Page 1

Version 2.2

R

SHARP Programmable Controller

New Satellite W series

Network module

Remote I/O slave module

User’s Manual

Produced in Oct. 1997

Model Name

JW-20CM

JW-20RS

Page 2

Thank you for purchasing the network module (JW-20CM), remote I/O slave module (JW-20RS) for the

SHARP programmable controller.

Read this manual thoroughly to completely familiarize yourself with the operation according to the

examples.

Besides this manual, the manuals of control module, support tool, and option module are available for the

respective programmable controller.

We ask you to also read these manuals as well as this manual.

Keep this manual for future reference. We are confident that this manual will be helpful whenever you

encounter a problem.

Note

★ This manual describes the JW-20CM, JW-20RS with 30Hn mark in front of the module. The

following functions are added for the JW-20CM and JW-20RS without [30Hn] marks.

① This module can be communicated with JW30H.

② For data link, available for use the following functions.

· Data link (memory capacity save function)

· Data memory start system for SEND/RECEIVE function.

In this manual, additional functions are represented by the V5 mark.

★ In this manual, programmable controller is referred to as “PC.”

★ In this manual, programmable controllers and I/O modules with model name "ZW-xx" are

referred to as "ZW model," and programmable controllers and I/O modules with model name

"JW-xx" are referred to as "JW model."

Note

· This manual is written with the utmost care.

· No part of this manual may be reproduced in any form without permission of SHARP corporation.

· The contents of this manual are subject to change without prior notice.

Page 3

Safety Precautions

Read this manual and attached documents carefully before installation, operation, maintenance and checking

in order to use the machine correctly. Understand all of the machine knowledge, safety information, and

cautions before starting to use. In this instruction manual, safety precautions are ranked into "danger" and

"caution" as follows.

Danger : Wrong handling may possibly lead to death or heavy injury.

Caution : Wrong handling may possibly lead to medium or light injury.

Even in the case of Caution , a serious result may be experienced depending on the

circumstances. Anyway, important points are mentioned. Be sure to observe them strictly.

The picture signs of prohibit and compel are explained below.

: It means don’ts. For example, prohibition of disassembly is indicated as ( ).

: It means a must. For example, obligation of grounding is indicated as ( ).

1) Installation

• Use in the environments specified in the catalog, instruction manual, and user's manual.

Electric shock, fire or malfunction may be caused when used in the environments of high

temperature, high humidity, dusty or corrosive atmosphere, vibration or impact.

• Install according to the manual.

Wrong installation may cause drop, breakdown, or malfunction.

• Never admit wire chips or foreign matters.

Or fire, breakdown or malfunction may be caused.

2) Wiring

• Be sure to ground.

Unless grounded, electric shock or malfunction may be caused.

• Connect the rated power source.

Connection of a wrong power source may cause a fire.

• Wiring should be done by a qualified electrician.

Wrong wiring may lead to fire, breakdown or electric shock.

Caution

Compel

Caution

Page 4

3) Use

• Don’t touch the terminal while the power is being supplied or you may have an electric shock.

• Assemble the emergency stop circuit and interlock circuit outside of the programmable

controller. Otherwise breakdown or accident damage of the machine may be caused by the

trouble of the programmable controller.

•“RUN” or “STOP’” during operation should be done with particular care by confirming safety.

Misoperation may lead to damage or accident of the machine.

• Turn on the power source in the specified sequence. Turning ON with wrong sequence may

lead to machine breakdown or accident.

4) Maintenance

• Don’t disassemble or modify the modules.

Or fire, breakdown or malfunction may be caused.

Danger

Caution

Prohibit

Caution

• Turn OFF the power source before detaching or attaching the module.

Or electric shock, malfunction or breakdown may be caused.

Page 5

■ Configuration of this manual

The network module JW-20CM has three functions: "remote I/O," "data link," and "computer link" functions.

Accordingly, this manual describes about these three functions. Read each section according to your use of

any of these functions.

Users who use the network module for the first time.

Read this manual from chapter 1.

First, thoroughly understanding general, precautions, name and function of each section. Then, read

the contents from chapter 5 for proper use.

Users who want to use the remote I/O function.

Read from chapter 1 to chapter 7 and properly install and connect wiring work of the module. Then set

switches and parameters by referring chapter 8 for correct use.

Switch setting

· Master module: JW-20CM ....... See page 8·9

· Slave module: JW-20RS .......... See page 8·14

Parameter setting

· Master module: JW-20CM ....... See page 8·19

· Slave module: JW-20RS .......... See page 8·30

Users who want to use the data link function (including the computer link function)

Read from chapter 1 to chapter 7 and properly install and connect wiring work of the module. Then set

switches and parameters by referring chapter 9 for correct use.

The module also can function the computer link as data link system with a host computer having a

network module: ZW-98CM/ZW-20AX.

Switch setting

· Master module ............... See page 9·17

· Slave module ................. See page 9·17

Parameter setting

· Master module ............... See page 9·22

· Slave module ................. See page 9·33

Users who want to use only the computer link function

Read from chapter 1 to chapter 7 and properly install and connect wiring work of the module. Then set

switches by referring chapter 10 for correct use.

Switch setting ......... See page 10·3

Users who want to save and load parameter contents using a support tool.

Carefully read the contents of chapter 11 for correct use.

Users who want to add a communication station.

Carefully read the contents of chapter 7 and add a station.

Page 6

Network module JW-20CM

Remote I/O slave module JW-20RS

- User’s Manual -

Chapter 1. Outline

Chapter 2. Safety Precautions

Chapter 3. System Configuration

Chapter 4. Name and Function of Each Part

Chapter 5. Installation

Chapter 6. Processing of Cables

Chapter 7. Wiring

Chapter 8. Remote I/O

Chapter 9. Data Link

Chapter 10. Computer Link

Chapter 11. Support Tools

Chapter 12. Specifications

Chapter 13. Appendix

Page 7

Table of contents

Chapter 1 Outline ................................................................................................................................... 1·1

Chapter 2 Safety Precautions ............................................................................................................... 2·1

2-1 Installation 2·1

2-2 Wiring 2·1

2-3 Treatment 2·3

2-4 Static electricity 2·3

2-5 Maintenance 2·3

Chapter 3 System Configuration .......................................................................................................... 3·1

Chapter 4 Name and Function of Each Part ........................................................................................ 4·1

4-1 JW-20CM 4·1

4-2 JW-20RS 4·3

Chapter 5 Installation............................................................................................................................. 5·1

5-1 JW-20CM 5·1

5-2 JW-20RS 5·4

Chapter 6 Processing of Cables ........................................................................................................... 6·1

6-1 Processing cable end 6·2

6-2 Connector crimping procedure 6·5

Chapter 7 Wiring .................................................................................................................................... 7·1

7-1 Cable trunk and branch lines 7·1

7-2 Relaying of trunk cables 7·1

7-3 Cable wiring procedure in control panel 7·2

7-4 Waterproof and insulation processing of connectors 7·4

7-5 Wiring of cables at outside control panels 7·5

7-6 Check after wiring 7·5

7-7 Wiring method for adding a communication station 7·6

7-8 Wiring to power supply module 7·8

Chapter 8 Remote I/O............................................................................................................................. 8·1

8-1 Description of remote I/O 8·1

8-2 Data transfer required time and communication timing 8·3

8-3 Outline of switch and parameter setting procedure 8·8

8-4 Error and treatment 8·46

Chapter 9 Data Link ............................................................................................................................... 9·1

9-1 Description for data link function 9·1

9-2 Communication method 9·2

9-3 Data transfer required time and communication delay time 9·12

9-4 Expansion of network 9·15

9-5 Switch setting of master station or slave station 9·17

9-6 Setting contents of slave station parameters 9·22

9-7 Setting contents of master station parameters 9·33

9-8 Error and treatment 9·53

Chapter 10 Computer link .................................................................................................................... 10·1

10-1 Description for computer link 10·1

10-2 Computer link function 10·2

10-3 Switch setting 10·3

10-4 Command 10·4

Page 8

Chapter 11 Support Tools ..................................................................................................................... 11·1

11-1 Record and load by ladder software (JW-50SP) 11·1

11-2 Remote function 11·5

Chapter 12 Specifications ....................................................................................................................12·1

12-1 JW-20CM 12·1

12-2 JW-20RS 12·4

Chapter 13 Appendix ........................................................................................................................... 13·1

13-1 Maintenance and check 13·1

13-2 Switch setting table 13·2

13-3 Parameter memory table 13·3

13-4 Address map of data memory 13·20

13-5 Instructions used with the F200 and F201 link function 13·22

13-6 Application instruction using instruction system 13·26

Page 9

Chapter 1 Outline

Using network module JW-20CM, you can construct a communications system (satellite net) which

can easily send and receive an ON/OFF signal (machine information) and numerical data (production

data) between PCs and a host computer using equipment control.

Using remote I/O slave module JW-20RS, you can construct a remote I/O system as master station for

PC that installed JW-20CM.

PCs which can use JW-20CM and JW-20RS are W70H/100H, JW50/70/100, and JW50H/70H/100H.

① Data link/computer link function

This function enables to send and receive ON/OFF signals and numeric data between modules on

a network (satellite net) which is connected PCs and personal computers having network module

ZW-20CM/JW-20CM/JW-22CM, network module ZW-98CM/ZW-20AX, and satellite net board Z335J.

② Remote I/O function

If remote I/O slave module ZW-20RS/JW-20RS are mounted on I/O modules located separately,

one PC having a network module JW-20CM can control these slave modules. (Connectable

maximum 63 modules of slave stations.)

· In the remote I/O function, the remote I/O can choose either of synchronous or asynchronous for

sending and receiving data with slave stations.

Synchronous type: Slave station scans input/output operation one time for each operation of

the PC.

Asynchronous type: When PC's operation time is longer than data transfer required time of the

remote I/O, the slave station scans input/output operation one time for each

operation of the PC. When PC's operation time is shorter than the data

transfer required time of the remote I/O, the slave station operate input and

output one time for several operation of the PC.

