Page 1

SERVICE MANUAL

CODE: 00ZMX3501/S1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

DUPLEX SINGLE PASS FEEDER

(DSPF)

MX-3501N

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . .2-1

[3] EXTERNAL VIEW AND INTERNAL

STRUCTURE

1. Identification of each section and

functions . . . . . . . . . . . . . . . . . . . . . . . .3-1

[4] OPERATIONAL DESCRIPTIONS

1. Document size detection . . . . . . . . . . .4-1

2. Timing chart . . . . . . . . . . . . . . . . . . . . .4-1

[5] DISASSEMBLY AND ASSEMBLY

1. Exterior section. . . . . . . . . . . . . . . . . . .5-1

2. Paper feed section . . . . . . . . . . . . . . . .5-2

3. Upper transport section . . . . . . . . . . . .5-6

4. Lower transport section . . . . . . . . . . . .5-8

5. Optical section . . . . . . . . . . . . . . . . . .5-12

6. Paper exit section . . . . . . . . . . . . . . . .5-16

7. Drive section. . . . . . . . . . . . . . . . . . . .5-17

8. Others . . . . . . . . . . . . . . . . . . . . . . . . .5-19

[6] MAINTENANCE

1. Maintenance system table . . . . . . . . . .6-1

[7] ADJUSTMENTS

1. Levelness adjustment . . . . . . . . . . . . . .7-1

2. Skew adjustment

(front surface mode) . . . . . . . . . . . . . . .7-1

3. Skew adjustment

(back surface mode) . . . . . . . . . . . . . . .7-2

4. Image focus adjustment

(front surface mode) . . . . . . . . . . . . . . .7-3

MODEL

5. Image focus adjustment

(back surface mode) . . . . . . . . . . . . . . 7-3

6. Image magnification in the main

scanning direction adjustment

(front surface mode) . . . . . . . . . . . . . . 7-4

7. Image magnification in the main

scanning direction adjustment

(back surface mode) . . . . . . . . . . . . . . 7-4

8. Image magnification in the sub

scanning direction adjustment . . . . . . . 7-4

9. Scanned image off-center

adjustment (front surface mode) . . . . . 7-5

10. Scanned image off-center

adjustment (back surface mode) . . . . . 7-5

11. Original scan position adjustment . . . . 7-6

12. Copied image loss/void area

adjustment . . . . . . . . . . . . . . . . . . . . . . 7-6

13. Paper width sensor for the paper

feed tray adjustment . . . . . . . . . . . . . . 7-7

14. Auto void adjustment

(Service installation adjustment) . . . . . 7-8

15. Shading adjustment. . . . . . . . . . . . . . . 7-9

16. CCD gamma adjustment

(CCD calibration) . . . . . . . . . . . . . . . . 7-10

[8] SELF DIAG AND TROUBLE CODE

1. Trouble code and troubleshooting . . . . 8-1

[9] ELECTRICAL SECTION

1. Electrical and mechanism relation

diagram . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Block diagram . . . . . . . . . . . . . . . . . . . 9-4

3. Actual wiring chart . . . . . . . . . . . . . . . . 9-5

MX-4501N

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

MX3501N

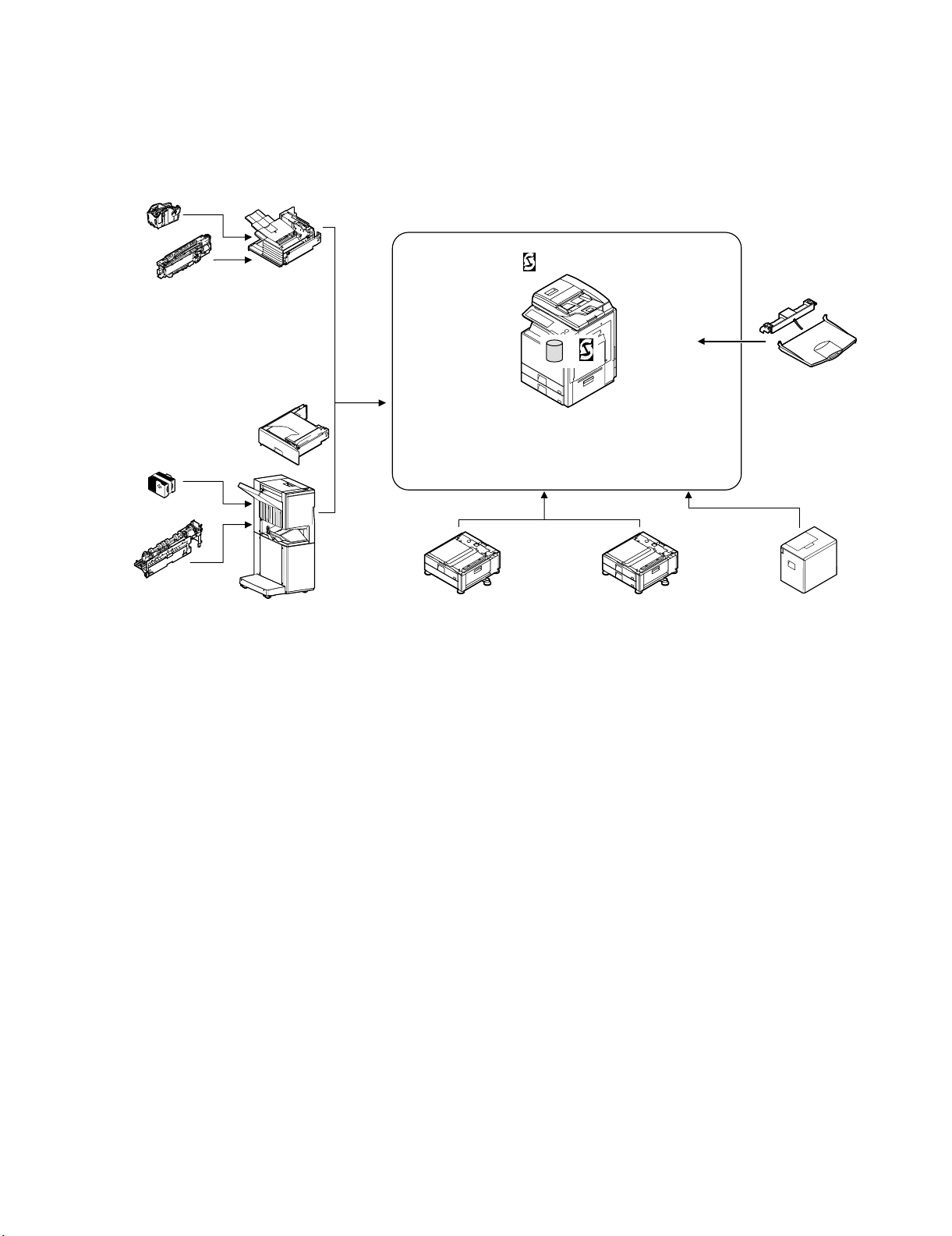

[1] PRODUCT OUTLINE

This model is the document feed unit which allows scanning duplex

document surfaces at the same time. It is installed to the digital

copier machine. It scans duplex document surfaces at the same

time and transport it automatically to make continuous copying.

Service Manual

Staple cartridge

(Approx. 5000 x 3)

(MX-SCX1)

Punch module

●

2-hole (MX-PNX1A)

●

3-hole (MX-PNX1B)

●

4-hole (MX-PNX1C)

●

4-hole (broad space)

Staple cartridge

(Approx. 5000 x 3)

(AR-SC2)

Punch module

●

2-hole (AR-PN1A)

●

3-hole (AR-PN1B)

●

4-hole (AR-PN1C)

●

4-hole (broad space)

(AR-PN1D)

(MX-PNX1D)

Finisher

(MX-FNX1)

Paper pass unit

(MX-RBX1)

Saddle stitch finisher

(MX-FNX2)

Stand/1x500 sheet

paper drawer

(MX-DEX3)

DSPF

HDD

Copier/Printer

/Scanner model

(MX-3501N)

(MX-4501N)

Stand/2x500 sheet

paper drawer

(MX-DEX4)

Exit tray unit

(MX-TRX2)

Large capacity tray

(MX-LCX1)

MX3501N PRODUCT OUTLINE 1 – 1

Page 3

MX3501N

[2] SPECIFICATIONS

Form DSPF (Duplex single pass feeder)

Scan speed Monochrome (A4/8.5 x 11) Color (A4/8.5 x 11)

Copy 1-sided: 45 sheets/minute (600 x 300dpi, 1bit)

Fax 1-sided: 60 sheets/minute (200 x 200dpi, 1bit)

Scanner 1-sided: 60 sheets/minute (200 x 200dpi, 1bit)

Internet Fax 1-sided: 60 sheets/minute (200 x 200 dpi, 1bit)

Document standard

location

Document sizes Inch type-1: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 8.5 x 5.5, A4, A3

Document weights 1-side:

Document carrying

capacity

Types of document that

may not be transported

Paper detection Yes

Paper detection size Auto detection (Switching one type of detection unit through system setting)

Paper feeding direction Right hand feeding

Document inversion No

Simultaneous doublesided scanning

2-sided: 60 pages/minute (600 x 300dpi, 1bit)

2-sided: 60 pages/minute (200 x 200dpi, 1bit)

2-sided: 60 pages/minute (200 x 200dpi, 1bit)

2-sided: 60 pages/minute (200 x 200 dpi, 1bit)

Center standard (Rear one-side standard for random feeding)

Inch type-2: 11 x 17, 8.5 x 13, 8.5 x 11, 8.5 x 11R, 8.5 x 5.5, A4, A3

AB type-1: A3, B4, A4, A4R, B5, B5R, A5, 8.5 x 11, 8.5 x 14, 11 x 17

AB type-2: A3, B4, A4, A4R, B5, B5R, A5, 8.5 x 11, 216 x 330, 11 x 17

AB type-3: 8K, A4, A4R, B4, 16K, 16KR, A5, 8.5 x 11, 216 x 330, 11 x 17

Long paper: 800mm (Monochrome 2 levels only)

Mixed feeding (same type / same width) possible

Random feeding (feeding of different types / different widths)

Only the following combinations of 2 size types are allowed: A3 and B4; B4 and A4R; A4 and B5; B5 and A5; and 11-inch and 8.5-inch.

