Page 1

Version 1.0

R

SSharp Programmable Controller

Hand-held programmer

User's Manual

Produced in Mar. 2004

Model name

JW-15PG

Page 2

Thank you for purchasing the JW-15PG hand-held programmer for the Sharp programmable controller satellite W

series.

This book (the user's manual) describes the operation of the JW-15PG.

Depending on the PLC model you are using, you may want to read this book together with the "Handling Manual for

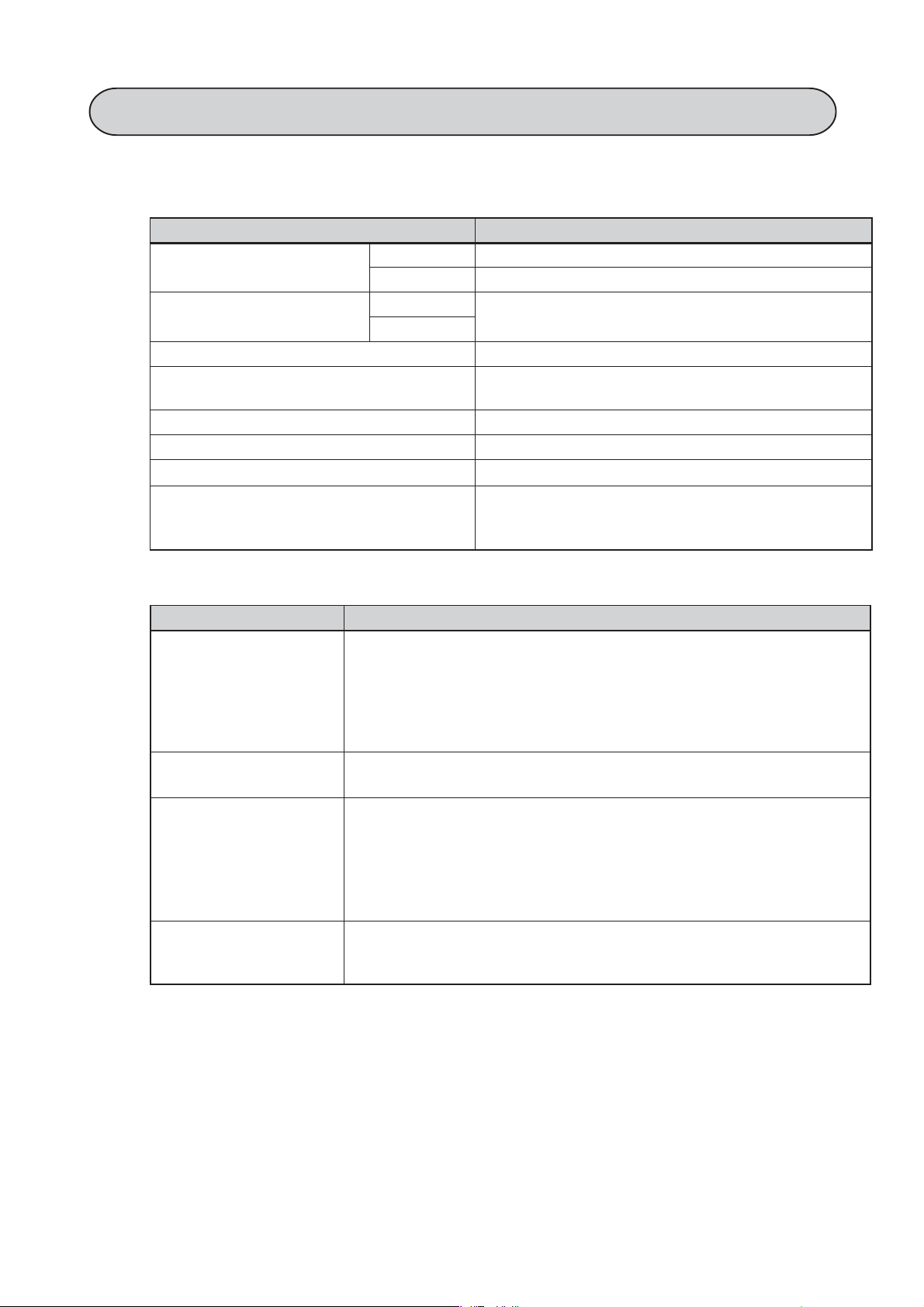

JW-14PG." Refer to the table below.

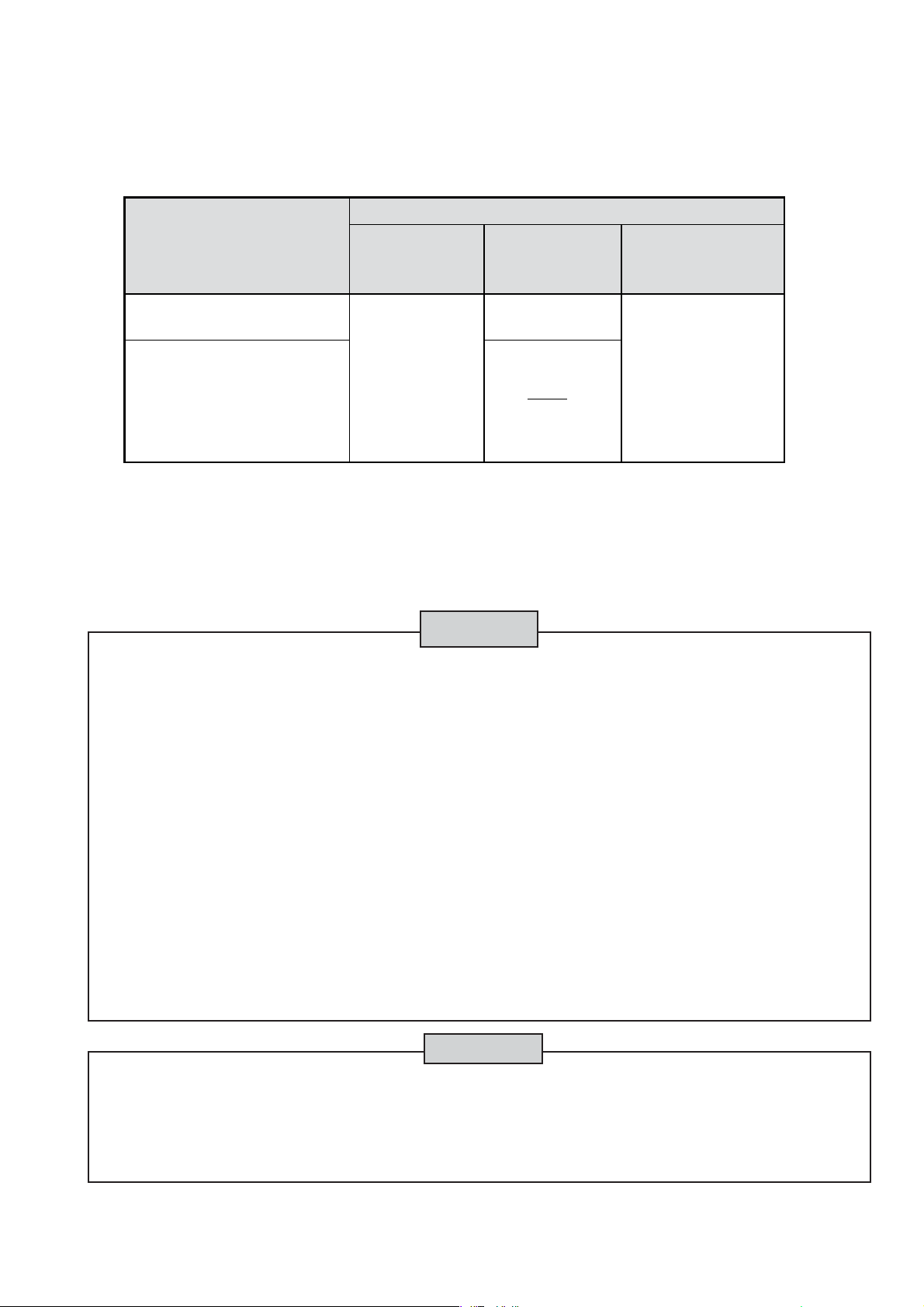

Reference manual

PLC model names

JW300

JW50H/70H/100H, JW50/70/100

JW30H, JW20H, JW20, JW10

J-board(Z500), J-board(Z300)

W100H, W70H, W100

W51, W16, W10

JW-32CV1/2/3

Table of functions

Table of operation

procedure

This manual

(Chapter 7, 8)

Operations

peculiar to

JW300

This manual

(Chapter 9)

Operation details

JW-14PG

instruction manual

*

* If you are using the JW300 series, the descriptions are the same as for the JW-14PG, except

for items marked "Operation specific to the JW300."

For other PLC models, all the operations are the same as for the JW-14PG.

To find the reference pages in the JW-14PG Handling Manual, see Chapter 8 in this manual.

- When using the JW300 or JW50H/70H/100H, set the MODE switches on the JW-15PG in order

to match the PLC model you are using. => See page 4-2

Precautions

- When you plan to use SHARP programmable controllers (hereafter referred to as "PLCs"), you are

requested to design each system so that even if a fault or malfunction occurs within the PLC, it will not

lead to a serious accident in your system. You should incorporate back-up measures and fail-safe features

in your system that will thoroughly protect your system from malfunctions if a fault or error occurs in the

PLC.

- SHARP PLCs are designed and manufactured with the idea that they will be used in general applications

in ordinary industries. Therefore, they must not be used in specific applications that can affect the health

or safety of the public, such as nuclear power plants and other power generating plants. Such applications

require a special warranty of quality that SHARP explicitly does NOT offer for these PLCs. However, if a

user will certify that he/she does not requires a special quality warranty on the PLC, and will limit the use

of the PLC to non-critical areas of these applications, SHARP will agree to such use.

If you are planning to use SHARP PLCs for applications that may affect the lives of human beings and

property, and you need particularly high reliability performance, such as in the fields of aviation, medicine,

transportation, combustion and fuel processing equipment, passenger cars, amusement park rides, and

safety equipment, please contact our sales division so that we can confirm the required specifications.

Notes

- Though this manual is produced with the almost care, if you have any questions and inquiries, please feel

free to contact our dealers.

- The whole or partial photocopy of this booklet is prohibited.

- Contents of this booklet may be revised for improvement without notice.

Page 3

Safety Precautions

Read this manual and attached documents carefully before installation, operation, maintenance and checking in

order to use the machine correctly. Understand all of the machine knowledge, safety information, and cautions

before starting to use. In this instruction manual, safety precautions are ranked into "danger" and "caution" as

follows.

Danger : Wrong handling may possibly lead to death or heavy injury.

Caution : Wrong handling may possibly lead to medium or light injury.

Even in the case of Caution , a serious result may be experienced depending on the

circumstances. Anyway, important points are mentioned. Be sure to observe them strictly.

The picture signs of prohibit and compel are explained below.

: It means don’ts. For example, prohibition of disassembly is indicated as ( ).

■Installation

Caution

• Use in the environments specified in the catalog and user's manual.

Electric shock, fire or malfunction may be caused when used in the environments of high

temperature, high humidity, dusty or corrosive atmosphere, vibration or impact.

• Install according to the manual.

Wrong installation may cause drop, trouble or malfunction.

■Use

• Assemble the emergency stop circuit and interlock circuit outside of the programmable controller.

Otherwise the machine breakdown or accident may be caused by the trouble of the programmable

controller.

• Manipulation for program change, forced output, run or stop during operation should be done with

particular care by confirming safety. Misoperation may lead to machine trouble or accident.

• To avoid eye strain, rest your eyes 10 to 15 minutes every when working for long periods of time.

Avoid continuous use for long periods of time.

■Maintenance

Danger

Caution

• Don’t disassemble or modify.

Or fire, trouble or malfunction may be caused.

Prohibit

S-1

Page 4

Chapter 1. Overview

Chapter 1 Outline

Chapter 2. Precautions for Use

Chapter 2 Data memory

Chapter 3. System Configuration

Chapter 3 Program memory, Parametor memor

Chapter 4. Name and Function of Each Part

Chapter 5. Connection/Installation Method

Chapter 6. Specifications

Chapter 7. Table of Functions

and PC card

Chapter 8. Table of Operation Procedure

Chapter 9. Operating the JW300

Chapter 10. Table of Messages

Chapter 4 System memory

Chapter 5 Operation of control module

Chapter 6 Block operation, logging, fault diagn

Chapter 7 List of instructions

Chapter 8 Description of basic instructions

Chapter 9 Description of application instruction

Chapter 10 Application instructions (F-00 to Fx1

Page 5

Table of Index

Chapter 1. Overview ............................................................................................................................................1-1

Chapter 2. Precautions for Use ......................................................................................................................... 2-1

(1) Installation and storage

(2) Connection

(3) Operation

(4) Static electricity

(5) Cleaning

Chapter 3. System Configuration ............................................................................................................... 3-1 to 2

Chapter 4. Name and Function of Each Part ............................................................................................ 4-1 to 2

(1) Keypad

(2) LCD unit

(3) Retention screw

(4) Connector

(5) Connector mounting plate

(6) Hand strap

(7) Corresponding model label

(8) MODE switch

Chapter 5. Connection/Installation Method .............................................................................................. 5-1 to 8

5-1 Changing the direction of the connector 5-1

5-2 Method for making cable connections 5-2

[1] Connections to a control module in the JW300 series 5-2

[2] Connecting to the JW50H/70H/100H control module 5-3

[3] Connecting to the JW30H, JW20H, and J-board control modules (board) 5-4

[4] Connecting to the JW10 basic module 5-4

[5] Connecting to a module other than the control module 5-5

[6] Mounting to a control panel surface 5-7

5-3 Direct mounting method 5-8

Chapter 6. Specifications ............................................................................................................................ 6-1 to 2

[1] General specifications 6-1

[2] Performance specification 6-1

[3] Dimensions 6-2

Chapter 7. Table of Functions ................................................................................................................... 7-1 to 6

- Buzzer ON/OFF selection

- EL backlight ON/OFF selection

7-1

Index-1

Page 6

- Contrast adjustment

- Auto repeat function

- Display mode selection

- Operation mode setting

- Menu selection

- Memory clear

- System memory (Read/Write)

- Enter program address

- Instruction entry method

- Program (Read/Write)

- Search program

- Modify program

- Edit program

- Check program

- Monitor program

- Monitor data

- Monitor break (debug function)

