Page 1

TopPage

LC-52D85UN

SERVICE MANUAL

No. S69Z7LC52D85N

LCD COLOR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

LC-52D85UN

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY

PRECAUTION.....................................................i

PRECAUTIONS A PRENDRE LORS DE

LA REPARATION...............................................ii

PRECAUTIONS FOR USING LEAD-FREE

SOLDER ........................................................... iii

PRECAUTIONS IN SERVICING THE

HDCP-KEY ROM .............................................. iii

CHAPTER 1. OPERATION MANUAL

[1] SPECIFICATIONS ......................................... 1-1

[2] OPERATION MANUAL .................................. 1-2

[3] DIMENSIONS ................................................ 1-8

CHAPTER 2. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ................... 2-1

CHAPTER 5. OVERALL WIRING/SYSTEM BLOCK

DIAGRAM

[1] OVERALL WIRING DIAGRAM ......................5-1

[2] SYSTEM BLOCK DIAGRAM .........................5-2

CHAPTER 6. PRINTED WIRING BOARD

ASSEMBLIES

[1] KEY Unit ........................................................6-1

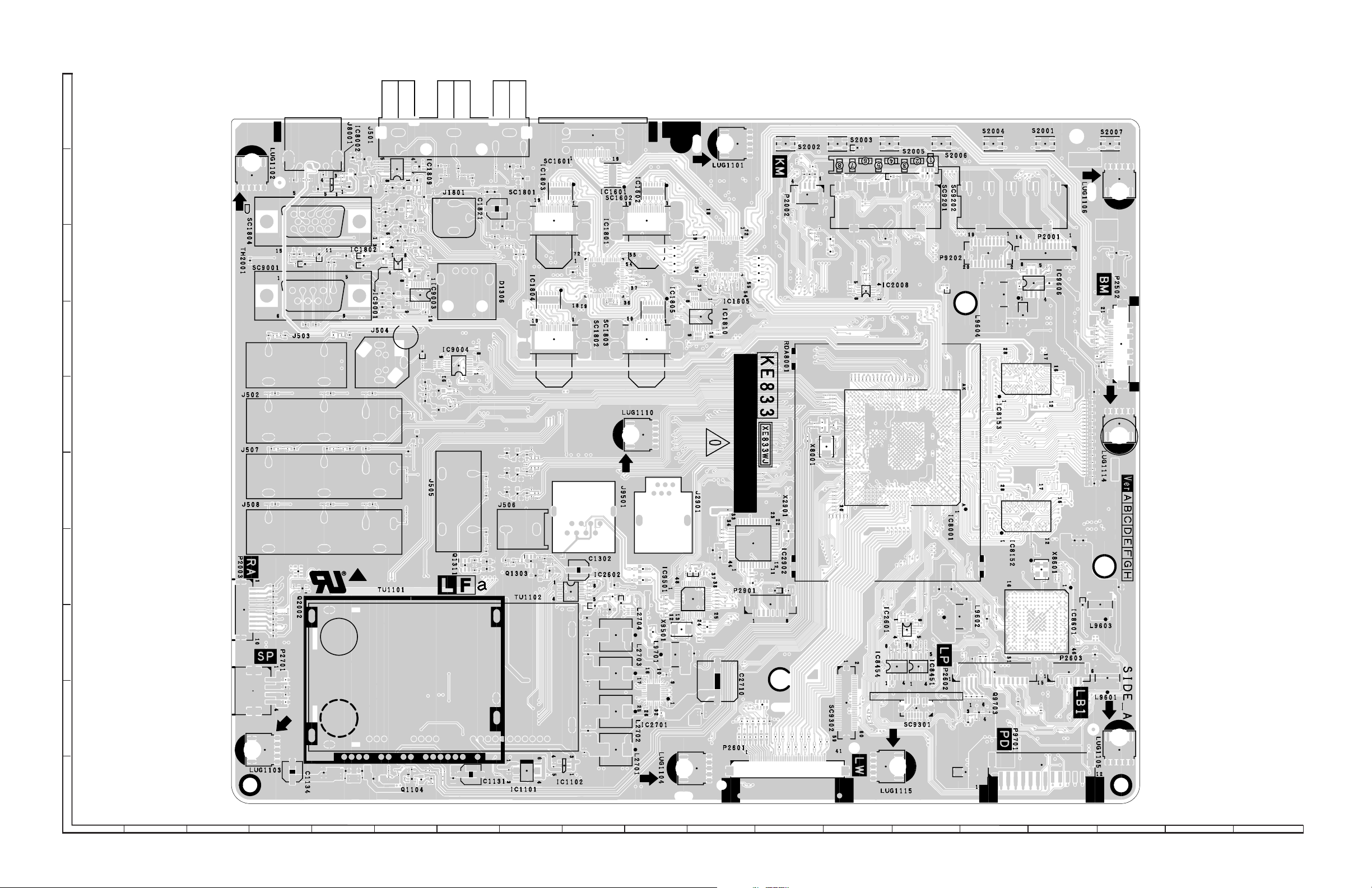

[2] MAIN Unit ......................................................6-2

[3] R/C, LED Unit ................................................6-6

CHAPTER 7. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC

DIAGRAM...................................................... 7-1

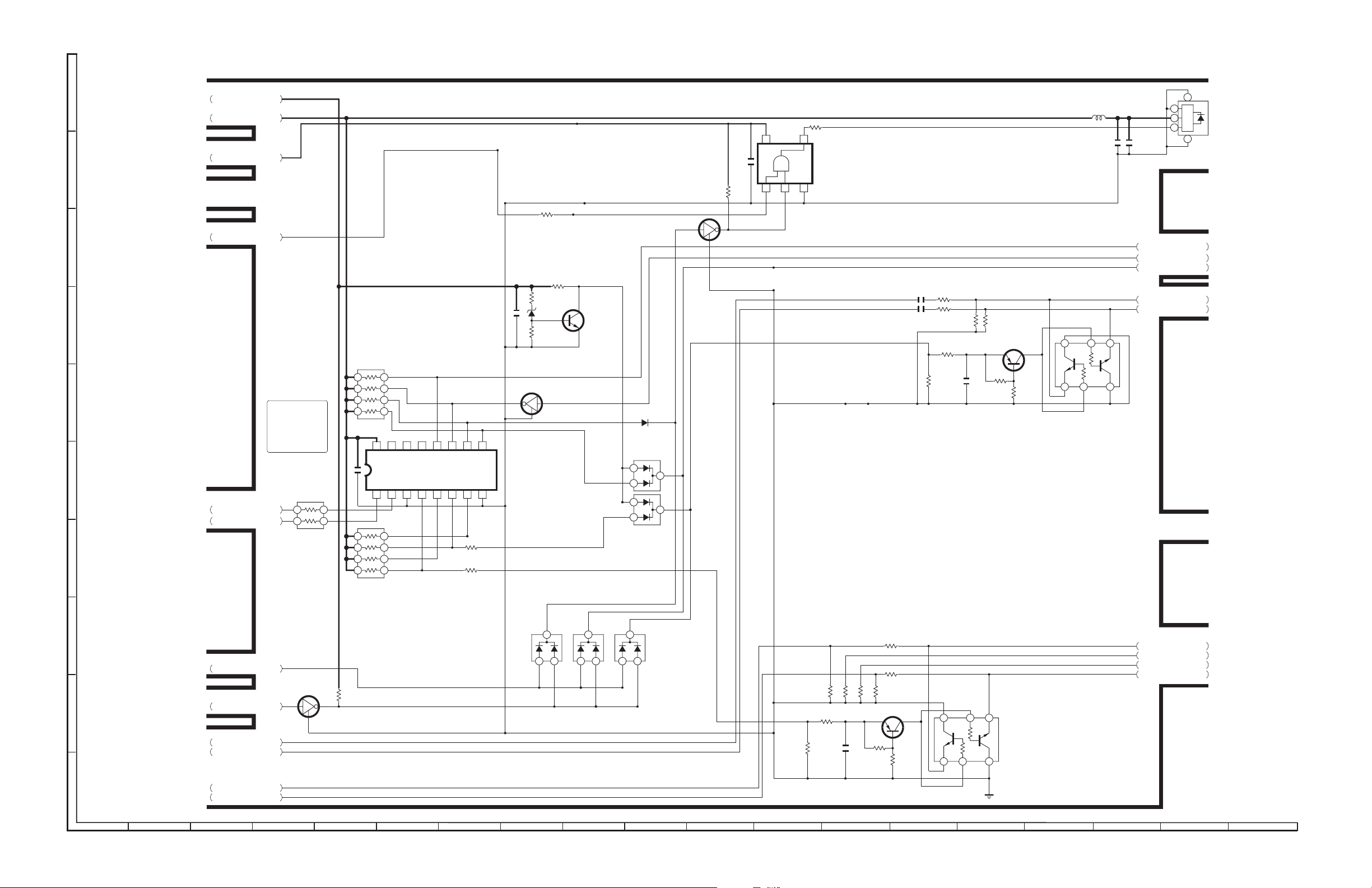

[2] KEY Unit ........................................................7-2

[3] MAIN Unit ......................................................7-3

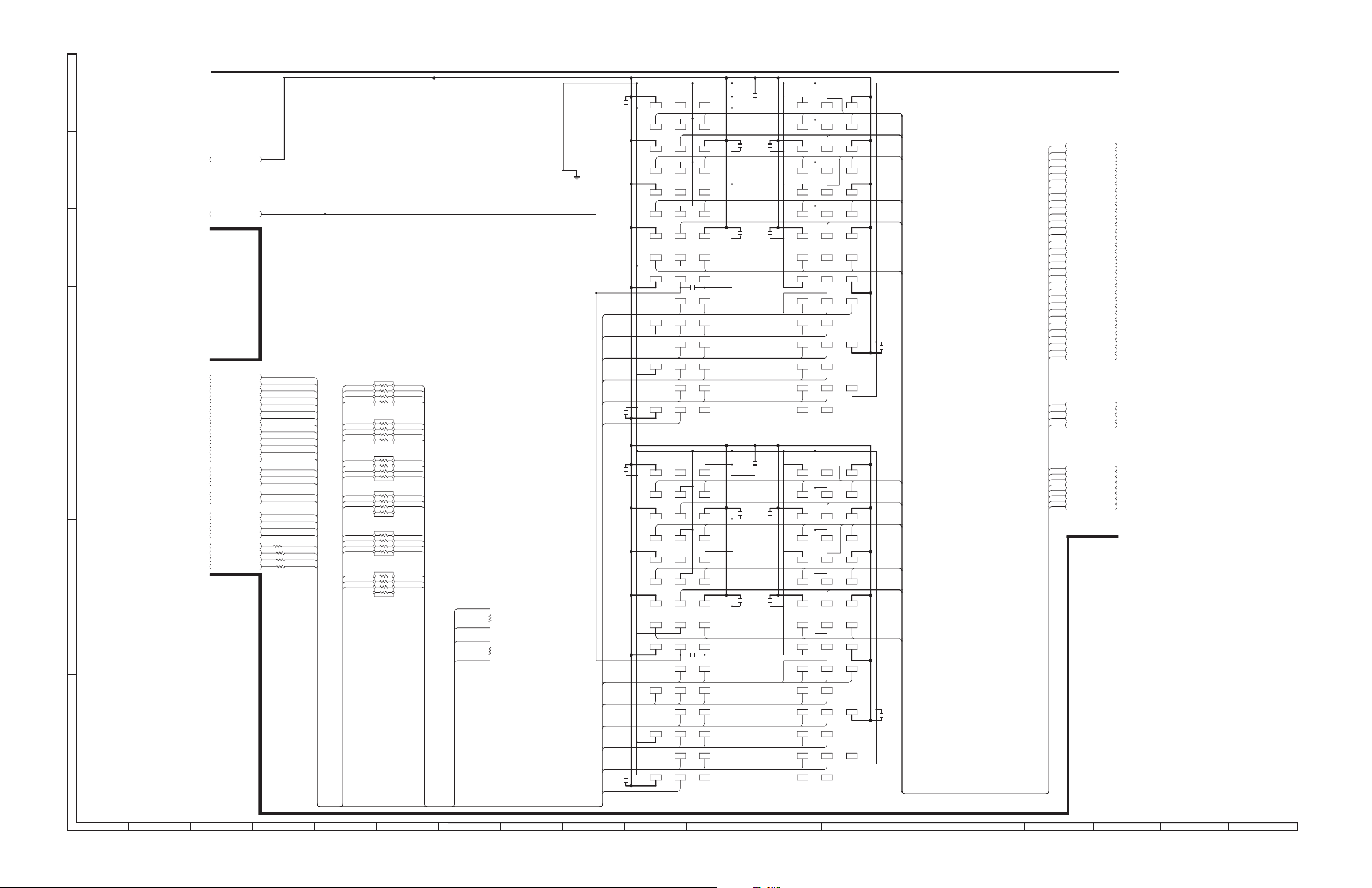

[4] R/C, LED Unit ..............................................7-19

CHAPTER 3. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE ....................... 3-1

[2] PUBLIC MODE SETTING

PROCEDURE .............................................. 3-16

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE ....................... 4-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

Parts Guide

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-52D85UN

LC52D85UN

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: FO R CO NT I N U ED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE .

F7000 (250V T6.3AH)

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

(for North America)

• Plug the AC cord directly into a 110-240 volt AC outlet.

(for Others)

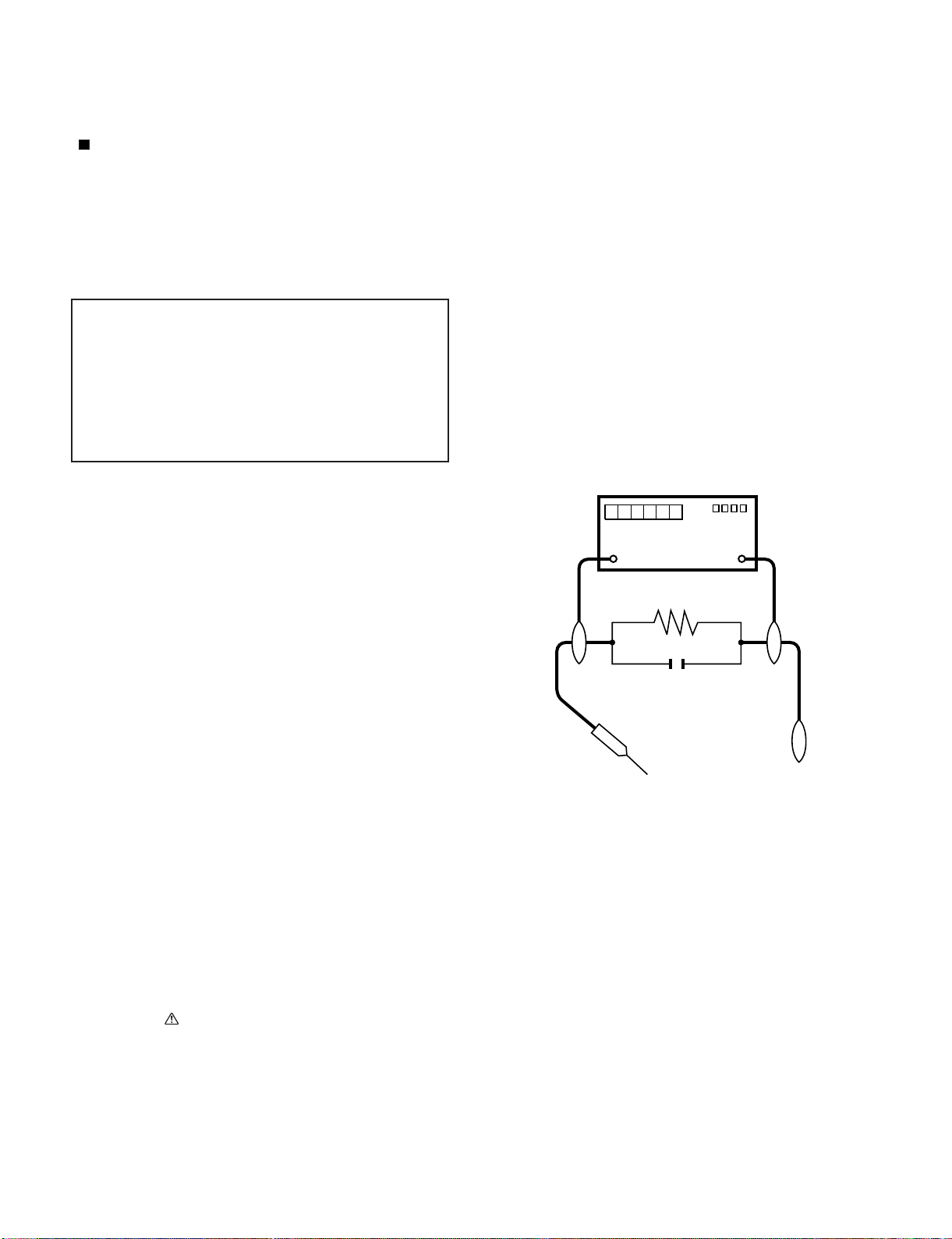

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

i

Page 3

LC-52D85UN

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

•

AVERTISSEMENT

1.

