Page 1

Version 2.2

R

SSharp Programmable Controller

New Satellite JW20H/30H

ME-NET module

User's Manual

Produced in April 2002

Model name

JW-21MN

Page 2

Thank you for purchasing the ME-NET module (JW-21MN) for the SHARP programmable controller.

Read this manual thoroughly to completely familiarize yourself with the operation according to the

examples.

Keep this manual for future reference. We are confident that this manual will be helpful whenever

you encounter a problem.

Note

- This manual describes the JW-21MN that will be compatible with the JW30H. The JW-21MN that

is applied to JW30H has a 30Hn mark in front of the module.

Beside this, the JW-21MN has models with 30H marks and without 30H marks.

30Hn mark

(Compatible

with JW30H)

8

7

9

6

0

5

1

4

2

3

8

8

7

7

9

9

6

6

0

0

5

5

1

1

4

4

2

2

3

3

JW-21MN Descriptions

Can be used when installing the JW-21MN into JW30H

With 30Hn mark

control module: JW-31CUH/32CUH/33CUH (conventional

models) and JW-31CUH1/32CUH1/33CUH1/33CUH2

/33CUH3 (new models).

Can be used when installing the JW-21MN into JW30H

With 30H mark

control module (conventional models). When installing the

JW-21MN into the new models, the control module can be

used as conventional models.

The JW-21MN cannot be used with the JW30H control

No mark

module (both conventional and new models). It can be used

only with the JW20/JW20H control module.

- New functions in the revised edition in order to apply to JW30H are represented by the V2 mark.

Marks used in this manual Descriptions

V2

Functions that can be used when the JW-21MN (compatible with the

JW30H) is installed into the JW20/JW20H/JW30H.

- In this manual, programmable controller is referred to as "PC." Number and symbol in

parentheses added to address or setting value indications represent the following:

Octal··················· (8)

Hexadecimal······ (H)

Decimal·············· (D) or no indication

Note

- This manual was written with the utmost care. However, if you have any questions or inquiries

concerning the product, please feel free to contact our dealers or service agents.

- No part of this manual may be reproduced in any form without the written permission of Sharp

corporation.

- The contents of this manual are subject to change without prior notice.

Page 3

Safety Precautions

Read this manual and attached documents carefully before installation, operation, maintenance and

checking in order to use the machine correctly. Understand all of the machine knowledge, safety

information, and cautions before starting to use. In this instruction manual, safety precautions are

ranked into "danger" and "caution" as follows.

Danger : Wrong handling may possibly lead to death or heavy injury.

Caution : Wrong handling may possibly lead to medium or light injury.

Even in the case of Caution , a serious result may be experienced depending on the

circumstances. Anyway, important points are mentioned. Be sure to observe them strictly.

The picture signs of prohibit and compel are explained below.

: It means don’ts. For example, prohibition of disassembly is indicated as ( ).

: It means a must. For example, obligation of grounding is indicated as ( ).

1) Installation

Caution

- Use in the environments specified in the catalog, instruction manual, and user's manual.

Electric shock, fire or malfunction may be caused when used in the environments of high

temperature, high humidity, dusty or corrosive atmosphere, vibration or impact.

-Install according to the manual.

Wrong installation may cause drop, breakdown, or malfunction.

-Never admit wire chips or foreign matters.

Or fire, breakdown or malfunction may be caused.

2) Wiring

- Be sure to ground.

Unless grounded, electric shock or malfunction may be caused.

- Connect the rated power source.

Connection of a wrong power source may cause a fire.

- Wiring should be done by a qualified electrician.

Wrong wiring may lead to fire, breakdown or electric shock.

Compel

Caution

Page 4

3) Use

- Don't touch the terminal while the power is being supplied or you may have an electric shock.

- Assemble the emergency stop circuit and interlock circuit outside of the programmable

controller. Otherwise breakdown or accident damage of the machine may be caused by the

trouble of the programmable controller.

- "RUN" or "STOP" during operation should be done with particular care by confirming safety.

Misoperation may lead to damage or accident of the machine.

- Turn on the power source in the specified sequence. Turning ON with wrong sequence may

lead to machine breakdown or accident.

4) Maintenance

- Don’t disassemble or modify the modules.

Or fire, breakdown or malfunction may be caused.

Danger

Caution

Prohibit

Caution

- Turn OFF the power source before detaching or attaching the module.

Or electric shock, malfunction or breakdown may be caused.

Page 5

ME-NET Module: JW-21MN

- User's Manual -

Chapter 1 Features and Functions

Chapter 2 Safety Precautions

Chapter 3 System Configuration

Chapter 4 Name and Function of Each Part

Chapter 5 Installation

Chapter 6 Processing of Cables

Chapter 7 Wiring Method

Chapter 8 Memory Address on the ME-NET

Chapter 9 Description for Data Link Operation

Chapter 10 Description for Computer Link Operation

Chapter 11 Setting of Switches and Parameters

Chapter 12 Errors and Countermeasures

Chapter 13 Replacement of the JW-21MN

Chapter 14 Support Tools

Chapter 15 Specifications

Chapter 16 Appendix

Alphabetical Index

Page 6

Table of contents

Chapter 1: Features and Functions .......................................................................... 1-1

Chapter 2: Safety Precautions ...........................................................................2-1 to 3

2-1 Installation.................................................................................................................................... 2-1

2-2 Wiring........................................................................................................................................... 2-1

2-3 Treatment..................................................................................................................................... 2-3

2-4 Static electricity ............................................................................................................................ 2-3

2-5 Maintenance ................................................................................................................................ 2-3

2-6 Allocation of relay number ........................................................................................................... 2-3

Chapter 3: System Configuration ............................................................................. 3-1

Chapter 4: Name and Function of Each Part ........................................................... 4-1

Chapter 5: Installation ............................................................................................... 5-1

Chapter 6: Processing of Cables ....................................................................... 6-1 to 6

6-1 Processing cable end .................................................................................................................. 6-2

6-2 Connector crimping procedure .................................................................................................... 6-5

Chapter 7: Wiring Method .................................................................................. 7-1 to 7

7-1 Cable trunk and branch lines ....................................................................................................... 7-1

7-2 Relaying of trunk cables .............................................................................................................. 7-1

7-3 Cable wiring procedure in control panel ...................................................................................... 7-2

7-4 Waterproof and insulation processing of connectors ................................................................... 7-4

7-5 Wiring of cables at outside control panels ................................................................................... 7-5

7-6 Check after wiring ........................................................................................................................ 7-5

7-7 Wiring method for adding a communication station ..................................................................... 7-6

Chapter 8: Memory Address on the ME-NET.................................................... 8-1 to 4

8-1 Memory address for data links..................................................................................................... 8-1

8-2 Memory addresses for computer links ......................................................................................... 8-3

Chapter 9: Description for Data Link Operation............................................... 9-1 to 7

9-1 Communication method ............................................................................................................... 9-1

[1] Data link (Standard function) ..................................................................................................... 9-1

[2] Data link (Save memory function) .............................................................................................. 9-2

9-2 Required transmission time and communication delay time........................................................ 9-3

[1] Required transmission time ....................................................................................................... 9-3

[2] Communication delay time......................................................................................................... 9-4

[3] Data transmission between master PC and slave PC ............................................................... 9-5

9-3 Expansion of network .................................................................................................................. 9-6

[1] Multiple installation of the JW-21MN.......................................................................................... 9-6

[2] Hierarchical link.......................................................................................................................... 9-7

Page 7

Chapter 10: Description for Computer Link Operation ............................... 10-1 to 14

10-1 Computer link function ............................................................................................................. 10-1

[1] Basic commands...................................................................................................................... 10-1

[2] Optional commands ................................................................................................................. 10-1

10-2 Basic commands ..................................................................................................................... 10-2

10-3 Optional commands ................................................................................................................. 10-3

[1] Read free memory size ............................................................................................................ 10-4

[2] Monitor TMR, CNT, and MD..................................................................................................... 10-4

[3] Reading PC mode.................................................................................................................... 10-5

[4] Setting PC mode ...................................................................................................................... 10-5

[5] Reading system memory ......................................................................................................... 10-6

[6] Writing system memory ........................................................................................................... 10-6

[7] Reading date............................................................................................................................ 10-7

[8] Setting date .............................................................................................................................. 10-7

[9] Reading time ............................................................................................................................ 10-8

[10] Setting time ............................................................................................................................ 10-8

[11] Correct clock time .................................................................................................................. 10-9

[12] Monitor step status: JW20/JW20H only ................................................................................. 10-9

[13] Read the optional parameters.............................................................................................. 10-10

