Page 1

SHARP

SERVICE

MANUAL

PDSMX81014-MZ

Single Floppy Disk

MZ-80SFD

FEATURES

• High

•

• Simultaneous reading and execution

•

• Expanding up

speed

reading and

Easy

deletion and additionofprograms.

Linking

programsby"CHAIN,

to

writingofdata and programs.

four

drivesbyone

SWAP"

SHARP

of

programby"RUN"

command.

I/O

card.

command.

CORPORATION

Page 2

------------Contents--------~'\

Specifications 1

of

Constitution

Operational principle

Inspection and replacement

Trouble shooting guide

Power supply

Circuit diagram and printed wiring board 15

Packing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled views ' . . . . . . . . . . . . . . . . ...21

Replacement parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

single floppy 1

of

floppy disk " 2

of

section.

disk drive main parts . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

..

..

..

11

13

20

23

6

Page 3

II

r$PE.qlf1t"iiO~$

I ·General specification.

(a

humidity

out

prior

such

partially

Specification

maximumoffour

(freeofmoisture condensation)

notice

cases,

items mentioned above may be

different

drives)

for

product improvement. In

from

the product.

to

change

--_.

--

---

---

with-

---_._-

------

--

Item

--

-----

AC

220V

AC

240V ±

DC 12V

DC5V

-

-

± 10%, 50Hz

10%.

50Hz

Daisy-chain system

5.25-inch both-sides flexible disk

Double

Soft

280K

140K

AC

AC

30W

5

20

Approx.

4

or

single density

sectored

bytes/driveat16 sectors/track (double density)

bytes/drive at 16 sectors/track (single density)

220V

± 10%, 50Hz

240V

± 10%, 50Hz

to

25°C in temperature

to

80% in

165 (W) x 102 (H) x 323 (D) mm

kg

* Specifications and design subject

1

>------

-----------------------

1----

• Power supply section specifications

Drive-to-drive connection

Recording medium

Recording

Numberoftracks 70 tracks

Sector

Formatted capacity

Power supply

Power Consumption

----

~._-----~---_._--

Operating conditions

External dimensions

Weight

Item Specification

Input

Output

{CONSTITUTION

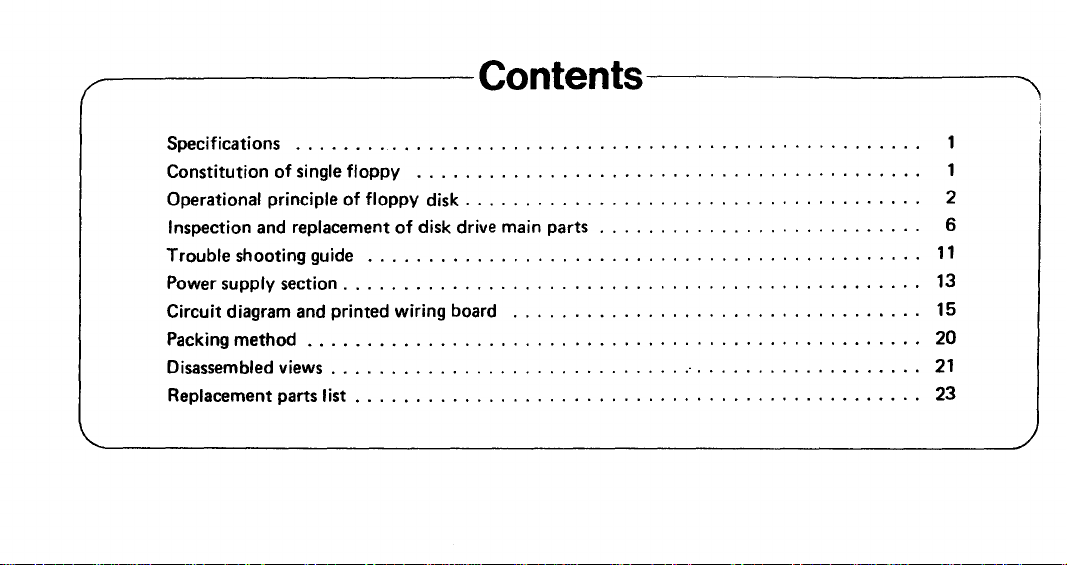

• Constitution and Block Diagram

MZ-80SFDisconstitutedbyfloppy

unit.

Its

floppy

disk driveisthe

sameasthe drives

Floppy

disk

OF

disk drive

drive

SINGLE

unit,

control

used

for

MZ-80FD/MZ-SOFDK/MZ-80FB/MZ.SOFBK.

[

r--

-

Block diagram

FLOPPY

PWB

unit,

terminal resistor

Power supply

Terminal resistor

Control

circuit

PWB

PWB

PWB

unit

and power supply

-1-

Page 4

_O_P_E_R_AT_I_O_NA_L_PR_I_N_CI_P_LE_O_F_F_LO_P_P_···.·y_·.····O..:....-.'

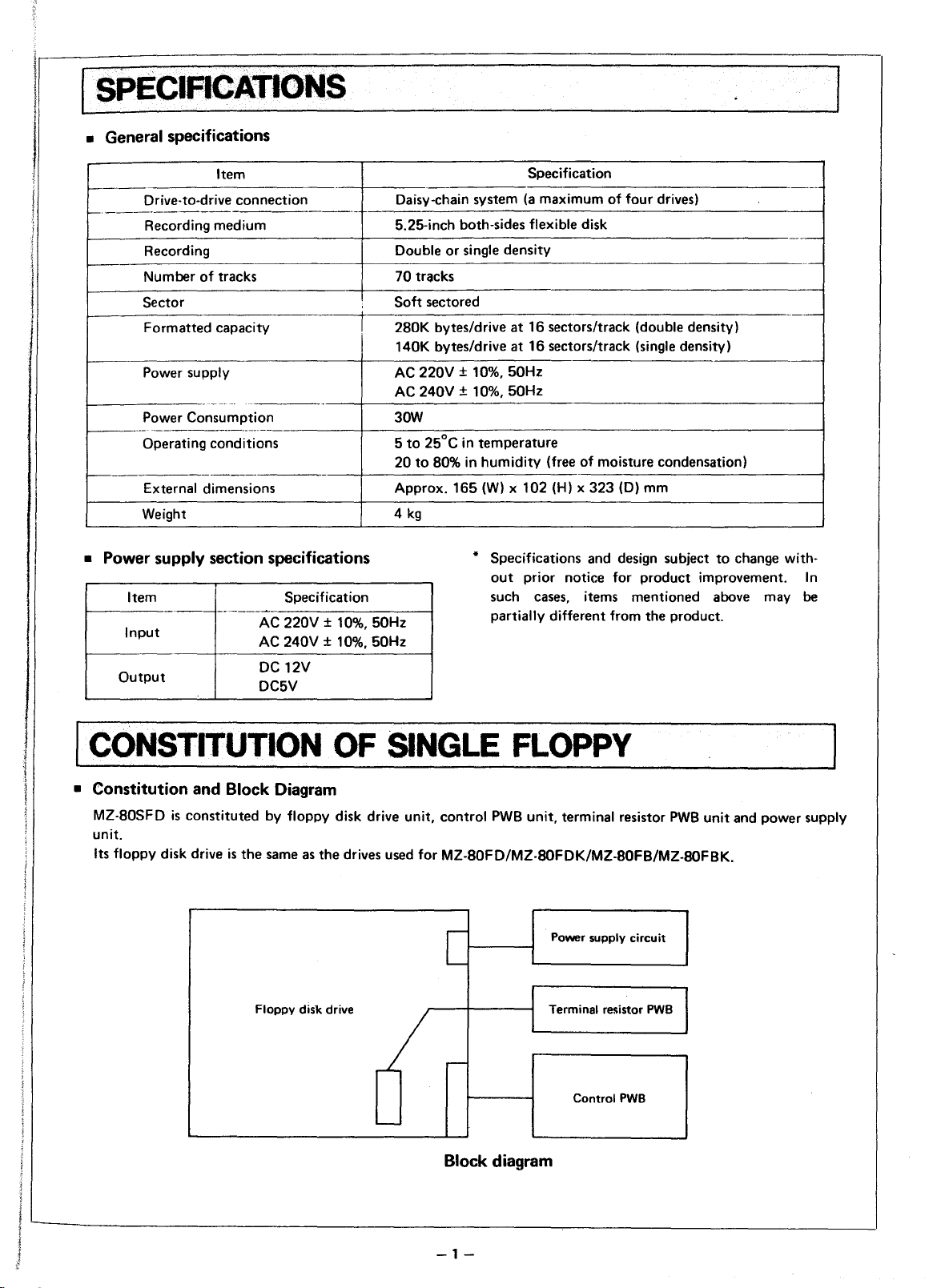

The

floppy diskisdesignedtorotate

"diskette,"

and write in dataathigh speeds

a magnetic disk storage unit,toread

the

by

bringing the

so-called

out

in

direct

magnetic head

sector of 70 tracks formed in

diskette.

contact

...........

$Kw...···

••.

