Page 1

PREPARED BY: DATE

LIQUID CRYSTAL DISPLAY GROUP

Sakai Display Products Corporation

SPEC No.

FILE No.

ISSUE : Dec, 20, 2012 APPROVED BY: DATE

PAGE :

LD-K24Z07

SPECIFICATION

CUSTOMER'S APPROVAL

DATE

BY BY

MODEL No.

DEVICE SPECIFICATION FOR

DEVICE SPECIFICATION FOR

TFT-LCD Open Cell

JE400D3HC2N

PRESENTED

K.Kobayashi

Center General Manager

Technology Center

Liquid Crystal Display Business Group

Sakai Display Products Corporation

Sakai Display Products Corporation

Page 2

RECORDS OF REVISION

MODEL No. : JE400D3HC2N

SPEC No. : LD-K24Z07

SPEC No. DATE

LD-K24Z07 2012/12/20

REVISED

No.

- - - 1st ISSUE

PAGE SUMMARY NOTE

Page 3

LD-K24Z07-1

1 Application

This specification applies to the color 40.0” TFT-LCD Open Cell JE400D3HC2N.

With parts (S-Dr, G-Dr, S-PWB) to drive it.)

(

* This specification sheets are proprietary products of Sakai Display Products Corporation (“SDP”) and include

materials protected under copyright of SDP. Do not reproduce or cause any third party to reproduce them in any

form or by any means, electronic or mechanical, for any purpose, in whole or in part, without the express written

permission of SDP.

* In case of using the device for applications such as control and safety equipment for transportation (aircraft, trains,

automobiles, etc.), rescue and security equipment and various safety related equipment which require higher

reliability and safety, take into consideration that appropriate measures such as fail-safe functions and redundant

system design should be taken.

* Do not use the device for equipment that requires an extreme level of reliability, such as aerospace applications,

telecommunication equipment (trunk lines), nuclear power control equipment and medical or other equipment for

life support.

* SDP assumes no responsibility for any damage resulting from the use of the device that does not comply with the

instructions and the precautions specified in these specification.

* Contact and consult with the SDP sales representative for any questions about this device.

2 Overview

This Open Cell (JE400D3HC2N) is a color active matrix LCD PANEL incorporating amorphous silicon TFT (Thin

Film Transistor), Polarizers, Source-PWBs, Source-Drivers, Gate-Drivers and Control-PWB(C-PWB). The following

content can be achieved in using C-PWB (JE0DZ1C0010) that SDP specifies.

Graphics and texts can be displayed on a 1920×RGB×1080 dots panel with one billion colors by using 10bit

LVDS (Low Voltage Differential Signaling) to interface, +12V of DC supply voltages.

In order to improve the response time of LCD, This C-PWB applies the Over Shoot driving (O/S driving)

technology for the control circuit. In the O/S driving technology, signals are being applied to the Liquid Crystal

according to a pre-fixed process as an image signal of the present frame when a difference is found between image

signal of the previous frame and that of the current frame after comparing them.

With combination of this technologies, motion blur can be reduced and clearer display performance can be realized.

[Caution] You should design thermal conductive interface pad and C-PWB cover enough to radiate heat from T-CON

IC in C-PWB.

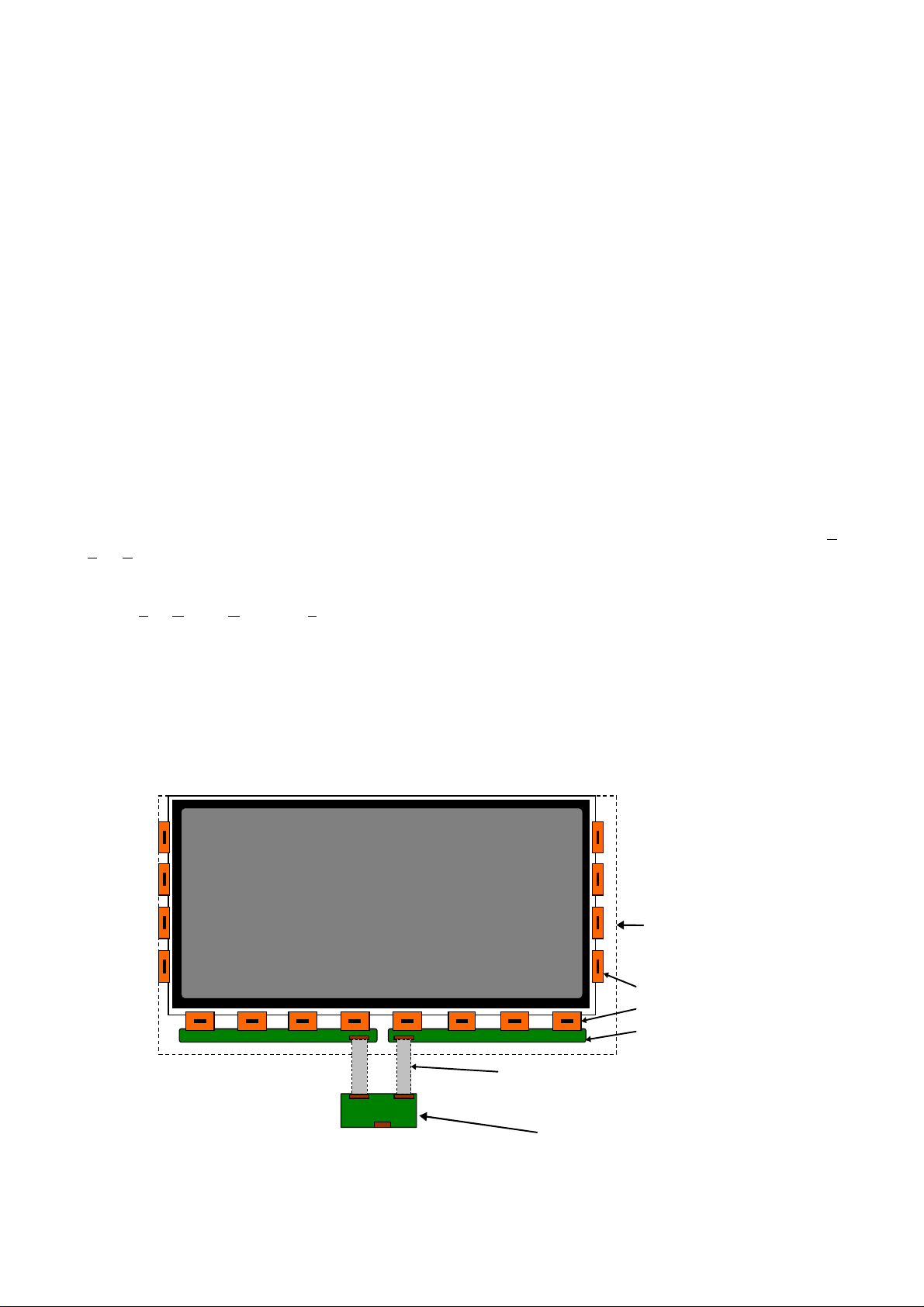

TFT LCD Panel

(1920 x RGB x 1080)

Fig.1 Overview of Open-Cell: JE400D3HC2N and C-PWB

Open Cell

Open Cell

Open CellOpen Cell

((((JE400D3HC2N

JE400D3HC2N))))

JE400D3HC2NJE400D3HC2N

Gate Driver

Source Driver

CN2

CN2

CN1

FFC (not attached)

CN3

CN1

1111

55551111

Control

Control----PW

ControlControl

PWB (JE0DZ1C0010)

PWPW

Source PWB (S-PWB)

B (JE0DZ1C0010)

B (JE0DZ1C0010)B (JE0DZ1C0010)

Page 4

Pin No.

