Page 1

TopPage

LC-32PX5M/X/LC-37PX5M/X

SERVICE MANUAL

No. S17B1LC37PX5M

LCD COLOR TELEVISION

LC-32PX5M/X

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified be used.

LC-37PX5M/X

OUTLINE

This model is based on the LC-32BX5H/M, LC-37BX5H/M and partially modified.

For the contents not covered in this Service Manual, accordingly, please refer to the LC-32BX5H/M,

LC-37BX5H/M (S56T7LC32BX5M) Service Manual.

CONTENTS

DIFFERENCES FROM BASE MODEL

LIST OF CHANGED PARTS ............................. i

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION ......................................................... v

Precautions for using lead-free solder............. vi

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS.........................................1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL.................................. 2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS................................................ 3-1

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS................... 4-1

CHAPTER 5. BLOCK DIAGRAM/OVERALL WIRING

DIAGRAM

[1] BLOCK DIAGRAM..........................................5-1

[2] OVERALL WIRING DIAGRAM (LC-

32PX5M/X) .....................................................5-3

[3] OVERALL WIRING DIAGRAM (LC-

37PX5M/X) .....................................................5-5

CHAPTER 6. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM .............................................................6-1

[2] SCHEMATIC DIAGRAM .................................6-2

CHAPTER 7. PRINTED WIRING BOARD

[1] OPERATION UNIT PRINTED WIRING

BOARD ...........................................................7-1

[2] LED, R/C UNIT PRINTED WIRING

BOARD ...........................................................7-2

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-32PX5M/X/LC-37PX5M/X

LC-37PX5M

DIFFERENCES FROM BASE MODEL

Service Manual

LIST OF CHANGED PARTS

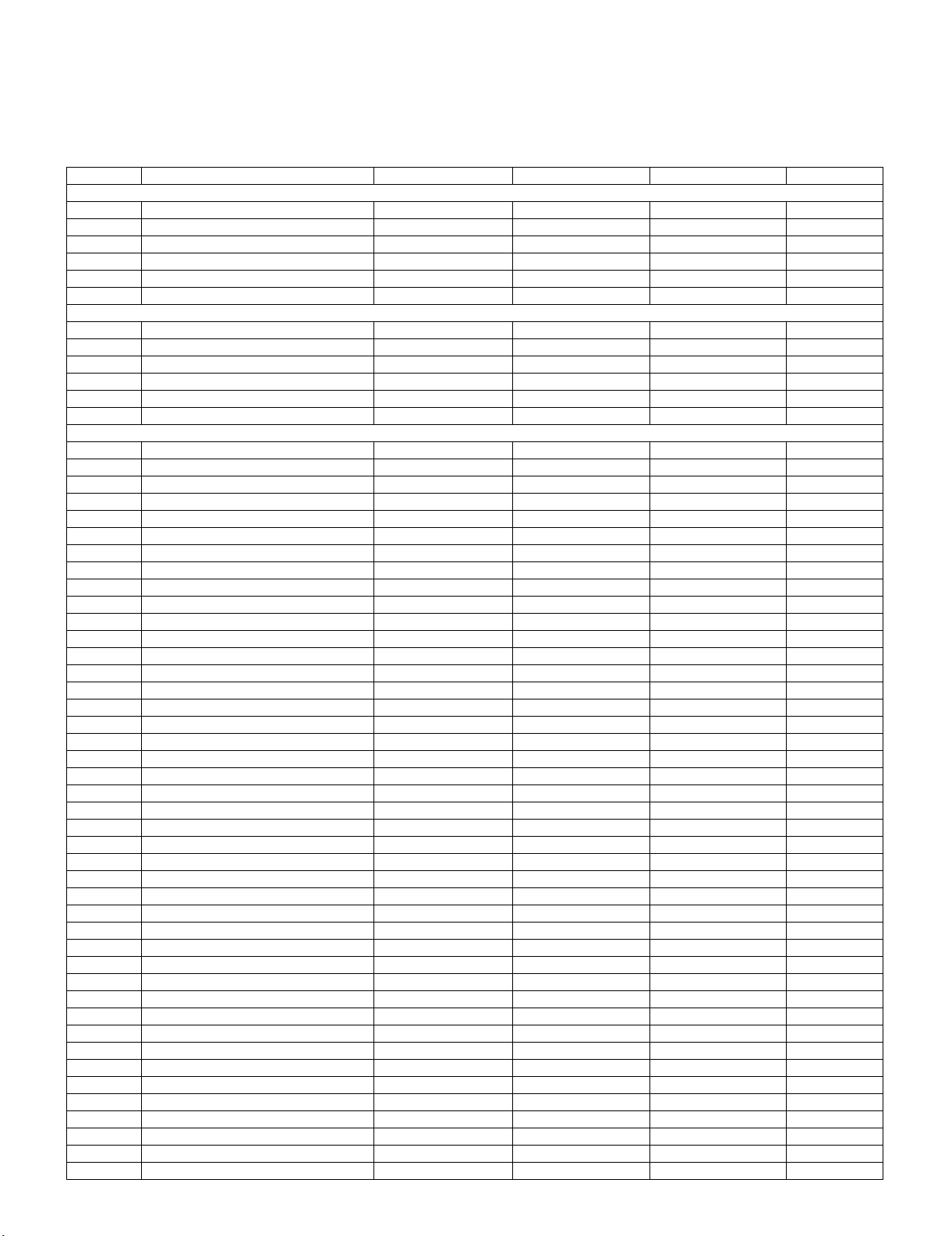

LC-32PX5M / LC-32PX5X

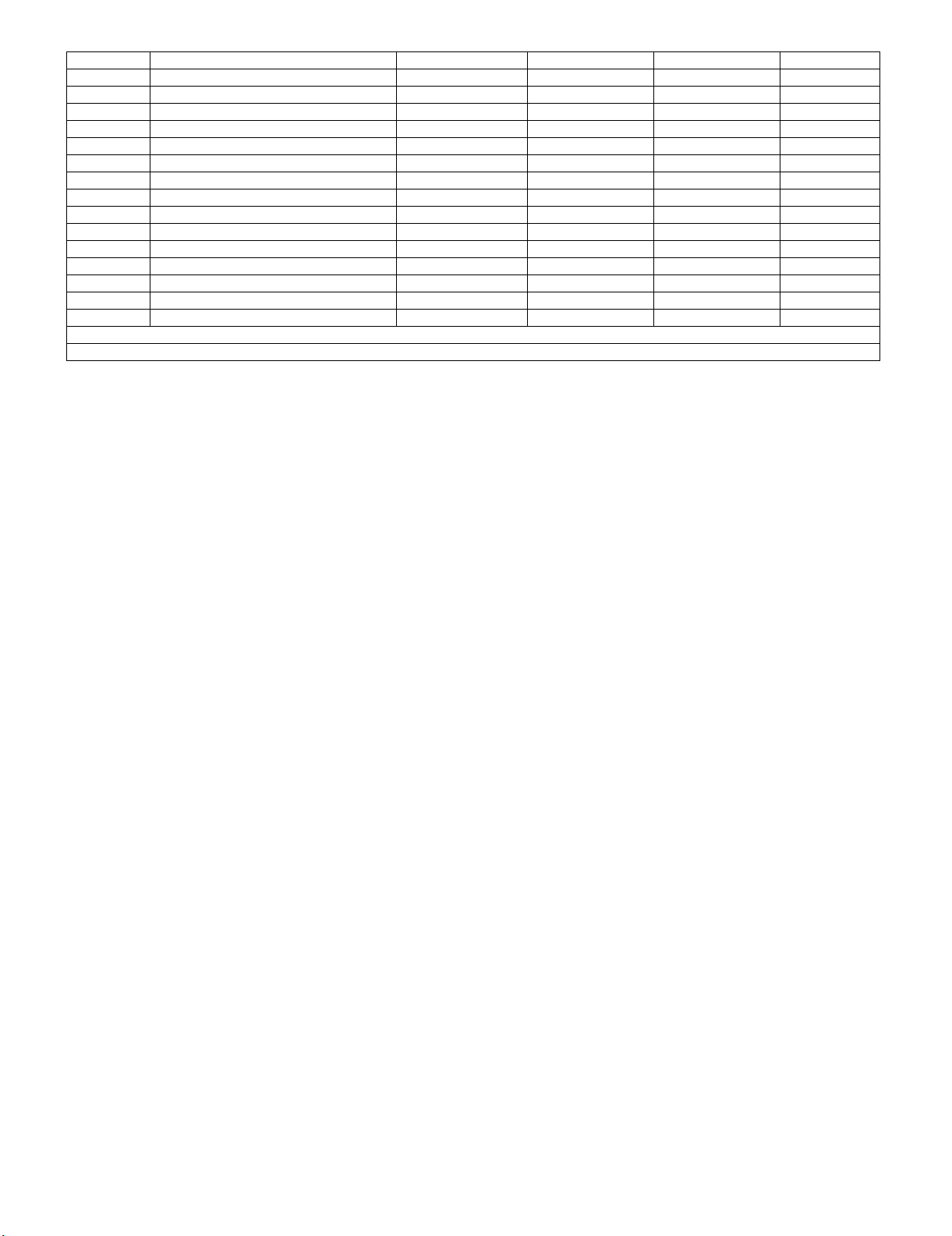

Ref. No. Description LC-32BX5M LC-32PX5M LC-32PX5X Note

PRINTED WIRING BOARD ASSEMBLIES (NOT REPLACE ITEM)

OPERATION Unit DUNTKD685FM03 DUNTKE097FM02 DUNTKE097FM02 Changes

MAIN Unit DUNTKD892FM03 DUNTKD892FM50 DUNTKD892FM51 Changes

SUB Unit DUNTKD893FM03 DUNTKD893FM50 DUNTKD893FM51 Changes

LED, R/C Unit DUNTKD897FM03 DUNTKE095FM02 DUNTKE095FM02 Changes

VIDEO-IN3 Unit DUNTKD898FM03 - - Delete

POWER Unit exchange RDENCA182WJQZ RDENCA182WJQZ RDENCA182WJQZ No Changes

LED, R/C UNIT (DUNTKD095FM02)

J101 Jack QJAKJA014WJZZ - - Delete

R111 Resistor 22 1/4W Metal Oxide VRS-TW2ED220JY - - Delete

R112 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R113 Resistor 22 1/4W Metal Oxide VRS-TW2ED220JY - - Delete

R114 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R115 Resistor 1k 1/16W Metal Oxide VRS-CY1JF102JY - - Delete

SUB UNIT (DUNTKD893FM50 / DUNTKD893FM51)

C1319 Capacitor 220 6.3V Electrolytic VCEASX0JN227MY - - Delete

C1320 Capacitor 10 16V Ceramic RC-KZA510WJPZY - - Delete

C1321 Capacitor 0.1 25V Ceramic VCKYCY1EF104ZY - - Delete

C1322 Capacitor 220 6.3V Electrolytic VCEASX0JN227MY - - Delete

C1326 Capacitor 1000p 50V Ceramic VCKYCY1HB102KY - - Delete

C1327 Capacitor 1000p 50V Ceramic VCKYCY1HB102KY - - Delete

C1328 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C1329 Capacitor 33 10V Electrolytic VCEASX1AN336MY - - Delete

C1330 Capacitor 0.1 25V Ceramic VCKYCY1EF104ZY - - Delete

C1337 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C1901 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C1902 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C3447 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C3448 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C3449 Capacitor 0.1 16V Ceramic VCKYCY1CB104KY - - Delete

C5002 Capacitor 0.01 50V Ceramic VCKYCY1HB103KY - - Delete

C5003 Capacitor 4700p 50V Ceramic VCKYCY1HB472KY - - Delete

C5004 Capacitor 4700p 50V Ceramic VCKYCY1HB472KY - - Delete

D1901 Diode DA221TL VHDDA221///-1Y - - Delete

FB5001 Ferrite Bead BLN-0051TA RBLN-0051TAZZY - - Delete

FB5002 Ferrite Bead BLN-0051TA RBLN-0051TAZZY - - Delete

FL5001 Filter RFILN0017TAZZY - - Delete

FL5002 Filter RFILN0017TAZZY - - Delete

FL5003 Filter RFILN0017TAZZY - - Delete

IC1302 IC BH3544F-E2 VHIBH3544F+-1Y - - Delete

IC1901 IC TC4W66F (TE12L,F) VHITC4W66F/-1Y - - Delete

IC1902 IC TC4W66F (TE12L,F) VHITC4W66F/-1Y - - Delete

IC2001 IC M30626FHPFPU5C RH-IXA648WJN2Q RH-IXA650WJN1Q RH-IXA650WJN1Q Changes

L1303 Coil Peaking 100uH VPCNN101J7R7NY - - Delete

P5009 Plug 14pin (VD) QPLGNA334WJZZY - - Delete

Q1302 Transistor PDTC144EE VSRDTC144EE-1Y - - Delete

Q1901 Transistor 2SC3928A VS2SC3928AR-1Y - - Delete

Q1902 Transistor UM6K1N TN VSUM6K1NTN+-1Y - - Delete

Q1903 Transistor QS6K1 VSQS6K1++++-1Y - - Delete

Q1904 Transistor PDTA144EK VSRDTA144EK-1Y - - Delete

Q2002 Transistor PDTC144EE VSRDTC144EE-1Y - - Delete

R1309 Resistor 18 1/4W Metal Oxide VRS-TW2ED180JY - - Delete

R1310 Resistor 18 1/4W Metal Oxide VRS-TW2ED180JY - - Delete

R1312 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R1313 Resistor 470 1/16W Metal Oxide VRS-CY1JF471JY - - Delete

R1314 Resistor 470 1/16W Metal Oxide VRS-CY1JF471JY - - Delete

R1901 Resistor 1k 1/16W Metal Oxide VRS-TV1JD102JY - - Delete

R1902 Resistor 1k 1/16W Metal Oxide VRS-TV1JD102JY - - Delete

i

Page 3

LC-32PX5M/X/LC-37PX5M/X

Ref. No. Description LC-32BX5M LC-32PX5M LC-32PX5X Note

R1903 Resistor 4.7k 1/16W Metal Oxide VRS-CY1JF472JY - - Delete

R1904 Resistor 150k 1/16W Metal Oxide VRS-CY1JF154JY - - Delete

R1907 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

R1908 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

R1909 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

R1910 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

R1911 Resistor 150k 1/16W Metal Oxide VRS-CY1JF154JY - - Delete

R1912 Resistor 0 1/16W Metal Oxide - VRS-CJ1JF000JY VRS-CJ1JF000JY Add

R2002 Resistor 1k 1/16W Metal Oxide VRS-CY1JF102JY - - Delete

R2003 Resistor 22k 1/16W Metal Oxide VRS-CY1JF223JY - - Delete

R2005 Resistor 22k 1/16W Metal Oxide VRS-CY1JF223JY - - Delete

R2008 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R2034 Resistor 15k 1/16W Metal Oxide VRS-CY1JF153JY - - Delete

R2051 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY VRS-CY1JF102JY VRS-CY1JF102JY Changes

R2075 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY - - Delete

R3465 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY - - Delete

R3466 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY - - Delete

R5008 Resistor 1k 1/16W Metal Oxide VRS-CY1JF102FY - - Delete

R5011 Resistor 47k 1/16W Metal Oxide VRS-CY1JF473JY - - Delete

R5014 Resistor 0 1/16W Metal Oxide VRS-CY1JF000JY - - Delete

OPERATION Unit (DUNTKE097FM02)

All parts are changed.

In trouble shooting table, “No audio heard (4)” and “No external video screen <INPUT3>” are abolished.

Refer to the PARTS GUIDE for CABINET PARTS, SUPPLIED ACCESORIES, PACKING PARTS and SERVICE JIGS.

ii

Page 4

LC-32PX5M/X/LC-37PX5M/X

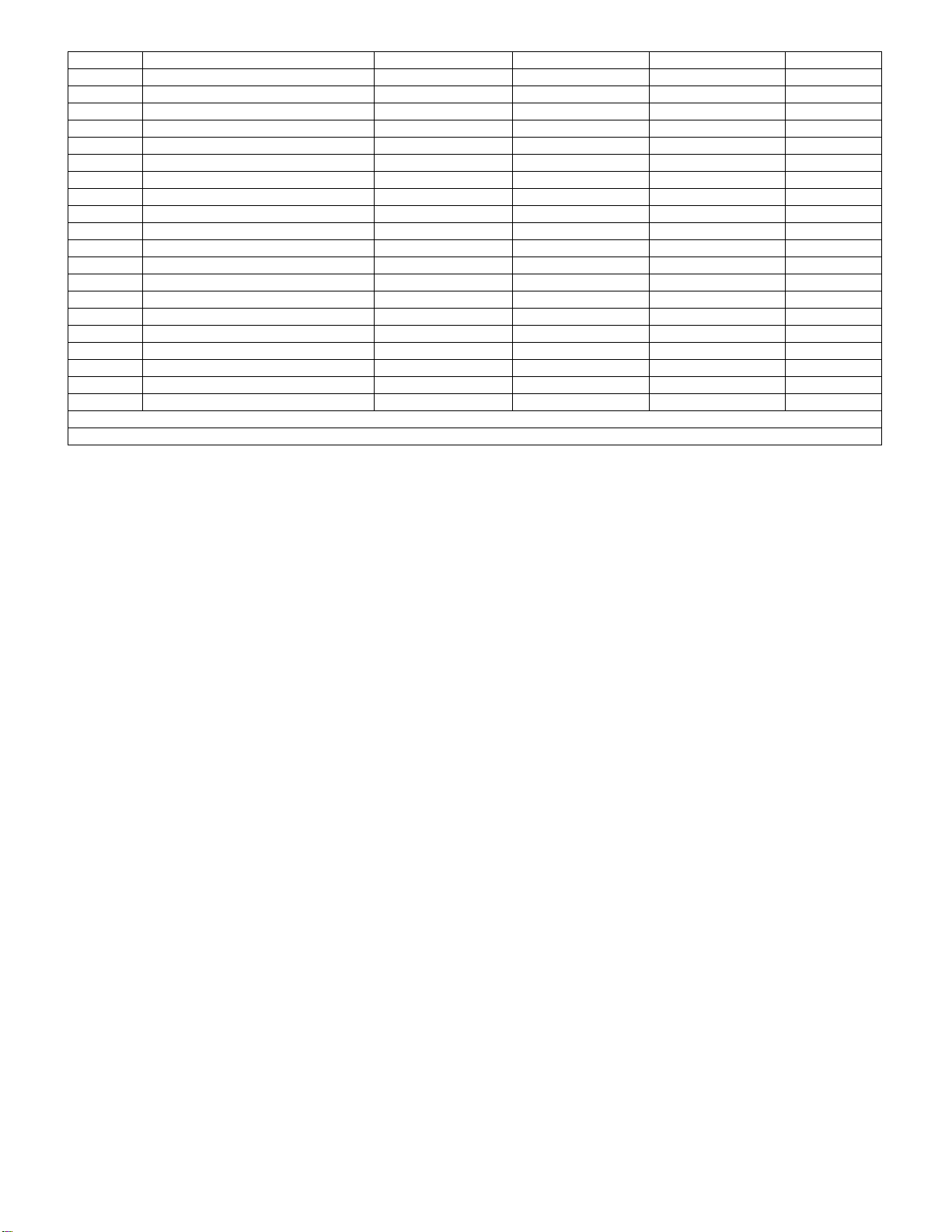

LC-37PX5M / LC-37PX5X

Ref. No. Description LC-37BX5M LC-37PX5M LC-37PX5X Note

PRINTED WIRING BOARD ASSEMBLIES (NOT REPLACE ITEM)

