Page 1

LC-15L1E

SERVICE MANUAL

S03K3LC-15L1E

LCD COLOUR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countr ies) the set should be restored to its original condition and only parts identical to those specified should be used.

CONTENTS

» IMPORTANT SERVICE SAFETY PRECAUTION .........................................................................................2

» SPECIFICATIONS ........................................................................................................................................4

» OPERATION MANUAL .................................................................................................................................5

» DIMENSIONS ...............................................................................................................................................8

» REMOVING OF MAJOR PARTS ..................................................................................................................9

» ADJUSTING PROCEDURE OF EACH SECTION .....................................................................................15

» TROUBLE SHOOTING TABLE...................................................................................................................18

» CHASSIS LAYOUT .....................................................................................................................................29

» BLOCK DIAGRAM......................................................................................................................................32

» OVERALL WIRING DIAGRAM ...................................................................................................................36

» DESCRIPTION OF SCHEMATIC DIAGRAM .............................................................................................38

» SCHEMATIC DIAGRAM .............................................................................................................................39

» PRINTED WIRING BOARD ASSEMBLIES..............................................................................................104

» REPLACEMENT PARTS LIST..................................................................................................................121

» PACKING OF THE SET ............................................................................................................................147

LC-15L1E

Page

SHARP CORPORATION

Page 2

LC-15L1E

1

1

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be performed only by qualified ser vice technicians who are

thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE F3801(5A, 250V), F3802(1.6A, 250V),

F3803 (1.25A, 250V), F3804 (4A, 250V), F5701(2A,

250V) AND F9001 (6.3A, 250V) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 110~240 volt A C outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

test).

• Using two clip leads, connect a 50k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to an earth ground.

• Use an AC voltmeter ha ving with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V peak (this corresponds to 0.5

mA. peak AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the monitor to the owner.

DVM

AC SCALE

50k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage , wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams.

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified b y " å"

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

Replacement Parts Lists and

2

Page 3

LC-15L1E

Precautions for using lead-free solder

1 Employing lead-free solder

"WIRELESS CENTER", "SWITCH, LED", "MAIN", "OPERATION", "DC JACK", "INVERTER", "R/C, LED",

"BATTERY CONNECTOR" PWBs of this model employs lead-free solder. The LF symbol indicates lead-free

solder, and is attached on the PWBs and service manuals. The alphabetical character following LF shows the

type of lead-free solder.

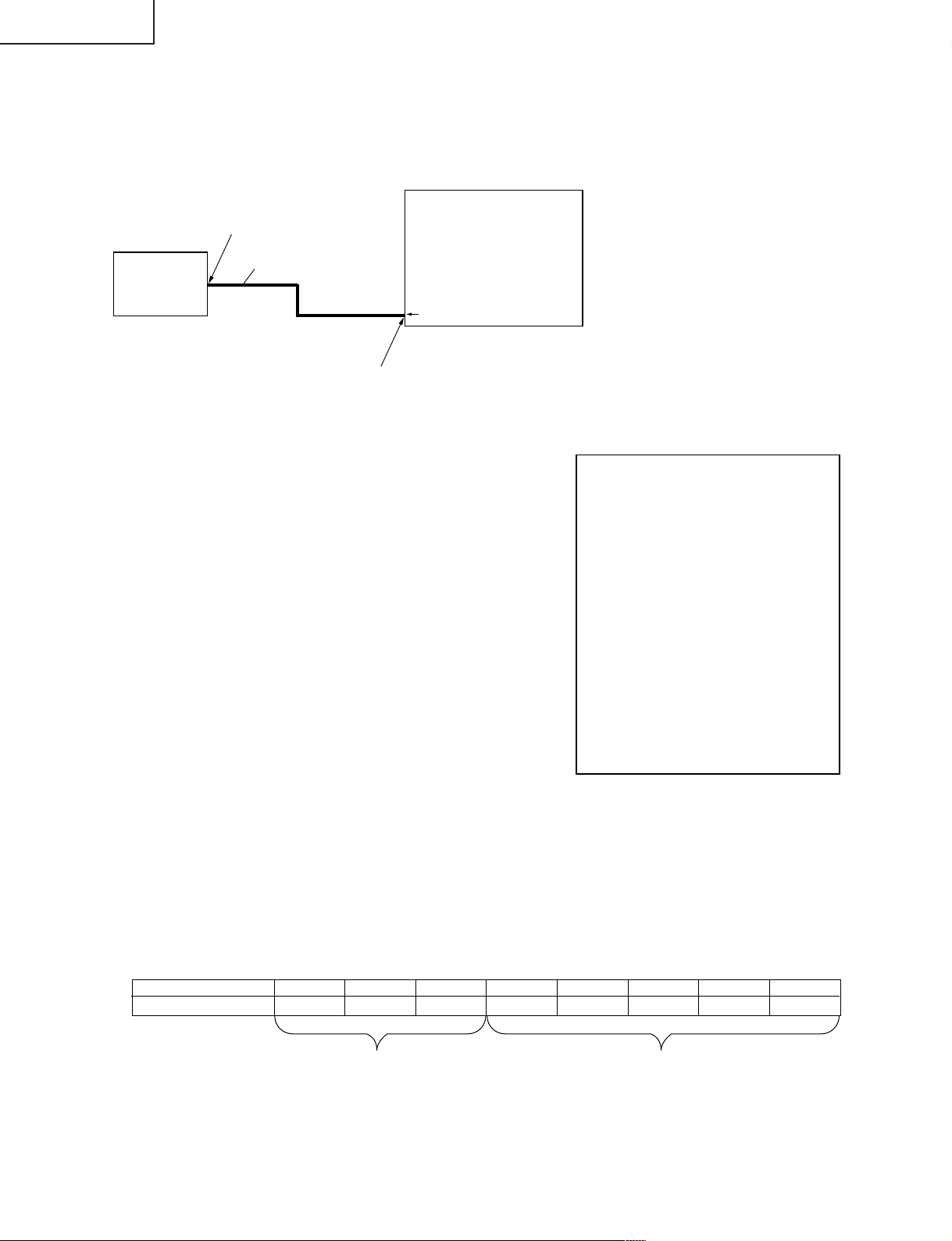

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit,

contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remov e the bit from the PWB as soon as you confirm the steady soldering

condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is allo y ed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

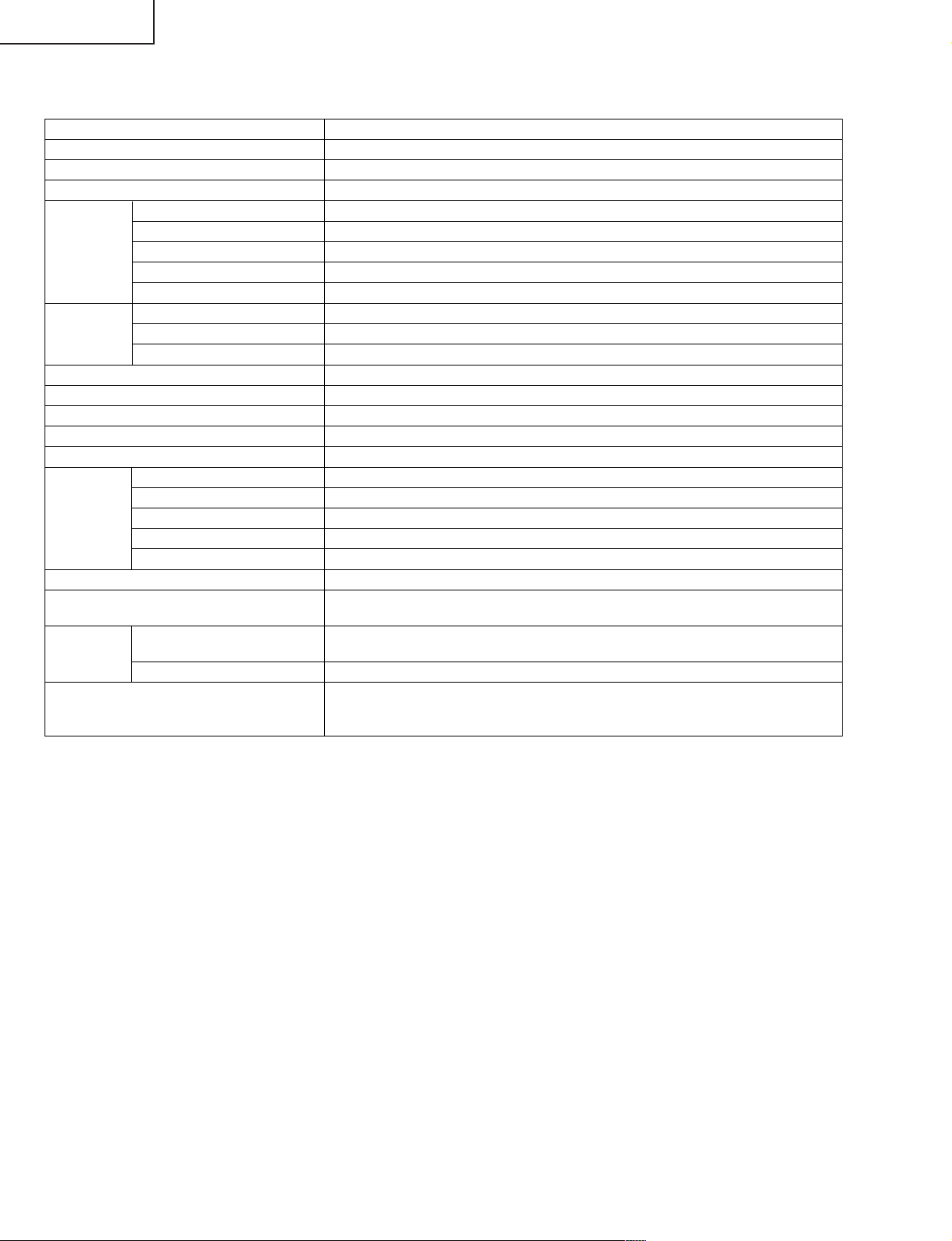

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

3

Page 4

LC-15L1E

SPECIFICATIONS

Item 15" LCD COLOUR TV, Model: LC-15L1E

LCD panel 15" Advanced Super View & BLACK TFT LCD

Number of dots 921,600 dots

Video colour system PAL/SECAM/NTSC

TV TV-Standard (CCIR) B/G, I, D/K, L

TV-Tuning System Auto preset 200 ch.

STEREO/BILINGUAL NICAM, A2

AUTO PRESET YES

CATV ~Hyper Band

Transmitter Channel A 2.412 GHz

(3 Channel) Channel B 2.437 GHz

Channel C 2.462 GHz

Brightness 430 cd/m

Lamp life 60,000 hours

Viewing angles H: 170° V: 170°

Audio amplifier 2.1 W 2

Speakers 4 cm 2 pcs.

