Page 1

CODE : 00ZARM207/A1E

AR-M162

AR-M165

AR-M207

With the RSPF installed

[ 1 ] GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[ 3 ] CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . 4 - 1

DIGITAL COPIER

AR-M207

AR-M165

MODEL AR-M162

CONTENTS

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 5 - 1

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[ 7 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[ 8 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 -1

[ 9 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . 10 - 1

[11] KEY OPERATOR PROGRAM. . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1

[12] FRASH ROM VERSION UP PROCEDURE . . . . . . . . . . . . . . 12 - 1

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 1

Parts marked with “ “ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

Page 3

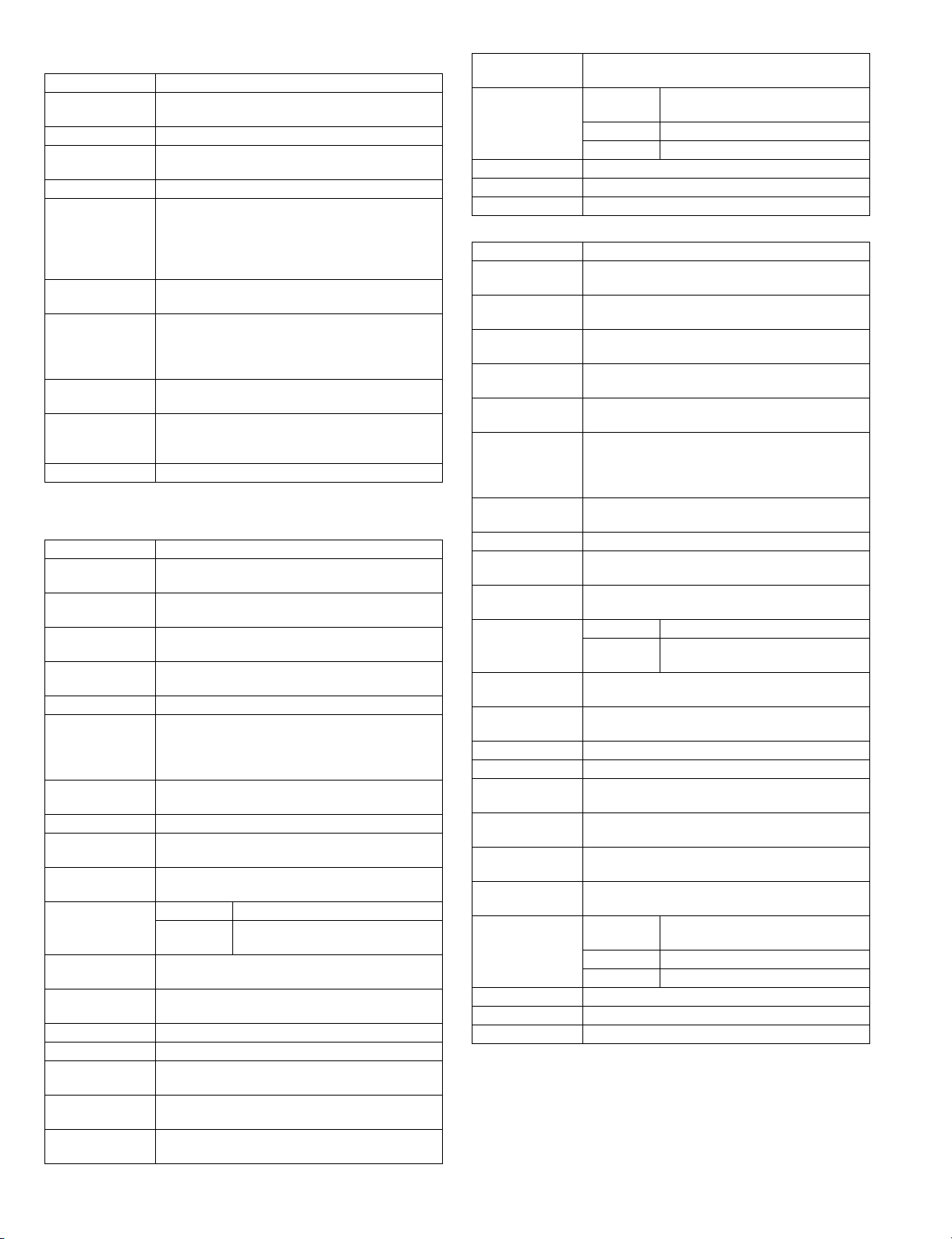

CONTENTS

[1] GENERAL

1. Cautions on using . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2. Installation requirements . . . . . . . . . . . . . . . . . . . . . . . .1-1

3. Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

[2] SPECIFICATIONS

1. Basic specificatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

[3] CONSUMABLE PA RTS

1. Supply system table. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

2. Environmental conditions. . . . . . . . . . . . . . . . . . . . . . . .3-2

3. Production number identification . . . . . . . . . . . . . . . . . .3-2

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

2. Internal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

3. Operation Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4. Display(base screen) . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

5. Motor, solenoid, clutch. . . . . . . . . . . . . . . . . . . . . . . . . .4-6

6. Sensor, switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

7. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

8. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

[5] UNPACKING AND INSTALLATION

1. Installing conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2. Removal of protective material and fixing screw . . . . . .5-1

3. Installing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

4. Removal and storage of fixing screw. . . . . . . . . . . . . . .5-2

5. Changing the paper size setting of a trey. . . . . . . . . . . .5-3

[6] ADJUSTMENTS

1. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. Copier adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

[7] SIMULATIONS

1. Entering the simulation mode. . . . . . . . . . . . . . . . . . . . .7-1

2. Canceling the simulat i o n mode . . . . . . . . . . . . . . . . . . .7-1

3. List of simulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

4. Contents of simulati ons . . . . . . . . . . . . . . . . . . . . . . . . .7-3

[8] TROUBLE CODE LIST

1. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Details of trouble codes . . . . . . . . . . . . . . . . . . . . . . . . 8-2

[9] MAINTENANCE

1. Maintenance table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Maintenance display system. . . . . . . . . . . . . . . . . . . . . 9-2

3. Note for replacement of consumable parts. . . . . . . . . . 9-2

[10] DISASSEMBLY AND ASSEMBLY

1. High voltage section/Duplex transport section . . . . . . . 10-1

2. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

3. Fusing section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

4. Paper exit section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

5. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

6. Optical frame unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

7. LSU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

8. Tray paper feed section/Paper transport section. . . . . . 10-10

9. Manual multi paper feed section. . . . . . . . . . . . . . . . . . 10-11

10. Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

11. Deve lo p i n g sec tio n . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

12. Process section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

13. Others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

[11] KEY OPERATOR PROGRAM

1. Custom setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

[12] FLASH ROM VERSION UP PROCEDURE

1. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. Driver Installation procedure. . . . . . . . . . . . . . . . . . . . . 12-1

3. Download procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

4. V ersion confirming procedure. . . . . . . . . . . . . . . . . . . . 12-5

[13] ELECTRICAL SECTION

1. Block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. Circuit descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

3. Actual wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 13-8

Page 4

[1] GENERAL

1. Cautions on using

A. Warning

•The fusing area is hot. Exercise care in this area when removing misfed

paper.

Fusing unit

•Do not look directly at the light source. Doing so may damage your eyes .

2. Installation requirements

Improper installation may damage this product. Please note the following

during initial installation and whenever the

machine is moved.

1. The machine should be installed near an accessible power outlet for

easy connection.

2. Be sure to connect the power cord only to a power outlet that meets

the specified voltage and current requirements. Also make certain the

outlet is properly grounded.

•For the power supply requirements, see the name plate on the back of

the main unit.

Note: Connect the machine to a power outlet which is not used for other

electric appliances. If a lighting fixture is connected to the same

outlet, the light may flicker.

3. Do not install your machine in areas that are:

•damp, humid, or very dusty

•exposed to direct sunlight

•poorly ventilated

• su bject to extreme temperature or humidity changes, e.g., near an air

conditioner or heater.

4. Be sure to allow the required space around the machine for servicing

and proper ventilation.

8" (20 cm)

B. Cautions

•Do not switch the machine rapidly on and off. After turning the machine

off, wait 10 to 15 seconds before turning it back on.

•Place the machine on a firm, level surface.

• When the machine is not used for a long time, for example, during

prolonged holidays, turn the power switch off and remove the power

cord from the outlet.

• When moving the machine, be sure to turn the power switch off and

remove the power cord from the outlet.

•Do not cover the machine with a dust cover, cloth or plastic film while

the power is on. Doing so may prevent heat dissipation, damaging the

machine.

•Do not make any modifications to this machine. Doing so may result in

personal injury or damage to the machine.

•Do not make copies of anything which is prohibited from copying by law.

The following items are normally prohibited from printing by national

law . Other items may be prohibited by local law.

Money, Stamps, Bonds, Stocks

Bank drafts, Checks, Passports, Driver’s licenses

•Do not touch the photoconductive drum. Scratches or smudges on the

drum will cause dirty prints.

•Store spare toner car tridges in a cool dry plac e without removing from

the package before use.

• If they are exposed to direct sunlight or excessive heat, poor copies

may result.

8"

(20 cm)

8"

(20 cm)

