach the lamp cage

cover.

Slide the lamp cage cover in the

direction of the arrow. Then

tighten the user service screws.

24

Page 25

OPTICAL ADJUSTMENT AND MEASURING

1.Adjustment of Color Wheel Sensor

» Adjustment needed

1. When the color wheel unit has been replaced.

2. When the color wheel sensor has been replaced.

3. When the optical drive unit has been replaced (If a deviation from normal setting is found).

» Tools Required

1. Personal computer (run on Windows 95/98)

2. RGB cable

PG-M15X

PG-M15S

AN-M15T

25

Page 26

PG-M15X

PG-M15S

AN-M15T

2.Color Wheel Index Adjustment

1. Choose R.G.B.W 4-color image.

1-1. Execute the “M15 Pattern dmw” command.

1-2. Click on “Color and Gray Scale”.

1-3. Left-click on the mouse to switch the pattern and to

provide the “R.G.B.W 4-color Image” (64 Intensities

for Primary Colors) output.

2. Select “DMD” on the process mode screen.

2-1. Tur n on the power. Press the ON/OFF button on the

projector or the POWER button on the remote controller .

2-2. Make sure the message “Turn Power OFF?” on the

screen. With this message still onscreen, press the

buttons in this order: “'”, “'”, “"” and “"” on the

remote controller, or “+”, “+”, “-” and “-” on the projector .

2-3. Be sure the process adjustment menu appears on

the screen, and select DMD .

3. Choose "Color Wheel Index" to do adjustment.

4. Use "+" and "-" keys on Keypad to adjust the value

to make the image have no abnormal color.

2-2

RemoteController

2-1

2-1

2-2

Projector

5. Press "Enter" key and "MENU" to go back to the

original image.

26

Page 27

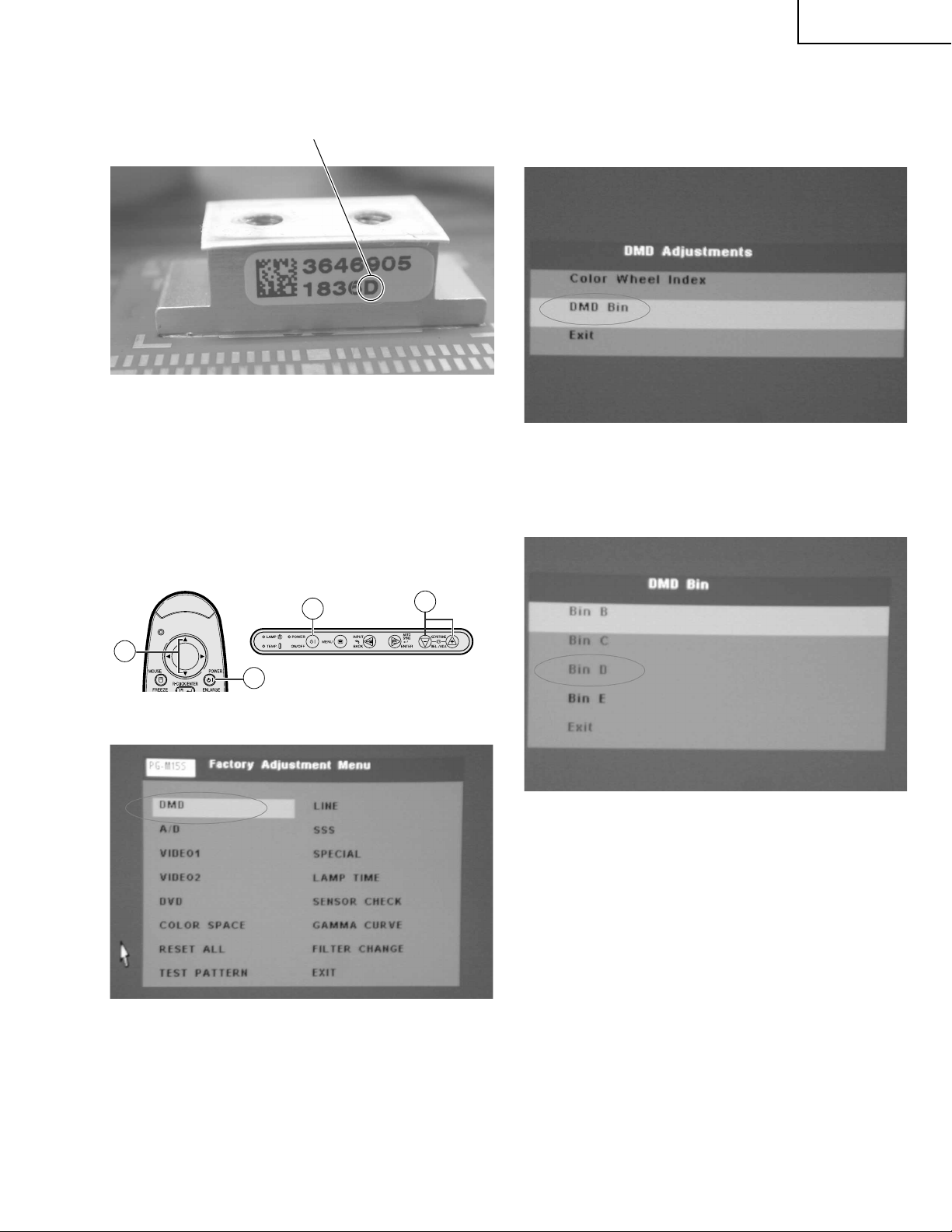

3.DMD Type Setting Sop

PG-M15X

PG-M15S

AN-M15T

1. Record type of DMD chip (An English letter in

capital) before assembly.

2. Select “DMD” on the process mode screen.

2-1. Tur n on the power. Press the ON/OFF button on the

projector or the POWER button on the remote controller .

2-2. Make sure the message “Turn Power OFF?” on the

screen. With this message still onscreen, press the

buttons in this order: “'”, “'”, “"” and “"” on the

remote controller, or “+”, “+”, “-” and “-” on the projector .

2-3. Be sure the process adjustment menu appears on

the screen, and select DMD .

3. Choose "DMD Bin" to do setting.

4. Use "+" and "-" keys on Keypad to choose DMD

type same as the type of new one

2-2

RemoteController

2-1

2-1

2-2

Projector

5. Press "Enter" key and then Press "MENU" key to go

back to the original image.

Note: Be sure to make this DMD Type Setting to keep up the

DMD chip reliability .

