Page 1

TopPage

LC-40/46LE810E, LC-40/46LX810E

SERVICE MANUAL

No. S30E940LE810E

LCD COLOUR TELEVISION

LC-40LE810E

LC-46LE810E

LC-40LX810E

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

LC-46LX810E

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION ............................................................i

Precautions for using lead-free solder ...............ii

End of life disposal ............................................ iii

OUTLINE

MAJOR SERVICE PARTS ................................iv

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS ......................................... 1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL .................................. 2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS (LC-40LE810E/LX810E)......... 3-1

[2] DIMENSIONS (LC-46LE810E/LX810E)......... 3-2

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS

(LC-40LE810E/LX810E) ................................ 4-1

[2] REMOVING OF MAJOR PARTS

(LC-46LE810E/LX810E) ................................ 4-6

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE ......................5-1

CHAPTER 6. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE ......................6-1

[2] LED flashing specification at the time of the

error .............................................................6-13

CHAPTER 7. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS .........................7-1

CHAPTER 8. OVERALL WIRING/BLOCK DIAGRAM

[1] OVERALL WIRING DIAGRAM

(LC-40LE810E/LX810E)................................8-1

[2] OVERALL WIRING DIAGRAM

(LC-46LE810E/LX810E)................................8-2

[3] SYSTEM BLOCK DIAGRAM .........................8-3

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-40/46LE810E, LC-40/46LX810E

LC-40LE810E

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION:

FOR CONTINUED PROTECTION AGAINST A

RISK OF FIRE REPLACE ONLY WITH SAME

TYPE FUSE.

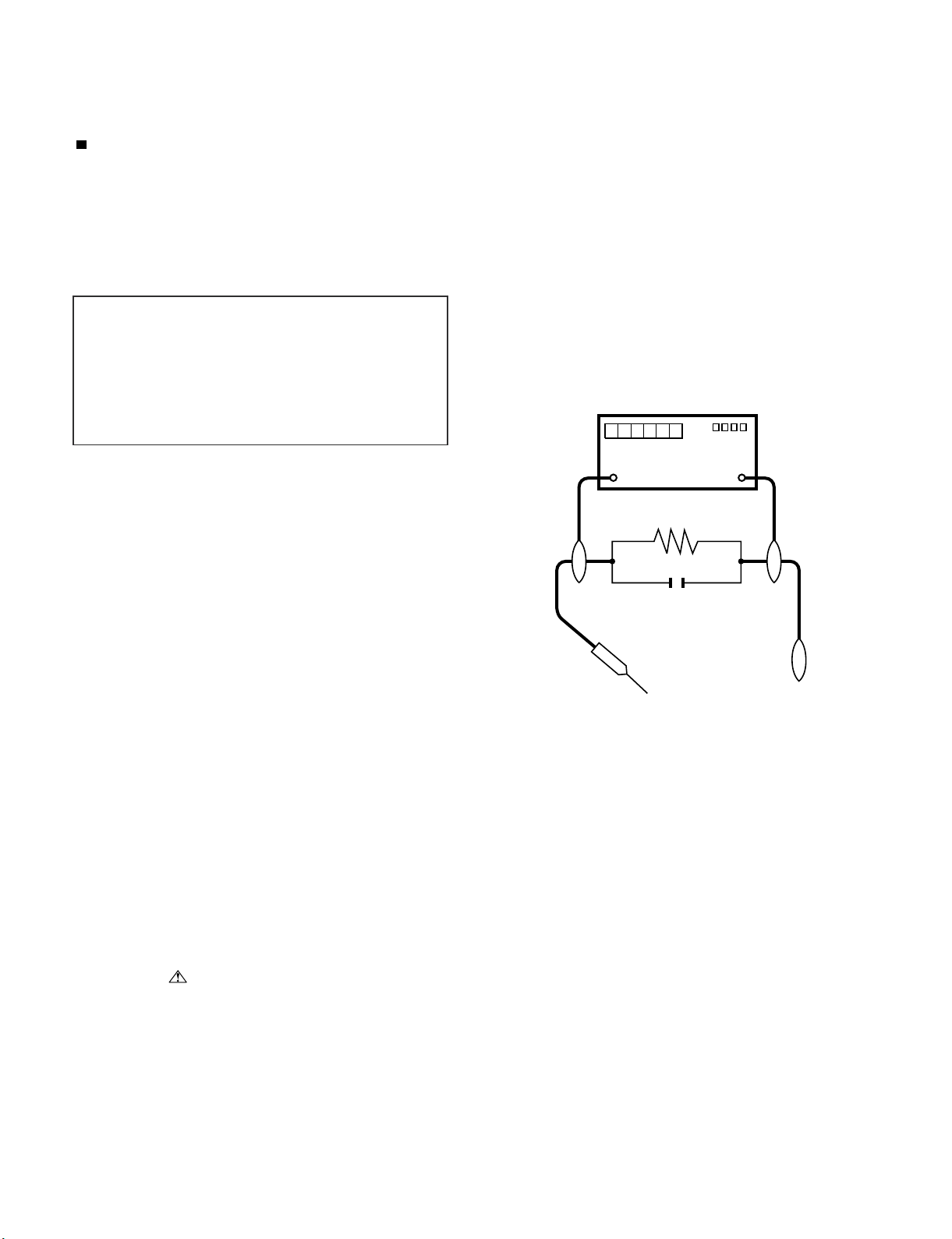

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 1.05 V peak (this corresponds to 0.7 mA peak AC.)

or more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

40 inch model: F7000, F7001 (3.15A/250V)

46 inch model: F7000, F7001 (5A/250V)

DVM

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 220~240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by “ ” and shaded areas in the Replacement Parts

List and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

i

Page 3

LC-40/46LE810E, LC-40/46LX810E

Precautions for using lead-free solder

Employing lead-free solder

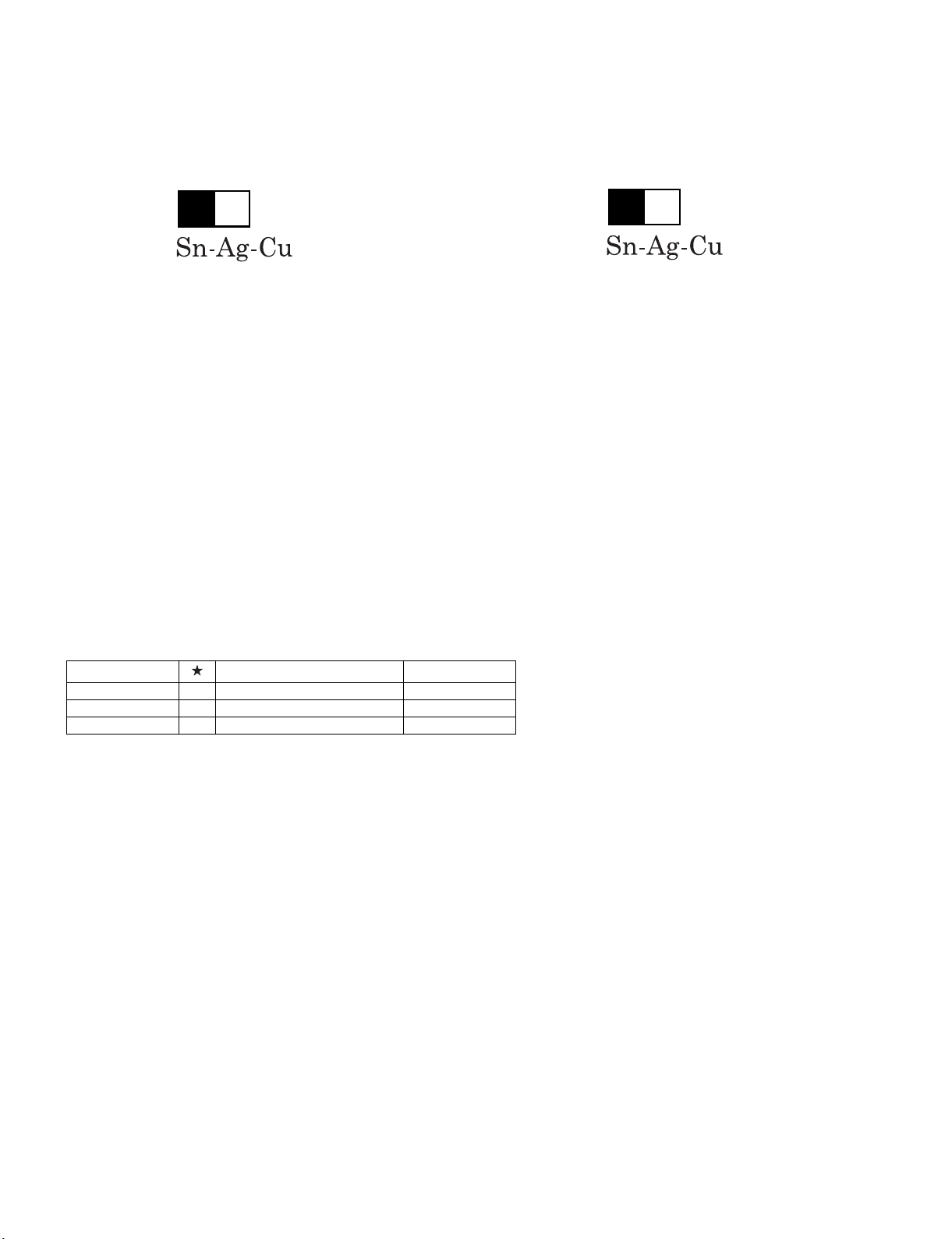

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

ii

Page 4

LC-40/46LE810E, LC-40/46LX810E

End of life disposal

End of life disposal

iii

Page 5

LC-40/46LE810E, LC-40/46LX810E

LC-40LE810E

OUTLINE

Service Manual

MAJOR SERVICE PARTS

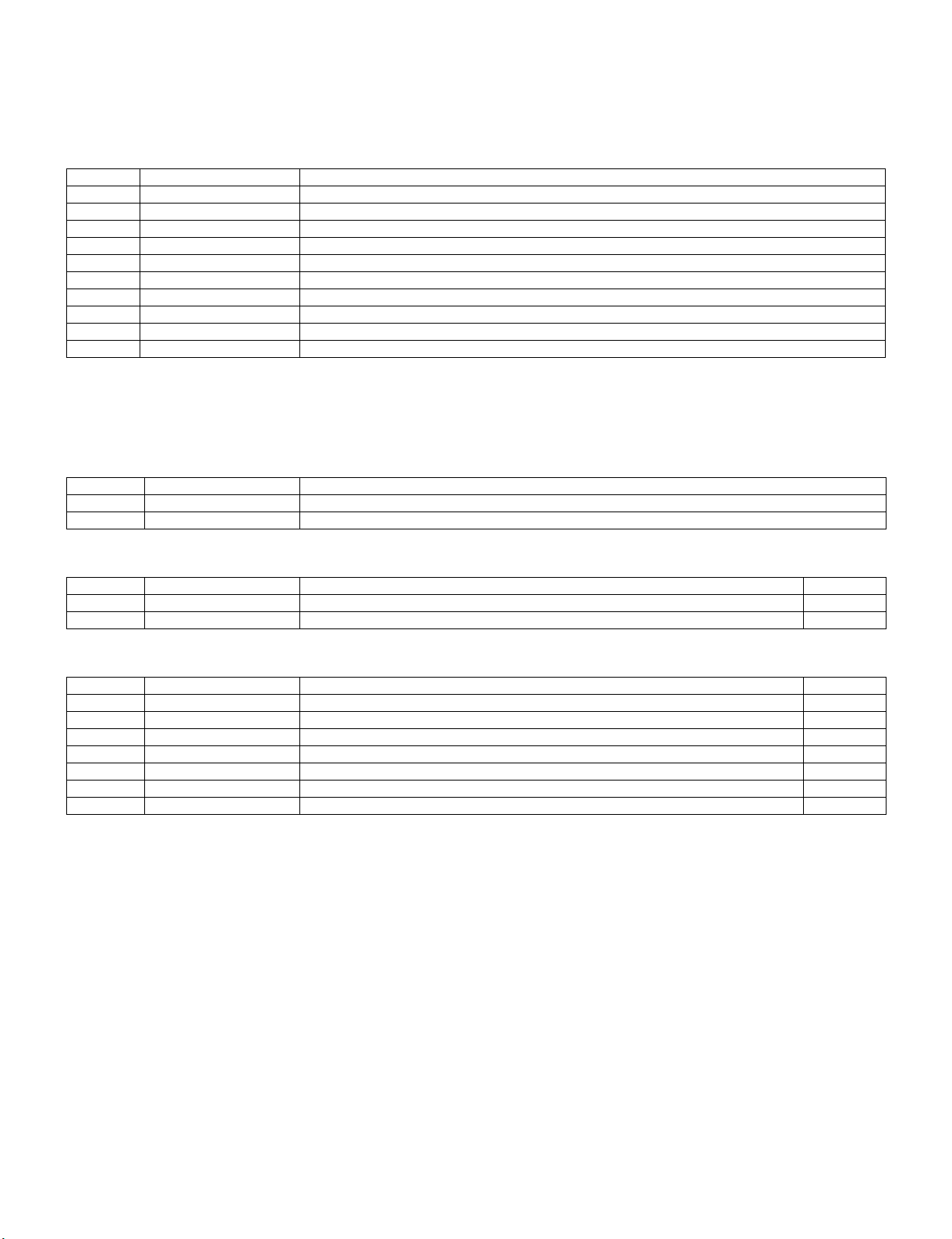

PWB UNIT

Ref No. Parts Code Description

N DKEYDF455FM03 MAIN Unit (*1)

N DUNTKF494FM02 R/C, LED Unit

N DUNTKF493FM03 ICON Unit

N RUNTKA692WJQZ TOUCH SENSOR Unit (*2)

N RUNTKA685WJQZ POWER Unit (LC-40LE810E/LX810E)

N RUNTKA686WJQZ POWER Unit (LC-46LE810E/LX810E)

N RUNTK4512TPZC LCD CONTROL Unit (LC-40LE810E/LX810E)

N RUNTK4437TPZE LCD CONTROL Unit (LC-46LE810E/LX810E)

N RUNTK4462TPZZ LED PWB Unit, x4 (LC-40LE810E/LX810E)

N RUNTK4461TPZZ LED PWB Unit, x4 (LC-46LE810E/LX810E)

NOTE: (*1) Replace MAIN Unit (DKEYDF455FM03) in case of IC8401 or IC3302 failure.

(*2) TOUCH SENSOR Unit (RUNTKA692WJQZ) reuse will be impossible, once it is stuck on front cabinet and exfoliates.

Therefore, please exchange of a TOUCH SENSOR Unit in the case of front cabinet exchange.

OTHER UNIT

Ref No. Parts Code Description

N R1LK400D3LWF2Y 40” LCD Panel Module Unit (LC-40LE810E/LX810E)

N R1LK460D3LWA2Y 46” LCD Panel Module Unit (LC-46LE810E/LX810E)

IC FOR EXCLUSIVE USE OF THE SERVICE

Ref No. Parts Code Description Q’ty

IC501 RH-iXD108WJQZS IC 24LC21AT-I/SN 1

IC2002 RH-iXC786WJNJQ IC R5F364A6NFB 1

SERVICE JIGS

Ref No. Parts Code Description Q’ty

N QCNW-G616WJQZ Main Unit to LCD Control Unit (LW) 1

N QCNW-G625WJQZ Main Unit to Power Unit (PL) 1

N QCNW-H184WJQZ Main Unit to Power Unit (PD) 1

N QCNW-H185WJQZ Main Unit to Power (LED Drive) Unit (LB) 1

N QCNW-K594WJQZ Main Unit to R/C, LED Unit (RA) 1

N QCNW-K595WJQZ Main Unit to Speaker (SP) 1

N QCNW-K597WJQZ Main Unit to Woofer (SB) 1

iv

Page 6

LC-40/46LE810E, LC-40/46LX810E

LC-40LE810E

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

Service Manual

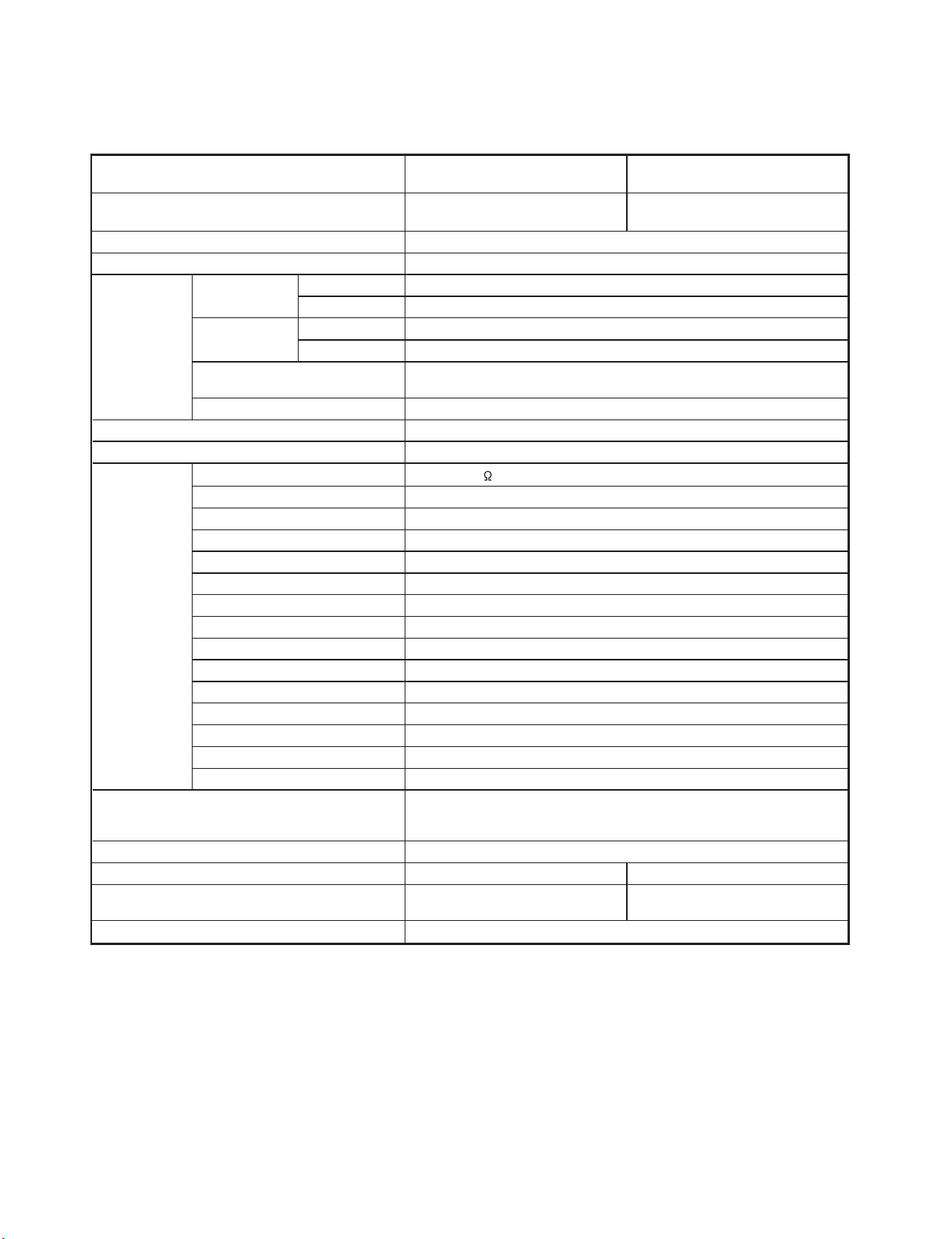

Item LCD COLOUR TV (40"/81.28 cm),

LCD panel Advanced Super View & BLACK TFT

Resolution 1,920 x 1,080 x 4 pixels

Video colour system PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV function TV-standard Analogue CCIR (B/G, I, D/K, L/L’)