1

③ Remote programming/remote monitor function

By constructing a satellite system using the JW-20CM, you can program and monitor other station’s

PC’s (master station’s PC in case that remote I/O function) on the satellite system using a support

tool.

· These remote programming and remote monitor functions are also available beyond one

hierarchical layer difference (satellite net ←→ satellite net, satellite net ←→ SUMINET-3200).

*“SUMINET-3200” is a trademark of Sumitomo Electric Industries, Ltd.

1·1

Page 10

Chapter 2 Safety Precautions

2-1 Installation

● Do not install or store the JW-20CM in the following conditions.

• Direct sunlight

• Ambient temperature exceeding the range of 0 to 55 ˚C (Storage temperature : -20 to 70 ˚C)

• The relative humidity exceeding the range of 35 to 90%.

• Sudden temperature changes which may cause condensation.

• Corrosive or inflammable gas

• Vibration or hard jolts

●Prior to installing or detaching the JW-20CM, make sure to turn OFF the power supply to the PCs.

● All screws must be tightened firmly.

2-2 Wiring

● Make sure to use only the recommended types (see page 6 · 1) for cables, connectors, and crimping

tools.

2

●When using connectors for branch or joint lines, provide jackets to protect connectors.

(When a connector touches with an external enclosure or the like, a communication error may occur.)

“T” jacket

(insulation cover)

“L” jacket

(insulation cover)

● Do not connect the ground terminal of the power supply module together with other equipment’s

ground lines. Make sure to provide class-3 grounding.

When the JW-20CM is used without connecting a class-3 grounding, malfunctions by noise may

occur.

● Communication cables should be arranged as far from any high voltage lines and strong power lines

as possible. Do not lay the communication cable parallel or proximate to these lines.

2·1

Page 11

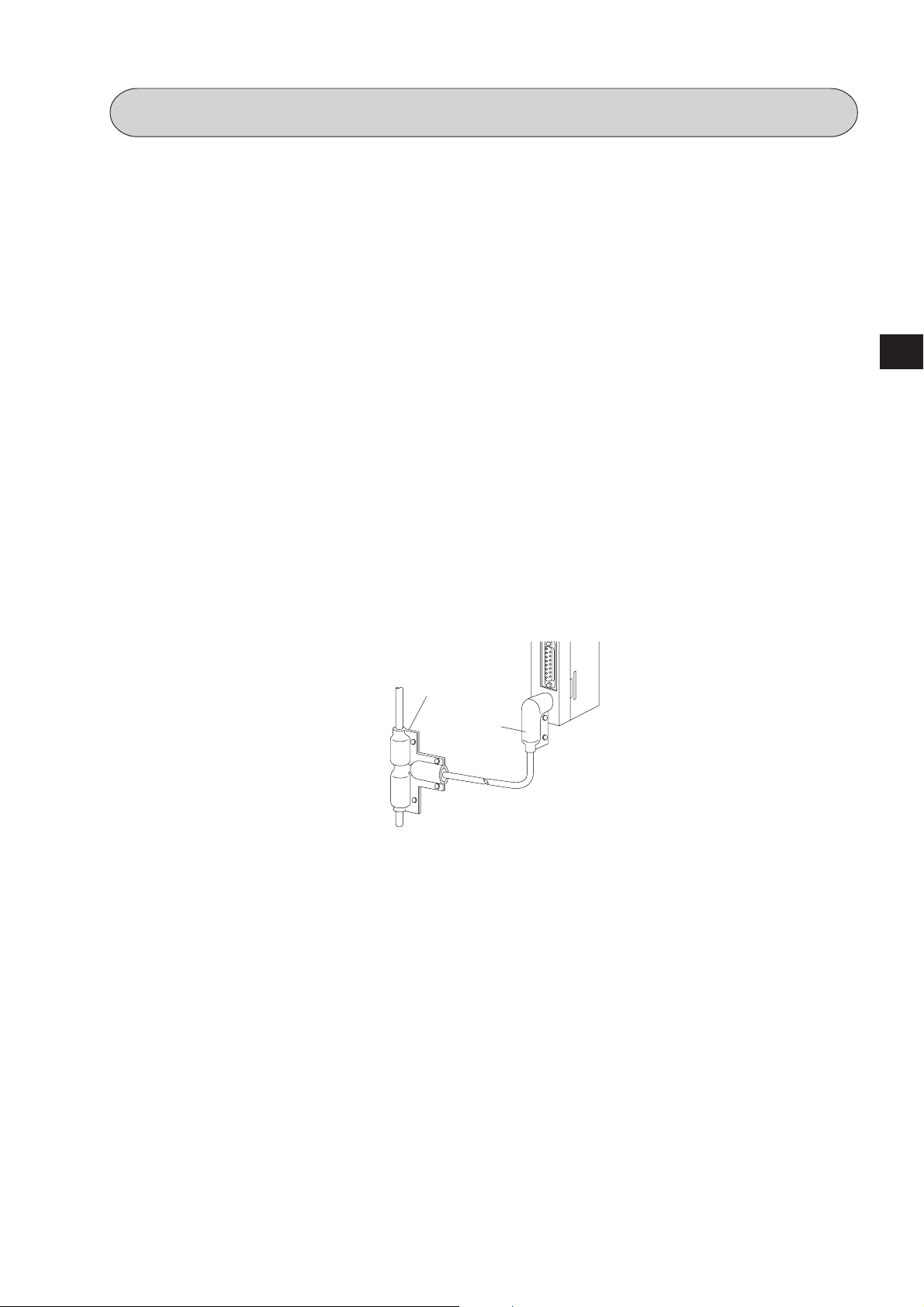

● Communication cables should be laid from the master station to the slave station one by one.

Multiple wiring from one point or wiring without terminators may cause communication errors.

Joint using a

connector

2

● Arrange total cable length within 1 km.

● Arrange branch cable line from a trunk within 400 mm.

● Prior to any electric welding around the JW-20CM, take out the coaxial cable from the JW-20CM.

While the coaxial cable is connected to the JW-20CM, any electric welding nearby the JW-20CM will

cause the welding current to enter the JW-20CM and may damage part of its circuit pattern.

JW-20CM

Turn “ON”

shield ground

FG

Note: In case enough

conductivity is not

established.

Coaxial cable

Wraparound current

Electric welder

JW-20CM

JW-20CM has a

fuse element here

Turn “ON”

shield ground

FG

Rack etc.

2·2

Page 12

2-3 Treatment

● For ventilation, holes are provided in the cabinet to prevent a temperature rise. Do not block the

ventilation holes. Good ventilation is necessary.

● Never allow a liquid such as water and chemical solution and a metallic object like a copper wire

inside the JW-20CM to avoid a possible hazard. Otherwise, it may be a cause of machine trouble.

● When a trouble or abnormal condition such as overheat, fume, or smoke is met, stop the operation

immediately, and call your dealer or our service department.

2-4 Static electricity

In extremely dry circumstances, the human body may have excessive static current. This excessive

static current may damage parts in the JW-20CM’s PC board. Therefore, prior to accessing the JW20CM, touch your hand to a grounded piece of metal to discharge the static current in your body.

2-5 Maintenance

Use a clean, dry cloth when cleaning the JW-20CM. Do not use volatile chemicals such as thinner or

alcohol as it may result in deformation and color fading.

2

2·3

Page 13

Chapter 3 System Configuration

(Example of system configuration)

Personal computer

(8)

Slave station

(8)

03

J-board

Z-335J

V5

Master station 00

JW-20CM

PC

(8)

Slave station 01

JW-20CM

PC

slave station 02

(8)

Network module

JW20

JW20H

JW30H

Slave station 77

JW-22CM

(8)

3

Data link system

Compuer link system

Slave station 01

JW-20RS

(64 stations max., Total extension length: 1km max.)

(8)

Slave station 02

(8)

ZW-20RS

Remote I/O system (slave station : 63 stations max., Total extension length: 1km max.)

“PC” indicates W70H/100H, JW50/70/100, and JW50H/70H/100H.

Slave station 77

JW-20RS

(8)

