Page 1

AR-PB2

[8] FUNCTION AND OPERATION

1. Multi Function

Multiple Functions

Arbitration of contention among printing, copying and faxing is controlled by the copier. The print controller only sends the print request to the copier.

The copier judges whether the requested print job is immediately performed or not by checking the current status of the copier. The printer controller

does not control contention caused by the status of the copier.

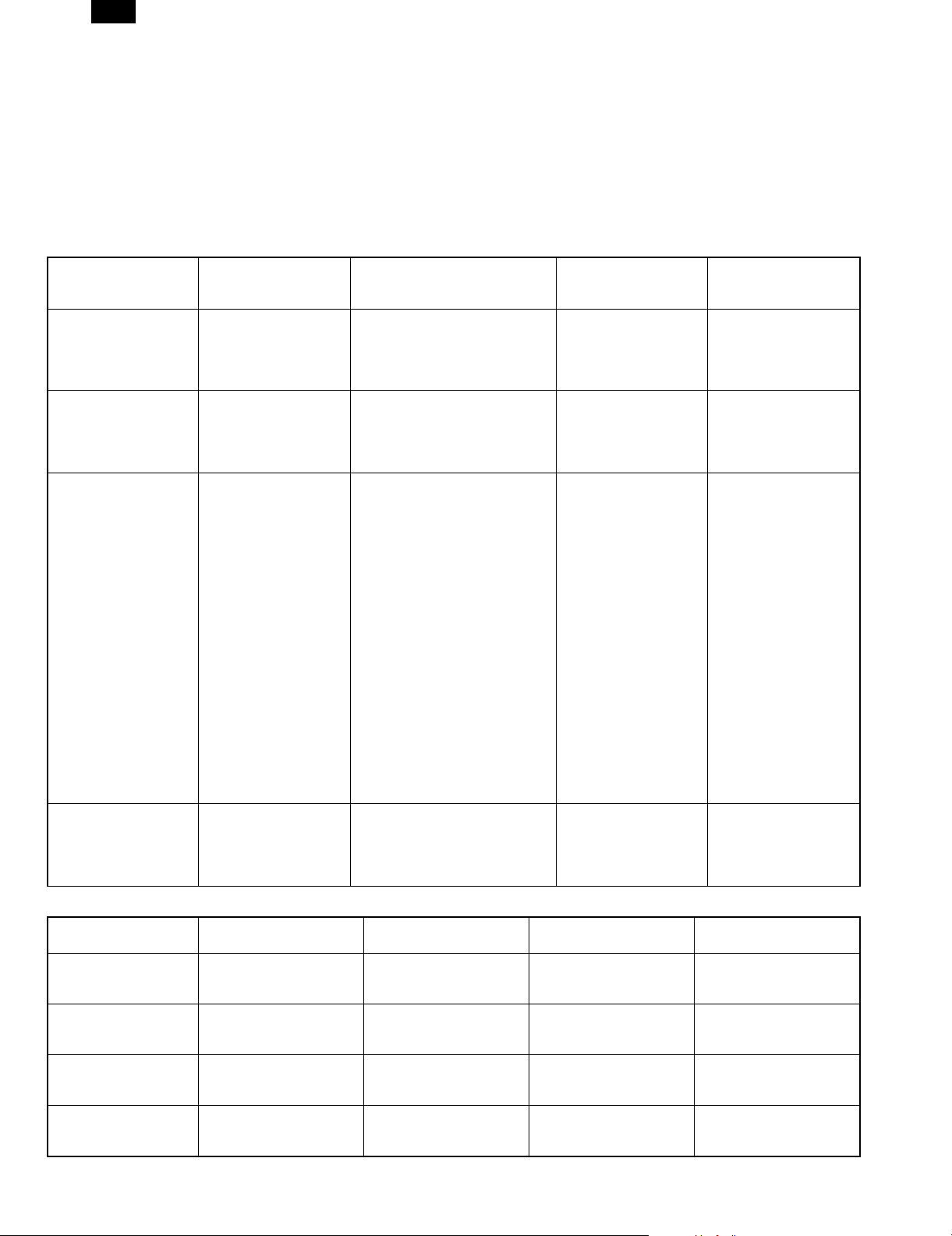

(1) Printer/Copier

From Printer Job to Copier Job

New Job

Current Job

Receiving Print Data

(PRT)

Rasterizing Print Data

(PRT)

Transferring Print Image

(PRT-Copier)

Printing Images

(Copier)

Panel operation

(Copier)

Enables copy panel

operation without

interruption.

Continually receiving

print data.

Enables panel operation

without interruption.

Continually rasterizing

print data.

Enables copy panel

operation without

interruption while the first

page of data is being

transferred.

Allows interrupt copy

panel operation while

print data of the second

or successive pages is

being transferred.

Enables copy panel

operation without

interruption.

Continually transferring

the print image.

Copy scan (scanning an original to

be copied )

(Copier)

Enables copy scanning without

interruption.

Continually receiving print data.

Enables copy scanning without

interruption.

Continually rasterizing print data.

Enables scanning without

interruption while the first page of

data is being transferred.

Allows interrupt copying (copy

scan) while print data of the

second or successive pages is

being transferred.

In either case, clears transferred

image data and requests that the

image data be transferred again.

Enables saving of copy data into

memory without interruption while

the first page of data is being

transferred.

Allows interruption of saving of

copy data into memory while print

data of the second or successive

pages is being transferred.

In either case, clears transferred

image data and requests that the

image data be transferred again.

After the current page is printed

out, allows interruption of scanning.

Memory copy (saving

copy data into memory)

(Copier)

Enables saving of copy

data into memory without

interruption.

