Page 1

SERVICE MANUAL

Ver 1.1 2004. 09

MDS-PC1

9-922-739-13

2004I02-1

© 2004.09

MiNi DiSC DECK

Sony Corporation

Audio Group

Published by Sony Engineering Corporaton

Page 2

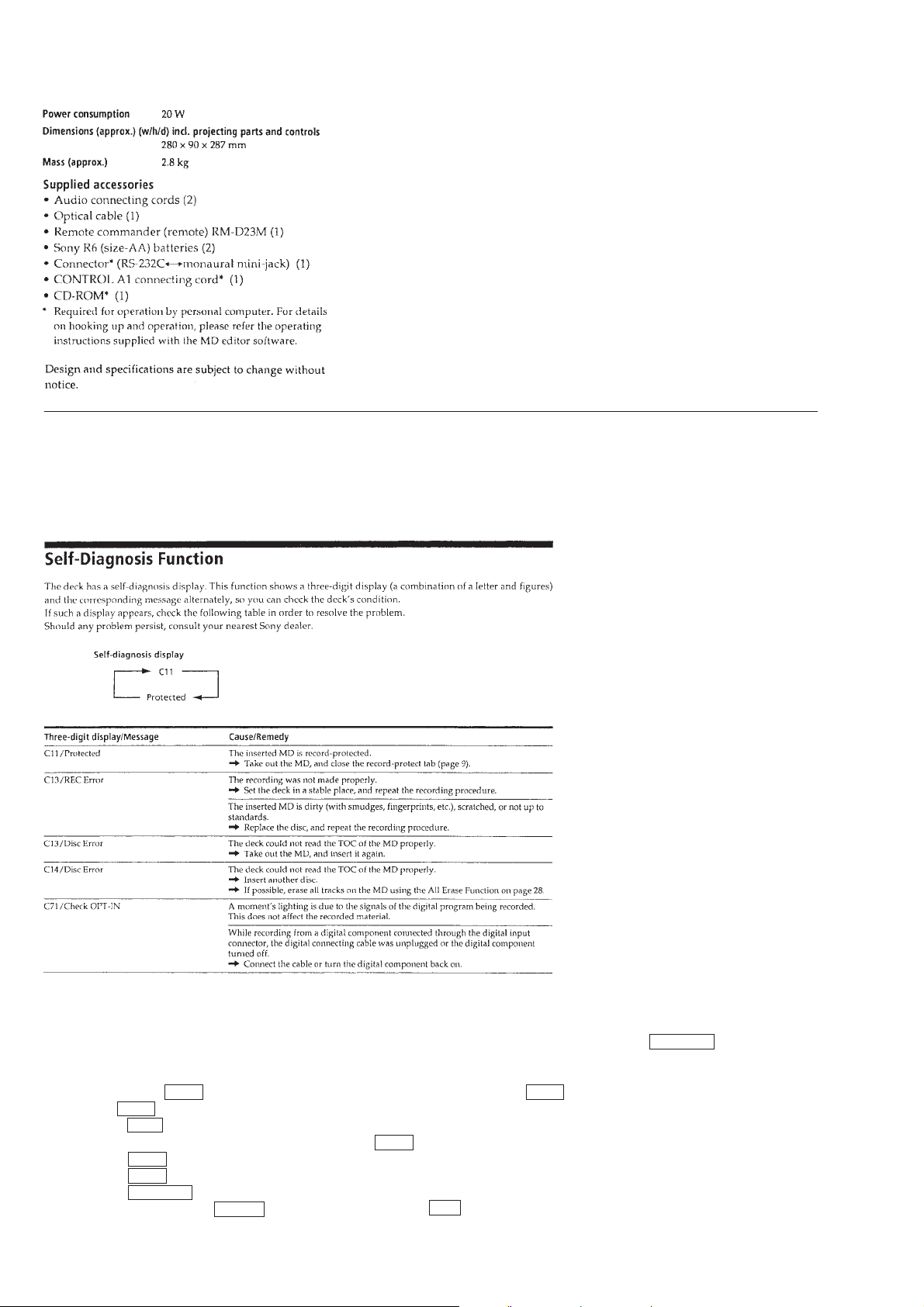

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for users which are displayed automatically when errors occur, and error codes which

show the error history in the test mode during servicing. For details on how to view error codes for users, refer to the following box in the

instruction manual. For details on how to perform checks during servicing, refer to the following “Procedure for Using the Self-Diagnosis

Function (Error History Display Mode)”.

Procedure for Using the Self-Diagnosis Function (Error History Display Mode)

Note: Perform the self-diagnosis function in the “error history display mode” in the test mode. The following describes the least required

steps. Be careful not to enter other modes by mistake. If other modes are set accidentally, press the EDIT/NO button to exit that

mode.

1. While pressing the AMS dial, connect the power plug to the outlet, and release the AMS dial.

2. Rotate the AMS dial until “ERR DP MODE” is displayed.

3. Pressing the YES button sets the error history mode and displays “total rec”.

4. Select the contents to be displayed or executed using the AMS dial.

5. Pressing the AMS dial displays or executes the contents selected.

6. Pressing the AMS dial another time returns to step 4.

7. Pressing the EDIT/NO button displays “ERR DP MODE” and exits the error history mode.

8. T o e xit the test mode, set the TIMER knob to “OFF”, and press the 1/u button. The unit sets into the STANDBY state, and the test mode

ends.

– 2 –

Page 3

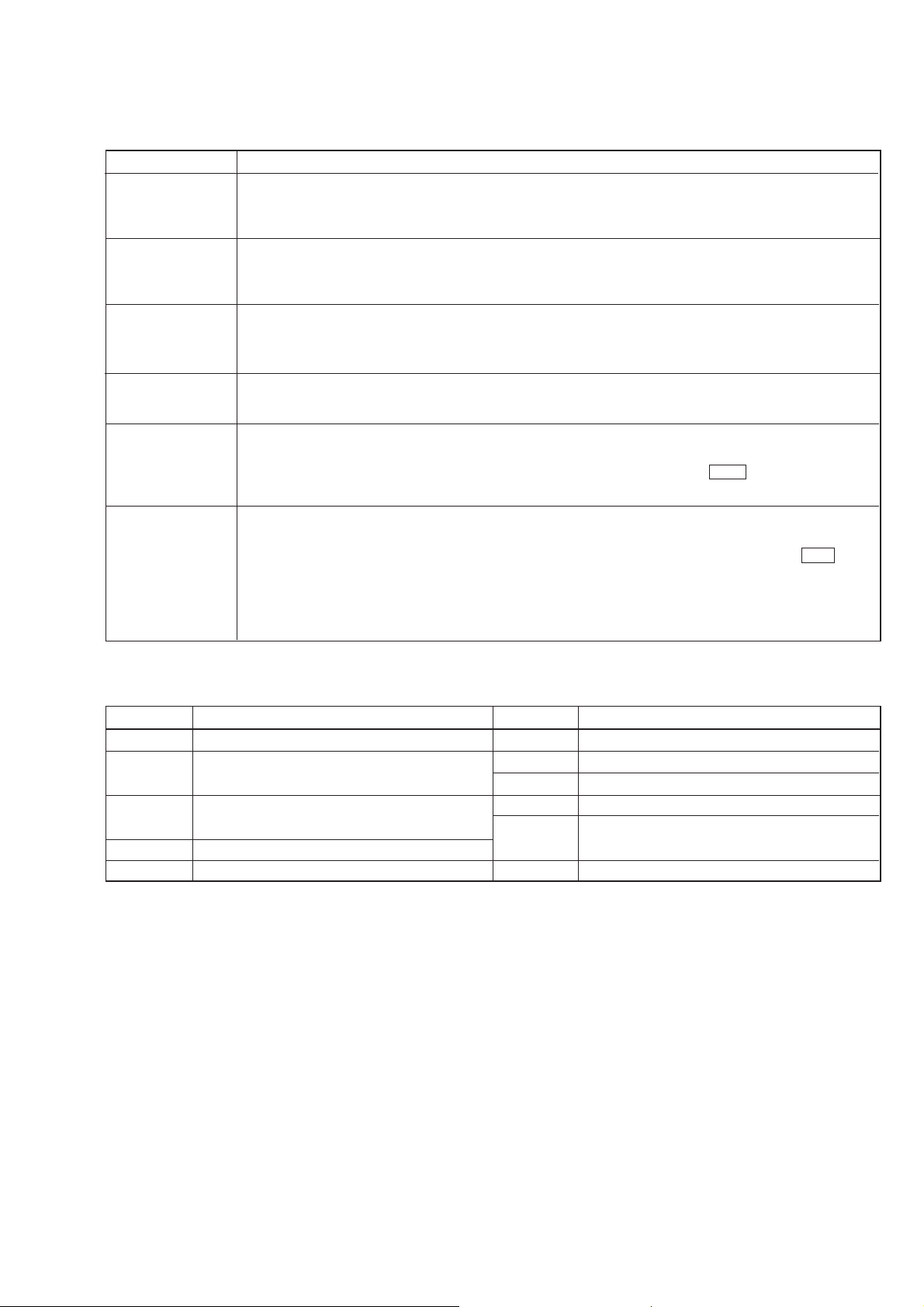

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

total rec

total play

retry err

total err

err history

er refresh?

Details of History

Displays the recording time in the form of “rππππππh”.

The displayed time is the total number of hours the laser is high power, which is about one-fourth of the actual

recording time. The time is displayed in decimal digits between 0h and 65535h.

Displays the playback time in the form of “pππππππh”.

The displayed time is the total actual play time. The paused time is not counted. The time is displayed in decimal

digits between 0h and 65535h.

Displays the total number of retries during recording and retry errors during playback in the form of “rππpππ”.

r indicates the retries during recording while p indicates the retry errors during playback. The number of retries is

displayed in hexadecimal digits between 00 and FF.

Displays the total number of errors in the form of “totalππ”.

The number of errors is displayed in hexadecimal digits between 00 and FF.

Displays the 10 latest errors in the form of “0π E@@”.

The π indicates the history number. The smaller the number, the newer is the error. (00 is the latest error.)

The @@ indicates the error code. Refer to the following table for details. Rotate the AMS dial to switch the error

history.

Mode which erases all the error histories.

The error history serves as a reference for when to replace the optical pick-up. Perform this procedure when the

optical pick-up has been replaced in order to erase past error histories and not at other times. Press the YES button

when “er refresh??” is displayed. The history will be erased and “Complete!” will be displayed momentarily. Be

sure to check the following when this mode has been executed.

*Check that the data has been erased.

*Perform recording and playback, and check that the mechanism operates normally.

Table of Error Codes

Error Code

E00

E01

E02

E03

E04

No error

Disc error. Cannot read PTOC

(Disc is ejected out)

Disc error. UTOC error

(Disc is not ejected out)

Loading error

Cannot read address (Servo has deviated)

Details of Error

Error Code

E05

E06

E07

E08

E09

E0A

Details of Error

FOK has deviated

Unfocused (Servo has deviated)

Recording retry

Recording retry error

Play retry error

(Access error)

Playback retry error (C2 error)

– 3 –

Page 4

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the equipment manufacturer.

Discard used batteries according to manufacture’s instructions.

ADVARSEL!

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilakting skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten.

Brukte batterier katterier kasseres i henhold til fabrikantens

VARNIG

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som rekommenderas

av apparattillverkaren.

Kassera använt batteri enligt gällande föreakrifter.

VAROITUS

Parist voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laite valmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

This caution

label is located

inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

PARTS No. MODEL

4-996-315-1π Singapore model

4-996-315-2π AEP, UK model

4-996-315-3π US model

– 4 –

Page 5

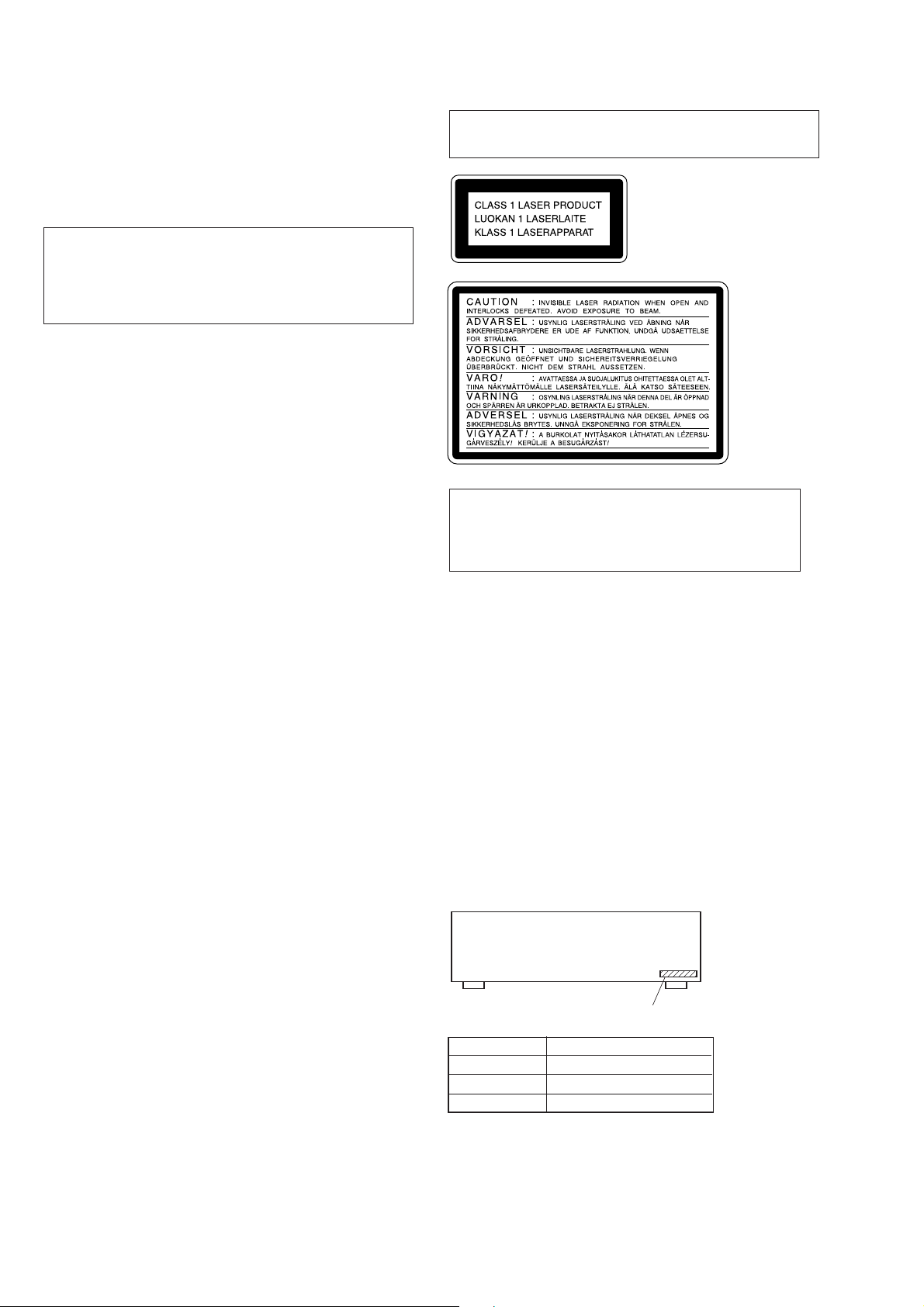

SAFETY CHECK-OUT

TABLE OF CONTENTS

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leaka ge. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