>............... J

witb a specifil!d track

both

surfacesofthe

1. Fundamental block diagram

Read

Write

Write gate

Write

protect

data

Head select

data

Read circuit

Drive

select

Write circuit

Write

la,*/'

Operation

.

d'

In

Icator

/'

0'

-~~

protectr"··"

)-1

(}--:":":'..,..-----""'1'---------.

Write

./

protect

senso!",

,/

,-!lr

IndeX~-'l'--

sen_s~:JJJ'

~

Head load-

.

.,

actuator

I

--'

__

Direction •

Track

...

..,;D~r;;;;iv;.;.e;..s::.,;el;.;.e-ct--f

Head select

Motor

2. Mechanism explanation

This device consists mainly

mechanisms.

1)

Read/write head

The head

spring.

diskette easily.

Signals read

through FPC (Flexible Printed Cable)tothe

amp. circuit.

2) Carriage assembly

2 units of read/write head are

carriage. The carriageislocated with

motor

3)

Head locating mechanism

This

mechanism using stepping

ball/V -groove system.

The

type.

One pulse of

by

15

L..-

track.

is

The

and lead screw.

is

a high-precision, reliable head locating

stepping

0

, thus pushing forward

1.-..--..----,...-'

Head select Head load • •

s_t_e;..p

__

--.1,.......L--L--L..,I-

Index

00

ON

attachedtothe

head can follow

out

motorisof

step

Control

of

the

signal causes a 2-step

circuit

of

arm

head are

mounted

motor

and screw-driven

7.5°/pulse, steel

the

the

through

the

transmitted

the

head

Index

I~

Motor

1-

__

following

a leaf

motion

read

on

stepping

plate

rotation

by

one

ON

-,

of

the

,I

. .

~.

Rea1/write~"""

~d

Diskette

Motor

control

circuit

41

Diskette driving mechanism

A small-sized

employed. The

through

hub, thereby causing

spindle pulley

check

5) Head load mechanism

This

into

the

._~

•

..".

~:I:

\t==:INIJ.-1IlrJ

'.

DC

motor

motor

the

drive belt, spindle pulley and spindle

is

provided with a stroboscope

rotation interval.

is

a mechanism in which

contact

head load actuator.

with

.

the

with tacho-generator

rotation

rotationofthe

diskette. Itisoperated

is

transmitted

diskette. This

the

headisbrought

~

__

~

to

by

is

_

-2-

Page 5

6)

Write protect detection section

A luminous diode and a photo-transistor are used

to detect write

jacket. (Writing

protect

is

notchofthe diskette and

not

possible when

the

notch

covered with labeL)

Center

hole

Label area

Write

protect

notch

3. Interface

1) Interface signal

All

lines areofTTL (transistor-transistor logic).

is

(1) Input signals

of

For input signals there are 10 kinds

input lines,

allofwhich are validatlow levels. These signal

lines are terminated

resistor fittedinthe

signal voltage levels are

High

level

Low level

Invalid 2.4to5.25V

I

Valid o

I

Input impedance

a 150-ohm

IC

socketofdrive1.The

as

follows.

to

OAV

Pull-up

to5Vat

int~rated

150-ohm

at

resistor

Head

window

Description

7)

Index detection section

This section consists

phototransistor. An index hole

Index

hole

of

diskette parts

of

a luminous diode and a

of

the

diskette

detected by this sectiontodetermine the starting

point

of

a track.

8) Track00 detection section

is

A carriage position

the

When

track

9)

Control electronics section

carriage has reached the track00point,

00

signalisemitted.

The electric circuit

composed of 2 sheetsofPWB.

DC

the

control

motor

other

functions with respect

load, and

other

detected with a limit switch.

to

control each mechanism

Oneisto

control circuit. The

otheristo

circuits, say, detection and other

to

read/write, step, head

signals.

10) Diskette protect mechanism

the

Shutting

pletely set in, can give damage

shortening its life-time.

back, this mechanism has been adopted so

front door

front door, with the diskette incom-

to

the

diskette, thus

To

prevent such a draw-

that

connot

be closed if

the

diskette

improperly in.

control

the

CD

Drive select signals (0

MZ-80SFDisconnectable up

is

These signals are used

the

four drive units.

At low levels of drive select signal,

to

3)

to

4 units.

to

select a desired one of

RIW

head

is

loadedtocause the operation indicatortolight up.

Note)

The drive requires

to

switch

is

thru 4).

@ Motor

meet the position of use (Drive No. 1

ON

signal

The drive motor starts when

comes low. This signal

2 seconds after completion

to

be set with a drive select

the

signal level be-

level

becomes high about

of

all operations,

if

no operationiscommanded next. It thus inter-

the

rupts

motor, extending the service life

of

motor.

@ Direction select signal

The signal

direction

is

input.

High

Low

@Step

signal

This signal

direction designated by the direction select signal.

The operation

from low levels

is

given

to

of

RIWhead, when the

level- - .

Out

direction (to diskette

designate

the

step

portion)

level

- - -INdirection (to diskette center)

is

giventomove the

is

doneinthe

to

high levels.

RNoJ

courseofchanging

shifting

pulse

outer

headinthe

is

-3-

Page 6

®Write data signal

is

This signal

Each time changing high levels

current flowing in

writeindata

This write-in performance

gate signal

@Write gate signal

This signal being

on

the

sequential

(j) Side 1 select signal

This signal

double-face

headofside 0 and

high levels and low levels, respectively.

usedtowriteindataonthe

the

RIW

bit.

is

isatlow levels.

at

low levels,

diskette.

operation

is

diskettetoreadorwrite. The

At

high levels, read-out

may be made.

given

to

decide which sideofa

thatofside 1 are selected

diskette.

to

low levels,

headisreversed

available when write

data

can be written

the

RIW

to

or

at

(2)

Output

There are

CD

Index signal

By

can

disketteisdetected

fed from

Usually, this signal level becomes low each time

the hole

leading edge

of

@Track00signal

The low-level state

the

outermost trackJ.

In

high levels.

When

at

signal

however,

By adding still

motor phaseisreturnedtocause track00signal

to

signals

the

following four kindsofoutput

this signal the. starting positionofeach track

be detected. Each time

with

the

drive unit.

is

detectedathigh levels. Therefore, the

of

the

signal indicates

a track.

of

RIW

headislocatedattrack00position (the

any position

the RIW headisat

the position by

to

become low.

other

than

the

step

outside

the

track00signal level becomes high.

another

signaltostep outside,

the

index hole

the

detector,

this signal signifies

track

track

00,

stopper evenifanother

is

given. At this time,

the

the

beginning

DO,

the

signalisat

the headisheld

signal.

track

that

the

of

@ Write protect signal

is

This signal

protect for the diskette

diskette with write

becomes low.

In

is

usual operation, a diskette with write protect

enables to protect write statement within

drive.

.~

Read data signal

The signal

diskette. Usually it

detection it comes

usedtodetect

protectisin,

is

giventotransfer

isathigh levels, while during

downtolow levels.

