Page 1

http://servis-manual.com/

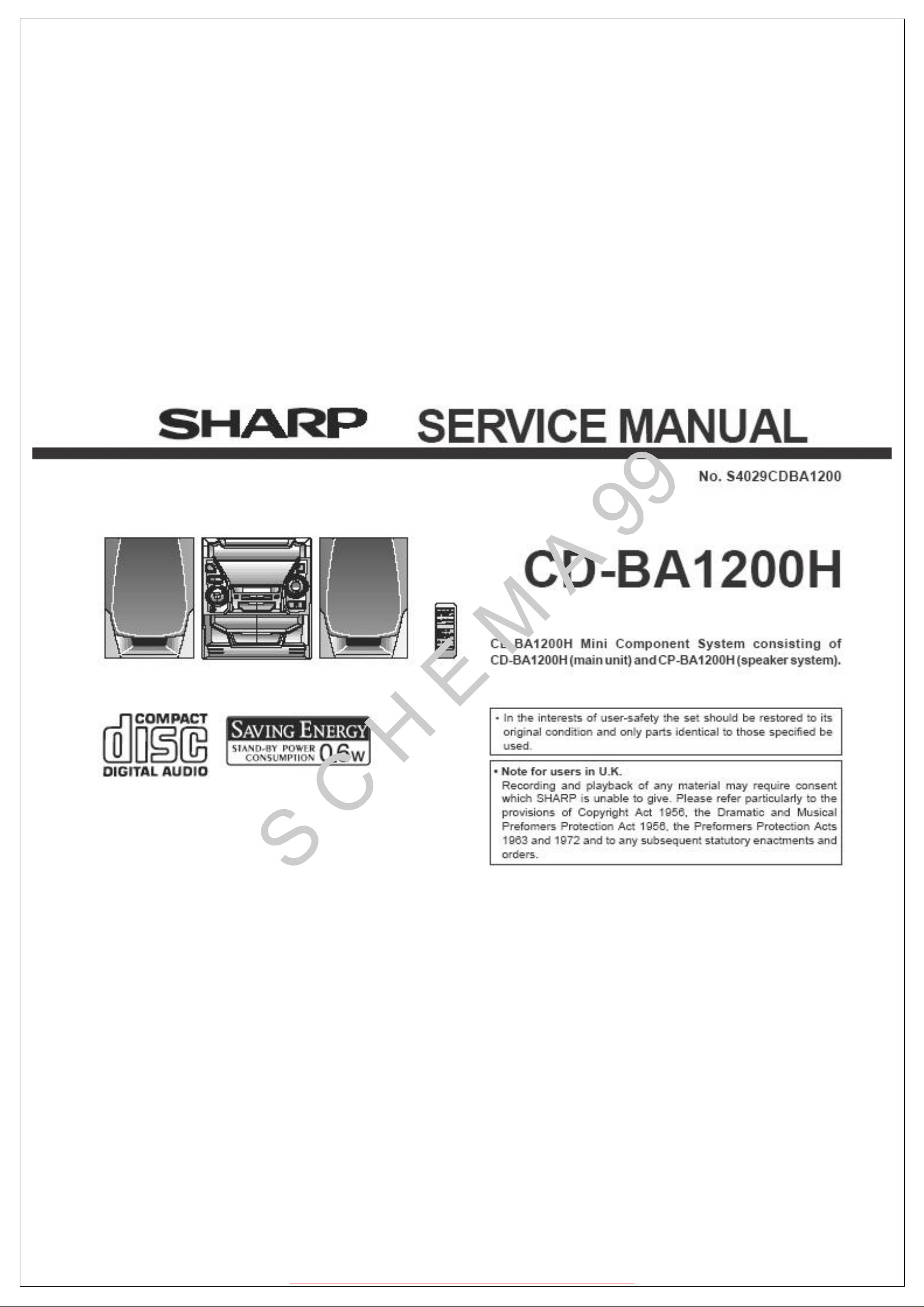

Page 2

CD-BA1200H

(L3) x2

(L2) x2

(L3) x2

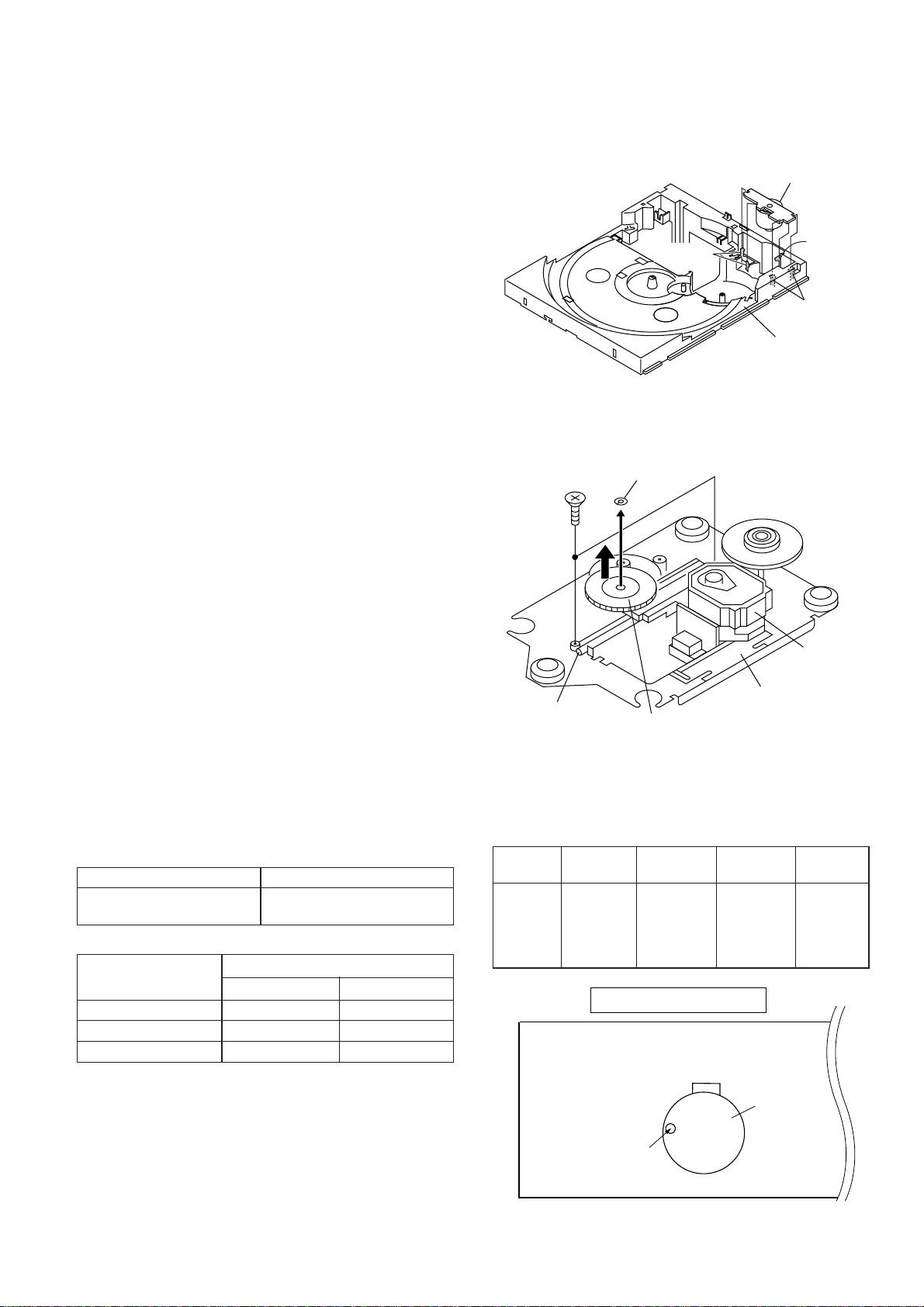

CD Servo

PWB

Slide Chassis

(L1)x1

ø3x8mm

(J2) x1

Clamp Lever

Turntable

CD Player Unit

(Top View)