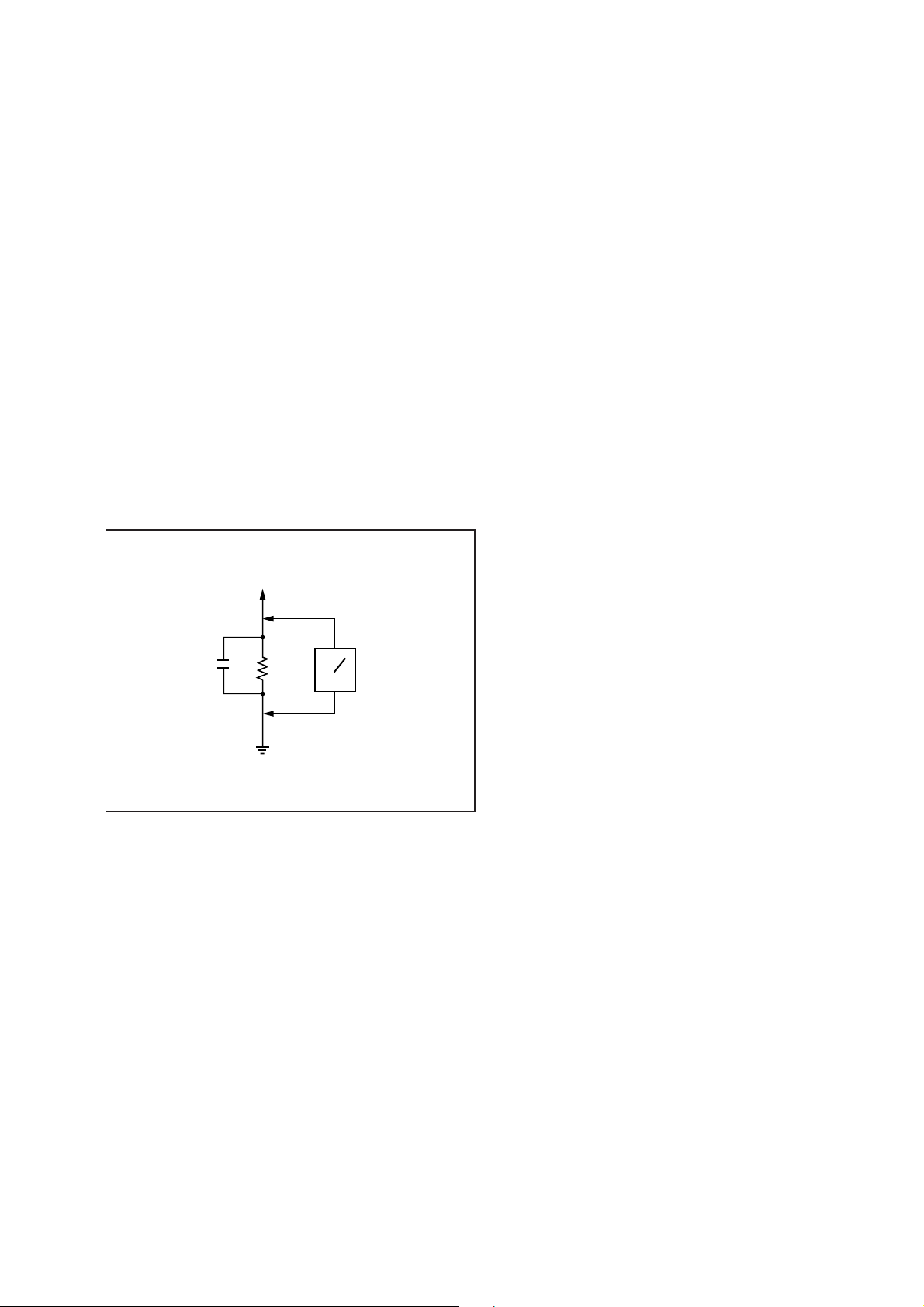

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C v oltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

AC

voltmeter

(0.75V)

1. SERVICING NOTE .......................................................... 6

2. GENERAL .......................................................................... 9

3. DISASSEMBLY

3-1. Front Panel ......................................................................... 29

3-2. Back Panel and Main Board ...............................................30

3-3. Bracket (T)/(L)/(R) ............................................................. 31

3-4. SUB Chassis ....................................................................... 31

3-5. Shutter Assembly ................................................................ 32

3-6. Slider Complete Assembly.................................................. 33

4. TEST MODE ..................................................................... 34

5. ELECTRICAL ADJUSTMENTS ............................... 38

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 43

6-2. Block Diagrams

• BD Section ....................................................................... 45

• Main Section ....................................................................47

6-3. Schematic Diagram – BD (1/2) Section –........................... 51

6-4. Schematic Diagram – BD (2/2) Section –........................... 53

6-5. Printed Wiring Board – BD Section –.................................55

6-6. Printed Wiring Board – SW Section – ................................57

6-7. Schematic Diagram – SW Section – ................................... 58

6-8. Printed Wiring Board – Main Section –.............................. 59

6-9. Schematic Diagram – Main (1/3) Section – ........................ 61

6-10. Schematic Diagram – Main (2/3) Section – ...................... 63

6-11. Schematic Diagram – Main (3/3) Section – ...................... 65

6-12. Printed Wiring Board – Panel Section –............................ 67

6-13. Schematic Diagram – Panel Section – .............................. 69

6-14. IC Block Diagrams ........................................................... 71

6-15. IC Pin Functions ............................................................... 76

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

7. EXPLODED VIEWS

7-1. Front Panel Section ............................................................. 84

7-2. Chassis Section ................................................................... 85

7-3. Mechanism Deck Section 1 (MDM-3B) .............................86

7-4. Mechanism Deck Section 2 (MDM-3B) .............................87

8. ELECTRICAL PARTS LIST ........................................ 88

– 5 –

Page 6

SECTION 1

SERVICING NOTE

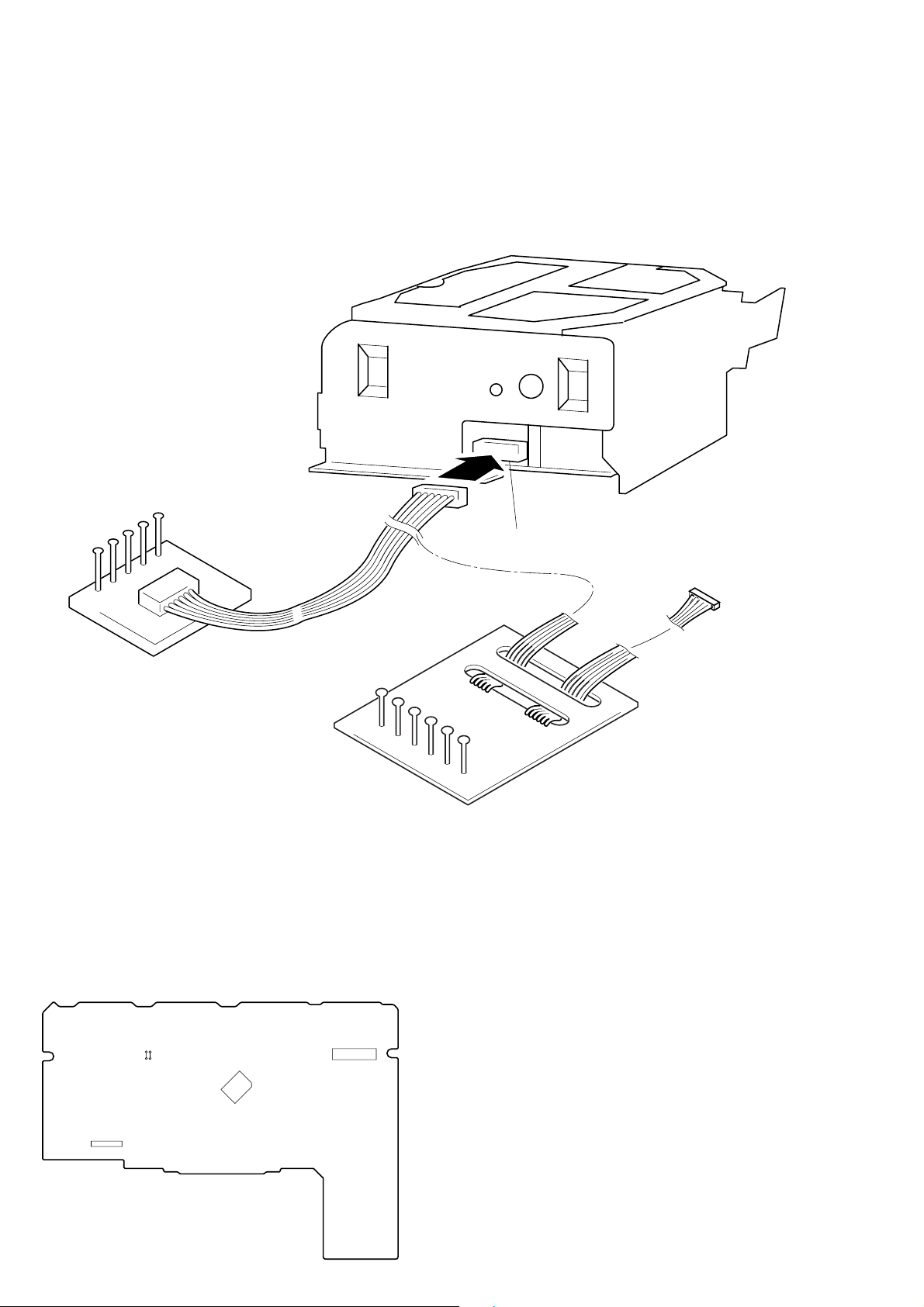

BD BOARD WAVEFORM CHECK TOOL

Use the jig (J-2501-124-A or J-2501-149-A) to facilitate the checking of the waveform of the BD board. The names and check items of each

terminal are as follows.

I+3V : For measuring the IOP (check if the optical pick-up laser has weakened)

IOP : For measuring IOP (check if the optical pick-up laser has weakened)

TEO : TRK error signal (traverse adjustment)

VC : Reference level for checking signals

RF : RF signal (jitter check)

Mechanism deck

Jig

RF

RF

VC

TEO

IOP

I+3V

GND

CN110

6P connector

Jig

(J-2501-149A)

GND can not be used.

H-3V

IOP

TEO

VC

(J-2501-124A)

[FORCED RESET]

Perform forced reset if the unit does not operate normally due to the hangup of the microprocessor.

It is recommended that this be performed when the test mode and retry cause display mode cannot be exited, or when the unit does not

operate normally when reassembled after being disassembled.

Method:Disconnect the power plug from the outlet, short-circuit the JW143 and 164 (RESET) of the MAIN board using a pair of tweezers,

and discharge the backup battery.

[MAIN BOARD] (Component Side)

JW143 JW164

CN307

IC401

IC101

– 6 –

Page 7

RETRY CAUSE DISPLAY MODE

* In this test mode, the causes for retry of the unit during recording and stop can be displayed on the fluorescent display tube. During

playback, the “track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

* The following will be displayed:

During recording and stop :Retry cause, number of retries, and number of retry errors.

During playback :Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

Procedure:

1. Load a recordable disc whose contents can be erased into the unit.

2. Press the MENU/NO button. When “Edit Menu” is displayed on the fluorescent display tube, rotate the AMS dial to display “All

Erase?”.

3. Press the YES button. (Or press the AMS dial)

4. When “All Erase??” is displayed on the fluorescent display tube, the music calendar number blinks.

5. Press the YES button to displa y “Complete!!”, and press the p button immediately . Wait for about 15 seconds while pressing the button.

(The AMS dial can be pressed instead of the YES button for the same results.)

6. When the “TOC” displayed on the fluorescent display tube goes off, release the p button.

7. Press the rREC button to set the recording standby state. Then press the ·P button to start recording.

8. Press the DISPLAY/CHAR button and check the test mode display (Fig. 1).

9. T o c heck the “track mode”, press the ·P button to start play. Then press the DISPLAY/CHAR button to display the test mode display

(Fig. 2), and check the display.

10. T o exit the test mode, press the 1/u button to turn OFF the power. When “TOC” disappears, disconnect the po wer plug from the outlet.

If the test mode cannot be exited, refer to “Forced Reset” on page 5.

Fig. 1 Reading the Test Mode Display (During recording and stop)

RTs@@c##e**

Fluorescent display tube display

@@: Cause of retry

## : Number of retries

** : Number of retry errors

Fig. 2 Reading the Test Mode Display (During playback)

@@####** $$

Fluorescent display tube display

@@: Parts No. (name of area named on TOC)

## : Cluster

** : Sector

$$ : Track mode (Track information such as copyright information of each part)

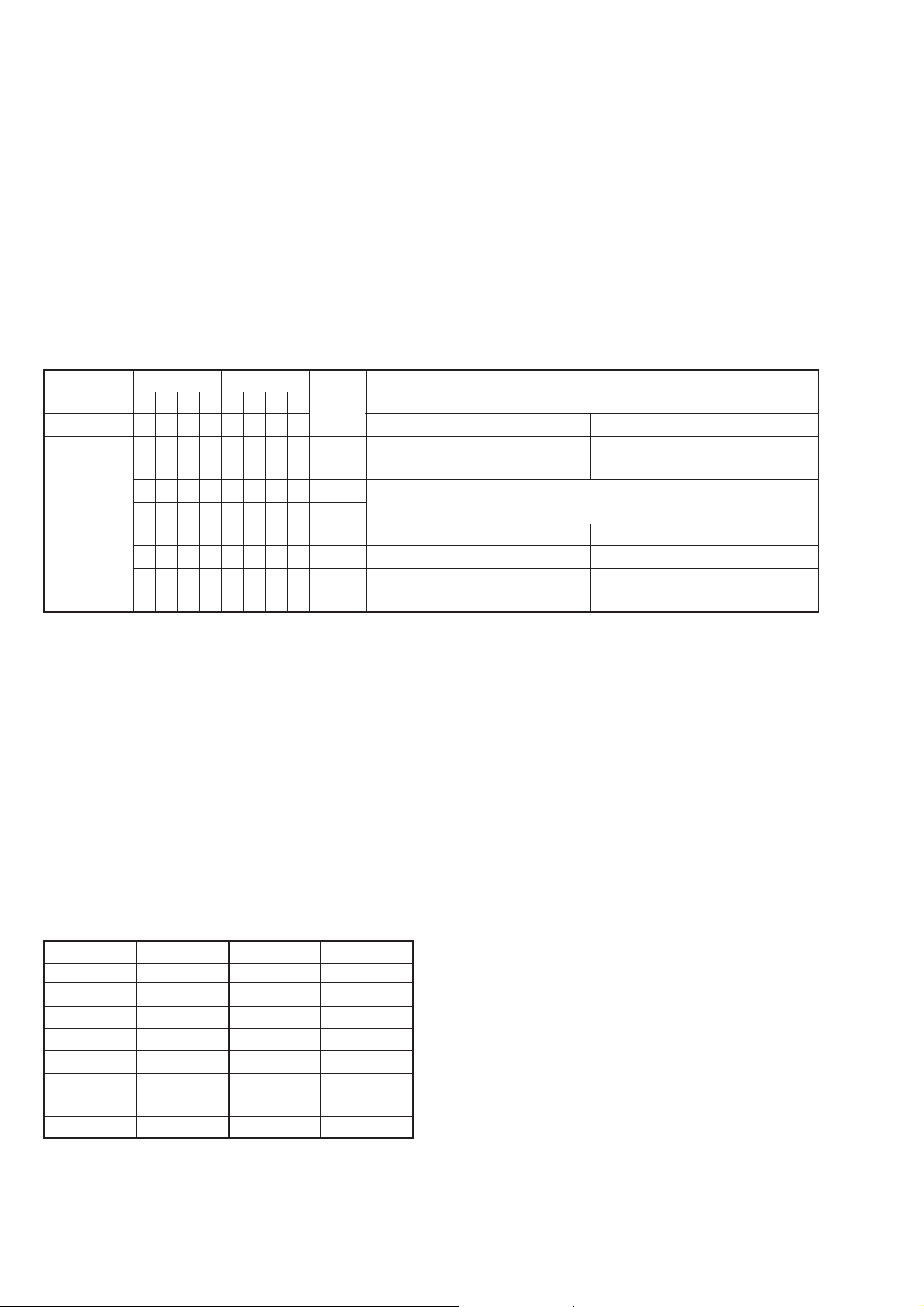

Reading the Retry Cause Display

Hexadecimal

Bit

Binary

Address (Physical address on disc)

}

Higher Bits Lower Bits

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

Cause of Retry Occurring conditions

shock

Discontinuous address

ader5

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

When track jump (shock) is detected

When ADIP address is not continuous

When ADER was counted more than five times

continuously

When DIN unlock is detected

When not in focus

When ABCD signal level exceeds the specified range

When CLV is unlocked

When access operation is not performed normally

– 7 –

Page 8

Reading the Display:

Convert the hexadecimal display into the binary display. If more than two causes, they will be added.