Digital DVB-T (2K/8K OFDM), DVB-C

Receiving

channel

TV-tuning system Auto Preset 999 ch (non-Nordic [DTV]), Auto Preset 9999 ch (Nordic [DTV]),

STEREO/BILINGUAL NICAM/A2

Audio amplifier 10 W x 2/15 W x 1

Speaker (234 mm x 22 mm) x 2/Ø 110 mm

Terminals Antenna

RS-232C D-Sub 9 pin male connector

EXT 1 SCART (AV input, Y/C input, RGB input, TV output)

EXT 2 RCA pin (AV input/AUDIO L/R)

EXT 3 15 pin mini D-sub

HDMI 1 (EXT 4) HDMI (ARC)

HDMI 2 (EXT 5) HDMI

HDMI 3 (EXT 6) HDMI

HDMI 4 (EXT 7) HDMI

USB USB

ETHERNET (10/100) Home network connector (only the 820 model series)

HDMI 2/EXT 3 AUDIO (L/R) Ø 3.5 mm jack*

DIGITAL AUDIO OUTPUT Optical S/PDIF digital audio output

C. I. (Common Interface) EN50221, R206001, CI Plus specification

OUTPUT/Headphones RCA pin (AUDIO R/L)/Ø 3.5 mm jack (audio output)

OSD language Czech, Danish, Dutch, English, Estonian, Finnish, French, German, Greek,

Power requirement

Power consumption (method IEC62087) 127 W (0.2 W standby*

Weight 16.0 kg (without stand),

Operating temperature

VHF/UHF

CATV

LC-40LE810E/LC-40LX810E

LCD (40

IR A ch-E69 ch (Digital), E2-E69 ch, F2-F10 ch, I21-I69 ch, IR A-IR J ch

Hyper-band, S1-S41 ch

Auto Preset 99 ch (ATV), Auto Label, Auto Sort

UHF/VHF 75 Din type (analogue & digital)

Hungarian, Italian, Latvian, Lithuanian, Norwegian, Polish, Portuguese, Russian,

Slovak, Slovene, Spanish, Swedish, Turkish, Ukrainian

AC 220 - 240 V, 50 Hz

19.5 kg (with stand)

0°Cto+40°C

"/81.28 cm)

1

2

) 147 W (0.2 W standby*2)

LCDCOLOURTV(46"/116.84 cm),

LC-46LE810E/LC-46LX810E

Advanced Super View & BLACK TFT

LCD (46

20.5 kg (without stand),

26.0 kg (with stand)

"/116.84 cm)

The HDMI 2 and EXT 3 terminals can both use the same audio input terminal.

*1

*2

Standby power consumption applies when the TV is set to not receive EPG data.

As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

•

improvement without prior notice. The performance specification figures indicated are nominal values of production units. There may be

some deviations from these values in individual units.

1 – 1

Page 7

LC-40LE810E

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

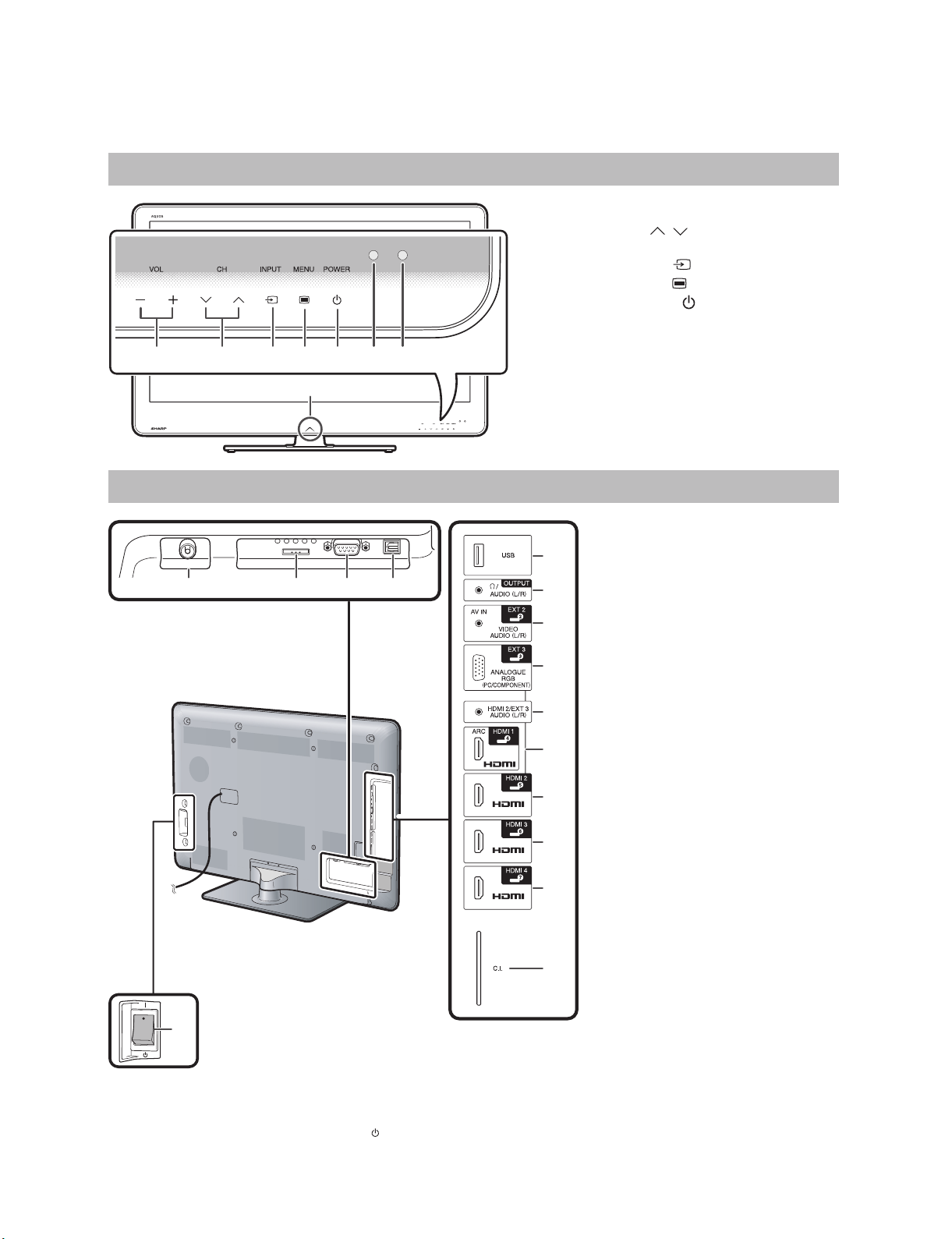

TV (front view)

1 3 458672

LC-40/46LE810E, LC-40/46LX810E

Service Manual

1

2

3

4

5

6

7

8

VOL -/+ (Volume buttons)

CH / (Programme [channel]

buttons)

INPUT (Input source button)

MANU (Menu button)

POWER (Power button)

OPC sensor

Remote control sensor

Illumination LED

TV (rear view)

1 2 3 4

5

6

7

8

9

10

11

12

13

14

*1

Antenna terminal

1

EXT 1 (RGB) terminal

2

RS-232C terminal

3

DIGITAL AUDIO OUTPUT

4

terminal

5

USB terminal

OUTPUT (Headphones/AUDIO

6

(L/R)) terminal

7

EXT 2 (AV IN/VIDEO/AUDIO (L/R))

terminal

8

EXT 3 (ANALOGUE RGB (PC/

COMPONENT)) terminal

9

HDMI 2/EXT 3 AUDIO (L/R) jack

10

HDMI 1 (HDMI/ARC) terminal

11

HDMI 2 (HDMI) terminal

HDMI 3 (HDMI) terminal

12

13

HDMI 4 (HDMI) terminal

14

C.I. (COMMON INTERFACE) slot

15

MAIN POWER switch

WARNING

Excessive sound pressure from earphones

•

and headphones can cause hearing loss.

•

Do not set the volume at a high level.

Hearing experts advise against extended

listening at high volume levels.

*2

15

The HDMI 2 and EXT 3 terminals can both use the same audio input terminal (HDMI 2/EXT 3 AUDIO (L/R)). However, the proper item

*1

must be selected in the “Audio select” menu.

*2

When the MAIN POWER switch is turned off ( ), the amount of electric power consumed will be reduced to 0.01 W or less. However,

unlike when unplugging the AC cord, the power is not completely disconnected.

2 – 1

Page 8

LC-40/46LE810E, LC-40/46LX810E

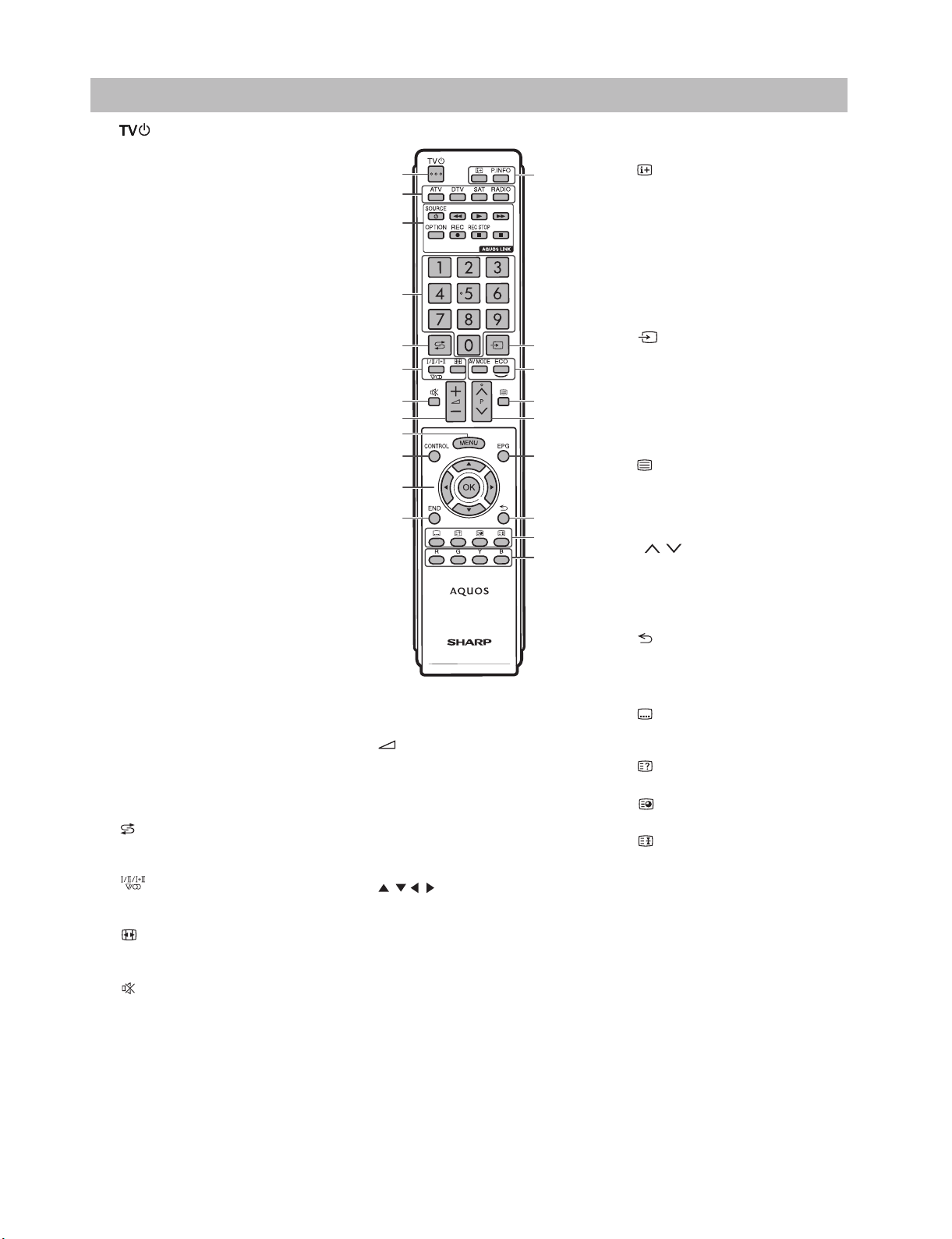

Remote control unit

1

2

3

(Standby/On)

ATV

Press to access conventional

analogue TV mode.

DTV

Press to access digital TV mode.

SAT

This function is not available.

RADIO

DTV: Switch between radio and

data mode.

•

When only data broadcasting

(no radio broadcasting) is

transmitted by DVB, the radio

broadcasting will be skipped.

AQUOS LINK buttons

If external equipment such as a

AQUOS BD player is connected via

HDMI cables and is AQUOS LINK

compatible, you can use these

AQUOS LINK buttons.

12

END

Exit the “Menu” screen.

113

13

2

3

4

5

6

7

8

14

15

16

17

14

15

9

10

18

16

11

12

19

20

21

17

18

(Display information)

Press to display the station

information (channel number, signal,

etc.) in the upper right corner of the

screen.

P. INFO

Press to display programme

information transmitted through

digital video broadcasting (DTV

only).

Select an input source.

AV MODE

Select a video setting.

ECO (Standard/Advanced/Off)

Select “Energy save” setting.

(Teletext)

ATV: Display analogue teletext.

DTV: Select MHEG-5 and teletext

for DTV.

P/

Select the TV channel.

EPG

DTV: Display the EPG screen.

(INPUT)

4

Numeric buttons 0_ 9

Set the channel.

Enter desired numbers.

Set the page in teletext mode.

•

When the five Nordic countries

(Sweden, Norway, Finland,

Denmark or Iceland) are selected

in the country setting from “Auto

installation”, DTV services are

four digits. When another country

is selected, DTV services are

three digits.

5

6

7

(Flashback)

Press to return to the previously

selected channel or external input.

(Sound mode)

Select a sound multiplex mode.

(Wide mode)

Select a wide mode.

(Mute)

TV sound on/off.

8

9

10

11

+/- (Volume)

Increase/decrease TV volume.

MENU

“Menu” screen on/off.

CONTROL

Press to display the panel to

operate some functions on the

screen.

/ / / (Cursor)

Select a desired item on the setting

screen.

OK

Execute a command within the

“Menu” screen.

ATV/DTV: Display “CH list” when no

other “Menu” screen is running.

19

20

21

(Return)

Return to the previous “Menu”

screen.

Buttons for useful operations

(Subtitle)

Switch subtitle languages on/off .

(Reveal hidden teletext)

(Subpage)

(Freeze/Hold)

Press to freeze a moving image on

the screen.

Teletext: Stop updating teletext

pages automatically or release the

hold mode.

R/G/Y/B (Colour) buttons

The coloured buttons are

correspondingly used to select the

coloured items on the screen (e.g.,

EPG, MHEG-5, teletext).

2 – 2

Page 9

LC-40/46LE810E, LC-40/46LX810E

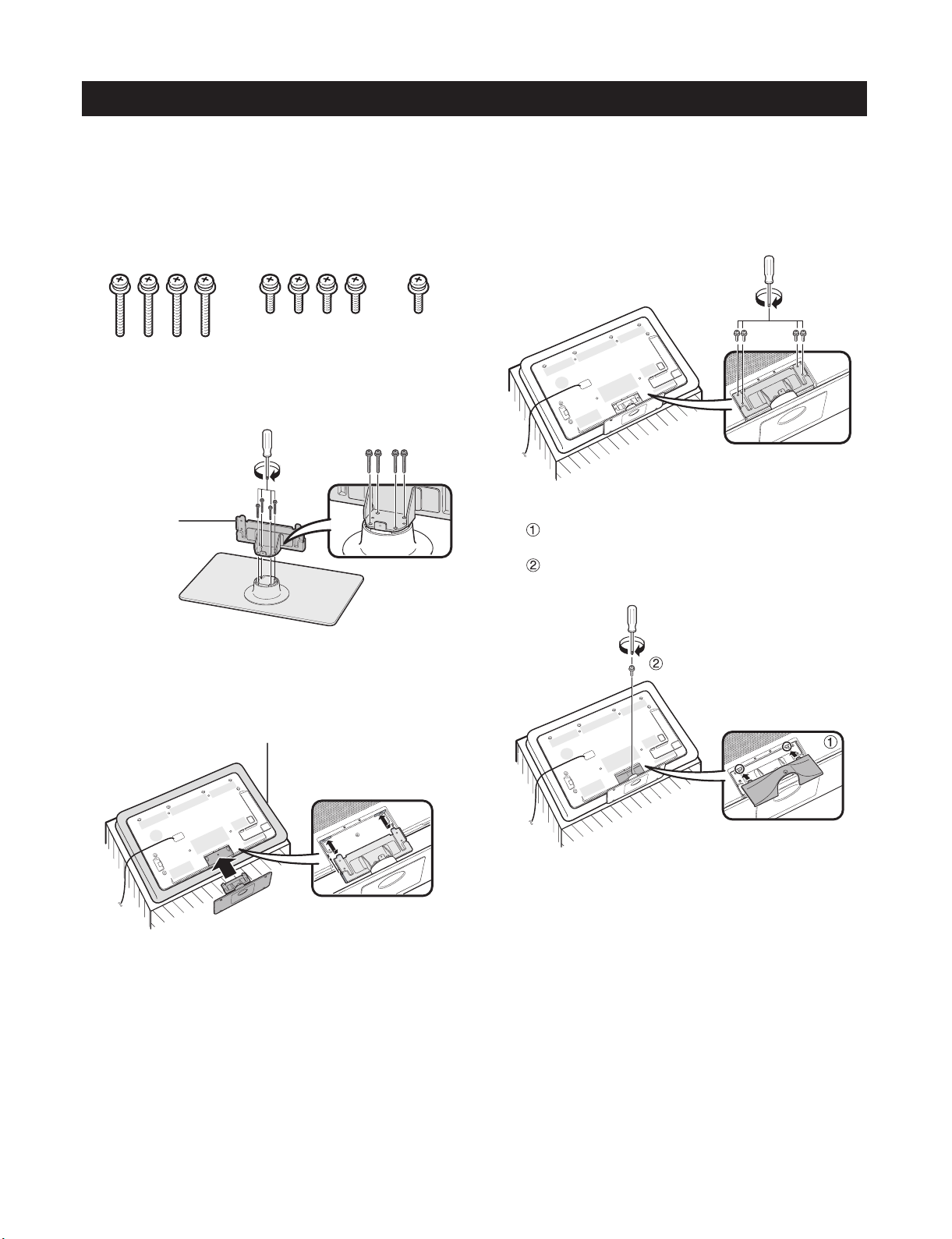

Attaching the stand unit

Before performing work, spread cushioning over the surface on which you will be laying the TV. This will prevent it from being damaged.

