SHARP DV-HR300U Service Manual

DV-HR300U

SERVICE MANUAL

SX3L5DV-HR300

DVD VIDEO RECORDER

MODEL

In the interests of user-safety (Required by safety regulations

in some countries) the set should be restored to its original

condition and only parts identical to those specified be used.

DV -HR300U

CONTENTS

Page

1. IMPORTANT SERVICE NOTES........................................................................................................ 2

2. FEATURES........................................................................................................................................ 6

3. SPECIFICATIONS ............................................................................................................................. 7

4. PART NAMES.................................................................................................................................... 9

5. DISASSEMBLY METHOD ............................................................................................................... 11

6. TROUBLESHOOTING..................................................................................................................... 15

7. BLOCK DIAGRAMS......................................................................................................................... 26

8. SCHEMATIC DIAGRAMS................................................................................................................ 34

9. PRINTED WIRING BOARD ASSEMBLIES ..................................................................................... 60

10. REPLACEMENT PARTS LIST / EXPLODED VIEWS ..................................................................... 75

11. PACKING OF THE SET................................................................................................................... 95

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

DV-HR300U

1. IMPORTANT SERVICE NOTES

Note:

This unit can be used only where the power

supply is AC 110V-240V, 50/60Hz.

It cannot be used elsewhere.

CAUTION:

USE OF CONTROLS OR ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

DO NOT STARE INTO THE LASER BEAM OR

VIEW WITH OPTICAL INSTRUMENT.

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS EQUIPMENT TO

RAIN OR MOISTURE.

TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, AND ANNOYING INTERFERENCE, USE

THE RECOMMENDED ACCESSORIES ONLY.

Laser Diode Properties

Material: AlGaInP

Wave length: 650 nm

Emission Duration: Continuous

Laser output: Max. 0.7 mW

Power Cord Protection

To avoid any malfunctions of the unit, and to protect

against electric shock, fire or personal injury, please

observe the following.

Hold the plug firmly when connecting or

disconnecting the AC power cord.

Keep the AC power cord away from heating

appliances.

Never put any heavy object on the AC power cord.

Do not attempt to repair or reconstruct the AC

power cord in any way.

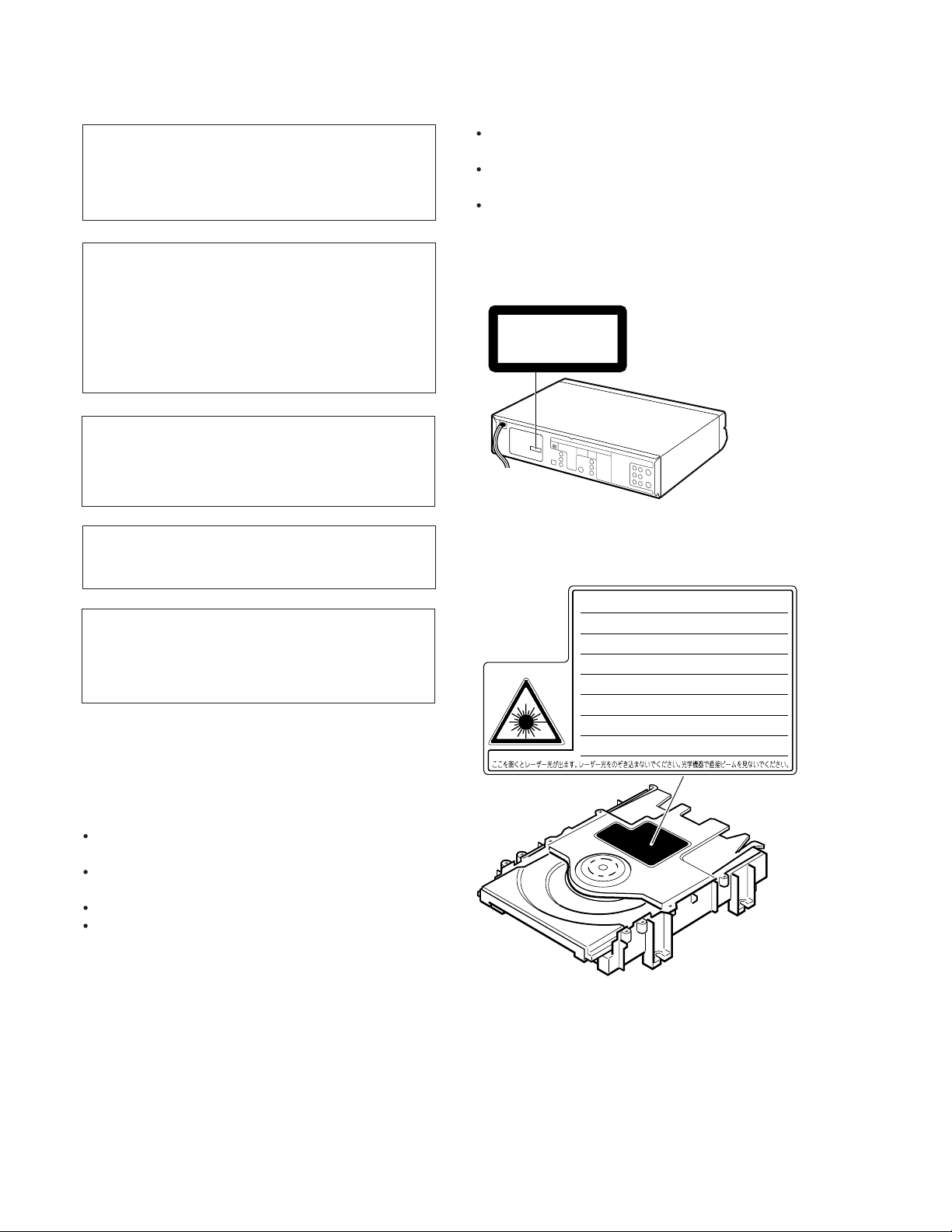

This Unit is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located

on the rear cover.

This product contains a low power laser device.

To ensure continued safety do not remove any

cover or attempt to gain access to the inside of

the product. Refer all servicing to qualified

personnel.

CLASS III

CLASS 1

LASER PRODUCT

LASER PRODUCT

(Rear of product)

(Rear of product)

CAUTION-LASER RADIATION WHEN OPEN. DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VORSICHT-LASERSTRAHLUNG, WENN GEFFNET. BLICKEN SIE NICHT IN DEN STRAHL

UND BETRACHTEN SIE DIESEN NICHT DIREKT MIT OPTISCHEN INSTRUMENTEN.

ATTENTION-RADIATION LASER EN CAS D'OUVERTURE. NE PAS FIXER LE

FAISCEAU NI REGARDER DIRECTEMENT DES INSTRUMENTS OPTIQUES.

VARNING-LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD. STIRRA EJ IN

SA005WJ

I STRÅLEN OCH BETRAKTA EJ STRÅLEN MED OPTISKA INSTRUMENT.

VARO ! AVATTAESSA OLET ALTTIINA LASERSÄTEILYLLE. ÄLÄ TUIJOTA

SÄTEESEEN ÄLÄKÄ KATSO SITÄ OPTISEN LAITTEEN LAPI.

VARNING-LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD. STIRRA EJ IN I

STRÅLEN OCH BETRAKTA EJ STRÅLEN GEMON OPTISKT INSTRUMENT.

ADVARSEL-LASERSTRÅLING NÅR DEKSEL ÅPNES. STIRR IKKE INN I

STRÅLEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

ADVARSEL-LASERSTRÅLING VED ÅBNING. SE IKKE IND I STRÅLEN-

HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA LASERSÄTEILYLLE.

ÄLÄ TUIJOTA SÄTEESEEN ÄLÄKÄ KATSO SITÄ OPTISEN LAITTEEN LÄPI.

VARNING - LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD.

STIRRA EJ IN STRÅLEN OCH BETRAKTA EJ STRÅLEN GENOM OPTISKT

INSTRUMENT.

2

IMPORTANT SERVICE NOTES

DV-HR300U

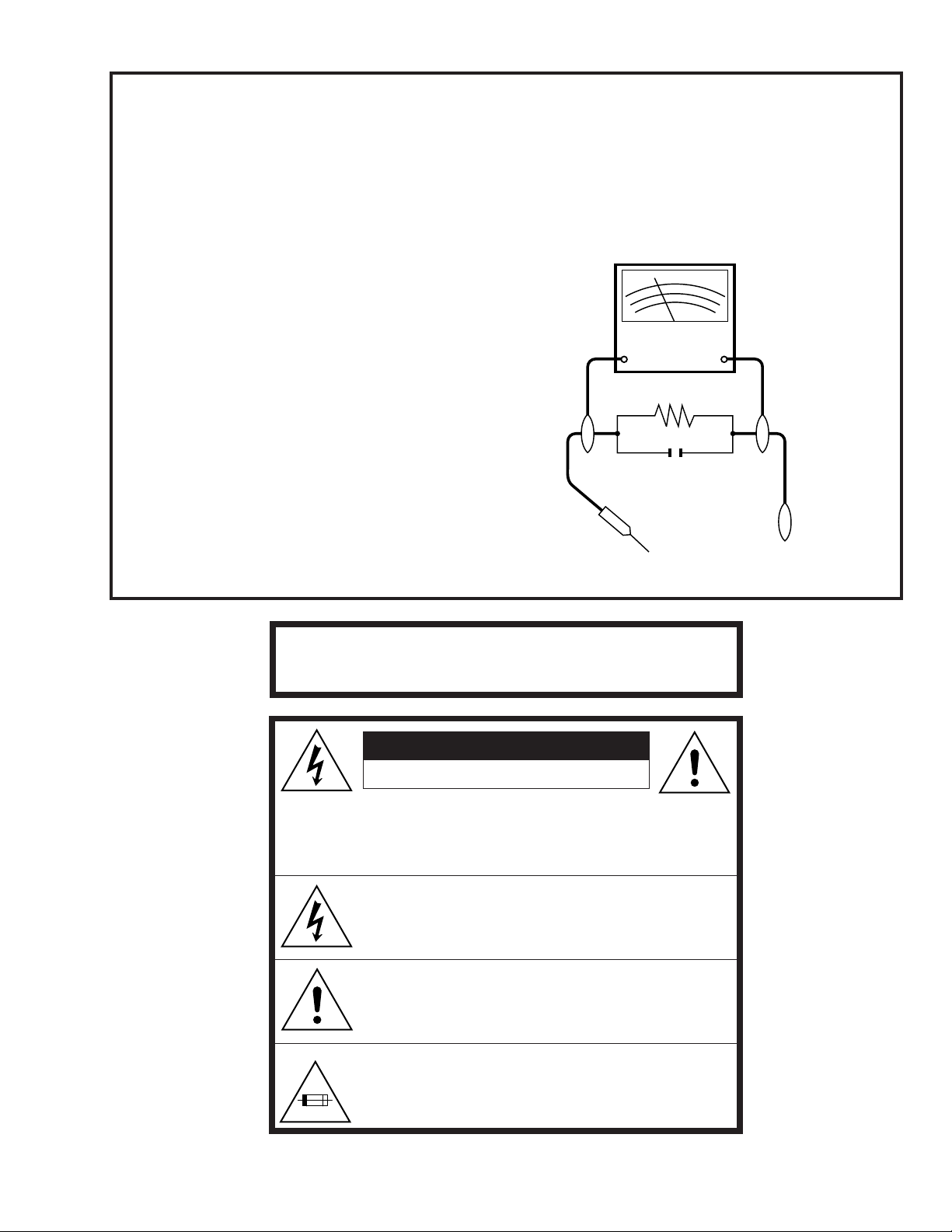

BEFORE RETURNING THE VCR/DVD COMBINATION MODEL

Before returning the video cassette recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the VCR/DVD

combination model.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

current in the following manner.

● Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

● Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as a water pipe or conduit.

● Use an SSVM or VOM with 1000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor (See Diagram).

● Move the resistor connection to earth exposed metal

part having a return path to the chassis (antenna,

metal cabinet, screw heads, knobs and control shafts,

etc.) and measure the AC voltage drop across the

resistor. Reverse the AC plug on the set and repeat

AC voltage measurements for each exposed part.

Any reading of 0.45V rms (this corresponds to 0.3mA

rms AC.) or more is excessive and indicates a potential shock hazard which must be corrected before

returning the VCR/DVD combination model to the

owner.

SSVM

AC SCALE

1.5k ohms.

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

WARNING :TO REDUCE THE RISK OF FIRE OR ELEC-

TRIC SHOCK, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK. DO

CAUTION:

3.0A 125V

NOT REMOVE COVER. NO USER-SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

This symbol warns the user of uninsulated voltage

within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are important

operating and maintenance instructions in the literature

accompanying this unit.

This symbol mark means fast operating fuse.

For continued protection against risk of fire, replace

only with same type fuse F901 (3.0A, 125V).

3

DV-HR300U

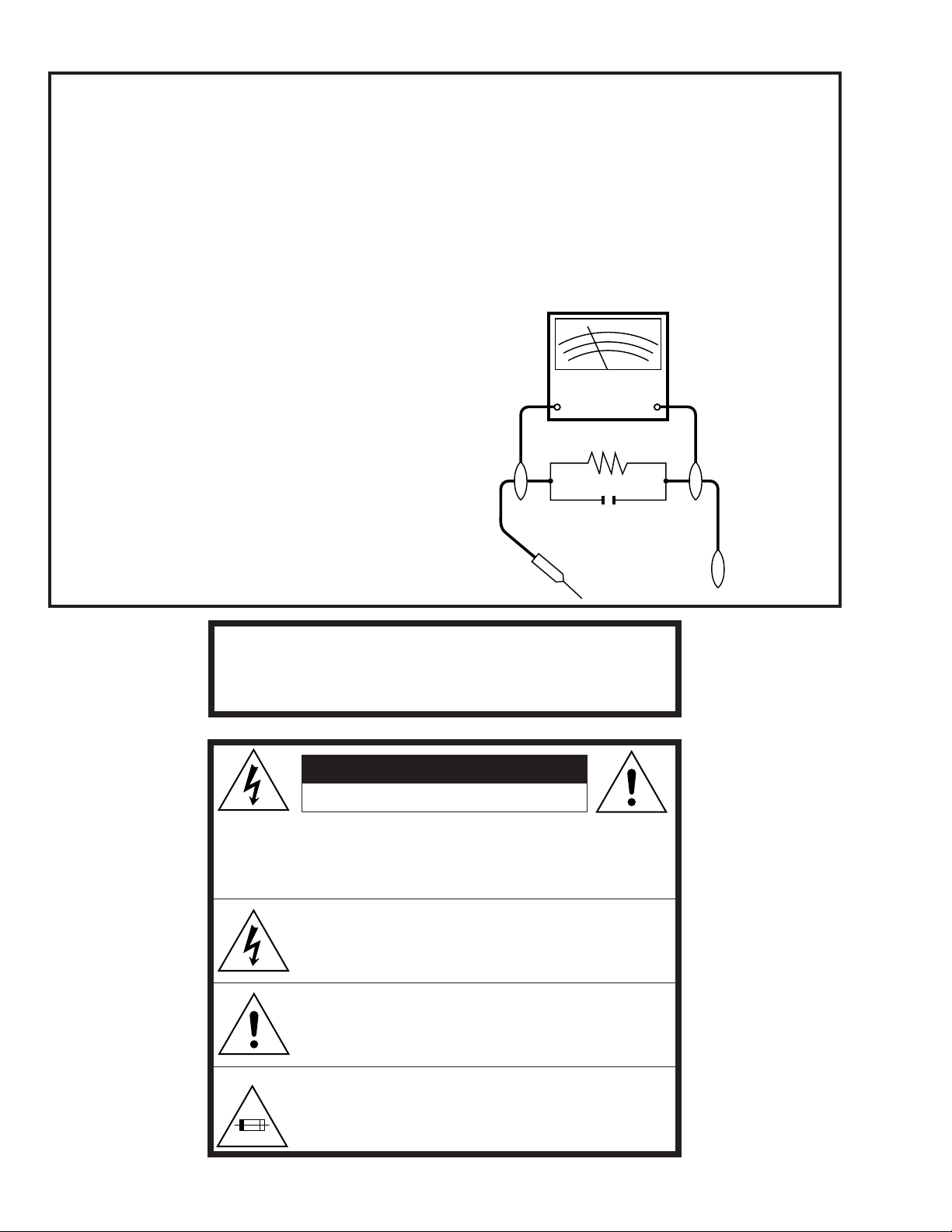

NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE VCR/DVD MAGNETOSCOPE

Avant de rendre le magnétoscope à l’utilisateur, effectuer

les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans

le VCR/DVD magnétoscope.

