Page 1

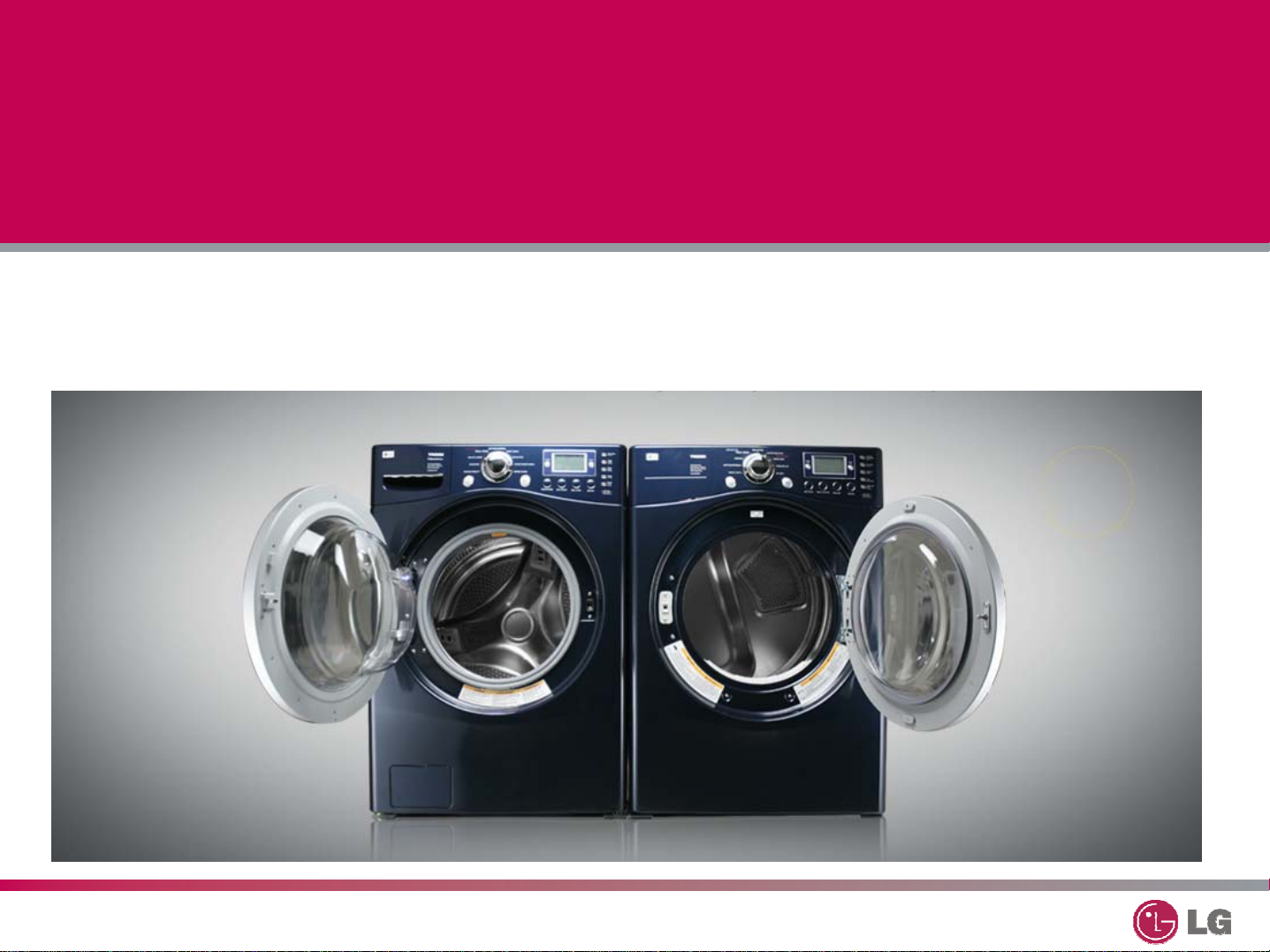

PRODUCT TRAINING

WM2688H*M Discovery Steam Washer

WM2688H*M Steam Washer Training

1

Page 2

Contact Information

Customer Service (and Part Sales) (800) 243-0000

Technical Support (and Part Sales) (800) 847-7597

USA Website us.lgservice.com

Customer Service Website us.lgservice.com

B2B Service Website biz.lgservice.com

LG CS Academy lgcsacademy.com

Published March 2006 by LG Technical Support and Training

WM2688H*M Steam Washer Training

2

T- 2

Page 3

Preliminary Matters (The Fine Print)

IMPORTANT SAFETY NOTICE

The information in this training manual is intended for use by persons

possessing an adequate background in electrical equipment, electronic

devices, and mechanical systems. In any attempt to repair a major

appliance, personal injury and property damage can result. The

manufacturer or seller maintains no liability for the interpretation of this

information, nor can it assume any liability in conjunction with its use.

When servicing this product, under no circumstances should the

original design be modified or altered without permission from LG

Electronics. Unauthorized modifications will not only void the warranty,

but may lead to property damage or user injury. If wires, screws, clips,

straps, nuts, or washers used to complete a ground path are removed

for service, they must be returned to their original positions and

properly fastened.

WM2688H*M Steam Washer Training

3

T- 3

Page 4

Preliminary Matters (The Fine Print)

CAUTION

To avoid personal injury, disconnect the power before servicing this

product. If electrical power is required for diagnosis or test purposes,

disconnect the power immediately after performing the necessary checks.

Also be aware that many household appliances present a weight hazard.

At least two people should be involved in the installation or servicing of

such devices. Failure to consider the weight of an appliance could result in

physical injury.

WM2688H*M Steam Washer Training

4

T- 3

Page 5

Preliminary Matters (The Fine Print)

ESD NOTICE

Some of the electronic in appliances are electrostatic discharge (ESD)

sensitive. ESD can weaken or damage the electronics in these appliances

in a manner that renders them inoperative or reduces the time until their

next failure. Connect an ESD wrist strap to a ground connection point or

unpainted metal in the appliance. Alternatively, you can touch your finger

repeatedly to a ground connection point or unpainted metal in the

appliance. Before removing a replacement part from its package, touch the

anti-static bag to a ground connection point or unpainted metal in the

appliance. Handle the electronic control assembly by its edges only. When

repackaging a failed electronic control assembly in an anti-static bag,

observe these same precautions.

WM2688H*M Steam Washer Training

5

T- 3

Page 6

Preliminary Matters (The Fine Print)

REGULATORY INFORMATION

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy, and,

if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures: Reorient or relocate the receiving antenna; Increase

the separation between the equipment and the receiver; Connect the

equipment to an outlet on a different circuit than that to which the receiver

is connected; or consult the dealer or an experienced radio/TV technician

for help.

WM2688H*M Steam Washer Training

6

T- 3

Page 7

Preliminary Matters (The Fine Print)

COMPLIANCE

The responsible party for this device’s compliance is:

LG Electronics Alabama, Inc.

201 James Record Road,

Huntsville, AL, 35824.

WM2688H*M Steam Washer Training

7

T- 3

Page 8

Introduction

The DISCOVERY series of washers and dryers is the top of

the line and includes every option and feature.

Most notable are the steam generator and the LCD display.

