Page 1

AYXP7FR

SERVICE MANUAL

S6512AYXP7FR/T

SPLIT TYPE

ROOM AIR CONDITIONER

INDOOR UNIT

MODELS

AY-XP7FR

AY-XP9FR

AY-XP12FR

In the interests of user-safety (Required by safety regulations in some countries) the set should

be restored to its original condition and only parts identical to those specified should be used.

CONTENTS

CHAPTER 1. SPECIFICATION

[1] SPECIFICATION............................................1-1

[2] EXTERNAL DIMENSION............................... 1-4

[3] WIRING DIAGRM ..........................................1-5

[4] ELECTRICAL PARTS....................................1-6

CHAPTER 2. EXPLAMATION OF CIRCUIT AND OPERATION

[1] BLOCK DIAGRAMS....................................... 2-1

[2] MICROCOMPUTER CONTROL SYSTEM........2-3

[3] FUNCTION.....................................................2-8

CHAPTER 3. FUNCTION AND OPERATION OF PROTECTIVE PROCEDURES

[1] PROTECTION DEVICE FUNCTIONS AND

OPERATIONS................................................3-1

[2] AIR CONDITIONER OPERATION IN

THERMISTOR ERROR .................................3-3

[3] THERMISTOR TEMPERATURE CHAR-

ACTERISTICS ...............................................3-5

[4] HOW TO OPERATE THE OUTDOOR

UNIT INDEPENDENTLY................................3-6

OUTDOOR UNIT

AE-X7FR

AE-X9FR

AE-X12FR

[5] GENERAL TROUBLESHOOTING CHART........3-6

[6] MALFUNCTION (PARTS) CHECK METH-

OD .................................................................3-8

[7] OUTDOOR UNIT CHECK METHOD...........3-10

[8] TROUBLESHOOTING GUIDE....................3-13

CHAPTER 4. REFRIGERATION CYCLE

[1] FLOW FOW REFRIGERANT ........................4-1

[2] STANDARD CONDITION..............................4-1

[3] TEMPERATURE AT EACH PART AND

PRESSURE IN 3-WAY VALVE......................4-1

[4] PERFORMANCE CURVES...........................4-2

CHAPTER 5. DISASSEMBLING PROCEDURE

[1] DISASSEMBLY OF INDOOR UNIT...............5-1

[2] DISASSEMBLY OF OUTDOOR UNIT...........5-7

REPLACEMENT P ARTS LIST

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AYXP7FR

AYXP7FR

CHAPTER 1. SPECIFICATION

Service Manual

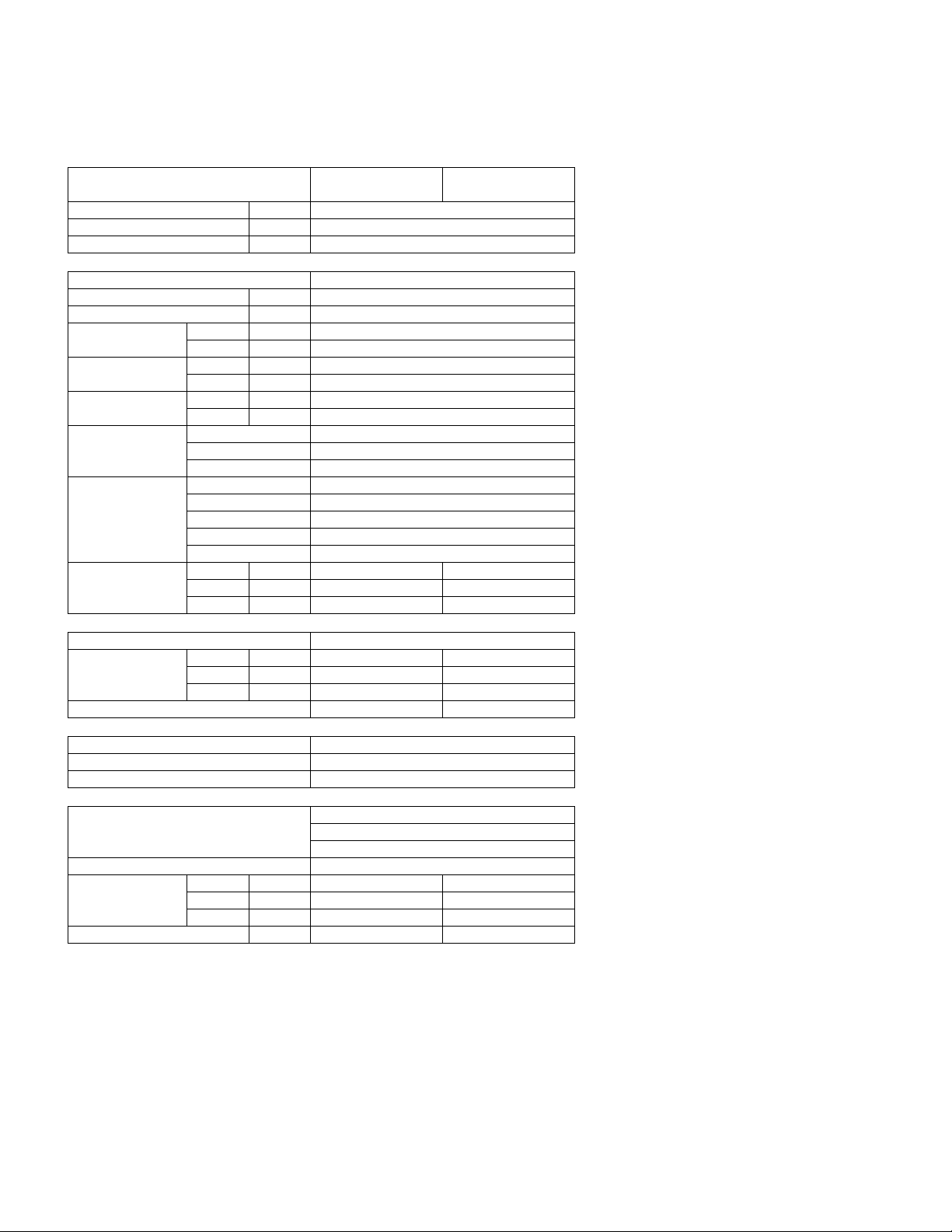

[1] SPECIFICATION

1. AY-XP7FR – AE-X7FR

MODEL INDOOR UNIT OUTDOOR UNIT

ITEMS AY-XP7FR AE-X7FR

Cooling capacity(Min. > Max.) kW 2.1 (0.9 - 2.5)

Heating capacity(Min. > Max.) kW 2.4 (0.9 - 3.4)

Moisture removal(at cooling) Liters/h

Electrical data

Phase Single

Rated frequency Hz 50

Rated voltage V 230

Rated current ✩

(Min - Max.)

Rated input ✩

(Min - Max.)

Power factor ✩ Cool % 92

Compressor Type Hermetically sealed rotary type

Refrigerant system Evaporator Louver Fin and Grooved tube type

Noise level

(at cooling)

Fan system

Drive Direct drive

Air flow quantity

(at cooling)

Fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D φ18

Others

Safety device Compressor: Thermal protector

Air filters Polypropylene net (Washable)

Net dimensions Width mm 790 730

Net weight kg 10 33

Cool A 2.5 (1.0 - 4.1)

Heat A 2.4 (0.9 - 4.5)

Cool W 530 (200 - 760)

Heat W 510 (160 - 1100)

Heat % 92

Model DA89X1F-23F

Oil charge 370cc (VG74)