Thin paper: 35 – 49g/m

Plain paper: 50 – 128g/m

2-side: 50 – 105 g/m

Maximum: 150 sheets (80g/m

The following documents are NOT allowed:

OHP, second original drawing, tracing paper, carbon paper, thermal paper, wrinkled / broken / torn document, document with cuts and

pastes, documents printed by an ink ribbon, and perforated document except 2-punched / 3-punched (Perforated document by punch

unit is allowed.)

Inch-1: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5, A4, A3

Inch-2: 11 x 17, 8.5 x 13, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5, A4, A3

AB-1: A3, B4, A4, A4R, B5, B5R, A5, 8.5 x 11, 8.5 x 14, 216 x 330, 11 x 17

AB-2: A3, B4, A4, A4R, B5, B5R, A5, 8.5 x 11, 216 x 330, 11 x 17

AB-3: 8K, B4, A4, A4R, 16K, 16KR, A5, 8.5 x 11, 216 x 330, A3

Allowed

2

(9 – 13 lbs)

2

(13 – 34 lbs)

2

(13 – 28 lbs)

2

, 21lbs), or Maximum: 19.5 mm, 3/4 inch or less

Service Manual

1-sided: 35 sheets/minute (600 x 600dpi, 4bit)

2-sided: 35 pages/minute (600 x 600dpi, 4bit)

N/A

1-sided: 35 sheets/minute (200 x 200dpi, 8bit)

2-sided: 35 pages/minute (200 x 200dpi, 8bit)

N/A

MX3501N SPECIFICATIONS 2 – 1

Page 4

MX3501N

[3] EXTERNAL VIEW AND INTERNAL STRUCTURE

Service Manual

1. Identification of each section and functions

A. Internal structure

3

9

No. Name Function/ Operation

1 Pickup roller Picks up a document and feeds it to the paper feed roller.

2 Paper feed roller Performs the paper feed operation of documents.

3 Separation roller Separate a document to prevent against double-feed.

4 No. 1 resist roller (Drive) Performs resist of document transport.

5 No. 1 resist roller (Idle) Applied a pressure to paper and the resist roller, and provides transport power of the resist roller to paper.

6 Transport roller 1 (Drive) Transports paper from No. 1 resist roller to No. 2 resist roller.

7 Transport roller 1 (Idle) Applied a pressure to paper and the transport roller, and provides the transport power of the transport roller to paper.

8 No. 2 resist roller (Drive) Make synchronization between the lead edge of a document and the scan start position.

9 No. 2 resist roller (Idle) Applies a pressure to paper and the resist roller, and provides transport power of the resist roller to paper.

10 Platen roller Applies a pressure to paper to prevent against fluctuations on operation of paper.

11 Transport roller 2 (Drive) Transports paper from the platen roller to the transport roller 3.

12 Transport roller 2 (Idle) Applies a pressure to paper and the transport roller and provides transport power of the transport roller to paper.

13 Transport roller 3 (Drive) Transports paper from the transport roller 2 to the paper exit roller.

14 Transport roller 3 (Idle) Applies a pressure to paper and the transport roller and provides transport power of the transport roller to paper.

15 Paper exit roller (Drive) Discharges paper.

16 Paper exit roller (Idle) Applies a pressure to paper and the paper exit roller and provides transport power of the paper exit roller to paper.

10 12 14 168 11 13 15

1257 46

MX3501N EXTERNAL VIEW AND INTERNAL STRUCTURE 3 – 1

Page 5

B. Sensors, switches

2

3 7 8 91

54 6

10

11

4

12

13

15

7

8

9

11 12

13 15

1410 16 17

1

3

2

6

5

14

16

17

Signal

No.

name

1 SPPD2 DSPF paper pass sensor 2 Transmission type Detects pass of the paper. L when paper is detected.

2 SPPD1 DSPF paper pass sensor 1 Transmission type Detects pass of the paper. L when paper is detected.

3 SCOV DSPF upper door open/close sensor Transmission type Detects open/close of the upper door. L when the upper door is open.

4 SPRDMD DSPF document random sensor Transmission type Detects the paper size in random paper feed. L when paper is detected.

5 STUD DSPF paper feed tray upper limit

6 SPED1 DSPF document upper limit sensor Transmission type Detects the upper limit of the DSPF document. L when paper is detected.

7 SPWS DSPF document width sensor Volume resistor Detects the document width of the paper feed

8 SPLS1 DSPF document length detection

9 SPLS2 DSPF document length detection

10 SPPD3 DSPF paper pass sensor 3 Transmission type Detects pass of the paper. L when paper is detected.

11 SPPD4 DSPF paper pass sensor 4 Transmission type Detects pass of the paper. L when paper is detected.

12 SOCD DSPF open/close sensor Transmission type Detects open/close of the DSPF unit. L when the DSPF unit is open.

13 SLCOV DSPF lower door open/close sensor Micro switch Detects open/close of the lower door. L when the lower door is open.

14 SPPD5 DSPF paper pass sensor 5 Transmission type Detects pass of the paper. L when paper is detected.

15 SPOD DSPF paper exit sensor Transmission type Detects paper exit of the document. L when paper is detected.

16 SPED2 DSPF document empty sensor Transmission type Detects document empty in the paper feed

17 STLD DSPF paper feed tray lower limit

sensor

short sensor

long sensor

sensor

Name Type Function/Operation Active condition

Transmission type Detects the upper limit of the paper feed tray. L when the upper limit of the

tray upper.

Transmission type Detects the document length of the paper feed

tray upper.

Transmission type Detects the document length of the paper feed

tray upper.

tray.

Transmission type Detects the lower limit of the paper feed tray. H when the lower limit of the

MX3501N EXTERNAL VIEW AND INTERNAL STRUCTURE 3 – 2

paper feed tray is detected.

—

H when paper is detected.

H when paper is detected.

L when paper is detected.

paper feed tray is detected.

Page 6

C. Motors, clutches, solenoids, PWB and lamps

11

8

10

9

2

6

7

5

1

3

4

15

13

12

14

17

16

No. Signal name Name Type Function/Operation

1 SPUM DSPF paper feed motor Hybrid step motor Drives the rollers, transport rollers and transport rollers in the

2 SPFM DSPF transport motor Hybrid step motor Drives the transport roller.

3 SPOM DSPF paper exit motor PM step motor Drives the paper exit roller.

4 SLUM DSPF lift-up motor PM step motor Lifts up or moves down the paper feed tray.

5 SPFC DSPF paper feed clutch Electromagnetic clutch Controls ON/OFF of the rollers in the paper feed section.

6 STRRC DSPF No.1 resist roller clutch Electromagnetic clutch Controls ON/OFF of No. 1 resist roller.

7 STRRBC DSPF No.1 resist roller brake clutch Electromagnetic clutch Performs braking of No. 1 resist roller.

8 STRC DSPF transport roller clutch Electromagnetic clutch Controls ON/OFF of the transport roller 1.

9 SRRC DSPF No.2 resist roller clutch Electromagnetic clutch Controls ON/OFF of No. 2 resist roller.

10 SRRBC DSPF No.2 resist roller brake clutch Electromagnetic clutch Performs braking of No. 2 resist roller.

11 SPFFAN DSPF cooling fan motor DC brush-less motor Cools the motors and the clutches.

12 — DSPF control PWB — Control PWB for DSPF

13 — DSPF flash PWB — Program ROM PWB for DSPF

14 — DSPF driver PWB — Driver PWB for DSPF

15 — DSPF CCD PWB — Scans document images.

16 — DSPF CL inverter PWB — Drives the copy lamp.

17 DSPF COPY LUMP DSPF copy lamp Xenon lamp Radiates light onto a document to allow the CCD to scan

paper feed section.

document images.

MX3501N EXTERNAL VIEW AND INTERNAL STRUCTURE 3 – 3

Page 7

SPWS

SPLS1

SPLS2

MX3501N

[4] OPERATIONAL DESCRIPTIONS

Service Manual

1. Document size detection

Size detection on the document tray

The document size is detected by the DSPF document width sensor (SPWS), and the document length is detected by the DSPF document

length sensors (SPLS1, SPLS2). The document size is judged from the document width and the document length as shown in the table below.

When, however, documents of different sizes are mixed and set on the document tray, the largest size is detected.

Document size

Document length sensor

SPLS1 SPLS2

AB series A5 OFF OFF

B5 OFF OFF

11" x 8.5" OFF OFF

A4 OFF OFF

B5R ON OFF

A4R ON OFF

8.5" x 13" ON ON

B4 ON ON

A3 ON ON

11" x 17" ON ON

Inch series 8.5" x 5.5" OFF OFF

11" x 8.5" OFF OFF

A4 OFF OFF

11" x 8.5"R ON OFF

8.5" x 13" ON ON

8.5" x 14" ON ON

A3 ON ON

11" x 17" ON ON

2. Timing chart

To increase the document replacement speed, pre-feed of the second and the later documents is performed for documents of A4/Letter or

smaller sizes. Therefore, a clutch is provided for each transport roller to perform individual control.

An electromagnetic brake is provided for each transport roller in order to reduce loads to the motor in comparison with a mechanical brake.