- Forced set/reset

- Read/write internal memory

- Change data memory

memory

7-1

7-2

7-3

-

Correct current register value

- Edit current register value

- Monitor process of I/O module

- I/O module monitor process

- Connect/remove I/O module live line

- I/O address assignment

- I/O module registration

- Set parameter

Set clock

-

- Monitor clock

- Set parameter such as network module

- Remote programming and remote monitor

- Monitor target station number

- Device function

- Write program to EEPROM

- Read program to ROM

- Verify program with ROM

- Transfer to ROM writer

7-4

7-5

SF monitor

-

- Symbol registration

- Monitor error

- Secret function

- OCT/DCML/HEX display of numerical value

- PC card

Index-2

7-6

Page 7

Chapter 8. Table of Operation Procedure ............................................................................................... 8-1 to 21

- Turn buzzer ON/OFF 8-1

- Turn EL backlight ON/OFF 8-1

- Adjust contrast 8-1

- Auto repeat function 8-1

- Change display mode 8-1

- Select operation mode 8-2

- Operation screen menu selection 8-2

- Clear memory 8-3

- Read/write system memory 8-3

- Set program address 8-4

-

Enter basic and application instruction 8-4 to 5

- Enter application instruction 8-5

- Read/write program 8-5 to 6

- Search program 8-6 to 7

- Modify program 8-7

- Edit program 8-7

-

Check program 8-8

- Monitor program 8-8

- Monitor data memory 8-9

- Break monitor (debug function) 8-10

- Forced set and reset 8-11

- Read/write internal memory with hexadecimal 8-11

- Change data memory 8-11

Modify register current value 8-12

-

- Edit register current value 8-12 to 13

- I/O module monitor process (JW100H, etc.) 8-13

- I/O module monitor process [JW20H, JW30H, etc.] 8-14

- Connect/remove live line of I/O module 8-14

- Enter I/O address 8-15 to 17

- Parameter setting [JW20H, JW30H, etc.] 8-17

- Parameter setting [JW300] 8-17

- Set the clock 8-18

- Monitor time 8-18

-

Set parameter for network module 8-18

- Remote programming 8-18

- Remote programming and remote monitor 8-19

- Monitor target station number 8-19

- Device function 8-19

- Write program to an EEPROM 8-19

- Read program from ROM 8-19

- Verify program with ROM 8-19

- Data transfer to ROM writer [JW20H, etc.] 8-19

- SF monitor [JW20H, etc.] 8-20

to 8

Index-3

Page 8

- Symbol registration [JW20H, etc.] 8-20

- Monitor error 8-20

- Secret function (JW30H, etc.) 8-20

- Indicates the base notation (octal/decimal/hexadecimal) of the values specified 8-20

- PC card 8-21

Chapter 9. Operating the JW300 .............................................................................................................. 9-1 to 19

9-1 Functions specific to the JW300 9-1

[1] Block programs 9-1

(1) Block move 9-3

(2) Start/end block (when a normal block is selected) 9-4

(3) Set/change the start relay (when a normal relay is selected) 9-5

(4) Refresh the I/O status display (when the main block is selected) 9-6

[2] PC card 9-7

(1) Save files 9-8

(2) Load files 9-9

9-2 Instructions specific to the JW300 9-10

[1] Basic instruction 9-10

(1) New instructions 9-10

(2) TNR/CNT instruction 9-11

[2] Index qualification 9-13

9-3 Additions and changes from conventional operations 9-14

[1] Display data memory 9-14

[2] Clear program memory 9-15

[3] Clear the file register 9-16

[4] Monitor program 9-16

(1) Monitor index register Z*** 9-16

(2) Monitor file register f******** 9-16

[5] Parameter setting 9-17

[6] Assigning I/O address 9-18

[7] Write and read programs to and from ROM 9-19

[8] Deleted functions 9-19

Chapter 10. Table of Messages ................................................................................................................ 10-1 to 4

[1] Message seen while checking programs 10-1 to 2

[2] Error messages 10-3 to 4

Index-4

Page 9

Chapter 1. Overview

The JW-15PG hand-held programmer (referred to as "programmer" in this manual) is a support tool for

Sharp’s programmable controller. The programmer is designed for ease of use in maintenance, as well

as for programming and monitoring the programmable controller.

The JW-15PG has added functions to the standard JW-14PG model, which are compatible with JW300

series PLCs.

- Display in two languages (Japanese/English), selectable.

- An EL backlight makes it easy to read in dark locations.

- Can display messages using the device function.

Up to three steps can be displayed at once.

- Equipped with various monitor functions including freely selected multiple points, simultaneous

monitoring of two stations, and data input/output.

- Equipped with a plenty of editing functions including programming, copying data memory, and

batch processing of instructions.

- Includes with error message display functions.

1-1

Page 10

Chapter 2. Precautions for Use

When using and storing JW-15PG, observe the following precautions.

(1) Installation and storage

1. Avoid installing the JW-15PG in a place where it will be exposed to:

- Area exposed to direct sunlight.

- Flammable gases permeate.

2. During storage, do not place anything on the JW-15PG.

(2) Connection

When connecting the JW-15PG to a control module of a programmable controller (hereafter referred

to as "PLC") with a connection cable (option), keep the cable away from high voltage lines, motor lines,

signal lines to the I/O module and power supply lines.

(3) Operation

1. Do not apply excessive force to the mounting screws or connectors.

2. Do not press the keypad with a sharp pointed object such as a pencil or ballpoint pen.

3. Keep the keypad away from welding sparks and hot solder.

4. If a malfunction or error (overheating, etc.) occurs in the JW-15PG, immediately stop operation,

disconnect the cable or the control module from the JW-15PG and contact your dealer or our service

company.

(4) Static electricity

In an extremely dry area, large amounts of static electricity may be generated in a person. Before

touching the programmer, discharge any static electricity by first touching a grounded metallic object.

(5) Cleaning

Use a soft, dry cloth to clean the programmer. Use of volatile chemicals (alcohol, thinner, freon, etc.) or

a wet cloth may cause deformation or discoloration.

2-1

Page 11

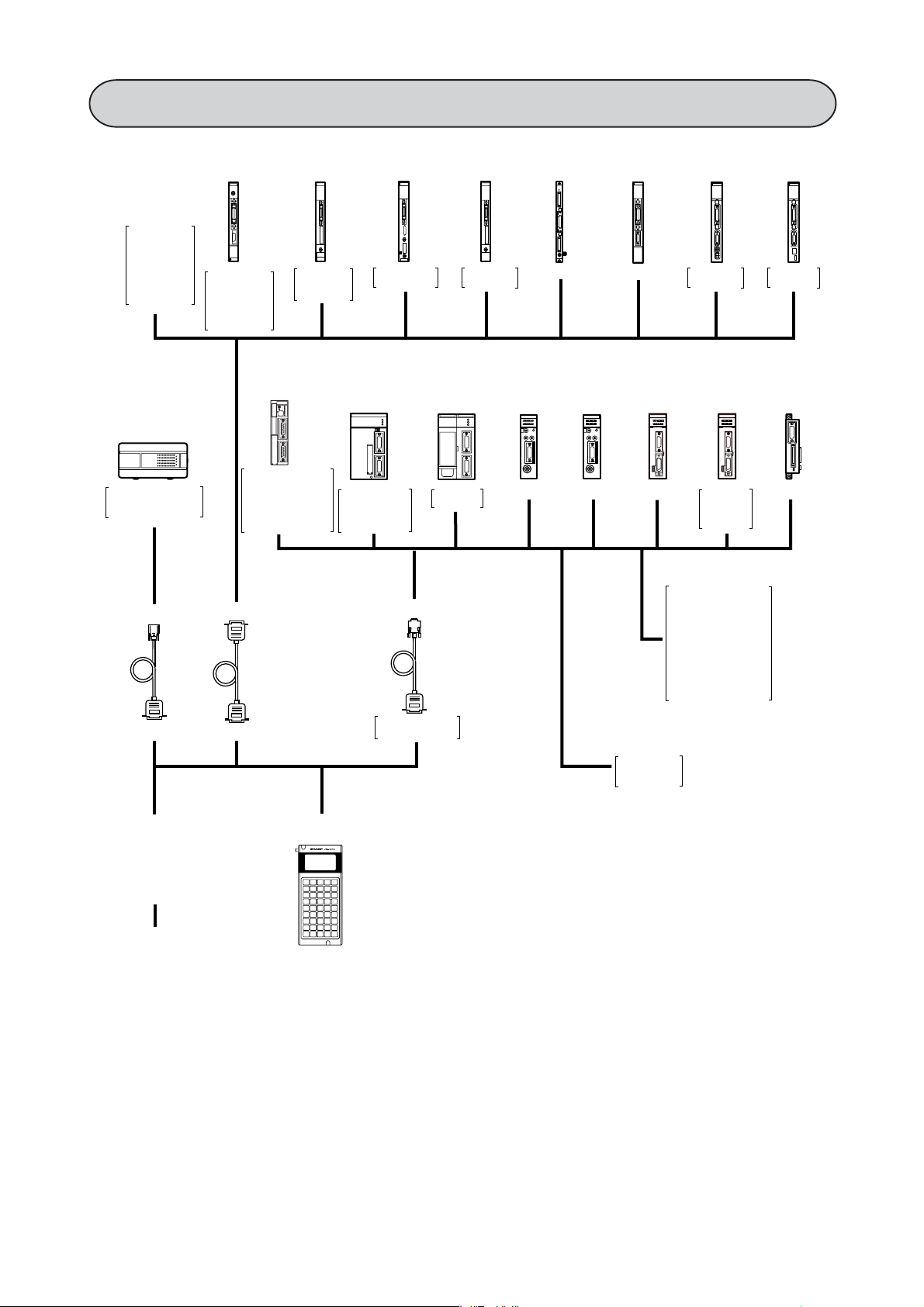

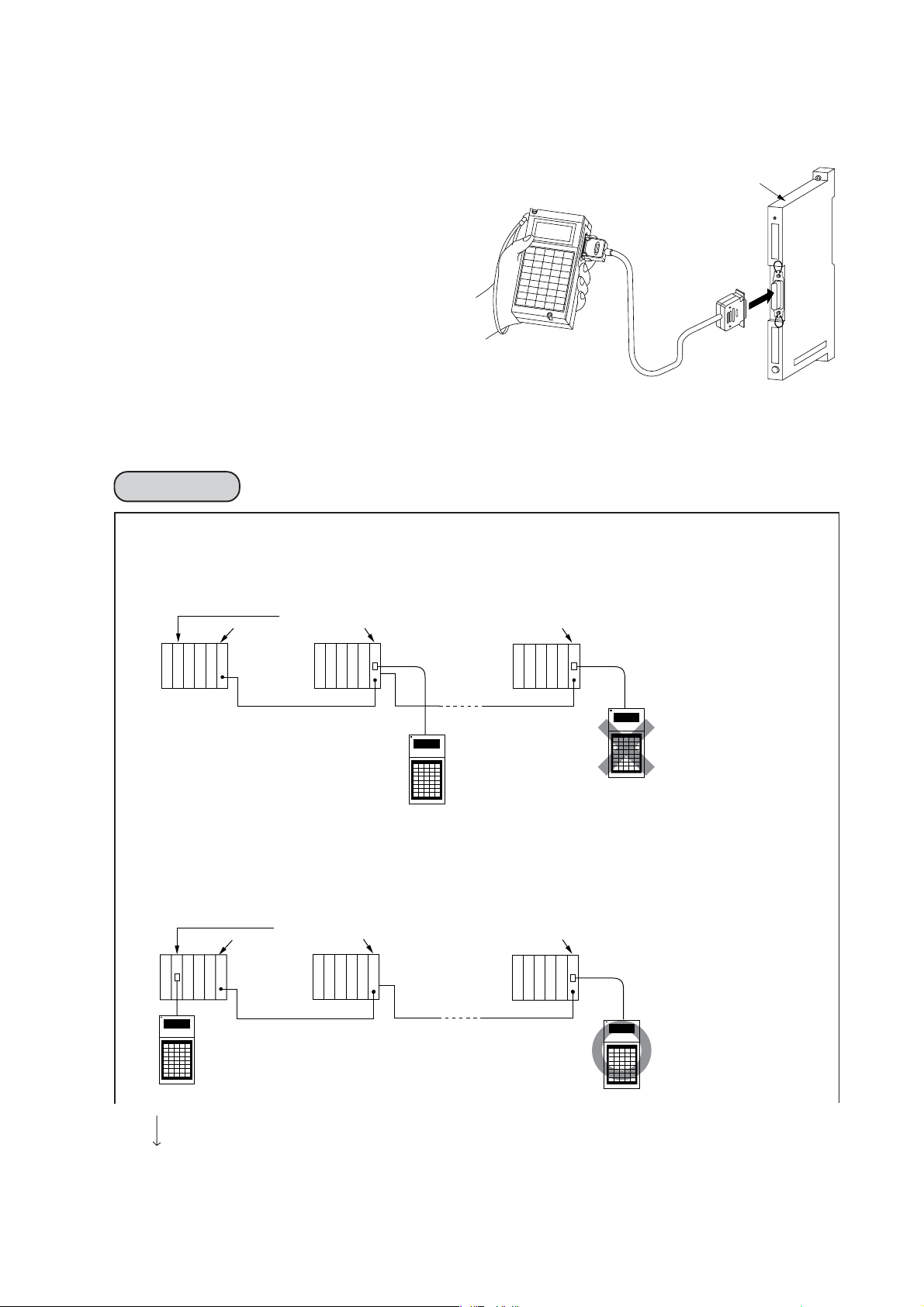

Chapter 3. System Configuration

W16

W51, W100

W70H/100H

control module

ZW-160CU

ZW-501CU3

ZW-1K0CU

ZW-1K1CU

ZW-1K2CU

ZW-1K3CU

ZW-70CU

ZW-1HCU

JW10

basic module

JW-1324K/1342K

JW-1424K/1442K

JW-1624K/1642K

Connection cable

[JW-12KC (2 m)]

JW50H/70H/100H

JW50/70/100

control module

JW-50CUH

JW-70CUH

JW-100CUH

JW-50CU

JW-70CU

JW-100CU

JW300

control module

JW-311CU/312CU

JW-321CU/322CU

JW-331CU/332CU

JW-341CU/342CU

JW-352CU

JW-362CU

Connection cable

[ZW-3KC (3 m)]

Network module

ZW-20CM

JW-20CM

ZW-20CM

ZW-30CM

JW30H

control module

JW-31CUH/H1

JW-32CUH/H1

JW-33CUH/H1

ME-NET module

ME-NET

JW-20MN

JW-20MN

ZW-20CM2

JW20H

JW20

control module

H2/H3

Connection cable

JW-22KC (2 m)

JW-24KC (4 m)

Remote I/O

slave module

JW-20RS

ZW-20RS

JW-21CU

JW-22CU

I/O bus

expansion

ZW-20RS

MODE

STA.NO

×10

×1

LT

(ON)

→

LG

(ON)

→

STATION NO.

adapter

[JW-2EA]

Serial interface

module

JW-10SU

[JW-10SU]

Ethernet module FL-net module

JW-50CM JW-50FLT

JW-50CM

JW-51CM

Network module

8

7

9

6

0

5

1

4

2

3

8

7

9

6

0

5

1

4

2

3

ME-NET

module

Ethernet module

8

7

9

6

0

5

1

4

2

8

7

9

6

0

5

1

4

2

3

3

8

8

7

7

9

9

6

6

0

0

5

5

1

1

4

4

2

2

3

3

[JW-22CM] [JW-21MN] [JW-255CM] [JW-32EA]

FL-net

module

JW-20FL5

JW-20FLT

JW-22FL5

JW-22FLT

J-board

- CPU board

Z-311J, Z-312J

Z-511J, Z-512J

- Satellite net board

Z-335J

- ME-NET board

Z-334J

- FL-net board

Z-336J、Z-336J2

- Ethernet board

Z-339J

VME built-in

controller

JW-32CV1

JW-32CV2

JW-32CV3

JW-50FL

JW-52FL

I/O bus

expansion

adapter

Connection cable

[ZW-10C3 (1.8 m)]

Hand-held

programmer

+

AC adapter

[ZW-10AC]

W10 basic module

[JW-15PG]

- Direct installation

The JW-15PG can be installed directly in the following PLC models.

