Page 1

SERVICE MANUAL

CODE: 00ZMXRPX1/S1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM OPTION

REVERSING SINGLE PASS FEEDER

MODEL

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the installation manual (00ZMX2700/I1E).

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 4-1

[5] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

MX-RPX1

[9] SELF DIAGNOSTICS AND TROUBLE CODE

* This model is not provided with the self diagnostics and the trouble code.

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

PARTS GUIDE

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] PRODUCT OUTLINE. . . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . .2-1

[3] UNPACKING AND INSTALLATION

* For how to unpacking and installation, refer to the

installation manual (00ZMX2700/I1E).

[4] EXTERNAL VIEW AND INTERNAL

STRUCTURE

1. Identification and functions of each

section . . . . . . . . . . . . . . . . . . . . . . .. . . . . .4-1

[5] OPERATIONAL DESCRIPTIONS

1. Document size detection . . . . . . . . .. . . . . .5-1

2. Paper feed and transport

operations . . . . . . . . . . . . . . . . . . . .. . . . . .5-1

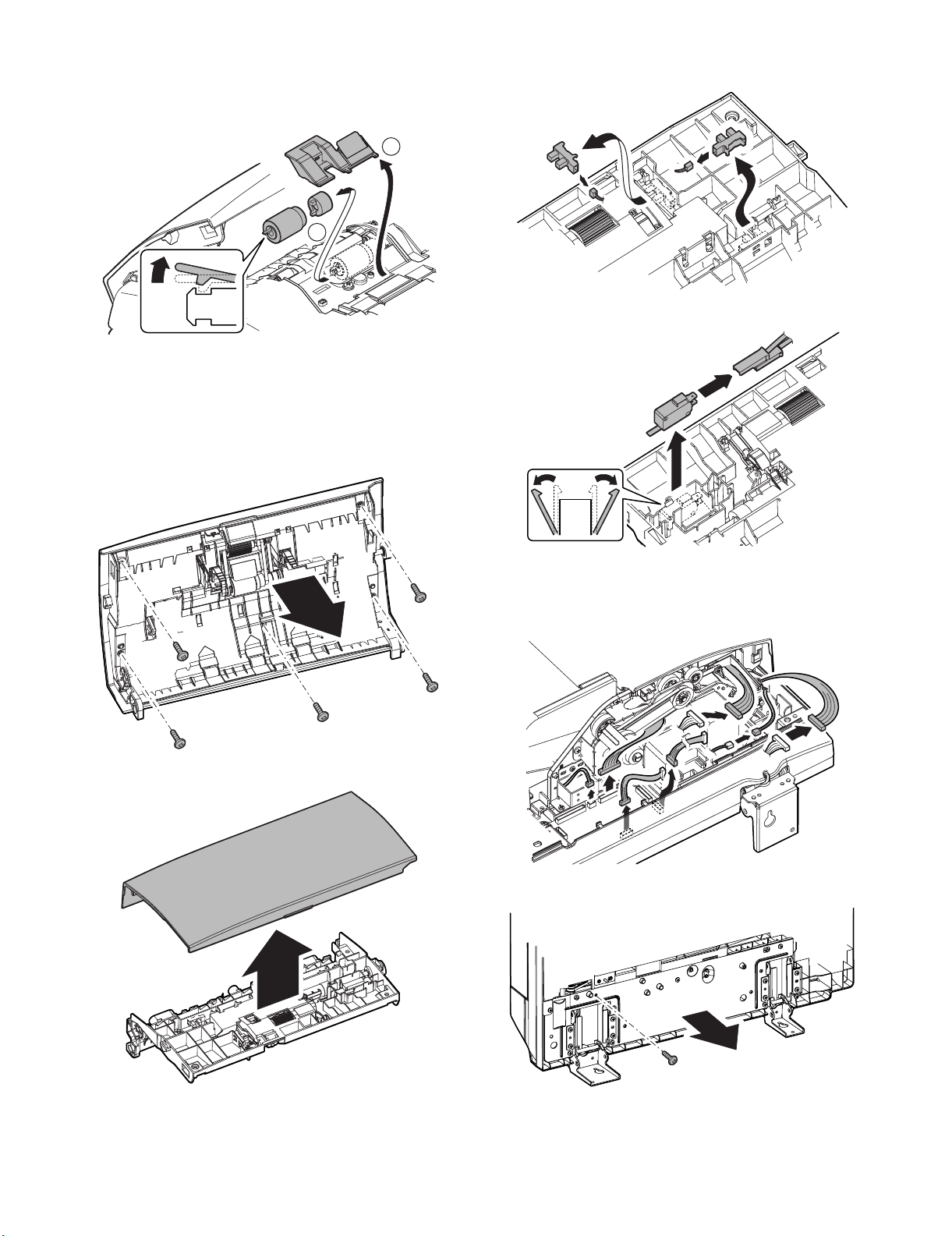

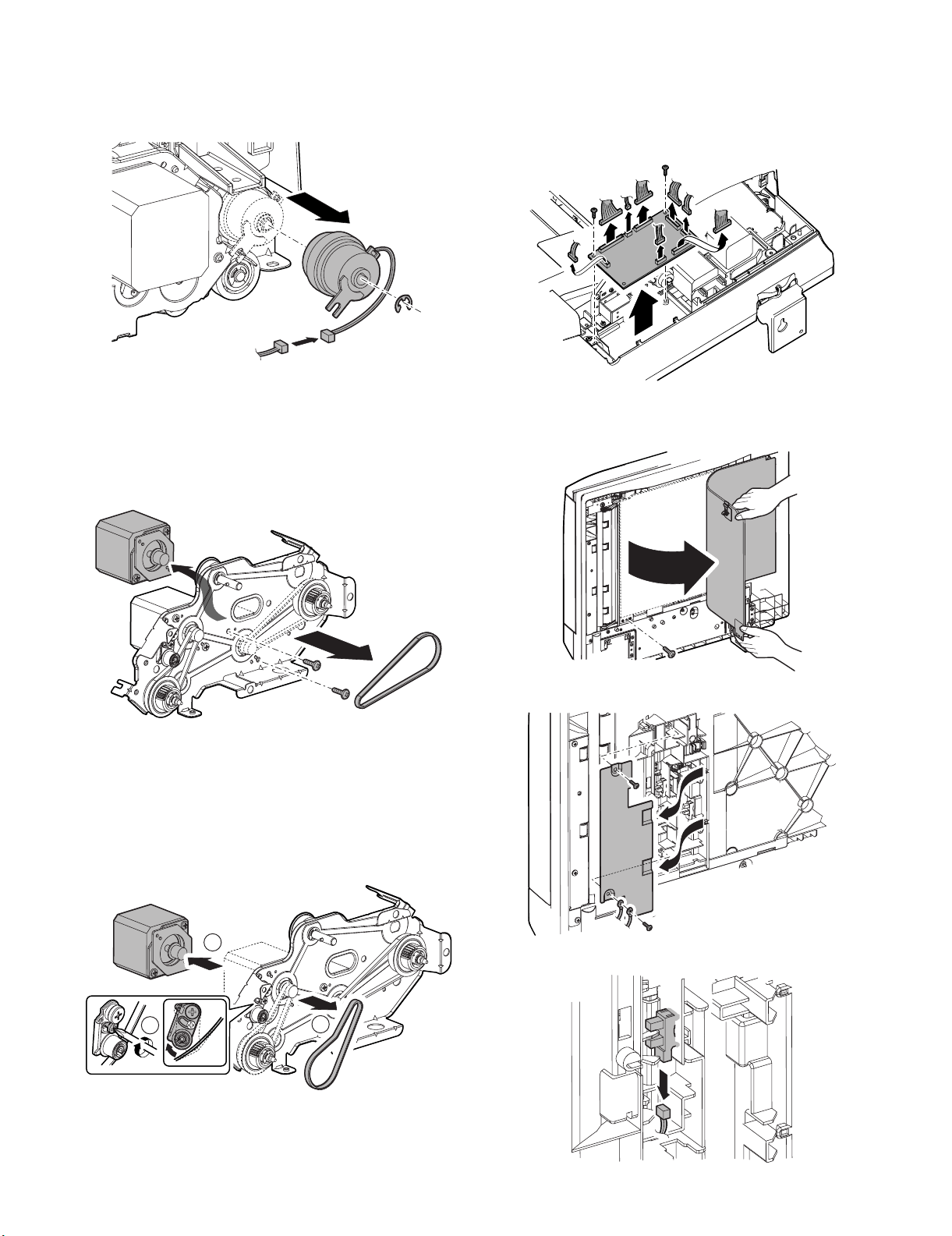

[6] DISASSEMBLY AND ASSEMBLY

1. Document tray section . . . . . . . . . . .. . . . . .6-1

2. Paper feed section/paper transport

section . . . . . . . . . . . . . . . . . . . . . . .. . . . . .6-2

3. Paper exit section . . . . . . . . . . . . . .. . . . . .6-5

4. Document reverse section . . . . . . . .. . . . . .6-6

5. Drive section . . . . . . . . . . . . . . . . . .. . . . . .6-7

6. Base tray section . . . . . . . . . . . . . . .. . . . . .6-8

[7] MAINTENANCE

1. Maintenance system table . . . . . . . .. . . . . .7-1

[8] ADJUSTMENTS

1. RSPF magnification ratio

adjustment . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. RSPF document off-center

adjustment . . . . . . . . . . . . . . . . . . . . . . . . 8-1

3. RSPF copy image position, void area

image adjustment . . . . . . . . . . . . . . . . . . . 8-2

4. RSPF scan position adjustment . . . . . . . . 8-2

5. RSPF height adjustment . . . . . . . . . . . . . 8-3

6. RSPF diagonal adjustment. . . . . . . . . . . . 8-5

7. SPF size width detection level

adjustment . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8. Auto void adjustment

(SPF adjustment) . . . . . . . . . . . . . . . . . . . 8-6

[9] SELF DIAGNOSTICS AND TROUBLE CODE

* This model is not provided with the self diagnostics and

the trouble code.

[10] ELECTRICAL SECTION

1. Electrical mechanism diagram . . . . . . . . 10-1

2. Block diagram. . . . . . . . . . . . . . . . . . . . . 10-3

3. Actual wiring diagram . . . . . . . . . . . . . . . 10-4

[11] OTHERS

1. RSPF mixed-loaded document select

switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

PARTS GUIDE

Page 3

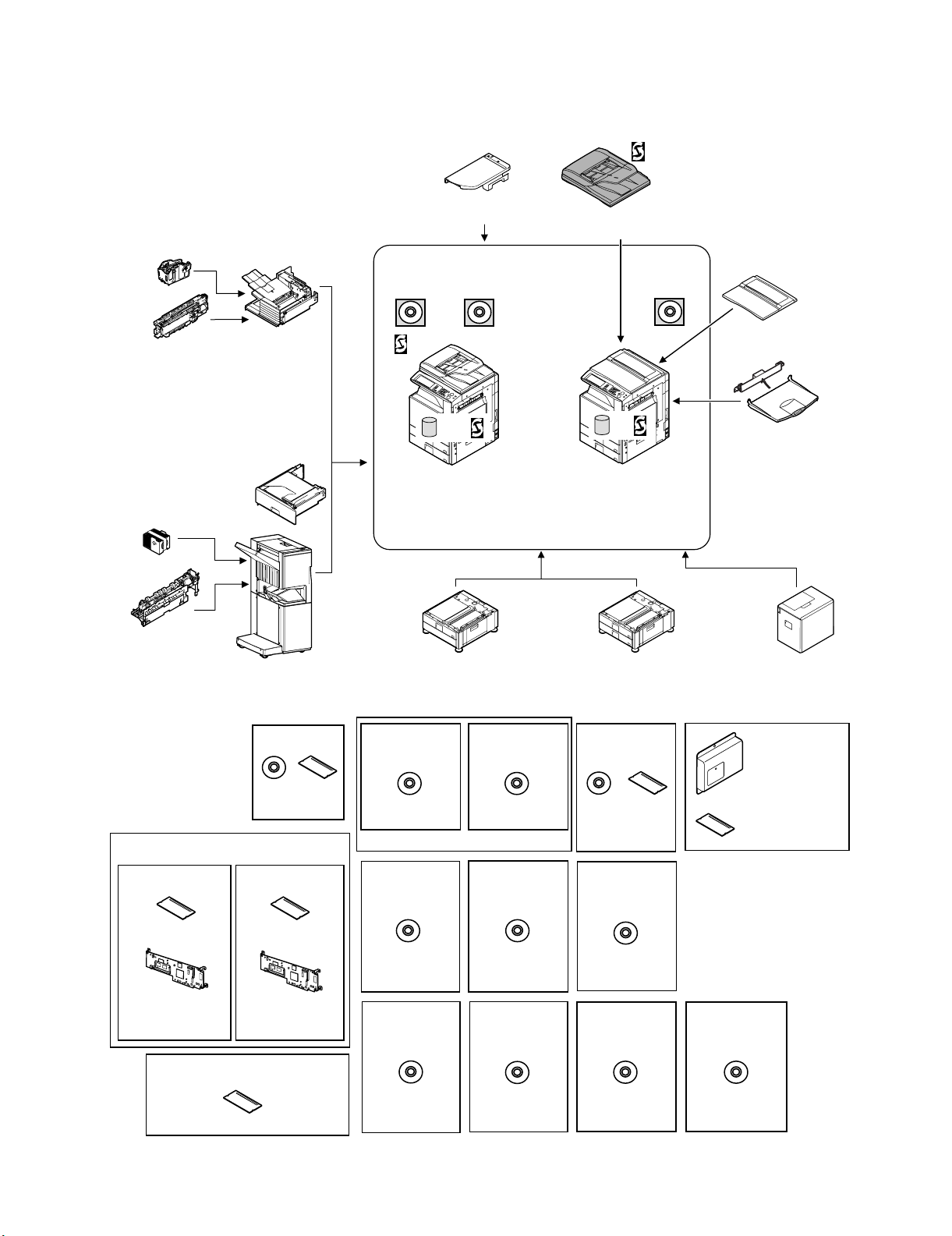

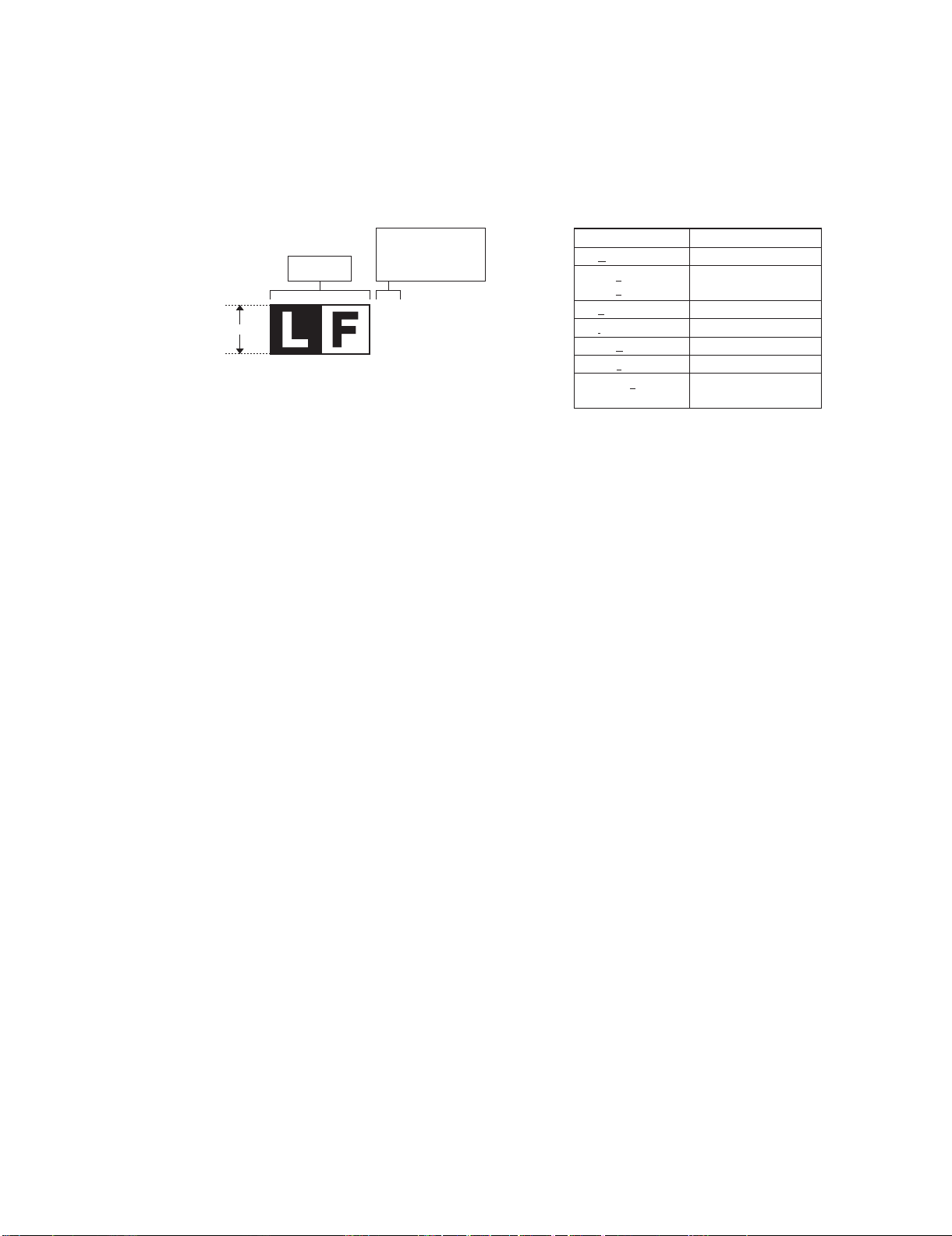

[1] PRODUCT OUTLINE

This product is the duplex auto document feeder unit to be installed

to a digital full color multifunctional system. It transports documents

automatically to perform continuous copying.

Service Manual

Staple cartridge

(Approx. 5000 x 3)

(MX-SCX1)

Punch module

●

2-hole (MX-PNX1A)

●

3-hole (MX-PNX1B)

●

4-hole (MX-PNX1C)

●

4-hole (broad space)

(MX-PNX1D)

Staple cartridge

(Approx. 5000 x 3)

(AR-SC2)

Punch module

●

2-hole (AR-PN1A)

●

3-hole (AR-PN1B)

●

4-hole (AR-PN1C)

●

4-hole (broad space)

(AR-PN1D)

(Including document control)

CC authentication

version

Security

ROM

For document

control PWB

(MX-FRX1)

Finisher

(MX-FNX1)

Paper pass unit

(MX-RBX1)

Saddle stitch finisher

(MX-FNX2)

Data security kit

Commercial

version

Barcode font kit

CD

ROM

(AR-PF1)

Security

ROM

For document

control PWB

(MX-FRX1U)

Device Tray with

USB Hub (MX-RKX1)

PCL5c/PCL6

driver

RSPF

HDD

Copier/Printer (PCL)

/Scanner model

(MX-2300N)

(MX-2700N)

Stand/1x500 sheet

paper drawer

(MX-DEX1)

Printer expansion

kit (PCL)

CD

(MX-PBX1)

(For MX-2300G/2700G)

Internet Fax

expansion kit

CD

(MX-FWX1)

Application

integration

module

Network

scanner

(Sharpdesk 1 license)

Network scanner

expansion kit

CD

(MX-NSX1)

Sharpdesk

1 license kit

Sharpdesk

5 license kit

CD

(MX-USX1/

USX5)

Sharpdesk

100 license kit

Reversing single pass feeder

(MX-RPX1)

SPLC-c

driver

HDD

Copier/Printer (SPLC-c)

model

(MX-2300G)

(MX-2700G)

Stand/2x500 sheet

paper drawer

(MX-DEX2)

PS3 expansion

kit

CD ROM

(MX-PKX1)

Sharpdesk

10 license kit

Sharpdesk

50 license kit

CD

(MX-US10/

US50)

Application

communication

module

External

account module

Document cover

(MX-VRX1)

Exit tray unit

(MX-TRX1)

Large capacity tray

(MX-LCX1)

Facsimile

expansion kit

(MX-FXX1)

FAX memory (8MB)

(packed together)

256MB expansion memory board

(MX-SMX1)

(For MX-2300G/2700G)

CD

(MX-AMX1)

CD

(MX-USA0)

MX-RPX1 PRODUCT OUTLINE 1 – 1

CD

(MX-AMX2)

CD

(MX-AMX3)

Page 4

[2] SPECIFICATIONS

Type RSPF (Duplex auto document feeder unit (reverse pass type))

Document set direction Face up

Paper feed type Take-up roller top feed

Paper exit type U-turn face down exit

Paper pass reference Center reference (Rear one-side standard for random feeding)

Document transport method Sheet-through method

Scan reference Left side when viewed from the front of the unit

Document size Inch type-1: 11" x 17", 8.5" x 14", 8.5" x 11", 8.5" x 11"R, 8.5" x 5.5", A3, A4

Document weight Single: 35 to 128g/m

Document set quantity 100 sheets (80g/m

Paper exit section load capacity Max. 100 sheets (80g/m

Copy magnification ratio 25 to 200%

External dimensions (W x D x H) 590 x 510 x 155 (mm), 23 15/64 x 20 5/64 x 6 7/64 (inch)

Weight Approx. 10kg (22.0 lbs)

Power source Supplied from the copier. (DC 3.3V, 5V, 24V)

Power consumption 35.8W

Document size detection Auto detection (The following 5 detection sizes can be selected by system setting.)