2. Vérifier tous les dispositifs de protection tels que les

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement, Ies

isolateurs mécaniques, etc.

3. Pour être sûr qu’il n’y a aucun risque de choc électrique,

vérifier le courant de fuite de la maniére suivante.

● Brancher le cordon d’alimentation secteur directement

dans une prise de courant de 120 volts. (Ne pas utiliser

de transformateur d’isolement pour cet essai).

● Utiliser deux fils à pinces et connecter une résistance

de 10 watts 1,5 kohm en parallèle avec un condensateur

de 0,15 µF en série avec des pièces du coffret

métallique exposées et une masse de terre connue

telle qu’un tuyau ou un conduit d’eau.

● Utiliser un VTVM ou VOM avec une sensibilité de 1000

ohms par volt ou plus ou mesurer la chute de tension

CA entre la résistance (voir diagramme).

● Déposer la connexion de la résistance à toutes les

pièces métalliques exposées ayant un parcours de

retour au châssis (connexions d’antenne, coffret

métallique, tétes de vis, boutons et arbres de

commande, etc.) et mesurer la chute de tension CA

entre la résistance. Inverser la fiche CA (une fiche

intermédiaire non polarisée doit être utilisée à seule fin

de faire ces vérifications.) sur l’appareil et répéter les

mesures de tension CA pour chaque piéce métallique

exposée. Toute lecture de 0,45 Vrms (ceci correspond

à 0,3 mArms CA) ou plus est excessive et signale un

danger de choc qui doit être corrigé avant de rendre le

VCR/DVD magnétoscope à son utilisateur.

VTVM

ECHELLE CA

1,5 KOHMS

10W

0,15 µF

SONDE D'ESSAI

VERS PIECES

METALLIQUES

EXPOSEES

CANNECTER A

UNE MASSE DE

TERRE CONNUE

ATTENTION: POUR REDUIRE LES RESQUES D'IN-

CENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A

LA PLUIE OU A L'HUMIDITE.

ATTENTION

RISQUE DE CHOC ELECTRIQUE

ATTENTION: AFIN DE REDUIRE LES RISQUES DE CHOC

ELECTRIQUE, NE PAS RETIRER LE COUVERCLE,

AUCUN ORGANE INTERNE NE PEUT ETRE

REPARE PAR L'UTILISATEUR. CONFIER

L'APPAREIL A UN DEPANNEUR QUALIFIE.

Ce symbole signale à l'utilisateur la présence d'une

tension non isolée à l'intérieur de l'appareil qui peut être

la cause de secousses électriques dangereuses.

Ce symbole avertit l'utilisateur que des instructions

importantes relatives à l'utilisation et àl'entretien se

trouvent dans le manuel accompagnant l'appareil.

PRECAUTION:

Cette marque indique le fusible à action in stantansée.

Pour la protection continue contre le risque d'incendie,

3,0A 125V

ne remplacer que par le fusible type F901 (3,0A, 125V).

NE PAS OUVRIR

4

DV-HR300U

Precautions for using lead-free solder

1 Employing lead-free solder

"Operation (R) PWB, Operation (L) PWB, Power PWB and UV PWB" of this model employs lead-free solder. The LF

symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The alphabetical character

following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend you

to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldening bit,

contact our service station or service ranch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead solder

by 40°C, and as it has poor solder wettabillty, you may be apt to keep the soldering bit in contact with the PWB for

extended period of time. However, Since the land may be peeled off or the maximum heat-resistance temperature

of parts may be excoeded, remove the bit from the PWB as soon as you conurm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tum on

and off the power of the bit as required.

if a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Becareful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

5

DV-HR300U

2. FEATURES

zz

z A new timer recording system:"Easy Recording

zz

Guide"

» The Recorder is equipped with a high-capacity hard disc, so

you'll have more chances than ever before for timer recording,

and the new timer recording system makes this even easier.

A schedule grid of times and channels is displayed on the

screen, and by simply designating cells in the grid with the

remote control, timer programming becomes as easy as

circling your favorite shows in the newspaper. You can also

see at a glance which time slots are already programmed,

and avoid any overlap.

xx

x High-capacity hard disc lets you record and view

xx

series and your favorite programs

*1

» For trendy dramas, series and other shows you want to watch

and record, without missing a week, use the "Stored Series

Program Timer" feature.

For news and information programs which you watch

everyday and don't need to store, set "Overwrite Program

Timer".

» Recorded programs can be viewed by simply calling them

up with the remote control, so there is no need to search

through a lot of programs.

Programs recorded with "Stored Series Program Timer" can

be batch dubbed onto DVD

*2

, so you can easily save your

favorite dramas on DVD.

*1

This function is only available with hard disc.

*2

Up to 5 titles can be dubbed in a batch.

cc

c DVD-RW/-R recording/playback with outstanding

cc

compatibility

» This Recorder is compatible with digital recording on

rewritable DVD-RW discs and one-time recordable DVD-R

discs. It has two recording formats:

"VR (Video Recording) mode" which has a wealth of editing

functions, and "Video mode" which can be played back with

existing DVD players. This lets you enjoy recording and

dubbing to suit your purpose.

2X or DVD-R Ver. 2.0/4X.

2 Rate conversion dubbing

The mode can be selected from 32 levels just like recording mode.

This enables recording at the optimal picture quality, given the

remaining empty space on the disc.

3 Exact dubbing

This automatically adjusts to the optimal record mode so that

the material is dubbed exactly into the remaining area on the

disc.

The time normally required for a program of an hour on High

Speed Dubbing to a double speed compatible disc

Recording Mode

FINE

SP

LP

EP

nn

n "Time Shift Viewing", "Chasing Playback" and

nn

Speed

Approx. 2✕

Approx. 4✕

Approx. 8✕

Approx. 12✕

Time Required

Approx. 30 min

Approx. 15 min

Approx. 7.5 min

Approx. 5 min

"Simultaneous Recording/Playback" —functions

you can only get with a hard disc

1 Time shift viewing

While you are watching a program, the phone rings.... At times

like this, you can pause the program being broadcast by

pressing a button, and then watch the rest of the program at

your leisure after you finish your phone call. You can also

switch to the current broadcast scene just by pressing

STOP/LIVE button.

2 Chasing playback

You return home earlier than expected while timer recording

is in progress.... At times like this, you don't have to wait for

recording to end. You can immediately view the program from

the beginning.

3 Simultaneous recording/playback

Even while recording to the hard disc, you can enjoy playback

of a DVD, or programs already recorded on hard disc.

You don"t have to wait for recording to finish.

vv

v High picture quality design (Used in all hard disc

vv

and DVD modes)

1 Progressive scanning playback

High-quality, high-density video with no jagged contours and

no flicker.

2 VBR (Variable Bit Rate) recording

Constantly maintains optimal high picture quality by varying

the bit rate (amount of video data) for each scene depending

on the video content (e.g. whether movement is fast or slow).

bb

b A variety of hard disc

bb

1 High speed dubbing

Enables high speed dubbing from hard disc to DVD so you can enjoy

creating your own video library.

*3For high speed dubbing, use discs conforming to DVDRW Ver. 1.1/

↔↔

↔ DVD dubbing functions

↔↔

*3

mm

m Comprehensive editing functions

mm

(Only titles recorded on the hard disc or in VR mode on

DVD-RW can be edited.)

1 Play list edit

This lets you gather only the needed parts (i.e. a "Play List")

from a recorded original video (title).

You can rearrange scenes and combine them with other

scenes, or rearrange titles. This is convenient when you want

to dub and save only the necessary scenes and titles.

2 Chapter edit

This lets you divide a title into chapter units during recording/

playback or using the edit screen. After dividing, a list of

recordings (thumbnails) can be displayed in chapter units,

so you can copy, erase or dub to the play list in chapter units.

3 Scene erase

This lets you erase unnecessary scenes. This is convenient

when you want to cut out the commercials in a recorded

program before dubbing.

6

DV-HR300U

4 Batch erasing of titles/chapters

Titles and chapters which become unnecessary after editing

can be batch erased by selecting them from the list of

recordings (thumbnails).

5 Edit undo function

If you mistakenly erase data during editing, this function lets

you restore it to its immediately preceding state, just like

"Undo" on a PC, so you can edit worry-free.

*4

Edit undo can only be used once. It only works when

"DELETEDIT" is assigned to a colored button (green)

displayed on the screen.

,,

, Simple operation and userfriendly design using a

,,

*4

new remote control

1 START MENU

Press START MENU button on the remote control, and

display the list of main functions on the screen.

After that, you can operate by using the Cursor buttons and

SET/ENTER button on the remote control, so this Recorder

can be used easily even by a person who is unfamiliar with

operation.

2 Colored buttons

The remote control has colored buttons with four different

colors. Functions are displayed in four different colors on the

screen, and the Recorder can be operated by directly

designating these functions.

3 Luminous buttons

Luminous buttons are used for key control buttons on the

remote control so they are easy to see in the dark.

..

. Digital connection (i.LINK) with a digital video/audio

..

source equipment

» The DV IN terminal allows you to uptake, edit and store

material from a digital camcorder equipped with a DV terminal.

//

/ MP3 file playback

//

» This Recorder allows you to playback MP3 files recorded on

CD-RW/R.

ZZ

Z VCR Plus+*5 System

ZZ

» The VCR Plus+ System allows you to program your Recorder

for timer recording simply by inputting the PlusCode

Programming number. The PlusCode numbers are listed in

most newspapers, television guides, and local CATV listings.

Simply by inputting this PlusCode number, you can program

your Recorder for timer recording, eliminating the need to

input program start time, stop time, channel, date and other

information which is necessary for ordinary timer

programming.

*5

VCR Plus+ and PlusCode are registered trademarks of

Gemstar Development Corporation. The VCR Plus+ System

is manufactured under license from Gemstar Development

Corporation.

3. SPECIFICATIONS

General

HDD capacity: 80 GB

Power supply: AC 120 V, 60 Hz

Power consumption (Normal): 40 W

Power consumption (Standby): 0.7 W

Dimensions: Approx. 430 mm x 59 mm x 323 mm (W x H x D)

Approx. 16 15/16" x 22 1/64" x 12 23/32"

Weight: Approx. 5.0 kg (11.1 lbs)

Operating temperature 41°F to 95°F (5°C to 35°C)

Storage temperature: –4°F to 131°F (–20°C to 55°C)

Operating humidity: 10% to 80% (no condensation)

TV systems: NTSC system, 525 lines, 60 fields

Recording

Recordable disc media: DVD-RW, DVD-R

Recording system (HDD): Video: MPEG

Audio: Dolby Digital (2ch)/Linear PCM (FINE mode only)

Recording system (DVD-RW/R): Video: DVD-Video Recording (VR mode)

DVD-VIDEO (Video mode)

Audio: Dolby Digital (2ch)/Linear PCM (FINE mode only)

Recording time (Hard disc): FINE (High picture quality): Approx. 20 hours

SP (Standard): Approx. 33 hours

LP (2X): Approx. 67 hours

EP (3X): Approx. 100 hours

MN (Manual): 32 levels between FINE and EP

(However, the maximum continuous recording time is 12 hours.)

Recording time

(With 4.7GB DVD-RW/R): FINE (High picture quality): Approx. 1 hour

SP (Standard): Approx. 2 hours

7

DV-HR300U

LP (2X): Approx. 4 hours

EP (3X): Approx. 6 hours

MN (Manual): 32 levels between FINE and EP

Playback

Playable discs: DVD Video, DVD-R/RW, Audio CD (CD-DA), Video CD, CD-R/ RW (CD-DA,

Video CD format, MP3 file format)

Tuner

Channel coverage: VHF 2-13

UHF 14-69

CATV 1-125

Timer

Programs: 32 programs/1 year

Clock: Quartz lock (12-hour digital display)

Memory backup: Approx. 1 hour

Input/Output

VHF/UHF antenna input/

output terminal: 75Ω (F-shape connector)

Video input: Input 1, 2 (rear), 3 (front)

Input level: 1 Vp-p (75Ω)

Jacks: RCA jack

Video output:

Output level: 1 Vp-p (75Ω)

Jacks: RCA jack

S-Video input: Input 1, 2 (rear), 3 (front)

Y-Input level: 1 Vp-p (75Ω)

C-Input level: 0.286 Vp-p (75Ω)

Jacks: 4 pin mini DIN

S-Video output:

Y-Output level: 1 Vp-p (75Ω)

C-Output level: 0.286 Vp-p (75Ω)

Jacks: 4 pin mini DIN

Component video output:

Output level: Y: 1 Vp-p (75Ω)

PB, PR: 0.7 Vp-p (75Ω)

Jacks: RCA jack

Audio input: Input 1, 2 (rear), 3 (front) L/R

Input level: 2 V rms (Input impedance: more than 22 kΩ)

Jacks: RCA jack

Audio output: L/R

Input level: 2 V rms (Output impedance: less than 1.5 kΩ)

Jack: RCA jack

Digital audio optical output:

Terminal: Square Optical terminal

DV input:

Terminal: 4 pin (i.LINK/IEEE 1394 standard)

LASER Specification

Wave length: DVD: 658 nm

Laser power: DVD: 100 mW

Specifications are subject to change without notice.

CD: 784 nm

CD: 225 mW

8

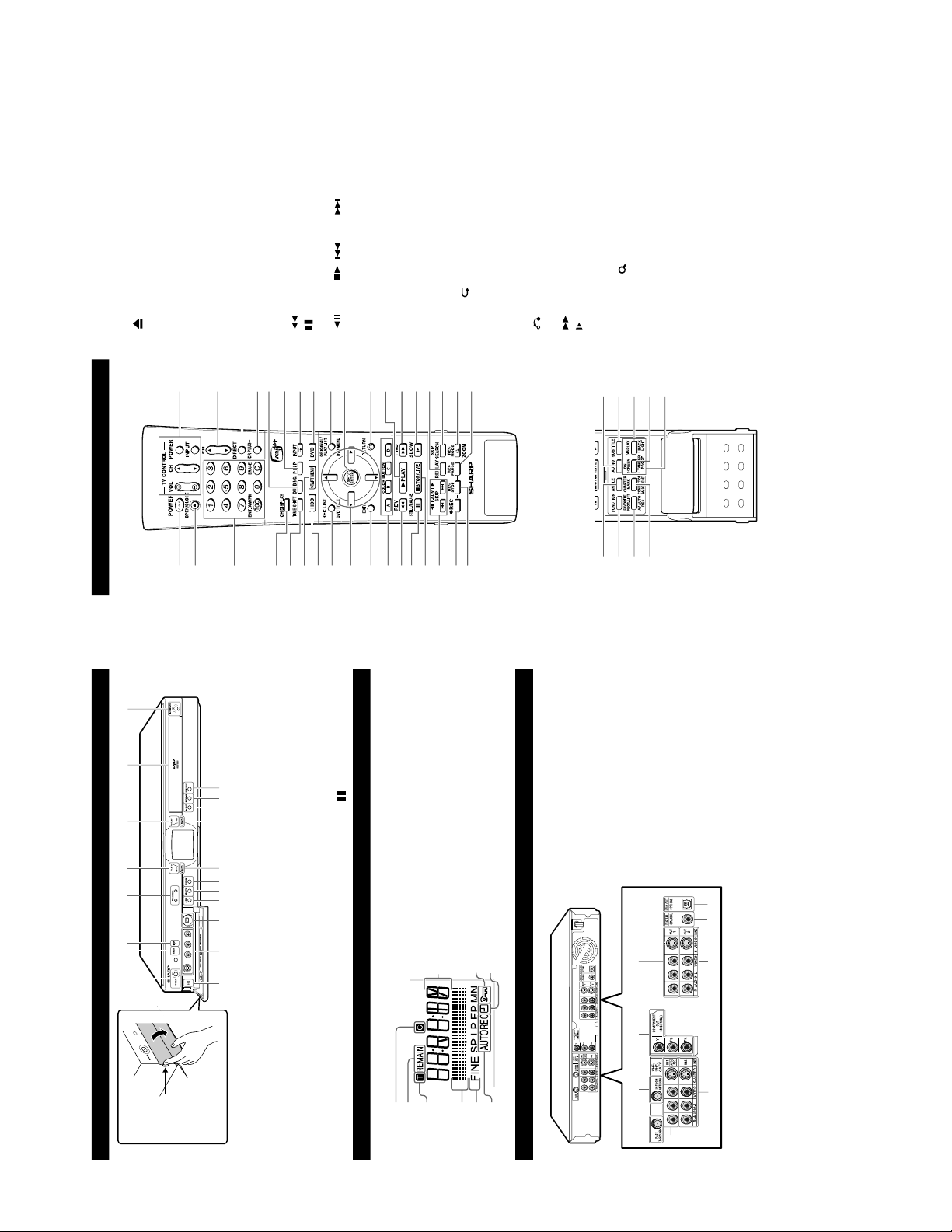

4. PART NAMES

1

2

6

8

10

15

16

121314

17

11

9

7

5

4

3

18

1920212223

24

25

26

28

3130323334

35

29

27

Remote Control Unit

4040

4036

4137

4238

4339

44

1

POWER

2

OPEN/CLOSE

3

Number buttons

4

CH DISPLAY 5TIME SHIFT

6

START MENU7HDD

8

REC LIST/DVD TITLE9Cursor buttons (' /"/\ /|)10EXIT11COLOR BUTTON

Blue (A), Red (B), Green (C), Yellow (D)

12

REV

13

STILL/PAUSE

14

■ STOP/LIVE

15

F.ADV ,

SKIP

16

ÆÆ

ÆÆ

Æ REC

17

REC STOP18TV CONTROL buttons

19

CH " /'20DIRECT21VCR PLUS+

22

DUBBING23P IN P24INPUT/ Repeat25DVD26ORIGINAL/PLAY LIST / DVD MENU

27

SET/ENTER

28

RETURN

29

| PLAY

30

FWD

31

SLOW

32

REPLAY 33SKIP SEARCH

34

REC MODE/

ZOOM

35

REC PAUSE36ANGLE37FUNCTION

38

FAVORITE PROG. LIST/AV AUTO REC39CHAPTER MARK / CONNECTION GUIDE/RESET

40

AUDIO41SUBTITLE

42

DISPLAY/BACKLIGHT

43

ON SCREEN

44

TAMPER PROOF

Main Unit (Front)

Front Panel Display

1

9

10 11 12 1314 15 16 17 18 19

23

4 5 6

8

7

To open the

front door, lay

your finger on

this part and pull

toward you.