JW50H/70H/100H, JW50/70/100, W70H/100H => See "Chapter 5. Connection/Installation Method."

3-1

Page 12

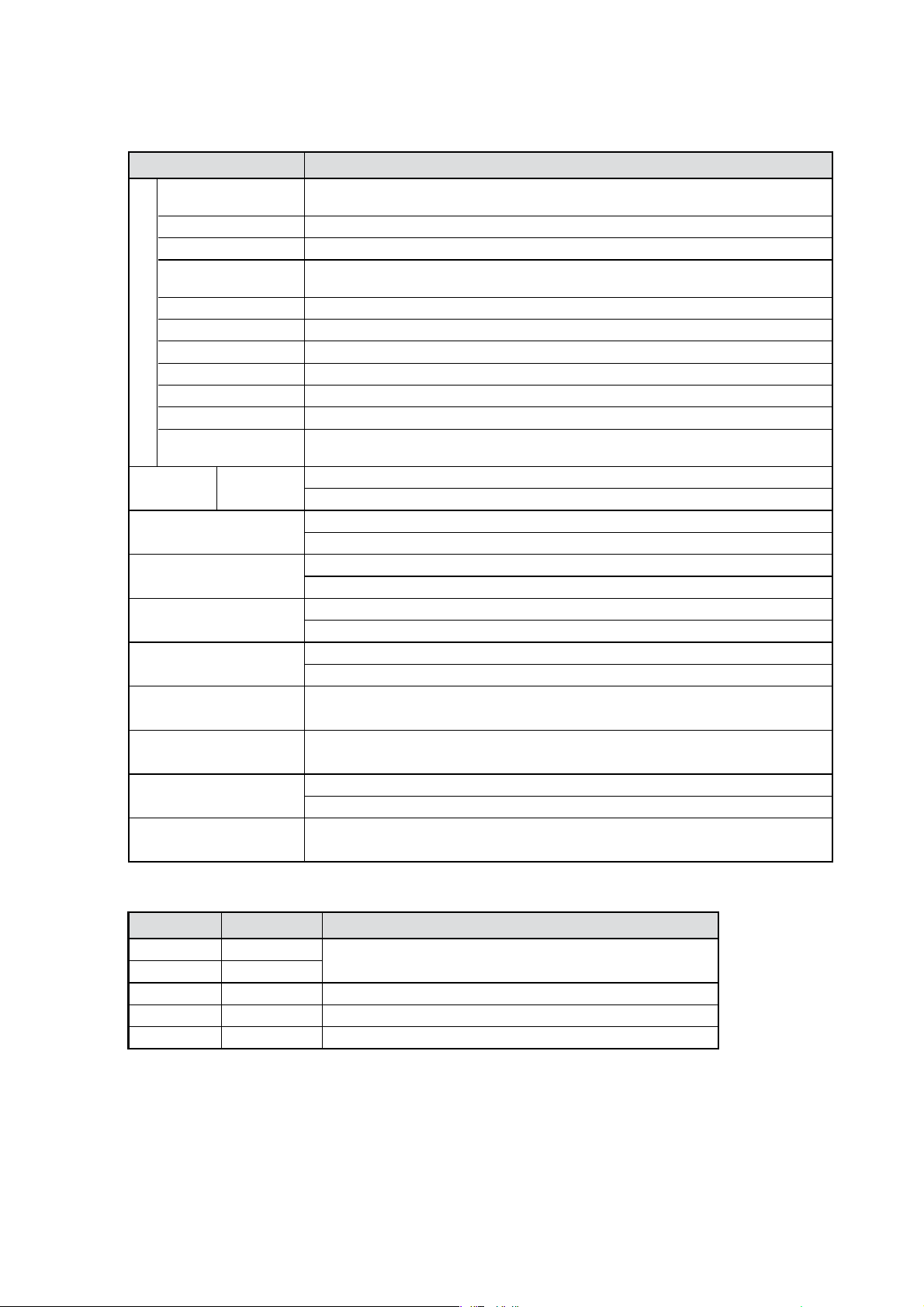

The following modules and cables can be connected to the JW-15PG.

■Connection module

Module name Model name

JW300

JW50H/70H/100H

JW50/70/100

JW30H

JW20H,JW20

JW10

W70H/100H

Control module

W100

W51

W16

W10

J-boardCPU board

Network module

ME-NET module

Ethernet module

FL-net module

Serial interface

module

JW-311CU, JW-312CU, JW-321CU, JW-322CU, JW-331CU, JW-332CU,

JW-341CU, JW-342CU, JW-352CU, JW-362CU

JW-50CUH, JW-70CUH, JW-100CUH

JW-50CU, JW-70CU, JW-100CU

JW-31CUH1, JW-32CUH1, JW-33CUH1, JW-33CUH2, JW-33CUH3,

JW-31CUH, JW-32CUH, JW-33CUH

JW-21CU, JW-22CU

JW-1324K, JW-1342K, JW-1424K, JW-1442K, JW-1624K, JW-1642K

ZW-70CU, ZW-1HCU

ZW-1K0CU, ZW-1K1CU, ZW-1K2CU, ZW-1K3CU

ZW-501CU3

ZW-160CU

ZW-28M124, ZW-28M114, ZW-28M111, ZW-28M122, ZW-28M324,

ZW-28M424

Z-511J, Z-512J

Z-311J, Z-312J

JW-20CM, ZW-20CM, ZW-30CM

JW-22CM

JW-20MN, ZW-20CM2

JW-21MN

JW-50CM, JW-51CM

JW-255CM

JW-50FL, JW-52FL

JW-20FL5, JW-20FLT, JW-22FL5, JW-22FLT

JW-10SU

Remote I/O slave

module

I/O bus expansion

adapter

VME built-in

controller

■Connection cable

Model name

Cable length

JW-22KC

JW-24KC

ZW-3KC

JW-12KC

ZW-10C3

2 m

4 m

3 m

2 m

1.8 m

JW-20RS, ZW-20RS

JW-2EA

JW-32EA

JW-32CV1, JW-32CV2, JW-32CV3

Remarks

Use for JW300, JW30H, JW20H, J-board (Z300/Z500),

etc.

Use for JW50H/70H/100H, etc.

Use for JW10

Use for W10 (ZW-10AC AC adapter is needed)

3-2

Page 13

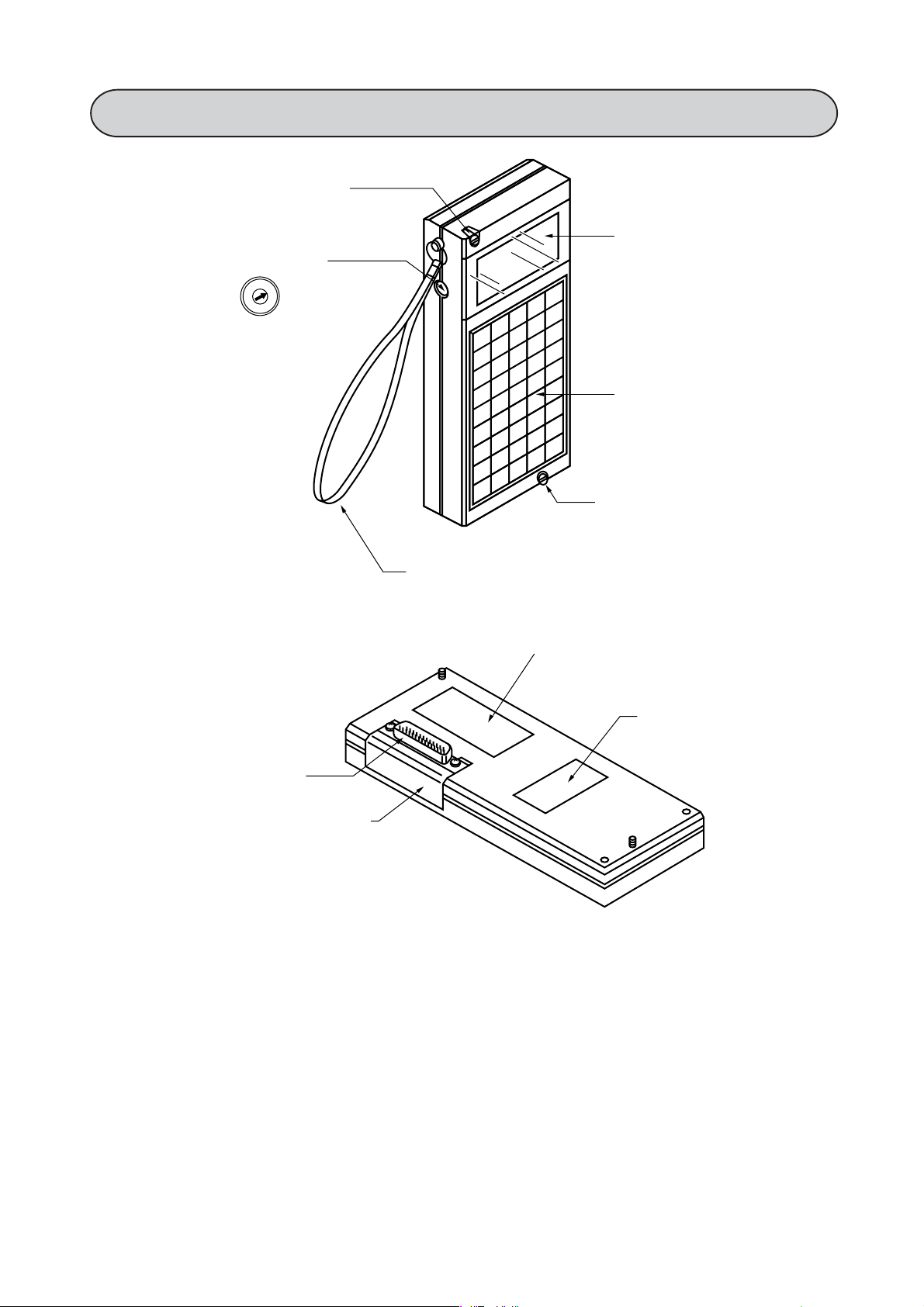

Chapter 4. Name and Function of Each Part

(3) Retention screw

(2) LCD unit

(8) MODE switch

0

9

1

8

2

7

3

6

4

5

(1) Keypad

(3) Retention screw

(6) Hand strap

(4) Connector

(5) Connector mounting plate

- As for function of (1) to (8) => See next page

(7) Corresponding model label

Rating plate

4-1

Page 14

(1) Keypad

Hand strap

For manipulating program writing, etc.

The key panel contains mode keys, control keys, instruction keys, and numeric keys. => See the figure

on the right.

(2) LCD unit

The liquid crystal full dot matrix display (16 characters

by 4 lines) shows instructions and data. The display is

fitted with an EL backlight.

(Display example)

FEDCBA98 76543210

AND 0 0 001

OR NOT 0 0 002

P00003

>STR NOT00003

(3) Retention screw

Used to secure the JW-15PG on a control module

(PLC) or control panel.

(4) Connector

Connects to a control module (PLC) or connection

cable. The mounting direction can be changed.

Mode keys

Control keys

Instruction keys

Numerical value keys

[Key layout of the keypad]

[Mounting example]

ZW-IPU

JW-70CU

(5) Connector mounting plate

The mounting direction of the connector can be

changed for direct mounting of the programmer or for

connection using the optional cable.

(6) Hand strap

Pass your hand through the strap when the programmer is connected via cable to prevent dropping it.

(7) Corresponding model label

This decal shows compatible PLC models and settings for the MODE switch.

(8) MODE switch

Used to select the PLC model you want to use and to change the display language (Japanese/English).

Setting value of

MODE switch

Display

(Japanese/English)

Corresponding

models (PLC)

1234

Japanese

English

Japanese

English

JW300

JW50H/70H/100H

(Unusable an expansion

relay)

JW50H/70H/100H

(Usable an expansion

relay)

JW30H, JW20H, JW20, JW10

MODE

0

9

1

8

2

7

3

6

4

5

(Setting when delivered : 1)

J-board (Z300/500), JW50/70/100

W10/16/51/100, W70H/100H

Note: Make sure to disconnect the cable from JW-15PG before setting the mode switch.

Positions other than "1" to "4" cannot be used.

4-2

Page 15

Chapter 5. Connection/Installation Method

This chapter describes the cable connections and installation of the JW-15PG.