OPERATION Unit DUNTKD685FM13 DUNTKE097FM04 DUNTKE097FM04 Changes

MAIN Unit DUNTKD892FM13 DUNTKD892FM52 DUNTKD892FM53 Changes

SUB Unit DUNTKD893FM13 DUNTKD893FM52 DUNTKD893FM53 Changes

LED, R/C Unit DUNTKD897FM13 DUNTKD897FM53 DUNTKD897FM53 Changes

VIDEO-IN3 Unit DUNTKD898FM13 - - Delete

POWER Unit exchange RDENCA182WJQZ RDENCA182WJQZ RDENCA182WJQZ No Changes

LED, R/C UNIT (DUNTKD897FM53)

J101 Jack QJAKJA014WJZZ - - Delete

R111 Resistor 22 1/4W Metal Oxide VRS-TW2ED220JY - - Delete

R112 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R113 Resistor 22 1/4W Metal Oxide VRS-TW2ED220JY - - Delete

R114 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R115 Resistor 1k 1/16W Metal Oxide VRS-CY1JF102JY - - Delete

SUB UNIT (DUNTKD893FM52 / DUNTKD893FM53)

C1319 Capacitor 220 6.3V Electrolytic VCEASX0JN227MY - - Delete

C1320 Capacitor 10 16V Ceramic RC-KZA510WJPZY - - Delete

C1321 Capacitor 0.1 25V Ceramic VCKYCY1EF104ZY - - Delete

C1322 Capacitor 220 6.3V Electrolytic VCEASX0JN227MY - - Delete

C1326 Capacitor 1000p 50V Ceramic VCKYCY1HB102KY - - Delete

C1327 Capacitor 1000p 50V Ceramic VCKYCY1HB102KY - - Delete

C1328 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C1329 Capacitor 33 10V Electrolytic VCEASX1AN336MY - - Delete

C1330 Capacitor 0.1 25V Ceramic VCKYCY1EF104ZY - - Delete

C1337 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C1901 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C1902 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C3447 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C3448 Capacitor 1 10V Ceramic VCKYCY1AB105KY - - Delete

C3449 Capacitor 0.1 16V Ceramic VCKYCY1CB104KY - - Delete

C5002 Capacitor 0.01 50V Ceramic VCKYCY1HB103KY - - Delete

C5003 Capacitor 4700p 50V Ceramic VCKYCY1HB472KY - - Delete

C5004 Capacitor 4700p 50V Ceramic VCKYCY1HB472KY - - Delete

D1901 Diode DA221TL VHDDA221///-1Y - - Delete

FB5001 Ferrite Bead BLN-0051TA RBLN-0051TAZZY - - Delete

FB5002 Ferrite Bead BLN-0051TA RBLN-0051TAZZY - - Delete

FL5001 Filter RFILN0017TAZZY - - Delete

FL5002 Filter RFILN0017TAZZY - - Delete

FL5003 Filter RFILN0017TAZZY - - Delete

IC1302 IC BH3544F-E2 VHIBH3544F+-1Y - - Delete

IC1901 IC TC4W66F (TE12L,F) VHITC4W66F/-1Y - - Delete

IC1902 IC TC4W66F (TE12L,F) VHITC4W66F/-1Y - - Delete

IC2001 IC M30626FHPFPU5C RH-IXA648WJN2Q RH-IXA650WJN1Q RH-IXA650WJN1Q Changes

L1303 Coil Peaking 100uH VPCNN101J7R7NY - - Delete

P5009 Plug 14pin (VD) QPLGNA334WJZZY - - Delete

Q1302 Transistor PDTC144EE VSRDTC144EE-1Y - - Delete

Q1901 Transistor 2SC3928A VS2SC3928AR-1Y - - Delete

Q1902 Transistor UM6K1N TN VSUM6K1NTN+-1Y - - Delete

Q1903 Transistor QS6K1 VSQS6K1++++-1Y - - Delete

Q1904 Transistor PDTA144EK VSRDTA144EK-1Y - - Delete

Q2002 Transistor PDTC144EE VSRDTC144EE-1Y - - Delete

R1309 Resistor 18 1/4W Metal Oxide VRS-TW2ED180JY - - Delete

R1310 Resistor 18 1/4W Metal Oxide VRS-TW2ED180JY - - Delete

R1312 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R1313 Resistor 470 1/16W Metal Oxide VRS-CY1JF471JY - - Delete

R1314 Resistor 470 1/16W Metal Oxide VRS-CY1JF471JY - - Delete

R1901 Resistor 1k 1/16W Metal Oxide VRS-TV1JD102JY - - Delete

R1902 Resistor 1k 1/16W Metal Oxide VRS-TV1JD102JY - - Delete

R1903 Resistor 4.7k 1/16W Metal Oxide VRS-CY1JF472JY - - Delete

R1904 Resistor 150k 1/16W Metal Oxide VRS-CY1JF154JY - - Delete

R1907 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

R1908 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

R1909 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

iii

Page 5

LC-32PX5M/X/LC-37PX5M/X

Ref. No. Description LC-37BX5M LC-37PX5M LC-37PX5X Note

R1910 Resistor 1M 1/16W Metal Oxide VRS-CY1JF105JY - - Delete

R1911 Resistor 150k 1/16W Metal Oxide VRS-CY1JF154JY - - Delete

R1912 Resistor 0 1/16W Metal Oxide - VRS-CJ1JF000JY VRS-CJ1JF000JY Add

R2002 Resistor 1k 1/16W Metal Oxide VRS-CY1JF102JY - - Delete

R2003 Resistor 22k 1/16W Metal Oxide VRS-CY1JF223JY - - Delete

R2005 Resistor 22k 1/16W Metal Oxide VRS-CY1JF223JY - - Delete

R2008 Resistor 100k 1/16W Metal Oxide VRS-CY1JF104JY - - Delete

R2034 Resistor 15k 1/16W Metal Oxide VRS-CY1JF153JY - - Delete

R2051 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY VRS-CY1JF102JY VRS-CY1JF102JY Changes

R2075 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY - - Delete

R3465 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY - - Delete

R3466 Resistor 100 1/16W Metal Oxide VRS-CY1JF101JY - - Delete

R5008 Resistor 1k 1/16W Metal Oxide VRS-CY1JF102FY - - Delete

R5011 Resistor 47k 1/16W Metal Oxide VRS-CY1JF473JY - - Delete

R5014 Resistor 0 1/16W Metal Oxide VRS-CY1JF000JY - - Delete

OPERATION Unit (DUNTKE097FM04)

All parts are changed.

In trouble shooting table, "No audio heard (4)" and "No external video screen <INPUT3>" are abolished.

Refer to the PARTS GUIDE for CABINET PARTS, SUPPLIED ACCESORIES, PACKING PARTS and SERVICE JIGS.

iv

Page 6

LC-32PX5M/X/LC-37PX5M/X

LC-37PX5M

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER (Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

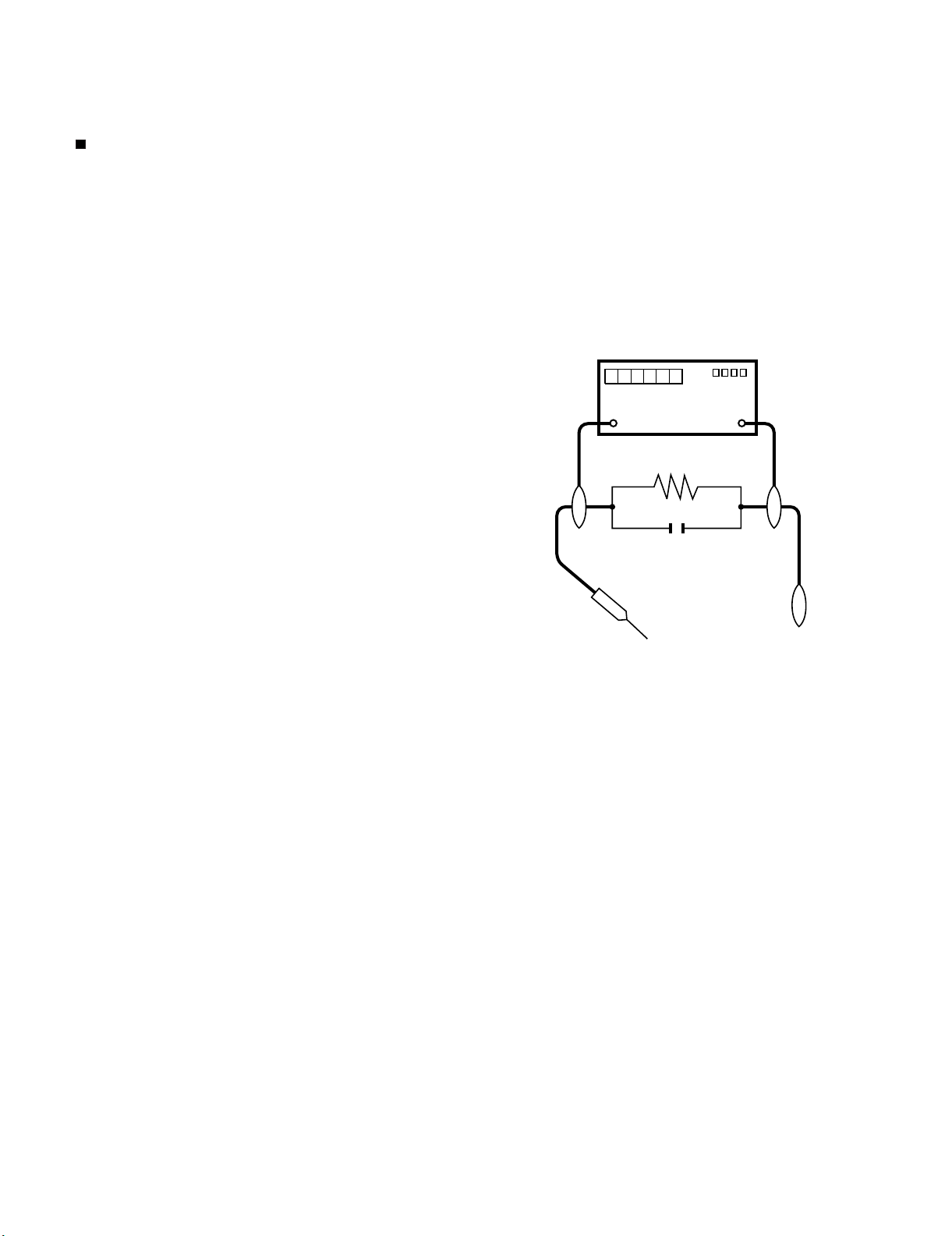

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 110 ~ 240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a non polarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.74 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts

Lists and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

v

Page 7

LC-32PX5M/X/LC-37PX5M/X

Precautions for using lead-free solder

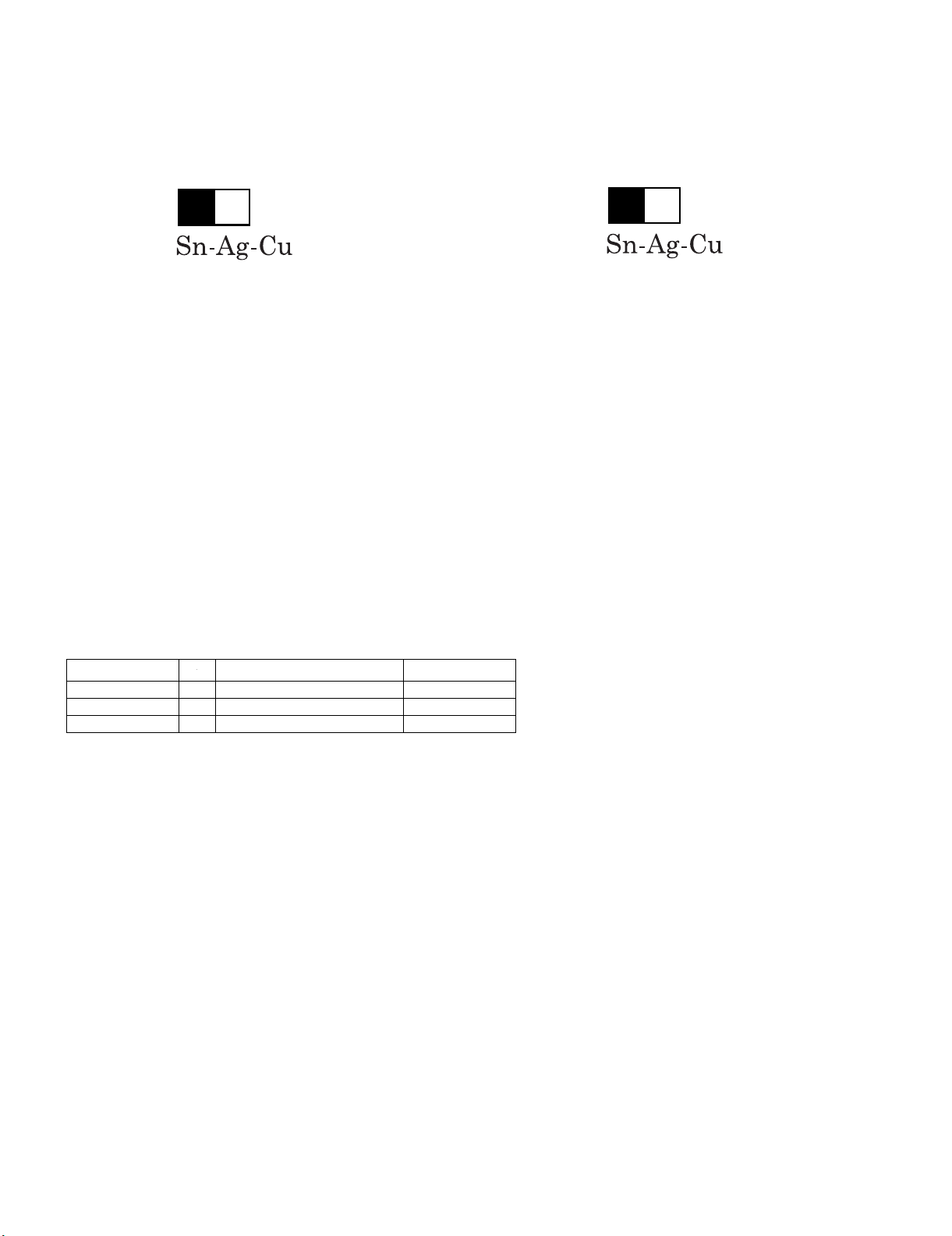

Employing lead-free solder

• “All PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals.

The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

vi

Page 8

LC-32PX5M/X/LC-37PX5M/X

LC-37PX5M

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

Service Manual

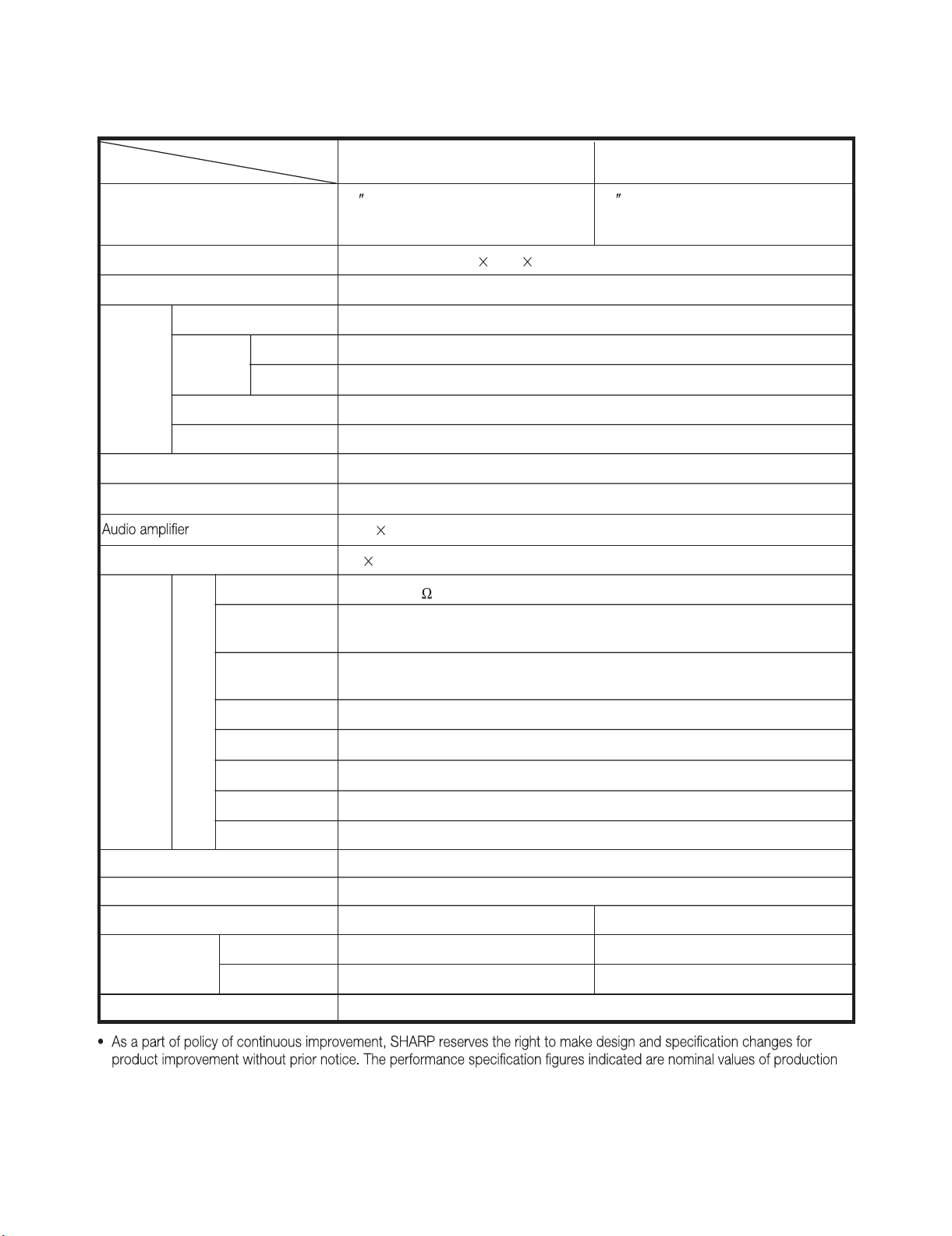

Model

Item

LCD panel

LC-32PX5M/X

32 (80 cm) Advanced

Super View & BLACK TFT

LCD

Video Colour System

TV

Function

TV-Standard

Receiving

VHF/UHF

PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

PAL: B/G, D/K, I SECAM: B/G, D/K, K/K

44.25—863.25 MHz

Channel

CATV

TV-Tuning System

STEREO/BILINGUAL

Brightness

S1—S41ch (including Hyperband)