27

Page 28

PG-M15X

PG-M15S

AN-M15T

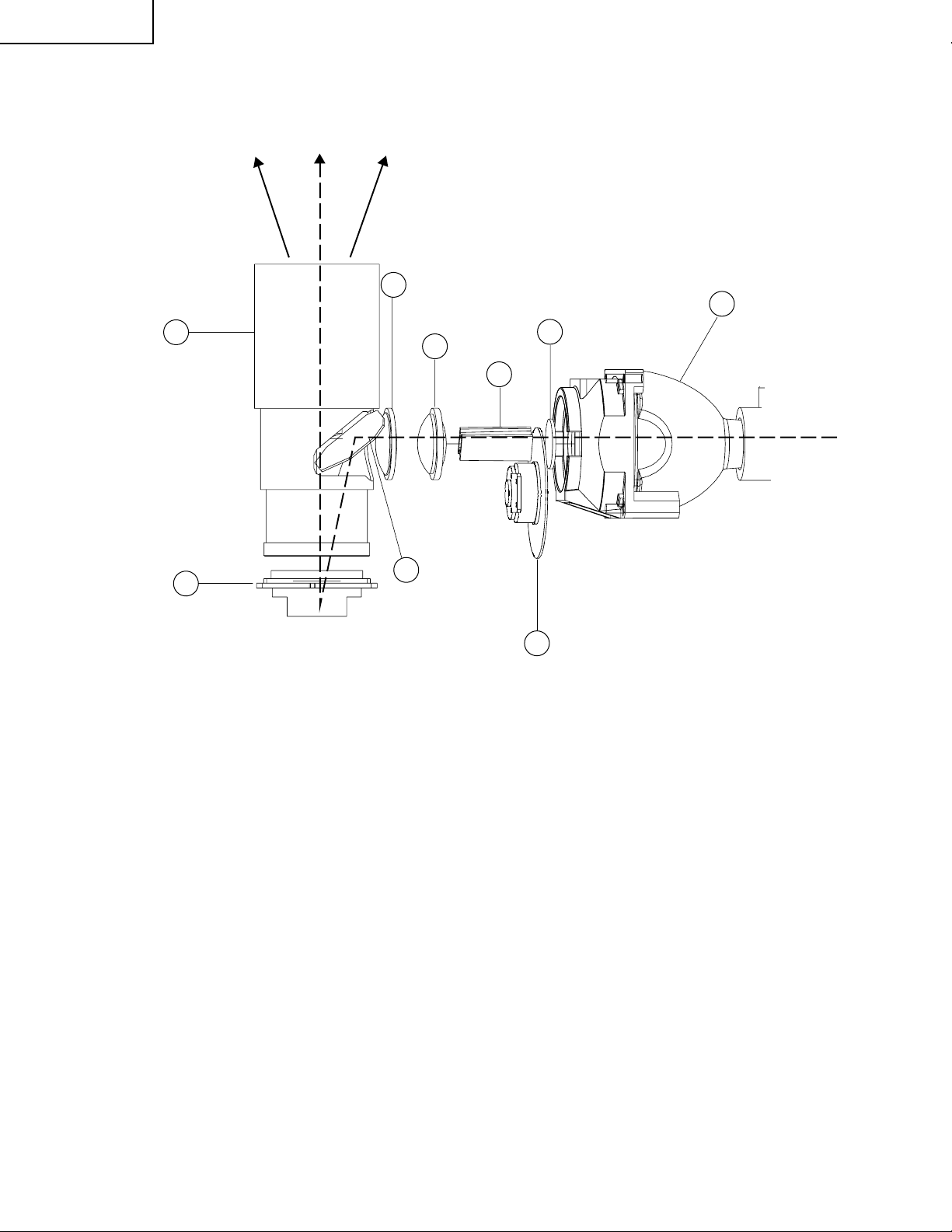

<Conceptual Drawing>

Projection Zoom Lens

8

THE OPTICAL UNIT OUTLINE

Condenser

Lens 2

6

UV-IR FilterCondenser

Lens 1

5

Rod Lens

4

2

Lamp

1

DMD Chip

9

1. OSRAM Elliptical Reflector Kind of

HID Lamp 130W

2. UV-IR Filter

3. Color Wheel

4. Rod Lens

5. Condenser Lens 1

<Basic Functions>

» UV-IR Filter : Filtering UV-IR out.

» Color Wheel : Separating the light beam into and produce R.G.B colors.

» Rod Lens : Making the light beam uniform.

» Condenser Lens 1, 2 : Condenses the illumination of Rod Lens and projects it to the effective area of

the reflection mirror.

» Reflection Mirror : This mirror reflects the light rojected to the effection area of the DMD.

» Projection Zoom Lens : Image from the DMD Chip will be projected on the screen through projection lens.

» DMD Chip : This chip turns on and off in proportion to each color component per dot depending

on the in put source.

7

Reflection Mirror

Color Wheel

3

6. Condenser Lens 2

7. Reflection Mirror

8. Projection Zoom Lens

9. DMD Chip

28

Page 29

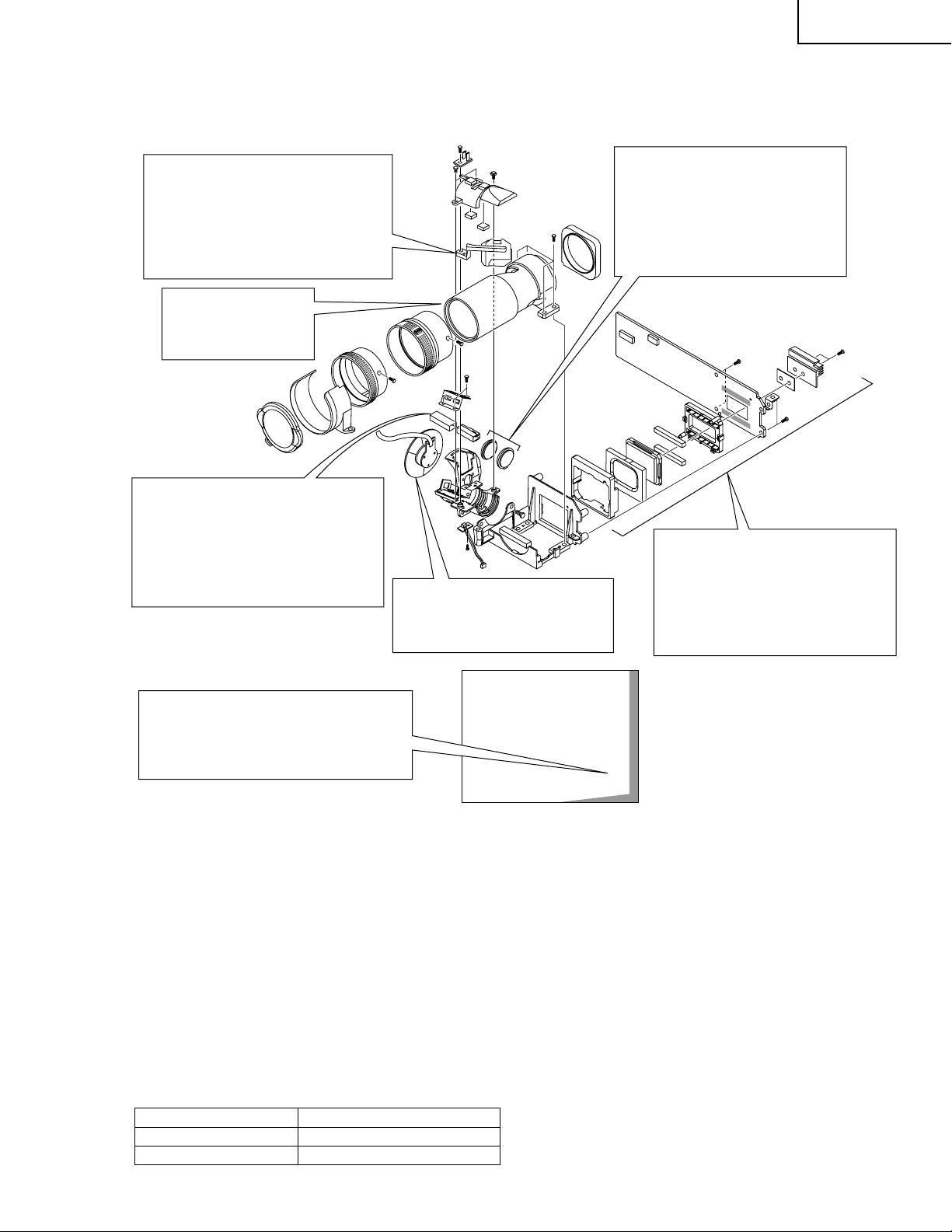

Æ Precautions in disassembling the optical mechanism

Note:If the optical mechanism needs repairs, preferably replace the entire optical mechanism assembly

with new one. This is because to very fine adjustments are needed for some parts.

