Page 1

LC-40/46/52/60LE820UN

SERVICE MANUAL

No. S30F140LE820U

LCD COLOR TELEVISION

LC-40LE820UN

LC-46LE820UN

LC-52LE820UN

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those spe cif ied sho uld be us ed .

LC-60LE820UN

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

PRECAUTIONS A PRENDRE LORS DE

LA REPARATION...............................................ii

PRECAUTIONS FOR USING LEAD-FREE SOLDER

OUTLINE

MAJOR SERVICE PARTS................................iv

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS (LC-40/46LE820UN)........ 1-1

[2] SPECIFICATIONS (LC-52/60LE820UN)........ 1-2

CHAPTER 2. OPERATION MANUAL

[1] Parts Name.................................................... 2-1

[2] OPERATION MANUAL..................................2-3

CHAPTER 3. DIMENSIONS

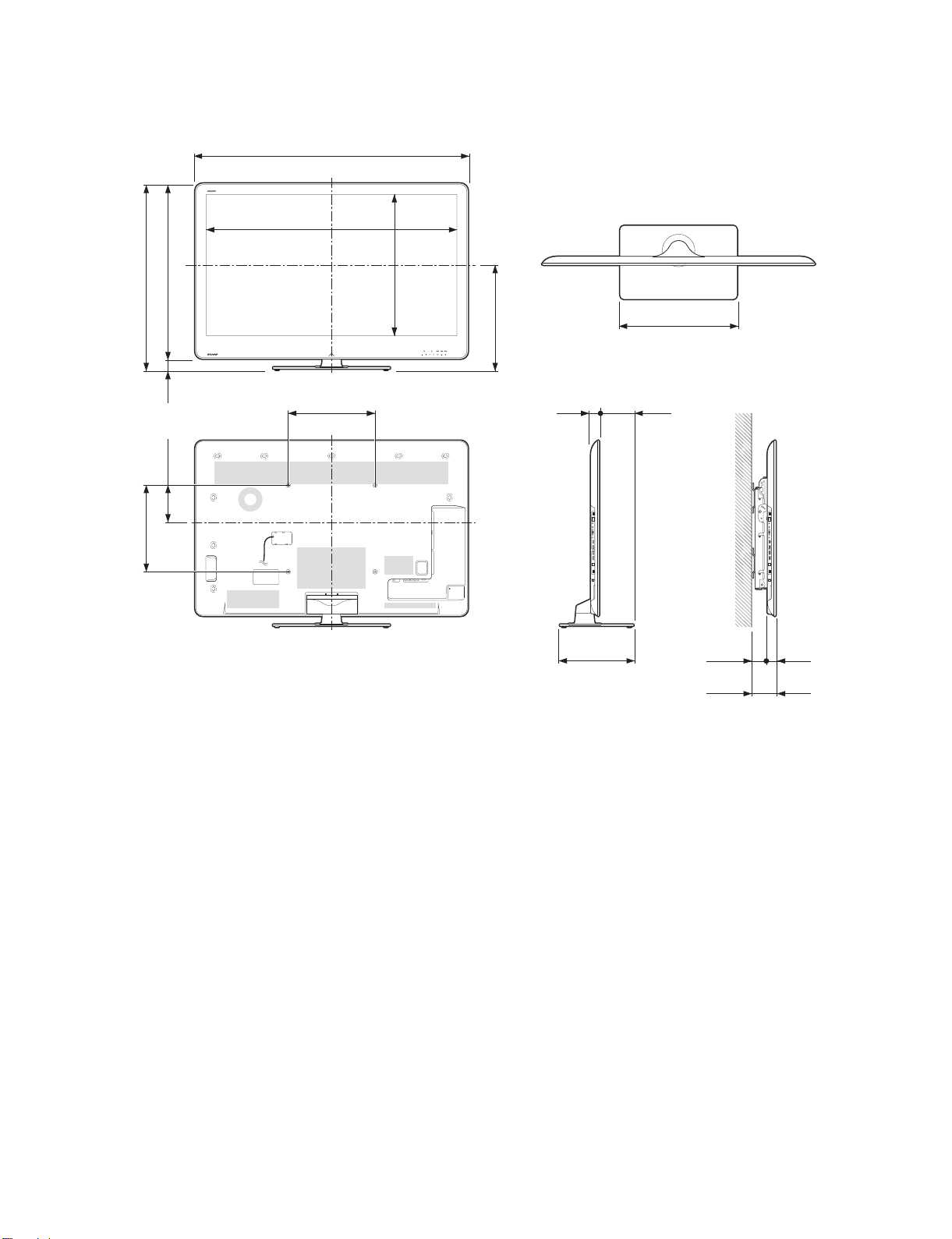

[1] DIMENSIONS (LC-40LE820UN)....................3-1

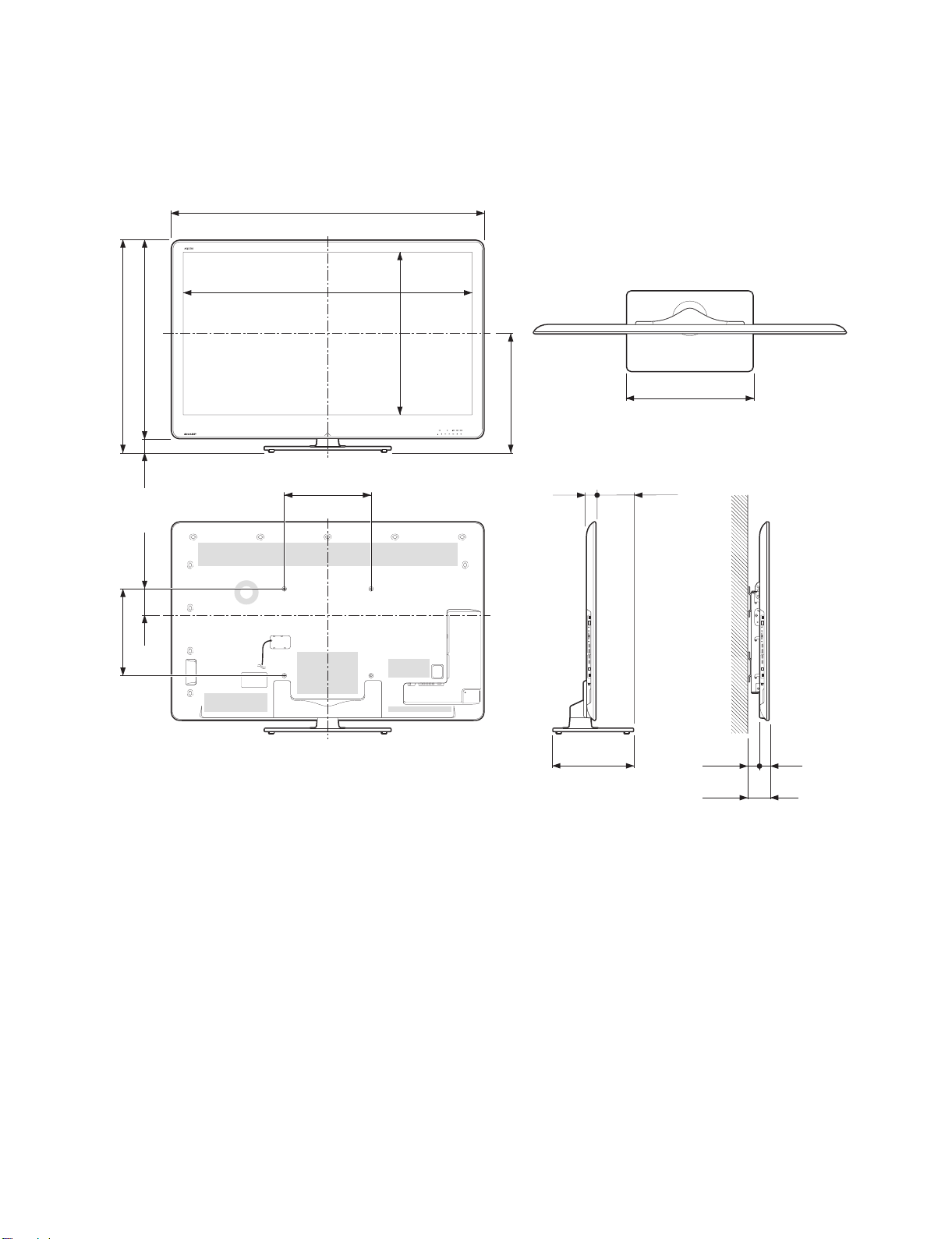

[2] DIMENSIONS (LC-46LE820UN)....................3-2

[3] DIMENSIONS (LC-52LE820UN)....................3-3

[4] DIMENSIONS (LC-60LE820UN)....................3-4

CHAPTER 4. REMOVING OF MAJOR PARTS

REMOVING OF MAJOR PARTS (LC-40LE820UN)

[1]

REMOVING OF MAJOR PARTS (LC-46LE820UN)

[2]

REMOVING OF MAJOR PARTS (LC-52LE820UN)

[3]

REMOVING OF MAJOR PARTS (LC-60LE820UN)

[4]

...............i

...........iii

........4-1

........4-6

...... 4-11

......4-16

[5] Caution Cleaning Glass...............................4-21

How to replace the touch key sensor PWB

[6]

CHAPTER 5. Enter the chapter title here.

[1] LC-40LE820UN .............................................5-1

[2] LC-46LE820UN .............................................5-2

[3] LC-52LE820UN .............................................5-3

[4] LC-60LE820UN .............................................5-4

CHAPTER 6. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE ......................6-1

[2] PUBLIC MODE SETTING PROCEDURE......6-15

CHAPTER 7. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE......................7-1

[2] LED flashing specification at the time of an

error (Center icon LED used) ......................7-14

CHAPTER 8. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS.........................8-1

CHAPTER 9. OVERALL WIRING/SYSTEM BLOCK

DIAGRAM

[1] OVERALL WIRING DIAGRAM......................9-1

[2] SYSTEM BLOCK DIAGRAM...................... ...9-2

Parts Guide

......4-23

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-40/46/52/60LE820UN

LC-40LE820UN

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: FO R CO N TI N UE D PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F7000 (250V 3.5A) (LC-40LE820UN)

F7001 (250V 3.5A) (LC-40LE820UN)

F7000 (250V 5A) (LC-46/52/60LE820UN)

F7001 (250V 5A) (LC-46/52/60LE820UN)

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

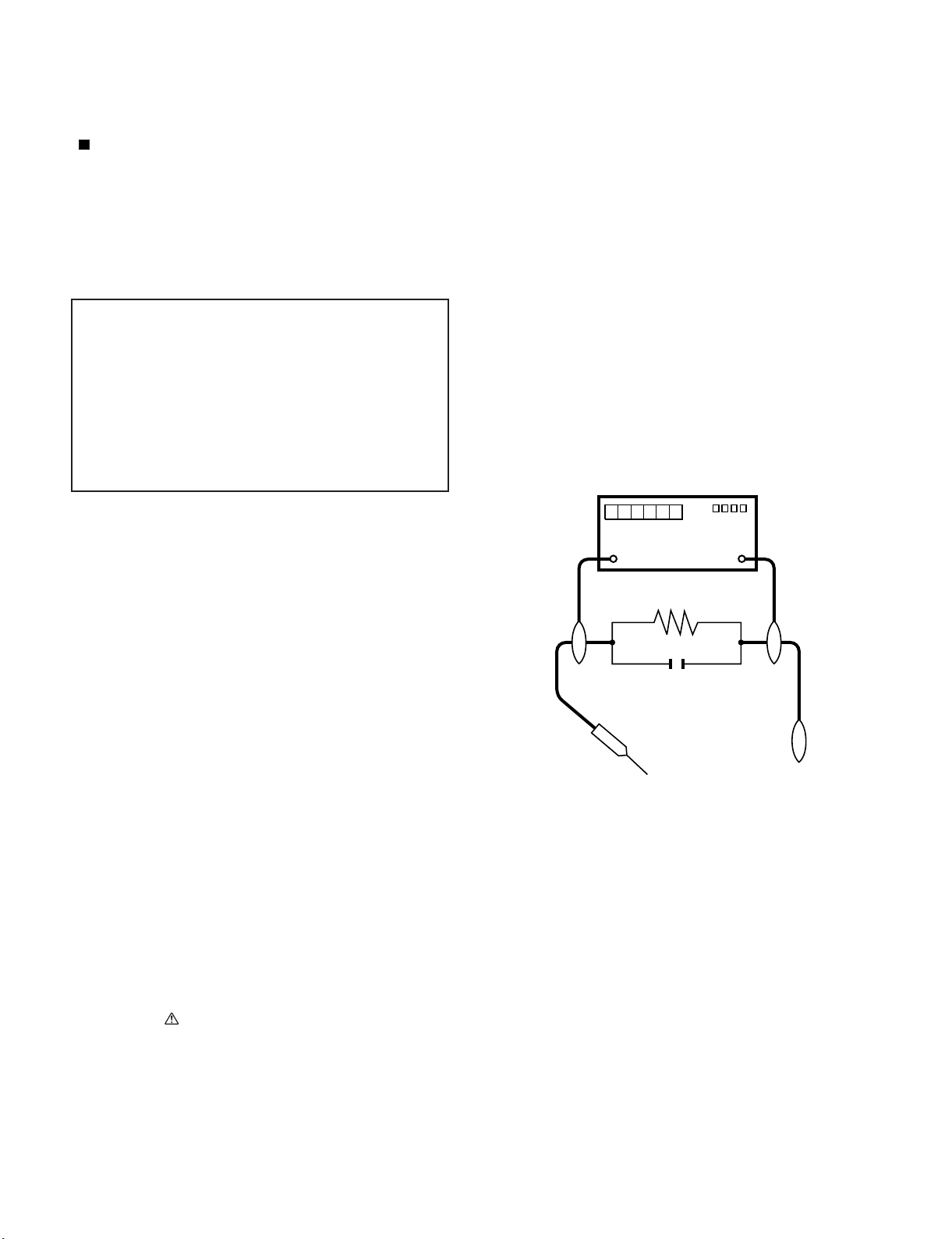

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

i

Page 3

LC-40/46/52/60LE820UN

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

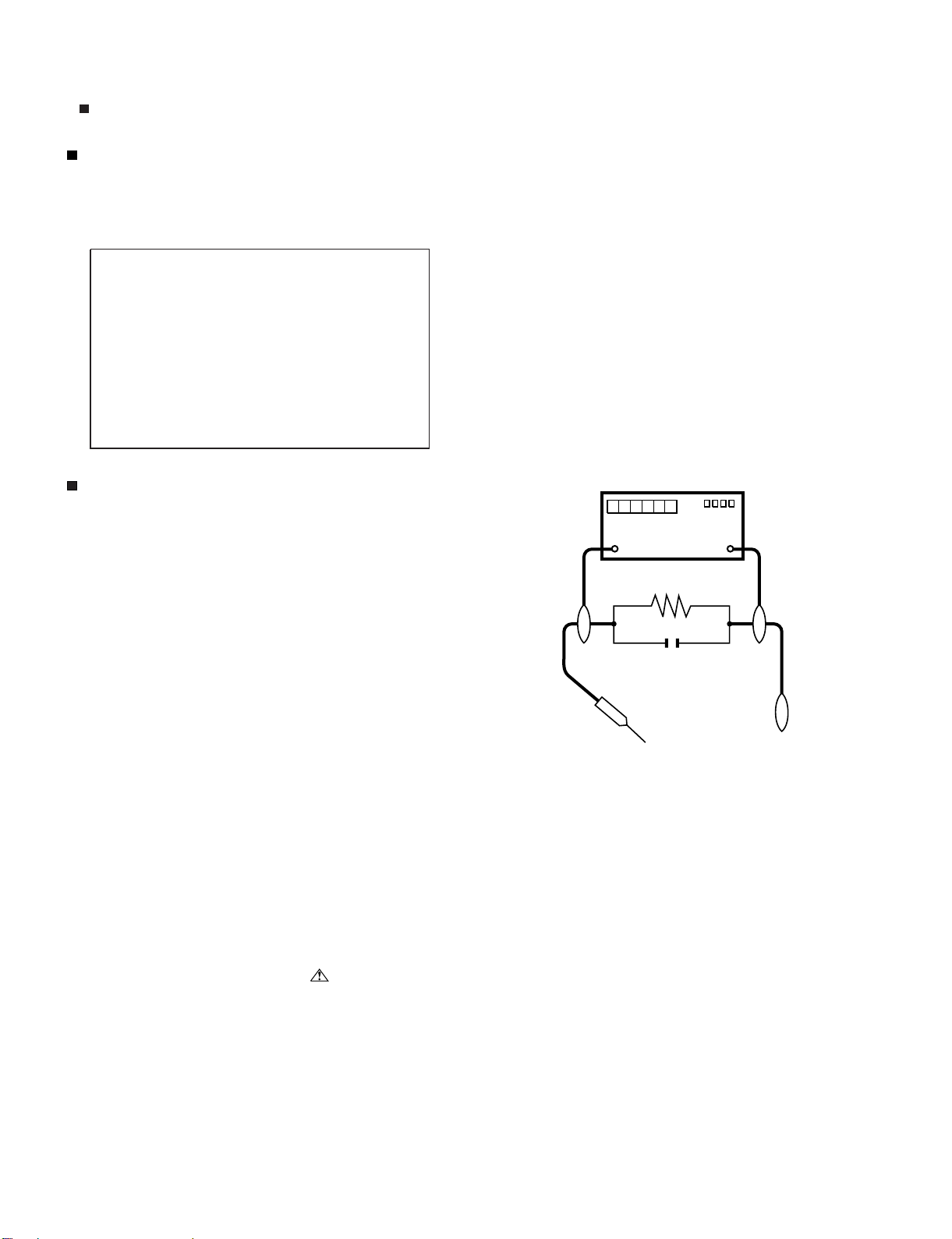

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ

AVERTISSEMENT

1.

N'entreprendre aucune modification de tout circuit. C'est dangereux.

Débrancher le récepteur avant toute réparation.

2.

PRECAUTION: POUR LA PROTECTION CONTINUE CONTRE LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F7000 (250V 3.5A) (LC-40LE820UN)

F7001 (250V 3.5A) (LC-40LE820UN)

F7000 (250V 5A) (LC-46/52/60LE820N)

F7001 (250V 5A) (LC-46/52/60LE820UN)

•

10 watts en parallèle avec un condensateur de 0.15µF en série

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pour

•

mesurer la chute de tension en travers de la résistance.

Toucher avec la sonde d'essai les pièces métalliques exposées qui

•

présentent une voie de retour au châssis (antenne, coffret métallique, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (correspondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifications suivantes.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

3.

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châssis et les autres pièces métalliques du récepteur.

Inspecter tous les dispositifs de protection comme les boutons de

4.

commande non-métalliques, les isolants, le dos du coffret, les couvercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

5.

fuite de courant, de la facon suivante:

Brancher le cordon d'alimentation directem-ent à une prise de cou-

•

rant de 120V. (Ne pas utiliser de transformateur d'isolation pour

cet essai).