3·1

Page 14

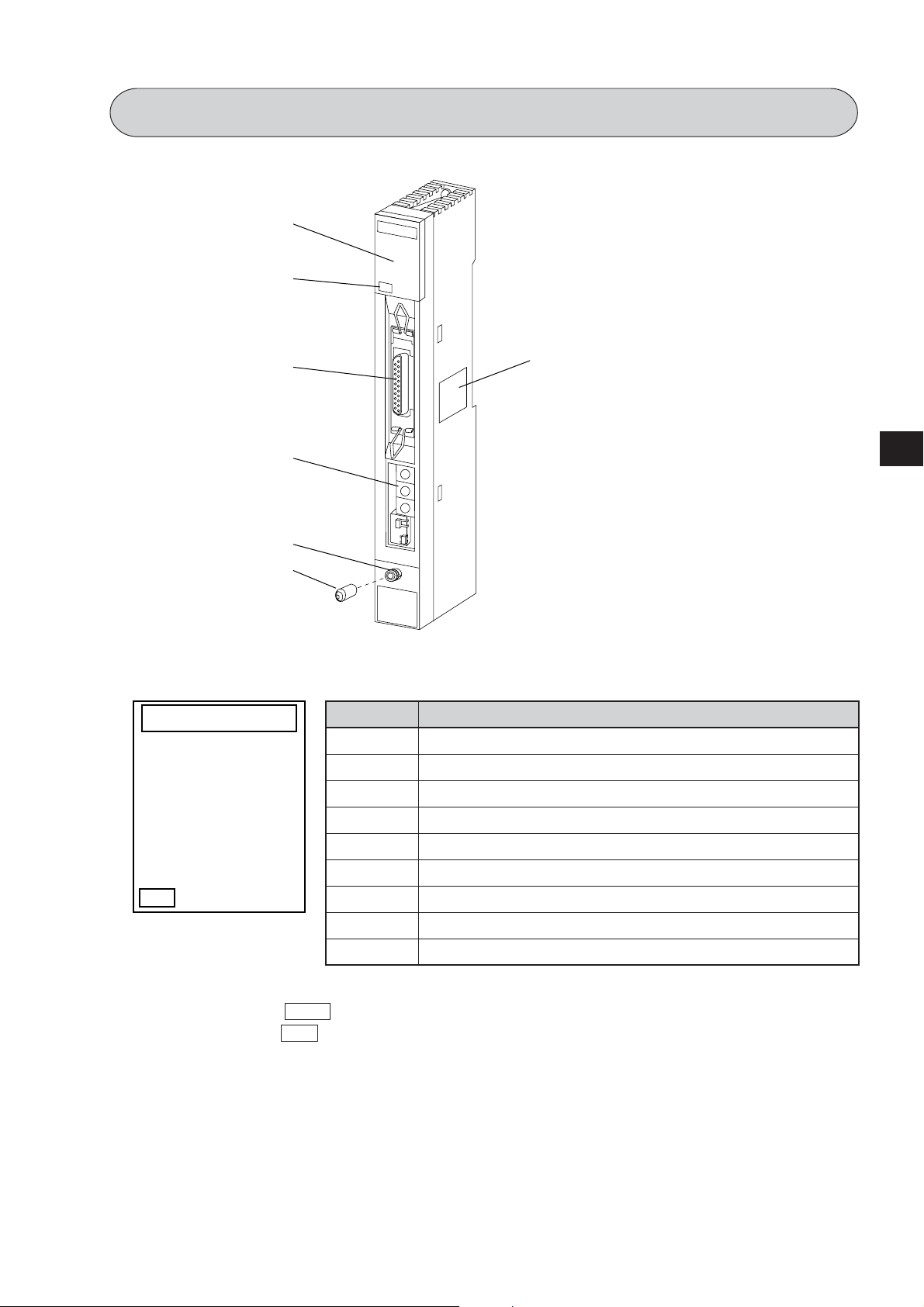

Chapter 4 Name and Function of Each Part

4-1 JW-20CM

①

②

③

④

⑤

⑥

① Indication lamps

Lamps light ON/OFF indicates operation condition.

JW–20CM

C O M M ○

S D ○

R D ○

C D ○

L T ○

T E S T ○

E R R O R ○

F A U L T ○

30Hn

○ S 0

○ S 1

○ S 2

○ S 3

○ S 4

○ S 5

○ S 6

○ S 7

emaN noitarepO

MMOCgnitacinummocgnirudsthgiL

DSgnidnesatadnehwsthgiL

DRgnivieceratadnehwsthgiL

DCreirracgnitcetednehwsthgiL

TLecnatsisernoitanimreteht"NO"gninrutnehwsthgiL

TSETgnitsetgnirudsthgiL

RORRErorrenoitacinummocatasthgiL

⑦

4

(View removing the cover on the setting section)

TLUAFremitgodhctawehtfopuemittasthgiL

0S ot 7S.sruccororrenehwedocrorresthgiL

② 30Hn mark (Applied to JW30H)

JW-20CMs having 30Hn mark can communicate with JW30H.

JW-20CMs having 30H can communicate with conventional modules of JW30H (JW-31CUH/32CUH/

33CUH). However, when they will communicate with new modules of JW30H (JW-31CUH1/32CUH1/

33CUH1/33CUH2/33CUH3), they recognizes these new modules as conventional modules.

4·1

Page 15

③ Support tool connection connector

Connect a support tool and set parameter etc.

④ Setting switch

Set functions of JW-20CM.

Set at delivery

D

C

E

B

A

F

9

0

8

MODE

STA.NO.

×10

×1

LT

(ON)

4

LG

(ON)

1

7

6

3

5

4

8

7

6

5

4

2

3

8

7

6

5

4

2

3

0

2

9

0

1

0

9

0

1

0

OFF

ON

· MODE switch .... Select functions

rebmuN noitcnuF

0yreviledtateS

1O/IetomeR

2

knilretupmoC

3

knilretupmoC

Fot4.testonoD

·S T A . N O.

××

× 10,

××

××

× 1

××

.... Set station number

)noitcnufdradnats(knilataD

)noitcnufevasyticapacyromem(knilataD

·L T .... Set ON/OFF of termination resistance

·L G .... Set shield ground ON/OFF of communication cable

⑤ Communication cable connection connector

BNC type receptacle (jack)

⑥ Connector protective cap

⑦ Rating plate

4·2

Page 16

4-2 JW-20RS

①

②

③

④

⑤

⑥

① Indication lamps

Lamps light ON/OFF indicates operation condition.

JW–20RS

C O M M ○

S D ○

R D ○

C D ○

L T ○

T E S T ○

E R R O R ○

F A U L T ○

30Hn

○ S 0

○ S 1

○ S 2

○ S 3

○ S 4

○ S 5

○ S 6

○ S 7

emaN noitarepO

MMOCgnitacinummocgnirudsthgiL

DSgnidnesatadnehwsthgiL

DRgnivieceratadnehwsthgiL

DCreirracgnitcetednehwsthgiL

TLecnatsisernoitanimreteht"NO"gninrutnehwsthgiL

TSETgnitsetgnirudsthgiL

RORRErorrenoitacinummocatasthgiL

⑦

4

TLUAFremitgodhctawehtfopuemittasthgiL

0S ot 7S.edocrorresetacidnI

② 30Hn mark (Applied to JW30H)

JW-20RSs having 30Hn mark can communicate with JW30H.

JW-20RSs having 30H can communicate with conventional modules of JW30H (JW-31CUH/32CUH/

33CUH). However, when they will communicate with new modules of JW30H (JW-31CUH1/32CUH1/

33CUH1/33CUH2/33CUH3), they recognizes these new modules as conventional modules.

4·3

Page 17

③ Support tool connection connector

Connect a support tool and set parameter etc.

④ Setting switch

Set functions of JW-20RS.

Set at delivery

D

C

E

B

A

F

9

0

8

MODE

STA.NO.

×10

×1

LT

(ON)

4

LG

(ON)

1

7

6

5

4

8

7

6

5

4

3

8

7

6

5

4

3

2

2

3

9

0

1

0

2

9

0

1

0

2

OFF

ON

· MODE switch .... Select functions

rebmuN noitcnuF

0.testonoD

1)O/I-WZ(O/IetomeR

2)O/I-WJ(O/IetomeR

Fot3.testonoD

·S T A . N O.

××

× 10,

××

××

× 1

××

.... Set station number

·L T .... Set ON/OFF of termination resistance

·L G .... Set shield ground ON/OFF of communication cable

Output hold

switch

HOLD

RST

⑤ Communication cable connection connector

BNC type receptacle (jack)

⑥ Connector protective cap

⑦ Rating plate

⑧ Output hold switch

Set the status of the output module when the JW-20RS stops operation.

Output hold

※

switch ⑧

HOLD

RST

·In case of using ZW-I/O

HOLD: Holds operation condition

RST: All points is OFF

· In case of using JW-I/O

Be sure to setting at HOLD.

Keep the switch marked with ※ as the setting at delivery (condition in the figure above).

4·4

Page 18

Chapter 5 Installation

5-1 JW-20CM

(1) Installation of cable for option module

Install the optional cable on the basic rack panel that installed JW-20CM.

emaneludomCP

H07WBK82-WZCC2-WZ

ledomWZ

H001WBK64-WZCC4/CC2-WZ

05WJBK82-WZCC2-WZ

07WJBK64-WZCC4/CC2-WZ

001WJUB4-WJCC2-WZ

ledomWJ

H05WJUB6-WJCC4/CC2-WZ

H07WJUB8-WJCC6/CC4/CC2-WZ

H001WJUB31-WJCC6/CC4/CC2-WZ

In case that install a basic rack panel JW-4BU to ZW-2CC

① Bend the optional cable

lenapkcarcisaB

emanledom

noitporofelbaC

eludom

O/IgnisurofelbaliavA

ledomWZfoeludomO/I

ledomWJfoeludomO/I

5

Basic rack panel face

Install the cable in a manner

that it may be slack towards

the rack panel.

5·1

Page 19

② Attach the connectors in the optional cable one after another, starting from the left side.

Basic rack panel

JW-4BU

Pay close attention to the

installation of the connector.

Cable for

option module

ZW-2CC

5

6 mounting screws

(Attached to cable for

option module)

5·2

Page 20

(2) Installation of JW-20CM

Attach the basic rack panel using the two attachment screws.

Before installation or removal, make sure to shut OFF the power supply to the PC.

(Example) Install on basic rack panel JW-4BU

· This module can be installed in any one of the optional slots.

· Be careful not to bend the connector pins on the module by applying too much force to them.

Module

Basic rack

panel

Phillips

screwdriver

· More than one modules of JW-20CM can be installed on one basic rack panel. However they

cannot communicate by crossing-over another network.

Unavailable

communication between

A and C.

Available communication

between A and B, B and

C, B and B, and C and C.

station

Master

A

5

Slave

station

Slave

station

Master

Station

B

C

Slave

station

C

Slave

station

Slave

station

Master

Station

B

C

Slave

station

C

· Optional slots have each port numbers. When an error occurs, the JW-20CM stores the port

number corresponding to the error occurred module into system memory #050 in the PC. This is

applied only error code 53: Optional error.

(Ex.: JW-13BU)

Control module

②③④ ⑤⑥ ⑦

▲

Port number

5·3

Page 21

5-2 JW-20RS

Choose type of basic rack panel of the remote I/O slave module (JW-20RS) considering kinds and

number of I/O modules to be installed.

seludomO/IfosdniK emanledomlenapkcaR

)seludom8rof(UB80-WZ

ledomWZfoeludomO/I

ledomWJfoeludomO/I

When I/O modules for JW model are used, maximum two modules of basic rack panel can be connected

per one remote I/O slave module. However, I/O bus expansion adapter (JW-1EA/JW-2EA) cannot be

used.

)seludom4rof(BK40-WZ

)seludom2rof(BK20-WZ

)seludom4rof(UB4-WJ

)seludom6rof(UB6-WJ

)seludom8rof(UB8-WJ

)seludom31rof(UB31-WJ

5

2 rack panel max.