(E2)x1

(E3)x1

(E2)x1

(E1)x7

ø3x10mm

Figure 10-1

Main PWB

(E2)x2

(F1)x3

ø3x8mm

Cam Gear Rib

Headphones

PWB

(E4)x1

(E1)x1

ø3x10mm

(J1) x2

1

Disc Tray

CD Player Unit

Figure 10-4

(K1) x3

2

(K1) x3

(G1)x9

ø3x10mm

(H1)x5

ø3x10mm

Tape

Mechanism

Figure 10-2

(G2)x1

Figure 10-3

Figure 10-5

Display PWB

Open

Cassette

Holder

Figure 10-6

– 10 –

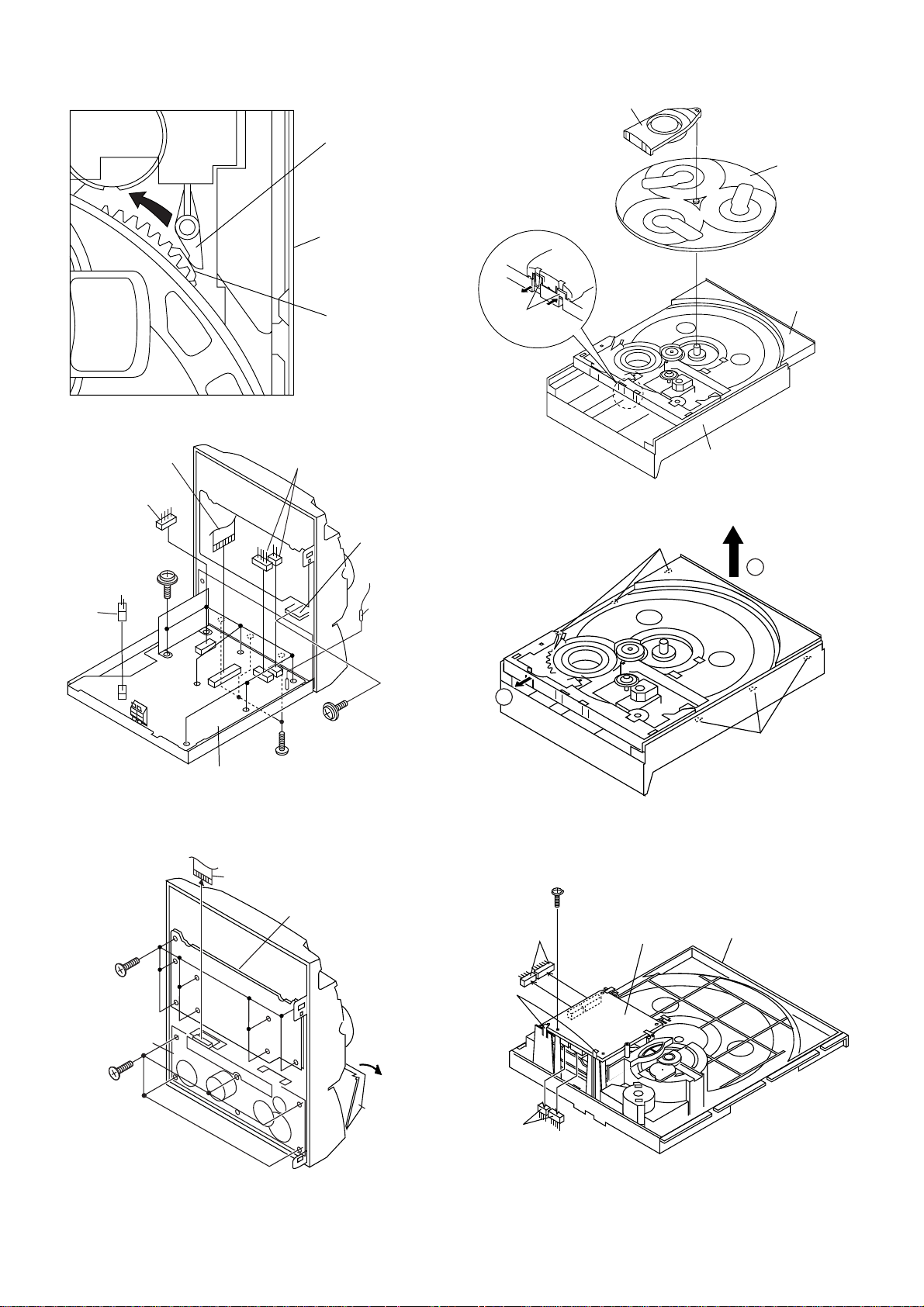

Page 3

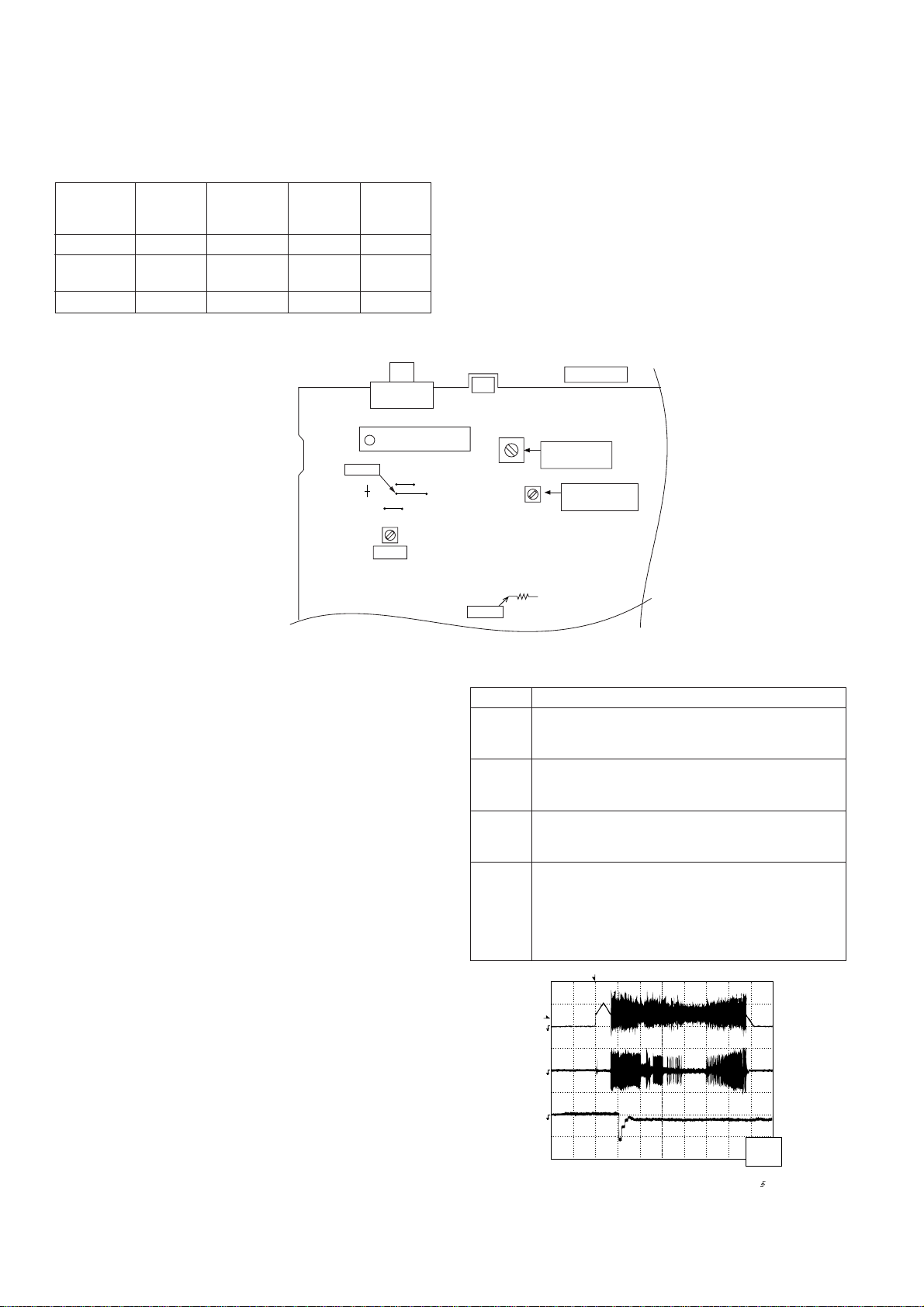

Cam Gear

CD-BA1200H

CD

Mechanism

(M1) x1

Figure 11-1

CP-BA1200H

STEP REMOVAL

1 Speaker 1. Net ..........................(A1) x1 11-2

2. Duct Panel .............. (A2) x1

3. Screw......................(A3) x4 11-3

(M2) x3

(M1) x1

PROCEDURE

Loading

Motor

PWB

(N1) x5

FIGURE

CP-BA1200H

(A1)x1

(A2)x1

Driver

Speaker Box

Speaker Box

Speaker

(A3)x4

ø3.5x13mm

Driver should be

pried away from

Speaker Box.

Direction of handle

Figure 11-2

Figure 11-3

– 11 –

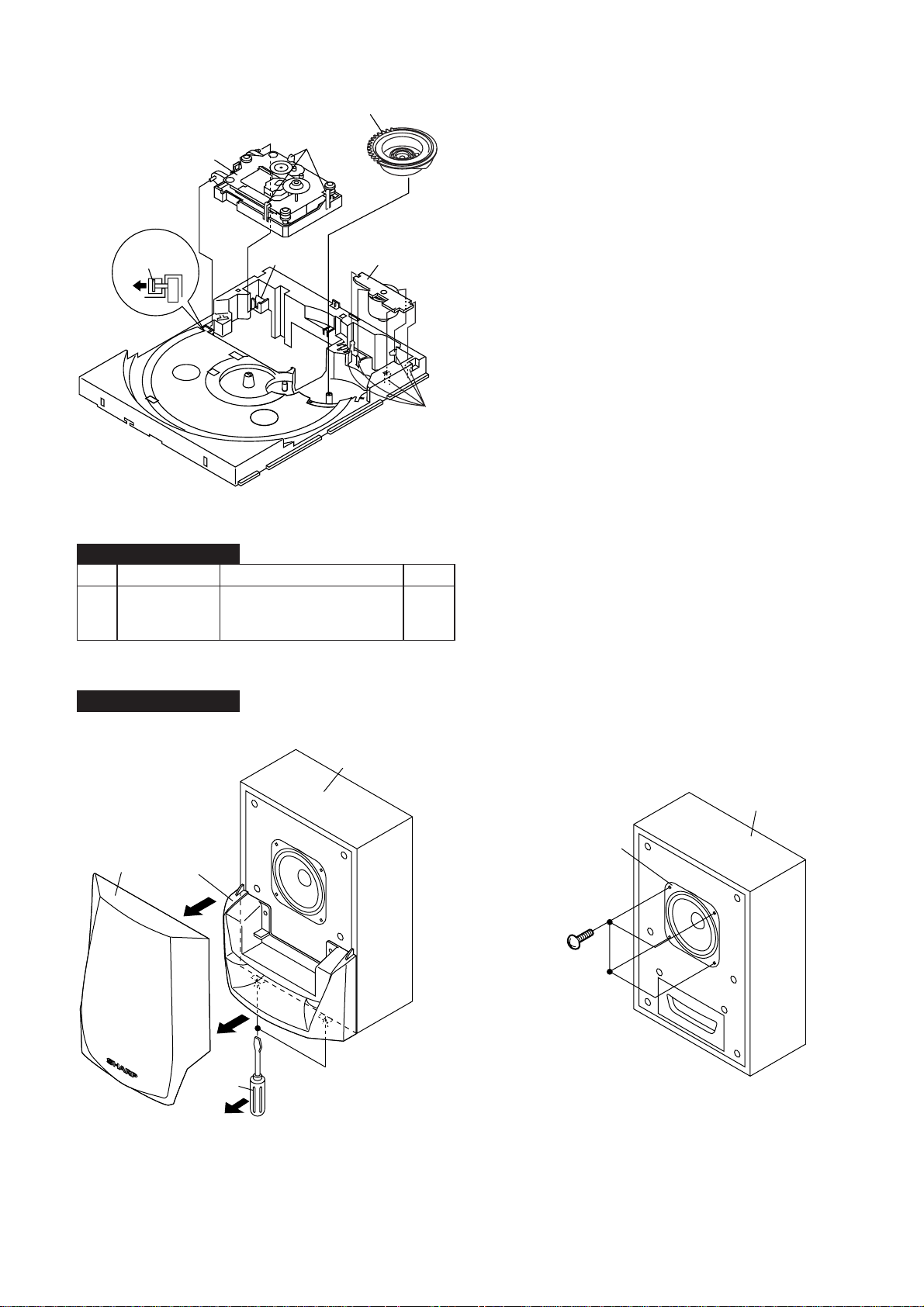

Page 4

CD-BA1200H

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1 to 6 and 8 of the disassembly method to

remove the tape mechanism.

How to remove the record/playback and erase

heads (TAPE 2) (See Fig. 12-1)

1. Carefully remove the record/playback head and erase head

screw (A1) x 2 pcs.

How to remove the playback head (TAPE 1)

(See Fig. 12-2)

1. Carefully remove the playback head screw (B1) x 2 pcs.

How to remove the pinch roller (TAPE 1/2)

(See Fig. 12-3)

1. Carefully bend the pinch roller pawl in the direction of the

arrow <A>, and remove the pinch roller (C1) x1 pc., in the

direction of the arrow <B>.

Note:

When installing the pinch roller, pay attention to the spring

mounting position.

Erase Head

(A1)x2

Ø2 x 9mm

Figure 12-1

TAPE 2

TAPE 1

Playback

Head

Record/Playback

Head

How to remove the belt (TAPE 2) (See Fig. 12-4)

1. Remove the main belt (D1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (D2) x 1 pc.

How to remove the belt (TAPE 1) (See Fig. 12-4)

1. Remove the main belt (E1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (E2) x 1 pc.

How to remove the motor (See Fig. 12-5)

