Page 1

Version 1.0

R

Sharp Programmable Controller

FL-net

User's Manual

Produced in June 2002

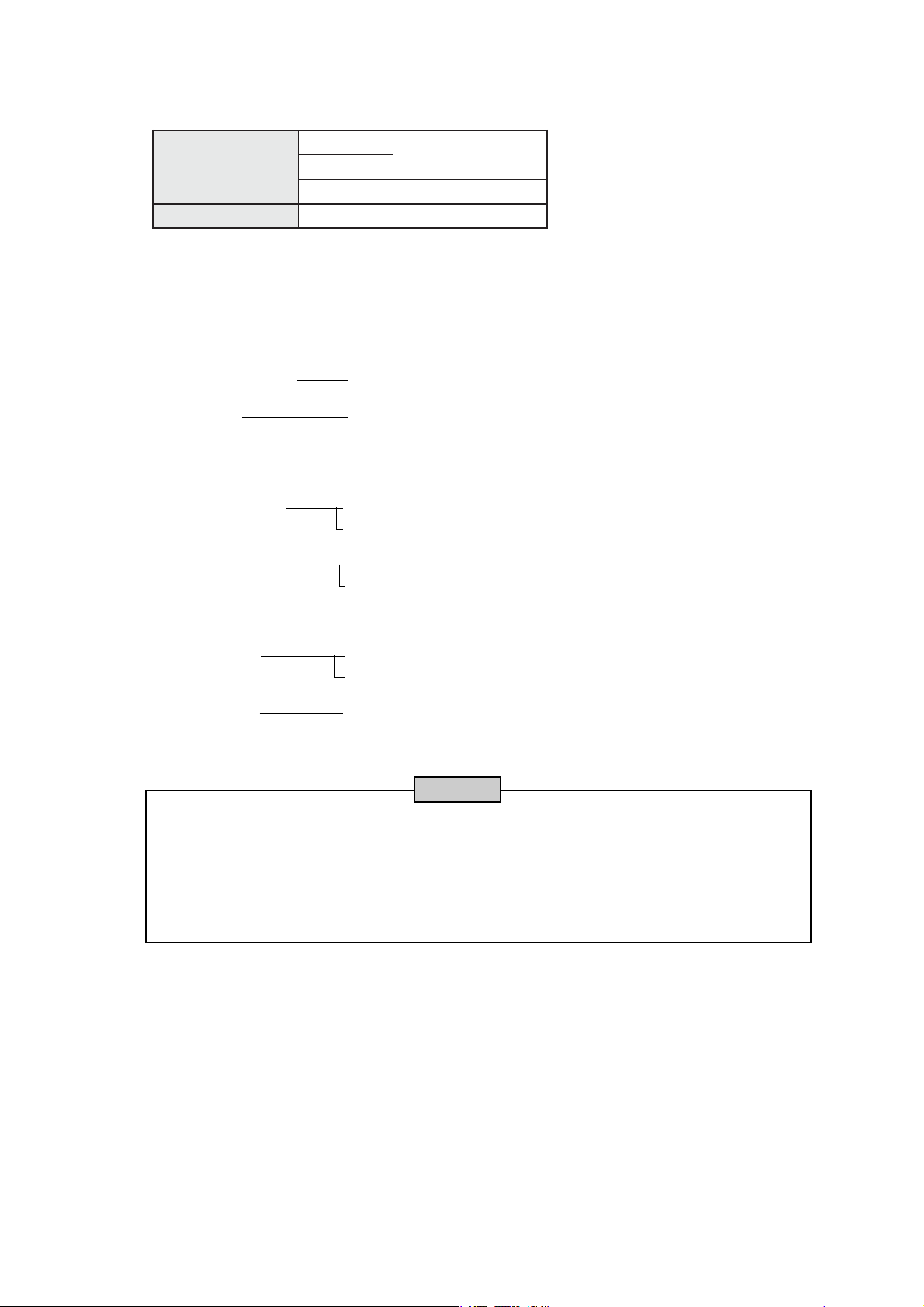

Module name

JW-20FL5

JW-20FLT

JW-50FL

Z-336J

Page 2

Thank you for purchasing the FL-net module (board) for use with the sharp programmable controller.

JW-20FL5

FL-net module

FL-net board Z-336J J-board

JW-20FLT

JW-50FL JW50H/70H/100H

(Installed PC)

JW20H/30H

Please familiarize yourself with the module by reading this user's manual thoroughly.

Keep this manual handy. We are confident that this manual will be helpful whenever you face a problem.

In addition to this manual, the following manuals are available for your further study.

- JW-20FL5/20FLT FL-net user's manual (this manual)

- JW-50FL FL-net user's manual (this manual)

- Z-336J FL-net user's manual (this manual)

- JW20H/30H

Control module User's manual - hardware version

Programming manual

- JW50H/70H/100H User's manual - hardware version

Control module Programming manual

- J-board Z-300 series

CPU board Z-311J/312J user's manual - hardware version

Z-313J* user's manual - hardware version

- J-board Z-500 series

CPU board Z-511J*User's manual - hardware version

* Z-313J and Z-511J (CPU boards) are manufactured on request.

Note

- Should you have any questions or inquires, please feel free to contact one of our dealers, or

our service department.

- Copying this manual in part of in total is prohibited.

- The contents of this manual may be revised without notice.

Page 3

Safety Precautions

Read this manual and attached documents carefully before installation, operation, maintenance and checking in order to use the machine correctly . Understand all of the machine knowledge, safety information, and

cautions before starting to use. In this instruction manual, safety precautions are ranked into "danger" and

"caution" as follows.

Danger : Wrong handling may possibly lead to death or heavy injury.

Caution : Wrong handling may possibly lead to medium or light injury.

Even in the case of Caution , a serious result may be experienced depending on

the circumstances. Anyway, important points are mentioned. Be sure to observe them

strictly.

The picture signs of prohibit and compel are explained below.

: It means don'ts. For example, prohibition of disassembly is indicated as ( ).

: It means a must. For example, obligation of grounding is indicated as ( ).

1) Installation

Caution

-Use in the environments specified in the user's manual.

Electric shock, fire or malfunction may be caused when used in the environments of high

temperature, high humidity, dusty or corrosive atmosphere, vibration or impact.

- Install according to the user's manual.

Wrong installation may cause drop, breakdown, or malfunction.

-Never admit wire chips or foreign matters.

Or fire, breakdown or malfunction may be caused.

2) Wiring

Compel

- Be sure to ground for programmable controller.

Unless grounded, electric shock or malfunction may be caused.

Caution

- Connect the rated power source.

Connection of a wrong power source may cause a fire.

-Wiring should be done by qualified electrician.

Wrong wiring may lead to fire, breakdown or electric shock.

Caution

- Make sure to follow the descriptions in the instruction manual and user manual when wiring

and installing a module/board.

Make sure to supply the electricians with the wiring and installation requirements.

If the wiring or installation do not meet the specifications, there may be a drop in the modules

ability to reject noise, or the modules may malfunction.

Page 4

3) Use

- Don't touch the terminal while the power is being supplied or you may have an electric shock.

- Assemble the emergency stop circuit and interlock circuit outside of the programmable

controller. Otherwise breakdown or accident damage of the machine may be caused by the

trouble of the programmable controller.

- Change of program during operation, or "Run" or "stop" during operation should be done with

particular care by confirming safety. Misoperation may lead to damage or accident of the

machine.

- Turn on the power source in the specified sequence. Turning ON with wrong sequence may

lead to machine breakdown or accident.

4) Maintenance

- Don't disassemble or modify the modules.

Or fire, breakdown or malfunction may be caused.

Danger

Caution

Prohibit

Caution

- Turn OFF the power source before detaching or attaching the module/board.

Or electric shock, malfunction or breakdown may be caused.

Page 5

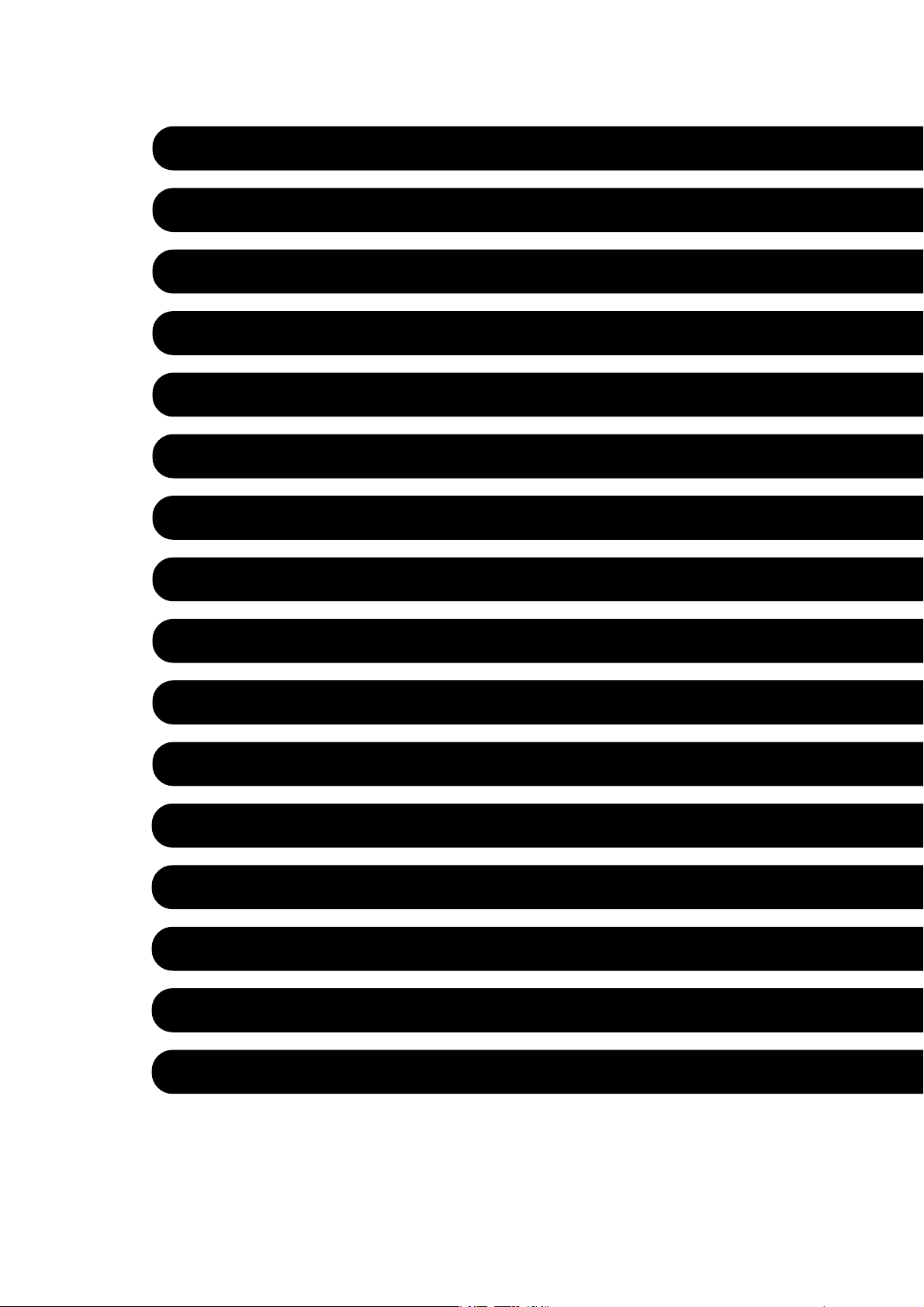

■ User's Manual

Chapter 1: Outline

Chapter 2: Handling Precautions

Chapter 3: System Configuration

Chapter 4: Name and Function of Each Part

Chapter 5: Installation

Chapter 6: Connection/Wiring

Chapter 7: Use Guide

Chapter 8: Cyclic Transfer

Chapter 9: Message Transfers

Chapter 10: Communication Control

Chapter 11: SEND/RECEIVE Function

Chapter 12: Parameters

Chapter 13: Troubleshooting

Chapter 14: Specifications

Chapter 15: Appendix

Alphabetical Index

索引

Page 6

Table of Contents

Chapter 1: Outline ...................................................................................................... 1-1

Chapter 2: Handling Precautions ............................................................................. 2-1

Chapter 3: System Configuration ............................................................................. 3-1

Chapter 4: Name and Function of Each Part ....................................................4-1 to 4

4-1 JW-20FL5 ..................................................................................................................................... 4-1

4-2 JW-20FLT ..................................................................................................................................... 4-2

4-3 Z-336J........................................................................................................................................... 4-3

4-4 JW-50FL ....................................................................................................................................... 4-4

Chapter 5: Installation ........................................................................................5-1 to 8

5-1 Installation of JW-20FL5/20FLT .................................................................................................... 5-1

5-2 Installation of Z-336J .................................................................................................................... 5-2

[1] Maximum number of boards to mount........................................................................................ 5-3

[2] Address allocation of I/O relay.................................................................................................... 5-4

(1) When mounted on Z-311J/312J .......................................................................................... 5-4

(2) When mounted on Z-313J................................................................................................... 5-5

(3) When mounted on Z-511J ................................................................................................... 5-6

5-3 Installation of JW-50FL ................................................................................................................. 5-8

Chapter 6: Connection/Wiring ...........................................................................6-1 to 9

6-1 Installing an Ethernet cable .......................................................................................................... 6-1

[1] Equipment layout........................................................................................................................ 6-1

[2] Wiring ......................................................................................................................................... 6-1

6-2 Connection.................................................................................................................................... 6-2

[1] Connection of JW-20FL5............................................................................................................ 6-2

(1) Connecting the transciever cable ........................................................................................ 6-2

(2) Wiring the power source...................................................................................................... 6-3

[2] When connecting to a JW-20FLT ............................................................................................... 6-4

[3] Connection of Z-336J ................................................................................................................. 6-5

(1) When connecting to a 10BASE5 ......................................................................................... 6-5

(2) When connecting to a 10BASE-T........................................................................................ 6-7

[4] Connection of JW-50FL.............................................................................................................. 6-8

(1) When connecting to a 10BASE5 ......................................................................................... 6-8

(2) When connecting to a 10BASE-T........................................................................................ 6-9

Chapter 7: Use Guide........................................................................................ 7-1 to 30

7-1 Ethernet ........................................................................................................................................ 7-1

[1] 10BASE5 system ....................................................................................................................... 7-1

[2] 10BASE-T system ...................................................................................................................... 7-4

[3] IP addresses on an Ethernet ...................................................................................................... 7-5

7-2 FL-net ........................................................................................................................................... 7-6

[1] Description of the FL-net ............................................................................................................ 7-6

[2] The number of modules and their node numbers ...................................................................... 7-8

[3] Data communication type........................................................................................................... 7-9

(1) Cyclic transfer.................................................................................................................... 7-10

(2) Message transfer............................................................................................................... 7-10

[4] Transfer data volume................................................................................................................ 7-10

Page 7

(1) Cyclic transfer.................................................................................................................... 7-10

(2) Message transfer................................................................................................................7-11

[5] Transfer cycle ............................................................................................................................7-11

[6] Data area and memory............................................................................................................. 7-12

[7] Communication management table.......................................................................................... 7-13

(1) Local node management table .......................................................................................... 7-13

(2) Participating node management table............................................................................... 7-14

(3) Network management table .............................................................................................. 7-14

[8] Cyclic transfer and data area ................................................................................................... 7-15

(1) Outline of the cyclic transfer process ................................................................................ 7-15

(2) Common memory.............................................................................................................. 7-16

(3) Area 1 and area 2.............................................................................................................. 7-17

(4) Guarantee of simultaneity ................................................................................................. 7-18

[9] Message transfers................................................................................................................... 7-19

(1) Outline of the message transfer process........................................................................... 7-19

(2) Table of support messages ............................................................................................... 7-20

(3) Details of the support messages ....................................................................................... 7-21

Chapter 8: Cyclic Transfer................................................................................ 8-1 to 13

8-1 Setting procedures........................................................................................................................ 8-3

8-2 Areas that can be allocated as the common memory area........................................................... 8-4