Transport speed 314mm/s Letter single-surface transport

SPFFAN

DSPF cooling fan motor

SPUM

DSPF paper feed motor

SPFM

DSPF transport motor

SPFC

DSPF paper feed clutch

SPFC

DSPF paper feed clutch

STRRC

DSPF No.1 resist roller clutch

STRRBC

DSPF No.1 resist roller brake clutch

SPRDMD

DSPF random sensor 1

SPPD1

DSPF paper pass sensor 1

SPPD2

DSPF paper pass sensor 2

STRC

DSPF transport roller clutch

SPPD3

DSPF paper pass sensor 3

SRRC

DSPF No.2 resist roller clutch

SRRBC

DSPF No.2 resist roller brake clutch

SPPD4

DSPF paper pass sensor 4

SPPD5

DSPF paper pass sensor 5

OC scanner scanning

Built-in scanner scanning

SPOD

DSPF paper exit sensor

SPOM

DSPF paper exit motor

Copy key ON

Timer from ON

Timer from ON

12.3mm

37.6mm

11.8mm

39.3mm

ON simultaneously with print start of each motor

OFF at 500ms after SPCD OFF of the last paper

ON simultaneously with SPPD2_ON

OFF at 69.4ms after SPPD2_OFF

ON at 12.3mm - 10ms (29ms) after SPPD3 ON

(SIM adjustment)

OFF at 11.8mm (38ms) after SPPD3 OFF

ON simultaneously with SPPD3 ON

OFF at 10ms before SRRC ON

Scanning start at 37.6mm (120ms) from

SPPD4 ON (SIM adjustment)

Scanning start at 39.3mm (125ms) from

SPPD5 ON (SIM adjustment)

Reduces the speed simultaneously with SPOD OFF,

reduces the speed up to 1855PPS in 15.7mm

Drives for 15mm and returns to 3709PPS in 15.7mm.

(Common to each paper size)

MX3501N OPERATIONAL DESCRIPTIONS 4 – 1

Page 8

MX3501N

[5] DISASSEMBLY AND

ASSEMBLY

1. Exterior section

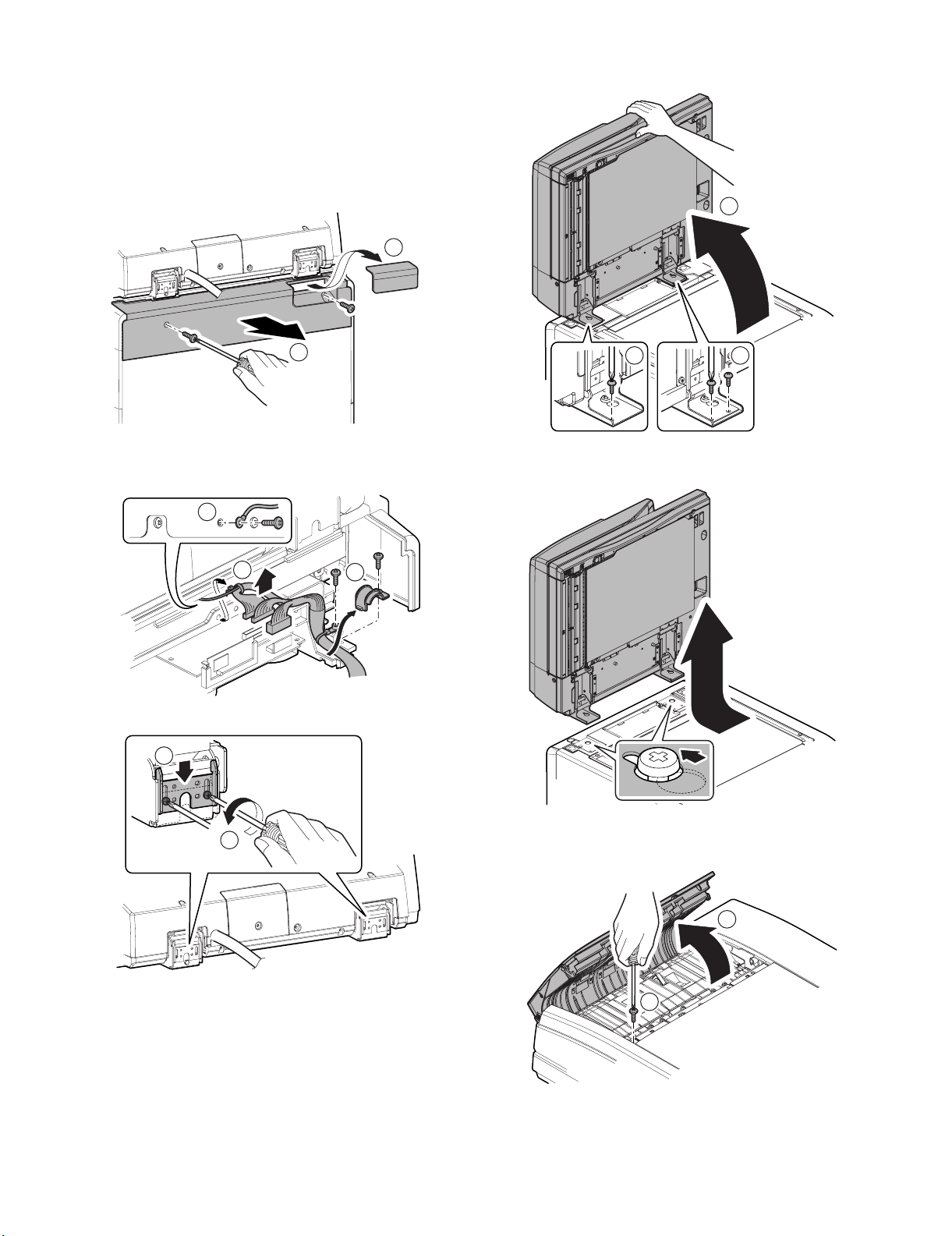

A. DSPF unit

1) Remove the upper cabinet rear cover lid. Remove the screw,

and remove the upper cabinet rear cover.

1

4) Open the DSPF unit to put it straight up, and remove the

Service Manual

screw.

1

2

2) Remove the screw, and remove the earth line. Disconnect the

connector, and remove the snap band. Remove the screw, and

remove the locking band and the interface harness cover.

1

2

3) Loosen the screw, and lower the angle adjustment plate.

2

3

22

5) Slide the DSPF unit to the rear side, and fit the step screw with

the key hole of the hinge, and lift it up to remove.

1

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 1

(1) Front cabinet

1) Open the upper door, and remove the screw.

1

2

Page 9

2) Remove the pawl, and remove the front cabinet.

2

(4) Upper door

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the spring. Remove the pawl. Remove the pressure

3

release axis holder. Remove the screw. Remove the pressure

release link lever.

4

1

(2) Rear cabinet

1) Open the upper door. Remove the screw. Remove the pawl.

Remove the rear cabinet.

2

1

4

1

3

3) Remove the resin E-ring, and remove the upper door.

1

4

2

(3) Paper feed cover

1) Open the upper door. Remove the screw. Remove the paper

feed cover.

2

3

2. Paper feed section

A. Paper feed tray unit

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Disconnect the connector. Remove the screw, and remove the

paper feed tray unit.

1

2

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 2

Page 10

(1) DSPF document length detection short sensor

1

2

(2) DSPF document length detection long sensor

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed tray unit. (Refer to "2. Paper feed section - A. Paper feed tray unit.")

4) Remove the screw, and remove the paper feed tray lower.

5) Disconnect the connector, and remove the DSPF document

length detection short sensor (a) and the DSPF document

length detection long sensor (b).

5) Remove the screw, and remove the rotation tray shaft.

Remove the paper feed rotation tray.

6) Disconnect the connector. Remove the pawl, and remove the

DSPF document width sensor.

a

b

(3) DSPF document width sensor

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed tray unit. (Refer to "2. Paper feed section - A. Paper feed tray unit.")

4) Remove the screw, and remove the paper feed tray lower. Disconnect the connector.