1. Remove the screws (F1) x 2 pcs., to remove the motor.

Motor

TAPE 2

(B1)x1

Ø2x9mm

Pinch Roller

(C1)x1

FF/REW

Belt

(D2)x1

Figure 12-2

Pull

Figure 12-3

(B1)x1

Ø2x5mm

<B>

Motor

Pull

TAPE2

Main Belt

(D1)x1

<A>

Pinch

Roller

Pawl

Motor

TAPE1

Main Belt

(E1)x1

(F1) x2

Ø 2.6 x 5mm

– 12 –

(D1)x1

(E1)x1

Figure 12-4Figure 12-5

TAPE 1

FF/REW

Belt

(E2)x1

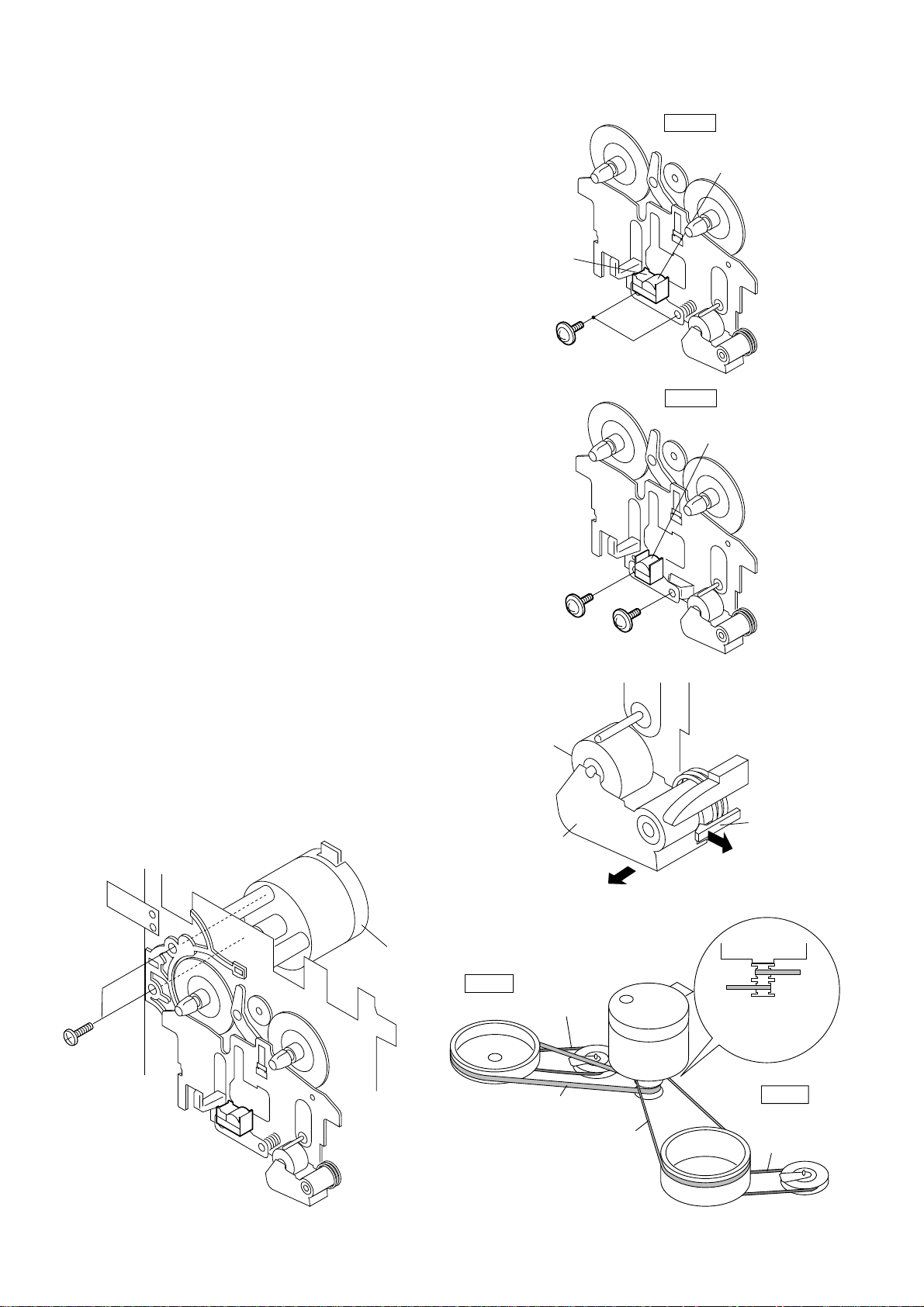

Page 5

CD MECHANISM SECTION

TAPE MECHANISM

Motor

Variable Resistor

in motor

Perform steps 1, 2, 3, 9 and 12 of the disassembly method to

remove the CD mechanism.

CD-BA1200H

How to remove the loading motor

(See Fig. 13-1)

1. Bend the hooks (A1) x 5 pcs., to remove the loading motor.

How to remove the pickup (See Fig. 13-2)

1. Remove the screws (B1) x 2 pcs., to remove the shaft (B2).

2. Remove the stop washer (B3) x 1 pc., to remove the gear

(B4).

3. Remove the pickup.

Note

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector to protect the optical pickup from

electrostatic damage.

(B1) x2

ø2.6 x6mm

Loading Motor

(A1)x1

(A1)x2

(A1)x2

Slide Chassis

Figure 13-1

Stop Washer

(B3) x1

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter

Play: TW-2111 Tape 1: Over 80 g

• Torque Check

Torque Meter

Tape 1

Play: TW-2111 30 to 80 g.cm 30 to 80 g.cm

Fast forward: TW-2231 — 70 to 180 g.cm

Rewind: TW-2231 — 70 to 180 g.cm

Specified Value

Tape 2: Over 80 g

Specified Value

Tape 2

Pickup

Shaft

(B2) x1

Gear

CD Mechanism

(B4) x1

Figure 13-2

• Tape Speed

Test Tape

Normal MTT-111 Variable 3,000 ± Speaker

speed Resistor in 30 Hz terminal

Adjusting

Point

motor. (Load

Specified

Value

Instrument

Connection

resistance:

6 ohms)

Figure 13-3

– 13 –

Page 6

CD-BA1200H

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage Frequency

AM IF 450 kHz 1,620 kHz T351 *1

AM Band — 522 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

AM Tracking 990 kHz 990 kHz (fL): T303 *1

*1. Input: Antenna Output: TP302

*2. Input: Antenna Output: TP301

Frequency

Display

Setting/

Adjusting

Parts

TP301

R381

Instrument

Connection

SO301

FM ANTENNA

TERMINAL

1

FE301

T351

• FM

Notes:

1: Description of the "FM IF Adjustment" is not carried on this

Manual. It is because the IF coil in the FM front end section

has been best adjusted in the factory so that its further

adjustment is not needed at the field. When replacing the

FM front end assembly, no adjustment is needed either.

2: The parts in the FM front end section are prepared in a

complete unit, so you can't obtain each part individually

CNP302

AM LOOP

ANTENNA

T303

T306

MAIN PWB

AM

TRACKING fL

AM BAND

COVERAGE fL

AM IF

Figure 14-1 ADJUSTMENT POINTS

CD SECTION

• Adjustment

Since this CD system incorporates the following automatic

adjustment functions, readjustment is not needed when

replacing the pickup. Therefore, different PWBs and pickups

can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each disc

can be performed under optimum conditions.

Items adjusted automatically

(1) Offset adjustment (The offset voltage between the head

amplifier output and the VREF reference voltage is

compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

(2) Tracking balance adjustment (waveform drawing Fig.

14-2 EFBL)

(3) Gain adjustment (The gain is compensated inside the IC

so that the loop gain at the gain crossover frequency will

be 0dB.)

* Focus gain adjustment

* Tracking gain adjustment

R357

TP302

CD ERROR CODE DESCRIPTION

Error State Code

0001 Cannot detect Pickup-in SW

0002 DSP access error

0101 Open/Close SW Low → High not functioning

0103 Open/Close SW High → Low not functioning

0201 Open/Close SW Low → High not functioning

0203 Open/Close SW High → Low not functioning

0302 Pickup-in SW is not detected

0306 During Disc 1 search, Open/Close SW or Clamp SW

0307 Clamp SW Low → High not functioning

0308 Clamp SW High → Low not functioning

[Servo System Error]

[Error during close operation]

[Error during open operation]

[Error during skip operation]

or Disc SW do not change to low.

T

T

1

3

Stopped

FDO

TE

CH1=500mV

DC 10:1

CH2=200mV

DC 10:1

CH3=1V

DC 10:1

1999/04/05 20:26:47

500ms/div

(500ms/div)

NORM:20kS/s

– 14 –

EFBL

2

Smoothing : ON CH1 : 0.000V

BW : FULL

CH2 : 0.000V

CH3 : 0.00V

CH4 : 0.00V

Figure 14-2

=Record Length=

Main : 100K

Zoom : 2k

CH2

v/DIV

200mV

=Trigger==Filter= =Offset=

Mode : SINGLE

Type : EDGE CH1

Delay : 0.0ns

Hold off : 0.2us

Page 7

NOTES ON SCHEMATIC DIAGRAM

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means micro-micro-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/withstand

voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

CD-BA1200H

• The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

( ) indicates AM

< > indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

REF. NO DESCRIPTION POSITION POSITION

SW1 OPEN/CLOSE ON—OFF

SW2 CLAMP ON—OFF

SW3 DISC NUMBER ON—OFF

SW4 PICKUP IN ON—OFF

SW701 ON/STAND-BY ON—OFF

SW702 CLOCK ON—OFF

SW703 TIMER/SLEEP ON—OFF

SW709 DISC SKIP ON—OFF

SW710 OPEN/CLOSE ON—OFF

SW711 EQUALIZER/X-BASS/DEMO ON—OFF

SW712 VOLUME UP ON—OFF

SW713 VOLUME DOWN ON—OFF

REF. NO DESCRIPTION

SW714 CD ON—OFF

SW715 TAPE ON—OFF

SW716 TUNING /TIME DOWN ON—OFF

SW717 MEMORY/SET ON—OFF

SW718 REWIND ON—OFF

SW719 FAST FORWARD ON—OFF

SW720 PLAY/REPEAT ON—OFF

SW721 STOP ON— OFF

SW723 REC/PAUSE ON—OFF

SW724 TUNING/TIME UP ON—OFF

SW725 TUNER (BAND) ON—OFF

FRONT

VIEW

FRONT

FRONT

VIEW

VIEW

E C B

(S) (G) (D)

(1) (2) (3)