(1) For the JW20H or J-board (Z-300 series) ........................................................................... 8-4

(2) For the JW30H or J-board (Z-500 series) ........................................................................... 8-5

(3) For the JW50H/70H/100H ................................................................................................... 8-6

8-3 Parameter settings for cyclic transfers.......................................................................................... 8-7

[1] Word addresses used for the top address.................................................................................. 8-8

(1) For the JW20H or J-board (Z-300 series) ........................................................................... 8-8

(2) For the JW30H or J-board (Z-500 series) ........................................................................... 8-9

(3) For the JW50H/70H/100H ..................................................................................................8-11

8-4 Communication time ................................................................................................................... 8-13

[1] Token round time...................................................................................................................... 8-13

[2] Round time when a communication error occurs ..................................................................... 8-13

Chapter 9: Message Transfers .........................................................................9-1 to 47

9-1 Message sending procedures and data reception details ............................................................ 9-2

9-2 Transmission buffer....................................................................................................................... 9-4

[1] Allocation of available areas for the transmission buffer ............................................................ 9-5

(1) For the JW20H or J-board (Z-300 series) ........................................................................... 9-5

(2) For the JW30H or J-board (Z-500 series) ........................................................................... 9-6

(3) For the JW50H/70H/100H ................................................................................................... 9-7

9-3 Message transaction codes and execution conditions ................................................................. 9-8

9-4 Use of virtual address space and PC memory space................................................................... 9-9

(1) For the JW20H or J-board (Z-300 series) ......................................................................... 9-10

(2) For the JW30H or J-board (Z-500 series) ..........................................................................9-11

(3) For the JW50H/70H/100H ................................................................................................. 9-14

9-5 Computer link function ................................................................................................................ 9-16

[1] Setting the computer link to send and receive data ................................................................. 9-17

[2] Basic format of computer link commands ................................................................................ 9-19

(1) Communication format ...................................................................................................... 9-19

(2) Memory address expression format .................................................................................. 9-20

Page 8

(3) Execution condition ........................................................................................................... 9-21

(4) Table of commands ........................................................................................................... 9-22

[3] Descriptions of each command ................................................................................................ 9-23

[4] Computer link error code table ................................................................................................. 9-42

[5] Two-layer communication with the Ethernet............................................................................. 9-43

9-6 Remote programming and remote monitor functions ................................................................. 9-45

[1] Function.................................................................................................................................... 9-45

[2] Example operation ................................................................................................................... 9-46

Chapter 10: Communication Control ..............................................................10-1 to 6

[1] Participating nodes list flag....................................................................................................... 10-2

[2] Operation status flag ................................................................................................................ 10-3

[3] Error status flag ........................................................................................................................ 10-4

[4] Local node management table ................................................................................................. 10-5

[5] Participating node management table...................................................................................... 10-6

[6] Network management table ..................................................................................................... 10-6

Chapter 11: SEND/RECEIVE function.............................................................. 11-1 to 8

11-1 Operation of SEND/RECEIVE instruction ..................................................................................11-2

[1] SEND ........................................................................................................................................11-2

(1) When the module is used (host PC: JW30H, J-board (Z-500 series)) ...............................11-2

(2) When the module is used (host PC: JW50H/70H/100H).....................................................113

[2] RECEIVE...................................................................................................................................11-5

(1) When the module is used (host PC: JW30H, J-board (Z-500 series)) ...............................11-5

(2) When the module is used (host PC: JW50H/70H/100H)....................................................11-6

11-2 Timeout time for SEND/RECEIVE instructions ..........................................................................11-8

Chapter 12: Parameters....................................................................................12-1 to 5

12-1 Table of parameters .................................................................................................................. 12-1

12-2 Details of each of the parameters............................................................................................. 12-2

(1) Enable/disable the use of the transmission buffer (Setting parameter address 37(8)) ..... 12-2

12-3 How to set parameters.............................................................................................................. 12-3

[1] When the JW-20FL5/20FLT or Z-366J is used......................................................................... 12-3

[2] When the JW-50FL is used ...................................................................................................... 12-4

Chapter 13: Troubleshooting ...........................................................................13-1 to 6

13-1 Before you conclude that the machine is faulty ........................................................................ 13-1

13-2 General network problems and countermeasures.................................................................... 13-2

[1] Problems concerning the network and appropriate countermeasures (when unable to communi-

cate) ......................................................................................................................................... 13-2

[2] Problems concerning the network and appropriate countermeasures (when communications are

unstable)................................................................................................................................... 13-3

[3] How to check an IP address using the Ping function on a personal computer ........................ 13-4

13-3 General precautions related to the FL-net ................................................................................ 13-5

13-4 Error indicators on the display panel ........................................................................................ 13-6

Chapter 14: Specifications ...............................................................................14-1 to 5

14-1 JW-20FL5/20FLT ...................................................................................................................... 14-1

[1] General specifications .............................................................................................................. 14-1

[2] Communication specifications.................................................................................................. 14-1

[3] External dimension drawings ................................................................................................... 14-2

14-2 Z-336J....................................................................................................................................... 14-3

Page 9

[1] General specifications .............................................................................................................. 14-3

[2] Communication specifications.................................................................................................. 14-3

[3] External dimension drawings ................................................................................................... 14-3

14-3 JW-50FL ................................................................................................................................... 14-4

[1] General specifications .............................................................................................................. 14-4

[2] Communication specifications.................................................................................................. 14-4

[3] External dimension drawings ................................................................................................... 14-5

Chapter 15: Appendix .....................................................................................15-1 to 63

15-1 System configuration guide ...................................................................................................... 15-1

[1] Brief description of the Ethernet ............................................................................................... 15-1

[2] 10BASE5 Specifications........................................................................................................... 15-2

[3] 10BASE-T Specifications ......................................................................................................... 15-3

[4] Other Ethernet Specifications................................................................................................... 15-4

(1) 10BASE2........................................................................................................................... 15-4

(2) Optical Ethernet Specifications ......................................................................................... 15-4

15-2 Examples of system configurations .......................................................................................... 15-5

[1] Small scale configuration ......................................................................................................... 15-5

[2] Basic configuration ................................................................................................................... 15-6

[3] Configuration of a large-scale network..................................................................................... 15-7

[4] Configuration of a long distance distribution system ................................................................ 15-8

[5] Configuration of local concentrations ....................................................................................... 15-9

[6] Configuration combining local and long distance distribution................................................. 15-10

[7] Principles of the FL-net system ...............................................................................................15-11

[8] Differences between a general-purpose Ethernet and FL-net ................................................15-11

15-3 Definition of network systems ................................................................................................. 15-12

[1] Communication protocol standards........................................................................................ 15-12

[2] Hierarchical structure of the communication protocols........................................................... 15-12

[3] Physical implementations of an FL-net .................................................................................. 15-13

[4] IP addresses on the FL-net .................................................................................................... 15-13

[5] FL-net sub net mask............................................................................................................... 15-14

[6] TCP/IP, UDP/IP protocols ....................................................................................................... 15-14

[7] FL-net port number................................................................................................................. 15-14

[8] FL-net data format.................................................................................................................. 15-15

(1) Outline of the FL-net data format .................................................................................... 15-15

(2) FL-net header format....................................................................................................... 15-17

[9] FL-net transaction code.......................................................................................................... 15-17

15-4 Network control of the FL-net ................................................................................................. 15-19

[1] Token control of the FL-net..................................................................................................... 15-19

(1) Token............................................................................................................................... 15-19

(2) Flow of the token ............................................................................................................. 15-20

(3) Token and data................................................................................................................ 15-21

(4) Interval between frames (minimum allowable interval between frames)......................... 15-22

[2] Joining and leaving an FL-net network................................................................................... 15-23

(1) Participation in the FL-net ............................................................................................... 15-23

(2) Leaving an FL-net network.............................................................................................. 15-25

[3] Node status control ................................................................................................................ 15-26

[4] FL-net Local node management table.................................................................................... 15-26

[5] FL-net Participating node management table ........................................................................ 15-27

Page 10

[6] Status management of the FL-net.......................................................................................... 15-28

[7] Control message sequence number of the FL-net ................................................................. 15-28

15-5 Parts needed to build a network ............................................................................................. 15-29

[1] Parts needed to configure an Ethernet................................................................................... 15-29

[2] Parts related to 10BASE5 ...................................................................................................... 15-30

(1) Transceiver...................................................................................................................... 15-30

(2) Coaxial cable................................................................................................................... 15-35

(3) Coaxial connectors.......................................................................................................... 15-35

(4) Relay connector .............................................................................................................. 15-36

(5) Terminator (terminating resistor) ..................................................................................... 15-36

(6) Ground terminal of a coaxial cable.................................................................................. 15-37

(7) Transceiver cable ............................................................................................................ 15-37

(8) 10BASE5/10BASE-T converter....................................................................................... 15-38

(9) Coaxial/optical converter, repeater.................................................................................. 15-39

[3] 10BASE-T related items ......................................................................................................... 15-40

(1) Hub.................................................................................................................................. 15-40

(2) 10BASE-T cable.............................................................................................................. 15-41

(3) 10BASE-T/optical converter, repeater............................................................................. 15-41

15-6 Installation of an FL-net network............................................................................................. 15-42

[1] Wiring 10BASE5 coaxial cable............................................................................................... 15-42

[2] 10BASE-T (UTP) .................................................................................................................... 15-56

15-7 Grounding the FL-net system ................................................................................................. 15-58

[1] Outline of the grounding procedures for the FL-net system ................................................... 15-58

[2] Wiring power lines and grounding equipment ........................................................................ 15-59

[3] Wiring the power lines and grounding the network equipment in an FL-net .......................... 15-60

[4] Installation of network equipment in an FL-net....................................................................... 15-61

[5] Wiring and grounding through wiring ducts and conduits....................................................... 15-62

15-8 FL-net installation check sheet ............................................................................................... 15-63

Alphabetical Index ...............................................................................................I-1 to 3

Page 11

Chapter 1: Outline

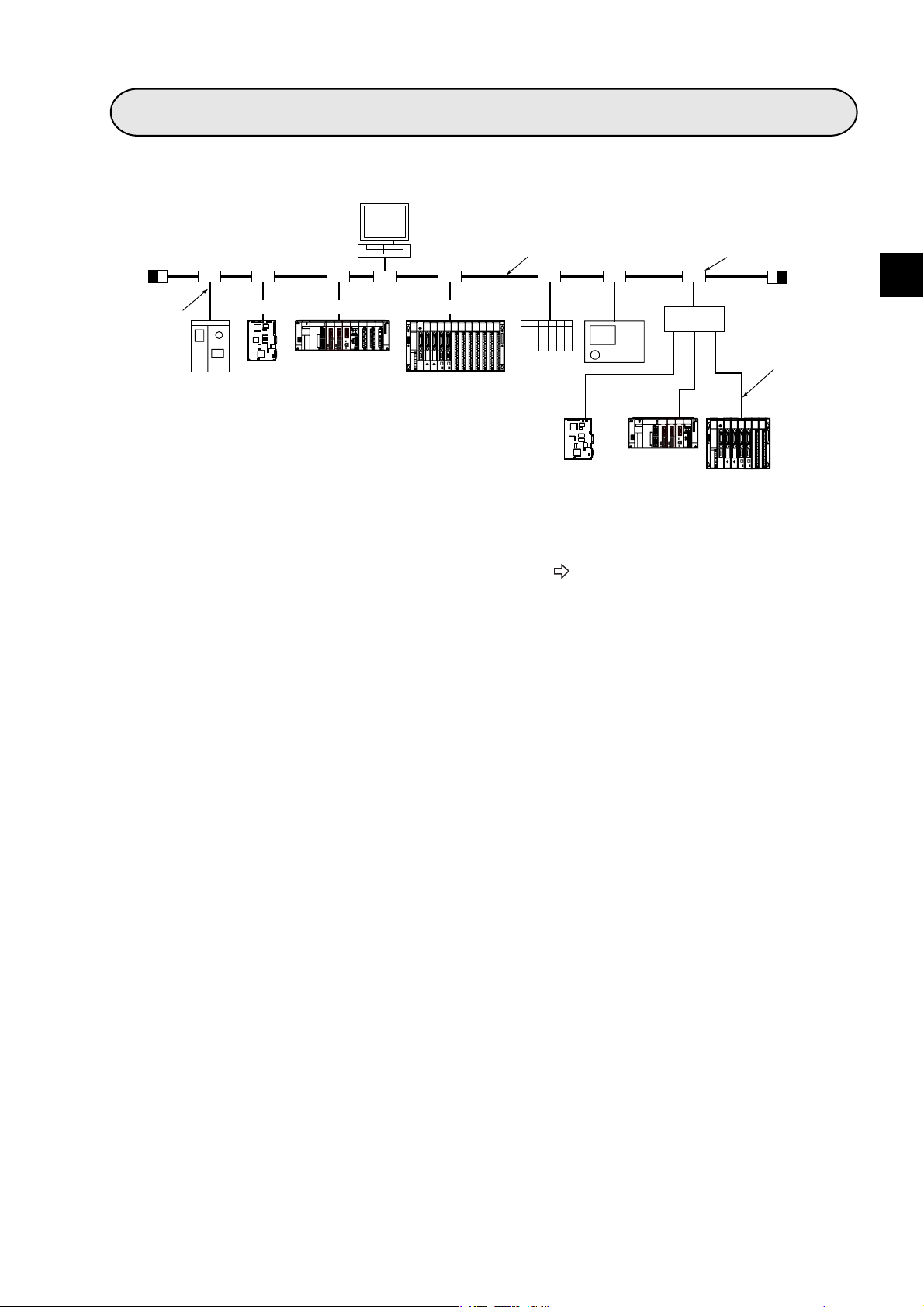

An FL-net module (JW-20FL5/20FL T, JW-50FL, FL-net board (Z-336J)) is an interface module use to connect a

programmable controller (JW20H/30H, JW50H/70H/100H), J-board to an FL-net. FL-net is an open network

that connects production equipment and controllers from multiple FA (factory automation) venders, to create a

unified production process. This network works as an intermediary between information networks and production networks, and makes it possible to connect control devices (such as personal computers or programmable

controllers, hereafter referred to as PCs), to numeric control devices (CNCs), and robot controllers (RCs). The

Ethernet is used as a world standard communication method to allow communication between pieces of OA

(Office Automation) equipment.

Server

BCR

Personal

computer

WAN

ID

Graphic

panel

Image

EWS

Robot

controller

Personal

computer

Gateway

PC

Personal

computer

Information network (Ethernet)

Nut

runner

Field network

NC

Personal

computer

FL-net

Printer

1

Sensor

actuator

FL-net employs an FA link protocol as an application layer.

Features of the FA link protocol

1 Uses the Ethernet UDP/IP communication protocol.

2 Using a Master-less, Token method, the system prevents data transmission conflicts and guarantees

the transfer of data within a specified time.

3 Employs a shared memory system (shares information between each of the nodes).

4 Nodes can automatically enter and leave the network.

Features of the JW-20FL5/20FLT, JW-50FL, Z-336J

1 FL-net compatible (uses the FA link protocol)

2 Supports cyclic transfers and message transfers.

3 Supports exchange of data between SHARP PCs using the SEND/RECEIVE function. (A unique

function of SHARP equipment)

4 Allows remote programming and remote monitor functions between SHARP PCs. (A unique function of

SHARP equipment)

- FL-net is an open network that was standardized by the Japan FA Open Systems Promotion Group (JOP) in

the Manufacturing Science Technology Center (MSTC).

- Ethernet is a registered trademark of XEROX CORPORATION, USA.

1-1

Page 12

Chapter 2: Handling Precautions

Make sure to follow the precautions bellow who using the JW-20FL5/20FL T, JW-50FL (hereafter referred to

as this module) and Z-336J (hereafter referred to as this board).

(1) Installation

- Do not install or store this unit in the following conditions.

1 Locations close to a heating element

2 Sudden temperature changes which may cause condensation

3 Corrosive or inflammable gas

4 Vibration or hard jolts

- The minimum distance between nodes is specified in the regulations. (2.5 m when the 10BASE5

is used.) When connecting devices, be sure to maintain these minimum distances.