PG-M15X

PG-M15S

AN-M15T

Reflection mirror

Place back just in the same

position and direction. Otherwise

shades may appear on the

projector screen. Each positioning

is needed.

Projection lens

This lens cannot be

disassembled.

Rod lens

Place back just in the same

position and direction. Otherwise

shades may appear on the

projector screen. Each positioning

is needed.

Color wheel

Once disassembled, this part

may need readjustment.

Condenser lens 1 and 2

Place back just in the same

position and direction.

Otherwise shades may appear

on the projector screen. Each

positioning is needed.

DMD assembly

This assembly can be

disassembled. But be careful not

to allow dust and fingerprint on it.

Otherwise the images may be

adversely affected.

If the rod lens or mirror has not been

correctly adjusted, there will be

shades on the projection screen.

Æ Initial factory settings

These models require no additional electrical adjustment. If by any chance the factory settings must be made

again, however, call the process adjustment mode first in the following procedure.

1. Calling the process adjustment mode

1) Turn on the power. Press the ON/OFF button on the projector or the POWER button on the remote controller.

2) Make sure the message “Turn Power OFF?” on the screen. With this message still onscreen, press the buttons

in this order: “'”, “'”, “"” and “"” on the remote controller, or “+”, “+”, “-” and “-” on the projector.

3) Be sure the process adjustment menu appears on the screen.

2. Using the “'” and “"” buttons on the remote controller or the “+” and “-” buttons on the projector, select “SSS” and

press the “ENTER” key.

3. Using the “'” and “"” buttons on the remote controller or the “+” and “-” buttons on the projector, select the

following setting according to the destination and press the “ENTER” key.

Setting Destination

"S4" Europe, Asia, Oceania

"S6" North America

29

Page 30

PG-M15X

PG-M15S

AN-M15T

1. Equipment Needed

» PG-M15X/S

» VGA Cable, Power Cord

» PC (Personal Computer)

» Audio Input, Video Input

» Screw Driver

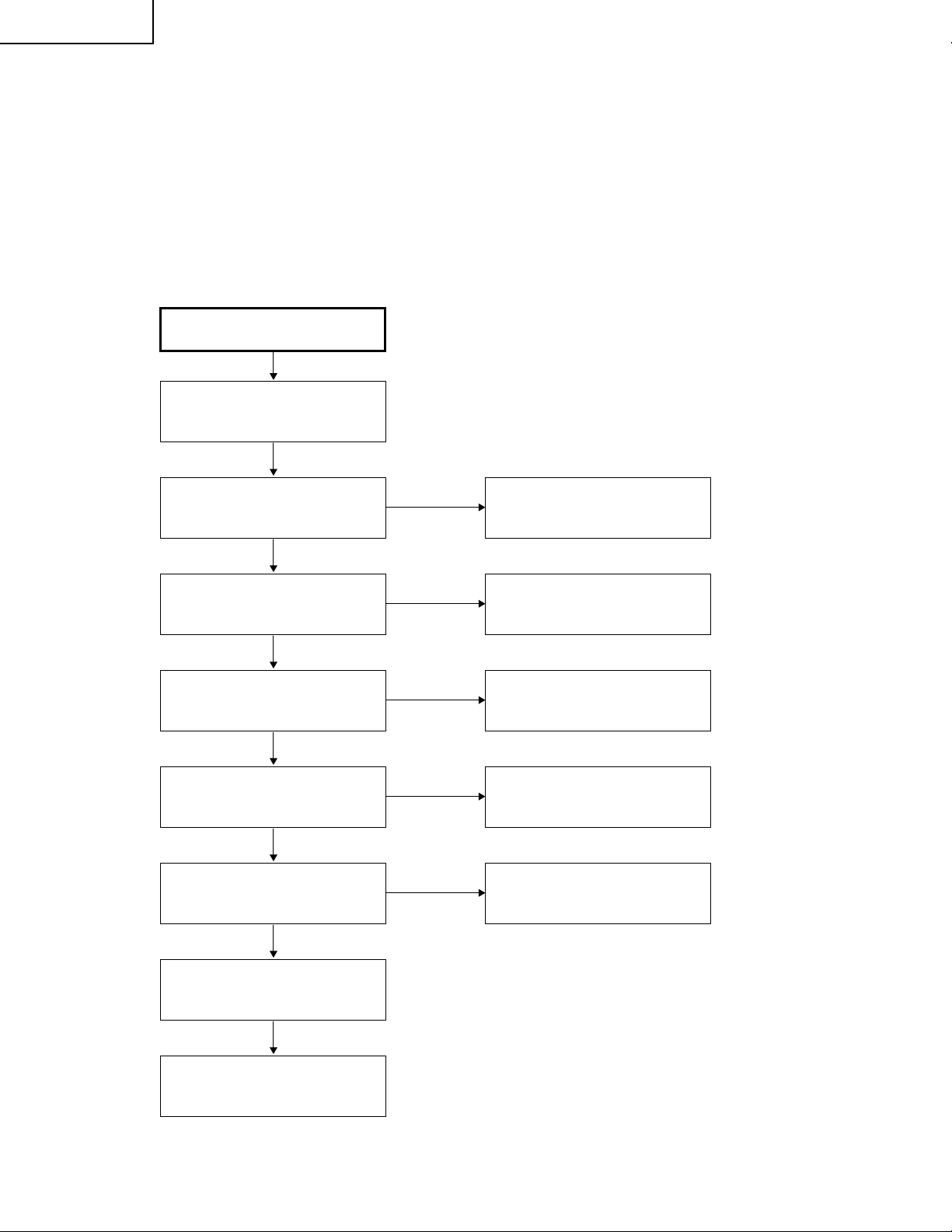

2. Main Procedure

Connect AC cord, VGA cable

and audio signal, then turn

power on

TROUBLE SHOOTING TABLE

Start

Is Lamp light on?

Yes

Is Image OK?

Yes

Is function OK?

Yes

Is Audio OK?

Yes

Is Remote Control OK?

Yes

No

No

No

No

No

A. Power Troubleshooting

B. Image Performance

Troubleshooting

C. Function

Troubleshooting

D. Audio Troubleshooting

Change Remote Control unit

No Fault Found

End

30

Page 31

2-1. A. Power Troubleshooting

Start

PG-M15X

PG-M15S

AN-M15T

Is LED indicator

OK?

Yes

Is Lamp OK?

Yes

Change Ballast

PWB unit

Yes

No

No

No

Check AC cord and

input power voltage

No

Supply

AC Cord

Change

Lamp unit

Main PWB unit

Troubleshooting

Yes

Lamp assembly

OK?

Yes

Change

DC to DC PWB unit

No

Main PWB unit

Troubleshooting

No

Change

Ballast PWB unit

No

Reassembly

lamp

End

31

Page 32

PG-M15X

PG-M15S

AN-M15T

2-2. B. Performance Troubleshooting

Start

Have image?