BCE

2SC1845 F

2SC3331

2SC380 O

KTA1266 GR

KTA1271 Y

KTA1273 Y

KTC3203 Y

KRC102 M

KRC104 M

KRC107 M

KTC2026

4204SRT7

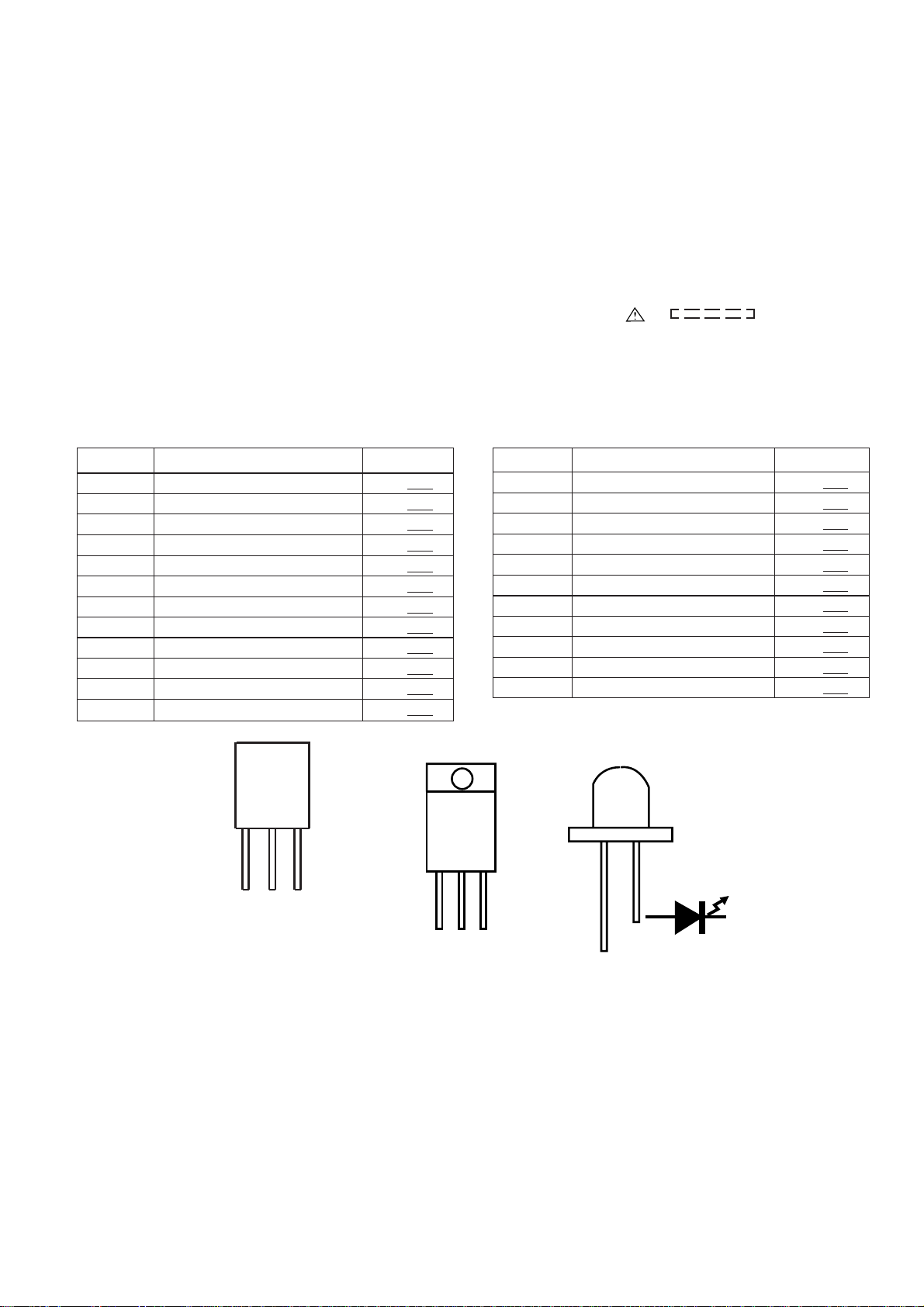

Figure 15 TYPES OF TRANSISTOR AND LED

– 15 –

Page 8

CD-BA1200H

5

1

3

4

4

3

1

1

2

IC2 24

IC2 23

IC2 24

IC2 72

IC1 18 ,

IC2 16

IC1 27

IC1 18 ,

IC2 16

IC2 72

IC2 24

Stopped

CH1=500mV

DC 10:1

T

FDO

1

TDO

3

Smoothing : ON CH1 : 0.000V

BW : FULL

1

T

2

3

Smoothing : ON CH1 : 0.000V

BW : FULL

2

T

1

Smoothing : ON CH1 : 0.0V

BW : FULL

T

2

CH2 : 0.0V

CH3 : 0.000V

CH4 : 0.00V

Stopped

CH1=500mV

DC 10:1

FDO

DRF

TE

CH Position To

-3div -1div 0div +1div +3div

CH2 : 0.0V

CH3 : 0.00V

CH4 : 0.00V

Stopped

CH1=10V

DC 10:1

TE

DRF

=Filter= =Offset=

CH2 : 0.00V

CH3 : 0.00V

CH4 : 0.00V

Stopped

CH1=200mV

DC 10:1

FDO

CH2=10V

DC 10:1

T

CH2=1V

DC 10:1

T

CH2=500mV

DC 10:1

CH3=500mV

DC 10:1

=Record Length=

Main : 100K

Zoom : 2K

CH3=1V

DC 10:1

=Record Length=

Main : 100K

Zoom : 2K

=Record Length=

Main : 100K

Zoom : 2K

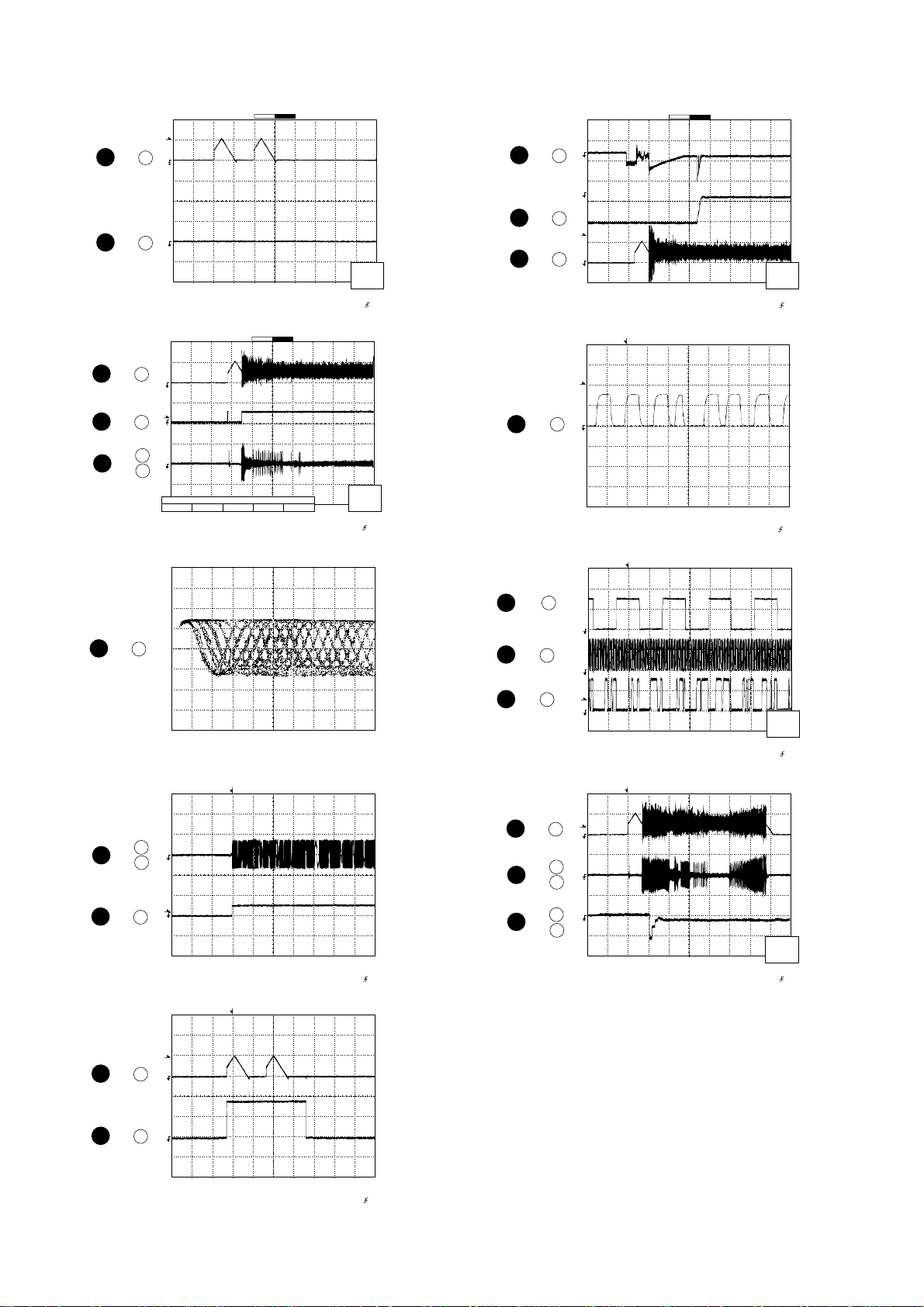

WAVEFORMS OF CD CIRCUIT

500ms/div

(500ms/div)

NORM:20kS/s

IC2 1

7

IC2 2

8

IC2 24

10

11

12

1

9

1

4

13

IC2 37

IC2 57

IC2 58

IC2 59

IC2 24

IC1 18 ,

IC2 16

IC1 13 ,

IC2 22

CH1

v/DIV

500mV

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH1

Delay : 0.0ns

Hold off : 0.2us

500ms/div

(500ms/div)

NORM:20kS/s

CH2

Position

0.20div

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH1

Delay : 0.0ns

Hold off : 0.2us

Vp-p=1.0V~1.3V

0.5mV/div,0.5µsec/div

100ms/div

(100ms/div)

NORM:100kS/s

=Trigger=

Mode : NORMAL

Type : EDGE CH1

Delay : 2.924ms

Hold off : 0.2us

1999/04/07 09:51:15

500ms/div

(500ms/div)

NORM:20kS/s

Stopped

PDO1

3

4

PDO2

T

FDO

1

Smoothing : ON CH1 : 0.000V

BW : FULL

Stopped

T

1

DOUT

Smoothing : ON CH1 : 0.00V

BW : FULL

Stopped

1

LRSY

2

DATACK

T

3

DATA

Smoothing : ON CH1 : 0.00V

BW : FULL

Stopped

T

FDO

1

TE

3

EFBL

2

Smoothing : ON CH1 : 0.000V

BW : FULL

CH1=500mV

DC 10:1

CH1=2V

DC 10:1

CH1=2V

DC 10:1

CH1=500mV

DC 10:1

CH2 : 0.0V

CH3 : 0.00V

CH4 : 0.00V

T

CH2 : 0.00V

CH3 : 0.00V

CH4 : 0.00V

T

CH2=2V

DC 10:1

CH2 : 0.00V

CH3 : 0.00V

CH4 : 0.00V

T

CH2=200mV

DC 10:1

CH2 : 0.000V

CH3 : 0.00V

CH4 : 0.00V

CH3=1V

DC 10:1

=Record Length=

Main : 100K

Zoom : 2K

=Record Length=

Main : 1K

Zoom : 100

CH3=2V

DC 10:1

=Record Length=

Main : 5K

Zoom : 100

CH3=1V

DC 10:1

=Record Length=

Main : 100K

Zoom : 2k

1999/04/05 17:33:17

CH4=1V

500ms/div

(500ms/div)

DC 10:1

NORM:20kS/s

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH2

Delay : 0.0ns

Hold off : 0.2us

1999/04/07 09:25:28

500ns/div

(500ns/div)

NORM:200MS/s

=Trigger==Filter= =Offset=

Mode : NORMAL

Type : EDGE CH1

Delay : 2.887ms

Hold off : 0.2us

1999/04/05 20:50:17

NORM:100kS/s

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH3

Delay : 0.0ns

Hold off : 0.2us

1999/04/05 20:26:47

500ms/div

(500ms/div)

NORM:20kS/s

=Trigger==Filter= =Offset=

Mode : SINGLE

Type : EDGE CH1

Delay : 0.0ns

Hold off : 0.2us

5us/div

(5us/div)

CH1

v/DIV

500mV

CH3

v/DIV

2 V

CH2

v/DIV

200mV

SPDO

IC2 25

6

1

=Filter= =Offset=

Smoothing : ON CH1 : 0.000V

BW : FULL

CH2 : 0.000V

CH3 : 0.00V

CH4 : 0.00V

=Record Length=

Main : 100K

Zoom : 2K

=Trigger=

Mode : NORMAL

Type : EDGE CH2

Delay : 2.924ms

Hold off : 0.2us

– 16 –

Page 9

TO MAIN SECTION

(TO IC601)

TO DISPLAY SECTION

SW1

OPEN/

CLOSE

12

CD-BA1200H

SW2

SW3

CLAMP

DISC

NUMBER

M

+

5

3

4

6

M3

T/T

UP/DOWN

MOTOR

-

BI4

XL1

16.9344MHz

12

R-CH

L-CH

AGND

DGND

+5V(+B4)

2

1

5

3

4

CNP11

CDINT

CE

DO

DRF

WRQ

217

DI

5

6

43

CLK

89

CD RES

CLAMP SW

GND

10

CNP12

12

56

3

4

3

4

56

CNS4

CNP4

Q2

CONT4

RFENV

FE

30

CONT3

CONT5

TE

CONT2

SLDO

SPDO

FDO

TDO

74

64

40

19

13

3

33

26

25

24

23

75

76

65

CE

CL

66

DI

67

DO

68

INT

69

WRQ

70

RES

71

72

DEF

XOUT

52

XIN

51

VDD5V

73

CONT7

CONT6

VVDD

ADAVDD

VDD

5

183644 49 50 7 14 15 16

47 48 32 31

45 46

LVSS

LCHO

IC2

LC78641E

SERVO/SIGNAL

CONTROL

LVDD

RVDD

XVDD

RVSS

RCHO

HFL

CONSTANT

VOLTAGR

+3.3V

PICKUP UNIT

+5V

+3.3V

1

2 1725 4142 3839

22

18 19 20

Q1

17

HFL

30

IC1

LA9235M

23

SERVO AMP.

