Page 1

SERVICE MANUAL

CODE: 00ZARP17//A1E

DIGITAL MULTIFUNCTIONAL

SYSTEM OPTION

PRINTER EXPANSION KIT

AR-PK1

MODEL

CONTENTS

[1] SYSTEM CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[3] INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] SETTING AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] CONFIGURATION REPORT AND TEST PAGE . . . . . . . . . . . . . . . . . . . . 6-1

[7] FLASH ROM VERSION UP PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] PRINTER STATUS MONITOR/PRINTER MANAGEMENT UTILITY . . . . 8-1

AR-P17

[9] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

Page 3

CONTENTS

[1] SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS

1. Basic specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Printer controller board . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

3. IMC controller board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

4. Network specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

5. Printer driver specification . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

A. System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

B. System requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

C. Print quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

D. Paper handling specifications. . . . . . . . . . . . . . . . . . . . 2-1

E. Print enable area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

F. Print reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

[3] INSTALLATION

1. AR-P17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

A. Parts included. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

B. Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

C. Mounting of additional memory . . . . . . . . . . . . . . . . . . 3-2

2. AR-PK1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

A. Parts included. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

B. Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

[4] SETTING AND ADJUSTMENTS

1. Printer condition settings . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

B. Operating procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

C. Setting item. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. AR-PK1 (PS expansion kit) setup . . . . . . . . . . . . . . . . . . . 4-2

A. Setup content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

B. Setup enable conditions . . . . . . . . . . . . . . . . . . . . . . . . 4-2

C. Setup menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

D. Function cancel menu . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3. Email alert status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

A. Setup contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

B. Setup enable conditions . . . . . . . . . . . . . . . . . . . . . . . . 4-2

C. Setup menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

D. Function cancel display . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4. Key operator program list. . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

[5] SIMULATION

1. Operating procedures and operations . . . . . . . . . . . . . . . 5-1

2. Simulation code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] CONFIGURATION REPORT AND TEST PAGE

1. Kinds of test pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Print method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] FLASH ROM VERSION UP PROCEDURE

1. Printer Control Board firmware download method . . . . . . 7-1

2. Others (Troubleshooting) . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

[8] PRINTER STATUS MONITOR/PRINTER ADMINISTRATION

UTILITY

1. Printer status monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

A. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

B. Operating environment . . . . . . . . . . . . . . . . . . . . . . . . 8-1

C. V3.1 limitations and notes . . . . . . . . . . . . . . . . . . . . . . 8-1

D. Outline of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Printer administration utility. . . . . . . . . . . . . . . . . . . . . . . . 8-3

A. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

B. Operating environment . . . . . . . . . . . . . . . . . . . . . . . . 8-3

C. Outline of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

D. Note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

[9] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Page 4

Page 5

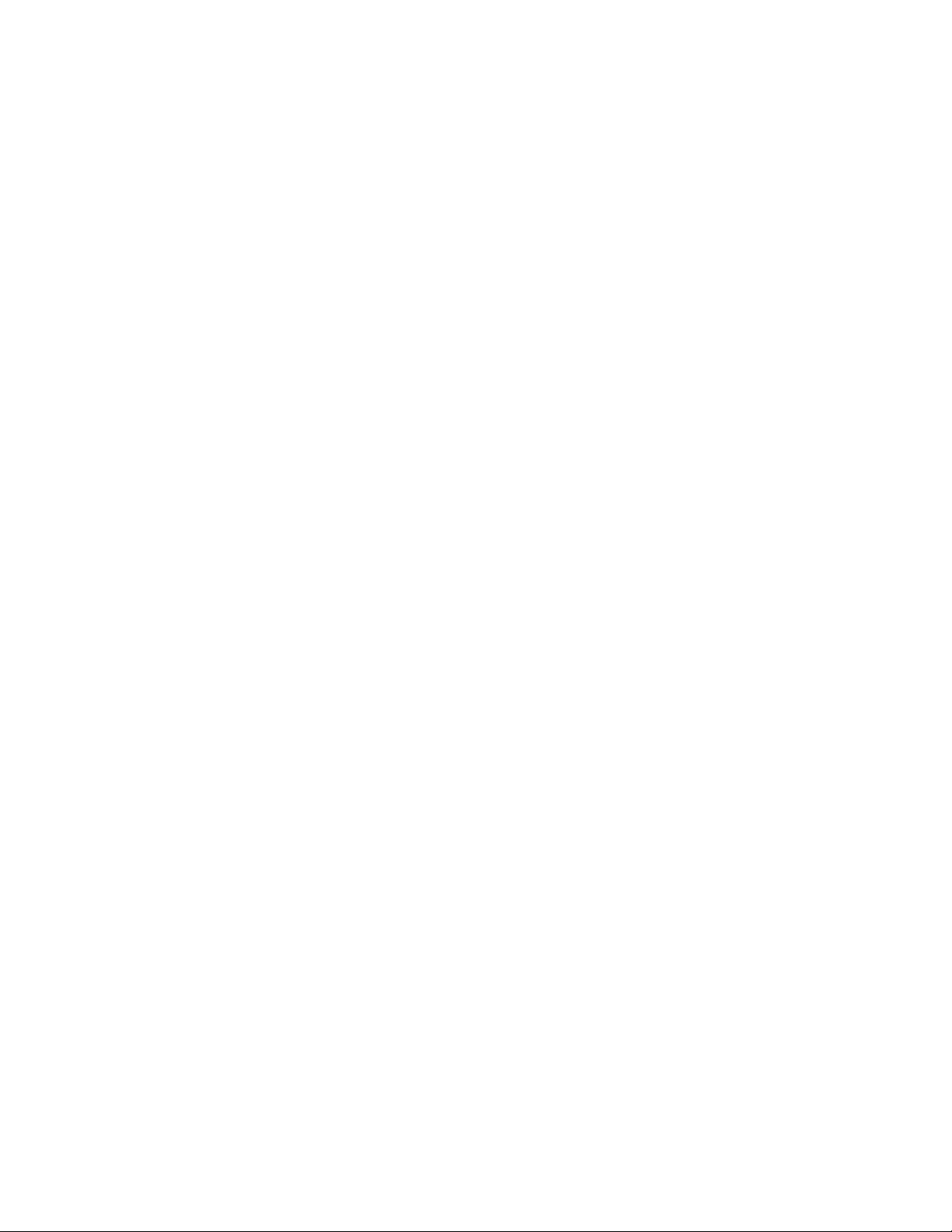

[1] SYSTEM CONFIGURATION

COPIER

ENGINE

M

B

U

S

System-BUS

M

B

U

S

Energy-saving I/F

correspondence

[2] SPECIFICATIONS

1. Basic specification

Item Detail

Print Speed AR-M276/M277:

Resolution 300dpi, 600dpi, 1200dpi*1

Smoothing 1200dpi x 600dpi

Standard memory 64 MB

Expansion memory *2, 3 DIMM 1 slot

Option memory 8MB flash DIMM

Toner save mode Standard

Input tray Multi Bypass tray

Duplex Print Standard

Finisher Option

NIC 10/100baseTX (Standard equipped

PostScript Level3 *3 Option

Bundled software Printer driver, PAU, Status monitor,

Barcode font Option

Operation Manual Standard (Online manual)

Platform IBM PC/AT (Include compatible

27ppm (600dpi)

13.5ppm (1200dpi)

AR-M236/M237:

23ppm (600dpi)

13.5ppm (1200dpi)

144 pin 128/256MB DIMM

Tray 1, Tray 2, Tray 3, Tray 4

(Depending on conditions of the

machine and option installation.)

with TCP/IP RF NIC. Others are

optional.)

Installer, Acrobat Reader

machine)

Macintosh

PCL CONTROLLER

CPU

PCI-BUS

32bit/33MHz

IO

ASIC

*1: 1200dpi mode print is supported only in PCL6 and PS3.

*2: Network scan needs one slot of memory (max. 256MB). When,

*3: PDF direct print is available with PostScript.

2. Printer controller board

Option

P

C

I

10/100BaseT

L

A

N

USB2.0

(Full speed mode correspondence)

U

S

B

1

2

8

4

P

C

I

PCI

Board

Ethernet

PC

PC

Item Detail

Support OS

(Printer

Driver)

Custom PS Windows 95/98/Me

Windows NT 4.0

Windows 2000

Windows XP

Custom

PCL5e

Windows 95/98/Me

Windows NT 4.0

Windows 2000

Windows XP

Custom

PCL6

Windows 95/98/Me

Windows NT 4.0

Windows 2000

Windows XP

PPD only Windows 95/98/Me

Windows NT 4.0

Windows2000

Windows XP

MacOS 8.6 to 9.x, 10.1 or later

PDL support PCL5e, PCL6, PostScript Level 3,

TIFF, PDF

Resident

For PS 136 Outline Fonts

Fonts

For PCL5e,

PCL6

80 Outline Fonts

Line Printer

For PCL Barcode Fonts (Option)

Screen Fonts For PS 136 Outline Fonts

For PCL5e,

136 Outline Fonts

PCL6

For PCL Barcode Fonts (Option)

therefore, network scan is installed, the max. available memory for

the printer is 320MB.

Processor MIPS 64bit

Base memory 64MB (Standard)