Continually receiving

print data.

Enables saving of copy

data into memory without

interruption.

Continually rasterizing

print data.

Enables copy printing

without interruption while

the first page of data is

being transferred.

Allows interrupt copy

printing while print data

of the second or

successive pages is

being transferred.

After the current page is

printed out, allows

interruption of saving of

copy data into memory.

Copy Printing

(Copier)

Enables copy printing

without interruption.

Continually receiving

print data.

Enables copy printing

without interruption.

Continually rasterizing

print data.

In either case, clears

transferred image data

and requests that the

image data be

transferred again.

After the current page is

printed out, allows

interruption of copy

printing.

From Copier Job to Printer Job

New Job

Current Job

Copy panel operation

(Copier)

Copy scan (scanning an

original to be copied)

(Copier)

Memory copy (saving

copy data into memory)

(Copier)

Copy Printing

(Copier)

Receiving Print Data

Continually receiving print

data until receiving bu ffer

becomes full.

Continually receiving print

data until receiving buffer

becomes full.

Continually receiving print

data until receiving buffer

becomes full.

Continually receiving print

data until receiving buffer

becomes full.

(PRT)

Rasterizing Print Data

(PRT)

Continually rasterizing print

data until image buffer

becomes full.

Continually rasterizing print

data until image buffer

becomes full.

Continually rasterizing print

data until image buffer

becomes full.

Continually rasterizing print

data until image buffer

becomes full.

8 – 1

Transferring Print Image

(PRT-Copier)

Disables print image

transfer.

Disables print image

transfer.

Disables print image

transfer.

Disables print image

transfer.

Printing Images

(Copier)

Disables print image

printing.

Disables print image

printing.

Disables print image

printing.

Disables print image

printing.

Page 2

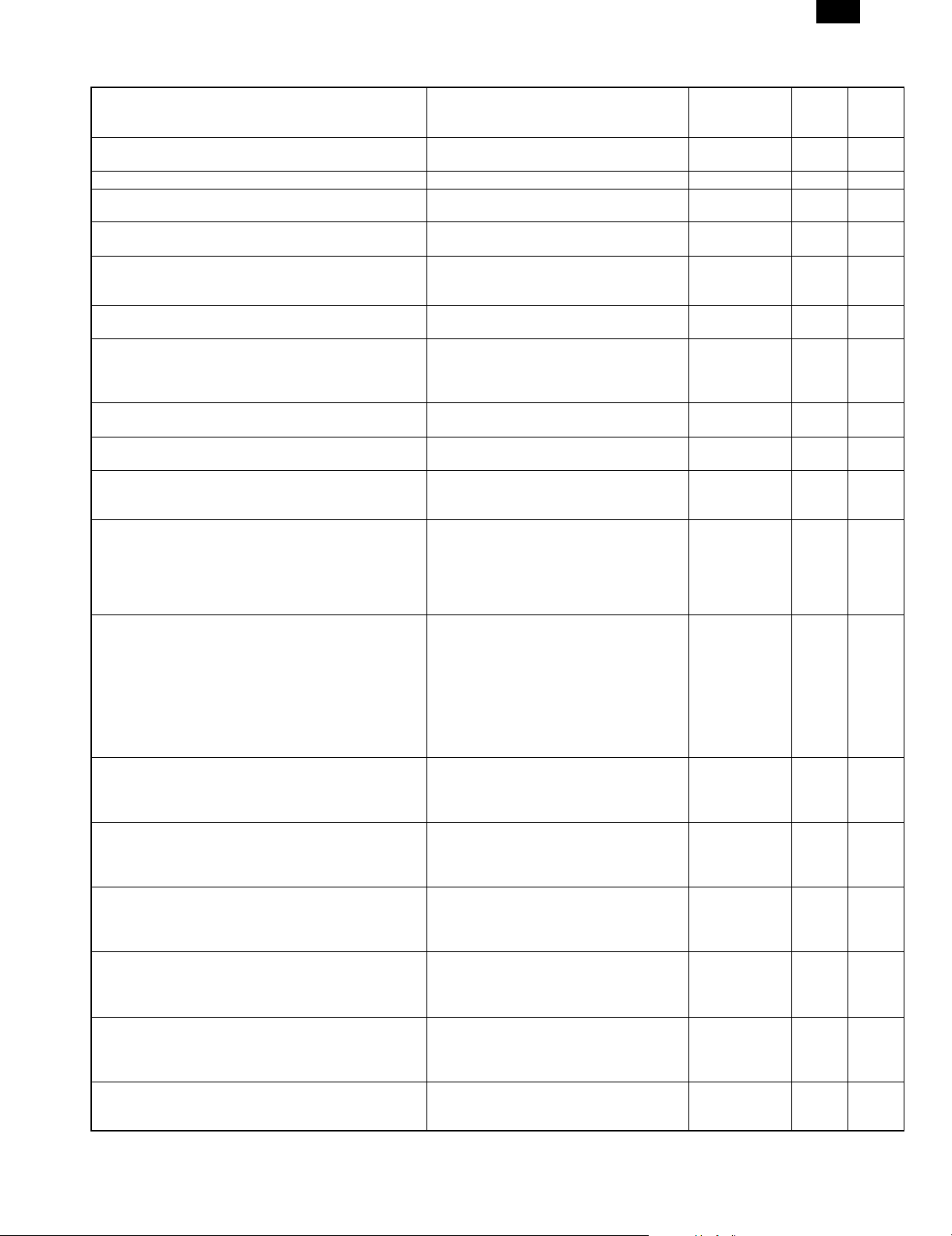

2. Printer Operation / Message Display

AR-PB2

State Display

During initializing the printer board <Displayed on dialog window>

INITIALIZING. PLEASE WAIT.