AR-M207 M165 M162 GENERAL 1-1

Page 5

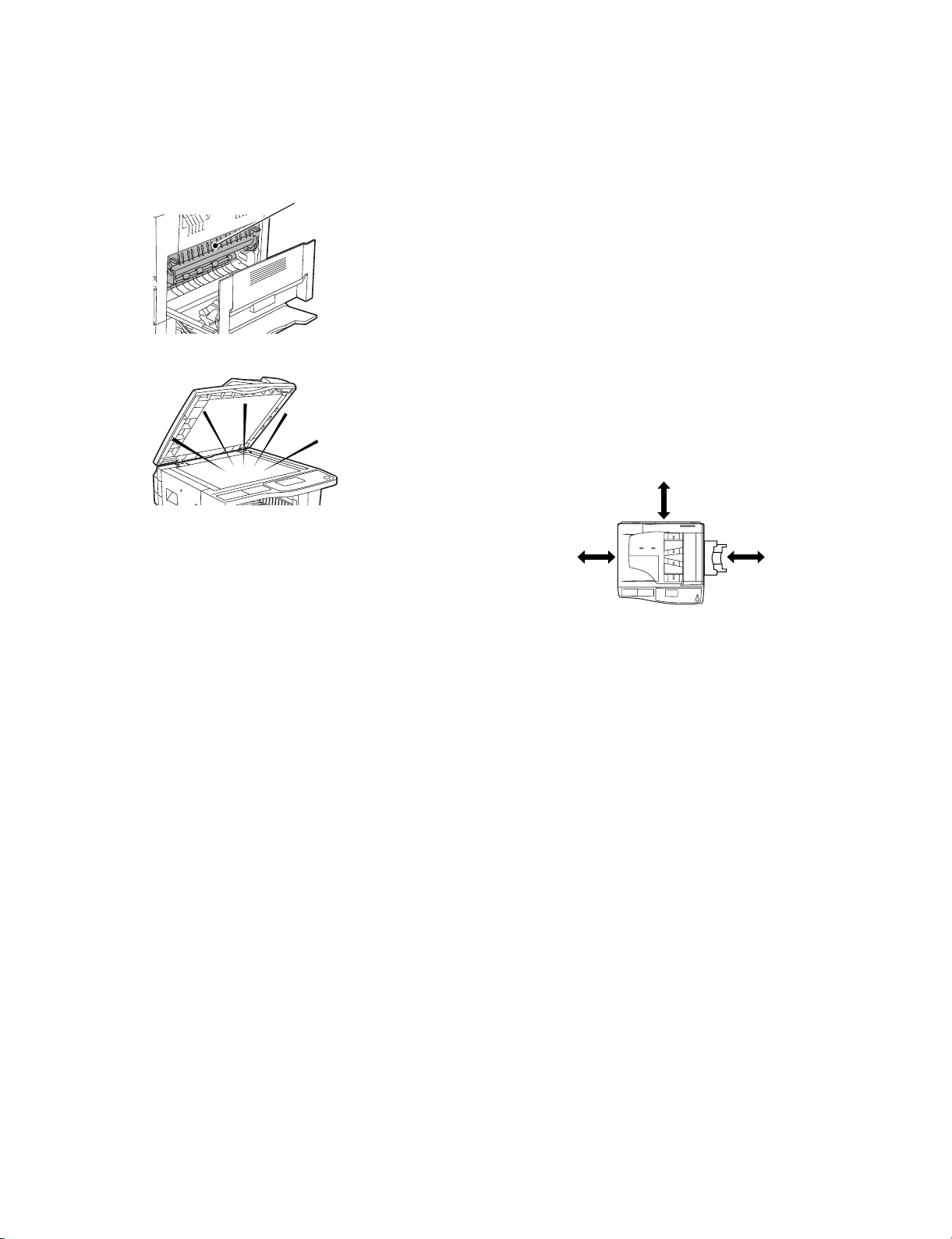

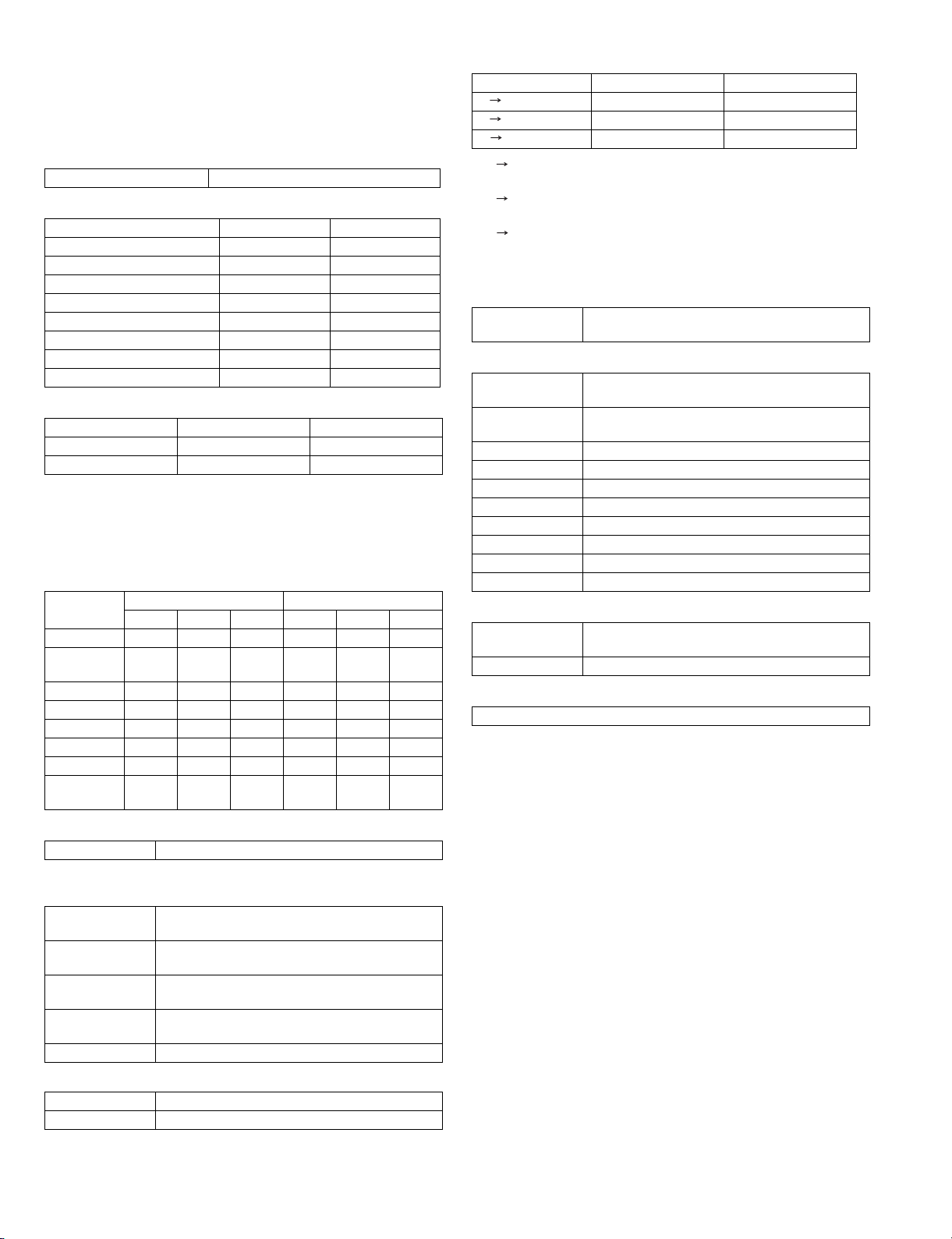

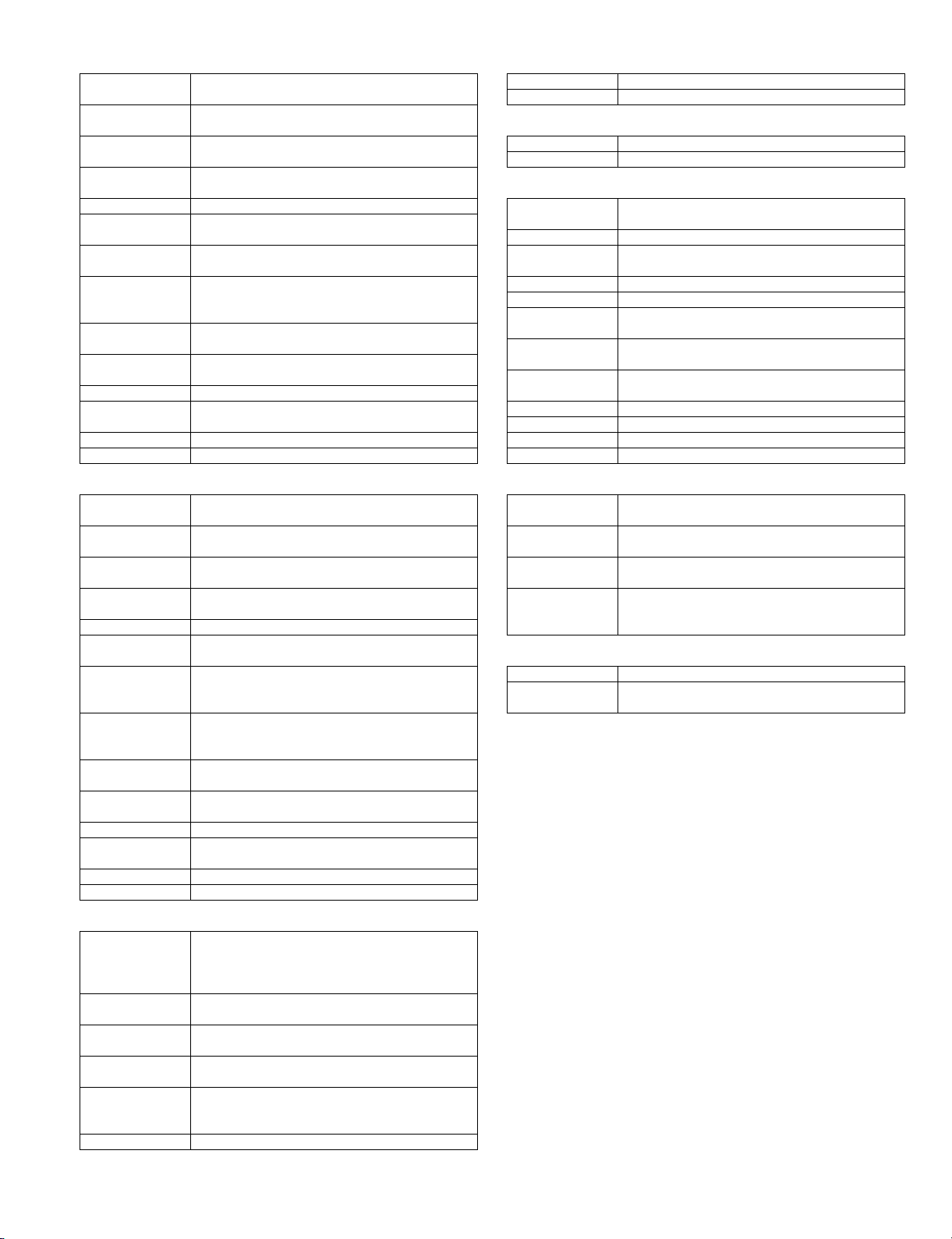

3. Configuration

A. System Configurations

Job separator

(AR-TR4)

RSPF(AR-RP6N)

SPF(AR-SP6N)

AR-M207

With the RSPF installed

Network Box

(AR-NB3)

AR-M165

AR-M162

2 X 250 sheet paper

feed unit

(AR-D25)

MODEL

OPTION

AR-RP6N REVERSING SINGLE PASS FEEDER OPT OPT NO

AR-SP6N SINGLE PASS FEEDER OPT OPT OPT

AR-VR5 DOCUMENT COVER OPT STD STD

AR-D24 250-SHEET PAPER FEED UNIT OPT OPT OPT

AR-D25 2 x 250-SHEET PAPE R FEED UNI T OPT OPT OPT

AR-TR4 JOB SEPARATOR TRAY KIT OPT OPT OPT

AR-EB9 DUAL FUNCTION BOARD STD*1 STD STD*1 *1

AR-NB3 NETWORK PRINTING / SCANNING

EXPANSION K I T

AR-FX11 FACSIMILE EXPANSION KIT OPT OPT OPT

AR-SM5 EXPANSION MEMORY OPT OPT OPT

AR-MM9 FAX EXPANSION MEMORY OPT OPT OPT

AR-PF1 BARCODE-FON T KI T OPT OPT OPT The AR-NB3 is

AR-PK1N PS3 KIT OPT OPT OPT The AR-NB3 is

AR-PF2 FLASH MEMORY KIT OPT OPT OPT The AR-NB3 is

AR-M207 AR-M165 AR-M162 Remark

OPT OPT OPT

250 sheet paper

feed unit

(AR-D24)

Option for

USA,CANADA.

required

required

required

AR-M207 M165 M162 GENERAL 1-2

Page 6

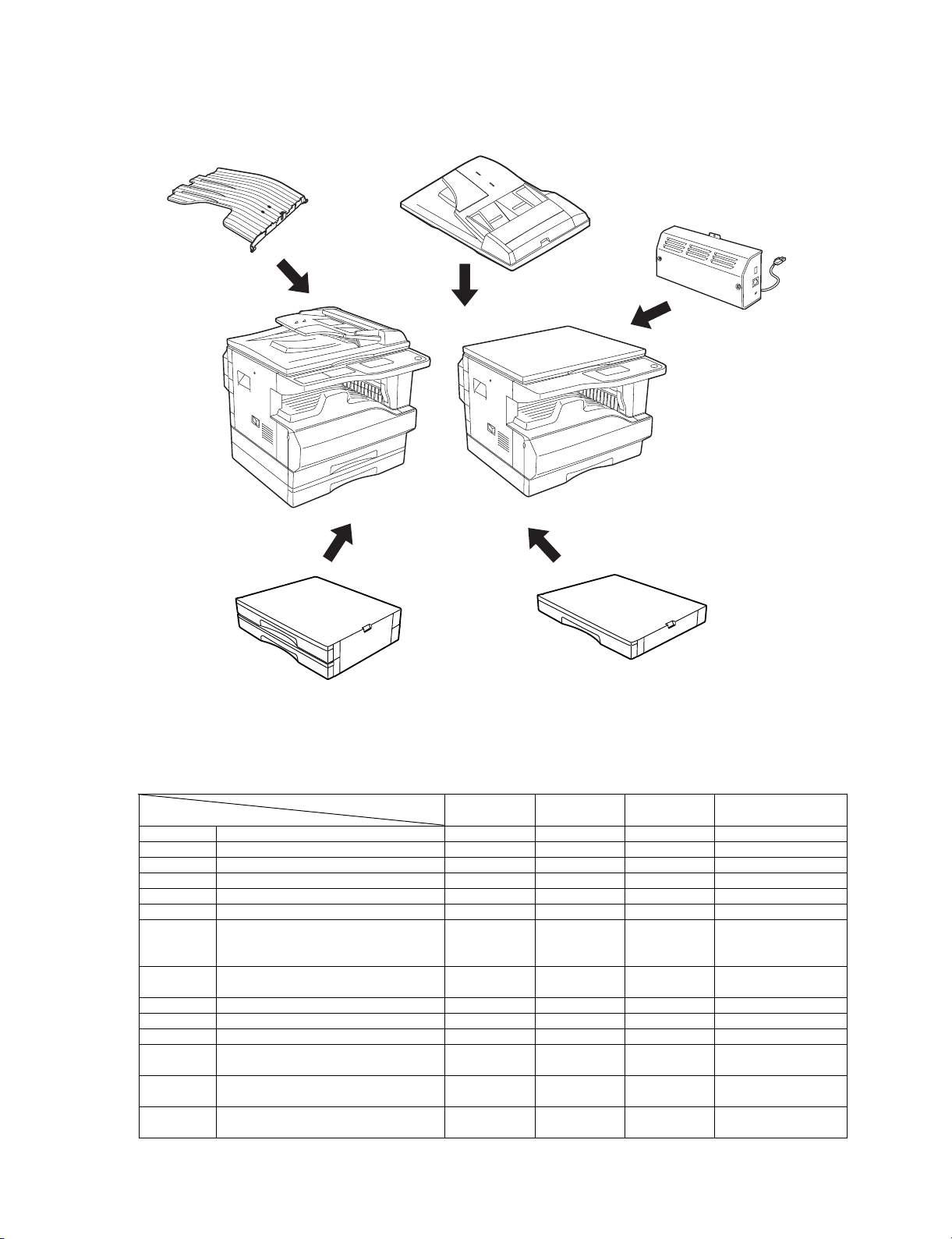

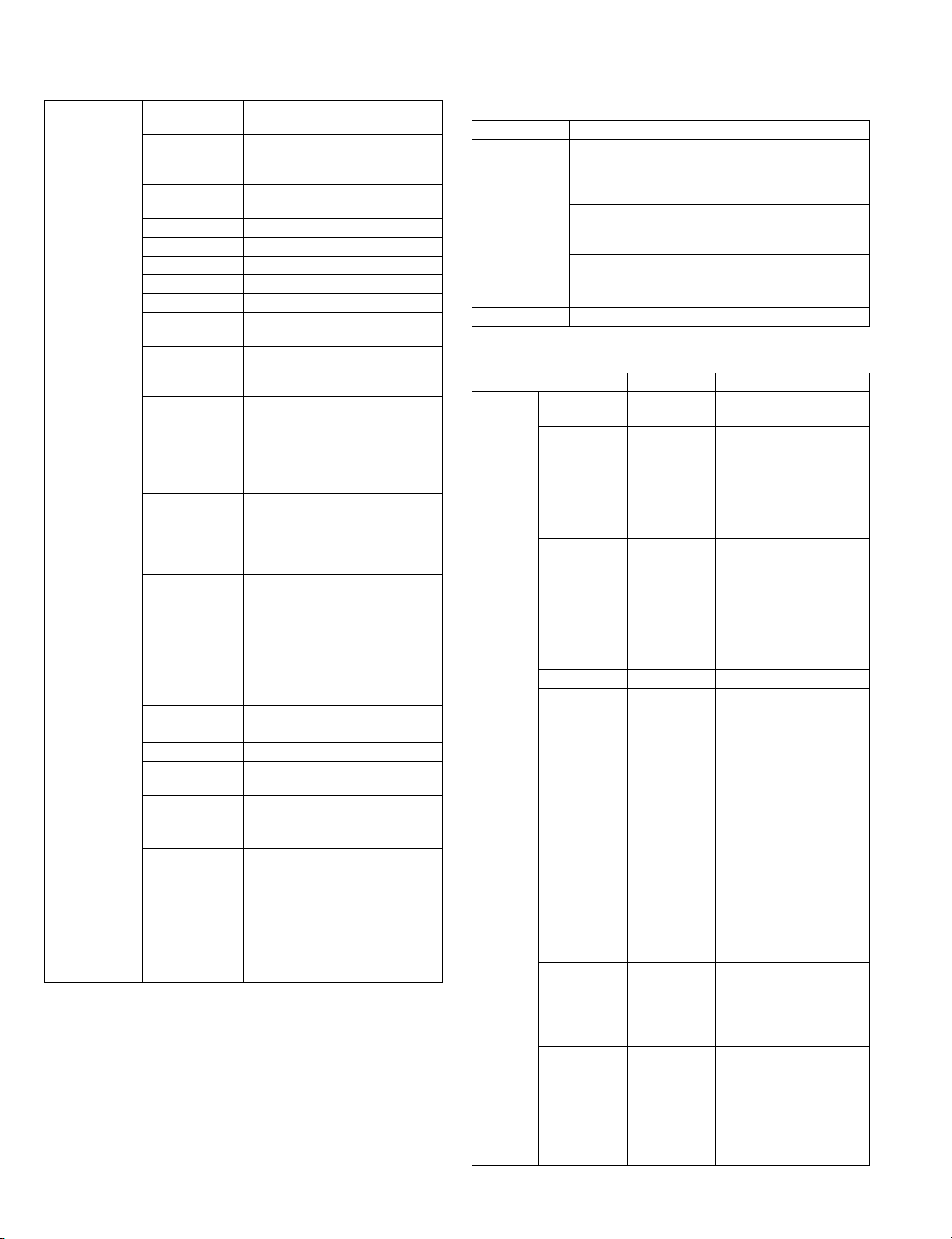

[2] SPECIFICATIONS

1. Basic Specification

A. Base Engine

(1) Type

AR-M207, AR-M162 / M165 Desk-top

(2) Engine speed

Paper size AR-M207 AR-M162 / M165

A4/8.5" x 11" 20ppm 16ppm

A4R/8.5" x 11"R 14/15ppm 12ppm

A5/5.5" x 8.5" 20ppm 16ppm

B5/16K 20ppm 16ppm

B5R/16KR 16/15ppm 14ppm

8.5" x 13" 12ppm 11ppm

B4/8.5" x 14 12ppm 10ppm

A3/11" x 17"/8K 11/10/11ppm 9/ 9/10ppm

(3) Print performance

AR-M207 AR-M162 / M165

GDI Print* 12ppm 12ppm

SPLC Print 20ppm(ROPM) 16ppm(ROPM)