•

CAUTION

Attach the stand in the correct direction.

•

Be sure to follow the instructions. Incorrect installation of the stand may result in the TV falling over.

•

Confirm that there are nine screws (four long

1

screws and five short screws) with the stand

unit.

Attach the supporting post for the stand unit

2

onto the base using the four long screws with

a screwdriver as shown.

Insert and tighten four short screws into the

4

four holes on the rear of the TV.

Supporting

post

Insert the stand into the openings on the

3

bottom of the TV (hold the stand so it will not

drop from the edge of the base area).

Soft cushion

5

Attaching the stand cover.

Slide the stand cover into the two catches on

the stand base.

Insert and tighten a short screw into the hole

on the centre of the stand cover.

NOTE

To detach the stand unit, perform the steps in reverse order.

•

A screwdriver is not supplied with this product.

•

The stand base is made of glass. Therefore, be careful not to

•

drop the stand base or apply pressure to it.

•

Do not place heavy objects on the stand base.

2 – 3

Page 10

LC-40/46LE810E, LC-40/46LX810E

LC-40LE810E

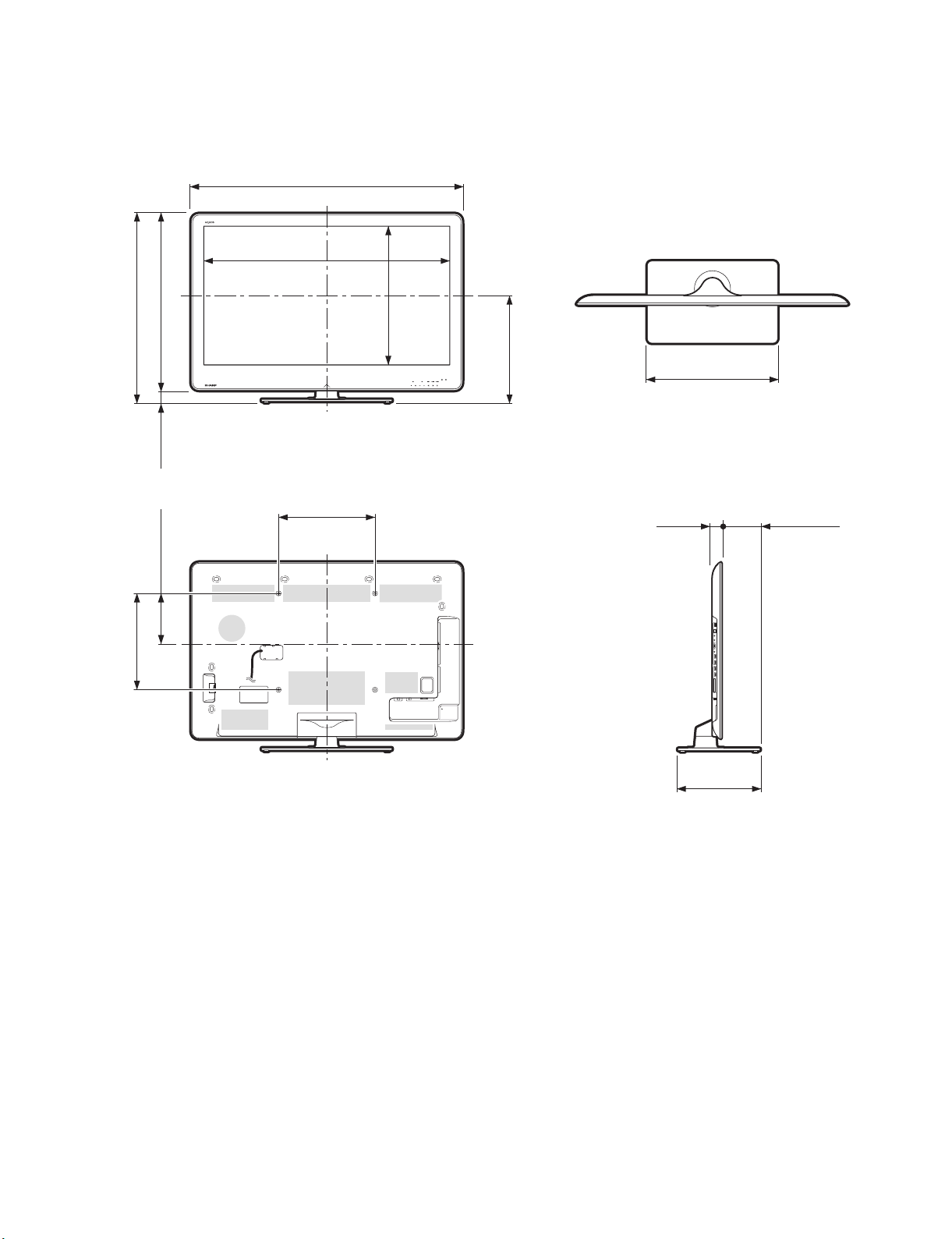

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS (LC-40LE810E/LX810E)

Service Manual

706.0

706,0

658.0

658,0

48.0

48,0

132.0

132,0

887.8

887,8

992.0

992,0

300.0

300,0

500.4

500,4

404.0

404,0

39.5

39,5

Unit: mm

450.0

450,0

124.0

124,0

300.0

300,0

275.0

275,0

3 – 1

Page 11

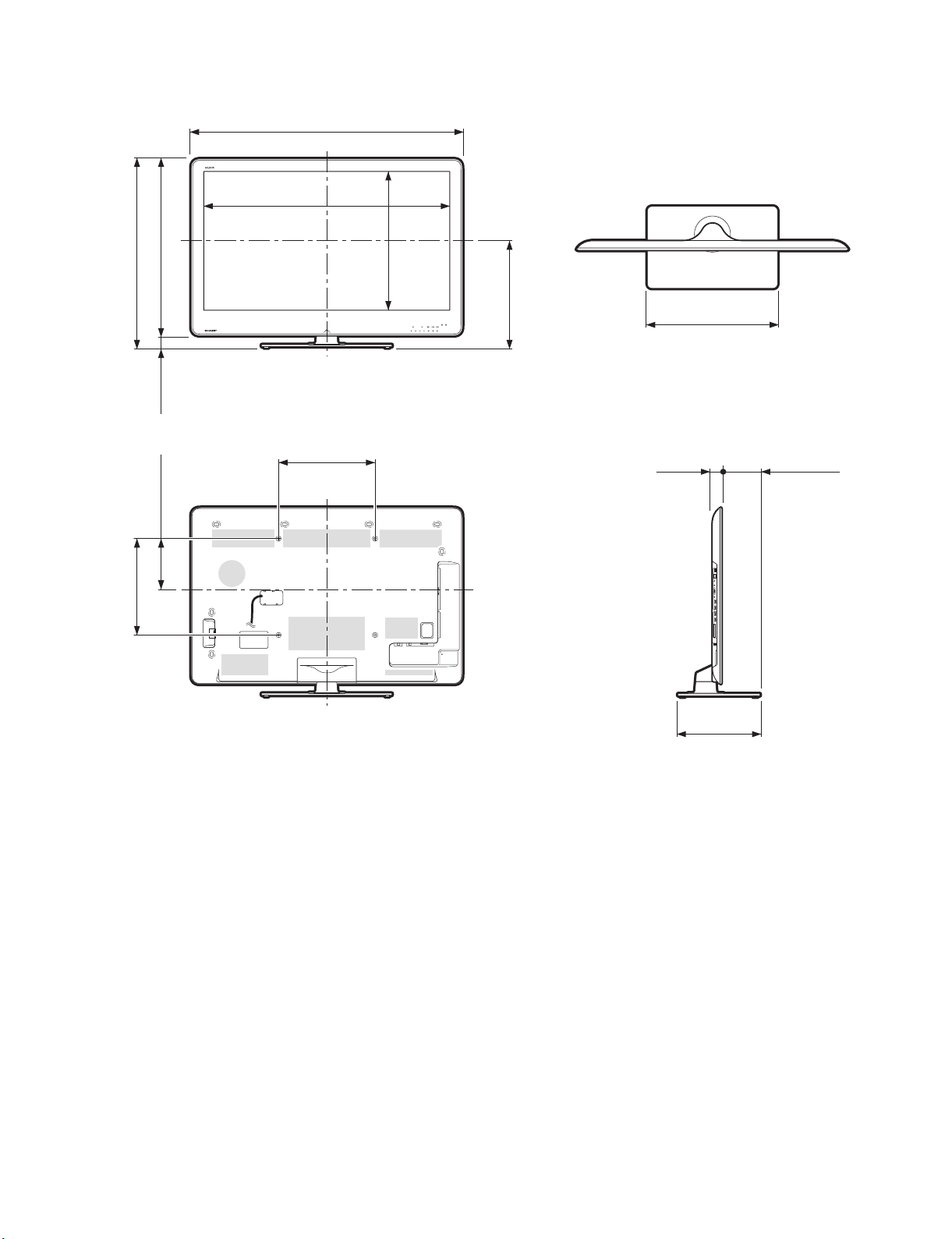

[2] DIMENSIONS (LC-46LE810E/LX810E)

LC-40/46LE810E, LC-40/46LX810E

784.0

784,0

733.0

733,0

51.0

51,0

211.0

211,0

1020.8

1020,8

1125.0

1125,0

400.0

400,0

575,4

575.4

444.0

444,0

39.5

39,5

Unit: mm

540.0

540,0

157.1

157,1

400.0

400,0

340.0

340,0

3 – 2

Page 12

LC-40/46LE810E, LC-40/46LX810E

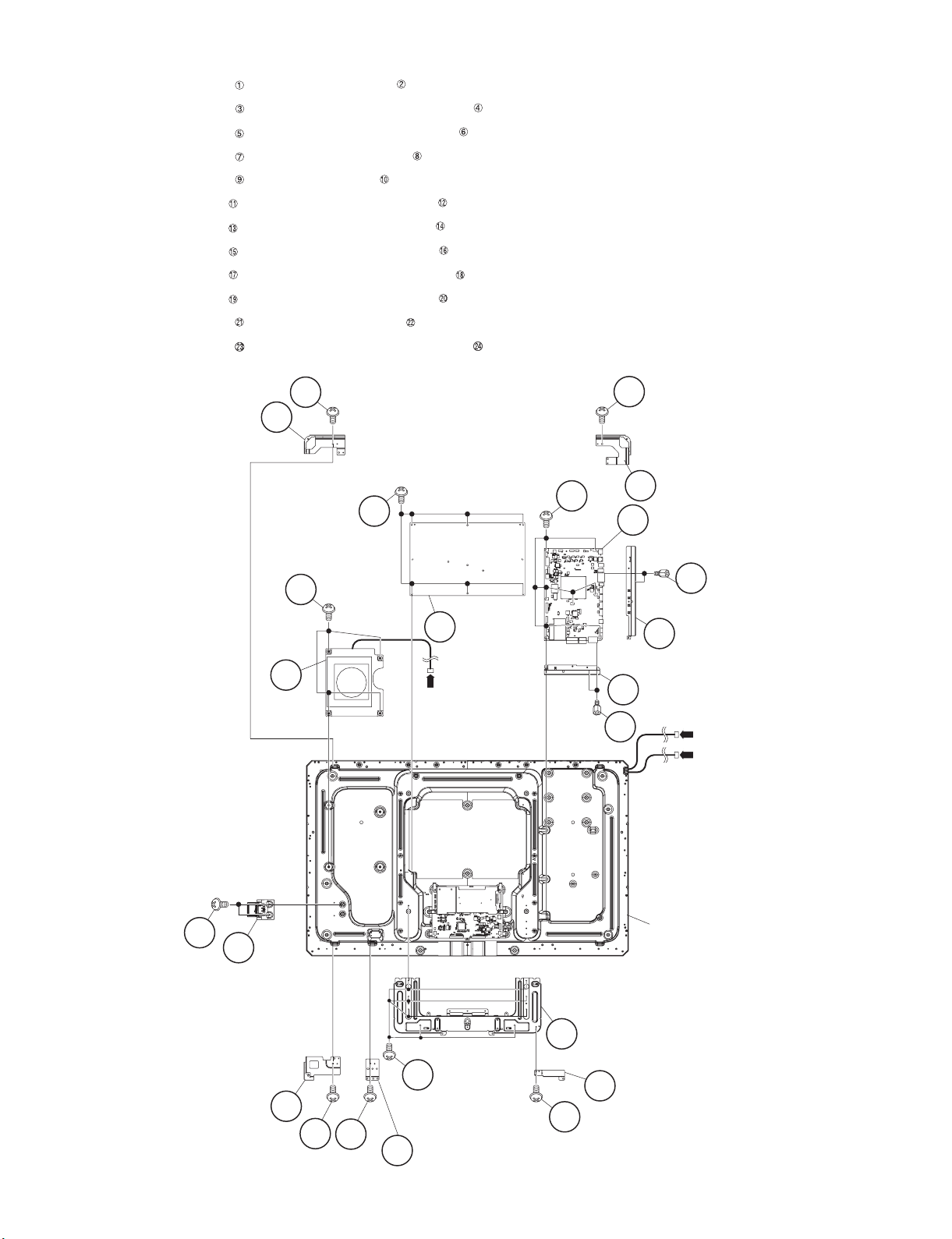

LC-40LE810E

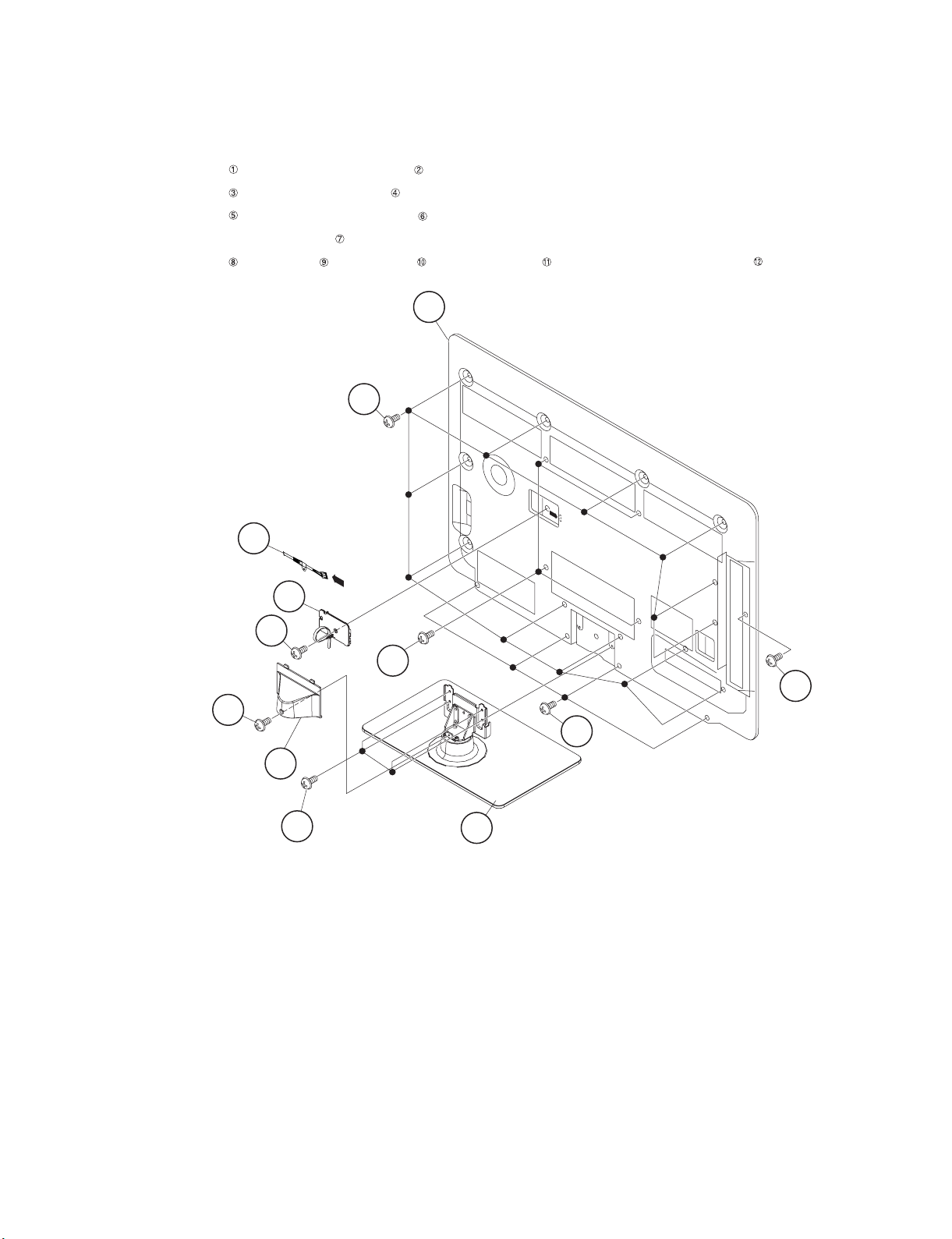

CHAPTER 4. REMOVING OF MAJOR PARTS

Service Manual

[1] REMOVING OF MAJOR PARTS (LC-40LE810E/LX810E)