Detection size Inch-1: 11" x 17", 8.5" x 14", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5", A3, A4

Not-specified documents OHP, second original paper, tracing paper, carbon paper, thermal paper, paper with wrinkles, folds, or breakage, pasted paper,

Mixed kinds of documents Mixed sizes of paper feed allowed (Same width only)

Random paper feed Random paper feed allowed (Single face only)

Document reverse Provided

Document replacement speed 300dpi: Max. 48CPM (A4/LT cross-sectional feed) (248mm/s)

Installation/maintenance Installed by service personnel

Optional detection Auto detection supported

Packaged items Parts for mounting, installation cautionary note

Inch type-2: 11" x 17", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 8.5" x 5.5", A3, A4

AB type-1: A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 14", 8.5" x 11"

AB type-2: A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 11", 216 x 330

AB type-3: A3, B4, A4, A4R, A5, 8K, 16K, 16KR, 11" x 17", 8.5" x 11", 216 x 330

(The FAX function supports max. 800mm of long document.)

Duplex: 50 to 105g/m

Thickness: Max. 13mm, 1/2 inch

Inch-2: 11" x 17", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5", A3, A4

AB-1: A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 14", 8.5" x 11"

AB-2: A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 11", 216 x 330

AB-3: A3, B4, A4, A4R, A5, 8K, 16K, 16KR, 11" x 17", 8.5" x 11", 216 x 330

torn document, documents with perforation other than 2- or 3-holes, document printed with ink ribbon, documents bound by

staple or clip, document with high surface friction such as photo or catalogue

(AB series: combinations of A3 and B4, B4 & A4R, A4 & B5, B5 & A5 only)

(Inch series: Combination of 8.5" width and 11" width only)

600dpi: Max. 35CPM (A4/LT cross-sectional feed) (157mm/s)

(Max. 27CPM (A4/LT cross-sectional feed) (124mm/s) * When MX-2300/2700 G/N is installed.)

2

(21 lbs))

2

(9 to 34 lbs)

2

(13 to 28 lbs)

2

(21 lbs))

Service Manual

MX-RPX1 SPECIFICATIONS 2 – 1

Page 5

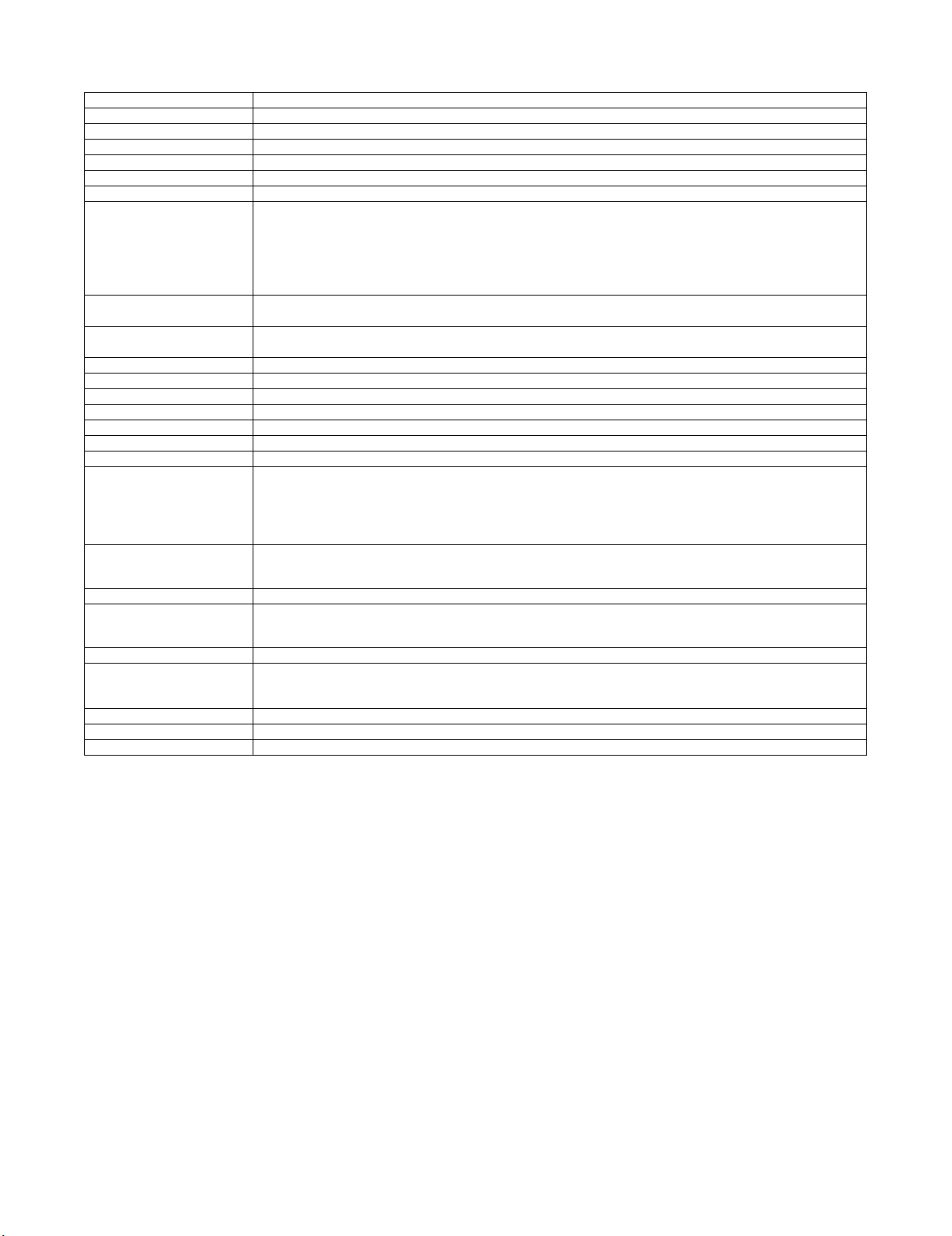

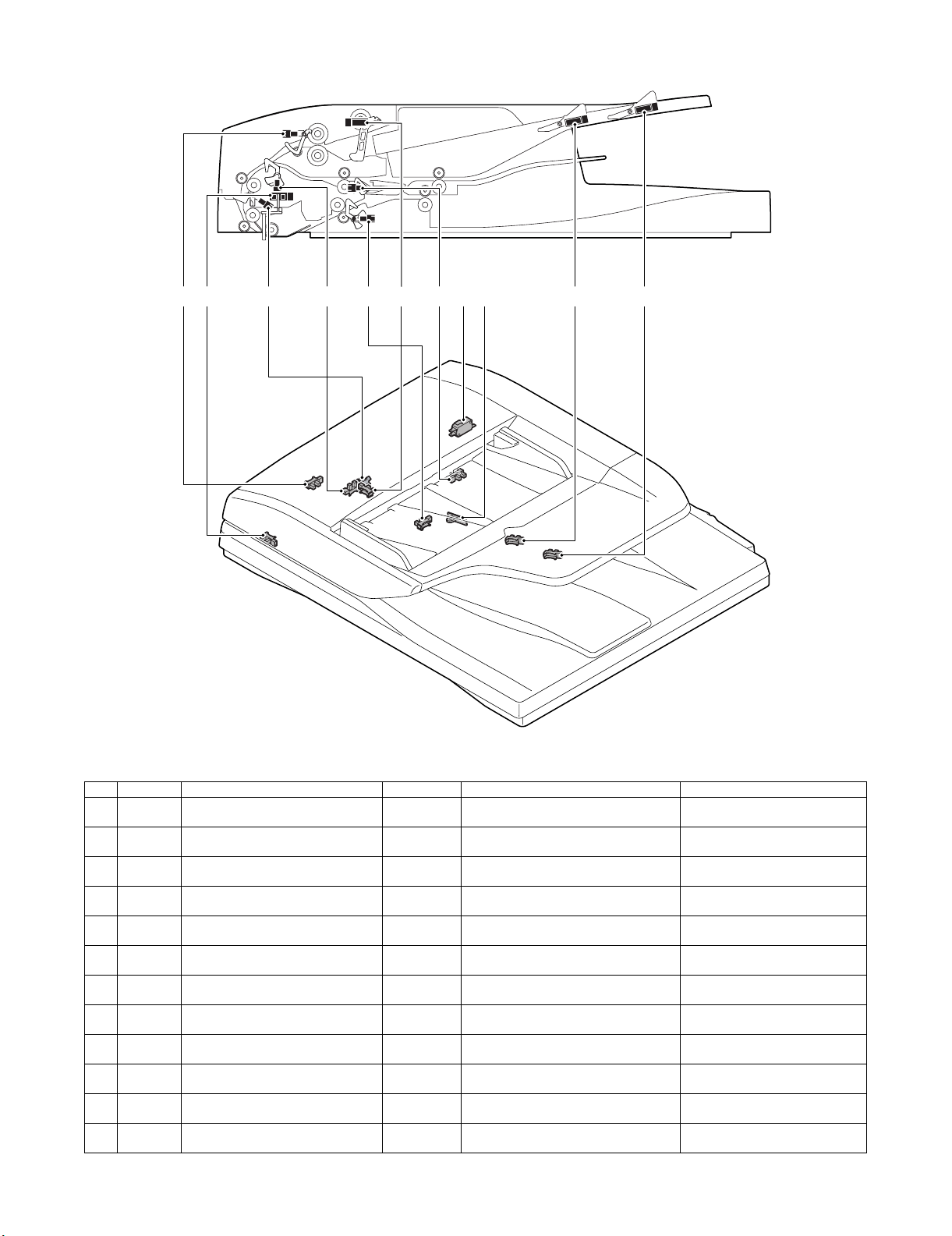

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

Service Manual

1. Identification and functions of each section

A. Internal structure

1

9 1187

10 1512 14 16 1713

246 3

5

No. Name No. Name

1 Pick-up roller 10 Scan rear roller

2 Paper feed separation roller 11 Transport follower roller

3 Separation roller 12 SWB pass section transport roller

4 U-turn roller 13 Transport follower roller

5 PS follower roller 14 Paper exit roller

6 PS roller 15 Paper exit follower roller

7 Transport follower roller 16 SWB roller

8 Scan front roller 17 Transport follower roller

9 Platen roller

MX-RPX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 1

Page 6

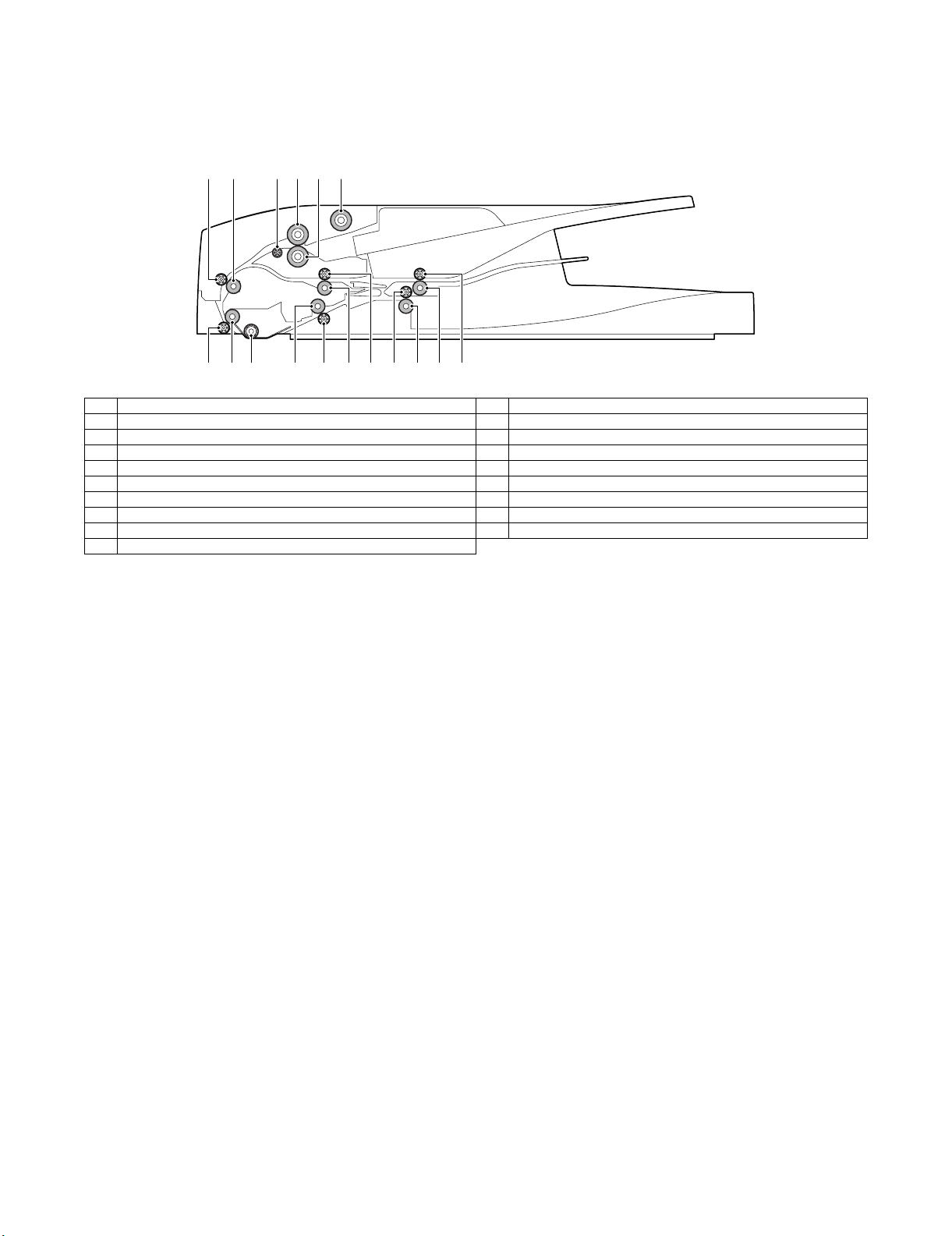

B. Sensors and switches

111092 5 874 3 6 1

No. Signal Name Type Function/operation Active condition

1 SCOV SPF cover SW Microswitch Detects open/close of the paper feed

2 SPPD1 SPF paper entry detection 1 sensor

(Commonly used for random detection)

3 SPPD2 SPF paper entry detection 2 sensor

(PS front)

4 SPPD3 SPF scan front sensor Transmission

5 SOCD SPF open/close sensor Transmission

6 SPPD5 SPF reverse rear sensor Transmission

7 SPPD4 SPF reverse gate front detection Transmission

8 SPED SPF document empty sensor Transmission

9 SPWS SPF document width sensor Volume

10 SPLS1 SPF document length short sensor Transmission

11 SPLS2 SPF document length long sensor Transmission

12 STMPU SPF stamp UN installation sensor – Detects installation of the finish stamp unit. H level when the finish stamp unit is

Transmission

type

Transmission

type

type

type

type

type

type

resistance

type

type

cover.

Detects paper entry and the paper size in

random feed.

Detects paper in front of the PS roller. H level when paper is detected.

Detects paper in front of the scan position. H level when paper is detected.

Detects open/close of the RSPF. L level when the RSPF is closed.

Detects reversed paper. H level when paper is detected.

Detects paper in front of the reverse gate. H level when paper is detected.

Detects paper empty on the tray. H level when paper is detected.

Detects the document width on the tray.

Detects the document length on the tray. H level when paper is detected.

Detects the document length on the tray. H level when paper is detected.

H level at cover open.

H level when paper is detected.

installed.

MX-RPX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 2

Page 7

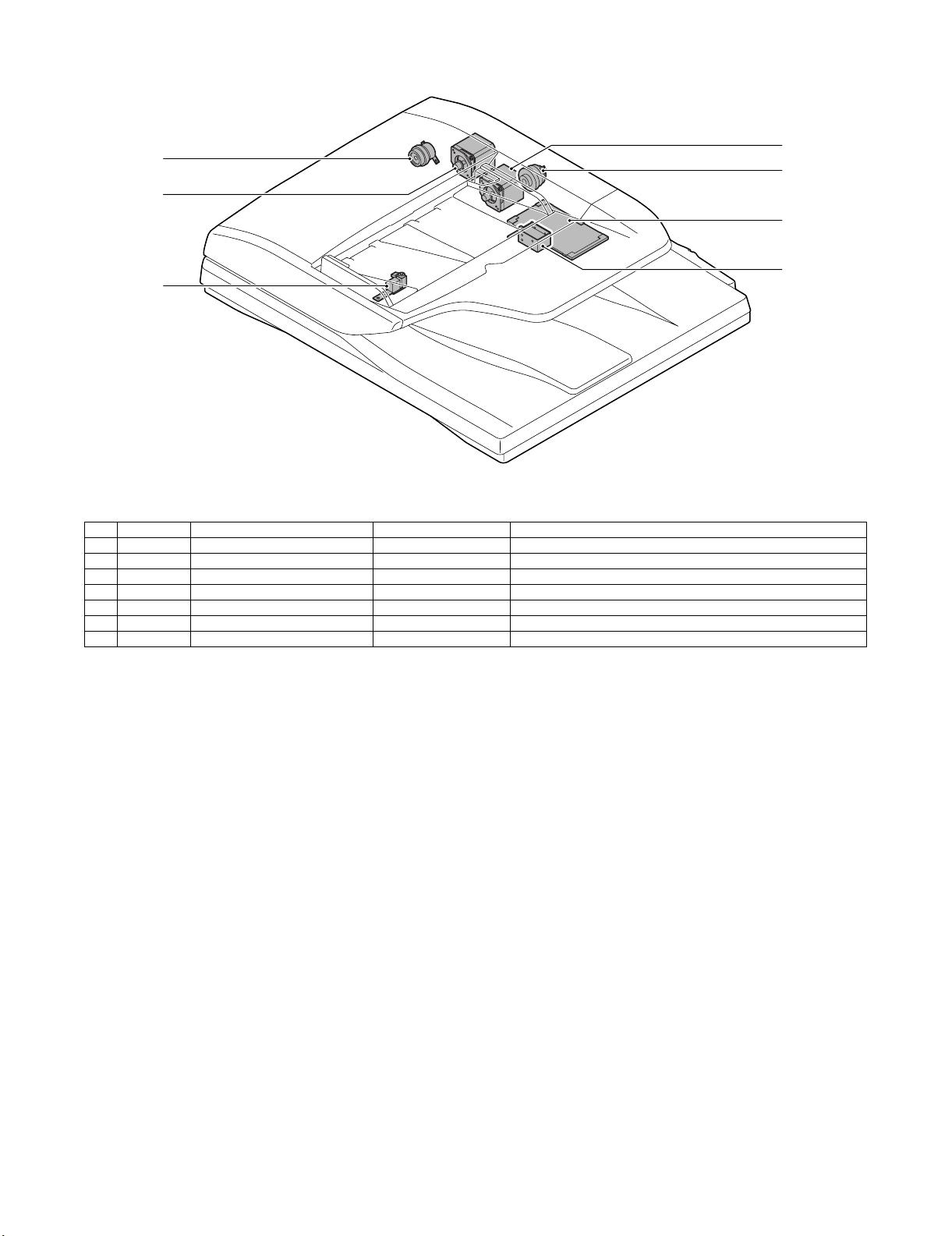

C. Motors, clutches, solenoids, and PWB

4

1

3

7

6

5

No. Signal Name Type Function/operation

1 SPFC SPF paper feed clutch Electromagnetic clutch Controls ON/OFF of the paper feed roller.

2 SPRM SPF paper feed reverse motor – Drives the paper feed system rollers and the SWB transport roller.

3 SPFM SPF transport motor – Drives the transport roller and the PS roller.

4 SRRC SPF resist roller clutch Electromagnetic clutch Controls ON/OFF of the resist roller.

5 STMPS Stamp solenoid – Drives the finish stamp.

6 SGS SPF document exit gate solenoid Electromagnetic solenoid Reverses the paper exit gate when ON.

7 – RSPF driver PWB – RSPF driver PWB

2

MX-RPX1 EXTERNAL VIEW AND INTERNAL STRUCTURE 4 – 3

Page 8

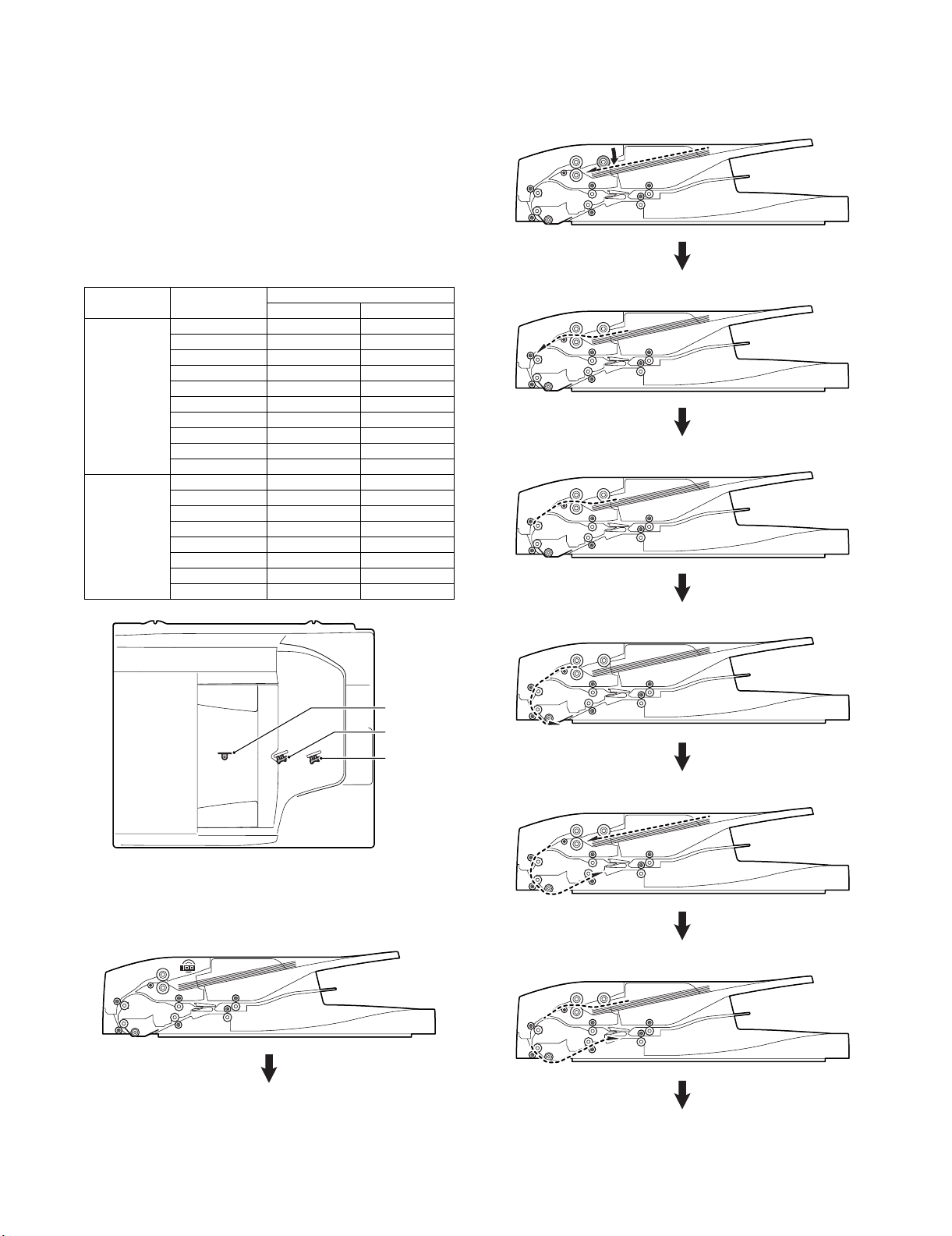

[5] OPERATIONAL DESCRIPTIONS

Service Manual

1. Document size detection

A. Document size detection

Size detection on the document tray

The document width is detected by the document width sensor

(SPWS), and the document length is detected by the document

length sensors (SPLS1, SPLS2). The document size is judged from

the document width and the document length as shown in the table

below.

