Page 1

Revised Edition

LCD COLOR TELEVISION

LC-19SK25U

LC-19SK25U-W

LC-19SB25U

LC-19SB25U-W

LC-19SB15U

N38B2LC19K25U

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

The revised edition added the schematic of SUB3(sound) after Page 81.

CONTENTS

ネ

IMPORTANT SERVICE SAFETY PRECAUTION ..........................................................................................2

ネ

SPECIFICATIONS .........................................................................................................................................5

ネ

OPERATION MANUAL ..................................................................................................................................7

ネ

DIMENSIONS ..............................................................................................................................................11

ネ

REMOVING OF MAJOR PARTS .................................................................................................................13

ネ

ADJUSTING PROCEDURE OF EACH SECTION ......................................................................................18

ネ

PUBLIC MODE SETTING PROCEDURE ...................................................................................................40

ネ

TROUBLESHOOTING TABLE .....................................................................................................................45

ネ

MAJOR IC INFORMATIONS .......................................................................................................................53

ネ

BLOCK DIAGRAM .......................................................................................................................................54

ネ

OVERALL WIRING DIAGRAM ....................................................................................................................56

ネ

DESCRIPTION OF SCHEMATIC DIAGRAM ..............................................................................................58

ネ

SCHEMATIC DIAGRAM

RC/LED Unit ..............................................................................................................................................59

MAIN Unit ..................................................................................................................................................60

SUB Unit ....................................................................................................................................................78

POWER_INVERTER Unit ..........................................................................................................................84

KEY Unit ....................................................................................................................................................86

ネ

PRINTED WIRING BOARD ASSEMBLIES .................................................................................................87

ネ

REPLACEMENT PARTS LIST ...................................................................................................................105

ネ

PACKING OF THE SET .............................................................................................................................124

LC-19D45U

Page

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

2

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

A V

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15 µF

TEST PROBE

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTIO N : FOR CON TINUED

PROTECTION AGAINST A RISK OF

FIRE REPLACE ONLY WITH SAME

TYPE F7502 (2.5A, 250V) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

Plug

•

Using two clip leads, connect a 1.5k ohm, 10 watt

•

the AC cord directly into a 120 volt AC outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

test).

resistor paralleled by a 0.15µF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as electrical conduit or electrical

ground connected to an earth ground.

Use an AC voltmeter having with 5000 ohm per volt,

•

or higher, sensitivity or measure the AC voltage drop

across the resistor.

Connect the resistor connection to all exposed metal

•

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

checks must be repeated with the AC cord plug

All

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V peak (this corresponds to 0.5

mA. peak AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the monitor to the owner.

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from

visual inspection, nor can protection afforded by

them be necessarily increased by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by "!"

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

Page 3

LC-19SK25U/U-W

A V

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15 µF

TEST PROBE

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

La réparation ne peut être effectuée que par un technicien spécialisé qui s'est

parfaitement accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. Pour la sécurité continue, n'entreprendre aucune

modification de tout circuit.

2. Débrancher l'alimentation CA avant la réparation.

PRECAUTION: POUR LA

PROTECTION CONTINUE

CONTRE LES RISQUES

D'INCENDIE, REMPLACER LE

FUSIBLE PAR UN FUSIBLE DE

MEME TYPE F7502 (2.5A, 250V).

AVANT DE RENDRE LE RECEPTEUR A L’UTILISATEUR (Incendie et choc électrique)

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne

soit pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme

les boutons de commande non-métalliques,

les isolants, le dos du coffret, les couvercles ou

blindages de réglage et de compartiment, les

réseaux de résistance-capacité, les isolateurs

mécaniques, etc.

3. S'assurer qu'il n'y ait pas de danger d'électrocution

en vérifiant la fuite de courant, de la facon suivante:

Brancher le cordon d'alimentation directem-ent à

•

une prise de courant de 120V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

A l'aide de deux fils à pinces, brancher une

•

résistance de 1.5kΩ 10 watts en parallèle avec un

condensateur de 0.15µF en série avec toutes les

pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise

de terre branchée à la terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins

•

5000Ω/V pour mesurer la chute de tension CA en

travers de la résistance.

Toucher avec la sonde d'essai les pièces métalliques

•

exposées qui présentent une voie de retour au

châssis (antenne, coffret métallique, tête des vis,

arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en travers

de la résistance. Toutes les vérifications doivent

être refaites après avoir inversé la fiche du cordon

d'alimentation. (Si nécessaire, une prise d'adpatation

non polarisée doit être utilisée dans le but de

terminer ces vérifications.)

tension de pointe mesurèe ne doit pas dépasser

La

0.75V (correspondante au courant CA de pointe de

0.5mA). Dans le cas contraire, il y a une possibilité

de choc électrique qui doit être supprimée avant de

rendre le récepteur au client.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques,

dans les téléviseurs de l'afficharge à cristaux liquides

présentent des caractéristiques spéciales relatives à la

sécurité.

Ces caracténstiques ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

identifiées par la marque "

" et hachurées dans la

!

liste des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d'origine.

L'utilisation de pièces qui n'ont pas les mêmes

caractéristiques que les pièces recommandées par

l'usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

3

Page 4

4

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

Precautions for using lead-free solder

1 Employing lead-free solder

"All PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on

the PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering

bit, contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn

on and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit

after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No,

ZHNDAi123250E J

ZHNDAi126500E J

ZHNDAi12801KE J

Descr

★

0.3mm 250g(1roll) BL

φ

0.6mm 500g(1roll) BK

φ

1.0mm 1kg(1roll) BM

φ

iption Code

Page 5

SPECIFICATIONS

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

Item

LCD panel

Resolution

TV

Function

TV-standard

Receiving

Channel

Audio multiplex

Audio out

Terminals

INPUT

INPUT 2

INPUT 3

INPUT 4

Headphone

ANTENNA

DIGITAL AUDIO OUTPUT

OSD language

Power Requirement

Power Consumption

1

(CCIR)

VHF/UHF

CATV(analog)

Digital Terrestrial

Broadcast (8VSB)

Digital Cable

(64/256 QAM)

Model: LC-19SK25U/LC-19SK25U-W/LC-19SB25U/LC-19SB25U-W/LC-19SB15U

18.5o screen size class Advanced Super View & BLACK TFT LCD

( Diagonal Measurement: 181/

1,049,088 pixels (1,366 g

768)

)

o

2

American TV Standard ATSC/NTSC System

VHF 2-13ch, UHF 14-69ch

1-135ch (STD, HRC, IRC)

2-69ch

*1

1-135ch

System

BTSC

2W g

2

COMPONENT in

AV in, S-VIDEO in

HDMI in with HDCP(480P, 720P/60Hz, 1080I/60Hz, VGA), HDMI Analog Audio in

15 pin mini D-sub female connector, PC Audio in (Ø 3.5 mm jack)

3.5 mm jack (Audio Output)

Ø

nbalance, F Type g 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

75 q U

Optical Digital audio output g

1 (Dolby Digital)

English/French/Spanish

120 V, 60 Hz

AC

44 W (0.5 W Standby with AC 120V)

Weight

TV + stand

TV only

Dimension

*2

(W g H g D)

TV + stand

TV only

Operating temperature

*1

Emergency alert messages via Cable are unreceivable.