Symbol

Function

Remark

1

GND

2

Reserved

It is required to set non

-

connection(OPEN)

3

Reserved

It is required to set non

-

connection(OPEN)

4

Reserved

It is required to set non

-

connection(OPEN)

5

Reserved

It

is required to set non

-

connection(OPEN)

6

Reserved

It is required to set non

-

connection(OPEN)

7

SELLVDS

Select LVDS data order

[Note

1,2]

Pull

down

8

Reserved

It is required to set non

-

connection(OPEN)

9

Reserved

It is required to set non

-

connection

(OPEN)

10

Reserved

It is required to set non

-

connection(OPEN)

11 GND

12

AIN0

- Aport (

-

)LVDS CH0 differential data input

13

AIN0+

Aport (+)LVDS CH0 differential data input

14

AIN1

- Aport (

-

)LVDS CH1 differential data input

15

AIN1+

Aport (+)LV

DS CH1 differential data input

16

AIN2

- Aport (

-

)LVDS CH2 differential data input

17

AIN2+

Aport (+)LVDS CH2 differential data input

18

GND

19

ACK

- Aport LVDS Clock signal(

-)

20

ACK+

Aport LVDS Clock signal(+)

21

GND

22

AIN3

- Aport (

-

)LVDS

CH3 differential data input

23

AIN3+

Aport (+)LVDS CH3 differential data input

24

AIN4

- Aport (

-

)LVDS CH4 differential data input

25

AIN4+

Aport (+)LVDS CH4 differential data input

26

GND

27

GND

28

BIN0

- Bport (

-

)LVDS CH0 differential data in

put

29

BIN0+

Bport (+)LVDS CH0 differential data input

30

BIN1

- Bport (

-

)LVDS CH1 differential data input

3 Mechanical Specifications

Parameter Specifications Unit

Display size

Active area 885.60(H) x 498.15 (V) mm

Pixel Format

Pixel pitch 0.46125 (H) x 0.46125 (V) mm

Pixel configuration R, G, B vertical stripe

Display mode Normally black

Cell Outline Dimensions[Note1] 921.18 (H) x 541.25(V) x 1.66(D) mm

Mass 1.72+0.3 kg

Surface treatment [Note2]

Underside Surface

treatment [Note2]

[Note1] Outline dimensions are shown in P20. Dimension "D" does not include the parts on S-PWB.

[Note2] With the protection film removed.

101.61 (Diagonal)

40.00 (Diagonal)

1920(H) x 1080(V)

1pixel = R + G + B dot)

(

Anti Glare

Hard coating : 2H and more

Hard coat less

4 Cell Driving Specifications

4.1 Driving interface of Control PWB SDP specifies

Parts code: JE0DZ1C0010

CN1 (Interface signals and +12V DC power supply) shown in Fig.1

Using connector : 91213-0510 (Aces Electronics Co., Ltd.)

Matching connector : FI-RE51HL, FI-RE51CL (Japan Aviation Electronics Ind., Ltd.) or

equivalent device

Matching LVDS transmitter : THC63LVD1023 or equivalent device

LD-K24Z07-2

cm

inch

pixel

Page 5

31

BIN1+

Bport (+)LVDS CH1 differential data input

32

BIN2

- Bport (

-

)LVDS CH2 differential data input

33

BIN2+

Bport (+)LVDS CH2 differentia

l data input

34

GND

35

BCK

- Bport LVDS Clock signal(

-)

36

BCK+

Bport LVDS Clock signal(+)

37

GND

38

BIN3

- Bport (

-

)LVDS CH3 differential data input

39

BIN3+

Bport (+)LVDS CH3 differential data input

40

BIN4

- Bport (

-

)LVDS CH4 differential d

ata input

41

BIN4+

Bport (+)LVDS CH4 differential data input

42

GND

43

GND

44

GND

45

GND

46

GND

47

VCC

+12V Power Supply

48

VCC

+12V Power Supply

49

VCC

+12V Power Supply

50

VCC

+12V Power Supply

51

VCC

+12V Power Supply

[Note] You should connect GND plane in Control PWB to module chassis.