Condenser Corrugate Fin and Grooved tube type

Control Expansion valve

Refrigerant (R410A) 830g

De-lce system Micro computer controled reversed systems

High dB(A) 37 45

Low dB(A) – –

Soft dB(A) 28 –

High m3/min. 8.0 23.2

Low m3/min. 6.8 –

Soft m3/min. 5.5 –

Fan motors: Thermal fuse

Fuse, Micro computer control

Height mm 278 540

Depth mm 198 250

1 – 1

Page 3

2. AY-XP9FR – AE-X9FR

MODEL INDOOR UNIT OUTDOOR UNIT

ITEMS AY-XP9FR AE-X9FR

Cooling capacity(Min. > Max.) kW 2.64 (0.9 - 3.0)

Heating capacity(Min. > Max.) kW 3.1 (0.9 - 4.8)

Moisture removal(at cooling) Liters/h

Electrical data

Phase Single

Rated frequency Hz 50

Rated voltage V 230

Rated current ✩

(Min - Max.)

Rated input ✩

(Min - Max.)

Power factor ✩ Cool % 92

Compressor Type Hermetically sealed rotary type

Refrigerant system Evaporator Louver Fin and Grooved tube type

Noise level

(at cooling)

Fan system

Drive Direct drive

Air flow quantity

(at cooling)

Fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D φ18

Others

Safety device Compressor: Thermal protector

Air filters Polypropylene net (Washable)

Net dimensions Width mm 790 730

Net weight kg 10 33

Cool A 3.7 (1.0 - 4.8)

Heat A 3.5 (0.9 - 6.1)

Cool W 780 (200 - 960)

Heat W 730 (160 - 1400)

Heat % 91

Model DA89X1F-23F

Oil charge 370cc (VG74)

Condenser Corrugate Fin and Grooved tube type

Control Expansion valve

Refrigerant (R410A) 830g

De-lce system Micro computer controled reversed systems

High dB(A) 39 45

Low dB(A) – –

Soft dB(A) 28 –

High m3/min. 8.6 23.3

Low m3/min. 7.3 –

Soft m3/min. 5.5 –

Fan motors: Thermal fuse

Fuse, Micro computer control

Height mm 278 540

Depth mm 198 250

AYXP7FR

1 – 2

Page 4

AYXP7FR

3. AY-XP12FR – AE-X12FR

MODEL INDOOR UNIT OUTDOOR UNIT

ITEMS AY-XP12FR AE-X12FR

Cooling capacity(Min. > Max.) kW 3.5 (0.9 - 3.8)

Heating capacity(Min. > Max.) kW 4.0 (0.9 - 6.0)

Moisture removal(at cooling) Liters/h

Electrical data

Phase Single

Rated frequency Hz 50

Rated voltage V 230

Rated current ✩

(Min - Max.)

Rated input ✩

(Min - Max.)

Power factor ✩ Cool % 95

Compressor Type Hermetically sealed rotary type

Refrigerant system Evaporator Louver Fin and Grooved tube type

Noise level

(at cooling)

Fan system

Drive Direct drive

Air flow quantity

(at cooling)

Fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D φ18

Others

Safety device Compressor: Thermal protector

Air filters Polypropylene net (Washable)

Net dimensions Width mm 790 730

Net weight kg 10 37

Cool A 5.0 (1.1 - 8.2)

Heat A 4.8 (1.0 - 8.0)

Cool W 1090 (210 - 1300)

Heat W 1030 (180 - 1900)

Heat % 93

Model 5RS102XBE01

Oil charge 320cc (RB68A or Freol Alpha 68M)

Condenser Corrugate Fin and Grooved tube type

Control Expansion valve

Refrigerant (R410A) 1030g

De-lce system Micro computer controled reversed systems

High dB(A) 40 48

Low dB(A) – –

Soft dB(A) 28 –

High m3/min. 9.8 26.7

Low m3/min. 8.5 –

Soft m3/min. 6.9 –

Fan motors: Thermal fuse

Fuse, Micro computer control

Height mm 278 540

Depth mm 198 250

NOTE: The condition of star”✩” marked item are ‘ISO5151’ : 1994(E), contition T1.

