Page 1

TopPage

1st Addition

SERVICE MANUAL

No.SZ12M1032LE250M

LCD COLOUR TELEVISION

MODEL : LC-32LE250M

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY

PRECAUTION................................................i

PRECAUTION FOR USING LEAD-FREE

SOLDER.........................................................ii

CHAPTER 1. OUTLINE

[1] OUTLINE...........................................1-1

CHAPTER 2. SPECIFICATIONS

[1] SPECIFICATION.................................2-1

CHAPTER 3.OPERATION MANUAL

[1] OPERATION MANUAL........................3-1

CHAPTER 4. DIMENSIONS

[1] DIMENSIONS......................................4-1

CHAPTER 6. ADJUSTMENT

[1] ADJUSTMENT....................................6-1

CHAPTER 7. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE .........................7-1

CHAPTER 8. OVERALL WIRING/BLOCK DIAGRAM

[1] SYSTEM BLOCK DIAGRAM............................8-1

CHAPTER 9. PRINTED WIRING BOARD ASSEMBLIES

[1] Main Unit .............................................9-1

CHAPTER 10. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC

DIAGRAM ...........................................10-1

CHAPTER 5. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS...........5-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-32LE250M

SAFETY PRECAUTION

SAFETY PRECAUTIONSAFETY PRECAUTIONSAFETY PR ECAUTION

LC32LE240M

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

5GTXKEG/CPWCN

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER (Fire &

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only fo r the purpose of completing these checks.)

Any reading of 0.74 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 110-240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15 F capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD colour television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can pr otection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

i

Page 3

LC-32LE250M

PRECAUTIONS FOR USING LEAD-FREE SOLDER

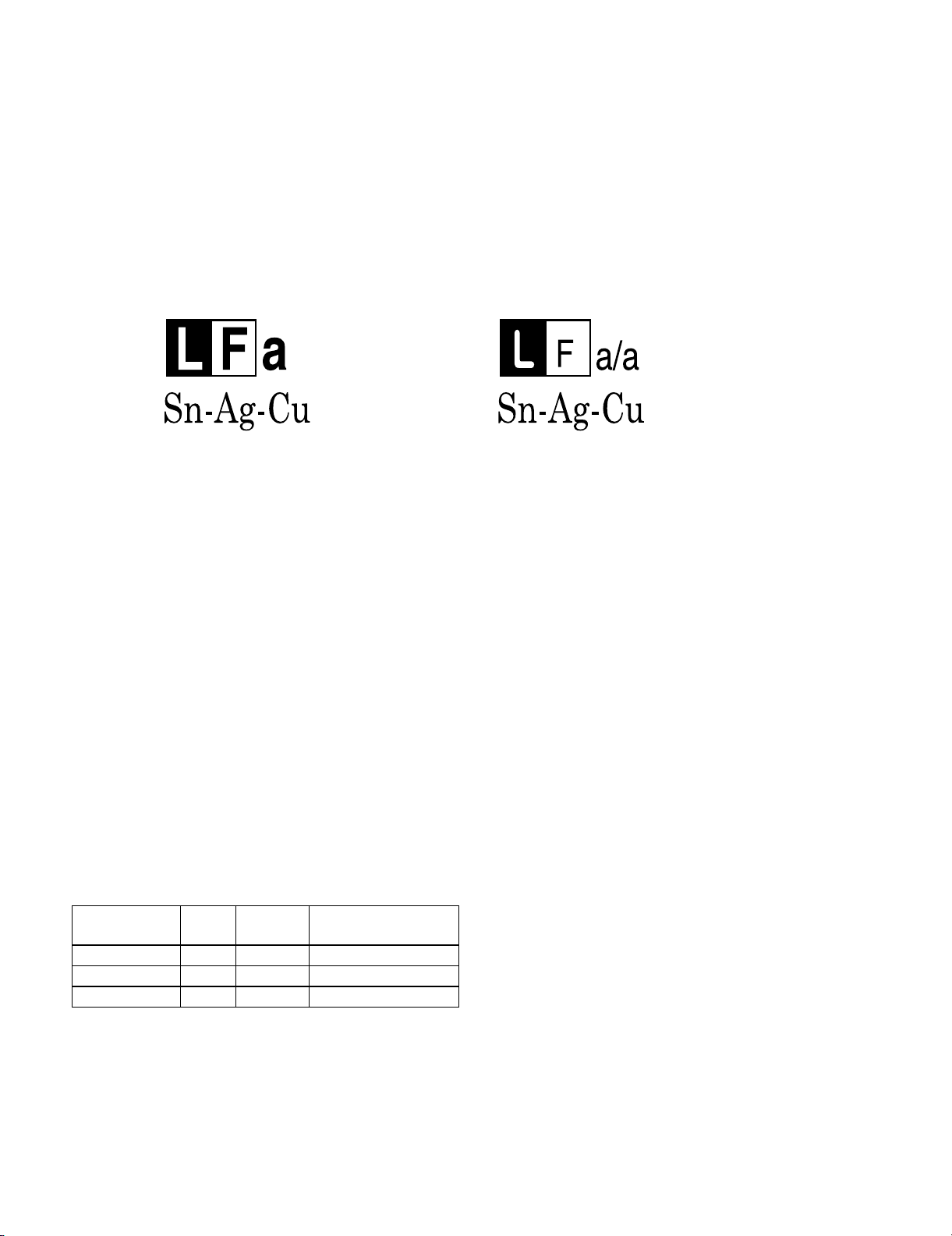

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs an d service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB solder ed with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead solder by 40 C, and as it has poor

solder wettability, you may be apt to kee p the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

PARTS CODE

ZHNDAi123250E BL J 0.3mm 250g (1roll)

ZHNDAi126500E BK J 0.6mm 500g (1roll)

ZHNDAi12801KE BM J 1.0mm 1kg (1roll)

PRICE

RANK

PART

DELIVERY

DESCRIPTION

ii

Page 4

LC-32LE250M

CHAPTER 1. OUTLINE

[1] OUTLINE

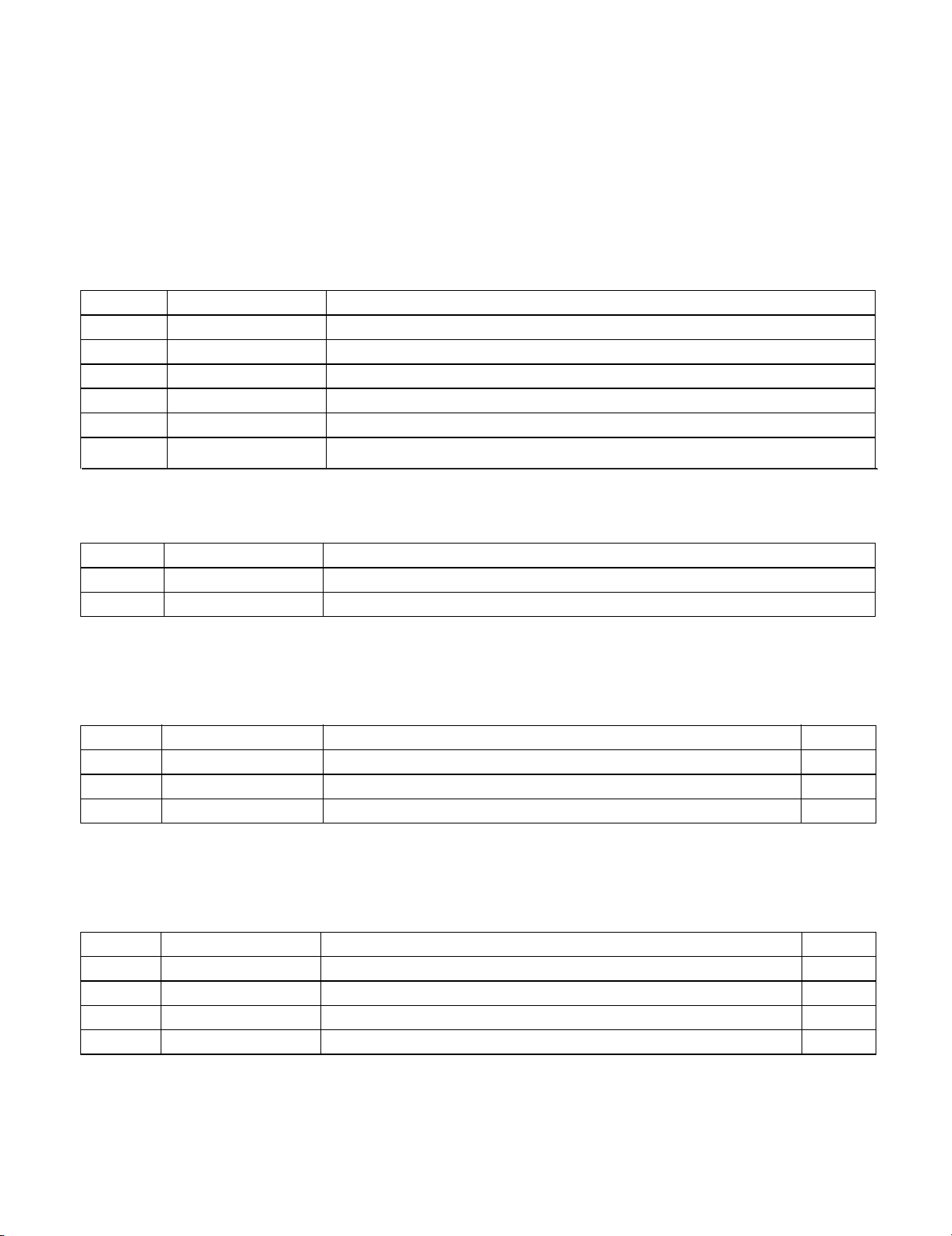

MAJOR SERVICE PARTS

PWB UNIT

Ref No. Part No. Description

N DKEYMG247FM01 MAIN Unit

N

N

N DUNTKG238FM01 LED IR Unit

N LED PWB A

N

DKEYMG247FM02

RDENCA462WJPZ

RUNTKB129WJZZ

RUNTKB130WJZZ

MAIN Unit

POWER Unit

LED PWB B

( ASIA )

(SPC)

OTHER UNIT

Ref No. Part No. Description

N R1LK315T3HB60W 32-INCH Panel Hiraki

IC FOR EXCLUSIVE USE OF THE SERVICE

Ref No. Part No. Description Q'ty

IC3104 RH-iXD606WJQZQ Flash IC 1

IC3104

RH-iXD614WJQZQ

Flash IC

( ASIA )

( SPC )

SERVICE JIGS

Ref No. Part No. Description Q’ty

N QCNW-N120WJQZ RA WIRE ( Main -IR board ) 1

N QCNW-N177WJPZ Extension Cable, LVDS FFC (Main-Panel Controller) 1

N

N

QCNW-N179WJQZ

QCNW-N180WJQZ

PD WIRE ( Main -Power Unit )

LED BL wire ( Main-Panel BL )

1

1

1

1 – 1

Page 5

CHAPTER 2. SPECIFICATIONS

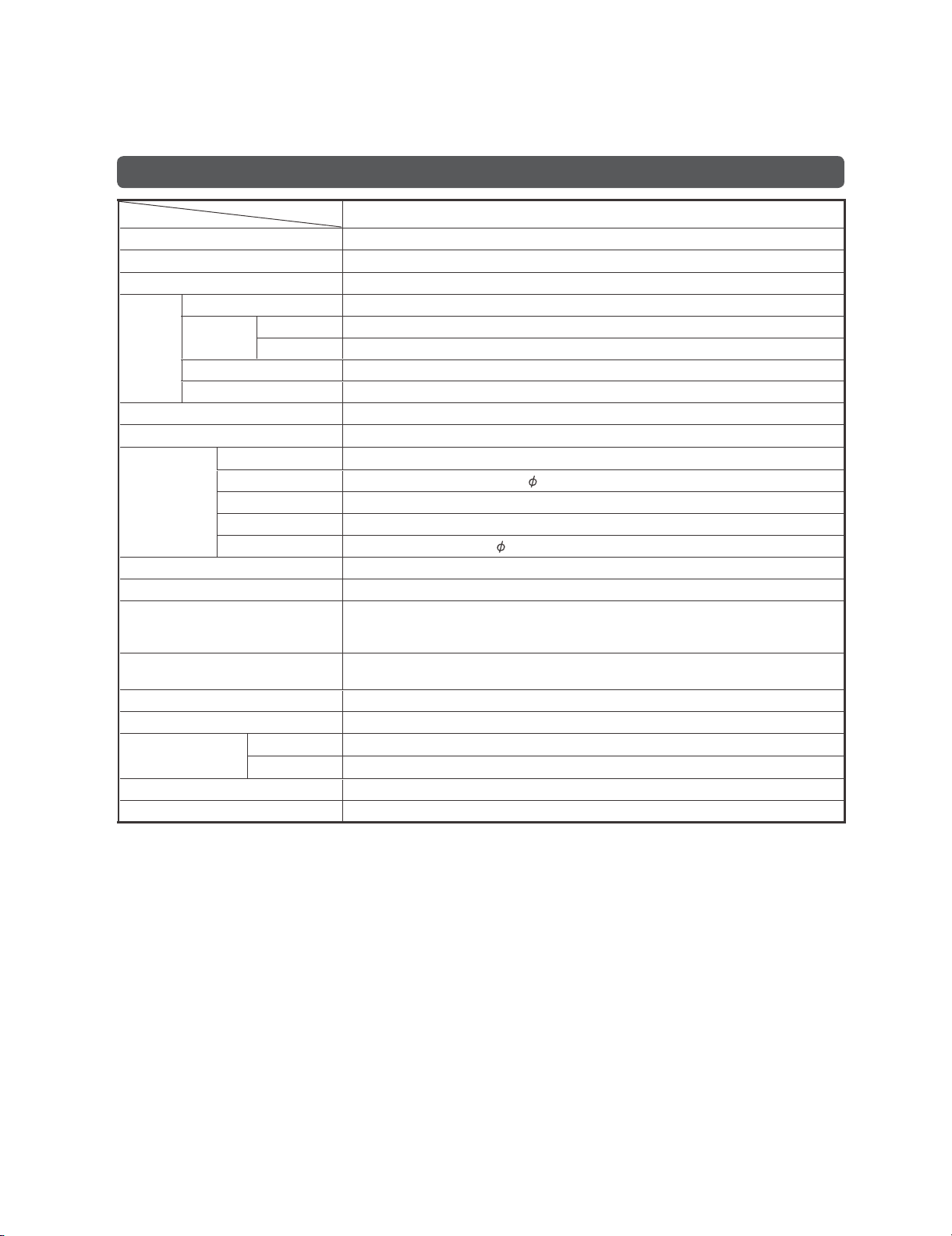

[1] SPECIFICATIONS

Specifications

LC-32LE250M

Item

LCD panel

Resolution

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV

Function

Audio amplifier/Speakers

Terminals Antenna input

USB device/File system USB Memory / FAT/FAT32

Photo file format JPEG (.jpg) (DCF2.0 compliant). Progressive format jpeg files are not supported.