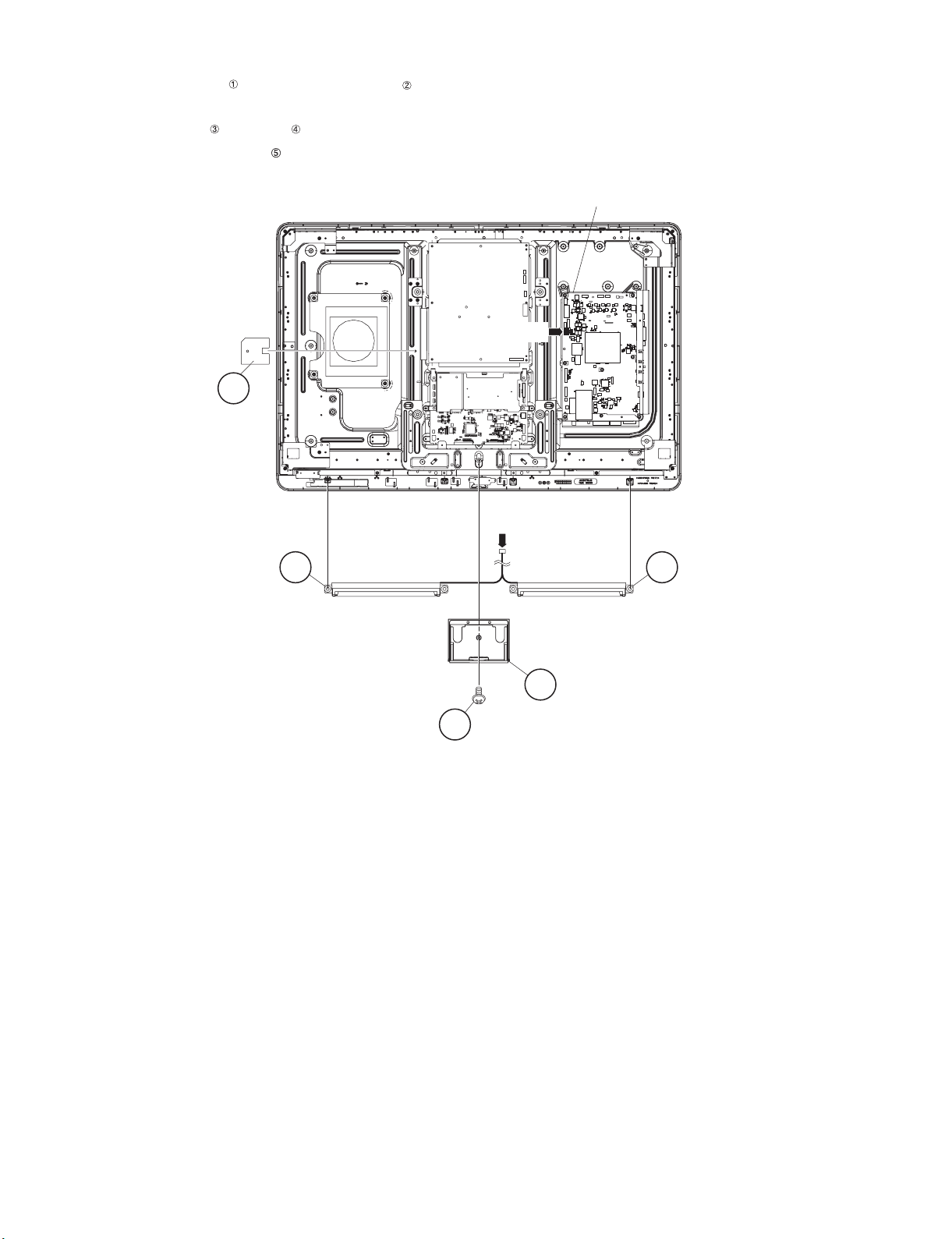

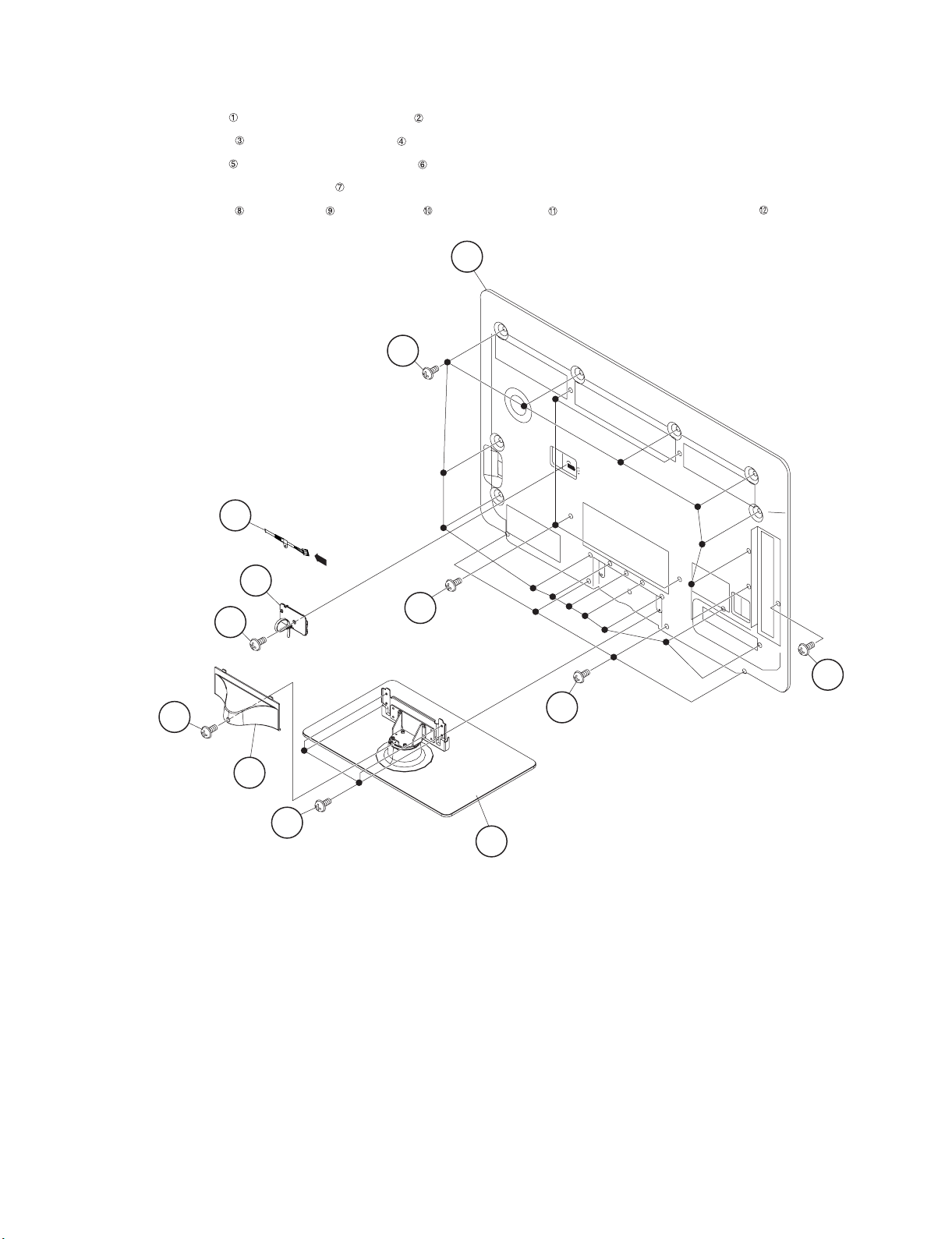

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 1 lock screw and detach the Support Cover .

2. Remove the 4 lock screw and detach the Stand Unit .

3. Remove the 1 lock screw and detach the AC Cord Cover .

4. Disconnect AC wire and detach the AC Cord .

5. Remove the 4 lock screw , 1 lock screw , 4 lock screws and 12 lock screws and detach the Rear Cabinet Ass’y .

Rear Cabinet Ass'y

12

11

7AC Cord

6AC Cord Cover

[AC]

[AC]

5

8

9

1

10

2Support Cover

3

4Stand Unit

4 – 1

Page 13

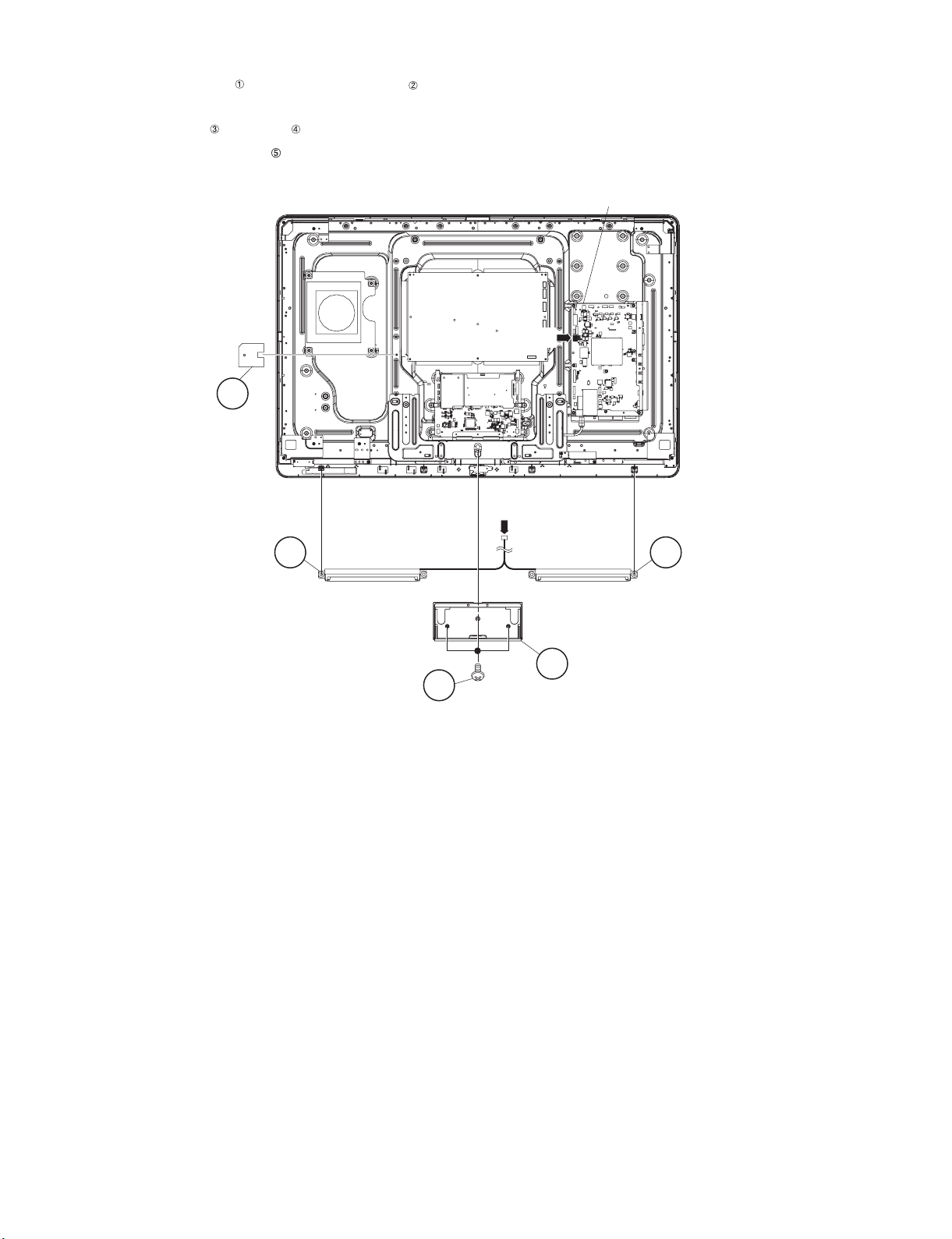

2. Removing of Speaker-L/R.

1. Remove the 1 lock screw and detach the Stand Cover .

2. Disconnect SP wire.

3. Detach the Speaker-L , Speaker-R .

4. Detach the Insulation Sheet (AC) .

5

Insulation

Sheet (AC)

LC-40/46LE810E, LC-40/46LX810E

MAIN Unit

[SP]

[SP]

4Speaker-R 3 Speaker-L

2 Stand Cover

1

4 – 2

Page 14

LC-40/46LE810E, LC-40/46LX810E

3. Removing of 40” LCD Panel Module Unit, TOUCH SENSOR Unit, ICON Unit, R/C, LED Unit, Front Cabinet

Ass’y.

1. Disconnect RA, SB wire.

2. Detach the TOUCH SENSOR Unit . (RK)

3. Detach the ICON Unit . (RI)

4. Detach the R/C, LED Unit . (RA)

5. Remove the 1 lock screw and detach the LCD Angle (Bottom-R) .

6. Remove the 5 lock screws , 3 lock screws , 4 Hooks and detach the 40” LCD Panel Module Unit .

NOTE: The TOUCH SENSOR Unit removed once is not reusable.

9

6

7

40" LCD Panel Module Unit

6

[SB]

7

[RA]

[SB]

6

6

8

6

8

5

LCD Angle

(Bottom-R)

4

8

8

3

R/C, LED Unit

[RA]

[RI]

[RK]

1 TOUCH SENSOR Unit

4 – 3

Front Cabinet Ass'y

2 ICON Unit

Page 15

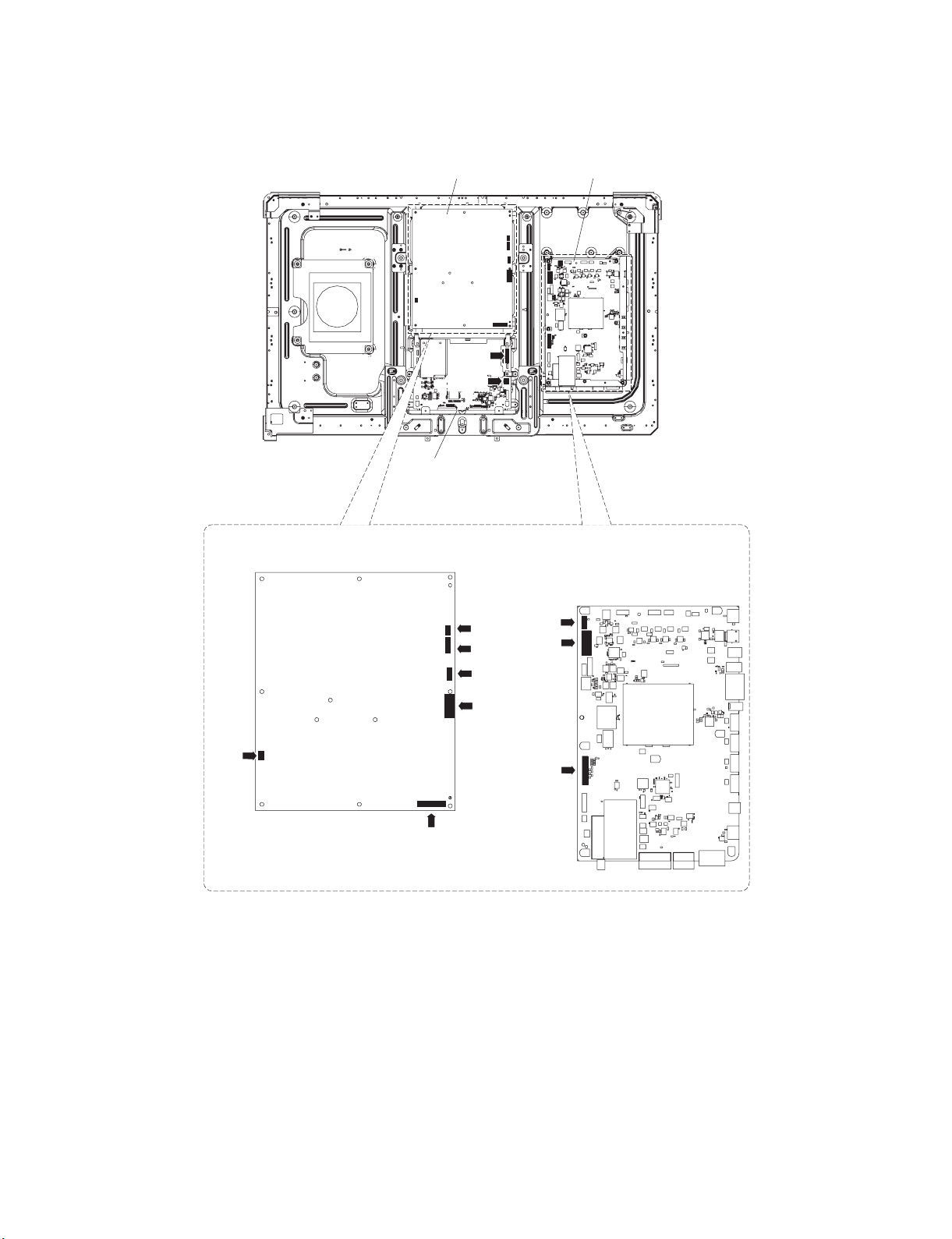

4. Removing of Connectors

1. Disconnect the following connectors from the MAIN Unit. (LB, PD, LW)

2. Disconnect the following connectors from the POWER Unit. (L1, L2, LB, PD, PL, AS)

3. Disconnect the following connectors from the LCD CONTROL Unit. (LW, PL)

[LW]

[PL]

LCD CONTROL Unit

LC-40/46LE810E, LC-40/46LX810E

MAIN UnitPOWER Unit

[AS]

[PL]

[L1]

[L2]

[LB]

[PD]

MAIN UnitPOWER Unit

[LB]

[PD]

[LW]

