Page 1

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

al condition and only parts

ose spec

used

SERVICE MANUAL

No.

LED COLOUR TELEVISION

LC-19LE320

LC-22LE320

LC-26LE320

LC-32LE320

LC-37LE320

MODELS LC-42LE320

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its origin

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION ................................................. ... .................2

Precautions for using lead-free solder ......……….........3

CHAPTER 1. OPERATION MANUAL

[1] SPECIFICATIONS ..................................................4

[2] OPERATION MANUAL ...........................................6

[3] DIMENSIONS ........................................................11

CHAPTER 2. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ..........................12

CHAPTER 3. ADJUSTMENT PROCEDURE

[1] ADJUSTMENT PROCEDURE...............................37

[2] SERVICE MODE....................................................50

[3]

SOFTWARE UPGRADE PROCEDURE................51

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE...............................52

CHAPTER 5. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS...............................127

CHAPTER 6. BLOCK DIAGRAM/WIRING DIAGRAM

[1] BLOCK DIAGRAM...............................................149

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

SHARP CORPORATION

identical to th

ified should be

CONTENTS

[2] POWER MANAGEMENT BLOCK DIAGRAM.........151

[3] WIRING DIAGRAM ................................................153

CHAPTER 7. PRINTED WIRING BOARD

[1] MAIN UNIT PRINTED WIRING BOARD .................158

[2] POWER UNIT PRINTED WIRING BOARD.............162

[3] KEY UNIT PRINTED WIRING BOARD ...................170

[4] IR UNIT PRINTED WIRING BOARD ......................171

[5] MEMC UNIT PRINTED WIRING BOARD................172

[6] RS232 UNIT PRINTED WIRING BOARD................174

[7] Convert UNIT PRINTED WIRING BOARD..............175

CHAPTER 8. SCHEMATIC DIAGRAM

[1] MAIN SCHEMATIC DIAGRAM ..............................177

[2] POWER SCHEMATIC DIAGRAM............................203

[3] KEY SCHEMATIC DIAGRAM..................................208

[4] IR SCHEMATIC DIAGRAM......................................209

[5] MEMC SCHEMATIC DIAGRAM...............................210

[6] RS232 SCHEMATIC DIAGRAM...............................215

[7] Convert SCHEMATIC DIAGRAM.............................216

CHAPTER 9. Parts Guide

[1] SPARE PARTS LIST...............................................218

[2] CABINET PARTS ...................................................311

[3] SUPPLIED ACCESSOORIES............................... ..323

[4] PACKING PARTS....................................................324

1

.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

■ Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

■ WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION:

FOR CONTINUED PROTECTION AGAINST A

RISK OF FIRE REPLACE ONLY WITH SAME

TYPE FUSE.

42" F901 (T6.3AH/250V)

26"/32" F901 (T5AH/250V)

BEFORE RETURNING THE RECEIVER

■

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 220~240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled

by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or

electrical ground connected to an earth ground.

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection,

nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics

are identified in this manual; electrical components having such

features are identified by “ ” and shaded areas in the Replacement

Parts List and Schematic Diagrams.

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 1.05 V peak (this corresponds to 0.7 mA peak AC.)

or more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

2

Page 3

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Precautions for using lead-free solder

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause

damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has

poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land

may be peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you

confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

3

Page 4

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

CHAPTER 1. OPERATION MANUAL

[1] SPECIFICATIONS

Specification

Item

LCD screen size

Number of dots

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV-Standard

TV Function

Audio amplifier 3W × 2 3W × 2 5W × 2

Speaker 30 (H) × 117 (W) × 23 (D) mm 30 (H) × 117 (W) × 23 (D) mm 38 (H) × 164 (W) × 23 (D) mm

Rear

Side

OSD language

Power Requirement AC 220–240 V, 50 Hz

Power Consumption

Weight

Operating temperature 0°C to + 40°C

• As a part of policy of continuous improvement, SHARP reserves the right to make design and specification change s for product improvement

without prior notice. The performance specification figures indicated are nominal values of production units. There may be some deviations

from these values in individual units.

NOTE

• Refer to the inside back cover for dimensional drawings.

• Audio cannot be output through the HDMI terminal.

Receiving

Channel

TV-Tuning System Auto Preset 999 ch, Auto Label, Auto Sort

STEREO/BILINGUAL NICAM/A2

Antenna UHF/VHF 75

RS-232C D-sub 9 pin male connector

SCART SCART (AV input, Y/C input, RGB input, TV output )

PC IN D-sub 15 pin (AV input), Ø 3.5mm jack (Audio input)

Component Y/Pb(Cb)/Pr(Cr), RCA pin (L/R)

SPDIF OUT Digital audio output

AV OUT RCA pin (AV output)

HDMI 1 Digital video and audio input

C. I. (Common Interface) EN50221, R206001, CI Plus specification

AV IN RCA pin (AV input)

USB Software update, multi-media play

Headphones Ø 3.5mm jack (Audio output)

HDMI 2 Digital video and audio input

Analogue CCIR (B/G, I, D/K, L/L’)

Digital DVB-T (2K/8K OFDM), DVB-C

VHF/UHF ATV : IRA-E69, DVB-T : E5-E69

CATV S-band, S1–S41ch

19” LCD COLOUR TV,

Model: LC-19LE320E

19” diagonal 22” diagonal 26” diagonal

3,147,264 dots

(1366 × 768 × 3 dots)

English, German, French, Italian, Dutch, Spanish, Greek, Portuguese, Swedish, Finnish, Russian,

Polish, Turkish, Hungarian, Czech, Slovak, Danish, Norwegian, Estonian, Latvian, Lithuanian,

Slovenian, Bulgarian, Croatian, Romanian, Serbian, Ukrainian, Gaelic, Belarussian.

20W (Standby < 0.3W)

(Method IEC62087)

3.3kg (Without stand),

3.7kg (With stand)

22” LCD COLOUR TV,

Model: LC-22LE320E

6,220,800 dots

(1920 × 1080 × 3 dots)

30W (Standby < 0.3W)

(Method IEC62087)

4.0kg (Without stand),

4.5kg (With stand)

26” LCD COLOUR TV,

Model: LC-26LE320E

3,147,264 dots

(1366 × 768 × 3 dots)

45W (Standby < 0.3W)

(Method IEC62087)

5.7kg (Without stand),

6.8kg (With stand)

4

Page 5

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Item

LCD screen size

Number of dots

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV-Standard

TV Function

Audio amplifier 10W × 2 10W × 2 10W × 2

Speaker 30 (H) × 164 (W) × 32 (D) mm 30 (H) × 164 (W) × 32 (D) mm 30 (H) × 164 (W) × 32 (D) mm

Rear

Side

OSD language

Power Requirement AC 220–240 V, 50 Hz

Power Consumption

Weight

Operating temperature 0°C to + 40°C

• As a part of policy of continuous improvement, SHARP reserves the right to make design and specification change s for product improvement

without prior notice. The performance specification figures indicated are nominal values of production units. There may be some deviations

from these values in individual units.

NOTE

• Refer to the inside back cover for dimensional drawings.

• Audio cannot be output through the HDMI terminal.

Receiving

Channel

TV-Tuning System Auto Preset 999 ch, Auto Label, Auto Sort

STEREO/BILINGUAL NICAM/A2

Antenna UHF/VHF 75

SCART 1 SCART (AV input, Y/C input, RGB input, TV output )

SCART 2

PC IN D-sub 15 pin (AV input), Ø 3.5mm jack (Audio input)

Component Y/Pb(Cb)/Pr(Cr), RCA pin (L/R)

SPDIF OUT Digital audio output

AUDIO OUT RCA pin (L/R)

HDMI 1 Digital video and audio input

HDMI 2 Digital video and audio input

RS-232C D-sub 9 pin male connector

C. I. (Common Interface) EN50221, R206001, CI Plus specification

AV IN RCA pin (AV input)

USB Software update, multi-media play

Headphones Ø 3.5mm jack (Audio output)

HDMI 3 Digital video and audio input

Analogue CCIR (B/G, I, D/K, L/L’)

Digital DVB-T (2K/8K OFDM), DVB-C

VHF/UHF ATV : IRA-E69, DVB-T : E5-E69

CATV S-band, S1–S41ch

32” LCD COLOUR TV,

Model: LC-32LE320E

32” diagonal 37” diagonal 42” diagonal

6,220,800 dots

(1920 × 1080 × 3 dots)

SCART (AV input, Y/C input, monitor output [analogue source - ATV, SCART 1, SIDE AV;

digital source - DTV] )

English, German, French, Italian, Dutch, Spanish, Greek, Portuguese, Swedish, Finnish, Russian,

Polish, Turkish, Hungarian, Czech, Slovak, Danish, Norwegian, Estonian, Latvian, Lithuanian,

Slovenian, Bulgarian, Croatian, Romanian, Serbian, Ukrainian, Gaelic,Belarussian.

90W (Standby < 0.3W)

(Method IEC62087)

8.8 kg (Without stand),

10.1 kg (With stand)

37” LCD COLOUR TV,

Model: LC-37LE320E

6,220,800 dots

(1920 × 1080 × 3 dots)

95W (Standby < 0.3W)

(Method IEC62087)

11.1 kg (Without stand),

13.1 kg (With stand)

42” LCD COLOUR TV,

Model: LC-42LE320E

6,220,800 dots

(1920 × 1080 × 3 dots)

115W (Standby < 0.3W)

(Method IEC62087)

14.1 kg (Without stand),

16.2 kg (With stand)

2008-03-14

5

Page 6

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

[2] OPERATION MANUAL

Remote control unit

(POWER)

Press to turn the LCD TV on or enter standby

mode.

(INPUT SOURCE)

Select an input source.

0-9 DIGIT BUTTONS

To select a TV channel directly.

EPG

Press this button to display electronic

programme guide when watching digital

channels.

PRE PR

To display the previous selected TV channel.

DTV/ATV

Press this button to switch between ATV and

DTV channels.

PR LIST

Press to display a list of channels. Then press

Red button to select the digital or analogue

channel list.(Only available when your input

source is TV).

ECO

Press this button to set the picture with less

brightness for saving energy.

Display programme information, if available.

(+/-)

Press to adjust the volume.

Press to toggle audio on and off. You can also

press

level.

Select picture format to Auto /Normal / Zoom

1/ Zoom 2 /Wide.

P (

Press to select the channel.

DUAL

Select MONO / STEREO / DUAL 1 / DUAL 2

for ATV channel. Select Audio language for

DTV channel.

AUDIO (ADJ)

Press to set the LCD TV to a predefined sound

setting.

Personal / Music / Speech

(+/-) to restore the previous volume

(Picture format)

)

VIDEO (ADJ)

Press to set the LCD TV to a predefined picture

setting.

Personal / Standard / Vivid /

Movie / Eco

SLEEP

Press to turn the LCD TV off within an amount

of time. (10 ~ 120 minutes.)

Press ooep to navigate and confirm your

selection.

OK

Press to activate a setting.

MENU

Press to activate the LCD TV OSD.

EXIT

Press to exit the LCD TV OSD or return to the

previous layer.

R/G/Y/B (COLOUR BUTTON)

Press buttons to select the pictures with various

colours of text. Different channels display

different functions.