N'entreprendre aucune modification de tout circuit. C'est dangereux.

2.

Débrancher le récepteur avant toute réparation.

PRECAUTION: POUR LA PROTECTION CONTINUE CONTRE LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F7000 (250V T6.3AH)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifications suivantes.

3.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châssis et les autres pièces métalliques du récepteur.

4.

Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les couvercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

5.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

fuite de courant, de la facon suivante:

•

Brancher le cordon d'alimentation directem-ent à une prise de courant de 120V. (Ne pas utiliser de transformateur d'isolation pour

cet essai). (pour l'Amérique du Nord)

• Brancher le cordon d'alimentation directem-ent à une prise de courant de 110-240V. (Ne pas utiliser de transformateur d'isolation

pour cet essai). (pour les autres régions)

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ

10 watts en parallèle avec un condensateur de 0.15µF en série

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

•

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pour

mesurer la chute de tension en travers de la résistance.

•

Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métallique, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (correspondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

µ

F

0.15

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur ACL présentent des caractéristiques spéciales relatives à la sécurité, qui ne sont souvent pas évidentes à vue. Le degré de protection ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incendies, radiations X ou autres accidents.

ii

Page 4

LC-52D85UN

PRECAUTIONS FOR USING LEAD-FREE SOLDER

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

PARTS CODE

ZHNDAi123250E BL J φ0.3mm 250g (1roll)

ZHNDAi126500E BK J φ0.6mm 500g (1roll)

ZHNDAi12801KE BM J φ1.0mm 1kg (1roll)

PRICE

RANK

PART

DELIVERY

DESCRIPTION

PRECAUTIONS IN SERVICING THE HDCP-KEY ROM

Applied part: HDCP-KEY ROM

IC8451 RH-IXC622WJQZY (updated ROM)

The HDCP-KEY ROM shall be protected and managed for its information inside. In servicing this ROM, therefore, take the following information protection/management measures.

1) When disposing of the component parts and PWBs, destruct the IC itself in a proper way.

(For repairing or replacing the component parts and PWBs as well as clearing those in stock)

2) In storing the component parts, protect and manage them against theft and disclosure.

(For storing the service parts, service units, etc.)

iii

Page 5

LC52D85UN

CHAPTER 1. OPERATION MANUAL

Service Manual

[1] SPECIFICATIONS

Item Model: LC-52D85UN

1

LCD panel

52" Class (52

Advanced Super View & BLACK TFT LCD

Resolution 2,073,600 pixels (1,920 x 1,080)

TV-standard (CCIR) American TV Standard ATSC/NTSC System

VHF/UHF VHF 2-13ch, UHF 14-69ch

CATV 1-135ch (non-scrambled channel only)

TV

Function

Receiving

Channel

Digital Terrestrial

Broadcast (8VSB)

Digital cable

*1

(64/256 QAM)

2-69ch

1-135ch (non-scrambled channel only)

Audio multiplex BTSC System

Backlight 60,000 hours (at Backlight Standard position)

Audio out 10W x 2

INPUT 1 AV in, COMPONENT in

INPUT 2 COMPONENT in, S-VIDEO in

INPUT 4 ANALOG RGB (PC) in (15-pin mini D-sub female connector), Audio in (Ø 3.5 mm jack)

INPUT 6 HDMI in with HDCP, Audio in (Ø 3.5 mm jack)

INPUT 7 HDMI in with HDCP

INPUT 8 HDMI in with HDCP

Rear

INPUT 9 HDMI in with HDCP

Terminals

ANT/CABLE 75 Unbalance, F Type x 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

AUDIO Audio in (Ø 3.5 mm jack)

DIGITAL AUDIO OUTPUT

Optical Digital audio output x 1 (PCM/Dolby Digital)

OUTPUT Audio out

RS-232C 9-pin D-sub male connector

INPUT 3 AV in

Side

INPUT 5 HDMI in with HDCP

SERVICE Software update

OSD language English/French/Spanish

Power Requirement AC 120 V, 60 Hz

Power Consumption 290 W (0.4 W Standby with AC 120 V)

Weight

Dimension

*2

(WxHxD)

Operating temperature

*1

Emergency alert messages via Cable are unreceivable.

*2

The dimensional drawings are shown on the inside back cover.

TV + stand 61.7 lbs./28.0 kg

TV only 51.8 lbs./23.5 kg

TV + stand

TV only

19

49

/64x3325/64x1261/64inch

19

49

/64x3111/32x325/32inch

+32°F to +104°F (0°C to +40°C)

• As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

improvement without prior notice. The performance specification figures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

/32"Diagonal)

LC-52D85UN

Optional Accessory

The listed optional accessory is available for the Liquid

Crystal Television. Please purchase it at your nearest shop.

• Additional optional accessories may be available in the near

future. When purchasing, please read the newest catalogue for

compatibility and check the availability.

1 – 1

Part name Model number

Wall mount bracket AN-52AG4

Page 6

LC-52D85UN

[2] OPERATION MANUAL

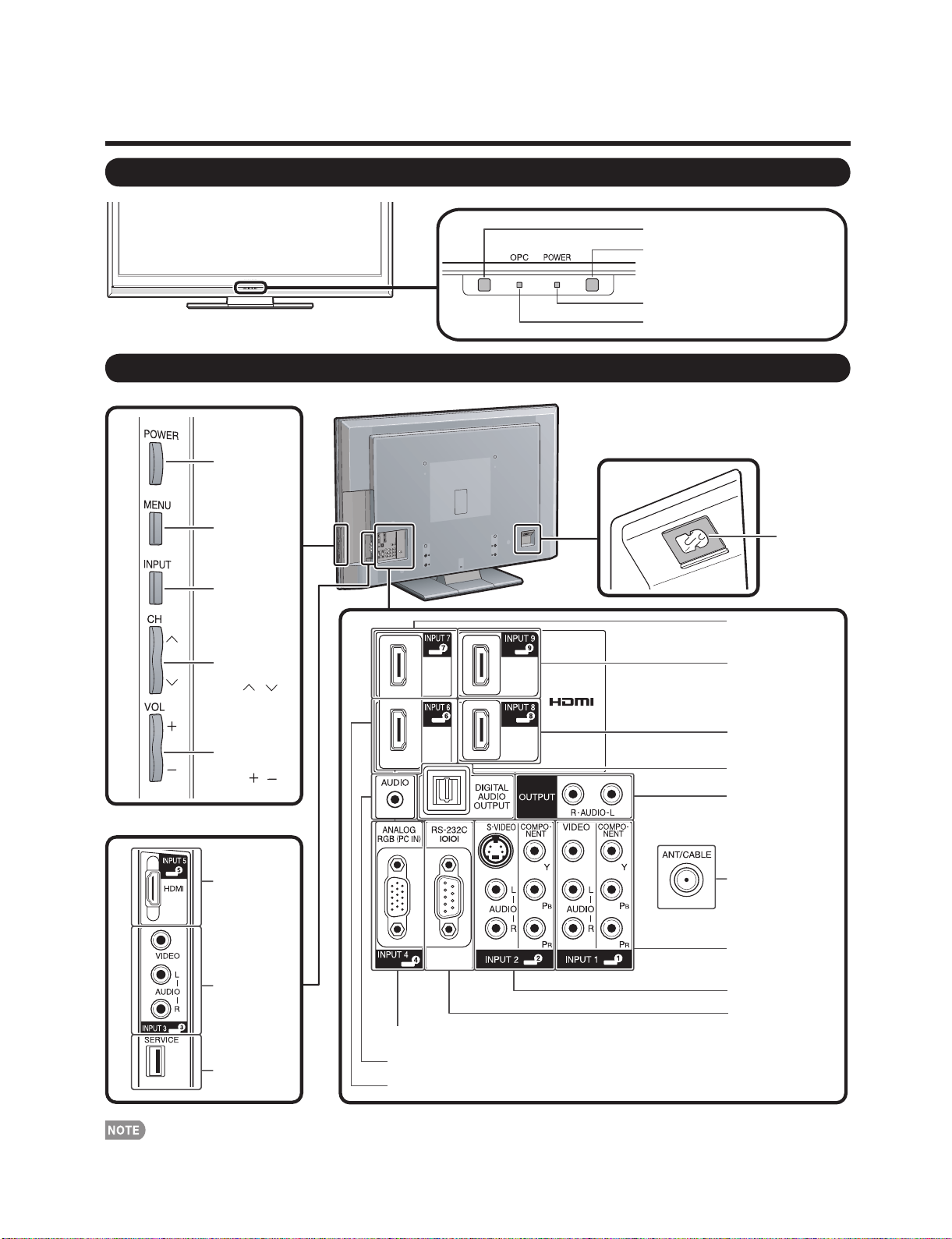

Part Names

TV (Front)

* OPC: Optical Picture Control

TV (Rear/Side)

POWER

button

Remote control sensor

OPC sensor

POWER indicator

OPC indicator

*

MENU

button

INPUT

button

Channel

buttons

(CH /)

Volume

buttons

(VOL /)

INPUT 5

terminal

(HDMI)

AC INPUT

terminal

INPUT 7 terminal

(HDMI)

INPUT 9 terminal

(HDMI)

INPUT 8 terminal

(HDMI)

DIGITAL AUDIO

OUTPUT terminal

AUDIO OUTPUT

terminals

Antenna/Cable in

INPUT 1 terminals

INPUT 3

terminals

INPUT 4 terminal (PC-IN)

SERVICE

terminal

• The illustrations in this operation manual are for explanation purposes and may vary slightly from the actual operations.

AUDIO terminal (shared for INPUT 4 and INPUT 6)

INPUT 6 terminal (HDMI)

INPUT 2 terminals

RS-232C terminal

1 – 2

Page 7

Part Names

LC-52D85UN

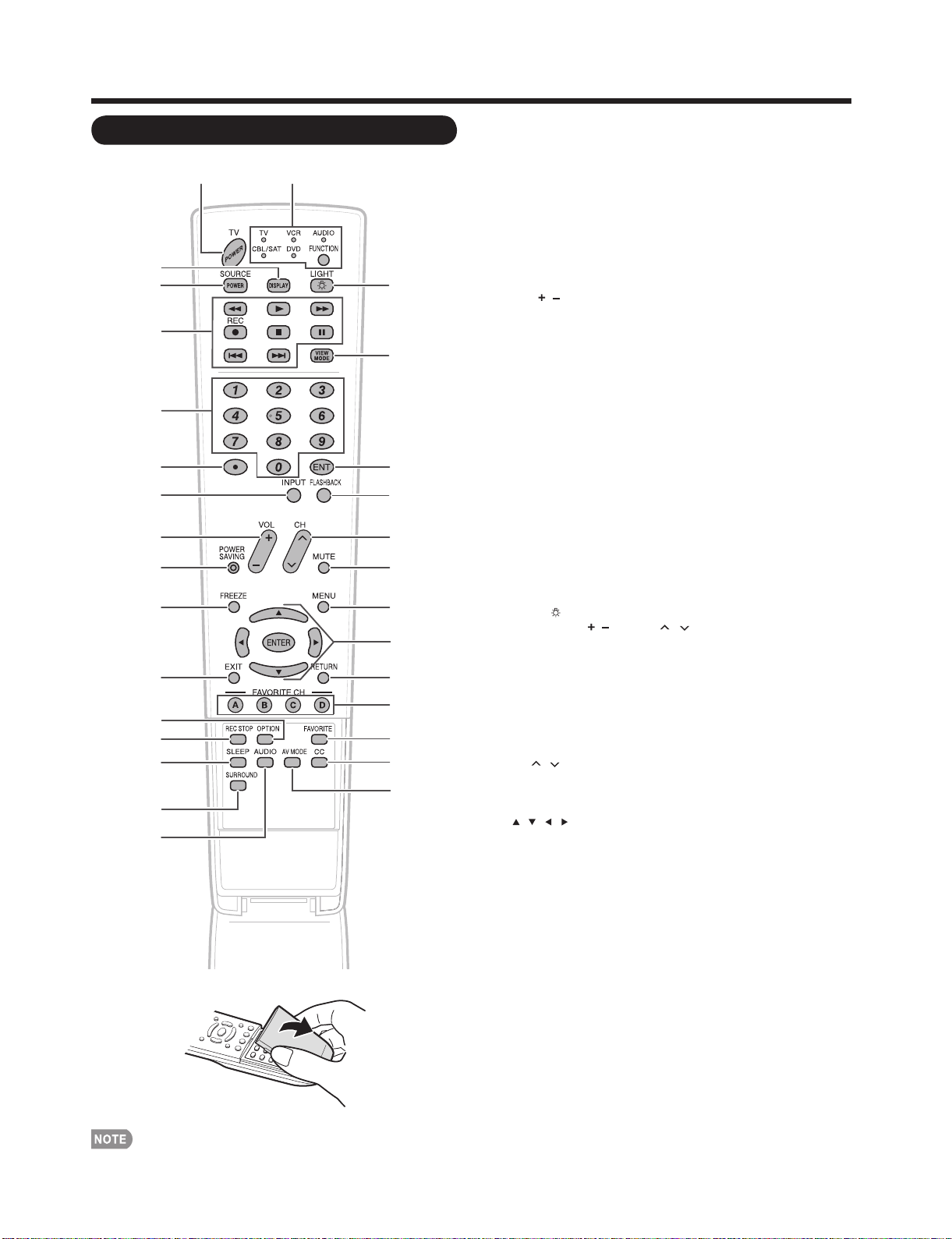

Remote Control Unit

117

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

29

30

1 TV POWER: Switch the TV power on or enter standby.

2 DISPLAY: Display the channel information.

3 SOURCE POWER: Turns the power of the external equipment

on and off.

4 External equipment operational buttons: Operate the external

equipment.

50 Set the channel.–9:

6 • (DOT):

7INPUT:Select a TV input source. (TV, INPUT 1, INPUT 2, INPUT

3, INPUT 4, INPUT 5, INPUT 6, INPUT 7, INPUT 8, INPUT 9)

8 VOL / : Set the volume.

9 POWER SAVING: Select Power Saving settings.

10 FREEZE: Set the still image. Press again to return to normal

screen.

11 EXIT: Turn off the menu screen.

12 OPTION: Display the AQUOS LINK MENU screen. This button

will function only when AQUOS LINK is used.

13 REC STOP: Stops one touch recording. This button will function

only when AQUOS LINK is used.

14 SLEEP: Set the sleep timer.

15 SURROUND: Select Surround settings.

16 AUDIO: Selects the MTS/SAP or the audio mode during multi-

channel audio broadcasts.

17 FUNCTION: Switches the remote control for TV, CBL/SAT, VCR,

DVD and AUDIO operation. Indicator lights up for the current

mode.

* To enter the code registration mode, you need to press

FUNCTION and DISPLAY at the same time.