[14] Set the optional parameters ................................................................................................. 10-10

[15] Read the special I/O parameters ..........................................................................................10-11

[16] Set the special I/O parameters ............................................................................................. 10-11

[17] Set the secret function: JW30H only .................................................................................... 10-12

[18] Release the secret function, register password: JW30H only.............................................. 10-12

[19] Check the secret function: JW30H only ............................................................................... 10-13

[20] Response on error ............................................................................................................... 10-14

Chapter 11: Setting of Switches and Parameter .......................................... 11-1 to 28

11-1 Operation procedure .................................................................................................................11-1

11-2 Switch setting of master station and slave station ....................................................................11-2

[1] Mode switch (MODE) ................................................................................................................11-2

[2] Module No. switch (UNIT NO.) .................................................................................................11-2

11-3 Setting contents of master station parameters ......................................................................... 11-5

[1] Setting contents ........................................................................................................................11-5

[2] Communication area map .........................................................................................................11-7

[3] Setting range of relay link area, register link area, and flag area............................................ 11-11

[4] Setting procedure....................................................................................................................11-13

11-4 Setting slave station parameters (common for all slave stations) ..........................................11-22

[1] Setting contents ......................................................................................................................11-22

[2] Setting range of flag area........................................................................................................11-23

[3] Setting procedure....................................................................................................................11-24

Chapter 12: Errors and Countermeasures...................................................... 12-1 to 7

12-1 Indication lamps ....................................................................................................................... 12-1

12-2 Flag .......................................................................................................................................... 12-2

[1] Flag table ................................................................................................................................. 12-2

[2] In the case of a master station ................................................................................................. 12-3

[3] In the case of slave station 01 to 77(8) ...................................................................................... 12-4

[4] Monitor operation condition by each station PC ...................................................................... 12-5

Page 8

12-3 Storage of error code ............................................................................................................... 12-6

Chapter 13: Replacement of the JW-21MN ............................................................ 13-1

Chapter 14: Support Tools ............................................................................... 14-1 to 2

Chapter 15: Specifications ............................................................................... 15-1 to 3

15-1 General specifications ............................................................................................................. 15-1

15-2 Communication specifications ................................................................................................. 15-1

15-3 Data link specifications ............................................................................................................ 15-2

15-4 Computer link specifications .................................................................................................... 15-3

Chapter 16: Appendix .....................................................................................16-1 to 16

16-1 Maintenance and check ........................................................................................................... 16-1

16-2 Recovery method at communication errors ............................................................................. 16-2

16-3 Table of parameter memory ..................................................................................................... 16-8

16-4 Special functions unique to the JW-21MN ............................................................................. 16-13

Page 9

Chapter 1: Features and Functions

JW-21MN is a ME-NET module for JW20/JW20H/JW30H. Using this module, you can construct an MENET combining various FA equipment such as personal computer and robot.

Using this module, you can easily transmit and receive ON/OFF signals and data with devices that

have a network module which is compatible with the ME-NET specifications.

[When you want to install a JW-21MN in the JW30H, make sure to select one that is compatible with

the JW30H. (See precautions inside the front page of this manual.)]

(1) Data link function

- Send and receive an ON/OFF signal (relay link) and data (register link)

between modules on the ME-NET.

Number of linkage pointsLinkage method

Relay link 2048 (256 bytes) in total

Register link 2048 bytes in total

*The amount of data that can be transmitted by one station is a maximum of 1024 bytes,

including both relay link and register link.

- In order to use memory effectively, the JW-21MN has a memory save function. When this

function is enabled, it only needs to receive the specifically required data.

.

(2) Computer link function

- Triggered on commands (instructions) from a host computer which has a network module

compatible with the ME-NET specifications, the JW-21MN starts reading and writing the memory

in the JW20/JW20H/JW30H.

- After an instruction is received from the host computer, the JW-21MN returns a response.

Therefore, the host computer is required to create an application program. For detailed

description of how to transmit instructions and receive responses, see the instruction manual for

the host computer.

1

(3) This module is available communication up to 64 stations. By using a cable, it can be

extended up to 1 km.

Reference

ME-NET is a communication network to link different brands of devices and equipment with different

models of facility control equipment. It has been developed under the support of Toyota Motor Co.,

Ltd.

1-1

Page 10

Chapter 2: Safety Precautions

2-1 Installation

Do not install or store the JW-21MN in the following conditions.

- Direct sunlight

- Ambient temperature exceeding the range of 0 to 55 ˚C (Storage temperature : -20 to 70 ˚C)

- The relative humidity exceeding the range of 35 to 90%.

- Sudden temperature changes which may cause condensation.

- Corrosive or inflammable gas

- Vibration or hard jolts

Prior to installing or detaching the JW-21MN, make sure to turn OFF the power supply to the JW20/

JW20H/JW30H (main PC of the system).

All screws must be tightened firmly.

2-2 Wiring

Make sure to use only the recommended types (see page 6-1) for cables, connectors, and

crimping tools. Cable and connector installation and changes must be performed only by specialists

approved by the ME-NET bureau.

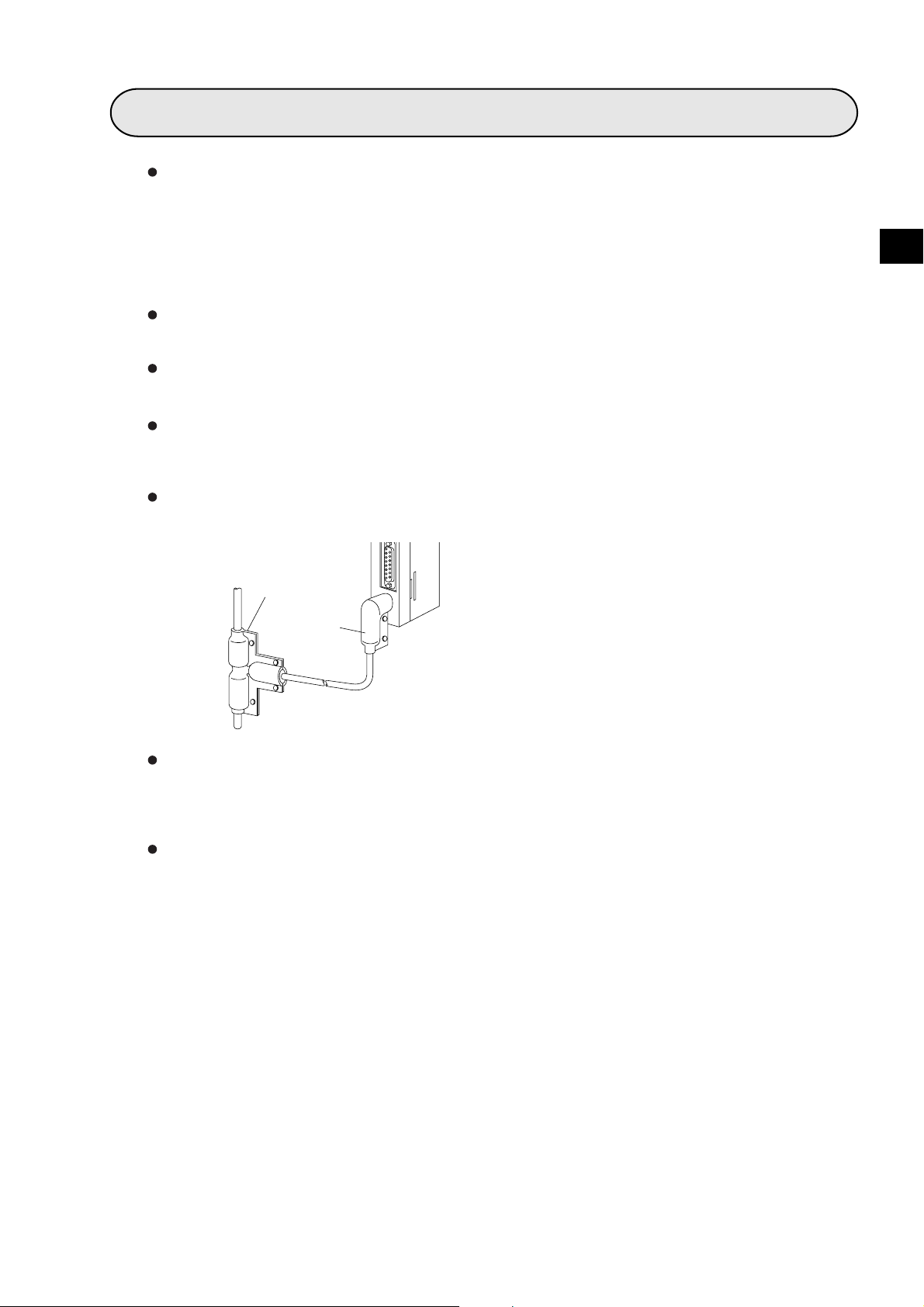

When using connectors for branch or joint lines, provide jackets to protect connectors.