* GDI print measurement c onditions: Host PC/CPU = 500 700MHz o r

above, Windows 98SE, Data = TestChart-B1.doc, USB1.1, when

supporting A4/Letter.

Measurement method: With setting to 11, from completion of the first

paper exit to completion of the 11th paper exit

(4) Copy speed(cpm)

AR-M207 AR-M162 / M165

Normal

A4/8.5"x11" 20 20 20 16 16 16

A4R/

8.5"x11"R

A5/5.5"x8.5" 20 20 20 16 16 16

B5/16K 20 20 20 16 16 16

B5R/16KR 16/15 16/15 16/15 14 14 14

8.5x13" 12 12 12 10 10 10

B4/8.5"x14 12 12 12 10 10 10

A3/11"x17"/8K11/10/1111/10/1111/10/119/9/10 9/9/10 9/9/10

14/15 14/15 14/15 12 12 12

Reducti on

Enlargement

Normal

Reduction

Enlargement

(6) Job Speed

AR-M207 AR-M162 / M165

S S 20 Sheets/min(100%) 16 Sheets/min(100%)

S D 9 Sheets/min(45%) D D 8 Sheets/min(40%) -

* S S(from No. 1 cassette): 10 sheets of A4/8.5" x 11" document, 5

copies

* S D(from No. 1 cassette): 10 sheets of A4/8.5" x 11" document, 5

copies

* D D(from No. 1 cassette): 10 sheets of A4/8.5" x 11" document(20

surfaces), 5 copies

(7) Continuous copying

Max. number of

multi copy

1-999copies(Can be changed to 1-99 in key

operator programs)

(8) Engine composition

Photoconductor

type

Photoconductor

drum dia.

Process cleaning Blade

Copy lamp Cold cathode fluorescent lamp(CCFL)

Developing system Dry 2-component magnetic brush development

Charging system Saw teeth charging

Transfer system (+)DC scorotro n

Separation system (-)DC scorotron

Fusing system Heat roller

Process speed 88mm/s

OPC(Organic Photo Conductor)

30mm

(9) Engine resolution

Resolution Reading: 600 x 300dpi1(600 x 600dpi selectable)

Gradation Reading: 256 gradation, Writing: 2 gradations

Writing: 600x600dpi

(10)Scanner section

Scanner(Document table)

(5) First copy time

First copy time 7.2sec or less

* Measurement conditions: When feeding paper of A4/8.5" x 11" from the

main unit tray, polygon rotation state

Main unit first

stage

Main unit second

stage

Option paper feed

first stage

Option paper feed

second stage

Manual tray 7.5sec or less

First copy time from the document feed unit

SPF 12sec or less

RSPF 12s ec or less

7.2sec or less

8.5sec or less

9.5sec or less

10.5sec or less

AR-M207 M165 M162 SPECIFICATIONS 2-1

Page 7

(11) Document table

Max. Document

size

Scan area 297 x 431mm

Document

reference position

Detection(Platen) Available

Detection size Automatic detection(supported by each unit for

OR guide display Left back corner

AB and inch can be switched to each other by Sim.

A3/11"x17"

Left back corner reference

inch/AB)

AB system: A3, B4, A4, A4R, A5,

Inch system: 11" x 17", 8.5" x 14",

(Print display)

Left side document

guide

Left side document

guide

Back side document

guide(Bookmark)

8.5" x 11", 8.5" x 11"R

Document reference

position “ ”

(From the back)

[Postal card] · [A6 ] · [B 6

] · [5-1/2] · [A5 ] · [B5 ] ·

[A4/A5 ] · [8-1/2] · [B4/B5

] · [11] · [A3/A 4 ]

(From the left)

[5-1/2] · [A5] · [B5] · [A4/

A5 ] · [8-1/2] · [B5 ] · [11]

· [A4 ] · [13] · [14] · [B4 ] ·

[A3 ] · [17]

B5(Vertical),

A4(Vertical), bookmark

at 8" - 1/2" position(From

the left)

(12) SPF/RSPF

Type SPF/RSPF Single/Duple x automatic

document feeder unit

Scan speed Single surface When copying: 20-sheet

Document

reference position

Document size AB system: A3-A5

Document weight 56 - 90g/m²(15 - 24lbs)

Document load

capacity

Inhibited kinds of

documents

Detection Avaiable

Detection size * Automatic detection(A kind of detection unit is used

Document tray

guide display

Center

Inch system: 11" x17" - 5.5" x 8.5"

when duplex: 56 - 90g/m²(15 - 24lbs)

40 sheets(30 sheets of 90g/m² loadable)(30 sheets

for B4/8.5" x 13" or above)40 sheets of 4mm

thickness or below loadable

Transparency film, Perforated sheets, photo,

catalogue

by switching the software destination.)

AB system: A3,B4,A4,A4R,B5,B5R,A5

Inch system: 11" x 17", 8.5" x 14", 8.5" x

Tray

center(Marked)

Document

guide(Marked)

model/20 sheets/min

16-sheet model/16 sheets/min

When FA X: 23 sheets/min

11", 8.5" x 11"R, 5.5" x 8.5"

Document insertion direction

“ ”document face-up set

command

(From the center)

A3/A4, 11", B4/B5, 8.5",

A4R/A5, B5R, A5R, 5.5"

(13) Operation panel

a. Display device

Type LCD display with backlight

System FSTN

Display dot

number

LCD drive display

area

LCD brightness

adjustment

Type 7 segment LED(x 3)

b. Key

Mode selection

area

Basic input section Start key/LED

LCD display

section

Panel language

support

c. Characters used in LCD

Kind ROM font

Dot 6(W)x 12(H)

119 x 73 dots

78.867 x 41.653 mm

Available

Copy mode key(mode LED)

Print mode key(mode LED/ONLINE LED/DATA

LED)

Scanner mode key(mode LED)

Fax mode key(mode LED/LINE LED/DATA LED)

Numeric keys

* AUDIT CLEAR key

# Read End key

Clear/Stop key

Interru p t key

All Clear key

Exposure key(Color mode/Program)

Paper ke y(Resolution/Program)

Zoom key(Address)

Auto% key(Format/Broadcast)

Duplex key(Duplex scan)

Sort(Documen t size)

Special function key

Fax status key

Arrows key

OK key

Back key

LINE STATUS indicator

(when the fax option is installed)

English(Factory setting)

For the languages other than English, the key

sheet is packed together with the machine or

manual kit. Attach it when installing.

(14) Controller board

CPU H8S2321(16bit 1-chip microprocessor,

Memory 16MB(Single surface model)

Interface

IEEE1284 Parallel 1 port

USB1.1 1 port

USB2.0 1 port(Standard/option area)

Ethernet 1 port(Network box)

19.6608MHz)

32MB(Duplex surface model)

(15) Paper feed section

Type 4-stage paper feed tray + multi manual paper feed

Paper feed system Front loading, paper feed from the top

AR-M207 M165 M162 SPECIFICATIONS 2-2

Page 8

Main unit tray

Size to be fed A3, B4, A4, A4R, B5, B5R, A5(No.1 tray only)

16K, 16KR, 8K,

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5"(No. 1 tray only)

Paper size setting Us er setting

Paper size setting A3, B4, A4, A4R, B5, B5R, A5,

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5"

(For A5/5.5" x 8.5", however, No. 1 cassette only)

Paper size setting

when shipping

Kind and weight of

applicable paper

Paper feed

capacity

Paper type Standard paper, Recyc led paper

Remaining

quantity detection

AB system: A4

Inch system: 8.5" x 11"

Standard paper 56 - 90g/m²

Standard paper

250 sheets(64g/m²)

Only empty detection available

(16) Manual paper feed section

Manual paper feed

form

Paper size A3 - A6,

Manual paper feed

guide display

Kind and weight of

applicable paper

Paper capacity Standard

Paper kind AB system: Standard paper/Recycled paper/

Paper size

detection

Paper empty

detection

Foldable manual paper feed tray

11" x 17" - 8.5" x 11"

A3/A4, B4/B5, A4R/A5, B5R, A5R, B6R, A6R

Standard paper

Thick paper(56 - 200g/m²)

Recycled paper, Envelope, Transparency film,

Labels

100 Sheets

paper

Envelope AB system: 10 Sheets

Other Single paper feed(Transparency film,

Transparency film/Labels/Postal card/Envelope/

Thick paper(-200g/m²)

Inch system: Standard paper/Recycled paper/

Transparency film/Labels/Postal card/Envelope/

Thick paper(-200g/m²)

None

Available

(Standard paper: 56 - 80g/m²)(Multi

paper feed: 56 -128g/m²)

Inch system: 5 Sheets

Labels, Postal card)

(17) Duplex

Standard 20-sheet m odel: Standard provision

Type Switchback system

Paper size A3, B4, A4, A4R, B5, B5R, A5,

Kind and weight of

applicable paper

16-sheet model: Not available

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11",

8.5" x 11"R

Standard paper: 56 - 90 g/m²/15 - 24lbs Bond

(18) Paper exit section

Paper exit

position/system

Paper exit section

capacity

Paper exit paper

size/kind

Paper exit paper

full detection

Face do wn

250 sheets

All feedable paper types and sizes

Upper stage: Available(Detected when the job

separator is installed)

Lower stage: None

*250 sheets of counted and detected.

(19) Exposure(Print density)

Density mode Auto/Text/Photo

NO. Of manual

adjustment

Toner save mode Available(Default OFF with the service simulation)

5 steps(Text/Photo)

(20) Void width

Void area Lead edge: 1 - 4mm, rear edge: 4mm or less,

both sides: 6mm

Image loss 4mm or less

* For void area/image loss, normal/single copy.

* For the first sheet of manual paper feed, the rear edge void is disable.

(21) Warm-up

Warm-up time 45sec or less

Pre heat Available

Jam recovery time 45sec or less

Left for 60 sec after door open.

Standard condition, polygon stop

(22) Copy magnification ratio

Fixed

magnification ratio

Zooming 25-400%(SPF/RSPF: 50-200%)

Independent

zooming

AB system: 25, 50, 70, 81, 86, 100, 115, 122, 141,

200, 400%

Inch system: 25, 50, 64, 77, 95, 100, 121, 129,

141, 200, 400%

Vertical/horizontal: 25-400%

(SPF/RSPF: 50-200%)

(23) Power source

Voltage 100V, 110V, 120V, 127V, 230V(200V), 240V

Frequency 50/60Hz

Power switch One power source

(24) Power consumption

Max. Power

consumption

Power

consumption in

operation

Power

consumption when

standby

* Must conform to energy saving laws, international standards, and

company regulations.

1200W

550W

10W

AR-M207 M165 M162 SPECIFICATIONS 2-3

Page 9

(25) Environment support

Support program International Energy-Star

Nordic swan

Canadian environment selection program

Blue angel

eco-label

Green purchase network

Green purchase law

Energy-saving law

Green products

(26) Noises

Noise level Must conform to SS, blue angel, Nordic swan.

(27) Ozone & dust

Regulated value Ozone: 0.02mg/m³ or less

Dust: 0.075mg/m³ or less

Styrene: 0.07mg/m³ or less

(28) External dimensions

1-stage cassette model(floor

surface - glass surface)

1-stage cassette model(floor

surface - OC)

1-stage cassette model(floor

surface - SPF)

2-stage cassette model(floor

surface - glass surface)

2-stage cassette model(floor

surface - OC)

2-stage cassette model(floor

surface - SPF)

3-stage cassette model(floor

surface - glass surface)

3-stage cassette model(floor

surface - OC)

3-stage cassette model(floor

surface - SPF)

4-stage cassette model(floor

surface - glass surface)

4-stage cassette model(floor

surface - OC)

4-stage cassette model(floor

surface - SPF)

590(W) x 595(D) x 435(H)

590(W) x 595(D) x 469(H)

590(W) x 595(D) x 568(H)

590(W) x 595(D) x 520(H)

590(W) x 595(D) x 554(H)

590(W) x 595(D) x 652(H)

590(W) x 595(D) x 605(H)

590(W) x 595(D) x 640(H)

590(W) x 595(D) x 738(H)

590(W) x 595(D) x 690(H)

590(W) x 595(D) x 725(H)

590(W) x 595(D) x 823(H)

(29) Occupying area

Main unit only

(excluding the handle)

Main unit(Multi manual feed open) 880(W ) x 595(D)

590(W) x 595(D)

(30) Weight

20-sheet model

(Electronic sort : Standard)

20-sheet model

(Electronic sort : Option)

16-sheet model

(Electronic sort/Duplex)

16-sheet model

(Electronic sort : Standard)

16-sheet model

(Electronic sort : Option)

34.2 (Kg)

33.8 (Kg)

30.6 (Kg)

30.0 (Kg)

29.7 (Kg)

(31) Printer basics

GDI/SPLC Print

Print speed GDI: 12PPM(GDI Print, USB2.0(Full speed), A4/

First Print 7.2sec or less

Resolution 600dpi

Duplex print Available

Paper feed system Paper feed tray and multi paper feed

Shifter Installed to the main unit paper exit section.