TELETEXT

Press this button to activate Teletext. Press

again to activate Teletext with TV.

Press again to turn off Teletext.

SUBTITLE

For DTV, press this button to toggle off /

between available subtitle languages.

For ATV, press this button to toggle

off / between available subtitle pages

in Teletext.

SIZE

Press this button to change the font size: Full

screen, Top half and Bottom half.

SUBPAGE

To select the subpage when the current page

contains subpage(s).

INDEX

Press this button to return to page 100 or the

index page; and then press 0 to 9. The teletext

page will be numbered and added to the page

you select or the secondary item.

HOLD

Press this button to stop the scrolling of pages.

The text decoder stops receiving data.

REVEAL

Reveal hidden information such as answers to a

quiz.

FREEZE

Press to freeze a moving image on the screen.

(Only available when your input source is TV).

Scart output signal will also be frozen when you

are watching digital channels.

In USB mode:

(You need to programme the setting with

remote control to control connected devices.)

Press to skip back to the previous title or track.

Press to stop playback.

Press to start/pause playback. Caution: Do not

freeze the video image for long periods of time.

You may damage the TV screen.

Press to skip forward to the next title or track.

6

Page 7

TV (Front view)

TV (Rear view)

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

2008-03-14

7

Page 8

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Preparation

Attaching/Detaching the Stand

• Before attaching (or detaching) the stand, unplug the AC cord from the AC INPUT terminal.

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from

Being damaged.

CAUTION:

• Attach the stand in the correct direction.

• Be sure to follow the instructions. Incorrect installation of the stand may result in the TV falling over.

1. Put the TV face down on a safe surface

that is covered by a soft and smooth cloth.

2. Adjust the TV stand to the bottom of the TV.

3. Fasten the screws by using a cross-head screwdriver(Not supplied).

CAUTION:

• Do not push to hard or put excessive pressure to the stand neck to avoid the damages when you turn the TV for the most comfortable viewing

angle.

NOTE:

To detach the TV stand, perform the steps in reverse order.

Wall mounting

TV screen

size(Inches)

19” 75 x 75 mm Metric 4 x 10 mm

22” 75 x 75 mm Metric 4 x 10 mm

26” 75 x 75 mm Metric 4 x 10 mm

32” 200 x 100 mm Metric 6 x 10 mm

37” 200 x 200 mm Metric 6 x 10 mm

42” 200 x 200 mm Metric 6 x 10 mm

NOTE

• At the time of purchasing wall bracket, please check if there is enough space between the wall bracket and TV terminals for the terminal connection.

VESAcompatible wall

bracket(millimeters)

(W x H)

Screw type

Installing Batteries in the Remote Control Unit

1. Insert two AAA batteries into Remote control. Make sure (+) and (-) are facing the proper

direction.

2. Replace the cover

NOTE

• If the remote control will not to be used for a long time, remove the batteries to avoid remote control

damage.

CAUTION:

Improper use of batteries can result in chemical leakage or explosion. Be sure to follow the instructions below.

• Do not mix batteries of different types. Different types of batteries have different characteristics.

• Do not mix old and new batteries. Mixing old and new batteries can shorten the life of new batteries or cause chemical leakage in old batteries.

• Remove batteries as soon as they are worn out. Chemicals that leak from batteries come in contact with skin can cause a rash. If you find any chemical

leakage, wipe thoroughly with a cloth.

• The batteries supplied with this product may have a shorter life expectancy due to storage conditions.

8

Page 9

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

• If you will not be using the remote control unit for an extended period of time, remove batteries from it.

Note on disposing batteries:

The batteries provided contain no harmful materials such as cadmium, lead or mercury. Regulations concerning used batteries stipulate that batteries may

no longer be thrown out with the household rubbish. Deposit any used batteries free of charge into the designated collection containers set up at

commercial businesses.

Installing Batteries in the Remote Control Unit

Use the remote control unit by pointing it towards the remote control sensor. Objects

between the remote control unit and sensor may prevent proper operation.

2008-03-14

9

Page 10

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Appendix

troubleshooting

problem possible Solution

No picture 1. Connect power cord correctly.

Abnormal colours Connect signal cable correctly.

Twisted picture 1. Connect signal cable correctly.

Picture too dark Adjust brightness and contrast.

Audio only, no images 1. Please check if input signal is connected correctly.

Picture only, no audio 1. Connect signal cable correctly.

Cannot use remote control 1. Please change battery.

Cannot receive sufficient channels through

antenna

No colour Please adjust the colour setup.

Blinking picture accompanied by ghost image 1. Check the connection of antenna/signal cable.

Broken lines or segments Adjust antenna.

Certain TV channels are blocked(Hope to

acquire some channels)

Overlapping images or ghost images Please use multi-directional outdoor antenna.(If your TV is subject to the influence of nearby mountains or

Cannot use a function If the item you choose turns gray, that item cannot be selected.

Cannot receive programmes Please use the Update Scan method to add the channels not included in memory.

2. Turn on power.

3. Connect signal cable correctly.

4. Press any button on the LCD TV.

2. Please use compatible signal.

2. TV-RF signal must not be lower than 50dB.

2. Adjust volume to proper level.

3. Connect audio signal cable correctly.

4. TV-RF signal must not be lower than 50dB.

2. Turn off power for 10 seconds; and then restart power.

Please use the Channel Scan function to increase the number of channels not included in memory.

2. Check if channel is in play mode.

3. Press signal source and change input mode.

Keep the TV away from noise sources, such as automobiles, neon lights, and hair dryers.

Please use the Update Scan method to add the channels not included in memory.

buildings).

10

Page 11

[3] DIMENSIONS

Dimension

/

]

71.054

[

/

))

0.273

/}}5.866{{ / }5.806{

((

]]

/

3.535

)

0.533

[[

(

(

246.0)/((246.0))/[389.97]/[[418.0]]/ {460.0} / {{500.0}}

(

468.4)/((536.0))/[647.35]/[[786.6]]/ {907.5} / {{1018.5}}

/

]

72.514

[

/

))

0.243

/}}5.036{{ / }0.865{

((

]]

/

3.005

)

0.403

[[

(

/

/

]]

}}0.83{{/ }0.83{

))

00.53

0.03

((

[[

/

/

)

]

0.13

1.01

(

[

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

(

411.205)/((477.64))/[577.25]/

[[

700.67]]/ {821.5} / {{932.5}}

/ }}0.002{{

}

0.002

(

38.6)/((38.6))/[39.6]/

[[

44.9]]/ {44.9} / {{44.9}}

(

70.3)/((70.3))/[87.49]/

[[

95.7]]/ {106.0} / {{118.5}}

/

]

71.523

[

/

))

11.962

/ }}5.525{{ / }0.364{

((

]]

/

)

73.593

508.132

[[

(

”73

”23

”24

/

]

45.252

[

/

))

0.012

/}}57.263{{ / }5.133{

((

]]

/

56.492

)

0.291

(

[[

(

170.0)/((170.0))/[215.98]/

[[

238.0]]/ {250.0} / {{260.0}}

{

/

]

]0.001

[[

(

) / ((75.0)) / [75.0]

75.0

[[

”91

”22

”62

200.0]]/{200.0}/ {{200.0}}

( ): 19"

(( )): 22"

[ ]: 26"

)]0.57[ / ))0.57(( /

0.57

(

2008-03-14

[[ ]]: 32"

{ } : 37"

{{ }} : 42"

11

Page 12

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

CHAPTER 2. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS(LC-19LE320)

1. Assy/Panel Removal

Notes: Please put your machine on soft material to avoid to scrape panel when you disassemble it.

Front view

Fig.1

Back view

Fig.2

Step 1. Remove the Base Assy and Base neck.

1. Remove the Base Assy as Fig.3.

Remove the 3 screws as Fig.3 and pull out the base as Fig.4

Fig.3

12

Page 13

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.4

2. Remove the 4 screws. Detach the Base neck as Fig.4.

Step 2. Remove the REAR COVER Assy.

1. Remove the 7 screws. Detach the REAR COVER as Fig.5.

Fig.5

Note: How to easy remove rear cabinet

Put left hand on the center of rear cabinet

Right hand fingers put under the machine rim

Press down

Pull up Pull up

Pull up Pull up

Step 3. Remove the Main, Power, Convert board and the Speakers.

2008-03-14

13

Page 14

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.6

1. Remove the 5 screws and disconnect 3 cables except the LVDS cable, the move the main board out from the side I/O BKT, then move down the main

board a little, now disconnect the LVDS from the panel firstly, then disconnect the LVDS from the main board. Detach the Main board as Fig.7 and Fig.8.

Note: Please disconnect the LVDS cable from the panel firstly, then disconnect the LVDS from the main board.

If you disconnect the LVDS cable with the Main board firstly, maybe the panel connector will be damaged because of the short LVDS cable.

Fig.7 Fig.8

2. Remove the 4 screws and disconnect 2 cables. Detach the Power board as Fig.9.

Note: Move the AC port left from the Main frame assy, then disconnect the AC cable from the power board.

Fig.9

14

Page 15

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

3. Remove the 2 screws and disconnect 1 cables. Detach the Convert board as Fig.10.

Fig.10

4. Release the speaker cable from its clamp, pull up and remove the speaker as Fig.11.

Fig.11

Step 4. Remove the Bracket and Bezel.

1. Remove the 9 screws. Detach the Bracket and panel as Fig.12.

Fig.12

2. Remove the 4 screws. Detach the Main frame as Fig.13. Disconnect the one FFC cable from the panel as Fig.14

2008-03-14

Fig.13 Fig.14

15

Page 16

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Panel:

Fig.15

Step 5. Remove the IR and Key board.

1. Remove the 2 screws and disconnect 2 cables. Detach the IR board as Fig.16.

Fig.16

2. Disconnect 1 cable. Detach the Key board as Fig.17.

Fig.17

2. Set Re-assembly

To re-assemble the whole set, execute all processes in reverse order.

Notes:

a. While re-assembling, make sure that all cables are placed and connected in their original position.

b. Pay special attention not to damage the EMC foams at the SSB shielding. Check that EMC foams are put

correctly on their places.

16

Page 17

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

REMOVING OF MAJOR PARTS(LC-22LE320)

1. Assy/Panel Removal

Notes: Please put your machine on soft material to avoid to scrape panel when you disassemble it.

Front view

Fig.1

Back view

Fig.2

Step 1. Remove the Base Assy and Base neck.

1. Remove the Base Assy as Fig.3.

Remove the 3 screws as Fig.3 and pull out the base as Fig.4

Fig.3

2008-03-14

17

Page 18

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.4

2. Remove the 4 screws. Detach the Base neck as Fig.4.

Step 2. Remove the REAR COVER Assy.

1. Remove the 7 screws. Detach the REAR COVER as Fig.5.

Fig.5

Note: How to easy remove rear cabinet

Put left hand on the center of rear cabinet

Right hand fingers put under the machine rim

Press down

Pull up Pull up

Pull up Pull up

Step 3. Remove the Main, Power, Convert board and the Speakers.

18

Page 19

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.6

1. Remove the 5 screws and disconnect 4 cables. Detach the Main board as Fig.7 and Fig.8.

Note: Please disconnect the LVDS cable from the panel firstly, then disconnect the LVDS from the main board.

