Page 1

"

Page 2

-~

..

Note

for

Users

in

UK

IMPORTANT

The

wires in

the

mains

lead

of

this aJJparatus are

coloured

In

accordance

with

the

following

code:

BLUE:

BROWN:

Neutral

Live

As

the

colours

of

the

wires in

the

mains

lead

of

this

apparatus

may

not

correspond

with

the

coloured

markings

identifying

the

terminals

in

your

plug,

proceed

as

follows:

..

The

wire

which

is

coloured

BLUE

must

be

connected

to

the

terminal

which

is

marked with

the

letter N

or

coloured BLACK .

..

The

wire

which

is

coloured

BROWN

must

be

connected

to

the

terminal

which

is

marked

with

the

letter L or

coloured

RED.

•

Page 3

\'.

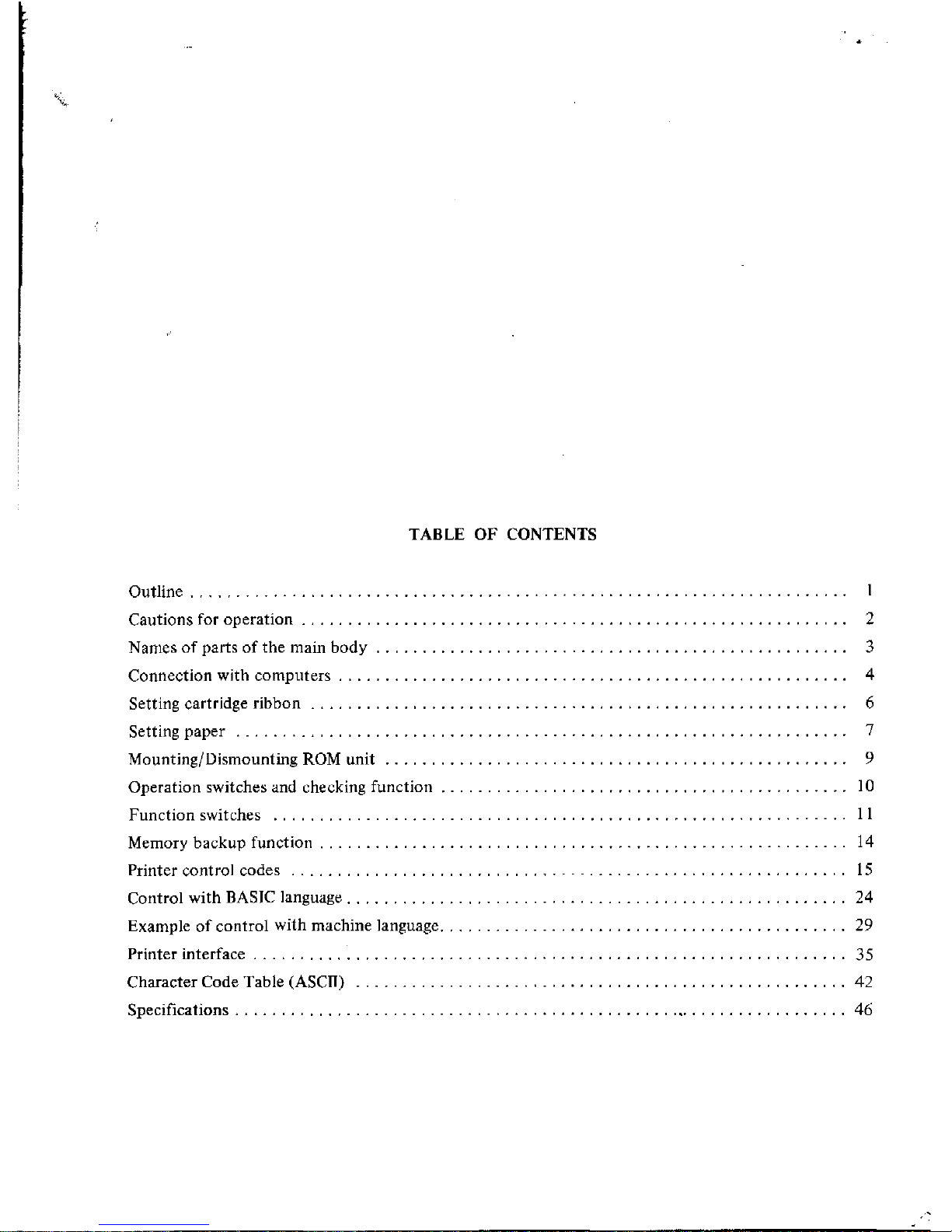

TABLE

OF

CONTENTS

Outline

......................................................................

.

Cautions for operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2

Names

of

parts

of

the

main

body.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3

Connection with computers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4

Setting cartridge ribbon

..........................

_ . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6

Setting paper . _

..............................

__

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

Mounting/Dismounting

ROM

unit

................

_ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

9

Operation switches and checking function . _

.. _ ..

__

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

10

Function

switches

..........

_ . _

... _ .. _ .................................

_

..

_ .

__

..

II

Memory backup function

.................................

_ . . . . . . . . . . . . . . . . . . . . .

..

14

Printer control codes

.............................

____

. . . . . . . . . . . . . . . . . . . . . . . . .

..

15

Control with BASIC language

.....................

_ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

24

Example

of

control with machine language

..........

__

................................

29

Printer interface

................................................................

35

Character Code Table (ASCII) . _

..

__

...

_ _

__

. _

.. _ ................................

42

Specifications

..................

_

... _ ....

_ . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . . . . .

..

46

Page 4

,

,.

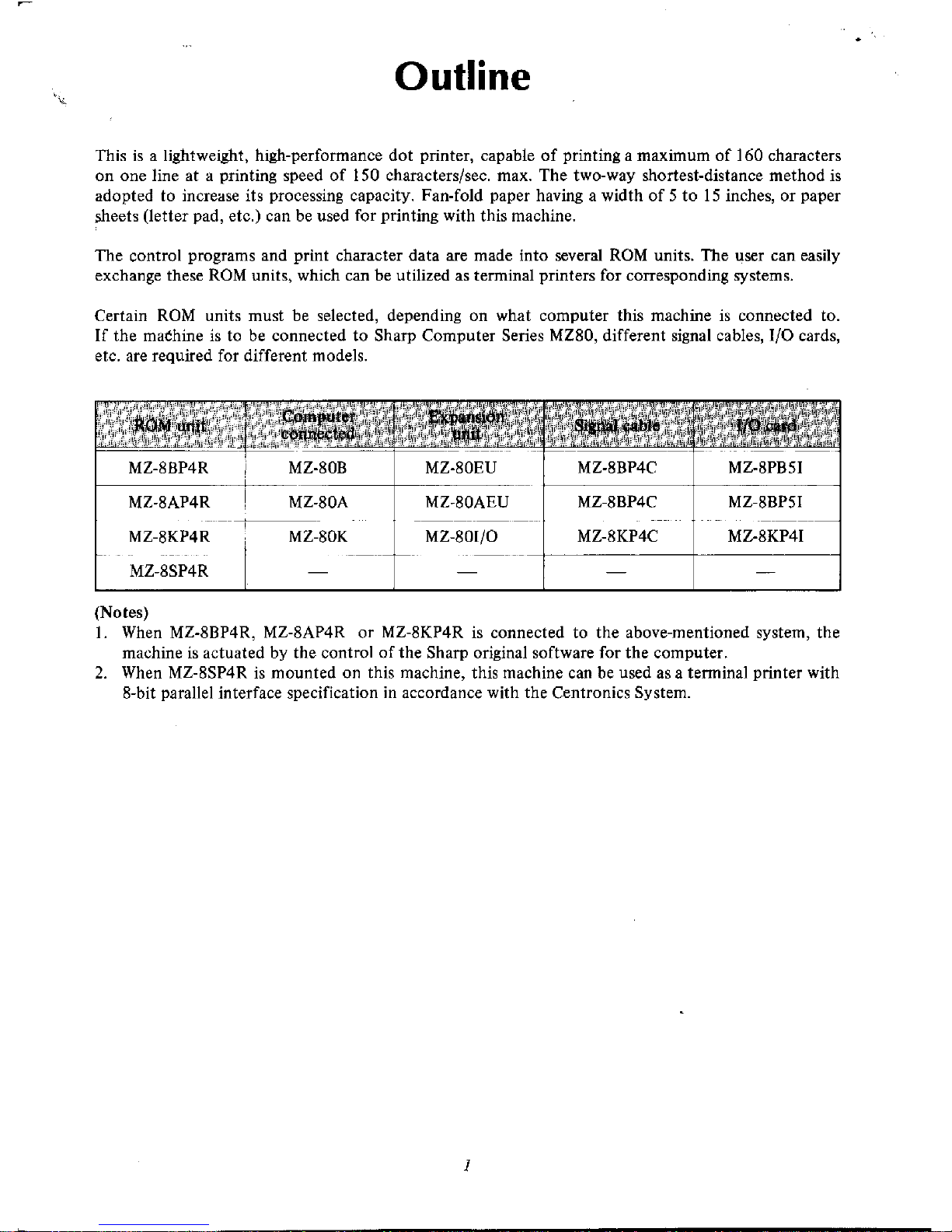

Outline

This

is

a lightweight, high-performance dot printer, capable

of

printing a maximum

of

160 characters

on

one line at a printing speed

of

150 characters/sec. max. The two-way shortest-distance method is

adopted to increase its processing capacity. Fan-fold paper having a width

of 5 to

15

inches, or paper

sheets (letter pad, etc.) can be used for printing with this machine.

The control programs and print character data are made into several

ROM

units. The user can easily

exchange these

ROM

units, which can be utilized

as

terminal printers for corresponding systems.

Certain

ROM

units must be selected, depending

on

what computer this machine is connected to.

If

the mathine is to be connected

to

Sharp Computer Series MZ80, different signal cables, I/O cards,

etc. are required for different models.

MZ-8BP4R

MZ-80B

MZ-80EU MZ-8BP4C

MZ-8PB51

MZ-8AP4R MZ-80A MZ-80AEU

MZ-8BP4C

MZ-8BP51

MZ-8KP4R MZ-80K

MZ-SOI/O

MZ-8KP4C

MZ-8KP41

. -

..

--+~~~~~~+~~~~~---j

MZ-8SP4R

(Notes)

l.

When

MZ-SBP4R, MZ-SAP4R

or

MZ-8KP4R is connected to the above-mentioned system, the

machine

is

actuated by the control

of

the Sharp original software for the computer.

2.

When MZ-8SP4R

is

mounted on this machine, this machine can be used

as

a terminal printer with

8-bit parallel interface specification

in

accordance with the Centronics System.

1

Page 5

Cautions for operation

• Installation

• Do

not

install this machine in the following places.

Humid place, excessively dry place

Place exposed directly to sunlight

Dusty place

Extremely hot/cold place

Place with a

lot

of

vibration

• Install this machine

as

horizontally

as

possible.

• Do

not

install this machine near equipment generating noise. Further, different power source

fnust be used for such equipment, since wrong operation may be caused

if

the same power source

is

employed.

• Voltage

of

power source used for this machine must conform to the specification on the rating

plate on the back

of

the machine. Do

not

connect other power source,

or

else trouble may be

caused.

• Connect/disconnect the

ROM

unit when power is turned off.

• Cautions during operation

• Do not

touch

the

printing head during operation.

•

If

water or other liquid

or

metallic articles such

as

needles and pins should enter this machine,

turn

off

power immediately, unplug the power cord, and contact the dealer.

If

the machine

is

opeHlted under such a condition, accident may be caused.

• Do

not

print characters when printing paper

or

cartridge ribbon

is

not

inserted. Otherwise, the

printing head may

be

damaged.

• Proper paper feeding function must be selected for specific paper used for printing .

. Fan fold paper Tractor system

• Paper sheets Friction system

The simultaneous use

of

the two systems

will

cause clogging

of

paper. When fan fold paper is

used, pull the paper release lever backwards

to

carry

out

tractor feed. (See page 7)

• Power cord

• Do

not

damage the power cord by placing it under a desk

or

chair, or by compressing it between

two articles.

•

It

is

dangerous

to

use damaged power cord. Furthermore, be sure to hold the plug when unplug-

ging the power cord.

• Impact

This machine consists

of

high-precision electronic components. Do

not

cause impact to this

machine,

by

hitting it with other articles or by dropping it.

• When this machine

is

not

to be operated for a long time

When this machine

is

not

to

be operated for a long time, be sure

to

unplug the power cord from the

outlet.

• Stain

Wipe

off

stain

on

this machine with soft cloth impregnated with water

or

detergent. The use

of

benzine, thinner,

or

other volatile substance,

or

insecticide will cause discoloration

of

the case.

