Sharp AY-XP9LSR,AY-XP12LSR,AE-X9LSR,AE-X12LSR Service Manual

TopPage

SPLIT TYPE

AIR CONDITIONER

AYXP9LSR

SERVICE MANUAL

No. S2005AYXP12LST

MODEL

INDOOR UNIT

AY-XP9LSR

AY-XP12LSR

In the interests of user-safety (Required by safety regulations in some countries) the set should

be restored to its original condition and only parts identical to those specified should be used.

CONTENTS

CHAPTER 1. SPECIFICATION

[1] SPECIFICATION............................................ 1-1

[2] EXTERNAL DIMENSION............................... 1-3

[3] WIRING DIAGRM .......................................... 1-4

[4] ELECTRICAL PARTS .................................... 1-5

OUTDOOR UNIT

AE-X9LSR

AE-X12LSR

[6] MALFUNCTION (PARTS) CHECK

METHOD ......................................................3-8

[7] OUTDOOR UNIT CHECK METHOD........... 3-11

[8] TROUBLESHOOTING GUIDE ....................3-14

[9] CHART ........................................................3-15

CHAPTER 2. EXPLAMATION OF CIRCUIT AND OPERATION

[1] BLOCK DIAGRAMS....................................... 2-1

[2]

MICROCOMPUTER CONTROL SYSTEM

[3] FUNCTION..................................................... 2-7

CHAPTER 3. FUNCTION AND OPERATION OF PROTECTIVE PROCEDURES

[1] PROTECTION DEVICE FUNCTIONS AND

OPERATIONS................................................ 3-1

[2] AIR CONDITIONER OPERATION IN

THERMISTOR ERROR ................................. 3-3

[3] THERMISTOR TEMPERATURE

CHARACTERISTICS..................................... 3-5

[4] HOW TO OPERATE THE OUTDOOR

UNIT INDEPENDENTLY................................ 3-5

[5]

GENERAL TROUBLESHOOTING CHART

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

.................. 2-3

................. 3-6

CHAPTER 4. REFRIGERATION CYCLE

[1] SCHEMATIC DIAGRAM................................4-1

[2] STANDARD CONDITION..............................4-1

[3] TEMPERATURE AT EACH PART AND

PRESSURE IN 3-WAY VALVE ......................4-1

[4] PERFORMANCE CURVES ...........................4-2

CHAPTER 5. DISASSEMBLING PROCEDURE

[1] INDOOR UNIT...............................................5-1

[2] HOW TO REMOVE PLASMACLUSTER

UNIT

(For the models with PLASMACLUSTER)

[3] DISASSEMBLY OF OUTDOOR UNIT...........5-5

Parts Guide

..................5-4

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

AYXP9LSR

AYX P9 LS R

CHAPTER 1. SPECIFICATION

Service Manual

[1] SPECIFICATION

1. AY-XP9LSR – AE-X9LSR

MODEL INDOOR UNIT OUTDOOR UNIT

ITEMS AY-XP9LSR AE-X9LSR

Rated cooling capacity (Min– Max.) kW 2.5 (0.9 - 3.0)

Rated heating capacity (Min–Max.) kW 2.9 (0.9 - 3.7)

Moisture removal (at cooling) Liters/h 0.8

Electrical data

Phase Single

Rated f requency Hz 50

Rated voltage V 220-240

Rated current I

(Min - Max.)

Rated input I

(Min - Max.)

Power factor I Cool % 84

Compressor Type Hermetically sealed rotary type

Refrigerant system Evaporator Louver Fin and Grooved tube type

Noise level

(at cooling)

Fan system

Drive Direct drive

Air flow quantity

(at cooling)

Fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D φ16

Others

Safety device Compressor: Thermal protector

Air filters Polypropylene net (Washable)

Net dimensions Width mm 860 730

Net weight kg 8.5 30

Cool A 4.0 (1.3 - 5.4 )

Heat A 4.0( 1.2 - 5.9 )

Cool W 770 (240- 1100)

Heat W 780 (220 - 1200)

Heat % 85

Model 43A23YBM&FJKE

Oil charge 370cc (Zegles RB68EP)

Condenser Corrugate Fin and Grooved tube type

Control Capillary tube

Refrigerant (R410A) 690g

De-lce system Micro computer controled reversed systems

High dB(A) 37 45

Low dB(A) 31 –

Soft dB(A) 23 –

High m3/min. 9.1 26.4

Low m3/min. 7.4 –

Soft m3/min. 4.7 –

Fan motors: Thermal fuse

Fuse, Micro computer control

Height mm 292 540

Depth mm 205 250

NOTE: The conditions of star ”I” marked item are “ISO5151:1994(E )”, condition T1’.

1 – 1

2. AY-XP12LSR – AE-X12LSR

MODEL INDOOR UNIT OUTDOOR UNIT

ITEMS AY-XP12LSR AE-X12LSR

Rated cooling capacity (Min– Max.) kW 3.5 (0.9 - 3.8)

Rated heating capacity (Min–Max.) kW 4.0 (0.9 - 4.7)

Moisture removal (at cooling) Liters/h 1.2

Electrical data

Phase Single

Rated frequency Hz 50

Rated voltage V 220-240

Rated current I

(Min - Max.)

Rated input I

(Min - Max.)

Power factor I Cool % 94

Compressor Type Hermetically sealed rotary type

Refrigerant system Evaporator Louver Fin and Grooved tube type

Noise level

(at cooling)

Fan system

Drive Direct drive

Air flow quantity

(at cooling)

Fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 1/2", 1/4"

Drain piping mm O.D φ16

Others

Safety device Compressor: Thermal protector

Air filters Polypropylene net (Washable)

Net dimensions Width mm 860 730

Net weight kg 9 32

Cool A 5.0 (1.3 - 6.0 )

Heat A 5.0(1.2 - 7.1 )

Cool W 1080 (240- 1250)

Heat W 1075 (220 - 1470)

Heat % 93

Model 43A23YBM&FJKE

Oil charge 370cc (Zegles RB68EP)

Condenser Corrugate Fin and Grooved tube type

Control Capillary tube

Refrigerant (R410A) 970g

De-lce system Micro computer controled reversed systems

High dB(A) 40 48

Low dB(A) 33 –

Soft dB(A) 23 –

High m3/min. 11.2 33.4

Low m3/min. 8.7 –

Soft m3/min. 5.5 –

Fan motors: Thermal fuse

Fuse, Micro computer control

Height mm 292 540

Depth mm 205 250

AYXP9LSR

NOTE: The conditions of star ”I” marked item are “ISO5151:1994(E)”, condition T1’.

1 – 2

AYXP9LSR

250

165

167.5

136

81

730

72

540

299

324

515

12

37.5

4.5

58

135

14

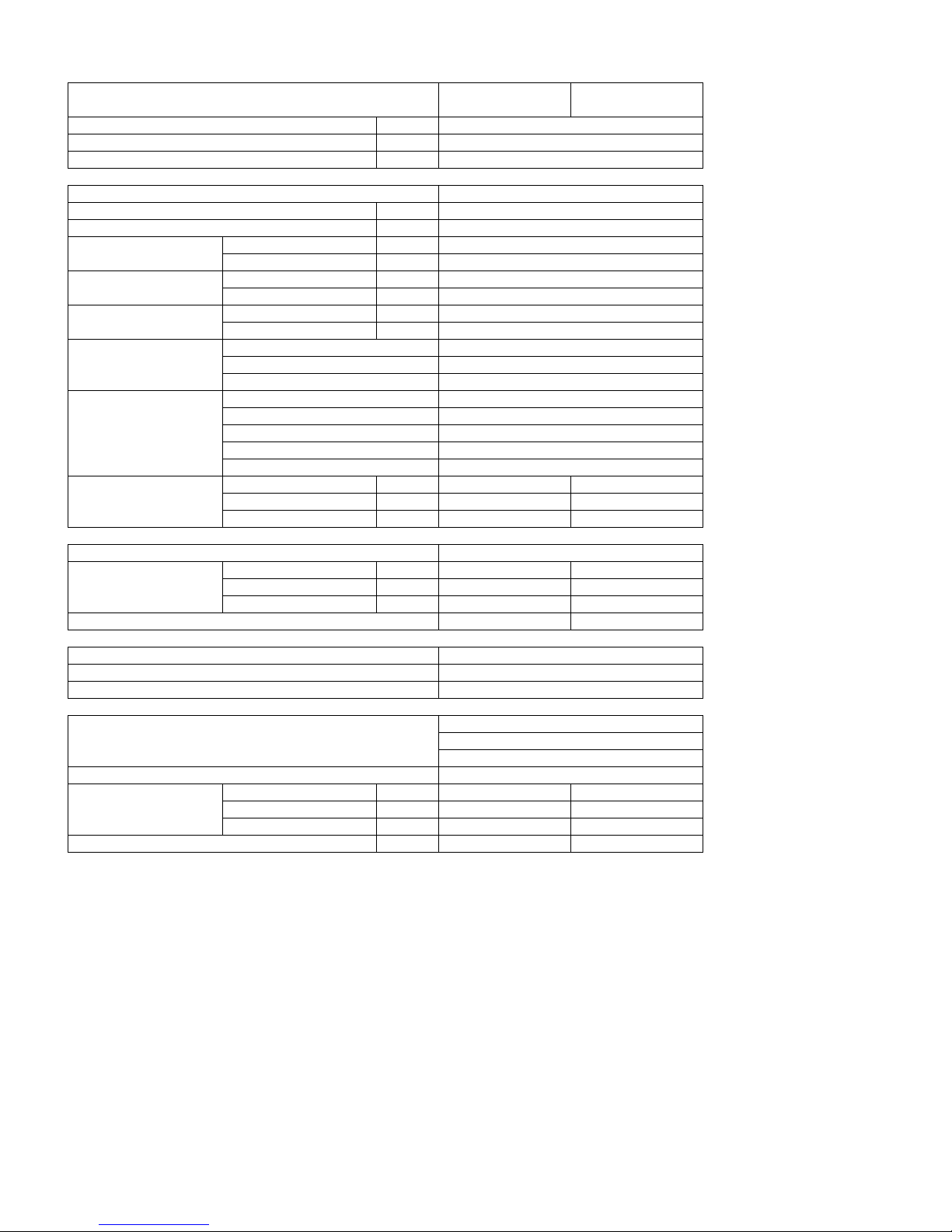

[2] EXTERNAL DIMENSION

1. Indoor unit

Length unit [mm]

Remote controller

17.5

140

57

205

292

2. Outdoor unit

Length unit [mm]

