Page 1

AR-PB9

CODE: 00ZARPB9//A1E

DIGITAL COPIER

OPTION PRINTER

EXPANSION KIT

MODEL AR-PB9

CONTENTS

[ 1 ] SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 3 ] SET UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[ 4 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . 4 - 1

[ 5 ] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . 5 - 1

[ 6 ] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . 6 - 1

● PARTS GUIDE

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-PB9

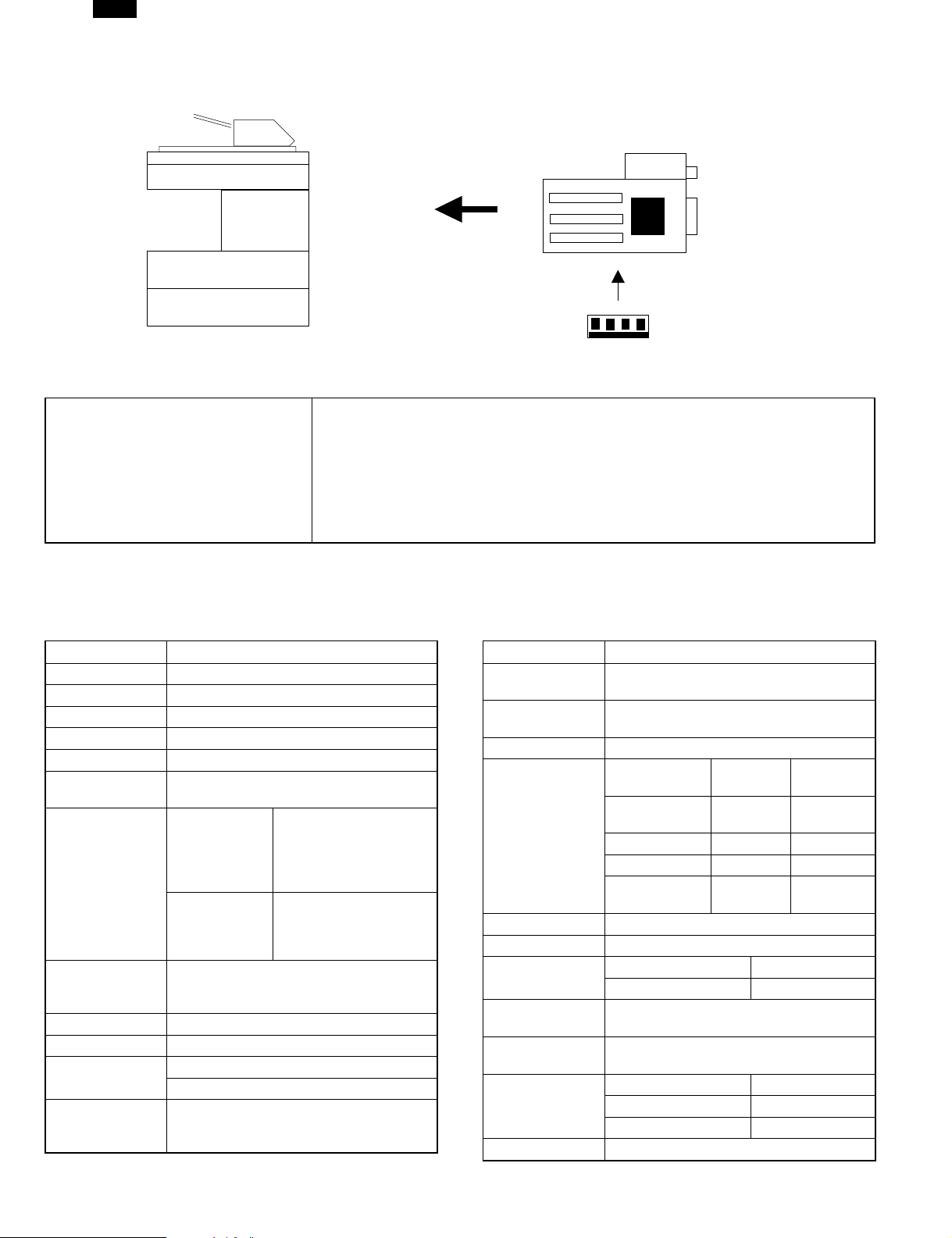

[1] SYSTEM CONFIGURATION

Printer expansion kit

(AR-PB9)

AR-150N/155N

●

●

●

Items supplied together(*)

*: USB and Parallel cables are not included.

●

●

●

●

●

[2] SPECIFICATIONS

1. Basic specifications

Item Contents

Print speed 15 PPM

First print 9.6 sec

Resolution 600 dpi, 300 dpi

Toner save No

Duplex print Yes (for duplex capable copier)

Paper feed tray

Paper size

Page description

language

(standard)

Dot emulation None

Page protection Yes

Interface

(Standard)

Applicable

Interface Cable

Multi bypass tray

Tray 1, Tray 2

A4R, B5R, A5R, 8.5" ×

Multi bypass

tray

Tray 1 ∼ 2

PCL6 (PCL XL) emulation

PCL5e emulation

IEEE1284 port × 1

USB port × 1

Parallel cable compliant IEEE1284 and less

than 2.0m (Shield and earth equipped)

USB cable less than 2.0 m

14", 8.5" × 11"R, 8.5" ×

5.5"R, 8.5" × 13", 8.5" ×

12.4"R, DL, C5, COM10,

Monarch

A4R, B5R, A5R, 8.5" ×

14"R, 8.5" × 11"R, 8.5"

× 5.5"R, 8.5" × 13"R,

8.5" × 12.4"R

Expansion memory

(Commercially available 168 pin EDO DIMM: 16MB/32MB/64MB)

Operation Manual

Instruction Manual

Printer drivers

Installer

Screen Fonts

Makedisk Software

Status Monitor Software

USB driver

Item Contents

Auto Interface

Switching

Auto Emulation

Switching

Plug and Play Yes

Printer Driver(*)

Resident Font 45 outline fonts compatible to PCL6

Screen Font 45 outline fonts compatible to PCL6

Memory

Expansion Slot

for Memory

Expansion

Memory

Operation Panel

Applicable PC IBM PC-AT Compatibles

*: Only Win 98 can be used for USB users.

No

Yes

MS

Windows3.1

MS Windows95 Yes Yes

MS Windows98 Yes Yes

MS Windows

NT4.0

Standard Maximum

8MB 72MB

One DIMM slots

64MB, 32MB, 16MB

(commercially-available DIMM:EDO)

Switches 1 (Online/Offline)

Lamps 2 (DATA, ONLINE)

Display None

PCL6

(PCL XL)

No Yes

Yes Yes

PCL5e

1 – 1

Page 3

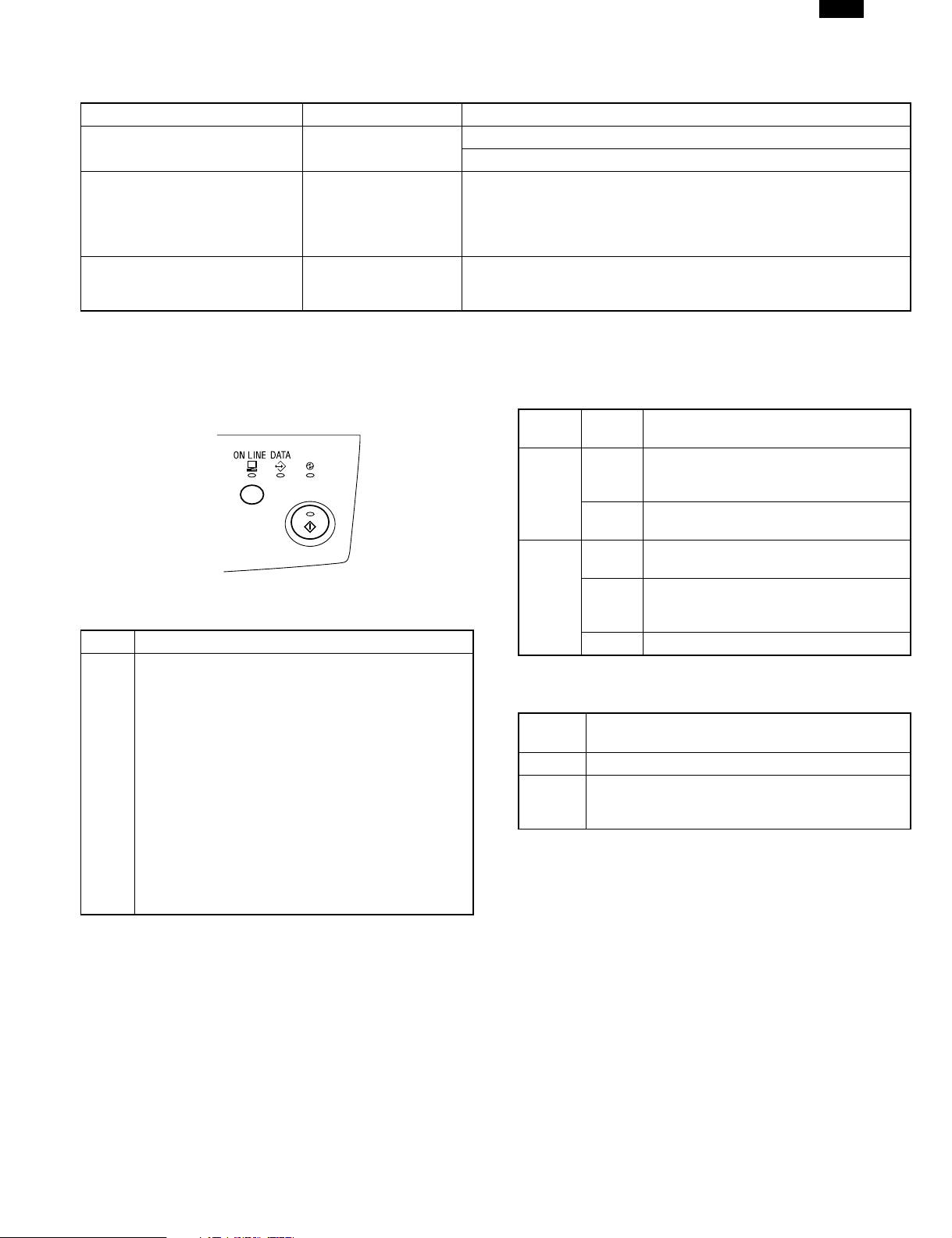

Operations when both of USB/parallel ports are connected at the same time.

The USB port has a priority over the parallel port.

Smartsharing is invalid.

Interface connected previously Interface connected later Operation

USB (Unfinished print job YES/NO) Parallel port

Parallel port (Unfinished print job

YES/NO)

Parallel port (Unfinished print job

YES/NO)

USB

USB

USB: Enable

Parallel port: Disable

When USB is connected after 30sec of no communication through the

parallel port, the mode is shifted to the USB mode instantaneously.

If no communication state does not reach 30sec yet, shifting to the USB

mode is retained until 30sec passes. During that time, print jobs are

performed through the parallel port.

After completion of unfinished print jobs, if there is no communication for

30sec, shifting to the USB mode is made.

Within 30sec, print jobs are performed through the parallel port.

2. Control panel

The following are the components of the control panel.

AR-PB9

The table below lists the functions of the LEDs:

The table below lists the functions of the keys:

Key Functions

If pressed when the machine is in online status:

●

If no print job is being processed (DATA LED unlit),

pressing the LINE key produces the offline. If “Data

Loss Error” or “Memory Full” was displayed, pressing

the LINE key is disregarded.

●

If a 1-sided print job is being processed (Data LED lit or

LINE

flashing), pressing the LINE key produces the offline. If

“Data Loss Error” or “Memory Full” was displayed,

pressing the LINE key is disregarded.

●

If a 2-sided print job is being processed (Data LED lit or

flashing), pressing the LINE key has no effect.

If pressed when the machine is in the offline status:

●

Pressing the LINE key produces the online status and

causes the display mode to Online Display Mode.

LED

name

ONLINE

DATA

The table below shows the initial states of the LEDs just after the

power is turned ON.

LED

names

ONLINE Lit (online)

DATA

State Description

The printer unit is not ready to receive

Unlit

Lit

Unlit

Lit

Flash Printer data is remained without printing.

Initial state

Unlit

Will light immediately, however, if data has already

arrived when the power is turned ON.

data.

(Offline status)

The printer unit is ready to receive data.

(Online status)

No data is being received or processed.

(No print job is being processed)

The printer data is being received or

processed or Printed.

(A print job is being processed.)

1 – 2

Page 4

AR-PB9

[3] SET UP

1. Installing Procedure

Parts included

PCL interface PWB, 1 pc.

PWB cover, 1 pc.

PCL PWB, 1 pc.

PWB cover lid 2, 1 pc.

