Page 1

MD-MT180

SERVICE MANUAL

No. S4224MDMT180S

PORTABLE MINIDISC RECORDER

MODEL MD-MT180(S)

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified be

used.

CONTENTS

Page

SPECIFICATIONS ................................................................................................................................................................. 2

NAMES OF PARTS ............................................................................................................................................................... 3

OPERATION MANUAL .......................................................................................................................................................... 4

DISASSEMBLY...................................................................................................................................................................... 9

REMOVING AND REINSTALLING THE MAIN PARTS....................................................................................................... 10

ADJUSTMENT ...................................................................................................................................................................... 12

MD ERROR MESSAGE DISPLAY CONTENT LIST ........................................................................................................... 25

NOTES ON SCHEMATIC DIAGRAM .................................................................................................................................. 26

TYPES OF TRANSISTOR AND DIODE .............................................................................................................................. 26

BLOCK DIAGRAM ............................................................................................................................................................... 27

SCHEMATIC DIAGRAM ...................................................................................................................................................... 28

WIRING SIDE OF P.W.BOARD........................................................................................................................................... 32

VOLTAGE ............................................................................................................................................................................ 43

WAVEFORMS OF MD CIRCUIT ......................................................................................................................................... 44

TROUBLESHOOTING ......................................................................................................................................................... 45

FUNCTION TABLE OF IC.................................................................................................................................................... 48

PARTS GUIDE/EXPLODED VIEW

PACKING METHOD

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

MD-MT180

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER TO

THE OPERATION MANUAL.

SPECIFICATIONS

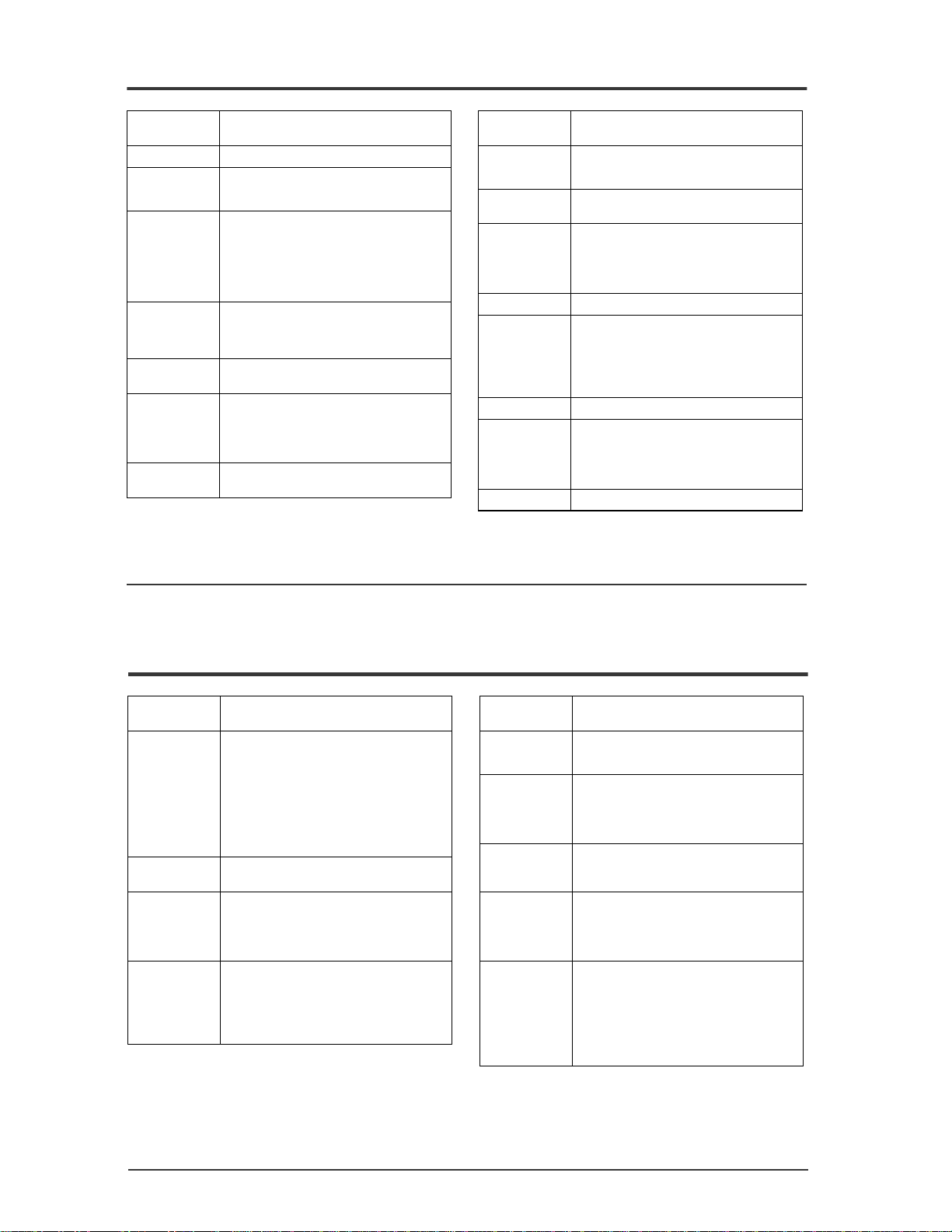

Power sourc e:

Power consumption:

Output power:

Charging time:

Dimensions:

Weight:

Input jack:

Output jack:

Type:

Signal readout:

Audio channels:

Frequency response:

Rotation speed:

Error correction:

Coding:

Recording method:

Sampling frequency:

Wow and flutter:

Battery life:

When using the rechargeable

battery (fully charged) included

with the unit

When using one, commercially

available, high capacity, "AA"

size (LR6), alkaline batt ery (The

rechargeable battery is in the

unit, discharged.)

When using one, commercially

available, high capacity, "AA"

size (LR6), alkal ine batter y with

the rechargeable battery (fully

charged)

DC 1.2 V: Rechargeable Nickel-Metal Hydride battery (AD-N55BT) x 1

DC 5 V: AC adaptor (AC 120 V, 60 Hz)

DC 1.5 V: Battery case (Commercially available, "AA" size (LR6), alkaline battery x 1)

DC 4.5 V: Optional car adapt or, AD-CA20 X (for cars with a 12 - 24 V DC negative ground

7 W (AC adaptor)

RMS: 20 mW (10 mW + 10 mW)

(0.2 % T.H.D.)

Approx. 3.5 hours (90 %)

Approx. 5.5 hours (fu lly charged) (When using the AC adaptor included with the unit)

Width: 3" (76 mm) Height: 29/32" (22.9 mm) Depth: 3-9/32" (83 mm)

0.33 lbs. (148 g) with rechargeable battery

Line/optical digital

Earphones (impedance: 32 ohms)

Portable MiniDisc recorder

Non-contact, 3-beam semiconductor laser pickup

Stereo 2 channels/mon aural 1 channel

20 - 20,000 Hz ( 3 dB)

Approx. 400 - 1,350 rpm

ACIRC (Advanced Cross Interleav e Reed-Solomon Code)

ATRAC/ATRAC3 (Adaptive T R ansform Acoustic Codin g), 24-bit computed type

Magnetic modulation overwrite method

44.1 kHz (32 kHz and 48 kHz signals are converted to 44.1 kHz, and then recorded.)

Unmeasurable (less tha n 0.001 % W. peak)

Continuous

recording:

Approx. 7

hours

Continuous

recording:

Approx. 6

hours

Continuous

recording:

Approx. 15.5

hours

electrical system)

Stereo 2 times long 4 times long

Continuous

play: Approx.

11 hours

Continuous

play: Approx.

15.5 hours

Continuous

play: Approx.

27 hours

Continuous

recording:

Approx. 9.5

hours

Continuous

recording:

Approx. 9.5

hours

Continuous

recording:

Approx. 23

hours

Continuous

play: Approx.

13 hours

Continuous

play: Approx.

19 hours

Continuous

play: Approx.

32 hours

Continuous

recording:

Approx. 12.5

hours

Continuous

recording:

Approx. 13

hours

Continuous

recording:

Approx. 30

hours

Continuous

play: Approx.

15 hours

Continuous

play: Approx.

22 hours

Continuous

play: Approx.

38 hours

Input sensitivity:

Reference input

level

LINE 100 mV 20 kohms

Output level:

Specified

output

Earphones - 10 mW +

LINE 250 mV

(-12 dB)

Specifications for this model are subject to change without prior

notice

Maximum

output level

10 mW

- 10 k ohms

Input impedance

Load

impedance

32 ohms

– 2 –

●

The continuous recording time is for analog inputs

when the volume lev el is set to "VOL 0".

●

The continuous play time shows the value when the

volume level is set to "VOL 15".

●

The above values are the standard values when the

unit is charged and used at an ambient temperature of

77°F (25°C).

●

The operating time when using an alkaline battery

may be different, depending on the type and manufacturer of the battery, and on the operating temperature.

Page 3

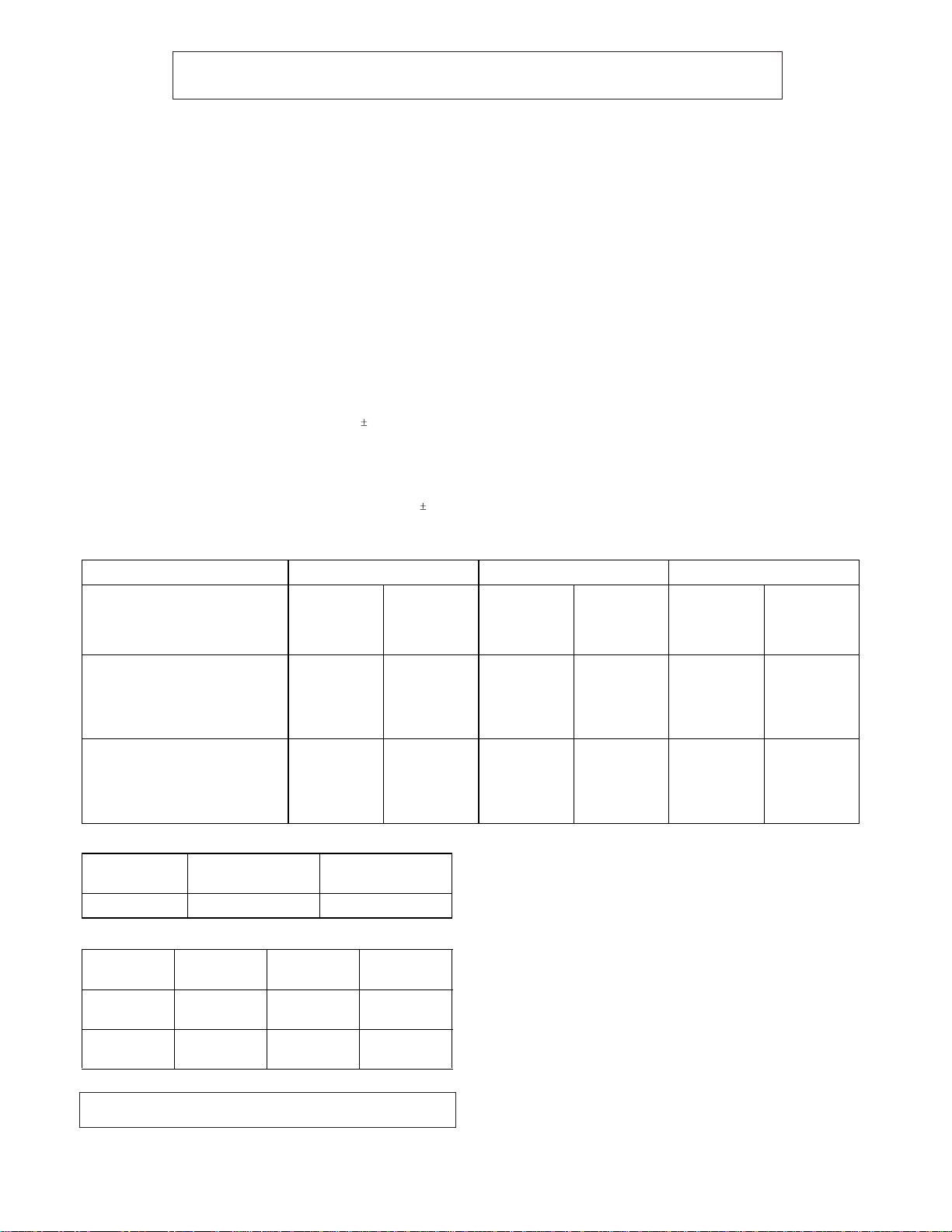

10

MD-MT180

NAMES OF P ARTS

1.Battery Case Connection Terminals

2.5 V DC Input Jack

3.Optical/Line Input Jack

1

8

7

6

5

2

3

4

9

11

13

12

15

16

17

14

18

19

20

25

26

27

28

21

22

23

24

4.Earphones/Line Output Jack

5.Recor d/Track Mark Button

6.Menu/Charge Button

7.Bass/Delete Button

8.Enter/Fast Play/Synchro Button

9.Volume/Cursor/Fast Forward/Fast Reverse /

Recording Level/

10.Open Lever

11.Stop/Power Off/Hold Button

12.Rechargeable Battery Cover

13.Play/Pause Button

14.Level Meter

15.Stereo Recor ding Indicator

16.Long-play/Recording Mode Indicator

17.Repeat Indicator

18.Monaural Mode Indicator

19.Record Indicator

20.Disc Mode Indicator

21. Synchro Reco rdin g In dicator

22.Total T rack Number Indicator

23.Disc Name Indicator

24.TOC Indicator

25.Battery Indicator

26.Random Indicator

27.Track Number Indicator

28.Character/Time Information Indicator

Name Select Button

– 3 –

Page 4

MD-MT180

OPERATION MANUAL

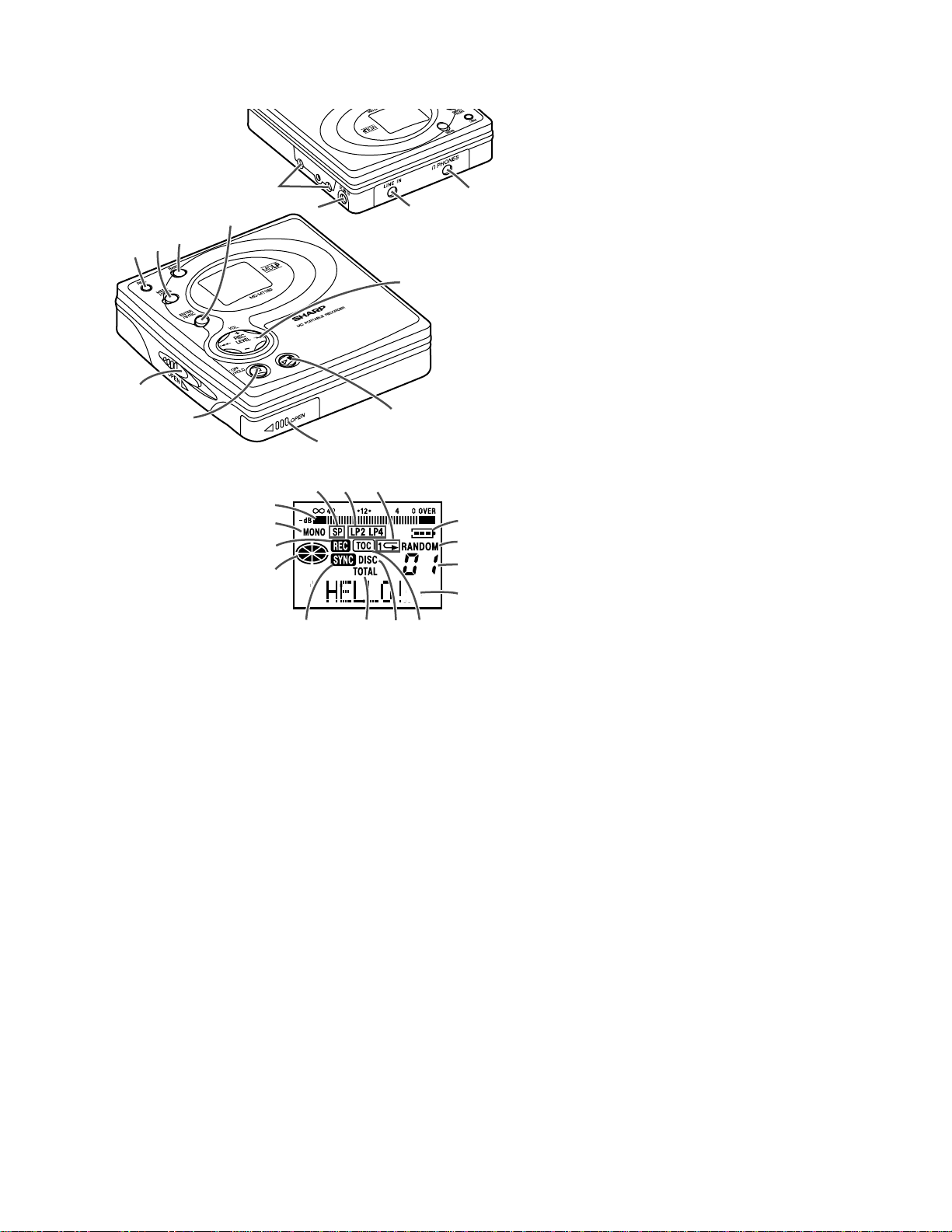

Using with the Rechargeab le Battery

Charging the rechargeable battery

■

Do not force the

battery cover

open too far.