1 – 3

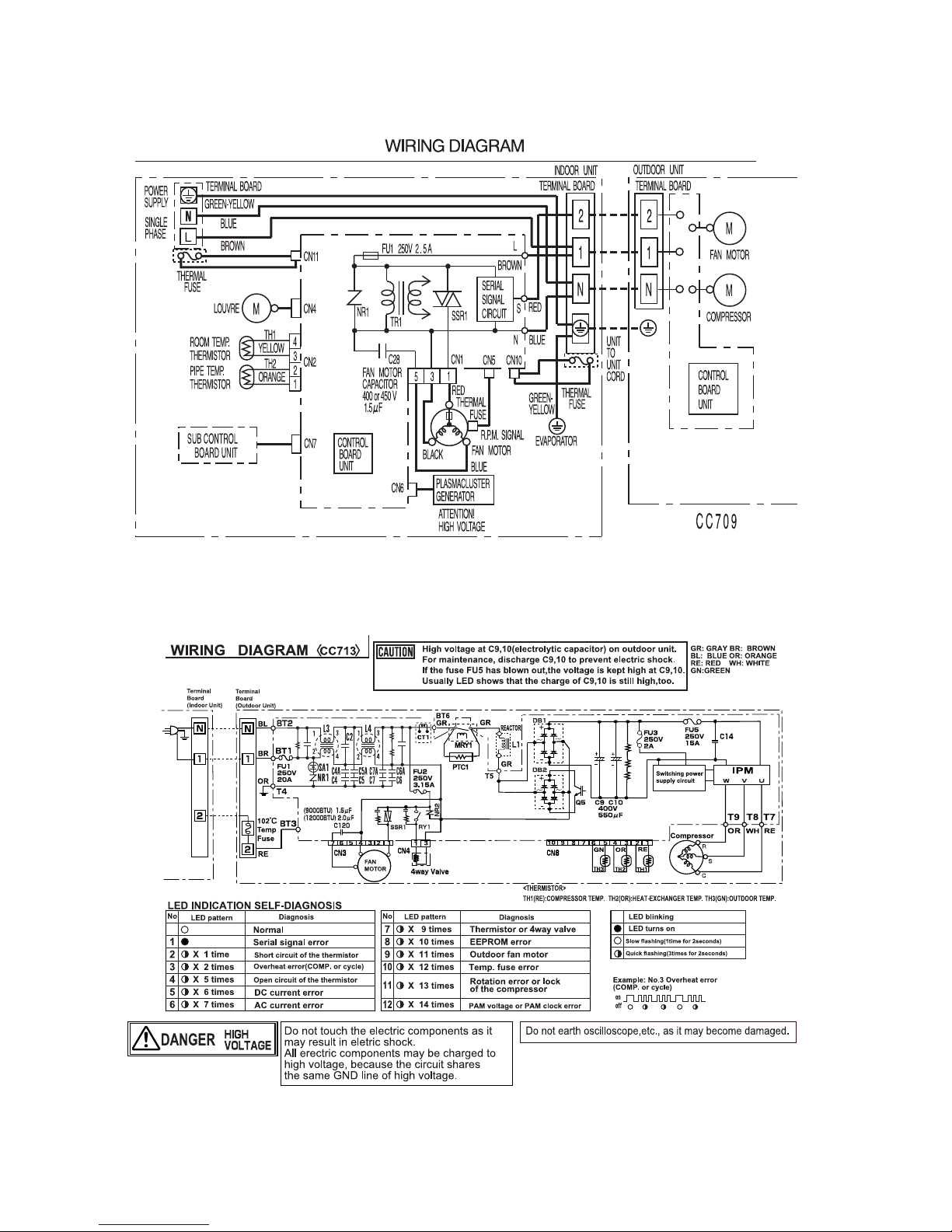

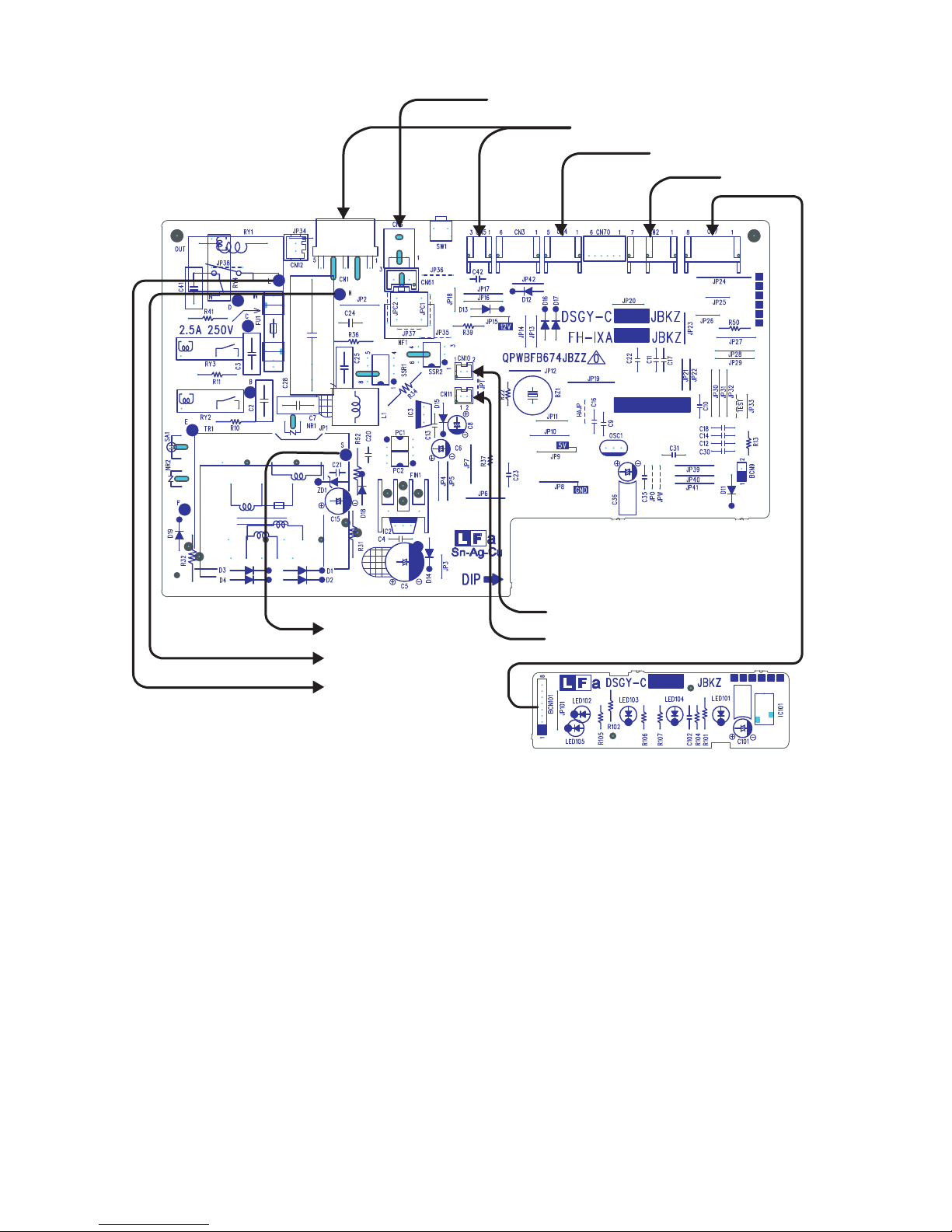

[3] WIRING DIAGRM

1. Indoor unit

AYXP9LSR

2. Outdoor unit

1 – 4

AYXP9LSR

[4] ELECTRICAL PARTS

1. Indoor unit

DESCRIPTION MODEL REMARKS

Indoor fan motor MLA521 AC Motor

Indoor fan motor capacitor DS401155BLSA RC-HZA512JBZZ (400V-1.5μF)

Transformer VRK4119–290mA RTRNPA030JBZZ

Fu1 – QFS-IA 001KK ZZ (250V, 2.5A)

2. Outdoor Unit

DESCRIPTION MODEL REMARKS

Compressor 43A23YBM&FJKE D.C. brush-less motor

Outdoor fan motor MLB452 AC Motor(AE-X12LSR)

Outdoor fan motor MLB453 AC Motor(AE-X9LSR)

Outdoor fan motor capacitor DS441155XLTD 440V, 1.5μF (AE-X9LSR) on PWB

DS441205XLTC 440V, 2.0μF (AE-X12LSR) on PWB

Fu3 – QFS-GA063JBZZ (250V, 2A)

Fu2 – QFS-GA062JBZZ (250V, 3.15A)

Fu1 – QFS-GA065JBZZ (250V, 20A)

Fu5 – QFS-GA066JBZZ (250V, 15A)

1 – 5

AC power

12V DC regulation

CPU

2.5A

Fuse

5VDC regulation

Fan motor phase control circuit

Rotation pulse input circuit

AC clock circuit

Remote controller signal reception circuit

Buzzer drive circuit

CPU reset circuit

CPU oscillator circuit

Room temp. detect circuit

Heat exchanger pipe thermo circuit

EEPROM

Select circuit

Serial I/O circuit

Auto restart circuit

Test run circuit

Auxiliary mode

Power on circuit

Cluster generator drive circuit

Indoor fan motor

Fan motor pulse detect

Wireless remote control operation

Audible operation confirmation

Room temp. thermistor

Heat exchanger pipe thermistor

Louvre angle, fan speed

Wireless, preheat, Model select

Indoor/outdoor control signal I/O

Test run (forced operation)

Auxiliary mode button ON/OFF

Self diagnostics, fault diagnosis

Cluster generator

Unit-unit wiring

(AC power and

serial signals)