2

1

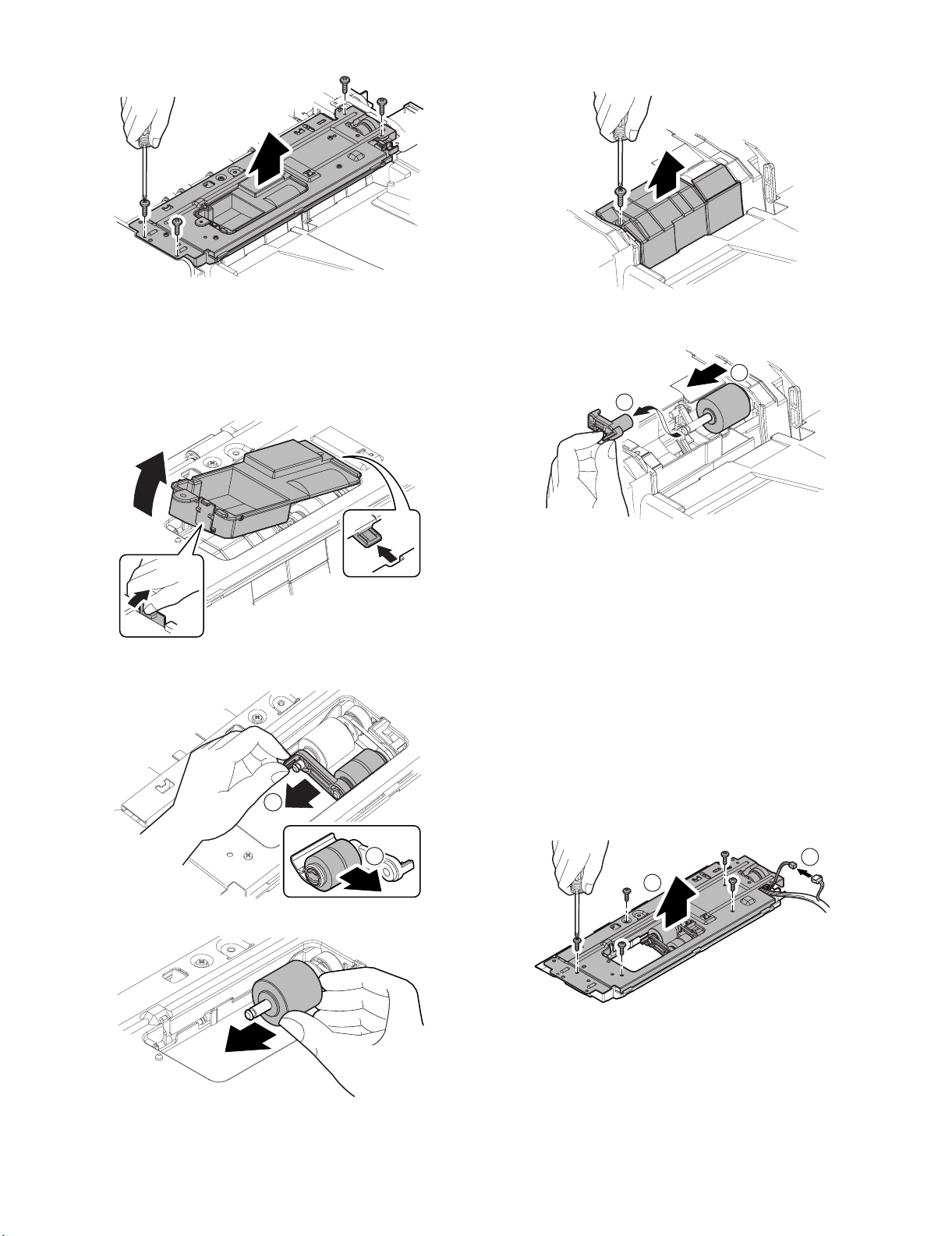

B. Paper feed unit

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed cover. (Refer to "1. Exterior section A. DSPF unit - (3) Paper feed cover.")

4) Disconnect the connector. Open the wire saddle. Remove the

snap band.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 3

Page 11

5) Remove the screw, and remove the paper feed unit.

5) Remove the screw, and remove the paper feed PG lower

cover.

(1) Pickup roller

(2) Paper feed roller

(3) Separation roller

1) Remove the paper feed cover. (Refer to "1. Exterior section A. DSPF unit - (3) Paper feed cover.")

2) Remove the pawl, and remove the paper feed PG upper cover.

3) Remove the pawl. Remove the pickup roller holder. Remove

the pickup roller from the pickup roller holder.

1

6) Disengage the pawl, and remove the reverse pressure release

lever. Remove the separation roller.

2

1

(4) DSPF paper feed tray upper limit sensor

(5) DSPF document upper limit sensor

(6) DSPF upper door open/close sensor

(7) DSPF paper pass sensor 1

(8) DSPF document random sensor

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed cover. (Refer to "1. Exterior section A. DSPF unit - (3) Paper feed cover.")

4) Remove the paper feed unit. (Refer to "2. Paper feed section B. Paper feed unit.")

5) Disconnect the connector. Remove the screw, and remove the

paper feed PG upper supporting plate.

4) Remove the paper feed roller.

2

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 4

1

2

Page 12

6) Disconnect the connector, and remove the DSPF paper feed

tray upper limit sensor (a), the DSPF document upper limit

sensor (b), the DSPF upper door open/close sensor (c), the

DSPF paper pass sensor 1 (d), and the DSPF document random sensor (e).

c

d

7) Remove the E-ring and the bearing. Lift the paper feed roller

shaft diagonally, and remove the DSPF paper feed clutch.

* When assembling, check to insure that the clutch rotation stop-

per is engaged with the plate.

e

a

b

(9) DSPF paper feed clutch

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed cover. (Refer to "1. Exterior section A. DSPF unit - (3) Paper feed cover.")

4) Remove the paper feed unit. (Refer to "2. Paper feed section B. Paper feed unit.")

5) Remove the pawl, and remove the paper feed PG upper cover.

3

2

1

C. Others

(1) Torque limiter

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed unit. (Refer to "2. Paper feed section B. Paper feed unit.")

4) Remove the DSPF No.1 resist roller brake clutch and remove

the DSPF No.1 resist roller clutch. (Refer to "3. Upper transport section - A. DSPF No.1 resist roller brake clutch, B. DSPF

No.1 resist roller clutch.")

5) Remove the drive unit. (Refer to "7. Drive section - A. Drive

unit.")

6) Remove the resin E-ring, and remove the No.1 resist roller

(idle).

6) Disconnect the connector. Remove the screw, and remove the

paper feed PG upper supporting plate.

1

2

2

1

7) Remove the screw. Lift the paper feed rotation tray, and

remove the paper feed PG lower.

2

1

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 5

Page 13

8) Remove the screw, and remove the separation roller supporting plate and the bearing. Remove the roller shaft, and remove

the torque limiter.

2

1

3

(2) DSPF paper feed tray lower limit sensor

(3) DSPF document empty sensor

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed tray unit. (Refer to "2. Paper feed section - A. Paper feed tray unit.")

4) Disconnect the connector, and remove the DSPF paper feed

tray lower limit sensor (a) and the DSPF document empty sensor (b).

b

3. Upper transport section

A. DSPF No.1 resist roller brake clutch

B. DSPF No.1 resist roller clutch

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector. Remove the resin E-ring. Remove

the DSPF No.1 resist roller brake clutch (a) and the DSPF

No.1 resist roller clutch (b).

* When assembling, check to insure that the clutch rotation stop-

per is engaged with the plate.

b

a

2

3

1

C. DSPF transport roller clutch

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector, and remove the snap band.

Remove the resin E-ring, and remove the DSPF transport

roller clutch.

* When assembling, check to insure that the clutch rotation stop-

per is engaged with the plate.

a

3

2

1

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 6

Page 14

D. No.1 resist roller (Drive)

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed unit. (Refer to "2. Paper feed section B. Paper feed unit.")

4) Remove the DSPF No.1 resist roller brake clutch and remove

the DSPF No.1 resist roller clutch. (Refer to "3. Upper transport section - A. DSPF No.1 resist roller brake clutch, B. DSPF

No.1 resist roller clutch.")

5) Remove the resin E-ring, and remove the No.1 resist roller

(idle).

2

1

8) Remove the E-ring and the bearing from the No.1 resist roller

(drive).

E. DSPF paper pass sensor 2

F. Transport roller 1 (drive)

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the screw, and remove the transport PG upper.

6) Remove the screw, lift the paper feed rotation tray, and remove

the paper feed PG lower.

2

1

7) Remove the resin E-ring and the bearing, and remove the

No.1 resist roller (drive).

2

4) Disconnect the connector, and remove the DSPF paper pass

sensor 2.

1

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 7

Page 15

5) Remove the DSPF transport roller clutch. (Refer to "3. Upper

transport section - C. DSPF transport roller clutch.")

6) Remove the E-ring, the washer, the spring, the collar, the polyslider, and the bearing. Remove the belt, the pulley, and the

bearing, and remove the transport roller 1 (drive).

1

C. DSPF No.2 resist roller brake clutch

D. DSPF No.2 resist roller clutch

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector. Remove the resin E-ring and

remove the DSPF No.2 resist roller brake clutch (a) and the

DSPF No.2 resist roller clutch (b).

* When assembling, check to insure that the clutch rotation stop-

per is engaged with the plate.

b

2

7) Remove the E-ring and the bearing from the transport roller 1

(drive).

1

4. Lower transport section

A. Platen roller

B. No.1 scanning plate

1) Open the DSPF unit, and clean the platen roller and the No.1

scanning plate.

1

a

3

2

E. DSPF paper pass sensor 3

F. DSPF paper pass sensor 4

G. No.2 resist roller (Drive)

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the upper door. (Refer to "1. Exterior section - A.

DSPF unit - (3) Upper door.")

4) Remove the screw, and remove the transport PG upper.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 8

Page 16

5) Loosen the screw, and lower the angle adjustment plate. Open

the DSPF unit.

2

10) Remove the screw and the connector, and remove the DSPF

paper pass sensor 3.

1

1

3

6) Remove the screw, and remove the left rear lower cabinet.

7) Remove the resin E-ring, and remove the PS knob.

2

1

2

11) Remove the screw, and remove the lift-up PG.

12) Remove the screw, and remove the spring. Remove the belt,

the pawl, and the platen roller.

2

8) Remove the screw, and remove the PS outer PG.

9) Remove the screw, and remove the PS front PG.

1

4

3

2

13) Disconnect the connector and remove the screw. Remove the

DSPF paper pass sensor 4.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 9

Page 17

14) Remove the DSPF No.2 resist roller brake clutch and the

DSPF No.2 resist roller clutch. (Refer to "4. Lower transport

section - C. DSPF No.2 resist roller brake clutch, D. DSPF

No.2 resist roller clutch.")

15) Remove the DSPF cooling fan motor. (Refer to "7. Drive section - C. Others - (1) DSPF cooling fan motor.")

16) Remove the E-ring, the washer, the spring, the collar, the polyslider, and the bearing.

17) Loosen the screw. Loosen the belt tension. Tighten the screw.

Slide the roller. Remove the pulley, the E-ring, and the bearing.

Remove the No.2 resist roller (drive).

1

5) Remove the screw, and remove the lift-up PG.

6) Remove the screw, and remove the intersecting point plate.

Remove the lower door.

2

1

3

2

H. DSPF paper pass sensor 5

I. Transport roller 2 (Drive)

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the OC mat. (Refer to "8. Others - A. OC mat.")