Music file format

(Files may not be playable

depending on the bitrate)

Power Requirement AC 110—240 V, 50/60 Hz

Power Consumption 53 W (0.8 W Stand by)

Dimensions

Operating Temperature 0°C — 40°C

s As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for

product improvement without prior notice. The performance specification figures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

TV-Standard PAL: B/G, D/K, I SECAM: B/G, D/K, K/K

Receiving

Channel

TV-Tuning System Auto Preset 99 ch

STEREO/BILINGUAL NICAM: B/G, I, D/K A2 stereo: B/G

INPUT 1 HDMI (HDMI input), AUDIO in (

INPUT 2 VIDEO in, AUDIO in, COMPONENT in

INPUT 3 VIDEO in, AUDIO in

OUTPUT AUDIO out, Headphone (

Model

VHF/UHF 43.25—863.25 MHz

CATV

without stand

with stand

LC-32LE250M

80cm

1,049,088 pixels (1366 g 768)

1

NTSC: M

S1—S41ch (including Hyperband)

º671:Vº671:HselgnagniweiV

10 Wg 2 / 4 g 10 cm 2pcs

UHF/VHF 75 q DIN type

3.5 mm jack), PC input

3.5 mm stereo)

MP3 (.mp3) Bitrate: 32 k, 40 k, 48 k, 56 k, 64 k, 80 k, 96 k, 112 k, 128 k, 160 k,

192 k, 224 k, 256 k, 320 kbps

Sampling frequency: 32 k, 44.1 k, 48 kHz

Vietnamese/Indonesian

735 (W) g 471 (H) g 113 (D) mm

735 (W) g 463 (H) g 167 (D) mm

)dnatshtiw(gk3.8/)dnatstuohtiw(gk8.7thgieW

/iahT/naisreP/naissuR/eseugutroP/hcnerF/cibarA/esenihCdefiilpmiS/hsilgnEegaugnalDSO

2 – 1

Page 6

LC-32LE250M

CHAPTER 3. OPERATION MANUAL

[1] OPERATION MANUAL

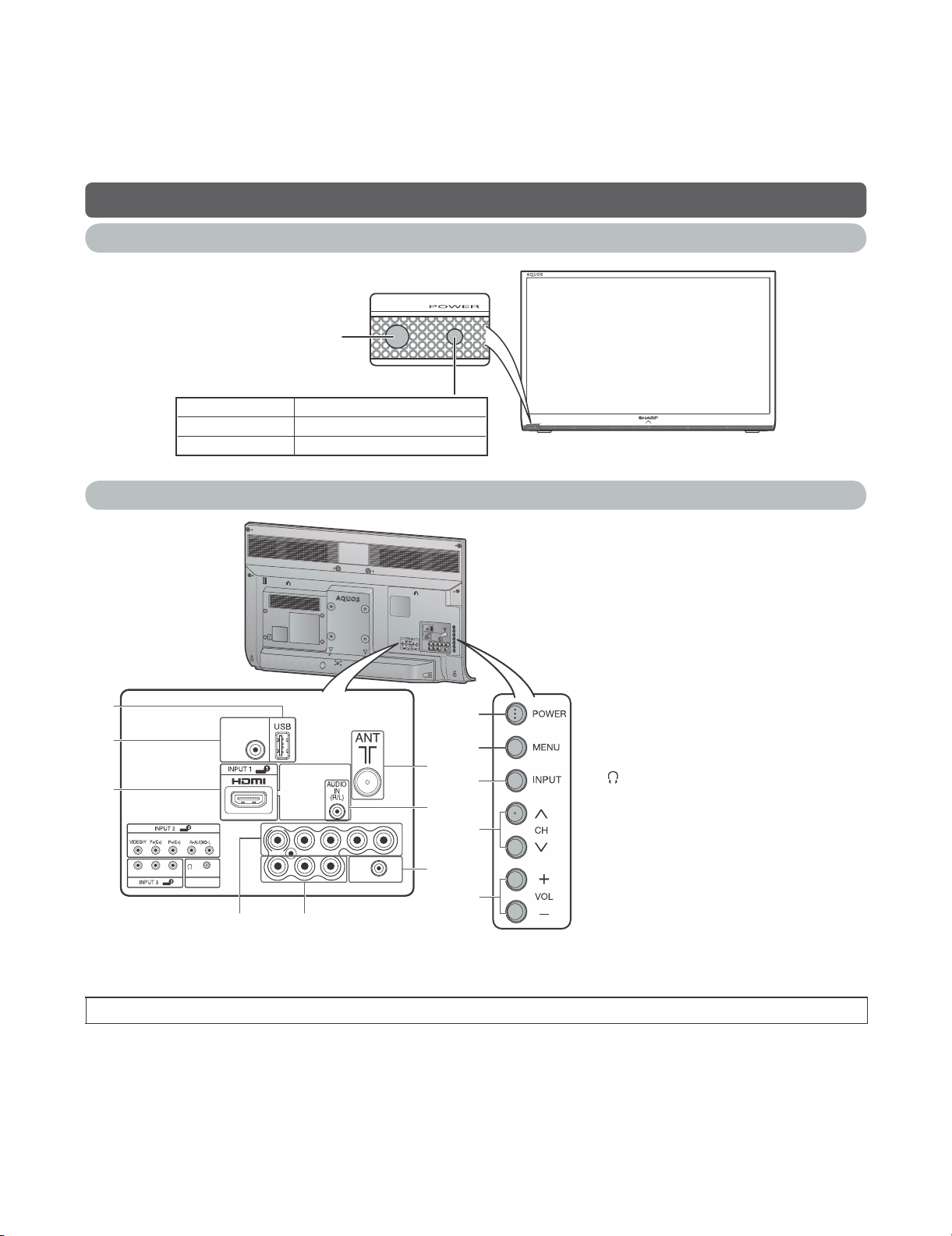

Part names

TV (Front)

Remote control sensor

POWER indicator

Light off Power off.

Lighted (Red) The TV is in standby mode.

Lighted (Green) The TV is on.

TV (Rear)

6

7

8

COMPONENT/AV INPUT

R-AUDIO-L

VIDEO

/

AUDIO (R/L)

OUTPUT

SERVICE

ONL Y

9

10

1 POWER (On/Off) button

2 MENU button

3 INPUT button

4 Channel up (r)/down (

) buttons

s

5 Volume up (e)/down (f) buttons

S

E

R

V

ICE

U

S

B

O

N

L

Y

AN

T

I

NP

U

T

1

A

UD

IO

IN

(

R/

L

)

C

O

M

P

O

N

E

N

T

/

A

V

IN

V

P

I

DE

UT

O

/

Y

R

-A

U

D

IO

-L

/

V

IDE

O

R-A

UDI

O

-L

A

UD

IO (R/L)

6 USB terminal*

7 SERVICE ONLY terminal**

8 INPUT 1 (HDMI) terminal

9 INPUT 2 (COMPONENT/AV INPUT)

terminals

1

2

11

3

10 INPUT 3 terminals

11 Antenna input terminal

12 AUDIO IN (R/L) terminal

13

/AUDIO OUTPUT terminal

12

4

13

5

* USB terminal use for USB Media Player.

** Usually do not connect anything to this terminal as it is reserved only for service personnel.

s The illustrations in this operation manual are for explanation purposes and may vary slightly from the actual operations.

3 – 1

Page 7

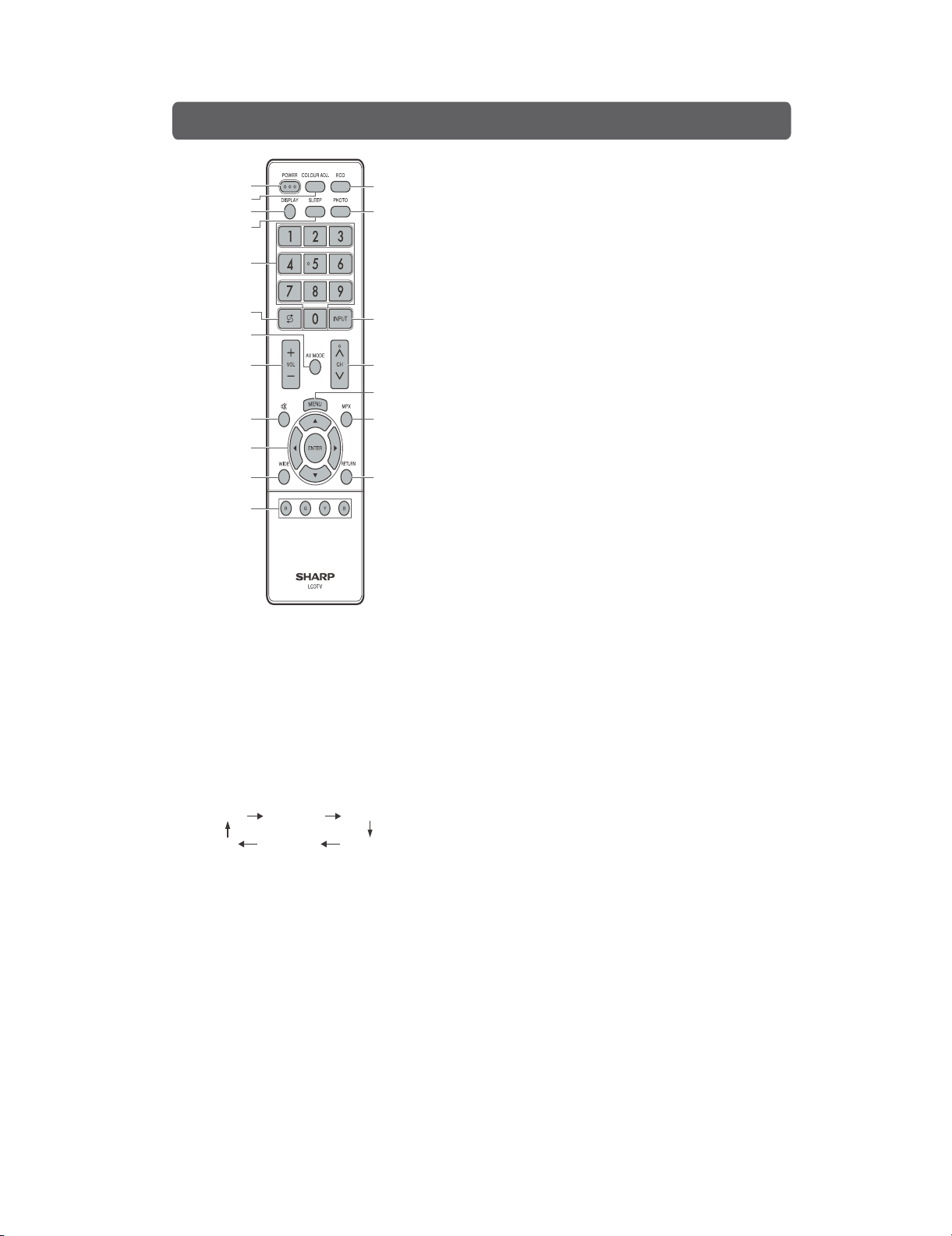

Remote control unit

7 AV MODE

1

2

3

4

5

6

7

8

9

10

11

12

1 POWER (STANDBY/ON)

To switch the power on and off.

2 COLOUR ADJ.

Adjust the colour tone of the image on screen.

3 DISPLAY

Display the channel or input information.

4 SLEEP

Set the Sleep Timer.

0 hr. 30 min. 1 hr. 0 min.

Off

2 hr. 30 min.

5 0 – 9

Set the channel.

6A (Flashback)

PressA to return to the previous selected channel

or external input mode.

13

14

15

16

17

18

19

1 hr. 30 min.

2 hr. 0 min.

8 VOLk/VOL

9e (Mute)

10a/b/c/d (Cursor)

11 WIDE

12 Colour (Red/Green/Yellow/Blue)

13 ECO

14 PHOTO

15 INPUT (INPUT SOURCE)

16 CHr/CH

17 MENU

18 MPX

19 RETURN

LC-32LE250M

Select an audio and video setting.

l

Set the volume.

(VOLk) Increase the volume.

(VOLl) Decrease the volume.

e s

Press

Presse again s Restores sound.

Mute will be cancelled after 30 minutes. However, the TV

will not suddenly output loud sound as the volume level will

be set to 0 automatically. Increase the volume level by

pressing VOLk.

Select a desired item on the setting screen.

ENTER

Execute a command.

Change the wide image mode.

The coloured buttons are correspondingly used to select the

coloured items on the screen.

Reduce overall power consumption based on user

preferences.

Display your pictures directly on the TV screen.

Select an input source.

TV input mode: Select the channel.

(CHr) Increase the channel number.

(CH

Display the menu screen.

Select the sound multiplex mode.

MENU mode: Return to the previous menu screen.

Mutes sound.

s

s

) Decrease the channel number.

3 – 2

Page 8

LC-32LE250M

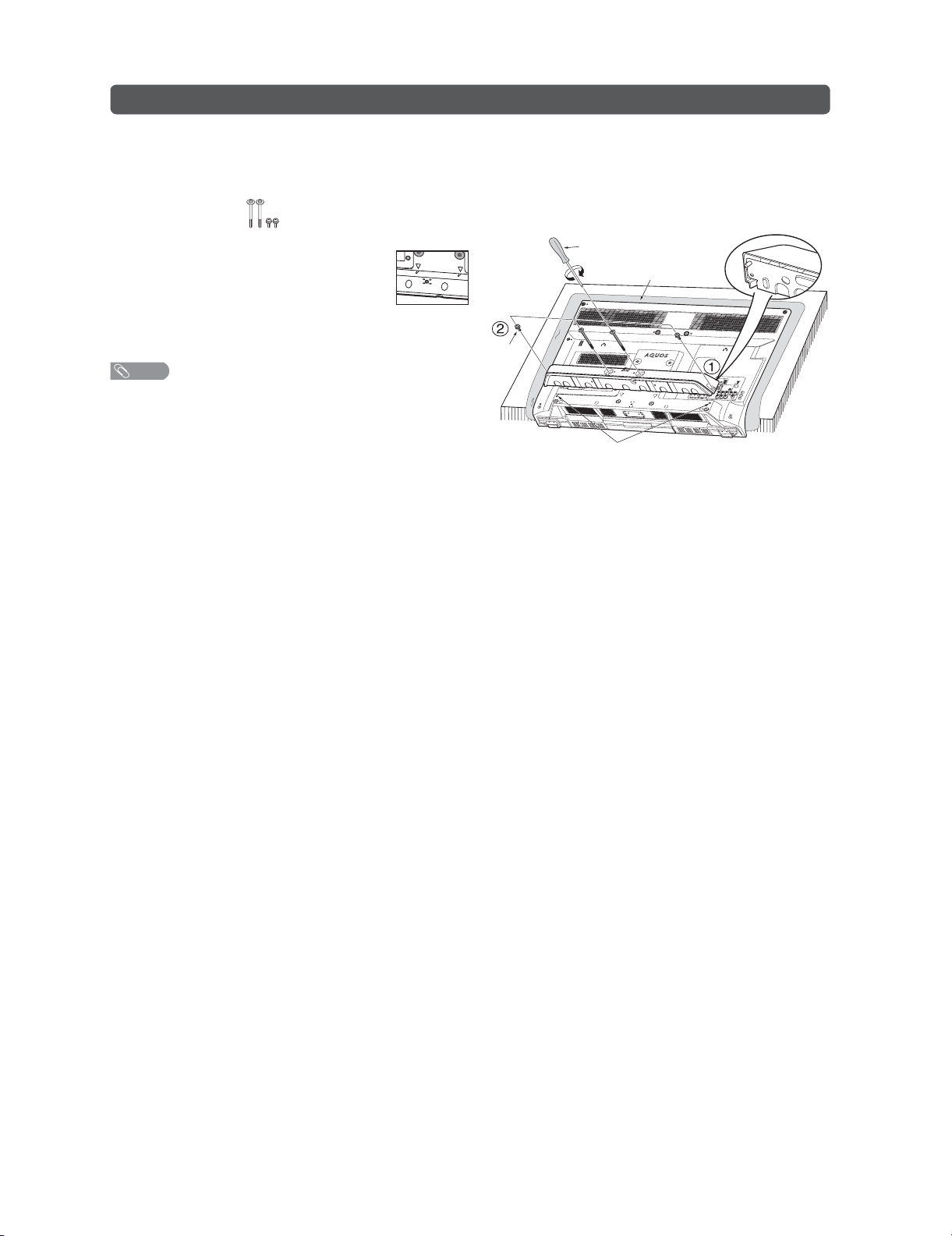

Attaching the stand

• Before attaching (or detaching) the stand, unplug the AC cord from the AC outlet.