Yes

Have garbage

pattern?

No

Uniformity OK?

Yes

Is color OK?

No

Have dot defect?

No

No

Yes

(White Screen)

No

No

Yes

Main PWB unit

Troubleshooting

Main PWB unit

Troubleshooting

Change

Optical Engine

Module

Main PWB unit

Troubleshooting

Change

DMD Module

No

Change

DMD Module

No

Change

DMD Module

No No

Change

DMD Module

Change

Optical Engine

Module

Have line bar?

No

Have noise?

No

End

Yes

Yes

Adjust

frequency

Adjust

tracking

No

No

Main PWB unit

Troubleshooting

Main PWB unit

Troubleshooting

32

Page 33

2-2-1. White Screen or Garbage Pattern

Start

Check JP1 H, V SYNC in

Check U9 GH, GV SYNC

Check U17 Pin (5) DCLK

Check U16 Pin (5) MCLK

PG-M15X

PG-M15S

AN-M15T

End

2-2-2. Color abnormal (VGA)

Start

Check JP1 Pins (25), (26) and

(27)(RGB input)

Check U9 A/D coverter or

U7 (for DVI)

Check U11

Check JP2 is short circuit or not

Change DMD PWB unit

End

* When you fix it, suggest use white frame or RGBW color display.

33

Page 34

PG-M15X

PG-M15S

AN-M15T

2-3. C. Function Troubleshooting

Start

Does OSD

No

show up?

Yes

Can function

No

be adjusted?

Yes

End

2-4. D. Audio Troubleshooting

Start

Can hear

No

sound?

Is SW PWB unit

OK?

No

Change

SW PWB unit

Main PWB unit

Troubleshooting

Main PWB unit

Troubleshooting

Yes

No

Is Remote

Controller OK?

No

Change

battery

No

Change

Remote Controller

Change

Spearker

Yes

Main PWB unit

Troubleshooting

Yes

Sound is clear

without noise?

Yes

End

No

Main PWB unit

Troubleshooting

34

Page 35

3. Main PWB unit Troubleshooting

»»

» Condition-1.

»»

PC Source

Check VGAIN-R/G/B,

HSYNCIN, VSYNCIN PATH

PG-M15X

PG-M15S

AN-M15T

Check U9 AD9886

Yes

Check U11 PW164

Yes

DMD PWB unit

»»

» Condition-2.

»»

VIDEO Source

S-VIDEO Source

Check CY_out, C_out/Y_out,

PATH

No

Change AD9886

No

Change PW164

Check U40 ADG663

Yes

Check U24 VPC3230

Yes

Check U11 PW164

Yes

DMD PWB unit

No

Change ADG663

No

Change VPC3230

No

Change PW164

35

Page 36

PG-M15X

PG-M15S

AN-M15T

»»

» Condition-3.

»»

Component-i Source

Check Cr/Pr, YIN, Cb/Pb

PATH

Check U2 LT1399

Check U24 VPC3230

Check U11 PW164

DMD PWB unit

»»

» Condition-4.

»»

DVI Source

No

Change LT1399

Yes

No

Change VPC3230

Yes

No

Change PW164

Yes

Check

RX0+/RX0-,

RX1+/RX1-,

RX2+/RX2-,

RXC+/RXC-,

PATH

Check U7 Sil151A

Yes

Check U11 PW164

Yes

DMD PWB unit

No

Change Sil151A

No

Change PW164

36

Page 37

»»

» Condition-5.

»»

PC Source Output

PG-M15X

PG-M15S

AN-M15T

Check U3 LT1399

MONITOR DISPLAY

»»

» Condition-6.

»»

AUDIO Source

Check U22 LM4832

Check U23 LM4871

No

Change LT1399

Yes

No

Change LM4832

Yes

No

Change LM4871

Yes

SPEAKER OUTPUT

»»

» Condition-7.

»»

RREMOTE MOUSE

Check IR RECEIVER

Front : JP3

Back : IR1

Yes

Check U25 CY7C63612

Yes

REMOTE MOUSE CONTROL

No

Change IR RECEIVER

No

Change CY7C63612

37

Page 38

PG-M15X

PG-M15S

AN-M15T

Technische Daten

Produkttyp

Modell

Videosystem

Wiedergabeverfahren

DMD-Panel

Objektiv

Projektionslampe

Kontrastverhältnis

Videoeingangssignal

S-Videoeingangssignal

Komponenten-Eingangssignal

Horizontale Auflösung

RGB-Computereingangssignal

Punktetakt

Vertikale Frequenz

Horizontale Frequenz

Audioeingangssignal

Audioausgang

Lautsprechersystem

Nennspannung

Eingangsspannung

Nennfrequenz

Nennaufnahme

Energieverbrauch

Betriebstemperatur

Lagertemperatur

Gehäuse

I/R-Trägerfrequenz

Abmessungen (ca.)

Gewicht (ca.)

Mitgeliefertes Zubehör

Ersatzteile

Digitaler Multimedia-Projektor

PG-M15X/PG-M15S

NTSC/NTSC 4.43/PAL/PAL-M/PAL-N/PAL 60/SECAM/DTV480i

Single Chip Digital Micromirror Device™ (DMD™) von Texas Instruments

Panelgröße: 0,7 (17,8 mm), 1 Chip XGA DMD/SVGA DMD

Anzahl der Bildpunkte: 786.432 Bildpunkte (1.024 [H] 768 [V])/PG-M15X

480.000 Bildpunkte (800 [H] 600 [V])/PG-M15S

1-1,2 Zoomobjektiv, F2,2–2,4, f = 28,5–34,2 mm

Hochintensive Entladungslampe (HID-Lampe), 130 W Wechselstromspannung

500:1

RCA-Stecker (INPUT 3): VIDEO, Gemischtes Video, 1,0 Vs-s, negatives Sync.-Signal, 75 Ω

terminiert

4-Pin Mini DIN-Stecker (INPUT 2)

Y (Luminanz-Signal): 1,0 Vs-s, negatives Sync.-Signal, 75 Ω terminiert

C (Chrominanz-Signal): Stoß 0,286 Vs-s, 75 Ω terminiert

29-Pin-Stecker (INPUT 1)

Y: 1,0 Vs-s, negatives Sync.-Signal, 75 Ω terminiert

B

: 0,7 Vs-s, 75 Ω terminiert

P

R

: 0.7 Vs-s, 75 Ω terminiert

P

580 Fernsehzeilen (Videoeingang)

29-Pin-Stecker (INPUT 1)

RGB getrennt/Sync. auf Grün-Typ analoger Eingang: 0–0,7 Vs-s, positiv, 75 Ω terminiert

ORIZONTALES SYNC

H

ERTIKALES SYNC

V

.-S

.-S

IGNAL

: TTL-Pegelsignal (positiv/negativ)

IGNAL

: Wie oben

25–135 MHz

56–85 Hz

31,5–80 kHz

INIJACK

3,5 ø M

: AUDIO, 0,4 Vrms mehr als 47 kΩ (Stereo)

2,0 W (monaural)

4 2,8 cm

100–240 V Wechselstromspannung

2,0 A

50/60 Hz

180 W

<680 BTU/Stunde

41° bis 95°F (5° bis 35°C)

14° bis 140°F (10° bis 60°C)

Magnesium-Legierung (Anschlußplatte, Lampenabdeckung und seitliche Belüftungsplatte

sind aus Kunststoff)