4) Loosen the screw, and lower the angle adjustment plate. Open

the DSPF unit.

2

3

7) Open the lower door. Remove the screw. Remove the transport PG lower. Disconnect the connector.

2

3

4

8) Disconnect the connector, and remove the DSPF paper pass

sensor 5.

1

1

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 10

3

Page 18

9) Remove the DSPF No.1 resist roller brake clutch and the

DSPF No.1 resist roller clutch. (Refer "3. Upper transport section - A. DSPF No.1 resist roller brake clutch - B. DSPF No.1

resist roller clutch.")

10) Remove the drive unit. (Refer to "7. Drive section - A. Drive

unit.")

11) Disconnect the connector. Remove the screw, and remove the

control PWB unit.

1

3

J. Transport roller 3 (drive)

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed unit. (Refer to "2. Paper feed section B. Paper feed unit.")

4) Remove the DSPF No.1 resist roller brake clutch and the

DSPF No.1 resist roller clutch. (Refer to "3. Upper transport

section - A. DSPF No.1 resist roller brake clutch, B. DSPF

No.1 resist roller clutch.")

5) Remove the drive unit. (Refer to "7. Drive section - A. Drive

unit.")

6) Remove the resin E-ring, and remove the No.1 resist roller

(idle).

1

2

2

12) Loosen the screw, and loosen the belt tension. Tighten the

screw. Remove the belt. Remove the E-ring and the pulley.

1

2

3

13) Remove the resin E-ring. Slide the bearing. Remove the transport roller 2 (drive). Remove the bearing, the E-ring, and the

spring pin from the transport roller 2 (drive).

2

3

2

1

7) Remove the screw. Lift the paper feed rotation tray, and

remove the paper feed PG lower.

2

1

8) Disconnect the connector. Remove the screw, and remove the

control PWB unit.

1

3

3

1

1

2

2

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 11

Page 19

9) Loosen the screw, and loosen the belt tension. Tighten the

screw. Remove the belt.

5) Remove the screw, and remove the intersecting point plate.

Remove the lower door.

1

2

10) Remove the resin E-ring and the bearing. Remove the transport roller 3 (drive). Remove the E-ring, the pulley, the spring

pin, and the bearing from the transport roller 3 (drive).

1

2

3

2

1

3

6) Remove the screw, and remove the intersecting point plate.

Remove the white reference plate.

1

5. Optical section

A. Lamp unit

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the OC mat. (Refer to "8. Others - A. OC mat.")

4) Remove the connector from the DSPF CL inverter PWB.

2

7) Remove the screw, and remove the scanning section cover.

Remove the screw, and remove the lamp unit.

3

4

2

1

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 12

Page 20

(1) Scanning glass

(2) DSPF copy lamp

(3) Reflector

1) Open the DSPF unit, and open the lower door.

2

2) Remove the cleaner.

4) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

5) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

6) Remove the OC mat. (Refer to "8. Others - A. OC mat.")

7) Remove the lamp unit. (Refer to "5. Optical section - A. Lamp

unit.")

1

8) Remove the screw, and remove the DSPF copy lamp.

9) Clean the scanning glass (back surface).

3) Use the cleaner to clean the scanning glass (surface).

10) Remove the screw, and remove the reflector.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 13

Page 21

B. Optical unit

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the upper door. (Refer to "1. Exterior section - A.

DSPF unit - (3) Upper door.")

4) Remove the OC mat. (Refer to "8. Others - A. OC mat.")

5) Remove the lamp unit. (Refer to "5. Optical section - A. Lamp

unit.")

6) Remove the screw, and remove the transport PG upper.

(1) Lens

(2) CCD

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the upper door. (Refer to "1. Exterior section - A.

DSPF unit - (3) Upper door.")

4) Remove the OC mat. (Refer to "8. Others - A. OC mat.")

5) Remove the lamp unit. (Refer to "5. Optical section - A. Lamp

unit.")

6) Remove the optical unit. (Refer to "5. Optical section - B. Optical unit.")

7) Remove the screw. Remove the pawl. Remove the dust-proof

cover. Remove the screw, and remove the dark box.

7) Remove the screw, and remove the harness cover. Disconnect

the connector.

* When assembling, arrange the harness so that it is placed in

the lower position than the rib height.

1

2

2

8) Remove the step screw, and remove the screw. Remove the

optical fixing plate. Remove the optical unit.

2

3

8) Remove the pawl, and remove the lens cover.

9) Clean the lens (a) and the CCD (b).

b

1

a

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 14

Page 22

(3) CCD unit

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the upper door. (Refer to "1. Exterior section - A.

DSPF unit - (3) Upper door.")

4) Remove the OC mat. (Refer to "8. Others - A. OC mat.")

5) Remove the lamp unit. (Refer to "5. Optical section - A. Lamp

unit.")

6) Remove the optical unit. (Refer to "5. Optical section - B. Optical unit.")

7) Remove the screw. Remove the pawl. Remove the dust-proof

cover. Remove the screw, and remove the dark box.

(4) Mirror

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the upper door. (Refer to "1. Exterior section - A.

DSPF unit - (3) Upper door.")

4) Remove the OC mat. (Refer to "8. Others - A. OC mat.")

5) Remove the lamp unit. (Refer to "5. Optical section - A. Lamp

unit.")

6) Remove the optical unit. (Refer to "5. Optical section - B. Optical unit.")

7) Remove the screw, and remove the mirror base cover.

8) Remove the screw, and remove the CCD unit.

8) Clean the mirror.

C. Others

(1) DSPF CL inverter PWB

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector, and remove the control PWB unit.

1

3

1

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 15

2

2

Page 23

3) Disconnect the connector, and remove the screw. Remove the

inverter PWB guide.

3) Use the cleaner to clean the white reference glass.

4) Remove the screw, and remove the DSPF CL inverter PWB.

(2) White reference glass

1) Open the DSPF unit, and open the lower door.

1

2

2) Remove the cleaner.

6. Paper exit section

A. Discharge brush

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed tray unit. (Refer to "2. Paper feed section - A. Paper feed tray unit.")

4) Remove the discharge brush.

* When attaching the discharge brush, attach it to the attachment

reference.

B. DSPF paper exit sensor

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed tray unit. (Refer to "2. Paper feed section - A. Paper feed tray unit.")

4) Disconnect the connector, and remove the DSPF paper exit

sensor.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 16

Page 24

C. Paper exit roller (drive)

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

3) Remove the paper feed tray unit. (Refer to "2. Paper feed section - A. Paper feed tray unit.")

4) Remove the DSPF No.1 resist roller brake clutch, and remove

the DSPF No.1 resist roller clutch. (Refer to "3. Upper transport section - A. DSPF No.1 resist roller brake clutch, B. DSPF

No.1 resist roller clutch.")

5) Remove the drive unit. (Refer to "7. Drive section - A. Drive

unit.")

6) Remove the resin E-ring, the gear, the bearing, and the paper

exit roller (drive).

4) Remove the screw, and remove the drive unit.

1

2

1

7. Drive section

A. Drive unit

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Remove the DSPF No.1 resist roller brake clutch and the

DSPF No.1 resist roller clutch. (Refer to "3. Upper transport

section - A. DSPF No.1 resist roller brake clutch, B. DSPF

No.1 resist roller clutch.")

3) Disconnect the connector, and open the edge saddle. Remove

the snap band.

(1) DSPF paper feed motor

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector, and open the edge saddle. Remove

the screw, and remove the DSPF paper feed motor.

(2) DSPF paper exit motor

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector, and open the edge saddle. Remove

the screw, and remove the DSPF paper exit motor.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 17

Page 25

(3) DSPF lift-up motor

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector, and open the edge saddle. Remove

the screw, and remove the DSPF lift-up motor.

B. Drive transport unit

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Remove the DSPF No.1 resist roller brake clutch and the

DSPF No.1 resist roller clutch. (Refer to "3. Upper transport

section - A. DSPF No.1 resist roller brake clutch, B. DSPF

No.1 resist roller clutch.")

3) Remove the DSPF transport roller clutch. (Refer to "3. Upper

transport section - C. DSPF transport roller clutch.")

4) Remove the DSPF cooling fan motor. (Refer to "7. Drive section - C. Others - (1) DSPF cooling fan motor.")

5) Loosen the screw, and loosen the belt tension. Tighten the

screw.

(1) DSPF transport motor

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Loosen the screw, and loosen the belt tension. Tighten the

screw.

3) Disconnect the connector, and remove the screw. Remove the

DSPF transport motor.

6) Remove the screw, and remove the drive transport unit.

C. Others

(1) DSPF cooling fan motor

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector, and remove the DSPF cooling fan

motor.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 18

Page 26

8. Others

A. OC mat

1) Open the DSPF unit, and remove the OC mat from the left

edge.

* When assembling, place the OC mat on the document table to fit

with the reference and close the DSPF unit.

C. DSPF lower door open/close sensor

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Disconnect the connector, and remove the screw. Remove the

lower door open/close sensor holder. Remove the DSPF lower

door open/close sensor from the lower door open/close sensor

holder.

D. DSPF driver PWB

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Disconnect the connector. Remove the screw, and remove the

DSPF driver PWB.

B. DSPF open/close sensor

1) Remove the front cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (1) Front cabinet.")

2) Disconnect the connector and remove the screw. Remove the

open/close sensor holder. Remove the DSPF open/close sensor from the open/close sensor holder.

E. DSPF flash PWB

1) Remove the screw, and remove the ROM cover.

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 19

Page 27

2) Release the lock, and remove the DSPF flash PWB.

2

1

F. DSPF control PWB

1) Remove the rear cabinet. (Refer to "1. Exterior section - A.