Expansion

memory

Parallel I/F IEEE 1284 compatible x 1

USB I/F USB 2.0 (Full speed mode correspondence) x 1

Network I/F 10/100baseTX x 1

AR-P17 SYSTEM CONFIGURATION 1 - 1

Standard: 144 pin DIMM x 1 slot

Max.: 320MB

Page 6

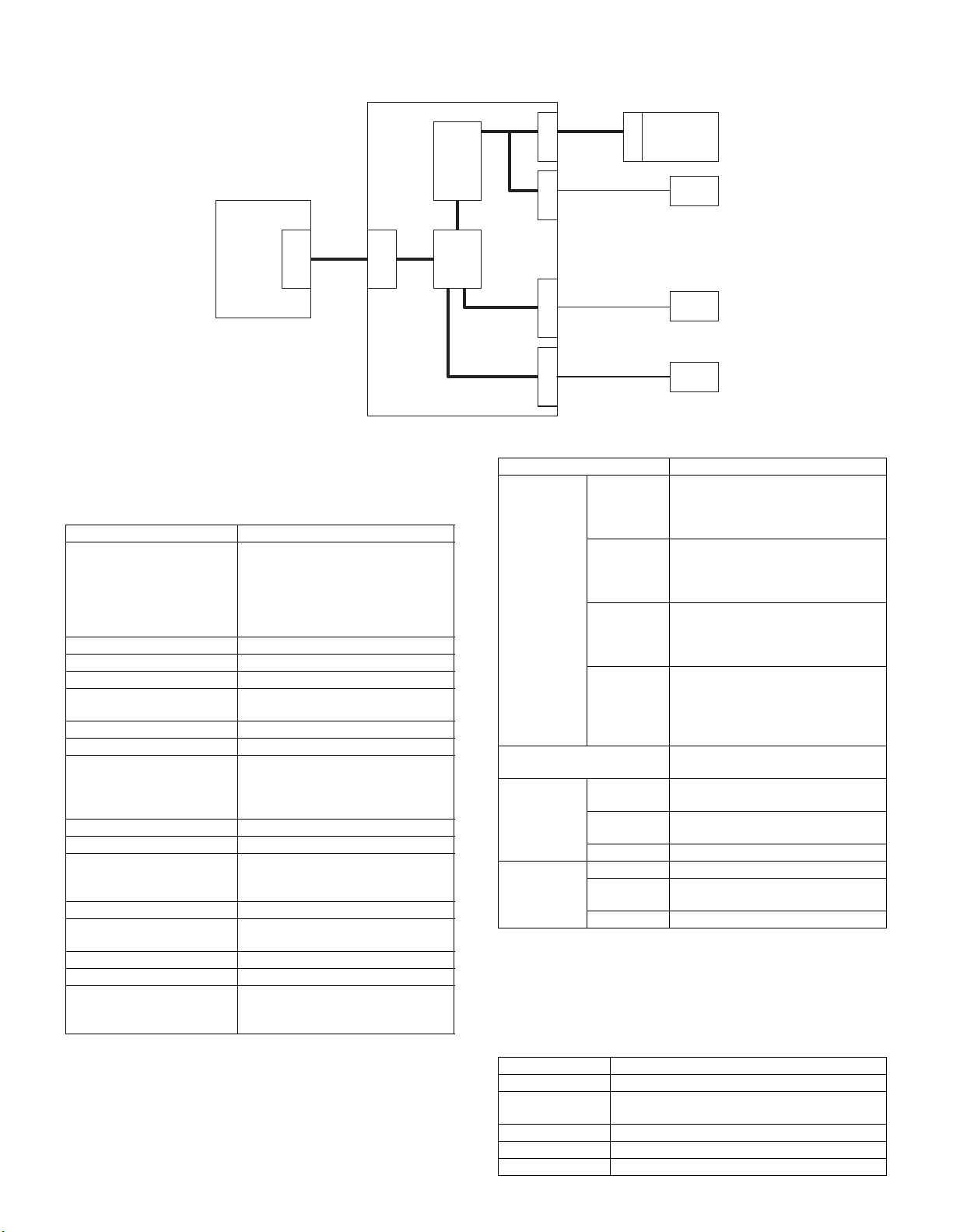

3. IMC controller board

Page memory 48MB

ROPM Base memory 32MB

ROPM Expansion memory Standard: 168 pin DIMM x 2 slot

Max.: 1056MB

4. Network specification

Interface Support OS Support Protocol

RF NIC 10Base-T

100Base-TX

AR-NC5J 10Base-T

100Base-TX

Windows TCP/IP only

NetWare,

Windows NT,

Mac OS

IPX/SPX, TCP/IP,

EtherTalk, Peer to Peer

(IPX/SPX, TCP/IP),

NetBEUI

5. Printer driver specification

A. System

Machine OS

IBM PC/AT

(Include

compatible

machine)

Macintosh MacOS8.6 to

Windows 95

Windows 98

Windows Me

Windows NT 4.0

Windows 2000

Windows XP

9.x, 10.1 or later

PCL6

Custom

PCL5e

Custom

Yes Yes Yes Yes

N/A N/A N/A Yes

PostScript

Custom

PPD

File

B. System requirement

Computer IBM PC/AT (Include compatible machine)

Operating

system

Note: Hardware requirements such as CPU and RAM for your operat-

Macintosh

Microsoft Windows 95

Microsoft Windows 98

Microsoft Windows Me

Microsoft Windows XP

Microsoft Windows NT 4.0

Microsoft Windows 2000

MacOS 8.6 to 9.x, 10.1 or later

ing system must be satisfied.

C. Print quality

Mode

Resolution 1200 dpi High Quality

Smoothing *1 On Smoothing function is ON.

Toner Save Mode *1 On Toner save function is ON.

Halftone

enhancement *1

*1: Functions on a image of 600dpi or 300dpi.

Controll

(*: Default)

600 dpi* Basic Resolution

300 dpi Alternate Resolution

Off* Smoothing function is OFF.

Off* Toner save function is OFF.

On* Halftone enhancement function

is ON.

Off Halftone enhancement function

is OFF.

Content

D. Paper handling specifications

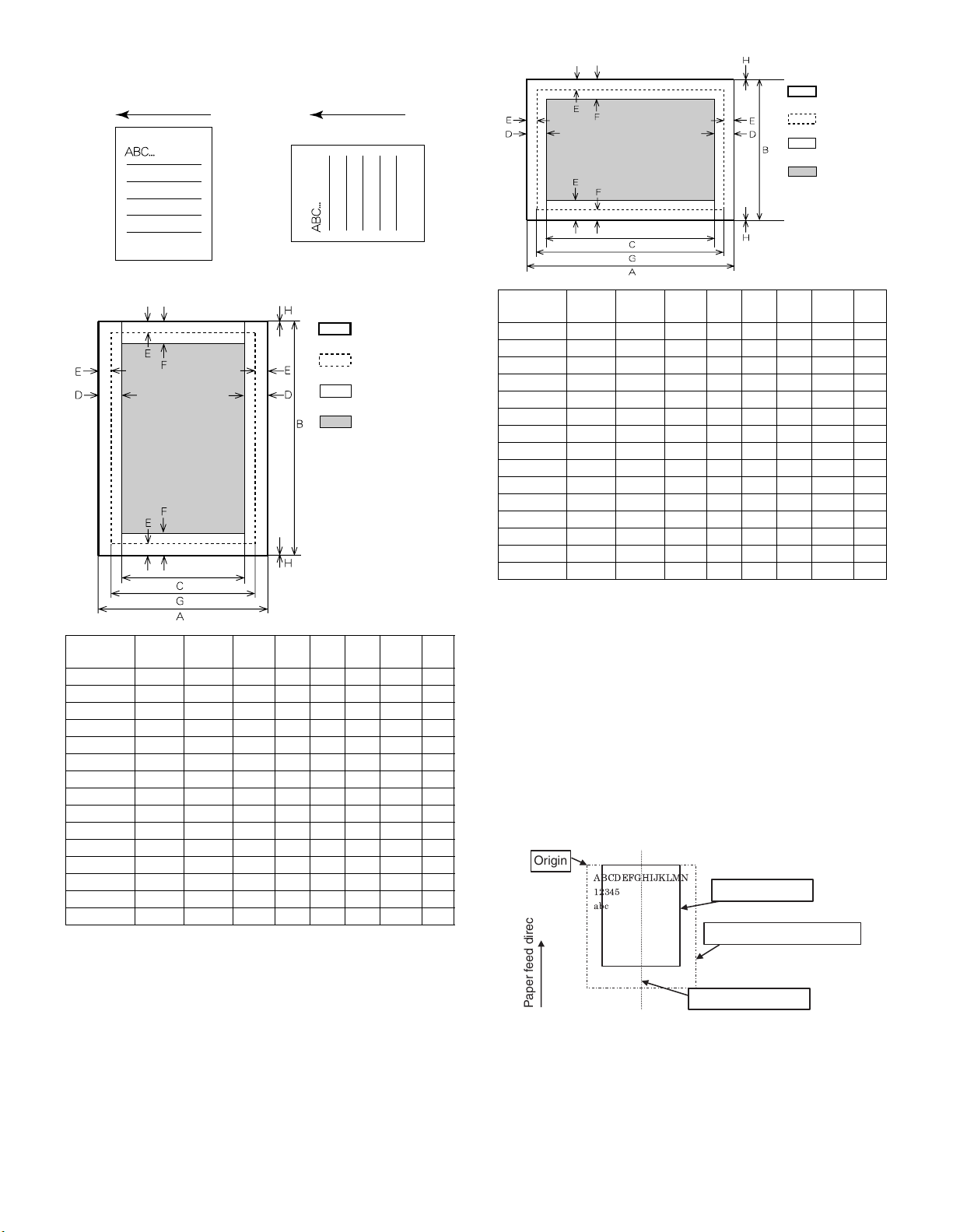

(1) Paper feed direction

a. Paper size and image transfer direction

Name

A6R 105 × 148 Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

B6R 128 × 182 Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

Invoice 215.9 × 139.7 (8.5” × 5.5”) Yes Yes N/A N/A N/A N/A Yes Yes Yes N/A N/A

Invoice-R 139.7 × 215.9 (5.5” × 8.5”) Yes N/A N/A N/A N/A N/A Yes Yes Yes N/A N/A

A5 210 × 148 Yes Yes N/A N/A N/A Yes Yes Yes Yes N/A N/A

A5R 148 × 210 Yes N/A N/A N/A N/A N/A Yes Yes Yes N/A N/A

B5 257 × 182 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

B5R 182 × 257 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes N/A

Executive-R 186.7 × 266.7 (7.35” × 10.5”) Yes N/A N/A N/A N/A N/A Yes Yes Yes Yes N/A

Letter 279.4 × 215.9 (11” × 8.5”) Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Letter-R 215.9 × 279.4 (8.5” × 11”) Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

A4 297 × 210 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

A4-R 210 × 297 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Folio 210 × 330 (8.3” × 13”) Yes N/A N/A N/A N/A N/A Yes Yes Yes Yes N/A

Legal 215.9 × 355.6 (8.5” × 14”) Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Foolscap 215.9 × 330.2 (8.5” × 13”) Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

B4 257 × 364 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

A3 297 × 420 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

Ledger 279.4 × 431.8 (11” × 17”) Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

8K 270 × 390 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes N/A

16K 270 × 195 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes N/A

16KR 195 × 270 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes N/A

COM10 4.12 × 9.5 Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

C5 162 × 229 Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

DL 110 × 220 Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

Transparency Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

Heavy stock Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

Label Yes N/A N/A N/A N/A N/A Yes Yes N/A N/A N/A

Size

mm (inch)