2

Page 6

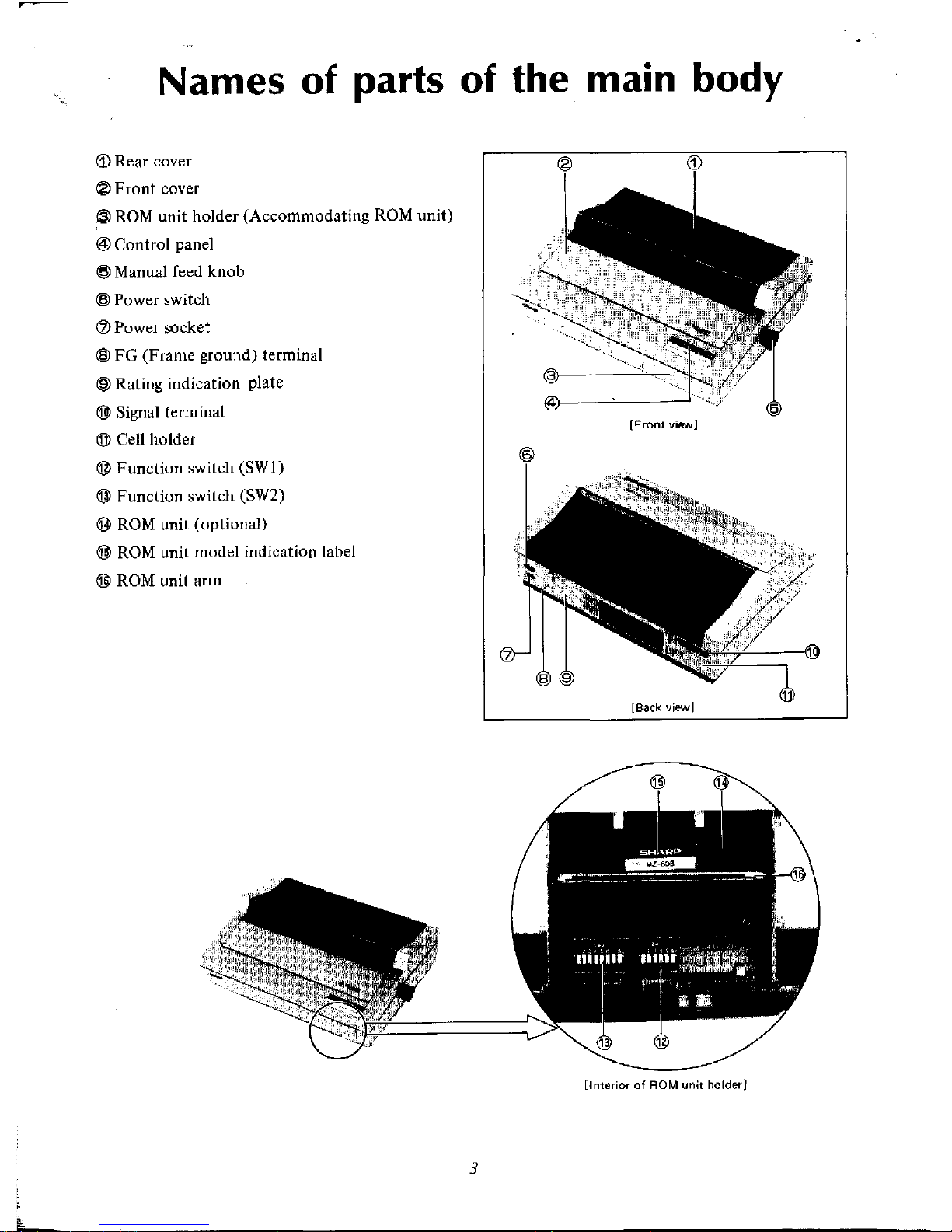

Names of parts of the

<D

Rear cover

®

Front

cover

@

ROM

unit holder (Accommodating

ROM

unit)

@ Control panel

@ Manual feed knob

@ Power switch

iZl

Power socket

@ FG (Frame ground) terminal

@ Rating indication plate

®l

Signal terminal

® Cell holder

@ Function switch

(SW

I)

® Function switch (SW2)

®>

ROM

unit (optional)

@

ROM

unit model indication lahel

@

ROM

unit arm

body

[Front

view]

[Back view]

[Interior

of

ROM unit holder}

Page 7

Connection with computers

(1)

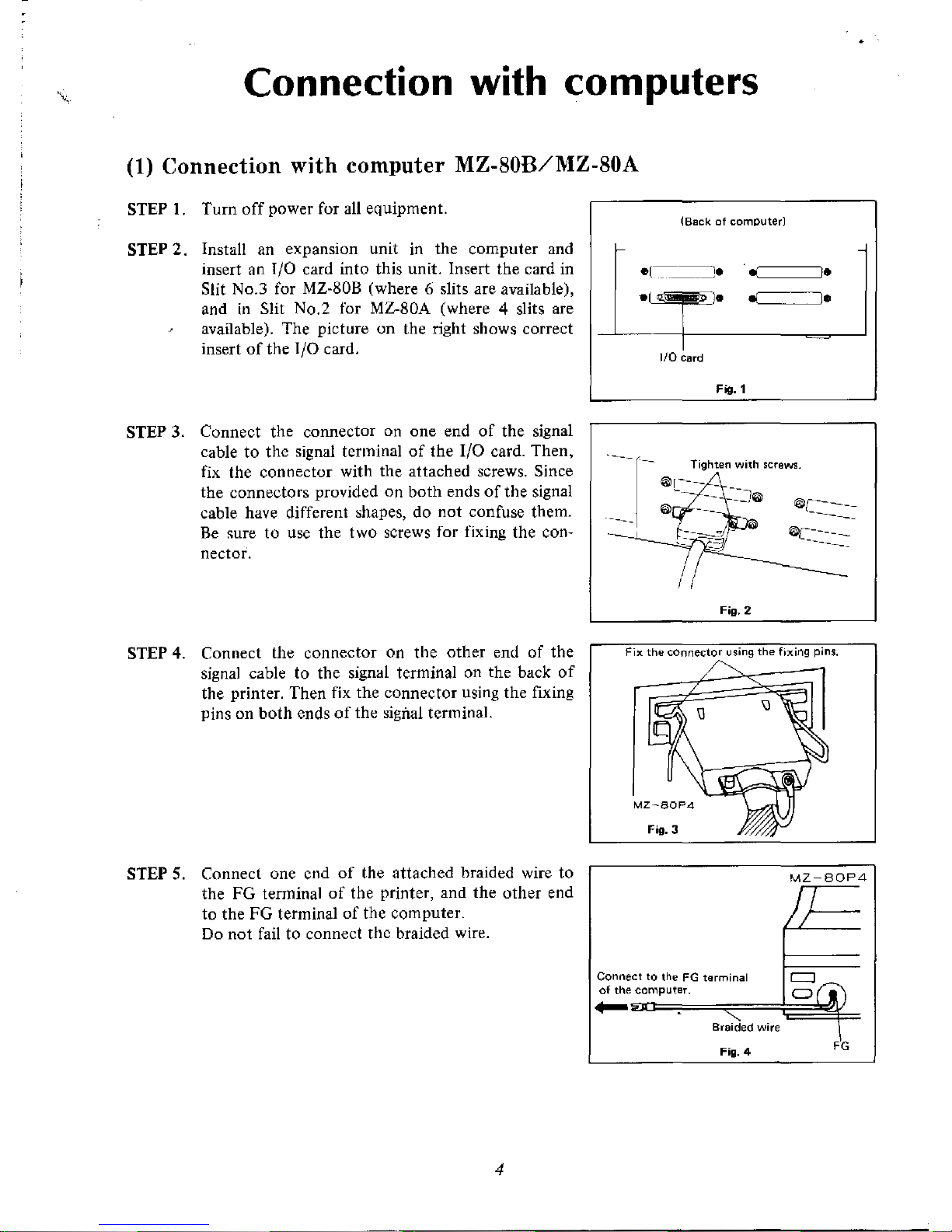

Connection with computer MZ-80B/MZ-80A

STEP

1. Turn

off

power for all equipment.

STEP

2.

Install an expansion unit

in

the computer and

insert an

I/O card into this unit. Insert the card in

Slit No.3 for MZ-80B (where 6 slits are available),

and

in

Slit No.2 for MZ-80A (where 4 slits are

available). The picture on the right shows correct

insert

of

the I/O card.

STEP

3. Connect the connector on one end

of

the signal

cable to the signal terminal

of

the I/O card. Then,

fix the connector with the attached screws.

Since

the connectors provided on

both

ends

of

the signal

cable have different shapes, do not confuse them.

Be

sure to use the two screws for fixing the con-

nector.

STEP

4. Connect the connector on the other end

of

the

signal cable to the signal terminal on the back

of

the printer. Then fix the connector using the fixing

pins on

both

ends

of

the signal terminal.

STEP

S.

Connect one cnd

of

the attached hraided wire to

the FG terminal

of

the printer, and the other end

to the FG terminal

of

the computer.

Do

not

fail

to connect the braided wire.

(Back of computer)

f-

-1-:------::=1-

•

I •

el

e

•

le

1/0

card

Fig. 1

®L-----

----

Fig. 2

Fix

the COnnector using the fixing pins.

Connect

to

the FG terminal

c:::J

-

of the computer. 0

......

..x=~~==lg~~

Braided wire

Fig. 4

FG

4

Page 8

r'

,

\i

..

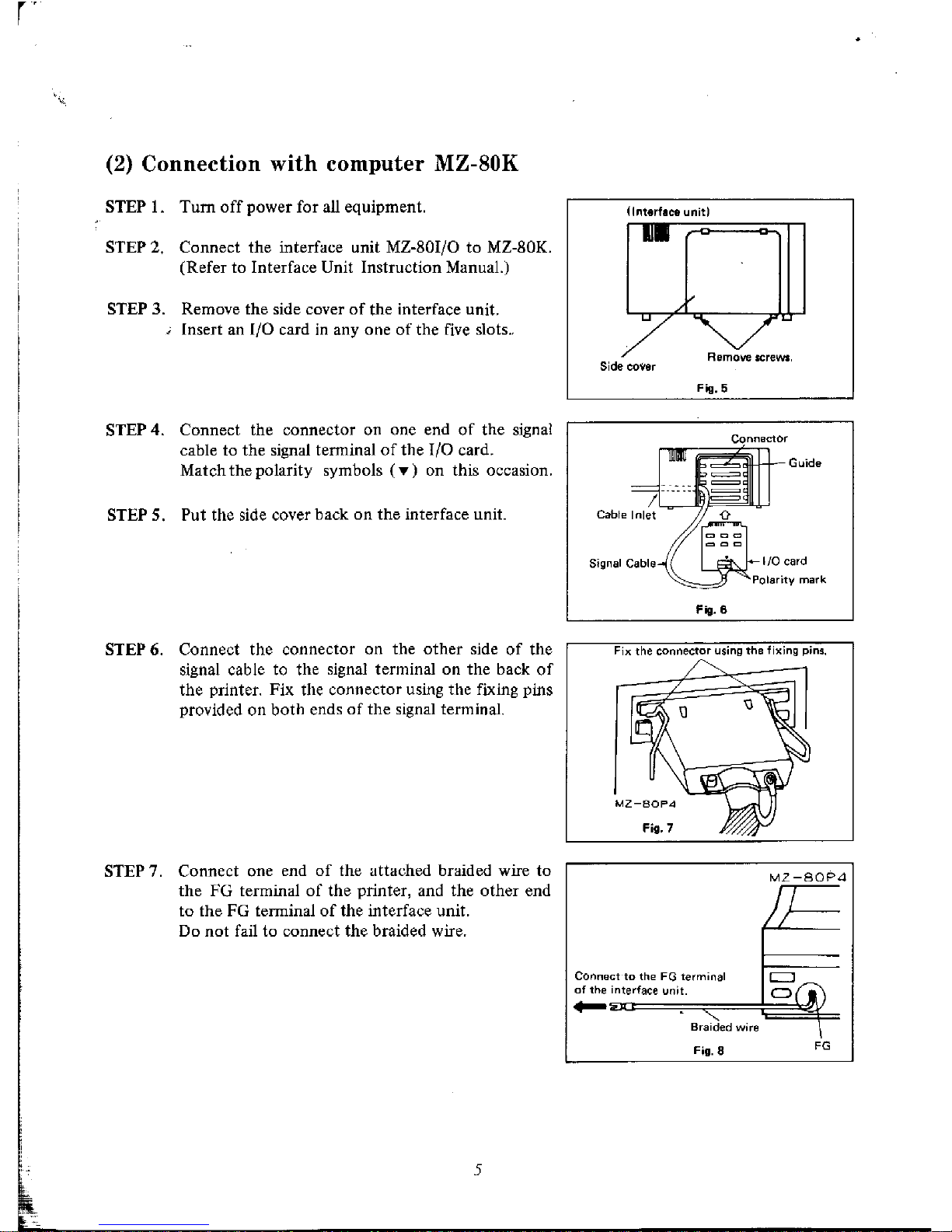

(2) Connection

with

computer MZ-80K

STEP 1. Turn

off

power for all equipment.