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

AUX PIECES

METALLIQUES

EXPOSEES

DVM

ECHELLE CA

1.5k ohm

10W

0.15

µ

SONDE D'ESSAI

F

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur ACL présentent des caractéristiques spéciales relatives à la sécurité, qui ne sont souvent pas évidentes à vue. Le degré de protection ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incendies, radiations X ou autres accidents.

ii

Page 4

LC-40/46/52/60LE820UN

PRECAUTIONS FOR USING LEAD-FREE SOLDER

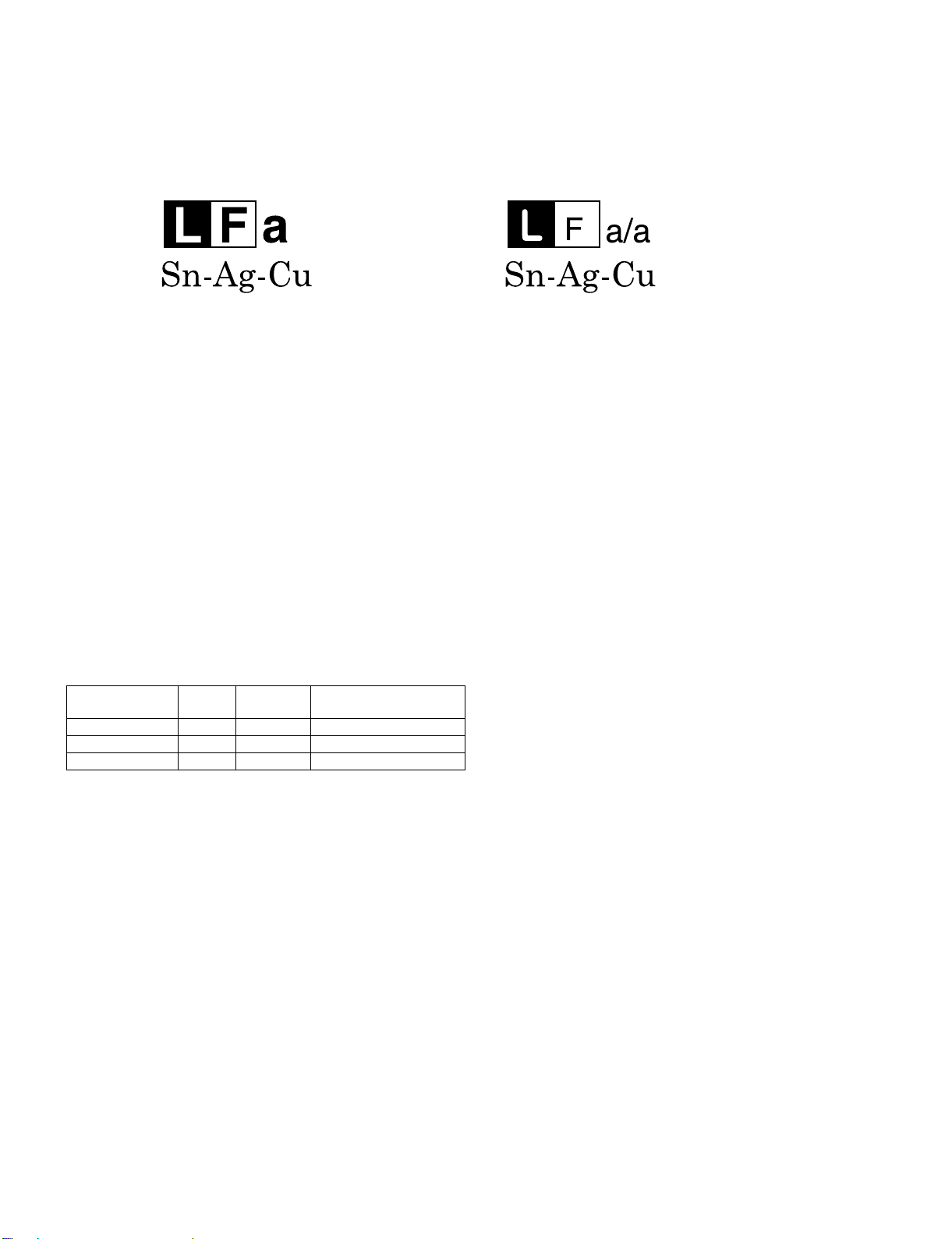

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

PARTS CODE

ZHNDAi123250E BL J φ0.3mm 250g (1roll)

ZHNDAi126500E BK J φ0.6mm 500g (1roll)

ZHNDAi12801KE BM J φ1.0mm 1kg (1roll)

PRICE

RANK

PART

DELIVERY

DESCRIPTION

iii

Page 5

LC-40LE820UN

OUTLINE

Service Manual

MAJOR SERVICE PARTS

PWB UNIT

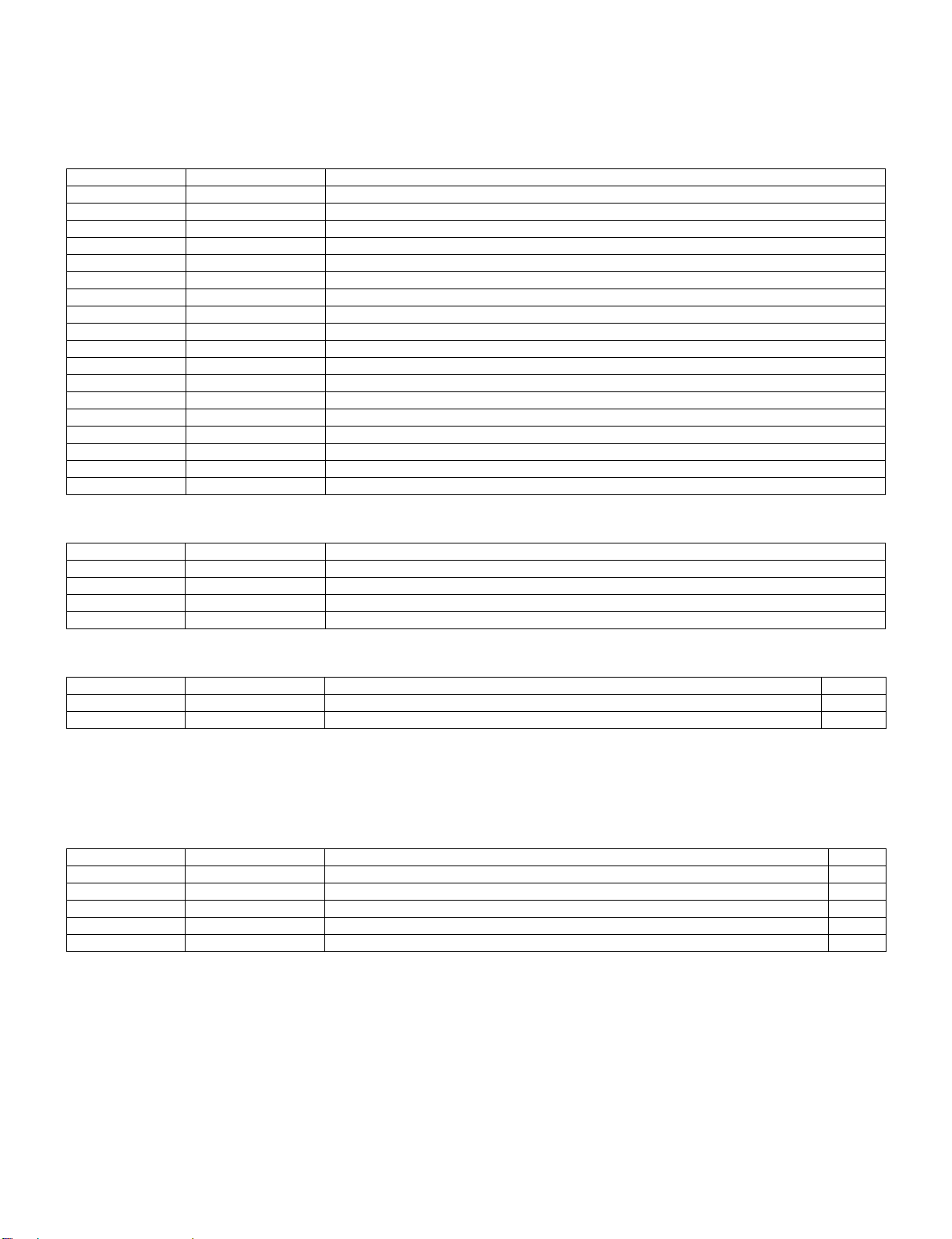

Ref No. Part No. Description

N DKEYMF452FM02 MAIN Unit *1

N DUNTKF493FM01 ICON Unit

N DUNTKF493FM02 LOGO Unit

N DUNTKF494FM01 R/C, LED Unit

N RUNTKA682WJQZ POWER/LED Drive Unit (LC-40LE820UN)

N RUNTKA683WJQZ POWER/LED Drive Unit (LC-46LE820UN)

N RUNTKA693WJQZ POWER/LED Drive Unit (LC-52LE820UN)

N RUNTKA684WJQZ POWER/LED Drive Unit (LC-60LE820UN)

N RUNTKA690WJQZ TOUCH SENSOR Unit *2

N RUNTK4437TPZZ LCD CONTROL Unit (LC-40LE820UN)

N RUNTK4437TPZA LCD CONTROL Unit (LC-46LE820UN)

N RUNTK4437TPZB LCD CONTROL Unit (LC-52LE820UN)

N RUNTK4437TPZC LCD CONTROL Unit (LC-60LE820UN)

N RUNTK4462TPZZ LED PWB Unit (LC-40LE820UN), x4

N RUNTK4461TPZZ LED PWB Unit (LC-46LE820UN), x4

N RUNTK4460TPZZ LED PWB Unit (LC-52LE820UN), x4

N RUNTK4458TPZZ LED PWB Unit (LC-60LE820UN), x4

N RUNTK4459TPZZ LED PWB Unit (LC-60LE820UN), x4

LC-40/46/52/60LE820UN

OTHER UNIT

Ref No. Part No. Description

N R1LK400D3LWF0Z 40” LCD Panel Module Unit

N R1LK460D3LWA0Z 46” LCD Panel Module Unit

N R1LK520D3LWA0Z 52” LCD Panel Module Unit

N R1LK600D3LW20Z 60” LCD Panel Module Unit

IC FOR EXCLUSIVE USE OF THE SERVICE

Ref No. Part No. Description Q'ty

IC509 VHiR24002AS1YS R1EX24002ASAS0A (RGB EDID) 1

IC2002 RH-iXC786WJNHQ R5F364A6NFB (MICON) 1

NOTE: *1 Replace MAIN PWB Units (DKEYMF452FM02) in case of IC8455, IC8401 or IC3302 failure.

*2 TOUCH SENSOR Unit (RUNTKA690WJQZ) reuse will be impossible, once it is stuck on front glass and exfoliates.

Therefore, please exchange of a touch sensor unit in the case of front glass exchange.

SERVICE JIGS

Ref No. Part No. Description Q'ty

N QCNW-C222WJQZ Connecting Cord L=1000mm 80pin LCD Control to LCD Panel Unit x2 2

N QCNW-H184WJQZ Connecting Cord L=1000mm 12pin Main to Power Unit (PD) 1

N QCNW-F676WJQZ Connecting Cord L=1000mm 41pin Main to LCD Control (LW) 1

N QCNW-G405WJQZ Connecting Cord L=1000mm 4pin Main to LCD Control (PL) 1

N QCNW-G394WJQZ Connecting Cord L=1000mm 9pin Main to Power (LB) 1

iv

Page 6

LC-40/46/52/60LE820UN

LC-40LE820UN

CHAPTER 1. SPECIFICATIONS

Service Manual

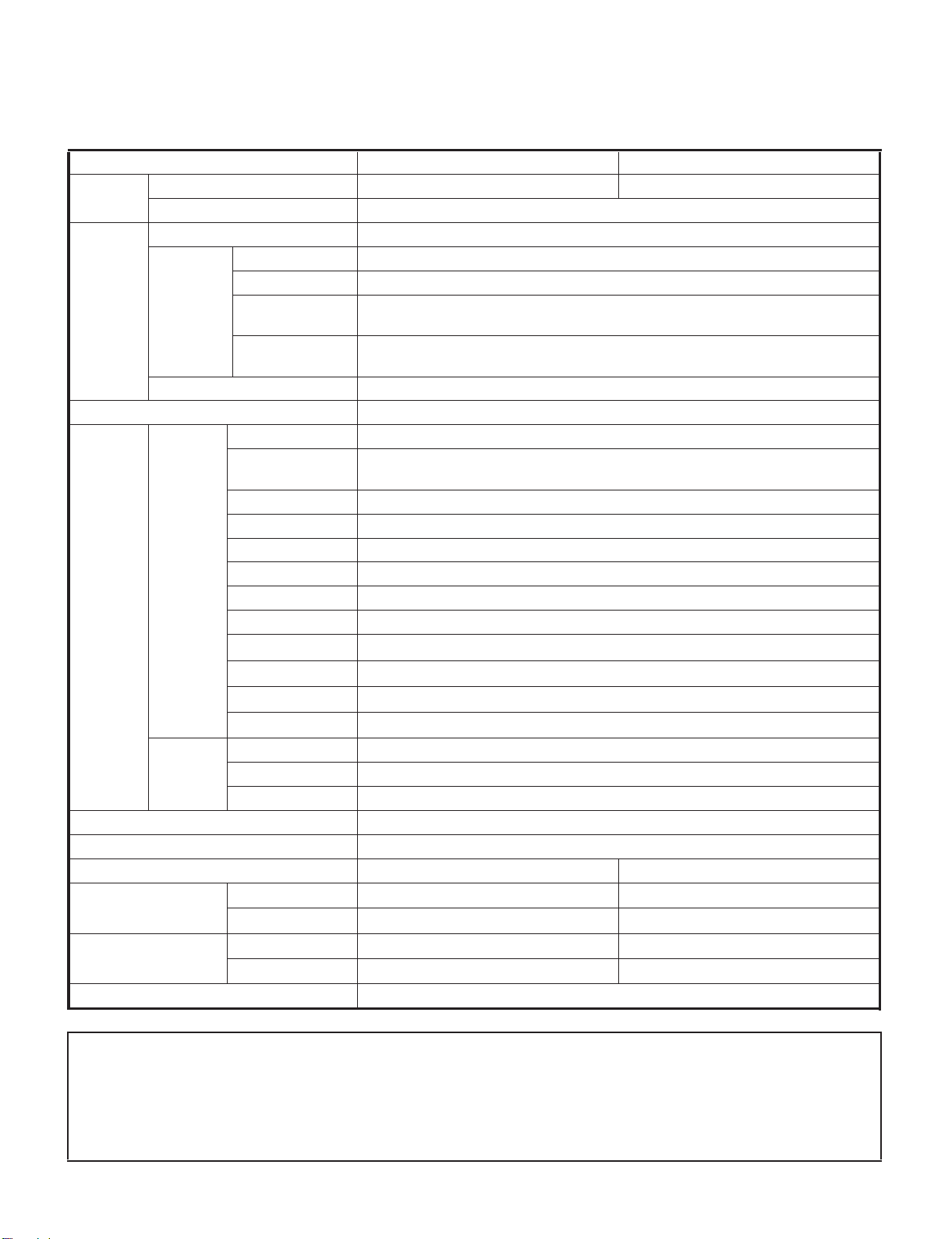

[1] SPECIFICATIONS (LC-40/46LE820UN)

Item Model: LC-40LE820UN Model: LC-46LE820UN

LCD

panel

Size 40" Class (40" Diagonal) 46" Class (45

Resolution 2,073,600 pixels (1,920 x 1,080)

TV-standard (CCIR) American TV Standard ATSC/NTSC System

VHF/UHF VHF 2-13ch, UHF 14-69ch

CATV 1-135ch (non-scrambled channel only)

TV

Function

Receiving

Channel

Digital Terrestrial

Broadcast (8VSB)

Digital cable

*1

(64/256 QAM)

2-69ch

1-135ch (non-scrambled channel only)

Audio multiplex BTSC System

Audio out 10W x 2 +15W (WF)

INPUT 2 AV in (AV mini plug and RCA plugs)

INPUT 3

ANALOG RGB (PC) in (15-pin mini D-sub female connector),

Audio in (Ø 3.5 mm stereo jack)

INPUT 4 HDMI in with HDCP, Audio in (Ø 3.5 mm stereo jack)

INPUT 5 HDMI in with HDCP

INPUT 6 HDMI in with HDCP

Back panel

vertical

inputs

Terminals

INPUT 7 HDMI in with HDCP

AUDIO IN Audio in (Ø 3.5 mm stereo jack)

AUDIO OUT Audio out (Ø 3.5 mm stereo jack)

DIGITAL AUDIO OUTPUT

Optical Digital audio output x 1 (PCM/Dolby Digital)

ETHERNET Network connector

USB 1 Photo/Music mode, Software update

USB 2 Photo/Music mode, Software update

Back panel

horizontal

inputs

INPUT 1 COMPONENT in

ANT/CABLE

75 Ω Unbalance, F Type x 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

RS-232C 9-pin D-sub male connector

OSD language English/French/Spanish

Power Requirement AC 120 V, 60 Hz

Power Consumption 140 W (0.5 W Standby with AC 120 V) 160 W (0.5 W Standby with AC 120 V)

TV + stand 51.8 lbs./23.5 kg 66.1 lbs./30.0 kg

Weight

TV only 43.0 lbs./19.5 kg 54.0 lbs./24.5 kg

Dimension

*2

(W x H x D)

Operating temperature

TV + stand

TV only

393/32x2727/32x1027/32inch

393/32x2561/64x135/64inch

+32°Fto+104°F(0°Cto+40°C)

443/8x3059/64x1325/64inch

443/8x2829/32x135/64inch

63

/64" Diagonal)

Cautions regarding use in high and low temperature environments

When the unit is used in a low temperature space (e.g. room, office), the picture may leave trails or appear slightly delayed.

•

This is not a malfunction, and the unit will recover when the temperature returns to normal.

Do not leave the unit in a hot or cold location. Also, do not leave the unit in a location exposed to direct sunlight or near a

•

heater, as this may cause the cabinet to deform and the Liquid Crystal panel to malfunction.

Storage temperature: − 4°F to e140°F (−20°C to +60°C)

1 – 1

Page 7

LC-40/46/52/60LE820UN

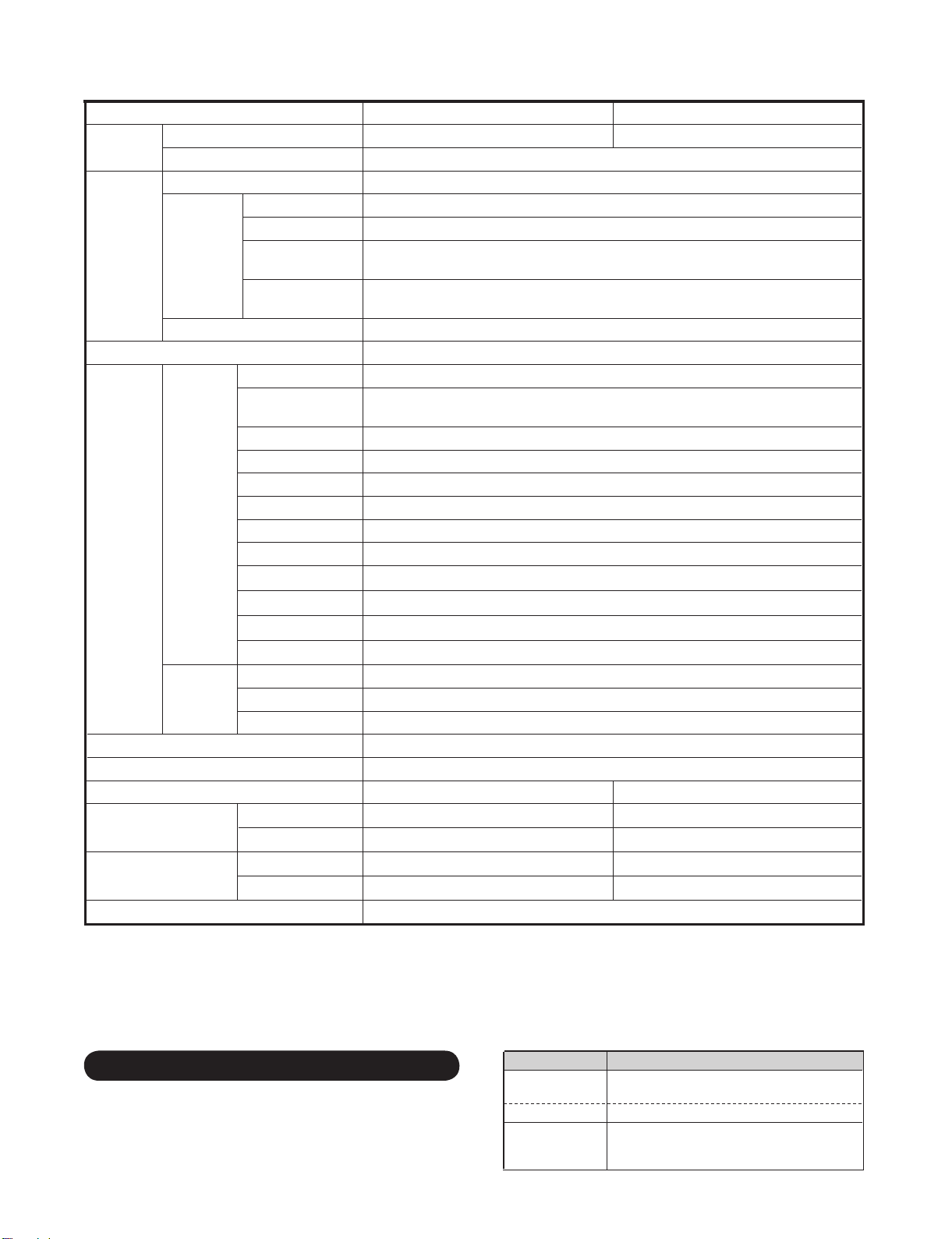

[2] SPECIFICATIONS (LC-52/60LE820UN)

Item Model: LC-52LE820UN Model: LC-60LE820UN

LCD

panel

Size 52" Class (52

Resolution 2,073,600 pixels (1,920 x 1,080)

TV-standard (CCIR) American TV Standard ATSC/NTSC System

VHF/UHF VHF 2-13ch, UHF 14-69ch

CATV 1-135ch (non-scrambled channel only)

TV

Function

Receiving

Channel

Digital Terrestrial

Broadcast (8VSB)

Digital cable

*1

(64/256 QAM)

2-69ch

1-135ch (non-scrambled channel only)

Audio multiplex BTSC System

Audio out 10W x 2 + 15 W (WF)

INPUT 2 AV in (AV mini plug and RCA plugs)

INPUT 3

ANALOG RGB (PC) in (15-pin mini D-sub female connector),

Audio in (Ø 3.5 mm stereo jack)

INPUT 4 HDMI in with HDCP, Audio in (Ø 3.5 mm stereo jack)

INPUT 5 HDMI in with HDCP

INPUT 6 HDMI in with HDCP

Back panel

vertical

inputs

Terminals

INPUT 7 HDMI in with HDCP

AUDIO IN Audio in (Ø 3.5 mm stereo jack)

AUDIO OUT Audio out (Ø 3.5 mm stereo jack)

DIGITAL AUDIO OUTPUT

Optical Digital audio output x 1 (PCM/Dolby Digital)

ETHERNET Network connector

USB 1 Photo/Music mode, Software update

USB 2 Photo/Music mode, Software update

Back panel

horizontal

inputs

INPUT 1 COMPONENT in

ANT/CABLE

75 Ω Unbalance, F Type x 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

RS-232C 9-pin D-sub male connector

OSD language English/French/Spanish

Power Requirement AC 120 V, 60 Hz

Power Consumption 170 W (0.5 W Standby with AC 120 V) 230 W (0.5 W Standby with AC 120 V)

Weight

Dimension

*2

(WxHxD)

Operating temperature

*1

Emergency alert messages via Cable are unreceivable.

*2

The dimensional drawings are shown on the inside back cover.

TV + stand 77.2 lbs./35.0 kg 112.4 lbs./51.0 kg

TV only 66.1 lbs./30.0 kg 89.3 lbs./40.5 kg

TV+stand

TV only

495/8x3329/32x1325/64inch

495/8x3115/16x135/64inch

+ 32°F to + 104°F (0°C to + 40°C)

• As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for

product improvement without prior notice. The performance specification figures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

1

/32" Diagonal) 60" Class (601/32" Diagonal)

5621/32x3825/64x141/2inch

5621/32x3561/64x137/64inch

Optional Accessory

The listed optional accessory is available for the Liquid

Crystal Television. Please purchase it at your nearest shop.

• Additional optional accessories may be available in the near

future. When purchasing, please read the newest catalogue for

compatibility and check the availability.