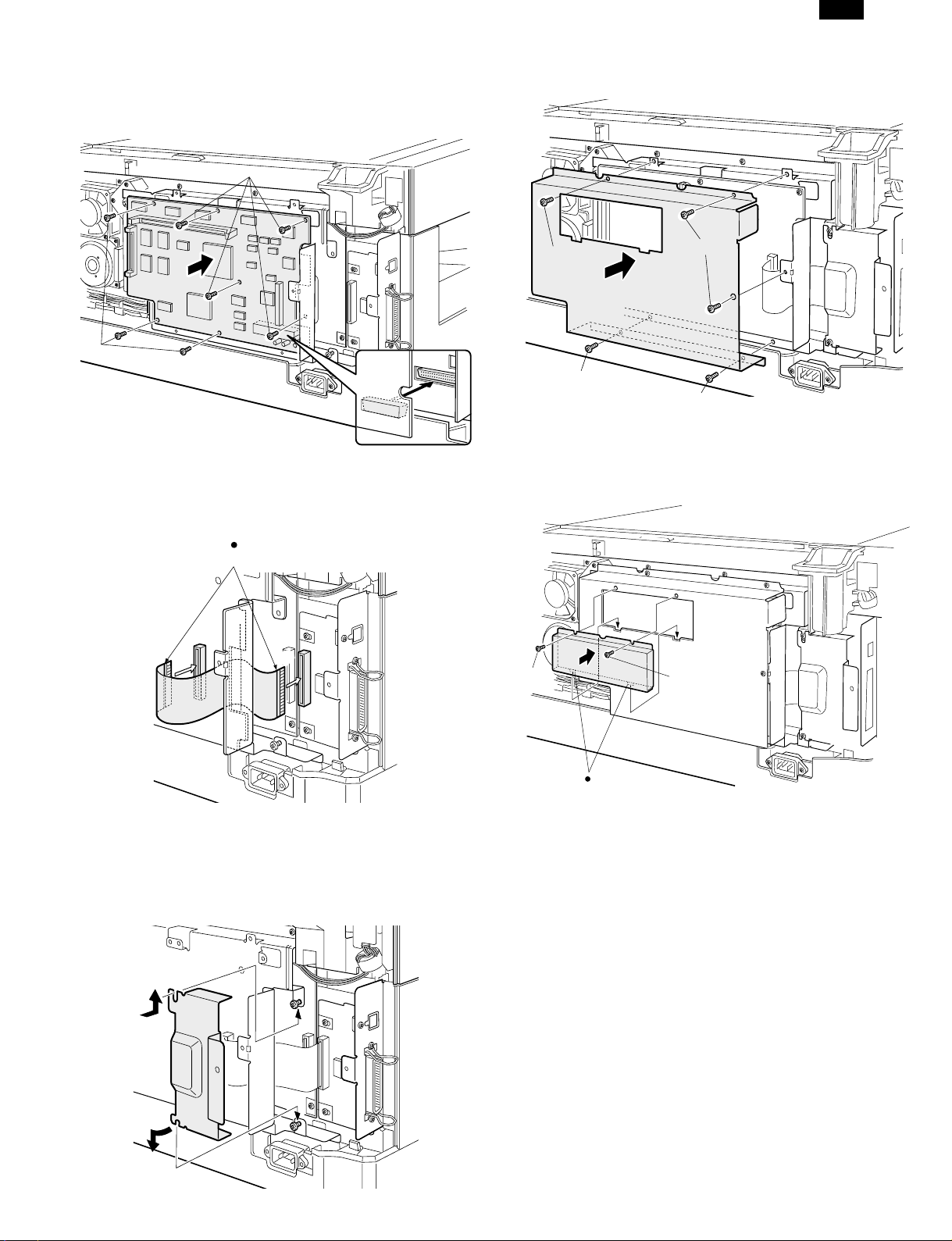

2) Remove the rear cabinet.

● Remove the four screws and then remove the rear cabinet.

3) Remove the PWB cover.

(1) Loosen the screw that secures the PWB cover lid.

(2) Push up the PWB cover lid and

(3) Rotate it counterclockwise to remove it.

2

1

PCL harness, 1 pc.

Screws (M3 x 6), 14 pcs.

Operation Manual

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

1) Remove the document cover.

● Remove the document cover from the copier.

Screws (M3 x 8), 5 pcs.

Installation manual, 1 sheet

CD ROM

3

1

4) Attach the PCL interface PWB.

● Fit the connector of the PCL interface PWB into the mounting posi-

tion of the copier, secure the side A with three screws, and then

secure the front B with two screws.

A

B

M3X8

M3X8

3 – 1

Page 5

AR-PB9

5) Attach the PCL PWB.

● While ensuring that the connector of the PCL PWB is securely connected to that of the copier, attach the PCL PWB to the PWB cover

with seven screws (M3 × 6) and connect the relay harness connector.

M3X6

M3X6

6) Attach the PCL harness.

● Attach the supplied PCL harness to the PCL PWB, then pass it

through the square hole of the PWB holder, and connect it to the

PCL interface PWB.

Note: Be careful about the direction of the blue lines.

Blue lines

8) Attach the PWB cover.

● Attach the supplied PWB cover with five screws (M3 × 6).

M3X6

M3X6

M3X6

M3X6

9) Attach the PWB cover lid 2.

● Hang the pawls of the supplied PWB cover lid 2 on the PWB cover

and attach the PWB cover lid 2 with two screws (M3 × 6).

1

2

7) Attach the PWB cover.

(1) Fit the upper part of the PWB cover lid to the upper screw

that has been loosened in step 3 above.

(2) While rotating the lower part of the PWB cover lid clock-

wise, fit it to the lower screw.

(3) Tighten the upper and lower screws to secure the cover lid.

2

3

M3X6

M3X6

Pawls

1

3

3 – 2

Page 6

AR-PB9

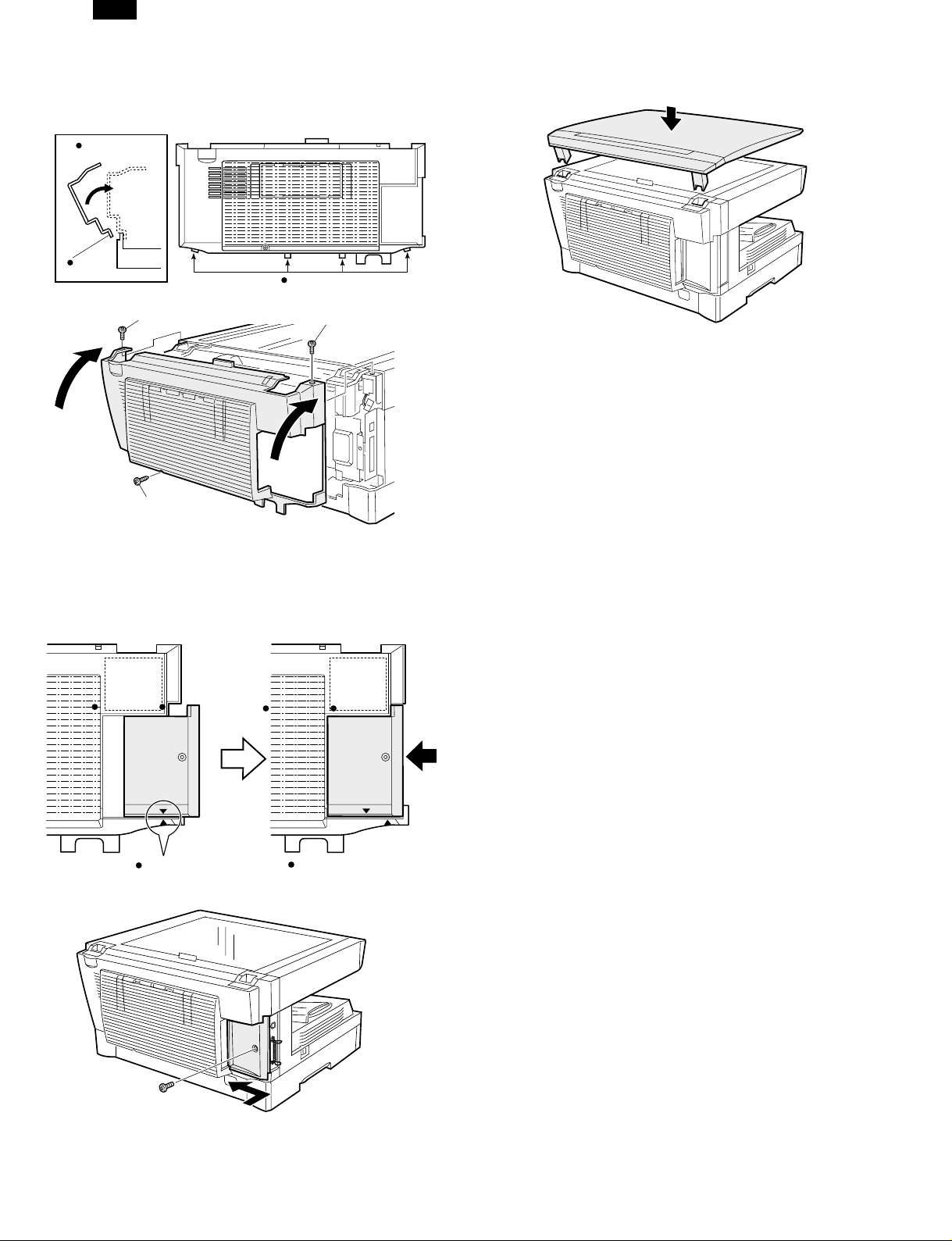

10) Attach the rear cabinet.

(1) Hang the four pawls shown in the illustration below on the

plate.

(2) Position the cabinet to the upper screw positions.

Side view

Pawl

Pawl

M3X8

M4X12

M3X8

12) Attach the document cover.

● Remove the document cover from the copier.

● Insert the power plug into the outlet and turn the main switch of the

copier to the “ON” position.

● Installation of the AR-PB9 is now complete.

2. INSTALLING THE PRINTER DRIVER

(Description of the printer driver)

The printer driver is the software program which runs the printer. It converts the data in your file into information that the printer can understand. It also controls communication between the printer and

computer as the data is printed.

11) Attach the cover to the rear cabinet.

(1) Align the arrow marks as shown in the illustration.

(2) Then slide the cover to the left.

(3) Secure the cover with a screw.

Arrow marks

After sliding

(Checking the hardware and software

requirements)

You will need the following hardware and software in order to install the

printer driver.

Computer type IBM PC/AT or compatible computer equipped

with a bi-directional parallel or USB interface,

and CD-ROM drive

Windows type Windows 3.1x, Windows 95, Windows 98*,

Windows NT 4.0 * USB is supported on Win-

dows 98 preinstalled only.

CPU 486DX 66MHz or better

Physical RAM Windows 95, Windows 3.1x: 8MB (16MB or

more is recommended.)

Windows NT 4.0: 12MB (16MB or more is

recommended.)

Windows 98: 16MB (32MB or more is recom-

mended.)

Display 640 × 480 dots (VGA) or better

Hard disk free space 10MB or more

Caution: The printer driver included in this product cannot be

used under Windows NT 3.5x, OS/2, pure MS-DOS

and other operating systems which are not described

above.

Note: The PCL6 printer driver is not available in Windows 3.1

environment.

(Installing the printer driver)

The software for your printer is provided on CD-ROM.

Before installing the printer driver, be sure to check the following items.

● Is the printer connected properly to the computer?

● Does the printer have paper?

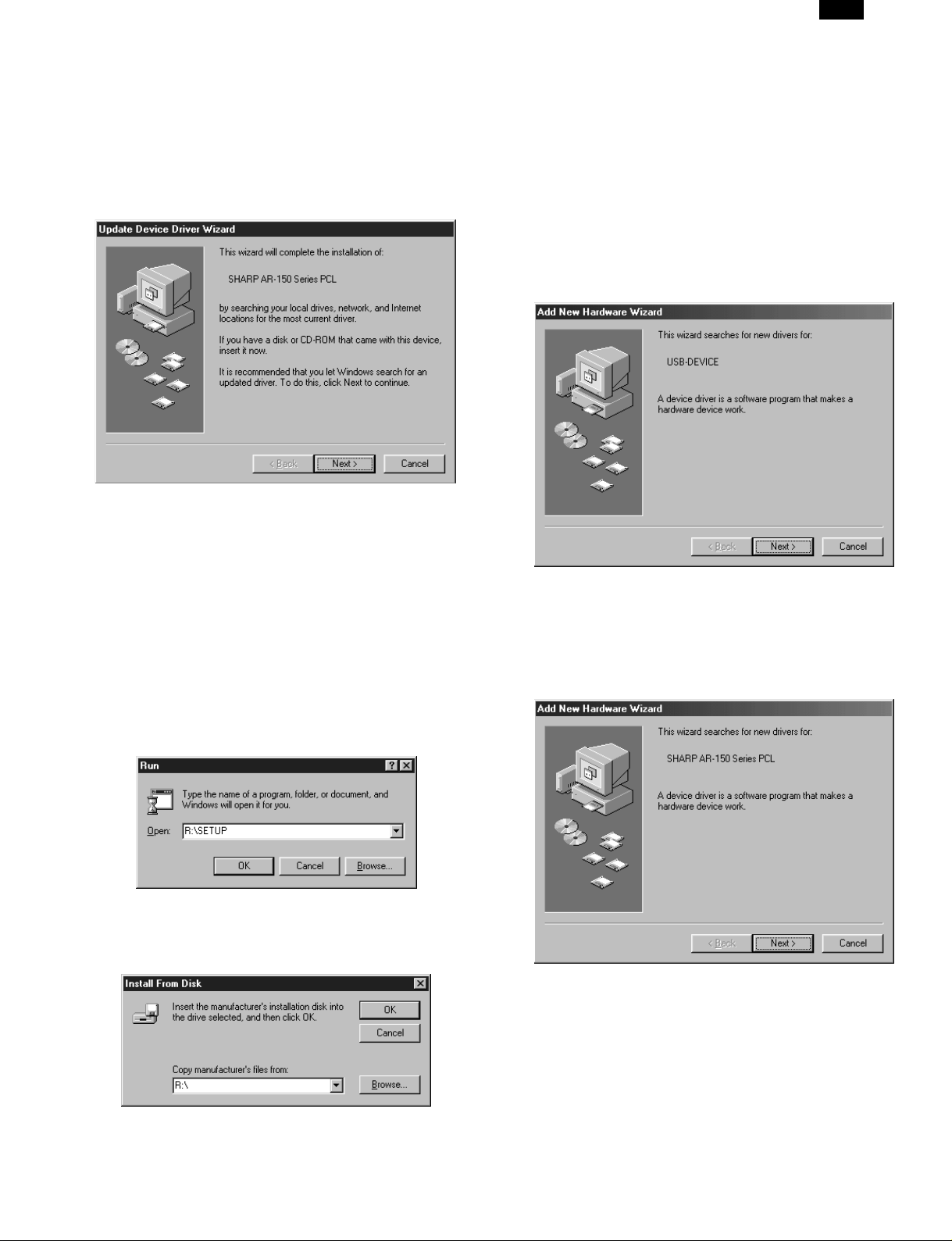

A. Windows 95/Windows NT 4.0 Installation

Instructions:

With both the computer and the printer turned off, connect the printer

to the computer with a parallel interface cable.

1) Load paper into the paper tray of the printer. For instructions

on loading paper, see the section LOADING COPY PAPER in

the copier operation manual.

2) Turn on the printer.

3 – 3

Page 7

AR-PB9

3) Turn on your computer and start Windows.

Note: Before installing the printer driver, be sure to close all

other applications which may be open.