1 – 3

Page 5

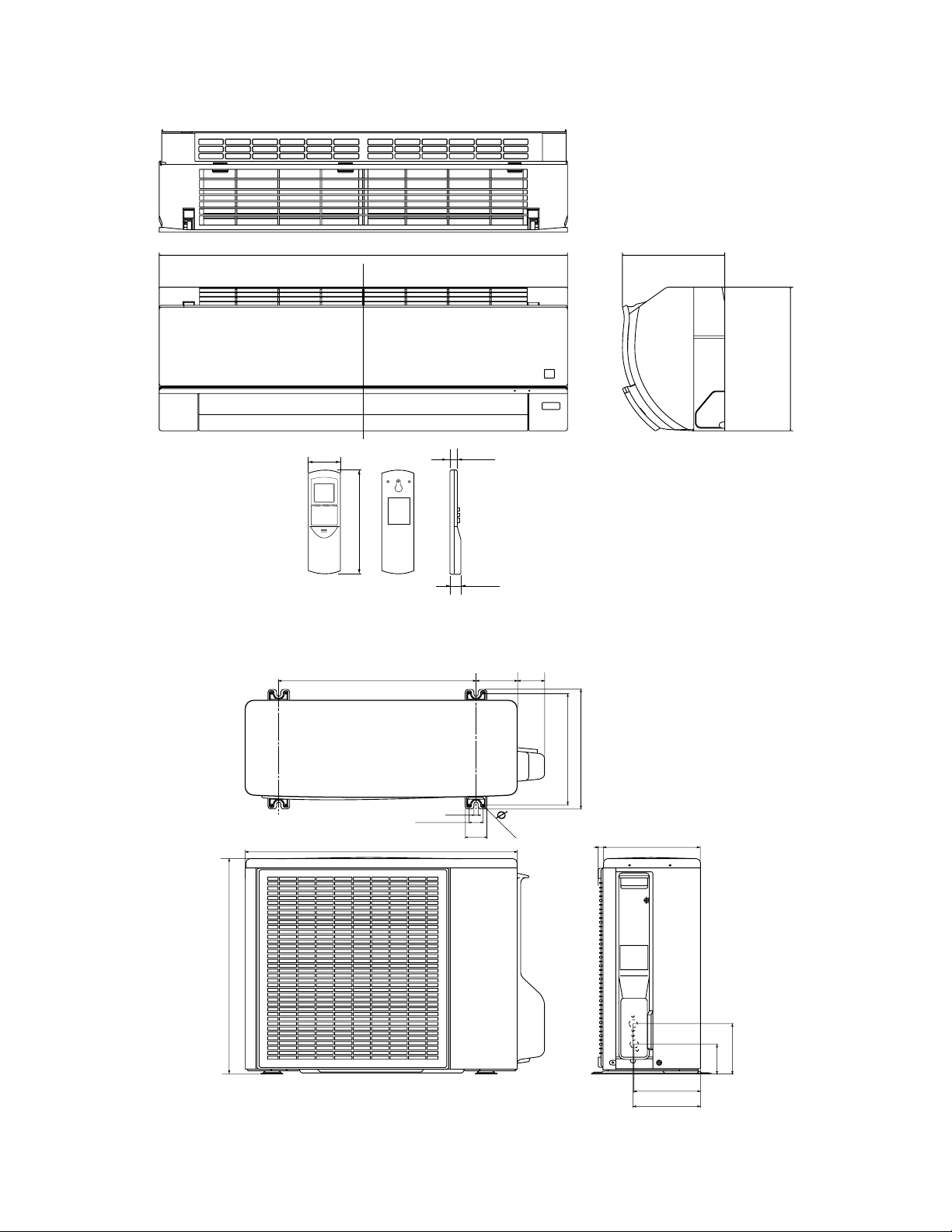

[2] EXTERNAL DIMENSION

1. Indoor unit

AYXP7FR

198790

278

2. Outdoor unit

58

INVERTERAIRCONDITIONER

175

515

730

37.5

12

18.5

22.0

58

135

4.5

72

299

324

14

250

540

1 – 4

165

167.5

81

136

Page 6

AYXP7FR

[3] WIRING DIAGRM

1. Indooa unit

2. Outdooa unit

2.1. AE-X7FR / AE-X9FR

2.2. AE-X12FR

420V

750μF

420V

750μF

1 – 5

Page 7

AYXP7FR

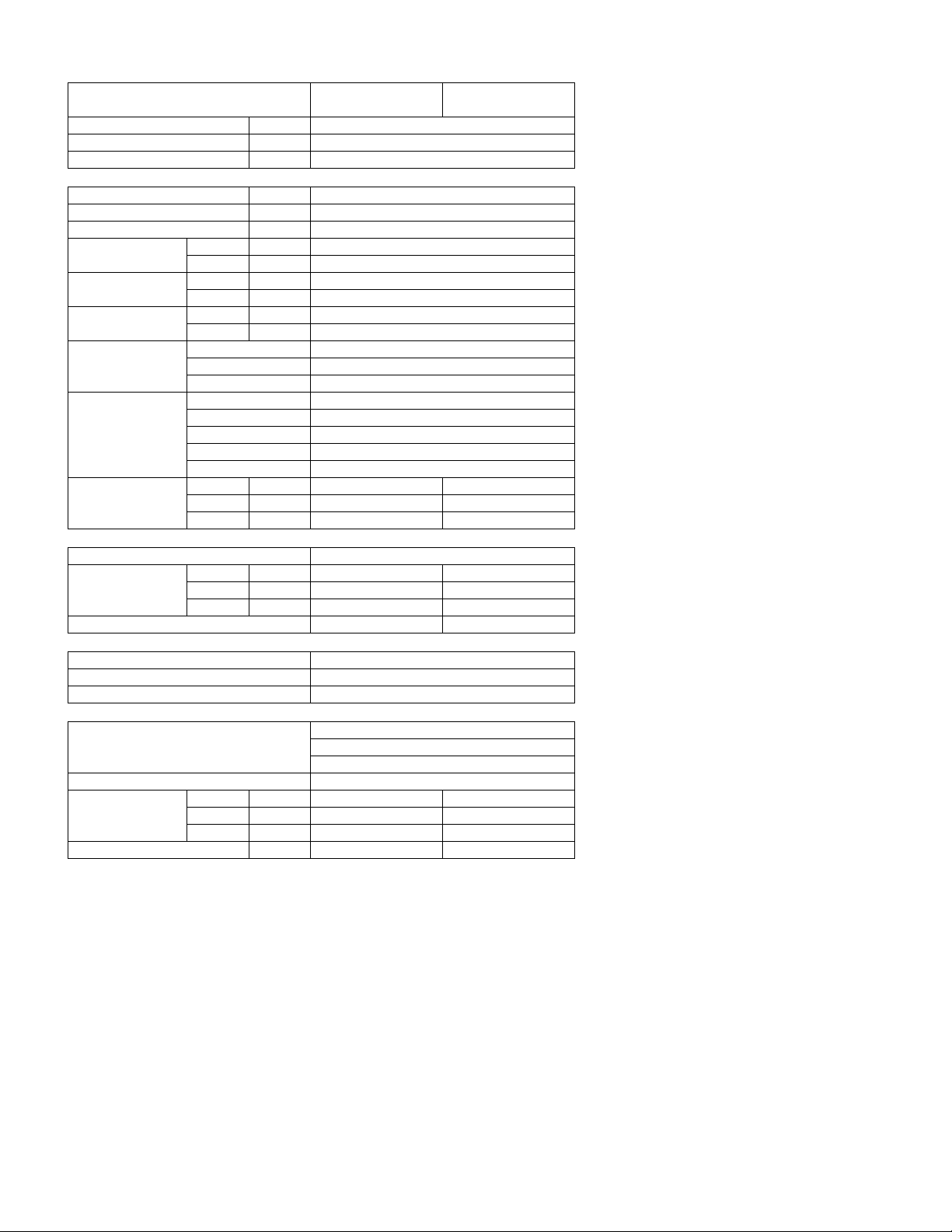

[8] TROUBLESHOOTING GUIDE

1. Self-Diagnosis Function and Display Mode

To call out the content of the self-diagnosis memory, hold down the emergency operation button for more than 5 seconds when the indoor unit is not

operating.

• The number of indications displayed by the LEDs on the outdoor unit differs from that for the 2001 cooling unit models (for detailed display of malfunction information).

The display of malfunction No. differs from that of the 2001 cooling unit models. To show detailed malfunction information, two types of numbers

flash alternately. (example: "21" ←→ "-0")

1) The content of the self-diagnosis memory can be called out and displayed on the seven-segment display section on the indoor unit. (The error

data cannot be called out for display by the LED on the outdoor unit.)

2) If the power cord is unplugged from the AC outlet or the circuit breaker is turned off, the self-diagnosis memory loses the stored data.

a) The self-diagnosis display function of the indoor unit indicates the content of diagnosis by showing the error main category (number) and the

error sub-category (-number) alternately in 1-second intervals on the seven-segment display section of the indoor unit.

Example of self-diagnosis display on indoor unit: Compressor high-temperature error

'TTQTOCKPECVGIQT[ 'TTQTUWDECVGIQT[

b) The self-diagnosis display function of the outdoor unit indicates the error information by flashing LED1 on the outdoor unit according to the con-

tent of self-diagnosis.

The self-diagnosis display function of the outdoor unit is active only for about 3 to 10 minutes after self-diagnosis is performed during operation,

and the display returns to normal condition after this display period.

The content of self-diagnosis cannot be called out by the self-diagnosis display function of the outdoor unit.

Example of self-diagnosis display on outdoor unit: Compressor high-temperature error

ON

OFF

c) The content of diagnosis is transferred to the indoor unit via serial communication, but it does not trigger a complete shutdown operation.

: Flashes in 2-sec intervals (normal), : On, : Off, : Flashes 3 times in 0.2-sec intervals (When LED1 on the outdoor unit flashes in 2-sec

intervals, the outdoor unit is in normal condition.)