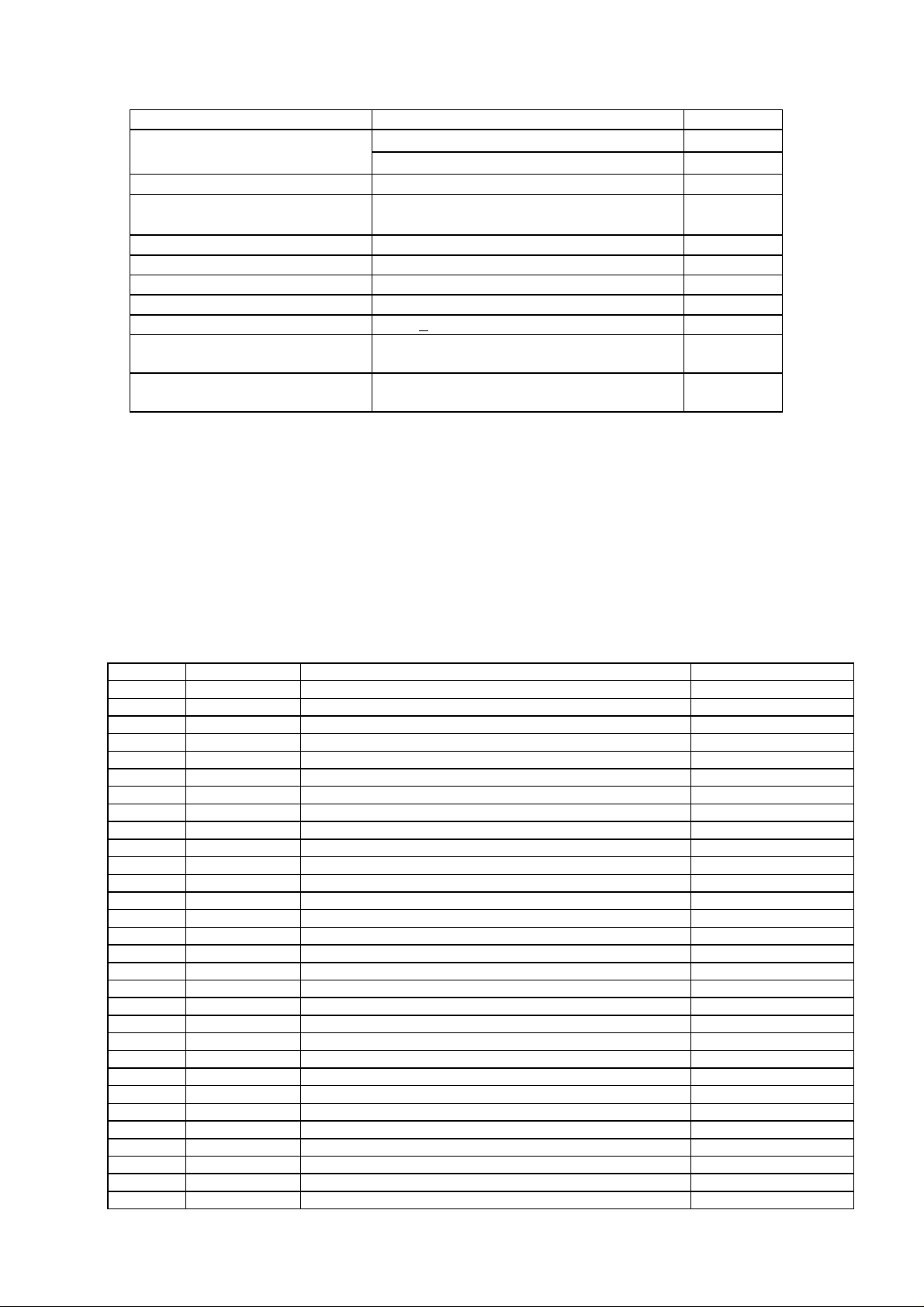

[Note 1] The equivalent circuit figure of the terminal:

Terminal

LD-K24Z07-3

4.7KΩ

Control PWB

Page 6

LD-K24Z07-4

[Note 2] LVDS Data order

SELLVDS

Data L(GND) or Open

[VESA]

TA0

TA1

TA2

TA3

TA4

TA5

TA6

TB0

TB1

TB2

TB3

TB4

TB5

TB6

TC0

TC1

TC2

TC3

TC4 NA NA

TC5 NA NA

TC6 DE(*) DE(*)

TD0

TD1

TD2

TD3

TD4

TD5

TD6

TE0

TE1

TE2

TE3

TE4

TE5

TE6

NA: Not Available

(*)Since the display position is prescribed by the rise of DE(Display Enable)signal, please do not fix DE signal

at ”High” during operation. And you should input DE signal in all LVDS port.

R0(LSB)

R1

R2

R3

R4

R5

G0(LSB)

G1

G2

G3

G4

G5

B0(LSB)

B1

B2

B3

B4

B5

R6

R7

G6

G7

B6

B7

N/A

R8

R9(MSB)

G8

G9(MSB)

B8

B9(MSB)

N/A

H(3.3V)

[JEIDA]

R4

R5

R6

R7

R8

R9(MSB)

G4

G5

G6

G7

G8

G9(MSB)

B4

B5

B6

B7

B8

B9(MSB)

R2

R3

G2

G3

B2

B3

N/A

R0(LSB)

R1

G0(LSB)

G1

B0(LSB)

B1

N/A

Page 7

SELLVDS= Low (GND) or OPEN::::VESA

ACK+,BCK+

ACK– ,BCK

AIN0+,BIN0+

AIN0–,BIN0

AIN1+,BIN1+

AIN1–,BIN1

–

–

–

G0 R5 R4 R3 R2 R1 R0 R0 R1 G0

B1 B0 G5 G4 G3 G2 G1 G1 G2 B1

AIN2+,BIN2+

AIN2–,BIN2

AIN3+,BIN3+

AIN3–,BIN3

–

–

DE

AIN4+,BIN4+

AIN4–,BIN4

–

SELLVDS= High (3.3V)::::JEIDA

ACK+,BCK+

ACK– ,BCK

AIN0+,BIN0+

AIN0–,BIN0

AIN1+,BIN1+

AIN1–,BIN1

AIN2+,BIN2+

AIN2–,BIN2

AIN3+,BIN3+

AIN3–,BIN3

AIN4+,BIN4+

AIN4

–

,BIN4

–

–

–

–

G4 R9 R8 R7 R6 R5 R4 R4 R5 G4

B5 B4 G9 G8 G7 G6 G5 G5 G6 B5

DE

–

–

DE: Display Enable, NA: Not Available (Fixed Low)

