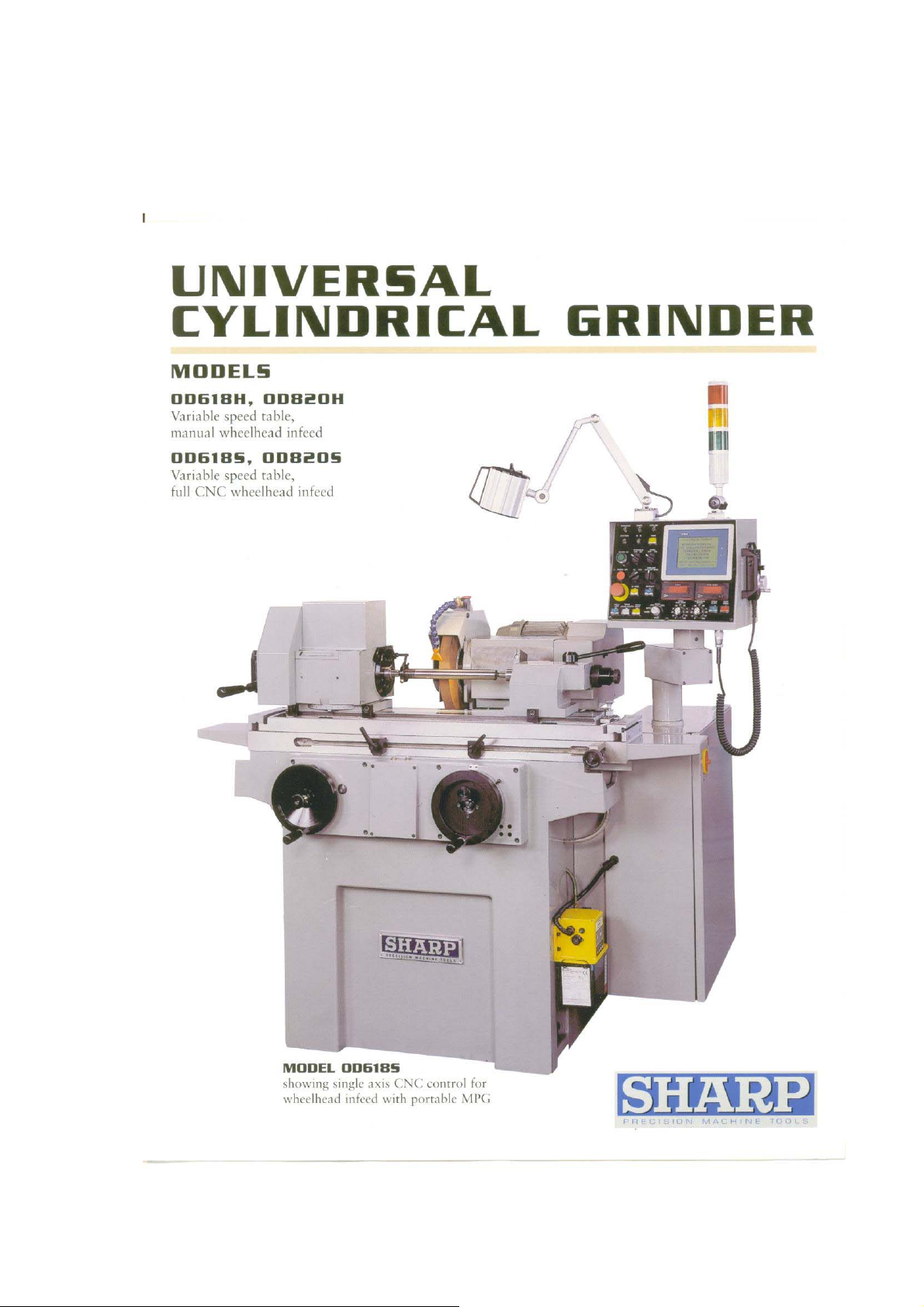

Page 1

Operation Manual

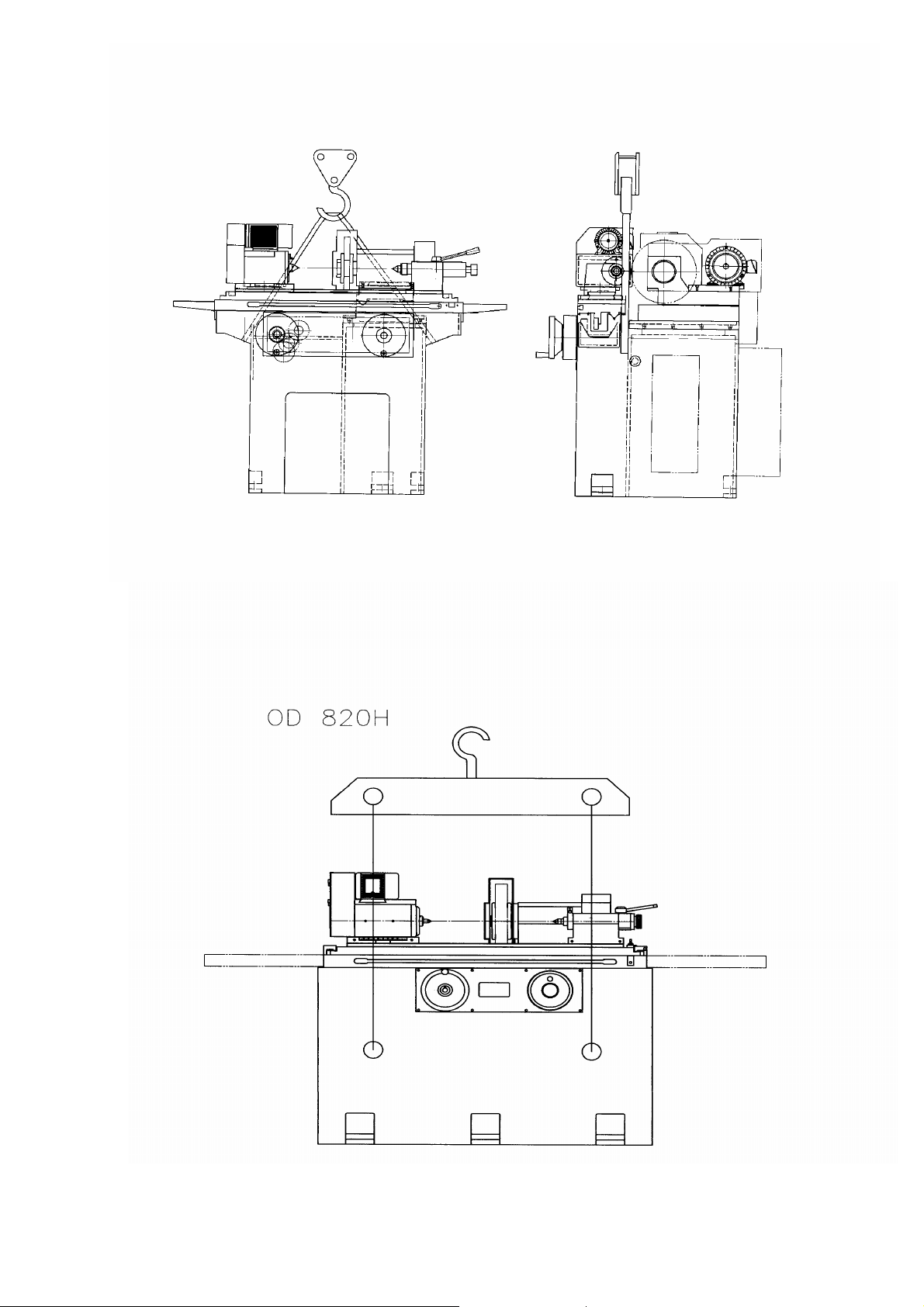

OD-618 S\H

OD-820 S\H

2

Page 2

Contents

z Operation Manual

z Electric Diagram

z Parts List

3

Page 3

Operation Manual

4

Page 4

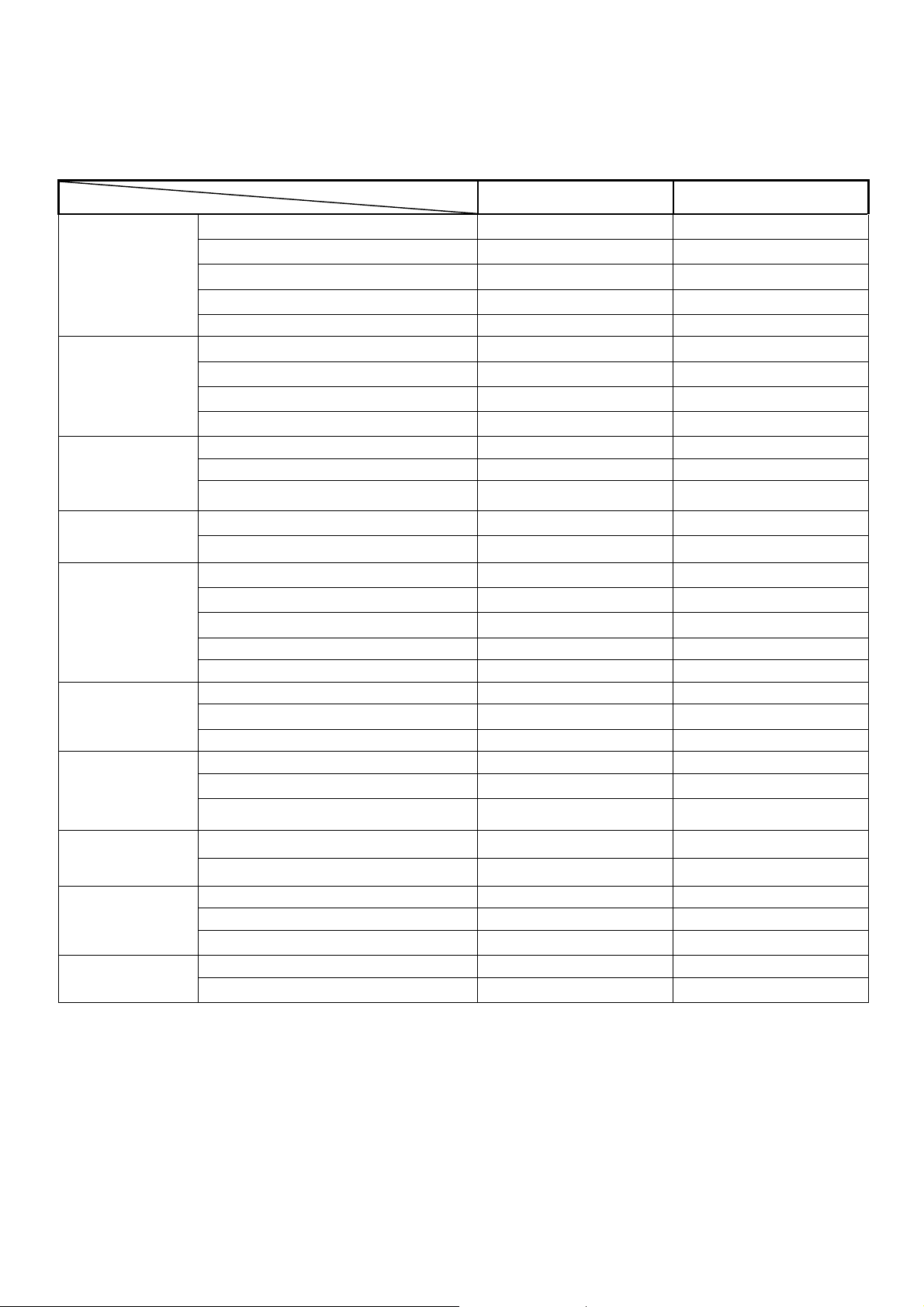

Specification & Floor Space

Descrption Model

Swing over table

Distance between centers

Capacity

Wheelhead

Automatic

modles only

Grinding wheel

Internal

grinding

[Optional]

Workhead

Table

Maximum grinding diameter

Effective grinding diameter

Maximum load between centers 130 lbs 176 lbs

Hand feed travel

Feed of handwheel per division

Feed of handwheel per revolution

Swivel angle

Auto infeed range(by diameter)

Auto infeed passes ; control input

Auto infeed spark out

Diameter x Width x Bore

Wheel speed

Grinding bore range

Max. grinding length

Max. chucking length x diameter

Spindle speed 14000rpm 14000rpm

Internal grinding wheel motor 1/2 HP 1/2 HP

Spindle speed( Variable ) 0 ~ 500 rpm 0 ~ 500 rpm

Swivel angle

Taper of center 5C 5C

Travel speed( Variable ) 0 ~ 20 ipm 0 ~ 20 ipm

Feed of handwheel per revolution

Swivel angle

OD-618 H\S

8〞 8〞

18〞 20〞

6〞 8〞

5.25〞 / >6〞

4.2〞 6.3〞

0.0002〞 0.0002〞

0.1〞 0.1〞

+7° ; -13° +7° ; -13°

12〞 x 1〞 x 3〞 14〞 x 2〞 x 5〞

1960 rpm 1960 rpm

0.6〞 ~ 2.75〞 0.6〞 ~ 2.75〞

2.75〞 2.75〞

10.75〞 x 4.3〞 10.75〞 x 4.3〞

±45° ±45°

3/8〞 3/8〞

±8°

OD-820 H\S

±7°

Quill travel

Tailstock

Motors

General

*S Models controller: A-TECH AT-200A

Taper of center

Wheel spindle motor 2 HP 3 HP

Wo rkhead motor 1/4 HP 1/4 HP

Table travel motor

Floor space(L x D x H)

Net weight(approximately)

Servo Driver: Mitsubishi J2S

Servo Motor: Mitsubishi

Display : Hi_Tech LCD Human machine

Note :