Auto Preset 99 ch

NICAM: B/G, I, D/K A2 stereo: B/G

450 cd/m

2

Viewing angles H : 176º V : 176º

10W 2

4 cm 2pcs, Ø 2 cm 2pcs

01srekaepS

Terminals

Rear

ANTENNA IN

UHF/VHF 75 DIN type

6631(stod462,741,3stodforebmuN 768 3dots)

LC-37PX5M/X

(94 cm) Advanced

37

Super View & BLACK TFT

LCD

1

NTSC: M

INPUT 1

INPUT 2

INPUT 3

INPUT 4

PC INPUT

MONITOR OUTPUT

RS-232C

OSD language

Power Requirement

Power Consumption

without stand

Weight

with stand

Operating Temperature

VIDEOin,AUDIOin,

COMPONENT in (480I, 576I, 480P, 576P, 720P/60Hz, 1080I/50Hz, 1080I/60Hz)

VIDEOin,AUDIOin,

COMPONENT in (480I, 576I, 480P, 576P, 720P/60Hz, 1080I/50Hz, 1080I/60Hz)

HDMI (HDMI input) (480P, 576P, 720P/60Hz, 1080I/50Hz, 1080I/60Hz), AUDIO in

HDMI (HDMI input) (480P, 576P, 720P/60Hz, 1080I/50Hz, 1080I/60Hz)

15 pin mini D-sub, AUDIO in (Ø 3.5mm jack)

VIDEO out, AUDIO out

9 pin D-sub male connector

English/Chinese/Arabic

AC 110—240 V, 50/60 Hz

158 W (0.8 W Standby)

16.5 kg

18.4 kg

171 W (0.8 W Standby)

20.3 kg

22.9 kg

0°C — 40°C

units. There may be some deviations from these values in individual units.

1 – 1

Page 9

LC-37PX5M

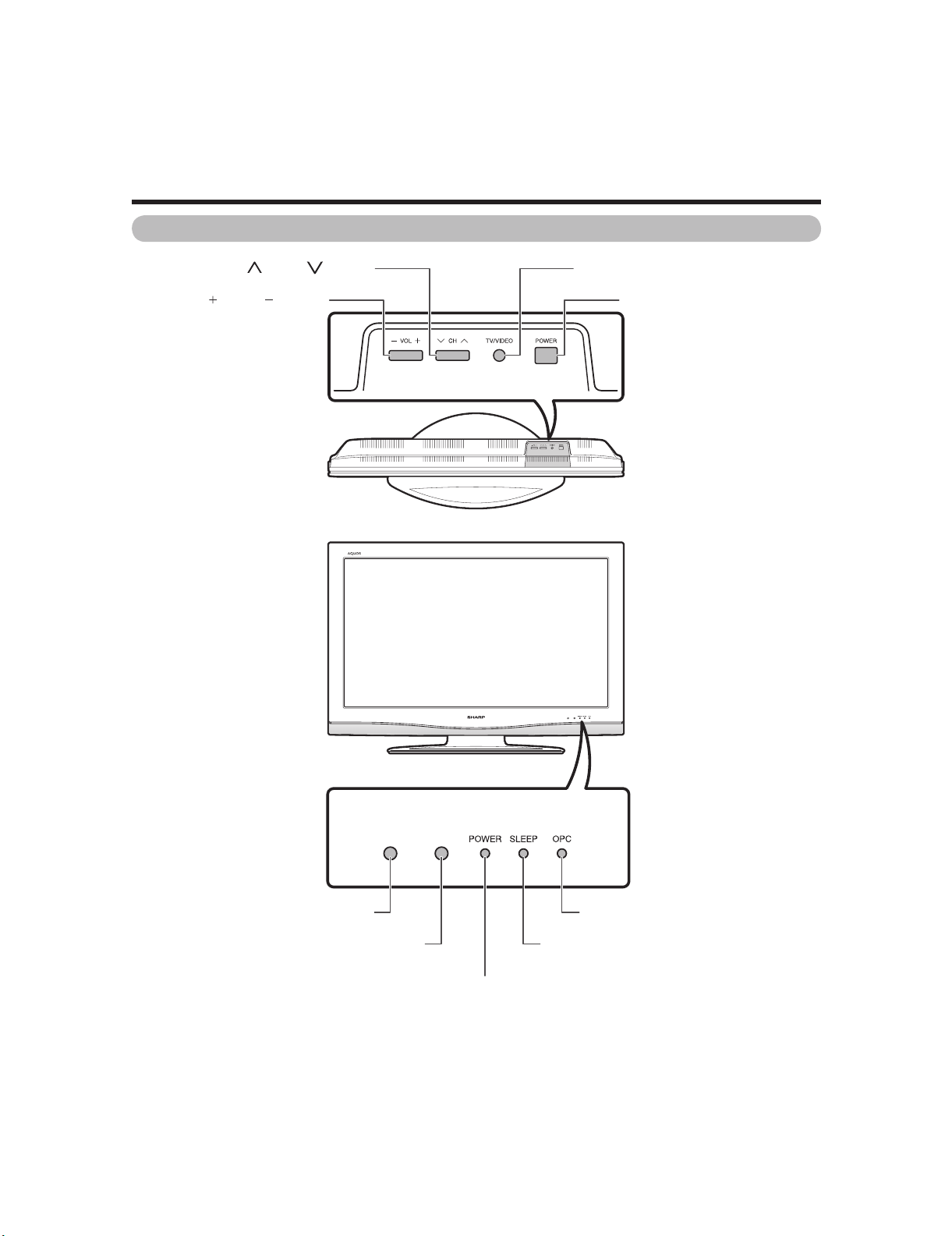

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

Part names

TV (Front)

LC-32PX5M/X/LC-37PX5M/X

Service Manual

Channel up ( )/down ( ) buttons

Volume up ( )/down ( ) buttons

TV/VIDEO button

POWER (On/Off) button

Remote control sensor

OPC sensor

POWER indicator

2 – 1

OPC indicator*

SLEEP timer indicator

*OPC: Optical Picture Control

Page 10

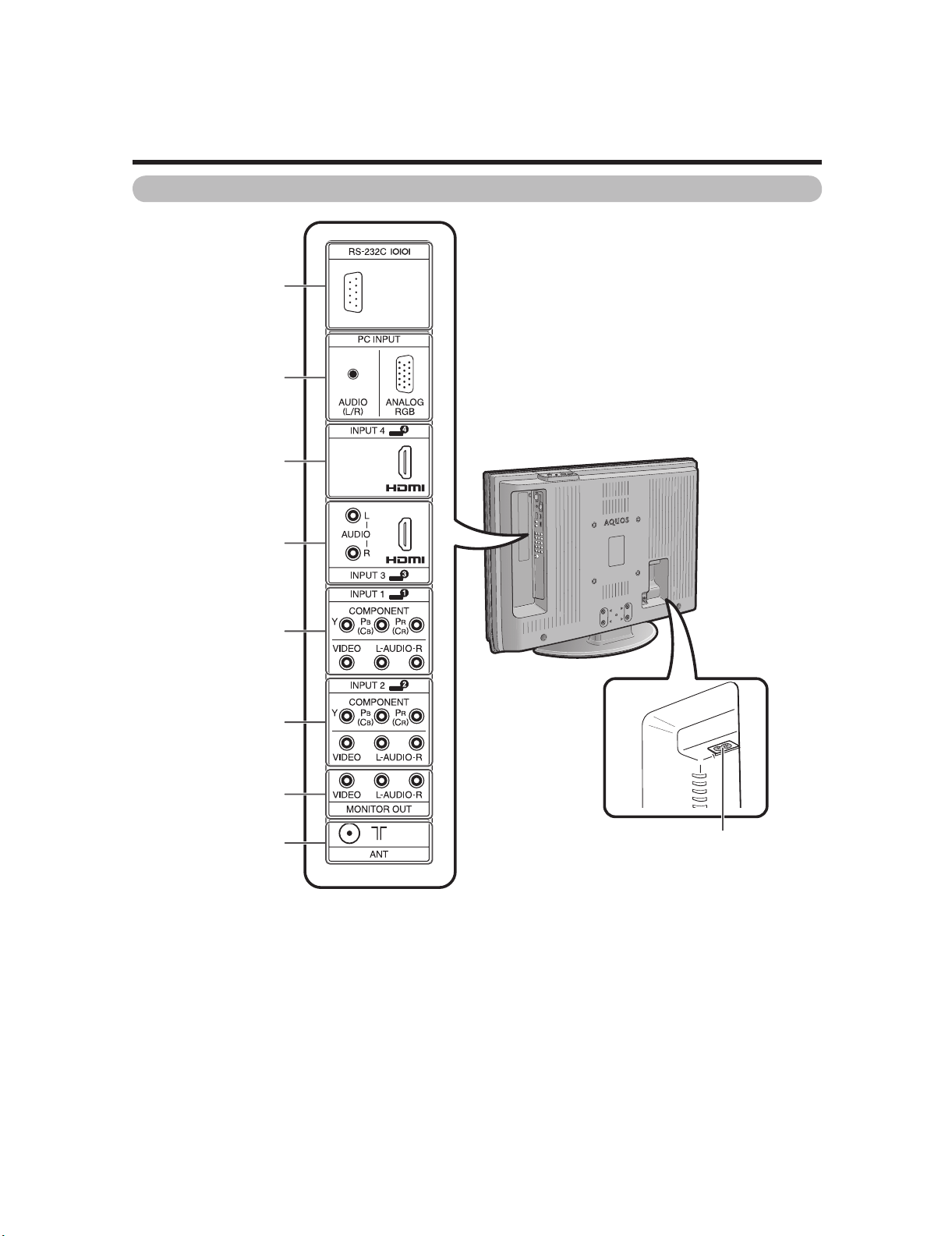

LC-32PX5M/X/LC-37PX5M/X

Part names

TV (Rear)

RS-232C terminal

PC INPUT terminals

INPUT 4 (HDMI) terminal

INPUT 3 (HDMI) terminals

INPUT 1 terminals

INPUT 2 terminals

MONITOR OUTPUT

terminals

Antenna input terminal

AC INPUT terminal

2 – 2

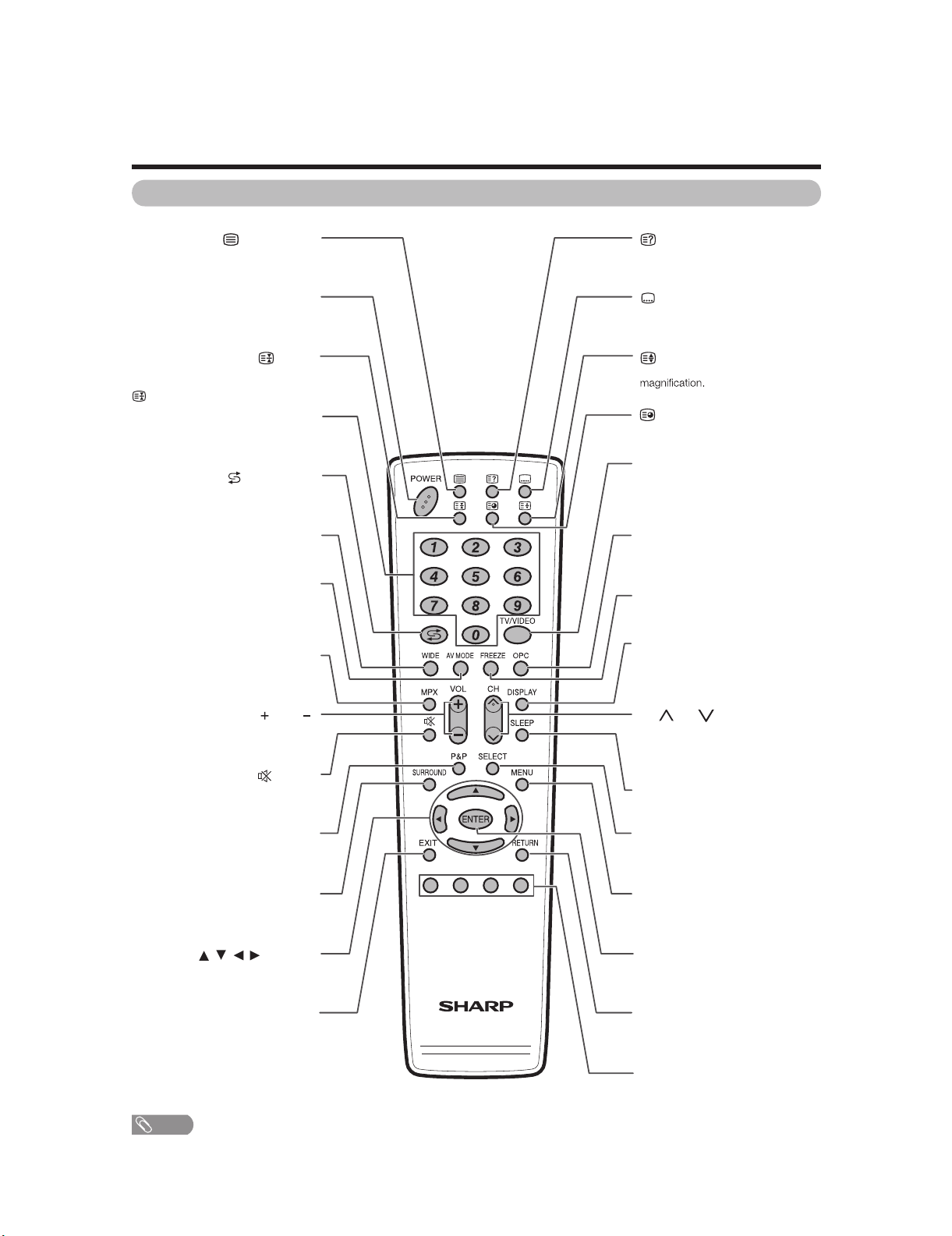

Page 11

Part names

Remote control unit

LC-32PX5M/X/LC-37PX5M/X

Select the TELETEXT mode. (all TV

image, all TEXT image, TV/TEXT

image)

POWER (STANDBY/ON)

(TELETEXT)

To switch the power on and off.

(Hold)

TELETEXT mode: Stop updating

Teletext pages automatically. Press

again to release the hold mode.

0—9

Set the channel.

TELETEXT mode: Set the page.

(Flashback)

Press to return to the previous channel

or external input mode.

WIDE

Change the wide image mode.

AV MO D E

Select a video setting: AV MODE

(STANDARD, MOVIE, GAME, USER,

DYNAMIC, DYNAMIC (FIXED)), PC MODE

(S TANDAR D , USER)

MPX

Select the sound multiplex mode.

(Reveal hidden for

TELETEXT)

TELETEXT mode: Display hidden

characters.

(SUBTITLE for TELETEXT)

To turn the subtitles on and off.

(Top/Bottom/Full)

TELETEXT mode: Set the area of

(Subpage)

Display the Teletext subpage directly.

TV/VIDEO (INPUT SOURCE)

Select an input source. (TV, INPUT 1,

INPUT 2, INPUT 3, INPUT 4, PC)

OPC

To switch Optical Picture Control on

and off.

FREEZE

Freeze a motion picture on the screen.

DISPLAY

Display the channel and input source.

Set the volume.

(Mute)

VOL /VOL

Mute the sound.

P&P

Set the dual picture mode. Press P&P

again to return to normal view.

SURROUND

Select Surround settings.

/ / / (Cursor)

Select a desired item on the setting

screen.

EXIT

Return to the default screen.

NOTE

• When using the remote control unit, point it at the TV.

CH /CH

TV input mode: Select the channel.

TELETEXT mode: Select the page.

SLEEP

Set the Sleep timer.

SELECT

To select either screen to be active in

Dual screen mode.

MENU

Display the menu screen.

ENTER

Execute a command.

RETURN

MENU mode: Return to the previous

menu screen.

Colour (Red/Green/Yellow/

Blue)

TELETEXT mode: Select a page.