*2

The dimensional drawings are shown on the inside back cover.

11.4 lbs./5.2 kg

lbs./4.7 kg

10.3

18

18

e

3

3

32°F

11

/16 g 1

/64 g 7 63/64 inch

4

/16 g 12 19/32 g 2 61/64 inch

to e104°F (0°C to e40°C)

• As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

improvement without prior notice. The performance specification figures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

5

Page 6

6

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

SPECIFICATIONS(Continued)

Item

LCD panel

Resolution

TV

Function

TV-standard

Receiving

Channel

Audio multiplex

Audio out

Terminals

INPUT

INPUT 2

INPUT 3

INPUT 4

Headphone

ANTENNA

DIGITAL AUDIO OUTPUT

OSD language

Power Requirement

Power Consumption

(CCIR)

1

VHF/UHF

CATV(analog)

Digital Terrestrial

Broadcast (8VSB)

Digital Cable

*1

(64/256 QAM)

Model: LC-19D45U

18.5o

screen size class Advanced Super View & BLACK TFT LCD

( Diagonal Measurement: 181/

1,049,088 pixels (1,366 g

768)

)

o

2

American TV Standard ATSC/NTSC System

VHF 2-13ch, UHF 14-69ch

1-135ch (STD, HRC, IRC)

2-69ch

1-135ch

System

BTSC

2

g

2W

COMPONENT in

AV in, S-VIDEO in

HDMI in with HDCP(480P, 720P/60Hz, 1080I/60Hz, VGA), HDMI Analog Audio in

15 pin mini D-sub female connector, PC Audio in (Ø 3.5 mm jack)

3.5 mm jack (Audio Output)

Ø

nbalance, F Type g 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

75 q U

Optical Digital audio output g

1 (Dolby Digital)

English/French/Spanish

120 V, 60 Hz

AC

44 W (0.5 W Standby with AC 120V)

Weight

TV + stand

TV only

Dimension

(W g

H g D)

*2

TV + stand

TV only

Operating temperature

*1

Emergency alert messages via Cable are unreceivable.

*2

The dimensional drawings are shown on the inside back cover.

11.9 lbs./5.4 kg

lbs./4.5 kg

10.1

3

18

/16 g 14 11/64 g 7 63/64 inch

3

/16 g 12 19/32 g 3 1/32 inch

18

32°F

to e104°F (0°C to e40°C)

e

• As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

improvement without prior notice. The performance specification figures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

Page 7

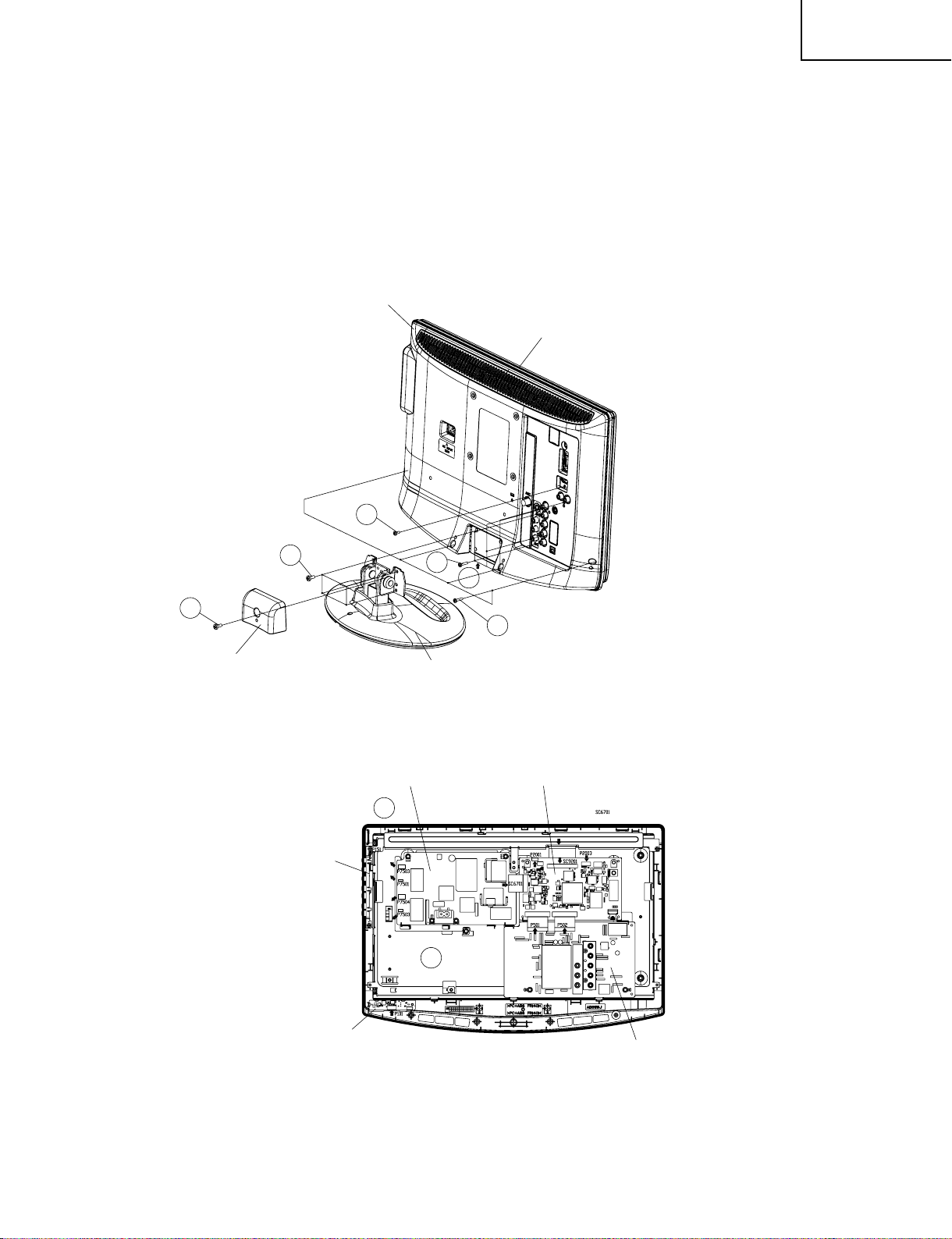

REMOVING OF MAJOR PARTS

Cabinet B

Cabinet A

3

3

3

2

1

4

Stand HINJI Cover

Stand

5

5

Inverter PWB

Main PWB

BTN PWB

LED PWB

(LC-19SK25U/LC-19SK25U-W)