5·4

Page 22

(1) Installation of power supply module

Attach the end left of rack panel using the two module attachment screws.

Module attachment screw hole

Phillips screwdriver

Output connector

5

Phillips screwdriver

Module attachment screw hole

Rack panel attachment screw

5·5

Page 23

(2) Installation of JW-20RS

Install the JW-20RS in the second slot from the left end using the two module attachment screws.

Before installation or removal, make sure to shut OFF the power supply to the PC.

Module attachment

screw hole

Power supply module

Phillips screwdriver

5

JW-20RS

5·6

Page 24

Chapter 6 Processing of Cables

Make sure to use the recommended models shown below for cables and connectors.

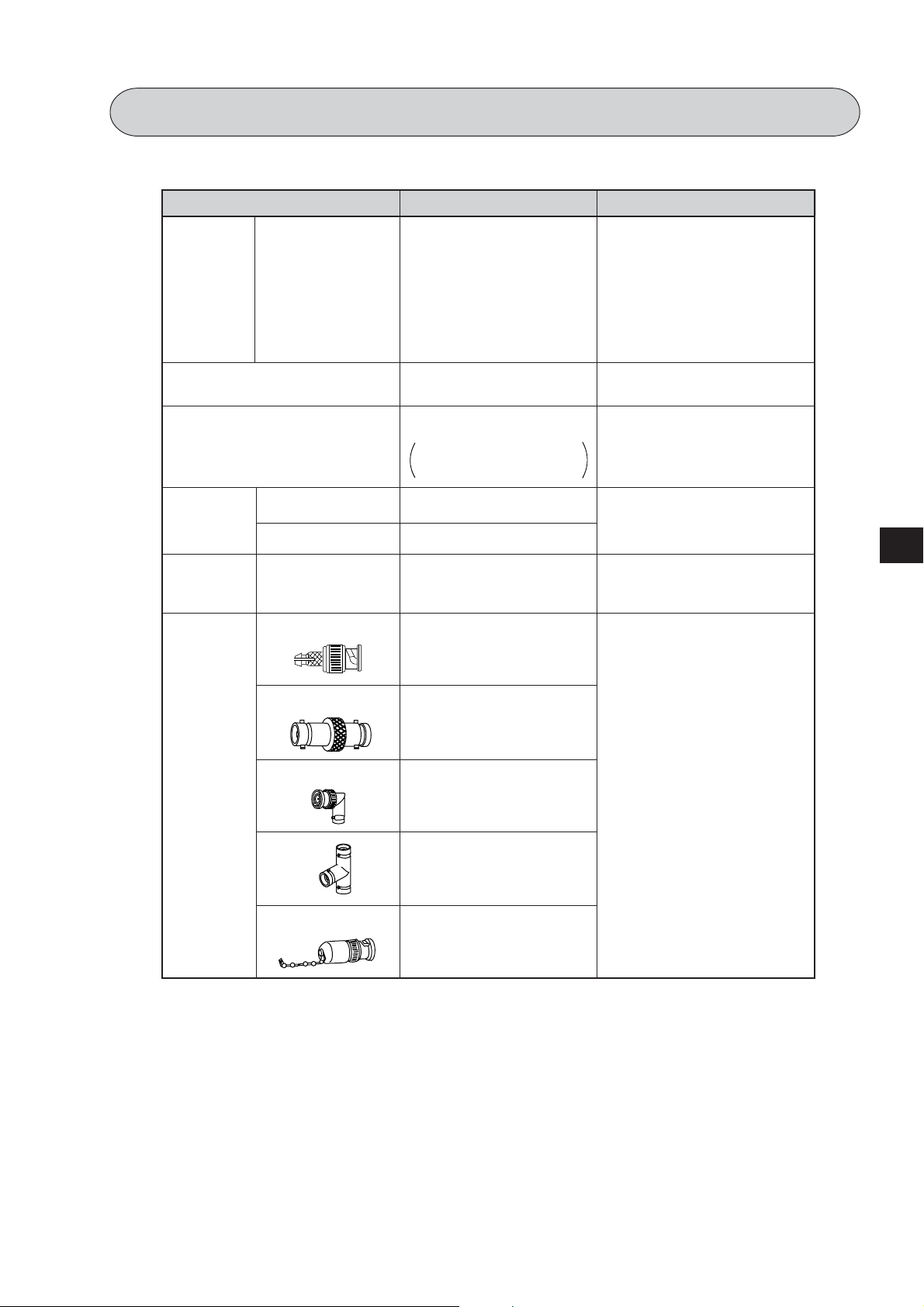

Name

Cable

Crimping tools

Stripper for high frequency

Jacket

Insulation

tape

High frequency

coaxial cable

coaxial cable

“L” jacket

“T” jacket

Self-adhesive tape

Connector

Model

ME-5C-2V

ME-42H

Dice: 67-42H

CST-TM

The system consists of the

main body, a blade cassette,

and a blade setting gauge

SB-2878

SB-2879

NO.11

ME-GP-01

Maker

Mitsubishi Cable

Industries,. Ltd.

Fujikura Cable,. Ltd.

Furukawa Denko

Corporation

Chugoku Cable,. Ltd.

Shinagawa Cable,. Ltd.

Toko Denshi Corporation

Nihon Weidmüller

Co., Ltd.

Shinagawa Shoko

Co., Ltd.

6

Nitto Denko

Corporation

Connectors

Straight

Elbow

T’s

Termination

ME-JJ-01

Toko Denshi Corporation

ME-LA-01

DDK Ltd.

ME-TA-01

ME-75

6·1

Page 25

6-1 Processing cable end

① Applicable cable

High frequency coaxial cable: ME-5C-2V

② Required tools

Stripper for high frequency coaxial cable: CST-TM

③ Processing procedure

<Basic operation>

Move the cam wheel of the stripper (amber colored

Cable holder

ring) back and forth and the cable holder moves back

and forth accordingly. Confirm this movement of the

stripper first.

To hold the stripper, put your forefinger through the

hole and move the cam while pushing back and forth

with your thumb.

<Pressure setting>

Set the operation range of the cable holder by moving

6

the slider at the bottom of the body. Move to the left

to increase pressure.

Blade cassette

In this example, set the slider to the cam wheel side’s

end (right side) to set the pressure to low.

Front

Blade (slashed area)

Cam wheel

Rear

<Adjustment of blade cutting depth>

Adjust the cutting depth of the blade by turning the

two screws at both ends of the screw holder. Set

the blade position to within 1 mm from the cutting

surface of the blade cassette prior to adjusting the

cutting depth. For the cutting depth adjustment, use

the “blade setting gauge” supplied as an accessory

and match the blade position with the caved position

of the gauge. Then move the cam wheel forward

and secure firmly. Turn right lightly both adjustment

screws at either end of the screw holder for

adjustment. (Be careful not to break the blade setting

gauge as it is made of aluminum.)

(Fine adjustment is required to get the

optimum cutting depth.)

To the next page

Left

Slider

Screw holder

Within 1 mm

Set the blade to within

1 mm in order not to

damage the blade by

the blade setting gauge.

Cam wheel

Right

Blade setting gauge

6·2

Page 26

Coating

(black)

External conductor

(meshed annealed copper wire)

From the previous page

<Cutting of coating, external conductor,

and insulator>

Put a coaxial cable while remaining approximately 10 mm into

the cable stripper and securely tighten the cable with the middle

finger, ring finger, and little finger of your left hand in order to

hold stable during turning the stripper.

Put your right hand forefinger into the cam wheel and execute

the procedure in order from step 1 below.

Internal conductor

(annealed copper single wire)

Insulator

(semi-transparent)

While holding the coaxial cable with your left hand, grip the

cable stripper so that it keeps a right angle against the coaxial

cable, and press out the cable stripper with your left hand’s

thumb.

When the adjustment

of the blade is not

required

Step 1

Press the cam wheel forward 3 times and turn

the stripper in the direction of arrow 2 to 3

times.

Step 2

Press the cam wheel forward 1 time and then

turn the stripper in the direction of arrow a

further 2 to 3 times.

Step 3

Press the cam wheel forward 1 more time and

turn the stripper in the direction of the arrow

another 2 to 3 times.

<Removal of coating, external conductor,

and insulator>

If the stripper cannot be removed smoothly,

adjustment of the blade is not appropriate. In this

case slide the cam wheel backward and remove

the coaxial cable. Then adjust the blade.

10

mm

6

<Fine adjustment of blade cutting depth>

When the cutting depth is too shallow or too deep, and

damages the external conductor or the internal conductor, turn

the screws on the screw holder and adjust the blade depth a

little.

To the next page

6·3

Page 27

From the previous page

<Display of blade setting>

We recommend that in order to keep the adjusted

position of the adjustment screws, after completion

of adjustment for the coaxial cable and the screw

holder, write the screw position etc. on a sticker

and adhere it to the adjustment screws.

K

A

E

C

A

A

D

A

A

D

F

S

F

G

H

H

G

KADAEA

KEDAADFS

<Replacement of blades>

Hold up the upper section of the screw holder with

Blade cassette

a minus driver, and open the screw holder.

Remove the blade cassette and reinsert by turning

the current blade back side front or insert a new

blade cassette from its top.

Screw holder

6

<Processing of cable end>

Cut the internal conductor of the coaxial cable,

which is already cut by the stripper, using a nipper

etc. to the optimum dimension of 4 mm.

10 mm±0.5 mm

BA

A: 10±0.5 mm

B: 4±0.5 mm

6·4

Page 28

6-2 Connector crimping procedure

9

.

1

.

TT-237

TT

237

① Required tools: Hand-held crimping tool

Model

Dice No.

Crimping width

: ME-42H

: 67-42H

: 10 mm

② Connector: ME-GP-01

③ Processing procedure

<Insert a sleeve>

Put through a sleeve to an end-processed high

frequency coaxial cable.

<Crimping contact>

Insert a contact into the internal conductor and crimp.

Sleeve

Connector parts

Contact

A: 10±0.5 mm

B: 4±0.5 mm

Shell

A

Sleeve

B

6

Put a contact into dice having a

diamond shape and closely stick its

end surface with the insulator and the

dice. Pull the moving frame to the

fixing frame side and crimp until the

ratchet is removed.