2 – 3

Page 12

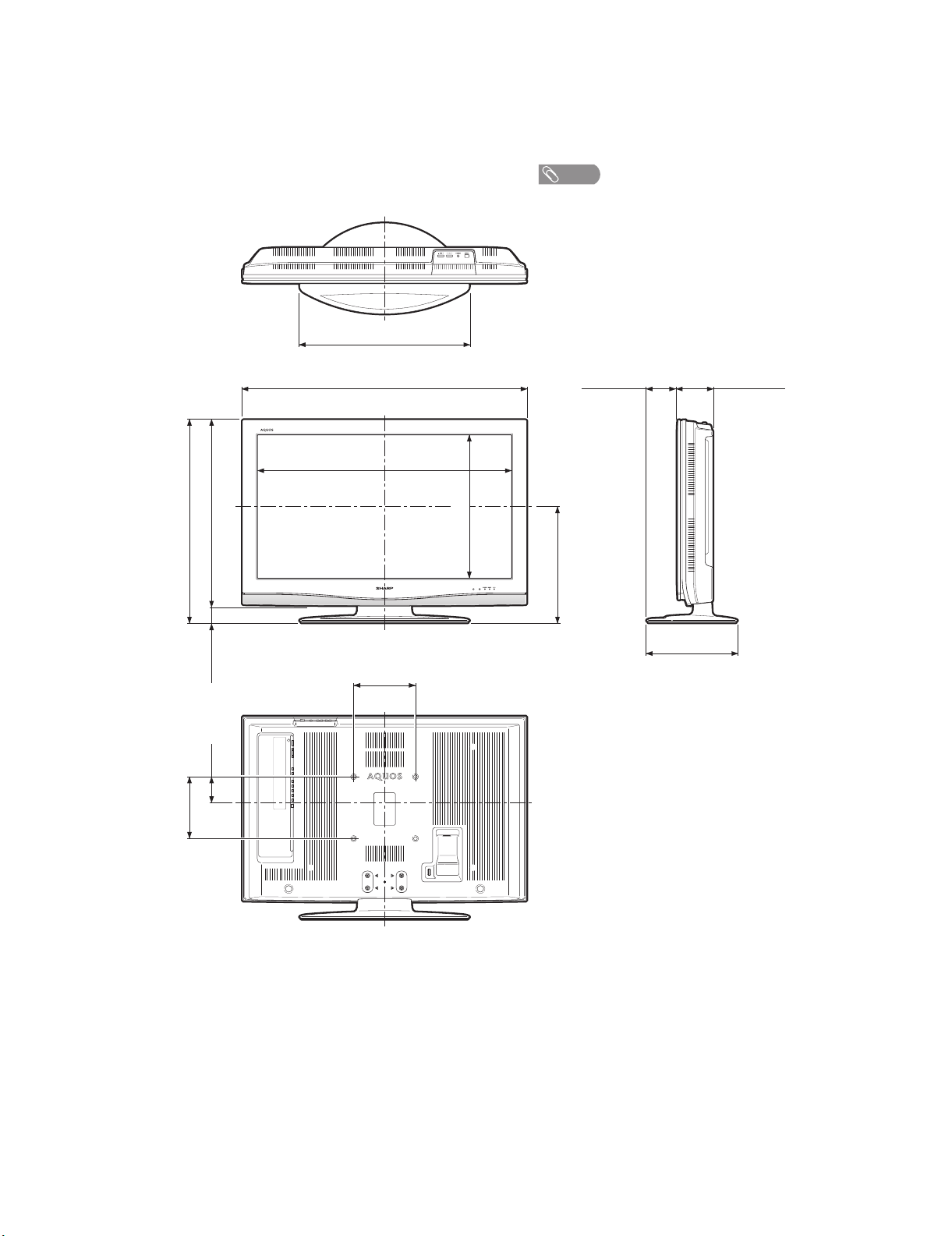

LC-32PX5M/X/LC-37PX5M/X

LC-37PX5M

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

Service Manual

LC-32PX5M/X, LC-37PX5M/X

700.4 (823)

533 (600)57.5 (57)

590.5 (657)

506 (542)

797 (920)

Unit: mm

NOTE

• Figures within parentheses are for LC-37PX5M/X.

100 (84) 116 (116)

395.1 (464)

343 (377)

200 (200)

250 (292)

200 (200)

85 (85)

3 – 1

Page 13

LC-32PX5M/X/LC-37PX5M/X

LC-37PX5M

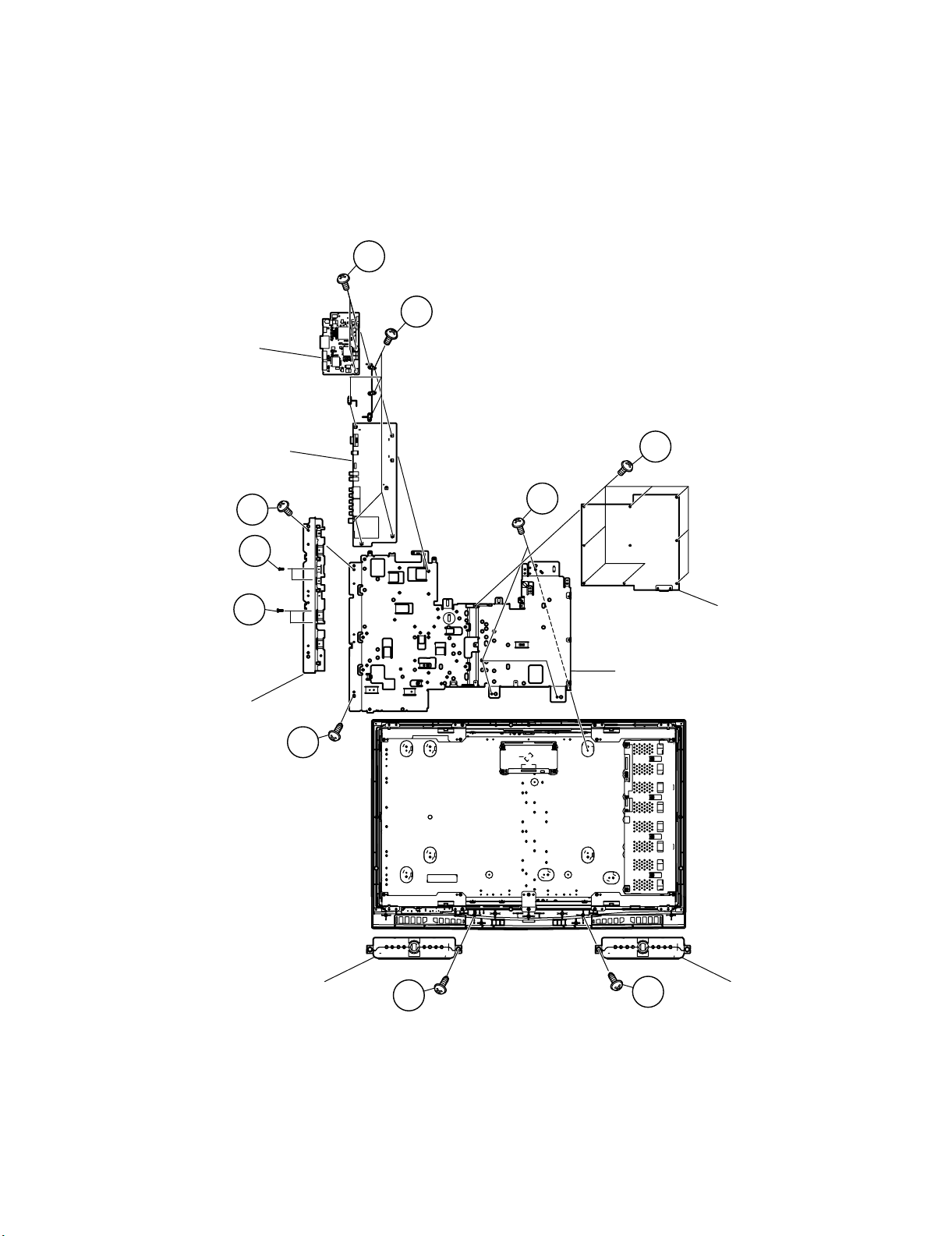

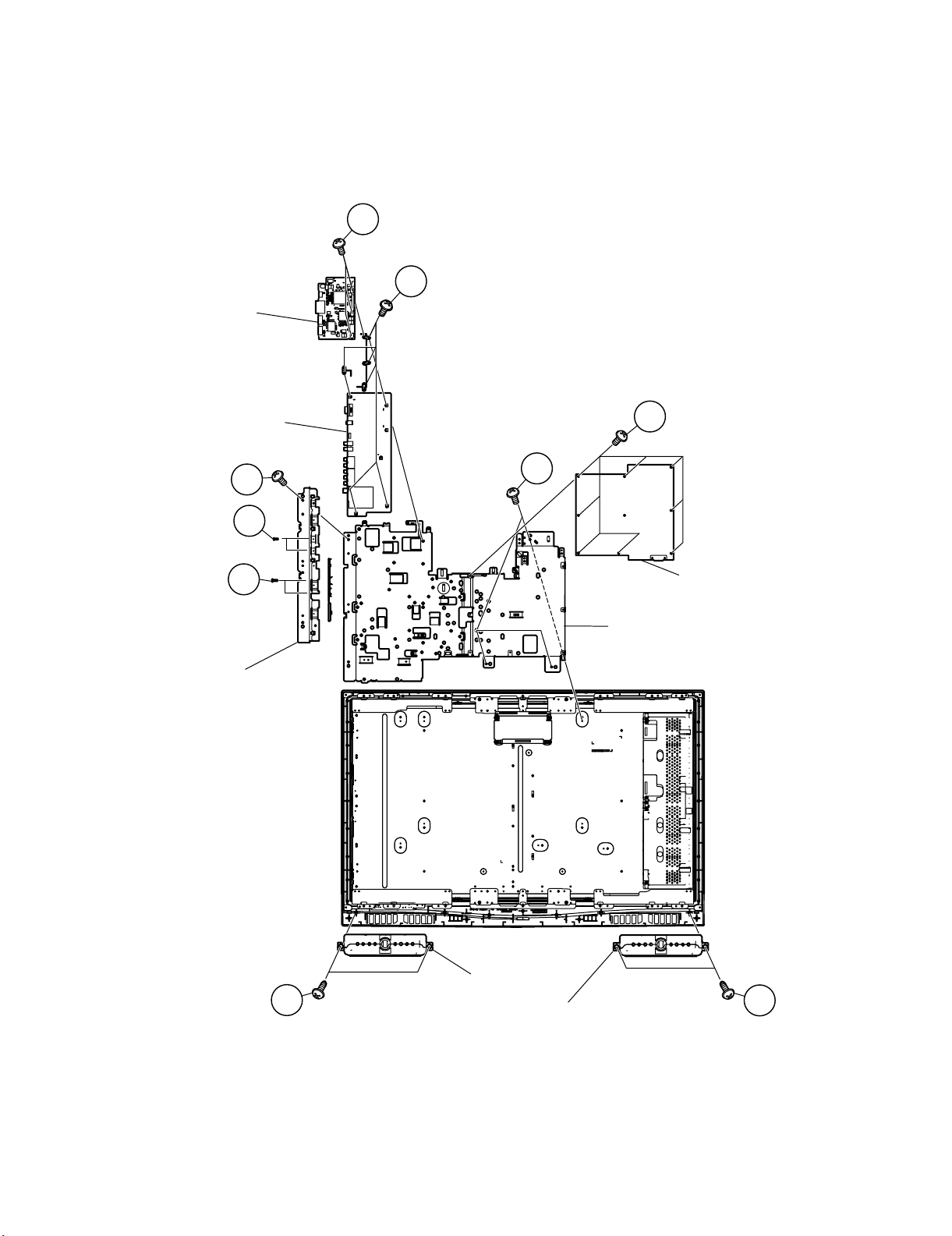

CHAPTER 4. REMOVING OF MAJOR PARTS

Service Manual

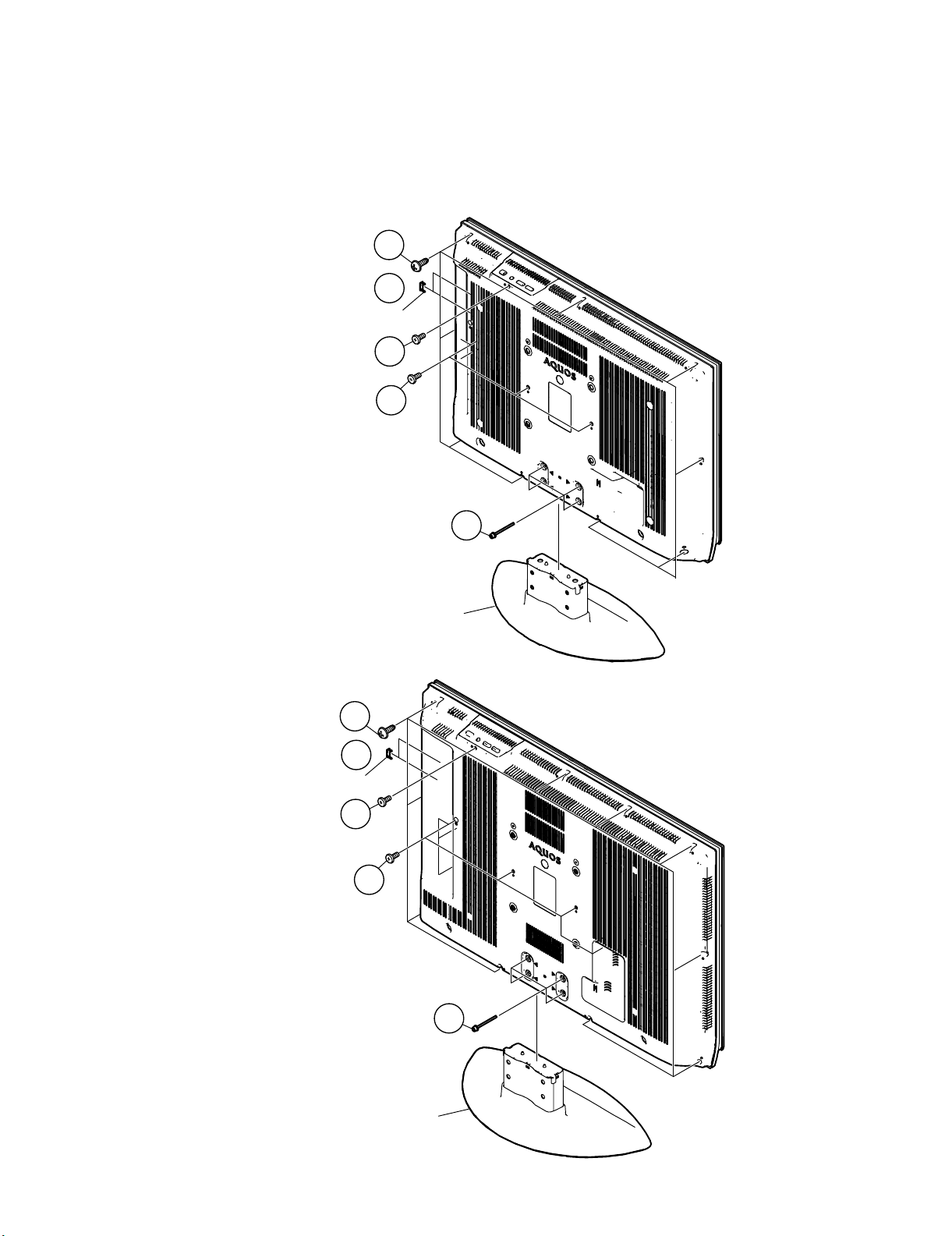

[1] REMOVING OF MAJOR PARTS

1. Detach the 2 BUS Covers [1].

2. Remove the 4 screws [2] and detach the Stand.

3. Remove the 1 screw [3], 4 (32PX5M/X)/6 (37PX5M/X) screws [4] and the 9 (32PX5M/X)/10 (37PX5M/X) screws [5].

Detach the Rear Cabinet.

(LC-32PX5M/X)

BUS Cover

5

1

3

4

2

Stand

(LC-37PX5M/X)

BUS Cover

5

1

3

4

2

Stand

4 – 1

Page 14

LC-32PX5M/X/LC-37PX5M/X

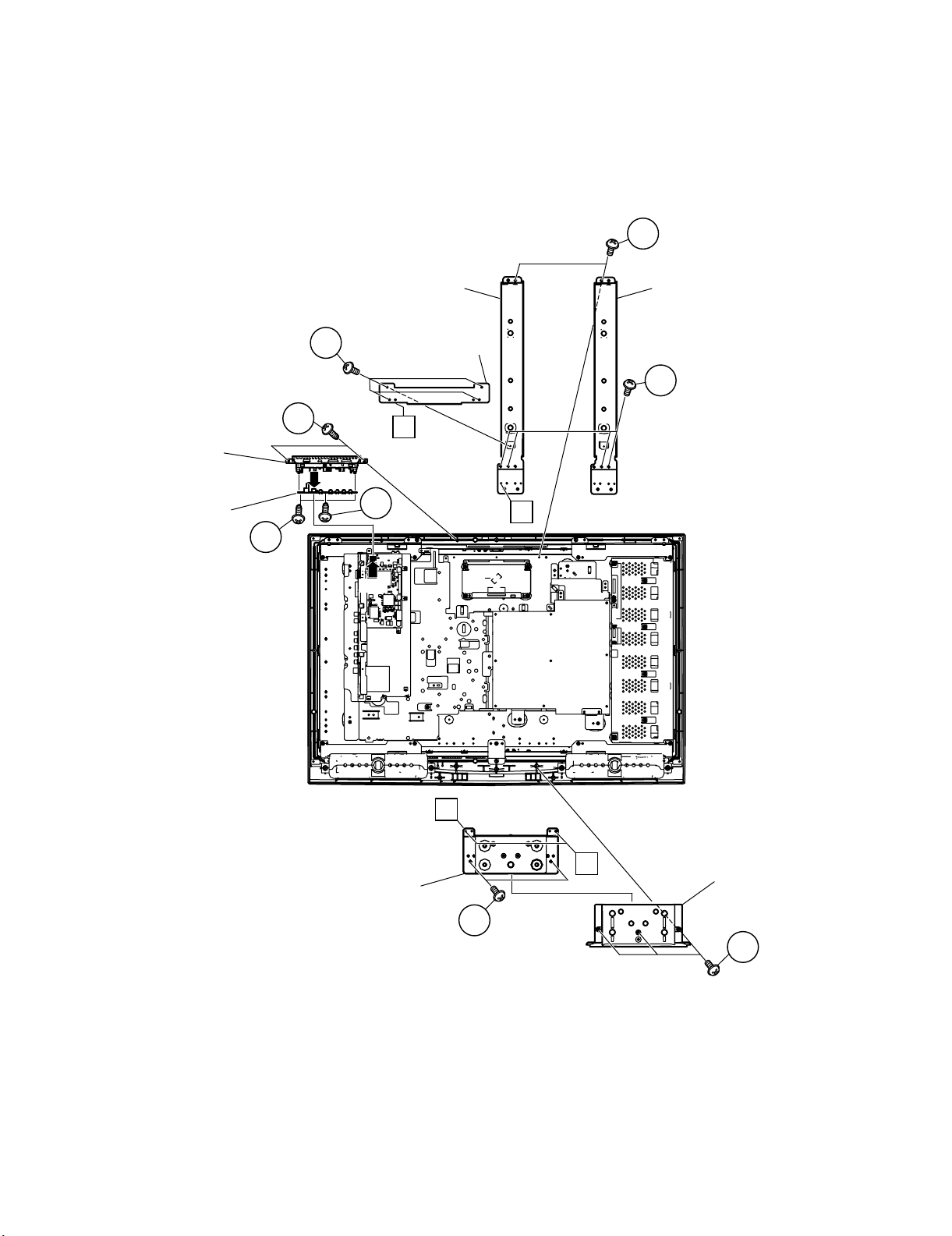

4. Remove the 4 screws [6] and detach the Support Angle.

5. Remove the 3 screws [7] and the Bottom Cover.

6. Remove the 2 (32PX5M/X)/4 (37PX5M/X) screws [8] and detach the Stand Angle.

7. Remove the 6 (32PX5M/X)/4 (37PX5M/X) screws [9].

Detach the SUS Angle-L and SUS Angle-R.