18 LIGHT : When this button is pressed, some buttons (for

example, VOL /

light. The lighting will turn off if no operations are performed within

about 5 seconds. This button is used for performing operations in

low-light situations.

19 VIEW MODE: Select the screen size.

20 ENT: Jumps to a channel after selecting with the 0–9 buttons.

21 FLASHBACK: Return to the previous channel or external input

mode.

22 CH / : Select the channel.

23 MUTE: Mute the sound.

24 MENU: Display the menu screen.

25 ///,ENTER: Select a desired item on the screen.

26 RETURN: Return to the previous menu screen.

27 FAVORITE CH

A, B, C, D: Select 4 preset favorite channels in 4 different

categories.

While watching, you can toggle the selected channels by pressing

A,B,C and

28 FAVORITE: Set the favorite channels.

29 CC: Display captions from a closed-caption source.

30 AV MODE: Select an audio or video setting.

(When the input source is TV, INPUT 1, 2 or 3: STANDARD,

MOVIE, GAME, USER, DYNAMIC (Fixed), DYNAMIC. When the

input source is INPUT 4, 5, 6, 7, 8 or 9: STANDARD, MOVIE,

GAME, PC, USER, DYNAMIC (Fixed), DYNAMIC)

and CH / ) on the remote control unit will

D.

• When using the remote control unit, point it at the TV.

1 – 3

Page 8

LC-52D85UN

QUICK REFERENCE

Attaching the Stand

• Before attaching (or detaching) the stand, unplug the AC cord from the AC INPUT terminal.

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from being damaged.

CAUTION

• Attach the stand in the correct direction.

• Do not remove the stand from the TV unless using an optional wall mount bracket to mount it.

• Be sure to follow the instructions. Incorrect installation of the stand may result in the TV falling over.

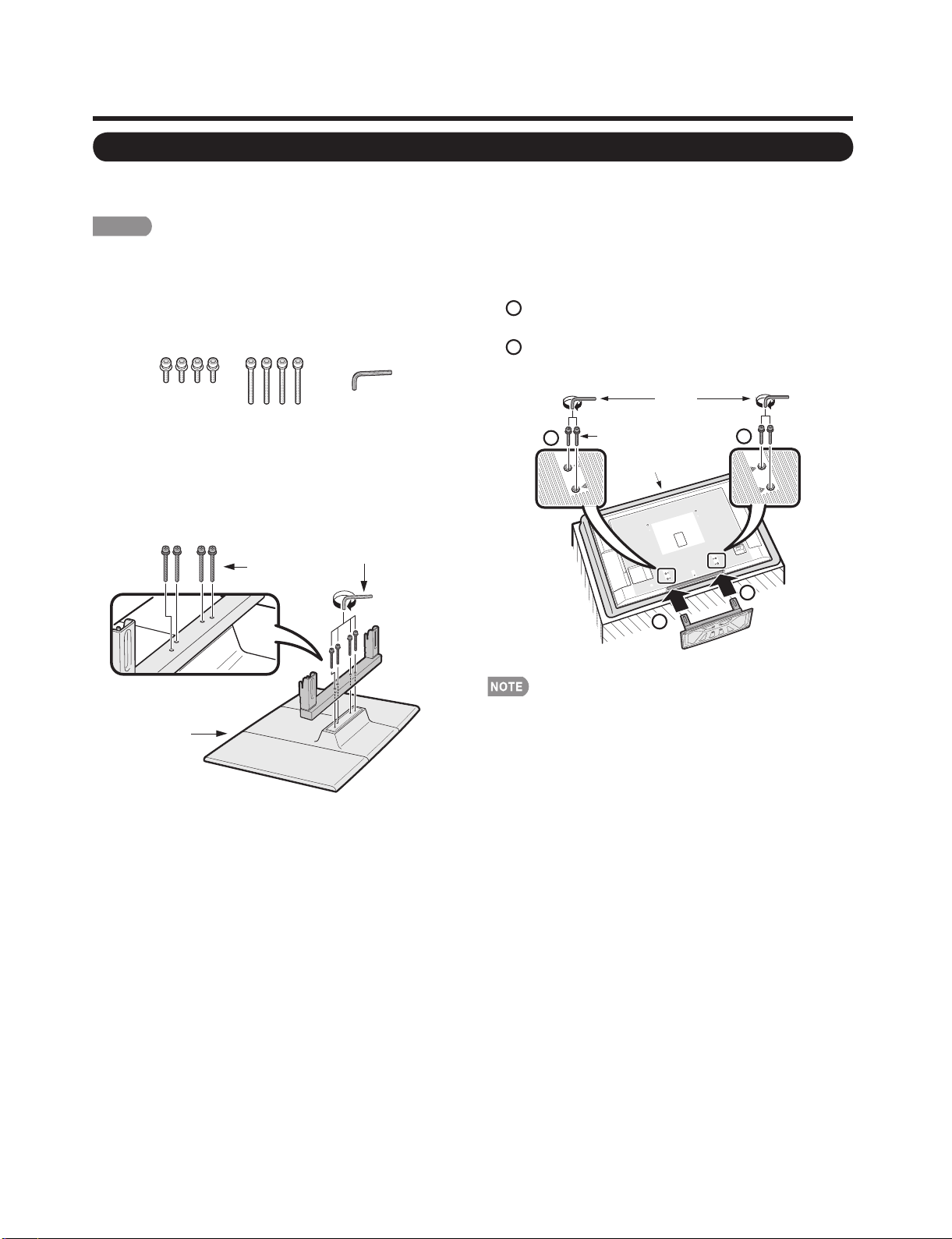

1 Confirm that there are 8 screws (4 short screws

and 4 long screws) and a hex key supplied with the

stand unit.

2 Attach the supporting post for the stand unit onto

the base using the box for the stand unit as shown

below.

The supporting post attaches to the base at an off-centered

•

location on the base. Be sure to attach the supporting post in

the direction indicated below and attach the stand to the TV

with the wider side of the base facing forward.

Long screws

Forward

Hex key

3 Insert the stand into the openings on the bottom

1

of the TV.

2

Insert and tighten the 4 short screws into the 4

holes on the rear of the TV.

Hex key

2

• To detach the stand, perform the steps in reverse order.

Short screws

Soft cushion

1

2

1

1 – 4

Page 9

LC-52D85UN

Appendix

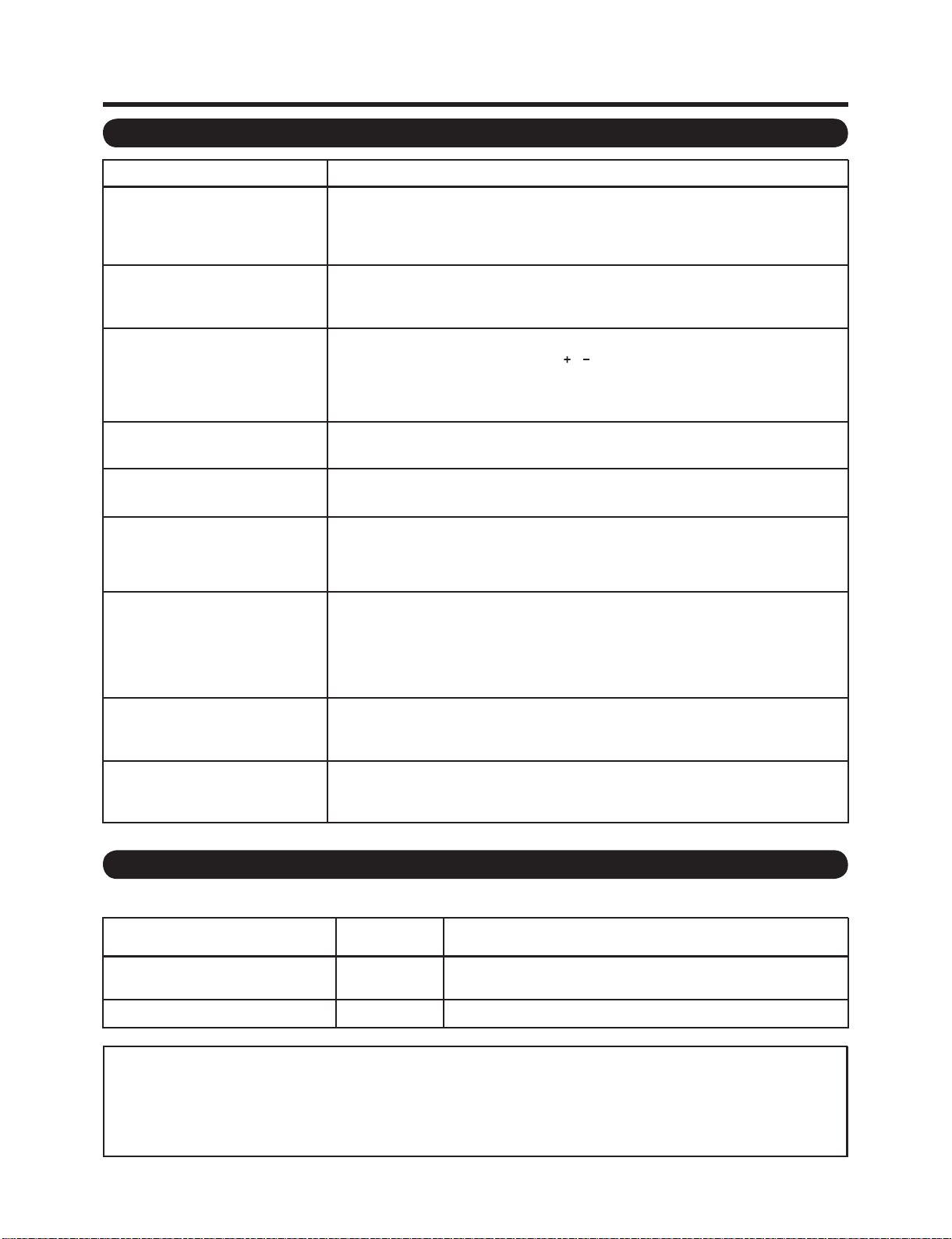

Removing the Stand

•

Before detaching (or attaching) the stand, unplug the AC cord from the AC INPUT terminal.

CAUTION

• Do not remove the stand from the TV unless using an optional wall mount bracket to mount it.

Before attaching/detaching the stand

• Before performing work, make sure to turn off the TV.

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from being

damaged.

1 2

Unfasten the four screws used to secure the stand in

place.

• To attach the stand, perform the above steps in reverse order.

Hex key

Detach the stand from the TV. (Hold the stand so it

will not drop from the edge of the base area.)

Setting the TV on the Wall

CAUTION

• This TV should be mounted on the wall only with the wall mount bracket AN-52AG4 (SHARP). The use of other wall

mount brackets may result in an unstable installation and may cause serious injuries.

• Installing the TV requires special skill that should only be performed by qualified service personnel. Customers

should not attempt to do the work themselves. SHARP bears no responsibility for improper mounting or mounting

that results in accident or injury.

Using an optional bracket to mount the TV

•

You can ask a qualified service professional about using an optional AN-52AG4 bracket to mount the TV on the wall.

• Carefully read the instructions that come with the bracket before beginning work.

Hanging on the wall

AN-52AG4

wall mount bracket.

(See the bracket instructions for details.)

About setting the TV angle

°

0

2

/

5

1

/

0

1

/

5

/

0

LC-52D85UN

• The center of the display:

19

/64inch (7.3 mm) under

the“f”position.

• Refer to the operation

manual of AN-52AG4 for

details.

Vertical mounting Angular mounting

• Detach the cable clamp on the rear of the TV when using the optional mount bracket.

• To use this TV mounted on a wall, remove the covers at the 4 locations on the rear of the TV, and then use the screws

supplied with the wall mount bracket to secure the bracket to the rear of the TV.

1 – 5

Page 10

LC-52D85UN

Appendix

Troubleshooting

Problem

• No power

• Unit cannot be operated.

• Remote control unit does not

operate.

• Picture is cut off/with sidebar

screen.

• Strange color, light color, or color

misalignment

• Power is suddenly turned off.

•Nopicture

Possible Solution

• Check if you pressed TV POWER on the remote control unit. If the

indicator on the TV does not light up, press POWER on the TV.

• Is the AC cord disconnected?

• Has the power been turned on?

• External influences such as lightning, static electricity, may cause improper operation.

In this case, operate the unit after first turning off the power of the TV or unplugging

the AC cord and replugging it in after 1 or 2 minutes.

•IstheFUNCTION set correctly? Set it to the TV setting position.

• Are batteries inserted with polarity ( , ) aligned?

• Are batteries worn out? (Replace with new batteries.)

• Are you using it under strong or fluorescent lighting?

• Is a fluorescent light illuminated near the remote control sensor?

• Is the image position correct?

• Are screen mode adjustments such as picture size made correctly?

• Adjust the picture tone.

• Is the room too bright? The picture may look dark in a room that is too bright.

• Is the sleep timer set?

• Check the power control settings.

• The unit's internal temperature has increased. Remove any objects blocking vent or

clean.

• Is connection to other components correct?

• Is correct input signal source selected after connection?

• Is the correct input selected?

• Is picture adjustment correct?

• Is “On” selected in “Audio Only”?

• Is a non-compatible signal being input?

• No sound

• The TV sometimes makes a

cracking sound.

• Is the volume too low?

• Is “Variable” selected in “Output Select”?

• Have you pressed MUTE on the remote control unit?

• This is not a malfunction. This happens when the cabinet slightly expands and

contracts according to change in temperature. This does not affect the TV's

performance.

Troubleshooting-Digital Broadcasting

The error message about reception of broadcast

The example of an error message

displayed on a screen

• Failed to receive broadcast.

• No broadcast now.

Error code

E202

E203 • Check the broadcast time in the program guide.

• Check the antenna cable. Check that the antenna is correctly

setup.

Possible Solution

Cautions regarding use in high and low temperature environments

• When the unit is used in a low temperature space (e.g. room, office), the picture may leave trails or appear slightly delayed

This is not a malfunction, and the unit will recover when the temperature returns to normal.

• Do not leave the unit in a hot or cold location. Also, do not leave the unit in a location exposed to direct sunlight or near a

heater, as this may cause the cabinet to deform and the Liquid Crystal panel to malfunction.

Storage temperature: -4°F to +140°F (-20°C to +60°C)

1 – 6

Page 11

On-Screen Display Menu

Menu Items

LC-52D85UN

For TV/INPUT 1/2/3 Mode

Picture Menu

OPC

Backlight

Contrast

Brightness

Color

Tint

Sharpness

Advanced

C.M.S.-Hue

C.M.S.-Saturation

C.M.S.-Value

Color Temp.

Fine Motion Enhanced

Active Contrast

Gamma Adjustment

Film Mode

Digital Noise Reduction

3D-Y/C

Monochrome

Range of OPC

Reset

Audio Menu

Treble

Bass

Balance

Surround

Bass Enhancer

Reset

Power Control Menu

Power Saving

No Signal Off

No Operation Off

For HDMI/PC-IN Mode

Picture Menu

OPC

Backlight

Contrast

Brightness

Color

Tint

Sharpness

Advanced

C.M.S.-Hue

C.M.S.-Saturation

C.M.S.-Value

Color Temp.

Fine Motion Enhanced

Active Contrast

Gamma Adjustment

Film Mode

Digital Noise Reduction

Monochrome

Range of OPC

Reset

Audio Menu

Treble

Bass

Balance

Surround

Bass Enhancer

Reset

Power Control Menu

Power Saving

No Signal Off

No Operation Off

Setup Menu

EZ Setup

CH Setup

Antenna Setup-DIGITAL

Input Skip

Input Label

Parental CTRL

Position

Language

Reset

Option Menu

AQUOSLINKSetup

Audio Only

Input Select

PC Audio Select

Output Select

Color System

Caption Setup

Digital Caption Info

Program Title Display

Favorite CH

Game Play Time

Operation Lock Out

Demo Mode

Digital Setup Menu

Audio Setup

Identification

Software Update

Setup Menu

Input Skip

Auto Sync.