From the end of initialization to the end of warm-up. WARMING UP. PLEASE WAIT Disabled Off Off / On

During the warm-up and waiting for starting a print job with

the data receiving /processing completed

During the idle

(Online with no data being received / printed)

During receiving the data

During processing the data

During transferring images to ERDH

During the output of print

(during printing the data stored in ERDH)

During suspending the print

(from when the print starts to be suspended by user’s

instruction during printing and to when the print job can be

actually stopped.

While the print is suspended by user.

(the data is held)

While the print data is being cleared.

(Job Cancel)

Offline

(The state in which no data is being received and printed,

and the user instruction causes Offline.)

When there is no paper in Bypass Tray during suspending

a job with Bypass Tray (manual) selected.

(The data is held.)

When there is paper in Bypass Tray during suspending a

job with Bypass Tray (manual) selected.

(The data is held.)

When there is no paper in Bypass Tray selected at the

start of printing the data, or when the print is suspended

due to paper-out.

(The data is held.)

When there is no paper in the selected tray at the start of

printing the data, or when the print is suspended due to

paper-out.

(The data is held.)

When Staple Unit is not installed properly

(the data is held)

When a stapler is empty (AR-FN1)

(The data is held.)

When a stapler is empty (AR-FN2)

(The data is held)

PLEASE WAIT. Disabled On On

READY TO PRINT.) Disabled On Off

PROCESSING PRINT DATA. Disabled On Blink

PRINTING IN PROGRESS. Disabled On Blink

<Displayed on a dialog window>

PRINTING IN PROGRESS.

PLEASE WAIT.

OFFLINE.

TO CLEAR DATA, PRESS [C].

PLEASE WAIT.

DATA IS BEING CLEARED.

OFFLINE. Disabled Off Off

ADD ******** PAPER INTO BYPASS-TRAY.

(When supplying paper as directed, the print

will start in three seconds. However, since

the size detection is not performed, the

paper sizes other than selected one will start

to be printed.)

CHANGE BYPASS-TRAY PAPER TO

********.

(When supplying paper as directed, the print

will start in three seconds. Even if the paper

in bypass tray continues to be used , the

paper needs to be reset by loading it again.

However, since the size detection is not

performed, the paper sizes other than

selected one will start to be printed.)

ADD ******** PAPER INTO BYPASS-TRAY.

(When supplying paper as directed, the print

will automatically restart in three seconds.)

OPEN * TRAY AND ADD PAPER.

(When supplying paper as directed, the print

will automatically restart after the lift-up

operation in the tray.)

CHECK STAPLER POSITION OR STAPLE

JAM.

(When checking and setting properly as

directed, the print will automatically restart.)

SLIDE THE FINISHER AWAY FROM THE

COPIER AND ADD STAPLES.

(when checking and setting properly as

directed, the print will automatically restart.)

ADD STAPLES.

(When checking and setting properly as

directed, the print will automatically restart.)

JOB

Cancel/(Clear)

Paper Selection

Disabled Off Off

Disabled Blink Blink

Enabled Off On

Enabled Off On

Enabled Off On

Enabled Off On

Enabled Off On

Enabled Off On

Enabled Off On

Enabled Off On

Enabled Off On

Online

LED

Data

LED

During suspending the print due to some errors

( Jam/Toner supply)

(The data is held)

<CONFORM TO COPIER OPERATION

SPECIFICATION.>

(Print will start just as the trouble is removed.)