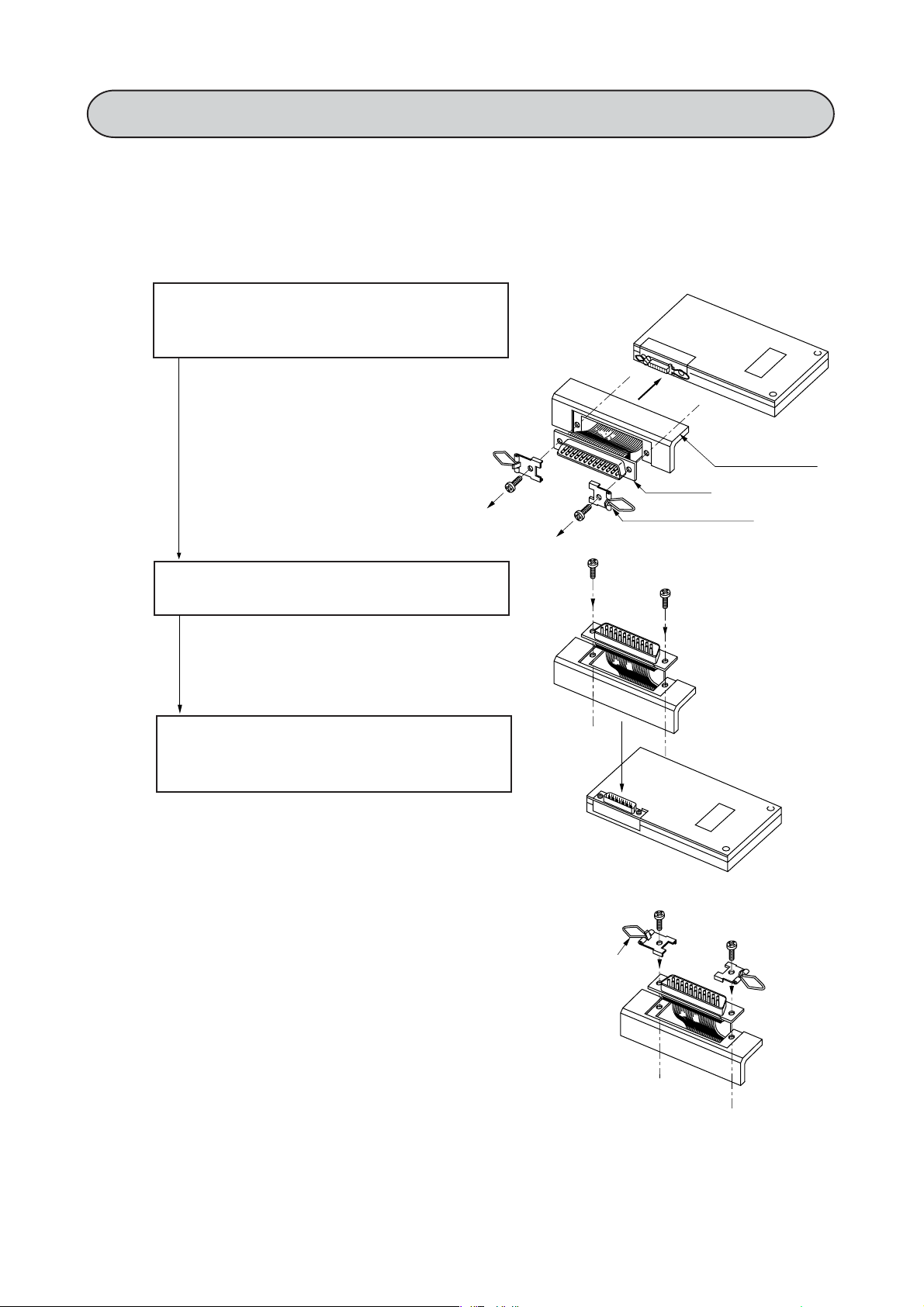

5-1 Changing the direction of the connector

The orientation of the cable connector on the JW-15PG can be changed as follows.

1) Remove the 2 screws securing the connector

then detach the connector and connector

mounting plate from the JW-15PG.

- Also remove the bail locks if attached.

Connector

mounting plate

Connector

Bail lock

2) Change the direction of the connector mounting plate.

3) Secure the connector and connector mounting plate to the programmer with the 2

screws.

Note: Do not attach the bail locks when di-

rectly mounting the programmer to the

control module. The connectors will not

contact properly if they are attached.

Bail lock

=> Refer to page 5-8

5-1

Page 16

5-2 Method for making cable connections

This method is used to connect the JW-15PG to a PLC using cables (JW-24KC etc.: optional). This

section describes the methods for connecting the following models.

JW300

JW50H/70H/100H

JW30H,JW20H,J-board

JW10

Modules other than control modules

Control panel (front face)

=> [1]

=> [2]

=> [3]

=> [4]

=> [5]

=> [6]

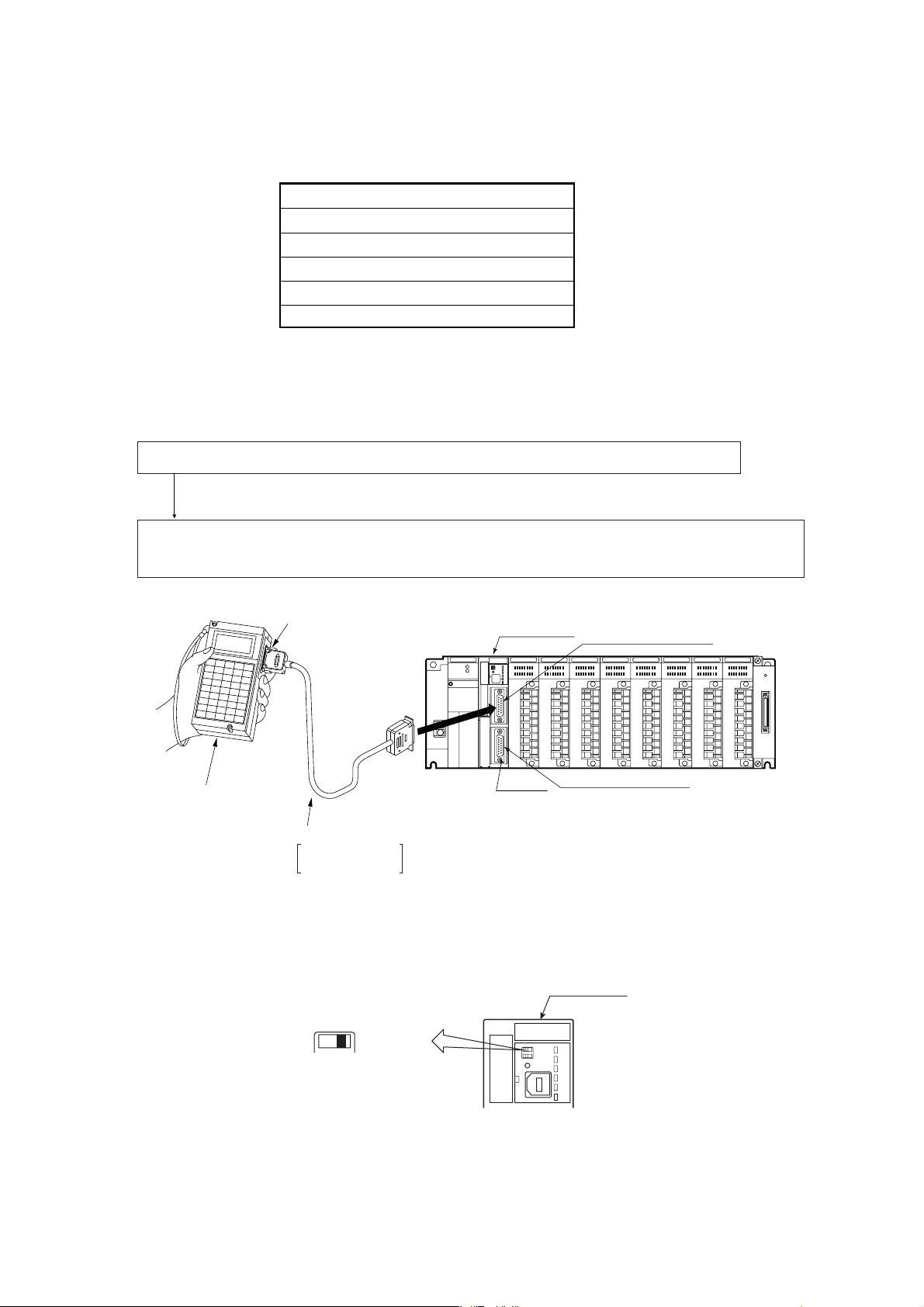

[1] Connections to a control module in the JW300 series

Connect a communication port (PG COMM1 or PG/COMM2) on a control module (JW-3**CU) to the

JW-15PG.

1) Connect the JW-15PG to a control module using a JW-22KC/24KC cable.

2) Secure the cable using the bail locks on the JW-15PG and screws on the communication port

connector.

Bail locks

JW300

JW-3**CU

←

PROTECT

RUN

O

F

INIT

F

FLT

RESET

CM1

CM2

C

USB

A

R

D

SV

PG/COMM1 port

▲

PULL

PG/COMM1

電池交換

時期

This

battery

expires

電池の交換

は5分以内

に行ってく

ださい

Exchange

the battery

within

5minutes.

PG/COMM2

JW-15PG

Screw

PG/COMM2 port

Cable

JW-22KC (2 m)

JW-24KC (4 m)

[Reference] If you want to connect or disconnect the JW-15PG while the power to the JW300 remains

ON, set the PROTECT switch on the control module to the ON position. When it is in that

position, the program and system memory on the JW300 will be protected.

JW-3**CU

->

ON

O

PROTECT

F

F

←

PROTECT

RUN

O

F

AUTO LD

F

FLT

RESET

CM1

CM2

C

USB

A

R

D

MW

5-2

Page 17

[2] Connecting to the JW50H/70H/100H control module

A common procedure is used to connect the programmer to the JW50H/70H/100H control module.

Connect the cable to the programmer’s

connector and to the control module’s

support tool connector. Firmly secure both

the programmer’s end and the control

module’s end of the cable with the bail

locks.

[Reference]

- Set the memory protect switch to "ON" when connecting or disconnecting the programmer while

the JW50H/70H/100H’s power is "ON." This protects the JW50H/70H/100H’s memory.

Programmer

(JW-15PG)

Memory protect switch

Support tool connector

Control module

Cable

(ZW-3KC)

Control module

ON (Input)

OFF (Output)

Notes

When the JW-15PG connected, a condition may occur where a "beep" is emitted and nothing is

displayed. This occurs when the control module has been set to the device function.

5-3

Page 18

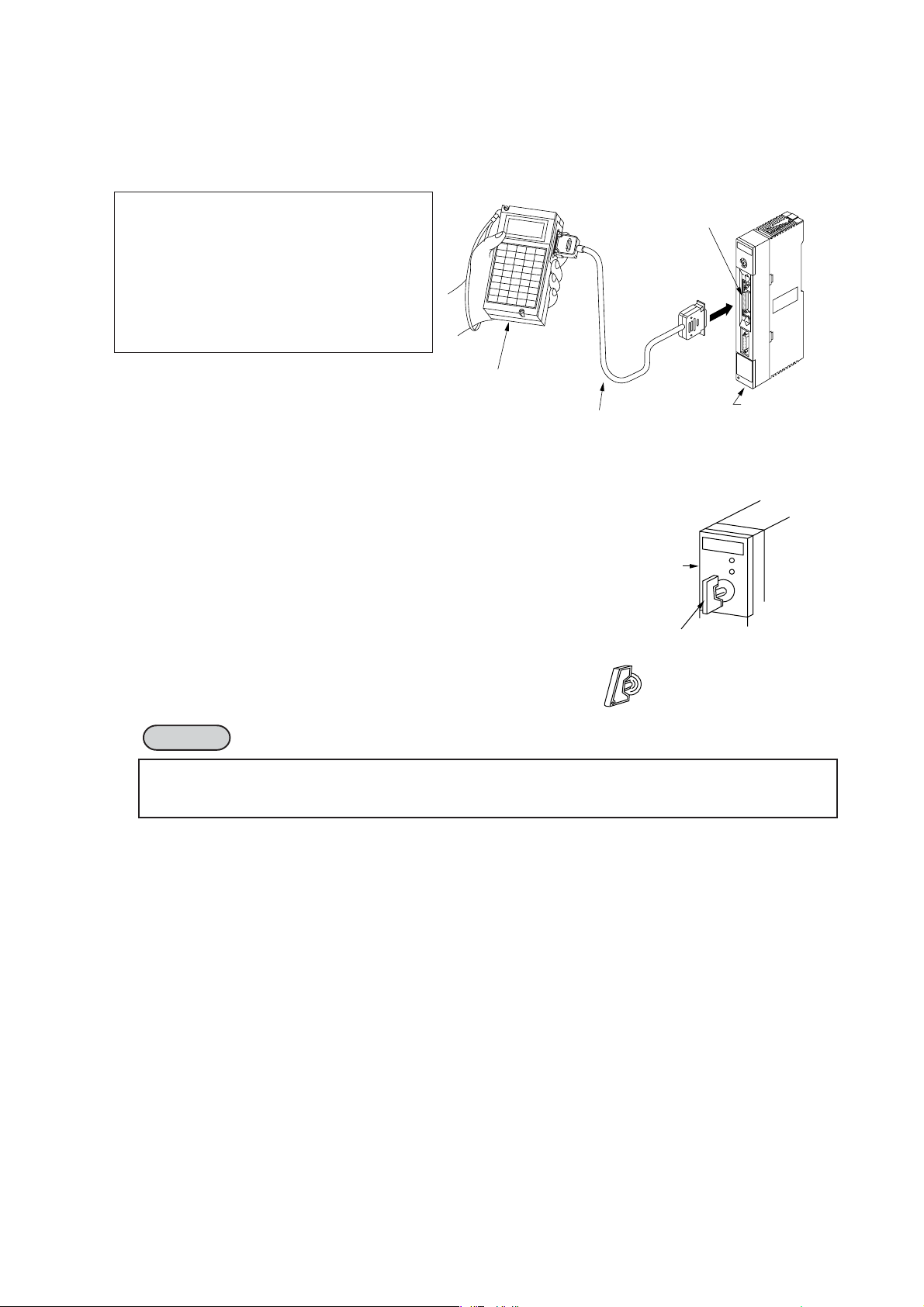

[3] Connecting to the JW30H, JW20H, and J-board control modules (board)

A common procedure is used to connect the programmer to the control modules.