NA NA

B7 B6 G7 G6 R7 R6 R6 R7 NA NA

B9 B8 G9 G8 R9 R8 R8 R9 NA NA

NA NA

B3 B2 G3 G2 R3 R2 R2 R3 NA NA

B1 B0 G1 G0 R1 R0 R0 R1 NA NA

1 cycle

B5 B4 B3 B2 B2 B3

1 cycle

B9 B8 B7 B6 B6 B7

LD-K24Z07-5

DE

DE

Page 8

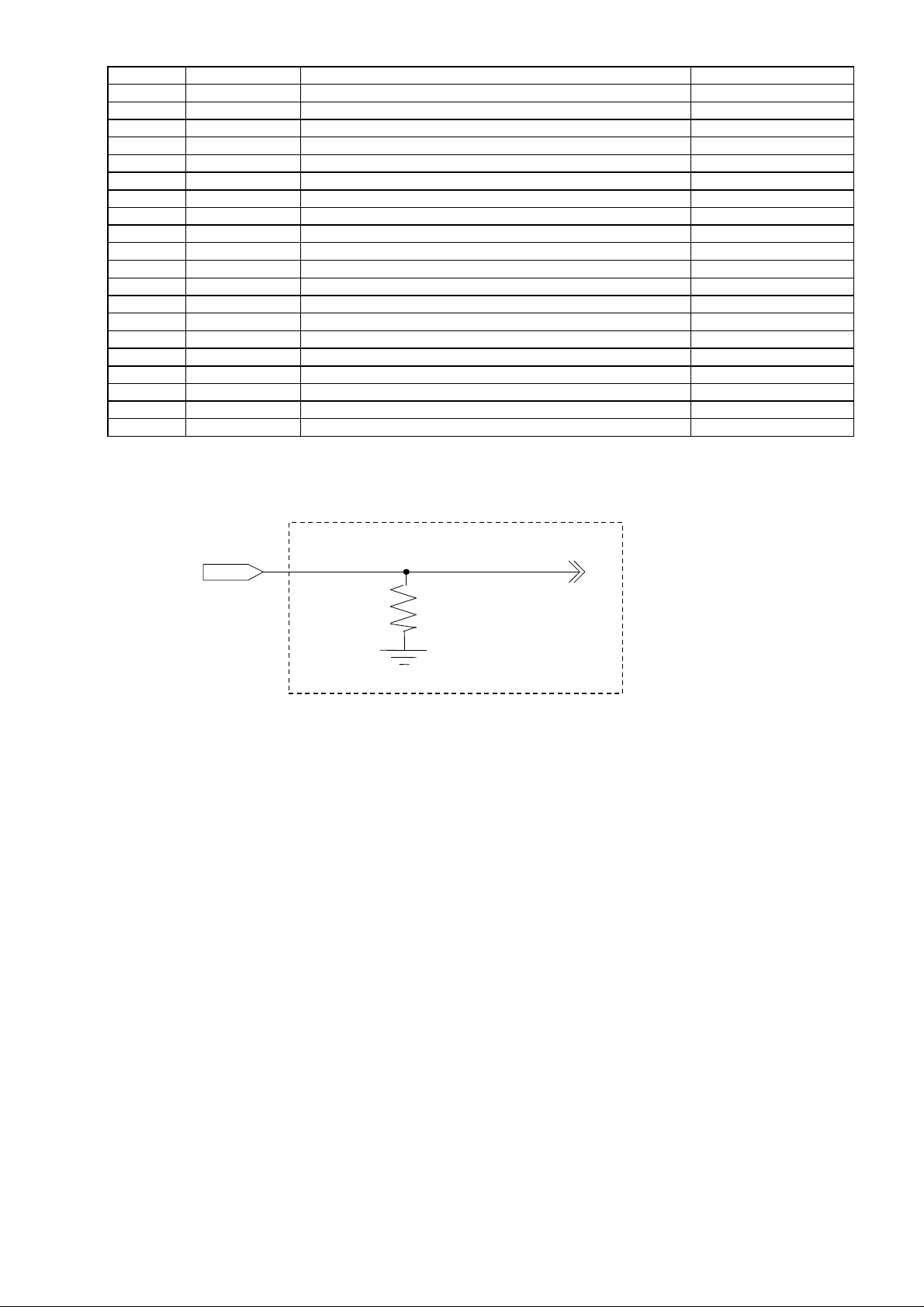

INPUT SIGNALS

GATE DRIVER

SOURCE

DRIVER

CN4

SOURCE

PWB SOURCE

PWB

INPUT SIGNALS

I2C SCL

4.2

4.2

Interface block diagram

4.24.2

SELLVDS

AIN0- AIN0+

AIN1- AIN1+

AIN2- AIN2+

AIN3- AIN3+

AIN4- AIN4+

ACK- ACK+

BIN0- BIN0+

BIN1- BIN1+

BIN2- BIN2+

BIN3- BIN3+

BIN4- BIN4+

BCK- BCK+

POWER SUPPLY

+12V DC

4.3

4.3

Display position of data

4.34.3

LCD PANEL

1920×3(RGB)×1080

GATE DRIVER

Signals &

Power Supply

Signals &

Power Supply

C-PWB

CN1

Fig.2 Interface block diagram

LD-K24Z07-6

I2C SDA

B1 G1 R1 B2 G2 R2

(1,1) (1,2)

1,1 1,2 1,3

2,1 2,2

3,1

B G R

1080,1

S-PWB S-PWB

1,1920

1080,1920

[Note] You should assemble Open-Cell for S-PWBs to be located at the downside of your TV set.

Page 9

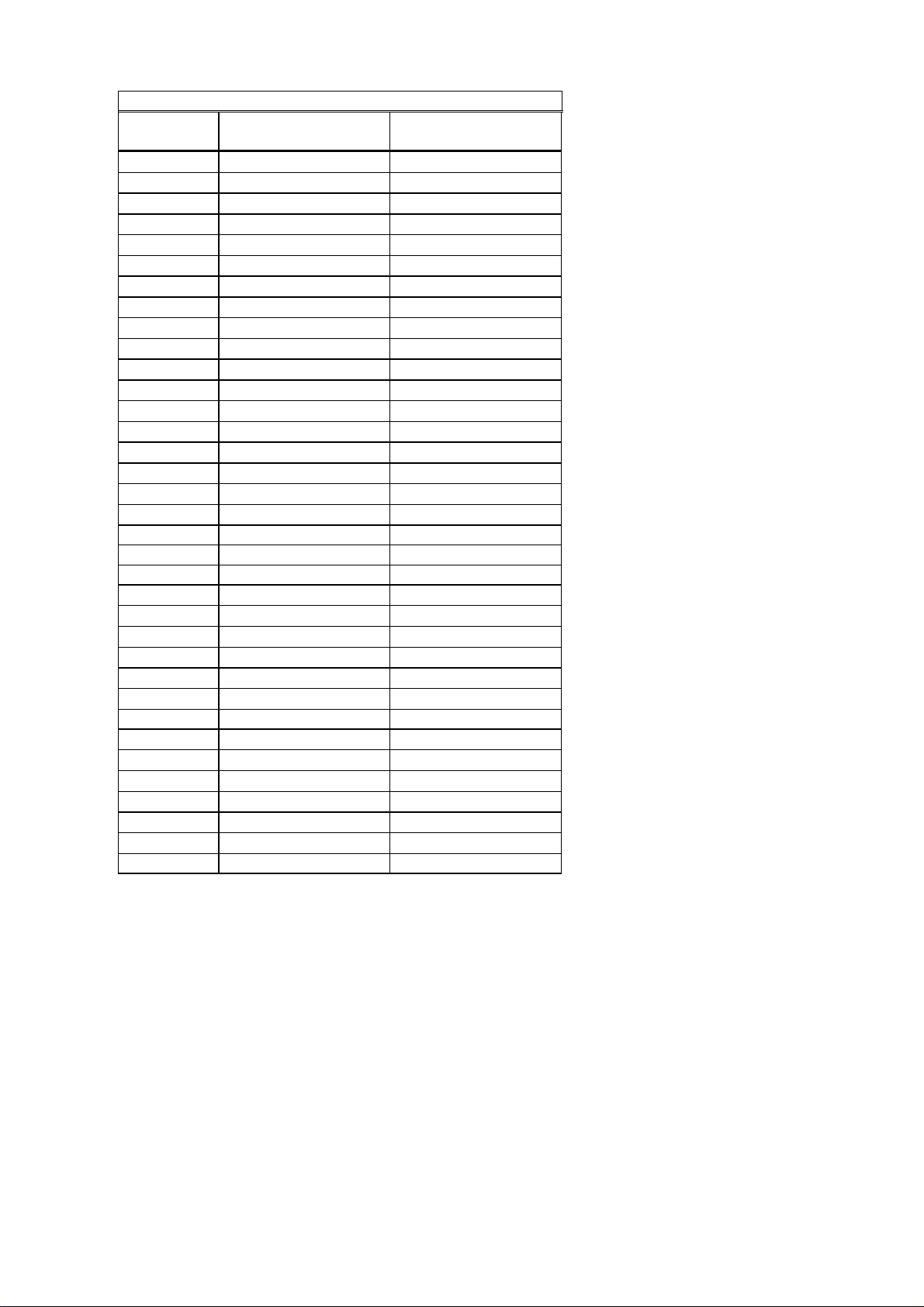

4.4 Vcom Adjusting interface of Control PWB SDP specifies [JE0DZ1C0010]

1 pixel

For the prevention of long-time image sticking of TFT-LCD panel, be sure to adjust Vcom

flicker to be minimized on the center of display by visual or flicker meter.

