Page 1

PG-M10SU/SE

PG-M10XU/XE

SERVICE MANUAL

SERVICE-ANLEITUNG

S90i7PG-M10SU

DLP PROJECTOR

DLP PROJEKTOR

PG-M10SU/SE

MODELS

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

CONTENTS / INHALT

Page

• SPECIFICATIONS.............................................. 2

• NOTE TO SERVICE PERSONNEL....................3

• OPERATION MANUAL ...................................... 4

• DISASSEMBL Y AND REASSEMBLY...............10

• REPLACING THE LAMP.................................. 15

• BLOCK DIAGRAM OF OPTICAL SYSTEM

PRINCIPLE ...................................................... 16

• OPTICAL ADJUSTMENT AND MEASURING ..17

• SAFETY DEVICE............................................. 20

• TROUBLE SHOOTING TABLE ........................ 21

• BLOCK DIAGRAM ........................................... 43

• PARTS LIST ..................................................... 44

• PACKING OF THE SET ................................... 51

PG-M10XU/XE

Seite

• TECHNISCHE DATEN ..................................... 22

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................. 23

• BEDIENUNGSANLEITUNG ............................. 24

• ZERLEGUNG UND ZUSAMMENBAU ............. 30

• AUSWECHSELN DER LAMPE........................ 35

• BLOCKDIAGRAMM FÜR OPTISHES

SYSTEMPRINZIP ............................................ 36

• OPTISCHE EINSTELLUNGEN UND

MESSUNG ....................................................... 37

• SICHERHEITSEINRICHTUNG ........................ 40

• FEHLERSUCHTABELLE ................................. 41

• BLOCKSCHALTBILD ....................................... 43

• ERSATZTEILLISTE.......................................... 44

• VERPACKEN DES GERÄTS ........................... 51

SHARP CORPORATION

1

Page 2

PG-M10SU/SE

PG-M10XU/XE

Specifications

2

Page 3

PG-M10SU/SE

5

PG-M10XU/XE

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the DLP

projector emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

234567890123456789012345678901212345678901234

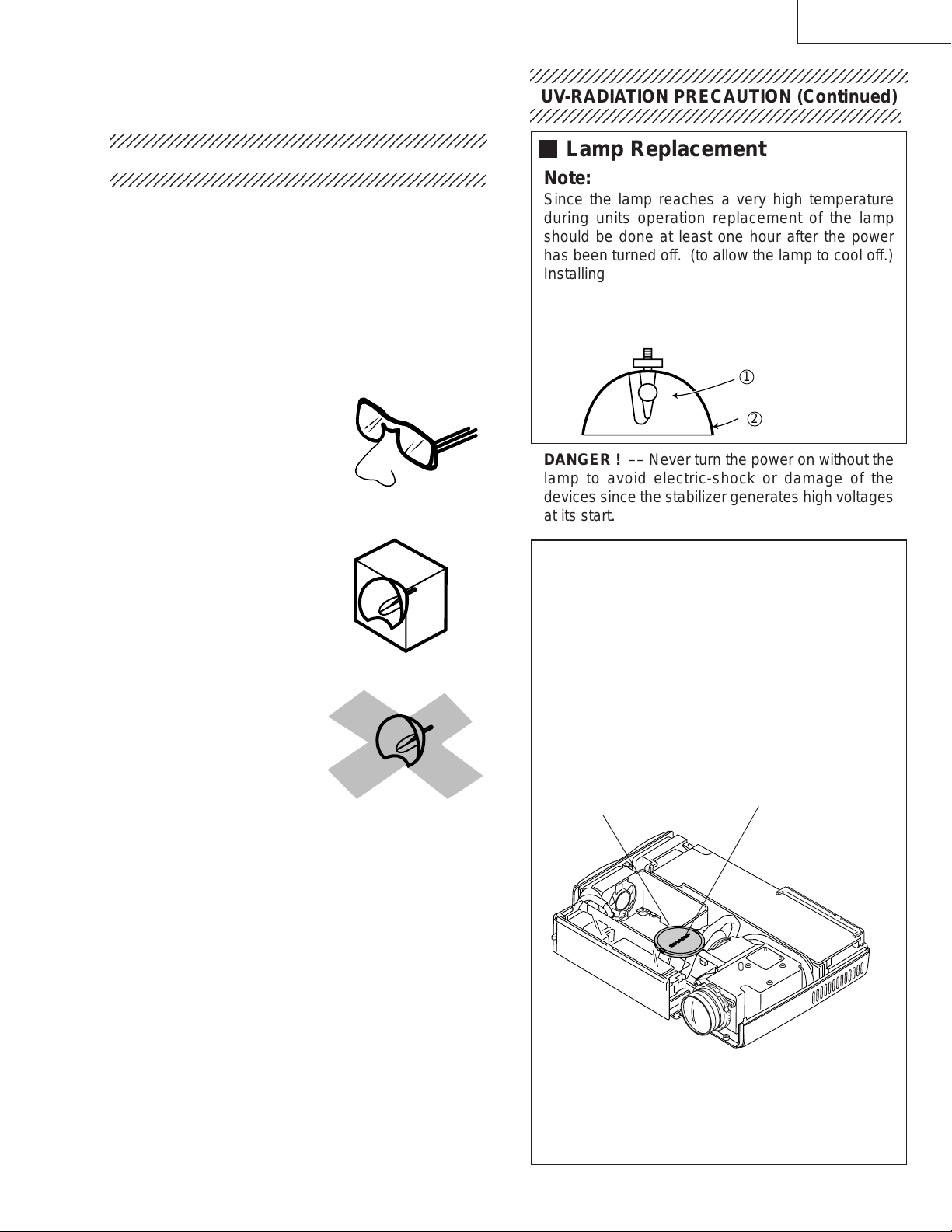

UV-RADIATION PRECAUTION (Continued)