AYXP9LSR

CHAPTER 2. EXPLAMATION OF CIRCUIT AND OPERATION

Service Manual

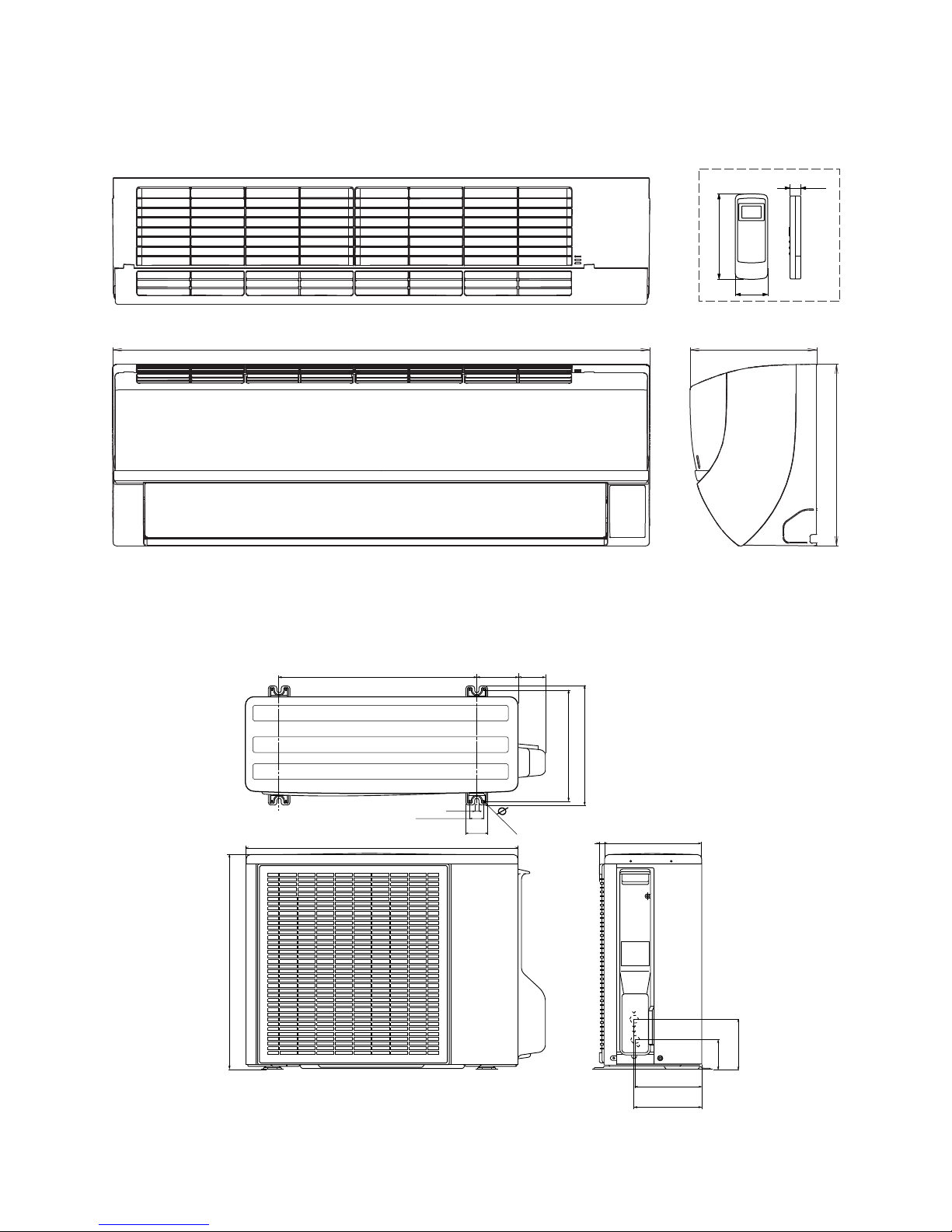

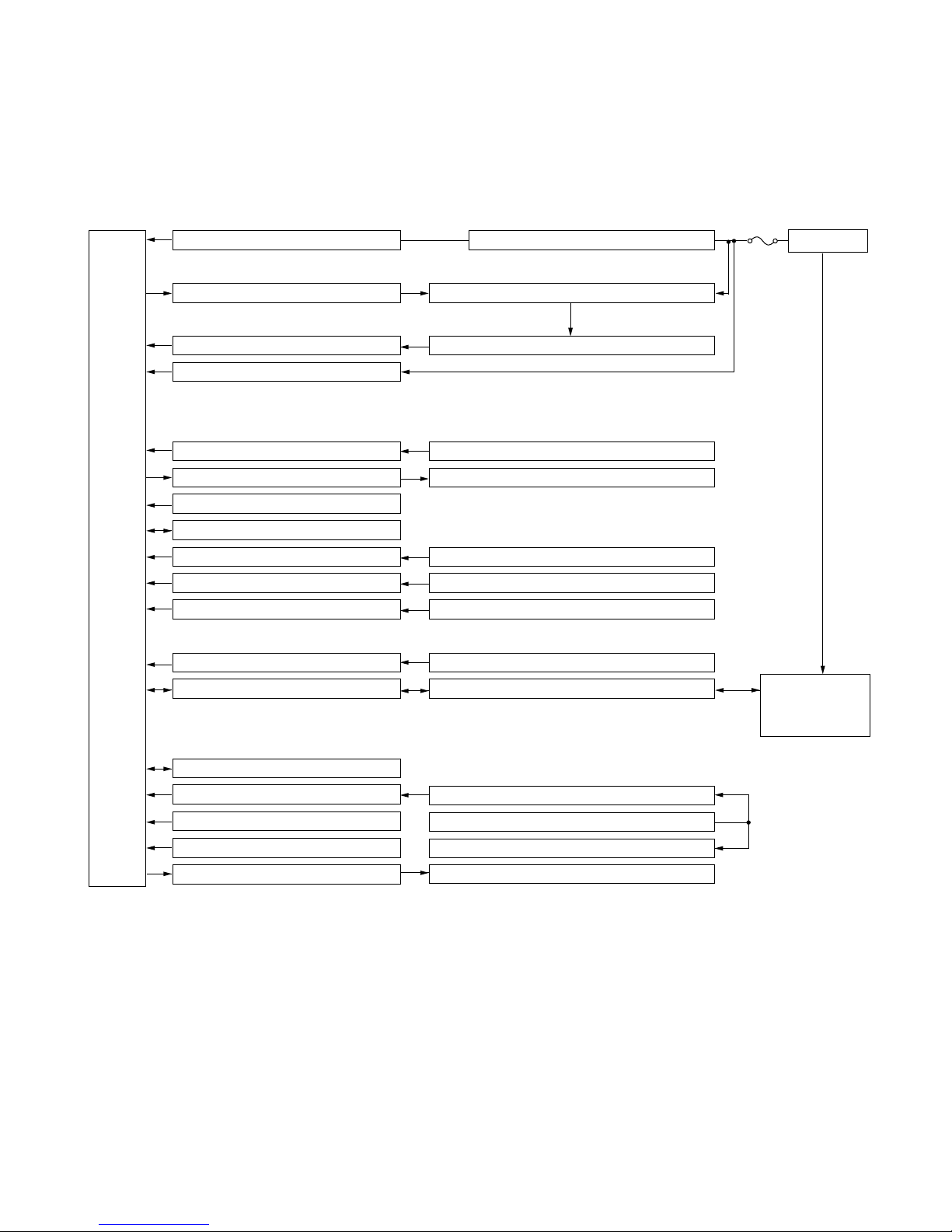

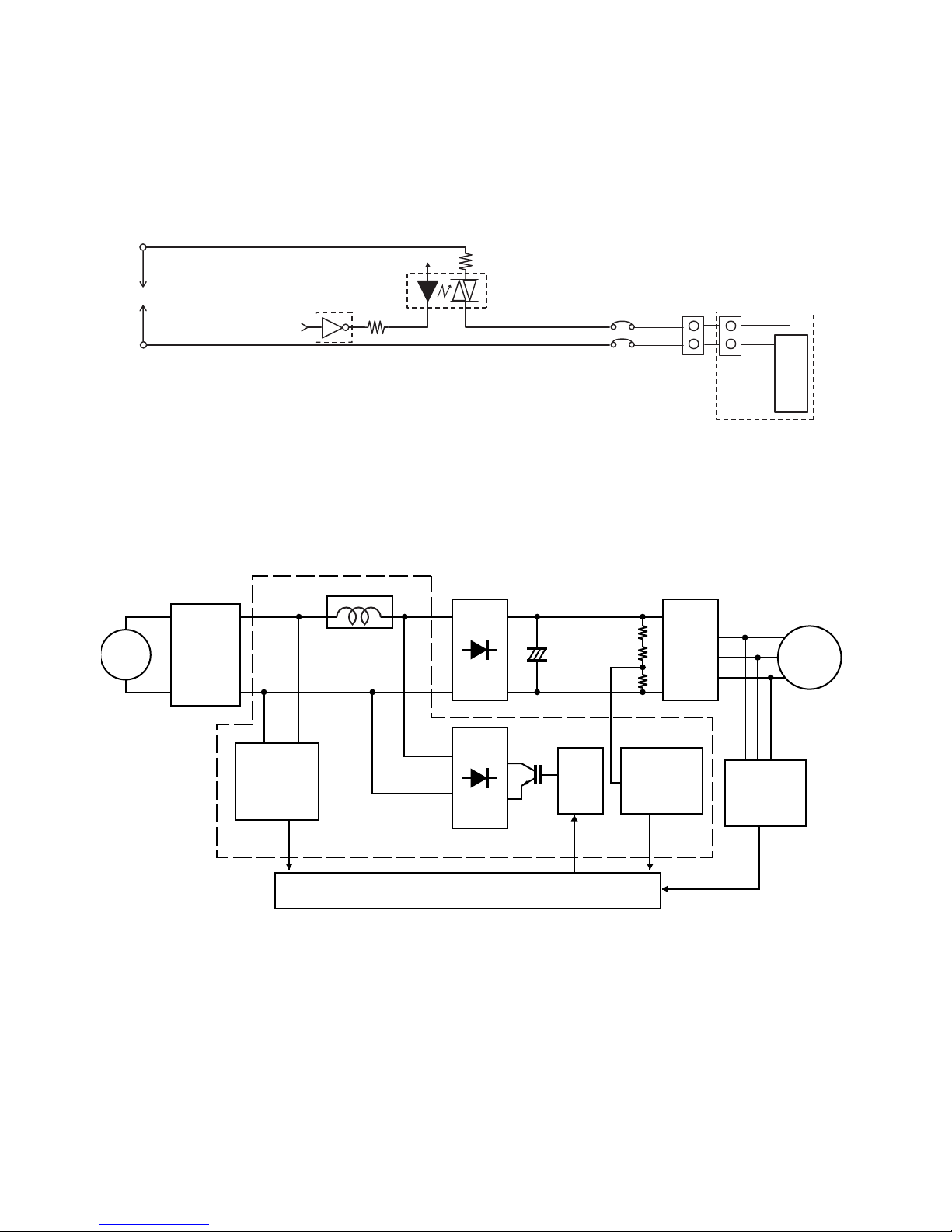

[1] BLOCK DIAGRAMS

1. Indoor unit

AYXP9LSR

2 – 1

AYXP9LSR

CPU

20A

protection

Fuse detector cirunit Terminal board temp.fuse

IPM heat sink temp.fuse

15A

protection

Power supply circuit

CPU oscillator circuit

DC overvoltage detection circuit

Outdoor fan drive circuit

4-way valve relay drive circuit

Power transistor module drive circuit

Serial I/O circuit

CPU reset circuit

AC overcurrent detection circuit

Compressor thermo circuit

Heat exchanger pipe thermo circuit

Outdoor temp. thermo. circuit

EEPROM

LED drive circuit

Test mode circuit

Filter

circuit

Smoothing

circuit

Pulse amplitube modulation circuit

AC clock circuit

DC overcurrent detection circuit

IGBT

Unit-unit wiring (AC power

and serial signals)