Input Label

Fine Sync.

Position

Language

Reset

Option Menu

AQUOSLINKSetup

Audio Only

HDMI Setup

PC Audio Select

Output Select

Game Play Time

Operation Lock Out

Demo Mode

Digital Setup Menu

Software Update

Some menu items may not be displayed depending on the selected input source.•

1 – 7

Page 12

LC-52D85UN

[3] DIMENSIONS

(848)

(796)

64

32

/

/

25

11

33

31

32

/

3

(53)

2

49

459/16(1157)

19

/64(1252)

41

64

/

25

(651)

(474)

64

/

43

18

Unit: inch (mm)

2121/32(550)

32

/

23

5

(400)

4

/

3

15

(145)

153/4(400)

27

4

(123)

25

/

32

3

/

32

(96)

61

12

/

64

(329)

1 – 8

Page 13

LC52D85UN

CHAPTER 2. REMOVING OF MAJOR PARTS

Service Manual

[1] REMOVING OF MAJOR PARTS

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 4 lock screws and detach the Stand Unit.

2. Remove the 4 VESA Hole Covers .

3. Remove the 1 lock screw .

4. Remove the 1 lock screw .

5. Remove the 12 lock screws and detach the Rear Cabinet Ass’y.

Rear Cabinet Ass'y

LC-52D85UN

5

Front Cabinet Ass'y

2

4

1

Stand Unit

3

2 – 1

Page 14

LC-52D85UN

2. Removing of Bottom Cover, Speaker-L/R, R/C, LED Unit, KEY Unit Ass’y.

1. Remove the 1 lock screw and detach the Bottom Cover.

2. Disconnect SP-Wire and detach the Speaker-L/R.

3. Detach the R/C, LED Unit, and disconnect RA-Wire .

4. Detach the KEY Unit Ass'y .

5. Detach the KEY Unit from the KEY Button Cover, and disconnect KM-Wire .

4

KEY Unit Ass'y

KEY Unit

KEY Button

Cover

5

KM

Speaker-R

SP

2

RA

3

SP

R/C, LED Unit

2

RA

3

SP

Speaker-L

2

Bottom Cover

1

2 – 2

Page 15

3. Removing of Side AV Cover, Main Shield.

1. Remove the 2 lock screws and detach the Side AV Cover.

2. Remove the 5 lock screws , 4 lock shafts , 4 lock screws , 2 lock screws and detach the Main Shield.

2

4

5

3

Main Shield

Side AV Cover

1

LC-52D85UN

2 – 3

Page 16

LC-52D85UN

4. Removing of Connectors.

1. Disconnect all the connectors from all the PWBs.

KM

1

LB2

LA

LP

PD

PL

LW

LP

LB1

PD

PL

LB2

1

1

LA

1

LW

2 – 4

Page 17

5. Removing of Heat Sink Ass’y, MAIN Unit, POWER Unit.

1. Remove the 3 lock screws and detach the Heat Sink Ass'y.

2. Remove the 9 lock screws and detach the MAIN Unit.

3. Remove the 6 lock screws and detach the POWER Unit Ass'y.

4. Remove the 5 lock screws and detach the POWER Unit from the Power PWB Holder.

MAIN Unit

LC-52D85UN

1

Heat Sink Ass'y

4

2

Power PWB Holder

3

POWER Unit

2 – 5

Page 18

LC-52D85UN

6. Removing of Main Fix Angle, Panel Support Angle, Control Shield and LCD Panel Module Unit.

1. Remove the 14 lock screws and detach the Panel Support Angle.

2. Remove the 4 lock screws and detach the Control Shield.

3. Remove the 6 lock screws and detach the LCD Panel Module.

4. Remove the 8 lock screws and detach the Corner Lug.

5. Remove the 2 lock screws and detach the Center Lug.

4

Corner Lug

LCD Panel Module

1

Panel Support Angle

1

Control Shield

3

2

3

4

Corner Lug

Corner Lug

4

Corner Lug

5

5

Center Lug

3

3

3

3

4

2 – 6

Page 19

7. Removing of LCD Panel Module.

1. Remove the 16 lock screws , 2 lock screws and detach the Bezel Ass’y .

2. Detach the Lens Sheet and Diffusion Plate .

3. Detach the 2 pieces Lamp Holder Unit , Socket and detach the following 18 pieces Lamp from BL Chassis Ass'y .

BL Chassis Ass'y

9

Socket

8

Lamp Holder Unit

6

LC-52D85UN

7

1

1

3

Bezel Ass'y

5

4

Lens Sheet

Lamp

Diffusion Plate

Lamp Holder Unit

6

2

2 – 7

Page 20

LC-52D85UN

LC52D85UN

CHAPTER 3. ADJUSTMENT

Service Manual

[1] ADJUSTMENT PROCEDURE

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.

• When replacing the following units, make sure to prepare the new units loaded with updated software.

MAIN Unit: DUNTKE833FM07

• When replacing the LCD control PWB, perform the VCOM adjustment.

2. Upgrading of each microprocessor software

CAUTION: Never “POWER OFF” the unit when software upgrade is ongoing.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgrade

The model employs the following software.

• Main software (please use a software version after HLNAC300.USB.)

• Monitor microprocessor software (please use a software version after HLNAVC03.USB and HLNAM300.BIN.)

The main software, monitor microprocessor software can be upgraded by using a general-purpose USB Memory.

The followings are the procedures for upgrading, explained separately for the main software, monitor microprocessor software.

2.2. Main software version upgrade

2.2.1 Get ready before you start

• USB Memory of 128MB or higher capacity.

• PC running on Windows 98/98SE/ME/2000/XP operating system.

• USB Memory reader/writer or PC with a USB port.

• The file system of a USB memory is FAT. (FAT32 supports)

• Use the USB memory without other functions. (lock and memory reader...etc)

2.2.2 Preparations

To upgrade the main software, it is necessary to get ready the USB Memory for version upgrade before you start.

Follow the steps below and create the USB Memory for version upgrade.

1. Copy the file HLNACxxx.USB for version upgrade to the root directory (folder) of the USB Memory.

NOTE: In the USB Memory drive, do not store other folders or unrelated files, or more than one file for version upgrade.

Now the USB Memory for version upgrade is ready.

2.2.3 How to upgrade the software

1. Unplug the AC cord.

2. Insert the USB Memory for version upgrade (prepared as above) into the service socket located Right side of Main Board terminals, under INPUT3

terminal.

3. Plug in the AC cord with power button pressed down after 5 seconds, unpress the power button.

4. After the unit startup, the system upgrade screen as shown below appears within 20-40 seconds.

3 – 1

D85U

Page 21

LC-52D85UN

5. Even a single failure in the process will trigger the upgrade failure screen.

D85U

NOTE: In the event of a failure, repeat the upgrade process. If the process repeatedly fails, it is likely that the hardware need fixing.

6. Upon completion of the whole process, the upgrade success screen as shown below appears. You can check the new software version on this

screen. The version information appears after the upgrade is complete.

D85U

7. Unplug the AC cord and remove the USB Memory for version upgrade.

8. Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the main

software version information.

3 – 2

Page 22

LC-52D85UN

2.3. Monitor microprocessor software version upgrade

Create the USB memory for monitor microprocessor software version upgrade in the same manner as explained in the “Main software version

upgrade”.

Copy the file HLNAVCxx.USB and HLNAMxxx.BIN (named temporarily) for monitor microprocessor software version upgrade to the USB memory

2.3.1 How to upgrade the software

1. Unplug the AC cord.

2. Insert the USB Memory for version upgrade (prepared as above) into the service socket located Right side of Main Board terminals, under INPUT3

terminal.

3. Plug in the AC cord with power button pressed down.

4. After 5 seconds, unpress the power button.

CAUTION: • The moment this operation is done, the upgrading of the monitor microprocessor software starts. While the upgrade is ongoing, never

5. After the unit startup, the upgrade starts. The power led will blink continuously. Also, an upgrade screen will be shown during a minor upgrade.

power off the unit. Otherwise the upgrade will fail and the system may be serious damaged beyond recovery (inability to start).

• After the monitor microprocessor software is upgraded, also perform the 'Industry Init'.

D85U

6. If the upgrade fails, power led will stop blinking. Also, the upgrade failure screen will be shown if upgrade screen was shown at 5.

D85U

NOTE: In the event of a transient failure, upgrade will be automatically retried up to three times. If the process repeatedly fails, hardware may be the

cause.

7. Up on completion of the whole process, power and OPC LED will blink alternately. Also, the upgrade success screen will be shown if upgrade

screen was shown at 5.

D85U

8. Unplug the AC cord and remove the USB Memory for version upgrade.

9. Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the mon-

itor microprocessor software version information and panel size information.

3 – 3

Page 23

LC-52D85UN

3. Entering and exiting the adjustment process mode

1) Before entering the adjustment process mode, the AV position RESET in the video adjustment menu.

2) While holding down the “VOL (–)” and “INPUT” keys at a time, plug in the AC cord of the main unit to turn on the power.

The letter “<K>” appears on the screen.

3) Next, hold down the “VOL (–)” and “CH ( )” keys at a time.

(The “VOL (–)” and “CH ( )” keys should be pressed and held until the display appears.)

Multiple lines of blue characters appearing on the display indicate that the unit is now in the adjustment process mode.

When you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC cord from the outlet to make a forced shutdown. (When the

power was turned off with the remote controller, once unplug the AC cord and plug it again. In this case, wait 10 seconds or so before plugging.)

CAUTION: Use due care in handling the information described here lest your users should know how to enter the adjustment process mode. If the

4. Remote controller key operation and description of display in adjustment process mode

1) Key operation

Remote controller key Main unit key Function

CH ( / )

VOL (+/–) VOL (+/–) Changing a selected item setting (+1/ –1)

Cursor (UP/DOWN) ————— Turing a page (PREVIOUS/NEXT)

Cursor (LEFT/RIGHT) ————— Changing a selected line setting (+10/ –10)

INPUT ————— Input switching (toggle switching)

ENTER ————— Executing a function

settings are tampered in this mode, unrecoverable system damage may result.

CH ( / )

Moving an item (line) by one (UP/DOWN)

*Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

2) Description of display

(2) Current selected input

(1) Current page/ (4) Destination

Total pages

1/40 INPUT5 AUTO USA 52_UNDER

MAIN Version 1.09 (U 2007/07/19 2 A)

BOOT Version HLNA 1.01

Monitor/Monitor BOOT Version

LCD Con Version 1.00

EQ DATA CHECKSUM ROM

TEMPERATURE 7B

LAMP ERROR 0

MONITOR ERR CAUSE 0

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE 1) 0 2) 0 3) 0

(3) Current color system

1.02/1.00

0

0H 0M 0H 0M 0H 0M

4) 0 5) 0

0H 0M 0H 0M

(5) LCD Panel size/Speaker type

(6) Adjustment

process menu

header

(7) Parameters

3 – 4

Page 24

LC-52D85UN

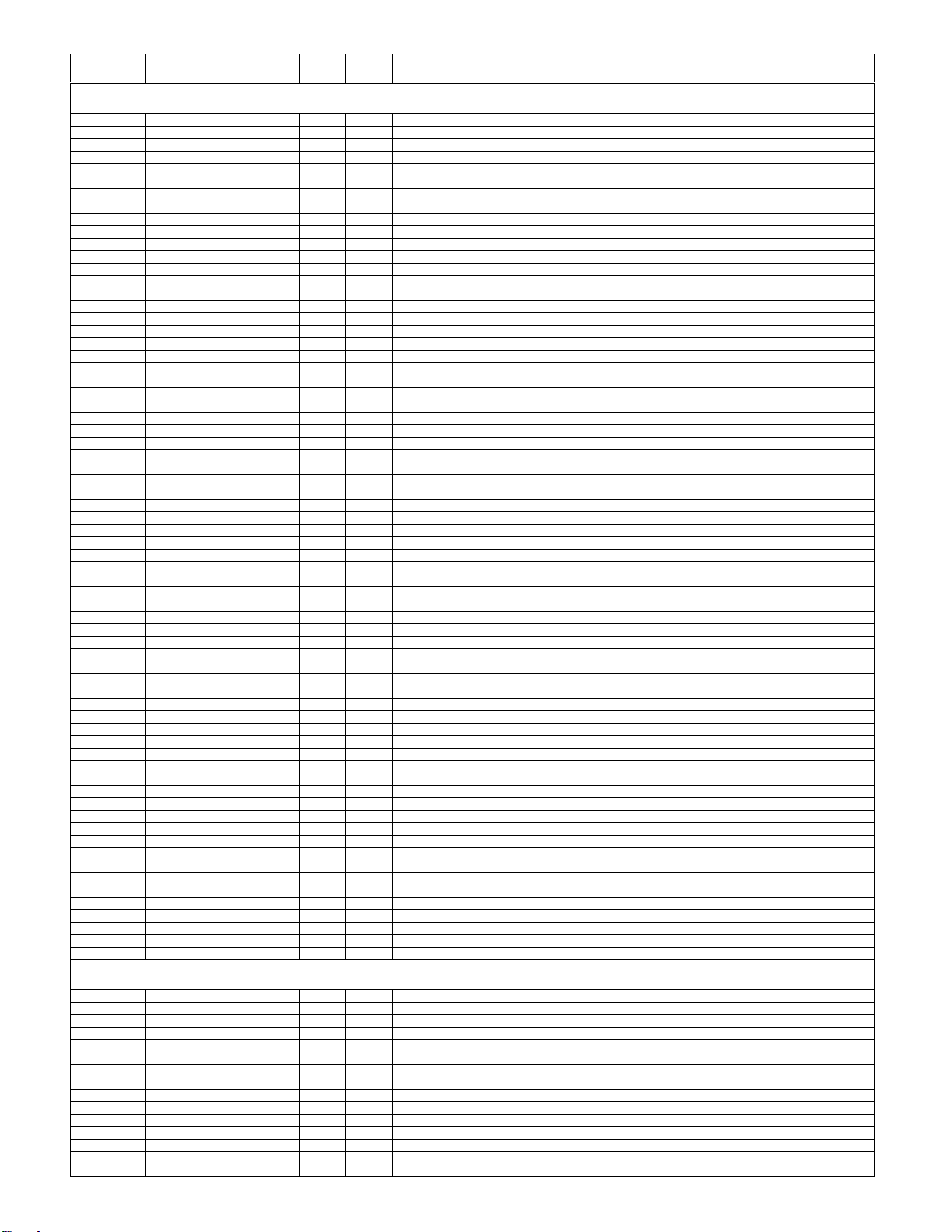

5. List of adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

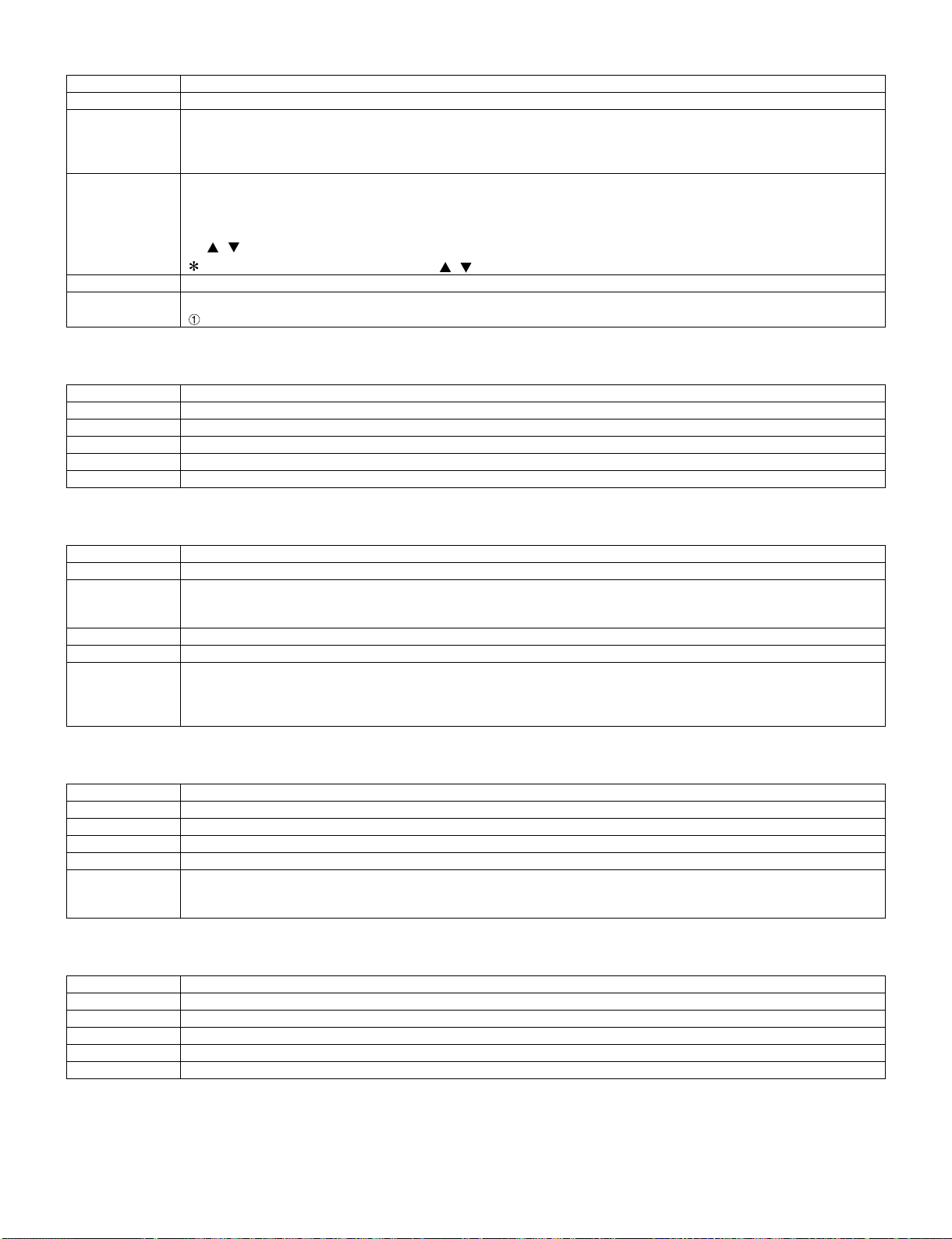

Page Line Item Description Remarks (adjustment detail, etc.)