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type BQCPGM10X//-1 rated 85V/130W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure (Fig. 1).

Notes:

» Please obtain a lens cap before servicing a model

PG-M10SU/SE, PG-M10XU/XE that is received

without one.

» The color wheel is running at high speed. Do not

touch it nor bring anything nearby.

COLOR WHEEL LENS CAP

Figure 1.

3

Page 4

PG-M10SU/SE

PG-M10XU/XE

Location of Controls

4

Page 5

PG-M10SU/SE

PG-M10XU/XE

5

Page 6

PG-M10SU/SE

PG-M10XU/XE

Reomte Control

6

Page 7

Connections

PG-M10SU/SE

PG-M10XU/XE

7

Page 8

PG-M10SU/SE

PG-M10XU/XE

8

Page 9

Pin Assignments

PG-M10SU/SE

PG-M10XU/XE

Dimensions

9

Page 10

PG-M10SU/SE

PG-M10XU/XE

DISASSEMBLY AND REASSEMBLY

1.Preparations and precautions

● Tools required

1. Phillips screwdriver, Nos. 1 and 2

2. Phillips and bladed precision screwdrivers

3. Anti-static wrist band

4. Hexagonal wrench (opposite side: ___ mm)

● Precautions for disassembly and reassembly

1. Before starting the procedure, unplug the power cable.

2. Some parts are still hot immediately after operation. Wait until they have cooled down.

3. Restore the components, screws and wires in their original positions.

4. Follow the important notes in handling the components and carrying out the job.

5. Be careful not to confuse the specific component parts for different models.

6. Do not tamper with the unit to ensure safety.

2.Disassembly and reassembly

1) Front panel (See Fig. 1 and Fig. 1-A.)

Remove the two screws (S-8) shown in Fig. 1.

Remove the front panel as shown in Fig. 1-A.

Note: Take care not to damage the IR cable.

2) Top cover (See Fig. 2.)

Remove the two louver screws (S-8) shown in Fig.

2.

Remove the top cover as shown in Fig. 2.

Note: Take care not to damage the speaker cable.

Top Cover

S-8

Fig. 1

2

Louver

Screw

S-8

Louver

Screw

Fig. 2

1

Front Panel

Fig. 1-A

10

Page 11

PG-M10SU/SE

PG-M10XU/XE

3) Speaker, buttons, etc. (See Fig. 3.)

As shown in Fig. 3, remove the nuts, speaker button

OP, and LED lens. Undo the hooks and remove

front buttons.

Speaker Ass’y

Front Foot

S-25

LED

Lens

Button

OP

S-25

Top Cover

5) Disassembling the front panel (See Fig. 5.)

Remove the screw (S-12) shown in Fig. 5, and

detach the front door.

Remove the screw (S-4) and take out the IR PWB.

Remove the two screws (S-1) and detach the plates.

Remove the screw (S-4) each off the right and left

front hooks, and detach the hooks.

S-4

S-18

Front Door

S-12

S-1

S-4

S-4

Fig. 3

4) Insulation barrier, urethane foam shield, etc. (See

Fig. 4.)

As shown in Fig. 4, the front cabinet is lined with

the barrier sheet.

Top Cover

Fig. 5

6) F/E PWB (See Fig. 6.)

Remove the screw (S-13) and two screws (S-5)

shown in Fig. 6, and disconnect the connectors.

Remove the screw (S-13) and two RGB spacers,

and detach the connector panel.

S-13

S-23

S-5

S-23

S-13

RGB Spacer

S-5

S-23

F/E PWB

Connector

Panel

Fig. 4

Fig. 6

11

Page 12

PG-M10SU/SE

PG-M10XU/XE

7) Lamp driver (See Fig. 7.)

Remove the two screws (S-16 and S-17 each)

shown in Fig. 7, and dismount the lamp driver.

S-16

S-19

Lamp Driver

S-17

Fig. 7

8) Lens base (See Fig. 8.)

Remove the four screws (S-7) shown in Fig. 8, and

detach the lens base.

Note: When disassembling or reassembling, be careful

not to get the wires caught. Do not dismount

the spherical mirror and the cylinder mirror out

of the lens base. Otherwise the adjustment will

be lost to produce shadows at the corners of

the screen.

S-7

9) Heat sink (See Fig. 9.)

Remove the two screws (S-1 1) shown in Fig. 9, and

detach the heat sink.