1) Connect the JW-15PG with the control module

using the cable.

2) Secure the cable at the JW-15PG's end with

the bail locks and at the control module’s end

with the screws.

[Reference]

Set the PROTECT (memory protect) switch to "ON"

when connecting or disconnecting the JW-15PG

while the JW30H, etc.’s power is "ON." This protects the JW30H, etc.’s memory.

Programmer

(JW-15PG)

Memory module

Support tool

connector

Cable

JW-22KC

()

JW-24KC

Memory protect switch

ON

JW-22CU

Notes

(In case of JW20H)

When the JE-15PG is connected, a condition may occur where a "beep" is emitted and nothing is

displayed. This occurs when the control module has been set to the device function.

[4] Connecting to the JW10 basic module

Connect the JW-15PG and basic module using connection cable JW-12KC.

Connect the cable with the JW-15PG using the bail locks. Connect the cable with the basic module

using connector retention screws.

Basic module

Connector

retention

screw

Programer

(JW-15PG)

Connection cable

(JW-12KC)

5-4

Page 19

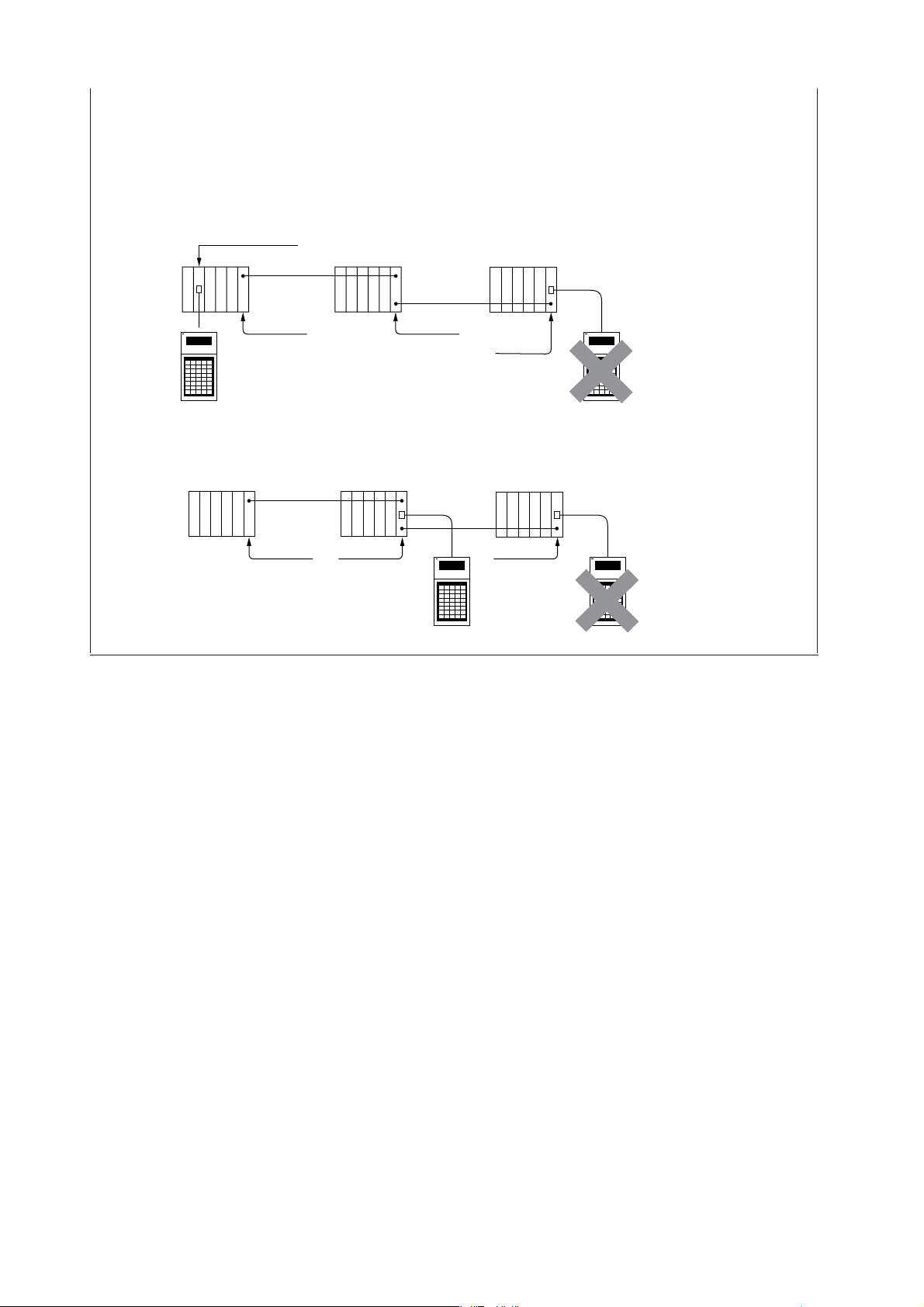

[5] Connecting to a module other than the control module

Installation methods of the JW-15PG are common for all the modules.

This section describes connection procedures to the JW-2EA I/O bus expansion adapter.

The modules other than control modules are as follows:

- I/O bus expansion adapter: JW-2EA, JW-32EA => See the precautions below.

- Network module: JW-20CM/22CM, ZW-20CM/30CM

- Remote I/O slave module: JW-20RS, ZW-20RS

- ME-MET module: JW-20MN/21MN, ZW-20CM2

- FL-net module: JW-50FL, JW-52FL,

JW-20FL5/T, JW-22FL5/T

- Serial interface module: JW-10SU

- Satellite net board: Z-335J

- ME-NET board: Z-334J

- FL-net board: Z-336J, Z-336J2

- Ethernet module (board): JW-50CM, JW-51CM, JW-255CM, Z-339J

- VME built-in controller : JW-32CV1/32CV2 /32CV3

JW-2EA

Precautions

(Connect with JW-2EA or JW-32EA)

●In case of JW300

- Only one support tool at a time (JW-300SP, JW-15PG) can be connected to the JW-32EA.

[Example]

Control module

JW-31EA

JW-32EA

JW-32EA

Support tool

Support tool

- With the JW300, when one support tool (JW-300SP, JW-15PG) is connected to the control module,

you can also connect another support tool to the JW-32EA.

[Example]

Control module

JW-31EA

JW-32EA

JW-32EA

Support tool

To the next page

Support tool

5-5

Page 20

●In case of JW50H/70H/100H, JW30H

Only one support tool can be connected to the JW-2EA, JW-32EA. If a support tool is already

connected to the control module or to another JW-2EA, JW-32EA, do not connect the programmer.

Connecting the programmer will cause a malfunction.

[Example]

Control module

[Example]

JW-1EA

Support tool Support tool

JW-1EA JW-2EA JW-2EA

JW-2EA

JW-2EA

Support toolSupport tool

5-6

Page 21

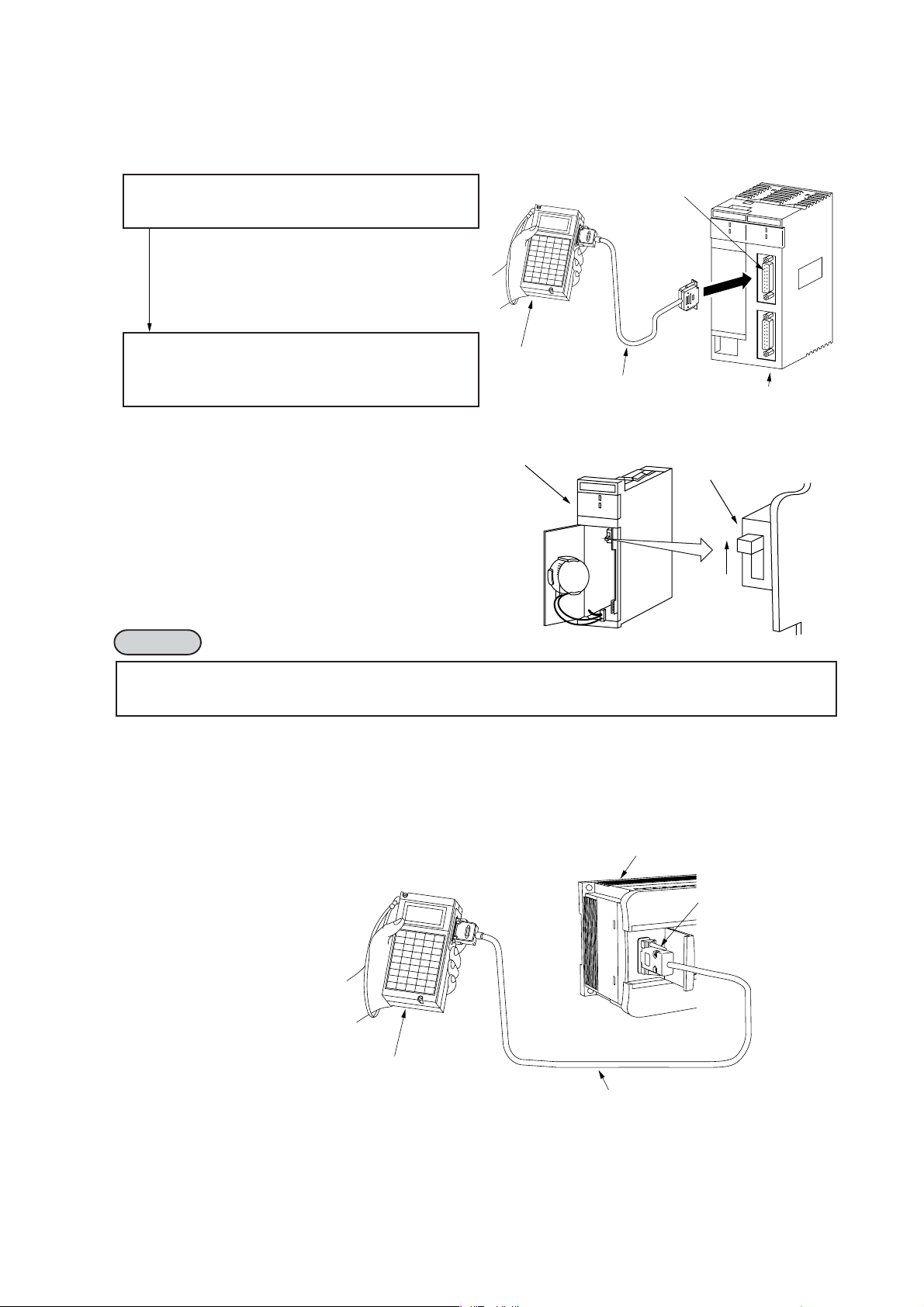

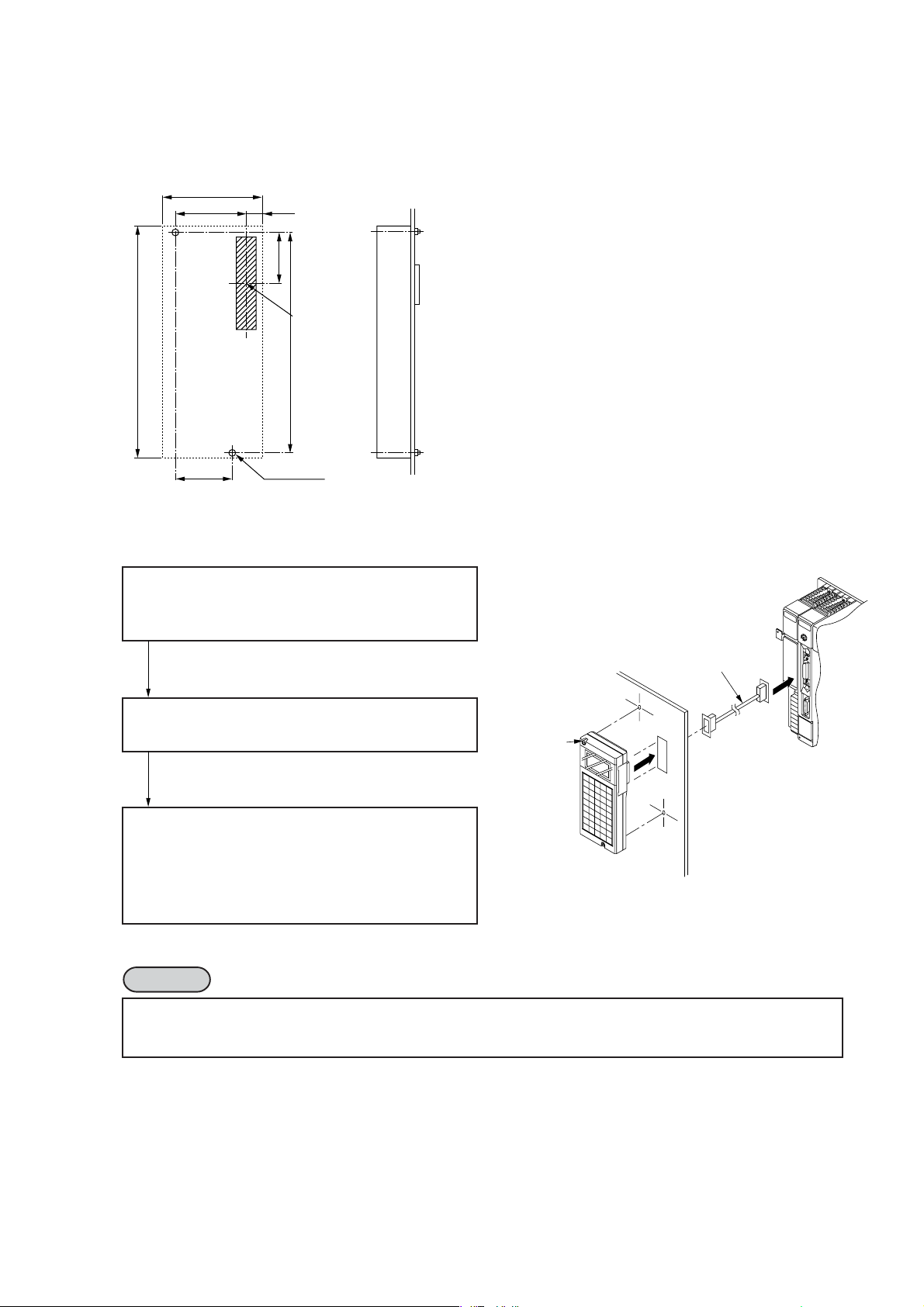

[6] Mounting to a control panel surface

The programmer can be connected by cable and mounted apart from the PLC. For example, the PLC

can be mounted in a control panel and the JW-15PG can be mounted to the door on the control panel.