whetherornot

is

provided. When a

the

signal level

data

read from the

write

the

-4-

Page 7

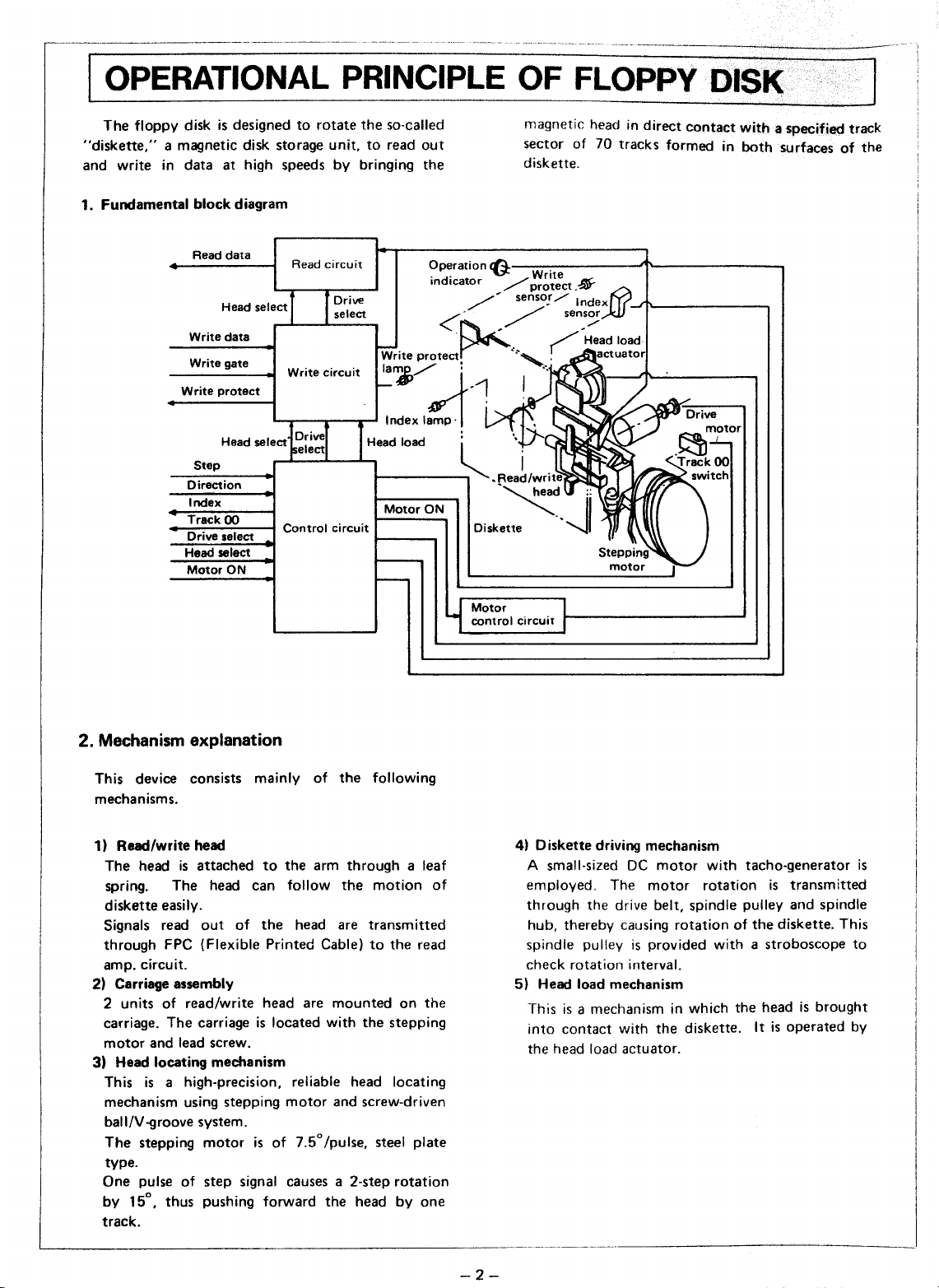

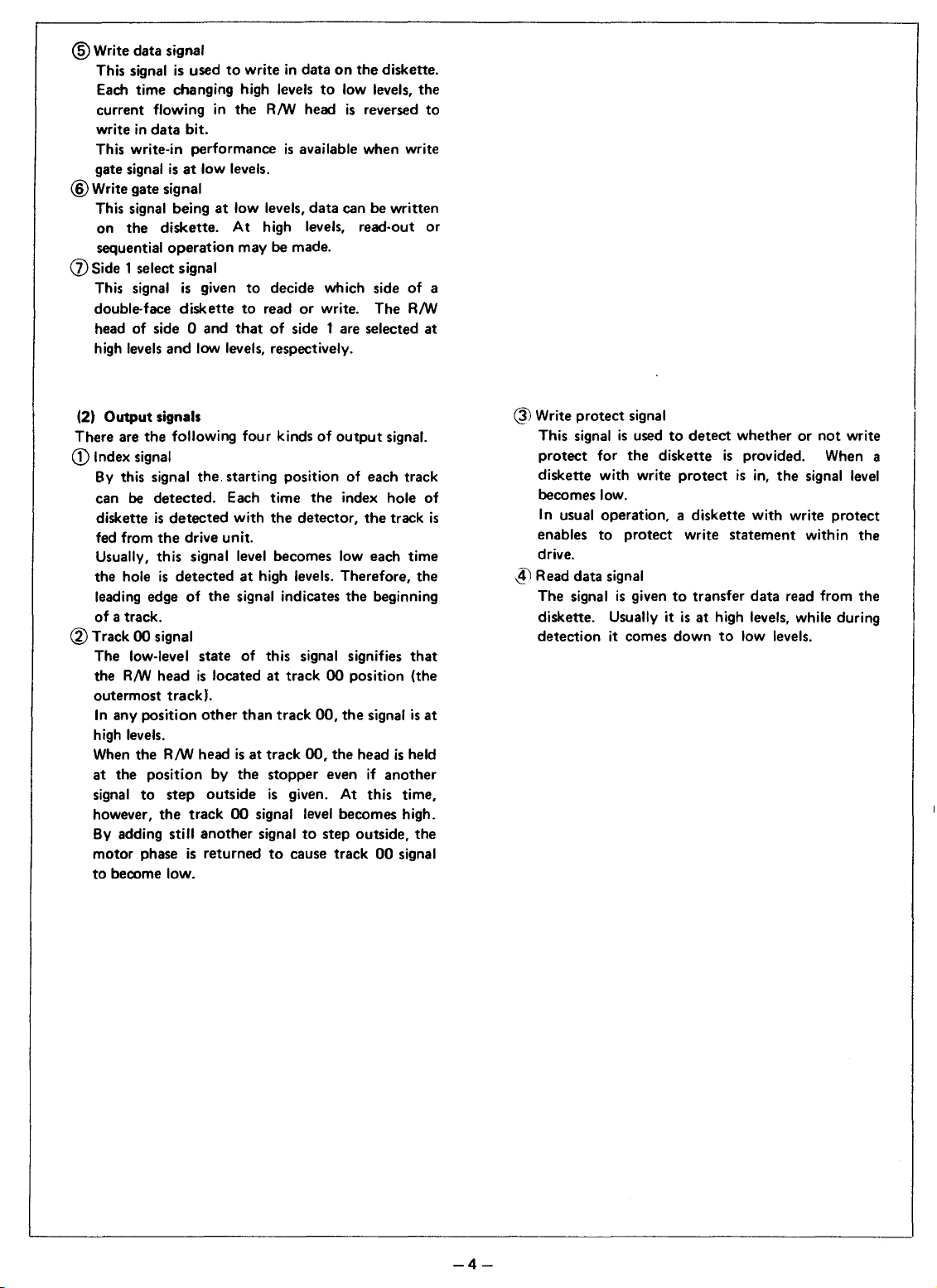

3) Timing

~\

DC

POWER

MOTOR

ON

DRIVE

SELECT

VALID

AND WRT

OUTPUT

SIDE ONE

WRITE

TR

VALID

INDEX

DIRECTIO

SELECT

STEP

SELECT

WRITE

GATE

DATA

-

-

KOO

PRT

N

-

-

--

....

1s

I-

-100ms

I--Soons

I

MAX--j

1J,Ls

MI~

1J,LS

-MIN

-

\

~

....

t:::j

MIN

MAX

~soons

~

4

1--1J,LS

-

MAX

--

MIN

'---

~~

20ms

MIN

10ms

MIN

--

-

..

SOms

MIN

1sec

MIN

~1tlsMIN

1:=35m.

100J,LS

-aJ,Ls

--

'd

~~

((

II

1/

II

u

II

{{

I}

MIN

MIN

({

II

MAX

"

II

1000J,Ls

1000tlsMIN

I

MIN-

-

1

[

-

100J,Ls

-~

if-

--1

VALID

READ

DATA

2) Power supply unit interface

Specified supply voltageofDCSV/DC 12Visfed from the power supply

control

PWB.

