Page 1

TopPage

INSTALLATION MANUAL

CODE: 00ZMXB401/I2E

DIGITAL MULTIFUNCTIONAL

SYSTEM

MX-B381

MODEL

CONTENTS

CONFIGURATION

[1] MX-B381/B401 (MAIN UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] MX-CSX1/CSX2 (500-SHEET PAPER FEED UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] MX-FN12 (FINISHER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] MX-FXX3 (FACSIMILE EXPANSION KIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] AR-PF1 (BARCODE FONT KIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] MX-FR16U (DATA SECURITY KIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MX-FWX1 (INTERNET FAX EXPANSION KIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] MX-PUX1 (XPS EXPANSION KIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] MX-AMX1 (APPLICATION INTEGRATION MODULE) . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MX-AMX2 (APPLICATION COMMUNICATION MODULE) . . . . . . . . . . . . . . . . . . . . . 10-1

MX-B401

[11] MX-AMX3 (EXTERNAL ACCOUNT MODULE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] MX-SMX3 (EXPANSION MEMORY BOARD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MAIN UNIT . . . . . . . . . 13-1

[14] DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MX-CSX1/CSX2 . . . . . 14-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

CONFIGURATION

1. System configuration . . . . . . . . . . . . . . . . . . . . . .i

2. Machine configuration . . . . . . . . . . . . . . . . . . . . ii

3. Option list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

[1] MX-B381/B401 (MAIN UNIT)

1. Installing (use) conditions . . . . . . . . . . . . . . . 1-1

2. Transit and delivery . . . . . . . . . . . . . . . . . . . . 1-2

3. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

4. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

[2] MX-CSX1/CSX2 (500-SHEET PAPER FEED UNIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

[3] MX-FN12 (FINISHER)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3. Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

[4] MX-FXX3 (FACSIMILE EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] AR-PF1 (BARCODE FONT KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] MX-FR16U (DATA SECURITY KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[8] MX-PUX1 (XPS EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] MX-AMX1 (APPLICATION INTEGRATION MODULE)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MX-AMX2 (APPLICATION COMMUNICATION

MODULE)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] MX-AMX3 (EXTERNAL ACCOUNT MODULE)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

[12] MX-SMX3 (EXPANSION MEMORY BOARD)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] DEHUMIDIFIER HEATER KIT (SERVICE PARTS)

FOR THE MAIN UNIT

1. Heater kit contents list . . . . . . . . . . . . . . . . . 13-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

3. Check after installation. . . . . . . . . . . . . . . . . 13-4

[14] DEHUMIDIFIER HEATER KIT (SERVICE PARTS)

FOR THE MX-CSX1/CSX2

1. Heater kit contents list . . . . . . . . . . . . . . . . . 14-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

3. Check after installation. . . . . . . . . . . . . . . . . 14-5

[7] MX-FWX1 (INTERNET FAX EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Page 3

MX-B381/B401 CONFIGURATION - i

MX-B401

Service Manual

CONFIGURATION

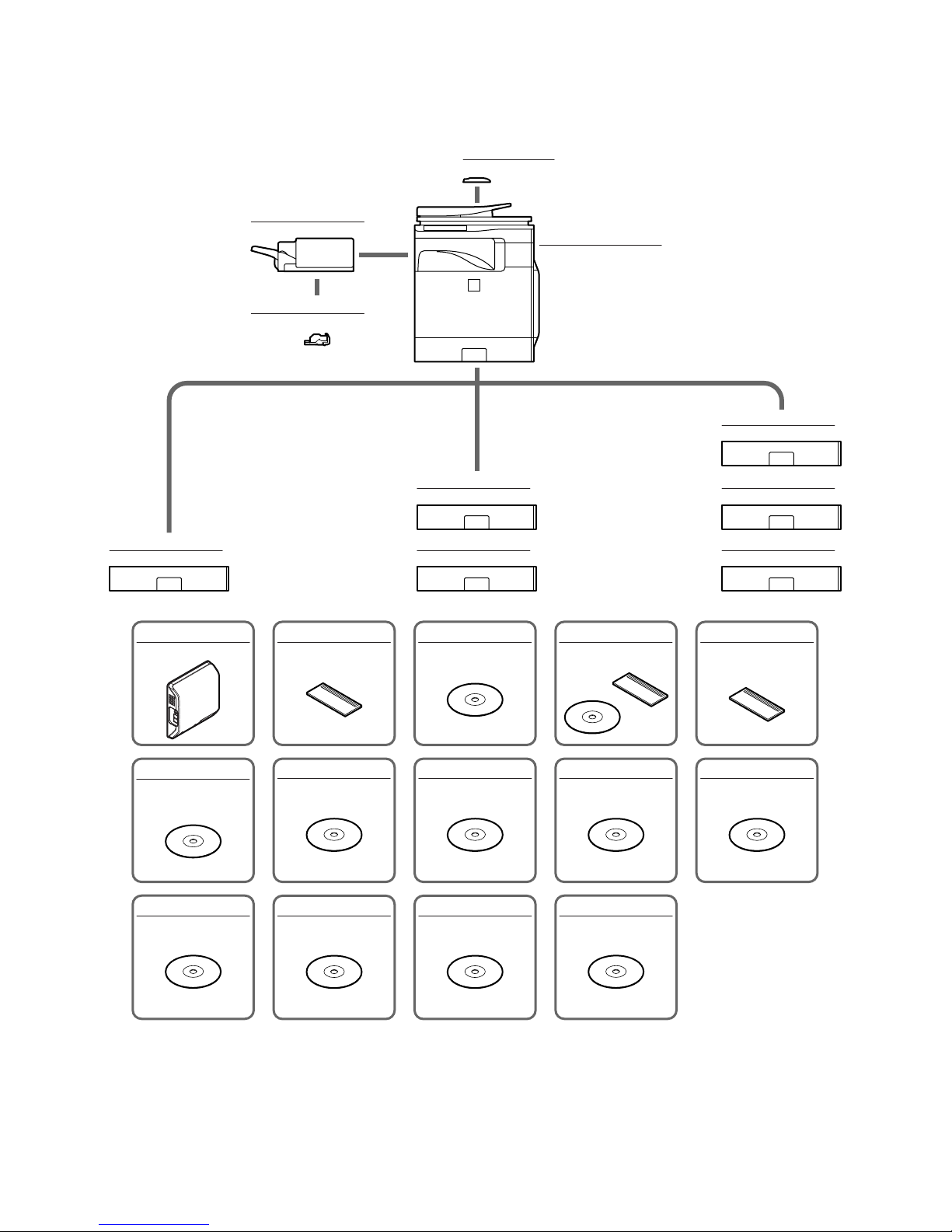

1. System configuration

MX-B381/B401

Digital multifunctional system

MX-CSX1

500-sheet paper feed unit

MX-CSX1

500-sheet paper feed unit

MX-CSX1

500-sheet paper feed unit

MX-BTX1

Business card feeder

MX-CSX2

500-sheet paper feed unit

MX-CSX2

500-sheet paper feed unit

MX-FN12

Finisher

MX-CSX2

500-sheet paper feed unit

AR-PF1

Bar code font kit

MX-FWX1

Internet fax expansion kit

MX-PUX1

XPS expansion kit

MX-USX1

Sharpdesk 1 license kit

MX-AMX1

Application integration

module

MX-AMX2

Application communication

module

MX-AMX3

External account module

MX-FXX3

Facsimile expansion kit

MX-SMX3

Expansion memory board

MX-USX5

Sharpdesk 5 license kit

MX-US10

Sharpdesk 10 license kit

MX-US50

Sharpdesk 50 license kit

MX-USA0

Sharpdesk 100 license kit

MX-FR16U

Data security kit

(Commercial version)

MX-SCX1

Staple cartridge

Page 4

MX-B381/B401 CONFIGURATION - ii

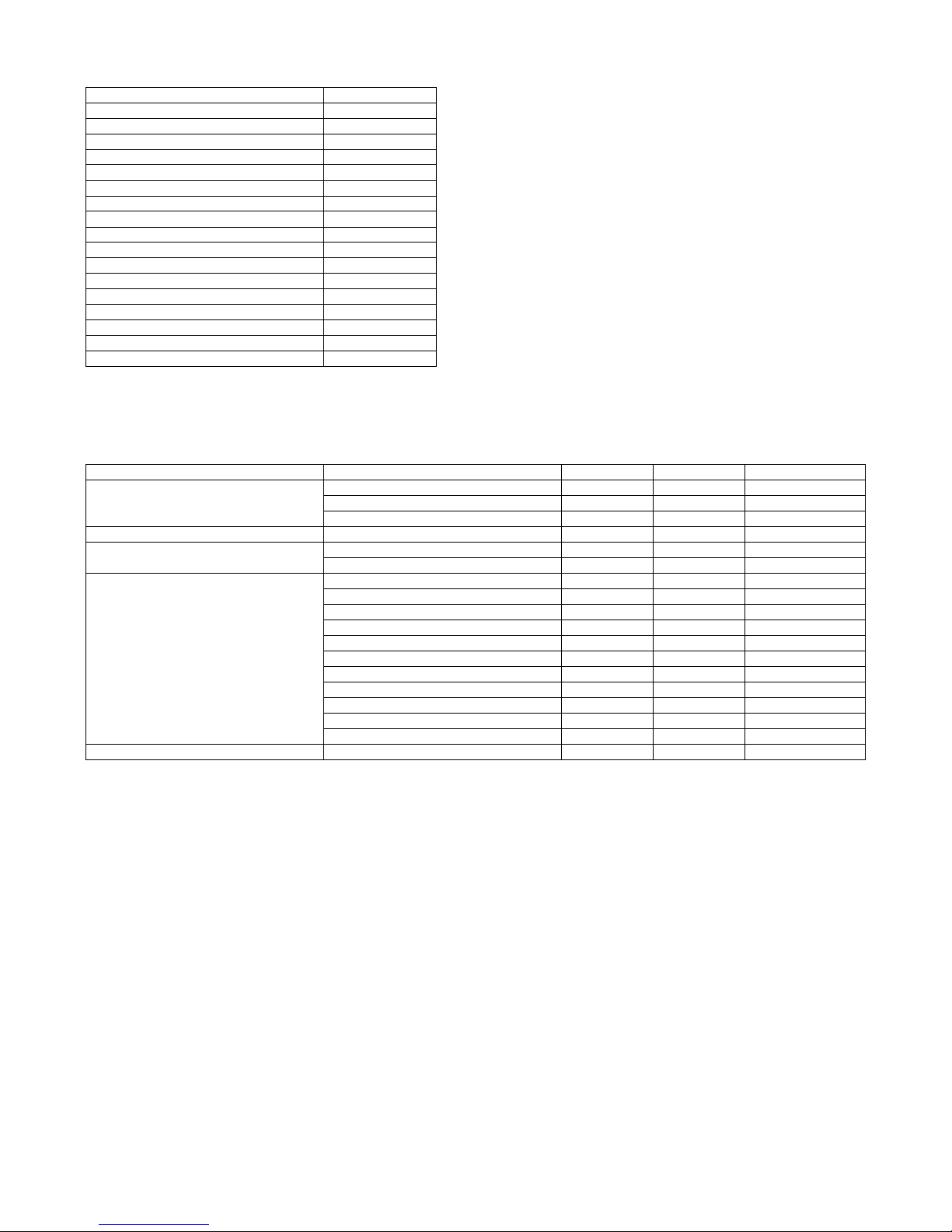

2. Machine configuration

STD: Standard provision, OPT: Option, –: No setting

*1: Product key target

3. Option list

STD: Standard provision, OPT: Option, –: No setting

*1: To install the MX-PUX1, the MX-SMX3 is required.

MX-B381/B401

Main body LCD CL 8.5

RSPF STD

Automatic duplex STD

HDD STD

System memory (For Program, Printer) 512MB

Local memory (Copier) 512MB

Copier STD

GDI printer –

SPDL/PCL printer STD

PS printer STD

EFI printer –

FAX OPT

Internet Fax OPT *1

Network scanner STD

Filing STD

Security OPT *1

OSA Expansion enable

Model Name Model name MX-B381/B401 Product key target

Paper feed system 500-sheet paper feed unit MX-CSX1 OPT –

500-sheet paper feed unit MX-CSX2 OPT –

Business card feeder MX-BTX1 OPT –

Paper exit system Finisher MX-FN12 OPT –

Electrical system (ROM) Bar code font kit AR-PF1 OPT –

Data security kit MX-FR16U OPT Yes

Electrical system (Software) Internet fax expansion kit MX-FWX1 OPT Yes

XPS expansion kit MX-PUX1 OPT *1 Yes

Sharpdesk 1 license kit MX-USX1 OPT –

Sharpdesk 5 license kit MX-USX5 OPT –

Sharpdesk 10 license kit MX-US10 OPT –

Sharpdesk 50 license kit MX-US50 OPT –

Sharpdesk 100 license kit MX-USA0 OPT –

Application integration module MX-AMX1 OPT Yes

Application communication module MX-AMX2 OPT Yes

External account module MX-AMX3 OPT Yes

Facsimile expansion kit MX-FXX3 OPT –

Memory Expansion memory board MX-SMX3 OPT –

Page 5

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 1

MX-B401

Service Manual

[1] MX-B381/B401 (MAIN UNIT)