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from

being damaged.

Con-rm the screws supplied with the TV.

1

Screws (m4)

(used in step 3)

Insert the stand base guide pins to the

2

stand holes on the rear of the TV. (1)

•

Make sure the symbol on the stand base

is parallel with the triangle symbol located

at the back of the TV.

Insert and tighten the 4 screws into the 4 holes

3

on the rear of the stand assembly.(2)

NOTE

•

To detach the stand, perform the steps in reverse order.

•

The TV position setting is set to 7 backward after attaching

the stand.

•

Do not remove the plastic wrap before attaching the stand

base to protect it from scratches.

•

The bottom area of the set (curvy area) must be beyond the

table’s edge to prevent the TV from damage.

Screw

Screw driver

Soft cushion

Guide pin holes

V

I

D

E

V

I

D

E

O

Stand base

guide pins

S

E

R

V

I

C

E

U

S

O

N

L

Y

I

N

P

U

T

1

C

O

M

P

O

N

E

N

T

/A

V

I

N

P

UT

O

/

Y

R

-

A

U

D

I

O

-

L

/

R

A

U

D

A

I

O

U

D

L

I

O

(

R

/

L

)

B

A

N

T

A

U

D

I

O

I

N

(

R

/

L

)

3 – 3

Page 9

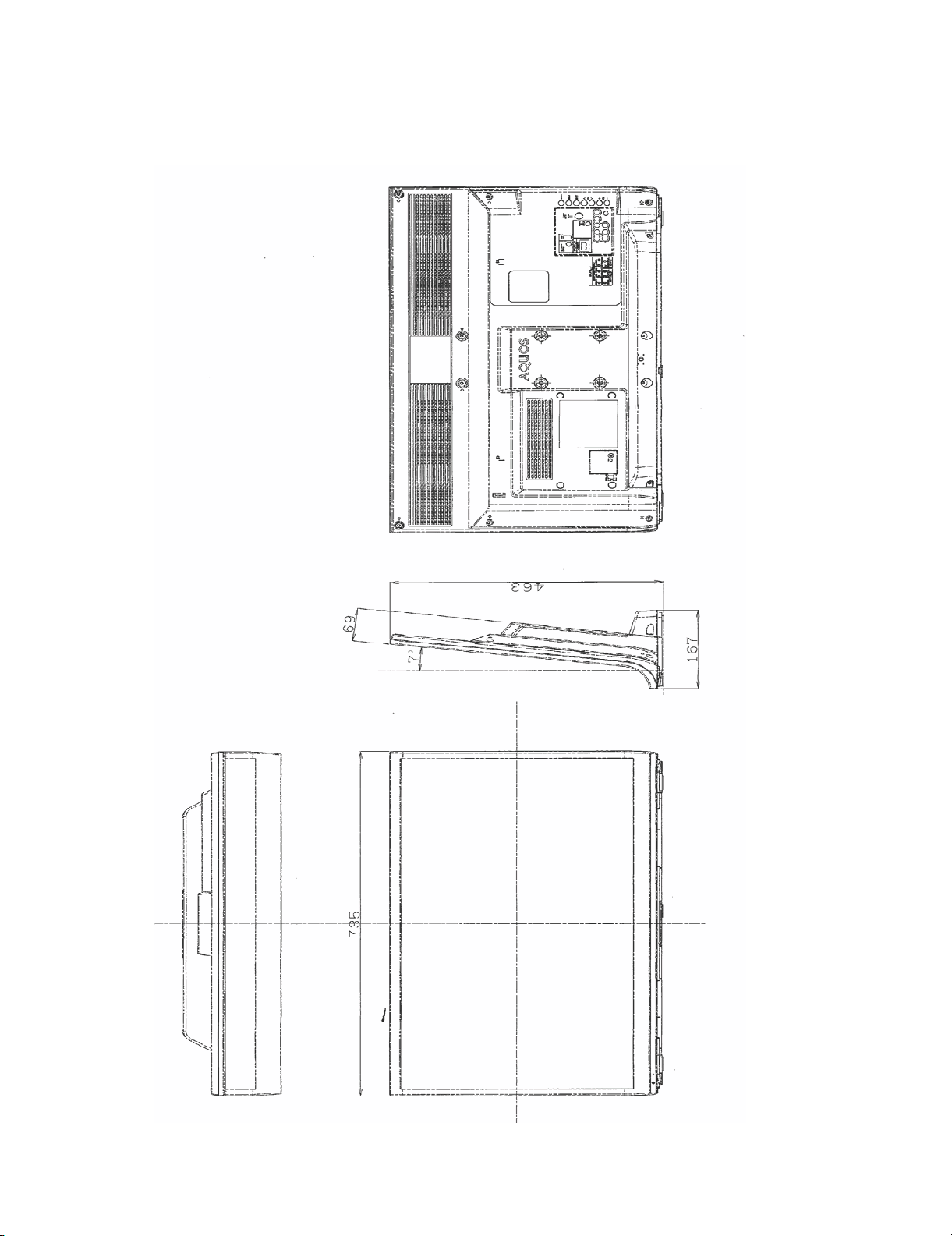

CHAPTER 4. DIMENSIONS

[1] DIMENSIONS

Unit mm

LC-32LE250M

4 – 1

Page 10

LC-32LE250M

CHAPTER 5. REMOVING OF MAJOR

PARTS

R

E

M

O

V

I

N

G

O

F

M

A

J

[1] REMOVING

OF MAJOR PARTS

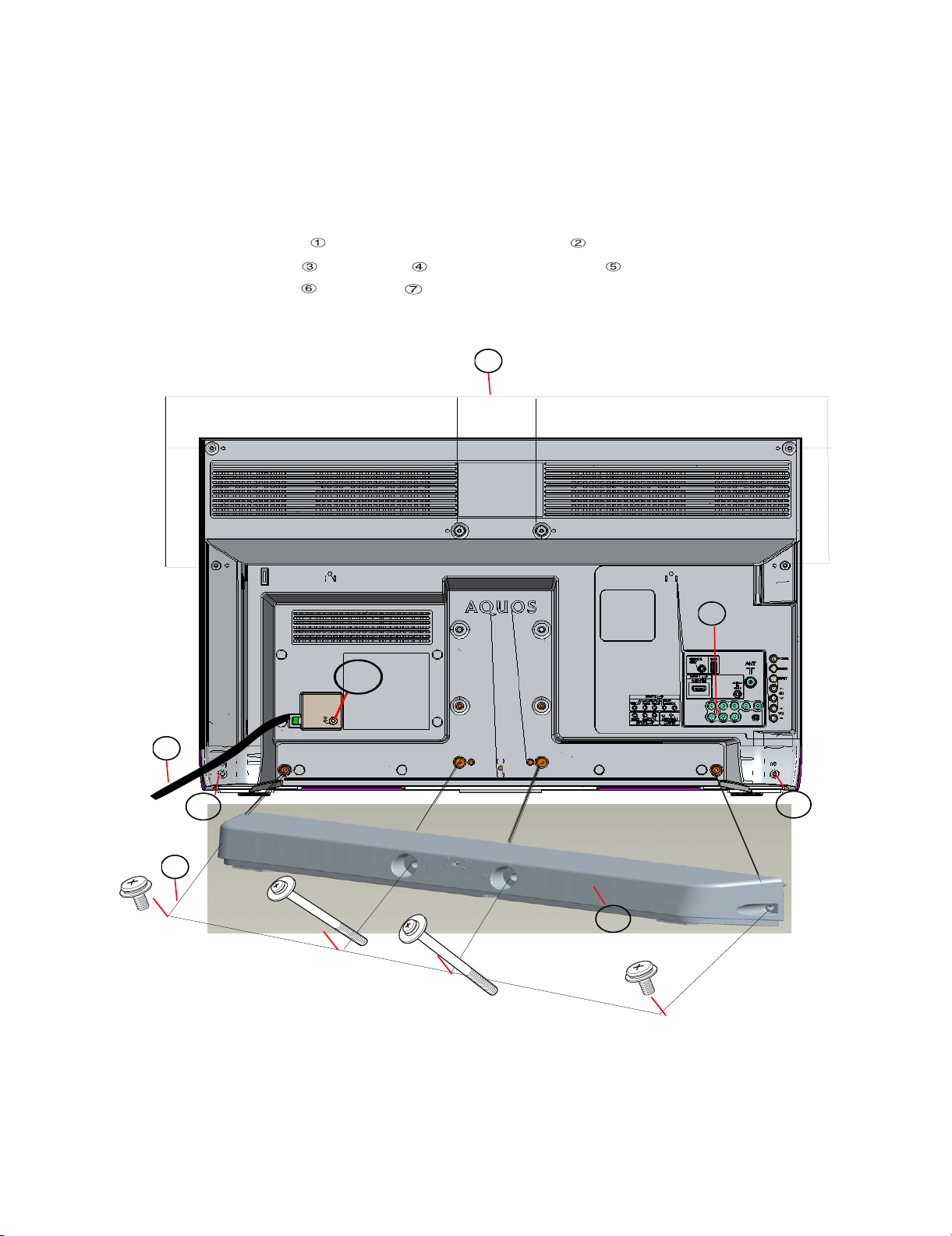

1. Remo ving of the Rear Cab in et Ass ’y and S tand assembly.

1. R e move the 4 scr ews and detach the S tand assembly

2.R e move the 2 scr ew , 1 screws and .

3. R emove the 1 scr ew , 6 screws

Detach the Rear Cabinet Ass’y

4.

.

O

R

P

A

R

T

R

E

M

O

V

I

N

G

O

F

detech AC cord

M

A

J

O

R

P

A

R

T

R

E

M

O

V

I

N

G

7

O

F

M

A

J

O

R

P

A

R

T

R

E

M

O

V

I

N

G

O

F

M

A

J

O

R

P

A

R

T

R

E

M

O

V

I

N

G

O

F

M

A

J

O

R

P

A

R

T

.