(Crimping width: 2.2 mm)

Widen a little

Crimp

Dice blade shape

2.2 mm

Closed contact

* Use the crimping tool in the direction

shown in the illustration right.

Using the crimping tool in the reverse

direction will not crimp correctly.

Internal conductor

Crimping dice

Moving frame

Insulator

Crimping dice

-

TT

237

9

.

.

1

Contact

Fixing frame

Contact

Closed

contact

To the next page

6·5

Page 29

From the previous page

TT

237

<Fixing the connector>

Slightly widen the external conductor of the

coaxial cable, which is crimped to a contact on

the internal conductor, in order to smoothly enter

the shell inside the external conductor. Press in

the external conductor end of the coaxial cable

to just before the crimping part of the shell and

put the sleeve into the crimping section. Then

press in the coaxial cable until a “click” sound

can be heard. Confirm that the contact end point

touches your finger cushion.

Widen a little

Sleeve

Shell

Crimping section

Finger

<Crimping external conductor>

Crimp the external conductor.

Completely put into

the crimping section.

Insert thoroughly the sleeve into the

crimping section of the shell and crimp.

Put the sleeve in the hexagonal dice

and closely stick the shell to the

crimping dice. Pull the moving frame

6

to the fixing frame side while pressing

the coaxial cable and shell from both

10

Dice blade shape

sides, and crimp until the ratchet is

removed.

(Crimping width: 10 mm)

Dice blade shape

looking from this side

Crimping dice

Push

Closed contact

* Use the crimping tool in the direction

shown in the illustration right.

Using the crimping tool in the reverse

direction will not crimp correctly.

-

TT

237

9

.

.

1

Insulation test of shell and contact

Using a tester, check the conductivity

between the internal conductor and

the external conductor in the

connector. When the indication of

the tester shows ∞ ohms, the

insulation is appropriate.

Conductivity test

After short-circuiting the one end

of the connector crimped to the

coaxial cable, check that

conductivity is attained.

<Insulation test>

<Conductivity test>

6·6

Page 30

Chapter 7 Wiring

7-1 Cable trunk and branch lines

① On the illustration of the cable wiring below, a bold line means a trunk and the thin lines branched

from the trunk with a “T” shape are called branch lines.

Branch line

400 mm max.

Trunk cable

② The length of branch lines branched from the trunk should be within 400 mm.

400

mm

③ Total cable length should be within 1 km.

Branch line

Trunk cable

7-2 Relaying of trunk cables

① To relay trunk cables, use the straight joint (ME-JJ-01).

ME-JJ-01

② Relaying of trunk cables should be limited to indispensable cases only. Inadvertent relaying of

trunk cables may cause a communication fault such as a weakened signal level due to contact

resistance in the junction connector (straight).

7

Junction

Junction

7·1

Page 31

7-3 Cable wiring procedure in control panel

[1] Fixing of the cable

In order not to put any force on the cable and the

JW-20CM, fasten the cable to an line nearby input

of a control panel or a “T” branch point to the JW20CM using saddles etc.

[2] Extra length of cable

Provide an extra length of the cable of 2 to 3 m

inside a control panel for easier processing of the

cable end and easier wiring when changing module

positions.

Saddle

JW-20CM

Saddle

Anextralengthof

cableof2to3m

[3] Connection to the JW-20CM

The connector to the JW-20CM should be turned

Communication cable

connection connector

right to secure locking, not merely inserted.

7

[4] Insulation cover

When the connector touches with a high voltage

section or external enclosures, communication

errors may occur. Make sure to install an insulation

cover.

“T” jacket

(insulation cover)

“L” jacket

(insulation cover)

7·2

Page 32

[5] Grounding of power supply module

Make sure to connect the GND terminal of the power supply module to a class-3 grounding.

• If the power supply module is not grounded, the JW-20CM cannot conduct with the ground after

turning “ON” the shield ground switch.

In case of AC power supply module (JW-1PU)

Power supply module (JW-1PU)

SHORT

Class-3

grounding

200 VAC

SHORT

100 VAC

INPUT

AC/AC

100V 200V

GND

HALT

OUTPUT

Detail of the terminal block

Input power voltage

switching terminal

Power input

terminal

GND (ground)

terminal

Halt signal

output terminal

7

7·3

Page 33

7-4 Waterproof and insulation processing of connectors

In order to prevent water intrusion into the “T” branch connectors and the straight connectors, we

recommend to wind a self-adhesive tape and provide waterproof processing for them. For insulation

purposes, cover these connectors with jackets.

[1] “T” branch connector

To wind a self-adhesive tape, cut the tape at about 10 cm each and start winding from position ①.

Start winding cut tapes from ② and ③ as well.

②

①

T’s

7

[2] Straight connector

To wind the self-adhesive tape, cut the tape at about 15 cm each and start winding from position ① .

①

Self-adhesive tape

③

Self-adhesive tape

Straight

Remarks

Prior to adhering the tape, clean the surface of the connectors and stick the adhesive side of

the tape on the connector surface. Wind to lightly spread on the connector surface, and overlap

with the next wrap to half of the tape width. Wind the tape for each wrap evenly so that the

connector metal portion is completely covered with the tape.

Be careful not to excessively stretch the tape.

7·4

Page 34

7-5 Wiring of cables at outside control panels

① Do not bundle the coaxial cable (the trunk and branch lines) together with power cables, and

separate from power cables at least by 100 mm. Do not put the coaxial cable into a power line wired

duct. The best way is to put the communication line in an independent duct.

② Be careful that the coaxial cable does not receive any load by laying under a heavy weight such as

other cables.

When other cables run in the same duct as the coaxial cable, run the coaxial cable on the top

position.

③ Do not run the coaxial cable outdoors as it may cause damage to the JW-20CM due to inductive

lightning or atmospheric charge during lightning.

7-6 Check after wiring

Check the items below after completion of wiring.

1

The recommended connector types are used.

2

The connectors are securely locked.

3

The connectors are insulated by T jacket or L jacket.

4

The recommended coaxial cable type is used.

5

Curved radius of the coaxial cables are more than 45 mm.

6

No heavy load is on the coaxial cables.

The coaxial cable is not bundled with a power line cable.

7

(Away from power line cables more than 100 mm.)

8

Length of branch lines is shorter than 400 mm.

9

Total length of the cable is less than 1 km.

Settings of the termination resistance switch and the shield ground switch are as per

10

the drawings.

Check contents

7

7·5

Page 35

7-7 Wiring method for adding a communication station

[1] Branching method

When branching a line for an additional station, be sure to branch from the trunk using a T connector.

Never branch from a branch line.

Station number

(8)

Station number

(8)

0 2

Station number

(8)

0 3

Station number

(8)

0 2

0 6

Trunk

cable

Station number

(8)

0 3

Trunk

cable

Branch

line

Addition

Station number

(8)

0 2

Station number

(8)

0 6

Junction

Station number

0 3

(8)

Branch line

[2] Station number of the additional station

Station number of the newly added station should be next largest number from the current largest

7

numbered station. Each station should not be required to be arranged in order of each station’s

number.

01(8)

02(8)

03(8)

04(8)00(8)

05(8)

Addition

Sequential number

00(8)

01(8)

02(8)

03(8)06(8)

means the termination resistance switch being turned “ON.”

7·6

04(8)

05(8)

Page 36

[3] Notes

When adding a communication station, follow the items below.

Item No.

Branch from the trunk cable.

1

Don’t use the same station number

2

twice.

Check the termination resistance

3

switch.

Provide extra length for the

4

expansion cable.

Do not exceed the 1 km limit for total

5

length of the cable.

Change the layout drawing for

6

installation.

Do not overlap with any PC’s

7

communication area.

Set the parameter memory of the

master station and that of the newly

8

added station.

Reason

Another branch line from a branch line may not give

appropriate communication by reflection wave.

The use of the same station number twice may cause

communication errors.

When the newly added station becomes a termination of

the circuit, change the setting of the LT switch.

Have enough cable length in order to provide easy wiring.

Longer wiring may cause communication error by signal

attenuation.

Maintain the added work data for future maintenance use.

When the communication area or the flag area of the

added station overlaps with other addresses in use,

communication errors may occur.

Without setting the parameter memory of the master

station and that of the slave station, the added station

cannot communicate.

7

7·7

Page 37

7-8 Wiring to power supply module

[1] JW-1PU

· Open the terminal block cover, fasten with the screw with torque of less than 12kg·cm.

·A maximum of three halt output lines can be connected serial. To use more than three sets, use

a relay for interconnection.

In case of 100 VAC input

In case of 100 VAC input

Terminal block cover

SHORT

200 VAC

SHORT

100 VAC

100 VAC

or 200 VAC

DC relay

The coil rating must conform to the power supply voltage.

7

In case of using DC output module, connect the AC relay in the halt output line and insert the

INPUT

GND

halt output

line

1

2

3

4

5

6

7

8

Terminal block

cover

contact with the emergency stop circuit.

In case of 200 VAC input

· In case of using 200 VAC, switched to the 200 V side in terminal block of power supply module.

· If 200 V is added with the clip connected to the 100 V side, it may damage the power supply

module.

In case of 100 VAC input

200 VAC

input

SHORT

200 VAC

SHORT

100 VAC

GND

1

2

3

4

5

6

71A

SSR

8

Halt output internal circuit

7·8

Page 38

[2] JW-2PU

· Open the terminal block cover, fasten with the screw with torque of less than 12kg·cm.

· Halt output lines can not be connected serial. To use more than two sets, use a relay for

interconnec-tion.

Terminal block

1

2

3

4

5

6

cover

Terminal block

cover

In case of 24 VDC input

Do not use.

INPUT

24 VDC

GND

-

+

DC relay

The coil rating must conform to the power supply voltage.

Halt output

line

7

8

Connect the DC relay in the halt output line and insert the contact with the emergency stop

circuit.

Remarks

留意点

· Connect without confusing polarities of input power supply and halt output signal.