8. Remove the 2 screws [10] and detach the Top Control Cover Ass'y.

Remove the 2 screws [11] , 1 screw [11A] and detach the OPERATION PWB Unit from Top Control Cover Ass'y.

(LC-32PX5M/X)

Top Control

Cover Ass'y

OPERATION

PWB Unit

11

10

6

䬌䎮䎰䬍

Center Angle-R

Support Angle

䎤

11A

䬌䎮䎰䬍

9

Center Angle-L

9

䎥

Stand Angle

䎥

䎤

Bottom Cover

8

7

4 – 2

Page 15

LC-32PX5M/X/LC-37PX5M/X

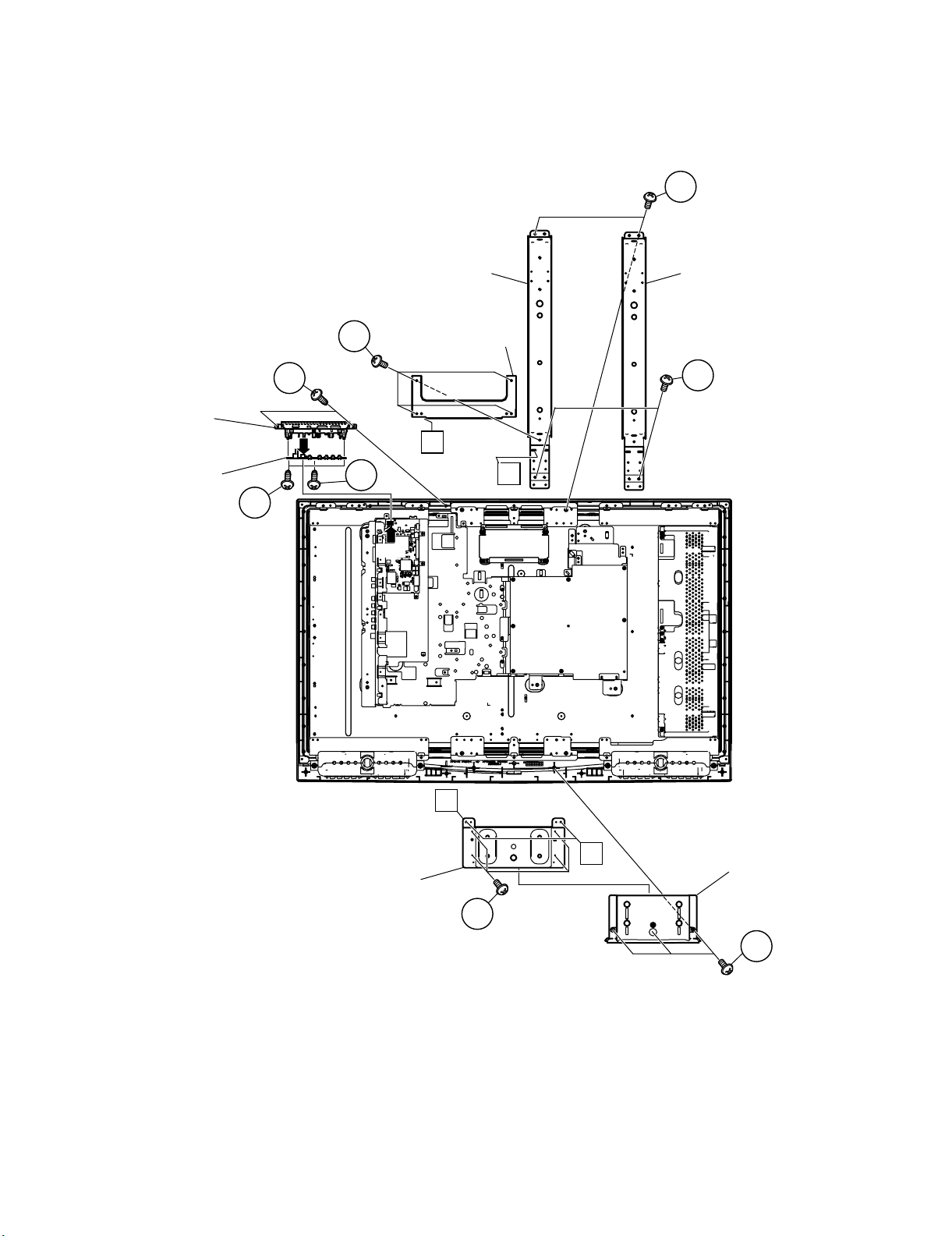

(LC-37PX5M/X)

Top Control

Cover Ass'y

OPERATION

PWB Unit

11

10

䬌䎮䎰䬍

6

11A

䬌䎮䎰䬍

Center Angle-R

Support Angle

䎤

9

Center Angle-L

9

䎥

Stand Angle

䎥

䎤

Bottom Cover

8

7

4 – 3

Page 16

LC-32PX5M/X/LC-37PX5M/X

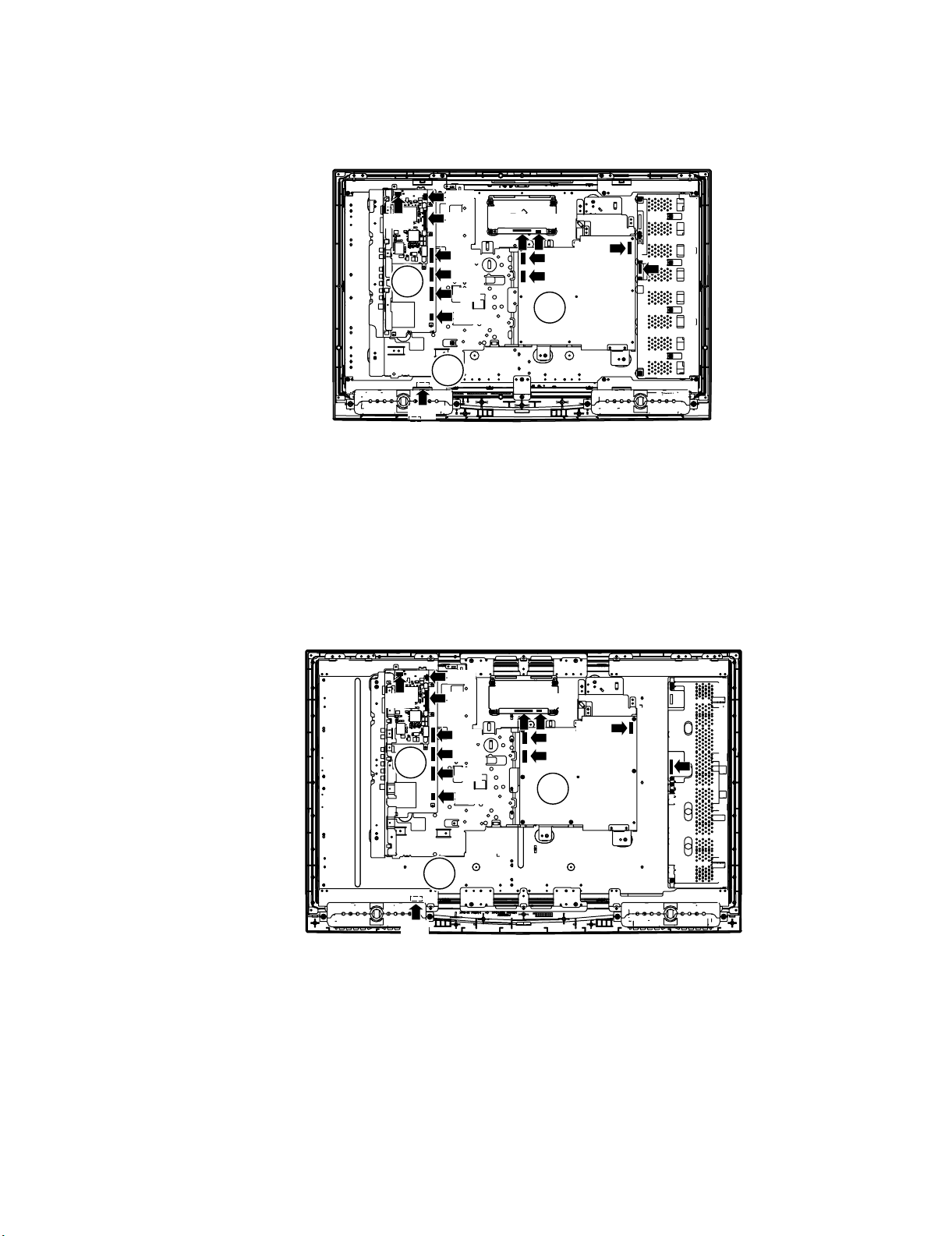

9. Remove all the connectors [12] from all the PWBs.

(LC-32PX5M/X)

䬌䎮䎰䬍

䬌䎮䎰䬍

䬌䎶䎫䬍

䬌䎯䎹䬍

䬌䎯䎹䬍

䬌䎶䎫䬍

(LC-37PX5M/X)

12

䬌䎮䎰䬍

䬌䎮䎰䬍

䬌䎵䎤䬍

12

䬌䎵䎤䬍

䬌䎳䎧䬍

䬌䎳䎨䬍

䬌䎶䎳䬍

䬌䎶䎫䬍

䬌䎯䎹䬍

䬌䎯䎹䬍

䬌䎦䎱䎔䬍

䬌䎦䎱䎕䬍

䬌䎦䎱䎖䬍

12

䬌䎶䎫䬍

12

䬌䎵䎤䬍

12

䬌䎵䎤䬍

䬌䎳䎧䬍

䬌䎳䎨䬍

䬌䎶䎳䬍

䬌䎦䎱䎔䬍

䬌䎦䎱䎕䬍

䬌䎦䎱䎖䬍

12

4 – 4

Page 17

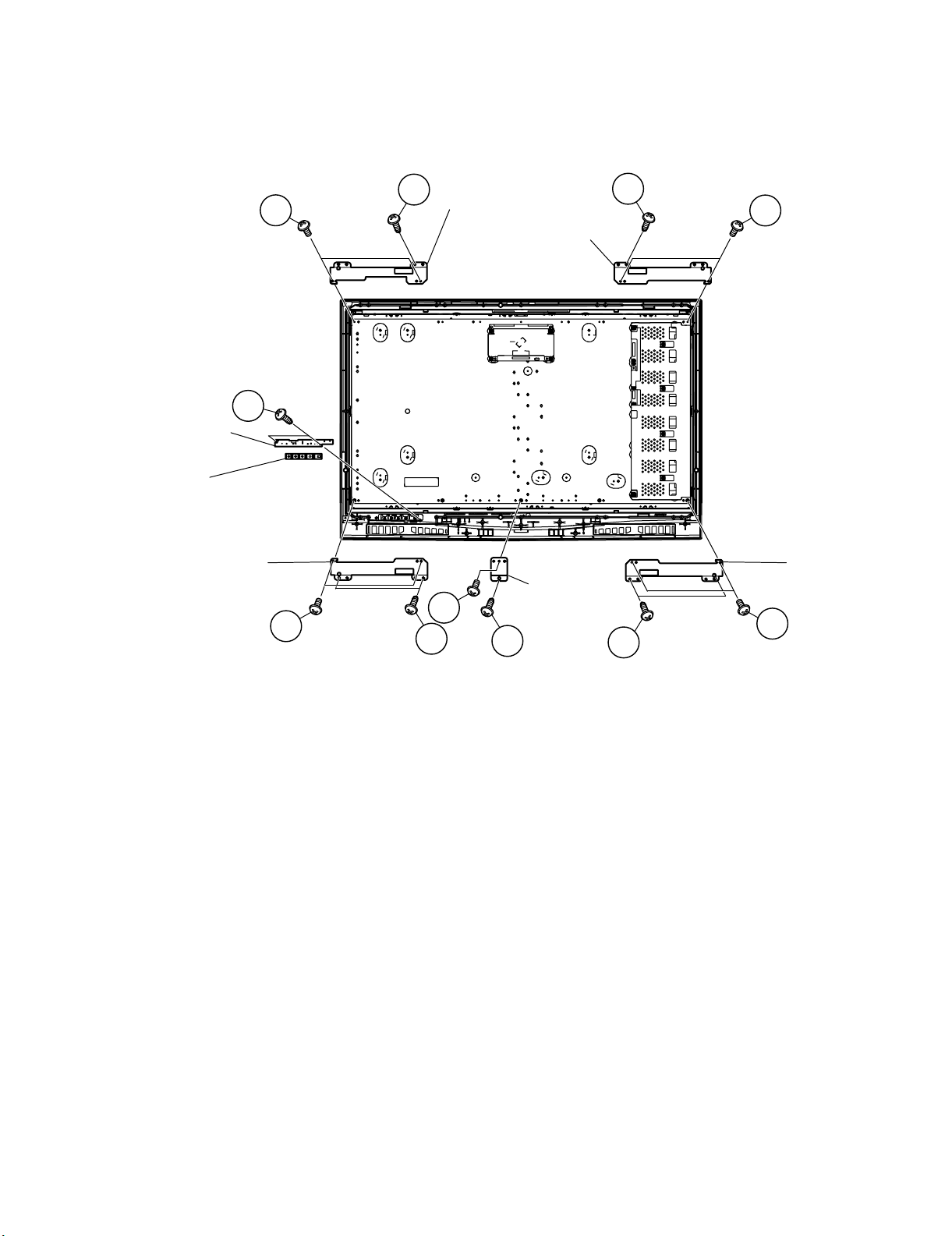

10.Remove the 2 (32PX5M/X)/4 (37PX5M/X) screws [13]. Detach the Speaker Box L and Speaker Box R.

11.Remove the 5 (32PX5M/X)/4 (37PX5M/X) screws [14] and detach Chassis Tray.

12.Remove the 2 screws [16] and 2 screws [17].

Detach the AV Terminal Cover.

13.Remove the 8 screws [18] and detach the POWER PWB Unit from Chassis Tray.

14.Remove the 6 screws [19] and detach the SUB PWB Unit from Chassis Tray.

15.Remove the 3 screws [20] and detach the MAIN PWB Unit from SUB PWB Unit.

(LC-32PX5M/X)

20

19

MAIN PWB Unit

LC-32PX5M/X/LC-37PX5M/X

SUB PWB Unit

AV Terminal Cover

14

17

16

18

14

POWER PWB Unit

Chassis Tray

14

Speaker Box R

13

4 – 5

13

Speaker Box L

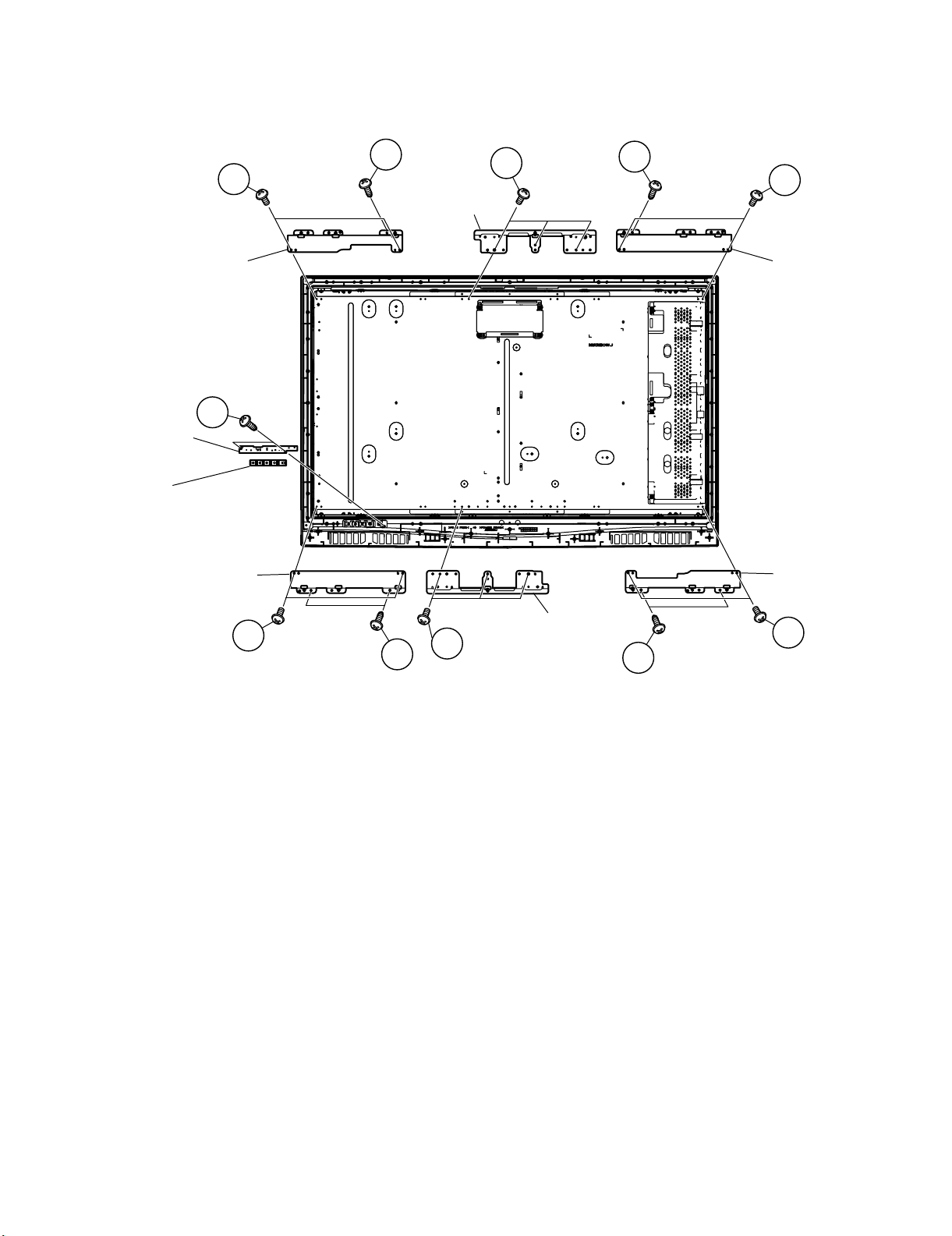

Page 18

LC-32PX5M/X/LC-37PX5M/X

(LC-37PX5M/X)

MAIN PWB Unit

20

19

SUB PWB Unit

AV Terminal Cover

14

17

16

18

14

POWER PWB Unit

Chassis Tray

13

Speaker Box R

Speaker Box L

4 – 6

13

Page 19

16.Remove the 7 (32PX5M/X)/6 (37PX5M/X) screws [21] and take out the LCD Panel from Front Cabinet.

