Page 1

-

SHARP

SERVICE MANUAL

CODE: OO

ZMZID04/1IE

GREEN

DISPLAY

MODEL

MZ-l

D04

(For

Model

700)

TheMZ.llJ04;,tbe_ditplayu.~.oedf"'t""1"",""ol_700Compu

...

Seris

SipoIioo""';,<ompooitlnpu,andIl><RCAPl

NMCJ(;,_

f

.. 'helnpo'lmninaI

.

R_

i"lft

__

, V

id<o"",oI'

,oq""ncy

R_

"'.lmol.

:

~:::.,"":~=

:

:::,

~.;::':~

_ Horiz<wIuoI

__

:

Il.

rll

eymetkod

_

So.o

__

--;".,

_..,....m9~

_:

H~""

_

....

IpU'

·

In

.....

'

odcif<~i._

C.~i""In"",.

bridJOrt<,m' d

~

~~~;

:

~tlon.

25.4<m

....

iJc.20.km

~~.29.2cmdi.oson

..

~lKnV("OjIA)

SHARP CORPORATION

Eiih'een

~~,~';.:.:I'qt

ll.l<mwld<,31.7cm

""

ep,28.'km/U91

:~~INJ

ACK

Com_itin"".,

;~P

'

..

'rue';"., ..........

A(cord

Page 2

Z-1004

FOR SAFER SERVICING

AND

SAFETY

CHECK-OUT

Please pay special attention to the following conditions during servicing and check-out.

1.

Observe cautions

Where

special attention

is

required on such

as

cabinet,

chassis, and component parts

is

noted with caution using

label or stamp.

You

have

to observe there cautions

as

well

as

those

in

Instruction Manual.

2.

Use

parts

of

rated performance

Since parts component used

in

the unit has specific rating

for safety performance such

as

non-inflamability, voltage

withstanding, etc.,

use

the item

of

identical characteristics.

Among

all,

parts components indicated with the "

&.

" mark

in the circuit diagram and parts list must

be

equal

in

its

property

as

it

is

critical to the performance

of

the unit.

3. Replace

the

parts and wiring

on

their original locations

For safety's sake, some

of

items are protected with

in-

sulating materials such

as

tube and tape, or the printed

board

is

isolated from other components. Also, internal

wirings

are

installed and held by such

as

clamp

to

keep

them away from heat generating component and high

tension parts. Whereas, these wirings

have

to be installed

back to their original locations.

2

4. Handle

the

CRT with care

The explosion-proof cathod ray tube

is

guaranteed

of

its

safety against explosion

as

long as it

is

installed in the

unit. However, pay special attention when it

was

removed

from the unit or when servicing it from the back

of

the

unit.

Never

give

impact

of

the cone section.

5. X-ray

The CRT and high tension circuits

have

safety measures

against X-ray. Therefore,

use

the specified parts

to

trouble-

shoot the CRT and high tension circuit, and, never try

to

modify the circuit under any circumstance.

Use

of

the parts

other than specified may cause to

rise

the high voltage

which generates

X-ray

from the CRT.

6. Perform check-out after servicing

After servicing,

be

sure to confirm safety by checking

that

all

removed screws, component parts, and wirings

were replaced

as

before and

see

that no damage has been

done to the serviced area. Besides, ensure insulation

of

the

input signal terminal against metal portion and plug edges.

Page 3

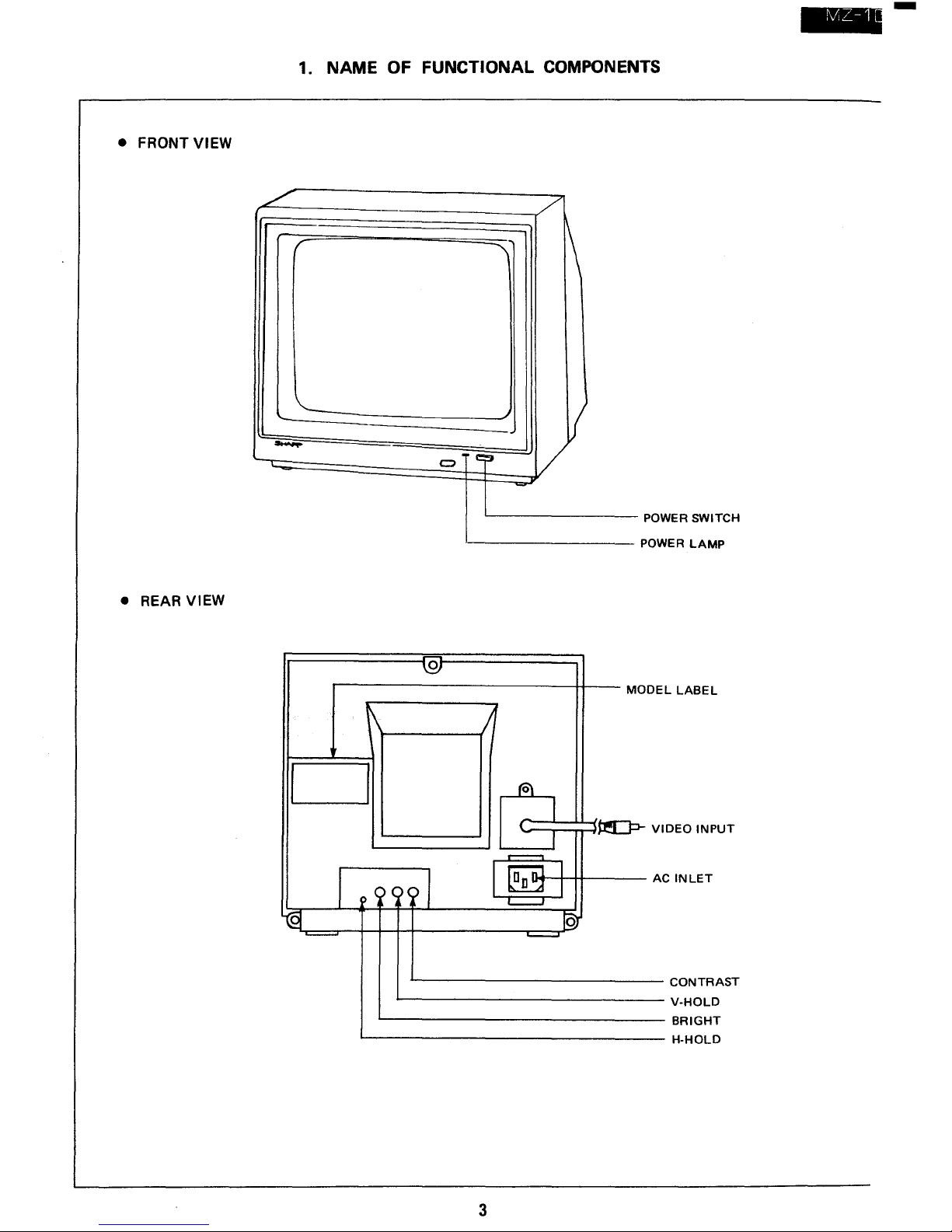