STEP 2. Connect the interface unit MZ-80I/O to MZ-80K.

(Refer to Interface Unit Instruction Manual.)

STEP 3. Remove the side cover

of

the interface unit.

< Insert

an

I/O card

in

anyone

of

the

five

slots

..

STEP 4. Connect the connector on one end

of

the signal

cable to the signal terminal

of

the I/O card.

Match the polarity symbols

(,.)

on this occasion.

STEP 5. Put the side cover back

on

the interface unit.

STEP 6. Connect the connector on the

other

side

of

the

signal cable to the signal terminal on the back

of

the printer. Fix the connector using the fixing pins

provided

on

both ends

of

the signal terminal.

STEP 7. Connect one end

of

the attached braided wire to

the FG terminal

of

the printer, and the other end

to the FG terminal

of

the interface unit.

Do

not

fail to connect the braided wire.

5

(Interface unit)

Side

cover

Signal Cable

--;::c:=c::;n

Remove

screws.

Fto,5

Connector

I1HImr~~~i+}-

Guide

F;g.6

1/0

card

Polarity mark

fix

the connector using the fixing pins.

MZ-BOP4

J/

Connect

to

the

FG

terminal

=

of

the interface unit.

O~

~

.

Br~ed

wire

Fig. 8

FG

Page 9

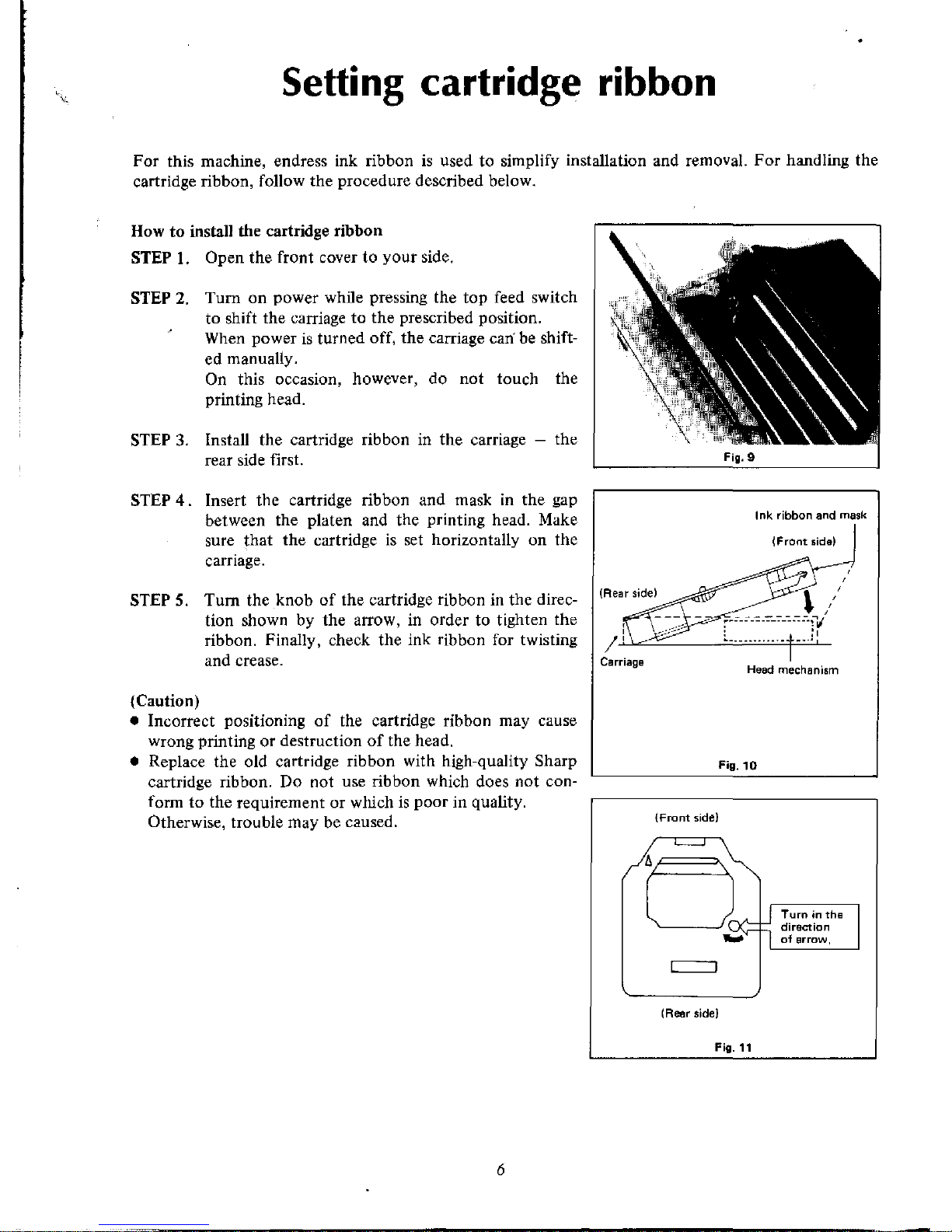

Setting cartridge ribbon

For

this machine, endress ink ribbon

is

used to simplify installation and removal.

For

handling the

cartridge ribbon, follow the procedure described below.

How

to

install the cartridge ribbon

STEP 1. Open the front cover

to

your

side.

STEP 2. Turn on power while pressing the top feed switch

to shift the carriage to the prescribed position.

When power

is

turned off, the carriage can' be shifted manually.

On this occasion, however, do

not

touch the

printing head.

STEP

3.

Install the cartridge ribbon

in

the carriage - the

rear side first.

STEP

4.

Insert the cartridge ribbon and mask

in

the gap

between the platen and the printing head. Make

sure

that

the cartridge

is

set horizontally on the

carriage,

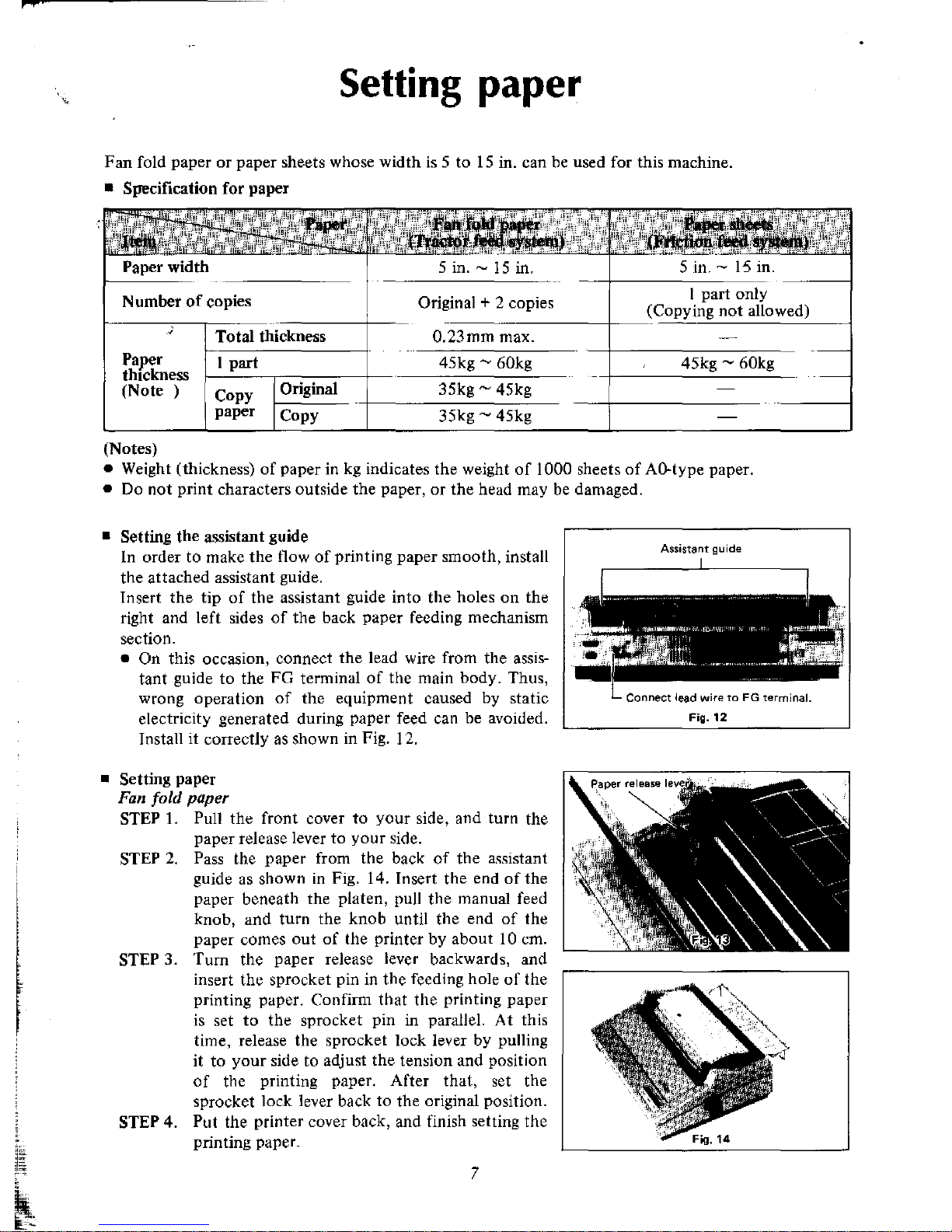

STEP 5. Turn the knob

of

the cartridge ribbon

in

the direction shown by the arrow, in order to tighten the

ribbon, Finally, check the ink ribbon for twisting

and

crease.

Carriage

(Caution)

• Incorrect positioning

of

the cartridge ribbon may cause

wrong printing or destruction

of

the head,

• Replace the old cartridge ribbon with high-quality Sharp

cartridge ribbon, Do not use ribbon which does

not

con-

form

to

the requirement

or

which

is

poor

in quality,

Otherwise, trouble may be caused,

6

(Front

side)

(Rear

side)

Ink ribbon

and

mask

(Front

side)

,

,

Head

mechanism

Fig,

10

Turn

in

the

direction

of

arrow,

Fig.

11

Page 10

Setting paper

F an fold paper

or

paper sheets whose width

is 5 to

15

in. can be used for this machine.

• Specification for paper

Paper width

5 in.

-

15

in.

5

in. -15

in.

Number

of

copies

Original + 2 copies

I part only

(Copying

not

allowed)

;

Total

thickness

0.23mm

max.

Paper

thIckness

I

part

45kg - 60kg

45kg

- 60kg

(Note )

Copy

Original

35kg

- 45kg

paper

Copy

35kg

- 45kg

(Notes)

• Weight (thickness)

of

paper in kg indicates the weight

of

1000 sheets

of

AD-type paper.

• Do not print characters outside

the

paper,

or

the

head may be damaged.