38 kHz

55

⁄64 1 31⁄32 6 59⁄64 (225 (B) 50 (H) 176 (T) mm) (nur Hauptgerät)

8

55

⁄64 2 19⁄32 6 31⁄32 (225 (B) 66 (H) 177 (T) mm) (einschließlich Drehfüße und

8

vorstehende Teile)

3,5 pfd. (1,6 kg)

Fernbedienung, Zwei Batterien der Größe AAA, Netzkabel für USA, Kanada usw. (5 11,

1,8 m), Netzkabel für Europa, ausgenommen Großbritannien (5 11, 1,8 m), Netzkabel für

Großbritannien, Hongkong und Singapur (5 11, 1,8 m), Netzkabel für Australien,

Neuseeland und Ozeanien (5 11, 1,8 m), DVI-Analog auf VGA-kabel, DVI-Analog auf

VGA-Adapter, PC-Audiokabel (6 7, 2,0 m), DIN-D-Sub RS-232C-Kabel, (6

1

/2, 16,5 cm)

RGB-Computerkabel (5 11, 1,8 m), USB-Maus-Steuerungskabel (5 11, 1,8 m),

Videokabel (5 11, 1,8 m), S-Videokabel (5 11, 1,8 m), AV-Audiokabel (5 11, 1,8 m),

Weiche Tragetasche, Objektivkappe mit Band, CD-ROM, Bedienungsanleitung des

Projektors, Kurzreferenz des Projektors

Fernbedienung (9HJ7583104001), Zwei Batterien der Größe AAA (9HJ4683101001),

Netzkabel für USA, Kanada usw. (9HJ4283114001), Netzkabel für Europa, ausgenommen

Großbritannien (9HJ4283116001), Netzkabel für Großbritannien, Hongkong und Singapur

(9HJ4283117001), Netzkabel für Australien, Neuseeland und Ozeanien (9HJ4283118001),

DVI-Analog auf VGA-Kabel (9HJ4283108001), DVI-Analog auf VGA-Adapter

(9HJ4283124001), PC-Audiokabel (9HJ4283120001), DIN-D-Sub RS-232C-Kabel

(9HJ4283123001), RGB-Computerkabel (9HJ4283111001), USB-Maus-Steuerungskabel

(9HJ4283122001), Videokabel (9HJ4283112001), S-Videokabel (9HJ4283113001), AVAudiokabel (9HJ4283121001), Weiche Tragetasche (9HJ5383101001), Objektivkappe mit

Band (9HJ7083117001), CD-ROM (9HJ3683104001), Bedienungsanleitung des Projektors

(9HJ3683107001), Kurzreferenz des Projektors (9HJ3683110001)

Dieser Projektor von SHARP verwendet ein DMD-Panel. Dieses

hochentwickelte Panel enthält 786.432 (PG-M15X)/480.000 (PGM15S) Pixel. Bei allen technologisch fortschrittlichen, elektronischen

Geräten, z. B. Großbild-Fernsehern, Videosystemen bzw.

Videokameras, sind bestimmte Toleranzgrenzen für die Funktionen

gegeben.

Änderungen der technischen Daten ohne vorherige Ankündigung vorbehalten.

Dieses Gerät hat einige inaktive, innerhalb akzeptierter

Toleranzgrenzen liegende Bildpunkte, die als inaktive Punkte auf der

Bildwand wiedergegeben werden. Dies hat keinen Einfluß auf die

Bildqualität und die Lebensdauer des Gerätes.

38

Page 39

HINWEIS FÜR DAS WARTUNGSPERSONAL

5

Objectivedeckel

PG-M15X

PG-M15S

AN-M15T

ACHTUNG: UV-STRAHLUNG

234567890123456789012345678901212345678901234

Die Lichtquelle im Projektor, eine Metall-HalogenLampe, gibt eine geringe UV-Strahlung ab.

DIREKTE BESTRAHLUNG AUF AUGEN

UND HAUT MUSS VERMIEDEN WERDEN.

Zur Gewährleistung der Sicherheit muß folgendes

beachtet werden:

1. Bei Arbeiten am Projektor bei eingeschalteter

Lampe und abgenommenem oberen Gehäuse

muß unbedingt eine Sonnenbrille getragen

werden.

2. Die Lampe darf nicht außerhalb des

Lampengehäuses eingeschaltet werden.

Ë Aus wechseln der Lampe

Hinweis:

Da die Lampe während des Betriebs sehr heiß wird,

sollte die Lampe erst ausgewechselt werden, nachdem

das Gerät mindestens eine Stunde ausgeschaltet war ,

damit die Lampe ausreichend abkühlen kann.

Beim Installieren der neuen Lampe muß darauf

geachtet werden, die Lampe selbst (Glaskolben)

nicht zu berühren. Vielmehr muß die Lampe am

Reflektor 2 gehalten werden.

[Es darf nur ein Original-Ersatzteil verwendet

werden.]

Lampe

1

2

Reflektor

GEFAHR! — Niemals die Spannungsversorgung

einschalten, ohne daß eine Lampe vorhanden ist,

um elektrische Schläge und Schäden am Gerät zu

vermeiden, da der Stabilisator anfangs hohe

Spannungen erzeugt.

3. Betrieb für länger als 2 Stunden bei

abgenommenem Gehäuse ist nicht zulässig.

Zur Beachtung bei UV-Strahlung

und Mitteldruck-Lampen

1. Vor dem Auswechseln der Lampe muß der

Netzstecker gezogen werden.

2. Vor Durchführung von Wartungsarbeiten muß das

Gerät eine Stunde abkühlen.

3. Nur mit dem gleichen Lampentyp ersetzen Typ

9HJ708311901 oder BQC-XGM15X//1;

Nennleistung 85 V/130 W.

4. Die Lampe gibt eine geringe UV-Strahlung ab,

daher muß direkter Augenkontakt vermieden

werden.

5. Die Mitteldruck-Lampe weist ein Explosionsrisiko

auf. Daher müssen die nachstehenden

Installationsanweisungen beachtet werden, und die

Lampe muß vorsichtig behandelt werden.

Da eine geringe UV-Strahlung aus einer Öffnung

zwischen der Schachtabdeckung und dem

Lampengehäuse austritt, sollte der Objektivdeckel

bei Wartungsarbeiten auf die Öffnung gesetzt

werden, um die Bestrahlung von Augen und Haut

zu vermeiden (Abb. 1).

Hinweis: Besorgen Sie sich einen Objektivdeckel,

bevor Sie Arbeiten an einem Modelle XGPG-M15X/S durchführen, das keinen

Objektivdeckel aufweist.

Abbildung 1.

39

Page 40

PG-M15X

PG-M15S

AN-M15T

Bedienelemente

Projektor

Ansicht von vorne und oben

Menü-Taste (MENU)

Betriebs-Taste (ON/OFF)

Betriebsanzeige

Lampenaustausch-Anzeige

Temperaturwarnanzeige

Kühlventilator (Luftauslaß)

Fernbedienungs-Sensor

Höheneinstellungs-Taste

(HEIGHT ADJUST)

Eingang-/Zurück-Taste

(INPUT/BACK)

Automatische

Synchronisierung-/EingabeTaste (AUTO SYNC/ENTER)

Trapezentzerrung-( )/Wahl-/

Einstellungs-Tasten ( )

(KEYSTONE/SEL./ADJ.)