8 – 2

Disabled Off On

Page 3

AR-PB2

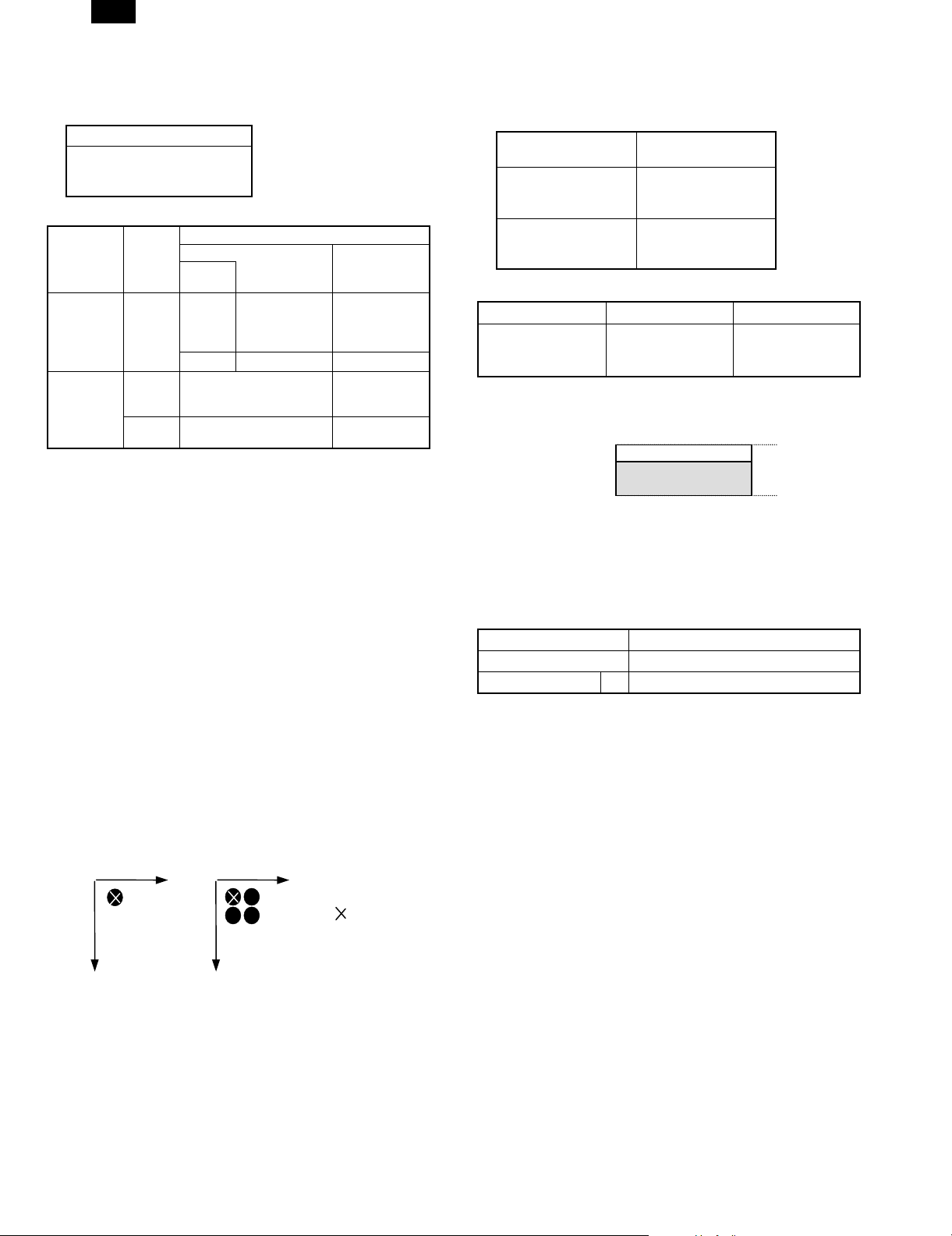

3. Emulation Switch

Emulation setting can be switched between automatic emulation

sensing (switching) and fixed emulation modes as shown below.

AR-PB2

Automatic (PCL ↔ PS)

PCL (fixed)

/ PostScript (fixed)

Emulation switching is performed in the following manner.

PJL

Command for

Specifying an

Emulation

No

Yes

Specified

Emulation

Yes

No

Automatic

Sensing

OK

NG

Uses the emulation specified. Uses the

Uses PCL Uses a default

Emulation Setting

Automatic

Uses the

emulation

automatically

selected.

Uses PCL

Fixed

Uses a default

emulation.

emulation

specified.

emulation.

In the automatic emulation sensing mode, for print data without the

PJL command, the emulation is automatically switched either to PostScript, to PCL5e based on data sensed. In other words, automatic

emulation sensing (switching) is available only between PostScript

and PCL5e. For print data with the PJL command, the emulation is

automatically switched to the specified one with out sensing the data.

When print data without the PJL command fails to be sensed, or

when the print data is given the PJL command but the specified

emulation is not present, the data is handled in the PCL emulation.

In the fixed emulation mode, for print data without the PJL command,

the fixed emulation is used to handle the print data.Print data with the

PJL command is switched to the specified emulation. When print data

is given the PJL command but the specified emulation is not present,

the data is processed by the default emulation.

The PJL Enter command specifies PostScript and PCL5e.

4. Resolution

The printer controller supports only 600-dpi binary images in single bit

per pixel mode. The print engine does not support resolution settings

other than 600 dpi (fixed at 600 dpi). When300 dpi is specified for

resolution, 4 pixels are represented as 1 dot to create 300dpi image.

In other words, the printer controller always sends 600-dpi images to

the engine.

Main Scan

600dpi

(1 dot)

Main Scan

300dpi

(1 dot)

Reference

Position

5. Font

A. Downloadable Font Types

The Cougar printing system supports the font types for download.

Page Description

Language

AR-PB2

PCL 5e TrueType

Bitmap

Intellifont

PostScript Level 2 Type 1

Bitmap

Type 42

B. Location of Font Data

Font Data Hardware Size

PCL Roman 47

Fonts

Flash ROM #5

3MB

PS Roman 35 Fonts

D. Font Data Memory Map

Physical Address

0x0f7fffff

0x0f000000

PCL Roman/PS Roman

Flash ROM

6. Language

A. Language Selection

The printing system will automatically switch to the correct emulation

or switch to the fixed emulation mode.

Emulation setting mode AR-PB2

Automatic PS ↔ PCL

Fixed 1 PS/PCL

B. Job, control

The job control commands support PJL (Printer Job Language) which

HP printers include. PJL is available for all emulations (PCL5e,PostScript).

7. Host I/O Port Selection

There are two host I/O ports, the P1284 port and the Network(NIC)

port, as described before. The host I/O port can be selected between

the I/O port automatic port switching and the I/O fixed port setting.

The automatic port switching has two settings, between jobs and after

I/O time-out.

Sub Scan

Sub Scan

8 – 3

Page 4

AR-PB2

Setting Behavior

Automatic

Switching

Between

Jobs

When receiving data is detected through

a port, sensing data receipt from each

port, considers the port as current (port

automatic sensing processing), and

processes the data received only through

the current port. Then until the job ends

in the situation described below in 1) or

2), the data through the current port is

only processed. After the print job ends,

the port automatic sensing processing

restarts.

1) The print job is completed by the

job-end command.

2) The current port gets into the state of

waiting for data receipt, and after no

data is received for a certain time (I/O

time-out value), print job ends by the

I/O time-out.