50ms

1sec

MIN

MIN

~

\

\

~

VALID

Control and data timing

-S-

MIN

3Sms

MIN~

100J,Ls

!--1000tlSMIN

VALID

I

unittothe J2 connectorofdrive

1

MIN-I--

I

VALID

Page 8

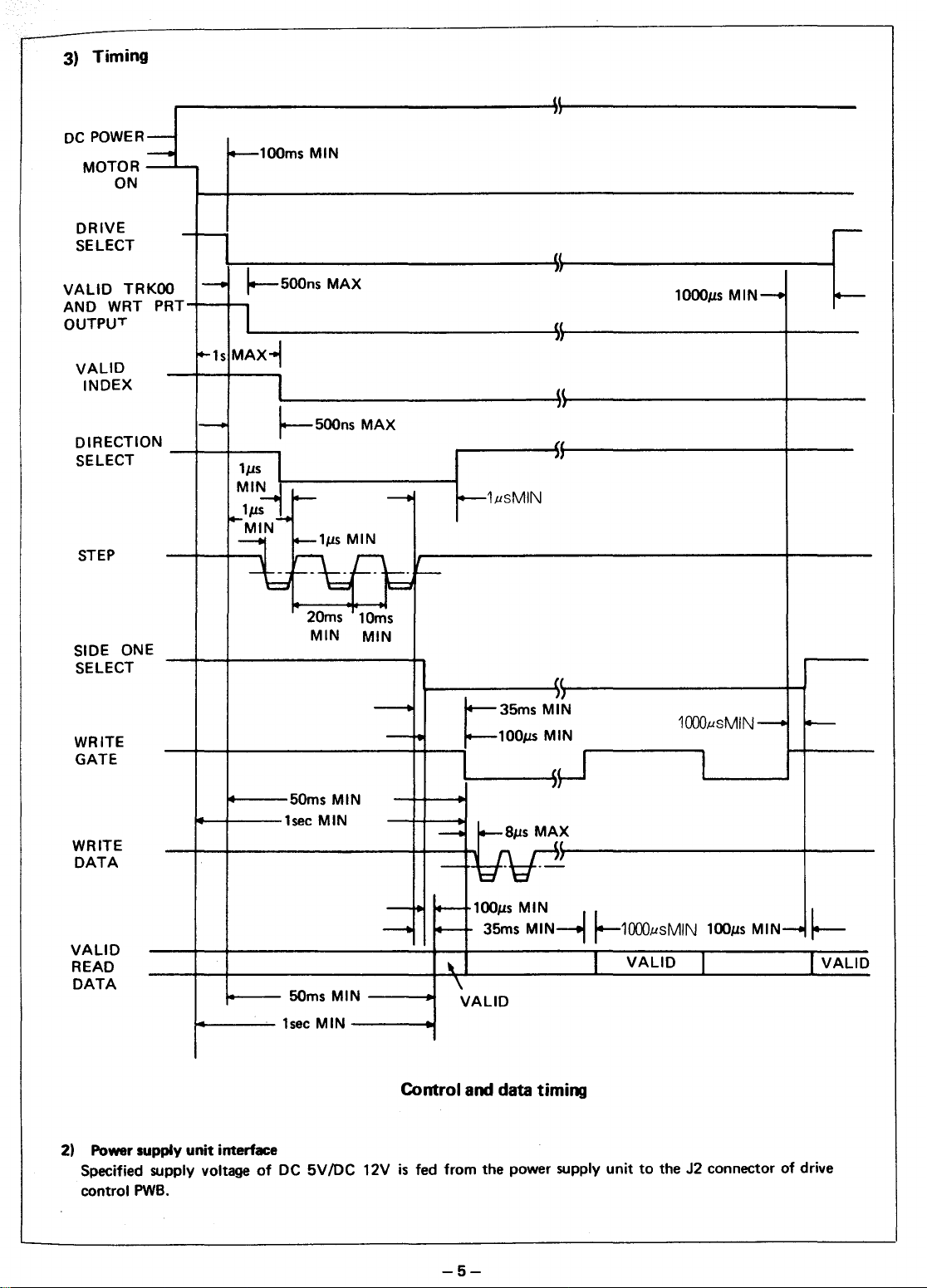

1. Belt

1) Inspeetion

to

see if

the

Check

Also make sure

beltisstained with

that

scratch and thinned part.

2)

Replacement

1)

Take

the

belt

off

the

the

pulley graduallybyhand.

2) For applying the belt,

motor

rotating

pulley and

the

thenonthe spindle pulley while

spindle pulley.

Note)

1.Inputtingonand

be

not

caughtbythe

2. Note

that

off

motor

thereisno

sidesofa new belt.

~

dustordirt.

there·isno

unevenness,

spindle pulley while rotating

put

the

the

belt, be careful so

belt first on

the

that

pulley flange.

difference between

Motor

pullev

Keep

belt

off

the flange.

both

2.

PWB

unit

1)

Replacement

1) Take connectors

2) Remove 3

3) Detach

PWB

4) For reassembly, take

Note)

In

replacing

which short pins

J3

andJ4off

PWB

unit fixing screws (3 mm).

unit.

the

reverse order.

PWB

unit, itisnecessarytocheck

to

cut

and

PWB.

whether

or

not

terminal resistorisrequired, depending on which

to

drive unit

Short

•

it

use (DRIVE No.).

pin: Detach

PWB

unit·

the

short pins from

and apply

them

to

the

a new

old

PWB.

• Terminal resistor:

If

the

old

PWB

unit

has no

terminal resistor, remove terminal

PWB.

fixing

3 pes.

,...--'0-----=--1

unit

J2

connector

(power)

J3

connector

J1

signa'

connector

J4

connector

resistor from a new

PWB

unit

screw(3mm):

PWB

Socket

-6-

Page 9

3. Index lamp assembly

1) Inspeetion

CD

Connect power sockettoconnector J2ofPWB

unit. Turn power on.

®

Make

sure

that

thereisa voltage rangeofDC1to

1.7V between

pin from power socket) and

the 11th pin from power socket), both belonging

to

connector J3.

B-11

(lower white lead of the 11th

A-11

(black lead

of

2) Replacement

CD

Remove

® Disconnect 2 lead wires

from the housingofconnector J3.

@

Cut

lamp assembly (be careful

wires), and open

@)

Take lead wires off the guide groove of carrier, and

draw

and fingers.

®

To

® Carry

left.

Index

lamp

PWB

unit (refertopage 6).

of

index lamp assembly

off the tie band fixing lead wiresofindex

nottodamage lead

the

front door.

out

the index lamp assembly with tweezers

attach, take

out

assembly

the

reverse order.

inspection, referringtodescription at

Note)

When

attaching

carrier, fit the housing and

time.

the

index lamp assemblytothe

LEDinat

the same

-0

-7-

Page 10

4.

Media guide l assembly (with write

1) Inspection

ill

Connect power sockettoconnectorJ2of

unit. Turn power on.

@ Before inserting a diskette, check

items.

a)

Write protect lamp

Make sure

to

1.7V between

13th pin from power socket) and A-13 (black

leadofthe

belongingtoconnector J3.

b) Write protect sensor

Make

to

O.5V

14th pin from power socket) and A-14 (black

leadofthe

belongingtoconnector J3.

that

thereisa voltage rangeofDC

B-13

(lower yellow leadofthe

13th pin from power socket), both

sure

that

thereisa voltage rangeofDC

between

B-14

(orange lead below the

14th pin from power socket), both

the

@ Put a write protect diskette (with write

seal being applied at the write protect notch of

diskette)inplace, and shut the

check

the

following item.

• Write protect sensor

Make

sure

that

thereisa voltage rangeofDC

2.5

to

5.25V between 8-14 and A-14

connector J3.

front

door. Then

protect

PWB

following

protect

of

sensor lamp)

1

0

2) Replacement

CD

Remove

PWB

unit (refertopage 6).

@ Open the front door.

@ Detach 4 lead wires

from the housing of connector J3.

of

media guide L assembly

@ Remove 2 media guide L assembly fixing screws

(3

mm) and take

out

the assembly.

@ To attach, take the reverse order.

® Carry

Note)

1. Attach the media guide L assembly by pushing it

2.

out

inspection, referring

left.

to

main frame stopper side and front bezel side.

Lamp and sensor cannot be individually replaced,

because they are built

assembly.

to

description at

in

the

media guide L

Push

Media

guide

L assembly fixing screw

Media

guideLassembly

Main

frame

stopper

Write

protect

Front

lamp

bezel

-8-

Page 11

5. Operation indicator

1) Inspection

CD

Connect power sockettoconnectorJ2of

PWB

unit and turn power on.

(Z;

Let drive select 0ofinterface signals beatlow

levels (make a short between J1·B terminal

and

PWB

Ground). and make short pin

circuit shorted. (Do

Note

that

the voltage range between connector

J3·B10 (red lead of

socket) and J

pin from power socektl will be

the lamp

2)

Replacement

CD

Remove

is

PWB

lit.

not

prolong this test.)

the

10th pin from power

3-A

10 (upper black leadofthe 10th

DC1to

unit (refertopage 14).

of

PWB

DSO

2V when

@ Datach 2 lead wires of operation indicator from

the

housingofconnector J3, and take lead wires

outofthe

CID

Open

@)

Remove 2 front bezel fixing screws (3 mm) and

the front bezel itself by pulling it forward.

@)

Draw

direction. Take

right.)

@ Draw

take the reverse order. .

(j) Carry

instruction.

wire holder.

the

front door.

out

the

holder 2 with tweezersinthe

out

LED

outofthe

out

inspection, referring

LED

holder. (See the sketch

LED

holder. To assemble,

to

the above

arrow

Front

bezel

LED

holder

Pull-out

direction

at

Note:

1.

Attach the

front

bezel assembly, by pushing it

to

main frame side and main frame stopper. (See the

sketch below.)

2.

Do not pull up the carrier with fingers, otherwise

excessive force

is

appliedtothe

head arm.

Main frame side

Front

bezel

Front

door

-9-

Main frame stopper

1)'

Push

Main frame side

Front

bezel

fixing

screw

Page 12

6.

Drive

11

Inspection

<!>

Connect _

"";t.

(%ll.ed

lmab

_

motor

T

....

in,

..

.01'>

PW8

assembly

__

face

mol..ON .i!lnols be

...

bel',,""

Groundl

>ocr..,

Oft.

JI·16

and

IDe

'0

cannectot

l......

run

mOlor

iNf

tIM

mol

and

n

of

a,

low ....e/s

0'

PW8

...

100

mOlor

PWB

uni,

....

,

cortl.al

PV/e

21

<D

<2>

<:p

unill

Rtplocemonl

R

....

Put

Cu.

_

d

.....

.-

off

1M

olf

tIM

mol<><

lead

PWB

""il.

bfoIl.

,iI

bind

eont.....

.....

CR.'

...

to

lR,I..10 _

I

..

fi

.....

fIWB

pogo

unit.

6,1

Iud

lk

6.1

wi

...

_,lui

of

......t

nol

..

to

prolong

<])

Pul.

@

amy

(8)

Make

•

pindl.

Note)

The

oIIiftiflll

to 1.5 pc;..M.