Supported OS Windows95/98/Me/NT4.0(Workstation SP5 or

Emulation GDI

Interface IEEE1284(ECP, Compatible)

PnP Support Windows 95/98/Me/2000/XP

Software Status Window

ROPM When the Dual function board (AR-EB9) is

WHQL Yes(XP/2000) after a few month later from first lot.

Letter)

Measurement conditions:

Host PC/CPU: 500 700MHz, RAM: 256MB or

above, Windows98SE

Data Testchart-B1, dot

SPLC: According to the main machine speed.

Shit amount: 1 inch(25.4mm)journalizing according

to every print j o b.

later)/2000(Professional)/XP(Home/Professional)

SPLC(JBIG-GDI): When the Dual function board

(AR-EB9) is installed (Standard or option).

USB1.1

USB2.0(When the Dual function board (AR-EB9)

is installed (Standard or option).

installed (Standard or option).

(32) Scanner basics

Type Flat bed color scanner

Scan system Document table/document feed unit

Light source Whit e CCFL

Resolution Basic 600 x 600 dpi

Document Sheet/Book

Effective scan

range

Scan speed 2.88msec /Line(C olor)

Input data 1bit or 12bit

Output data 1bit or 8bit

Scan color Black and white binary/Gray scale/Full color

Protocol TWAIN/WIA(XP Only)/STI

Interface USB1.1

Scanner utility Sharpdesk

Drop-out color Provided

Scanner button Destination selection by LCD

Duplex scan Available

Supported OS Windows98/Me/2000(Professional)/XP(Home/

Void area Lead edge/rear edge: 2.5mm

WHQL Yes(XP/2000) after a few month later from first lot.

Set range: 50 - 9600dpi

OC/SPF/RSPF: about 297(length)x 431(width)mm

USB2.0

Professional)

Side Left/right: 3.0mm

AR-M207 M165 M162 SPECIFICATIONS 2-4

Page 10

(33) Network box basics

Standard memory 64MB

Expansion

memory

Interface RJ45, USB port(for connection with the main unit)

LED Power LED, 10/100BASE-Tx mode LED,

Switch Status Switch

Supported OS

Setting software Internet Explorer 5.5 or later, Netscape Navigator 6

Expansion option PS expansion kit(AR-PK1N)

Network protocol TCP/ I P, IPX/SPX(NetWare), NetBEUI,

Emulation PCL/PS(PS is cancelled by the soft key.)

E-RIC Canceled by the soft key.

1DIMM 1 slot

144pin 128/256MB SO-DIMM

LAN status LED, USB status LED

Windows 95/98/Me/NT4.0(Workstation SP5 or

later)/2000 professional/XP Home Edition/XP

Professional Edition/Windows Sever 2003

Mac OS 8.6 - 9.2.2, 10.1.5, 10.2 - 10.2.8 (excluding

10.2.2), 10.3 - 10.3.4 (when PS option)

or later

Barcode font kit(AR-PF1)

Flash ROM kit(AR-PF2)

Sharpdesk(Shar p desk license kit AR-U seri es)

Ether Talk(Apple Talk)

ESC/P Font Kanji: Mincho, Gothic(Bitmap)

ANK: Roman, Sans Serif(Bitmap)

B. Peripheral devices basic specifications

(1) Single pass feeder(SPF)

Document set Face up

Document

reference position

Document

transport system

Document feed

direction

Document size AB system : A3 - A5

Document weight 56 - 90g/m²(15 - 24lbs)

Document set

quantity

External

dimensions

Weight 5.0kg

Power Supplied from the machine(Power consumption:

Document size

detection

Detection size AB system A3, B4, A4, A4R, B5, B5R, A5

Guide display (From the center)

Documents out of

specifications

Multi copy S-S, S-D(Duplex model)

Document mixture Not available

Random paper

feed

Document

reversion

Display

section(LED)

Right side center

Sheet through type

Document feed from the top

Inch system: 11" x 17" - 5.5" x 8.5"

40 sheets(40 sheets of 4mm thickness or less can

be loaded.)

(30 sheets of 90g/m² can be loaded. 30 sheets for

B4 or 8.5" x 13" or above.)

583 mm(W) x 435 mm(D) x 133 mm(H)

21W)

On the document feed trey

Inch system 11" x 17", 8.5" x 14", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5"

A3/A4, 11", B4/B5, 8.5", A4R/A5, B5R, A5R, 5.5"

Transparency film/Perforated document, photo,

catalogue

Not availabl e

Not availabl e

None

Reliability(MCBJ/

MCBF)

Document

replacement

speed(Standard

copy)

Item included Installation manual

Case color Frosty white

Installation Must be installed easily.

Conforms to the main unit.

S-S 16-sheet model: 100%

20-sheet model: 100%

S-D 20- sheet model: 45%(9 sheets/min)

D-D -

(2) Reversing single pass feeder(RSPF)

Document set Face up

Document

reference position

Document

transport system

Document feed

direction

Document size AB system: A3 - A5

Document weight 56 - 90g/m²(15 - 24lbs)

Document set

quantity

External

dimensions

Weight 5.4kg

Power Supplied from the machine(Power consumption:

Document size

detection

Detection size AB system A3, B4, A4, A4R, B5, B5R, A5

Guide display (From the center)

Documents out of

specifications

Multi copy S-S, S-D, D-D, D-S(Duplex model)

Document mixture Not available

Random paper

feed

Document

reversion

Display

section(LED)

Reliability(MCBJ/

MCBF)

Document

replacement

speed(Standard

copy)

Item included Installation manual

Case color Frosty white

Installation Must be installed easily

Right side center

Sheet through type

Document feed from the top

Inch system: 11" x 17" - 5.5"x8.5"

Duplex: 56 - 90g/m²(15 - 24lbs)

40 sheets(40 sheets of 4mm thickness or less can

be loaded.)

(30 sheets of 90g/m² can be loaded. 30 sheets for

B4 or 8.5" x 13" or above.)

583 mm(W) x 435 mm(D) x 133 mm(H)

26.4W)

On the document feed trey

Inch system 11" x 17", 8.5" x 14", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5"

A3/A4, 11", B4/B5, 8.5", A4R/A5, B5R, A5R, 5.5"

Transparency film, Perforated document, photo,

catalogue

Not availab le

Available(Not availab le for 5.5" x 8.5" and

5.5" x 8.5"R)

None

Conforms to the main unit

S-S 16-sheet model: 100%

20-sheet model: 100%

S-D 20- sheet model: 45%(9 sheets/min)

D-D 20-sheet model: 40%(8 sheets/min)

AR-M207 M165 M162 SPECIFICATIONS 2-5

Page 11

(3) 1-stage paper feed unit

Paper feed

capacity

Paper size

detection

Paper empty

detection

Paper size A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14",

Paper weight 56 - 90g/m²(15 - 24lbs)

Factory setting

size

Size selection A3, B4, A4, A4R, B5, B5R,11" x 17", 8.5" x 14",

Cassette

installation/

removal

Power Supplied from the machine(Power consumption:

External

dimensions

Weight 5.0Kg

Reliability(MCBJ/

MCBF)

Item included Installation manual, Paper size label

Case color Frosty white

250 Sheets

Not available(The paper size can be set with the

function menu.)

Available

8.5" x 13", 8.5" x 11", 8.5" x 11"R, 16K, 16KR, 8K

AB system: A4

Inch system: 8.5" x 11"

8.5" x 13", 8.5" x 11", 8.5" x 11"R

Can be made by the user

5.6W)

590 mm(W) x 471 mm(D) x 88mm(H)

Conforms to the main unit

(4) 2-stage paper feed unit

Paper feed

capacity

Paper size

detection

Paper empty

detection

Paper size A3, B4, A4, A4R, B5, B5R, 11" x 17", 8.5" x 14",

Paper weight 56 - 90g/m²(15 - 24lbs)

Factory setting

size

Size selection A3, B4, A4, A4R, B5, B5R

Cassette

installation/

removal

Power Supplied from the machine(Power consumption:

External

dimensions

Weight 10.0Kg

Reliability(MCBJ/

MCBF)

Item included Installation manual, Paper size label

Case color Frosty white

250 Sheets x 2

Not available(The paper size can be set with the

function menu.)

Available

8.5" x 13", 8.5" x 11", 8.5" x 11"R, 16K, 16KR, 8K

AB system: A4

Inch system: 8.5" x 11"

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11",

8.5" x 11"R

Can be made by the user

8.4W)

590 mm(W) x 471 mm(D) x 174 mm(H)

Conforms to the main unit

(5) Dual function board

Expansion

function

Electronic sort

compress function

Memory fo r

electronic sort

Electronic sort

scan quantity

Memory

expansion

Item included Installation manual,

Electronic sort function, 2In1/4In1, Rotation copy,

Edge erase/Center erase, Margin shift, Card shot

USB2.0(High-speed support),SPLC print(JBIGGDI), ROPM function

JBIG

16MB

A4 standard document(Test chart B)100 sheets

DIMM Memory slot x 1

Max. 256MB x 1slot + 16MB(Max 272MB in total)

(Externally described as max. 256MB x 1)

(6) Original cover(OC)

Function Up/down open/close mechanism

Item included Installation manual

(7) 256MB expansion memory

Memory 256MB

Item included Installation manual

(8) Job separator

Installation

conditions

Bin number 1 bin

Distribution

system

Paper size Conforms to the main unit paper feed paper.

Paper weight Conforms to the main unit paper feed paper.

Paper exit section

capacity

Paper exit job Upper stage: FAX output or printer output

Paper exit full

detection

Power None

Item included Installation manual

Case color Frosty white

Installation Must be installed easily

Install when the printer or the FA X is expanded.

Perf orms paper exit for every job

Controlled by the main unit.

Upper stage: 100 Sheets

Lower stage: 150 Sheets

Lower stage: Copy output or printer output

Upper stage: Available

Lower stage: YES (Full detection by the counter)

(9) Network box

Function Supports the network printer(PCL/PS)and the

Power Supplied from the machine

External

dimensions

Item included USB2. 0code x 1

network scanner.

(Power consumption: 5.5W)

248 mm(W) x 127 mm(D) x 59 mm(H)

Software CD(Driver/Network setting/application)

Installation manual

(10) Facsimile expansion kit

Function FAX expansion option

Item included One-touch dial key, destination label, installation

manual

(11) Barcode font kit

Same as the AR-PF1.

(12) Flash memory kit

Same as the AR-PF2.

(13) PS3 expansion kit

Same as the AR-PK1N.

(14) Facsimile expansion memory

Same as the AR-MM9.

AR-M207 M165 M162 SPECIFICATIONS 2-6

Page 12

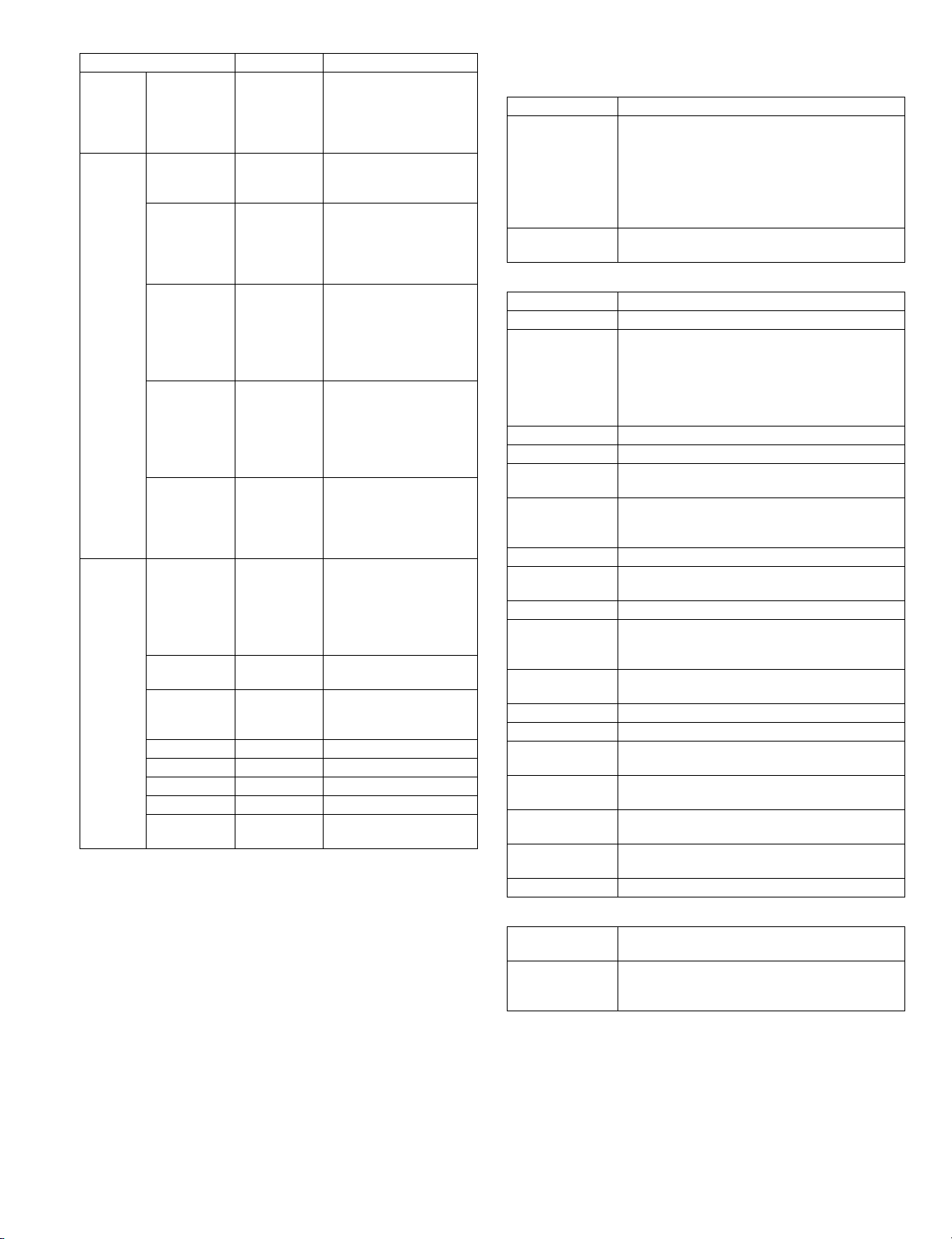

C. Various functions specifications

(1) Copy function specification

Function/

Special function

Automatic paper

selection

Automatic

magnification

ration selection

Auto tray

switching

Memory copy Yes

Rotation copy Yes (When electronic sort)

Electronic sort Yes (Standard or option)

Rotation sort No

X Y zoom Yes

Dual page copy Yes (Enlargement invalid/SPF

Sort function Yes (Standard or option)

Margin shift Yes (When electronic sort)

Edge erase Yes (When electronic sort)

Center erase Yes (When electronic sort)

Black/white

reverse

2in1/4in1 Yes (When electronic sort)

Sorter Yes (Offset function)

Card shot Yes (When electronic sort)

Preheating Yes (Set by the key operator

Auto shut-off Yes (Set by the key operator

Total counter Yes

Duplex Yes (Standard provision for the

Toner save Yes (Set according to the

Department

management

Yes

Yes

Yes

invalid(Patent rotation)

100 sheets of A4 standard

document (Test Chart B)are sorted.