Cables used for 10BASE5 systems have marks every 2.5 m. Position each transceiver directly

on one of these marks.

- Mount the transceivers on electrically insulated objects, such as a wooden mounting block.

- Prior to installing or detaching the JW20H/30H or JW50H/70H/100H, make sure to turn OFF the

power supply to the PCs.

- Prior to connect the board, make sure to turn OFF the power to the J-board.

- Isolate the hub case electrically from the control panel chassis.

(2) Treatment

JW-20FL5/20FLT and JW-50FL

- For ventilation, holes are provided in the cabinet to prevent a temperature rise. Do not block

the ventilation holes. Good ventilation is necessary.

- Never allow a liquid such as water and chemical solution and a metallic object like a copper wire

inside this module to avoid a possible hazard. Otherwise, it may be a cause of machine

trouble.

- When a trouble or abnormal condition such as overheat, fume, or smoke is met, stop the

operation immediately, and call your dealer or our service department.

Z-336J

A J-board is a PC board which contains sensitive electronic parts. Therefore, be careful when handling it.

1 Before touching the board with your hand, make sure to discharge all static electricity from

your body.

2 Do not touch the board if your hands are dirty or wet.

3 Do not put the board down on a conductive object (such as a metal plate).

(If a J-board with a CPU is placed on a conductive object, the battery terminals may be short

circuited and the back up memory will be lost.)

4 Do not handle any switches, connectors, or terminal blocks on the J-board using excessive

force.

2

(3) Grounding

- Connect the J-board FG terminal (on the terminal block on the CPU board) to an independent

class 3 ground. Do not share the ground with high voltage equipment.

- The hexagonal standoffs (supplied with each board) for assembling the J-board are used for

connecting the ground (FG). Make sure to tighten them securely.

(4) Wiring precautions

- Install the communication lines at a distance of 60 cm or more away from motor power lines or

high voltage lines.

- Do not route wires near equipment that generates electrical noise.

- Use category 5 10BASE-T shielded twisted pair cable.

- Use an isolated shield transformer to provide power to the hubs.

- We recommend using a transceiver cable that is 2 m or shorter.

2-1

Page 13

Chapter 3: System Configuration

[Connection example]

Personal

computer

Terminator

Transceiver

cable

(max. 50 m)

RC

FL-net

J-board

2

1

Z-336J

JW20H/30H

JW-20FL5

10BASE5 coaxial cable (max. 500 m)

JW50H/70H/100H

RC

JW-50FL

Other

maker’s

PC

J-board

Z-336J

NC

JW20H/30H

2

1

JW-20FLT

Transceiver

Hub

10BASE-T

twisted pair cable

(max. 100 m)

JW50H/70H

/100H

JW-50FL

- A basic system (segment) configuration consists of a 10BASE5 coaxial cable between 10m and 500 m long

with nodes connected to this cable. (A maximum of 100 nodes can be connected per segment)

- If the distance between nodes exceeds 500 m, use a repeater (maximum length 2,500 m).

See 7-1[1] 10BASE5 system.

Note: 10BASE5 coaxial cable, transceivers, transceiver cables, terminators, hubs, and 10BASE-T twisted

pair cable is supplied and installed by the customer.

3

3-1

Page 14

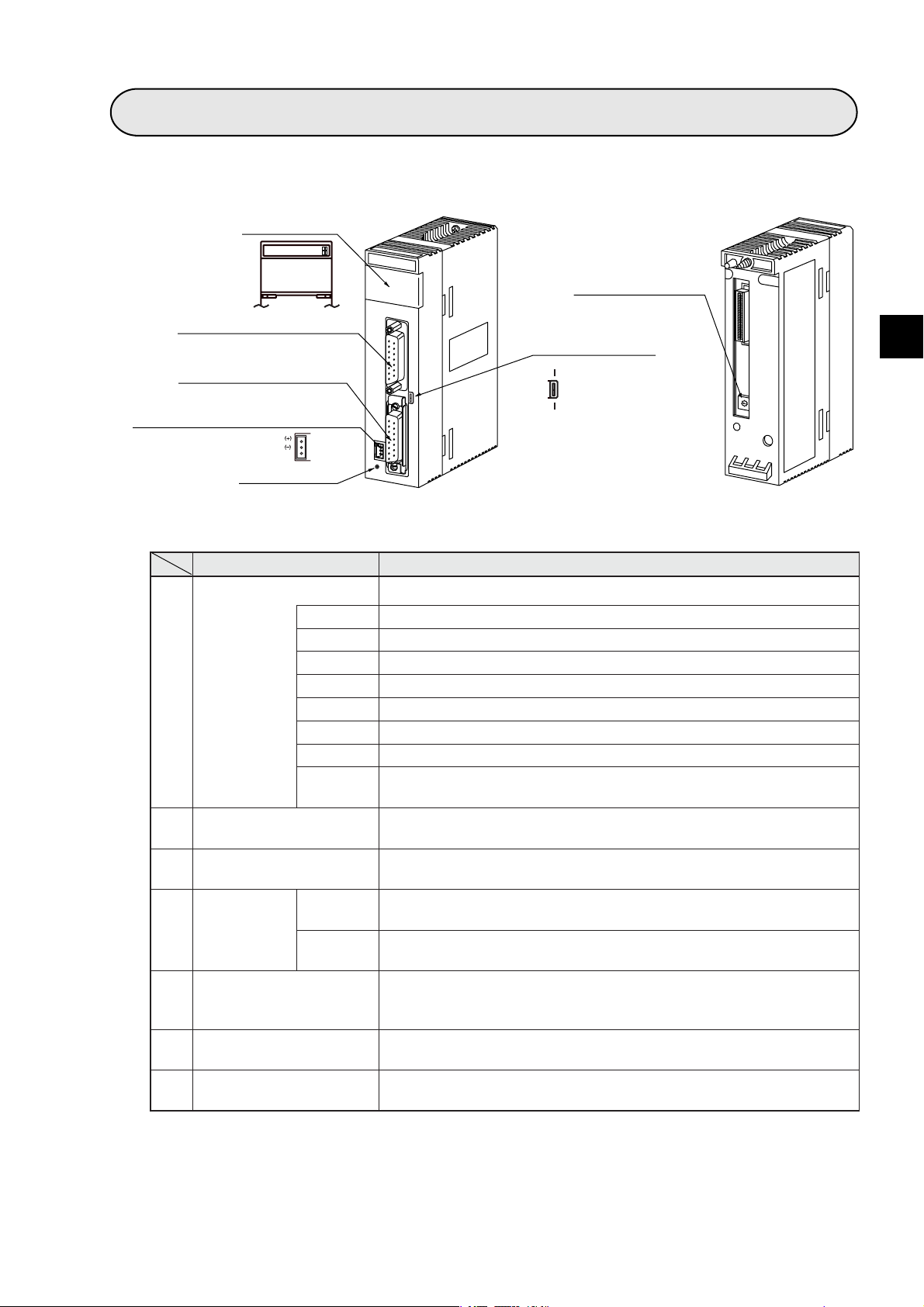

Chapter 4: Name and Function of Each Part

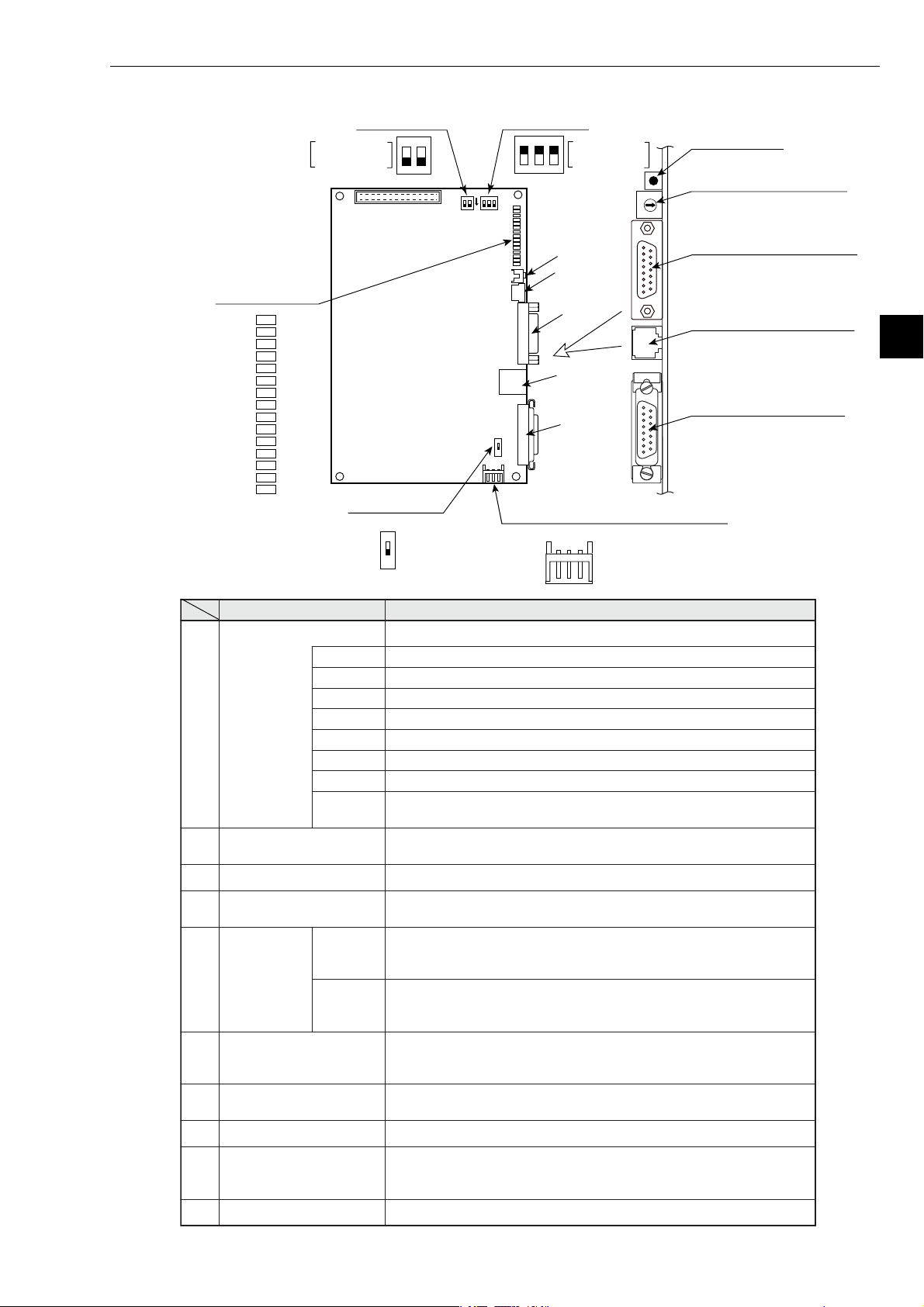

4-1 JW-20FL5

1Display panel

JW-20FL5

LNTXRX12V TPEHE

S7S6S5S4S3S2S1S0

2Connector for programmer

3Connector for 10BASE5

512 VDC power supply input terminal

FG

7Reset switch

Chapter 4: Name and Function of Each Part

6Module No. switch

(Factory setting: 0)

Connector for shield

4

switch for 10BASE5

ON

S

H

I

E

OFF

L

D

2

3

1

4

0

5

9

6

8

7

(Factory setting: ON)

4

(Front) (Rear)

Name Function

Display panel Displays the JW-20FL5 operating status using LEDs.

LN Lights when communicating normally.

TX Blink at transmitting data.

RX Blink at receiving data.

1

12 V Lights when 12 VDC is supplied. (Only when 10BASE5 is used.)

T Lights at test mode. (Normally, this is not used.)

PE Lights at parameter setting error.

HE Lights at this module error.

Displays the station number when operating normally. Displays an error

code if an error occurs.

Connect a JW-14PG programmer or similar equipment to set the

parameters on the JW-20FL5.

Connect the 10BASE5 transceiver cable.

Make sure to slide the lock securely to the "lock" position.

The shield on the coaxial cable and the FG (base) terminal on this

module will be shorted together.

The shield on the coaxial cable is not shorted to the base.

- Ground the FG line on the 12 VDC connector separately.

When 10BASE5 is used, connect a commercially available DC power

supply that is designed to supply power to transceivers. The DC power

supply must provide 12VDC ±5% and 0.5 A or more.

Specify a module number from 0 to 6.

-Becareful do not use the same number for another option module.

Connector for programmer

2

Connector for 10BASE5

3

Connector for

Shield switch

4

for 10BASE5

12 VDC power supply

5

input terminal

Module No. switch

6

S0 to S7

ON

OFF

Reset switch Only used by SHARP engineers. Users should not press this switch.

7

4-1

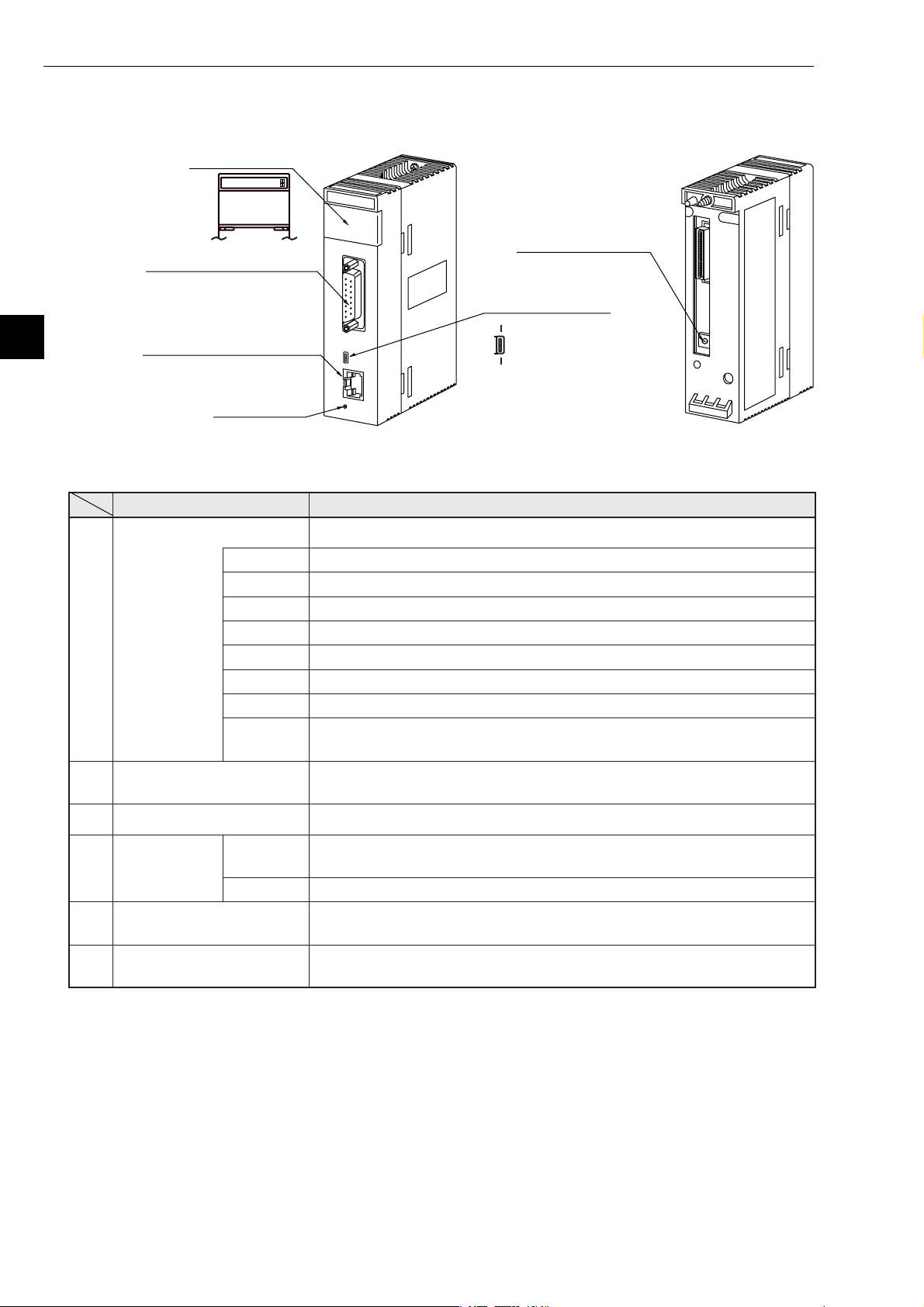

Page 15

Chapter 4: Name and Function of Each Part

4-2 JW-20FLT

1Display panel

JW-20FLT

LNTXRX12V TPEHE

S7S6S5S4S3 S2S1 S0

2Connector for programmer

4

3Connector for 10BASE-T

6Reset switch

5Module No. switch

(Factory setting: 0)

4

Connector for shield

switch for 10BASE-T

ON

S

OFF

H

I

E

L

D

2

3

1

4

0

5

9

6

8

7

(Factory setting: ON)

(Front) (Rear)

Name Function

Display panel Displays the JW-20FLT operating status using LEDs.