.

[Note 1] Please adjust VCOM voltage at below pattern:

V0

V0

V0

V0

V512

V512

V512

V0

V0

V512

V512

V0

V0

V512

V0

V512

V0

V512

V512

V0

V512

V0

V512

V512

V0

V0

V512

1 dot

[Note 2] VCOM voltage can be adjusted through via hole (CN4). Potentiometer IC and via hole are as follows:

IC for adjusting VCOM : ISL24837A (Intersil)

Using Via Hole : 1.5mm Pitch (φ0.7mm )

Mating connector : (housing)5P-SZN,

(contact)SZN-002T-P0.7K (JST Co.,Ltd.)

Communication method

: I2C

CN4

Pin No.

symbol Function Remark

1 SCL I2C CLK Pull up:3.3V[Note3]

2 SDA I2C DATA

3 BUS_EN

4

- -

-

Pull up:3.3V[Note3]

Required to set NC

5 GND GND -

[Note3] The equivalent circuit figure of the terminal

3.3[V]

3.3[V]

2.2 [kΩ]

Terminal

Terminal

Terminal

LD-K24Z07-7

Page 10

4.5 Driving interface of S-PWB

CN1 and CN2 on the S-PWB: Input signal from C-PWB

- Using connector: 25P80B120 (ZXEC) or equivalent connector

Pin No.

CN1 on the S-PWB CN2 on the S-PWB

GND GND

1

Gate Power (L) Gate Power (L)

2

Gate Power (H) Gate Power (H)

3

Gate Start Pulse2 Gate Start Pulse 2

4

Gate Start Pulse1 Gate Start Pulse 1

5

Gate Clock Gate Clock

6

Gate Output Enable Gate Output Enable

7

Gate Scan Control Gate Scan Control

8

MPD Control 1 MPD Control 1

9

MPD Control 2

10

MPD Control 3

11

MPD Control 4

12

MPD Control 5

13

MPD Control 6

14

MPD Control 7

15

MPD Control 8

16

MPD Control 9

17

MPD Control 10

18

MPD Control 11

19

MPD Control 12

20

21 Vcom Vcom

22 Gray Level 9 (H) Gray Level 9 (H)

23 Gray Level 8 (H) Gray Level 8 (H)

24 Gray Level 7 (H) Gray Level 7 (H)

25 Gray Level 6 (H) Gray Level 6 (H)

26 Gray Level 5 (H) Gray Level 5 (H)

27 Gray Level 4 (H) Gray Level 4 (H)

28 Gray Level 3 (H) Gray Level 3 (H)

29 Gray Level 2 (H) Gray Level 2 (H)

30 Gray Level 1 (H) Gray Level 1 (H)

31 miniLVDS data(+) GND

32 miniLVDS data(-)

33 miniLVDS data(+)

34 miniLVDS data(-)

35 miniLVDS data(+)

36 miniLVDS data(-)

37 GND

38 miniLVDS clock(+)

39 miniLVDS clock(-)

40 GND

41 miniLVDS data(+)

42 miniLVDS data(-)

43 miniLVDS data(+)

44 miniLVDS data(-)

45 miniLVDS data(+) miniLVDS Scan Control

46 miniLVDS data(-)

47 Logic Circuit Power Logic Circuit Power

48 Logic Circuit Power Logic Circuit Power

MPD Control 2

MPD Control 3

MPD Control 4

MPD Control 5

MPD Control 6

MPD Control 7

MPD Control 8

MPD Control 9

MPD Control 10

MPD Control 11

MPD Control 12

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

miniLVDS Cascade

Control 2

miniLVDS Cascade

Control 1

LD-K24Z07-8

Page 11

49 Reserved Reserved

50 Polarity Control Polarity Control

51 Latch Strobe Latch Strobe

52 GND GND

miniLVDS Cascade

53

Control 2

54 miniLVDS Scan Control miniLVDS data(-)

miniLVDS Cascade

55

Control 1

56 GND miniLVDS data(-)

GND

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

Analog circuit power Analog circuit power

Analog circuit power Analog circuit power

Gray Level 1 (L) Gray Level 1 (L)

Gray Level 2 (L) Gray Level 2 (L)

Gray Level 3 (L) Gray Level 3 (L)

Gray Level 4 (L) Gray Level 4 (L)

Gray Level 5 (L) Gray Level 5 (L)

Gray Level 6 (L) Gray Level 6 (L)

Gray Level 7 (L) Gray Level 7 (L)

Gray Level 8 (L) Gray Level 8 (L)

Gray Level 9 (L) Gray Level 9 (L)

GND GND

miniLVDS data(+)

miniLVDS data(+)

miniLVDS data(+)

miniLVDS data(-)

GND

miniLVDS clock(+)

miniLVDS clock(-)

GND

miniLVDS data(+)

miniLVDS data(-)

miniLVDS data(+)

miniLVDS data(-)

miniLVDS data(+)

miniLVDS data(-)

LD-K24Z07-9

Page 12

5 Absolute Maximum Ratings

Parameter Symbol Condition Ratings Unit Remark

Input voltage

(for Control)

12V supply voltage

(for Control)

VI

VCC

Ta=25 °C

Ta=25 °C

LD-K24Z07-10

-0.3 ~ +3.60 V [Note 1]

0 ~ + 14 V [Note 2]

Storage temperature Tstg

Operation temperature

(Ambient)

Source driver chip

surface temperature

[Note 1] Applies to the input signals to C-PWB SELLVDS, SCL, SDA.

[Note 2] Applies to the supply voltage of C-PWB.

[Note 3] Applies to the JE400D3HC2N(Open-Cell) and C-PWB

-

Humidity: 95%RH Max.(Ta < 40oC)

-

Maximum wet-bulb temperature at 39oC or less. (Ta > 40oC)

-

No condensation.

[Note 4] Recommended operating condition:chip surface temperature ≦ 115℃.

※Please take measures of the heat radiation .

Topa

Tc

-

-

-

-25 ~ +60

0 ~ +50

+115

°C

°C

℃

[Note 3]

[Note 4]

Page 13

LD-K24Z07-11

=10.8V

V2

=9.1V

ON

t4

0.9Vcc

0.1Vcc

t3

OFF

ON

OFF

Data1

t2

t5-1t5-

2

ON

2

0.9Vcc

0.1Vcc

0.1Vcc

ON

t1

t3

OFF

t8-1t8-

2

ON

6 Electrical Characteristics of input signals

Parameter Symbol Min. Typ. Max. Unit Remark

Supply voltage Vcc 11.4 12 12.6 V [Note 1]

+12V supply

voltage

Permissible input ripple voltage VRP - - 100 mV

threshold voltage

Input Low voltage VIL 0 - 0.7 V

Input High voltage VIH 2.3 3.3 3.6 V

Input leak current (Low) IIL - - 1500 µA

Input leak current (High) IIH - - 700 µA

[Note]VCM: Common mode voltage of LVDS driver.