When, however, mixed sizes of documents are loaded on the tray,

the maximum size is detected.

Document size

AB series A5 OFF OFF

B5 OFF OFF

11" x 8. 5" OF F O F F

A4 OFF OFF

B5R ON OFF

A4R ON OFF

8.5" x 13" ON ON

B4 ON ON

A3 ON ON

11" x 17" ON ON

Inch series 8.5" x 5.5" OFF OFF

11" x 8. 5" OF F O F F

A4 OFF OFF

11" x 8. 5"R O N OF F

8.5" x 13" ON ON

8.5" x 14" ON ON

A3 ON ON

11" x 17" ON ON

Document length sensor

SPLS1 SPLS2

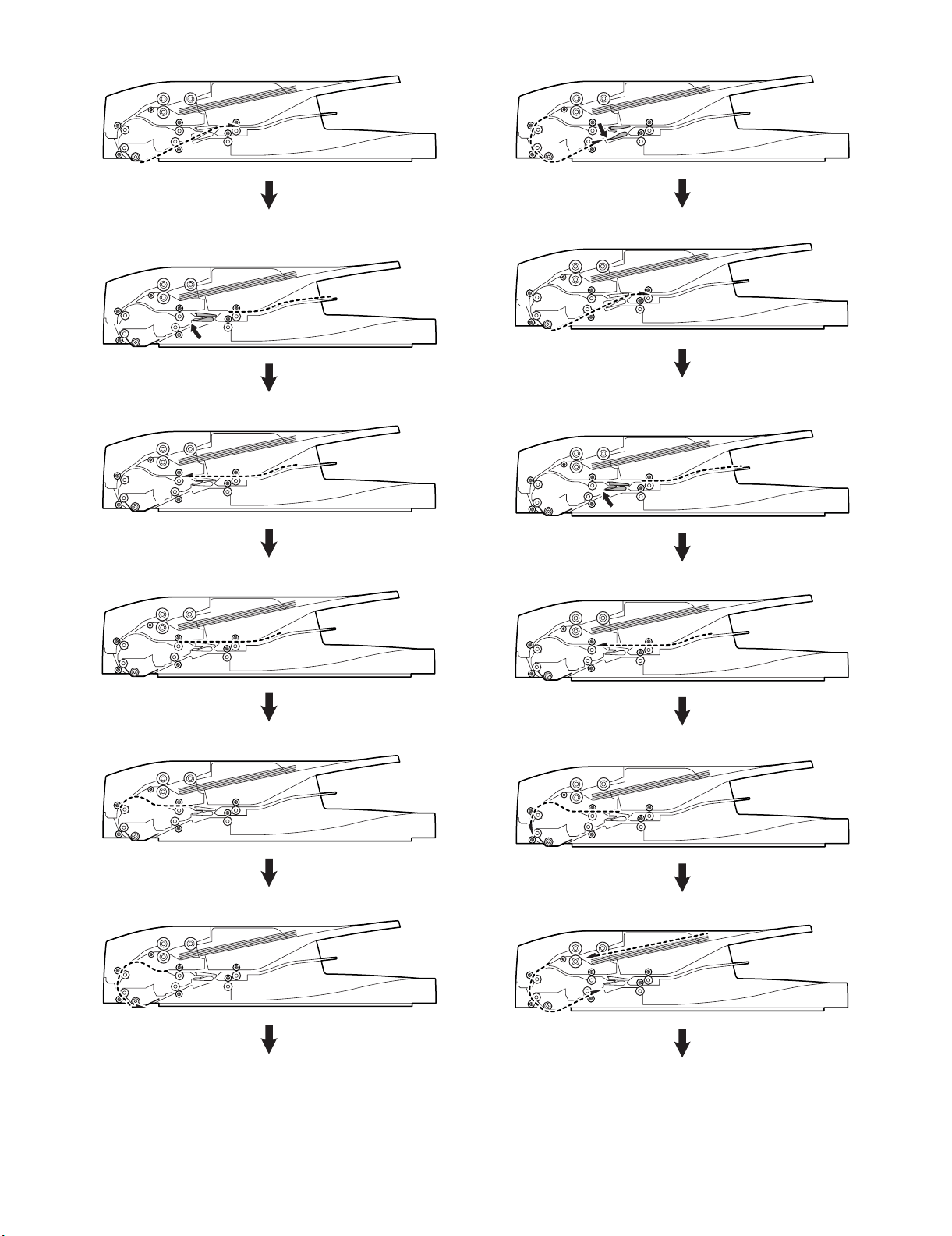

2) Preliminary paper feed start (1st sheet)

The pick-up roller descends.

3) Preliminary paper feed complete/Paper feed start (1st sheet)

4) Resist operation (1st sheet)

5) Scanning start (1st sheet)

SPWS

SPLS1

SPLS2

2. Paper feed and transport operations

A. Single face scanning

1) Document set (Document empty sensor ON)

6) Preliminary paper feed start (2nd sheet)

7) Preliminary paper feed complete (2nd sheet)

MX-RPX1 OPERATIONAL DESCRIPTIONS 5 – 1

Page 9

8) Paper feed start (2nd sheet)

9) Scanning complete (1st sheet)/Resist operation (2nd sheet)

10) Scanning start (2nd sheet)

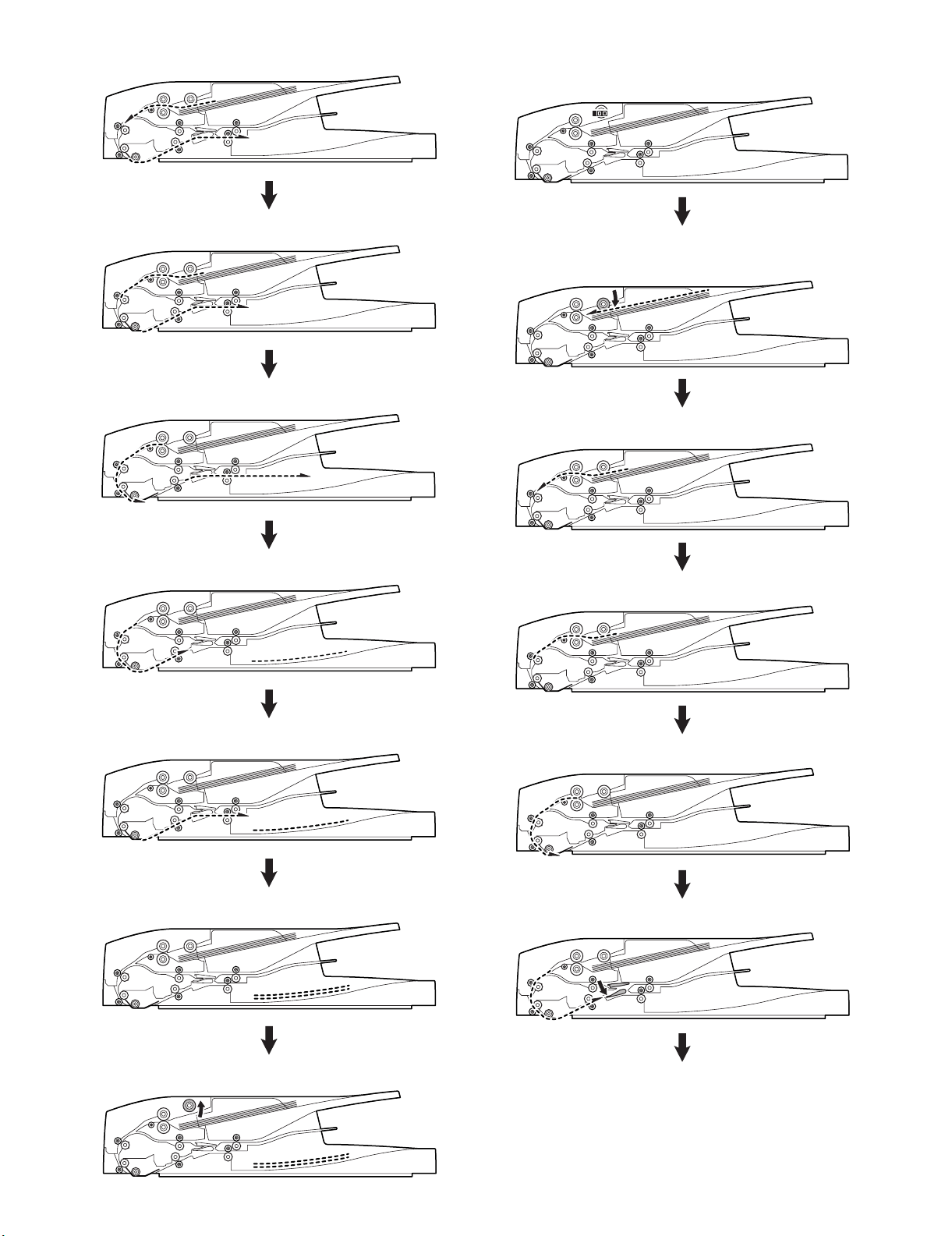

B. Duplex scanning

1) Document set (Document empty sensor ON)

2) Preliminary paper feed start (1st sheet)

Pick up roller descending

3) Preliminary paper feed complete/Paper feed start (1st sheet)

11) Paper exit complete (1st sheet)

12) Scanning complete (2nd sheet)

13) Paper exit complete (2nd sheet)

4) Resist operation (1st sheet, front surface)

5) Scanning start (1st sheet, front surface)

6) Gate descending (1st sheet, front surface)

14) Pick-up roller lifting up

MX-RPX1 OPERATIONAL DESCRIPTIONS 5 – 2

Page 10

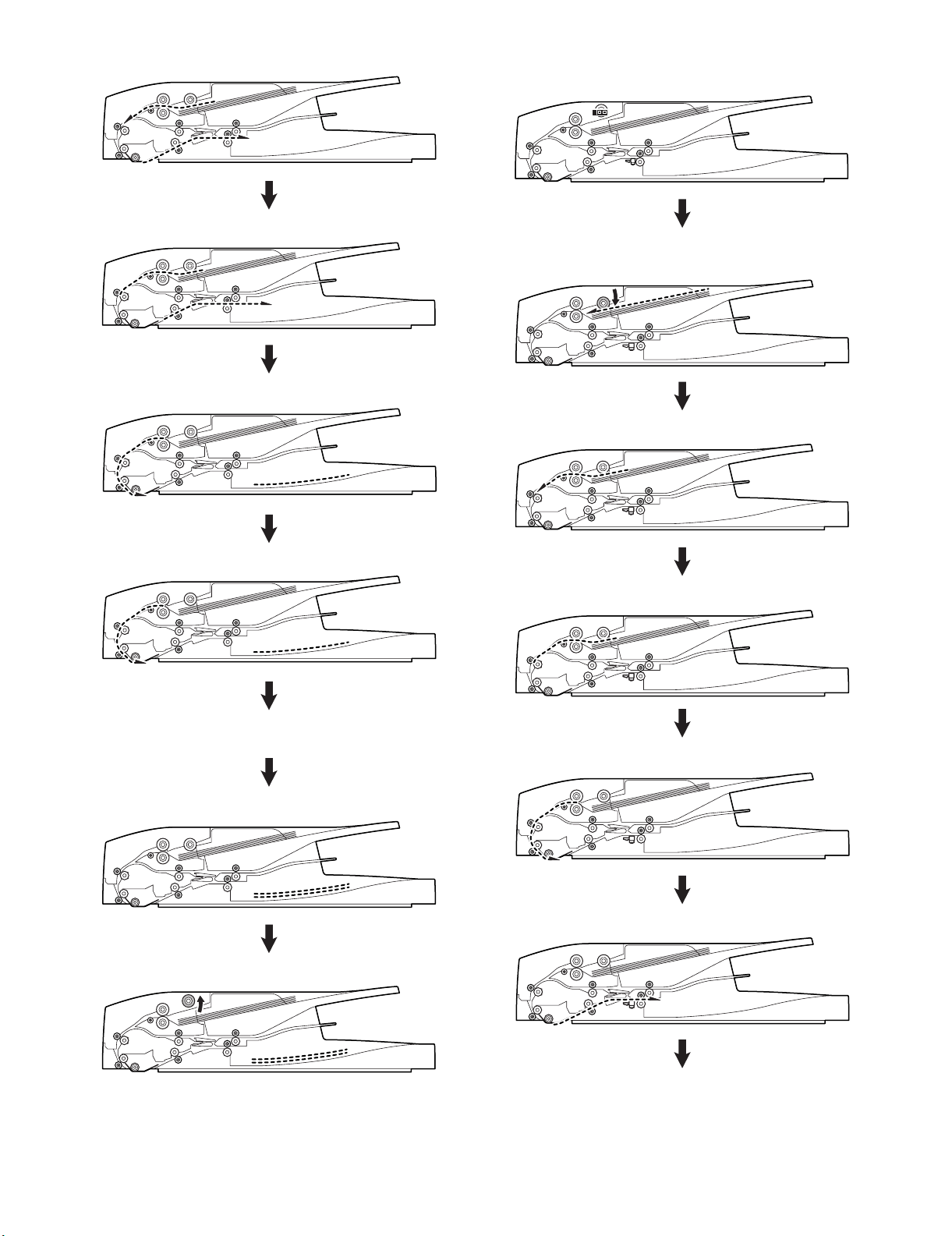

7) Scanning complete (1st sheet, front surface)

13) Gate descending (1st sheet, back surface)

8) Reverse stop

Gate lifting up

9) Reverse start

10) Resist operation after reverse

14) Scanning complete (1st sheet, back surface)

15) Reverse stop

Gate lifting up

16) Reverse start

11) Resist operation (1st sheet, back surface)

12) Scanning start (1st sheet, back surface)

17) Document transport continued

18) Preliminary paper feed start (2nd sheet)

MX-RPX1 OPERATIONAL DESCRIPTIONS 5 – 3

Page 11

19) Preliminary paper feed complete/Paper feed start (2nd sheet)

20) Resist operation (2nd sheet, front surface)

21) Paper exit complete (1st sheet)

C. Stamp operation

1) Document set (Document empty sensor ON)

2) Preliminary paper feed start (1st sheet)

Pick-up roller descending

3) Preliminary paper feed complete/Paper feed start (1st sheet)

22) Scanning start (2nd sheet, front surface)

23) Same operation as "5) Scanning start (1st sheet, front surface)" and later

24) Paper exit complete (2nd sheet)

25) Pick-up roller lifting up

4) Resist operation (1st sheet)

5) Scanning start (1st sheet)

6) Scanning complete (1st sheet)

MX-RPX1 OPERATIONAL DESCRIPTIONS 5 – 4

Page 12

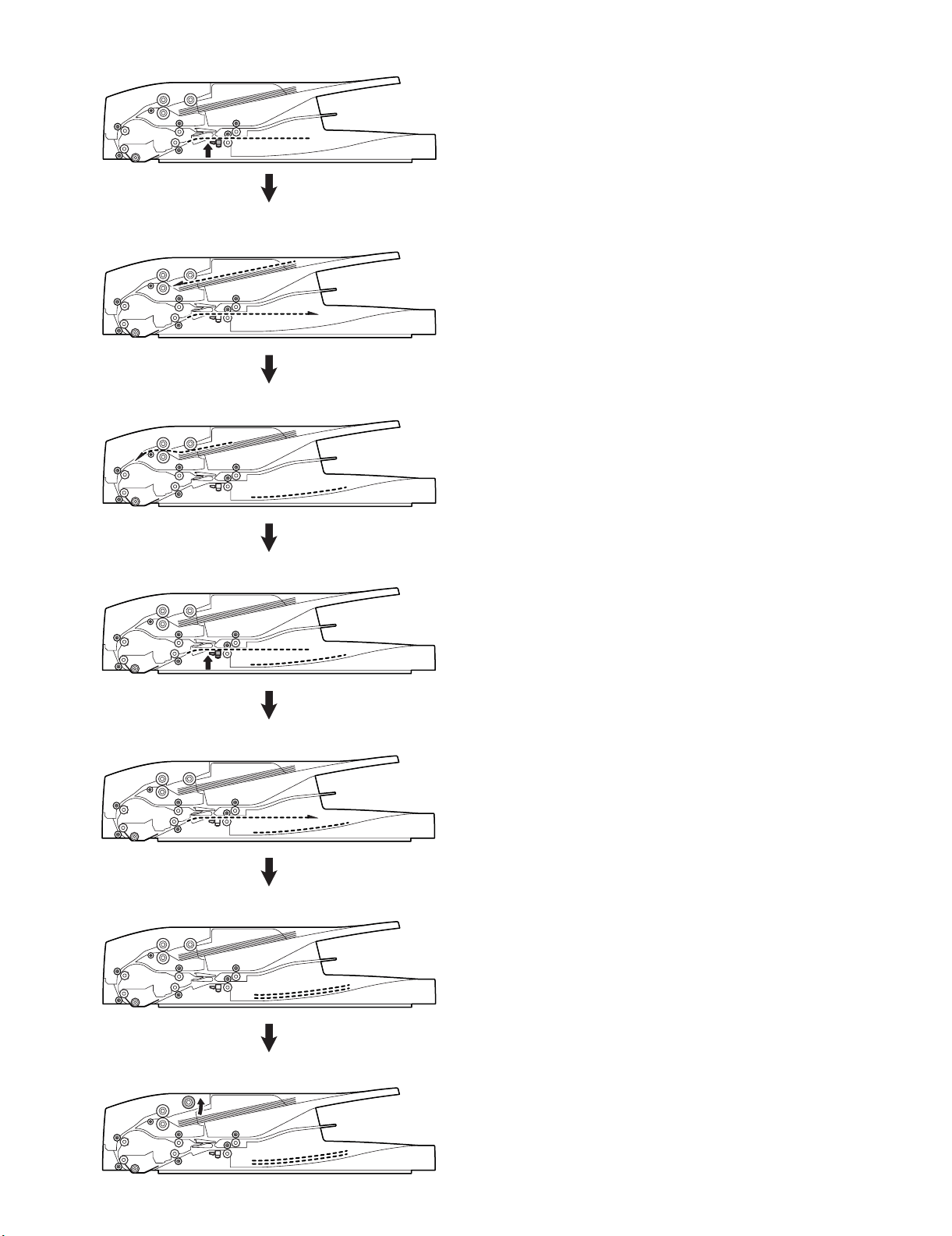

7) Stop at the stamp position/Stamp operation (1st sheet)

8) Paper exit start (1st sheet)/Preliminary paper feed start (2nd

sheet)

9) Paper exit complete (1st sheet)

10) Stop at the stamp position/Stamp operation (2nd sheet)

11) Paper exit start (2nd sheet)

12) Paper exit complete (2nd sheet)

13) Pick-up roller lifting up

MX-RPX1 OPERATIONAL DESCRIPTIONS 5 – 5

Page 13

[6] DISASSEMBLY AND ASSEMBLY

Service Manual

1. Document tray section

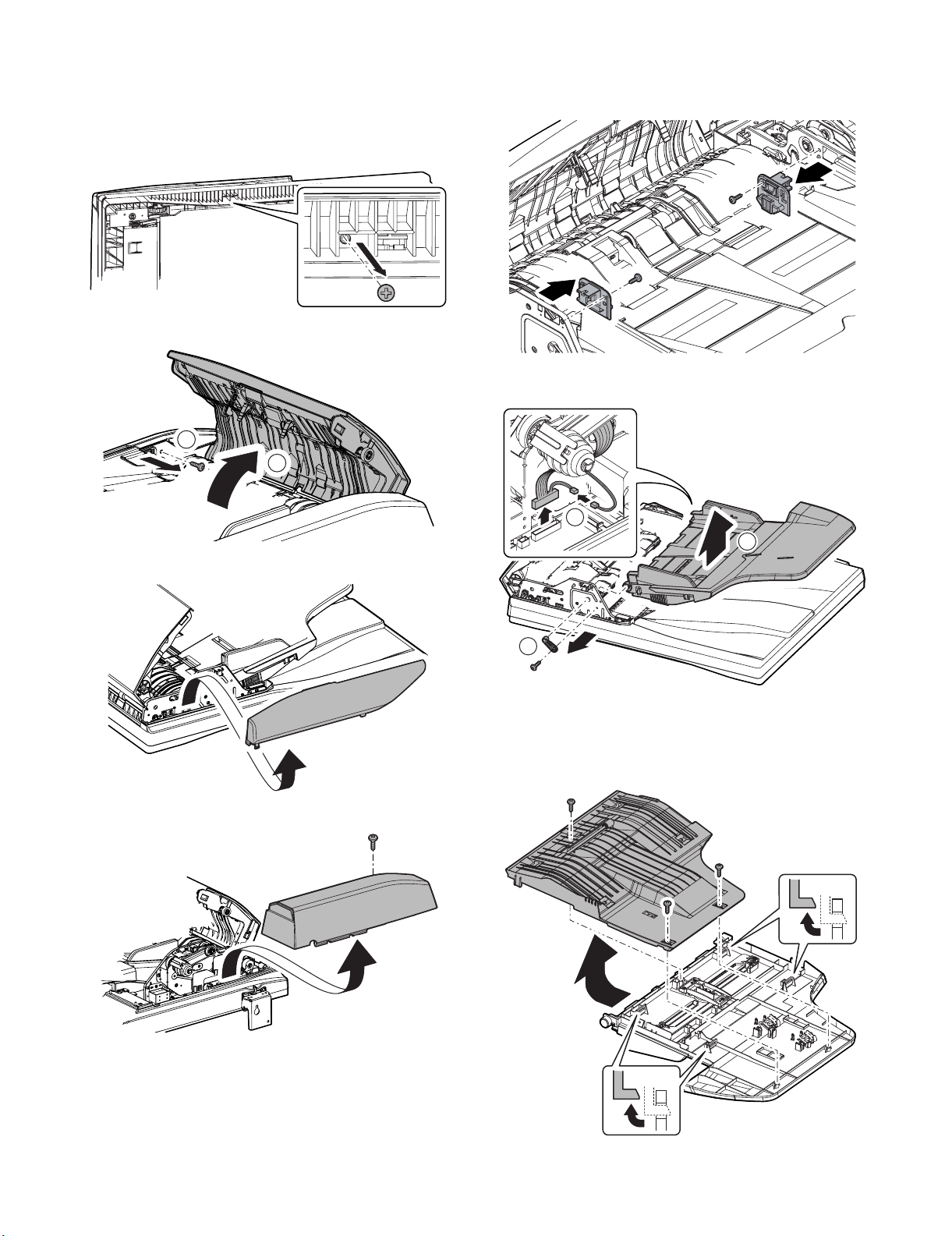

A. Document tray unit

1) Remove the RSPF unit bottom fixing screw.