Bypass

Tray

Tray 1 Tray 2 Tray 3 Tray 4 Duplex

Exit Tray 2tray Finisher

Center

Tray

Upper

Tray

Top

Tray

Offset

Tray

Staple

AR-P17 SPECIFICATIONS 2 - 1

Page 7

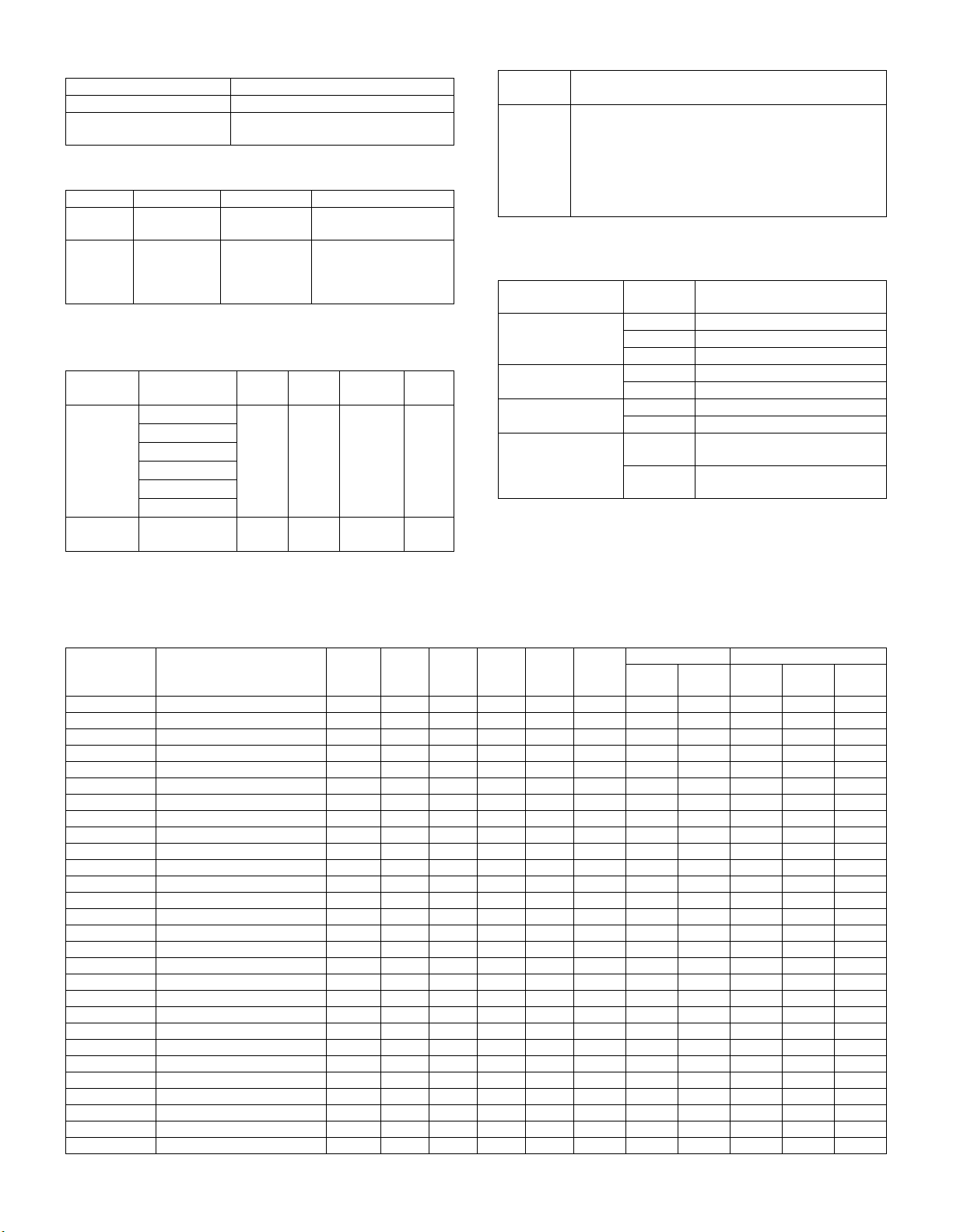

Setting direction toward paper

feed port = Long side

Transfer direction

Setting direction toward paper

feed port = Short side

Transfer direction

Actual page

size

Print area

Logic paper

size

HP/GL

picture

frame

E. Print enable area

Actual page size

Print area

Logic paper size

HP/GL

picture frame

Paper

Size

A3 7014 9920 6730 142 100 300 6814 0

B4 6070 8597 5786 142 100 300 5870 0

A4 4960 7014 4676 142 100 300 4760 0

B5 4298 6070 5770 142 100 300 4098 0

A5 3508 4960 3224 142 100 300 3308 0

Ledger 6600 10200 6300 150 100 300 6400 0

Legal 5100 8400 4800 150 100 300 4900 0

Letter 5100 6600 4800 150 100 300 4900 0

Invoice 3300 5100 3000 150 100 300 3100 0

Foolscap 5100 7800 4800 150 100 300 4900 0

Folio 4980 7800 4680 150 100 300 4780 0

Executive 4350 6300 4050 150 100 300 4150 0

COM-10 2474 5700 2174 150 100 300 2274 0

C5 3826 5408 3542 142 100 300 3626 0

DL 2598 5196 2314 142 100 300 2398 0

ABCDEFGH

Paper

Size

ABCDEFGH

A3 9920 7014 9684 118 100 300 9720 0

B4 8597 6070 8361 118 100 300 8397 0

A4 7014 4960 6778 118 100 300 6814 0

B5 6070 4298 5830 118 100 300 5870 0

A5 4960 3508 4720 118 100 300 4760 0

Ledger 8400 5100 8160 120 100 300 8200 0

Legal 8400 5100 8160 120 100 300 8200 0

Letter 6600 5100 6360 120 100 300 6400 0

Invoice 5100 3300 2860 120 100 300 4900 0

Foolscap 7800 5100 7560 120 100 300 7600 0

Folio 7800 4980 7560 120 100 300 7600 0

Executive 6300 4350 6060 120 100 300 6100 0

COM-10 5700 2474 3460 120 100 300 5500 0

C5 5408 3826 5172 118 100 300 5208 0

DL 5196 2598 4960 118 100 300 4996 0

∗ Top margin

The set value is received from the digital copier, and data are made

according to the set value.

∗ Left margin

Since the paper size sensor is not set, the digital copier cannot recognize the size and direction of paper which is actually inserted.

Therefore, the left margin is set according to the paper size specified in

the print data sent from the computer, and print process is performed.

If the computer does not specify the paper size, or in the case of the

custom size, the left margin is set according to the default paper size.

F. Print reference

This machine employs the center reference system.

Since the digital copier is not provided with the tray size detection feature, formatting and center distribution are performed not by the actual

paper size but by the paper size specified by the computer.

Origin

ABCDEFGHIJKLMN

12345

abc

Actual paper size

Size specified by the HOST

Paper feed direction

AR-P17 SPECIFICATIONS 2 - 2

Center reference line

Page 8

Page 9

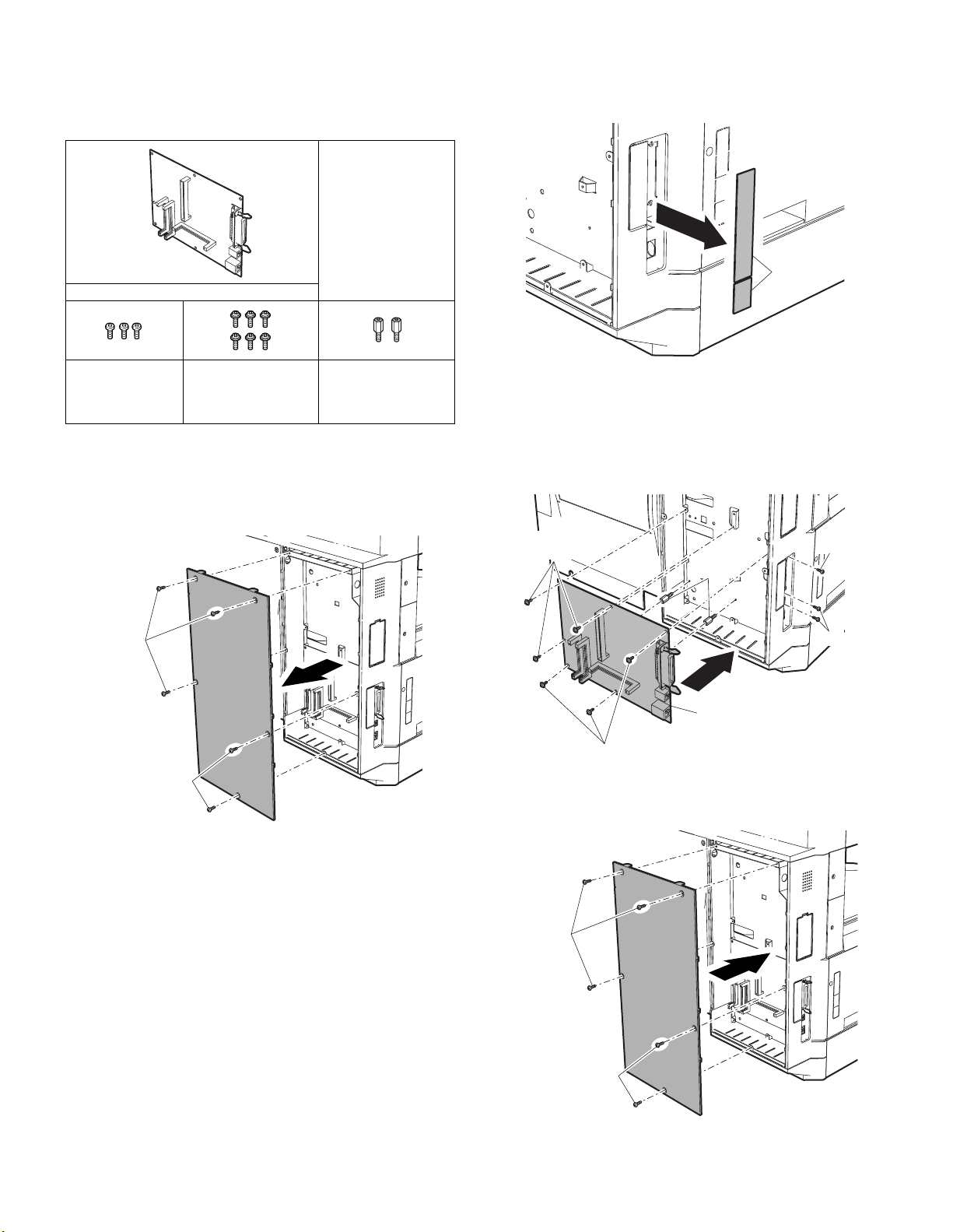

[3] INSTALLATION

1. AR-P17

A. Parts included

PCL PWB: 1 pc.

2) Cut and remove the cut-out portion from the left rear cabinet.

Cut and remove the cut-out portion from the left rear cabinet using

a tool such as nippers. (Be careful about the direction of the tool so

that the cut surface is flat.)

CD-ROM: 1 pc.

Operation manual

Installation caution

sheet

Cut-out portion

M3 screws: 3 pcs.

(For installation of

the parallel and the

USB connectors)

M3 screws with

spring washer: 6 pcs.

(For installation of the

PCL PWB)

Support post: 2 pcs.

B. Installation procedure

Turn off the main switch of the copier and then remove the power

plug of the copier from the outlet.

1) Remove the shielding plate.

Remove five screws and remove the shielding plate.

Screws

Screws

3) Attach the PCL PWB unit.

Attach the support post to the mounting plate of machine options.

Then connect the PCL PWB connector to the mother board connector and fit the PCL PWB with the six screws with M3 spring

washer (packed with the unit).

Then, attach the parallel and USB connector portion using the supplied three screws.

M3 screws with

spring washer

M3 screws with

spring washer

4) Attach the shielding plate.

Attach the shielding plate using five screws.

Support

post

PCL PWB

M3 screw

M3 screws

Screws

AR-P17 INSTALLATION 3 - 1

Screws

Page 10

Insert the power plug of the copier to the outlet and turn on the

main switch. Then, carry out the following procedure.

5) Check for the PCL PWB.

Press the PRINT key on the operation panel to check to see if the

copier enters the print mode.

6) Check for the language.

Check for the language setting (26-22) following the procedure

described in the service manual (section of simulation).

7) Check for printing.

For installation of printer drivers on a computer, see the supplied

operation manual.

Then, connect a parallel cable to the computer and execute print-

ing to check to see if printing can be executed properly.

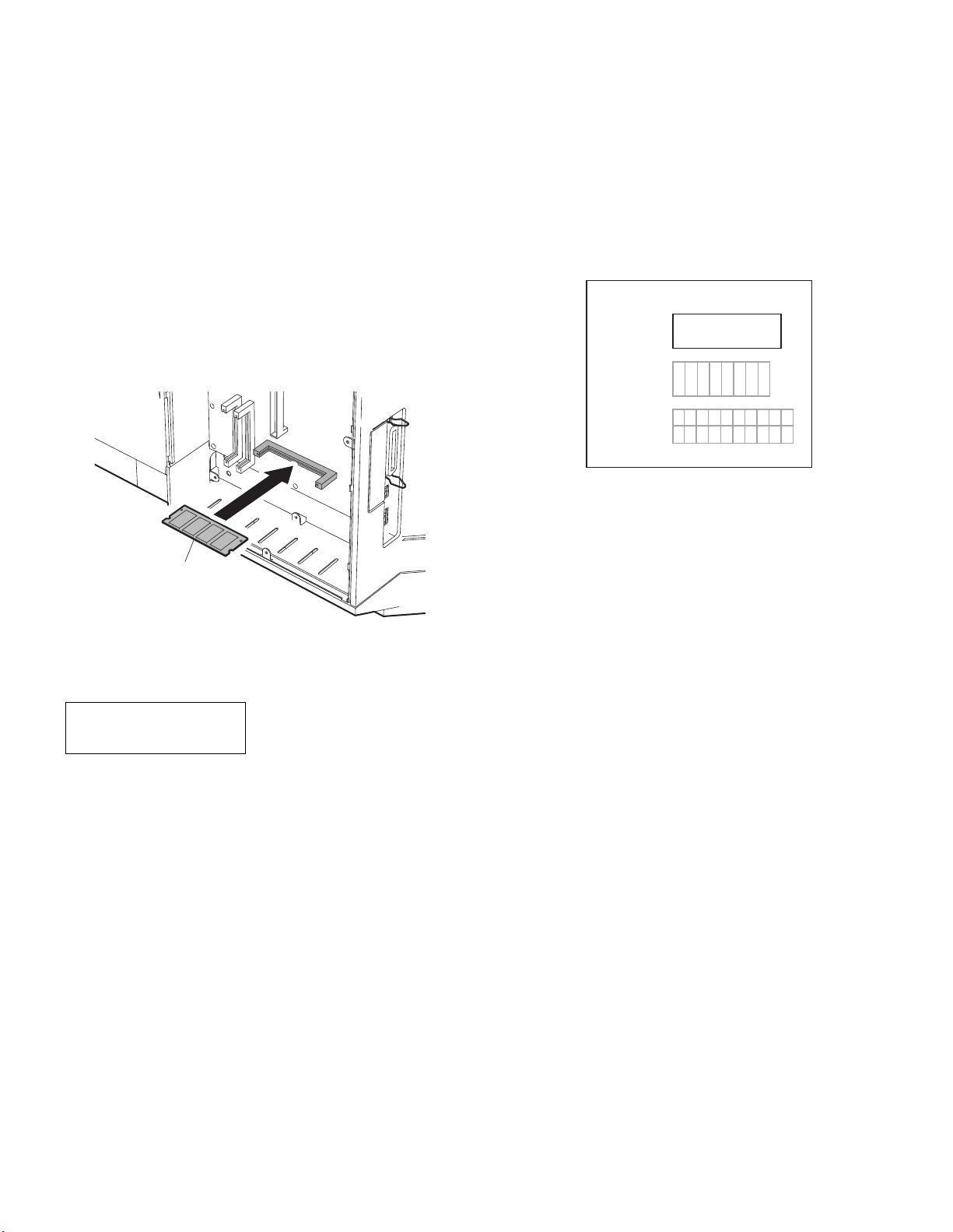

C. Mounting of additional memory

(After mounting it, Installation proceed to step 4.)