Example

When 44 is displayed:

Upper bit : 4=0100 n b6

Lower bit : 4=0010 n b2

In this case, the retry cause is combined of “CVL unlock” and “ader5”.

When A4 is displayed:

Upper bit : A=1010 n b7+b5

Lower bit : 4=0010 n b2

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

Reading the Track Mode Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into the binary display. Several cause are added and displayed.

Example

When 84 is displayed:

Upper bit : 8=1000 n b7

Lower bit : 4=0100 n b2

In this case, as b2 and b7 are 1 and others are 0, the cause is combined of “Emphasis OFF”, “Monaural”, “Original”, Copyrighted” and

“Write permitted”.

When 07 is displayed:

Upper bit : 0=0000 n all 0

Lower bit : 7=0111 n b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, the cause is combined of “Emphasis ON”, “Stereo”, “Original”, Copyrighted” and

“Write prohibited”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Hexa-

decimal

01

02

04

08

10

20

40

80

When 0 When 1

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

Details

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Hexadecimal/Decimal Conversion Table

Hexadecimal Binary Hexadecimal Binary

0

1

2

3

4

5

6

7

0000

0001

0010

0011

0100

0101

0110

0111

8

9

A

B

C

D

E

F

1000

1001

1010

1011

1100

1101

1110

1111

– 8 –

Page 9

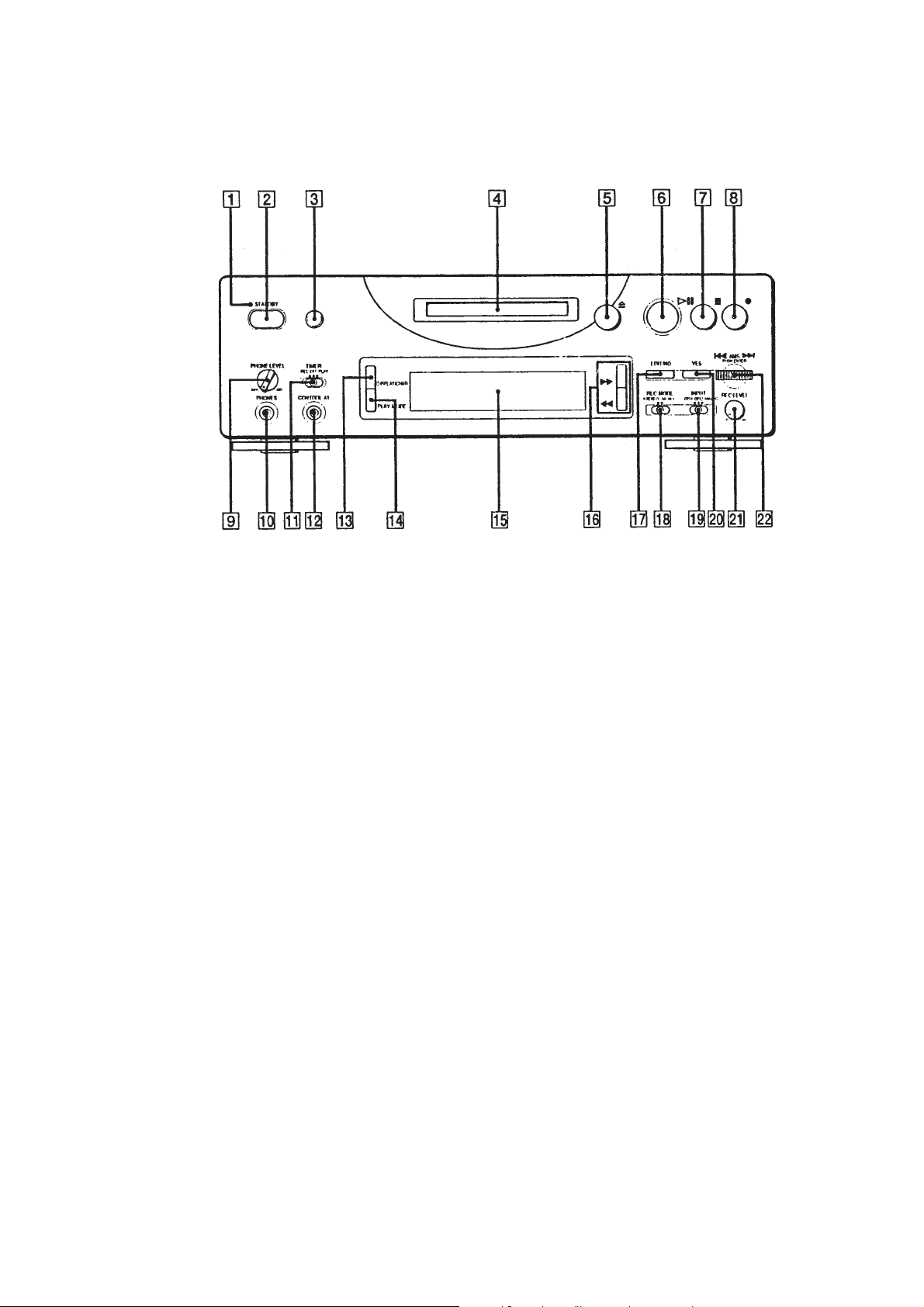

Front Panel

SECTION 2

GENERAL

Location of Parts and Controls

1 STANDBY lamp

2 1/u (Power) switch

3 Remote sensor

4 DISK compartment

5 § button

6 ·P button

7 p button

8 r button

9 PHONE LEVEL knob

10 PHONES jack

11 TIMER switch

12 CONTROL A1 jack

13 DISPLAY/CHAR button

14 PLAY MODE button

15 DISPLAY window

16 0/) button

17 EDIT/NO button

18 REC MODE switch

19 INPUT switch

20 YES button

21 REC LEVEL knob

22 AMS dial

• AMS is the abbreviation for Automatic Music Sensor.