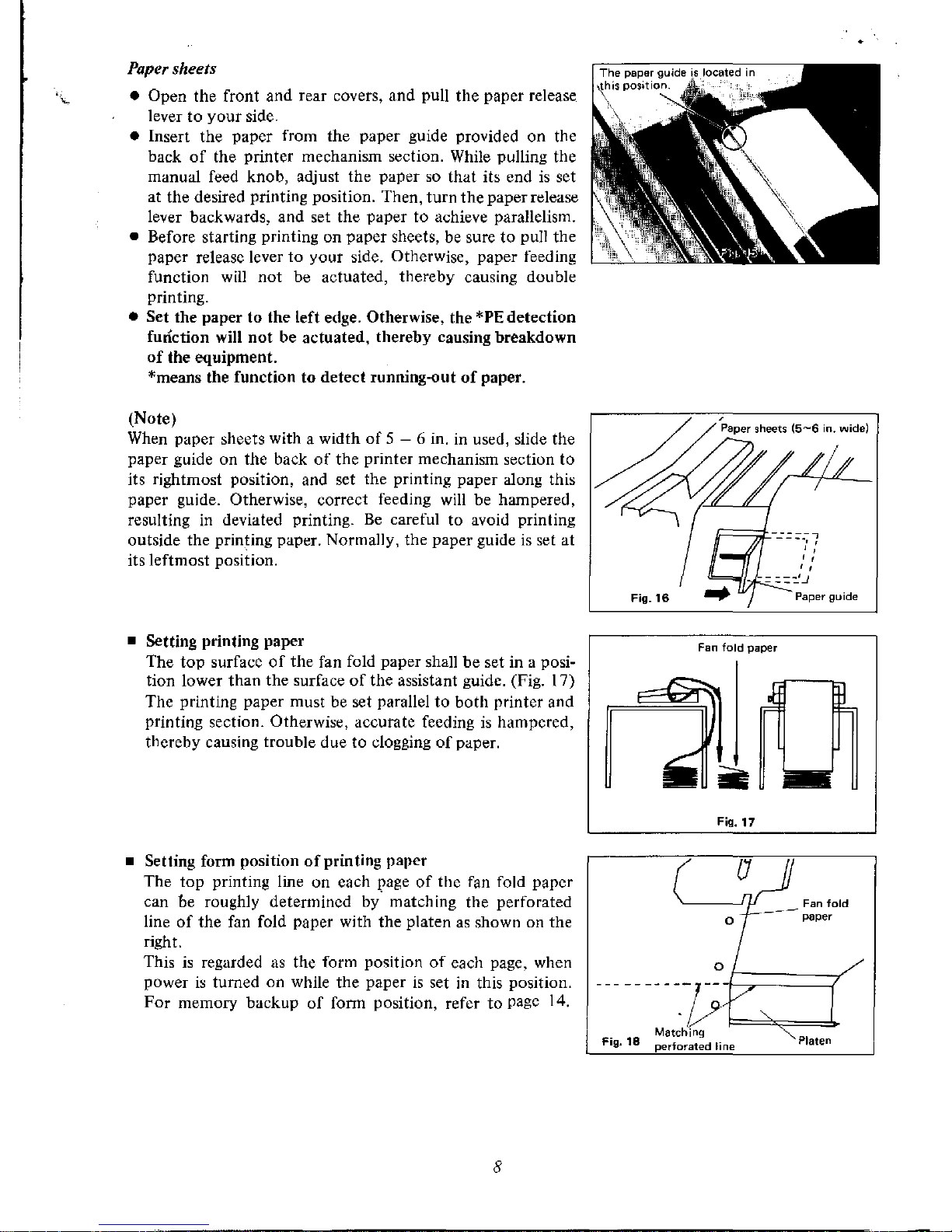

• Setting

the

assistant guide

In order to make

the

now

of

printing paper smooth, install

the attached assistant guide.

I nsert

the

tip

of

the assistant guide into

the

holes

on

the

right and left sides

of

the back paper feeding mechanism

section.

• On this occasion, connect

the

lead wire from the assis-

tant guide

to

the FG terminal

of

the main body. Thus,

wrong operation

of

the equipment caused by static

electricity generated during paper feed can be avoided.

Install it correctly as shown in Fig. 12.

• Setting paper

Fan fold paper

STEP 1. Pull the front cover

to

your

side, and turn the

paper release lever

to

your

side.

STEP

2.

Pass the

paper

from

the

back

of

the

assistant

guide

as

shown

in

Fig. 14. Insert the end

of

the

paper beneath the platen, pull

the

manual feed

knob,

and

turn the

knob

until

the

end

of

the

paper comes

out

of

the printer by about 10 cm.

STEP 3. Turn the paper release lever backwards, and

insert the sprocket pin in

the

feeding hole

of

the

printing paper. Confirm

that

the printing paper

is

set

to

the sprocket pin in parallel. At this

time, release the sprocket lock lever by pulling

it

to

your

side to adjust

the

tension and position

of

the printing paper. After that, set the

sprocket lock lever back

to

the original position.

STEP 4. Put the printer cover back, and finish setting the

printing paper.

7

Assistant guide

Fig.

12

Page 11

Paper sheets

.". • Open the front and rear covers, and pull

the

paper release

lever

to

your

side.

• Insert the paper from

the

paper guide provided

on

the

back

of

the printer mechanism section. While pulling the

manual feed knob, adjust the paper so that its end

is

set

at the desired printing position. Then,

turn

the

paper release

lever backwards, and set the paper

to

achieve parallelism.

• Before starting printing

on

paper sheets, be sure

to

pull the

paper release lever

to

your side. Otherwise, paper feeding

function will

not

be actuated, thereby causing double

printing.

• Set the paper

to

the

left edge. Otherwise, the *PE

detection

function will

not

be actuated, thereby causing breakdown

of

the equipment.

*means the function

to

detect

running-out

of

paper.

(Note)

4

When paper sheets with a width

of

5 - 6 in. in used, slide the

paper guide

on

the back

of

the printer mechanism section

to

its rightmost position, and set the printing paper along this

paper guide.

Otherwise, correct feeding will be hampered,

resulting in deviated printing.

Be

careful

to

avoid printing

outside the printing paper. Normally, the paper guide

is

set at

its leftmost position.

,

Paper sheets

(5~6

in.

wide)

• Setting printing paper

The

top

surface

of

the

fan fold paper shall

be

set in a posi-

tion lower than the surface

of

the assistant guide. (Fig. 17)

The printing paper must be set parallel

to

both

printer and

printing section.

Otherwise, accurate feeding

is

hampered,

therehy causing trouble due to clogging

of

paper.

• Setting form position

of

printing paper

The

top

printing line

on

each rage

of

the fan fold paper

can be roughly determined by matching the perforated

line

of

the

fan fold paper with

the

platen

as

shown on the

right.

This

is

regarded as the form position

of

each page, when

power

is

turned

on

while the paper

is

set

in

this position.

For

memory backup

of

form position, refer

to

page

14.

8

Fig.

16

F=:;;/:.-.: =

=.~

-:

, ,

, ,

,

,

==-=:!...J

Fan

fold

paper

Fig. 17

a

Paper guide

Fan

fold

paper

o .{=;.===={

---

------.;;-

Matching

~=""'~==:!,..

Fig.18

perforated line Platen

Page 12

, ,

Mounting/Dismounting

ROM unit

When installing the

ROM

unit in this machine

or

replacing it, follow the procedure described below.

Since the

ROM

unit

is

susceptible to electric shock, such

as

static electricity, adequate precautions

must be taken in handling

Or

storing it.

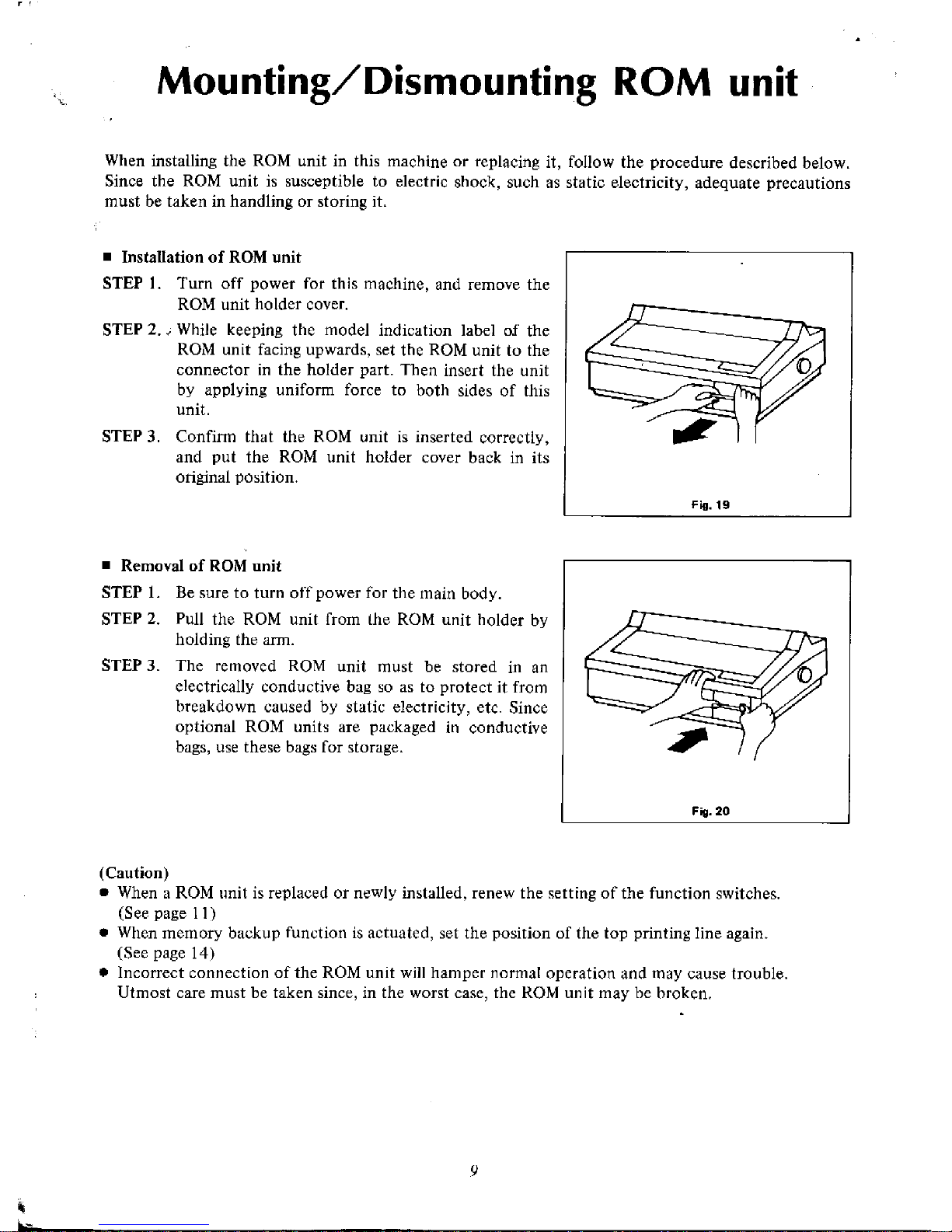

• Installation

of

ROM

unit

STEP

l.

Turn

off

power for this machine, and remove the

ROM

unit holder cover.

STEP 2.

,While

keeping the model indication label oJ the

ROM

unit facing upwards, set the

ROM

unit to the

connector

in

the holder part. Then insert the unit

by

applying uniform force to both sides

of

this

unit.

STEP 3. Confirm that the

ROM

unit

is

inserted correctly,

and

put

the

ROM

unit holder cover back in its

original position.

• Removal

of

ROM

unit

STEP

l.

Be

sure to turn

off

power for the main body.

STEP

2.

Pull the

ROM

unit from the

ROM

unit holder by

holding the arm.

STEP 3. The removed

ROM

unit must be stored

in

an

electrically conductive bag

so

as

to protect it from

breakdown caused by static electricity, etc. Since

optional

ROM units are packaged

in

conductive

bags,

use

these bags for storage.

(Caution)

Fig.

19

F;g.20

• When a

ROM

unit

is

replaced

or

newly installed, renew the setting

of

the function switches.

(See page

I

1)

• When memory backup function

is

actuated, set the position

of

the top printing line again.

(See page 14)

• Incorrect connection

of

the

ROM

unit

will

hamper normal operation and may cause trouble.

Utmost care must be taken since, in the worst case, the

ROM

unit may be broken.