WM2688H*M Steam Washer Training

8

T- 6

Page 9

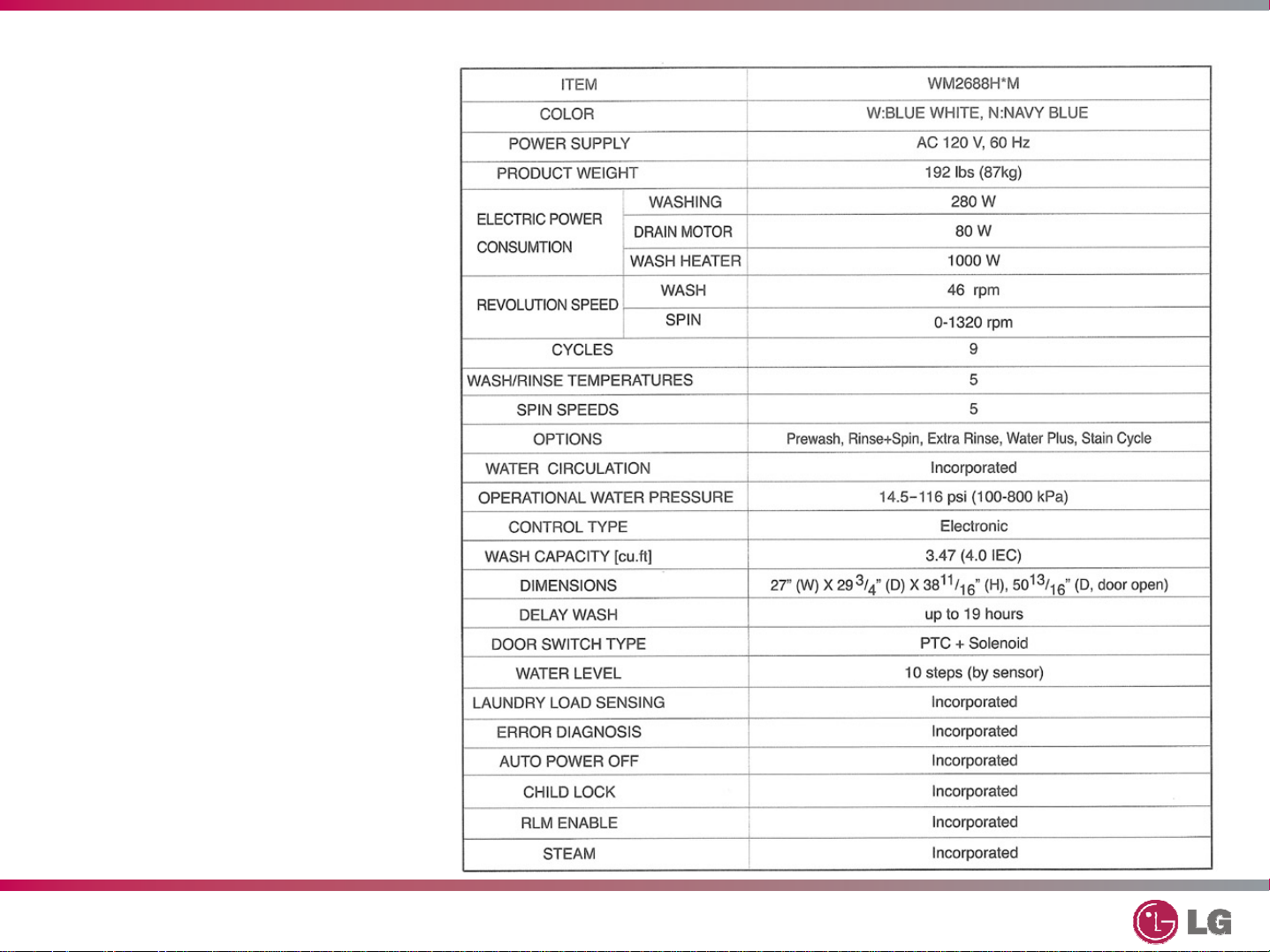

Specifications

WM2688H*M Steam Washer Training

9

T- 6

Page 10

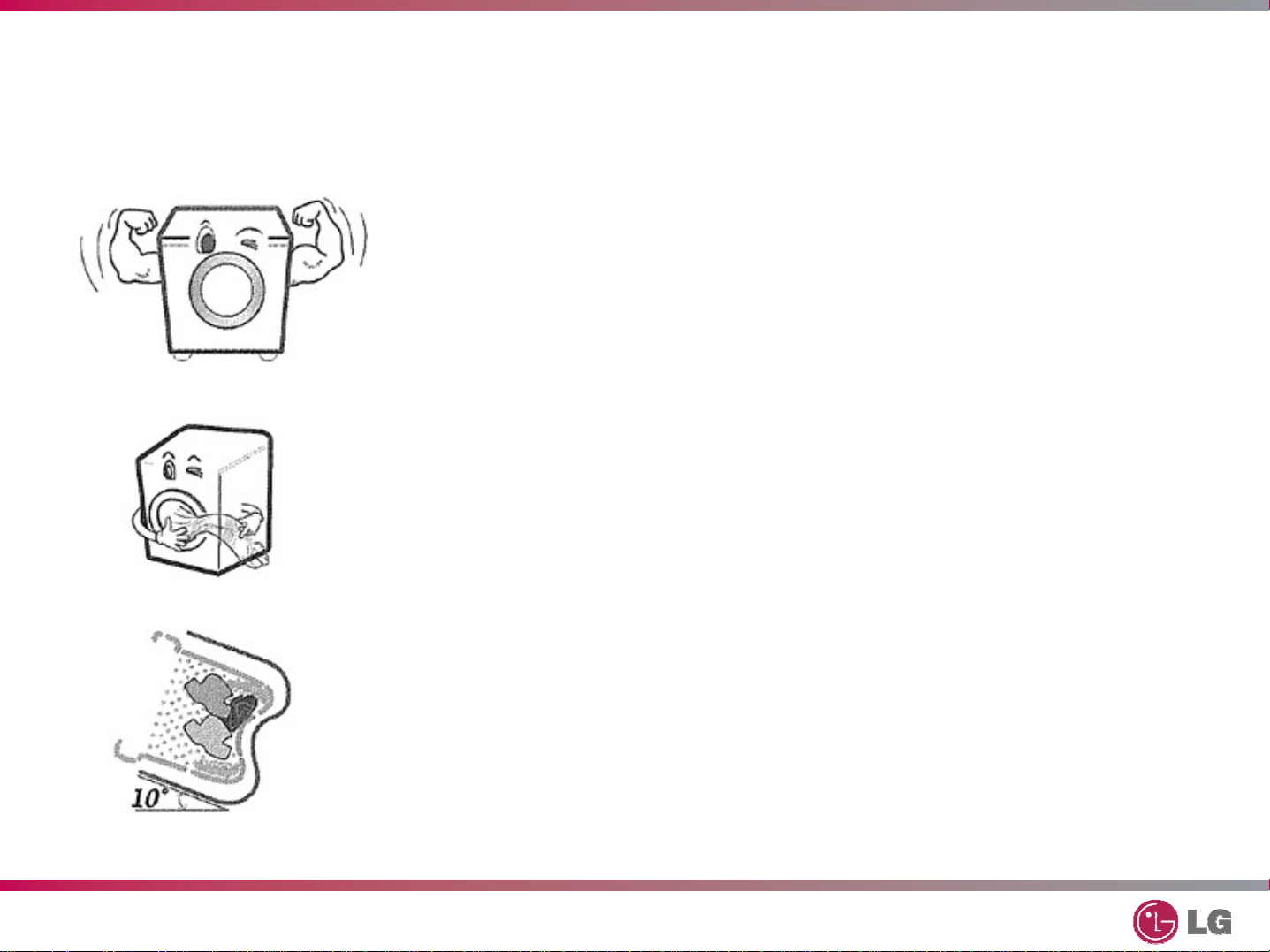

Features

LARGE CAPACITY

The larger drum (4.0 cu. ft.) allows washing of

larger (heavier) loads and oversized items

(comforters, curtains, blankets, etc.) There is less

wrinkling and tangling of the laundry.

DIRECT DRIVE

The brushless DC motor drives the drum directly

WM2688H*M Steam Washer Training

without belts, pulleys, or transmissions. The

maximum spin speed of 1,320 RPM extracts more

water from the laundry, reducing drying times.

TILTED DRUM/LARGE DOOR

The tilted drum (10°) and large door opening allow

easier loading and unloading.

10

T- 7

Page 11

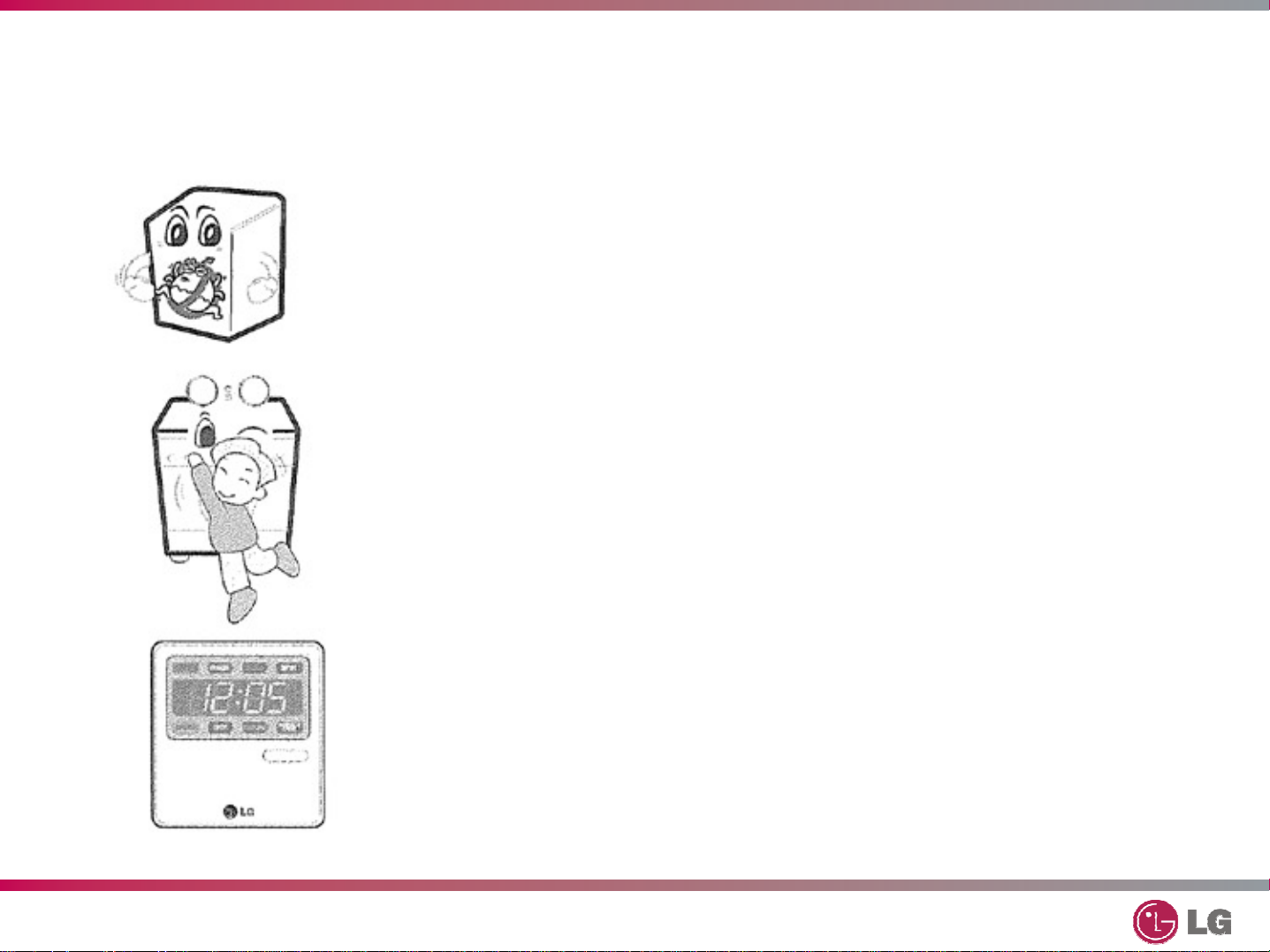

Features (continued)