· Wrong polarity connection may damage the power supply module when charged.

7

1A

8

Halt output internal circuit

7

7·9

Page 39

Chapter 8 Remote I/O

8-1 Description of remote I/O

· If remote I/O slave module JW-20RS is installed on I/O modules located separately, one PC (master

station) having a network module JW-20CM can control these I/O modules.

· Connect between a master station JW-20CM and slave station JW-20RS using one coaxial cable. As

the network module JW-20CM and remote I/O slave module JW-20RS control communication, there is

no need any special program for the PC.

· More than one master stations can be mounted on one PC.

· Maximum 63 modules of slave stations can be connected within the cable total extension length 1 km.

· If a JW model PC has a master station, it can connect with stave stations having JW model I/O modules

and slave stations having ZW model I/O modules. However, mixed installation of JW and ZW model

I/O modules on one slave station is not available.

If a master station is installed on a ZW model PC, it can connect only with slave stations

[]

having ZW model I/O modules.

Master staion 00

JW-20CM

PC

(8)

Slave staion 01

JW-20RS

(JW-I/O)

Slave staion 02

(8)

ZW-20RS

(8)

Slave staion 77

JW-20RS

(JW-I/O)(JW-I/O)

(Slave station : 63 stations max., cable total extension length : 1km max.)

(8)

8

8·1

Page 40

·Rack panel can use 2 sets max. per slave station. But, unavailable for use I/O bus expansion adapter

(JW-1EA,JW-2EA).

2 rack panels max.

· Special I/O module of JW model has the following limitation for number of modules to be used.

noitatsevalsO/IetomerreP

noitatsevalsO/IetomerllA

emaneludoM emanledoM setybdeipuccoforebmuN

tupnigolanADA8-WJsetyb63

tuptuogolanAAD2-WJsetyb8

retnuocdeeps-hgiHCH2-WJsetyb8

noitatsretsamknilO/IML13-WJsetyb46ot2

eludomlortnocDI

8

· Allocation of number of I/O points per remote I/O slave station have “fixed allocation” and “manual

allocation.”

noitacollA

dohtem

dexiF

·rostniop46yreverofetacollA

noitacolla

·

·

launaM

noitacolla

eludomgninoitisoPMP21-WJsetyb61

stniop821

UD11-WJ

UD21-WJ

stnetnoC

4201ot8neewtebetacollA

tinutniop8nistniop

evalselbatcennocforebmuN

forebmunlatotdnasnoitats

36,detimilerastniopO/I

tastniop6904dnasnoitats

tonodluferaceb,mumixam

.snotiatimilesehtdeecxe

eludomO/IlaicepsfolatoT.xamseludom8

eludomO/IlaicepsfosetybforebmunlatoT.xamsetyb821

eludomO/IlaicepsfolatoT.xamseludom23

eludomO/IlaicepsfosetybforebmunlatoT.xamsetyb215

setyb46mumixaM

O/IforebmuN

noitatsrepstniop

stniop46snoitats36

stniop821snoitats23

)1elpmaxE(

stniop46foesacnI

)2elpmaxE(

4201foesacnI

stniop

snoitats36

snoitats4

rofelbaliavA

rebmundetcennoc

snoitatsevalsfo

rebmunlatoT

stniopO/Ifo

stniop2304

)setyb405(

stniop6904

)setyb215(

stniop6904

)setyb215(

stniop6904

)setyb215(

8·2

Page 41

8-2 Data transfer required time and communication timing

(1) Required time for data transfer

Time required for a master station to communicate with all the slave stations is determined by number

of connected stations and number of points of all slave stations, as well as number of data bytes of

JW model special I/O modules.

(N + 136 x P) x 2

T = + 1.4P + 5.3 + 2.5 (P + 1) + α [ms]

1250 : Baud rate; 1.25 M bit/sec.

1.4P + 5.3 : Data processing time of the master station

1250

N : Total number of data bytes of all the slave station’s I/O model and JW model special I/O

modules (value to be calculated by number of bytes ×8 points)

P : Number of slave stations

136 : Use 136 bits for station address on the communication format and error check function.

2.5 : Total sequential send processing of the communication stations.

α : Communication time at executing remote program/remote monitor.

Remarks

· If "synchronous" is selected, one scan cycle time of a PC will vary with change of transfer

required time.

· Number of data bytes on the JW model special I/O module is a value set in parameter

address 000600 to 000777

on the master station.

(8)

8

8·3

Page 42

(2) Communication timing

· For communication with slave stations, either of "synchronous" and "asynchronous" can be selected

for operation with the master station PC.

· When "synchronous" is selected, the JW-20CM communicates with synchronize with operation (one

scan) of the master station PC.

· When "asynchronous" is selected, the JW-20CM communicates with slave stations regardless of

operation of the master station PC. Therefore, even if communication of all stave stations is not

completed, the JW-20CM starts data exchange with the master station and PC.

Communication control port

S

I

O

Modem

Communication lines

Processing of JW-20CM

JW-20CM

RAM

Communication

control

CPU

Bus/interface port

ROMROM

CTCCTC

RAMRAM

Interface

CPU

SIO

Processing of PC side

Check PC

hardware

Zero-cross

synchronization

Buffer

memory

Bus bonding

PC

Data

memory

8

I/O processing

NO

Data exchange with

data memory

Remote

communication

complete?

Data exchange with

remote I/O master

YES

station RAM

Remote I/O

communication processing

NO

Communication

complete?

YES

PC operation

Remarks

The slave station will not performs the zero-cross operation even if the master station PC is

“set zero-cross (zero-cross switch 07367 at OFF)”.

8·4

Page 43

① Operational synchronous

When more than one JW-20CM is installed while using the remote I/O function, set only one module

as “operational synchronous.” When a link module ZW-10CM or JW-10CM is used for remote I/O, the

JW-20CM should be set as “operational asynchronous.”

a. When operation interval (one scan) of the master station PC is longer than data transfer

time of the remote I/O:

I/O processing

at PC side

PC scan cycle

Data exchange with the buffer memory

I/O processing at PC side

PC operation time

Remote I/O data

transfer processing

Remote I/O data

transfer processing

b. When operation interval (one scan) of the master station PC is shorter than data transfer

time of the remote I/O:

I/O processing at PC side

PC scan cycle

Data exchange with the buffer memory

I/O processing at PC side

PC operation time

Remote I/O data transfer processing

Waiting time

※ A waiting time is provided after the PC process to match with end timing of the data transfer

process of the remote I/O so that the remote I/O can synchronize with the PC scan cycle.

8

② Operational asynchronous

The special I/O module can not be used with the remote I/O slave module as the special I/O module

cannot synchronize with the master station PC for data exchange.

a. When operation interval (one scan) of the master station PC is longer than data transfer

time of the remote I/O:

Same as operational synchronous above.

b. When operation interval (one scan) of the master station PC is shorter than data transfer

time of the remote I/O:

I/O processing

at PC side

PC scan cycle

Remote I/O data transfer processing Remote I/O data transfer processing

Data exchange with the buffer memory

I/O processing at PC side

PC operation time PC operation time

PC operation time

8·5

Page 44

(2) Data flow with slave module

I/O processing of the slave module shall be carried out after completion of communication with the

master station.