Terminals AV-IN 1 21 pin Euro-SCART

AV-IN 2 21 pin AV-SCART

AV-IN 3/4 S-VIDEO, VIDEO, AUDIO

Antenna (IN, OUT) DIN

Headphones 3.5 mm ø jack (Rear)

OSD language English/German/French/Spanish/Italian/Swedish/Dutch/Russian

Power requirement TV main unit: DC 15 V, AC 110 – 240 V, 50/60 Hz

Wireless Centre: DC 12 V, AC 110 – 240 V, 50/60 Hz

Weight Main unit 5.4 kg (without table stand)

(approx.) 6.3 kg (with table stand)

Wireless Centre 1.2 kg

Accessories Wireless remote control, Remote control holder, R-03 dry batteries ( 2), AC

adapters ( 2), AC cord, Table stand, Battery, Wireless Centre, Wireless Centre

stand, Cable clamps ( 2), Operation manual, Screws ( 3), Video controller

2

×

×

× ×

×

Ë As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product improve-

ment without prior notice. The performance specification figures indicated are nominal values of production units. There may be some

deviations from these values in individual units.

4

Page 5

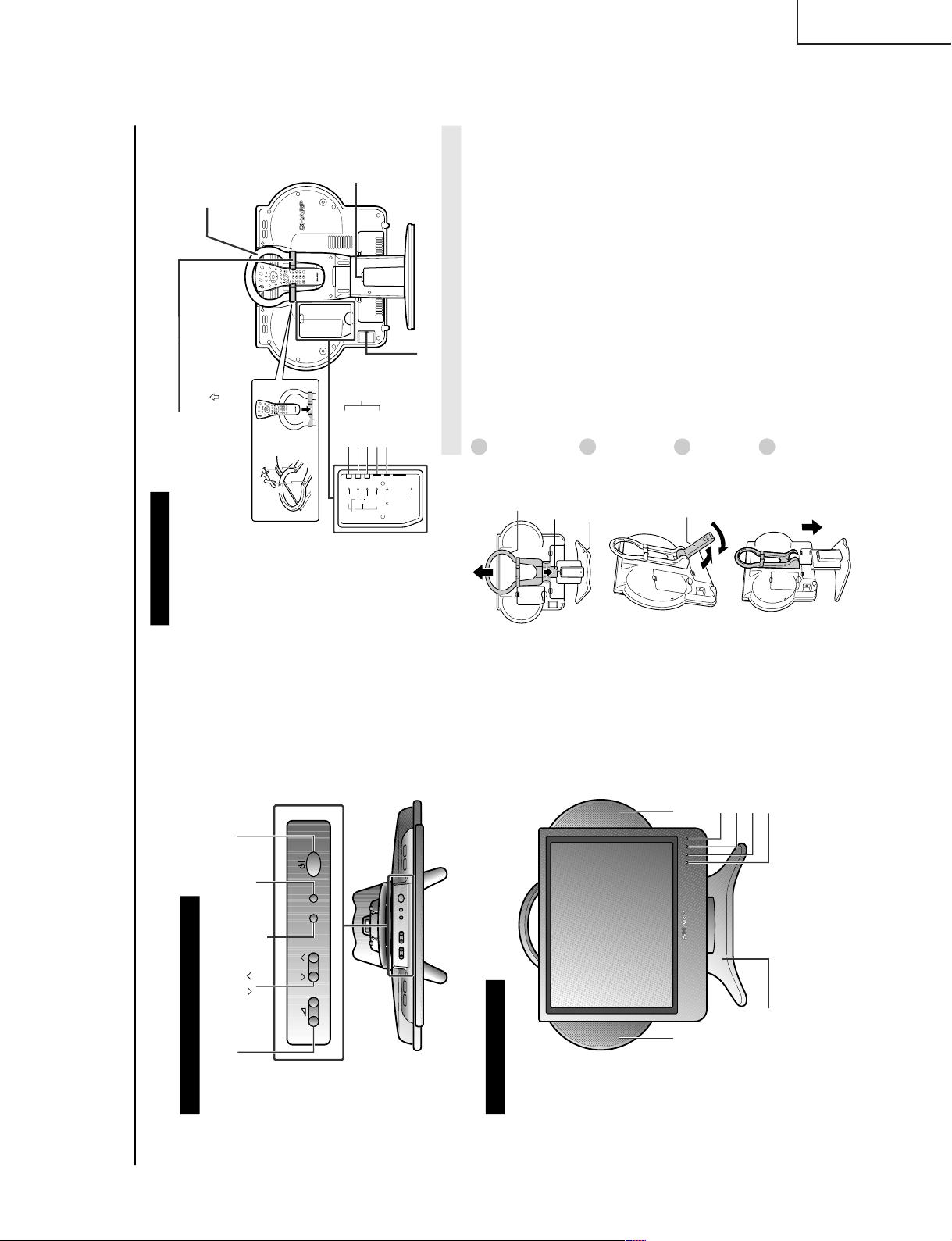

Main Unit Part Names

CH

MENU TV/VIDEO

-

+

Volume (–)/(+)

CH ( )/( )

MAIN POWER

TV/VIDEO

MENU

Charge indicator

Power/Standby indicator

Remote sensor windowTable stand (Detachable)

Left speaker

Right speaker

Remote sensor indicator

Main unit (Top view: Control section)

Main unit (Front view)

Main unit (Rear view)

AUDIO

AV-IN4

VIDEO

S-VIDEO

FACTORY

SETTING

L

R

CH

MENU

E

TV/VIDEO

R

E

V

E

A

L

H

O

L

D

E

N

D

M

MENUSOUND

S

U

BT

IT

L

E

SUBPAGE

T

E

X

T

R

O

T

A

T

E

W

I

D

E

T

CH

OK

E

TV/VIDEO

R

E

V

E

A

L

H

O

L

D

E

N

D

MENUSOUND

S

U

BT

IT

L

E

SUBPAGE

T

E

X

T

R

O

T

A

T

E

BR

I

G

H

T

T

M

T

Power input DC 15 V

Headphones jack

S-VIDEO

VIDEO

AV-IN4

AUDIO(R)

AUDIO(L)

Remote control holder

The remote control can be placed in the

remote control holder when moving the TV.

1 Attach the remote control holder to the

handle with the arrow ( ) in the centre of

the holder facing upward.

2 Place the remote control in the remote

control holder.

Table stand

release button

Handle

1

2

CH

MENU

E

TV/VIDEO

RE

V

E

A

L

H

O

L

D

END

M

MENUSOUND

S

UB

T

I

T

L

E

SUBPAGE

T

E

X

T

R

O

T

A

T

E

W

I

D

E

T

CH

OK

E

TV/VIDEO

RE

V

E

A

L

H

O

L

D

END

MENUSOUND

S

UB

T

I

T

L

E

SUBPAGE

T

E

X

T

R

O

T

A

T

E

B

R

I

G

H

T

T

M

T

Removing and Attaching the Table Stand

Handle

Table stand

release button

Table stand

Stand

Lift the main unit straight up by holding the handle while depressing the table

stand release button.

Unfold the stand.

• Securely unfold the stand until you hear a clicking sound. Only use the

stand after first unfolding until a clicking sound is heard to ensure that it is

stable.

Fold up the stand.

• Return the stand to its original unfolded position.

Insert the main unit straight into the table stand.

• The main unit cannot be inserted if inclined on an angle. Inserting the main

unit with force can cause damage or a malfunction.

1

2

3

4

LC-15L1E

OPERATION MANUAL

5

Page 6

LC-15L1E

Wireless Centre Part Names

* Failure to securely fasten the stand may cause the Wireless

Centre to tip over during use.

* When placing the Wireless Centre upright, make sure to use

the SCART to SCART flat cable (commercially available) for

a connection. The use of this cable can prevent the Wireless

Centre from falling down.

Wireless Centre

stand

Rubber foot

Rubber foot

Power Indicator

When the TV is turned off with the remote control, the

Wireless Centre is switched to standby (power indicator

is lit red). (There may be a time lag of about 5 to 6

seconds.)

Setting Up the Wireless Centre

IN

OUT

AV-IN2

(

AV

)

AV-IN3

AV-IN3 IR

MOUSE

POWER

INPUT

DC12V

FACTORY

SETTING

VIDEO

S-VIDEO

AUDIO

AV-IN1

(

RGB

)

L

R

SIGNAL LEVEL

Transmission

SIGNAL LEVEL

indicator

(Reception gain)

· Green:

Communication

in progress

· Red:

Difficulty

in transmission

· Not lit:

Not communicating

Power indicator

· Green:

Operation in

progress

(when power is on)

· Red: Standby

Power

button

Front

Antenna

input

terminal

Antenna

output

terminal

Rear

AV-IN1 (RGB)

(21-pin Euro-SCART)

S-VIDEO

VIDEO

AUDIO (R)

AUDIO (L)

AV-IN3

Factory

adjustment

terminal

Power input

DC 12V

Video control

terminal

AV-IN2 (AV)

(21-pin AV-SCART)

Wireless Centre

Main unit

• The Wireless Centre can be placed horizontally or upright.

• When placing horizontally:

The side on which the rubber feet are attached is the

bottom.

• When placing upright:

Fasten the stand to the bottom of the Wireless Centre with

the screws provided.

Placing the Wireless Centre Where You Want It

We recommend placing the Wireless Centre in an area

where there are no obstructions to impede radio wave

transmission/reception.

(Do not place the Wireless Centre in a box.)

Power Connection

Antenna Connection

Connect to the DC input terminal of each product.

To enjoy a clearer picture, we recommend that you use

an outdoor antenna. The following is a brief explana-

tion of the types of connection that are used for coaxial

and feeder cables:

(1)If your outdoor antenna uses a 75-ohm coaxial

cable, change this for a new standard DIN45325

(IEC169-2) plug and plug it into the antenna

terminal of the Wireless Centre via the antenna

cable (not supplied).

(2)If your outdoor antenna uses a 300-ohm twin-lead

flat feeder, change this for a 300-ohm to 75-ohm

impedance converter and plug it into the antenna

terminal of the Wireless Centre via the antenna

cable (not supplied).

Note:

Note:

• Always turn the

(MAIN POWER) button of the LCD TV set and the power button of the Wireless Centre to OFF when

connecting the AC adapters.

• If there is a Sharp product close to the video controller, the product may malfunction during transmission of the video controller.

• Unplug the AC adapters from the LCD TV set, Wireless Centre unit and AC wall outlet when the LCD TV set is not to be used

for a long period of time.

IN

OUT

AV-IN2

(

AV

)

AV-IN3

AV-IN3 IR

MOUSE

POWER

INPUT

DC12V

FACTORY

SETTING

VIDEO

S-VIDEO

AUDIO

AV-IN1

(

RGB

)

L

R

Wireless Centre

TV/VCR/DVD etc.

TV

75-ohm coaxial cable (round cable)

300-ohm twin-lead flat feeder

To antenna

input terminal

( )

VCR

DVD

* Product shape varies in some countries.

AC wall

outlet

AC adapter

AC cord*

TV main unit

AC wall

outlet

AC adapter

AC cord*

IR

MOUSE

POWER

INPUT

DC12V

FACTORY

SETTING

Wireless

Cent

6

Page 7

Remote Control Part Names

CH

MENU

E

TV/VIDEO

R

EVEA

L

H

O

L

D

E

N

D

M

MENUSOUND

S

UB

T

ITLE

SUBPAGE

TEXT

R

OTA

T

E

WIDE

T

CH

OK

E

TV/VIDEO

R

EVEA

L

H

O

L

D

E

N

D

MENUSOUND

S

UB

T

ITLE

SUBPAGE

TEXT

R

OTA

T

E

BRIGHT

T

M

T

OK, Programme Table

SUBTITLE

Displays the Teletext

Subtitle directly.