1 – 2

Part name Model number

Wall mount

bracket

AN-37AG2 (for LC-40LE820UN)

Attachment AN-37P30 (for LC-40LE820UN)

Wall mount

bracket

AN-52AG4

(for LC-46LE820UN/LC-52LE820UN/

LC-60LE820UN)

Page 8

LC-40/46/52/60LE820UN

LC-40LE820UN

CHAPTER 2. OPERATION MANUAL

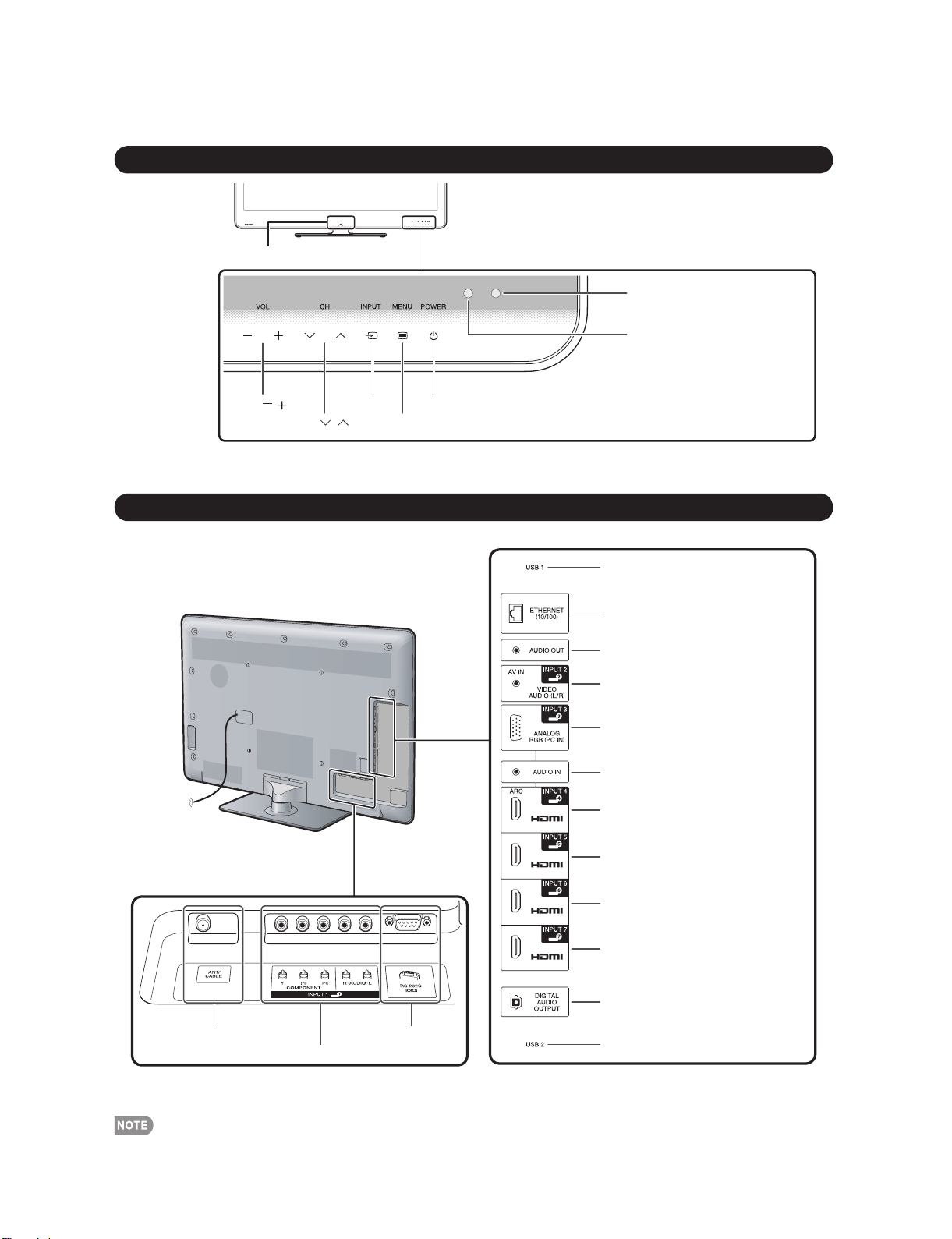

[1] Parts Name

TV (Front)

Center Icon illumination

Service Manual

Remote control sensor

OPC sensor *1

TV (Rear)

VOL /

CH /

POWER *2INPUT

MENU

*1 OPC: Optical Picture Control.

*2 Using the touch sensor panel.

*1

USB 1 terminal

ETHERNET terminal

AUDIO OUT terminal

INPUT 2 terminal

INPUT 3 terminal (PC-IN)

AUDIO IN terminal

(shared for INPUT 3 and INPUT 4) *2

INPUT 4 terminal (HDMI)

ARC: Audio Return Channel

INPUT 5 terminal (HDMI)

*1

INPUT 6 terminal (HDMI)

INPUT 7 terminal (HDMI)

DIGITAL AUDIO OUTPUT terminal

RS-232C terminalAntenna/Cable in

INPUT 1 terminals

*1 External equipment connection.

*2 Details on the Audio Select function.

• The illustrations in this operation manual are for explanation purposes and may vary slightly from the actual operations.

• The examples used throughout this manual are based on the LC-52LE820UN model.

USB 2 terminal

2 – 1

Page 9

LC-40/46/52/60LE820UN

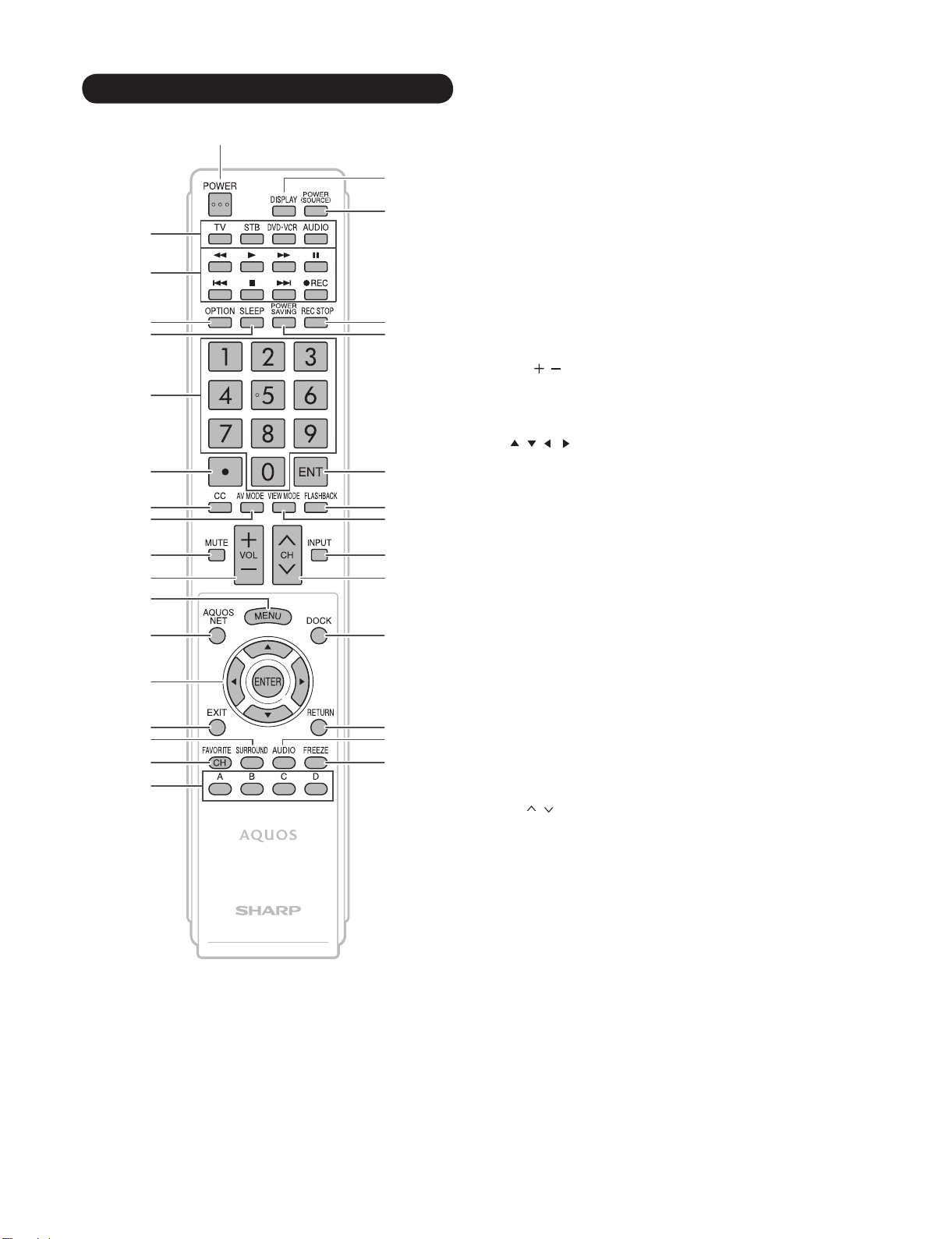

Remote Control Unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

1 POWER: Switch the TV power on or enter standby.

2TV,STB,DVD•VCR,AUDIO: Switches the remote control for

TV, STB, DVD, BD, VCR and AUDIO operation.

* To enter the code registration mode, you need to press an

appropriate button (STB,DVD•VCR or AUDIO)andDISPLAY

at the same time.

3 External equipment operational buttons: Operate the external

equipment.

4 OPTION: Display the Link Operation Menu screen. This button

will function only when AQUOS LINK is used.

5 SLEEP: Set the sleep timer.

0–9: Set the channel.

6

7

•(DOT)

8CC:Display captions from a closed-caption source.

9 AV MODE: Select an audio or video setting.

10 MUTE: Mute the sound.

11 VOL / : Set the volume.

12 MENU: Display the menu screen.

13 AQUOS NET: Switches the display to the Sidebar Widget,

TV+Web, Web or TV screen.

14

///,ENTER: Select a desired item on the screen.

15 EXIT: Turn off the menu screen.

16 SURROUND: Select Surround settings.

17 FAVORITE CH: Set the favorite channels.

18 A, B, C, D: Select 4 preset favorite channels in 4 different

categories.

While watching, you can toggle the selected channels by pressing

A,B,C and D.

19 DISPLAY: Display the channel information.

20 POWER (SOURCE): Turns the power of the external equipment

on and off.

21 REC STOP: Stops one touch recording. This button will function

only when AQUOS LINK is used.

22 POWER SAVING: Select Power Saving settings.

23 ENT: Jumps to a channel after selecting with the 0–9 buttons.

24 FLASHBACK: Return to the previous channel or external input

mode.

25 VIEW MODE: Select the screen size.

26 INPUT: Select a TV input source. (TV, INPUT 1, INPUT 2, INPUT 3,

INPUT 4, INPUT 5, INPUT 6, INPUT 7)

27 CH / : Select the channel.

28 DOCK:

29

30 AUDIO: Selects the MTS/SAP or the audio mode during multi-

31 FREEZE: Set the still image. Press again to return to normal

Display the DOCK.

RETURN: Return to the previous menu screen.

channel audio broadcasts.

screen.

2 – 2

Page 10

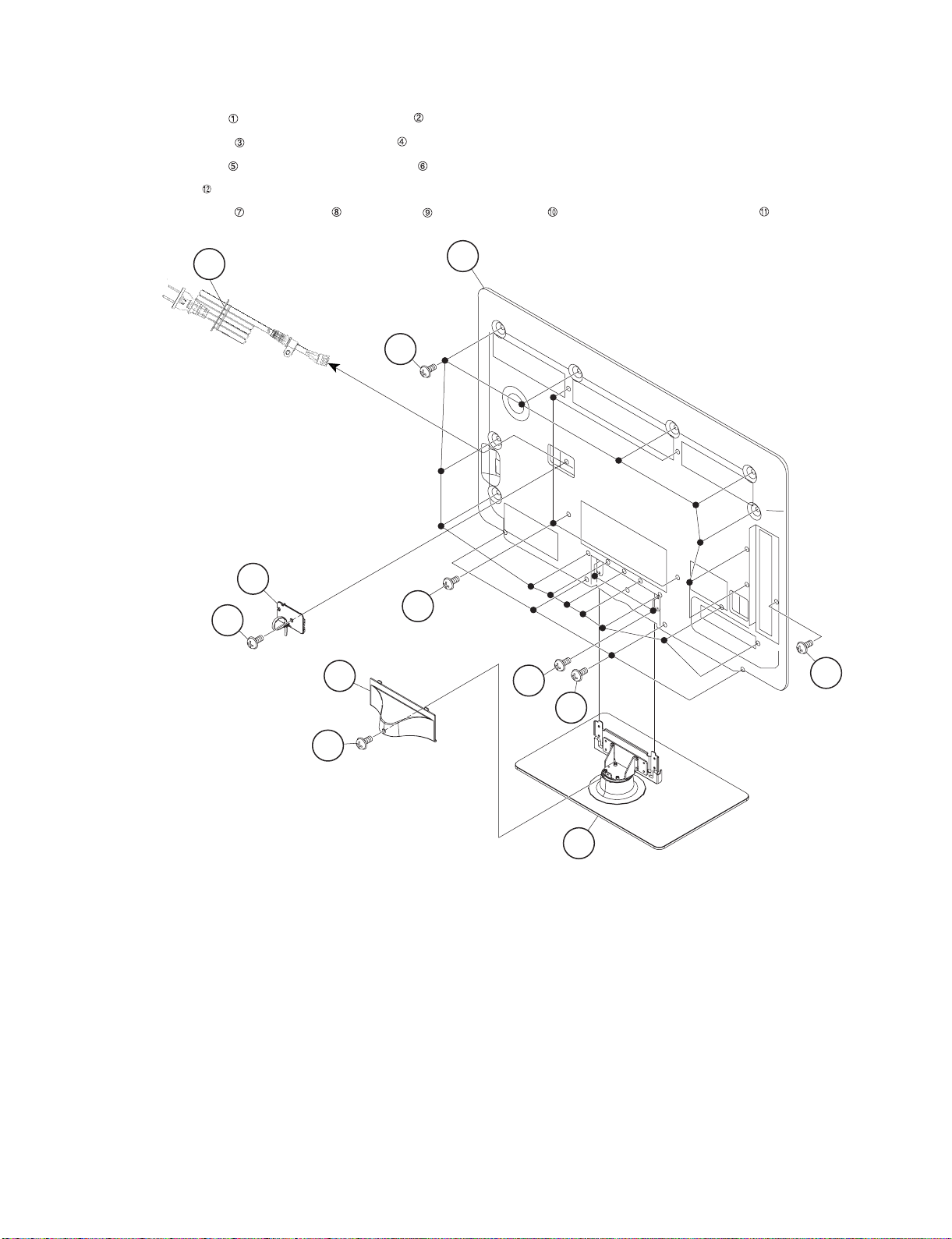

LC-40/46/52/60LE820UN

[2] OPERATION MANUAL

QUICK REFERENCE

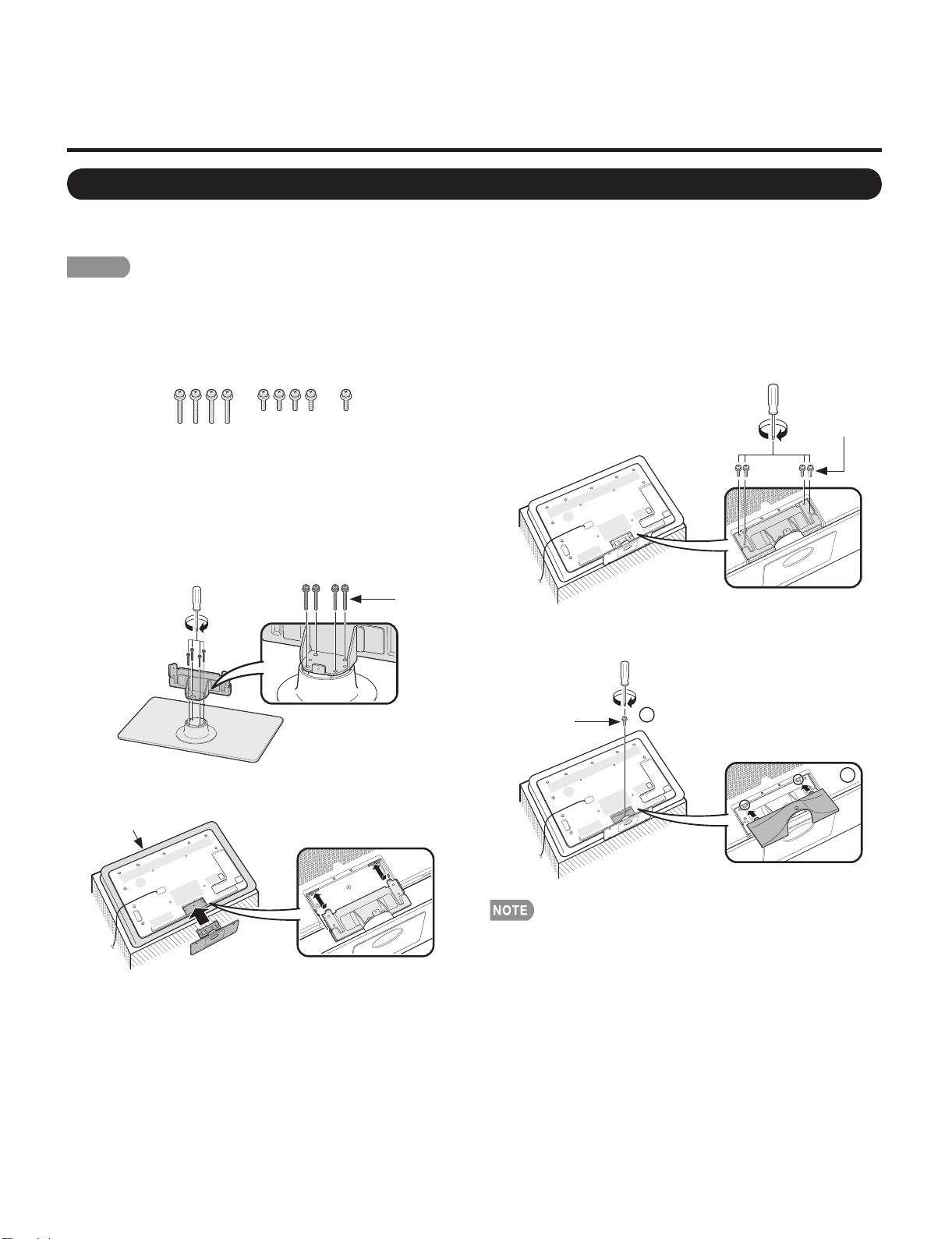

Attaching the Stand

• Before attaching (or detaching) the stand, unplug the AC cord.

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from being damaged.

CAUTION

• Attach the stand in the correct direction.

• Do not remove the stand from the TV unless using an optional wall mount bracket to mount it.

• Be sure to follow the instructions. Incorrect installation of the stand may result in the TV falling over.

Confirm that there are 9 screws (5 short screws

1

and 4 long screws) supplied with the stand unit.

Attach the supporting post for the stand unit onto

2

the base using the box for the stand unit as shown

below.

The supporting post attaches to the base at an off-

•

centered location on the base. Be sure to attach the

supporting post in the direction indicated below and

attach the stand to the TV with the wider side of the

base facing forward.

Long screws

Insert the stand into the openings on the rear of the

3

TV.

Soft cushion

Insert and tighten the 4 screws into the 4 holes on

4

the rear of the stand unit.

Insert the stand cover.

1

5

Insert the screw to secure the stand cover.

2

Short screw

2

Short screws

1

2 – 3

• To detach the stand, perform the steps in reverse

order.