Note: Be careful to fit the heat sink in the correct

direction.

Heat Sink A

S-11

Heat Sink B

Fig. 9

10)DMD and F/M PWB (See Fig. 10.)

Remove the four screws (S-9) shown in Fig. 10,

and detach the DMD and F/M PWB from the lens

base.

Note: Take care not to touch the elastomer, DMD

surface or terminals, and F/M PWB terminals

by finger. When reassembling, be careful not to

allow dust or dirt on the parts. Special care

should be taken in handling the DMD, elastomer

and F/M PWB, which will directly affect the image

quality .

Fig. 8

S-7

S-7

Lens Base

12

F/M PWB

DMD

Elastomer

Fig. 10

F/M Angle

Elastomer

Holder

S-9

Page 13

11)Projection lens (See Fig. 11.)

Wheel Cover

Wheel Sensor

S-4

Light Tunnel

Aperture

S-4

S-7

S-7

Remove the three screws (S-7) shown in Fig. 11,

and detach the projection lens.

Note: When reassembling, be careful not to damage

the spherical mirror inside of the lens base.

S-7

PG-M10SU/SE

PG-M10XU/XE

Projection lens

S-7

Fig. 11

12)Color wheel (See Figs. 12 and 13.)

Remove the two screws (S-9) shown in Fig. 12, and

detach the color wheel from the lens base.

Remove the two screws (S-4) shown in Fig. 13, and

detach the wheel cover from the color wheel.

Remove the wheel screw shown in Fig. 13, and

detach the wheel sensor.

Note: When reassembling, be careful not to tighten

the screws too much. Otherwise the color wheel

mat come in contact with other components

nearby and fail to rotate. Readjustment will be

needed if the color wheel and the wheel sensor

have been replaced. (Refer to page __.)

Fig. 13

13)Light tunnel and aperture (See Fig. 14.)

Remove the three screws (S-7) shown in Fig. 14,

and detach the light tunnel from the lens base.

Remove the two screws (S-4) shown in Fig. 14, and

detach the aperture from the lens base.

Note: Do not disassemble the light tunnel.

Fig. 12

Color wheel

S-9

Fig. 14

S-9

13

Page 14

PG-M10SU/SE

PG-M10XU/XE

14)Lamp housing (See Fig. 15.)

Remove the three screws (S-7) shown in Fig. 15,

and detach the lamp housing from the bottom cover .

Remove the screws (S-15) shown in Fig. 15, and

detach the thermistor and thermistor plate.

Remove the screw (S-7) shown in Fig. 15, and

detach the ballast lock base.

With the lamp housing taken out, the 40 fan

assembly (DC) can be detached.

Note: Take note of the wiring for the 40 fan assembly ,

which goes below the lamp housing.

40FAN(DC)

S-7

S-7

Lamp housing

S-15

Thermistor

Ass’y

Thermistor

Plate

S-15

16)Front and rear feet (See Fig. 17.)

As shown in Fig. 17, press the hook (1) first and

then the hook (2). Remove the front feet.

Turn the rear feet away out of place.

Remove the screw (S-7) shown in Fig. 17, and

detach the lamp limit switch.

S-7

Rear Foot

Front Foot

Lamp Limit

Switch

Fig. 15

15)Power unit (See Fig. 16.)

Remove the two screws (S-7) shown in Fig. 16, and

detach the fan base from the cover.

Remove the screws (S-5 and S-10 one each) and

the two D/M spacers shown in Fig. 16, and detach

the power unit.

S-5

D/M Spacer

Power Unit

40FAN(L)

S-7

Fan Base

S-10

S-7

Fig. 17

Fig. 16

14

Page 15

REPLACING THE LAMP

● Tools required

1. A soft sheet on which the projector is placed upside down. It is to protect the unit against scratches.

2. Phillips screwdriver No. 1

● Precautions in replacing and handling the lamp

1. Be sure to unplug the power cable before starting the procedure. (For prevention of electric shock)

2. Make sure that the lamp has cooled down before replacement. (For prevention of burns)

3. Do not give intense shock or vibration to the lamp. (For prevention of breakage and injury)

4. Do not disassemble the lamp.

● Replacement procedure

1) Remove the screw off the lamp cover.

5) Install a new lamp unit into position.

PG-M10SU/SE

PG-M10XU/XE

2) Detach the lamp cover.

3) Remove the three screws off the lamp unit.

4) Take out the lamp unit by holding its grip.

6) Tighten up the three screws in the lamp unit.

7) Mount the lamp cover and fix it with the screw.

8) Reset the total lamp timer.

●Select the lamp time menu, and keep pressing the

POWER ON button of the remote controller for 10

seconds or longer.

15

Page 16

PG-M10SU/SE

PG-M10XU/XE

BLOCK DIAGRAM OF OPTICAL SYSTEM PRINCIPLE

1

●Names of parts and operating specifications

1 Lamp

2 RGBW color filter

G B R W

2

3

6

7

5

4

The AC light source lamp flickers 300 times per second.

This color filter splits the light into RGB and W components.