After I/O

Time-out

When receiving data is detected through

a port, sensing data receipt from each

port, considers the port as current (port

automatic sensing processing) and

processes the data received only through

the current port. Then until the I/O

time-out in the situation described below

in 1), the data through the current port is

only processed. After the I/O time-out,

the port automatic sensing processing

restarts.

1) The current port gets into the state of

waiting for data receipt, and after no

data is received for a certain time (I/O

time-out value), the print job ends by

the I/O time-out. (When the print job

has not been completed , it ends

simultaneously.

Fixed Disables

P1284 Port

Disables

Network

Receives data only through the Network

(NIC) port.

Receives data only through the P1284

port.

(NIC) Port

Note: In the I/O time-out, the count starts at the point that data is not

acquired via the receiving buffer. When receiving the data until

the I/O time-out, the count is reset to stop.

In the between jobs setting of the automatic switching, the

conditions that a print job will be completed are as follows.

Job Start Job End

Common • PJL JOB command

PCL • PJL ENTER

LANGUAGE

command (PCL)

• PJL EOJ command

↔

• I/O Timeout

• UEL command

• <ESC>E

↔

• I/O Timeout

• Jobs starting with the

PCL data

PS • PJL ENTER

LANGUAGE

command

(POSTSCRIPT)

• UEL command

• <Ctrl-D>

• I/O Timeout

↔

• Jobs starting with the

PostScript data.

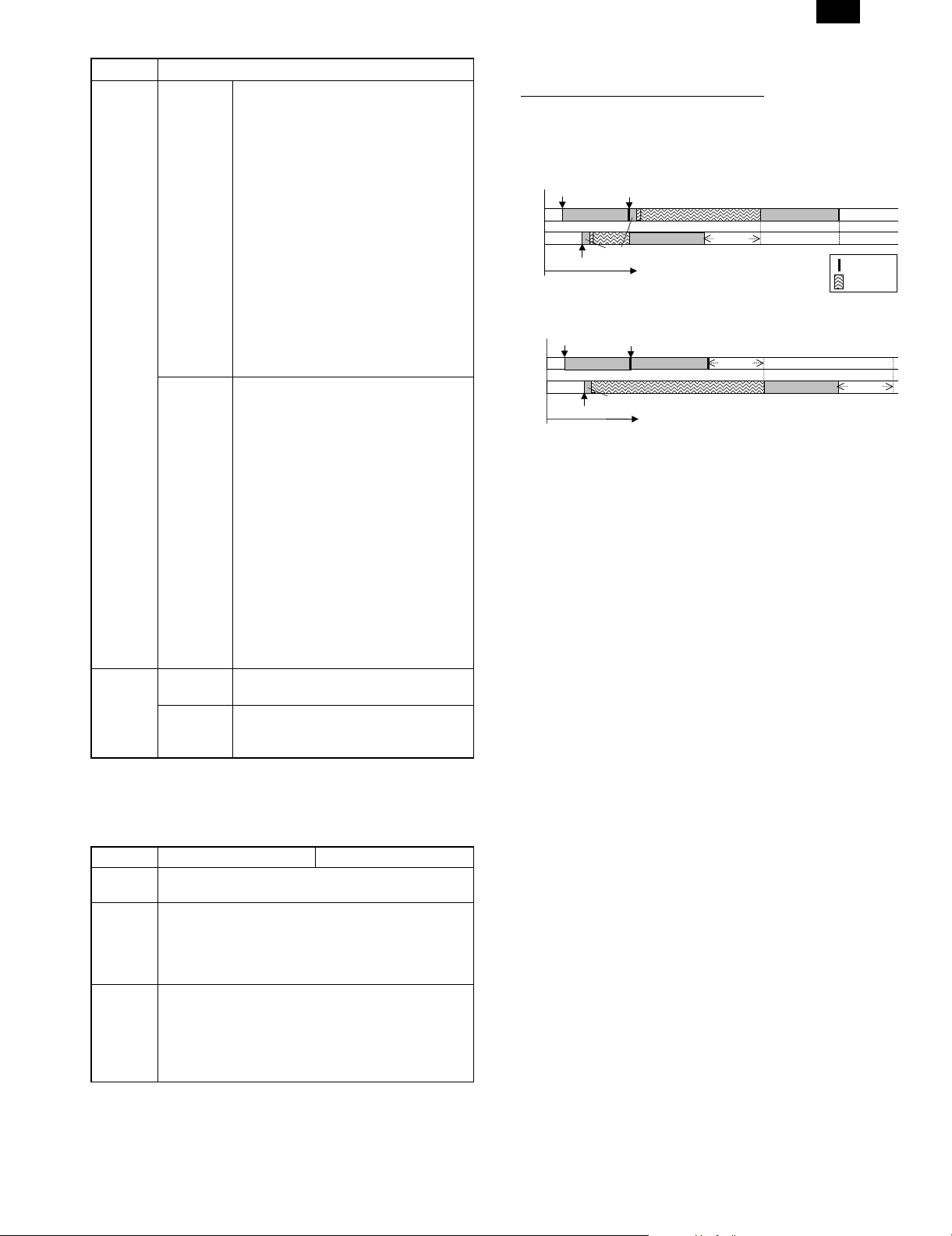

[Example of Automatic Switching]

Receiving Port Job End Data

Job1: NIC Port Yes

Job2: 1284 Port No

Job3: NIC Port Yes

1) Automatic Switching - Between Jobs

Receive Job1

NIC

1284

Receive Job2

Job1

Receive to Buffer

Receive Job3

Job2

I/O Timeout

2) Automatic - After I/O Time Out

Receive Job1

NIC

1284

Receive Job2

Job1

Receive to Buffer

Receive Job3

Job3

I/O Timeout

Job3

Job2

Job End Data

Wait

I/O Timeout

8 – 4

Page 5

AR-PB2

8. ERDH Operation

A. Hard Disk Capacity and Operation

Output behavior when Document page is longer than HD limitation.