If you disconnect the LVDS cable with the Main board firstly, maybe the panel connector will be damaged because of the short LVDS cable.

Fig.7 Fig.8

2. Remove the 4 screws and disconnect 3 cables. Detach the Power board as Fig.9.

Note: Move the AC port left from the Main frame assy, then disconnect the AC cable from the power board.

2008-03-14

Fig.9

19

Page 20

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

3. Remove the 2 screws and disconnect 2 cables. Detach the Convert board as Fig.10.

Fig.10

4. Release the speaker cable from its clamp, pull up and remove the speaker as Fig.11.

Fig.11

Step 4. Remove the Bracket and Bezel.

1. Remove the 5 screws. Detach the Bracket and panel as Fig.12.

Fig.12

2. Remove the 4 screws. Detach the Main frame as Fig.13. Disconnect the two FFC cables from the panel as Fig.14

Fig.13 Fig.14

Panel:

20

Page 21

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.15

Step 5. Remove the IR and Key board.

1. Remove the 2 screws and disconnect 2 cables. Detach the IR board as Fig.16.

Fig.16

2. Disconnect 1 cable. Detach the Key board as Fig.17.

Fig.17

2. Set Re-assembly

To re-assemble the whole set, execute all processes in reverse order.

Notes:

a. While re-assembling, make sure that all cables are placed and connected in their original position.

b. Pay special attention not to damage the EMC foams at the SSB shielding. Check that EMC foams are put

correctly on their places.

2008-03-14

21

Page 22

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

REMOVING OF MAJOR PARTS(LC-26LE320)

1. Assy/Panel Removal

Notes: Please put your machine on soft material to avoid to scrape panel when you disassemble it.

Front view

Fig.1

Back view

Fig.2

Step 1. Remove the Base Assy and Base neck.

1. Remove the Base Assy as Fig.3.

Remove the 4 screws as Fig.3 and pull out the base as Fig.4

Fig.3

2. Remove the 4 screws. Detach the Base neck as Fig.4.

22

Page 23

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.4

Step 2. Remove the REAR COVER Assy.

1. Remove the 10 screws. Detach the REAR COVER as Fig.5.

Fig.5

Note: How to easy remove rear cabinet

Step 3. Remove the Main, Power board and the Speakers.

2008-03-14

23

Page 24

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.6

1. Remove the 7 screws and disconnect 4 cables. Detach the Main board as Fig.7 and Fig.8.

Fig.7 Fig.8

2. Remove the 4 screws and disconnect 2 cables. Detach the Power board as Fig.9.

Note: Move the AC port left from the Main frame assy, then disconnect the AC cable from the power board.

Fig.9

3. Release the speaker cable from its clamp, pull up and remove the speaker as Fig.10.

24

Page 25

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.10

Step 4. Remove the Bracket and Bezel.

1. Remove the 6 screws. Detach the Bracket as Fig.11.

Fig.11

2. Remove the panel from the bezel as Fig.12

Panel:

Fig.12

Step 5. Remove the IR and Key board.

1. Disconnect 2 cables, then release the clips. Detach the IR board as Fig.13.

Fig.13

2. Disconnect 1 cable. Detach the Key board as Fig.17.

2008-03-14

Fig.17

25

Page 26

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

2. Set Re-assembly

To re-assemble the whole set, execute all processes in reverse order.

Notes:

a. While re-assembling, make sure that all cables are placed and connected in their original position.

b. Pay special attention not to damage the EMC foams at the SSB shielding. Check that EMC foams are put

correctly on their places.

26

Page 27

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

REMOVING OF MAJOR PARTS(LC-32LE320)

1. Assy/Panel Removal

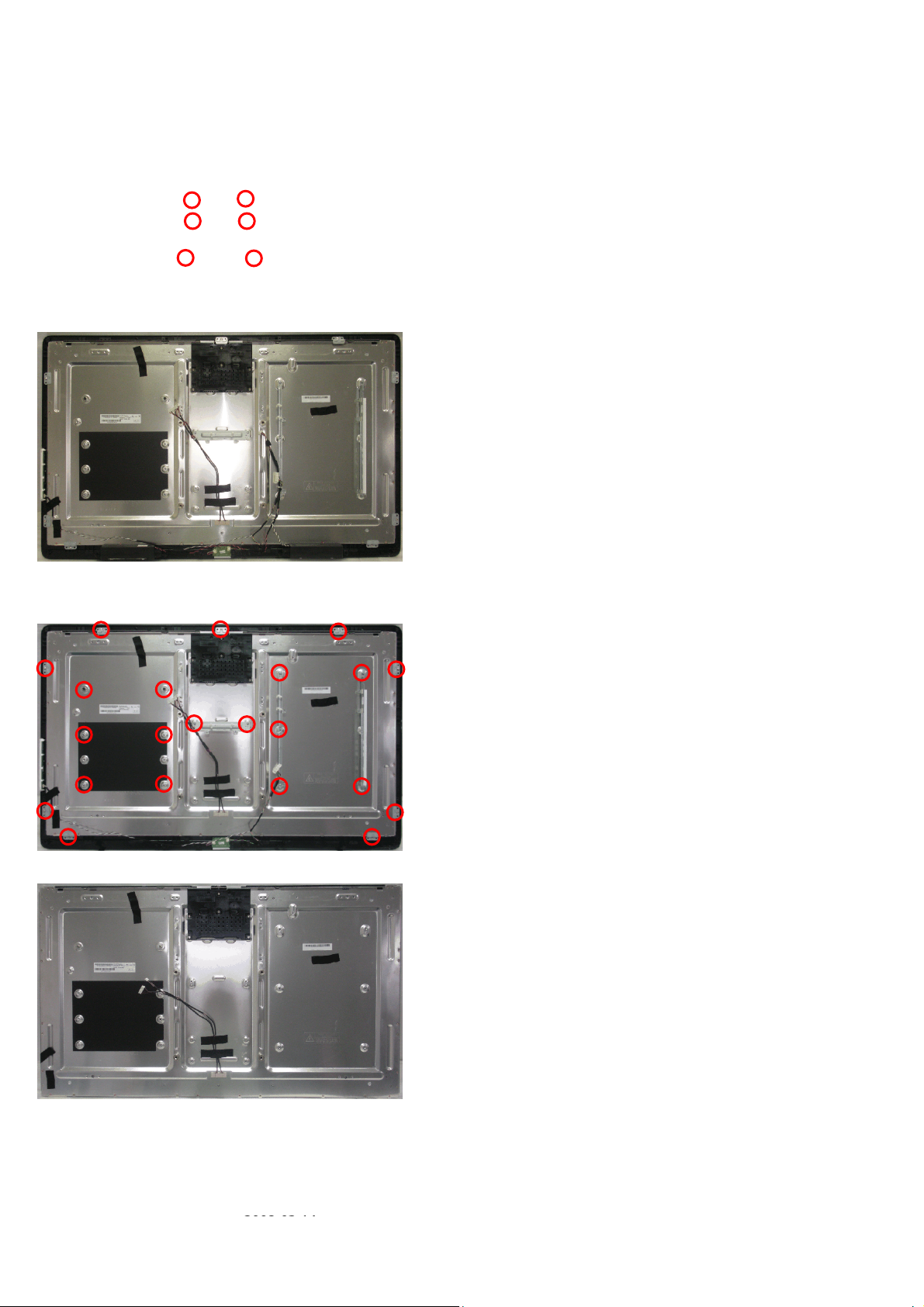

Notes: Please put your machine on soft material to avoid to scrape panel when you disassemble it.

Front view

Fig.1

Back view

Fig.2

Step 1. Remove the Base Assy and Base neck.

1. Remove the Base Assy as Fig.3.

Remove the 4 screws as Fig.3 and pull out the base as Fig.4

Fig.3

2. Remove the 4 screws. Detach the Base neck as Fig.4.

2008-03-14

27

Page 28

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.4

Step 2. Remove the REAR COVER Assy.

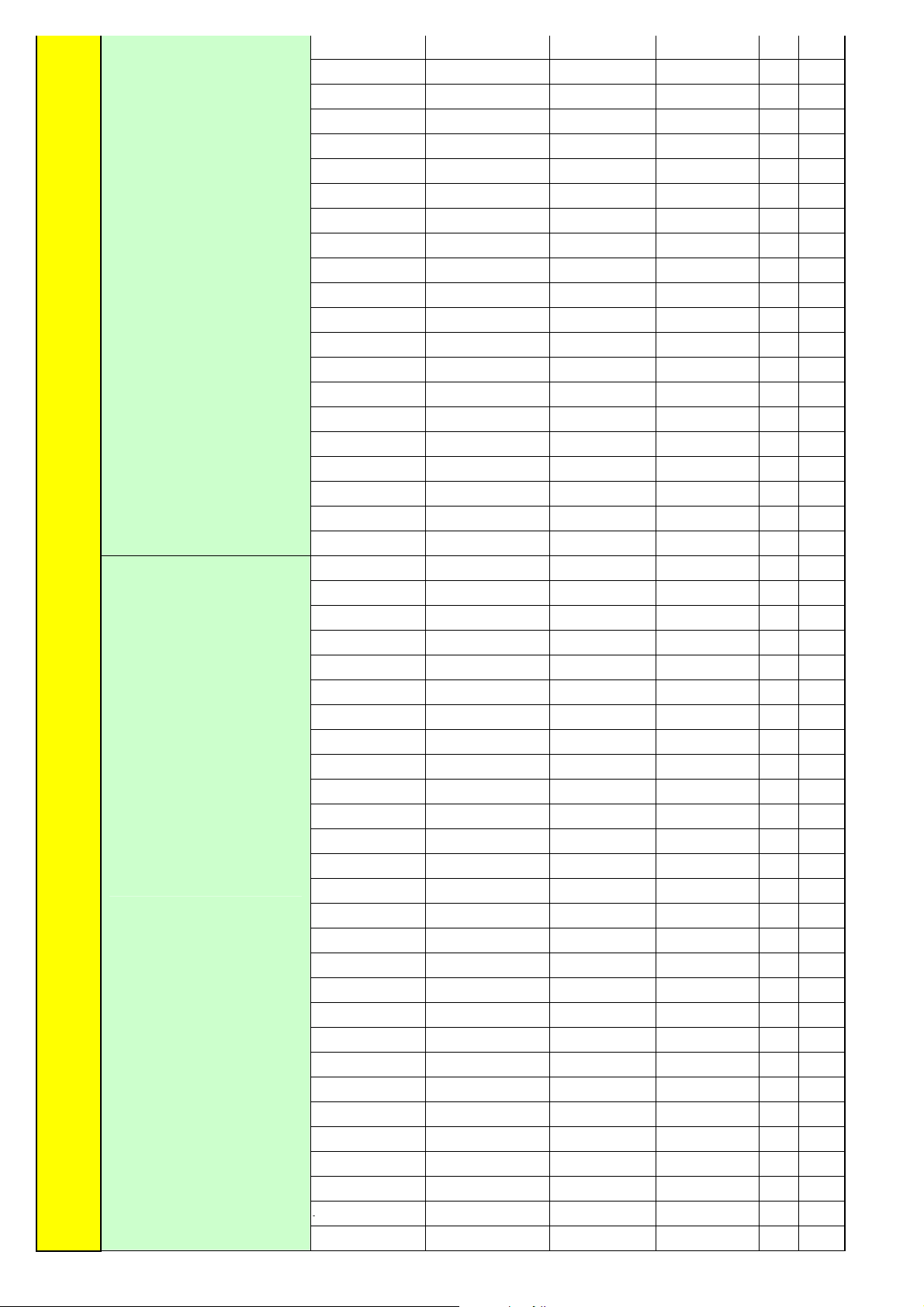

1. Remove the 12 screws. Detach the REAR COVER as Fig.5.

Fig.5

Step 3. Remove the Main, RS232, Power and MEMC board.