(When a connector touches with an external enclosure or the like, a communication error may

occur.)

2

"T" jacket

(insulation cover)

"L" jacket

(insulation cover)

Do not connect the ground terminal of the power supply module together with other equipment's

ground lines. Make sure to provide class-3 grounding.

When the JW-21MN is used without connecting a class-3 grounding, malfunctions by noise may

occur.

Communication cables should be arranged as far from any high voltage lines and strong power

lines as possible. Do not lay the communication cable parallel or proximate to these lines.

2-1

Page 11

Communication cables should be laid from the master station to the slave station one by one.

Multiple wiring from one point or wiring without terminators may cause communication errors.

Joint using a

connector

2

Arrange total cable length within 1 km.

Arrange branch cable line from a trunk within 400 mm.

Prior to any electric welding around the JW-21MN, take out the coaxial cable from the JW-21MN.

While the coaxial cable is connected to the JW-21MN, any electric welding nearby the JW-21MN

will cause the welding current to enter the JW-21MN and may damage part of its circuit pattern.

JW-21MN

Turn "ON"

shield ground switch

FG

Coaxial cable

Wraparound current

(Note)

Electric welder

JW-21MN

Turn "ON"

shield ground switch

FG

Rack etc.

Note: In case enough conductivity is not

established.

2-2

Page 12

2-3 Treatment

For ventilation, holes are provided in the cabinet to prevent a temperature rise. Do not block the

ventilation holes. Good ventilation is necessary.

Never allow a liquid such as water and chemical solution and a metallic object like a copper wire

inside the JW-21MN to avoid a possible hazard. Otherwise, it may be a cause of machine trouble.

When a trouble or abnormal condition such as overheat, fume, or smoke is met, stop the operation

immediately, and call your dealer or our service department.

2-4 Static electricity

In extremely dry circumstances, the human body may have excessive static current. This excessive

static current may damage parts in the JW-21MN's PC board. Therefore, prior to accessing the JW21MN, touch your hand to a grounded piece of metal to discharge the static current in your body.

2-5 Maintenance

Use a clean, dry cloth when cleaning the JW-21MN. Do not use volatile chemicals such as thinner or

alcohol as it may result in deformation and color fading.

2-6 Allocation of relay number

JW20/JW20H/JW30H which installs JW-21MN are laid out 16 points to the JW-21MN as a relay

number. These 16 points are dummy area which is not used in JW-21MN.

2

2-3

Page 13

Chapter 3: System Configuration

- An example of system configuration using the JW-21MN as a master station

Robot

(8)

Slave station 77

(8)

Robot control section

ME-NET

module

Master station 00

JW20

JW20H

JW-21MN

JW30H

Slave station 01(8)

(8)

JW-21MN

Slave station 03

Personal computer

Slave station 02

(8)

Programmable controller

ME-NET module

ME-NET module

ME-NET (64 stations max., 1 km max.)

- An example of system configuration using some other module as a master station

Robot

Master station 00

JW50H

JW70H

JW-21MN

JW100H

(8)

Slave station 01

JW20

JW20H

JW30H

JW-21MN

Slave station 02

(8)

Programmable controller

ME-NET module

(8)

ME-NET (64 stations max., 1 km max.)

Slave station 03

Personal computer

ME-NET module

(8)

Slave station 77

Robot control section

ME-NET

module

(8)

3

3-1

Page 14

Chapter 4: Name and Function of Each Part

Ventilation hole

(Prevent temperature rise inside)

Indication lamp

(See page 12-1)

Module number switch(UNITNO.)

(See page 11-2)

Station number switch(STANO.)

(See page 11-3)

Support tool connection connector

Connect a support tool

and set parameters

Communication cable

connection connector

(Connect master station and slave station)

ME-NET mark

Module insertion guide

(Insert into a rack panel)

Mode switch (MODE)

(See page 11-2)

(Front view)

Module retention screw

(For fixing on a rack panel)

30Hn

mark

(Applied to JW30H)

Rating plate

Switch

Module No. switch

UNIT

NO.

STANO.

STANO.

Station No. switch

Mode switch

4

3

2

1

0

F

E

D

4

Factory

setting

8

7

9

6

0

5

1

4

2

3

8

7

9

6

0

5

1

4

2

3

×10

8

7

9

6

0

5

1

4

2

3

×1

5

6

7

8

9

MODE

A

B

C

0

0

0

2

Termination resistance switch (LT)

(See page 11-3)

Shield ground switch (LG)

(See page 11-4)

Module retention rib

(For fixing on a rack panel)

4

5

3

6

2

7

1

8

0

9

F

A

E

B

D

C

(Rear view)

4-1

Termination resistance

Shield ground switch

Ventilation hole

(Prevent temperature rise inside)

ON

OFF

ON

OFF

switch

LT

LG

OFF

ON

Page 15

Chapter 5: Installation

MODE

ON

OFF

LT

LG

ON

OFF

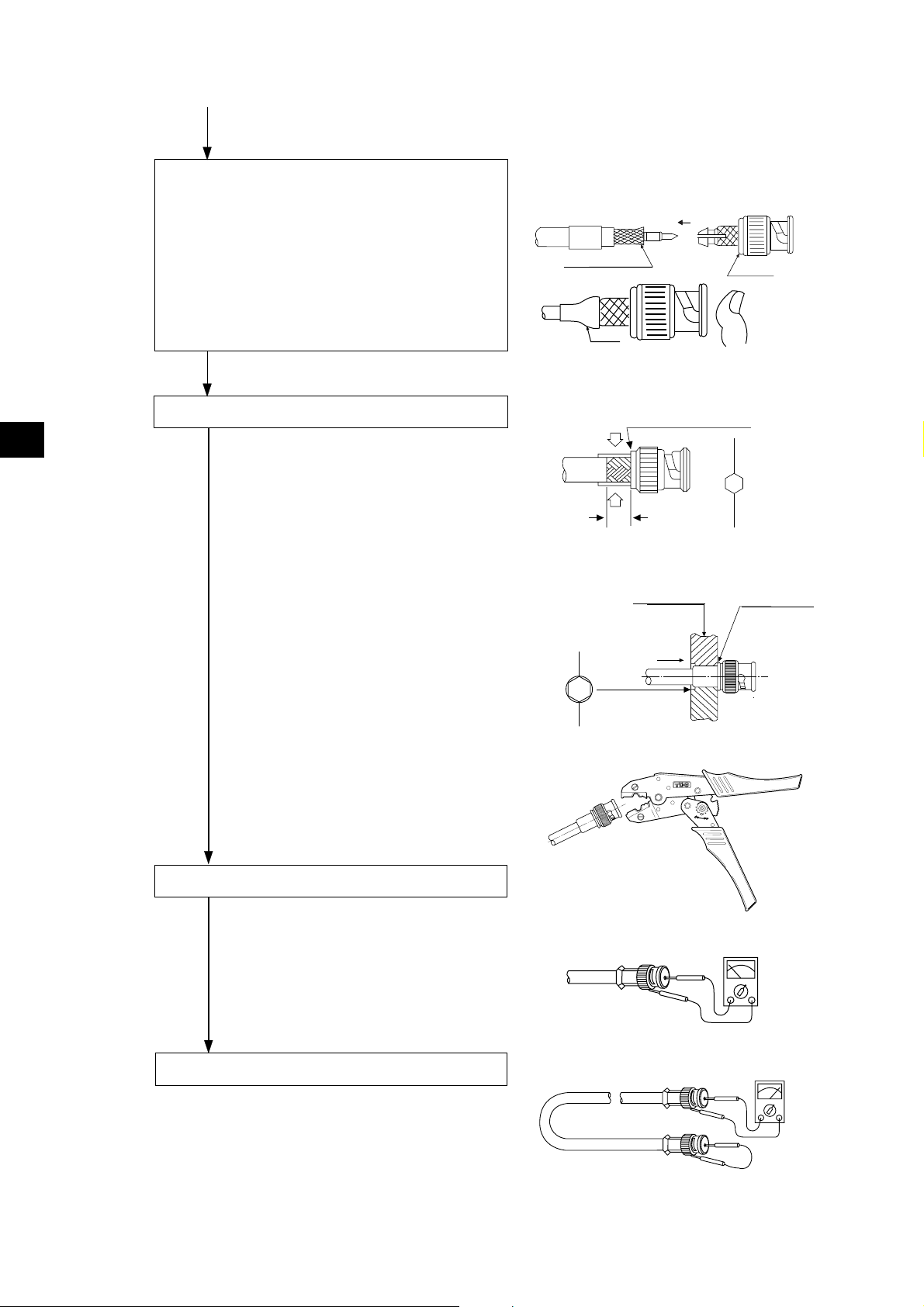

Installation procedure

Turn "OFF" the power supply to the JW20/JW20H/JW30H.