1 1 MAIN Version Main software version

2BOOT Version

3 Monitor/Monitor BOOT Version Monitor and monitor boot software version

4 LCD Con Version LCD controller software version Versions are always ‘C000000000’.

5 EQ DATA CHECKSUM Audio data checksum

6 TEMPERATURE Panel temperature

7 LAMP ERROR Number of termination due to lamp error

8 MONITOR ERR CAUSE

9 NORMAL STANDBY CAUSE Refer to *1 under the list for details

10 ERROR STANDBY CAUSE Refer to *2 under the list for details

2 1 INDUSTRY INIT Initialization to factory settings

2 INDUSTRY INIT(-Public)

3 PUBLIC MODE Public mode

4 Center Acutime Accumulated main operation time

5 RESET Reset

6 Backlight Acutime Accumulated monitor operation time

7 RESET Reset

8 LAMP ERROR RESET Reset LAMP ERROR

9 VIC XPOS X-coordinate setting for VIC READ

10 VIC YPOS Y-coordinate setting for VIC READ

11 VIC COLOR Collected color data setting for VIC READ

12 VIC SIGNAL TYPE Signal type setting for VIC READ

13 VIC READ Picture level acquisition function Level appears in green on the upper right

3 1 N358 ALL ADJ(INPUT1) CVBS and TUNER signal level adjustment

2 N358 ALL ADJ(INPUT3)

3 N358 MAIN ADJ(INPUT1) CVBS signal level adjustment

4 N358 MAIN ADJ(INPUT3)

5 TUNER DAC ADJ TUNER signal level adjustment

6 N358 CONTRAST A_GAIN

7 N358 CONTRAST D_GAIN

8 N358 CONTRAST OFFSET

9 TUNER CONTRAST A_GAIN

10 TUNER CONTRAST D_GAIN

11 TUNER CONTRAST OFFSET

4 1 TUNER VCHIP TEST(69ch) Tuning test and VCHIP test (69ch)

2 TUNER VCHIP TEST(7ch) Tuning test and VCHIP test (7ch)

3 TUNER VCHIP TEST(10ch) Tuning test and VCHIP test (10ch)

4 TUNER VCHIP TEST(15ch) Tuning test and VCHIP test (15ch)

5 INSPECT USB TERM

6 HDMI EDID WRITE

7 HDMI CEC TEST

5 1 COMP15K ADJ(INPUT1) Component 15K picture level adjustment (main)

2 COMP15K ADJ(INPUT2)

3 COMP15K Y A_GAIN

4 COMP15K Cb A_GAIN

5 COMP15K Cr A_GAIN

6 COMP15K Y OFFSET

7 COMP15K Cb OFFSET

8 COMP15K Cr OFFSET

6 1 COMP33K ADJ(INPUT1) Component 33K picture level adjustment (main)

2 COMP33K ADJ(INPUT2)

3 COMP33K Y A_GAIN

4 COMP33K Cb A_GAIN

5 COMP33K Cr A_GAIN

9 COMP33K Y OFFSET

10 COMP33K Cb OFFSET

11 COMP33K Cr OFFSET

3 – 5

Page 25

LC-52D85UN

Page Line Item Description Remarks (adjustment detail, etc.)

7 1 ANALOG RGB ADJ Analog RGB picture level adjustment

2 R A_GAIN

3 G A_GAIN

4 B A_GAIN

5R OFFSET

6 G OFFSET

7 B OFFSET

8 1 VCOM ADJ VCOM adjustment value

91FRC ON/OFF

10 1 LEV1 Standard value 1 Adjustment gradation setting.

3 LEV2 Standard value 2

4 LEV3 Standard value 3

5 LEV4 Standard value 4

6 LEV5 Standard value 5

7 LEV6 Standard value 6

11 1 MG1R WB adjustment Point 1, R adjustment value Parameter for six-point adjustment

2 MG1G WB adjustment Point 1, G adjustment value

3 MG1B WB adjustment Point 1, B adjustment value

4 MG2R WB adjustment Point 2, R adjustment value

5 MG2G WB adjustment Point 2, G adjustment value

6 MG2B WB adjustment Point 2, B adjustment value

7 MG3R WB adjustment Point 3, R adjustment value

8 MG3G WB adjustment Point 3, G adjustment value

9 MG3B WB adjustment Point 3, B adjustment value

12 1 MG4R WB adjustment Point 4, R adjustment value Parameter for six-point adjustment

2 MG4G WB adjustment Point 4, G adjustment value

3 MG4B WB adjustment Point 4, B adjustment value

4 MG5R WB adjustment Point 5, R adjustment value

5 MG5G WB adjustment Point 5, G adjustment value

6 MG5B WB adjustment Point 5, B adjustment value

7 MG6R WB adjustment Point 6, R adjustment value

8 MG6G WB adjustment Point 6, G adjustment value

9 MG6B WB adjustment Point 6, B adjustment value

13 1 MODE SELECT

2 POS SELECT

3POS MIN

4POS MID1

5POS MID2

6POS MID3

7POS MID4

8POS MID5

9POS MID6

10 POS MAX

14 1 CD MIN

2 CD MID1

3 CD MID2

4 CD MID3

5 CD MID4

6 CD MID5

7 CD MID6

8 CD MAX

15 1 CALC

2 RESET

3VAL1

4VAL2

5VAL3

6VAL4

7VAL5

8VAL6

3 – 6

Page 26

LC-52D85UN

Page Line Item Description Remarks (adjustment detail, etc.)

16 1 Audio Switch

2 Flat Mode

3 EEP STATUS INIT

4 input Trim DTV

5 input Trim ATV

6 input Trim Digital

7 input Trim Analog

17 1 -6dB(1)

2 -6dB(2)

3 -6dB(3)

4 Lim(5BandPEQ)

5Lim(Bass)

6 Lim(3Band PEQ)

18 1 MBE Bass Gain

2 MBE Output Gain

3 MBE BPF

4 MBE Force Dtct Mode

5 MBE Bass G Limit

6HPF Fc

19 1 MVS width

2 MVS Xtalk

3 MVS Clarity

4 MVS LR Gain

5 MVS Output Gain

6 MVS Bass Gain

7 MVS Fo

20 1 Bass CENTER ATT

2Bass Vol0 MAX

3Bass Vol60 MAX

4 Bass Vol60 CENTER

5Bass Vol0 MIN

6Bass Vol60 MAX

21 1 Treble CENTER ATT

2 Treble Vol0 MAX

3 Treble Vol60 MAX

4 Treble Vol60 CENTER

5 Treble Vol0 MIN

6 Treble Vol60 MIN

22 1 PEQ1 Fo

2 PEQ1 Q

3 PEQ1 Gain

4 PEQ1 G Limit

5 PEQ2 Fo

6 PEQ2 Q

7 PEQ2 Gain

8 PEQ2 G Limit

9 PEQ3 Fo

10 PEQ3 Q

11 PEQ3 Gain

12 PEQ3 G Limit

23 1 PEQ4 Fo

2 PEQ4 Q

3 PEQ4 Gain

4 PEQ4 G Limit

5 PEQ5 Fo

6 PEQ5 Q

7 PEQ5 Gain

8 PEQ5 G Limit

9 PEQ6 Fo

10 PEQ6 Q

11 PEQ6 Gain

12 PEQ6 G Limit

3 – 7

Page 27

LC-52D85UN

Page Line Item Description Remarks (adjustment detail, etc.)

24 1 PEQ7 Fo

2 PEQ7 Q

3 PEQ7 Gain

4 PEQ7 G Limit

5 PEQ8 Fo

6 PEQ8 Q

7 PEQ8 Gain

8 PEQ8 G Limit

25 1 AVC_L Fc

2 AVC_L Target Level

3 AVC_L Max Gain UP

4 AVC_L Attack Rate

5 AVC_L Release Rate

6 AVC_H Target Level

7AVC_H Max Gain UP

8 AVC_H Attack Rate

9 AVC_H Release Rate

26 1 Sub Vol.SP

2 Sub Vol. MON

3 Sub Vol. HP

4 Sub Vol.SW

5 Sub Vol. OPT

6 Clip Level SP

7 Clip Level MON

8 Clip Level HP

9 Clip Level SW

10 Clip Level OPT

27 1 PANNEL SELECT

2PWM

3PWM FREQ

4 PWM DUTY

5OSC FREQ

6 OSC DUTY

28 1 BRIGHTNESS DA0

2 BRIGHTNESS DA1

3 BRIGHTNESS DA2

4 BRIGHTNESS DA3

5 BRIGHTNESS DA4

6 BRIGHTNESS DA5

7 BRIGHTNESS DA6

8 BRIGHTNESS DA7

9 BRIGHTNESS DA8

10 BRIGHTNESS DA9

11 BRIGHTNESS DA10

12 BRIGHTNESS DA11

29 1 BRIGHTNESS DA12

2 BRIGHTNESS DA13

3 BRIGHTNESS DA14

4 BRIGHTNESS DA15

5 BRIGHTNESS DA16

6 BRIGHTNESS DA17

7 BRIGHTNESS DA18

8 BRIGHTNESS DA19

9 BRIGHTNESS DA20

10 BRIGHTNESS DA21

11 BRIGHTNESS DA22

3 – 8

Page 28

LC-52D85UN

Page Line Item Description Remarks (adjustment detail, etc.)

30 1 BRIGHTNESS DA23

2 BRIGHTNESS DA24

3 BRIGHTNESS DA25

4 BRIGHTNESS DA26

5 BRIGHTNESS DA27

6 BRIGHTNESS DA28

7 BRIGHTNESS DA29

8 BRIGHTNESS DA30

9 BRIGHTNESS DA31

10 BRIGHTNESS DA32

31 1 OPC33 ADLEVEL 0

2 OPC33 ADLEVEL 1

3 OPC33 ADLEVEL 2

4 OPC33 ADLEVEL 3

5 OPC33 ADLEVEL 4

6 OPC33 ADLEVEL 5

7 OPC33 ADLEVEL 6

8 OPC33 ADLEVEL 7

9 OPC33 ADLEVEL 8

10 OPC33 ADLEVEL 9

11 OPC33 ADLEVEL 10

12 OPC33 ADLEVEL 11

32 1 OPC33 ADLEVEL 12

2 OPC33 ADLEVEL 13

3 OPC33 ADLEVEL 14

4 OPC33 ADLEVEL 15

5 OPC33 ADLEVEL 16

6 OPC33 ADLEVEL 17

7 OPC33 ADLEVEL 18

8 OPC33 ADLEVEL 19

9 OPC33 ADLEVEL 20

10 OPC33 ADLEVEL 21

11 OPC33 ADLEVEL 22

33 1 OPC33 ADLEVEL 23

2 OPC33 ADLEVEL 24

3 OPC33 ADLEVEL 25

4 OPC33 ADLEVEL 26

5 OPC33 ADLEVEL 27

6 OPC33 ADLEVEL 28

7 OPC33 ADLEVEL 29

8 OPC33 ADLEVEL 30

9 OPC33 ADLEVEL 31

34 1 V6 OS THERMO 1

2V6 OS THERMO 2

3V6 OS THERMO 3

4V6 OS THERMO 4

5V6 OS THERMO 5

6V6 OS THERMO 6

7V6 OS THERMO 7

35 1 V5 OS THERMO 1

2V5 OS THERMO 2

3V5 OS THERMO 3

4V5 OS THERMO 4

5V5 OS THERMO 5

6V5 OS THERMO 6

7V5 OS THERMO 7

36 1 BL TEMP1

2BL TEMP2

3BL TDUTY

37 1 MONITOR TIME OUT

2 MONITOR MAX TEMP

3 MONITOR ERROR CAUSE

RESET

3 – 9

Page 29

LC-52D85UN

Page Line Item Description Remarks (adjustment detail, etc.)

38 1 LCD TEST PATTERN

2 LCD AGI TEST PATTERN

3 LCD EVA TEST PATTERN

4 YEL TEST PATTERN

5 TV TEST PATTERN 1

6 TV TEST PATTERN 2

39 1 READ/WRITE

2 SLAVE ADDRESS

3 REGISTER ADDRESS UPPER

4 REGISTER ADDRESS LOWER

5 WRITE DATA UPPER

6 WRITE DATA LOWER

7 READ DATA UPPER

8 READ DATA LOWER

40 1 KEY LOCK(1217)

2 KOUTEI AREA ALL CLEAR

3 A MODE AREA CLEAR

4 BACKUP AREA CLEAR

5 B MODE AREA CLEAR

6 EXECUTION

41 1 EEP SAVE Writing setting values to EEPROM

2 EEP RECOVER Reading setting values from EEPROM

3 STANDBY CAUSE RESET Reset stand by cause

4 SETTING FOR ADJ

5 PANEL LIMIT

6 PANEL RANGE LIMIT

*1 Details of P1.9 (NORMAL STANDBY CAUSE)

2 No operation off in the cause of “no operation off”

3 No signal off in the cause of “no signal off”

4 PC power management mode 1 in the cause of “Standby mode MODE1”

5 PC power management mode 2 in the cause of “Standby mode MODE2”

6 Off timer in the cause of “SLEEP timer”

8 Command from RS232C in the cause of command by RS-232C

*2 Details of P1.10 (ERROR STANDBY CAUSE)

11 Prolonged unspecified-signal input in PC mode in the cause of continuous “out of range”, PC input mode

17 Temperature error in the cause of abnormal temperature

1A Monitor trouble detected in the cause of abnormal monitor mode

22 LCD controller Rom error in the cause of software abnormality of LCD controller

3 – 10

Page 30

LC-52D85UN

6. Special features

* STANDBY CAUSE (Page 1/41)

Display of a cause (code) of the last standby

The cause of the last standby is recorded in EEPROM whenever possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

* EEP SAVE (Page 41/41)

Storage of EEP adjustment value

* EEP RECOVER (Page 41/41)

Retrieval of EEP adjustment value from storage area

7. Video signal adjustment procedure

*Adjustment process mode menu is listed in section 5.