Rectification

circuit

FAN Control

3.15A

protection

Outdoor fan

4-way valve

Power transistor module

Compressor

Current transformer

Compressor thermistor

Heat exchanger pipe thermistor

Outdoor temperature thermistor

LED

2. Outdoor unit

2 – 2

㧷㧵㧰㧢㧡㧜㧜㧠㧭㧲

㧤

㧵㧯㧠

㧝㧞㨂

㧥

㧭㧼㧼㧸㧵㧯㧭㨀㧵㧻㧺˴㧹㧻㧰㧱㧸˴㧦

㧭㨅㧙㨄㧼㧝㧞㧸㧿㧾

㧭㨅㧙㨄㧼㧥㧸㧿㧾

㨅㧱㧸㧸㧻㨃

㧳㧾㧱㧱㧺㧛

㧮㧾㧻㨃㧺

㨀㧱㧾㧹㧵㧺㧭㧸

㧿㨁㧼㧼㧸㨅

㧼㧻㨃㧱㧾

㧼㧴㧭㧿㧱

㧿㧵㧺㧳㧸㧱

㧮㧻㧭㧾㧰˴㧞

㨀㧱㧾㧹㧵㧺㧭㧸

㧺㧯

㧸

㧶㧼㧟㧤

㧹㧻㨀㧻㧾

㧲㧭㧺

㧮㧸㨁㧱

㧱㧭㧾㨀㧴

㨀㧱㧾㧹㧵㧺㧭㧸

㧮㧻㧭㧾㧰˴㧝

㧞㨃

㧝㧝㧷㨤㧞

㧰㧝㧥

㧰㧝㧺㧢㧜

㧮㧯㧺㧝㧜㧝

㧷㧾㧯㧝㧜㧢

㧯㧞㧤

㧽㧝㧝

㧷㧾㧯㧝㧜㧢

㧾㧞㧟

㧠㧚㧣㧷

㧼㧴

㧾㨄㧰

㨂㧰㧰

㧳㧺㧰

㧯㧺㧣㧜

㧢㧝㧠

㧟

㨀㨄㧰

㧾㧱㧿㧱㨀

㧲㧸㧹㧰㧜

㧞㧡

㧝㧷

㧝㧷

㧾㧞㧜

㧝㧜㧜㧷

㧡㨂

㧡㨂

㧾㧤

㧝㧜㧚㧜㧷㧲

㧝Ǵ

㧞㧚㧡㧭

㧡㧜㨂

㧜㧚㧝Ǵ

㧯㧠㧞

㧽㧞

㧷㧾㧯㧝㧜㧢

㧜㧚㧝Ǵ

㧡㧜㨂

㧯㧝㧟

㧗

㧝㧜㧜Ǵ 㧝㧜㨂

㧯㧤

㧰㧝㧠 㧰㧝㧡

㧗

㧝Ǵ

㧡㧜㨂

㧯㧟㧢

㧶㧼㧻

㧭㨁㨀㧻

㧾㧱㧿㨀㧭㧾㨀

㧶㧼㨃

㨃㧵㧾㧱㧸㧱㧿㧿

㧺㧯

㧺㧯

㧺㧯

㧾㧠㧞

㧾㧠㧟

㧲

㧰

㧵㧯㧠

㧡㧜㨂

㧡㧜㨂

㧔㧴㧻㧾㧵㨆㧻㧺㨀㧭㧸㧕

㧟

㧝

㧼㧯˴㨁㧺㧵㨀˴㧝

㧮㨆㧝

㧝㧞㨂

㧯㧺㧡

㧯㧺㧢

㧺

㧰㧻㧻㧾

㧻㨁㨀㧙

㧺

㧝

㧞

㧝㧛㧞㨃

㧠㧣㧜

㧾㧟㧣

㧝㧞㨂

㧿㧿㧾㧝

㧞㧣㧡㨂

㧜㧚㧜㧟㧟Ǵ

㧯㧞㧡

㧝㧞㧜

㧝㨃

㧾㧟㧢

㧷㧾㧯㧝㧜㧢

㧯㧺㧝

㧡㧝㧟

㧵㧯

㧴㧭㧸㧸

㧽㧝

㧝㧞㨂

㧝㧛㧠㨃㧝㧚㧤㧷

㧾㧞㧞

㧽㧝㧠

㧷㧾㧯㧝㧜㧢

㧝㧛㧠㨃

㧞㧚㧣㧷

㧾㧝㧟

㧯㧝㧜

㧜㧚㧜㧝Ǵ

㧾㧝㧠

㧠㧚㧣㧷

㨀㧱㧿㨀

㧿

㧟㧚㧟㧷

㧾㧡㧞

㧡㨂

㧾㧝㧞

㧡㧢㧷

㧼㧯㧝

㧼㧯㧞˴㧼㧯㧤㧡㧟㧴

㧾㧟㧝

㧴㨆㧞㧠㧙㧞

㨆㧰㧝

㧗

㧯㧝㧡

㧟㧡㨂

㧝㧜㧜Ǵ

㧜㧚㧜㧠㧣Ǵ

㧡㧜㨂

㧯㧞㧝

㧾㧝㧢

㧝㧜㧜㧷

㧜㧚㧜㧝Ǵ

㧞㧡㧜㨂

㧾㧝㧡

㧠㧚㧣㧷

㧯㧞㧜

㧼㧯㧤㧝㧣㨄

㧰㧝㧺㧢㧜

㧰㧝㧤

㧠

㧝

㧝

㧠

㧞

㧟

㧟

㧞

㧾㧟㧞

㧞㨃

㧰㧞

㧰㧝

㧰㧟

㧰㧠

㧰㧝㨪㧰㧠

㧝㧿㧾㧝㧟㧥㧙㧢㧜㧜㨀

㧽㧣

㧽㧢

㧝㧞㨂

㧔㧯㧸㨁㧿㨀㧱㧾㧕

㧸㧱㧰㧝㧜㧡

㧾㧝㧜㧞

㧠㧚㧣㧷

㧾㧡

㧝㧷

㧾㧠㧥

㧾㧡㧝

㧝㧷

㧔㧻㧼㧱㧾㧭㨀㧵㧻㧺㧕

㧸㧱㧰㧝㧜㧟

㧾㧝㧜㧡 㧝㧛㧠㨃

㧸㧱㧰㧝㧜㧞

㧝㧛㧠㨃㧾㧝㧜㧢

㧔㨀㧵㧹㧱㧾㧕

㧸㧱㧰㧝㧜㧠

㧵㧯㧝㧜㧝

㧤

㧗

㧯㧝㧜㧝

㧝㧜㨂

㧠㧣Ǵ

㧠㧣 㧝㧛㧞㨃

㧝㧛㧠㨃㧾㧝㧜㧣

㧝

㧾㧝㧜㧝

㧢㧣㧡㧠㧟

㧞

㧿㨃㧝˴㧦˴㧭㨁㨄㧚㧔㨀㧱㧿㨀˴㧾㨁㧺㧕

㧡㧜㨂

㧜㧚㧝Ǵ

㧯㧝㧜㧞

㧢㧣㧡㧠㧟㧞㧝

㧤

㧝㧜㧷

㧾㧞㧢

㧝㧷

㧾㧡㧜

㧜㧚㧝Ǵ

㧯㧝㧢

㧡㧜㨂

㧝㧜㧷

㧾㧠㧠 㧾㧠㧡 㧝㧷

㧹㧻㨀㧻㧾

㧸㧻㨁㨂㧱㧾

㧯㧺㧠

㧝㧞㧟㧠㧡

㧝㧜㧷

㧜㧚㧜㧝Ǵ

㧯㧞㧟

㧾㧞㧣

㧟㧟㧷

㧾㧞㧤

㧟㧟㧷㧞㧜㧷

㧡㨂

㧽㧝㧣

㧝㧟㧞

㧡㨂

㧺㧯

㧟㧟

㧟㧠

㧟㧡

㧟㧢

㧟㧣

㧟㧤

㧟㧥

㧠㧜

㧠㧝

㧠㧞

㧠㧟

㧠㧠

㧠㧡

㧠㧢

㧠㧣

㧠㧤

㧢㧠㧢㧟㧢㧞㧢㧝㧢㧜㧡㧥㧡㧤㧡㧣㧡㧢㧡㧡㧡㧠㧡㧟㧡㧞

㧝㧢

㧝㧡

㧝㧠

㧝㧟

㧝㧞

㧝㧝

㧝㧜

㧥

㧤