Nor-

mal

ing

Malfunction

No. dis-

played on

main unit

display sec-

tion *1

Sub-

Main

cate-

cate-

gory

gory

00 Normal – –

Status of

indoor/

outdoor

units

Indoor/

outdoor

units in

operation

Indoor/

outdoor

units in

complete

shutdown

Indication

by LED1

on out-

door unit

*2

flash-

1 time 1 -0 Outdoor unit

1 sec 1 sec 1 sec 1 sec 1 sec1 sec0.6 sec 0.6 sec0.6 sec 0.6 sec 1 sec

Content of diagnosis Inspection location/method Remedy

Main category Sub-category

Heat exchanger

thermistor

short-circuit

-1 Outside tempera-

-2 Suction thermistor

-3 2-way valve ther-

thermistor short-cir-

cuit error

ture thermistor

short-circuit error

short-circuit error

mistor short-circuit

error

(1) Measure resistance of the

outdoor unit thermistors.

(TH2 to TH5: Approx. 4.4

kΩ at 25°C)

(2) Check the lead wire of the

outdoor unit thermistor for

torn sheath and short-circuit.

(3) No abnormality found in

above inspections (1) and

(2).

1 sec 1 sec

(1) Replace the outdoor

unit thermistor assembly.

(2) Replace the outdoor

unit thermistor assembly.

(3) Replace the outdoor

unit control PWB

assembly.

3 – 13

Page 8

AYXP7FR

Status of

indoor/

outdoor

units

Indoor/

outdoor

units in

complete

shutdown

Indoor

unit in

operation

Outdoor

unit in

temporary stop

Indoor

unit in

operation

Outdoor

unit in

temporary stop

Indoor/

outdoor

units in

complete

shutdown

Indication

by LED1

on out-

door unit

*2

2 times 2 -0 Cycle tempera-

3 times 3 -0 Dry operation Temporary stop due

5 times 5 -0 Outdoor unit

Malfunction

No. dis-

played on

main unit

display sec-

tion *1

Sub-

Main

cate-

cate-

gory

gory

-1 Temporary stop due

-2 Temporary stop due

-3 Temporary stop due

-4 Temporary stop due

-1 Outside tempera-

-2 Suction thermistor

-3 2-way valve ther-

-4 Discharge ther-

Content of diagnosis Inspection location/method Remedy

Main category Sub-category

ture

thermistor

open-circuit

Compressor high-

temperature error

to compressor dis-

charge overheat *3

to outdoor unit heat

exchanger overheat

*3

to outdoor unit heat

exchanger overheat

*3

to 2-way valve

freeze *3

to dehumidifying

operation *3

Heat exchanger

thermistor open-cir-

cuit error

ture thermistor

open-circuit error

open-circuit error

mistor open-circuit

error

mistor open-circuit

error

(1) Check the outdoor unit air

outlet for blockage.

(2) Check if the power supply

voltage is 90 V or higher at

full power.

(3) Check the pipe connec-

tions for refrigerant leaks.

(4) Measure resistance of the

outdoor unit compressor

thermistor.

(TH1: Approx. 53 kΩ at

25°C)

(5) Check the expansion

valve for proper operation.

(Temporary stop for cycle protection)

(Temporary stop for cycle protection)

(Temporary stop for cycle protection)

(Temporary stop for cycle protection)

(Temporary stop for cycle protection)

(1) Check connector CN8 of

the outdoor unit thermistor for secure installation.

(2) Measure resistance of out-

door thermistors TH1 to

TH5.

(3) Check the lead wires of

thermistors TH1 through

TH5 on the outdoor unit

control PWB for open-circuit.

(4) No abnormality found in

above inspections (1)

through (3).

(1) Ensure unobstructed

air flow from the outdoor unit air outlet.

(2) Connect power sup-

ply of proper voltage.

(3) Charge the specified

amount of refrigerant.

(4) Replace the outdoor

unit compressor thermistor assembly.

(5) Replace the expan-

sion valve coil, expansion valve or outdoor

unit control PWB

assembly.

–

–

–

–

–

(1) Correct the installa-

tion.

(2) Replace the outdoor

unit thermistor assembly.

(3) Replace the outdoor

unit thermistor assembly.

(5) Replace the outdoor

unit control PWB

assembly.

3 – 14

Page 9

AYXP7FR

Status of

indoor/

outdoor

units

Indoor/

outdoor

units in

complete

shutdown

Indoor/

outdoor

units in

complete

shutdown

Indoor/

outdoor

units in

complete

shutdown

Indication

by LED1

on out-

door unit

*2

6 times 6 -0 Outdoor unit DC DC overcurrent error (1) IPM continuity check (1) Replace the outdoor

7 times 7 -0 Outdoor unit AC AC overcurrent error (1) Check the outdoor unit air

9 times 9 -0 Outdoor unit

Malfunction

No. dis-

played on

main unit

display sec-

tion *1

Sub-

Main

cate-

cate-

gory

gory

-1 IPM pin level error Check the IPM is attached

-1 AC overcurrent error

-2 AC maximum cur-

-3 AC current defi-

-3 Torque control error (1) Check if the refr igerant

Content of diagnosis Inspection location/method Remedy

Main category Sub-category

(2) Check the IPM and heat

sink for secure installation.

(3) Check the outdoor unit fan

motor for proper rotation.

(4) No abnormality found in

above inspections (1)

through (3).

(5) No abnormality found in

above inspections (1)

through (4).

correctly to the outdoor

unit control PWB.

outlet for blockage.

(2) Check the outdoor unit fan

for proper rotation.

(1) IPM continuity check (1) Replace the outdoor

in OFF status

(1) Check the outdoor unit air

outlet for blockage.

(2) Check the outdoor unit fan

for proper rotation.

(1) Check if there is an open-

circuit in the secondary

winding of the current

transformer of the outdoor

unit control PWB.

(2) Check if the refrigerant

volume is abnormally low.

(3) Check if the refrigerant

flows properly.