Insert the memory module until it clicks.

The memory module is lock when it is inserted. However, be sure to

check that the module slit is engaged with the connector rib when it is

inserted.

3) Check the PS3.

Make the following sequence of selections on the control panel.

• Press Special Functions , highlight Configuration and press OK.

• Use the up and down keys to highlight Test print menu and

press OK.

• Use the up/down keys to highlight Configuration page and press

OK.

A configuration page will be printed.

Check that the option memory capacity is 128 MB or more.

Check that the PS3 has been installed.

Please keep below important information.

This information will use for other products.

APPLICATION

NUMBER

MACHINE

SERIAL

NUMBER

PRODUCT

KEY

Memory module

(S.O.DIMM)

2. AR-PK1

A. Parts included

CD-ROM: 1*

License agreement

Installation caution sheet

*NOTE: Do not use the CD-ROM packed in AR-PK1, but use the CD-

B. Installation procedure

To enable the PS3, the product key must be acquired.

(For the method of acquiring the product key, contact the SHARP

authorized dealer.)

1) Check that AR-P17 operates normally.

2) Enable the PS3.

ROM packed together with the AR-P17 for setting the PS

driver.

• Turn on the power and wait until warming up is complete.

• Press the PRINT key on the operation panel of the main unit.

• If the LCD in the operation panel of the main unit switches to the

print mode normally, AR-P17 is operating normally.

• If it is not operating normally, follow the AR-P17 Installation Manual to check and modify the system configuration settings and

check the operation.

To enable the system configuration, use the keys on the main unit

to set the mode.

Enter the product key with the key operator program. (Refer to the

Operation Manual of Key Operator Program.)

Setting of the product key is complete. To update the system,

press the CA key to exit the setting mode.

AR-P17 INSTALLATION 3 - 2

Page 11

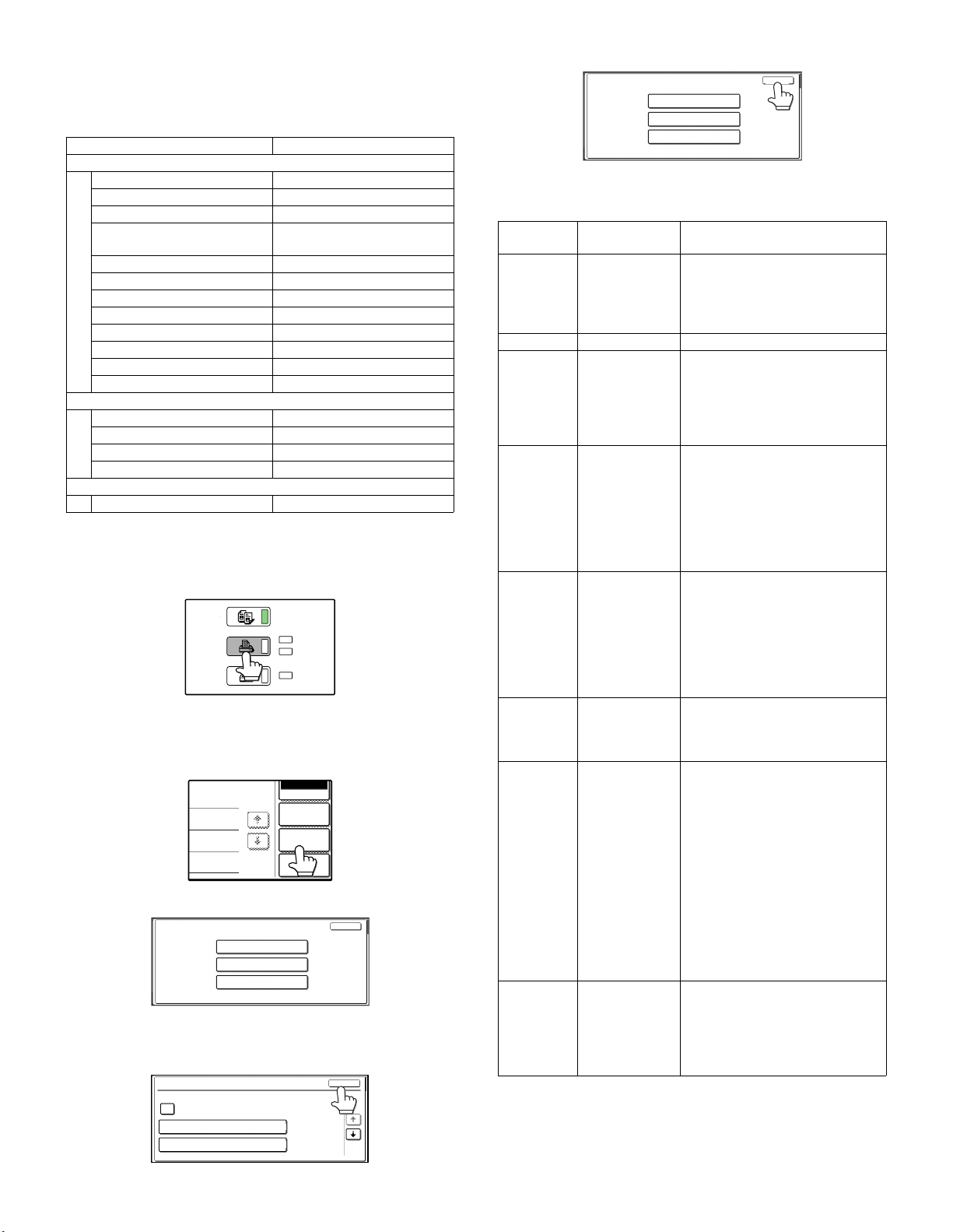

[4] SETTING AND ADJUSTMENTS

1. Printer condition settings

A. List

Item Default

Default settings

Toner save OFF

Copies 1

Orientation Portrait

Default paper size AB series: A4

Inch series: 8 1/2 x 11

Default paper source Auto

Default paper type Auto

Smoothing OFF

Resolution 600dpi

Extra print mode OFF

2-sided print 1-sided

Page protection ON

ROPM OFF

PCL settings

PCL symbol set setting 3 (PC-8)

PCL font setting Internal font: 0 (courier)

Line feed code 0

Wide A4 OFF

PostScript settings*

Print PS errors OFF

* Displayed when installing the PS expansion kit (AR-PK1).

B. Operating procedure

1) Press the [PRINT] key.

The basic menu of the printer mode is displayed.

COPY

PRINT

SCAN

2) Touch the [CONDITION SETTINGS] key.

Any print jobs that have already been sent to the machine, includ-

ing print hold jobs stored in the machine, will be printed using the

printer condition settings that were effect when the job was sent.

3) Touch the target item to display the setting menu.

CONDITION SETTINGS

DEFAULT SETTINGS

PCL SETTINGS

PostScript SETTINGS

4) On the setting menu of the target item, set the desired set value

and touch the [OK] key.

To set another item continuously, repeat procedures 3) and 4).

DEFAULT SETTINGS

TONER SAVE

COPIES

ORIENTATION

ON LINE

DATA

DATA

ONLINE

OFFLINE

BYPASS SELECT

CONDITION

SETTINGS

DELETE

1

P

EXIT

OK

5) To terminate setting, touch the [END] key.

CONDITION SETTINGS

DEFAULT SETTINGS

PCL SETTINGS

PostScript SETTINGS

EXIT

C. Setting item

Default settings

Item

Toner save

Copies 1* – 999 Sets how many copies to print.

Orientation Portrait*,

Default

paper size

Default

paper source

Default

paper type

Smoothing

Resolution 300dpi, 600dpi*,

Set value

(*: Default value)

ON, OFF*

Landscape

5 1/2 x 8 1/2,

8 1/2 x11*,

8 1/2 x 13,

8 1/2 x 14,

11 x 17, A5,

B5, A4*, B4, A3

AUTO*,

BYPASS

(MANUAL),

BYPASS (AUTO)

TRAY1,

TRAY2,

TRAY3,

TRAY4

AUTO*, PLAIN,

RECYLED,

LETTER HEAD,

COLOUR

ON, OFF*

1200dpi

Description

Sets whether toner save mode is in

effect or not. Toner is saved by

printing a little lighter. When the

resolution is 1200dpi, toner save

does not function.

Sets the page orientation for printing.

Specify "PORTRAIT" to print the

paper with its long side (longer edge)

vertical. Specify "LANDSCAPE" to

print the paper with its long side

(longer edge) horizontal.

Sets the size of the paper where

data will be printed. If this size is

different from the paper size present

in the tray, the size set for this item

takes precedence.

* Depending on where the printer

was purchased, the default value is

either "A4" or "Letter".

Sets the tray used for paper feeding.

When set to "Auto," the tray loaded

with the paper set by "Default paper

size" is automatically selected.

* Tray 3 and 4 (option) can be

selected only when installed.

Select the paper type to be used.

When set to "Auto," the tray loaded

with the paper set by "Default paper

size" is automatically selected.

Sets whether smoothing is done or

not. Angles and curves included in an

image are smoothed to improve the

image quality. If smoothing is set

when the resolution is set to 600dpi,

an image corresponding to 1200dpi is

printed. (Printing at 1200dpi provides

a higher print quality, but consumes a

greater memory space, resulting in a

low print speed. When the resolution

is set to 1200dpi, smoothing cannot

be selected.) To print a bitmap image,

it is better not to select smoothing to

have a better print quality.

Sets the printing resolution. When

1200dpi is selected, smoothing and

toner save cannot be selected.

Since 1200dpi printing consumes a

large memory space, resulting in a

low print speed.

AR-P17 SETTING AND ADJUSTMENTS 4 - 1

Page 12

Item

Extra print

mode

2-sided print

Page

protection

ROPM ON, OFF*

Set value

(*: Default value)

ON, OFF* This function is used to reduce wait

1-SIDED*,

2-SIDED

(BOOK),

2-SIDED

(TABLET)

ON*, OFF Sets page protection. Page

PCL settings

Item

PCL symbol

set setting

PCL font

setting

Line feed

code

Set value

(*: Default value)

1 – 35 (3*) Specify the PCL symbol set.

Internal font

(0* – 80),

extended font

(1 –)

0* – 3 The line feed code is set by

Description

time between print jobs and

proceeds efficient print processes

mainly when there are many single

print jobs. Normally it is not used.

When this function is set, multiple

print jobs are processed as a single

job when all of the jobs have the

same print format. On the job status

display, it is displayed with one job

key. When printing is made with the

print hold function, this function

does not work. When the print type

is changed such as when the paper

size is changed, this function is

terminated.

When "2-SIDED (BOOK)" is

selected, duplex print is made on

the assumption that the left edge of

paper is bound. When "2-SIDED

(TABLET)" is selected, duplex print

is made on the assumption that the

top of paper is bound.

protection is a function designed to

prevent data loss errors when

complex data is printed.

Sets whether the ROPM function is

enabled. If the ROPM function is

enabled, print data will be stored in

the printer memory once for printing

onto multiple sheets. This function can

reduce transmission quantity between

the printer and your computer.

Description

The number of the PCL symbol set

can be checked by printing [PCL

symbol set list] in [list print] of

CUSTOM SETTING.