,his

dish".

on

hod

.ur.

pulley

,-.1

'11"

,ata

I"'"

In

p1_

load.

III.

.ppo

olwol>oplale

and

moboplate

...

10

V.._-",_

__

clme

be

.tationary.

is

...

1M I<on,

attaclled

allowflj to

_01

......

<100<.

on

be

_'

.........6.....

IIII'

""

<!>

A_

<:on1r01

ing

tID

R.m"".

13

Ootacll

'rom

@}

For

CV

Catty cu,

"".

P\W

of

""""oct

2

mml

ar>d

the

Ih.

mlin

auernbly.

3

Iud

u

J3.

met

2

DC

DC

meto,

frame.

tak.

insI>ection.

.ir........,..,.'"

10

conntlC<Of

tontrol

motor

tho

and

,,,,,er.

PWB

fixing

molD'

,.,.ttinll

t......

JJ_lrom

Unil

fixing ocrew.

OC'I'WO13mml

oontrel

ord.,.

to

....."iption

tM

1M

PWB

motor

I>ooJs.

.

unit

al

No•• l

In

.pl""I.

be

mOlJnlI~

pull.y

73

.iOA

'III'

mm"'III<Iwn

DC

mOlD'.

and mOtor pulley

abo

til.

••.

dl.tl~

.hould

be kept to

bet,veon

_10_

3f

Adju.'mon,

Q)

Alto,

Idiu"

unit

p1llely

,h.

cOmpletion

the

...

'"

,hal

Ilatio"",y

ilbl.,••

'1>0

ltroboplat.

of

i"",

th.

lbo

••

0'

molD! controf

appe_l

chock ilom

PWB

10 be

tom·

•.

Page 13

[

TROUBLE

SHOOTING

Startofdisk system

GUIDE

Yes

~--------'~

Yes

No

End

• Check by replacing several sheetsofdiskettetosee if errors occur duetofaulty diskette (data deterioration

caused by foreign matters, deformation, wear-out, damage, magnetism, etc.).

• Troubles

• Replace suspected parts

• The signal circuits of floppy disk and I/O card operate at TTL levels of

micro-computer peripheral devices for MZ-80 series

+5.25V).

• The disk drive needs a

it must be expanded.

in

disk system often cause error messages. Trace the cause from the contents of error message.

in

the disk system with normal ones. Check again the trouble section.

1)

Personal computer

2) Interface unit or expansion port

3) I/O card

4) Diskette

5)

Signal cable

6) Disk drive

RAM

areaofmore 36K bytes.Ifthe

Check repair procedure for power

supply section.

(See pages

Trace

of

to

seeifsignal levels are

13 and

14.1

the

cause from

error

message. (See page

OV,

+5V. Connect any system other than

RAM

areaofyour machineisless than 36K bytes,

the

contents

12.1

out

of the range of 0

to

+5V (max.

-11-

Page 14

• Error

chart

for disk system

Error code

[Error message]

1)

50

[NO READY] a Diskette

Drive fails

to

is

a Motor does not normally run.

a Index detection circuit

a Flat cable

a

No

is

select signal comesatdrive.

a Drive unit door (front door)

closed.

a Diskette

is

a Write operation

protect state.

1)

54

[UNFORMAT] a Head position

Drive

(off-track state)

a Head and amp. circuit are defective.

2) Diskette

a Diskette not formatted

41

[DISK DATA

ERROR]

a CRC error

a 10 field

1)

Drive

a SEEK error

a Head shift

in10field.

is

broken down.

is

Contents

be ready.

wrongly inserted.

Check item and corrective action

a Fit diskette in correctly.

a Check belt and/or drive

is

improper.

improperly fitinor

broken.

a Check index lamp, drive

a Check flat cable.

a Check floppy disk I/O card.

is

not

faulty. a Replace diskette.

is

attemptedinwrite

is

not

aligned. a

isinuse.

a Close front door.

Replace drive unit.

Replace drive unit and/or drive

a

o Initialize again, or replace diskette

a Check drive unit and diskette

Replace,ifrequired.

improper.

a Replace drive unit.

motor

PWB,

assembly.

index sensor.

PWB

unit.

2) Diskette

a CRC error

a Data field

a 10 field

in

data field.

is

broken down.

is

defective.

a Data mark detection error.

iO

Initialize again,orreplace diskette.

-12-

Page 15

!

POWER

Block DiagramofPower Supply Section

supplv

SEcnON

.---

~

'-'

AC

INPUT

'-F

WaveformofEach

..

Gl

~

I--

LL

"--

Waveformofpin@ofIC201

and

pin

(5)

..---

..

Gl

E

..

~

c

..

..

...

:......-

of

t--

'---

Part

IC301.

Rectifying

Smoothing

Circuit

'"'-

Rectifying and

Somoothing

Circuit

and

~

Waveformofpin

([j)

Transistor

Chopping

Circuit

Transistor

Chopping

Circuit

of

IC201.

Control

Circuit

1

Control

Circuit

1

Q202 collector waveform.

+12

...-<>

+5

v

G

~

v

Waveformofpin

([j)

of

IC301.

15V

/-22~s-i

40~s~

0302

collector

15~s

waveform.

40~s

I

22V

22V

24~s

4(j~s

-13-

Page 16

•

Trouble

Shooting Chart

Problem 1: No voltage appearsatany

~

Is

there AC

for U.K.I present across

C101?

220V

(240V

V~

Problem 2: +12Visnot

Is

there AC

present across

red lead

20V

the

of

n01

7

Nrl

I.-

Check

developed.

n01.

output

Check

AC

socket,

AC

switch

N~

terminal.

AC

Check

COrdi

F101,

F102

and

C101.

n01

Check

0201

~

Check IC201

Check

circuit.

appear

peripheral

~

r---

V;:

Leave R203beopen;

does

there

1Vp-p pulseatpin

No.

11ofIC201.

output

f---

and

parts.

switching

its

V~

present across

Problem 4: +5V is

Is

there AC

present across

yellow leadofT101 7

14V

the

n

L-

Is

present

V~

Is

thereDC20V

not

developed.

Check

n01.

thereDC14V

across

C2027

C302?

.--

f--

V~

No

r-t

V~

Does waveformofthe

chart

appear

collectorofQ2027

Check

Does waveform

chart

appearincollector

of

03027

in

0301.

of

~V~

the

t---

Yes

~

Check L201

C205,C209.

No

r-

Yes

Leave

R303beopen;

there

does

1Vp-p pulseatpin

No.

11ofIC301.

Check L301, C305.

and

C309, C310.

and

~

appear

Check IC301

peripheral

Check

switching circuit.

output

f--

and

parts.

its

-14-

Page 17

...

...

...

o

co

CD

"'"

0)

U'1

~

eN

~

....

I

...

U1

I

&T~~~lmA

,

I

I

&:

SWlIOI

&

C'O'

I

o.047J1neovAc

I

I

I

&f~~mA

Parts marked with " & " are

the

safetyofthe

specified ones for maintaining

mance

of

the

set.Besuretoreplace these parts with

set,

important

the

safety and perfor-

.6

TIOI

r--------,

, • I

L _

for maintaining

J

II

~:>

I

II

~>

IIOOV

I

0.-,

~>

~.Ol~

~

~>

:

..

~>

f

)c::>

I

)c:>

I

O.l,,~~OJ

RZIO

I.IIC

10

D

:

I

OJ"

~IOOV

I

:=

~

~

I !OOOJI/2SV - -

~

010'

4 SIV810 J

>

.a

~ao.

:

4.1IC

:

C~I~

010'

l

IIV8IO

rI"

II

II

If

II

II

II

"

II

II

If

II

I

II

II

II

II

II

II

II

II

II

_.J

>

RI,O

I.SIC

nr

:

:

:.~:-

VRSO'

o.,,,etS:~

'OO~~~

M04~

2.Zte

4

~

II

,

MO"

~

4.1IC

n

-

~

'U04

..

2.21C

l~

,.