2) Open the paper feed unit, and remove the screw.

2

1

3) Remove the front cabinet.

5) Remove the stopper.

6) Disconnect the connector. Remove the paper feed PG holder,

and remove the document tray unit.

1

3

4) Remove the screw, then remove the rear cabinet.

2

(1) SPF document length short sensor/SPF document

length long sensor/SPF document width sensor

1) Remove the document tray unit.

2) Remove the lower document tray.

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 1

Page 14

3) Remove the SPF document length short sensor and the SPF

document length long sensor.

2) Remove the upper transport auxiliary PG.

4) Remove the SPF document width sensor.

2. Paper feed section/paper transport

section

A. Paper feed unit

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Disconnect the grounding wire. Remove the spring, the paper

feed PG holder, and remove the paper feed unit and the upper

PG link arm.

3) Remove the holder guide, and remove the pick-up roller and

the paper feed roller.

(2) Take-up torque limiter

1) Remove the front cabinet and the rear cabinet.

2) Remove the paper feed unit.

3) Remove the pick-up roller and the paper feed roller.

4) Remove each part.

3

2

(1) Pick-up roller/Paper feed roller

1) Open the paper feed unit.

1

5) Remove the paper feed shaft, the pick-up roller holder, and the

take-up torque limiter.

3

2

1

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 2

Page 15

(3) Separation roller/Torque limiter SPF

1) Open the paper feed unit.

2) Remove the separation roller cover. Remove the separation

roller and the torque limiter SPF.

1

2

(4) SPF paper entry detection 1 sensor/SPF document

empty detection sensor/SPF cover switch

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the paper feed unit.

4) Remove the screws.

6) Remove the SPF paper entry detection 1 sensor and the SPF

document empty sensor.

7) Remove the SPF cover switch.

5) Remove the upper cover.

B. Transport unit

1) Remove the front cabinet and the rear cabinet.

2) Disconnect the connector.

3) Remove the RSPF unit bottom fixing screws.

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 3

Page 16

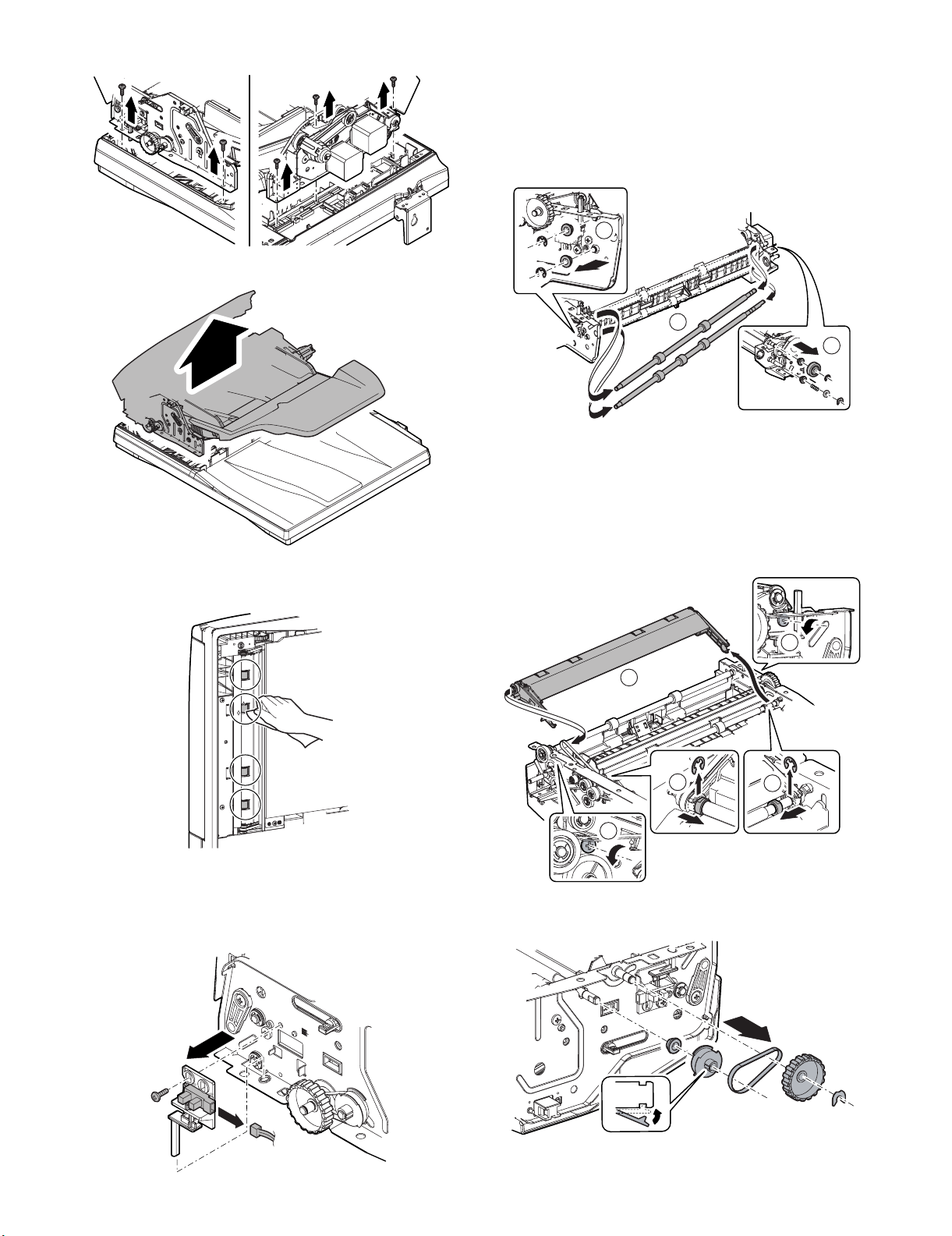

4) Remove the screws.

2

2

3

1

1

5) Remove the transport unit.

(1) Platen roller

1) Clean the platen roller from the bottom of the RSPF unit.

(3) PS roller/Scan front roller

1) Remove the front cabinet and the rear cabinet.

2) Remove the paper feed unit.

3) Remove the transport unit.

4) Remove the PS clutch.

5) Remove the parts, and remove the PS roller and the scan front

roller.

2

3

1

(4) Scan rear roller

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the drive unit.

5) Loosen the screws. Remove the E-rings, and slide the bearing.

Remove the scan plate unit.

(2) SPF open/close sensor

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the SPF open/close sensor mounting plate.

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 4

6) Remove the resin E-ring, and remove the JAM release knob

and the belt. Remove the bearing.

Page 17

7) Loosen the tension holder screw to loosen the belt tension,

and remove the parts.

2

1

8) Remove the scan rear roller, and remove the parts.

2

2

1

3. Paper exit section

A. Paper exit section parts

(1) Discharge brush

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the discharge brush.

• Discharge brush attachment reference

Fit the discharge brush with the mark-up reference and

attach it.

(5) SPF paper entry detection 2 sensor/SPF scan front

sensor

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the drive unit.

5) Remove the scan plate unit.

6) Remove the sensor mounting plate.

(2) Paper exit roller

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the drive unit.

5) Remove the parts.

6) Remove the parts and remove the paper exit roller.

2

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 5

1

1

Page 18

4. Document reverse section

A. Reverse section parts

(1) SPF document exit gate solenoid

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the solenoid adjustment plate. Remove the SPF document exit gate solenoid.

* When assembling, insert the pin of the SPF document exit

gate solenoid into the gate.

2

1

(3) SWB pass section transport roller/SPF reverse

rear sensor

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the paper feed unit.

4) Remove the document tray unit.

5) Remove the drive unit.

6) Remove the separation roller.

7) Remove the separation transport PG.

(2) SWB roller

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the drive unit.

5) Remove the paper exit roller.

6) Remove the parts, and remove the intermediate tray unit.

1

1

2

7) Remove the intermediate tray PG. Remove the E-ring and the

bearing. Remove the SWB roller.

8) Remove the parts. Remove the separation shaft and the

spring.

2

3

1

1

9) Remove the intermediate PG.

1

3

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 6

2

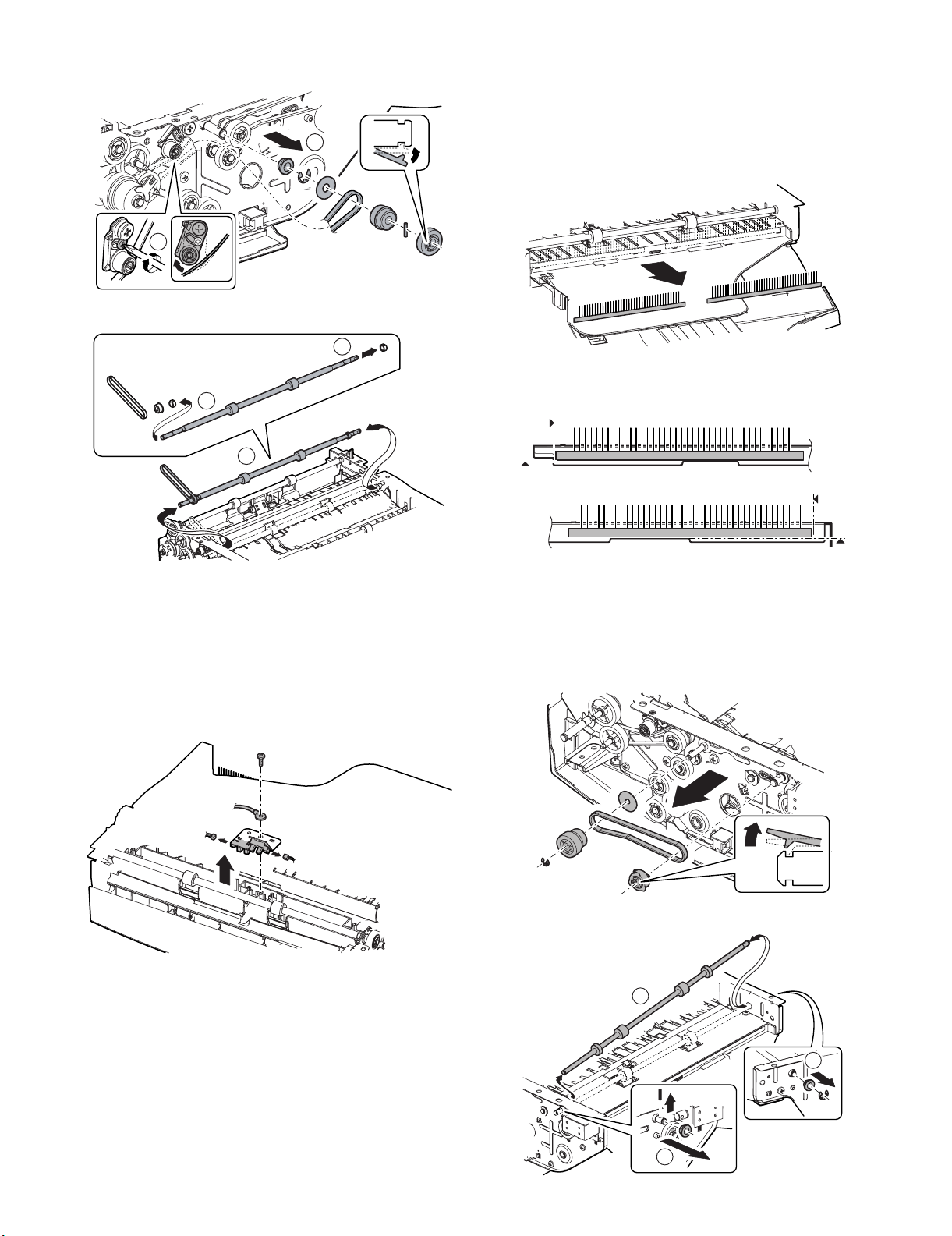

Page 19

10) Remove the parts, and remove the SWB pass section trans-

1

2

3

3

port roller.

1

11) Remove the scan rear roller.

12) Remove the scan rear PG.

2

1

5. Drive section

A. Drive unit

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the resin E-ring and the bearing. Remove the drive

unit and the parts.

(1) Belts

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the drive unit.

13) Remove the SPF reverse rear sensor.

(2) SPF paper feed clutch

1) Remove the rear cabinet.

2) Remove the resin E-ring, and remove the SPF paper feed

clutch.

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 7

Page 20

(3) Resist roller clutch

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the E-ring, and remove the SPF resist roller clutch.

(4) SPF paper feed reverse motor

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the drive unit.

5) Remove the SPF paper feed reverse motor.

6. Base tray section

A. Base tray section parts

(1) RSPF driver PWB

1) Remove the rear cabinet.

2) Remove the RSPF driver PWB.

(2) SPF reverse gate front sensor

1) Remove the screw, and peel off the OC mat.

(5) SPF transport motor

1) Remove the front cabinet and the rear cabinet.

2) Remove the transport unit.

3) Remove the document tray unit.

4) Remove the drive unit.

5) Loosen the tension holder screw to loosen the belt tension.

Remove the SPF transport motor.

2

1

2

2) Remove the sensor cover.

3) Remove the SPF reverse gate front sensor.