DSPF unit - (2) Rear cabinet.")

2) Remove the DSPF flash PWB. (Refer to "8. Others - E. DSPF

flash PWB.")

3) Disconnect the connector, and remove the screw. Remove the

control PWB unit.

1

3

1

2

4) Disconnect the connector, and remove the screw. Remove the

DSPF control PWB.

2

MX3501N DISASSEMBLY AND ASSEMBLY 5 – 20

Page 28

MX3501N

[6] MAINTENANCE

Service Manual

1. Maintenance system table

✕: Check (Clean, replace, or adjust according to necessity.) {: Clean ▲: Replace U: Adjust ✩: Lubricate : Shift the position.

No. Part name When calling

1 Paper feed

section/

2 Pickup roller {{

Transport

3 Separation roller {{

section

4 Torque limiter ✕✕Replacement reference: 100K

5 No. 1 resist roller (Drive) {{

6 Transport roller 1 (Drive) {{

7 No. 2 resist roller (Drive) {{

8 Platen roller {{

9 Transport roller 2 (Drive) {{

10 Transport roller 3 (Drive) {{

11 Paper exit roller (Drive) {{

12 Discharge brush ✕✕

13 No. 1 scanning plate {{

14 No. 2 scanning section, scanning glass {{

15 No. 2 scanning section, white reference glass {{

16 Optical section Lens {{

17 CCD {{

18 Mirror ✕✕

19 Copy lamp {{

20 Reflector {{

21 Drive section Gears (Grease) ✕✕UKOG-0299FCZZ (specified positions)

22 Belts ✕

23 Others OC mat {{

Paper feed roller {{Replacement reference: 100K or 1 year

Main unit

maintenance cycle

Remarks

5

17

18

15

6

7

8

13

9

10

11

12

16

19

20

14

1

4

2

3

23

22

22

21

22

MX3501N MAINTENANCE 6 – 1

Page 29

MX3501N

[7] ADJUSTMENTS

1. Levelness adjustment

This adjustment is needed in the following situations:

* The DSPF section has been disassembled.

* The DSPF unit has been replaced.

1) Close the DSPF unit and check the clearance between the

projections in the front side and the rear side and the SPF

glass holding resin surface.

2) Visually check to insure that the clearance A is 1mm or less

and the clearance B is 0mm (in contact).

4) After adjustments of A and B, check to insure that the projec-

Service Manual

tion on the front right side is in contact with the glass surface of

the main unit.

2. Skew adjustment (front surface mode)

This adjustment is needed in the following situations:

* The DSPF section has been disassembled.

* When replacing the DSPF unit.

* The DSPF unit generates skewed scanned images.

1) Create an adjustment chart by printing in duplex mode the selfprint pattern 71 (grid pattern) specified in Simulation 64-1.

Make sure that the print grid pattern is almost in parallel with

the paper edges, and apply position marks 'A', 'B', 'C' and 'D' to

the leading and trailing edges of the paper for both front and

back sides of the paper.

1mm

A

B

0mm

If the above requirement is not met, do step 3.

3) Turn the height adjustment screw to adjust the DSPF front/rear

frame horizontal level.

L

R

A

Paper pass direction

B

2) Copy the adjustment chart (created in step 1) to A3 (11" x 17")

paper in DSPF duplex mode, and then check the image for

skews (Set in the DSPF feed tray so that the mark on the

adjustment chart is at the edge).

• Check with one of the following methods.

[Check Method 1]

(Front side)

Make sure that the output satisfies the condition: |a-b| ± 1 mm

A

a

B

b

When the front frame side is higher (clearance B is more than

1mm): Turn the height adjustment screw R of the DSPF rear

frame clockwise.

When the rear frame side is higher (clearance A is more than

1mm): Turn the height adjustment screw L of the DSPF rear

frame counterclockwise.

Repeat steps 2 to 3 until an acceptable result is obtained.

MX3501N ADJUSTMENTS 7 – 1

(Back side)

Make sure that the output satisfies the condition: |c-d| ± 1 mm

C

c

D

d

Page 30

[Check Method 2]

Check that the squareness of the main scanning direction

print line for the longitudinal direction of paper is within

1.0mm.

0 - 1.0mm

[When the main scanning direction print line is shifted to the

left]

If a < b, then turn counterclockwise the DSPF skew

adjusting screw.

[When the main scanning direction print line is shifted to the

right]

If a > b, then turn clockwise the DSPF skew adjusting screw.

Repeat steps 2 to 5 until an acceptable result is obtained.

A

If the front surface copy image is as shown above and the

back surface copy is not as shown above, go to the step 3)

of "3. Skew adjustment (Back surface mode)."

If the above requirement is not met for the paper's front side,

then do step 3.

3) Loosen the hinge screws and lower the two attachments.

2

1

4) Open the DSPF and loosen the screw.

3. Skew adjustment (back surface mode)

This adjustment is needed in the following situations:

* The DSPF section has been disassembled.

* When replacing the DSPF unit.

* The DSPF unit generates skewed scanned images.

1) Create an adjustment chart by printing in duplex mode the selfprint pattern 71 (grid pattern) specified in Simulation 64-1.

Make sure that the print grid pattern is almost in parallel with

the paper edges, and apply position marks 'A', 'B', 'C' and 'D' to

the leading and trailing edges of the paper for both front and

back sides of the paper.

A

Paper pass direction

B

2) Copy the adjustment chart (created in step 1) to A3 (11" x 17")

paper in DSPF duplex mode, and then check the image for

skews (Set in the DSPF feed tray so that the mark on the

adjustment chart is at the edge).

• Check with one of the following methods.

[Check Method 1]

(Front side)

Make sure that the output satisfies the condition: |a-b| ± 1 mm

5) Adjust by turning the DSPF skew adjusting screw on the right

side of the DSPF rear frame.

MX3501N ADJUSTMENTS 7 – 2

A

a

(Back side)

Make sure that the output satisfies the condition: |c-d| ± 1 mm

C

c

B

b

D

d

Page 31

[Check Method 2]

Check that the squareness of the main scanning direction

print line for the longitudinal direction of paper is within

1.0mm.

0 - 1.0mm

A

If the back surface copy image is as shown above and the

front surface copy is not as shown above, go to the step 3)

of "2. Skew adjustment (Front surface mode)."

If the back surface copy is not as shown above, perform the

procedures of step 3) or later.

3) Open the upper door, and remove the adjustment cover.

[When the main scanning direction print line is shifted to the

left]

If c < d, turn the DSPF skew adjustment screw A

counterclockwise, or turn the adjustment screw B clockwise.

[When the main scanning direction print line is shifted to the

right]

If c > d, turn the DSPF skew adjustment screw A clockwise,

or turn the adjustment screw B counterclockwise.

* The adjustment screws A and B must be turned in proper

balance. For example, if the trouble is not removed by turning the adjustment screw A 180 degrees clockwise, do not

turn the adjustment screw A furthermore, but turn the adjustment screw B 180 degrees counterclockwise.

Repeat steps 2 to 5 until an acceptable result is obtained.

4. Image focus adjustment (front surface mode)

For details of this adjustment, refer to "[6] ADJUSTMENTS" of the

copier Service Manual (00ZMX3500NS1E).

5. Image focus adjustment (back surface mode)

This adjustment is required in the following cases:

* When the DSPF CCD unit is replaced.

* When the DSPF CCD unit is replaced.

* When the COPY/SCAN/FAX image focus is not properly

adjusted.

* When the DSPF unit is removed.

* When the DSPF unit is replaced.

1) Make a duplex copy in DSPF mode.

2) Make sure that the copied image on the back side of the paper

is satisfactorily focused.

If the image is not satisfactorily focused, do the following

steps.

3) Open the door. Remove the screws, and remove the transport

PG upper.

4) Turn the DSPF skew adjustment screw on the CCD unit to

adjust.

A

B

4) To prevent against shift of the CCD unit optical axis, mark the

CCD unit base as shown below.

MX3501N ADJUSTMENTS 7 – 3

Page 32

5) Loosen the CCD unit fixing screws (4 pcs.).

A4 size

(both sides)

10mm10mm

Paper pass direction

CLOSE

0

A

:

A㧦 50

B㧦 50

C㧦 50

D㧦 50

㧧 CCD(MAIN)

㧧 CCD(SUB)

㧧

SPF(MAIN)

㧧

SPF(SUB)

SIMULATIONNO.48㧙01

MAGNIFICATION AD JUSTMENT

XX

㨇 1㨪99 㨉

O

K

TEST

* Never loosen the screws marked with ✕.

Loosening these screws could possibly change the CCD

unit base optical axis. Once the optical axis has been

changed, it cannot be corrected through on-site adjustments. Solving such a problem requires the replacement of

the entire scanner unit.

6) Slide the CCD unit in the arrow direction (CCD sub scanning

direction) to change the installing position.

When the copy image is longer than the original scale, shift the

CCD unit in the direction B. When the copy image is shorter

than the original scale, shift the CCD unit in the direction A.

One scale of mark-off line corresponds to 0.2%.

At that time, fix the CCD unit so that it is in parallel with the

scale on the front and the rear side of the CCD unit base.

* Fix the CCD unit so that it is in parallel with the line marked

in procedure 4).

* Images are not correctly magnified in the main scanning direc-

tion.

1) On the DSPF original tray, place such an original as illustrated

below.

2) Make a normal duplex copy on A4 paper.

3) Measure the lengths of the copied image (back surface) and

the original image.

original

copy

10

100 150

50

250

200

10

100 150

50

250

200

7) Make a copy and check the copy magnification ratio again.

NOTE: By changing the CCD unit fixing position with the simula-

6. Image magnification in the main

For details of this adjustment, refer to "[6] ADJUSTMENTS" of the

copier Service Manual (00ZMX3500NS1E).