4) When using Windows 95 on a personal computer with plug &

play*, the “Update Device Driver Wizard” window will appear. Insert the installation CD-ROM into the CD-ROM drive. Click the

Next button and follow the on-screen instructions. If the “Copy-

ing Files” window appears during this operation, enter R:\ (if the

CD-ROM is designated as drive R), click the OK button and follow the on-screen instructions.

● If you use Windows 95 and the “New Hardware Found” window will

appear, select Driver from Disk Provided by Hardware Manufacturer

and then click the OK button. Proceed to step 6.

● If you use Windows 95 and the screen shown above or the “New

Hardware Found” window does not appear, proceed to step 5.

● If you use Windows NT 4.0, proceed to step 5.

* Plug & play

This feature is effective if both the computer and peripheral equipment

are equipped with IEEE 1284 compliant parallel interface.

Note: The screen displayed depends on the version of Win-

dows you are using.

5) Insert the installation CD-ROM into the CD-ROM drive.

Click the Start button and select Run. When the screen shown

below appears, type R:\SETUP (if the CD-ROM is designated

as drive R) and click the OK button. Follow the on-screen instructions.

B. Windows 98:

With both the computer and the printer turned off, connect the printer

to the computer with either a parallel or a USB interface cable.

1) Load paper into the paper tray of the printer. For instructions

on loading paper, see the section LOADING COPY PAPER

found in the copier operation manual.

2) Turn on the printer.

3) Turn on your computer and start Windows.

When using the USB interface:

● Connect your personal computer and the printer using a USB inter-

face cable if you have not already done so. (For information about

connecting the USB interface cable)

● When the “Add New Hardware Wizard” window appears, insert the

installation CD-ROM, click the Next button, follow the on-screen instructions, and finally click the Finish button.

Note: Before installing the printer driver, be sure to close all

other applications which may be open.

4) When using Windows 98 on a personal computer with plug &

play*, the “Add New Hardware Wizard” window will appear.

Click the Next button and follow the on-screen instructions.

● If the “Add New Hardware Wizard” window does not appear, proceed

to step 8.

6) The “Install From Disk” window will appear. Insert the installation CD-ROM into the CD-ROM drive. Type R:\ (if the CD-ROM

is designated as drive R) and click the OK button. Follow the

on-screen instructions.

Note: If you have any problem with the test print, check the

symptoms and solutions. Print the test page again after

resolving the problem.

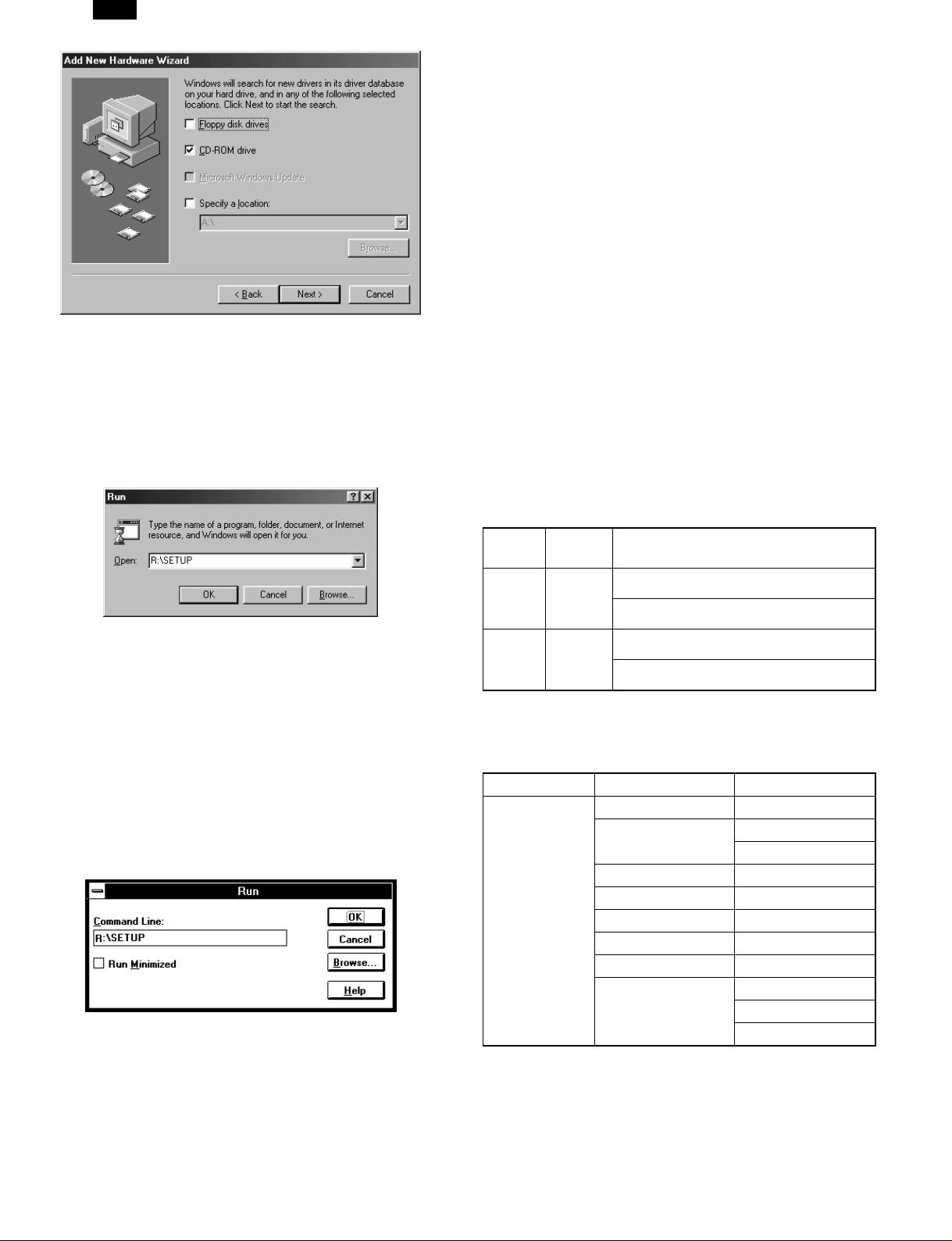

5) Select Search for the best driver for your device and click the

Next button.

6) Insert the installation CD-ROM into the CD-ROM drive. (If you

are using the USB interface, confirm that the installation CDROM is in the CD-ROM drive.) Select the CD-ROM drive and

click the Next button.

3 – 4

Page 8

AR-PB9

7) Windows driver file search will find the device “SHARP AR-150

Series PCL”. Click the Next button and follow the on-screen instructions.

8) Insert the installation CD-ROM into the CD-ROM drive. (If you

are using the USB interface, confirm that the installation CDROM is in the CD-ROM drive.) Click the Start button and select

Run. When the window shown below appears, type R:\SETUP

(if the CD-ROM is designated as drive R) and click the OK button. Follow the on-screen instructions.

For proper uninstallation, be sure to use the SHARP uninstall program

of the printer driver group.

Readme

The latest information on the printer driver is included in this document.

Read the Readme first.

Status Monitor

The Status Monitor window provides visual information about the

printer state and current job.

Status Monitor HELP

Assistance and information for Status Monitor.

● Be sure to read the “Readme” document found in the printer driver

group before using your SHARP AR-150 Series PCL printer.

● You cannot use both the status monitor and the Print Manager at the

same time in Windows 3.1 environment.

3. TEST PRINTING

To test print the configuration page and font list, use the following procedure:

1) Press and hold down the light and dark keys simultaneously for

more than 5 seconds until all the alarm indicators blink and “--”

appears in the display.

2) Set “6” (configuration page) or “7” (font list) using the left copy

quantity key. The selected number will blink in the left side of

the display.

3) Press the print key. The entered program number will be steadi-

ly lit and the currently selected parameter number for the program will blink on the right side of the display.

4) Select the desired parameter using the right copy quantity key.

The entered parameter number will blink on the right of the display.

C. Windows 3.1x:

With both the computer and the printer turned off, connect the printer

to the computer with a parallel interface cable.

1) Load paper into the paper tray of the printer. For instructions

on loading paper, see the section LOADING COPY PAPER in

the copier operation manual.

2) Turn on the printer and then start Windows on your computer.

Note: Before installing the printer driver, be sure to close all

other applications which may be open.

3) Insert the installation CD-ROM into the CD-ROM drive.

4) Choose File from the Menu bar in Program Manager, and then

choose the Run... command.

5) Type R:\SETUP (if the CD-ROM is designated as drive R) in

the command line box and then click the OK button.

6) Follow the on-screen instructions.

D. AR-150 Series PCL printer driver group

When you install the printer driver, the SHARP AR-150 Series PCL

printer driver group is automatically created. The printer driver group includes the following items:

Uninstall AR-150 Series PCL

The printer driver can be uninstalled. If the driver is uninstalled, printing

can no longer be performed on the printer.

Program

No.

6

7 Font list

5) Press the print key. The test page prints.

Note: To change the setting or to set another mode, press the

Configuration Page items

1st level item 2nd level item 3rd level item

Hardware Status

Mode Parameters

Configu-

ration

page

clear key. The printer will return to step 2.

0 → English 1 → French 2 → Spanish

3 → Italian 4 → German

0 → English 1 → French 2 → Spanish

3 → Italian 4 → German

Machine Information Language

Hardware Specs

Processor 64 bit RISC

Interface Menu I/O Timeout

ROM Version

Total Page Count

Version Information PCL6

Input Paper Tray

Basic Memory

Total Memory

Bypass Tray

Tray 1

Tray 2

3 – 5

Page 9

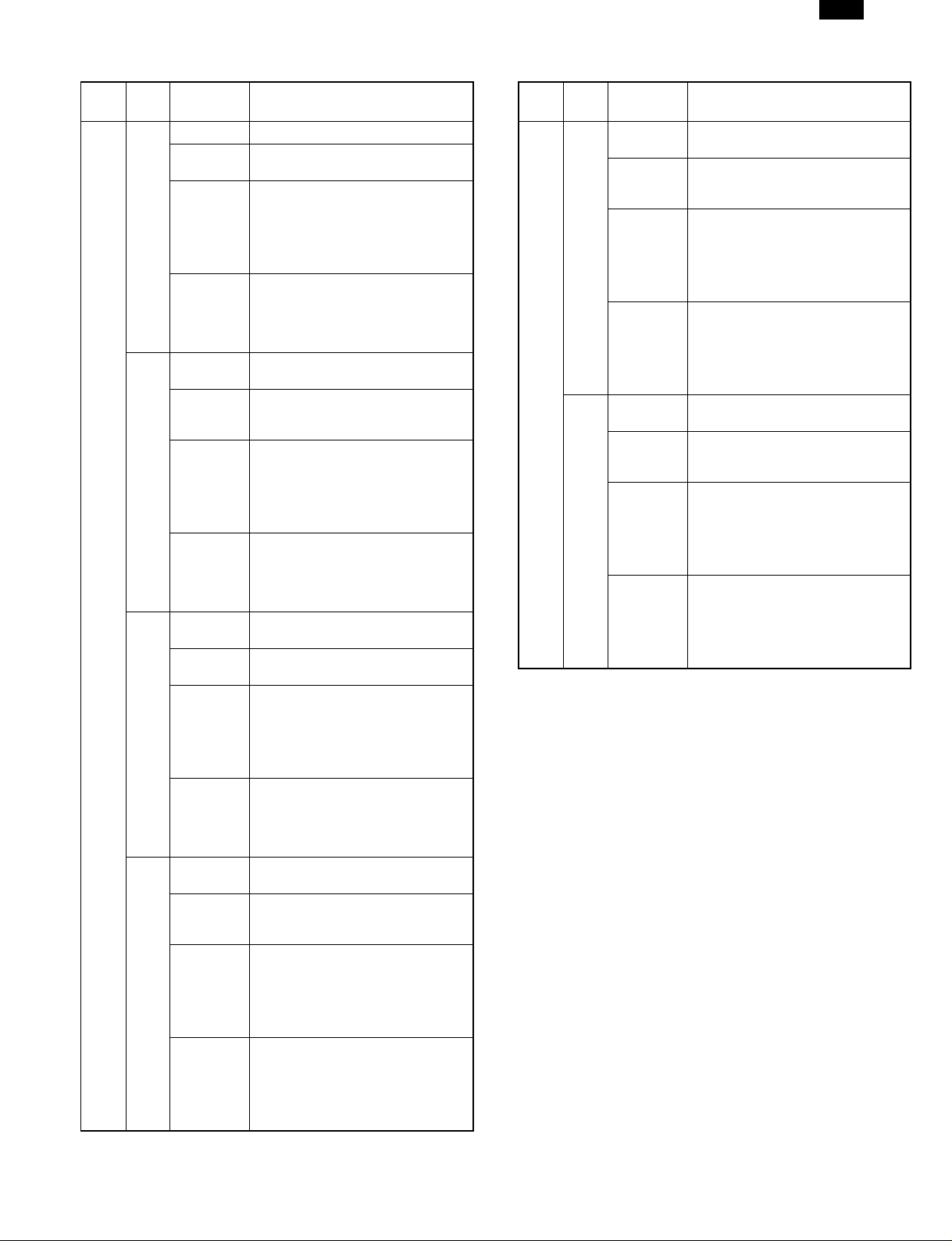

[4] TROUBLE CODE LIST

Main

Sub

code

code

F9 10 Content Printer PWB trouble

Detail Communication trouble between

Cause Printer PWB connector

Check

and

remedy

80 Content Printer PWB communication trouble

Detail Communication trouble between

Cause Printer PWB connector

Check

and

remedy

81 Content Printer PWB communication trouble

Detail Communication trouble between

Cause Printer PWB connector

Check

and

remedy

82 Content Printer PWB communication trouble

Detail Communication trouble between

Cause Printer PWB connector

Check

and

remedy

MCU and PRT

disconnection

Printer unit PWB MCU PWB

harness failure

Printer PWB ROM defect, data

failure

Check the connectors and harness

of the printer PWB and the MCU

PWB.

Check grounding of the machine.

Check the ROM of the printer PWB.

(protocol)

MCU and printer PWB (Protocol

error)

disconnection

Printer PWB MCU PWB harness

failure

Printer PWB ROM defect, data

failure

Check the connectors and harness

of the printer PWB and the MCU

PWB.

Check grounding of the machine.

Check the ROM of the printer PWB.