– 9 –

Page 10

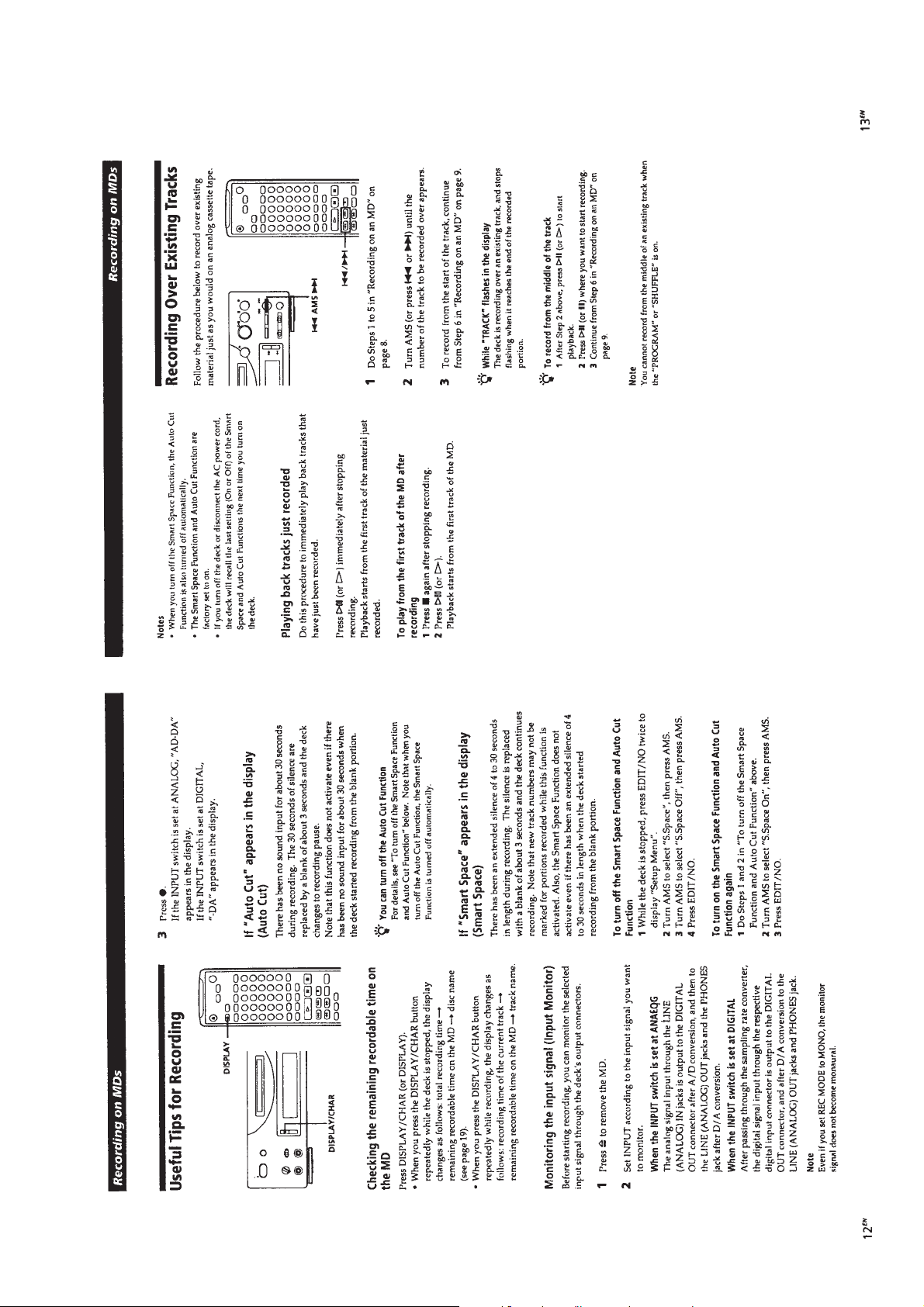

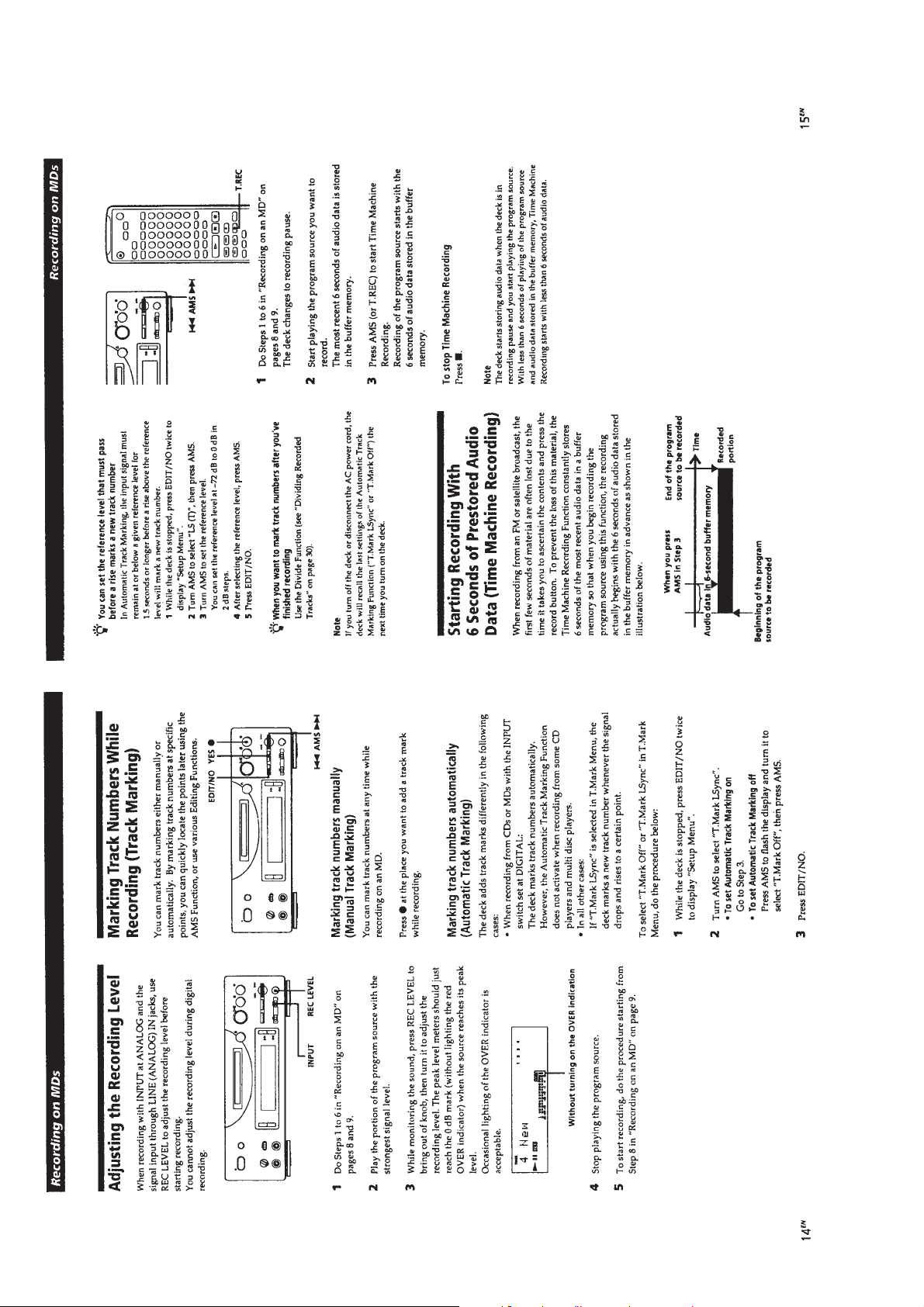

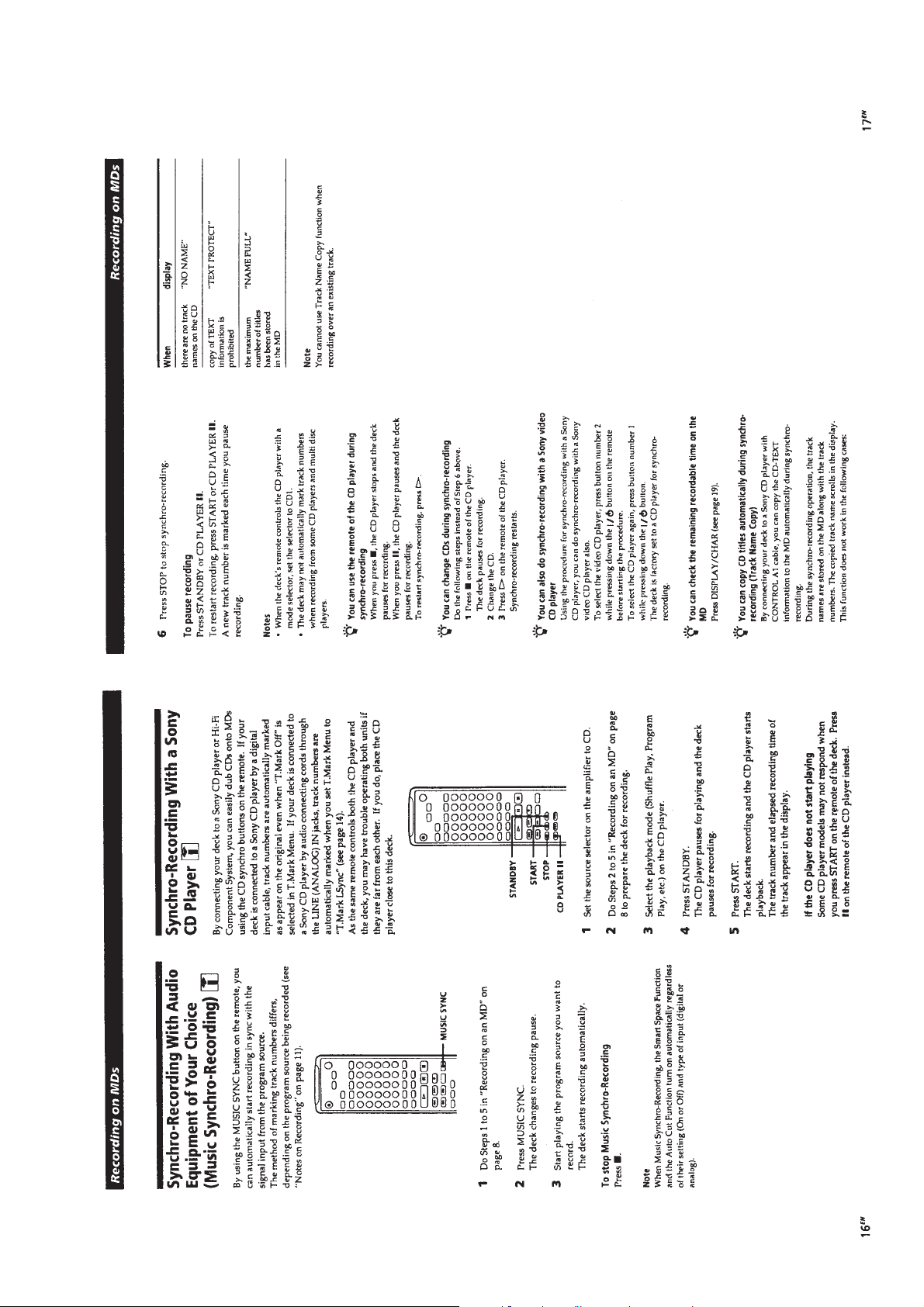

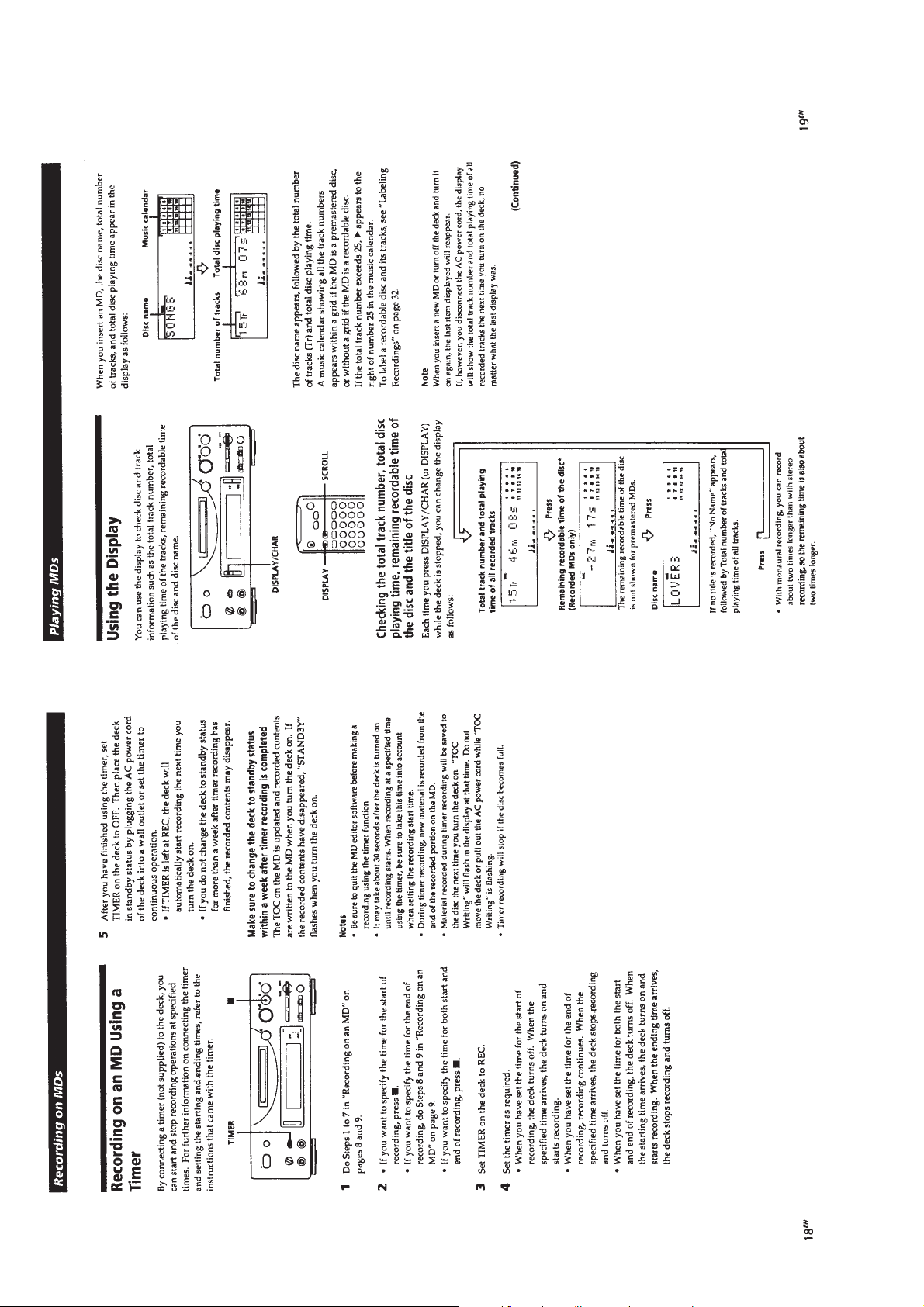

This section is extracted from

instruction manual.