The W (White) component contributes to the reproduction

of bright white color. The rotation-detecting sensor should

get in sync with the timing to turn off the lamp at the seam

of color filter. The maximum rotating speed is 7200 rpm.

3 Condenser lens and light tunnel

4 Reflection mirror 1 & 2

5 DMD chip

6 Projection lens

7 Screen

This lens condenses the light that is split in RGB and W

components by the color filter, and projects it to the

effective area of the reflection mirror 1. Adoption of the

light tunnel has enhanced the illuminance ratio in

peripheral area of image, reducing the difference in

brightness between screen center and peripheries. The

image can be reproduced clearly at every corner of the

screen.

This mirror reflects the light projected to the effective area

of the DMD.

This chip turns on and off in proportion to each color

component per dot depending on the input source.

This lens enlarges and projects the incident light coming

from the DMD.

Projected light (RGB and W components) is interpreted

by the viewer's eye as composite color image due to afterimage phenomenon.

16

Page 17

OPTICAL ADJUSTMENT AND MEASURING

Wheel Screw

Wheel Sensor

1.Adjustment of color wheel sensor

● Adjustment needed

1. When the color wheel unit has been replaced

2. When the color wheel sensor has been replaced

3. When the optical drive unit has been replaced (if a deviation from normal setting is found)

4. When the F/E PWB has been replaced (if a deviation from normal setting is found)

● Tools required

1. Personal computer (run on Windows 95/98)

2. RGB cable

3. Dedicated application program (white.exe program commonly used for both models UP and U2)

4. Wrench (5 mm)

5. Projection screen (normally white)

Note: During the adjustment, be careful not to touch the lamp and other hot components.

● Procedure

1. Adjustment should be done with the top cover and

the front panel removed.

2. Connect the projector to the PC (RGB mode).

3. Start up the dedicated application program

(white.exe) on the PC.

4. Press the "6" key on the keyboard. After the pattern

shown in Fig. 1 at right has appeared, press the

"R" key to get the red image displayed for checking.

Check the other colors as well (*1).

5. When part of the image does not appear in red,

loosen the wheel screw shown in Fig. 2 below and

slide the wheel sensor up or down. Fix the wheel

sensor again at the position where the color

deviation disappears.

6. Finally press the "Q" key on the keyboard to finish

the program.

Fig.1

PG-M10SU/SE

PG-M10XU/XE

Fig.2

●1:The basic black and white patterns are registered in the numeric keys 0 thru 9 on the keyboard. The colors can be

changed to any of White(W), Black(K), Red(R), Green(G), Blue(B), Magenta(M) and Cyanic(C).

17

Page 18

PG-M10SU/SE

PG-M10XU/XE

2.Measuring illuminance

● Tools required

1. Personal computer (run on Windows 95/98)

2. Projection screen (normally white)

3. Light distribution point display program (Lumens.exe program commonly used for both models UP and U2)

4. Illumination meter

● Measuring lumen value

Connect the projector to the PC, and starts lighting.

Start up the light distribution point display program

(Lumens.exe) on the PC. Make the room dark. (A

darkroom is recommended.) Measure the illuminance

at the nine points shown at right. Put the measured

illuminance into the following equation to obtain the

lumen value.

A

B

Lumen value (L) = (Average illuminance of 9 points) x (Projected area in m2)

={(P1+P2+ • • • +P9) / 9} x (A xB)

● Evenness of illuminance

Put the measured illuminance into the following equation to obtain the evenness of illuminance.

Evenness of illuminance (%) = (The lowest illuminance measured out of 9 points) / (Average illuminance of 9 points)

= [MIN.(P1~P9) / {(P1+P2+ • • • +P9) / 9}] x 100

● Peripheral illuminance ratio

Put the measured illuminance into the following equation to obtain the peripheral illuminance ratio.

Peripheral illuminance ratio (%) = (Average illuminance at P1, P3, P7 and P9) / (Illuminance at P5)

= {(P1+P3+P7+P9) / 4} / P5] x 100

The factory settings are as follows.

Model PG-M10X

Lumen value: Min. 500 Lm Evenness of illuminance: Min. 50% Peripheral illuminance ratio: Min. 80%

Model PG-M10S

Lumen value: Min. 500 Lm Evenness of illuminance: Min. 50% Peripheral illuminance ratio: Min. 80%

18

Page 19

3.Precautions in disassembling the optical mechanism

DMD assembly

Color wheel

Once disassembled, this part may

need readjustment.

This assembly can be disassembled. But be careful not to allow dust and fingerprint on it. Otherwise

the images may be adversely affected.

PG-M10SU/SE

PG-M10XU/XE

Condenser lens ass'y

If the condenser lens or mirror has not

been correctly adjusted, there will be

shades on the projection screen.

(Usually shades appear on the righthand edge or at the bottom right corner of the screen.)

Spherical

mirror

Do not separate the spherical

mirror and cylinder mirror from

the lens base (46).

Cylinder mirror

19

Page 20

PG-M10SU/SE

PG-M10XU/XE

SAFETY DEVICE

1.Internal temperature detection

The lamp housing has a built-in thermostat which puts out the lamp when the temperature becomes 110°C.