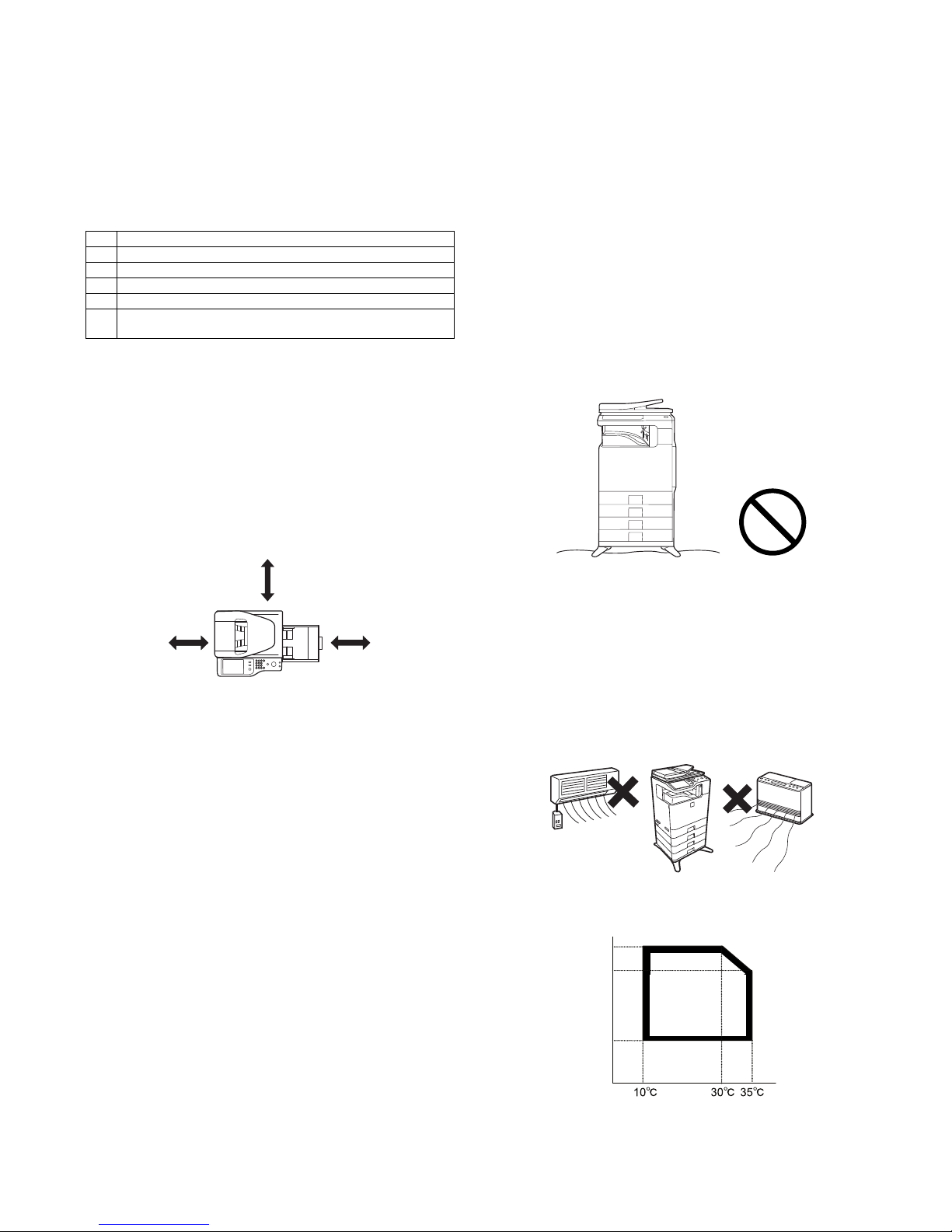

1. Installing (use) conditions

Before installing the machine, check that the following installing

(use) conditions are satisfied.

If the installing (use) conditions are not satisfied, the machine may

not display full performances, resulting in troubles. It may also

cause safety problems. Therefore, be sure to arrange the installing

(use) conditions before setting up the machine.

A. Bringing space

For installation of a large size machine, be sure to check that the

door size is wide enough before bringing in.

B. Installing space

The following space must be provided around the machine in order

to assure machine performances and proper operations.

If any option is installed, provide the additional space for installing

it.

Especially the space at the rear of the machine must be provided

sufficiently. If not, the machine cannot exhibit functions against heat

and dust, causing some troubles.

C. Power source (Capacity, voltage, frequency,

safety, plug)

If the power specifications are not satisfied, the machine cannot

exhibit full performances and may cause safety trouble.

Strictly observe the following specifications.

(1) Power capacity

Check that the following power capacity is satisfied. If not, additionally provide a power source.

Current capacity

Japan: 20A or more

100V: 15A or more

200V: 10A or more

(2) Power voltage

Measure the voltage during copying to check that the voltage is in

the range of the specified voltage 10%.

If the voltage is outside the specified range, use thicker lead wires

to reduce impedance.

(An electrical work is required.)

Use of a step-up transformer is also available. In this case, the

capacity must be great enough for the max. power consumption of

the machine.

(3) Power frequency, waveform

The frequency must be within the range of the specified frequency

2%. If power waveform is deformed, a trouble may occur.

(4) Safety

Be sure to properly ground the machine.

Grounding (earth connection) must be performed before inserting

the power plug into the power outlet.

When disconnecting the earth connection, be sure to disconnect

the power plug from the power outlet in advance.

(5) Power plug

Check the form of the power plug. If the shape does not match, do

not use it.

D. Floor strength and level

This machine is considerably heavy and becomes heavier with an

option installed.

The floor must be strong enough for assuring safety.

If the unit is not horizontally installed, the toner density control is not

performed normally, degrading the copy quality.

If not, color shift or image distortion may occur.

E. Direct rays of the sun, dust, temperature,

humidity, gasses, chemicals, vibration

(1) Temperature and humidity

This machine is designed to perform properly under the specified

temperature and humidity. If the temperature and humidity exceeds

the specified range, the machine may not operate properly and or

cause equipment failure.

Especially when the humidity is too high, paper absorbs humidity to

cause a paper jam or dirty copy.

Do not install the machine near a heater, a cooler, or a humidifier.

Dew may be formed inside the machine to cause a trouble. Use

enough care for ventilation.

• Working environment

Temperature: 10 to 35C

Humidity: 20 to 85% RH

Atmospheric pressure: 590 to 1013hPa (altitude: 0 to 2000 m)

No. Content

1 Bringing space

2 Installing space

3 Power source (Capacity, fluctuation, safety)

4 Floor strength

5 Direct rays of the sun, dust, temperature, humidity, gases,

chemicals

11-13/16”

(30cm)

11-13/16”

(30cm)

17-23/23”

(45cm)

85%

Humidity㧔RH㧕

60%

20%

Page 6

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 2

(2) Dust

If dust enters the machine, it may cause dirty copy and a paper

jam, resulting in a shortened lifetime.

(3) Direct rays of the sun

If the machine is installed under the rays of the sun, the exterior of

the machine may be discolored and abnormal copies may be produced.

(4) Gases and chemicals

Do not install the machine at a place where there are gases and

chemicals. Especially be careful to avoid installation near a diazotype copier, which produces ammonium gas.

Copy quality may be adversely affected and a trouble may be

caused.

(5) Vibration

Avoid installation near a machine which produces vibrations.

If vibrations are applied to the copier machine, copy images may be

deflected and a trouble may be caused.

2. Transit and delivery

A. Implements, facility, and manpower

It is recommendable to use a forklift for bringing in the machine for

safety.

If no forklift is available, man-power of two persons is required. The

machine is considerably heavy, and requires safety precautions for

delivery and installation.

Transit of the machine must be made in packed condition to the

installing place.

Since the hard disk drive is built in the machine, use care not to

exert vibrations or shocks to the machine when in transit.

B. Delivery

Remove the packing materials prior to installation in the office environment.

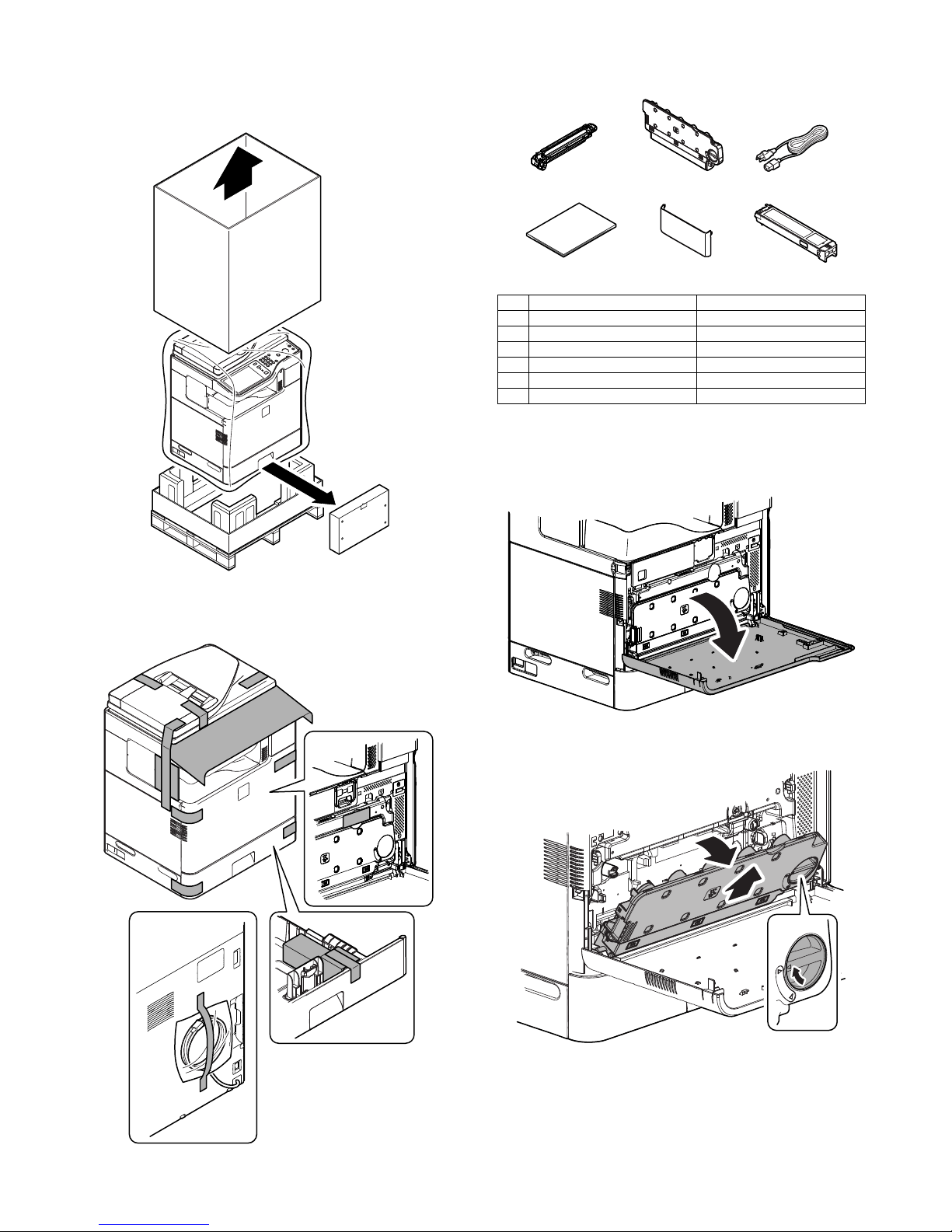

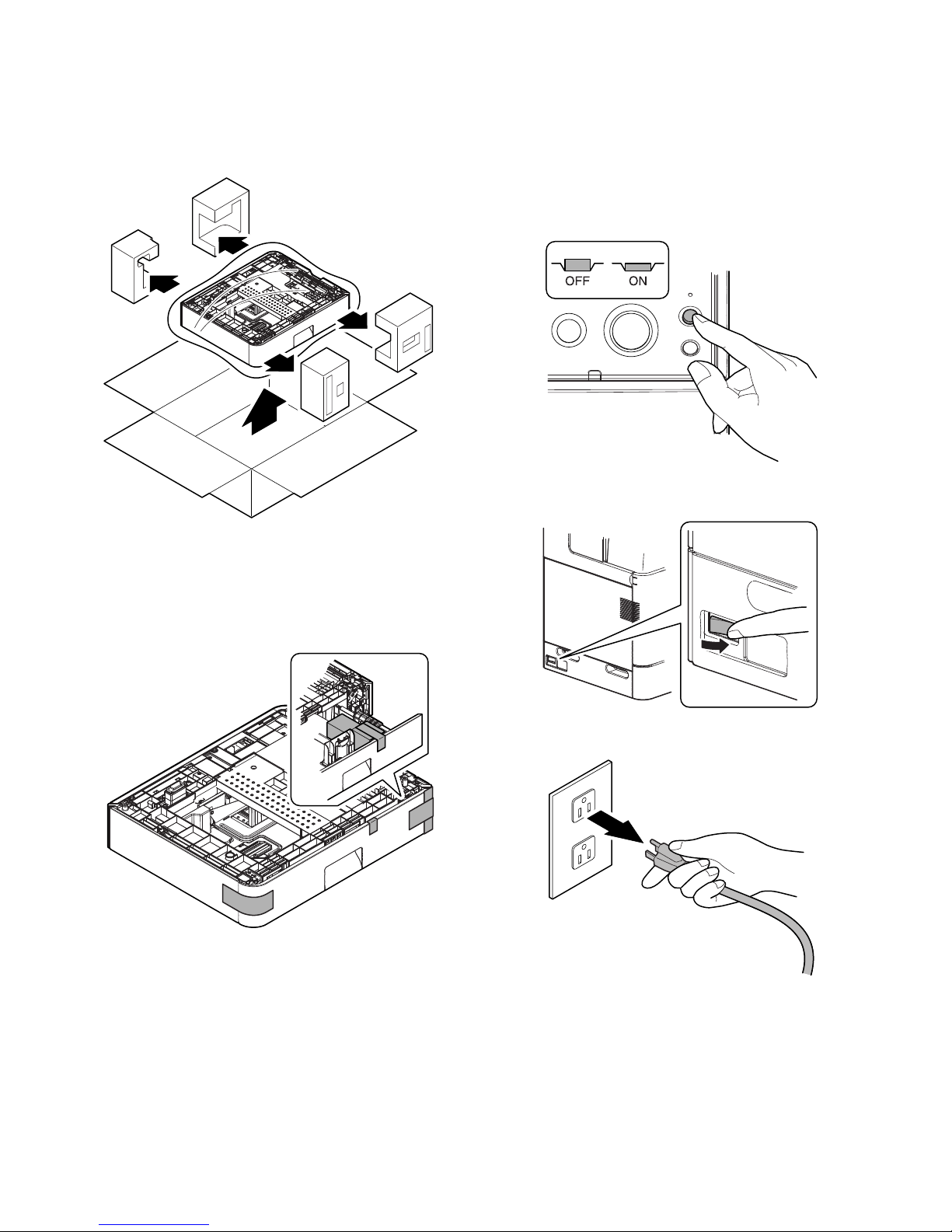

3. Unpacking

A. Unpacking procedure

1) Remove the PP band.

2) Remove the top case.

3) Remove the parts included in the package.

No. Content Method

1 Implements, facility,

and man power

Use a forklift. (If no forklift is available,

manpower of two persons is required.)