Fig.6

1. Remove the 8 screws and disconnect 8 cables. Detach the Main and RS232 boards as Fig.7 and Fig.8.

RS232 board

Main board

□

Fig.7 Fig.8

2. Remove the 6 screws and disconnect 3 cables. Detach the Power board as Fig.9.

28

Page 29

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Note: Move the AC port left from the Bracket, then disconnect the AC cable from the power board.

Fig.9

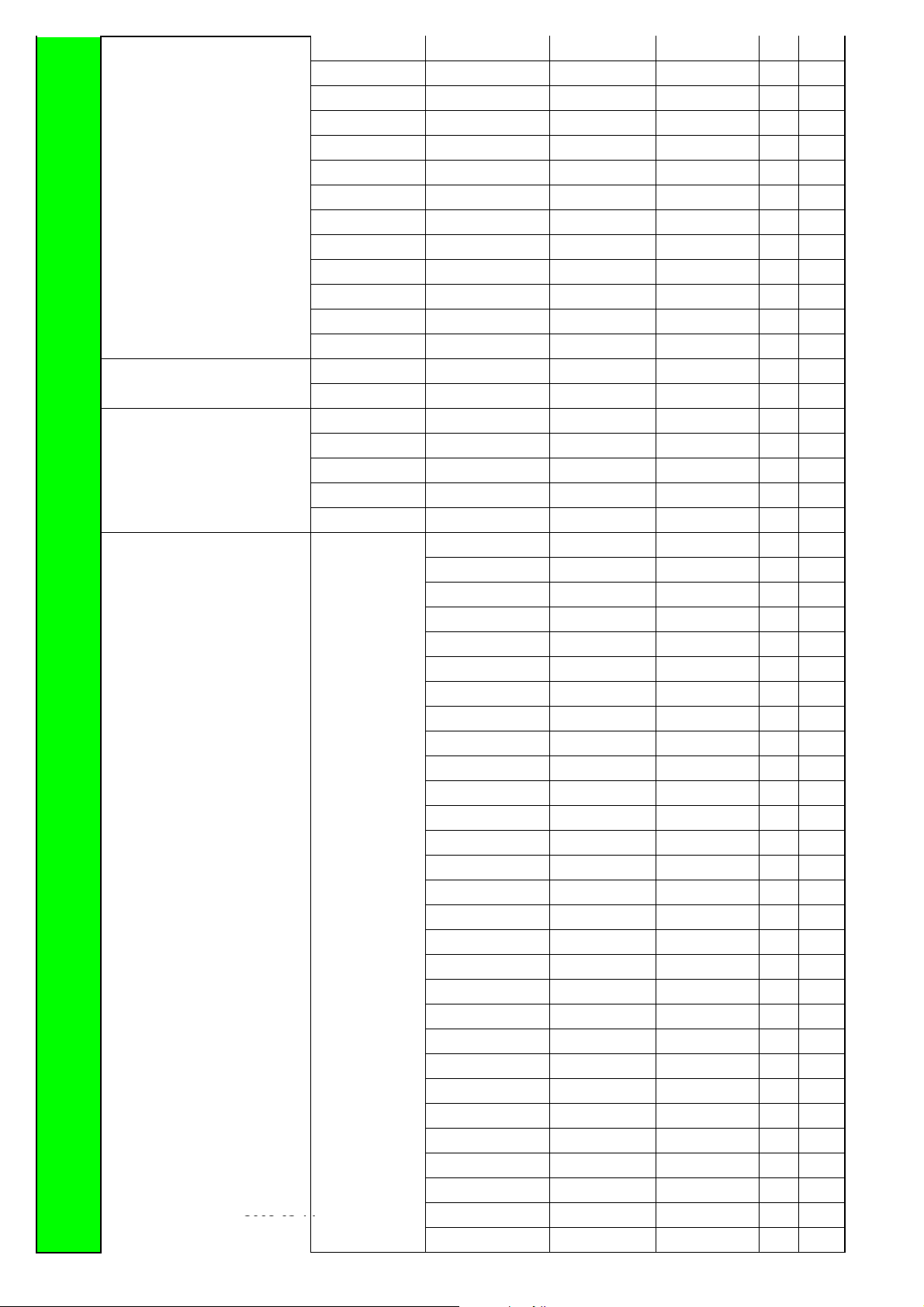

3. Remove the 4 screws and disconnect 4 cables. Detach the MEMC board as Fig.10.

Note: Please disconnect the LVDS cables with the panel firstly, then disconnect the LVDS with the MEMC board as Fig.11.

If you disconnect the LVDS cables with the MEMC board firstly, maybe the panel connector will be damaged because of the short LVDS cables.

Fig.10 Fig.11

Step 4. Remove the Bracket, Speakers and Bezel.

1. Remove the 16 screws. Detach the Bracket and Bracket screws as Fig.12.

2008-03-14

29

Page 30

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.12

2. Release the speaker cable from its clamp, pull up and remove the speaker as Fig.13.

Fig.13

3. Remove the 8 screws to detach the panel bracket from the bezel.Then take out of the panel from the bezel as Fig.14.

Panel:

Fig.14

Step 5. Remove the IR and Key board.

1. Disconnect 2 cables, then release the clips. Detach the IR board as Fig.15.

30

Page 31

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.15

2. Disconnect 1 cable. Detach the Key board as Fig.17.

Fig.17

2. Set Re-assembly

To re-assemble the whole set, execute all processes in reverse order.

Notes:

a. While re-assembling, make sure that all cables are placed and connected in their original position.

b. Pay special attention not to damage the EMC foams at the SSB shielding. Check that EMC foams are put

correctly on their places.

2008-03-14

31

Page 32

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

REMOVING OF MAJOR PARTS(LC-37LE320)

1. Assy/Panel Removal

Notes: Please put your machine on soft material to avoid to scrape panel when you disassemble it.

Front view

Fig.1

Back view

Fig.2

Step 1. Remove the Base Assy and Base neck.

1. Remove the Base Assy as Fig.3.

Remove the 4 screws as Fig.3 and pull out the base as Fig.4

Fig.3

2. Remove the 4 screws. Detach the Base neck as Fig.4.

32

Page 33

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.4

Step 2. Remove the REAR COVER Assy.

1. Remove the 17 screws. Detach the REAR COVER as Fig.5.

Fig.5

Step 3. Remove the Main, RS232, Power and MEMC board.

Fig.6

1. Remove the 8 screws and disconnect 8 cables. Detach the Main and RS232 boards as Fig.7 and Fig.8.

RS232 board

Main board

□

Fig.7 Fig.8

2. Remove the 6 screws and disconnect 3 cables. Detach the Power board as Fig.9.

2008-03-14

33

Page 34

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Note: Move the AC port left from the Bracket, then disconnect the AC cable from the power board.

Fig.9

3. Remove the 4 screws and disconnect 4 cables. Detach the MEMC board as Fig.10.

Note: Please disconnect the LVDS cables with the panel firstly, then disconnect the LVDS with the MEMC board as Fig.11.

If you disconnect the LVDS cables with the MEMC board firstly, maybe the panel connector will be damaged because of the short LVDS cables.

Fig.10 Fig.11

Step 4. Remove the Bracket, Speakers and Bezel.

1. Remove the 66 screws. Detach the base support as Fig.12.

34

Page 35

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.12

2. Release the speaker cable from its clamp, pull up and remove the speaker as Fig.13.

Fig.13

3. Remove the 22 screws to detach the Bracket and Bracket screws. Then take out of the panel from the bezel as Fig.14.

Panel:

Fig.14

Step 5. Remove the IR and Key board.

1. Disconnect 2 cables, then release the clips. Detach the IR board as Fig.15.

2008-03-14

35

Page 36

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Fig.15

2. Disconnect 1 cable. Detach the Key board as Fig.17.

Fig.17

2. Set Re-assembly

To re-assemble the whole set, execute all processes in reverse order.

Notes:

a. While re-assembling, make sure that all cables are placed and connected in their original position.

b. Pay special attention not to damage the EMC foams at the SSB shielding. Check that EMC foams are put

correctly on their places.