9

Page 13

,

"

Operation

switches

and

checking

function

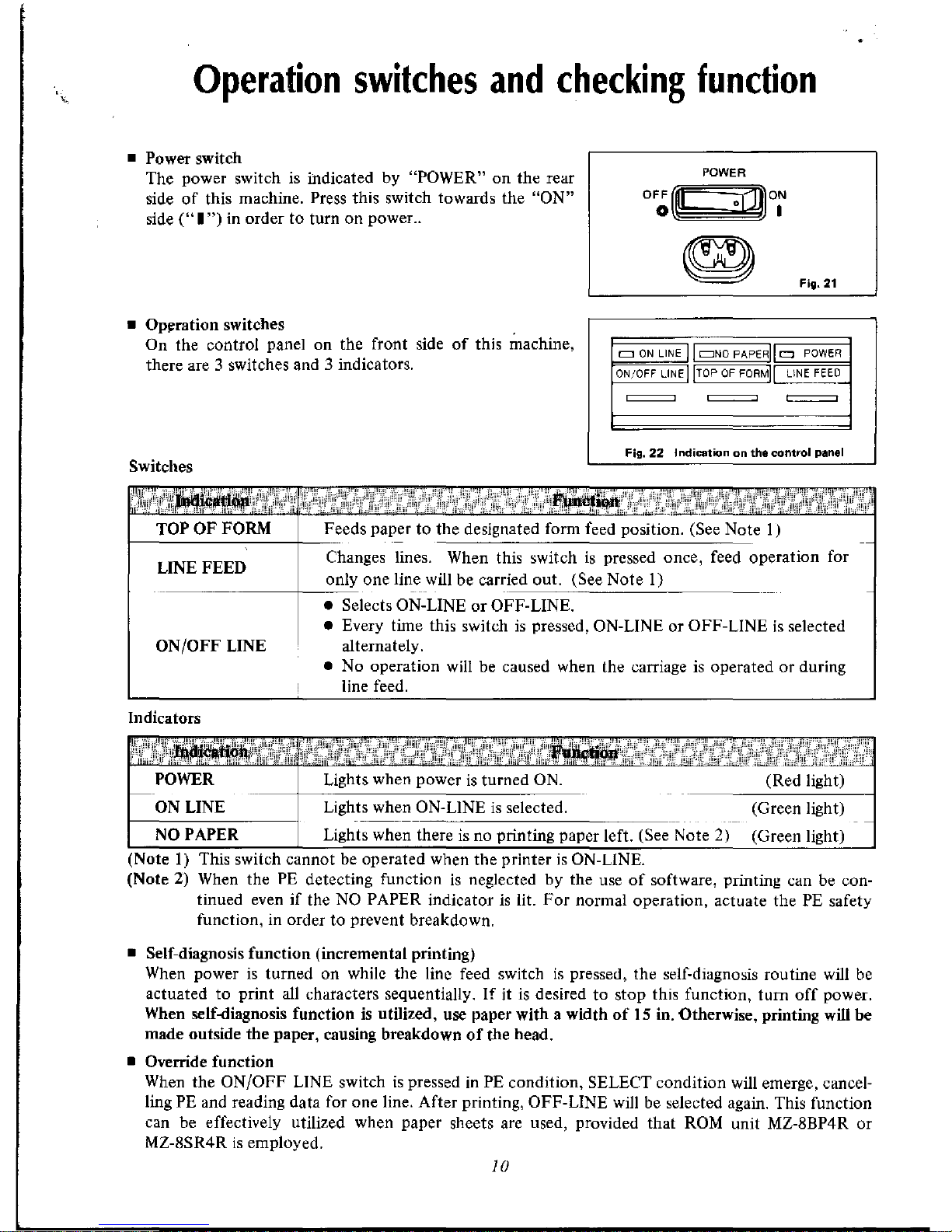

• Power switch

The power switch is indicated by

"POWER"

on

the rear

side

of

this machine. Press this switch towards the

"ON"

side

("

I")

in order to turn on power..

• Opl'ration switches .

POWER

Fig.

21

Cl

ON

LINE

11

=NO

PAPERiI

Cl

POWER

On the control panel on the front side

of

this machine,

there are 3 switches and 3 indicators.

ON/OFF

LINE

IITOP

OF

FORMiI

LINE

FEEO

I I I I I

I

Fig.22

Indication on the control panel

Switches

TOP

OF

FORM Feeds paper to the designated form feed position. (See Note

I)

1--=-=-=---=-=---=-=-=-==-----1--

LINE FEED Changes lines. When this switch

is

pressed once, feed operation for

~

______

--I-_.::o::n~IY

one line will be carried out. (See

Note

I)

ON/OFF LINE

Indicators

POWER

ON

LINE

NO

PAPER

• Selects ON-LINE

or

OFF-LINE.

•

Every time this switch

is

pressed, ON-LINE or OFF-LINE

is

selected

alternately.

• No operation

will

be caused when the carriage

is

operated

or

during

line feed.

Lights when power

is

turned ON. (Red light)

Lights when

ON-LINE

is

selected. (Green light)

Lights when there

is

no printing paper left. (See Note 2) (Green light)

(Note

1)

This switch cannot

be

operated when the printer

is

ON-LINE.

(Note 2) When the

PE

detecting function

is

neglected by the use

of

software, printing can be con-

tinued even

if

the NO PAPER indicator

is

lit.

For

normal operation, actuate the PE safety

function, in order

to

prevent breakdown.

• Self-diagnosis function (incremental printing)

When power

is

turned on while the line feed switch

is

pressed, the self-diagnosis routine

will

be

actuated to print all characters sequentially.

If

it

is

desired to stop this function, turn

off

power.

When self-diagnosis function

is utilized, use paper with a width

of

15 in. Otherwise, printing will be

made outside the paper, causing breakdown

of

the head.

• Override function

When the

ON/OFF LINE switch

is

pressed

in

PE

condition, SELECT condition will emerge, cancel-

ling

PE

and reading data for one line. After printing, OFF-LINE

will

be selected again. This function

can be effectively utilized when paper sheets are used, provided that

ROM

unit MZ-8BP4R

or

MZ-8SR4R

is

employed.

10

Page 14

Function switches

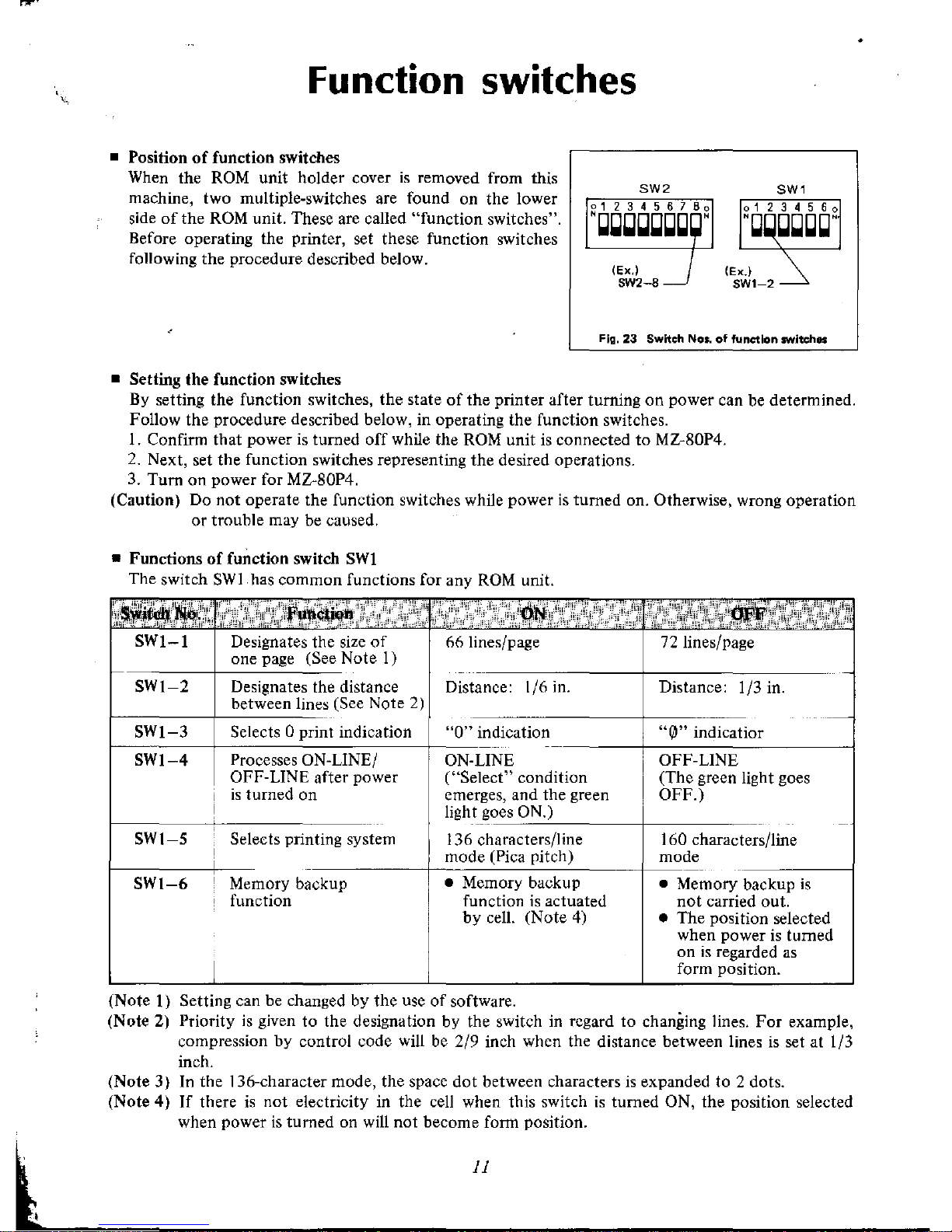

• Position

of

function switches

When the

ROM

unit holder cover

is

removed from this

machine, two multiple-switches are found on the lower

side

of

the

ROM

unit. These are called "function switches".

Before operating the printer, set these function switches

following the procedure described below.