LN Lights when communicating normally.

TX Blink at transmitting data.

RX Blink at receiving data.

1

12 V Cannot be used with the JW-20FLT.

T Lights at test mode. (Normally, this is not used.)

PE Lights at parameter setting error.

HE Lights at this module error.

S0 to S7

Connector for programmer

2

Connector for 10BASE-T Connect the 10BASE-T twisted pair.

3

Connector for

Shield switch

4

for 10BASE-T

Module No. switch

5

ON

OFF The shield on the twisted pair cable is not shorted to the base.

Displays the station number when operating normally. Displays an error

code if an error occurs.

Connect a JW-14PG programmer or similar equipment to set the

parameters on the JW-20FLT.

The shield on the twisted pair cable will be shorted to the FG (base) of

this module.

Specify a module number from 0 to 6.

-Becareful do not use the same number for another option module.

Reset switch Only used by SHARP engineers. Users should not press this switch.

6

4-2

Page 16

Chapter 4: Name and Function of Each Part

4-3 Z-336J

1Display panel

Factory setting

: ON

LN

TX

RX

12V

T

PE

HE

S7

S6

S5

S4

S3

S2

S1

S0

9Switch SWA 0Switch SW1

F

F

F

2

1O

5Switch SW6

SW6

(Factory setting: ON)

ON

SWA

O

F

F

ON

2

1

SWA

F

2

3

LN

TX

SW1

RX

12V

T

PE

HE

S7

S6

S5

S4

S3

S2

S1

S0

SW6

ON

612 VDC power supply input terminal

Factory setting

: ON

1O

SW1

⑧

⑦

②

③

④

8Reset switch

7Module No. switch SW4

8

7

9

6

0

5

1

4

2

3

(Factory setting: 0)

2Connector for programmer

3Connector for 10BASE-T

4

4Connector for 10BASE5

FG 0V 12V

Name Function

Display panel Displays this board operating status using LEDs.

LN Lights when communicating normally.

TX Blink at transmitting data.

RX Blink at receiving data.

1

12 V Lights when 12 VDC is supplied. (Only when 10BASE5 is used.)

T Lights at test mode. (Normally, this is not used.)

PE Lights at parameter setting error.

HE Lights at this board error.

S0 to S7

Connector for programmer

2

Connector for 10BASE-T Connect the 10BASE-T coaxial cable.

3

Connector for 10BASE5

4

Displays the station number when operating normally. Displays an error

code if an error occurs.

Connect a JW-14PG programmer or similar equipment to set the

parameters on this board.

Connect the 10BASE5 coaxial cable.

Make sure to slide the lock securely to the "lock" position.

The shield on the cable between a 10BASE-T connector and a

5

ON

Switch SW6

OFF

10BASE5 connector and the FG (base) on this module will be shorted

together.

The shield on the cable between a 10BASE-T connector and a

10BASE5 connector is not shorted to the base.

- Ground the FG line on the 12 VDC connector separately.

12 VDC power supply

6

input terminal

Module No. switch

7

Reset switch Only used by SHARP engineers. Users should not press this switch.

8

Number of communication

boards

9

Switch SWA

Switch SW1 No need to set this switch for the Z-336J. (Always set to OFF (default).)

0

When 10BASE5 is used, connect a commercially available DC power

supply that is designed to supply power to transceivers. The DC power

supply must provide 12VDC ±5% and 0.5 A or more.

Specify a module number from 0 to 6.

-Becareful do not use the same number for another option board.

Specify the number of communication boards actually installed

(including the Z-336J).

- See pages 5-3 to 5-7.

4-3

Page 17

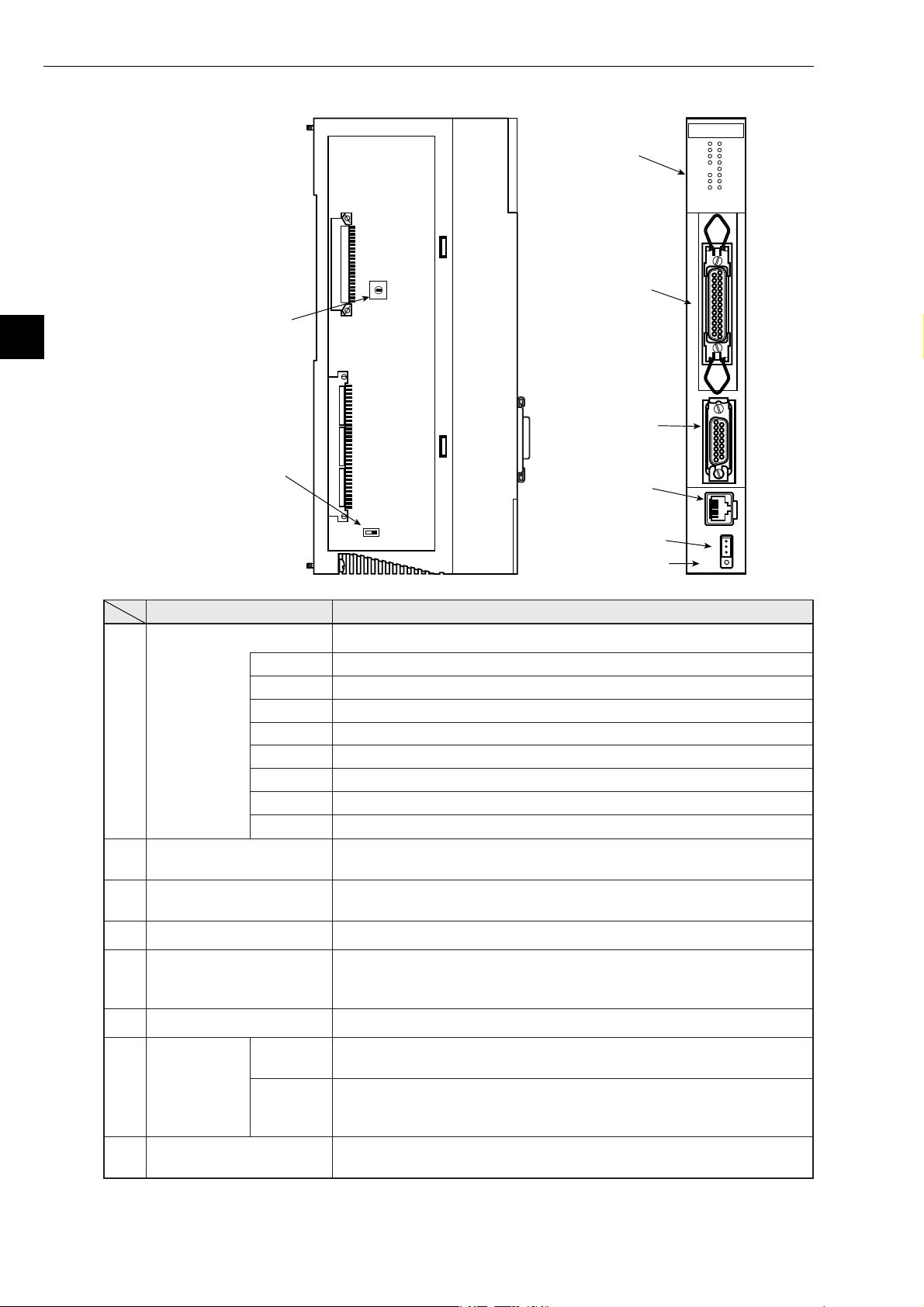

Chapter 4: Name and Function of Each Part

4-4 JW-50FL

1 LED indicator

JW-50FL

LNK

TX

RX

DC12V

TEST

PER

HER

S0

S1

S2

S3

S4

S5

S6

S7

4

8 Switch SW3

(Factory setting: 0)

3

2 Connector for

2

4

1

5

0

6

9

7

8

SW3

programmer

P

R

O

G

R

A

M

M

E

R

3 Connector for

7 Switch SW3

(Factory setting: ON)

10BASE5

4 Connector for

10B5

10BASE-T

10B-T

RESET

12VIN

(+)

(−)

FG

SW2

OFF ON

5 12 VDC power

supply input terminal

6 Reset switch

Name Function

Display panel Displays the JW-50FL operating status using LEDs.

LNK Lights at operating. Lights OFF at stopping.

TX Blink at transmitting data.

RX Blink at receiving data.

1

12 VDC Lights when 12 VDC is supplied. (Only when 10BASE5 is used.)

TEST Lights at test mode.

PER Lights at parameter setting error.

HER Lights at this module error.

S0 to S7 Indicates status of connection status monitor flag.

Connector for programmer

2

Connector for 10BASE5

3

Connector for 10BASE-T Connect 10BASE-T twisted-pair cable.

4

12 VDC power supply

5

input terminal

Reset switch Only used by SHARP engineers. Users should not press this switch.

6

ON

Switch SW2

7

OFF

When using a remote monitor or remote programming function, connect

a JW-14PG programmer.

Connect the 10BASE5 transceiver cable.

Make sure to slide the lock securely to the "lock" position.

When 10BASE5 is used, connect a commercially available DC power

supply that is designed to supply power to transceivers. The DC power

supply must provide 12VDC 5% and 0.5 A or more.

Turn ON when the shields on the 10BASE-T connectors or 10BASE5

connectors are connected to the FG (base) of the JW-50FL.

Turn OFF when the shields on the 10BASE-T connectors or 10BASE5

connectors are not connected to the FG.

- Ground the FG line on the 12 VDC connector separately.

Switch SW3

8

Specify a parameter address (in system memory) from 0 to 4.

- See page 12-4.

Note: Only 10BASE5 or 10BASE-T protocol is used. Mixed use of these two types is not permitted.

4-4

Page 18

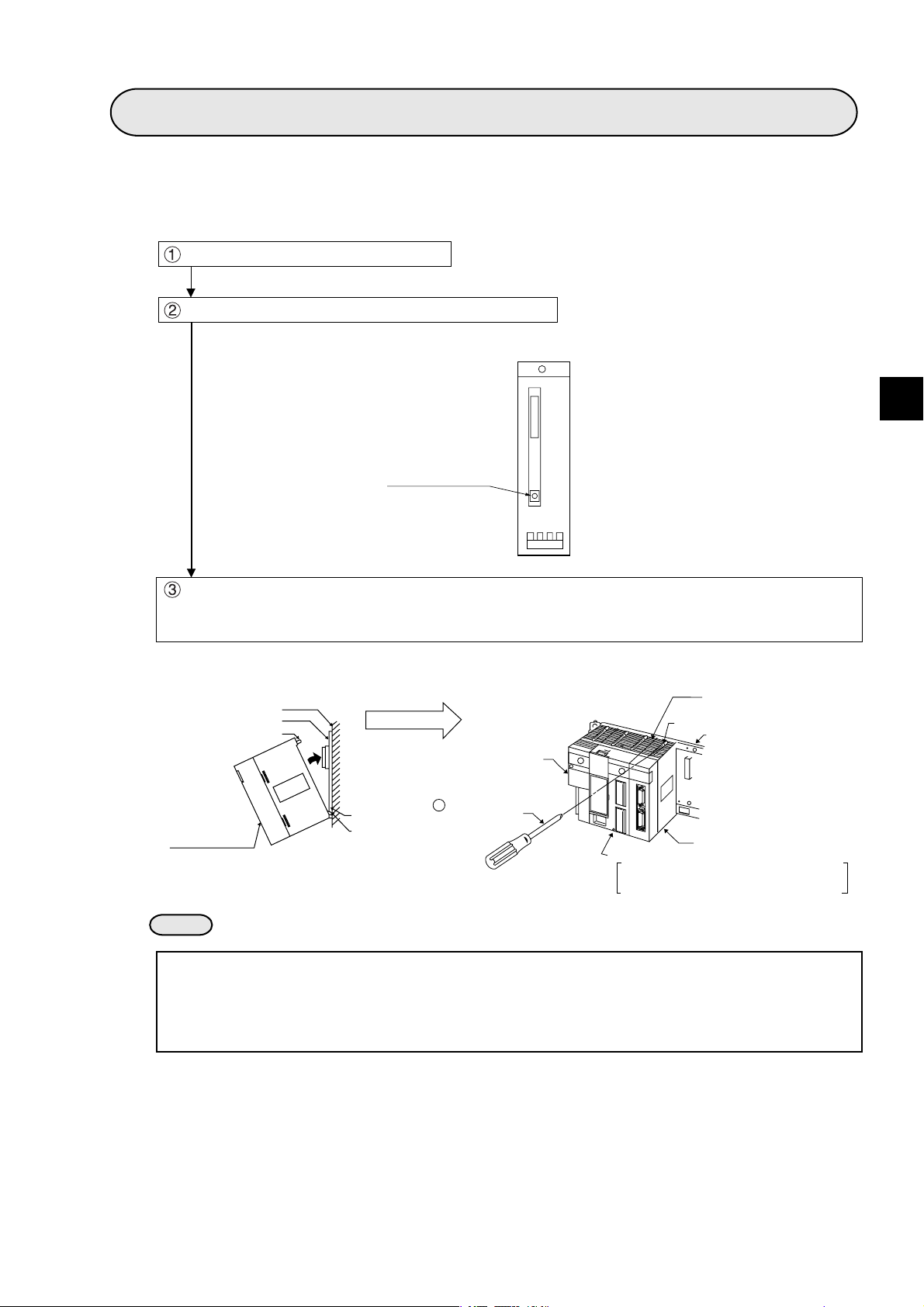

Chapter 5: Installation

Chapter 5: Installation

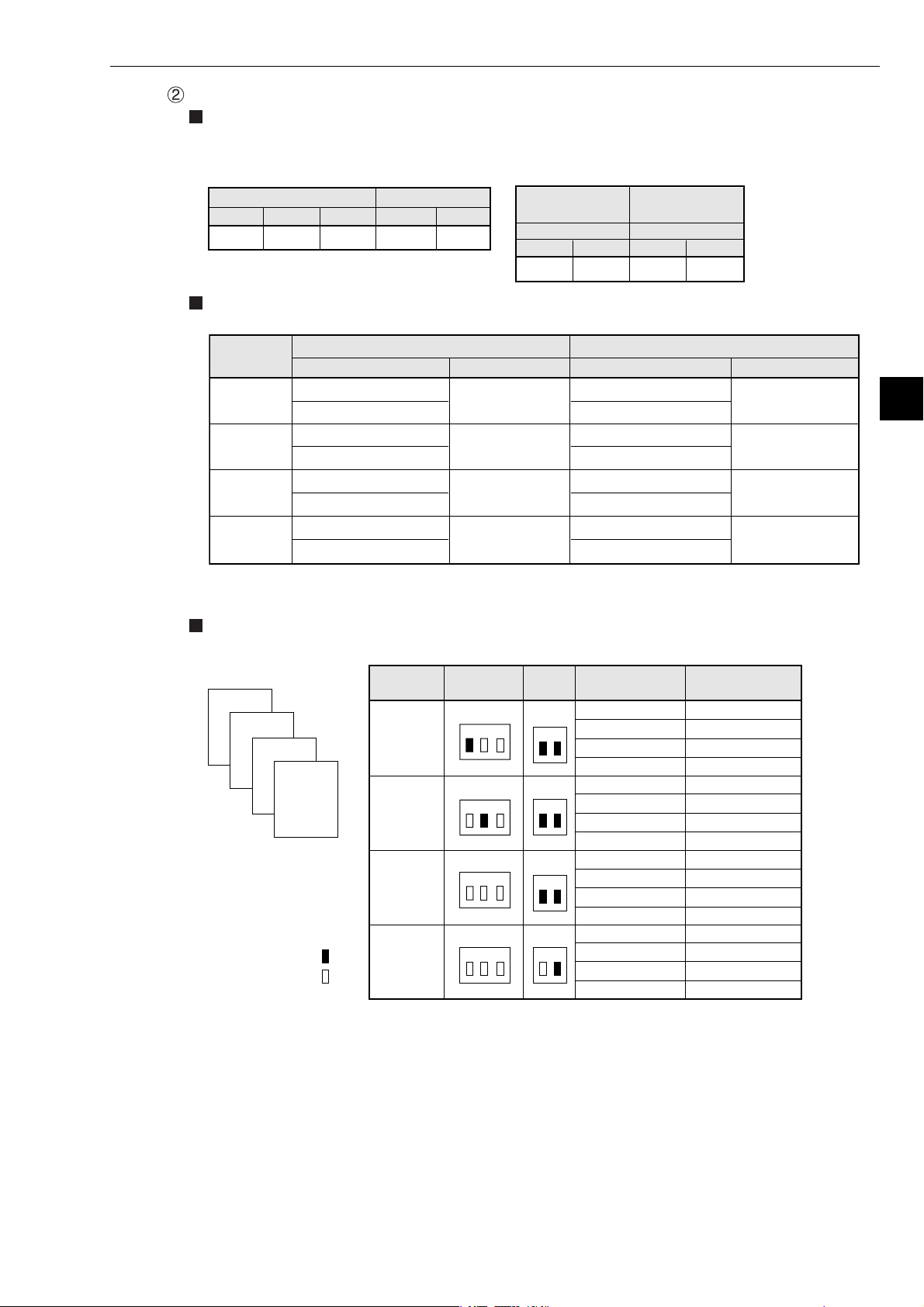

5-1 Installation of JW-20FL5/20FLT

This section describes the installation procedures for the JW-20FL5/20FLT (hereafter referred to as the