• FRONT VIEW

•

REAR VIEW

1. NAME OF FUNCTIONAL COMPONENTS

./

r

'-

........

c::::I

0

~

CJ

I

000/

l(§I

~

/'

\

-

V

e~

~

;1

f6\

I

(

I

.....----.

1~1

'---'

r§)

'---'

3

POWER SWITCH

POWER

LAMP

MODE

LLABEL

~VI

DEOINPUT

A C

INLET

CONTRAST

V-HOLD

BRIGHT

H-HOLD

--

Page 4

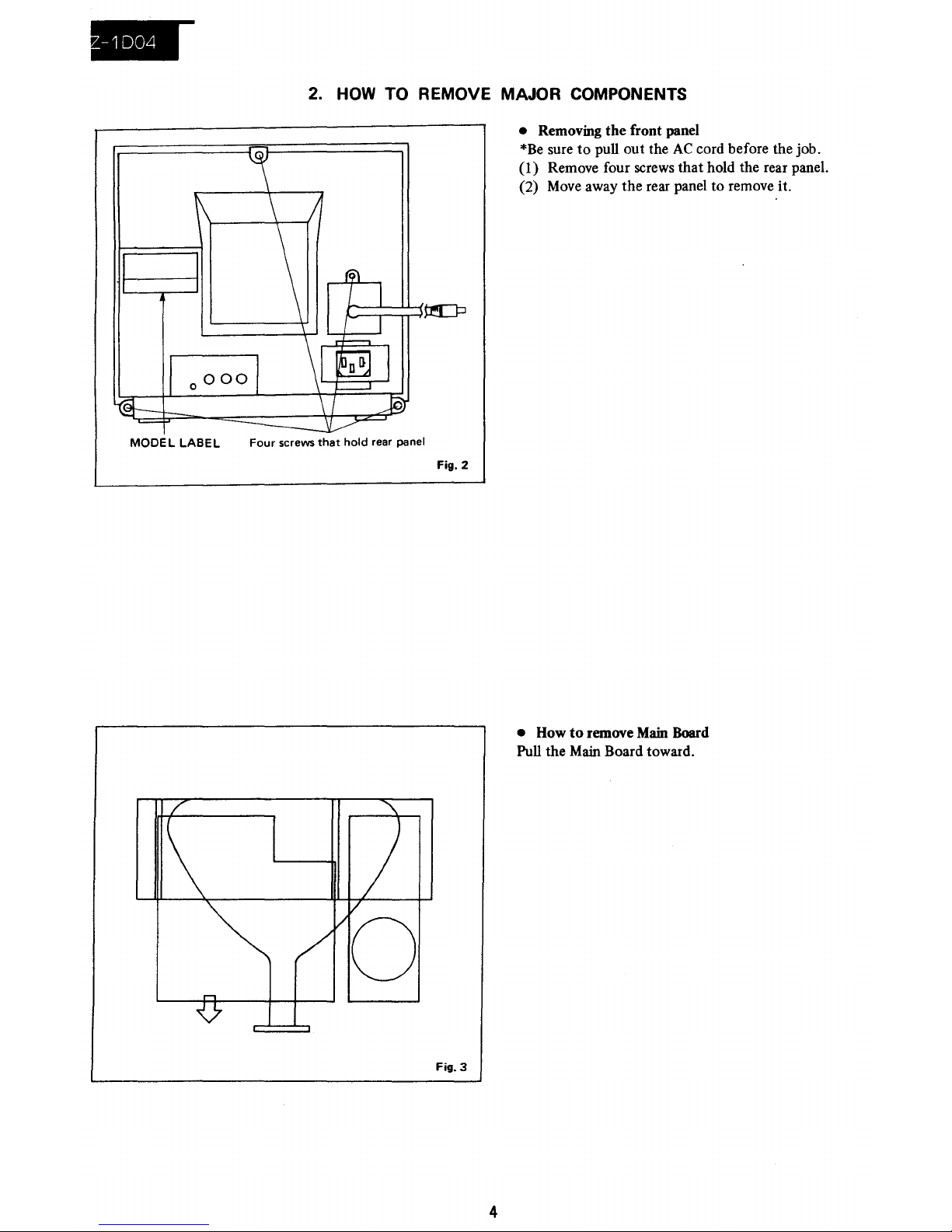

MOOEL LABEL

2.

HOW

TO REMOVE MAJOR COMPONENTS

Four

screws

that

hold

rear panel

Fig. 2

Fig. 3

4

• Removing

the

front panel

*Be

sure to pull out the

AC

cord before the job.

(l)

Remove four screws

that

hold the rear panel.

(2)

Move

away the rear panel to remove it.

• How

to

remove

Main

Board

Pull the

Main

Board toward.

Page 5

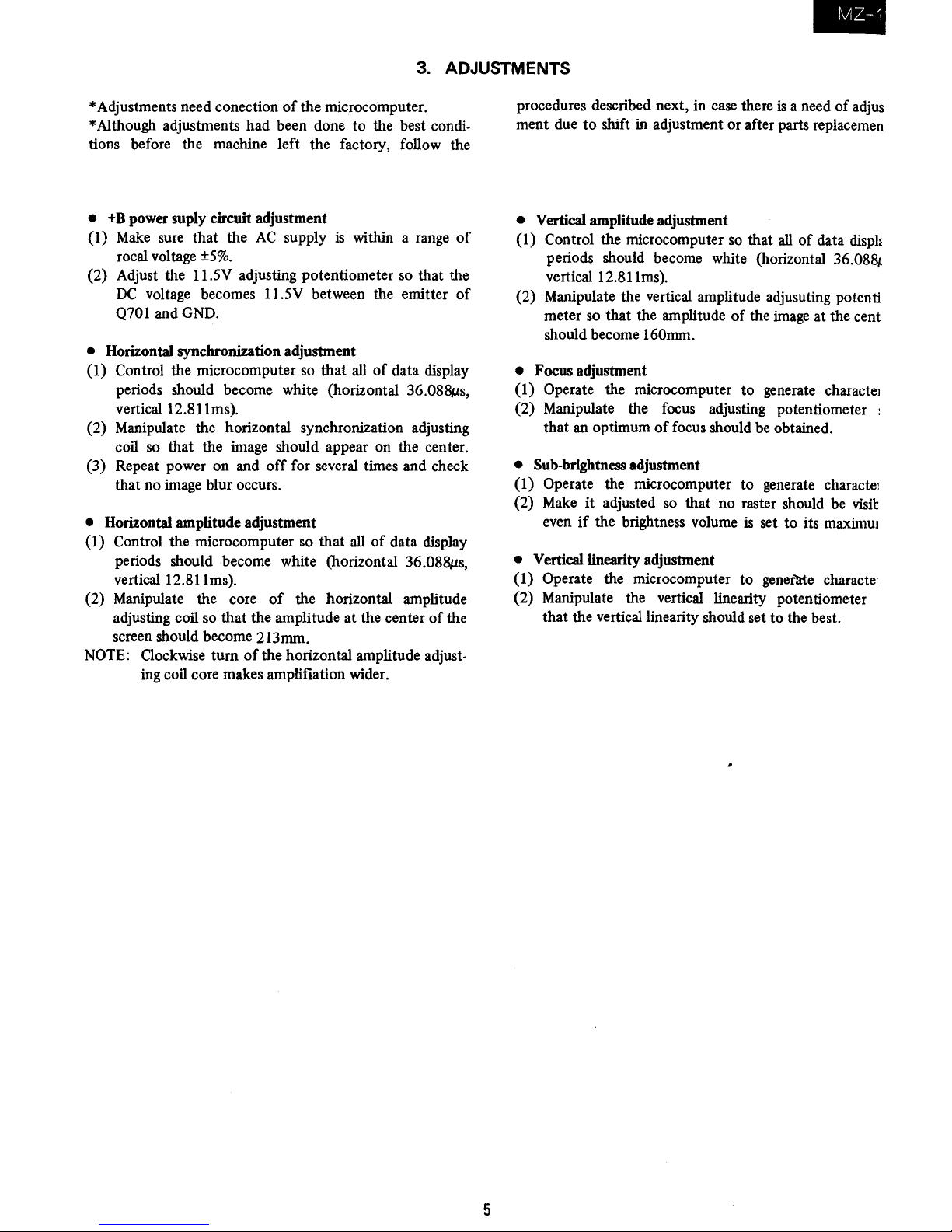

3. ADJUSTMENTS

* Adjustments need conection

of

the

microcomputer.

* Although adjustments had been done to the best condi-

tions before the machine left the factory, follow the

•

+8

power suply circuit adjustment

(1)

Make

sure that the

AC

supply is within a range

of

rocal voltage

±5%.

(2) Adjust the 11.5V adjusting potentiometer so that the

DC

voltage becomes 11.5V between the emitter

of

Q701 and GND.

• Horizontal synchronization adjustment

(I)

Control the microcomputer so that

all

of

data display

periods should become white (horizontal

36.088tLs,

vertical 12.81Ims).

(2) Manipulate the horizontal synchronization adjusting

coil so that the image should appear on the center.

(3) Repeat power on and

off

for several times and check

that no image blur occurs.

• Horizontal amplitude adjustment

(1) Control the microcomputer so that

all

of

data display

periods should become white (horizontal

36.088tLs,

vertical12.811ms).

(2) Manipulate the core

of

the horizontal amplitude

adjusting coil so that the amplitude

at

the center

of

the

screen should become 213mm.

NOTE: Clockwise

turn

of

the horizontal amplitude adjust-

ing coil core makes amplifiation wider.

5

procedures described next, in case there

is

a need

of

adjus

ment due

to

shift in adjustment or after parts replacemen

• Vertical amplitude adjustment

(1) Control the microcomputer so that

all

of

data disph

periods should become white (horizontal

36.08&,.

vertical 12.81lms).

(2) Manipulate the vertical amplitude adjusuting potenti

meter so that the amplitude

of

the image

at

the cent

should become

160mm.

•

Focus adjustment

(1) Operate the microcomputer

to

generate charactel

(2) Manipulate the focus adjusting potentiometer

that an optimum

of

focus should be obtained.

• Sub-brightness adjustment

(1) Operate the microcomputer to generate characte]

(2)

Make

it

adjusted so that no raster should be visit

even

if

the brightness volume is set to its

maximUl

• Vertical linearity adjustment

(1)

Operate the microcomputer

to

gener1rte

characte

(2) Manipulate the vertical linearity potentiometer

that the vertical linearity should set

to

the best.

Page 6

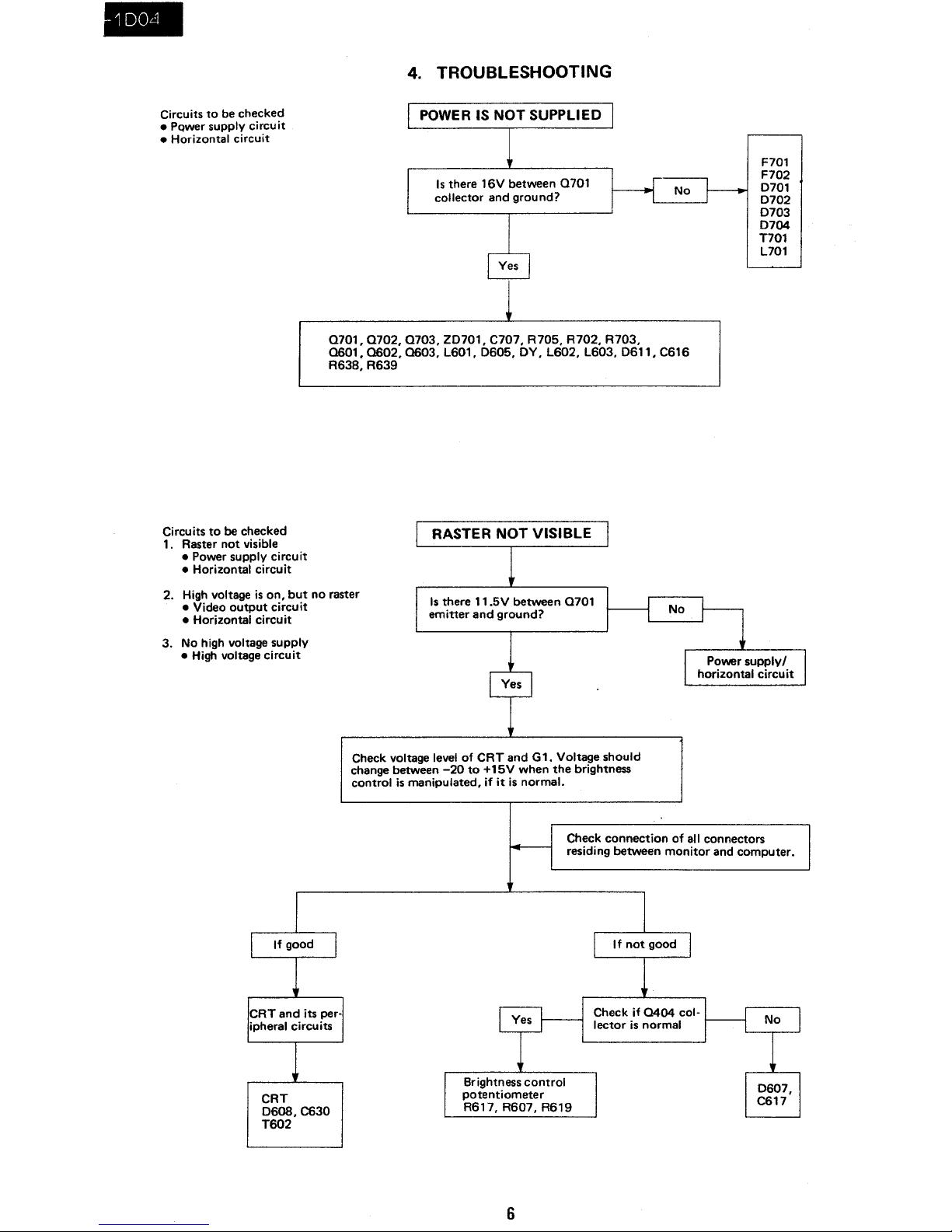

Circuits

to

be

checked

• PQwer supply circuit

• Horizontal circuit