HOLD

Temporarily holds the

current Teletext page.

(Mute)

Switches the sound on and off.

Yellow, Timer functions

Cyan, Status Display

Turns on the status display

when the menu is not

displayed.

TV/VIDEO

Switches the input source

between AV1, AV2, AV3, AV4 and

TV mode.

Channel Select

MENU

Displays the TV menu.

Volume (+)/(

-

)

(Flashback)

Returns to the previous

channel.

Red, Picture menu

Upwards/ Downwards

Selection, Zoom Display

Function (Teletext mode)

END

Returns to normal screen.

TEXT

Displays the Teletext mode

screen.

(Power)

SOUND

Switches the sound mode.

REVEAL

Displays hidden information

such as solutions to riddles

and puzzles.

Right / Left Selection

SUBPAGE

Displays the Teletext

Subpage directly.

ROTATE

Rotates the display in every

direction.

BRIGHT

Selects the brightness

of the display.

Green, Sound menu

CH ( )/( )

Selects next higher channel.

Selects next lower channel.

Installing Batteries in the Remote Control

Before using the LCD TV set for the first time, install the two R-03 (“AAA” size, UM/SUM-4) batteries supplied in the remote

control. When the batteries become depleted and the remote control fails to operate, replace the batteries with new R-03

(“AAA” size, UM/SUM-4) batteries.

1

Open the battery cover.

2

Insert two R-03 (“AAA” size,

UM/SUM-4) batteries.

3

Replace the battery cover.

Ë Position the positive and

negative ends of the

batteries as indicated in

the compartment.

Caution!

Precautions regarding batteries

Ë Improper use of batteries can result in a leakage of chemicals and/or explosion. Be sure to follow the instructions below.

• Place batteries with their terminals corresponding to the (+) and (–) indications.

• Different types of batteries have different characteristics. Do not mix batteries of different types.

• Do not mix old and new batteries. Mixing old and new batteries can shorten the life of new batteries and/or cause old

batteries to leak chemicals.

• Remove batteries as soon as they are depleted. Chemicals that leak from batteries can cause a rash. If chemical

leakage is found, wipe it off with a cloth.

• The batteries supplied with the product may have a shorter life expectancy due to storage conditions.

• If the remote control is not to be used for an extended period of time, remove the batteries from the remote control.

Ë Close the cover while

engaging the lower

claw with the remote

control.

Ë Slide the cover while

pressing the ( ) part.

"

LC-15L1E

7

Page 8

LC-15L1E

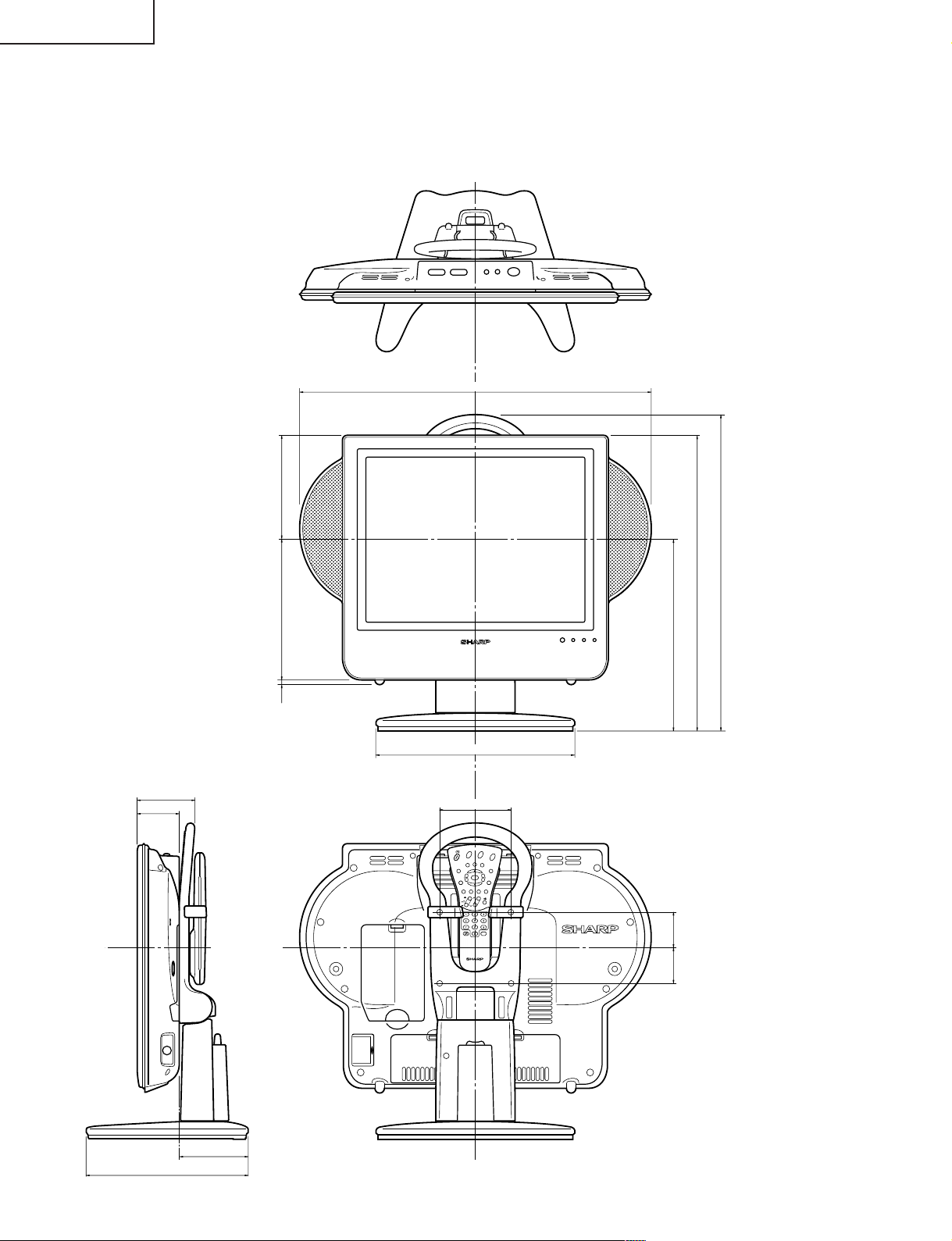

DIMENSIONS

Unit: mm

494

415

445

269.5

5.5 198.5 145.5

280

81

59

100

T

TE

TE

E

H

D

G

I

X

X

I

T

T

R

W

B

R

R

O

O

T

T

A

A

T

T

E

E

T

T

T

SUBPAGE

SUBPAGE

R

R

E

E

D

D

V

V

L

L

E

E

O

O

A

A

H

H

L

L

E

E

L

L

E

E

IT

IT

N

N

T

T

D

D

B

B

U

U

S

S

E

E

MENU

OK

MENUSOUND

MENUSOUND

M

M

CH

CH

TV/VIDEO

TV/VIDEO

50 50

228

97

8

Page 9

REMOVING OF MAJOR PARTS

Ë

TV section

1. Remove the four lock screws from the stand, and detach the table stand.

2. Detach the terminal cover.

3. Detach the battery cover.

4. Remove the lock screw from the terminal block.

5. Remove the three lock screws from the battery compartment.

6. Remove the twelve lock screws from the cabinet B, and detach the cabinet B.

7. Disconnect the connectors from the PWBs.

6

6

Terminal Cover

4

LC-15L1E

Cabinet A

SS(RX) PWB

DC Jack PWB

1

Stand

1

P4001

2

6

~

6

5

Cabinet B

6

3

Battery Cover

Table Stand(Detachable)

Note~: Be careful for a screw to

bind tight too much.

Operation PWB

Charger PWB

7

7

P9901

CN1

P3802

7

P4051

P3204

CN2

P2001

7

P2002

P3205

F3803

F3801

7

P3201

7

7

CN2

F3802

P4051

7

7

P6504

P3202

7

SC1203

CN2

P9002

7

P4051

P3203

7

SC1204

P2003

P9001

P9003

7

7

CN1

CN3

P2004

7

SC1202

CN3

Inverter PWB

CN1

Main PWB

Battery Connector PWB

7

7

R/C, LED PWB

9

Page 10

LC-15L1E

» Precautions in reassembling the SS unit

1. Do not touch by hand the antennas that are on the ANT PWBs to be coupled to the SS unit. Place these

PWBs in position with enough care to keep the antennas in the original shape.

(If by any chance the antenna gets bent or deformed, do not reshape it by hand, nor use the PWB again.

Otherwise communication failure may result.)

2. Insert the connectors of the ANT PWBs from just above tightly to their counterparts on the SS unit. (Do not

insert them slantwise.)

To disconnect the antenna connectors from the SS unit, hold and pull them out vertically. Do not hold the

cables to disconnect. (Otherwise the cables may get broken or the connectors damaged.)

3. Handling the SS unit RF cable

With the SS unit fit in position, dress and secure the RF cable, free of extra load, in its original route.

8. Remove the two lock screws from the operation panel (top cover), and detach the operation panel (top cover)

assembly.

9. Remove the two lock screws from the DC jack PWB and the lock screw from the angle. Detach the DC jack

PWB and the angle.

10. Remove the two lock screws from the R/C, LED PWB, and detach the R/C, LED PWB.

11. Remove the two lock screws from the battery connector PWB, and detach the battery connector PWB.

12. Remove the lock screws one each from the SS (RX) antenna PWBs, and detach the SS (RX) antenna PWBs.

13. Remove the lock screws two each from the speakers, and detach the speakers.

SS(RX) Antenna PWB

12

Speaker (R)

13

DC Jack PWB

9

Angle

8

Top cover

SS(RX) Antenna PWB

12

Operation PWB

13

Speaker (L)

Battery Connector PWB

10

R/C, LED PWB

11

10

Page 11

14. Remove the three lock screws from the inverter PWB, and detach the inverter PWB.

15. Remove the two lock screws from the charger PWB, and detach the charger PWB.

16. Remove the two lock screws from the SS (RX) PWB, and detach the SS (RX) PWB.

17. Remove the five lock screws from the main PWB, and detach the main PWB.

18. Remove the two lock screws from the chassis frame, and detach the chassis frame.

19. Remove the lock screw from the LCD panel unit, and detach the LCD panel unit.

LC-15L1E

17

Main PWB

SS(RX) PWB

17

Charger PWB

16

14

15

18

Inverter PWB

18

19

Chassis Frame

LCD Panel Unit

11

Page 12

LC-15L1E

» Precautions in handling the LCD panel

1. Handle the panel in a clean room (at humidities of over 50%).

2. Be sure to wear a wrist band to handle the panel.

3. Be careful not to drop or vibrate the panel.

4. Use an ionizer (within 30 cm).

20. Remove the two lock screws from the LCD panel unit, and detach the LCD panel unit.

21. Detach the diffusion sheet, prism sheet and reflection/deflection sheet.

22. Detach the four reflectors (top, bottom, right and left).

23. Detach the two reflection sheets (covers).

24. Detach the light guide plate.

25. Detach the fluorescent lamp.

26. Detach the two reflection sheets.

22

Reflection Mirror

Reflection Sheet (Cover)

(PSHEP0307CEZZ)

Lamp Unit

(KLMP-0122CEZZ)

25

23

Back Shield

20

LCD Panel Unit

20

21

Diffusion Sheet

(PSHEP0283CEZZ)

Prism Sheet

(PSHEA141WJZZ)

Reflection/Deflection Sheet

(PSHEP0281CEZZ)

24

Light Guide Plate

(PGiDM0070CEZZ)

22

Reflection Mirror

Reflection Sheet-2

(PSHEP0285CEZZ)

26

Reflection Sheet-1

(PSHEP0284CEZZ)

12

Page 13

Ë

Wireless center Section

1. Removing the top cabinet

1-1.Remove the four rubber legs from the bottom cabinet, and the four lock screws from the top cabinet.