Default

AB system: 10mm(5, 10, 15,

20mm)

Inch system: 1/2 Inch(1/4, 1/2, 3/4,

1 Inch)

Default

AB system: 10mm(5, 10, 15,

20mm)Inch system: 1/2 Inch(1/4,

1/2, 3/4, 1 Inch)

Default

AB system: 10mm(5, 10, 15,

20mm)

Inch system: 1/2 Inch(1/4, 1/2, 3/4,

1 Inch)

No

program.)

program.)

model of 20-sheet model only)

destination) (No setting. * Default

OFF with the service simulation.)

Yes

(Copy/printer/scanner: 50 Dept,

Fax 50 dept)

(2) Printer function specification

a. GDI/SPLC Printer

<Summary>

Platform IBM PC/AT(Include compatible machine)

Supported OS IEEE1284 Windows95/98/Me/

USB1.1 Windows98/Me/

USB2.0 Windows2000(Professional)/

Emulation GDI/JBIG GDI

Memory Environments for full operations of the above OS

<GDI/SPLC Printer function>

Only the summary is described on this item.

Function Content

Main Copies 1-999 Makes prints of the set

Collate Collate

Document

Style

N-up *1 2/4 The set pages are printed

N-up Order Z

N-up Border Yes/No Border lines are printed

Duplex 1-sided

Paper Paper Size A3/B4/A4/B5/

Custom Paper

Size *2

Fit to Page Yes/No The print size is changed

Image

Orientation

Paper

Selection

Rotate 180

Degree

NT4.0(Workstation SP5)/

2000(Professional)/XP(Home/

Professional)

2000(Professional)/XP(Home/

Professional)

XP(Home/Professional)

number of copies.

Uncollate

1-sided

2-sided(Book)

2-sided(Tablet)

2-sided(Book)

2-sided(Tablet)

A5/A6/B6/

Ledger/Legal/

Foolscap/

Folio/Letter/

Invoice/

Executive/8K/

16K/COM-10/

DL/C5/

Custom/Postal

card

1 size Width: 100 - 297mm

Portrait

Landscape

Auto

Bypass

Tray 1/2(3/4)

Yes/No Data are rotated 180

When this item is set to

"Collate," prints of two or

more copies are collated.

When set to "Uncollated,"

two or more copies of each

page are

printed(uncollated).

Single face or double face

print is made according to

the setting. When set to

duplex, the printing

direction differs depending

on book or tablet.

on one sheet.

between pages printed on

one sheet.

Print is made in the set

paper size. Even when the

actual paper size differs

from the set paper size,

images are formed printed

in the set paper size.

Length: 148-431.8mm

according to the set

content.

Printing is made in the set

direction.

Paper is fed from the set

paper feed tray.

degrees and printed.

AR-M207 M165 M162 SPECIFICATIONS 2-7

Page 13

Function Content

Paper Output Tray

Selection

Advanced Print Quality Draft

Image

Adjustment

Brightness 0 - 100% The image brightness is

Contrast 0 - 100% T he image contrast is

Pured Black

print

Watermarks

Watermarks None/TOP

User Setting Add/Update/

Position Center

Size 6 - 300

Angle ± 90

Grayscale 0 - 255

Edit Font Yes

On First Page

only

Upper Tray

Center Tray

Normal

Photo

Yes/No Contrast and brightness of

Yes/No A docum ent ma de by a

SECRET/

CONFIDENTI

AL/DRAFT/

ORIGINAL/

COPY

Delete

X: ± 50

Y : ± 50

Yes /No

When the job separator is

installed, selection is made

between the upper stage

and the center stage of the

paper exit tray.

Draft/Normal (only for

Windows 9x, Me)

images are adjusted. For

Windows NT4.0/2000/XP,

enable only for the Photo

mode of Print Quality.

adjusted by moving the

scale from 0 to 100. The

illustration image on the

left upper corner of the

display is changed.

adjusted by moving the

scale from 0 to 100. The

illustration image on the

left upper corner of the

display is changed.

CAD program is printed in

black to provide clear print

of color line images and

texts.

(3) Scanner function Specification

a. PUSH Scan(USB)

Supported OS Win98/Me/2000/XP

Hardware

environment

Selectable

destination

b. PULL Scan(TWAIN)

Supported OS Win98/Me/2000/XP

Hardware

environment

Duplex scan Yes

Color mode Black and white(Simple binary)/Black and

Resolution Pull: 600 x 600dpi

Preview function Yes

Zoom preview

function

Rotation scan Yes (90 degrees/180 degrees/270 degrees)

Brightness/

contrast

adjustment

Gamma

adjustment

Color matching None/Printer/CRT/LCD display/ICM

Edge emphasis None/Normal/Strong/Blur

Black/white

reverse

Light source

selection

Threshold value

setting

Void area addition Available(Top/End edge = 2.5mm /Left/Right =

Set contents save Yes

(System)Must meet the operating conditions of

each OS.

(HDD)8MB or above: 100MB or above

recommendable

(Monitor)800 x 600 dots or above, 256 colors or

more must be displayed.

(Other)USB port(1.1 or 2.0)

SharpDesk/E-mail software/Fax software/OCR

software/MS Word

USB TW AIN

(System)Must meet the operating conditions of

each OS.

(HDD)8MB or above: 100MB or above

recommendable

(Monitor)800 x 600 dots or above, 256 colors or

more must be displayed.

(Other)USB port

white(Error diffusion)/Gray scale/Full color

Emulation: 50-9600dpi

Custom: 50-9600dpi

Yes

Auto/Manual(-100 - +100)

Yes

Yes

Yes (Red/Green/Blue/White)

Auto/Manual(1 - 254)

3.0mm)

c. Network Push scan(When the network box is installed)

Selectable

destination

Destination

selection method

AR-M207 M165 M162 SPECIFICATIONS 2-8

Scan to E-mail/FTP/Desktop

Address book

LDAP retrieval/selection

Ad-Hoc(10-key input)

Page 14

[3] CONSUMABLE PARTS

1. Supply system table

A. USA / CANADA

NO Name Content Life Product name Remark

1 Toner cartridge(Black)

<With IC>

2 Developer Developer

3 Dru m kit Drum

B. Europe / Australia / New Zealand

NO Name Content Life Product name Remark

1 Toner cartridge(Black)

<With IC>

2 Developer Developer

3 Dru m kit Drum

Toner

(Toner: Net Weight 537g)

Vinyl bag

(Developer : Net Weight 400g)

Drum fixing plate

Toner

(Toner: Net Weight 537g)

Vinyl bag

(Developer : Net Weight 400g)

Drum fixing plate

x10

160K AR-202MT Life setting by A4 6% document

x10

x10 500K AR-202MD

x1x150K AR-202DR

x10

160K AR-202LT Life setting by A4 6% document

x10

x10 500K AR-202LD

x1x150K AR-202DM

AR-M207 M165 M162 CONSUMABLE PARTS 3-1

Page 15

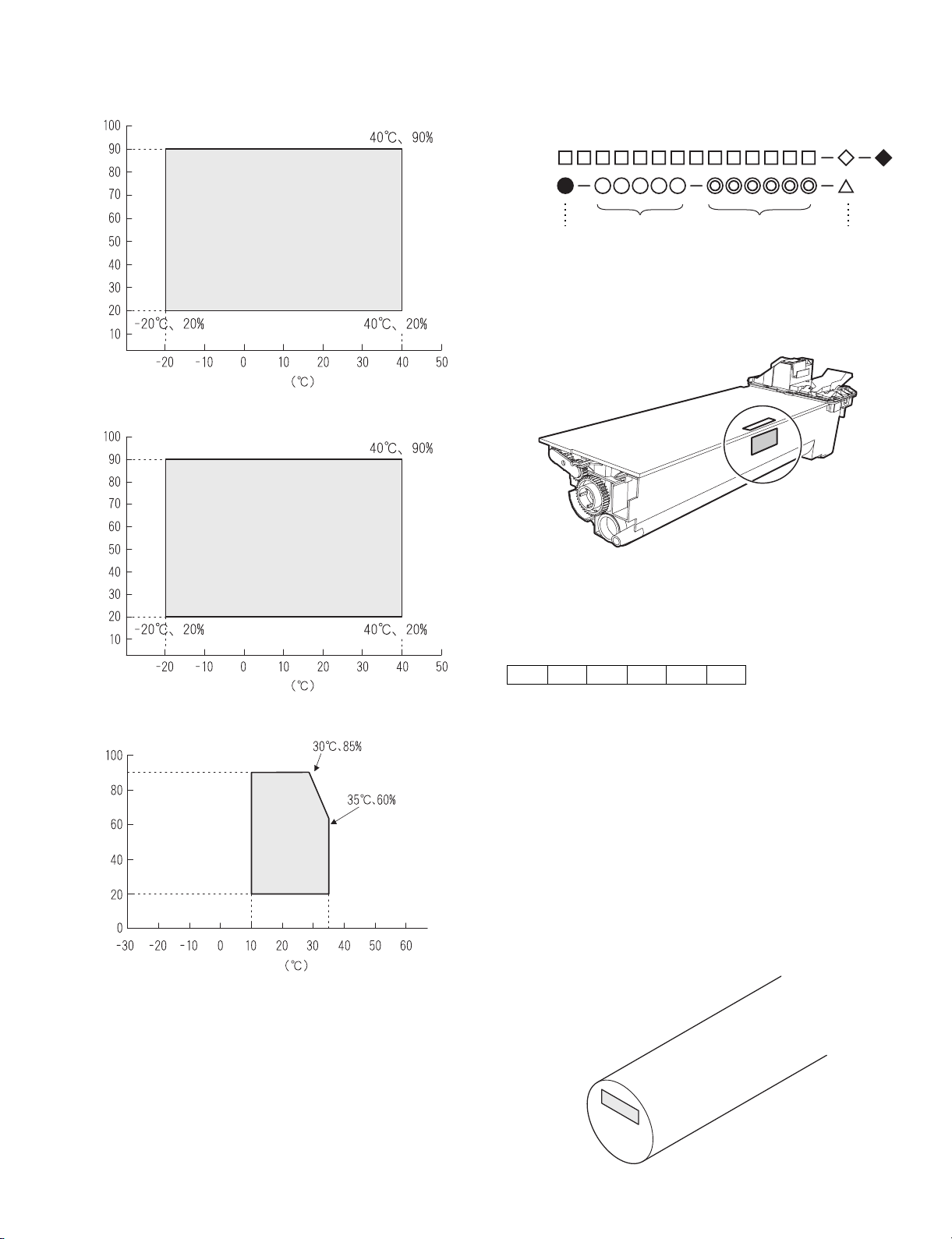

2. Environmental conditions

A. Transport conditions

(1) Transport conditions

3. Production number identification

<Toner cartridge>

The label on the toner cartridge shows the date of production.

Humidity (%)

Temperature

(2) Storage conditions

Humidity (%)

Temperature

Ver.No.Production

place

Serial

number

Year/

Month/

Day

<Drum cartridge>

The lot number, printed on the front side flange, is composed of 6 digits,

each digit showing the following content:

123456

B. Use conditions

Use environment

conditions

Humidity (%)

Temperature

C. Life(packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

1 Alphabet

Indicates the model conformity code. A for this model.

2 Number

Indicates the end digit of the production year.

3 Number or X, Y, Z

Indicates the month of packing.

X stands for October, Y November, and Z December.

4/5 Number

Indicates the day of the month of packing.