17.Remove the 9 (32PX5M/X)/14 (37PX5M/X) screws [22] and detach the LCD Angles.

18.Remove the 2 screws [24] and detach the LED, R/C PWB Unit.

(LC-32PX5M/X)

LC-32PX5M/X/LC-37PX5M/X

LED, R/C

PWB Unit

LED Cover

24

LCD Angle

Bottom R

22

22

21

LCD Angle Top R

22

21

LCD Angle Top L

LCD Angle

Bottom C

21

21

22

LCD Angle

Bottom R

22

21

4 – 7

Page 20

LC-32PX5M/X/LC-37PX5M/X

(LC-37PX5M/X)

LCD Angle Top R

LED, R/C

PWB Unit

LED Cover

22

24

LCD Angle

Bottom L

22

21

21

LCD Angle

Top C

22

22

LCD Angle

Bottom C

21

22

LCD Angle Top L

LCD Angle

Bottom R

22

21

4 – 8

Page 21

-MEMO-

LC-32PX5M/X/LC-37PX5M/X

4 – 9

Page 22

LC-32PX5M/X/LC-37PX5M/X

㪦

㪚

㪇

LC-37PX5M

CHAPTER 5. BLOCK DIAGRAM/OVERALL WIRING DIAGRAM

Service Manual

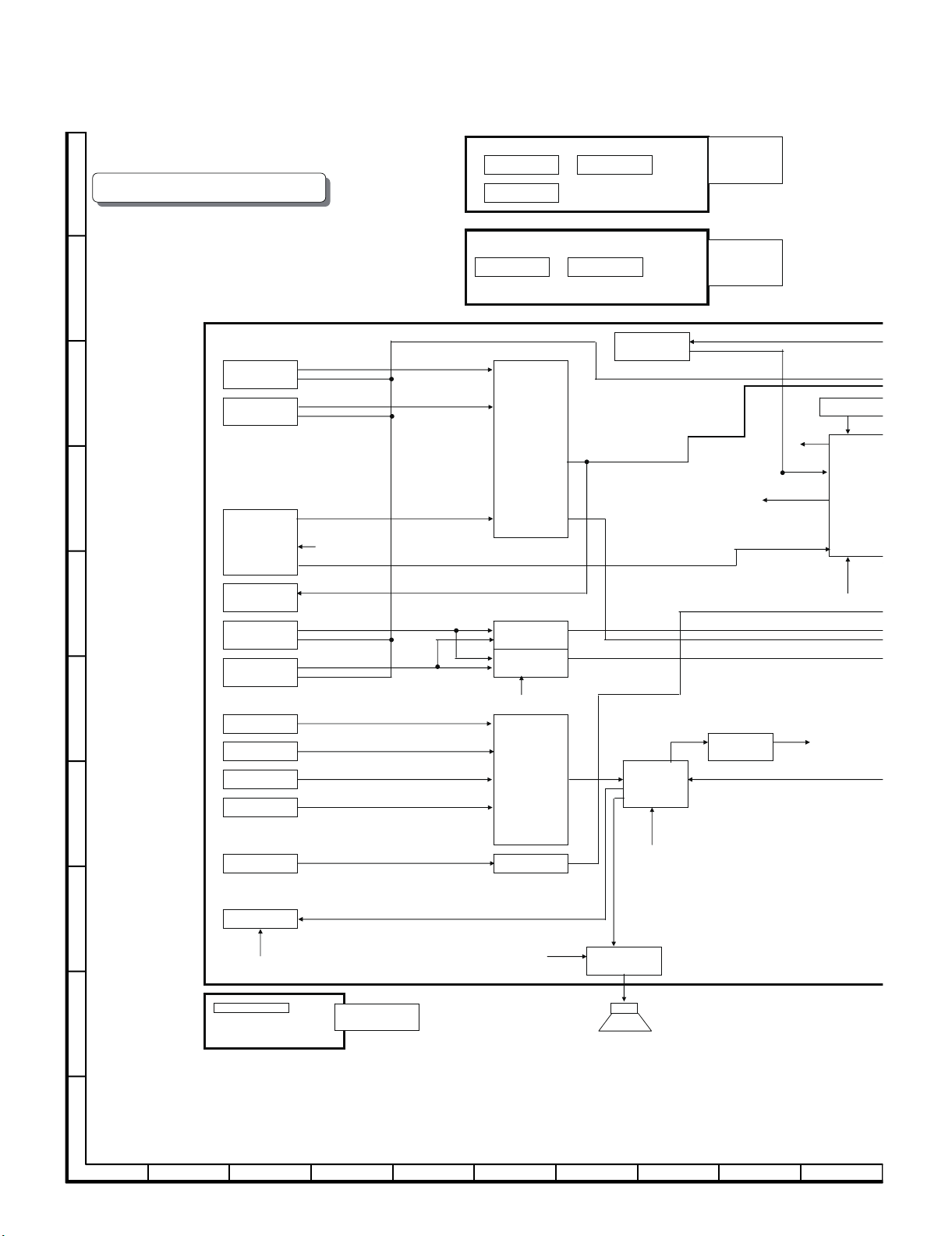

[1] BLOCK DIAGRAM

㪣㪜㪛

㪫㪦㩷㪪㪬㪙

J

㪣㪚㪊㪉㪆㪊㪎㪧㪯㪌㩷㪙㫃㫆㪺㫂㩷㪛㫀㪸㪾㫃㪸㫄

㪙㪬㪂㪌㪭㪃㪙㪬㪂㪊㪅㪊㪭㪃㪦㪧㪚㪂㪊㪅㪊㪭㪃㪩㪆㪚㪃㪧㪦㪮㪞㪶㪣㪜㪛㪃㪧㪦㪮㪩㪶㪣㪜㪛㪃㪣㪜㪛㪶㪰㪦㪰㪘㪢㪬㪃㪣㪜㪛㪶㪦㪧㪚㪃㪦㪧㪚㪃㪟㪧㪶㪣㪃㪟㪧㪶㪩㪃㪟㪧㪶㪧㪣㪬㪞㪃㪟㪧㪶㪞㪥㪛

㪫㪦㩷㪪㪬㪙

I

㪦㪧㪚

㪠㪚㪈㪇㪈

㪣㪜㪛

㪛㪈㪇㪊㪆㪈㪈㪋㪆㪈㪈㪌

㪦㪧㪜㪩㪘㪫㪠㪦㪥

㪚㪦㪥㪫㪩㪦㪣㩷㪪㪮

㪪㪈㪎㪈㪄㪪㪈㪎㪌

㪙㪬㪂㪊㪅㪊㪭㪃㪢㪜㪰㪈㪃㪢㪜㪰㪉㪃㪪㪫㪙㪰㪶㪧㪦㪮

㪪㪬㪙

㪠㪥㪧㪬㪫㪈㩷㪭㪠㪛㪜㪦㩷㪠㪥

㪡㪊㪋㪇㪉

H

㩷

㪡㪊㪋㪇㪍

㪠㪥㪧㪬㪫㪉㩷㪭㪠㪛㪜㪦㩷㪠㪥

㪡㪊㪋㪇㪉

㪠㪥㪧㪬㪫㪈㪶㪚㪭㪙㪪

㪠㪥㪧㪬㪫㪉㪶㪚㪭㪙㪪

㪭㪉㪶㪭

㪭㪊㪶㪭

㪘㪭㩷㪪㪮

㪭㪟㪠㪤㪤㪈㪋㪐㪉㪙㪝㪄㪈㪰

㪌㩷㫀㫅㫇㫌㫋㩷㪄㪉㩷㫆㫌㫋㫇㫌㫋

㪍㪻㪙㩷㪘㪤㪧

㪇㪈㪇㪇㪄

㪠㪩㩷㪩㪼㪺㫀㪼㫍㪼㫉

㪩㪤㪚㪈㪇㪈

㪇㪈㪎㪈㪄

㪧㪦㪮㩷㪪㪮

㪪㪈㪎㪎

㪩㪪㪄㪉㪊㪉㪚

㪨㪪㪦㪚㪥㪇㪋㪊㪏㪝㪡㪱㪱

㪠㪥㪧㪬㪫㪈㪆㪉㩷㪭㪠㪛㪜㪦㪃㪠㪥㪧㪬㪫㪈㪆㪉㩷㪰㩷㪻㪼㫋㪼㪺㫋

㪠㪚

㪉㪭㫇㫇㩷㪦㪬㪫㪧㪬㪫㪄㪫㪜㪩㪤㪠㪥㪘㪫㪠㪦㪥

㪭㪦㪬㪫㪈 㪚㪭㪙㪪 㪠㪩㪜㪤

G

㪤㪫㪭㪶㪭 㪉㪭㫇㫇㩷㪦㪬㪫㪧㪬㪫㪄㪫㪜㪩㪤㪠㪥㪘㪫㪠㪦㪥

㪫㪬㪥㪜㪩㩷㪭㩷㪦㪬㪫

㪫㪬㪊㪋㪇㪈

㪭㪫㪉㪮㪌㪚㪛㪌㪌㪈

㪫㪬㪥㪜㪩㪶㪚㪭㪙㪪 㪪㪫㪭㪶㪭 㪭㪦㪬㪫㪉

㪉㪭㫇㫇㩷㪦㪬㪫㪧㪬㪫㪄㪫㪜㪩㪤㪠㪥㪘㪫㪠㪦㪥

㪪㪚㪣㪃㪪㪛㪘㩿㪌㪭㪀

㪘㪝㪫㪃㪘㪞㪚

㪧㪈㪇㪈

㪨㪧㪣㪞㪥㪘㪊㪊㪌㪮㪡㪱㪱㪰

㪈㪌㫇㫀㫅

㪧

㪨㪧㪣㪞㪥㪘㪊㪋㪐㪮㪡㪱㪱㪰

㪧㪈㪎㪈

㪨㪧㪣㪞㪥㪘㪇㪌㪐㪮㪡㪱㪱㪰

㪌㫇㫀㫅

㪧

㪨㪧㪣㪞㪥㪘㪊㪉㪌㪮㪡㪱㪱㪰

㪩㫏㪃㪫㫏

㪦㪧㪚

㪪㪧㪶㪤㪬㪫㪜

㪘㪚㪶㪚㪫㪩㪣㪃㪧㪦㪮

㪘㪚㪶㪛㪜㪫㪜㪚㪫

㪠㪚㪉㪇㪈㪇

㪤

㪠㪚㪉

F

E

D

C

B

㪤㪦㪥㪠㪫㪦㪩㩷㪭㩷㪦㪬㪫

㪠㪥㪧㪬㪫㪈

㪚㪦㪤㪧㪦㪥㪜㪥㪫㩷㪠㪥

㪡㪊㪋㪇㪋

㪠㪥㪧㪬㪫㪉

㪚㪦㪤㪧㪦㪥㪜㪥㪫㩷㪠㪥

㪡㪊㪋㪇㪋

㪠㪥㪧㪬㪫㪈㩷㪘㪬㪛㪠㪦㩷㪠㪥

㪡㪊㪋㪇㪉

㪠㪥㪧㪬㪫㪉㩷㪘㪬㪛㪠㪦㩷㪠㪥

㪡㪊㪋㪇㪉

㪠㪥㪧㪬㪫㪊㩷㪘㪬㪛㪠㪦㩷㪠㪥

㪡㪊㪋㪇㪌

㪧㪚㩷㪘㪬㪛㪠㪦㩷㪠㪥

㪡㪊㪋㪇㪍

㪫㪬㪥㪜㪩㩷㪪㪄㪠㪝㩷㪦㪬㪫

㪫㪬㪊㪋㪇㪈

㪤㪦㪥㪠㪫㪦㪩㩷㪣㪆㪩㩷㪦㪬㪫

㪣㪶㪤㪬㪫㪜

㪠㪥㪭㪜㪩㪫㪜㪩

㪣㪚㪛㩷㪤㪦㪛㪬㪣㪜

㪚㪭㪙㪪㩿㪪㪚㩷㪤㪠㪯㪀 㪪㪟

㪭㪉㪶㪣㪆㪩

㪭㪊㪶㪣㪆㪩

㪤㪫㪭㪶㪣㪆㪩

㪪㪫㪭㪶㪣㪆㪩

㪚㪦㪤㪧㪦㪥㪜㪥㪫㩷㪪㪮

㪭㪟㪠㪪㪤㪌㪊㪇㪈㪚㪪㪄㪈㪰

㪚㪦㪤㪧㪦㪥㪜㪥㪫㩷㪪㪮

㪭㪟㪠㪪㪤㪌㪊㪇㪈㪚㪪㪄㪈㪰

㪛㪶㪪㪜㪣

㪝㪶㪪㪜㪣㪈㪆㪉

㪘㪭㩷㪪㪮

㪠㪚

㪭㪟㪠㪤㪤㪈㪋㪐㪉㪙㪝㪄㪈㪰

㪪㪠㪝㵘㪘㪤㪧

㪨

㪪㪶㪪㪫㪙㪰㪃㪣㪶㪤㪬㪫㪜㪉

㪰㪃㪧㪹㪃㪧㫉

㪘㪬㪛㪠㪦㩷㪘㪤㪧

㪘㫌㪻㫀㫆

㪭㫆㫃㫌㫄㪼㪆㪜㪨㪆㪟㪧

㪘㪤㪧㪆㪪㫌㫉㫉㫆㫌㫅㪻

㪪㪧㪶㪣㪆㪩

㪪㪧

㪪㪧㪶㪣㪆㪩 㪩㪆㪣㪂㪄

㩿㪠㪉㪪㪀

㩿㪪㪶㪠㪝㪀

㪘㫌㪻㫀㫆㩷㪘㪤㪧

㪠㪥㪧㪬㪫㪈㪶㪰㪃㪧㪹㪃㪧㫉 㪰㪃㪧㪹㪃㪧㫉

㪠㪥㪧㪬㪫㪉㪶㪰㪃㪧㪹㪃㪧㫉

㪠㪥㪧㪬㪫㪈㩷㪣㪆㪩

㪠㪥㪧㪬㪫㪉㩷㪣㪆㪩

㪠㪥㪧㪬㪫㪊㩷㪣㪆㪩 㪣㪆㪩

㪧㪚㩷㪣㪆㪩

㪪㪶㪠㪝

㪠㪥㪭㪜㪩㪫㪜㪩

㪚㪦㪥㪥㪜㪚㪫㪜㪩

㪫㪦㩷㪤㪘㪠㪥

A

12345678910

5 – 1

Page 23

LC-32PX5M/X/LC-37PX5M/X

㫏

㪤㪘㪠㪥

㪧㪚㪶㪟㪃㪧㪚㪶㪭

㪧㪚㪶㪩㪆㪞㪆㪙

㪟㪧㪛㪚㪫㪣㪈㪆㪉

㪟㪧㪛㪈㪆㪉

㪪㪿㫄㫀㫋㫋㩷㫋㫉㫀㪾㪼㫉

㪘㪚㪶㪛㪜㪫㪜㪚㪫

㪠㪚㪉㪇㪈㪈

㪩㪜㪪㪜㪫

㪦㪧㪚

㪜㪤

㪤㪚㪬

㪠㪚㪉㪇㪇㪈

㪧㪦㪮 㪊㪅㪊㪭

㪪㪟㪦㪩㪫㪶㪛㪜㪫 㪚㪭㪙㪪

㪬㪘㪩㪫 㪈㪅㪌㪭

㪠㪚㪉㪇㪇㪍

㪜㪜㪧㪩㪦㪤

㪠㪚㪉㪇㪇㪐

㪫㪟㪜㪩㪤㪠㪪㪫㪦㪩

㪫㪟㪉㪇㪇㪈

㪛㪭㪧㪶㪊㪊㪚㪫㪩㪣 㪦㪝㪣㪶㪧㪮㪤

㪠㪥㪭㪶㪧㪦㪮㪃㪦㪝㪣㪶㪛㪘㪚 㪉㪎㪤㪟䌺㩷㪚㫉㫐㫊㫋㪸㫃

㪫㪦㩷㪠㪥㪭㪜㪩㪫㪜㪩 㫧㪊㪇㫇㫇㫄

㪉㪎㪤㪟䌺㩷㪚㫉㫐㫊㫋㪸㫃

㪊㪅㪊㪭 㪊㪅㪊㪭

㪈㪅㪌㪭 㪉㪅㪌㪭

㪛㪭㪧㪄㪤㪉

㪠㪚㪏㪇㪈

㪪㪶㪠㪝

㪜㪜㪧㪩㪦㪤

㪠㪉㪪

㪏㪹㫀㫋 㪏㪹㫀㫋 㪪㪛㪘㪃㪪㪚㪣

㪰㪃㪧㪹㪃㪧㪩

㪠㪚㪋㪇㪉

㪛㪭㪧㪄㪯

㪠㪚㪏㪇㪈

㪟㪃㪭

㪧㪚㩷㪠㪥

㪪㪚㪋㪇㪈

㪨㪪㪦㪚㪥㪘㪈㪇㪈㪮㪡㪱㪱㩷㩿㪛㪊㪇㪀

㪨㪪㪦㪚㪥㪘㪌㪉㪐㪮㪡㪱㪱

㪪㪛㪘㪃㪪㪚㪣

㪜㪜㪧㪩㪦㪤

㪠㪚㪋㪇㪈

㪠㪥㪧㪬㪫㪊㪆㪋

㪟㪛㪤㪠㩷㪠㪥㩷㪈㪆㪉

㪪㪚㪋㪇㪉

㪩㪆㪞㪆㪙

㪪㪛㪘

㪪㪚㪣

㪪㪛㪘㪃㪪㪚㪣

㪩㪩㪈㪯㪚㪆㪇㪆㪈㪆㪉㪄㪆㪂

㪟㪛㪤㪠㩷㪩㪼㪺㫀㪼㫍㪼㫉

㪤㪪㪫㪊㪊㪏㪍

㪠㪚㪏㪎㪇㪈

㪊㪅㪊㪭㩷㪉㪊㪌㫄㪘

㪉㪅㪌㪭㩷㪈㪈㪏㫄㪘

㪈㪋㪅㪊㪈㪏㪤㪟䌺㩷㪚㫉㫐㫊㫋㪸㫃

㪟㪛㪚㪧

㪜㪜㪧㪩㪦㪤

㫧㪊㪇㫇㫇㫄

㪠㪚㪏㪎㪇㪋

㪜㪜㪧㪩㪦㪤

㪠㪚㪋㪇㪊

㪄

㪣㪆㪩

㪬㪶㪛㪃㪣㪶㪩

㪚㪣㪢㪠㪥㪄㪆㪂㪃㪩㪠㪥㪈㪆㪉㪆㪊㪄㪆㪂

㪣㪭㪛㪪

㪚㪦㪥㪥㪜㪚㪫㪜㪩

㪣㪚㪛㩷㪤㪦㪛㪬㪣㪜

㪣㪚㪛

10 11 12 13 14 15 16 17 18 19

㪨㪪㵘㪚㪦㪥㪥㪜㪚㪫㪜㪩

5 – 2

Page 24

LC-32PX5M/X/LC-37PX5M/X

[2] OVERALL WIRING DIAGRAM (LC-32PX5M/X)