– 10 –

Page 11

– 11 –

Page 12

– 12 –

Page 13

– 13 –

Page 14

– 14 –

Page 15

– 15 –

Page 16

– 16 –

Page 17

– 17 –

Page 18

– 18 –

Page 19

– 19 –

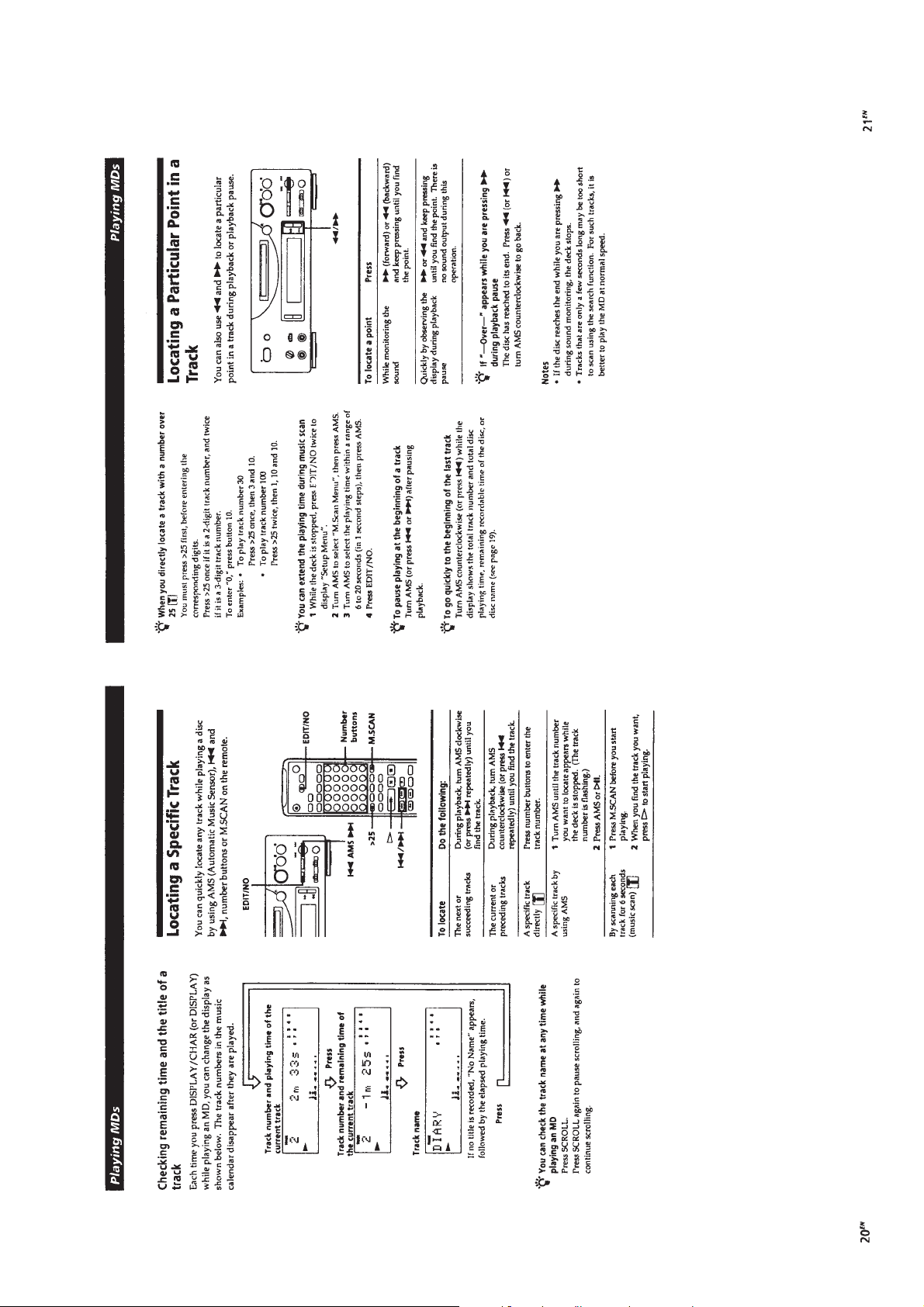

Page 20

– 20 –

Page 21

– 21 –

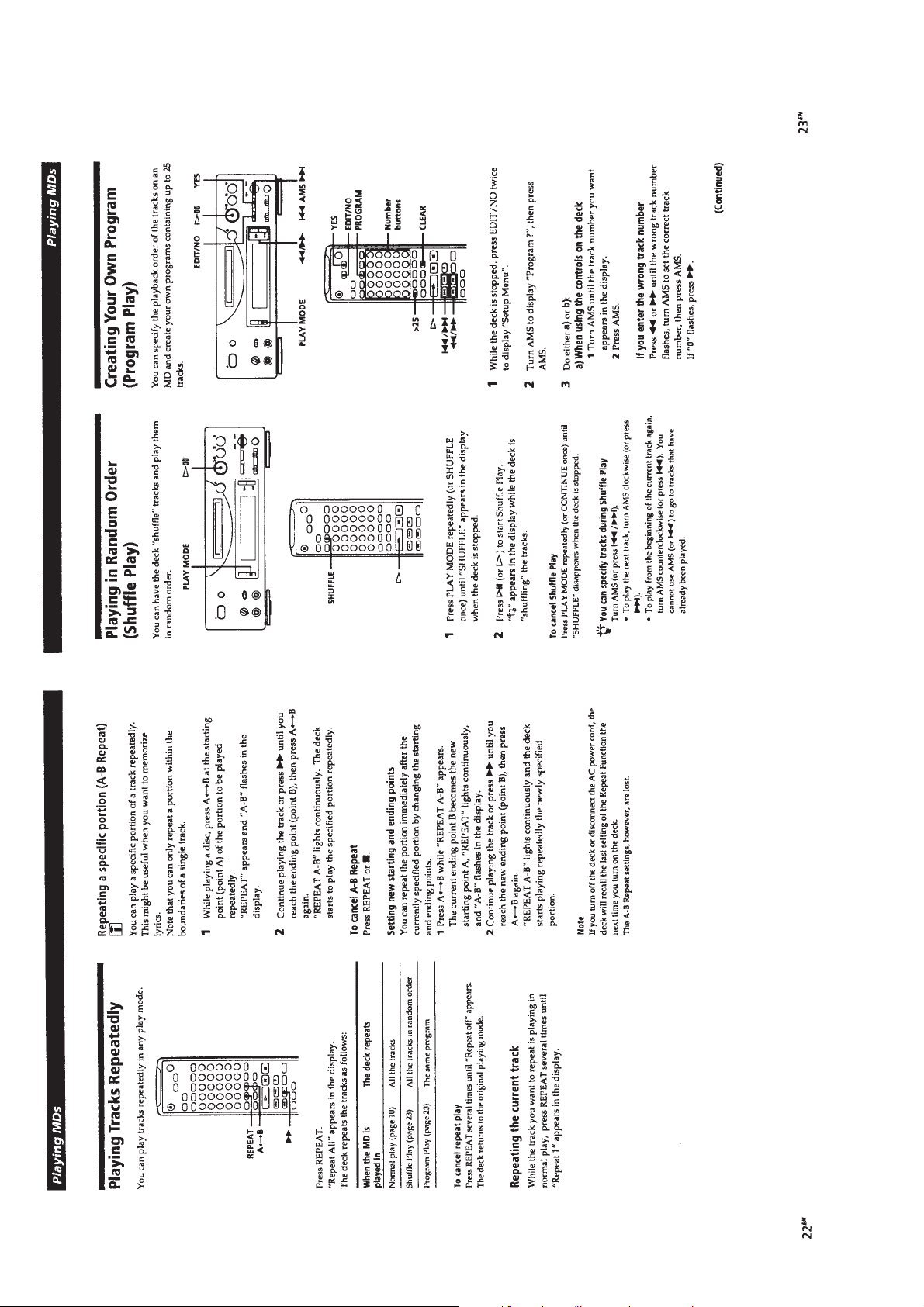

Page 22

– 22 –

Page 23

– 23 –

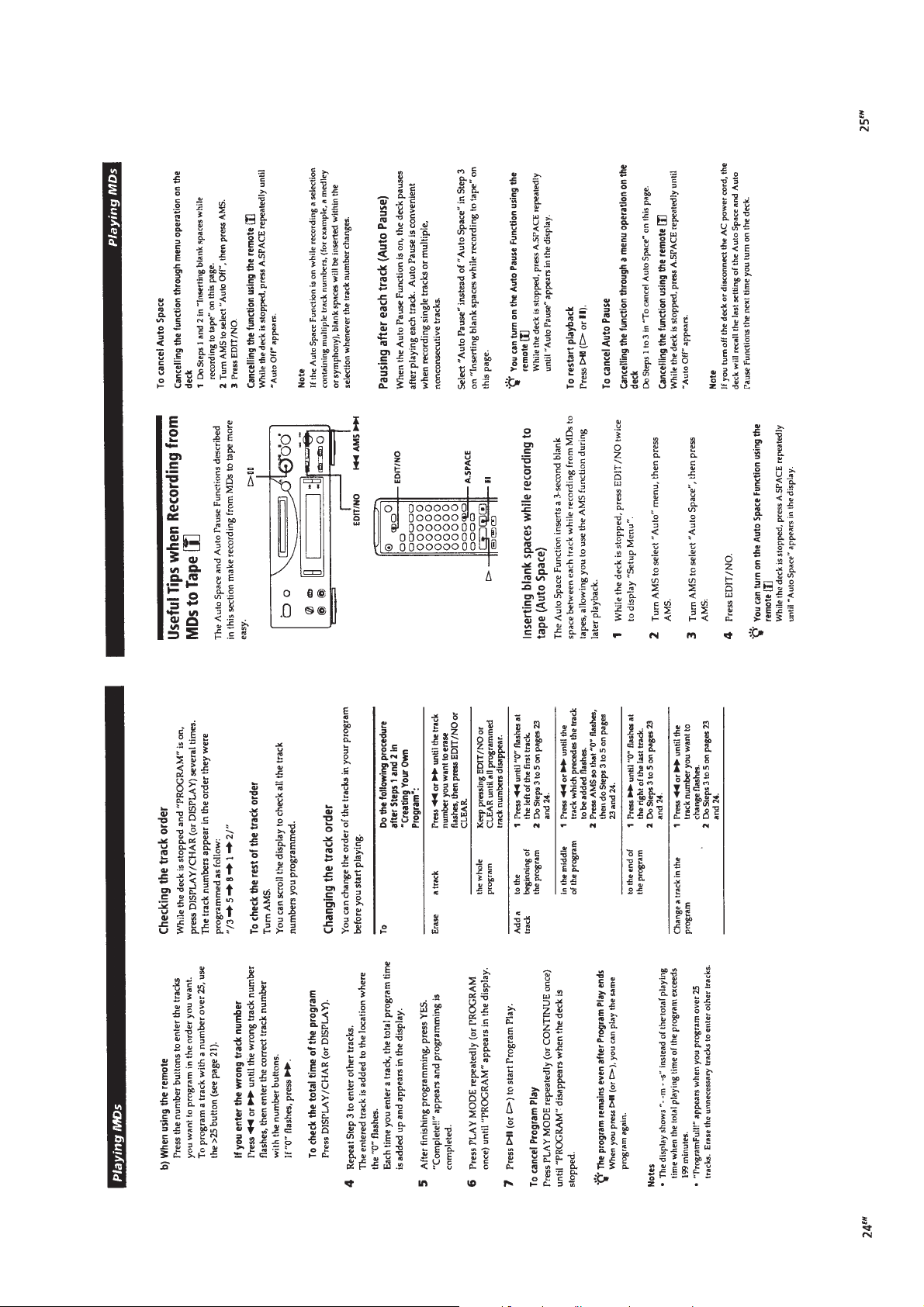

Page 24

– 24 –

Page 25

– 25 –

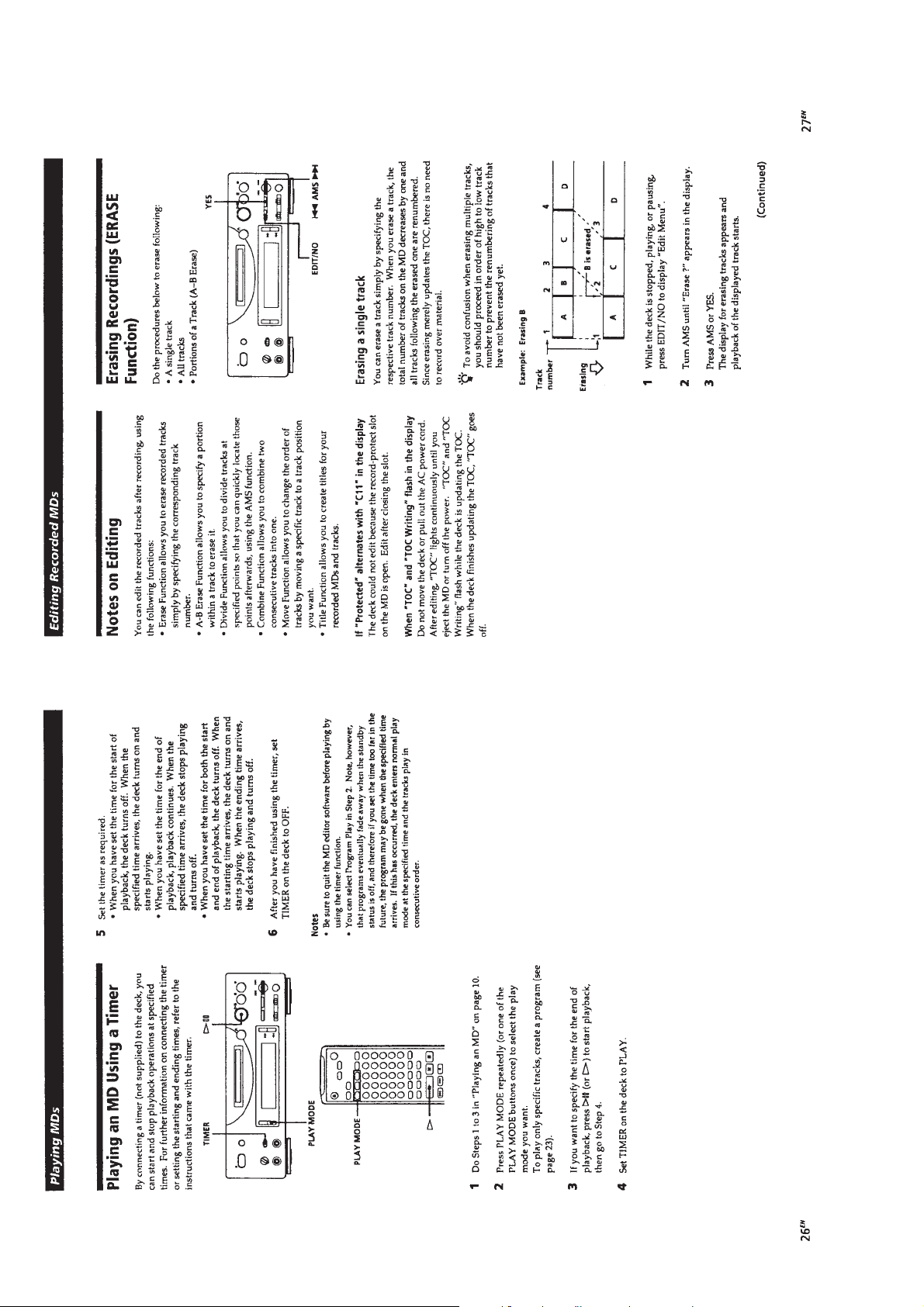

Page 26

– 26 –

Page 27

– 27 –

Page 28

– 28 –

Page 29

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

3-1. FRONT PANEL

7

Front panel assembly

3

Connector (CN403)

2

Connector

(CN800)

6

Three claws

5

Four screws (BVTP3x10)

4

Lead (With connector)

1

Flat type wire

(23core)

– 29 –

Page 30

3-2. BACK PANEL AND MAIN BOARD

!£

Back panel

!¢

Main board

8

Two screws (BVTP3x10)

2

Connector (CN301)

3

Two screws

(PTTWH3x6)

1

Connector (CN306)

4

Two screws

(PTTWH3x6)

7

Flat type wire

(29core)

5

Power

trnasformer

6

Flat type wire

(19core)

!™

Four screws (BVTP3x10)

!º

Three screws (BVTP3x10)

9

Screw

(BVTP3x10)

Note for installation

Install the Back panel as shown

in the figure.

Back panel

!¡

PC board holder

Chassis

– 30 –

Page 31

3-3. BRACKET (T)/(L)/(R)

2

Bracket (T)

6

Two screws

(BVTT2x3)

7

Bracket (L)

1

Four screws

(BVTT2x3)

4

Screw

(BVTT2x3)

5

Bracket

(joint)

3

Screw

(BVTT2x3)

3-4. SUB CHASSIS

1

Two step screws

5

Sub chassis

3

Two insulators

Part A

2

Two step screws

4

Two insulators

8

Two screws

(BVTT2x3)

Part A

Part A

9

Bracket (R)

NG

OK

– 31 –

Take care so that the part A

may be right position when installing.

Page 32

3-5. SHUTTER ASSEMBLY

2

Shaft (shutter)

1

Stopper washer

3

Shutter assembly

Shutter assembly

Shaft (lid)

Shaft (shutter)

Hole A

When installing, install the shaft (shutter) into the hole A

as shown in the figure before installing the shaft (lid) into

the hole B.

Hole B

– 32 –

Page 33

3-6. SLIDER COMPLETE ASSEMBLY

1

Screw

(M1.7x2)

2

Retainer (gear)

3

Set the shaft of Gear (LA) to be at the

position in the figure.

4

Remove the slider complete assembly

in the direction of arrow with putting

out of two claws.

Install the part A of lever (head up)

to pass over the slider complete assembly.

Take care not to damage the

detective switch.

Part A

OK

NG

Slider complete assembly

45˚

claw

claw

• Note for installation of Slider complete assembly

– 33 –

Page 34

SECTION 4

TEST MODE

4-1. PRECAUTIONS FOR USE OF TEST MODE

(1)As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc is

stopped before setting and removing it.

Even if § button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will not stop

rotating.

Therefore, it will be ejected while rotating.

Be sure to press the EDIT/NO button to stop the disc rotation before pressing the § button.

(2)Detection of the rec-proof tab is not performed in the test mode. Therefore, the contents of the recorded contents will be erased when

operations in the mode for emitting the recording laser are performed (4-1-1) or when the r button is pressed. Consequently, be careful

not to set the continuous recording mode and traverse adjustment mode with a disc whose contents cannot be erased in the test mode.

4-1-1. Recording Laser Emission Mode and Operating Buttons

*Continuous recording mode (CREC MODE)

*Traverse adjustment mode (EFBAL ADJUST)

*Laser power adjustment mode (LDPWR ADJUST)

*Laser power check mode (LDPWR CHECK)

*Traverse (MO) check (EF MO CHECK)

*Traverse (MO) adjustment (EF MO ADJUST)

*When pressing the r button.

4-2. SETTING THE TEST MODE

While pressing the AMS dial, connect the power plug to the outlet and release the AMS dial.

4-3. EXITING THE TEST MODE

With the TIMER knob set to “OFF”, press the POWER button. The STANDBY state will be set.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the AMS dial, YES button, and EDIT/NO button.

The functions of these buttons are as follows.

Function name

AMS knob

YES button

EDIT/NO button

Changes parameters and modes

Proceeds onto the next step. Finalizes input.

Returns to previous step. Stops operations.

Function

– 34 –

Page 35

4-5. SELECTING THE TEST MODE

There are altogether 23 test modes, shown in the following table. Rotating the AMS dial to the right switches to the mode below the current

mode in the table while rotating to the left switches to the mode above. Each time the EDIT/NO button is pressed, the display changes in the

following order;

“TEMP CHECK” n “TEMP ADJUST” n “SLED MO VE” n “TEMP CHECK”...

Display

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

CPLAY MODE

CREC MODE

Scurve CHECK

DETRK CHECK

TEMP ADJUST

LDPWR ADJUST

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

EEP MODE

MANUAL CMD

SVDATA READ

ERR DP MODE

SLED MOVE

ACCESS MODE

0920 CHECK

HEAD ADJUST

V er@@@@@

Contents

Temperature compensation offset check

Laser power check

Traverse (MO) check

Traverse (CD) check

Focus bias check

Continuous playback mode

Continuous recording mode

S curve check

Detrack check

Temperature compensation offset adjustment

Laser power check

Traverse (MO) check

Traverse (CD) check

Focus bias check

Nonvolatile memory control

Command transfer

Status display

Error history display, clear

Sled check

Access check

Outermost circumference check

Head position check

Microprocessor version display

Mark

(X)

(X)

(X) (!)

(X)

(X)

(X)

(X)

(X)

(X)

• For details of each adjustment mode , refer to the items in “5. Electric Adjustments”. For details of “ERR DP MODE”, refer to the selfdiagnosis function on page 2.

• If other modes are set accidentally, press the EDIT/NO button to exit that mode.

• As items marked (X) in the “Mark” column are not used during servicing, they are not described here. If these modes ar e set accidentally,

press the EDIT/NO button to exit that mode. Be especially careful with items marked (!) as they will overwrite the non-volatile memory,

and as a result, the unit will not operate normally.

4-5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

(1) Set the disc in the unit. (Recordable discs or discs for playback only).

(2) Rotate the AMS dial and display “CPLAY MODE”.

(3) Press the YES button to change the display to “CPLAY MID”.

(4) When access completes, the display changes to “C1=

Note: The numbers “

” displayed indicate the error rate and “ADER”.

AD= ”.

2. Changing the part to be played back

(1) When th YES button is pressed during continuous playback, the display changes as below, and the played back part can be changed.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

(2) When access completes, the display changes to “C1=

Note: The numbers “

” displayed indicate the error rate and “ADER”.

AD= ”.

3. Ending the continuous playback mode

(1) Press the EDIT/NO button. The display changes to “CPLAY MODE”.

(2) Press the § button to remove the disc.

Note:The playback start addresses for IN, MID, and OUT are as follows. To display the playback position address on the display, press

the DISPLAY/CHAR button to display “CPLAY(

)”.

IN: 40h cluster

MID: 300h cluster

OUT:700h cluster

– 35 –

Page 36

4-5-2. Operating the Continuous Recording Mode

1. Entering the continuous recording mode

1 Set a recordable disc in the unit. (Refer to Note 3.)

2 Rotate the AMS dial and display “CREC MODE”.

3 Press the YES button to change the display to “CREC MID”.

4 When access completes, the display changes to “CREC ( )” and the REC display lights up.

Note: The numbers “

” displayed indicate the recording position address.

2. Changing the part to be recorded

1 When th YES button is pressed during continuous recording, the display changes as below and the recorded part can be changed.

The REC display is off while changing.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

2 When access completes, the display changes to “CREC MODE”, and the REC display lights up.

Note: The numbers “

” displayed indicate the recording position address.

3. Ending the continuous recording mode

1 Press the EDIT/NO button. The display changes to “CREC (

)”, and the REC display lights up.

2 Press the § button to remove the disc.

Note 1: The recording start addresses for IN, MID, and OUT are as follows.

IN: 40h cluster

MID: 300h cluster

OUT: 700h cluster

Note 2: The EDIT/NO button can be used to stop recording anytime.

Note 3: The rec-proof tab will not be detected during the test mode. Be careful not to set the continuous recording mode with a disc whose

contents cannot be erased.

Note 4: Do not perform continuous recording for long periods of time above 5 minutes.

Note 5: During continuous recording, be careful not to apply vibration.

4-5-3. Non-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If set accidentally, press the EDIT/NO button immediately to exit it.

4-6. FUNCTIONS OF OTHER BUTTONS

Function

·P

p

)

0

r REC

POWER (*NOTE)

(TIMER : PLAY or REC)

PLAY MODE

DISPLAY/CHAR

§

POWER (*NOTE)

(TIMER: OFF)

Sets continuous playback when pressed in the STOP state. T urns ON/OFF the tracking servo when pressed during continuous

playback.

Stops the continuous playback and recording.

Moves the sled to the external circumference only while the button is pressed.