6

5

3

2

3

5 – 1

Page 11

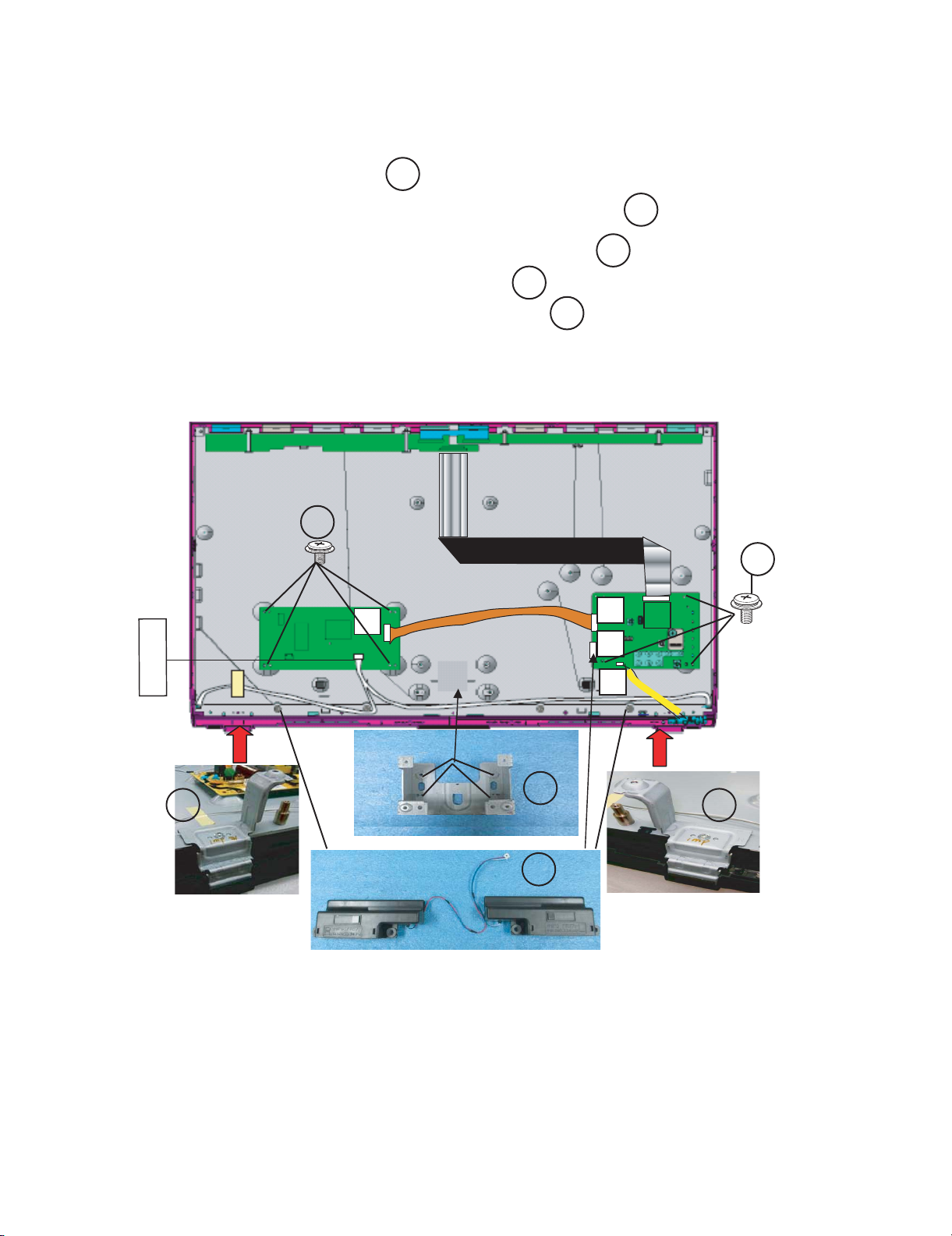

2. Removing of the Bottom Bracket and speaker L/R

LC-32LE250M

1. Remove 4 screw bottom bracket

1

2, Disconnect SP wayer & remove speaker from L/Rpanel bosses

3. Remove 1 screw from front angle L/R & remove front angle

4. Disconnect PD,LW,RA & remove 3 screw main unit

5. Disconnect LED wayer & remove 4 screw sub main unit

5

PD

4

5

PD

SP

2

3

4

LW

LED WAYER

RA

1

33

2

5 – 2

Page 12

LC-32LE250M

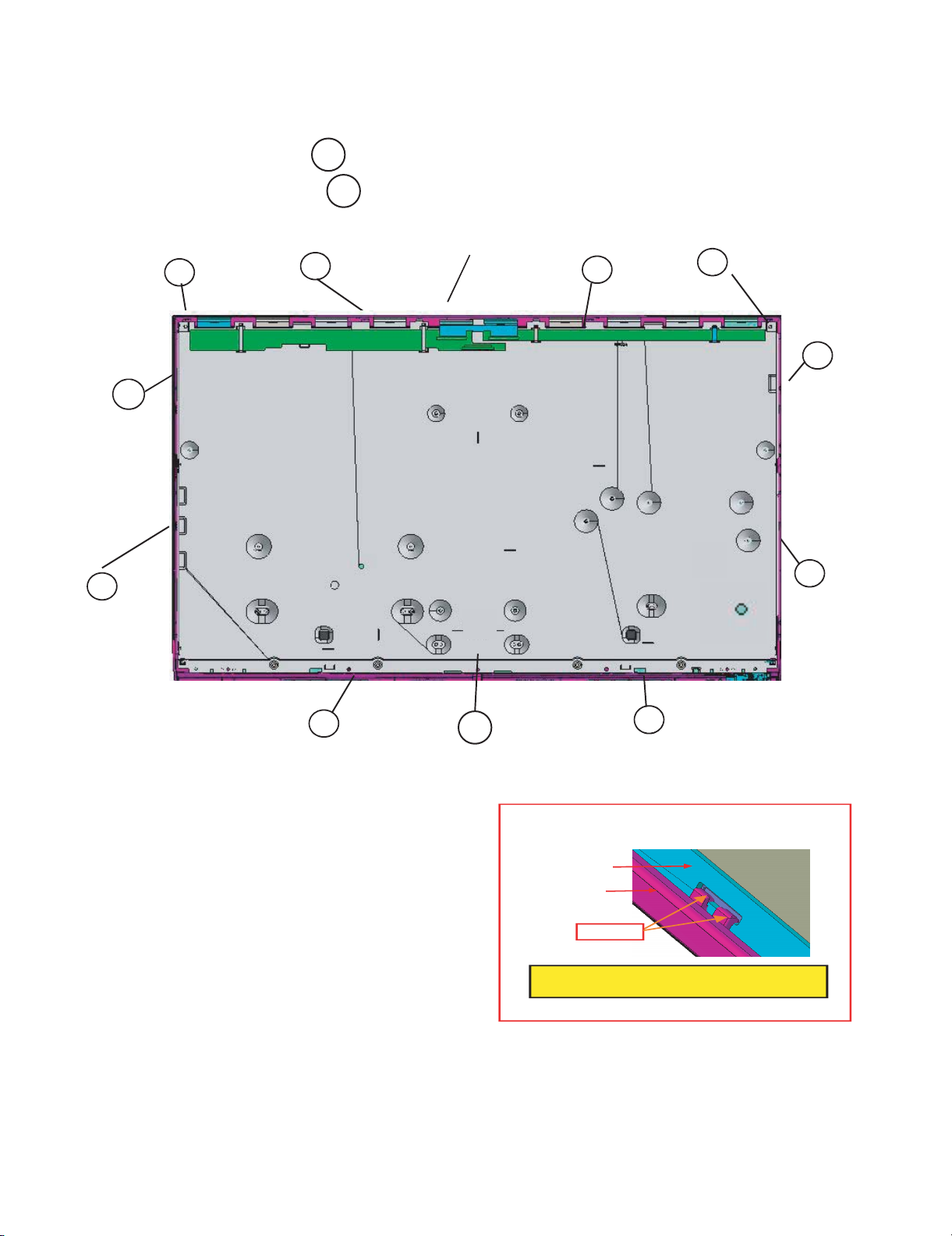

3. Removing of the LCD Panel Module

1. Detech the 10 lock hook refer figure 1.

2, and detech the LCD Module

1

2

Rear Cabinet Ass'y

Hook

1

Hook

Hook

Hook

Hook

Hook

Hook

Hook

Hook

2

Hook

Figure 1

KS-Bezel

Cab-A

Lock

Note:

Make sure perfectly detech lock

5 – 3

Page 13

LC-32LE250M

CHAPTER 6. ADJUSTMENT

[1] ADJUSTMENT

[1] ADJUSTMENT PROCEDURE

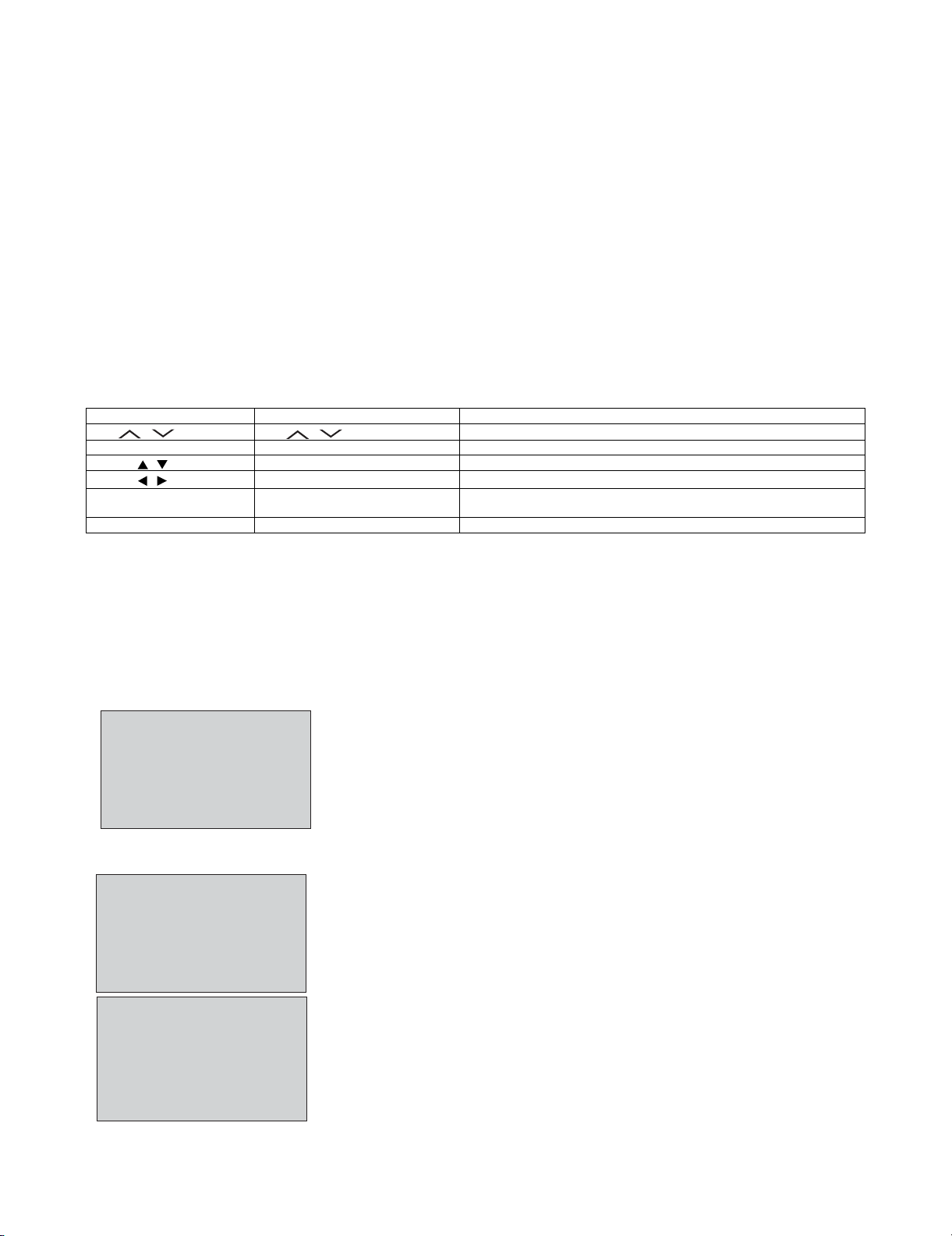

1. Entering and cancel the adjustment process mode

1) While holding down the TV/VIDEO and Volume DOWN keys at the same time, plug in the AC cord to turn on the power. (“K” standing for inspection process mode is displayed on the upper left position of the screen.)

2) Press the Channel DOWN and Volume DOWN keys at the same time. (The adjustment process mode screen appears.)

3) To cancel it, turn off the power using the Power switch or remote control.

2. Remote controller key operation and description of display in adjustment process mode.

1. key operation

Remote controller key Main unit key Function

CH ( / )

VOL (+ / –) VOL (+ / –) Changing volume (UP/DOWN)

Cursor ( / )

Cursor ( / )

INPUT button on remote

controller

ENTER —————— ——————

* Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

CH ( / )

—————— Turning a page (PREVIOUS/NEXT)

—————— Changing a selected line setting (+10/-10)

INPUT button Input source switching (toggle switching)

Changing channel (UP/DOWN)

(TV INPUT1 INPUT2 INPUT3 USB )

3. Software upgrading.

1) Plug off the LCD TV.

2) Insert the USB device to the USB terminal at the LCD TV.

(Make sure that the latest software is installed in the USB device).

3) Hold the LCD TV power key and plug on the LCD TV.

4) LCD TV is on and detecting the USB device.

Binary

file detecting

5) A few seconds later, the software upgrading will start automatically.

Do not power off

Chip erasing

.......................

Do not power off

Chip programming

.......................

6 – 1

Page 14

LC-32LE250M

A

6) Let the process running & entering verification.

7) Software is successfully installed when the following appears at the end of the process.

Do not power off

Verifying

.........................

Verify Pass

Please re-boot the system

Update Finished

8) Plug off the LCD TV and plug ON again as usual.

9) LCD TV is running with the latest software.

LCD TV ADJUSTMENT ITEM

1. EDID DATA INPUT

No need to input EDID

2. SIGNAL ADJUSTMENT

A. PICTURE ADJUSTMENT

Confirmation of signal from generator (setting to spec level)

PAL Composite signal • 0.7Vp-p 0.02Vp-p (pedestal to white level)

15K Component signal (50Hz) • Ylevel • 0.7Vp-p 0.02Vp-p (pedestal to white level)

Pb, Pr level • 0.7Vp-p : 0.7Vp-p 0.02Vp-p

33K Component signal • Ylevel • 0.7Vp-p 0.02Vp-p (pedestal to white level)

Pb, Pr level • 0.7Vp-p

a) Adjustment Mode

ITEM CONDITION PROCEDURE

1

djustment M ode Press the test key at the test remote control

+

–

+

–

+

–

+

–

0.7Vp-p 0.02Vp-Com

•

+

–

6 – 2

Page 15

b) Component 15K 50Hz Signal Adj ustment (COMP-SD)

A

A

ITEM CONDITION PROCEDURE

LC-32LE250M

1Setting [Signal]

2 Auto Adjustment Test Mode page4

COMP 15K 50Hz

(576i)

100% Full- field Col our

Bar

[Terminal]

COMPONENT

INPUT 3

(COMP SD)

• Feed the CO MPONENT 15K 50Hz (576i ) 100% Ful l-fiel d

Colour Bar signal(100% colour saturation) to

COMPONENT INPUT 3

100% White

t the related page, move cursor to [COMP SD ADJ], press

ENTER.

[OK] appears when finished.

c) Component 33K 60Hz Signal Adjustment (COMP-HD)

ITEM CONDITION PROCEDURE

1 Setting [Signal]

2 Auto Adjustment Test Mode page 5

COMP 33K 60Hz

(1080i)

100% Full-field Colour

Bar

[Terminal]

COMPONENT

INPUT 3

(COMP HD)

• Fe ed the COMPONENT 33K 60Hz (108 0i) 100% Full-f ield

Colour Bar sig nal(100% col our saturati on) to

COMPONENT INPUT 3

100% White

t the related page, move cursor to [COMP HD ADJ], press

ENTER.

[OK] appears when finished.

••

••

Black

Black

6 – 3

Page 16

LC-32LE250M

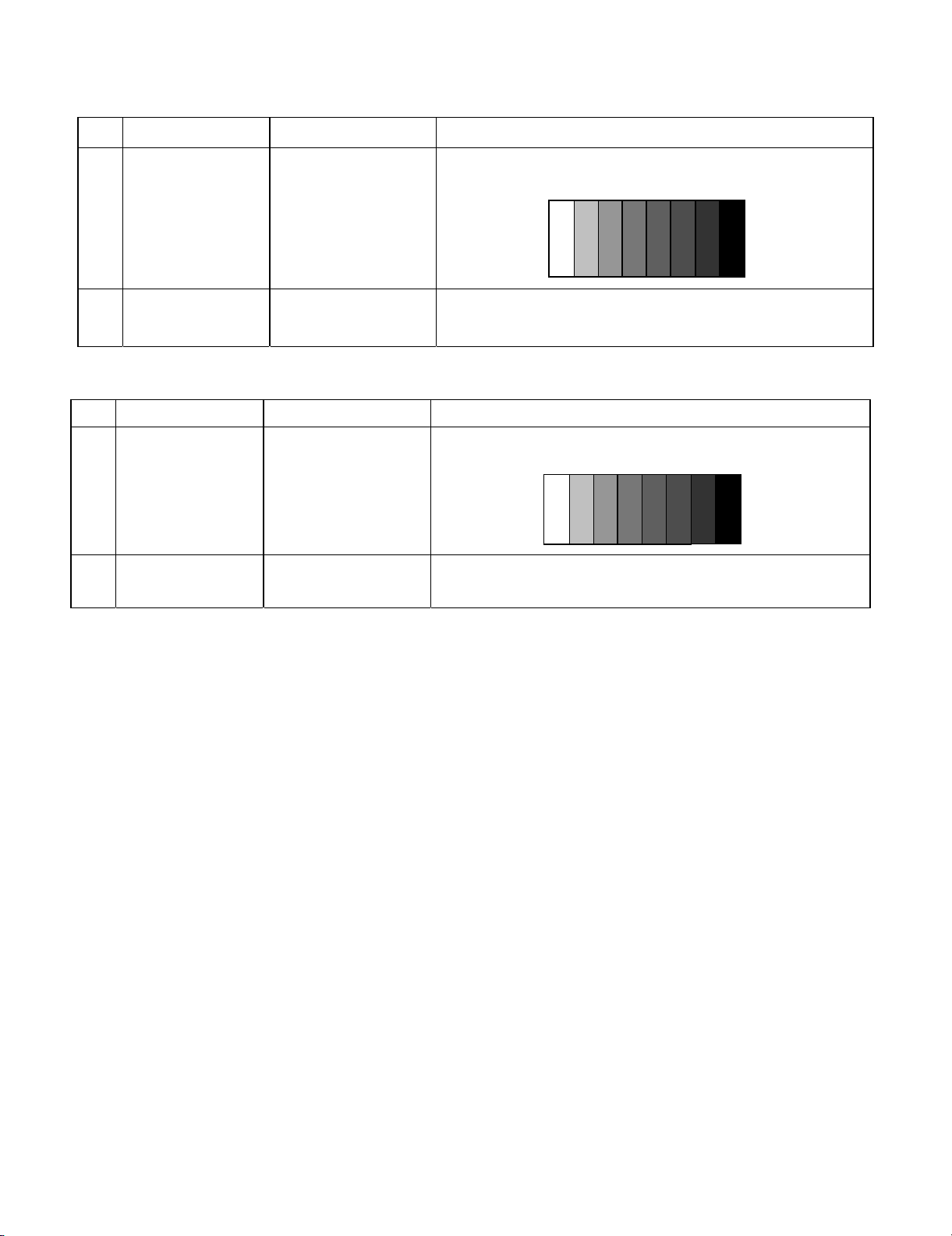

B. WHITE BALANCE ADJUSTMENT

a) White Bal ance Adjustment

ITEM CONDITION PROCEDURE

1Setting Backlight : MAX

AV Mode : DYNAMIC

ActiveBacklight:OFF

Set the luminance

meter on the centre of

the screen

2Auto

Adjustment

[command]

Adjustment Mode

KRSW0001

KKT10037

FACT0001

Setting

KYOF0001

OSDS0001

SBSL16_ _

Multi point adj. Mode

MSET0000

WBI20255

Point 2

WBI20229

MG2G****

MG2B****

MG2R****

Point 1

WBI10051

MG1G****

MG1B****

MG1R****

Set Max.Level

MGMG****

MGMR****

MGMB****

Write

MSET0003

For the details of w hite balance adjustment procedure, please ref er to whit e

balance adjustment spec for Kameyama model.