2 Delivery Transit must be made in packed condition.

Page 7

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 3

4) Remove the carton.

5) Remove the parts included in the package.

6) Remove the main unit from the bottom padding, and remove

the polyethylene bag.

B. Removal of the fixing tape and protection

material

C. Check the packed items

1) Check that all the parts are in the package.

4. Installation

A. Installation of the developer cartridges

1) Open the front cover.

2) Turn the lock lever until it stops to release the lock, and

remove the waste toner box.

NOTE:

For North America, the power

cable is attached vertically to

the machine.

No. Packed part names Quantity

1 Developer cartridge 1

2 Waste toner box 1

3 AC cord 200V series only: 1 piece

4 Operation Manual 1 set

5 Operation Manual pocket Yes

6 Toner cartridge Europe only: 1 piece

12

456

3

Page 8

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 4

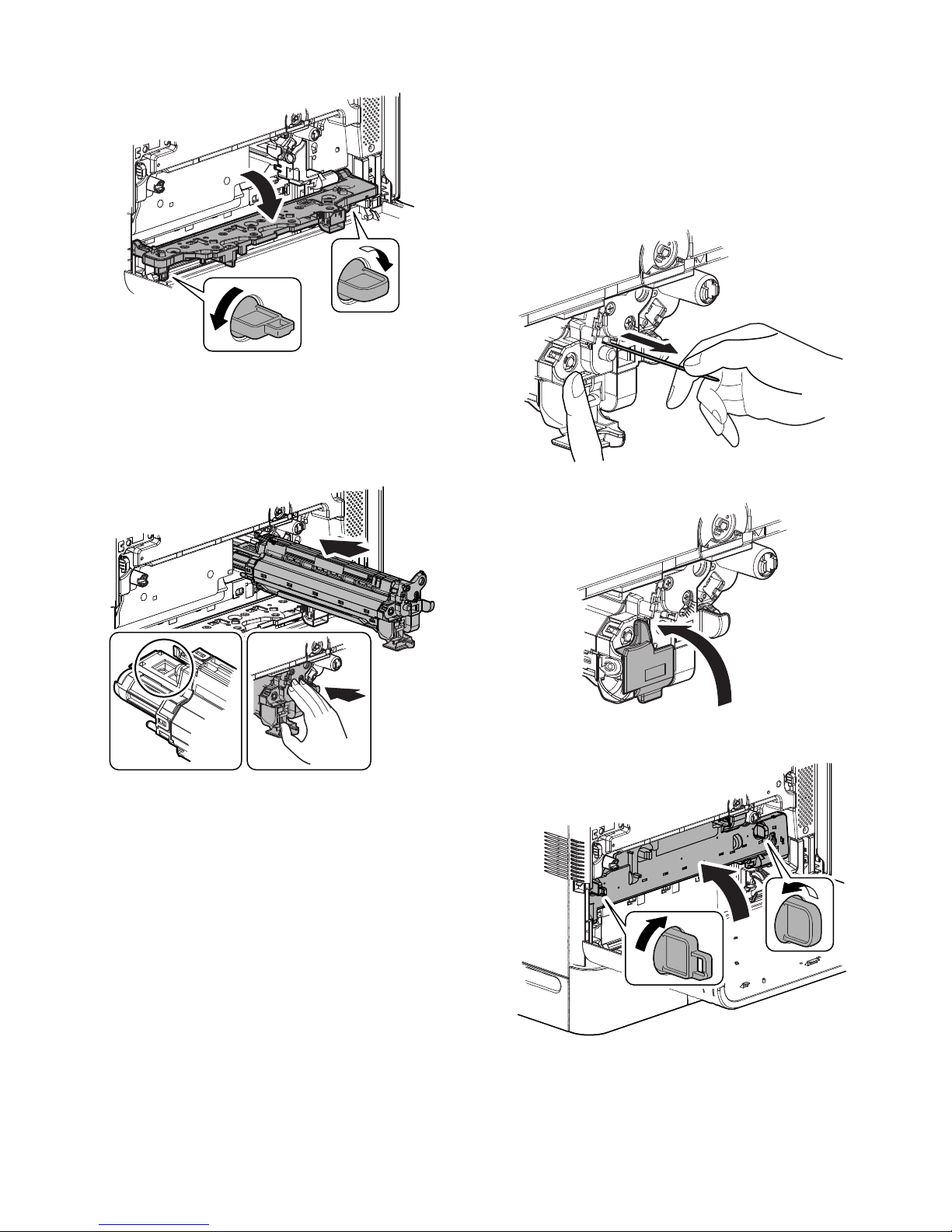

3) Turn the lock lever to the horizontal position to release the

lock, and open the drum positioning plate unit.

4) Shake the developer cartridge 5 - 6 times horizontally, and

remove the protection material from the developer cartridge.

Insert the developer cartridge straight and horizontally until it

locks.

NOTE: When handling the developer cartridge, do not touch the

magnet roller section and the shutter section.

5) While pressing the developer cartridge, pull out the heat seal

straight.

NOTE: If the heat seal is pulled out with a strong force or diago-

nally, it may be broken off. Be sure to pull it slowly and

straight.

After puling out the heat seal completely, check to confirm

that there is a red mark at the edge of the heat seal.

If there is no red mark, it means that the heat seal has been

broken. In such a case, the developer cartridge must be

replaced with a new one.

6) Close the lock cover of the developer cartridge.

7) Close the drum positioning plate unit, and put the lock lever

upright to lock.

Page 9

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 5

B. Cleaning of LSU's dust-proof glass

* Dust from the transfer belt or shutter or some other adjacent part

may fall onto the LSU during transport or installation. Be sure to

clean the dust-proof glass before checking the image quality.

1) Remove the LSU cleaning rod from the front cover.

2) Face the cleaner downward, and slowly insert the LSU cleaning rod into the LSU cleaning hole.

* The LSU cleaning hole is indicated with a label.

3) After inserting the LSU cleaning rod to the bottom, pull it out

until the lead edge of the cleaning unit is separated from the

LSU clearing surface. Repeat 2 - 3 times for cleaning.

4) Return the LSU cleaning rod to the front cover.

5) Install the waste toner box, and turn the lock lever to the left

until it stops to lock the waste toner box.

6) Close the front cover.

C. Installation of the operation manual pocket

1) Install the Operation Manual pocket (included in package)

cover to the left side of the machine.

a) First, insert the pawl on the lower side of the Operation

Manual pocket.

b) Then, lift the pawl on the upper side and insert it, and slide

down to install.

D. Tray size setup

1) Gently pull out the tray until it stops. If paper remains in the

tray, remove it.

Cleaning

side

Page 10

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 6

2) Adjust the guide plates A and B to the vertical size and the horizontal size of paper.

The guide plates A and B are movable. Hold the fixing knob to

slide the guide plates A and B to match the paper size.

3) Insert the tray slowly.

The machine automatically detects the set paper size.

4) Close the cabinet and turn on the power.

The toner concentration adjustment operation is automatically

started, and "Please wait. Do not turn the power off." is displayed.

When the toner concentration adjustment operation is completed, the message of "Install the toner cartridge." is displayed. Do not make any operations until the message is

displayed.

E. Installation of toner cartridges

* The life of each toner cartridge is as follows:

Equivalent to approximately 2.5K (A4/LT 5%)

1) Shake the toner cartridge (included in package) horizontally

several times.

2) Remove the heat seal.

3) Insert the toner cartridge horizontally and straight until it locks.

NOTE: Do not forcibly insert the toner cartridge. Keep holding the

cartridge and completely insert it.

NOTE: When the machine is transported with the developing unit

removed, be sure to remove the toner cartridge. (if not

toner may become clogged.)

NOTE: Do not remove or insert the toner cartridge with the devel-

oper cartridge removed.

F. Specifications setting

Use SIM26 to set to the specifications according to the customer's

request.

To customize one of the following items after destination setting,

change the set value of the item.

SIM No Content

26 6 Destination setting

SIM No Content

26 3 Auditor specifications, mode setting

18 Toner save mode enable/disable setting (Japan and UK

versions only)

* For the other destinations, this setting is made by the user

program.

52 Count-up enable/disable setting of non-print paper passing for

each counter

53 User auto calibration enable/disable setting

65 Staple limit quantity setting

Page 11

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 7

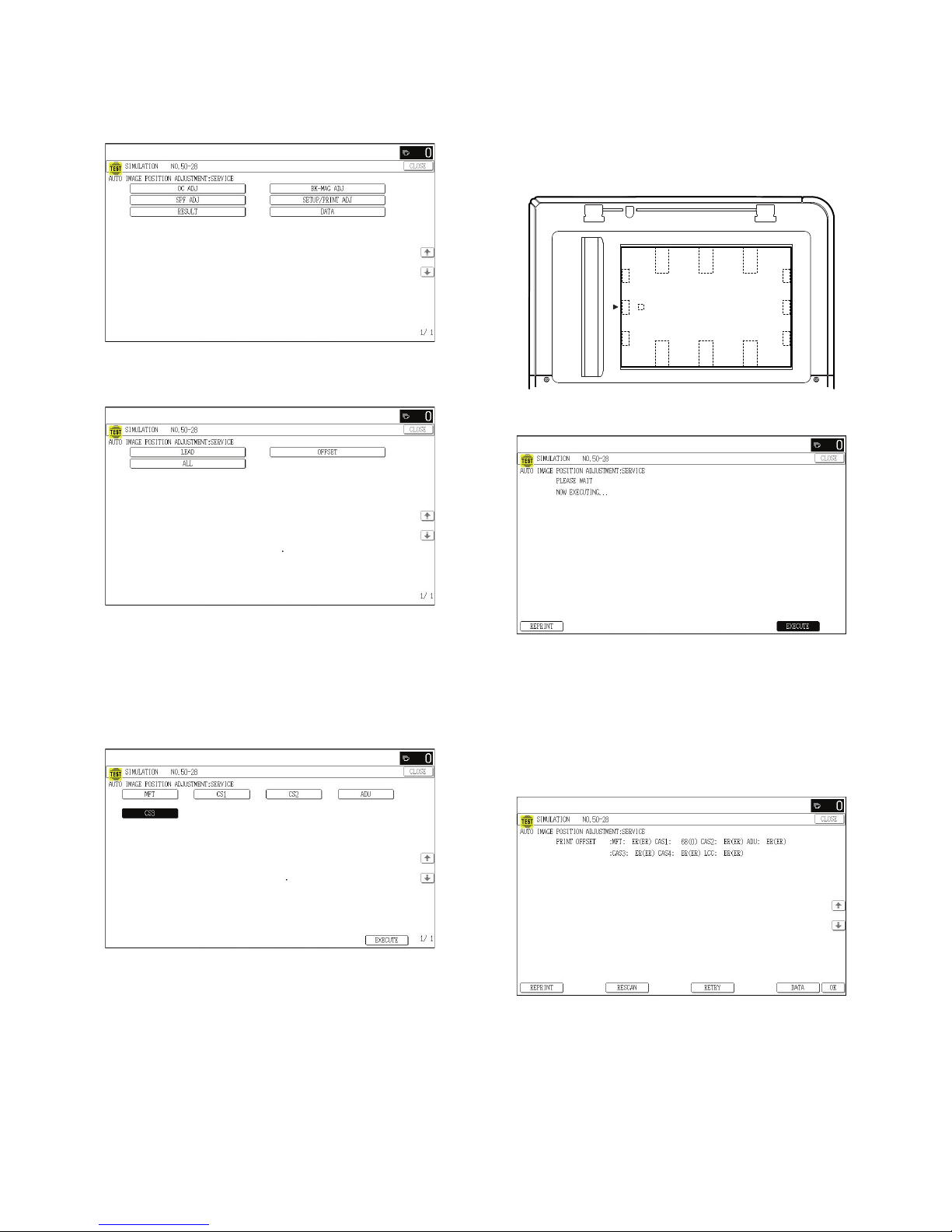

G. Image off-center adjustment

Make a copy in the document table mode and in the RSPF mode,

and check to confirm that the void area is within the specified range

shown below.

NOTE: When an option cassette is installed, execute this adjust-

ment.

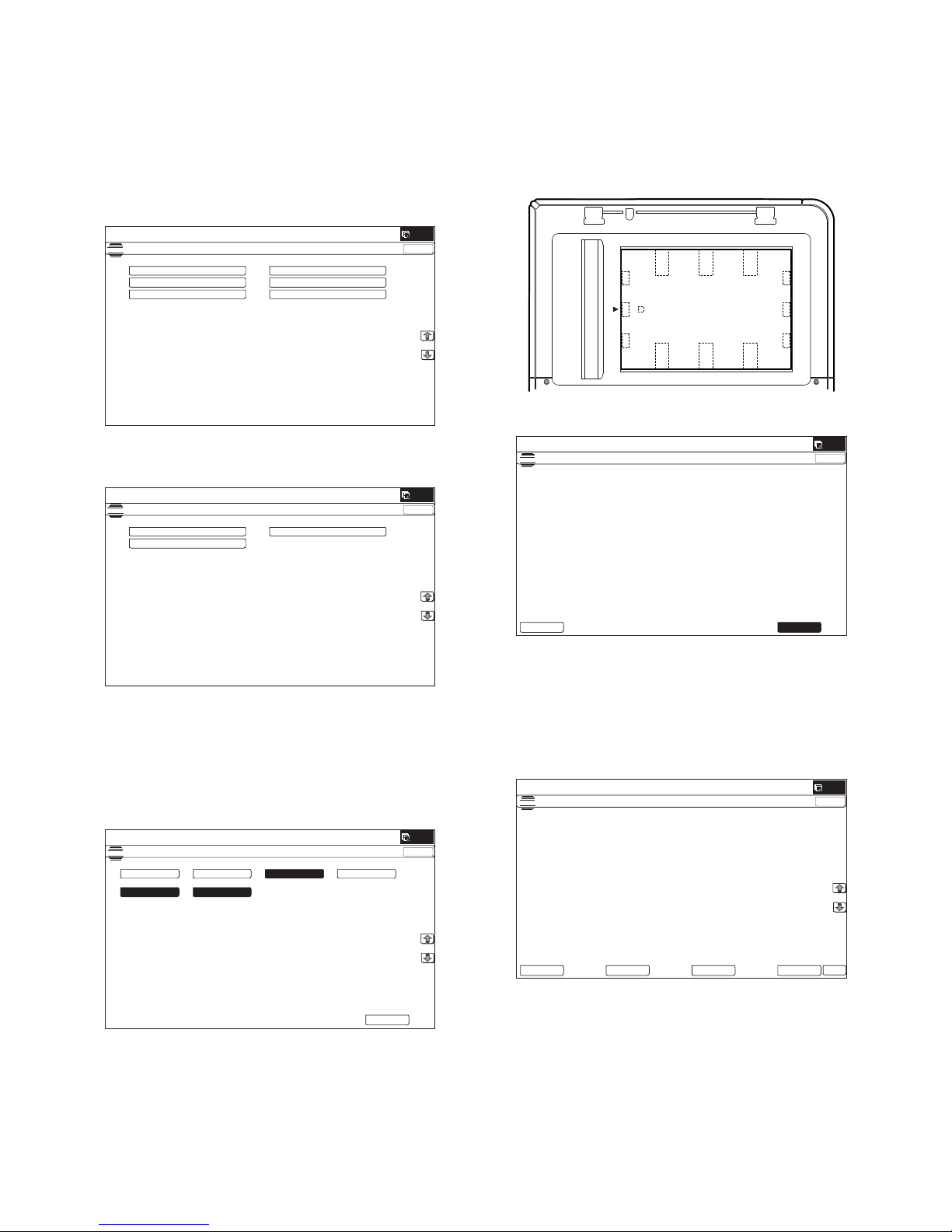

(1) Image off-center automatic adjustment

(Document table mode)

1) Enter the SIM50-28 mode.