1

456

7

8

9

3

2

Main Unit (Rear)

1

45

2 3

7 8

6

9

1

POWER 2STANDBY indicator

3

TIMER indicator

4

CHANNEL "/'5PLAY/REC indicators

(for HDD)

6

PLAY/REC indicators

(for DVD)

7

Disc tray

8

OPEN/CLOSE

9

RESET10LINE IN 3

• AUDIO Input jacks

• VIDEO Input jack

• S-VIDEO Input jack

11

DV IN terminal

12

●

REC

13

REC STOP14REC PAUSE15HDD

16

DVD

17

|

PLAY

18

■ STOP/LIVE

19

STILL/PAUSE

1

Chapter indicator

2

Disc Remaining Time indicator

3

Title indicator

4

Dubbing indicator

5

Recording Mode indicator

6

AV AUTO REC indicator

7

Information Display

8

Tamper Proof indicator

9

Simple Recording Timer indicator

1

PASS THROUGH jack2IN FROM ANTENNA jack (antenna or cable

input)3COMPONENT Video Output jacks

4

LINE IN 1 (AUTO REC)

• AUDIO Input jacks

• VIDEO Input jack

• S-VIDEO Input jack

5

LINE IN 2

• AUDIO Input jacks

• VIDEO Input jack

• S-VIDEO Input jack

6

LINE OUT 1

• AUDIO Output jacks

• VIDEO Output jack

• S-VIDEO Output jack

7

LINE OUT 2

• AUDIO Output jacks

• VIDEO Output jack

• S-VIDEO Output jack

8

DIGITAL AUDIO Output COAXIAL jack9DIGITAL AUDIO Output OPTICAL terminal

DV-HR300U

9

DV-HR300U

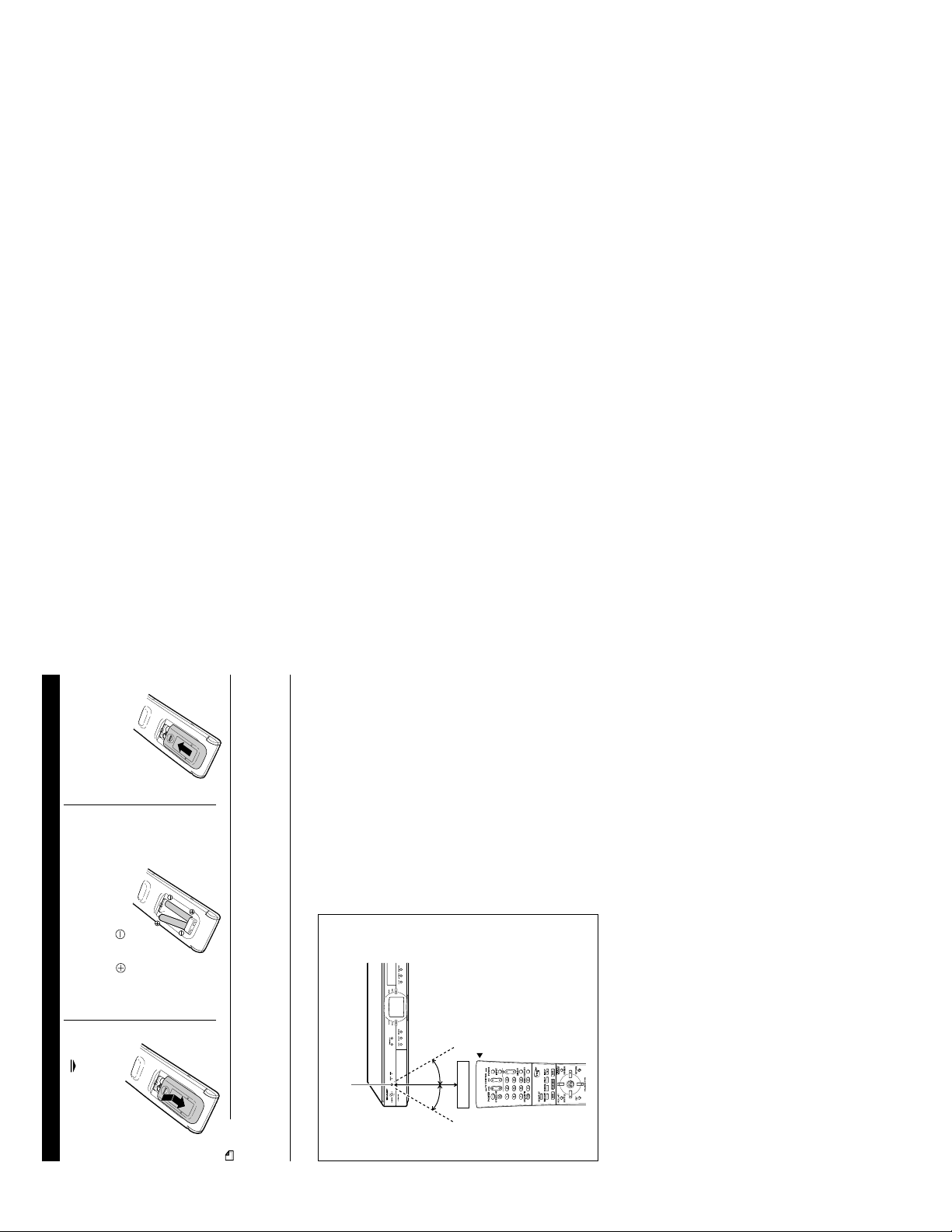

1

While pressing down,

slide the battery cover in

the direction of the

arrow.

2

Load the batteries.

Load the two “AAA” size batteries (R-03,

UM/SUM-4) supplied with the remote

control unit. Make sure that the battery

poles

and

are positioned as

indicated.

3

Slide the battery cover

in the direction of the

arrow until it clicks.

About 30ϒ

About 30ϒ

Front 22.96ft.

Remote control

unit

Operating range of remote control

NOTE

» Do not subject the remote control unit to shock, water or excessive humidity.

» The remote control unit may not function if the Recorder s remote sensor is in direct sunlight or any other strong light.

» Incorrect use of batteries may cause them to leak or burst. Read the battery wa rnings and use the batteries properly.

» Do not mix old and new batteries, or mix dif ferent brands.

» Remove the batteries if you will not use the remote control unit for an extended period of time .

Loading the Batteries

Remote sensor

10

5. DISASSEMBLY METHOD

DV-HR300U

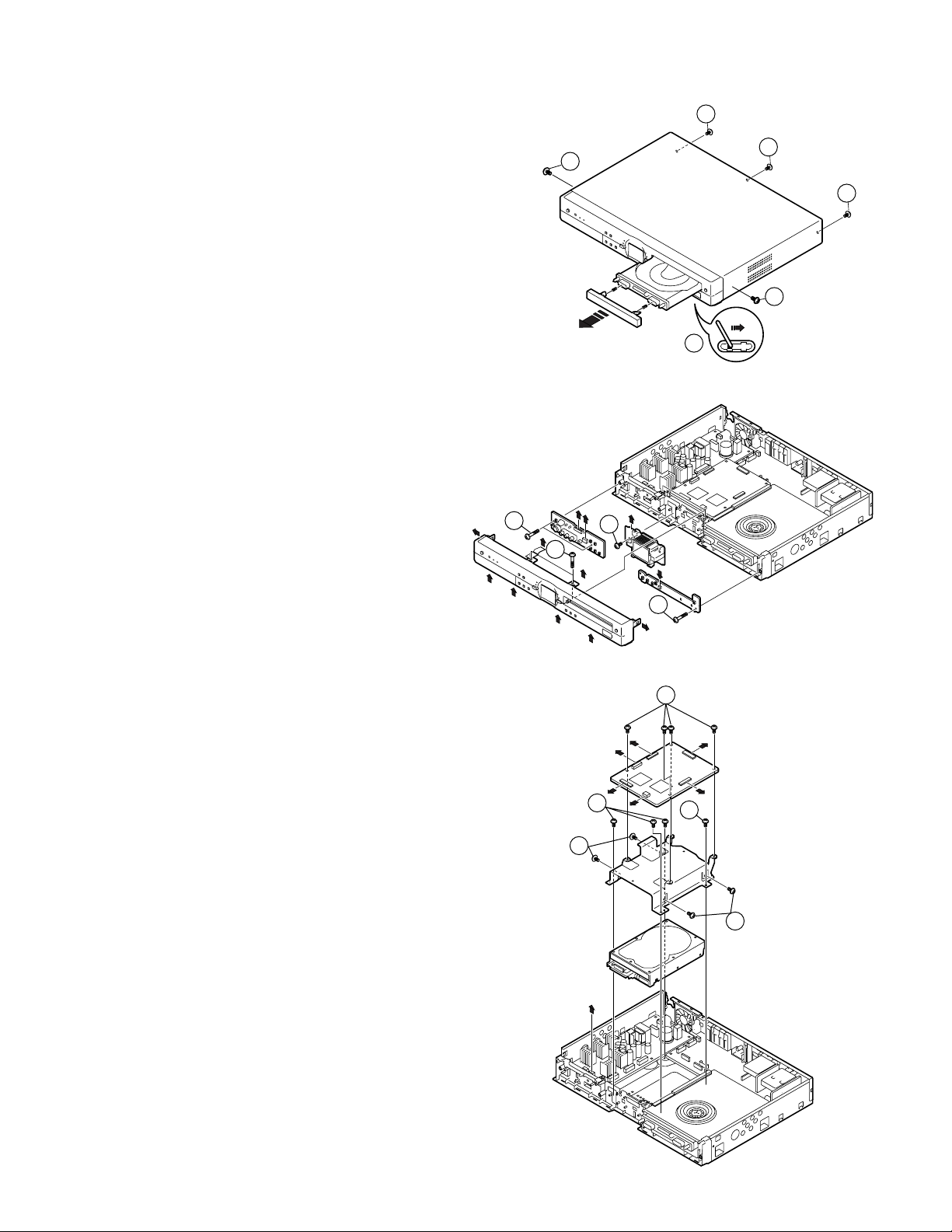

5-1. DISASSEMBLY METHOD

(1) Removing the top cabinet

1.Remove five screws 1.

2.Slide back the top cabinet by 10 mm and remove upward.

(2) Removing the panel

1. Push a protruding part shown in a at the bottom with a

screwdriver, etc.

2.Remove the tray decoration assembly (detach springs from

four claws on the backside of the tray).

3.Remove two screws 2 and spring.

4.Pull the panel to remove as detaching from the eight claws.

(3) Removing the operation PWB and LCD PWB

1.Remove the FFC and four harnesses.

2.Remove two screws 3, a screw 4 and a screw 5.

3.Pull each PWB to remove.

1

1

a

3

2

5

1

1

1

(4) Removing the main PWB

1.Remove four screws 6.

2.Remove the FFC and six harnesses.

3.Remove the main PWB upward.

(5) Removing the HDD unit

1.Remove four screws 7.

2.Remove the HDD unit (with the angle) upward.

3.Remove four screws 8.

4.Remove the HDD unit.

5.Disconnect the flat cable and power cable.

4

6

7

8

7

8

11

DV-HR300U

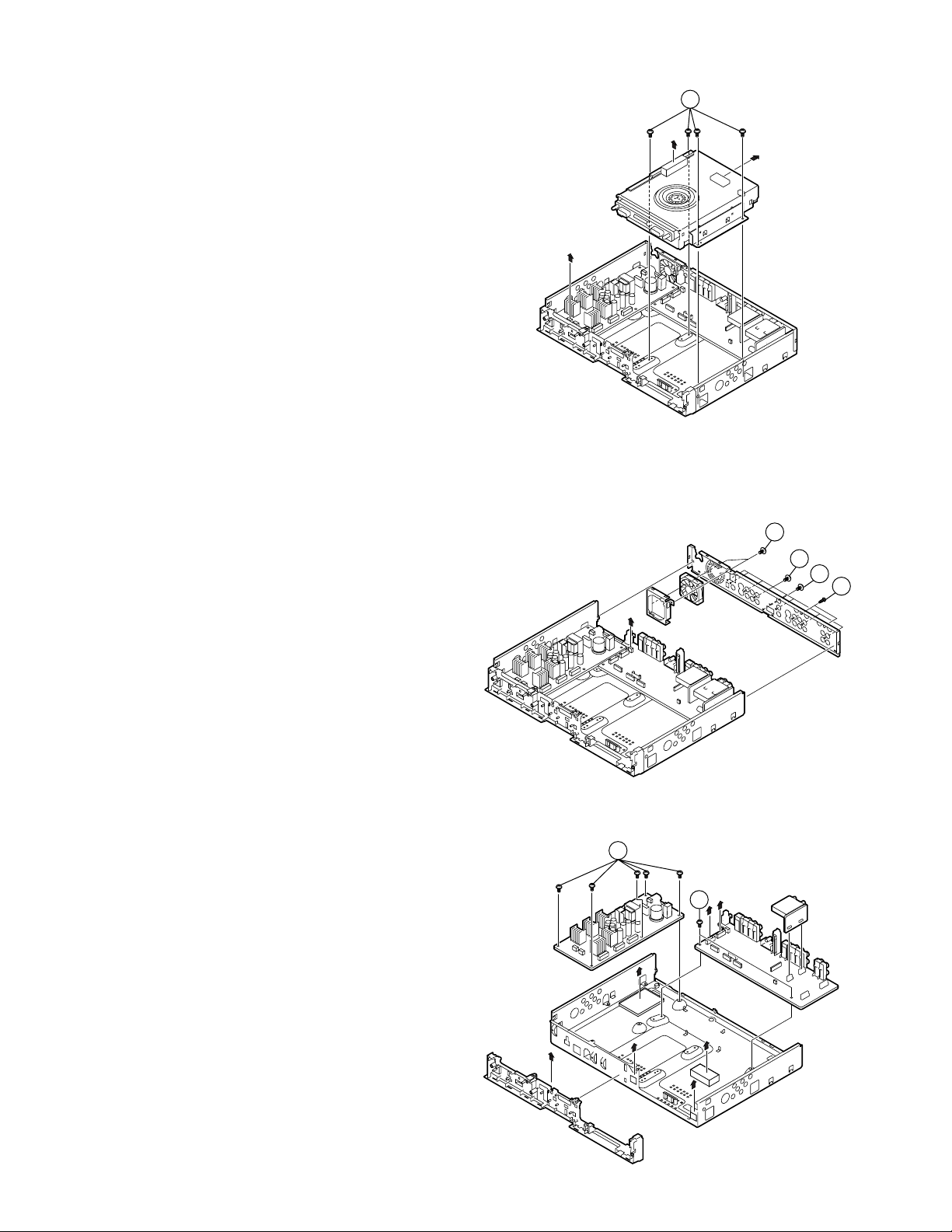

(6) Removing the DVD unit

1.Remove four screws 9.