• Setting the function switches

SW2

SW1

~~~~~~~~~~

IEx.1

J lEx.!

SW2-8

J

SWI-2

Fig.

23 Switch Nos.

of

function sw.ltehes

By setting the function switches, the state

of

the printer after turning

on

power can be determined.

Follow the procedure described below, in operating the function switches.

I.

Confinn that power

is

turned

off

while the

ROM

unit is connected

to

MZ-80P4.

2.

Next, set the function switches representing the desired operations.

3.

Turn on power for MZ-80P4.

(Caution)

Do not operate the function switches while power

is

turned on. Otherwise, wrong operation

or

trouble may be caused.

• Functions

of

function switch SWl

The switch

SW

I has common functions for any

ROM

unit.

SWl-l

Designates the size

of

66 lines/page

72 lines/page

one page

(See Note

1)

--

----

. -

SW\-2

Designa tes the distance

Distance: 1/6 in. Distance:

1/3 in.

between lines (See Note 2)

--

SWl-3

Selects 0 print indication

"Q"indication

"0" indicatior

SWI-4

Processes ON-LINE/ ON-LINE OFF-LINE

OFF-LINE after power

("Select" condition

(The green light goes

is

turned on emerges, and the green OFF.)

light goes

ON.)

_.

SW\-S

Selects printing system

136 characters/line

160 characters/line

i

mode (Pica pitch) mode

SW\-6

Memory backup

• Memory backup

• Memory backup

is

function function

is

actuated

no! carried out.

by

cell. (Note 4)

• The position selected

when power

is

turned

I

on

is

regarded

as

form position.

(Note

l)

Setting can be changed by the use

of

software.

(Note 2) Priority

is

given to the designation by the switch

in

regard to changing lines.

For

example,

compression by control code will be 2/9 inch when the distance between lines is set at 1/3

inch.

(Note 3) In the I 36-character mode, the space

dot

between characters

is

expanded to 2 dots.

(Note 4)

If

there

is

not

electricity in the cell when this switch

is

turned ON, the position selected

when power

is

turned on

will

not

become fonn position.

11

Page 15

\

,

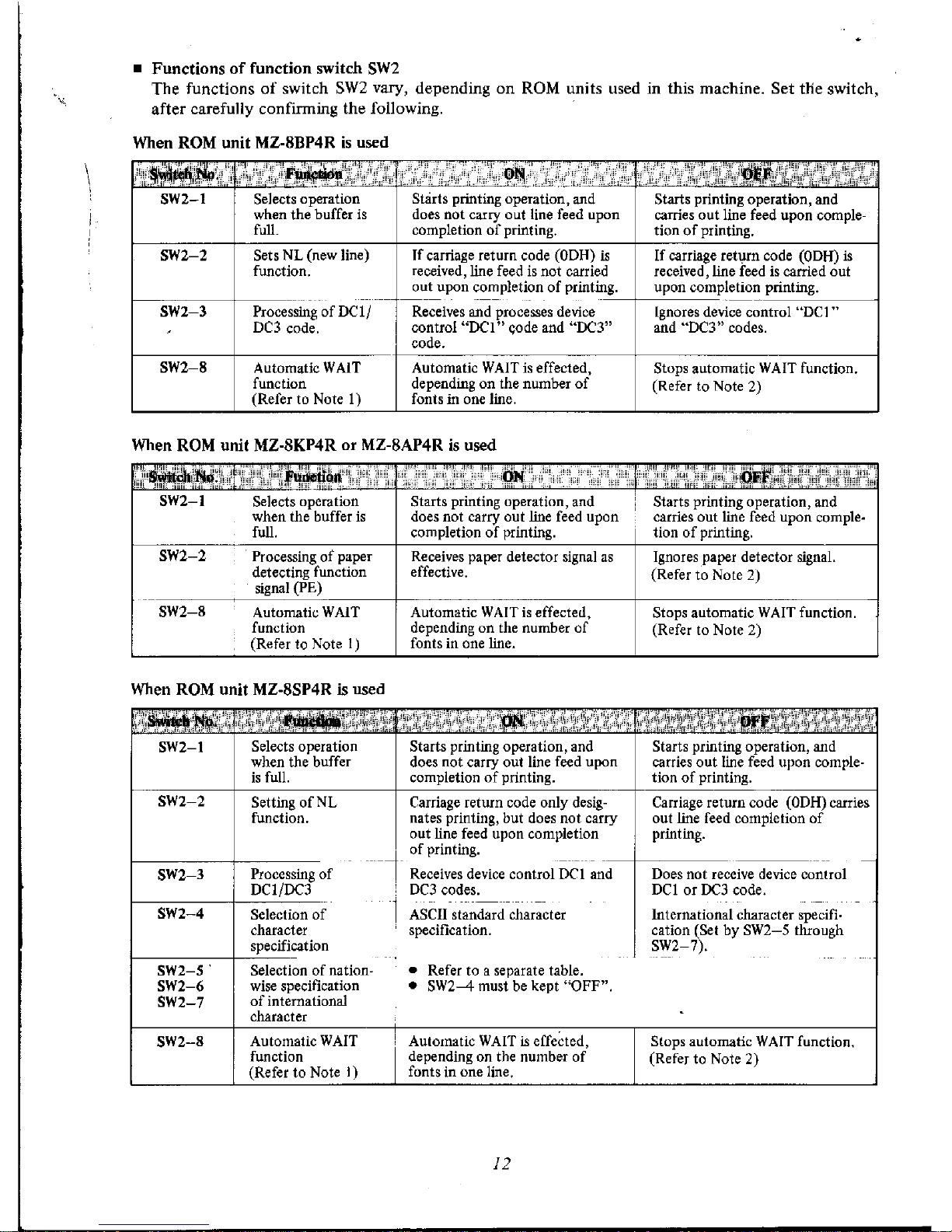

• Functions

of

function switch

SW2

The functions

of

switch

SW2

vary, depending on

ROM

units used in this machine. Set

tHe

switch,

after carefully

confIrming the following.

When

ROM

unit MZ-8BP4R

is

used

···~~:tM:

·l

..

·::,''':····/:·'~''·'·

..

',;·

i"""

',1,-

...............

·····'9l!!

'.

....

·;

..

I:

....

····,·'···:i".'~

(':,~,I'-,

'L,"

~

t

_);,,,,,

:.:,!:

ill

:',,)11"":

"I";

,I",,"

L

,-"

I",

;I~,,/II~"

,,','

,;"1

1

,[.,'

;11_':';,'::,

"""

,}'[,I',

,,'

I'

...

"":"'"

I""

,,:...,,'~

-~

......

,

SW2-\

Se1ects operation Starts printing operation, and

Starts printing operation, and

when the buffer

is

does

not

carry

out

line feed

upon

carries

out

line feed upon comple-

full. completion

of

printing.

tion

of

printing.

SW2-2

Sets NL (new line)

If

carriage return code

(ODH)

is

If

carriage return code

(ODH)

is

function.

received,

line

feed

is

not

carried

received, line feed

is

carried out

out upon completion

of

printing .

upon completion printing.

------

---

.

_-

._--

SW2-3

Processing

of

DCII

Receives

and

processes

device

Ignores device control "DC I "

DC3

code,

control

"DCl

t!

(fode

and

"DC3"

and "DC3" codes.

code.

SW2-8

Automatic WAIT Automatic

WAIT

is

effected,

Stops automatic

WAIT

function.

function depending

on

the number

of

(Refer

to

Note 2)

(Refer to Note

I)

fonts

in

one line.

When

ROM

unit MZ-8KP4R or MZ-8AP4R

is

used

'"I~

iI'I~:).'!'~,1t'

i~iloli'!.

'111:'11'

""

..

",_..Ii.H.HH

\:,

'.

,·:,;"

..

,·;;···,HN

•...

,······.·······,

..

... . .........

,.....

..........

:t.l".i,;,"~,~

,,;'~,r:,l:";·n!;;,

.............

····,1·".·

..

;"

':,,::"·:.j'i'

SW2-\

Se1ects operation Starts printing operation, and

,

Starts printing operation, and

i

when the buffer

is

does not carry out line feed upon

carries out line feed upon comple.

full.

completion

of

printing.

tion

of

printing .

SW2-2

. Processing

of

paper

Receives paper detector sign.l

.s

Ignores paper detector signal.

detecting function effective.

(Refer

to

Note 2)

signal

(PE)

SW2-8

Automatic

WAIT

Automatic

WAIT

is

effected,

Stops automatic

WAIT

function.

function depending

on

the number

of

(Refer to Note 2)

(Refer to Note I) fonts in one line.

When

ROM

unit MZ-8SP4R is used

..

~"

...

,'I

"

'11

"

" 1

);'1,"

";,,,,'",,),iON:

i

;:

'.r:;)'·:

!trr

,'''''1

,""_

.', ' ;,'I!,

11,,,

'Ii."!,

":,_:11,:'

,

'''

..

,')"1'

[>"I"l"

SW2-\

Selects operation

Starts printing operation, and Starts printing operation, and

when the buffer does

not

carry out line feed upon carries

out

line feed upon comple-

is

full. completion

of

printing. tion

of

printing.

SW2-2

Setting

of

NL Carriage return code only desig- Carriage return code

(ODH)

carries

function.

nates printing, but does

not

carry

out line feed completion

of

out line feed upon completion

printing.

of

printing.

.

._--

-------

-

SW2-3

Processing

of

Receives device control DCI and

Does

not

receive

device

control

DCI/DC3

DC3

codes. DCI or

DC3

code.

...

_-----

_ .

- -

SW2-4

Selection

of

ASCII standard character

International

character

specifi.

character

specification. cation

(Set by SW2-S through

specification SW2-7).

...

SW2-S'

Selection

of

nation-

•

Refer

to

a separate table.

SW2-6

wise specification

•

SW2--4 must be kept "OFF".

SW2-7

of

international

character

.

SW2-8

Automatic

WAIT

!

Automatic

WAIT

is effected,

Stops

automatic WAIT function.

function depending on the number

of

(Refer

to

Note 2)

(Refer

to

Note I)

fonts in one line.

12

Page 16

Languagewise international character setting

\,

For

differences

in

languagewise international characters, refer to the Character Code Table on page 45.

(ASCII standard)

ON

French

OFF OFF

ON

ON

German

OFF

ON

OFF

ON

Danish

OFF

OFF OFF

ON

Swedish

OFF

ON

ON

OFF

Itali~n

OFF OFF

ON

OFF

Spanish

OFF

ON

OFF

OFF

(Note 1) Automatic WAIT

When automatic WAIT function

is

effected, the

dot

duty calculating routine is actuated

to

auto-

matically creat

lag

time when the capacity

of

the head

is

exceeded.

•

When stopping the automatic

WAIT

function, pay attention to what

is

printed. Do

not

use image print

or quasi-graphic pattern when the automatic

WAIT

function

is

stopped. Further, avoid printing the

same character cOl1tinuously. Especially, limit the number

of

fonts per minute to less than 70,000 dots.

(Note 2)

Not

applicable to incremental printing.

13

Page 17

Memory

backup function

This machine

is

capable

of

memory backup by cells. (Cells

are sold separately, though.) When the memory backup

func-

tion

is

effected, form position will

not

be affected by turning

on/off

of

power. Thus, handling

of

fan-fold paper can

be simplified. This function can be stopped

by

operating

pertinent function switch inside the machine.

.,

• How

to

set form position

STEP

1.

Confirm that power source for the printer

is

turned

OFF

when the

ROM

unit

is

connected.

STEP 2. Insert 2 dry cells (SUM-3) into the cell case provid-

ed inside the main body.

For

details

of

the cells,

read the cautions given below.

STEP 3. Turn the function switch

(SWI-6)

ON, then supply

power to the printer.

STEP 4. Press the form feed switch. After form feed, pull

the manual feed knob to determine the form

position

of

paper. (See page 8)

(Caution)

Fig.

24

SW2

SW1

Install

2 cells

!SU

Set

SW1-6

at

"ON"

pOSitIOn.

-

Fig. 25

•

When

PE

condition emerges, set the paper in accordance with the above-mentioned procedure again.

• When the memory backup function

is

to

be

utilized, do not turn the manual feed knob. Otherwise,

form position may be deviated.

• Wrong use

of

dry cells

will

cause leakage or breakdown.

Keep the following

in

mind when using them.

\.

Set the cells with their plus

(+)

and minus

(-)

sides correctly positioned

as

indicated on this

machine.

2.

Do

not

mix new and old dry cells for use.

3. Do

not

use

different kinds

of

dry cells. They may differ

in

voltage, even if their shapes are the

same.

4. Remove dry cells from this machine,

if

they are

not

to be used over a long period

of

time.

5.

There are charging-type and non-charging-type cells.

Read the cautions written

on

them, before using these cells.

• Do

not

turn

off

power when the following operation

is

carried out during memory backup.

Otherwise, form position may be deviated .

• Line feed

• Form feed operation

•

If

ROM

units are exchanged during memory backup, readjust form position

of

paper.

• Replace old cells with new ones every year, although the life

of

ce\1

differs depending

on

internal

discharge and frequency

of

use. (Trouble may occur to some cells,

due

to corrosion, etc.)

14

Page 18

•

Printer control codes

The printer control differs, depending

on

the

kinds

of

ROM

units used in this machine,

(OOH)

(OAH)

(OBH)

(OCH)

• When CR code

is

input,

data

inside

the

buffer

is

printed.

• When there

is

not

data before CR code

is

received,

the

carriage does

not

shift.

• When the internal function switch

is

turned

OFF,

linefeed

is carried

out.

(Refer to the function

of

SW2-2.)

---------------------

• Line feed code.

• This code

is

used

both

as

line change instruction and printing in-

struction.

• Vertical tabulation (VT)

• This

is

a multiple-line feed code. Operation is carried

out

in

ac-

cordance with

the

tabulation previously set in RAM.

• Printing instruction code. When this VT code

is

received, stored data

will be printed, and after that, automatic feeding will be carried

out

to

the line previously set by tabulation.

• Tabulation in excess

of

the set page length will be ignored, and

the

same operation as by (OAH) code will be carried out.

------------------~

•

Form

feed

, • This

is

a multiple-line feed code. Automatic feeding

is

carried

out

to

the form feed position set in the memory.

• This

is

also used

as

printing instruction.

•

If

the

buffer already has printing data, the data will be printed first

before automatic feeding

is

started.

-----~------

-----------------------

(09H)

(11

H)

(12H)

• Horizontal tabulation

• When this code

is

received, data for tabulation set in

RAM

will be

reorganized, for storage in the buffer.

• Excess over the maximum

number

of

characters designated by

(lB)+

(J

9H)+(HEX)

will

be ignored.

• This

is

not a printing inspection.

• Device control 1 (DC

I)

• This

is

a printer select instruction code.

• This code can be ignored by manipulating

the

internal function

switches.

• When the data are received, the on-line indicator lights up.

• The I36-character/line mode will be selected.

• When this code

is

received, the carriage returns to its

home

position

for line feed, and the I 36-character/line mode

will

be selected.

15

Page 19

•

(MZ-SBP4R)

~~~N

(13H)

• Device control 3 (DC3)

• This

is

a printer deselect instruction code.

• This code

is

ignored when the printer is in DESELECT mode.

1---------+----------

-------

(l4H)

(ISH)

.,

(OEH)

(OFH)

(IBH)

(1B)+<OO)

(lB)+(02)

(IB)+(] 9H)+(HEX)

(lB)+(OSH)

•

Instruction

to

cancel enlarged characters.

• This code can be set

in

any place in the data code string.

• This code

is

ignored when the 136 character/line mode

is

selected.

• Cancel code

• This cancel code clears printing data before this code

is

received

as

well

as

SO/SI.

•

This code

is

not

applicable to image printing.

• Shift

out

(SO)

•

This code is enlarged character instruction, and can be inserted in

any place during data receiving.

• Data after receipt

of

SO

is

effective until

SI

code

is

received. They

will

not

be cancelled by changing lines.

• Even

if

SO code

is

received after the previous

SO

code

is

received and

before

SI

code

is

received, the

SO

will be ignored.

• Shift

in

(SI)

• When this code

is

received, the printer prints the data stored

in

the

buffer, makes the carriage to return, and changes into the

160

characters/line mode.

• This code will be ignored when the 160 characters/line mode

is

already selected.

• Escape code

• HEX code following this code controls various printers.

• Compression mode

• After this code is received, 1/9 inch line feed will be made.

• This code will

not

be cancelled until

(I

B)+(02)

is

received.

• This code can be received any time during data receiving.

• This code will be ignored when 1/9 inch feed

is

already selected_

•

Cancels compression mode.

• When this code

is

received, automatic line feed

is

started. Line feed

will take place every 1/6 inch.

• The

<HEX)

value following

(lBH)+(

19H) designates the maximum

number

of

printing characters.