Slave station 1 Slave station 2

子局1

ZW-20RSI/Oユニット

I/O moduleJW-20RS

I/O処理

I/O processing

I/O processing

I/O処理

I/O processing

I/O処理

Input signal

入力信号

子局2

ZW-20RSI/Oユニット

I/O moduleJW-20RS

I/O processing

I/O処理

Output signal

出力信号

I/O processing

I/O処理

I/O処理

I/O processing

データ交換

Data exchange

I/O processing

I/O処理

データ交換

Data exchange

I/O processing

I/O処理

データ交換

Data exchange

Master station

親局

PCZW-20CM

PC JW-20CM

Communication

子局1との通信

with slave station 1

Communication

with slave station 2

子局2との通信

Communication

with slave station 1

子局1との通信

Communication

with slave station 2

子局2との通信

8

8·6

Page 45

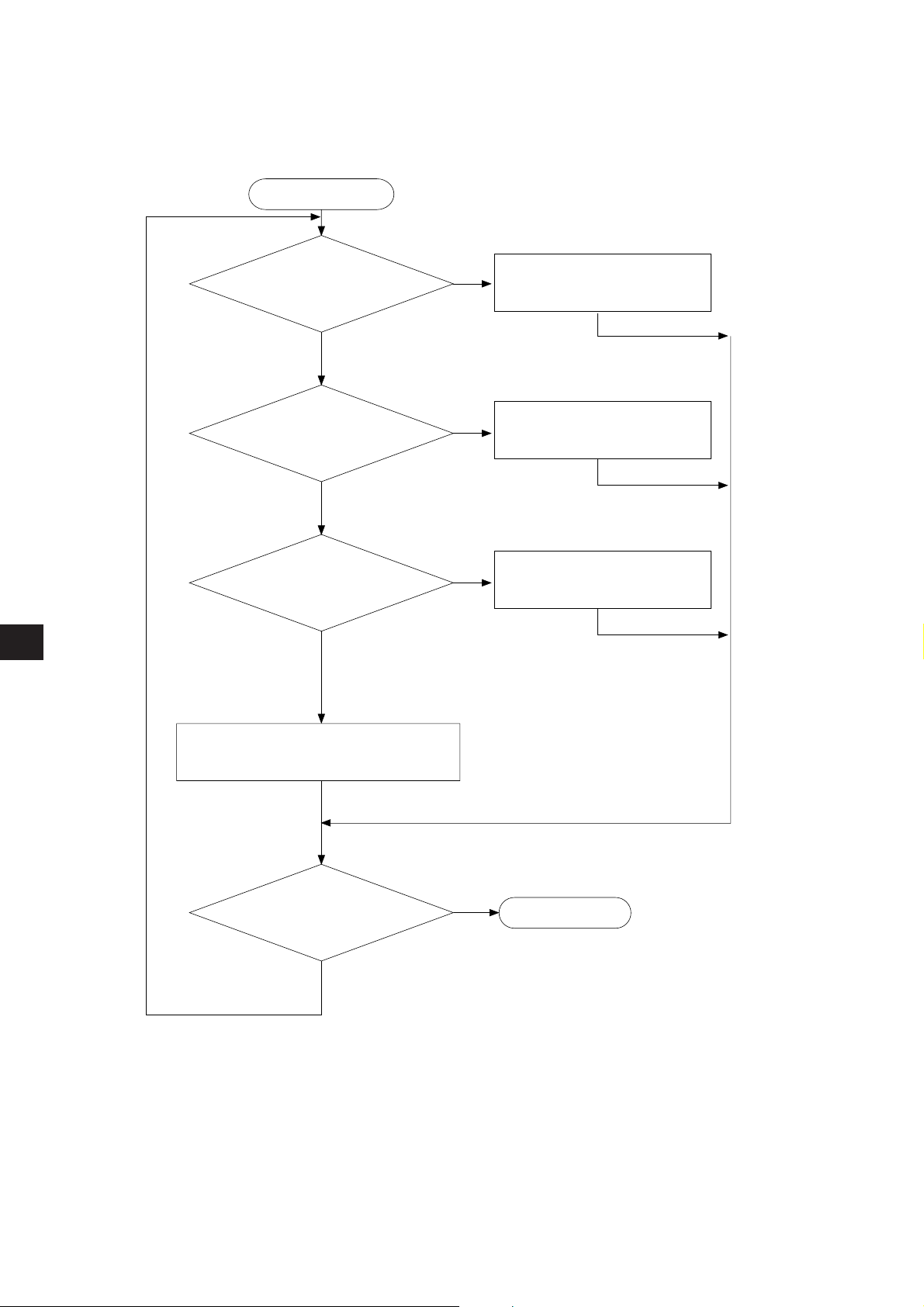

(4) Voltage interruption time of slave module

The voltage interruption operation of slave module is carried out for service interruption signal (PF

signal) of power supply module, watchdog timer of slave module, and check 5 V power regardless of

setting voltage interruption time (#246) of master module.

Start

RST

Yes

No

· The PF signal of the power supply module goes “OFF” below

85% of the rated voltage.

· The watchdog timer of the slave module goes time-up in “320

ms.”

· When output hold switch is “RST,” the all halt output and output

module become “OFF” when communication with master station

have interruption of 320 ms.

No

PF signal OFF

Communicating

at remote I/O

I/O processing of I/O module

Yes

Yes

Output hold

Watchdog timer

5V power 4.5V max.

Halt output “open”

All output module “OFF”

No

switch

No

time-up

No

Yes

End

· When the check of 5 V power is gone below 4.5 V, all are forced to reset. The power supply characteristics

varies according to the consumption current of the power supply module as following diagrams.

120

100

80

Hold time [ms]

60

40

20

0

85V/170V

Output hold time

5.1V,7A load

(ZW-1PU)

5.1V,5A load

(ZW-2PU)

100V/200V 120V/240V 132V/264V

AC input voltage

280

240

200

Hold time [ms]

160

120

80

40

Output hold time

100 VAC 50H input

(ZW-1PU)

24 VDC input

(ZW-2PU)

8

20V 24V 28V 32V

DC input voltage

8·7

0

7654321

Load current [A]

Page 46

8-3 Outline of switch and parameter setting procedure

In brackets: See page

Start

Power “OFF” master/slave station

Set switch of master module

Set switch of slave module

Set parameter of slave module

Set parameter of master module

End

[8·9]

[8·14]

[8·19]

[8·30]

Remarks

8

· Make sure to turn “OFF” the power of the PC prior to setting the switch.

· Parameter must be started from the slave module first.

· Prior to setting the parameters of master module, set the operation mode of the JW-20CM

to “program mode.”

·Make sure to write the set parameters into the EEPROM on the JW-20CM after setting.

8·8

Page 47

(1) Switch setting of master module (JW-20CM)

Operation procedure

Power “OFF” master/slave station

In brackets: See page

Start

Remove the setting switch cover.

Set MODE (function) switch

Set STA. NO. (station number) switch

Set LT (termination resistance) switch

Set LG (shield ground) switch

Attach label

End

[8·10]

[8·10]

[8·10]

[8·11]

[8·12]

8

[8·13]

8·9

Page 48

Turn master module and slave module

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

STA.NO.

X10

X1

power “OFF.”

Remove the setting switch cover of master

module JW-20CM.

·With your fingertips over the top and bottom

of the switch cover, pull the cover towards

you to remove it.

· Keep the cover saved as it must be installed

after switch setting.

Set MODE (function) switch

· Be sure to setting “1.”

eulavgnitteS noitcnuF

D

C

E

B

A

0yreviledtateS

1O/IetomeR

MODE

F

9

0

8

1

7

2

6

3

5

4

dradnats(knilataD

2

)noitcnuf

knilretupmoC

yromem(knilataD

8

3

)noitcnufevasyticapac

knilretupmoC

edomtseT

F-4

esulliwnamecivresA

rofsehctiwseseht

.tnemtsujda

Do not set “4 to F.”

Set STA. NO. (station number) switch

· Set the station address to “00.”

To the next page

8·10

Page 49

From the previous page

Set LT (termination resistance) switch

• When a JW-20CM master module is at either

end the communication line, make sure to

set the termination resistance switch "ON."

Turn ON the termination resistance

switches on these two stations.

Reference: Function of the termination resistance switch

If the communication line does not have a termination resistance, the high frequency signal will

be reflected at the ends of the cable. These reflected signals can collide with the original

communication signals, so that some stations will not be able to communicate normally. The

use of termination resistance suppresses reflected signals. If the termination resistance switch

on any of the stations in between the end of the cable is turned ON, the station will generate a

reflection wave signal or attenuate the original signal and may not communicate normally.

LT

(ON)

LG

(ON)

· When the trunk line has a branch in it, turn ON the termination resistance at the station on the

trunk cable.

Termination

resistance (ON)

Trunk cable

Drop cable

(branch line should

be less than 400 mm)

"T" branch

· If you use a terminator (termination resistance made by Toko Denshi: ME-75) at the end of a

signal cable, turn OFF the termination resistance at the station on the end of the cable.

TerminatorTerminator

Less than 1 km

Terminator: ME-75

8

To the next page

8·11

Page 50

From the previous page

Set LG (shield ground) switch

· For communication lines, use a coaxial cable.

· As coaxial cable is an unbalanced circuit,

ground its shield by turning “ON” the shield

ground switch.

LT

(ON)

LG

(ON)

Turn “ON” shield ground

switch

Coaxial cable

Turn “ON” shield ground

switch

• Make sure to provide a class-3 grounding for the GND terminal of the power supply module.

Without grounding the power supply module, the JW-20CM cannot become conductive with the

ground after turning “ON” the shield ground switch. (See page 7·2.)

• Prior to any electric welding around the JW-20CM, take out the coaxial cable from the JW-20CM.

While the coaxial cable is connected to the JW-20CM, any electric welding nearby the JW-20CM

will cause the welding current to the JW-20CM and may damage part of its circuit pattern.

8

Note: In case enough

JW-20CM

Turn “ON” shield

ground switch

conductivity is not

established.

FG

Coaxial cable

Wrap around current

Note:

Electric welder

JW-20CM

JW-20CM has a fuse element here.

Turn “ON” shield

ground switch

Rack etc.

To the next page

8·12

Page 51

From the previous page

LINK FUNCTION

REMOTE I/O

MASTER

STATION NO.

FIX

Attach label

· Attach the remote I/O master station label to

this module, make setting “remote I/O master

station function” clear.

·Write “FIX” on this label.

Switch setting end of master module

8

8·13

Page 52

(2) Switch setting of slave module (JW-20RS)

Operation procedure All slave module in common for setting method

Start

Power “OFF” master/slave station

In brackets: See page

Set output hold switch

Remove the setting switch cover.

Set MODE (function) switch

Set STA. NO. (station number) switch

8

Set LT (termination resistance) switch

Set LG (shield ground) switch

Attach label

[8·15]

[8·15]

[8·15]

[8·16]

[8·16]

[8·17]

[8·18]

End

8·14

Page 53

Power “OFF” master/slave station

Output hold

※2

switch

Set output hold switch

HOLD

RST

· Set this switch whether to "latch" or "turn OFF

all points" of output circuits when the slave

module JW-20RS stops operation.

· In case of using I/O module of JW model, be

sure to setting “HOLD”.

gnitteshctiwS stnetnoC

O/IgnisufoesacnI

ledomWZfoeludom

O/IgnisufoesacnI

ledomWJfoeludom

DLOH"dloH"

※1

TSR

DLOH"dloh"tagnitteS

"FFOstniopllA"

Keep *2 switch above as

[

delivered condition.

※ 1 When the slave module JW-20RS stopped, the halt output turns “open” and output module

sets “all points OFF”. (See page 8·50).

Remove the setting switch cover of master

module JW-20RS.

]

· With your fingertips over the top and bottom

of the switch cover, pull the cover towards

you to remove it.

· Keep the cover saved as it must be installed

after switch setting.

Set MODE (function) switch

D

C

E

B

A

· Select the model of I/O module that installed

on respective slave module.

MODE

F

9

0

8

1

7

2

6

3

5

4

eulavgnitteS eludomO/IfoledoM

1ledomWZfoeludomO/I

2ledomWJfoeludomO/I

The mode switch is set to “2” at delivery.

Positions "3 to F" will be used only by our service

man. Do not set the switch to these positions.

· If the master station PC is JW model, it can connect to the slave modules having "ZW model I/O

module" and "JW model I/O module" on the same circuit.

To the next page

8

8·15

Page 54

From the previous page

8

Set STA. NO. (station number) switch

· Set "STA. NO" (station number) in octal

notation in sequential numbers from 01 to 77.

Be careful that there is no doubled setting or

lacked number setting. (Number of

STA.NO.