Lufteinlaß

Steckanschluß

Lautsprecher

/+–

'/"

Fokussierring

Seiten- und Rückansicht

S-Videoeingangsanschluß 2

(4-Pin Mini DIN)

DVI-DIGITAL/ANALOG

Eingangs-Port 1 (29-Pin)

Analoger Ausgangs-Port für

Eingang 1 (HD 15)

(ANALOG OUTPUT)

Fernbedienungs-Sensor

Zoom-Knopf

Videoeinganganschluß 3

(RCA) (VIDEO INPUT 3)

Audioeingangsanschluß

(AUDIO INPUT)

(3,5 mm Stereo-Minibuchse)

RS-232C/Maus-Port

(7-Pin Mini DIN)

(RS-232C/MOUSE)

Einstellfuß

40

Standardanschluß für

Kensington-Sicherheitssperre

Page 41

Betrieb mit der drahtlosen Maus-Fernbedienung

Vorderansicht Ansicht von hinten

Fernbedienung

Maus-( )/

Einstellungs-( )

Tasten

Standbild-Taste

(FREEZE)

Maustaste ( )

MAUS-Taste

(MOUSE)

Eingangs-Taste

(INPUT)

Menü-Taste

(MENU)

T r apezverzeichnungs-

Tasten

(KEYSTONE)( )

Lautstärke-Tasten

(VOLUME)

Netz-Taste

(POWER)

Rechte Klick-/

Eingabe-Taste

(R-CLICK/ENTER)

Vergrößern-Taste

(ENLARGE)

Auto-Synchron-Taste

(AUTO SYNC)

Größe-Taste (RESIZE)

Linke Klick-/

Zurück-taste

(L-CLICK/

BACK)

AV-StummschaltungsTaste (AV MUTE)

GAMMA-Taste

Abdeckung

Maustaste ( )

Einsetzen der Batterien

1

Auf den Vorsprung

drücken und die

Batteriefachabdeckung in

Pfeilrichtung öffnen.

23

Zwei Batterien der Größe

AAA einlegen und

sicherstellen, daß die

Pole mit der und

Markierung im

Batteriefach

übereinstimmen.

Die V orsprünge auf dem

Ende der

Batteriefachabdeckung

in die Schlitze schieben

und die Abdeckung auf

das Batteriefach

drücken.

Öffnen der Abdeckung

Fenster für die Übertragung des

Fernbedienungs-Signals

• Wenn die Fernbedienung naß wird, sollte sie sofort trocken gewischt werden.

• Die Fernbedienung sollte nicht übermäßiger Wärme oder Feuchtigkeit ausgesetzt werden.

• Wenn die Fenbedienung für längere Zeit nicht verwendet wird, sollten die Batterie entfernt werden.r

• Niemals neue und alte Batterien oder verschiedene Batterietypen mischen.

• Einige Bedienvorgänge können nur mit der Fernbedienung ausgeführt werden. Die Fernbedienung sorgfältig behandeln.

'/"

'

/"

\

|

Anzeige für die

Übertragung des

Fernbedienungs-Signals

(Blinkt, wenn die

Fernbedienung ein Signal

sendet.)

+/–

–+

PG-M15X

PG-M15S

AN-M15T

41

Page 42

PG-M15X

PG-M15S

AN-M15T

Pinbelegung

DVI EINGANG 1-Port: 29-Pin

C5

C4 C3

C2 C1

•*1Rückkehrcode für 5 V, H-Sync. und V-Sync.

2

Diese Stifte werden mit diesem Gerät nicht

•*

verwendet.

24 17

816 1

RGB-EingangDVI-Eingang

Pin Nr. Name

9

1 T.M.D.S. Daten 2

2 T.M.D.S. Daten 2

3 T.M.D.S. Daten 2/4 Abschirmung

4 T.M.D.S. Daten 4*

5 T.M.D.S. Daten 4*

2

2

6 DDC Taktgeber

7 DDC Daten

8 Vertikales Sync.-Signal

9 T.M.D.S. Daten 1

10 T.M.D.S. Daten 1

11 T.M.D.S. Daten 1/3 Abschirmung

12 T.M.D.S. Daten 3*

13 T.M.D.S. Daten 3*

14 5 V Stromversorgung

15 Masse*

1

2

2

16 Hot Plug festgestellt

17 T.M.D.S. Daten 0

18 T.M.D.S. Daten 0

19 T.M.D.S. Daten 0/5 Abschirmung

20 T.M.D.S. Daten 5*

21 T.M.D.S. Daten 5*

2

2

22 T.M.D.S. Taktgeber Abschirmung

23 T.M.D.S. Taktgeber

24 T.M.D.S. Taktgeber

C1 Analoger Eingang Rot

C2 Analoger Eingang Grün

C3 Analoger Eingang Blau

C4 Horizontales Sync.-Signal

C5 Masse

Pin Nr. Name

1 Nicht belegt

2 Nicht belegt

3 Nicht belegt

4 Nicht belegt

5 Nicht belegt

6 DDC Taktgeber

7 DDC Daten

8 Vertikales Sync.-Signal

9 Nicht belegt

10 Nicht belegt

11 Nicht belegt

12 Nicht belegt

13 Nicht belegt

14 5 V Stromversorgung

15 Masse

16 Nicht belegt

17 Nicht belegt

18 Nicht belegt

19 Nicht belegt

20 Nicht belegt

21 Nicht belegt

22 Nicht belegt

23 Nicht belegt

24 Nicht belegt

C1 Analoger Eingang Rot

C2 Analoger Eingang Grün

C3 Analoger Eingang Blau

C4 Horizontales Sync.-Signal

C5 Masse

KOMPONENTE-Eingang

Pin Nr. Name

1 Nicht belegt

2 Nicht belegt

3 Nicht belegt

4 Nicht belegt

5 Nicht belegt

6 Nicht belegt

7 Nicht belegt

8 Nicht belegt

9 Nicht belegt

10 Nicht belegt

11 Nicht belegt

12 Nicht belegt

13 Nicht belegt

14 Nicht belegt

15 Masse

16 Nicht belegt

17 Nicht belegt

18 Nicht belegt

19 Nicht belegt

20 Nicht belegt

21 Nicht belegt

22 Nicht belegt

23 Nicht belegt

24 Nicht belegt

C1 Analoger Eingang Pr

C2 Analoger Eingang Y

C3 Analoger Eingang Pb

C4 Nicht belegt

C5 Masse

42

Page 43

AUSGANG (EINGANG 1)-Signalport: 15-Pin Mini-D-Sub-Buchse

RGB-Ausgang

Analog

1 Videoausgang (rot)

11

15

6

1

10

5

2 Videoausgang

(Grün/Sync. auf Grün)

3 Videoausgang (blau)

4 Nicht belegt

5 Nicht belegt

6 Erdung (rot)

7 Erdung (Grün/Sync. auf Grün)

8 Erdung (blau)

9 Nicht belegt

10 MASSE

11 MASSE

12 Nicht belegt

13 Horizontales Sync.-Signal

14 Vertikales Sync.-Signal

15 Nicht belegt

PG-M15X

PG-M15S

AN-M15T

KOMPONENTE-Ausgang

Analog

R

(CR)

1P

2Y

B

(CB)