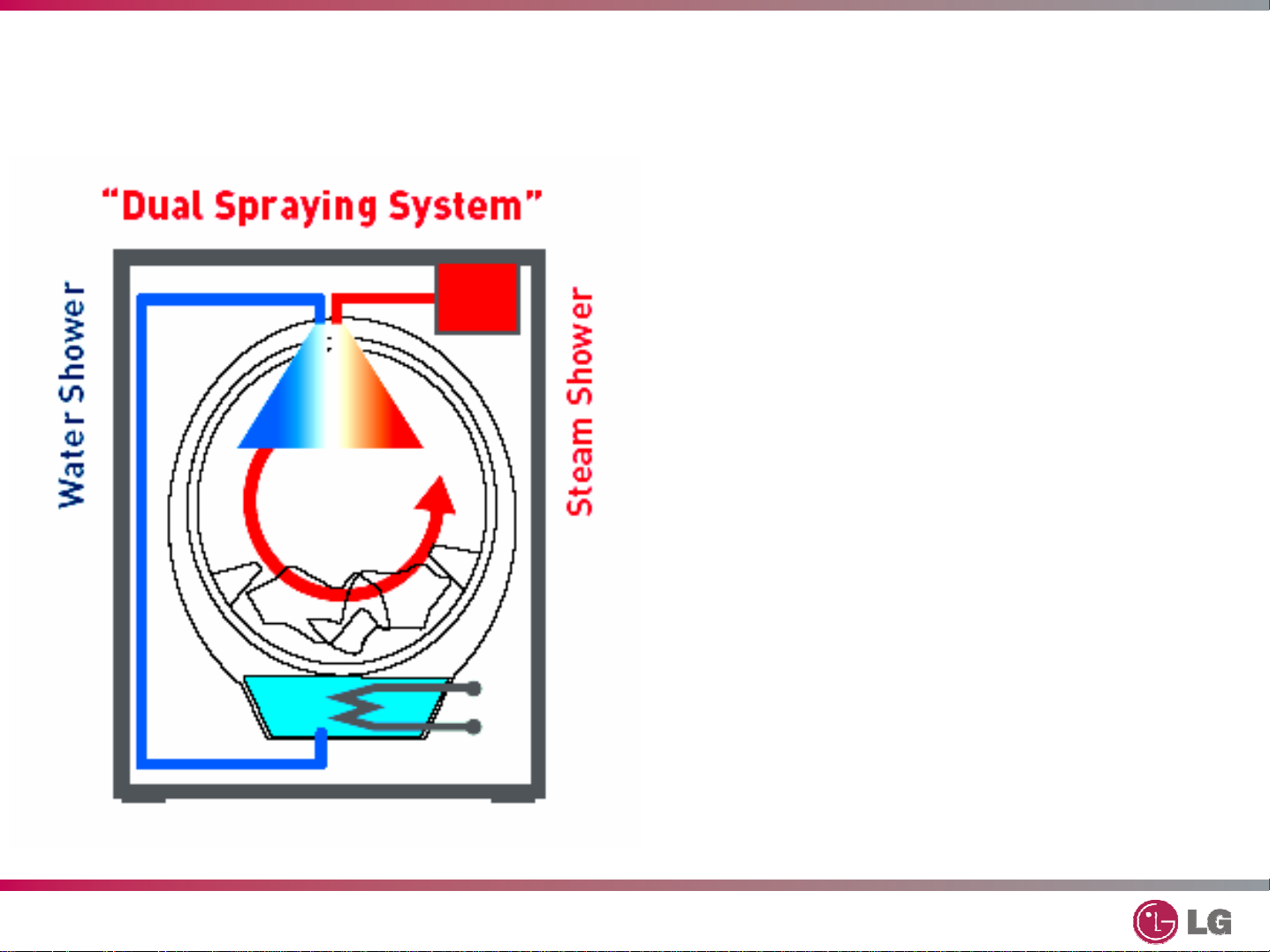

STEAM WASHING/SteamFresh®

The steam feature works with the recirculating pump to

increase washing performance while maintaining low energy

and water usage. SteamFresh® removes wrinkles from dry

clothes.

ROLLER JETS and BALLS

The baffles pick up water as the drum turns and allow it to

pour through the clothing as it tumbles. The balls enhance

the washing performance while maintaining fabric care.

AUTOMATIC LOAD DETECTION

The microprocessor reads the current required to turn the

drum and determines the weight of the load. This input is

used to make numerous decisions during the wash cycle.

WM2688H*M Steam Washer Training

11

T- 7

Page 12

Features (continued)

BUILT-IN HEATER

The internal heater helps maintain the water at

its optimal temperature for selected cycles.

The SANITARY cycle kills most common germs

and bacteria.

CHILD LOCK

This allows the user to lock the controls. Children

then cannot play with the buttons and disturb the

WM2688H*M Steam Washer Training

wash cycle.

REMOTE LAUNDRY MONITOR

Available separately, the remote monitor displays the

cycle and remaining time of the washer and dryer. It

can be plugged in to any outlet in the house.

12

T- 8

Page 13

Features (continued)

WM2688H*M Steam Washer Training

LCD Display

The bright display replaces numerous LEDs and

shows instructions when the controls are set.

13

T-8

Page 14

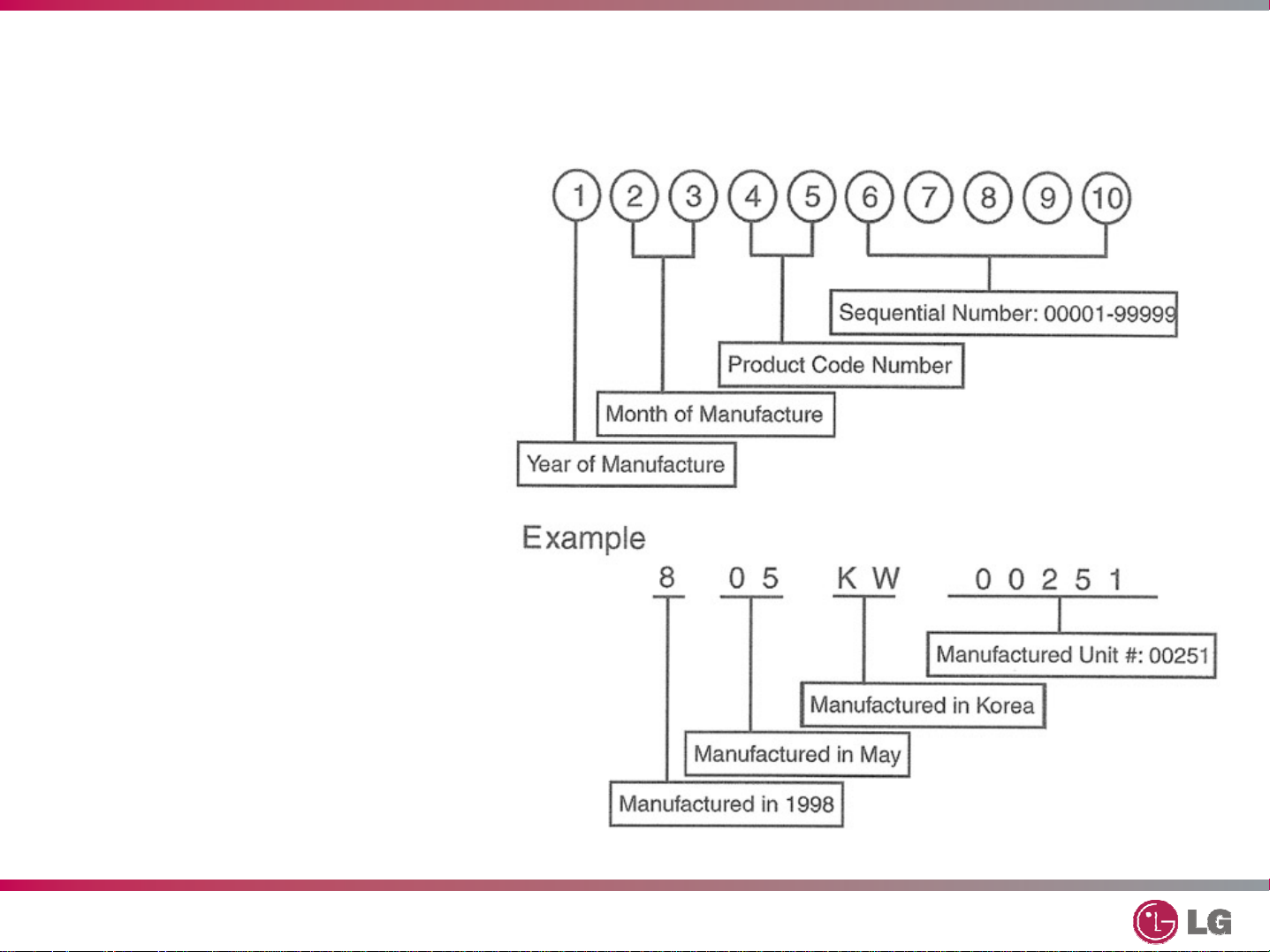

Serial Number Identification

The serial number is

unique to each product.

It gives information

concerning the time and

place of manufacture. The

serial number is required to

be paid for warranty

service and to get the

correct part in the event a

running production change

was made. Some models

may have four (4) letters

instead of two (2) for the

product code number. The

third and fourth letters are

significant only to the

manufacturing facility.