J

I

H

G

F

E

D

C

B

A

12345678910

5 – 3

Page 25

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

5 – 4

Page 26

LC-32PX5M/X/LC-37PX5M/X

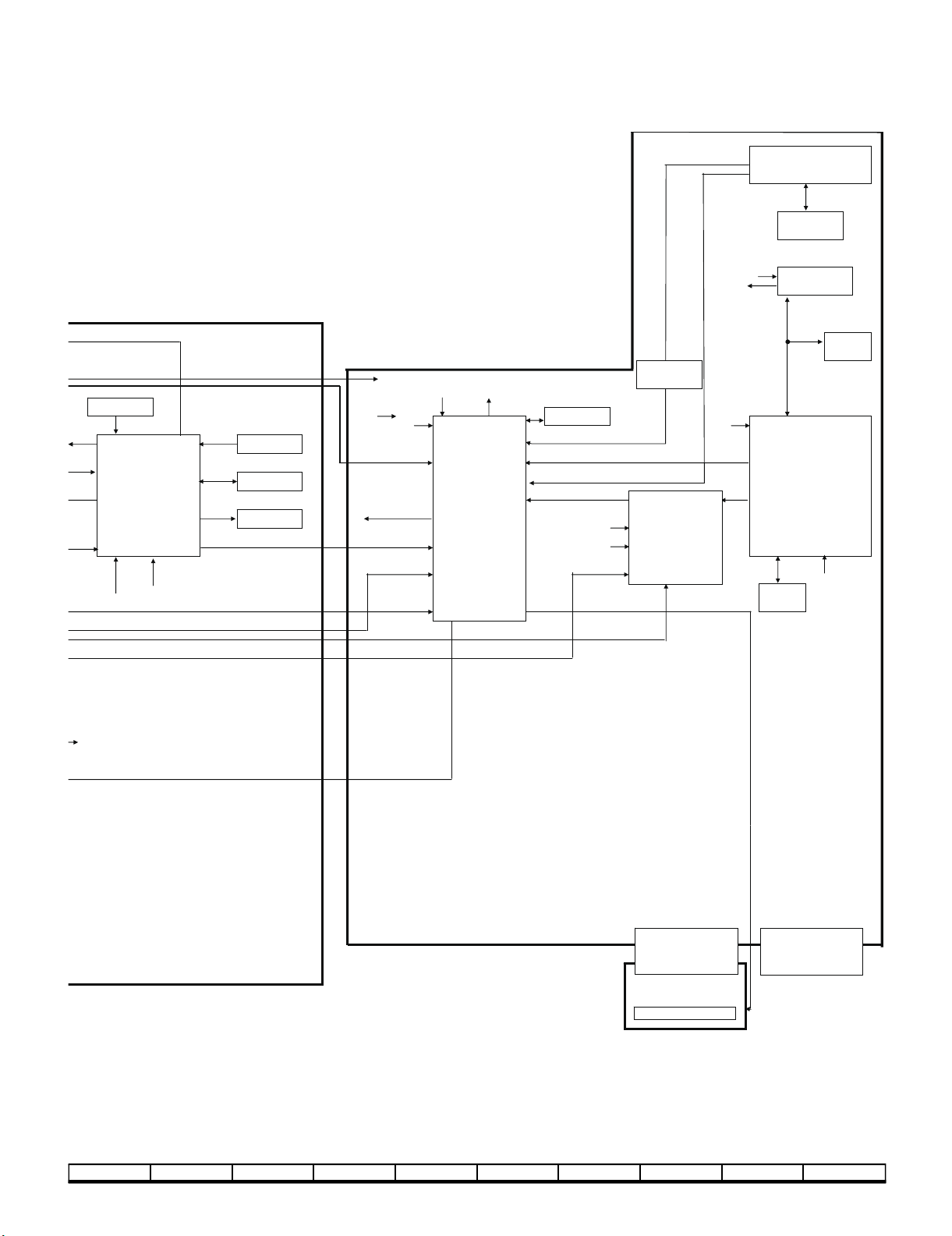

[3] OVERALL WIRING DIAGRAM (LC-37PX5M/X)

J

I

H

G

F

E

D

C

B

A

12345678910

5 – 5

Page 27

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

5 – 6

Page 28

LC-32PX5M/X/LC-37PX5M/X

-MEMO-

5 – 7

Page 29

LC-37PX5M

CHAPTER 6. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. The voltages at test points are measured on exclusive AC adaptor and the stable supply voltage of AC 110-240V.

Signals are fed by a colour bar signal generator for servicing purpose and the above voltages are measured with a 20k ohm/V

tester.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(K= ± 10%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

LC-32PX5M/X/LC-37PX5M/X

Service Manual

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC OUTLET BEFORE REPLACING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE REGARDED AS POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “ ” ( ) ARE IMPORTANT FOR MAINTAINING THE SAFETY OF THE SET. BE SURE TO REPLACE THESE PARTS WITH SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

6 – 1

Page 30

LC-32PX5M/X/LC-37PX5M/X

[2] SCHEMATIC DIAGRAM

1. LED, R/C Unit (LC-32PX5M/X, LC-37PX5M/X)

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 2

Page 31

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 3

Page 32

LC-32PX5M/X/LC-37PX5M/X

2. OPERATION Unit (LC-32PX5M/X, LC-37PX5M/X)

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 4

Page 33

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 5

Page 34

LC-32PX5M/X/LC-37PX5M/X

3. SUB Unit-1 (LC-32PX5M/X, LC-37PX5M/X)

(1/8) (1/8) Please peel off and refer to page 6-8. (2/8) (2/8) Please peel off and refer to page 6-9.

(5/8) (5/8) Please peel off and refer to page 6-12. (6/8) (6/8) Please peel off and refer to page 6-13.

6 – 6

Page 35

LC-32PX5M/X/LC-37PX5M/X

(3/8) (3/8) Please peel off and refer to page 6-10. (4/8) (4/8) Please peel off and refer to page 6-11.

(7/8) (7/8) Please peel off and refer to page 6-14. (8/8) (8/8) Please peel off and refer to page 6-15.

6 – 7

Page 36

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 8

Page 37

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 9

Page 38

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 10

Page 39

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 11

Page 40

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 12

Page 41

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 13

Page 42

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 14

Page 43

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 15

Page 44

LC-32PX5M/X/LC-37PX5M/X

4. SUB Unit-2 (LC-32PX5M/X, LC-37PX5M/X)

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 16

Page 45

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 17

Page 46

LC-32PX5M/X/LC-37PX5M/X

5. SUB Unit-3 (LC-32PX5M/X, LC-37PX5M/X)

(1/8) (1/8) Please peel off and refer to page 6-20. (2/8) (2/8) Please peel off and refer to page 6-21.

(5/8) (5/8) Please peel off and refer to page 6-24. (6/8) (6/8) Please peel off and refer to page 6-25.

6 – 18

Page 47

LC-32PX5M/X/LC-37PX5M/X

(3/8) (3/8) Please peel off and refer to page 6-22. (4/8) (4/8) Please peel off and refer to page 6-23.

(7/8) (7/8) Please peel off and refer to page 6-26. (8/8) (8/8) Please peel off and refer to page 6-27.

6 – 19

Page 48

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 20

Page 49

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 21

Page 50

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 22

Page 51

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 23

Page 52

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 24

Page 53

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 25

Page 54

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 26

Page 55

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 27

Page 56

LC-32PX5M/X/LC-37PX5M/X

6. SUB Unit-5 (LC-32PX5M/X, LC-37PX5M/X)

(1/8) (1/8) Please peel off and refer to page 6-30. (2/8) (2/8) Please peel off and refer to page 6-31.

(5/8) (5/8) Please peel off and refer to page 6-34. (6/8) (6/8) Please peel off and refer to page 6-35.

6 – 28

Page 57

LC-32PX5M/X/LC-37PX5M/X

(3/8) (3/8) Please peel off and refer to page 6-32. (4/8) (4/8) Please peel off and refer to page 6-33.

(7/8) (7/8) Please peel off and refer to page 6-36. (8/8) (8/8) Please peel off and refer to page 6-37.

6 – 29

Page 58

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 30

Page 59

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 31

Page 60

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 32

Page 61

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 33

Page 62

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 34

Page 63

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 35

Page 64

LC-32PX5M/X/LC-37PX5M/X

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 36

Page 65

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 37

Page 66

LC-32PX5M/X/LC-37PX5M/X

7. SUB Unit-6 (LC-32PX5M/X, LC-37PX5M/X)

J

I

H

G

F

E

D

C

B

A

12345678910

6 – 38

Page 67

LC-32PX5M/X/LC-37PX5M/X

10 11 12 13 14 15 16 17 18 19

6 – 39

Page 68

LC-32PX5M/X/LC-37PX5M/X

LC-37PX5M

CHAPTER 7. PRINTED WIRING BOARD

[1] OPERATION UNIT PRINTED WIRING BOARD

J

I

H

OPERATION Unit (Side-A)

G

Service Manual

F

E

D

C

OPERATION Unit (Side-B)

B

A

12345678910

7 – 1

Page 69

[2] LED, R/C UNIT PRINTED WIRING BOARD

J

I

LED, R/C Unit (Side-A)

H

LC-32PX5M/X/LC-37PX5M/X

G

R117

Q104

Q105

R108

D103

R105

R110

Q103

Q102

R109

R107

R104

R106

R123

D114

Q106

R121

R124

Q107

R122

D115

C106

3

R132

R127

R126

D101

R101

Q110

R130

R131

IC101

C104

C102

R135

C105

R136

P101

C107

F

R128

RMC101

SLD101

R129

LED, R/C Unit (Chip Parts Side-A)

E

D

C

B

LED, R/C Unit (Side-B)

A

12345678910

7 – 2

Page 70

LC-32PX5M/X/LC-37PX5M/X

-MEMO-

7 – 3

Page 71

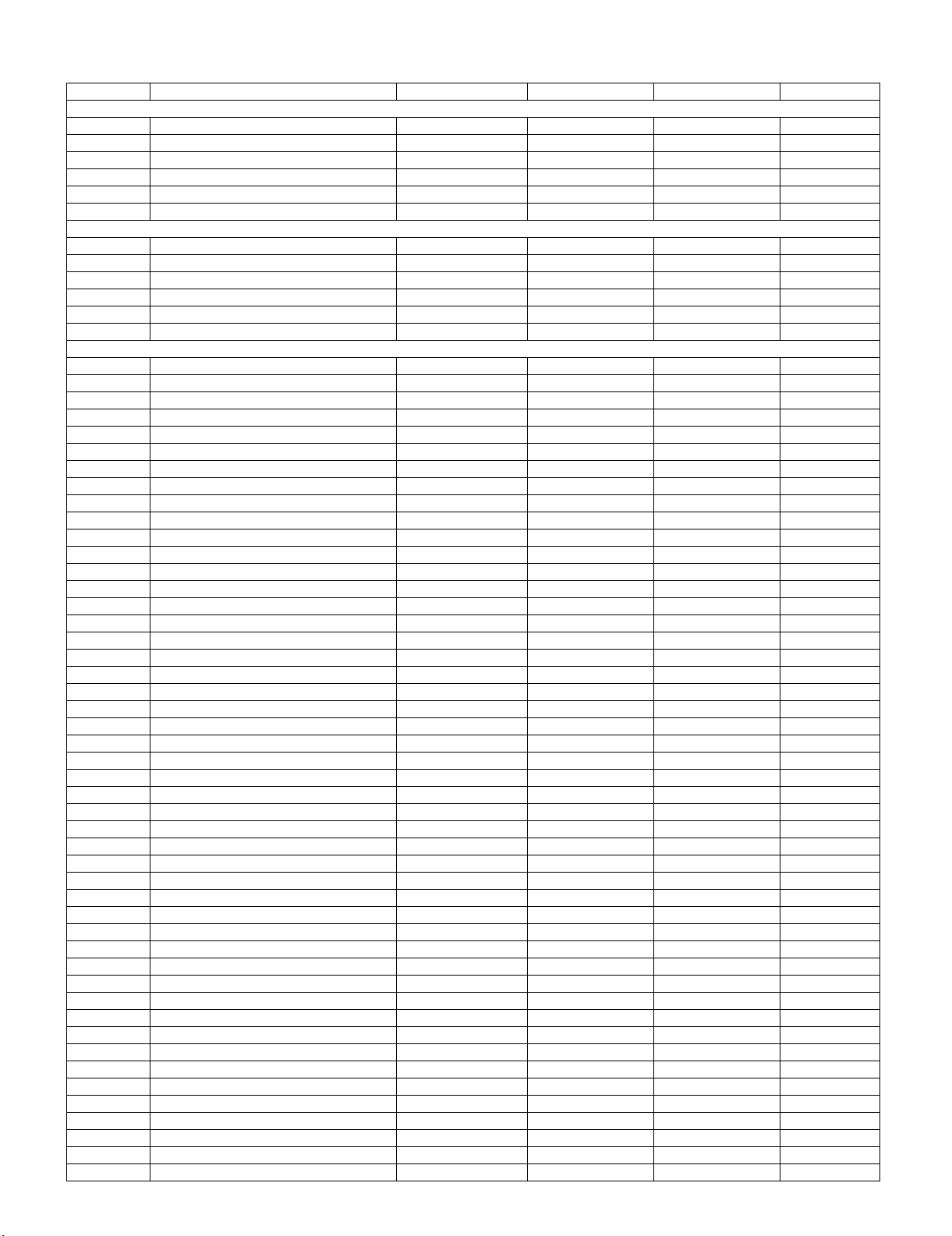

PartsGuide

LC-32PX5M/X/LC-37PX5M/X

PARTS GUIDE

No. S17B1LC37PX5M

LCD COLOR TELEVISION

LC-32PX5M/X

MODELS

CONTENTS

[1] PRINTED WIRING BOARD

ASSEMBLIES (NOT

REPLACEMENT ITEM)

[2] DUNTKD893FM50 (LC-32PX5M) /

DUNTKD893FM51 (LC-32PX5X) /

DUNTKD893FM52 (LC-37PX5M) /

DUNTKD893FM53 (LC-37PX5X)

(SUB Unit)

[3] DUNTKE097FM02 (LC-32PX5M/X) /

DUNTKE097FM04 (LC-37PX5M/X)

(OPERATION Unit)

LC-37PX5M/X

[4] CABINET PARTS (LC-32PX5M/X)

[5] CABINET PARTS (LC-37PX5M/X)

[6] SUPPLIED ACCESSORIES

[7] PACKING PARTS (NOT

REPLACEMENT ITEM)

[8] SERVICE JIG

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 72

LC-32PX5M/X/LC-37PX5M/X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELYVERY

DESCRIPTION

[1] PRINTED WIRING BOARD ASSEMBLIES (NOT REPLACEMENT ITEM)

N DUNTKE097FM02 AN N V OPERATION Unit (LC-32PX5M)

N DUNTKD892FM50 BV N V MAIN Unit (LC-32PX5M)

N DUNTKD893FM50 BT N V SUB Unit (LC-32PX5M)

N DUNTKE095FM02 AQ N V LED, R/C Unit (LC-32PX5M)

N RDENCA182WJQZ BS V POWER Unit exchange (LC-32PX5M)

N DUNTKE097FM02 AN N V OPERATION Unit (LC-32PX5X)

N DUNTKD892FM51 BV N V MAIN Unit (LC-32PX5X)

N DUNTKD893FM51 BT N V SUB Unit (LC-32PX5X)

N DUNTKE095FM02 AQ N V LED, R/C Unit (LC-32PX5X)

N RDENCA182WJQZ BS V POWER Unit exchange (LC-32PX5X)

N DUNTKE097FM04 AN N V OPERATION Unit (LC-37PX5M)

N DUNTKD892FM52 BV N V MAIN Unit (LC-37PX5M)

N DUNTKD893FM52 BT N V SUB Unit (LC-37PX5M)

N DUNTKD897FM53 AQ N V LED, R/C Unit (LC-37PX5M)

N RDENCA182WJQZ BS V POWER Unit exchange (LC-37PX5M)

N DUNTKE097FM04 AN N V OPERATION Unit (LC-37PX5X)

N DUNTKD892FM53 BV N V MAIN Unit (LC-37PX5X)

N DUNTKD893FM53 BT N V SUB Unit (LC-37PX5X)

N DUNTKD897FM53 AQ N V LED, R/C Unit (LC-37PX5X)

N RDENCA182WJQZ BS V POWER Unit exchange (LC-37PX5X)

[2] DUNTKD893FM50 (LC-32PX5M) / DUNTKD893FM51 (LC-32PX5X) / DUNTKD893FM52 (LC-37PX5M) /

DUNTKD893FM53 (LC-37PX5X) (SUB Unit)