(1) Check to make sure out-

door unit thermistor TH2

(heat exchanger) and TH5

(2-way valve) are installed

in correct positions.

(2) Measure resistance of

thermistors TH1 and TH5.

(3) Check the 4-way valve for

proper operation.

(4) No abnormality found in

above inspections (1)

through (3).

volume is abnormally low.

(2) Check the 4-way valve for

proper operation.

(3) check to see compressor

type is correct.

cooling/heating

switchover

rent error

ciency error

Thermistor installa-

tion error or 4-way

valve error

unit control PWB

assembly.

(2) Correct the installa-

tion (tighten the

screws).

(3) Replace the outdoor

unit fan motor.

(4) Replace the outdoor

unit control PWB

assembly.

(5) Replace the compres-

sor.

Replace the outdoor

unit control PWB

assembly.

(1) Ensure unobstructed

air flow from the outdoor unit air outlet.

(2) Check the outdoor unit

fan motor.

unit control PWB

assembly.

(1) Ensure unobstructed

air flow from the outdoor unit air outlet.

(1) Check the outdoor unit

fan motor.

(1) Replace the outdoor

unit control PWB

assembly.

(2) Charge the specified

amount of refrigerant.

(3) Correct refrigerant

clogs.

(2-way valve, 3-way

valve, pipe, expansion valve)

(1) Correct the installa-

tion.

(2) Replace the ther-

mistor assembly.

(3) Replace the 4-way

valve.

(4) Replace the outdoor

unit control PWB

assembly.

(1) Change the specified

amount of refrigerant.

(2) Replace the 4-way

valve.

(3) Replace the compres-

sor with the correct

part.

3 – 15

Page 10

AYXP7FR

Status of

indoor/

outdoor

units

Indoor/

outdoor

units in

complete

shutdown

Indoor/

outdoor

units in

complete

shutdown

Indoor/

outdoor

units in

complete

shutdown

Indoor/

outdoor

units in

operation

Indoor

unit in

operation

Outdoor

unit in

complete

shutdown

Indication

by LED1

on out-

door unit

*2

11

times

13

times

14

times

Malfunction

No. dis-

played on

main unit

display sec-

tion *1

Sub-

Main

cate-

cate-

gory

gory

11 -0 Outdoor unit DC

13 -0 DC compressor Compressor startup

-1 Compressor rota-

14 -0 Outdoor unit

-1 PAM clock error (1) Check the PAM clock for

17 -0 Wires between

18 -0 Serial short-circuit (1) Check the wires between

-1 Serial erroneous wir-

Content of diagnosis Inspection location/method Remedy

Main category Sub-category

fan

PAM

units

Outdoor unit DC fan

rotation error

error

tion error

(120° energizing

error)

PAM over voltage

error

Compressor rota-

tion error

Serial open-circuit (1) Check the wires between

Outdoor unit does

not turn on due to

erroneous wiring

ing

(1) Check connector CN3 of

the outdoor unit DC fan

motor for secure installation.

(2) Check the outdoor unit fan

motor for proper rotation.

(3) Check fuse FU3. (3) Replace the outdoor

(4) Outdoor unit control PWB (4) Replace the outdoor

(1) Check the colors (red,

white, orange) of the compressor cords for proper

connection. (PWB side,

compressor side)

(2) Check if the IPM terminal

resistance values are uniform.

(3) No abnormality found in

above inspections (1) and

(2).

(4) No abnormality found in

above inspections (1)

through (3).

(1) Check the AC power sup-

ply voltage for fluctuation.

(2) No abnormality found in

above inspection (1).

proper input.

units.

(2) Check voltage between

Nos. 1 and 2 on the

indoor/outdoor unit terminal boards.

(1) Check the wires between

units.

(2) Check the outdoor unit

fuse.

(3) Check 15-V, 13-V and 5-V

voltages on the PWB.

Check resistance between

IPM terminals.

(4) Check pins No. 5 and 7 of

connector CN3 of the outdoor unit fan motor for

short-circuit.

(5) Outdoor unit control PCB (5) Replace the outdoor

units.

(1) Check the wires between

units.

(1) Correct the installa-

tion.

(2) Replace the outdoor

unit fan motor.

unit control PWB

assembly.

unit control PWB

assembly.

(1) Correct the installa-

tion.

(U: Red, V: White, W:

Orange)

(2) Replace the outdoor

unit control PWB

assembly.

(3) Replace the outdoor

unit control PWB

assembly.

(4) Replace the compres-

sor.

(1) Connect stable power

supply.

(2) Replace the outdoor

unit control PWB

assembly.

(1) Replace the outdoor

unit control PWB

assembly.

(1) Connect stable power

supply.

(2) Replace the outdoor

unit control PCB

assembly.

(1) Correct the wiring.

(2) Replace the fuse/out-

door unit control PCB

assembly.

(3) Replace the outdoor

unit control PCB

assembly.

(4) Replace the outdoor

unit fan motor.

unit control PCB

board.

(1) Correct the wiring.

(1) Correct the wiring.

3 – 16

Page 11

AYXP7FR

Status of

indoor/

outdoor

units

Indoor/

outdoor

units in

complete

shutdown

Indoor/

outdoor

units in

operation

Indoor/

outdoor

units in

operation

Indication

by LED1

on out-

door unit

*2

Malfunction

No. dis-

played on

main unit

display sec-

tion *1

Sub-

Main

cate-

cate-

gory

gory

19 -0 Indoor unit fan Indoor unit fan error (1) Check the indoor fan

20 -0 Indoor unit con-

88 Control and dis-

Content of diagnosis Inspection location/method Remedy

Main category Sub-category

motor for proper rotating

operation.(Check fan

lock.)