MX-RPX1 DISASSEMBLY AND ASSEMBLY 6 – 8

Page 21

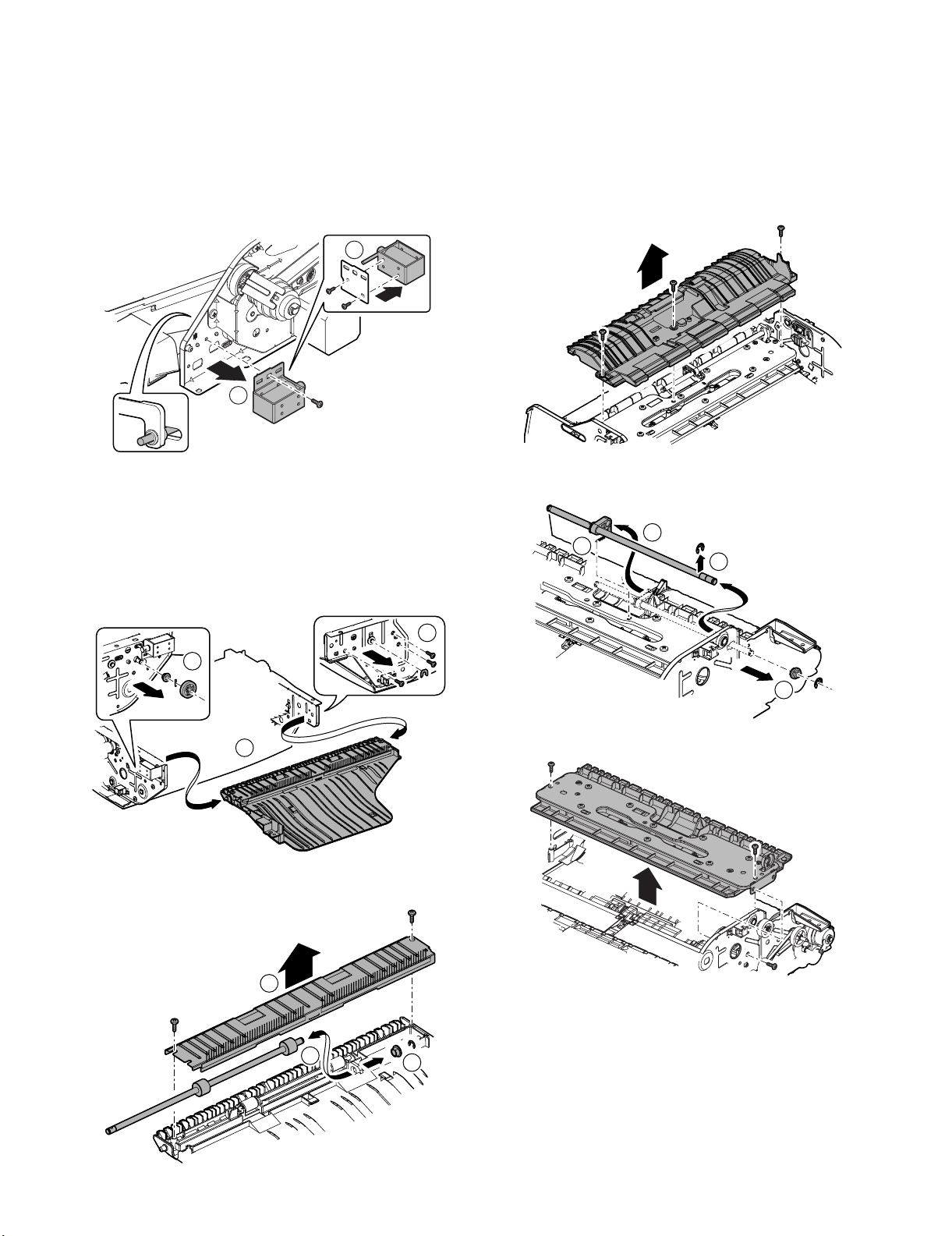

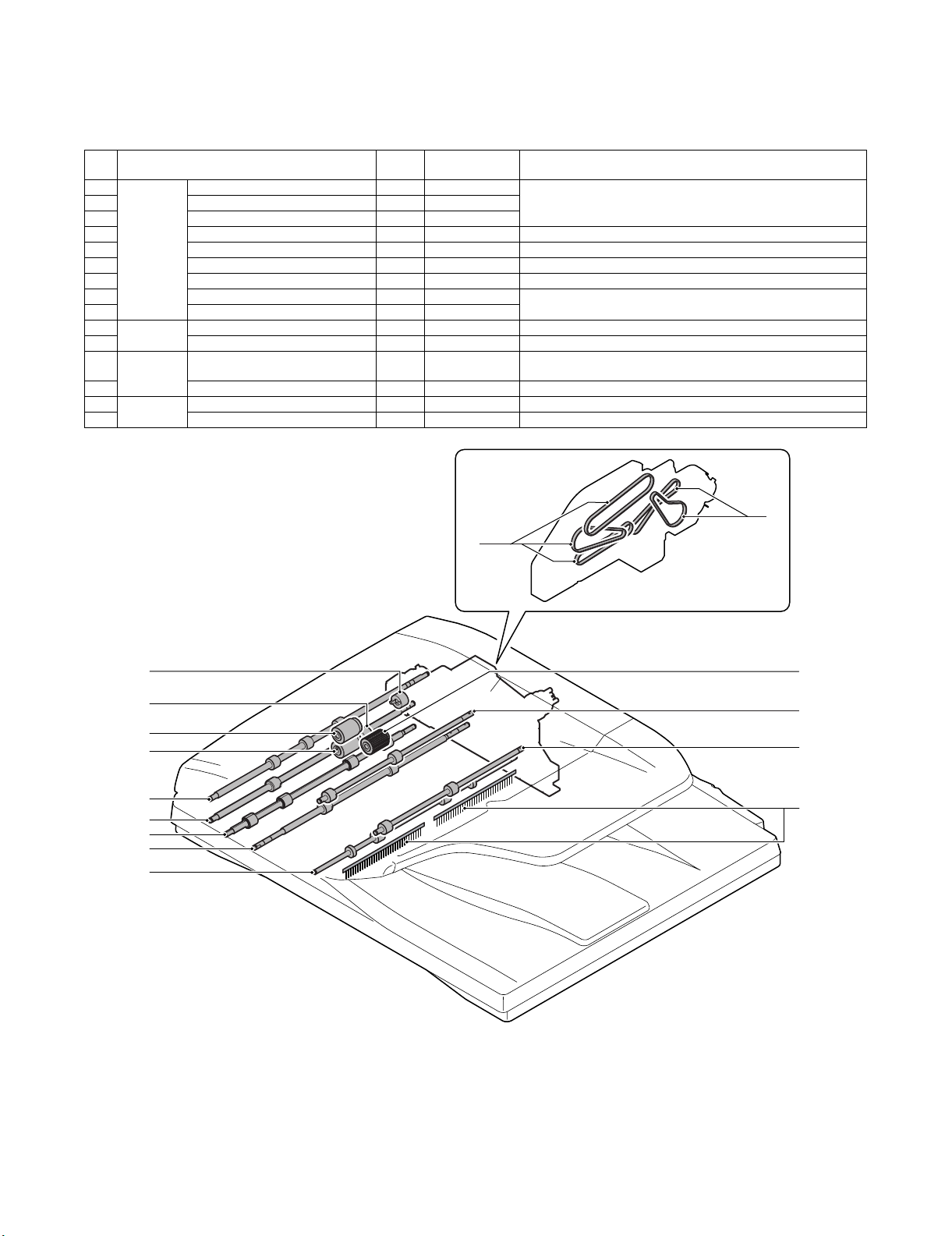

[7] MAINTENANCE

Service Manual

1. Maintenance system table

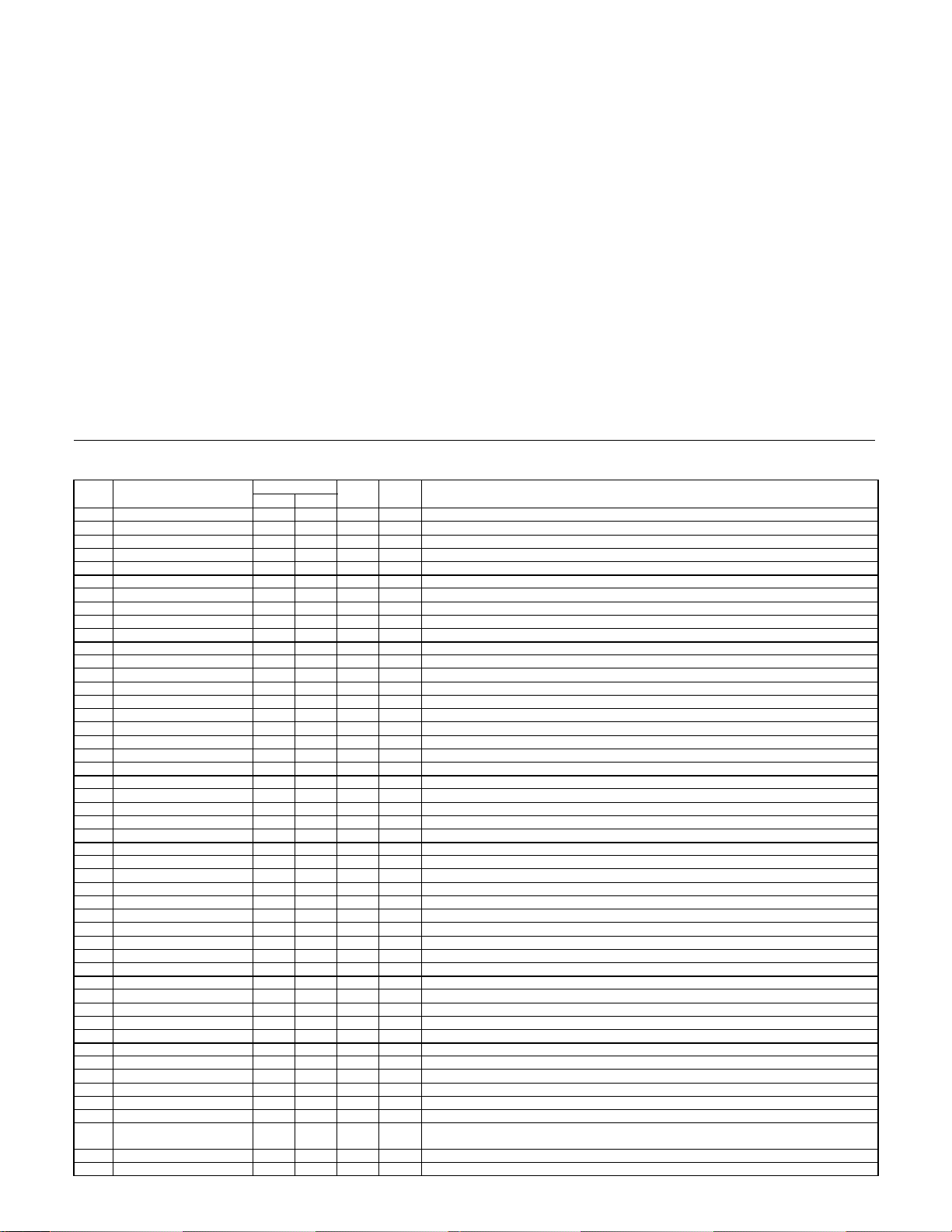

✕: Check (Clean, replace, adjust if necessary.) {: Clean ▲: Replace U: Adjust ✩: Lubricate : Shift position

No. Part name

1 Paper feed/

transport

2 Pick-up roller {{

section

3 Separation roller {{

4 PS roller (Drive) {{

5 Scan front roller (Drive) {{

6 Platen roller (Drive) {{

7 Scan rear roller (Drive) {{

8 Torque limiter SPF (for separation) ✕✕Replacement reference: RSPF document feed 400K (SIM22-8), or

9 Take-up torque limiter (for pick up) ✕✕

10 Paper exit

section

11 Discharge brush ✕✕

12 Reverse

section

13 SWB roller (Drive) {{

14 Drive

section

15 Belts ✕

Paper feed roller {{Replacement reference: RSPF document feed 100K (SIM22-8), or

Paper exit roller SPF {{

SWB pass section transport roller

(Drive)

Gears ✕✕

When

calling

Follows the

main unit cycle.

after 1 year of use

after 2 years of use

{{

Remark

15

15

9

8

1

3

4

5

6

7

10

2

13

12

11

MX-RPX1 MAINTENANCE 7 – 1

Page 22

A

K

0

A

:

A㧦 99

B㧦 50

㧧 OC

㧧 SPF(SIDE1)

SIMULATIONNO.50-12

ORGINAL CENTER OFFSET SETUP

99

㨇 1㨪 99 㨉

OK

TEST

CLOSE

C㧦 50 㧧 SPF(SIDE2)

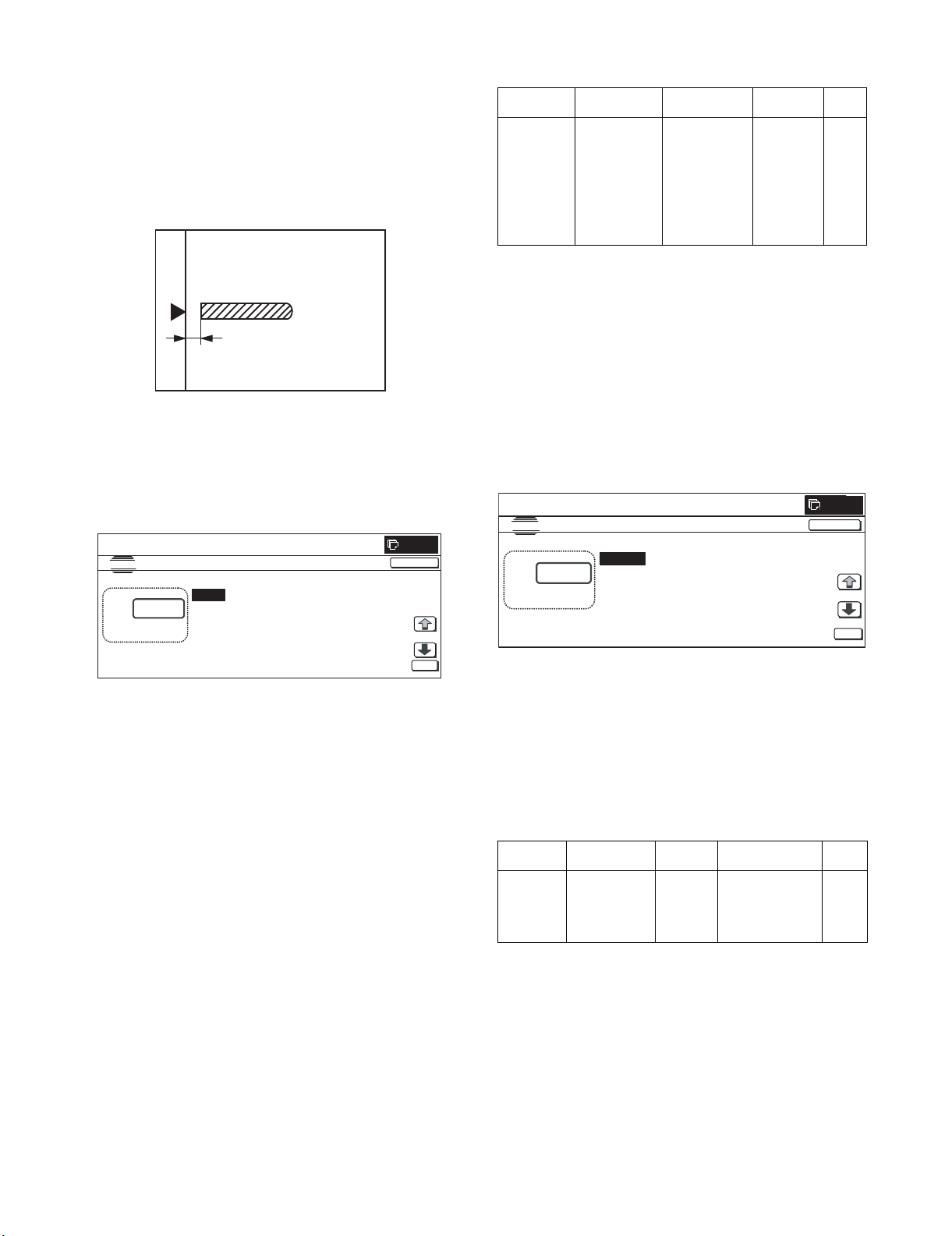

[8] ADJUSTMENTS

<Adjustment specifications>

Service Manual

1. RSPF magnification ratio adjustment

NOTE: To execute this adjustment, the CCD unit must have been

properly installed. To execute this adjustment, the OC

mode adjustment when copying must have been completed.

1) Place a scale on the document table as shown in the figure

below, and make a normal copy to make a test chart.

Note: Since the copied scale is used as a test chart,

place the scale in parallel to the sides.

2) Set the test chart on the RSPF, and make a normal copy.

3) Compare the outputted copy with the test chart. If it is judged

from comparison that an adjustment is required, perform the

following procedures.

4) Execute SIM48-1.

SIMULATIONNO.48-01

TEST

MAGNIFICATION ADJUSTMENT

:

㨇 1㨪99 㨉

80

A㧦 80

B㧦 50

C㧦 50

D㧦 50

㧧 CCD(MAIN)

㧧 CCD(SUB)

㧧

SPF(MAIN)

㧧

SPF(SUB)

0

CLOSE

Mode Specifications SIM Set value

Magnification

ratio

adjustment

Normal ±1.0% SIM48-1

<Main scanning

direction>

C: Front surface

E: Back surface

<Sub scanning

direction>

D: Front surface

F: Back surface

Add 1: 0.1%

enlarged.

Subtract 1:

0.1%

reduced.

Default: 50

Set

range

1 – 99

2. RSPF document off-center adjustment

NOTE: To execute this adjustment, the paper off-center must have

been adjusted properly.

1) Set the test chart for center position adjustment (which is

made by yourself) on the RSPF.

<Adjustment specifications>

Draw a straight line on paper in the scanning direction.

2) Make a normal copy from the manual paper feed tray. Com-

pare the printed copy and the test chart. If an adjustment is

required, perform the following procedures.

3) Execute SIM50-12.

㩷㩷

5) Change the mode to "C: SPF (MAIN)." The current magnification ratio correction value is displayed in 2 digits on the display

section.

6) Enter a set value and press [OK] key. The correction value is

saved and a copy is made.

7) Change the mode to "E: SPFB (MAIN)." The current magnification ratio correction value is displayed in 2 digits on the display section.

8) Enter a set value and press [OK] key. The correction value is

saved and a copy is made.

9) Change the mode to "D: SPF (SUB)." The current magnification ratio correction value is displayed in 2 digits on the display

section.

10) Enter a set value and press [OK] key. The correction value is

saved and a copy is made.

11) Change the mode to "F: SPFB (SUB)." The current magnification ratio in the back surface sub scanning direction is displayed in 2 digits on the display section.

12) Enter a set value and press [OK] key. The correction value is

saved and a copy is made.

O

MX-RPX1 ADJUSTMENTS 8 – 1

4) Change the mode to "B: SPF (SIDE1)." The current off-center

adjustment value is displayed in 2 digits on the display section.

5) Enter a set value and press [START] key. The correction value

is saved and a copy is made.

6) Change the mode to "C: SPF (SIDE2)." The current back surface off-center adjustment value is displayed in 2 digits on the

display section.

7) Enter a set value and press [OK] key. The correction value is

saved and a copy is made.

<Adjustment specifications>

Mode Specifications SIM Set value

Document

off-center

adjustment

Center position

(Default): 3750

pixel

SIM50-12

B: Front

surface

C: Back

surface

Add 1: Shift to R

side by 0.1mm.

Subtract 1: Shift to

F side by 0.1mm.

Set

range

1 – 99

Page 23

3. RSPF copy image position, void area

A

image adjustment

1) Place a scale on the OC table as shown in the figure below.

Note: Since the copied scale is used as a test chart,

place the scale in parallel to the sides.

2) Make a copy. Use the output copy as the original document,

and make a copy of it from the RSPF.

3) Check the output result. If an adjustment is required, perform

the following procedures.

4) Execute SIM50-6.

0

SIMULATIONNO.50-06

TEST

LEAD EDGE ADJUSTMENT VALUE(RSPF)

:

㨇 1㨪 99 㨉

26

A㧦 26

B㧦 50

C㧦 15

D㧦 20

㧧 SIDE1

㧧 SIDE2

㧧 LEAD ED GE

㧧 FRONT_ REAR

CLOSE

4. RSPF scan position adjustment

1) Enter SIM53-08 mode, and press [OK] button.

<<Description of adjustment display>>

Set

Item Display item Description

A ADJUST VALUE RSPF scan position

adjustment

• When the set value is increased by 1, the distance from the

home position to the RSPF scan position is increased.

• When the set value is changed by 1, the position is shifted

by 0.1mm.

* Since the SPF scan position distance are changed, RRCA is

not changed by the adjustment value.

[Note]

• After completion of the RSPF scan position adjustment, execute the RSPF lead edge adjustment (for both sides).

2) Check to confirm that the lead edge is not shifted. (Both surfaces) (If the original lead edge adjustment is proper, the scan

position after change automatically follows.)

Default

range

1 – 99 50

value

OK

5) Set the RSPF lead edge position set value so that an image

similar to the image adjusted in the previous OC image lead

edge position is outputted.

<<Set range and default value of each set value>>

Set

Item Display item Descriptions

A SIDE1 Front surface

B SIDE2 Back surface

C Image

loss

quantity

setting,

D FRONT_REAR

SIDE1

E TRAIL_EDGE

F Image

loss

quantity

setting,

G FRONT_REAR

SIDE2

H TRAIL_EDGE

LEAD_EDGE

(SIDE1)

(SIDE1)

(SIDE1)

LEAD_EDGE

(SIDE2)

(SIDE2)

(SIDE2)

document scan

start position

adjustment (CCD)

document scan

start position

adjustment (CCD)

Front surface lead

edge image loss

quantity setting

Front surface side

image loss

quantity setting

Front surface rear

edge image loss

quantity setting

Back surface lead

edge image loss

quantity setting

Back surface side

image loss

quantity setting

Back surface rear

edge image loss

quantity setting

Default

range

1 – 99 50

1 – 99 50

0 – 99 30

0 – 99 20

0 – 20 0

0 – 99 30

0 – 99 20

0 – 20 0

value

A, B: The greater the value is, the slower the scanning timing is.

C – H: The greater the adjustment value is, the greater the image

loss is.

A – H: 1 step = 0.1mm

The SPF rear edge image loss is provided against the shade. The

default value is 0.

MX-RPX1 ADJUSTMENTS 8 – 2

Page 24

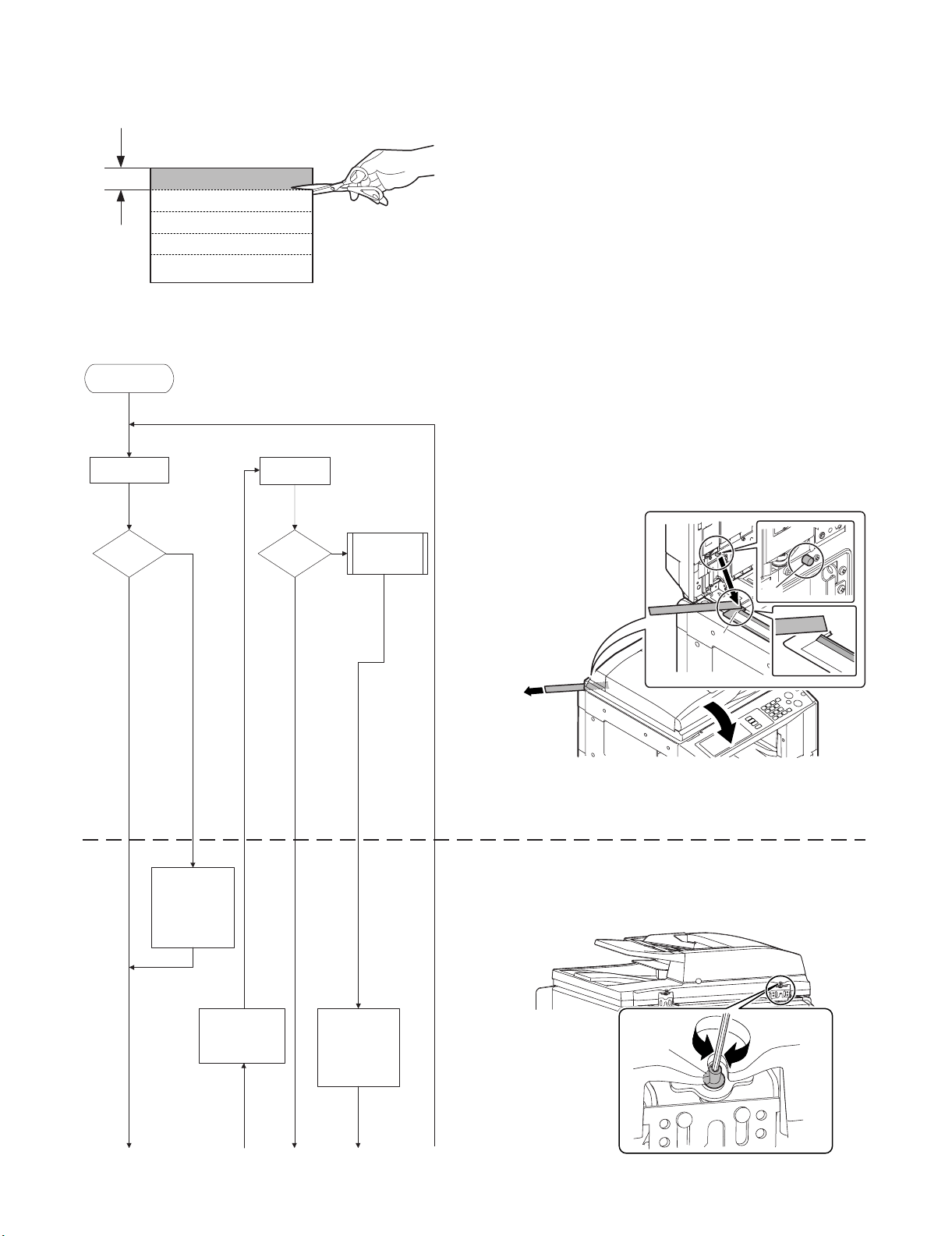

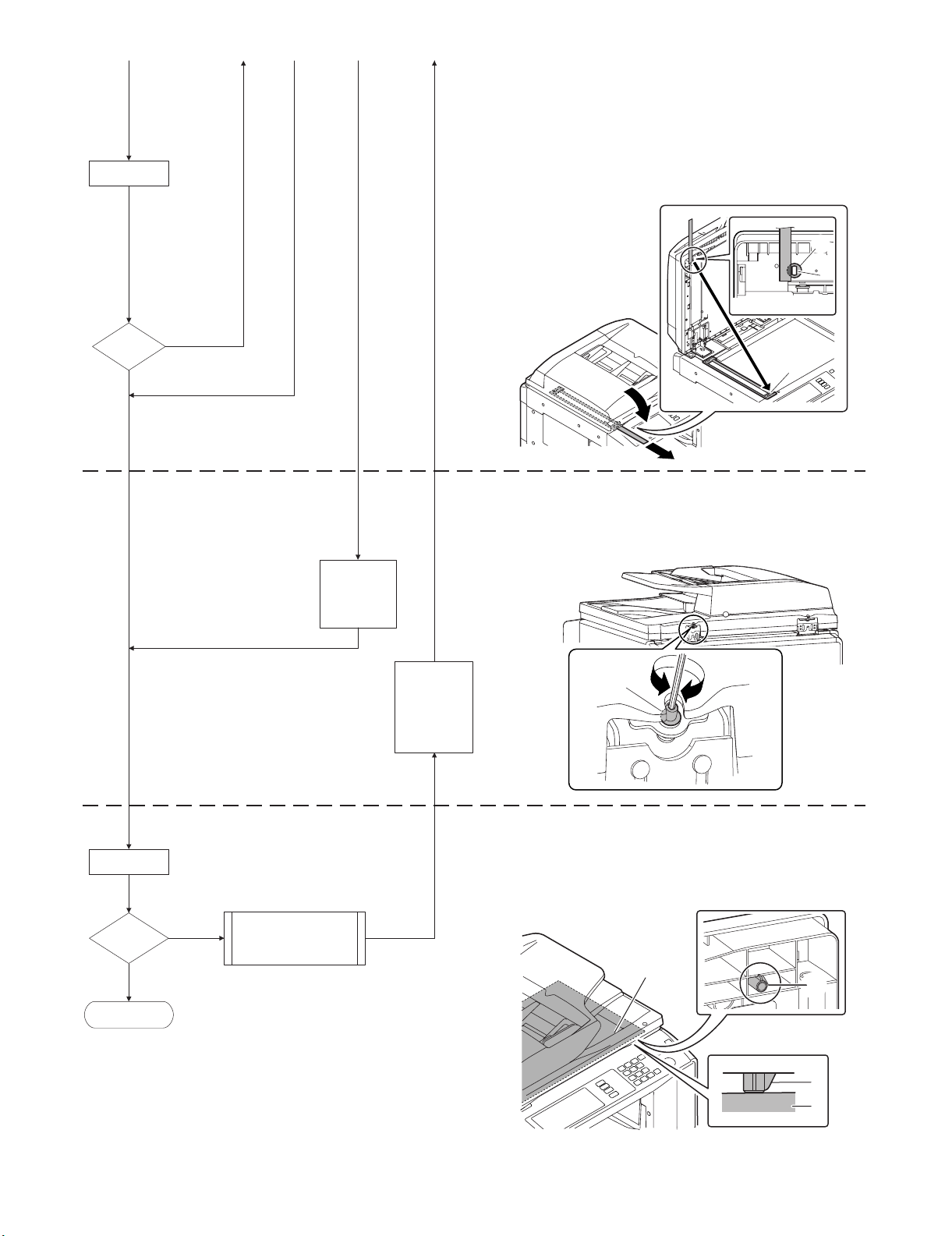

5. RSPF height adjustment

1) Make an RSPF height adjustment sheet

Cut copy paper in the longitudinal direction.