2.Remove the DVD unit (with the angle) upward.

3.Disconnect cables including the flat cable and power cable.

4.Remove the gasket.

(7) Removing the rear terminal board and fan

1.Detach the fan cable from the main unit.

2.Remove two screws 0.

3.Detach the fan and fan cover.

4.Remove a screw q, two screws (tuner) w and eight screws e

(terminals)

5.Pull the rear terminal board backward to remove.

9

10

13

11

12

(8) Removing the UV PWB, BS PWB, power PWB and terminal PWB

1.Remove UV PWB upward.

2.Disconnect the connection cables from the power PWB and terminal PWB.

3.Remove five screws r.

4.Remove the power PWB upward.

5.Remove two screws t.

6.Remove the terminal PWB upward.

7. Remove two hooks and the PWB holder in the direction of the

arrow.

8.Remove one insulation sheet and three gasket.

12

14

15

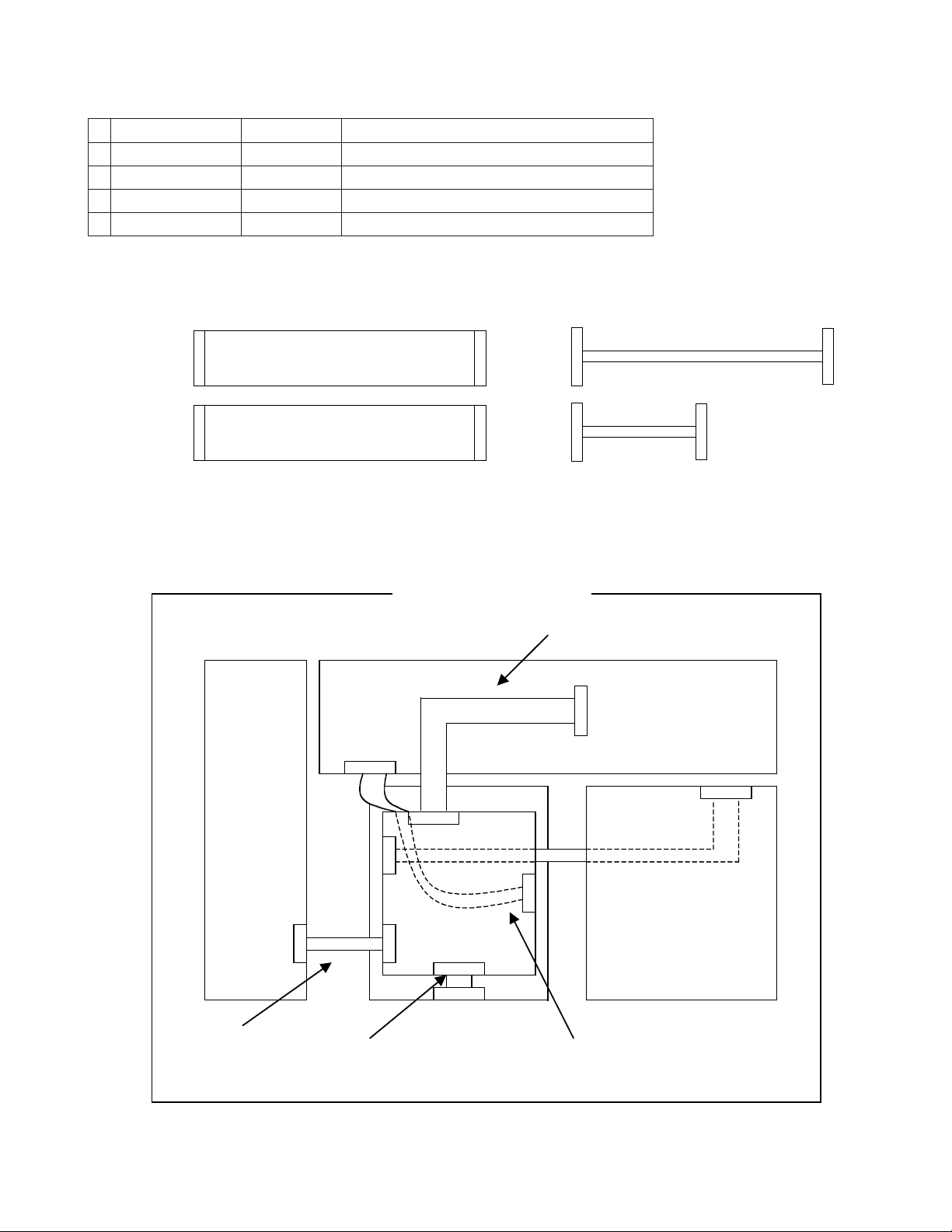

5-2. EXTENSION CABLE DIAGRAM

Parts Code Price Code Parts name / Use

1 QCNW-C072WJZZ AD Main to Sub Signal Line CN3001—S2202

2 QCNW-C073WJZZ AD Main to Sub Control Line CN3003↔S2201

3 QCNW-C074WJZZ AT Main to Power CN3004↔P9005

4 QCNW-B712WJZZ AH ATAPI cable for HDD CN4502↔ATAPi

DV-HR300U

1

2

25pin

21pin

POWER Unit

Sub PWB

12pin 12pin

3

40pin

4

Development for repair

Extension with QCNW-C072WJZZ

1

HDD Unit

Extension with

3

QCNW-C074WJZZ

Extension with

4

QCNW-B712WJZZ

Main PWB

Extension with

2

QCNW-C073WJZZ

13

DVD RW Unit

DV-HR300U

5-3. Notes for servicing

1. After replacing the HDD or main PWB, register the HDD-ID again.

2. After replacing I54R NOR flash (IC7502) or NAND flash (IC7509), upgrade the version using the CD.

All the data in the HDD will be formatted by replacing the main PWB unit.

The following parts cannot be replaced as the system information needs to be written. (Replace the PWB.)

1. EEPROM for I54R, IC7507 and IC7508

Setting procedure after replacement of HDD or main PWB

1) HDD installation

The unit can be started after installing the HDD, but key operation is impossible since the HDD-ID is not registered.

Perform HDD aging to register the HDD-ID.

2) HDD aging

The test mode can be accessed after replacing the HDD.

[1] Enter the test mode with the keys on the main unit (press the channel UP key and recording stop key simulta-

neously).

[2] Enter “4” to open the drive screen.

[3] Press the play key to enter the HDD aging mode.

“0” appears on the LCD of the front panel. It increases to 58 and then changes to “777” when the aging is

completed.

Should “EEE” appear, replace the HDD and start the process over. Aging takes approx. 2.5 hours.

[4] The aging is completed when “777” appears, and the HDD-ID is registered automatically.

If the main PWB unit is replaced, enter the test mode and press the “10/0” key on the remote control to register

the HDD-ID.

[5] Restart the unit and check the operation.

3) Factory setting

Initialize all the settings. Enter the test mode and press the “11” key on the remote control. The display stays black

during the initialization process.

Initialization is completed when the test mode appears on the LCD display following “507”.

Note: The descriptions in red are temporary (as of September 2, 2003) and subject to change.

5-4. Writing of software

1. Press the power key to turn on the power.

2. Open the tray with the tray open/close key and place the version upgrade CD.

3. Close the tray. Upgrade begins automatically.

“200” appears on the main unit display.

4. When the upgrade finishes, the tray opens and “208” appears on the main unit display.

5. Turn off the power to complete the upgrade.

• Upgrade the writer in the same way. In this case, “300” and “307” appear on the main unit display during the process.

14

DV-HR300U

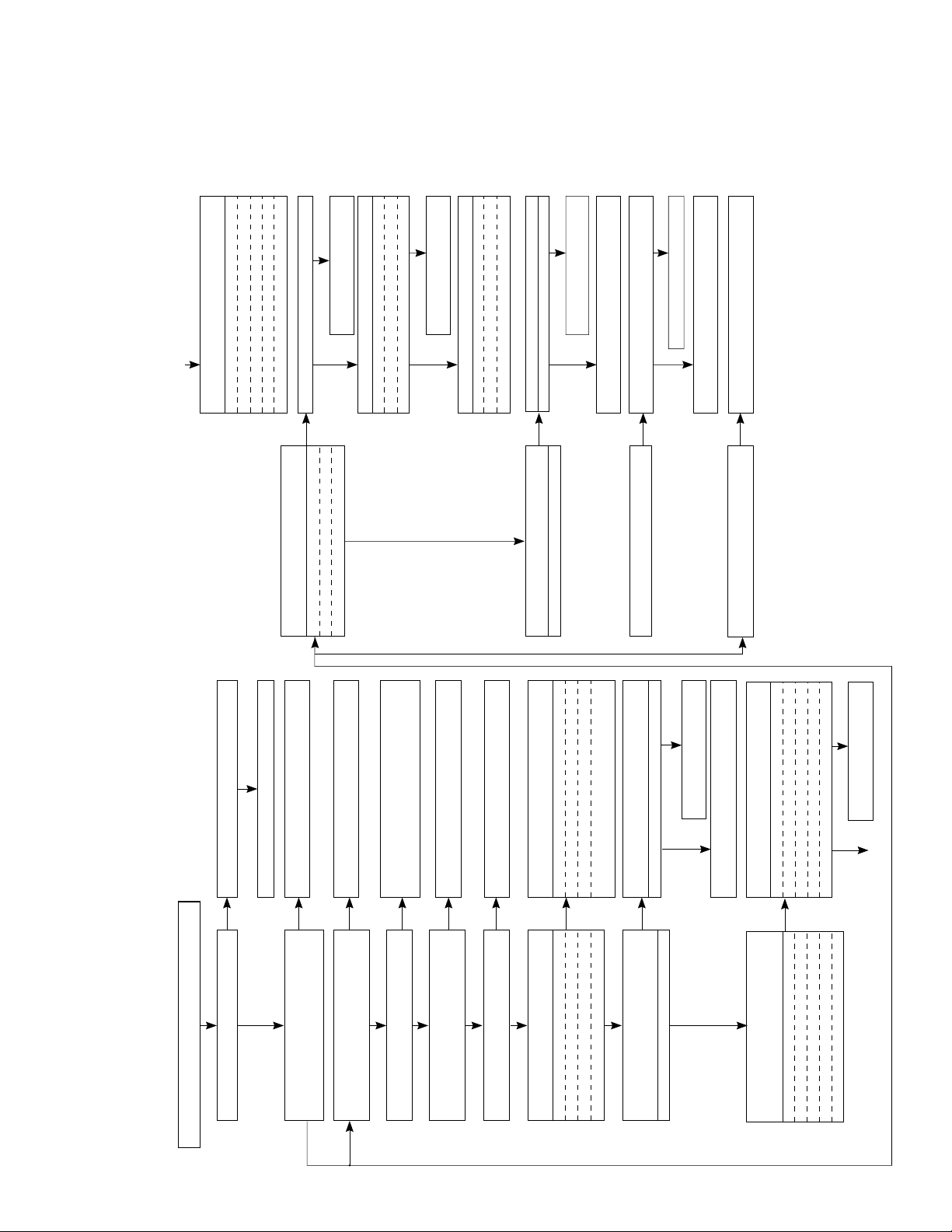

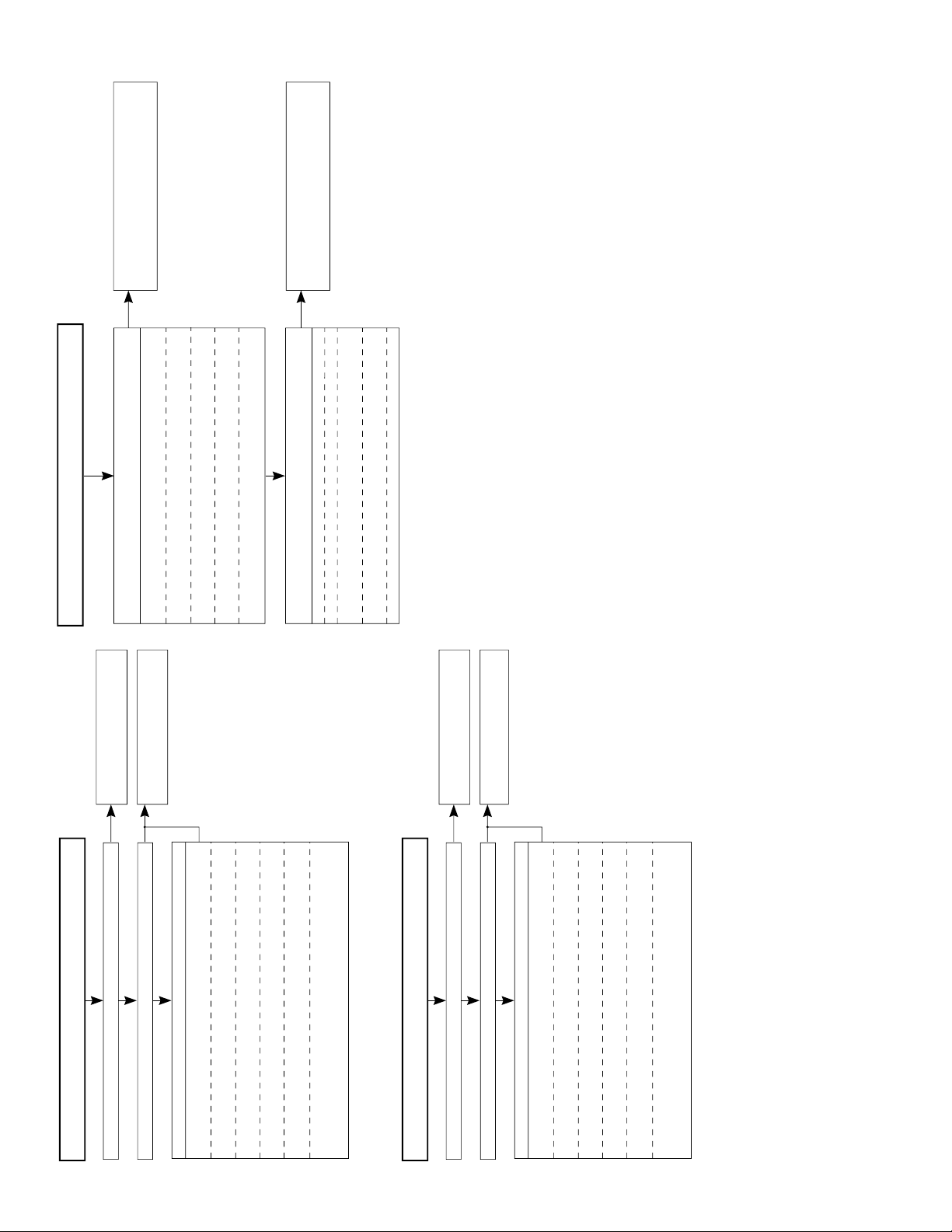

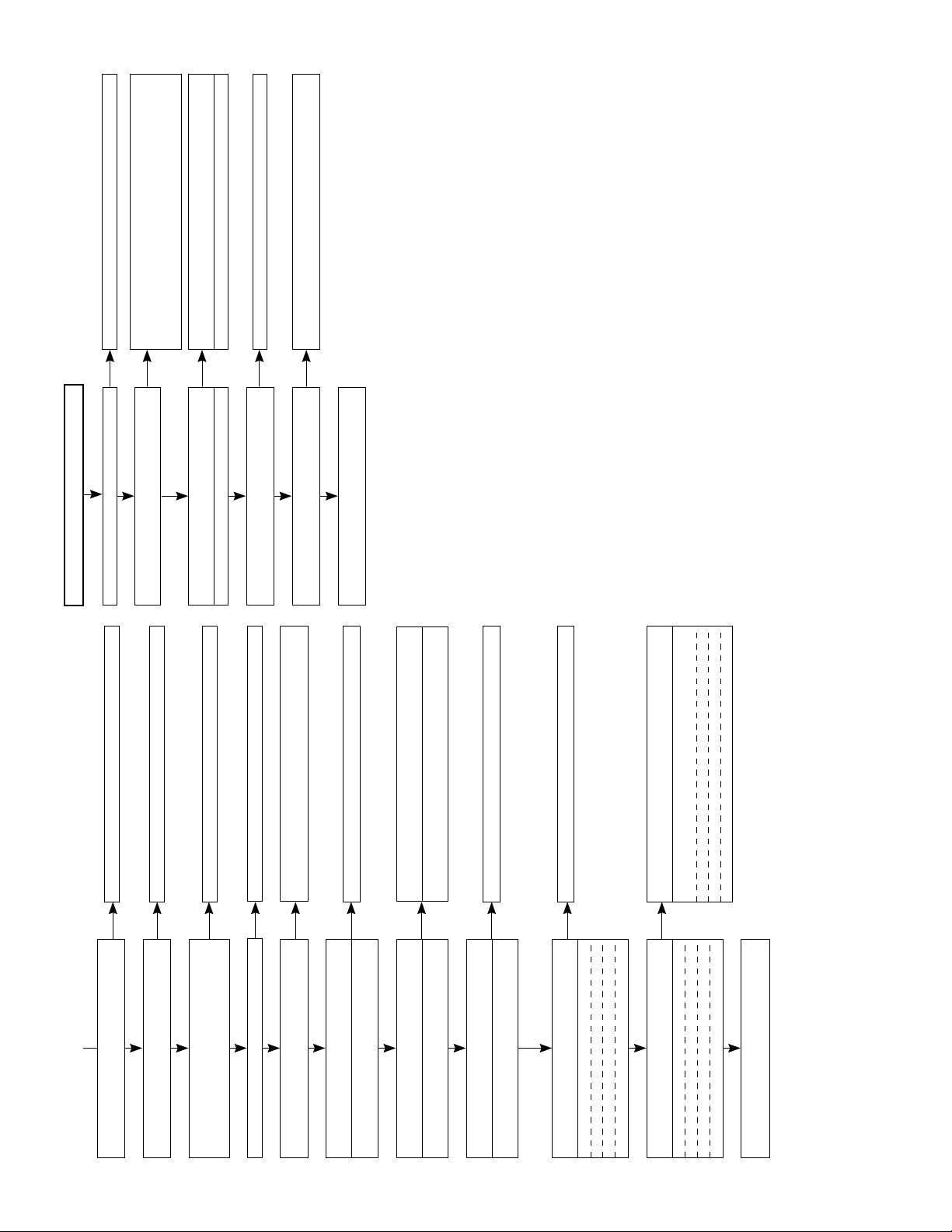

FLOW CHART No.1

With power on, circuits on main PWB do not work properly.