2) Select [SETUP/PRINT ADJ].

3) Select [OFFSET].

(Note)

When [ALL] is selected, the adjustments of the following two

items are performed at a same time.

* [LEAD]: Print image lead edge image position adjustment

* [OFFSET]: Print image off-center adjustment

4) Select a paper feed tray to be adjusted.

Set A4 (11" x 8.5") paper in each paper feed tray in advance.

5) Press [EXECUTE] key.

The adjustment pattern is printed out. (Paper is fed from the

selected paper feed tray, and the adjustment pattern of each

paper feed tray is printed out.)

6) Set the adjustment pattern to the center reference position on

the document table.

NOTE: Fit the adjustment pattern correctly with the document

guide.

7) Press [EXECUTE] key.

The following item is automatically adjustment.

* Print image lead edge image position adjustment

* Print image off-center adjustment

Perform the procedures of 6) - 7) for the printed adjustment

pattern of each paper feed tray.

8) Press [OK] key.

The adjustment result becomes valid.

NOTE: When an error occurs in the automatic adjustment of

SIM50-28, place white paper on the adjustment pattern and

perform the adjustment.

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

$872,0$*(326,7,21$'-8670(176(59,&(

2&$'-

%.0$*$'-

63)$'-

66(78335,17$'-

5(68/7

'$7$

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

$872,0$*(326,7,21$'-8670(176(59,&(

/($'

2))6(7

$//

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

$872,0$*(326,7,21$'-8670(176(59,&(

(;(&87(

0)7

&6

$'8

&6

&6

&6

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

$872,0$*(326,7,21$'-8670(176(59,&(

3/($6(:$,7

12:(;8&87,1*

(;(&87(

5(35,17

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

$872,0$*(326,7,21$'-8670(176(59,&(

35,17/($'0)7&$6$'8

&$6'6.

35,172))6(70)7&$6&$6$'8

&$6&$6

'$7$

5(6&$1

5(35,17

5(75<

2.

Page 12

MX-B381/B401 MX-B381/B401 (MAIN UNIT) 1 – 8

H. Remote operation panel function Enable

setting

(1) General

To use the remote operation panel function, the password for the

remote operation panel function must be entered on the password

input menu displayed on the VNC boot screen. Note that, therefore,

the password must be set in advance to use the remote operation

panel function.

Let the user make the password, and use SIM26-78 to set it.

(2) Remote operation panel function password setting

procedures

1) Enter the SIM26-78 mode.

2) Enter the password with 10 key. (Within 5 - 8 digits)

The entered password is displayed on the column of "NEW."

To modify the entered password, use clear key to delete the

password digit by digit.

3) Press [SET] key, and the password is set.

I. Functional operation check

Check to confirm that the following operations are normal.

J. USB PORT selection

There are two USB ports, one on the rear frame side and the other

on the front frame side. Only either of them can be used.

When shipping, the port on the front frame side is valid and the port

on the rear frame side is invalid.

The valid port can be switched by changing the setting of the MFP

PWB DIP SW.

Select the valid USB port according to the user's request.

K. Storing setting and adjustment data

Use SIM22-6 to print and store the settings and adjustments data

(list).

• When a memory trouble occurs, if the above information is not

available, all the adjustments must be performed from the beginning.

• If the above information is available, the setting and adjustment

values can be directly entered, shortening the servicing time.

L. Procedures required for transit of the machine

1) If the following option is installed, remove it from the machine.

• Finisher

2) Remove the following consumable parts from the machine.

• Paper

• Toner cartridge

• Developer cartridge

NOTE: When moving take extreme care to prevent shock or vibra-

tion to the machine as there is a hard drive built into this

product.

Check item Equipment

Key input operation (Operation panel)

Display (Operation panel)