AC 120V,

60Hz

Insert the

– side first.

When the rechargeable battery is used for the first time

or when you want to use it after a long period of disuse,

be sure to charge it fully.

1

Insert the rechargeable battery.

A rechargeable battery other than the AD-N55BT

cannot be charged.

2

Plug the AC adaptor into the AC outlet, and

then insert the plug on the other end into

the DC IN 5V jack.

3

Press the MENU/CHRG button.

The battery indicator will scroll, and battery will be-

gin charging.

●

To the DC IN

5V jack

After the rechargeable battery is charged or used, it

will get slightly warm. This is normal.

●

When the portable MD is turned on or operating, the

battery will not be charged.

Using with the Alkaline Battery

Use one commercially available alkaline battery (LR6,

"AA" size).

Open

2

Press

1

Back of the

portable MD

When using the alkaline battery, be sure to insert the

rechargeable battery also.

1

Open the case cover.

2

Insert an alkaline battery into the battery

case.

3

Attach the battery case to the portable MD.

Caution:

●

While you are using the rechargeable battery and the

alkaline battery at the same time, do not remove either

of them. If you do, when the unit is in the play mode,

playback will stop. When in the recording mode, the

recorded contents will be erased, and the power may

be disconnected.

Do not replace the battery or the rechargeable battery

●

during operation.

Do not use a rechargeable battery (nickel-cad-

●

mium battery etc.) in the battery case.

●

If the unit is not used for a long period of time, remove

the battery. (Even if the power is turned off, the battery

will be drained slowly but continuously.)

Scrolling

RELEASE LOCK

– 4 –

Page 5

Error Messages

MD-MT180

ERROR MES-

SAGES

BATT ENPTY

BLANK MD

Can't COPY

Can't EDIT

Can't PLAY

Can't READ (*)

Can't REC

MEANING

The battery has run down.

●

Nothing is recorded.

●

(Replace the disc with a recorded disc.)

You tried to record from a copy pr ohib-

●

ited MiniDisc.

(Record using the analog cable.)

●

You tried to record signals other than

music (such as data).

●

A track cannot be edite d.

(Change the stop posit ion of the track and

then edit it.)

●

You tried to play back a tra ck that can not be played with this equipment.

●

The disc data cannot be read because

the disc is damaged.

(Reload the Minidisc or rep lac e i t with an other one.)

Recording cannot be performed cor-

●

rectly due to vibration or shock.

ERROR MES-

SAGES

Can'tSTAMP

Can'tWRITE

DEFECT!

DISC FULL

Er-MD (**)

HOLD

LOCKED

NO DISC

●

Stamp function does not work.

(Check the nu m b e r of tracks.)

Cannot save the TOC information cor-

●

rectly to a MiniDisc.

●

The disc is scratched.

(If the recorded sound is not right, retry

recording or replace the disc with a recordable one.)

The disc is out of recording space.

●

●

The microprocessor has reported a

system fault and the unit is out of order.

(To have it repaired, go to the distributor

where you purchased the un it.)

●

The unit is in the hold mode.

●

You removed a MiniDisc whe n re cording or editing.

(Turn off the power before removing the

MiniDisc.)

●

A disc has not been loaded.

MEANING

Number or symbol appears in (*) position.

ERROR MES-

SAGES

NO SIGNAL

PLAY MD

PROTECTED

SORRY

MEANING

Poor connection of the digital cable.

●

No output signal comes out from the

●

connected unit to playback.

(Use the AC power for the connected

unit.)

The input signal has improper sam-

●

pling frequency.

●

You tried to rec ord on a p layback -only

disc.

●

The write protection tab of a MiniDisc

is set to the protected position.

●

You tried to rec ord on a p layback -only

disc.

Since a track number is currently be-

●

ing located or updated, the unit cannot

accept your command.

(Wait for a while and try the operation

again.)

ERROR MES-

SAGES

TEMP OVER

TOC FORM

(**)

TOC FULL

Tr. Protect

? DISC

●

The temperature is too high .

(Turn off the power, and wait for a while .)

●

There is an error in the recording signal.

(Erase all of the tracks, and then record

again.)

There is no space left for recording

●

character information (track names,

disc names, etc.).

●

The track has be en prote cted f rom being erased.

(Edit the track with the dev ice on wh ich it

was recorded.)

A disc which contains data other than

●

music was played.

(A disc which contains nonmusic data

cannot be played.)

There is an error in the sign al recorded

●

on the disc.

MEANING

Number or symbol appears in (*) position.

– 5 –

Page 6

MD-MT180

MiniDisc System Limitations

The unit may have the following symptoms when recording or editing. The unit is not out of order.

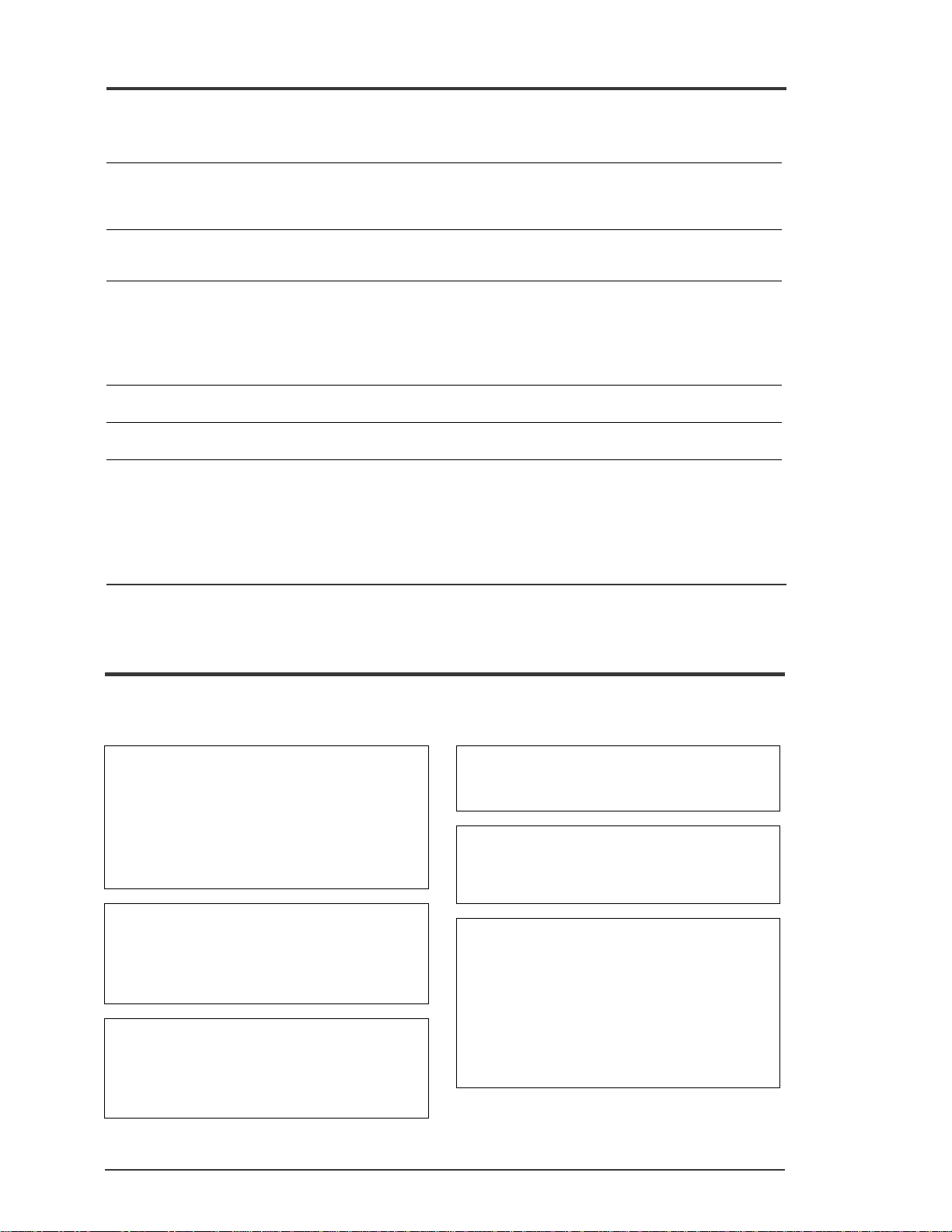

SYMPTOM LIMITATIONS

"DISC FULL" or "TOC FULL" appears

even though the MiniDisc still has recording time left.

The remaining recording time does not

increase even though you erased

tracks.

The total of the recorded time and the

remaining time does not match the maximum recordable time.

Combine function does not work.

Sound skips in fast reverse/forward.

A track number is created in the middle

of a track.

More than 255 tracks (maximum) cannot be recorded regardless of

the recording time. If the MiniDisc is recorded or edited repeatedly or

if it has scratches (recording skips scratched parts), you may not be

able to record the maximum tracks above.

The unit does not count non-recorded portions that last 12 or fewer

seconds to display the remaining recording time. The time may not

increase even if you erase short tracks.

One cluster (approximately 2 seconds) is the minimum unit for recording. For example, a 3-second track uses 2 clusters (approximately 4 seconds). Therefore, the actual recordable time may be

shorter than the displayed time.

(The number of seconds indicates that in the stereo recording mode

(SP). It varies depending on the recording mode.)

A MiniDisc on which recording and editing are repeated may not allow the combine function.

If one track is divided and recorded in separate places on a repeatedly recorded or edited MiniDisc, sound may skip.

A track number may be created if there are scratches or dust on the

MiniDisc.

Troubleshooting

Many potential "problems " can be resolved by the owner wit hout calling a service techn ician. If so mething seems to be wrong

with this product, check the following before calling your authorized SHARP dealer or service center.

The unit does not turn on.

●

Is the AC adaptor disconnected?

●

Is the battery exhausted?

●

Is the unit in the hold mode?

Has condensation formed inside the unit?

●

Is the unit being influenced by mechanical shock or b y

●

static electricity?

No sound is heard from the earphones.

●

Is the volume set too low?

Is the earphones plugged in?

●

●

Are you trying to pl ay a MiniDisc with data on it instead

of a MiniDisc containing music?

When the operation buttons are pressed, the unit does

not respond.

Is the unit in the hold mode?

●

Is the battery exhausted?

●

Is the earphones plug inserted firmly?

●

Some sounds are skipped.

●

Is the battery exhausted?

●

Is the unit being subjected to excessive vibration?

The MiniDisc cannot be ejected.

Has the track number or character information been

●

written on the disc yet?

Is the unit in the recording or editing mode?

●

Recording and editing are impossible.

Is the MiniDisc protected against accidental erasure?

●

●

Is the unit connect ed prope rly to the other equipment?

Is the AC adaptor unplug ged or did a power f ailure oc-

●

cur when recording or editing?

●

Is the unit in the hold mode?

Is an optical signal being output from the stereo sys-

●

tem? Read the operation manual for the stereo system.

– 6 –

Page 7

1

2

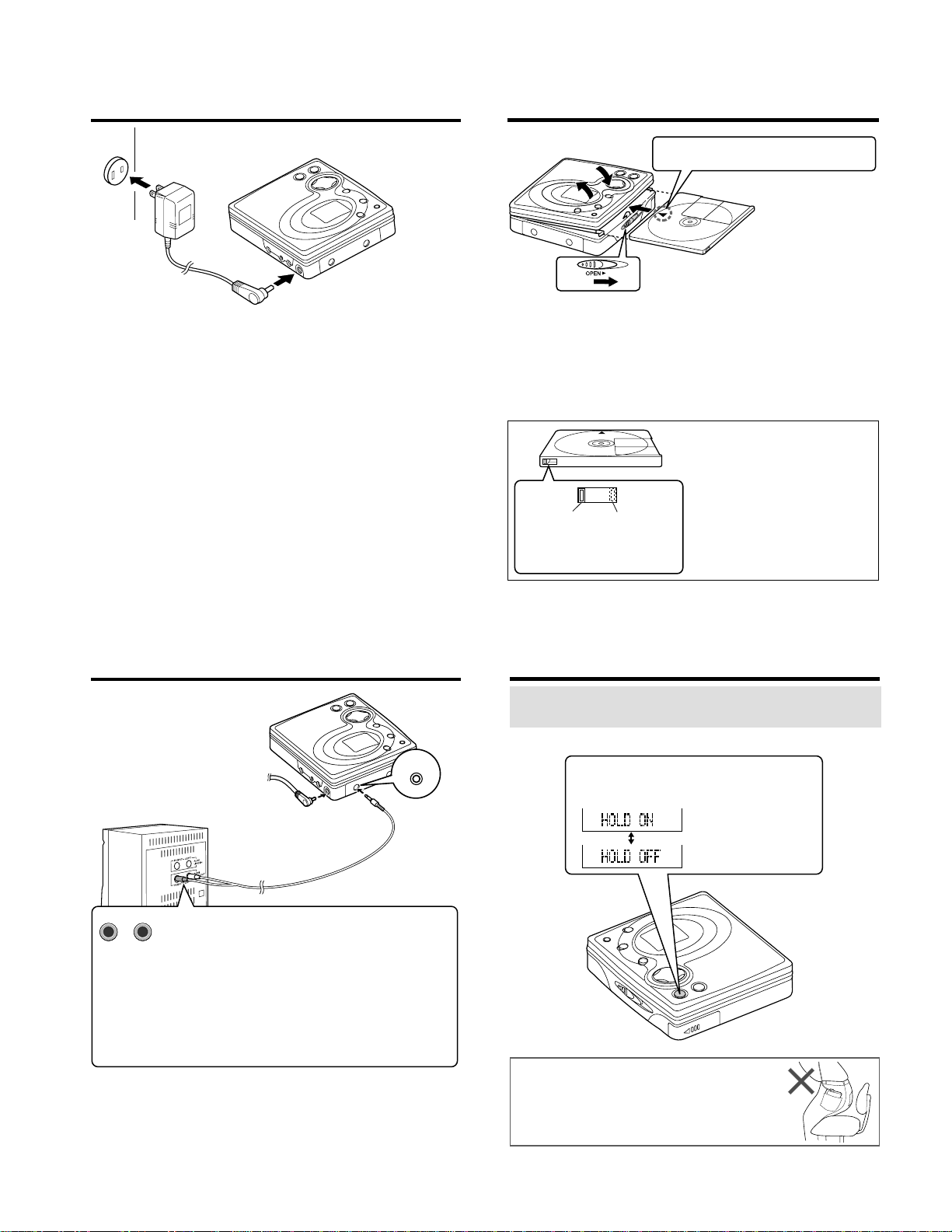

Inserting a MiniDisc

Inserción de un minidisco

1

Slide the OPEN lever to release the compartment door.

Deslice la palanca OPEN para

abrir la puerta del compartimiento.

2

Lift it up.

Levántela.

3

Insert a MiniDisc as shown.

Inserte un minidisco como se

muestra.

4

Close the compartment door.

Cierre la puerta del compartimiento.

When you record on a MiniDisc,

check that the erase prevention tab

is set to the “Recordable” position.

Cuando grabe en un MD, compruebe

que la lengüeta de prevención contra borrado esté puesta en la posición

"Grabable".