The PCL font to be used for printing

can be specified. One type of font can

be selected from the internal fonts or

the expansion fonts (bar code font kit

or flash ROM kit). The default is "0"

(Internal font: Courier).

The types of available fonts can be

checked by printing the font list in

the [list print] of the [CUSTOM

SETTING]. The font list includes the

font names, the numbers and print

out sample assigned to the fonts. In

this setting, the number assigned to

the font to be used is set.

combination of "CR" (Carriage

Return) code, "LF" (Line Feed"

code, and "FF" (Form Feed) code.

The default is set so that printing is

made by the sent code. To change

the setting, there are four kinds of

combination to select.

Item

Wide A4 ON, OFF* When this item is set, 80 digits of

Set value

(*: Default value)

Description

10CPI font can be printed in one line

on A4 size paper. When setting is

canceled, the print digit number in

one line becomes 78 characters.

PostScript settings

"PS setting" is allowed only when the PS expansion kit is installed.

Item

Print PS

errors

Set value

(*: Default value)

ON, OFF* When it is set, if a PostScript error

occurs, the error content is printed.

Description

2. AR-PK1 (PS expansion kit) setup

A. Setup content

• The soft key is supplied by registering the manufacturing number

and the model name of the machine and the application number

attached to the PS expansion kit via the Web site.

Enter the soft key to the machine, and the PS3 function can be operated.

If, however, the setup enable conditions are not satisfied, inputs are

disabled.

• When the soft key is erroneously inputted:

When the function lock is canceled: the function lock turns to work.

When the function lock is working: the function lock is kept working.

B. Setup enable conditions

• The printer expansion kit (including the standard equipment) should

be installed.

• The Japanese font ROM should be installed to the printer board.

(Japan only)

• The printer function should be provided as standard provision.

C. Setup menu

Enter the soft key the machine from “KEY OPERATOR MENU".

D. Function cancel menu

• When the diag menu or the key operator program menu is displayed,

the current machine state (the key is canceled or not) is displayed.

• Display content

ON: The function lock is working.

OFF: The function lock is canceled.

• Regardless of the display position

3. Email alert status

A. Setup contents

• The soft key is supplied by registering the manufacturing number

and the model name of the machine and the fixed application number via the Web site.

Enter the soft key to the machine, and the email alert and status

function can be operated.

If, however, the setup enable conditions are not satisfied, inputs are

disabled.

• When the soft key is erroneously inputted:

When the function lock is canceled: the function lock turns to work.

When the function lock is working: the function lock is kept working.

B. Setup enable conditions

• The printer expansion kit (including the standard equipment) should

be installed.

• The network card kit (NIC) should be installed.

C. Setup menu

Enter the soft key the machine from “KEY OPERATOR MENU".

AR-P17 SETTING AND ADJUSTMENTS 4 - 2

Page 13

D. Function cancel display

• When the diag menu or the key operator program menu is displayed,

the current machine state (the key is canceled or not) is displayed.

• Display content

ON: The function lock is working.

OFF: The function lock is canceled.

• Regardless of the display position

4. Key operator program list

Key operator programs Set value (∗: Default value) Remarks

Print settings

Default settings Prohibit notice page printing ON / OFF∗

Print density level 1 / 2 / 3∗ / 4 / 5

Prohibit test page printing ON / OFF∗

Rotated print ON∗ / OFF

Forced output of print ON / OFF∗

Exclude bypass-tray from ATS ON∗ / OFF

Disable default setting changes ON / OFF∗

Interface settings Hexadecimal dump mode ON / OFF∗

I/O timeout 1 – 999 (Increment of 1sec.) 60 (sec.)∗

Parallel port emulation switching Auto∗ / PostScript (When the PS3

expansion kit is installed.) / PCL

USB port emulation switching Auto∗ / PostScript (When the PS3

expansion kit is installed.) / PCL

Network port emulation switching Auto∗ / PostScript (When the PS3

expansion kit is installed.) / PCL

Network settings

(When the print server

card installed.)

Initialise and/or store

settings

Port switching method Switch at end of job∗ / Switch after I/O

Enable parallel port ON∗ / OFF

Enable USB port ON∗ / OFF

Enable network port ON∗ / OFF

Enable ECP ON / OFF∗

IP address

setting

DHCP

IP address

IP subnet mask

IP gate way ON∗ / OFF

Enable TCP/IP *

Enable NetWare *

Enable EtherTalk *

Enable NetBEUI *

1)

1)

1)

1)

Reset the NIC —

Restore factory default —

Store current configuration —

Restore configuration

timeout

ON∗ / OFF To enable the changed setup, the

ON∗ / OFF

ON∗ / OFF

ON∗ / OFF

ON∗ / OFF

ON∗ / OFF

ON∗ / OFF

power must be rebooted.

*1) Displayed when the AR-NC5J is

installed. Not displayed when only

the AR-P17 is installed.

—

To enable the changed setup, the

power must be rebooted.

AR-P17 SETTING AND ADJUSTMENTS 4 - 3

Page 14

Page 15

[5] SIMULATION

1. Operating procedures and operations

* Entering the simulation mode

1) #/P key (program) ON

Asterisk (*) key ON → Ready for input of a main code of simulation

2) Entering a main code with the 10-key

3) Entering a sub code with the 10-key

4) Select an item with the scroll key and the item key.

5) The machine enters the mode corresponding to the selected item.

Press START key to start the simulation operation.

To cancel the current simulation mode or to change the main code

and the sub code, press the CUSTOM SETTINGS key.

* Canceling the simulation mode to return to the normal mode

1) Press CLEAR ALL key.

2. Simulation code list

Code

Main Sub

22 1 Used to check the counter value of each section.

24 9 Used to clear the printer counter and other

67 14 Used to check write/comparison of flash programs.

→ Asterisk (*) key ON → CLEAR key ON →

→ START key ON

→ START key ON

Function

counters. (The counter is cleared after completion

of maintenance.)

24-9

Purpose Data clear

Function

(Purpose)

Section Printer

Item Counter Printer

Operation/procedure

1. Select the counter to be cleared with the 10-key.

2. Press the [START] key.

The confirmation menu is shown.

3. Select "1: YES."

1: YES (Cleared)

2: NO (Not cleared) (Default)

1 PRINTER

2IMC

3DUPLEX

4OTHERS

Used to clear the printer counter and other counters.

(The counter is cleared after completion of

maintenance.)

Item Content

Printer counter

IMC counter

DUPLEX counter

The other counters

3. Details

22

22-1

Purpose Adjustment/setting/operation data output/check

(display/print)

Function

(Purpose)

Item Counter

Operation/procedure

Each counter is displayed.

TOTAL Total

MAINTENANCE Maintenance

DEVE Developer counter *1

DRUM Drum counter

COPY Copy counter

PRINTER Printer counter

IMC IMC counter

DUPLEX Duplex counter

OTHERS The other counters

FAX SEND FAX Send counter

FAX RCV FAX receive counter

FAX OUTPUT FAX print counter

The counter display is in 7 digits.

Used to check the counter value of each section.

67-14

Purpose Flash ROM version up

Function

(Purpose)

Section Printer

Item Operation

Operation/procedure

1. Press the [START] key.

"PLEASE SEND DATA" is displayed.

2. Data are sent from the PC (MS-DOS) by use of "fcopy" command

(FCOPY: file name). (Refer the “[7] FLASH ROM VERSION UP

PROCEDURE”)

Used to overwrite and check the flash device while displaying its

process status.

After completion, the result is displayed.

3. Press the [CA] key to cancel the simulation and reset.

(Flash Device)

PROGRAM

BOOTROM

PS KANJI FONT

ESC/P KANJI FONT

OPTION FONT

* Execution of the simulation which performs communication with the

PCL board is inhibited until Notice Page storage is completed. (Only

when the serviceman call error occurs.)

In the other case than the serviceman call error, entering the simulation is inhibited during the system check operation is displayed.

Used to check write/comparison of flash programs.

(Processing state)

RECEIVE

ERASE

WRITE

VERIFY

AR-P17 SIMULATION 5 - 1

Page 16

Page 17

[6] CONFIGURATION REPORT AND TEST PAGE

DATA

LINE

CUSTOM SETTINGS

LIST PRINT

RECEIVE MODE

1. Kinds of test pages

Test pages are available in the following 6 kinds:

• Printer settings list

• PCL symbol set list

• PCL internal font list

• PCL extended font list (Only when an option font or an option Flash

ROM kit is installed. When a Flash ROM kit is installed, it is displayed only when fonts are downloaded.)

• PCL internal font list (With PS installed)

• PS extended font list (Displayed only when PS is installed, an option

Flash ROM is installed, and fonts are downloaded.)

• NIC page

2. Print method

1) Press the [CUSTOM SETTINGS] key.

2) Touch the [LIST PRINT] key.

3) Touch the [PRINTER TEST PAGE] key.

PRINTER TEST PAGE

4) Touch the list key to be printed.

PRINTER SETTINGS

LIST

PCL SYMBOL SET

LIST

PCL INTERNAL FONT

LIST

PCL EXTENDED FONT

LIST

* It is printed by priority even when there is a job waiting for printing.

AR-P17 CONFIGURATION REPORT AND TEST PAGE 6 - 1

Page 18

Page 19

[7] FLASH ROM VERSION UP

PROCEDURE

(Necessary items for version-up)

A Personal computer

B Centro (printer) cable

C Software for version-up

(ROM type)

The flash ROM is directly installed to each PWB.

(Target PWB)

1 PCL PWB

Outline of Version-up Procedure

(PC)

C

Download

data

RS232C connector

(9pin or 25pin)

A

Centro connector

1. Printer Control Board firmware

download method

Please follow the procedure below:

1) Make sure copier is turned off, and connect PC and Printer Control

board of the copier by parallel cable beforehand.

∗ Note: It is okay to use serial cable instead.

2) Turn on the copier.

3) Start up in copier test command mode, and execute Sim67-14

"FLASHDOWNLOAD".

4) And then, press OK key when notice message "PRESS OK KEY"

appears on the panel. Another message "Please Send Data" will

appear after a while.

5) Start up the maintenance program on PC. Select model name

"AR-M236/M276/M237/M277 Series" from the model selection

dialogue box.

6) Expand "Printer Control Board", and double-click on "Printer Con-

trol Board Firmware Download".

B

Centro cable

Operation

panel

I/F circuit (9pin)

MCU-PWB

IMC

FAX-PWB

PWB

(AR-M236/M276/M237/M277)

Finisher

Centro connector

PCL-PWB

1

Prepare following files necessary for program download

• Maintenance software: maintenance.exe

• Andromeda module file: ProcModelC.mdl (for AR-M236/M276/

M237/M277 series)

Double click it.

7) Dialog box will appear to select download file.

8) Select Download file(*.sfu) and press "Open" button.

9) Download procedure will starts automatically.

10) Notice message "Data Send Complete" will appear on PC.

11) Notice message "Download is complete. Check the copier panel

to make sure the download is complete." will appear on PC.

12) Close maintenance program, and reset the machine by pressing

CA key.

This is the end of the download procedure.

AR-P17 FLASH ROM VERSION UP PROCEDURE 7 - 1

Page 20

2. Others (Troubleshooting)

Followings are the error possibly occur during the download process and troubleshooting method.

No Warning/error message Detail

1 Incorrect destination. Continue with the

download process?

2 Incorrect download file. Invalid download file for the machine is selected, or the file format is not correct.

3 No downloadable data included. Unable to find appropriate data in selected download file.

4 This option not available. Download procedure is executed on uninstalled optional kit.

5 The data size exceeds the Flash ROM size.

Try again with the appropriate size of data.

6 Time out error. Transmission error

7 Communication (incoming) error. Incorrect download procedure.

8 Checksum error. Transmission error

9 Error during the download process. Error

code: 0xXXXXXXXX

10 An error. [0xXXXXXXXX] The error occurred except the above errors.

Destination of download file and copier doesn't match.

Possible to select either continue or cancel the job.

[TROUBLESHOOTING]

To change destination, select "Yes". If not, select "No" and cancel download process.

[TROUBLESHOOTING]

Confirm the download file. Possibly the improper download file is selected.