1. Confirm the set condition.

2. Connect the white balance jig.

3. Through RS-232C command, adjustment mode screen is displayed.

[Adj ustment Procedure]

1. Using t he R/C, set the LCD TV to adjustment mode.

2. Measure Max brightness (L

3. Calculate min. brightness (L

4. Measure Point 2 brightness (L

5. Set the reference value R,G,B of Point 2 (Ref.2)=3664 x(229 /P2)

whereP2=255x[(L

6.

Set the specified gradation for point 2, fix the most faint colour to get

high–Lmin

max

min

).

)=L

high

)/(L

/3000.

max

).

max–Lmin

1/2.2

)]

reference value, adjust others 2 colour to minus adjustment for

reference val ue of point 2.

7. Measure Point 1 brightness (L

8. Set the reference value R,G,B of Point 1 (Ref.1)=816 x(51 /P1)

whereP1=255x[(L

low–Lmin

).

low

)/(L

max–Lmin

1/2.2

)]

9. Set the specified gradation for point 1. Set G of point 1 to the default

value [ (Ref.1 x G value of point 2 / Ref.2), wit h fractions rounded] and

adjust RB to the reference value of point 1.

10. Set the G of point Max. to the default value (4080 x G value of point 2 /

Ref.2). Set the R,B Max. value [G

of point 2)].

–Gvalueofpoint2+(R,Bvalue

max

11. Adjusted value is writing at [command] MSET0003.

12. Shut down the AC power.

• Ini tial val ue at RGB 2 point : 3664

• Ini tial val ue at RGB 1 point : 816

6 – 4

Page 17

[Adjustment value]

A

• Teaching set send by engineering dept is set as reference.

[Reference val ues for adjustment ref erence]

Equipment : Luminance meter [Minolta CA-210]

Ref. : For inspect ion, set the LCD TV as below.

3. FACTORY SETTING

AC power is plug off after shipment setting is done.

Level

Point 2

ref.

values

Point 1

ref.

values

229

51

AV MODE : [D YNAMIC ] (R es et)

Aging Tim e : Minim um 60 minutes

Spec

Data

x=0.272

y=0.277

x=0.272

y=0.277

djustment

Spec.

• 0.0010 • 0.0020

• 0.0045 • 0.0090

Inspect ion

Spec.

LC-32LE250M

Caution: Do not plug on again after shipment setting i s done. If do, please re-do the shipment setting. Do not off

with remote control.

ITEM CONDITION PROCEDURE

Factory setting AC power off to exit the

factory setting.

1. Setting is done with test remote control.

2. Press the ‘Factory Setting’ key on the remote control continuously.

3. When Green background appears on screen and ‘K’ mark

disappears, setting is completed.

The followings are initialised to factory setting

1) User setting

2) Channel data (e.g. broadcast frequencies)

3) Manufacturer’s option settings

4) Password data

5) Setting values are set based on model destination

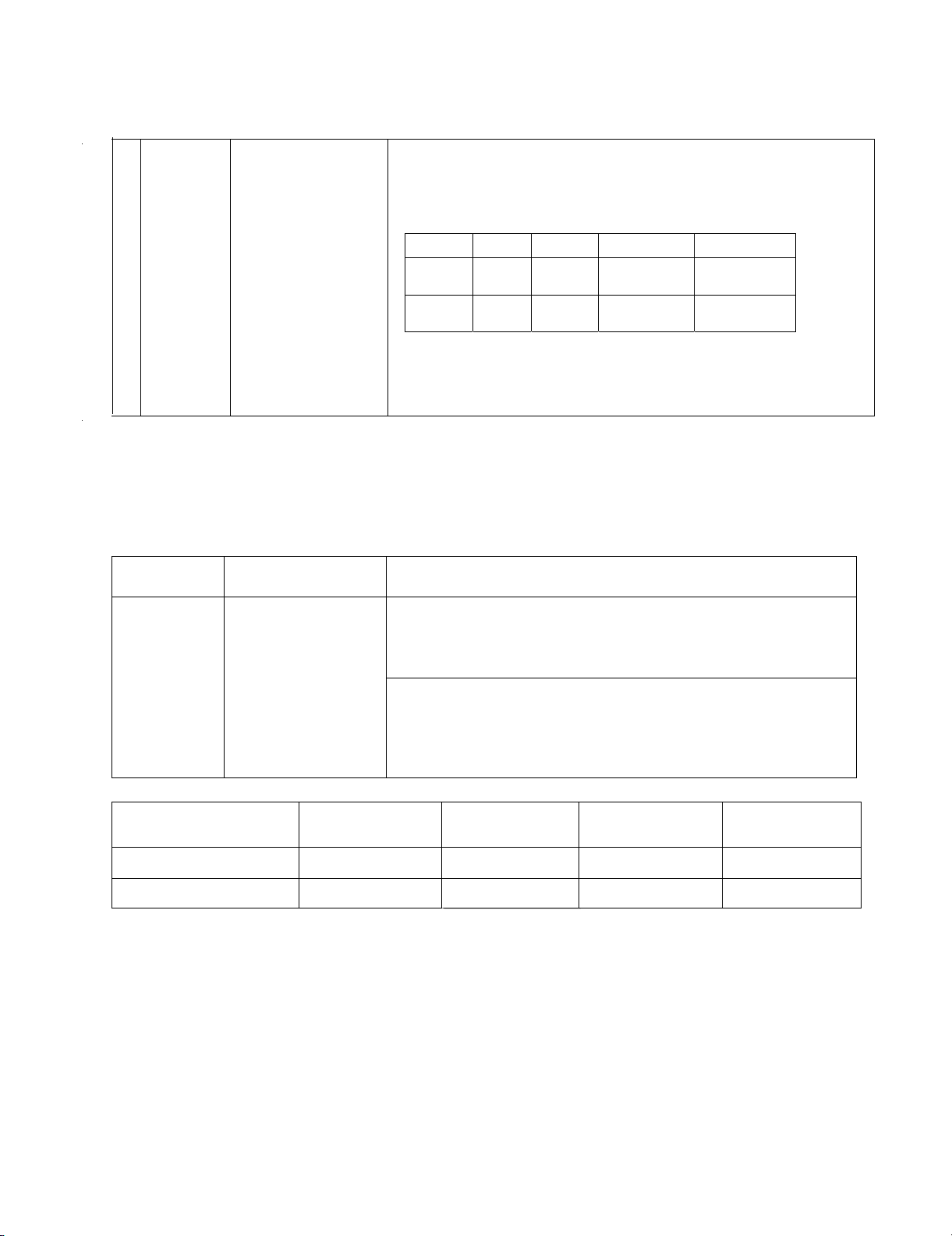

Model Name Factory Setting Key

Asia ,Near and Middle

East

PHILIPPINES

M-Setting 100000001010110 B/G ENGLISH

P-Setting 100000001011110 M ENGLISH

**Please do inspection for A3KLED3P

Name

(PHILIPPINES)

Remote Control

Code

using NTSC signal.

S-System Setting OSD Language

Setting

6 – 5

Page 18

LC-32LE250M

CHAPTER 7. TROUBLESHOOTING

TABLE

[1] TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE

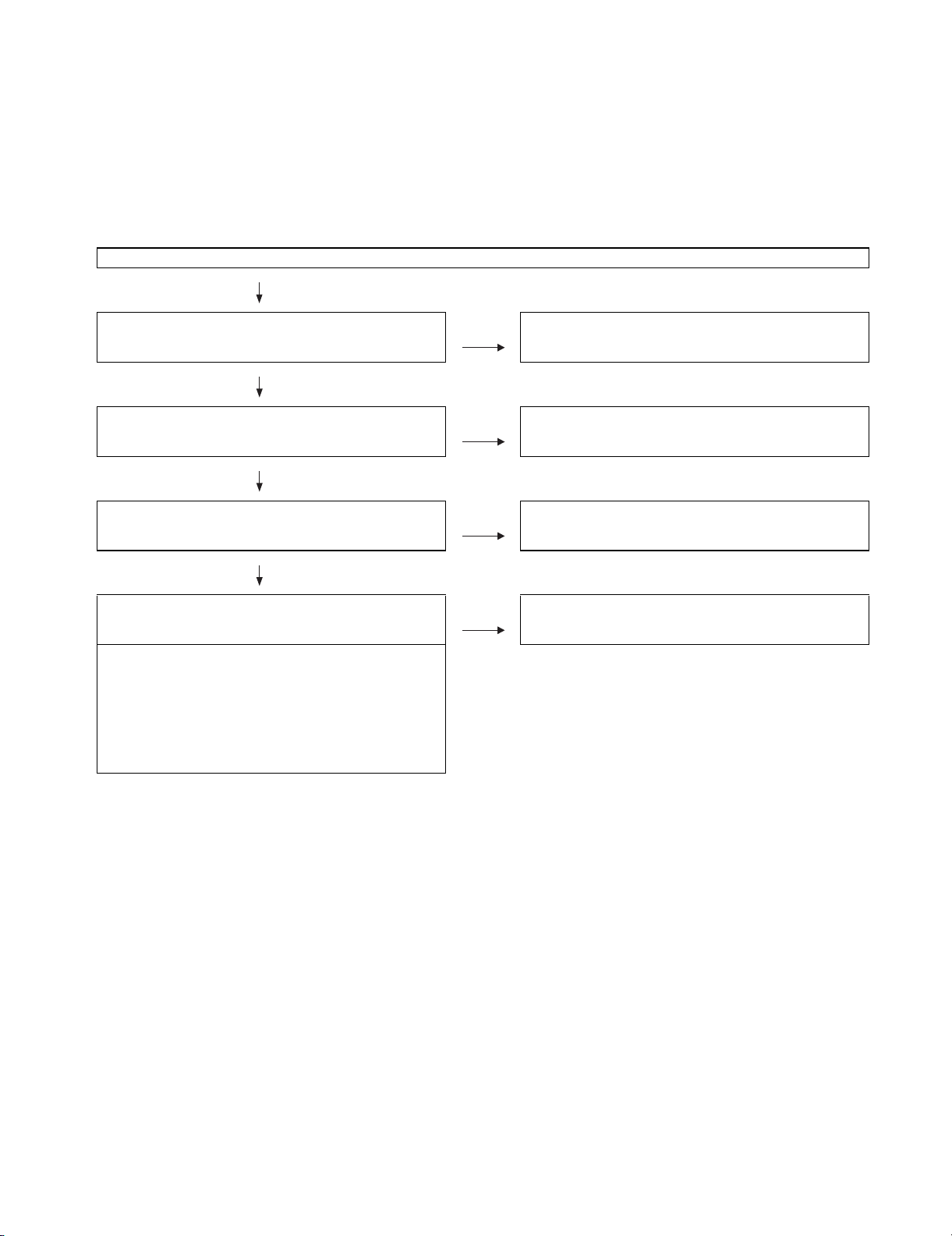

No power (front LED failure to light up) or no startup (front LED failure to turn from red to green)

Is the AC cord connector tightly connected to the set? NO Reconnect the AC cord tightly and turn on the power again.

YES

Are the wire harnesses and other cables properly connected in

the set?

NO Reconnect the wire harnesses and other cables properly in the

set.

YES

Is there the AC_CT RL and POWER_LED signal input at pins

(70 ) and (44) of IC3301

YES

Are the DC/DC converter outputs and the output voltages along

the control lines as specified?

1) M+5.6V (IC9601)

2) D+1.26V (IC9602)

3) D+5V (IC9601)

4) D+3.3V (IC9603)

5) D+1.8V (IC9606)

6) D+2.5V (IC9608)

NO Check the AC_CTRL signal line POWER_LED signal line.

NO Check the DC/DC converters and the control lines. Replace

defective parts as required.