change without notice

The contents of this brochure are reference only and are subject to

1〞 1〞

MT #2 MT #3

1/4 HP 1/4 HP

2300 lbs 3500 lbs

5

Page 5

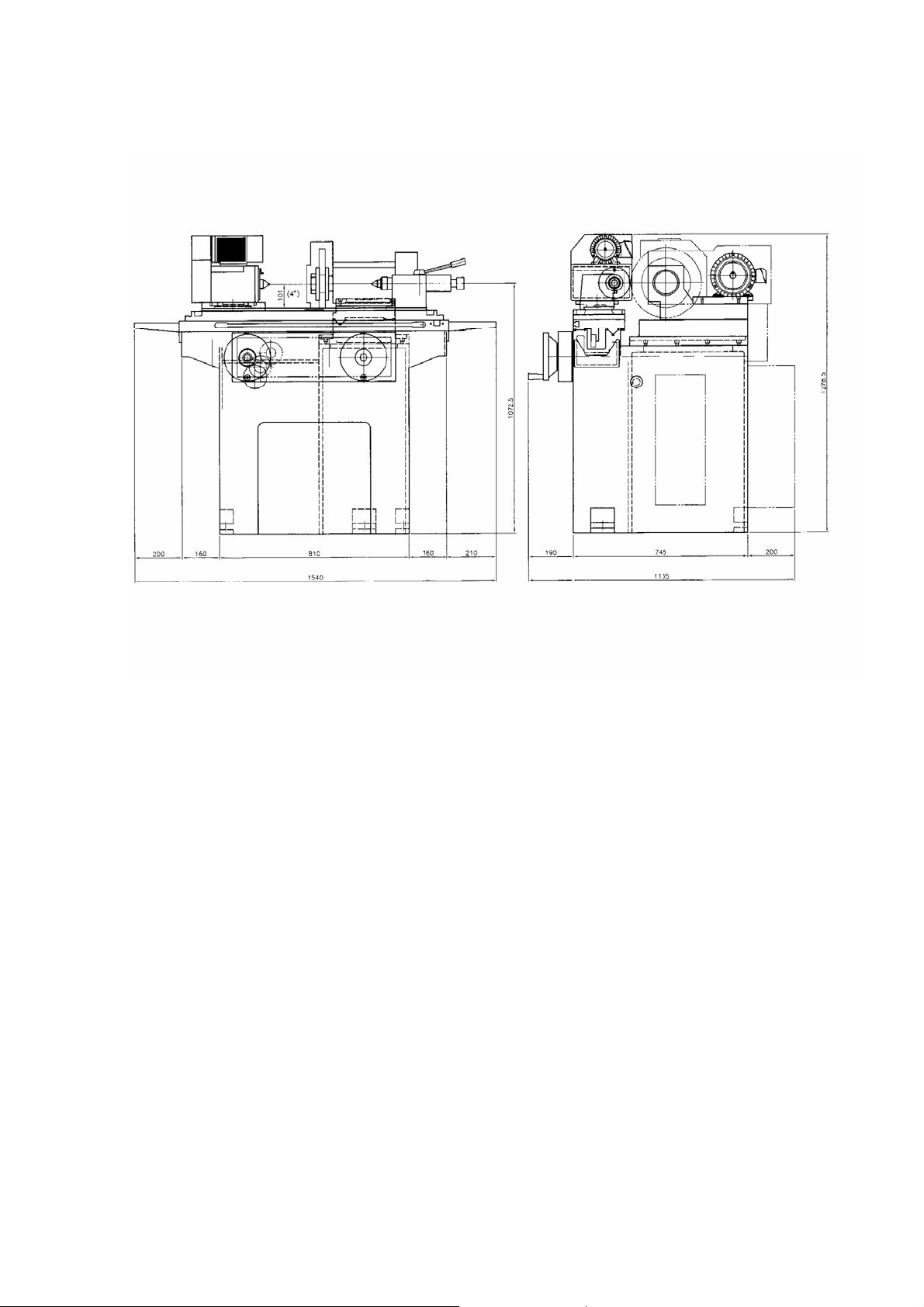

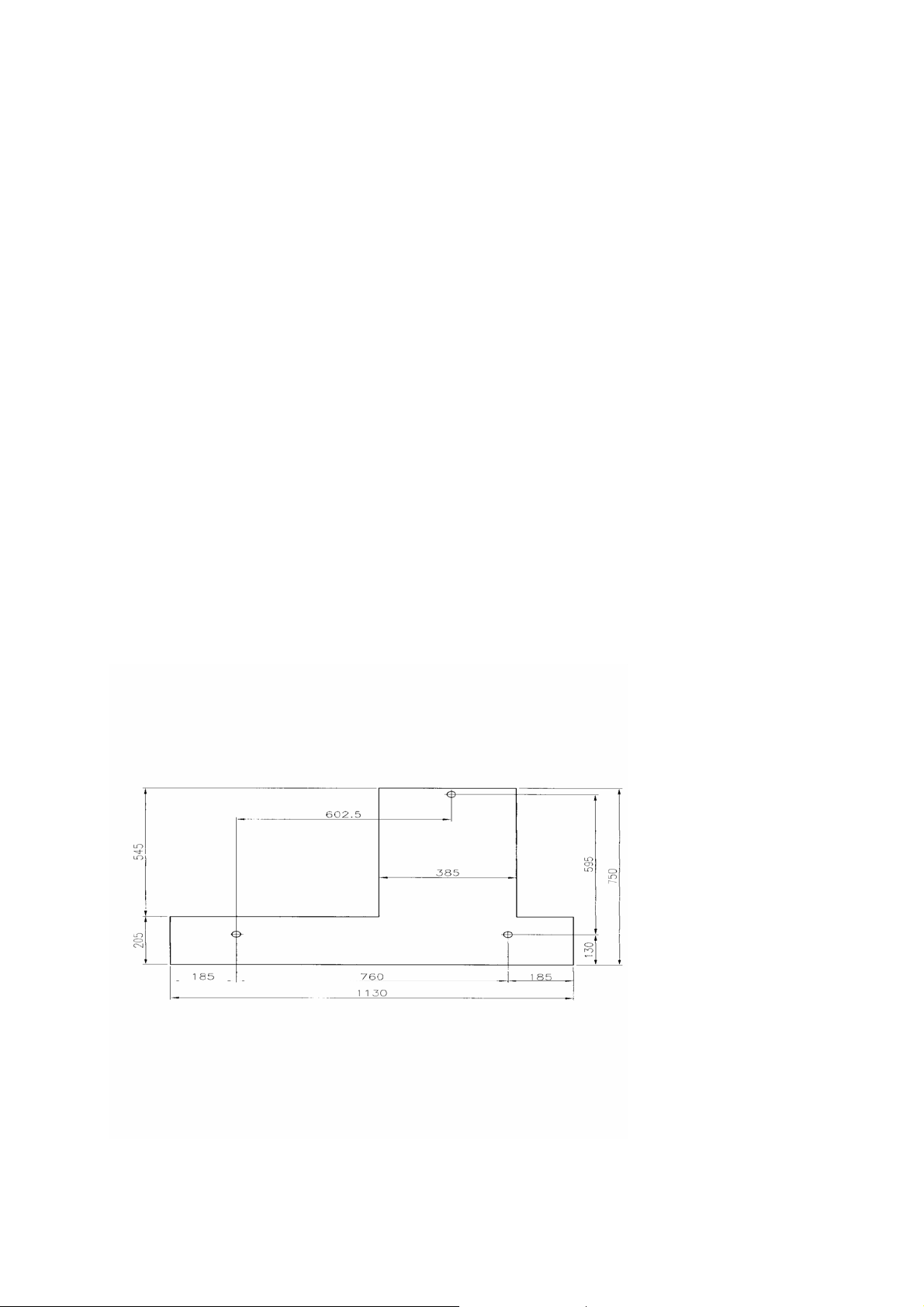

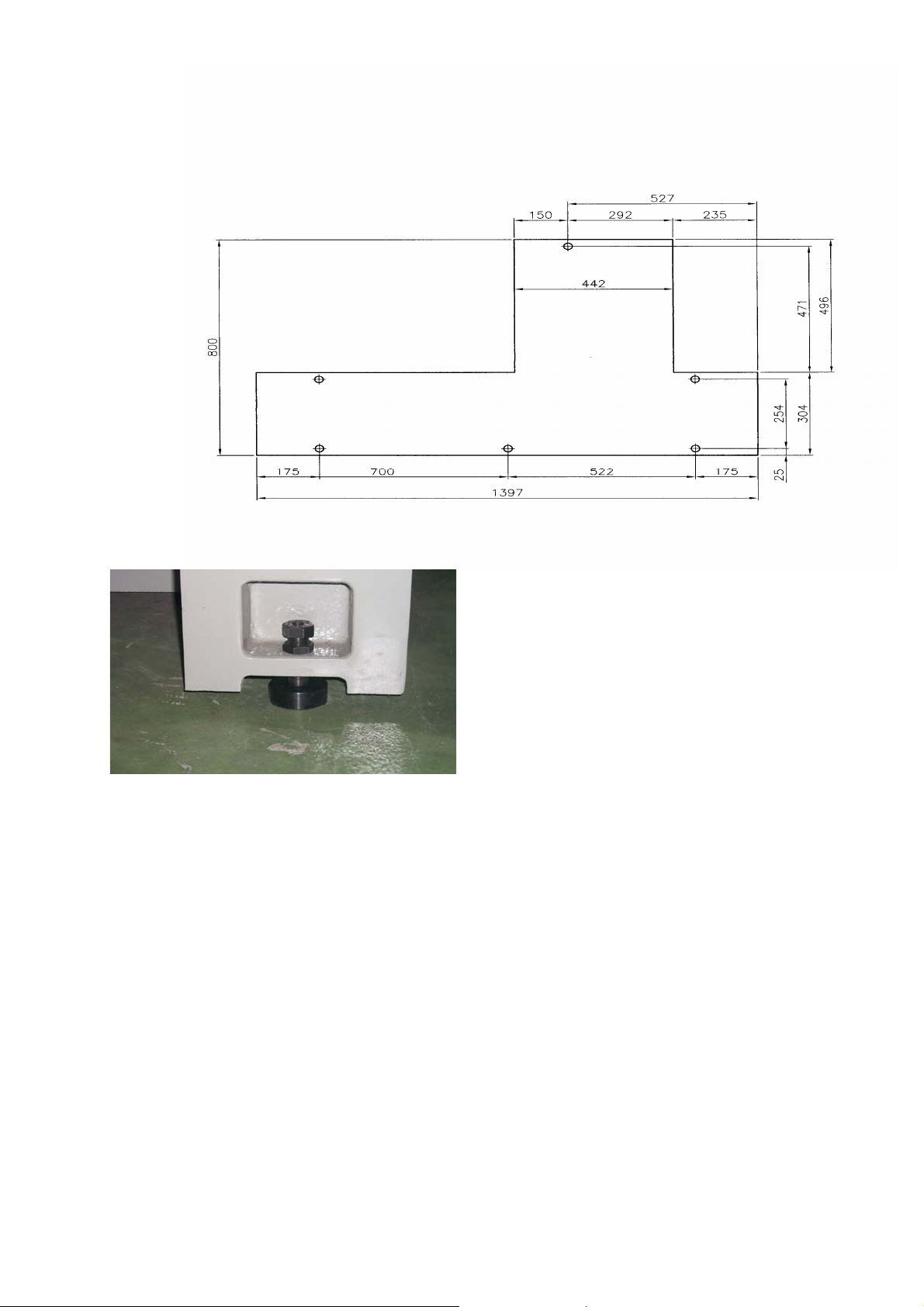

FLOOR SPACER OD-618H/S

6

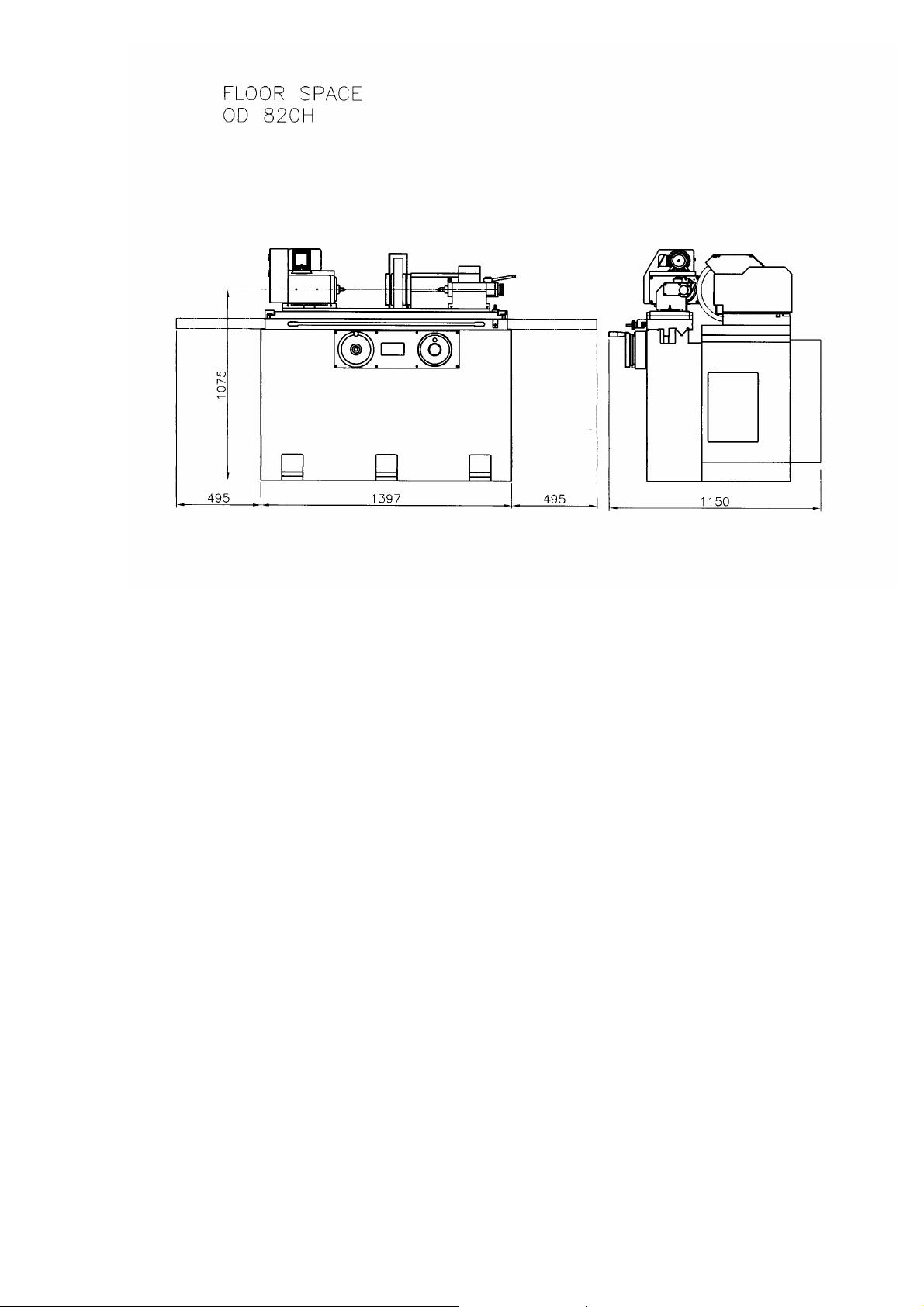

Page 6

Transportation:

The table and wheelhead are fixed with red pressed plate before transportation to avoid

any damage .It must to remove all these red plates before operate machine

The wires outside the electrical cabinet and control are covered in flexible conduit for

protect from any damage ,and there is oil in auto-lubrication system

Before lifting the machine ,prepare an adequate cable .Hook the cable unto the eye-bolts

fixed at base .Please take a note of the following items while lift machine.