Set the mode switch, the termination resistance switch, and the shield ground switch on

the rear side of the JW-21MN.

(See page 11-2 to 11-4 for settings)

(Rear view of the JW-21MN)

Applicable screwdriver

Mode switch

Termination

resistance switch

Shield ground switch

2to3mm

5

0.5mm

Hang the module retention rib of the JW-21MN on the retention rib insertion hole of the JW20/

JW20H/JW30H's basic rack panel, and press in the JW-21MN. Then tighten the module retention

screws at the top of the JW-21MN module using a Phillips screwdriver.

Partition plate or control panel

Basic rack panel

Module insertion guide

JW-21MN

Module retention rib insertion hole

Module retention rib

(Installation example)

Power supply

module

Phillips

screwdriver

Controlmodule

JW-21CU/22CU,JW-31CUH/32CUH/33CUH

JW-31CUH1/32CUH1

JW-33CUH1/33CUH2/33CUH3

Ventilation hole

Module retention screw

Basic rack panel

JW-21MN

Remarks

- The JW-21MN cannot be installed on the expansion rack panel.

- Number of installations of the JW-21MN on the same JW20/JW20H/JW30H basic rack panel should

be within 7 in total including other option module (including JW-21MN). Installation of more than seven

modules of the JW-21MN will not allow the JW20/JW20H/JW30H to function.

- Make sure to tighten the module retention screws securely. Looseness of the screws may cause

malfunctions.

5-1

Page 16

Chapter 6: Processing of Cables

Make sure to use the qualified products shown below for cables and connectors. Cable and connector

installation and changes must be performed only by specialists approved by the ME-NET bureau.

Name

Cable

Crimping tools

Stripper for high frequency

Jacket

Insulation

tape

High frequency

coaxial cable

coaxial cable

"L" jacket

"T" jacket

Self-adhesive tape

Connector

Model

ME-5C-2V

ME-42H

Dice: 67-42H

CST-TM

The system consists of the

main body, a blade cassette,

and a blade setting gauge

SB-2878

SB-2879

NO.11

ME-GP-01

Maker

Mitsubishi Cable

Industries,. Ltd.

Fujikura Cable,. Ltd.

Furukawa Denko

Corporation

Chugoku Cable,. Ltd.

Shinagawa Cable,. Ltd.

Toko Denshi Corporation

Nihon Weidmüller

Co., Ltd.

Shinagawa Shoko

Co., Ltd.

Nitto Denko

Corporation

6

Connectors

Straight

Elbow

T’s

Termination

ME-JJ-01

Toko Denshi Corporation

ME-LA-01

DDK Ltd.

ME-TA-01

ME-75

6-1

Page 17

6-1 Processing cable end

Applicable cable

High frequency coaxial cable: ME-5C-2V

Required tools

Stripper for high frequency coaxial cable: CST-TM

Processing procedure

<Basic operation>

Move the cam wheel of the stripper (amber colored

Cable holder

ring) back and forth and the cable holder moves back

and forth accordingly. Confirm this movement of the

stripper first.

To hold the stripper, put your forefinger through the

hole and move the cam while pushing back and forth

with your thumb.

6

<Pressure setting>

Set the operation range of the cable holder by moving

the slider at the bottom of the body. Move to the left

to increase pressure.

In this example, set the slider to the cam wheel side’s

end (right side) to set the pressure to low.

Blade cassette

Front

Cam wheel

Rear

Blade (slashed area)

<Adjustment of blade cutting depth>

Adjust the cutting depth of the blade by turning the

two screws at both ends of the screw holder. Set

the blade position to within 1 mm from the cutting

surface of the blade cassette prior to adjusting the

cutting depth. For the cutting depth adjustment, use

the "blade setting gauge" supplied as an accessory

and match the blade position with the caved position

of the gauge. Then move the cam wheel forward

and secure firmly. Turn right lightly both adjustment

screws at either end of the screw holder for

adjustment. (Be careful not to break the blade setting

gauge as it is made of aluminum.)

(Fine adjustment is required to get the

optimum cutting depth.)

To the next page

Left

Slider

Screw holder

Within 1 mm

Set the blade to within

1 mm in order not to

damage the blade by

the blade setting gauge.

Cam wheel

Right

Blade setting gauge

6-2

Page 18

Coating

(black)

External conductor

(meshed annealed copper wire)

Insulator

(semi-transparent)

From the previous page

<Cutting of coating, external conductor, and insulator>

Put a coaxial cable while remaining approximately 10 mm into

the cable stripper and securely tighten the cable with the middle

finger, ring finger, and little finger of your left hand in order to

hold stable during turning the stripper.

Put your right hand forefinger into the cam wheel and execute

the procedure in order from step 1 below.

Internal conductor

(annealed copper single wire)

While holding the coaxial cable with your left hand, grip the

cable stripper so that it keeps a right angle against the coaxial

cable, and press out the cable stripper with your left hand’s

thumb.

When the adjustment

of the blade is not

required

Step 1

Press the cam wheel forward 3 times and turn

the stripper in the direction of arrow 2 to 3

times.

Step 2

Press the cam wheel forward 1 time and then

turn the stripper in the direction of arrow a

further 2 to 3 times.

Step 3

Press the cam wheel forward 1 more time and

turn the stripper in the direction of the arrow

another 2 to 3 times.

<Removal of coating, external conductor, and insulator>

If the stripper cannot be removed smoothly,

adjustment of the blade is not appropriate. In this

case slide the cam wheel backward and remove

the coaxial cable. Then adjust the blade.

6

10mm

<Fine adjustment of blade cutting depth>

When the cutting depth is too shallow or too deep, and

damages the external conductor or the internal conductor, turn

the screws on the screw holder and adjust the blade depth a

little.

To the next page

6-3

Page 19

From the previous page

We recommend that in order to keep the adjusted

position of the adjustment screws, after completion

of adjustment for the coaxial cable and the screw

holder, write the screw position etc. on a sticker

and adhere it to the adjustment screws.

<Display of blade setting>

KADAEA

KEDAADFS

K

A

E

C

A

A

D

A

A

D

F

S

F

G

H

H

G

<Replacement of blades>

Blade cassette

Hold up the upper section of the screw holder with

a minus driver, and open the screw holder.

6

Remove the blade cassette and reinsert by turning

the current blade back side front or insert a new

blade cassette from its top.

Screw holder

<Processing of cable end>

Cut the internal conductor of the coaxial cable,

which is already cut by the stripper, using a nipper

etc. to the optimum dimension of 4 mm.

10mm±0.5mm

6-4

BA

A:10±0.5mm

B: 4±0.5mm

Page 20

6-2 Connector crimping procedure

9

.

1

.

TT-237

TT

237

Required tools: Hand-held crimping tool

Model

Dice No.

Crimping width

: ME-42H

: 67-42H

: 10 mm

Connector: ME-GP-01

Processing procedure

<Insert a sleeve>

Put through a sleeve to an end-processed high

frequency coaxial cable.

<Crimping contact>

Insert a contact into the internal conductor and crimp.

Sleeve

Connector parts

Contact

A:10±0.5mm

B: 4±0.5mm

Shell

A

Sleeve

B

6

Put a contact into dice having a

diamond shape and closely stick its

end surface with the insulator and the

dice. Pull the moving frame to the

fixing frame side and crimp until the

ratchet is removed.

(Crimping width: 2.2 mm)

Widen a little

Crimp

Dice blade shape

2.2 mm

Closed contact

* Use the crimping tool in the direction

shown in the illustration right.

Using the crimping tool in the reverse

direction will not crimp correctly.

Internal conductor

Crimping dice

Moving frame

Insulator

Crimping dice

-

TT

237

9

.

.

1

Contact

Fixing frame

Contact

Closed

contact

To the next page

6-5

Page 21

From the previous page

TT

237

<Fixing the connector>

Slightly widen the external conductor of the

coaxial cable, which is crimped to a contact on

the internal conductor, in order to smoothly enter

the shell inside the external conductor. Press in

the external conductor end of the coaxial cable

to just before the crimping part of the shell and

put the sleeve into the crimping section. Then

press in the coaxial cable until a “click” sound

can be heard. Confirm that the contact end point

touches your finger cushion.