4 – 4

Page 16

LC-40/46LE810E, LC-40/46LX810E

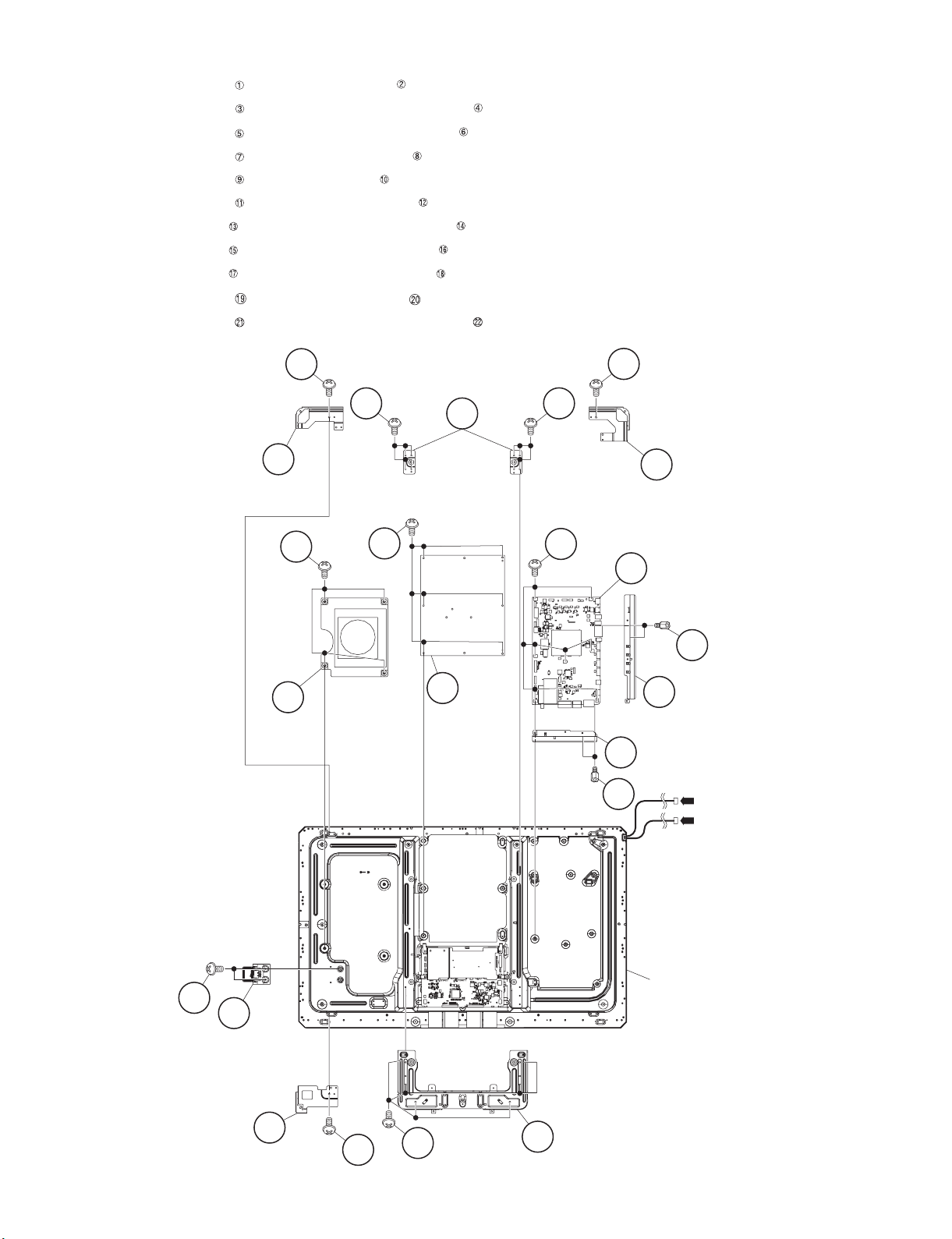

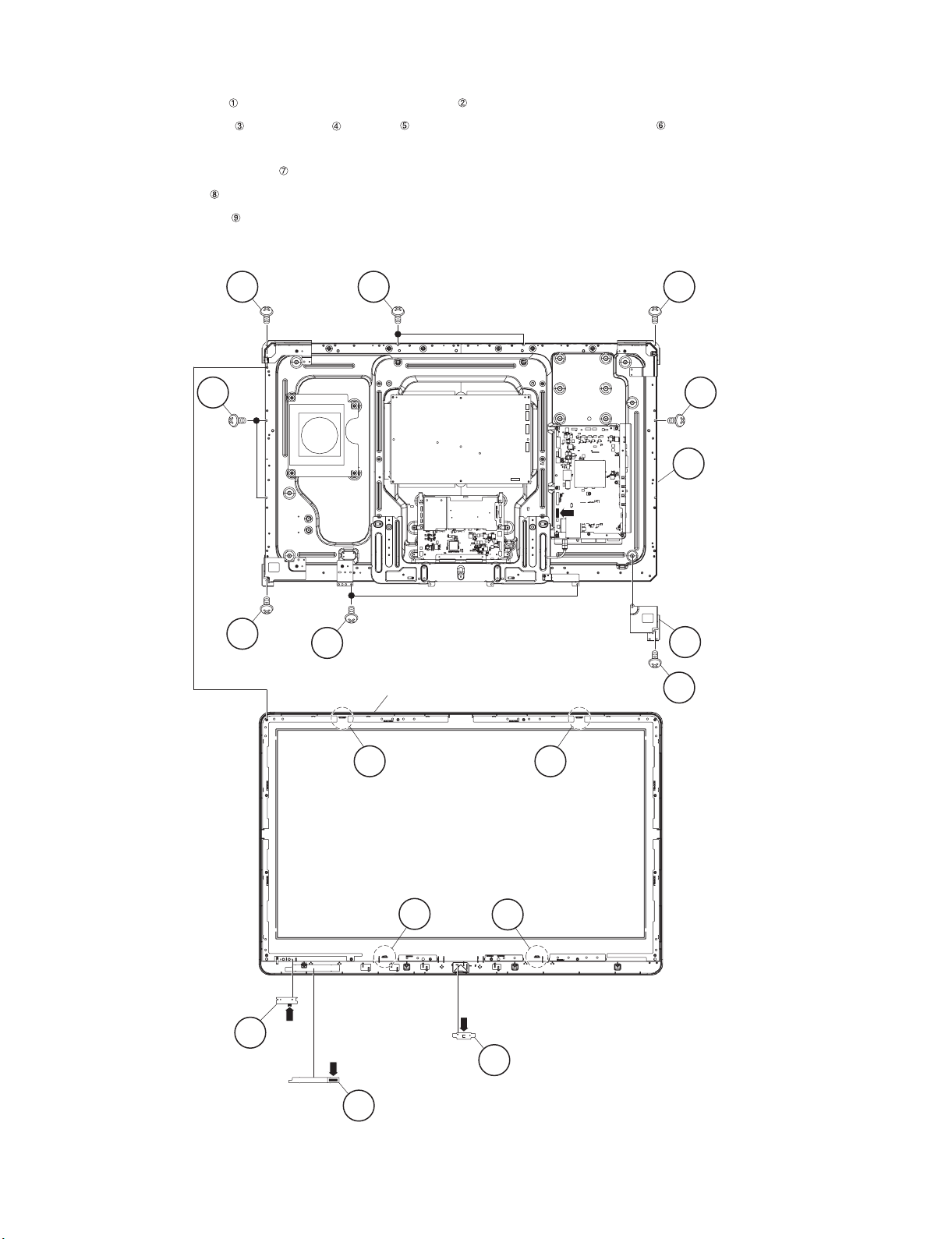

5. Removing of MAIN Unit, POWER Unit, Woofer, Stand Angle.

1. Remove the 7 lock screws and detach the MAIN Unit

2. Remove the 2 lock screws and detach the Terminal Angle (Bottom) .

3. Remove the 2 lock screws and detach the Terminal Angle (Side) .

4. Remove the 6 lock screws and detach the POWER Unit .

5. Remove the 4 lock screws and detach the Woofer .

6. Remove the 8 lock screws and detach the 2 VESA Angle .

7. Remove the 1 lock screw and detach the LCD Angle (Bottom-L) .

8. Remove the 1 lock screw and detach the LCD Angle (Top-R) .

9. Remove the 1 lock screw and detach the LCD Angle (Top-L) .

10.Remove the 6 lock screws and detach the Stand Angle .

11.Remove the 2 lock screws and detach the ECO Switch with Holder .

LCD Angle

(Top-L)

17

18

9

10

Woofer

11

VESA

15

Angle

12

11

LCD Angle

16

(Top-R)

7

1

2 MAIN Unit

5

8

POWER

6 Terminal Angle

(Side)

Unit

4 Terminal Angle

(Bottom)

3

[L1]

[L2]

21

22

ECO Switch

with Holder

LCD Angle

(Bottom-L)

14

13

19

40" LCD Panel

Module Unit

20 Stand Angle

4 – 5

Page 17

LC-40/46LE810E, LC-40/46LX810E

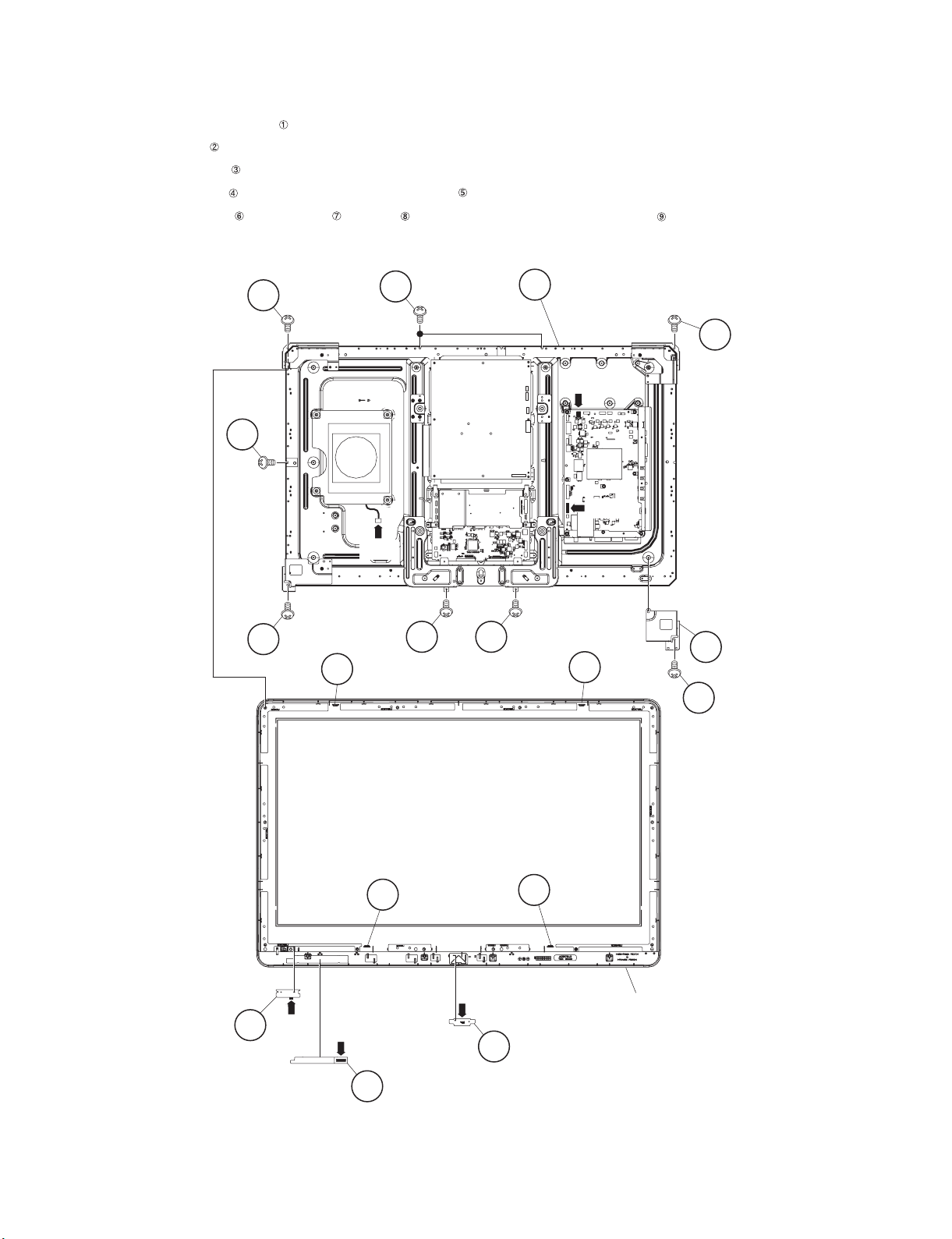

[2] REMOVING OF MAJOR PARTS (LC-46LE810E/LX810E)

1. Removing of Stand Unit and Rear Cabinet Ass’y.

1. Remove the 1 lock screw and detach the Support Cover .

2. Remove the 4 lock screws and detach the Stand Unit .

3. Remove the 1 lock screw and detach the AC Cord Cover .

4. Disconnect AC wire and detach the AC Cord .

5. Remove the 4 lock screws , 1 lock screw , 4 lock screws and 16 lock screws and detach the Rear Cabinet Ass’y .

Rear Cabinet Ass'y

12

11

[AC]

7AC Cord

[AC]

6AC Cord Cover

8

5

9

1

10

2Support Cover

3

4 Stand Unit

4 – 6

Page 18

LC-40/46LE810E, LC-40/46LX810E

2. Removing of Speaker-L/R.

1. Remove the 3 lock screws and detach the Stand Cover .

2. Disconnect SP wire.

3. Detach the Speaker-L , Speaker-R .

4. Detach the Insulation Sheet (AC) .

5

Insulation

Sheet (AC)

MAIN Unit

[SP]

[SP]

4Speaker-R 3 Speaker-L

2 Stand Cover

1

4 – 7

Page 19

LC-40/46LE810E, LC-40/46LX810E

3. Removing of 46” LCD Panel Module Unit, TOUCH SENSOR Unit, ICON Unit, R/C, LED Unit, Front Cabinet

Ass’y.

1. Remove the 1 lock screw and detach the LCD Angle (Bottom-R) .

2. Remove the 5 lock screws , 5 lock screws , 4 Hooks and detach the 46” LCD Panel Module Unit .

3. Disconnect RA wire.

4. Detach the TOUCH SENSOR Unit . (RK)

5. Detach the ICON Unit . (RI)

6. Detach the R/C, LED Unit . (RA)

NOTE: The TOUCH SENSOR Unit removed once is not reusable.

33

4

4

4

6

46" LCD Panel

[RA]

3

3

Module Unit

LCD Angle

2

(Bottom-R)

Front Cabinet Ass'y

1

9

R/C, LED Unit

[RA]

5 5

5

[RI]

[RK]

7 TOUCH SENSOR Unit

4 – 8

5

8 ICON Unit

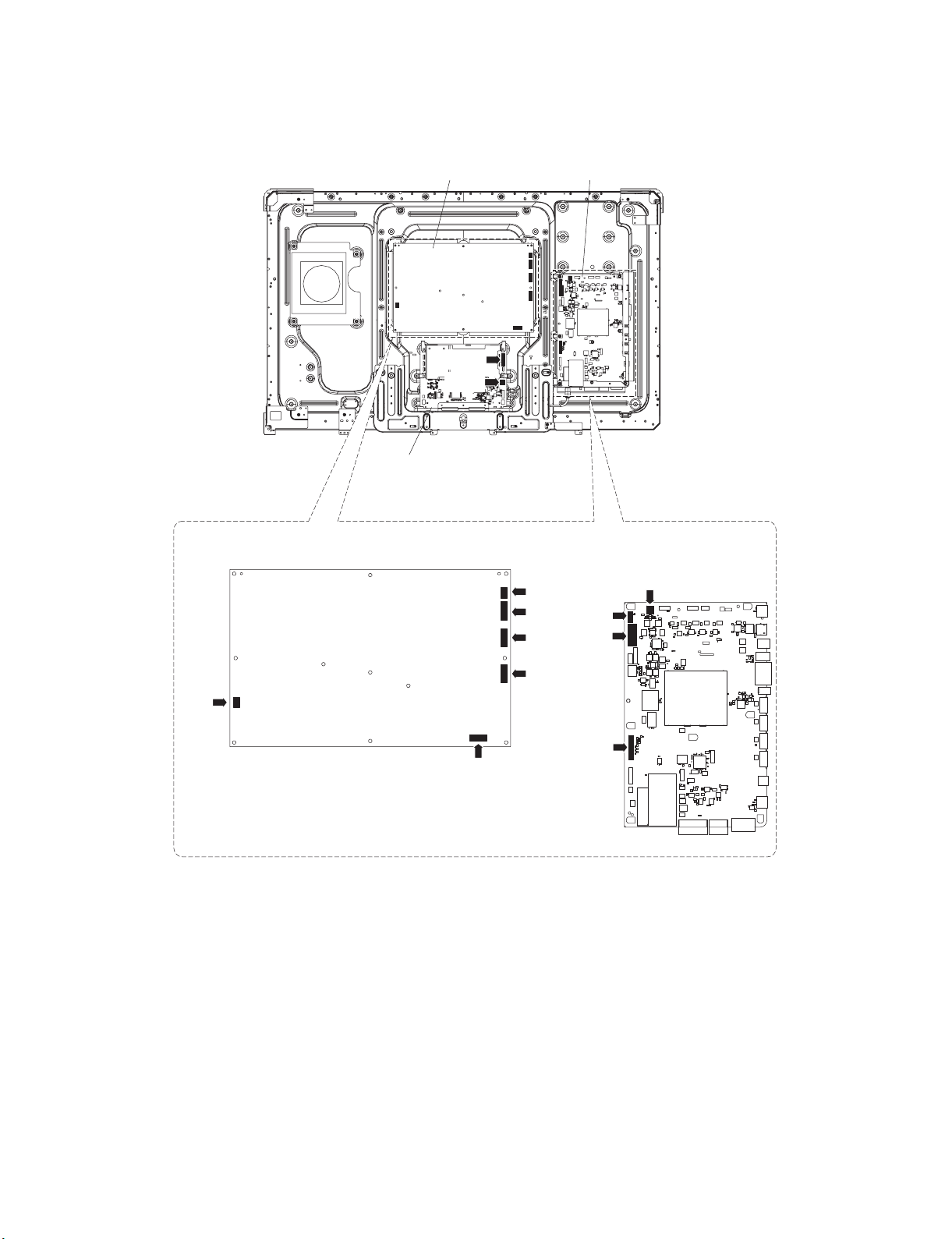

Page 20

LC-40/46LE810E, LC-40/46LX810E

4. Removing of Connectors

1. Disconnect the following connectors from the MAIN Unit. (SB, LB, PD, LW)

2. Disconnect the following connectors from the POWER Unit. (L1, L2, LB, PD, PL, AS)

3. Disconnect the following connectors from the LCD CONTROL Unit. (LW, PL)

[LW]

[PL]

LCD CONTROL Unit

MAIN UnitPOWER Unit

[AS]

[PL]

[L1]

[L2]

[LB]

[PD]

MAIN UnitPOWER Unit

[SB]

[LB]

[PD]

[LW]

4 – 9

Page 21

5. Removing of MAIN Unit, POWER Unit, Sub Woofer, Stand Angle.

1. Remove the 7 lock screws and detach the MAIN Unit

2. Remove the 2 lock screws and detach the Terminal Angle (Bottom) .

3. Remove the 2 lock screws and detach the Terminal Angle (Side) .

4. Remove the 6 lock screws and detach the POWER Unit .

5. Remove the 4 lock screws and detach the Woofer .

6. Remove the 1 lock screw and detach the LCD Angle (Top-R) .

7. Remove the 1 lock screw and detach the LCD Angle (Top-L) .

8. Remove the 1 lock screw and detach the LCD Angle (B-C-A) .

9. Remove the 1 lock screw and detach the LCD Angle (Bottom-L) .

10.Remove the 1 lock screw and detach the LCD Angle (B-C-B) .

11.Remove the 8 lock screws and detach the Stand Angle .

12.Remove the 2 lock screws and detach the ECO Switch with Holder .

LC-40/46LE810E, LC-40/46LX810E

LCD Angle

(Top-L)

13

14

9

10

Woofer

11

LCD Angle (Top-R)

7

1

12

2 MAIN Unit

5

8 POWER

Unit

[SB]

6

Terminal Angle

(Side)

4 Terminal Angle

(Bottom)

3

[L1]

[L2]

23

24

ECO Switch

with Holder

LCD Angle

(Bottom-L)

18

17

15

21

16

LCD Angle (B-C-A)

4 – 10

46" LCD Panel

Module Unit

22 Stand Angle

20 LCD Angle (B-C-B)

19

Page 22

LC-40/46LE810E, LC-40/46LX810E

LC-40LE810E

CHAPTER 5. ADJUSTMENT

Service Manual

[1] ADJUSTMENT PROCEDURE

1. Adjustment method after PWB and/or IC replacement due to repair

The unit is set to the optimum at the time of shipment from the factory.

If any value should become improper or any adjustment is necessary due to the part replacement, make an adjustment according to the following procedure.

1. Procure the following units in order to replace the main unit

MAIN UNIT: DKEYDF455FM03

NOTE: [Caution when replacing ICs in the main unit (IC501, IC2002)]

The above ICs are EEPROMs storing the EDID data of PC, and Monitor microcomputer.

Before replacing the relevant part, procure the following parts in which the data have been rewritten.

IC501 RH-iXD108WJQZS PC EDID

IC2002 RH-iXC786WJNJQ Monitor microcomputer

NOTE: [Caution when replacing ICs in the main unit (IC8401, IC3302)]

When replacing either IC8401 or IC3302, exchange MAIN units for DKEYDF455FM01

Each part should not be individually exchanged.

IC8401 RH-iXC147WJQZQ Flash

IC3302 RH-iXC951WJN1Q Main CPU

NOTE: HDMI ROM Writing

After replacing IC1504, execute “HDMI EDID WRITE” on the page 5/21

Please execute it after checking MODEL NAME & INCH SIZE. are correct.