WM2688H*M Steam Washer Training

14

T- 9

Page 15

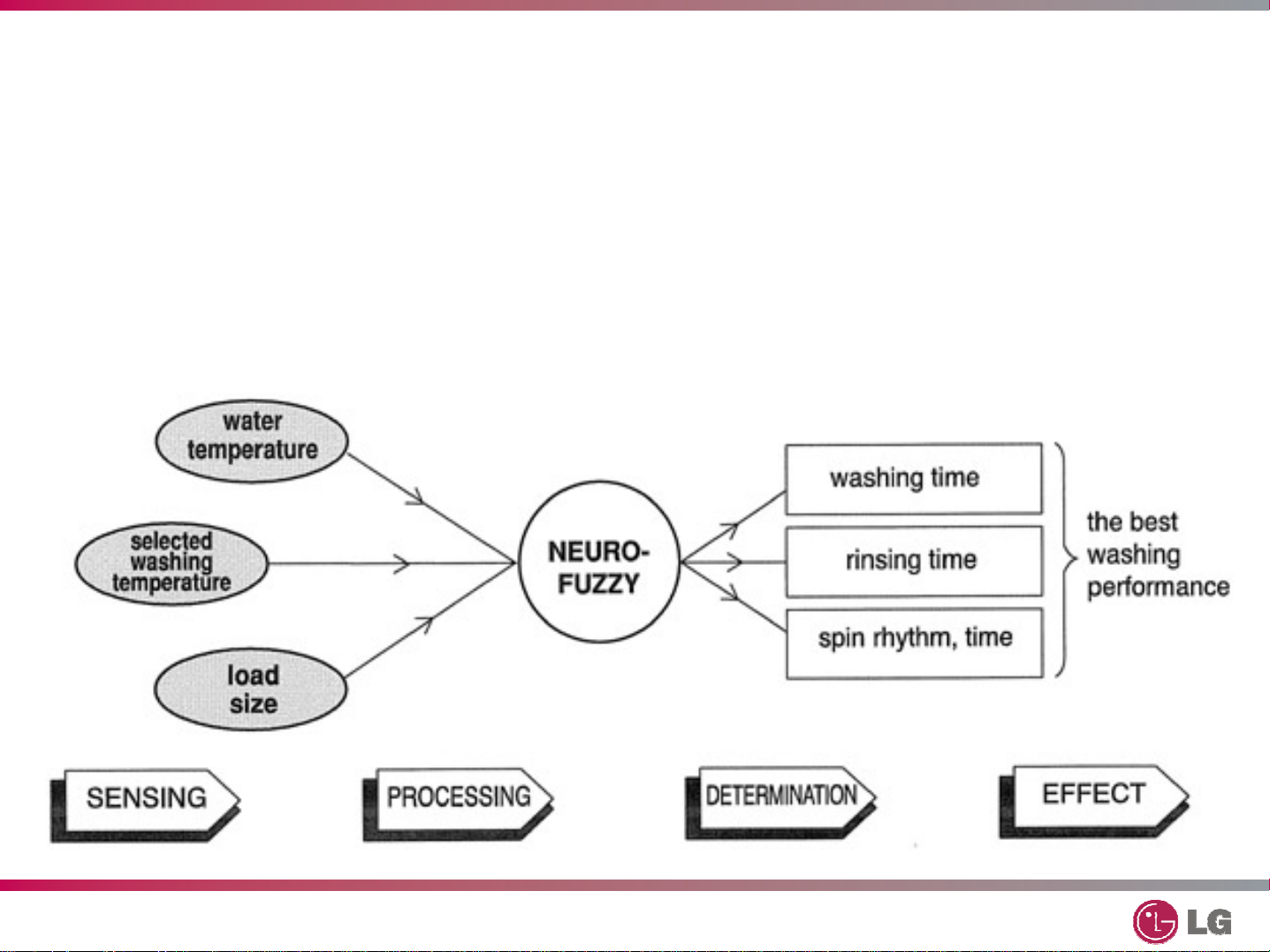

Fuzzy Logic

To get the best washing performance, the user selects one of the standard

cycles. Sensors in the COMBO make an infinitely variable number of

adjustments as the cycle progresses. Adjustments are automatically made

for load size, incoming water temperature, soil level, rinses required, and

other variables.

WM2688H*M Steam Washer Training

15

T- 10

Page 16

Door Lock

The door has an automatic, electrically operated lock system. When the

machine is off or paused, the door can be opened by pulling it. When the

machine is operating, the electric latch keeps the door closed.

The door cannot be opened:

•When the COMBO is operating

•When the power failed or the washer is unplugged

(until the capacitor discharges and releases the lock)

•When the DOOR LOCK light is on

•When the drum is still turning

WM2688H*M Steam Washer Training

16

T- 10

Page 17

Door Locked Lamp

DOOR LOCKED LAMP

The DOOR LOCK lamp lights:

• When the COMBO is operating

• When the water level sensor frequency is lower than 22.9 kHz

• When the temperature inside the tub is over 45° C (113°F)

WM2688H*M Steam Washer Training

17

T- 10

Page 18

Water Circulation

The recirculation pump circulates the water during most of the cycle.

During the WASH cycle, it runs continuously for the first 3 minutes and

then intermittently throughout the cycle. During the RINSE cycle, it runs

continuously as soon as the appropriate amount of rinse water has been

added. This recirculated water enters the drum at the top of the door at a

small shower head. This spray not only keeps the window and gasket

clean, it allows the clothes to be soaked with detergent or rinse water more

quickly and can be used to control an oversudsing event.

WM2688H*M Steam Washer Training

18

T- 11

Page 19

Water Recirculation

The recirculation pump is separate

from the drain pump, but they are

attached to opposite sides of the filter

housing.

The steam is not pumped; it comes

into the washer drum under its own

pressure. When steam or the sanitary

cycle is used, the door will remain

locked until the laundry has cooled to

WM2688H*M Steam Washer Training

a safe temperature.

The pumps and filter are located at

the bottom left front corner. The filter

can be unscrewed, cleaned, and

replaced.

19

T- 11

Page 20

Water Circulation

Use the small drain hose to

evacuate the water

remaining in the bottom of

the tub before removing the

filter.

The drain pump is on the

left and exhausts the water

via the gray corrugated

hose.

WM2688H*M Steam Washer Training

20

The recirculating pump is

on the right and recirculates

water from the tub to the

shower spray at the top of

the door gasket via the

smaller black hose.

T- 11

Page 21

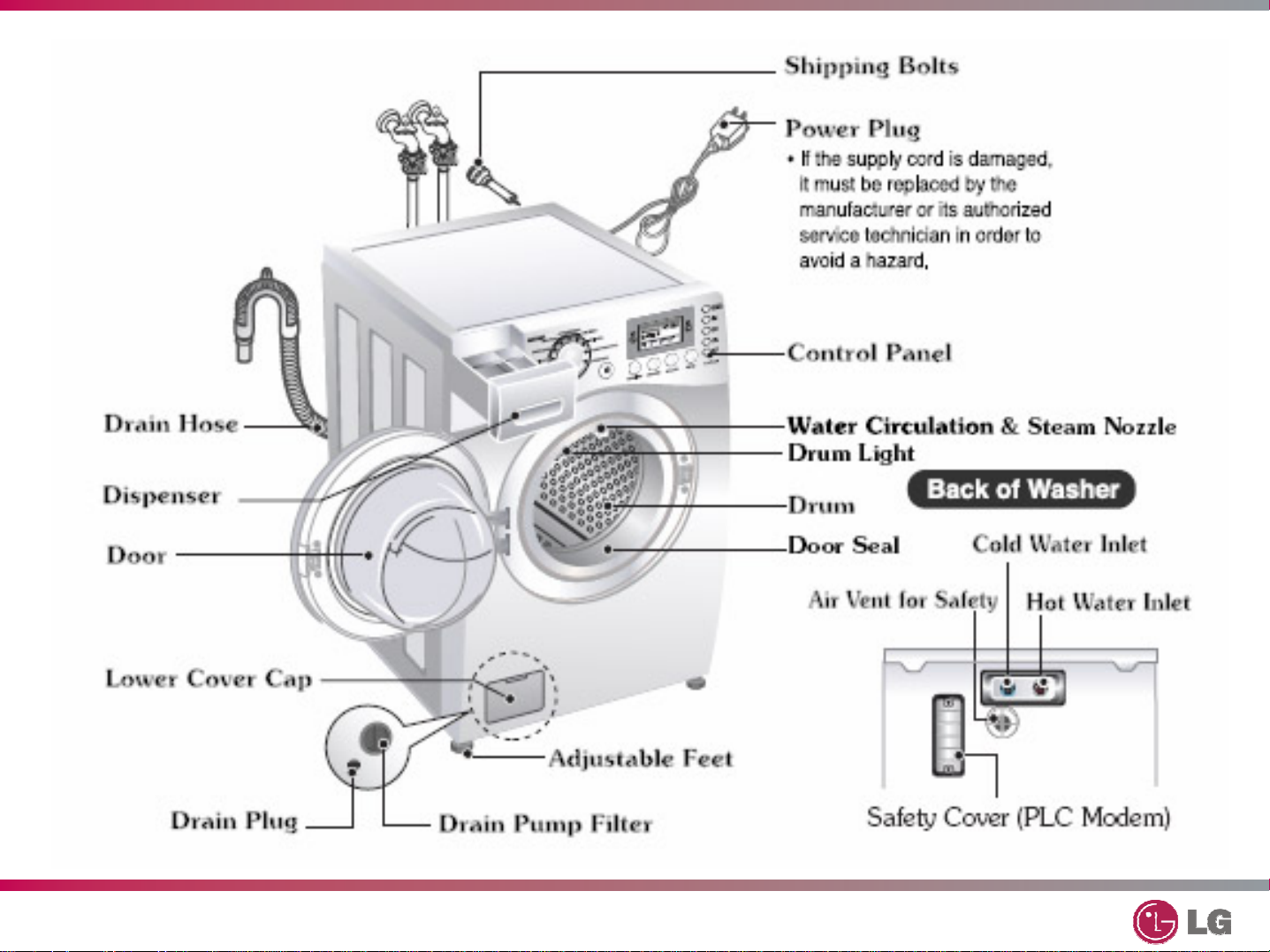

Parts Identification

WM2688H*M Steam Washer Training

21

T- 12

Page 22

Air Vent

The air vent on the back of the machine must be left open and clear at all

times.

If the washer is installed in a closet or closed laundry alcove, there must be

sufficient clearance and ventilation. The closet should have a full louvered

door with at least 800 square inches (0.5 m2) of open area for ventilation.

The washer requires a space of at least 1 inch (2.5 cm) between the wall

and the machine on each side and at least 4 inches (10 cm) between the

back of the washer and the wall.

Additional space may be needed for servicing.