(HD limitation for printer ; 60pages)

Face Up Face Down(Option)

N=1

61

1

120

1 set

1

60

N>1 (1) 1 set output mode (1) 1 set output mode

61

1

120

1 set

1

60

Notice Page

Notice Page

Separater

sheet and

Offset

Separater

sheet and

Offset

1 set

1 set

120

61

60

1

120

61

60

1

60

1

Notice Page

(2) N set output mode (2) N set output mode

Notice Page

61

•20

61

N set

User can select the Long Document mode by Key Operator Program.

•20

1

60

1

60

• Notice Page; ON/OFF

• Output mode; 1 set /N set

Offset...The offset function at the output device is available.

9. Printing Modes

Basic Printing Modes

The printer controller and copier / ERDH supports the following two

printing modes.

Mode-A (concurrently operates the printing operation

and storing of print data into ERDH)

This mode is intended to accelerate the first print time in the device

configuration in which Face-down delivery is supported. In the first set

of a print job, copier/ ERDH prints the first set while receiving print

data from the printer controller and storing it into itself. From the

second set on, printing is performed by reading stored data from the

ERDH. In addition, in the Face-down delivery, Mode-A is operated by

ERDH Reverse order being OFF. Typically, in this case, the Reverse

Order printing is selected in the application.

Mode-B (starts printing after copier/ ERDH has received

an entire print job)

With Face-up delivery, as the ERDH is in charge of reversing page

order, it starts printing the last page of a print job first after it has

received the entire print job from the printer controller. In addition,

when features such as Duplex or Booklet are specified, all paper

sizes conform to the operation of Mode-B. In Mode-B operation,

Notice Page

120

61

120

Separater

sheet and

Offset

determining the contents of the print job (e.g. the number of the

pages available for stapling,and multiple sizes of paper specified)

before the start of printing allows a suitable paper destination to be

selected and Finishing to be performed.

N set

61

60

1

60

1

Face-up /Face-down Selection and Mode-A /

Mode-B Control

Users are allowed to select either Face-up or Face-down.

Basically, Face-up/Face-down controls are selected for an entire print

job. However, when the multiple sizes of paper are selected, the

output into multiple destinations and Face-up /Face-down deliveries

may be performed in one job.

In both Face-up and Face-down modes, if an entire print job can be

stored in the ERDH, the document will be output in the correct page

order.

• In Reverse order feature by ERDH in the copier, users are allowed

to select either ON/OFF. (When only Face-up delivery is present,

ERDH Reverse order feature is set to OFF, which allows the

reverse order printing by the application without limiting the number of pages.)

• Users are not allowed to select either Mode-A or Mode-B. When

ERDH reverse is ON, Mode-B is automatically set,and when

ERDH reverse is OFF, Mode-A is set.

Separater

sheet and

Offset

8 – 5

Page 6

AR-PB2

Limitations in Mode-A Operation

In output devices, The output destinations available for Face-down delivery are Tray2, 3 of 3tray Finisher and Tray2 of 2tray Finisher. These support

the Mode-A operation. Limitations in the Mode-A operation are described as follows:

Output Device

STD. Face-up

Tray

3trayFIN.

Tray2/3

2tray FIN.

Tray2

ERDH

Reverse Order

ON Face-up Mode-B Mode-B for any job.

OFF Face-up Mode-A Duplex Mode-B to support the image rotation and Muti-size printing.

ON Face-up Mode-B Paper Size Mode-B. The paper output destination will be forwarded to Tray

OFF Face-up Mode-A Paper Size The paper output destination will be forwarded to Tray 1 for

OFF

(by selecting

Face-down)

ON Face-up Mode-B Paper Size Mode-B. The paper output destination will be forwarded to Tray

OFF Face-up Mode-A Paper Size The paper output destination will be forwarded to Tray 1 for

OFF

(by selecting

Face-down)

Face-up/

down

Face-down Mode-A Paper Size The paper output destination will be forwarded to Tray 1 for

Face-down Mode-A Paper Size The paper output destination will be forwarded to Tray 1 for

Basic Operation

Mode

Limitation Control

Booklet Mode-B

1for the original that includes at least one A6R, 5.5x8.5 in.,post

card, A5 or EXTRA size paper.

A6R, 5.5 x 8.5 in. post card, A5 and EXTRA sizes. If above

sized paper is included in the original, remaining output will be

forwarded to Tray 1.

Staple

(Tray3)

Duplex Mode-B to support the image rotation and Multi-size printing.

Booklet Mode-B.

Duplex Mode-B to support the image rotation and Multi-size

Booklet Mode-B because the last page data is required to be output for

Staple The selection is inhibited in the driver.

Staple Mode-B for Staple jobs.

Duplex Mode-B to support the image rotation and Multi-size printing.

Booklet Mode-B.

Duplex Mode-B to support the image rotation and Multi-size

Booklet Mode-B because the last page data is required to be output for

Staple The selection is inhibited in the driver.

Basically, this mode is used to print in the reverse order by the

application. Mode-B for Staple jobs to determine the number of

paper..

A6R,5.5x8.5 in. post card, A5 and EXTRA sizes. If above sized

paper is included in the original, remaining output will be

forwarded to Tray 1. The forwarded output will be in

incorrect(reverse) order.

printing.Face-down delivery.

the Booklet placement. Face-down delivery.