Similarly , the power supply unit and lamp driver have thermostats which terminate power supply and driver operation

when the temperature reaches 120°C and 115°C, respectively.

2.Lamp unit interlocking switch

The lamp will not light up unless the lamp cover is mounted.

3.Fault-finding status LED indicator

When the lamp fails to light up, the status LED indicator starts flickering. Different flickering intervals help identify

the cause. (Refer to the figure at right and the table below.)

LED condition Meaning Correction

OFF (kept off)

ON (kept on)

Flickers with a cycle of one

second (0.5 sec. ON and

0.5 sec. OFF)

Flickers with a cycle of 4

seconds (2 sec. ON and 2

sec. OFF)

Flickers with a cycle of 8

seconds (4 sec. ON and 4

sec. OFF)

Normal condition

Total lamp timer has exceeded

1000 hours.

Lamp cover is not mounted cor-

rectly .

Temperature protector is activated.

Temperature protector still activated. Power may fail to come

on if the main power switch is

turned on just after it has turned

off.

Lamp light-up voltage error detector is activated.

Fan is nor running.

Replace the lamp with new one, and reset the

total lamp timer.

Mount the lamp cover correctly.

If room temperature is too high, relocate the projector to cooler area. If the projector's internal

temperature rises abnormally, check the cooling fan vent hole and the unit's bottom vent hole.

Clean them if they are clogged.

Wait for one minute, and try again to turn on the

power switch.

Wait for one minute, and try again to turn on the

power switch.

Check the fan.

Flickers with a cycle of 12

seconds (6 sec. ON and

6sec. OFF)

Lamp fails to light up.

Wait for one minute or longer, and try again to

turn on the power switch. Make internal check

if the condition is not improved.

20

Page 21

TROUBLESHOOTING TABLE

1.Troubleshooting in general

Symptom Possible causes Correction

PG-M10SU/SE

PG-M10XU/XE

Power is not supplied.

The unit does not go into

stand-by mode.

Image does not appear.

Lamp does not light up.

(Status LED indicator

flickers.)

Image does not appear.

Lamp is on.

Image is distorted.

Image is blurred.

Image is dislocated either horizontally or

vertically.

Remote controller is

not working.

Wireless mouse does

not work.

Status indicator LED

flickers.

Characters flitter or

colors deviate with

RGB input.

1.Power cable not connected to power

outlet.

2.Power cable damaged.

3.No power supplied to power outlet.

1.Lamp blown out.

2. Total lamp time exceeding 1100

hours.

3.Lamp cover not mounted correctly.

4.Protector circuit activated due to high

internal temperature.

1.Incorrect input selection.

2.Incorrect cable connection.

3.Cable disconnected or connector pin

broken.

4.Brightness or contrast set to

minimum.

5.Closed shutter.

6. Turning on PC power switch before

connecting to the projector when

notebook PC is used.

1.Incorrect placement of the projector.

1.Lens out of focus.

2.Incorrect angle between the

projection screen and the projector.

3. Projection distance out of the range

for correct focusing.

4.Dew condensation on the lens.

5.Stained lens or optical unit.

1.Screen's horizontal or vertical position

maladjusted.

2.Clock frequency maladjusted.

3.Resolution and frequency not

corresponding to input signal.

1. Does signal transmission indicator

(LED) flicker? If no flickering,

batteries are dead. Even when the

indicator flickers, signal transmission

may be ineffective due to low battery

voltage.

2.Obstruction between the remote

controller and receiver on the

projector.

3. Operation out of effective range of

remote controller.

4. Intense light or fluorescent lamp

existing near the receiver.

1. Wrong connection between the PC

and the projector's mouse terminal.

2. PC started up before connecting to

the projector's mouse terminal.

1. Refer to the description for the status

LED (on page 20).

1.Poor adjustment in AUTO mode.

2.Adjustment made in MANU mode.

1.Connect the power cable correctly.

2.Replace the power cable.

3.Check the circuit breaker.

1.Replace the lamp.

2.Replace the lamp, and reset the total lamp timer.

3.Mount the lamp cover correctly.

4. Check the operating environment. Check to see if

the vent holes are not blocked.

1.Select the correct input.

2.Check the cable connection.

3.Replace the cable.

4.Make adjustment with the program menu.

5.Open the shutter.

6.First hook up the PC to the projector and then turn

on the PC power.

1.Check the placement condition.

1.Adjust focus with the focus ring.

2.Set the screen and the projector lens at right angles.

3. Make the projection distance within the range for

correct focusing.

4.Wait until dew condensation disappears.

5.Clean the lens or optical unit.

1.Make adjustment with the program menu.

2.Manually adjust the clock frequency and phase.

3.Check the PC's resolution setting.

1.Replace the batteries with new ones.

2.Remove obstruction or change the operation

position.

3.Use the remote controller within its effective range.

4. Relocate the projector to a place not affected by

intense light, or turn off the light.

1.Check the connection.

2.Start up the PC after connection.

1.Check the flickering intervals and take proper

measures.

1.Manually adjust the clock frequency and phase.