I 2

RJ07

4.ne

n

II<

RIDS

IS

14

2 I

~~~~

RIll

'SK

C102.

Itl0S

411C

15

14

S

It

101

410K

It

lit

S.tte

( J

TL494CN

.f

TL494CN

.~I"¥

'00

rUOS

.!OOOJI

CIOe

IS",.

~

'I

IC201

r

0.0..,/5OV

.I~CIOS

t

~~

CSOI

sa,,/1

~

IS

IC301

e201

IS5V

V

12

~

:=

125V

IV

'I

"

I

~1tlO.

2{te

l.Ck

II

RIOt

1.71<

10

T

'00

.~

~'r.

. CS04

10

.,

J:

1t10i

2i,.1tt.

T

r

O.O,."/SOV

CIO'

2.H

0201

ArrOY

g

~

020~~)

A673C

CI04

0.00'1'

Iti0S

I.Tte

•

I

~

0301

A770Y

¥d

~

0302

ItSOS

2.11C

•

1

L.-

).

0.00'"

~

: =I

~

~

11M

V

0101

IIt"'-00412

~.

I.",

110

DIGI

I:R'''-OO412

L201

ZOOO7

roo

I

It

~

DIOS

zoom

~

I • +

V

UOO,.II.IV

Dioa

+

JI_·~I~

...

"IV

RI'I

O.'AI2W

csotVR20'

O.OI"/IOV

.1_

ItSIr

o.'AI2W

::

001"

eS05

~caoe

:

!!>D.a"IO

:=

cs

'0

tiel

;',(1.>.

...

z

•

:.

o

•

-a

o

+12V

-

-

~

JO.

V

GNO

+5V

i

..

en

c

-a

'"0

<"

n

~.

;:;.'

,...

(t:)

en

--I

...•

c::

[<!:::Ii

"

..,

K<d

a.

OS'

-

lO

.....

.,

OJ

ill)

3

Q)

::::J

;,1·

C.

~

.,

:i"

~i~):E

,...

(t:)

c.

~"

..,

.-

:i"

(Q

Z

CT

o

Q)

..,

a.

•

OJ

(il

en

~

c:

....

C"

:z

(b'

~

,..

--I

o

o

1ft

::r

OJ

::::J

a

~

~

;::+'

::r

~

o

c:

,..

"C

..,

•

-

cS"

z

..,

::::J

I)

o

,..

(=i'

~

CD

»

a:J

o

o

m

-n

G')

o

»

:rJ

'0

J:

Page 18

A B

c

o E

F

G

H

1

2

•

Power

Supply

PWB

3

4

5

6

Primary

7

8

9

10

F0410PA

Secondary

11

-16-

Page 19

A B

c D

E F

G.

H

I

J K

L M

N

o

P

1

2

• Disk Drive

HEAOO

R/W

ERASE

PWB

.~

~

I

r I

:

I I

>_'H:'g:~J4~-~A~3:::+~*'

Circuit (Reference diagram)

,J4:!:!:-A!'.!.7

,I

'T

IA

tl

J4-A6

J4-A5 3.6K

J4-A4

C2

10.u

"""-I

At

09

,,-_

05

::

D~I

Vj

D

Yr-

---1r-

[;:7t-'j---j-_

v

.'--=

r--J-;

'Lj---t"

:06

r

15

C3

~

RA GND Vee 1

17"

,,0.01"

v I C5

------,,;:04 I

~.--=:-r_-----'''13

108

I 16PIN 0 4 V

14

AS

WA

f:01B4392

1.

"J4.Al

v,

r

~

.D'

'2

116

ITp@)

+5V

A'-'-jf-----i;;>---j-..l--{;J--'""1=<

C4 R20

47~Op

330

A21

Bf2~4,7'IOO;r.P-<3=30J--k_-<6=8::>0_-i47Op

C 3

II

ffP28]'TP2AI

[!p@

R6

680

AS

C6

(TPGI

-

~+5V

r1

AN3,

4.7KL.f:,J3

,...;9~28pe::.8--c4~1:3iEE""}6"___!-___I-___I

LS04

rS'-<l~3~8//

1

.:

12 11

13

1~

~:

10 2

V

07

3E

,_-_

__

680

1

680

=.,-

AN1

RN2

7K

4.:.:.:. 3

_

2SA883

4

7K

.

..r:-'::.

3 4 -

1.#

'1

01

-+5V

1.2K

4~-

'--

1.2K

ANl

5

AN2

'K

-~6

':..JIfh,

lK

_.

6

3

4

HEAD

R/W

ERASE

1

~~

J4-B7

, "

, , f--

: :

I I

I I

(

~'"

:'6-~J4~.B~3L+~'f.',0-"__i.

, 4 Bl v

L"

J

""4,,,-Be>6,-,

1~J4,,_B,,-,,-S_+-_~_3_.6_K_j---

r-

J4-B4

J -

J

I J3.B13 7 5

4

.

A2

-

ntT

C1

-J,.

v,

L-----+---r--.-=

R2

-----'

,,),t','D:!..'!.':Oc-l-_-i3Ck-:i1~I..J

-r

8 ,

:,

ri

~:

U'fJ1S0;

'SV

,RN6

~

1

I

RN5

47K

RN3'

.7

L~'

~K>--l.!E~G~~S~~~C

R9

43

('hWl

T,

+SV

T'TP'"'

l.l..C!J

+5V

l

_,02

J.

'I'

Il11T

±

'T'

1l11T'

....

1

,AN7

I:

C13

001

G14

0

4.7K

I

. "

01p·

452

~V

r::;7,:505-I~'~'

R3

"1"2f-"'°"l'ffi

WA

WG

INS

IF

RS

C7

E 5

l000p

4-

F 6 T

L1

82{)pH

'~.·R7

430

AS

430

~

Dll

I

fEG)

(WGrl

__

~f-

+._+.

,4A

,w

LS05 9 8 1I 52

l~=J:!=~~~f=~====~==~~======t===~=~J

6 - - r 2

(PRl

"-,r--'--------+-+--

7 (EG)

-+-.1'-----

t---t------+-----==--"-'------t-----'

--t------=:'-:-----,--t------'-"-'

{WPI

(PAl

(WD)

l 9

............

:e"8~..:5'-j4~,'>_:6'_-+___,r_--2-;:c2S,,A-"8B=3."-.----------JS

?L:S04

__

CO",-+---j

38

/07

~.t====j-t--<31"-">4-:c:-r-t'2'i

·~'+--c;-<:c"-o--.-I----;7'·'_4_-S2-_-:

__

~

4S

/"

--

LS04

~

02

...

----

I B

.,

48

__

.....

:3

Pi-''-,---;--:;r==--

-=-.,J,

I ..J>15 I

_.J"j"

,,,.

STEPPING

MOTOR

J3·A5

_-fYY"L-,¢A

):>i'13,----,.,_:·~'J-"J3~-A~6~__6_-..rYY1.___l.8

~D16

I

~

'-----"<1>,!9C>::':r-r-tr--:-:::T'+.

r 1 ¢

11*f1

-=L"S:::04-=---t_L'-<.j'>--.10

:C;04

L_'.

3

r>:126

6

,

I

1

8

452_~:

;,

S

I .

~I

..

.D17

J3-A7

__

,..,.n_~

I C

~~B~~j'J!Sl----..=~·'~rJ:!'3!:'.8~7'-1-f'<rY''-~

_452

_-:

I

~

';"1

¢O

q

r;:-:

....,..,.-----

5

WRITE

PROTECT" J3-814 w

SENSOR

INEDNESOxR.----o1

S

r:-

~

Y n

t;:

I

J3-A14

I

J3-A13

J3-811 5 3

I

=J:3~-8~'~2~==

'-J3-A'2

.06~+5V

O:·=~

i5

'-----0

TRACK

SWITCH

00

I

J3-A9

I'

; 1

__

R1S

680

38

._

RN6

,50

"

..

~i:

.......

;r

I'

: L

+_''_'3q''113B12

All

680

~:.z,,>06"-----'S:.q'3Q>'6'----~4'-----..j.--__i-t31:"IC'~·

7lS14

RN?

~47K

?LSI.

10

lS14"'" j

3~

/LSOS

~

(If.~,

INDEX

--+-------·:..:.'---Il'-J-S~51-+-+1r---,

11

11 '-----I:::J---

~"

. LS05 12

r

12 L 13

~

(INDEX)

LS04

t----""l'r;s

VlS04

13

10 (WG) +5V 15 14

L~02

C"5:F~

-1m

10

, 9

3C

lSOo/

8

TOO

i A23 LS123 L .

820

l.-<=-r!.rl

r

10;;c::~;2~EJ'

'6 7

D19 LS123

~6gK

5

...

2-.:9q'

2S

8 r

399';;'1_+____i~-+____i~r---!.!(I~R'"D'.:'V~I____i~+_+-+__+-_,

"'1..505

-+5V-r-

t--=':...P"R:...'

+--+_'

'+C8

A4

47K

2 2E 4

__

____'3 v r

:::'F4.7pF

,,.l.

i

1111

03

2S860,

r----

,I

: I

..

t:

[...l

3~tO,::74'--+-+---I-t-~D

....

-.t·---I-I.,(_n)1I1+

~~4

~.~~F

i.;~F

"I

,,,

lS04

-,

I - I

.-----------'

-

D1S

,.

1_.-+12V

+12v-r-

D12

-C''!W~P:'I.l'-'2,i2"''

+5V

'-J,,3"'-B"'S'---o-~----j

'

J3·86

83

J3-

J3-81

J3·62

JfI

----:},"'-'~,~U2~AJ-~I~I~J,,'..:-2"'8'-?

IDS

13

38

'r:;

--o

+12V

I

.AI

0 MOTOR

DRIVE

I

WRITE

I

PROTECT

6

7

NO

NC

MOTOR

HEAD

SELECT

tu:C>--O---""

--A

·---·~~·__nk~81r4

ON

ONE

o

0-=-'

J3-A8

T

J3·B9

J'·16

1 Jl-4

0

..:.:--=----0

1

J'-32

..

0 ..

--r'------------

n

13

I

150 I i

1

HL

11

2'

Dj-~--;::::==I==i._.-+--+-.--.--:-:c;:---t--+--+L'

....

c_

--.

-j

H

-----------'

~

....

HI'

8

-+5V

AN6

150 1 2

,A_

,~

-"~~-1

I r I I

,

i i i

__

IRN4

41K

rs

+

__

-'4~~LS':"')/~

I,'

(PAd

l'I'~!--!l-.l",'C~'

~,-.

'--+--.

3C

"6

l

C26;J;;

-l-

11

lOOp

r~=--"'~DS~I-t=d~~~==~~j====~~===~j==~j=t=R~N~7--4~.~1K~lb~'"S~I+-t_t__j-t_-t----t_J

8 I

10

9

'MOTOR

------ -_.

sr---..

,,,)(;....

LSoy-

ON'

HM

e

6 v

-·--+-+---"-IS·T-CE"P..J

r-+-+------·------'

-_t__t_--.

__

_--=--3

'_H.'S.'

" 4

q

q,~

>-f-t-+-----------,

j

:-_++_---'9'j".§,~8'-.-r-+-----+---+::.IM::.O:.T:..0:.R-=-=D::.N:..:)+--+--+-----'

LS04

~C25

I'

PS

rD

I

y-.

+-+-'Pc:

C]--L-1.

M

"------l--+-......:L::S::04......:+--+-,,'H,,'''-SI'-----t-'

]------=--'-'---

0,01/J I (OS} 1f). 2

R15

V

+SV

11

.c

.;"f'"K-t_f---"-j5

1

01

--+-----j--t----=--='------t--t--+.----j------t--==----t

5+61

b..'0<:J.:6~--t_-+_--,-,,'P1II=I_-+_+--+---+..J

T+5V

'

(TOO~

(rpO)

+SVT,--=c-c:

R1B

I

-t-----+-------"~¢.".."

-

.......

07

,MDTOR

(TOO)

2

'-'

..!,-U3~E_\.?3'--"'J1'--"'-~

aNI

38

220

-'

J3-Bl0

J3-Al0

J3-A' I

I

IN

TRACK

MOTOR

USE LED

00

ON

45

(IDS'

(IN

IR

(IDSI"

DEX)

1

2

~9~"",

8 R

2A

38

3

J,-g

I

SIGNAL

INDEX

8

9

10

DRIVE

WRITE

WAITE

DIRECTION

STEP

SELECT

GATE

DATA

+12V

"2VRETo-="---,-----X--'-"----.------------,

SV

+

I !

o 0

,

2

3 0

Q---"-'----

1

0

0

O

b

,l.

~-

Q---='------

I 0

rD::~

Jl·lO

I

Jl-l2

Jl·14

'JI-6

---"-=--------'

Jl-24

I Jl-22

...

J"-''-·:..:18''------J-+-----------=-...:::::::-----____if-!'~D£'R.!.'_-_112~2CC'

JI-2.,0"---

I

J2-1

J2.2

J2-4

-

------t_-i!-e

..

"-~--

-+---e:

tj

+5V_~~-r_,

8 9 1

18

150t.:f---::f--c

~;~~-I----''t-''-=21---~1''-°hl

1i 0 I I

7 6 5 1

C23

..

~-----------------

+.....1-

C24

~.

+

~

J

:f--::'I'--'150 5 I

3

1

1