(Parity)

MCU and printer PWB (Parity error)

disconnection

Printer PWB MCU PWB harness

failure

Printer PWB ROM defect, data

failure

Check the connectors and harness

of the printer PWB and the MCU

PWB.

Check grounding of the machine.

Check the ROM of the printer PWB.

(Overrun)

MCU and printer PWB (Overrun

error)

disconnection

Printer PWB MCU PWB harness

failure

Printer PWB ROM defect, data

failure

Check the connectors and harness

of the Printer PWB and the MCU

PWB.

Check grounding of the machine.

Check the ROM of the Printer

PWB.

Detail of trouble

AR-PB9

Main

code

Sub

code

F9 84 Content Printer PWB communication trouble

Detail Communication trouble between

Cause Printer PWB connector

Check

and

remedy

88 Content Printer PWB communication trouble

Detail Communication trouble between

Cause Printer PWB connector

Check

and

remedy

(Framing)

MCU and printer PWB (Framing

error)

disconnection

Printer PWB MCU PWB harness

failure

Printer PWB ROM defect, data

failure

Check the connectors and harness

of the Printer PWB and the MCU

PWB.

Check grounding of the machine.

Check the ROM of the Printer

PWB.

(Time-out)

MCU and printer PWB (Time-out

error)

disconnection

Printer PWB MCU PWB harness

failure

Printer PWB ROM defect, data

failure

Check the connectors and harness

of the Printer PWB and the MCU

PWB.

Check grounding of the machine.

Check the ROM of the Printer

PWB.

Detail of trouble

4 – 1

Page 10

AR-PB9

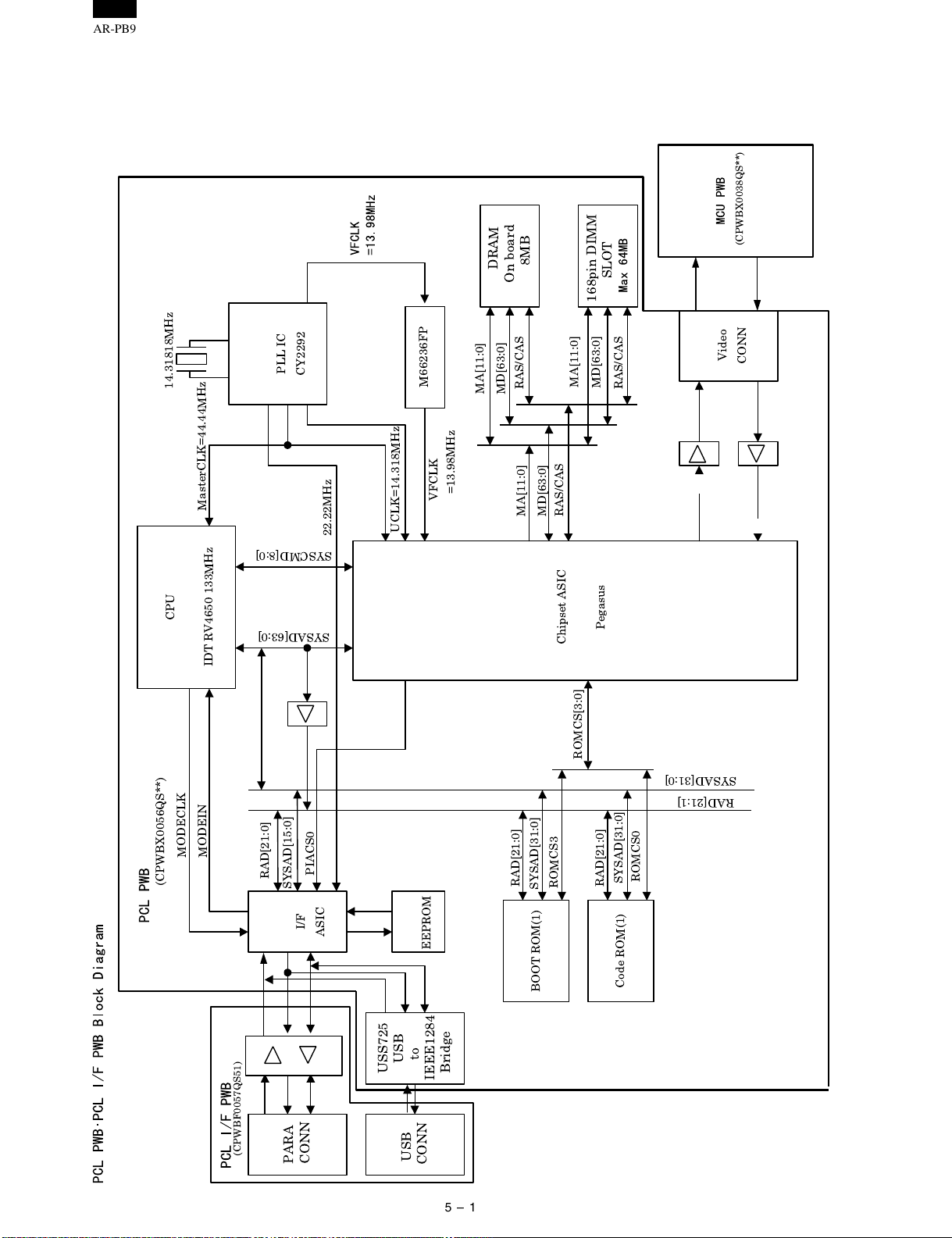

[5] ELECTRICAL SECTION

1. Block diagram

A. Overall block diagram

PLL IC

14.31818MHz

CY2292

M66236FP

DRAM

On board

MA[11:0]

MD[63:0]

8MB

RAS/CAS

SLOT

168pin DIMM

MA[11:0]

MD[63:0]

RAS/CAS

(CPWBX0038QS**)

Video

CONN

MasterCLK=44.44MHz

CPU

IDT RV4650 133MHz

MODECLK

MODEIN

(CPWBX0056QS**)

RAD[21:0]

SYSAD[15:0]

I/F

22.22MHz

SYSCMD[8:0]

SYSAD[63:0]

PIACS0

ASIC

=13.98MHz

VFCLK

UCLK=14.318MHz

EEPROM

MD[63:0]

MA[11:0]

RAD[21:0]

ROMCS3

SYSAD[31:0]

RAS/CAS

Chipset ASIC

ROMCS[3:0]

Pegasus

ROMCS0

SYSAD[31:0]

RAD[21:0]

SYSAD[31:0]

RAD[21:1]

(CPWBF0057QS51)

PARA

CONN

to

USB

USS725

USB

Bridge

IEEE1284

CONN

5 – 1

BOOT ROM(1)

Code ROM(1)

Page 11

AR-PB9

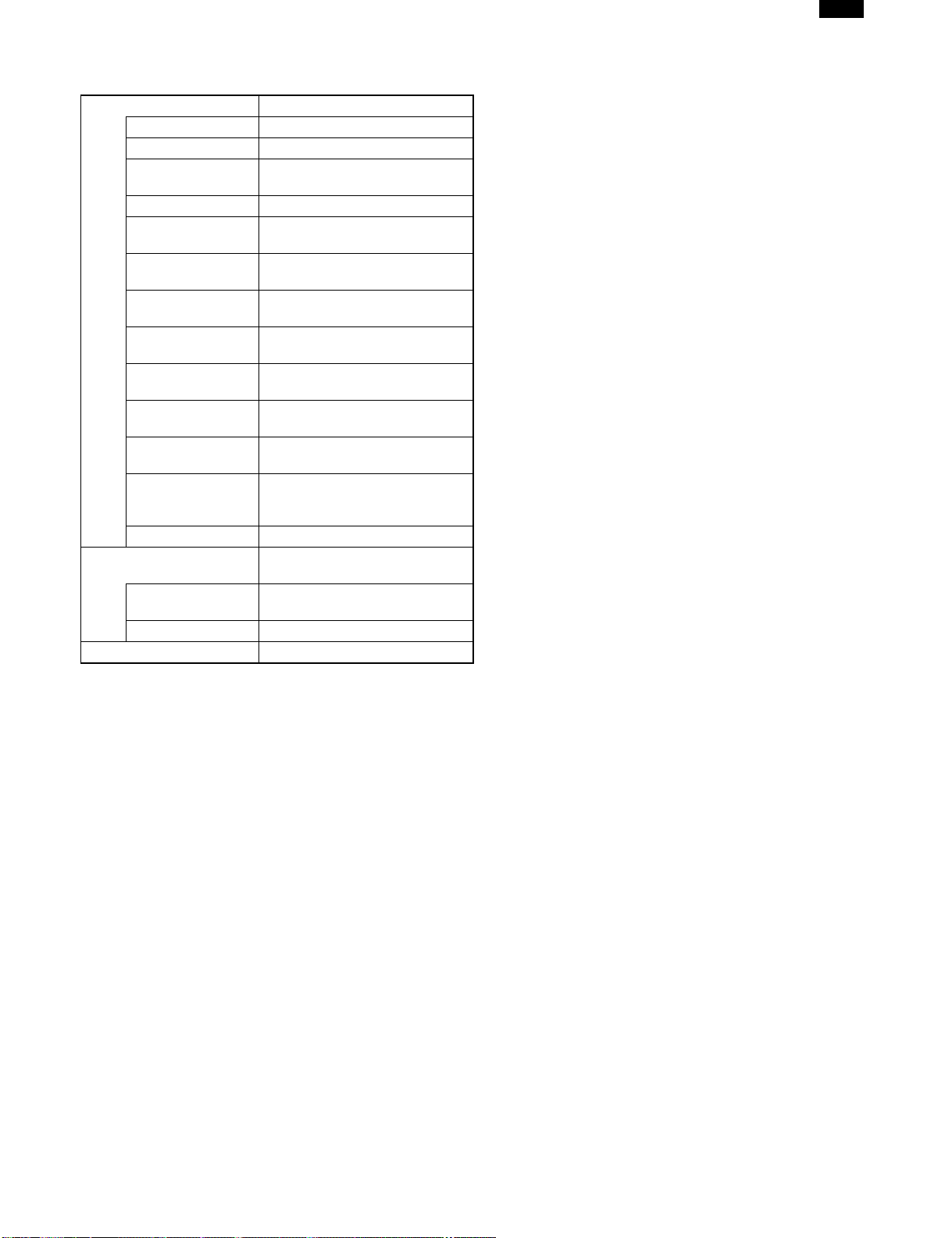

2. Block diagram functional descriptions

Descriptions of each block

PCL PWB Controls PCL print.

CPU Control IC

Chipset ASIC Image forming, ROM/RAM access

PLL IC

M66236FP Jitter adjustment IC

I/F ASIC

EEPROM

BOOTROM (1)

Code ROM (1)

USS725 USB to

IEEE1284 Bridge

DRAM On board 8MBWork RAM for the system and

168 pin DIMM

SLOT Max 64 MB

Video CONN

14.31818 MHz PLL IC reference clock

PCL I/F PWB Interface PWB for connection of

PARACONN

USB CONN USB connector

MCU PWB Digital copier main control PWB

CPU/ASIC/M66236fp clock

generation

IEEE1284 parallel conversion

ASIC

Stores device ID and data

necessary for control.

Stores data necessary for booting

programs.

Stores PCL process program and

fonts.

Converts USB standard signals

into IEEE1284 standard signals.

PCL process

Work RAM for PCL process

(Expanded by expansion RAM.)

Interface connector for

communication between MCU

PWB and PCL PWB

external device and PCL PWB

IEEE1284 conforming Centronics

connector

Operational descriptions

Connected to PARACONN or USBCONN of PCL I/F PWB

(CPWBF0057QS51).

Print data made by page description language is inputted from an external device.

The PCL I/F PWB (CPWBF0057QS51) is provided with two kinds of

connectors for external devices. The suitable connector is determined

according to the connection type with an external device as follows:

● An external device is connected to PARACONN, and not connected

to USBCONN.

→ Data sent from the external device connected to

PARACONN is printed.

● An external device is not connected to PARACONN, but connected

to USBCONN.

→ Data sent from the external device connected to USBCONN

is printed.

● An external device is connected to PARACONN, and connected to

USBCONN.

→ Data sent from the external device connected to USBCONN

is printed.

The external device connected to PARACONN is not recognized.

Data inputted to PCL I/F PWB is inputted to PCL PWB and PCLdecoded and converted to generate BITMAP data for print.

To generate BITMAP data for print, DRAM On board 8 MB and the expansion RAM inserted into the 168 pin DIMM are used as the work

area.

BITMAP data generated in PCL PWB are subject to jitter adjustment by

M66236FP, and inputted to MCU PWB through Video CONN to perform laser output and print.