Circuits

to

be checked

1. Raster

not

visible

• Power supply circuit

• Horizontal circuit

4.

TROUBLESHOOTING

POWER

IS

NOT

SUPPLIED

Is

there

16V

between

0701

collector

and

ground?

0701,0702,0703,

Z0701,

C707,

R705, R702, R703,

0601,0602,0603,L601,0605,OY,L602,L603,0611,C616

R638,

R639

RASTER

NOT

VISIBLE

2. High voltage

is

on,

but

no raster

Is

there

11.5V

between

0701

emitter

and

ground?

• Video

output

circuit

• Horizontal circuit

3.

No high voltage supply

• High voltage circuit

Check voltage level of

CRT

and

Gl.

Voltage

should

change between

-20

to

+15V

when

the

brightness

control

is

manipulated, if

it

is

normal.

F701

F702

0701

0702

0703

0704

T701

L701

Check

connection

of

all connectors

residing

between

monitor

and

computer.

CRT

D608,C630

T602

Brightness

control

potentiometer

R617,

R607,

R619

6

0607,

C617

Page 7

Circuit

to

be

checked

Video

and

its peripheral

circuits

Circuit

to

be checked

• Horizontal synchronization

circuit

Circuit

to

be

checked

• Vertical synchronization

circuit

I

PICTURE DOES NOT APPEAR

Observe

the

video signal

at

Q405 base

on

the

oscilloscope.

Is

the

video signal on7

Observe

the

video signal

at

0404

base

on

the

oscilloscope.

Is

the video signal on?

SYNCHRONIZATION NOT POSSIBLE

Horizontal synchronization

is

not

possible

1

0602,0603,

eG06, A623

and

their

per·

ipheral circuit.

I

MZ-1 D04

NOTE: IF

no

picture should appear,

try

to

turn

the

sub-brightness

knob

all

the

way

to

the

right before

going

into

checking.

Check

the

video

input

circuit

and

its

peripherals

Input

cable,

input

socket,

computer

Horizontal

and

vertical

synchornization are

not

possible

With

the

vertical synchro-

nization in

normal condition

I

VERTICAL

SYNCHRONIZATION NOT POSSIBLE I With

the

horizontal synchro·

nization in normal condition

·Check A510 (V-HOLD)

and

its peripheral circuit.

VERTICAL

SWEEP

IS NOT DONE

7

NOTE: During

the

check,

drop

the

brightness

to

prevent

the

CAT from being damaged.

Page 8

4 .

rv1Z-1DO--l

SW701

D2rel

DIL!J

~

R50

R505

V-SIZEg]J)

8

~

0

V-LIN

R607

~SUB-BRIGHT

r--

,

,

,

:

,

T602

F.

B.T

5. CHASSIS LAYOUT

Q406

JI~

~J2

•

1501

L602

1

0

0703

©

•

L603

~R705

= +B-ADJ

@

A2

A3

A4 e

K620

• • •

1.0601

0602

•

e

K602

R633

BRIGHTNESS

R510

V-

HOLD

8

R402

CONTRAST

rel

B2

~BI

C705

EUQ4

01

•

0702

•

0605

[;]CI

•

C2

0701

K604

0405

e •

Page 9

Page 10

MZ-1D04

1

2

J

•

5

6

7. PRINTED WIRING

BOAD

ASSEMBLIES

A

....

,

•

c

o

E

F

G

P.W.B·A Mother Board

{Wi'i~

Side)

H

1

2 J

•

5 6

1 1

Page 11

•

MZ-1D04

7

,

9

10

11

12

A

,

P .

W.B

-B

CRT

Socket

Bo ... d (Wiring Sidel

c

~

-

L

FI092TA

o

E

P.

W.S-C

Switch

Bond

(Wiring

Side'

F

G

P.W.B-D LED

Bo.rd

(Wiring Side)

H

7

,

9

10

11

12

12

Page 12

•.

Description

of

wiring

diagram

(1) Because

this

wiring diagram

is

of

the basic circuit,