1. The cable must be capable of lifting weight more than 2 tons.

2. Place wooden wedge or rags between cable & machine to prevent the machine from

damage.

3. Lifting cable must be strong enough with diameter over 10mm.

4. Table must be truly fastened to avoid any slip during movement

Machine Transportation & Installation

7

Page 7

8

Page 8

Cleaning:

All sideways and ground surface are coated with anti-rust preventive before

delivery .Remove the coating with solvent agent prior to operation.

Installations:

While doing the installation ,special cares must be paid to the followings:

1. Never install the machine at an area where has direct sun light to maintain a

longer life ,preferable at an area has constant temperature.

2. Never install the machine at an area where is dusty ,not at an area next to

high-shocking machines ,such as ,air compressor ,press machine ,etc.

3. Machine is supplied with leveling and blocks as standard to facilitate and to avoid

any vibration.

Leveling:

It is essential to level the machine before operation . Please take a note of the following

items while leveling.

1. Prepare a level having the sensitivity of 0.02 mm/M( or 0.0002〞/ 10〞).

2. Clean the table surface before leveling .

3. Adjust the level as Figure indicates to place level.

4. After checking the table ,check torsion by traversing the table to left and right to

check if the table is distorted.

5. Check leveling which may be varied due to work load and others in 30 days after

installation .And check semiannually afterwards to retain grinding accuracy.