5 – 2

Page 12

AR-PB9

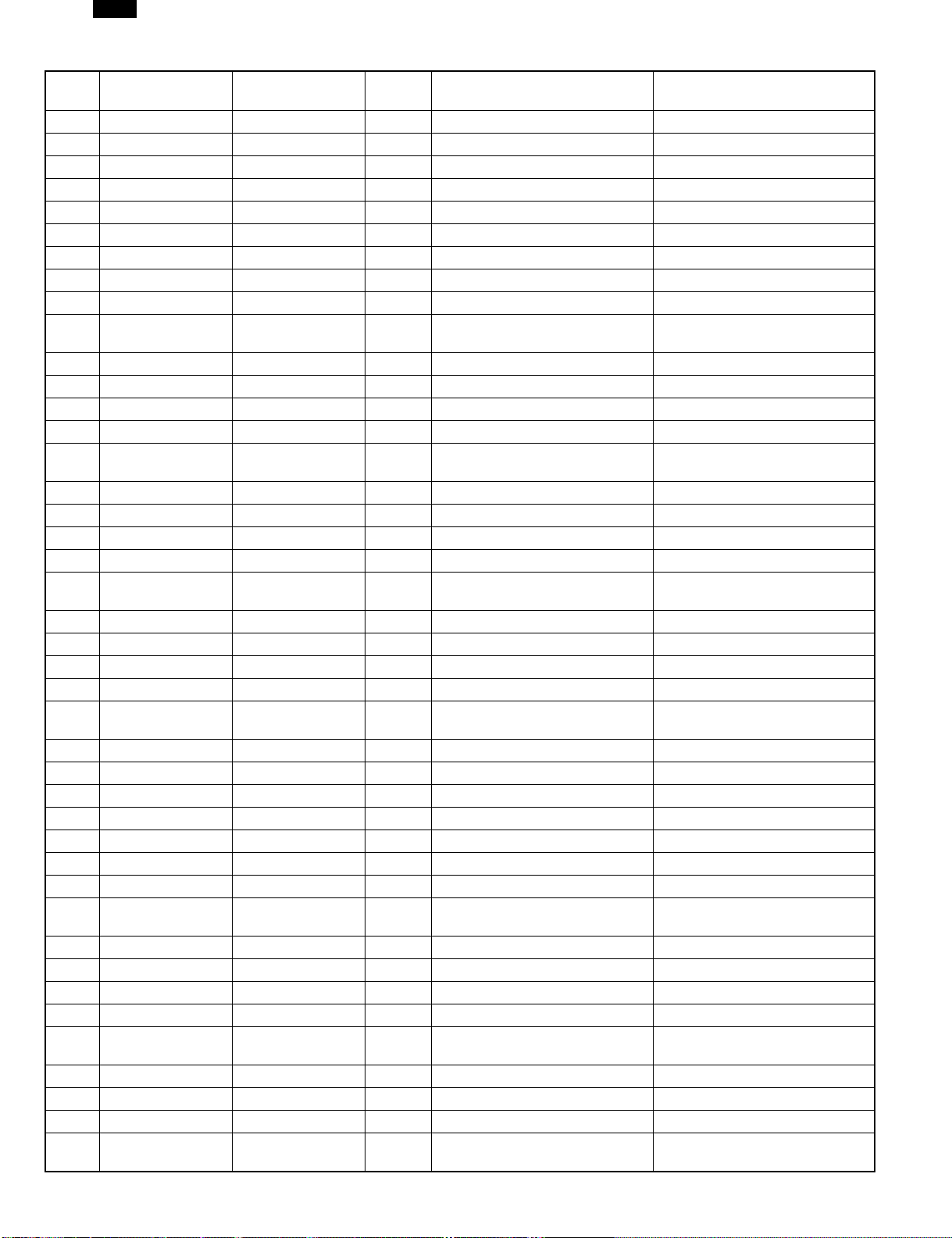

CPU (VHIIDT79RC465) I/O pin arrangement list (PCL Model)

PIN

No.

Pin name Signal name IN/OUT Destination Function

1 N.C N.C N.C,

2 N.C N.C N.C

3 N.C N.C N.C

4 N.C N.C N.C

5 N.C N.C N.C

6 N.C N.C N.C

7 N.C N.C N.C

8 N.C N.C N.C

9 N.C N.C N.C

10 SYSAD11 SYSAD11 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

11 V

12 V

SS

CC

GND IN GND

3.3V IN Power source

13 SYSCMD8 SYSCMD8 OUT ASIC (KZ4H167V06) System command data bus

14 SYSAD42 SYSAD42 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

15 SYSAD10 SYSAD10 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

16 SYSCMD7 SYSCMD7 OUT ASIC (KZ4H167V06) System command data bus

17 V

18 V

SS

CC

GND IN GND

3.3V IN Power source

19 SYSAD41 SYSAD41 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

20 SYSAD9 SYSAD9 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

21 SYSCMD6 SYSCMD6 OUT ASIC (KZ4H167V06) System command data bus

22 SYSAD40 SYSAD40 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

23 V

24 V

SS

CC

25 SYSAD8 SYSAD8 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

GND IN GND

3.3V IN Power source

System address data bus

8M FLASH, 74LVC16245

26 SYSCMD5 SYSCMD5 OUT ASIC (KZ4H167V06) System command data bus

27 SYSADC4 IN NC (3.3V pull up)

28 SYSADC0 IN NC (3.3V pull up)

29 V

30 V

SS

CC

GND IN GND

3.3V IN Power source

31 SYSCMD4 SYSCMD4 OUT ASIC (KZ4H167V06) System command data bus

32 SYSAD39 SYSAD39 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

33 SYSAD7 SYSAD7 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

34 SYSCMD3 SYSCMD3 OUT ASIC (KZ4H167V06) System command data bus

35 V

36 V

SS

CC

GND IN GND

3.3V IN Power source

37 SYSAD38 SYSAD38 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

38 SYSAD6 SYSAD6 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

39 MODECLOCK MODECLK OUT ASIC(KZ3H008302) Boot mode clock

40 WR RDY READY_ IN External IC write ready

41 SYSAD37 SYSAD37 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

42 SYSAD5 SYSAD5 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

5 – 3

Page 13

AR-PB9

PIN

No.

43 V

44 V

Pin name Signal name IN/OUT Destination Function

SS

CC

GND IN GND

3.3V IN Power source

45 N.C N.C N.C

46 N.C N.C N.C

47 N.C N.C N.C

48 N.C N.C N.C

49 N.C N.C N.C

50 N.C N.C N.C

51 N.C N.C N.C

52 N.C N.C N.C

53 N.C N.C N.C

54 N.C N.C N.C

55 N.C N.C N.C

56 N.C N.C N.C

57 SYSCMD2 SYSCMD2 OUT ASIC (KZ4H167V06) System command data bus

58 SYSAD36 SYSAD36 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

59 SYSAD4 SYSAD4 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

60 SYSCMD1 SYSCMD1 OUT ASIC (KZ4H167V06) System command data bus

61 V

62 V

SS

CC

GND IN GND

3.3V IN Power source

63 SYSAD35 SYSAD35 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

64 SYSAD3 SYSAD3 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

65 SYSCMD0 SYSCMD0 OUT ASIC (KZ4H167V06) System command data bus

66 SYSAD34 SYSAD34 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

67 V

68 V

SS

CC

69 SYSAD2 SYSAD2 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

GND IN GND

3.3V IN Power source

System address data bus

8M FLASH, 74LVC16245

70 INT5 IN NC (3.3V pull up)

71 SYSAD33 SYSAD33 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

72 SYSAD1 SYSAD1 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

73 V

74 V

SS

CC

GND IN GND

3.3V IN Power source

75 INT4 IN NC (3.3V pull up)

76 SYSAD32 SYSAD32 IN/OUT ASIC(KZ4H167V06) System address data bus

77 SYSAD0 SYSAD0 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

78 INT3 PARINTR_ IN ASIC(KZ3H008302) Print request interruption input

79 V

80 V

SS

CC

GND IN GND

3.3V IN Power source

81 INT2 INTR2_ IN ASIC(KZ4H167V06) ASIC interruption 2

82 SYSAD16 SYSAD16 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

83 SYSAD48 SYSAD48 IN/OUT ASIC (KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16244

84 INT1 INTR1_ IN ASIC(KZ4H167V06) ASIC interruption 1

5 – 4

Page 14

AR-PB9

PIN

No.

85 V

86 V

87 SYSAD17 SYSAD17 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

Pin name Signal name IN/OUT Destination Function

SS

CC

GND IN GND

3.3V IN Power source

System address data bus

8M FLASH

88 SYSAD49 SYSAD49 IN/OUT ASIC (KZ4H167V06), 74LVC244 System address data bus

89 INT0 INTR0_ IN ASIC(KZ4H167V06) ASIC interruption 0

90 SYSAD18 SYSAD18 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

91 V

92 V

SS

CC

GND IN GND

3.3V IN Power source

93 SYSAD50 SYSAD50 IN/OUT ASIC (KZ4H167V06), 74LVC244 System address data bus

94 VALID IN VALIN_ IN ASIC (KZ4H167V06) VALID INPUT (from ASIC)

95 SYSAD19 SYSAD19 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

96 SYSAD51 SYSAD51 IN/OUT ASIC (KZ4H167V06), 74LVC244 System address data bus

97 V

98 V

SS

CC

GND IN GND

3.3V IN Power source

99 VALID OUT VALOUT_ OUT ASIC (KZ4H167V06) VALID OUTPUT(to ASIC)

100 SYSAD20 SYSAD20 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

101 N.C N.C N.C

102 N.C N.C N.C

103 N.C N.C N.C

104 N.C N.C N.C

105 N.C N.C N.C

106 N.C N.C N.C

107 N.C N.C N.C

108 N.C N.C N.C

109 N.C N.C N.C

110 N.C N.C N.C

111 N.C N.C N.C

112 N.C N.C N.C

113 N.C N.C N.C

114 SYSAD52 SYSAD52 IN/OUT ASIC (KZ4H167V06), 74LVC244 System address data bus

115 EXT RQST EXTRQ_ IN ASIC(KZ4H167V06) External request

116 V

117 V

CC

SS

118 SYSAD21 SYSAD21 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

3.3V IN Power source

GND IN GND

System address data bus

8M FLASH

119 SYSAD53 SYSAD53 IN/OUT ASIC (KZ4H167V06), 74LVC244 System address data bus

120 RDRDY READY_ IN ASIC(KZ4H167V06) External IC read ready

121 MODEIN MODEIN IN ASIC(KZ3H008302) Boot mode data input

122 SYSAD22 SYSAD22 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

123 SYSAD54 SYSAD54 IN/OUT ASIC (KZ4H167V06) System address data bus

124 V

125 V

CC

SS

3.3V IN Power source

GND IN GND

126 RELEASE RLS_ OUT ASIC(KZ4H167V06) Interface open state

5 – 5

Page 15

AR-PB9

PIN

No.

127 SYSAD23 SYSAD23 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

Pin name Signal name IN/OUT Destination Function

System address data bus

8M FLASH

128 SYSAD55 SYSAD55 IN/OUT ASIC (KZ4H167V06) System address data bus

129 NMI NMI_ IN ASIC(KZ4H167V06) Non-maskable interruption

130 V

131 V

CC

SS

3.3V IN Power source

GND IN GND

132 SYSADC2 3.3V IN Power source

133 SYSADC6 3.3V IN Power source

134 SYSAD24 SYSAD24 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

135 V

136 V

CC

SS

3.3V IN Power source

GND IN GND

137 SYSAD56 SYSAD56 IN/OUT ASIC (KZ4H167V06) System address data bus

138 SYSAD25 SYSAD25 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

139 SYSAD57 SYSAD57 IN/OUT ASIC (KZ4H167V06) System address data bus

140 V

141 V

CC

SS

3.3V IN Power source

GND IN GND

142 N.C N.C N.C

143 SYSAD26 SYSAD26 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

144 SYSAD58 SYSAD58 IN/OUT ASIC (KZ4H167V06) System address data bus

145 N.C N.C N.C

146 V

147 V

CC

SS

148 SYSAD27 SYSAD27 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

3.3V IN Power source

GND IN GND

System address data bus

8M FLASH

149 N.C N.C N.C

150 N.C N.C N.C

151 N.C N.C N.C

152 N.C N.C N.C

153 N.C N.C N.C

154 N.C N.C N.C

155 N.C N.C N.C

156 N.C N.C N.C

157 N.C N.C N.C

158 N.C N.C N.C

159 SYSAD59 SYSAD59 IN/OUT ASIC (KZ4H167V06) System address data bus

160 COLD RESET COLDRES_ IN ASIC(KZ4H167V06) Clod reset

161 SYSAD28 SYSAD28 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

162 V

163 V

CC

SS

3.3V IN Power source

GND IN GND

164 SYSAD60 SYSAD60 IN/OUT ASIC (KZ4H167V06) System address data bus

165 RESET CPURES_ IN ASIC(KZ4H167V06) CPU reset

166 SYSAD29 SYSAD29 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

167 SYSAD61 SYSAD61 IN/OUT ASIC (KZ4H167V06) System address data bus

5 – 6

Page 16

AR-PB9

PIN

No.

168 SYSAD30 SYSAD30 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

Pin name Signal name IN/OUT Destination Function

System address data bus

8M FLASH

169 V

170 V

CC

SS

3.3V IN Power source

GND IN GND

171 SYSAD62 SYSAD62 IN/OUT ASIC (KZ4H167V06) System address data bus

172 SYSAD31 SYSAD31 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH

173 SYSAD63 SYSAD63 IN/OUT ASIC (KZ4H167V06) System address data bus

174 V

175 V

176 V

CC

SS

OK VCCOK IN ASIC (KZ4H167V06),

CC

3.3V IN Power source

GND IN GND

VCC states effective

ASIC(KZ3H008302)

177 SYSADC3 IN NC (3.3V pull up)

178 SYSADC7 IN NC (3.3V pull up)

179 N.C N.C N.C

180 N.C N.C N.C

181 N.C N.C N.C

182 N.C N.C N.C

183 N.C N.C N.C

184 N.C N.C N.C

185 V

P 3.3V IN Power source

CC

186 VSSP GND IN GND

187 MASTER CLOCK MASTERCLK IN ASIC(KZ4H167V06), PLL

Master clock

IC(CY2292)

188 V

189 V

CC

SS

3.3V IN Power source

GND IN GND

190 SYSADC5 IN NC (3.3V pull up)

191 SYSADC1 IN NC (3.3V pull up)

192 V

193 V

CC

SS

GND IN GND

3.3V IN Power source

194 SYSAD47 SYSAD47 IN/OUT ASIC (KZ4H167V06), 74LVC16244 System address data bus

195 SYSAD15 SYSAD15 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

196 SYSAD46 SYSAD46 IN/OUT ASIC (KZ4H167V06), 74LVC16244 System address data bus

197 V

198 V

CC

SS

199 SYSAD14 SYSAD14 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

3.3V IN Power source

GND IN GND

System address data bus

8M FLASH, 74LVC16245

200 SYSAD45 SYSAD45 IN/OUT ASIC (KZ4H167V06), 74LVC16244 System address data bus

201 SYSAD13 SYSAD13 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

System address data bus

8M FLASH, 74LVC16245

202 SYSAD44 SYSAD44 IN/OUT ASIC (KZ4H167V06), 74LVC16244 System address data bus

203 V

204 V

SS

CC

205 SYSAD12 SYSAD12 IN/OUT ASIC(KZ4H167V06), 16M FLASH,

GND IN GND

3.3V IN Power source

System address data bus

8M FLASH, 74LVC16245

206 SYSCMDP IN NC (3.3V pull up)

207 SYSAD43 SYSAD43 IN/OUT ASIC(KZ4H167V06), 74LVC16244 System address data bus

208 N.C N.C N.C

5 – 7

Page 17

ChipsetASIC (VHIKZ4H167V06) I/O pin arrangement list (PCL Model)

AR-PB9

PIN

No.