there may be some differences depending

of

the

unit used.

(2) Parts components noted with the "

Lt

" mark are

critical for the safety

of

the unit.

To replace these items,

use

the specified items for the

safety's

sake,as

well

as

maintaining proper perfor-

mance.

(3) Voltage values and waveforms are measured at supply

voltage

of

lOcal

voltage

±S%

with the video input

of

OV

(screen not bright). Notation (H) and (V) in the

waveform represents the repeat frequency.

,

iv1Z-1

D04

I

(4) Legends for resistors and capacitors

I Resistor I

Unit:

No

mark

00.

ohms K

...

Kohms M

...

Mohms

I Capacitor I

Rated power:

No

mark 0

••

1/4W

Unit:

No

mark or

Il.

0 •

oll.F

P.

0 0 pF

Rated voltage:

No

mark

...

SOV

[Kinds)

Resistor Capacitor

No

mark

Carbon

film

resistor

No

mark

Ceramic capacitor

C

Sol

id

resistor

ML

Mylar

capacitor

S

Oxide

metal

film

PF

Polyprepylene

film

resistor capacitor

N

Metal

film

resistor

TA

Tantalum capacitor

W

Cement resistor

T

Special resistor

8.

HOW

TO

SHAPE

UP

AND THREAD LEAD WIRES

When

any

wire

held by the wire holder

was

removed

at

the time

of

servicing must be set to its original position.

CRT

lead

Taped

U L tube cover

in

use

Shield wire, braid wire,

WH

13

Improper wire threading may

give

bad effects to the safety

and performance.

SoW

lead WH

C.V sheet earth

(braidwire)

UL

tube cover in

use

Page 13

•

Safety check-out

at

the

time

of

servicing

1.

Servicing must always be reliable.

(l)

Use

the specified item to replace any component

parts. (Fuse,

AC

cord, high tension parts, power

supply parts, internal wiring, and high tension lead

wire)

(2) Check to

see

that everything have been set on their

original position, including wirings.

Parts location, space, wire shape, soldered condition

(such

as

jutted solder, excessive solder, tunnel, etc.).

Insulation materials (such

as

tape, tube,

PVC

sheet

treatment).

2. Safety check-out even after servicing

(1) Remove dust, then check intrusion

of

any alien object

such

as

solder fragments and cloth fragments.

(2) Test insulation using the ohmmeter. (Between both

terminals

of

the

AC

plug and metal exposed section

of

the

DIN

terminal)

3. About high voltage circuit

Since the high voltage sections

have

been set

to

their

rated values before the machine left the factory, never try

to change high voltage value. Impression

of

unnecessary

high voltaged may cause

to

emit X-ray or discharge corona.

9.

PACKING

OF

THE

SET

Setting Position

of

the knobs

POWER

....••.•..•....

OFF

V·HOLD.

• . . . • . . . . • .

NORMAL

BRIGHT

...............

BEST

Buffer

material

ACcord

Set cover

Tape

-_-IL--::&i;;:;;:-:

Serial number card

-----11----'

14

Instruction

manual

Tape

-f>-------

Packing case

Card sack

Page 14

MZ-1004

DJ

CRT,IC

PARTS

LIST

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK

MARK

RANK

1

VBE2292B31N1A

BU

B Picture tube

2

RH

iXOO35TAZZ

AN

B

I.C.

[1501]

[2J

Transistors