~~~=~~;>=j~V,~L~S~0~4

~

OSl 3 -- 1 T 4 - 1 .

RN6

DS2,

.~'~:::i¥-'J

2LG

500

2 __

I

+5V

It;o-

LS05

10

MX.

- I

as'!.

150

+SV-r-

rC;jRN4

i4.7K

'30

LSQ5

-4

e12

2 ----..l

38

9 n

ell

C18

8

LS14

C19 3

rrrr

--'--

HS

+--+--I--;2~f;;:,

~

7fJT

,------+

I

'--I---++------

--

--1

S 2

3

iWGl

_+

-+---'·E-G-'-----,,·-----------"-!WD

iSTEP)

3~~_i4~;---.L-----"~3

L

......

....

_._...:::~

'r-n-r-

38

.....

+12V

..c..:.:::c____

twO) 5 v

2

,""3C

l"'"'\.i

LS14

~

~~02

LSOO

~

RN4

......

3

L-:

4.1K

---'-q"/

~~_O_}

.+~V

:J

1

~

,/

,,=~~---;:Dt3~C

_

11

13L50

'2

07

--+SV

2

LOT-

1QOK;(r

r-=t

3

lfF'-J

4

1~~~~'o/"'3'--1-t-!_-+--+-_

~5V

2 RN4 4.7K 3 17

-

LS04 4 ""I--'-=6'----:c+ ----'11+SV -r-+5V

-

38

12~C

13

LSD

+5V

t

"S""":O-r.:

"

\..

~-'--.':q'TJp.;'2'::c--,--..J

RN3

.~'

~:Jf~.~~=~.::..::..::..:.::..J

~4.·1K

~

V LS'f4

-+5V

L

I'l

Rn

13

c---':'=:--'c~--

WS/RS

10

PR

6

..

--;",~~:!-;;--,

INDEX

15

1>0

RDY

DS

WG

'-=14

,_

EG

DR/2STE~TEP

1

RN3

a.

2SC2901

1 2

1-5

1....-...J

MB'430'

'8

20

11

~

7K

PIN.

CP

DLIRD

7

"'--.+------'

cc

GND

RM

121

b________

8

(INDEX

..

''':H<lL11---1.--_+____I, 10 38

8

18T+

9T_

7l1r-

2~OO'

I

{AOY)

.--+--+---+-+--+---'-'-"=.:..'---1----'

L_.!.'"IR"'D"-V'-I'--t

lHU

'---r_----".=-~.-----~

;---_,;9..L

5V

C15

O.Oli-!

9 I

10

R10

18K

2 10

1

.Jr.

1/11

Rll

820

15 14

LS123

-r_

10

3

-

-+5V

:*Cl0

T 1QOp

22

;;:

1;'3:.2.....

0

1-_~L...:R~~U2~A:J)--{-J

nir

'-------------------------'

9

+12V..,-L_--;=

---=-'I;C

2

R13

9.1K

7

(IDS)

(RD)

452

"l

6

LS123

'D

11

C16

22Op.

,rml-~3~gU~-'.='--1AEAD

3Dl~

........

r-""

5

2A

12

r==--r--"J3"'-",A~2---<DI

:!:-C22

1""'"

0.011i

0,--",J,,,,-3,,4,--0

r_"J"'3-"'B,,4-,,----,

-'

' 1 I

J3-A4

6

Jl·3Q

rIT1J1-3...33 0

At9

lOOK

HEAD

SOLENOID

RETURN

FR

AM

GROUND

LOAD

DATA

E

11

+5V

RET

..:::J2,,3e-

b

I

T_"______

-17-

a.olp

x 4

.------"l

+SV

niT

41K

-18-

Page 20

A

B c D

E F

G

H

1 • Disk Drive

2

3

J4

PWB

(Reference diagram)

4

5

6

7

B

",~,i,~,~",.~.~;

I

, "

Il>,•••

"c'

:

C'

",'.

,',','C'T'

~

.•..

••

"C'

o , "

-t"

• "

'-~

.......

~1:

'<';~"''i-~,~,:"

'f

;'77~'

~_... •

"I

".

...

~

..

~.

~

f)'1i

.

" '

..,

"",

'4~~~~~

•

•

•

'"

'!"

.

J

ill

to

..

•

I'

~C'

..

i

••

'"

'ti'")/-,,'it'--1'

'--

1

-'

9

10

11

Penpective View

[::=I

c=J

Parts·fitted face

Opposite side

-19-

Page 21

I

rPACKING

METHOO---------

Packing

Add.

(SPAKA0078PAZZ)

(TiNSE0040PAZZ)

Instruction

(SSAKH0021PAZZ)

l

lnstruction

AC. Cord

(OACCKOO50AFZZ)

(OACCBOOO1

Manual (English)

Manual Sack

PAZZ

.

l

Label-O------~~""-

(TLBH0002PAZZ)

Sack

(SSAKH0016PAZZ)

.....

)

for

U.K., SESA

Drive

Number

(TLABZOO29PAZZ)

(TLABZ0033PAZZ)

(TLABZ0034PAZZ)

(TLABZOO35PAZr~

Terminal Resistor / J

(RR-KZ0056PAZZ)

Label\

8)

B

Packing

Add.

(SPAKAOO79PAZZ)

Packing

(SPAKA0035PAZZ)

~

Sack

I

(SSAKH0013PAZZ)

Add.

Packing

(SPAKC0212PAZZ)

Case

Packing

Add.

(SPAKA0035PAZZ)

-20-

Page 22

REPLACEMENT PARTS LIST

To

have

NOTES:

Be

suretouse

portant

and performance

for

MODEL

PART

REF.

NO.

NO.

* * * POWER SUPPLY

OBOXOO039PAZZ

INTEGRATED CIRCUITS

IC201 }

IC301

TRANSISTORS

0201 }

0301

0202

0302

0201 }

0301

0202

0203

0302

0303

RH·iX0275PAZZ

VS2SA770·Y/·l

}

VS2SA673·C/l

VHOS2VBlO//·1

VHOERB81·004/

1

AND

DIODES

E

"HOW

your order filled promptly

1.