圖表 1

9

Page 9

10

Page 10

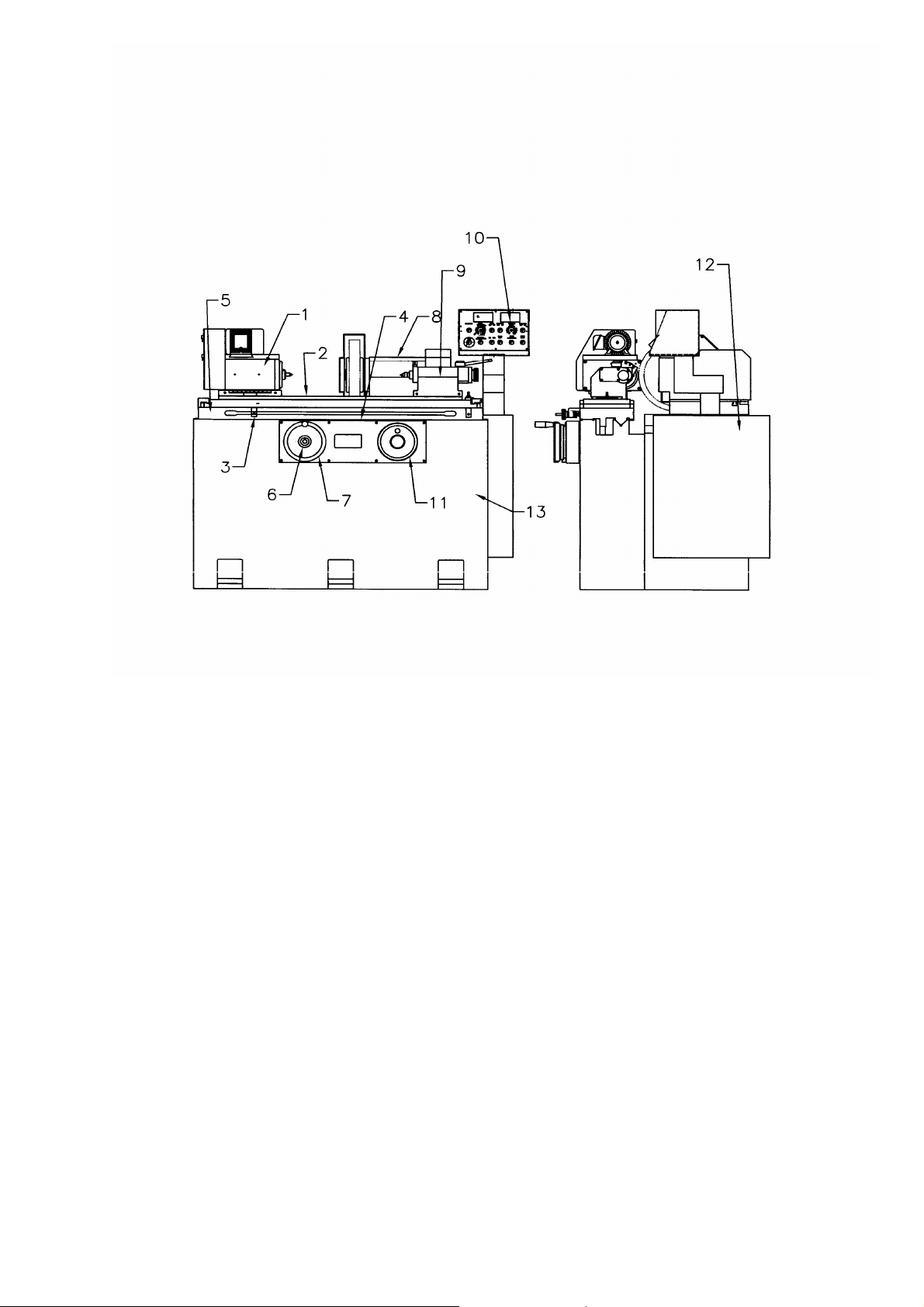

Description of Machine

ILLUSTRATIONS OF MACHINE

1. WORKHEAD

2. TOP TABLE SLIDE

3. TABLE TRAVEL LIMIT DOG

4. REVERSE LIMIT SWITCH

5. BOTTOM TABLE SLIDE

6. AUTO/MANUAL OPERATING KNOB

7. TABLE HANDWHEEL

8. WHEELHEAD

9. TAILSTOCK

10. CONTROL PANEL

11. WHEELHEAD HANDWHEEL

12. ELECTRICAL CABINET

13. BASE

11

Page 11

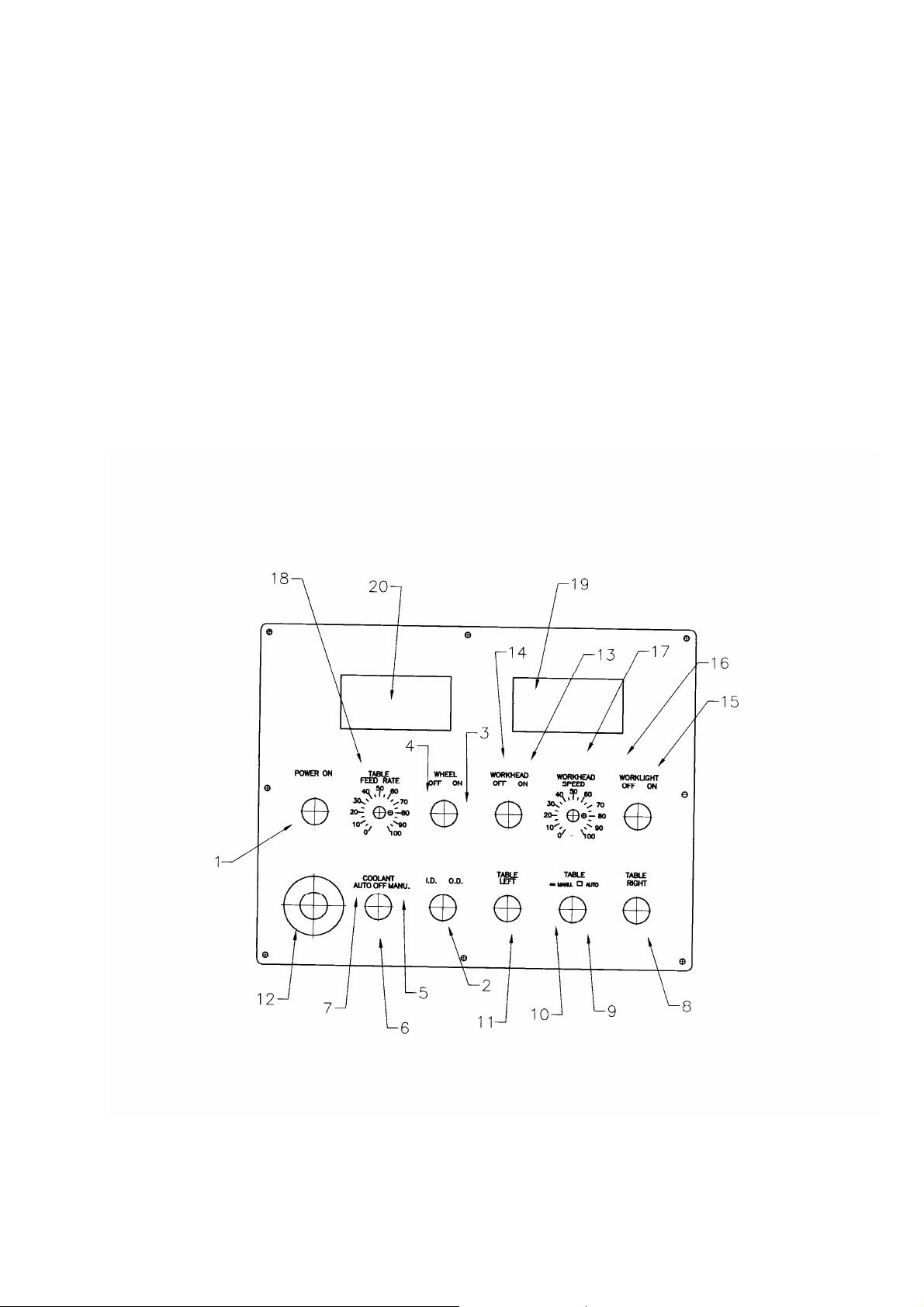

ILLUSTRATIONS OF CONTROL PANEL FOR OD 618H/820H

1. POWER “ON” BUTTON

2. I.D./O.D. SELECTION SWITCH

3. WHEEL “ON” SWITCH.

4. WHEEL”OFF” SWITCH

5. COOLANT ON “MANU.” POSITION

6. COOLANT OFF

7. COOLANT ON “AUTO” POSITION

8. TABLE RIGHT SIDE MOVEMENT BUTTON

9. T ABLE AUTO MOVEMENT BUTTON

10. TABLE MANU. MOVEMENT BUTTON

12

Page 12

11. TABLE LEFT SIDE MOVEMENT BUTTON

12. EMERGENCY STOP SWITCH

13. WORKHEAD SWITCH “ON” POSITION

14. WORKHEAD SWITCH “OFF” POSITION

15. WORKLIGHT ON

16. WORKLIGHT OFF

17. WORKHEAD SPEED ADJUSTING KNOB

18. TABLE FEED RATE ADJUSTING KNOB

19. LED DISPLAY FOR WORKHEAD SPEED

20. LED DISPLAY FOR TABLE FEED RATE

13

Page 13

Electrical Power & Motors

Electrical equipment:

Rotation of motors:

Check the rotation of motors in details before operating the machine .

Wheelhead motor: The grinding wheel should rotate inward in the operator’s

Workhead motor: The tipped center should rotate inward in the operator’s

Coolant pump : Clockwise ( CW )

Table travel motor : Push up the button “TABLE AUTO MANUAL”,

then push the button “TABLE LEFT” or “TABLE

Note:

The rotation of motors are checked in the plant before delivery. In case any of the motors

run in opposite direction ,just switch any of the “R/S/T” cables in the electrical cabinet .

In case there are more than 2 motors run in opposite direction, a cable change from the

Individual motor connection is required.

Check the machine voltage with power source before connection. And check the

rotation of motors before operation.

direction.(Clockwise CW)

direction.(Clockwise CW)

RIGHT” .Check the table if move on the correct

direction.

14

Page 14

Lubrications System & Coolant System

Lubrication system :

Coolant system :

Recommended coolants :

material finish and wheel’s life .

There is an automatic lubrication supplied as standard for lubrication on all

slideways .The volume of the unit of 1 liter ( 2 liters for OD-820 Models)

The volume of coolant tank is of 72 liters . Just hook up the pipe to the coolant

nozzle before connecting power .

An appropriate coolant is essential for precision grinding ,and is resulted in the