(Unit: mm)

200

87

62 15

49

45

80×18

rectangular

190

hole

2-M3 tap

Make the M3 tapping holes used to secure the

JW-15PG and a hole for the connector in the

door on the control panel.

Connection

cable

ZW-IPU

JW-70CU

Mount the JW-15PG to the holes in the door on

the control panel.

Retention

screw

Connect the cable to the JW-15PG’s connector

and to the control module’s support tool connector. Firmly secure both the JW-15PG’s end and

the network module’s end of the cable with the

bail locks.

Notes

Keep the cable away from high voltage lines, power lines and the signal lines and power supply

lines to the I/O module.

5-7

Page 22

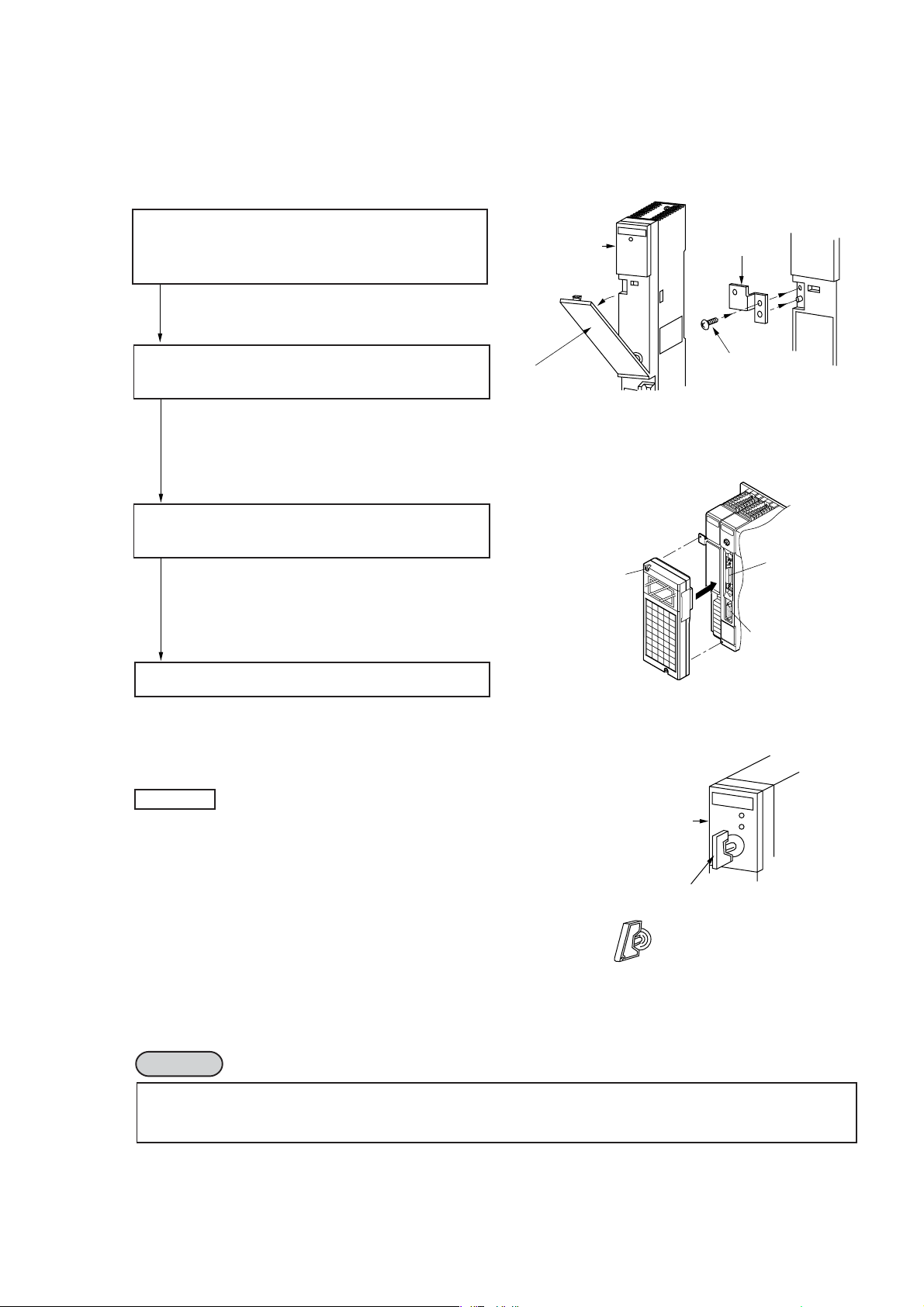

5-3 Direct mounting method

ZW-IPU

JW-70CU

Programmer

mounting screw

Communication

port

Support tool

connector

When JW50H/70H/100H, JW50/70/100, and W70H/100H PLC are used, you can install the JW-15PG

directly on the control module. The method to connect the JW-15PG with the control module directly is

shown below.

1) Detach the cover from the power supply

module and fasten the programmer mounting

bracket with the bracket screw.

2) Attach the power supply module cover and

detach the communication port cover. *

3) Connect the JW-15PG's connector to the

control module’s support tool connector.

Power supply

module

Power supply

module cover

Mounting

bracket

Bracket

screw

4) Tighten the 2 programmer mounting screws.

Reference

Set the memory protect switch to "ON" when

Control module

mounting or dismounting the programmer

while the JW50H/70H/100H, etc.’s power is

Memory protect switch

"ON." This protects the JW50H/70H/100H,

etc.’s memory.

ON (Input)

OFF (Output)

* Detach the communication port connector cover when directly mounting the programmer to the JW70H/

100H or JW70/100. Keep the detached cover.

Notes

- When the JW-15PG is connected, a condition may occur where a "beep" is emitted and nothing is

displayed. This occurs when the control module has been set to the device function.

5-8

Page 23

Chapter 6. Specifications

This chapter gives the general specifications and the performance specifications for the JW-15PG.

[1] General specifications

Items

Ambient temperature

Ambient humidity

Ambient operating atmosphere

Vibration resistance

Shock resistance

Consumption current

Weight

Accessories

[2] Performance specification

Items

- Control module - Ethernet module

- Network module - FL-net module

Modules to connect with

- ME-NET module - VME built-in controller

- Remote I/O slave module - J-board

- I/O bus expansion adapter

- Serial interface module *

Operation

Storage

Operation

Storage

Specifications

0 to 40oC

–20 to 60oC

35 to 85% RH (non-condensing)

Free from corrosive gas and dust.

Conform to JIS B 3502

(2 hours each in X, Y and Z axes)

Conform to JIS B 3502

110 mA

Approx. 400 g

Bail lock set 1

Programmer mounting bracket 1

Programmer mounting bracket screw (M3x6) 1

Specifications

Connection method

Display device

Keys

* Use the MODE switches on the JW-15PG to set it for the model that it is connected to (and to change

between Japanese/English). => Refer to page 4-2.

- Cable connection (for all module for connection listed above)

- Direct mounting (JW50H/70H/100H, JW50/70/100, W70H/100H)

Liquid crystal full dot matrix display (16 characters by 4 lines)

- With EL backlight

(Auto OFF: Turns OFF: after about 10 minutes from the last key

operation.)

- Contrast adjustment (key operation)

- Selectable between Japanese and English displays

45 flat keys

- Audible alarm is emitted at an invalid operation

- Key click sound is ON/OFF selectable

*

6-1

Page 24

[3] Dimensions

MODE

8

7

9

6

5

0

4

1

3

2

(Unit: mm)

200

6

87 3030 6

6-2

Page 25

Chapter 7. Table of Functions

Shown below are the functions of the JW-15PG and the compatible PLC models.

- The function usable in each PLC is indicated by circle mark.

- The key procedures for each function are shown in Chapter 8. (The right hand column in the table below

shows the pages to refer to.)

Functions

Buzzer ON/OFF

selection

EL backlight

ON/OFF selection

Contrast

adjustment

Auto repeat

function

Display mode

selection

Program

Monitor

Change

Terminal

Initial

Operation mode setting

Menu selection

JW300

JW50H/70H/100H

JW50/70/100

PLC models

JW30H

J-board (Z500)

JW20H, JW20

J-board (Z300)

JW10

W100

W70H

W100H

W10

W16

W51

Key

operation

(See

page)

○○ ○ ○○○○

8-1

○○ ○ ○○××

○

○

○

×

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

×

○

○

○

×

×

○

○

×

×

8-2

○

○

○○ ○ ○○○○

System memory

Program memory

Data memory

File register

(file 1)

Files 2 to 7

Memory clear

Files C, D, E

Files 2, 3

10 to 2C

Read

Write

Write

System memory

check code

Enter program

address

Instruction entry

method

Write

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○○ ○ −−○○

−

−

−

○

○

○

−

−

−○−−−−

○○○○○○

−

−

−

−

○

−

−

−

8-3

○○ ○ ○○○×

○○ ○ ○○○○

8-4

to

8-6

Program

Read

- The VMEs with built-in controllers (JW-32CV1/2/3) can be read the same as the "JW30H (JW-32CUH1)."

7-1

Page 26

Function

Search

instruction

Search

NOP

instruction

Search

Non-NOP

instruction

Search

Search program

data

memory

Retry search

Change

instruction

PLC models

JW300

JW50H/70H/100H

JW50/70/100

JW30H

J-board (Z500)

JW20H, JW20

J-board (Z300)

JW10

W100

W70H

W100H

W10

W16

W51

○○ ○ ○○○○

Key

operation

(See

page)

8-6

8-7

Insert

instruction

Delete

instruction

Write during

RUN

Change TMR,

Modify program

CNT, MD

preset value

Change

application

instruction

constant

Copy

program

(write)

insert copy

Block write

and insert

program

Edit program

Delete

program

block

Check parity

○○ ○ ○○○○

*1

○○ ○ ○○○

*2

8-7

○○ ○ ○○○○

×○*3×××

×

×

×

××

8-7

8-8

Check

program

Check program

Monitor program

○

○

○

○

*1: Version 2.1 or later basic rack panel.

*2: W10 --- ×, W16/51 --- ○

*3: JW50H/70H/100H (the expansion relays can be used) --- ×

7-2

○

○○

8-8

Page 27

Functions

Monitor

relay

Monitor

TMR, CNT,

MD

Monitor

register

Monitor

multiple

Monitor data memory

point

JW300

○○ ○ ○○○○

JW50H/70H/100H

JW50/70/100

PLC models

JW30H

J-board (Z500)

JW20H, JW20

J-board (Z300)

JW10

W100

W70H

W100H

W10

W16

W51

Key

operation

(See

page)

8-9

Monitor

break

Break at

designated

program

address

Break at

END

instruction

Break at

designated

register

Monitor break (debug function)

One step

run of

break

monitor

○○○

×

○

Forced set/

reset

Read internal

memory by

hexadecimal

designation

×

Write internal

memory by

hexadecimal

designation

Read/write internal memory

Set/rest

latched

relay

Set/reset

timer and

counter

Change

register

Change data memory

block

○○ ○ ○○○○

○

××

×

○○

○

8-10

×

×

○

8-11

7-3

Page 28

Functions

Insert current

register value

Delete

current

Correct current

register value

register value

Copy write

or insert

register

Block write

or insert

register

Delete

Edit current register

value

register block

Monitor I/O

JW300

JW50H/70H/100H

JW50/70/100

*

×○

PLC models

JW30H

J-board (Z500)

×

JW20H, JW20

J-board (Z300)

×

JW10

W100

W70H

W100H

W10

W16

W51

×××

Key

operation

(See

page)

8-12

8-12

8-13

Search I/O

Clear and

execute

Monitor process of

I/O module

I/O verify

I/O module

monitor process

Connect/remove

I/O module

live line

Auto I/O

module

registration

Enter rack

top address

Enter number

of dummy

points

Assign

special I/O

data register

Auto

I/O address assignment

registration

Create table

×

○

×

○

×

○

×

○

×

×

○

×

○

×

○

×

×××

×××

8-13

8-14

8-15

8-16

I/O module

registration

Set parameter

××

×

○

○○

* JW50H/70H/100H (the expansion relays can be used) --- ×

7-4

8-17

Page 29

Function

Set clock

Monitor clock

Set parameter

such as network

module

Connect

standard

network

Connect

satellite net

expansion

and remote monitor

Remote programming

function

Monitor target

station number

Display

output

function

Key input

function

Device

function

PLC models

JW300

JW50H/70H/100H

JW50/70/100

JW30H

J-board (Z500)

JW20H, JW20

J-board (Z300)

×○ ○ ○

[Applicable models]

JW-20CM/20RS/22CM

ZW-20CM/20RS/30CM

JW-20MN/21MN

ZW-20CM2

Z-334J/Z-335J

JW-50CM

JW-51CM

JW-255CM

JW-25TCM

Z-339J

Only setting of parameter

×○ ○

- Set the parameters for the JW22CM, JW-21MN, JW-255CM,

and JW-25TCM in the optional

parameters for the control

module on the JW300.