IF MODEL NAME & INCH SIZE. are not correct, set them previously. (Refer to 2)

The ROM data based on information of MODEL NAME & INCH SIZE

1) Enter the process adjustment mode in TV.

2) Use the cursor keys ( / ) and CH keys ( / ) of R/C to select the item [HDMI EDID WRITE] on the page 5/21.

2. After replacing the LCD panel or LCD control/MAIN UNIT, check MODEL NAME in the following procedure.

1) Enter the process adjustment mode in TV.

2) Use the cursor keys ( / ) and CH keys ( / ) of R/C to select the item [MODEL NAME] on the page 21/21.

3) Verify that the Model name is displayed.

4) If the Model name doesn't match, select the values of the Model name with the VOL keys (+/-).

5) After selection in Step 4), press the OK key, and it is completed with OK displayed.

6) Use the cursor keys ( / ) and CH keys ( / ) of R/C to select the item [PANEL_SIZE] on the page 21/21.

7) Verify that the panel size is displayed.

8) If the size doesn't match, select the values of the panel size with the VOL keys (+/-).

9) After selection in Step 8), press the OK key, and it is completed with OK displayed.

3. After replacing the LCD panel or LCD control PWB, adjust the VCOM in the following procedure.

1) Enter the process adjustment mode.

2) Use the cursor keys ( / ) and CH keys ( / ) of R/C to select the item [VCOM ADJ] on the page 10/21.

3) Press the OK key to verify that the adjustment pattern is displayed.

4) Use VOL keys (+/-) of R/C to adjust the flicker in the center of the screen to minimum.

5) When the optimal state is achieved in Step 4, press the OK key to turn the pattern to OFF.

5 – 1

Page 23

LC-40/46LE810E, LC-40/46LX810E

2. Method of shuts down for Power supply

Please execute the following procedures to shut down Power supply from the state of normal operation.

1) Keep touching the power supply key on the set for 5 seconds from the state of watching.

* The screen disappears when power supply key is touched, but Keep pushing the power supply key.

2) A central icon lights between 500ms when the power supply shuts down.

Please separate the finger from the power supply key when lighting of a central icon is confirmed

3. Entering and exiting the adjustment process mode

Please execute the following procedures to enter the adjustment process mode when the power supply shuts down.

1) While holding down the “VOL (-)” and “INPUT” keys on the set at once, touch the power supply key on the set.

Please separate the fingers from key on the set when boot-up is confirmed with lighting of a central icon etc.

After a while, The letter “K” appears on the screen. This state is in Inspection mode.

2) Next, hold down the “VOL (-)” and “CH ( )” keys on the set at once.

Multiple lines of blue characters appearing on the screen indicate that the set is now in the adjustment Process mode.

If you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

3) To exit the adjustment process mode after the adjustment is done, unplug the AC power cord to force off the power.

(When the power is turned off with the remote controler, once unplug the AC power cord and plug it in again. In this case, wait for 10 seconds or

so after unplugging.)

CAUTION: Use due care in handling the information described here lest the users should know how to enter the adjustment process mode.

If the settings are tampered with in this mode, unrecoverable system damage may result.

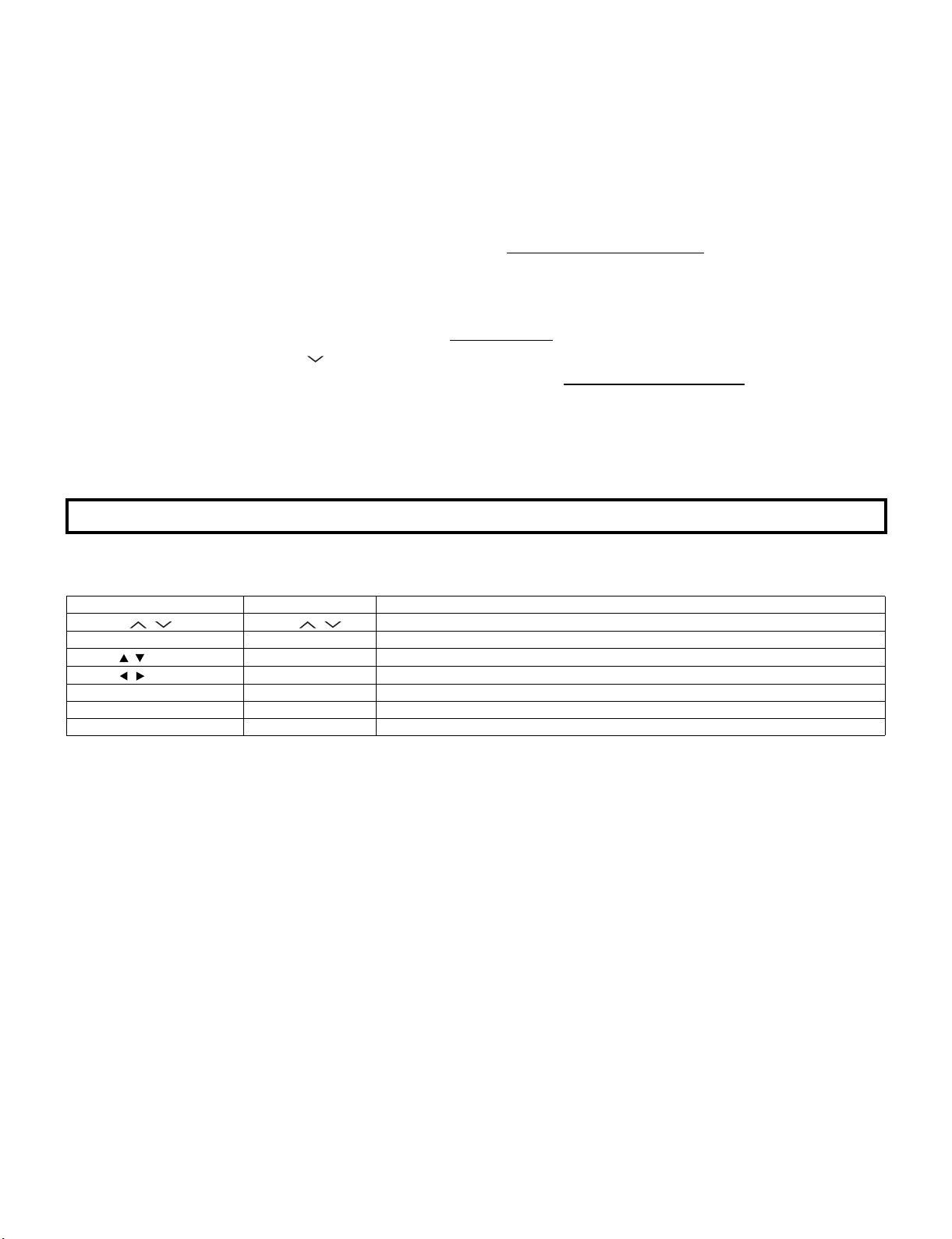

4. Remote controler key operation and description of display in adjustment process mode.

1. Key operation

Remote controler key Main unit key Remote controler key Main unit key Function

CH keys ( / ) CH ( / )

VOL keys (+/-) VOL (+/-) Changing a selected item setting (+1/-1)

Cursor ( / )

Cursor ( / )

INPUT INPUT Input source switching (toggle switching) (TV→EXT1~9, USB)

OK — Executing a function

RETURN — Returning to a present page

Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

— Turning a page (PREVIOUS/NEXT)

— Changing a selected line setting (+10/-10)

Moving an item (line) by one (UP/DOWN)

5 – 2

Page 24

LC-40/46LE810E, LC-40/46LX810E

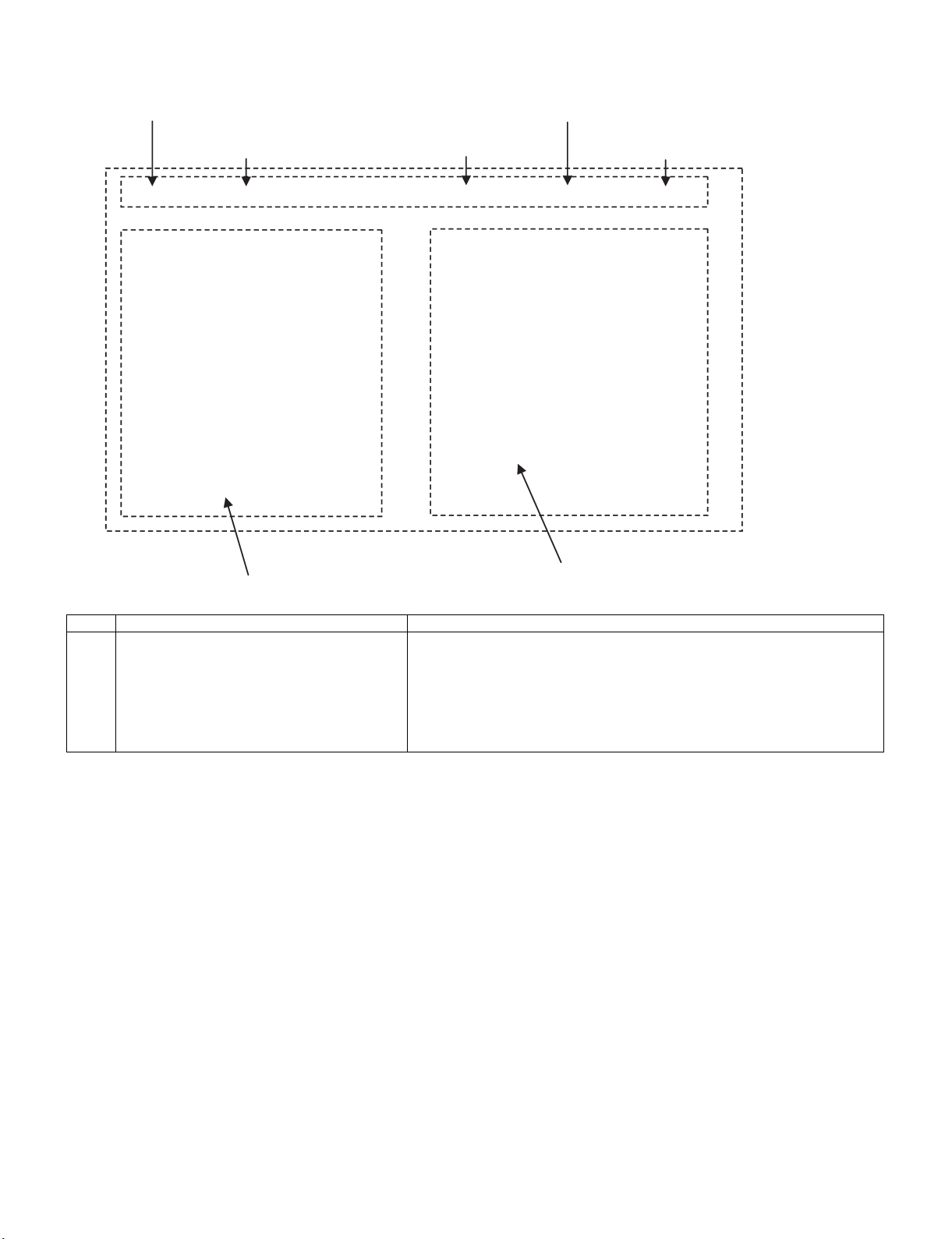

5. Description of display

(1) Present page / number of total pages (4) Inducing display

(3) Present colour system

(2) Input that has been selected now (5) Inch setting and Model name display

1/21 INPUT1 AUTO EURO xxxxx

MAIN Version

BOOT Version

Monitor Version

T-CON Version/LED CON Version

CPLD Version

CI+INFO/SECURE BOOT

FRC-N Auto Script Version

TCON Master/Slave Serial Version

TOUCH SENSOR UCON VERSION

LAMP ERROR

MONITOR ERR CAUSE

1.00 (E 2009/**/** )

xxxxxxx

xxxxxxx

xxxxxxxx/xxxx

xxxxxxx

xxxxx/YES

xxxxxxx

xxxxxxx

xxxxxxx

0

1)xxxxxx 2)xxxxxx

3)xxxxxx 4)xxxxxx

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

(6) Item name

No. Description Display specification

(1) Present page/number of total pages 2char/2char Decimal Number mark.

(2) Input that has been selected now TUNER/DTV/INPUT1/INPUT2/INPUT3/INPUT5/INPUT6/INPUT7

(3) Present colour system AUTO/N358/N443/PAL/SECAM/480i/580i/1080i/50 etc. ⋅⋅⋅

(4) Inducing display EUROPE

(5) Inch setting and Model name display Inch setting and Model name display

(6) Item name Max. 30 char

(7) Parameter Max. 60 char

0

0000

(7) Parameter

5 – 3

Page 25

LC-40/46LE810E, LC-40/46LX810E

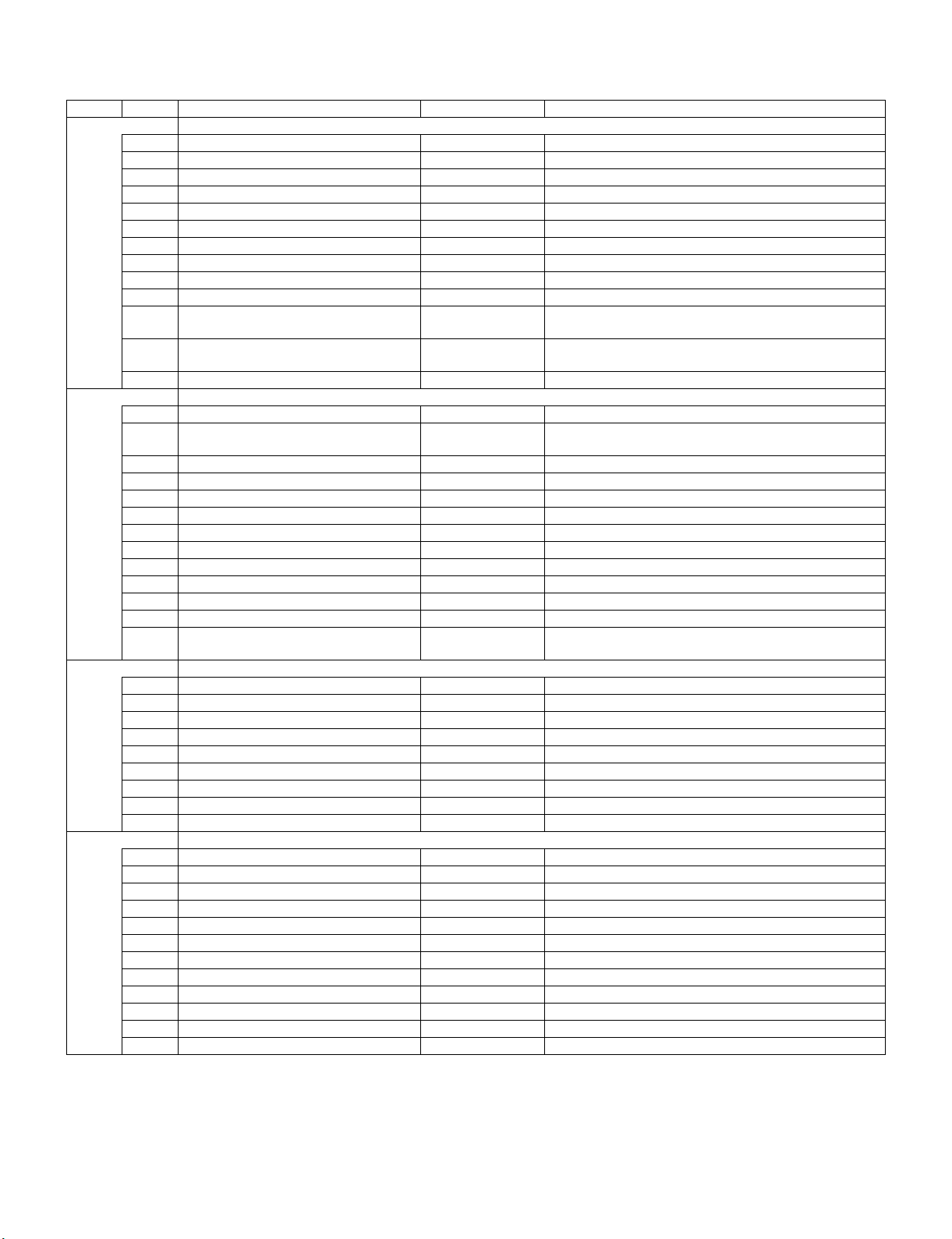

6. Adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

Page Line Item Description Remarks (adjustment detail, etc.)

1/21

1 MAIN Version 1xxx (xxxxx) Main software version

2 BOOT Version xxxxxxx BOOT Version.

3 Monitor Version xxxxxxx Monitor software version

4 T-CON Version/LED CON Version xxxxxxxx/xxxx T-CON/H.264 Version

5 CPLD Version xxxxxxx CPLD Version.

7 CI+INFO/SECURE BOOT xxxxx/YES CI+ Key Information/SECURE BOOT

8 FRC-N Auto Script Version xxxxxxx

9 TCON Master/Slave Serial Version xxxxxxx

10 TOUCH SENSOR UCON VERSION xxxxxxx

11 LAMP ERROR 0 Number of termination due to lamp error.

12 MONITOR ERR CAUSE 1) xxxxxx 2) xxxxxx

3) xxxxxx 4) xxxxxx

13 NORMAL STANDBY CAUSE 0 Situation that became standby at the end.

14 ERROR STANDBY CAUSE 0 0 0 0 Error standby cause

2/21

1 INDUSTRY INIT Enter Initialization to factory settings execution.

2 INDUSTRY INIT (-Public) OFF Initialization to factory settings execution.

3 PUBLIC MODE OFF Public mode ON/OFF setting

4 Center Acutime — Main operating hours.

5 RESET OFF Main operating hours reset.

6 Backlight Acutime — Backlight operating hours.

7 RESET OFF Backlight operating hours reset.

8 LAMP ERROR RESET OFF Lamp error reset.

9 ADJ PARAM SET Enter ADJ PARAM SET

10 VIC XPOS 0 X-coordinate setting for VIC READ

11 VIC YPOS 0 Y-coordinate setting for VIC READ

12 VIC SIGNAL TYPE MAIN Signal type setting for VIC READ

13 VIC READ OFF Picture level acquisition function

3/21

1 TUNER ADJ Enter TUNER auto adjustment execution

2 PAL+TUNER ADJ Enter PAL TUNER auto adjustment execution

3 TUNER ADJ (SMPTE) Enter TUNER auto adjustment execution (SMPTE)

4 PAL+TUNER ADJ (SMPTE) Enter PAL TUNER auto adjustment execution (SMPTE)

5 TUNER ADJ (SMPTE CH57) Enter TUNER auto adjustment execution (SMPTE CH57)

6 PAL+TUNER ADJ (SMPTE CH57) Enter PAL TUNER auto adjustment execution (SMPTE CH57)

7 TUNER CONTRAST A_GAIN 16 TUNER signal level adjustment

8 TUNER CONTRAST D_GAIN 2073 TUNER signal level adjustment

9 TUNER CONTRAST OFFSET 256 TUNER signal level adjustment

4/21

1 PAL ADJ Enter PAL adjustment

2 SECAM ADJ Enter SECAM adjustment

3 N358 ADJ Enter N358 adjustment

4 PAL CONTRAST A_GAIN 14 PAL contrast adjustment

5 PAL CONTRAST D_GAIN 2149 PAL contrast adjustment

6 PAL CONTRAST OFFSET 255 PAL contrast adjustment

7 SECAM CONTRAST A_GAIN 14 SECAM contrast adjustment

8 SECAM CONTRAST D_GAIN 2123 SECAM contrast adjustment

9 SECAM CONTRAST OFFSET 256 SECAM contrast adjustment

10 N358 CONTRAST A_GAIN 14 N358 contrast adjustment

11 N358 CONTRAST D_GAIN 2192 N358 contrast adjustment

12 N358 CONTRAST OFFSET 255 N358 contrast adjustment

Last error standby cause.