6 Alphabet

Indicates the production factory. "A" for Nara Plant, “C“ for

SOCC

AR-M207 M165 M162 CONSUMABLE PARTS 3-2

Page 16

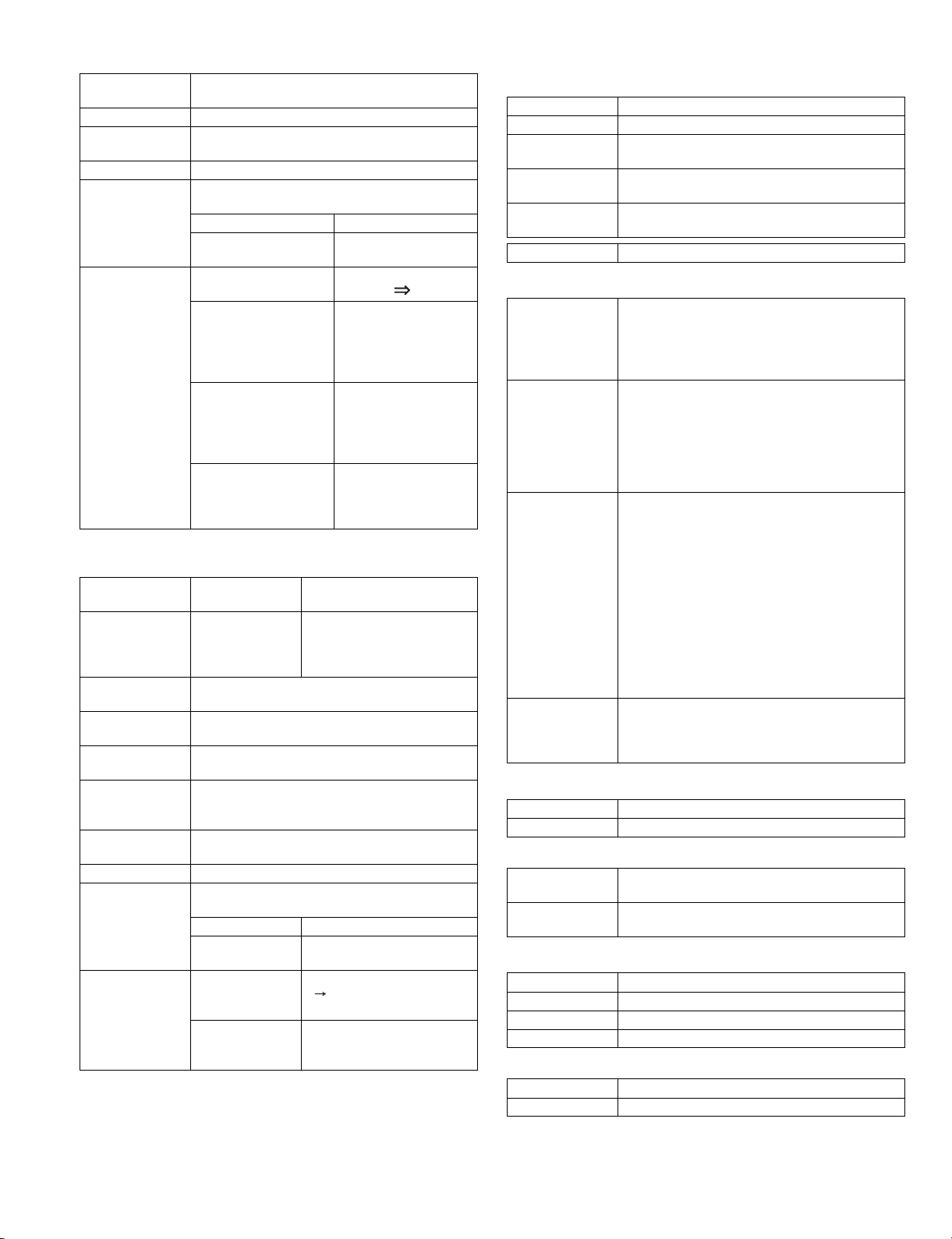

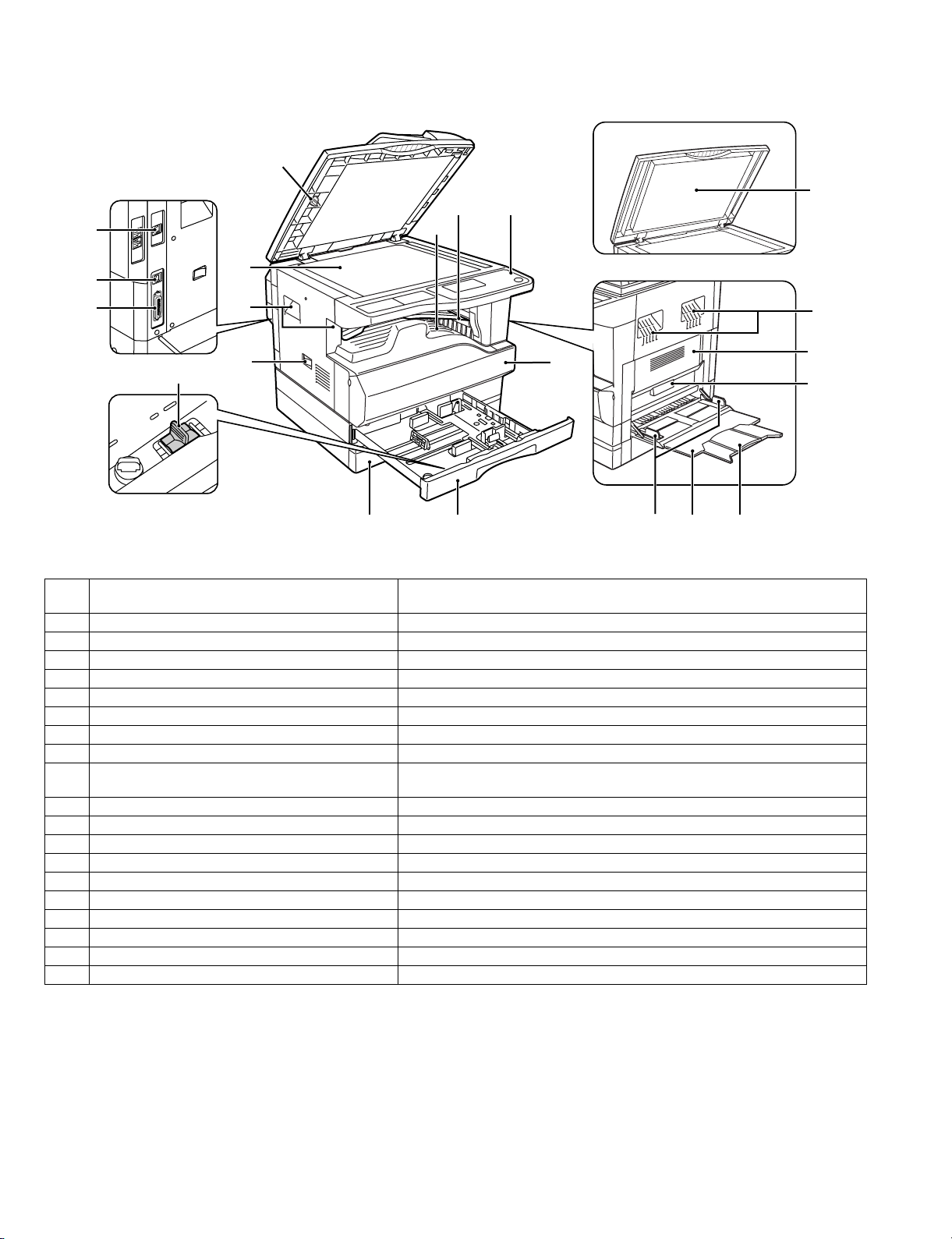

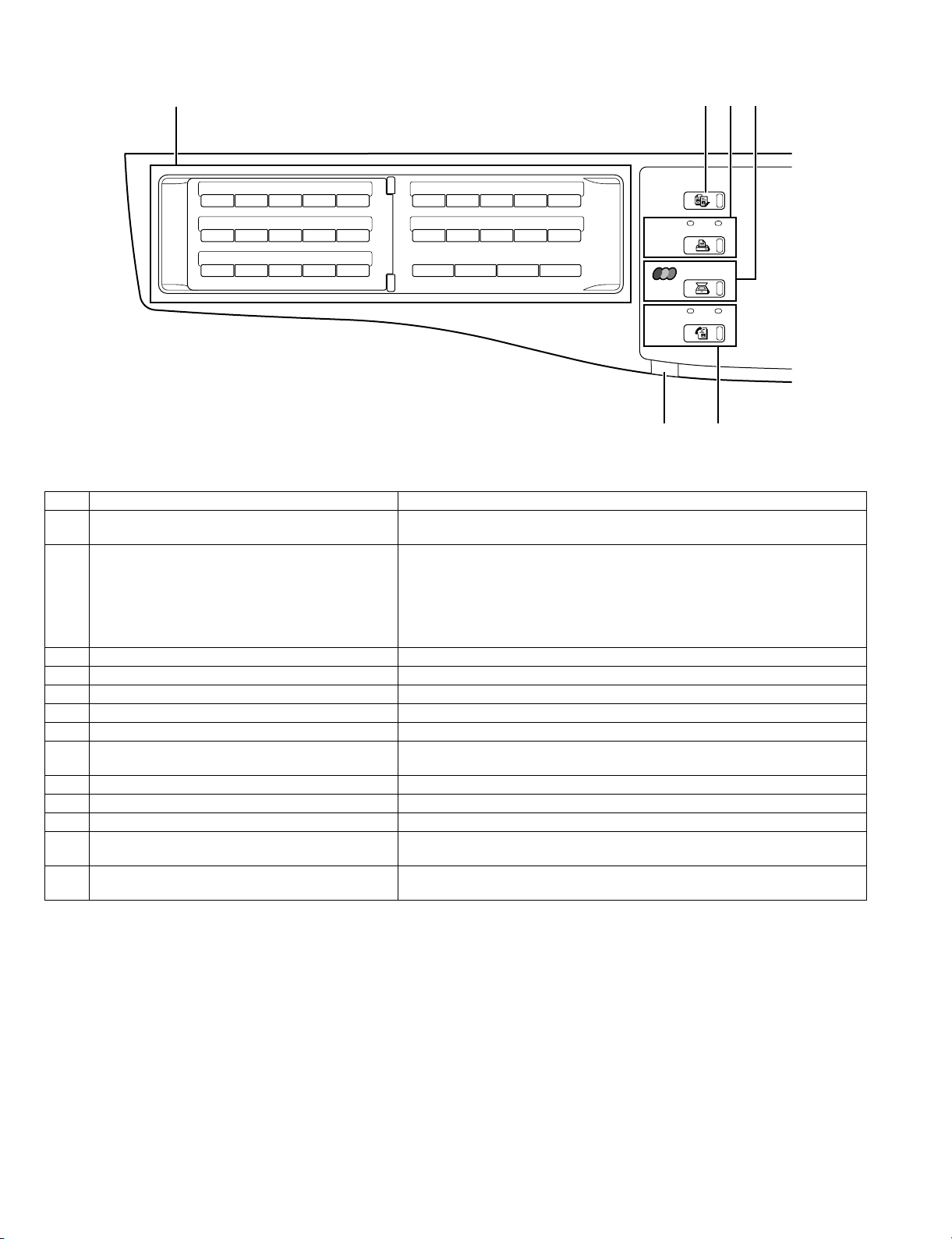

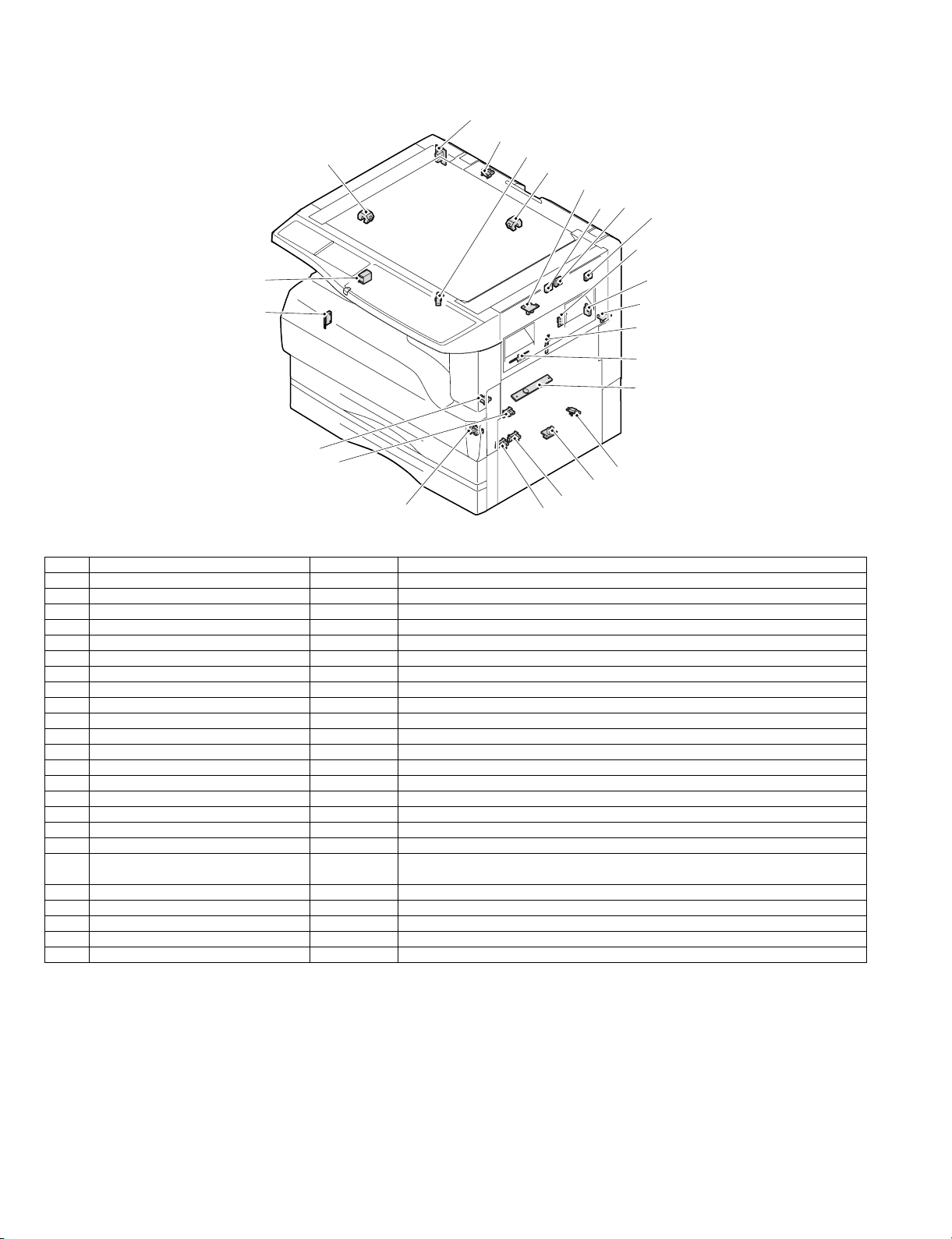

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

5

10

1

9

11

15

2

3

4

1 USB 2.0 port (USB-2)

(when the dual function board is installed)

2 USB 1.1 port (USB-1) Connect to your computer to this port to use the printer and scanner functions.

3 Parallel port Connect to your computer to this port to use the printer function.

4 Charger cleaner Use to clean the transfer charger.

5 Glass cleaner Use to clean the original scanning glass.

6 Document glass Place an original that you wish to scan face down here.

7 Handles Use to move the machine.

8 Power switch Press to turn the machine power on and off.

9 Center tray Copies and printed pages are output to this tray.

10 Upper tray (when the job separator tray kit is installed) Received faxes (when the fax option is installed) and print jobs are deliv ered to this

11 Operation panel Contains operation keys and indicator lights.

12 Front cover Open to remove paper misfeeds or replace the toner cartridge.

13 Tray 1 Tray 1 can hold approximately 250 sheets of copy paper (64 g/m²).

14 Tray 2 Tray 2 can hold approximately 250 sheets of copy paper (64 g/m²).

15 Document cover (when installed) Open to make a copy from the document glass.

16 Side cover Open to remove misfed paper.

17 Side cover handle Pull to open the side cover.

18 Bypass tray guides Adjust to the width of the paper when using the bypass tray.

19 Bypass tray Special paper (heavy paper or transparency film) can be fed from the bypass tray.

20 Bypass tray extension Pull out when feeding large paper such as 11" x 17" and 8-1/2" x 14" (A3 and B4).

6

7

8

12

7

16

17

14 13

Connect to your computer to this port to use the printer and scanner functions.

tray.