1for the original that includes paper other than A4, 8.5 x 11in.

and B5 size paper.

others than A4, Letter and B5 sizes. If above sized paper is

included in the original, remaining output will be forwarded to

Tray 1.

others than A4, Letter and B5 sizes. If above sized paper is

included in the original, remaining output will be forwarded to

Tray 1. The forwarded output will be in incorrect (reverse)order.

printing.Face-down delivery.

the Booklet placement. Face-down delivery.

• N-up is capable of the Mode-A operation.

• In the Group mode, Face-up/down, and Mode-A/Mode-B control are carried out as well as the Collate mode.

• Different First Page is capable of the Mode-A operation.

• OHP interleave paper is capable of the Mode-A operation.

The paper sizes in the table above are those at the job beginning.

When the paper unavailable for output is fed during the processing of

a job, the following operations are performed.

For example, when 2tray finisher Tray2 / Face-down is selected;

a) When the paper impossible for output, such as A3

• Mode-B and Face-up printing in N to 1 order is performed and

delivered to Tray 1.

• When the beginning is possible to output like A4 and the job

includes paper that is impossible to output such as A3:

• Mode-A and Face-down printing in 1 to N order is performed.

b) The paper of A3 size is escaped to Tray 1. This causes the

reversed (incorrect) order printing of remaining when the original

output mode was Face-down.

• Even if the A4 size paper will come after that of A3 size, the

destination is not returned to Tray 2. In other words, only one

destination change can occur in one job.

• If the output has been separated into two output trays, the

following are performed in accordance with incorrect order

printing:

• If key operator "OUTPUT METHOD WHEN MEMORY IS

FULL" is set to"1 set", cancel printing after second set.

8 – 6

Page 7

AR-PB2

• If Notice Page printing was allowed by the key operator

"PROHIBIT NOTICE PAGE PRINTING", a Notice Page is

printed. (This will be done in both case when the output after

second set is canceled or not.)

Note: Every Finisher’s paper sizes available for output are uniformed

in the Face-up and the Face-down modes.

Finisher Tray Face-up/down Paper Size

3tray Finisher Tray1 Face-up All sizes

Face-down Not used.

Tray2 Face-up B5 - 11 x 17

Face-down

Tray3 Face-up B5 - 11 x 17

Face-down

2tray Finisher Tray1 Face-up All sizes

Tray2 Face-up B5/A4/Letter

Face-down

10. Basic Face-up /down Controls and

Defaults

Exit

Device

STD Exit

tray

2bin Exit

Exit Tray

Selection

Exit Tray1ON N/A Face-up

Exit Tray1 ON N/A Face-up

ERDH

Reverse

order

Finishing

select

OFF N/A Mode-A

Tray

OFF N/A Mode-A

Exit Tray2 ON N/A Face-up

OFF N/A Mode-A

3 tray

Exit Tray1 ON N/A Face-up

Finisher

OFF N/A Mode-A

Exit Tray2 ON N/A Face-up Mode-B

OFF N/A Face-up Mode-A

OFF N/A Face-

Exit Tray3 ON Offset Face-up Mode-B

OFF Offset Face-up Mode-A

OFF Offset Face-

ON Staple Face-up Mode-B

OFF Staple Face-up Mode-B

2 tray

Exit Tray1 ON N/A Face-up

Finisher

OFF N/A Face-up Mode-A

Exit Tray2 ON Offset Face-up Mode-B

OFF Offset Face-up Mode-A

OFF Offset Face-

ON Staple Face-up Mode-B

OFF Staple Face-up Mode-B

Although Tray 1 of the 3 tray Finisher supports Face-down, it cannot

be used in the Printer mode.

Paper Destination of a Print Job with No Paper

Destination Specified

The output of print jobs with no paper destination specified is all

directed to the default exit tray. (In all exit devices, the default tray is

Top Tray, face up.)

Face-up/

down

select

only

only

only

only

down

down

only

down

Operation

Mode

Mode-B

Mode-B

Mode-B

Mode-B

Mode-A

(Mode-B)

Mode-A

(Mode-B)

Mode-B

Mode-A

(Mode-B)

11. Duplex with Multiple Paper Sources

For duplex printing, selecting a new paper size, or source empties the

duplex module and printing resumes on the next odd face. In N - 1

Print Order printing this may be accomplished by inserting a blank

page sid e into the job s tream in order to fill in the back side of a page.

This does not apply for o nly an image orien tation change . This is

best illustrated by the example below.

For the job shown below, printing 8 faces on 2 sizes of paper, a face

down duplex printer will produce the mix of duplex pages shown

below

1

23

5 letter and 3 legal

sides

Should print on 5

sheets in this order

4

2

1

3

5

5

67

7

6

8

8

The system will insert blank pages if necessary to create the same

output for both 1 - N Print Order and N - 1 Print Order print jobs.

In the above-mentioned case, inserted blank pages are NOT

counted.

12. Binding Edge

The Binding Edge controls the appearance of both simplex and

duplex documents. This determines how pages will be rotated by the

system so that when bound all of the pages will have the correct

orientation in the document.

All three Binding Edge controls are supported.

Mode Control Description

Binding Edge Left Side*

(Book Style)

Text

1 (odd)

Text

1 (odd)

Right Side

(Book Style)

Text

4 (even)

In Left Side (Book Style) binding

successive faces are bound on the

edges as shown below.

Simplex

Text

2 (even)

Text

3 (odd)

Text

4 (even)

Duplex

Text

2 (even)

Text

3 (odd)

Text

4 (even)

In Right Side (Book Style) binding

successive faces are bound on the

edges a s shown below. Note the

page numbering change.