WM2688H*M Steam Washer Training

22

T- 13

Page 23

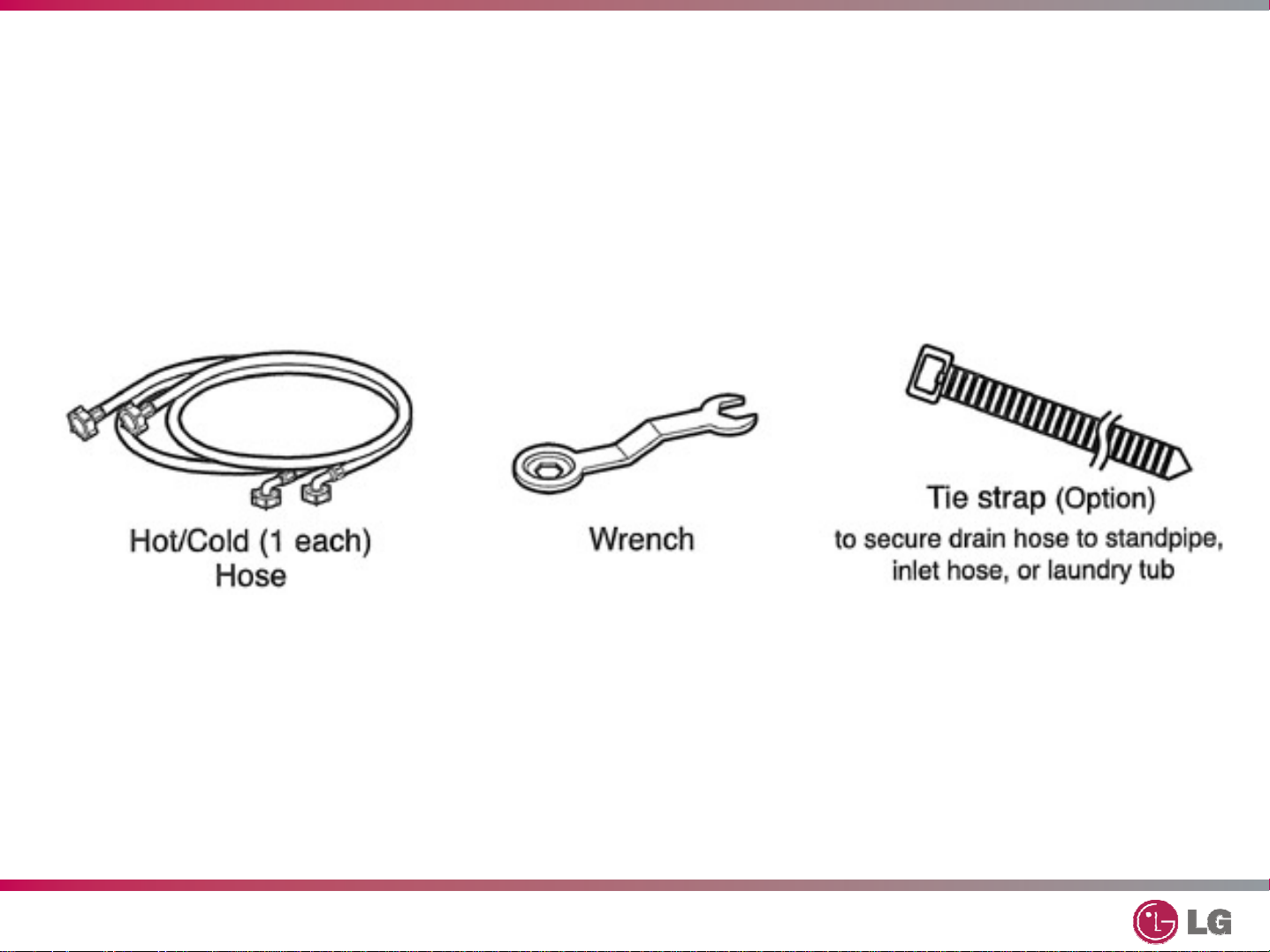

Accessories

The washer comes with the two input hoses. The blue stripe is for cold

water and the red stripe is for hot water. While the hoses are mechanically

identical, it is critical to the performance of the washer to have the hot and

cold hoses connected correctly.

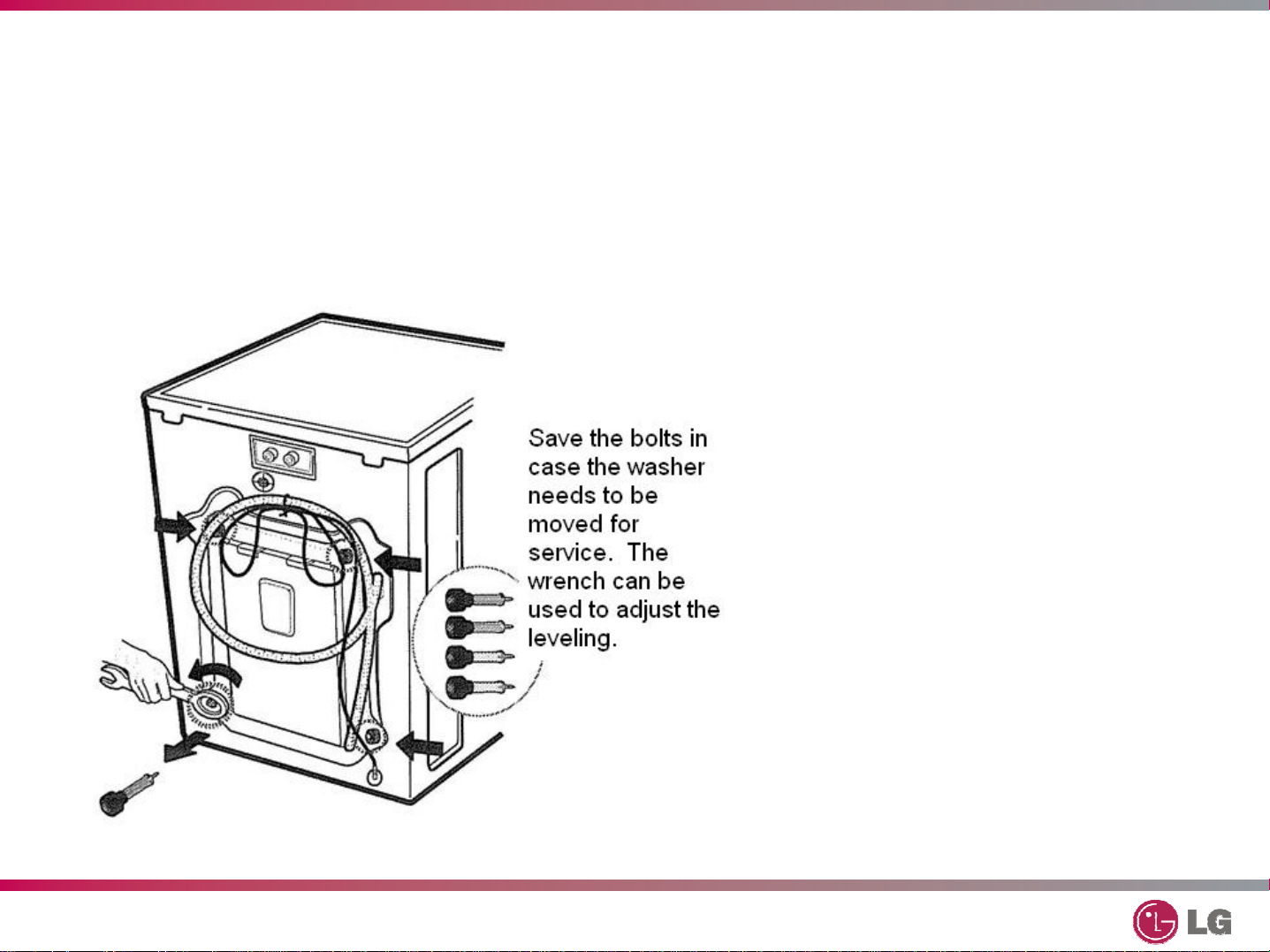

The wrench is used to remove (and replace) the shipping bolts and to

adjust the leveling feet. Be sure to leave it and encourage the customer to

retain the wrench, the four shipping bolts, and the manual in a safe place

in the event the washer requires service or the customer moves.

The shipping bolts MUST BE REMOVED before operating the washer.

WM2688H*M Steam Washer Training

23

T- 13

Page 24

Remote Laundry Monitor and Modem

The remote laundry monitor

(RLM) allows the user to

monitor the progress of both

washer and dryer, provided they

are quipped with a modem.

WM2688H*M Steam Washer Training

24

T- 14

Page 25

Install The Washer Modem

Remove the cover and install

the modem on the back of the

washer.

Save the small socket cover

and screws in the event you

need to remove the modem for

some reason. The socket

should be covered at all times.

WM2688H*M Steam Washer Training

25

T- 14

Page 26

Install the Dryer Modem

If you’re installing both the washer

and the dryer at this time, you might

as well install the dryer modem now.

Remove the cover and

install the modem on the

back of the dryer.

Save the small socket cover

and screws in the event you

need to remove the modem

for some reason. The

socket should be covered at

all times.

After installation is complete,

plug in the washer, dryer,

WM2688H*M Steam Washer Training

26

and monitor, in that order.

Turn on the washer and

dryer. Press and hold the

SET button on the monitor.