[TROUBLESHOOTING]

Confirm the download file. Possibly the improper download file is selected.

[TROUBLESHOOTING]

Confirm installed optional kit.

Confirm the download file. Possibly the improper download file is selected.

Panel flash ROM size is not enough to execute download procedure.

[TROUBLESHOOTING]

Confirm the download file. Possibly the improper download file is selected.

Exchange the flash ROM to the one which has more capacity.

Unable to receive data from the machine among the certain period of time.

[TROUBLESHOOTING]

Restart maintenance program after confirming communication port or communication cable.

The machine did not proceed download procedure correctly.

[TROUBLESHOOTING]

Restart maintenance program after confirming communication port or communication cable.

Make sure the communication device of PC(either COM or parallel) is under right condition.

The check sum value of the transmission data is mismatch.

[TROUBLESHOOTING]

Restart maintenance program after confirming communication device of PC (either COM or

parallel) is under right condition.

Download data file operation error.

[TROUBLESHOOTING]

Restart maintenance program after confirming the selected download file is not abnormal and

not using other application.

[TROUBLESHOOTING]

Restart maintenance program after confirming communication device of PC(either COM or

parallel) is under right condition.

AR-P17 FLASH ROM VERSION UP PROCEDURE 7 - 2

Page 21

[8] PRINTER STATUS MONITOR/PRINTER ADMINISTRATION UTILITY

1. Printer status monitor

A. Purpose

• Is printing enabled or disabled?

• Is toner sufficiently supplied?

• Is paper sufficiently supplied?

• Is duplex print enable?

• Is the previous printing completed?

This application provides easy and simple view of the above items.

B. Operating environment

Windows95, Windows98, WindowsMe, WindowsNT4.0 Workstation

(SP3 or later), Windows2000 Professional, Windows XP Home Edition

Professional TCP/IP necessary

C. V3.1 limitations and notes

(1) Requisites of printer to be monitored

• The printer driver should have been installed. (Necessary)

• The driver should allow peer-to-peer printing.

For the AR-M237/M277/M236/M276 series, the SC-Print2000 (Windows 95/98/Me) should be installed, and the "Print destination port"

of the printer should be set to TCP/IP port,

or

• In the case where the driver is shared with the printer server, the

printer should be connected with TCP/IP. In this case, monitoring is

allowed after printing once.

(2) Install and uninstall

In the case of WindowsNT/2000/XP, the administrator authority is

required for install and uninstall.

(3) Status display when in the auto power shut off

The status information when the printer is in the "Auto power shut off"

mode is the status information immediately before entering the "Auto

power shut off mode.

D. Outline of functions

(1) Status display

Simple view: For beginners

Detailed view: For experts

Simple/Detailed selection allowed

(2) Status change notification

Device status when the machine is sending a job

Print enable

Print disable

Paper jam

Toner empty

Toner Low

Printer Warning

Paper Empty

Cover open

Off-line

Printer error (Service call)

Output Tray Full

Notifying method:

Status window pop-up

Tip pop-up

Sound

(3) Selection of printer to be monitored

The printer to be monitored can be switched by the following two ways.

• Switch by the printer menu

• Switch by the setting dialog

(4) Job complete notification

Status of the job which was sent by the machine

Print complete

Temporary interruption of print by an error

1) Tool bar

Displays the status window, revises the display to the latest state,

makes setups, and displays Help.

2) Status window

Displays the printer status.

Selection of Simple/Detailed view is allowed.

Pop-up to indicate a change in the status is also allowed by setup.

1)

2)

3)

4)

3) Tip

Turns on for a certain time (when setting) when the status

changes.

4) Task tray icon

Memory-resident. Displays the printer status which is monitored.

AR-P17 PRINTER STATUS MONITOR/PRINTER MANAGEMENT UTILITY 8 - 1

Page 22

(6) Job complete notification

When a print job is completed (or interrupted by an error), a notification

from the printer is received and displayed.

The dialog pop-up shows the notification.

1)

2)

1)

3)

4)

5)

6)

1) "Normal" icon

2) Message

3) Notifying time

(7) Status advice immediately before printing (23-page machine/27-page machine)

4) Printer driver name

5) Job name

6) "CLOSE" button

1) "Error" icon

2) Message

3) Notifying time

4) Printer driver name

2)

3)

4)

5)

6)

7)

5) Job name

6) "CLOSE" button

7) "DETAIL" button

If any trouble

occurs

The status is checked when printing is performed. The dialog to select Continue or Cancel printing is

AR-P17 PRINTER STATUS MONITOR/PRINTER MANAGEMENT UTILITY 8 - 2

displayed.

Page 23

2. Printer administration utility

A. Purpose

This application provides easy and simple view of the following items:

• What kinds of network printers are connected in the network?

• Are the network printers operating normally?

• What functions does the printer have?

B. Operating environment

Windows 95, Windows 98, Windows Me, Windows NT4.0 Workstation

(SP3 or later)/2000 Professional, Windows XP Home Edition Professional TCP/IP, Winsock2 necessary

C. Outline of functions

(1) Network printer retrieval/list display

• Retrieval and list display of the network printers which conform to the

Printer MIB (RFC1759) specifications.

• Printer status display by the color of the icon

– Normal state (No color)

On-line

– Warning state (Yellow)

Paper low, toner near empty, printer warning

– Error state (Red)

Paper empty, cover open, toner empty, paper jam, printer error,

Specified output tray full

• List display filter function

(2) Alert/log function

• Alert by the pop-up/sound when the printer status changes.

• Making of the alert/log file

(3) Printer property display

• Device information

Model name, status, name, installing place, RAM size, max. print

speed, etc.

• Paper exit tray information

Tray name, number of trays, paper empty/presence of each tray,

paper exit method, printing sequence, etc.

• Paper feed tray information

Number of trays, tray name, paper empty/presence of each tray,

paper size etc,

• Print setup

Channel & PDL information, default PDL, paper direction, single/

duplex print information

• Resource information

Print quantity, toner status

• Summary information

Information on the system and network

• SHARP NIC information

NetWare setup, IP address, hardware address, etc.

D. Note

(1) Install and uninstall

For NT/2000/XP, the administrator authority is required.

(2) Status display when auto power shut off

• The various information when the printer is in the "Auto power shut

off" mode is information immediately before entering the "Auto

power shut off mode.

3)

1)

2)

1) Main window

List display of network printers.

The status of a printer is indicated by the color of the icon.

2) Printer property page

Detailed information (on the functions and status) of a printer is displayed.

3) Pop-up alert

The pop-up-alert can be displayed by the setup when the printer

status changes.

AR-P17 PRINTER STATUS MONITOR/PRINTER MANAGEMENT UTILITY 8 - 3

Page 24

Printer property page (Select a printer from the list and double

click it to display this page.)

[Device tab]

1)

2)

3)

4)

Toner Low Toner Empty

Offline Paper Jam

Paper Empty Printer Error

Cover Open Printer Warning

[Paper feed tab]

1)

2)

3)

4)

5)

6)

7)

1) Paper feed tray for normal use:

If the driver does not specify any paper feed tray, the printer uses

this tray.

2) List of paper feed trays:

3) Description: = Tray name

4) Model name: (Not set in some models.)

5) Paper size: Length x width (mm)

6) Paper kind: Name defined by ISO/IEC

10175DPA

Information on the

tray selected from

the list is

displayed.

7) Max. paper capacity: AR-M230/M270

series detects the presence of paper only.

[Print setup tab]

Specified Output Tray

Full

1) Model

2) Name : Can be set.

3) Installing place : Can be set.

4) Property :

RM size

Max. paper size

Max. print speed

Paper path

[Paper exit tab]

1)

2)

3)

4)

5)

6)

7)

1) Paper exit tray for normal use:

If the driver does not specify any paper exit tray, the printer uses

this tray. No change allowed for some models.

2) List of paper output trays:

3) Description: = Tray name

4) Model name: (Not set in some models.)

5) Paper exit method: Face-up or face-down

6) Printing sequence: "First To Last" or "Last

To First"

7) Max. paper capacity: The paper presence

Information on the

tray selected from

the list is

displayed.

is detected and displayed only when the job

separator is installed.

1)

2)

3)

4)

1) Channel list : List of the effective channels

2) Paper direction : If the driver does not specify the direction, the

printer uses this direction for normal use. (No change allowed for

some models.)

3) Default PDL: If the driver does not specify any PDL, the printer uses

this PDL for normal use. (No change allowed for some models.)

4) Single/Duplex print : If the driver does not specify single/duplex

print, the printer uses this print path for normal use. (No change

allowed for some models.)

[Resource type]

2)

1)

1) Total Impressions : The quantity of printouts and outputs of copy

and FAX.

2) Toner status : OK or toner empty or toner low.

(Only toner empty or not is detected in some models.)

AR-P17 PRINTER STATUS MONITOR/PRINTER MANAGEMENT UTILITY 8 - 4

Page 25

[Summary tab]

1) Network and device information:

Device information

– Descriptions, operating time, etc.

Network information

– TCP, IP, the number of send/receive packet of SNMP

[SHARP NIC tab]

1)

1)

2)

3)

Setup

[Application]

3)2)1)

1) Setup : Used to set that the icon is minimized when booting or not,

and that the setup content is stored when terminating or not.

2) Network printer retrieval interval: Used to set automatic retrieval of

a printer on the network.

The printers to be retrieved can be set with the "Printer retrieval

(TCP/IP)" tab.

The retrieval interval is 1min to 60min. The default is 3min.

3) State and alert revision interval:

Used to set automatic revision of the printer status.

The revision interval is 10sec to 90sec. The default is 30sec.

[Confirmation]

4)

1) NetWare setup: Setup of NetWare enable/disable

If set to enable, setup and display and changes are made on the

following items:

NDS mode or Bindery mode

NDS tree name, context name

Bindery server name

Print server name

Ethernet frame name

2) TCP/IP setup : TCP/IP address, sub-net mask, default gateway

3) Hardware address : Hardware address of the network card in the

target printer.

4) Link to the device Web page (Provided only the models which

have an assembly Web server.)

1)

1) Confirmation message: Used to set that the confirmation pop-up

menu is displayed when;

the device setup is changed.

the device is deleted,

the filter setup is deleted,

the log file is deleted,

the application is terminated.

AR-P17 PRINTER STATUS MONITOR/PRINTER MANAGEMENT UTILITY 8 - 5

Page 26

[Printer retrieval (TCP/IP)]

1) 2)

1) Printer retrieval on the local network:

When this box is checked, the local network address is obtained

from the IP address and the sub net mask of the PC where PAU is

installed, and a printer on the local network is retrieved.

2) Retrieval by IP address:

A certain IP address can be obtained.

Only when this box is checked, the printers which have IP

addresses listed on the list can be retrieved.

System diagram

3)

3) Advanced retrieval dialog box

Used to set the printer retrieval on an external network.

To specify an external network to be retrieved, enter the network

address and the sub net mask of that network.

Manager

Printer status monitor

User

User

PAU

Printer status monitor

User

Printer status monitor

User

Printer status monitor

Printer status monitor

User

Printer

status

monitor

User

AR-P17 PRINTER STATUS MONITOR/PRINTER MANAGEMENT UTILITY 8 - 6

Page 27

[9] TROUBLE CODE LIST

Trouble code

Main

Sub

code

code

F9 00 Content MCU-PRT communication trouble

Details Communication establishment error/

Cause Printer PWB connector disconnection

Check

and

remedy

10 Content Printer PWB trouble

Details Communication trouble between MCU and

Cause Printer PWB connector disconnection

Check

and

remedy

80 Content Printer PWB communication trouble

Details Communication trouble between MCU and

Cause Printer PWB connector disconnection

Check

and

remedy

81 Content Printer PWB communication trouble

Details Communication trouble between MCU and

Cause Printer PWB connector disconnection

Check

and

remedy

Details of trouble

framing/parity/protocol error

Harness trouble between the printer PWB

and the MCU PWB

Motherboard connector pin breakage

Printer PWB ROM trouble/Data

disturbance

Check the connectors and harness of the

printer PWB and MCU PWB.

Check the grounding of the copier.