IC2001 RH-IXA650WJZZQ AT N V IC M30626FHPFPU5C

P2002 QPLGN0581FJZZY AF J Plug 22pin

R1912 VRS-CJ1JF000JY AA J Resistor 0 1/16W Metal Oxide

R2051 VRS-CY1JF102JY AA J Resistor 1k 1/16W Metal Oxide

R2078 VRS-CY1JF000JY AA J Resistor 0 1/16W Metal Oxide

[3] DUNTKE097FM02 (LC-32PX5M/X) / DUNTKE097FM04 (LC-37PX5M/X) (OPERATION Unit)

D171 RH-EX0641GEZZY AA J Zener Diode MTZJT-7212C

D172 RH-EX0641GEZZY AA J Zener Diode MTZJT-7212C

D173 RH-EX0641GEZZY AA J Zener Diode MTZJT-7212C

P171 QPLGNA059WJZZ AC N J Plug

R171 VRD-RA2BE822JY AA J Resistor 8.2k 1/8W Carbon

R172 VRD-RA2BE123JY AA J Resistor 12k 1/8W Carbon

R173 VRD-RA2BE822JY AA J Resistor 8.2k 1/8W Carbon

R175 VRD-RA2BE103JY AA J Resistor 10k 1/8W Carbon

R176 VRD-RA2BE101JY AA J Resistor 100 1/8W Carbon

S171 QSW-K0003AJZZ+ AB J Switch

S172 QSW-K0003AJZZ+ AB J Switch

S173 QSW-K0003AJZZ+ AB J Switch

S174 QSW-K0003AJZZ+ AB J Switch

S175 QSW-K0003AJZZ+ AB J Switch

S177 QSW-P0035GEZZ AF J Switch

2

Page 73

[4] CABINET PARTS (LC-32PX5M/X)

LC-32PX5M/X/LC-37PX5M/X

42

13

47

1-2

42

29

45

42

25

39

19

27

䎩

2-1

䎤

2-5

2-9

2-4

42

42

16

S4

X7

47

14

2-6

2-8

䎥

11

䎨

X8

3-2

3-4

36

48

䎴

38

1-11

1-8

䎤

䎲

6

1-11

䎳

15

42

䎧

35

25

䎪

34

䎧

33

䎫

17

䎦

䎩

5

45

9

42

䎥

42

10

18

43

26

42

42

10

44

2

7

42

26

42

3-1

3

3-5

3-3

8

46

44

䎤

1

1-1

1-10

1-10

1-10

1-3

30

䎮

䎦

䎲

1-5

1-6

1-10

1-10

䎳

1-10

42

37

28

28

42

22

21

1-4

䎮

23

23

1-8

䎧

䎰

1-7

1-7

䎧

1-9

31

䎱

32

䎴

䎫

䎰

䎱

䎪

24

47

19

2-4

41

42

47

2-7

47

12

47

42

47

42

13

40

41

45

2-3

2-2

䎤

2-3

2-5

42

20

X10

䎨

X9

3

Page 74

LC-32PX5M/X/LC-37PX5M/X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

[4] CABINET PARTS (LC-32PX5M/X)

1 CCABAB613WJ03 BR S V Front Cabinet Ass'y

1-1 Not Available - - Front Cabinet

1-2 GCOVAC066WJ4A N V Front Cover

1-3 Not Available - - Badge, "SHARP"

1-4 HDECQA684WJSA V Decoration Cover

1-5 HDECSA005WJKA AN V Shine Trim

1-6 HPNLSA098WJSA AX V Speaker Sheet

1-7 PSPAHB079WJZZ AE V Spacer (Top, Bottom), x2

1-8 PSPAHB080WJZZ AD V Spacer (Side), x2

1-9 PSPAHB085WJZZ AB V Spacer (LED Cover), x2

1-10 PSPAZB264WJZZ AD V Spacer, x6

1-11 XEBS930P08000 AA J Screw, x4

2 CCABBA998WJ01 BH S V Rear Cabinet Ass'y

2-1 Not Available - N - Rear Cabinet

2-2 HINDPC167WJ4A AH S V Terminal Label

2-3 PSPAHB074WJZZ AB V Spacer, x2

2-4 PSPAHB146WJ4Z AC N V Spacer, x2

2-5 PSPAHB147WJ4Z AD N V Spacer, x2

2-6 PSPAHB148WJ4Z AD N V Spacer

2-7 PSPAHB149WJ4Z AB N V Spacer

2-8 PSPAHB150WJ4Z AB N V Spacer, x2

2-9 PSPAHB151WJ4Z AB N V Spacer

3 CCOVAC064WJ01 AN N V Top Cover Ass'y

3-1 Not Available - N - Top Cover

3-2 JBTN-A645WJ4A AE N V Power Bottom

3-3 JBTN-A646WJ4A AG N V Operate Bottom

3-4 MSPRCA070WJ2J AB J Spring

3-5 PSPAHB152WJ4Z AB N V Spacer

5 DUNTKD892FM50 BV N V Main Unit (LC-32PX5M)

5 DUNTKD892FM51 BV N V Main Unit (LC-32PX5X)

6 DUNTKD893FM50 BT N V Tuner/Av Unit (LC-32PX5M)

6 DUNTKD893FM51 BT N V Tuner/Av Unit (LC-32PX5X)

7 DUNTKE095FM02 AQ N V LED, R/C Unit

8 DUNTKE097FM02 AN N V

9 GCOVAB731WJSA AS J AV Terminal Cover

10 GCOVAB736WJKA AD J Bus Cover, x2

11 GCOVAB937WJ4A AH V Stand Area Cover

12 HINDPC148WJSA AE N V Model Label (LC-32PX5M)

12 HINDPC147WJSA AE N V Model Label (LC-32PX5X)

13 LANGKA638WJFW AL V LCD Angle A, x2

14 LANGKA672WJFW AF V LCD Angle C

15 LANGKA792WJFW AG J Pwb Bracket B

16 LANGKA908WJFW AH V Support Angle

17 LANGKA934WJFW AR V Sus Angle (L)

18 LANGKA985WJFW AS S V Sus Angle (R)

19 LANGKB020WJFW AL N V LCD Angle B, x2

20 LANGTA413WJFW AU V Stand Angle

21 LCHSMA369WJZZ BB S V Chassis Tray

22 LHLDFA028WJKZ AC J Wire Holder A

23 LHLDWA120WJKZ AB J Wire Holder B, x2

24 LHLDWA134WJKZ AB J Wire Holder C

25 LX-HZA003WJFN AC J Screw, x2

26 PSPAGA344WJZZ AC N J Spacer, x4

27 PSPAHA702WJZZ AB N V Spacer

28 PSPAZB366WJZZ AE N V Rubber Spacer, x2

29 QCNW-E756WJQZ AH N V Connecting Cord (SH)

30 QCNW-E758WJQZ AL N V Connecting Cord (LA)

31 QCNW-E759WJQZ AL J Connecting Cord (PE)

32 QCNW-E760WJQZ AK J Connecting Cord (PD)

33 QCNW-E762WJQZ AP J Connecting Cord (RA)

34 QCNW-E764WJQZ AK N V Connecting Cord (SP)

35 QCNW-F068WJPZ AZ N V Connecting Cord (LV)

36 R1LK315T3LZ4BX EE N V 32" LCD Panel Module Unit

37 RDENCA182WJQZ BS N V Power Unit

38 RSP-ZA203WJZZ BB V Speaker (L)

39 RSP-ZA204WJZZ BB V Speaker (R)

40 TLABNB947WJZZ AB N V No Label (LC-32PX5M)

TLABNB946WJZZ AB N V No Label (LC-32PX5X)

40

41 XBBS830P08000 AA J Screw, x4

42 XBPS730P06WS0 AA J Screw, x43

43 XBPS830P06000 AA J Screw, x2

44 XEBS930P08000 AA J Screw, x3

45 XEBS930P10000 AA J Screw, x5

46 XEBS930P16000 AB J Screw, x2

47 XEBS940P16000 AB J Screw, x19

48 QCNW-F546WJQZ V Connecting Cord (KM)

Operation Unit

DESCRIPTION

4

Page 75

[5] CABINET PARTS (LC-37PX5M/X)

3

䎤

1-2

1

1-1

1-10

1-6

1-10

1-10

1-10

1-3

30

䎮

䎦

䎲

䎳

1-8

1-5

1-10

1-10

42

36

27

27

42

21

20

1-4

1-7

䎧

䎨

1-7

1-9

䎮

䎰

22

22

23

3-1

46

䎧

3-5

3-3

8

37

䎫

LC-32PX5M/X/LC-37PX5M/X

42

15

45

3-2

3-4

35

48

䎴

44

31

䎱

32

䎴

䎰

䎱

䎪

1-8

䎧

1-11

䎤

29

42

24

䎪

34

䎧

28

䎫

1-11

18

䎦

䎲

䎳

䎩

33

14

42

6

9

45

2

7

40

40

18

25

䎥

40

42

5

42

10

43

10

45

24

40

38

25

16

䎩

䎤

2-5

2-1

2-4

13

42

42

17

2-6

42

45

42

45

42

45

42

17

47

41

41

2-4

䎥

19

11

䎨

2-3

47

12

2-5

45

16

26

42

15

39

45

41

2-2

䎤

42

5

Page 76

LC-32PX5M/X/LC-37PX5M/X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

[5] CABINET PARTS (LC-37PX5M/X)

1 CCABAB582WJ04 BU S V Front Cabinet Ass'y

1-1 Not Available - - Front Cabinet

1-2 GCOVAC065WJ4A N V Front Cover

1-3 Not Available - - Badge, "SHARP"

1-4 HDECQA667WJSA V Decoration Cover

1-5 HDECSA004WJKA AP V Shine Trim

1-6 HPNLSA097WJSA AX V Speaker Sheet

1-7 PSPAHA933WJZZ AE V Spacer (Top, Bottom)

1-8 PSPAHA934WJZZ AD V Spacer (Side)

1-9 PSPAHB085WJZZ AB V Spacer (LED Cover), x2

1-10 PSPAZB264WJZZ AD V Spacer, x6

1-11 XEBS930P08000 AA J Screw, x4

2 CCABBA999WJ01 BK S V Rear Cabinet Ass'y

2-1 Not Available - N - Rear Cabinet

2-2 HINDPC167WJ4A AH N V Terminal Label

2-3 PSPAHB149WJ4Z AB N V Spacer

2-4 PSPAHB153WJ4Z AC N V Spacer

2-5 PSPAHB154WJ4Z AD N V Spacer

2-6 PSPAHB155WJ4Z AD N V Spacer

3 CCOVAC064WJ01 AN S V Top Cover Ass'y

3-1 Not Available - N - Top Cover

3-2 JBTN-A645WJ4A AE N V Power Bottom

3-3 JBTN-A646WJ4A AG N V Operate Bottom

3-4 MSPRCA070WJ2J AB J Spring

3-5 PSPAHB152WJ4Z AB N V Spacer

5 DUNTKD892FM52 BV N V Main Unit (LC-37PX5M)

5 DUNTKD892FM53 BV N V Main Unit (LC-37PX5X)

6 DUNTKD893FM52 BT N V Tuner/Av Unit (LC-37PX5M)

6 DUNTKD893FM53 BT N V Tuner/Av Unit (LC-37PX5X)

7 DUNTKD897FM53 AQ N V LED, R/C Unit

8 DUNTKE097FM04 AN N V Operation Unit

9 GCOVAB738WJSA AS J AV Terminal Cover

10 GCOVAB736WJKA AD S J Bus Cover, x2

11 GCOVAB907WJ4A AK S V

12 HINDPC150WJSA AE N V Model Label (LC-37PX5M)

12 HINDPC146WJSA AE N V Model Label (LC-37PX5X)

13 LANGFA330WJFW AL V Support Angle

14 LANGKA792WJFW AG J Pwb Bracket B

15 LANGKA939WJFW AK V LCD Angle L

16 LANGKB021WJFW AK N V LCD Angle R

17 LANGKB025WJFW AM N V LCD Angle Center, x2

18 LANGTA403WJFW AV V Center Angle, x2

19 LANGTA421WJFW AT V Stand Angle

20 LCHSMA369WJZZ BB S V Chassis Tray

21 LHLDFA028WJKZ AC J Wire Holder A

22 LHLDWA120WJKZ AB J Wire Holder B, x2

23 LHLDWA134WJKZ AB J Wire Holder C

24 LX-HZA003WJFN AC J Screw, x4

25 PSPAGA344WJZZ AC S J Spacer, x4

26 PSPAHB156WJ4Z AB N V Spacer

27 PSPAZB366WJZZ AE S V Rubber Spacer, x2

28 QCNW-E752WJQZ AP J Connecting Cord (RA)

29 QCNW-E756WJQZ AH N V Connecting Cord (SH)

30 QCNW-E758WJQZ AL N V Connecting Cord (CN1)

31 QCNW-E759WJQZ AL N V Connecting Cord (PE)

32 QCNW-E760WJQZ AK N V Connecting Cord (PD)

33 QCNW-F068WJPZ AZ N V Connecting Cord (LV)

34 QCNW-F613WJQZ AK N V Connecting Cord (SP)

35 R1LK370T3LZ5BX EZ N V 37" LCD Panel Module Unit

36 RDENCA182WJQZ BS N V Power Unit

37 RSP-ZA203WJZZ BB V Speaker (L)

38 RSP-ZA204WJZZ BB V Speaker (R)

39 TLABNB949WJZZ AB N V No Label (LC-37PX5M)

39 TLABNB945WJZZ AB N V No Label (LC-37PX5X)

40 XBBS740P06000 AA J Screw, x4

41 XBBS830P08000 AA J Screw, x6

42 XBPS730P06WS0 AA J Screw, x43

XBPS830P06000 AA J Screw, x2

43

44 XEBS930P08000 AA J Screw

45 XEBS930P10000 AA J Screw, x13

46 XEBS930P16000 AB J Screw, x2

47 XEBS940P16000 AB J Screw, x13

48 QCNW-F564WJQZ V Connecting Cord (KM)

Stand Area Cover

DESCRIPTION

6

Page 77

[6] SUPPLIED ACCESSORIES

Remote control unit “AAA” size battery ( drocCA)2

X1 X2 X3

LC-32PX5M/X/LC-37PX5M/X

X4 X5 X6

X7 X8 X9

Stand base Stand post

Short screws (

X11

4)

Long screws

(

pmalcelbaCpmalcdrocCA

Cable tie

Operation manualStand unit

X10 X12

4)

NO. PARTS CODE

[6] SUPPLIED ACCESSORIES

X1 RRMCGA563WJSA AS N V Remote Control Unit

X2 Not Available - - "AAA" size Battery, x2

!

!

X3 QACCKA013WJPZ AN J AC Cord 4m (LC-32/37PX5M)

X3 QACCLA039WJPZ AX V AC Cord 4m (LC-32/37PX5X)

X4 LHLDWA012WJKZ AC J AC Cord Clamp

X5 LHLDWA131WJKZ AE J Cable Clamp

X6 LHLDWA083WJ00 AD J Cable Tie

X7 CDAI-A334WJ01 V Stand Base Ass'y (LC-32PX5M/X)

X7 CDAI-A336WJ01 V Stand Base Ass'y (LC-37PX5M/X)

X8 CDAI-A335WJ01 N V Stand Support Ass'y (LC-32PX5M/X)

X8 CDAI-A328WJ01 N V Stand Support Ass'y (LC-37PX5M/X)

X9 LX-BZA147WJF8 AE J Short Screws, x4

X10 LX-BZA146WJF7 AC J Long Screws, x4

X11 UKOGLA006WJZZ V Tool for Stand (LC-32PX5M/X)

X11 UKOGLA001WJZZ V Tool for Stand (LC-37PX5M/X)

X12 TINS-C948WJZZ AR N V Operation Manual (LC-32/37PX5M)

X12 TINS-C949WJZZ AK V Operation Manual (LC-32/37PX5X)

PRICE

RANK

NEW

MARK

Hex key

PAR T

DELIVERY

DESCRIPTION

7

Page 78

LC-32PX5M/X/LC-37PX5M/X

[7] PACKING PARTS (NOT REPLACEMENT ITEM)

X12

S7

X1

S6

X3

S5

S5

X2

X4

X5

X6

X7

X8

X9

X10

X11

S2

S4

S3

S2

S8

S1

8

Page 79

LC-32PX5M/X/LC-37PX5M/X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

DESCRIPTION

[7] PACKING PARTS (NOT REPLACEMENT ITEM)

S1 SPAKCD257WJZZ - - Packing Case (LC-32PX5M)

S1 SPAKCD256WJZZ - - Packing Case (LC-32PX5X)

S1 SPAKCD260WJZZ - N - Packing Case (LC-37PX5M)

S1 SPAKCD261WJZZ - N - Packing Case (LC-37PX5X)

S2 SPAKXB390WJZZ - - Packing Add. (LC-32PX5M/X)

S2 SPAKXB392WJZZ - S - Packing Add. (LC-37PX5M/X)

S3 SPAKPA611WJZZ - - Wrapping Paper (LC-32PX5M/X)

S3 SPAKPA613WJZZ - - Wrapping Paper (LC-37PX5M/X)

S4 CDAI-A334WJ02 - - Stand Ass'y (LC-32PX5M/X)

S4 CDAI-A336WJ02 - - Stand Ass'y (LC-37PX5M/X)

S5 SPAKXB389WJZZ - - Packing Add. (LC-32PX5M/X)

S5 SPAKXB391WJZZ - S - Packing Add. (LC-37PX5M/X)

S6 SSAKA0128AJZZ - N - Polyethylene Bag (Small)

S7 SSAKA0005PEZZ - - Polyethylene Bag (A4)

S8 TLABV0182AJZZ - - No. Label

[8] SERVICE JIG

N QCNW-E540WJQZ CD J Extension Cable, 26pins B to B (DM)

N QCNW-C222WJQZ AW J Extension Cable, 80pins Panel

N QCNW-E341WJQZ BG J Extension Cable, 30pins MAIN to LCD (LV)

N QCNW-E977WJQZ AY J Extension Cable, 14pins PWR to INVERTOR (LA) (37PX

N QCNW-E995WJQZ AY J Extension Cable, 14pins PWR to INVERTOR (LA) (32PX

9

Page 80

LC-32PX5M/X/LC-37PX5M/X

COPYRIGHT

No Part of this publication may be reproduced,

stored in a retrieval system, ortransmitted in

any from or by any means, electronic, mechanical,

photocopying, recording, orotherwise, without

prior written permission of the publisher.

©

2007 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

Apr. 2007 Printed in Japan

TQ2156-S SY. KG

SHARP CORPORATION

AV Systems Group

CS PromotionCenter

Yaita,Tochigi 329-2193, Japan

Loading...

Loading...