2.Press the AUTO button.

21

Page 22

PG-M10SU/SE

B

A

C

D

E

F

1 2 3 4 5 6 7 8 9 10

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

BLOCK DIAGRAM / BLOCKSCHALTBILD

SPEAKER

IR-SENSOR

PORM

POPA

POSP

CN20

CN2

CN1

COLOR

DC

WHEEL

POWER

F/E PWB

SUPPLY

UNIT

PODC

PODB

POLB

POLA

PODA

WHEEL-SENSOR

LAMP

DRIVER

LAMP-SW

LAMP

POFA

POFB

TEMPERTURE

-SENSOR

J2

RAMP

-FAN

DV-PSU

-FAN

43

F/M PWB

Page 23

PG-M10SU/SE

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PARTS LIST

ERSATZTEILLISTE

PARTS REPLACEMENT

Parts marked with "å" are important for maintaining the safety of

the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

Les pieces marquées "å" sont importantes pour maintenir la sécurité

de l'appareil. Ne remplacer ces pieces que par des pieces dont le

numéro est spécifié pour maintenir la sécurité et protéger le bon

fonctinnement de l'appareil.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF . NO.

3. PART NO. 4. DESCRIPTION

5. CODE 6. QUANTITY

in USA: Contact your nearest SHARP Parts Distributor.

For location of SHARP Parts Distributor,

Please call Toll-Free; 1-800-BE-SHARP

in CANADA: Contact SHARP Electronics of Canada Limited

Phone (416) 890-2100.

★ MARK: SPARE PARTS-DELIVERY SECTION

AUSTAUSCH VON TEILEN

Ersatzteile, die besondere Sicherheitseigenschften haben, sind in

dieser Anleitung markiert. Elektrische Komponenten mit solchen

Eigenshaften sind in den Ersatzteil durch "å" gekenn-zeichnet.

Der Gebrauch von Ersatzteilen, die nicht deselben Sicherheitseigenschaften haben wie die vom Hersteller empfohlenen ud in der

Bedienungsanleitung angegebenen, können zur Ursache von

Blitzeinschlägen, Bränden und anderen Gefahren werden.

"WIE MAN ERSATSTEILE BESTELLT"

Damit Ihre Bestellung promt und korrekt ausgeführt wird, geben Sie

bitte folgende Informationen.

1. MODELL NR. 2. REF . NR.

3. ERSATZTEIL NR. 4. BESCHREIBUNG

5. KODE 6. QUANTITÄT

★ MARKIERUNG : ERSATZTEILE-LIEFERUNG

Ref. No. Part No. ★ Description Code

PRINTED WIRING BOARD ASSEMBLIES

(UNIT REPLACEMENT ITEM)

9FU770503000 J IR Sensor Unit AZ

9FU770821500 J F/E Unit (PG-M10X) DU

9FU770821600 J F/E Unit (PG-M10S) DU

9FU770508000 J Lamp Driver Unit CW

9FU770507000 J DC Power Supply Unit CV

CABINET AND MECHANICAL PARTS

1 9FU770821210 J Top Cover Ass’y (PG-M10S) CC

1 9FU770820310 J Top Cover Ass’y (PG-M10X) CC

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 9FU770519000 J Speaker Ass’y BA

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

TOP CABINET SECTION

– Top Cover —

– Button OP —

– LED Lens —

– Foot Button —

– Foot Button Spring —

– Sensor Cover R —

– Insulation Board —

– Heat Conductive Both —

Sides T ape S

– Heat Conductive Both —

Sides T ape B

– Insulation Board Friction —

Tape

– Insulation Board Spacer —

– Top Cover Urethane Form L —

– Top Cover Mesh —

– Insulation Sheet F/E —

– U3 Gasket —

Ref. No. Part No. ★ Description Code

18 9FU770821300 J Front Panel (PG-M10S) BT

18 9FU770820500 J Front Panel (PG-M10X) BT

19 9FU177032504 J Slider Plate AL

20 9FU770326000 J Slider Spring (1) AD

21 9FU770328000 J Slider Spring (2) AD

22 9FU770327000 J Slider Holder AE

23 9FU177041806 J Push Slider AN

24 9FU770503000 J IR PWB AZ

25 9FU770511000 J IR Cable Ass’y AL

26 9FU770408000 J Front Hook (1) AF

27 9FU770409000 J Front Hook (2) AF

28 9FU770821410 J Front Door Ass’y (PG-M10S)BG

28 9FU770820610 J Front Door Ass’y (PG-M10X) BG

29

30

31

32

33 9FU770329000 J Louver Screw AD

34 9FU770413000 J Spacer D/M AH

Not Available

Not Available

Not Available

Not Available

– Front Door —

– Front Door Slide Sheet (1) —

– Front Door Slide Sheet (2) —

– Front Door Reflect Sheet —

44

Page 24

PG-M10SU/SE

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

J

1

2

I

H

G

10

12

14

9

15

11

34

5

6

S-8

7

4

16

3

S-20

S-8

17

F

13

S-1

8

S-20

E

33

S-7

D

18

C

28

S-8

B

27

22

S-22

19

21

S-12

23

26

20

S-2

S-4

25

S-7

S-8

32

29

30

A

31

S-8

24

1 2 3 4 5 6 7 8 9 10

45

Page 25

PG-M10SU/SE

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET AND MECHANICAL PARTS

(Continued)