1-2.Remove the three lock screws from the terminal block.

1-3.Undo the three arrow-marked hooks from the front panel. Slide the top cabinet backward and detach it.

Top Cabinet

1-2

1-3

1-3

LC-15L1E

1-3

1-3

Front Cabinet

2. Removing the front cabinet

2-1.Remove the five lock screws from the shielding case, and

detach the shielding case.

2-2.Disconnect the cables from between the switch, LED PWB and

the wireless center PWB.

2-3.Remove the two lock screws from the front cabinet, undo the

three arrow-marked hooks, and detach the front cabinet.

2-4.Remove the two lock screws from the switch, LED PWB and

separate the switch, LED PWB from the front cabinet.

Rubber Leg

2-2

Bottom Cabinet

1-1

Shielding Case

2-3

2-1

Wireless Center PWB

Switch, LED PWB

2-3

2-3

13

2-3

Front Cabinet

2-4

Page 14

LC-15L1E

» Precautions in reassembling the SS unit

1. Do not touch by hand the antennas that are on the antenna PWBs to be coupled to the SS unit. Place these

PWBs in position with enough care to keep the antennas in the original shape.

(If by any chance the antenna gets bent or deformed, do not reshape it by hand, nor use the PWB again.

Otherwise communication failure may result.)

2. Insert the connectors of the antenna PWBs from just above tightly to their counterparts on the SS unit. (Do

not insert them slantwise.)

To disconnect the antenna connectors from the SS unit, hold and pull them out vertically. Do not hold the

cables to disconnect. (Otherwise the cables may get broken or the connectors damaged.)

3. Handling the SS unit RF cable

With the SS unit fit in position, dress and secure the RF cable, free of extra load, in its original route.

3. Removing the SS (TX) antenna PWBs

3-1.Disconnect the cables from between the SS (TX)

PWB and the wireless center PWB.

3-2.Remove the lock screws one each from the wire

holders.

3-3.Remove the lock screws one each from the SS (TX)

antenna PWBs, disconnect the cables from the SS

(TX) PWB, and detach the SS (TX) ANTENNA

PWBs.

4. Remove the four lock screws from the SS (TX) PWB,

and detach the SS (TX) PWB.

5. Remove the lock screw from the wireless center

PWB, and separate the wireless center PWB and

the shield from the bottom cabinet.

5

Wireless Center PWB

SS(RX) Antenna PWB

4

3-3

3-1

3-2

Wire

Holder

Wire Holder

SS(RX) PWB

3-1

3-2

SS(RX) Antenna PWB

3-3

Shield

Bottom Cabinet

14

Page 15

LC-15L1E

ADJUSTING PROCEDURE OF EACH SECTION

The best adjustment is made before shipping. If any position deviation is found or after part replace is performed,

adjust as follows.

Preparations for adjustment

Use dedicated AC adapter or stable DC power.

Adjust TV main unit and wireless center as a pair.

Wireless center

AC adapter : UADP-A040WJPZ

DC power : 12V, 1.5A

TV Main unit

AC adapter : UADP-A039WJPZ

DC power : 15V, 4.0A

1.Adjustment procedure

Power ON → Adjustment process mode → COM BIAS and white balance adjustment

Perform adjustment after reducing radio interference by switching RF channels A, B, C and D of SS wireless unit.

2.How to enter process adjustment mode (Main unit only)

Use either one of the following procedures.

• Turn on the power with either KEY4 (pin (81) of microprocessor) or KEY5 (pin (82) of microprocessor) connected

to "GND".

• Turn on the power switch while holding down the "TV/VIDEO" key and the "MENU" key simultaneously. ("K"

appears on top left of the screen, indicating the entry into the inspection process mode.) Then hold down the

"CH (Ù)" key and the "Volume (–)" key simultaneously. (Thus the adjustment process mode screen appears.)

To exit, shut off the power . (Y ou ma y either turn off the power s witch or shut off the pow er using remote controller .)

3.Key operation in adjustment process mode

Receiving channel selection

• Use the "CH (ù)/(Ù)" keys to select receiving channel (actual channel).

Single pressing ... Moves the channel UP/DOWN one by one.

Holding down ... Performs the UP/DOWN search for next receiving channel.

• Various adjustments

Perform adjustment item by item using the "MENU" key, "Cursor UP/DOWN" keys, "CH (ù)/(Ù)" keys and

"Volume (+)/(–)" keys (on main unit and remote controller).

• Select adjustment item using the "Cursor UP/DOWN" keys.

• You can move to the next adjustment item by "MENU" key input.

When bottom item is selected, the "MENU" key input will move the selection to top item of the next page.

• Auto preset key input will move the selection to top item of the next page regardless of the current selection.

Page 1 → Page 2 → ... → Page 84 → Page 1

• Manual memory key input will move the selection to top item of the same page regardless of the current selection.

• Use the "Volume (+)/(–)" keys to increase or decrease the value of the selected adjustment item.

• Direct jump to item

You can jump the cursor directly to the desired item in the adjustment process. Using "GREEN" key on the remote

controller, go to the 3-digit number entry mode. Enter the numbers using "Channel Select" key on the remote

controller.

~ ~ ~

Specify the item number on the page.

Specify the page number.

(For example, enter 237 if you wish to bring the cursor to the 7th item on page 23.)

4.Initialization

4-1. Connect both pin (81) and pin (82) of IC2001 (microprocessor) to GND. Turn on the power.

4-2. Select MODEL (A662&663). *Note: You have no option for MODEL.

4-3. Select INCH SIZE (15). *Note: You cannot change INCH SIZE.

15

Page 16

LC-15L1E

5.Adjustment

5-1. +B adjustment

1) Receive with E-12 channel.

2) With TV Main unit, change +B-ADJ in the first page of adjustment process and adjust TP1101 voltage to

5.00V±0.02V.

3) With wireless center, turn R5707 volume (semi-fixed) and adjust TL5403 voltage to 5.00V±0.02V.

Note) Adjustment to 5.00V must be precise, since 5.00V is used as reference voltage for all power voltages.

5-2. COMMON BIAS adjustment

Very the "CON BIAS" setting on Page 2 of the adjustment process mode so that the contrast be sharpest be

sharpest (black looks most sinking).

5-3. TAMP adjustment (Wireless center only)

1) Receive with E-12 channel. (Field intensity: Min. 80dB)

2) Enter the adjustment process mode. Using TAMP key on the remote controller, enter TAMP adjustment mode.

(Individual TAMP item display status)

3) When AGC GAIN VALUE reading differs from PAL TAMP reading, adjust PAL TAMP to make both readings

identical.

4) Whenever PAL TAMP has been adjusted, enter the adjusted value to SECAM TAMP manually.

Note) Perform the adjustment using a signal with good S/N ratio under field intensity of 80dB or higher. Screen

brightness may be reduced if field intensity is lower than specified or S/N ratio is poor.

5-4. Auto adjustment of battery shutoff voltage

1) Warm up the set.

2) Ensure that there is no connection to the main unit DC connector.

3) Insert the specified jig to the main unit battery connector. Apply DC9.3±50mV externally.

4) Change AUTO BATV ADJ on page 82 of the adjustment process from OFF to RUN.

5) Check that RUN is replaced by OK.

6) When auto adjustment has failed, NG is displayed.

5-5. White balance adjustment

Adjust RCUTOFF, BCUTOFF, RGAIN and BGAIN on page 2 of the adjustment process, so that the same color

level is attained as the standard set.

Page 82 of the adjustment process

8 2

BAT V

BAT TEMP

AUTO BATV ADJ OFF

BATV OFFSET 0

TV ON BATV LVL4 B3

TV ON BATV LVL3 95

TV ON BATV LVL2 8D

TV ON BATV LVL1 7A

PAIRING MODE OFF

BAT WARN OSD ON

SS NUIT ON

16

RUN

Page 17

LC-15L1E

6. Factory Setting

6-1. Perform a factory setting after completing all adjustments.

6-2. A "POWER" keys is made on with pushing an "TV/VIDEO" and "MENU" keys at the same time.

6-3. "K" of the inspection process mode is displayed on the screen upper left.

6-4. CH (ù) and VOL (+) keys are pushed about 2 seconds at the same time.

6-5. Release keys, if "E" is displayed on the screen upper left and “COMPLETE” is displayed on the bottom of it.

6-6. After a while, a power will be in a standby mode and a setup will be finished.

Note) "First installation" serves on "Deutsch".

7. Lamp error detection

7-1. Functional description

This LCD colour television has a function (lamp error detection) to be turned OFF automatically for safety

when the lamp or lamp circuit is abnormal.

If the lamp or lamp circuit is abnormal, or some other errors happen, and the lamp error detection is executed,

the followings occur.

1 The main unit of television is turned OFF 5 seconds after it is turned ON. (The power LED on the front

side of TV turns from green to red.)

2 If the situation 1 happens 5 times sequentially, television can not be turned ON. (The power LED remains

red.)

7-2. Countermeasures

7-2-1.Check when turning OFF the lamp error detection

When television is turned OFF by the lamp error detection mentioned above, it enters the adjustment

process with the power LED red. Entering the adjustment process turns OFF the error detection and turns

ON TV.

This enables the operation check to detect errors in the lamp or lamp circuit.

Check whether "ERROR NO RESET" on line 3, page 1 of the adjustment process is 1 or more. If it is 1 or

more, it indicates the lamp error detection was executed.

7-2-2.Resetting of the lamp error count

After confirming that the lamp or lamp circuit is normal, reset the lamp error count. Select "ERROR NO

RESET" on line 3, page 1 of the adjustment process and set the number to 0 using the volume button.

Page 1 of the adjustment process

1

MODEL A662&663

INCH SIZE 15

+B–ADJ 130

ERROR NO RESET 5

PUBLIC MODE OFF

EXT CONTROL OFF

UPDATE MODE NORMAL

TEXT RESET OFF

SS BER LEVEL 00

ROM VER A662 1.00A A663 1.00A

ID No ~~~~~~~~

17

Reset 0

Page 18

LC-15L1E

No picture and no sound at all

(When using AC adapter)

Check that microcomputer adjustment process menu is set correctly.

No fluorescent lamp lighting

Is F3801 normal?

Replace F3801.

Is F3804 normal? Replace F3804.

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Is loaded-side short-circuited

when F3801 is removed?

Are T3701 secondary

outputs +34V, +9V, +5V and

-11V normal?

Is oscillation waveform

normal at T3701 primary?

Check T3701 secondary

loading.

Check J9901 periphery and

connector cable.

Check S4050 and connector

cable.

Is pin (120) of IC1201 at "H"

level?