Paper feed

operation

Manual paper feed

Main unit paper feed

tray

Option paper feed unit With the option paper feed

unit installed

Paper size

detection operation

Manual paper feed tray

RSPF operation /

Duplex copy

operation

S-S mode

D-S mode

S-D mode

D-D mode

Stapling operation With the finisher installed

Offset operation With the finisher installed

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

523(3$66:25'6(77,1*

35(6(17˖

ǂǂ1(:˖

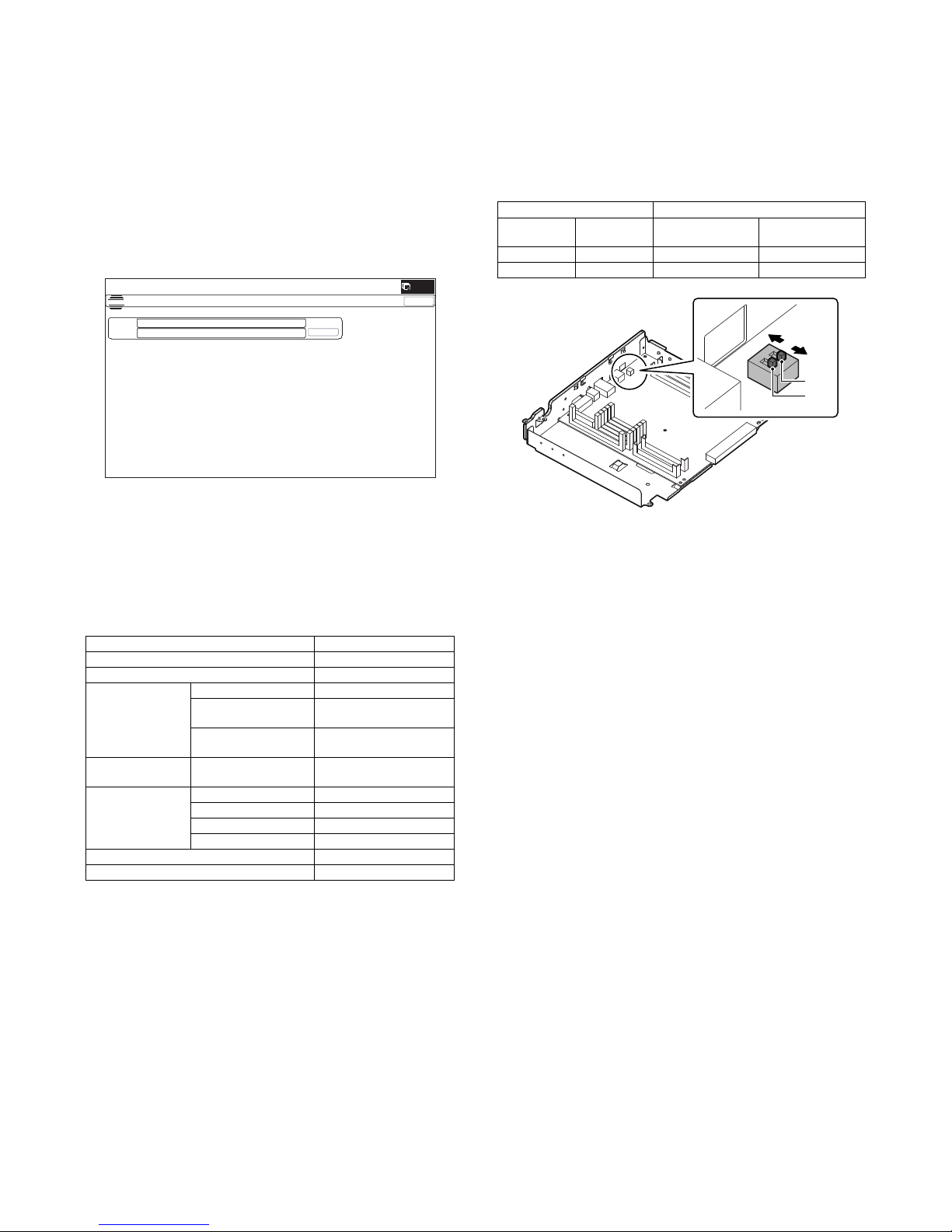

MFP PWB DIP SW USB I/F

SW 1 SW 2

Port on the front

frame side

Port on the rear

frame side

OFF OFF Valid Invalid

OFF ON Invalid Valid

SW1

ON

OFF

SW2

Page 13

MX-B381/B401 MX-CSX1/CSX2 (500-SHEET PAPER FEED UNIT) 2 – 1

MX-B401

Service Manual

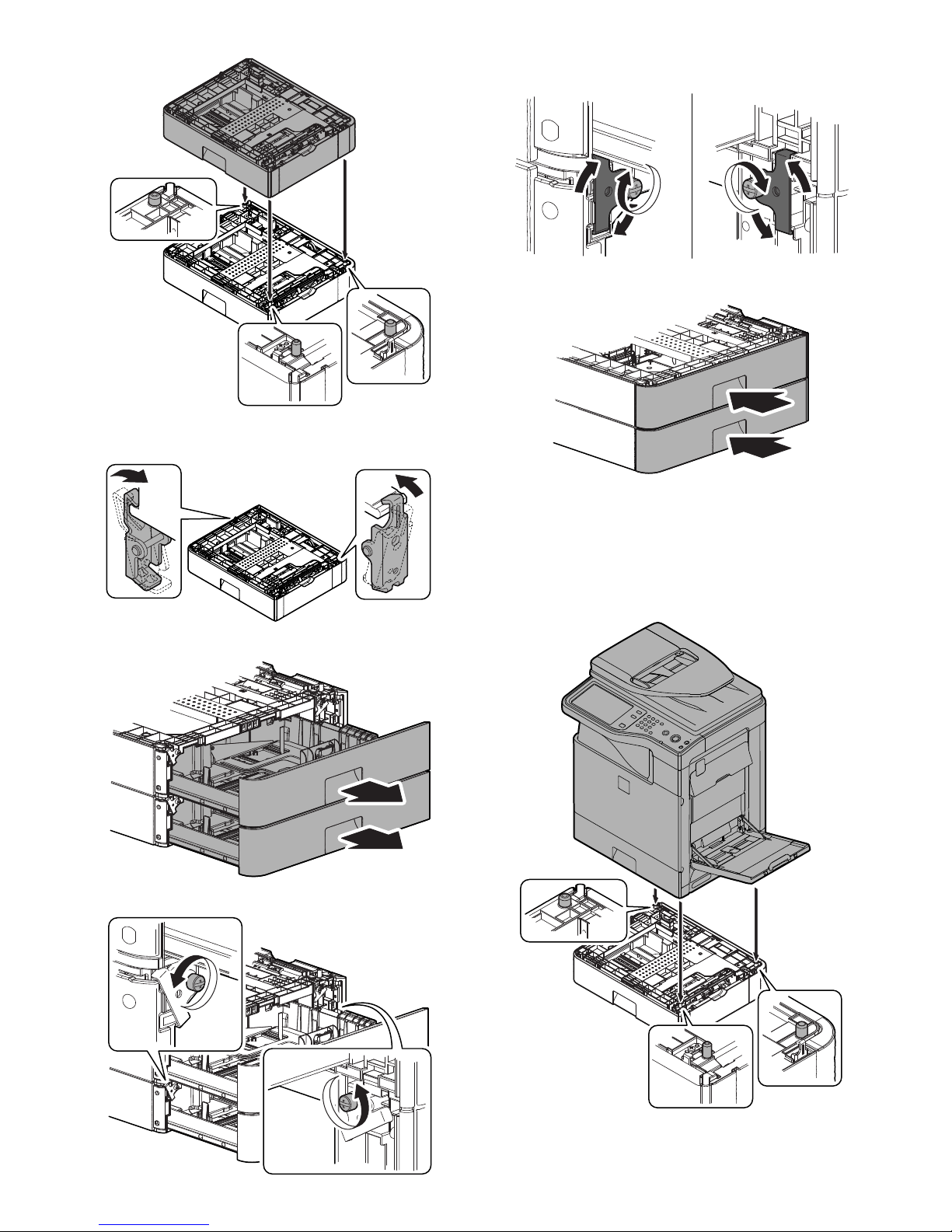

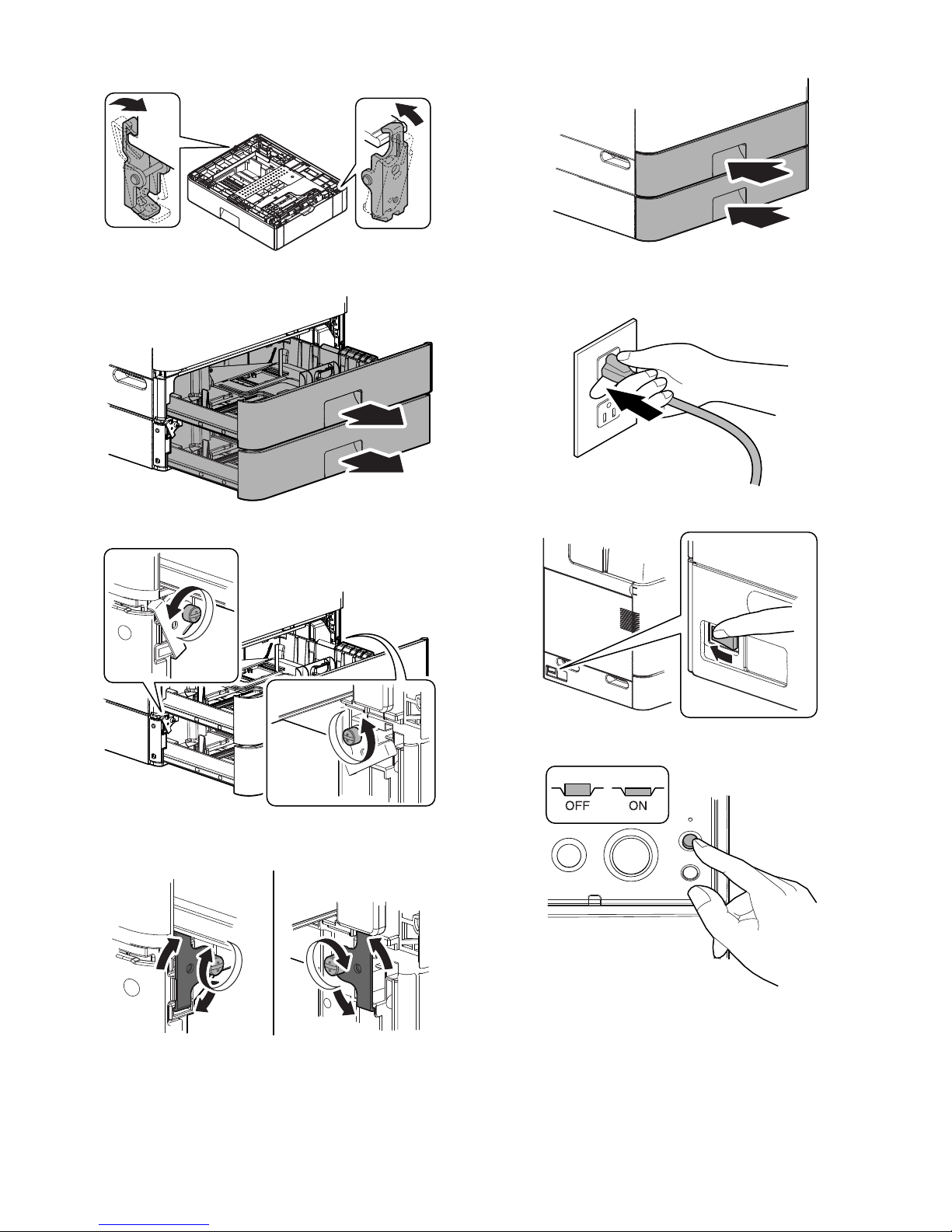

[2] MX-CSX1/CSX2 (500-SHEET PAPER FEED UNIT)

1. Unpacking

A. Removal of the 500 sheet paper feed unit

(1) MX-CSX1/CSX2

B. Removal of the fixing tape and protection

material

(1) MX-CSX1/CSX2

1) Remove the 500 sheet paper feed unit from the polyethylene

bag, and remove the fixing tape and the protection material.

2. Installation

<Precautions for installation>

Before execution of installation, check to confirm that the communication lamp on the operation panel and the data lamp under it are

not lighted or blinking.

A. Turn off the power of the main unit

1) Turn OFF the power switch on the operation panel.

2) Check to confirm that the operation panel is turned OFF, and

then turn OFF the power switch.

3) Disconnect the power plug from the power outlet.

B. Install the MX-CSX1 or the MX-CSX2 to the MX-

CSX2.

* In the example below, installation of the MX-CSX1 to the MX-

CSX2 is described. Installation of the MX-CSX2 to another MXCSX2 is performed similarly.

1) Put the MC-CSX1 on the MX-CSX2 so that they fit together.

NOTE: When holding the main unit with the MX-CSX2 and the

MX-CSX1 installed, use two persons.

Page 14

MX-B381/B401 MX-CSX1/CSX2 (500-SHEET PAPER FEED UNIT) 2 – 2

* When the MX-CSX1 is put on the MX-CSX2, it is automati-

cally locked at the left and the right of the rear side.

2) Pull out the trays of the MX-CSX1 and the MX-CSX2.

3) Loosen the hand screws on the left and the right sides.

4) Hang the fixing clasp on the main unit, and tighten the hand

screws.

5) Push in and close the trays.

C. Install the main unit to the MX-CSX1.

NOTE: If the main unit is combined with the MX-CSX1 only, it must

be used as a desktop machine and must not be used on

the floor in order to prevent against falling.

1) Put the main unit on the MX-CSX1 so that they fit together.

NOTE: When holding the main unit, use two persons.

Page 15

MX-B381/B401 MX-CSX1/CSX2 (500-SHEET PAPER FEED UNIT) 2 – 3

* When the main unit is put on the MX-CSX1, it is automati-

cally locked at the left and the right of the rear side.

2) Pull out the tray of the main unit and that of the MX-CSX1.

3) Loosen the hand screws on the left and the right sides.

4) Hang the fixing clasp on the main unit, and tighten the hand

screws.

5) Push in and close the trays.

D. Turn on the power of the main unit

1) Power to the main unit.

2) Turn ON the power switch.

3) Turn ON the power switch on the operation panel.

Page 16

MX-B381/B401 MX-CSX1/CSX2 (500-SHEET PAPER FEED UNIT) 2 – 4

3. Adjustments

A. Image off-center automatic adjustment

(Document table mode)

1) Enter the SIM50-28 mode.

2) Select [SETUP/PRINT ADJ].

3) Select [ALL].

NOTE: When [ALL] is selected, the adjustments of the follow-

ing two items are performed at a same time.

* [LEAD]: Print image lead edge image position adjustment

* [OFFSET]: Print image off-center adjustment

4) Select the paper feed trays to be adjusted. (Select all the

trays.)

Set A4 (11" x 8.5") paper in each paper feed tray in advance.

5) Press [EXECUTE] key.

The adjustment pattern is printed out. (Paper is fed from the

selected paper feed tray, and the adjustment pattern of each

paper feed tray is printed out.)

6) Set the adjustment pattern in the center reference on the document table.

NOTE: Fit the adjustment pattern correctly with the document

guide.

7) Press [EXECUTE] key.

The following item is automatically adjustment.

* Print image lead edge image position adjustment

* Print image off-center adjustment

Perform the procedures of 6) - 7) for the printed adjustment

pattern of each paper feed tray.

8) Press [OK] key. (For the 4.3 Inch LCD model, press the OSA

shortcut key.)

The adjustment result becomes valid.

NOTE: When an error occurs in the automatic adjustment of

SIM50-28, place white paper on the adjustment pattern and

perform the adjustment.

Page 17

MX-B381/B401 MX-FN12 (FINISHER) 3 – 1

MX-B401

Service Manual

[3] MX-FN12 (FINISHER)

1. Unpacking

A. Removal of the finisher

B. Removal of the fixing tape and protection

material

1) Remove the finisher from the polyethylene bag, and remove

the fixing tape and the protection materials.

C. Check the packed items

2. Installation

<Precautions for installation>

Before execution of installation, check to confirm that the communication lamp on the operation panel and the data lamp under it are

not lighted or blinking.

A. Turn off the power of the main unit

1) Turn OFF the power switch on the operation panel.

2) Check to confirm that the operation panel is turned OFF, and

then turn OFF the power switch.

3) Disconnect the power plug from the power outlet.

No. Packed part names Quantity

1 Machine connection unit 1

2 Paper exit tray 1

3 Staple position label (For RSPF) 1

4 Staple position label (For OC) 1

21

43

Page 18

MX-B381/B401 MX-FN12 (FINISHER) 3 – 2

B. Installation of the machine connection unit

1) Remove the full detection actuator and the paper exit auxiliary

plate at the paper exit port of the main unit.

2) Disengage the pawls, and remove the paper exit cover.

3) Open the front cover.

4) Remove the coin screw, and remove the paper exit tray.

5) Install the machine connection unit (included in the package)

to the machine.

6) Slide the lock lever to " (Lock)" position and fix it.

C. Installation of the finisher

1) Install the finisher to the machine connection unit.

NOTE: When holding the finisher, hold the front frame side and

the rear frame side together.

2) Close the front cover of the finisher.

Page 19

MX-B381/B401 MX-FN12 (FINISHER) 3 – 3

3) Close the front cover of the main unit.

D. Installation of the paper exit tray

1) Install the paper exit tray (included in the package) to the finisher.

E. Staple position label attachment

1) Attach the staple position label (included in the package) for

the RSPF to the RSPF unit.

2) Attach the staple position label (include in the package) for the

OC to the scanner unit.

F. I/F cable connection

1) Remove the cap of the connector for connecting the finisher to

the rear side of the machine.

Connect the I/F cable of the finisher, and loosen the manual

screw of the connector and fix it.

Non LPS

Do not connect to devices other than specified peripheral

devices of our company.

G. Turn on the power of the main unit

1) Insert the power plug into the power outlet.

Page 20

MX-B381/B401 MX-FN12 (FINISHER) 3 – 4

2) Turn ON the power switch.

3) Turn ON the power switch on the operation panel.

3. Adjustments

The adjustments of this machine are executed only when a

trouble occurs.

If the adjustment value is changed when there is no trouble in the

machine, a trouble may be generated such as improper alignment

of paper, paper exit jam, attachment of roller marks on paper, etc.

A. Paper alignment width adjustment

This adjustment is executed when a trouble occurs in paper alignment.

1) Execute Sim3-10.

2) Select "A: FPAM ADJUST".

3) Enter the set value with 10-key. (Press [C] key to clear the

entered values.)

Initial value: 50

When the adjustment value is increased by 1, the alignment

plate F/R width is narrowed by 0.419mm in alignment operation.

When the adjustment value is decreased by 1, the alignment

plate F/R width is widened by 0.419mm in alignment operation.

The alignment plate F and the alignment plate R cannot be

adjusted separately. The shift amount on the F side and that

on the R side are alternatively corrected every-time the adjustment value is increased by 1. (Correction with 51 for the F

side, and 52 for the R side. ... 59 for the F aide, and 60 for the

R side. Similar when the set value is decreased.)

4) Press [OK] key to save the set value. (For the 4.3 Inch LCD

model, press the OSA shortcut key.)

5) After completion of the adjustment, make staple copies.

Alignment specification: Within 2.5mm

B. Paper delivery roller descending position

adjustment

This adjustment is executed when a paper exit jam occurs or when

roller marks of the paper delivery roller are attached to paper.

1) Execute Sim3-10.

2) Select "B: FDRLM ADJUST".

3) Enter the set value with 10 key. (Press [C] key to clear the

entered values.)

Initial value: 50

When the adjustment value is increased by 1, the shift amount

of the paper delivery roller is changed by 0.11mm toward the

pressure increasing side (*1).

When the adjustment value is decreased by 1, the shift

amount of the paper delivery roller is changed by 0.11mm

toward the pressure decreasing side (*1).

*1: The pressure increasing side means the direction to

increase the paper delivery roller pressure onto paper, and

the pressure decrease side means the direction to

decrease the paper delivery roller pressure onto paper.

4) Press [OK] key to save the set value.

B

Page 21

MX-B381/B401 MX-FXX3 (FACSIMILE EXPANSION KIT) 4 – 1

MX-B401

Service Manual

[4] MX-FXX3 (FACSIMILE EXPANSION KIT)

1. Unpacking

A. Check the packed items

2. Installation

<Precautions for installation>

Before execution of installation, check to confirm that the communication lamp on the operation panel and the data lamp under it are

not lighted or blinking.

A. Turn off the power of the main unit

1) Turn OFF the power switch on the operation panel.

2) Check to confirm that the operation panel is turned OFF, and

then turn OFF the power switch.

3) Disconnect the power plug from the power outlet.

B. FAX unit installation

1) Remove the two screws on the rear cabinet of the main unit.

Attach the step screw (included in the package) to one of the

removed screw positions.

No. Packed part names Quantity

1 FAX memory 1

2 Ferrite core 1

3 Line cable 1

4 Screw (M3) 1

5 Step screw 1

6 Clamp 1

7 Instructions for installation 1

2

45 76

1

3

Australia

Page 22

MX-B381/B401 MX-FXX3 (FACSIMILE EXPANSION KIT) 4 – 2

2) Hang the FAX unit on the step screw. Fix the FAX unit with the

screws which were removed in the step 1).

C. FAX memory installation

1) Open the front cover and the tray 1.

2) Remove the stopper, and slide the left cabinet to the front side

to remove.

3) Remove the screw, and remove the controller cover.

4) Install the FAX memory (included in the package) to the slot E

for an option of the MFPC PWB.

D. I/F cable connection

1) Connect the I/F cable to the FAX unit of the MFPC PWB.

Attach the clamp (included in the package) and pass the I/F

cable through the clamp.

NOTE: Check to confirm that the connector is not inserted

obliquely.

Page 23

MX-B381/B401 MX-FXX3 (FACSIMILE EXPANSION KIT) 4 – 3

2) Cut off the notch section of the rear cabinet. Attach the I/F

cable to the rear cabinet and the frame, and fix the banding

band with the screw (M3) (included in the package).

3) Attach the controller cover, and fix it with the screw.

4) Attach the left cabinet by using care for the hook, and fix the

stopper.

5) Close the front cover and the tray 1.

E. Turn on the power of the main unit

1) Insert the power plug into the power outlet.

2) Turn ON the power switch.

3) Turn ON the power switch on the operation panel.

F. Set the destination and the logo type.

1) Switch the operation panel to the copy mode and use the key

operation [P], [], [C], and [] to enter the simulation mode.

2) Use the numeric keys to enter [26] in the main code entry

screen shown below and press the [START] key.

SIMULATION

INPUT A MAIN NUM BY 10-KEY, AND PRESS START

01: SCANNER CHECK

02: SPF CHECK

03: AFTER PROCESS CHECK

04: DESK/LCC CHECK

05: PANEL/LAMP CHECK

06: MFP CHECK

07: AGING

TEST

1/9

CLOSE

26

Page 24

MX-B381/B401 MX-FXX3 (FACSIMILE EXPANSION KIT) 4 – 4

3) Use the numeric keys to enter [06] in the sub-code entry

screen shown below and press the [START] key.

4) Press the desired destination on the touch panel and press

[EXECUTE] to highlight it.