Recordable

Grabable

Recording

prevented

Grabación

prevenida

3

1

2

44

3

Insert according to the direction of the arrow.

Insértelo de acuerdo con la dirección de la flecha.

Preparation for use

Preparación para su utilización

The unit does not work if the unit is in the hold mode.

El aparato no funciona si está en el modo de retención.

Hold

Retención

Release

Liberación

Press the HOLD button for 2 seconds or more.

Pulse el botón

HOLD

durante 2 o más segundos.

CAUTION:

It is not recommendable to put the MiniDisc into a rear

pocket, as this may damage the product when sitting.

PRECAUCIÓN:

No es recomendable poner el MD en un bolsillo trasero,

porque esto podría dañar el producto al sentarse.

Connect the AC adaptor

Conecte el adaptador de CA

AC 120V, 60 Hz

120V CA, 60Hz

1

To an AC outlet

A un tomacorriente

de CA

1

Plug the AC adaptor into the

AC outlet.

Enchufe el adaptador de CA en

el tomacorriente de CA

Before using the unit with a rechargeable battery, the battery has to be charged.

Antes de emplear el aparato con una batería recargable, se deberá cargar la

batería.

To the DC IN 5V jack

A la toma DC IN 5V

.

2

Insert the plugs firmly.

Inserte firmemente las clavijas.

2

Insert the plug on the other

end into the DC IN 5V jack.

Inserte la clavija del otro

extremo en la toma DC IN 5V.

MD-MT180

3

Connections /

Conexiones

LINE OUT

To the DC IN 5V jack

A la toma DC IN 5V

White: To Left

To a stereo system with

jacks.

Note:

LEFTRIGHT

If the audio system has only one pair of jacks then they are usually

for input only and recording via this connection is not possible.

Para un sistema estéreo con tomas "LINE OUT" o

"AUDIO OUT"

Nota:

Si el sistema de audio tiene sólo un par de tomas, son

usualmente sólo para entrada y no puede realizarse la grabación

mediante esta conexión.

Blanco: A la izquierda

.

“LINE OUT” or “AUDIO OUT”

Red: To Right

Rojo: A la derecha

LINE IN

– 7 –

Page 8

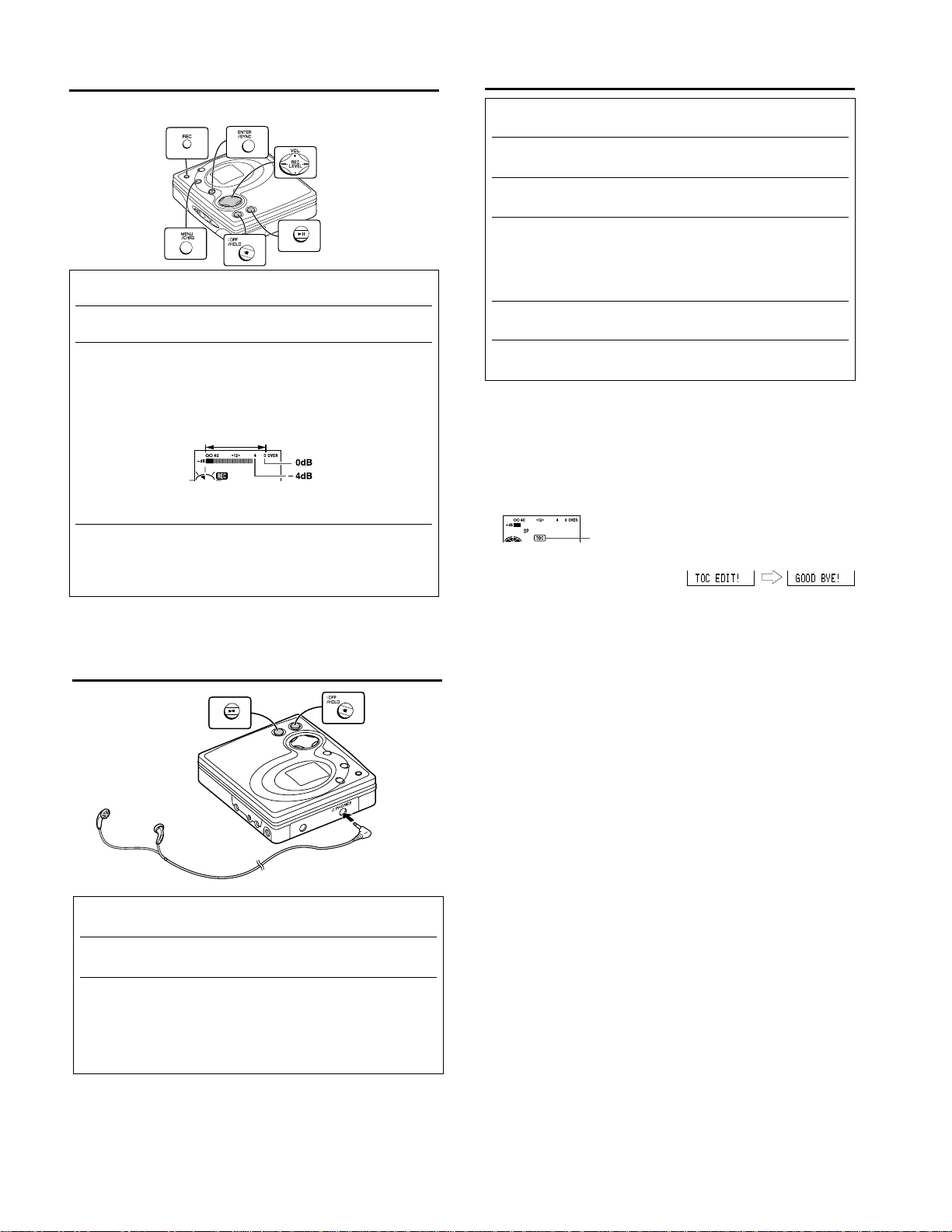

MD-MT180

Recording /

Check that the unit is connected to the stereo system.

Compruebe que el aparato esté conectado al sistema estéreo.

1

Press the REC button.

Pulse el botón REC.

2

Begin playback on the stereo system connected to this portable MD.

Inicie la reproducción en el sistema estéreo conectado a este MD portátil.

3

Press the REC LEVEL

Adjust the recording level so that the maximum sound volume from the source makes

the reading swing somewhere between –4 dB and 0 dB.

Pulse el botón REC LEVEL

Ajuste el nivel de grabación de modo que el nivel máximo de volumen del sonido de la

fuente haga que la indicación oscile entre –4 dB y 0 dB.

This unit can adjust the digital recording level just the same as the analog recording.

Este aparato puede ajustar el nivel de grabación digital del mismo mode que en el caso

de la grabación analógica.

4

Press the PA USE b utton on the stereo system to enter the playback pause mode.

Here you can search for the track to record.

Pulse el botón PAUSE del sistema estéreo para establecer el modo de pausa de

reproducción.

Aquí podrá buscar la pista a grabarse.

Level meter indicator

Indicador del medidor de nivel

Grabación

55

5 or

55

55

5

o

55

44

4 button

44

44

4

44

to adjust the recording level.

para ajustar el nivel de grabación.

5 Press the MENU/CHRG button repeatedly to select the "REC MODE".

Pulse repetidamente el botón MENU/CHRG para seleccionar "REC MODE".

6 Press the ENTER/SYNC button.

Pulse el botón ENTER/SYNC.

7 Press the MENU/CHRG button repeatedly to select recording mode.

Pulse repetidamente el botón MENU/CHRG para seleccionar el mode de grabación.

8 Press the ENTER/SYNC button.

The mode will be set automatically after 7 seconds even if the ENTER/SYNC

button is not pressed.

Pulse el botón ENTER/SYNC.

El mode se establecerá automáticamente después de 7 segundos aunque no se pulse el

botón ENTER/SYNC.

9 Press the

Pulse el botón

10

Begin playback on the stereo system, and the output will be recor ded.

Inicie la reproducción en el sistema estéreo, y se grabará la salida.

To stop recording

Press the :OFF/HOLD button.

When “TOC” appears, the MiniDisc

recorded contents have not yet been

updated.

Para detener la grabación

Pulse el botón :OFF/HOLD.

Mientras aparece “TOC”, aún no se habrá

actualizado el contenido grabado en el MD.

0606

06 button to start the MiniDisc unit recording.

0606

0606

06

para iniciar la grabación del aparato de MD.

0606

To update the recor ded contents

■

■

TOC display

Visualización

TOC

of the MiniDisc

Press the :OFF/HOLD button when

in the stop mode.

The power turns off after recorded

contents have been updated on the

MiniDisc.

Para actualizar el contenido

grabado del MD

Pulse el botón :OFF/HOLD mientras

esté en el modo de parada.

La alimentación se desconectará

después de haber actualizado el

contenido grabado en el MD.

■

■

Playback /

Right

channel

Canal

derecho

1 Insert the earphones plug into the PHONES jack.

Inserte la clavija de los auriculares en la toma PHONES.

2 Insert a MiniDisc.

Inserte un MD.

3 Press the

Playback starts automatically with a playback only MiniDisc or a MiniDisc

which is protected against accidental erasure (Auto-play function).

Pulse el botón

La reproducción empezará automáticamente con un MD de sólo reproducción o un

MD que está protegido contra borrado accidental (Función de reproducción

automática).

To stop playback

Press the :OFF/HOLD button.

If the unit is not operated for at least 2

minutes when in the stop mode, the

power will shut off automatically.

■

Left

channel

Canal

izquierdo

06 06

06 button.

06 06

Reproducción

To the PHONES jack

A la toma PHONES

0606

06

.

0606

Para detener la reproducción

Pulse el botón :OFF/HOLD.

Si el aparato no se utiliza durante un

mínimo de 2 minutos en el modo de

parada, la alimentación se desconectará

automáticamente.

■

– 8 –

Page 9

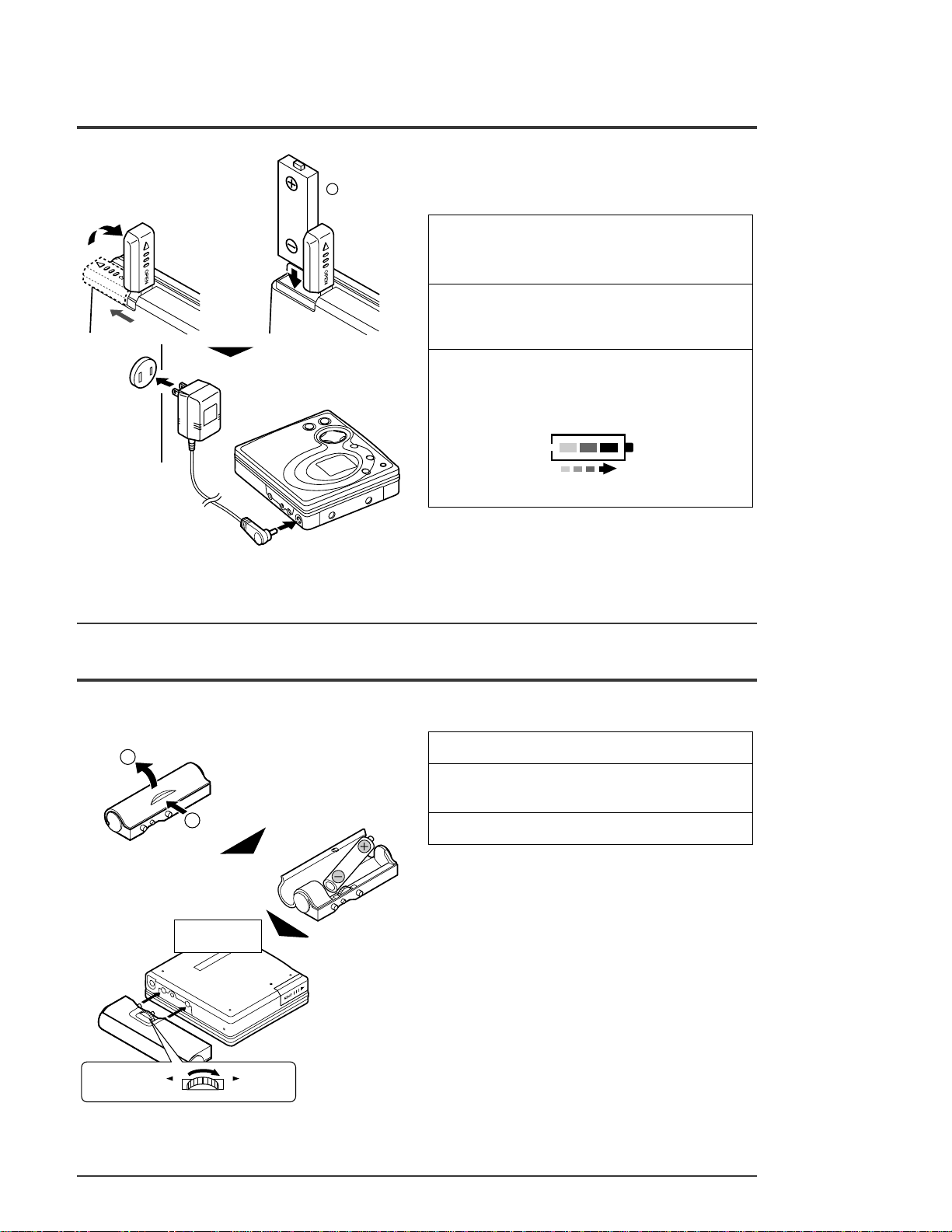

DISASSEMBLY

Cares before disassembling

When assembling the machine after disassembling or

repair, observe the following requirements so as to ensure

safety and performance.

1. Remove the batteries from the machine, and take out the

mini-disc.

2. When assembling after repair, be sure to position the

wires in the same location.

Use the specified screws to fix the cabinet and the

mechanism unit. The use of the screws with length other

than specified may cause contact with the mechanism

unit resulting in malfunction.

3. When repairing, pay close attention so not to damage the

IC from static electricity.

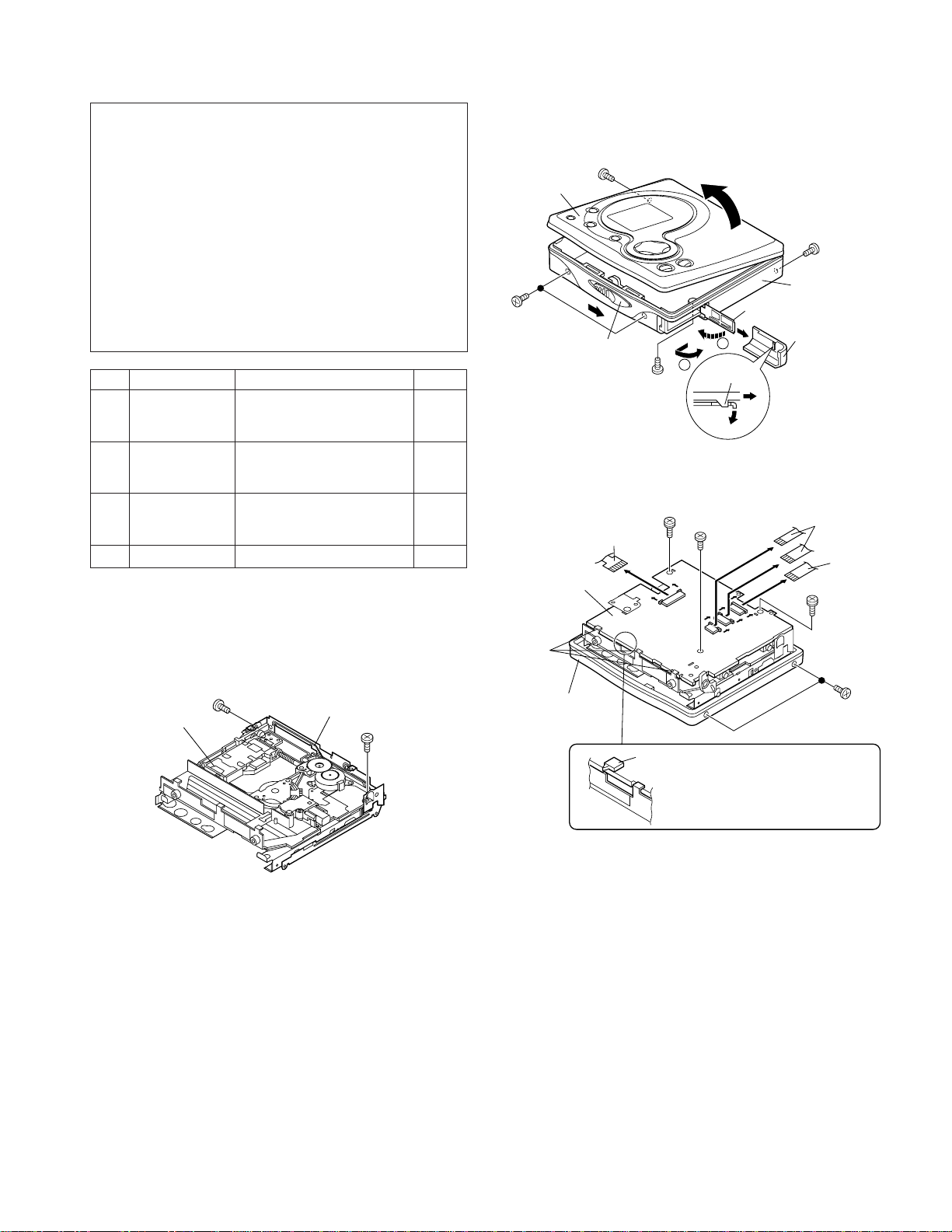

STEP

REMOVAL

1 Bottom Cabinet 1. Screw ..................... (A1) x5 9-1

2 Top Cabinet 1. Open the Top cabinet. 9-1

3 Main PWB 1. Screw .................... (C1) x3 9-2

4 Mechanism Unit 1. Screw .................... (D1) x2 9-3

PROCEDURE

2. Open the Battery Door.

3. Hook .......................(A2) x1

2. Screw .....................(B1) x2 9-2

3. Flexible PWB..........(B2) x2

2. Flexible PWB......... (C2) x2

3. Hook ...................... (C3) x3

(D1) x1

ø1.4 x1.5mm

Mechanism Unit

Bracket

FIGURE

(D1) x1

ø1.4 x1.5mm

Top Cabinet

(A1) x2

ø1.4 x4mm

Main PWB

Hook

(C3) x3

Top Cabinet

(A1) x1

ø1.4 x2.5mm

Open Lever

(A1) x1

ø1.4 x4mm

(C1) x1

ø1.4 x2.5mm

*(C2) x1

Hook

1

(A2) x1

Figure 9-1

(C1) x1

ø1.4 x2mm

Pull

EJECT SWITCH

Be careful not to break the EJECT

SWITCH when remove and attach

the bottom cabinet.