Check ROM on printer PWB.

printer PWB

Harness trouble between the printer PWB

and the MCU PWB

Motherboard connector pin breakage

Printer PWB ROM trouble/Data

disturbance

Check the connectors and harness of the

printer PWB and MCU PWB.

Check the grounding of the copier.

Check ROM on printer PWB.

(Protocol)

printer PWB (Protocol error)

Harness trouble between the printer PWB

and the MCU PWB

Motherboard connector pin breakage

Printer PWB ROM trouble/Data

disturbance

Check the connectors and harness of the

printer PWB and MCU PWB.

Check the grounding of the copier.

Check ROM on printer PWB.

(Parity)

printer PWB (Parity error)

Harness trouble between the printer PWB

and the MCU PWB

Motherboard connector pin breakage

Printer PWB ROM trouble/Data

disturbance

Check the connectors and harness of the

printer PWB and MCU PWB.

Check the grounding of the copier.

Check ROM on printer PWB.

Trouble code

Main

Sub

code

code

F9 82 Content Printer PWB communication trouble

Details Communication trouble between MCU and

Cause Printer PWB connector disconnection

Check

and

remedy

84 Content Printer PWB communication trouble

Details Communication trouble between MCU and

Cause Printer PWB connector disconnection

Check

and

remedy

88 Content Printer PWB communication trouble

Details Communication trouble between MCU and

Cause Printer PWB connector disconnection

Check

and

remedy

99 Content Machine-PCL board language error

Details The machine language setup does not

Cause PCL board connection error

Check

and

remedy

Details of trouble

(Overrun)

printer PWB (Overrun error)

Harness trouble between the printer PWB

and the MCU PWB

Motherboard connector pin breakage

Printer PWB ROM trouble/Data

disturbance

Check the connectors and harness of the

printer PWB and MCU PWB.

Check the grounding of the copier.

Check ROM on printer PWB.

(Framing)

printer PWB (Framing error)

Harness trouble between the printer PWB

and the MCU PWB

Motherboard connector pin breakage

Printer PWB ROM trouble/Data

disturbance

Check the connectors and harness of the

printer PWB and MCU PWB.

Check the grounding of the copier.

Check ROM on printer PWB.

(Timeout)

printer PWB (Timeout error)

Harness trouble between the printer PWB

and the MCU PWB

Motherboard connector pin breakage

Printer PWB ROM trouble/Data

disturbance

Check the connectors and harness of the

printer PWB and MCU PWB.

Check the grounding of the copier.

Check ROM on printer PWB.

coincide with the PCL board language

setup.

SIM setup error

Check the firmware of the PCL board and

the combination of the panel screen data,

and download the correct version, if

necessary.

Check the machine language information.

(Machine language setup: SIM 26-22)

AR-P17 TROUBLE CODE LIST 9 - 1

Page 28

[10] ELECTRICAL SECTION

1. Block diagram

PCI connector

RJ45

ConnectorConnectorConnector

(MAC/PHY)

For Debug

M-BUS

PCI BUS 32bit/33MHz

DP83816

Driver

Driver

UART1

TMPR4927

UART0

ADDR[19:0]

DATA[63:0]

PIO

PIO

DATA[15:0]

DATA

[63:0]

DATA[31:0]

DATA[31:0]

DATA[31:0]

IO ASIC(Unicorn2)

System

Bus I/F

1284

Cont.

DATA

[31:0]

SDRAM-DIMM

128MB or 256MB

SPD

EEPROM

MROM-DIMM

32MB(PS Font)

1284

Driver

SDRAM

64MB

256Kb

Flash DIMM

12MB

Flash-DIMM

8MB(Option)

(Japan Only)

Connector

Energy-saving I/F correspondence

USB2.0(FS)

ML60852A

USB2.0 (Full speed mode correspondence)

Image

Cont.

RTC

I/F

PIO IO I/F

AR-P17 ELECTRICAL SECTION 10 - 1

Page 29

q

PARTS GUIDE

CODE:00ZARP17//P1/

プリンタ

プリンタ コントローラー

プリンタプリンタ

PRINT CONTROLLER

コントローラー

コントローラーコントローラー

MODEL

このパーツガイドに掲載されている表示価格ランクは消費税抜きです。

CONTENTS

1

梱包&付属品 (Packing material & Accessories)

2

PCL PWB UNIT(PCL PWB UNIT)

■

索引 (Index)

AR-P17

本書はサービス活動用に作成した資料です。

一部内容が製品の改良・改善等により予告

なしに変わることがあります。

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 30

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : メンテナンスパーツ、メンテナンスパーツには入っていないがメンテナンスパーツに近い消耗パーツ。

Bランク : 性能・機能パーツ(センサー、クラッチ等の電気パーツ)、消耗パーツ。

Eランク : 基板含むユニットパーツ。

Dランク : 整備パーツ(外装、パッキング、同梱パーツ)。

Cランク : 上記ランク以外のパーツ(基板の子部品を除いたもの)。

DEFINITION

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

! 印の商品は、安全上重要な部品です。交換をする時は、安全及び性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F

当モデルのサービス資料には、この資料以外にサービスマニュアル ( 回路図含む ) があります。合わせてご利用下さい。

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1

梱包&付属品 (Packing material & Accessories)

NO. PARTS CODE

1 CDSKA0033QS31 BA FX N D

4 SPAKA399ACCZZ AB DD D

6 TCADZ0288QSZZ AD DJ N D

TINSJ1076QSZZ AQ EQ N D

TINSE1077QSZZ AP EQ N D

7

TINSF1078QSZZ AS EQ N D

TINSS1079QSZZ AS EQ N D

9 LX-BZ0024QSZZ AA DD C

10 SSAKA0006UCZZ AA DD D

11 XBPSD30P06KS0 AA DD C

101 LSUPM0002QSZZ AE DJ N C

102 VHI29L12802QS BQ LP N B

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

CD ROM J [Japan] CD ROM J

Vinyl bag ポリ袋

Inst.manual [Except USA,Canada,LAG] 設置手順書

OPE.manual [Japan] 取扱説明書

OPE.manual [ENGLISH] 取扱説明書

OPE.manual [FRENCH] 取扱説明書

OPE.manual [SPANISH] 取扱説明書

Screw(3×8) ビス

Vinyl bag(50×60mm) ポリ袋

Screw(3×6KS) ビス

Support post サポートポスト 7

PRG DIMM [Japan] PRG DIMM

DESCRIPTION

– 1 –

Page 31

1

梱包&付属品 (Packing material & Accessories)

10

9

4

11

2

3

1

5

7

6

2

PCL PWB UNIT(PCL PWB UNIT)

NO. PARTS CODE

1 QCNCM0041QSZZ AP EQ C

3 QCNCW0025QSZZ AL EB C

4 QCNCW0071GCZZ AH DX C

5 QCNCW7045XCZZ AG DS C

6 QSOCN0010QSZZ AV FG N C

9 QSOCZ0079FCZZ AN EQ C

11 RCILZ0353AFZZ AH DX C

12 RCORF1013ACZZ AD DJ C

13 RCORF1057ACZZ AB DJ C

14 RCRUA0019QSZZ AR EQ N B

15 RCRUA0020QSZZ AL EB N B

16 RFILN0010QSZZ AB DD C

18 RH-IX1013ACZZ BK HC B

RMPTR4103ACZZ AB DD B

19

RMPTR4103ACZZ AB DD B

RMPTR4330ACZZ AB DD B

RMPTR4330ACZZ AB DD B

20

RMPTR4330ACZZ AB DD B

RMPTR4330ACZZ AB DD B

21 RMPTR4472ACZZ AB DD B

22 RMPTR4560ACZZ AA DD B

25 VCCCCZ1HH100D AA DD C

26 VCCCCZ1HH101J AA DD C

28 VCCCCZ1HH680J AA DD C

29 VCCUCY1AJ105Z AC DD C

30 VCEAPH1CC106M AC DD C

32 VCEAPS1CC226M AC DJ C

33 VCEAPZ1CW107M AD DJ C

34 VCEAPZ1CW477M AE DS C

35 VCKYCZ1AB683K AB DD C

VCKYCZ1CB103K AA DD C

36

VCKYCZ1CB103K AA DD C

37 VCKYCZ1CF104Z AB DD C

PRICE RANK

Ex. Ja.

MARK

NEW

PRP01669

PART

RANK

Connector(TX25-100P12) [CN3] コネクター

Connector(TX24-60R-12) [CN9] コネクター

Connector(57pin) [CN11] コネクター

Connector(USB) [CN10] コネクター

Socket(RJ-45) [CN12] ソケツト

Socket(100pin) [Japan][CN8] ソケツト

Chock coil(PLP3216S121SL2) [L1] チョークコイル

Core(BLM41P600S) [L10∼13] コア

Ferrite beads(BLM21P221SG) [L2] フェライトビーズ

Crystal(25.00M OSC) [X1] クリスタル

Crystal(12.00M OSC) [X2] クリスタル

Noise filtet(BLM18BB121SN1D) [L3∼6,14,15] ノイズフイルタ -

IC(SDRAM 256M) [IC5,6] IC

Block resistor(10KΩ×4) [RN27,41,44,49,51] ブロックテイコウ

Block resistor(10KΩ×4) [RN54,56,58,60] ブロックテイコウ

Block resistor(33Ω×4) [RN1,2,6,8,20,22,23,25,26] ブロックテイコウ

Block resistor(33Ω×4) [RN28∼40,42,43,45∼48] ブロックテイコウ

Block resistor(33Ω×4) [RN50,52,53,55,57,59] ブロックテイコウ

Block resistor(33Ω×4) [RN65,66,67,68,71∼76] ブロックテイコウ

Block resistor(4.7KΩ×4) [RN24,61∼64,69,70] ブロックテイコウ

Block resistor(56Ω×4) [RN3,4,5,7,9∼19,21] ブロックテイコウ

Capacitor(50WV 10pF) [C91] コンデンサー

Capacitor(50WV 100pF) [C61∼67,72∼88] コンデンサー

Capacitor(50WV 68pF) [C3,209,210] コンデンサー

Capacitor(10WV 1.0µF) [C96] コンデンサー

Capacitor(16WV 10µF) [C113,145,146] コンデンサー

Capacitor(16WV 22µF) [C39,90,114] コンデンサー

Capacitor(16WV 100µF) [C4] コンデンサー

Capacitor(16WV 470µF) [C46,47] コンデンサー

Capacitor(10WV 68µF) [C147,150] コンデンサー

Capacitor(16WV 0.010µF) [C97∼105,108,110,112] コンデンサー

Capacitor(16WV 0.010µF) [C118,120,205,215] コンデンサー

Capacitor(16WV 0.10µF) [C1,2,6∼38,40,42∼45] コンデンサー

DESCRIPTION

– 2 –

Page 32

2

PCL PWB UNIT(PCL PWB UNIT)