18 19 20

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-1

Page 17

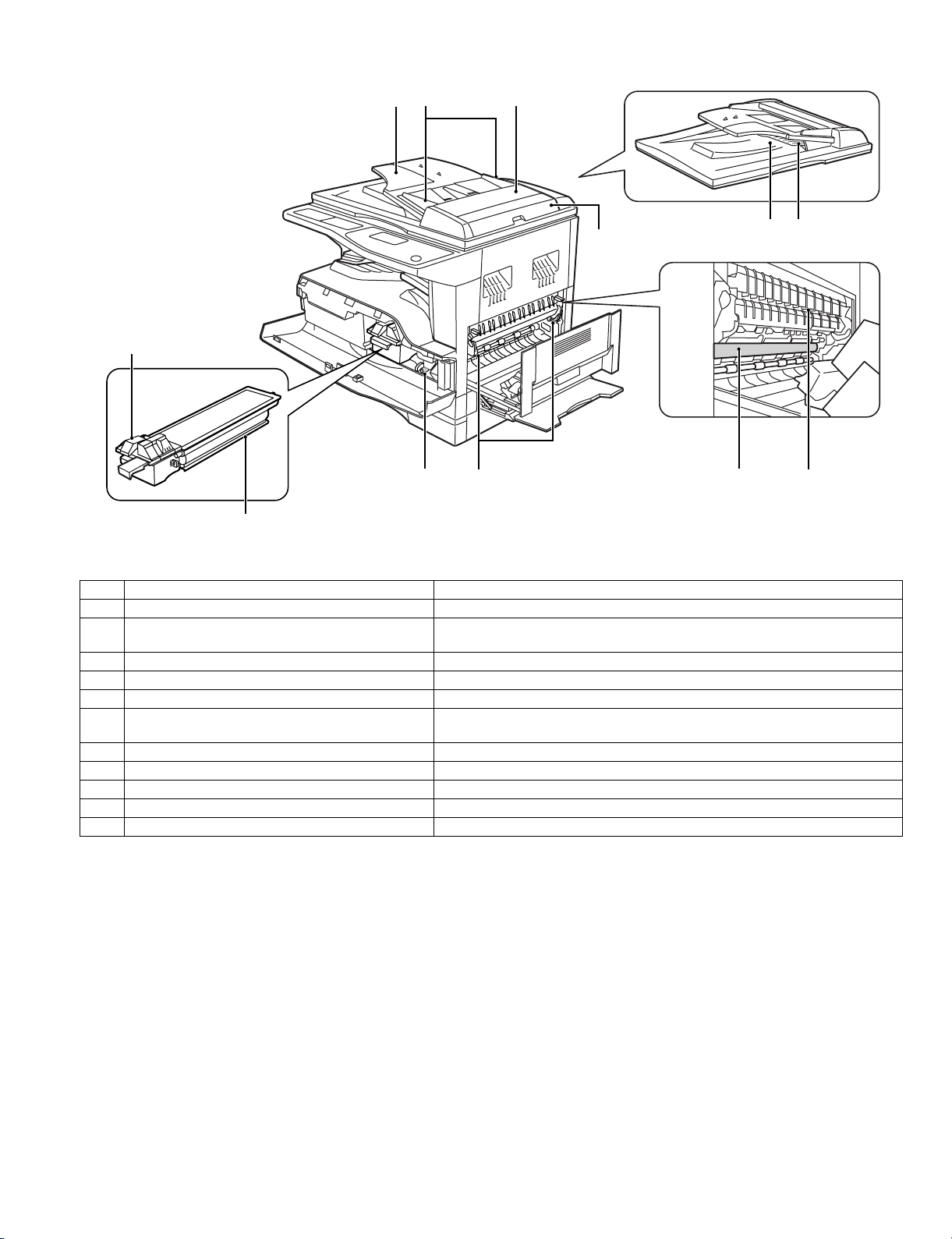

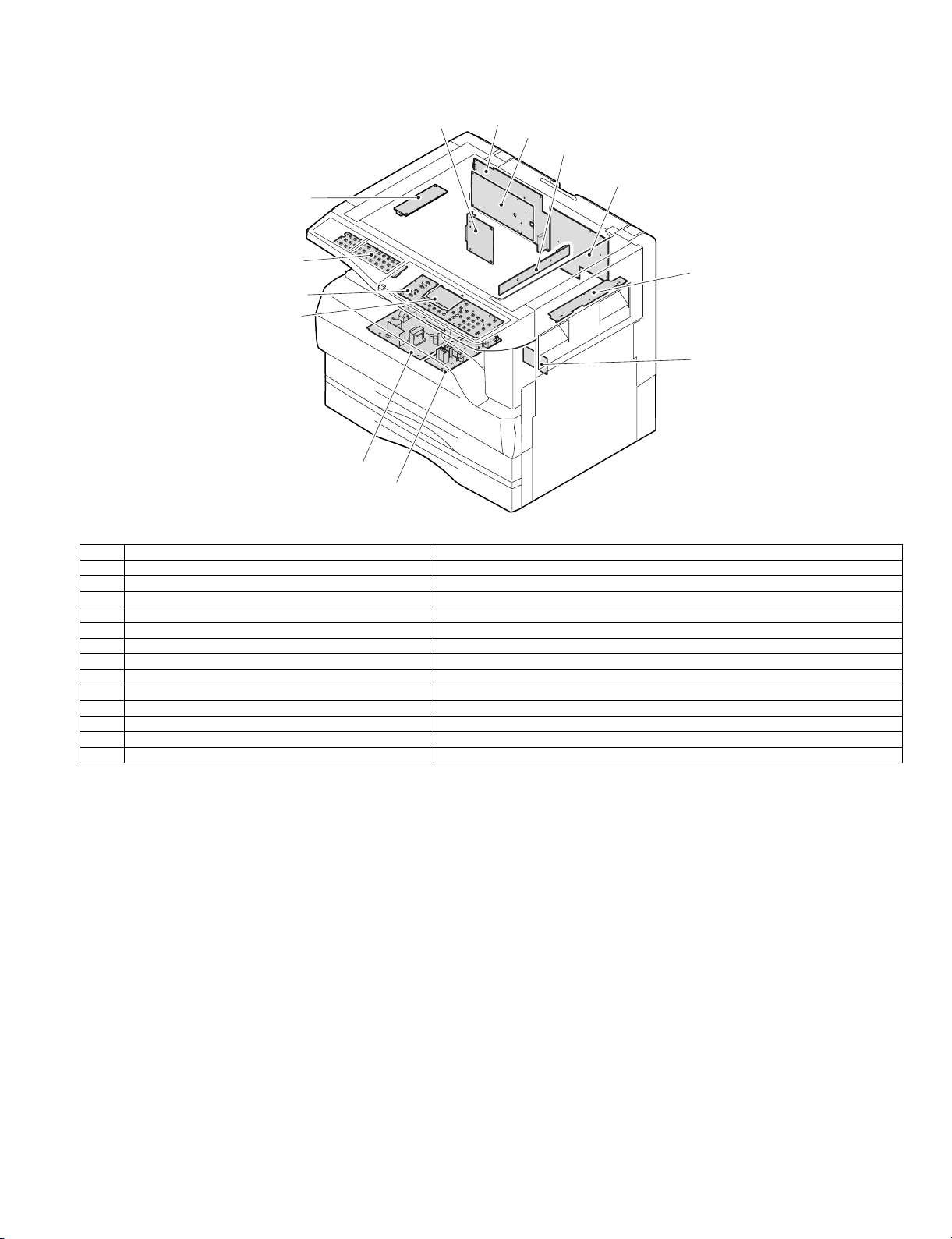

2. Internal

21

22

23 24

25

26

2728

29 30

31 32

21 T oner cartridge lock release lever To replace the toner cartridge, pull out the toner cartridge while pushing on this lever.

22 Toner cartridge Contains toner.

23 Document feeder tray (when the SPF is installed) Place the original(s) that you wish to scan face up here. Up to 40 sheets can be

24 Original guides (when the SPF is installed) Adjust to the size of the originals.

25 Feeding roller cover (when the SPF is installed) Open to remove misfed originals.

26 Right side cover (when the SPF is installed) Open to remove misfed originals.

27 Fusing unit release levers To remove the paper misfed in the fusing unit, push down on these levers and

28 Roller rotating knob Rotate to remove misfed paper.

29 Exit area (when the SPF is installed) Originals exit the machine here after copying/scanning when the SPF is used.

30 Reversing tray (when the RSPF is installed) Pull out to remove misfed originals.

31 Photoconductive drum Images are formed on the photoconductive drum.

32 Fusing unit paper guide Open to remove misfed paper.

Warning: The fusing unit is hot. Do not touch the fusing unit when removing misfed paper. Doing so may cause a burn or injury.

Caution: Do not touch the photoconductive drum (green portion) when rem oving the misfed paper. Doing so may damage the drum and cause

smudges on copies.

Note: The model name is on the front cover of the machine.

placed.

remove the paper.

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-2

Page 18

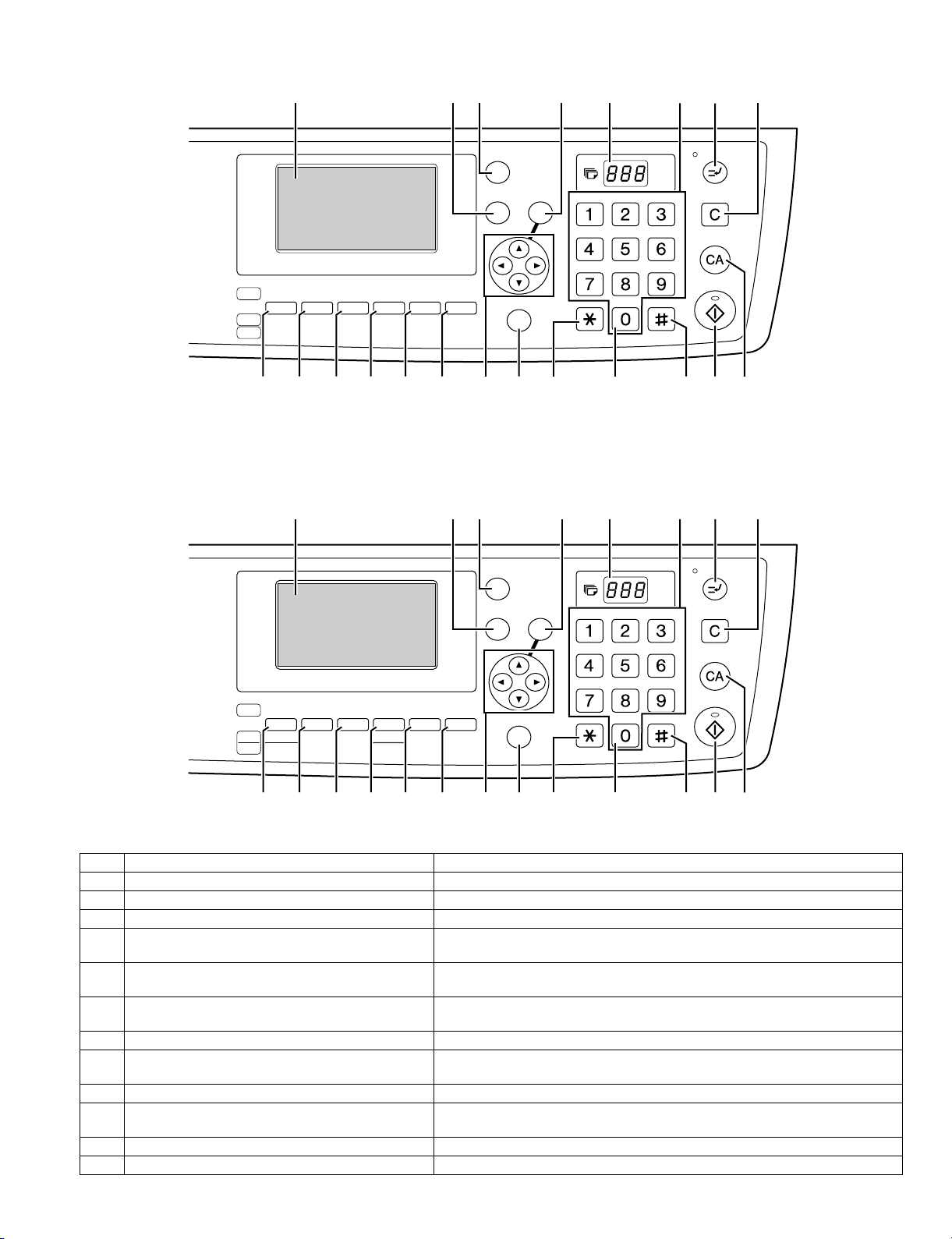

3. Operation panel

2134

26 27 28 29 30

ABCDE

31 32 33 34 35

FGH I J

36 37 38 39 40

KLMNO

41 42 43 44 45

PQR TS

46 47 48 49 50

U V W XYZ SP

SPEAKER

REDIAL/PAUSE SPEED

SHIFT

COMM. SETTING

SYMBOL

SPACE/

COPY

PRINT

SCAN

FAX

13

ON LINE

LINE

DATA

DATA

14

1 Keys for fax function (when the fax option is installed) These are used in fax mode.

2 [COPY] key/indicator Press to select copy mode. If pressed when "Ready to copy." appears or during

warm-up, the total number of sheets used appears while the key is pressed.