㧣

㧢

㧡

㧠

㧟

㧞

㧝 㧼㧝㧞㧜

㧼㧠㧟

㧼㧠㧞

㧼㧠㧝

㧼㧠㧜

㧾㧱㧿㧱㨀

㧼㧝㧞㧠

㧼㧝㧞㧟

㧲㧸㧹㧰㧜

㨄㧞

㨄㧝

㧾㧱㧳㧯

㨂㧿㧿

㧱㨂㧿㧿

㨂㧰㧰

㧱㨂㧰㧰

㧭㧺㧝㧣

㧭㧺㧝㧢

㧭㧺㧝㧡

㧭㧺㧝㧠

㧭㧺㧝㧟

㧼㧞㧞

㧼㧞㧝

㧼㧞㧜

㧼㧝㧟㧜

㧼㧜㧠

㧼㧜㧟

㧼㧜㧞

㧼㧜㧜

㧵㧺㨀㧼㧢

㧭㨂㧿㧿

㧭㨂㧾㧱㧲

㨀㨤㧰㧜

㧾㨤㧰㧜

㧼㧟㧝

㧼㧡㧜

㧼㧡㧝

㧼㧡㧞

㧼㧡㧟

㧼㧟㧜

㧼㧝㧣

㧼㧝㧢

㧼㧝㧡

㧼㧝㧠

㧼㧝㧟

㧼㧝㧞

㨀㧵㧜㧜㧝

㧿㧯㧸㧜

㧼㧢㧞

㧿㧰㧭㧜

㧼㧢㧟

㧼㧟㧟

㧼㧣㧣

㧼㧣㧢

㧼㧣㧡

㧼㧣㧠

㧼㧣㧟

㧼㧣㧞

㧼㧣㧝

㧼㧣㧜

㧼㧜㧢

㧝㧣㧝㧤㧝㧥㧞㧜㧞㧝㧞㧞㧞㧟㧞㧠㧞㧡㧞㧢㧞㧣㧞㧤㧞㧥㧟㧜㧟㧝

㧟㧞㧠㧥

㧡㧜

㧡㧝

㧵㧺㨀㧼㧟

㧝㧜㧚㧜㧷㧲

㧾㧢

㧽㧟

㨀㧴㧝

㧾㧻㧻㧹˴㨀㧱㧹㧼㧚

㧝㧜㧷ǡ㧔㧞㧡㧕

㧠㧟㧞

㧝

㨀㧾㧝

㧝㧜㧜㧜Ǵ㧟㧡㨂

㧯㧡

㧗

㧻㧿㧯㧝

㧡㨂

㧝㧞㨂

㧺㧯㧺㧯㧺㧯

㧯㧞㧞

㧝㧜㧜㧜㨜

㧡㧜㨂

㧡㧜㨂

㧜㧚㧝Ǵ

㧯㧠

㧝㧞㧭㧼㧵

㧷㧵㧭㧣㧤

㧾㧞㧠

㧽㧤

㧷㧾㧯㧝㧜㧢

㧝㧜㧜㧜㨜

㧯㧝㧣

㧡㧜㨂

㧯㧝㧝

㧜㧚㧜㧝Ǵ

㧡㧜㨂

㧯㧟㧝

㧜㧚㧝Ǵ

㧠㧚㧣㧷

㧾㧞㧡

㧡㨂

㧺㧯

㧺㧯

㧺㧯

㧡㨂

㧳㧺㧰

㧯㧟㧡

㧡㧜㨂

㧜㧚㧝Ǵ

㧯㧟㧡

㧾㧝㧣

㧝㧜㧜㧷

㧺㧯

㧺㧯

㧵㧯㧞

㧵㧯㧟

㧷㧵㧭㧣㧤

㧜㧡㧭㧼㧵

㧯㧺㧝㧜

㧝㧞㨂

㧞㧡㨂㧠㧣Ǵ

㧯㧢

㧗

㧡㨂

㧽㧡

㧷㧾㧯㧝㧜㧢

㧷㧾㧯㧝㧜㧢

㧷㧾㧯㧝㧜㧢

㧷㧾㧭㧝㧜㧢

㧡㧜㨂

㧯㧥

㧴㧭㧶㧼

㧿㧭㧺

㧺㧯

㧼㧝㧠㧝

㧮㨁㨆

㧵㧯㧝

Ǵ㧼㧰㧣㧤㧲㧜㧡㧟㧠

㧞㧡㧜㨂

㧲㨁㧝

㧝㧢㧹㧴㨦

㧯㧣

㧞㧣㧡㨂

㧜㧚㧝Ǵ

㧺㧾㧝

㧝㧛㧠㨃

㧞㧝

㧯㧺㧣

㧯㧺㧞

㧾㧟㧜

㧠㧜㧜㨂

㧝㧚㧡Ǵ

㧺㧯

㧺㧯

㧺㧯㧺㧯㧺㧯

㧺㧯

㧝㧷

㧣㧡㧜

㧞㧞㧜

㧣㧡㧜

㧲㨁㧿㧱

㧝㧜㧞

㨀㧱㧾㧹㧵㧺㧭㧸

㧾㧱㧰

㧡㧜㨂

㧝㧜㧷

㧾㧞㧝

㧡㧜㨂

㧯㧝㧠

㧝㧜㧜㧜㨜

㧝㧜㧷

㧾㧝㧤

㧶㧼㧯㧞

㧝㧞㨂

㧾㧟㧥

㧝㧛㧠㨃

㧯㧝㧞

㧝㧜㧜㧜㨜

㧡㧜㨂

㧝㧜㧚㧜㧷㧲

㧾㧡

㧾㧡㧝

㧝㧷

㧝㧡㧷ǡ㧔㧞㧡㧕

㧼㧵㧼㧱˴㨀㧱㧹㧼㧚

㨀㧴㧞

㧯㧺㧝㧝

㧝㧞

㧲㨁㧿㧱

㧝㧜㧞

㧸

㧺

㨅㧱㧸㧸㧻㨃

㧳㧾㧱㧱㧺㧛

㧸㧝

㧜㧚㧜㧝Ǵ

㧞㧣㧡㨂

㧯㧞㧠

㧺㧯

㧶㧼㧞

㧝㧞㨂

㧝㧛㧞㨃

㧠㧣㧜

㧿㧿㧾㧞

㧝㧞㧜㧷㧝㨃

㧾㧟㧠

㧶㧼㧯㧝

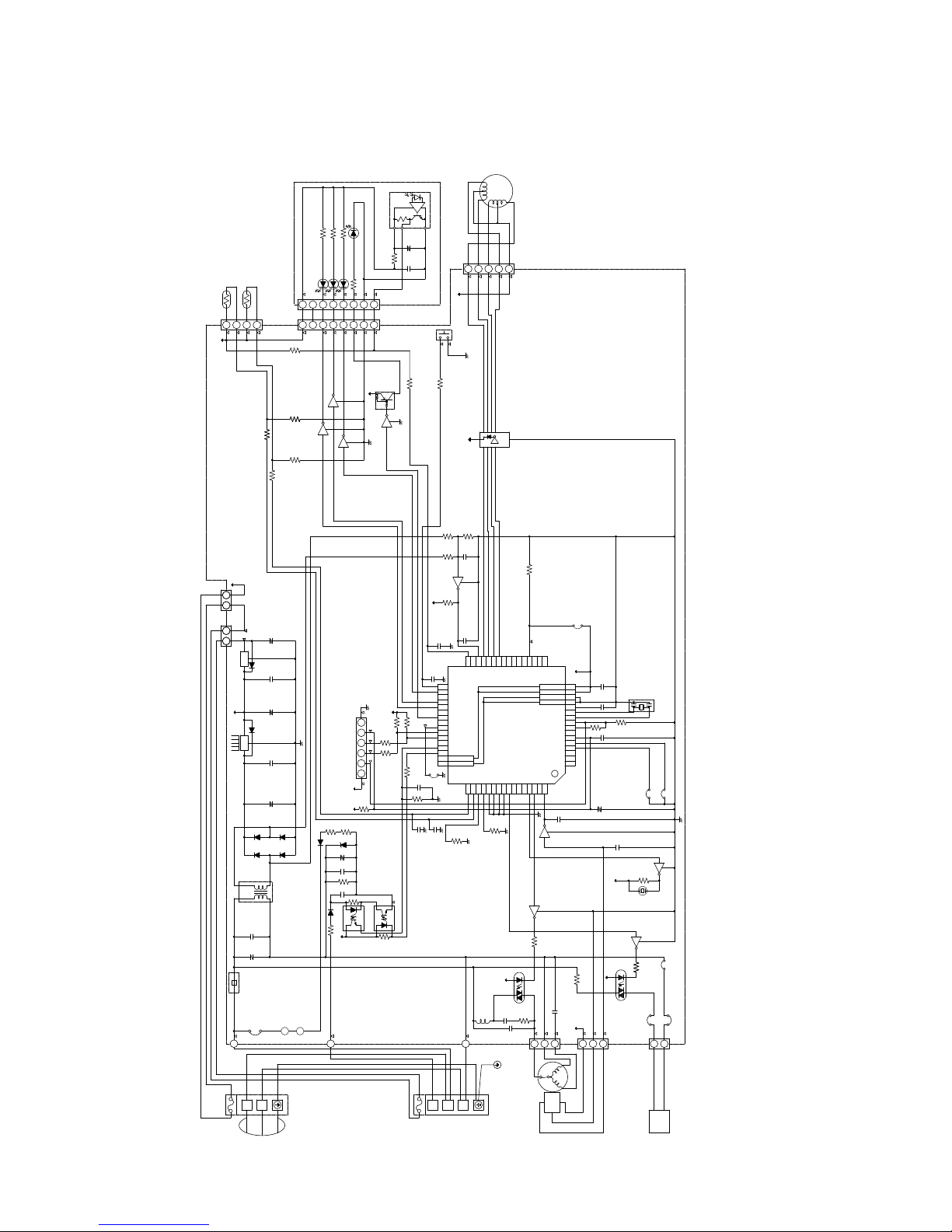

[2] MICROCOMPUTER CONTROL SYSTEM

1. Indoor unit

1.1. Electronic control circuit diagram

AYXP9LSR

2 – 3

AYXP9LSR

1.2. Printed wiring board

Plasumacluster Generator

Fan Motor

Louver Motor

Thermistor

Terminal board "2"

Terminal board "N"

Terminal board "1"

Terminal board 4P

Terminal board 3P

2 – 4

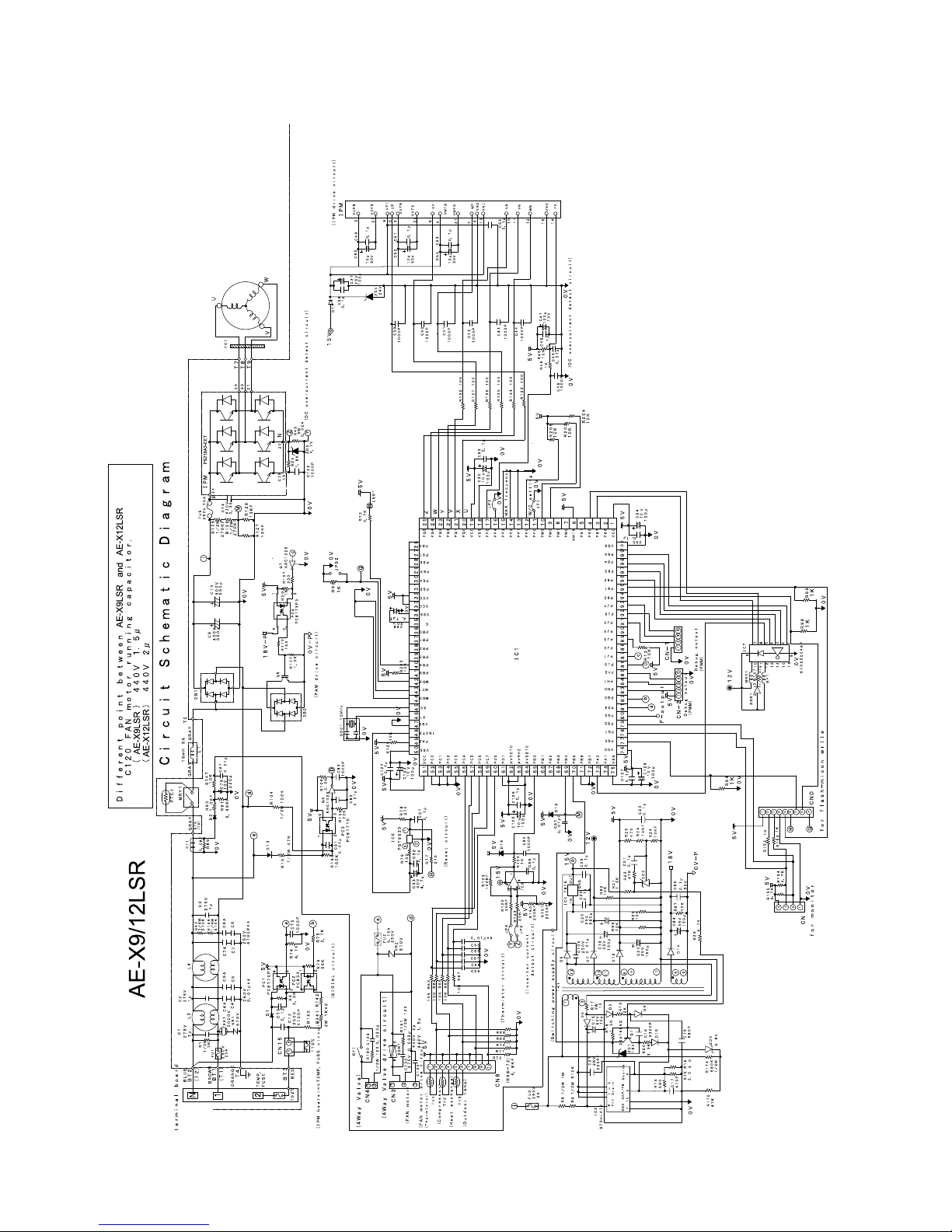

2. Outdoor unit

2.1. Electronic control circuit diagram

AYXP9LSR

2 – 5

AYXP9LSR

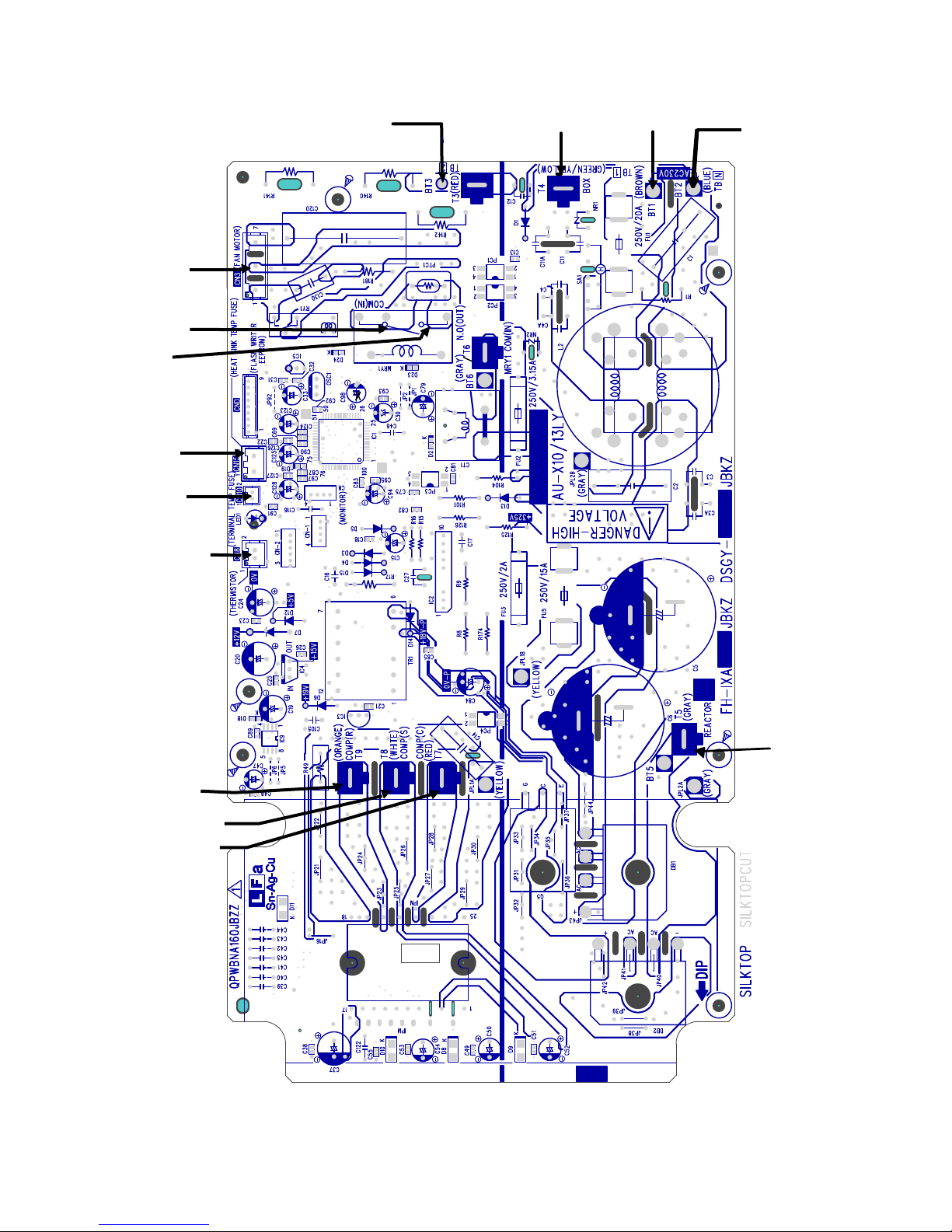

2.2. Printed wiring board

From Fan

Motor

To PWB

BT6(Gray)