7.1. Signal check

Signal generator level adjustment check (Adjustment to the specified level)

• Composite signal : 0.714Vp-p ± 0.02Vp-p (Pedestal to white level)

• 15K component signal : Y level : 0.714Vp-p ± 0.02Vp-p (Pedestal to white level)

PB, PR level : 0.7Vp-p ± 0.02Vp-p

• 33K component signal : Y level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

PB, PR level : 0.7Vp-p ± 0.02Vp-p

• Analog RGB : RGB level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

7.2. Entering the adjustment process mode

Enter the adjustment process mode according to the steps described in section 3.

7.3. N358 composite signal adjustment (Tuner)

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment N358 signal

US-10ch

2 Auto adjustment

performance

Page 3/41 Bring the cursor on [•N358 ALL ADJ (INPUT1)] and press [ENTER].

Feed the NTSC (3.58) split field color bar signal (75% color saturation)

to VIDEO 1 input. Feed the RF signal (by use of US-10ch) to TUNER-A.

[Video input signal] [US-10CH]

100% white 100% white

[•N358 ALL ADJ (INPUT1) OK] appears when finished.

7.4. Component 15K signal adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment 480i signal Feed the 100% color bar signal to INPUT 1 component input.

2 Auto adjustment

performance

100% white

Page 5/41 Bring the cursor on [•COMP 15K ADJ (INPUT1)] and press [ENTER].

[•COMP 15K ADJ (INPUT1) OK] appears when finished.

3 – 11

Page 31

7.5. Component 33K signal adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment 1080i signal Feed the 100% color bar signal to INPUT 1 component input.

100% white

2 Auto adjustment

performance

Page 6/41 Bring the cursor on [•COMP 33K ADJ (INPUT1)] and press [ENTER].

[•COMP 33K ADJ (INPUT1) OK] appears when finished.

7.6. Analog RGB signal adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment Analog RGB signal: XGA

(1024 x 768) 60Hz

SYNC: HV separate

Feed the XGA 100% color bar signal to ANALOG RGB input.

LC-52D85UN

2 Auto adjustment

performance

7.7. Tuner/V-Chip test

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment NTSC RF signal

US-7 (AIR) ch

2 Auto adjustment

performance

100% Color saturation

100% white 0% black

Bring the cursor on [•ANALOG RGB ADJ] and press [ENTER].

[•ANALOG RGB ADJ OK] appears when finished.

Feed the NTSC signal to RF ANTENNA input.

Bring the cursor on [•TUNER VCHIP TEST (*07ch)] and press

[ENTER]. (*Select the channel according to the RF signal.)

[•A-OK (***.**)/VM-OK] appears in blue when finished. (If [A-NG/VMNG] appears in yellow or red, the test is incomplete.)

Make sure a displacement of ±0.0625 MHz from the center frequency is

acceptable.

XGA

100% color bar

3 – 12

Page 32

LC-52D85UN

8. Adjustment of white balance

8.1. White balance adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Setting For detailed adjustment procedure, refer to “Kameyama Model Integral Monitor WB

2 Automatic adjust-

ment execution

[Command]

Process mode

KRSW0001

KKT10037

Setting

KYOF0000

OSDS0001

SBSL0016

Multi-point adjustment

mode

MSET0001

Point 6

WBI60928

MG6G****

MG6B****

MG6R****

Point 5

WBI50784

MG5G****

MG5B****

MG5R****

Adjustment Specifications V1.6”.

1) Make the following settings for the set.

AV MODE: [DYNAMIC]

Backlight: +16

Active Backlight: OFF

Aging time: Min. 60 minutes

2) Connect the white balance adjustment tool to the set.

[Adjustment procedure]

1) Using the remote controller, transmit the “monitor adjustment process” code.

2) Set the 6th point to the specified gradation level. With the strongest color being fixed,

turn down the R, G and B settings to their reference levels.

3) Set the 5th point to the specified gradation level. Correct the G setting (3136 x 6thpoint G setting / 3712) (rounded off), and make the R and B settings to their reference

levels.

4) Set the 4th point to the specified gradation level. Correct the G setting (2320 x 6thpoint G setting / 3712) (rounded off), and make the R and B settings to their reference

levels.

5) Set the 3rd point to the specified gradation level. Correct the G setting (1680 x 6thpoint G setting / 3712) (rounded off), and make the R and B settings to their reference

levels.

6) Set the 2nd point to the specified gradation level. Correct the G setting (1136x 6thpoint G setting / 3712) (rounded off), and make the R and B settings to their reference

levels.

7) Set the 1st point to the specified gradation level. Correct the G setting (736 x 6thpoint G setting / 3712) (rounded off), and make the R and B settings to their reference

levels.

8) With the MSET0003 command, write the adjustment values and turn off the AC

power.

* Initial R, G and B settings at point 6: Gradation level set at 3712

* Initial R, G and B settings at points 1 thru 5: Corrected G setting at each point

(This is because the adjustment is made to achieve the same remainder of RGB setting /

4 at each point.)

[Adjustment value]

•As per the “standard set” submitted by Engineering Department Teaching set

[Adjustment reference] Instrument: Minolta CA-210 Engineering instrument

Point 4 Level Reference Adj. spec Ins. spec

WBI40580 Point 6 928 X=0.272 ±0.0010 ±0.0020

MG4G**** y=0.277

MG4B**** Point 5 784 X=0.272 ±0.0010 ±0.0020

MG4R**** y=0.277

Point 4 580 X=0.272 ±0.0015 ±0.0030

Point 3 y=0.277

WBI30420 Point 3 420 X=0.272 ±0.0020 ±0.0040

MG3G**** y=0.277

MG3B**** Point 2 284 X=0.272 ±0.0030 ±0.0060

MG3R**** y=0.277

Point 1 184 X=0.272 ±0.0040 ±0.0080

y=0.277

Point 2

WBI20284

MG2G****

MG2B****

MG2R****

Point 1

WBI10184

MG1G****

MG1B****

MG1R****

Writing

MSET0003

Note Set conditions for inspection

AV MODE: [DYNAMIC] (Reset)

Monochro: ON

Active Contrast: OFF

Aging Time: Min. 60 minutes

3 – 13

Page 33

LC-52D85UN

8.2. Adjusting procedure by use of [RS-232C]

1. Get ready the PC with COM port (RS-232C) running on Windows 95/98/ME/2000/XP operating system, as well as the RS-232C cross cable.

2. Start the unit with the RS-232C cable connected.

3. Start the terminal software. (The freeware readily available on the Internet will do.)

4. Make the following settings.

Baud rate 9,600 bps

Data LENGTH 8 bit

Parity bit None

Stop bit 1 bit

Flow control None

5. If the settings are correct, the terminal software indicates “ERR” against pressing of the “ENTER” key.

6. After the settings are done correctly, it is possible to make an adjustment by typing in the command shown in the table below and pressing the

“ENTER” key on the keyboard.

7. Command entry is successful if the terminal software indicates “OK” when the “ENTER” is pressed. If “ERR” is shown, retry to enter the command.

8. Send the process mode switching command to switch from the RS232C operation mode to the process mode.

KRSW0001: “ERR” is returned.

KKT10037: When “OK” is returned, the process mode becomes active. When “ERR”, start over from KRSW0001.

9. Send each adjustment command.

9. Initialization to factory settings

CAUTION: When initialization is performed, all user setting data including the channel settings are initialized. Be cautious when making this adjust-

ment.

(The adjustments done in the adjustment process mode are not initialized.)

Adjustment item Adjustment conditions Adjustment procedure

1 Initialization It turns off with AC power

supply.

After the adjustment, cancel the adjustment process mode.

To exit the adjustment process mode, unplug the AC power cable from the outlet to make a

forced shutdown. (When the power was turned off with the remote controller, once unplug the

power cable and plug it again. In this case, wait 10 seconds or so before plugging.)

Enter the adjustment process mode.

Bring the cursor on to [INDUSTRY INIT] in page 2/40.

Set to [ON] using [VOL] key, and press [ENTER] to execute the initialization.

When the version number screen shows up on the green background and “SUCCESS”

gets displayed at the top on screen, it means the procedure has been successfully carried out.

(If an error occurs, “ERROR” is displayed on the red background.)

•Turn off the AC power.

*Never shut off the power during the initialization process.

The following settings are initialized in this adjustment.

1) User setting

2) Channel data (e.g. broadcast frequencies)

3) Password data

4) Operation time

5) Auto installation flag

6) V-CHIP block setting

3 – 14

Page 34

LC-52D85UN

MDK

TUNER

10. Model number ID plug

Model numbers are identified by inserting the destination ID plug (QCNCMA275WJQZ) in its specified slot of the destination ID connector SC9201/

SC9202 (QCNCWA715WJQZY).

Destination ID connector locations

1

4

HDMI

PC Audio IN

V/LR

SC9202

SC9201

䇼KM䇽

HDMI

Optical

OUT

S-video

DDR

position

MAIN Unit

E 833

L/R

䇼LB1䇽

䇼LP䇽

1

6

1

15

䇼LW䇽

䇼PD䇽

1

12

1

41

SC9201 SC9202

LC-52D85UN 㽶㽴

Plug locations

㽲

㽳

㽴

㽵

㽶

㽷

㽸

㽹

USB

Analog RGB

RS-232C

䇼RA䇽

1

10

䇼SP䇽

1

4

3 – 15

Page 35

LC-52D85UN

[2] PUBLIC MODE SETTING PROCEDURE

1. How to start Public Mode

• There are the following two ways to get the public mode setup screen displayed.

In the adjustment process mode, turn on “PUBLIC MODE”. Also press the “CH ( )” and “VOL (+)” keys on the set at once and turn on the

power.

1) Press the “INPUT” and “VOL (+)” keys on the set at once and turn on the power.

2) Get the password input screen displayed.

Procedure

˴The input starts with the leftmost digit.

˴Use the numeric keys [1] thru [9] and [0] keys on the remote controller.

˴The other keys are not acceptable.

˴With a numeric-key input, "_" will change to "˴".

˴The input position will move one digit to the right.

˴With all the 3 digits entered, the password will be verified.

3) The 3-digit password is now verified.

The password [0] [2] [7] provides for the public mode screen. (This screen comes on with whatever adjustment process settings.)

With any other passwords, the screen changes to the normal mode.

2. How to exit Public Mode

There are the following ways to quit the public mode setup screen.

• Turn off “PUBLIC MODE” in the adjustment process mode. ( ) ← This way alone is not for quitting the setup screen, but for quitting the mode itself.

• Turn off the power with the “POWER” key. ( )

• Select “EXECUTE”. ( )

... “PUBLIC MODE” stays on in the adjustment process mode.

... The settings will be back to the factory ones.

3. Public Mode Setting Values

• With the factory settings made, the public mode settings get initialized. (The adjustment process remains intact.)

3 – 16

Page 36

LC-52D85UN

4. Public Mode Menu

The guidance is not displayed on screen.

Setup procedure

• To move the cursor up and down, use the “cursor UP/DOWN” key (remote controller) and “CH ( )/( )” key (remote controller and set).

• To change the settings, use the “cursor RIGHT/LEFT” key (remote controller) and “VOL (+)/(–)” key (remote controller and set).

• To save new settings, keep the cursor at “EXECUTE” and use “ENTER” key (remote controller and set).

PUBLIC MODE

POWER ON FIXED [VARIABLE ]

MAXIMUM VOLUME [ 60 ]

VOLUME FIXED [VARIABLE ]

VOLUME FIXED LEVEL [ 20 ]

RC BUTTON [RESPOND ]

PANEL BUTTON [RESPOND ]

MENU BUTTON [RESPOND ]

AV POSITION FIXED [VARIABLE ]

ON SCREEN DISPLAY [YES ]

INPUT MODE START [NORMAL ]

INPUT MODE FIXED [VARIABLE ]

LOUD SPEAKER [ON ]

RC_PATH_THROUGH [OFF ]

232C POWON [DISABLE ]

PUBLIC MODE [OFF ]

RESET

EXECUTE

3 – 17

Page 37

LC-52D85UN

5. On Setting Items

* “EZ-SETUP” discussed below indicates “EZ-SETUP after the first power-on”.

1) POWER ON FIXED

Selection Selection between “Variable” and “Fixed” (loop provided)

Default – (Variable)

Explanation In “Fixed” setting, the power-off by the power key of the unit is invalidated and the image is kept being received. The power can

Limit in Setting Refer to the “Power-On Fixed” sheet.

Exception None

Remarks • In “Variable” setting, the power operation is in wait for 1 sec. and then turned off when the main power switch is off.

2) MAXIMUM VOLUME

Selection Adjustment from 0 to 60 (no loop)

Default 60

Explanation Sound volume can not be adjusted higher than the preset value.

Limit in Setting • When the sound volume is set lower than 59, only figures are displayed and the sound volume bar is not displayed.

Exception

Remarks • When the sound volume is set higher than the MAX setting by the adjusting process, the sound volume control operation is

3) VOLUME FIXED

be turned off by stopping the power supply from AC.

• The maximum sound volume for ON-timer (Wake up timer) is limited also to the preset value.

prohibited for turn-up and the sound volume should be turned down to MAX in this state.

Selection Selection between “Variable”, “Fixed”, “ACON (AC CTRL)” and “AC/RCON (AC/RC CTRL)” (loop provided)

Default Variable

Explanation • FIXED: Fixed at the level adjusted for a fixed volume.

• AC CTRL: Start-up at the level specified for a fixed volume at ACON.

• AC/RC CTRL: Start-up at the level specified for a fixed volume at start.

Limit in Setting • The sound volume for the ON-timer (Wake up timer) is fixed also without display of menu. Besides, the setting is made

impossible. (Basically, the menu is not displayed.)

• The following keys become invalid:

• Sound volume Up/Down (VOL +/–) [for both remote control and the unit]

• Mute (MUTE)

Exception • In the item “VOLUME” of adjustment process, the sound volume can be set freely irrespective of this setting.

Remarks • As for sound volume fixing and sound volume MAX level, the sound volume fixing has priority.

• Once the sound volume has been changed by adjustment process, it should be set back to the sound volume preset by

sound volume fixing level when the adjustment process ends.

4) VOLUME FIXED LEVEL

Selection Adjustment from 1 to 60 (no loop)

Default 20

Explanation The sound volume to be fixed by “Volume fixed” is determined.

Limit in Setting None

Exception None

Remarks Setting is valid only when “Volume fixed” is selected for “fixed”.

5) R/C BUTTON

Selection Selection between “Respond”, “No Respond” and “Limited” (loop provided)

Default Respond

Explanation Making the remote controller settings.

• At the “No Respond” setting, the remote controller keys are disabled. Its power key (reception/standby key) is disabled too.

• At the “Limited” setting, some channel-related keys alone are operative. All the other remote controller keys (power, volume

/ , channel / , light control (brightness sensor), broadcast select) are inoperative.

Limit in Setting

Exception • Adjustment process, inspection process and hotel only keys are valid irrespective of setting.

Remarks

In “No respond” setting, all the keys (including the power key) are not accepted.

•

All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

3 – 18

Page 38

LC-52D85UN

6) PANEL BUTTON

Selection Selection between “Respond” and “No respond” (loop provided)

Default Respond

Explanation All the operations by keys (except the power key) of the unit can be invalidated.

Limit in Setting

Exception • Adjustment process, inspection mode and hotel menu mode can be started irrespective of setting.

• All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

Remarks

7) MENU BUTTON

Selection Selection between “Respond” and “No respond” (loop provided)

Default Respond

Explanation In “No respond” setting, the menu operation by the menu key of the remote control and the menu key of the unit are invali-

dated.