A. Purpose of using coolant system.

a. Refrain material from temperature rise.

b. Flush off the grinding dust & peel-off grains.

c. Lubrication the material.

B. Category of coolant system.

a. Soluble coolant : Mainly with non-organic solution ,mostly suitable for

cast iron ,cast steel grindings .

1. Emulsion type

2. Soluble solution type

3. Solution type

b. Non-soluble coolant: A coolant with mineral oil in sulfuric

objects, suitable for lubrication.

15

Page 15

Table traverse and adjustment

The table can be driven both by manual and mechanical :

1. Manual traverse : Release the AUTO/MANUAL operating knob at the clutch

gear from the clutch unit. Swivel the handwheel to drive table manually.

2. Motorized auto drive : Adjust the table travel limit dogs to a desired

position. Tighten the AUTO/MANUAL operation knob at the table handwheel

to engage the clutch gear with the clutch unit .Push the “TABLE RIGHT” or

“TABLE LEFT” movement buttons to drive table automatically .The table’s

speed is variable that can be altered by Digital Variable Speed (DVS)System .

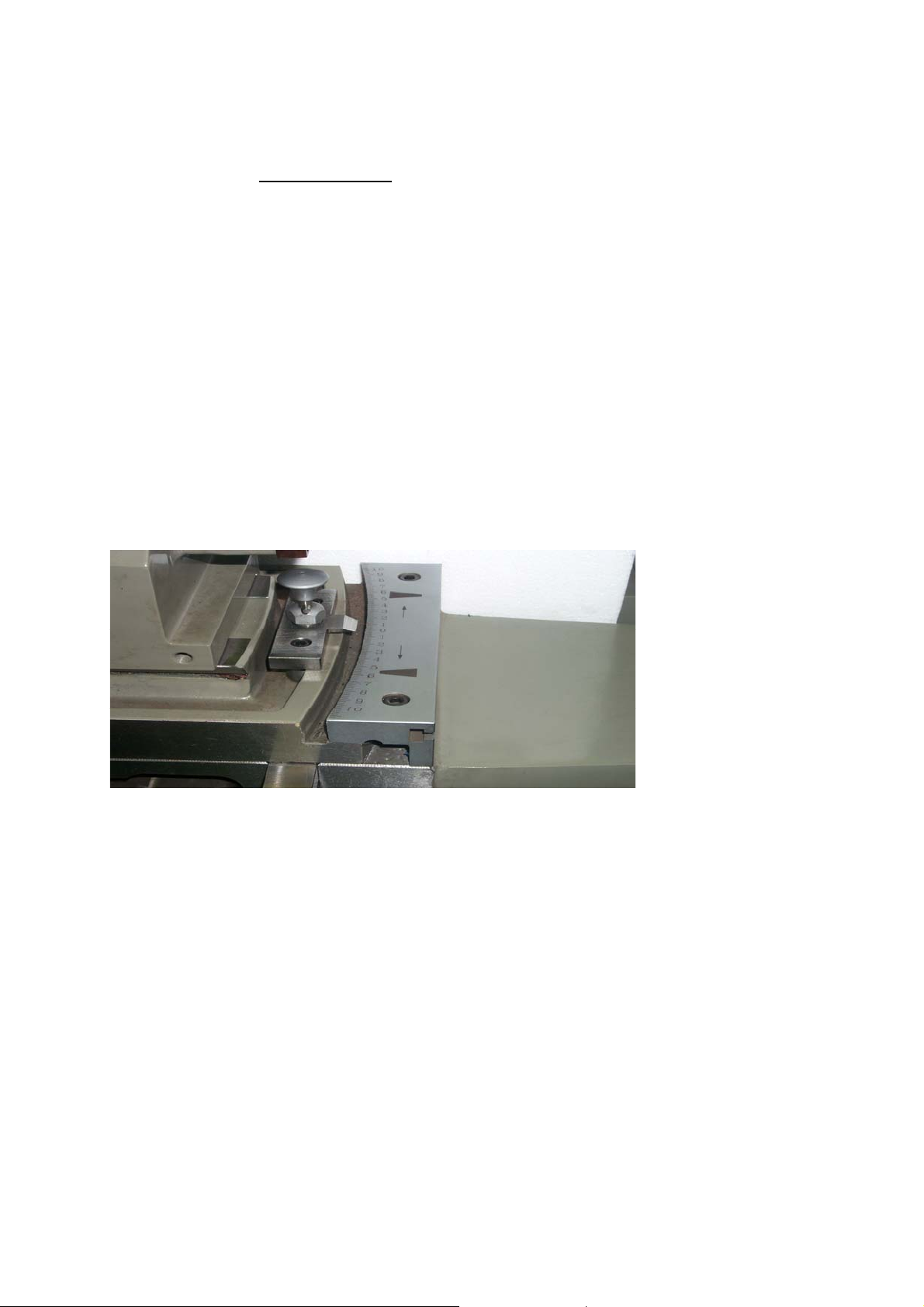

Adjustment of table inclination

The table consists of top & bottom slides in which the top slid is adjustable as foloows:

1. Release the two hex bolts at both table ends .

2. Pull up the knob .

3. Turn the adjusting knob in conjunction of the indicator to desired angle .

4. Tighten the two hex bolts at both table ends then begin grinding .

Table

16

Page 16

17

Page 17

Workhead

Structure of workhead :

1. The workhead is furnished with 1/4 HP motor and is capable of variable speed that can be

altered by Digital Variable Speed ( DVS ) System.

2. Dead center and live center are available for supporting workpiece. Use a dead center for

external grinding. When using a 3-jaw chuck ,the spindle can be shift for a free rotation.

Adjustment of workhead :

1. Movement of workhead : Release the two fixed bolts at front of the unit to move the

workhead to desire position .Then clamp the two bolts .Clean the table surface before

moving is to be made .

2. Inclination of workhead: Release the two setting nuts at bottom of the unit to swivel the

workhead ±45° to an desire angle. Then clamp the nuts .

3. Alternation of dead center & live center: The spindle rotates when a chuck is used .Pull out

the plunger unit at back of the unit & press the clutch of driving plate into the groove of

spindle nose for free rotation. Star the procedures reversely while changing the live center to

dead center.