module) on the JW20H/30H basic rack panel.

Turn off the power to the JW20H/30H.

Set the module No. switch on the back of the module.

(Back of the communication module)

Module No. switch

5

Insert the mounting rib on the module into the rib insert holes on the JW20H/30H basic rack panel

and push in. Then, tighten module-mounting screws at the top of the module using a Phillips-head

(+) screwdriver.

Intermediate plate

or control panel

Basic rack panel

Module insert guide

This module

Module rib

insert hole

Module rib

(Installation example)

Power supply module

+Phillips-head

screwdriver

Control module

JW-21CU/22CU, JW-31CUH1/32CUH1

JW-33CUH1/33CUH2/33CUH3

Ventilation hole

Module mounting screw

Basic rack panel

The module

(The figure shows a JW-20FL5.)

Notes

- The module cannot be installed into an expansion rack panel.

- More than two communication modules can be installed on the same control module (basic rack panel

for the JW20H/30H). However, be careful not to use the same module No. switch setting for any other

module (including JW-20FL5/20FLT).

- Make sure to tighten the module mounting screws securely. Loose screws may cause a malfunction.

5-1

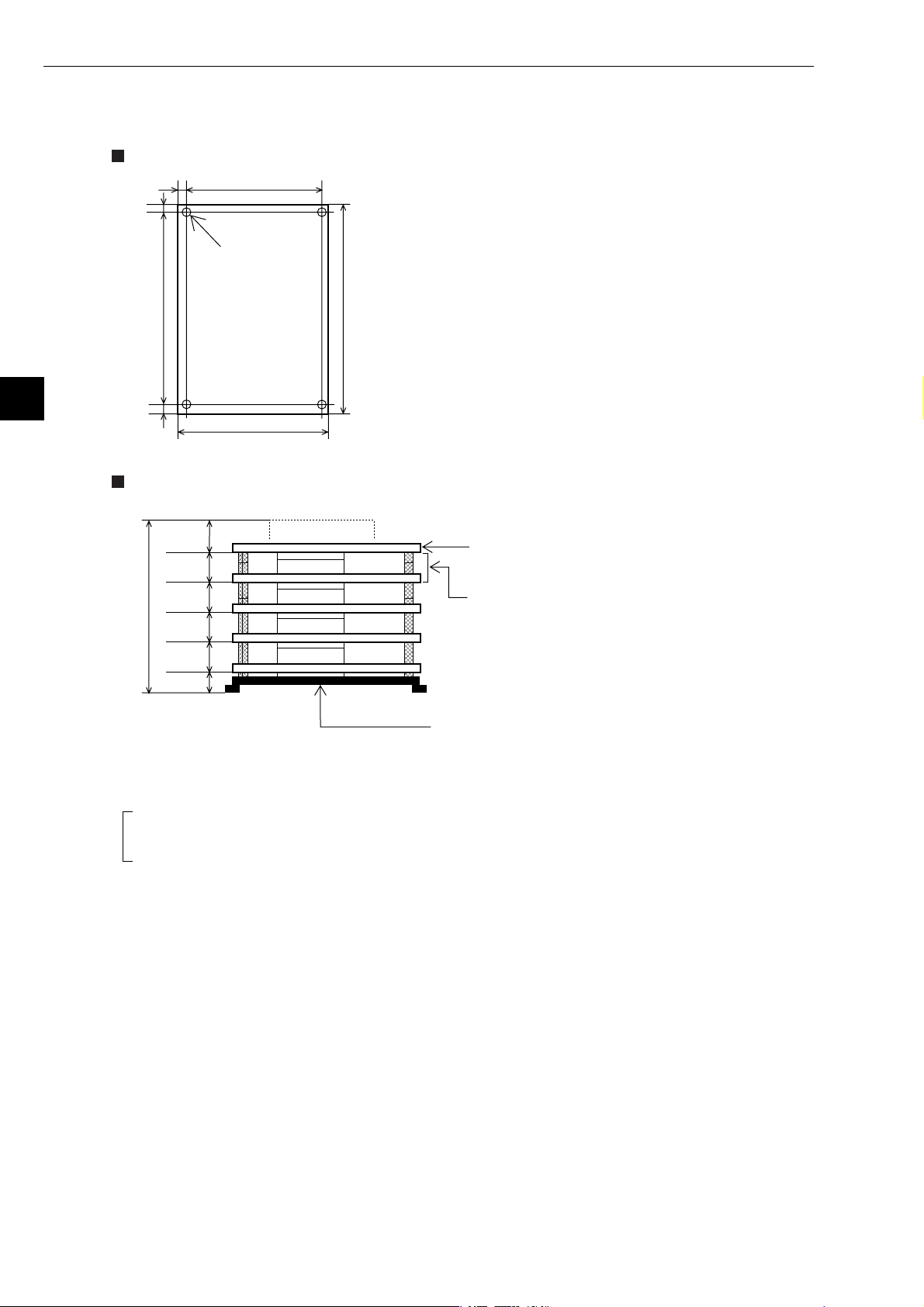

Page 19

Chapter 5: Installation

5-2 Installation of Z-336J

Board dimensions and assembled dimensions of the Z-336J are shown below.

Board dimensions

5

5

100

Boss hole: 4-φ4

[Unit: mm]

5

5

Assembled dimensions

25.0

21.6

D

D2

D2

D2

15.0

110

180170

The dimensions on the left do not include metal fittings.

[Unit: mm]

* CPU board (when Z-311J/312J is mounted)

When installing the Z-336J under the CPU board.

In the case metal fixing A is used.

* The CPU board can only be installed at the upper most position.

- For details about assembly/installation dimensions, see the manuals below.

J-board Z-311J/312J User's Manual: Hardware Version.

J-board Z-313J User's Manual: Hardware Version.

J-board Z-511J User's Manual: Hardware Version.

Dimensions D and D2 correspond to D and D2 "board sizes" of the manuals above.

- Make sure to ensure there is conductivity between the installation metal and installation section.

5-2

Page 20

This paragraph describes the maximum number of Z-336J boards to install on the J-board and allocation of I/O

relays.

Allocation of I/O relays When mounted on the Z-311J/312J See the next page.

When mounted on the Z-313J See page 5-5.

When mounted on the Z-511J See page 5-6.

Chapter 5: Installation

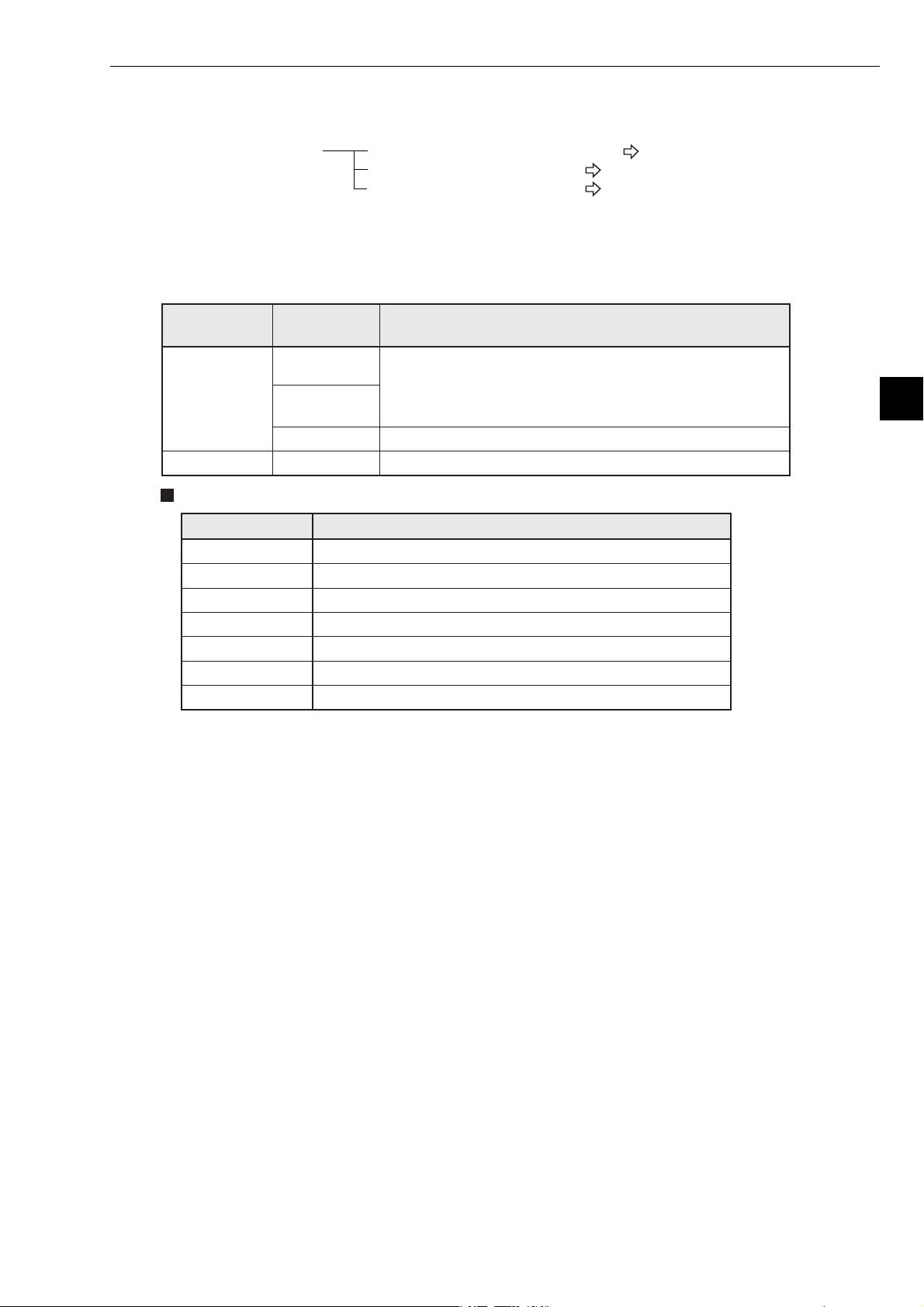

[1] Maximum number of boards to mount

The Z-336J is a kind of communication board of the J-board. Maximum number of boards mounted on

the J-board shall be the total number of communication boards mounted.

J-board CPU board

Z-311J

Z-300 series

Z-500 series Z-511J * Maximum 2

Types of communication boards

Z-312J

Z-313J * Maximum 1

Total number of boards able to be mounted including

Z-336J and other communication boards

Maximum 2

- When the total current flow at5Vofeach mounted

board exceeds 800 mA, the number of boards shall be

limited.

5

Module name Specifications

Z-331J * Data link or computer link, satellite I/O link master station

Z-332J Data link or computer link

Z-333J Satellite I/O link master station

Z-334J * ME-NET board (with branch line extension function)

Z-335J Satellite net board

Z-336J FL-net board

Z-337J DeviceNet board

* Manufactured on request.

5-3

Page 21

Chapter 5: Installation

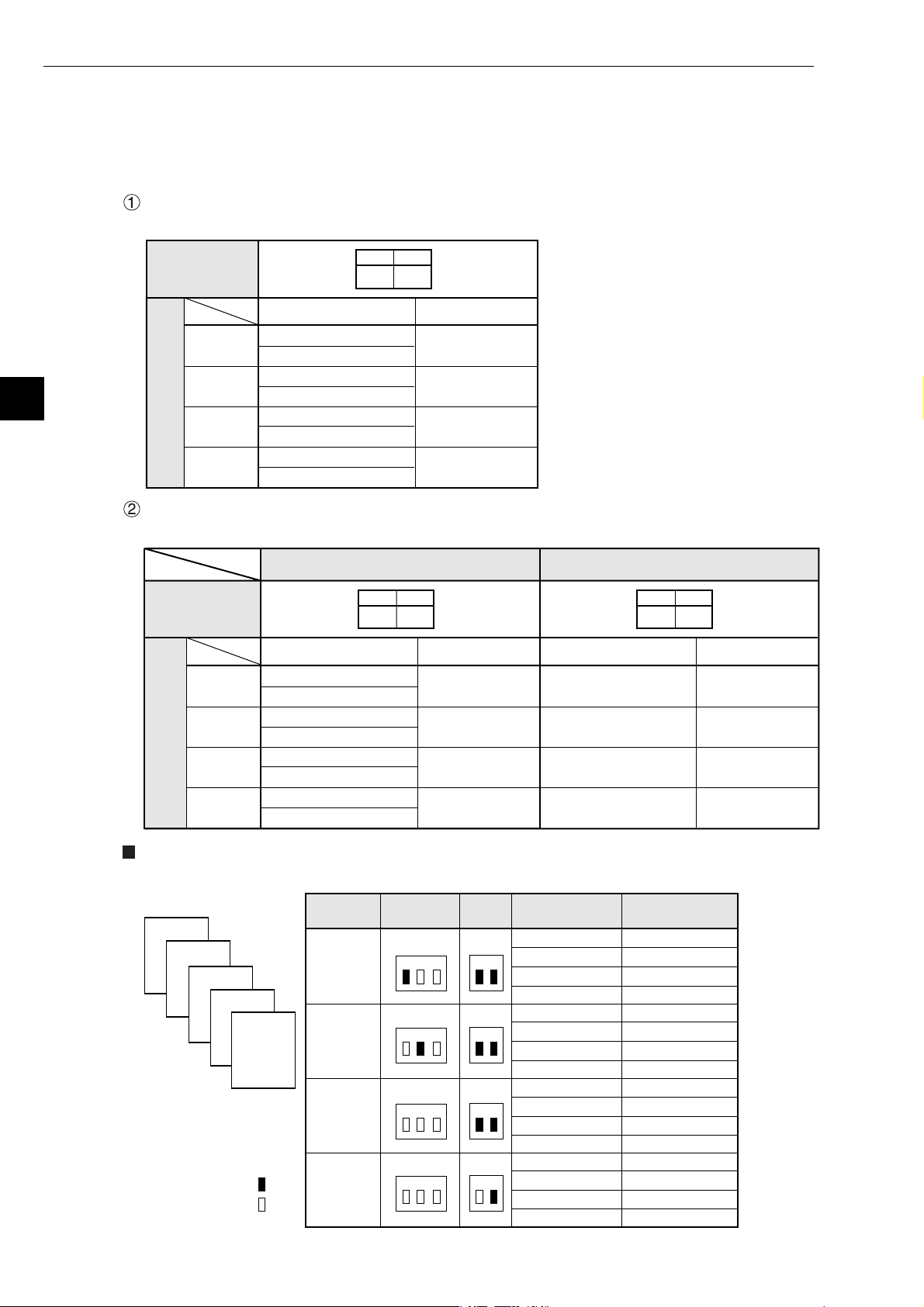

[2] Address allocation of I/O relay

This section describes I/O relay addresses allocated to the Z-336J.