[Note1]

Input voltage sequences Dip conditions for supply voltage

Vcc

SCL

SDA

※ Data1: ACK±, AIN0±, AIN1±, AIN2±, AIN3±, AIN4±,BCK±, BIN0±, BIN1±, BIN2±, BIN3±, BIN4±

※ Data2: SELLVDS

※ About the relation between data input and back light lighting, we recommend the above-mentioned input

Current dissipation

Inrush current I

High VTH - - 100 mV Differential input

Icc - 0.56 1.4 A [Note 2]

1 - 4.0 - A

RUSH

P-P

Vcc = +12.0V

VCM = +1.2V

Low VTL -100 - - mV

Terminal resistor RT - 100 -

Ω

Differential

50us < t1 < 20ms 9.1V < Vcc < 10.8V

20ms < t2 < 50ms td < 10ms

20ms < t3 < 50ms

0 < t4 < 1s This case is based on input voltage sequences.

1s < t

0 < t

1s < t

1s < t

6 -1

5-1

7

8-1

1s < t

0 < t

1s < t

5-2

6 -2

8-2

Vcc

V1

t7

td

t6-1

OFF

t6-

Ta=25 °C

t1=500us

[Note 4]

[Note 3]

SELLVDS

VI = 0V

SCL,SDA

VI = 3.3V

SELLVDS

input

Page 14

LD-K24Z07-12

(3V/div)

sequence. If the back light is switched on before a panel operation begins or after a panel operation stops,

the screen may not be displayed properly. But this phenomenon is not caused by change of an incoming

signal, and does not give damage to a liquid crystal display.

[Note 2] Typical current situation: 1024 gray-bar patterns. (Vcc = +12.0V)

The explanation of RGB gray scale is seen in section 8.

RGB

GS0→GS1→GS2→ ・・・・・・ →GS1023

Vcc=+12.0V

CK=74.25MHz

TH=14.8µs

[Note 3] ACK±, AIN0±, AIN1±, AIN2±, AIN3±, AIN4±, BCK±, BIN0±, BIN1±, BIN2±, BIN3±, BIN4±

[Note 4] Vcc12V inrush current waveform is as follows. (I

: t1=500us)

RUSH

Vcc

I

1

RUSH

(2A/div)

4.0A

t

1

200us/div

Page 15

7

Aport DATA

B

port DATA

7 Timing characteristics of input signals

Timing characteristics of input signals for C

77

Timing characteristics of input signalsTiming characteristics of input signals

for C----PWB

for C for C

PWB

PWBPWB

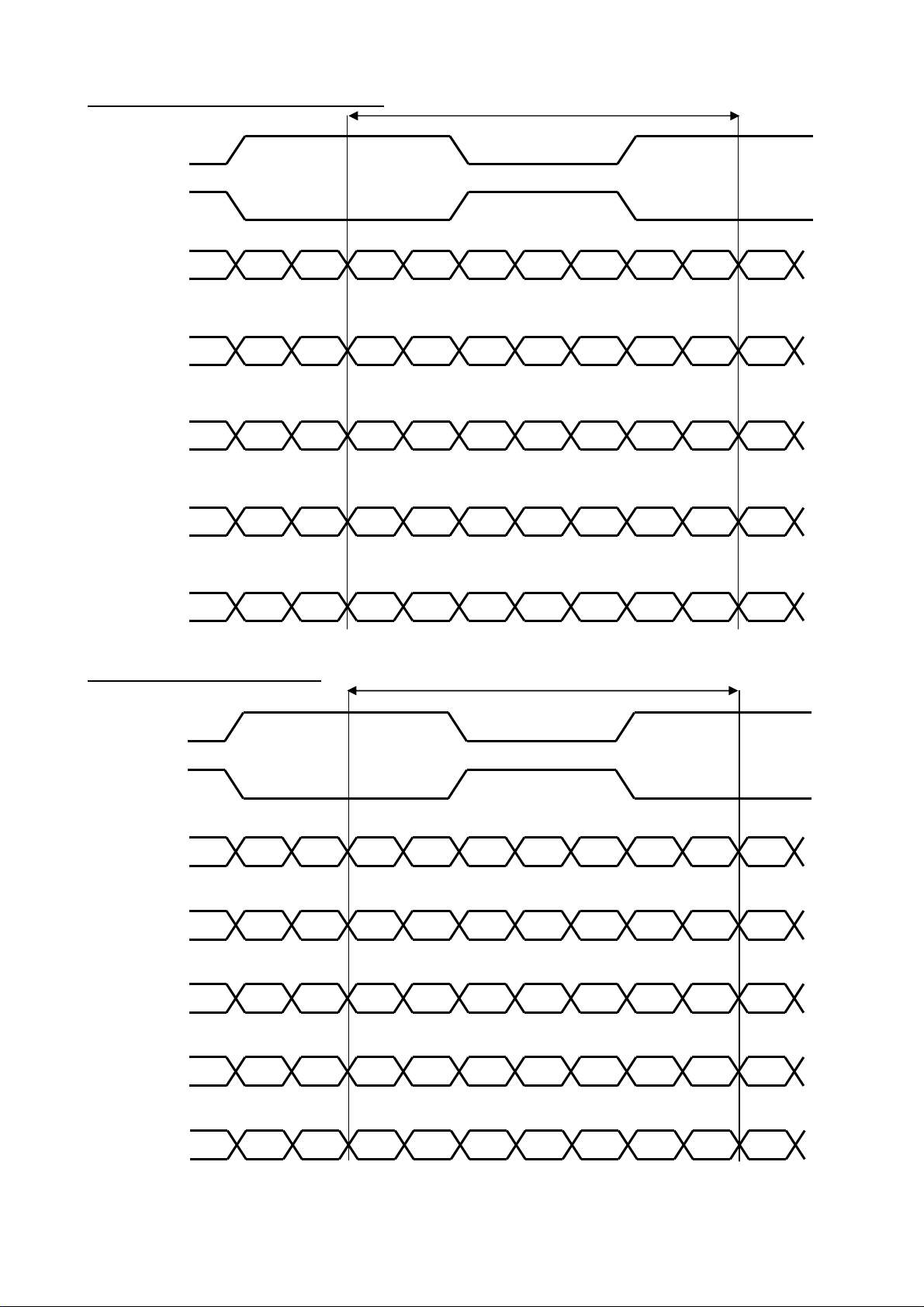

7.1 Timing characteristics

Timing diagrams of input signal are shown in Fig.3.

Clock Frequency

Horizontal period TH

Horizontal period

Data enable

signal

(High)

Vertical period

Vertical period

(High)

1/Tc 69

1050 1100

14.2 14.8

THd

TV

960 960

1109 1125 1350

47

TVd 1080 1080 1080 line

[Note]-When vertical period is very long, flicker and etc. may occur.

-Please turn off the module after it shows the black screen.

-Please make sure that length of vertical period should become of an integral multiple of horizontal

length of period. Otherwise, the screen may not display properly.

-As for your final setting of driving timing, we will conduct operation check test at our side, please

inform your final setting.

TH

DE

(R, G, B)

1919

1

(R, G, B)

1920

Tc

2

DE

Fig3. Timing characteristics of input signal.