(2) Check the lead wire of the

indoor fan motor for opencircuit.

(3) Check CN1 of the indoor

unit fan motor for secure

installation.

(4) No abnormality found in

above inspections (1)

through (3).

EEPROM data error (EEPROM read data

trol PCB

play PCB

Communication

error

error)

(1) Check for disconnected

connector between control

PCB and display PCB,

and open-circuit in lead

wires.

(2) Check that control PCB

outputs signals correctly.

(1) Replace the indoor fan

motor.

(2) Replace the indoor fan

motor.

(3) Correct the installa-

tion of CN1 of the

indoor fan motor.

(4) Replace the indoor

unit control PWB.

Replace the indoor

unit control PWB.

(1) Insert connectors cor-

rectly, or replace control PWB.

(2) Replace control PWB.

3 – 17

Page 12

Malfunction indications due to erroneous wiring during air conditioner installation

Inter-unit wiring error mode Symptom

1 Indoor unit relay

Malfunction diagnosis display

Indoor

unit

1

N

2

1

N

2

Outdoor

unit

Turns On momentarily, then turns Off.

"18-1"

AYXP7FR

2 Indoor unit relay

1

Indoor

N

unit

2

3 Indoor unit relay

1

Indoor

N

unit

2

4 Indoor unit relay

1

Indoor

N

unit

2

5 Indoor unit relay

1

Indoor

N

unit

2

1

N

2

1

N

2

1

N

2

1

N

2

Outdoor

unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

Malfunction diagnosis display

Malfunction diagnosis display

Malfunction diagnosis display

Malfunction diagnosis display

Relays turns Off after about 30 minutes.

None

(Displays "18-0" when malfunction code is called out.)

Relays turns Off after about 30 minutes.

None

(Displays "18-0" when malfunction code is called out.)

Turns On momentarily, then turns Off.

"18-1"

Turns On momentarily, then turns Off.

"18-1"