36

Page 37

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

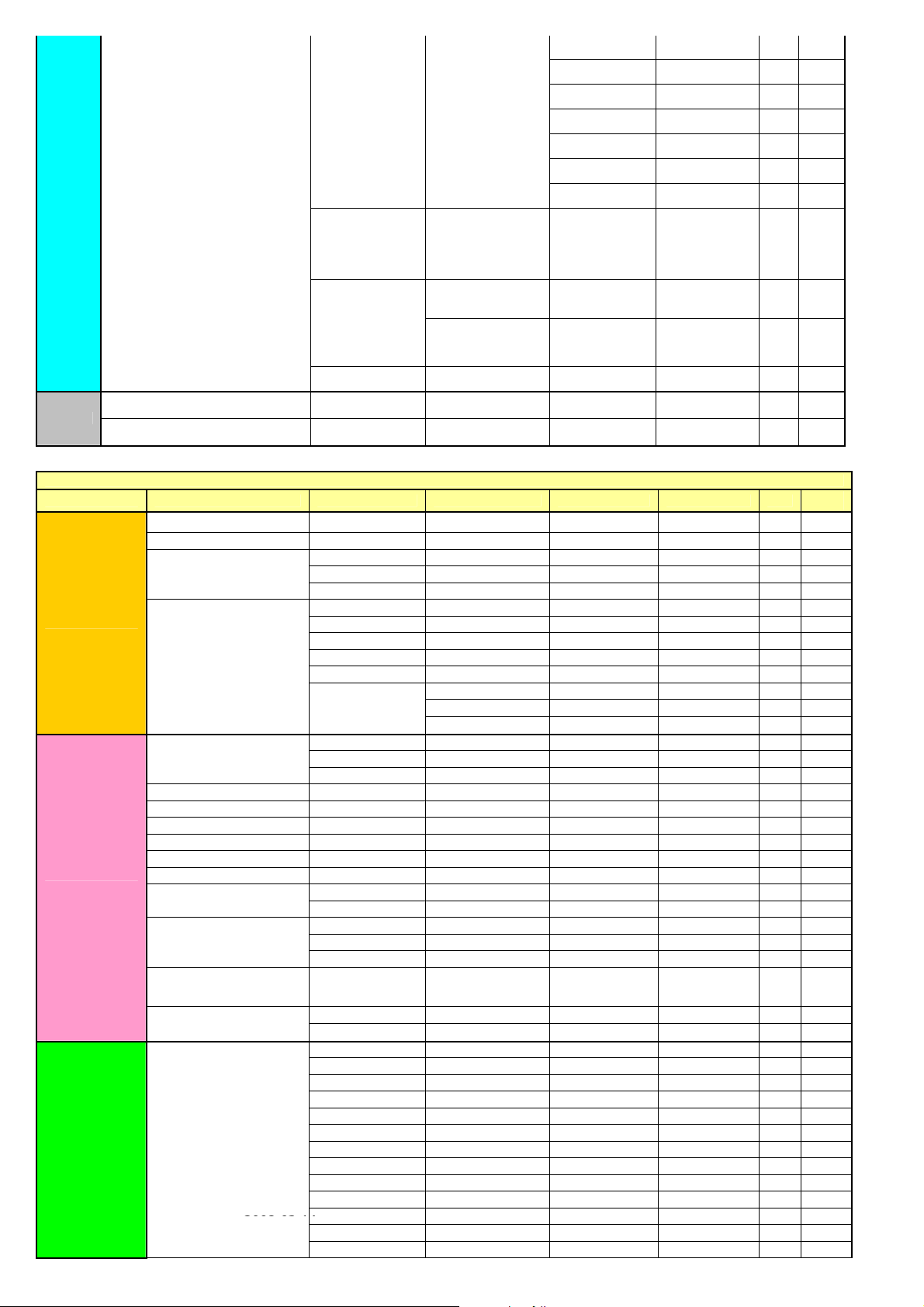

CHAPTER 3. ADJUSTMENT PROCEDURE

PROCEDURE

[1] ADJUSTMENT PROCEDURE

1. OSD Menu

2K10 Sharp DVB OSD tree-Video

OSD

Layer 1

Picture

Sound

2 3 4 5 6 Note

Personal

Standard

Smart Picture

Brightness slider All

Contrast slider All

Color slider All

Tint slider All

Sharpness slider All

Color Temperature

Advanced Control(have sub page)

Sound Mode

Equilizer 120Hz slider All

Equilizer 500Hz slider All

Equilizer 1.5KHz slider All

Equilizer 5KHz slider All

Equilizer 10KHz slider All

Balance slider All

Virtual Surround

Digital Audio Out

SPDIF Delay

2008-03-14

Vivid

Movie

Eco

Normal (default) All

Cool All

Warm All

Noise Reduction

Flesh Tone

Back Light(if DCR is

Off)

DCR

Personal

Music

Speech

On All

Off All

PCM All

Off All

Dolby Digital All

slider(from 0 to 250,

interval of 10

between two items)

Model

All

All

All

All

All

Off All

Low All

Medium All

HIGH All

Auto All

On All

Off All

slider All

On All

Off All

All

All

All

All

37

Page 38

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

AVL

Type(if source is DTV)

Off All

On All

Normal All

Hard of Hearing All

Audio Description All

TV

Audio Description(if Type=Audio

Description)

Tuner Mode

Country(30)

1st Audio(28)(DTV only)

Volume slider

Antenna

Cable

UK

Italy

Luxembourg

Netherlands

Norway

Sweden

Croatia

Hungary

Ireland

Poland

Portugal

Romania

Serbia

Slovakia

Slovenia

Turkey

Iceland

Russia

Ukraine

Austria

Belgium

Bulgaria

Switzerland

Czech Republic

Germany

Greece

Denmark

Spain

Finland

France

English

Finnish

French

Gaelic

Galician

German

Greek

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

38

Page 39

2nd Audio(28)(DTV only)

2008-03-14

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Hungarian

Italian

Norwegian

Polish

Portuguese

Romanian

Russian

Serbian

Slovak

Slovenian

Spanish

Swedish

Turkish

Welsh

Basque

Bulgarian

Catalan

Croatian

Czech

Danish

Dutch

English

Finnish

French

Gaelic

Galician

German

Greek

Hungarian

Italian

Norwegian

Polish

Portuguese

Romanian

Russian

Serbian

Slovak

Slovenian

Spanish

Swedish

Turkish

Welsh

Basque

Bulgarian

Catalan

Croatian

Czech

Danish

Dutch

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

39

Page 40

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Audio Carrier(ATV only)

Channels(have sub page)

Features Menu Language(28)

Mono

Stereo

Dual I

Dual II

Channel Scan

Update Scan

Single RF Scan

Analog Manual

Scan

Channel Skip(have

sub page)

Channel Sort(have

sub page)

Channel Edit(have

sub page)

Decoder(for ATV) (Channel munber…) All

Analog Ch Fine

Tune

English

Deutsch

Français

Italiano

Español

Português

Nederlands

Dansk

Suomi

Svenska

Norsk

Polski

esky

All

All

All

All

ATV

ATV and DTV( if

Antenna mode)

Digital channels: All

ATV and DTV( if

Cable mode)

Frequency(KHz) All

Scan

Digital channels: All

Status: scanning… All

Analogue channels: All

Digital channels: All

RF Channel .. slider All

Signal Strength.. All

Signal Quailty.. All

Start Frequency xxMHz All

Scan Up All

Scan Down All

(Channel munber…) All

(Channel munber…) All

(Channel munber…) All

(Channel munber…)

(have sub page)

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

Status:

scanning…

Analogue

channels:

Status:

scanning…

Analogue

channels:

Scan Mode Full/Advance All

(if Advance mode

select)

(do fine tune) All

All

All

All

All

Modulation

=>Auto/16/32/64/

128/256 QAM

Symbol

Rate(Ksym/s)

Network ID All

Status:

scanning…

Analogue

channels:

All

All

All

All

40

Page 41

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Hrvatski

Magyar

Român

Slovenský

Slovenšina

Srpski

Türkçe

Gaeilge

Latviski

Eesti

Lietuviskai

ykpaiHcbka

4:3 mode

Picture Format(if video exist)

Time (have sub page ) Time Zone

4:3

16:9

Auto

Normal

Zoom1

Zoom2

Wide

2008-03-14

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

As Broadcaster All

GMT +0:00 All

GMT +1:00 All

GMT +2:00 All

GMT +3:00 All

GMT +3:30 All

GMT +4:00 All

GMT +4:30 All

GMT +5:00 All

GMT +5:30 All

GMT +5:45 All

GMT +6:00 All

GMT +6:30 All

GMT +7:00 All

GMT +8:00 All

GMT +9:00 All

GMT +9:30 All

GMT +10:00 All

GMT +11:00 All

GMT +12:00 All

GMT +12:45 All

GMT +13:00 All

GMT -12:00 All

GMT -11:00 All

GMT -10:00 All

GMT -9:00 All

GMT -8:00 All

GMT -7:00 All

GMT -6:00 All

41

Page 42

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

GMT -5:00 All

GMT -4:00 All

GMT -3:30 All

GMT -3:00 All

GMT -2:00 All

GMT -1:00 All

SCART(have sub page)

(Only availabe in SCART source)

Subtitle(have sub page)

Time(have sub

page)

Sleep Timer

SCART1

SCART2(If have

I/O)

Analog Subtitle

1st Subtitle(28)

Auto synchronization

( On/Off)

Date ( 20xx/x x/xx ) All

Time ( xx:xx:xx) All

Timer (Off/On) All

Off Time ( xx:xx:xx) All

Off All

10 Min All

20 Min All

30 Min All

40 Min All

50 Min All

60 Min All

90 Min All

120 Min All

Auto All

Mixed All

RGB All

Composite All

S-Video All

Auto All

Composite All

S-Video All

On All

On during mute All

Off All

English

Finnish

French

Gaelic

Galician

German

Greek

Hungarian

Italian

Norwegian

Polish

Portuguese

Romanian

Russian

Serbian

Slovak

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

42

Page 43

Teletext Language(have sub page)

2008-03-14

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

2nd Subtitle(28)

Subtitle Type

Digital Teletext

Lang.

Slovenian

Spanish

Swedish

Turkish

Welsh

Off

Basque

Bulgarian

Catalan

Croatian

Czech

Danish

Dutch

English

Finnish

French

Gaelic

Galician

German

Greek

Hungarian

Italian

Norwegian

Polish

Portuguese

Romanian

Russian

Serbian

Slovak

Slovenian

Spanish

Swedish

Turkish

Welsh

Off

Basque

Bulgarian

Catalan

Croatian

Czech

Danish

Dutch

Normal All

Hearing Impaired All

English All

Spanish All

French All

German All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

43

Page 44

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Italian All

Danish All

Swedish All

Basque All

Bulgarian All

Catalan All

Croatian All

Czech All

Dutch All

Finnish All

Gaelic All

Galician All

Greek All

Hungarian All

Norwegian All

Polish All

Portuguese All

Romanian All

Russian All

Serbian All

Slovak All

Slovenian All

Turkish All

Welsh All

WEST EUR All

EAST EUR All

Russia All

Russia-2 All

Common Interface(have sub page)

HDMI Scan Info

(Only available in HDMI source)

Reset Default All

SW Ver. All

Parental Password(have sub page)

Decode Page Lang.

(display some info &

status..)

Automatic All

Underscan All

Overscan All

Channel Block(have

sub page)

Parental

Guidance(have sub

page)

Greek All

Turkey All

Arab/Hbrw All

Farsian All

Arab All

All

(Channel munber…) All

Age Rating

18 All

None All

4 All

5 All

6 All

7 All

8 All

9 All

10 All

44

Page 45

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

11 All

12 All

13 All

14 All

15 All

16 All

17 All

Input Block(have

sub page)

Set password (have

sub page)

Clear All All

Off All

Eco

On All

(Source list..)

(TV,YPbPr,AV,SCAR

T,PC,HDMI)

New Password (xxxx) All

Confirm Password

(xxxx)

All

All

2K10 Sharp DVB OSD tree--PC

OSD Layer 1 2 3 4 5 6 Note

Brightness slider All

Contrast slider All

Normal (default) All

Color Temperature

Picture

Advanced Video(have sub

page)

Audio Mode

Equilizer 120Hz slider All

Equilizer 500Hz slider All

Equilizer 1.5KHz slider All

Equilizer 5KHz slider All

Equilizer 10KHz slider All

Sound

Features Menu Language(28)

Balance slider All

Virtual Surround

Digital Audio Out

SPDIF Delay

AVL

2008-03-14

Cool All

Warm All

Auto Config Auto Config All

Horizontal slider All

Vertical slider All

Phase slider All

Clock slider All

Resolution(if

ambiguous timings)

Personal

Music

Speech

On All

Off All

PCM All

Off All

Dolby Digital All

slider(from 0 to 250,

interval of 10

between two items)

Off All

On All

English

Deutsch

Français

Italiano

Español

Português

Nederlands

Dansk

Suomi

Svenska

Norsk

Polski

1360*768 All

1024*768 All

1280*768 All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

Model

45

Page 46

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Picture Format

Reset Default

SW Ver. All

Parental Password(have sub page)

esky

Hrvatski

Magyar

Român

Slovenský

Slovenšina

Srpski

Türkçe

Gaeilge

Latviski

Eesti

Lietuviskai

ykpaiHcbka

Full screen

Native ( if is native

timing)

4:3

Parental

Guidance(have sub

page)

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

All

18 All

None All

4 All

5 All

6 All

7 All

8 All

Age Rating

9 All

10 All

11 All

12 All

13 All

14 All

15 All

16 All

17 All

(Source list..)