Power turns off approx. 5 seconds after turned on.

NO

NO

Are voltages of 3.3V (VDDP3.3, VDDADC3.3,

VDDP_A3.3) and 1.8V (VDDC1.8) applied to

pins of IC7506?

After power on, is 154_RS signal ("H" → "L"

when reset) input to IC7506 pin 257?

YES

Reset

Check

Is IC7506 pin 279 BOOTSEL1 at "L" level and

pin 278 BOOSTSEL0 at "H" level?

YES

With power on, is data input to IC7506 pins 81,

82, 86, 87, 91-94, 96-98, 101-104 and 108

(RAMDAT [31:16])?

YES

Is serial communication established between

IC7506 and sub unit IC501?

IC7506 pin 34 FPCDOUT (SUBMIC_D_OUT)

IC7506 pin 36 FPCSTB (SUBMIC_CS)

IC7506 pin 38 FPCCLK (SUBMIC_CLK)

IC7506 pin 39 FPCDIN (SUBMIC_D_IN)

YES

NO

NO

NO

NO

NO

Is reset signal ("H" → "L" when reset) input to

pins of each IC?

IC3502 pin 84 YCDEC_RST

IC7304 pin 151 ENCRST

IC4005 pin 1 DV_RST

IC3009 pin 5 DACADC_RST

IC3005 pin 13 AD_RST

NO

With power on, is fan running?

Fan is defective or power supply failure.

Check D_3.3V (1) and 1.8V lines (IC7506).

Check IC4501 and peripheral

circuits.

Check 154_RST line between IC501 pin 98 and

IC7506 pin 257.

Check BOOTSEL1 (DOWN L [H]) line between IC501

pin 22 and IC7506 pin 257 as well as BOOTSEL0 line

between Q7507 collector and IC7506 pin 278.

Check lines between pins of IC7502 and IC7506.

Check lines between pins of IC7506 and sub PWB

IC501.

IC7506 pin 34 ← IC501 pin 16 TU_D_OUT

IC7506 pin 36 → Q532, 533 → IC501 pins 2, 3 TU_CS

IC7506 pin 38 → Q534, 535 → IC501 pin 14 TU_CLK

IC7506 pin 39 → Q536, 537 → IC501 pin 15

MAIN_DATA

YES

With power on, is data input to IC7506 pins 63,

64, 66-69, 73 and 74 NVMDA [7:0]?

After power on, is reset signal ("H" → "L"

when reset) input to IC4501 pin 54?

IC4501 pin 54 SV_RST

YES

NO

Check lines between pins of IC7509 and IC7506.

Check SV_RST line between IC7506 pin 29 and

IC4501 pin 54.

YES

NO

Is 27MHz clock signal input to pins of the

following ICs?

IC7506 pins 252, 256 27MHz_OSC

IC7304 pins 28, 34 MPENC_SCLK

IC4005 pins 50, 202 INVCK4

Check lines between pins of IC4501 and other ICs.

IC4501 pin 113 → IC3502 pin 84 YCDEC_RST

IC4501 pin 139 → IC7304 pin 151 ENCRST

IC4501 pin 78 → IC4005 1 pin DV_RST

IC4501 pin 99 → IC3009 pin 5 DACADC_RST

IC4501 pin 64 → IC3005 pin 13 AD_RST

NO

Check IC7506 and peripheral

circuits.

NO

YES

YES

YES

NO

Check X3001 and peripheral

circuits.

Check IC3004 and peripheral

circuits.

Is 27MHz clock signal output to X3001 pin 4?

NO

Check X3502 and peripheral circuits.

Is 27MHz clock signal to each pin of IC3004?

IC3004 pin 14 27MHz_OSC

IC3004 pin 18 MPENC_SCLK

IC3004 pin 16 INVCK4

Check lines between pins of IC3004 and other ICs.

IC3004 pin 14 → IC7506 pins 252, 256 27MHz_OSC

IC3004 pin 18 → IC7304 pins 28, 34 MPENC_SCLK

IC3004 pin 16 → IC4005 pins 50, 202 INVCK4

NO

YES

NO

Check IC7506 and peripheral

circuits.

NO

YES

YES

YES

Is 27MHz clock signal input to IC4501 pins 18,

91?

IC4501 pins 18, 91 SBCLK

Is 135MHz clock signal PCLK input to IC7510/

7511pin 38?

Is 24.576MHz clock signal output on IC3502

pin 43?

NO

Check IC7506 and peripheral circuits.

Is 135MHz clock signal PCLK output to IC7506 pin

134?

Check SBCLK (RP_SBCLK) line between IC7506

pin 208 and IC4501 pins 18, 91.

Check lines between IC7506 pin 134 and IC7510/

7511 pin 38.

NO

YES

Clock

Check

Clock

Check

After power on, is reset signal ("H" → "L" when reset)

output to IC7506 pin 79?

IC7506 pin 79 SV_RST

1

1

Is reset signal ("H" → "L" when reset) output to each

pin of IC4501?

IC4501 pin 113 YCDEC_RST

IC4501 pin 139 ENCRST

IC4501 pin 78 DV_RST

IC4501 pin 99 DACADC_RST

IC4501 pin 64 AD_RST

NO

Is 27MHz clock signal output to IC7506 pin 208?

IC7506 pin 208 RP_SBCLK

6. TROUBLE SHOOTING

15

DV-HR300U

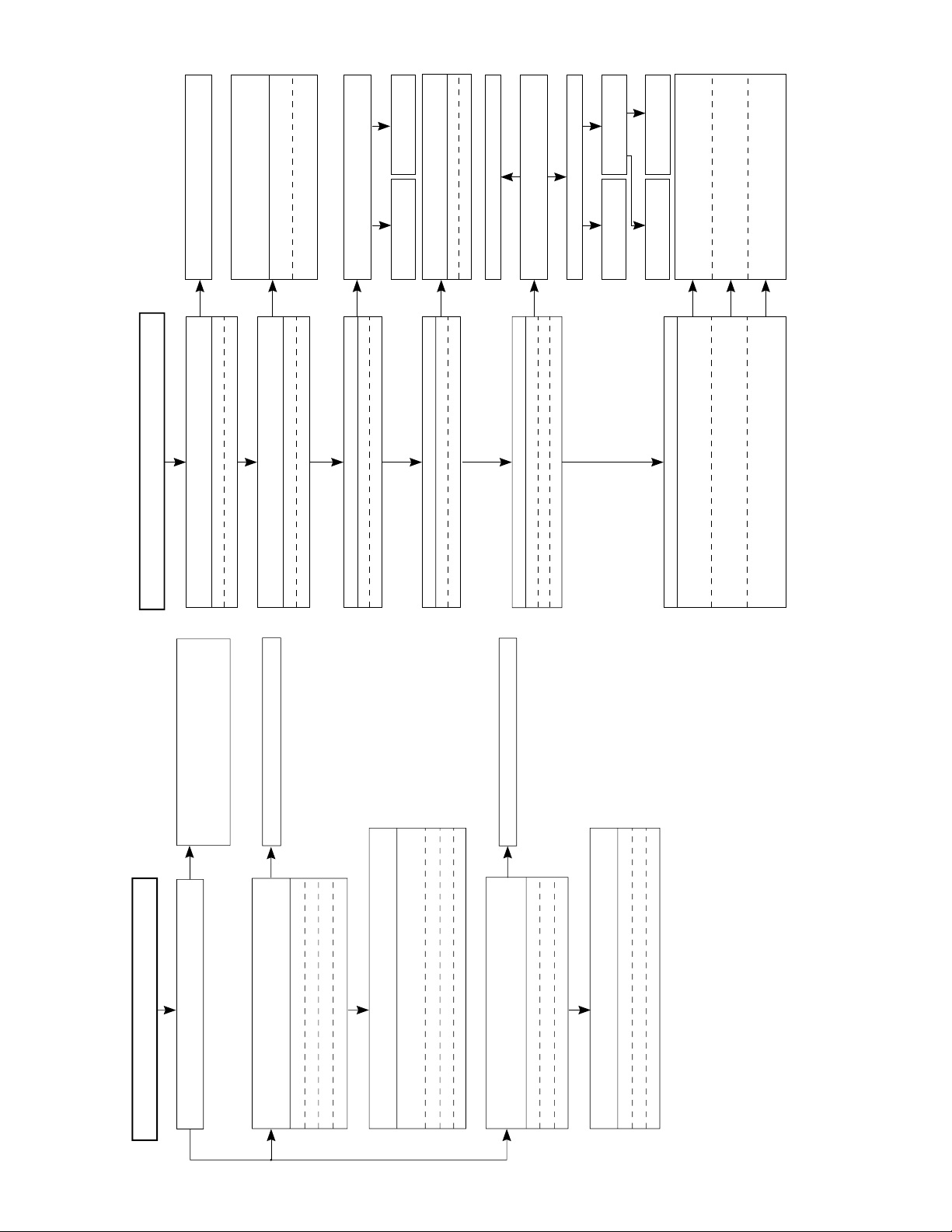

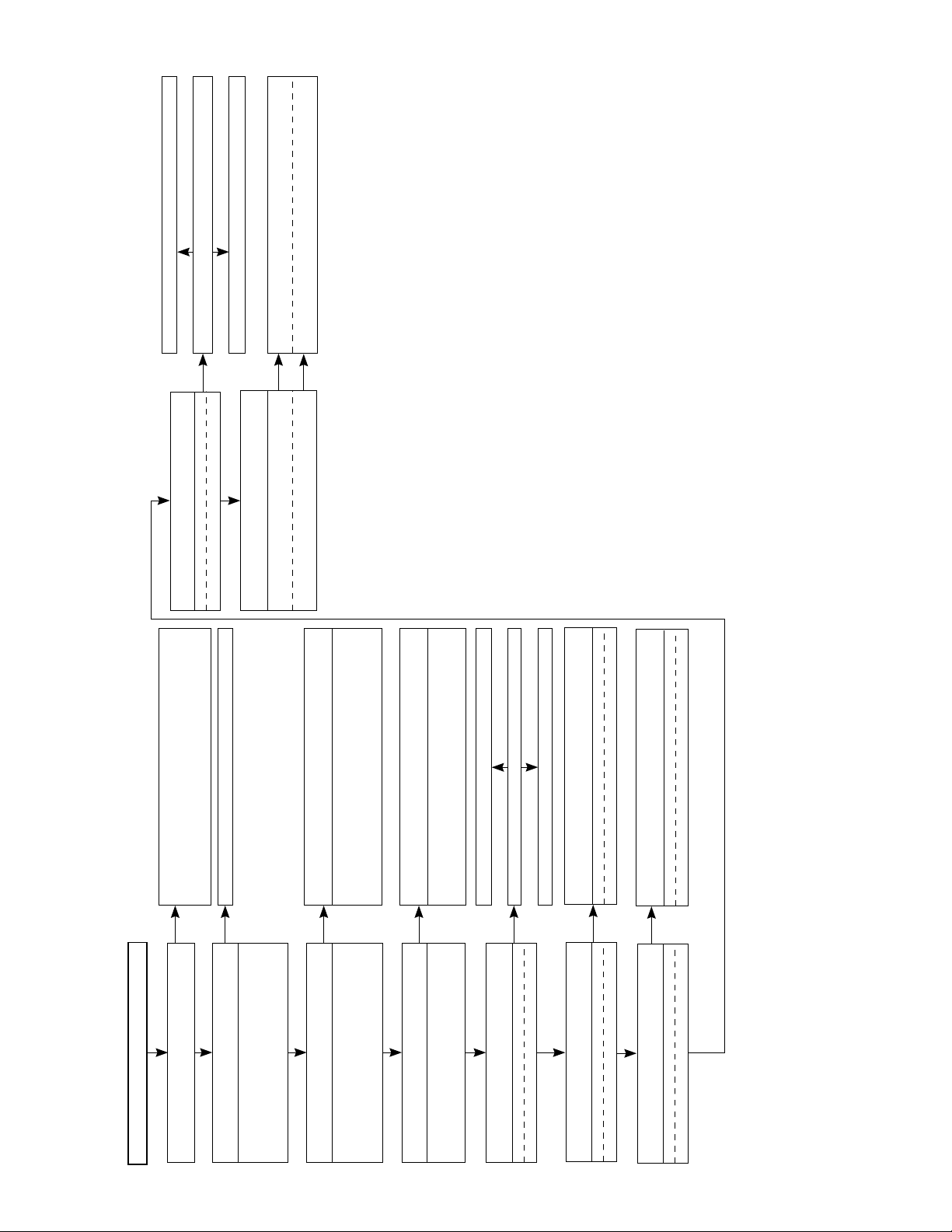

FLOW CHART No.2

Drive is not working properly (communication failure with IC7506).

Is ATAPI reset released? (CN4501 pin 1 R4537: "H" level)

NO

Check IC7506 and peripheral

circuits.

YES

YES

Check following items.

NO

Check power unit and PC_12V

and PC_5V circuits.

Communicating with drive via ATAPI?

Access drive when CN4501 pin 37 CS0 and pin 38 CS1 are at "L"

level. (Communication is ongoing if intermittently set at LOW.)

CN4501 pin 35 DA0, pin 33 DA1, pin 36 DA2 and ATAPI register

address (Intermittently set at LOW).

CN4501 pin 31 INTRQ is at "H" level when drive interrupts. Output

after processing transfer command from IC7506, etc.

CN4501 pin 21 DMARQ is at "L" level when drive requests data

transfer.

CN4501 pin 29 DMACK is at "L" level when IC7506 receives data

transfer for DMARQ from drive.

When CN4501 pin 25 DIOR and pin 23 DIOW are at "L" level,

IC7506 sends REASD/WRITE to drive. (Communication is ongoing

if CS and DA are intermittently set at LOW.)

Are 12V and 5V applied to drive?

FLOW CHART No.3

HDD is not working properly (communication failure with IC7506).

Is ATAPI reset released? (CN4502 pin 40 R4566: "H" level)

NO

Check IC7506 and peripheral

circuits.

YES

YES

Check following items.

NO

Check power unit and PC_12V

and PC_5V circuits.

Communicating with drive via ATAPI?

Access drive when CN4502 pin 4 CS0 and pin 3 CS1 are at "L"

level. (Communication is ongoing if intermittently set at LOW.)

CN4502 pin 6 DA0, pin 8 DA1, pin 5 DA2 and ATAPI register

address (intermittently set at LOW).