18

Page 18

5Ctype of workhead:

1. Clean inside of spindle nose and the collet .

2. Push in lock pin ( To engage lock pin ,turn spindle until pin lines up with the notch ) .

3. Disengage adjusting finger.

4. Place collet in the tube making sure the slot in the colet lines up with the pin in the spindle.

5. Apply light pressure to collet while turning “Shell Guard” making sure the threads

engage. Do not use force. If the collet does not go in smoothly, check for burs or damaged

threads.

6. Insert workpiece in the collet, move lever to the left or closed position and turn shell guard

toward the oprator until the collet seats.

7. Move lever to the right or released position and turn shell guard two notches toward the

oprator on the adjusting finger.

8. Move lever to the left or closed position and test the workpiece for correct tightness, if not

correct, make any adjustments needed and lock the adjusting finger .

19

Page 19

Tailstock

1. Move the tailstock in position according to workpiece length. Clean the table surface before

moving the tailstock to maintain accuracy.

2. Adjusting the tension of carbide tip center from the knob at rear of tailstock according to

workpiece length and forms. Turn the knob clockwise to increase tension whilst turn

counterclockwise to release. The workpiece may possibly be deflected or its center bore

expended in case the center tension is too great. To the contrary, workpiece would vibrate if

it is small.

3. Clean the center bore of workpiece and tailstock before clamping to ensure grinding

accuracy.

20

Page 20

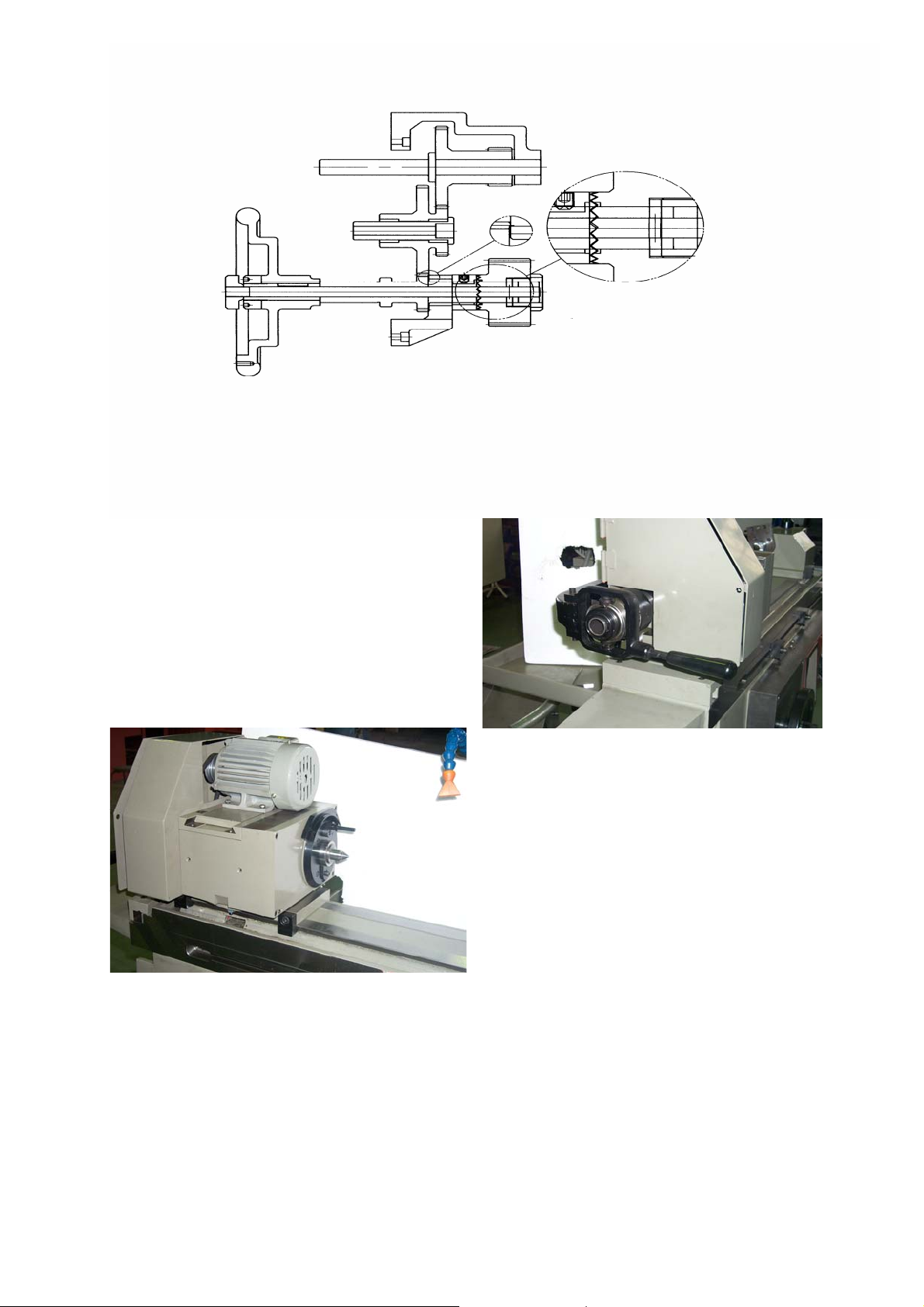

Wheelhead

The wheelhead comprises of whellhead base ,rotary base ,saddle and saddle side, etc.That can

be driven both by manual and automatically and is inclinable for taper grinding.

Wheel spindle and bearings:

The wheelhead is the key part of the machine that adopts 4 pieces of precision angular contact

ball bearing providing a higher rigidity so as obtain a finer straightness and roundness.

Wheel spindle drive mechanism & adjustment

The wheel spindle is driven by a multiple V belt. A big tension may cause a poor surface finish

while a small tension cause vibration .Therefore it is imperative to keep an adequate belt tension

that can be adjusted through the bolts at back of motor.

Grinding Wheels

Selection of grinding wheels

A successful grinding is based on a qualified operator who knows well about the forms ,types and

property of grinding wheels and knows how to use them in different conditions .

Standard Marking System Chart

455x205x305 – WA – 80 – L - 5 - V – 2100

1. D x T

2. Abrasive symbol.

3. Grit size.

4. Grade.

5. S

6. Bond type.

7. Max. M/min (or M.P.M.)

1. 2. 3. 4. 5. 6. 7.

x H( mm ).

tructur

z D x T x H(mm)

The size of the grinding wheels .

z Abrasive:

Chemical composition of wheel grains used.

e.

:

21

Page 21

z Grit size:

Size of grain which will pass through a silk screen having that number of meshes to the

linear inch ( not square inch ) ,but will not pass through next smallest screen .Sizes smaller

than 220 are separated by hydraulic flotation and sedimentation or air classification .

z Grade:

Strength with which bond holds grains together ,or a measure of resistance which bond

exerts against a force tending to tear abrasive from wheel .It has nothing to do with abrasive

hardness as compared to a diamond .However ,a given wheel can be made to act relatively

harder or softer by varying work speed ,wheel speed ,depth of cut ,area of contact ,rate of

relative longitudinal movement of wheel and work .A given wheel and work .A given wheel

will act softer ( loses its grain readily ) if work speed (peripheral ) is increased or wheel

speed decreased .Decreasing area of contact makes a wheel act softer .Increasing infeed

( depth of cut ) or traverse rate will make a wheel act softer .The reverse of any of above will

make a given wheel act harder .

z Structure:

Is determined by porosity of wheel amount and size of air spaces between grains .( What

might be called swiss cheese effect where holes or pores are scientifically determined .) It is a

measure of closeness of adjacent grains ,or density .

z Bond type:

Material used for holding abrasive grains in wheel shape .Each grain is held in wheel by

coating of bond and joined to others by a network of bonding material .

z Max. M/min. ( or M.P.M. )

Max allowable M.P.M ( M/min ) .Keep the M.P.M. under the max M.P.M. can protect the

wheel from broken . ( R.P.M. = M.P.M. / πD )

Recommeneded Wheels for External Grindings

Parts Material

Wheel Specs

Wheel Outside Dia. ( ~ 355 mm )

Carbon Steel

Alloy Steel

Tool Steel

≦ HRC 25

> HRC 25

≦ HRC 55

> HRC 55

≦ HRC 60

> HRC 60

FA60MV

WA60MV

WA60LV

WA60KV

WA60KV

WA60JV

Stainless Steel WA60KV

Cast Iron C60JV

Special Cast Iron GC60IV

Chilled Cast Iron GC60IV

Malleable Cast Iron FA60MV

Brass C46JV ~ C36JV

Bronze 10A54LV ~ 10A36LV

22

Page 22

Aluminum Alloy C46JV ~ C36JV

Sintered Carbide GC80IV ~ GC60IV

Alnico WA46KV

Rubber C/GC 36 ~ 60 H ~ LV

Grinding Wheel :

1. Dimension of grinding wheel :

OD-618 S\H D x T x H = ∮12〞 x 1〞 x 3〞

OD-820 S\H D x T x H = ∮14〞 x 2〞 x 5〞

23

Page 23

圖表 2

24

Page 24

2. Assembly of grinding wheel:

a. Check the support surface, groove of wheel flange ,nut ,and screw holes for ant defects.

b. Put the flange into wheel bore slightly. The clearance between the wheel bore and flange

must be equal, namely, the wheel flange can not stay at one side

c. Screw up the flange cover with spanner.

d. After eight hours grinding service, screws should be checked for any looseness cause by

necessary to restore the original tension.

3. Installation of wheel:

25

Page 25

a. Clean the wheel bore and flange surface before mounting.

b. Put the assembled wheel onto spindle slightly .

c. Turn the nut C.C.W. to clamp the flange .

4. Extract of grinding wheel :

a. Remove the splash guard and open the wheel door .

b. Insert and turn wheel extractor C.W. to remove the wheel clamping nut .

c. Insert the wheel extractor into the wheel slightly .In no any condition ,it is strictly

prohibited to use a hammer or punch to take off the wheel forcibly .