T- 14

Page 27

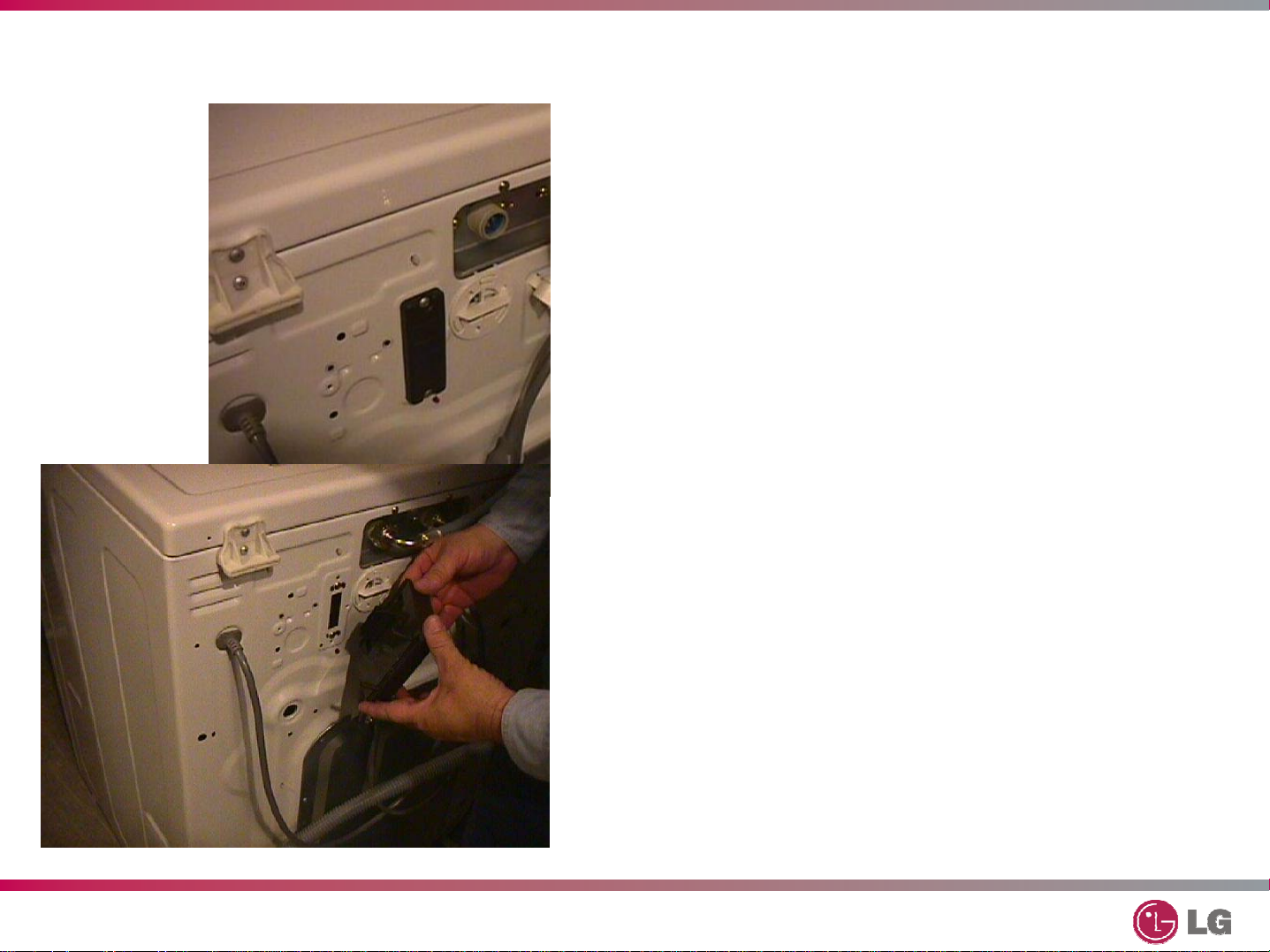

Remove The Shipping Bolts

Remove the shipping bolts.

WM2688H*M Steam Washer Training

27

T- 15

Page 28

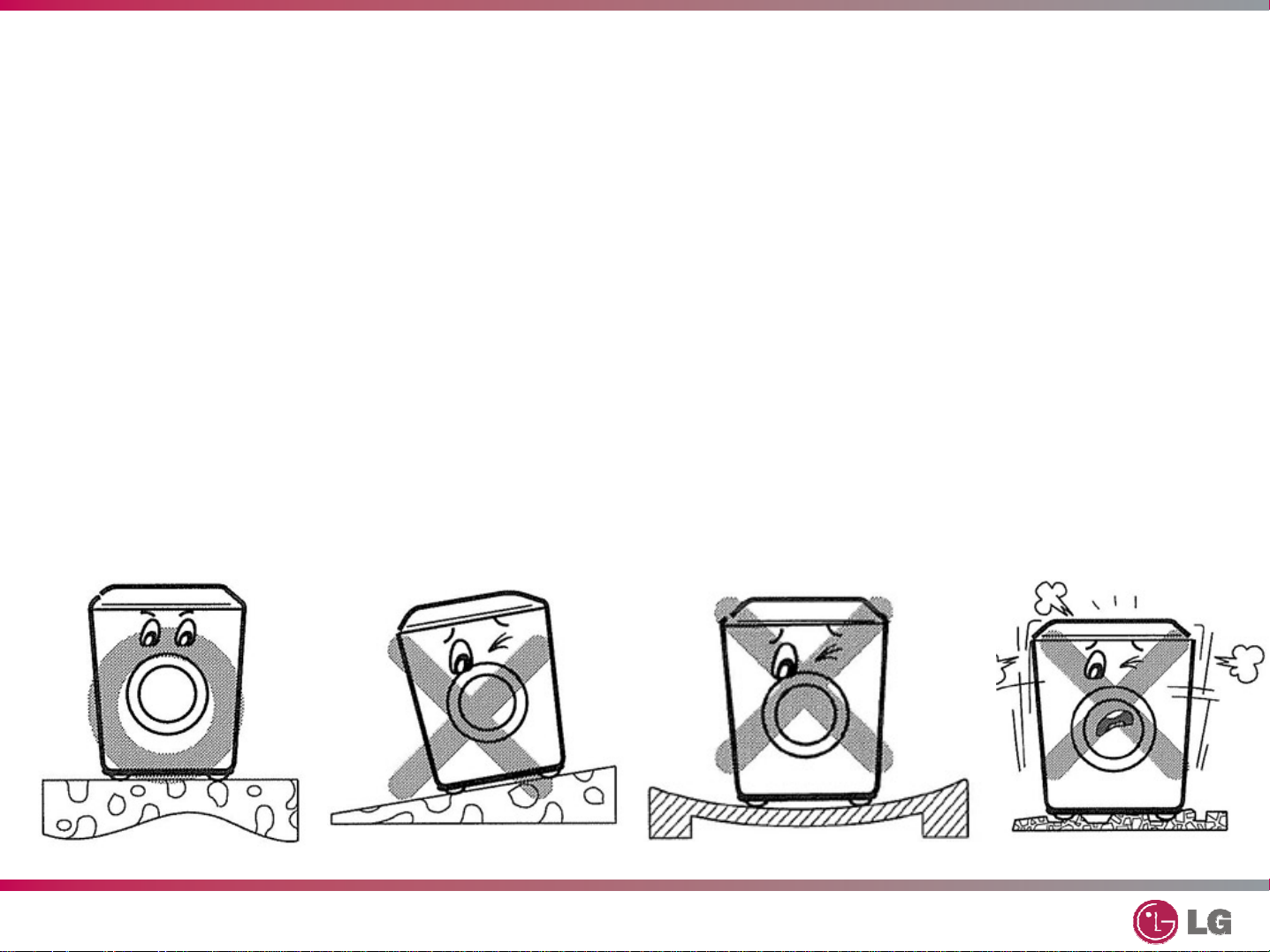

Install On A Firm, Flat Surface

WM2688H*M Steam Washer Training

28

T- 15

Page 29

Level The Washer

Rock the corners to determine which leg is off.

Adjust the front legs to get the washer level both front-to-back

and side-to-side. Push it into position and fine-tune the leveling.

Lock the adjusters when you are finished.

WM2688H*M Steam Washer Training

29

T- 15

Page 30

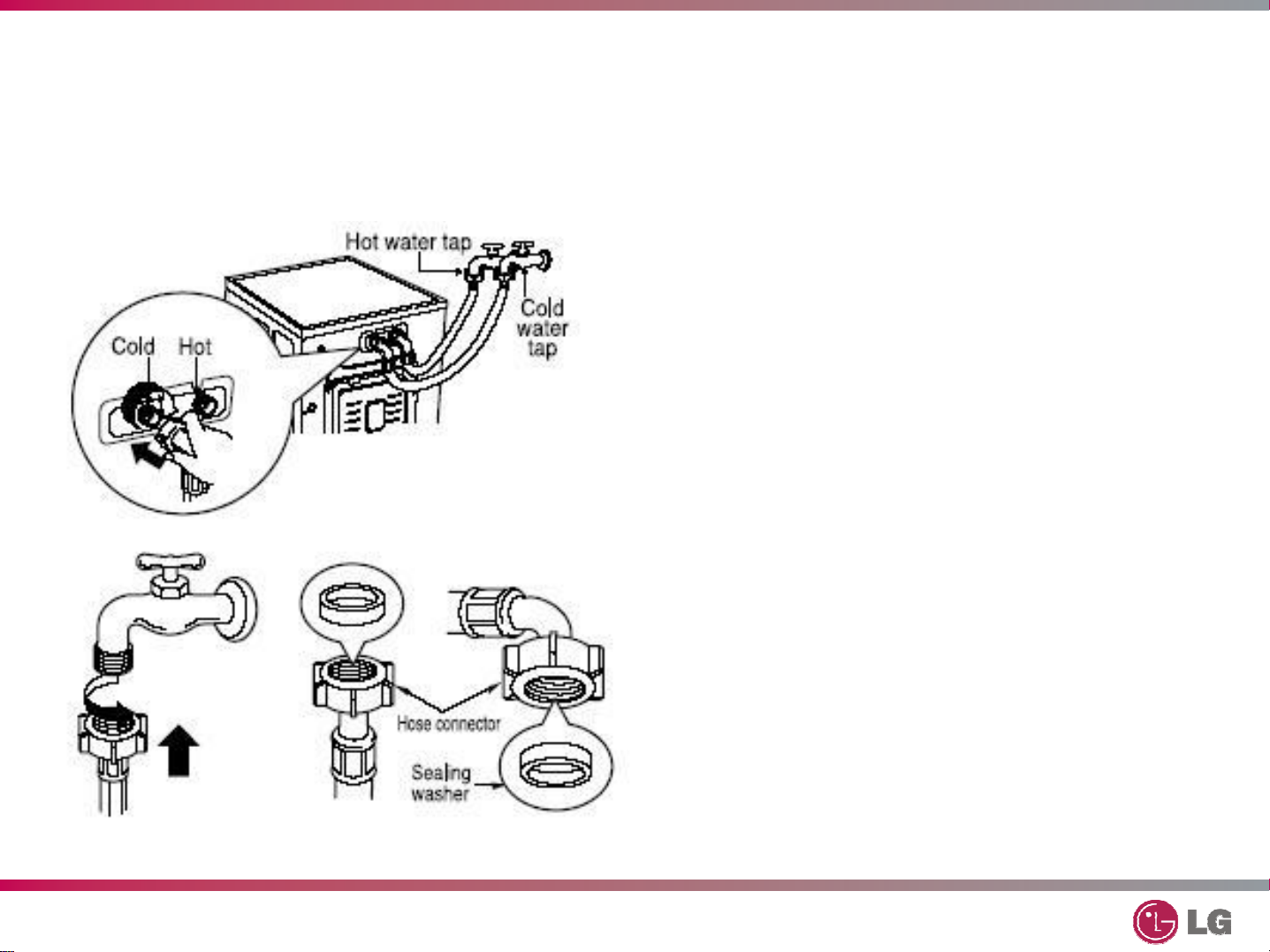

Water Connections

Be sure the rubber washer is inside

the hose end. Attach the hoses to the

washer (red is HOT, blue is COLD).