(TV,YPbPr,AV,SCAR

T,PC,HDMI)

New Password (xxxx) All

Confirm Password

(xxxx)

All

All

Eco

Input Block(have

sub page)

Set password (have

sub page)

Clear All All

Off All

On All

46

Page 47

2. Display adjustment

YPbPr Mode display adjustment

1 Auto color for signal slicering

1.1 General set-up

Equipment Requirements:

Knoica Minolta CS-200

Input requirements:

Input signal type: YPbPr signal

1. 1080i/25mode, TVBar100 pattern by QuantumData 881.

2. Select Picture mode to “Personal” mode and adjust the x, y data.

Input Signal Strength: 1 Vpp for Y signal ; 700 mVpp for Pb & Pr signal

Input Injection Point: YPbPr (RAC jack)

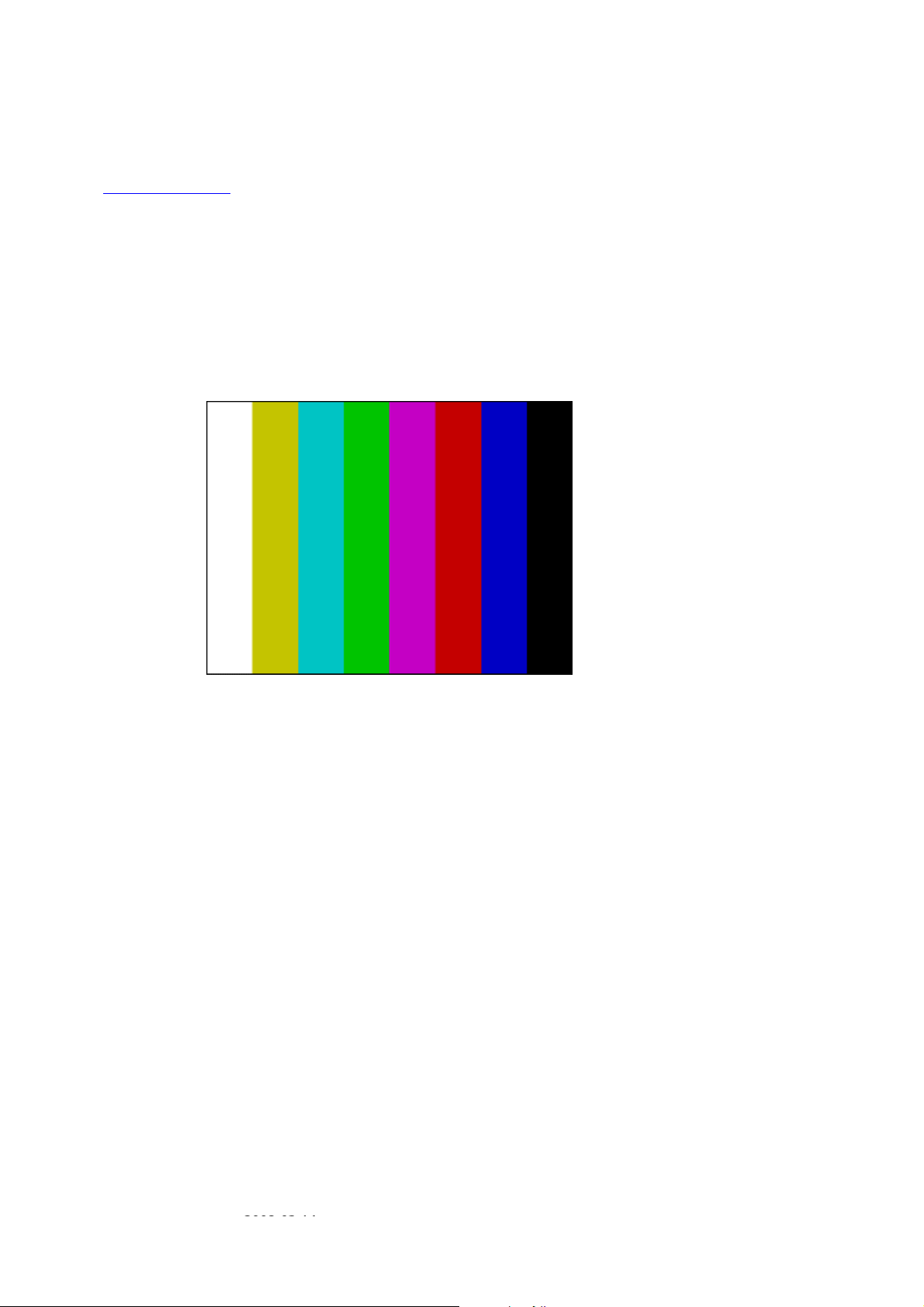

1080i/25, TVBar100 pattern

or equivalent instrument. Quantum Data Pattern Generator 881 or equivalent instrument.

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Alignment method:

Initial Set-up:

1. Select source as “YPbPr”.

2. Set Smart Picture mode as “Personal” and then adjust Contrast = 58, Brightness=48, Color=58, set Color Temp. to be “cool” mode.

3. Apply “TVBar100” pattern which is color bar pattern by signal generator.

4. Enter “factory mode menu”: press MENU + Numeric keys “1999”

Alignment:

1. At factory mode menu, select AUTO_COLOR item. Then press “OK” key of remote control to adjust ADC_GAIN_R, ADC_GAIN_G,

ADC_GAIN_B and ADC_OFFSET_R, ADC_OFFSET_G, ADC_OFFSET_B. Then store those values to NVM.

2. Check the 16 grayscale pattern should be distinguished and color bar is correct

3. Reset AV setting, picture mode shall be recalled to be “Vivid” and Contrast=58, Brightness=48; Color=58.

Note:

Sharp EU 2k10 models have no need to operate “AUTO_COLOR” function, due to EFUSE is set “Disable” within NVM for defult. These ADC values will

be produced by Main chip (MT5363) interal defination.

White balance adjustment

Alignment method:

Initial Set-up:

1. Select source as “YPbPr”.

2. Set Contrast = 58 and Brightness=48, Color=58, at normal menu mode.

3. Apply “80% white pattern or Flat 80 pattern by Component video generator.

4. Enter factory mode menu: press MENU + Numeric keys 1999”.

2008-03-14

47

Page 48

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Alignment:

1. Apply Flat80 pattern (80% white pattern).

2. Set color temperature to “NORMAL”.

3. At factory mode menu, adjust the Scaler R Gain

below. Then store those values to NVM

4. Set color temperature to “COOL”.

5. At factory mode menu, adjust the Scaler R Gain

Then store those values to NVM

6. Set color temperature to “WARM”.

7. At factory mode menu, adjust the Scaler R Gain

below. Then store those values to NVM

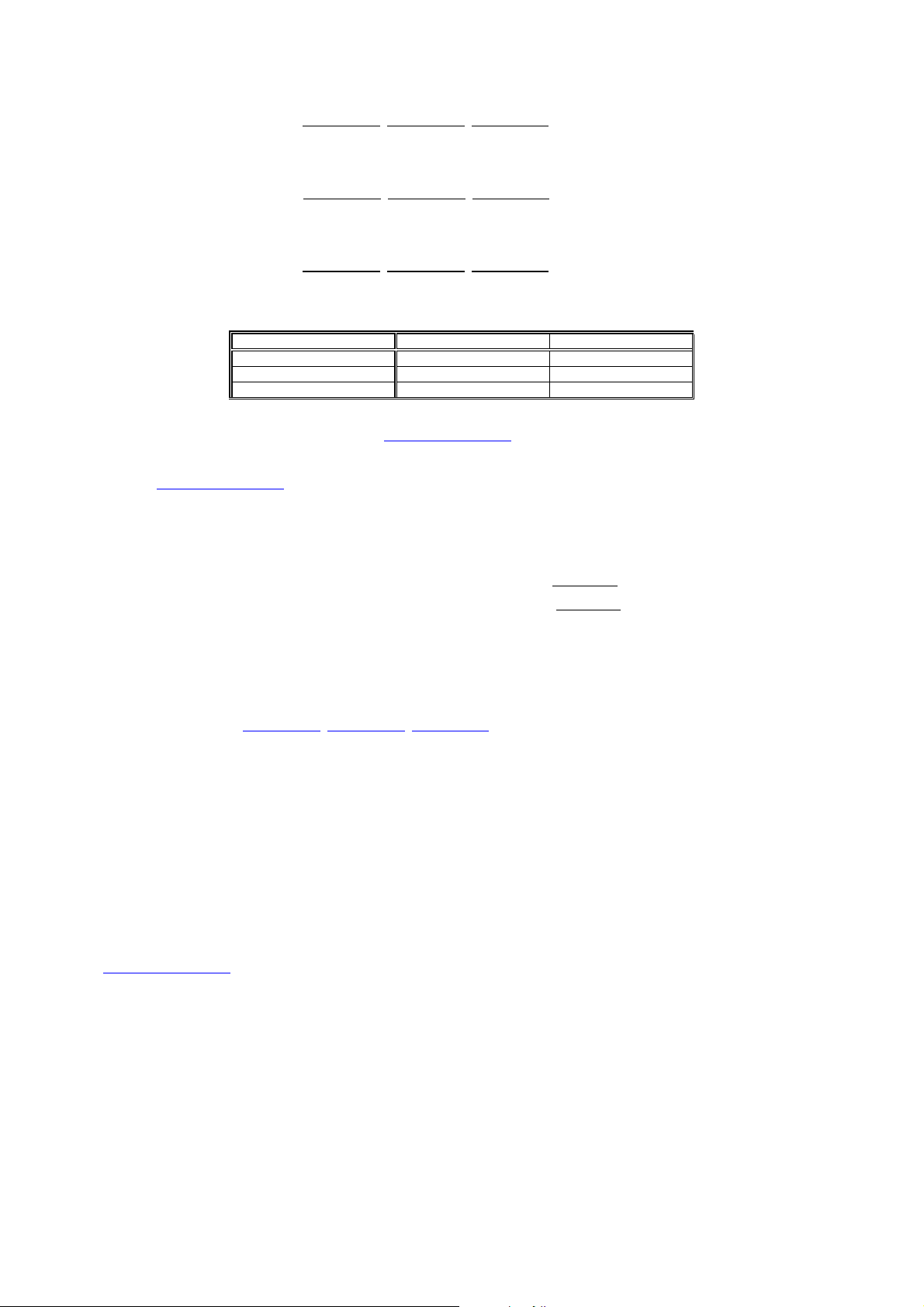

Color temperature Normal/Warm/Cool (x, y) co-ordinates specification:

`

Picture Mode x y

Normal (9000K) 0.289±0.003 0.291±0.003

Cool (12000K) 0.272±0.003 0.277±0.003

Warm (6500K) 0.314±0.003 0.319±0.003

Table 5: Reading with Knoica Minolta CS-200

Note:

1. Use Knoica Minolta CS-200

for color coordinates and luminance check.

2. For suitable mass production at factory, colour analyzers CA-210 can be applied. But, befor measureing ,all CA-210 should be

coordinates and proofread with a Charoma Meter (CS-200) or equivalent instrument and a reference TV set.