1. Remove the Stand HINGI Cover fixing screw (1 pc.).

2. Remove the stand fixing screws (4 pcs.).

3. Remove the cabinet B fixing screws (10 pcs.).

4. Remove the cabinet B after opening from the direction of an arrow.

5. Disconnect all the connectors from all the PWBs.

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

13

Page 8

14

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

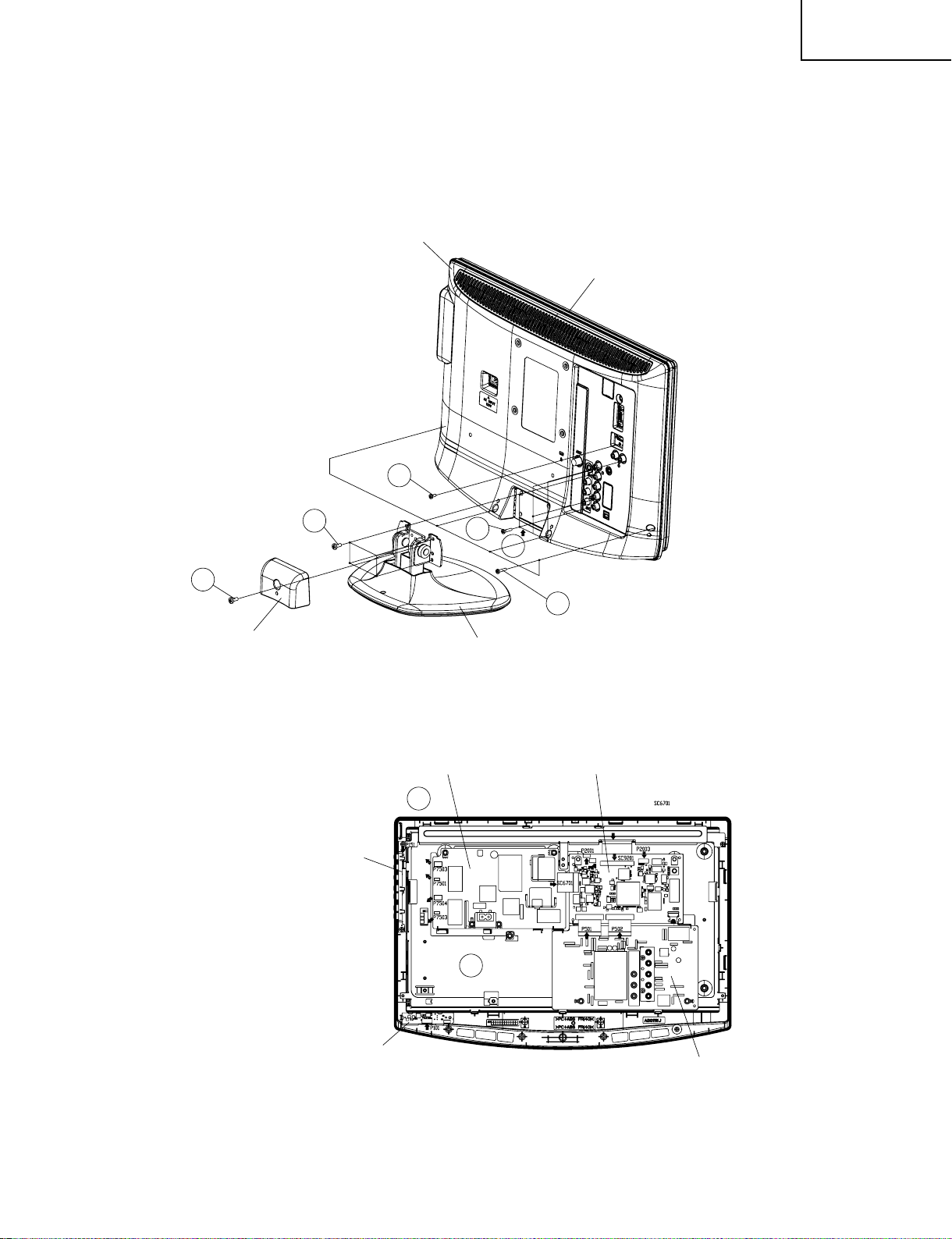

Cabinet B

Cabinet A

3

2

1

3

3

4

Stand HINJI Cover

Stand

1

5

5

Inverter PWB

Main PWB

BTN PWB

LED PWB

Sub PWB

(LC-19D45U)

1. Remove the Stand HINGI Cover fixing screw (1 pc.) and the handle fixing screws (4 pcs).

2. Remove the stand fixing screws (4 pcs.).

3. Remove the cabinet B fixing screws (10 pcs.).

4. Remove the cabinet B after opening from the direction of an arrow.

5. Disconnect all the connectors from all the PWBs.

Page 9

(LC-19SB25U/LC-19SB25U-W/LC-19SB15U)

Cabinet B

Cabinet A

3

2

1

5

5

3

3

4

Stand HINJI Cover

Stand

Inverter PWB

Main PWB

BTN PWB

LED PWB

Sub PWB

1. Remove the Stand HINGI Cover fixing screw (1 pc.).

2. Remove the stand fixing screws (4 pcs.).

3. Remove the cabinet B fixing screws (10 pcs.).

4. Remove the cabinet B after opening from the direction of an arrow.

5. Disconnect all the connectors from all the PWBs.

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

15

Page 10

16

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

Main PWB

Power PWB

Sub PWB

LED PWB

LED PWB

Speaker (L)

Speaker Angle (L)

Speaker Angle (R)

Speaker (R)

8

8

8

9

8

7

6

6

9

10

11

12

12

11

6. Remove the vesa angle fixing screws (4 pcs.).

7. Remove the 3 lock screws from Main Shield.

8. Remove the 9 lock screws from the sub PWB and main PWB and power PWB and AC angle. Detach the sub

PWB and main PWB and power PWB from LCD assembly.

9. Remove the 3 lock screws from the control button assembly and the source PWB Shield.

10. Remove the LED PWB fixing screws (1 pcs.).

11. Remove the 2 lock screws each from the right and left speakers ass’y and take out both the speakers ass’y.

12. Remove the 4 lock screws each from the right and left speaker angle.

Page 11

LC-19SK25U/U-W

5

5

Inverter PWB

Main PWB

BTN PWB

LED PWB

Sub PWB

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

Precautions in servicing the side-B (backside) of the main PWB unit

ネ

1. Remo

2. Connect the service-specific extension cable (QCNW-E542WJZZ) between the main PWB (SC1201) and the

3. Connect the service-specific extension cable (QCNW-E542WJZZ) between the main PWB (SC1202) and the

4. Connect the service-specific extension cable (QCNW-D431WJZZ) between the main PWB (SC1204) and the

5. Connect the service-specific extension cable (QCNW-C458WJQZ) between the main PWB (SC9201) and the

Precautions in servicing the side-B (backside) of the power PWB unit

ネ

1. Remo

2. Connect the service-specific extension cable (QCNW-D431WJZZ) between the power PWB (SC7501) and the

Precautions in servicing the side-B (backside) of the sub PWB unit

ネ

1. Remo

2. Connect the service-specific extension cable (QCNW-E542WJZZ) between the sub PWB (P501) and the main

3. Connect the service-specific extension cable (QCNW-E542WJZZ) between the sub PWB (P502) and the main

ve the lock screws (2 pcs.) from the main PWB, detach the PWB from the set, and then turn it over.

sub PWB (P501).

sub PWB (P502).

power PWB (SC7501).

panel PWB (CN1).

ve the lock screws (4 pcs.) from the power PWB unit, detach the PWB from the set, and then turn it over.

main PWB (SC1204).

ve the lock screws (2 pcs.) from the sub PWB unit, detach the PWB from the set, and then turn it over.

PWB (SC1201).

PWB (SC1202).