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK MARK

RANK

1

VS2SA673-C/1A

AC

B Transistor

[

601]

2

VS2SA952

L 1

1

AD

B Transistor

[

605]

3

V S 2 S

C 1 2 1 3

CIA

AC

B Transistor

[

602]

4

VS2SC1514//

1

AE

B

Transistor

[

404]

5

VS2SC1815YW

1

AB

B Transistor

[

402]

6

V S 2 S

C 1

826

Y1A

AH

B Transistor

[

701]

7

V S 2 S

C 2 0 0 1

M 1

AC

B

Transistor

[Q4051

406]

8

V S 2 S

C 2 0 0 2

K1A

AD

B

Transistor

[

702]

9

VS2SC2373L/1E

AG

B

Transistor

[

603]

10

VS2SC945AP2

1

AB

B

Transistor

[

703]

[I]

Diodes

and

LED'S

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK MARK

RANK

1

RH-DX0038CEZZ

AB

B

Diode

[0605]

2

RH-DX0087TAZZ

AE

B

Diode

[0611]

3

RH-DXOl15TAZZ

AC

B

Diode

[0701-0704]

4

RH-DX0117TAZZ

AC

B Diode

1[_606/607/60S/609]

5

RH-DX0142CEZZ

AC

B

Diode

[D501601604404k'

6

RH-EXOO24CEZZ

AF

B Zener diode

[ZD701 ]

7

RH-PXOO19TAZZ

AD

B Photo transistor

[0706]

8

VHD1N34A///

1

AB

B Diode

[0602/603]

[IJ

Coil

and

Transformers

NO.

PARTS

CODE~

PRICE

NEW

PART

DESCRIPTION

RANK MARK

RANK

1

RCiLB0031TAZZ

AF

C

Oscillation coil

[L601]

2

RCiLFOO68CEZZ

AH

C

Coil

(Filter)

[L701]

3

RCiLH4108TAZZ

BB

B Deflection yoke

4

RCiLZ0104TAZZ

AH

C

Coil

(H

Line)

[L602]

5

RCiLZ0130TAZZ

AL

C

Coil(H

Size)

[L603]

6

RTRNF2129TAZZ

BA

N B H

Volt transformer

[T602]

7

RTRNP0372TAZZ

BG

N B Power transformer

(EUROPE

except U.K.)

8

RTRNP0373TAZZ

BG

N

B Power transformer

(U.

K.

only)

9

RTRNTOO17TAZZ

AF

B

Choke transformer

[T60l]

10

VP

L K 2 7 2 K 0 0 0 0

AD

C

PeakinJ;!

coil

[L401 ]

~

Controls

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK MARK

RANK

1

RVR-B4374CEZZ

AE

B Variable resistor

FOCUS)

[R63?]

2

RVR-B7029TAZZ

AD

C

Variable resistor

V-HOLD)

[R510]

3

RV

R-B

7 0 3 1

TA

Z Z

AE

C

Variable resistor

BRIGHT)

[R633]

4

RVR-B7052TAZZ

AE

C Variable resistor CONTRAST)

[R401

]

5

RVR-M7204TAZZ

AC

C

Variable resistor

+B

ADJ)

[R705]

6

RVR

M7208TAZZ

AF

C

Variable resistor V

SIZE)

[R505]

7

RVR

M7209TAZZ

AC

C

Variable resistor V

LINE)

[R50S]

8

RVR

M7210TAZZ

AC

C Variable resistor

SUB

BRI

[R60?]

[ID

Capacitors

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK

MARK

RANK

1

RC-EZ0027TAZZ

AK

C

Capacitor

[C620]

2

RC-EZ0138TAZZ

AN

N

C

Capacitor

(25V 4700.uF)

[C705]

3

RC-FZOO04CEZZ

AH

C

Capacitor

4

VCCSPA1HL121J

AD

C

Capacitor (50WV 120pF)

[C412]

5

VCCSPA1HL560J

AB

N

C

Capacitor (50WV 56pF)

[C421]

6

VCEAAU1AW107M

AB

C Capacitor

(1

OO.u

F 10V)

[C420]

7

VCEAAU1AW226M

AC

C

Capacitor (10WV 22.uF)

[C40l]

8

VCEAAU1AW227M

AB

C

Capacitor{220.uF

10Vl

[C50S]

9

VCEAAU1AW476M

AB

C

Capacitor (47 uF 10VJ

[C505]

10

VCEAAA1CW106M

AC

C

Capacitor 16WV 10uF)

[C511/415]

11

VCEAAAICW107M

AB

C

Capacitor Japan onlv)(lOOuF 16V)

[C650]

12

VCEAAA1CW108M

AD

C

Capacitor 16WV 100OuF)

[C641/509]

13

VCEAAA1CW227M

AC

C

Capacitor

220uF 16V)

[C616]

14

VCEAAA1CW476M

AB

C