3 – 18

Page 13

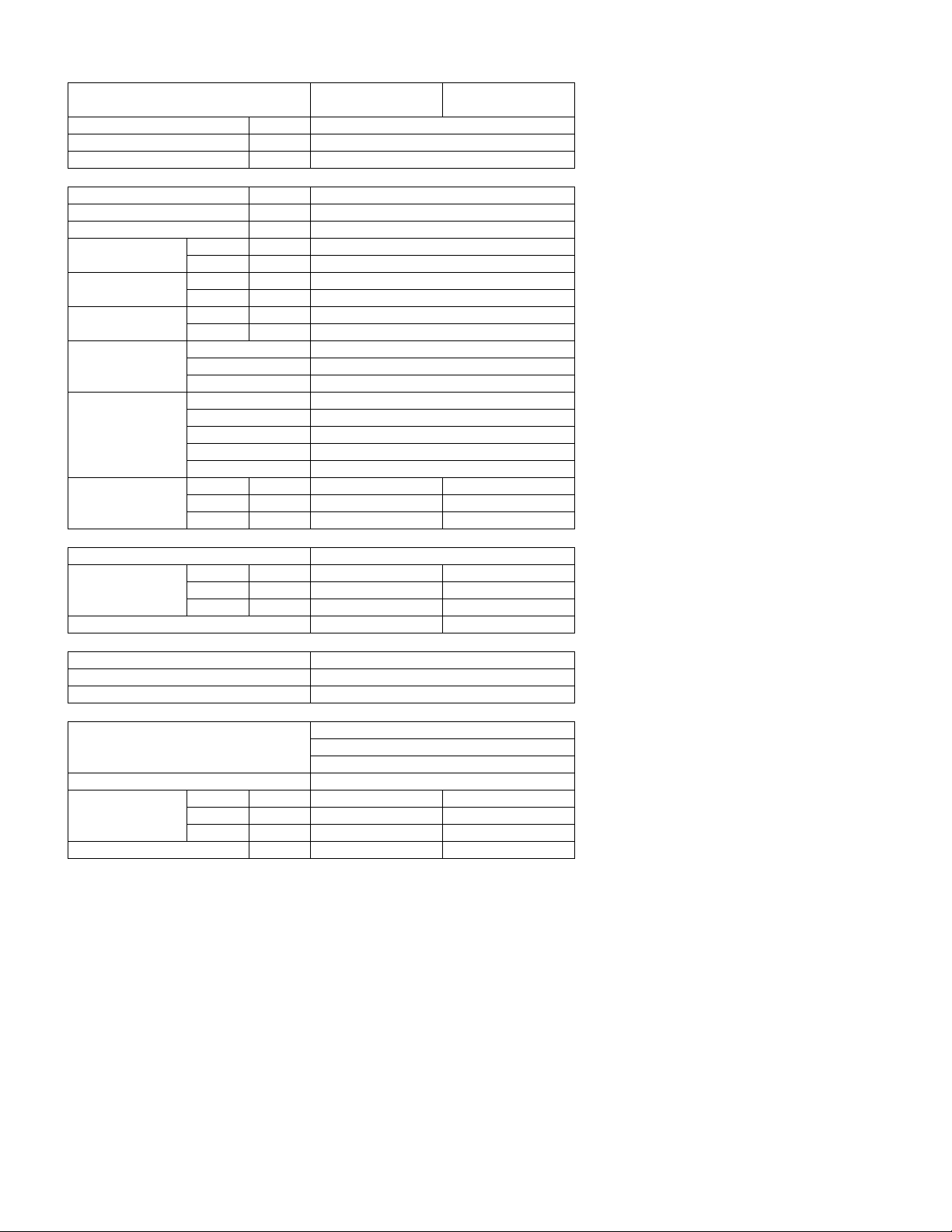

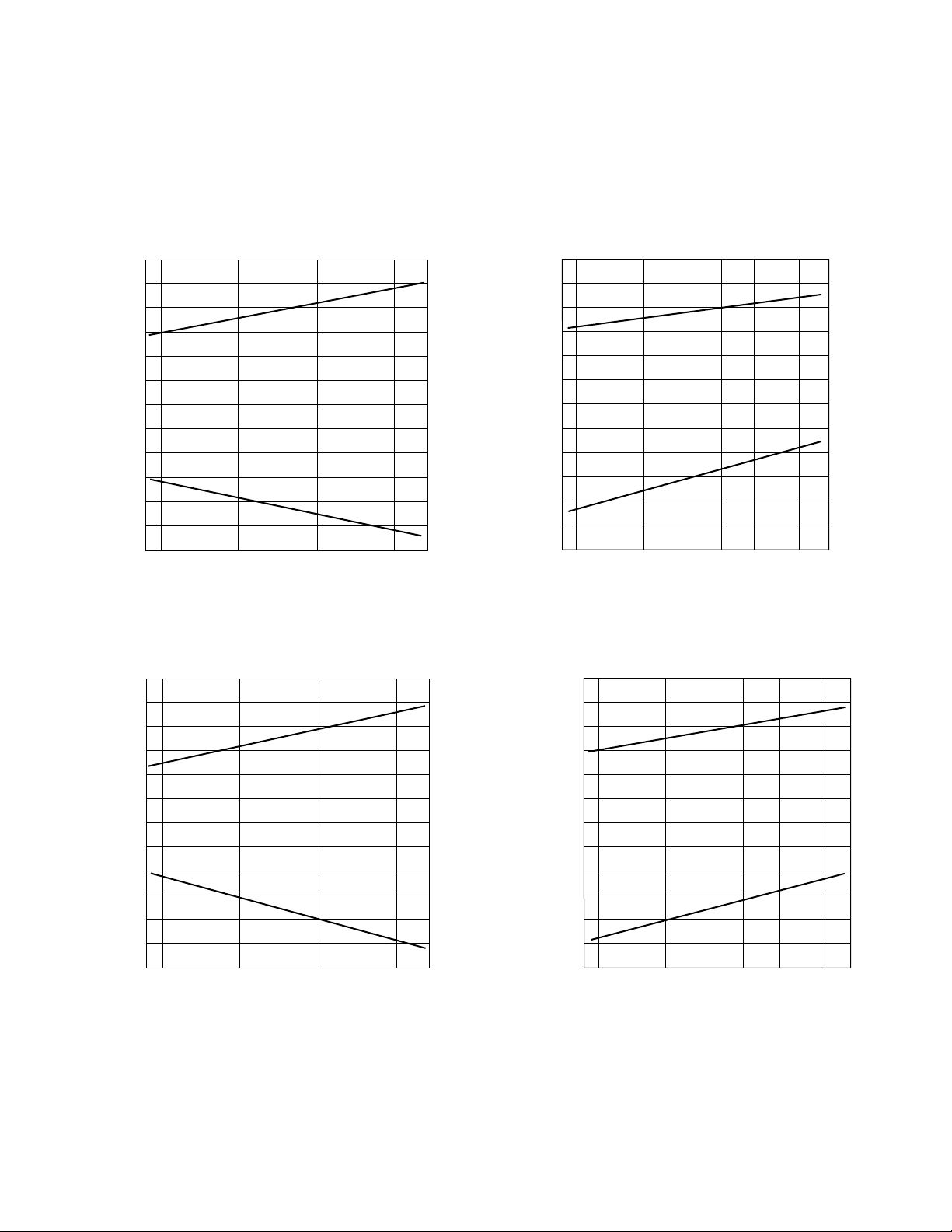

[4] PERFORMANCE CURVES

NOTE

1) Indoor fan speed: Hi

2) Vertical adjustment louver "45°”, Horizontal adjustment louver "front"

3) Indoor air temp. : Cooling 27°C, Heating 20°C

4) Power source : 230V, 50Hz

1. AY-XP7FR

1.1. At Cooling 1.2. At Heating

AYXP7FR

600

500

400

Input(W)

300

2.6

2.4

2.2

2.0

Cooling capacity(kW)

25 30 35 40

Outside air temp.(ºC)

600

500

400

Input(W)

3.0

2.5

2.0

1.5

Heating capacity(kW)

-5 0 7510

2. AY-XP9FR

2.1. At Cooling 2.2. At Heating

900

800

700

Input(W)

600

800

700

600

Input(W)

Outside air temp.(ºC)

3.2

3.0

2.8

2.6

2.4

Cooling capacity(kW)

25 30 35 40

Outside air temp.(ºC)

4 – 2

3.5

3.0

2.5

2.0

Heating capacity(kW)

-5 0 5 7 10

Outside air temp.(ºC)

Page 14

AYXP7FR

3. AY-XP12FR

3.1. At Cooling 3.2. At Heating

1200

1200

1100

1000

Input(W)

900

1100

1000

900

Input(W)

800

4.0

3.8

3.6

3.4

3.2

Cooling capacity(kW)

25 30 35 40

Outside air temp.(ºC)

4.5

4.0

3.5

3.0

2.5

Heating capacity(kW)

-5 0 5 7 10

Outside air temp.(ºC)

4 – 3

Loading...

Loading...