Tighten them firmly but don’t strip the

plastic threads on the washer

connections.

WM2688H*M Steam Washer Training

30

T- 16

Page 31

Drain Connections

The drain pipe should be firmly

attached to the standpipe or the

laundry tub or sink where it drains.

The pump has sufficient power to

cause the pipe to move around

when the water is expelled. The

pump can lift the drain water a

maximum of 96 inches (2.4 m),

but there is no minimum height

WM2688H*M Steam Washer Training

requirement. The vacuum breaker

in the drain line will prevent

drainage by gravity or siphoning.

The hose can lay flat into a floor

drain as long as the end of it is not

submerged.

31

T- 16

Page 32

Electrical Connections

The steam washer requires a 120 VAC, 60 Hz., dedicated, 20-amp circuit.

WM2688H*M Steam Washer Training

32

T- x

Page 33

Control Panel

WM2688H*M Steam Washer Training

33

T- 17

Page 34

Option Buttons

Press to add a pre-wash cycle. (Press and hold to select or

deselect the Child Lock function)

Press after power-up without selecting a cycle to rinse and

spin ONLY, without washing! (Press and hold to turn the

drum light on while the washer is operating.)

Press to add an extra rinse cycle.

(Press and hold to run a tub cleaning cycle. The washer

must be empty!)

Press to add additional washing time.

Press to add extra water to the wash and rinse cycles.

(Press and hold this button with the washer OFF and then

press POWER to access the language menu.)

To select the optional feature, follow the instructions in

parentheses.

WM2688H*M Steam Washer Training

34

T- 18

Page 35

Program Chart

WM2688H*M Steam Washer Training

35

T- 19

Page 36

Safety Revisited

BEFORE PERFORMING SERVICE

•Be careful to avoid electric shock when disconnecting parts

for troubleshooting.

•Most terminals in the steam washer have 120 VAC or DC on them,

sometimes even when the washer is off.

•The steam generator operates at a high temperature. Be careful when

servicing it. It can be drained in place by removing the drain cap,

but have a hose or a big towel ready to soak up the spillage.

WM2688H*M Steam Washer Training

36

T- 19

Page 37

Dispenser

Main Wash

(Siphon box for

liquids in place)

Liquid Bleach

The dispenser drawer is a multichambered reservoir that allows the

user to add all the appropriate laundry

additives before starting the cycle. It

has a place for pre-wash detergent,

main wash detergent, fabric softener,

and bleach. Powdered or liquid

detergents may be used, but softener

and bleach must be liquids.

Detergents should carry the HE

Liquid Softener

Pre Wash

(Liquid or Powder)

WM2688H*M Steam Washer Training

designation.

Do not use regular detergents in the

washer or oversudsing will occur.

37

T- 20~21

Page 38

Dispenser

The dispenser works by using

various solenoids to apply water

to different compartments. The

liquid products are dispensed

from a siphon box. As the

appropriate chamber is flooded,

WM2688H*M Steam Washer Training

38

the box fills and the water

flushes the laundry product into

the tub. It is mixed with water

before contacting the laundry to

prevent spotting or damaging

the fabric.

T- 20~21

Page 39

Dispenser

Notice that the pre-wash and

main wash fill tubes enter the

dispenser at an angle. If one

or the other fill valve is

opened, the water goes into

the appropriate detergent

compartment.

However, if they are opened

simultaneously, the streams

deflect and dispense the

WM2688H*M Steam Washer Training

39

softener. Some water may run

through the main and prewash compartments, but

since the detergent has

already been dispensed in an

earlier part of the cycle, this is

of no consequence.

T- 20~21

Page 40

Dispenser

If liquid detergent is added to the prewash box, it will run immediately into

the tub. This does not affect the

operation of the cycle.

To use liquid detergent in the main

wash, place the detergent siphon box

in the main wash compartment.

WM2688H*M Steam Washer Training

Otherwise, the main wash liquid

detergent will run into the tub along

with the pre-wash detergent, causing

oversudsing in the pre-wash and no

cleaning in the main wash.

40

T- 20~21

Page 41

Dispenser

The siphon boxes are designed to

hold a liquid laundry product until

the appropriate time for dispensing

into the load.

When the box fills with water, it

begins to discharge its contents

into the washer fill stream. Once

the siphon action has started, it will

continue until the siphon box has

WM2688H*M Steam Washer Training

emptied itself.

Use only regular viscosity bleaches

and softeners; the ultra versions

are usually much thicker and do not

dispense well, if at all.

41

T- 20~21

Page 42

Direct Drive Motor

The motor is a direct-drive,

brushless, DC motor. It is

attached to the drum via a splined

shaft, eliminating belts, pulleys,

transmissions, and the inherent

problems associated with them.

The rotor is attached to the shaft

by one large bolt.

WM2688H*M Steam Washer Training

42

T- 22

Page 43

Direct Drive Motor

The DC motor can be driven from

stopped to maximum speed in infinite

steps in either direction. There are 36

poles on the stator; 12 permanent

magnets spaced around the rotor.

There are no brushes to wear out.

Unlike a more traditional brushless

motor, the rotor surrounds the stator

WM2688H*M Steam Washer Training

rather than being attached to it.

A Hall Effect sensor determines the

speed and direction of the motor.

It also can read that the load is off

balance when the drum speed

fluctuates.

43

T- 22

Page 44

Motor

WM2688H*M Steam Washer Training

44

T- 23

Page 45

Motor/Hall Effect Sensor

The Hall Effect sensor is

easily removed and

replaced. You’ll have to

remove the rotor and stator

to access the sensor. When

replacing the rotor, you’ll

probably need a helper to

hold the drum in place when

you push the rotor onto the

shaft. Otherwise, the drum

WM2688H*M Steam Washer Training

45

may move forward enough

to make replacing the bolt

difficult. The helper can also

hold the drum from turning

while you tighten the bolt.

T- 23

Page 46

Motor/Hall Effect Sensor

Before going to this trouble,

check the connector on the

main board. It is the red

connector closest to the

WM2688H*M Steam Washer Training

46

heat sink.

Pull the connector off and

verify the board is receiving a

signal from the sensor.

T- 23

Page 47

Test Mode

The steam washer

must be empty and

off to enter the

test mode.

Press and hold

SPIN SPEED and

SOIL LEVEL.

Press POWER.

Press

START/PAUSE

to cycle through

the test modes.

WM2688H*M Steam Washer Training

47

T- 24

Page 48

Check Water Level Frequency

WM2688H*M Steam Washer Training

48

T- 24

Page 49

Error Display

WM2688H*M Steam Washer Training

49

T- 25

Page 50

Error Display

WM2688H*M Steam Washer Training

50

T- 25

Page 51

Error Display

WM2688H*M Steam Washer Training

51

T- 26

Page 52

Diagnosis

No Power

Water Inlet Issue

WM2688H*M Steam Washer Training

52

T- 27

Page 53

Diagnosis

Door Error

WM2688H*M Steam Washer Training

53

T- 28

Page 54

Diagnosis

Drain Issue

WM2688H*M Steam Washer Training

54

T- 28

Page 55

Diagnosis

Oversudsing

WM2688H*M Steam Washer Training

55

T- 29

Page 56

Diagnosis

Dispenser Issue

Error Code – Service

WM2688H*M Steam Washer Training

56

T- 29

Page 57

Troubleshooting

No Power

WM2688H*M Steam Washer Training

57

T- 30

Page 58

Troubleshooting

Vibration/Spin Noise

WM2688H*M Steam Washer Training

58

T- 31

Page 59

Troubleshooting

No Water Supply

WM2688H*M Steam Washer Training

59

T- 32

Page 60

Troubleshooting

Dispenser

WM2688H*M Steam Washer Training

60

T- 33

Page 61

Troubleshooting

Unusual Noise

WM2688H*M Steam Washer Training

61

T- 33

Page 62

Troubleshooting

Heater Error

WM2688H*M Steam Washer Training

62

T- 34

Page 63

Troubleshooting

Drain Issue

WM2688H*M Steam Washer Training

63

T- 34

Page 64

Troubleshooting

Wash Heater Issue

WM2688H*M Steam Washer Training

64

T- 35

Page 65

Troubleshooting

Over-Temp Issue

WM2688H*M Steam Washer Training

65

T- 35

Page 66

Troubleshooting

No Circulation

WM2688H*M Steam Washer Training

66

T- 36

Page 67

Troubleshooting

Spin Issue

WM2688H*M Steam Washer Training

67

T- 37

Page 68

Troubleshooting

dE Error

WM2688H*M Steam Washer Training

68

T- 37

Page 69

Disassembly and Repair

The following pages will show the instructions for disassembly, repair,

replacement of parts, and re-assembly. Many times, electrical components

may be tested by connecting the appropriate meter to the leads or

connectors on the main PC Board.

(Refer to the block wiring diagram, next slide.)

Proper diagnosis will eliminate unnecessary labor and expedite repairs.

WM2688H*M Steam Washer Training

69

T- 38

Page 70

Block Wiring Diagram

WM2688H*M Steam Washer Training

70

T- 38

Page 71

Disassembly and Repair

Control Panel

1. Remove two screws on the back

of the top plate.

2. Pull the top plate backward and

lift, as shown.

3. Remove the detergent drawer.

WM2688H*M Steam Washer Training

4. Remove two screws behind the

detergent drawer.

5. Disconnect the connector for

the Display PWB.

71

T- 39

Page 72

Disassembly and Repair

Control Panel, continued

6. Remove one screw from the

7. Lift the top away from the

corner of the control panel.

support rail and pull the control

panel up and away to remove.