CN4502 pin 10 INTRQ is at "H" level when drive interrupts. Output

after processing transfer command from IC7506, etc.

CN4502 pin 20 DMARQ is at "L" level when drive requests data

transfer.

CN4502 pin 12 DMACK is at "L" level when IC7506 receives data

transfer for DMARQ from drive.

When CN4502 pin 16 DIOR and pin 18 DIOW are at "L" level,

IC7506 sends REASD/WRITE to drive. (Communication is ongoing

if CS and DA are intermittently set at LOW.)

Are 12V and 5V applied to HDD?

Is MPEG2_PS data signal properly connected between pins of

IC7304 and IC4501?

IC7304 pin 66 → IC4501 pin 138 OSSTD (stream data strobe)

IC7304 pins 56-59, 61, 63-65 → IC4501 pins 3-7, 10-12

OS [7:0] (stream data)

IC7304 pin 70 ← IC4501 pin 141 OSREQ ("L" level when

IC4501 requests data transfer.)

IC7304 pin 68 → IC4501 pin 13 OSVLD (stream data valid)

IC7304 pin 67 → IC4501 pin 19 OSSYNC (stream data sync)

FLOW CHART No.4

Recording is impossible (MPEG stream check)

NO

Check IC7304, IC4501 and peripheral

circuits as well as lines between pins of

IC7304 and IC4501.

YES

NO

Check IC4501, IC7506 and peripheral

circuits as well as lines between pins of

IC4501 and IC7506.

Is MPEG2_PS data signal properly connected between pins of

IC4501 and IC7506?

IC4501 pin 18 ← IC7506 pin 208 SBCLK (transfer clock 27MHz)

IC4501 pin 23 → IC7506 pin 240 SBDAT (stream data)

IC4501 pin 22 → IC7506 pin 234 SBVALID ("H" level when

transferred data is valid)

IC4501 pin 21 ← IC7506 pin 213 SBREQ ("H" level when

IC7506 requests data transfer)

IC4501 pin 20 → IC7506 pin 239 SBSOS (sector head signal)

16

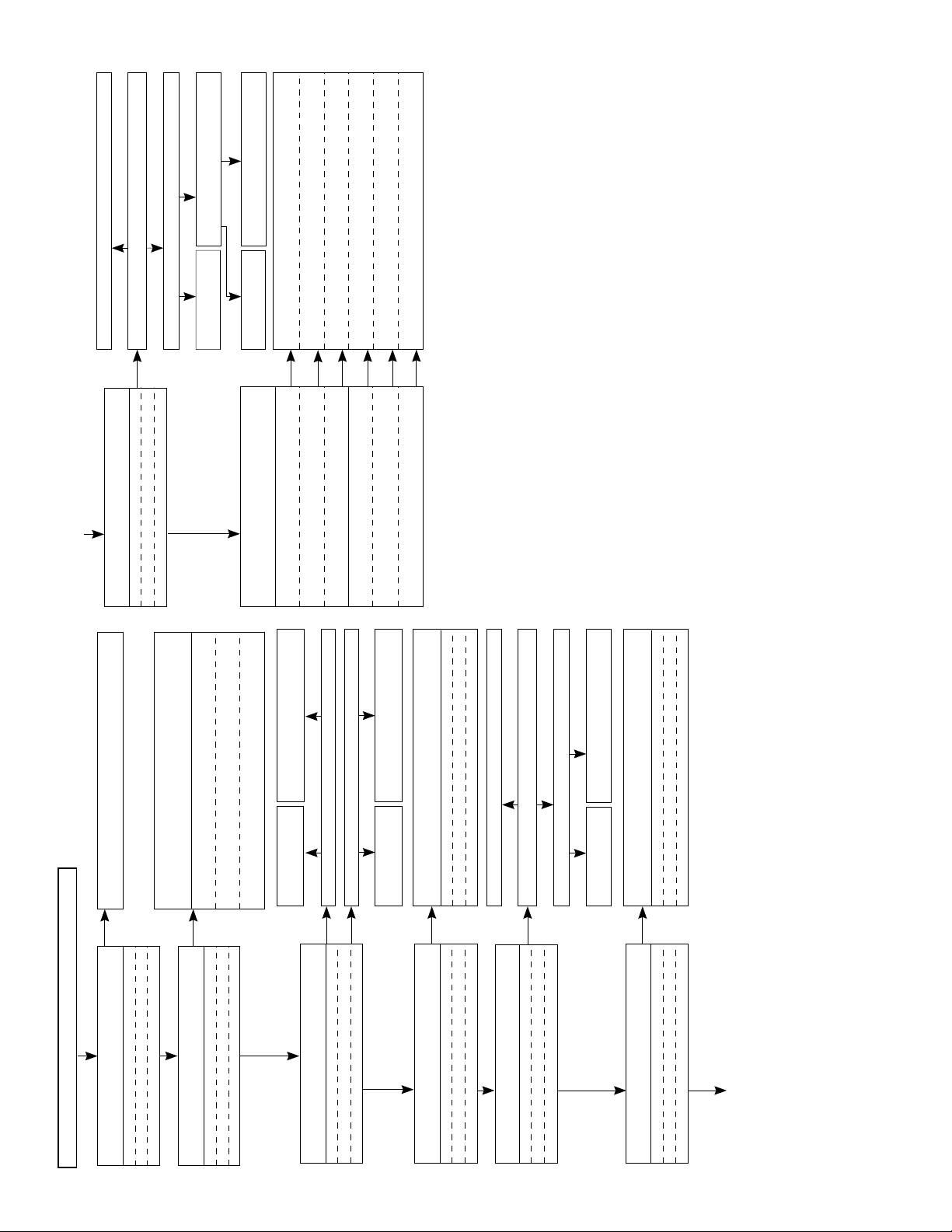

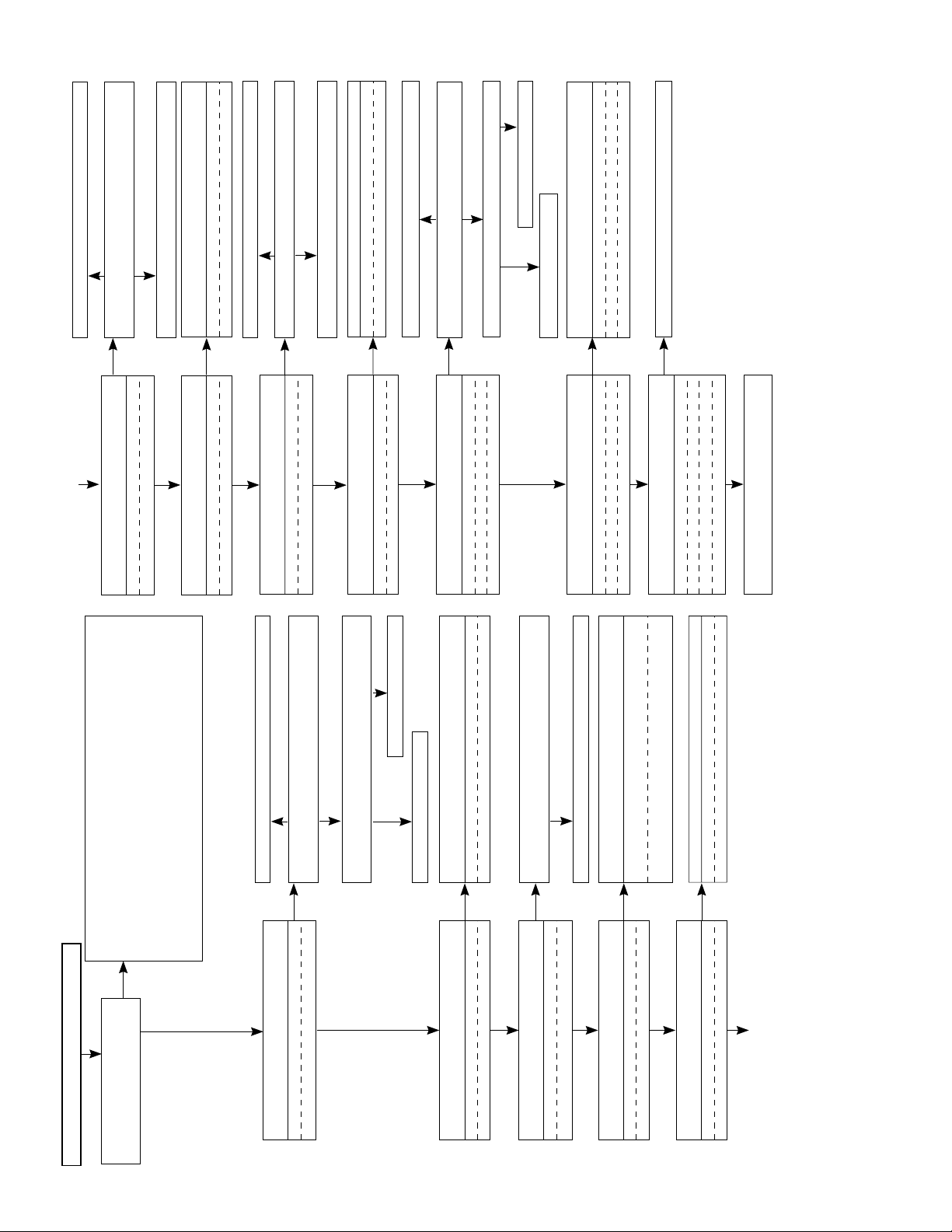

DV-HR300U

Y/C/C

B

/C

R

output

Is video signal output to each pin of IC7506?

IC7506 pin 218 (R7742) Y OUT (Q7506 pin 5 B)

IC7506 pin 214 (R7744) C OUT (Q7505 pin 5 B)

IC7506 pin 245 (R7724) C

B

(B_U) OUT (Q7503 B)

IC7506 pin 224 (R7737) C

R

(R_V) OUT (Q7502 B)

FLOW CHART No.5

Playback video signal is not output from main PWB.

Is drive control of IC7506 working properly?

Is HDD control working properly?

YES

Check lines between pins of IC7506 and CN3001 as well as

circuits on lines.

IC7506 pin 218 (R7742) → Q7506 → Q7509 (FL7501 →

Q7508 in LP mode) → IC7512 → CN3001 pin 23 154_Y

IC7506 pin 214 pin (R7744) → Q7505 → CN3001 pin 25 154_C

IC7506 pin 245 pin (R7724) → Q7503 → CN3001 pin 19 154_B/U

IC7506 pin 224 pin (R7737) → Q7502 → CN3001 pin 20 154_R/V

NO

NO

Refer to Flow chart No.2 "Drive is not working

properly (communication failure with IC7506)"

or Flow chart No.3 "HDD is not working

properly (communication failure with IC7506)".

Check IC7506 and peripheral circuits.

YES

Y/P

B

/P

R

output (progressive mode)

Is video signal output to each pin of IC7506?

IC7506 pin 223 (R7738) Y (G_Y) OUT (Q7501 B)

IC7506 pin 245 (R7724) P

B

(B_U) OUT (Q7503 B)

IC7506 pin 224 (R7737) P

R

(R_V) OUT (Q7502 B)

NO

YES

Check IC7506 and peripheral circuits.

Check lines between pins of IC7506 and CN3001 as well as

circuits on lines.

IC7506 pin 223 pin (R7738) → Q7501 → CN3001 pin 18 154_G/Y

IC7506 pin 245 pin (R7724) → Q7503 → CN3001 pin 19 154_B/U

IC7506 pin 224 pin (R7737) → Q7502 → CN3001 pin 20 154_R/V

Is video signal output to pins of main unit connector CN3001?

CN3001 pin 23 154_Y

CN3001 pin 25 157_C

FLOW CHART No.6

Playback images do not appear properly (from video/S output).

NO

Refer to Flow chart No.5 "Playback video

signal is not output from main PWB".

Check circuits and lines between pins of

main unit connector CN3001 and input pins

of IC2802.

CN3001 pin 23 → S2202 pin 23 → Q2502,

2504, 2507 → IC2802 pin 2 OSD_Y_IN

CN3001 pin 25 → S2202 pin 25 → Q2501,

2503, 2506 → IC2802 pin 4 OSD_C_IN

YES

NO

Check lines between IC2501 pin 21 and

S-OUT 1/2 Y terminals (J2402) as well as

S-OUT 1/2 terminals (J2402).

Check lines between IC2501 pin 26 and

S-OUT 1/2 C terminals (J2402) as well as

S-OUT 1/2 terminals (J2402).

Check lines between IC2501 pin 23 and

VIDEO OUT 1/2 terminals (J2402) as well as

VIDEO OUT 1/2 terminals (J2402).

Is video signal input to each pin of sub unit IC2802?

IC2802 pin 2 OSD_Y_IN

IC2802 pin 4 OSD_C_IN

YES

NO

Is 5V applied to IC2501 pins 1, and 28?

Is 5V applied to IC2802 pin 7?

Is IC2501 pin 3 at "H" level?

Check PC_5V (1) line

Check PC_5V (1)

line.

NO

NO

Is video signal output to each pin of IC2802?

IC2802 pin 8 OSD_Y

IC2802 pin 6 OSD_C

YES

Is video signal input to each pin of IC2501?

IC2501 pin 6 OSD_Y

IC2501 pin 2 OSD_C

YES

Is video signal output to each pin of IC2501?

IC2501 pin 21 Y_OUT

IC2501 pin 26 C_OUT

IC2501 pin 23 V_OUT

Check lines between pins of IC2802 and

IC2501.

IC2802 pin 8 → IC2501 pin 6 OSD_Y

IC2802 pin 6 → IC2501 pin 2 OSD_C

YES

NO

NO

NO

Is video signal output to each output terminal?

SIs Y signal output to S-OUT 1/2 terminals (J2402)?

Is C signal output to S-OUT 1/2 terminals (J2402)?

Is CVBS signal output to VIDEO OUT 1/2 terminals (J2402)?

NO

YES

ICheck or replace

IC2501.

YES

Check or replace

IC2801.

YES

YES

Is T_V_MUTE line

at "L" level?

NO

NO

Check Q2510 and

R2515.

Check T_V_MUTE

line.