3P

4 Nicht belegt

5 Nicht belegt

6 Erdung (P

7 Erdung (Y)

8 Erdung (P

9 Nicht belegt

10 Nicht belegt

11 Nicht belegt

12 Nicht belegt

13 Nicht belegt

14 Nicht belegt

15 Nicht belegt

R

)

B

)

RS-232C-Anschlußstelle: 7-Pin Mini DIN-Steckanschluß

6

7

5

4

21

Pin Nr. Signal Name

1 VCC (USB) USB-Stromversorgung

2 RD Daten empfangen

3 SD Daten senden

4 USB () USB-Daten ()

3

5 MASSE Signalerdung

6 USB () USB-Daten ()

7 NC (Reserviert)

RS-232C-Anschlußstelle: 9-Pin D-Sub-Stecker des DIN-D-Sub RS-232C-Kabels

15

69

Pin Nr. Signal Name

1CD

2 RD Daten empfangen

3 SD Daten senden

4ER

5 SG Signalerdung

6 DR Datensatz bereit

7 RS Anforderung zum Senden

8 CS Bereit zum Senden

9CI

USB-Anschluß: 4-Pin USB-Anschluß für das USB-Maus-Steuerungskabel

Pin Nr. Signal Name

1 VCC USB-Stromversorgung

4321

2 USB USB-Daten

3 USB USB-Daten

4 SG Signal Masse

43

Page 44

PG-M15X

PG-M15S

AN-M15T

Abmessungen

Ansicht der Rückseite

Ansicht von oben

Seitenansicht

(176)

64

/

59

6

855/64 (225)

1

3

/64 (76,5)

(3)

3

/

1

(13)

64

/

33

(24,5)

32

/

31

1 (25,5)

(120,5)

4

/

3

4

(66)

Ansicht von vorne

32

/

19

2

Ansicht von unten

61/32 (153)

Einheit: Zoll (mm)

44

Page 45

ENTFERNEN DER HAUPTTEILE

Erforderliche Werkzeuge

1. Kreuzschlitz-Schraubendreher (Spitze = 1 und 2)

2 Steckschlüssel (2,5 mm)

3. Kugelend-Sechskantschlüssel (5,0 mm)

1.Zerlegung des oberen Abdeckmoduls,

der Hauptplatineneinheit und der DC zu DC-Platineneinheit

1-1. Die vier Schrauben von der unteren Abdeckung losdrehen. (Auf die Schritte 1 und 2, Bezug nehmen.)

PG-M15X

PG-M15S

AN-M15T

Step 1 Step 2

Schritt 1 Schritt 2

1-1

45

Page 46

PG-M15X

Terminal sheet

1-5

PG-M15S

AN-M15T

1-2. Die obere Abdeckung anheben und die beiden an die IR-Platineneinheit and die Haupt-Platineneinheit

angeschlossenen Kabel abziehen. (Auf Schritte 3 bis 5 Bezug nehmen.)

1-3. Die obere Abdeckung entfernen.

1-4. Die Schraube losdrehen, dann die IR-Platineneinheit und die Abdeckung der IR-Platineneinheit entfernen.

1-5. Die vier D-SUB-Stifte von den D-SUB-Anschlüssen entfernen, dann die Anschlußplatte abnehmen. (Auf

Schritte 6 und 7 Bezug nehmen.)

1-21-2

Step 3 Step 4 Step 5

Schritt 3 Schritt 4 Schritt 5

1-3

Schritt 6

Step 6

1-4

Abdeckung der IR-Platineneinheit

IR PWB Unit Cover

IR-Platineneinheit

IR PWB Unit

Step 7

Schritt 7

Anschlußplatte

46

Page 47

PG-M15X

PG-M15S

AN-M15T

2.Zerlegung des Optik Motormoduls

2-1. Die vier Schrauben von der Hauptplatimeneinheit entfernen.

2-2. Einen Kugelend-Sechskantschlüssel verwenden und die beiden Schrauben lockern, welche den Halter der

Anschlußplatte befestigen. (ca. 4 Umdrehungen)(Schritt 8.)

2-3. Ein Werkzeug zwischen die Hauptplatineneinheit und die Formatiererplatineneinheit schieben, dann den

Steckverbinder abziehen. (Schritt 9.)

2-4. Die Haupteinheit nach außen ziehen und die Hauptplatineneinheit danach entfernen. (Schritte 10 und 11.)

DC zu DC-

DC to DC PWB Unit

Platineneinheit

2-1

2-2 2-3

Step 8 Step 9

Schritt 8 Schritt 9

2-1

2-4

Step 10 Step 11

Schritt 10 Schritt 11

47

Page 48

PG-M15X

PG-M15S

AN-M15T

2-5. Die Schraube für die DC zu DC-Platineneinheithalter losdrehen, die drei Kabel abziehen, dann die DC zu

DC-Platineneinheithalter abnehmen. (Schritte 12 und 13.)

2-6. Die Schubstange, die Schubstangenfeder und den Gummi entfernen. (Auf Schritte 14 bis16 Bezug

nehmen.)

Cut three cable tie

Die drei Kabelbänder

from Optical Engine

vom Optikmotormodul

Module.

abschneiden.

Schritt 12

Step 12

2-5

Schritt 13

Step 13

2-6 2-6

Die drei Kabel der DC

Unplug three

zu DC-Platineneinheit

Connecting Cords

abziehen.

of DC to DC PWB Unit

Step 14 Step 15 Step 16

Schritt 14 Schritt 15 Schritt 16

48

Page 49

2-7. Die sechs Kabel der Thermoplatineneinheit abziehen. (Schrutt 17.)

2-8. Die fünf Schrauben vom Optik-Motormodul losdrehen (Schritte 18 bis 20).

2-9. Die beiden Schrauben vom Projektionsobjektivdeckel losdrehen (Schritt 21).

2-10.

Das Optik-Motormodul, den Projektionsobjektivdeckel und die Thermoplatine entfernen.

(Schritte 22 und 23.)

2-7

PG-M15X

PG-M15S

AN-M15T

Schritt 17

Step 17

Schritt 18 Schritt 19

Schritt 20 Schritt 21

2-8 2-8

Step 18 Step 19

2-9

Step 20 Step 21

2-10

Step 22 Step 23

Schritt 22 Schritt 23

49

Page 50

PG-M15X

PG-M15S

AN-M15T

Speaker

Lautsprecher

Projektionslinsen-Objektivdeckel

Projection Lens Cover

2-9

2-7

Thermal PWB Unit

Thermo-Platineneinheit

DMD-Off-

DMD Off-Light Vent

Lampenluftschlitz

Optik-Motormodul

Optical Engine Module

2-8

2-6

Push Bar Spring

Schubstangenfeder

Pudh Bar

Schubstange

50

Abdichtgummi

Leakage Rubber

Page 51

3.Ausbau des Ballast-Platineneinheit

3-1. Die beiden Schrauben losdrehen und den Anschlußplattenhalter entfernen.

3-2. Die beiden Schrauben losdrehen und die Erdungsplatte entfernen.

3-3. Die beiden Schrauben losdrehen und die Wechselstromkabelbefestigung entfernen.

3-4. Die beiden Schrauben losdrehen und das Zündkabel vom Lampengehäuse entfernen.

3-5. Die beiden Schrauben losdrehen und das Ballast-Platineneinh entfernen.