Page 11

LC-40LE820UN

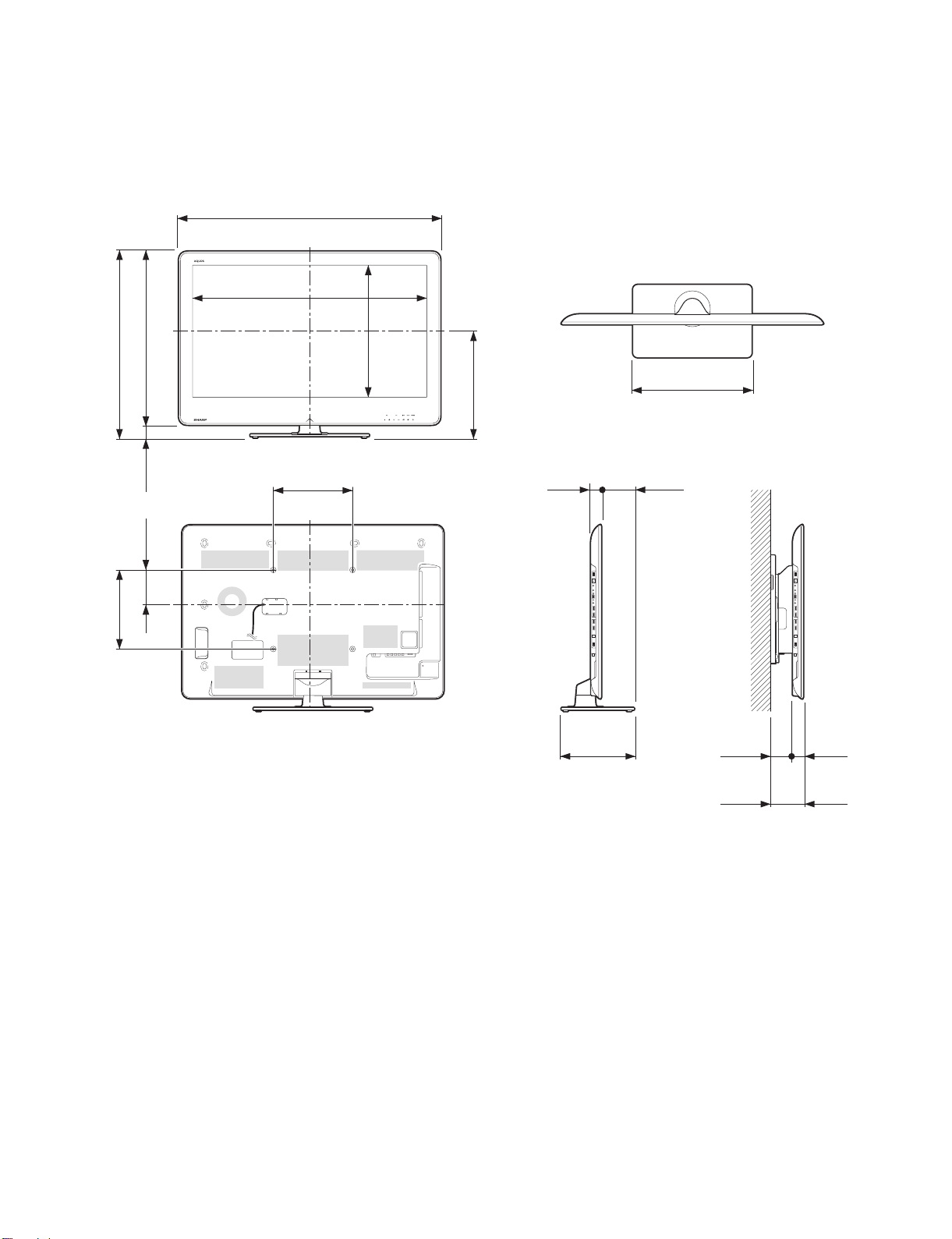

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS (LC-40LE820UN)

LC-40/46/52/60LE820UN

Service Manual

Unit: inch (mm)

(707)

32

/

27

27

64

/

57

1

64

/

13

5

(300)

16

/

13

11

(659)

64

/

61

25

(48)

(132)

351/

(890.6)

16

393/

1113/

32

16

(993)

16

/

13

19

(300)

(503.2)

(404)

64

/

59

15

135/

(39)

64

1747/

459/

(125)

64

64

(450)

AN-37P30

+

AN-37AG2

1027/

(275)

32

35/

(84)

427/

(123)

16

32

135/

(39)

64

3 – 1

Page 12

LC-40/46/52/60LE820UN

[2] DIMENSIONS (LC-46LE820UN)

Unit: inch (mm)

(785)

64

/

59

30

64

/

1

2

16

/

5

8

(400)

4

/

3

15

(734)

32

/

29

28

(51)

(211)

4019/

(1023.4)

64

443/

153/

(1127)

8

(400)

4

3

4

/

22

(577.6)

(444)

64

/

31

17

135/

(39)

64

2117/

615/

(158)

64

(540)

64

AN-52AG4

1325/

(340)

64

241/

(67)

411/

(106)

64

64

135/

(39)

64

3 – 2

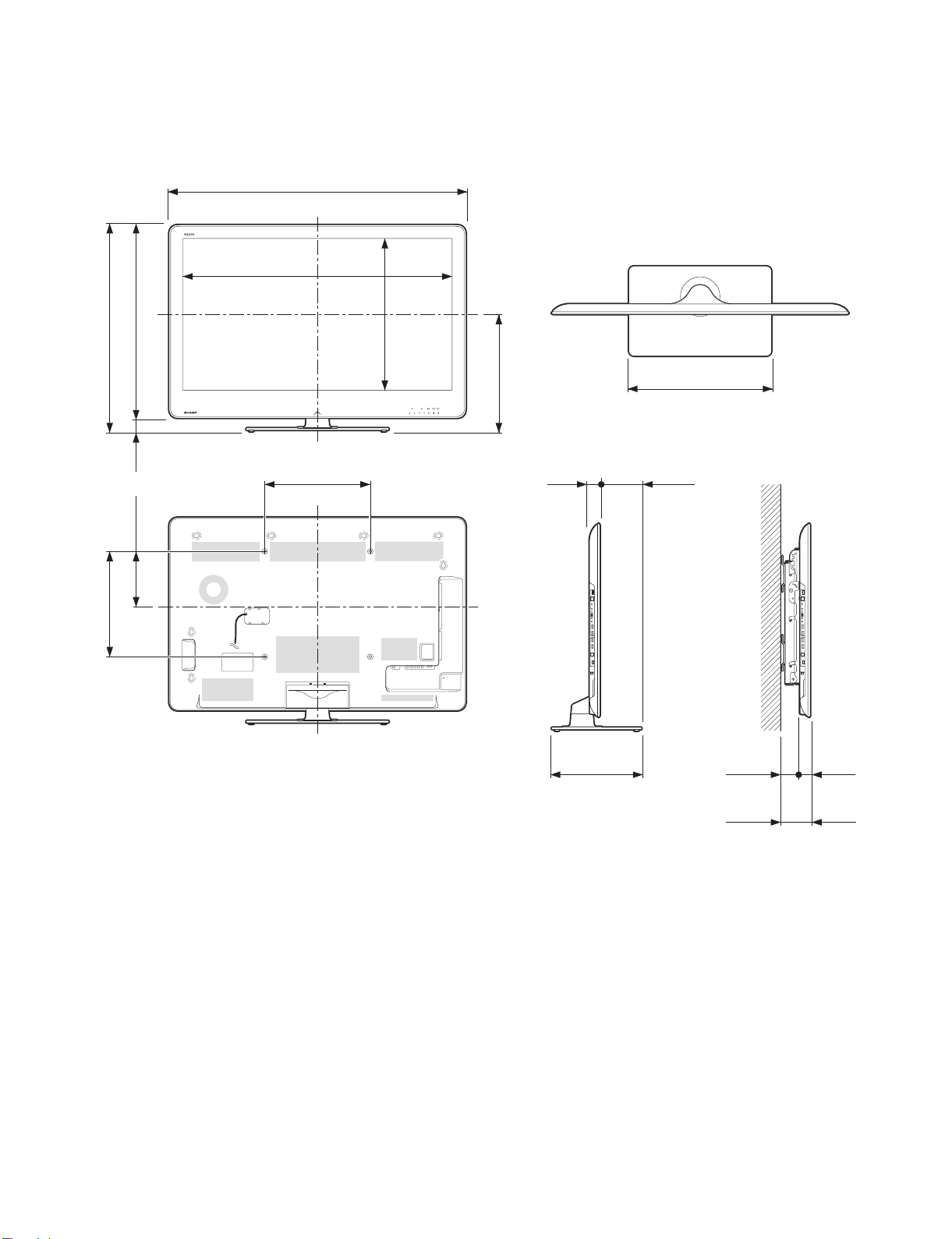

Page 13

[3] DIMENSIONS (LC-52LE820UN)

495/

(1260)

8

459/

(1157)

16

(861)

(811)

32

16

/

/

29

15

33

31

64

/

63

25

1

32

/

6

(50)

(172)

153/

(400)

4

23

32

/

25

(653)

(484)

16

/

1

19

135/

(39)

LC-40/46/52/60LE820UN

Unit: inch (mm)

2117/

(540)

64

64

615/

(158)

64

AN-52AG4

(400)

4

/

3

15

1325/

(340)

241/

64

64

(67)

411/

64

135/

(39)

64

(106)

3 – 3

Page 14

LC-40/46/52/60LE820UN

[4] DIMENSIONS (LC-60LE820UN)

Unit: inch (mm)

(975)

64

/

25

38

64

/

29

2

64

/

49

4

(400)

4

/

3

15

(913)

64

/

61

35

(62)

(121)

5217/

(1334.2)

32

5621/

153/

32

4

(400)

(1439)

64

/

41

29

(752.6)

(546)

2

/

1

21

137/

(40)

2227/

64

655/

(174)

(580)

32

64

AN-52AG4

141/

(368)

2

241/

(67)

47/

32

137/

64

64

(40)

(107)

3 – 4

Page 15

LC-40/46/52/60LE820UN

LC-40LE820UN

CHAPTER 4. REMOVING OF MAJOR PARTS

Service Manual

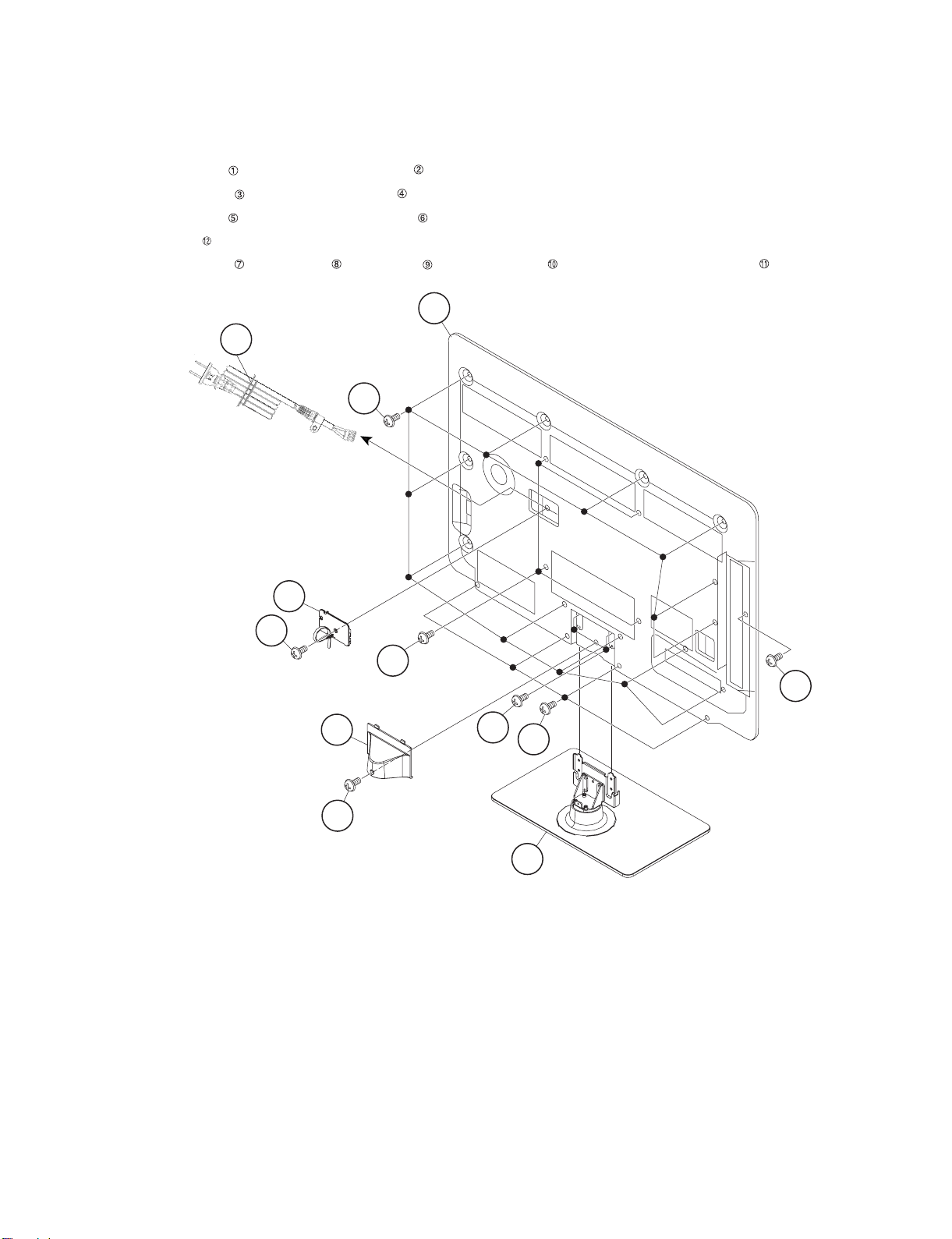

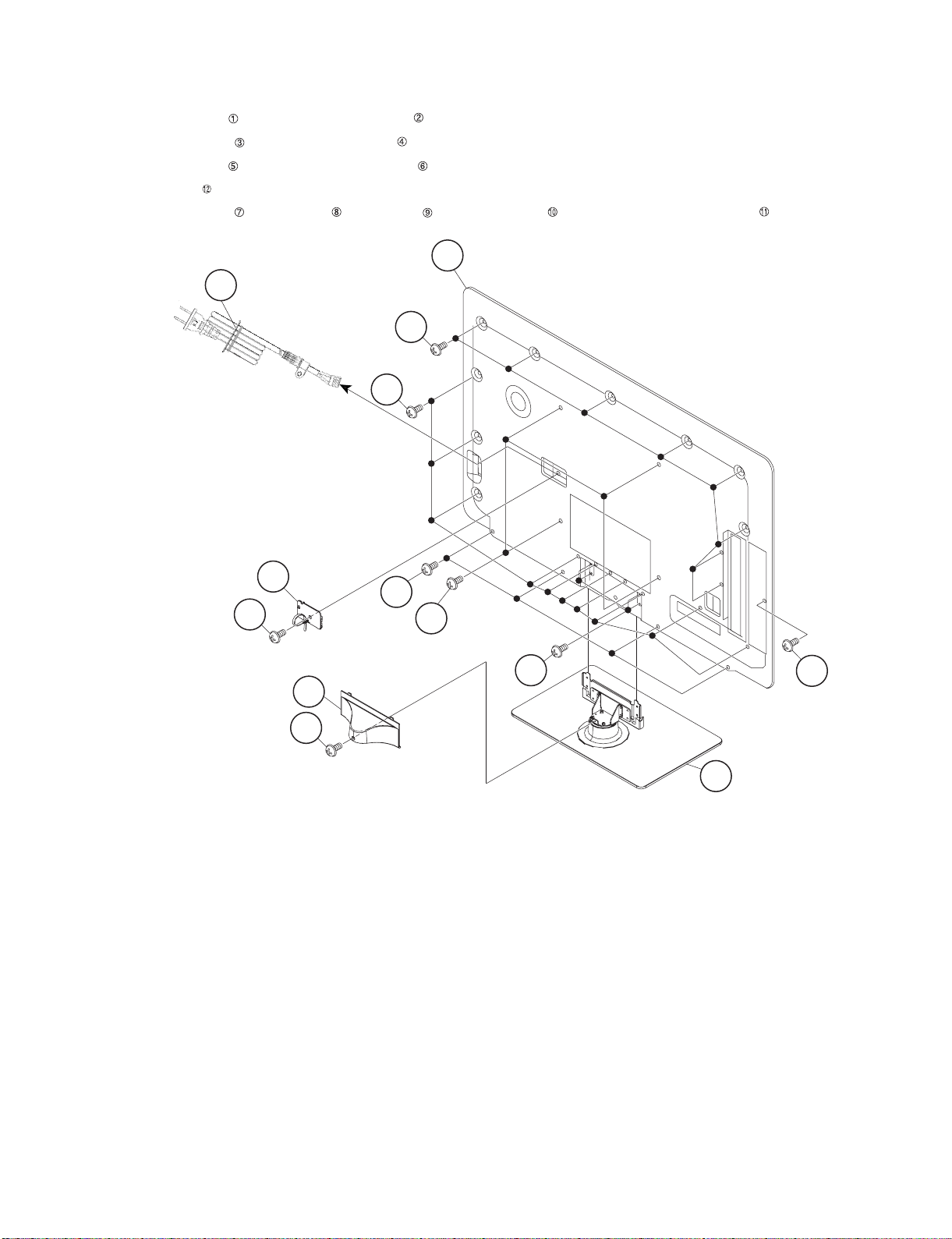

[1] REMOVING OF MAJOR PARTS (LC-40LE820UN)

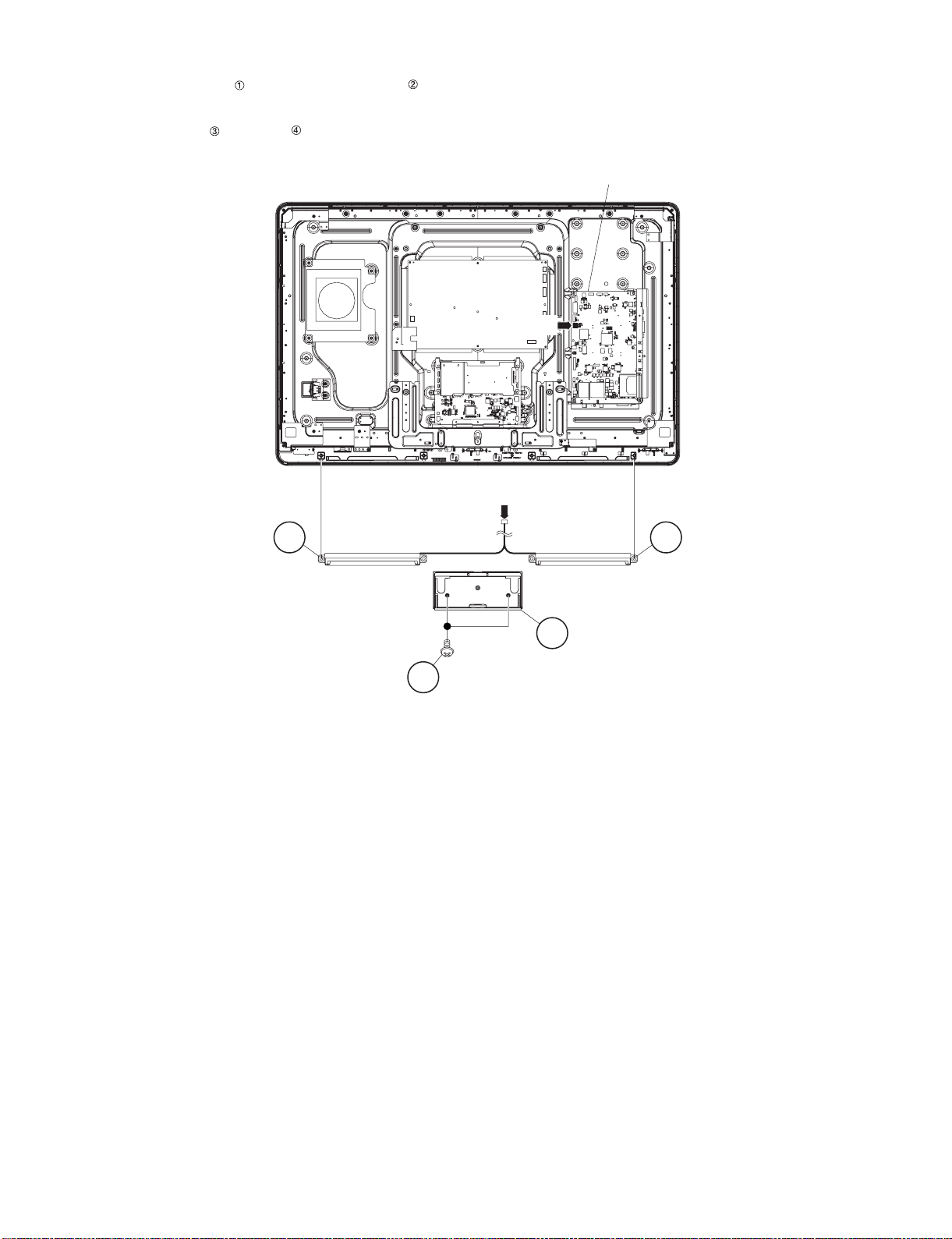

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 1 lock screw and detach the Support Cover .