To Reactor

(Gray)

From heatsink

TEMP fuse

From Terminal Board

(Themal fuse)

From Thermistor

To Terminal Board

(3)(Red)

To Control Box

(Green/Yellow)

To Terminal Board

(1)(Brown)

To Terminal Board

(N)(Blue)

From Compressor(R)

(Orange)

From Compressor(S)

(White)

From Compressor(C)

(Red)

To Reactor

(Gray)

2 – 6

[3] FUNCTION

Compressor operation

ON operation on

remote control

OFF operation on

remote control

Compressor ON

Compressor ON Compressor can

turn ON

Compressor remains OFF

for 180 seconds

Indoor unit heat exchanger temperature

38

23

35

21

Set fan speed

Indoor unit fan at low speed

Indoor unit fan in non-operation

20 min or more 20 min or more 20 min or more

Defrosting

Max. 10 min

Defrosting

Max. 10 min

Start of

heating

operation

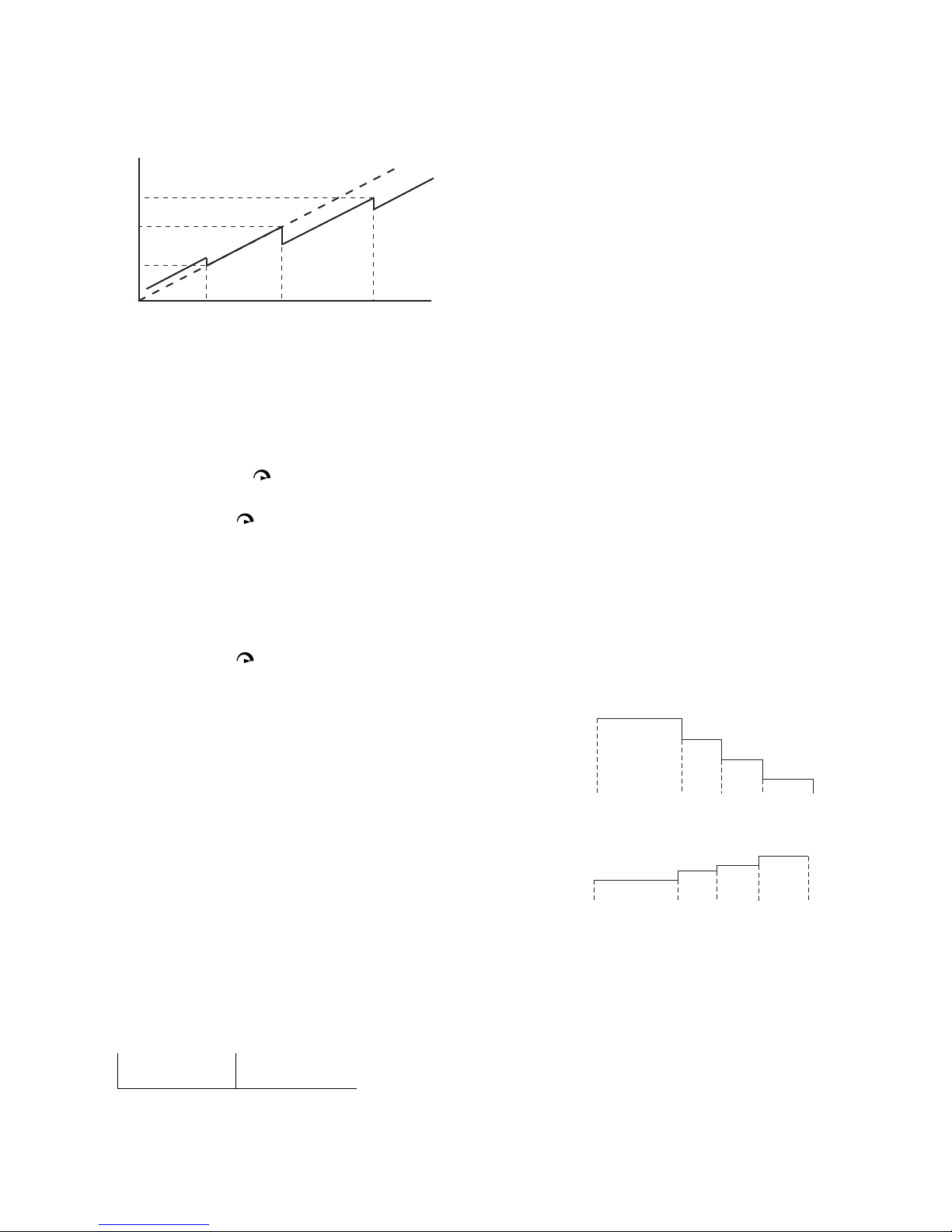

1. Function

AYXP9LSR

1.1. Restart control

Once the compressor stops operating, it will not restart for 180 seconds to protect the compressor.

Therefore, if the operating compressor is shut down from the remote

control and then turned back on immediately after, the compressor will

restart after a preset delay time.

(The indoor unit will restart operation immediately after the ON switch

is operated on the remote control.)

1.2. Cold air prevention control

When the air conditioner starts up in heating mode, the indoor unit fan

will not operate until the temperature of the indoor unit heat exchanger

reaches about 23°C in order to prevent cold air from blowing into the

room.

Also, the indoor unit fan operates at low speed until the temperature of

the indoor unit heat exchanger reaches about 38°C so that people in

the room will not feel chilly air flow.

1.5. Indoor unit overheat prevention control

During heating operation, if the temperature of the indoor unit heat

exchanger exceeds the indoor unit heat exchanger overheat prevention temperature (about 45 to 54°C) which is determined by the operating frequency and operating status, the operating frequency is

decreased by about 4 to 15 Hz. Then, this operation is repeated every

60 seconds until the temperature of the indoor unit heat exchanger

drops below the overheat protection temperature.

Once the temperature of the indoor unit heat exchanger drops below

the overheat protection temperature, the operating frequency is

increased by about 4 to 10 Hz every 60 seconds until the normal operation condition resumes.

If the temperature of the indoor unit heat exchanger exceeds the overheat protection temperature for 60 seconds at minimum operating frequency, the compressor stops operating and then restarts after about

180 seconds, and the abovementioned control is repeated.

1.6. Defrosting

1.6.1 Reverse defrosting

The defrost operation starts when the compressor operating time

exceeds 10 minutes during heating operation, as shown below, and

the outside air temperature and the outdoor unit heat exchanger temperature meet certain conditions. When the defrost operation starts,

the indoor unit fan stops. The defrost operation stops when the outdoor unit heat exchanger temperature rises to about 10°C or higher or

the defrosting time exceeds 10 minutes.

1.3. Indoor unit heat exchanger freeze prevention control

If the temperature of the indoor unit heat exchanger remains below

0°C for 4 consecutive minutes during cooling or dehumidifying operation, the compressor operation stops temporarily in order to prevent

freezing.

When the temperature of the indoor unit heat exchanger rises to 2°C

or higher after about 180 seconds, the compressor restarts and

resumes normal operation.

1.4. Outdoor unit 2-way valve freeze prevention control

If the temperature of the outdoor unit 2-way valve remains below 0°C

for 10 consecutive minutes during cooling or dehumidifying operation,

the compressor operation stops temporarily in order to prevent freezing.

When the temperature of the 2-way valve rises to 10°C or higher after

about 180 seconds, the compressor restarts and resumes normal

operation.

1.7. Outdoor unit overheat prevention control

During cooling operation, if the temperature of the outdoor unit heat

exchanger exceeds the outdoor unit heat exchanger overheat prevention temperature (about 55°C), the operating frequency is decreased

by about 4 to 15 Hz. Then, this operation is repeated every 60 seconds until the temperature of the outdoor unit heat exchanger drops to

about 54°C or lower.

Once the temperature of the outdoor unit heat exchanger drops to

about 54°C or lower, the operating frequency is increased by about 4

to 10 Hz every 60 seconds until the normal operation condition

resumes.

If the temperature of the outdoor unit heat exchanger exceeds the outdoor unit heat exchanger over heat protection temperature for (120 sec

: outdoor temperature ≥ 40°C, 60 sec : outdoor temperature < 40°C)

at minimum operating frequency, the compressor stops operating and

then restarts after about 180 seconds, and the abovementioned control is repeated.

2 – 7

AYXP9LSR

Modes and Temperature Settings

the figures in ( ) are temperature settings

1)Press the SWING button on the remote control once.

T uvre will swing continuously.

2)Press the SWING button again when the vertical airflow louvre is at

the desir ed position.

The louvre will stop moving within the range shown in the diagram.

The adjusted position will be memoried and will be automatically set

to the same position when operated the next time.

AIR FLOW DIRECTION

he vertical airflow lo .

the vert

i am.

AIR FLOW DIRECTION

.

the vert

i am.

AIR FLOW DIRECTION

٨

٨

٨

"The remote control will display"

٨

1.8. Compressor overheat prevention control

If the temperature of the compressor exceeds the compressor overheat prevention temperature (110°C), the operation frequency is

decreased by about 4 to 10 Hz. Then, this operation is repeated every

60 seconds until the temperature of the compressor drops below the

overheat protection temperature (100°C).

Once the temperature of the compressor drops below the overheat

protection temperature, the operating frequency is increased by about

4 to 10 Hz every 60 seconds until the normal operation condition

resumes.

If the temperature of the compressor exceeds the overheat protection

temperature (for 120 seconds in cooling operation or 60 seconds in

heating operation) at minimum operating frequency, the compressor

stops operating and then restarts after about 180 seconds, and the

above mentioned control is repeated.

1.9. Startup control

When the air conditioner starts in the cooling or heating mode, if the

room temperature is 2°C higher than the set temperature (in cooling

operation) or 3.5°C lower (in heating operation), the air conditioner

operates with the operating frequency at maximum. Then, when the

set temperature is reached, the air conditioner operates at the oper ating frequency determined by fuzzy logic calculation, then enters the

normal control mode after a while.

1.10. Peak control

If the current flowing in the air conditioner exceeds the peak control

current (see the table below), the operation frequency is decreased

until the current value drops below the peak control current regardless

of the frequency control demand issued from the indoor unit based on

the room temperature.