5) Press the [CA] key or the [SYSTEM SETTINGS] key to exit

from the simulation mode. The message [PLEASE TURN

MAIN POWER OFF THEN ON] is displayed.

Restart the machine to change the destination.

• List of destinations

G. Clear the FAX related software switches.

1) Switch the operation panel to the copy mode and use the key

operation [P], [], [C], and [] to enter the simulation mode.

2) Use the numeric keys to enter [66] in the main code entry

screen shown below and press the [START] key.

3) Use the numeric keys to enter [02] in the sub-code entry

screen shown below and press the [START] key.

4) Use numeric keys [0] and [1] to enter the desired 8-digit country code.

After entry, press [SET], [EXECUTE], and [YES] in this order.

• Country code list screen

* Press the [DEST CODE] button on the initial screen to move to

the country code list screen.

To return to the input screen, press the [BACK] button.

Display Description

01: U.S.A U.S.A.

02: CANADA Canada

03: INCH Inch system, other destinations

04: JAPAN Japan

05: AB_B AB system (B5 size detectable), other destinations

06: EUROPE Europe

07: U.K. U.K.

08: AUS. Australia

09: AB_A AB system (A5 size detectable), other destinations

10: CHINA China

SIMULATION NO.26

INPUT A SUB NUM BY 10-KEY, AND PRESS START

01: RIGHT TRAY SETUP

02: SIZESETUP

03: AUDITOR SETUP

06: DESTINATION SETUP

10: NETWORK SCANNER TRIAL MODE SETUP

18: TONER SAVE MODE SETUP

30: CE MARK CONTROL SETTING

TEST

1/3

CLOSE

06

SIMULATION NO.26-06

DESTINATION SETUP

01:

TEST

05:

09:

03:

07:

02:

06:

10:

04:

08:

1/1

00

U.S.A.

AB_B

AB_A

CANADA

EUROPE

CHINA

INCH

U.K.

JAPAN

AUS.

CLOSE

EXECUTE

SIMULATION

INPUT A MAIN NUM BY 10-KEY, AND PRESS START

01: SCANNER CHECK

02: SPF CHECK

03: AFTER PROCESS CHECK

04: DESK/LCC CHECK

05: PANEL/LAMP CHECK

06: MFP CHECK

07: AGING

TEST

1/9

CLOSE

66

Country code list

JAPAN : 00000000 SWITZERLAND : 10100110

U.S.A. : 10110101 AUSTRIA : 00001010

AUSTRALIA : 00001001 INDONESIA : 01010100

U.K. : 10110100 THAILAND : 10101001

FR ANC E : 0 01111 01 MA LAYSI A : 011 011 00

GERMANY : 00000100 INDIA : 01010011

SWEDEN : 10100101 PHILIPPINES : 10001001

NE WZE AL AND : 0 1111110 HO NGKO NG : 01 010 00 0

CHINA : 00100110 RUSSIA : 10111000

SI N GA P ORE : 1 0 01110 0 SO UTH A FR I CA : 100 11111

TW : 11111110 SPAI N : 1 010 0 00 0

MIDDLEAND

NEAREAST

: 111111 0 1 PO RTU GUE S E : 1 0 00 1 011

SL OVAK I A : 111111 0 0 LU XEM B URG : 0 11 010 01

OT H ER 3 : 11111 0 11 BE LGI U M : 00 001111

FI NLA N D : 0 0 111100 C Z ECH : 0 010 1110

NORWAY : 10000010 HUNGARY : 01010001

DENMARK : 00110001 GREECE : 01000110

NE THE RL AND S : 0 1111011 PO LAN D : 1 000 10 10

ITALY : 01011001 BRAZIL : 00010110

SIMULATION NO.66

INPUT A SUB NUM BY 10-KEY, AND PRESS START

01: FAX SOFT SW. SETTING.

02: FAX SOFT SW. CLEAR.

03: FAX PWB MEMORY CHECK.

04: SIGNAL OUTPUT CHECK. (LEVEL MAX)

05: SIGNAL OUTPUT CHECK.(SOFT SW.)

06: PASS CODE PRINT OUT.

07: IMAGE MEMORY PRINT OUT.

TEST

1/5

CLOSE

02

SET

SIMULATION NO.66-02

CLOSE

FAX SOFT SW.CLEAR-U.S.A.

TEST

10110101PRESENT:

NEW:

SURE? YES

NO

EXECUTE

DEST CODE

SIMULATION NO.66-02

FAX SOFT SW.CLEAR

-

U.S.A.

JAPAN :00000000

AUSTRALIA :00001001

FRANCE :00111101

SWEDEN :10100101

U.S.A. :10110101

U.K. :10110100

GERMANY :00000100

NEWZEALAND :01111110

TEST

1/5

CLOSE

BACK

Page 25

MX-B381/B401 MX-FXX3 (FACSIMILE EXPANSION KIT) 4 – 5

H. Clear the image memory.

1) Switch the operation panel to the copy mode and use the key

operation [P], [], [C], and [] to enter the simulation mode.

2) Use the numeric keys to enter [66] in the main code entry

screen shown below and press the [START] key.

3) Use the numeric keys to enter [10] in the sub-code entry

screen shown below and press the [START] key.

4) In the sub menu screen shown below, press [EXECUTE] on

the touch panel.

After [YES] on the panel lights up, press it.

5) The screen shown below is displayed and memory clear operation is executed.

6) After several minutes, memory clear operation is completed

and the [YES] button goes out. Press the [CA] key to exit from

the simulation mode.

Then the main unit is automatically rebooted.

I. Line cable connection

1) Connect the line cable on the line to the modular jack indicated

as "LINE."

* When an external telephone is used, wind the line cable

around the ferrite core (included in the package) two turns,

and connect it to the modular jack indicated as "TEL."

* After connection, perform the setting of "External telephone

connection" of the system setting (administrator).

J. Installation completion check

1) Execute SIM 22-10 to check to confirm that the FAX box and

the FAX memory are properly installed.

When the FAX1 is properly connected, "MX-FXX3" is displayed.

When the FAX memory is properly connected, "AR-MM9" is

displayed.

SIMULATION

INPUT A MAIN NUM BY 10-KEY, AND PRESS START

01: SCANNER CHECK

02: SPF CHECK

03: AFTER PROCESS CHECK

04: DESK/LCC CHECK

05: PANEL/LAMP CHECK

06: MFP CHECK

07: AGING

TEST

1/9

CLOSE

66

SIMULATION NO.66

INPUT A SUB NUM BY 10-KEY, AND PRESS START

01: FAX SOFT SW. SETTING.

02: FAX SOFT SW. CLEAR.

03: FAX PWB MEMORY CHECK.

04: SIGNAL OUTPUT CHECK. (LEVEL MAX)

05: SIGNAL OUTPUT CHECK. (SOFT SW.)

06: PASS CODE PRINT OUT.

07: IMAGE MEMORY PRINT OUT.

TEST

1/5

CLOSE

10

SIMULATION NO.66-10

CLOSE

IMAGE MEMORY CLEAR.

TEST

SURE? YES NO

EXECUTE

SIMULATION NO.66-10

CLOSE

IMAGE MEMORY CLEAR.

TEST

SURE? YES NO

EXECUTE

App

r

oximately

1

0cm

SIMULATION NO.22-10

MACHINE SYSTEM

MACHINE : MX-B401

SPF : STANDARD

DESK : MX-CSX1

FINISHER : MX-FN12

FAX1:MX-FXX3

FAX MEMORY : AR-MM9

PS : MX-PKX5

XPS : MX-PUX1

SECURITY : MX-FR16U

AIMY : MX-AMX1

TEST

1/2

CLOSE

Page 26

MX-B381/B401 AR-PF1 (BARCODE FONT KIT) 5 – 1

MX-B401

Service Manual

[5] AR-PF1 (BARCODE FONT KIT)

1. Unpacking

A. Check the packed items

2. Installation

A. Turn off the power of the main unit

1) Turn OFF the power switch on the operation panel.

2) Check to confirm that the operation panel is turned OFF, and

then turn OFF the power switch.

3) Disconnect the power plug from the power outlet.

B. MFP PWB cover removal

1) Open the front cover and the paper feed tray 1.

2) Remove the stopper, slide the left cabinet to the front side and

remove.

3) Remove the screw, and remove the MFP PWB cover.

No. Packed part names Quantity

1 CD-ROM 1

2 Operation Manual 1

3 Bar code Font ROM 1

AR-PF1 barcode font ROM PWB

12

Page 27

MX-B381/B401 AR-PF1 (BARCODE FONT KIT) 5 – 2

C. Bar code Font ROM installation

1) Install the Bar code Font ROM.

D. MFP PWB cover installation

1) Install the MFP PWB cover.

2) Install the left cabinet.

3) Close the front cover and the tray 1.

E. Turn on the power of the main unit

1) Insert the power plug into the power outlet.

2) Turn ON the power switch.

3) Turn ON the power switch on the operation panel.

Page 28

MX-B381/B401 AR-PF1 (BARCODE FONT KIT) 5 – 3

F. PCL expansion font list check

1) PCL expansion font list check

Select the PCL expansion font list by the procedures described

in the printer test page in the system setup guide.

Check to confirm that the bar code font list is printed.

Font No. Font name

1 Code128TT-Regular

2 Code128-NarrowTT-Regular

3 Code128-WideTT-Regular

4 Code39HalfInch-Regular

5 Code39OneInch-Regular

6 Code39QuarterInch-Regular

7 Code39SmallHigh-Regular

8 Code39Slim-Regular

9 Code39SmallLow-Regular

10 Code39SmallMedium-Regular

11 Code39Wide-Regular

12 Codabar-Regular

13 Interleaved2of5-Regular

14 Interleaved2of5-Thin-Regular

15 OCR-A

16 OCR-B

17 OCR-B-C39-Regular

18 UPC-Half

19 UPC-Half-Bars

20 UPC-HalfMusic

21 UPC-HalfNarrow

22 UPC-HalfThin

23 UPC-Tall-Regular

24 UPC-TallBarsThin-regular

25 UPC-TallMusicThin-Regular

26 UPC-TallNarrow-Regular

27 UPC-TallThin-regular

28 ZipCodeBarcode-Regular

Page 29

MX-B381/B401 MX-FR16U (DATA SECURITY KIT) 6 – 1

MX-B401

Service Manual

[6] MX-FR16U (DATA SECURITY KIT)

1. Unpacking

A. Check the packed items

1) Check to confirm that all the parts are included in the package.

2. Installation

<Note before installation>

• To enable the data security function, the product key must be

acquired. (For the acquisition procedures of the product key,

inquire the distributor.)

• Before installing the data security kit, be sure to back up the data

stored in the memory (including the HDD) of the machine.

When the data security kit is installed, all the job data stored in

the memory (including the HDD) of the machine are deleted.

• When the printer lamp and the image send communication lamp

and the data lamp on the operation panel are lighted or blinking,

unprocessed data remain in the memory (including the HDD) of

the machine. In this case, perform all the output/send operations

so that no data remain in the machine, then perform installation.

(Check to confirm that the communication lamp on the operation

panel and the data lamp under it are not lighted and not blinking.)

A. Turn off the power of the main unit

1) Turn OFF the power switch on the operation panel.

2) Check to confirm that the operation panel is turned OFF, and

then turn OFF the power switch.

3) Disconnect the power plug from the power outlet.

B. MFP PWB cover removal

1) Open the front cover and the paper feed tray 1.

2) Remove the stopper, and shift the left cabinet to the front side

to remove.

No. Packed part names Quantity

1 PROGRAM ROM 1 1

2 PROGRAM ROM 2 1

3 Operation manual 1

4 USB memory (with the program data in it) 1

1

2

34

Page 30

MX-B381/B401 MX-FR16U (DATA SECURITY KIT) 6 – 2

3) Remove the screw, and remove the MFP PWB cover.

C. ROM replacement

1) Replace the ROM. (Install the accessory DSK ROM.)

D. MFP PWB cover installation

1) Install the MFP PWB cover.

2) Install the left cabinet.

3) Close the front cover and the tray 1.

E. DSK firmware installation

1) Insert the accessory USB memory into the USB slot of the

machine. (Use the USB I/F of the operation panel.)

2) When the power is turned ON, the main program error is displayed.

3) The above error message is displayed for 10 sec. Then the following message is displayed.

4) The machine enters the boot mode which indicates that there

is an error in the main program.

Main Program Error!!

Emergency Prog Init

Please wait

Version Check

IcM:UNUSUAL

Page 31

MX-B381/B401 MX-FR16U (DATA SECURITY KIT) 6 – 3

(1) Operations in the boot mode

When the machine is booted in the boot mode, the firmware version check, the firmware install, and the version-up operation can be performed.

When a HDD is installed to the machine and the above operation is performed, the firmware must be installed.

* In the boot mode, the following keys are used for operation. Note that the functions of the keys in the boot mode differ from those in the nor-

mal mode.

a. Key functions and operations in the boot mode

(2) Functions in the boot mode

The following two functions are available in the boot mode.

a. Selection of functions in the boot mode

There are two functions available in the boot mode. These modes

can be selected by pressing MENU key and BACK key.

b. Firmware install and version-up procedures in the boot

mode

1) Boot the machine in the boot mode. When the Version Check

display is indicated, press [MENU] key, and the machine

enters the Firm Update mode.

2) Insert the USB memory which includes the update firmware file

(SFU file) into the USB port of the machine, and press [OK]

key.

SFU file display

3) Select the firmware file (SFU file) of the target.

Use [UP] key and [DOWN] key to select the target file.

When [OK] key is pressed with the directory name displayed,

the control can enter the lower level directory. (However, onestep lower level)

When [BACK] key is pressed in the lower level directory, the

control can return to the upper level directory.

4) Press [OK] key.

The selected firmware file (SFU) is read. (It takes about 1

minute.)

Display of reading file data

Key name in the normal mode Key name in the boot mode Function

Start key [OK] key Performs the selected item or function.

Home key [MENU] key Selects a menu.

Clear key [BACK] key Selects a menu. (Serves as a cancel key in the execution check screen.)

Job status key [UP] key Selects an item.

System setting key [DOWN] key Selects an item.

Function Content

Firmware version check function Displays the firmware version of the ICU PWB, the SCU PWB, the PCU PWB, and the FAC PWB.