○

JW10

W100

W70H

W100H

W10

W16

W51

○××

×

×

×

Key

operation

(See

page)

8-18

8-19

Write program to

EEPROM

Read program

to ROM

Verifiy program

with ROM

Transfer to ROM

writer

××

×

*3

○○○ ○ ○

*1

○

×

*2

××

○

*1 W10・・・○, W16/51・・・×

*2 W10・・・○, W16/51・・・×

*3 W100・・・×, W70H/100H・・・×

×

7-5

Page 30

Functions

SF monitor

Symbol

registration

JW300

JW50H/70H/100H

JW50/70/100

PLC models

JW30H

J-board (Z500)

JW20H, JW20

J-board (Z300)

JW10

W100

W70H

W100H

W10

W16

W51

Key

operation

(See

page)

×× × ○×××

Monitor error

Secret function

OCT/DCML/

HEX display of

numerical value

PC card

○○ ○ ○○○○

8-20

○× ○ ×○××

×× ○ ×○××

○× × ××××

8-23

7-6

Page 31

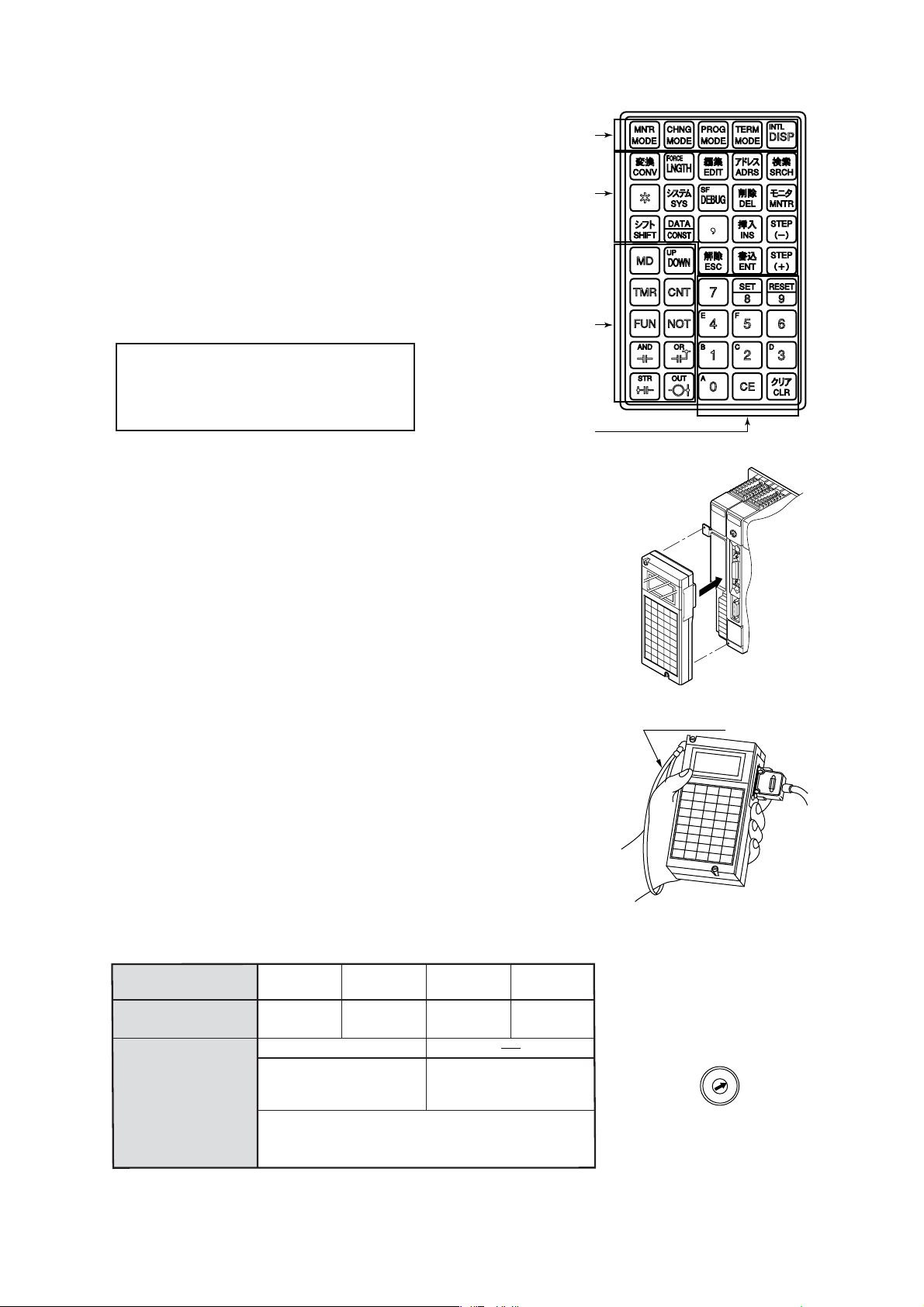

Chapter 8. Table of Operation Procedure

This chapter shows the key procedures for the functions (described in Chapter 7) on the JW-15PG.

The table can be read as follows:

Reference pages in the

JW-14PG Instruction Manual

The page numbers refer

to pages with tables that

describe which models

can use the function.

Function

Operation mode

selection

(P, M, C, T, I)

Mode sign which the

operation is allowed

Function name

Operation procedure

P: Program mode

M: Monitor mode

C: Change mode

T: Terminal mode

I: Initial mode

JW-14PG

(See page)

(Program mode)

(Monitor mode)

(Change mode)

Operation procedure is shown here.

39 7-1

PLC model

(See page)

Function

Turn buzzer

ON/OFF

(P, M, C, , I)

Turn EL

backlight

ON/OFF

(P, M, C, , I)

Adjust contrast

(P, M, C, , I)

Auto repeat

function

(P, M, C, , )

Change display

mode

(P, M, C, , )

Monitor program

address or data

memory address

Operation procedure

(ON)

(OFF)

(ON)

(OFF)

(Darker)

(Brighter)

Turn ON 1 second

( )

or longer

Turn OFF 1 second

( )

or longer

2PG mode1PG mode

Repeat

address +1.

Repeat

address -1.

JW-14PG

(See page)

34

35

36

37

38

PLC model

(See page)

7-1

8-1

Page 32

Function

Select operation

mode

(P, M, C, T, I)

Program mode

3rd

Operation procedure

(Program mode)

(Monitor mode)

(Change mode)

(Terminal mode)

Turn ON/OFF EL back light

(Initial mode)

JW-14PG

(See page)

39

PLC model

(See page)

Operation screen

menu selection

(P, M, C, T, I)

1st

2nd

4th

5th

Normal key operation

6th

7th

Turn ON/OFF buzzer

Monitor time

Monitor target station

number

Connect/remove live lines

of I/O module

Monitor error

Monitor I/O

Change display mode

Initial mode

Monitor mode

Change mode

Program mode,

clear memory

Device function

7-1

41

Check parity

Check program

8-2

Page 33

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

Clear memory

(P, , , , )

Read system

memory

(P, M, C, , )

*1

Set file

register

number

Set the program

capacity after

expansion

to

Set the system

memory address.

Clear system memory

Clear program memory

Clear data memory

Clear file register

Clear assigned file

register

Clear data memory,

program memory

Initialize all

Clear expansion

program memory

(initialization)

*2

*3

(Read in address

incrementing direction)

(Read in address

decrementing direction)

42

7-1

53

Write system

memory

(P, , , , )

System memory

write

(1 byte)

(1 word)

Set data

HEX/ OCT/DCML

bit pattern

Write system

memory

Read/write system memory

check code

(P, , , , )

*1: On the JW300, if you press or you can select the block of program memory to clear.

*2: On the JW300, you cannot perform a "clear the specified file register" operation.

*3: On the W16/51, W100, and W70H/100H, a "clear the file register (file 1)" can be performed.

55

57

=> See page 9-15

=> See page 9-16

8-3

Page 34

Function

Set program

address

(P, M, C, , ) *1

to

Set address

Operation procedure

JW-14PG

(See page)

60

PLC model

(See page)

Entry method

of basic

instructions

- TMR

- CNT

Instruction key

*2

TMR/CNT

number

- MD

instructions

entry method

- UTMR

*3

- UCNT

- UP(TMR/CNT)

- DTMR

- DCNT

instructions

- DOWN(TMR/CNT)

entry method

(BCD/BIN)

- F-XX instruction

Function number

- FcXX instruction

Enter basic and application instruction

Application

instructions

Function number

Register/constant

entry method

(Repeat setting for the number of instruction words)

Relay number

BCD

BIN

Set value

*4

TMR/CNT

number

Set value

*4

F-XX(FcXX)

F-XXw(FcXXw)

F-XXd(FcXXd)

61

62

7-1

63

F-80

IORF

: Rack number

R

: Slot number

S

: Specify conversion

B

R, S, B

byte position

Slot number

Function number

Rack number

Specify conversion

byte position

Items *1 to *4 below only apply to the JW300.

*1: Method to block move a program. => Refer to page 9-1 to 3

*2: How to enter basic instruction (STR POS etc.). => Refer to page 9-10

*3: How to enter index qualifications. => Refer to page 9-13

*4: Registers can be used to set values for the TMR, CNT, UTMR, UCNT, DTMR, and the DCNT instructions.

To use this function, press the key to change the memory pointer and enter an address. => Refer to page 9-11

In addition, you can also specify a register in the JW10.

8-4

Page 35

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

Application

instruction

entry

method

Register

area

F-202

OPCH

P

c

ST

N

n

Press the key to change the register area.

[Example of JW300]

00000

P, C

File N

ST

: Rack port number

: Channel number

: Communication

station number

: File number

: File address

b00000 009000 E0000 Z000

selection

Enter basic and application instruction

Assign

indirect

Register number @register number

address

Function

n

Channel

number

Port number

number

64

Communication

station number

File number

File address

(Word instruction

only)

f 00000000

(File register)

65

7-1

Display 0000 Address

Set the

Display b0000 Address

register

address

Display 09000

Display b0000 Address

Enter application instruction

- Write from address 00000

- Write from a specified address

Write

program

(P, , , , )

Read/write program

Enter program

address

(Refer to 8-10)

- Write from an address where no program is written

Instruction word

Search for NOP

instruction

Enter register

number

(0 to 9)

Instruction

word

Instruction

word

Address

66

8-5

Page 36

Function

Read

program

(P, M, C, , )

Operation procedure

- Read by specifying an address

Set program

address

(Refer to page 8-4)

- Search an instruction and read

Search

(Read in address incrementing direction)

instruction

(As follows)

(Read in address decrementing direction)

(Read in address

incrementing direction)

(Read in address

decrementing direction)

JW-14PG

(See page)

75

PLC model

(See page)

7-1

Read/write program

- Search data memory and read

Search

instruction

(P, M, C, , )

Search NOP

instruction

(P, M, C, , )

Search

non-NOP

Search program

instruction

(P, M, C, , )

Search data

memory

(As follows)

Specify search

start address

(Refer to page 8-4)

Specify search

address

(Refer to page 8-4)

Specify search

start address

(Refer to page 8-4)

(Read in address incrementing

direction)

(Read in address decrementing

direction)

Specify instruction

to search.

Address incrementing direction

Address decrementing

direction

Continuous search

Address increment direction

Address

decrement

direction

Address increment

direction

Address

decrement

direction

76

78

7-2

79

Search data

memory

(P, M, C, , )

Set data memory address

Data memory

address

(Address incrementing direction)

Continue

(Address decrementing

direction)

Press the key to change the data memory area. *

[Example of JW20H]

Relay number

(00000 to 15777)

Label number

(LB0000 to LB1377)

TMR/CNT/MD number

(000 to 777)

Register

(E0000 to E1777)

Byte address

(0000 to 1577)

Register

(09000 to 99777)

Byte address

(b0000 to b1777)

* Change the data memory in the JW300 => Refer to page 9-14.

80

8-6

Page 37

Function

Re-execute

search

(P, M, C, , )

Search programModify program

Search

instruction

(Refer to page 8-6)

Search data

memory

(Refer to page 8-6)

Operation procedure

Search with the modified contents

(Address incrementing direction)

Modify

program

(Address decrementing direction)

(Address incrementing direction)

(Address decrementing direction)

(Continuous operation)

JW-14PG

(See page)

83

PLC model

(See page)

Change

instruction

(P, , , , )

Insert

instruction

(P, , , , )

Delete

instruction

(P, , , , )

Write during

running

program

( , , C, , )

Change TMR,

CNT, and MD

preset value

(P, , C, , )

Change

application

instruction

constant

(P, , C, , )

Specify address to

modify

(Refer to page 8-4)

Specify address to

insert

(Refer to page 8-4)

Read the instruction

to delete

(Refer to page 8-6)

Read set value

currently programming

(Refer to page 8-6)

Search program

address

(Refer to page 8-4)

Specify instruction

to modify

Specify instruction

to insert

Modify program

Change set

value

Change set

value

84

86

88

7-2

89

90

92

Copy

write/insert

program

(P, , , , )

Edit program

(Display the

edit menu

screen)

(Select

program

process)

Enter last address

of copy source

Enter top address

of copy source

(Select

copy)

Enter top address

of copy source

94

Continuous copy

(Copy write)

(Copy insert)

8-7

Page 38

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

Write/insert

program block

(P, , , , )

Edit program

Delete

program block

(P, , , , )

(Display the

edit menu

screen)

(Select

program

process)

Enter top address

to write/insert

Enter last address

to write/insert

Continuous write/insert

Block write

Block insert

(Display the

edit menu

screen)

(Select

program

process)

Enter top address

to block delete

Enter last address

to block delete

(Select

block

process)

(Select

block

process)

(Select

block

delete)

(Select

block

delete)

Continuous

delete

Continuous check

98

101

7-2

Check parity

(P, , , , )

Check program

Check program

(P, , , , )

Monitor program

( , M, C, , )

Mode change to program mode

(Omit if already in program mode)

- Read program

Specify program

address

(Refer to page 8-4)

Search instruction

(Refer to page 8-4)

Search data memory

(Refer to page 8-6)

Continuous check

(Address incrementing

direction)

(Address decrementing

direction)

103

104

108

8-8

Page 39

Function

Operation procedure

Continuous monitor

JW-14PG

(See page)

PLC model

(See page)

Monitor relay

(P, M, C, , )

Monitor

TMR, CNT,

and MD

Press the key to change the data memory area. *

(P, M, C, , )

[Example of JW20H]

Relay number

(00000 to 15777)

Monitor

register

Monitor data memory

(P, M, C, , )

Display 0000 Address

Display b0000 Address

Monitor

multiple point

Display 09000

(P, M, C, , )

Display b0000 Address

Enter data

memory address

(Address incrementing

direction)

(Address decrementing

direction)

TMR/CNT/MD number

(000 to 777)

Register

(E0000 to E1777)

Enter register

Byte address

(0000 to 1577)

Register

(09000 to 09777)

Byte address

(b0000 to b1777)

Address

number

(0 to 9)

* Change the data memory in the JW300 => Refer to page 9-14.