Replace and check

fluorescent lamp.

Is oscillation waveform

normal at primary of T6501,

T6502,

T6503 and T6504?

Check Q6501, Q6502,

Q6503, Q6504, Q6511,

Q6512, Q6513, Q6514,

T6501, T6502, T6503, T6504

and their peripheries.

Check relevant line, IC1201

and periphery.

Are Q3807 and Q3803

normal?

Are T3701 primary periphery,

Q3703, Q3705 and S4050

short-circuited?

TROUBLE SHOOTING TABLE

18

Page 19

TROUBLE SHOOTING TABLE (Continued)

No picture and no sound at all

(When using battery)

Check that microcomputer adjustment process menu is set correctly.

Is F9001 normal?

Replace F9001.

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

No power (Normal operation with AC adapter)

Is battery voltage (1.8-2.2V) present at pin (94) of IC2001?

Is temperature detection voltage (0.5-1.8V) present at pin (93) of IC2001?

Is battery detection of pin (68) of IC2001 at "L" level?

Are pins (2) and (4) of Q3806 at "L" level?

Check IC2011, F9001, battery and their peripheries.

Check IC2011, battery and their peripheries.

Check IC2011, battery and their peripheries.

Check Q3801, Q3802 and their peripheries.

Check Q3806.

No operation with battery

Is loaded side short-

circuited when F9001

is removed?

Are T3701 secondary

outputs +34V, +9V,

+5V and -11V normal?

Is oscillation waveform

normal at T3701

primary?

Check T3701

secondary loading.

Check P9004

periphery and

connector cable.

Check S4050 and

connector cable.

Are Q3806 and Q3801

normal?

Are T3701 primary

periphery, Q3703,

Q3705 and S4050

short-circuited?

LC-15L1E

19

Page 20

LC-15L1E

No picture (1/2)

No picture at all

No picture for TV

No picture for Video 1 No picture for Video 2

Check that microcomputer adjustment process menu is set correctly.

NO

NO

NO NO NO NO

NO

NO

NO

NO

NO

NO

YES YES

No SCART R/G/B

NO

NO

YES

YES

YES

YES YES

No picture for Video 3

NO

NO

NO

YES

YES

YES YES

YES

YES

YES

No picture (2/2)

Check that microcomputer adjustment process menu is set correctly.

NONO

No colour

No colour for TV

No colour for Video 2 No colour for Video 3No colour for Video 1 No colour for Video 4

Check that microcomputer adjustment process menu is set correctly.

NO

No picture for TV, Video

1, Video 2 and Video 3

No picture

for Video 4

Is IC801

I/O

normal?

Is IC1201

I/O

normal?

Check LCD panel

voltage and waveform.

Check

IC801 and

periphery.

Are inputs

at pins (2),

(3) and (4)

of IC5408

normal?

Are inputs

at pins (1),

(2), (3) and

(79) of

IC5401

normal?

Check outputs

at pins (40),

(39), (38), (37),

(34), (33), (32)

and (31)

of IC5401.

Check

IC5408 and

periphery.

Is IC5402

I/O

normal?

Is input at

pin (73) of

IC5401

normal?

Check

IC5402 and

periphery.

Check

power line.

Check

relevant

line.

Check

relevant

line.

Is input at

pin (7) of

IC5402

normal?

Check

relevant

line.

Is input at

pin (12) of

IC5402

normal?

Are inputs

at pins (72)

and (73) of

IC801

normal?

Check SY

line, SC line

and

peripheries.

Check

IC5402 and

periphery.

Is IC5402

output

normal?

Check

IC5402 and

periphery.

Is IC5402

output

normal?

Check

IC5402 and

periphery.

Is IC5402

output

normal?

Check

tuner and

periphery.

Is input at

pin (9) of

IC5402

normal?

Check

relevant

line.

No Video 1 output

from SCART1

Is output at pin (5)

of IC5202 normal?

Check IC5202 and

its periphery.

Is output at pin (4)

of IC5202 normal?

Check IC5202 and

its periphery.

NO

Is output at pin (19)

of SCART normal?

Check relevant line.

NO

Is output at pin (40)

of SCART normal?

Check relevant line.

No Video 2 output

from SCART2

Check

IC5402 and

periphery.

Are voltages

at pins (1),

(13) and (15)

of tuner

normal?

Is output at

pin (23) of

tuner normal?

Is IC5402

output

normal?

Check

relevant line.

Is input at

pin (47) of

IC5402

normal?

Check

relevant

line.

Check

IC5401 and

periphery.

Check

IC1201 and

periphery.

Is IC801 input normal?

Check IC801 and periphery.

TROUBLE SHOOTING TABLE (Continued)

20

Page 21

TROUBLE SHOOTING TABLE (Continued)

No sound

No sound from both speakers

No sound from headphone?

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

消音を

Check X3201 periphery.

Check IC3201 periphery.

No sound in all input modes (TV and Video

1/2/3/4)?

Check the following.

1 Is the volume not low?

2 Is the set not muted?

3 Is headphone not inserted?

Is voltage normal at pin (7) (power input terminal)

of IC3206? (Approx. +15V)

Is voltage normal at pin (5) (standby control

terminal) of IC3206? (Approx. +1.8V)

Is control signal input available at each pin of IC3201?

Pin (2) of IC3201 SCL1

Pin (3) of IC3201 SDA1

Is oscillation waveform normal at pins (71) and (72) of

IC3201?

Is audio signal output available at pins (27) (Rch) and

(28) (Lch) of IC3201?

Check pins (27) (Rch) and (28) (Lch) of IC3201 up to

pins (4) (Rch) and (2) (Lch) of IC3206, as well as the

peripheries of IC3204, IC3205 and IC3207.

Is power voltage normal in each circuit?

Pin (8) of IC3204, IC3205 and IC3207, and pin

(39) of IC3201 Approx. +8V

Pins (11), (12), (13), (65) and (66) of IC3201

Approx. +5V

Check again after doing the following.

1Raise the volume.

2 Cancel the mute.

3 Remove the headphone.

Check headphone jack, speaker and

speaker cable.

Check AC adapter up to pin (7) of IC3206.

Check pin (56) of IC2001 up to Q3206.

Check pins (25) and (26) of IC2001 up to

pins (2) and (3) of IC 3201.

Check the following.

+8V line....Check Q3713 periphery up to

pin (8) of IC3204, IC3205 and

IC3207, and pin (39) of

IC3201.

+5V line....Check T3701 output

B5V500MA line up to each

+5V input pin of IC3201.

Check the following.

1 No TV sound....Check the peripheries

of Q5212, Q5213, Q5214 and

TU5201.

2 No Video 1 sound....Check pins (2)

and (6) of SCART up to pins (57) and

(56) of IC5901.

3 No Video 2 sound....Check pins (23)

and (27) of SCART up to pins (54)

and(53) of IC5901.

4 No Video 3 sound....Check J5201 up

to pins (51) and (50) of IC5901.

5 No Video 4 sound....Check J3201 up

to pins (54) and (53) of IC3201.

Check that microcomputer adjustment process menu is set correctly.

NO

NO

No Audio 1 output

from SCART1

Are outputs at pins

(36) and (37) of

IC5901 normal?

Check IC5901 and

its periphery.

Are outputs at pins

(33) and (34) of

IC5901 normal?

Check IC5901 and

its periphery.

NO

Are outputs at pins

(7) and (1) of IC5903

normal?

Check relevant line.

NO

Are outputs at pins

(7) and (1) of IC5902

normal?

Check relevant line.

NO

Are outputs at pins

(1) and (3) of SCART

normal?

Check relevant line.

NO

Are outputs at pins

(22) and (24) of

SCART normal?

Check relevant line.

No Audio 2 output

from SCART2

LC-15L1E

21

Page 22

LC-15L1E

1.Checking normal startup with terminal software

After entering the command described below, turn on the power again. If the same contents as shown on the

next page appear on the screen, you can confirm that "SS unit" has been started up normally.

1. Preparations:

1 PC (with Teraterm communication software installed)

2 Dedicated connector cable

(Connection diagram)

PC

(with Teraterm

installed)

Caution:

After starting Teraterm, set to "Serial"

port on initial screen.

(Checkup procedure)

Serial port

Dedicated connector cable

(QCNW-1914TAZZ)

φ2.5 Jack

Wireless Center or

TV receiver

"Factory setting terminal" on the

rear face

1 When you are done with the connection as shown above, turn on the power.

2 Sev eral seconds after powering up , the screen will stabilize. Then, hold down Shift k ey and ~ ke y simultaneously

for a few seconds to call the prompt.

~ Wireless Center prompt = "$"

TV receiver prompt = "%"

When the sequence ~~~.. appears, press Enter key once to

show a single prompt.

3 Enter the following command, and press Enter.

"eepw_0x80_0x03" (_ indicates a space.)

Example of Teraterm screen (Wireless Center side

L1 PAL TX Version 2C

MPEG Version 05

Before MPEG CMD

MPEG CMD OK

Before MPEG Standby Cmd

MPEG Standby Cmd OK

4 Turn the power off and then on again.

5 When you have finished checking all display items on the next

page, repeat the steps starting from 1. In the step 3, enter

"0xFF" instead of "0x03" to put the setting back to a default.

Debug Monitor Special Version 1.1

Copyright 2001 SHARP CORPORATION.

All Rights Reserved.

$ ~~~~~~~~

Syntax Error

ERROR

$ eepw 0x80 0x03

OK

$

)

2. Writing and reading the ID code

When either the transmitter or receiver of the SS unit has been replaced, it is necessary to match the ID code

of the transmitter and receiver.

1 Writing the ID code

• Using the terminal software, call the above screen and key in the following command. Then press the Enter

key. (Turn the power off and on again. The program gets started with the new ID code.)

"idw_~~~~~~~~" (~ represents a new ID code.) (_ means a space.)

Note: If either the transmitter or the receiver has been replaced, note the ID code of the existing transmitter

or receiver and enter the same ID code to the new transmitter or receiver.

If both the transmitter and the receiver have been replaced, rewrite a new ID code for both of them,

referring to the following chart.

No. of digits 8 7 6 5 4 3 2 1

[Service ID]

2 Reading the ID code

00F00000

Fixed value (for servicing only)

Lower 5 digits of serial number on the

model label applied on the TV set

• Using the terminal software, call the above screen and key in the following command. Then press the Enter

key.

"idr"

• Press the Enter key again, and the ID code will appear.

Note: Be sure to enter the ID code assigned to the set in order to avoid confusion with other sets.

22

Page 23

2.Terminal software (Teraterm) checkup screen

» Wireless Center (sender) side normal screen

L1 PAL TX Version 2C Power turned on (microcomputer started)

POWER OK

SHARP L1 Transmitter mode with AUDIO

VENUS Task startupInit composit mode

L1 PAL TX Version 2C Second version display

Before MPEG FORWARD

MPEG FORWARD End

MPEG Audio FORWARD End

MPEG Audio FORWARD Finish End

MPEG Version 05

Before MPEG CMD

MPEG CMD OK

Before MPEG Standby Cmd

Standby Cmd adr 0x01 = 00

MPEG Standby Cmd OK

MPEG Start Cmd OK MPEG setup complete

APOLLO2 startup APOLLO2 setup started

Root mode

RSB=17, Retry=3

Set Cycle OK

RSB=17, Retry=3

Set Cycle OK

SS Channel = 00[ch]

APOLLO2 startup ok

SS Default Channel = 0x00[ch]

Scramble ID = 0x80010000

Root(Tx) : Link(WakeUp) Process Start !! All settings initialized

Searching.....