Firmware install (update) function Installs (revises) the firmware by transmitting data from the PC which is connected to the ICU PWB, the SCU PWB, the

PCU PWB, the FAX PWB, and other options with the USB memory or the USB cable.

JOB STATUS

IMAGE SEND

HOME

PRINT

READY

DAT A

DAT A

LINE

SYSTEM

SETTINGS

LOGOUT

DOWN keyUP key BACK key

MENU key OK key

Version Check

IcM:UNUSUAL

Firm Update

From USB Memory

MENU key

BACK key

MENU key

BACK key

Firm Update

From USB Memory

Firm Update

> 0100P200.sfu

Firm Update

Reading Data

Page 32

MX-B381/B401 MX-FR16U (DATA SECURITY KIT) 6 – 4

5) After completion of reading, the firmware is installed (updated).

(It takes about 5 - 6 minutes.)

Display of firmware install (Update) process

* The abbreviated name of the firmware which is currently

installed (updated) is displayed sequentially.

* The screen may flash instantaneously during the install

(update) process. This is a normal operation.

6) Check the result of install (update) of the firmware.

Use [UP] key and [DOWN] key to check the results of install

(update) of all the firmware programs.

Display of firmware update results

OK: Update success

NG: Update failed

Not Update: The update process is not executed.

Cause of Update process not executed:

The option unit for the target firmware is not connected.

7) Turn OFF the power to terminate the boot mode.

8) Use SIM22-05 to check to confirm that the DSK firmware has

been installed.

F. Preparation for validating the DSK

1) To validate the DSK, enter the product key by the key operation on the machine.

a) Press the [SYSTEM SETTINGS] key on the operation

panel.

b) Enter page 2/2 of the system setting, and touch [Product

key input] key.

c) Touch [Data security kit] key.

d) Enter the product key with numeric key (10-key), and

touch [Registration] key.

2) When inputting the product key is completed, check to confirm

that "Turn on the power again" is displayed, and turn OFF the

power switch and the main power switch, and then turn ON

them again.

Firm Update

IcuM

Firm Updat

IcuM

Firm Updat

IcuM

Firm Updat

IcuM

Page 33

MX-B381/B401 MX-FWX1 (INTERNET FAX EXPANSION KIT) 7 – 1

MX-B401

Service Manual

[7] MX-FWX1 (INTERNET FAX EXPANSION KIT)

1. Unpacking

A. Check the packed items

2. Installation

<Note before installation>

• In order to enable the Internet Fax send function, the product key

must be acquired.

• In order to specify the address of the Internet Fax with the PC-

FAX driver, the PC-FAX driver must be updated by the Internet

Fax expansion kit.

A. Preparation for enabling the Internet Fax send

function

1) In order to enable the Internet Fax send function, enter the

product key by the key operation on the operation panel.

a) Press the system setting key on the operation panel.

b) Select page 2/2 of the system setting, and touch [Product

key input] key.

c) Touch [Internet Fax expansion kit] key.

d) Enter the product key with numeric key (10-key), and

touch [Registration] key.

2) After completion of entry of the product key, turn OFF the

power switch on the operation panel. Turn OFF the main

power switch, then turn ON the power switch and the main

power switch again.

* After completion of 1) and 2), the Internet Fax send function

from the main unit becomes enable. To enable the Internet

Fax send with the PC-FAX driver, the following steps 3) and

4) are required.

3) Use the CD-ROM packed together with the machine to install

the PC-FAX driver.

For installing procedures, refer to the software setup guide.

4) Update the PC-FAX driver with the CD-ROM packed together

with the machine.

* Install and setting of the driver to the PC server must be per-

formed by the user or by the request from the user.

B. Operation check of the Internet Fax send

function

1) After completion of entry of the product key, check to confirm

that the Internet Fax send is performed normally from the

machine.

2) After completion of update of the PC-FAX driver, press the

print button on the test page of the PC-FAX driver to check to

confirm that the Internet Fax send is performed normally.

No. Packed part names Quantity

1 CD-ROM 1

2 Product key sheet 1

12

Page 34

MX-B381/B401 MX-PUX1 (XPS EXPANSION KIT) 8 – 1

MX-B401

Service Manual

[8] MX-PUX1 (XPS EXPANSION KIT)

1. Unpacking

A. Check the packed items

2. Installation

<Note before installation>

To enable XPS, an expansion memory (MX-SMX3) must be

installed.

To install an expansion memory, refer to the descriptions of "[12]

MX-SMX3" on this manual.

A. Preparation for enabling XPS

1) To enable XPS, enter the product key by the key operation of

the copier machine.

a) Press the system setting key on the operation panel.

b) Select page 2/2 of the system setting, and touch [Product

key input] key.

c) Touch [XPS expansion kit] key.

d) Enter the product key with numeric key (10-key), and

touch [Registration] key.

2) After completion of entry of the product key, turn OFF the

power switch on the operation panel. Turn OFF the main

power switch, then turn ON the power switch and the main

power switch again.

3) Use the CD-ROM packed together with the machine to install

the XPS driver.

For installing procedures, refer to the software setup guide.

Installation of the driver must be performed by the user or the

serviceman with assistance or the user.

No. Packed part names Quantity

1 CD-ROM 1

2 Operation manual 1

1 2

APPLICATION

NUMBER

MACHINE

SERIAL

NUMBER

PRODUCT

KEY

Please keep below important information.

This information will use for other products.

Page 35

MX-B381/B401 MX-AMX1 (APPLICATION INTEGRATION MODULE) 9 – 1

MX-B401

Service Manual

[9] MX-AMX1 (APPLICATION

INTEGRATION MODULE)

1. Unpacking

A. Check the packed items

2. Installation

<Note before installation>

To enable the Application Integration Module function, the product

key must be acquired.

A. Make preparations to enable the Application

Integration Module function.

1) To enable the Application Integration Module function, enter

the product key by the key operation of the operation panel.

a) Press the system setting key on the operation panel.

b) Select page 2/2 of the system setting, and touch [Product

key input] key.

c) Touch [Application expansion kit] key.

d) Enter the product key with numeric key (10-key), and

touch [Registration] key.

2) After entering the product key information, turn OFF the power

switch and the main power switch of the machine, and turn

them ON again. (For the models with the main power switch

only, turn OFF/ON the main power switch only.)

B. Check the operation of the Application

Integration Module function.

1) Send image data and meta data by referring to MX-AMX1

GETTING STARTED GUIDE (included in package). Check to

confirm that image data and meta data are properly received.

No. Packed part names Quantity

1 CD-ROM 2

2 MX-AMX1 GETTING STARTED GUIDE 1

3 Sharpdesk license kit Operation Manual 1

12 3

Page 36

MX-B381/B401 MX-AMX2 (APPLICATION COMMUNICATION MODULE) 10 – 1

MX-B401

Service Manual

[10] MX-AMX2 (APPLICATION

COMMUNICATION MODULE)

1. Unpacking

A. Check the packed items

2. Installation

<Note before installation>

* To enable the external account kit, the product key must be

acquired.

A. Make preparations for enabling the Application

Communication Module

To enable the Application Communication Module, enter the product key by key operations on the operation panel.

1) Press the [SYSTEM SETTINGS] key.

2) Touch the [Admin Password] key.

3) Touch the [Password] key and enter the administrator password.

4) Touch the [OK] key.

5) Touch the [Product Key] key.

You may have to scroll down the screen to show this key.

6) Touch the [Application Communication Module] key.

7) Enter the product key with the 10-key, and touch [OK] key.

• The product key can be entered from the Web page.

For details, refer to [HELP] on the right upper side of the Web

page.

B. OSA Settings

1) By performing procedure A, "OSA setting" key is added to the

menu screen of the system setting or the key operator program.

2) When "OSA setting" key is touched, the menu below is displayed.

3) When the [Default Display Setting] key is touched, the screen

for setting the default display that appears when the [DOCUMENT FILING] key is pressed will appear.

• To set the base screen of document filing as the default dis-

play, touch the [Document Filing] key.

• To set the external application selection screen as the

default display, touch the [OSA] key.

4) After selecting the setting, touch the [OK] key.

• "Default Display Setting" also appears in "Document Filing

Settings" in the system settings (administrator).

• If the [CA] key is pressed in document filing mode or OSA

mode, the base screen of that mode will appear regardless

of the default display setting.

C. External application setup

1) Click the [Login] button that appears in the upper right-hand

corner of the Web page.

2) Select [Administrator] in [Login Name] and then enter your

password.

3) Click [External Applications Setup] in the menu frame.

4) Configure the standard application settings.

• Up to 8 standard applications can be stored.

• For each setting item, refer to [Help].

No. Packed part names Quantity

1 CD-ROM 1

2 Operation manual 1

12

Page 37

MX-B381/B401 MX-AMX3 (EXTERNAL ACCOUNT MODULE) 11 – 1

MX-B401

Service Manual

[11] MX-AMX3 (EXTERNAL

ACCOUNT MODULE)

1. Unpacking

A. Check the packed items

2. Installation

<Note before installation>

* To enable the external account kit, the product key must be

acquired.

A. Make preparations for enabling the external

account kit.

1) To enable the external account kit, enter the product key by

key operations on the operation panel.

a) Press [SYSTEM SETTINGS] key.

b) Touch [Administrator Password] key.

c) Touch [Password] key and enter the administrator pass-

word.

d) Touch [OK] key.

e) Scroll the screen, and touch [Product Key] key.

f) Touch [External Account Module] key.

g) Enter the product key with 10-key, and touch [OK] key.

• The product key can be entered from the Web page. For

details, refer to [HELP] on the right upper side of the Web

page.

2) Make the OSA setting.

a) By the procedure of 1), "OSA setting" key is added to the

menu screen of the system setting or the key operator

program.

b) When "OSA setting" key is touched, the menu below is

displayed.

c) When [External Account Setting] key is touched, the

screen for setting the calculation by the external application and for enabling user authentication is displayed.

(The two settings are linked together.)

• When the check box of [External Account Management

is Enabled] is checked:

The result of the job completion is notified to the external application set on the Web page. (The default is

"Disabled.")

• If the check box is OFF, check cannot be made.

• When the check box of [Authentication by the External

Account Application is Enabled] is checked:

When the machine is booted, the login screen can be

acquired from the application set on the Web page.

(The default is "Disabled.")

d) After setting, when [OK] key on the force account setting

screen is touched, the message to urge rebooting of the

machine is displayed. To enable the setting, touch [OK]

key and reboot the machine.

B. Set the external application.

1) Click [Login] button on the right upper side of the Web page.

2) Select [Administrator] from [Login Name] and enter the password.

3) Click [External Application Setting] on the menu frame.

4) Click [External Account].

5) Set the external account application.

• For each setting item, refer to [HELP]. To enable the setting

on the Web page, reboot the machine.

No. Packed part names Quantity

1 CD-ROM 1

2 Operation manual 1

12

Page 38

MX-B381/B401 MX-SMX3 (EXPANSION MEMORY BOARD) 12 – 1

MX-B401

Service Manual

[12] MX-SMX3 (EXPANSION MEMORY BOARD)

1. Unpacking

A. Check the packed items

2. Installation

A. Turn off the power of the main unit

1) Turn OFF the power switch on the operation panel.

2) Check to confirm that the operation panel is turned OFF, and

then turn OFF the power switch.

3) Disconnect the power plug from the power outlet.

B. Controller cover and left cabinet removal

1) Open the front cover and the tray 1.

2) Remove the stopper, and slide the left cabinet to the front side

to remove.

3) Remove the screw, and remove the controller cover.

No. Packed part name Quantity

1 Expansion memory board 1

1

Page 39

MX-B381/B401 MX-SMX3 (EXPANSION MEMORY BOARD) 12 – 2

C. Installation of an expansion memory board

1) Install an expansion memory board to the DIMM2 slot of the

MFPC PWB.

* Note for installation

a) Insert the expansion memory board into the slot diago-

nally from below.

NOTE: When handling an expansion memory board, be

careful not to touch the terminals.

NOTE: Avoid diagonal insertion of the expansion memory

board for the slot.

NOTE: Do not push one end of the expansion memory

board by one hand.

b) Hold the both ends of the expansion memory board with

both hands, and put down the expansion memory so that

it is vertical to the PWB.

At that time, check to confirm that the hooks on the left

and the right sides of the slot are securely locked.

D. Installation of the controller cover and the left

cabinet

1) Attach the controller cover, and fix it with the screw.

Page 40

MX-B381/B401 MX-SMX3 (EXPANSION MEMORY BOARD) 12 – 3

2) Attach the left cabinet by using care for the hook, and fix the

stopper.

3) Close the front cover and the tray 1.

E. Turn on the power of the main unit

1) Insert the power plug into the power outlet.

2) Turn ON the power switch.

3) Turn ON the power switch on the operation panel.

Page 41

MX-B381/B401 DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MAIN UNIT 13 – 1

MX-B401

Service Manual

[13] DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MAIN UNIT

1. Heater kit contents list

2. Installation

<Note before installation>

Start installation after checking that the LINE indicator and the

DATA indicator below it on the operation panel are neither lit nor

blinking.

A. Turn off the power of the main unit

1) Turn OFF the power switch on the operation panel.

2) Check to confirm that the operation panel is turned OFF, and

then turn OFF the power switch.

3) Disconnect the power plug from the power outlet.