2. Remove the 4 lock screws and detach the Stand Unit .

3. Remove the 1 lock screw and detach the AC Cord Cover .

4. Disconnect AC Cord .

5. Remove the 4 lock screws , 4 lock screws , 1 lock screw and 12 lock screws and detach the Rear Cabinet Ass’y .

Rear Cabinet Ass'y

11

AC Cord

12

10

6AC Cord Cover

5

7

9

2Support Cover

3

8

1

4Stand Unit

4 – 1

Page 16

LC-40/46/52/60LE820UN

2. Removing of Speaker-L/R.

1. Remove the 1 lock screw and detach the Stand Cover .

2. Disconnect SP wire.

3. Detach the Speaker-L , Speaker-R .

MAIN Unit

[SP]

[SP]

4Speaker-R 3 Speaker-L

2 Stand Cover

1

4 – 2

Page 17

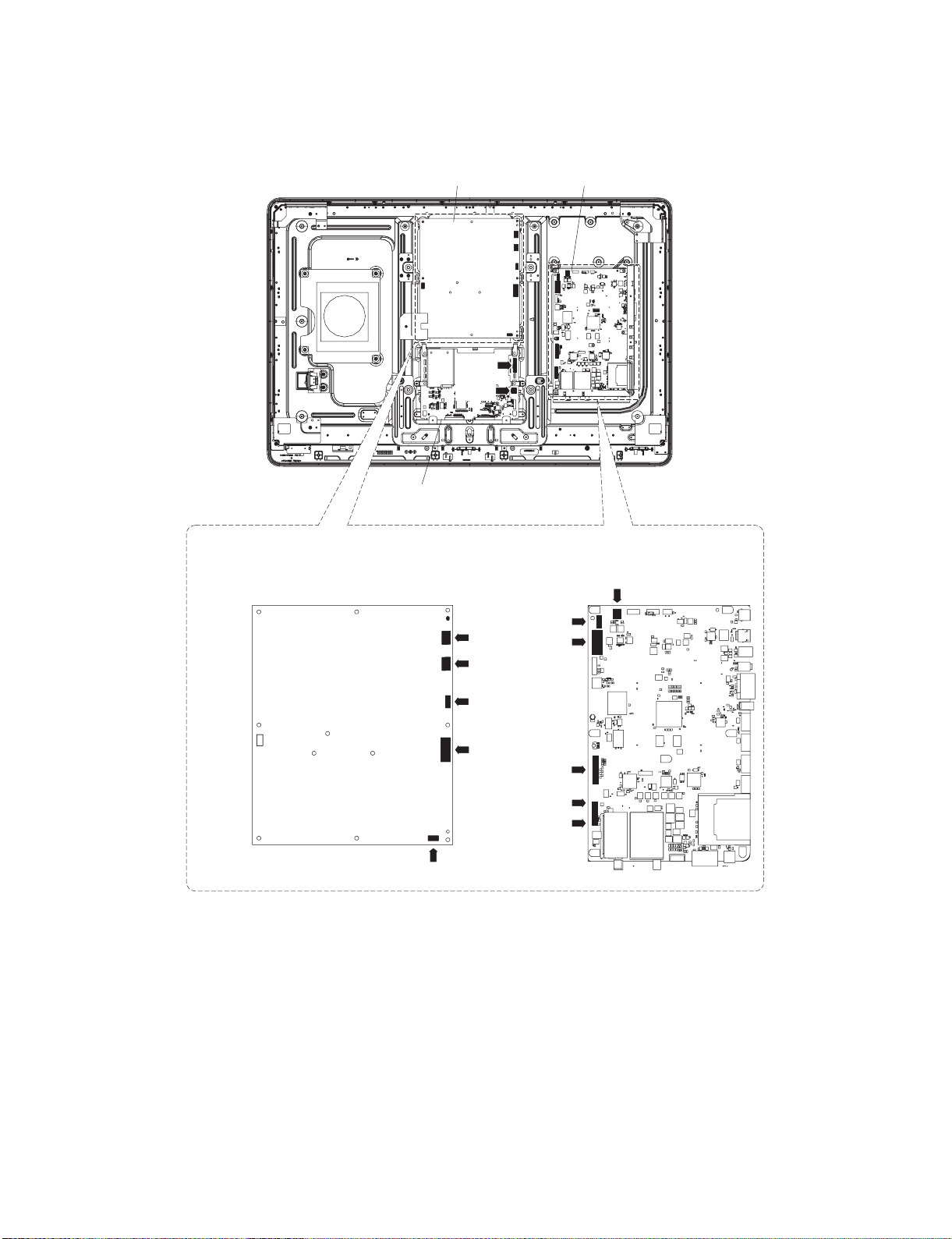

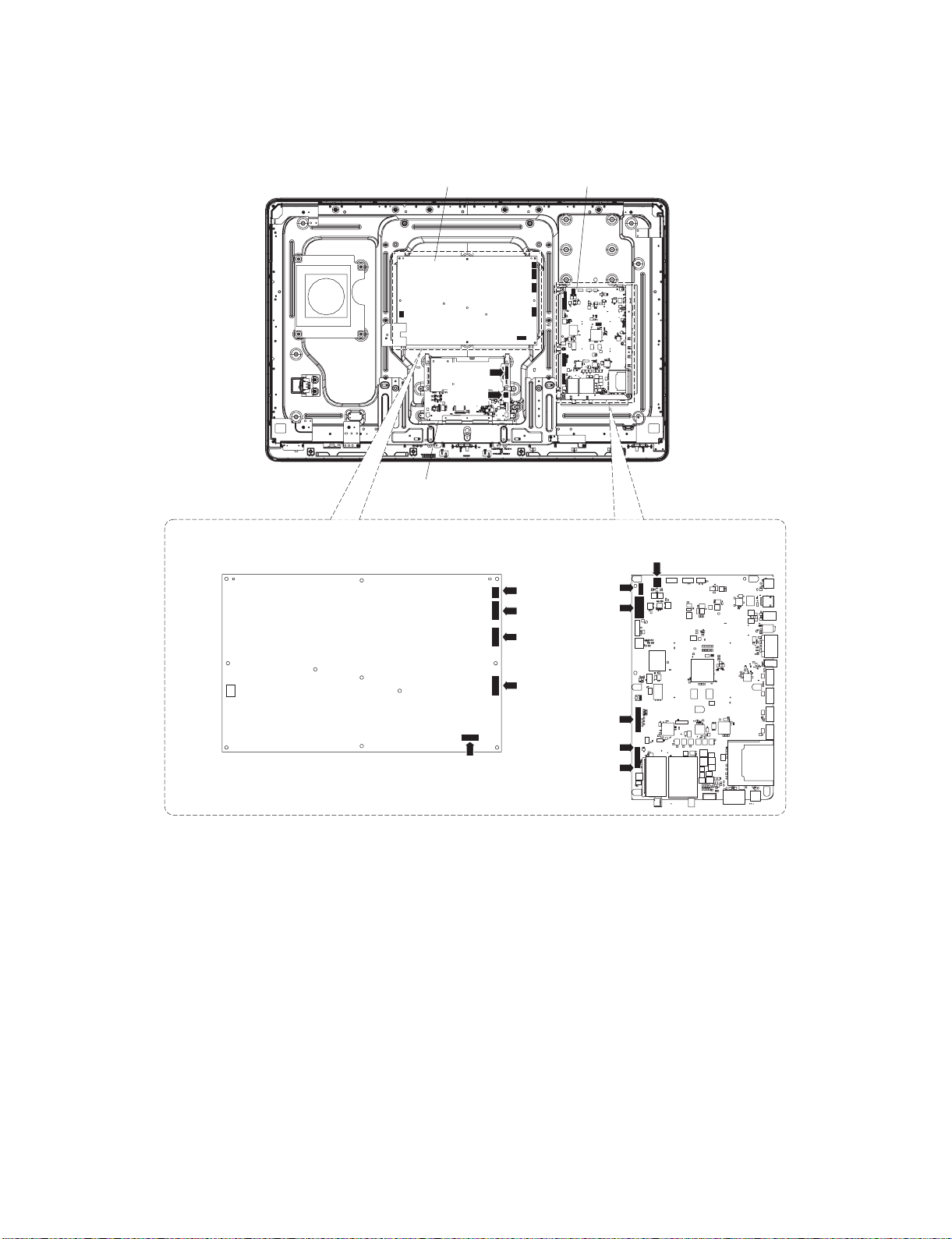

3. Removing of Connectors

1. Disconnect the following connectors from the MAIN Unit. (SB, LB, PD, LW, RA, RL)

2. Disconnect the following connectors from the POWER/LED Drive Unit. (L1, L2, LB, PD, PL)

3. Disconnect the following connectors from the LCD Control Unit. (LW, PL)

MAIN UnitPOWER/LED Drive Unit

[LW]

[PL]

LC-40/46/52/60LE820UN

LCD Control Unit

POWER/LED Drive Unit

[PL]

[L1]

[L2]

[LB]

[PD]

MAIN Unit

[SB]

[LB]

[PD]

[LW]

[RA]

[RL]

4 – 3

Page 18

LC-40/46/52/60LE820UN

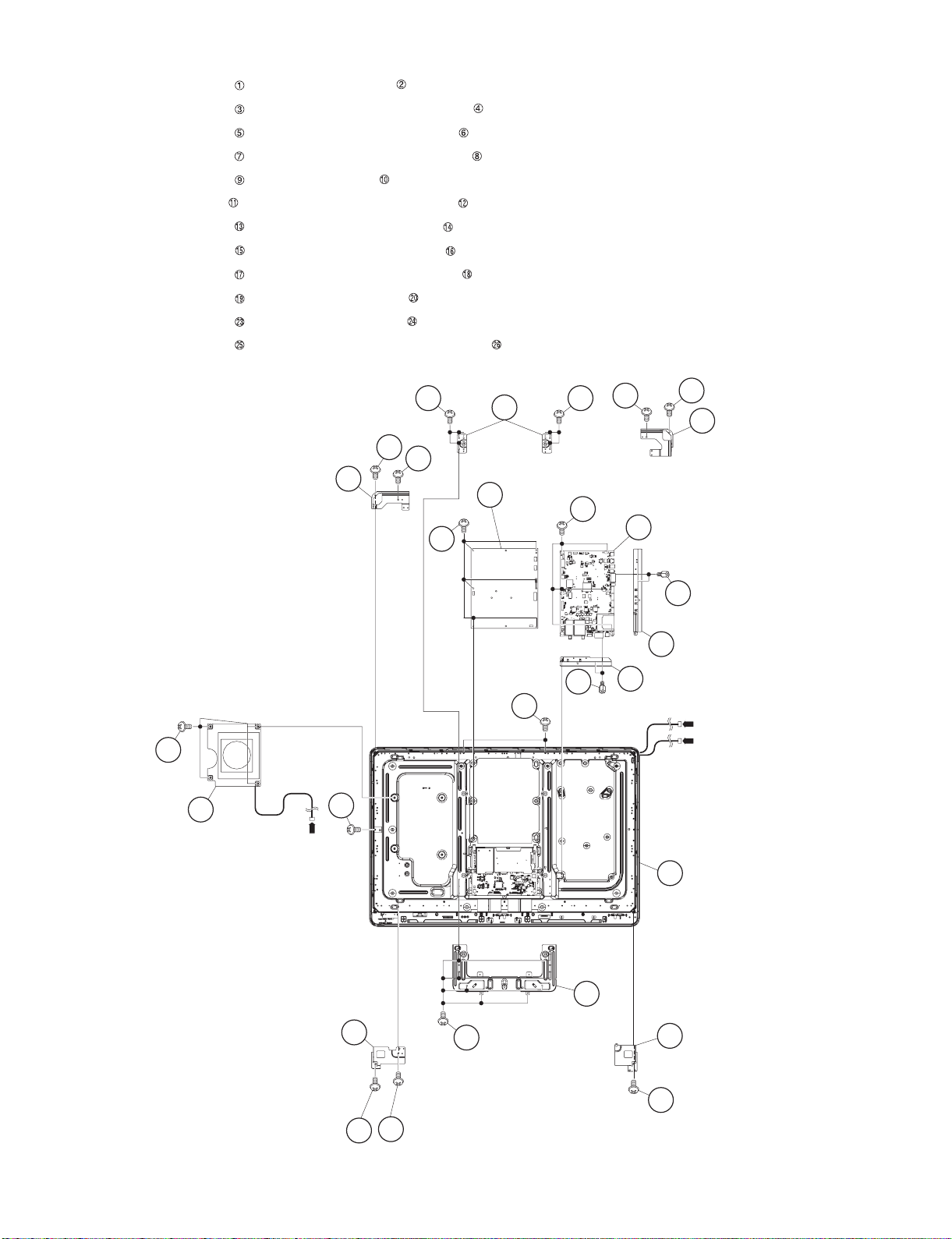

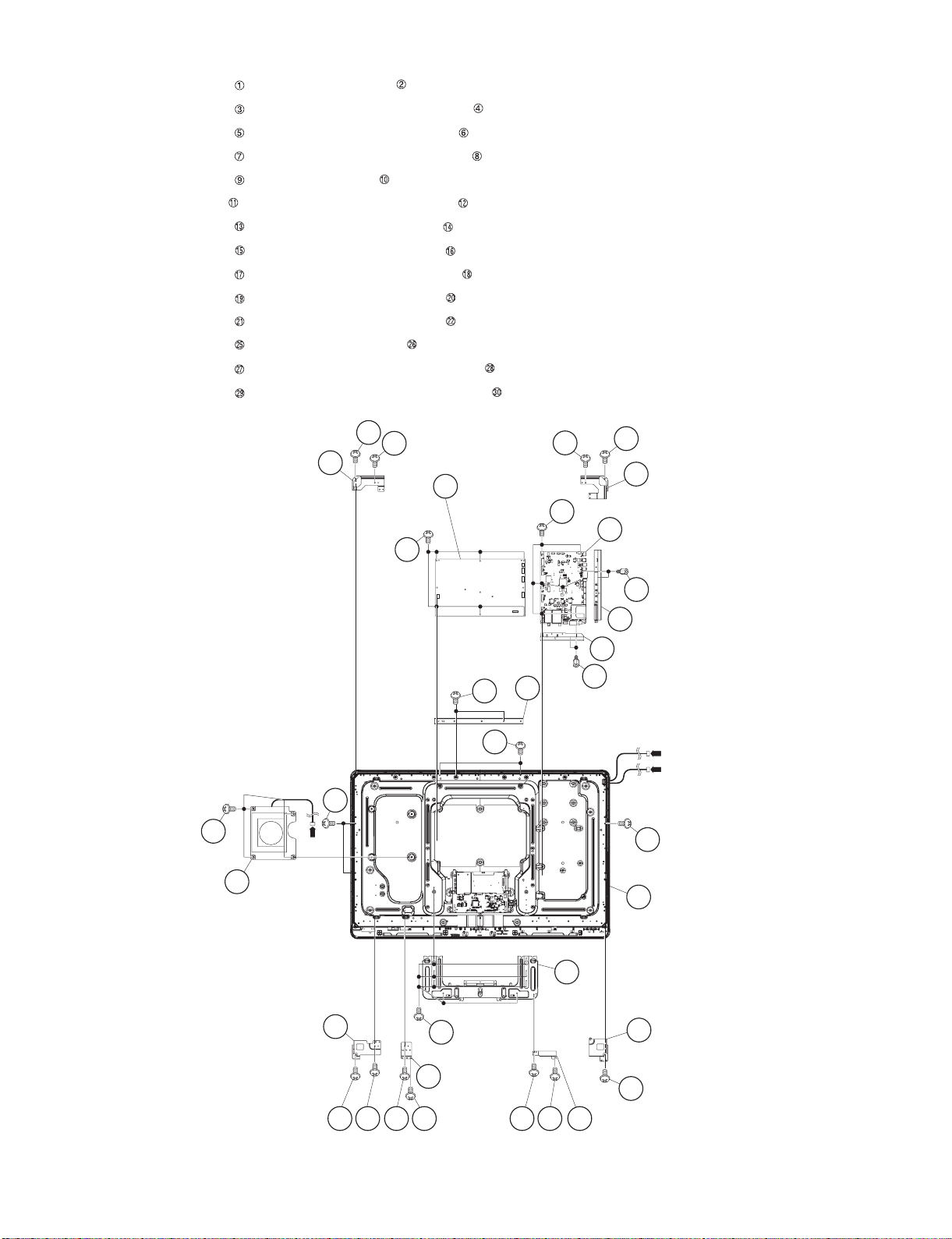

4. Removing of MAIN Unit, POWER/LED Drive Unit, Woofer, Stand Angle, 40” LCD Panel Module Unit.

1. Remove the 5 lock screws and detach the MAIN Unit .

2. Remove the 2 lock screws and detach the Terminal Angle (Bottom) .

3. Remove the 2 lock screws and detach the Terminal Angle (Side) .

4. Remove the 6 lock screws and detach the POWER/LED Drive Unit .

5. Remove the 4 lock screws and detach the Woofer .

6. Remove the 1 lock screw and detach the LCD Angle (Bottom-R) .

7. Remove the 2 lock screws and detach the LCD Angle (Top-L) .

8. Remove the 2 lock screws and detach the LCD Angle (Top-R) .

9. Remove the 2 lock screws and detach the LCD Angle (Bottom-L) .

10.Remove the 8 lock screws and detach the VESA Angle .

11.Remove the 8 lock screws and detach the Stand Angle .

12.Remove the 3 lock screws and detach the 40” LCD Panel Module Unit .

9

Woofer

10

(Top-L)

[SB]

25

19

VESA Angle

20

19

15

15

16 LCD Angle

13

13

14LCD Angle

7

POWER/LED

8

Drive Unit

1

2 MAIN Unit

(Top-R)

5

6

Terminal Angle

(Side)

4

3

25

Terminal Angle

(Bottom)

[L1]

[L2]

LCD Angle

(Bottom-L)

18

17

17

23

4 – 4

24

Stand

Angle

26

40" LCD Panel

Module Unit

LCD Angle

12

(Bottom-R)

11

Page 19

LC-40/46/52/60LE820UN

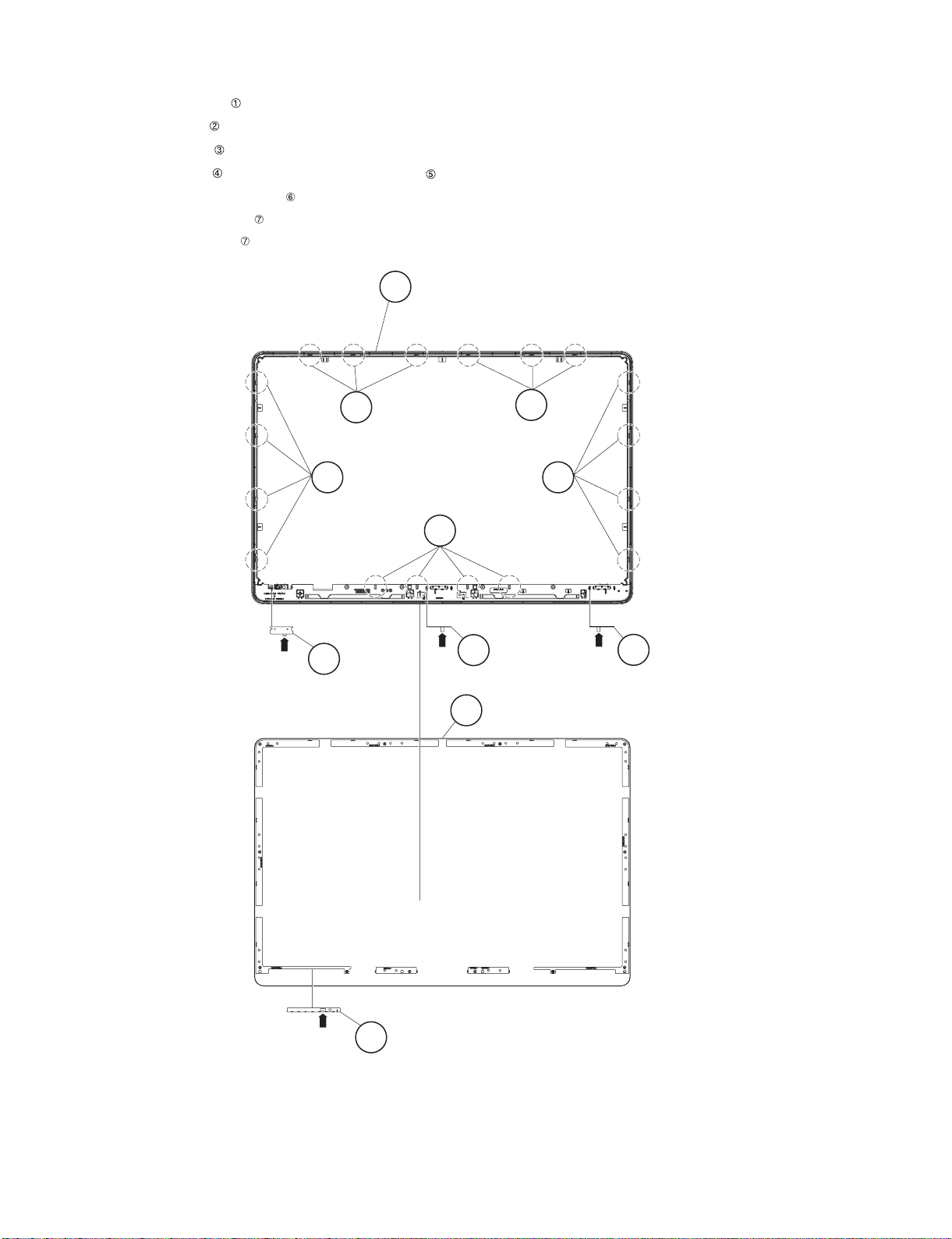

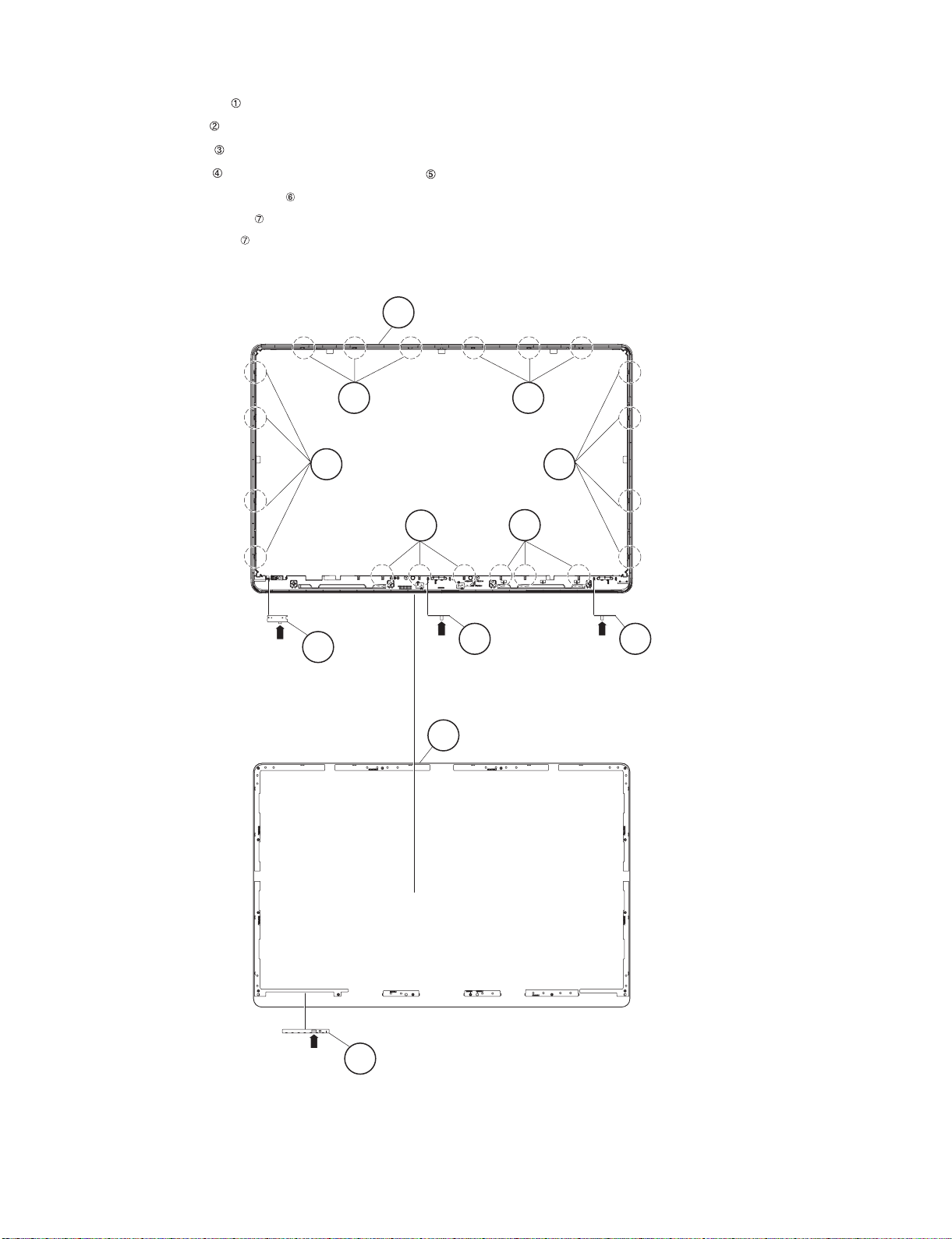

5. Removing of R/C, LED Unit, ICON Unit, LOGO Unit, Front Cabinet Ass’y, Glass Front Panel Ass’y, TOUCH

SENSOR Unit.