Capacitor(ExpOrt onlv) (47

uF

16V)

[C409/C513]

15

VCEAAA1CW477M

AD

C

Capacitor (470.uF 16V)

[C601/70?]

16

VCEAAA1CW227M

AC

C

Capacitor (2201lF 25V)

[C406]

17

VCEAAA1CW475M

AC

N

C

Capacitor (25WV 4.7

.uF)

[C503]

18

VCEAAA1HW105M

AB

C

Capacitor (50WV 1.0.uF)

[C629]

19

VCEAAA1HW335M

AB

C

Capacitor (50WV

3.3.uF)

[C60?]

20

VCEAAA2CW105A

AB

C Capacitor {160WV

1MFL

[C615/61?]

21

VCEAAU2CW106Y

AC

C Capacitor (160WV 10.uF)

[C612]

22

VCEAAH1CW228M

AF

C Capacitor12200.uF

16V~

[C512]

15

Page 15

Lt,

Lt,

[ID

Capacitors

NO.

PARTS CODE

PRICE

RANK

23

VCEABA1CW226M

AC

24

VCKYAT1HX103N

AC

25

VCKYPA2HB221K

AB

26

VCKZPA1HB102K

AB

27

VCKZPA1HB332K

AC

28

VCKZPA1HB682K

AC

29

VCKZPA1HB821K

AB

30

VCQPSB2GA223K

AB

31

VCQPSB2JA103K

AB

32

VCQYKH1HM103J

AB

33

VCQYKH1HMI03K

AC

34

VCQYKHIHMI04K

AD

35

VCQYKHIHM223K

AC

36

VCQYKHIHM333K

AC

37

VCQYKH1HM472K

AC

38

VCQYKHIHM473J

AB

39

VCQYKUIHM473K

AB

40

VCSATAIVEI05K

AC

[1J

Resistors

NO.

PARTS CODE

PRICE

RANK

1

RR-XZOO15CEZZ

AC

2

RR-XZ0037TAZZ

AC

3

VRC-MB2EG273J

AB

4

VRD

R A 2

BEl

0 3 J

AB

5

VRD-RA2BE104J

AB

6

VRD-RA2BE182J

AA

7

VRD-RA2BE394J

AB

8

VRD-RA2EE102J

AA

9

VRD-RA2EEl03J

AA

10

VRD-RA2EE104J

AA

11

VRD-RA2EE122J

AA

12

VRD-RA2EE123J

AA

13

VRD-RA2EE152J

AA

14

VRD-RA2EE153J

AB

15

VRD

R A 2

EEl

5 4 J

AB

16

VRD

R A 2

EEl

8 4 J

AB

17

VRD

R A 2 E E 2 2 1 J

AA

18

VRD-RA2EE222J

AB

19

V R D-RA

2 E E 2 7 2 J

AA

20

VRD-RA2EE332J

AA

21

VRD-RA2EE392J

AA

22

VRD-RA2EE470J

AB

23

V

R.D

- R A 2 E E 4 7 2 J

AA

24

VRD-RA2EE473J

AA

25

VRD-RA2EE560J

AA

26

VRD

R A 2 E E 5 6 1 J

AA

27

VRD-RA2EE563J

AB

28

VRD-RA2EE680J

AA

29

VRD-RA2EE682J

AA

30

VRD-RA2EE822J

AA

31

VRD-RA2EE823J

AA

32

VRD-RA2HDR50J

AB

33

VRD-RA2HD1R2J

AA

34

VRD-RA2HD2R2J

AA

35

VRD-RA2HD2R7J

AA

36

VRD

R A 2 H D 2 7 4 J

AA

37

VRD

R A 2 H D 3 R 9 J

AA

38

VRD-RA2HD560J

AA

39

VRS-PV3AB680J

AB

40

VRS-PV3DBI50J

AB

41

VRS-PV3DB330J

AC

42

VRS-PV3DB392J

AC

43

VRS-PV3DB472J

AB

44

VRW-KV41C220J

AE

[]]

Miscellaneous

Parts

NO.

PARTS

CODE

PRICE

RANK

1

P R D A F

0 1 2 7 T A Z Z

AC

2

PRDAF0169TAFW

AD

3

PRDAF0170TAFW

AB

4

PRDAF0187TAFW

AG

5

PSLDM0374TAZZ

AH

6

PSLDM0375TAZZ

AH

7

PSLDM0378TAZZ

A L

8

PSLDM0379TAZZ

AM

9

PSLDM0387TAZZ

AE

10

PSLDM0388TAZZ

AC

NEW

MARK

N

N

N

NEW

MARK

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NEW

MARK

N

N

N

N

N

N

N

N

N

N

PART

DESCRIPTION

RANK

C Capacitor

(22uF

16Vl

[C506/507]

C

Capacitor(Japan only) (O.OluF 50V)

[C701

/703/704

]

C

Capacitor

(220pF 500V)

[C643]

C Capacitor (50WV 1000pF)

[C413]

C

Capacitor (50WV

3300pF)

[C501/502]

C

Capacitor (50WV

6BOOpF)

[C61B]

C Capacitor (50WV B20pF)

[C402]

C Capacitor

(0.022pF

400V)

[613/614/642]

C

Capacitor (630WV O.OlpF)

[C632]

C Capacitor.(O.OlpF

50y}

[C60B]

C

Capacitor (O.OlpF

50V)

[C602]

C

Capacitor(50WV

0.10pF)

[C430]

C

Cap~citor(0.022}LF

50V)