(1) When mounted on Z-311J/312J

The total number of Z-336J boards able to be mounted including other communication boards is two

at maximum. Below the switch settings of the Z-336J and allocation of I/O relay are shown.

When using one communication board (Z-336J)

Set switch SWA for number of communication boards on the Z-336J as follows.

5

Setting of

switch SWA

on the Z-336J

I/O relay address

Z-336J

(optional)*

Dummy

(vacant)

Dummy

(vacant)

Dummy

Allocation of Z-336J

I/O relay

(vacant)

When using two communication boards

Depending on at which position the Z-336J is used, the allocation of I/O relay varies.

Setting of

switch SWA

on the Z-336J

Z-336J

(optional)*

Dummy

(vacant)

Dummy

(vacant)

Dummy

Allocation of Z-336J

I/O relay

(vacant)

コ0000

コ0001

コ0002

コ0003

コ0004

コ0005

コ0006

コ0007

Use Z-336J as first unit

I/O relay address

コ0000

コ0001

コ0002

コ0003

コ0004

コ0005

コ0006

コ0007

1

ON

1

ON

2

ON

Address to set

R = 0, S = 0

R = 0, S = 1

R = 0, S = 2

R = 0, S = 3

2

ON

Address to set

R = 0, S = 0

R = 0, S = 1

R = 0, S = 2

R = 0, S = 3

* Though it is allocated as optional,

it will be a dummy area not

functionally used.

Use Z-336J as 2nd unit

2

1

ON

OFF

I/O relay address

コ0010

コ0011

コ0012

コ0013

コ0014

コ0015

コ0016

コ0017

Address to set

R = 0, S = 4

R = 0, S = 5

R = 0, S = 6

R = 0, S = 7

Examples of allocation

Below the switch setting and I/O allocation when using two Z-336J is shown.

Z-336J

4

3

Z-336J

Z-322J

2

1

Z-322J

Z-311J

/312J

ON

OFF

Mounted

position

1

2

3

4

SW1

(RACK NO)

1 2 3

1 2 3

1 2 3

1 2 3

SWA

(SW2)

SW2

1 2

SW2

1 2

SWA

1 2

SWA

1 2

I/O relay

address

コ0020, コ0021

コ0022, コ0023

コ0024, コ0025

コ0026, コ0027

コ0030, コ0031

コ0032, コ0033

コ0034, コ0035

コ0036, コ0037

コ0000, コ0001

コ0002, コ0003

コ0004, コ0005

コ0006, コ0007

コ0010, コ0011

コ0012, コ0013

コ0014, コ0015

コ0016, コ0017

Address to set

R=1, S=0

R=1, S=1

R=1, S=2

R=1, S=3

R=2, S=0

R=2, S=1

R=2, S=2

R=2, S=3

R=0, S=0

R=0, S=1

R=0, S=2

R=0, S=3

R=0, S=4

R=0, S=5

R=0, S=6

R=0, S=7

5-4

Page 22

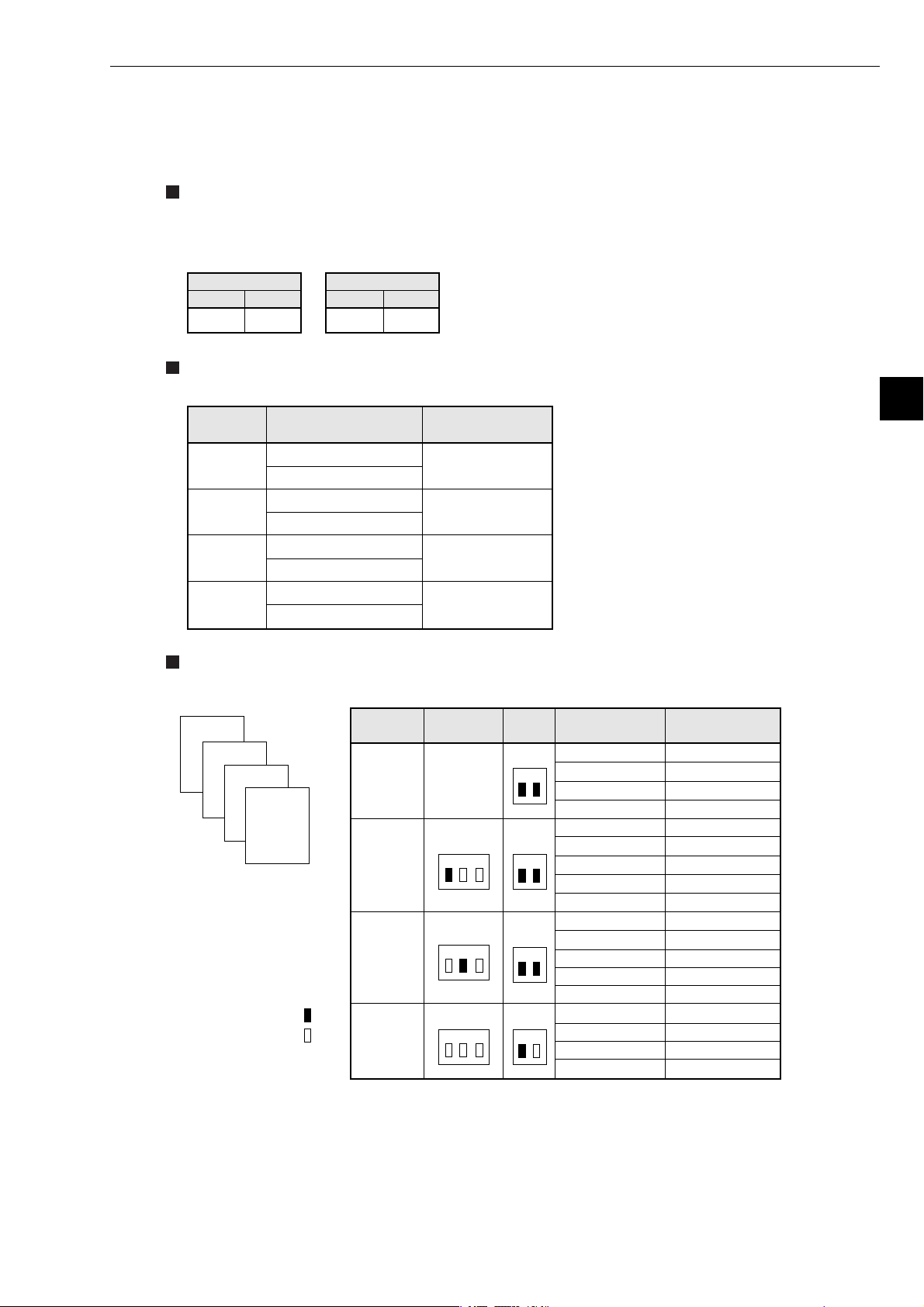

(2) When mounted on Z-313J

The number of boards available mounted on the Z-336J including other communication boards is

one at maximum.

Below shows the switch setting of the Z-313J and Z-336J as well as I/O relay allocation of the Z336J.

Switch setting

The set switch SWA on the Z-313J and the number of communication boards setting switch SWA of

the Z-336J are as shown below.

Chapter 5: Installation

- Z-313J

Switch SWA

1 2

ON ON

Allocation of I/O relay

I/O relay address of the Z-336J shall be allocated as shown below.

Allocation

details

Z-336J

(optional)*

Dummy

(vacant)

Dummy

(vacant)

Dummy

(vacant)

Allocation examples

Below shows switch setting and I/O relay allocation when using one Z-336J.

- Z-336J

Switch SWA

1 2

OFF ON

I/O relay address

コ0010

コ0011

コ0012

コ0013

コ0014

コ0015

コ0016

コ0017

Address to set

R = 0, S = 4

R = 0, S = 5

R = 0, S = 6

R = 0, S = 7

* Though it is allocated as optional,

it will be a dummy area not

functionally used.

5

Z-336J

4

3

Z-325J

Z-325J

2

1

Z-313J

ON

OFF

Mounted

position

1

2

3

4

SW1

(RACKNO.)

1 2 3

1 2 3

1 2 3

(SW2)

NO

SWA

SWA

1 2

SW2

1 2

SW2

1 2

SWA

1 2

I/O relay

address

コ0000, コ0001

コ0002, コ0003

コ0004, コ0005

コ0006, コ0007

コ0020, コ0021

コ0022, コ0023

コ0024, コ0025

コ0026, コ0027

コ0030, コ0031

コ0032, コ0033

コ0034, コ0035

コ0036, コ0037

コ0040, コ0041

コ0042, コ0043

コ0010, コ0011

コ0012, コ0013

コ0014, コ0015

コ0016, コ0017

Address to set

R=0, S=0

R=0, S=1

R=0, S=2

R=0, S=3

R=1, S=0

R=1, S=0

R=1, S=1

R=1, S=2

R=1, S=3

R=2,S=0

R=2,S=0

R=2,S=1

R=2,S=2

R=2,S=3

R=0,S=4

R=0,S=5

R=0,S=6

R=0,S=7

5-5

Page 23

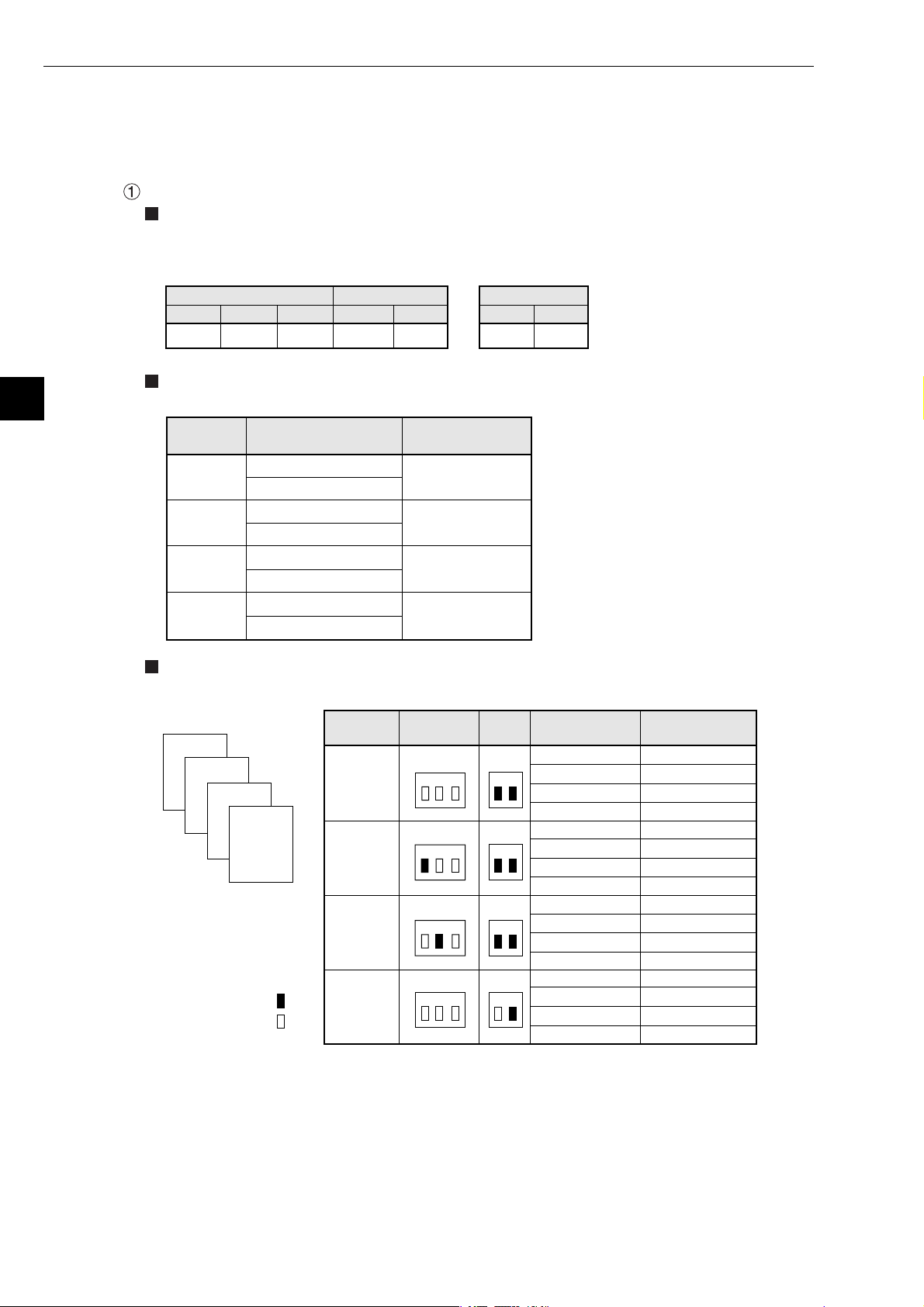

Chapter 5: Installation

(3) When mounted on Z-511J

5

The number of boards available mounted on the Z-336J including other communication boards is

two at maximum.

Below shows the switch setting of the Z-511J and Z-336J as well as I/O relay allocation of the Z336J.

When using one communication board (Z-336J)

Switch setting

The set switches SW1 and SWA on the Z-511J and the number of communication boards setting

switch SWA on the Z-336J are as follows.

- Z-511J

Switch SWA Switch SWASwitch SW1

1 2 3

OFF OFF OFF

Allocation of I/O relay

I/O relay address of the Z-336J shall be allocated as shown below.

1 2

ON ON

- Z-336J

1 2

OFF ON

Allocation

details

Z-336J

(optional)*

Dummy

(vacant)

Dummy

(vacant)

Dummy

(vacant)

Allocation examples

Below shows switch setting and I/O relay allocation when using one Z-336J.

Z-336J

Z-322J

4

Z-322J

3

2

I/O relay address

コ0010

コ0011

コ0012

コ0013

コ0014

コ0015

コ0016

コ0017

Z-511J

1

ON

OFF

Mounted

position

1

2

3

4

Address to set

R = 0, S = 4

R = 0, S = 5

R = 0, S = 6

R = 0, S = 7

SW1

(RACK NO)

1 2 3

1 2 3

1 2 3

1 2 3

SWA

(SW2)

SWA

1 2

SW2

1 2

SW2

1 2

SW2

1 2

* Though it is allocated as optional,

it will be a dummy area not

functionally used.

I/O relay

address

コ0000, コ0001

コ0002, コ0003

コ0004, コ0005

コ0006, コ0007

コ0020, コ0021

コ0022, コ0023

コ0024, コ0025

コ0026, コ0027

コ0030, コ0031

コ0032, コ0033

コ0034, コ0035

コ0036, コ0037

コ0010, コ0011

コ0012, コ0013

コ0014, コ0015

コ0016, コ0017

Address to set

R=0, S=0

R=0, S=1

R=0, S=2

R=0, S=3

R=1, S=0

R=1, S=1

R=1, S=2

R=1, S=3

R=2, S=0

R=2, S=1

R=2, S=2

R=2, S=3

R=0, S=4

R=0, S=5

R=0, S=6

R=0, S=7

5-6

Page 24

When using two communication boards (Z-336J)

Switch setting

The set switches SW1 and SWA on the Z-551J and the number of communication boards setting

switch SWA on the Z-336J are as follows.