PWB Section

35 9FU770821600 J F/E PWB (PG-M10S) DU

35 9FU770821500 J F/E PWB (PG-M10X) DU

36 9FU770820800 J Connector Panel AY

37 9FU770820900 J Connector Sheet AG

38 9FU770415000 J Spacer RGB AH

39 9FU770426000 J Lens Base Urethane Form AC

40 9FU770414000 J Lamp Driver Stud AM

41 9FU770505000 J Limit SW Board Ass’y AZ

42 9FU770508000 J Lamp Driver-U CW

43 9FU770802600 J Insulate Sheet L/D-N BB

45 9FU770407000 J Lamp Driver Lodk Base AG

46 9FU770821000 J Louver Panel AY

56

58

F

57

S-7

S-3

55

47 9FU770417100 J Lamp House Ass’y-U BC

48

49

50

51

52

Not Available

Not Available

Not Available

Not Available

Not Available

– Lamp House-U —

– Lamp House Mesh —

– Lamp House Guard —

– Insulation Varrier —

– Lamp House Mesh Tape —

53 9FU770814700 J Lamp fan Spacer AL

54 9FU770821700 J Thermistor Ass’y AR

55 9FU770814600 J 40 Fan Ass’y L-H BK

56 9FU770517000 J 40 Fan Ass’y DC BK

57 9FU770412000 J Fan Cushion AD

58 9FU770405000 J Fan Vibration Proof Rubber AC

59 9FU770406000 J Fan Guard AD

60 9FU770402000 J Fan Base AH

61 9FU770524000 J Core AR

62 9FU177044200 J Fan Fence AG

63 9FU770522000 J Ground Lead AG

62

S-7

60

S-13

S-18

63

S-5

35

S-18

S-13

38

37

36

E

S-7

61

59

53

D

S-7

46

48

52

47

52

49

41

S-7

50

S-5

54

S-16

51

S-7

39

S-7

C

45

40

S-7

S-7

B

43

44

A

S-17

42

1 2 3 4 5 6 7 8 9 10

46

Page 26

PG-M10SU/SE

B

A

C

D

E

F

1 2 3 4 5 6 7 8 9 10

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET AND MECHANICAL PARTS

(Continued)

BOTTOM COVER SECTION

64 9FU770820400 J Bottom Cover BW

65 9FU177043004 J Inlet Spacer AL

66 9FU770413000 J Spacer D/M AH

67 9FU770826800 J Spacer Tube AD

68 9FU770507000 J DC Power Unit CV

69 9FU770825000 J Insulation Sheet DC-1 BB

70 9FU770825200 J Insulation Sheet DC-2 BB

71 9FU770424000 J Insulation Sheet DC-3 AH

72 9FU770314000 J Rear Foot AL

73 9FU770320000 J Rear Foot Rubber AF

74 9FU770322000 J Front Foot BA

75 9FU770820710 J Lamp Cover Ass’y BC

76

77

78

79

80 BQC-PGM10X//1 J Lamp Ass'y CS

Not Available

Not Available

Not Available

Not Available

– Lamp Cover —

– Lamp Cover Screw —

– Lamp Cover Screw Spring —

– Lamp Cover Guard —

65

S-10

66

67

S-21

S-5

70

66

69

71

68

72

73

73

64

80

S-19

79

75

74

78

76

77

73

47

Page 27

PG-M10SU/SE

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET AND MECHANICAL PARTS

(Continued)

OPTICAL SECTION

81 9FU770800000 J Lens Base Ass’y CM

82

83

84

85

86

87

88 9FU770801900 J Insulation Sheet LB-U AN

89 9FU770800100 J Projection Lens Unit CR

F

E

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

95

94

– Lens Base —

– Spherical Mirror —

– Cylinder Mirror —

– Aparture —

– Lens Base Cover —

– Lens Base Sheel —

S-14

92

90 9FU770157000 J Condenser Lens Ass’y CD

91 9FU770130000 J Colour Wheel Ass’y CE

92 9FU770139000 J Wheel Cover AQ

93 9FU770140000 J Rubber Sheet BB

94 9FU770504000 J Wheel Sensor Board Ass’y AZ

95 9FU770416000 J Wheel Screw AD

96 9FU770439000 J Wire Sticker SD-10 AD

97 9FU770551000 J DMD Set, 97-A~D GE

97 9FU770510000 J DMD Set, 97-A~D HL

98 9FU177041004 J Push F/M Board AL

99 9FU177040303 J Heat Sink A AG

100 9FU177040403 J Heat Sink B AG

97-D

(PG-M10S)

(PG-M10X)