Step Part No. Description

2 QCNW-E542WJZZ Extension Cable 23-pin Main (SC1201)-Sub (P501)

3 QCNW-E542WJZZ Extension Cable 23-pin Main (SC1202)-Sub (P502)

4 QCNW-D431WJZZ Extension Cable 15-pin Main (SC1204)-Power (SC7501)

5 QCNW-C458WJQZ Extension Cable 80-pin Main(SC9201)-Panel(CN1)

17

Page 12

18

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MainPWB P801

1 D5V TXD MPU 2

3 RESET MPU MODEMPU 4

5 RXD MPU M32TDI 6

7 BU3.3V M32TDO 8

9 M32TRST M32TCK 10

11 GND M32TMS 12

13 ASEBRKAK_N ASEMDO 14

15 TRST_N TCK 16

17 TDI TDO 18

19 TMS RESET_N 20

EJ-WriterDTV

1 TCK GND/NC 8

2 TRST_N GND/ASEMD0 9

3 TDO GND 10

4 ASEBRKAK_N NC/3.3V 11

5 TMS GND 12

6 TDI GND 13

7 RESET_N GND 14

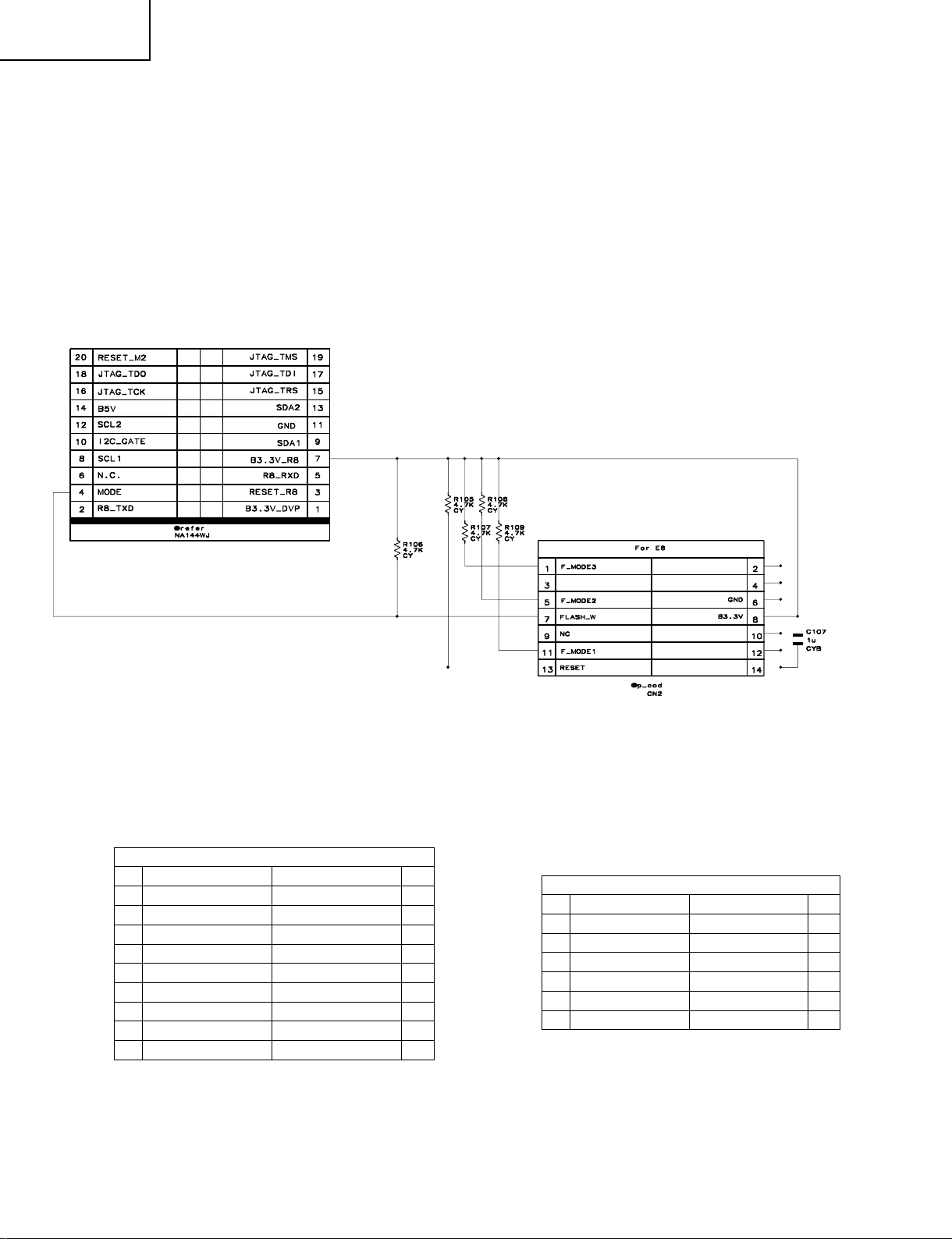

ADJUSTING PROCEDURE OF EACH SECTION

The adjustment values are set to the optimum conditions at the factory before shipping .If a value should become

improper or an adjustment is required due to part replacement, make an adjustment according to the following

procedure.

1. After replacement of the any PWB and/or IC for repair, please note the following

1.1

When replacing the unit DUNTKE352FM02, make sure to prepare the new unit loaded with updated software.

1.2 Special Equipment

1.2.1 Renesas E8A, the SUB microprocessor software Writer

1.2.2 Sophia systems DTV EJ-Writer, the Main software Writer

1.2.3 Convertor 1, please refer to following schematic and make one.

1.2.4 Convertor 2, please refer to following instruction and make one.

Page 13

36

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

3. Adjustment procedure

3.1 Plug the AC power cord directly into a wall outlet.

3.2 Calling the adjustment process mode

There are two ways to call this mode.

appears at the top left of the screen to indicate the inspection process mode.)---Press the CH (s)key

and VOL(−)key at once.(The adjustment process mode screen shows up.)_To quit, turn off the power.

(Or turn off the power switch or turn off the remote controller.)

3.3

Basic operation

Continuous press: The next receivable channel is searched.

the cursor key and VOL(+)(−) keys

a page is already selected and the MENU key is pressed, the top item on the next page is selected.

page is selected.

selected item.

Hierarchical shift

item shows up.

3.4

3.4.1 AD TRANSFORM LEVEL Adjustment

Signal: color BAR.

Setting: 02: 1080i/59.94(30sf)

H: 33.72 KHz V: 29.97Hz

Note: Please use the third color Bar of LT448 generator

Setting: 15: 480i/60

H: 15.73 KHz V: 29.97Hz

Note: Please use the third color Bar of LT448 generator

When “AUTO GAIN-OFFSET OK” appears , this adjustment is complete

Turn on the power and press the “ADJUST PROCESS” key on the remote controller.

∗

For servicing: Hold down the INPUT key and VOL (−) key at once, and turn on the power switch.(“K”

∗

Key operation in the adjustment process

Selecting the receiving channels

Using the CH(r)/(s) keys, turn up and down an actual receiving channel.

∗

Snap press: The channels are turned up and down one by one .

Various adjustments: The items are adjusted one by one by selecting on the menu screen and using

∗

With the CURSOR UP/DOWN keys, select an adjustment item.

∗

Using the MENU key, the adjustment items are selected one after another. When the bottom item on

∗

If any item on a page is selected and the preset key is pressed, the top item on the next page is selected.

∗

Page1- Page2- Page3- Page7- Page9- Page10…..