Moves the sled to the internal circumference only while the button is pressed.

Turns ON/OFF recording during continuous playback.

Switches between bit and groove when pressed.

Switches the spindle servo mode (CLVS ˜ CLV A).

Switches the displayed contents when pressed.

Ejects the disc.

Exits the test mode.

*Note: The function of the POWER button changes according to the position of the TIMER knob.

Contents

– 36 –

Page 37

4-7. DISPLAYS DURING TEST MODE

Mode display

Error rate display

Address display

Auto gain display (Not used in servicing)

Detrack check display (Not used in servicing)

IVR display (Not used in servicing)

The display changes according to the following sequence each time the DISPLAY/CHAR button is pressed.

1. Mode display

“TEMP ADJUST” and “CPLAYMODE” are displayed.

2. Error rate display

The error rate is displayed as follows.

C1=ππππ AD=ππ

C1=:Indicates the C1 error.

AD=:Indicates ADER.

3. Address display

The address is displayed as follows.

(MO:Recordable discs, CD:Discs for playback only)

At this time, pressing the 1/u button with the TIMER knob set to

PLAY switches the display between groove and bit.

h=ππππs=ππππ(MO bit and CD)

h=ππππa=ππππ (MO groove)

h=Indicates the header address.

s=Indicates the SUBQ address.

a=Indicates the ADIP address.

Note:Displayed as “–” when servo is operated.

4. Auto gain display (Not used in servicing)

The auto gain is displayed as follows.

AG=ππ/ππ.ππ

5. Detrack check display (Not used in servicing)

The detrack is displayed as follows.

ADR=πππππππ

6. IVR display (Not used in servicing)

IVR is displayed as follows.

[ππ][ππ][ππ

Meanings of other displays

Display

¢

P

REC

–SYNC

A.SPACE

OVER

REPEAT

A-B

TRACK

DISC

DATE

CLOCK

Currently continuous playback (CLV:ON)

Tracking servo OFF

Recording mode ON

CLV low speed mode

ABCD adjustment completed

Tracking offset cancel ON

Tracking auto gain OK

Focus auto gain OK

Bit

High reflection rate

CLV-S

CLV LOCK

When Lit

Contents

When Off

STOP (CLV:OFF)

Tracking servo ON

Recording mode OFF

CLV normal mode

Tracking offset cancel OFF

Groove

Low reflection

CLV-A

CLV UNLOCK

– 37 –

Page 38

SECTION 5

d

ELECTRICAL ADJUSTMENTS

5-1. PRECAUTIONS FOR CHECKING LASER DIODE

EMISSION

When checking the emission of the laser diode during adjustments,

never view directly from the top as this may cause blindness.

5-2. PRECAUTIONS FOR USE OF OPTICAL PICK-

UP (KMS-260A)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the flexible board when using it.

Before disconnecting the connector, solder first. Before connecting

the connector, be careful not to remove the solder . Also take adequate

measures to prevent damage by static electricity . Handle the flexible

board with care as it breaks easily.

Pick-up

Laser tap

Flexible boar

5-3. PRECAUTIONS FOR ADJUSTMENTS

1) When replacing the following parts, perform adjustments and

checks marked ¬ in the order shown in the following table.

Optical

Pick-up

1. Temperature

compensation

offset

adjustment

2. Laser power

adjustment

3. Traverse

adjustment

4. Focus bias

adjustment

5. Error rate check

IC171

¬¬G¬

¬G¬¬

¬G¬¬

¬G¬¬

¬G¬¬

2) Perform the adjustment in the test mode.

After completing the adjustments, exit the test mode.

3) Perform the adjustments in the order shown.

4) Use the following tools and measuring devices.

• Check disc (MD) TDYS-1

(Parts No.:4-963-646-01)

• Laser power meter LPM-8001

(Parts No.:J-2501-046-A)

• Oscilloscope (Measure after calibration of the probe).

• Digital voltmeter

• Thermometer

• Jig for checking the BD board waveform

(Parts No.:J-2501-124-A)

5) When observing several signals on the oscilloscope, etc., make

sure that the VC and ground do not connect inside the

oscilloscope.

(The VC and ground will short-circuit.)

6) Using the above jig enables the waveform to be checked without

the need for soldering.

(Refer to Servicing Note on page 5.)

BD Board

IC101, IC121, IC192

D101

5-4. CREATING THE CONTINUOUSLY RECORDED

DISC

• The disc is used for the focus bias adjustment and error rate check.

The following describes how to create a continuously recorded

disc.

1. Insert a disc (blank disc) commercially available.

2. Rotate the AMS knob to display “CREC MODE”.

3. Press the YES button to display “CREC MID”.

“CREC (0300)” will be momentarily displayed and recording

started.

4. Complete recording within 5 minutes.

5. Press the NO button and stop recording.

6. Press the § button and remove the disc.

Create the continuous recorded disc for adjusting the focus bias

and checking the error rate as described above.

Note:

• Be careful not to apply vibrations during continuous recording.

– 38 –

Page 39

5-5. TEMPERATURE COMPENSATION OFFSET

ADJUSTMENT

Save the current temperature data in the non-volatile memory as

the 25 °C standard data.

Note:

1. Normally, this adjustment should not be performed.

2. Set the surrounding temperature to 22 to 28 °C when performing

this adjustment.

Also perform this adjustment immediately after the power is

turned on when the internal temperature of the unit is the same

as the surrounding temperature (22 to 28 °C).

3. After replacing D101, perform this adjustment after the

temperature of parts reach the surrounding temperature.

Adjusting Procedure:

1. Rotate the AMS knob, to display “TEMP ADJUST”.

2. Press the YES button and select the “TEMP ADJUST” mode.

3. “TEMP= ” and the current temperature data are displayed.

4. To save the data:Press the YES button.

If not saving the data:Press the NO button.

5. When the YES button is pressed, “TEMP= SAVE” is

displayed, and then “TEMP ADJUST” is displayed again.

“TEMP ADJUST” is displayed again immedia tely after the NO

button is pressed.

Specification:

TEMP= should be E0 to EF. F0 to FF, 00 to 0F, 10 to 1F and 20

to 2F.

5-6. LASER POWER ADJUSTMENT

Connection:

Laser power

meter

2. Rotate the AMS knob to display “LDPWR ADJUST”.

(Laser power:For adjustment)

3. Press the YES button once to display “LD 0.9mW $@@”.

4. Rotate the AMS knob so that the laser power meter reads 0.86

to 0.92 mW. Set the range knob of the laser power meter to 10

mW, press the YES button, and save the adjustment results in

the non-volatile memory. (“LD SAVE $ ” is displayed

momentarily.)

5. “LD 7.0 mW $ ” is next displayed.

6. Rotate the AMS knob so that the laser po wer meter reads 6.9 to

7.1 mW, press the YES button, and sa ve the adjustment results

in the non-volatile memory. (“LD SAVE $ ” is displayed

momentarily.)

Note:Do not emit 7.0 mW continuously for more than 15

seconds.

7. Rotate the AMS knob to display “LDPWR CHECK”.

8. Press the YES button once to display “LD 0.9mW $ ”.

Check that the laser power meter reading is 0.85 to 0.91 mW.

9. Press the YES button another time to display “LD 7.0mW $

”.

Check that the readings of the laser power meter and digital

voltmeter become the specified v alue.

Specified value

Laser power meter reading:7.0 ± 0.1 mW

Digital voltmeter reading:Value displayed on optical pick-up label

± 10%

(Optical pick-up label)

KMS

260A

27X40

B0825

N

Iop = 82.5 mA in this case

Iop (mA) = Digital voltmeter reading (mV)/1 (Ω)

Optical pick-up

objective lens

Digital

Voltmeter

BD board

CN110 Pin

CN110 Pin

5

4

(I+3V)

(IOP)

Adjusting Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up from the disc slot. (If it cannot be set properly, pr ess the

0 or ) button to move the optical pick-up).

Connect the digital voltmeter to Pin 5 (I+3V) and Pin 4 (IOP)

of CN110.

10.Press the NO button to display “LDPWR CHECK” and stop

the laser emission.

(The NO button is effective at all times to stop the laser

emission.)

– 39 –

Page 40

5-5. TEMPERATURE COMPENSATION OFFSET

ADJUSTMENT

Save the current temperature data in the non-volatile memory as

the 25 °C standard data.

Note:

1. Normally, this adjustment should not be performed.

2. Set the surrounding temperature to 22 to 28 °C when performing

this adjustment.

Also perform this adjustment immediately after the power is

turned on when the internal temperature of the unit is the same

as the surrounding temperature (22 to 28 °C).

3. After replacing D101, perform this adjustment after the

temperature of parts reach the surrounding temperature.

Adjusting Procedure:

1. Rotate the AMS knob, to display “TEMP ADJUST”.

2. Press the YES button and select the “TEMP ADJUST” mode.

3. “TEMP= ” and the current temperature data are displayed.

4. To save the data:Press the YES button.

If not saving the data:Press the NO button.

5. When the YES button is pressed, “TEMP= SAVE” is

displayed, and then “TEMP ADJUST” is displayed again.

“TEMP ADJUST” is displayed again immedia tely after the NO

button is pressed.

Specification:

TEMP= should be E0 to EF. F0 to FF, 00 to 0F, 10 to 1F and 20

to 2F.

5-6. LASER POWER ADJUSTMENT

Connection:

Laser power

meter

2. Rotate the AMS knob to display “LDPWR ADJUST”.

(Laser power:For adjustment)

3. Press the YES button once to display “LD 0.9mW $@@”.

4. Rotate the AMS knob so that the laser power meter reads 0.86

to 0.92 mW. Set the range knob of the laser power meter to 10

mW, press the YES button, and save the adjustment results in

the non-volatile memory. (“LD SAVE $ ” is displayed

momentarily.)

5. “LD 7.0 mW $ ” is next displayed.

6. Rotate the AMS knob so that the laser po wer meter reads 6.9 to

7.1 mW, press the YES button, and sa ve the adjustment results

in the non-volatile memory. (“LD SAVE $ ” is displayed

momentarily.)

Note:Do not emit 7.0 mW continuously for more than 15

seconds.

7. Rotate the AMS knob to display “LDPWR CHECK”.

8. Press the YES button once to display “LD 0.9mW $ ”.

Check that the laser power meter reading is 0.85 to 0.91 mW.

9. Press the YES button another time to display “LD 7.0mW $

”.

Check that the readings of the laser power meter and digital

voltmeter become the specified v alue.

Specified value

Laser power meter reading:7.0 ± 0.1 mW

Digital voltmeter reading:Value displayed on optical pick-up label

± 10%

(Optical pick-up label)

KMS

260A

27X40

B0825

N

Iop = 82.5 mA in this case

Iop (mA) = Digital voltmeter reading (mV)/1 (Ω)

Optical pick-up

objective lens

Digital

Voltmeter

BD board

CN110 Pin

CN110 Pin

5

4

(I+3V)

(IOP)

Adjusting Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up from the disc slot. (If it cannot be set properly, pr ess the

0 or ) button to move the optical pick-up).

Connect the digital voltmeter to Pin 5 (I+3V) and Pin 4 (IOP)

of CN110.

10.Press the NO button to display “LDPWR CHECK” and stop

the laser emission.

(The NO button is effective at all times to stop the laser

emission.)

– 39 –

Page 41

5-8. FOCUS BIAS ADJUSTMENT

Adjusting method:

1. Load a continuously recorded disc (Refer to “5-4. Creating the

Continuously Recorded Disc”.)

2. Rotate the AMS knob to display “CPLAY MODE”.

3. Press the YES button to display “CPLAY MID”.

4. When “C1= AD= ” is displayed, press the NO button.

5. Rotate the AMS knob to display “FBIAS ADJUST”.

6. Press the YES button to display “ / a= ”.

The first four digits indicate the C1 error rate, the two digits

after the “/” indicate ADER and the two digits after “a=” indicate

the focus bias value.

7. Rotate the AMS knob in the clockwise direction, and look for

the focus bias value at which the C1 error rate becomes

approximately 220 (Refer to Note 2).

8. Press the YES button to display “ / b= ”.

9. Rotate the AMS knob in the counterclockwise direction, and

look for the focus bias value at which the C1 error rate becomes

220.

10. Press the YES button to display “ / b= ”.

11. Chec k that the C1 error rate is below 50 and that ADER is 00,

and press the YES button.

12. If the value of “( )” in the “ - - ( )” displayed is

above 20, press the YES button.

If below, press the NO button and start from step 2 again.

13. Press the § button and remove the continuously recorded disc.

Note 1: The following figure shows the relation between the C1

error and focus bias value. Look for points a and b in the

following figure by the adjustment above. The focus

position (point c) is automatically calculated from points a

and b.

Note 2: As the C1 error rate changes, use the average value in the

adjustment.

C1 error

220

Focus bias value

(F. BIAS)

bc a

5-9. ERROR RATE CHECK

5-9-1. CD ERROR RATE CHECK

Checking Procedure:

1. Load a check disc (MD) TDYS-1.

2. Rotate the AMS knob to display “CPLAY MODE”.

3. Press the YES button to display “CPLAY MID”.

4. “C1= AD= ” is displayed.

5. Check that the C1 error rate is below 20.

6. Press the NO button to stop playback. Then press the § button

and remove the check disc (MD).

5-9-2. MO Error Rate Checking

Checking Procedure:

1. Load a continuously recorded disc (Refer to “5-4. Creating the

Continuously Recorded Disc”.)

2. Rotate the AMS knob to display “CPLAY MODE”.

3. Press the YES button to display “CPLAY MID”.

4. “C1= AD= ” is displayed.

5. Check that the C1 error rate is below 50 and ADER is 00.

6. Press the NO button to stop playback. Then press the § button

and remove the disc.

5-10. FOCUS BIAS CHECK

Change the focus bias value and check the focus tolerance amount.

Checking Procedure:

1. Load a continuously recorded disc (Refer to “5-4. Creating the

Continuously Recorded Disc”.)

2. Rotate the AMS knob to display “CPLAY MODE”.

3. Press the YES button to display “CPLAY MID”.

4. When “C1= AD= ” is displayed, press the NO button.

5. Rotate the AMS knob to display “FBIAS CHECK”,

6. Press the YES button to display “

The first four digits indicate the C1 error , the two digits after the

“/” indicate ADER and the two digits after “c=” indicate the

focus bias value.

Check that the C1 error is below 50 and ADER is 00.

7. Press the YES button to change the display to “ / b=

”.

Check that the C1 error does not drop below 220 and ADER

does not remain above 00.

8. Press the YES button to change the display to “ / a=

”.

Check that the C1 error does not drop below 220 and ADER

does not remain above 00.

9. Press the NO button, press the § button next, and remov e the

continuously recorded disc.

/ c= ”.

Note 1:If the C1 error is above 220 or ADER is above 00 only for

point a (step 8 above) and point b (step 7 above), the focus

bias may not be adjusted properly. In this case, adjust again.

– 41 –

Page 42

5-11. ADJUSTING POINTS AND CONNECTING POINTS

[BD BOARD] (SIDE A)

CN110

RF I+3V

VC

CN101

D101

[BD BOARD] (SIDE B)

NOTE

IOP

TEO

IC192

IC171

IC101

IC121

NOTE:It is useful to use the jig. for checking the waveform. (Refer

to Servicing Note on page 6.)