7 – 1

Page 19

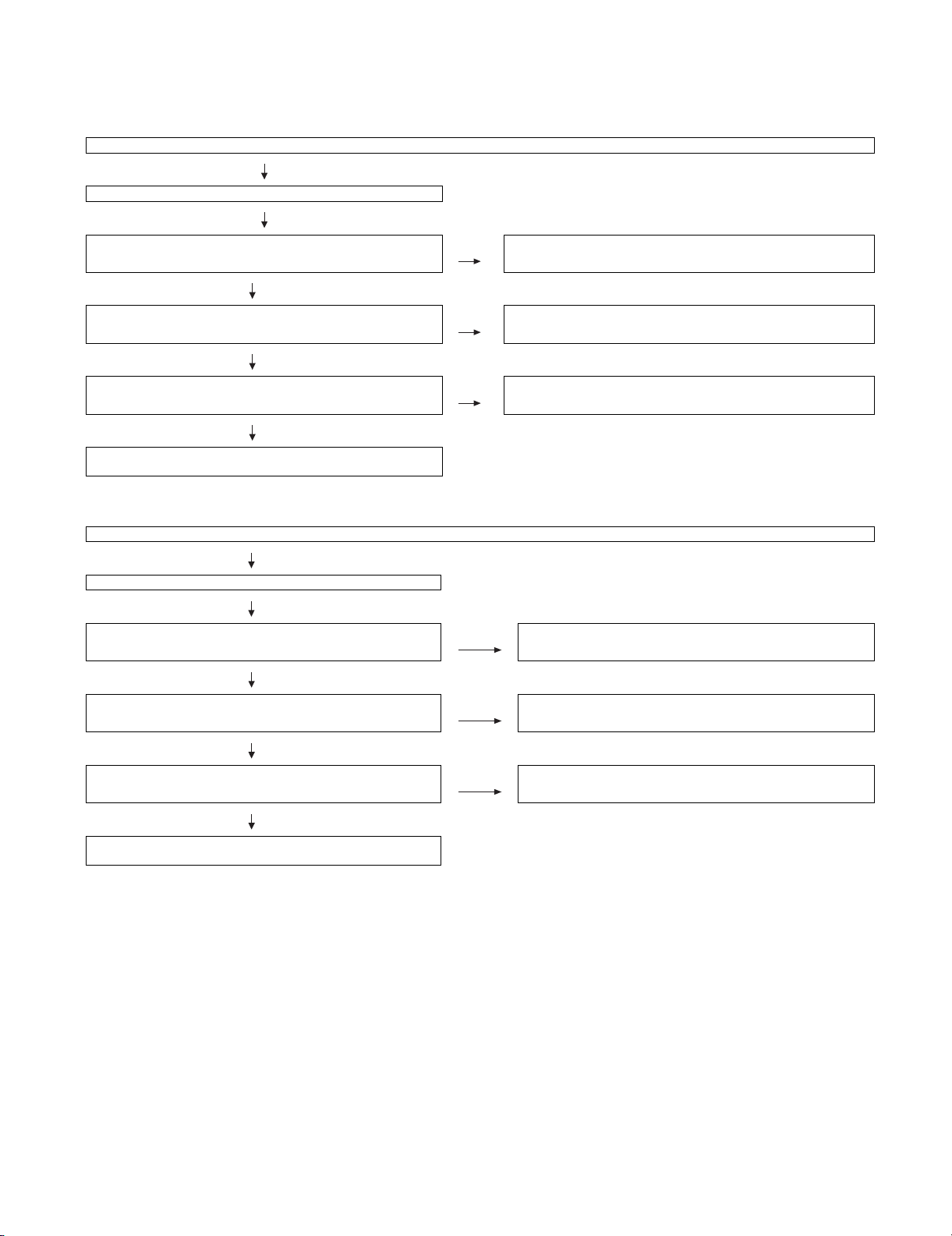

With [RF] signal input No video onscreen (1)

No video in the UHF/VHF reception

Is there IF output from the tuner pin( 8 ) of TU1101 as specified? NO Check TU1101 and its peripheral circuits.

LC-32LE250M

Is there VIF input at pin 38 & 39 of IC3301? NO Check the circuit between TU1101 & IC3301.

Are there the signal outputs of IC3301? NO Check IC3301 and its peripheral circuit.

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

With <Video> signal input No video onscreen (3)

No external input video onscreen <INPUT 3>

Is INPUT 3 selected on the input select menu screen? NO Select INPUT 3 on the input select menu screen to pick up the

Is there the video signal input at pin (19 ) of IC3301? NO Check the line between pin (9) of TL539 and pin (19) of IC3301.

YES

YES

YES

right input signal.

YES

Are there signal outputs of IC3301? NO Check IC3301 and its peripheral circuits.

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

YES

YES

7 – 2

Page 20

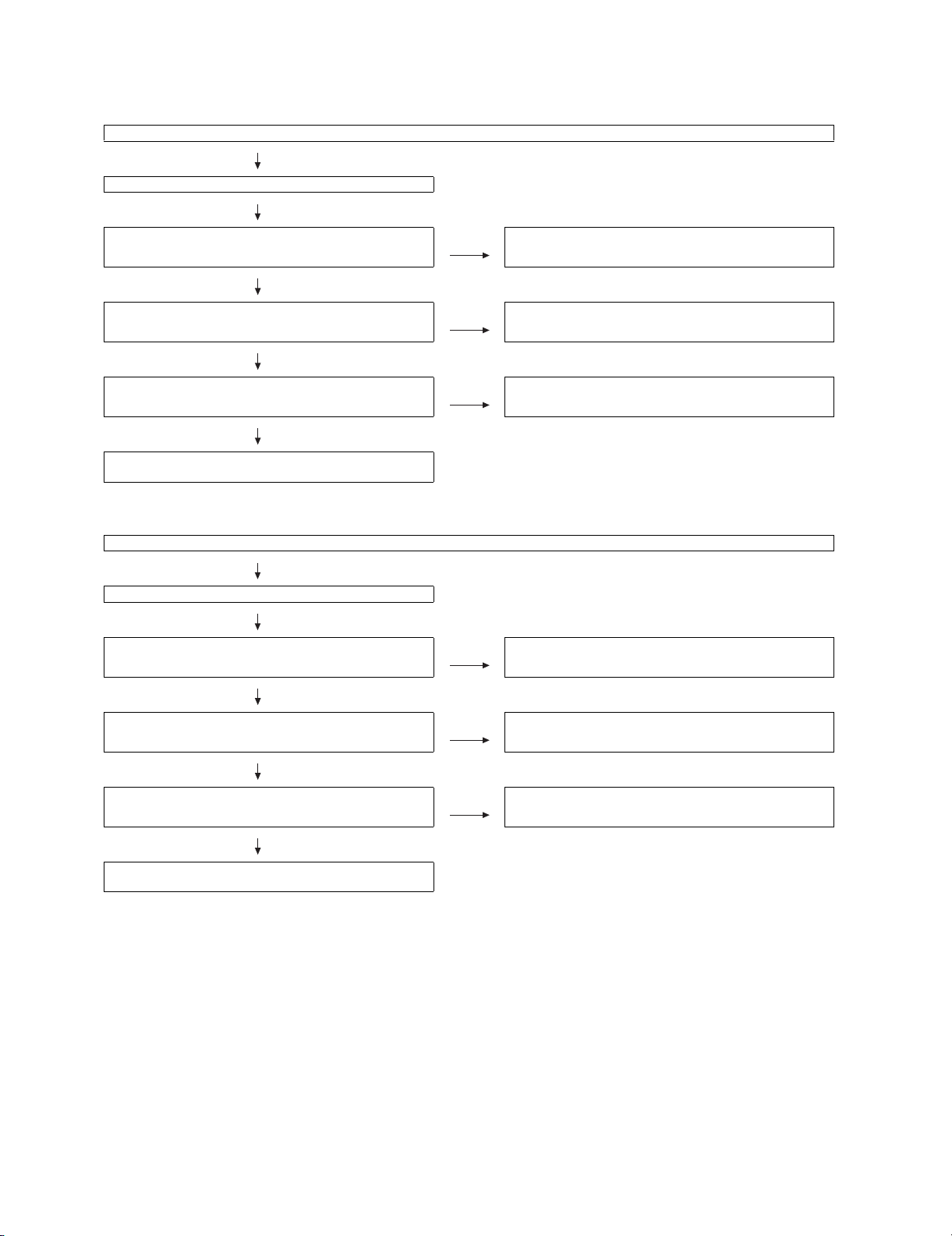

LC-32LE250M

With <Component> signal input No video onscreen (2)

No external input video onscreen <INPUT 2>

Is INPUT 2 selected on the input select menu screen? NO Select INPUT 2 on the input select menu screen to pick up the

YES

Are there the Y, Pb and Pr signal inputs at pins (13), (11) and

(15 ) of IC 3301 respectively?

YES

Is input waveform of IC3301 normal?

Y=(13) pin, Pb=(11) pin, Pr=(15) pin

YES

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

With <HDMI> signal input No video onscreen (4)

No external input video onscreen <INPUT 1>.

Is INPUT 1 selected on the menu screen? NO Select INPUT 1 on the input select menu screen to pick up the

NO Check the line between pins (6) /(14)/(18) of TL563 and pins

NO Check IC3301 and its peripheral circuits.

right input signal.

(11) /(15 )of IC3301.

(13)/

right signal input.

YES

Are there signal outputs from SC1501 to IC3301? NO Check peripheral circuits between SC1501 and IC3301.

YES

Are there signal outputs of IC3301? NO Check IC3301 and its peripheral circuits.

YES

Check LVDS cable, LCD controller (incl. panel) and their peripheral circuits.

7 – 3

Page 21

No audio heard (1)

No sound in the UHF/VHF reception.

Is the IF output from the tuner pin (8) of TU1101 as specified? NO Check TU1101 and its peripheral circuits.

YES

Is there the I2C signal input at pins (42), (43) of IC3301? NO Check IC3301 and its peripheral circuits.

YES

Is there audio signal intput at pin(22),(32) of IC1702? NO Check connection between IC3301 and IC1702 and its

peripheral circuits.

YES

Is the L-ch audio signal output at pin(10),(11),(16),(17) of IC1702 NO Check IC1702 and its peripheral circuits.

Is the R-ch audio signal output at pin(2),(3),(8),(9) of IC1702 normal ?

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1)/(2) of

P1702 normal?

NO Check circuit between IC 1702 & P1702.

YES

Check speakers and their peripheral circuits.

normal ?

LC-32LE250M

7 – 4

Page 22

LC-32LE250M

No audio heard (2)

No external audio heard

<INPUT 2>

Is there the L-ch audio signal input from pin (30) of input terminal

TL563 to pin (26 ) of IC 3301?

Is there the R-ch audio signal input from pin (26) of input terminal

TL563 to pin(27) of 3301?

<INPUT 3>

Is there the L-ch audio signal input from pin (20) of input terminal

TL539 to pin (23) of 3301?

Is there the R-ch audio signal input from pin (15) of input terminal

TL539 to pin (24 ) of IC3301?

YES

Is there the I2C signal input at pin (42), (43) of IC3301? NO Check IC3301 and its peripheral circuits.

YES

Is there audio signal input at pin(22),(32) of IC1702? NO Check connection between IC3301 and IC1702 and its periph-

eral circuits.

YES

Is the L-ch audio signal output at pin(10),(11),(16),(17) of NO Check IC1702 and its peripheral circuits.

Is the R- ch audio signal output at pin(2),(3),(8),(9) of IC1702

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1)/(2) of

P1702 normal?

NO Check circuit between IC1702 & P1702 .

YES

Check speakers and their peripheral circuits.

IC1702

normal ?

7 – 5

Page 23

No HDMI sound heard. <INPUT 1>

(*INPUT 1 is digital audio.)

LC-32LE250M

No audio heard (3)

Does the HDMI image appear onscreen? NO Refer to “<INPUT 1> in No external input video onscreen

YES

No audio output from <INPUT 1> NO Check the EDID.

YES

Are waveforms input in to the pins of IC3301 normally? NO Check peripheral circuits IC3301.

YES

Is there audio signal input at pin(22),(32) of IC1702 NO Check connection between IC3301 and IC1702 and its periph-

YES

Is the L-ch audio signal output at pin(10) ,(11),(16),(17) of IC1702 NO Check IC1702 and its peripheral circuits.

normal ?

Is the R-ch audio signal output at pin (2),(3),(8),(9) of IC1702

normal ?

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1) /(2) of

P1702 normal?

(HDMI)”.

eral circuits.

NO Check circuit between IC1702 & P1702.

YES

Check speakers and their peripheral circuits.

7 – 6

Page 24

LC-32LE250M

No audio heard (4)

No sound from the HDMI sound input terminal.

(INPUT 1 analog audio)

YES

Is there the L-ch audio signal input from pin (2) of external input

terminal J501 (HDMI AUDIO IN) to pin (28) of IC3301?

Is there the R-ch audio signal input from pin (3) of external input

terminal J501 (HDMI AUDIO IN) to pin (29) of IC3301?

YES

Are I2S signal output from the pins (42), (43) of IC3301 normally? NO Check peripheral circuits of IC3301.

YES

Is there audio signal input at pin(22),(32) of IC1702 NO Check connection between IC3301 and IC1702 and its periph-

eral circuits.

YES

Is the L-

ch audio signal output at pin ( 10 ),(11),(16),(17) of NO Check IC1702 and its peripheral circuits.

Is the R-

ch audio signal output at pin(2),(3),(8),(9) of IC1702

nor

mal?

YES

Are the audio signal L-ch and R-ch output at (3)/(4) and (1)/(2) of

P1702 normal?

NO Check circuit between IC1702 & P1702.

YES

Check speakers and their peripheral circuits.

IC1702 normal ?

7 – 7

Page 25

CHAPTER 8. OVERALL WIRING /

BLOCK DIAGRAM

[1] SYSTEM BLOCK DIAGRAM

LC-32LE250M

㪫㪜㪩㪤㪠㪥㪘㪣

㪜㪜㪧㪩㪦㪤㩷㪠㪚㪌㪇㪏

㪭㪟㪠㪙㪩㪉㪋㪫㪇㪉㪡

㪚㪭㪙㪪㪆㪚㪦㪤㪧㩷㪠㪥㩷㪡㪌㪇㪉

㪚㫆㫄㫇㩷㪘㫌㪻㫀㫆㩷㪠㪥㩷㪡㪌㪇㪊

㪬㪪㪙㩷㪠㪥㩷㪡㪌㪇㪈

㪤㫆㫅㩷㪣㪆㪩㩷㪦㪬㪫㩷㪡㪌㪇㪌

㪟㪧㩷㪡㪌㪇㪋

㪮㪧㪶㪚㪫㪩㪣

㪧㪚㩷㩷㪛㪪㪬㪙㩷㪈㪌㫇㫀㫅

㪪㪚㪌㪇㪉

㪧㪚㩷㪘㫌㪻㫀㫆㩷㪡㪌㪇㪍

㪤㪘㪠㪥

㪰㪆㪧㪹㪆㪧㫉

㪚㪭㪙㪪㩷㪸㫅㪻㩷㪘㫌㪻㫀㫆㩷㪣㪆 㪩

㪣㪆㪩

㪛㪧㪆㪛㪥

㪤㫆㫅㩷㪘㫄㫇㩷㪺㫀㫉㪺㫌㫀㫋

㪟㪧㩷㪘㫄㫇㩷㪺㫀㫉㪺㫌㫀㫋㩷

㪠㪉㪚

㪫㪜㪤㪧㩷㪪㪜㪥㪪㪦㪩

㪫㪟㪊㪊㪇㪈

㪪㪘㪩㩿㪉㪀

㪤㪪㪫㪍㪈㪇㪇㪭㪪

㪩㪼㪽㩷㪥㫆㪅㪠㪚㪊㪊㪇㪈

㪩㪟㪄㪠㪯㪛㪇㪊㪌㪊㪮㪡㪱㪱㪨

㪟㪆㪮㩷㪩㪜㪪㪜㪫

㪩㪜㪪㪜㪫

㪠㪚㪊㪊㪇㪉

㪢㪜㪰㪆㪩㪚㪆㪣㪜㪛

㪢㪜㪰㪆㪪㪮

㪢㪜㪰㪈㪆㪉㪆㪧㪦㪮㪜㪩㩷㪪㪮

㪪㪘㪩㩿㪇㪀㩷

㪪㪘㪩㩿㪈㪀

㪠㪩㩷㪩㪼㪺㫀㪼㫍㪼㫉

㪠㪩㩷㪠㪥

㪛㪩㪘㪤㩷㪠㪝

㪛㪛㪩㪉㩿㪈㪉㪏㪤㪹㪀

㪠㪚㪊㪌㪇㪈

㪩㪟㪄㪠㪯㪛㪊㪍㪈㪮㪡㪨㪱

㪣㪜㪛

㵘㵘㵘㵘

㪣㪜㪛㪶㪞

㪣㪜㪛㪶㪩

㪠㪩㪜㪤

㪞㪧㪠㪦㪍

㪞㪧㪠㪦㪊㪎

㩷

POWER UNIT

㪧㪛

㪧㪛

㪬㪩㪂㪈㪉㪅㪉㪭

㪬㪩㪂㪈㪉㪅㪉㪭

㪞㪥㪛

㪞㪥㪛

FFC

㪧㪪㪶㪦㪥

㪧㪪㪶㪦㪥

㪜㪩㪩㪦㪩

㪜㪩㪩㪦㪩

㪦㪝㪣

㪪㪫㪙

㪉㪐㪑㩷㪈㪉㪭

㪧㪉㪍㪇㪈

㪊㪇㩷㫇㫀㫅

CN1

㪦㪝㪣

2pin

㪪㪫㪙

LED1_A

LED1_K

LED BAR

CN1(2pin)