If any item on a page is selected and the manual memory key is pressed, the top item on the same

∗

Using the CURSOR LEFT/RIGHT keys and VOL(+)(−) keys, turn up and down the setting of a

∗

When the ENTER key is pressed on any item other than I2C DATA on page 4,the setting page of the

∗

To quit the setting page, press the front screen key.

∗

Adjustment

3.4.1.1 Input 1080i signal

Input 1080i color bar signal (75%)

1

Signal generation: LEADER LT448

Adjusting AUTO GAIN-OFFSET in page 3 of DVP (M2-HD) to RUN .

2

When “AUTO GAIN-OFFSET OK” appears , this adjustment is complete

3.4.1.2 Input 480i signal

Input 480i color bar signal (75%)

1

Signal: color BAR.

Adjusting AUTO GAIN-OFFSET in page 4 of DVP (M2-SD) to RUN .

2

Signal generation: LEADER LT448

3.4.1.3 Input PC XGA signal

Input XGA color bar signal (RGB)

1

Page 14

Signal: color BAR (SATURATION 75%)

Setting: 28: XGA

H: 48.36KHz V: 60Hz

SYNC: OFF

Note: Please use the color Bar of SATURATION

When “AUTO GAIN-OFFSET OK” appears , this adjustment is complete

Adjusting AUTO GAIN-OFFSET in page 5 of DVP(M2-PC)to RUN .

2

NOTE: If want to set all item to ON,please set to RUN in ADJUST PROCESS.

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

3.5

TEMP Adjustment

3.5.1 Receive US-10ch(JPN-8ch) the standard color bar signal

3.5.2 See if the “YDATA” reading (maximum) on Adjustment Process Page 1 is within the range in the

follow table. If not, adjust the “TEMP ALL” setting on the same page to have the “YDATA” reading

(maximum) within this range.

MODEL A3KL19SK25U

SETTING VALUE (NTSC) 96-100

Refence

(Adjustment Process Menu Page 1)

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

0 D V P 1

1

T A M P 1 L 9 6

●

2 Y D A T A 9 9

3 T A M P 1 H 1 0 0

4 T A M P A L L O F F

5 N T S C T A M P 1 3 2

6 P A L - M T A M P 3 9

7 P A L - N T A M P 3 9

37

Page 15

38

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

㪈㩷 㪉㩷 㪊㩷 㪋㩷 㪌㩷 㪍 㪎㩷 㪏㩷 㪐㩷 㪈㪇㩷 㪈㪈 㪈㪉 㪈㪊 㪈㪋 㪈㪌 㪈㪍

㪈㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪉㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪊㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪋㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪌㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪍㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪎㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪏㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪐㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪇㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪈㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪉㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪊㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪋㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪌㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪍㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪎㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪏㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪈㪐㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

㪉㪇㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷 㩷

3.5.3 Common bias Adjustment

Feed in built-in signal (See follow picture)

1

Adjust the “COM BIAS” setting so that the peak-to-peak of the wave be minimized.

2

Page 16

3.5.4 White balance adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Setting Backlight: +16

(MAX)

2 Automatic adjust-

ment execution

For detailed adjustment procedure refer to "Kameyama Model Integral WB Adjustment

Specifications".

1) Make the following settings for the set.

AV MODE: [DYNAMIC]

Backlight: +16

Aging time: Min. 30 minutes

2) Connect the white balance adjustment tool to the set.

3) The cross is displayed by execute command of RS232C and the probe position is

set to the center of the screen(please attention the operation manual of CA210).

4) The cross is disappeared by execute command of RS232C.

Adjusting the picture by execute command of RS232C

[Adjustment prcedure]

1) Using the remote controller,transmit the "monitor adjustment process" code.

2) Set the 6

turn down the R,G and B settings to their reference levels.

3) Set the 5

Correct the G setting (304 x 6th point G setting /816) (rounded off), and make the R

and B settings to their reference levels.

* Initial R, G and B settings at point 6: Gradation level set at 816

* Initial R and B settings at points 5:Correct the setting same remainder of RGB setting

at each point (This is because the adjustment is made to achieve the same remainder

of RGB setting/4 at each point).

th

point to the specified gradation level,With the strongest color being fixed,

th

point to the specified gradation level.

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

[Adjustment value]

As per the "standard set" submitted by Engineering Department

[Adjustment reference] Instrument:[Minolta CA-210] Engineering instrument

Level Reference Adj.spec Ins.spec

point 6 816

point 5 304

Note Set conditions for inspection

X=0.272

y=0.277

X=0.272

y=0.277

AV MODE: [DYNAMIC] (Reset)

Monochrome: ON

Aging Time: Min. 30 minutes

3.6 Factory setting

3.6.1 Making factory settings

Use the adjustment remote controller for the factory settings.

3.6.1.1 Hold on the remote controller’s FACTORY SETTING key.

3.6.1.2

If background of screen is green,the settings are complete.

Sever seconds later, "SETTING COMPLETE""TV VER *.**" appears at the center of the screen.

SETTING COMPLETE

0.001

±

0.002

±

0.002

±

0.004

±

TV VER ∗.

∗∗

3.6.1.3 Power off the set.

Note: Do not turn on the power once the factory settings have been made. Otherwise the factory

setting must be made again.

3.7 Software version

The software version will be reported at the Conversion Judgment Meeting. Possible modifications that will

follow will be reported using the Modifications Report.

∗

Main microprocessor

∗ Monitor microprocessor

∗ EDIT data(HDMI/analog RGB)

39

Page 17

40

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

PUBLIC MODE SETTING PROCEDURE

1. How to start Public Mode

There are the following two ways to get the public mode setup screen displayed.

•

In the adjustment process mode, turn on "HOTEL MODE". Also press the "CH (r)" and "VOL (+)" keys

1

on the set at once and turn on the power.

1) Press the "INPUT" and "V

2

2) Get the password input screen displayed.

— — —

— —

✽

OL (+)" keys on the set at once and turn on the power.

Procedure

The input starts with the leftmost digit.

•

Use the numeric keys [1] thru [9] and [0] keys on the remote con-

•

troller. The other keys are not acceptable.

With a numeric-key input, "–" will change to "✽". The input position

•

will move one digit to the right.

With all the 3 digits entered, the password will be verified.

•

✽

✽

✽

3) The 3-digit password is now verified.

The password [0] [2] [7] provides for the public mode screen. (This screen comes on with whatever ad-

justment process settings.)

With any other passwords, the screen changes to the normal mode.

Page 18

LC-19SK25U/U-W

LC-19SB25U/U-W

2. How to exit Public Mode

There are the following ways to quit the public mode setup screen.

Turn off "HOTEL MODE" in the adjustment process mode. (✩) ←

•

screen, but for quitting the mode itself.

Turn off the power with the "POWER" key. (★)

•

Select "ENTER". (★)

•

... "HOTEL MODE" stays on in the adjustment process mode.

★

... The settings will be back to the factory ones.

✩

This way alone is not for quitting the setup

3. Public Mode Setting Values

With the factory settings made, the public mode settings get initialized. (The adjustment process remains in-

•

tact.)

4. Public Mode Menu

The guidance is not displayed onscreen.

Setup procedure

To move the cursor up and down, use the "cursor UP/DOWN" key (remote controller) and "CH (

•

(remote controller and set).