Balance of Grinding Wheel :

1. Insert the flange into wheel tighten it .

2. Mount the wheel onto spindle switch on the spindle and dressing the wheel with

coolant .stop the coolant after dressing and let the wheel rotate for 10 minute or so to drop

the water off the wheel .

3. Dismantle the wheel set from spindle and put the balancing arbor thru flange bore ,and put

the wheel set on balance stand .Clean the flange bore and balance arbor tapered surface

before mounting .

4. Set the wheel for free rotation to locate its gravity center “S” and mark it with a chalk .

5. Put a balance weight at “S” position .Turn the wheel for 90 degree see in which side (S&G)

weight more .

6. Place 2 balance weight “K” at weightier side with same distance from “G” .

7. Turn the wheel for 90 degree see if the wheel is balanced .If not ,move the balance weight

“K” till the wheel is balance no matter in which position the wheel rotates .

Dressing of Grinding Wheel:

Installation of diamond dresser:

Put the diamond bit into the seat, front the tailstock body ,and tighten it .

Notes for wheel dressing;

a. A sufficient coolant is required whiled dressing the wheel .In the even of insufficient

coolant, the diamond bit will become carbonized due to high heat generated because

of friction. In this case, the life of diamond bit will be shortened and deteriorated if

keep using.

26

Page 26

b. The feed rate for each dressing should not be large as the diamond is an element of

hard and crispy, and is unbearable of impact .In order to prevent the diamond bit

from impact against grinding wheel, start the dressing from the middle of wheel

thru both ends.

c. A fixed moderate dressing rate: less than 5μm (0.0002) for a period of time and

cause a poor at times to regain a good and sharp dressing angle.

d. Formula of dressing speed :

F = D x N F : feed rate (mm /min )

2.5 x 1000 D: wheel grain size (μm)

N: wheel speeds (rpm)

Reference Table of Grinding Conditions :

A. Workpiece periphery speed range : UNIT :M.P.M(M/min)

R.P.M. = M.P.M. / πD (D = workpiece’s diameter ,M )

Type of Grinding Soft Steel

Coarse

Grinding

External

Grinding

Internal

Grinding

B. Feed rate per grinding : UNIT : mm

(1 mm = 0.039370〞≒ 0.04〞)

Type of Grinding Soft Steel

Fine

Grinding

Precision

Grinding

Fine

Grinding

10 ~ 20 15 ~ 20 15 ~ 20 10 ~ 15 25 ~ 30 25 ~ 40

6 ~ 15 6 ~ 16 6 ~ 16 6 ~ 15 14 ~ 20 18 ~ 30

5 ~ 10 5 ~ 10 5 ~ 10 5 ~ 10 5 ~ 10 5 ~ 10

10 ~ 40 16 ~ 50 6 ~ 40 20 ~ 50 40 ~ 60 40 ~ 70

Quenched

Steel

Tool Steel Cast Steel

Quenched

Steel

Tool Steel

Bronze

Steel

Stainless

Steel

Aluminum

Steel

Cast Steel

Plunge

Grinding

External

Grinding

Traverse

Grinding

Internal Grinding

Fine

Grinding

Coarse

Grinding

Fine

Grinding

Coarse

Grinding

Fine

Grinding

Coarse

Grinding

0.005 ~ 0.01 0.01 ~ 0.002 0.005 ~ 0.01 0.005 ~ 0.01 0.005 ~ 0.01

0.02 ~ 0.04 0.03 ~ 0.04 0.02 ~ 0.03 0.02 ~ 0.03 0.02 ~ 0.04

0.005 ~ 0.04 0.005 ~ 0.01 0.02 ~ 0.005 0.02 ~ 0.005 0.005 ~ 0.01

0.015 ~ 0.04 0.02 ~ 0.04 0.005 ~ 0.01 0.005 ~ 0.01 0.015 ~ 0.04

0.005 ~ 0.01 0.005 ~ 0.01 0.005 ~ 0.01 0.005 ~ 0.01 0.005 ~ 0.01

0.015 ~ 0.03 0.015 ~ 0.03 0.005 ~ 0.015 0.005 ~ 0.015 0.015 ~ 0.03

27

Page 27

Machine Alignment

Machine Alignment :

Check the machine accuracy as below in maintenance .

1. Alignment of table :

a. Place a dial gage on top of table and against dovetail surface of the upper table .

b. Turn the table handwheel to check if the zero-setting is obtained .

c. If not, adjustment can be made in reference of procedures as stated in Page 10 .

2. Alignment of workhead and tailstock :

a. Place a dial gage on top of table and a test bar into the spindle bore.

b. Direct the stylus to the test bar.

c. Turn the table handwheel to check if the zero-setting is obtained .

d. If not, adjust it in reference of procedures as stated in Page. 12 (adjustment of

workhead inclination) .

e. Test grind a bar of 300 mm long and measure the diameter at both ends see if it has the

same diameter. If not, realign the table.

28

Page 28

Safety Rule of Grinding Wheels

1. Carefully store grinding wheels in proper condition ,i.e. away from heat and humidity

sources .

2. Select correct wheel in accordance with grinding requirements.”Ring “ wheel and inspect

for cracks. Never use cracked wheel.

3. Strictly prohibit exceeding maximum safe operation speed established for wheel .

4. Use clean recessed matching flanges at least 1/3 wheel diameter .

5. Never alter hole in wheel or force wheel on spindle .

6. Wheel newly mounted or rarely used must run idle for at least 3 minutes before starting to

grind .