LED1_A

LED1_K

䊝䉳䊠䊷䊦

㪉㪐㩷㪑㩷㪮㪯㪞㪘

㩷

㪪㪧㪣

㪋㪆㪏㱅㪌

㪘㪬㪛㪠㪦㪶㪦㪬㪫

㪠㪉㪪

㪘㪬㪛㪠㪦㩷㪘㪤㪧

㪠㪚㪉㪎㪇㪋

㪭㪟㪠㪰㪛㪘㪈㪍㪋㪛㪱㪄㪈㪰

㪪㪧㪶㪣

㪪㪧㪧㪉㪎㪇㪈

㪨㪧㪣㪞㪥㪙㪇㪐㪉㪮㪡㪱㪱㪰

㪪㪧㪶㪣

㪜㪩㪩㪦㪩

㪦㪝㪣

㪧㪥㪣㩷㪪㪫㪙

㪣㪭㪛㪪㩿㪏㪹㫀㫋㪀

㪯㪫㪘㪣㩿㪉㪋㪅㪇㪤㪟㫑㪀

㪯㪠㪥㪆㪯㪦㪬㪫

㪯㪊㪊㪇㪈

㪠㪉㪚㩷㪘㪛㪛㪩㪜㪪㪪䋺㪘㪏

㪜㪜㪧㪩㪦㪤㩿㪟㪛㪚㪧㪀

㪠㪉㪚

㪠㪚㪏㪋㪇㪊

㪩㪟㪄

㪠㪉㪚㩷㪘㪛㪛㪩㪜㪪㪪䋺㪘㪋

㪜㪜㪧㪩㪦㪤㩿㪛㪘㪫㪘㪀

㪠㪉㪚

㪪㪧㪠㩷㪝㪣㪘㪪㪟㩷㪮㪩㪠㪫㪜

㪚㪟㪜㪢㪜㪩㩷㪣㪘㪥㪛

㪠㪚㪏㪋㪇㪉

㪭㪟㪠㪩㪉㪋㪈㪉㪏㪘㪪㪄㪈㪰

㪪㪧㪠㩷㪠㪆㪝

㪪㪧㩷㪤㪬㪫㪜

㪠㪉㪪

㪪㪧㪶㪩

㪪㪧㪶㪩

㪪㪧㪩

㪋㪆㪏㱅㪌

㪪㪧㪠㩷㪝㪣㪘㪪㪟

㪪㪧㪠

㪠㪚㪏㪋㪇㪋

㪩㪟㪄

㪟㪛㪤㪠

㪠㪥㪧㪬㪫㪈

㪟㪛㪤㪠㩷㪈㩷㪪㪚㪈㪌㪇㪈

㪨㪪㪦㪚㪱㪘㪈㪎㪌㪮㪡

㪺㫃㫂㩿㪉㪀

㪻㪸㫋㪸㩿㪋㪀

㪠㪉㪚㩿㪟㪛㪤㪠

㪟㪧㪛㪇㪶㪠㪥㪆㪛㪌㪭

㪟㪛㪤㪠㩷㪠㪥㪈

㪚㪜㪚㩷㪠㪥

㪟㪛㪤㪠㩷㪛㪛㪚㪈

㪧㪚㩿㪩㪞㪙㪀

㪟㪛

㪭㪛

㪧㪚㩷㪛㪛㪚

㪣㪆㪩

㪚㪭㪙㪪

㪚㪦㪤㪧

㪘㪬㪛㪠㪦

㪬㪪㪙㩷㪠㪝

㪤㫆㫅㫀㫋㫆㫉㩷㪘㫌㪻㫀㫆㩷

㪟㪧㩷㪘㫌㪻㫀㫆㩷㫆㫌㫋

㪟㪧㩷㪛㪼㫋

㵘

㪫㪬㪥㪜㪩

㪫㪬㪥㪜㪩

㪫㪬㪈㪈㪇㪈

㪩㪫㪬㪥㪨㪘㪇㪍㪎㪮㪡㪨㪱

㪠㪝

㪜㪛㪠㪛

㪠㪚㪈㪌㪇㪈

㪠㪝㩷㪘㪤㪧㩷

㪭㪠㪝㩷㪪㪘㪮

㪪㪠㪝㩷㪪㪘㪮

㪝㫀㫃㫋㪼㫉㩷㪝㪣㪈㪈㪇㪉

㪝㫀㫃㫋㪼㫉㩷

㪪㪠㪝㪂

㪪㪠㪝㪄

㪭㪠㪝㪂

㪭㪠㪝㪄

㪪㪠㪝㩷㪠㪥

㪭㪠㪝㩷㪠㪥

㵘㵘㵘

㵘㵘㵘㵘㵘㵘㵘

8 – 1

Page 26

LC-32LE250M

CHAPTER 9. PRINTED WIRING

BOARD ASSEMBLIES

[1] MAIN Unit / LED PWB

H

Main Unit ( Side-A )

G

F

E

D

C

B

A

1

2 109

3

54

6

7

8

9 – 1

Page 27

LC-32LE250M

H

G

F

E

D

C

B

A

1

2 109

3

54

6

7

8

9 – 2

Page 28

LC-32LE250M

LED A -Chip

H

G

F

E

LED A -Symbol

D

C

B

A

1

2 109

3

54

6

7

8

9 – 3

Page 29

LC-32LE250M

LED B -Chip

H

G

F

E

D

C

B

A

1

2 109

3

54

6

7

8

9 – 4

Page 30

LC-32LE250M

CHAPTER 10. SCHEMATIC DIA-

GRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM

1. VOLTAG

1

)

The voltages at test point

g

enerator for ser v

EMEA

icing pur

SURE

MENT CONDITION:

s are measured on exclusive AC adaptor

pose and the above volt

2. INDICATION OF RESISTOR & C

RESISTOR

1

)The unit of re

(K=k =1000 , M=M ).

2

) All resistors are ± 5%, unless otherwi

(K= ± 10%, F= ± 1%

3

)

All

resistors are 1/16W,

C

A

P

ACITO

1)

A

l

l cap

(P=pF

2

)

All

capa

CAUTION:

T

his circuit diagram is original one

d

if

e

f

ence from your

r

SAFETY NOTES:

1

) DISCONNE

BEFORE REPLACING P

2) SEMICONDUC

POTENT

OPERA

sist

ance

""i

s omitted.

, D= ± 0.5%)

unless otherwise noted.

R

a

ci

tors

are

F

, unless oth

=

F)

.

citors are

50V

,

s.

CT THE AC PLUG

T

OR

H

IAL

SHOCK HAZARDS WHEN THE CHAS

ING

T

.

erwise

unless otherwi

therefor

,

FROM THE AC OUTLET

ART

S.

EA

T

SINKS SHOU

se noted.

noted.

se noted.

and the st

ages are measured with a 20k ohm/V tester

AP

ACITOR:

e ther e may b

LD BE REG

e

aslight

ARDED AS

SIS IS

able s

upply volt

age of A

.

C

110-240V

.Si

gnals are fe

dbyaco

lour

bar

signal

IMP

ORT

ANT SA

FETY NOT

A

P

R

T

S MARKED WITH "

FO

R MAINTA

REPLACE THESE PA

TAI N ING T

INING

HE SAFE

ICE:

(

"

T

HE SAFETY OF

RTS WITH SPECIFIED

T

YA

ND PERFORMA

THE S

)

ARE IMPORT

ET

.BESURETO

ONES FOR MAIN-

N

CE OFT

HE S

ANT

ET.

10 – 1

Page 31

LC-32LE250M

LC -32LE 250M

MAIN 1 (T UN E R )

H

TU1101

QZ

QA068WJ

A

D

S

L

S

C

F

-

A

I

F

+

A

I

F

+

D

I

IF-

D

A

GC

F

_

I

V

8

1

.

V

3

3

.

E

T

S

R

E

V

5

G

0

3

1

1

C

.1u

0

V

2

5

1

1

0

B

1

F

T

A

5

3

2

0

0

5

1

1

8

2

1

C

1

0

P

0

0

1

V

5

F

0

C

0

u

1

V

6

1

R

1

1

6

1

1

1

0

K

3

2

8

1

0

0

1

1

1

1

L

L

T

T

T

E

S

E

R

5

4

9

3

0

0

1

1

1

1

L

L

T

T

2

1

C11

u

.01

0

7

6

4

2

0

0

1

1

1

1

L

L

T

T

9

8

7

6

0

0

1

1

1

1

L

L

T

T

5

0

0

R11

1

1

R

IN-

IN+

_

F

IF_

I

1

1

1

0

1

0

1

1

1

1

1

1

L

L

T

T

6

0

0

1

1

R

7

0

0

1

0

K

L

DAT

C

_

_

C

C

2

2

I

I

TL1114

2

1

1

1

L

T

0

8

1

1

R

0

1

0

E

6

1

1

C

1

u

.1

0

5

V

2

2

0

1

B

1

F

A

3

T

2

5

D

7

1

1

1

4

1

1

1

C

P

0

0

0

1

V

0

5

C

u

0

1

V

6

1

C

0

T

T

E

E

RES

RES

2

2

1

1

C

u

.1

0

N

-

I

IF_

N

+

I

IF_

B

A

T

D

_

I2C

K

L

C

_

I2C

A

GC

T

A

1

2

3

54

6

7

8

109

10 – 2

Page 32

LC-32LE250M

ER)

PP (2012.06.14)

O MAIN10(POWER)

T

0

1

0

.3V

3

D

+

0

1

V

.8

1

D

+

0

.8

V

1

+

D

U)

(CP

TO MAIN4

E

TR

E

E

T

S

E

S

R

2

2

1

1

C

u

1

.

0

IN-

IF_

IN+

IF_

T

D

A

_

I2C

K

C

L

C

_

I2

C

G

A

T

1

3

1

1

C

u

1

.

0

2

3

1

1

C

u

1

.

0

1110

5

1

1

1

R

0

1

0

1

1

R

3

3

IL

2

0

1

1

C

P

0

8

1

2

0

1

1

R

3

3

C

3

0

1

1

L

H

n

0

0

1

12

Z

C

4

0

1

R

1

1

5

Z

C

3

0

1

1

R

1

5

13

0

2

1

1

C

u

1

.

0

1

2

1

1

C

u

1

.

0

14

15

16

17

4

0

0

0

0

0

0

0

0

0

0

0

0

E

T

E

S

R

_

E

R

N

U

T

4

M

IF

V

4

P

IF

V

4

4

4

T

D

A

C

_

I2

K

C

L

_

I2C

C

G

A

T

18

19

10 – 3

Page 33

LC-32LE250M

LC -32LE 250M

MAIN2( T E R MINA L )

H

T

L564

T

L565

T

G

R547

75

1/4W

U

S

B:

5

0

0

m

A

F

E

max

T

L

9

50

4

G

ND

4

US

B

_DP

3

USB

_

D

N

J9501

2

ZA330WJQZ

+

5V

1

T

L9

5

03

T

L9502

T

L9

5

01

L9501

F

A

154W

J

4

2

3

1

T

L

9

505

C9501

10

u

16V

K

Z

A

5

10

W

J

P

Z

V

V

A

9502

V

V

X

X

A

074W

J

39V

1.

1

p

F

1

5

V

out

I

C

9

501

3

4

7

9

A

5

0

O

N

G

ND

1

USB

_

D

0P

USB

A

9

5

03

A

074W

39V

.

1pF

P

2

_D0N

J

4

V

i

n

C9502

10u

16V

K

Z

A

510W

J

P

Z

C

S

3

C9503

0.1u

R9501

1K

Y

_

1

MP

CO

L566

R5

4

9

R5

4

8

75

75

1/4W

1/4W

b

r

P

P

_

_

1

1

P

M

MP

O

CO

C

D

R50

T

L50

5

2

T

L50

6

3

T

L50

4

1

J

501

J

A

02

7W

J

HD

M

IA

UD

I

O

I

C

N

3

J

10K

C5

0

1

R50

5

56P

12K

CH

R

50

4

10K

J

C50

2

R50

6

56P

1

2K

CH

P

C

_A

U

D_

L

C50

3

100

0P

CH

P

C_A

UD_

R

C50

4

100

0P

CH

B

A

1

2

3

54

6

7

8

109

10 – 4

Page 34

LC-32LE250M

C

O

M

P

1

P

r

PP (2012.07.11)

HP

J50

R525

N

I

_

HP

3

JA03

0

W

JQZ

4357

26

4

5

3

1

1

1

5

5

5

L

L

T

T

TL

R5

2

2

100

K

C521

10P

33

UT

O

_

L

_

HP

1

6

1

5

TL

R

5

23

1

0

0

K

C522

10P

TO MAI

N

4

(

C

PU

CO

MP

1_

Y

CO

M

P

1_P

b

CO

MP

1

_

P

r

CV

B

S

1

C

O

MP

_A

UD_L

CO

MP

_A

U

D

R

5

26

3

3

T

U

O

R_

_

P

H

_R

C

V

B

S

_

A

UD_L

CV

B

S

_A

U

D_

R

HP

_

IN

RC

IR_P

A

S

S

UA

R

T

_DE

B

UG

_

T

X

UA

R

T

_DE

B

UG

_

RX

P

C_A

UD_L

P

C

_

A

UD_R

US

B

_

D0P

U

S

B

_D0

N

)

004

CO

M

P

1_Y

004

CO

MP

1

_

P

b

0

04

CO

MP

1_P

r

004

C

V

B

S

1

004

CO

MP

_A

U

D

_L

0

0

4

CO

MP

_

A

UD_R

004

CV

B

S

_A

U

D_

L

0

0

4

CV

B

S

_A

UD

_

R

0

0

4

HP

_IN

004

RC

004

IR_P

A

S

S

0

0

4

UA

R

T

_DE

B

UG

_

T

X

004

UA

RT

_DE

B

UG

_RX

004

P

C

_

A

UD_L

0

0

4

P

C_A

U

D_

R

0

04

U

S

B

_D0

P

004

US

B

_D0N

J502

ZA10

7

W

4

G

B

TL563

TL539

R533

75

1/4W

_

N

5

4

6

1

7

Y

L

8

5

9

1

T

L

5

T

T

L5

40

1

S

B

CV

L543

C532

5

6

P

R536

R5

10K

R535

1

R

5

12K

2

K

R

UD_

A

_

S

B

CV

RD

L

8

1

W

RD

H

0

2

42

T

L524

C

5

30

C5

5

6P

56P

R513

10K

3

4

10K

R511

32

12K

L

_

UD

A

_

S

B

CV

J

5

2

W

RD

H

6

0

2

3

C520

0

.