• When the I 36-character mode

is

specified, 0 < HEX

-;;;

136

• When the l60-character mode

is

specified, 0 < HEX

-;;;

160

•

Not applicable

to

image printing.

•

When

this code

is

received, line reed

will

be

carried

out

twice.

For

example, if 1/6 inch feed

is

specified before tbis code

is

received,

1/3 inch line feed

will

be started_

16

Page 20

(M7

_RRP<1 J;I

:t~:~:

'''I i,

;:';'

I~"

"",""""~'"''

'''/''

c,

"",><

"C.i,,}C(

I

~

i

",:""

,

',_"1,"';';,11,;1",'11""1 "

(lB)+(06H)

• Code to cancel (I B)+(OSH)

(lB)+(08H)

~"'"

• When this code

is

received, PAPER EMPTY (PE)

will

be ignored.

(I

B)

+<09H)

•

Makes PAPER EMPTY (PE) signal effective.

(lB)+(

I IH)+<HEX,)

• Sets vertical ta bulation.

+ .....

+(HEXn)+(OO)

•

Following

(lB)+(1IH),

transfers

tabulation

setting position

in

hexadecimal number.

• Upon completion

of

tabulation setting, transfers

(00)

NULL code.

,"

The maximum tabulation value shall be [specified page length

-I]

.

Example: When page 'Iength

is

72 lines, tabulation value

will

be

71

or less.

• Tabulation value can be set in a random manner.

• Tabulation value

is

an absolute value from home position.

-

(IB)+(]4H)

• Clears vertical tabulation setting.

(1

B)+( 12H)+<HEX)

• Sets the number

of

lines per page.

• Any number up to 72 lines can be set in

<HEX)

following

(lB)+

(

12H>.

• Any number in excess

of

72 liens

will

be ignored.

• 0 line

will

be ignored.

• When this code

is

received, form feed will be executed automatically.

(lB)+(

13H)+<HEX,)

• Sets horizontal tabulation.

+ ..... +<HEXn )+(

00)

• n value can be up

to

135 lines.

• n values can

be

transferred in

no

particular order.

• Upon completion

of

tabulation setting, NULL code shall be trans-

ferred.

(IB)+(ISH)

• Clears horizontal tabulation setting.

f-----

-

(I

B)+( 18H)+<HEX,)

• Image print instruction.

+<HEX,)

•

The number

of

image data to be transferred following (I

B)+O

8H)

+<Data string)

shall be transferred

in

2 bytes: (HEX,)+(HEX,). (HEX,) represents

lower 8-bit data, while

(HEX,) represents upper 8-bit data. If the

number

of

transfer bytes

is

16

bytes,

(I

B)+( 18H)+ ( I

OH

)+(OOH)

+( 16-byte data).

When this code

is

received, line feed is started automatically after

printing the 16-byte data.

• This code will be ignored when <HEX,)+<HEX,) = (00)+(00).

17

Page 21

•

•

~WhBjeln~R~oIMHln~n~it~M~Z~-E83K~P4~R~o~r~M~Z~-8~A1P~4~Rji~S~UCsetd~E~~~tF~~~~~(~M~Z-8KP4R/MZ-'8AP4R)

(ODH)

(OBH)

(OCH)

(OFH)

(09H)

(OAH)

.

(09H)+(09H)+

(ASCII)H +(ASCII)L

(09H)+(09H)+(09H)

• Prints data

in

the buffer by CR code input.

•

If

there

is

not

data before CR code

is

received, only line feed

is

carried out.

• Control code to create enlarged characters.

• Enlarges each character

as

80 characters/line (in the l60-character

mode) or

as

68 characters/line (in the I 36-character model.

• Enlarged characters cannot be changed into ordinary characters when

lines are changed. (The function cannot be cancelled.)

• Command to cancel enlarged characters.

• Executes form feed.

• Also functions

as

printing instruction.

•

If

data already exist in the buffer, feed operation

is

automatically

carried out upon completion

of

printing.

• Compression mode (1/9 inch feed)

• Cannot be cancelled by changing lines.

• When this code

is

executed, automatic line feed

is

carried out

to

can cell the compression mode.

• Specifies the number

of

lines on one page.

• ASCII (two bytes) following (09H)+(09H) expresses hexadecimal

data. (Ex.)

If

HEX.

. .

..

16H

transfers

(ASCII)II

.....

31

(ASCII)L

.....

36

•

If

error

IS

found

in

continuous data, the control

will

be ignored.

• Any number

of

lines can be specified par page up

to

72 lines.

• By transferring (09H) continuously three times, the 160-character

mode can

be

selected.

• The mode when power

is

turned on can also be set the function

switch

SW1-S.

• After the mode change, line feed

is

carried

out

automatically.

•

If

data exist in the buffer, the carriage returns to the home position

after printing, line feed

is

carried out, and modes are changed.

18

Page 22

(09H)+(09H)+(OBH)

(OBH)+(OBH)+

(Data string)

(MZ-8KP4

R/MZ-IlAP4R)

• I 36-character mode can be selected.

• The mode when power

is

turned

on

can also be set the function

switch

SWl-S.

• After the mode change, line feed

is

carried

out

automatically.

•

If

data exist in the buffer, the carriage returns

to

the home position

after printing, line feed is carried out, and modes are changed.

• Permits image printing.

•

(OBH)

is

transferred continuously twice, and the hexadecimal data

are transferred in 2-byte

ASCII expression.

(Ex.)

For

image printing

of

l6-byte data, data string

will

be

as

follows: Data string

--+

(HEXl)+

...... +( HEX16)

(Note)

(HEXl) -(HEXI6)

above

is

hexadecimal data in ASCII

expression.

• Printing instruction for image print

is

given by

ODH,

as

in

the case

of

ordinary character printing.

•

If

continuous data have an error, this code will be ignored.

19

Page 23

''':'

09H

OAH

,

OBH

OCH

ODH

OEH

Horizontal

tabulation

Line feed

Vertical

tabulation

Form feed

Carriage return

Shift

out

(SO)

•

When this code

is

received, data for tabulation pre-

viously set

in

RAM

will be reorganized and stored in

the buffer.

• This functions both

as

line change instruction and

as

printing instruction.

•

If

no

printing data exists prior to line feed, the paper

will

be

fed by only one line.

• Paper

is

fed to the tabulation position previously set

in

RAM.

• This code also functions

as

a printing instruction.

•

If

no tabulation

is

set, the same operation

as

in Line

Feed

will

be carried out.

• When the horizontal tabulation code

is

received,

stored data

will

be printed and then paper

is

automatically fed to the line predetermined by tabulation

setting.

• Automatic feeding

is

carried

out

to

the form feed

position set in the memory.

• This code also functions

as

printing instruction.

•

If

the buffer already has printing data, automatic

feeding will

be

carried

out

after printing.

• Printing instruction code

• Whether to change lines after printing can be also

determined

by

the internal function switch.

• The carriage will

not

be shifted

if

there

is

no data

before this code

is

received.

However,

if

the internal function switch

SW2-2

is

turned OFF, line feed will be carried out.

• This

is

an enlarged character instruction code.

• Printing characters after

SO

are received will be en-

larged until

SI

code

is

received. (Ordinary characters

cannot be resumed

by

changing lines.)

•

SO

code can be input in any place during printing.

•

If

ordinary characters and enlarged characters are

mixed on one line, the position where a certain

en-

larged character falls on the

l35th

digit when con-

verted into ordinary characters will be regarded

as

the

end

of

the line.

20

Page 24

I

I

T'

----------------

OFH

IIH

l3H

ISH

ESC+(OOH>

[ESC=IBH]

ESC+<02H>

ESC+(04H)

Shift

in (SI)

Device

control I

(DCI)

Device

control 3

(DC3)

Cancel

code

Compression

mode

instruction

Cancellation

of

compression

mode

13

6-character

mode instruction

• Input

of

SI

code cancels enlarged characters. :ters.

•

When

SO

and

SI

are mixed, printing will be carried

out

as

follows.

A) Input

SO+"A"+CR+LF

Printing: A (enlarged character)

B) Input

SO+"A"+SI+"A"+CR+LF

Printing: A A

• This

is

a printer select instruction code.

• This code can be ignored by the operation

of

the

internal function switch.

• When this code

is

received, the ON-LINE indicator

will

go

on.

• This

is'

a printer deselec1 instruction code.

• This code

will

be ignored when the printer

is

execu-

ting deselect operation.

• This code can be ignored

by

seIecting the relevant

function switch.

• This

is

a cancel code, which cancels data

in

the buffer

stored before this code

is

received. SO/SI code

is

also

cancelled.

• N

at

applicable to image printing.

• After this code

is

received, 1/9 inch line feed

will

be

carried

out.

•

This code cannot be cancelled until ESC+02H

is

received or power

is

turned off.

• This code can

be

received anywhere during data re-

ceiving operation.

• After this code

is

received, 1/6 inch line feed

will

be

resumed.

After automatic feeding

is

executed to the next line

position, 1/6 inch feed

will

be started.

• When this code

is

received, the carriage returns

to

the home position and then the 136-character mode

will

be

selected.

• Printing after this code

is

received will have the

following printing construction -

Or

gap between

characters. (Ex.)

HH

[DOG~

= 2 dots I

21

Page 25

ESC+(03H>

ESC+(05H>

ESC+<06H>

ESC+<OSH>

ESC+(09H>

ECS+(\

IH)+

<HEX,)+ .... +

<HEXn)+

<OOH)

ESC+(\ 2H)+

<HEX)

I 36-character

mode

instruc-

tion

160-character

mode instruction

1/3 line feed

instruction

Cancellation

of

1/6 line feed

•

If

the buffer contains data, they

will

be printed

before line feed. After that, the 136 character mode will

be selected.

•

If

the 136-character mode

is

already selected, this

code

will

be ignored.

• When this code is received, the carriage returns

to

the

home position.

• Printing after this code

is

received

will

have the

following printing construction - or gap between

characters. (Ex.)

HH

•

If

the buffer contains data, the 160-character mode

will

be selected after printing them.

•

If

the 160-character mode

is

already selected, this

code will be ignored.

• After this code

is

received, 1/3 inch line feed

is

carried out.

If

compression

is

instructed, however, 2/9 inch feed

will

be carried out.

• After this code

is

received, 1/6 inch line feed

is

carried out.

If

compression

is

instructed, however, 1/9 inch line

feed will be carried out.

• Ignores signals from the paper detector.

• Receives signals from the paper detector

as

effective.

• Carries

out

vertical tabulation setting.

• Tabulation can be set by the hexadecimal number following ESC+(\

IH>.

• Tabulation value shall not exceed 71.

(When

One

page contains 72 lines.) (Refer to Note I)

• Tabulation can

be

set in a random manner.

• Tabulation value

is

an absolute value from the form position on the

printing paper.

• Sets the number

of

lines per page.

• The num ber in excess

of

72 lines

is

ignored.

• 0 (zero)

is

ignored.

• When this code is received, form feed

is

automatically carried out.

22

I

~

Page 26

ESC+(]3H)+

(HEX1) + .....

-+

(HEXn)+<OOH)

ESC+(]8H)+

<HEX1

)+(HEX, )

+<Data string)

. ,

ESC+(]4H)

ESC+06H)

ESC+(]

9H>+

(HEX)

• Sets

horizontal tabulation.

• n value shall be 135

at

maximum.

• n values may

be

transferred

in

no

particular order.

• Tabulation setting shall be completed with the NULL code.

• The number

of

image data following (]B)+(] 8H) shall be transferred in 2

bytes: (HEX1)+(HEX,).

•

The number

of

transferred bytes shall be expressed in 2-byte hexadecimal

number.

(HEXl) shall represent lower 8-bit data whereas (HEX2) upper

8-bit data. (Ex.) When the number

of

transferred bytes

is

16

bytes .

(I

BH)+<18H)+(l0H)+(Q0H)+(\ 6

byte

data)

• Clears vertical tabulation setting.

• Clears horizontal tabulation setting.

• Sets the maximum number

of

characters printed on one line.

• Specifies the number

of

characters with (HEX) fonowing ESC+(] 9H).

• In the 160-character mode, 0 < HEX

~

160

•

In the I 36-character mode, 0 < HEX ~ 136

(Note I)

When

one page contains 66 lines, the tabulation value shall be up to 65.

(Note 2) Character codes shall be

20H ~ 7EH. Character codes

of

7FH and larger shall be ignored.

23

•

Page 27

-

Control with

BASIC

language

This printer can be easily controlled with the use

of

Sharp BASIC language. Note, however,

that

different computers employed have different versions

of

BASIC language and commands to the printer.

For

details, refer to the BASIC Language

ManUal

.