WM2688H*M Steam Washer Training

8. Remove eight screws to

separate the control panel

and PWB.

9. Reassembly is the reverse of

these steps.

72

T- 39

Page 73

Disassembly and Repair

Main Board

Often, you can diagnose a failed part by removing its connector on the

main board and connecting the tester to the leads in the connector.

1. Disconnect the POWER

connector and the

Water Level Sensor Switch.

WM2688H*M Steam Washer Training

2. Remove the protective cover.

Press the plastic tabs out of the

way to remove the cover. The

main board is potted, so no

repairs to it are possible.

73

T- 40

Page 74

Disassembly and Repair

Main Board, continued

3. Disconnect the connectors on the

main board. They are all different,

keyed, and color-coded to prevent

incorrect connection.

4. Pull the wires out of the way.

5. Remove one screw on the back of

the washer to release the main

board housing.

WM2688H*M Steam Washer Training

6. Remove the main board by sliding

it to the right and lifting it up.

Replacement is accomplished by pressing

it toward the back of the washer and

sliding it toward the left.

74

T- 40

Page 75

Disassembly and Repair

Dispenser

1. Remove the top plate.

2. Remove the dispenser drawer.

3. Remove two screws to release

4. Loosen the clamp on the large

the dispenser.

hose that runs from the

WM2688H*M Steam Washer Training

dispenser to the drum.

Have an old towel handy to stuff under

the dispenser to soak up any spillage.

75

T- 41

Page 76

Disassembly and Repair

Dispenser, continued

5. Disconnect the connector from

#1 Blue; yellow and black wires

#2 Red; violet and black wires

the solenoid. Make a note of

the color codes and

connections.

WM2688H*M Steam Washer Training

#3 White; white and black wires

#4 Blue; gray and black wires

#5 Red; blue and black wires (hot)

6. Remove two screws from the

back of the cabinet

76

T- 41

Page 77

Disassembly and Repair

Noise Filter

WM2688H*M Steam Washer Training

77

1. Remove the connectors

from the noise filter.

2. Remove the screw from

the top bracket.

T- 41

Page 78

Disassembly and Repair

Front Cover

1. Remove the top plate.

2. Remove the control panel.

3. Remove four screws that

secure the front panel.

WM2688H*M Steam Washer Training

4. Remove the screw that

secures the filter cover.

78

T- 42

Page 79

Disassembly and Repair

Front Cover, continued

5. Use a flat screwdriver or a putty

knife to loosen the filter cover

and pull it out.

6. Stick the screwdriver into the

cover slot and pry it out

sideways to free it.

7. Drain the sump by pulling out

WM2688H*M Steam Washer Training

79

the little hose by the filter cover.

Let the water (maybe as much

as a quart) drain into a shallow

pan. Don’t pull the hose out so

far you kink it or the water will

not flow.

T- 42

Page 80

Disassembly and Repair

Front Cover, continued

8. Open the door.

9. Remove the clamp using

special tool 383EER4001A.

10. Lean the cabinet front forward, being

careful to avoid breaking the glass.

The door is HEAVY.

11. Disconnect the door switch connector.

WM2688H*M Steam Washer Training

(Remember to replace it upon

reassembly.)

12. Lift the door and front cover off the

cabinet base as an assembly. Lay it

face down on a blanket or some other

protective surface.

80

T- 43

Page 81

Disassembly and Repair

Door Remove the door with the front cover still

on the machine.

1. Open the door.

2. Remove seven screws from the

hinge cover.

3. Pry off the hinge cover with a

flat screwdriver.

WM2688H*M Steam Washer Training

4. Remove the screw at the bottom

of the hinge.

5. Lift the door off the hinge.

CAUTION! The door is HEAVY!

81

T- 44

Page 82

Disassembly and Repair

Door Switch Removal

1. Open the door.

2. Remove the gasket clamp

using special tool

383EER4001A.

3. Remove the two screws

holding the switch.

4. Push the gasket aside to

remove the switch.

5. Unplug the switch to

WM2688H*M Steam Washer Training

82

change it.

6. Make sure the wires don’t

fall back in before you can

replace the switch.

T- 44

Page 83

Disassembly and Repair

Pump

1. Remove the front cabinet.

2. Drain the water from the

3. Remove the clamps and

4. Remove two screws and push

sump.

hoses.

the pump backward and up.

WM2688H*M Steam Washer Training

5. Press down the plastic tab on

the base to slide the pump

assembly backward.

83

T- 45

Page 84

Disassembly and Repair

Pump

6. You can tilt the pump

in either direction to

remove/replace the

WM2688H*M Steam Washer Training

84

individual pumps

without having to

remove the tub.

Have a towel handy

to catch the spillage.

T- 44

Page 85

Disassembly and Repair

Heater

1. Remove the front cabinet.

2. Drain the water from the

3. Remove the push-on

4. Remove the nut that holds

sump.

connectors from the heater.

WM2688H*M Steam Washer Training

85

the ground wire. Then loosen

but do not remove the nut

that secures the heater

clamp and pull the heater

out. You may have to wiggle

it to release the gasket.

T- 46

Page 86

Disassembly and Repair

Thermistor

1. Remove the front cabinet.

WM2688H*M Steam Washer Training

2. Drain the water from the

sump.

3. Unplug the white connector.

4. Hold the bracket and pull

the thermistor out.

86

T- 46

Page 87

Disassembly and Repair

Removal of Foreign Objects

1. Remove the top cover.

WM2688H*M Steam Washer Training

2. Remove the front cabinet

cover.

3. Remove the heater.

4. Fish out the foreign object(s)

using a wire or bar.

87

T- 47

Page 88

Disassembly and Repair

Interior Light

1. Remove the top cover.

2. Separate the connector near

3. Remove the lamp assembly

4. Replacement is the reverse of

the lamp.

and lead wire from the gasket.

this procedure.

WM2688H*M Steam Washer Training

88

T- 47

Page 89

Disassembly and Repair

Motor

For technical information concerning the

direct drive DC motor, refer to page 22.)

1. Remove the back cover.

WM2688H*M Steam Washer Training

2. Remove the large bolt in the

center shaft. (Your helper can

hold the inside of the drum.)

3. Pull the rotor off the shaft.

89

T- 48

Page 90

Disassembly and Repair

Motor

1. Remove two screws from the

2. Remove six bolts on the stator.

tub bracket.

WM2688H*M Steam Washer Training

3. Unplug two connectors on the

stator.

4. Pull the stator off the shaft.

90

T- 48

Page 91

Disassembly and Repair

Motor

5. When re-installing, the

clamps and the ground screw

must be installed and the

connectors pressed into place

WM2688H*M Steam Washer Training

91

before the rotor is bolted onto

the shaft.

T- 48

Page 92

Disassembly and Repair

Tub and Drum

Removing the tub/drum assembly is

major surgery. It is much lighter if you

remove the weights and the motor.

Generally speaking, you’ll have to

remove all that anyway.

1. Remove the motor.

2. Drain the water from the sump.

3. Remove the control panel.

WM2688H*M Steam Washer Training

4. Remove the front cabinet.

5. Disconnect all hoses and

electrical connections.

92

T- 49

Page 93

Disassembly and Repair

6. Separate the three dampers.

Tub and Drum

You can remove just one end

now and the other one after

WM2688H*M Steam Washer Training

the drum is out.

7. Pry apart the retainer clip.

8. Carefully lift the tub up off the

springs and remove it from

the machine.

93

T- 49

Page 94

Disassembly and Repair

Tub and Drum

[photo goes here]

WM2688H*M Steam Washer Training

9. Unbolt the bolts around the

circumference of the seam.

Separate the halves. Be

careful to avoid damaging the

gasket. Do not pry on the

surfaces between the halves.

94

T- 49

Page 95

Disassembly and Repair

Dampers

1. Disconnect the dampers from

the tub and the base. (See

photos, left.)

WM2688H*M Steam Washer Training

95

Be sure to press in the safety

tab before pushing the pin out

of the damper. You can use a

socket to hold the tab in while

you squeeze the pin with the

special tool 383EER4003A.

T- 50

Page 96

Disassembly and Repair

Dampers

2. The flat end goes on the

pointed end and the split

WM2688H*M Steam Washer Training

96

end allows the head end to

pass through while the pin

is pushed out.

The color and/or

appearance of the damper

may vary by model.

T- 50

Page 97

Disassembly and Repair

3. Use special tool 383EER4003A

Dampers

to remove the damper pins. If

you are replacing the dampers,

you’ll have to remove both

ends. If you are removing the

tub for major repair work,

disconnect the damper ends at

the base and leave the other

ends connected until you

remove the tub. When putting

WM2688H*M Steam Washer Training

the tub back into the machine,

connect the dampers to the tub

first. It is much easier that way.

4. Be careful not to pull the

dampers apart while they are

disconnected.

97

T- 50

Page 98

Disassembly and Repair

Turbo Steam Generator (TSG)

The TSG (Turbo Steam

Generator) is supplied as an

assembly only; parts like the

sensor, thermistor, or heater

cannot be replaced individually.

Diagnosis is limited to determining

malfunction and replacing as an

assembly.

WM2688H*M Steam Washer Training

98

Have a hose available to slip onto

the connector or a large towel to

catch the water so it doesn’t run

down into the machine cabinet. If

you remove the steam generator

before draining it, be sure to avoid

tipping it and spilling the water.

T- 51

Page 99

Disassembly and Repair

Turbo Steam Generator (TSG)

1. The steam generator can be

2. Unplug the washer.

removed as an assembly for

diagnosis and replacement.

WM2688H*M Steam Washer Training

3. Disconnect all electrical

connections, including

ground.

4. Drain the water. (You can

drain the water later and it

is easier.)

99

T- 51

Page 100

Disassembly and Repair

Turbo Steam Generator (TSG)

5. Remove all the cable straps by

squeezing the tabs and pulling

them out. They can be reused.

WM2688H*M Steam Washer Training

6. Remove the four screws

holding the support rail in place

and two screws attaching

the steam generator.

7. Disconnect the hoses (water

input and steam output.)

100

T- 51

Loading...

Loading...