01u

T

L545

T

T

L527

1

4

C517

56P

R516

10K

R515

12K

R

UD_

A

_

P

M

CO

L568

T

L559

T

L5

6

2

T

L538

T

L529

L

D_

U

A

_

P

M

O

C

R520

1K

R

5

24

10K

T

O

MA

I

N

9

(

AU

D

I

O_

A

HP

_L_O

UT

HP

_R

_O

UT

S

E

RVI

C

UA

RT

_DE

B

UG

_TX

U

A

RT

_DE

B

UG

_R

X

11

12

13

14

15

16

17

E

2

T

L517

3

T

L5

1

8

1

T

L51

9

J

5

04

J

A

02

7W

J

18

MP)

00

9

H

P

_L_OU

T

00

9

HP

_R_O

UT

TO

M

AI

N

1

0

(

POW

ER

)

01

0

M+

5.6

V

01

0

D

+

3.3V

19

10 – 5

Page 35

LC-32LE250M

LC -32LE 250M

MAIN 3 (H D MI-T E R M)

H

G

F

TOP

INP UT 1

4

E

0

2

2

2

2

2

4

1

3

5

S

C15

1

0

A

Z

7

2

1

J

W

QZ

2

6

8

7

5

1

0

2

1

4

1

6

1

1

9

1

1

3

5

1

T

1

L

0

5

4

T

1

L

0

5

1

2

1

1

8

7

1

9

1

3

2

R

1

5

0

5

1

K

D

1

1

5

0

D

B

S

2

1

3

L

0

D

1

1

5

6

D

B

S

2

1

3

L

0

R

1

1

5

1

4

K

7

C

Z

Q1

501

L

TC04

3

1

R

5

1

6

1

4

K

7

2

4

4EEB

L

TC044EEB

D

C

H

D

MI0

C

_

K

L

N

H

D

MI0

C

_

L

P

K

H

D

MI0

D

_

0

N

H

D

MI0

D

_

0

P

H

D

MI0

D1

_

N

H

D

MI0

D

_

1

P

HD

MI0

D

_

2

N

H

D

MI0

D

_

2

P

B

A

1

2

3

54

6

7

8

109

10 – 6

Page 36

LC-32LE250M

)

D+

5

V

D+

.3V

3

R1

1

5

0

1

K

Q1503

0

CZ

L

T

1

0

5

6

PP (2012.

0

6.

14

)

TO MAIN10(

POWER)

D+

V

5

D+

3

.3V

RT1N441U

TO MAI

N4

(

CP

U)

HPD0

N

_

LTC044EEB

Q1502

I

HP

D

_

CT

RL

HP

D0

IN

_

HP

D_

C

T

RL

HDMI0

HDM

HDMI

HDM

HDM

HDM

HDMI

HDM

HDMI

DAT

_

HDMI

CL

_

K

_

CLK

N

I

_

0

CLKP

_

0

D0N

I

_

0

D0P

I

_

0

D1N

_

I0

D1P

_

0

D2N

I

_

0

D2P

HDMI

HDM

HDMI

HDM

HDM

HDMI

HDMI0

HDMI

HDMI

HDM

DA

_

T

I

CL

_

K

_

0

CLKN

I

_

0

CLKP

I

_

0

D0N

_

0

D0P

_

D1N

_

0

D1P

_

0

D2N

I

_

0

D2P

1110

12

13

14

15

16

17

18

19

10 – 7

Page 37

LC-32LE250M

A

V

D

D

A

D

C

3

3

L

V

B

C

K

P

LC -32L E 250M

MAIN4 (C P U )

H

O

WER)

N

10(P

TOMAI

10

0

.5

V

D+2

0

1

0

.3

V

D+3

0

1

0

V

.2

6

D+1

R

E

)

U

N

N

(T

1

M

A

I

O

T

G

V

P

IF

M

IF

V

S

E

T

R

_

E

U

N

E

R

T

C

C

K

_

L

I2

D

A

T

I2

C

_

V

P

IF

V

M

IF

T

R

E

S

E

E

R

_

T

U

N

C

K

L

I2

C

_

D

A

T

I2

C

_

3

B

3

0

3

F

5

T

4

A

0

2

6

0

C

3

3

u

1

8

1

C

3

3

u

1

0

V

1

0

6

J

W

A

7

Z

1

K

1

A

0

T

3

4

3

5

B

2

F

0

7

0

B

3

3

T

E

K

N

D

L

0

_

T

S

C

T

C

A

S

C

A

A

D

_

D

I_

_

I

P

P

I_

O

S

S

D

D

S

S

I_

I_

P

P

S

S

F

4

5

T

A

0

2

L

R

T

C

_

C

A

F

0

1

0

3

3

)

L

A

IN

R

E

M

N

(T

2

I

M

A

O

T

0

V

B

S

1

C

0

0

Y

P

_

1

C

O

M

0

0

P

b

P

_

1

C

O

M

0

0

P

r

P

_

1

C

O

M

E

0

0

P

IN

_

H

0

0

L

U

D

_

B

S

A

_

C

V

0

0

R

U

D

_

B

S

A

_

C

V

0

0

L

A

U

D

_

M

P

_

C

O

0

D

0

R

A

U

D

_

M

P

_

C

O

0

0

L

_

A

_

U

D

P

C

0

0

R

_

A

_

U

D

P

C

0

0

P

B

D

_

0

U

S

0

0

N

B

D

_

0

U

S

0

0

R

C

0

0

S

P

A

S

_

IR

0

0

X

T

G

_

E

B

U

R

T

D

_

U

A

0

0

X

R

G

_

E

B

U

D

_

R

T

U

A

3

3

.

0

7

5

3

3

R

C

8

6

.0

0

4

5

R

3

3

2

3

3

.0

0

7

6

R

3

3

0

1

0

5

5

R

3

3

2

3

3

.0

0

6

5

R

3

3

2

3

3

.

0

1

7

R

3

3

8

6

.

0

2

0

6

3

C

3

V

0

L

U

D

_

B

S

A

_

C

V

2

R

U

D

_

B

S

A

_

C

V

2

L

A

U

D

_

M

P

_

C

O

2

R

A

U

D

_

M

P

_

C

O

2

L

_

A

_

U

D

P

C

2

R

_

A

_

U

D

P

C

2

2

2

2

2

2

2

1

1

A

9

6

K

Z

u

.2

2

V

0

1

3

6

3

C

3

A

9

6

K

Z

u

.2

2

5

1

3

C

3

V

0

1

1

A

9

6

K

Z

u

.2

2

V

0

1

6

1

3

C

3

A

9

6

K

Z

u

.2

2

1

0

3

C

3

V

0

1

1

A

9

6

K

Z

u

.2

2

V

0

1

3

0

3

C

3

A

9

6

K

Z

u

.2

2

4

0

3

3

R

2

0

C

)

R

E

M

I-T

H

D

M

(

3

IN

M

A

O

T

C

K

L

N

M

I0

_

H

D

C

K

L

P

M

I0

_

H

B

D

D

N

0

M

I0

_

H

D

D

P

0

M

I0

_

H

D

D

N

1

M

I0

_

H

D

D

P

1

M

I0

_

H

D

D

N

2

M

I0

_

H

D

D

P

2

M

I0

_

H

D

A

T

M

I_

D

H

D

K

L

M

I_

C

H

D

N

I

D

_

0

H

P

R

L

D

C

_

T

H

P

t

u

in

p

V

S

B

C

8

0

C

3

3

u

7

4

0

6

6

3

3

u

7

4

3

3

C

u

7

4

6

7

C

3

3

P

0

0

C

3

3

u

7

4

C

3

3

u

7

4

0

C

3

3

u

7

4

0

J

W

J

W

1

J

W

J

W

1

J

W

J

W

1

IN

B

S

_

1

C

_

V

R

C

A

0

C

O

M

V

t

in

u

p

t

n

e

n

o

p

C

m

o

5

5

5

5

7

P

Y

_

IN

1

O

M

P

C

G

IN

S

_

O

1

O

M

P

C

6

P

P

IN

b

P

_

1

C

O

M

9

P

IN

P

_

r

1

O

M

P

C

4

Y

M

IN

P

_

1

C

O

M

P

IN

_

H

t

u

in

p

D

IO

U

A

0

D

L

_

A

U

D

R

_

0

A

U

1

D

L

_

A

U

D

R

_

1

A

U

2

D

L

_

A

U

D

R

_

2

A

U

P

B

D

_

0

U

S

N

B

D

_

0

U

S

R

C

S

P

A

S

_

IR

X

T

G

_

E

B

U

D

_

R

T

U

A

X

B

U

R

G

_

E

U

A

R

T

D

_

C

K

L

N

M

I0

_

H

D

C

K

L

P

M

I0

_

H

D

D

N

0

M

I0

_

H

D

D

P

0

M

I0

_

H

D

D

N

1

M

I0

_

H

D

D

P

1

M

I0

_

H

D

D

N

2

M

I0

_

H

D

D

P

2

M

I0

_

H

D

A

T

M

I_

D

H

D

K

L

M

I_

C

H

D

N

I

D

_

0

H

P

R

L

D

C

_

T

H

P

3

0

3

Q

3

S

V

C

1

4

N

1

1

R

T

1

1

3

C

3

u

.1

0

V

0

1

1

2

3

D

G

N

4

3

IC3

G

2

H

C

B

u

I2

C

9

2

3

C

3

u

.1

0

V

0

1

D

1

N

G

D

2

D

V

2

0

3

IC3

U

9

2

4

8

T

S

P

TIC

E

S

E

R

4

4

3

R

3

K

0

1

C

V

C

8

R

3

7

2

M

P

T

E

6

T

4

4

3

C

3

H

5

u

1

.0

0

4

0

D

6

P

6

S

W

s

3

2

3

R

3

2

0

3

Q

3

K

.7

4

U

1

4

N

1

1

R

T

1

0

3

3

T

L

S

V

T

4

U

O

D

3

C

0

3

3

C

3

u

1

.0

0

B

C

Z

D

N

_

0

U

S

B

B

D

P

_

0

U

S

O

F

_

L

M

0

W

P

P

P

I_

W

S

C

K

L

D

C

A

_

D

A

T

C

A

D

_

D

D

T

C

D

_

E

Y

/D

1

K

E

E

M

P

T

Y

_

2

K

E

R

C

IN

_

W

P

S

S

E

T

R

_

E

H

W

Y

2

K

E

3

4

3

K

.7

1

0

3

3

H

Z

Q

J

W

7

A

5

0

X

E

M

P

T

Y

_

2

K

E

2

R

S

_

W

S

A

4

2

3

R

3

K

2

2

S

E

T

R

_

E

H

W

5

2

3

R

3

K

1

5

0

R

3

3

K

7

.

4

9

7

3

C

3

u

.1

0

J

W

3

A

1

5

K

Z

7

1

3

C

3

u

.2

2

V

.3

6

2

0

3

3

L

T

5

4

7

8

3

3

0

0

2

2

0

0

3

3

3

3

3

3

3

3

R

R

R

R

5

7

6

7

P

0

D

M

_

7

7

P

0

D

P

_

8

7

G

N

D

9

7

0

P

M

W

0

8

1

P

M

W

1

8

K

A

C

_

D

D

C

2

8

A

C

A

D

_

D

D

3

8

D

A

D

IO

_

V

D

4

8

R

0

S

A

5

8

R

1

S

A

6

8

N

I

IR

7

8

C

C

E

8

8

S

E

T

R

E

9

8

D

G

N

0

9

G

T

P

U

L

H

O

1

9

N

D

C

K

R

X

2

9

P

D

C

K

R

X

3

9

D

N

0

R

X

4

9

D

P

0

R

X

5

9

D

_

C

D

D

D

D

6

9

D

N

1

R

X

7

9

D

P

1

R

X

8

9

C

_

C

D

D

D

D

9

9

D

N

2

R

X

100

D

P

2

R

X

D

G

N

1

u

.1

0

0

8

3

C

3

1

0

2

3

3

0

3

3

0

0

0

3

3

3

3

3

3

3

3

3

R

R

R

R

R

1

0

3

3

P

T

5

3

C

3

3

1

3

C

3

3

u

1

.

0

u

1

0

6

1

6

2

6

3

6

4

6

5

6

6

6

7

6

8

6

9

0

6

7

1

7

2

7

3

7

4

7

I

K

O

Z

S

D

S

C

A

T

A

K

D

O

2

1

M

_

_

D

D

D

D

V

V

A

A

2

C

D

C

S

S

0

C

P

N

0

Y

IN

S

B

H

4

3

8

2

3

C

3

u

1

P

M

D

0

0

D

]

B

B

]

V

[0

V

V

5

L

L

O

[6

I

P

O

I

G

P

G

0

0

M

C

P

IN

P

0

0

N

0

G

Y

IN

IN

O

IN

S

G

G

S

R

V

9

8

7

6

5

P

M

M

P

M

D

2

2

1

1

K

B

O

B

B

B

C

V

V

V

V

M

B

L

L

L

L

_

V

D

L

D

V

A

1

0

3

IC3

Q

Z

W

J

5

6

4

IX

D

5

2

C

D

A

1

_

P

M

P

IN

P

D

1

1

1

1

G

D

N

N

I

I

IN

O

V

IN

G

S

A

0

1

R

G

B

5

6

1

1

3

1

4

1

2

1

1

1

4

3

3

C

3

u

.2

2

Z

Q

J

6

0

W

3

7

3

6

B

3

F

A

A

IN

P

P

M

P

N

N

K

K

L

0

L

L

R

D

C

C

T

_

_

_

C

I0

I0

I0

_

M

M

M

D

D

D

D

P

H

H

H

H

1

2

3

54

6

7

P

N

N

P

P

T

2

2

K

1

1

0

L

A

D

D

D

D

D

_

_

C

_

_

_

D

I0

I0

I_

I0

I0

I_

I0

M

M

M

M

M

M

M

D

D

D

D

D

D

D

H

H

H

H

H

H

H

8

P

G

N

IN

rI

IN

IN

O

b

P

Y

Y

S

P

_

_

_

_

_

1

1

1

1

1

P

P

P

P

P

M

M

M

M

M

O

O

O

O

O

C

C

C

C

C

109

10 – 8

Page 38

LC-32LE250M

5

5

6

5

5

7

5

8

5

9

5

0

6

P

K

C

B

V

L

3

3

C

D

A

_

D

D

V

A

6

1

F

2

0

M

P

M

P

M

1

0

0

3

3

A

A

A

B

B

V

V

V

V

V

L

L

L

L

L

1

T

U

0

1

O

2

S

M

S

S

S

B

O

B

B

B

V

V

V

V

C

C

V

C

C

C

2

0

1

2

2

9

1

8

1

7

1

8

7

3

C

3

8

3

3

C

3

u

.1

0

u

.1

0

9

0

3

3

B

A

T

4

5

4

0

3

3

T

P

IN

_

1

S

B

V

0

C

M

_

A

O

C

C

V

R

11

)

7

.13

2.0

1

2

0

(

P

P

3

3

1

B

3

F

A

T

4

2

5

0

4

1

C

3

3

0

1

u

6

1

V

P

Z

0

1

5

J

W

K

A

Z

3

3

9

3

R

0

0

1

C

)

N

L

E

A