To change the settings, use the "cursor RIGHT/LEFT" key (remote controller) and "VOL (+)/(–)" key (remote

•

controller and set).

To save new settings, keep the cursor at "EXECUTE" and use the "ENTER" key (remote controller).

•

r

LC-19SB15U

LC-19D45U

)/(s)" key

Public mode

Power on fixed [Variable ]

Maximum volume [ 60 ]

Volume fixed [Variable ]

Volume fixed level [ 60 ]

RC button [Respond ]

Panel button [Respond ]

Menu button [Respond ]

On screen display [Yes ]

Blue screen [No ]

Input mode start [Normal ]

Input mode fixed [Variable ]

Reset

ENTER

41

Page 19

42

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

5. On Setting Items

* "EZ-SETUP" discussed below indicates "EZ-SETUP after the first power-on".

(1) POWER ON FIXED

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

(2) MAXIMUM VOLUME

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

Variable" and "Fixed" (loop provided)

"

Variable

Fixed" setting, the power-off by the power key of the unit is invalidated and the image is kept being re-

In

"

ceived. The power can be turned off by stopping the power supply from AC.

Refer to the

Power-On Fixed" sheet.

"

None

Adjustment from 0 to 60 (no loop)

60

Sound volume can not be adjusted higher than the preset value.

•

When the sound volume is set lower than 59, only figures are displayed and the sound volume bar is

not displayed.

•

The maximum sound volume for ON-timer (Wake up timer) is limited also to the preset value.

None

•

In line output (sound volume variable), the sound volume can be adjusted from 0 to 60 irrespective of

pre-adjusted value.

•

When the sound volume is set higher than the MAX setting by the adjusting process, the sound volume

control operation is prohibited for turn-up and the sound volume should be turned down to MAX in this

state.

(3) VOLUME FIXED

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between "Variable" and "Fixed" (loop provided)

Variable

Sound volume is fixed and made invariable.

•

The sound volume for the ON-timer (Wake up timer) is fixed also without display of menu. Besides, the

setting is made impossible. (Basically, the menu is not displayed.)

•

The following keys become invalid:

•

Sound volume Up/Down (VOL +/-) [for both remote control and the unit]

•

Mute (MUTE)

None

•

In line output (sound volume variable), the sound volume can be adjusted from 0 to 60 irrespective of

pre-adjusted value.

•

As for sound volume fixing and sound volume MAX level, the sound volume fixing has priority.

•

Once the sound volume has been changed by adjustment process, it should be set back to the sound

volume preset by sound volume fixing level when the adjustment process ends .

(4) VOLUME FIXED LEVEL

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Adjustment from 1 to 60 (no loop)

60

The sound volume to be fixed by

None

None

Setting is valid only when "Volume fixed" is selected for "fixed".

Volume fixed" is determined.

"

Page 20

(5) R/C BUTTON

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

Respond

Keys acceptable by remote control are limited or reception of keys can be prohibited.

In "No respond" setting, all the keys (including the power key) are not accepted.

•

•

All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

•

All the keys can be used also in the initial EZ-Setup after power-ON irrespective of setting.

(6) PANEL BUTTON

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

Respond

All the operations by keys (except the power key) of the unit can be invalidated.

•

Inspection mode and hotel menu mode can be started irrespective of setting.

•

All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

•

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

Respond" and "No respond" (loop provide)

"

Adjustment process, factory setting, inspection process and hotel only keys are valid irrespective of setting.

Respond" and "No respond" (loop provide)

"

In U.S.A model, all the keys can be used also in the initial EZ-Setup after power-ON irrespective of setting.

(7) MENU BUTTON

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

Respond

No respond" setting, the menu operation by the menu key of the remote control and the menu key of

In

"

the unit are invalidated.

•

Inspection mode and hotel menu mode can be started irrespective of setting.

•

All the keys can be used in adjustment process, inspection mode and hotel menu irrespective of setting.

•

All the keys can be used also in the initial EZ-Setup after power-ON irrespective of setting.

(8) ON SCREEN DISPLAY

Selection

Default

Explanation

Limit in Setting

Others

Exception

Remarks

Selection between

Yes

The following OSD displays are made ineffective.

Displays of menu group, channel call, sound volume bar and direct key call

•

ON-timer (Wake-up timer) is cleared and set to "OFF".

•

Set time of the OFF-timer (SLEEP TIMER) is cleared.

•

Setting of the no-signal power-OFF (AUTO POWER OFF) is cleared to "OFF".

•

Setting of the no-operation power-OFF is cleared to "OFF".

•

Keys falling under any of the following items become invalid.

1Appearance of screen changes and the sound changes.

2Personal functions which are hard to restore.

Screen display, menu, OFF-timer, ON-timer, AV MODE, screen size switching, clock setting, treble

emphasis, AUDIO ONLY, sound changeover, LANGUAGE, CLOSED CAPTION

•

Simple input switching is generated. Those which are restored soon after leaving as they are and may

be requested for change by customer are not prohibited.

Br

ightness sensor (BACKLIGHT) .

•

Such a caution which is displayed independently is displayed as it is.

Non-responding signal caution.

•

When CC has already been ON, CLOSED CAPTION is displayed.

Respond" and "No respond" (loop provide)

"

Yes" , "NO" (loop provide)

"

43

Page 21

44

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

(9) BLUE SCREEN

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

(10) INPUT MODE START

Selection

Default

Explanation

About options

Limit in Setting

Exception

Remarks

Selection between

Yes" , "NO" (loop provide)

"

No

In "Yes" setting, when don't receive any signal or no signal input, the screen is blue.

None

None

Selection between

Normal" , "Air/Cable(CH~)

"

INPUT 1/2/3/4" (loop provide)

", "

Normal

In power-ON, the input source to be started or channel can be set.

(In standard mode, the operation follows the last memory.)

•

All the input sources in the model are made selectable.

•

When the input/output switchable input source is selected and the input source is set to output, the set-

ting of input/output switching is changed to input at the execution of hotel menu. In addition, the input/

output switching by menu is prohibited.

•

In TV mode, the channel to be set follows the last memory and the content of the last memory is includ-

ed in the notation by options. Ex.) TV (CH2), TV (CH4) etc.

•

The display of channel setting menu and the channel setting operation are prohibited.

None

•

In setting at "Normal", the setting of "Input mode fixed" is changed to "Variable" and selection should

be prohibited.

(11) INPUT MODE FIXED

Selection

Default

Explanation

Limit in Setting

Exception

Remarks

Selection between

– (Variable)

The input mode is fixed at the input source or the channel set at the

put sources and channels can be made non-selectable.

•

With the execution of hotel mode, the input source is forced to change to that set by "Input mode start"

and the channel switching and input switching are prohibited thereafter.

•

ON-timer's (Wake-up timer) channel items are not displayed or the operation is prohibited. (Basically,

they are not displayed.)

•

The following keys are invalidated.

CH '", direct tuning button, FLASHBACK, input

~However, the keys (input switching and CH '" keys) of the unit for menu operation remain valid.

None

•

In the following case, setting is cancelled and mode is changed to "Variable".

1When the setting of

Variable" and "Fixed" (loop provide)

"

Input mode start" is set to

"

NORMAL.