Battery Terminal

2

Pull

Pull

Pull

Pull

MD-MT180

(A1) x1

ø1.4 x2.5mm

Bottom Cabinet

Battery Door

(B2) x2

(C2) x1

(C1) x1

ø1.4 x2.5mm

(B1) x2

ø1.4 x2.5mm

Figure 9-3

Caution:

Carefully handle the main PWB and flexible PWB. After removing the

flexible PWB (*) for the optical pickup from the connector, do not touch

directly the front end of flexible PWB with your hand so as to prevent

damage of optical pickup by static electricity.

Figure 9-2

– 9 –

Page 10

MD-MT180

REMOVING AND REINSTALLING THE MAIN PARTS

Remove the mechanism according to the disassembling methods 1 to 4. (See Page 9.)

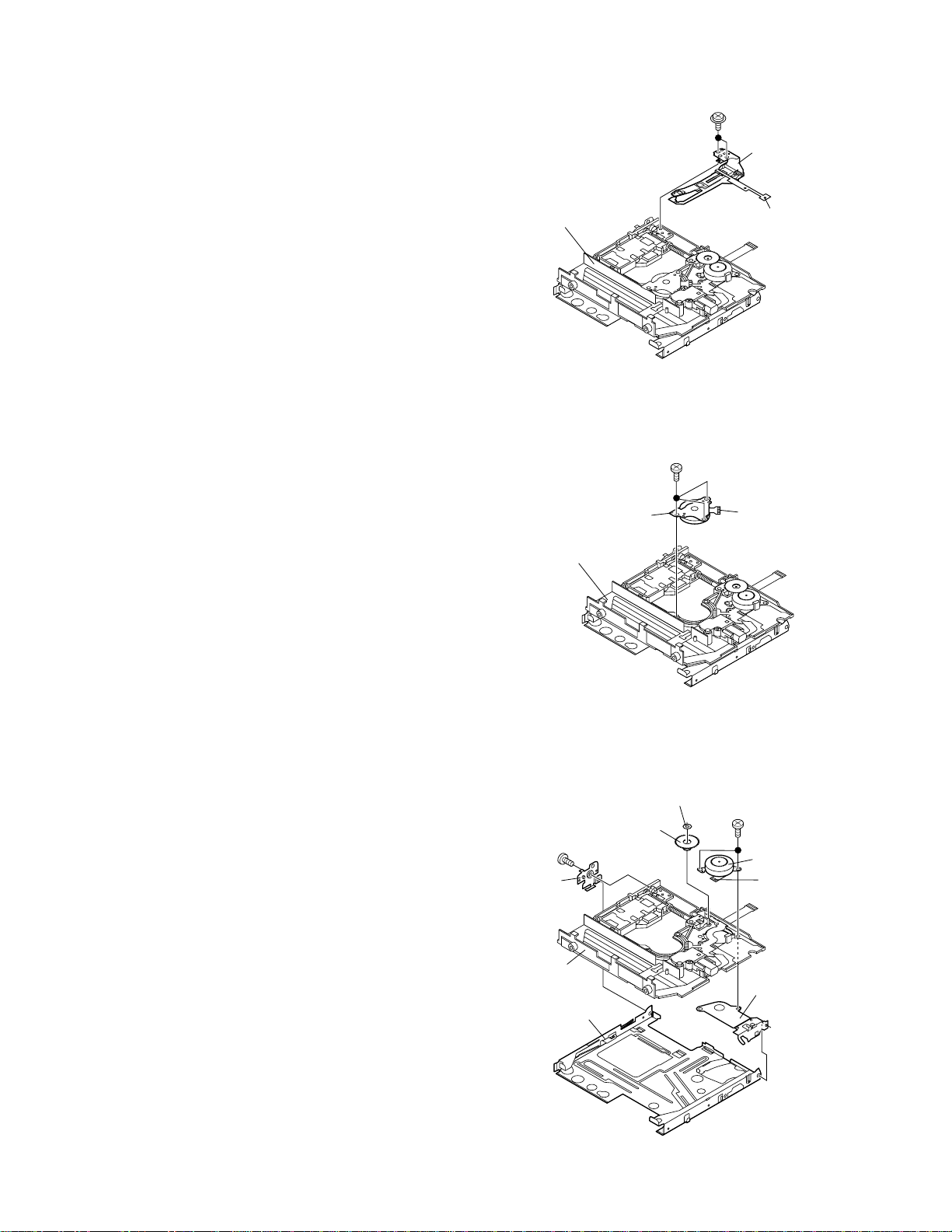

How to remove the magnetic head (See Fig. 10-1.)

1. Remove the solder joints (A1) x 2 of the head flexible plate.

2. Remove the screws (A2) x 2 pcs. of the magnetic head.

Note:

Mount carefully so as not to damage the magnetic head.

How to remove the spindle motor (See Fig. 10-2.)

1. Remove the solder joints (B1) x 4 of flexible PWB.

2. Remove the screws (B2) x 3 pcs., and remove the spindle

motor.

MD Mechanism

(A2) x2

ø1.4 x1.8mm

Magnetic Head

Solder Joints

(A1)x2

How to remove the sled motor (See Fig. 10-3.)

1. Remove the stop washer (C1) x 1 pc., and remove the drive

gear (C2) x 1 pc.

2. Remove the solder joints (C3) x 3 of flexible PWB.

3. Remove the screws (C4) x 2 pcs., and remove the sled

motor and the left bracket.

4. Remove the screw (C5) x 1 pc., and remove the right

bracket.

Note:

Take care so that the motor gear is not damaged.

(If the gear is damaged, noise is caused.)

MD Mechanism

(C5) x1

ø1.7 x3.5mm

Right

Bracket

Figure 10-1

(B2) x3

ø1.4 x3mm

Spindle

Motor

Figure 10-2

Stop Washer

(C1)x1

Drive Gear

(C2)x1

Solder Joints

(B1)x4

(C4) x2

ø1.4 x1.5mm

Sled Motor

Solder Joints

(C3)x3

– 10 –

MD Mechanism

Cartridge Holder

Left

Bracket

Figure 10-3

Page 11

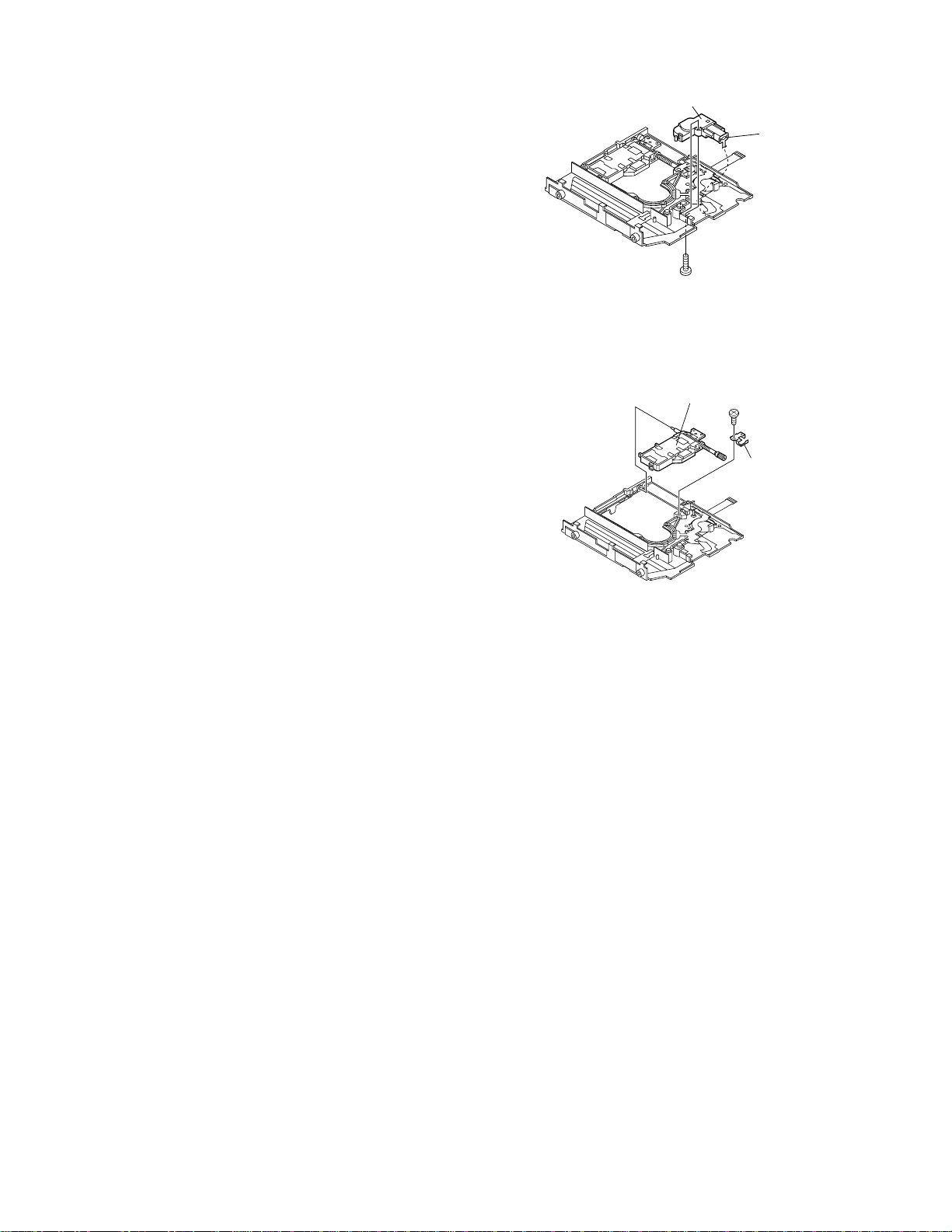

How to remove the Lift motor (See Fig. 11-1.)

1. Remove the solder joints (D1) x 2 of the lift motor lead wire.

2. Remove the screw (D2) x 1 pc., and remove the lift motor.

Note:

Take care so that the motor gear is not damaged.

(If the gear is damaged, noise is caused.)

How to reinstall the optical pickup

(See Fig. 11-2.)

1. Remove the screw (E1) x 1 pc., and remove the spring.

2. Slowly raise the optical pickup.

MD-MT180

Lift Motor

SolderJoints

(D1)x2

(D2) x1

ø1.4 x5mm

Figure 11-1

Optical Pickup Unit

Figure 11-2

(E1) x1

ø1.7 x3.5mm

Spring

– 11 –

Page 12

MD-MT180

ADJUSTMENT

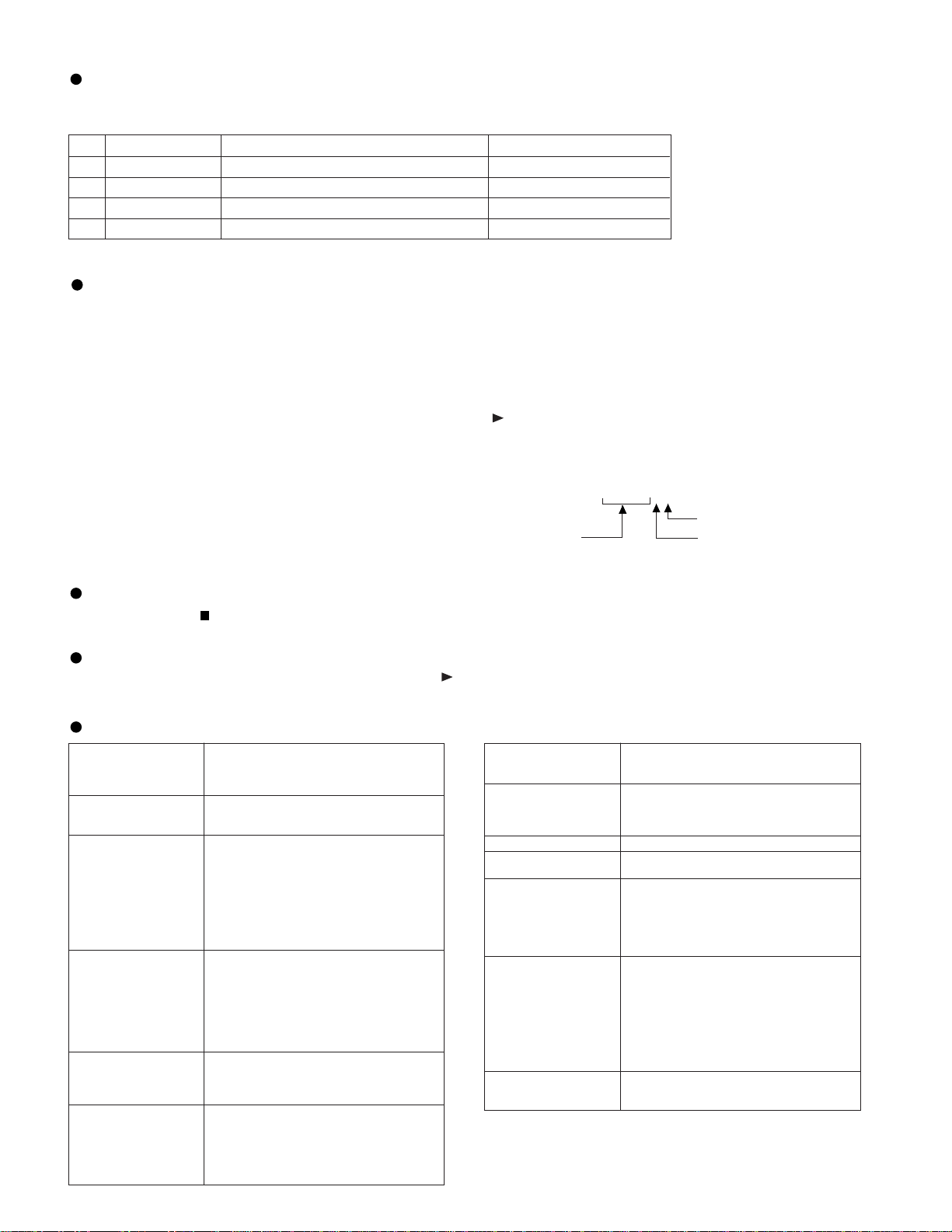

Test disc

MD adjustment needs two types of disc, namely recording disc (low reflection disc) and playback-only disc (high

reflection disc).