PG-M15X

PG-M15S

AN-M15T

Grounding Sheet

Erdungsplatte

3-2

3-3

Netzkabelbefestigung

AC Code Fix

3-4

Ballast-Platineneinheit

Ballast PWB unit

Terminal Sheet Holder

Anschlußleiste

3-1

3-5

51

Page 52

PG-M15X

PG-M15S

AN-M15T

4.Ausbau des Lampengehäuses

4-1. Die beiden Schrauben lockern und die Lampenabdeckung entfernen.

4-2. Die drei Schrauben lockern und die Lampe anheben.

4-3. Die Schraube losdrehen und die Entlüftungsführung sowie den Entlüftungsgummikanal entfernen.

4-4. Die drei Schrauben losdrehen und das Lampengehäuse entfernen.

4-5. Die Schraube losdrehen und das Gebläse vom Lampengehäuse entfernen.

4-6. Vier Schrauben losdrehen, dann das Gebläse-Windrohr vom Lampengehäuse entfernen.

4-7. Die Sicherung vom Lampengehäuse entfernen.

Lampen

4-2

4-1

Lampenabdeckung

4-4

4-6

Sicherung

4-7

Distanzstück

Umströmungsführung

Entlüftungsgummikanal

Lampengehäuse

4-3

Ausblasluftführung

52

Gebläse

4-5

Bottom Cover

Page 53

PG-M15X

PG-M15S

AN-M15T

4-8. Die Schraube losdrehen und die Schalttafel sowie die inneinandergreifende Schutzabdeckung entfernen.

4-9. Die Schraube losdrehen und den Anschlußschalter entfernen.

4-8

Ineinandergreifende

Interlock Protection Cover

Schutzabdeckung

Schalterplatineneinheit

SW PWB unit

4-8

Unterseite Abdeckung

Bottom Cover

Thermal

Thermoschalter

Switch 70°

70°

4-9

53

Page 54

PG-M15X

PG-M15S

AN-M15T

5.Ausbau des Gebläsemoduls

5-1. Die beiden sechskantigen Kupferscheiben entfernen und die Gebläseeinheit abnehmen.

5-2. Die beiden Schrauben losdrehen und die Ausblasfenstereinheit entfernen.

5-3. Die beiden Schrauben losdrehen und das Gebläse sowie den Gummi entfernen.

Fan Ass'y

Gebläseeinheit

Hexagon Copper Sticker

Sechskant-Kupferfolie

5-1

Gebläse

Fan

Gummi

Rubber

Luftausblasfenster

Exhaust Window

5-3

Rubber

Gummi

5-2

Fan

Gebläse

54

Page 55

LAMPENBETRIEBSZEIT-TIMERS

PG-M15X

PG-M15S

AN-M15T

Wartungsanzeigen

Temperaturwarnanzeige

LamapenaustauschAnzeige

Die Temperatur im

Gerät ist zu hoch.

Die Anzeige blinkt rot.

Die Lampe leuchtet

nicht auf.

Die Lampe muß

ausgewechselt

werden.

Lampenaustausch-Anzeige

Betriebs-anzeige

Temperaturwarnanzeige

• Belüftungsöffnungen

blockiert.

• Kühlventilator beschädigt.

• Interne Schaltkreise

beschädigt.

• Kühlung des Gerätes • Warten, bis die Anzeige nicht mehr blinkt

• Ausgebrannte Lampe.

• Lampen-Schaltkreis

beschädigt.

• Die Abdeckung des

Lampenkäfigs ist nicht

richtig angebracht.

• Die Lampe wurde über

1.400 Stunden verwendet.

• Die Warnanzeigen auf dem Projektor weisen auf

Fehlfunktionen im Projektors hin.

• Die folgenden zwei Warnanzeigen sind vorhanden: eine

Temperaturwarnanzeige, die aufleuchtet, wenn der

Projektor zu warm wird und eine LampenaustauschAnzeige, die den Zeitpunkt zum Auswechseln der Lampe

anzeigt.

• Wenn ein Problem auftritt, leuchtet entweder die

Temperaturwarnanzeige oder die LampenaustauschAnzeige rot auf. Nach dem Ausschalten des Gerätes den

unten aufgeführten Schritten folgen.

ProblemWartungsanzeige Symptom Abhilfe

• Den Projektor an einem besser belüfteten

Ort aufstellen.

• Den Projektor zu einem von Sharp

autorisierten Händler für Projektoren oder

dem Kundendienst zur Reparatur geben.

und erlischt.

• Die Lampe vorsichtig austauschen.

• Den Projektor zu einem von Sharp

autorisierten Händler für Projektoren oder

dem Kundendienst zur Reparatur geben.

• Wenn die Temperaturwarnanzeige aufleuchtet, sollten die obigen Abhilfen befolgt und dann gewartet werden, bis der Projektor vollständig

abgekühlt ist, bevor das Gerät wieder eingeschaltet wird. (Mindestens fünf Minuten.)

• Wenn das Gerät ausgeschaltet und dann nach einer kurzen Pause wieder eingeschaltet wird, kann die Lampenaustausch-Anzeige aktiviert

werden und das Einschalten des Gerätes verhindern. In diesem Fall sollte der Netzstecker von der Steckdose abgetrennt und erneut

angeschlossen werden.

Rückstellung des Lampentimers

Das Netzkabel

1

anschließen.

Das Netzkabel am

Steckanschluß des Projektors

anschließen.

Den Lampentimer zurückstellen.

2

1 KEYSTONE (+) und KEYSTONE

(–) gleichzeitig gedrückt halten

und dann ON/OFF drücken.

1

„LAMP. 0000H“ wird zum

Zurückstellen des

Lampentimers angezeigt.

• Der Lampentimer sollte nur nach dem Austauschen der Lampe zurückgestellt wer den.

55

Page 56

PG-M15X

PG-M15S

AN-M15T

Lampe

Die Lampe dieses Projektors kann abhängig von der Betriebsumgebung etwa 1.500 Stunden verwendet werden.

Es wird empfohlen, die Lampe nach 1.400 Betriebsstunden oder wenn eine sichtbare V erschlechter ung der Bildund Farbqualität auftritt, auszutauschen. Die Verwendungszeit der Lampe kann mit der Anzeige auf der Bildwand

überprüft werden .

VORSICHT

• Gefährliche Lichtstrahlen. Niemals beim Betrieb des Projektors in die Öffnung oder das Objektiv schauen.

• Wenn die Betriebsumgebung große Unterschiede aufweist, kann die Verwendungdauer der Lampe weniger als 1.500 Stunden betragen.

• Die obige Angabe von „1.500 Stunden“ bedeutet eine durchschnittliche Verwendungsdauer und ist nur als Referenz gedacht. Dies

unterscheidet sich von der Garantiezeit.

• Aus Sicherheitsgründen wird das Gerät nach dem Ausschalten nicht ein viertes Mal eingeschaltet, ohne daß die Lampe nach einer

Nutzungszeit von 1.500 Stunden ausgewechselt wird.

Symptom

Die Lampenaustausch-Anzeige leuchtet rot

auf und „LAMP.“ wird in der unteren linken

Ecke des Bildes gelb angezeigt.

Eine sichtbare Verschlechterung der Bildund Farbqualität tritt auf.

Das Gerät wird automatisch ausgeschaltet

und der Projektor auf Betriebsbereitschaft

geschaltet.

„LAMP.“ wird in der unteren linken Ecke des

Bildes rot angezeigt und das Gerät wird

automatisch ausgeschaltet.

Das Gerät ausschalten.

1 3

ON/OFF auf dem Projektor oder