Widen a little

Sleeve

Shell

Crimping section

Finger

<Crimping external conductor>

Crimp the external conductor.

6

Insert thoroughly the sleeve into the

Completely put into

the crimping section.

crimping section of the shell and crimp.

Put the sleeve in the hexagonal dice

and closely stick the shell to the

crimping dice. Pull the moving frame

to the fixing frame side while pressing

the coaxial cable and shell from both

10

Dice blade shape

sides, and crimp until the ratchet is

removed.

(Crimping width: 10 mm)

Dice blade shape

looking from this side

Crimping dice

Push

Closed contact

* Use the crimping tool in the direction

shown in the illustration right.

Using the crimping tool in the reverse

direction will not crimp correctly.

-

TT

237

9

.

.

1

Insulation test of shell and contact

Using a tester, check the conductivity

between the internal conductor and

the external conductor in the

connector. When the indication of

the tester shows ¥ ohms, the

insulation is appropriate.

Conductivity test

After short-circuiting the one end

of the connector crimped to the

coaxial cable, check that

conductivity is attained.

<Insulation test>

<Conductivity test>

6-6

Page 22

Chapter 7: Wiring Method

7-1 Cable trunk and branch lines

On the illustration of the cable wiring below, a bold line means a trunk and the thin lines branched

from the trunk with a "T" shape are called branch lines.

400mm max.

The length of branch lines branched from the trunk should be within 400 mm.

Branch line

Trunk cable

7

400mm

Total cable length should be within 1 km.

Branch line

Trunk cable

7-2 Relaying of trunk cables

To relay trunk cables, use the straight joint (ME-JJ-01).

ME-JJ-01

Relaying of trunk cables should be limited to indispensable cases only. Inadvertent relaying of trunk

cables may cause a communication fault such as a weakened signal level due to contact resistance

in the junction connector (straight).

Junction

Junction

7-1

Page 23

7-3 Cable wiring procedure in control panel

(1) Fixing of the cable

In order not to put any force on the cable and the

JW-21MN, fasten the cable to an line nearby input of

a control panel or a "T" branch point to the JW21MN using saddles etc.

(2) Extra length of cable

Provide an extra length of the cable of 2 to 3 m

inside a control panel for easier processing of the

cable end and easier wiring when changing module

positions.

7

(3) Connection to the JW-21MN

The connector to the JW-21MN should be turned

right to secure locking, not merely inserted.

Communication cable

connection connector

Saddle

JW-21MN

Saddle

Anextralengthof

cableof2to3m

(4) Insulation cover

When the connector touches with a high voltage

section or external enclosures, communication

errors may occur. Make sure to install an insulation

cover.

"T" jacket

(insulation cover)

"L" jacket

(insulation cover)

(5) Grounding of power supply module (JW-22PU/31PU)

Make sure to use a class-3 grounding to connect the GND terminal of the power supply module.

- If the power supply module is not grounded, the JW-21MN cannot conduct with the ground after

turning "ON" the shield ground switch.

When using a JW-31PU AC power supply module

Class-3

grounding

POWER

INPUT

100-120VAC

HALT

OUTPUT

100-120VAC

(24VDC)

1A

SHORT

GND

L

Power input terminal for

85 to 132 VAC

N

GND (ground) terminal

Halt output terminal

7-2

Page 24

(6) Bending radius of the signal cable should be less than 45 mm (outside).

R45 or larger

- Specification of the cable manufacturer is that bending radius should be 6x of the cable finish

outside diameter (approx. 7.5 mm).

(7) When you install morethan one module of the JW-21MN into one programmable controller, we

recommend to put identification tag on each dable.

7

(8) Before transport or store the JW-21MN, put a protection cap on the connector of the JW-21MN.

7-3

Page 25

7-4 Waterproof and insulation processing of connectors

In order to prevent water intrusion into the "T" branch connectors and the straight connectors, we

recommend to wind a self-adhesive tape and provide waterproof processing for them. For insulation

purposes, cover these connectors with jackets.

(1) "T" branch connector

To wind a self-adhesive tape, cut the tape at about 10 cm each and start winding from position .

Start winding cut tapes from and as well.

Self-adhesive tape

T’s

7

(2) Straight connector

To wind the self-adhesive tape, cut the tape at about 15 cm each and start winding from position

.

Self-adhesive tape

Straight

Remarks

Prior to adhering the tape, clean the surface of the connectors and stick the adhesive side of

the tape on the connector surface. Wind to lightly spread on the connector surface, and overlap

with the next wrap to half of the tape width. Wind the tape for each wrap evenly so that the

connector metal portion is completely covered with the tape.

Be careful not to excessively stretch the tape.

7-4

Page 26

7-5 Wiring of cables at outside control panels

Do not bundle the coaxial cable (the trunk and branch lines) together with power cables, and

separate from power cables at least by 100 mm. Do not put the coaxial cable into a power line wired

duct. The best way is to put the communication line in an independent duct.

Be careful that the coaxial cable does not receive any load by laying under a heavy weight such as

other cables.

When other cables run in the same duct as the coaxial cable, run the coaxial cable on the top

position.

Do not run the coaxial cable outdoors as it may cause damage to the JW-21MN due to inductive

lightning or atmospheric charge during lightning.

7-6 Check after wiring

Check the items below after completion of wiring.

Check contents

1 The recommended connector types are used.

7

2 The connectors are securely locked.

3 The connectors are insulated by "T" jacket or "L" jacket.

4 The recommended coaxial cable type is used.

5 Curved radius of the coaxial cables are more than 45 mm.

6Noheavy load is on the coaxial cables.

The coaxial cable is not bundled with a power line cable.

7

(Away from power line cables more than 100mm.)

8 Length oh branch lines is shorter than 400mm.

9 Total length of the cable is less than 1km.

Settings of the termination resistance switch and the shield ground switch are as

10

per the drawings.

7-5

Page 27

7-7 Wiring method for adding a communication station

(1) Branching method

When branching a line for an additional station, be sure to branch from the trunk using a T

connector.

Never branch from a branch line.

(2) Station number of the additional station

Station number

(8)

0 2

Trunk

cable

Station number

Branch

line

0 3

(8)

Addition

Station number

(8)

0 2

Station number

(8)

0 2

Trunk

cable

Station number

(8)

0 6

Station number

(8)

0 6

Station number

Junction

Station number

0 3

0 3

(8)

(8)

Branch line

7

Station number of the newly added station should be next largest number from the current largest

numbered station. Each station should not be required to be arranged in order of each station’s

number.

01(8)

02(8)

03(8)

Addition

Sequential number

00(8)

01(8)

02(8)

03(8)06(8)

means the termination resistance switch being turned "ON."

04(8)00(8)

04(8)

05(8)

05(8)

7-6

Page 28

(3) Notes

When adding a communication station, follow the items below.

No.

Branch from the trunk cable.

1

Don’t use the same station number

2

twice.

Check the termination resistance

3

switch.

Provide extra length for the

4

expansion cable.

Do not exceed the 1 km limit for total

5

length of the cable.

Change the layout drawing for

6

installation.

Do not overlap with any PC’s

7

communication area.

Set the parameter memory of the

master station and that of the newly

8

added station.

Item Reason

Another branch line from a branch line may not give

appropriate communication by reflection wave.

The use of the same station number twice may cause

communication errors.

When the newly added station becomes a termination of

the circuit, change the setting of the LT switch.

Have enough cable length in order to provide easy wiring.

Longer wiring may cause communication error by signal

attenuation.

Maintain the added work data for future maintenance use.

When the communication area or the flag area of the

added station overlaps with other addresses in use,

communication errors may occur.

Without setting the parameter memory of the master

station and that of the slave station, the added station

cannot communicate.

7

7-7

Page 29

Chapter 8: Memory Address on the ME-NET

The ME-NET employs a system for addressing individual memory banks in all of the connected

equipment by allocating address throughout the ME-NET. Therefore, the top address in any link area

which will contain in the data link parameters and memory addresses used for computer link

instructions must be a valid memory address in the ME-NET.

The relationship between memory addresses in Sharp PCs (JW20/JW20H/JW30H) and those on the

ME-NET are shown below.

8-1 Memory address for data links

The memory addresses(8) on the ME-NET correspond to the file addresses(8) in a Sharp PC (JW20/

JW20H/JW30H).