1. Detach the R/C, LED Unit .

2. Detach the ICON Unit .

3. Detach the LOGO Unit .

4. Remove the 18 Hooks and detach the Front Cabinet Ass’y

5. Detach the Glass Front Panel Ass’y .

6. Detach the Touch Sensor Unit .

NOTE: The Touch Sensor unit removed once is not reusable.

Front Cabinet Ass'y5

[RA]

4

4

1

R/C, LED

Unit

4

2 ICON Unit

[R]

Glass Front Panel Ass'y6

4

4

3 LOGO Unit

[RL]

[RK]

7 TOUCH SENSOR Unit

4 – 5

Page 20

LC-40/46/52/60LE820UN

[2] REMOVING OF MAJOR PARTS (LC-46LE820UN)

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 1 lock screw and detach the Support Cover .

2. Remove the 4 lock screws and detach the Stand Unit .

3. Remove the 1 lock screw and detach the AC Cord Cover .

4. Disconnect AC Cord .

5. Remove the 4 lock screws , 4 lock screws , 1 lock screw and 16 lock screws and detach the Rear Cabinet Ass’y .

11

AC Cord

12

Rear Cabinet Ass'y

10

6AC Cord Cover

7

5

2Support Cover

3

9

8

1

Stand Unit

4

4 – 6

Page 21

2. Removing of Speaker-L/R.

1. Remove the 2 lock screws and detach the Stand Cover .

2. Disconnect SP wire.

3. Detach the Speaker-L , Speaker-R .

LC-40/46/52/60LE820UN

MAIN Unit

[SP]

[SP]

4Speaker-R 3 Speaker-L

2 Stand Cover

1

4 – 7

Page 22

LC-40/46/52/60LE820UN

3. Removing of Connectors

1. Disconnect the following connectors from the MAIN Unit. (SB, LB, PD, LW, RA, RL)

2. Disconnect the following connectors from the POWER/LED Drive Unit. (L1, L2, LB, PD, PL)

3. Disconnect the following connectors from the LCD Control Unit. (LW, PL)

MAIN UnitPOWER/LED Drive Unit

[LW]

[PL]

LCD Control Unit

[L1]

[L2]

[LB]

[PD]

[PL]

MAIN UnitPOWER/LED Drive Unit

[SB]

[LB]

[PD]

[LW]

[RA]

[RL]

4 – 8

Page 23

LC-40/46/52/60LE820UN

4. Removing of MAIN Unit, POWER/LED Drive Unit, Woofer, Stand Angle, 46” LCD Panel Module Unit.

1. Remove the 7 lock screws and detach the MAIN Unit .

2. Remove the 2 lock screws and detach the Terminal Angle (Bottom) .

3. Remove the 2 lock screws and detach the Terminal Angle (Side) .

4. Remove the 6 lock screws and detach the POWER/LED Drive Unit .

5. Remove the 4 lock screws and detach the Woofer .

6. Remove the 1 lock screw and detach the LCD Angle (Bottom-R) .

7. Remove the 2 lock screws and detach the LCD Angle (Top-L) .

8. Remove the 2 lock screws and detach the LCD Angle (Top-R) .

9. Remove the 2 lock screws and detach the LCD Angle (Bottom-L) .

10.Remove the 2 lock screws and detach the LCD Angle (B-C-A) .

11.Remove the 2 lock screws and detach the LCD Angle (B-C-B) .

12.Remove the 8 lock screws and detach the Stand Angle .

13.Remove the 2 lock screws and detach the BL Chassis Support Angle .

14.Remove the 5 lock screws and detach the 46” LCD Panel Module Unit .

9

10

Woofer

(Top-L)

[SB]

13

13

15

14LCD Angle

POWER/LED

8

Drive Unit

15

16 LCD Angle

(Top-R)

1

2 MAIN Unit

7

5

6

TERMINAL Angle

(Side)

BL Chassis

Support Angle

28

27

29

4

TERMINAL Angle

(Bottom)

3

[L1]

[L2]

29

29

30

46" LCD Panel

Module Unit

LCD Angle

(Bottom-L)

18

25

20 LCD Angle

(B-C-A)

19 19 21 21

1717

4 – 9

26

Stand

Angle

1211LCD Angle

(Bottom-R)

22 LCD Angle

(B-C-B)

Page 24

LC-40/46/52/60LE820UN

5. Removing of R/C, LED Unit, ICON Unit, LOGO Unit, Front Cabinet Ass’y, Glass Front Panel Ass’y, TOUCH

SENSOR Unit.

1. Detach the R/C, LED Unit .

2. Detach the ICON Unit .

3. Detach the LOGO Unit .

4. Remove the 20 Hooks and detach the Front Cabinet Ass’y

5. Detach the Glass Front Panel Ass’y .

6. Detach the Touch Sensor Unit .

NOTE: The Touch Sensor unit removed once is not reusable.

Front Cabinet Ass'y

5

4 4

[RA]

4

1

R/C, LED

Unit

4

4

2 ICON Unit

[R]

Glass Front Panel Ass'y

6

4

3 LOGO Unit

[RL]

[RK]

7 TOUCH SENSOR Unit

4 – 10

Page 25

LC-40/46/52/60LE820UN

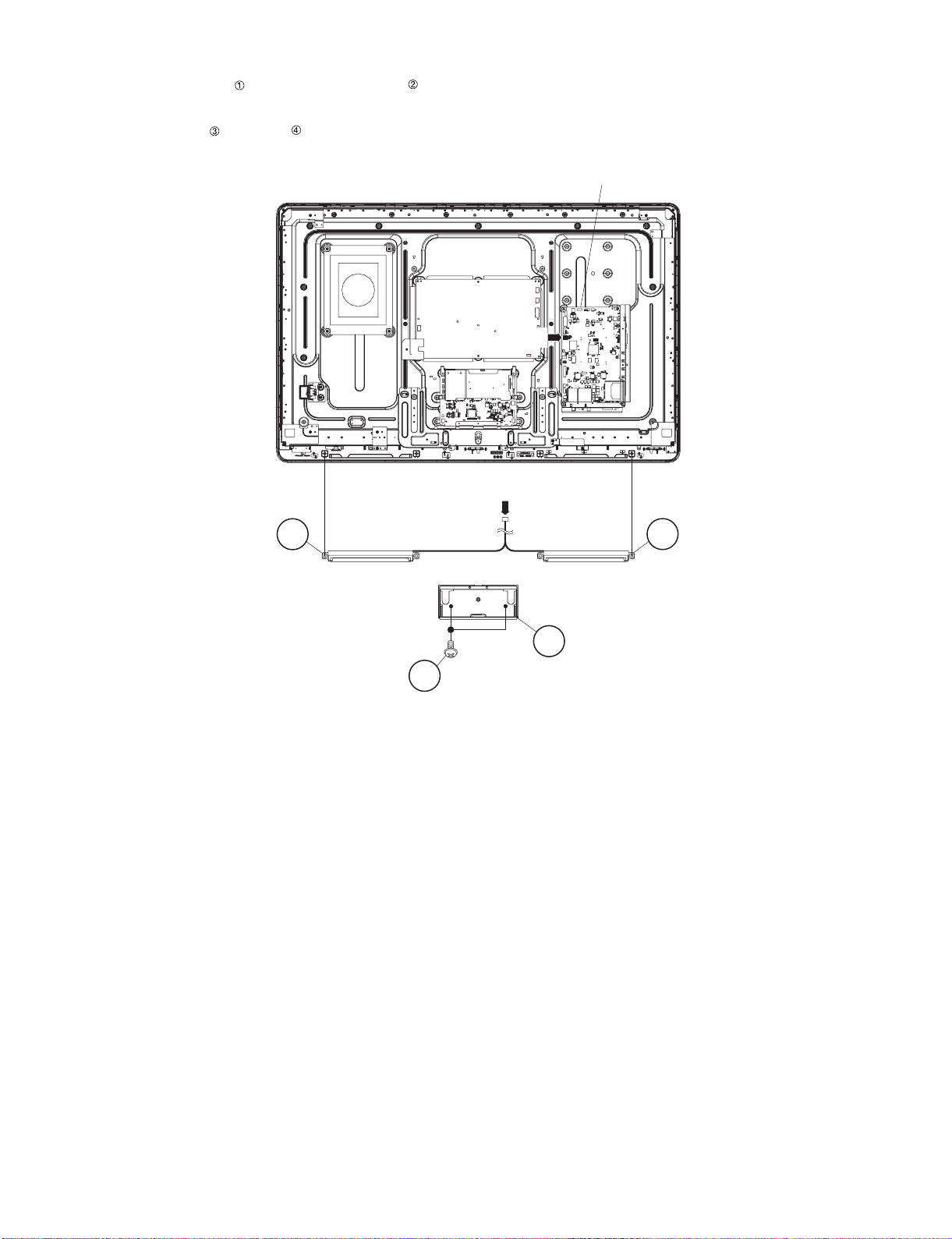

[3] REMOVING OF MAJOR PARTS (LC-52LE820UN)

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 1 lock screw and detach the Support Cover .

2. Remove the 4 lock screws and detach the Stand Unit .

3. Remove the 1 lock screw and detach the AC Cord Cover .

4. Disconnect AC Cord .

5. Remove the 4 lock screws , 4 lock screws , 1 lock screw and 18 lock screws and detach the Rear Cabinet Ass’y .

Rear Cabinet Ass'y

11

AC Cord

12

10

10

6AC Cord Cover

8

5

7

3

9

2Support Cover

1

4 – 11

4

Stand Unit

Page 26

LC-40/46/52/60LE820UN

2. Removing of Speaker-L/R.

1. Remove the 2 lock screws and detach the Stand Cover .

2. Disconnect SP wire.

3. Detach the Speaker-L , Speaker-R .

MAIN Unit

[SP]

[SP]

4Speaker-R

3 Speaker-L

2 Stand Cover

1

4 – 12

Page 27

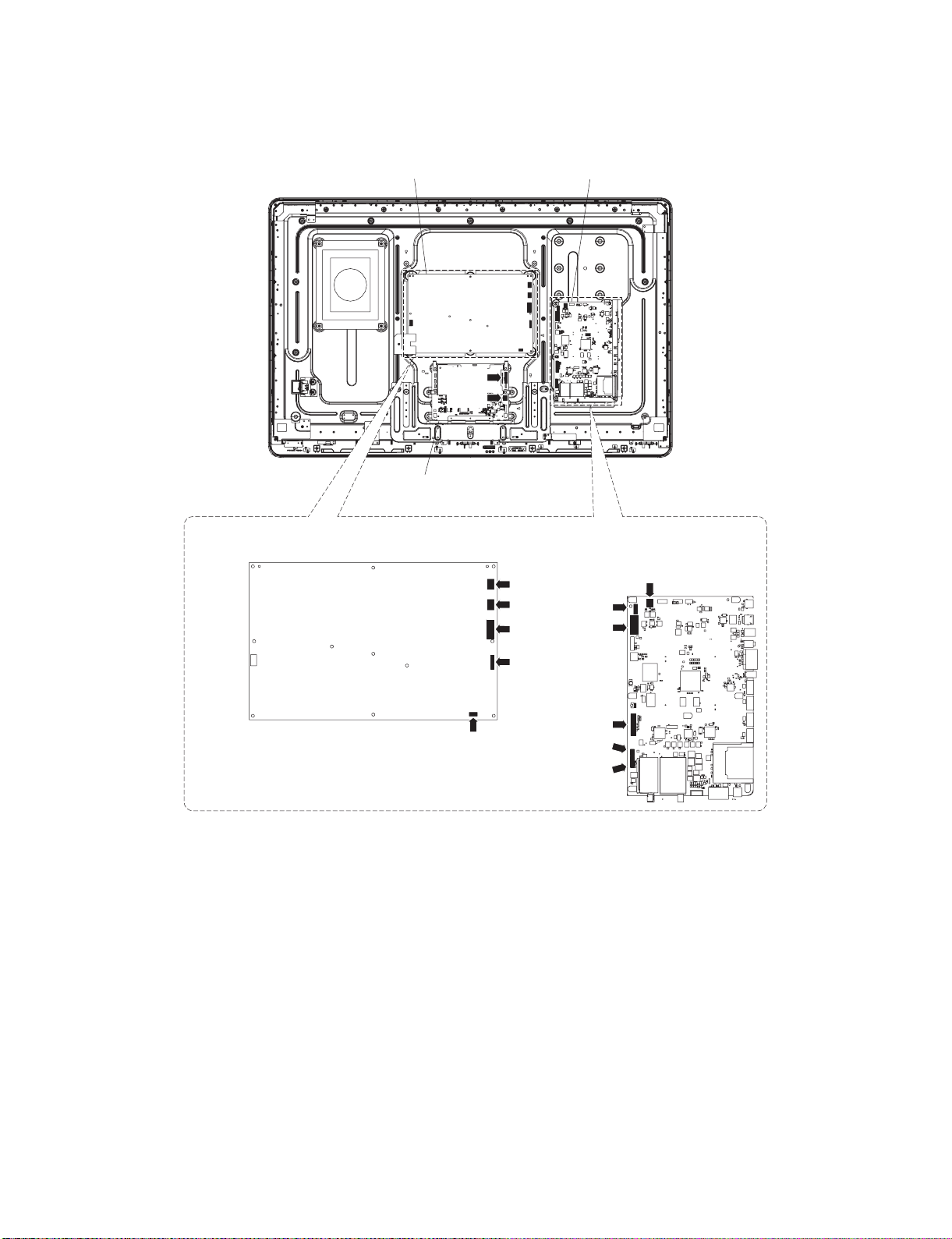

3. Removing of Connectors

1. Disconnect the following connectors from the MAIN Unit. (SB, LB, PD, LW, RA, RL)

2. Disconnect the following connectors from the POWER/LED Drive Unit. (L1, L2, LB, PD, PL)

3. Disconnect the following connectors from the LCD Control Unit. (LW, PL)

MAIN UnitPOWER/LED Drive Unit

[LW]

[PL]

LC-40/46/52/60LE820UN

LCD Control Unit

POWER/LED Drive Unit

[PL]

[L1]

[L2]

[LB]

[PD]

MAIN Unit

[SB]

[LB]

[PD]

[LW]

[RA]

[RL]

4 – 13

Page 28

LC-40/46/52/60LE820UN

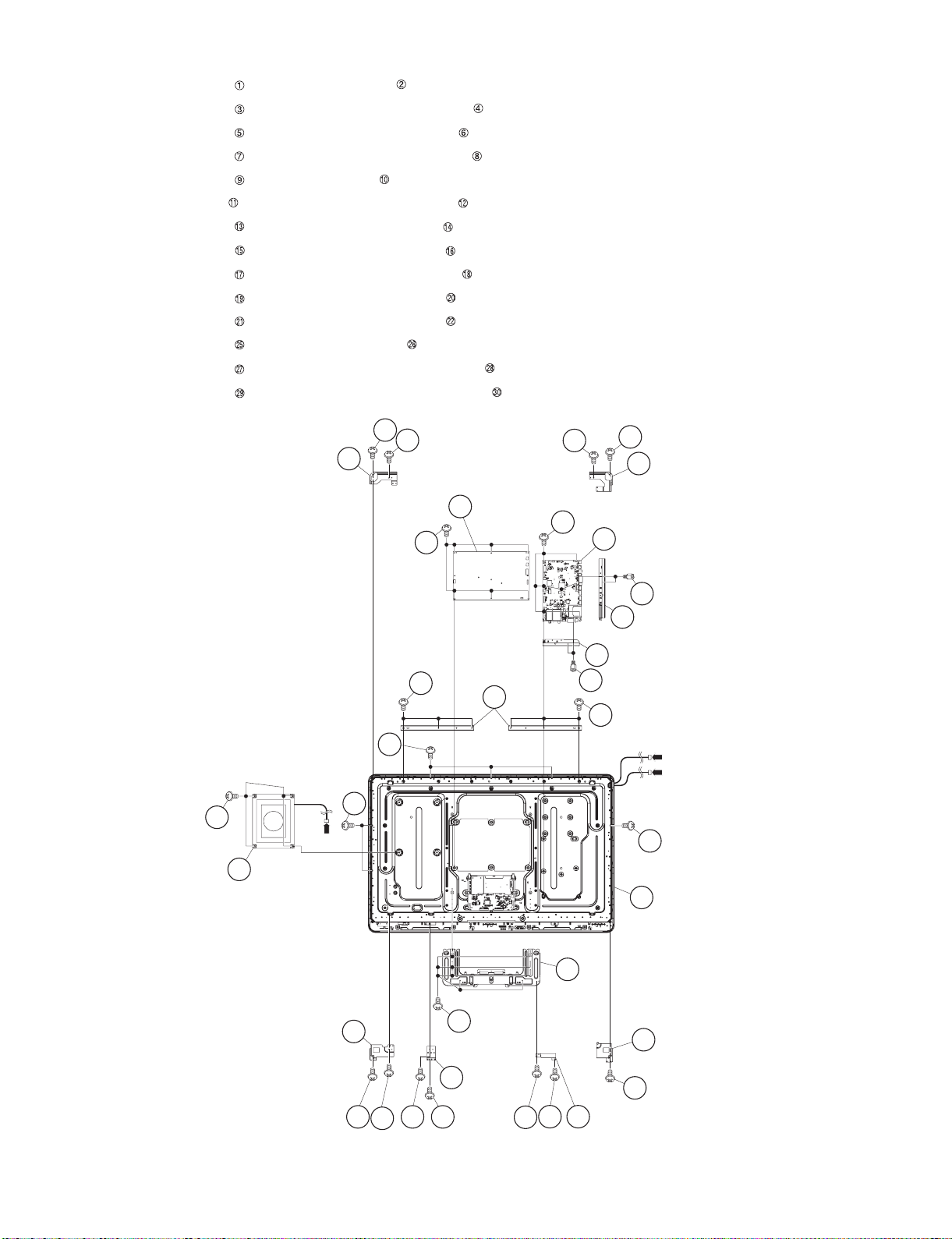

4. Removing of MAIN Unit, POWER/LED Drive Unit, Woofer, Stand Angle, 52” LCD Panel Module Unit.

1. Remove the 7 lock screws and detach the MAIN Unit .

2. Remove the 2 lock screws and detach the Terminal Angle (Bottom) .

3. Remove the 2 lock screws and detach the Terminal Angle (Side) .

4. Remove the 6 lock screws and detach the POWER/LED Drive Unit .

5. Remove the 4 lock screws and detach the Woofer .

6. Remove the 1 lock screw and detach the LCD Angle (Bottom-R) .

7. Remove the 2 lock screws and detach the LCD Angle (Top-L) .

8. Remove the 2 lock screws and detach the LCD Angle (Top-R) .

9. Remove the 2 lock screws and detach the LCD Angle (Bottom-L) .

10.Remove the 2 lock screws and detach the LCD Angle (B-C-A) .

11.Remove the 2 lock screws and detach the LCD Angle (B-C-B) .

12.Remove the 8 lock screws and detach the Stand Angle .

13.Remove the 6 lock screws and detach the BL Chassis Support Angle .

14.Remove the 6 lock screws and detach the 52” LCD Panel Module Unit .