20mm

A4/Letter size

2) Perform the adjustment according to the flowchart below.

Start of the

adjustment

Check section A.

Check section

A again.

<Work procedure><Flow chart>

a) Check section A.

Place the RSPF height adjustment sheet between section A

and the SPF glass height adjustment resin surface (a), and

close the RSPF unit.

Slowly pull out the RSPF height adjustment sheet.

Check to insure that a slight resistance is felt when pulling out

the RSPF height adjustment sheet.

Be careful not to cover the convex section of the glass

*

holding resin surface with the height adjustment sheet.

No

Is

there a resist-

ance?

Yes Yes

Adjust hinge D

until there is a

resistance in

section A.

(Counterclockwise)

Is

there a resist-

ance?

No

The height on

the right side

is not proper.

A

a

If it cannot be pulled out or there is no resistance to pull out,

b)

turn section D to adjust.

Turn section D clockwise to lift the RSPF unit. Turn it

*

counterclockwise to move down the RSPF unit.

Adjust hinge

D until there is

a resistance in

section B.

Adjust hinge

D until there is

a resistance in

section A.

(Counterclockwise)

D

MX-RPX1 ADJUSTMENTS 8 – 3

Page 25

Check section B.

Is

there a re-

sistance?

Yes

No

Adjust hinge E

until there is a

resistance in

section B.

(Clockwise)

c) Check section B.

Place the RSPF height adjustment sheet between section B

and the SPF glass height adjustment resin surface (a), and

close the RSPF unit.

Slowly pull out the RSPF height adjustment sheet.

Check to insure that a slight resistance is felt when pulling out

the RSPF height adjustment sheet.

Be careful not to put the book sensor (b) on the height

*

adjustment sheet.

a

If it cannot be pulled out or there is no resistance to pull out,

d)

turn section E to adjust.

Turn section E clockwise to lift the RSPF unit. Turn it

*

counterclockwise to move down the RSPF unit.

B

b

Check section C.

Is there

a separating

section.

Yes

End of the

adjustment

No

The bosses in section A

and B are excessively

pressed. (The right side

is separating.)

Adjust hinge E

until the

separation in

section C is

deleted.

(Counterclockwise)

E

e) Check section C.

Check to confirm that the projection in section C in the right

front side of then RSPF bottom is in contact with the glass

surface (b).

b

C

C

b

MX-RPX1 ADJUSTMENTS 8 – 4

Page 26

6. RSPF diagonal adjustment

1) Set a test chart (A3) on the RSPF document tray, and make a

copy.

2) Measure (a) and (b) on the copied test chart. If (a) – (b) =

±1mm or more, perform the diagonal adjustment.

a

TEST CHART

A3 size

b

* In the case of (A), turn the RSPF diagonal adjustment screw

counterclockwise.

In the case of (B), turn the RSPF diagonal adjustment screw

clockwise.

A

B

3) Remove the hex nut cover in the RSPF diagonal adjustment

screw section.

4) Raise the RSPF unit upright, and loosen the fixing screw of the

hinge.

2

2

5) Close the RSPF unit, and loosen the hex nut of the RSPF

diagonal adjustment screw section.

Turn the hex wrench of the RSPF diagonal adjustment screw

to adjust the alignment.

2

1

3

1

6) Make a copy again and measure (a) and (b) on the copied test

chart. Repeat procedures 2) to 5) until the condition ((a)(b)=±1mm or less) is satisfied.

7) Tighten the hinge section fixing screw which was loosened in

the procedure 4) to tighten the hinge section.

7. SPF size width detection level

adjustment

1) Go to SIM53-6.

2) Set the tray document guide to the max. width position, and

press [EXECUTE] key. The button is highlighted and the tray

size volume maximum value adjustment is started.

* During the adjustment, "EXECUTING..." is displayed.

* After completion of the tray size volume maximum value

adjustment, the set value is saved to EEPROM and RAM

and the display is shifted to the tray volume A4R size adjustment value start screen. (Each set value is saved to

EEPROM and RAM at each setting.)

3) Set the tray document guide to A4R (11 x 8.5R) width position

and press [EXECUTE] button. The pressed button is highlighted and the tray A4R size adjustment is started.

4) Adjust the tray volume A5R (8.5 x 5 1/2R) size and the tray

size volume minimum value according to the above procedures.

5) After completion of the adjustment, "COMPLETE" is displayed.

If the adjustment is not completed normally for any reason,"ERROR"is displayed. In that case, the adjustment must

be executed again.

MX-RPX1 ADJUSTMENTS 8 – 5

Page 27

<Adjustment item and content>

No. Display Content

1 TRAYVOLMAX Tray size volume maximum value

2 TRAYVOLA4R Tray volume A4R size adjustment value

3 TRAYVOLA5R Tray volume A5R size adjustment

4 TRAYVOLMIN Tray size volume minimum value

When one of 1-4 in the above table is selected, the guide plate is

shifted to each position of the four widths of the guide plate shown

in the table below. The value of the document width sensor

(RSPF_WIDTH) A/D value is saved to EEPROM.

<Guide plate positions and widths on the mechanism and A/D

values to be saved>

Guide plate

No.

position

1 Maximum

position

2Middle

position (L)

3Middle

position (S)

4 Minimum

position

Widths on the mechanism A/D value,

AB

INCHI

series

series

299 299 WIDTH_MAX AD_MAX

210 21 5.9 WIT H_P1 AD_P1 A4R OR

148.5 139.7 WITH_P2 AD_P2 A5 R OR

118 118 WITH_MIN AD_MIN

Code in the

figure below

code in

the figure

below

Remark

LTR

INVR

[Initial screen]

0

SIMULATION NO.53-06

TEST

SPF TRAY ADJUSTMENT

TRAYVOLMAX TRAY ADJUSTMENT.

PRESS [EXECUTE] TO START

CLOSE

EXECUTE

8. Auto void adjustment (SPF adjustment)

1) Go to SIM50-28.

0

SIMULATION NO.50-28

TEST

AUTO IMAGE POSITION ADJUSTMENT: SERVICE

OC ADJ BK-MAG ADJ

SPF ADJ

RESULT DATA

SETUP/PRINT ADJ

CLOSE

4) Select one of the cassettes that can be used to print SPF

adjustment patterns.

5) Press the [EXECUTE] button, and the machine starts self-print

of SPF adjustment patterns.

* The screen shows a message indicating that the machine is

self-printing SPF adjustment patterns.

When self-print finishes, the next screen appears where you

can start SPF adjustments.

6) SPF adjustment patterns are loaded into the SPF.

* By pressing the [REPRINT] button, you can return to the

cassette selection screen and have the machine self-print

SPF adjustment patterns again.

7) Press the [EXECUTE] button, and the machine starts reading

SPF adjustment patterns (for the front side).

* The screen shows a message indicating that the machine is

reading and calculating SPF adjustment patterns (for the

front side).

The machine starts calculating the adjustment amount (for

the front side) after it has read the patterns for the front side.

After the machine has finished calculating the adjustment

amount for the front side, the next screen appears where

you can have the machine start reading SPF adjustment

patterns (for the back side).

<Adjustment Item List>

• SPF original leading edge adjustment (front side)

• SPF original off-center adjustment (front side)

• SPF original sub-scan magnification adjustment (front side)

8) SPF adjustment patterns are loaded into the SPF.

1/1

2) Press the [SPF ADJ] button.

0

SIMULATION NO.50-28

TEST

AUTO IMAGE POSITION ADJUSTMENT:SERVICE

SIDE1

ALL

SIDE2

CLOSE

1/1

3) Proceed to one of the three screens for selecting the cassette

used to print SPF adjustment patterns by selecting the corresponding button:

SIDE1: SPF adjustment for the front side

SIDE2: SPF adjustment for the back side

ALL: SPF adjustment for both the front and back sides

MX-RPX1 ADJUSTMENTS 8 – 6

* By pressing the [REPRINT] button, you can return to the

cassette selection screen and have the machine self-print

SPF adjustment patterns again.

Page 28

9) Press the [EXECUTE] button, and the machine starts loading

SPF adjustment patterns (for the back side).

* The screen shows a message indicating that the machine is

reading SPF adjustment patterns (for the back side).

The machine starts calculating the adjustment amount (for

the back side) after it has read the patterns for the back side.

After the machine has finished calculating the adjustment

amount for the back side, the next screen appears where

you can view the results of the adjustments.

<Adjustment Item List>

• SPF original leading edge adjustment (back side)

• SPF original off-center adjustment (back side)

• SPF original sub-scan magnification adjustment (back side)

10) The adjustment result screen appears.

This screen shows the current values along with the previous

values in parentheses.

* By pressing the [REPRINT] button, you can return to the

cassette selection screen and have the machine self-print

SPF adjustment patterns (for the front and back sides)

again.

* To have the machine start re-reading the SPF adjustment

patterns (front and back sides), press the [RESCAN] button.

* To return to the top menu without saving the adjustment val-

ues into EEPROM and RAM, press the [RETRY] button.

* To display the data used for adjustment, press the [DATA]

button.

11) To save the adjustment values into EEPROM and RAM and

return to the top menu, press the [OK] button.

* To return to the result screen, press the [BACK] button.

MX-RPX1 ADJUSTMENTS 8 – 7

Page 29

[10] ELECTRICAL SECTION

1. Electrical mechanism diagram

A. Paper feed section

CN-H

B6B-PH-K-R(RED)

CN-E

B11B-PH-K-S

+24VPD_SRRC

SRRC/

SPED

GND

+5V_SPED

+5VPD

SPPD1

GND

+24VPD

GND

+24VPD_SW

RSPF DRIVER

PWB

SPRMA/

+24VPD

SPRMA

SPRMB

+24VPD

SPRMB/

1

2

3

4

5

6

1

2

PHNR-8-H

3

4

5

6

7

8

9

10

11

PHNR-08-H

7182

6

554

4

3

2

1

BU08P-TR-P-H(LF)

179228-3

SPED

PHR-3

3 +5VPD

2

1 GND

PS-187-2V

1

2 +24VPD_SW

GND12

+5V_SPED3

SPPD1

+24VPD

3

6

7

8

SPPD1

SPED

Service Manual

A/

OR

+24V

BL

BR A

B

RE

+24V

WH

YE

B/

SCOV

SPWS

SPLS1

SPRM

SPFC

SPLS2

CN-D

B12B-PH-K-S

SPLS1

GND

+5VPD_LPLS1

SPLS2

GND

+5VPD_SPLS2

AVCC

SPWS

GND

SPFC/

GND

+24VPD_SW_SPFC

1

2

3

4

5

6

7

8

9

10

11

12

B. Reverse section

SMP-02V-BC

1221

SMR-02V-B

PHNR-03-H

BU03P-TR-P-H(LF)

PHNR-03-H

113

22

3

SPPD5

179228-3

179228-3

1

2

3

1

2

3

BL

BR

GY

SPLS1

GND

+5VPD_LPLS1

SPLS2

GND

+5VPD_LPLS2

AVCC

SPWS

GND

SPFM

SPFMB/

6

YE

SPFMB

+24VPD

4

WH

B

+24V

SPFMA

BL

A

+24V

SPFMA/

+24VPD

1

253

ORB/REA/BR

B6B-PH-K-S

CN-F

+24VPD

SPRMB/

56234

WH

YE

+24V

B/

RSPF DRIVER PWB

B6B-PH-K-R(RED)

GND

CN-H

N.C.

+24VPD

SPRMA/

SPRMA

SPRMB

1

12

13

BU12P-TR-P-H(LF)

ORREBR A

+24VBLB

A/

1

GND

SPRM

SPPD5

11

291

2

SPPD5

+5VPD

10

3

101112

3 +5VPD

+5VPD_SOCD

SOCD

GND

GND

72834

4

7

6

8

6

753

PHR-3

SPPD3

569

8

+5VPD

GND

101112

SPPD2

2549

+5VPD

1

1

CN-G

B13B-PH-K-S

PHNR-12-H

PHNR-12-H

SPPD4

GND

1

2

GND

SPPD4

STMPU

+24VPD_STMPS

STMPS/

+5VPD

56723

4

PHR-3

3

+5VPD

GND

B7B-PH-K-S

1

N.C

SGS/

+24VPD_SGS

B3B-PH-K-S

CN-B

CN-C

3

2

1

SPPD4

SGS

MX-RPX1 ELECTRICAL SECTION 10 – 1

Page 30

C. Transport section

CN-F

+24VPD_SW

SRRC/

+24VPD_SRRC

RSPF DRIVER PWB

+24VPD_STMPS

STMPS/

STMPU

B6B-PH-K-S

SPFMB/

+24VPD

SPFMB

SPFMA

+24VPD

SPFMA/

CN-E

B11B-PH-K-S

GND

+24VPD

GND

SPPD1

+5VPD

+5V_SPED

GND

SPED

CN-G

B13B-PH-K-S

N.C.

GND

SPPD5

+5VPD

+5VPD_SOCD

GND

SOCD

GND

SPPD3

+5VPD

GND

SPPD2

+5VPD

CN-B

B7B-PH-K-S

GND

SPPD4

+5VPD

GND

6

5

4

3

2

1

11

10

9

8

7

6

5

4

3

2

1

13

12

11

10

9

8

7

6

5

4

3

2

1

7

6

5

4

3

2

1

PHNR-12-H

1

2

3

4

5

6

7

8

9

10

11

12

BU12P-TR-P-H(LF)

179228-4

4

+24VPD_STMPS

3

STMPS/

2

STMPU

1

GND

PHNR-12-H

12

11

10

9

8

7

6

5

4

3

2

1

175694-4

179228-4

1

2

3

4

YE

WH

RE

BRBA

BL

OR

PHNR-2-H

1

21

BU02P-TR-P-H(LF)

179228-3

3 +5VPD_SOCD

GND

2

SOCD

1

PHR-3

GND

SPPD3

2

31+5VPD

PHR-3

1

GND

2

SPPD2

3

+5VPD

B/

+24V

+24V

A/

PHNR-02-H

2

SOCD

SPPD2

SPPD3

STMPS

SRRC

SPFM

MX-RPX1 ELECTRICAL SECTION 10 – 2

Page 31

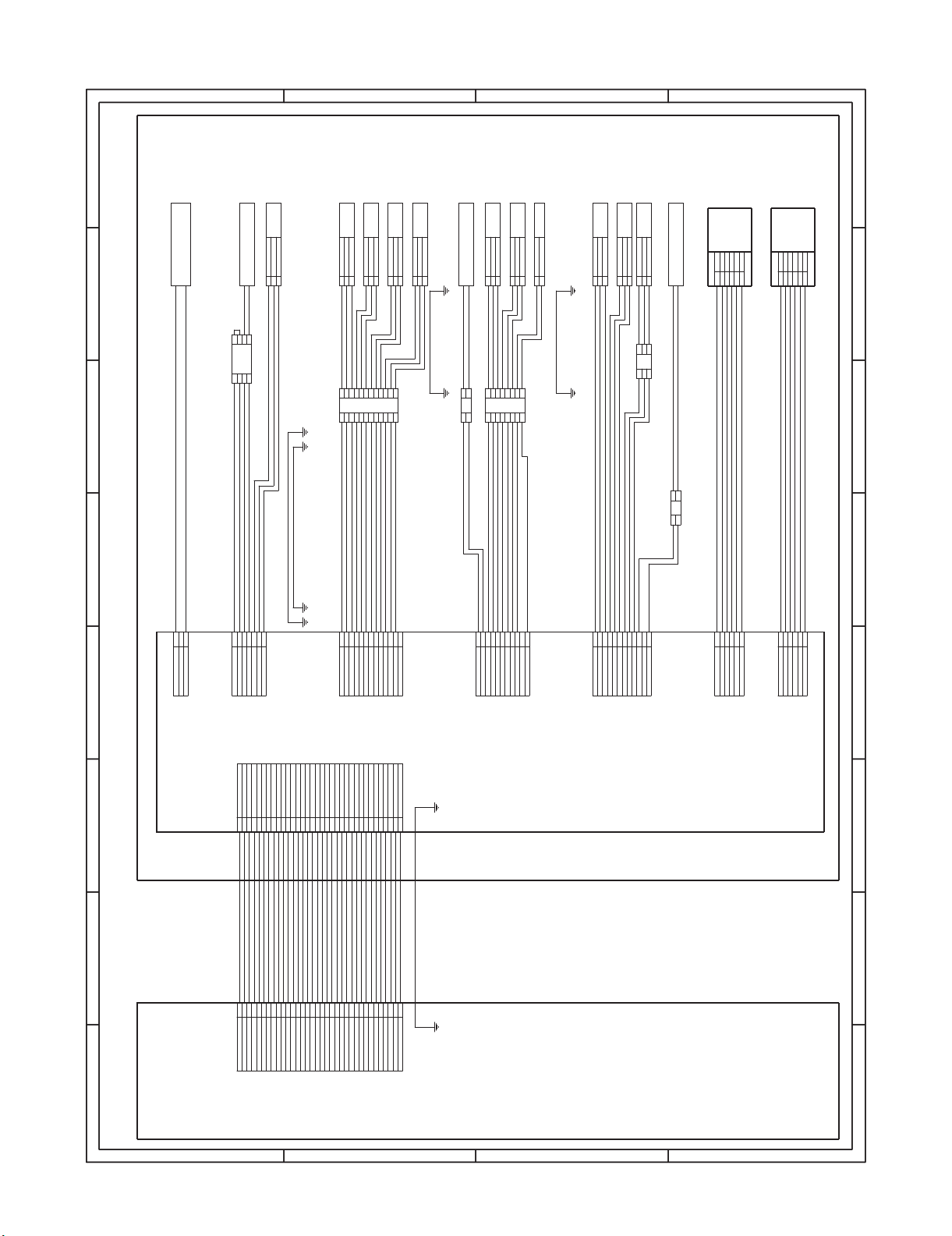

2. Block diagram

SPF Cover Switch

Option

(Japan only)

SPF Paper Feed Motor

+24VPD

SPFM

4

SLA7066M

Chopping circuit

3

SPFMO1SPFMO1

SPFMO2SPFMO2

SPF Paper Return Motor

+24VPD

SPRM

4

STA7101M

Chopping circuit

4

SPRMO1SPRMO1

SPF Paper Empty Detector

+5V_SPED

SPED

SPF Open Cover Detector

+5VPD_SCOD

SOCD

Cover SW monitor

SCOV

circuit

Multiplexer

(74HC151)

SPF Paper Length senser1

SPF Paper Length senser2

+5VPD_LPLS1

+5VPD_LPLS2

SPLS1

SPLS2

SPF STMP UN

GND

STMPU

SPF Paper Pass Detector1

+5VPD

SPPD1

SPF Paper Pass Detector2

+5VPD

SPPD2

SPF Paper Pass Detector3

+5VPD

SPPD3

SPF Paper Pass Detector4

+5VPD

SPPD4

SPF Paper Pass Detector5

+5VPD

SPPD5

SPF Paper Width Sensor

AVCC

SPWS

SPF Paper Feed Clutch

+24VPD

SPFC

SPF Gate Solenoid

+24VPD

SGS

(TD62003AP)

Transistor array

SPF Resisit Roller Clutch

+24VPD

SRRC

Stamp Solenoid

+24VPD

STMPS

Transistor

(2SK3065)

RSPF DRIVER PWB

RSPF

Scanner

MX-RPX1 ELECTRICAL SECTION 10 – 3

AVCC

+5V

+5VPD

GND

+24VPD

2

4

Page 32

3. Actual wiring diagram

SPF paper feed reverse motor

SPRM

A

A

A

A

SPF transport motor

SPFM

+24V

B/

WH

YE

ORB/REA/BR

B

A

+24V

+24V

BL

YE

WH

21

21

21

21

3

3

3

3

B

B

B

SPF cover SW

SCOV

+24VPD

+24VPD_SW

1

2

B

SPF document width detection

SPWS

GND

SPWS

AVCC

BRGYBL

1

3

PHNR-03-H

22

1

3

BU03P-TR-P-H(LF)

PHNR-03-H

SPF paper feed clutch

SPFC

1

2

SMR-02V-B

2

1

SMP-02V-BC

A/

ORREBR A

+24VBLB

SPLS1

123

179228-3

SPF document length sensor

short

SPLS1

GND

+5VPD_LPLS1

SPLS2

179228-3

SPF document length sensor

long

SPLS2

GND

+5VPD_LPLS2

213

+5VPD

3

1

SPF paper entry detection 2

SPPD2

SPPD22

2549

C

C

C

C

SPF paper entry sensor 1

PS front

PF scan front detection S

SPPD3

GND

+5VPD

SPPD3

1

2

3

PHR-3

6

753

101112

8

7

6

GND

1

8

4

179228-3

101112

3

SPF open/close detection

SOCD

GND

SOCD

2

1

3 +5VPD_SOCD

291

BU12P-TR-P-H(LF)

PHR-3

+5VPD

3

SPF reverse rear detection

SPPD5

SPPD5

2

GND

1

SPF resist roller clutch

SRRC

2

PHNR-02-H

1

21

PHNR-2-H

SPF document empty detection

SPED

+5V_SPED3

SPED2GND

1

2

179228-3

1823

PHNR-08-H

6

7

BU02P-TR-P-H(LF)

PHNR-8-H

PHR-3

546

3 +5VPD

SPPD1

SPPD1

7

24315

Common with random detection

1 GND

8

PS-187-2V

BU08P-TR-P-H(LF)

D

D

D

D

1/1

12345678

12345678

12345678

12345678

Stamp solenoid

SPF reverse gate front

SPF document exit gate solenoid

SGS

179228-4

175694-4

179228-4

detection

GND

STMPS

+5VPD

SPPD4

3

1

2 SPPD4

PHR-3

1

4

3

STMPS/ 2

+24VPD_STMPS4

STMPU

GND1

2

3

PHR-3

PHNR-12-H

PHNR-12-H

1

B3B-PH-K-S

CN-C

+24VPD_SGS

RSPF

569

72834110

SPPD2

11

12

13

SPPD5

+5VPD

GND

GND

+5VPD_SOCD

SOCD

+5VPD

SPPD3

GND

GND

N.C.