×10

×1

7

9

6

0

5

1

4

2

3

8

7

9

6

0

5

1

4

2

3

connectable slave stations: See page 8·2)

LT

Set LT (termination resistance) switch

• When a JW-20RS slave module is at either

end the communication line, make sure to

(ON)

LG

(ON)

set the termination resistance switch "ON."

Turn ON the termination resistance

switches on these two stations.

Reference: Function of the termination resistance switch

If the communication line does not have a termination resistance, the high frequency signal will

be reflected at the ends of the cable. These reflected signals can collide with the original

8

communication signals, so that some stations will not be able to communicate normally. The

use of termination resistance suppresses reflected signals. If the termination resistance switch

on any of the stations in between the end of the cable is turned ON, the station will generate a

reflection wave signal or attenuate the original signal and may not communicate normally.

· When the trunk line has a branch in it, turn ON the termination resistance at the station on the

trunk cable.

· If you use a terminator (termination resistance made by Toko Denshi: ME-75) at the end of a

signal cable, turn OFF the termination resistance at the station on the end of the cable.

To the next page

Termination

resistance (ON)

Drop cable

(branch line should

be less than 400 mm)

Trunk cable

Less than 1 km

Terminator: ME-75

"T" branch

TerminatorTerminator

8·16

Page 55

From the previous page

Set LG (shield ground) switch

· For communication lines, use a coaxial cable.

· As coaxial cable is an unbalanced circuit,

ground its shield by turning “ON” the shield

ground switch.

LT

(ON)

LG

(ON)

Turn “ON” shield ground

switch

Coaxial cable

Turn “ON” shield ground

switch

• Make sure to provide a class-3 grounding for the GND terminal of the power supply module.

Without grounding the power supply module, the JW-20CM cannot become conductive with

the ground after turning “ON” the shield ground switch. (See page 7·2.)

• Prior to any electric welding around the JW-20CM, take out the coaxial cable from the JW20CM. While the coaxial cable is connected to the JW-20CM, any electric welding nearby the

JW-20CM will cause the welding current to the JW-20CM and may damage part of its circuit

pattern.

JW-20CM

Turn “ON”

shield ground

FG

Coaxial cable

Wrap around current

Note:

JW-20CM

JW-20CM has a

fuse element here

Turn “ON”

shield ground

FG

Rack etc.

8

To the next page

Note: In case enough

conductivity is not

established.

Electric welder

8·17

Page 56

From the previous page

STATION NO.

01

FIX

Write in label

· Write “FIX” and “STA. NO.” on label of remote

I/O slave station, make setting contents clear.

Switch setting end of slave module

8

8·18

Page 57

(3) Parameter setting of slave module (JW-20RS)

Set the following parameter address after setting switch. Setting item varies with using I/O module

(JW model or ZW model).

O: Necessity for setting

metI

O/Iymmudfo.ongnitteS

stniop

tnacavrepetyb1esU·

stols2

O/IlaunamylnotateS·

noitartsigerelbat

eludomO/IfosdnikteS

tolsrepetyb1esU·

O/IlaunamylnotateS·

noitartsigerelbat

tolsdnaskcar.xamteS

rebmun

elbatO/IlaunamteS

noitartsiger

royllacitamotuaretsigeR

rewoptaelbatO/Iton

.tupni

potO/IetomerteS

sserdda

setybO/Ifo.onkcehC05730000

setybO/Ifo.onteS

,MORPEEehtotgnitirW

pots/noitarepotrats

.gnittes

sserddA

)8(

000000

ot

710000

001000

ot

731000

00010000

10010000

20010000

400100

500100

25730000

35730000

77730010

eulavlaitinI

)H(

00

tuptuostniop61:19

tuptuostniop23:29

tuptuostniop46:49

00

00

.dedeenton

tuptuostniop61:1A

tuptuostniop23:2A

tuptuostniop46:4A

eludomO/IlaicepS:1D

eludomO/IlaicepS:1F

eludomO/Ifosdnik

eludomO/Ifosdnik

noitartsigerotuA:00

.pmal)US(eludom

stnetnocgnitteS O/I-WJ W/I-WZ egapeeS

stniopoN:stniopO/Iymmudfo.oN:0

)setyb2(stniop61:stniopO/Iymmudfo.oN:1

)setyb4(stniop23:stniopO/Iymmudfo.oN:2

)setyb6(stniop84:stniopO/Iymmudfo.oN:3

)setyb8(stniop46:stniopO/Iymmudfo.oN:4

)setyb01(stniop08:stniopO/Iymmudfo.oN:5

)setyb21(stniop69:stniopO/Iymmudfo.oN:6

)setyb41(stniop211:stniopO/Iymmudfo.oN:7

○−8・52

)setyb61(stniop821:stniopO/Iymmudfo.oN:8

)setyb81(stniop441:stniopO/Iymmudfo.oN:9

)setyb02(stniop061:stniopO/Iymmudfo.oN:A

)setyb22(stniop671:stniopO/Iymmudfo.oN:B

)setyb42(stniop291:stniopO/Iymmudfo.oN:C

)setyb62(stniop802:stniopO/Iymmudfo.oN:D

)setyb82(stniop422:stniopO/Iymmudfo.oN:E

)setyb03(stniop042:stniopO/Iymmudfo.oN:F

)stniopO/Iymmudsirewol(tolstnacaV:00

○−8・62

rebmunkcaR:stib4reppU

rebmuntolS:stib4rewoL

dnastniopO/IymmudrofgnitteslaunaM:46

eludomO/Ifosdnikrofgnittesotua

dnelamronsignittesnehW:00

noitartsigerotuaehttibihorP:30

hcraesgnisuylnonehwlatconisserddaelifteS

setybO/Ifo.onehtkcehcoN:00

setybO/Ifo.onehtkcehC:54

signittessiht,821ot000noitatonlamicedgnisu

noitarepoO/IetomerpotS:00

noitarepoO/IetomertratS:10

noitarepopots,MORPEEehtotgnitirW:08

noitarepotrats,MORPEEehtotgnitirW:18

retemarapehtezilaitinI:80

○−8・82

dnastniopO/IymmudhtobrofgnitteslaunaM:06

○−

rofgnittesotuadnastniopO/Iymmudrof00:56

○−

○−8・92

−○

ehtybdesuebotsetybO/Iforebmungnikcehc"fI

"kcehcotton"otdetcelessinoitcnuf"eludomO/I

−○

○○

8

8・ 72

8・ 42

8・ 22

8・ 32

· There is no difference of parameter setting between "fixed allocation" and "manual allocation."

8·19

Page 58

Operation procedure

In brackets : See page

Turn “ON” the power of slave station PC

In case of using ZW-I/O

Connect support tools

Stop remote I/O operation

(parameter address 003777

(8)

In case of using ZW-I/O

Use the slave module having set to

default condition at delivery (initialized

the parameters), and use it as

automatic I/O registration function.

= 00

[8·22]

[8·22]

(H)

No

Yes

A

8

⑥

Set of prohibit the auto I/O table

registration at power “ON”

(parameter address 001002

(8)

= 03

[8·27]

(H)

)

①

Set of check no. of I/O bytes

(parameter address 003750

②

Set no. of I/O bytes

(8)

= 45

[8·24]

[8·24]

No

No check the no. of I/O bytes

①

Set of check no. of I/O bytes

(H)

)

(parameter address 003750

Yes

(8)

= 00

Not short for I/O processing time

Yes

(H)

)

Not use I/O search

Yes

Writing to the EEPROM, start operation

(parameter address 003777

End

(8)

= 81

No

No

(H)

)

8·20

Page 59

[I/O table registration in case of using JW-I/O]

1. In case of not setting dummy I/O

Register I/O table based on the installed I/O module. (Set parameter address 001001

(8)

= 65

procedure B in the flow chart.)

However, in case of parameter address of JW-20RS 001002

= 00

(8)

(default setting), the JW-20CM

(H)

automatically registers I/O table when the power is input and there is no need to register I/O table.

(Procedure A in the flow chart.)

2. In case of setting dummy I/O

Set number of dummy I/O points for each slot and registers I/O table based on this setting and the

installed I/O module. (Set parameter address 001001

(8)

= 64

, procedure C in the flow chart.)

(H)

Procedure D in the flow chart is special method to set byte of I/O module for each slot. Normally set

I/O module type using steps 1 and 2 above.

(Manual I/O registration)

Not setting dummy I/O

Auto setting the kinds of I/O module

Yes

(Auto I/O

registration)

No

③

Set no. of dummy I/O points

[8·25]

(H)

, the

Not setting the kinds of I/O module

(auto setting)

Yes

B

C

No

④

⑤ ⑤ ⑤

Registration of I/O table

(parameter address 001001

(8)

= 65

(H)

)

Registration of I/O table

(parameter address 001001

(8)

= 64

(H)

)

(parameter address 001001

⑦

Set max. racks, slot number

[8·28]

① to ⑧ are applied to page 8·24 to 29.

⑧

Set remote I/O top address

[8·29]

D

Set the kinds of I/O module

[8·26]

Registration of I/O table

(8)

= 64

[8·27]

8

(H)

)

8·21

Page 60

Turn “ON” the power of slave module

Connect support tools

· Connect a support tool with the slave module

JW-20RS and prepare the setting parameter.

<Usable support tools>

JW-13PG/12PG

JW-50SP

JW-50PG, Z-100LP2S

• For operation of each support tool, see the instruction manual attached. The following describes

an example of JW-13PG’s key operation.

Stop operation of remote I/O [HEX (hexadecimal), byte]

· Setting of the parameter is only available when the operation of the JW-20RS is stopped.

· Write “00

” to parameter address 003777

(H)

and stop operation of the JW-20RS.

(8)

(Operation example of JW-13PG)

Parameter

(

setting

Display the contents of

)

parameter address 007777 by

hexadecimal.

(

Write

00

)

.

(H)

Screen display of JW-13PG

07775 HEX 00

07776 HEX 1F

I PARAM.

>07777 HEX 00

8

Reference Function of JW-13PG

• key: Changeover unit of figures

HEX (hexadecimal)

→

• key: Byte display Changeover word display

←→

OCT (octal)

→

DCM (decimal)

→

→