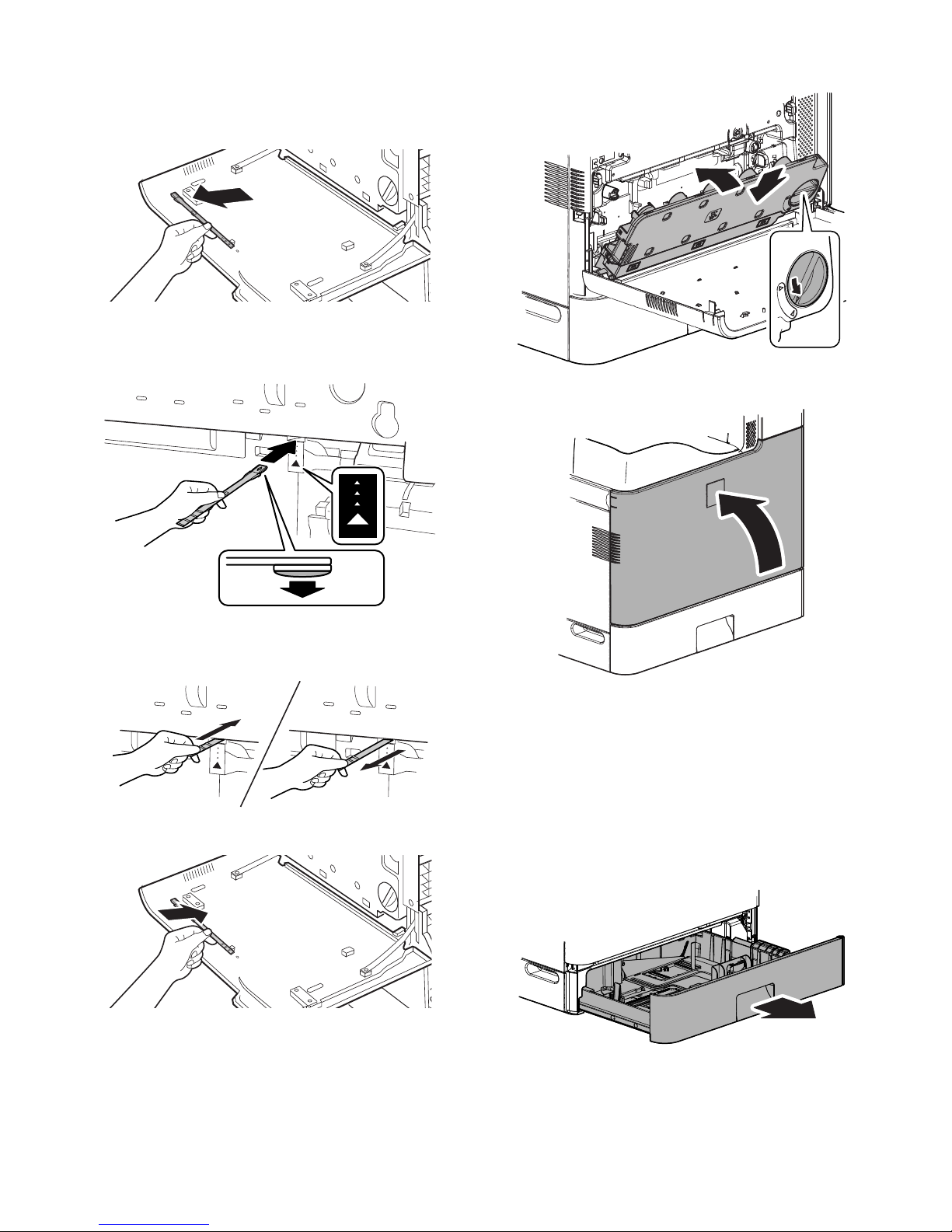

B. Remove the rear cabinet of the machine.

1) Remove five screws from the rear cabinet.

2) Release the locks at the bottom.

3) Remove the rear cabinet from the machine.

No. Part Name

DKIT-0416FCZZ DKIT-0417FCZZ

120V series 230V series

Part code Qty. Part code Qty.

1 Dehumidifier heater unit CPLTM7785FC51 1 CPLTM7785FC52 1

2 Heater switch label EX Pa TLABZ5256FCZZ 1 TLABZ5256FCZZ 1

3 "Caution: HOT" label TLABZ5459FCZZ 1 TLABZ5459FCZZ 1

4 WH harness DHAI-4367FCPZ 1 DHAI-4367FCPZ 1

5 Saddle LHLDW1970FCPZ 1 LHLDW1970FCPZ 1

6 Dehumidifier heater switch QSW-C9294QCZZ 1 QSW-C9294QCZZ 1

7 WH PWB CPWBF1858FC31 1 CPWBF1858FC32 1

8 PWB Mylar sheet PSHEP0620FCPZ 1 PSHEP0620FCPZ 1

9 PWB supporter LSUPP0117FCZZ 3 LSUPP0117FCZZ 3

10 M3 x 6 screw XHBS730P06000 1 LBNDJ0037FCZ1 2

11 WH earth harness 200 DHAI-4390FCPZ 1

12 M3 x 8 screw XBPS730P08KS0 1

Page 42

MX-B381/B401 DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MAIN UNIT 13 – 2

C. Install the WH PWB unit.

1) Insert three PWB supporters (No.9) into the paper feed drive

unit.

* Insert the lead edge with flange into the metal plate.

2) Insert the PWB Mylar sheet (No.8) into the PWB supporter.

3) Insert the WH PWB (No.7) into the PWB supporter.

Check to confirm that the PWB supporter hook is securely

engaged with the WH PWB.

4) Insert the saddle (No.5) into the WH PWB.

D. Attach the WH harness (No.4).

1) Attach the WH harness to the wire saddle. (4 positions)

2) Connect the connector. (4 positions).

3) Pass the WH harness under the metal plate and extend it out

from the square hole in the metal plate.

E. Attach the dehumidifier heater switch (No.6).

1) Attach the dehumidifier heater switch to the connector.

* Since there is no designation for polarity, insert into any ter-

minal.

* Insert fully to the bottom until it clicks.

2) Insert the dehumidifier heater switch into the square hole in the

metal plate.

* Insert so that the connector connected to the dehumidifier

heater switch is on the right side when viewed from the rear.

F. Install the WH earth harness 200. (200V series

only)

1) Remove the protection Mylar from the dehumidifier heater unit.

2) Install the WH earth harness 200 to the plate of the dehumidifier heater unit with the M3 x 6 screw (No. 10).

In this case, use care so that the terminals of the WH earth

harness 200 do not extend from the edges of the plate.

3) Install the protection Mylar which was removed in the procedure 1).

In this case, pass the harness of the dehumidifier heater unit

and the WH earth harness 200 through the square hole of the

protection Mylar.

Page 43

MX-B381/B401 DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MAIN UNIT 13 – 3

G. Installation of the dehumidifier heater unit to

the main unit.

1) Pull out the paper tray, and pass the harness of the dehumidifier heater through the hole in the upper section of the lift-up

unit.

For the 200V series, pass the WH earth harness 200 through

the hole in the upper section of the lift-up unit.

2) Engage the pawls of the dehumidifier heater unit with the

square holes (4 positions) in the metal plate of the main unit.

3) Fix the dehumidifier heater installation plate FT with the M3 x 6

screw (No.10).

* At that time, arrange so that the rear section of the dehumid-

ifier heater installation plate FT is on the lift-up unit.

4) Pass the harness of the dehumidifier heater through the wire

saddle.

5) Connect the connector of the dehumidifier heater harness to

CN3 of the WH PWB.

6) Pass the WH earth harness 200 through three clamps of the

machine. (200V series only)

7) Fix the terminal of the WH earth harness 200 to the machine

frame with the M3 x 8 screw (No. 12).

When installing the dehumidifier heater kit to the MX-CSX1/

CSX2, hereinafter perform the operations described on the

chapter of "[15] DEHUMIDIFIER HEATER KIT (SERVICE

PARTS) OF THE MX-CSX1/CSX2."

When the MX-CSX1/CSX2 is not installed, or when the MXCSX1/CSX2 is installed but the dehumidifier heater kit is not

installed to the MX-CSX1/CSX2, perform the procedures from

item H below.

H. Dehumidifier heater resistance check

1) Insert a tester between pin 1 and pin 3 of CN3 of the WH PWB,

and check to confirm that the resistance is as shown below.

120V series: 2.304K - 3.456K

230V series: 4.232K - 6.348K

Lift up unit

200V Only

Page 44

MX-B381/B401 DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MAIN UNIT 13 – 4

I. Addition of the holes for the dehumidifier

heater switch

1) Cut off the notch of the square hole for the dehumidifier heater

switch on the rear cabinet.

2) Attach the heater switch label EX Pa (No.2) to the concaved

section of the rear cabinet.

* Be careful of the attachment direction of the heater switch

label EX Pa.

3) Cut the inside section of the rear cabinet where the harness

passes through.

J. High temperature caution label attachment

1) Where the "Caution: HOT" label will be placed. (see illustration). Clean with alcohol.

2) Attach the "Caution: HOT" label to the paper tray.

K. Attach the rear cabinet.

3. Check after installation

1) Turn ON the dehumidifier heater switch. (Press the upper section of the switch.)

2) Measure the resistance between the earth terminal and the AC

terminal at the lead edge of the AC cord with a tester, and

check to confirm that the resistance is infinite.

* Check the resistance between the non-grounding side (Live)

and the grounding side and between the non-grounding side

(Neutral) and the grounding side.

* If there is conduction between the grounding terminal and

the AC terminal, the harness on the primary side may be in

contact with the grounding wire (the wire may be pinched or

in some trouble). In this case, disassemble it again and

check to confirm that there is no pinching or wiring mistake.

0 - 0.5mm

0 - 0.5mm

Page 45

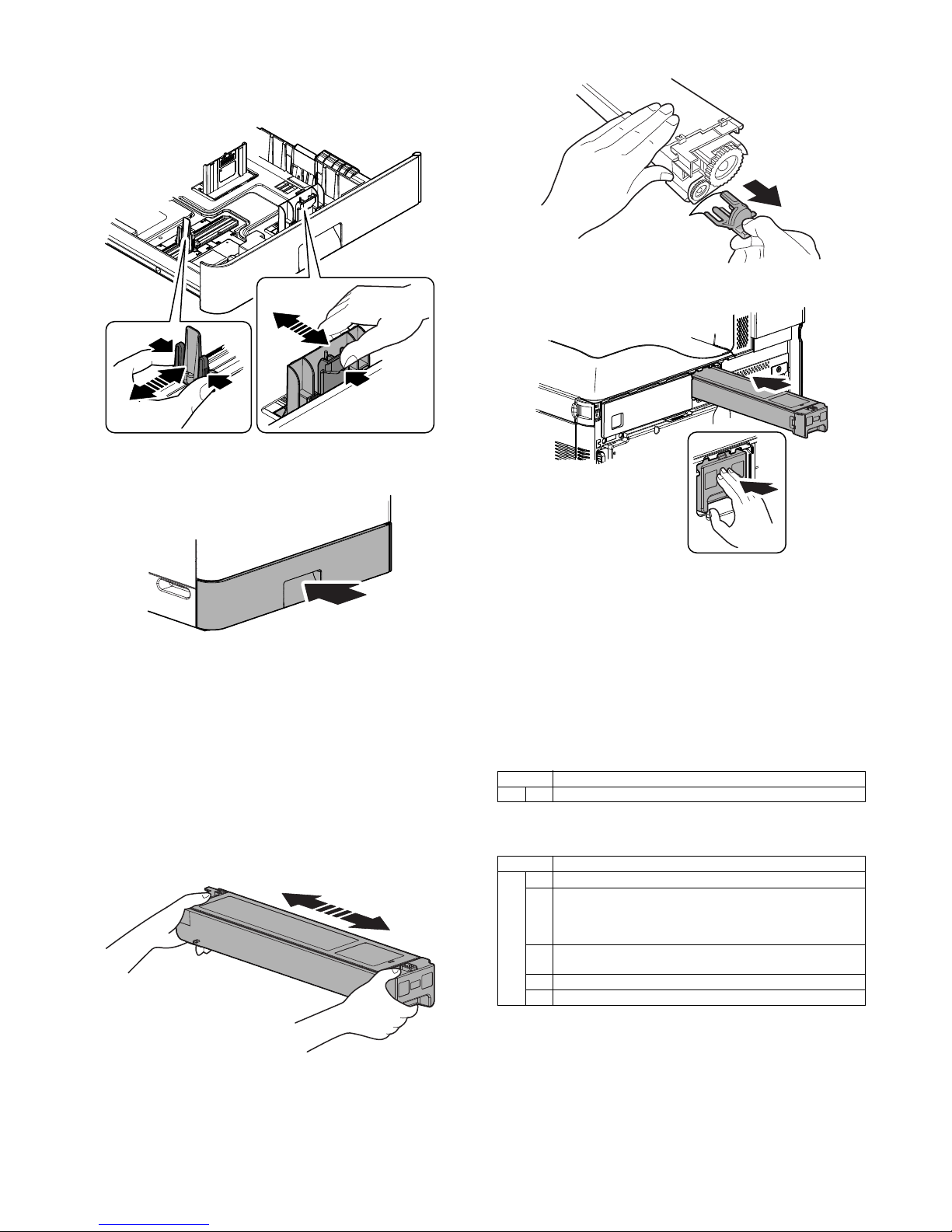

MX-B381/B401 DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MX-CSX1/CSX2 14 – 1

MX-B401

Service Manual

[14] DEHUMIDIFIER HEATER KIT (SERVICE PARTS) FOR THE MX-CSX1/

CSX2

1. Heater kit contents list

2. Installation

<Note before installation>

• Confirm that the line and data indicator (below) on the operation

panel are not lite or blinking. Then turn off machine.

• The dehumidifier heater kit for the MX-CSX1/CSX2 cannot be

installed without the main unit dehumidifier kit.

Be sure to install the dehumidifier heater kit for the main unit first,

and then install the dehumidifier heater kit for the MX-CSX1/

CSX2.

• After completion of the procedure in item G of the installation procedures of the dehumidifier heater kit for the main unit, perform

the following procedures.

A. Desk cabinet removal

* The descriptions are made on the MX-CSX1. If the MX-CSX2 is

also installed, perform the same procedures for the MX-CSX2.

1) Pull out the paper tray, and loosen the hand screw which is on

the left side when viewed from the front.

2) Slide the desk left cabinet to the front side.

3) Remove a screw.

4) Open the desk right side cabinet.

No. Part Name

DKIT-0418FCZZ DKIT-0419FCZZ DKIT-0420FCZZ

120V series 127V series 230V series

Part code Qty. Part code Qty. Part code Qty.

1 Desk dehumidifier heater unit CHLDZ2043FC51 1 CHLDZ2043FC52 1 CHLDZ2043FC53 1

2 PWB supporter (KGLS-3S) LBSHZ2029SCZZ 4 LBSHZ2029SCZZ 4 LBSHZ2029SCZZ 4

3 Mini clamp (UAMS-07-0) LHLDW0734FCZZ 2 LHLDW0734FCZZ 2 LHLDW0734FCZZ 2

4 Heater interface PWB CPWBF1862FC31 1 CPWBF1862FC31 1 CPWBF1862FC31 1

5 M4 x 10P tight screw XEBS740P10000 4 XEBS740P10000 4 XEBS740P10000 4