- Z-511J

Switch SW1

1 2 3

OFF OFF OFF

Allocation of I/O relay

I/O relay address of the Z-336J shall be allocated as shown below.

Allocation

details

Z-336J

(optional)*

Dummy

(vacant)

Dummy

(vacant)

Dummy

(vacant)

* Though it is allocated as optional, it will be a dummy area not functionally used.

Use Z-336J as 1st unit Use Z-336J as 2nd unit

I/O relay address

コ0000

コ0001

コ0002

コ0003

コ0004

コ0005

コ0006

コ0007

Switch SWA

1 2

ON ON

Address to set

- Z-336J

Use Z-336J

as 1st unit

Switch SWA Switch SWA

1 21 2

ON ON

R = 0, S = 0

R = 0, S = 1

R = 0, S = 2

R = 0, S = 3

Use Z-336J

as 2nd unit

OFF ON

I/O relay address

コ0010

コ0011

コ0012

コ0013

コ0014

コ0015

コ0016

コ0017

Chapter 5: Installation

Address to set

R = 0, S = 4

R = 0, S = 5

R = 0, S = 6

R = 0, S = 7

5

Allocation examples

Below shows switch setting and I/O relay allocation when using two Z-336Js.

Z-336J

4

3

Z-336J

Z-322J

2

1

Z-511J

ON

OFF

Mounted

position

1

2

3

4

SW1

(RACK NO)

1 2 3

1 2 3

1 2 3

1 2 3

SWA

(SW2)

SWA

1 2

SWA

1 2

SWA

1 2

SWA

1 2

I/O relay

address

コ0020, コ0021

コ0022, コ0023

コ0024, コ0025

コ0026, コ0027

コ0030, コ0031

コ0032, コ0033

コ0034, コ0035

コ0036, コ0037

コ0000, コ0001

コ0002, コ0003

コ0004, コ0005

コ0006, コ0007

コ0010, コ0011

コ0012, コ0013

コ0014, コ0015

コ0016, コ0017

Address to set

R=1, S=0

R=1, S=1

R=1, S=2

R=1, S=3

R=2, S=0

R=2, S=1

R=2, S=2

R=2, S=3

R=0, S=0

R=0, S=1

R=0, S=2

R=0, S=3

R=0, S=4

R=0, S=5

R=0, S=6

R=0, S=7

5-7

Page 25

Chapter 5: Installation

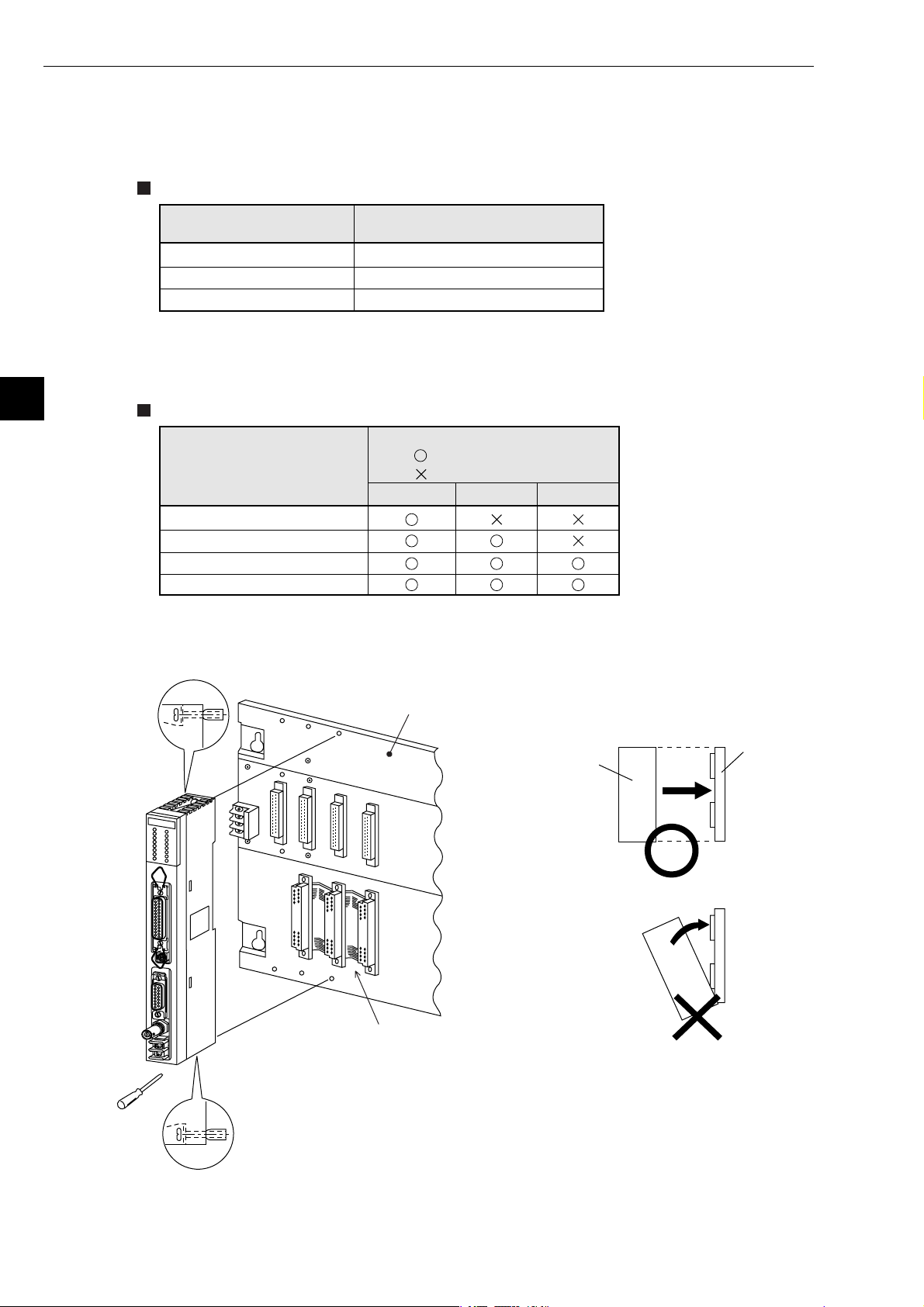

5-3 JW-50FL

(1) Installation of cable for option module

Install the optional cable on the basic rack panel that installed JW-50FL.

Cable type for option module

5

Cable for option module

ZW-2CC

ZW-4CC

ZW-6CC

* If the ZW-6CC is used, a maximum of 6 optional modules can be installed. However, a limit of

5 optional modules can be used with JW-50FL, due to a parameter (address area) setting limitation.

Rack panel type

Model name of the rack

panel on which optional

cable is installed

JW-4BU

JW-6BU

JW-8BU

JW-13BU

(2) Installation of JW-50FL

Attach the rack panel using the two attachment screws.

Before installation or removal, make sure to shut OFF the power supply to the PC.

Maximum number of JW-50FL

that can be installed

2

4

Note *

5

Cable for option module

(: Can be installed

ZW-2CC ZW-4CC

: Cannot be installed)

ZW-6CC

Phillips screwdriver

Install on rack panel JW-4BU

Module

Appearance when ZW-2CC optional

cable is installed

- This module can be installed in any one of the optional slots.

Be careful not to bend the connector pins on the module by applying

too much force to them.

Rack panel

5-8

Page 26

Chapter 6: Connection/Wiring

Chapter 6: Connection/Wiring

6-1 Installing an Ethernet cable

Workers who will install or hook up an Ethernet cable must have special training and knowledge, such as

the safety procedures and standards required by this technology (JIS X5252).

We recommend that you contact a specialist for perform any installation or hook up. (Sharp Document

Systems Co., Ltd. is providing the Ethernet installation work service, and supplying network products

from Allied System Co., Ltd.)

[1] Equipment layout

- The minimum distance between nodes is specified in the regulations. (2.5 m when the 10BASE5 is

used.) When connecting devices, be sure to maintain these minimum distances.

Cables used for 10BASE5 systems have marks every 2.5 m. Position each transceiver directly on one

of these marks.

-Mount the transceivers on electrically insulated objects, such as a wooden mounting block.

[2] Wiring

- Separate (60 cm or more) the data transmission cables from power cables.

- Do not run cables near any noise generating source.

- Both ends of the coaxial cable must be terminated with a termination resistance. Make sure to install

termination resistance on each end.

6

6-1

Page 27

Chapter 6: Connection/Wiring

6-2 Connection

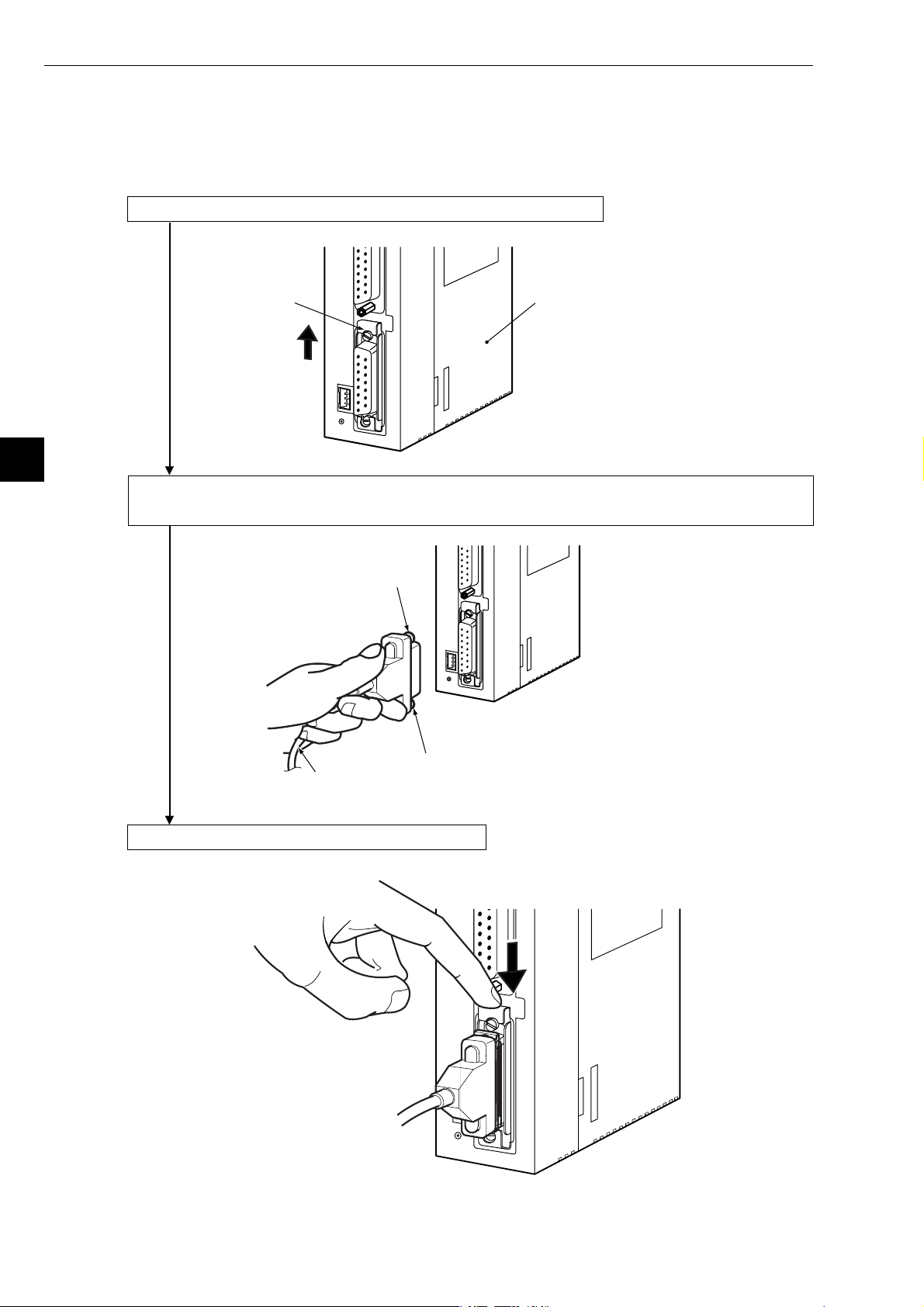

[1] Connection of JW-20FL5

This paragraph describes how to connect 10BASE5 cable to the JW-20FL5.

(1) Connecting the transceiver cable

1 Slide the lock on the 10BASE5 connector (on the JW-20FL5) up.

6

Slide lock

R

E

S

E

T

JW-20FL5

2 Insert the connector so that the two locking posts on the cable connector match the holes on

the slide lock.

Locking post

RESET

Locking post

Transceiver cable

3 Slide the lock down to lock the cable connector.

RESET

6-2

Page 28

Chapter 6: Connection/Wiring

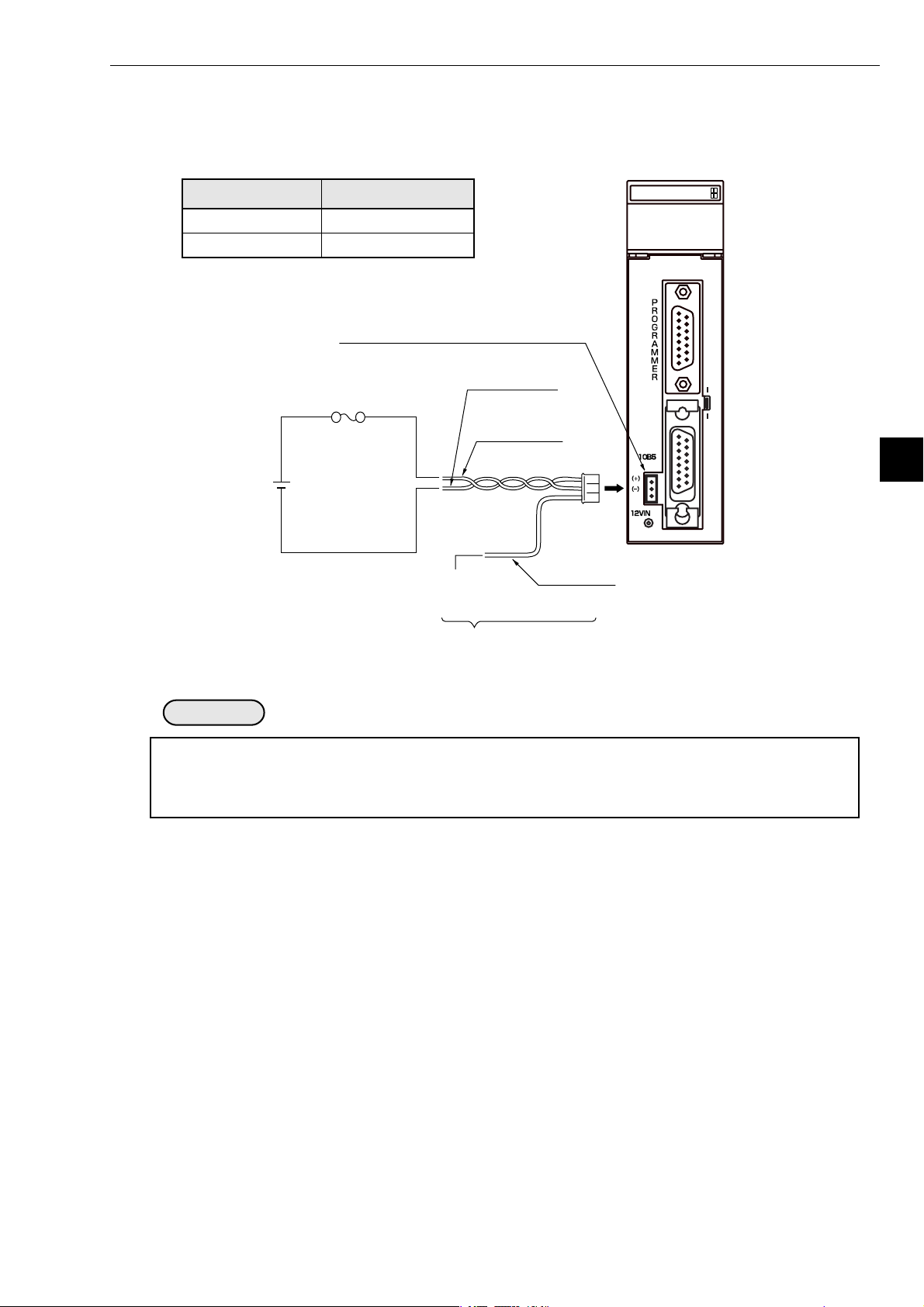

(2) Wiring the power source

When a 10BASE5 is used, 12 VDC power should be supplied to the transceiver.