114

117

7-3

120

124

8-9

Page 40

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

Monitor break

(P, , C, , )

Break by

- Break by specifying program address

specifying

program

address

(P, , C, , )

- Break at END instruction

Break at END

instruction

(P, , C, , )

- Break at register designation

(Specify comparison result)

(Match)

Break at

register

Break monitor (debug function)

destination

(P, , C, , )

(Does not

match)

(Write multiple register addresses)

Program monitor

(Refer to page 8-19)

Enter

break

(Select

program)

(Select END

instruction)

address

(Enter program

address)

[01 to 99 with the JW-20H]

Enter

break

(Select

register)

(PLC stop after

execution)

(PLC run after

execution)

address

(Enter register

address)

(No register to monitor)

(Register to monitor exists)

Enter number

of scans

(executions)

(0001 to 9999)

[01 to 99 with the JW20H]

Enter number of

scans (executions)

(0001 to 9999)

To 1 step run or

procedure after PLC stop.

Enter number of

registers to

monitor.

(1 to F

HEX

)

126

129

136

Specify

comparison

data

7-3

142

One step

operation of

the break

monitor

(P, , C, , )

Enter register

address

- Procedure after PLC stops operation

To each monitor operation

(Repeat 1 step execution)

Break by assigned

program address

Break by END

instruction

Break at assigned

register

8-10

(1 step operation)

Reset break

(Break)

condition

149

Page 41

Function

Forced set

and reset

( , , C, , )

Operation procedure

- Read the forced set/reset area

()

(Forced set/

reset screen

display)

(Specify 00 to 77)

- Set to a forced set area

Read forced set

area (00 to 37)

Enter relay

number

Specify

address

in octal

(Address

incrementing

direction)

(Address

incrementing

direction)

(Forced set)

JW-14PG

(See page)

PLC model

(See page)

- Set to a forced reset area

Read forced reset

area (40 to 77)

- Release forced set/reset relay

(Release in units of one point)

Read forced set/reset area

(Release all the points)

Read forced set/reset area

Read internal

memory

with

hexadecimal

(P, M, C, , )

Write internal

memory

with

hexadecimal

(P, , , , )

Read/write internal memory with

hexadecimal

Enter relay

number

Enter file number

or address

(in hexadecimal)

(Address incrementing direction)

(Address decrementing direction)

Enter file number

or address

(in hexadecimal)

Enter data

152

(Forced reset)

7-3

155

159

Set/reset latch

relay

(P, , C, , )

Set and reset

TMR and CNT

( , , C, , )

Change

Change data memory

register current

value

(P, , C, , )

Monitor relay

(Refer to page 8-9)

Monitor TMR or CNT

(Refer to page 8-9)

(Refer to page 8-9)

(Set)

(Reset)

Current valueMonitor register

8-11

(Set)

(Reset)

162

164

166

Page 42

Function

Enter

register

b area (b0000 to b1777)

current value

(P, , , , )

Delete

Register (09000 to 99777)

Register (E0000 to E1777)

Registers from file 1 to file E (000000 to 177777 each)

register

current value

Modify register current valueEdit register current value

(P, , , , )

Operation procedure

area (0000 to 1577)

Press the key

3 times.

Press the key

4 times.

Press the key

5 times.

Press the key

6 times.

Press the key

7 times.

Enter data length

(1 byte, 1 word

or 2 words)

Enter address

Enter

Register area

(09 to 99)

Enter address

Enter file

number

(1 to 7, C, D, E)

Enter data

(Enter with hexadecimal, octal,

decimal, bit pattern, or ASC)

Enter

address

Enter

address

(Insert)

(Delete)

JW-14PG

(See page)

170

174

PLC model

(See page)

Write copy

register

(P, , , , )

Insert copy

register

(P, , , , )

Block write

register

(P, , , , )

Block insert

register

(P, , , , )

(Display the

edit menu

screen.)

(Select data

memory

process.)

Enter last

address of

copy source

(Write copy)

(Insert copy)

(Display the

edit menu

screen)

(Select data

memory

process.)

Enter top address

to write/insert

Enter last address

to write/insert

Enter data to

write/insert

(Select

copy.)

Continuous edit

(Select

block

process)

Enter top address

of copy source

Enter top

address of copy

source

(Select block

write)

Continuous write

(Block write)

Continuous insert

7-4

176

181

(Block insert)

8-12

Page 43

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

(Display the

edit menu

screen)

Block register

delete

(P, , , , )

Enter top address of

register for block delete

Enter last address of

Edit register current valueI/O module monitor process (JW100H, etc.)

register for block delete

Monitor I/O

(P, M, C, , )

Enter slot number

(in hexadecimal)

- Search I/O by specifying byte address

Enter byte address

(in octal)

Search I/O

( , M, C, , )

- Search I/O by specifying a rack

number and slot number

(Select data

memory

process)

(Select I/O

monitor)

(Select

block

process)

Continuous delete

Enter rack

number (in octal)

Continuous monitor

(Select I/O

search)

(Select block

delete)

(Select byte

address

designation)

Continuous check

(Goes

ON)

(Goes

OFF)

185

188

7-4

191

Release and

execution of

I/O verification

(P, M, C, , )

Enter rack number

(in octal)

(Goes

(Goes

Continuous check

ON)

OFF)

Enter rack number

(in octal)

(With verification)

(Without verification)

(Select I/O

search)

(Select rack

and slot

designation)

Enter slot number

(in hexadecimal)

Enter slot number

(in hexadecimal)

195

8-13

Page 44

Function

Operation procedure

- Monitor by specifying the rack number and slot number

(Select rack and slot)

JW-14PG

(See page)

PLC model

(See page)

I/O module

monitor process

[JW20H,

JW30H, etc.]

( , M, C, , )

Connect/remove

live line of

I/O module

( , M, C, , )

Enter slot number

(in hexadecimal)

Continuous monitor

Module monitor

- Monitor by specifying the switch setting

(Select switch

specification)

Specify I/O

Enter set value

Option

I/O link

Module monitor

- Install/remove I/O module

- Restart operation

Enter rack

number

198

7-4

203

8-14

Page 45

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

[JW300]

Auto I/O

module

registration

*

( , , , , I)

[JW50H to

100H, etc.]

Auto I/O

module

registration

( , , , , I)

Enter I/O address

Change to

program mode

Auto I/O module

registration

"Auto registration

at power ON"

(I/O

assignment)

Auto I/O module

registration

"Auto registration

at power ON"

Auto I/O

module

registration

"Auto registration

after power ON"

Change to initial

mode

Change to initial modeChange to program mode

(I/O module

address)

(Data register

address of

special I/O module)

(I/O module

address)

(Data register

address of

special I/O module)

(Select I/O)

(Does not register)

(Register)

(Select I/O)

)

(No

)(Yes

)(No

)(Yes

(No

)

)(Yes

)(No

)(Yes

END

END

END

END

END

−

205

7-4

Change to

initial mode

Enter rack

number

(1 to 7)

[JW50H to

100H, etc.]

Enter rack

top address

(Free I/O

Change to

program mode

(Create

I/O table)

*

(Select

rack

address)

module

registration)

( , , , , I)

(Stop)

(Do not create)

(Create)

To *

(Continue)

* JW300 auto I/O registration => Refer to page 9-18

END

(Select

I/O)

(I/O assignment)

Enter top byte

address

(0000 to 1577)

207

8-15

Page 46

Function

Operation procedure

- Assign the number of dummy points (Free registration)

JW-14PG

(See page)

PLC model

(See page)

[JW50H to

100H, etc.]

Enter number

of dummy

points

(Free I/O

module

registration)

( , , , , I)

Change to

program mode

(Refer to page 8-2)

*1

(Create

I/O table)

(Select

dummy)

Enter number

of dummy points

(1 to 15)

- Reset table

Change to

program mode

(Refer to page 8-2)

(Create

I/O table)

(Select

dummy)

Change to

initial mode

(Refer to page 8-6)

Enter rack

number

(0 to 7)

Change to

initial mode

(Refer to page 8-2)

Rack number: 0

Slot number: 0

Number of dummy points: 0 point

(Select I/O) (Specify I/O)

Enter

slot number

(0 to F

(H)

)

(Stop)

(Do not create)

END

(Create)

To *1

(Continue)

(Select I/O) (Specify I/O)

(Stop)

(Create)

211

7-4

Enter I/O address

[JW50H to

100H, etc.]

Enter

special I/O

data register

(Free I/O

module

registration)

( , , , , I)

[JW30H, etc.]

Auto

registration

( , , , , I)

- Assign data register’s top address of special I/O

(Connect to control module)

Change to

program mode

(Refer to page 8-2) (Refer to page 8-2)

*2

(Create

I/O table)

(Select

dummy)

(0 to 7)

Change to

initial mode

Enter rack

number

(Select I/O) (Specify I/O)

Enter

slot number

(0 to F

Enter register

top address

Change to

program mode

Auto registration

"Auto registration

at power ON"

Change to

initial mode

(Stop)

(Continue)

(Select I/O)

(No)

(Yes)

(H)

)

(Do not create)

(Create)

To *2

END

214

END

218

8-16

Page 47

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

[JW30H, etc.]

Table

creation

( , , , , I)

Enter I/O address

[JW20H, etc.]

I/O

registration

( , , , , I)

Parameter

setting

[JW20H,

JW30H, etc.]

( , , , , I)

Change to

program mode

(Refer to page 8-2)

*

Enter rack

(Create

I/O table)

(Select

number

dummy)

Change to

program mode

(Refer to page 8-2)

(Refer to page 8-2)

Change to

program mode

(Refer to page 8-2) (Refer to page 8-2)

Change to

initial mode

(Refer to page 8-2)

(1 to 3) ( 0000 to 1577)

(Stop)

(Continue)

(Do not create)

Change to

initial mode

Program mode

Change to

initial mode

Change to

monitor or

change mode

Set parameter

address

Monitor

Set value

parameter

(Address incrementing

direction)

(Address decrementing

direction)

[Connect to control module]

(Select I/O)

Enter top byte

address

END

(Create)

*

To

(Select

I/O)

(Select

parameter)

During monitor

or change mode

(Registration)

(Stop)

Enter switch

set value

(Module No. SW)

(Select

special I/O)

(Select

option)

Continuous

operation

219

220

7-4

223

(Parameter)

Parameter

setting

[JW300]

*

Set parameter

address

( P, M, C, , )

Monitor

parameter

* JW300 parameter setting => Refer to page 9-17

(Select

special I/O)

(Select

option)

Set value

(Address incrementing

direction)

(Address decrementing

direction)

8-17

Enter switch

preset value

(Module No. SW)

Continuous

operation

−

Page 48

Function

Operation procedure

JW-14PG

(See page)

PLC model

(See page)

Set the clock

( , , , , I)

Monitor time

( P, M, C, , )

Set parameter

for network

module

( , , , , I)

Change to

program mode

(Refer to page 8-2) (Refer to page 8-2)

Enter

year

(Last 2 digits of Western calendar year)

Enter day

of-the-week

Change to

initial mode

Enter

month

Enter

hours

(Select clock)

Enter day

Enter

minutes

Enter seconds

(Monitor)

Release the monitor using the key.

- When Network Module or ME-NET Module is connected

Change to

initial mode

(Refer to page 8-2)

(Select

parameter address)

Enter parameter

address

- When Remote I/O Slave Module is

connected

Change to initial mode when connected

226

229

7-5

230

Read

parameter

- When Network Module or ME-NET Module is connected

Change to

initial mode

(Refer to page 8-2)

Connect

standard

network

- Connecting the JW-15PG

to the remote I/O slave

module

( , , , , I)

Change to initial mode

when connected

Remote programming

Write data

Specify the number of

the communication

station (target station)

Continuous write

(Address incremen ting direction)

(Address decremen ting direction)

(Select display mode)

(Select

link)

(Select

1PG 2PG1

mode)

(Select 2PG2

mode.)

After remote operation,

read/write parameter.

236

8-18

Page 49

Function

Satellite net

expansion

function

( , , , , I)

Operation procedure

- When Network Module or ME-NET Module is connected

(Select display mode)

Change to

initial mode

(Refer to page 8-2)

(Select

link)

(Select

1PG, 2PG1

mode)

(Select 2PG2

mode.)

Change to initial mode

when connected

(Select

junction

station

assignment)

Enter station

number of the

junction station

Enter rack

number of the

junction station

JW-14PG

(See page)

241

PLC model

(See page)

Enter slot number

Remote programming and remote monitor

of the junction

station

Remote operation

Monitor target

station number

(P, M, C, , I)

Device function

( , , , T, )

Change to terminal mode

(Refer to page 8-2)

Write program

to an EEPROM

(P, , , , )

(Display the

edit menu

screen)

(Select the

EEPROM

process)

Read program

from ROM

(P, , , , )

(Display the

edit menu

screen)

(Select

the ROM

process)

(Display target)

*

(Select

write to

EEPROM)

*

(Select

read from

ROM)

Enter station

number of the

junction station

(Write)

(Stop)

(Read)

(Stop)

245

246

252

254

7-5

Verify program

with ROM

[W10]

(P, , , , )

Data transfer to

ROM writer

[JW20H, etc.]

(P, M, C, , )

(Display the

edit menu

screen)

(Display the

edit menu

screen)

(Select

the ROM

process)

(Select

the ROM

process)

(Select

to verify

with ROM)

(Select

the

COMPORT)

(Verify)

(Stop)

(Transfer)

(Stop)

256

257

* On the JW300, operate the dotted rectangle above using the following operations. => Refer to page 9-19.

8-19

Page 50

Function

32 points/

1 point

monitor

( , M, C, , )

Enter step

number

0 to 77

SF monitor [JW20H, etc.]Secret function (JW30H, etc.)

Executing

step monitor

( , M, C, , )

(Select symbol registration)

Operation procedure

Enter process

(Select

32 pts.)

number

(1 point select)

(Free monitor)

(Step incrementing

direction monitor)

(8)

(Step decrementing

direction monitor)

Specify

(Select

execution

monitor)

process number

Enter data memory address

(8)

0 to 3

Continuous monitor

Continuous search

JW-14PG

(See page)

259

263

PLC model

(See page)

Symbol

registration

[JW20H, etc.]

(P, , , , )

Monitor error

(P, M, C, , )

Register

password

(P, , , , )

Delete

password

(P, , , , )

Secret ON

(P, , , , )

Enter process

number

Symbol display

Password (4 digits)

(0 to F)

Enter step

number

(8)

)

(0 to 77

(8)

)(0 to 3

265

Character

selection

Symbol registration

7-6

(Step incrementing

direction monitor)

(Step decrementing

270

direction monitor)

(Registration)

(Stop)

(Delete)

(Stop)

274

(ON)