9

10

Woofer

(Top-L)

[SB]

13

13

15

14LCD Angle

15

16 LCD Angle

(Top-R)

POWER/LED Drive

8

Unit

7

1

2 MAIN Unit

5

6

TERMINAL Angle

(Side)

4

TERMINAL Angle

(Bottom)

3

27

BL Chassis

Support Angle

28

27

29

[L1]

[L2]

29

29

30

52" LCD Panel

Module Unit

LCD Angle

(Bottom-L)

18

17

17

19

25

20

19

4 – 14

LCD Angle

(B-C-A)

21

26

Stand

Angle

22 LCD Angle

21

11

(B-C-B)

12

LCD Angle

(Bottom-R)

Page 29

LC-40/46/52/60LE820UN

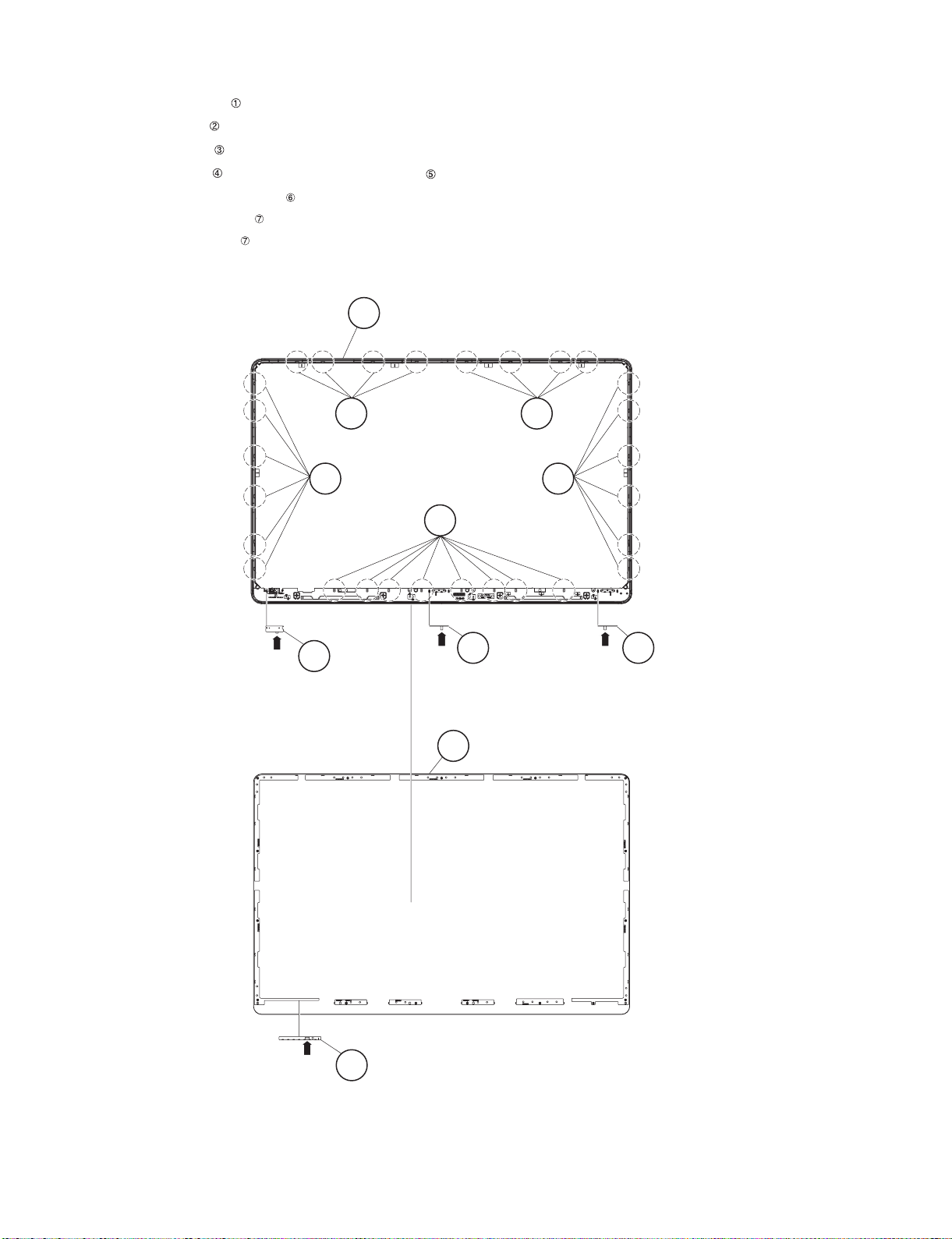

5. Removing of R/C, LED Unit, ICON Unit, LOGO Unit, Front Cabinet Ass’y, Glass Front Panel Ass’y, TOUCH

SENSOR Unit.

1. Detach the R/C, LED Unit .

2. Detach the ICON Unit .

3. Detach the LOGO Unit .

4. Remove the 28 Hooks and detach the Front Cabinet Ass’y

5. Detach the Glass Front Panel Ass’y .

6. Detach the Touch Sensor Unit .

NOTE: The Touch Sensor unit removed once is not reusable.

Front Cabinet Ass'y

5

4 4

44

[RA]

1

R/C, LED

Unit

4

2 ICON Unit

[R]

Glass Front Panel Ass'y

6

3 LOGO Unit

[RL]

[RK]

7 TOUCH SENSOR Unit

4 – 15

Page 30

LC-40/46/52/60LE820UN

[4] REMOVING OF MAJOR PARTS (LC-60LE820UN)

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 3 lock screw and detach the Support Cover .

2. Remove the 4 lock screws and detach the Stand Unit .

3. Remove the 1 lock screw and detach the AC Cord Cover .

4. Disconnect AC Cord .

5. Remove the 4 lock screws , 5 lock screws , 2 lock screws and 18 lock screws and detach the Rear Cabinet Ass’y.

Rear Cabinet Ass'y

AC Cord

11

Support Cover

1

10

10

7

6AC Cord Cover

5

2

8

3

9

4 – 16

4Stand Unit

Page 31

2. Removing of Speaker-L/R.

1. Remove the 2 lock screws and detach the Stand Cover .

2. Disconnect SP wire.

3. Detach the Speaker-L , Speaker-R .

LC-40/46/52/60LE820UN

MAIN Unit

[SP]

[SP]

4Speaker-R

3 Speaker-L

2 Stand Cover

1

4 – 17

Page 32

LC-40/46/52/60LE820UN

3. Removing of Connectors

1. Disconnect the following connectors from the MAIN Unit. (SB, LB, PD, LW, RA, RL)

2. Disconnect the following connectors from the POWER/LED Drive Unit. (L1, L2, LB, PD, PL)

3. Disconnect the following connectors from the LCD Control Unit. (LW, PL)

MAIN UnitPOWER/LED Drive Unit

[LW]

[PL]

LCD Control Unit

POWER/LED Drive Unit

[PL]

[L1]

[L2]

[LB]

[PD]

MAIN Unit

[SB]

[LB]

[PD]

[LW]

[RA]

[RL]

4 – 18

Page 33

LC-40/46/52/60LE820UN

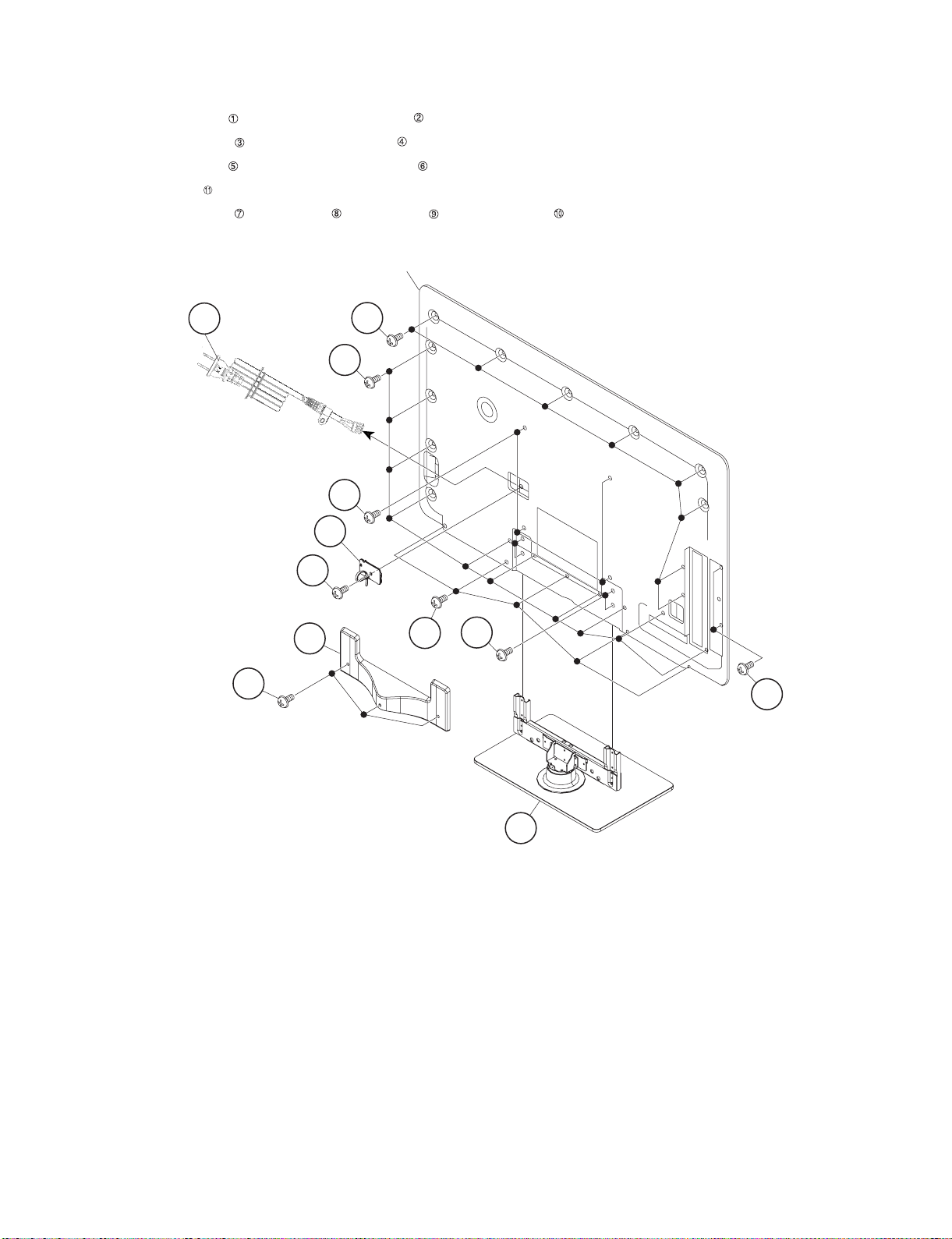

4. Removing of MAIN Unit, POWER/LED Drive Unit, Woofer, Stand Angle,60” LCD Panel Module Unit.

1. Remove the 7 lock screws and detach the MAIN Unit .

2. Remove the 2 lock screws and detach the Terminal Angle (Bottom) .

3. Remove the 2 lock screws and detach the Terminal Angle (Side) .

4. Remove the 6 lock screws and detach the POWER/LED Drive Unit .

5. Remove the 4 lock screws and detach the Woofer .

6. Remove the 1 lock screw and detach the LCD Angle (Bottom-R) .

7. Remove the 4 lock screws and detach the LCD Angle (Top-L) .

8. Remove the 2 lock screws and detach the LCD Angle (Top-R) .

9. Remove the 2 lock screws and detach the LCD Angle (Bottom-L) .

10.Remove the 12 lock screws and detach the 2 Stand Angle .

11.Remove the 4 lock screws and detach the 4 FIX Angle (B-MA) .

12.Remove the 2 lock screws and detach the Back Light Chassis Support Angle .

13.Remove the 9 lock screws and detach the 52” LCD Panel Module Unit .

9

10

Woofer

(Top-L)

[SB]

25

14LCD Angle

25

13

13

15

15

16 LCD Angle

POWER/LED

8

Drive Unit

1

(Top-R)

2 MAIN Unit

7

5

6

TERMINAL Angle

(Side)

4

TERMINAL Angle

(Bottom)

3

23

Back Light Chassis

24

Support Angle

[L1]

[L2]

25

60" LCD Panel

Module Unit

(Bottom-L)

18LCD Angle

17

20

Stand Angle

17

FIX Angle

(B-MA)

4 – 19

22

20

Stand Angle

21

1919

12

11

LCD Angle

(Bottom-R)

Page 34

LC-40/46/52/60LE820UN

5. Removing of R/C, LED Unit, ICON Unit, LOGO Unit, Front Cabinet Ass’y, Glass Front Panel Ass’y, TOUCH

SENSOR Unit.

1. Detach the R/C, LED Unit .

2. Detach the ICON Unit .

3. Detach the LOGO Unit .

4. Remove the 25 Hooks and detach the Front Cabinet Ass’y

5. Detach the Glass Front Panel Ass’y .

6. Detach the Touch Sensor Unit .

NOTE: The Touch Sensor unit removed once is not reusable.

Front Cabinet Ass'y5

4 4

4 4

[RA]

1 RC,LED

Unit

4

2 ICON Unit

[R]

6

3 LOGO Unit

[RL]

Glass Front Panel Ass'y

[RK]

7 TOUCH SENSOR Unit

4 – 20

Page 35

[5] Caution Cleaning Glass

glass

glass

cushion material

flat mat

1. Glass handling

CAUTION:(1) As for handling, wear clean gloves, protective footwear

and mask.

LC-40/46/52/60LE820UN

(5) Two people have handling equally by the work.

(Maintain it so that glass is not warped.)

protective footwear

(2) Inner gloves are covered in the Nitrile gloves.

Inner gloves Nitrile gloves

(3) Nitrile gloves are exchanged with the following

standard.

• When it touched a face and so on.

• When another work was done.

• By the work of fifty times.

• In the time for recess.

• When it became dirty.

• When it tore.

changed to new Nitrile gloves

Inner gloves

Nitrile gloves

mask

(6) When it is put horizontally, it is put on the flat mat.

glass

flat mat

(7) A cushion material is put between glass.

It doesn't touch it [the front and the front].

It can be put to two glass.

(8) It has a module part before the CAB-B installation.

(It has a module part.)

A module isn't added.

You must not have it.

(4) It has a black mask part.

You must not have a clear surface.

4 – 21

Page 36

LC-40/46/52/60LE820UN

l

2. Glass cleaning

CAUTION:(1) Visual inspection is done on the black mat.

black mat

(2) Dust and trash are taken with an air blow.

Air blow

glass

(3) Dirt is wiped out with cloth.

Front side: Moufas

Back side: Cotton (clean wiper SF-30C)

Moufas

(4) When dirt doesn't clean, it is wiped out with Alcohol.

Alcoho

Cotton

Cotton

(5) Dirt is wiped out with the Ethanol and clean cloth.

When wipe off a dirt the trace which wiped do not be left.

4 – 22

Page 37

[6] How to replace the touch key sensor PWB

1. Replace the touch key sensor PWB in a clean room.

Be sure to remove the dust from the unit before carrying it into the clean room.

2. Remove the touch key sensor PWB from the front glass.

3. Clean the bonding surface with alcohol.

Depending on the dirt, water solution of 80%vol can be effective.

4. Adhere a spacer before bonding the touch unit.

Product Manual Touch Sensor with ITO (Transparent Electrode)

LC-40/46/52/60LE820UN

FPCB/ITO connecting tape FPCB

i) Remove the touch sensor from the front glass.

Pull tap of double-sided tape

Pull tap of double-sided tape

ITO

Pull tap of protective sheet

* When peeling the ITO section, check that there is no glue

residue on the front glass.

If glue residue, dirt, fingerprints, etc. are found, wipe them

off with anhydrous alcohol.

Do not apply anhydrous alcohol to the double-sided tape

on the metal part attaching to the glass.

ii) Adhere the spacer to the back of the FPCB section.

RL

Spacer

Release paper

RL

4 – 23

ii-1. Peel the release paper of the double-sided

tape on the FPCB section.

ii-2. Adhere the spacer to the FPCB section.

(Use the right and upper sides of the FPCB

section as a reference.)

* Check that the spacer does not contact with

the ITO section.

Page 38

LC-40/46/52/60LE820UN

iii) Adhere the ITO section to the front glass. (Use the positioning jig.)

Tape fixing the FPCB and ITO sections (Adhered by the supplier)

iv) Adhere the FPCB section to the front glass.

iii-1. Peel the release paper of the double-sided tape

on the ITO section.

iii-2. Slowly adhere it from the end using a roller.

(Position the touch sensor using the jig.)

* Check that there are no bubbles in the ITO section

after adhered.

* Adhering error: r1.0mm

ζ-1. Lift the FPCB section to peel the release paper of the

double-sided tape on the spacer.

* Be careful not to apply stress to the joint of FPCB and ITO.

ζ-2. Adhere the FPCB section to the front glass.

* Be careful not to apply stress to the joint of FPCB and ITO.

RL

ζ-3. Peel the tape fixing the FPCB and ITO sections.

Light shielding sheet

ζ-4. Peel the protective sheet of the ITO section.

ζ-5. Adhere the light shielding sheet.

(Use the lower side of the FPCB section and the notch

on the ITO section as a reference.)

* Be careful not to get the ITO section dirty with

fingerprints, etc.

RL

* Be careful no tot leave space between the light

shielding sheet and the FPCB section.

ζ-6. Peel the protective sheet.

4 – 24

Page 39

5. Attach the touch unit bonding procedure.

It includes peeling of the protective sheet.

How to mount the touch sensor

i) Adhere after positioned using the positioning jig.

ii) Peel the protective sheet by means of the pull tap for peeling the protective sheet.

iii) Adhere the FPCB to the glass. (Do not warp the FPCB if possible.)

Pull tap for peeling the protective sheet of the double-sided tape in the FPCB section.

LC-40/46/52/60LE820UN

Glass outline

iv) Peel the protective sheet of the OCA.

Lift the ITO section, then peel the protective sheet by about half by means of the pull tap.

* Peeling it completely reduces workability.

Check the order due to workability.

v) Contact the FPCB and joint end of the transparent electrode film with the glass.

* Grasp the opposite end. Note that the ITO is positioned by adhering.

*Note: Do not bend the PWB (FPCB section)

Adhere first.

and sheet (ITO section).

4 – 25

Page 40

LC-40/46/52/60LE820UN

vi) Adhere the transparent electrode completely.

Pull tap for peeling the front protective sheet

Peel the front protective sheet.

If bubbles are found, press those portions with glass

cleaning cloth, etc. to remove them as much as possible.

• Use a rubber roller since pressure exerted by it removes bubbles easily. See photo below.

• For the TOUCH SENSOR Unit positioning figure, see page 5-1, 5-2, 5-3, 5-4.

4 – 26

Page 41

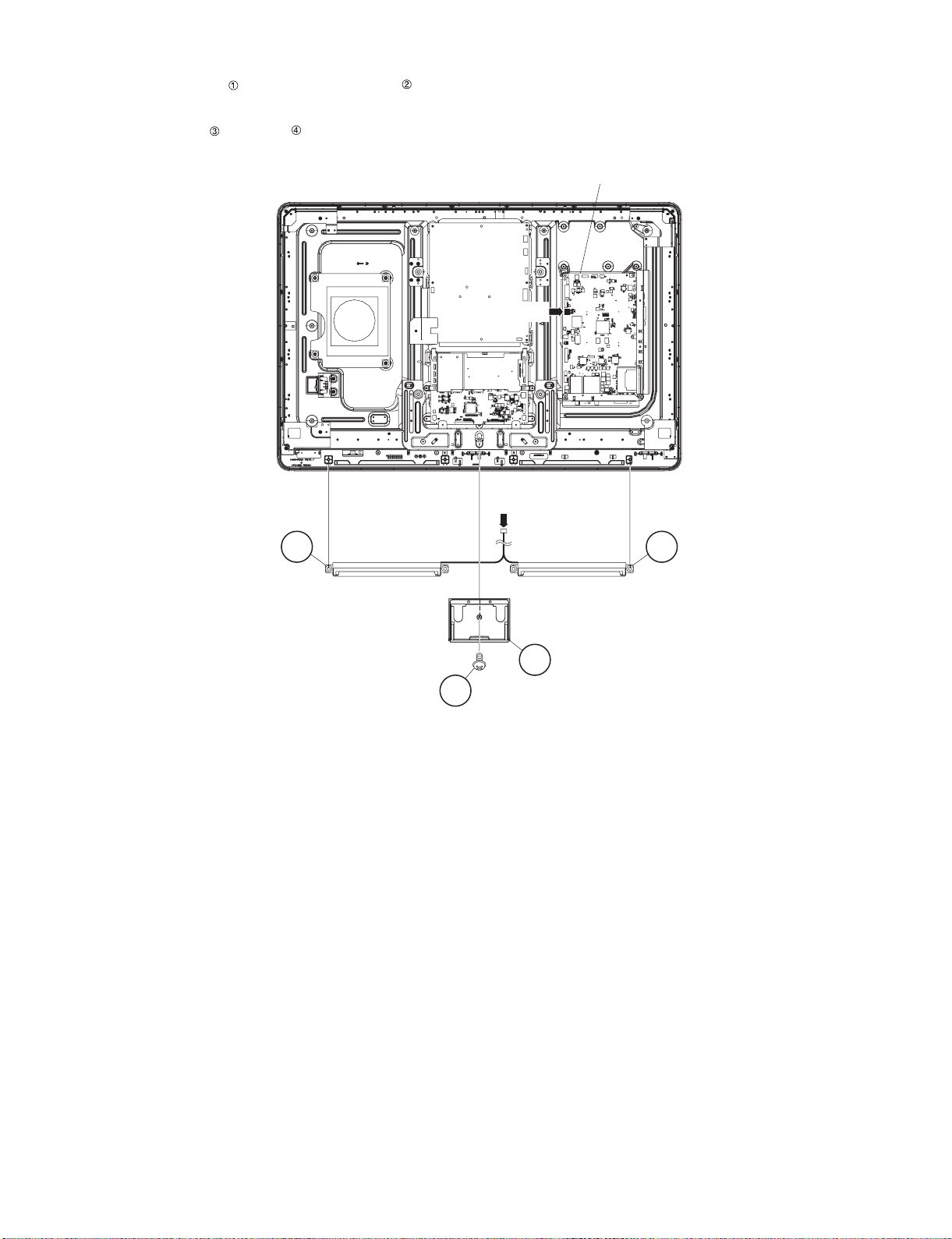

LC-40LE820UN

CHAPTER 5. Enter the chapter title here.

[1] LC-40LE820UN

LC-40/46/52/60LE820UN

Service Manual

TOUCH SENSOR Unit

5 – 1

Page 42

LC-40/46/52/60LE820UN

[2] LC-46LE820UN

TOUCH SENSOR Unit

5 – 2

Page 43

[3] LC-52LE820UN

LC-40/46/52/60LE820UN

TOUCH SENSOR Unit

5 – 3

Page 44

LC-40/46/52/60LE820UN

[4] LC-60LE820UN

TOUCH SENSOR Unit

5 – 4

Page 45

LC-40/46/52/60LE820UN

LC-40LE820UN

CHAPTER 6. ADJUSTMENT

Service Manual

[1] ADJUSTMENT PROCEDURE

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.

• When replacing the following units, make sure to prepare the new units loaded with updated software.

MAIN Unit: DKEYMF452FM02

• When replacing the LCD control PWB, perform the VCOM adjustment.

2. Upgrading of each microprocessor software

CAUTION:Never “POWER OFF” the unit when software upgrade is ongoing.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgrade

The model employs the following software.

• Main software (please use a software version after HLNIBxxx.USB).

• Monitor microprocessor software (please use a software version after HLNIBxxx.USB and HLNIMxxx.BIN.)

The main software, monitor microprocessor software can be upgraded by using a general-purpose USB Memory.

The followings are the procedures for upgrading, explained separately for the main software, monitor microprocessor software.