97

91

S-4

93

S-7

96

D

90

S-7

C

88

S-7

B

89

S-7

83

S-9

87

97-A

86

82

84

97-C

97-B

85

S-7

81

98

S-9

S-11

100

99

A

1 2 3 4 5 6 7 8 9 10

48

Page 28

PG-M10SU/SE

B

A

C

D

E

F

1 2 3 4 5 6 7 8 9 10

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET AND MECHANICAL PARTS

(Continued)

Label Section

101 9FU770821900 J Standard Label (PG-M10S) AQ

101 9FU770821800 J Standard Label (PG-M10X) AQ

102 9FU770822000 J Hot Caution Label AD

105

102

103 9FU770822100 J Lens Attention Indication AE

Plate

104 9FU770822200 J Lamp Caution Sheel A AF

105 9FU770824000 J Hot Caution Sheel 3 AD

106 9FU770824100 J Thunder Caution Indication AD

Plate

107 9FU770826700 J Attention Indication Board AE

(Swedish)

103

101

105

106

104

107

49

Page 29

PG-M10SU/SE

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

SCREWS, NUTS AND WASHERS

S-1 9FU957620020 J Washer, x1 AB

S-2 9FU951122551 J Screw, x4 AB

S-3 9FU953930650 J Screw, x1 AB

S-4 9FU951220450 J Screw, x4 AB

S-5 9FU952320430 J Screw, x3 AB

S-6 9FU952320450 J Screw, x1 AB

S-7 9FU951220550 J Screw, x27 AB

S-8 9FU951220430 J Screw, x5 AB

S-9 9FU951220830 J Screw, x7 AB

S-10 9FU952140510 J Screw, x1 AB

S-11 9FU959161220 J Screw, x2 AC

S-12 9FU953120351 J Screw, x1 AB

S-13 9FU953220530 J Screw, x2 AB

S-14 9FU951221010 J Screw, x1 AB

S-15 9FU953226510 J Screw, x1 AB

S-16 9FU953230650 J Screw, x1 AB

S-17 9FU951630550 J Screw, x1 AC

S-18 9FU957220530 J Washer, x2 AB

S-19 9FU958440200 J Cut Washer, x1 AB

S-20 9FU958615000 J Push Nut, x9 AB

S-21 9FU957240810 J Washer, x1 AB

S-22 9FU957220650 J Washer, x3 AB

SUPPLIED ACCESSORIES

108 9FU770822600 J Packing Case (PG-M10S) AQ

108 9FU770822500 J Packing Case (PG-M10X) AQ

109 9FU770612000 J Sleeve AW

110 9FU770824800 J Polyethylene Bag AG

111 9FU770611000 J Accessory Box AM

112 9FU753321500 J Bag (for Operation Manual AC

113 9FU770822800 J Operation Manual BD

114 9FU770822900 J Quick Start Guide AG

115 9FU770825700 J User Registration Form AH

115 9FU770826300 J User Registration Form (for AG

115 9FU770826400 J User Registration Form (for AG

116 9FU770823000 J Warranty Card AL

116 9FU770825800 J Warranty Card (for USA) AE

116 9FU770826100 J Warranty Card (for AE

117 9FU770826500 J Bag (for Card) AG

117 9FU770825500 J Envelope (for USA) AF

117 9FU770826200 J USA Label AD

117 9FU770825900 J Sticker (for USA) AG

117 9FU770825600 J User Guide Line (for USA) AG

117

117

118 9FU770823200 J Carrying Case BQ

119 9FU770625000 J Accessory Pad AF

120 9FU770823400 J Inner Case BA

121 9FU770823300 J Remote Controller BX

122 9FU770822400 J Remote Controller Label AH

123

124 9FU770726000 J AC Cord (1.8m) for USA AW

124 9FU770727000 J AC Cord (1.8m) for Europe AX

124 9FU770728000 J AC Cord (1.8m) for UK BA

124 9FU770729000 J AC Cord (1.8m) Australia AX

124 9FU770826600 J AC Cord Attention Label AF

125 9FU770703000 J Viideo Cable (1P 1m) AN

126 9FU770704000 J Audio Adapter AS

127 9FU770709000 J S-Video Cable (1m) AR

128 9FU770708000 J RGB Cable (1m) BB

129 9FU770710000 J MINI Jack Cable (1m) AP

130 9FU770706000 J PS/2 Mouse Cable AS

131 9FU770707000 J USB Mouse cable AS

Not Available

Not Available

Not Available

(for Machine)

and Accessories)

(for USA)

Canadian English area)

Canadian French area)

Canadian English area)

– No. Card —

– Carton Label —

– Batteries —

and Canada

50

Page 30

PG-M10SU/SE

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PACKING OF THE SET / VERPACKEN DES GERÄTS

131

130

128

126

127

121

PLUS

112

125

122

123

129

124

112

113

114

115

116

117

120

119

108

109

118

111

110

109

51

Page 31

PG-M10SU/SE

PG-M10XU/XE

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

COPYRIGHT © 2000 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

DJapan PJapanTQ0986-S

Sept. 2000 Printed in Japan

In Japan gedruckt

SY. KY

SHARP CORPORATION

AV Systems Group

Quality & Reliability Control Center

Yaita, Tochigi 329-2193, Japan

52

Loading...

Loading...