SSCCA count = 1

SSCCA count = 0

SSCCA count = 0

SSCCA count = 0

SSCCA count = 0

SSCCA count = 0

SSCCA count = 0

SSCCA count = 0

LC-15L1E

» TV unit (receiver) side normal screen

L1 PAL RX Version 26 Power turned on

POWER OK

SHARP L1 Receiver mode with AUDIO

VENUS Task startup

Video Parameter OK

L1 PAL RX Version 73 Second version display

MPEG Audio FORWARD End

MPEG Audio FORWARD Finish End

MPEG Version 27 MPEG setup complete

.....Register Dump.....

ADD +0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

00 00 00 00 00 83 83 83 83 11 11 11 11 10 10 10 10

10 01 01 01 01 00 00 00 00 00 00 00 00 00 00 00 00

20 01 01 01 01 11 11 11 01 11 01 11 11 00 00 00 00

30 00 00 00 00 00 00 00 00 a0 a0 a0 a0 00 00 00 00

40 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 03 03 03 03 c0 c0 c0 c0 00 00 00 00 00 00 00 00

60 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 ee ee ee ee

80 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

90 00 00 00 00 0a 0a 0a 0a 81 81 81 81 00 00 00 00

a0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

b0 ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff

c0 00 00 00 00 01 01 01 01 dd dd dd dd 00 00 00 00

d0 00 00 00 00 0f 0f 0f 0f 00 00 00 00 04 04 04 04

e0 07 07 07 07 00 00 00 00 00 00 00 00 01 01 01 01

f0 44 44 44 44 ff ff ff ff 00 00 00 00 00 00 00 00

System Instruction OKAPOLLO2 startup

Leaf mode

RSB=17, Retry=3

Set Cycle OK

RSB=17, Retry=3

Set Cycle OK

SS Channel = 00[ch]

APOLLO2 startup o k APOLLO2 setup started

SS Default Channel = 0x00[ch]

Scramble ID = 0x80010000

Start Link Process. Wait a moment...

Leaf(Rx) : Link Process Start !! All settings initialized

Searching.....

(microcomputer started)

23

Page 24

LC-15L1E

NO

* How to check or change ID

» Checking ID

In the step 3 of the checkup procedure with terminal software

(p.22), enter the following command and press Enter to check ID.

"idr"

» Changing ID

(1) Using the same procedure as above, enter the following

command and press Enter.

"idw-~~~~~~~~"

Enter a new ID (8 digits) in place of **.

(2) Turn the power off and then on again.

YES

No sound

No picture

Teraterm screen (TX)

L1 PAL TX Version 2C

MPEG Version 05

Before MPEG CMD

MPEG CMD OK

Before MPEG Standby Cmd

MPEG Standby Cmd OK

Debug Monitor Special Version 1.1

Copyright 2001 SHARP CORPORATION.

All Rights Reserved.

$ —————

Syntax Error

ERROR

$ idr ←ID verified

00C00001

ok

$ idw 00C00002

←ID changed

ok

$

No link?

• TV receiver side screen shows "No radio wave reception".

• Wireless Center side reception sensitivity lamp is off.

Determine which is faulty, Wireless Center

(sender) or TV receiver.

Remote controller

does not work.

Replace either one with a good module, and check if operation is

normal. (* To do this, you need to match both IDs. See below.)

Go to fault-finding flowchart

with normal link.

Determine which is faulty, Wireless Center

(sender) or TV receiver.

Replace either one with a good module, and check if link is

normal. (* To do this, you need to match both IDs. See below.)

Go to fault-finding

flowchart with no link.

3.Troubleshooting

» 1st step fault-finding flowchart for SS (wireless) module

24

Page 25

LC-15L1E

YES

NO

NO

NO

YES

NO

NO

NO

NO

NO

NO

IC5704 failure

YES

No sound No picture

YES

YES

YES

YES

YES

YES

Is audio input signal supplied correctly

to pins (27) and (29) of CN5001?

Pin (27)→ L, Pin (29)→ R

Is DC voltage normal at each of the

following pins?

Pin (8) of IC6501

→ +5.0V

Pins (1), (2), (14) and (24) of

IC6500→ +3.3V

Is output signal waveform at pins (3)

and (6) of IC6500 similar to

the above input signal waveform?

Pin (3)→ R, Pin (6)→ L

Is pin (7) of IC6500 at HI (+3.3V)

level?

Is signal waveform normal at pin (12)

of IC6500?

Is control signal normal at each of pins

(9), (10) and (11) of IC6500?

Check for connector

damage or cable

disconnection.

Is video input signal supplied correctly to

each of the following pins?

Check for connector

damage or cable

disconnection.

Check for connector

damage or cable

disconnection.

Check the continuity

between pin (24) of

IC5704 and pin (24)

of CN5001.

Remote controller does not work.

* Pictures and sounds are produced.

Is there an output of data signal

waveform at pin (24) of CN5001?

Is there an output of data signal

waveform at pin (24) of IC5704?

Perform the following checks by

actually operating the remote

controller for a video source.

IC6000 failure

(Not serviceable)

Check each IC and

the peripheries of

L6500 and L6501.

Check IC6501

periphery.

IC5704 failure

IC6500 failure

IC6000 failure

(Not serviceable)

IC6000 failure

(Not serviceable)

» Wireless Center side fault-finding flowchart with normal link

~Perform the following checks while maintaining the link and feeding AV input signals to Wireless Center.

Reference waveform: VIDEO → Colour bar

AUDIO → 1KHz SIN wave

25

Page 26

LC-15L1E

YES

NO

YES

YES

YES

YES

NO

YES

YES

NO

NO

NO

NO

YES

NO

NO

NO

YES

NO

NO

YES

IC1100 failure

NO

NO

YES

No sound

YES

YES

IC704 failure

IC1500 failure

NO

YES

NO

YES

YES

YES

No picture

NO

NO

NO

YES

Is DC voltage normal at each of the

following pins?

Pin (8) of IC1501

→ +8.0V

Pins (1), (2), (14) and (24) of

IC1500→ +3.3V

Is output signal waveform at pins

(19) and (20) of IC1500 similar to

that of the input signal supplied to

Smart Link transmitter?

Pin (19)→ L, Pin (20)→ R

Are pins (7) and (8) of IC1500 at HI

(+3.3V) level?

Is control signal normal at each of

pins (9), (10) and (11) of IC1500?

Is signal waveform normal at pin

(15) of IC1500?

Check each IC

and the

peripheries of

L1500 and

L1501.

Check IC1501

periphery.

Check for

connector

damage or cable

disconnection.

Is output signal waveform available at

pins (1), (3) and (5) of CN1?

Is output signal waveform available at

pins (26), (27) and (31) of IC1100?

Is normal +5.0V available at pin (5) of

IC1300 and pin (8) of IC1302?

Are the waveforms normal at pins (2), (5)

and (6) of IC1302?

Does TP_PWM show normal waveform?

IC1501 failure

Check the

peripheries of

L1101-L1103.

IC1000 failure

(Not serviceable)

Check for connector

damage or cable

disconnection.

IC704 failure

Q701 failure

IC1000 failure

(Not serviceable)

Check the periphery

of each IC.

Check the

peripheries of

IC1302 and XC1301.

Are the waveforms of clock signal

at pin (44) and data signal at pin

(41) of IC1100 normal?

Remote controller does not work.

* Pictures and sounds are

produced.

Perform the following checks by

actually operating the remote

controller for a video source.

Is there an output of data signal

waveform at pin (12) of CN1?

Is there an output of data signal

waveform at pin (19) of IC704?

Is normal +8.0V

available at pins

(3) and (5) of

IC1501?

Check for

connector

damage or

cable

Q1501 and

Q1502 failure

IC704 failure

Q1500 failure

Is output signal

waveform at pins (1)

and (7) of IC1501

similar to the waveform

mentioned on the left?

Pin (1)→ R, Pin (7)→ L

Is output signal

mentioned above

available at pins (7) and

(9) of CN2?

Pin (7)→ R, Pin (9)→ L

Are base terminals of

Q1501 and Q1502 at

LOW (0V) level?

Is base terminal of

Q1500 at HI (+3.3V)

level?

IC1000 failure

(Not serviceable)

IC1000 failure

(Not serviceable)

» TV receiver side fault-finding flowchart with normal link

~Perform the following checks while maintaining the link and feeding the signals to Wireless Center.

Reference waveform: VIDEO → Colour bar

AUDIO → 1KHz SIN wave

26

Page 27

» Wireless Center (TX) side fault-finding flowchart with no link

NO

NO

NO

NO

NG

NO

NO

NO

NO

NO

Go to the

step A.9.

OK

YES

NO

Replace

the cable.

YES

YES

OK

YES

OK

YES

Check the microprocessor operation using terminal software.

A. No display

YES

No link

YES

YES

OK

YES

OK

2 Is normal +3.3V output available

at pin (4) of IC5906?

C. MPEG setup OK is not

displayed.

1 Is normal +1.5V available at

both ends of L6000, and

+3.3V at both ends of L6001?

D. No display after APOLL2

startup

1 Check IC6701 periphery.

3 Go to the step E.

2.

E. All displays are normal.

3 Replacement of UNT6700

did not help recover normal

operation.

4 Check the peripheries of

pins (40)-(43) of IC5704.

5 Check CN5200 peripheries.

1 Using a spectrum analyzer

or the like, check that output

signal has RF waveform.

2 Check that the cable

connecting CN5200 and

UNT6700 has no

interference or damage.

2 Is normal +3.3V available at

each of the following pins of

IC6701?

(1), (8), (31), (37), (44), (54),

(67), (73), (80), (90), (103),

(109), (116), (126), (133) and

(139)

3 Is output signal waveform normal

at pin (13) of IC5704?

4 Is normal +3.3V output available

at pin (4) of IC5706?

6 Check IC5704 and Q5705

peripheries.

7 Check IC5902 periphery.

8 Is normal +1.5V available at

TP5902?

9 Is normal +3.3V available at

TP5900?

0 Is normal +5.0V output available

at pin (4) of IC5907?

q Check IC6500 periphery.

IC5704 failure

1 Is normal +9V available at pins

(1)-(3) of CN5002?

Check for connector

damage or cable

disconnection.

Check IC5906

periphery.

Check L6000

and L6001.

Not serviceable

Check FL5701

periphery.

Check IC5706

periphery.

Check Q5904

periphery.

Check Q5902

periphery.

Check IC6501 and

Q5903 peripheries.

LC-15L1E

27

Page 28

LC-15L1E

Not serviceable

IC1704 failure

OK

OK

OK

A. No display

YES

YES

YES

YES

NO

NO

NO

NO

NO

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

OK

No link

Check the microprocessor operation using terminal software.

OK

NG

OK

1Is normal +9V available at pins

(1)-(3) of CN2?

B. No second time Version display

C. MPEG setup OK is not

displayed.

D. No display after APOLL2

startup

E. All displays are normal.

1 Using a spectrum analyzer

or the like, check that output

signal has RF waveform.