2.2. Main software version upgrade

2.2.1 Get ready before you start

• USB Memory of 128MB or higher capacity.

• PC running on Windows 98/98SE/ME/2000/XP operating system.

• USB Memory reader/writer or PC with a USB port.

• The file system of a USB memory is FAT. (FAT32 supports)

• Use the USB memory without other functions. (lock and memory reader...etc)

2.2.2 Preparati o n s

To upgrade the main software, it is necessary to get ready the USB Memory for version upgrade before you start.

Follow the steps below and create the USB Memory for version upgrade.

1. Copy the file HLNIBxxx.USB for version upgrade to the root directory (folder) of the USB Memory.

NOTE: In the USB Memory drive, do not store other folders or unrelated files, or more than one file for version upgrade.

Now the USB Memory for version upgrade is ready.

6 – 1

Page 46

LC-40/46/52/60LE820UN

2.2.3 How to upgrade the software

1. Plug AC cord and turn on the TV.

2. After picture displayed, touch the power key for 5seconds.

NOTE: Picture will disappear when you touch the power key, but keep touching it.

3. When the center icon LED blinks, release your finger from the power key.

4. Next, touch the “POWER” and “CH ( )” keys at the same time.

5. When the center icon LED turns on, release your finger form the keys.

6. After the unit startup, the system upgrade screen as shown below within 20-40 seconds.

7. Even a single failure in the process will trigger the upgrade failure screen.

LE820UN

LE820UN

NOTE: In the event of a failure, repeat the upgrade process. If the process repeatedly fails, it is likely that the hardware need fixing.

8. Upon completion of the whole process, the upgrade success screen as shown below appears. You can check the new software version on this

screen. The version information appears after the upgrade is complete.

LE820UN

9. Unplug the AC cord and remove the USB Memory for version upgrade.

10.Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the main

software version information.

6 – 2

Page 47

LC-40/46/52/60LE820UN

2.3. Monitor microprocessor software version upgrade

Create the USB memory for monitor microprocessor software version upgrade in the same manner as explained in the “Main software version

upgrade”.

Copy the file HLNIBxxx.USB and HLNIMxxx.BIN (named temporarily) for monitor microprocessor software version upgrade to the USB memory.

2.3.1 How to upgrade the software

1. Plug AC cord and turn on the TV.

2. After picture displayed, touch the power key for 5seconds.

NOTE: Picture will disappear when you touch the power key, but keep touching it.

3. When the center icon LED blinks, release your finger from the power key.

4. Next, touch the “POWER” key with the “CH ( )” key touching.

5. When the center icon LED turns on, release your finger form the keys.

CAUTION:• The moment this operation is done, the upgrading of the monitor microprocessor software starts. While the upgrade is ongoing, never

power off the unit. Otherwise the upgrade will fail and the system may be serious damaged beyond recovery (inability to start).

• After the monitor microprocessor software is upgraded, also perform the 'Industry Init'.

6. After the unit startup, the upgrade starts. The power led will blink continuously. Also, an upgrade screen will be shown during a minor upgrade.

LE820UN

7. If the upgrade fails, power led will stop blinking. Also, the upgrade failure screen will be shown if upgrade screen was shown at 5.

LE820UN

NOTE: In the event of a transient failure, upgrade will be automatically retried up to three times. If the process repeatedly fails, hardware may be the

cause.

8. The upgrade success screen will be shown if upgrade screen was shown at 5.

LE820UN

9. Unplug the AC cord and remove the USB Memory for version upgrade.

10.Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the mon-

itor microprocessor software version information and panel size information.

6 – 3

Page 48

LC-40/46/52/60LE820UN

3. Entering and exiting the adjustment process mode

1) Before entering the adjustment process mode, the AV position RESET in the video adjustment menu.

2) At the state TV is turned on, touch the power key for 5seconds.

NOTE: Picture will disappear when you touch the power key, but keep touching the power key.

3) When the center icon LED blinks, release your finger from the power key.

4) Next, touch the “POWER” key with the “VOL (—)” and “INPUT” key touching.

TV will turn on and the letter “<K>” appears on the screen.

5) Next, touch the “VOL (—)” and “CH ( )” keys at the same time.

6) When the center icon LED turns on, release your finger form the keys.

(The “VOL (—)” and “CH ( )” keys should be pressed and held until the display appears.)

Multiple lines of blue characters appearing on the display indicate that the unit is now in the adjustment process mode.

When you fail to enter the adjustment process mode (the display is the same as normal startup), retr y the procedure.

7) To exit the adjustment process mode after the adjustment is done, unplug the AC cord from the outlet to make a forced shutdown. (When the

power was turned off with the remote controller, once unplug the AC cord and plug it again. In this case, wait 10 seconds or so before plugging.)

CAUTION:Use due care in handling the information described here lest your users should know how to enter the adjustment process mode. If the

4. Remote controller key operation and description of display in adjustment process mode

1) Key operation

Remote controller key Main unit key Function

CH ( / )

VOL (+/–) VOL (+/–) Changing a selected item setting (+1/ –1)

Cursor (UP/DOWN) ————— Turing a page (PREVIOUS/NEXT)

Cursor (LEFT/RIGHT) ————— Changing a selected line setting (+10/ –10)

INPUT ————— Input switching (toggle switching)

ENTER ————— Executing a function

settings are tampered in this mode, unrecoverable system damage may result.

CH ( / )

Moving an item (line) by one (UP/DOWN)

*Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

2) Description of display

(1) Current page/

Total pages

1/24 INPUT5 AUTO USA 46_UNDER

MAIN Version

BOOT Version

Monitor/Monitor BOOT Version

LCD CON Version / LED CON Version

Netflix ESN

FRC-N Auto Script Version

TCON Master / Slave Serial Version

TOUCH SENSOR UCON VERSION

TEMPERATURE 66

LAMP ERROR

MONITOR ERR CAUSE

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

(2) Current selected input

(3) Current color system

2.00 (U 2010/03/19 1 A)

HLNI086

1.02 / 1.00

20100114f2014681 / 00

ERR

0912090000000000

20100114f2014681 / 20100114f2014681

B00ZD012110

0

1) 00 0000000000000 2) 00 0000000000000

3) 00 0000000000000 4) 00 0000000000000

0

50 50 50 50 0

(4) Destination

(5) LCD Panel size/Speaker type

(6) Adjustment

process menu

header

(7) Parameters

6 – 4

Page 49

LC-40/46/52/60LE820UN

5. List of adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

Page Line Item Description Remarks (adjustment detail, etc.)

1 1 MAIN Version Main software version

2BOOT Version

3 Monitor/Monitor BOOT Version Monitor and monitor boot software version

4 LCD CON Version / LED CON Ver-

sion

5 Netflix ESN

6 FRC-N Auto Script Version Audio data checksum

7 TCON Master/Slave Serial Version

8 TOUCH SENSOR UCON VERSION

9 TEMPERATURE Panel temperature

10 LAMP ERROR Number of termination due to lamp error

11 MONITOR ERR CAUSE

12 NORMAL STANDBY CAUSE Refer to *1 under the list for details

13 ERROR STANDBY CAUSE Refer to *2 under the list for details

2 1 INDUSTRY INIT Initialization to factory settings

2 INDUSTRY INIT(-Hotel)

3 PUBLIC MODE Public mode

4 Center Acutime Accumulated main operation time

5 RESET Reset

6 Backlight Acutime Accumulated monitor operation time

7 RESET Reset

8 LAMP ERROR RESET Reset LAMP ERROR

9 VIC XPOS X-coordinate setting for VIC READ

10 VIC YPOS Y-coordinate setting for VIC READ

11 VIC COLOR Collected color data setting for VIC READ

12 VIC SIGNAL TYPE Signal type setting for VIC READ

13 VIC READ Picture level acquisition function Level appears in green on the upper right

3 1 N358 ALL ADJ(INPUT2) CVBS and TUNER signal level adjustment

2 N358 MAIN ADJ(INPUT2) CVBS signal level adjustment

3 TUNER DAC ADJ TUNER signal level adjustment

4 N358 CONTRAST A_GAIN

5 N358 CONTRAST D_GAIN

6 N358 CONTRAST OFFSET

7 TUNER CONTRAST A_GAIN

8 TUNER CONTRAST D_GAIN

9 TUNER CONTRAST OFFSET

4 1 TUNER VCHIP TEST(69ch) Tuning test and VCHIP test (69ch)

2 TUNER VCHIP TEST(7ch) Tuning test and VCHIP test (7ch)

3 TUNER VCHIP TEST(10ch) Tuning test and VCHIP test (10ch)

4 TUNER VCHIP TEST(15ch) Tuning test and VCHIP test (15ch)

5 INSPECT USB TERM

6 HDMI EDID WRITE

7 HDMI CEC TEST

5 1 COMP15K ADJ(INPUT1) Component 15K picture level adjustment (main)

2 COMP15K Y A_GAIN

3 COMP15K Cb A_GAIN

4 COMP15K Cr A_GAIN

5 COMP15K Y OFFSET

6 COMP15K Cb OFFSET

7 COMP15K Cr OFFSET

6 1 COMP33K ADJ(INPUT1) Component 33K picture level adjustment (main)

2 COMP33K Y A_GAIN

3 COMP33K Cb A_GAIN

4 COMP33K Cr A_GAIN

5 COMP33K Y OFFSET

6 COMP33K Cb OFFSET

7 COMP33K Cr OFFSET

LCD controller software version Versions are always ‘090626000T0001’.

6 – 5

Page 50

LC-40/46/52/60LE820UN

Page Line Item Description Remarks (adjustment detail, etc.)

7 1 ANALOG RGB ADJ Analog RGB picture level adjustment

2 R A_GAIN

3 G A_GAIN

4 B A_GAIN

5 R OFFSET

6 G OFFSET

7 B OFFSET

8 1 VCOM ADJ VCOM adjustment value

9 1 LEV1 Standard value 1 Adjustment gradation setting.

2 LEV2 Standard value 2

3 LEV3 Standard value 3

4 LEV4 Standard value 4

5 LEV5 Standard value 5

6 LEV6 Standard value 6

10 1 MG1R WB adjustment Point 1, R adjustment value Parameter for six-point adjustment

2 MG1G WB adjustment Point 1, G adjustment value

3 MG1B WB adjustment Point 1, B adjustment value

4 MG1Y WB adjustment Point 1, Y adjustment value

5 MG2R WB adjustment Point 2, R adjustment value

6 MG2G WB adjustment Point 2, G adjustment value

7 MG2B WB adjustment Point 2, B adjustment value

8 MG2Y WB adjustment Point 2, Y adjustment value

9 MG3R WB adjustment Point 3, R adjustment value

10 MG3G WB adjustment Point 3, G adjustment value

11 MG3B WB adjustment Point 3, B adjustment value

12 MG3Y WB adjustment Point 3, Y adjustment value

11 1 MG4R WB adjustment Point 4, R adjustment value Parameter for six-point adjustment

2 MG4G WB adjustment Point 4, G adjustment value

3 MG4B WB adjustment Point 4, B adjustment value

4 MG4Y WB adjustment Point 4, Y adjustment value

5 MG5R WB adjustment Point 5, R adjustment value

6 MG5G WB adjustment Point 5, G adjustment value

7 MG5B WB adjustment Point 5, B adjustment value

8 MG5Y WB adjustment Point 5, Y adjustment value

9 MG6R WB adjustment Point 6, R adjustment value

10 MG6G WB adjustment Point 6, G adjustment value

11 MG6B WB adjustment Point 6, B adjustment value

12 MG6Y WB adjustment Point 6, Y adjustment value

13 MG6Y OFFSET

12 1 MODE SELECT

2 POS SELECT

3POS MIN

4POS MID1

5POS MID2

6POS MID3

7POS MID4

8POS MID5

9POS MID6

10 POS MAX

13 1 CD MIN

2 CD MID1

3 CD MID2

4 CD MID3

5 CD MID4

6 CD MID5

7 CD MID6

8 CD MAX

6 – 6

Page 51

LC-40/46/52/60LE820UN

Page Line Item Description Remarks (adjustment detail, etc.)

14 1 CALC

2 RESET

3VAL1

4VAL2

5VAL3

6VAL4

7VAL5

8VAL6

15 1 MONITOR TIME OUT

2 MONITOR MAX TEMP

3 MONITOR ERROR CAUSE RESET

16 1 LCD TEST PATTERN

2 LCD TEST PATTERN1

3 LCD TEST PATTERN2

4 LCD TEST PATTERN3

5 LCD TEST PATTERN4

6 TV TEST PATTERN 1

7 TV TEST PATTERN 2

17 1 FRC-N Firmware Version

2 FRC-N Boot Script Version

3 FRC-N Device Version

4 TCON FPGA1 Serial Flash Version

5 TCON FPGA2 Serial Flash Version

6 TCON FPGA1 Config Rom Version

7 TCON FPGA2 Config Rom Version

18 1 READ/WRITE

2 SLAVE ADDRESS

3 RESISTER ADDRESS UPPER

4 RESISTER ADDRESS LOWER

5 WRITE DATA UPPER

6WRITE DATA LOWER

7 READ DATA UPPER

8 READ DATA LOWER

19 1 POWER LED BRIGHTNESS

2 MENU LED BRIGHTNESS

3 INPUT LED BRIGHTNESS

4 CH UP LED BRIGHTNESS

5 CH DOWN LED BRIGHTNESS

6 VOL UP LED BRIGHTNESS

7 VOL DOWN LED BRIGHTNESS

8 LOGO LED BRIGHTNESS

9 ICON LED BRIGHTNESS

10 ICON LED BRIGHTNESS

(STANDBY)

20 1 POWER KEY SENSITIVITY

2 MENU KEY SENSITIVITY

3 INPUT KEY SENSITIVITY

4 CH UP KEY SENSITIVITY

5 CH DOWN KEY SENSITIVITY

6 VOL UP KEY SENSITIVITY

7 VOL DOWN KEY SENSITIVITY

21 1 KEY STRENGTH GET MODE

2 POWER KEY STRENGTH

3 MENU KEY STRENGTH

4 INPUT KEY STRENGTH

5 CH UP KEY STRENGTH

6 CH DOWN KEY STRENGTH

7 VOL UP KEY STRENGTH

8 VOL DOWN KEY STRENGTH

22 1 KEY LOCK (1217)

2 KOUTEI AREA ALL CLEAR

3 A MODE AREA CLEAR

4 BACKUP AREA CLEAR

5 B MODE AREA CLEAR

6EXECUTION

6 – 7

Page 52

LC-40/46/52/60LE820UN

Page Line Item Description Remarks (adjustment detail, etc.)

23 1 ERROR STANDBY CAUSE1

2 ERROR STANDBY CAUSE2

3 ERROR STANDBY CAUSE3

4 ERROR STANDBY CAUSE4

5 ERROR STANDBY CAUSE5

6 ERROR STANDBY CAUSE RESET

24 1 EEP SAVE Writing setting values to EEPROM

2 EEP RECOVER Reading setting values from EEPROM

3MODEL NAME

4 PANEL SIZE

5 SETTING FOR ADJ

6 PANEL LIMIT

7 PANEL RANGE LIMIT

8 SHORT CHECK MODE

9 SHORT CHECK CURRENT

10 CURRENT SW

*1 Details of P1.9 (NORMAL STANDBY CAUSE)

2 No operation off in the cause of “no operation off”

3 No signal off in the cause of “no signal off”

4 PC power management mode 1 in the cause of “Standby mode MODE1”

5 PC power management mode 2 in the cause of “Standby mode MODE2”

6 Off timer in the cause of “SLEEP timer”

8 Command from RS232C in the cause of command by RS-232C

*2 Details of P1.10 (ERROR STANDBY CAUSE)

11 Prolonged unspecified-signal input in PC mode in the cause of continuous “out of range”, PC input mode

17 Temperature error in the cause of abnormal temperature

1A Monitor trouble detected in the cause of abnormal monitor mode

22 LCD controller Rom error in the cause of software abnormality of LCD controller

6. Special features

* STANDBY CAUSE (Page 1/24)

Display of a cause (code) of the last standby

The cause of the last standby is recorded in EEPROM whenever possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

* EEP SAVE (Page 24/24)

Storage of EEP adjustment value

* EEP RECOVER (Page 24/24)

Retrieval of EEP adjustment value from storage area

6 – 8

Page 53

LC-40/46/52/60LE820UN

1/4 3/4

1/2

1/2

7. Microprocessor software writing

7.1. Main microprocessor/monitor microprocessor software writing (Main PWB: QPWBXF452WJZZ)

Adjustment item Adjustment conditions Adjustment procedure

1 Main microprocessor/moni-

tor microprocessor software writing

<Main PWB>

Software Version Up

File version check

USB memory check

* When IC is failure Please exchange to another PWB unit when IC8453 (NAND Flash) is failure.

7.2. Model/inch discrimination writing (Main PWB: QPWBXF452WJZZ)

• When writing the sub microprocessor software, the model data is configured with the software from the USB memory mounted to the checker.

• Reference and setting change are enabled through the process menu and RS-232C communication.

8. Signal adjustment

8.1. LCD section adjustment [LCD mo du le adj ustment]

1. Insert a USB memory for the main/monitor microprocessor into the service connector.

2. Supply AC power and write the main software to IC8453 and the monitor microprocessor software to IC2002.

3. Check that writing is normally completed and turn off the power.

CAUTION:When the USB memory is not inserted or reading error occurs, nothing

is written. (The former models have read the main software from the

writing jig. However, this model reads the main/monitor software from

the USB memory.)

(Because the software can't be written with USB memory, when the new IC is

exchanged from broken IC)

Adjustment item Adjustment conditions Adjustment procedure

1 Opposite bias adjustment

(LCD module adjustment

item)

Adjustment in the center

position of the panel

1. Enter the process mode using the process adjustment remote control.

2. Select [VCOM ADJ] using the Channel / keys on the remote control.

3. Press the Enter key to check that the pattern for adjustment is displayed.

4. Make adjustment so that the flicker located in the center of the screen is minimized using the Volume +/- keys on the remote control.

5. If the optimum condition is obtained in step 4, press the Enter key to turn off the

pattern.

CAUTION:* Make adjustment with no ANT signal (since the brightness is

changed by the active backlight).

[Adjustment position]

8.2. Image adjustment

8.2.1 Device check

Before adjustment, check that the adjustment jig and signal source are set for Sharp LCD US.

Signal adjustment works at only the default View Mode.

Before adjustment, confirm the View Mode is set as follows.

Adjustment Type Default View Mode

Composite/Tuner S.Stretch

Comp15k S.Stretch

Comp33k Stretch

Analog RGB Stretch

6 – 9

Page 54

LC-40/46/52/60LE820UN

Signal generator level adjustment check (Adjust to the standard value level.)

•Composite signal: 0.714Vp-p ± 0.02Vp-p (Pedestal to white)

•15K component signal: Y level: 0.714Vp-p± 0.02Vp-p (Pedestal to white)

PB/PR level: 0.7Vp-p ± 0.02Vp-p

•33K component signal: Y level: 0.7Vp-p ± 0.02Vp-p (Pedestal to white)

PB/PR level: 0.7Vp-p ± 0.02Vp-p

•Analog RGB: RGB level: 0.7Vp-p ± 0.02Vp-p (Pedestal to white)

8.2.2 Process mode

Adjustment point Adjustment conditions Adjustment procedure

Process mode Enter the process adjustment mode using the process adjustment remote control.

8.2.3 Composite N358 signal/tuner adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting N358 signal

US-10ch

•Send the N358 color bar (color saturation: 75%) signal to the Video 2 video input.

•Send the in-house signal (use US-10ch) to TUNER.

[Video input signal] [In-house US-10ch]

Color saturation: 75%

0% black

2 Automatic adjustment exe-

cution

100% white 100% white

Point the cursor to [ N358 ALL ADJ(INPUT2)] and press the [Enter] key.

The adjustment is complete when [ N358 ALL ADJ(INPUT2) OK] is displayed.

8.2.4 Component 15K signal adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting 480i signal •Send the 100% color bar signal to the Video 1 component input.

Color saturation: 100%

480i

100% color bar

100% white 0% black

2 Automatic adjustment exe-

cution

Point the cursor to [ COMP15K ADJ(INPUT1)] and press the [Enter] key.

The adjustment is complete when [ COMP15K ADJ(INPUT1) OK] is displayed.

8.2.5 COMPONENT 33K signal adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting 1080i signal •Send the 100% color bar signal to the Video 1 component input.

2 Automatic adjustment exe-

cution

Color saturation: 100%

1080i

100% color bar

100% white 0% black

Point the cursor to [ COMP33K ADJ(INPUT1)] and press the [Enter] key.

The adjustment is complete when [ COMP33K ADJ(INPUT1) OK] is displayed.

6 – 10

Page 55

8.2.6 Analog RGB signal adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting Signal: XGA

(1024x768) 60Hz

SYNC: HV separate

LC-40/46/52/60LE820UN

•Send the 100% color bar signal to the Video 4 analog RGB input.

XGA (1024x768)

100% color bar

100% white 0% black

2 Automatic adjustment exe-

cution

8.2.7 Tuner/V-CH IP adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting NTSC RF signal

US-7(AIR)ch

2 Automatic adjustment exe-

cution

Point the cursor to [ ANALOG RGB ADJ] and press the [Enter] key.

The adjustment is complete when [ ANALOG RGB ADJ OK] is displayed.

•Send the NTSC signal to the RF antenna input.

Point the cursor to [ TUNER VCHIP TEST(*07ch)] and press the [Enter] key. (*

Adjust the selected channel to the in-house signal.)

The adjustment is OK when [ A-OK(***.**)/VM-OK] is displayed in green.

(NG when A-NG/VM-NG is displayed in red.)

It is OK when the deviation from the center frequency is ±0.0625MHz or less.

6 – 11

Page 56

LC-40/46/52/60LE820UN

9. White balance adjustment

9.1. White balance adjustment (For details about the adjustment procedure, refer to “Kameyama Model Integrated Monitor