Simplex

Text

3 (odd)

Text

2 (even)

Text

1 (odd)

8 – 7

Page 8

AR-PB2

Mode Control Description

Duplex

Text

4 (even)

Top

(Tablet Style)

Text

3 (odd)

Text

2 (even)

Text

1 (odd)

In Top Side (Tablet Style) binding

successive faces are bound on the

edges as shown below.

Simplex

Text

Text

1 (odd)

1 (odd)

Text

Text

2 (even)

2 (even)

Text

Text

3 (odd)

3 (odd)

Text

Text

4 (even)

4 (even)

Duplex

Text

1 (odd)

Text

2 (even)

Text

3 (odd)

Text

4 (even)

* Default

Limitations:

1) Binding Edge can only be selected for an entire print job.

2) Access to the three Binding Edge controls will be controlled by the

print drivers. Left and Top binding will be available in Custom &

PPD driver. Right binding will only be available in Custom driver.

(Interaction of Page Orientation and Binding Edge

for Duplex Printing)

There are a total of 6 combinations of Binding Edge and Page Orientation settings, however, both Right and Left Edge Binding require the

same final page orientations and hence are combined. The 4 resultant, unique duplex document appearances are shown below.

Settings of Page

Orientation and

Binding Edge

1 Page Orientation:

Portrait

Binding Edge:

Left or Right (Book)

2 Page Orientation:

Portrait

Binding Edge:

Top (Tablet )

Appearance of

Document

Texttext

Tex

Text

HP 5 Si

Nomenclature

Portrait

Book

Portrait

Tablet

13. Memory Configuration

The following ROM are supported.

EPROM: Boot & Simulation Program

Flash ROM: Program &Font data

Boot ROM is selectable between EPROM and Flash ROM #5 using

the jumper switching.

Flash ROM #5

4MB

Main Program

Flash ROM #5 3MB PCL Roman 47 Fonts

PS Roman 35 Fonts

Flash ROM #5 1MB Boot/Simulation Program

ROM Memory Map

Physical Address

0x1fff ffff

0x1fd0 0000

0x1fc0 0000

0x0f80 0000

0x0f10 0000

0x0100 0000

Boot & Diag Program

PCL/PS Roman Fonts

Main Program

Power On Reset

Exception Vector

Flash ROM #5

8MB

14. Printer control PWB switch (short pin)

and LED display

Switch, LED Function

Switch RESET switch

(SW102)

ABORT switch

(SW101)

LED POWER-LED

(D114)

RUN-LED

(D113)

Software

status

STO-LED

(D109)

ST1-LED

(D110)

ST2-LED

(D111)

ST3-LED

(D112)

Processor and peripheral device

initialization

MMI* generation to processor

PWB power ON. Lighted when

supplying power.

Processor operating status.

Lights up when operating.

Lights UPD71055-A port 0 bit 4 at

"0."

Lights UPD71055-A port 0 bit 5 at

"0."

Lights UPD71055-A port 0 bit 6 at

"0."

Lights UPD71055-A port 0 bit 7 at

"0."

3 Page Orientation:

Landscape

Binding Edge:

Top (Tablet )

4 Page Orientation:

Landscape

Binding Edge:

Left or Right (Book)

Text

Text

Landscape

Book

Texttext

Landscape

Tablet

8 – 8

Page 9

AR-PB2

(Error message)

F9 0 Content ICU-PRT communication trouble

Detail

Cause SCSI LSI abnormality

ICU PWB defect

SCSI connector connection defect

Printer PWB defect

Check and remedy Replace the printer PWB.

Check the SCSI connector.

Replace the printer PWB.

Replace the ICU PWB.

F9 01 Content PRT DRAM trouble

Detail DRAM trouble in the option printer board. (Check when turning on the power)

Cause DRAM module is broken and access cannot be made.

DRAm module installation trouble

Check and remedy Check with SIM 57-1.

F9 02 Content PRT Centro port check error

Detail Option printer board Centro port trouble

Cause Centro port defect

Printer PWB defect

Check and remedy Replace the printer board.

F9 03 Content Network card trouble.

Detail Network card self test trouble.

Cause Network card defecft.

Printer PWB defect.

Network card connector connection defect.

Check and remedy Check the Network card connector.

Replace the printer PWB.

Replace the Network card.

F9 04 Content Printer program error.

Detail Program data trouble in the option printer board.

Cause Flash memory data is destroied.

Check and remedy Replace or rewrite the Flash memory.

F9 05 Content Short of memory capacity on the ICU PWB

Detail Total memory is less than 16MB on the ICU PWB.

Cause Memory defect

Check and remedy Replace the ICU PWB

F9 10 Content PRT SCSI LSI abnormality

Detail An error occurred in SCSI communication with the option printer board.

Cause SCSI LSI abnormality

Check and remedy Replace the printer PWB.

F9 90 Content ICU-PRT communication trouble (PRT detection)

Detail

Cause SCSI LSI abnormality

Check and remedy Replace the printer PWB.

Replace the printer PWB.

SIMM memory connector connection defect

ICU PWB defect

Wrong type SIMM memory is installed

Replace the memory

Check the memory connector

ICU PWB defect

Printer PWB defect

SCSI connector connection defect

Check the SCSI connector.

Replace the printer PWB.

Replace the ICU PWB.

ICU PWB defect

SCSI connector connection defect

Printer PWB defect

Check the SCSI connector.

Replace the printer PWB.

Replace the ICU PWB.

Page 10

AR-PB2

q

COPYRIGHT © 1998 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Printing & Reprographic Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1998 December Printed in Japan N

Loading...

Loading...