7. Image magnification in the main

This adjustment is required in the following cases:

* The MFP control PWB has been replaced.

* The EEPROM on the MFP control PWB has been replaced.

* The scan control PWB has been replaced.

* The EEPROM on the scan control PWB has been replaced.

* When a U2 trouble occurs.

A

B

If the copy magnification ratio is not in the range of 100 ± 1%,

repeat the procedures of 4) – 6) until the condition is satisfied.

tion 48-1 adjustment value at 50, the copy magnification

ratio is adjusted within the specified range (100 ± 1.0%)

and the specified resolution is obtained based on the optical system structure.

scanning direction adjustment (front

surface mode)

scanning direction adjustment (back

surface mode)

MX3501N ADJUSTMENTS 7 – 4

4) Determine the image magnification factor using the following

formula:

Image magnification factor (%) = Copy dimension/original

dimension x 100

Image magnification factor (%) = 99 / 100 x 100 = 99

If the image magnification factor is within the spec (100±0.8%),

no adjustment is required; otherwise, do the following steps.

5) Enter the simulation 48-1 mode.

1) Select the item corresponding to be adjusted with scroll key.

2) Press [START] key.

3) Enter the image magnification adjustment value with the 10key.

4) Press [START] key.

Pressing the [START] key starts copy operation as well as

applying the adjustment value.

Repeat the above adjustments until an acceptable result is

obtained.

8. Image magnification in the sub

scanning direction adjustment

This adjustment is required in the following cases:

* Images are not correctly magnified in the sub-scanning direction.

* The MFP control PWB has been replaced.

* The EEPROM on the MFP control PWB has been replaced.

* The scan control PWB has been replaced.

Page 33

* The EEPROM on the scan control PWB has been replaced.

A

K

A㧦 50

* When a U2 trouble occurs.

1) On the DSPF original tray, place such an original as illustrated

below.

10mm

Paper pass direction

A4 size

10mm

2) Make a normal copy on A4 paper.

3) Measure the lengths of the copied image and the original

image.

10 50 100 150 200

10

50 100

original

1) Enter the simulation 48-1 mode.

0

SIMULATION NO.48㧙05

TEST

MOTOR SPEED AD JUSTMENT

A:

㨇 1㨪99 㨉

XX

A㧦 50

B㧦 50

C㧦 50

D㧦 50

㧧 MR(HI)

㧧 MR(MID)

㧧 MR (LO)

㧧 DSP F(HI))

CLOSE

OK

1) Select the item corresponding to be adjusted with scroll key.

2) Press [START] key.

3) Enter the image magnification adjustment value with the 10key.

Make adjustments by changing the adjustment value for high

revolution mode if the copy magnification is not correct for

microcopies; or the adjustment value for low revolution mode if

the copy magnification is not correct for blowbacks.

4) Press [START] key.

This applies the adjustment value.

9. Scanned image off-center adjustment

(front surface mode)

For details of this adjustment, refer to "[6] ADJUSTMENTS" of the

copier Service Manual (00ZMX3500NS1E).

150

200

copy

4) Determine the image magnification factor using the following

formula:

Image magnification factor (%) = Copy dimension/original

dimension x 100

Image magnification factor (%) = 99 / 100 x 100 = 99

If the image magnification factor is within the spec (100±0.8%),

no adjustment is required; otherwise, do the following steps.

5) Enter the simulation 48-1 mode.

0

SIMULATIONNO.48㧙01

TEST

MAGNIFICATION ADJUSTME NT

:

㨇 1㨪99 㨉

XX

A㧦 50

B㧦 50

C㧦 50

D㧦 50

㧧 CCD(MAIN)

㧧 CCD(SUB)

㧧

SPF(MAIN)

㧧

SPF(SUB)

CLOSE

O

1) Select the adjustment item DSPF (SUB) with scroll key.

This adjustment items is intended to adjust the image magnification in the sub-scanning direction in DSPF mode. (DSPF

(SUB))

2) Press [START] key.

3) Enter the image magnification adjustment value with the 10key.

4) Select [START] key.

Pressing the [START] key starts copy operation as well as

applying the adjustment value.

Repeat the above adjustments until an acceptable result is

obtained.

NOTE: After adjusting the image magnification in the sub-scanning

direction through Simulation 48-1, do the following steps if

making a copy at a different magnification factor fails to

produce a correctly scaled copy.

10. Scanned image off-center adjustment (back surface mode)

This adjustment is required in the following cases:

* The MFP control PWB has been replaced.

* The EEPROM on the MFP control PWB has been replaced.

* The scan control PWB has been replaced.

* The EEPROM on the scan control PWB has been replaced.

* The scanner (reading) section has been disassembled.

* The scanner (reading) unit has been replaced.

* When a U2 trouble occurs.

* The DSPF section has been disassembled.

* The DSPF unit has been replaced.

(Adjustment mode selection)

1) Enter the simulation 50-12 mode.

SIMULATION NO.50㧙12

TEST

ORIGINAL CENTER OFFSET SETUP

XX

A:

㨇 1㨪 99 㨉

㧧 OC

B㧦 50

㧧 SP F(SIDE1 )

C㧦 50 㧧 SPF(SID E2)

(UNIT: 0.1mm/STEP When the value is increased, the image is

shifted to the front side.)

Item Set range Default

0 TRAY SELECT Paper feed tray

selection

1 COPY START Copy START (Default) – –

2 MAGNIFICATION Print magnification ratio

setting

(Off-center adjustment value)

3 PLATEN OC mode adjustment 0 – 99 50

4 SPF SIDE1 DSPF front surface

adjustment

5 SPF SIDE2 DSPF back surface

adjustment

1 – 6 –

25 – 400% 100

0

CLOSE

OK

MX3501N ADJUSTMENTS 7 – 5

Page 34

2) Using the scroll key, select the adjustment item DSPF SIDE1,

Image loss (LIL)

LIL = 1.5 mm

LV = 3.5 mm

TV = 3.5 mm

FV+RV

= 7.0 mm

Papar lead edge Papar tail edge

10 20

No Image

No Image

No Image

No Image

Void (TV)

Void (LV)

Void (FV)

Void (RV)

which is intended to adjust the off-center in DSPF back surface

mode.

3) Press [START] key.

(Scan off-center adjustment)

1) On the DSPF original tray, place such an original as illustrated

below.

2) Press [START] key.

Since the front side and back side images are copied onto separate sheets, check the off-center of the back side image.

If the off-center is 0±2.7 mm, no adjustment is required.

1) Make a copy in DSPF (front surface) mode, and make sure

that the printed image at the leading edge of the copied image

is free from shadows.

Papar lead edge

Image area

original copy

a

b

If the above requirement is not met, do the following steps.

3) Enter the scanned image off-center position adjustment value

with the 10-key.

(The adjustment value should be changed in steps of 0.1mm.)

(When the adjustment is increased, the print image is shifted

to the front side.)

4) Press [START] key.

Pressing the [OK]t key starts copy operation as well as applying the adjustment value.

5) Check the off-center of the printed image.

Repeat the above adjustments until an acceptable result is

obtained.

11. Original scan position adjustment

This adjustment is required in the following cases:

* The MFP control PWB has been replaced.

* The EEPROM on the MFP control PWB has been replaced.

* The scan control PWB has been replaced.

* The EEPROM on the scan control PWB has been replaced.

* The scanner (reading) section has been disassembled.

* The scanner (reading) unit has been replaced.

* When a U2 trouble occurs.

* The PF section has been disassembled.

* The DSPF unit has been replaced.

This adjustment is intended to adjust the scanner read position in

DSPF mode front face scan.

An incorrect adjustment would deviate the scanner stop position

from the required position, thus possibly causing a shadow of the

original table to appear at the leading edge of an image generated

by DSPF (front surface) mode scan.

Shadow image of SPF

If the printed image at the leading edge of the copied image

contains a shadow of the original table, then do the following

steps.

2) Enter the simulation 53-8 mode.

0

SIMULATION NO.53 㧙08

SIMULATION NO.53 㧙08

TEST

TEST

SPF SCANNING POSITION ADJUSTMENT

SPF SCANNING POSITION ADJUSTMENT

A:

A:

㨇 1㨪 99 㨉

㨇 1㨪 99 㨉

50

XX

A㧦 50

A㧦 50

㧧 ADJUST VALUE

㧧 ADJUST VALUE

CLOSE

CLOSE

OK

OK

0

3) Enter the adjustment value and press the [START] key.

Repeat the above adjustments until an acceptable result is

obtained.

12. Copied image loss/void area adjustment

This adjustment is required in the following cases:

* The MFP control PWB has been replaced.

* The EEPROM on the MFP control PWB has been replaced.

* The scan control PWB has been replaced.

* The EEPROM on the scan control PWB has been replaced.

* The scanner (reading) section has been disassembled.

* The scanner (reading) unit has been replaced.

* When a U2 trouble occurs.

* The PF section has been disassembled.

* The DSPF unit has been replaced.

MX3501N ADJUSTMENTS 7 – 6

Page 35

1) Enter the simulation 50-6 mode.