Input mode start" in 9 and other in-

"

Page 22

TROUBLESHOOTING TABLE

No power supply (Front LED does not light up) and no power-up even is turned on (Front LED light up to blue)

Yes

No

No

Yes

No

Yes

No

Yes

Replace F7502 when the fuse is brown.

Connect the harness and Cable properly.

Connect the AC cord and turn on the power.

Is the AC cord connected?

Are the harness and Cable connected

properly?

No

Connect the harness and Cable properly.

Are the harness and Cable connected

properly?

Is the voltage of C7528 approx. 168V?

Are F7502 normal?

Yes

No

Is the main unit normal?

Yes

No

Yes

Check the rectifier circuit of UR12V

Does AC-CTRL (pin9 of SC7501) become High (approx. 3.3V)?

Are UR12V supplied?

Turn on the power again,and check if

the unit works normally.

Check if L7501,TH7501 and D7527 are normal.

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

45

Page 23

46

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

No audio output during UHF/VHF reception

Yes

No

No

Yes

No

Yes

Yes

No

Yes

Check IC501/IC502 and peripheral circuits.

Check circuits between IC1101 and IC501/IC502.

Check the filter circuits (Q1102, Q1103) and

peripheral circuits.

Check the tuner and peripheral circuits.

Is SIF output from the tuner (TU1101_Pin15) normal?

Is input signal fed to pin21 of IC1101?

Are audio signals from pins 30 and 29 of IC1101 to pins

13 of IC501 and IC502 normal?

Check the connector (P301) of MAIN_UNIT and around the

speakers.

Are audio outputs of pin 3 of IC501 and IC502 normal?

Are I2S signals output from pin 2,pin 4,pin 7 and pin 8 of

IC302 to pin W5,pin W6, pin Y6 and pin AA6 of IC801 normal?

No

Yes

Check the circuits between IC501/502 and IC302.

Are audio input of pin 10 and pin 12 of IC302 normal?

Yes

No

Check IC1302 and peripheral circuits.

Is audio output from IC1302 normal?

No

Check the circuits between IC302 and IC801.

No

Yes

Check IC801 and peripheral circuits.

Are audio signal output from pin AA3 and pin AA4 of

IC801 to pin 5 and pin 9 of IC1302 normal?

TROUBLESHOOTING TABLE (Continued)

Page 24

TROUBLESHOOTING TABLE (Continued)

No audio output from external input

<<HDMI>>[INPUT-3]

Is L-ch audio signal fed from input terminal J503 to pin 1 of IC501?

Is R-ch audio signal fed from input terminal J503 to pin 1 of IC502?

<<PC>>[INPUT-4]

Is L-ch audio signal fed from input terminal J401 to pin 5 of IC501?

Is R-ch audio signal fed from input terminal J401 to pin 5 of IC502?

Are audio signals from pin 3 of IC501 and IC502 to pins 10 and 12 of

IC302 normal?

<<INPUT-1>>

Is L-ch audio signal fed from input terminal J501 to pin 12 of IC501?

Is R-ch audio signal fed from input terminal J501 to pin 12 of IC502?

<<INPUT-2>>

Is L-ch audio signal fed from input terminal J502 to pin 14 of IC501?

Is R-ch audio signal fed from input terminal J502 to pin 14 of IC502?

No

Check the circuits between IC501/IC502 and IC302.

Check the Circuits between IC302 and IC801.

Is audio input from pin 4 of IC302 to pin W6 of IC801 normal?

No

Check IC1302 and peripheral circuits.

Is audiio output from IC1302 normal?

No

Check the connector (P1301) of SUB_UNIT and around the speakers

Yes

Yes

Yes

Yes

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

47

Page 25

48

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

<Component video signal input> No video output (INPUT-1)

Yes

No

Check between J501 and pins 7,8 and 9 of P501.

(Q501, Q502, Q503)

Select INPUT-1 and the input signal on the input switching

menu screen.

No video output from extermal input <<INPUT-1>>

Is video signal fed to pins 7, 8 and 9 of P501?

No

Yes

No

Yes

Check IC801 and peripheral circuits.

Check between IC801 and IC501.

Is video signal fed to pins K2, M2 and P3, T2 of IC801?

Are signals from A6, A1, E1, E2, W5, W6, W7, Y6, AA6 of

IC801 normal?

Check IC9201 and peripheral circuits.

Yes

TROUBLESHOOTING TABLE (Continued)

Page 26

TROUBLESHOOTING TABLE (Continued)

<Composite video signal/S-video signal input> No video output (INPUT2)

Yes

No

No

No

Check between J502 and pin 13 and 14 of P501.

Check between J502 and pin 11 of IC501.

Select INPUT-2 and the input signal on the input switching

menu screen.

No video output from extermal input <<INPUT-2>>

<Composite video signal input>

Is video signal sent to pin L3 of IC801 from P501?

<S-video signal input>

Are Y and C signals sent to pins L1 and N1 of IC801 from

P501 respectively?

Check between IC801 and P501.

Yes

No

Yes

Are signals from A6, A1, E1, E2, W5, W6, W7, Y6, AA6 of

IC801 normal?

Check IC9201 and peripheral circuits.

Check IC801 and peripheral circuits.

<Composite video signal input>

Is video signal fed to pin 11 of P501?

Yes

<S-video signal input>

Are Y and C signals fed to pins 13 and 14 of P501

respectively?

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

49

Page 27

50

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

No video output during ANALOG broadcasting reception

Yes

No

No

Yes

Check pin 13 of TU1101 to pin 1 of P502.

Check or replace the tuner's peripheral circuits.

Is video signal sent to output terminal pin 13 of tuner

(TU1101)?

Is video signal out from pin 1 of P502?

Is video signal fed to pin L2 of IC801(DVP) from P502?

Check between IC801 and P502.

No

Yes

No

Yes

Are signals from A6, A1, E1, E2, W5, W6, W7, Y6, AA6 of

IC801 normal?

Check IC9201 and peripheral circuits.

Check IC801 and peripheral circuits.

TROUBLESHOOTING TABLE (Continued)

Page 28

TROUBLESHOOTING TABLE (Continued)

No video output from HDMI input (INPUT3)

No

YesYes

Is IC403(E2PROM) accessed with IIC when connectiong

HDMI device and is DDC_IIC_CLOCK/DATA data read

out?

Are signals fed from HDMI (SC402) connector to input

terminals RRX0± (pins 16 and 17),RRX1(pins 19 and

20),RRX2(pins 22 and 23),DDCSCL and DDCSDA(pins 31

and 32?

Check IC403 and peripheral circuits.

Are cables connected securely?

No

Check the setting of HDMI device.

No

Check IC801 and peripheral circuits.

Are signals fed from SC402 to input terminals of IC801?

No

Yes

Yes

Are signals from A6, A1, E1, E2, W5, W6, W7, Y6, AA6 of

IC801 normal?

Check IC9201 and peripheral circuits.

Check IC801 and peripheral circuits.

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

51

Page 29

52

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

No video output from PC input (INPUT4)

Are signal fed from pins 1,2,3(Analog-R/G/B),and 13,14(H Sync/V Sync) of input terminal (SC401) to pins U2, N3, R, K1, J1 of

IC801 (C4US)?

No

Check peripheral circuits of IC801 and Q402,Q405,Q406.

Digital broadcasting cannot be received.