1V

Pin name Signal name IN/OUT Destination Function

CC

3.3V IN Power source

2 SYSAD16 SYSAD16 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

3 SYSAD17 SYSAD17 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

4 SYSAD18 SYSAD18 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

5 SYSAD19 SYSAD19 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

6 SYSAD20 SYSAD20 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

7 SYSAD21 SYSAD21 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

8 SYSAD22 SYSAD22 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

9V

CC

3.3V IN Power source

10 GND GND IN GND

11 SYSAD23 SYSAD23 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

12 SYSAD24 SYSAD24 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

13 SYSAD25 SYSAD25 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

14 SYSAD26 SYSAD26 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

15 SYSAD27 SYSAD27 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

16 SYSAD28 SYSAD28 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

17 SYSAD29 SYSAD29 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

18 V

CC

3.3V IN Power source

19 GND GND IN GND

20 SYSAD30 SYSAD30 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

21 SYSAD31 SYSAD31 IN/OUT CPU, 16M FLASH, 8M FLASH System address data bus

22 SYSAD32 SYSAD32 IN/OUT CPU System address data bus

23 SYSAD33 SYSAD33 IN/OUT CPU, 74LVC16244 System address data bus

24 SYSAD34 SYSAD34 IN/OUT CPU, 74LVC16244 System address data bus

25 SYSAD35 SYSAD35 IN/OUT CPU, 74LVC16244 System address data bus

26 SYSAD36 SYSAD36 IN/OUT CPU, 74LVC16244 System address data bus

27 V

CC

3.3V IN Power source

28 GND GND IN GND

29 SYSAD37 SYSAD37 IN/OUT CPU, 74LVC16244 System address data bus

30 SYSAD38 SYSAD38 IN/OUT CPU, 74LVC16244 System address data bus

31 SYSAD39 SYSAD39 IN/OUT CPU, 74LVC16244 System address data bus

32 SYSAD40 SYSAD40 IN/OUT CPU, 74LVC16244 System address data bus

33 SYSAD41 SYSAD41 IN/OUT CPU, 74LVC16244 System address data bus

34 SYSAD42 SYSAD42 IN/OUT CPU, 74LVC16244 System address data bus

35 SYSAD43 SYSAD43 IN/OUT CPU, 74LVC16244 System address data bus

36 GND GND IN GND

37 GND GND IN GND

38 GND GND IN GND

39 V

CC

3.3V IN Power source

40 SYSAD44 SYSAD44 IN/OUT CPU, 74LVC16244 System address data bus

41 SYSAD45 SYSAD45 IN/OUT CPU, 74LVC16244 System address data bus

42 SYSAD46 SYSAD46 IN/OUT CPU, 74LVC16244 System address data bus

43 SYSAD47 SYSAD47 IN/OUT CPU, 74LVC16244 System address data bus

44 SYSAD48 SYSAD48 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16244

45 SYSAD49 SYSAD49 IN/OUT CPU, 74LVC244 System address data bus

46 SYSAD50 SYSAD50 IN/OUT CPU, 74LVC244 System address data bus

5 – 8

Page 18

AR-PB9

PIN

No.

Pin name Signal name IN/OUT Destination Function

47 SYSAD51 SYSAD51 IN/OUT CPU, 74LVC244 System address data bus

48 V

CC

3.3V IN Power source

49 GND GND IN GND

50 SYSAD52 SYSAD52 IN/OUT CPU, 74LVC244 System address data bus

51 SYSAD53 SYSAD53 IN/OUT CPU, 74LVC244 System address data bus

52 SYSAD54 SYSAD54 IN/OUT CPU System address data bus

53 SYSAD55 SYSAD55 IN/OUT CPU System address data bus

54 SYSAD56 SYSAD56 IN/OUT CPU System address data bus

55 SYSAD57 SYSAD57 IN/OUT CPU System address data bus

56 SYSAD58 SYSAD58 IN/OUT CPU System address data bus

57 SYSAD59 SYSAD59 IN/OUT CPU System address data bus

58 V

CC

3.3V IN Power source

59 GND GND IN GND

60 SYSAD60 SYSAD60 IN/OUT CPU System address data bus

61 SYSAD61 SYSAD61 IN/OUT CPU System address data bus

62 SYSAD62 SYSAD62 IN/OUT CPU System address data bus

63 SYSAD63 SYSAD63 IN/OUT CPU System address data bus

64 V

CC

3.3V IN Power source

65 GND GND IN GND

66 MASTERCLK MASTERCLK IN PLL IC(CY2292) Master clock

67 TESTMODE IN Test pin (3.3V)

68 DC2_TEST IN Test pin (GND)

69 SCAN_TEST IN Test pin (GND)

70 SCAN_EN IN Scan enable (GND)

71 PLL_EN RESET_ IN 74LS244 PLL enable

72 PLL_TEST IN Test pin (GND)

73 GND GND IN GND

74 V

75 V

CC

CC

3.3V IN Power source

3.3V IN Power source

76 CPOUT OUT Charge pump output

77 PLLGND GND IN PLL GND

78 PLLVDD 3.3V IN PLL power

79 VCOIN IN Loop filter input

80 GND GND IN GND

81 SYSCMD8 SYSCMD8 IN/OUT CPU System command data bus

82 SYSCMD7 SYSCMD7 IN/OUT CPU System command data bus

83 SYSCMD6 SYSCMD6 IN/OUT CPU System command data bus

84 SYSCMD5 SYSCMD5 IN/OUT CPU System command data bus

85 SYSCMD4 SYSCMD4 IN/OUT CPU System command data bus

86 SYSCMD3 SYSCMD3 IN/OUT CPU System command data bus

87 SYSCMD2 SYSCMD2 IN/OUT CPU System command data bus

88 SYSCMD1 SYSCMD1 IN/OUT CPU System command data bus

89 V

CC

3.3V IN Power source

90 GND GND IN GND

91 SYSCMD0 SYSCMD0 IN/OUT CPU System command data bus

92 /DACK3 N.C NC

93 /DACK2 N.C NC

5 – 9

Page 19

AR-PB9

PIN

No.

Pin name Signal name IN/OUT Destination Function

94 /DACK1 N.C NC

95 /DACK0 PARACK_ OUT ASIC(KZ3H008302) ACK_ signal to interface ASIC

96 /CPURST CPURST_ OUT CPU CPU reset signal

97 /CRST COLDRES_ OUT CPU Cold reset signal

98 VCCOK VCCOK OUT CPU, ASIC(KZ3H008302) V

99 V

CC

3.3V IN Power source

states effective

CC

100 GND GND IN GND

101 /NMI NMI_ OUT CPU Non-maskable interruption output

102 /INTR2 INTR2_ OUT CPU Interruption output 2

103 /INTR1 INTR1_ OUT CPU Interruption output 1

104 /INTR0 INTR0_ OUT CPU Interruption output 0

105 /EXREQ EXREQ_ OUT CPU Bus open request

106 /READY READY_ OUT CPU Command reception ready from

CPU

107 /VALIN VALIN_ OUT CPU VALID INPUT(to CPU)

108 /PIARD PIARD_ OUT 74LVC16245, ASIC(KZ3H008302) External peripheral Read Enable

109 V

CC

3.3V IN Power source

110 GND GND IN GND

111 GND GND IN GND

112 GND GND IN GND

113 SCLK SCLK IN PLL IC(CY2292) Serial clock

114 /DREQ3 IN NC (3.3V pull up)

115 /DREQ2 IN NC (3.3V pull up)

116 /DREQ1 IN NC (3.3V pull up)

117 /DREQ0 PARREQ_ IN ASIC(KZ3H008302) DREQ_ signal from interface ASIC

118 /POR RESET_ IN 74LS244 Power on reset

119 /RLS RLS_ IN CPU Bus open recognition

120 /VALOUT VALOUT_ IN CPU VALID OUTPUT(from CPU)

121 /WAIT IN GND

122 /PIAWE PIAWE_ OUT ASIC(KZ3H008302) External peripheral Write Enable

123 /PIACS5 NC

124 /PIACS4 NC

125 /PIACS3 NC

126 /PIACS2 NC

127 V

CC

3.3V IN Power source

128 GND GND IN GND

129 /PIACS1 NC

130 /PIACS0 LDTOE_ , 1284CS_ OUT 74LVC16245, ASIC(KZ3H008302) Interface ASIC chip select

131 /ROMCS3 RCS3_ OUT NC

132 /ROMCS2 RCS2_ NC

133 /ROMCS1 RCS1_ OUT LH28F800SUT Boot ROM chip select

134 /ROMCS0 RCS0_ OUT LH28F016SUT Code ROM chip select

135 /MWE MWE_ OUT 74LVC16244 DRAM write enable

136 /MOE MOE_ OUT 74LVC16244 DRAM output enable

137 V

CC

3.3V IN Power source

138 GND GND IN GND

139 /CAS7 CAS7_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

5 – 10

Page 20

AR-PB9

PIN

No.

Pin name Signal name IN/OUT Destination Function

140 /CAS6 CAS6_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

141 /CAS5 CAS5_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

142 /CAS4 CAS4_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

143 /CAS3 CAS3_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

144 /CAS2 CAS2_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

145 /CAS1 CAS1_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

146 /CAS0 CAS0_ OUT 16M Flash, DIMM168 DRAM CAS_ signal

147 GND GND IN GND

148 V

149 V

CC

CC

3.3V IN Power source

3.3V IN Power source

150 /RAS3 RAS3_ OUT NC

151 /RAS2 RAS2_ OUT 74LVC16244 DRAM RAS_ signal

152 /RAS1 RAS1_ OUT 74LVC16244 DRAM RAS_ signal

153 /RAS0 RAS0_ OUT 16M Flash DRAM RAS_ signal

154 MD63 MD63 IN/OUT 16M Flash, DIMM168 DRAM data signal

155 MD31 MD31 IN/OUT 16M Flash, DIMM168 DRAM data signal

156 MD62 MD62 IN/OUT 16M Flash, DIMM168 DRAM data signal

157 MD30 MD30 IN/OUT 16M Flash, DIMM168 DRAM data signal

158 V

CC

3.3V IN Power source

159 GND GND IN GND

160 MD61 MD61 IN/OUT 16M Flash, DIMM168 DRAM data signal

161 MD29 MD29 IN/OUT 16M Flash, DIMM168 DRAM data signal

162 MD60 MD60 IN/OUT 16M Flash, DIMM168 DRAM data signal

163 MD28 MD28 IN/OUT 16M Flash, DIMM168 DRAM data signal

164 MD59 MD59 IN/OUT 16M Flash, DIMM168 DRAM data signal

165 MD27 MD27 IN/OUT 16M Flash, DIMM168 DRAM data signal

166 MD58 MD58 IN/OUT 16M Flash, DIMM168 DRAM data signal

167 V

CC

3.3V IN Power source

168 GND GND IN GND

169 MD26 MD26 IN/OUT 16M Flash, DIMM168 DRAM data signal

170 MD57 MD57 IN/OUT 16M Flash, DIMM168 DRAM data signal

171 MD25 MD25 IN/OUT 16M Flash, DIMM168 DRAM data signal

172 MD56 MD56 IN/OUT 16M Flash, DIMM168 DRAM data signal

173 MD24 MD24 IN/OUT 16M Flash, DIMM168 DRAM data signal

174 MD55 MD55 IN/OUT 16M Flash, DIMM168 DRAM data signal

175 MD23 MD23 IN/OUT 16M Flash, DIMM168 DRAM data signal

176 V

CC

3.3V IN Power source

177 GND GND IN GND

178 MD54 MD54 IN/OUT 16M Flash, DIMM168 DRAM data signal

179 MD22 MD22 IN/OUT 16M Flash, DIMM168 DRAM data signal

180 MD53 MD53 IN/OUT 16M Flash, DIMM168 DRAM data signal

181 MD21 MD21 IN/OUT 16M Flash, DIMM168 DRAM data signal

182 MD52 MD52 IN/OUT 16M Flash, DIMM168 DRAM data signal

183 MD20 MD20 IN/OUT 16M Flash, DIMM168 DRAM data signal

184 GND GND IN GND

185 GND GND IN GND

186 GND GND IN GND

5 – 11

Page 21

AR-PB9

PIN

No.

187 V

Pin name Signal name IN/OUT Destination Function

CC

3.3V IN Power source

188 MD51 MD51 IN/OUT 16M Flash, DIMM168 DRAM data signal

189 MD19 MD19 IN/OUT 16M Flash, DIMM168 DRAM data signal

190 MD50 MD50 IN/OUT 16M Flash, DIMM168 DRAM data signal

191 MD18 MD18 IN/OUT 16M Flash, DIMM168 DRAM data signal

192 MD49 MD49 IN/OUT 16M Flash, DIMM168 DRAM data signal

193 MD17 MD17 IN/OUT 16M Flash, DIMM168 DRAM data signal

194 MD48 MD48 IN/OUT 16M Flash, DIMM168 DRAM data signal

195 V

CC

3.3V IN Power source

196 GND GND IN GND

197 MD16 MD16 IN/OUT 16M Flash, DIMM168 DRAM data signal

198 MD47 MD47 IN/OUT 16M Flash, DIMM168 DRAM data signal

199 MD15 MD15 IN/OUT 16M Flash, DIMM168 DRAM data signal

200 MD46 MD46 IN/OUT 16M Flash, DIMM168 DRAM data signal

201 MD14 MD14 IN/OUT 16M Flash, DIMM168 DRAM data signal

202 MD45 MD45 IN/OUT 16M Flash, DIMM168 DRAM data signal

203 MD13 MD13 IN/OUT 16M Flash, DIMM168 DRAM data signal

204 V

CC

3.3V IN Power source

205 GND GND IN GND

206 MD44 MD44 IN/OUT 16M Flash, DIMM168 DRAM data signal

207 MD12 MD12 IN/OUT 16M Flash, DIMM168 DRAM data signal

208 MD43 MD43 IN/OUT 16M Flash, DIMM168 DRAM data signal

209 MD11 MD11 IN/OUT 16M Flash, DIMM168 DRAM data signal

210 MD42 MD42 IN/OUT 16M Flash, DIMM168 DRAM data signal

211 MD10 MD10 IN/OUT 16M Flash, DIMM168 DRAM data signal

212 MD41 MD41 IN/OUT 16M Flash, DIMM168 DRAM data signal

213 V

CC

3.3V IN Power source

214 GND GND IN GND

215 MD9 MD9 IN/OUT 16M Flash, DIMM168 DRAM data signal

216 MD40 MD40 IN/OUT 16M Flash, DIMM168 DRAM data signal

217 MD8 MD8 IN/OUT 16M Flash, DIMM168 DRAM data signal

218 MD39 MD39 IN/OUT 16M Flash, DIMM168 DRAM data signal

219 MD7 MD7 IN/OUT 16M Flash, DIMM168 DRAM data signal

220 MD38 MD38 IN/OUT 16M Flash, DIMM168 DRAM data signal

221 MD6 MD6 IN/OUT 16M Flash, DIMM168 DRAM data signal

222 V

223 V

CC

CC

3.3V IN Power source

3.3V IN Power source

224 GND GND IN GND

225 MD37 MD37 IN/OUT 16M Flash, DIMM168 DRAM data signal

226 MD5 MD5 IN/OUT 16M Flash, DIMM168 DRAM data signal

227 MD36 MD36 IN/OUT 16M Flash, DIMM168 DRAM data signal

228 MD4 MD4 IN/OUT 16M Flash, DIMM168 DRAM data signal

229 MD35 MD35 IN/OUT 16M Flash, DIMM168 DRAM data signal

230 MD3 MD3 IN/OUT 16M Flash, DIMM168 DRAM data signal

231 MD34 MD34 IN/OUT 16M Flash, DIMM168 DRAM data signal

232 V

CC

3.3V IN Power source

233 GND GND IN GND

5 – 12

Page 22

AR-PB9

PIN

No.