[C604]

C Capilcitor(Ex2Qrt

only1l50WV

0.033pF),

[C414/510/611

]

C

Capacitor

(4700uF

50V)

[C603]

C

Capacitor(Export only) (0.047

uF

50V)

[C609]

C

Capacitor (0.047

uF

50V)

[C605/C606]

C

Capacitor(Export only)

(luF

35V)

[C504]

PART

DESCRIPTION

RANK

C

Resistor

[R640]

C

Resistor [R651 ]

C Resistor

(1/4W

27KO

±5%)

[R512]

C

Resistor

ll/BW

10KO ±5o/o)

[R426]

C Resistor

l/BW

lOOKO

+5%}

lR403]

C

Resistor

l/BW

1.BKO

+5%}

[R70l]

C

Resistor

l/BW

390KO

+5~

[R427]

C Resistor

l/4W

1.0KO

+5%)

[R4l3]

C Resistor(ExPQrt only}

(lOKO

l/4W

+5%)

[R4lB/R502]

C Resistor

(l/4W

lOOKO

+5°

,)

[R622]

C Resistor

(l/4W

1.2KO

+5%)

[R702]

C Resistor

(l/4W

l2KO

±5%:

[R50l]

C Resistor (1.5KO

l/4W

+5%)

[R602/6lB/62l]

C Resistor

(1/4W

l5KO

±5%)

[R4l9]

C

Resistor.l1/4W

150KO

±5~)

[R636]

C

Resistor

(1/4W

1BOKO

±5%)

[R619]

C

Resistor

J.l/4W

2200

±59'0)

[R429/R613/R402]

C

Resistori!/4W

2.2KO

+5%)

[R520]

C Resistor

1/4W

2.7KO

+5~

[R503]

C

Resistor

1/4W

3.3KO

+5%}

[42B/60B/609]

C

Resistor

1/4W

3.9KO

+5

%)

[R611 ]

C

Resistor

1/4W

470

+5%)

[R421]

C

Resistor

1/4W

4.7KO

±5

%)

[R605]

C Resistor

(1/4W

47KO

±5%)

[R635]

C

Resistor

(1/4W

560

±59'0)

[R616]

C Resistor(Japan only)

(5600

1/4W

±5%)

[R603/417/706]

C Resistor

(1/4W

56

KO

±5%)

[R617]

C Resistor

(1/4W

6BO

±5%)

[R450/R612]

C

ResistorJl/4W

6.BKO

±5%)

[R606]

C Resistor

(l/4W

8.2KO

+5%)

[R504/R620]

C

Resistor

(l/4W

B2KO

+526)

[R420]

C Resistor

(1/2W

0.500

+5~

[R509]

C Resistor

(l/2W

1.20

+5%)

[R63B]

C Resistor

(1/2W

2.20

±5%)

[R513]

C Resistor

(2.70

1/2W

±5%)

[R514]

C

Resistor

(1/2W

270KO

±5%)

[R624/R650]

C Resistor

(3.90

1/2W

±5%)

[R639]

C

Resistor

(1/2W

560

±5%)

[R614]

C

Resistor(l W 6BO ± 5%)

[R703]

C

Resistor(ExPQrt only)

(150

2W + 5%)

[R615]

C

Resistor

2W

330

+5%)

[R601]

C Resistor

2W

3.9KO + 5%).

[R623]

C

Resistor 4.7KO

2W

+5%}

')("

[R412]

C

Resistor 15W

220

+5%}

[R704]

PART

DESCRIPTION

RANK

C

Heat sink

[Hon-P]

C Heat sink

C

Heat sink

C

Heat sink

C

Shield

C

Shield

C I Shield

C

, Shield

C

Shield

C

' Shield

16

Page 16

,.15

'·0·

[ID

Miscellaneous Parts

NO.

PARTS

CODE

PRICE

NEW

PART

DESCRIPTION

RANK

MARK

RANK

11

PSLOM0389TAZZ

AD

N

C

Shield

~~--~--

-~

12

PSLOM0397TAZZ

AK

N

C

Shield

13

PZETVOl17TAZZ

AD

N

C

Insulator

14

P Z E T V 0 1 1 9 T A Z Z

AC

N

--

C

Insulator

15

QACCZOO26TAZZ

AY

0

AC

cord

(EUROPE

except

U.K.)

--

16

QACCBOO11TAZZ

BB 0

AC

cord

(U.K.

only)

17

QCNW

0346TAZZ

AK

N

C

Connecting

cord

18

QCNW-0365TAZZ

AM

N

C

ConnectinK

cord

~-----

19

QCNW-0383TAZZ

N

C

Connecting~

cord

20

QEARP0038TAFW

AC

N

C

Ground-part

--

21

QEARPOO58TAFW

AB

N

C

Ground-part

22

QFS-C2521TAZZ

AE

A

Fuse

[F702]

23

QFS-C3111TAZZ

AE

A

Fuse

[F501]

24

QFSH01002CEZZ

AA

C

Fuse

holder

25

QPLGN0207CEZZ

AA

C

Plug

--

26

QPLGN0304CEZZ

AB

C

Plug

27

QPLGN0304CEZZ

AB

C

Plug