– 42 –

Page 43

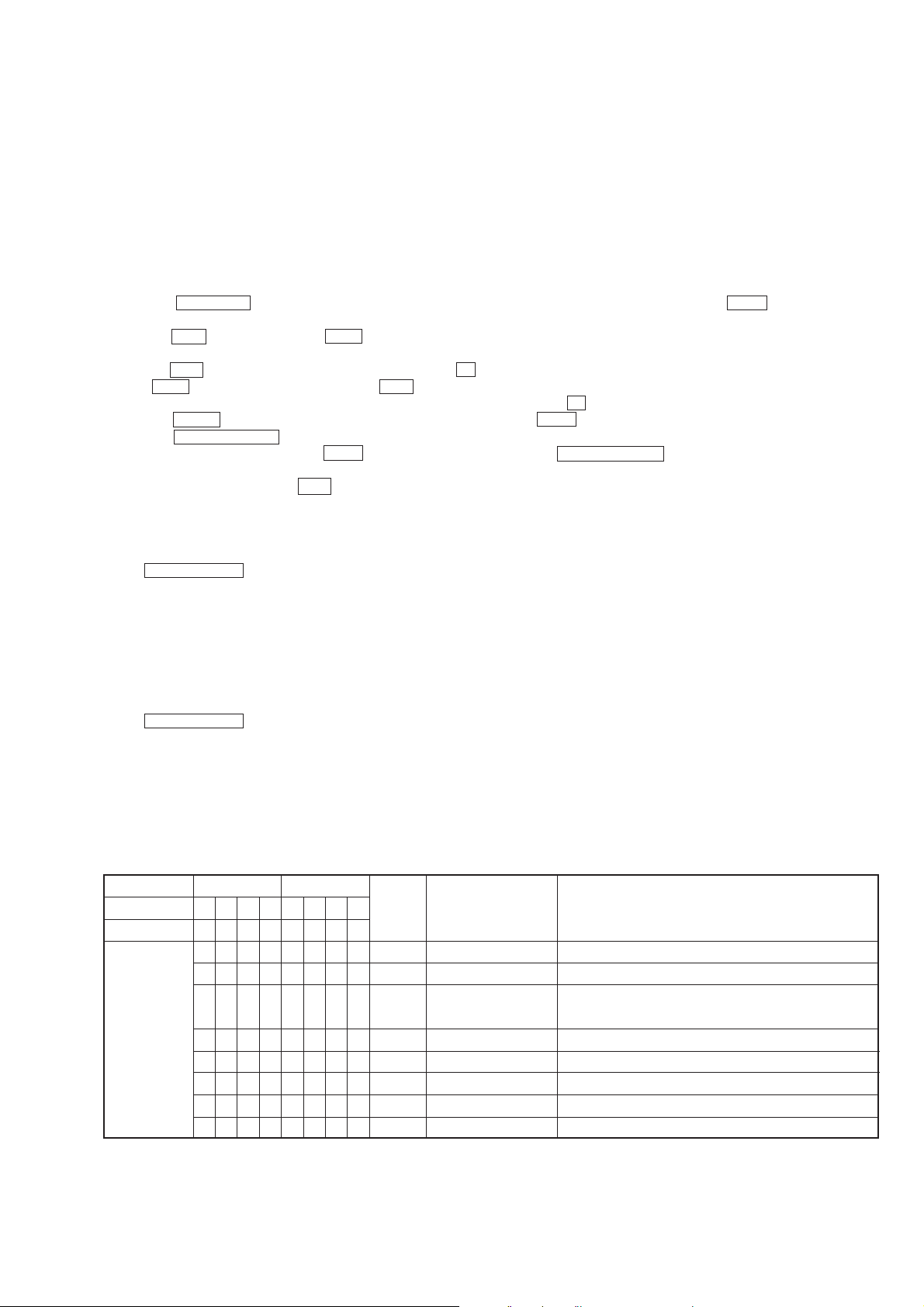

6-1. CIRCUIT BOARDS LOCATION

d

TRANS board

SW board

SECTION 6

DIAGRAMS

BACK UP board

VOLTAGE SELECTOR board

MAIN boar

PANEL board

BD board

ROTARY ENCODER (S701)

VOLUME board

– 43 –

Page 44

MDS-PC1

6-2. BLOCK DIAGRAMS

– BD SECTION –

• SIGNAL PATH

: PB

: REC

:PB(Digital out)

:REC(Digital in)

OPTICAL PICK-UP BLOCK

(KMS-260A/J1N)

DETECTOR

F

IJ

C

B

D

A

E

VC

PD

LD

ILCC

HR901

OVER WRITE

HEAD

VC

D101

LASER ON

SW

Q101

15

14

10

APC

Q162,163

HEAD

DRIVE

Q181,182

I

1

J

2

A

4

B

5

C

6

D

7

E

8

F

9

VC

3

TEMPR

TEMPI

PD

48 47 46 40

RFO

MORFI

MORFO

RF AMP

IV AMP

IV AMP

CVB

TEMP

AMP

APC

11

11

14

15

17

AGCI

BALANCE

APCREF

12

VCC

E-F

4

IC122

RF AMP

IC101

RF AGC & EQ

BPF

EQADJ

1

2

OVER WRITE HEAD DRIVE

IC181

3

18 2

9

P-P

PEAK

&

BOTTOM

ABCD

AMP

FOCUS

ERROR

AMP

AT

AMP

TRACKING

ERROR

AMP

SERIAL

VICONV

3TADJ

2522 23

WBLADJ

PARALLEL

DECODER

1

18

RF

38

AUX

33 66

BOTM

36

PEAK

37

ABCD

35

FE

34 65

BPF

ADFM

ADIN

ADFG

CSLED

SWDT

SCLK

XLAT

FOCNT

VC

31

29

30

32

TE

26

SE

28

27

16

17

18

20

VC

VC

Q180

FILTER

VC

DIGITAL SERVO SIGNAL PROCESSOR, DIGITAL SIGNAL PROCESSOR

EFM/ACIRC ENCODER/DECODER, SHOCK-PROOF MEMORY CONTROLLER,

EFMO

100

PCO

58

FILI

59

FILO

60

CLTV

61

RFI

55

AUX1

BOTM

63

PEAK

62

ABCD

64

EE

VC

67

TE

74

SE

73

ADFG

78

DTRF

82

CKRF

81

XLRF

80

FOCNT

79

ATRAC ENCODER/DECODER, 2M-BIT DRAM

PLL

ANALOG

MUX

ADIP

DEMODULATOR/

DECODER

SPINDLE

SERVO

SPRD

93

ACIRC,

ENCODER/

DECODER

SPFD

94

EFM,

FG IN

95 10

IC121

XRST

RECP

13

15 14

TX

SHOCK

RESISTANT

MEMORY

CONTROLLER

APC

APCREF

FFDR

XINIT

A/D

CONVERTER

PWM

GENERATOR

FRDR

TFDR

TRDR

ATRAC

ENCODER/

DECODER

SAMPLING

RATE

CONVERTER

SERVO

DSP

3

20

SFDR

SRDR

D0 D3 A0 A9

91928586898883

47 • 46 • 48 • 49

DIGITAL

AUDIO

I/F

CLOCK

GENERATOR

SUBCODE

PROCESSOR

MONITOR

CONTROL

CPU

I/F

AUTO

SEQUENCER

32 29 • 34 38 • 43

DIN

ADDT

DADT

DOUT

XBCK

LRCK

OSCI

SQSY

DQSY

MNT3

MNT2

MNT1

MNT0

SENS

SRDT

SCLK

SWDT

XLAT

XWE

XRAS

XCAS

XOE

21

23

24

22

26

25

16

11

12

4

3

2

1

9

8

6

5

7

45

44

42

41

1 5

BUFFER

IC123

DRAM

IC124

3

XWE

4

XRAS

17

XCAS

16

XOE

1

DQ1

•

2

•

18

•

DQ4

19

A0

6

9

•

11

15

•

A9

5

SCTX

XINT

DIN

ADDT

DADT

DOUT

BCK

LRCK

512FS

SQSY

DQSY

MNT3

MNT2

MNT1

MNT0

SENS

SRDT

SCLK

SWDT

XLAT

LDON

MAIN

SECTION

HF

MODULE

TRAKING

COIL

FOCUS

COIL

M902

SLED MOTOR

M901

SPINDLE MOTOR

09

TRK–

TRK+

FSC+

FSC–

SLED+

M

SLED–

SPDL+

M

SPDL–

HF MODULE

SW

IC103,Q102-104

SLED/SPINDLE MOTOR DRIVE

FOCUS/TRACKING COIL DRIVE

IC152

10

DRIVER

12

21

DRIVER

23

27

DRIVER

25

6

DRIVER

8

PSB

5

EEP ROM

IC171

TFDR

85

TRDR

86

FRDR

89

FFDR

88

SFDR

92

SRDR

91

SPFD

94

SPRD

93

XRST

16

M903

LOADING MOTOR

SDA

DETECT SW

S681 - 683,

S685 - 688

M

6

WRPWR

MOD

SDA

SCLSCL

LIMIT

REFLECT

PROTECT

CHACK IN

PACK OUT

PB P

REC P

LOAD-IN

LOAD-OUT

XRST

– 45 – – 46 –

Page 45

MDS-PC1

– MAIN SECTION –

DIN

DOUT

ADDT

DADT

SCTX

XINT

BCK

LRCK

512FS

SQSY

DQSY

MNT3

MNT2

MNT1

MNT0

SENS

SRDT

SCLK

SWDT

XLAT

BD

SECTION

09

LIMIT

REFLECT

PROTECT

CHACK IN

PACK-OUT

PB-P

REC-P

LDON

WRPWR

MOD

LOAD-IN

LOAD-OUT

SDA

SCL

XRST

BCK

LRCK

512FS

SCLK

SWDT

XLAT

2

10

DRIVE

LOADING MOTOR

DRIVE

IC311

1

DRIVE

DIGITAL

OUT

IC352

LOADING

Q311, 312

SLOCK

XBUSY

4

SW

DIGITAL

INPUT SELECTOR

IC315

8

2

5

18

76

68

66

77

65

32

33

31

71

74

70

72

51

53

60

59

69

75

73

5

54

6

55

56

78

79

67

1

13

80

20

XINT

SQSY

DQSY

MNT3 (SLOCK)

MNT2 (XBUSY)

MNT1 (SHOCK)

MNT0 (FOK)

SENS

SRDT

SCLK

SWDT

XLATCH

LIMIT-IN

REFLECT

PROTECT

CHACK IN

PACK-OUT

PB-P

REC-P

SYSTEM CONTROL

LDON

WR PWR

MOD

LDIN

LDOUT

LD LOW

SDA

SCL

DIG-RST

XOUT

13 15

X402

7MHz

2

4

86

SCTX

IC401

XIN

BUFFER

IC314 (1/2)

5

OPT SEL

AMUTE

CONTROL A1 OUT

CONTROL A1 IN

MONO/ST

KEY0

KEY1

KEY2

TIMER SW

SOURCE SW

JOG1

JOG0

REMOCOM

FLCLK

FLDATA

FLCS

P DOWN

CLOCKSET1

CLOCKSET0

STBY

A/D, D/A CONVERTER

MCK1

15

35 36

22

256CK

I/O

22MHz

XOUT

X201

IC201

XIN

5

BA501

LITHIUM

BATTERY

BACK +3.3V

+3V REG

IC192

SYS +3.3V

ANA +5V

CONVERTER

CONVERTER

PH +5V

RV702

INLM

55

INLP

A/D

D/A

1

INRP

INRM

+ L1

– L2

+ R1

– R2

1

5

4

6

56

1

2

41

39

30

32

SRESET

212

R-ch

R-ch

SWITCHING REG

+5V REG

+3.3V REG

+5V REG

BACK UP

IC501

BUFFER

IC314 (2/2)

24 23

17

16

1310

FRONT-END

IC101

LPF 1

15

MUTE

4

+6V

3

+B

–6V

–32V

14

+6V REG

IC541

–6V REG

–32V REG

+B

IC551

IC310

REC LEVEL

2526

R-ch

MUTE

SW

Q306

RECT

31

–B

23

13

D001,

D002

RECT

D007,

D008

RECT

D005,

006

RECT

D003,

004

FL701

RECT

D009

MUTE

Q102

AC

AC

2122

R-ch

R-ch

HEADPHONE

AMP

IC308

3 1

TR001

POWER

TRANSFORMAER

L

R

(ANALOG)

R

L

RV701

PHONE LEVEL

J401

S-LINK

CONTROL A1

CONTROL A1

AEP,UK

MAIN

POWER

S301

SP

VOLTAGE

SELECTOR

S301

IN

J101

LINE

OUT

R-ch

J702

J701

PHONES

AC

IN

• R-CH is omitted.

1

3

3

48ADA RES

12 3 RSTSYSTEM RST

49

87

7

100

97

95

94

91

88

21

22

83LED0 (POWER)

6

37

35

34

19

82

81

50

MATRIX

LED DRIVE

Q701

3 RM

DISPLAY DRIVER

SCK

62

SDATA

63

CS

61

RST

60

IC353

DIGITAL

IN

RESET

IC502

SW

IC701

+3.3V

(DIN)

SIRCS

RECEIVER

IC702

S1

S36

39

40

D1

54

D15

4

12

BCK

LRCK

512FS

27

18

16 DPD

SWDT

SCLK

XLAT

LEVEL SHIFT

Q203

D701

STANDBY

DADT

RES

CONTROL A1 DRIVER

FL701

FLUORESCENT

INDICATOR

TUBE

10 11

25 28 26

PH +5V

AC

I/O

CPU INTERFACE

19 20 21

Q485

+3V

(BD)

• SIGNAL PATH

: PB

: REC

:PB(Digital out)

:REC(Digital in)

• Abbreviation

SP :Singapore model.

– 47 – – 48 –

Page 46

THIS NOTE IS COMMON FOR PRINTED WIRING

0.46Vp-p

3.1Vp-p

22.581MHz

3.2Vp-p

44.1kHz

3.8Vp-p

11.29MHz

3.3Vp-p

44.1kHz

2.9Vp-p

22.578MHz

5Vp-p

22.58MHz

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

WAVEFORMS

– BD SECTION – – MAIN SECTION –

1

1

– PANEL SECTION –

1

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

¢

•

• C : panel designation.

Note: The components identified by mark ! or dotted line

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

with mark ! are critical for safety.

Replace only with part number specified.

under no-signal (detuned) conditions.

no mark : STOP

( ) : PLAY

< > : REC

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

E : PB

q : REC

a : PB (DIGITAL OUT)

r : REC (DIGITAL IN)

SP : Singapore model.

: Can not be measured.

∗

1

4

/

W or less unless otherwise

For printed wiring boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

•

p : parts mounted on the conductor side.

®

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

: Through hole.

IC101 1, 2 I, J (PLAY mode)

2

IC101 4 A (PLAY mode)

3

IC101 8, 9 E, F (PLAY mode)

4

IC121 !§ OSCI

5

IC121 @∞ LRCK

6

2.822MHz

IC121 @§ XBCK

7

0.1Vp-p

0.06Vp-p

3.8Vp-p

7MHz

IC401 !£ XOUT

2

IC201 0 LRCK1, @• LRCK

3

2.822MHz

IC201 !¡ BCK1, @§ BCK

4

IC201 !∞ MCK1, @™ 256CK

22.553MHz

5

IC201 @∞ 512FS

6

IC201 #∞ XOUT

3.4Vp-p

3.6Vp-p

5.6Vp-p

3.7Vp-p

2.361MHz

IC701 %ª OSC1

Caution:

Pattern face side: Parts on the pattern f ace side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

• Indication of transistor

• Indication of transistor

C

These are omitted

EB

• Indication of transistor

ECB

These are omitted

IC121 @¶ FS256

8

3.2Vp-p

176.4kHz

IC121 (º FS4

– 49 – – 50 –

Page 47

MDS-PC1

6-3. SCHEMATIC DIAGRAM – BD (1/2) SECTION –

• See page 50 for Waveforms.