NO

17

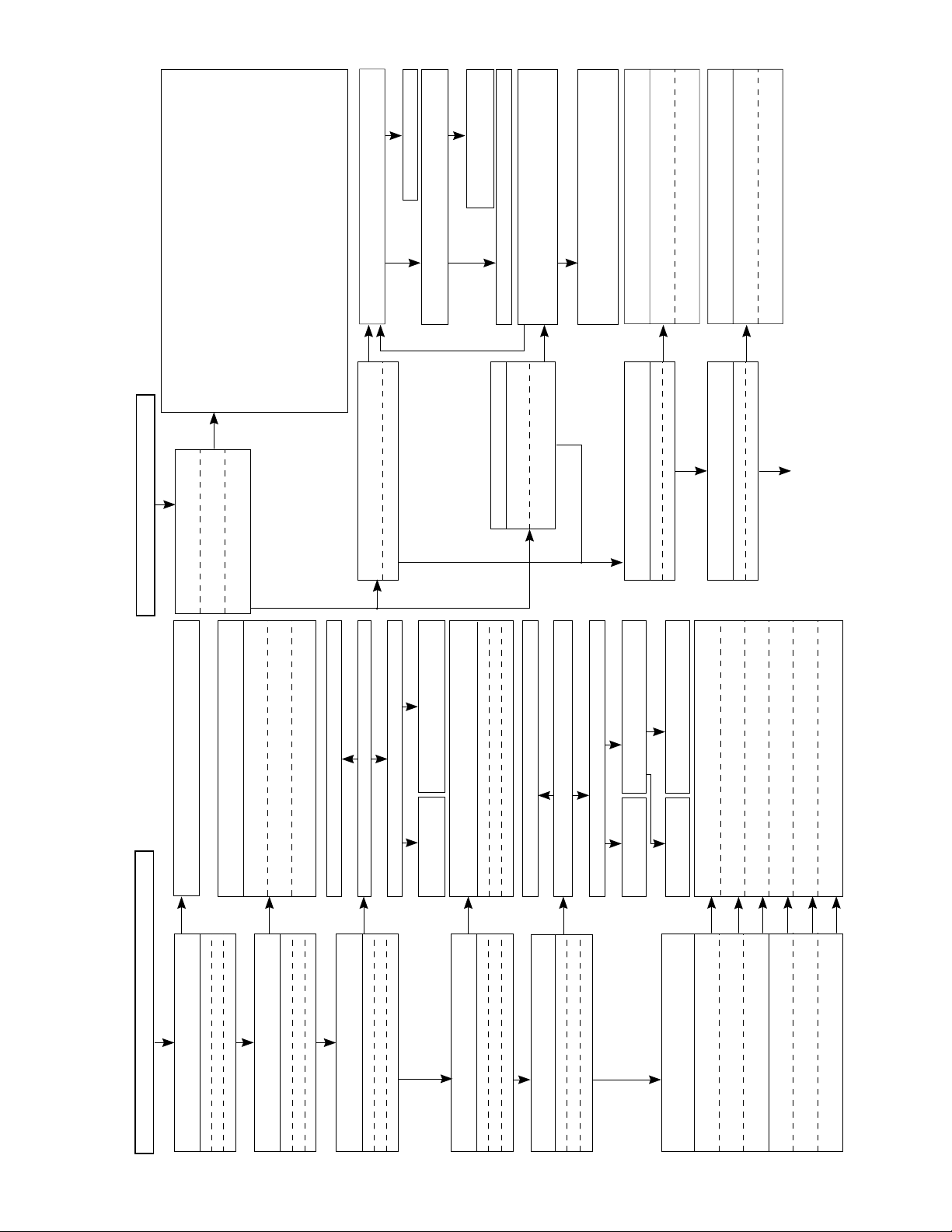

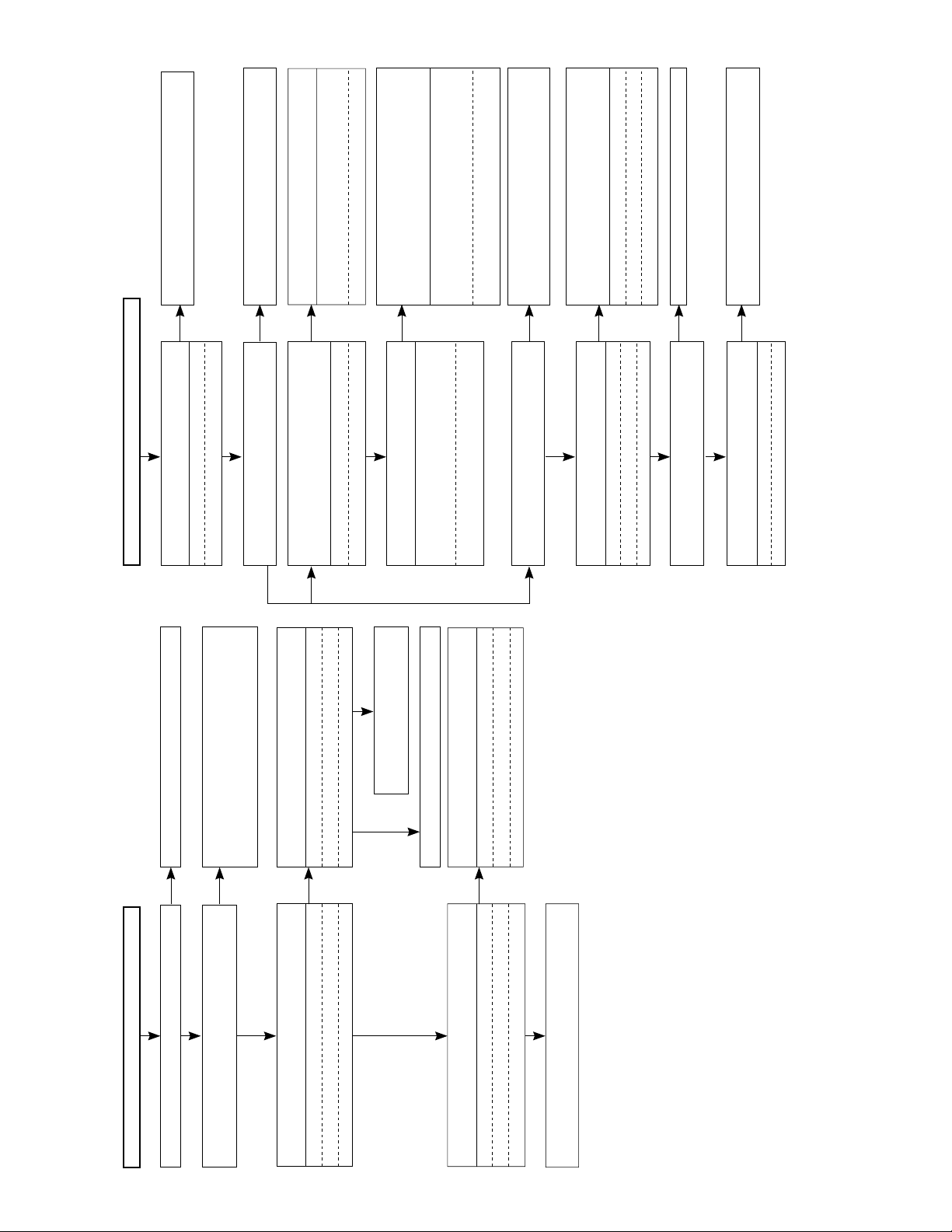

DV-HR300U

Is video signal output to pins of main unit

connector CN3001?

CN3001 pin 23 154_Y

CN3001 pin 19 154_B/U

CN3001 pin 20 154_R/V

FLOW CHART No.7

Playback images do not appear properly (from Y/C

B

/C

R

output).

NO

Refer to Flow chart No.5 "Playback video signal is not output

from main PWB".

YES

NO

Is video signal input to pins of sub unit IC2802

and 2801?

IC2802 pin 2 OSD_Y_IN

IC2801 pin 1 OSD_PB_IN

IC2801 pin 14 OSD_PR_IN

YES

YES

Is 5V applied to IC2802 pin 7?

Is 5V applied to IC2801 pin 13?

Is video signal input to pins of IC2802 and

2801?

IC2802 pin 8 OSD_Y

IC2801 pin 3 OSD_P

B

IC2801 pin 5 OSD_P

R

YES

NO

NO

NO

Check lines between pins of IC2802 and 2801 and pins of

IC2502.

IC2802 pin 8 → IC2502 pin 8 OSD_Y

IC2801 pin 3 → IC2502 pin 11 OSD_PBIC2801 pin 5 → IC2502 pin 16 OSD_P

R

Is video signal input to each pin of IC2502?

IC2502 pin 8 OSD_Y

IC2502 pin 11 OSD_PBIC2502 pin 16 OSD_P

R

NO

Check or replace

IC2801.

YES

YES

Check or replace

IC2801.

Check PC_5V (1) line.

Check PC_5V (1) line.

NO

Check circuits and lines between pins of main unit connector

CN3001 and input pins of IC2802/2801.

CN3001 pin 23 → S2202 pin 23 → Q2502, 2504, 2507 →

IC2802 pin 2 OSD_Y_IN

CN3001 pin 19 → S2202 pin 19 → Q2512, 2515 →

IC2801 pin 1 OSD_ P

B

_IN

CN3001 pin 20 → S2202 pin 20 → Q2513, 2516 →

IC2801 pin 14 OSD_ P

R

_IN

Check line between IC2501 pin 20 and component Y terminal

(J2403) as well as component terminal (J2403).

Check line between IC2501 pin 18 and component C

B

terminal

(J2403) as well as component terminal (J2403).

Check line between IC2501 pin 16 and component C

R

terminal

(J2403) as well as component terminal (J2403).

Check line between IC2501 pin 20 and DY terminal (CN2401) as

well as component terminal (CN2401).

Check line between IC2501 pin 18 and D C

B

terminal (CN2401)

as well as component terminal (CN2401).

Check line between IC2501 pin 16 and D C

R

terminal (CN2401)

as well as component terminal (CN2401).

YES

NO

Is 5V applied to IC2502 pin 13?

Is IC2502 pin 12 PROGRE (H) line at "L" level?

Check PC_5V (1) line.

Is video signal input to each pin of IC2502?

IC2502 pin 6 COM_Y

IC2502 pin 5 C

B

IC2502 pin 3 C

R

YES

NO

NO

NO

NO

NO

NO

Is video signal output to each output terminal?

Is Y signal output to component terminal

(J2403)?

Is C

B

signal output to component terminal

(J2403)?

Is C

R

signal output to component terminal

(J2403)?

Is Y signal output to D terminal (CN2401)?

Is C

B

signal output to D terminal (CN2401)?

Is C

R

signal output to D terminal (CN2401)?

NO

YES

Check or replace

IC2502.

YES

YES

Check PROGRE (H) line.

NO

Check Q2510 and

R2515.

Check T_V_MUTE line.

NO

NO

Check lines between pins of IC2502 and IC2501.

IC2502 pin 6 -> IC2501 pin 10 COM_Y

IC2502 pin 5 -> IC2502 pin 12 C

B

IC2502 pin 3 -> IC2502 pin 14 C

R

Is video signal input to each pin of IC2501?

IC2501 pin 10 COM_Y

IC2502 pin 12 C

B

IC2502 pin 14 C

R

YES

NO

Is 5V applied to IC2501 pins 1 and 28?

Is IC2501 pin 13 at "H" level?

Check PC_5V (1) line.

Is video signal output to each pin of IC2501?

IC2501 pin 20 COMPO_Y

IC2501 pin 18 C

B

_OUT

IC2501 pin 16 C

R

_OUT

NO

YES

Check or replace

IC2501.

YES

Is T_V_MUTE line at "L" level?

NO

1

1

18

DV-HR300U

Is video signal output to pins of main unit

connector CN3001?

CN3001 pin 18 154_G/Y

CN3001 pin 19 154_B/U

CN3001 pin 20 154_R/V

FLOW CHART No.8

Playback images do not appear properly (from Y/C

B

/C

R

output).

NO

YES

NO

Is video signal input to each pin of IC2502?

IC2502 pin 9 154_Y

IC2502 pin 14 154_P

B

IC2502 pin 1 154_P

R

YES

NO

Is 5V applied to IC2502 pin 13?

Is IC2502 pin 12 PROGRE (H) at "H" level?

Check PC_5V (1) line.

Is video signal input to each pin of IC2502?

IC2502 pin 6 COM_Y

IC2502 pin 5 C

B

IC2502 pin 3 C

R

YES

NO

Check lines between pins of IC2501 and pins of IC2502.

IC2502 pin 6 → IC2501 pin 10 COM_Y

IC2502 pin 5 → IC2501 pin 12 C

B

IC2502 pin 3 → IC2501 pin 14 C

R

Is video signal input to each pin of IC2501?

IC2501 pin 10 COM_Y

IC2501 pin 12 C

B

IC2501 pin 14 C

R

NO

YES

Check or replace

IC2502.

YES

Check PROGRE (H) line.

NO

Check circuits and lines between pins of main unit connector

CN3001 and input pins of IC2502.

CN3001 pin 18 → S2202 pin 18 → Q2511, 2514, 2518 →

IC2502 pin 9 154_Y

CN3001 pin 19 → S2202 pin 19 → Q2512, 2515 →

IC2502 pin 14 154_ P

B

CN3001 pin 20 → S2202 pin 20 → Q2513, 2516 →

IC2502 pin 1 154_ P

R

Check line between IC2501 pin 20 and component Y terminal

(J2403) as well as component terminal (J2403)?

Check line between IC2501 pin 18 and component P

B

terminal

(J2403) as well as component terminal (J2403)?

Check line between IC2501 pin 16 and component P

R

terminal

(J2403) as well as component terminal (J2403)?

Check line between IC2501 pin 20 and DY terminal (CN2401)

as well as D terminal (CN 2401)?

Check line between IC2501 pin 18 and D P

B

terminal (CN2401)

as well as D terminal (CN 2401)?

Check line between IC2501 pin 16 and D P

R

terminal (CN2401)

as well as D terminal (CN 2401)?

YES

NO

Is 5V applied to IC2501 pins 1 and 28?

Is IC2501 pin 13 at "H" level?

Check PC_5V (1) line.

Is video signal output to each pin of IC2501?

IC2501 pin 20 COMPO_Y

IC2501 pin 18 C

B

_OUT

IC2501 pin 16 C

R

_OUT

YES

NO

NO

NO

NO

NO

NO

Is video signal output to each output terminal?

Is Y signal output to component terminal

(J2403)?

Is P

B

signal output to component terminal

(J2403)?

Is P

R

signal output to component terminal

(J2403)?

Is Y signal output to D terminal (CN2401)?

Is P

B

signal output to D terminal (CN2401)?

Is P

R

signal output to D terminal (CN2401)?

NO

YES

Check or replace

IC2501.

YES

YES

Is T_V_MUTE line at "L" level?

NO

Check Q2510 and

R2515.

Check T_V_MUTE line.

NO

Is video signal input to IC2203 pins

1, 8, 15, 23 and 47?

Is luminance signal input to IC 2203

pins 3, 10 and 17?

Is chroma signal input to IC 2202

pins 5, 12 and 19?

FLOW CHART No.9

Image E-E does not appear.

1 In external video input mode

■ Check line between rear video input 1 terminal (J2401) and IC2203 pin 8.

■ Check line between rear video input 2 terminal (J2402) and IC2203 pin 15.

■ Check line between front video input 3 terminal (J2702) and IC2203 pin 1.

2 In external S input mode

■ Check line between rear S Y input 1 terminal (J2401) and IC2203 pin 10.

■ Check line between rear S Y input 2 terminal (J2401) and IC2203 pin 17.

■ Check line between front S Y input 3 terminal (J2701) and IC2203 pin 3.

■ Check line between rear S C input 1 terminal (J2401) and IC2203 pin 12.

■ Check line between rear S C input 2 terminal (J2401) and IC2203 pin 19.

■ Check line between front S C input 3 terminal (J2701) and IC2203 pin 5.

3 In U/V tuner mode

Check line between pin 18 of U/V tuner (TU1501) and IC2203 pin 47.

4 In BS tuner mode

Check line between pin 18 of BS tuner (TU1701) and IC2203 pin 23.

YES

NO

Is video signal input to pins of main unit

connector CN3001?

CN3001 pin 1 CVBS/Y signal

CN3001 pin 3 C signal

NO

In external video input 1/2/3 mode, U/V tuner mode or

BS tuner mode:

Is video signal output to IC2203 pin 43?

Is 9V applied to IC2203 pin 34?

Check or replace IC2203.

Check PC_9V line.

NO

YES

YES

NO

YES

YES

NO

Is signal input to pin 26 PLL_SCL and pin 27 PLL_SDA

controlling IC2203?

Check PLL_SCL and

PLL_SDA lines.

YES

NO

YES

In external S input 1/2/3 mode:

Is luminance signal output to IC2203

pin 43?

Is chroma signal output to IC2203

pin 45?

Are these lines at "L" level: IC501 pin 29 AUX1_S_SOCK (rear

AUX1), pin 64 AUX3_S_SOCK (rear AUX2), and pin 28

F_SJACK (front AUX3)?

NO

Check these lines: AUX1_S_SOCK (rear AUX1),

AUX3_S_SOCK (rear AUX2) and F_SJACK (front

AUX3).

Check circuits and lines between IC2203 pin 43 and CN3001

pin 1 and between IC2203 pin 45 and CN3001 pin 3.

IC2203 pin 43 → Q2207 → S2202 pin 1 → CN3001 pin 1

CVBS/Y signal

IC2203 pin 45 → Q2208 → S2202 pin 3 → CN3001 pin 3 C

signal

Is video signal input to each pin of IC3502?

IC3502 pin 135 CVBS/Y signal

IC3502 pin 149 C signal

NO

Check lines between pins of CN3001 and IC3502 as well as

circuits on lines.

CN3001 pin 1 → Q3502, 3505, 3501 → IC3502 pin 135

CVBS/Y signal

CN3001 pin 3 → Q3504, 3507, 3503 → IC3502 pin 149 C

signal

1

Refer to Flow chart No.5 "Playback video signal is not output

from main PWB".

19

DV-HR300U

YES

NO

Check 1.5V line, 1.5VREG.IC3504 and peripheral circuits.

Check YCDEC_RST line.

NO

Are D_3.3V (1) and A_3.3V applied to each pin

of IC3502?

Check D_3.3V (1) and A_3.3V lines.

Is 1.5V applied to each pin of IC3502?

YES

NO

After power on, is IC3502 pin 84 YCDEC_RST

line at "L" level and changed to "H" level?

YES

NO

Is 3.3V applied to each pin of IC3503?

Check D_3.3V (1) line.

YES

NO

NO

Is clock signal SDRCLK input to IC3503 pin 35?

Is digital data YC_656 [2-9] output to each pin of

IC3502?

IC 3502 pins 56, 58, 59, 61, 62, 64, 65 and 67

YC_656 [2-9]

Check SDRCLK line between IC3502 pin 17 and IC3503 pin 35.