11

9

TIN2

TIN1

FIN2

FIN1

12

34

+5V

21

FE

TE

7

FE-

TE-

PD

LDD

RFEV

LASER

DRIVER

Q3

+3.3V

8

M1

SPINDLE

MOTOR

FOCUS COIL

TRACKING COIL

M2

SLED

MOTOR

VCC1

18

VCC4

+5V

40

24

23

28

VCC2

VCC3

FOCUS/TRACKING/

SPIN/SLED DRIVER

45671516 26 27

M

M

IC3

M63001FP

35

29

22

21

14

8

SW4

PICKUP IN

Figure 17 BLOCK DIAGRAM (1/3)

– 17 –

Page 10

CD-BA1200H

Q

FM

ANTENNA

TAPE

MOTOR

SOLENOID

T2 PLAY

T1 PLAY

R.PLAY

F.PLAY

TAPE1

PBHEAD

TAPE2

RECPBHEAD

AM LOOP

ANTANNA

L341

BALUN

MOTOR

DRIVER

Q706

M

Q704

Q705

IC701

54PIN

IC701

53PIN

IC701

56PIN

IC701

55PIN

FROMCDSECTION

CNP11

L-CH

R-CH

REC

P.B.

L-CH

R-CH

ACBIAS

ERASE

HEAD

8

AM TRACKING

T303

+2B

+2B

SWITCHING

Q104~

Q107

TA7358AP

FM FRONT END

2

6

CNS601

1

2

3

4

5

POP

REDUCE

Q108

Q109

SWITCHING

Q114

L104

BIAS

OSC

FE301

3

7

FMOSC

T306

PLAYBACKANDRECORD

1

L(T1)

R(T1)

24

L(T2)

2

R(T2)

23

LNF

3

RNF

22

6

LREC

9

RREC

16

14

REF

12

1

5

4

AM BAND

COVERAGE

IC101

AN7345K

/PLAYBACKAMP.

P.B

T1/T2

REC

NOR/

15

12

SWITCHING

Q103

Q101

SWITCHING

CF301

H/N

T1/T2HIGH

19

Q102

FM +B

+B3

13

L

4

R

21

5

20

RECRL

7

18

LNF

8

RNF

17

ALC

10

Q112

L103

SWITCHING

Q301

VT

SWITCHING

Q360

+B3

PB

BIAS

Q113

20

FM

CF302

1

AM IF

21

AM

MIX

IC303

LA1832S

FM IF DET./FM MPX./AM IF

AMRFIN

FMAFC

15

16

IC302

LC72131

PLL(TUNER)

FM/AM

7

L

TAPE

R

TUNER

L

242122

9

X352

4.5MHZ

OSC

23

AMOSCIN

22

R

L

CD

R

CF352T351

4

5

GND

FM/AM

CE

3

OUT

18

9

CL

DI

4

5

2

1

AM IF

7

STEREO

11

MO/ST

10

9

16

10

15

1

14

IC601

LC75341

AUDIOPROCESSOR

12

13

17

8

7

CF351

FMFM+B

DET

16

6

18

8

DO

VCO

17

+B3

23

3

X351

456kHz

13

17

MO/ST

FM/AMMPXIN

12

MUTING

L

14

R

15

CE

CL

Q110

Q111

+B3

1

DI

2

24

R

21

4

Q601

Q602

L

SYSTEM

MUTE

REC/PLAY

T1/T2

BAIS

Figure 18 BLOCK DIAGRAM (2/3)

– 18 –

Page 11

CD-BA1200H

+B3

Q701

1

SP.DET.

FL701

DISPLAY

2

10 111315 16 19 20 22 261417 182127

3

5556

575859

71

78

VLOAD

79

80

91

92

MICROCOMPUTER

99

100

VDD

145

9

6

10

7

+B6

Q901

Q902

RESET

Q707

IC701

IX0337AW

SYSTEM

RESET

11

12 13 15 16

XL701

4.1943 MHz

+B6

30

+B6

VDD

VDD

17

RESET IC

IC704

3

KIA7042PA

31

CEDICL

20

21222324

2

32 33

SYS.STOP

AVDD

1

404142434445464748495051525354

39

38

37

36

35

+B6

34

33

31

DO

+B6

KEY

SW701-SW703

SW709-SW721

SW723-SW725

TO CD

SECTION

JK901

HEADPHONES

+B2

SO901

SPEAKER

IC901

L

2

LA4282

POWER

R

Q601

Q602

L

SYSTEM

MUTE

R

5

AMP.

Vcc

10

Q904

R-OUT

7

L-OUT

11

9

4

F901

T2.5A L 250V

PT801

MAIN POWER

TRANSFORMER

D907 910

Q903

IC902

KIA7810AP

VOLTAGE

REGULATOR

IC904

KIA7810AP

VOLTAGE

REGULATOR

+5V

5W

+B5

UNSWITCH

5V

+B1

D806

VOLTAGE REGULATOR

D911 D914

IC903

AN7805

CONSTANT

F902

T1.6A L 250V

Q803

D802~805

T.F.

PT802

SUB POWER

TRANSFORMER

REC/PLAY

T1/T2

BAIS

VF1

VF2

+B2

+B3

+B4

M10V

A10V

+5V

+B6

TERMINAL

RL801

L801

LINE

FILTER

SO902

AC INPUT

AC POWER

SUPPLY CORD

AC 230V,50Hz

Figure 19 BLOCK DIAGRAM (3/3)

– 19 –

Page 12

CD-BA1200H

B

P

A

D

F

P

S

3

0

8

2

9

7

A

Vcc

7

7

Vref

6

B

6

E

5

5

A

4

4

B

3

3

F

2

2

C

1

1

C

D

CD SERVO PWB-B

CNS1A

CNS1B

7

7

6

6

R51 68K

5

5

R52 68K

4

4

R53 68K

3

3

R54 68K

2

2

1

1

CNP1

R56

68K

+B

C51

C53

47/10

0.001

Q3

KTA1266GR

LASER DRIVER

0.1

C41

100/10

C23

0.047

C24

2.2/50

C22

100P

R15

10K

R43

220K

8

R12

680

R79

R1

1.5M

68

C

C21

0.1

0.0

R11

12K

R1

R80

1M

1.2

C27

0.1

C26

0.047

PH(R

A

C2

C28

0.1

47/10

2

R44

1K

EFBL

+B

R50

47

TIN1

FIN1

FIN2

TIN2

R55

68K

FIN1

1

REF

FIN2

2

REF

TIN1

C55

C54

0.01

47/10

C7

10/16

C8

0.1

+B

R25

10K

R47

3.3

TIN2

C6

100/10

REF1

VREF

LDD

GND

LDON

AGON

EFBL

TEST0

TES1

3

REF

4

REF

5

6

7

8

9

10

11

12

13

14

15

REF

APC

ODRV

AGCON

IC1

LA9235M

SERVO AMP.

REF

REF

LPF

REF

C11

0.47/6.3

VCC

30

ODRV

REF

AGCON

REF

PH

DH

ODRV

PH/BH

REF

LPF

REF

LPF

REF

REF

REF

C12

0.1

RFSW

29

R42

120K

RF-

28

RF

27

NC

26

PH

25

BH

24

23

RFEV

22

FE-

21

FE

20

TE-

19

TE

18

HFL

17

16

TEST

100K

10K

C18

R7

3P

6.8K

(CH)

R6

R5

27K

39K

5

C13

0.01

C14

0.33

R3

R4

4

C19

C17

0.0047

DS1SS133

100/10

C20

0.1

C82

0.022

D93

C25

R10

27K

R8

330

C42

68P

E

TR+

FO+

FO-

F

TR-

ACTUATOR

PICKUP UNIT

G

CD MOTOR PWB-C

M1

SPINDLE

MOTOR

M2

SLED

MOTOR

SW4

PICKUP IN

H

13

TDO

LD_M+

LD_MVCC4

LOADING M+

LOADING M-

GND

VCC3

SP-

SP+

SPDO

SPO

VCC2(SPN)

C47

100/16

+B

+B

C52

0.01

+B

TDO

C50

100/16

FDO

0.022

C46

GND

SLDO

VCC1

STANDBY

MUTE

TO

FD

FO

FO+

FO-

TR+

TR-

SL-

SL+

Vref

C49

TRTR+

FO+

FOGND

+

M

+

M

-

VR

LD

CNP3A

1

1

2

2

3

3

4

4

5

5

6

6

PD

7

7

CNS2B

CNS3B

6

6

5

5

4

4

3

3

2

1

1

1

2

3

4

5

6

7

88

6

5

4

3

22

1

CNS2A

CNS3A

TR-

1

TR+

2

FO+

3

FO-

4

GND

5

PD

6

VR

7

LD

88

CNP2

+B

R48

6.8K

SP-

6

SP+

5

SL+

4

SL-

3

PUIN

2

GND(D)

1

CNP3

+B

100/16

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

-

+

+

-

+

-

+

IC3

M63001FP

FOCUS/TRACKING/

-

-

+

+

+

-

SPIN/SLED DRIVER

+B

+

42

-

+

-

41

+

40

-

39

38

37

36

35

34

33

32

31

30

29

28

27

26

-

-

25

+

+

+

24

-

+

23

-

+

-

22

FDO

• NOTES ON SCHEMATIC DIAGRAM can be found on page 15.

1

23456

Figure 20 SCHEMATIC DIAGRAM (1/10)

– 20 –

Page 13

CD-BA1200H

+B

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

C19

C17

0.0047

0.022

DS1SS133

13

LD_M+

LD_MVCC4

LOADING M+

LOADING M-

GND

VCC3

SPSP+

SPDO

SPO

VCC2(SPN)

100/10

R10

27K

C20

0.1

C82

D93

R8

330

C42

68P

C47

100/16

C25

0.1

C41

100/10

+B

+B

C23

0.047

C24

2.2/50

C22

100P

R15

10K

R43

220K

CD SIGNAL

R94

10K

R95

DEFECT

EFMO

JITER

DEFECT

CONTROL

A/DSW

R39

470

+B

80

D/A

SLDO

+B

Q2

KRC102M

10K

79 78

FRAME SYNC

DEFECT,PROTECT

EFM DECODE

CLV

CONTROL

SW

AUTO

ADJUST

LASER

27

28

FG(D_Vref)

+B

R22

470

D22

DS1SS133

FSEQ

1

8

7

R12

680

PD01

R13

680

C81

0.022

PCKIST

R14

1.2K

SLCIST

EFMIN

0.1

PH(RFENV)