B11B-PH-K-S

CN-E

1

SPED

GND

+24VPD_SRRC

SRRC/

569

+5V_SPED

+5VPD

72834

SPPD1

10

11

GND

+24VPD

GND

+24VPD_SW

1

SPLS1

B12B-PH-K-S

CN-D

+5VPD_LPLS1

SPLS2

GND

569

72834

+5VPD_SPLS2

AVCC

GND

SPWS

GND

101112

+24VPD_SW_SPFC

GND

SPFC/

1

+24VPD

SPRMA/

B6B-PH-K-R(RED)

CN-H

SPRMA

SPRMB

56234

+24VPD

SPRMB/

B6B-PH-K-S

CN-F

1

SPFMA/

253

+24VPD

SPFMA

4

SPFMB

+24VPD

6

SPFMB/

56723

4

B7B-PH-K-S

CN-B

1

GND

STMPU

SPPD4

+5VPD

+24VPD_STMPS

STMPS/

GND

CN-G

+5VPD

B13B-PH-K-S

3

2

SGS/

N.C

RSPF DRIVER PWB

+5V

GND

GND

+24VPD

+24VPD

SPPD2

CN-A

1

GND

CN-101

B34B-XADSS-F

2

GND

SPPD1

352641B34B-PHDSS-B

SPPD1

SPPD2

SPFMCK

AVCC

SPFMM1

SPFMM2

SPFMO1

SPFMO2

10

1191481825132316

610411735

9

13

+5V

+24V

+24V

SPFMCK

AVCC

SPFMM1

SPFMM2

SPFMO1

SPFMO2

SPRMA

142212

SPRMA

SPRMA/

15

SPRMA/

SPRMB

SPRMB

SPRMB/

17

172416

SPRMB/

SGS

SPRMO1

SGS

SPRMO1

STMPS

20

STMPS

SPWS

SELB

SPPD4

SRRC

SELC

SPFC

SELA

SPFFAN

SSELO

SPPD3

GND

GND

SPPD5

5VPD

26

221219

28724

2930313233

27

25192326201518

2730313233

SELB

SELC

SSELO

28829

SPPD4

SPFFAN

SPPD3

SPPD5

34

34

GND

GND

5VPD

87654

87654

87654

87654

21

21

SPWS

SRRC

SPFC

SELA

Scanner

D

D

D

D

B

B

B

C

C

C

C

B

MX-RPX1 ELECTRICAL SECTION 10 – 4

A

A

A

A

Page 33

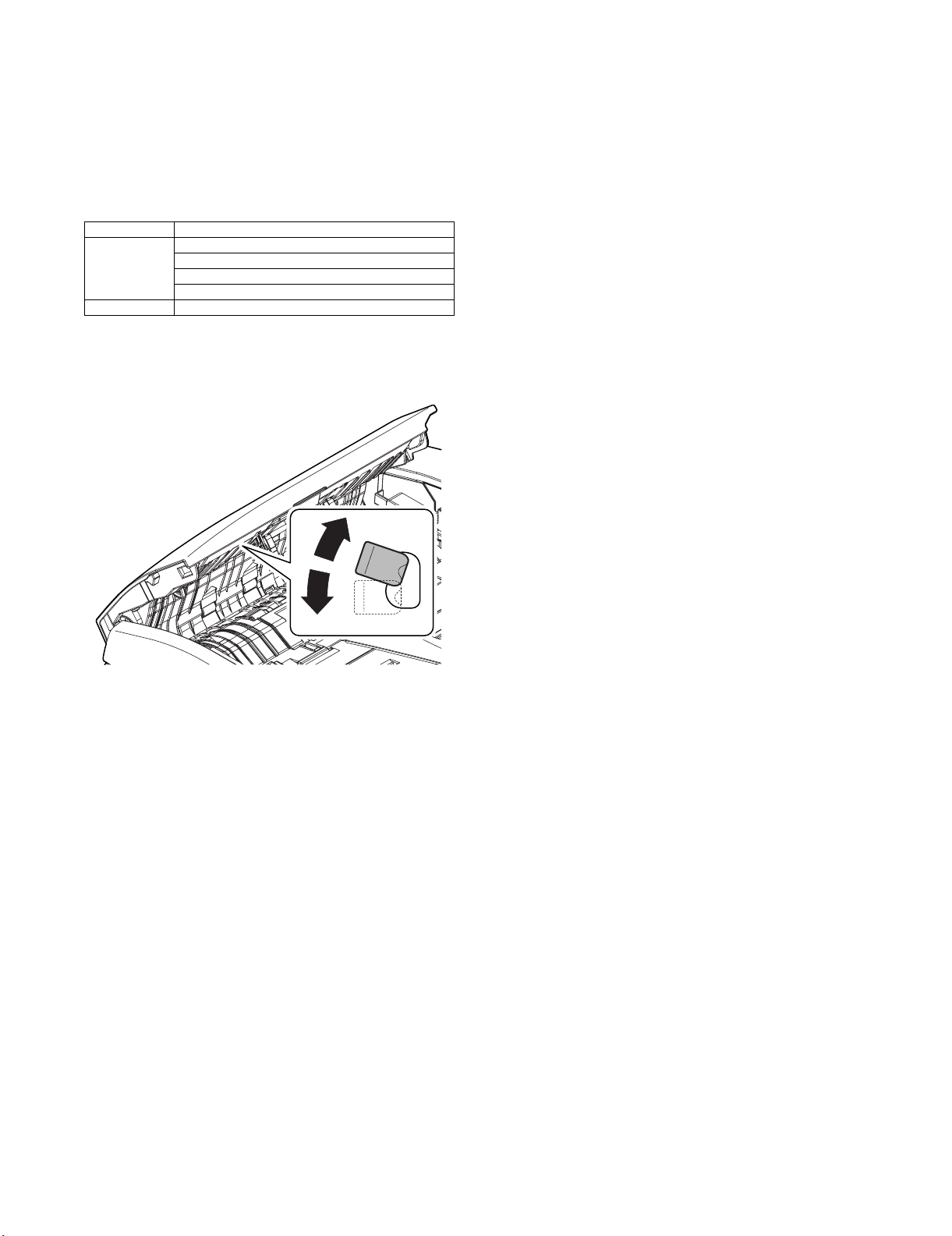

[11] OTHERS

1. RSPF mixed-loaded document select switch

This machine is provided with the random paper feed function

which feeds mixed-loaded documents of different sizes.

Random paper feed can use only one side document of the following combination

Destination Random possible combination

AB series A3 and B4

B4 and A4R

A4 and B5

B5 and A5

Inch width 8.5" and 11" width

To use the mixed-loaded document mode, set the mixed-loaded

document select switch to ON.

Without the mixed-loaded document mode, set the mixed-loaded

document select switch to OFF.

Service Manual

OFF

ON

MX-RPX1 OTHERS 11 – 1

Page 34

Memo

Page 35

q

PARTS GUIDE

1

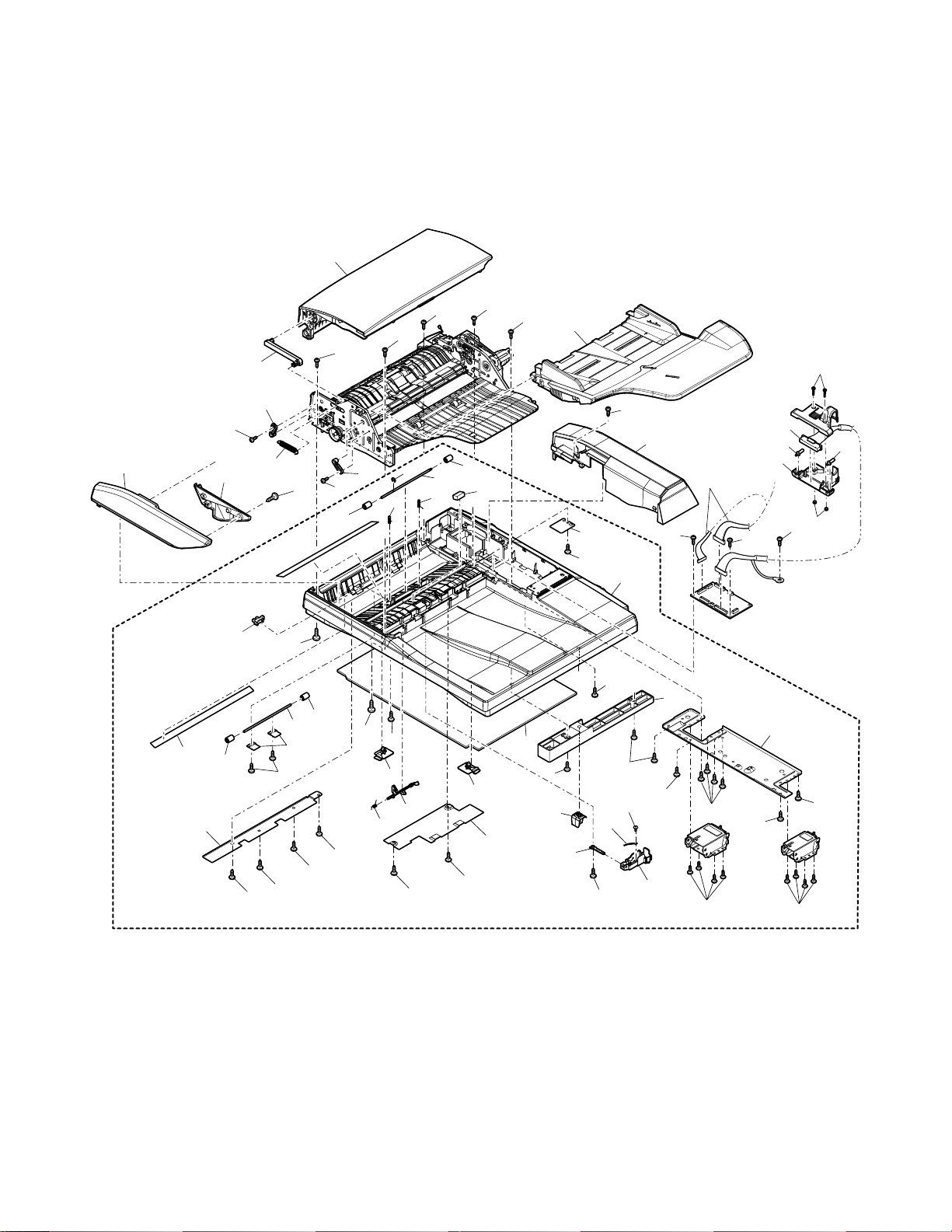

外装部 (Exteriors)

2

原稿トレイ (Original tray)

3

給紙部 (Paper feeding section)

4

分離部 (Separation section)

5

搬送部 1(Transport section 1)

6

搬送部 2(Transport section 2)

7

搬送部 3(Transport section 3)

MODEL

このパーツガイドに掲載されている表示価格ランクは消費税抜きです。

CONTENT

MX-RPX1

8

中間トレイ (Middle tray)

9

駆動ユニット (Drive unit)

F

梱包&付属品 (Packing material & Accessories)

G

RSPF ドライバー基板ユニット (RSPF driver PWB unit)

■ 索引 (Index)

SHARP CORPORATION

Page 36

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : メンテナンスパーツ、メンテナンスパーツには入っていないがメンテナンスパーツに近い消耗パーツ。

Bランク : 性能・機能パーツ(センサー、クラッチ等の電気パーツ)、消耗パーツ。

Eランク : 基板含むユニットパーツ。

Dランク : 整備パーツ(外装、パッキング、同梱パーツ)。

Cランク : 上記ランク以外のパーツ(基板の子部品を除いたもの)。

DEFINITION

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

!

印の商品は、安全上重要な部品です。交換をする時は、安全及び性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F

当モデルのサービス資料には、この資料以外にサービスマニュアル ( 回路図含む ) があります。合わせてご利用下さい。

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1

外装部 (Exteriors)

NO. PARTS CODE

1 CGIDM2137DS51 BN LE N E

2 CSOU-0205DS51 BH GX N E

3 GCAB-1107FCZZ AS EZ N D

4 DHAI-3760FCZZ AN EQ N C

5 XEBS740P10000 AA DD C

6 PSHEZ5374FCZZ AD DJ N C

7 XHBS730P06000 AC DD C

8 XBBS730P16000 AA DD C

10 DHAI-3759FCZZ AU FG N C

11 LX-BZ1028FCZZ AC DD N C

12 PCOVP1930FCZZ AE DS N C

13 XNES730-24000 AA DD C

15 LSOU-0203FCZ1 BG GT N D

16 LPLTM6553FCZZ AM EG C

17 XEBS740P10000 AA DD C

20 PCOVP1824FCZZ AE DS N C

21 LX-BZ0531FCPZ AB DD C

22 DHAI-3761FCZZ AH DX N C

23 XEBS730P08000 AC DD C

24 LHLDZ1540FCZZ AG DS C

25 XEBS730P10000 AC DD C

26 PCOVP1855FCZZ AF DS N C

27 CCLEZ0020QS01 AK EB D

28 PHAG-0005FCZZ AC DJ N C

29 MLEVP0930FCZZ AC DJ N C

30 MSPRD3375FCZZ AB DJ C

31 PCOVP1856FCZ1 AE DS N C

32 LPLTM6554FCZZ AC DJ C

33 NSFTZ0009QSPZ AL EB C

34 NROLP1517FCZZ AA DJ N C

35 PSHEZ5372FCZZ AE DJ N C

36 VHPGP1A71L3-1 AG DS B

38 MSPRC3352FCZZ AB DJ C

39 PMLT-1418FCZZ AA DJ N C

40 XEBS730P08000 AC DD C

41 NSFTZ2914FCZZ AP EQ N C

42 XRESP30-06000 AA DD C

43 LHLDZ1640FCZZ AC DJ N C

44 LX-BZ0930FCPZ AC DD N C

45 GCAB-1106FCZZ AN EG N D

46 GCOV-0249FCZZ AF DS N D

47 MSPRT3390FCZZ AC DJ C

48 PSHEZ5400FCZ1 AX FG N D

49 XHBS740P08000 AA DD C

50 MARMP0325FCZZ AC DJ N C

51 PCOVP2017FCZZ AL EB N C

501 CSOU-0203DS51 BW RJ N E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Paper feeding roller unit 給紙ローラーユニット

Original tray unit 原稿トレイユニット

RSPF rear cabinet RSPF 後キャビネット

Transport interface main harness 搬送中継メインハーネス

Screw(4×10) ビス

OC positioning sheet OC 位置決めシート

Screw(3×6) ビス

Screw(3×16) ビス

RSPF connection harness RSPF 接続ハーネス

Screw ELCON 段ビス

Harness cover lower ハーネスカバー下

Nut(M3) 六角ナット

RSPF base tray RSPF ベーストレイ

Hinge fixing plate ヒンジ取付板

Screw(4×10) ビス

Stamp cover スタンプカバー

Screw(4×8) ビス

Base tray harness ベーストレイハーネス

Screw(3×8) ビス

Fulcrum holder 支点ホルダー

Screw(3×10) ビス

Sensor cover センサーカバー

SPF glass cleaner AS SPF ガラスクリーナー AS

OC mat fixing hook OC マット取付フック

Paper exit actuator 出紙アクチュエーター

Paper exit return spring 出紙復帰スプリング

Follower roller cover 従動ローラーカバー

Follower roller fixing plate 従動ローラー押え板

Transport follower shaft 搬送従動軸

Delivery follower roller RSPF 排紙従動ローラー RSPF

Reading front sheet 読取前シート

Photo sensor(GP1A71L3) フォトセンサー

Follower pressure spring 従動加圧スプリング

Gate stopper cushion ゲートストッパーモルト

Screw(3×8) ビス

Follower roller shaft 従動ローラー軸

E-ring(E3) E リング

Paper feeding PG holder 給紙 PG ホルダー

Screw(4×6) ビス

RSPF front cabinet RSPF 前キャビネット

F cabinet cover F キャビネットカバー

Link arm return spring リンクアーム復帰スプリング

OC mat OC マット

Screw(4×8) ビス

Upper PG link arm 上 PG リンクアーム

Base lower right cover ベース右下カバー

Base tray unit(Without No.5,7,27,40,48) ベーストレイユニット

DESCRIPTION

(No.5,7,27,40,48 除く )

– 1 –

Page 37

1

外装部 (Exteriors)

1

45

501

35

31

46

34

49

36

17

50

43

47

23

17

33

32

17

34

28

39

26

5

7

2

8

49

10

48

17

27

24

6

21

25

22

3

4

5

15

5

17

23

51

7

17

20

17

11

12

7

16

17

7

17

11

13

17

5

43

5

30

38

40

28

5

29

42

17

41

38

5

44

5

34

5

34

17

17

FCP08991

– 2 –

Page 38

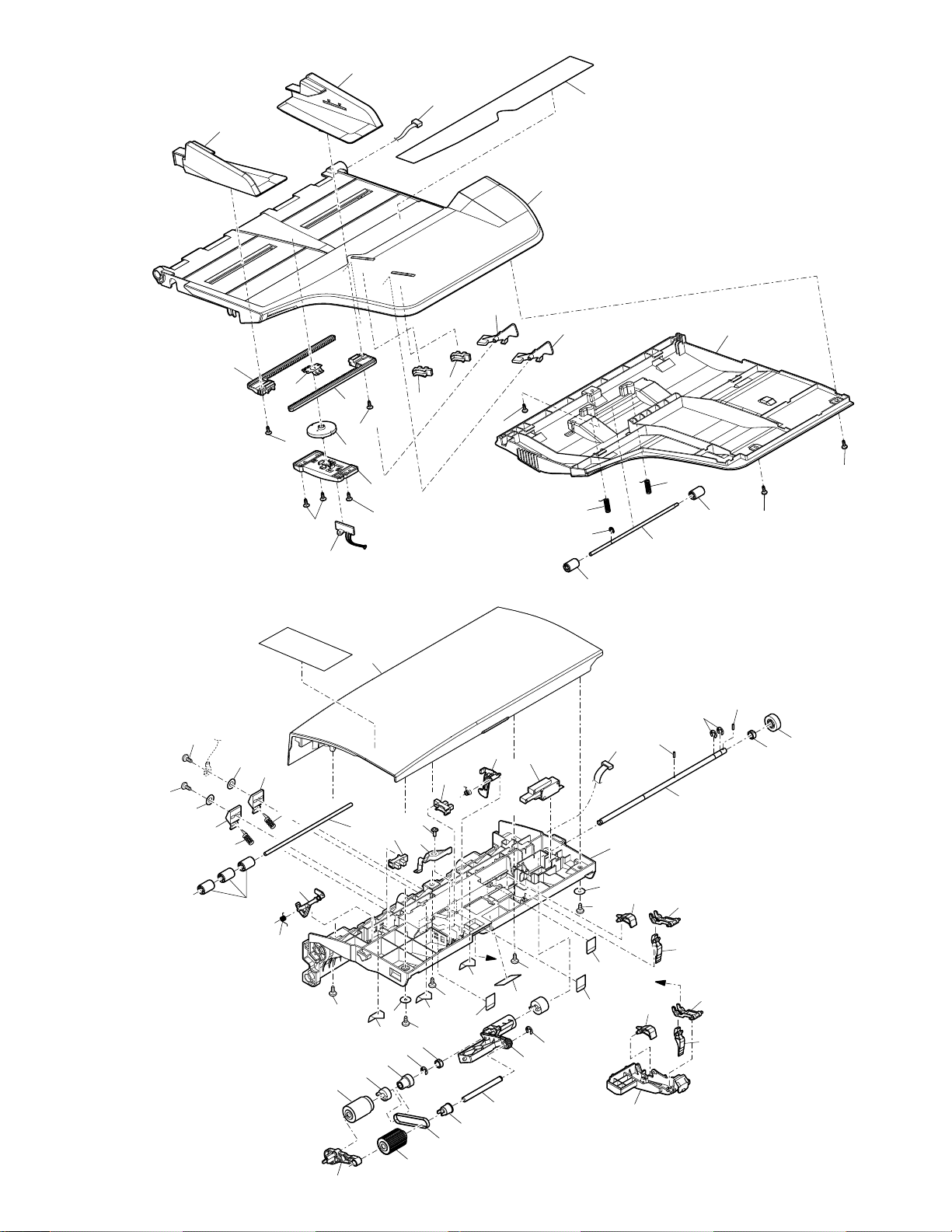

2

原稿トレイ (Original tray)