MODEL NAME

3.

PART NO.

regular Darts

maintilining

of

the set.

for

the

safetyofthe

securing the safety and

MZ-80SFD

DESCRIPTION

UNIT

SECTION * * *

Assembled Power Supply

(for

220V,

(Not

TL494CN

2SA770Y

2SA673C

S2VS10

ERB81-004

(or

240V)

replacement item)

VHORK14////·1l

TO

ORDER REPLACEMENT PARTS"

and

correctly.

set.Besuretoreplace these parts

CODE

please

furnish the following information.

2.

REF. NO.

4.

DESCRIPTION

reliabilityofthe set. Parts marked

REF.

NO.

PART

with

NO.

CAPACITORS

Unit

AP

AH

AC

AG

AG

""'Cl0l

&Cl02

C201

C301

C202 }

C203

C204

C304

C205

C206 }

C306

C207 }

C307

C208}

C209

C308

C302 }

C303

C305

C309 }

C310

}

RC·CZOl80PAZZ

}

RC·OZOO03PAZZ

VCEAAU1VM108M

}

VCOYKU1HM102K

VCEAAU

VCEAAU1VM336M

VCKYPU1NB104Z

VCOYKU1HM183K

VCEAAU1EM108M

VCEAAUOJM338M

VCOYKU1HM103K

1CM228M 2,200MFO,

specified ones

0.047MFD,

O.lMFO.

l,OOOMFO,35V,

O.OOlMFO,

33MFO,

O.lMFO,

0.018MFO,

l,OOOMFO,

3,300MFO,

O.OlMFO,

with"

"'"..( ) are im·

for

maintaining the safety

DESCRIPTION

260V,

100V,

50V,

16V,

35V,

12V, Ceramic

50V,

25V,

6.3V,

50V,

Film

Film

Aluminum

Film

Aluminum

Aluminum

Film

Aluminum

Aluminum

Film

CODE

AH

AB

AE

AA

AE

AS

AS

AS

AD

AF

AB

RESISTORS

R201 }

R301

R202

R203

R209

R302

R303

R309

R204

R205}

R305

R206 }

R306

R207 }

R307

R208}

R308

R210 }

R310

R211

R212 }

R312

R304

R311

VR201}

VR301

VRO·RU2EE101J

VRO·RU2EE272J

1

VRO·ST2EF222J

VRO·RU2EE473J

VRO·ST2EF472J

VRO·RU2EE472J

VRO·RU2EE474J

VRO·RU2EE332J

VRO·RU2EE

VRW·KT300Rl0K

VRO·RU2EE222J

VRO·RU2EE392J

RVR·M0010PAZZ

153J

100

ohm,

1/4W

2.7K

ohm,

1/4W

2.2K

ohm,

1/4W

47K

ohm,

1/4W

4.7K

ohm,

1/4W

4.7K

ohm,

1/4W

470K

ohm,

1/4W

3.3K

ohm,

1/4W

15K

ohm,

1/4W

0..1

ohm,

2W

2.2K

ohm,

ohm,

1/4W

1/4W

3.9K

Variable Resistor 1K

ohm

TRANSFORMER

&T101

AA

&llOl

L201}

L301

AA

MISCEllANEOUS

S0101

AA

iliSW101

AA

41"101

&Fl02

AA

AA

AA

AA

AA

AC

MISCELLANEOUS

AA

AA

CNl

AC

AND

COILS

RTRNP0069PAZl

RTRNZOOO51'AlZ

RTRNZOO07PAZZ

OS~AOOO3PAtZ

OSW-COOO3PAZZ

}

OFS.cOOOl

OFSHAOOOl

1

OSOCN0165PAZZ

2

LANGOO037PAZZ

3

PROAR0059PAZZ

* *

...

OPWB·0254PAZZ

OSOCN0166PAZZ

PAll

PAZZ

CONTROL

Power Supply Transformer

(for

220V,

240VJ

Line

COil

Choke Coil

Appliance

AC,

Fuse,T315mA

Fuse

4·Pin Socket

AC, Switch,

Radiator

PWB

Assembled

(Not

37·Pin Connecter

Flat

Inlet

Switch

Holder

with

Inlet

UNIT

SECTION

Control

replacement item)

Cable

Lead Wire

Fixing

* * *

PWB

with

Meta

unit

BK

AL

AP

AI'

AO

AD

AA

AL

AF

AK

SO

-23-

Page 23

-

-&

CD

-

-

•

~

•

\ \

\

,

,,-

--+-----

€8>-

..

------n=::.::::::;:::lp,

____________

J I

-

:;

o

c

-

]

---1--------.';

o

-

/

~.

LJ

,", ~

\ I

~

\

,

- /

,

/

/

/

,

~

_

..

_.-

~

I:

_._~~;

,

~,

".

w

o

u

en

~

>

o

W

..J

m

:i

w

-

'"

+

'"

<f

'"

-

I'

\

\

\.

,

._._.

,

~

'.

.

"

\

\

\.

\

..

\

\

\,

'.

'.

'.

"----

...

~.

,

\

'.

,

N

,

-~~.

,

, .

\,~,

'\

'\

\

",

" \ ,

.

';'"tli

~

/

/

,

,

/ /

/

/

/

,

,

,

,

/

,

,

,

/

/

,

I

,

,

,

11&-.-

lD

m

<t

en

-

o

-----.

-

..

N

-21-

LO

•

en

-22-

Page 24

PARTS LIST

REF.

NO.

CN2}

CN3

SW1

*

TERMINAL

PART

OPLGZ0115PAZZ

OSW-DOO02PAZZ

RESISTOR

DPWB-0318PAZZ

MISCELLANEOUS

CNI

DSOCN0167PAZZ

OSOCZ0019PAZZ

RR-KZOO56PAZZ

* * * DISK

95AF

141336-01

4

5

6

7

8

95AF120138-14

95AF140630-01

95AF

120151-01 Medium Guide L Ass'y BN

95AF

140640-01 Operation

95AF

130246-01

NO.

DRIVE

DESCRIPTION

37-Pin Socket

Din-Switch (4 contacts)

PWB

UNIT

SECTION *

Assembled Terminal Resistor

PWB

unit

(Not

replacement item)

14-Pin Connecter

Flat Cable

14-Pin IC Socket

Terminal Resistor

UNIT

SECTION * * *

Belt

PWB

Unit

Index Lamp Ass'y

(with

Write Protect Sensor,

Lamp)

Drive

Motor

(with

Motor

A~y

/

Indicator

Ass'y

Control

with

PWB)

CODE

BB

AQ

AW

AF

AE

BA

BL

AZ

BY

REF.

NO.

9

GCABA3500PASA

10

GCABB3500PASA

11

GCABC3500PASA

12

GCOVAOOO2PAZZ

13

GCOVAOOO3PAZZ

14 GCOVAOO16PASA

15 GLEGPOOO3PAZZ

16 GLEGPQ004PASA

17 HBDGDOOO2PAZZ

18

LHLDF0023PAZZ

19

LANGF0068PAZZ

20

LANGF0069PAZZ

21

QT

ANNOOO3PAZZ

22

LX-BZ0068PAFN

23

LX-BZOO86PASA

24

LX-BZOO75PAZZ

25

6

&

&

&'.

..

LX-WZOO03VAFE

OACCKOO5OAFZZ

QACCSOOO1'AZZ

TLABtiOQli2PAZZ

TSPCEOI)32PAZZ

TSPCEo031PAU

TiNSE0040PAZZ

DTiP-0047PAZZ

TLABZOO29PAZZ

26

TLABZOO33PAZZ

27

TLABZOO34PAZZ

28

TLABZOO35PAZZ

29

PART

NO.

•

••

OTHER SECTION

DESCRIPTION

CODE

•••

Cabinet [i. (upper)

Cabinet B

Cabinet C (rear)

Cushion

Cushion

Terminal Resistor Cover

Foot

Rubber

Badge

PWB Holder

Frame (Right)

Frame

Frame

Screw, Drive Fixing Screw

Screw, Round-head

Screw

Screw, Socket

Washer

AC.Cord

AC,

.14C.

(bottom)

Foot

(Left)

Ground

Terminal

Fixing

for

FG Terminal

(for'SE:~f

Corif

(for

C~~·

SU~;~l.

(1W$UK..~)

Flat-foot

Screw

.

Speclfteatlon~tf(Ji220V)

sPeciflc:ation

Instruction

Braided Wire

Drive Number Label

Drive Number Label

Drive Number Label

Drive Number Label

Panet

(for

Manual (English)

~V)

DRIVE

DRIVE

DRIVE

DRIVE

BF

BF

AN

AE

AB

AC

AG

AB

AN

AA

AG

AG

AK

AH

AC

AG

AA

AQ

AD

AC

..

AE

AI:

AR

AN

1

A.B

2

AB

3

AB

4

AB

-24-

Loading...

Loading...