Supply power to the 12 VDC power supply input terminal using a commercial constant voltage power

supply unit.

Item Specifications

Supply voltage

Current capacity

12 VDC –5%

0.5 A minimum.

12 VDC power supply input terminal

* Fuse (0.6 A)

(+)

12 VDC

(−)

* Use a fuse melt with time lag

(Accessory: Connector, cable length 1.5 m)

Black wire (-)

Red wire (+)

Twisted pair wires

Case

Cable

Green wire

(ground)

JW-20FL5

LN TX RX 12V T PE HE

S7 S6 S5 S4 S3 S2 S1 S0

FG

RESET

ON

OFF

S

H

I

E

L

D

6

Remarks

- Use a power supply that is dedicated for use by the JW-20FL5.

- Do not reverse the positive and negative connections to the power terminals. Reversing the polarity

may damage the JW-20FL5.

6-3

Page 29

Chapter 6: Connection/Wiring

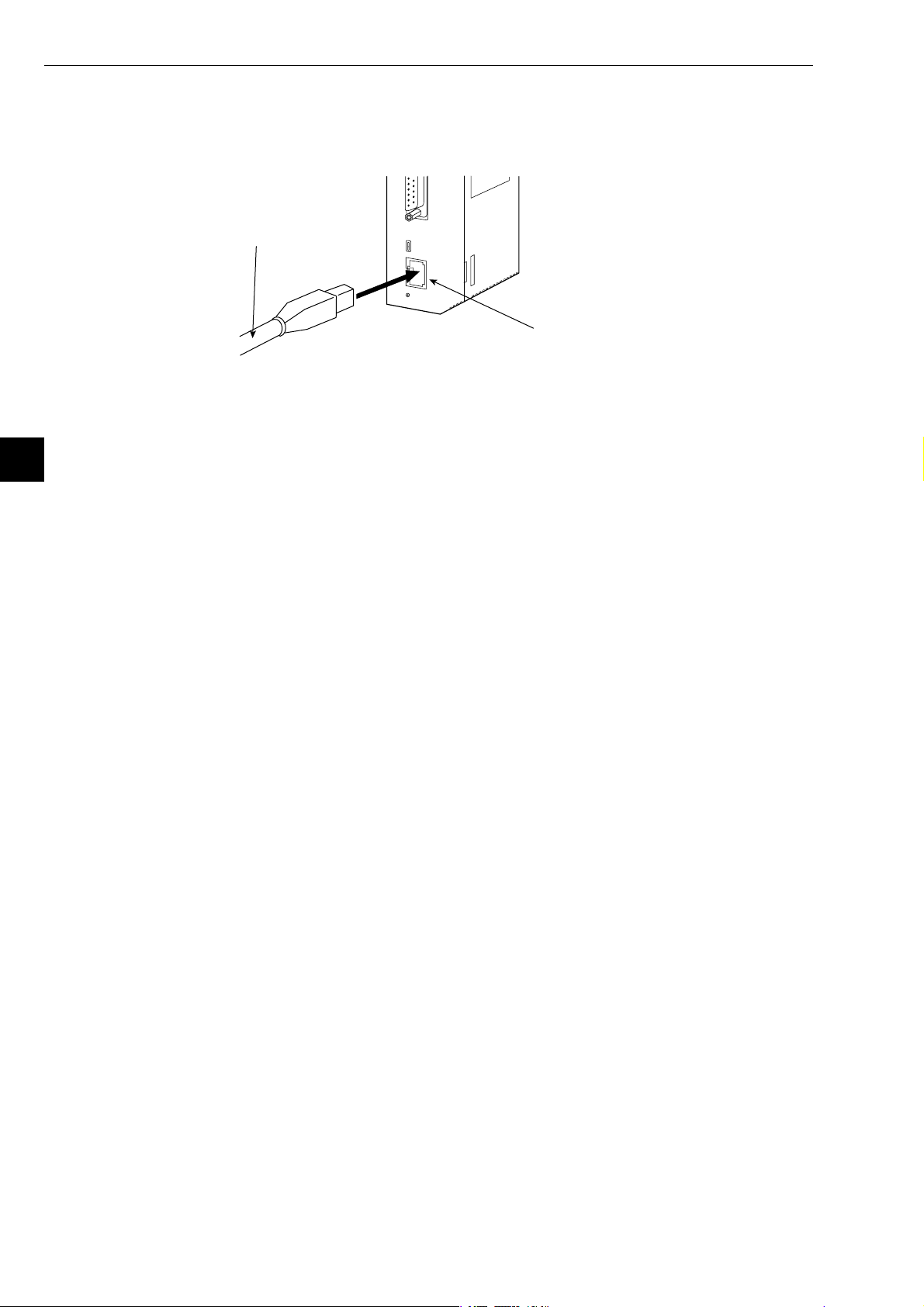

[2] When connecting to a JW-20FLT

Connect a 10BASE-T twisted pair cable to the 10BASE-T connector on the JW-20FLT.

6

10BASE-T twisted

pair cable

10BASE-T connector

6-4

Page 30

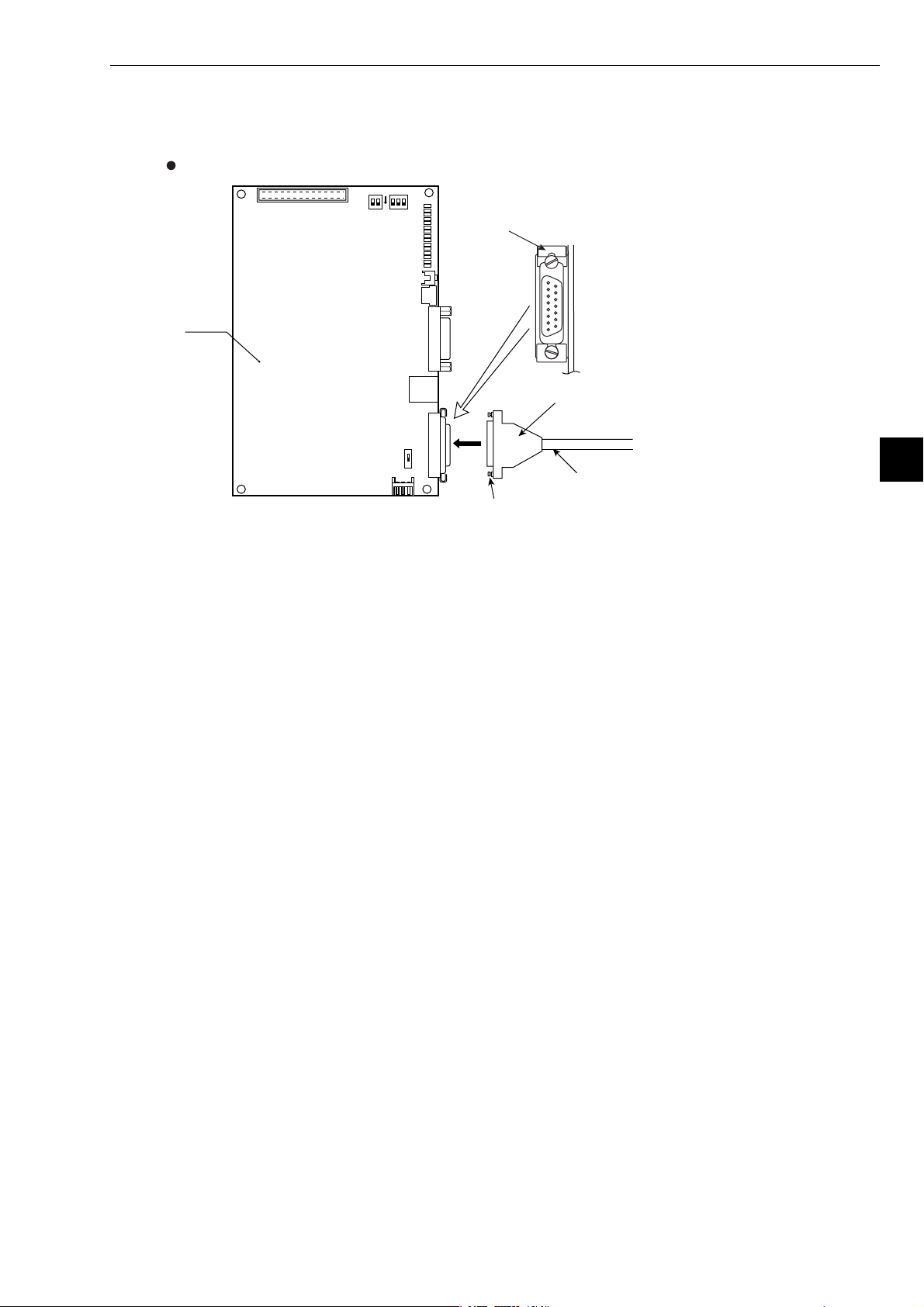

[3] Connection of Z-336J

(1) When connecting to a 10BASE5

This paragraph describes how to connect 10BASE5 cable to the Z-336J.

Connecting the transceiver cable

Z-336J

Chapter 6: Connection/Wiring

O

F

F

ON

2

1

SWA

SW1

LN

TX

RX

12V

T

Slide lock

PE

HE

S7

S6

S5

S4

S3

S2

S1

S0

10BASE5 connector

1

↑↓

3

Cable connector

SW6

ON

2

Transceiver cable

Locking post

1 Slide the lock on the 10BASE5 connector (on the Z-336J) up.

2 Insert the connector so that the two locking posts on the cable connector match the holes on

the slide lock.

3 Slide the lock down to lock the cable connector.

6

6-5

Page 31

Chapter 6: Connection/Wiring

Wiring the power source

When a 10BASE5 is used, 12 VDC power should be supplied to the transceiver.

Supply power to the 12 VDC power supply input terminal of the Z-336J using a commercial constant

voltage power supply unit.

Z-336J

6

O

F

F

ON

2

1

SWA

LN

TX

SW1

RX

12V

T

PE

HE

S7

S6

S5

S4

S3

S2

S1

S0

Item Specifications

Supply voltage

Current capacity

12 VDC –5%

0.5 A minimum.

12 VDC power supply input terminal

SW6

ON

Twisted pair wires

Red wire (+)

Green wire

(ground)

Cable

(Accessory: Connector,

cable length 1.5 m)

Black wire (-)

Case

* Fuse (0.6 A)

* Use a fuse that will melt with

time lag

(+)(−)

12 VDC

Remarks

- Use a power supply that is dedicated for use by the Z-336J.

- Do not reverse the positive and negative connections to the power terminals. Reversing the polarity

may damage the Z-336J.

6-6

Page 32

Chapter 6: Connection/Wiring

(2) When connecting to a 10BASE-T

Connect a 10BASE-T twisted pair cable to the 10BASE-T connector on the Z-336J.

O

F

F

ON

2

1

SWA

LN

TX

SW1

RX

12V

T

PE

HE

S7

S6

S5

S4

S3

S2

S1

S0

10BASE-T connector

10BASE-T twisted pair cable

Z-336J

SW6

ON

6

6-7

Page 33

Chapter 6: Connection/Wiring

[4] Connection of JW-50FL

(1) Connection of 10BASE5

This paragraph describes how to connect 10BASE5 cable to the JW-50FL.

Connecting the transceiver cable

6

Locking post

②

①

↑↓

③

10BASE5 connector

Locking post

Transceiver cable

1 Slide the lock on the 10BASE5 connector (on the JW-50FL) up.

2 Insert the connector so that the two locking posts on the cable connector match the holes on

the slide lock.

3 Slide the lock down to lock the cable connector.

Wiring the power source

When a 10BASE5 is used, 12 VDC power should be supplied to the transceiver.

Supply power to the 12 VDC power terminals using a commercial constant voltage power supply

unit.

Slide lock

Item Specifications

Supply voltage

Current capacity

12 VDC –5%

0.5 A minimum.

10B5

Black wire (-)

* Fuse (0.6 A)

10B-T

RESET

(+)

(−)

FG

12VIN

12 VDC

(+)

(−)

* Use a fuse melt with time lag

Red wire (+)

Twisted pair wires

Case

Green wire

(ground)

Cable

(Accessory: Connector, cable length 1.5 m)

Remarks

- Use a power supply that is dedicated for use by the JW-50FL.

- Do not reverse the positive and negative connections to the power terminals. Reversing the

polarity may damage the JW-50FL.

6-8

Page 34

Chapter 6: Connection/Wiring

(2) When connecting to a 10BASE-T

Connect a 10BASE-T twisted pair cable to the 10BASE-T connector on the JW-50FL.

10BASE-T twisted

pair cable

10BASE-T connector

6

6-9

Page 35

Chapter 7: Use Guide

7-1 Ethernet

[1] 10BASE5 system

The basic configuration of a10BASE5 system consists of one coaxial cable, with a maximum length of

500 m, and nodes connected to this cable as shown below. Each node is connected to the coaxial cable

using a transceiver and a transceiver cable (AUI cable). Two types of transceivers are available: Single

port transceivers to connect a single transceiver cable (AUI cable), and multi-port transceivers to connect more than one cable.

This basic configuration unit is referred to as "segment." A maximum of 100 nodes can exist in one

segment.

Chapter 7: Computer Link Function

Max. 500 m

Segment

: Coaxial cable

: Transceiver cable (AUI cable)

: Singe port transceiver

: Multi-port transceiver

Basic connection method for a 10BASE5 system (maximum 500 m without a repeater)

: Node

: Terminator

7

7-1

Page 36

Chapter 7: Computer Link Function

If the distance between nodes is greater than 500 m, connect a repeater as shown below, or to increase

the number of segments by branching. The figure below is an example of a system with a maximum of

1500 m of cable. Arrange the configuration so that there are never more than two repeaters between

any two nodes along any path.

7

Basic connections in a 10BASE5 system (maximum 1500 m using repeaters)

CAUTION

Connect the repeater to the coaxial cable through a transceiver and transceiver cable. Repeaters

can be connected to any transceiver in the same segment. The installation distance between

transceivers is considered to be a multiple of "2.5m" lengths. That is, any cable length should be

evenly divisible by 2.5 m and not have a remainder.

7-2

Page 37

Chapter 7: Computer Link Function

Link segment 1

Link segment 2

Link segment 3

Segment B

Segment A

Segment C

Segment D

: Area inside this

rectangle is treated

as one repeater

The example shown below allows up to 2,500m between nodes. In order to extend communication

distance, link cables are used (with repeaters at both ends). The maximum length of one link is 500

m. These cables are referred to as "link segments."

The link segments must not connect nodes directly. However, the areas surrounded by dotted lines,

including repeaters at both ends, are treated as a single repeater. This does away with the limitation

on the total number of repeaters between nodes in a system.

Basic connections in a 10BASE5 system (maximum 2500 m using repeaters)

CAUTION

Each link segment must be 500 m or less.

Do not connect a node to the link segment.

A link segment is treated as one repeater, even though it includes a repeater at each end (enclosed

with dotted lines).

No more than two repeaters shall exist along the path between any two nodes.

Only one segment in the network can be connected to more than two repeaters.

7

7-3

Page 38

Chapter 7: Computer Link Function

Parameters related to the system configuration are summed up below.

General specifications for configuring an Ethernet system

Maximum length of a segment 500 m

Maximum number of transceivers that can be

installed within one segment

Maximum distance between nodes 2500 m or less (except for the transceiver cables)

Maximum number of nodes in a system 254