(1) Memory address map (against JW20/JW20H)

JW20/20H address ME-NET address

Byte address

1 address = 1

point

I/O relay 00000 to 03777

Byte address

(8)

1 address = 8

コ 0000 to コ 0377

points

File address

(8)

1 address = 8

000000 to 000377 0000 to 00FF 000000 to 000377

points

(8)

Byte unit:

Hexadecimal

Byte unit: Octal

Auxiliary relay 04000 to 06777

Latched relay 07000 to 07777

General-purpose

relay

TMR/CNT contact

point

TMR/CNT current

value

Register

Self diagnosis

result storage

register

10000 to 15777

T-C000 to T-C777 001600 to 001777 0380 to 03FF 001600 to 001777

コ 0400 to コ 0677

コ 0700 to コ 0777

コ 1000 to コ 1577

b0000 to b1777 002000 to 003777 0400 to 07FF 002000 to 003777

09000 to 09777 004000 to 004777 0800 to 09FF 004000 to 004777

19000 to 19777 005000 to 005777 0A00 to 0BFF 005000 to 005777

29000 to 29777 006000 to 006777 0C00 to 0DFF 006000 to 006777

39000 to 39777 007000 to 007777 0E00 to 0FFF 007000 to 007777

49000 to 49777 010000 to 010777 1000 to 11FF 010000 to 010777

59000 to 59777 011000 to 011777 1200 to 13FF 011000 to 011777

69000 to 69777 012000 to 012777 1400 to 15FF 012000 to 012777

79000 to 79777 013000 to 013777 1600 to 17FF 013000 to 013777

89000 to 89777 014000 to 014777 1800 to 19FF 014000 to 014777

99000 to 99777 015000 to 015777 1A00 to 1BFF 015000 to 015777

E0000 to E1777 016000 to 017777 1C00 to 1FFF 016000 to 017777

000400 to 000677 0100 to 016F 000400 to 000677

000700 to 000777 0170 to 01FF 000700 to 000777

001000 to 001577 0200 to 0037F 001000 to 001577

8

- For details about the address range of relay link, register link, and the JW-21MN flag, see page

11-11 in this manual.

- The addresses that can be used vary with PC model in which the JW-21MN is installed and with

the memory capacity of the PC. For details, see the instruction manual for a particular PC.

8-1

Page 30

(2) Memory address map (against JW30H)

JW30H address ME-NET address

Byte address

1 address=1point

Relay 00000 to 15777

TRM/CNT contact

point

T-C0000 to T-C0777 001600 to 001777 0380 to 03FF 001600 to 001777

TMR/CNT current

value

(8)

Byte address

1 address = 8

コ 0000 to コ 1577

b0000 to b1777 002000 to 003777 0400 to 07FF 002000 to 003777

09000 to 09777 004000 to 004777 0800 to 09FF 004000 to 004777

19000 to 19777 005000 to 005777 0A00 to 0BFF 005000 to 005777

29000 to 29777 006000 to 006777 0C00 to 0DFF 006000 to 006777

39000 to 39777 007000 to 007777 0E00 to 0FFF 007000 to 007777

49000 to 49777 010000 to 010777 1000 to 11FF 010000 to 010777

points

File address

(8)

1 address = 8

point

(8)

Byte unit:

Hexadecimal

Byte unit: Octal

000000 to 001577 0000 to 037F 000000 to 001577

Register

59000 to 59777 011000 to 011777 1200 to 13FF 011000 to 011777

69000 to 69777 012000 to 012777 1400 to 15FF 012000 to 012777

79000 to 79777 013000 to 013777 1600 to 17FF 013000 to 013777

89000 to 89777 014000 to 014777 1800 to 19FF 014000 to 014777

8

99000 to 99777 015000 to 015777 1A00 to 1BFF 015000 to 015777

E0000 to E5777 016000 to 023777 1C00 to 27FF 016000 to 023777

Register (storable

error history)

TMR/CNT current

value

Expansion relay 20000 to 75777

TMR/CNT contact

point

T-C1000 to T-C1777

E6000 to E7777 024000 to 025777 2800 to 2BFF 024000 to 025777

b2000 to b3777 026000 to 027777 2C00 to 2FFF 026000 to 027777

コ 2000 to コ 7577

コ 7600 to コ 7777

030000 to 035577 3000 to 3B7F 030000 to 035577

035600 to 035777 3B80 to 3BFF 035600 to 035777

File 1 000000 to 037777 1-000 to 3FFF 000000 to 037777

File 2 000000 to 177777 2-000 to FFFF 000000 to 177777

File 3 000000 to 177777 3-000 to FFFF 000000 to 177777

000000 to 177777 10-000 to FFFF 000000 to 177777

000000 to 177777 11-000 to 3FFFF 000000 to 177777

000000 to 177777 1F-000 to FFFF 000000 to 177777

000000 to 177777 20-000 to FFFF 000000 to 177777

000000 to 177777 21-000 to FFFF 000000 to 177777

File

register

File 10

(H)

File 10

(H)

::::

File 1F

(H)

File 20

(H)

File 21

(H)

::::

File 2C

(H)

000000 to 177777 2C-000 to FFFF 000000 to 177777

* ME-NET addresses for file 10 to 2C(H) are out of the range the ME-NET specification.

These are special addresses for the JW-21MN.

- As for address setting range of relay link, register link, and flag of the JW-21MN, see page 11-12

in this manual.

- Available addresses vary with PC model on which the JW-21MN is installed and its capacity. For

details, see an instruction manual for each PC.

8-2

Page 31

8-2 Memory addresses for computer links

- Data memory byte addresses in the computer link must be entered the same way a data link address

is entered.

- The relay numbers and TMR/CNT numbers are the same for the ME-NET. However the TMR/CNT

contact points correspond to the even addresses from 16000 to 17777(8).

- Program addresses correspond to addresses of file (SEG)8.

For details about the detailed addresses to use on the host computer, see the instruction manual for

the host computer.

(1) Memory address map (against JW20/JW20H)

JW20/20H

address

I/O relay 00000 to 03777 SEG0 00000.0 to 00377.7 2048 points

Auxiliary relay/JW20H 04000 to 06777 SEG0 00400.0 to 00677.7 1536 points

Latched relay 07000 to 07777 SEG0 00700.0 to 00777.7 512 points

General-purpose relay 10000 to 15777 SEG0 01000.0 to 01577.7 3072 points

TMR/CNT contact point T-C000 to T-C777

I/O relay

コ 0000 to コ 0377

(8)

ME-NET address

Even addresses of SEG0

01600.0 to 01777.7

SEG0 00000 to 00377 256 bytes

(8)

Capacity Remarks

512 points

Bit

address

Auxiliary relay

Latched relay

General-purpose relay

TMR/CNT current value b0000 to b1777 SEG0 02000 to 03777 1024 bytes

Register

TMR/CNT number 000 to 777 0000 to 0777 512 pieces -----

Program

address

JW-21CU/22CU 000000 to 006777 SEG8 000000 to 006777 3584 step -----

JW-22CU 000000 to 016777 SEG8 000000 to 016777 7680 step -----

コ 0400 to コ 0677

コ 0700 to コ 0777

コ1000 to コ1577

09000 to 09777 SEG0 04000 to 04777 512 bytes

19000 to 19777 SEG0 05000 to 05777 512 bytes

29000 to 29777 SEG0 06000 to 06777 512 bytes

39000 to 39777 SEG0 07000 to 07777 512 bytes

49000 to 49777 SEG0 10000 to 10777 512 bytes

59000 to 59777 SEG0 11000 to 11777 512 bytes

69000 to 69777 SEG0 12000 to 12777 512 bytes

79000 to 79777 SEG0 13000 to 13777 512 bytes

89000 to 89777 SEG0 14000 to 14777 512 bytes

99000 to 99777 SEG0 15000 to 15777 512 bytes

E0000 to E1777 SEG0 16000 to 17777 1024 bytes

SEG0 00400 to 00677 192 bytes

SEG0 00700 to 00777 64 bytes

SEG0 01000 to 01577 384 bytes

Byte

address

8

- Relay addresses 07300 to 07377(8) and 15760 to 15767(8) in the JW20/JW20H are special

address ranges for relays.

- Available addresses vary with PC model on which the JW-21MN is installed and its capacity.

For details, see an instruction manual for each PC.