3. Check the luminance at the center of the screen with 100% White. And to set Brightness control at 100; Contrast control at 100.

2

Luminance > 200cd/m

> 200 cd/m

> 400 cd/m

> 450 cd/m

> TBD cd/m

> TBD cd/m

4. The defult values of Scaler R Gain

(Typ.) [ For LC-19LE320E/RU only at color temp.- *warm mode ]

2

(Typ.) [ For LC-22LE320E/RU only at color temp.- *warm mode ]

2

(Typ.) [ For LC-262LE320E/RU only at color temp.- cool mode ]

2

(Typ.) [ For LC-32LE320E/RU only at color temp.- cool mode ]

2

(Typ.) [ For LC-37LE320E/RU only at color temp.- cool mode ]

2

(Typ.) [ For LC-42LE320E/RU only at color temp.- cool mode ]

, Scaler G Gain, Scaler B Gain are all 128. When panel WD is made adjustment, the three values

could not be over 128. That is preventing color saturation after adjusting Contrast and Brithness setting at main menu.

PC mode display adjustment

1. Display quality adjustment

Use timing mode as describe in 2.2, and use the POPO (pixel on pixel off) pattern to adjust the clock until no stripe and adjust the phase until clear

picture.(“Auto” will be done every time switching to PC mode and mode change) Check all preset 7 modes.

2. Auto color for signal slicering (B)

2.1 General set-up

Equipment Requirements:

Knoica Minolta CS-200

Input requirements:

Input Signal Type:

PC VGA signal

1. 1024X7684/60Hz PC mode with ”5 white block” pattern. (see pattern-1)

Input Signal Strength:

0.7 Vp-p linear voltage.

Input Injection Point:

PC D-SUB input

or Equivalent Color analyzer. Chroma 2250 or equivalent PC signal generator.

, Scaler G Gain, Scaler B Gain values to meet “NORMAL” color coordinates specification

, Scaler G Gain, Scaler B Gain values to meet “COOL” color coordinates specification below.

, Scaler G Gain, Scaler B Gain values to meet “WARM” color coordinates specification

.

48

Page 49

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

Pattern-1

Alignment method:

Initial Set-up:

1. Select source as “PC”.

2. Set Contrast = 58 (Sharp) and Brightness=100 (Sharp) , at normal menu mode.

3. Apply “5 white block”(pattern-1) pattern by VGA pattern generator.

4. Enter factory mode menu: press MENU + Numeric keys “1999” (factory mode menu).

Alignment:

At factory mode menu, select AUTO_COLOR item. Then press “OK” key to adjust ADC_GAIN_R, ADC_GAIN_G, ADC_GAIN_B and

ADC_OFFSET_R, ADC_OFFSET_G, ADC_OFFSET_B. Then store those values to NVM.

Set Contrast = 100 (Sharp) and Brightness=100 (Sharp)

Check color temperature specification with PC mode.

Color temperature Normal/Warm/Cool (x, y) co-ordinates specification:

Table 5: Reading with Knoica Minolta CS-200

Note:

1. Use Knoica Minolta CS-200

2. For suitable mass production at factory, colour analyzers CA-210 can be applied. But, befor measureing ,all CA-210 should be coordinates

and proofread with a Charoma Meter (CS-200) or equivalent instrument and a reference TV set.

3. Check the luminance in the center of the screen with 100% White. And to Brightness control at 100; Contrast control at 100

Luminance > 200 cd/m

> 200 cd/m

> 360 cd/m

> 360 cd/m

> 360 cd/m2 (Typ.) [ For LC-37LE320E/RU only at color temp.- cool mode ]

> 360 cd/m2 (Typ.) [ For LC-42LE320E/RU only at color temp.- cool mode ]

Picture Mode x y

Cool (12000K) 0.272±0.010 0.277±0.010

Normal (9000K) 0.289±0.015 0.291±0.015

Warm (6500K) 0.314±0.015 0.319±0.015

.

. for color coordinates and luminance check.

2

(Typ.) [ For LC-19LE320E/RU only at color temp.- *warm mode ]

2

(Typ.) [ For LC-22LE320E/RU only at color temp.-*warm mode ]

2

(Typ.) [ For LC-26LE320E/RU only at color temp.- cool mode ]

2

(Typ.) [ For LC-32LE320E/RU only at color temp.- cool mode ]

2008-03-14

49

Page 50

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

[2] SERVICE MODE

Enter factory mode menu: press MENU + Numeric keys “1999” to enter factory mode.

50

Page 51

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

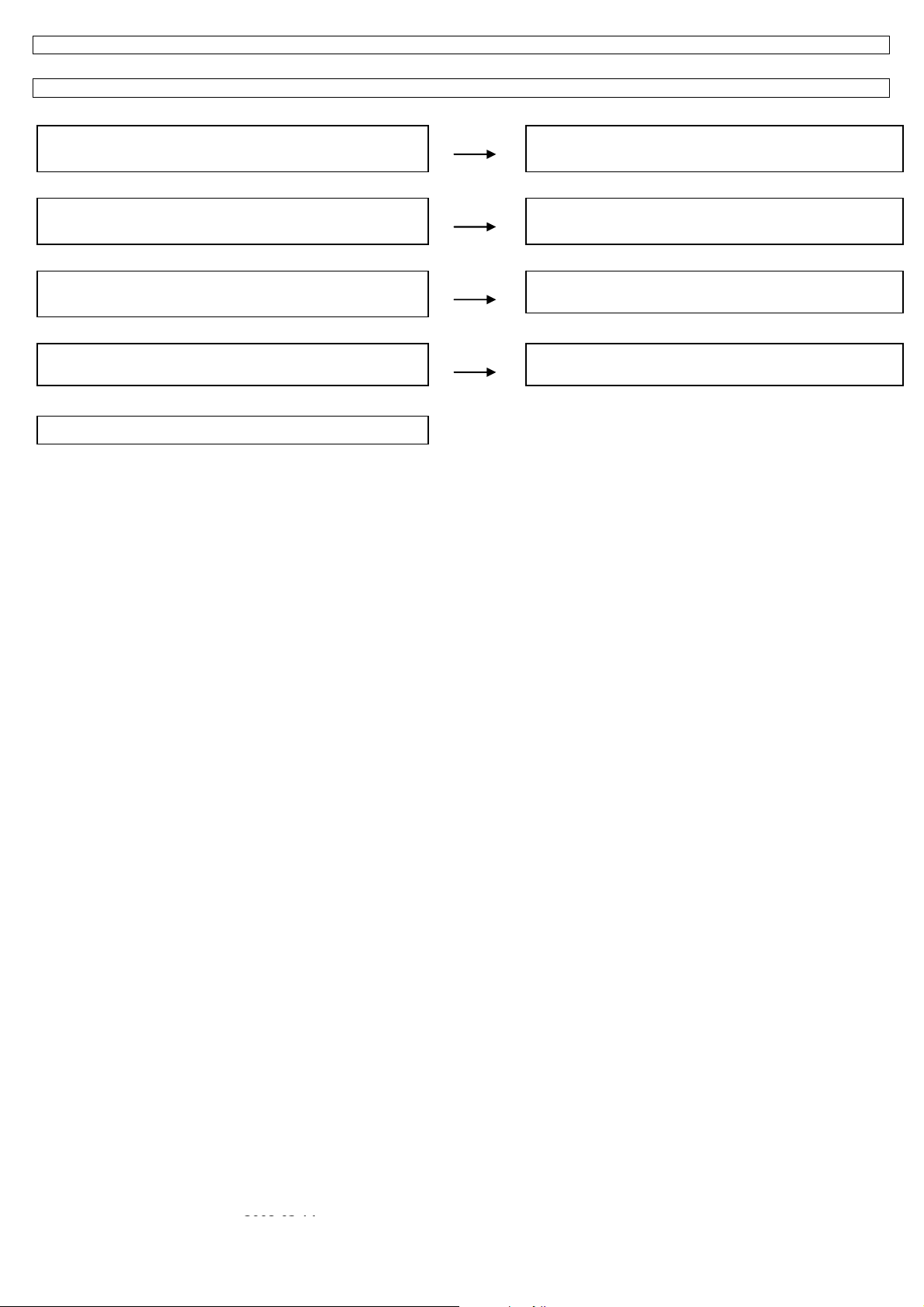

[3] SOFTWARE UPGRADE PROCEDURE

Flow chart Step Photo Remark

Sharp model Firmware upgrade SOP by USB flash drives

1. Equipment and

warm-up

2.Upgrade step

1、USB flash drives(need USB2.0)

2、Upgrade firmware

1、 Copy the firmware from your computer to the

USB flash drives.

2、Change firmware name to upgrade.pkg

3、AC ON(Figure3.1、Figure3.2)

4、Plug the USB flash drives into the USB port

(service port) on the side I/O port of TV.(Figure 3.3)

Need USB2.0

Please check the firmware name

(3.1)

(3.2)

again before rework.

(3.3)

5、DC ON(You can use Keypad or Remote control

power key)

6、When display Upgrade MENU (Figure 3.4),

select “Yes” by remote control to implement update

firmware

7、When finished upgrade 100%,Please remove the

USB flash drives then press “Power” to renew the

TV(Figure3.5)

8、Press “MENU”+1999 to enter factory Menu by

remote control. Then select “2.Main MCU Ver” to

check upgrade firmware Version(Figure3.6)

9、Implement “Exit” Icon to exit factory Menu . After

exit factory mode, pls power off then turn off the AC

power. congratulation, upgrade step is finish.

If there is no display upgrade

MENU,can you DC ON/OFF once

more

(3.4)

(3.5)

(3.6)

2008-03-14

51

Page 52

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

p

CHAPTER 4. TROUBLESHOOTING TABLE

[1] 19” TROUBLESHOOTING TABLE

Power unit operation check.

Are the power cord and harness in the unit properly connected?

LINE_FILTER_UNIT: YES

Is F901 F902 normal?

POWER_UNIT

Is BD901 (+320V) output?

YES

YES

Is a voltage of +5.3V applied to pin (4,5) of connector (CN902)?

YES

Is a voltage of +16V applied to pin (9,10) of connector (CN902)?

NO

NO

NO

NO

NO

Connect the power cord and harness properl y, and turn on the

ower.

LINE_FILTER_UNIT:

Isn't C908, RV901, L902, C900, C901, etc. out of order?

Moreover, whether the short-circuit with the circumference circuit

is checked.

Does the circuit operate normally?

Check circuit around (BD901, Q903, ZD906, IC901, D901 etc ).

Does the switching circuit operate normally?

Check circuit around the primary side (T901, ZD906, D901,

D903, Q903, D904, IC901, Q901, D904 etc.), the secondary side

(D905, L904, C921 etc.), the DC_DET circuit (IC902, ZD903,

IC903, IC901, etc.), and the protection circuit.

Does the inverter circuit operate normally?

Check circuit around (D902, L903, C914, Q908, ZD902 etc.), and

the protection circuit.

52

Page 53

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

The sound is not emitted from the speaker though the picture has come out.

No sound output in all modes?

TEREMINAL UNIT:

Is the audio signal output of pin (U36)(AR3), (V37)(AL3) of IC U401

normal?