2 Check that the cable

connecting CN200 and

UNT1700 has no

interference or damage.

3 Replacement of UNT1700

did not help recover normal

operation?.

4 Check pins (40)-(43) of

IC704 and the peripheries.

5 Check CN200 and the

peripheries.

2

Is normal +3.3V available at each

of the following pins of IC1701?

(1), (8), (31), (37), (44), (54),

(67), (73), (80), (90), (103),

(109), (116), (126), (133) and

(139)

1

Check IC1701 and the periphery.

3

Go to the step E.

2

.

1 Is normal +1.5V available at

both ends of L6000, and

+3.3V at both ends of L6001?

3 Is signal waveform normal at pin

(44) of IC1100?

1 Check IC1100 and the periphery.

4 Check the following connections.

Between pin (23) of IC1100 and

pin (21) of IC704

Between pin (24) of IC1100 and

pin (23) of IC704

2 Is output normal at the following

pins of IC1100?

(1), (11), (20), (28) and (30): +3.3V

2 Is normal +3.3V output

available at pin (4) of IC906?

3 Is output signal waveform

normal at pin (13) of IC704?

4 Is normal +3.3V output

available at pin (4) of IC706?

6 Check IC704, Q705 and their

peripheries.

7 Check IC902 and the periphery.

8 Is normal +1.5V available at

TP902?

9 Is normal +3.3V available at

TP900?

0 Is normal +5.0V output

available at pin (4) of IC907?

q Check IC1500 periphery.

Check for

connector

damage or cable

disconnection.

Check IC906

periphery.

Go to the step

A.9.

Go to the step

A.8.

Check L6000

and L6001.

Go to the

step A.9.

Replace the

cable.

Check FL701

periphery.

Check IC706

periphery.

Check Q904

periphery.

Check Q902

periphery.

Check IC1501

and Q903

peripheries. Go

to the step B.1.

» TV receiver (RX) side fault-finding flowchart with no link

28

Page 29

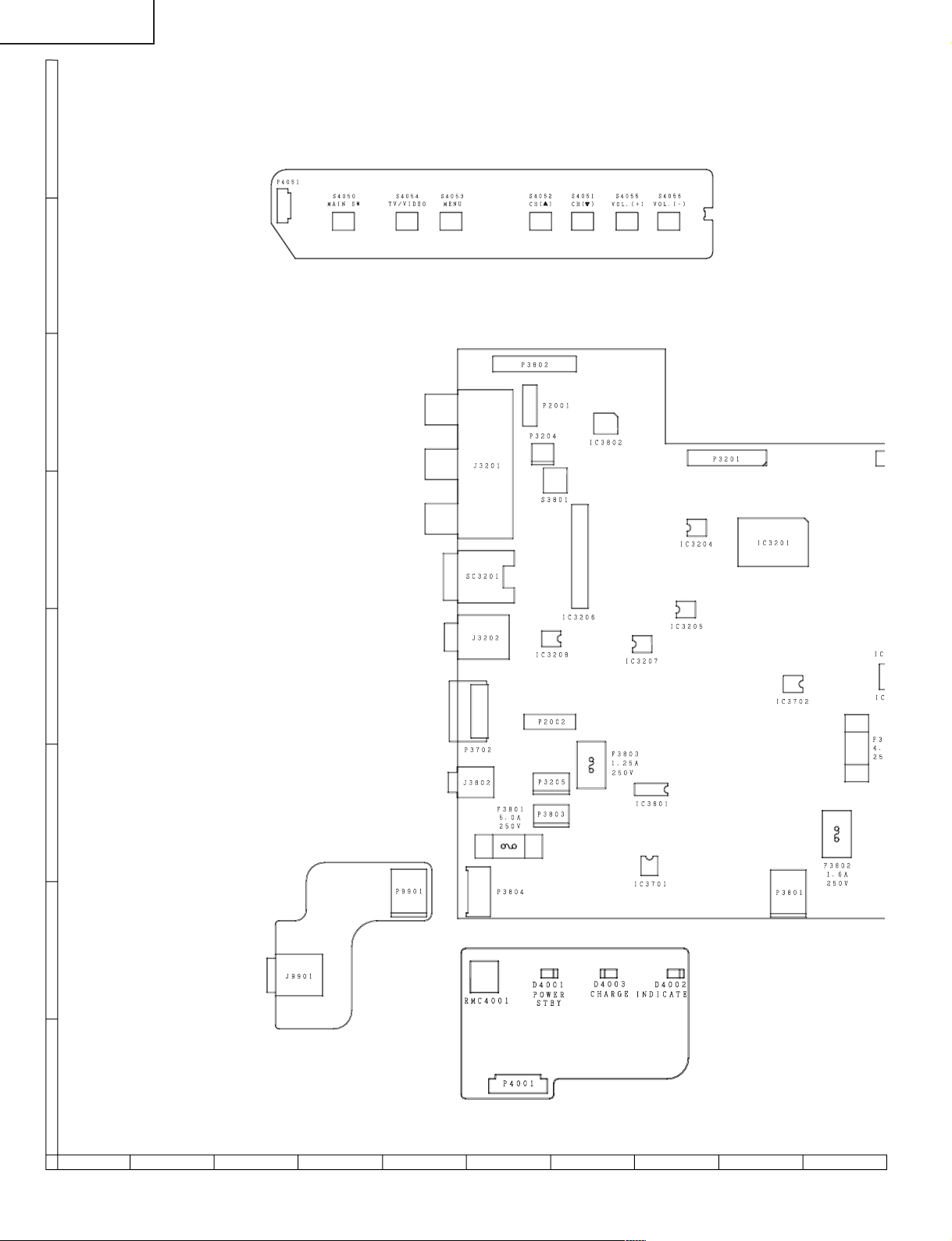

LC-15L1E

654321

A

B

C

D

E

F

G

H

CHASSIS LAYOUT-1/2 (WIRELESS CENTER)

SWITCH, LED Unit

WIRELESS CENTER Unit

29

Page 30

LC-15L1E

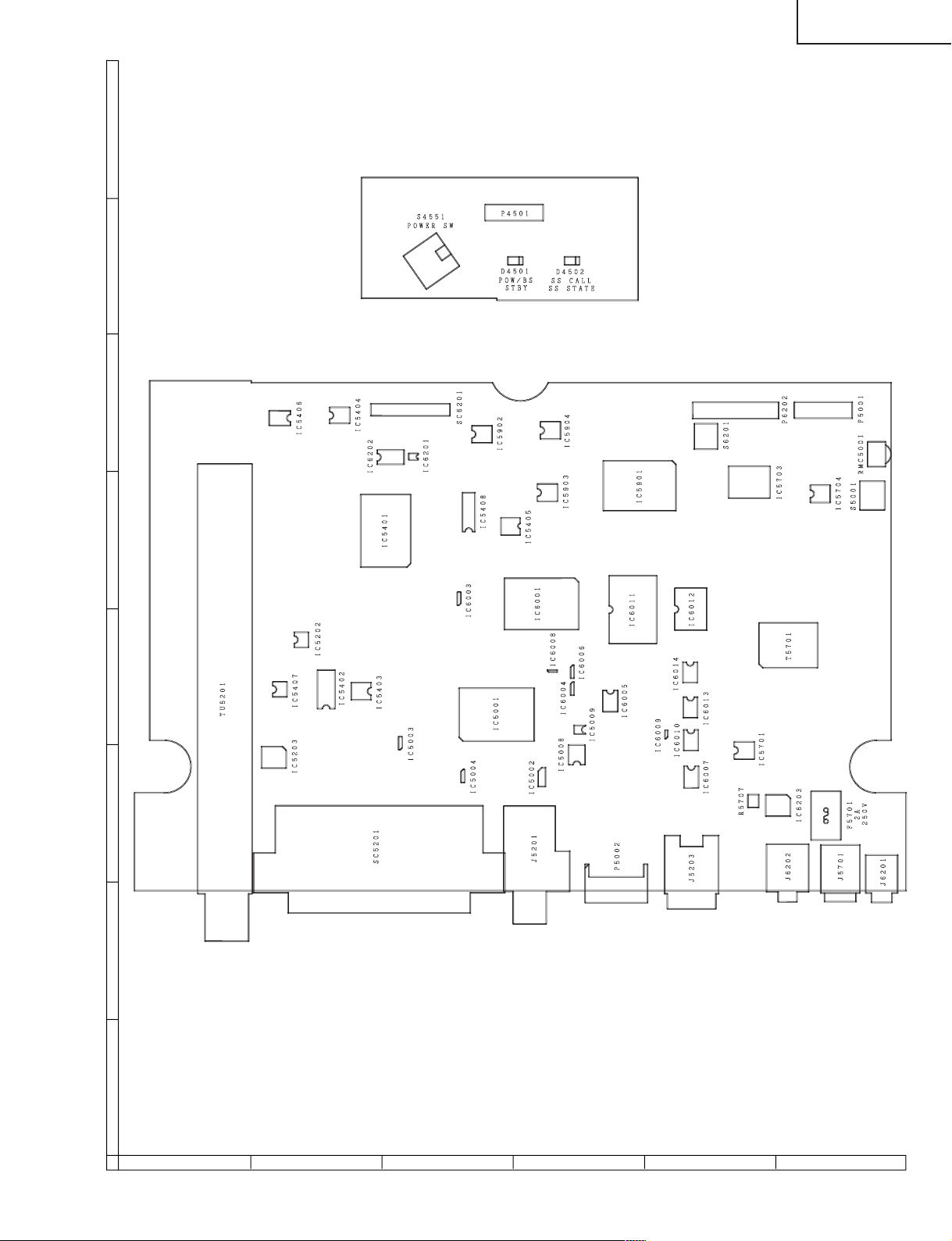

CHASSIS LAYOUT-2/2 (TELEVISION)