Typ. Parameter Symbol Min.

NTSC PAL

74.25

60 50

THd

3 1919

4 1920

1 2 1080 1079

TVd

TV

LD-K24Z07-13

Max. Unit Remark

76

MHz

1300 clock

16.1 µs

960 clock

1400

63

line

Hz

Page 16

7.2

7.2 LVDS signal characteristics

7.27.2

CLK-

Voc

CLK+

Voc

Data x-

Voc

Data x+

Voc

CLKCLK+

Data xData x+

tpd0

Vdiff=0 Vdiff=0

tpd1

tpd2

tpd3

t

CLK

Vod

Vod

tpd4

tpd5

tpd6

The item Symbol

min. typ. max. unit

Differential voltage Vod 200 400 600

Common mode voltage Voc 600 1200 1800

LVDS clock period t

Delay time, CLK rising

edge to serial bit position 0

Delay time, CLK rising

edge to serial bit position 1

Delay time, CLK rising

edge to serial bit position 2

Data

position

Delay time, CLK rising

edge to serial bit position 3

Delay time, CLK rising

edge to serial bit position 4

Delay time, CLK rising

edge to serial bit position 5

Delay time, CLK rising

edge to serial bit position 6

12.35 13.50 13.69

CLK

tpd0

tpd1

tpd2

tpd3

tpd4

tpd5

tpd6

-0.25 0 0.25

1*

t

2*

3*

4*

5*

6*

CLK

t

CLK

t

CLK

t

CLK

t

CLK

t

CLK

/7-0.25 1*

/7-0.25 2*

/7-0.25 3*

/7-0.25 4*

/7-0.25 5*

7-0.25 6*

t

CLK

t

CLK

t

CLK

t

CLK

t

CLK

t

CLK

/7 1*

/7 2*

/7 3*

/7 4*

/7 5*

/7 6*

t

t

t

t

t

t

CLK

CLK

CLK

CLK

CLK

CLK

/7+0.25

/7+0.25

/7+0.25

/7+0.25

/7+0.25

/7+0.25

LD-K24Z07-14

mV

ns

Page 17

LD-K24Z07-15

8 Input Signal, Basic Display Colors and Gray Scale of Each Color

Colors &

Gray scale

Black – 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Blue – 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1

R0 R1 R2 R3 R4 R5 R6 R7 R8 R9 G0 G1 G2 G3 G4 G5 G6 G7 G8 G9 B0 B1 B2 B3 B4 B5 B6 B7 B8 B9

Gray

Scale

Data signal

Green

Cyan – 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Red – 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Basic Color

Magenta – 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1

Yellow

White

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Brighter GS1021 1 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

– 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

– 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

– 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

↓

↓

↓

↓

↓

↓

↓

↓

Gray Scale of Red

GS1022 0 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red GS1023 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Brighter GS1021 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

Gray Scale of Green

GS1022 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

↓

↓

↓

↓

↓

↓

↓

↓

Green GS1023 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

Brighter GS1021 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 1 1

Gray Scale of Blue

GS1022 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1

Blue GS1023 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1

↓

↓

↓

↓

↓

↓

↓

↓

0: Low level voltage, 1: High level voltage.

Each basic color can be displayed in 1024 gray scales from 10 bits data signals. According to the combination of

total 30 bits data signals, one billion-color display can be achieved on the screen.

Page 18

9 Optical Specifications

Parameter Symbol Condition

Viewing angle

range

Horizontal

Vertical

θ

θ

θ

θ

21

22

11

12

CR>10

Ta=25°C, Vcc=12.0V, Frame rate:60Hz (typical)

Min. Typ.

Max. Unit

80 88 - Deg.

80 88 - Deg.

LD-K24Z07-16

Remark

[Note1,4]

Contrast ratio CRn

Response time

White

Red

Chromaticity

Green

Blue

Transmittance

White

τ

DRV

x

y

x

y

x

y

x

y

θ

=0 deg.

4000 5000

- 6 - ms [Note3,4,5]

Typ.-0.03

Typ.-0.03

Typ.-0.03

Typ.-0.03

Typ.-0.03

Typ.-0.03

Typ.-0.03

Typ.-0.03

0.281

0.285

0.640

0.354

0.324

0.624

0.152

0.056

6.01 %

-Optical characteristics are based on SDP standard module.

-The measurement shall be executed 60 minutes after lighting at rating.

[Note]The optical characteristics are measured using the following equipment.

Detector(EZ-CONTRAST/ Photodiode)

400mm

Center of the screen (θ=0°)

Center of the screen (θ=0°)

TFT-LCD Module

TFT-LCD Module

Fig.4-1 Measurement of viewing angle range and

Response time.

Viewing angle range: EZ-CONTRAST

Response time: Photodiode

Fig.4-2 Measurement of Contrast, Luminance,

Chromaticity.

- - [Note2,4]

Typ.+0.03

Typ.+0.03

Typ.+0.03

Typ.+0.03

Typ.+0.03

Typ.+0.03

Typ.+0.03

Typ.+0.03

-

-

-

-

-

-

-

-

Detector (SR-3A-UL1,

or equivalent one)

Field=1°

[Note4]

Page 19

LD-K24Z07-17

0%

90%

100%

time

(Relative Value)

[Note 1] Definitions of viewing angle range:

Normal line

θ

11

θ

21

θ

12

θ

22

6 o’clock direction

[Note 2] Definition of contrast ratio:

The contrast ratio is defined as the following.

Luminance (brightness) with all pixels white

Contrast Ratio

=

Luminance (brightness) with all pixels black

[Note 3] Definition of response time

The response time (τd and τr) is defined as the following figure and shall be measured by switching the input

signal for “any level of gray (0%, 25%, 50%, 75% and 100%)” and “any level of gray (0%, 25%, 50%, 75%

and 100%)”.

0%

25% 50% 75%

100%

0%

25%

50%

75%

100%

td: 25%-0%

td: 50%-0% td: 50%-25

td: 75%-0% td: 75%-25

td: 100%-0

%

tr:0%-25%

td: 100%-25

tr:0%-50% tr:0%-75% tr:0%-100%

%

%

%

tr: 25%-50

td: 75%-50

td: 100%-50

%

tr25%-75% tr: 25%-100

%

%

tr: 50%-75

td:100%-75

t*:x-y...response time from level of gray(x) to level of gray(y)

τr = Σ(tr:x-y)/10 , τd = Σ(td:x-y)/10

Bright

Dark

Bright

Photodetector

10%

Output

τd

τr

[Note 4] This shall be measured at center of the screen.

[Note 5] This value is valid when O/S driving is used at typical input time value.

%

%

tr: 50%-100

tr: 75%-100

%

%

%

Page 20

10 Shipping and Packing

del No.

10.1 Packing form

a) Open Cell quantity in 1 cell box : 20 pcs

b) Piling number of cell box : 12 pcs (Max.)

c) 1 palette size : 1390(W)×1150 (D)×1038(H) [mm]

d) Total mass of 1 palette filled with full open cells : 480 kg (Max.)