Check IC3502 and peripheral circuits.

YES

NO

Is video signal output to each pin of IC7506?

IC7506 pin 218 (R7742) Y (Q7506 pin 5 B)

IC7506 pin 214 (R7744) C (Q7505 pin 5 B)

IC7506 pin 245 (R7724) CB (B_U) (Q7503 B)

IC7506 pin 224 (R7737) CR (R_V) (Q7502 B)

Check IC7506 and peripheral circuits.

FLOW CHART No.10

Video signal recording is impossible.

1

YES

NO

Is video signal output to each pin of CN3001?

CN3001 pin 23 154_Y

CN3001 pin 25 154_C

CN3001 pin 19 CB (154_B/U)

CN3001 pin 20 CR (154_R/V)

YES

Refer to Flow chart No.6/No.7 "Playback images do

not appear properly".

Check lines between pins of IC7506 and CN3001 as well as circuits

on lines.

IC7506 pin 218 (R7742) → Q7506 → Q7509 → IC7512 →

CN3001 pin 23 154_Y

IC7506 pin 214(R7744) → Q7505 → CN3001 pin 25 154_C

IC7506 pin 245 (R7724) → Q7503 → CN3001 pin 19 154_B/U

IC7506 pin 224 (R7737) → Q7502 → CN3001 pin 20 154_R/V

Is E-E signal output?

YES

NO

NO

Are drive controls of IC7506 and HDD working

properly?

Refer to Flow chart No.2 "Drive is not working properly

(communication failure with IC7506)" or Flow chart No.3

"HDD is not working properly (communication failure with

IC7506)".

YES

NO

Is digital data input to each pin of IC7304?

IC7304 pins 16-23 VDI_656 [0-7]

YES

NO

Is 81MHz clock signal MMCLK output to IC7304 pin

118?

Check IC7304 and peripheral circuits.

YES

NO

Is 81MHz clock signal MMCLK output to pin 38 of

IC7306 and 7307?

Refer to Flow chart No.4 "Recording is impossible

(MPEG stream check)".

Check MMCLK lines between IC7304 pin 118 and pin 38 of

IC7306 and 7307.

YES

Refer to Flow chart No.9 "Image E-E does not appear".

Check digital data lines between pins of IC3507 and IC7304.

IC3507 pins 11-18 → IC7304 pins 16-23 VDI_656 [0-7]

NO

Are signals VIDICLK, VIDIHD and VIDIVD input to

each pin of IC7506?

IC7506 pin 184 VIDICLK, pin 177 154_VIDIHD, pin

178 154_VIDIVD

Check VIDICLK, VIDIHD and VIDIVD lines.

YES

YES

NO

Is digital data VDI_656 [0-7] input to each pin of

IC7506?

IC7506 pins 194, 186, 187, 188, 189, 181, 182 and

183 VDI_656 [0-7]

YES

Check lines between pins of IC3502 and IC7506 as well as circuits

on lines.

IC 3502 pins 56, 58, 59, 61, 62, 64, 65 and 67 → IC3507 → IC7506

pins 194, 186, 187, 188, 189, 181, 182 and 183

20

Is drive control of IC7506 working properly?

Is HDD control working properly?

FLOW CHART No.11

Playback sound is not output properly.

NO

Refer to Flow chart No.2 "Drive is not working properly

(communication failure with IC7506)" or Flow chart No.3

"HDD is not working properly (communication failure with

IC7506)".

YES

NO

Is audio digital signal output to each pin of

IC7506?

IC7506 pin 235 154_AMCLK

IC7506 pin 217 154_ABCLK

IC7506 pin 222 154_ALRCK

IC7506 pin 209 154_ADATA

YES

YES

NO

Is 5V applied to IC3009 pin 14?

Check or repair IC3009.

Check A_5V line.

Is audio signal output to each pin of IC3009?

IC3009 pin 11 AUDIO_OUT_L

IC3009 pin 10 AUDIO_OUT_R

YES

NO

YES

Check IC7506 and peripheral circuits.

Check lines between IC6501 pin 1 and AUDIO OUT (L) 1/2

terminals (J2402) as well as AUDIO OUT (L) 1/2 terminals (J2402).

Check lines between IC6501 pin 7 and AUDIO OUT (R) 1/2

terminals (J2402) as well as AUDIO OUT (R) 1/2 terminals (J2402).

NO

Is 5V applied to IC6501 pin 8, and -5V applied to pin 4?

Check IC6501 peripheral circuits or replace IC6501.

Check PC_5V (1) line and PC_-5V line.

Is audio signal output to each pin of IC6501?

IC6501 pin 1 OUT1_L OUT2_L

IC6501 pin 7 OUT1_R OUT2_R

YES

NO

NO

Is audio signal output to each output terminal?

Is audio signal (L) output to AUDIO OUT (L) 1/2

terminals (J2402)?

Is audio signal (R) output to AUDIO OUT (R)

1/2 terminals (J2402)?

NO

YES

NO

Check lines between pins of IC3009 and CN3001.

IC3009 pin 11 → CN3001 pin 11 VOUT_L

IC3009 pin 10 → CN3001 pin 12 VOUT_R

Is audio signal output to pins of main unit

connector CN3001?

CN3001 pin 11 VOUT_L

CN3001 pin 12 VOUT_R

YES

NO

Check lines between pins of CN3001 and IC6501.

CN3001 pin 11 → S2202 pin 11→ IC6501 pin 3 VOUT_L

CN3001 pin 12 → S2202 pin12 → IC6501 pin 5 VOUT_R

Is audio digital signal output to each pin of

IC6501?

IC6501 pin 3 VOUT_L

IC6501 pin 5 VOUT_R

YES

NO

Check lines between pins of IC7506 and IC3009.

IC7506 pin 235 → IC3009 pin 1 154_AMCLK

IC7506 pin 217 → IC3009 pin 2 154_ABCLK

IC7506 pin 222 → IC3009 pin 4 154_ALRCK

IC7506 pin 209 → IC3009 pin 3 154_ADATA

Is audio digital signal output to each pin of

IC3009?

IC3009 pin 1 154_AMCLK

IC3009 pin 2 154_ABCLK

IC3009 pin 4 154_ALRCK

IC3009 pin 3 154_ADATA

YES

NO

Check lines between pins of IC7506 and IC3009.

IC7506 pin 263 → IC3009 pin 8 SPIDAO

IC7506 pin 264 → IC3009 pin 7 SPICLK

IC7506 pin 268 → IC3009 pin 6 DAC1_L

Is system control signal output to each pin of

IC3009?

IC3009 pin 8 SPIDAO

IC3009 pin 7 SPICLK

IC3009 pin 6 DAC1_L

DV-HR300U

21

DV-HR300U

Is audio signal input to IC6101 pins

1, 2, 4, 5, 11, 12, 14 and 15?

FLOW CHART No.12

Sound E-E is not output.

1In external input mode

■ Check lines between rear audio input 1 terminal (J2401) and IC6101 pins 5/14.

■ Check lines between rear audio input 2 terminal (J2701) and IC2461 pins 3/13

as well as lines between IC2461 pins 4/14 and IC6101 pins 4/11.

■ Check lines between front audio input terminal (J2702) and IC6101 pins 2/15.

2In U/V tuner mode

Check these: periphery of U/V tuner (TU1501), line between pin 15 of U/V tuner

and IC1401 pin 15, periphery of IC1401, and lines between IC1401 pins 24/23

and IC6101 pins 1/12.

NO

Is audio signal input to each pin of IC6102?

IC6102 pin 3 INPUT_L

IC6102 pin 5 INPUT_R

NO

Is audio signal output to each pin of IC6101?

IC6101 pin 3 INPUT_L

IC6101 pin 13 INPUT_R

Is 5V applied to IC6101 pin 16, and -5V applied to pin 7?

Check or replace IC6101.

Check PC_5V (1) line and PC_-5V line.

NO

YES

YES

YES

NO

Are voltages of control signal lines T_A MUTE, AUX2 (H)

and AUX1 (H) of pins 6/9/10 controlling IC6101 normal?

Check each control signal line.

Check PC_5V (1) line and PC_-5V line.

YES

NO

Check EE_AMCLK line.

NO

Check lines between pins of IC6101 and IC6102.

IC6101 pin 3 → IC6102 pin 3 INPUT_L

IC6101 pin 13 → IC6102 pin 5 INPUT_R

Is audio signal output to pins of main unit

connector CN3001?

CN3001 pin 8 AUD_L_ADIN

CN3001 pin 7 AUD_R_ADIN

NO

Check lines between pins of IC6102 and CN3001.

IC6102 pin 1 → S2202 pin 8 → CN3001 pin 8

AUD_L_ADIN

IC6102 pin 7 → S2202 pin 7 → CN3001 pin 7

AUD_R_ADIN

Is audio signal input to each pin of IC3002?

IC3002 pin 13 AUD_L_ADIN

IC3002 pin 3 AUD_R_ADIN

NO

YES

YES

Check lines between pins of CN3001 and IC3002.

CN3001 pin 8 → IC3002 pin 13 AUD_L_ADIN

CN3001 pin 7 → IC3002 pin 3 AUD_R_ADIN

1

NO

NO

YES

Refer to Flow chart No.11 "Playback sound is not

output properly".

Check or replace IC3005.

YES

YES

Check IC7506 or peripheral circuits.

1

YES

NO

NO

Is audio digital signal output to each pin of IC7506?

IC7506 pin 235 154_AMCLK

IC7506 pin 217 154_ABCLK

IC7506 pin 222 154_ALRCK

IC7506 pin 209 154_ADAT A

Is audio digital signal output to each pin of IC7506?

IC7506 pin 248 AD_DOUT

IC7506 pin 221 AD_BCK

IC7506 pin 230 AD_LRCK

Is audio digital signal output to each pin of IC3005?

IC3005 pin 9 AD_DOUT

IC3005 pin 12 AD_BCK

IC3005 pin 10 AD_LRCK

Is audio signal output to each pin of IC3005?

IC3005 pin 2 AUD_L_ADIN

IC3005 pin 1 AUD_R_ADIN

ICheck lines between pins of IC3005 and IC7506.

IC3005 pin 9 → IC7506 pin 248 AD_DOUT

IC3005 pin 12 → IC7506 pin 221 AD_BCK

IC3005 pin 10 → IC7506 pin 230 AD_LRCK

YES

Is audio signal output to each pin of IC6102?

IC6102 pin 1 INPUT_L

IC6102 pin 7 INPUT_R

Is 5V applied to IC6102 pin 8, and -5V applied to pin 4?

NO

Is 5V applied to IC3005 pin 6, and 3.3V applied to pin

7?

Is EE_AMCLK signal input to IC3005 pin 11?

Check A_5V line and D_3.3V (1) line.

YES

YES

YES

YES

NO

Check lines between pins of IC3003 and IC3005.

IC3003 pin 7 → IC3005 pin 2 AUD_L_ADIN

IC3003 pin 1 → IC3005 pin 1 AUD_R_ADIN

YES

YES

Is audio signal output to each pin of IC3003?

IC3003 pin 7 AUD_L_ADIN

IC3003 pin 1 AUD_R_ADIN

Is 5V applied to IC3003 pin 8, and -5V applied to pin 4?

Check A_5V line and PC_-5V line.

NO

YES

NO

Check IC3003 peripheral circuits or replace IC3003.

IIs audio signal output to each pin of IC3003?

IC3003 pin 5 AUD_L_ADIN

IC3003 pin 3 AUD_R_ADIN

NO

YES

Check lines between pins of IC3002 and IC3003.

IC3002 pin 14 → IC3003 pin 5 AUD_L_ADIN

IC3002 pin 4 → IC3003 pin 3 AUD_R_ADIN

Is audio signal output to each pin of IC3002?

IC3002 pin 14 AUD_L_ADIN

IC3002 pin 4 AUD_R_ADIN

Is 5V applied to IC3002 pin 16, and -5V applied to pin

7?

Check A_5V line and PC_-5V line.

NO

YES

NO

Check IC3002 peripheral circuits or replace IC3002.

22

FLOW CHART No.13

Audio signal recording is impossible.

Is E-E signal output?

Refer to Flow chart No.12 "E-E sound is not output".

YES

YES

YES

YES

YES

Are drive controls of IC7506 and HDD working properly?

Refer to Flow chart No.2 "Drive is not working

properly (communication failure with IC7506)" or

Flow chart No.3 "HDD is not working properly

(communication failure with IC7506)".

Are the following signals including data output from

IC3008?

Are the following signals including data output from

IC3005 pins to IC3008 pins?

Check lines between pins of

IC3005 and IC3008.

IC3008 pin 7 AIN_ABCK

IC3008 pin 9 AIN_ALRCK

IC3008 pin 12 AIN_ADAT

Are the following signals including data output from

IC7304?

Refer to Flow chart No.4 "Recording is impossible (MPEG

stream check)".

NO

NO

NO

NO

NO

Check IC3008 peripheral circuits or replace IC3008.

IC7304 pin 8 AIN_ABCK

IC7304 pin 7 AIN_ALRCK

IC7304 pin 9 AIN_ADAT

IC3005 pin 12 → IC3008 pin 5 AD_BCK

IC3005 pin 10 → IC3008 pin 11 AD_LRCK

IC3005 pin 9 → IC3008 pin 14 AD_DOUT

Check lines between pins of IC3008 and IC7304.

IC3008 pin 7 → IC7304 pin 8 AIN_ABCK

IC3008 pin 9 → IC7304 pin 7 AIN_ALRCK

IC3008 pin 12 → IC7304 pin 9 AIN_ADAT

Picture/sound input is impossible from DV input terminal.

Is serial communication normal between pins

of IC4005 and IC7506?

IC4005 pin 149 -> IC7506 152 (DV_TXD)

Check IC4005, IC7506 and peripheral circuits, and

lines between pins of IC4005 and IC7506.

YES

Is 27MHz clock signal INVCK4 input from

IC3004 pin 16 to IC4005 pin 50?

Check IC3004 and peripheral circuits, and line

between IC3004 pin 16 and IC4005 pin 50.

Picture

Are video data and video clock input from

IC4005 pins to pins of IC3508 and IC3509?

Check IC4005 and peripheral circuits, and lines bet-

ween IC4005 pins and pins of IC3508 and IC3509.

Is AMCLK input from IC4008 pin 3 to IC4005

pins 103 and 104?

Sound

Check IC4012 and peripheral circuits, and lines

between IC4012 pin 4, IC4008 and IC4005 pins

103 and 104.

IC3508 pins 2-9 DV_656 [7-0]

IC3509 pin 2 DV_DCK

Are video data and video clock input to pins of

IC7506 and IC7304?

IC7506 pins 181-183, 184 and 186-189

VDI_656 [7-0]

IC7506 pin 184 VIDICLK

IC7304 pins 16-23 VDI_656 [7-0]

IC7304 pin 25 VIDICLK

IC3508 pins 11-18 → IC7506 pins 181-183, 184 and

186-189 VDI_656 [7-0]

IC3509 pin 6 → IC3506 → IC7506 pin 184 VIDICLK

IC3508 pins 11-18 -> IC7304 pins 16-23 VDI_656 [7-0]

IC3509 pin 6 → IC3506 → IC7304 pin 25 VIDICLK

IC4005 pins 40-47 → IC3508 pins 2-9

DV_656 [7-0]

IC4005 pin 51 → IC3509 pin 2 DV_DCK

Is clock signal input to each pin of IC4002?

Check IC4005, IC4008 and peripheral circuits, lines

between pins of IC4005 and IC4002 and peripheral

circuits on lines.

IC4002 pin 10 ALRCK

Is audio signal output to each pin of IC4002?

IC4002 pin 15 DV_AUD_L

IC4002 pin 16 DV_AUD_R

IC4005 pin 93 → IC4002 pin 10 ALRCK

IC4002 pin 11 ADMCLK

IC4005 pin 101 → IC4008 → IC4002 pin 11 ADMCLK

IC4002 pin 12 ABCK

IC4005 pin 94 → IC4002 pin 12 ABCK

Is DAC data PCM1 output to IC4005 pin 96?

Check IC4005 and peripheral circuits.

Check line between IC4005 pin 96 and IC4002 pin 9,

IC4002 and peripheral circuits.

FLOW CHART No.14

IC4005 pin 150 <- IC7506 156 (DV_RXD)

Check these: IC3508 and peripheral circuits, lines

between pins of IC3508, IC7506 and IC7304, IC3509,

line between IC3509 output pin and IC7506, lines

between pins of IC7304 and peripheral circuits on lines.

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

YES

NO

DV-HR300U

23