Type

Test disc

Parts No.

1 High reflection disc MMD-110 (TEAC Test MD) 88GMMD-110

2 Low reflection disc MMD-212 (TEAC Test MD) 74-minute disc 88GMMD-212

3 Low reflection disc MMD-213A (TEAC Test MD) 80-minute disc 88GMMD-213A

4 Low reflection disc Recording minidisc UDSKM0001AFZZ

Note: Use the low reflection disc on which music has been recorded.

Entering the TEST mode

1. Setting at port (power nonconnected state)

(1) Set the port as follows.

TEST1 : "Low" (TP416)

TEST0 : "High"

(2) Turn the Power ON.

(3) Test Mode START [ T E S T _ ]

2. Setting by special button operation (in standby state)

(1) Holding down the MENU button and ENTER button, press the PLAY button.

(2) Normal mode setting initialization (BASS setting, VOL setting, etc.)

*Since the unit is changed to the setting for production line inspection , be sure to set it to the default setting state in the following default

setting procedure before returning it to the user.

(3) Test Mode START [ T E S T _ ]

(4) When the VOL.+ button is pressed, indication of microcomputer version for one second [ Y 1 2 A c X ]

Destination

Microcomputer version

(5) When the VOL.– button is pressed, whole LCD lighting for 2 seconds

EEPROM version

Leaving the TEST mode

(1) Press the STOP button in the TEST mode stop state.

Shipping setting method

Holding down simultaneously the VOLUME – Button and PLAY Button of the set unit without disc, supply the power from the DC IN plug.

After the indication "INIT" -> "BYE OK" disappears, release the power supply of DC IN.

Test Mode

1. AUTO 1 Mode • Perform preliminary automatic adjustment.

2. AUTO 2 Mode

3. TEST-PLAY Mode

4. TEST-REC Mode

5. MANUAL 1 Mode

6. MANUAL 2 Mode

• If the combination of mechanism and pickup

PWB has been changed, be sure to start from

AUTO1.

• Perform ATT (attenuator) automatic adjustment.

• Perform continuous playback (error rate display,

jump test)

• Continuous playback from the specified address

is performed.

• 1 line, 10 lines or 384 lines manual jump is

performed.

• C1 error rate display (pit section), ADIP error

rate display (groove section)

• The temperature correction is performed only when

servo start is performed, but the posture correction

is not performed during continuous playback.

• Continuous record from the specified address

is performed.

• Change of record laser output(servo gain is also

changed according to laser output).

• The temperature correction is performed only

when servo start is performed, but the posture

correction is not performed during continuous

recording.

• Temperature is displayed. (Updating in real time)

• Seeing the displayed adjustment value, perform

preliminary manual adjustment.

(Error rate indication, jump test)

• Temperature is displayed. (Updating in real time)

• Seeing the displayed adjustment value perform

manfully the preliminary adjustment.

(Error rate indication, jump test)

• Continuous playback is performed

(Error rate display, jump test).

7. RESULT 1 Mode

8. RESULT 2 Mode

9. DIGITAL INPUT Mode

10. ERROR INFORMATION

Mode • Error information is initialized

11. NORMAL Mode

12. EEPROM Mode

13.AUTO J Mode

• The value adjusted in AUTO1 or MANUAL1 is

indicated.

• (Execution in servo "OFF" state").

• The value adjusted in AUTO 2 or MANUAL 2 is

indicated.

• Adjustment value is changed manually.

(Error rate display, jump test).

• Digital input information is displayed.

• Error information is displayed.

• The mode is changed from the TEST mode to

the normal mode without adjustment.

• In the normal mode the internal operation mode,

memory capacity, etc. areindicated.

• In the normal mode both temperature correction

and posture correction are perfomed.

• Factors of digital servo are changed manually.

(Each servo is turned on individually.)

• Cut-off frequency of BASS1, BASS2 and BASS3

is selected manually.

• Temperature detection terminal voltage is

measured, and the reference value is set.

• Defaults are selected and set.

• Setting of EEPROM protect area is updated.

(In case of protect releasing)

•

AUTO 1/2, focus balance adjustment, TEST-

PLAY (ADIP/C1 error check), EEPROM are

updated sequentially.

– 12 –

Page 13

Operation in each TEST mode

1. AUTO1 Mode

• When the STOP button is pressed while the AUTO1 menu

appears or during automatic adjustment, the mode changes

to the TEST mode stop state. At this time the adjustment

value is not output.

• Be sure to adjust, using the specified disc MMD-213A or

MMD-212.

At this time release the EEPROM (IC402) protection. (Refer

to EEPROM write procedure.)

• Adjustment NG; Adjustment item out of range, focus ON

failure, and adjustment error

• When the PLAY button is pressed while ADJ. OK is

displayed, AUTO2 is executed.

MD-MT180

• Whenever the MENU button is pressed in the continuous

playback mode, the indication changes as follows.

* Pre-mastered disc

Continuous playback (SUBQ address indication)

Continuous playback (C1 error indication)

Continuous playback (SUBQ address indication)

* Recordabl disc

Continuous playback (ADIP address indication)

Continuous playback (C1 error indication)

Continuous playback (ADIP error indication)

[ S Q ]

[ C E ]

[ S Q ]

[ A P ]

[ C E ]

[ A E ]

2. AUTO2 Mode

• When the STOP button is pressed while the AUTO2 menu

appears or during automatic adjustment, the mode changes

to the TEST mode stop state. At this time the adjustment

value is not output.

• Adjustment NG; Adjustment item out of range, and adjustment error.

• When the PLAY button is pressed while ADJ. OK is

displayed, TEST_PLAY is executed.

3. TEST-PLAY Mode

• When the STOP button is pressed while the TEST-PLAY

menu appears, or in TEST-PLAY or continuous playback

mode, the mode changes to the TEST mode stop state.

• When the PLAY button is pressed while the TEST-PLAY

menu appears, continuous playback is initiated from the

current pickup position.

• Whenever the MENU button is pressed in the TEST-PLAY

menu, the target address changes as follows.

0032 → 03C0 → 0700 → 08A0 → 0950 → 0032 →

When the PLAY

is displayed, continuous playback is performed after searching that address.

• Each time the ENTER button is pressed while the TESTPLAY mode target address is displayed, the digit which is

changed by pressing the FAST FORWARD/FAST REVERSE

/ button is changed as follows.

0032 → 0032 → 0032 → 0032 →

• When the FAST FORWARD button is pressed in the

TEST-PLAY mode target address is displayed, the digit of

address specified by the ENTER button is set to +1h. (0 to F)

• When the FAST REVERSE button is pressed in the

TEST-PLAY mode target address is displayed, the digit of

address specified by the ENTER button is set to -1h. (0 to F)

*

When the FAST FORWARD/FAST REVERSE /

button is held down, the setting changes continuously, one

cycle being 100 ms.

• When the BASS button is pressed in the continuous playback mode, the number of jump lines changes as follows.

1 → 10 → 384 → 1 →

* After the number of jump lines is indicated for one second,

the address indication is restored [ T R _ ]

• When the FAST FORWARD button is pressed in the

continuous playback mode, the specified number of lines

is jumped in the FWD direction.

• When the FAST REVERSE button is pressed in the

continuous playback mode, the specified number of lines

is jumped in the REV direction.

* When the FAST FORWARD/FAST REVERSE

button is held down, jump is repeated every

approx. 100 ms.

button is pressed while a target address

........

........

........

/

Continuous playback (ADIP address indication)

[ A P ]

4. TEST-REC Mode

• When the STOP button is pressed while the TEST-REC

menu appears, or in the TEST-REC mode or continuous

record mode, the mode changes to the TEST mode stop

state.

•

When the PLAY button is pressed while the TEST-REC

menu appears, the continuous record is initiated from the

current pickup position.

• Whenever the MENU button is pressed in the TEST-REC

menu, the target address changes as follows.

0032 → 03C0 → 0700 → 08A0 → 0950 → 0032 →

When the PLAY

address is displayed, continuous playback is performed

after searching that address.

• Whenever the ENTER button is pressed in the TEST-REC

mode target address is displayed, the digit which is

changed by the FAST FORWARD/FAST REVERSE /

button changes as follows.

0032 → 0032 → 0032 → 0320 →

• When the FAST FORWARD button Is pressed in the

TEST-REC mode target address is displayed, the digit of

address specified by the BASS button is set to +1h.

• When the FAST REVERSE button is pressed in the

TEST-REC mode target address is displayed, the digit of

address specified by the BASS button is set to -1h.(0 to F)

*

When the FAST FORWARD/FAST REVERSE /

button is held down, the setting changes continuously,

one cycle being 100 ms.

button is pressed while a target

........

........

(0 to F)

– 13 –

Page 14

MD-MT180

5. NORMAL Mode

• When the STOP button is pressed while the NORMAL

menu appears, the mode changes to the TEST mode stop

state.

• Indication during operation

Indication of memory capacity on main unit LCD

[ ] + Level meter

: Internal mode

: Address (Cluster section)

: Address (Sector section)

• Selection of sound volume, BASS, etc. is possible (without

indication)

• Recording is also possible.

• If the STOP button is pressed during operation in the

NORMAL mode, the NORMAL mode is canceled, and the

power is turned off.

6. Error data display Mode

• Reversing when FAST REVERSE button is pressed

• When the STOP button is pressed while the error data

indication menu appears or during error data indication, the

mode changes to the TEST mode stop state.

• Error data 0 is the latest error.

• Error which occurred in the TEST mode is also stored in the

memory.

• When the MENU button is pressed while the error data

indication menu appears, the error data is initialized.

[ C L E A R _ ]

• : Error Code

Explanation of error history code

13h :

Excessive number of retry to draw servo during its

adjustment.

16h : COUT detection time over during servo adjustment.

17h : The level of input signal from the RF amplifier is out of

the allowable range.

1Fh :Cannot clear the factor of ENDEC DINT.

21h : Cannot focus on the disc.

22h : Cannot start up the spindle.

23h : Track search time over.

32h : Cannot read P-TOC.

42h : Cannot read U-TOC.

44h : Cannot write U-TOC.

45h : Cannot perform write test of U-TOC.

52h : Cannot write SD. (Sound Data)

71h : Time over during initialization of the pickup position.

72h : Check sum error occurred when reading EEPROM.

73h :

Cannot operate the recording head (by using the EJECT

lever).

91h :

The ambient temperature is out of the allowable range.

7. Auto J Mode

• AUTO 1/2, focus balance adjustment, TEST-PLAY (ADIP/C1

error check), EEPROM are updated sequentially.

• If the STOP button is pressed while processed, the same

operation as the normal STOP button operation will be

performed.

– 14 –

Page 15

MD-MT180

EEPROM (IC402) writing procedure

1. Procedure to replace EEPROM and write initial

value of microcomputer in EEPROM

(1) Replace EEPROM.

(2) Refer to the latest EEPROM data list.

(3) Press the MENU button, ENTER button and Play

button to start the test mode.

(4) Press the VOL.+ button, version display

[ V e r . ]

(5) Press the VOL.– button, the whole LCD lights.

(6) Test mode stop state.

[ T E S T ]

(7) Press the "BASS" button, and press 3 times the "FAST

REVERSE

[ E E P R O M ]

(8) Perform the operation to display "EEPROM SETTING

ENTER CHART", compare the EEPROM DATA LIST

with the display, and set according to the EEPROM

DATA LIST with the VOL.+ or VOL.– button.

(9) Set the temperature reference. (Refer to the Tem-

perature Reference Setting Method.)

(10)

Set according to the EEPROM DATA LIST.

(11)

Press the Stop button.

[ T E S T ]

(12)

Press the Stop button.

(13)

After data is written in EEPROM, turn off power .

(14)

Restore protection of EEPROM.

X

EEPROM version (c ~ z)

Microcomputer ROM version

" button.

2. Temperature reference setting method

[1] Measurement, calculation and setting procedure

(1) Set the TEST mode.

• Set TEST 1, 0 = '01', and turn on power

(or set PLAY ON in standby state).

(2) Press the MENU button, ENTER button and Play

button to start the test mode.

(3) Start the EEPROM mode 'Temp' menu.

• Button operation in order of BASS, FAST REVERSE

x 3 times, PLAY , PLAY in the test mode

STOP state.

• 'TM§§ ' is displayed. (§§= Temperature code,

= Temperature reference)

(4) Once press FAST FORWARD , and determine

the displayed microcomputer TEMP input AD value.

• 'TPin##' is displayed. (## = TEMP input AD value)

(5) At the ambient temperature, determine the tempera-

ture corrected value from the temperature measurement value correction table.

(6) Determine the temperature reference, using the fol-

lowing formula.

• Temperature reference = Microcomputer TEMP

input AD value + Temperature corrected value

(7) Set the temperature reference value by button opera-

tion, and check whether the temperature code indication corresponds to "Temperature Code Identification

Table".

[2] Temperature measurement value correction table

Ambient

temperature

+ 9oC ~ +11oC - 05h + 10.0oC

+12oC ~ +14oC - 04h + 12.7oC

+15oC ~ +16oC - 03h + 15.4oC

+17oC ~ +19oC - 02h + 18.2oC

+20oC ~ +22oC - 01h + 20.9oC

+23oC ~ +24oC ± 00h + 23.6oC

+25oC ~ +27oC + 01h + 26.3oC

+28oC ~ +30oC + 02h + 29.0oC

+31oC ~ +33oC + 03h + 31.8oC

Temperature

correction

Center

temperature

[3] Temperature code identification

Ambient

temperature

– 9oC ~ +10oC 08h + 0.5oC

+ 3oC ~ +21oC 07h + 12.5oC

+15oC ~ +33oC 06h + 23.6oC

+26oC ~ +43oC 05h + 35.0oC

– 15 –

Temperature

correction

Center

temperature

Page 16

MD-MT180

EEPROM DATA LIST (EEPROM version c)

TEMP setting

Item display Set values

T M _ _ Calculate values

Focus setting

Item display Set values

F G 1 _ 4 0 H

F Z H _ E D H

F L n _ 0 9 H

F L p _ 0 6 H

F T s _ 1 8 H

F S B _ 4 0 H

F T B _ 2 8 H

T O 1 _ 5 0 H

T O R _ 5 8 H

Tracking setting

Item display Set values

T G 1 _ 1 4 H

T B o _ 2 0 H

T B t _ 1 2 H

T K o _ 2 0 H

T K t _ 0 D H

T D o _ 6 7 H

T D t _ 3 4 H

S C t _ 3 A H

C L p _ 2 4 H

C L r _ 3 0 H

J P I _ 0 E H

K 1 0 _ 6 5 H

T H P _ 0 2 H

T H G _ 0 2 H

T O P _ 0 0 H

T O G _ F 2 H

T 1 P _ 2 0 H

Spindle setting

Item display Set values

S P G _ 3 0 H

S P i _ 9 A H

S P m _ 6 2 H

S P o _ 4 F H

S D 1 _ 7 F H

S D 2 _ 7 F H

S P K _ E B H

S P W _ 0 F H

S P B _ 6 6 H

S R i _ C 0 H

S R m _ 9 A H

S R o _ 7 B H

S B R _ 6 0 H

O S L _ 1 4 H

P J G _ 4 6 H

Sled setting

Item display Set values

S K S _ 7 F H

S K L _ 7 F H

S L C _ 2 4 H

S T L _ 0 7 H

S T M _ 4 2 H

S T E _ A 6 H

S D V _ 6 0 H

S J P _ 0 3 H

W T m _ 1 8 H

S R V _ 5 4 H

S L T _ 5 C H

M V S _ 0 A H

S L S _ 2 8 H

Sled setting (Continued)