NO. PARTS CODE

VCKYCZ1CF104Z AB DD C

VCKYCZ1CF104Z AB DD C

37

VCKYCZ1CF104Z AB DD C

VCKYCZ1CF104Z AB DD C

38 VCKYCZ1HB102K AA DD C

39 VHDD1FM3+++-1 AD DJ B

40 VHIDP83816+-1 BE GN B

44 VHIPST598IN-1 AF DS B

46 VHI24WC256K-1 AV FG B

47 VHI60852ATB-1 AX FG B

48 VHI74LCX08FT1 AF DS B

49 VHI74LCX14FT1 AF DS B

50 VHI74LCX244FT AH DX B

51 VHI74LCX245FT AH DX B

52 VHI74LVX16128 AP EQ B

53 VHI93C46VI+-1 AE DS N B

54 VHPLT1P67A+-1 AC DJ B

55 VHVICPS1.2/-1 AF DS B

VRS-CZ1JD000J AA DD C

56

VRS-CZ1JD000J AA DD C

VRS-CZ1JD000J AA DD C

VRS-CZ1JD100J AA DD C

57

VRS-CZ1JD100J AA DD C

VRS-CZ1JD100J AA DD C

VRS-CZ1JD102J AA DD C

58

VRS-CZ1JD102J AA DD C

VRS-CZ1JD103J AA DD C

VRS-CZ1JD103J AA DD C

59

VRS-CZ1JD103J AA DD C

VRS-CZ1JD103J AA DD C

60 VRS-CZ1JD121J AA DD C

61 VRS-CZ1JD152J AA DD C

62 VRS-CZ1JD153J AA DD C

63 VRS-CZ1JD220J AA DD C

64 VRS-CZ1JD221J AA DD C

65 VRS-CZ1JD302J AA DD C

VRS-CZ1JD330J AA DD C

VRS-CZ1JD330J AA DD C

VRS-CZ1JD330J AA DD C

66

VRS-CZ1JD330J AA DD C

VRS-CZ1JD330J AA DD C

67 VRS-CZ1JD470J AA DD C

68 VRS-CZ1JD471J AA DD C

VRS-CZ1JD472J AA DD C

VRS-CZ1JD472J AA DD C

69

VRS-CZ1JD472J AA DD C

VRS-CZ1JD472J AA DD C

70 VRS-CZ1JD560J AA DD C

71 VRS-CZ1JD822J AA DD C

72 VRS-TS2AD220J AA DD C

73 VRS-TX2HDR24J AA DD N C

74 VRSCY1JR49R9F AA DD C

75 VRSCY1JR54R9F AA DD C

76 VSDTC114YK/-1 AC ZZ B

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Capacitor(16WV 0.10µF) [C48∼53,68∼71,89] コンデンサー

Capacitor(16WV 0.10µF) [C92∼95,115∼117,119] コンデンサー

Capacitor(16WV 0.10µF) [C121,124∼140,143,144] コンデンサー

Capacitor(16WV 0.10µF) [C152∼204,206,208,214] コンデンサー

Capacitor(50WV 1000pF) [C106,107,109,111,148,149] コンデンサー

Diode(DIFM3) [D2] ダイオード

IC(DP83816) [IC24] IC

IC(PST598IN) [IC31] IC

EEPROM(24WC256K) [IC3] EEPROM

IC(60852ATB) [IC21] IC

IC(74LCX08FT1) [IC2] IC

IC(74LCX14FT1) [IC4] IC

IC(TC74LCX244) [IC8,10,12,15,20,30] IC

IC(74LCX245FT) [IC7,9,11,13,18,19] IC

IC(74LVX16128) [IC22] IC

IC(93C46VI) [IC26] IC

Diode(LT1P67A) [D1] ダイオード

IC protecrot(ICPS1.2) [F1] IC プロテクター

Resistor(1/16W 0Ω ±5%) [R85∼92,165∼176] テ イコウ

Resistor(1/16W 0Ω ±5%) [R180∼184,189,197,209] テイコウ

Resistor(1/16W 0Ω ±5%) [R213,214,248,255∼257] テイコウ

Resistor(1/16W 10Ω ±5%) [R94,136∼150,187,205,219] テイコウ

Resistor(1/16W 10Ω ±5%) [R220,223∼226,229∼232] テイコウ

Resistor(1/16W 10Ω ±5%) [R245,267∼274] テイコウ

Resistor(1/16W 1.0KΩ ±5%) [R2∼6,18,32,34∼37] テイコウ

Resistor(1/16W 1.0KΩ ±5%) [R156,157,247] テイコウ

Resistor(1/16W 10KΩ ±5%) [R17,19,26,29,30,31,38,39,95] テイコウ

Resistor(1/16W 10KΩ ±5%) [R99,110∼113,118,120,121] テイコウ

Resistor(1/16W 10KΩ ±5%) [R158,159,178,179,185,186] テイコウ

Resistor(1/16W 10KΩ ±5%) [R204,206,210,263,264,291] テイコウ

Resistor(1/16W 120Ω ±5%) [R100] テイコウ

Resistor(1/16W 1.5KΩ ±5%) [R160] テイコウ

Resistor(1/16W 15KΩ ±5%) [R228] テイコウ

Resistor(1/16W 22Ω ±5%) [R24] テイコウ

Resistor(1/16W 220Ω ±5%) [R154] テイコウ

Resistor(1/16W 300KΩ ±5%) [R227] テイコウ

Resistor(1/16W 33Ω ±5%) [R9,10,13∼16,20∼23,25,42] テイコウ

Resistor(1/16W 33Ω ±5%) [R43,45,46,50,51,53,55,56] テイコウ

Resistor(1/16W 33Ω ±5%) [R57,59,60∼66,93,102∼109] テイコウ

Resistor(1/16W 33Ω ±5%) [R114∼117,119,258,260∼262] テイコウ

Resistor(1/16W 33Ω ±5%) [R265,266,275∼287] テイコウ

Resistor(1/16W 47Ω ±5%) [R44,47,48,49,243] テイコウ

Resistor(1/16W 470Ω ±5%) [R188,198] テイコウ

Resistor(1/16W 4.7KΩ ±5%) [R40,41,52,69,70] テイコウ

Resistor(1/16W 4.7KΩ ±5%) [R74∼76,101,123,124] テイコウ

Resistor(1/16W 4.7KΩ ±5%) [R151,152,155,161] テイコウ

Resistor(1/16W 4.7KΩ ±5%) [R217,221,246,249] テイコウ

Resistor(1/16W 56Ω ±5%) [R54,96,97,98] テイコウ

Resistor(1/16W 8.2KΩ ±5%) [R27,28,77∼84] テイコウ

Resistor(1/10W 22Ω ±5%) [R162,163,164] テイコウ

Resistor(1/2W 0.24Ω ±5%) [R222] テイコウ

Resistor(1/10W 49.9Ω ±5%) [R190,200] テイコウ

Resistor(1/10W 54.9Ω ±5%) [R193,202] テイコウ

Transistor(DTC114YK) [TR1] トランジスター

DESCRIPTION

– 3 –

Page 33

■

索引 (Index)

PARTS CODE

[C]

CDSKA0033QS31

[L]

LSUPM0002QSZZ

LX-BZ0024QSZZ

[Q]

QCNCM0041QSZZ

QCNCW0025QSZZ

QCNCW0071GCZZ

QCNCW7045XCZZ

QSOCN0010QSZZ

QSOCZ0079FCZZ

[R]

RCILZ0353AFZZ

RCORF1013ACZZ

RCORF1057ACZZ

RCRUA0019QSZZ

RCRUA0020QSZZ

RFILN0010QSZZ

RH-IX1013ACZZ

RMPTR4103ACZZ

RMPTR4330ACZZ

RMPTR4472ACZZ

RMPTR4560ACZZ

[S]

SPAKA399ACCZZ

SSAKA0006UCZZ

[T]

TCADZ0288QSZZ

TINSE1077QSZZ

TINSF1078QSZZ

TINSJ1076QSZZ

TINSS1079QSZZ

[V]

VCCCCZ1HH100D

VCCCCZ1HH101J

VCCCCZ1HH680J

VCCUCY1AJ105Z

VCEAPH1CC106M

VCEAPS1CC226M

VCEAPZ1CW107M

VCEAPZ1CW477M

VCKYCZ1AB683K

VCKYCZ1CB103K

VCKYCZ1CF104Z

VCKYCZ1HB102K

VHDD1FM3+++-1

VHI24WC256K-1

VHI29L12802QS

VHI60852ATB-1

VHI74LCX08FT1

VHI74LCX14FT1

VHI74LCX244FT

VHI74LCX245FT

VHI74LVX16128

VHI93C46VI+-1

VHIDP83816+-1

VHIPST598IN-1

VHPLT1P67A+-1

VHVICPS1.2/-1

VRSCY1JR49R9F

VRSCY1JR54R9F

VRS-CZ1JD000J

VRS-CZ1JD100J

VRS-CZ1JD102J

VRS-CZ1JD103J

VRS-CZ1JD121J

VRS-CZ1JD152J

VRS-CZ1JD153J

VRS-CZ1JD220J

VRS-CZ1JD221J

VRS-CZ1JD302J

VRS-CZ1JD330J

VRS-CZ1JD470J

VRS-CZ1JD471J

VRS-CZ1JD472J

VRS-CZ1JD560J

VRS-CZ1JD822J

VRS-TS2AD220J

JAPAN ONLY

ORDER CODE

578 966 0138 1- 1 BA FX N D

578 233 0027 1- 101 AE DJ N C

578 970 0222 1- 9 AA DD C

578 510 0271 2- 1 AP EQ C

578 510 0243 2- 3 AL EB C

578 510 0211 2- 4 AH DX C

578 510 0250 2- 5 AG DS C

578 527 0033 2- 6 AV FG N C

578 527 0029 2- 9 AN EQ C

596 614 0565 2- 11 AH DX C

596 615 0063 2- 12 AD DJ C

596 615 0149 2- 13 AB DJ C

578 616 0072 2- 14 AR EQ N B

578 616 0073 2- 15 AL EB N B

578 621 0076 2- 16 AB DD C

596 573 4270 2- 18 BK HC B

567 631 0100 2- 19 AB DD B

567 631 0109 2- 20 AB DD B

567 631 0102 2- 21 AB DD B

596 631 0499 2- 22 AA DD B

505 902 5004 1- 4 AB DD D

541 906 1016 1- 10 AA DD D

572 913 1007 1- 6 AD DJ N D

578 916 0817 1- 7 AP EQ N D

578 916 0818 1- 7 AS EQ N D

578 916 0833 1- 7 AQ EQ N D

578 916 0819 1- 7 AS EQ N D

521 593 0027 2- 25 AA DD C

521 593 0028 2- 26 AA DD C

567 593 0316 2- 28 AA DD C

596 593 0899 2- 29 AC DD C

521 594 0001 2- 30 AC DD C

593 594 0584 2- 32 AC DJ C

567 594 0133 2- 33 AD DJ C

575 594 0013 2- 34 AE DS C

572 593 0354 2- 35 AB DD C

595 593 1450 2- 36 AA DD C

521 593 0017 2- 37 AB DD C

521 593 0030 2- 38 AA DD C

523 570 0014 2- 39 AD DJ B

578 573 1200 2- 46 AV FG B

578 573 1359 1- 102 BQ LP N B

572 573 2910 2- 47 AX FG B

521 573 0491 2- 48 AF DS B

572 573 2024 2- 49 AF DS B

521 573 0388 2- 50 AH DX B

594 573 1659 2- 51 AH DX B

578 573 1048 2- 52 AP EQ B

578 573 1358 2- 53 AE DS N B

567 573 1648 2- 40 BE GN B

523 573 0081 2- 44 AF DS B

578 574 0048 2- 54 AC DJ B

567 577 0014 2- 55 AF DS B

567 581 0630 2- 74 AA DD C

596 581 3342 2- 75 AA DD C

521 581 0082 2- 56 AA DD C

567 581 0524 2- 57 AA DD C

521 581 0093 2- 58 AA DD C

521 581 0085 2- 59 AA DD C

567 581 0526 2- 60 AA DD C

521 581 0175 2- 61 AA DD C

567 581 0528 2- 62 AA DD C

567 581 0532 2- 63 AA DD C

567 581 0533 2- 64 AA DD C

572 581 2072 2- 65 AA DD C

521 581 0202 2- 66 AA DD C

521 581 0170 2- 67 AA DD C

567 581 0617 2- 68 AA DD C

521 581 0088 2- 69 AA DD C

572 581 2084 2- 70 AA DD C

572 581 2066 2- 71 AA DD C

500 581 5044 2- 72 AA DD C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

VRS-TX2HDR24J

VSDTC114YK/-1

[X]

XBPSD30P06KS0

JAPAN ONLY

ORDER CODE

578 581 0720 2- 73 AA DD N C

507 576 5005 2- 76 AC ZZ B

541 970 0016 1- 11 AA DD C

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 4 –

Page 34

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks

indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

Example:

Solder composition

code (Refer to the

Lead-Free

5mm

table at the right.)

a

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread.

Never use conventional lead solder thread, which may cause a break-

down or an accident.

Since the melting point of lead-free solder thread is about 40°C higher

than that of conventional lead solder thread, the use of the exclusiveuse soldering iron is recommendable.

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is

about 40°C higher than that of conventional lead solder, and its soldering capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB

when completion of soldering is confirmed.