Peak control current

Cooling operation Heating operation

Approx. 6.1 A Approx. 8.2 A

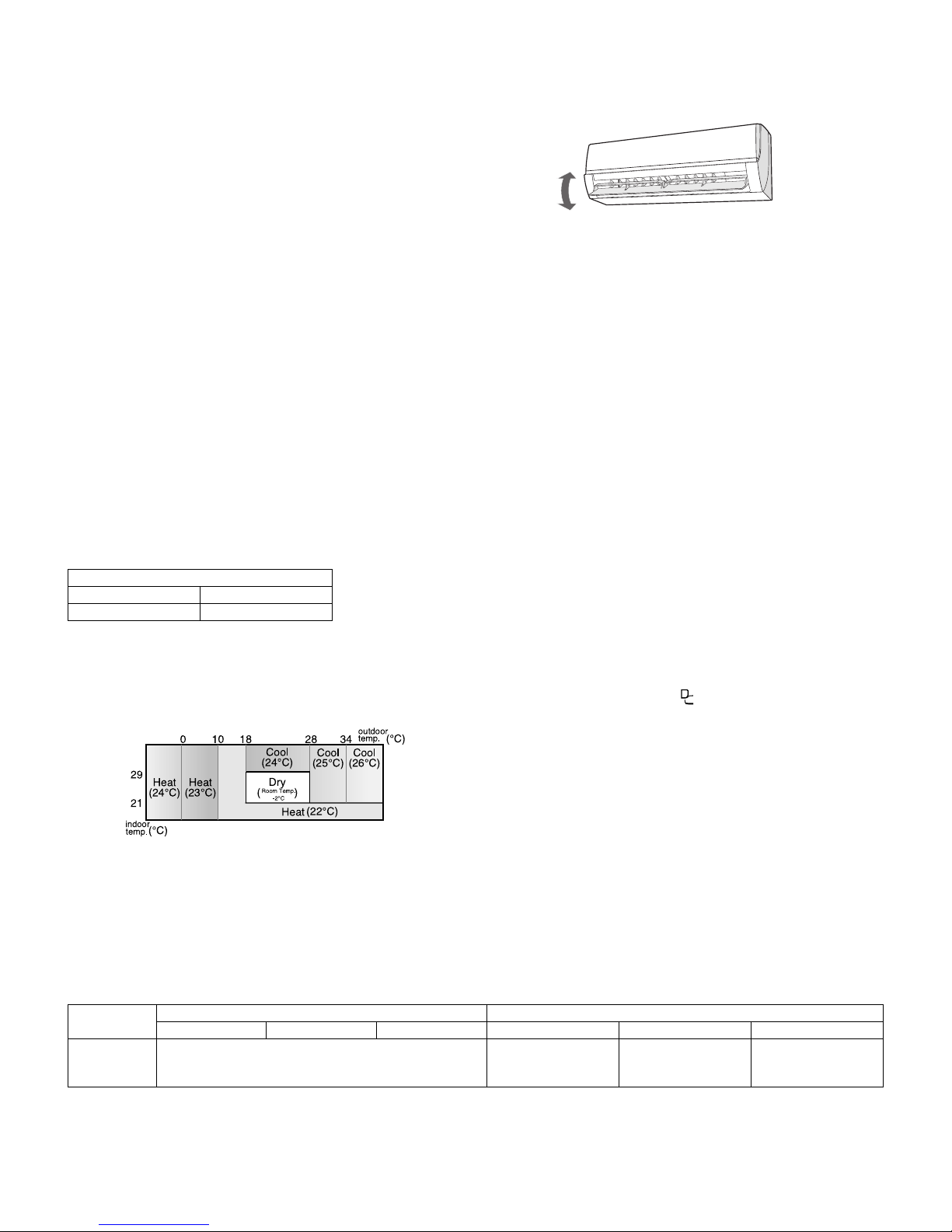

1.11. AUTOMATIC AIR CONDITIONING

In the AUTO mode, the temperature setting and mode are automatically selected according to the room temperature and outdoor temperature when the unit is turned on.

1.12. Airflow control

CAUTION:

Never attempt to adjust the louvres manually.

•Manual adjustment on the louvres can cause the unit to malfunction.

Position in the COOL or DRY mode for an extended period of time,

•When the vertical airflow louvre is positioned at the lowest

condensation may result.

1.12.1 COANDA Airflow

Press the COANDA AIRFLOW button during cooling or dry operat ion

when you do not want to feel cold air.

Vertical airflow louvre is set obliquely upward to deliver cool air to the

ceiling.

Press the button during heating operation. Vertical airflow louvre is set

downward to deliver the warm air down to the floor and warm you.

During operation, press the COANDA AIRFLOW button.

During operation, if the outdoor temperature changes, the temperature

settings will automatically slide as shown in the chart.

1.13. Difference of operation in Auto and Manual modes

In the Auto mode, the temperature setting is automatically determined based on the outside air temperature. In addition, the air conditioner operation

differs from the operation in the Manual mode as explained below.

1.13.1 Difference relating to set temperature

Auto mode Manual mode

Cooling Heating Dehumidifying Cooling Heating Dehumidifying

Temperature

setting

method

Automatic temperature setting based on inside air temperature. Can be changed within ±2°C using remote control.

TO CANCEL

Press the COANDA AIRFLOW button again.

NOTE:

•The COANDA AIRFLOW setting is cancelled

When you press Full power button while COANDA AIRFLOW is set.

•If you want COANDA AIRFLOW operation in Full power mode,

press COANDA AIRFLOW button during Full power operation.

Can be changed

between 18 and 32°C

using remote control.

Can be changed

between 18 and 32°C

using remote control.

Automatic setting.

Can be changed

within ±2°C.

2 – 8

1.14. Dehumidifying operation control

27ºC

+0

+0.5

-1.0

-1.5

25ºC

25ºC

28ºC

22ºC

22ºC

Room Temperature

Preset temperature

-

The remote control will display” “

The temperature display will go off.

The green Full power lamp ( ) on the unit will light up.

٨

٨

٨

The green Full power lamp ( ) on the unit will turn off.

٨

Heating operation Fan operation

24OC

Outside air temperature

Heating operation

Set temperature

Activation of

OFF timer

1hour

later

Max.

1.5 hours

later

Max.

2 hours

later

Timer setting

reached

1hour

later

Max.

1.5 hours

later

Max.

2 hours

later

Timer setting

reached

Activation of

OFF timer

Set temperature

-1

O

C

-1

O

C

-1

O

C

0.3

O

C

0.3

O

C

0.3

O

C

Cooling/dehumidifying operation

In the Dehumidifying mode, the temperature setting is automatically

determined based on the outside air temperature. In addition, the air

conditioner operation differs from the operation in the Manual mode as

explained below.

1.15. Full power Operation

In this operation, the air conditioner works at the maximum power to

make the room cool rapidly.

During operation, press the Full power button.

AYXP9LSR

1.17. Plasmacluster Ion function

The Plasmacluster Ion generator inside the air conditioner will release

positive and negative plasmacluster ions into the room.

ApproXimately the same numbers of positive and negative ions

released into the air will reduce some airborne mold.

If the Plasmacluster Ion generation function is operated together with

the air conditioner operation, the indoor unit fan speed and louver

direction are in accordance with the air conditioner settings.

If the Plasmacluster Ion generation function is used without operating

the air conditioning function, the indoor unit fan operates at a very low

speed and the upper louver is angled upward and the lower louver

remains horizontal. (The airflow volume and direction can be changed

by using the remote control.)

1.18. Power ON start

If a jumper cable is inserted in the location marked with HAJP on the

indoor unit control printed circuit board (control PCB), connecting the

power cord to an AC outlet starts the air conditioner in either cooling or

heating mode, which is determined automatically by the room temperature sensor.

When a circuit breaker is used to control the ON/OFF operation,

please insert a jumper as described above.

1.19. ON timer

The ON timer can be activated by pressing the ON timer button. When

the ON timer is activated, the operation start time is adjusted based on

fuzzy logic calculations 1 hour before the set time so that the room

temperature reaches the set temperature at the set time.

TO CANCEL

Press the Full power button again.

The Full power operation will also be cancelled when the operation

mode is changed, or when the unit is turned off.

NOTE:

•The air conditioner will operation at “Extra HIGH” fan speed for 5

minutes, and then shift to “HIGH” fan speed.

• You can not set the temperature or fan speed during the Full power

operation.

• To turn off the Full power lamp, press the DISPLAY button.

1.16. Self Clean operation

Heating or Fan operation and Cluster operation are performed simultaneously.

The judgment of whether Heating or Fan operation is used is based on

the outside air temperature at 3 minutes after the start of internal

cleaning.

The operation stops after 40 minutes.

• During this operation the horizontal louver moves and stays two posi-

tions.

It turns to the lower direction and stays for 30 minutes.

Next moves upward and stays for 10 minutes.

1.20. OFF timer

The OFF timer can be activated by pressing the OFF timer button.

When the OFF timer is set, the operation stops after the set time.

When this timer is set, the compressor operating frequency lowers for

quieter operation, and the room temperature is gradually varied after

one hour (reduced 1°C three times (max. 3°C) in heating, or increased

0.3°C three times (max. 1°C) in cooling or dehumidifying operation) so

that the room temperature remains suitable for comfortable sleeping.

1.21. Auto restart

When power failure occurs, after power is recovered, the unit will automatically restart in the same setting which were active before the

power failure.

1.21.1 Setting not memorized

• Timer setting

• Full power operation setting

• Self clean operation

2 – 9

AYXP9LSR

1

3

SSR2

R39

Q11

Microcomputer output

1

4

Cluster unit

JPC1

JPC2

AC220-240V

12V

R34

PAM drive circuit block diagram

Reactor L1

[PAM drive circuit]

+

Microcomputer (IC1)

AC

230V

Compressor

Noise

filter

AC clock

detection

circuit

DB1

IPM

DB2

Compressor

position

detector

IGBT

drive

circuit

IGBT

Overvoltage

detection

circuit

1.21.2 Disabling auto restart function

By removing (cutting) jumper O (JP O) on the printed circuit board

(PCB), the auto restart function can be disabled.

2. Explanation of cluster circuit

The cluster unit generates cluster ions, which are circulated throughout the room by the air flow created by the blower fan (indoor unit fan motor) in

the air conditioner unit.

1) When microcomputer output turns "H," the Q11 output changes to "Lo," turning ON the SSR2 and applying 100 V to the cluster unit for the generation of cluster ions (positive and negative ions).