• BASIC for MZ-80B/BASIC for MZ-80A

LIST/P

PRINT/P

LIST/P

LIST/P-IOO

LIST /P

100-500

LIST/P

500-

PRINT/P

A$

PRINTjP CHR$ (N)

PRINT/P CHR$(5)

Form feed

PRINT/P CHR$(6)

Initialization

PRINT/P CHR$(16)

Cancellation

of

line-

to-line compression

mode

PRINT /P

CHR$(l7)

Line-ta-line

compression mode

PRINT /P CHR$(18)

Enlarged character

instruction

Outputs

all

the lists in the BASIC text to the printer.

Outputs BASIC

text

as

far

as

statement No. 100 to the

printer.

Outputs BASIC text from statement Nos.IOO to 500

to

the printer.

Outputs BASIC

text

above the statement No.500 to the

printer.

Outputs the contents

of

string variable

A$

to

the printer.

If

32 ~ N ~ 255, N shall be regarded

as

ASCII code, and

the character corresponding to it shall be

output

to

the

printer. IF N

= 65,

"A"

shall be printed.

Paper shall be fed

to

the top (form position)

of

the next

page. The function

of

the printer control button (TOP

OF FORM)

will be carried

out

by software.

Resets

all

the control codes

to

their initial positions.

At this instance, form feed

is

carried out.

• The 136 characters/line mode can be resumed.

1/6 inch line feed

is

selected.

1/6 inch line feed

is

selected.

1/9 inch line feed is selected.

The mode in which the present printing character size

is

doubled

is

set.

If

the 136-character mode is set presently,

the 68-character mode will be selected.

If

the 160-

character mode

is

set presently, the 80-character mode

will be selected.

24

Page 28

PRINT/P

..

IMAGE/P

COPY/P

'i!I"

PRINT/P CHR$(19)

Cancellation

of

enlarged characters

!"'"r~_m(MZ-80B/80A)

The 136-character mode

or

160-character mode

is

re-

sumed.

PRINT /P CHR$(20) The space between characters is compressed.

Character-ta-character (The

160-character mode will be selected.)

compression

PRINT/P CHR$(21)

Cancellation

of

character-ta-character

compression

IMAGE/P

"A"

COPY!P I

COPY!P

2

Cancels character-ta-character compression.

(The

I 36-character mode shall be selected.)

ASCII code

of

character"

A",

or

bit pattern correspond-

ing to 41H,

will

be printed in the vertical direction.

LSB

-+ • This

dot

is

0

printed.

0

IMAGE/P

"A"

..

0

)41H

= 01000001

0

t t

0

MSB

LSB

•

MSB

.....

0

IMAGE/P CHR$(65) equals IMAGE/P "A". This print-

int

is

called the "Bit Image Mode".

(Note 1) Bit image data are given

as

string data.

(Note 2) The length

of

bit image data shall be 960/line.

If

the data exceeds 960, the remainder will be

printed after line feed.

(Note

3)

BASIC

for MZ-80A does

not

have this

[MA

GEl

Pcommand.

COpy

/P command

is

used for

output

of

pattern

in-

dicated on the computer CRT screen (or more strictly,

data in V-RAM region)

to

the printer

as

it

is

displayed

on one screen.

The following four copy formats are available.

However,

BASIC

language for MZ-80A does

not

have

COPY/P2, COPY/PJ, or COPY/P4 commands.

If

the CRT screen displays data

in

V-RAM region for

characters, the data

on

one screen win be output to the

printer.

Outputs

one-screen data accommodated in graphic

region

lout

of

2-screen

V-RAM

regions for graphic use

(graphic region 1 and graphic region

2)

to the printer,

and carries

out

bit

image pattern printing.

25

Page 29

COPY/P 3

COPY/P

COPY/P

4

COPY/PN

PAGE/P

Outputs

one-screen data accommodated in graphic

region 2 to the printer, and carries

out

bit image pattern

printing.

OR

of

the bits

of

the data accommodat'ed in graphic

regions

I and 2 will be regarded

as

output

data

to

the

printer. Therefore, the patterns obtained by

COPY /P2

and

COpy

/P3 will be superposed for printing.

The value. specified by N shall be the maximum number

of

lines to be printed

on

one page.

The number

of

lines here means the value for 1/6 inch

line feed. N shall be an integer selected from

I through

72. In the initial stage, one page

is

allowed

to

contain 66

lines.

(Note

I)

If

M = 0 - 4, 7 - IS,

or

22 -

31

in

PRINTjP CHR$(M), it will be ignored.

(Note

2)

M

in

CHR$(M) can be expressed in hexadecimal number.

For

example, since

(32)'0

= 20H,

the indication shall be CHR$($20). $ in the parentheses in front

of

the hexadecimal

number indicates hexadecimal representation.

(Note 3)

If

NO

PAPER takes place during the printing operation

of

the printer, ERROR in the

BASIC language will be

NOT READY I ERR65 I

in

order to actuate the over function.

I ERR67

Iwill

not be indicated.

26

Page 30

._-

--

--

-~

--

-~

~-~

~-~

---

.--.

--

• BASIC

for

MZ-80K

LlST/P

PRINT/P

LlST/P

LlST/P~IOO

LlST/P

100~150

LlST/P

500~

PRINT/P A$

PRINT/P CHR$(N)

PRINT/P

"m"

Form

feed

PRINT/p

"11"

Clear form

Outputs

all the lists in

the

BASIC

text

to

the printer.

Outputs

BASIC

text

as

far

as

statement No.1

00

to

the

printer.

Outputs

BASIC

text

from statement Nos.1

00

to

500

to

the

printer.

Outputs

BASIC

text

from

statement

No.500

on

to

the

printer.

Outputs

the contents

of

string variable A$

to

the

printer.

If

32 ~ N

;:;;

255, N will be regarded as ASCII code, and

the

character corresponding

to

it will be

output

to

the

printer.

IfN

= 65,

"A"

will be printed.

Paper

is

fed

to

the

top (form position)

of

the

next

page.

The function

of

the printer control

button

(TOP

OF

FORM) will be carried

out

by the use

of

software.

t-----

--.--.--

--

--

-----j

Cancels line-to-line compression

and

enlarged characters.

1---------+----------

PRINT/P

"0"

Enlarged character

instruction

The

80 characters/line mode 68 characterS/line

mode

will be selected.

-----/----

---

--.--.--

--

--.--

PRINT/P

"0"

Line-to-line

compression mode

PRINT/P

"DO

XX"

(xx = number

of

lines)

Page setting

1/9 inch line feed will be selected.

• Designates the

number

of

lines per page.

• One page can contain a maximum

of

72

lines.

• The

number

of

lines can be designated in hexadecimal

number.

(Ex.)

If

it

is

desired

to

print I1 lines on

one

page,

hexadecimal representation

of

1I

(OBH)

shall

be transmitted.

PRINT/P

"DD

OB

"

•

If

no designation

is

made by software,

the

number

of

lines

as

designated by

the

function switch

SW

I ~ I will

be adopted (66 lines

or

72 lines).

27

Page 31

PRINT/P

1-"""

'I"

"

PRINT

/P"DDXX"

(xx = data string in

bit pattern)

Image print

PRINT/P

"

DDD

"

PRINT /P "

aDD"

• Permits image printing.

• Bit pattern data expressed

in

hexadecimal number

will be printed in the vertical direction

as

previously

determined.

(Ex.)

PRINT/p

"DD

01"

If

0 I H is converted into

a binary indication,

LSB

.....

'

.~

~This

OIH =

0000

000

I

- - -

tal

t

MSB

LSB

o

o

o

o

MSB

.....

o

• 160 characters/line mode

is

selected.

• 136 characters/line mode

is

selected.

28

dot

is

printed.

,

I\"

Page 32

Example

of

control

with

machine

language'

The example

of

program for controlling this printer with machine language

is

shown below. The

method

of

control varies, depending

on

the

ROM

unit used. The example shown below represents

reference subroutine program which constitutes the most basic part

of

the control.

• Control

as

printer for MZ-80B/MZ-80A

[Concept

of

printer control I

Start

.------+1

Checks BUSY signal

Yes

Is

the

printer

ON

LINE?

Transmits control

code

or printing

data code to the

printer.

Is

there

transfer

data?

No

[Printing data transfer routine I

No

No

29

Start

BUSY signal

input

Low level?

Transfers data

code

Makes

DATA

STH

signal high.

BUSY signal input

High

level?

Makes

DATA

STB

signal low.

Return

IN

A. (FEH)

~

Ace. - Data code

/

OUT

(FEH), A

S Ace.

+-

SOH

/

OUT

(FEll),

A

IN A, (FE

H)

[

When

the

printer]

receives data

code,

BUSY

signal becomes

high.

S Ace.

+-

oon

lOUT

(FEH), A

Page 33

•

••

ZeD

ASSEMBLER

88-7201

PAGE

01

01

0000

02

0000

03

0000

04

0000

05

0000

P

06

0000

P

07

0000

O~:

0000

09

0000

10

0000

11

0000

12

0000

13

0000

14

0000

15

0000

16 0000,

17

0000

18

0000

F5

19

0001

3EOO

CD1600

Fl

D3FF

20

21

22

0003

0006

0007

23

0009

24

OOOB

25

OOOD

26

OOOF

27

0012

28

0013

3E80

D3FE

3EOl

CD1600

AF

D3FE

29

0015

C9

30

0016

31

0016

32

0016

3~:

0016

34

0016

35

0016

36

0016

37

0016

38

001b

39

0016

40

0016

41

0017

42

0018

43

0019

44

0018

45

001 E

46

0020

47

0022

48

0023

49

0025

50

0026

C5

D5

57

lEoe

010000

DBFE

E60D

BA

200:3

Dl

Cl

51

0027

(:9

52

0028

OB

53

0029

7B

54

002A

81

55

002B

20F1

56

0020

10

57

002E 20EE

58

0030

01

59

0031

Cl

60

00:32 C:30000

61

0035

E

·

.........................

. '

............

.

1 1 • 1 , • 1 , , , 1 , 1 , , , , , , , I , , r r I I , , I 1 , , 1 1 1 1 1 1 ,

PRINTER

MZ-80P4

CONTROL

SUBROUTINE

·

......................................

.

, , 1 1 I I I , , , 1 , • , ,

•••

, • , , ,

••

, ,

••

1 1 , • 1 1 • 1 • 1 •

PORT I I:

EQU

FEH

PORTIO:

EQU

FFH

, JP

ABNML:NO

POWER,NO

PAPER,DISELECT

OR

MECHANICAL

TROUBLE

· ........................ , ..... ,

...

, ..... , ............ .

• , , , 1 1 , 1 , , , , , 1 , • , , , , , , , , , , , , , , , , , 1 , , • , , 1 , ,

••

, ,

•••

, , , I • 1

DATA

CODE

TRANSFER

SUBROUTINE

,

BEFORE

CALL

"PRINT",SET

TRANSFERED

PRINT

CODE

IN

ACC

:

ALL

REGISTOR

RESERVED

ON

NORMAL

RETURN

~

; ; ; ; ;

;: ;:

i i ; i

;:

i j i i i ; ; j i j j j j j j i j j i j ; ; l ; ; i i ; ; ; ; ; ; ; ; ; ; ; ; ; ; ;

PRINT:

ENT

PUSH

LD

CALL

POP

OUT

LD

OUT

LD

CALL

XOR

(JUT

RET

AF

A,OOH

BUSY/C

AF

(PORTIO)

,A

A,80H

(PORTI!)

,A

A,OIH

BIJSY/C

A

(PORT/I)

,A

lBUSY

SIGNAL

IS

LOW'

,DATA

TRANSFER

,IT

MAKES

DATA

STB

HIGH

lBUSY

SIGNAL

IS HIGH'

lIT

MAKES

DATA

STa

LOW

.......................................................

1 , 1 1 , , , , , 1 , , 1 1 , 1 , , , 1 • 1 • , 1 1 1 , , , , 1 ,

••

, , , 1 1 , , , , • , I I 1 J 1 , 1 , 1

BUSY

SIGNAL

CHECK

SUBROUTINE

ONLY

ACC.

IS

BROKEN

ON

NORMAL

RETURN

RESURVED

EXCEPT

ACCUMULATION

(A)

BEFORE

CALL

"BU8Y/C",SET

FOLLOWING

CODE

IN

ACC.

A'O:CHECKS IF

BUSY

IS

LOW

LEVEL

A·l:CHECKS IF

BUSY

IS

HIGH

LEVEL

;;

; ; i

;; ; ;;

i ; j ; ; ; ; ; ; ; ; ; ; ; j ; ; j ; ; ; ; ; j ;

j:j ; jj

; ;

j:j