H

OPERATION Unit

G

F

MAIN Unit

E

D

C

DC JACK Unit

R/C, LED Unit

B

A

87109654321

30

Page 31

INVERTER Unit

LC-15L1E

BATTERY CONNECTOR Unit

31

1716 1918151413121110

Page 32

LC-15L1E

M

C

/

C

5

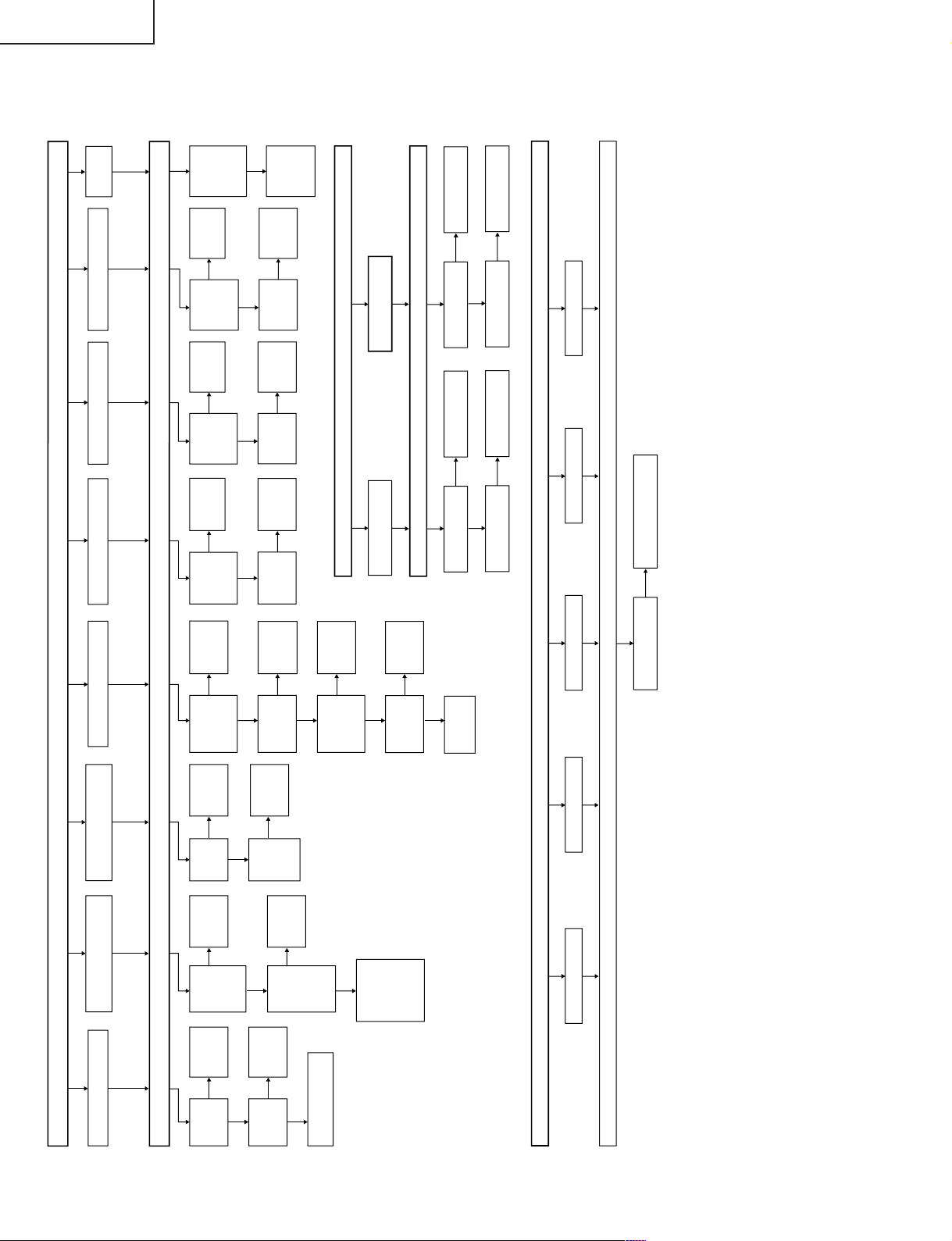

BLOCK DIAGRAM-1/2 (WIRELESS CENTER)

H

ANTENNA

G

SC5201

SCART

(AV1,2)

AUDIO IN

VIDEO SELECTOR

IC5202

TUNER

TV_V

SC1/2_L/RO

AUDIO

OUT

VIDEO

OUT

F

SDA/RXD

SCL/TXD

V_OUT1/2

TV/AV

SELECTOR

IC5402

I2C/UART

VIDEO IN

SC_R/G/B

SC2_C

E

J5203

S

V3_SC

SIF1

V1/2_L/R

2

I

C

V1/2_V

CHROMA

SELECTOR

IC5405

AUDIO AMP

IC5902,5903

6dB AMP

IC5403(1/2)

V_OUT

(AV3) INPUT

V3SY

J5201

VIDEO

V3_V

INPUT

D

VIDEO

SELECTOR

IC5407

IC5403(1/2)

(AV3)

AUDIO

V3_L/R

ANA_IN1+

SC1/2_IN_L/R

SC1/2_OUT_L/R

SC3_IN_L/R

SC_IN

LPF

FL5402

6dB AMP

R/G/B/FB

SWITCH

IC5408

LPF

FL5401

I

CV

R

VOUT

SYN

IC

V2V0

INPUT

TX_FB

REG IC5002

J5701

C

DC12V

INPUT

REG IC5203

+5V

+5V

REG IC5003

+3.3V

SS_POWER_ON

REG IC5703

+9V

RE

PWM IC5701

REG IC5704(1/2)

B

DC/DC

VCC

SIGVCC

CONVERTER

+9V

T5701

+5V

A

87109654321

+32V

REG

REG

REG

32

Page 33

1+

R

UT_L/R

N_L/R

F

401

MSP

IC5901

CVBS/SY_IN

R/G/B_IN

I2C

DACM_L/R

VPC

IC5401

AUDIO AMP

IC5904

2

C

I

SS_L/RCH IN

VPC_0~7

LLC2

LC-15L1E

SS-TX

LLC2 ITU_0~7

SS INTERFACE

IC6201,6202

VOUT

E2PROM

SYNC SEP

IC5008

IC5404

V2V0

2

I

UART

CSYNC

C

MICON

IC5001

RESET

SS_POWER_ON

RESET

IC5004

LEVEL

SHIFT

Q6002,6004,

6006

TX_R/G/B

FB

N

)

REG IC6203

+32V

REG IC5406

REG IC6005

+5V

REG IC5704(1/2)

+3.3V

+2.5V

+8V

CVBS

TELETEXT

CPU

R/G/B

2

C

I

SRAM 2M

IC6012

IC6001

FLASH 4M

REG IC6007

+3.3V

IC6011

33

1716 1918151413121110

Page 34

LC-15L1E

H

E

E

S

D

3

BLOCK DIAGRAM-2/2 (TELEVISION)

H

DACM_L/R

DACA_L/R

2

I

C

AU

IC

SS-RX

SS_L/R_IN

SC1_IN_L/R

MSP

IC3201

SC2_IN_L/R

G

IC2001

MUTE

Q321

RE

4

SS_Y/C

6dB AMP

IC804(1/2)

FL801

LPF

CVBS/SY_IN

SC_IN

VPC

IC801

F

LPF FL802

SC3201

S

(AV4)INPUT

E

J3201 V4_V

VIDEO

V4_SY

V4_SC

SELECTOR

IC803

6dB AMP

IC804(1/2)

VOUT

SYNC SEP

IC802

2

UART/I

C

CSYNC

I

VPC_Y0~7

2

E

PROM

IC2006

2

C

MICON

INPUT

(AV4)

AUDIO

INPUT

D

J9901

DC15V

BAT_V

TEMP_DET

B15V1A

INPUT

INV_VCC

AUDIO_+B

VCC

+B

C

BATT_+B

TEMPV

B

BATTERY

BATT+B

BUFFER

IC2011

TMPDET

BATTERY

CHARGER

A

KEY

CHGVCC

POW

SWITCH

Q3703

SIGVCC

POWER

SUPPLY

SELECTOR

Q3806,3807

IC3801

REG IC3802

REG IC2004

REG IC705

DC/DC

CONVERTER

T3701

PWM IC3701

+9V

SS9V_ON/OFF

+5V

REG IC2002

+3.3V

+34V

REG IC3702

+9V

REG Q3713

-11V

REG IC703

+5V

REG IC805

REG IC706

REG IC704

RES

L_

+3.3V

+23V

+8V

-8V

+3.3V

+1.8V

+3.3V

34

87109654321

Page 35

LC-15L1E

_L/R

2

I

C

L/R

M

ICON

C2001

AUDIO AMP

IC3208

MUTE

Q321

4

RESET

RESET

L_ERR

AUDIO ACTIVE FILTER

IC3204,3205,3207

HP_MUTE

YIN0~7

SYNC SIGNAL

CONTROL SIGNAL

OSD R/G/B

RESET

IC2003

RESET

IC2008

SMUTE

DPS

IC1201

OFL

L/R_IN

MUTE

Q3212,3213

MPDA_5

MPCLK_5

DAC1CS

OUTCON

REV

AUDIO

POWER AMP

IC3206

AUDIO_+B(+15V)

GRADATION

POWER

IC1101

R0~7 G0~7 B0~7

V0 V7 V21 V64

V112 V176 V235 V255

DRIVER

Q1102,1103

DRIVER

Q1105,1106

LSP/RSP

HP_L/R

VGL

VCOM

CSCOM

SPEAKER

HEADPHONE

JACK

LCD

PANEL

P3203

P3204

J3202

SC1202

SC1203

SC1204

+3.3V

+23V

+8V

-8V

+3.3V

+1.8V

+3.3V

LEVEL SHIFT

Q2012

LAMP4

OFL1

INV ERR

LAMP ERROR

DETECTOR

Q6506,6507

DC/AC

INVERTER

CONTROLLER

IC6501

INV_VCC(+15V)

DC/AC

INVERTER

DRIVE

Q6501~6504

Q6511~6514

DC/AC

TRANS

T6501

~T6504

LAMP1~3

HV1/3

BACK

LIGHT

LAMP

REMOTE

CONTROL

RECEIVER

P3205

P6500

P6501

P4001

35

1716 1918151413121110

Page 36

LC-15L1E

OVERALL WIRING DIAGRAM

H

G

F

E

TV

D

C

B

A

36

87109654321

Page 37

LC-15L1E

37

1716 1918151413121110

Page 38

LC-15L1E

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. The voltages at test points are measured on

exclusive A C adaptor and the stable supply voltage

of AC 120V. Signals are fed by a color bar signal

generator for servicing purpose and the above

voltages are measured with a 20k ohm/V tester.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise

noted.

C : Solid

S : Oxide Film T : Special

N : Metal Coating

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

W

: Cement

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) A R E

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

38

Page 39

LC-15L1E

654321

A

B

C

D

E

F

G

H

SCHEMATIC DIAGRAM

Ë

OPERATION Unit

39

Page 40

LC-15L1E

Ë

H

G

F

WIRELESS CENTER Unit-1/7

E

D

C

B

A

87109654321

40

Page 41

LC-15L1E

41

1716 1918151413121110

Page 42

LC-15L1E

Ë

H

G

F

WIRELESS CENTER Unit-2/7

E

D

C

B

A

87109654321

42

Page 43

LC-15L1E

43

1716 1918151413121110

Page 44

LC-15L1E

Ë

H

G

F

WIRELESS CENTER Unit-3/7

E

D

C

B

A

87109654321

44

Page 45

LC-15L1E

45

1716 1918151413121110

Page 46

LC-15L1E

Ë

H

G

F

WIRELESS CENTER Unit-4/7

E

D

C

B

A

87109654321

46

Page 47

LC-15L1E

47

1716 1918151413121110

Page 48

LC-15L1E

Ë

H

G

F

WIRELESS CENTER Unit-5/7

E

D

C

B

A

87109654321

48

Page 49

LC-15L1E

49

1716 1918151413121110

Page 50

LC-15L1E

Ë

H

G

F

WIRELESS CENTER Unit-6/7

E

D

C

B

A

87109654321

50

Page 51

LC-15L1E

51

1716 1918151413121110

Page 52

LC-15L1E

Ë

H

G

F

WIRELESS CENTER Unit-7/7

E

D

C

B

A

654321

52

Page 53

LC-15L1E

654321

A

B

C

D

E

F

G

H

Ë

SWITCH, LED Unit

53

Page 54

LC-15L1E

Ë

H

G

F

MAIN Unit-1/7

E

D

C

B

A

87109654321

54