8-3

Page 32

(2) Memory address map (against JW30H)

Relay

Extension relay

TMR/CNT contact points

Relay

Extension relay

JW30H address

00000 to 15777

20000 to 75777

T-C0000 to T-C0777

T-C1000 to T-C1777

コ 0000 to コ 1577

コ 2000 to コ 7577

(8)

TMR/CNT current value b2000 to b3777 SEG0 26000 to 27777 1024 bytes

09000 to 09777 SEG0 04000 to 04777 512 bytes

19000 to 19777 SEG0 05000 to 05777 512 bytes

29000 to 29777 SEG0 06000 to 06777 512 bytes

39000 to 39777 SEG0 07000 to 07777 512 bytes

49000 to 49777 SEG0 10000 to 10777 512 bytes

Register

59000 to 59777 SEG0 11000 to 11777 512 bytes

69000 to 69777 SEG0 12000 to 12777 512 bytes

79000 to 79777 SEG0 13000 to 13777 512 bytes

89000 to 89777 SEG0 14000 to 14777 512 bytes

99000 to 99777 SEG0 15000 to 15777 512 bytes

E0000 to E5777 SEG0 16000 to 23777 3072 bytes

Register (storable error

history)

E6000 to E7777 SEG0 24000 to 25777 1024 bytes

TMR/CNT number 0000 to 1777 0000 to 1777 1024 pcs. -----

8

File 1 000000 to 037777 SEG1 000000 to 037777 16 K bytes

File 2 000000 to 177777 SEG2 000000 to 177777 64 K bytes

File 3 000000 to 177777 SEG3 000000 to 177777 64 K bytes

000000 to 177777 SEG10 000000 to 177777 64 K bytes

000000 to 177777 SEG11 000000 to 177777 64 K bytes

000000 to 177777 SEG1F 000000 to 177777 64 K bytes

000000 to 177777 SEG20 000000 to 177777 64 K bytes

000000 to 177777 SEG21 000000 to 177777 64 K bytes

File

register

*

File 10

(H)

File 10

(H)

:: : :

File 1F

(H)

File 20

(H)

File 21

(H)

:: : :

File 2C

(H)

000000 to 177777 SEG2C 000000 to 177777 64 K bytes

JW-31CUH/H1 000000 to 016777 SEG8 000000 to 016777 7680 steps

JW-32CUH 000000 to 036777 SEG8 000000 to 036777 15872 steps

Program

address

JW-32CUH1

000000 to 036777 SEG8 000000 to 036777 15872 steps

000000 to 076777 SEG8 000000 to 076777 32256 steps

JW-33CUH/H1 000000 to 076777 SEG8 000000 to 076777 32256 steps

JW-33CUH2/H3

000000 to 076777,

100000 to 176777

ME-NET address

(8)

Capacity Remarks

SEG0 00000.0 to 1577.7 7168 points

SEG0 30000.0 to 35577.7 23552 points

SEG0 01600.0 to 01777.7 512 points

SEG0 35600.0 to 35777.7 512 points

SEG0 00000 to 01577 896 bytes

SEG0 30000 to 35577 2944 bytes

SEG8 000000 to 076777,

SEG9 000000 to 076777

64512 steps

Bit

address

Byte

address

Byte

address

-----

* ME-NET addresses (SEG10 to 2C) of file 10 to 2C(H) are out of ranges of the ME-NET

specification. These are special addresses for the JW-21MN.

- Available addresses vary with PC model on which the JW-21MN is installed and its capacity.

For details, see an instruction manual for each PC.

8-4

Page 33

Chapter 9: Description for Data Link Operation

The data link function is used to send and receive ON/OFF signals (relay link) and data (register link)

between modules by assigning one module from PCs or FA devices as the master station and other

units as slave stations in the satellite net system. Up to 64 sets of PCs and FA devices can be

connected in the satellite net.

Each station sends data in its sending area cyclically and stores data received from other stations in its

receiving area. For the JW-21MN to execute automatically these sending and receiving procedures, a

special program for communications is required.

When the JW-21MN is assigned as a slave station, it has the standard function and save memory

function for data link, but the data contents for receiving from other stations is different between these

two functions. (When the JW-21MN is used as a master station, only the standard function is available.)

[When all of a master station and slave stations are JW-21MN]

- Master station Data link (Standard function)

- Slave station Data link (Standard function)

Data link (Save memory function)

For the standard function and the save memory function of the JW-21MN, see page 15-2.

9-1 Communication method

[1] Data link (Standard function)

Each station cyclically sends and receives ON/OFF signals and data of the relay link area and register

link area set to a master station parameter.

(1) Relay link

Mainly used for sending and receiving ON/OFF information

[Example] In the case of sending 1-byte data from a master station and slave stations 01 and 02.

Receiving data of all of the relay link area and

}

all of the register link area of all the stations.

In order to effectively use the

memory, unify a partial data area or

sending/receiving address (program)

of slave stations.

9

Master station (PC00) Slave station (PC01) Slave station (PC02)

コ0200

コ0201

コ0202

PC00 Program PC01 Program PC02 Program

02010

02020

02000

02000

02010

02020

02000

02010

02020

:

Send

:

Receive

- The link relay of the receiving station must be programmed as input signal by the PC programming. Also, it may be used as source (S) side of application instruction.

- The sending and receiving data correspond in bits of one point unit.

(Master station) (Slave station)

コ0200

コ0201

7 6 5 4 3 2 1 0

7 6 5 4 3 2 1 0

Is the same value as

コ0201 of the slave station.

コ0200

コ0201

7 6 5 4 3 2 1 0

Is the same value as

7 6 5 4 3 2 1 0

コ0200 of the master station.

9-1

Page 34

(2) Register link

Mainly used for sending and receiving numerical data.

[Example] In the case of sending 1 byte data from a master station and slave station 01 and 02.

Masterstation(PC00) Slavestation(PC01) Slavestation(PC02)

09200

09201

09202

:Send

:Receive

Register

F-00 コ0000 09200 09200

Register

09201

Register

09202

F-00 コ0000 09201

Register

09202

Register

09200

Register

09201

F-00 コ0000 09202

- The register link of the sending station may be used as D (Destination) side of the application

instruction of the PC program.

- The register link of the receiving station may be used as S (Source) side of the application

instruction of the PC program.

[2] Data link (Save memory function)

The save memory function is to provide a part of the data link area in the slave station data memory as

9

a receiving area. A slave station can receive only the required area by relay link/register link so that the

slave stations can save on use of the memory area.

As this function can unify the receiving area address and the sending area address of each slave

station, the same program can be used for each slave station. Mixed allocation of the addresses with

the data link (standard function) is also possible.

Slave station "n" (JW-21MN: Set to save memory function)

Top address of

master station

link area

Number of

sending bytes of

the master station

Receiving area

from slave station

1 to (n to 1)

Receiving area

from slave station

"n"

Master station 00

:Send

:Receive

Number of offset bytes of

slave station "n"

Address

Top address of slave station

"n" link area

Number of sending bytes

of slave station "n"

+

Memory inside

JW-21MN

Top address of

slave station

"n" link area

Memory inside

control module

Available setting

each slave station

V2

Number of sending

bytes of slave

station "n"

Addresses are allocated as

receiving and sending alternately

*

- Top address of receiving area in a slave station shall be set by the number of offset bytes from

the link area's top. (0 £ Number of offset bytes £ total number of bytes of link area)

Setting item

Set location

Top address of master station link area

Number of sending bytes of the master station

Master station’s parameter

Number of offset bytes of slave station

Number of sending bytes of the slave station

Top address of slave station link area

Number of receiving bytes of slave station

V2

Module No. switch of slave station

Slave station's parameter

*

* When JW-21MNs without 30Hn mark and 30H mark are used, these cannot set each slave

station.

Automatically allocated with the same number of the sending bytes of the slave station.

9-2

Page 35

9-2 Required transmission time and communication delay time

[1] Required transmission time

This is the time required for the master station to complete communication with all stations, and is

determined by the number of connected stations with and the number of data items to transmit.

Transmission T operation cycle = + 2.5 × P + α + 16 (ms)

N:Total number of link points (value to be calculated by relay link bytes and register link bytes

8 points).

P:Number of connected stations (master + slave)

136 : 136 bits are used for station address and error check data on the communication format.

1250 : Transmission rate: 1.25M bits per second

2.5 : Inter-station wait time plus processing time to move to next station (unit : ms)

α : Communication recovery operation time

• When an error occurs at any station, the master station periodically treats the error.

α = 3.5 × number of error stations ms

16 : Time to maintain token bus. It can enter at random intervals.

[Example] In the case of two connected stations and 8 bytes of link points,

N + 136 × P

1250

PC operation

cycle

Master station

(PC00)

Slave station

(PC01)

Note: Data exchange time between a PC and the JW-21MN can be obtained by the following

Transmission T operation cycle =

8 bytes×8 points×2 stations + 136×2 stations

1250

+ 2.5 × 2 stations + 16 = 21.32 ms

I/O processing

PC operation PC operation

Data exchange Note

T : Send

: Receive

I/O processing

Data exchange

formula:

When the control module is JW-31CUH1/32CUH1/33CUH1/33CUH2/33CUH3,

0.5 ms + 0.5μs x number of bytes to transfer.