[FRONT-END SECTION]

Yes

Are IF_OUT_P/N signal send from

pin (20) (19) of TU1101 respectively?

No

No

Are signal fed to pins Y1, A1

of IC801?

Check signal from A6, A1, E1, E2, W5,

W6, W7, Y6, AA6 of IC801 normal?

Check IC801 and peripheral circuits.

Check IC9201 and peripheral circuits.

Yes

Yes

No

Check the TU1101.

Check between TU1101 and

IC801.

Yes

Yes

Yes

No

Yes

Are signals from A6, A1, E1, E2, W5, W6, W7, Y6, AA6 of

IC801 normal?

Check IC9201 and peripheral circuits.

Check IC801 and peripheral circuits.

TROUBLESHOOTING TABLE (Continued)

Page 30

LC-19SK25U/U-W

Top View

PGBA 2323-345 Pins

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAJOR IC INFORMATIONS

IC801 (RH-IXC238WJQZQ)

This is a system LSI for digital TV integrating a VSB/QAM demodulator, a system decode, an analog front-end with

a 3D comb filter, an MPEG2 video decoder, an AC3 audio decode, a display procesor and a 2D graphics engine

into a single product.Also integrates a 32-bit RISC-type SuperHarchitecture SH3 CPU for user application software,

and an M32R CPU as a sub CPU for the software control of its real-time functions.

53

Page 31

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

PDN

INPUT3

SC402

IC8201

DDR2 256M

LCD

PANEL

LK185T3GW

AMP_HOGO

L_MUTE

IC9201

T-COM

LVDS

RSDS

CONNECTOR

RSDS

IC8701

FLASH 64M

IC802

EEPROM

TXD_MPU

RXD_MPU

H

V

AV4-PC_H / V

REGULATORS

UN12V

AC_CTL

STBY_POW

KEY1/KEY2

POWER

MODULE

OPERATION

UNIT

R/C

OPC

POWG_LED

POWR_LED

LED/OPC

UNIT

LED_OPC

MUTE

CIRCUIT

LAMP_CTL

LAMP_ON

LAMP_ERR

AC_CTL

TERM

IC2002

SYSTEM-MCU

R8C/24

IC801

DTV-C4US

RH-IXC238WJQZQ

MUTE_A_SUB

RESET_N

UARTRXD/M32TMS

UARTTXD/M32TRST

ICC_SDA/SCL

or

LCD_ON

V_BRT

MUTE_A_C4

IC1302

D-AMP

YDA147SZ

HDMI

SP

SP

SUB

INPUT1

J501

Y

Pb

Pr

EF

MAIN

AV1 COMP-Y

AV1 COMP-Pb

AV1 COMP-Pr

AV2 S-Y

AV2 S-C

AV2 CVBS

AV2 S.DET

IC1101

BTSC

AN5832

SIF

AFT

IC1301

HP-AMP

BH3544

Lch-OUT

Rch-OUT

HP-MUTE

J1301

HP

L

R

D508 SPDIF

HP-DET

L_MUTE

INPUT4

SC401

R

G

B

H

V

INPUT4

AV4-PC_RGB

AV4-PC_H / V

IC302

AUDIO

-ADC

ACLK

BCLK

LRCLK

ADATA

IC501/502

AUDIO-SW

HD74HC4051

㬍2

䋨D-SUB䋩

INPUT1

L

INPUT2

L

R

R

INPUT3

L

R

AL1

AR1

AL2

AR2

AL3

AR3

L

R

AL4

AR4

SPDIF

IFD+ / IF_AGC

TUN_CVBS

TUN_L/R CH

TUN_SDA/SCL

MUTE

CIRCUIT

IC301

A-ADC

RESET

IC801

DTV-C4US

RH-IXC238WJQZQ

TUN_SEL

INPUT2

J502

CVBS

Y

C

TU1101

TUNER

AA016WJQZ

䋨HDMI䋩

EF

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

BLOCK DIAGRAM

54

Page 32

1716 1918151413121110

LC-19SK25U/U-W

PDN

INPUT3

SC402

IC8201

DDR2 256M

LCD

PANEL

LK185T3GW

AMP_HOGO

L_MUTE

IC9201

T-COM

LVDS

RSDS

CONNECTOR

RSDS

IC8701

FLASH 64M

IC802

EEPROM

TXD_MPU

RXD_MPU

H

V

AV4-PC_H / V

REGULATORS

UN12V

AC_CTL

STBY_POW

KEY1/KEY2

POWER

MODULE

OPERATION

UNIT

R/C

OPC

POWG_LED

POWR_LED

LED/OPC

UNIT

LED_OPC

MUTE

CIRCUIT

LAMP_CTL

LAMP_ON

LAMP_ERR

AC_CTL

TERM

IC2002

SYSTEM-MCU

R8C/24

IC801

DTV-C4US

RH-IXC238WJQZQ

MUTE_A_SUB

RESET_N

UARTRXD/M32TMS

UARTTXD/M32TRST

ICC_SDA/SCL

or

LCD_ON

V_BRT

MUTE_A_C4

IC1302

D-AMP

YDA147SZ

HDMI

SP

SP

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

55

Page 33

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

OVERALL WIRING DIAGRAM

56

Page 34

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

57

Page 35

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. The voltages at test points are measured on the

stable supply voltage of AC 120V. Signals are

fed by a color bar signal generator for servicing

purpose and the above voltages are measured

with a 20k ohm/V tester.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(K= ± 10%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

CAPACITOR

1. All capacitors are µF

(P=pF=

All capacitors are 50V, unless otherwise noted.

2.

10-6µ

F).

, unless otherwise noted.

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC

OUTLET BEFORE REPLACING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE

REGARDED AS POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “Α”

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

( ) A R E

AVIS DE SECURITE IMPORTANT:

LES PIECES MARQUEES “Α” ( )SONT

IMPORTANTES POUR MAINTENIR LA SECURITE

DE L'APPAREIL.

NE REMPLACER CES PIEDES QUE PAR DES

PIECES DONT LE NUMERO EST SPECIFIE POUR

MAINTENIR LA SECURITE ET PROTEGER LE

BON FONCTIONNEMENT DE L'APPAREIL.

58

Page 36

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

SCHEMATIC DIAGRAM

R/C LED Unit

59

Page 37

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 1/9

60

Page 38

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

61

Page 39

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 2/9

62

Page 40

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

63

Page 41

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 3/9

64

Page 42

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

65

Page 43

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 4/9

66

Page 44

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

67

Page 45

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 5/9

68

Page 46

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

69

Page 47

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 6/9

70

Page 48

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

71

Page 49

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 7/9

72

Page 50

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

73

Page 51

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 8/9

74

Page 52

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

75

Page 53

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

MAIN Unit - 9/9

76

Page 54

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

77

Page 55

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

SUB Unit - 1/2

78

Page 56

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

79

Page 57

87 109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

SUB Unit - 2/2

80

Page 58

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

81

Page 59

82

87109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

SUB Unit - 3/3

Page 60

83

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

Page 61

84

87109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

POWER_INVERTER Unit

Page 62

85

1716 1918151413121110

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

Page 63

87109654321

A

B

C

D

E

F

G

H

LC-19SK25U/U-W

LC-19SB25U/U-W

LC-19SB15U

LC-19D45U

KEY Unit

86

Loading...

Loading...