• See page 55 for Printed Wiring Board.

• See page 71 for IC Block Diagrams.

• See page 76 for IC Pin Functions.

– 51 –

(Page 54)(Page 53)

– 52 –

Page 48

6-4. SCHEMATIC DIAGRAM – BD (2/2) SECTION –

(Page 65) (Page 58) (Page 61)

(Page 51) (Page 52)

• See page 50 for Waveforms.

• See page 55 for Printed Wiring Board.

• See page 72 for IC Block Diagrams.

• See page 77 for IC Pin Functions.

MDS-PC1

– 53 –

– 54 –

Page 49

MDS-PC1

6-5. PRINTED WIRING BOARD – BD SECTION –

• See page 43 for Circuit Boards Location.

(Page 57)

• Semiconductor

Location

Ref. No. Location

D101 E-3

D181 C-9

D183 C-9

IC101 F-14

IC103 B-15

IC121 D-12

IC122 C-4

IC123 E-10

IC124 F-12

IC152 B-12

IC171 F-9

IC181 D-9

IC192 G-6

Q101 C-14

Q102 B-15

Q103 B-14

Q104 B-14

Q162 B-14

Q163 B-15

Q180 D-6

Q181 B-9

(Page 59) (Page 59)

Q182 B-9

– 55 –

– 56 –

Page 50

MDS-PC1

(Page 53)

6-6. PRINTED WIRING BOARD – SW SECTION –

• See page 43 for Circuit Boards Location.

(Page 55)

6-7. SCHEMATIC DIAGRAM – SW SECTION –

– 57 – – 58 –

Page 51

MDS-PC1

6-8. PRINTED WIRING BOARD – MAIN SECTION –

• See page 43 for Circuit Boards Location.

(Page 67)

(Page 67)

(Page 68)

(Page 56)

(Page 56)

: US

: AEP, UK, SP

• Semiconductor Location

Ref. No. Location

D001 E-10

D002 E-10

D003 E-10

D004 E-10

D005 D-11

D006 D-11

D007 D-9

D008 D-9

D009 E-9

D350 F-1

D485 A-8

D486 A-10

D501 C-10

D531 E-8

D541 C-3

D599 B-3

IC101 C-2

IC201 E-2

IC308 D-3

Ref. No. Location

IC310 E-8

IC311 G-1

IC314 B-5

IC315 B-6

IC352 A-4

IC353 A-3

IC401 D-5

IC501 C-9

IC502 A-10

IC541 C-3

IC551 B-3

Q102 D-3

Q202 D-3

Q203 E-3

Q306 D-10

Q311 G-1

Q312 G-1

Q485 A-9

– 59 – – 60 –

Page 52

6-9. SCHEMATIC DIAGRAM – MAIN (1/3) SECTION –

• See page 50 for Waveforms.

• See page 82 for IC Pin Functions.

MDS-PC1

(Page 53)

(Page 69)

– 61 –

(Page 65)

(Page 63)

(Page 65)

– 62 –

Page 53

MDS-PC1

6-10. SCHEMATIC DIAGRAM – MAIN (2/3) SECTION –

• See page 50 for Waveforms.

• See page 59 for Printed Wiring Board.

• See page 73 for IC Block Diagrams.

• See page 80 for IC Pin Functions.

(Page 69)

(Page 62)

L805 0µH

US

AEP, UK, SP

1µH

(Page 65)

– 63 – – 64 –

(Page 66)

Page 54

6-11. SCHEMATIC DIAGRAM – MAIN (3/3) SECTION –

• See page 50 for Waveforms.

• See page 59 for Printed Wiring Board.

• See page 75 for IC Block Diagrams.

MDS-PC1

(Page 63) (Page 64)

(Page 61)

(Page 62)

– 65 –

(Page 53)

(Page 70)

– 66 –

Page 55

MDS-PC1

6-12. PRINTED WIRING BOARD – PANEL SECTION –

• See page 43 for Circuit Boards Location.

(Page 60)

(Page 59)

(Page 59)

• Semiconductor

Location

Ref. No. Location

D701 D-1

D750 A-2

IC701 B-6

IC702 C-2

Q701 D-2

– 67 – – 68 –

Page 56

6-13. SCHEMATIC DIAGRAM – PANEL SECTION –

• See page 50 for Waveforms.

MDS-PC1

(Page 64)

(Page 65)

– 69 –

(Page 62)

– 70 –

Page 57

6-14. IC BLOCK DIAGRAMS

• BD section

IC101 CXA2523AR

MORFO47MORFI46RFO45OPN

48

RFA1

+

–

1I

2J

CVB

3VC

4A

IVR

5B

IVR

6C

IVR

7D

IVR

8E

IVR

9F

IVR

GSW IV

10PD

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

IC121 CXD2652AR

EFMO

DVSS

TEST3

TEST2

TEST1

FGIN

SPFD

100

99 98 97 96 95 94 93

OPO43ADDC42COMPP41COMPO40AGCI39RF AGC38RF37PEAK

44

USROP

–

+

RFA2

–

–

–

–

–

–

–

AA

BB

CC

DD

EE

FF

1

2

1

2

GRVA

CFST

FBAL

HLPT

–1

–2

PTGR

–2

–1

GRV

+

+

+

+

ABCDA

+

+

–

FEA

–

–

–

+

+

ATA

+

EE'

–

+

–

EFB TESW

FF'

AUXSW

COMMAND

–

+

–

+

+

–

BPF3T

BPF22

WBL

WBL

RF AGC EQ

USRC

PEAK

BOTTOM

WBL

PTGR

ADIP

AGC

PEAK3T

P-P

WBL

3T

EQ

BGR

3T

3T WBL

PBH

DET

–1

–2

–1

–2

DET

TEMP

EQ

BPFC

SEA

TEA

VI CONV

TG

TG

36

BOTM

35

ABCD

34

FE

33

AUX

32 ADFG

31 ADAGC

30 ADIN

29 ADFM

28 SE

27 CSLED

26 TE

25 WBLADJ

1

MNT0

2

MNT1

MNT2

MNT3

SWDT

SCLK

XLAT

SRDT

SENS

XRST

SQSY

DQSY

RECP

XINT

OSCI

OSCO

XTSL

TESTG

D VSS

DIN

DOUT

ADDT

DADT

LRCK

MONITOR

CONTROL

3

4

5

6

CPU I/F

7

8

9

10

11

SUBCODE

PROCESSOR

12

13

14

15

TX

16

17

GENERATOR

18

19

20

21

22

23

24

25

CLOCK

26

XBCK

27

28

FS256

EACH

BLOCK

DVDD

IC152 BH6511FS-E2

EACH

BLOCK

SPRD

SPINDLE

SERVO

ADIP

DEMODULATOR/

DECODER

EACH

BLOCK

DIGITAL

AUDIO

SFDR91SRDR90FS489FRDR88FFDR87DVDD86TFDR85TRDR84LDDR83APCREF82DTRF81CKRF80XLRF79F0CNT78ADFG77APC76DCHG

92

PWM

GENERATOR

SERVO

DSP

APC

SHOCK RESISTANT

MEMORY CONTROLLER

SAMPLING

I/F

ENCODER/DECODER

RATE

CONVERTER

ATRAC

ADDRESS/DATA BUS A00 - A11, D0 - D3

39

40

A1138A0837A0736A0635A0534A0433A1032A0031A0130A0229A03

CONVERTER

41

XOE

DVSS

42

A/D

43

XCAS

A09

AUTO

INTERFACE

44

XRAS

SEQUENCER

DECODER

ENCODER/

EFM/ACIRC

COMP

DRAM

XWE

ANALOG

MUX

49D348D247D046D145

PLL

50

MVCI

75

AUX2

74

TE

73

SE

72

AVSS

71

ADRB

70

ADRT

69

AVDD

68

ADIO

67

VC

66

AUX1

65

FE

64

ABCD

63

BOTM

62

PEAK

61

CLTV

60

FILO

59

FILI

58

PCO

57

PDO

56

AVSS

55

RFI

54

BIAS

53

AVDD

52

ASYI

51

ASYO

+

–

11APC

12APCREF

14

13

GND

TEMPI

15

TEMPR

SCRI - PARA

DECODE

17

16

SWDT

SCLK

18

XLAT

19

XSTBY

VREF

20

F0CNT

CAPA–

CAPA+

IN2R

IN2F

VM2

OUT2F

PGND2

OUT2R

VM12

OUT1R

PGND1

OUT1F

VM1

IN1F

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17

24

23

22

21

EQADJ

3TADJ

VCC

CHARGE

PUMP.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

GND

VREF

OSC

VG

INTERFACE

INTERFACE

IN4R

IN4F

AMP

AMP

VM4

OUT4F

PGND4

AMP

OUT4R

VM34

AMP

OUT3R

PGND3

AMP

AMPAMPAMP

OUT3F

PREDRIVEPREDRIVE

PREDRIVEPREDRIVE

VM3

INTERFACE

INTERFACE

IN3F

IN1R

IN3R

V

PSB

DD

V

DD

PSB

– 71 – – 72 –

Page 58

IC171 BR24C01AF

1024 BIT EEPROM ARRAY

SLAVE WORD

7BIT

ADDRESS RESISTOR

START STOP

CONTROL CIRCUIT

VOLTAGE

DET

ACK

8BIT

DATA

RESISTOR

8

CC

V

TEST

7

6

SCL

5

SDA

GND

1

A0

A1

2

3

A2

4

7BIT

ADDRESS

DECODER

HIGH VOLTAGE

GENERATION CIRCUIT

IC192 L88MS33T-TL

START UP

CIRCUIT

1 2 3 4 5

VIN STB GND CN VOUT

REFERENCE

VOLTAGE

ON/OFF

CONTROL

ERROR

AMP

PROTECTOR

CURRENT

LIMITER

• MAIN section

IC101 LA9615

1

LINE02

2

PMUTE

3

LINE01

MUTE

4

5

LINE/MIC

V

DD

6

7

+D/A1

8

+D/A1

9

+D/AO1

LP1N1

10

LPOUT1

11

GND1

12

LPOUT2

13

14

LPIN2

15

D/AO2

–D/A2

16

+D/A2

17

18

CC

V

V

IC201 CXD8607N

VOLTAGE

REFERENCE

+

56

INLP

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

INLM

REFO

LVSS

LVDD

AVSS(LF)

NU

NU

VSS1(LF)

TEST3

TEST2

VSS1

VDD1

VDD1

VDD2

L1

AVDDL

L2

AVSSL

XVSS

XIN

XOUT

XVDD

AVSSR

R2

AVDDR

R1

VDD2

–

+

1

EE

INRP

INRM

REFI

AVDD

AVSS

APD

TEST1

LRCK1

BCK1

ADDT

V35A

VSS1 (LF)

MCKI

DPD

VSS2(LF)

INIT

MODE

SHIFT

LATCH

256CK

V35D

VSS2

512CK

BCK2

DADT

LRCK2

2

–

3

4

5

6

7

NU

8

NU

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

INTERFACE

MODULATOR MODULATOR

DECIMATION

FILTER

LOW CUT

FILTER

ATT PLM

CPU

I/O

ATT PLM

I/O

OVER

SAMP

FILTER

OVER

SAMP

FILTER

DECIMATION

FILTER

LOW CUT

FILTER

SHAPER

SHAPER

MOIZE

NOIZE

36

LINE1

V

EE

+

–

–

+

+

–

+

–

13.2k

13.2k

13.2k

–

+

–

+

CC

–

2.35k

+

+

–

2.35k

+

–

+

–

–

+

V

35

MIC1

34

33

SW01

SWI1

32

–A/D1

31

30

INV1

+A/D1

29

A/DREF

28

27

VREF

+A/D2

26

INV2

25

24

–A/D2

23

SWI2

SWO2

22

MIC2

21

GND2

20

19

LINE2

– 73 –

Page 59

IC308 M5218AL

3

2

1

OUT1

–IN1

+IN1

4

V–

IC310 M5293L

GND

2

REFERENCE

4

ON/OFF

VOLTAGE

1

IN

5

+IN2

7

6

–IN2

OUT2

PROTECTION

8

V+

+

–

OVERHEAT

5k

27k

OVERCURRENT

LIMITTER

REFERENCE

5

VOLTAGE

3

OUT

IC311 LB1641

PRE

DRIVER

INPUT LOGIC BLOCK

21

GND OUT1 P1 VZ IN1 IN2 V

109876543

CC1VCC2 P2 OUT2

– 74 –

Page 60

IC501 LA5620

PH5

1

2

STBY

3

CC

V

ANA5

4

5

SYS3.3

6

BACK

AC

7

–

+

–

+

–

+

–

+

3.3V

CD1

8

9

P. DOWN

10

GND

11

CD2

S. RESET

12

IC502 M62016L

COM

+

–

INTERRUPT SIGNAL

GENERATING BLOCK

DELAY

CIRCUIT

DELAY

CIRCUIT

–

+

–

+

VREF

COM

+

–

2 3

1

GND INT RESET CD VCC

RESET SIGNAL

GENERATING BLOCK

4

5

– 75 –

Page 61

6-15. IC PIN FUNCTIONS

• IC101 RF Amplifier (CXA2523R) (BD Board)

Pin No. Pin Name I/O Function

1

2

3

4 to 9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

I

J

VC

A to F

PD

APC

APCREF

GND

TEMPI

TEMPR

SWDT

SCLK

XLAT

XSTBY

F0CNT

VREF

EQADJ

3TADJ

Vcc

WBLADJ

TE

CSLED

SE

ADFM

ADIN

ADAGC

ADFG

AUX

FE

ABCD

BOTM

PEAK

RF

RFAGC

AGCI

COMPO

COMPP

ADDC

OPO

OPN

RFO

MORFI

MORFO

I

I-V converted RF signal I input

I

I-V converted RF signal J input

O

Middle point voltage (+1.5V) generation output

I

Signal input from the optical pick-up detector

I

Light amount monitor input

O

Laser APC output

I

Reference voltage input for setting laser power

—

Ground

I

Temperature sensor connection

O

Reference voltage output for the temperature sensor

I

Serial data input from the CXD2652AR

I

Serial clock input from the CXD2652AR

I

Latch signal input from the CXD2652AR “L”: Latch

I

Stand by signal input “L”: Stand by

I

Center frequency control voltage input of BPF22, BPF3T, EQ from the CXD2652AR

O

Reference voltage output (Not used)

I/O

Center frequency setting pin for the internal circuit EQ

I/O

Center frequency setting pin for the internal circuit BPF3T

—

+3V power supply

I/O

Center frequency setting pin for the internal circuit BPF22

O

Tracking error signal output to the CXD2652AR

—

External capacitor connection pin for the sled error signal LPF

O

Sled error signal output to the CXD2652AR

O

FM signal output of ADIP

I

ADIP signal comparator input ADFM is connected with AC coupling

—

External capacitor connection pin for AGC of ADIP

O

ADIP duplex signal output to the CXD2652AR

3 signal/temperature signal output to the CXD2652AR

I

O

(Switching with a serial command)

O

Focus error signal output to the CXD2652AR

O

Light amount signal output to the CXD2652AR

O

RF/ABCD bottom hold signal output to the CXD2652AR

O

RF/ABCD peak hold signal output to the CXD2652AR

O

RF equalizer output to the CXD2652AR

—

External capacitor connection pin for the RF AGC circuit

I

Input to the RF AGC circuit The RF amplifier output is input with AC coupling