(When the number of bytes to transfer is maximum (2304 bytes), 0.5 ms + 0.5μs x 2304 =

1.65 ms)

9

9-3

Page 36

[2] Communication delay time

The communication data on the ME-NET may have the delay shown below.

PC00 PC01

PC00

PC01

ON

I/O

PC00

JW-21MN

JW-21MN

PC01

I/O

9

Delay of input module

Time required for PC to detect input state (one operation cycle max.)

1

2

Operation cycle

3

4

(Communication)

5

6

7

ON

Operation time of sending PC (one operation cycle)

Time to complete sending of operation result (one communication cycle max.)

Time required for receiving PC to write receive data in PC data memory (one operation cycle max.)

Operation time of receiving PC (one operation cycle)

Delay of output module

Communication delay time is the total time of to above.

Remarks

The buffer memory contents of the JW-21MN is renewed for each PC operation cycle.

Therefore, a contact point which turns "ON" for only one operation cycle of a PC may

not be transferred.

9-4

Page 37

[3] Data transmission between master PC and slave PC

Providing synchronous transfer gives positive data communication.

[An example of synchronized transfer by OUT instruction]

Master station (PC00) Slave station (PC01)

コ0200

コ0203

コ0200

コ0203

Program in master station

00000

02000

F-44

02030

:Send

02000

02000

: Receive

Program in slave station

02000 02030

- 00000 is turned "ON" at the master station side.(OUT 02000 is a self-holding circuit.)

-When 02000 is turned "ON" at the slave station side, OUT 02030 is also turned "ON." This is sent

back to the master station side.

9

9-5

Page 38

9-3 Expansion of network

The JW-21MN can transmit data between 64 stations at maximum. If more than 64 stations are

required for data link, you can add communication stations with the procedure below.

[1] Multiple installation of the JW-21MN

Mounting more than one JW-21MN on the basic rack panel of the JW20/JW20H/JW30H can increase

the number of stations.

[In the case of mounting 4 sets of JW-21MN]

Master MasterMasterMaster

Slave

01 02 03 04 05 73 74 75 76 77

63 stations max.

Slave

01 02 03 04 05 73 74 75 76 77

63 stations max.

Slave

01 02 03 04 05 73 74 75 76 77

72

63 stations max.

9

Slave

01 02 03 04 05 73 74 75 76 77

63 stations max.

Remarks

-When installing multiple number of modules on a single PC, make them allocated so that relay

link area, register link area, and flag area may not overlap with each other.

- When installing multiple number of modules on a single PC, pay attention to the total communication data volume and the number of bytes available for communication area.

- Though more than one JW-21MN can be mounted on single basic rack panel, they cannot

directly communicate with other stations beyond one network.

72

: Master station

Slave station number 01 to 77: octal

: Slave station

9-6

Page 39

[2] Hierarchical link

When 2 sets of JW-21MN are mounted on the basic rack panel of the JW20/JW20H/JW30H,

hierarchical link communication is possible and can increase the number of stations.

Master

Slave

01

Slave

20

02

63 slaves

21

Master

Slave

Master

03

04 05 06 07 10 11 12 13 14 15 16 17 20 21

63 slaves

63 slaves

63 slaves

63 slaves

22

23 24 25 73 74 75 76 77

63 slaves

63 slaves

63 slaves

:Masterstation

:Slavestation

63 slaves

63 slaves

63 slaves

63 slaves

63 slaves

63 slaves

Slave station number 01 to 77 : octal

GroupC

ThisPCisthemasterofgroupA

whileservingasaslaveingroupC.

Slave

Master

ThisPCisthemasterofgroupBwhile

servingasaslaveingroupC.

63 slaves

63 slaves

9

Slave

Slave

GroupA

Slave

Slave

Slave

GroupB

Slave

Remarks

- Pay attention to hierarchical link system consisting of more than two levels as it takes time for

communication between the stations at the highest level and at the lowest level.

- Though more than one JW-21MN can be mounted on single basic rack panel, they cannot

directly communicate with other stations beyond one network.

9-7

Page 40

Chapter: 10 Description for Computer Link Operation

When connected to a host computer with a network module that is compatible with the ME-NET

specifications, the JW-21MN can transfer data.

10-1 Computer link function

The host computer communicates with each station number one by one. On the computer link, the

host computer can communicate with any required station regardless of whether it is the master or

slave station.

(1) The host computer instructs station number/communication contents/memory address/data etc. of

the communicating station as a "command."

(2) The "command" receiving station processes this data and returns the result as "response."

(System example)

Master station (00) Slave station 01(8)

Slave station 02(8) Slave station 03(8)

Command

Response

In order to use the computer link function above, the host computer needs program application

software. For programming this software, see the instruction manual attached with the network

module.

Computer link commands of the ME-NET can be roughly classified into basic commands and

optional commands.

Host computer

[1] Basic commands

Commands mainly used with PCs.

These commands are the functions used to read and write relays and registers. The JW-21MN

supports all of the basic commands (for both the 47 and 57 family). See the next page.

Reference

The 47 and 57 family: ME-NET computer link commands are divided into the 47 and 57 families of

commands, which use different communication formats. However, you do not

need to be concerned about the differences in these families when using the

computer link function.

[2] Optional commands

Commands other than the basic commands. These are individual commands specific to each device.

See page 10-3.

10

10-1

Page 41

10-2 Basic commands

Meaning and available memory address ranges of each command are shown in the table below

- Numeric values of each command are command numbers specified by the ME-NET.

- Write mode assignment shows write enabled/disabled to the PC memory. (See command No. F9(H).)

10

Command

Reading Relay

20

(H)

Relay start/reset

30

(H)

Reading register current value

24

(H)

Write to register

34

(H)

Write the same data into

register

35

(H)

Set/reset TMR/CNT

32

(H)

Read program memory 04

(H)

Write program memory

14

(H)

Read PC operation status

E8

(H)

Stop PC operation

F8

(H)

Restart PC operation

P8

(H)

Read write mode status

E9

(H)

Assign write mode

F9

(H)

Read manufacturer code

6F

(H)

Setting available address range (octal) and notes for use

JW20/JW20H JW30H

00000 to 15777 (relay)

T-C000 to 777 (TMR/CNT contact

point)

00000 to 15777,

20000 to 75777 (relay)

T-C0000 to 0777,

T-C1000 to 1777 (TMR/CNT contact)

Set in units of one points

00000 to 15777 (relay)

00000 to 15777

20000 to 75777 (relay)

Set in units of one points (SET = 1, RESET = 0)

コ 0000 to コ 1577

b0000 to b1777

09000 to 09777, 19000 to 19777

29000 to 29777, 39000 to 39777

49000 to 49777, 59000 to 59777

69000 to 69777, 79000 to 79777

89000 to 89777, 99000 to 99777

E0000 to E1777

コ 0000 to コ 1777, コ 2000 to コ 7777

b0000 to b1777, b2000 to b3777

09000 to 09777, 19000 to 19777

29000 to 29777, 39000 to 39777

49000 to 49777, 59000 to 59777

69000 to 69777, 79000 to 79777

89000 to 89777, 99000 to 99777

E0000 to E1777

- For details about the file register,

see page 8-4.

Can be set to read up to 1024 bytes at one time.

Write to register 24

.

(H)

The allowable address ranges are the same as shown in "Reading the

register's current value 24

Can be set up to 1024 bytes at one time.

."

(H)

You must enter a value for the number of bytes that will be written.

The allowable address ranges are the same as shown in "Reading the

register's current value 24

Can be set up to 1024 bytes at one time.

."

(H)

000 to 777 000 to 0777, 1000 to 1777

Set in units of one points (SET = 1, RESET = 0)

Different with control module and

memory module types

- JW-21CU: 000000 to 006777

- JW-22CU: 000000 to 006777

When using memory

module JW-21MA

/21MO/21ME)

000000 to 016777

(When using memory

Different with control module

- JW-31CUH/H1: 000000 to 016777

- JW-32CUH: 000000 to 036777

- JW-32CUH1: 000000 to 036777

or 000000 to 076777

- JW-33CUH/H1: 000000 to 0076777

- JW-32CUH2/H3: 000000 to 076777,

1000000 to 176777

module JW-22MA)

Can be set up to 512 steps per one reading.

Data are read out with machine language.

The allowable address ranges are the same as shown in "Reading program

memory 04

Can be set up to 512 steps per one writing

.

(H)