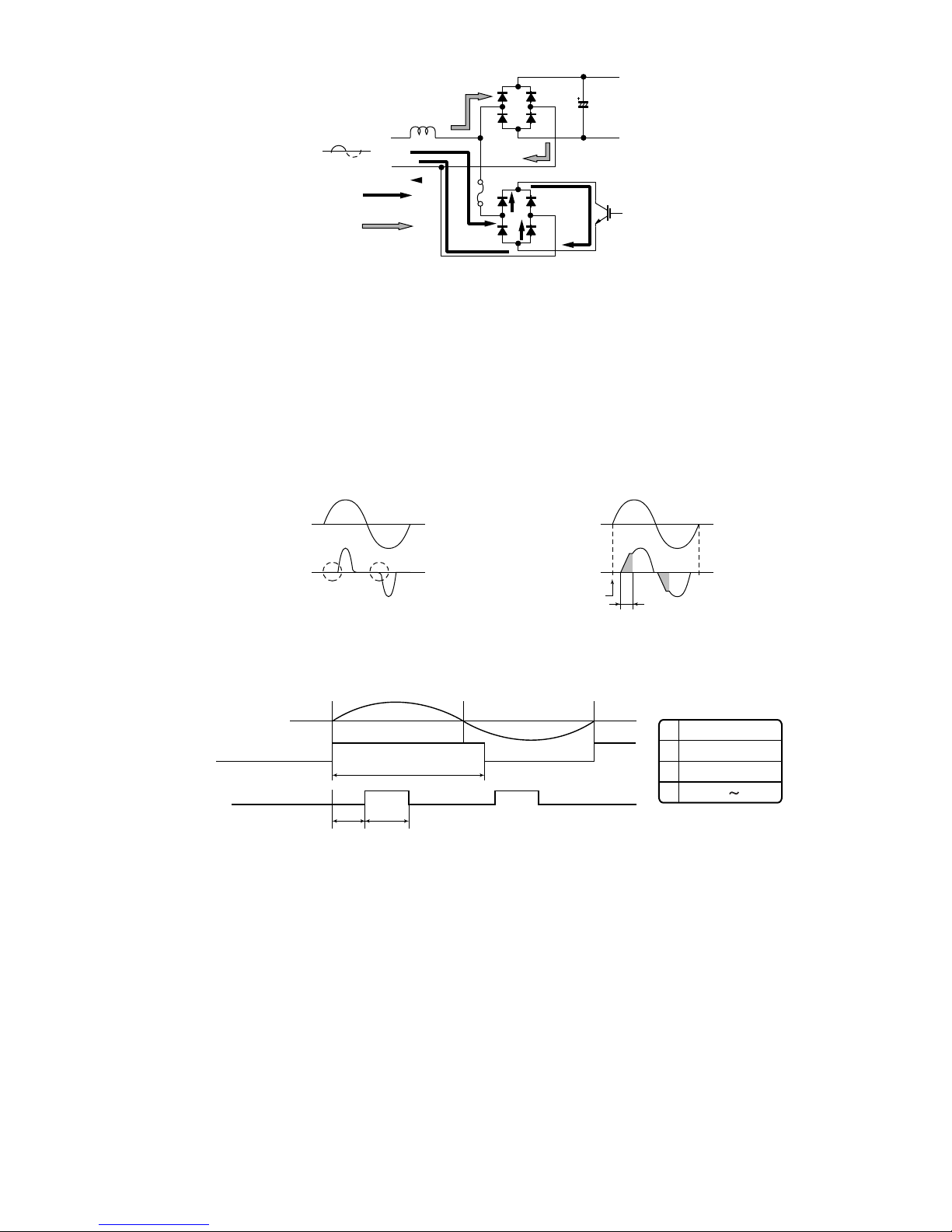

3. Outline of PAM circuit

3.1. PAM (Pulse Amplitude Modulation)

The PAM circuit varies the compressor drive voltage and controls the rotation speed of the compressor.

The IGBT shown in the block diagram charges the energy (electromotive force) generated by the reactor to the electrolytic capacitor for the inverter

by turning ON and OFF.

When the IGBT is ON, an electric current flows to the IGBT via the reactor (L1) and diode bridge (DB2).

When the IGBT turns OFF, the energy stored while the IGBT was ON is charged to the voltage doubler capacitor via the diode bridge (DB1).

As such, by varying the ON/OFF duty of the IGBT, the output voltage is varied.

2 – 10

AYXP9LSR

Stored energy

Reactor

L1

DB1

DB2

IGBT

IGBT ON

IGBT OFF

AC voltage waveform

AC voltage and current waveform when PAM is ON

AC current waveform

IGBT ON period

Zero-cross detection

AC voltage waveform

AC current waveform

AC voltage and current waveforms when PAM is OFF

AC voltage waveform

Clock

IGBT ON

A

BC

A

B

C

50Hz

11mS

1.0mS

0.25 2.3mS

CDQWV

CDQWV

3.2. High power factor control circuit

This circuit brings the operating current waveform closer to the waveform of commercial power supply voltage to maintain a high power factor.

Because of the capacitor input, when the PAM circuit is OFF, the phase of the current waveform deviates from the voltage waveform as shown below.

To prevent this deviation, a current is supplied during the periods indicated by "O" in the diagram.

To determine the length of period to supply a current, the zero-cross timing of the AC input voltage is input to the microcomputer via the clock circuit.

The power source frequency is also determined at the same time.

The IGBT turns ON after the time length determined by the zero-cross point to supply a current to the IGBT via the reactor.

This brings the current waveform closer to the voltage waveform in phase.

As described above, the ON/OFF operation of the IGBT controls the increase/decrease of the compressor power supply voltage (DC voltage) to

improve the compressor efficiency and maintain a high power factor by keeping the current phase closer to that of the supply voltage.

3.2.1 Detailed explanation of PAM drive circuit sequence

3.2.2 AC clock (zero-cross) judgment

• The clock circuit determines the time from one rising point of the clock waveform to the next rising point.

The detected clock waveform is used to judge the power source frequency (50Hz).

• The zero-cross of the AC voltage is judged as the rising of the clock waveform, as shown in the diagram above.

3.2.3 IGBT ON start time (delay time B)

• Based on the zero-cross of the AC voltage, the IGBT turns ON after a delay time set according to the power source frequency.

3.2.4 IGBT ON time (C)

• After the above delay time, the IGBT turns ON to supply a current to the reactor.

• The ON time of the IGBT determines the amount of energy (level of DC voltage rise) supplied to the reactor.

DC voltage level in each operation mode (varies depending on external load conditions)

– Cooling operation --- 220 to 290 V

2 – 11

AYXP9LSR

R125

270K

C10C9

R126

270K

R127

13K

R128

13K

0V

0V

5V

(Overvoltage detection)

During abnormal voltage output

IC

69

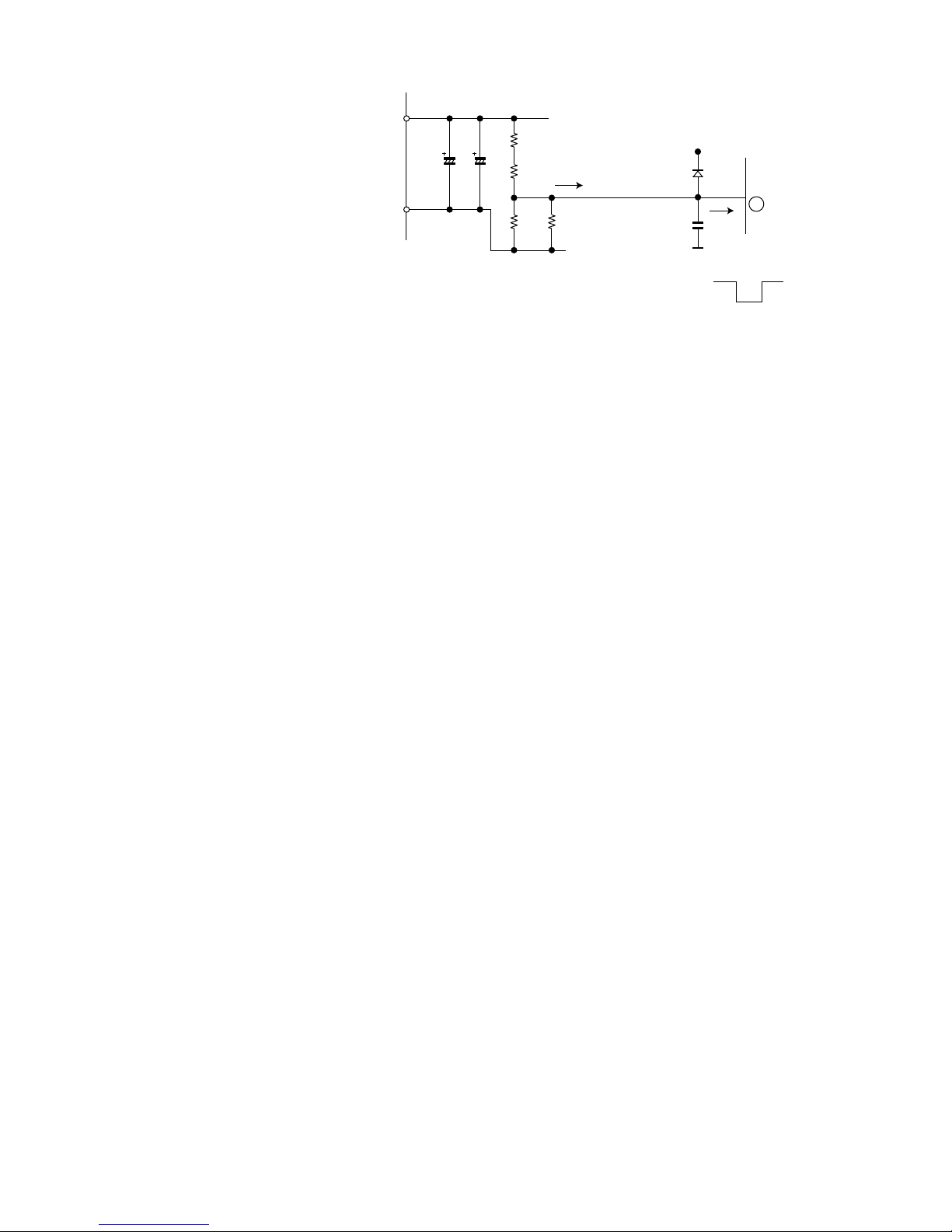

3.3. PAM protection circuit

To prevent excessive voltage of PAM output from

damaging the IPM and electrolytic capacitor as well

as the control printed circuit board (PCB), this circuit

monitors the PAM output voltage and turns off the

PAM control signal and PAM drive immediately

when an abnormal voltage output is generated. At

the same time, it shuts off the compressor operation.

The protection voltage level is as follows.

3.3.1 Details of troubleshooting procedure

for PAM

1) PAM shutdown due to error

1) When the DC voltage detection circuit sends a

signal exceeding the specified voltage to the

microcomputer

DC voltage of 400 V or higher

DC voltage of 184 V or less.

– When an error is detected

• PAM IGBT turns OFF.

• Compressor turns OFF.

• All units shut down compietely when the error occurs four times.

2) When the outdoor unit clock waveform differs from the specified value immediately before the PAM IGBT turns ON

When there is no clock waveform input

When a clock signal of other than specified power source frequency (50Hz) is input

– When an error is detected

• PAM IGBT does not turn ON.

• Compressor operates normally.

• Complete shutdown does not occur.

2) PAM error indication

In case of error “1)”

– An error signal is sent to the indoor unit as soon as an error is generated.

• Malfunction No. 14-0 is indicated when the error code is called out by the indoor unit's self-diagnosis function.

– The LED on the outdoor unit flashes 14 times when an error is generated.

• The LED continues flashing in the 14-time cycle even after the compressor stops operating.

• The LED turns off (data is deleted from the memory) when the outdoor unit power is turned off.

In case of error “2)”

– An error signal is sent to the indoor unit as soon as an error is judged.

• Malfunction No. 14-1 is indicated when the error code is called out by the indoor unit's self-diagnosis function.

– The LED on the outdoor unit flashes 14 times when an error is judged.

• The LED on the outdoor unit flashes in normal pattern when the compressor stops operating.

(Compressor OFF or Thermostat OFF from remote control)

* When a user complains that the air conditioner does not provide sufficient cool air or warm air

In addition t o conventional er ror-generating reasons, there is a possibility that the PAM IGBT does not turn ON even if the compressor is operating.

In that case, the DC voltage does not rise even though the compressor is operating, and lowers to the 180-VDC level.

– Check items

• Clock circuit check

•PAM IGBT check

• Fuse (Fu6) open-circuit check

2 – 12

Loading...

Loading...