ADAVDD

C29

0.1

ADAVSS

PHREF

BHREF

R44

1K

R35

TDO

FDO

PD02

VVSS

VVDD

SLCO

JITTV

JITTC

VREF

TBLO

1K

HFL

TDO

FDO

1

2

3

PLL

VCEC

4

5

FR

6

7

8

SLICE

LEVEL

9

CONTROL

10

11

12

BH

13

14

FE

15

TE

16

17

18

+

-

19

20

21

S/H

22

23

24

26

25

SPDO

1

R38

270

SLDO

SPDO

6

R21

470

D21

DS1SS133

R79

1.5M

C21

0.1

R11

12K

R80

1M

C27

C26

0.047

C28

47/10

2

EFBL

DISC_NO

V/vP

77

76

GENERAL

PROCESSEROR

CONT2

CONT1

30

29

R40 1.2K

32

O/C

R67 1K

R68 1K

CONT7

CONT6

75

SERVO

GENERAL

CONT3

31

R45 1.2K

C71 100P

C72 0.01

C73 100P

C74 100P

C75 100P

C76 100P

C77 100P

C78 100P

C80

VSS

0.1

VDD5V

74

CONT5

CONT4

33

32

R17 1K

R46 1K

+B

+B

34

+B

DEF

RES

WRQ

73

72

70

71

IC2

LC78641E

SERVO/SIGNAL

CONTROL

INTERPOLATION

MUTE

ERROR

AUDIO

CORRECT

OUT

FSX

35

37

36

38

VDD

C2F

PCK

DOUT

C31

100/10

R16

10K

INT

69 68

SERIAL

EXTERNAL

ATTENUATION

DEEMPHASIS

DIGITAL

1BIT

39

C30

0.1

COMMAND

INTERFACE

OUT

AUDIO IN

FILTER

DAC

EFLG

40

67

SUBCODE

DECODE

CRC

TEST

CLDIDO

66

CLOCK

9

R71 1K

R72 1K

R73 1K

R74 1K

R75 1K

R76 1K

R77 1K

R78 1K

CE

65

GENERATOR

LPF

+B

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

L62

2.2µH

SBCK

PW

SBSY

SFSY

16M

DATA

DATACK

LRSY

ASDFIN

ASDACK

ASLRCK

XVSS

XOUT

XIN

XVDD

RVDD

RCHO

RVSS

LVSS

LCHO

LVDD

MUTER

MUTEL

EMPH

L61

0.82µH

16.9344MHz

R20

220

+B

+B

C38

10/16

C39

+B

10/16

47

R19

+B

CONSTANT VOLTAGE

Q1

KTC3203Y

+B

ZD61

DZ3.9BSB

C34

0.022

R82

2.2K

R81

2.2K

100/10

XL1

C44

0.1

C45

12

11

10

330/6.3

C56

C64

C40

0.0015

C43

0.0015

R58

0.47/6.3

DRF

RES

WRQ

INT

DO

DI

CL

CE

+B

R-CH

1

AGND

+B

DGND

INT

WRQ

DRF

CE

DO

DI

CL

RES

L-CH

+B

3

4

5

2

P22 1 - B

CNS601

3

TO MAIN PWB

4

+5V

5

CNP11

CDINT

1

WRQ

2

DRF

3

CE

4

5

6

7

8

9

10

CNP12

CNS4

1

1

2

2

3

4

5665

DO

DI

CLK

CD RES

CLAMP SW

GND

BI4

1

2

3

4

6

P25 12 - B

CNS702

TO DISPLAY PWB

SW1

OPEN/

CLOSE

SW2

CLAMP

SW3

DISC

NUMBER

+

M3

M

T/T

UP/DOWN

LOADING

10K

R84

10K

R83

C83

0.022

+B

220

+B

O/C

GND(D)

DISC_NO

M+

M-

CNP4

CD LOADING

MOTOR PWB-E

3

• The numbers 1 to 13 are waveform numbers shown in page 16.

7

8 9 10 11 12

Figure 21 SCHEMATIC DIAGRAM (2/10)

– 21 –

Page 14

CD-BA1200H

V

M

C138 220/10

Q

S

A

1

1

2

2

P21 12 - D

CNP11

TO CD SERVO

PWB

B

C

3

4

5

CNS601

P26 1 - G

3

4

5

17

4

18

12

TO POWER PWB

19

BI601

R-CH

A_GND

L-CH

CD_GND

+5v +B

L

GND

R

+5V

GND

D902

1SS133

(A_GND)

(CD_GND)

IC601

LC75341

AUDIO PROCESSOR

DI

1

CE

2

VSS

C607 10/50

C609

0.1(ML)

R615

3.9K

C611

R617

3.3K

0.1(ML)

C613 0.0027

C617 1/50

C629 1/50

C625

1/50

R609

R601

330

+B

+B

R602

330

R604

1.8K

R603

1.8K

10K

SYSTEM MUTE

Q601

2SC3331

Q602

2SC3331

SYSTEM MUTE

R610

10K

C601

0.001

C602

0.001

R607

2.2K

R608

2.2K

C603

22/25

R625

22K

C633

0.001

3

LOUT

4

LBASS

5

LTRE

6

LIN

7

LSEL0

8

L4

9

C623

1/50

L3

10

L2

11

L1

12

C627

1/50

CCB

INTERFACE

-

+

-

+

+

-

+

AUX

DECK

TUN

CD

CLK

24

23

VDD

+

VREF

+

-

-

-

+

22

ROUT

21

-

+

RBASS

20

RTRE

19

RIN

18

RSEL0

17

R4

16

R3

15

R2

14

R1

13

C610

0.1(ML)

C612

0.1(ML)

C614

0.0027

C618

1/50

C624

1/50

C626

1/50

C630

1/50

C628

1/50

C606

22/50

C608

10/50

+B

C604

100/25

C605

0.022

R616

3.9K

R618

3.3K

D

E

F

G

R-CH

L-CH

PLAYBACK HEAD

ERASE

HEAD

R-CH

L-CH

TAPE1

PLAYBACK

HEAD

TAPE2

RECORD/

FM SIGNAL

PLAYBACK SIGNAL

RECORD SIGNAL

CD SIGNAL

1

1

1

2

2

2

3

3

3

CNS101A

CNS101B

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

CNS102A

CNS102B

TAPE1_R

A_GND

TAPE1_L

M_GND

ERASE

TAPE2_R2

A_GND

TAPE2_R1

TAPE2_L1

TAPE2_L2

LUG1

MECHA BASE GND

1

2

3

CNP101

1

2

3

4

5

6

7

CNP102

C105

180P

C103

560P

C104

180P

C102

560P

SWITCHING

Q104

2SC1845F

Q106

2SC1845F

SWITCHING

SWITCHING

Q107

2SC1845F

Q105

2SC1845F

SWITCHING

C101

0.047

R101

10K

Q101

KTA1266 GR

SWITCHING

R106

2.2K

R108

3.3K

R109

3.3K

R107

2.2K

R102

10K

R103

4.7K

R111

4.7K

R113

47K

SWITCHING

2

1

SWITCHING

R137

15K

R104

1K

R105

1K

Q108

2SC3331

R110 47K

R112 4.7K

Q109

2SC3331

Q102

KRC104 M

3

1

32

Q103

KRC104 M

SWITCHING

C107

560P

SWITCHING

C106

560P

+B

R157

100

C108

100/16

IC101:PLAYBACK AND RECORD/

C116

100/25

C118

0.033

L102

R114

2.2mH

1K

C114

C112

330P

330P

24

23

R

L

C113

C115

330P

330P

R115

L101

1K

2.2mH

C119

0.033

C117

100/25

R117

56

R142

220K

MUTING

Q110

2SC3331

0V

0.7V

R140

10K

R134

100

C132

0.0033

R132

1.5K

C126

270P

C130

0.022

C128

22/25

16

17

56K

Hich=CHROME

+

56K

-

9

8

C129

22/25

R133

100

C127 270P

C131

0.022

C133 0.0033

R131 1.5K

R130

R126 68K

R128

IC101

AN7345K

C139

3.3/50

R127

0V

3.9K

6.8K

18

7

6.8K

R129 3.9K

PLAYBACK AMP.

R124

R116

33K

56

R122

C122

5.6K

1/50

R118

R120

100K

3.9K

22

112K

+ +

Hich=T1

+

112K

-

321

R121

R119

3.9K

100K

R138

15K

C146

0.001

C120

560P

20

21

19

4

R123

5.6K

C121

560P

C123

1/50

5

C137

0.022

R125

33K

6

R136

10K

C134

47/25

15

Nor/CrO2

ALC

10

C135

47/25

R135

10K

REC_R

2

R141

10K

0.7

C136 22/25

14

RIPPLE

ALC

11

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 15.

1

23456

Figure 22 SCHEMATIC DIAGRAM (3/10)

– 22 –

Page 15

L

S

MAIN PWB-A1(1/3)

K

6

8K

5

CD-BA1200H

+B

R140

10K

C132

0.0033

16

56K

56K

9

C135

47/25

C133 0.0033

R616

3.9K

R136

C134

47/25

15

ALC

10

R135

10K

C604

100/25

C605

0.022

R618

3.3K

R141

10K

0.7V

10K

C136 22/25

14

RIPPLE

Nor/CrO2

ALC

11

REC_R

MUTING

Q111

2SC3331

0V

0V

R139

180

C138 220/10

13

Vcc

GND

12

R143

220K

LK

24

23

DD

EF

UT

S

RE

IN

0

R4

R3

R2

R1

3.9K

.

18

1

K

7

6.8

R129 3.9K

22

21

20

19

18

17

16

C624

15

1/50

C626

14

1/50

13

0V

0V

C126

270P

C127 270P

C610

0.1(ML)

C612

0.1(ML)

C614

0.0027

C618

1/50

C630

1/50

C628

1/50

R142

220K

MUTING

Q110

2SC3331

0.7V

R134

R132

1.5K

C130

C128

22/25

17

+

Hich=CHROME

+

-

8

C129

22/25

R133

C131

R131 1.5K

C606

22/50

C608

10/50

100

0.022

100

0.022

REC_L

+B

C145

470P

+B

+B

+B

Q112

KTA1266 GR

SWITCHING

L103

100µH

R146

82

(1/2W)

R147

47K

R148

22K

C148

0.047

(D_GND)

GND

10

GND

(A_GND)

+B

+B

11.7V

0V

C140

0.0082

(PP)

+B

C141

0.039

(ML)

11.6V

R144

47K

R145

4.7K

11.6V

Q114

KTC3203 Y

BIAS OSC

0V

0V

2

L104

330µH

1

Q113

KRC104 M

BIAS

0V

0V

R149

4.7

+B

+B

+B

3

0V

+B

VF2

M_10V

P26 1 - G

TO POWER PWB

+B

(D_GND)

GND

SW_5V

POWER

C142

47/25

+B

A_10V

-VP

VF1

51514 16 21 10 12 22 11 13 20

+B

+B

UN_SW_5V

AC_RLY_CONT

+B

AC_RLY_CONT

(M_GND)

GND

UN_SW 5V

T_BIAS

T_T1/T2

REC/PLAY

M_GND

M_10V

SMUTE

D_GND

SW_5V

POWER

A_10V

CE

DI

CLK

TUN_R

TUN_L

DO

SM

SM

CE

DO

DI

CLK

VF1

-VP

VF2

4

5

7

6

9

2

3

8

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

CNP701

P29 12 - H

TO TUNER PWB

1

21

FCC21

CNP701

P25 12 - D

TO DISPLAY PWB

7

8 9 10 11 12

Figure 23 SCHEMATIC DIAGRAM (4/10)

– 23 –

Page 16

CD-BA1200H

X

0

0

0

0

0

0

0

A

B

C

D

E

C708

1/50

R743

33

+B

+B

+B

R748 10K

R749 10K

R750 10K

R751 10K

R753 10K

C705

100/10

D712

1SS133

FL701

FL DISPLAY

F

F

P16

P15

2

1

43

R742 1K

R741 1K

R737 1K

R736 1K

R735 1K

R734 1K

R733 1K

P13

5

D701

1SS133

P11

P14

P20

8

7

6

+B

P10

10

9

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

15

13

11

14

12

818283 84 85 86 87 88 89

VLOAD

P9

P8

80

P10

P11

P14

P20

P13

P16

P15

DIST0

DIST1

DIST2

DIST3

SPN

DISTOUT/SW OUT

KARAOKE LATCH

MIC IN

FPB

FPA

T1 RUN

VDD

AC RLY_CONT

SPK_DET

POWER

504948 47 46 45 44 43 42

R778 1K

R792 1K

R732 1K

R730 1K

19

20

17

18

16

90 91 92 93 94 95 96 97 98 99

P1P2P3P4P5P6P7

P19

P12

P18

IC701

IX0337AWZZ

SYSTEM

MICROCOMPUTER

KEY 0

31

KEY 1

32

KEY 2

33

T2 PLAY SW_B

54

T1 PLAY SW_A

53

CD CLAMP SW

52

T2 RUN

51

SMUTE

T_SOL_A

T_MOTOR

TIMER LED

T_SOL_B

41 40 39 38 37 36 35 34 33 32 31

R726 2.2K

R727 2.2K

R728 2.2K

R729 2.2K

LED722

4204SRT7

P19

P12

P18GP2P37G6GP4P55GP6P7P8P9

22

23

24

21

5G

6G7G8G1G2G3G4G

P17

100

NO USE

REMOCON

VSS

SP_RLY

R724

1K

R722

+B

P18

25

27

26

-20dBATT

9G

REC/PLAY

RES OUT

M-BUSY/TUN SM

SPEANA3

SPEANA2

SPEANA1

SPEANA0

AVDD

SYS STOP

AVref

R721

1K

10K

29

28

S-BUSY

T-BIAS

T_T1/T2

WRQ

RESET

VPP/IC

CD INT

VDD

CD CLK

CD DI

CD DO

CD CE

AVSS

R720

F9G4G3G2G1GP17

30

32

31

2

100

VDD

1

2

3

R7

4

R7

5

R7

6

R7

7

R7

DRF

8

R7

9

R7

10

X2

11

X1

12

13

XT2

14

R7

15

16

R7

17

R7

18

R7

19

R7

20

R7

CE

21

R7

22

CLK

R7

23

DI

R7

DO

24

25

R7

26

27

28

29

30

R719

1K

1K

R755

4.7K

+B

+B

F

TAPE MECHANISM PWB-E

B

M

T2 PLAY

SOLENOID

SOLENOID

R.PLAY

T1 PLAY

F.PLAY

A

+

- -

PH

PH

FFC13

T2 PLAY

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

11

12

13

+5V

T2 RUN

+MTR

SOL2

SOL1

T1 RUN

T1 PLAY

GND

F_REC

CNP703

C710

47/25

D702

1SS133

TAPE

MOTOR

G

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 15.