YES

Is audio signal input to pin (4)(LINN), pin (11)(RINN) of IC U601

(AMP)?

YES

Is MUTE circuit [ Shutdown, OFF_MUTE] normal?

YES

Is the audio signal output of pin (3, 4) (L-ch) and pin (1, 2) (R-ch) of

CN601 (AOUDIO-CONNECTOR) normal?

YES

Check Speaker Box (right and left) and wire harness.

NO

NO

NO

NO

Check IC U401 and its peripheral circuits.

Check the line between IC U605 and IC U601.

Check the Mute circuit. (Q601, Q602 etc.)

Check IC U601 and its peripheral circuits.

2008-03-14

53

Page 54

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

(2)(

No sound (during the reception of TV broadcasting)

Does not the sound go out though the picture has come out when TV is received?

MAIN UNIT:

Is the IF signal output from pin (16) and pin (17) of TUNER

(TU102)?

NO

Check the tuner and its peripheral circuits. Replace as required.

YES

Is the IF signal sent to pin (AH35) and pin (AH37) of IC U401?

NO

Check IC U401 its peripheral circuits.

YES

Refer to “No sound output in all modes”.

No sound from external input devices (1)

Does not the sound of the audio signal input to SCART1 go out?

TEREMINAL UNIT:

Is the audio signal properly sent to pin (6)(S CT1_AUL_IN) and pin

SCT1_AUR_IN) of SCART1 (CN151)?

NO

Check the setting of an external input device that connects of

CN151

YES

Is the audio signal properly sent to pin (AA32) and pin (AB33) of IC

U401?

NO

Check the line between CN151 and IC U401

YES

Refer to “No sound output in all modes”.

No sound from external input devices (2)

Does not the sound of the audio signal input to AV1 (Component) go out?

MAIN UNIT:

Is the audio signal properly sent to pin (2)(AV1_AudioLIN) and pin

(4)(AV1_AudioRIN) of CN116?

NO

Check the connection to CN116 and the external input device.

YES

Is the audio signal properly sent to pin (AD33) and pin (AC34) of IC

U401?

NO

Check the line between CN116 and IC U401.

YES

Refer to “No sound output in all modes”.

54

Page 55

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

No sound from external input devices (3)

Does not the sound of the audio signal input to AV3(Composite) go out?

MAIN UNIT:

Is the audio signal properly sent to pin (4)(AV3_AudioLIN) and pin

(6)(AV3_AudioRIN) of CN136?

YES

Is the audio signal properly sent to pin (AD35) and pin (AB35) of IC

U401?

YES

Refer to “No sound output in all modes”.

No sound from external input devices (4)

Does not the sound of the audio signal input to VGA go out?

MAIN UNIT:

Is the audio signal properly sent to pin (2)(VGA_AudioLIN) and pin

(3)(VGA_AudioRIN) of CN102?

YES

Is the audio signal properly sent to pin (AA36) and pin (Y37) of IC

U401?

YES

Refer to “No sound output in all modes”.

No sound from external input devices (5)

Does not the sound of the audio signal input to HDMI go out?

Is picture of the signal input from HDMI displayed?

YES

Refer to “No sound output in all modes”.

NO

NO

NO

NO

NO

Check the connection to CN136 and the external input device.

Check the line between CN136 and IC U401.

Check the connection to CN102 and the external input device.

Check the line between CN102 and IC U401.

Refer to “Does not the picture of the HDMI signal i nput to HDMI

go out?”.

2008-03-14

55

Page 56

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

The audio signal is not output (1)

The audio signal of UHF/VHF is not output from SCART1.

TEREMINAL UNIT:

Is audio signal output from IC U106 sent to pin

(3)(SCT1_AUL_OUT) and pin(1)(SCT1_AUR_OUT) of

SCART1(CN151)?

YES

Check the connection to SCART1 and external devices.

NO

Is audio signal output from IC U401 is sent to pin (2) (1IN-) and pin

(6) (2IN-)of IC U106?

YES

Check the line between IC U401 and IC U106.

NO

Check IC U401 and its peripheral circuits.

The audio signal is not output (2)

No audio signal output from LINE_AUDIO_OUTPUT terminal.

TEREMINAL UNIT:

Is audio signal output from IC U107 sent to

pin(4)(Audio_Line_Out_L) and pin (6)(Audio_Line_Out_R) of

LINE_AUDIO_OUT connector(CN140)?

YES

Check the connection to LINE_AUDIO_OUT and external

devices.

NO

Is audio signal output from IC U401 is sent to pin (2) (1IN-) and pin

(6) (2IN-)of IC U107?

YES

Check the line between IC U401 and IC U107.

NO

Check IC U401 and its peripheral circuits.

The audio signal is not output (3)

No audio signal output from SPDIF_OUTPUT terminal.

TEREMINAL UNIT:

Is ASPDIF audio signal output from pin (K33) of IC U401 to pin (6)

of connector CN116?

YES

Check the connection to SPDIF_OUT and external devices.

NO

Check IC U401 and its peripheral circuits.

56

Page 57

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

The audio signal is not output (4)

No sound from HEADPHONE_OUTPUT terminal.

MINI AV_UNIT:

Is the HP_DET# signal input into pin (AE6) of IC U401 from pin (6)

of a headphone terminal (CN602)?

YES

Is the audio signal output from IC U602 to pin(2) (HPOUTL ) and pin

(3) (HPOUTR) of headphone terminal CN602?

YES

Is the audio signal output from IC U401 pin(V35) and pin(U34) sent

to pin(1)(INL-) and pin(4)(INR-) of IC U602?

YES

Check IC U401 and its peripheral circuits.

NO

NO

NO

Check the connection to CN602 and external headphone is plug

in well.

Check the line between IC U602 and CN602.

Check the line between IC U401 and IC U602.

2008-03-14

57

Page 58

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

No picture on the display (1)

The picture doesn't appear in all modes.

MAIN UNIT:

Is LVDS signal output from 1st_channel and 2nd_channel of IC U401 in each mode?

(A0N/A0P),(A1N/A1P),(A2N/A2P),(A3N/A3P),(CK1N/CK1P)

NO

Check IC U401 and its peripheral control circuits.

YES

Is the above-mentioned LVDS signals output to connector CN408?

NO

Check the line between IC U401 and CN408.

YES

Is LCD controller's control signal normal?

PANEL_UNIT:

Similarly, is the LVDS signal input to connector of the panel

YES

NO

NO

Control signals BRIGHT_ADJ, INVERTER_ON_OFF,

PANEL_VCC_ON/OFF, and it peels off and whether normality is

checked.

Wire harness is checked.

YES

Check the panel module.

No picture on the display (2)

Does not the picture come out when TV (Antenna) is received?

TERMINAL UNIT:

Is the voltage of regulation for a TUNER circuit and the power

supply terminal of IC U401 supplied?

YES

Is IF signal output from pin (16), (17) of TUNER (TU102) to pin

(AH35), pin (AH37) of IC U401 ?

NO

NO

Each power supply circuit is checked.

Check the tuner, IC U401 and their peripher al circuits. Replace

as required.

MAIN_UNIT: YES

Do X4150 (54.00MHz) oscillate?

NO

Check X4150 and its peripheral circuits.

YES

Refer to “The picture doesn't appear in all modes.”

58

Page 59

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

No picture on the display (3)

Does not the picture come out when TV (Cable) is received?

TERMINAL UNIT:

Is the voltage of regulation for a TUNER circuit and the power

supply terminal of IC U401 supplied?

YES

Is IF signal output from pin (16), (17) of TUNER (TU102) to pin (29),

pin (30) of IC U101 ?

YES

Is MPEG data (CI_INDATA0, TSYNC, TCK) signal from pin (11),

(8) (9) of IC U101 are output to IC U401?

MAIN_UNIT:

Do X4150 (54.00MHz) oscillate?

YES

YES

Refer to “The picture doesn't appear in all modes.”

<External input SCART1>No pict u re on the di sp lay (4 )

Does not the picture of the CVBS signal input to SCART1 go out?

TERMINAL UNIT:

Is CVBS signal sent to pin (20) of SCART1 (CN151)?

MAIN_UNIT: YES

Is CVBS signal sent to pin (AP33) of IC U401?

Refer to “The picture doesn't appear in all modes.”

YES

NO

NO

NO

NO

NO

NO

Each power supply circuit is checked.

Check the tuner, IC U101 and their peripher al circuits. Replace

as required.

Check IC U101 and their peripheral circuits. Replace as required.

Check X4150 and its peripheral circuits.

Check the setting of an external input device that connects of

CN151.

Check the line between IC U401 and CN151.

2008-03-14

59

Page 60

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

<External input SCART1>No pict u re on the di sp lay (5 )

Does not the picture of the R/G/B video signal input to SCART1 go out?

TERMINAL UNIT:

Is RGB signal sent to pin (15)/R, (11)/G, (7)/B, of SCART1

(CN151)?

MAIN_UNIT: YES

Is RGB signal sent to pin (AU30)/R, (AP29)/G, (AR28)/B of IC

U401?

YES

NO

NO

Check the setting of an external input device that connects of

CN151.

Check the line between IC U401 and CN151.

YES

Refer to “The picture doesn't appear in all modes.”

<External input SCART1 >No picture on the display (6)

Does not the picture of the Y/C signal input to SCART1 go out?

TERMINAL UNIT:

Is Y/C signal sent to pin (20) and (15) of SCART1 (CN151)?

MAIN_UNIT:

Is Y/C signal sent to pin (AP33)/Y, (AU30)/C of IC U401?

Refer to “The picture doesn't appear in all modes.”

YES

YES

<External input AV3(Composite)>No picture on the display (6)

NO

NO

Check the setting of an external input device that connects of

CN151.

Check the line between IC U401 and CN151.

Does not the picture of the composite video signal input to AV3(Composite) go out?

TERMINAL UNIT:

Is CVBS signal sent to pin (2) of AV3 (CN136) ?

MAIN_UNIT: YES

Is CVBS signal sent to pin (AU36) of IC U401?

Refer to “The picture doesn't appear in all modes.”

YES

NO

NO

Check the setting of an external input device that connects of

CN136.

Check the line between IC U401 and CN136.

60

Page 61

LC-19LE320, LC-22LE320, LC-26LE320, LC-32LE320, LC-37LE320, LC-42LE320

<External input HDMI1>No picture on the display (7)

Does not the picture of the HDMI signal input to HDMI1 go out?

MINI AV_UNIT:

Is the HOT_PLUG detection function of pin (19) of a HDMI terminal

(CN502) normal?

YES

Are EDID data pin (6)(SCL) of IC U503 (EEPROM), pin (5)(SDA)

accessed, and is it read from pin (15), pin (16) of a HDMI

terminal(CN502)?

Is TMDS signal input into pin(AP15, AT15)/RX2-2±,(AR14,

AU14)/RX2-1±, (AP13, AT13)/RX2-0±, (AR12, AU12)/RX2-C± of IC

YES

YES

Refer to “The picture doesn't appear in all modes.”

NO

NO

NO

Check the line between pin (AN16) of IC U401 and CN502.

Check the connection and setup with the external HDMI devices.

Is access possible in the re-writing or exchange of EDID data of

IC U503?

NO