Limit in Setting

Exception • Adjustment process, inspection mode and hotel menu mode can be started irrespective of setting.

• All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

Remarks

8) ON SCREEN DISPLAY

Selection Selection between “Yes”, “No” (loop provided)

Default Yes

Explanation • At the “No” setting, the following items are not displayed on screen: register, setting, adjustment menu, channel call and vol-

ume bar.

On the wide-screen models, an input selection is immediately made because the menu is not displayed.

• At the “Limited” setting, some items cannot be displayed on screen.

On the Japan-destined models, the channel call “Message” alone cannot be displayed. (This is because the channel call mes-

sage may be confused with a message being sent from the hotel.)

On the North America-destined models, the OSD works the same as at the “No” setting.

Limit in Setting • Keys falling under any of the following items become invalid.

Appearance of screen changes and the sound changes.

Personal functions which are hard to restore.

Screen display, menu, OFF-timer, ON-timer, AV MODE, screen size switching, clock setting, treble emphasis, AUDIO ONLY,

sound changeover, LANGUAGE, CLOSED CAPTION

Others • Simple input switching is generated. Those which are restored soon after leaving as they are and may be requested for

change by customer are not prohibited.

Brightness sensor (BACKLIGHT) and PIC. FLIP

Exception • Such a caution which is displayed independently is displayed as it is.

Non-responding signal caution

Remarks • When CC has already been ON, CLOSED CAPTION is displayed.

9) INPUT MODE START

Selection

Default Normal

Explanation In power-ON, the input source to be started or channel can be set.

About options • All the input sources in the model are made selectable.

Limit in Setting • The display of channel setting menu and the channel setting operation are prohibited.

Exception

Remarks • In setting at “Normal”, the setting of “Input mode fixed” is changed to “Variable” and selection should be prohibited.

Selection between “Normal”, “Air ( )”, “Blu-ray”, “INPUT 1/2/3”, “PC”, “HDMI 1/2/3/4/5”, “DVI” (loop provided)

(In standard mode, the operation follows the last memory.)

• In TV mode, the channel to be set follows the last memory and the content of the last memory is included in the notation by

options. Ex.) Air (2), Cable (98.1) etc.

3 – 19

Page 39

LC-52D85UN

10)INPUT MODE FIXED

Selection Selection between “Variable”, “Fixed”, “ACON (AC CTRL)” and “AC/RCON (AC/RC CTRL)” (loop provided)

Default – (Variable)

Explanation • At the “Fixed” setting, the TV set gets started with the settings of “Input mode start”, and then any other channels and inputs

are not accepted.

• At the “ACON (AC CTRL)” setting, the TV set gets started with the settings of “Input mode start” under AC control.

• At the “AC/RCON (AC/RC CTRL)” setting, the TV set gets started with the settings of “Input mode start” under either control.

Limit in Setting • With the execution of hotel mode, the input source is forced to change to that set by “Input mode start” and the channel

Exception None

Remarks • In the following case, setting is cancelled and mode is changed to “Variable”.

11)RC_PATH_THROUGH

Selection Selection between “OFF”, “ON: TV RCE” and “ON: TV RCD” (loop provided)

Default OFF

Explanation Function to feed the remote controller-received signal to Pin 9 (open) on the RS232C.

Limit in Setting None

Exception None

Remarks None

switching and input switching are prohibited thereafter.

• ON-timer's (Wake-up timer) channel items are not displayed or the operation is prohibited. (Basically, they are not displayed.)

• The following keys are invalidated.

CH / , direct tuning button, FLASHBACK, input

However, the keys (input switching and CH / keys) of the unit for menu operation remain valid.

When the setting of “Input mode start” is set to “Normal”.

12)AV POSITION FIXED

Selection Selection between “Variable” and “Fixed” (loop provided)

Default Variable

Explanation In case of “Fixed” setting,

– Menu “Picture” and “Audio” setting can't be changed like “Dynamic (Fixed)”.

– When “AV Mode” key is pressed, TV just displays current AV Mode (cannot be changed.).

Limit in Setting None

Exception None

Remarks • When receiving with AV Position key, OPC, Dolby key and other direct audio select keys, the current display stays on and no

setting can be changed.

• Even by initializing personal information, the hotel-mode settings are kept intact. In this way, the AV positions, video and

audio adjustment settings are not initialized.

13)LOUD SPEAKER (ON/OFF)

Selection Selection between “ON” and “OFF” (loop provided)

Default ON

Explanation If “OFF” is selected, TV stops Speaker output even without Headphone connected.

Limit in Setting None

Exception None

Remarks • Press the volume UP/DOWN key, and the mute icon appears for 4 seconds.

• The mute key and audio-related keys are displayed with caution.

• Usually, the headphones and monitor audio outputs can be adjustable.

14)232C POWON

Selection Selection between “Disable” and “Enable” (loop provided)

Default Disable

Explanation In the standby mode, the power-on by the 232C command is enabled or disabled.

Limit in Setting None

Exception None

Remarks None

3 – 20

Page 40

LC-52D85UN

15)PUBLIC MODE (ON/OFF)

Selection Selection between “ON” and “OFF” (loop provided)

Default OFF

Explanation In case of “ON”, public mode settings are effected.

Limit in Setting None

Exception None

Remarks The public-mode settings are operable only when this item is set at ON.