7. Under grinding ,carefully protect eyes and organ of breath .

29

Page 29

Electric Diagram

30

Page 30

31

Page 31

32

Page 32

33

Page 33

34

Page 34

35

Page 35

OD-820H\S

PARTS LIST

36

Page 36

37

Page 37

R

W

KEY PART NUMBER DESCRIPTION QUANTITY

1 GOD-61510 WHEELHEAD MOTOR COVE

2 EM03754P WHEELHEAD MOTOR 1

3 GOD-65280 MOTOR UPPER BASER 1

4 GOD-65220 MOTOR LOWER BASE 1

5 GOD-65210 SIDE COVER 1

6 SHS05012 SOCKET HEAD SCREW 2

7 GOD-65110 DRIVING PLATE 1

8 SHS-06012 SOCKET HEAD SCREW 1

9 GOD-65120 LOCATING PIN 1

10 SS05010 SET SCREW 2

11 SHS10016 SOCKET HEAD SCREW 2

12 GOD-65250 SLIDE FIXED BLOCK 2

13 GOD-61120 SLIDE BLOCK BASE 1

14 RHS-04016 REDIOUS HEAD SCREW 2

15 GOD-65350 ANGLE INDICATOR 1

16 RHS04006 REDIUS HEAD SCREW 2

17 GOD-65330 PLATE 1

18 GOD-67310 PULLY SIDE COVER BASE 1

19 GOD-67320 COVER 1

20 GOD-65160 HNOB 1

21 GOD-65322 MOTOR PULLY 1

22 BELT 1

23 DRK04020 KEY 4

24 SS05006 SET SCREW 1

25 GOD-65230 TAPER PLATE 1

26 SHS06014 SOCKET HEAD SCREW 1

27 HHS05016 H EX HEAD SC RE

28 SHS06016 SOCKET HEAD SCREW 4

1

4

38

Page 38

39

Page 39

KEY PART NUMBER DESCRIPTION QUANTITY

1 GOD- 65020 RIGHT COVER 1

2 SHS06025 SOCKET HEAD SCREW 4

3 OS-V110A OIL SEAL 1

4 GOD- 67290 DRIVEN PLATE 1

5 SHS08016 SOCKET HEAD SCREW 4

6 GOD-67270 P ULLEY 6

7 GOD- 61390 5C COLLET HOUSE 1

8 GOD- 86020 CARBIDE CENTER 1

9 SHS-06016 SOCKET HEAD SCREW 1

10 GOD- 65100 DRIVEN PLATE 1

11 GCT-11160 KEY SCREW 1

12 GOD- 67280 LOCKED NUT 1

13 BB-6911DDU BALL BEARING 2

14 VB-70A V STYLE BELT 1

15 RHS-08016 REDIOUS HEAD SCREW 1

16 W08B SPRING WASHER 1

17 GOD-65180 PULLY 1

18 VB-70A V STYLE BELT 1

19 RR-42 RETAINNG RING 2

20 BB-6004Z Z BALL BEARING 2

21 GOD- 65190 PULLY SHAFT 1

22 GOD- 65200 SLEEVE FOR SH AFT 1

23 SS08016 SET SCREW 2

24 GOD-65312 PULLY 1

25 VB BELT 1

26 GCT-14010 YOKE SHAFT 1

27 GCT-14130 HANDLE ROD 1

28 GCT-14110 KNOB 1

29 GCT-14060 O UTER RING 1

30 GCT-14140 BALL BEARING 1

31 GCT-14190 NUT 1

40

Page 40

KEY PART NUMBER DESCRIPTION QUANTITY

32 GCT-14210 BUSH BLOCK 1

33 SRR-32 SHAFT RETAINING RING 6

34 GOD-67100 COLLE T TU BE 1

35 GCT-14180 1

36 HN012F NUT 2

37 GCT-14040 SET SCR EW 2

38 GOD67330 LINK S H A FT 1

39 GCT14200 JAW 3

40 SP08100B PIN 3

41 SP0308B PIN 1

42 GCT-14100 NATCH 1

43 GCS2020 ADJUSTABLE NUT 1

44 GCT-14230 KEY PIN 1

45 GOD67250 S PINDLE 1

46 GOD67260 S PACE R 1

47 GCT14050 PIN 2

48 OS-V70A OIL SEAL 1

49 GCT KNO B 1

50 SP04016 PIN 1

51 GOD65290 SLEEVE 1

52 GCT- SPRING 1

53 GOD-65300 SHAFT 1

54 GOD-67240 WORKHEAD BASE 1

55 BB-7010CP4UL BALL BEARING 4

56 GOD-6 OUTER SPACE 1

57 GOD-6 INNER SPACE 1

41

Page 41

42

Page 42

18 PART NU M BER DESCR IPTION QUA NTITY

R

1 GOD62130 LOC K ED N U T 1

2 GOD62140A SP ACER 1

3 GOD61900 S PIND LE P U LLEY 1

4 GOD62060 INNER LO C KED N U T 1

5 GOD62050 OU TE R LO C KED N U T 1

6 GOD62030 REAR BEARING COVER 1

7 GOD62040 SP ACER 1

8 BB7011CP4UL BALL BEARING 4

9 GOD62021 SPINDLE SLEEVE 1

10 GOD62011 S PINDLE 1

11 GOD62040 S PACE R 1

12 GOD62070 S PACE R 1

13 GOD62040 S PACE R 1

14 GOD62080 FR O N T C O VER 1

15 SHS08020 SO CK ET H EA D S C R EW 6

16

17 GOD62090 F RO NT LOCKED N U T 1

18 GOD62160 WHEEL COVER BODY 1

19 GOD62100 WHE E L FLAN G E 1

20 GOD62110 FLANGE COVER 1

21 GOD62150 BALANCE BLOCK 3

22 BB03B BALL 3

23 GOD62120 N UT 1

24 GOD62140 S PACE R 1

25 GOD6222N LOCKED N U T 1

26 GOD62180 C OVE R 1

27 GOD62170 SWIVEL CO VE

1

28 GOD62210 FITTING BLOCK 1

29 GOD62270 S PACE R 1

30 SS08060 SET SCR EW 3

圖表 1

43

Page 43

44

Page 44

KEY PART NUMBER DESCRIPTION QUANTITY

1 SHS08020 SO C KET H E AD SC R E W 8

2 GOD61110 WHEEL B O DY C O VE R 1

3 GOD6108S WHEEL HEADSTOCK 1

4 IM024P 2HP4P MOTOR 1

5 GLS1880 SUPPO R T BLOC K 1

6 GOD61140 MOTOR SUPPOR T PLATE 1

7 SHS08035 SC O KET H E AD SC R E W 4

8 GOD61100 SUPPORT BLOCK BASE 1

9 SHS06045 SO C KET H E AD SC R E W 2

10 GOD68330 P LATE 1

11 GOD68340 PROTECT RUBBER 1

12 SHS06012 REDIUS HEAD SCREW 2

13 GOD61420 R EA R C O VER 1

14

15 SS06012 SET SCR EW 3

16 GOD61910 M O TO R P U LLEY 1

17 SRK08025 SINGLE REDIUS HEAD KEY 1

18 VB V TYLE B ELT 2

19 GOD61860 M O U N TING BO LT 2

20 GOD61850 M R TO R P U LLY C O VE R 1

21 GOD63080 BEARING BASE 2

22 SHS06020 SCO K ET H EA D S C R EW 4

23 GOD68240 S TO P B LO CK 1

24 GOD68250 ACTIVE STOP BLOCK 1

25 GOD65350 INDICATOR PLATE 1

26

27 GOD6108S WHEEL HEADSTOCK 1

28 GOD61090 WHEEL HEADSTOCK BASE 1

29 GOD61490 SUPPORT PLATE 1

30

圖表 2

45

Page 45

46

Page 46

KEY PART NUMBER DESCRIPTION QUANTITY

1 SHS06020 SO C KET H E AD SC R E W 2

2 GOD64130 BEARING SUPPORT 1

3 NBNA5904 NEDDLE BEARING 253723 1

4 GOD64050 C LUTC H G EA R 1

5 GOD64050 38T CLU TC H G EAR 1

6 SP05040 PIN 1

7 GOD64070 LOC K ED N U T 1

8

9 GOD64080 CLUTCH ROD 1

10 SS08080 SET SCR EW 1

11 GOD64100 53& 19T G E AR 1

12 NBF2016 NEDDLE BEARING F202016 3

13 SHS10100 SO CK ET H EA D S C R EW 1

14 GOD64090 SLEEVE 1

15 GOD64110 53T16T R AC K G EAR 1

16 GOD64140 GEAR BASE 1

17 GOD64120 G EAR S H A FT 1

18

19 SHS06020 SO CK ET H EA D S C R EW 2

20

21 FR80M10 KNO B 1

22 GOD64030S LEFT SIDE HAN D WHEE L 1

23 GOD64020 N UT 1

24 SRD06020 SINGLE REDIUS KEY 1

25 GOD64010 LO C KED NUT 1

26 GOD64020 LO C KED NUT

27 GOD6108S WHEEL HEADSTOCK 1

28 GOD61090 WHEEL HEADSTOCK BASE 1

29 GOD61490 SUPPORT PLATE 1

30

47

Page 47

48

Page 48

圖表 3

5

KEY PART NUMBER DESCRIPTION QUANTITY

1 GOD63140 76T G EA R 1

2 TLK3001822 CLAM P ING R ING 1pr.

3 WS010 FLAT WASHER 1

4 SHS10016 SO C KET H E AD SC R E W 1

5 GOD63120 19T PINION G EAR 1

6 DRK05030 DOUBLE REDIUS KEY 1

7 GOD63250 BU SH 1

8 GOD63110 GE AR SH A FT 1

9 BB6005ZZ BALL BEARING 4

10 GOD63080 BEARING HOUSE 2

11 SHS08016 SOCKET HEAD S C RE W 8

12 SDR05020 SINGEL REDIUS KEY 4

13 GOD63090 CONN EC TION BU SH 2

14 GOD63100 M IDDLE SHAFT 1

15 SS06006 SET SCR EW 4

16 CP04 CUPPER PLUG 4

17 GOD63070 WHEEL SHAFT 1

18 SHS08025 SOCKET HEAD S C RE W 1

19 GOD63410 LO C KED ROD 1

20 GOD63400 STO PPE R 1

21 HN08N NILON NUT 1

22 GOD63420 HANDLE STUD 1

23 GOD63430 S TO P ROD 1

24 GOD63450 N UT 2

25 SS05006 SET SCR EW 2

26 GOD63460 HA N D LE SH AF T 1

27 FR02

BLACK COLOR KNOB 1

28 GCT SCREW 1

29 GOD63040 WHEEL BASE 1

30

31 GOD63020 WHE EL 1

32 GOD63010 N UT 1

33 GOD63440 B OLT 1

49

Page 49

KEY PART NUMBER DESCRIPTION QUANTITY

34 GOD6306S SHAFT RING 1

35 GOD63030 WASHER 1

36 SHS08025 SOCKET HEAD SCREW 1

37 DDR05030 DOUBLE REDIUS KEY 1

38 SHS06030 SOCKET HEAD SCREW 4

39 FR80M10 KNOB 1

40

41 GOD63050 INDICATOR RING 1

42 GOD63190 LEAD SCREW 1

43 PN-020 PRECISION NUT 2

44 OSTC204207 OIL SEAL 4

45 GOD63170 BEARING COVER 2

46 BB6005ZZ BALL BEARING 4

47 GOD63180 BEARING HOUSE 2

48 GOD63210 SCREW NUT 1

49 GOD63220 NUT 1

50 GOD63230 SHIM 1

51 SHS08025 SOCKET HEAD SCREW 4

52 SHS05025 SOCKET HEAD SCREW 4

53 GOD63200 SCREW NUT 1

54 SHS08025 SOCKET HEAD SCREW 4

55 GOD63160 BUSH 1

56 GOD63150 BUSH 1

57 WS080 WASHER 1

58 SHS08025 SOCKET HEAD SCREW 1

50

Page 50

51

Page 51

KEY PART NUMBER DESCRIPTION QUANTITY

W

A

1 GOD66050 HANDLE BLOCK 1

2 GOD66010 BASE 1

3 SHS06014 SOCKET HEAD SCREW 2

4 SS08010 SET SCREW 1

5 DDNO-05 DIAMOND DRESSER 1

6 GOD66080 TAILSTOCK 1

7 GOD66070 ACTIVE PIN 1

8HN08 HEX. NUT 1

9 SS08010 SET SCREW 1

10

11 SHS06016 SOCKET HEAD SCREW 6

12 GOD65120 LOCKED BLOCK 2

13 SHS10016 SOCKET HEAD SCREW 2

14 KNOB 1

15 HANDLE 1

16 ADJUSTABLE HANDLE 1

17 GOD66040A CUPPER PLUG 1

18 GOD66040B CUPPER NUT 1

19 OSG35 OIL RING 1

20 SHS06030 SOCKET HEAD SCRE

4

21 CARBIDE CENTER 1

22 GOD66030 SHAFT 1

23 GOD66140 SEF SCREW 1

24 HN014F FINE NUT 1

25 GOD66120 SPRING 1

26 GOD66100 FIXED NUT 1

27 GOD66130

DJUSTMENT NUT 1

28

52

Page 52

53

Page 53

KEY PART NUMBER DESCRIPTION QUANTITY

1

2 OIL PAN 1

3 FITTING 1

4 RECYLE TANK 1

5 LUBRICATION UNIT 1

6 OIL TUBE 1

7 OIL LINE PLATE 1

8 OIL PLUG 1

9 FITTING 1

10 FITTING 1

54

Loading...

Loading...