(Excluding the error)

(Public mode is excluded)

(Level appears in green on the upper right)

5 – 4

Page 26

LC-40/46LE810E, LC-40/46LX810E

Page Line Item Description Remarks (adjustment detail, etc.)

5/21

1 HDMI CEC TEST Enter HDMI CEC test

2 INSPECT USB TERM Enter Reading inspection of USB memory terminal

3 HDMI EDID WRITE Enter HDMI EDID WRITING

4 MONIDATA READ [TEMP/OPC] OFF MONITOR Temperature/OPC Acquisition tool.

5 CAUSE RESET Enter Reset of standby cause

6/21

1 COMP15K ALL ADJ Enter Component 15K picture level adjustment

2 COMP15K MAIN Y GAIN 141 Y GAIN adjustment value

3 COMP15K MAIN CB GAIN 150 Cb GAIN adjustment value

4 COMP15K MAIN CR GAIN 150 Cr GAIN adjustment value

5 COMP15K Y OFFSET 64 Y OFFSET adjustment value

6 COMP15K CB OFFSET 128 Cb OFFSET adjustment value

7 COMP15K CR OFFSET 128 Cr OFFSET adjustment value

7/21

1 HDTV ADJ Enter HDTV video level adjustment

2 HDTV Y GAIN 141 HDTV Y GAIN adjustment value

3 HDTV CB GAIN 150 HDTV Cb adjustment value

4 HDTV CR GAIN 150 HDTV Cr adjustment value

5 HDTV Y OFFSET 64 HDTV Y OFFSET adjustment value

6 HDTV CB OFFSET 128 HDTV Cb OFFSET adjustment value

7 HDTV CR OFFSET 128 HDTV Cr OFFSET adjustment value

8/21

1 ANALOG PC ADJ Enter DVI ANALOG video level adjustment

2 R OFFSET 64 R CUTOFF adjustment value

3 G OFFSET 64 G CUTOFF adjustment value

4 B OFFSET 64 B CUTOFF adjustment value

5 R GAIN 44 R DRIVE adjustment value

6 G GAIN 44 G DRIVE adjustment value

7 B GAIN 44 B DRIVE adjustment value

9/21

1 SCART RGB ADJ Enter SCART RGB level adjustment

2 SCART R CUTOFF 64 SCART R CUTOFF adjustment value

3 SCART G CUTOFF 64 SCART G CUTOFF adjustment value

4 SCART B CUTOFF 64 SCART B CUTOFF adjustment value

5 SCART R GAIN 44 SCART R GAIN adjustment value

6 SCART G GAIN 44 SCART G GAIN adjustment value

7 SCART B GAIN 44 SCART B GAIN adjustment value

10/21

1 VCOM ADJ 0 Common bias adjustment

11/ 21

1 R GAIN (LO) 0 R DRIVE adjustment value

2 G GAIN (LO) 0 G DRIVE adjustment value

3 B GAIN (LO) 0 B DRIVE adjustment value

4 R GAIN (HI) 0 R DRIVE adjustment value

5 G GAIN (HI) 0 G DRIVE adjustment value

6 B GAIN (HI) 0 B DRIVE adjustment value

12/21

1 MONITOR TIME OUT ON Monitor and the main communication time-out setting

2 MONITOR MAX TEMP 45 MONITOR MAX temperature setting

3 MONITOR EEP READ/WRITE WRITE MONITOR EEPROM READ/WRITE Setting/execution

4 MONITOR EEP ADR 0x 0 MONITOR EEPROM arbitrary addressing

5 MONITOR EEP DATA 0x 0 MONITOR EEPROM arbitrary data specification

13/21

1 LCD TEST PATTERN OFF Pattern with built-in LCD controler display

2 LCD TEST PATTERN 1 OFF

3 LCD TEST PATTERN 2 OFF

4 LCD TEST PATTERN 3 OFF

5 LCD TEST PATTERN 4 OFF

5 – 5

Page 27

LC-40/46LE810E, LC-40/46LX810E

Page Line Item Description Remarks (adjustment detail, etc.)

14/21

1 FRV-N Firmware Version xxxxx

2 FRC-N Boot Script Version xxxxx

3 FRC-N Device Version xxxxx

4 TCON FPGA1 Serial Flash Version xxxxx

5 TCON FPGA2 Serial Flash Version xxxxx

6 TCON FPGA1 Config Rom Version xxxxx

7 TCON FPGA2 Config Rom Version xxxxx

15/21

1 POWER LED BRIGHTNESS 0

2 MENU LED BRIGHTNESS 0

3 INPUT LED BRIGHTNESS 0

4 CH UP LED BRIGHTNESS 0

5 CH DOWN LED BRIGHTNESS 0

6 VOL UP LED BRIGHTNESS 0

7 VOL DOWN LED BRIGHTNESS 0

8 LOGO LED BRIGHTNESS 99

9 ICON LED BRIGHTNESS 99

10 ICON LED BRIGHTNESS (STANDBY) 30

16/21

1 POWER KEY SENSITIVITY 0

2 MENU KEY SENSITIVITY 0

3 INPUT KEY SENSITIVITY 0

4 CH UP KEY SENSITIVITY 0

5 CH DOWN KEY SENSITIVITY 0

6 VOL UP KEY SENSITIVITY 0

7 VOL DOWN KEY SENSITIVITY 0

17/21

1 KEY STRENGTH GET MODE Enter

2 POWER KEY STRENGTH

3 MENU KEY STRENGTH

INPUT KEY STRENGTH

4 CH UP KEY STRENGTH

5 CH DOWN KEY STRENGTH

6 VOL UP KEY STRENGTH

7 VOL DOWN KEY STRENGTH

18/21

1 READ/WRITE READ Read/Write

2 SLAVE/ADDRESS SLAVE0 Slave address

3 REGISTER ADDRESS 0x 0 Register address

0x 0

4 WRITE DATA 0x 0 Writing data

0x 0

5 READ DATA 0x 0 Reading data

0x 0

19/21

1 RF AGC BG 6 RF-AGC BG adjustment execution

2 RF AGC DK 5 RF-AGC DKG adjustment execution

3 RF AGC I 6 RF-AGC I adjustment execution

4 RF AGC L/L' 4 RF-AGC L/L' adjustment execution

20/21

1 ERROR STANDBY CAUSE 1 NO RECORD ERROR STANDBY CAUSE

2 ERROR STANDBY CAUSE 2 NO RECORD

3 ERROR STANDBY CAUSE 3 NO RECORD

4 ERROR STANDBY CAUSE 4 NO RECORD

5 ERROR STANDBY CAUSE 5 NO RECORD

6 STANDBY CAUSE RESET OFF Reset stand by cause.

5 – 6

Page 28

LC-40/46LE810E, LC-40/46LX810E

Page Line Item Description Remarks (adjustment detail, etc.)

21/21

1 EEP SAVE OFF Writing setting values to EEPROM.

2 EEP RECOVER OFF Reading setting values from EEPROM.

3 MONITOR ERROR CAUSE RESET OFF Reset of monitor error cause

4 MODEL NAME LE705 MODEL NAME

5 PANEL SIZE 40 Panel size setting. (40/46/52)

6 SHORT CHECK MODE Enter Check LED Back light

7 SHORT CHECK CURRENT 60

8 CURRENT SW LOW

9 PRODUCT EEP ADR 0x 0 Don't touch when serving (for producer of factory)

10 PRODUCT EEP DATA 0x 0 Don't touch when serving (for producer of factory)

11 PRODUCT FACTORY 1 Don't touch when serving (for producer of factory)

7. Special features

1. NORMAL STANDBY CAUSE (Page 1/21)

Display of a cause (code) of the last standby.

The cause of the last standby is recorded in EEPROM whenever it is possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

2. EEP SAVE (Page 21/21)

Storage of EEP adjustment value

3. EEP RECOVER (Page 21/21)

Retrieval of EEP adjustment value from storage area.

4. MONITOR ERR CAUSE (Page 1/21)

Display of a cause (code) of Error from sub-Microcomputer.

The cause of Error is recorded in EEPROM whenever it is possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

1) This displays Error code and time when the error occurred.

The latest error is displayed on “1)”

The error that happens ahead of “1)” is displayed on “2)”.

2) The character depends on the way how to acquire Time Information

T: Time is acquired from digital broadcasting

This doesn't contain “Time offset” which is considered a time difference and Daylight-Saving Time, etc. ...

U: Time is acquired from analog broadcasting (teletext)

B: Accumulation time of Backlight

In the case that Time information cannot be acquired, “B” is displayed.

Example) In this example, it is shown that the error occurred 3 times.

1) 16 T07/01/01 12:03 Error code: 16 (lamp error) Time: 07/01/01 12:03

* It is latest Error.

* Time is acquired from digital broadcasting.

* Time is UTC which doesn't have Time offset.

2) 16 U01/01/01 04:07 Error code: 16 (lamp error) Time: 07/01/01 04:07

* It is Error that happens ahead of “1)”.

* Time is acquired from analogue broadcasting.

3) 16 B00000004:11 Error code: 16 (lamp error) Accumulation time: It is displayed that 4:11 have passed after Backlight driving.

* It is Error that happens ahead of “2)”.

4) 00 0000000000000 No error (“00” shows that the error is not occurred.)

5 – 7

Page 29

LC-40/46LE810E, LC-40/46LX810E

8. Lamp Error detection

1. Function

This LCD colour TV set incorporates a Lamp error detection feature that automatically turns off the power for safety under abnormal lamp or lamp

circuit conditions. If by any chance anything is wrong with the lamp or lamp circuit or if the lamp error detection feature is activated for some reason, the following will result.

1) The power is interrupted in about 500ms after it is turned on.

(A central icon on the front of the TV flash on and off.: ON for 400ms and OFF for 1600ms.).

2) If the above phenomenon 1) occurs 5 times, it becomes impossible to turn on the power.

(A central icon keep flashing on/off.)

2. Measures

1) Set the lamp error detection to OFF

Enter the adjustment process mode, referring to “4. Entering and exiting the adjustment process mode.”

The adjustment process mode can ignore “5 times count”, so If the above phenomenon 1) occurs 1~4 times, the lamp will go out.

If Lamp Error detection pin (6pin of LB: P9602) is “High” by a trouble with the lamp and lamp circuit, it can boot-up by the adjustment process

mode.

Please execute “Lamp Error detection off-mode”.

While holding down the “VOL (-)” and “CH ( )” keys on the set at once, touch the power supply key on the set.

After a central icon flash off, separate the fingers from key on the set.

Touch the power supply key on the set again, so the power will boot-up.

Then, you can check the operation to see if the lamp and lamp circuit are in trouble.

If you fail boot-up, retry the procedure.

2) Resetting the lamp error count

After the lamp and lamp circuit are improved from a trouble, reset the lamp error count.

(Because the power cannot be turned on, if a lamp error is detected 5 consecutive times)

a) Enter the adjustment process mode, referring to “4. Entering and exiting the adjustment process mode.”

b) Using the cursor ( / ) key, move to the cursor to [LAMP ERROR RESET], Line 8 on adjustment process mode service page 2/21.

c) With the cursor ( / ) keys, select the [LAMP ERROR RESET] value.

Finally press the cursor (OK)., the count is reset.

Check LAMP ERROR Count on adjustment process mode Page 2/21.

Table of contents of adjustment process mode Page 2/21

INDUSTRY INIT Enter

INDUSTRY INIT (-Publicl) OFF

Public MODE OFF

Center Acutime

RESET OFF

Backlight Acutime

RESET OFF

LAMP ERROR RESET OFF

ADJ PARAM SET Enter

VIC XPOS

VIC YPOS

VIC SIGNAL TYPE MAIN

0

0

VIC READ OFF

Resetting to "0"

5 – 8

Page 30

LC-40/46LE810E, LC-40/46LX810E

9. Public Mode

1. Starting the Public Mode

• There are two following ways to display the PUBLIC Mode setting screen.

1) Method of needing password

a) Turn off the power, refer to “3. Method of shuts down for Power supply”

b) While holding down the “INPUT” and “Volume (+)” keys on the set at once, touch the power supply key on the set.

Please separate the finger from the power supply key when boot-up is confirmed with lighting of a central icon etc.

After a while, value of Public Mode appears on the screen.

c) Display the Pass Word input screen.

Public Mode

Operation procedure

• The initial input position is the digit at the left end.

• For the numeric keys “0” to “9” of R/C, key input is accepted.

Input of the other keys is prohibited.

• Change “—” to “ * ” by inputting the numeric key at the input position, and shift the input position rightward one digit.

• When three digits are completely input, the Pass Word is judged.

d) Check the Pass Word by inputting three digits.

If the Pass Word “0” “2” “7”, it shifts to the PUBLIC Mode setting screen.

In another case, the screen is erased, and it operates in the ordinary mode.

2. Exiting the Public Mode Setting screen

• There are two following ways to exit the Public Mode setting screen.

1) Turn off the power.

2) Select “Execution” in the PUBLIC_Mode to execute it.

Activate the restart under the set content.

Here, the START input SOURCE setting is excluded since this item is referred to only when the power is turned on.

3. Set value of the Public Mode

• When the shipment setting is done, a set each value in Public Mode is initialized.

(PUBLIC MODE in the process mode Setting of a flag is also initialized)

• Separately, the shipment beginnings when all except for each set value in Public Mode is initialized are provided for a process mode.

(INDUSTRY INIT (-Public))

• Only when turning on the PUBLIC MODE item, each setting is effective.

• After it decides it with EXECUTE, it AC OFF/ON it to reflect a set value.

Public Mode

Public Mode

5 – 9

Page 31

4. Basic operation in the Public Mode

No Power off by remote control.

LC-40/46LE810E, LC-40/46LX810E

Vol (+/-) or Cursor ( / )

CH ( / ) or Cursor ( / )

Decision (ok) Execution (Used by the items “Execution” and “RESET”.)

Public Mode setting screen.

Public Mode

POWER ON FIXED [VARIABLE]

SHUT DOWN MODE [NORMAL]

MAXIMUM VOLUME [60]

VOLUME FIXED [VARIABLE]

VOLUME FIXED LEVEL [20]

RC BUTTON [RESPOND]

PANEL BUTTON [RESPOND]

MENU BUTTON [RESPOND]

AV POSITION FIXED [VARIABLE]

ON SCREEN DISPLAY [YES]

INPUT MODE START [NORMAL]

INPUT MODE FIXED [VARIABLE]

LOUD SPEAKER [ON]

RC PATH THROUGH [OFF]

232C POWON [DISABLE]

PUBLIC MODE [ON]

RESET

EXECUTE

Change or execution of the set value.

Movement to the selected item.

5. Operation after “RESET”

Select “RESET” in the PUBLIC Mode, and it operates as follows when it is executed (refer to the basic operation).

• The set contents in the PUBLIC mode are initialized.

• It does not exit the PUBLIC mode.

• If “EXCUTE” is not executed, the content that does RESET is not reflected.

6. Setting items (* Item names and selective items are expressed in English.)

1) Power ON fixed [POWER ON FIXED]

Option “VARIABLE”, “FIXED_ALL”, “FIXED_BODYKEY” or “RCRESPOND” (loop enabled)

Default “VARIABLE”

Function • VARIABLE : “POWER/RECEPTION” key on TV unit or remote control is enabled.

• FIXED_ALL“ : “POWER/RECEPTION” key on TV unit or remote control is disabled.

• FIXED_BODYKEY : only the “MAIN POWER” key on TV unit is disabl ed (the remote control is enabled).

• RC RESPOND : the main unit’s POWER switch toggles between ON and Standby (the same operation by

the remote control).

Key disabled when set

other than default

Remarks • When selecting to “FIXED_ALL”, function related standby factors (see below) doesn't work. and not selecting

If the power button is pressed in the ordinary mode in setting to “FIXED_ALL” and “FIXED_BODYKEY”, the caution is displayed for 5 seconds.

When power button on the main unit is pressed When power button on R/C is pressed

• OFF TIMER (SLEEP) (* Only when setting to FIXED_ALL)

OFF TIMER (Sleep)

No operation OFF

No signal OFF (including the power management)

* These items does not exist according to the model.

No Power off by power button.

* The OSD display is an example.

If another ODS is previously displayed, the status is reset (MENU or similar).

5 – 10

Page 32

LC-40/46LE810E, LC-40/46LX810E

2) Instantaneous current shutdown setting in turning off the power [SHUT DOWN MODE]

Option “NORMAL” or “QUICK”

Default NORMAL

Function • This function decides whether scanning digital tuner is enabled or disabled when the power is standby.

NORMAL : Scanning digital tuner is enabled when the power is standby.

QUICK : Scanning digital tuner is disable

It is possible to put into the standby state instantaneously due to power off input, when the

power is standby.

Immediately, state is a complete standby.

Remarks In selecting “QUICK”, the function does not work for the following items (selection impossible.)

• ON TIMER, QUICK START, DIGITAL FIXED, etc.

* These items does not exist according to the model.

3) Volume maximum level [MAXIMUM VOLUME]

Option 0~60 (loop disabled)

Default 60

Function The volume cannot be increased more than the adjusted value (the main unit’s speaker only).

Remarks • When setting to 59 or less, only the figure is displayed in the normal mode; the volume bar is not displayed.

• The volume of the headphones is limited. or monitor output

• The setting is impossible when VOLUME FIXED is set to FIXED.

4) Volume fixed [VOLUME FIXED]

Option “VARIABLE”, “FIXED”, “ACCTRL” or “AC/RCCTRL” (loop enabled)

Default “VARIABLE”

Function • VARIABLE : The volume is not fixed.

• FIXED : The volume is fixed to the value adjusted in the volume fixed level.

• AC CTRL : The unit starts at the volume specified in the volume fixed level, when power is turned on in

• AC/RC CTRL : The unit starts at the volume specified in the volume fixed level, when power is turned on in

Exception • In the adjustment process, the volume can be set to any level regardless of this setting.

Disabled key when setting

to FIXED

Remarks • [MAXIMUM VOLUME] has priority to [VOLUME FIXED]

• VOLUME UP/DOWN [both remote control and main unit]

•MUTE

* When setting to FIXED, Maximum volume is fixed.