Pin name Signal name IN/OUT Destination Function

234 MD2 MD2 IN/OUT 16M Flash, DIMM168 DRAM data signal

235 MD33 MD33 IN/OUT 16M Flash, DIMM168 DRAM data signal

236 MD1 MD1 IN/OUT 16M Flash, DIMM168 DRAM data signal

237 MD32 MD32 IN/OUT 16M Flash, DIMM168 DRAM data signal

238 MD0 MD0 IN/OUT 16M Flash, DIMM168 DRAM data signal

239 MA11 MA11 IN/OUT 74LVC16244 DRAM address signal

240 MA10 MA10 IN/OUT 74LVC16244 DRAM address signal

241 V

CC

3.3V IN Power source

242 GND GND IN GND

243 MA9 MA9 IN/OUT 74LVC16244 DRAM address signal

244 MA8 MA8 IN/OUT 74LVC16244 DRAM address signal

245 MA7 MA7 IN/OUT 74LVC16244 DRAM address signal

246 MA6 MA6 IN/OUT 74LVC16244 DRAM address signal

247 MA5 MA5 IN/OUT 74LVC16244 DRAM address signal

248 MA4 MA4 IN/OUT 74LVC16244 DRAM address signal

249 MA3 MA3 IN/OUT 74LVC16244 DRAM address signal

250 V

CC

3.3V IN Power source

251 GND GND IN GND

252 MA2 MA2 IN/OUT 74LVC16244 DRAM address signal

253 MA1 MA1 IN/OUT 74LVC16244 DRAM address signal

254 MA0 MA0 IN/OUT 74LVC16244 DRAM address signal

255 TXD1 CMD OUT 74LVC244 Serial data output 1

256 TXD2 N.C NC

257 /SYNCEN SYNCEN_ OUT M66236FP Jitter adjustment circuit control

signal

258 GND GND IN GND

259 GND GND IN GND

260 GND GND IN GND

261 V

CC

3.3V IN Power source

262 VFCLK VFCLK IN M66236FP Video I/F clock

263 RXD1 STS IN 74LS244 Serial data input 1

264 RXD2 IN NC (3.3V pull up)

265 /HSYNC HSYNC_ IN 74LS244 Print horizontal sync signal

266 /TC NC

267 /PAGE PAGE_ OUT 74LVC244 PAGE sync signal

268 /VDATA VDATA_ OUT 74LVC244 VIDEO data

269 /ROMWE ROMWE_ OUT 74LVC244 Flash ROM write enable

270 /BUFOE NC

271 /BUFDIR BUFDIR OUT 74LVC244 BUS buffer direction

272 V

CC

3.3V IN Power source

273 GND GND IN GND

274 SYSAD0 SYSAD0 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

275 SYSAD1 SYSAD1 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

276 SYSAD2 SYSAD2 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

5 – 13

Page 23

AR-PB9

PIN

No.

277 SYSAD3 SYSAD3 IN/OUT CPU, 16M FLASH, 8M FLASH,

Pin name Signal name IN/OUT Destination Function

System address data bus

74LVC16245

278 SYSAD4 SYSAD4 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

279 SYSAD5 SYSAD5 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

280 SYSAD6 SYSAD6 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

281 V

CC

3.3V IN Power source

282 GND GND IN GND

283 SYSAD7 SYSAD7 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

284 SYSAD8 SYSAD8 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

285 SYSAD9 SYSAD9 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

286 SYSAD10 SYSAD10 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

287 SYSAD11 SYSAD11 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

288 SYSAD12 SYSAD12 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

289 SYSAD13 SYSAD13 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

290 V

CC

3.3V IN Power source

291 GND GND IN GND

292 SYSAD14 SYSAD14 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

293 SYSAD15 SYSAD15 IN/OUT CPU, 16M FLASH, 8M FLASH,

System address data bus

74LVC16245

294 GND GND IN GND

295 GND GND IN GND

296 V

CC

3.3V IN Power source

5 – 14

Page 24

AR-PB9

Interface ASIC (VHIKZ3H008302) I/O pin arrangement list (PCL Model)

PIN

No.

1V

Pin name Signal name IN/OUT Destination Function

DD

3.3V IN Power source

2 CPUD13 LDT13 IN/OUT 74LVC16245 Data bus

3 CPUD14 LDT14 IN/OUT 74LVC16245 Data bus

4 CPUD15 LDT15 IN/OUT 74LVC16245 Data bus

5 MODECLK MODECLK OUT 74LS244 Boot mode clock

6 MODEIN MODEIN OUT CPU CPU boot mode setup serial data

output

7 CPUINTR_1 PARINTR_ OUT CPU Print request interruption output

8 DAMMY 1284-EN_ , USB-

EN_ , USB-ON

OUT USS-725, 74LVX244, I/F_CN IEEE1284/USB selection enable

signal

9 EREADY_1 PREADY_ OUT 74LVC244 Print ready signal

10 SRDY_1 SRDY_ OUT 74LVC244 PCL side reception ready signal

11 GND GND IN GND

12 GND GND IN GND

13 AD2 RAD2 IN/OUT 74LVC16244, 8M Flash, 16M Flash Address bus

14 AD3 RAD3 IN/OUT 74LVC16244, 8M Flash, 16M Flash Address bus

15 AD4 RAD4 IN/OUT 74LVC16244, 8M Flash, 16M Flash Address bus

16 AD5 RAD5 IN/OUT 74LVC16244, 8M Flash, 16M Flash Address bus

17 READY_1 EREADY_ IN 74LS244 MCU side ready signal

18 CRDY_1 CRDY_ IN 74LS244 MCU side reception ready signal

19 PSON_1 IN NC (3.3V pull up)

20 NETON_1 IN NC (3.3V pull up)

21 EXON_1 USB-IN IN I/F_CN USB input detection signal

22 SCK SCK IN 24C16 EEPROM serial clock

23 SDAOUT SDAOUT IN 24C16 EEPROM serial data output

24 SDAIN SDAIN IN 24C16 EEPROM serial data input

25 BSEL4 IN Process speed setup JP (3.3V pull

up)

26 BSEL3 IN Process speed setup JP (GND pull

down)

27 BSEL2 IN Process speed setup JP (GND pull

down)

28 BSEL1 IN Process speed setup JP (GND pull

down)

29 BSEL0 IN Process speed setup JP (3.3V pull

up)

30 SLCT SLCT OUT 74LCX244, USS-725 Printer selection state

31 FAULT_1 FAULT_ OUT 74LCX244, USS-725 Printer error

32 PE PE OUT 74LCX244, USS-725 Paper end

33 BUSY BUSY OUT 74LCX244, USS-725 Printer busy state

34 ACK_1 ACK_ OUT 74LCX244, USS-725 ACK status

35 STB_1 STB_ IN 74LCX244 STROBE control signal

36 AUTOFD_1 AUTOFD_ IN 74LCX244 Automatic new-line control signal

37 SLCTIN_1 SLCTIN_ IN 74LCX244 Printer selection

38 INIT_1 INIT_ IN 74LCX244 Printer initializing

39 PARAD7 PARAD7 IN 74LCX245, USS-725 Parallel I/F data bus

40 V

41 V

DD

DD

3.3V IN Power source

3.3V IN Power source

42 PARAD6 PARAD6 IN 74LCX245, USS-725 Parallel I/F data bus

5 – 15

Page 25

AR-PB9

PIN

No.

Pin name Signal name IN/OUT Destination Function

43 PARAD5 PARAD5 IN 74LCX245, USS-725 Parallel I/F data bus

44 GND GND IN GND

45 PARAD4 PARAD4 IN 74LCX245, USS-725 Parallel I/F data bus

46 PARAD3 PARAD3 IN 74LCX245, USS-725 Parallel I/F data bus

47 PARAD2 PARAD2 IN 74LCX245, USS-725 Parallel I/F data bus

48 V

DD

3.3V IN Power source

49 PARAD1 PARAD1 IN 74LCX245, USS-725 Parallel I/F data bus

50 PARAD0 PARAD0 IN 74LCX245, USS-725 Parallel I/F data bus

51 GND GND IN GND

52 GND GND IN GND

53 REV_1 REV_ OUT 74LCX245, I/F_CN Data direction control

54 SCAN_EN GND IN GND

55 SCAN_TEST GND IN GND

56 PDACK_1 PARACK_ IN ASIC(KZ4H167V06) DMA acknowledge signal from

ChipsetASIC

57 PDREQ_1 PARREQ_ OUT ASIC(KZ4H167V06) DMA request signal to ChipsetASIC

58 SCLK GA2CLK IN PLL IC (CY2292) Clock

59 DEVCS_1 1284CS_ IN ASIC(KZ4H167V06) OS_ signal to interface ASIC

60 DEVWR_1 PIAWE_ IN ASIC(KZ4H167V06) Write signal to interface ASIC

61 DEVRD_1 PIARD_ IN ASIC(KZ4H167V06), 74LVC16245 Read signal to interface ASIC

62 RES_1 RESET_ IN CPU Reset signal

63 VCCOK VCCOK IN ASIC(KZ4H167V06) VCC states effective

64 CPUD0 LDT0 IN/OUT 74LVC16245 Data bus

65 CPUD1 LDT1 IN/OUT 74LVC16245 Data bus

66 CPUD2 LDT2 IN/OUT 74LVC16245 Data bus

67 CPUD3 LDT3 IN/OUT 74LVC16245 Data bus

68 CPUD4 LDT4 IN/OUT 74LVC16245 Data bus

69 GND GND IN GND

70 CPUD5 LDT5 IN/OUT 74LVC16245 Data bus

71 CPUD6 LDT6 IN/OUT 74LVC16245 Data bus

72 V

DD

3.3V IN Power source

73 CPUD7 LDT7 IN/OUT 74LVC16245 Data bus

74 CPUD8 LDT8 IN/OUT 74LVC16245 Data bus

75 CPUD9 LDT9 IN/OUT 74LVC16245 Data bus

76 GND GND IN GND

77 CPUD10 LDT10 IN/OUT 74LVC16245 Data bus

78 CPUD11 LDT11 IN/OUT 74LVC16245 Data bus

79 CPUD12 LDT12 IN/OUT 74LVC16245 Data bus

80 V

DD

3.3V IN Power source

5 – 16

Page 26

AR-PB9

[6] CIRCUIT DIAGRAM

11

E

D

4.7K

4.7K

4.7K

4.7K

BR558-2

BR520-2

BR558-1

BR541-4

SYSAD30

SYSAD27

SYSAD28

SYSAD29

SYSAD27

SYSAD30

SYSAD28

SYSAD29

10

10

BR542-410BR540-2

BR542-2

4.7K

4.7K

BR516-3

BR541-2

SYSAD32

SYSAD31

SYSAD32

SYSAD31

-7-5-3-5-1-6-2-7-4

33

4.7K

4.7K

BR518-1

BR524-2

SYSAD34

SYSAD33

SYSAD34

SYSAD33

-5-7-7-7-5

4.7K

4.7K

4.7K

4.7K

BR538-2

BR519-1

BR528-3

BR518-4

SYSAD37

SYSAD38

SYSAD36

SYSAD35

SYSAD37

SYSAD36

SYSAD38

SYSAD35

10

10

BR509-710BR523-410BR523-2

BR510-810BR510-510BR511-610BR513-7

-5.-8-8-5-6-8-5-8-6-5-7-6-8

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

BR530-4

BR543-2

BR543-4

BR543-3

BR543-1

BR530-2

BR519-4

SYSAD42

SYSAD41

SYSAD40

SYSAD43

SYSAD44

SYSAD45

SYSAD39

SYSAD41

SYSAD43

SYSAD40

SYSAD42

SYSAD44

SYSAD45

SYSAD39

-6-7-8-6-7-2-7-5-5

10

10

10

10

BR535-210BR537-4

BR535-4

BR529-310BR533-110BR531-210BR533-410BR537-2

BR525-3

-6-6-7-8-5-7-6-7-8

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

BR517-1

BR516-1

BR517-3

BR526-1

BR520-3

BR526-3

BR555-4

BR521-4

BR521-2

SYSAD54

SYSAD53

SYSAD49

SYSAD48

SYSAD52

SYSAD51

SYSAD50

SYSAD46

SYSAD47

SYSAD54

SYSAD49

SYSAD50

SYSAD52

SYSAD48

SYSAD51

SYSAD53

SYSAD47

SYSAD46

-2-7-2-4-6-5-4-5-4

10

10

10

10

10

10

BR514-510BR546-110BR546-3

BR551-310BR542-3

BR549-3

BR515-510BR549-1

BR514-710BR515-710BR544-110BR542-1

BR513-5

44

(4-2C,2-4C,4-4A,5-4A)