~~~-

28

QPLGN0404CEZZ

AB

C

Plug

(4pin

OY)

--

29

QPLGN0408CEZZ

AB

C

Plug

(4pin

PT)

--

30

QSOCAOO16TAZZ

AK

C

Socket

31

QSOCN0210CEZZ

AB

N

C

Socket

32

QSOCN0302CEZZ

AB

N

C

Socket

33

QSOCN0604CEZZ

AC

N

C

Socket

34

QSOCV0026TAZZ

AC

--

C

Socket

35

QSPGC0011CEZZ

AC

C

SlliIrkKao

[SG601/602/604J

36

QSPGHOO05CEZZ

AG

N

C Spafi

~p_

[SG603]

37

QSW-P0137CEZZ

AL

A

Switch

[SW701J

38

QTANZOO12TAZZ

AM

C

Terminal

[ID

The Others Pa rts

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK

MARK

RANK

1

SPAKC5266TAZZ

AP N 0

Packing

case

(EUROPE

except

U.K.)

2

SPAKC5267TAZZ

AP N 0

Packing

case

(U.

K.

only]

3

SPAKP4128TAZZ

AD

0

Wrapping

paper

4

SSKAOO03GEZZ/

AB

N 0

Polyethylene

bag

5

TiNSZ5266TAZZ

AG

N 0

Instruction

book

[ill Cabinet Parts

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK

MARK

RANK

1

OCABA5267TA01

BD

N

0

Cabnet

(U.K.

only)

2

OCABA5266TA01

BD

N 0

CabnetJEUROPE

except

U.K.)

3

GCABA5266TASA

BB

N 0

Cabnet

4

GCABB5266TASA

BB

N

0

Cabnet

6

GLEGG9009CEZZ

AB

0

Foot

7

HBOGBI002CESA

AD

0

Badge

8

JBTN-1091CESB

AE

C

Button

9

TCAUA0057TAZZ

AC

N 0

Caution

card

10

TLABKOOO1TAZZ

AA

0

Label

11

TLABMOOO4TAZZ

AA

N 0

Label

{EUROPE

excE!!lt

U.

K.)

12

TLABNOO22TAZZ

AA

0

Label

13

TLABSOO21TAZZ

AD

N 0

Label

14

TLABMI005TAZZ

AA

N

0

Label

(U.K.

only)

Ill] Mechanical Parts

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK

MARK

RANK

1

LANGK0198TAZZ

AG

N C

Fixing

metal

2

LANGQ0187TAZZ

AC

N

C

Fixing

metal

3

LANGR5045CEZZ

AN

N

C

Fixing

metal

[l]

Screws,Nuts,Washers and Wire holder

NO.

PARTS CODE

PRICE

NEW

PART

DESCRIPTION

RANK

MARK

RANK

1

LHLOW1006GEZZ

AB

N

C

Holder

2

LHLOW1033CEOO

AB

N

C

Holder

3

LHLOW1046CEZZ

AB

N

C

Holder

4

LHLOW9003TAZZ

AA

C

Holder

5

LX

BZ3086CEFO

AB

N

C

Screw

6

LX

NZOO60TAZZ

AB

N C

Nut

7

LX

UZOOO3TAFO

AB

N C

Screw

8

LX-WZOO15TAFN

AB

N

C

Washer

9

XBMS030P08000

AB

N

C

Screw

10

XBPBN30P05000

AB

N

C

Screw

11

XCAS030P08000

AA

C

Screw

12

XCAS040P10000

AB

N C

Screw

13

X

CAS

0 4 0 P 1 2 0 0 0

AA

C

Screw

14

X T A S 0 4 0 P 1 6 0 0 0

AB

C

Screw

-------

15

X U A S 0 3 0

PlO

0 0 0

AA

C

Screw

17

Page 17

,

ML-1D04

T

[2J

Screws,Nuts,Washers and Wire holder

NO.

PARTS CODE

PRICE

NEW

PART

I

DESCRIPTION

RANK

MARK

RANK

16

XWSSN30-08000

AA

N

C

Washer

17

GNETC0034TAZZ

AH

N

C

Net

18

QLUGZ0105CEZZ

AB

N

C

Lug

20

QTiPMOOO8CEZZ

AB

N

C

Tip

21

QTiPM0025TAZZ

AB

N

C

Tip

22

QTiPNOO19CEZZ

AB

N

C

Tip

23

SPAKA5135TAZZ

AP

D

Packing

add.

18

Loading...

Loading...