CLOSE

0

SIMULATION NO.50㧙06

TEST

LEAD EDG E ADJUSTMENT VALUE(SPF)

A:

㨇 1㨪 99 㨉

0 TRAY SELECT Paper feed tray

1 COPY START Copy START (Default) – –

2 MAGNIFICATION Print magnification ratio

(Lead edge adjustment value)

3 SIDE1 Front surface document

4 SIDE2 Back surface document

(Image loss set value: SIDE 1)

5 LEAD_EDGE Front surface lead edge

6 FRONT_REAR Front surface side edge

7 TRAIL_EDGE Front surface rear edge

(Image loss set value: SIDE 2)

8 LEAD_EDGE Back surface lead edge

9 FRONT/REAR Back surface side edge

10 TRAIL_EDGE Back surface rear edge

50

A㧦 50

㧧 SIDE1

B㧦 50

㧧 SIDE2

C㧦 20

㧧 LEAD EDGE

D㧦 20

㧧 FRONT_REAR

Item

selection

setting

scan start position

adjustment value

scan start position

adjustment value

image loss set value

image loss set value

image loss set value

image loss set value

image loss set value

image loss set value

(Leading edge image loss adjustment)

1) Set the adjustment values for leading edge image loss (LEAD

EDGE) for the front and back sides as follows:

(Standard setting)

5 LEAD EDGE: 15

8 LEAD EDGE: 15

* Set the adjustment value for "5 LEAD_EDGE" and

"8 LEAD_EDGE" to 15 by entering "15" into the (LEAD

EDGE) adjustment value field and then pressing the

[START] key.

2) In SPF mode, make a duplex copy at 100% magnification, and

make sure that the leading edge image loss is 1.5 mm for both

the front and back sides. (Select duplex mode from the paper

selection mode as described in Simulation 50-6). (Enter "100"

into the (MAGNIFICATION) field, and then press the [START]

key).

Papar lead edge

TIL = 1.5 mm

TV = 3.5 mm

Image area

Image loss (TIL)

Void (TV)

CLOSE

Set

range

1 – 6 –

200%

0 – 99 50

0 – 99 15

0 – 20 0

0 – 99 15

0 – 20 0

Default

25 –

OK

–

20

20

3) Repeat the process of changing the (SIDE1 & SIDE2) adjustment values and then pressing the [START] key until attaining

an acceptable level.

SIDE1: Adjustment value for the position at which to read the

leading edge of the original in DSPF front side mode.

SIDE2: Adjustment value for the position at which to read the

leading edge of the original in DSPF back side mode.

(The adjustment value should be changed in steps of 0.1 mm.)

(The timing in which to start reading the image should be

determined based on the timing in which detector SPPD4

detects the leading edge of the original.)

Repeat steps 2 to 3 until an acceptable result is obtained.

(Trailing edge image loss adjustment)

1) Select duplex mode from paper selection mode as described

in Simulation 50-6, enter "100" into the (MAGNIFICATION)

field, and then press the [START] key to make a duplex copy at

100% magnification in SPF mode, and make sure that the trailing edge image loss is 1.5 mm for both front and back sides.

Papar trail edge

TIL = 1.5 mm

Image area

TV = 3.5 mm

Image loss (TIL)

Void (TV)

No Image

If an acceptable result is not obtained, do the following steps.

2) Repeat the process of changing the (TRAIL EDGE) adjustment value and then pressing the [START] key until attaining

an acceptable level.

Repeat the above adjustments until an acceptable result is

obtained.

(Front/rear frame direction image loss adjustment)

Set the (FRONT/REAR) adjustment value to 20 by entering "20"

into the (FRONT/REAR) adjustment value field and then pressing

the P key.

Note that changing this adjustment value shifts the image position

in the front/rear frame direction.

13. Paper width sensor for the paper feed

tray adjustment

This adjustment is needed in the following situations:

* The paper feed tray section has been disassembled.

* The paper feed tray unit has been replaced.

* When a U2 trouble occurs.

* The scanner PWB has been replaced.

* The EEPROM on the scanner PWB has been replaced.

1) Enter the simulation 53-6 mode.

SIMULATION NO.53 06

TEST

SPF TRAY ADJUSTMENT

TRAYVOLMAX TRAY ADJUSTMENT.

PRESS [EXECUTE] TO START

0

No Image

If an acceptable result is not obtained, do the following steps.

MX3501N ADJUSTMENTS 7 – 7

EXECUTE

Page 36

2) Open the DSPF paper feed guide to the maximum width posi-

CLOSE

ALL

CLOSE

EXECUTE

1/1

CLOSE

SIMULATION NO.50 28

TEST

AAUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

CLOSE

EXECUTE

NOW EXECUTING…

tion.

3) Press [EXECUTE] key.

The maximum width detection level is recognized.

4) Open the DSPF paper feed guide to the width for the A4R size.

5) Press [EXECUTE] key.

The A4R width detection level is recognized.

6) Open the DSPF paper feed guide to the width for the A5R size.

7) Press [EXECUTE] key.

The A5R width detection level is recognized.

8) Open the DSPF paper feed guide to the minimum width position.

1) Enter the simulation mode 50-28 to select [SPF ADJ].

SIMULATION NO.5028

TEST

AUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

OC ADJ BK-MAG ADJ

SPF ADJ

RESULT DATA

SETUP/PRINT ADJ

2) Select an adjustment item (front, back, both).

<List of adjustment items>

Menu display item Content

SIDE1 SPF adjustment front surface

SIDE2 SPF adjustment back surface

ALL SPF adjustment front/back surface

SIMULATION NO.50 28

TEST

AUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

SIDE1

SIDE2

0

1/1

0

1/1

9) Press [EXECUTE] key.

The minimum width detection level is recognized.

* When each of the above operations has been completed, the

"COMPLETE" message appears; when any of the operations

has failed, the "ERROR" message appears.

14. Auto void adjustment (Service

installation adjustment)

This adjustment is required in the following cases:

* The MFP control PWB has been replaced.

* The EEPROM on the MFP control PWB has been replaced.

* The scan control PWB has been replaced.

* The EEPROM on the scan control PWB has been replaced.

* The scanner (reading) section has been disassembled.

* The scanner (reading) unit has been replaced.

* When a U2 trouble occurs.

* The PF section has been disassembled.

* The DSPF unit has been replaced.

This adjustment is used to adjust the DSPF (front/back) document

lead edge, off-center, sub operation magnification ratio.

3) The display shows the tray select screen for printing the SPF

adjustment pattern. Select a tray for SPF adjustment printing.

0

SIMULATION NO.50 28

TEST

AUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

MFT

CS1

CS2

4) Self-print of the SPF adjustment pattern is performed.

0

5) After completion of printing, the SPF adjustment start screen is

displayed.

0

SIMULATION NO.50 28

TEST

AUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

PLEASE SET THE PRINTER PATTERN PA PE R ON THE SPF

THEN PRESS㨇EXECUTE㨉 TO START

REPRINT

EXECUTE

CLOSE

MX3501N ADJUSTMENTS 7 – 8

Page 37

6) Load the SPF adjustment pattern on the DSPF.

1

2

SIMULATION NO.63

02

TE

ST

SHADING EXEC UTION

EXECUT

E

0

CLOSE

PRESS [EXECUTE] TO SHADING START

SIM

ULATIONNO.63

02

TEST

SHAD

ING

EXECUTION

EXECUTE

0

CLOSE

SELECT

OC SHAD

ING/DSPFSHADING, AND PRESSEXECUTE

OC S HADING DSP F S HADING

15. Shading adjustment

1) Fold 2 or 3 sheets of A3 paper (recommendable paper for

color copy) as shown below.

7) Press [EXECUTE] key, and scanning of the SPF adjustment

pattern selected in step 2) is started.

0

SIMULATION NO.50 28

TEST

AUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

PLEASE WAIT

NOW EXECUTING…

REPRINT

8) When [ALL] is selected, load the SPF adjustment pattern on

the DSPF again, and perform the adjustment of the back surface in the similar procedures.

9) The adjustment result screen is displayed.

The value of this time is displayed, and the value of the last

time is displayed in the parenthesis ( ).

CLOSE

EXECUTE

320mm

A3

1

279mm

2

10

15mm

2) Open the lower door, place the folded sheets of paper as

shown, and close the lower door.

SIMULATION NO.50 28

TEST

AUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

SPF㧔SI DE1㧕㧦LEAD㧖㧖㧔㧖㧖㧕 OFFS ET㧦㧖㧖㧔㧖㧖㧕 SUB㧦㧖㧖㧔㧖㧖㧕

SPF㧔SI DE2㧕㧦LEAD㧖㧖㧔㧖㧖㧕 OFFS ET㧦㧖㧖㧔㧖㧖㧕 SUB㧦㧖㧖㧔㧖㧖㧕

* When [REPRINT] button is pressed, the display returns to

the cassette select screen to allow self-print of the SPF

adjustment pattern (front, back) again.

* When [RESCAN] button is pressed, the SPF adjustment

pattern (front, back) is scanned again.

* When [RETRY] button is pressed, the adjustment value is

not saved in EEPROM and RAM and shifted to the top menu

screen.

* When [DATA] button is pressed, the data used in execution

of the adjustment are displayed.

10) When [OK] button is pressed, the adjustment value is saved in

EEPROM and RAM and the display is shifted to the end

screen.

SIMULATION NO.5028

TEST

AUTO IMAGE POSITION ADJUSTMENT㧦SERVICE

SIMULATION COMPLETE

PLEASE PUSH CA KEY

0

CLOSE

3) Enter the simulation 63-2 mode.

RETRYRESCANREPRINT

DATA

OK

4) Select, [DSPF SHADING].

0

CLOSE

1/1

MX3501N ADJUSTMENTS 7 – 9

Page 38

5) When [EXECUTE] button is pressed, it is highlighted and

shading is started.

* During execution, "SHADING EXECUTING..." is displayed.

* When [EXECUTE] button is pressed during execution, the

operation is interrupted.

* When shading is completed normally, [EXECUTE] button

returns to the normal display and "COMPLETED" is displayed.

* When [SYSTEM SETTINGS] key is pressed during other

than printing, the display returns to the sub number entry

screen.

<Descriptions of buttons>

Display Content

OC

SHADING

DSPF

SHADING

OC analog correction level correction, and shading