3 – 21

Page 41

LC52D85UN

CHAPTER 4. TROUBLESHOOTING TABLE

Service Manual

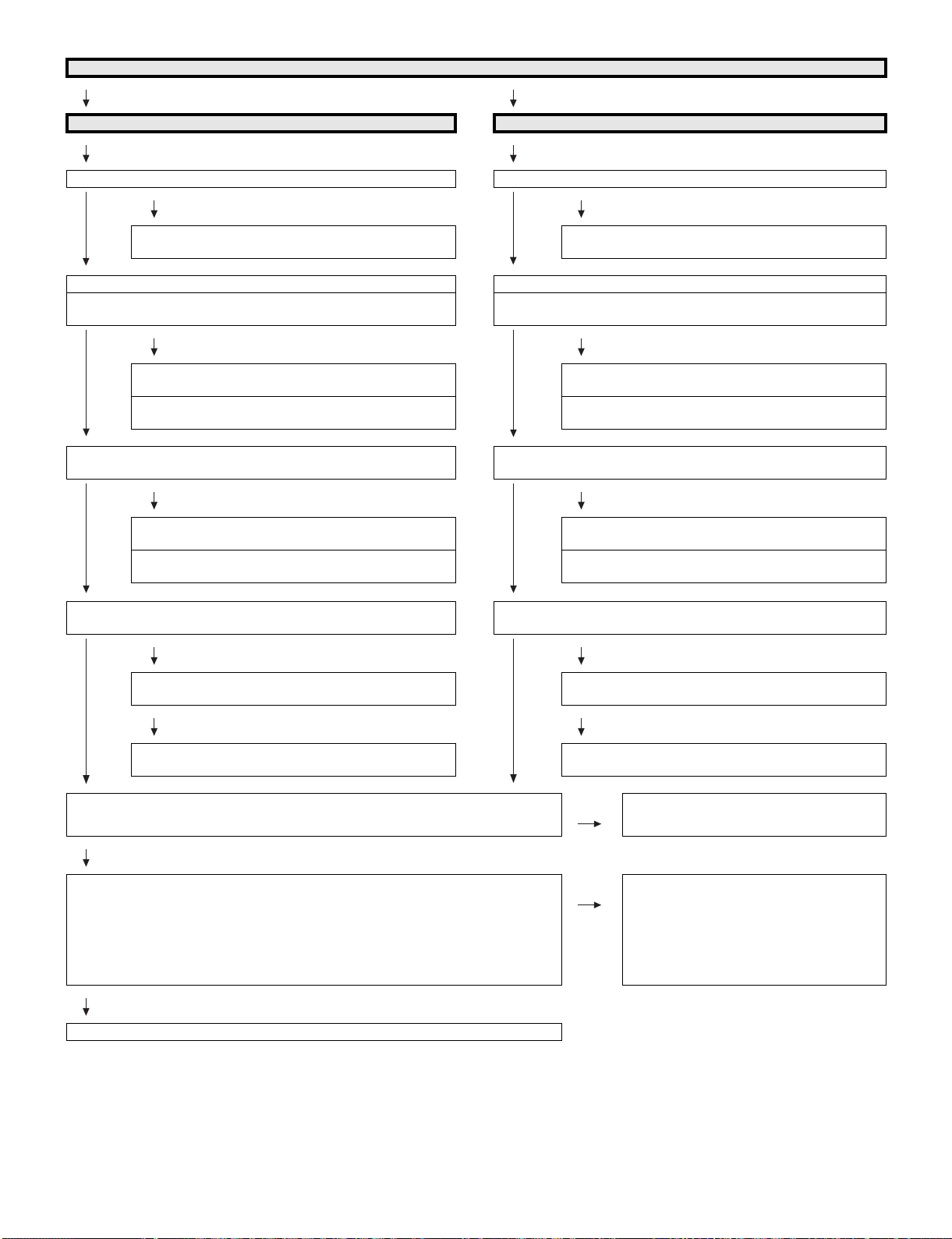

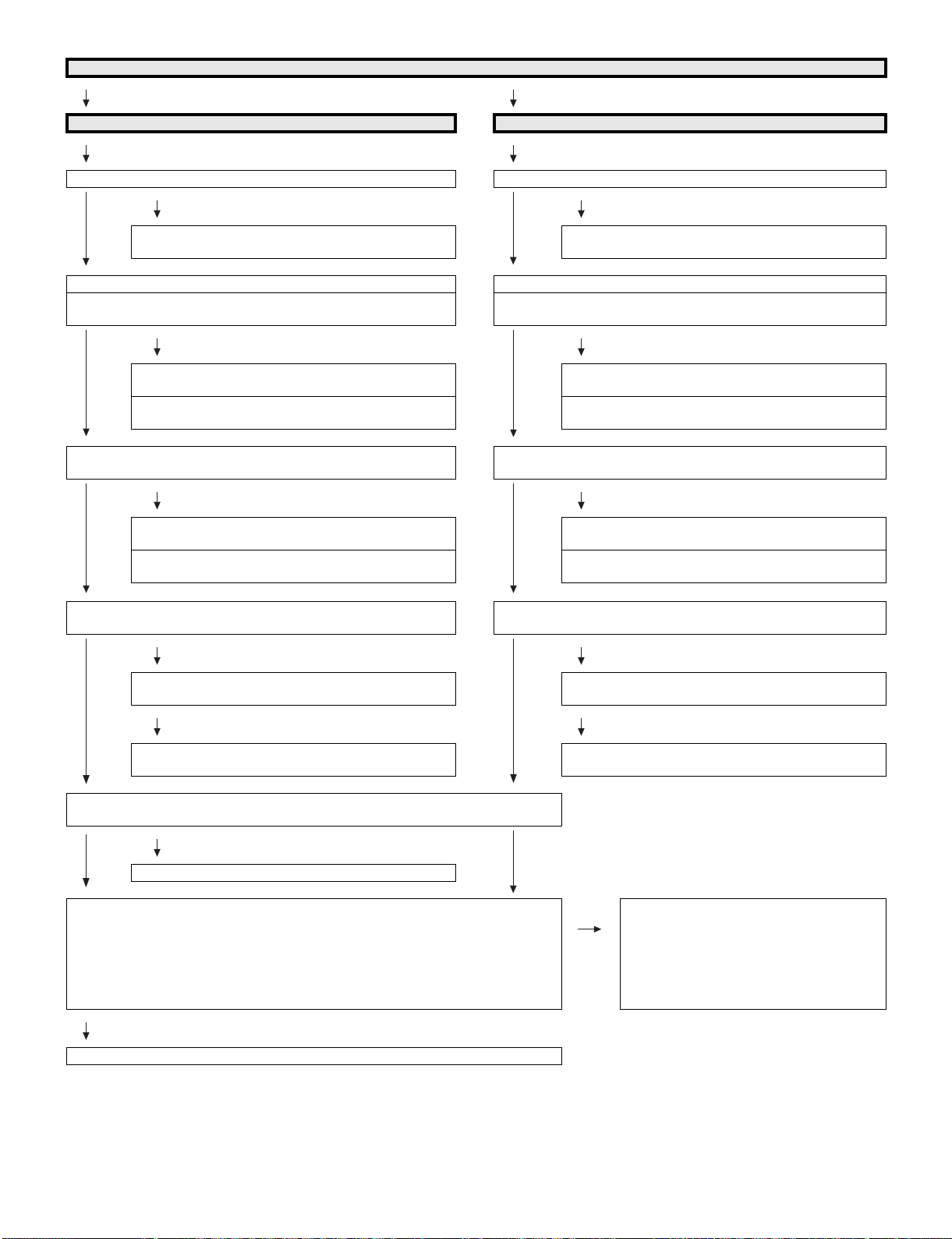

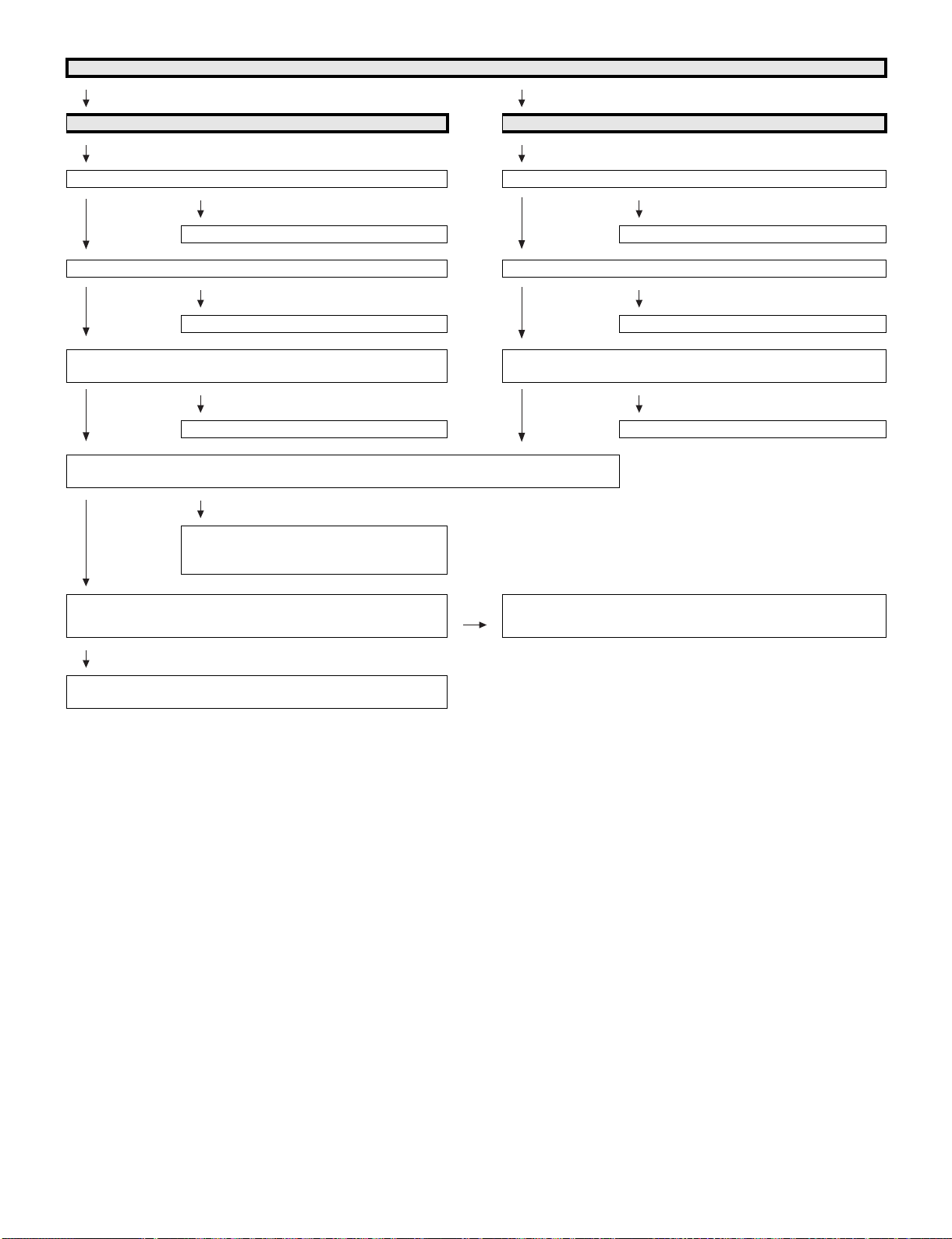

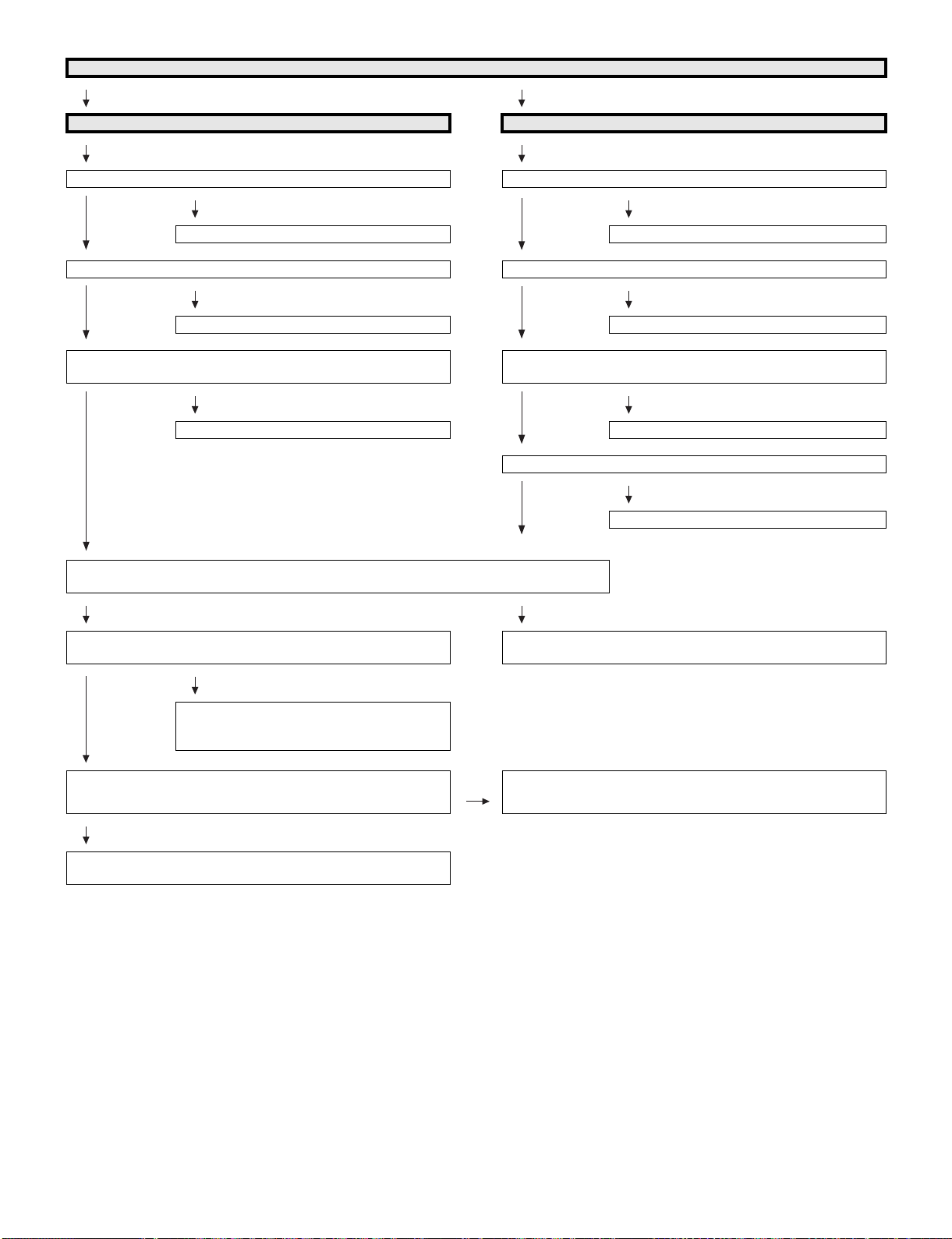

[1] TROUBLESHOOTING TABLE

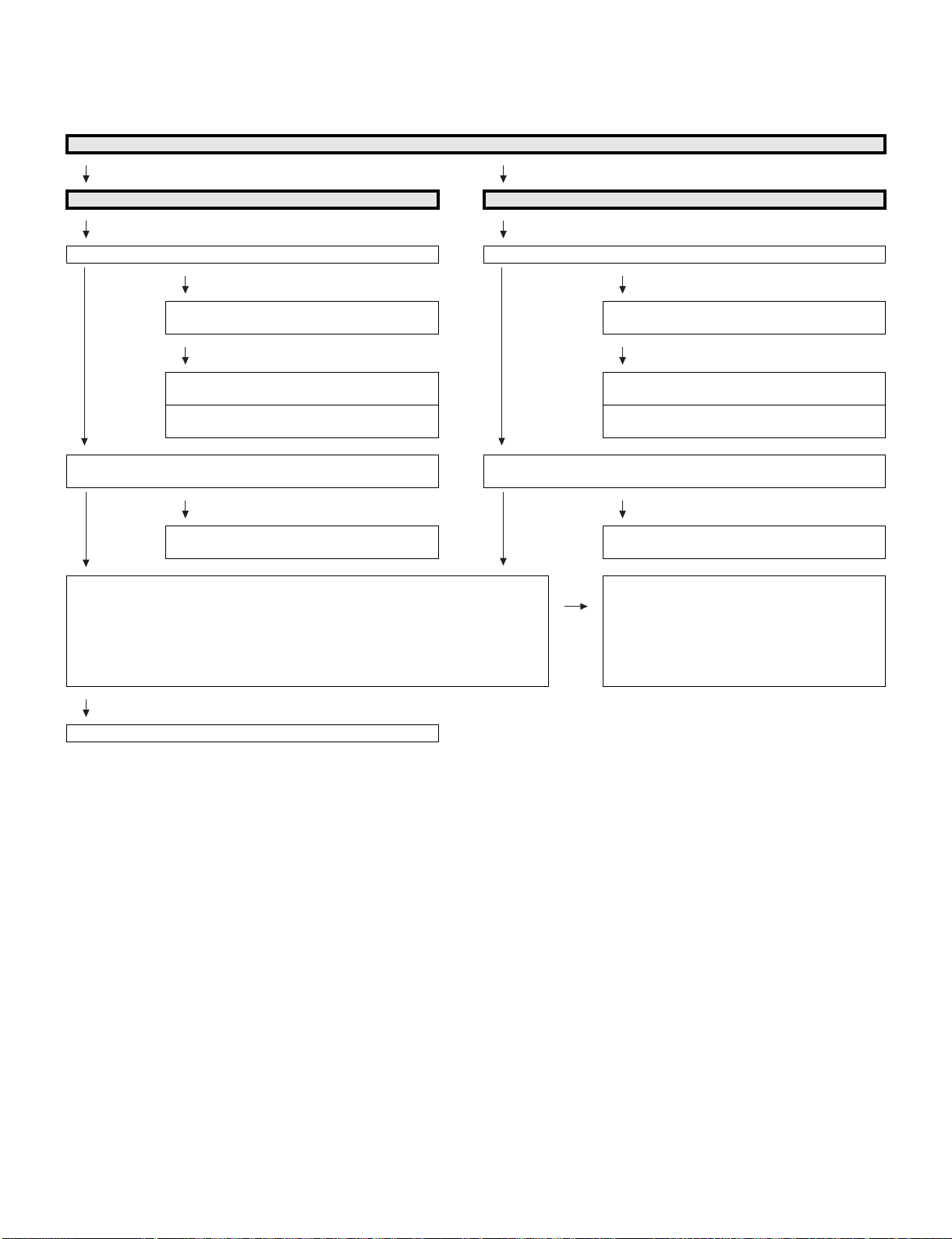

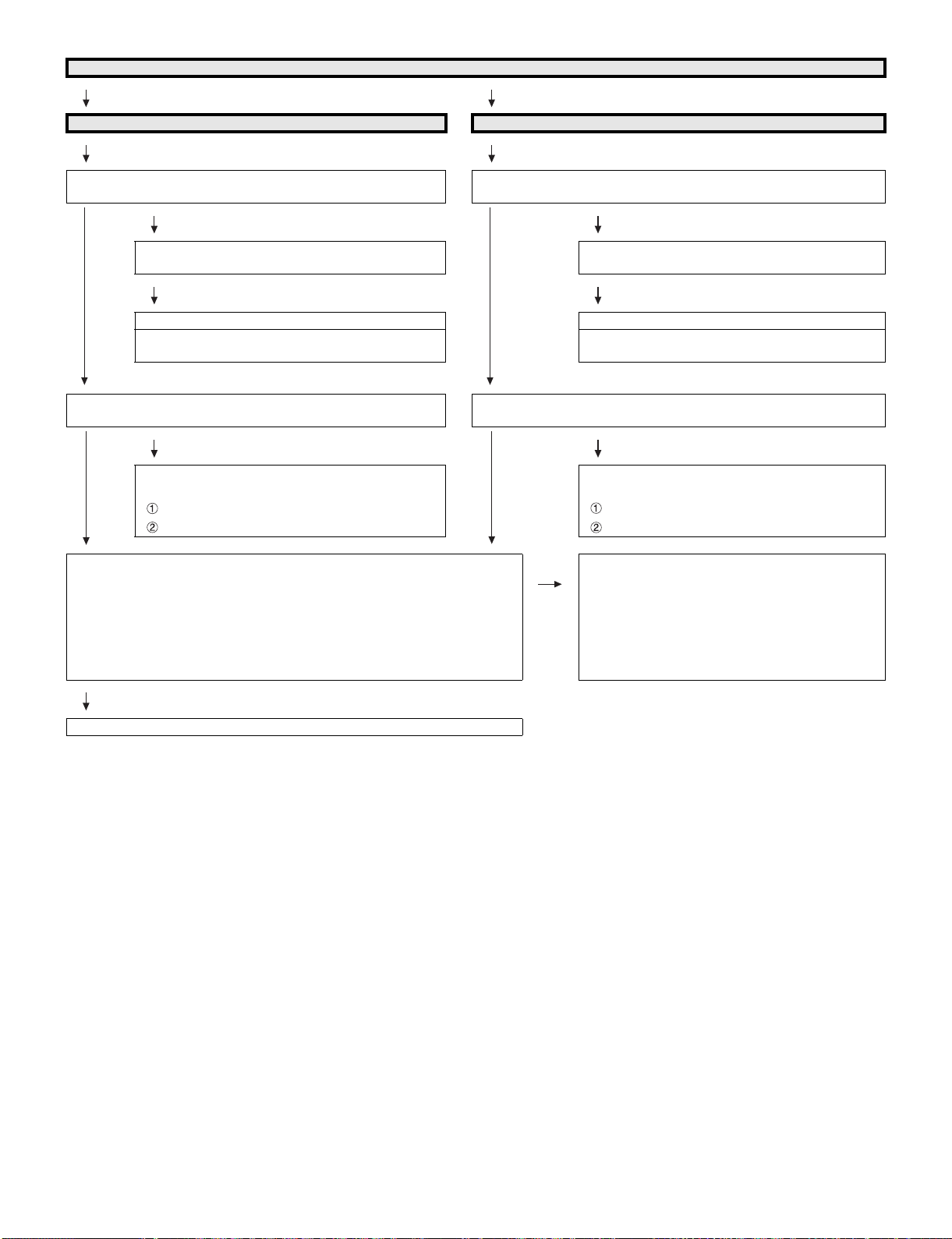

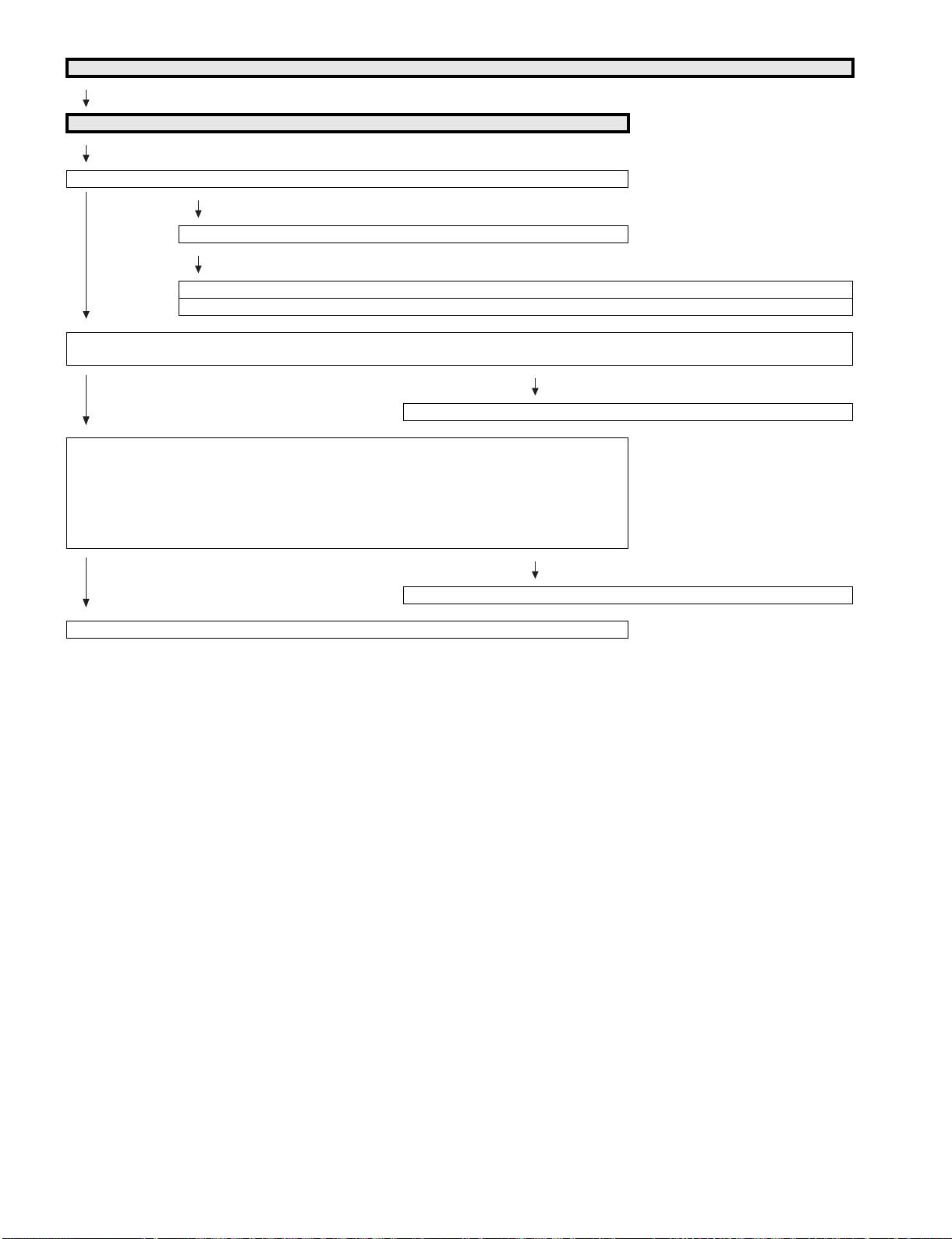

No video (1)

COMPOSITE: No external input video [INPUT-1] COMPOSITE: No external input video [INPUT-3]

Is INPUT-1 selected on the input select menu screen? Is INPUT-3 selected on the input select menu screen?

LC-52D85UN

NO

Select INPUT-1 on the input select menu