NO. PARTS CODE

1 LPLTP6485FCZZ AG DX N C

2 LPLTP6486FCZZ AG DX N C

3 DHAI-3764FCZZ AK DX N C

4 TLABZ5063FCZZ AP EQ N D

5 LSOU-0204FCZZ AV FG N D

6 LSOU-0205FCZZ AU EZ N D

7 XEBS740P10000 AA DD C

8 NROLP1517FCZZ AA DJ N C

9 NSFTZ2914FCZZ AP EQ N C

10 XRESP30-06000 AA DD C

11 MSPRC3352FCZZ AB DJ C

12 CPWBF1594FCE2 AS EQ E

13 XEBS730P08000 AC DD C

14 LPLTP0321QSZZ AE DS C

15 NGERP0168QSZZ AD DJ C

16 VHPGP1S73P+-1 AF DS B

17 XEPS730P08X00 AA DD C

18 NGERR0169QSZZ AE DS C

19 MSPRP0315QSZZ AD DJ C

20 MLEVP0098QSZZ AC DJ C

3

給紙部 (Paper feeding section)

NO. PARTS CODE

1 PCOVP1851FCZZ AT EZ N C

2 QSW-M0502FCPZ AH DX N B

3 DHAI-3763FCZZ AH DX N C

4 PGIDM2137FCZZ AV FG N C

5 NSFTZ2913FCZZ AX FQ N C

6 LPINS0089FCZZ AA DD C

7 XRESP50-06000 AA DD C

8 XPSSP20-10000 AA DD N C

9 NBRGM0096FCZ1 AC DJ C

10 NGERH0863FCBZ AD DJ C

11 MARMP0324FCZZ AB DJ N C

12 MARMP0339FCZZ AC DJ N C

13 MARMP0330FCZZ AC DJ N C

14 PGIDM2138FCZZ AD DJ N C

16 XRESP40-06000 AA DD C

17 LHLDR1650FCZZ AD DJ N C

18 NSFTZ2915FCZZ AM EG N C

19 NPLYZ0452FCZZ AC DJ N C

20 NBLTH0442FCZZ AD DJ B

21 NROLR1542FCZZ AH DX N B

22 PGIDM2139FCZZ AC DJ N C

23 NROLR1541FCZZ AG DX N B

24 NCPL-0049FCZZ AH DX B

25 NPLYZ0437FCZZ AT EZ C

26 LX-WZ0443FCPZ AB DD C

28 XEBS740P10000 AA DD C

29 PSHEP5442FCZZ AC DJ N C

30 PMLT-1417FCZZ AC DJ N C

31 MSPRD3378FCZZ AB DJ C

32 MLEVP0932FCZZ AC DJ N C

33 MLEVP0953FCZZ AC DJ C

34 VHPGP1S73P+-1 AF DS B

35 VHPGP1A71L3-1 AG DS B

36 NSFTZ0009QSPZ AL EB C

37 NROLP1517FCZZ AA DJ N C

38 LHLDZ1755FCZZ AC DJ N C

39 MSPRC3571FCZZ AB DJ N C

41 XWHS730-05080 AA DD C

42 XEBS730P16000 AA DD C

43 PSHEP5466FCZZ AA DJ N C

44 MLEVP1034FCZZ AC DJ N C

46 XEPS730P08X00 AA DD C

PRICE RANK

Ex. Ja.

PRICE RANK

Ex. Ja.

NEW

MARK

NEW

MARK

PART

RANK

RSPF regulation plate F RSPF 規制板 F

RSPF regulation plate R RSPF 規制板 R

Original tray harness 原稿トレイハーネス

Original size label (Except Japan) 原稿サイズラベル

RSPF original tray upper RSPF 原稿トレイ上

RSPF original tray lower RSPF 原稿トレイ下

Screw(4×10) ビス

Delivery follower roller RSPF 排紙従動ローラー RSPF

Follower roller shaft 従動ローラー軸

E-ring(E3) E リング

Follower pressure spring 従動加圧スプリング

SPF VR PWB LF SPF VR 基板 LF

Screw(3×8) ビス

Width detection fixing plate TLPD 幅検知取付板 TLPD

Width detection gear(36T) 幅検知ピニオン

Photo sensor(GP1S73P) フォトセンサー

Screw(3×8X) ビス

Width detection rack gear 幅検知ラック TLP

Regulation plate spring TLPD 規制板スプリング TLPD

Original detect actuator 原稿検知アクチュエーター

PART

RANK

Upper cover 上カバー

Interlock switch(51632C531N) インターロックスイッチ

Paper feeding roller harness 給紙ローラーハーネス

Paper feeding transport upper guide 給紙搬送上ガイド

Paper feeding shaft 給紙軸

Spring pin スプリングピン

E-ring(E5) E リング

Spring pin(φ2-10) スプリングピン

Bearing 軸受

Pick up gear(18T) ピックアップギヤ

Lock arm ロックアーム

Lock release arm ロック解除アーム

Paper lock arm 紙ロックアーム

Upper transport auxiliary guide 上搬送補助ガイド

E-ring(E4) E リング

Pick up roller holder ピックアップローラーホルダー

Pick up shaft ピックアップ軸

Pick up pulley(18P) ピックアッププーリー

Belt(132) ベルト

Pick up roller ピックアップローラー

Holder guide ホルダーガイド

Paper feeding separation roller 給紙分離ローラー

Oneway coupling ワンウェイカップリング

Paper feeding pulley RSPF(18P) 給紙プーリー RSPF

Washer ワッシャー

Screw(4×10) ビス

PS front sheet PS 前シート

Pick up silence cushion ピックアップ消音モルト

Detection return spring 入紙検知復帰スプリング

Detection actuator 入紙検知アクチュエーター

PE actuator PE アクチュエーター

Photo sensor(GP1S73P) フォトセンサー

Photo sensor(GP1A71L3) フォトセンサー

Transport follower shaft 搬送従動軸

Delivery follower roller RSPF 排紙従動ローラー RSPF

PS pressure welding holder PS 圧接ホルダー

PS pressure welding spring PS 圧接スプリング

Washer(φ3-8t0.5) ワッシャー

Screw(3×16) ビス

PS rear sheet PS 後シート

Change lever 切替レバー

Screw(3×8X) ビス

DESCRIPTION

DESCRIPTION

– 3 –

Page 39

2

原稿トレイ (Original tray)

2

1

18

3

給紙部 (Paper feeding section)

19

17

13

12

18

17

15

14

13

16

3

20

16

7

4

5

20

11

10

11

9

8

6

7

8

7

FCP08992

42

41

42

38

39

41

37

38

31

39

32

23

28

22

36

24

1

8

7

10

9

25

29

35

26

6

43

28

43

26

3

5

4

11

14

12

13

12

11

13

33

2

34

46

44

29

28

29

43

28

9

7

19

20

21

28

30

16

17

18

FCP08993

– 4 –

Page 40

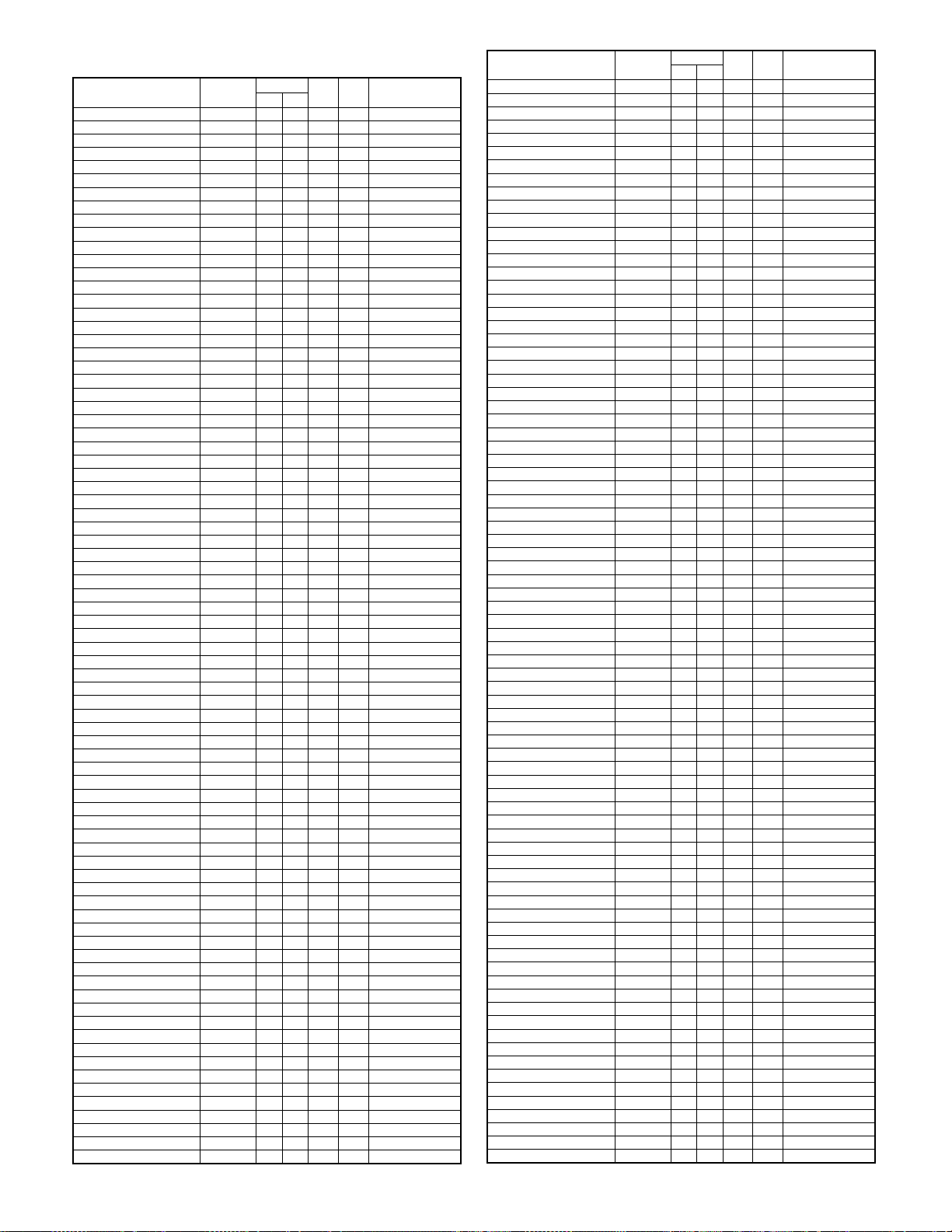

4

分離部 (Separation section)

NO. PARTS CODE

1 PCOVP1850FCZZ AD DJ N C

3 XHBS740P08000 AA DD C

4 PCLR-0461FCZZ AC DJ C

5 PGIDM2136FCZZ AL EB N C

6 NSFTZ0009QSPZ AL EB C

7 NROLP1517FCZZ AA DJ N C

8 PSHEZ3130FCZZ AB DD C

9 MSPRC3355FCZZ AB DJ C

10 NROLR1555FCZZ AG DX N B

12 LPINS0089FCZZ AA DD C

13 XRESP50-06000 AA DD C

14 NSFTZ2912FCZZ AX FG N C

15 LHLDZ1670FCZZ AC DJ C

16 MSPRT3391FCZZ AB DJ C

17 XEBS740P10000 AA DD C

18 LPLTM6557FCZZ AH DX N C

21 PGIDM2135FCZZ AN EG N C

23 NBRGP0668FCZZ AE DJ C

24 XRESP40-06000 AA DD C

26 XEBS730P08000 AC DD C

(Unit)

901 CGIDM2136DS51 BF GN N E

4

分離部 (Separation section)

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Separation roller cover 分離ローラーカバー

Screw(4×8) ビス

U-turn collar U ターンコロ

Separation transport guide 分離搬送ガイド

Transport follower shaft 搬送従動軸

Delivery follower roller RSPF 排紙従動ローラー RSPF

Rotation plate sheet 回転板シート

Roller spring 圧縮従動ローラースプリング

Separation roller 分離ローラー

Spring pin スプリングピン

E-ring(E5) E リング

Separation shaft 分離軸

Separation roller fulcrum holder 分離ローラー支点ホルダー

SPF pressure spring SPF 圧接スプリング

Screw(4×10) ビス

Separation PG reinforce plate 分離 PG 補強板

Middle guide 中間ガイド

Stopper bearing ストッパー軸受

E-ring(E4) E リング

Screw(3×8) ビス

Separation roller guide unit 分離ローラーガイドユニット

DESCRIPTION

901

1

7

3

3

4

3

4

5

6

26

24

23

15

8

13

12

14

16

17

18

9

9

10

17

7

17

26

– 5 –

21

FCP08994

Page 41

5

搬送部 1(Transport section 1)

NO. PARTS CODE

1 NBRGM0501FCZZ AB DJ C

2 MSPRC3357FCZZ AA DJ C

3 XWHS760-08115 AA DD N C

4 PRNGP0090FCZZ AA DJ C

5 PCLC-0337FCZZ BA FX N B

6 XRESP40-06000 AA DD C

7 NGERH1681FCZZ AC DJ N C

8 XRESP30-04000 AA DD C

9 NGERH1682FCZZ AT EZ C

10 XRESP50-06000 AA DD C

11 NPLYZ0454FCZZ AC DJ C

12 NBLTH0444FCZZ AS EQ N B

13 PSHEZ5377FCZZ AA DJ N C

15 XPSSP20-10000 AA DD N C

17 NPLYZ0453FCZZ AC DJ N C

19 NROLR1545FCZ1 BD GJ N B

20 NROLR1552FCZZ AX FG N B

21 NROLR1543FCZZ AU EZ N B

22 CFRM-1167FC01 AL EB N C

23 CFRM-1183FC01 AR EQ C

24 LX-WZ5002BCZZ AA DD C

5

搬送部 1(Transport section 1)

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Metal bearing メタル軸受

Brake spring ブレーキスプリング

Washer ワッシャー

E-ring(E5) 樹脂 E リング

SP clutch SPF PS クラッチ SPF

E-ring(E4) E リング

Gear(36T) ギヤ

E-ring(E3) E リング

Oneway gear(32T) ワンウェイギヤ

E-ring(E5) E リング

Gear pulley(25/24) ギヤプーリー

Belt(200) ベルト

Pulley sheet(25) プーリーマイラー

Spring pin(φ2-10) スプリングピン

Drive pulley(24P) 駆動プーリー

Delivery roller 排紙ローラー

Reading front roller 読取前ローラー

PS roller PS ローラー

Frame F AS フレーム F AS

Frame R AS フレーム R AS

Washer ポリスライダー

DESCRIPTION

10

24

1

10

24

22

5

4

3

2

1

8

7

6

8

11

13

10

24

23

9

1

17

15

1

12

21

20

19

1

10

1

FCP08995

– 6 –

Page 42

6

搬送部 2(Transport section 2)

NO. PARTS CODE

1 NROLR1535FCZZ AT EZ N B

2 XEBS740P10000 AA DD C

3 PGIDM2130FCZZ AV FG N C

4 CFRM-1183FC01 AR EQ C

6 NGERH1680FCZZ AC DJ N C

7 XRESP30-04000 AA DD C

8 XHBS740P08000 AA DD C

10 XRESP50-06000 AA DD C

12 NGERH1646FCZZ AC DJ N C

13 NBRGP0041GCZZ AD DJ C

14 PRNGP0090FCZZ AA DJ C

15 NGERH1620FCZZ AC DJ C

16 XPSSP20-10000 AA DD N C

17 NBRGM0501FCZZ AB DJ C

18 PGIDM2150FCZZ AE DJ N C

19 MSPRD3380FCZ1 AB DJ N C

20 MLEVP0963FCZZ AC DJ N C

21 CSOU-0206DS51 BA FX N D

22 PGIDM2152FCZZ AL EB N C

23 PSHEZ5375FCZZ AD DJ N C

24 PGIDM2134FCZZ AN EG N C

25 MLEVP0974FCZZ AD DJ N C

26 MSPRD3377FCZZ AB DJ C

27 MSPRC3353FCZZ AB DJ C

28 VHPGP1A71L3-1 AG DS B

29 LPLTM6556FCZZ AC DJ C

31 NBRGM0501FCZZ AB DJ C

32 CFRM-1167FC01 AL EB N C

34 DHAI-3762FCZZ AK DX N C

35 MSPRD3376FCZZ AB DJ C

36 MLEVP0931FCZZ AC DJ N C

37 MLEVP0930FCZZ AC DJ N C

38 MSPRD3375FCZZ AB DJ C

39 XRESP50-06000 AA DD C

40 PMLT-1418FCZZ AA DJ N C

41 PCOVP2018FCZZ AC DJ N C

42 PCOVP2019FCZZ AC DJ N C

43 PSHEP5461FCZZ AA DJ N C

501 DUNT-7479DSZZ BG GT N E

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

SWB transport roller SWB 搬送ローラー

Screw(4×10) ビス

Transport guide 搬送ガイド

Frame R AS フレーム R AS

Gear(20T) ギヤ

E-ring(E3) E リング

Screw(4×8) ビス

E-ring(E5) E リング

Gear(25T) ギヤ

Bearing 軸受

E-ring(E5) 樹脂 E リング

Gear(32T) ギヤ

Spring pin(φ2-10) スプリングピン

Metal bearing メタル軸受

Reversal rear guide 反転後ガイド

Gate spring ゲートスプリング

Reversal gate link lever 1 反転ゲートリンクレバー 1

Middle tray unit 中間トレイユニット

Reversal guide 反転ガイド

Reading rear PG sheet 読取後 PG シート

Delivery upper guide 排紙上ガイド

Reversal rear actuator 反転後アクチュエーター

Reversal rear spring 反転後スプリング

Reading plate spring 読取板圧接スプリング

Photo sensor(GP1A71L3) フォトセンサー

Paper feeding sensor fixing plate 給紙センサー取付板

Metal bearing メタル軸受

Frame F AS フレーム F AS

Transport harness 搬送ハーネス

Reading front spring 読取前スプリング

Reading front actuator 読取前アクチュエーター

Paper exit actuator 出紙アクチュエーター

Paper exit return spring 出紙復帰スプリング

E-ring(E5) E リング

Gate stopper cushion ゲートストッパーモルト

PS shaft cover F PS 軸カバー F

PS shaft cover R PS 軸カバー R

PS guide sheet PS ガイドマイラー

Transport paper guide unit 搬送ペーパーガイドユニット

DESCRIPTION

7

搬送部 3(Transport section 3)

NO. PARTS CODE

1 NROLR1540FCZZ AV FG N B

2 LPINS0089FCZZ AA DD C

3 LPLTM6555FCZ1 AN EG N C

4 MSPRC3453FCZZ AB DJ C

5 LHLDZ1649FCZZ AD DJ C

6 NBRGC0017QSZZ AC DJ C

7 NPLYZ0451FCZZ AC DJ C

8 XRESP50-06000 AA DD C

9 PCLR-0520FCZZ AB DJ N C

10 LX-BZ0833FCPZ AC DD C

11 LHLDZ1641FCZZ AC DJ N C

12 MSPRT3392FCZZ AB DJ C

13 CFRM-1183FC01 AR EQ C

14 XRESP30-04000 AA DD C

15 NPLYZ0434FCZZ AC DJ N C

16 NGERH1646FCZZ AC DJ N C

17 XPSSP20-10000 AA DD N C

18 NPLYZ0456FCZZ AT EZ C

19 NBLTH0435FCZZ AS EQ N B

20 PSHEZ5377FCZZ AA DJ N C

21 NBRGM0096FCZ1 AC DJ C

22 PSHEZ5394FCZZ AA DJ N C

23 XHBS730P08000 AB DD C

24 LPLTM6492FCZZ AC DJ C

25 RPLU-0366FCZZ AQ EQ N B

26 XBBS730P04000 AA DD C

27 NBLTH0438FCZZ AS EQ N B

29 NBRGM0501FCZZ AB DJ C

30 XWHS730-05080 AA DD C

32 LHLDZ1651FCZZ AC DJ N C

34 MSPRC3356FCZZ AA DJ C

35 PTME-0030QSZZ AC DJ C

36 PSHEP5422FCZZ AH DX N C

37 NROLR1544FCZZ AY FQ N B

38 CFRM-1167FC01 AL EB N C

40 NBLTH0441FCZZ AD DJ B

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Roller プラテンローラー

Spring pin スプリングピン

Reading plate 読取板

Reading plate rotation spring 読取板回転スプリング

Reading plate holder R 読取板ホルダー R

Bearing 軸受

Pulley(20P) プーリー

E-ring(E5) E リング

Tension collar テンションコロ

Screw 回転板用段ビス

Tension holder A テンションホルダー A

Tension spring テンションスプリング

Frame R AS フレーム R AS

E-ring(E3) E リング