1

23456

Figure 24 SCHEMATIC DIAGRAM (5/10)

+B

D703

1SS133

– 24 –

R757

R756

68K

C712

10/16

D704

1SS133

Q705

KTA1271Y

68K

C711

10/16

R761

1K

R762

0V

Q704

KTA1271Y

0V

R758

10K

47K

12V

12V

12V

R759

R760

1K

Q703

2SC3331

R766

12V

R767

10K

10K

D705

10K

R763

1SS133

47K

+B

Q702

2SC3331

R768

10K

Q706

KTA1273Y

R775

10K

R776

10K

+B

R777

10K

Page 17

CD-BA1200H

P4

R

K

1

LAY

29

VDD

DRF

WRQ

VDD

100

X2

X1

XT2

CE

CLK

DI

DO

1K

30

31

1

2

3

R702 1K

4

R703 1K

5

R704 1K

6

R705 1K

7

R706 1K

8

R707 1K

9

R708 1K

10

11

12

13

14

R709 1K

15

16

R710 1K

17

R711 1K

18

R712 1K

19

R713 1K

20

R714 1K

21

R715 1K

22

R716 1K

23

R717 1K

24

25

R718 1K

26

27

28

29

30

R719

1K

R755

F F9G4G3G2G1G

32

33

Q701

KRC107M

213

R744

1K

R745

100K

XL701

4.7K

C703

15P

C704

18P

+B

+B

R725

1K

C707

1/50

C701

0.022

R779

3.3 (1/2W)

+B

+B

C702

220/10

+B

+B

C713

0.1/50

RD13

680

SW714

CD

RD25

680

SW711

EQUALIZER/

X-BASS/DEMO

SW701

ON/STAND-BY

SW715

TAPE

RD01

680

L701

100µH

RD14

820

SW702

CLOCK

RD10

820

RD02

820

D707

1SS133

C714

0.01

RD15

1K

SW716

TUNING/

TIME

DOWN

RD11

1K

SW712

VOLUME UP

RD03

1K

+B

R770

47K

Q707

RD16

1.5K

SW717

MEMORY/

SET

RD12

1.5K

RD04

1.5K

SW703

TIMER/

SLEEP

WRQ(DSP)

RES OUT

CLAMP SW

R769

10K

+B

5V BACK UP

D708

1SS133

RESET

3

2

1

KRC102M

D709

1SS133

RD17

2.2K

SW718

REWIND

RD05

2.2K

+B

+B

KIA7042AP

C715

3.3/50

R771

100K

RD18

2.7K

SW719

FAST

FORWARD

SW713

VOLUME

DOWN

RD06

2.7K

+B

R772

4.7K

IC704

RESET

3

C716

0.022

SW720

PLAY/

REPEAT

RD07

3.9K

BI702

CD INT

DRF

CD CE

CD DO

CD DI

CD CLK

CD_GND

D706

1SS133

2

RD19

3.9K

SW721

CD INT

1

1

WRQ(DSP)

2

2

DRF

3

3

CD CE

4

4

5

5

6

6

7

7

8

8

9

9

10

10

CD DO

CD DI

CD CLK

RES OUT

CLAMP SW

D_GND

P21 12 - F

CNP12

TO CD SERVO

PWB

CNS702

FFC21

1

TUN SM

2

CE

3

DO

4

DI

5

CLK

6

T_BIAS

7

T_T1/T2

8

REC/PLAY

9

M_GND

10

M_10V

11

SMUTE

12

VF1

13

-VP

14

VF2

AC_RLY CONT

15

16

UN_SW 5V

17

D_GND

18

SW_5V

19

POWER

20

SPAN

21

SW OUT

1

21

CNP701

+B

D710

+B

1

REMOTE SENSOR

C717

10/50

RD20

5.6K

STOP

RD08

56K

SW709

RD26

6.8K

DISC

SKIP

1SS133

RX701

RD21

10K

SW723

REC/

PAUSE

3 2 1

RD22

15K

RD09

100K

C718

0.022

RD23

33K

SW724

TUNING

UP

D711

1SS133

R773

100

C719

47/16

DISPLAY PWB-A2

RD24

100K

SW725

TUNER

(BAND)

SW710

OPEN/

CLOSE

P23 12 - D

CNP701

TO MAIN PWB

P17

P18

P19

P12

6G

17

6

87 88 89

P1

IX0337AWZZ

ICROCOMPUTER

31

32

33

54

53

52

51

T_MOTOR

44 43 42

728 2.2

P18GP2P37G

22

23

24

21

6G7G8G1G2G3G4G

5G

P17

100

25

19

20

18

90 91 92 93 94 95 96 97 98 99

P19

P12

P18

IC701

SYSTEM

KEY 0

KEY 1

KEY 2

T2 PLAY SW_B

T1 PLAY SW_A

CD CLAMP SW

T2 RUN

SYS STOP

NO USE

REMOCON

VSS

SMUTE

T_SOL_A

T_SOL_B

R726 2.2K

R727 2.2K

4204SRT7

SP_RLY

41 40 39 38 37 36 35 34 33 32 31

R724

1K

R722

+B

LED722

28

27

26

-20dBATT

S-BUSY

9G

T-BIAS

T_T1/T2

REC/PLAY

RES OUT

RESET

VPP/IC

CD INT

CD CLK

CD DI

CD DO

CD CE

AVSS

M-BUSY/TUN SM

SPEANA3

SPEANA2

SPEANA1

SPEANA0

AVDD

AVref

R721

1K

10K

R720

+B

+B

1

R775

10K

R776

10K

R777

10K

73Y

7

8 9 10 11 12

Figure 25 SCHEMATIC DIAGRAM (6/10)

– 25 –

Page 18

CD-BA1200H

K

D

1

4

A

B

C

NF1

1

C937

100P

C906

1

47/25

R905

C907

SP. DET.

Q902

KRC102 M

R915

820

C905

0.022

C903

470P

C904

470P

1

22

33

Q901

KRC102 M

SP. DET.

R914

22K

IN1

2

120

100/25

CH1

RIPPLE

FILTER

R907

1K

C909

0.082(ML)

LA4282

POWER AMP.

CH2

IN2

PRE-GND

43

5

C936

100P

R906

1K

C908

0.082

(ML)

IC901

NF2

6

C918

220P

R910

(1/2W)

270

R908

C910

120

100/25

VOL. PROTECTOR

MUTE

CIRCUIT

OUT2

8

7

C914

470/25

C912

0.1(ML)

C916

0.1(ML)

R912

4.7

OVERTHERMAL

R909

POWER

9

56K

GND2

C919

10/50

C911

0.022

Vcc

10

R911

270

(1/2W)

OUT1

11

C915

POWER

12

470/25

GND1

C913

C917

0.1(ML)

R913

4.7

0.1(ML)

R OUT

L OUT

D

E

F

G

H

4

POWER

22

L

17

GND

(A_GND)

4

18

12

19

5

15

TO MAIN SECTION

14

P22 1 - C, P23 11 - H

16

21

10

12

R

+5V (CD +B)

GND (CD_GND)

A 10V

VF1

-VP

VF2

M 10V

GND (D_GND)

SW_5V

11

13

20

GND (M_GND)

UN SW 5V

AC_RLY_CONT

C946

2200/35

C933

68P

IC905

R925

C944

0.022

R922

22K

3

KTC2026

22K

C935

22/25

C938

47/25

IC904

KIA7805P

2

D918

R923

+B

3

C939

1

1SS133

IC902

33

KIA7810AP

VOLTAGE

REGULATOR

1

2

0.1 (ML)

C945

0.1 (ML)

D904

1SS133

C940

0.1 (ML)

D911

C947

3300/25

R929

220

R928

1N4004S

D913

1N4004S

12K

R930

+B

+B

220

C954

100/50

ZD903

1

D9

1N

C955

MTZJ6.2A

+B +B

C934

0.047(ML)

GND

(A_GND)

IC903

AN78L05

+B

+B

C941

+B

+B

+B

+B

+B

CONSTANT

VOLTAGE REGULATOR

3

1

2

C942

47/25

0.047(ML)

D903

1SS133

+B

VOLTAGE REGULATOR

+B

C943

47/25

R926

10K

+B

• NOTES ON SCHEMATIC DIAGRAM can be found on page 15.

1

23456

Figure 26 SCHEMATIC DIAGRAM (7/10)

– 26 –

Page 19

FM SIGNAL

MAIN PWB-A1 (2/3)

CD-BA1200H

HEADPHONES PWB-A3

1

1

946

200/35

R OUT

L OUT

R921

6.8

C923

0.022

C927

0.022

D907

RL203F

D909

RL203F

L901

0.29µH

D908

RL203F

D910

RL203F

R919

6.8

C925

0.022

C929

0.022

C950

0.047

(ML)

T2.5A L250V

C951

0.047

(ML)

F901

0.29µH

R920

6.8

C924

0.022

C928

0.022

L902

R918

6.8

C926

0.022

C930

0.022

5

C932

C931

0.001

0.001

C388

0.001

56

R94056R939

SPEAKER

TERMINAL

+

+

–

–

FW902

SO901

SP_Lch

SP_Rch

SP_Lch_GND

SP_Rch_GND

R916

5

SPEAKER

330

L903

2.2mH

C921

220P

When Servising, pay attention as the

area enclosed by this line( ) is

directly connection with AC main voltage.

C922

220P

R917

330

JK901

HEADPHONES

C947

3300/25

R929

220

R928

D911

1N4004S

D913

1N4004S

12K

R930

220

7

C954

100/50

ZD903

D912

1N4004S

D914

1N4004S

C955

KTA1266GR

MTZJ6.2A

47/50

Q904

C952

0.047

(ML)

C956

R927

1

47/50

2.2K

ZD902

DZ30BSB

C957

47/50

R806

10K

C953

0.047

(ML)

C958

100/50

D917

1N4004S

F902

T1.6A L 250V

D915

IN4004S

C959

D916

1N4004S

D806

1SS133

47K

R805

100/50

CNP901

220

R804

+B

Q803

2SC3331

2

3

4

5

6

C804

1000/6.3

1

2

3

4

5

6

TRANSFORMER

C805

0.001

PT801

MAIN POWER

C803

470/35

D802

1N4004S

D805

1N4004S

T.F

D803

1N4004S

D804

1N4004S

C802

0.047(ML)

CNP801

1

212

PT802

SUB POWER

TRANSFORMER

D801

1SS133

8 9 10 11 12

Figure 27 SCHEMATIC DIAGRAM (8/10)

– 27 –

RL801

C801

SO902

AC INPUT

SOCKET

L801

LINE

FILTER

0.0047/250

AC POWER

SUPPLY CORD

AC 230V, 50Hz

Page 20

CD-BA1200H

1K

22K

C380

A

AM LOOP

ANTENNA

B

1

1

2

2

C

CNP302

D302

1SS133

C302

0.001

D301

1SS133

L341

BALUN

AM TRACKING fL

T303

C323

0.022

AM ANT.