Item display Set values

S K E _ 0 E H

S D E _ 1 C H

B P E _ 7 1 H

B P W _ 7 5 H

B P 1 _ 3 3 H

B R E _ 9 5 H

B R W _ 3 3 H

S R S _ 3 C H

Bass setting

Item display Set values

B 1 A _ 0 0 H

B 2 A _ 0 0 H

B 3 A _ 0 0 H

ADJ. SET setting

Item display Set values

C O K _ 2 8 H

F A B _ 6 4 H

H S G _ 1 1 H

L S G _ 1 2 H

Control setting

Item display Set values

C T 0 _ 0 2 H

C T 1 _ 0 1 H

C T 2 _ 3 2 H

C T 3 _ 5 0 H

T S A _ 2 0 H

U S A _ 1 8 H

P L E _ A 0 H

R C E _ 9 4 H

S D F _ 1 F H

F B 0 _ F C H

B H S _ 0 0 H

B S 0 _ 1 7 H

B S 1 _ 7 0 H

B U 0 _ 0 1 H

B D 0 _ 0 5 H

B D 1 _ D C H

B M K _ 1 E H

B E C _ 0 0 H

C S T _ 6 9 H

I J U _ 8 1 H

I J D _ 5 5 H

M C T _ A 1 H

E R C _ 5 A H

C V 0 _ 1 6 H

C V 1 _ 1 0 H

S S K _ B 9 H

A C T _ 6 3 H

C 1 E _ 5 2 H

A D E _ 0 0 H

F G 2 _ 7 0 H

T G 2 _ 2 A H

M F P _ ◊ ◊ H

S P M _ ◊ ◊ H

M S L _ ◊ ◊ H

U S 0 _ ◊ ◊ H

U S 1 _ ◊ ◊ H

U S 2 _ ◊ ◊ H

◊ ◊ H : CHECK-SUM

– 16 –

Page 17

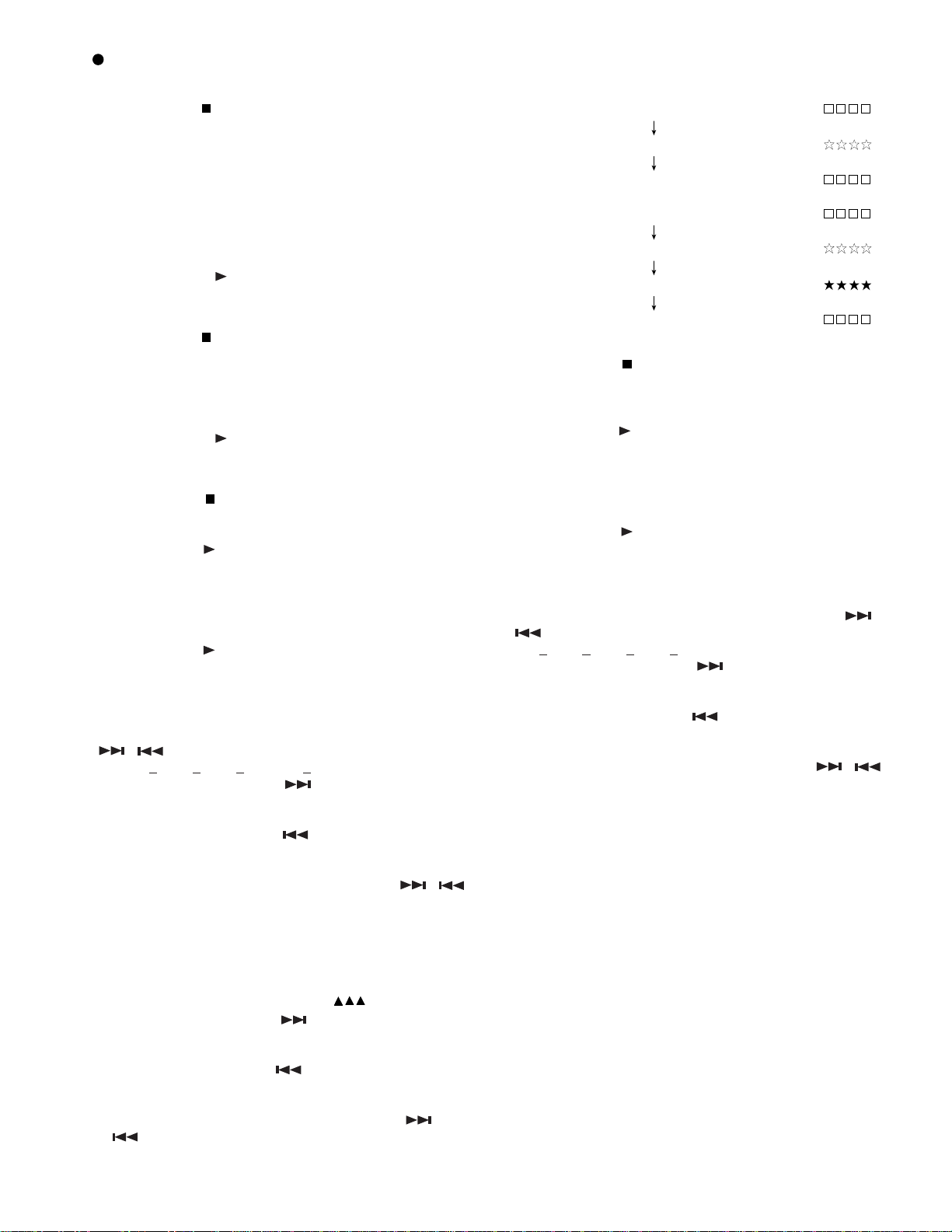

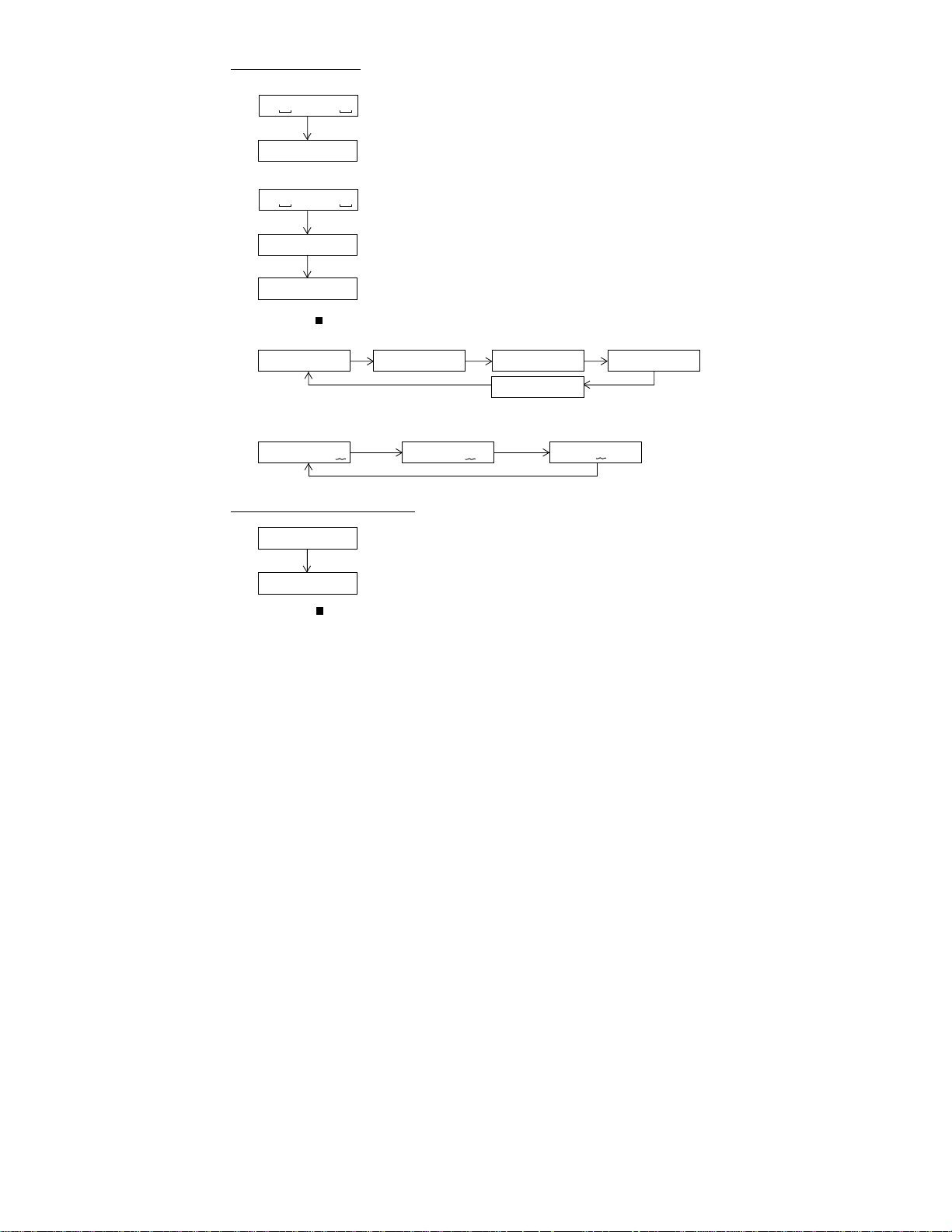

Test Mode Change Chart

Test Mode Menu

MD-MT180

T E S T

FAST FORWARD

Slide external

periphery move

BASS

FAST REVERSE

Slide internal

periphery move

FAST REVERSE

A U T O 1

FAST FORWARD FAST REVERSE

A U T O J

FAST FORWARD FAST REVERSE

A U T O 2

FAST FORWARD FAST REVERSE

T P L A Y

FAST FORWARD FAST REVERSE

T R E C

FAST FORWARD FAST REVERSE

M A N U 1

FAST FORWARD FAST REVERSE

M A N U 2

FAST FORWARD FAST REVERSE

R S L T 1

FAST FORWARD FAST REVERSE

R S L T 2

FAST FORWARD FAST REVERSE

D i n M o n

FAST FORWARD FAST REVERSE

E D A T A

FAST FORWARD FAST REVERSE

N O R M A L

FAST FORWARD

FAST REVERSE

E E P R O M

FAST FORWARD

: Test Mode STOP

: Pre-auto adjustment menu

: Auto 1 & 2, Focus balance adjustment menu

: ATT auto adjustment menu

: Pre-manual adjustment menu

: ATT manual adjustment menu

: Pre-adjustment value check menu

: ATT adjustment value check menu

: Continuous playback menu

: Continuous record menu

: Test mode normal playback menu

: Digital input signal monitor menu

: Error history display menu

: EEPROM setting menu

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [PLAY ] button operation is performed in the specific menu, the operation of this

menu is executed.

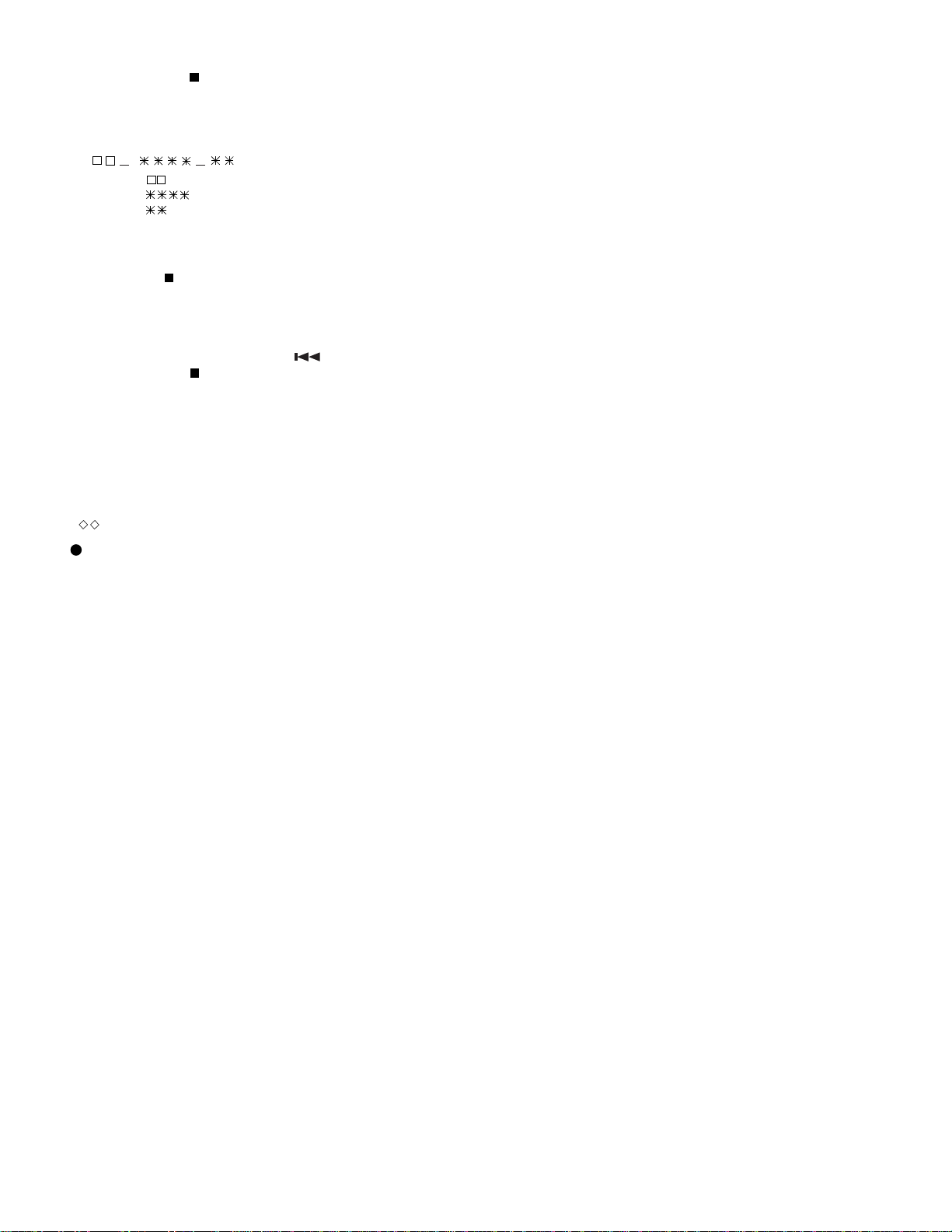

Preautomatic Adjustment

A U T O 1

PLAY

A T 1

Adjustment error

Normal end

A D J . N G

A D J . O K

PLAY

A T 2

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* " " represent the adjustment number as follows.

0 0 : Innermost periphery move

0 2 : ABEF offset tentative measurement

0 4 : RF side focus gain coarse adjustment

0 5 : Focus ATT tentative setting

0 6 : RF side bit section tracking gain adjustment

0 7 : COUT level setting for pit section adjustment

0 8 : External periphery move

0 9 : RF side groove section tracking gain adjustment

1 0 : COUT level setting for groove section adjustment

1 1 : RF side TCRS gain adjustment

1 2 : Tracking ATT initial setting

1 3 : RF side focus gain minor adjustment

1 4 : Focus ATT initial setting

1 5 : S gain "High" ABEF offset measurement

1 6 : TCRS offset measurement

1 7 : S gain "Low" ABEF offset measurement

: Preautomatic Adjustment menu

: During preadjustment adjustment

: Preadjustment error (adjustment value output)

: Preadjustment normal end (adjustment value output)

: During ATT automatic adjustment

– 17 –

Page 18

MD-MT180

ATT Auto Adjustment

A U T O 2

PLAY

A T 2

Adjustment error

Normal end

A D J . N G

A D J . O K

ENTER

b # # #

PLAY

S Q # # # #

A P # # # #

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* " " represent the adjustment number as follows.