• The volume of the headphones is fixed.

• When setting to “FIXED”, the volume is not displayed in operating Disabled key

• In menu operation, the main unit's keys (Vol (+/-)) are enabled.

the case of the AC-ON only.

any case. (AC→ON, remote control→ON, main unit's key→ON)

5) Volume fixed level [VOLUME FIXED LEVEL]

Option 0~60 (loop disabled)

Default 20

Function The volume is fixed to the adjusted value (the main unit’s speaker only).

Exception • In the adjustment process, the volume can be set to any level regardless of this setting.

Remarks • When [VOLUME FIXED] is set to “VARIABLE”, the setting cannot be changed.

6) Remote control operation [RC BUTTON]

Option “RESPOND”, “NORESPOND” or “LIMITED” (loop enabled)

Default “RESPOND”

Function The operation of the remote control’s keys is set.

RESPOND : the remote control’s keys in the normal state are enabled.

NO RESPOND : the remote control’s keys in the normal state are disabled.

The POWER key (RECEPTION/STANDBY key) is also disabled.

LIMITED : only a part of keys (CHANNEL, etc.) is enabled and other keys are disabled.

Exception • In the adjustment process mode, inspection mode are enabled regardless of this setting.

Remarks The enable keys when setting to “LIMITED” are depended on keys of controler for Public.

• All the keys are enabled regardless of this setting while entering the adjustment process mode, inspection mode

or Public Mode setting screen.

It is different according to Model.

5 – 11

Page 33

LC-40/46LE810E, LC-40/46LX810E

7) Main Unit Operation [PANEL BUTTON]

Option “RESPOND” or “NORESPOND” (loop enabled)

Default “RESPOND”

Function • RESPOND : The main unit’s keys are enabled.

• NO RESPOND : The main unit’s keys are disabled excluding the POWER key (RECEPTION/STANDBY

Exception • The start operation in the adjustment process mode, inspection mode are enabled regardless of this setting.

8) Menu operation [MENU BUTTON]

Option “RESPOND” or “NO RESPOND” (loop enabled)

Default “RESPOND”

Function The MENU key on the main unit and remote control is decided whether it is enabled or disabled.

Exception • RESPOND : The menu key is enabled.

Disabled key excluding

Menu key when setting to

not default

Remarks When setting to “NO RESPOND”

• All the keys are enabled regardless of this setting while entering the adjustment process mode, inspection mode

or Public Mode setting screen.

• For the models with the MENU key on the main unit, menu operation is possible regardless of the setting during

the initial setting when the power is turned on for the first time.

• NO RESPOND : The menu key is disabled.

All the direct transition keys to menu display (AUTO PRESET, MANUAL MEMORY and others)

* These keys does not exist according to the model.

• For the models with the MENU key on the main unit, menu operation is possible regardless of the setting while

the initial setting when the power is turned on for the first time

key).

: The start operation in the adjustment process mode, inspection mode is enabled regard-

less of this setting.

: All the keys are enabled regardless of this setting while entering the process mode, inspec-

tion mode or Public Mode setting screen.

9) AV position fixed [AV POSITION FIXED]

Option “VARIABLE” or “FIXED” (loop enabled)

Default “VARIABLE”

Function • VARIABLE : AV position is not fixed.

• FIXED : AV position is fixed.

: The image/sound adjustment items in the menu are fixed in the selected state.

: When receiving “AV POSITION” of the remote control, only the actual state is displayed,

and setting is not changed.

Remarks • When receiving the sound select direct keys (AV POSITION key, OPC, DOLBY key, etc.), only the actual state is

displayed; no setting is changed.

* These keys does not exist according to the model.

• The settings for the Public mode are retained after the personal data is initialized, each item for the AV position

and image/sound adjustment are not initialized.

5 – 12

Page 34

LC-40/46LE810E, LC-40/46LX810E

10)OSD display [ON SCREEN DISPLAY]

Option “YES”, “NO” or “LIMITED” (loop enabled)

Default “YES”

Function • YES : OSD is displayed

Key which may be enabled

(Example of the confusing

key)

Disabled key when setting

to not default

Remarks • When setting to “NO”,

11)Start mode [INPUT MODE START]

Option “NORMAL” or “Input source 1 (input selection or channel)” . . . (loop enabled)

Default “NORMAL”

Function which kinds of input source or channel is decided when the power turning on.

Remarks • When setting to not Normal,

“LIMITED” is looped only in case of need (destination).

• NO : the following OSD is not displayed.

Registration, setting, adjustment menu, channel call, volume bar, and input select

• LIMITED : only a part of OSD (CH call: “New Information” etc. ...) is not displayed.

• It is OK in the case that simple input select occure or the original state returns soon automatically.

• When setting to “NO”, the keys which is related to visibility of the screen and sound cannot be used.

STILL IMAGE, SCREEN DISPLAY, OFF TIMER, AV POSITION, BRIGHTNESS SENSOR, SCREEN SIZE

SELECT, AUTO PRESET, MANUAL MEMORY, IMAGE SELECT, SOUND SELECT, LANGUAGE, Closed caution

* Disabled keys dependeds on the models.

ON TIMER (Watching reservation) is cleared.

OFF TIMER “SLEEP” is cleared.

* These items does not exist according to the model.

• When setting to “NO”,

These Displays (Version-up, Public mode setting screen, Pass Word input screen of Public Mode,

the adjustment process mode, K mark of inspection mode) are enabled regardless of this setting.

NORMAL : the content of the last memory is followed.

ON TIMER (Watching reservation) has priority.

• When setting to “NORMAL”, [INPUT MODE FIXED] is set to “VARIABLE”. and [INPUT MODE FIXED] is prohib-

ited to select. (selection impossible.)

Example of option: “NORMAL”

“TVD (002TV)”, “INPUT1”, “INPUT2”, “INPUT3”, “HDMI1”, “HDMI2”, “HDMI3”, “HDMI4”.

12)Input fixed [INPUT MODE FIXED]

Option “VARIABLE” “FIXED”, “ACCTRL” or “AC/RCCTRL” (loop enabled)

Default VARIABLE

Function VARIABLE : If [INPUT MODE START] is set to Normal, input mode is not fixed.

FIXED : when “INPUT MODESTART” is active, it is impossible to switch to another channel or input

source.

AC CTRL : when “INPUT MODESTART” is active the unit starts at the input mode which is selected

when power is turned on in the case of the AC-ON only.

AC/RC CTRL : when “INPUT MODESTART” is active the unit starts at the input mode which is selected

when power is turned on in any case (AC→ON, remote control→ON, main unit's key→ON)

Disabled key when setting

to “FIXED”

Remarks • If [INPUT MODE START] is Normal, this function cannot be set.

CHANNEL (+/-), DIRECT CHANNEL buttons, FLASHBACK, INPUT SELECT, TV/VIDEO, AUTO PRESET, MANUAL

MEMORY, i.LINK, DIRECTINPUTSELECT, ATV, DTV, EPG, RADIO etc. ...

Set to “VARIABLE” automatically.

• When setting to “FIXED”,

The item related to the channel setting and input selection in Menu are not displayed.

ON TIMER (Watching reservation) is not active.

* These items does not exist according to the model.

5 – 13

Page 35

LC-40/46LE810E, LC-40/46LX810E

13)Speaker ON/OFF selection [LOUD SPEAKER]

Option “ON” or “OFF” (loop enabled)

Default ON

Function ON : The sound from the speakers is output.

OFF : The sound from the speakers is not output even if the headphones are not used.

Remarks • When the VOL (+/-) key is pressed, the mute icon is displayed for 4 seconds.

• For the MUTE key and sound-related keys, caution is displayed.

• For the headphones, normal operation is possible.

14)Remote control path through [RC PATH THROUGH]

Option “OFF”, “ON: TVRCE” or “ON: TVRCD” (loop enabled)

Default OFF

Function The item decide whether the signal received by the remotecontrol’ slight-receiving section is output to the blankpin

(9pin) of RS232C.

OFF : this function is not active.

ON: TVRCE : this function is active, and remote control is active, too

ON: TVRCD : this function is active, but remote control is not active

Exception • In the case of “ON:TV RCD”, the start operation in the adjustment process mode, inspection mod are enabled

regardless of this setting.

• In the case of “ON: TV RCD”, all the keys are enabled regardless of this setting while entering the adjustment pro-

cess mode, inspection mode or Public mode setting screen.

Remarks * Remote control path through does not exist according to the model.

15)232C power ON control [232C POWON]

Option “ENABLE” or “DISABLE” (loop enabled)

Default DISABLE

Function The item decide whether Power ON by the 232C command is enabled/disabled in the standby state.

The same function as 232C command “RSPW”.

ENABLE : POWR0001 is always enabled.

DISABLE : Start-up may be impossible at POWR0001.

16)Public mode setting [PUBLIC MODE]

Option “OFF” or “ON” (loop enabled)

Default OFF

Function The item decide whether Public mode setting menu are enabled or disabled.

The same item as [PUBLIC MODE] in the adjustment process menu.

OFF : Public mode is not active

ON : Public mode is active

Remarks Each operation of the Public mode is impossible unless this item is set to ON.

(If the 232C command reception module is set to OFF, the command is invalid.)

10. Video signal adjustment procedure

The adjustment process mode menu is listed in Section 5.

Signal generator level adjustment check (Adjustment to the specified level)

• Composite signal PAL/SECAM : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

• RGB signal : 0.7Vp-p ± 0.02Vp-p

• 15K component signal (50 Hz) : Y level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

: PB, PR level : 0.7Vp-p ± 0.02Vp-p

• 33K component signal (50 Hz) : Y level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

: PB, PR level : 0.7Vp-p ± 0.02Vp-p

• ANALOG RGB signal : RGB level : 0.7Vp-p ± 0.02Vp-p

10.1. Entering the adjustment process mode

Enter the adjustment process mode according to Section 4.

5 – 14

Page 36

LC-40/46LE810E, LC-40/46LX810E

100% white Black

100% white Black

10.2. PAL signal adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting [Signal]

PAL

Full field colour bar composite

signal

[Terminal]

EXT1 SCART IN

• Feed the PAL full field colour bar signal (75% colour saturation) to EXT1

SCART IN.

[VIDEO input signal]

2 Auto adjustment

performance

* ATTENTION: Please execute [3. TUNER adjustment] afterwards if you adjust [2. PAL signal adjustment] after all adjustments are completed.

Adjustment process

[PAL ADJ]

page 4/21

Bring the cursor on [PAL ADJ] and press [OK].

[PAL ADJ OK] appears when finished.

10.3. TUNER adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting [Signal]

PAL split field colour Bar

RF signal UV

[Terminal]

TUNER

• Feed the PAL Split Field colour bar signal (E-12ch) to TUNER.

• Make sure the PAL colour bar pattern has the sync level of 7:3 with the

picture level.

Signal level: 55 dB µV ± 1dB (75Ω LOAD)

[E-12CH]

100% white

2 Auto adjustment

performance

Adjustment process

[TUNER ADJ]

page 3/21

Bring the cursor on [TUNER ADJ] and press [OK].

[TUNER ADJ OK] appears when finished.

10.4. SECAM adjustment

Adjustment point Adjustment conditions Adjustment procedure

1 Setting [Signal]

SECAM

Full field colour Bar Signal

[Terminal]

EXT1 SCART IN

2 Auto adjustment

performance

Adjustment process

[SECAM ADJ]

page 4/21

• Feed the SECAM full field colour bar signal (75% colour saturation) to

EXT1 SCART IN.

[VIDEO input signal]

Bring the cursor on [SECAM ADJ] and press [OK].

[SECAM ADJ OK] appears when finished.

5 – 15

Page 37

10.5. ADC adjustment (Component 15K)

100% white Black

100% white Black

100% white Black

100% white Black

Adjustment point Adjustment conditions Adjustment procedure

1 Setting [Signal]

COMP15K, 50Hz

100% Full field colour bar Signal

[Terminal]

EXT3 COMPONENT IN

LC-40/46LE810E, LC-40/46LX810E

• Feed the COMPONENT 15K 100% full field colour bar signal (100%

colour saturation) to EXT3 COMPONENT IN.

2 Auto adjustment

performance

Adjustment process

[COMP15k ALL ADJ]

page 6/21

10.6. ADC adjustment (Component 33K)

Adjustment point Adjustment conditions Adjustment procedure

1 Setting [Signal]

COMP33K, 50Hz

100% Full field colour bar Signal

[Terminal]

EXT3 COMPONENT IN

2 Auto adjustment

performance

Adjustment process

[HDTV ADJ]

page 7/21

10.7. PC signal adjustment (ANALOG RPG)

Adjustment point Adjustment conditions Adjustment procedure

1 Setting [Signal]

XGA, 60Hz

100% Full Field Colour Bar Signal

Bring the cursor on [COMP15k ALL ADJ] and press [OK] [COMP15k ALL

ADJ] [OK] appears when finished.

• Feed the COMPONENT 33K 100% full field colour bar signal (100%

colour saturation) to EXT3 COMPONENT IN.

Bring the cursor on [HDTV ADJ] and press [OK].

[HDTV ADJ OK] appears when finished.

• Feed the XGA 60Hz 100% full field colour bar signal (100% colour saturation) to EXT3 PC IN.

[Terminal]

EXT3 PC IN

2 Auto adjustment

performance

Adjustment process

[ANALOG PC ADJ] menu

page 8/21

10.8. RGB (SCART) adjustment (RGB 15K)

Adjustment point Adjustment conditions Adjustment procedure

1 Setting [Signal]

RGB 15K, 50Hz

100% Full field colour bar signal

[Terminal]

EXT1 SCART RGB IN

2 Auto adjustment

performance

Adjustment process

[SCART RGB ADJ] menu

page 9/21

Bring the cursor on [ANALOG PC ADJ] and press [OK].

[ANALOG PC ADJ OK] appears when finished.

• Feed the RGB 15k 50Hz 100% full field colour bar signal (100% colour

saturation) to EXT1 SCART IN.

Bring the cursor on [SCART RGB ADJ] and press [OK].

[SCART RGB ADJ OK] appears when finished.

5 – 16

Page 38

LC-40/46LE810E, LC-40/46LX810E

11. White Balance Adjustment

For white balance adjustment, adjust the offset values on pages 11/21.

[Condition of the unit for inspection] : Modulated light (+16), Colour temperature (High)

AV MODE: DYNAMIC

Active Backlight: OFF

OPC: OFF

Asing Time: Min,60 minute

[Input signal condition] : HDMI 1080i 15IRE (LO), 78IRE (HI)

[Adjustment reference device] : Minolta CA-210

[Adjustment procedure]

1) Display the current adjustment status at R/G/B_GAIN (HI). (Page 11/21 of process adjustment)

The signal of 78IRE is input.

2) Read the value of the luminance meter. x = 0.272, y = 0.277

3) Change R_GAIN (HI)/B_GAIN (HI) (Adjustment offset value) on page 11/21 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

(Basically, G is not changed. If adjustment fails with R and B, change G. When G is lowered, the weaker of R or B must be fixed.)

4) Display the adjustment status of the current R/G/B_GAIN (LO).

The signal of 15IRE is input.

Change R_GAIN (LO)/B_GAIN (LO) (adjustment offset value) on page 11/21 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

5) Both HI and LO are repeating the step from 1 to 4 until becoming an aim value.

[Adjustment reference standard value]

Adjustment spec ± 0.002 Inspection spec ± 0.004 (point LO)

Adjustment spec ± 0.001 Inspection spec ± 0.002 (point HI)

6) After completing adjustments, set EEP SAVE (21/21) to ON in the process menu to save the white balance adjustment value.

12. Confirmation item

1. HDMI-CEC Inspection

After repairing the CEC function, check the operation about HDMI-CEC circuit

2. CI card Inspection

After repairing the CI function, check that the DTV signal is received in the UK setting by inserting CAM

And check the KEY certification by inserting CAM which is prepare for CI+

5 – 17

Page 39

LC-40/46LE810E, LC-40/46LX810E

Menu(Setup Software Update)

13. Initialization to factory settings

CAUTION: When the factory settings have been made, all user setting data, including the channel settings, are initialized.

(The adjustments done in the adjustment process mode are not initialized.) Keep this in mind when initializing these settings.

Adjustment point Adjustment conditions Adjustment procedure

1 Factory settings ends by turning off the

MAIN POWER key.

(See to below caution)

After adjustments, exit the adjustment process mode.

To exit the adjustment process mode, unplug the AC power cord from the outlet to forcibly turn off the power.

When the power is turned off with the remote control, unplug the AC power cord and plug it back in (wait approximately 10 seconds before plugging

in the AC power cord)

Please execute the initialized in the factory setting again when you turn on the power supply after the initialized in the factory setting is set.

[Factory setting with adjustment process mode]

• Enter the adjustment process mode.

• Move the cursor to [INDUSTRY INIT] on page 2/21.

• Use the R/C key to select a region from [EUROPE/RUSSIA] and press the [OK] key.

• “EXECUTING” display appears.

• After a while, “SUCCESS” display appears, the setting is completed.

When succeeding: Background colour (green)

When failing: Background colour (red)

The following items are initialized in the factory setting.

1) User settings

2) Channel data (e.g. broadcast frequencies)

3) Maker option setting

4) Password data

14. Upgrading the software

1. Turn on the AC power.

2. Insert the upgrading USB flash memory for upgrade into the service slot.

(After a while, an external input changes into USB automatically.)

3. Use the Menu button and cursor keys ( / / / ), CH keys ( / ) of R/C or on the set to select Menu - Setup - Information - Software update

on OSD menu.

4. The message (Insert the USB memory device contains the software update file) shows up.

Push OK when if there is no problem.

5. After a while, if software update file is detected in the USB memory device, the following screen shows up.

Select OK when if there is no problem.

NOTE: If there is no software update file in the USB memory device, caution shows up.

Please insert the correct file and retry software update.

NOTE: If software update file in the USB memory device doesn't mutch this model, caution shows up.

Please insert the correct file and retry software update.

NOTE: If software update file in the USB memory device is already installed, caution shows up.

Please reconfirm the software version and reinstall (if necessary).

Software update file is detected

in the USB memory device

start update

current version : xxxxxx

update version : xxxxxx

YES NO

5 – 18

Page 40

LC-40/46LE810E, LC-40/46LX810E

Menu(Setup Software Update)

Menu(Setup Software Update)

6. The caution for update showes up.

• The picture will temporary go dark until the software update display apeeares

• Wait several minutes and don't unplug the AC cord

Select OK when if there is no problem.

7. Software update starts.

Please wait for a while until the bar shows 100%

NOTE: Do not take out the USB memory device during updating.

Now Updating

Don't unpluged AC cord

update version xxxxxxx

8. When all the procedures are complete, the following upgrade success screen shows up.

The new software version can be confirmed on screen.

After a while, Turn off power and boot-up automatically.

NOTE: TV is restarted automatically, the AC code need not be pulled out.

LExxx

xx %

Software Update Complete

9. After boot-up, the following caution shows up.

Select OK when if there is no problem.

Software update is completed, please remove the USB memory device.

system software was

succesfully updated

Remove the USB memory device.

LExxx