E

D

SYSAD[63:0]

3.3V

-5-8-6-6-7-6-8-7-6

4.7K

4.7K

BR524-1

BR516-4

SYSAD2

SYSAD1

SYSAD0

SYSAD2

SYSAD1

SYSAD0

4.7K

4.7K

BR518-3

BR524-3

SYSAD3

SYSAD3

4.7K

4.7K

BR538-1

BR528-2

SYSAD5

SYSAD4

SYSAD5

SYSAD4

-3-4-6-1-7-1-8-1-7

4.7K

4.7K

BR538-3

BR519-2

SYSAD6

SYSAD7

SYSAD6

SYSAD7

-5-8-7-7-5-7-8-6-6

4.7K

4.7K

4.7K

BR536-1

BR530-3

BR538-4

SYSAD10

SYSAD9

SYSAD8

SYSAD10

SYSAD9

SYSAD8

4.7K

4.7K

BR536-3

BR536-2

SYSAD12

SYSAD11

SYSAD12

SYSAD11

10

10

BR535-110BR537-110BR535-3

BR533-310BR531-410BR531-110BR529-210BR525-210BR523-310BR523-110BR509-610BR510-710BR511-710BR511-510BR513-8

MODEL

QS

4.7K

4.7K

BR521-1

BR536-4

SYSAD13

SYSAD14

SYSAD13

SYSAD14

-6-5-6-8-1-8-8-6-3

4.7K

4.7K

BR516-2

BR521-3

SYSAD16

SYSAD15

SYSAD16

SYSAD15

SC,SIMPLEX

51

-5-7-7-5-6-7-5-8-5

4.7K

4.7K

4.7K

BR526-4

BR517-2

BR517-4

SYSAD18

SYSAD19

SYSAD17

SYSAD18

SYSAD19

SYSAD17

10

BR515-810BR514-610BR514-810BR513-610BR537-3

SC,DUPLEX

52

4.7K

4.7K

4.7K

BR557-3

BR520-4

BR526-2

SYSAD21

SYSAD22

SYSAD20

SYSAD21

SYSAD20

SYSAD22

-5-1-5-5-5-3-7-3-7

10

BR515-610BR549-410BR551-4

4.7K

BR557-2

SYSAD23

SYSAD23

10

BR549-2

-6-6-7-8-7-6-8-7-5

4.7K

4.7K

4.7K

BR557-1

BR558-3

BR558-4

SYSAD26

SYSAD25

SYSAD24

SYSAD25

SYSAD24

SYSAD26

10

BR546-410BR544-410BR546-210BR544-210BR540-4

4.7K

4.7K

BR555-3

BR555-2

SYSAD56

SYSAD55

SYSAD55

SYSAD56

4.7K

4.7K

BR554-4

BR555-1

SYSAD58

SYSAD57

SYSAD57

SYSAD58

-6-8-6-8-6-6-8-6-8

10

BR544-3

4.7K

4.7K

BR554-2

BR554-3

SYSAD60

SYSAD59

SYSAD59

SYSAD60

22

-6

4.7K

4.7K

BR541-3

BR554-1

SYSAD62

SYSAD61

SYSAD62

SYSAD61

10

BR540-3

4.7K

BR541-1

SYSAD63

SYSAD63

-8

10

BR540-1

180,181,182,183,184,

142,145,149,150,151,152,153,154,155,156,157,158,179,

101,102,103,104,105,106,107,108,109,110,111,112,113,

NC:1,2,3,4,5,6,7,8,9,45,46,47,48,49,50,51,52,53,54,55,56,

38

42

59

64

69

72

77

C

B

A

SYSAD1

SYSAD0

SYSADC1

SYSADC0

IC505

28

132

191

SYSADC2

SYSADC1

SYSADC0

-1

4.7KBR548-7

4.7KBR539-8

4.7KR953

3.3V

BR518-7

3.3V

BR528-8

BR528-5

BR530-1

BR519-6

BR522-8

BR522-7

BR522-6

BR522-5

SYSAD3

SYSAD2

SYSADC3

SYSADC2

27

177

SYSADC4

SYSADC3

4.7KR954

4.7KBR539-5

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

4.7K

SYSAD5

SYSAD4

SYSADC5

SYSADC4

190

SYSADC5

4.7K

BR539-7

-2

-1

-4

-8

-3

-1

-2

-3

-4

SYSAD7

SYSAD6

SYSADC7

SYSADC6

178

133

SYSADC7

SYSADC6

-3-1-2-4-2

4.7KBR539-6

BR548-8 4.7K

SYSAD9

SYSAD8

SYSCMD0

65

10BR510-3

SYSCMD0

SYSAD11

SYSAD10

SYSCMD2

SYSCMD1

57

60

10BR509-1

10BR509-4

SYSCMD1

SYSCMD2

SYSAD13

SYSAD12

SYSCMD4

SYSCMD3

31

34

10BR525-5

10BR525-8

SYSCMD4

SYSCMD3

SYSAD15

SYSAD14

SYSCMD6

SYSCMD5

21

26

10BR529-5

10BR529-8

SYSCMD6

SYSCMD5

SYSAD1782SYSAD16

SYSCMD8

SYSCMD7

13

16

-2-3-4-1-4-1-8-5-6

10BR533-7

10BR531-6

SYSCMD8

SYSCMD7

SYSAD1990SYSAD18

SYSCMDP

206

4.7K

R952

3.3V

3.3V

SYSAD21

SYSAD20

EXTRQST_

126

115

EXREQ_

(2-4A)

SYSAD24

SYSAD23

SYSAD22

RDRDY_

RELEASE_

WRRDY_

40

120

READY_

RLS_

(2-4A)

(2-4A)

SYSAD25

VALIDIN_

94

VALIN_

SYSAD28

SYSAD27

SYSAD26

MASTERCLK

VALIDOUT_

99

187

VALOUT_

(2-4A)

(2-4A)

4.7KBR556-8

4.7KBR556-6

4.7KBR556-7

4.7KR797

4.7KR798

4.7KBR548-6

SYSAD31

SYSAD30

SYSAD29

INT1_

INT0_

84

89

MASTERCLK

(2-1B,2-1C,2-3C)

-1

-3

-2

-3

81

INT2_

SYSAD3376SYSAD32

INT3_

78

INT4_

75

SYSAD3566SYSAD34

INT5_

70

4.7KBR524-5

3.3V

SYSAD3758SYSAD36

NMI_

129

SYSAD39

SYSAD38

VCCOK

176

SYSAD4122SYSAD40

RESET_

COLDRES_

39

165

160

SYSAD44

SYSAD4314SYSAD42

MODEIN

MODECLK

121

SYSAD46

SYSAD45

SYSAD47

3.3V

3.3V

SYSAD4983SYSAD48

SYSAD5193SYSAD50

185

SYSAD53

SYSAD52

VCCP

C579

SYSAD54

C569

C561

+

C514

C553

C556

C501

C507

+

C555

+

SYSAD56

SYSAD55

0.1u

0.1u

SYSAD58

SYSAD57

VSSP

186

22u

0.1u

0.1u

0.1u

0.1u

22u

22u

SYSAD59

SYSAD61

SYSAD60

SYSAD63

SYSAD62

17

11

GND

GND

VCC

VCC

VCC

24

18

12

85

79

73

67

61

35

23

GND

GND

GND

GND

GND

GND29GND

GND

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

86

80

74

68

62

36

30

116

0.1u

C682

0.1u

C683

0.1u

C684

0.1u

C685

0.1u

C686

C687

0.1u

0.1u

C688

0.1u

C689

0.1u

C690

189

175

170

163

136

131

125

117

GND

GND

GND

GND

GND

GND

GND

GND

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

188

174

169

162

140

135

130

124

C515

C516

C517

C518

C525

C526

C531

C533

C534

C535

203

198

193

147

141

97

43

GND

GND

GND

GND

GND

GND91GND

GND

VCC92VCC

VCC

VCC

VCC

VCC

VCC

98

44

204

197

146

192

C709

+

C708

+

0.1u

0.1u

0.1u

0.1u

0.1u

0.1u

0.1u

0.1u

0.1u

0.1u

C537

0.1u

0.1u

C538

C544

0.1u

0.1u

C548

0.1u

C550

0.1u

C554

0.1u

C559

0.1u

C560

0.1u

C562

0.1u

C563

IDT79RV4650-133DT

22u

22u

C

B

A

173

171

167

164

159

144

139

137

128

123

119

114

96

88

194

196

200

202

207

19

32

37

41

63

71

172

168

166

161

148

143

138

134

127

122

118

100

95

87

195

199

201

205

10

15

20

25

33

CPU

SYSCMD[8:0]

(2-4A)

INTR0_

(2-4A)

(2-4A)

INTR1_

INTR2_

PARINTR_

(2-4A)

(3-4A)

NMI_

(2-4A)

VCCOK

CPURES_

COLDRES_

(2-3A)

(2-3A)

(2-3A,3-3A)

MODEIN

MODECLK

(3-2A)

(3-3A)

6 – 1

Page 27

AR-PB9

3.3V

L507

SBO-02SAN

MD[63:0]SYSAD[63:0]

E

D

(6-4E)

MD0

238

IC512-2

254

MA0

MA[11:0]

(4-4C)

MD1

MD2

MD3

MD4

MD5

MD7

MD6

MD8

MD9

MD11

MD10

MD14

MD15

MD13

MD12

MD16

MD17

MD19

MD18

MD22

MD23

MD21

MD20

236

234

230

228

226

221

219

217

215

211

209

207

203

201

199

197

193

191

189

183

181

179

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

RAS0_

RAS1_

RAS2_

RAS3_

CAS0_

CAS1_

CAS2_

CAS3_

CAS4_

253

252

249

248

247

246

245

244

243

240

239

153

152

151

150

146

145

144

143

142

-1-3-2-1-3-2-4

BR563-8 10

BR563-7 10

BR563-6 10

BR563-5 10

(4-3C)

RAS2_

(6-4A,6-4C)

(6-4A,6-4C)

(6-3A,6-3C)

CAS1_

CAS0_

BR562-8 10

(6-3A,6-3C)

(6-2A,6-3C)

CAS2_

CAS3_

CAS4_

MA1

MA2

MA3

MA4

MA5

MA6

R768 10

MA7

MA8

MA9

MA10

MA11

(6-4A)

(4-3D)

RAS0_

RAS1_

MD25

MD24

175

173

171

MD23

MD24

CAS5_

CAS6_

141

140

139

-4

BR562-7 10

BR562-5 10

BR562-6 10

(6-2A,6-3C)

(6-1A,6-3C)

(6-1A,6-3C)

CAS5_

CAS6_

MD26

169

MD25

CAS7_

CAS7_

MD26

MD27

165

136

(4-3C)

MD27

MOE_

MOE_

MD28

163

135

(4-3C)

MD29

161

MD28

MWE_

MWE_

MD29

MD30

157

MD31

155

MD30

134

R748 10

(5-2A)

MD32

MD33

237

235

MD31

MD32

ROMCS0_

ROMCS1_

133

132

-1

BR561-8 10

(5-3A)

RCS0_

RCS1_

MD35

MD34

231

229

MD33

MD34

ROMCS2_

ROMCS3_

131

-210

BR561-7

(5-3A)

RCS3_

MD38

MD39

MD37

MD36

227

MD35

269

(4-2A)

225

220

MD36

MD37

ROMWE_

270

ROMWE_

MD38

BUFOE_

MD46

MD41

MD42

MD44

MD47

MD40

MD43

MD45

MD48

218

216

212

210

208

206

202

200

198

194

MD39

MD40

MD41

MD42

MD43

MD44

MD45

MD46

MD47

BUFDIR

PLL_TEST72PLL_EN71VCOIN79CPOUT76PLLVDD78PLLGND

SCAN_EN70SCAN_TEST69TESTMODE

271

20K

(4-2A)

(2-3A,3-3A,7-4D)

R934

RESET_

BUFDIR

R933 75

C587

MD49

192

MD48

MD49

DC2_TEST

68

0.01u

MD50

190

67

3.3V

MD50

MD51

188

MD51

MD52

182

MD55

MD56

MD60

MD57

MD54

MD53

MD59

MD58

MD61

180

178

174

172

170

166

164

162

160

MD52

MD53

MD54

MD55

MD56

MD57

MD58

MD59

MD60

MD61

10

77

C581

10u

+

0.1u

C583

3.3V

0.1u

C575

+

C609

+

C622

C638

C637

C628

C610

MD62

MD63

156

154

VCC1VCC9VCC18VCC27VCC39VCC48VCC58VCC64VCC74VCC75VCC89VCC99VCC

MD62

MD63

10u

C571

10u

C572

0.1u

C573

0.1u

C574

0.1u

C691

0.1u

GND

GND

GND90GND80GND73GND65GND59GND49GND38GND37GND36GND28GND19GND

111

110

100

0.1u

C576

0.1u

0.1u

0.1u

0.1u

0.1u

GND

GND

GND

GND

138

128

112

C590

0.1u

0.1u

C577

C580

C582

C584

109

127

VCC

GND

GND

159

147

0.1u

C591

0.1u

0.1u

C599

0.1u

0.1u

C600

0.1u

0.1u

C611

137

148

149

158

167

176

187

195

204

213

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

177

168

233

224

214

205

196

186

185

184

C632

C612

C614

C618

C619

C620

222

223

VCC

VCC

GND

GND

251

242

0.1u

0.1u

0.1u

0.1u

C633

0.1u

0.1u

C634

0.1u

C635

0.1u

C636

232

241

250

261

272

281

290

VCC

VCC

VCC

VCC

VCC

VCC

VCC

GND

GND

GND

GND

GND

GND

GND

294

291

282

273

260

259

258

E

0.1u

0.1u

296

VCC

GND

GA1

295

D

C

B

A

(4-2C,1-4E,4-4A,5-4A)

SYSAD1

SYSAD2

SYSAD3

SYSAD0

274

275

276

277

SYSAD0

SYSAD1

SYSAD2

SYSCMD091SYSCMD188SYSCMD287SYSCMD386SYSCMD485SYSCMD584SYSCMD683SYSCMD782SYSCMD8

IC512-1

SYSCMD1

SYSCMD2

SYSCMD0

SYSCMD3

ASIC (1)

SYSCMD[8:0]

(1-4A)

SYSAD4