0 0 : Innermost periphery move

0 3 : Pit section tracking ATT setting

0 4 : Pit section focus ATT setting

0 6 : External periphery move (low reflection only)

0 7 : TCRS ATT setting (low reflection only)

0 8 : Groove section tracking ATT setting (low reflection only)

0 9 : Groove section focus ATT setting (low reflection only)

: ATT auto adjustment menu

: During ATT auto adjustment

: ATT adjustment error (adjustment value output)

: ATT adjustment normal end (adjustment value output)

: Focus balance Adjustment mode

: Continuous playback (high reflection)

: Continuous playback (low reflection)

: Focus balance

# # # : Jitter error

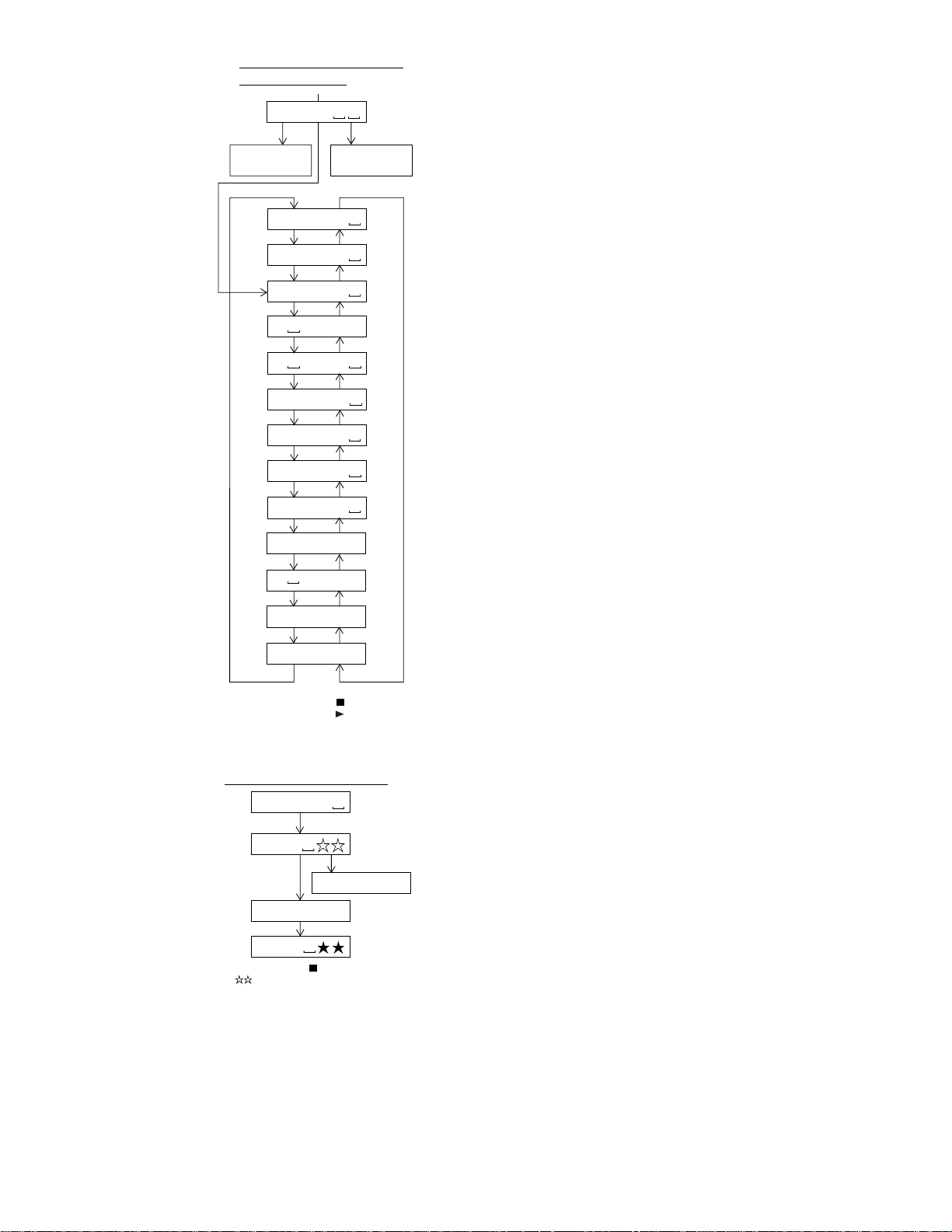

Continuous Playback

• Continuous playback from current pickup position

T P L A Y

PLAY

S Q # # # #

A P # # # #

• Continuous playback from any address

T P L A Y

MENU

A d 0 0 3 2

PLAY

S Q # # # #

A P # # # #

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* In the start address set state the start address changes as follows when the [MENU] button is pressed.

0 0 3 2

H (initial value) 0 3 C 0 H 0 7 0 0 H 0 8 A 0 H

A d 0 0 3 2

* In the start address setting state the start address change digit changes when the [ENTER] button is pressed.

1st digit (initial value) 2nd digit 3rd digit

ENTER ENTER

A d 0 0 3 2

* In the start address set state the value of selection digit changes in the range of "0h to Fh"

when the [FAST FORWARD/REVERSE / ] button is pressed.

* In the continuous playback state the number of jump lines changes as follows shown

the [BASS] button is pressed.

1 (initial value) 10 384

BASS

1 T R

* When the [FAST FORWARD ] button is pressed in the continued playback mode, jump of specified

number of lines occurs in the external periphery direction.

If the key is held down jump occurs continuously (100 ms cycle).

* When the [FAST REVERSE ] button is pressed in the continuous playback mode, jump of

specified number of lines occurs in the internal periphery direction.

If the key is held down, jump occurs continuously (100 ms cycle).

: Continuous playback menu

: Continuous playback (pit section)

: Continuous playback (groove section)

# # # # : Address

: Continuous playback menu

: Start address setting

: Continuous playback (pit section)

: Continuous playback (groove section)

# # # # : Address

A d 0 3 C 0

MENUMENU

A d 0 7 0 0

A d 0 9 5 0 H

A d 0 0 3 2

1 0 T R

A d 0 0 3 2

BASS

3 8 4 T R

MENU

A d 0 8 A 0

MENU

0 9 5 0 H

ENTER

BASS

– 18 –

Page 19

Continuous Rrecord

• Continuous record from the current pickup position

T R E C

PLAY

A P # # # #

• Continuous record playback from any address

T R E C

PLAY

A d 0 0 3 2

PLAY

A P # # # #

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* In the start address set state the start address changes as follows when the [MENU] button is pressed.

0 0 3 2 H (initial value) 0 3 C 0 H 0 7 0 0 H 0 8 A 0 H

A d 0 0 3 2

* In the start address setting state the start address change digit changes when the [ENTER] button is pressed.

1st digit (initial value) 2nd digit 3rd digit

A d 0 0 3 2

A d 0 3 c 0 A d 0 7 0 0

ENTER

: Continuous record menu

: Continuous record

# # # #: Address

: Continuous record menu

: Start address setting

: Continuous record

# # # #: Address

MENUMENU

A d 0 0 3 2

A d 0 9 5 0

ENTER

A d 0 0 3 2

ENTER

MENU

A d 0 8 A 0

MENU

MD-MT180

Test Mode Normal Playback

N O R M A L

PLAY

@@@@@@

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the NORMAL mode is canceled, the power is turned off.

: TEST mode normal playback menu

: Continuous playback

@@@@@@: Mode and address display

– 19 –

Page 20

MD-MT180

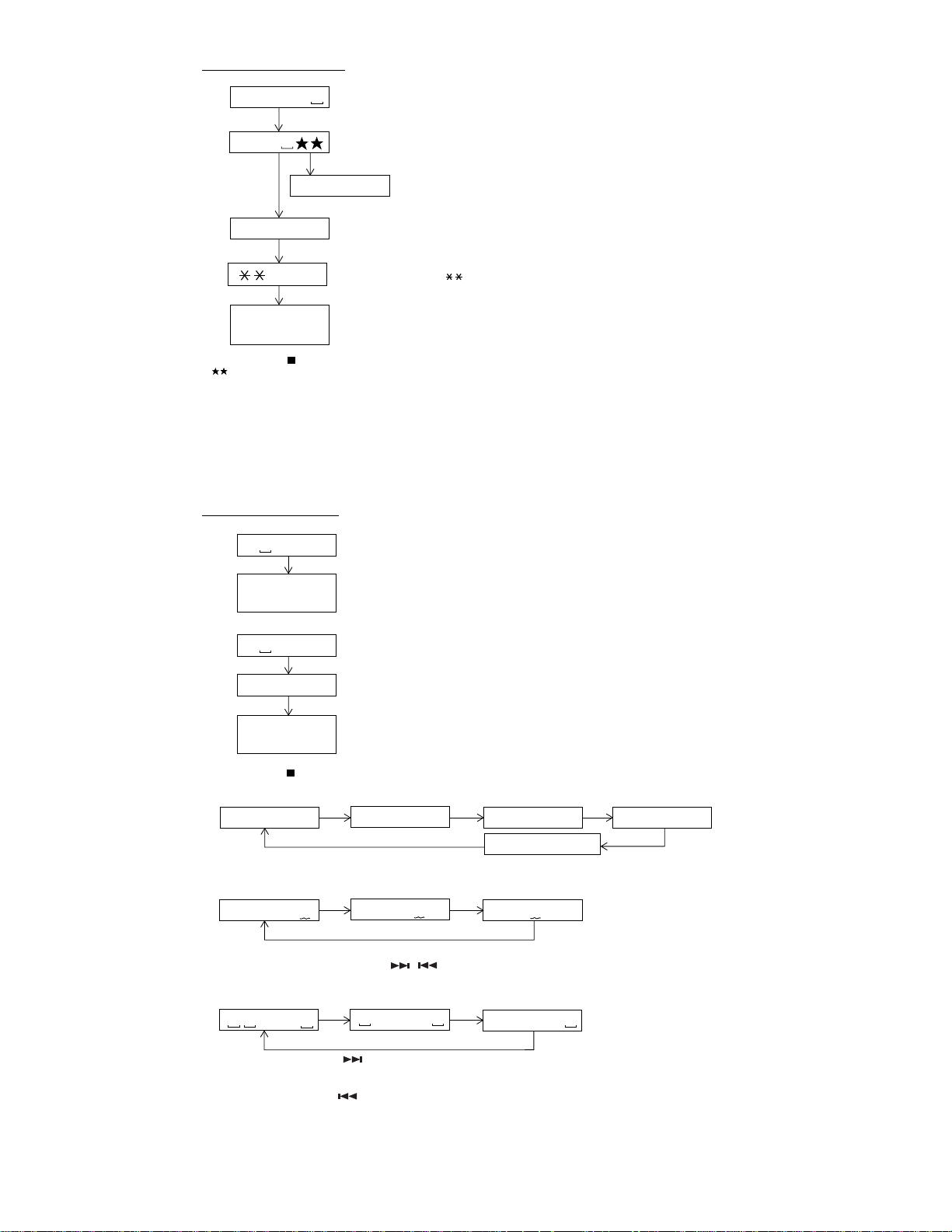

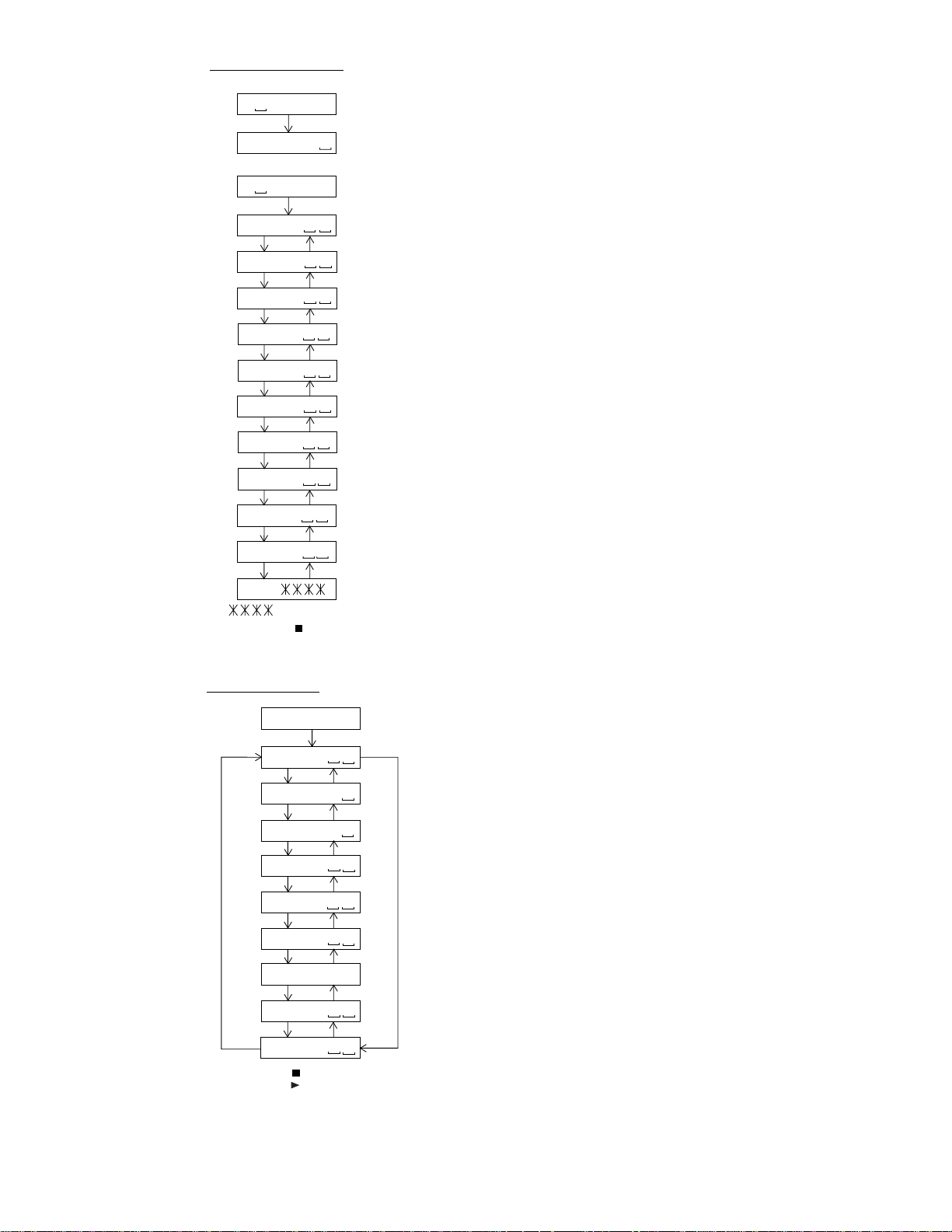

Error History Display

• Error history clear

E D A T A

MENU

C L E A R

• Error history display

E D A T A

PLAY

E 0 § §

FAST FORWARD FAST REVERSE

E 1 § §

FAST FORWARD FAST REVERSE

E 2 § §

FAST FORWARD FAST REVERSE

E 3 § §

FAST FORWARD FAST REVERSE

E 4 § §

FAST FORWARD FAST REVERSE

E 5 § §

FAST FORWARD FAST REVERSE

E 6 § §

FAST FORWARD FAST REVERSE

E 7 § §

FAST FORWARD FAST REVERSE

E 8 § §

FAST FORWARD FAST REVERSE

E 9 § §

FAST FORWARD FAST REVERSE

: Error history display menu

: Error history clear

: Error history display menu

: Error history 0 display

§ § : Error code

: Error history 1 display

§ § : Error code

: Error history 2 display

§ § : Error code

: Error history 3 display

§ § : Error code

: Error history 4 display

§ § : Error code

: Error history 5 display

§ § : Error code

: Error history 6 display

§ § : Error code

: Error history 7 display

§ § : Error code

: Error history 8 display

§ § : Error code

: Error history 9 display

§ § : Error code

RC :

: Total Recording Time

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

EEPROM Setting

E E P R O M

PLAY

T e m p

FAST FORWARD FAST REVERSE

FAST REVERSE

F o c u s

FAST FORWARD FAST REVERSE

T r a c k

FAST FORWARD FAST REVERSE

S p i n

FAST FORWARD FAST REVERSE

S l e d

FAST FORWARD FAST REVERSE

B a s s

FAST FORWARD FAST REVERSE

A D J S E T

FAST FORWARD FAST REVERSE

C T R L

FAST FORWARD FAST REVERSE

FAST FORWARD

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [PLAY ] button operation is performed in the specific state, the specific setting menu is set.

L S I _I F

: EEPROM setting menu

: TEMP setting menu

: Focus setting menu

: Tracking setting menu

: Spin setting menu

: Sled setting menu

: BASS setting menu

: Adjustment setting menu

: Control setting menu

: LSI setting menu

– 20 –

Page 21

Focus Setting

MD-MT180

F o c u s

PLAY

: Focus setting menu

F G 1

FAST FORWARD FAST REVERSE

F Z H

FAST FORWARD FAST REVERSE

F L n

FAST FORWARD FAST REVERSE

F L p

FAST FORWARD FAST REVERSE

F T S

FAST FORWARD FAST REVERSE

F S B

FAST FORWARD FAST REVERSE

F T B

FAST FORWARD FAST REVERSE

T O 1

FAST FORWARD FAST REVERSE

T O R

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [MENU] button operation is performed in the specific state, the menu changes to

"TEMP SETTING menu".