+B +B

AM BAND

COVERAGE fL

T306

AM OSC.

C335

560P

C334

27P(UJ)

C330

15P

(UJ)

R323

SVC348S

68K

VD301

C331

0.047

C332

0.022

R336

10K

+B

C342

0.022

R358

3.9K

R351

5.6K

C362

24

AM OSC OUT

FM IF IN

1

3.3/50

23

AM OSC IN

C361

22

FM AFC

AM MIX OUT

32

0.022

REG

0.022

C363

21

AM RF IN

D

E

F

G

SO301

FM ANTENNA

TERMINAL

D303

1SS133

D304

1SS133

C301

0.022

7

8

ANT

GND

C321

100/16

C346

0.022

R369

C345

0.022

L342

2.2mH

15

6 5 4

VCC

GND

FE301

FM FRONT END

13

CF302

2

+B

C397

0.022

R382

150

C381

12P(CH)

X352

4.5MHz

C382

33

R347

6.8K

CF301

R348

680

R349

Q301

2SC380-O

C347

4.7K

R345

VT

0.022

123

470

R344

R346

330

C341

0.022

2

3

F OUT

1

GND

IF OUT

15P(CH)

IC302: PLL(TUNER)

C352

22

1

10/16

R381

10K

X OUT

X IN

C350

21

20

VSS

AOUT

R374

0.022

C394

47/16

C393

1/50

IC302

LC72131

CE

1K

R380

1.5K

DI

R373

T351

AM IF

C392

0.001

R379

18

19

PD

AIN

DO

CL

6

5432

1K

R378

1K

R372

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 15.

1

23456

Figure 28 SCHEMATIC DIAGRAM (9/10)

– 28 –

Page 21

C342

4

5MH

0.022

R358

3.9K

R351

5.6K

C362

24

AM OSC OUT

3.3/50

23

AM OSC IN

22

C361

FM AFC

0.022

21

AM RF IN

0.022

C363

0.022

R350

2.7K

C367

1/50

C365

C364 10/16

20

19

18

VSM

FM/AM OUT

AM LOW CUT

FM IF DET./FM MPX./AM IF

L354

LOW PASS

FILTER

IC303

LA1832S

X351

456kHz

17

MPX VCO

C368

1/50

16

MPX IN

R357

R356

C369

470K

1K

27P(UJ)

C374

15

R-CH OUT

0.018

14

C373

0.018

C371

1/50

C372

1/50

13

L-CH OUT

MO/ST

R364

R361

1.2K

R362

1.2K

15K

R363

15K

CD-BA1200H

MAIN PWB-A1(3/3)

FM SIGNAL

AM SIGNAL

C397

0.022

82

0

z

.

L(TUNER)

C352

22

1

10/16

R381

X OUT

X IN

10K

1

C350

21

20

VSS

AOUT

1K

R374

0.022

C394

47/16

C393

1/50

IC302

LC72131

CE

R380

1.5K

DI

R373

32

T351

AM IF

C392

0.001

18

19

PD

AIN

DO

CL

6

5432

1K

1K

R372

REG

AM MIX OUT

FM IF IN

R379

R378

17

C380

2.2K

VDD

7

1K

R352

1

10/16

FM/AM

1K

C387

16

2

FM IN

IF

8

0.022

15

CONT

AM IF IN

4

3

L351

100µH

C385

0.01

AM IN

9

CF352

14

FM/AM

GND

SD

STEREO

FM DET

VCC

IF OUT

9

R395

47K

R360

4.7K

C398

10

100/10

11

C356

0.001

C355

PHASE

C357

2.2/50

22P

+B

ST IND

R377

C386

330P

R376

47K

1K

C354

7

0.022

+B

8

R353

270

CF351

C399

0.022

+B

5

6

C353

0.022

R393

1K

13

12

SD

IF IN

MO/ST

10

11

R387

C358

5.6K

1/50

R355

3.3K

R388

3.9K

PHASE

(FM/AM)

12

1/50

C370

L352

R359

1.8K

100µH

SWITCHING

KTA1266GR

R385

5.6K

5.6K

R384

+B

C396 100/10

C395 0.022

+B

Q360

C391

47/16

ZD351

DZ5.1BSB

R392

270

R391

270

R383

5.6K

+B

1K

R370

R386

22K

7

8 9 10 11 12

+B

SM

12 345678910

C388

0.001

L

R

TO MAIN SECTION

+B

A GND

A+12V

P23 12 - B

D GND

CLK

DOTPCE

DI

Figure 29 SCHEMATIC DIAGRAM (10/10)

– 29 –

Page 22

CD-BA1200H

IC1

PIN

VOLTAGE

NO.

1.6V

1

1.6V

2

1.6V

3

1.6V

4

1.6V

5

1.6V

6

0V

7

2.6V

8

0V

9

0V

10

0V

11

3.3V

12

1.6V

13

1.6V

14

1.6V

15

0V

16

0V

17

1.6V

18

1.6V

19

1.6V

20

1.6V

21

1.6V

22

0V

23

1.6V

24

0V

25

0V

26

0V

27

1.6V

28

1.6V

29

3.3V

30

IC3

PIN

VOLTAGE

NO.

1.6V

1

1.6V

2

1.8V

3

2.1V

4

2.1V

5

2.1V

6

2.1V

7

0V

8

0V

9

0V

10

0V

11

0V

12

0V

13

0V

14

2.1V

15

2.1V

16

1.6V

17

4.9V

18

3.5V

19

1.6V

20

0V

21

0V

22

4.9V

23

4.9V

24

1.6V

25

2.1V

26

2.1V

27

1.9V

28

0V

29

0V

30

0V

31

0V

32

0V

33

0V

34

0V

35

4.2V

36

0V

37

2.1V

38

2.1V

39

4.9V

40

2.1V

41

2.1V

42

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

IC2

VOLTAGE

0.7V

0V

0V

0V

3.3V

2.4V

0V

0V

1.6V

0V

4.7V

1.7V

0V

1.6V

1.6V

1.6V

1.6V

3.3V

0V

1.6V

1.6V

1.6V

1.6V

1.6V

1.6V

1.6V

1.6V

0V

0V

2.1V

2.1V

0V

3.3V

3.5V

3.3V

3.3V

3.3V

1.6V

1.6V

0V

0V

3.3V

3.3V

3.0V

1.5V

0V

0V

1.5V

3.0V

3.3V

1.8V

3.0V

0V

0V

0V

0V

1.7V

3.3V

0V

3.0V

1.6V

0V

2.4V

0V

0V

0V

0V

4.8V

4.9V

4.9V

4.6V

0V

4.9V

0V

0V

0V

3.2V

0V

0V

3.4V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PIN

NO.

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

IC101

VOLTAGE

0V

0V

0.55V

2.16V

0V

1.25V

0V

0.58V

3.17V

3.55V

0V

0V

4.72V

4.37V

0V

3.67V

0.38V

0V

0V

0V

2.16V

0.55V

0V

0V

IC301

VOLTAGE

0.8V (0V)

1.5V (0V)

3.6V (0.4V)

1.5V (0V)

0V (0V)

3.6V (0.4V)

2.8V (0.2V)

3.5V (0.3V)

3.6V (0.3V)

IC302

VOLTAGE

2.15V

0V

0V

0V

0V

4.83V

9.87V

4.4V

0V

0V

4.64V

2.27V

4.66V

0V

2.13V

0V

4.86V

0.73V

0.73V

6.3V

0V

2.33V

VOLTAGE

IC901

PIN

VOLTAGE

NO.

0V

1

0V

2

16.27V

3

0V

4

0V

5

0V

6

16.72V

7

0V

8

0V

9

34.2V

10

16.6V

11

0V

12

IC902

PIN

VOLTAGE

NO.

19.12V

1

0V

2

10.04V

3

IC904

PIN

VOLTAGE

NO.

19.12V

1

0.64V

2

5.64V

3

Q903

PIN

VOLTAGE

NO.

10.04V

1

19.05V

2

9.57V

3

IC704

PIN

VOLTAGE

NO.

4.9V

1

0V

2

4.9V

3

IC601

PIN

VOLTAGE

NO.

0V

1

0V

2

0V

3

4.96V

4

4.96V

5

4.96V

6

4.96V

7

4.89V

8

4.78V

9

4.78V

10

4.78V

11

4.78V

12

4.78V

13

4.78V

14

4.78V

15

4.78V

16

5.1V

17

5.5V

18

5.0V

19

4.66V

20

5.03V

21

4.97V

22

10.0V

23

0V

24

PIN

VOLTAGE

NO. NO.

4.78V

1

0V

2

5.0V

3

0V

4

4.69V

5

4.74V

6

4.75V

7

0V

8

4.85V

9

4.30V

10

2.25V

11

1.16V

12

0V

13

0V

14

4.85V

15

4.78V

16

4.67V

17

0V

18

4.69V

19

0V

20

0V

21

0V

22

0V

23

4.82V

24

0V

25

0.3V

26

0V

27

0V

28

0V

29

0V

30

4.81V

31

4.81V

32

4.81V

33

4.9V

34

5.0V

35

4.9V

36

0V

37

0V

38

5.0V

39

0V

40

1.7V

41

9.45V

42

9.45V

43

9.45V

44

3.8V

45

4.89V

46

0V

47

4.89V

48

4.79V

49

4.78V

50

PIN

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

IC701

VOLTAGE

4.29V

0V

4.81V

4.81V

4.81V

4.81V

0V

0V

27.8V

–27.8V

0V

0V

0V

0V

0V

0V

–27.7V

–27.7V

–27.1V

–28.2V

–21.7V

–18.6V

–12.9V

–24.4V

–25.9V

–15.7V

–22.2V

–22.3V

–27.8V

–18.6V

–12.9V

–24.4V

–24.4V

–27.1V

–27.1V

–24.4V

–24.4V

–27.1V

–27.1V

–24.4V

–27.1V

–24.4V

–27.1V

–24.4V

–24.4V

–24.4V

–24.4V

–24.4V

–24.4V

–24.4V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

IC303

VOLTAGE

2.12V

4.78V

2.12V

2.11V

0V

4.65V

4.65V

3.02V

4.78V

4.08V

1.63V

1.13V

2.08V

1.31V

1.29V

2.07V

0V

1.43V

1.99V

1.44V

2.08V

2.08V

4.48V

3.35V

– 36 –

Page 23

CD-BA1200H

TROUBLE SHOOTING

When the CD does not function

When the CD section does not operate when the objective lens of the optical pickup is dirty, this section may not operate. Clean

the objective lens, and check the playback operation. When this section does not operate even after the above step is taken, check

the following items.

Remove the cabinet and follow the trouble shooting instructions.

"Track skipping and/or no TOC (Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup

lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Parts code

1. CD optical pickup Lens cleaner disc UDSKA0004AFZZ

HOW TO USE

1.

Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the

brush on the CD cleaner disc which has the mark next to it.

2.

Place the CD cleaner disc onto the CD disc tray with the brush side down, then

press the play button.

3.

You will hear music for about 20 seconds and the CD player will automatically stop.

If it continuous to turn, press the stop button.

Cleaner Fluid

CAUTION

The CD lens cleaner should be effective for 30-50 operations, however if the

brushes become worn out earlier then please the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft

cloth.

Do not drink the cleaner fluid or allow it to come in contact with the eyes. In the

event of this happening then drink and / or rinse with clean water and seek medical

advice.

The CD cleaner disk must not be used on car CD players or on computer CD ROM

drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting this product

Cleaner disc

When a CD cannot be played

1. "E-CD01" is displayed.

(1) Check the power to IC2 (LC78641E), the presence of the clock signal (16.93 MHz) and the status of the RESET terminal