10.2 Label

a) Cell Label

This label is stuck on the protection film of front polarizer. (Please trace the Cell lot number after the film is

peeled off.)

ex) JE400D3HC2NM

Sakai Display Products

JE400D3HC2N

b) C-PWB Label & Lot No.

Mo

Barcode

2ZL00001 M

Lot No.

Lot No.: ○○○ ○○

Production year(The last figure of the Christian Era)

[Note1] L:Kameyama, Z:Sakai, N:NSEC, G:SMM, P:SMPL, X:SEMEX

How to express Lot No.

○○ ○ ○○○○○ ○

Production year(The last figure of the Christian Era)

Management code

Production Lot (A~Z,a~z)

Production month (1~9,X,Y,Z)

K0075Z 1-12Z-HD 000001

① ② ③ ④ ⑤

①Parts code

②Management code

③Production year and months:

The last two figures of the Christian

Era + Month (1~9,X,Y,Z)

④Plant code

⑤Serial No.

LD-K24Z07-18

Management code

Serial No.

Plant code [Note1]

Production month (1~9,X,Y,Z)

Page 21

c) Packing Label

This label is stuck on the packing case (cell box) and carton.

社内品番:

(4S) JE400D3HC2NM (①)

Bar code

LotNo. :

Quantity:

Bar code

ユーザ品番:

Bar code

(1T) 2013.2.1 (②)

Bar code

(Q) 20 pcs (③)

JE400D3HC2N (④)

堺ディスプレイプロダクト物流用ラベルです。

Model No. & Suffix Code

①

Lot No. (Date)

②

Quantity

③

Model No. for USER

④

LD-K24Z07-19

11 Carton storage condition.

Temperature 0°C to 40°C

Humidity 95%RH or less

Reference condition : 20°C to 35°C, 85%RH or less (summer)

: 5°C to 15°C, 85%RH or less (winter)

· the total storage time (40°C, 95%RH) : 240H or less

Sunlight Be sure to shelter a product from the direct sunlight.

Atmosphere Harmful gas, such as acid and alkali which bites electronic components and/or

wires must not be detected.

Notes Be sure to put cartons on palette or base, don’t put it on the floor, and store them

keeping off the wall. Please take care of ventilation in storehouse and around cartons,

and control temperature not to exceed the limit one of natural environment.

Storage life 1 year

Page 22

LD-K24Z07-20

I

oniz

ed air

12 Reliability

Reliability test item:

No.

1

2

3

4

5

6

7

High temperature storage test

Low temperature storage test

High temperature and high humidity

High temperature operation test

Low temperature operation test

(Cell Box with full Open Cells)

(Cell Box with full Open Cells)

Test item Condition

Ta = 60°C 500h

Ta = -25°C 500h

Ta = 40°C ; 95%RH 500h

operation test

Vibration test

Drop test

(No condensation)

Ta = 50°C 500h

Ta = 0°C 500h

X and Y direction: 15min, Z direction: 60min.

5Hz to 50Hz acceleration velocity: 1.0G

Sweeping ratio: 3min

Height: 15cm (1 face and 2 sides)

Number: 3 times (1 time in each of drop direction)

13 Precautions

1) Be sure to turn off the power supply when inserting or disconnecting the cable.

2) Be sure to design the cabinet so that the Open Cell can be installed without any extra stress such as warp or

twist.

3) Since the polarizer is easily damaged, pay attention not to scratch it.

4) Since long contact with water may cause discoloration or spots, wipe off water drop immediately.

5) When the polarizer is soiled, wipe it with absorbent cotton or other soft cloth.

6) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface. Handle with

care.

7) Precautions of peeling off the protection film.

- Be sure to peel off slowly (recommended more than 7sec) and constant speed.

- Peeling direction shows below Fig.5.

- Be sure to ground person with adequate methods such as the anti-static wrist band.

- Be sure to ground S-PWB while peeling of the protection film.

- Ionized air should be blown over during peeling action.

- The protection film must not touch drivers and S-PWBs.

- If adhesive may remain on the polarizer after the protection film peeling off,

please remove with isopropyl-alcohol.

Fig.5 Direction of peeling off a protection film.

Ionizing blower

Page 23

LD-K24Z07-21

8) Since the Open Cell consists of TFT and electronic circuits with CMOS-ICs, which are very weak to

electrostatic discharges, persons who are handling the Open Cell should be grounded through adequate

methods such as the anti-static wrist band. Connector pins should not be touched directly with bare hands.

- Reference : Process control standard of SDP

Item Management standard value and performance standard

1 Anti-static mat (floor) 1 to 50 [M ohm]

2 Anti-static mat (shelf, desk) 1 to 100 [M ohm]

3 Ionizer Attenuate from +1000V to +100V within 2 sec

4 Anti-static wrist band 0.8 to 10 [M ohm]

5 Anti-static wrist band entry and

ground resistance

6 Temperature

7 Humidity 60 to 70 [%RH]

9) The Open Cell has some PWBs, take care to prevent them from any stress or pressure when handling or

installing the Open Cell, otherwise some of electronic parts on the PWBs may be damaged.

10) Be sure to turn off the power supply when inserting or disconnecting the cable.

11) Be sure to design the module and cabinet so that the Open Cell can be installed without any extra stress

such as warp or twist.

12) When handling the Open Cell and assembling them into module and cabinets, please be noted that

long-term storage in the environment of oxidization or deoxidization gas and the use of such materials as

reagent, solvent, adhesive, resin, etc. which generate these gasses, may cause corrosion and discoloration

of the Open Cell.

13) Applying too much force and stress to PWB and driver may cause a malfunction electrically and

mechanically.

14) The Open Cell has high frequency circuits. Sufficient suppression to EMI should be done by system

manufacturers.

15) The chemical compound, which causes the destruction of ozone layer, is not used.

16) Instruction of connector upon usage.

a) Do with the actuator opened completely , and insert it in the interior of the insertion entrance surely

Horizontally When you insert FFC. (Please put the FFC tab in the ditch of the housing surely with the FFC

tab. ) Might it become short defective, and it cause the corner to transform the caught terminal into the terminal

by the pitch gap when inserting it right and left and diagonally.

Below 1000 [ohm]

22 to 26 [℃]

O

b) Please add force in the direction where the actuator is held and do by rotating it pushing in parallel to the

C-PWB direction when becoming 90°or less as shown in the figure below until the angle of the actuator

becomes 90°or less when you shut the actuator. Please do not add the force to rotary axis of actuator in the

direction that the actuator is off.

X

Page 24

LD-K24Z07-22

c) About the lock operation

When you lock, it should be push on both sides of the actuator. And it is necessary to confirm that the

actuator is surely shut.

Half lock

17) Please be careful since image retention may occur when a fixed pattern is displayed for a long time.

18) This Open Cell is corresponded to RoHS. ‘‘R.C.’’ label on the side of palette shows it.

19) When any question or issue occurs, it shall be solved by mutual discussion.

Page 25

Loading...

Loading...