* In specific state the setting changed in the range of "00h to FFh" when the [VOL.+/–] button

is pressed.

(The upper limit varies depending on the items)

* When the [ENTER] button is pressed in each state, the set digit is changed.

Spin Setting

S p i n

PLAY

: Spin setting menu

S P G

FAST FORWARD FAST REVERSE

S P i

FAST FORWARD FAST REVERSE

S P m

FAST FORWARD FAST REVERSE

S P o

FAST FORWARD FAST REVERSE

S D 1

FAST FORWARD FAST REVERSE

S D 2

FAST FORWARD FAST REVERSE

S P K

FAST FORWARD FAST REVERSE

S P W

FAST FORWARD FAST REVERSE

S P B

FAST FORWARD FAST REVERSE

S R i

FAST FORWARD FAST REVERSE

S R m

FAST FORWARD FAST REVERSE

S R o

FAST FORWARD FAST REVERSE

S B R

FAST FORWARD FAST REVERSE

O S L

FAST FORWARD FAST REVERSE

P J G

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [MENU] button operation is performed in the specific state, the menu changes to

"TEMP SETTING menu".

* In specific state the setting changed in the range of "00h to FFh" when the

[VOL.+/–] button is pressed.

(The upper limit varies depending on the items)

* When the [ENTER] button is pressed in each state, the set digit is changed.

– 21 –

Page 22

MD-MT180

Tracking Setting

T r a c k

PLAY

T G 1

FAST FORWARD FAST REVERSE

T B o

FAST FORWARD FAST REVERSE

T B t

FAST FORWARD FAST REVERSE

T K o

FAST FORWARD FAST REVERSE

T K t

FAST FORWARD FAST REVERSE

T D o

FAST FORWARD FAST REVERSE

T D t

FAST FORWARD FAST REVERSE

S C t

FAST FORWARD FAST REVERSE

C L p

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [MENU] button operation is performed in the specific state, the menu changes to

"TEMP SETTING menu".

* In the specific state the setting changes in the range of "00h to FFh" when the [VOL.+/–] button

is pressed. (The upper limit varies depending on the items)

* When the [ENTER] button is pressed in each state, the set digit is changed.

: Tracking setting menu

FAST FORWARD FAST REVERSE

C L r

FAST FORWARD FAST REVERSE

J P I

FAST FORWARD FAST REVERSE

K 1 0

FAST FORWARD FAST REVERSE

T H P

FAST FORWARD FAST REVERSE

T H G

FAST FORWARD FAST REVERSE

T O P

FAST FORWARD FAST REVERSE

T O G

FAST FORWARD FAST REVERSE

T 1 P

Sled Setting

S l e d

PLAY

: Sled setting menu

S K S

FAST FORWARD FAST REVERSE

S K L

FAST FORWARD FAST REVERSE

S L C

FAST FORWARD FAST REVERSE

S T L

FAST FORWARD FAST REVERSE

S T M

FAST FORWARD FAST REVERSE

S T E

FAST FORWARD FAST REVERSE

S D V

FAST FORWARD FAST REVERSE

S J P

FAST FORWARD FAST REVERSE

W T m

FAST FORWARD FAST REVERSE

S R V

FAST FORWARD FAST REVERSE

S L T

FAST FORWARD FAST REVERSE

M V S

FAST FORWARD FAST REVERSE

S L S

FAST FORWARD FAST REVERSE

S K E

FAST FORWARD FAST REVERSE

S D E

FAST FORWARD FAST REVERSE

B P E

FAST FORWARD FAST REVERSE

B P W

FAST FORWARD FAST REVERSE

B P 1

FAST FORWARD FAST REVERSE

B R E

FAST FORWARD FAST REVERSE

B R W

FAST FORWARD FAST REVERSE

S R S

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [MENU] button operation is performed in the specific state, the menu changes to

"TEMP SETTING menu".

* In the specific state the setting changes in the range of "00h to FFh" when the

[VOL.+/–] button is pressed.

(The upper limit varies depending on the items)

* When the [ENTER] button is pressed in each state, the set digit is changed.

– 22 –

Page 23

TEMP Setting

MD-MT180

T e m p

PLAY

T M § §

FAST FORWARD FAST REVERSE

T p i n

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [MENU] button operation is performed in the specific state, the menu changes to

"TEMP SETTING menu".

* In the specific state the setting changes in the range of "00h to FFh" when the

[VOL.+/–] button is pressed.

* When the [ENTER] button is pressed in each state, the set digit is changed.

: Temp setting menu

: TEMP reference

: TEMP A/D input value

: Reference

§ § : Temperature code

: Measurement value

Adjustment Setting

A D J S E T

PLAY

: Adjustment setting menu

C O K

FAST FORWARD FAST REVERSE

F A B

FAST FORWARD FAST REVERSE

H S G

FAST FORWARD FAST REVERSE

L S G

* When the [STOP ] button is pressed in specific menu, the "TEST MODE STOP" state is set.

* When the [MENU] button operation is performed in the specific state, the menu changes to

"TEMP SETTING menu".

* In the specific setting display state the setting change digit changes when the [ENTER]

button is pressed.

1st digit (initial value) 2nd digit

* In the specific state the setting changes in the range of "0h to Fh" when the [VOL.+/–]

button is pressed.

* When the [ENTER] button is pressed in each state, the set digit is changed.

ENTER

ENTER

– 23 –

Page 24

MD-MT180

Control Setting

C T R L

PLAY

: Control setting menu

C T 0

FAST FORWARD FAST REVERSE

C T 1

FAST FORWARD FAST REVERSE

C T 2

FAST FORWARD FAST REVERSE

C T 3

FAST FORWARD FAST REVERSE

T S A

FAST FORWARD FAST REVERSE

U S A

FAST FORWARD FAST REVERSE

P L E

FAST FORWARD FAST REVERSE

R C E

FAST FORWARD FAST REVERSE

S D F

FAST FORWARD FAST REVERSE

F B O

FAST FORWARD FAST REVERSE

B H S

FAST FORWARD FAST REVERSE

B S 0

FAST FORWARD FAST REVERSE

B S 1

FAST FORWARD FAST REVERSE

B U 0

FAST FORWARD FAST REVERSE

B D 0

FAST FORWARD FAST REVERSE

B D 1

FAST FORWARD FAST REVERSE

B M K

FAST FORWARD FAST REVERSE

B E C

FAST FORWARD FAST REVERSE

C S T

FAST REVERSE

FAST FORWARD

U S 2

FAST FORWARDFAST REVERSE

U S 1

FAST FORWARDFAST REVERSE

U S 0

FAST FORWARDFAST REVERSE

M S L

FAST FORWARDFAST REVERSE

S P M

FAST FORWARDFAST REVERSE

M F P

FAST FORWARDFAST REVERSE

T G 2

FAST FORWARDFAST REVERSE

F G 2

FAST FORWARDFAST REVERSE

A D E

FAST FORWARDFAST REVERSE

C 1 E

FAST FORWARDFAST REVERSE

A C T

FAST FORWARDFAST REVERSE

S S K

FAST FORWARDFAST REVERSE

C V 1

FAST FORWARDFAST REVERSE

C V 0

FAST FORWARDFAST REVERSE

E R C

FAST FORWARDFAST REVERSE

M C T

FAST FORWARDFAST REVERSE

I J D

FAST FORWARDFAST REVERSE

I J U

– 24 –

Page 25

MD ERROR MESSAGE DISPLAY CONTENT LIST

MD-MT180

Display content

Can' t READ*

Can' t READ*

Can' t READ*

Can't LOCK

Er-MD41

Er-MD80

TOC FORM** Abnormal data DISC detection L*: UTOC SELECTOR is Loop * indicates the detailed factor.

NAME FULL

OPEN The disc compartment is open. Open lid is detected while the

Readout of the information

completed.

Readout of the TOC information

is not completed.

Readout of the U-TOC information

is not completed.

The EJECT lever cannot be locked.

Judged it abnormal by the U-TOC

write test.

EEPROM readout Check sum error

The number of characters for names

exceeds the specification limit.

Error content

is not

f: Focus error

r: READ ERR

s: Search time over

w: SD write time over

p: Time over at spindle start-up

a_: Address abnormal

t_: FTNO > LTNO

Error code

* indicates the detailed factor.

system is running.

Remarks

– 25 –

Page 26

MD-MT180

NOTES ON SCHEMATIC DIAGRAM

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means micro-micro-farad and the unit of the

capacitor without such a symbol is microfarad. As to electrolytic capacitor, the expression “capacitance/withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

TOP VIEW

B

(G)

(3)

E

TOP

VIEW

C

(D)

(2)

(S)

1

2SB1462 J

MA132WK

2SD1819 AS

DTC123 TKA

KTA2015 Y

MCH3409

UN5210

UN5213

• The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the chassis with no signal given.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

REF. NO

SW401 EJECT OFF—ON

SW403 LID OPEN OFF—ON

SW601 DISC PROTECT OFF—ON

TOP VIEW

DESCRIPTION

S

POSITION

TOP

VIEW

F10J2E

F05J2L

GD

2SJ520 TL

TOP VIEW

HRB0103B

TOP VIEW

RB731U

Figure 26 TYPES OF TRANSISTOR AND DIODE

TOP VIEW

SBE803

XP01401

– 26 –

Page 27

+2.5V

VCCMICOM

SPINFG

PCNT1

+2.5V

VCC+2.5V

+2.5V

+2.5V

+2.5V

+2.5V

+2.5V

+2.5V

–2.5V

+2.5V

FT

+2.5V

+2.5V

+2.5V

+4.5V

+4.5V

–2.5V

VGBATT

DC-IN (5V)

J801

PS801

CHARGING

TERMINAL(1.5V)

BATTERY

(1.2V)

MMM

SPINDLE

MOTOR

LIFT

MOTOR

SLED

MOTOR

M902

M903

M901

MOTOR

DRIVER

LB1930M

IC651

REGULATOR

62FP1602

IC902

ENDEC/SERVO/

ATRAC

LR378161

IC201

HEAD DRIVER

74ACT02T

MCH6616

CPH5608

IC351

IC353

IC354

MAGNETIC

HEAD

RF SIGNAL

PROCESSOR

IR3R58M

IC101

OPTICAL PICUP

LASER

OPIC

PICK

16M BIT

D-RAM

IX2824AF

IC202

LCD UNIT

OPTICAL/

LINE-IN

J701

AUDIO AMP.

IR3R54N

IC701

AUDIO AMP.

IR3R59N

IC703

HEADPHONES

KEY SWITCH

PWB

SW401 EJECT

SW403

LID OPEN

J703A

AD/DA

CONVERTER

AK4551VT

IC501

PWM/MOTOR DRIVER

LV8201W

IC601

EEPROM

58X2402T

IC402

SYSTEM

MICROCOMPUTER

IX0529AW

IC401

2.3V

REGULATOR

6204B23M

IC771

4.5V

REGULATOR

6204B45M

IC873

1.1A

F841

IC801 MM3032A

3.0V REGULATOR

IC802 XP04501

IC803 S80819LN

RESET

Q801,Q803,Q891

Q250,Q251,Q257

Q851

Q461

DC/DC

CONVERTER

IR3M14N

IC852

0.4A,DC60V

2.5V UP

CONVERTER

6372C251

IC841

EXCLUSIVE

OR GATE

74HC1G86

IC871

RESET

S80820LN

IC431

IC253,260,809 XP04313

IC256 XP04315

IC258,259,892 XP04501

IC255 NJM022V OPE AMP.

IC257 S80808LN RESET

IC251 FTD2017 N-CH MOS FET

PLAYBACK SIGNAL

RECORD SIGNAL

MD-MT180

– 27 –

Figure 27 BLOCK DIAGRAM

Page 28

MD-MT180

+

+

B

A

A

G

O

N

N

Y

Y

9

4

5

6

7

8

E

3

4

D

D

2

MAIN PWB-A

1+2

DIFF

+B

1

C107

C112

0.033

PIN

3+4

BIAS

FIN

EIN

R137

R138

390K

TP351

VCCHEAD

SPDRF

SLCNT3

SLCNT2

SLCNT1

L605

22µH

C109

1

1

0.22

C108

C110

0.033

C106

220K

R112

GND1

VCC1

EFMAGC

BIAS

NIN

PITG

GND2

BPF

MODE

FSW

TCGO

EOUT

BOUT

AOUT

FOUT

TCGI

56K

TP130

TP131

TP132

TP133

R140

390K

+B

L171

10µH

C172

33/6.3

C171

33/6.3

Q901

UN5210

100K

R920

SPIN

IC651

LB1930M

MOTOR

DRIVER

6

5

G

G

4

7

O2

I2

3

8

I1

O1

2

9

VCC

10

1

LDCNT2

R603

R604

100K

33

SEL

34

PWM

VS3

35

GND1

OUT3

36

PGND3

37

SWO

38

PGND4

39

SVO

40

VS4

41

SUO

42

FG

43

49

CP2

VCC2

44

CP1

50

IN3

45

S3

46

S2

47

S1

RF

VS

CPC1

CPC2

VG

48

49 50

51 5253 54 55 565758 59 60 6162 63 64

C612

0.1

C611

0.1

1

1M

R605

C615

1

PWM/MOTOR DRIVER

C605

1

EFMO

DCNF

373839404142434445464748

C131

0.1

2-1

36

ADAGI

35

ADAGC

34

AGC

ADIP

ADIPNF

33

ADIPO

32

31

WBO

30

VCC2

29

OPICPW

SW

28

CK102

DISC

27

SGAIN

26

TEMP

25

DTEMP

RFADD

R139

39K

0.22

C133

LDON

LDVAR

OPICGA

TP171

+B

TP665

C652

0.1

D651

F10J2E

LDCNT1

+B

1

C621

330K

120K

R602

20212223242526272829303132

RMIN

VCTL

RMAX

VCOIN

VCREF

S/S

17

OUT2F

BRK

PGND2

18

PGND1

VCO

19

OUT1F

OUT1R

WCIN

63

COMIN

64

WOUT

UOUT

RF2

UCIN

VS

VOUT

C617

0.0047

IC601

LV8201W

C113

R403

13

MUTE

OUT2R

VCC1

GND2

C132

1K

3

VS2

VS1

IN2R

IN2F

IN1R

VCIN

COM

C618

C111

R132

R134

1

5P(CH)

C114

1234

RF1

1

RF2

2

and

RF3

3

SW

RF4

4

1

REFI

5

TP144

6

AOUT

7

ASW

R131

8

120K

AIN

9

BIN

10

BSW

11

R133

820K 820K

12

120K

BOUT

R136

390K

12K

R111

R

REFO

ESW

EOU

13 14 15 16 17 18 19 20 21 22 23 24

56K

R135

A

IC101

IR3R58M

RF SIGNAL

PROCESSOR

1

C103

C102

B

15

+B

L101

100mA

C

CN101

TP101

1234

1

LDVAR

TP103

TP102

LDON

DGND

5

DGND

TP105

VCC

TP107

TP111

TP110

TP108

TP106

10 1112 13 14 15 1617 18 19 202122

8

9

6

7

A

B

RF2

COM

MP/R

CVCC

AGND

OPIC

VCC

TP115

TP114

RF4

RF3

TP116

E

TP117

F

RF1

TP119

TP118

T+

TP120

F+

OPTICAL PICKUP (1)

+B

D

C357

0.1

43

5

S

G2

G1

C351

D2

D1

12

IC354

E

CPH5608

HEAD DRIVER

GND

8

7

9

6

1

0

5

1

4

1

2

3

1

3

2

1

VCC

4

1

1

C354

0.1

C353

10/6.3

D351

SBE803

3

4

(CH)

C361

0.039

5

R361

15

2

1

IC353

MCH6616

HEAD

DRIVER

47P

T–

6

123

F–

5

D1

S1

TP121

TP122

22

4

G2

G1

2

IC351

S2

D2

R161

1.2K

F–

F+

T+

T–

C165

0.033

HEAD

DRIVER

74ACT02T

F

1

R611

R610

TP661

TP659

TP658

TP657

TP656

TP660

TP655

TP654

TP653

TP652

TP651

CN601

4321

8

9

1011

6

5

G

MAGNETIC

HEAD(20)

M

M901

SPINDLE

MOTOR

7

11

COM

W

V

U

MECHANISM

FLEXIBLE PWB (19)

1