3 [PRINT] key/indicator Press to select print mode.

• ONLINE indicator

Print jobs can be received when this indicator is lit.

• DATA indicator

This lights steadily when there is a print job in memor y that has not been print ed,

and blinks during printing.

4 [SCAN] key/indicator Press to select scan mode.

5 Display Shows various messages. For more information see page 5-5.

6 [BACK] key Press to return the display to the previous screen.

7 [FAX STATUS] key This key is used in fax mode.

8 [OK] key Press to enter the selected setting.

9 Copy number display The selected number of copies appears. During copying, this shows the remaining

number of copies.

10 Numeric keys U se to select the number of copies.

11 [INTERRUPT] key/INTERRUPT indicator Interrupts a copy run to allow an interrupt copy job to be performed.

12 [C] key Press to clear the set number of copies or stop a copy run.

13 Information lamp

(when the fax option is installed)

14 [FAX] key/indicator (when the fax option is installed)

Information lamp blinks, when facsimile is received, or when the paper remains in

the tray.

This key is used in fax mode.

LINE indicator, DATA indicator

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-3

Page 19

For U.S.A.

5967 8 1011 12

FAX STATUS

For other country

COPY

EXPOSURE

PAPER ZOOM

SCAN

COLOR MODE

RESOLUTION

FAX

PROGRAM

ADDRESS FORMAT

ADDRESS

RESOLUTION

BROADCAST

15 16 17 18 19

5967 8 1011 12

AUTO %

OUTPUT DUPLEX

ORIGINAL SIZE DUPLEX SCAN

ORIGINAL SIZE

20

BACK

DUPLEX SCAN

OK

SPECIAL FUNCTION

21 22 27262523 24

FAX STATUS

BACK

OK

ACC. #-C

ABC DEF

JKLGHI MNO

TUVPQRS WXYZ

@.-

READ-END

ABC DEF

_

JKLGHI MNO

TUVPQRS WXYZ

PAPER

COPY

SCAN

COLOUR MODE

FAX

EXPOSURE

PROGRAM

COPY

SELECT

RATIO

RESOLUTION

ADDRESS

BROADCAST

15 16 17 18 19

AUTO

IMAGE

FORMAT

2-SIDED

OUTPUT

COPY

SPECIAL FUNCTION

ORIGINAL SIZE DUPLEX SCAN

20

21 22 27262523 24

ACC. #-C

_

@.-

READ-END

15 [EXPOSURE] key Use to select the exposure mode. "AUTO", "TEXT", or "PHOTO" can be selected.

16 [PAPER] key (PAPER SELECT key) Use to manually select a paper tray.

17 [ZOOM] key (COPY RAT IO key) Press to select a reduction or enlargement copy ratio.

18 [AUTO%] key (AUTO IMAGE key) Press to have the copy ratio selected automatically.

19 [SORT] key (Only effective when the dual function

Use to select the sort function.

board is installed)

20 [DUPLEX] key (2-SIDED COPY key) (only on models

Select the two-sided copying mode.

that support two-sided printing)

21 Arrow keys Press to move the highlighting (which indicates that an item is selected) in the

display.

22 [SPECIAL FUNCTION] key Press to select special functions.

23 [ACC.#-C] key Press the end the use of an account and return the display to the account number

entry screen.

24 [0] key Press during a continuous copy run to display the number of copies completed.

25 [READ-END] key When copying in sort mode from the document glass, press this key when you have

finished scanning the original pages and are ready to start copying.

26 [START] key/indicator Copying is possible when this indicator is on. Press the key to start copying.

27 [CA] key Clears all selected settings and returns the machine to the default settings.

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-4

Page 20

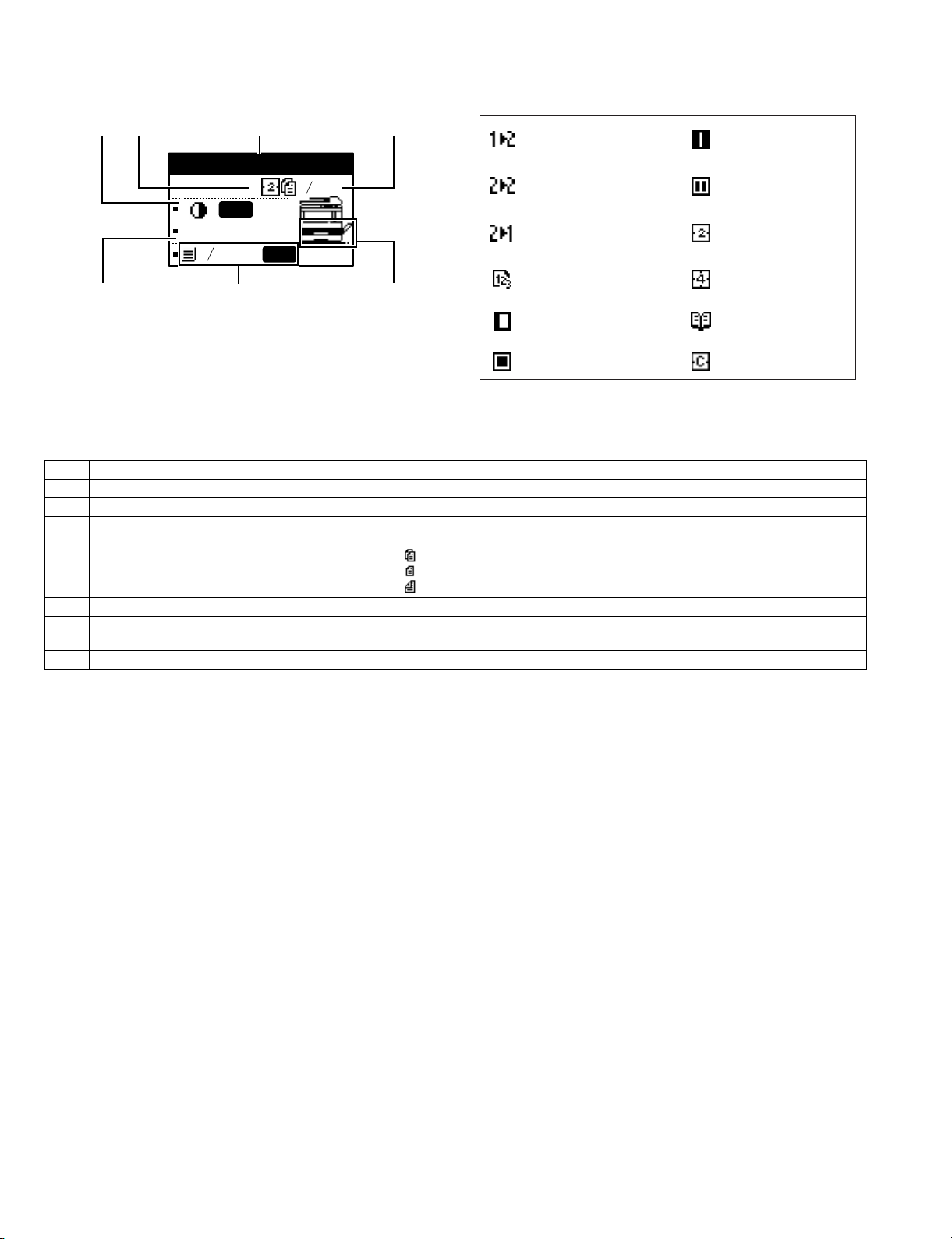

4. Display(base screen)

Example: Copy mode

23 4

1

Ready to copy.

AUTO

100%

1

2

8 x11

8 x11

AUTO

1

2

Icons appearing in the special function icon display

1-sided to 2-sided

copy

2-sided to 2-sided

copy

2-sided to 1-sided

copy

Center erase

copy*

Edge + Center

erase*

2 in 1 copy*

Sort function* 4 in 1 copy*

5

76

Margin shift copy* Dual page copy

* The display shown is the AR-M207 (when the optional

RSPF is installed) display.

* These only appear when the dual function board is

1 Exposure display Indicates the selected exposure mode.

2 Special function icon display Icons of enabled special functions will appear.

3 Message display Messages are displayed regarding machine status and operation.

4 Original size display The size of the placed original and the icon of the original scanning mode will

appear.

: One-sided scanning in the SPF.

: Scanning on the document glass

: Two-sided scanning in the RSPF.

5 Copy ratio display Displays the copy ratio for reduction or enlargement.

6 Paper size display Displays the selected paper size. When "AUTO" appears, the most suitable size of

paper is automatically selected.

7 Paper tray display The selected paper tray is highlighted.

Erase copy* Card shot*

installed.

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-5

Page 21

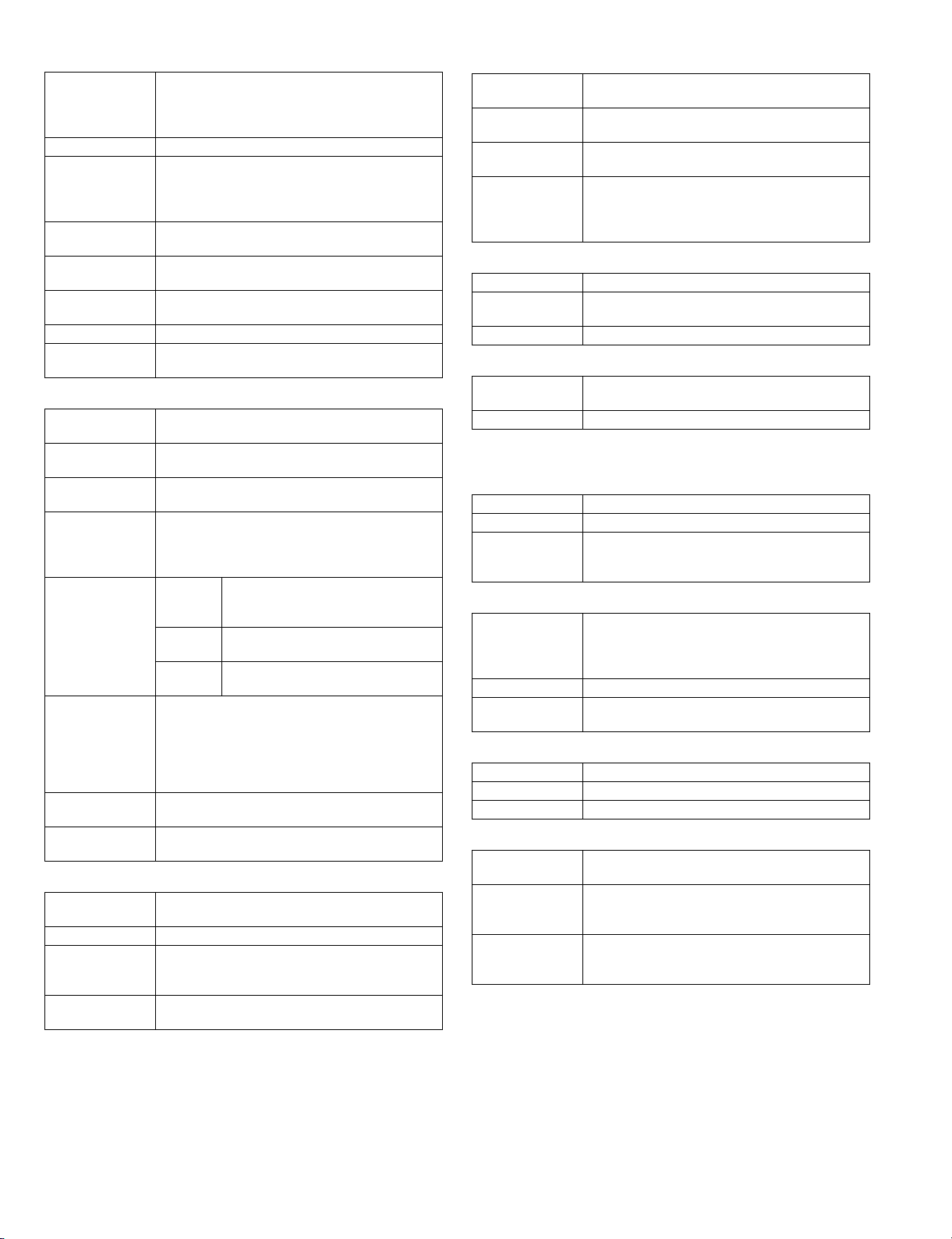

5. Motor, solenoid, clutch

1

2

3

4

18

5

6

7

19

8

9

10

11

12

13

14

15

16

17

No.

1 Mirror motor MRM Drives the optical mirror base (scanner unit).

2 Shifter motor SHTM Shifts the paper exit tray.

3 Toner motor TM Toner supply

4 Duplex motor DPX Switchback operation and paper exit motor in duplex.

5 Cooling fan motor CFM Cools the inside of the machine.

6 Main motor MM D r ives the machine.

7 1st tray paper feed clutch CPFC1 Drive the pick up roller

8 PS clutch RRC Drives the resist roller

9 Paper feed solenoid CPSOL1 Solenoid for paper feed from cassette

10 Resist roller solenoid RRS Resist roller rotation control solenoid

11 Manual paper transport clutch MPTC Drives the manual paper transport roller.

12 Manual paper feed clutch MPFC Drives the manual paper feed roller.

13 Manual paper feed solenoid MPFS Manual paper feed solenoid

14 2nd tray transport clutch CPFC2 Dr i ves the 2nd tray transport roller.

15 2nd tray transport solenoid FSOL1 2nd tray transport solenoid

16 2nd tray paper feed clutch CPFC 1 Drives the 2nd tray paper feed roller.

17 2nd tray paper feed solenoid PSOL2 2nd tray transport solenoid

18 Exhaust fan motor VFM Cools the inside of the machine.

19 Job separator motor Job separator tray up/down

Name

Code

Function operation

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-6

Page 22

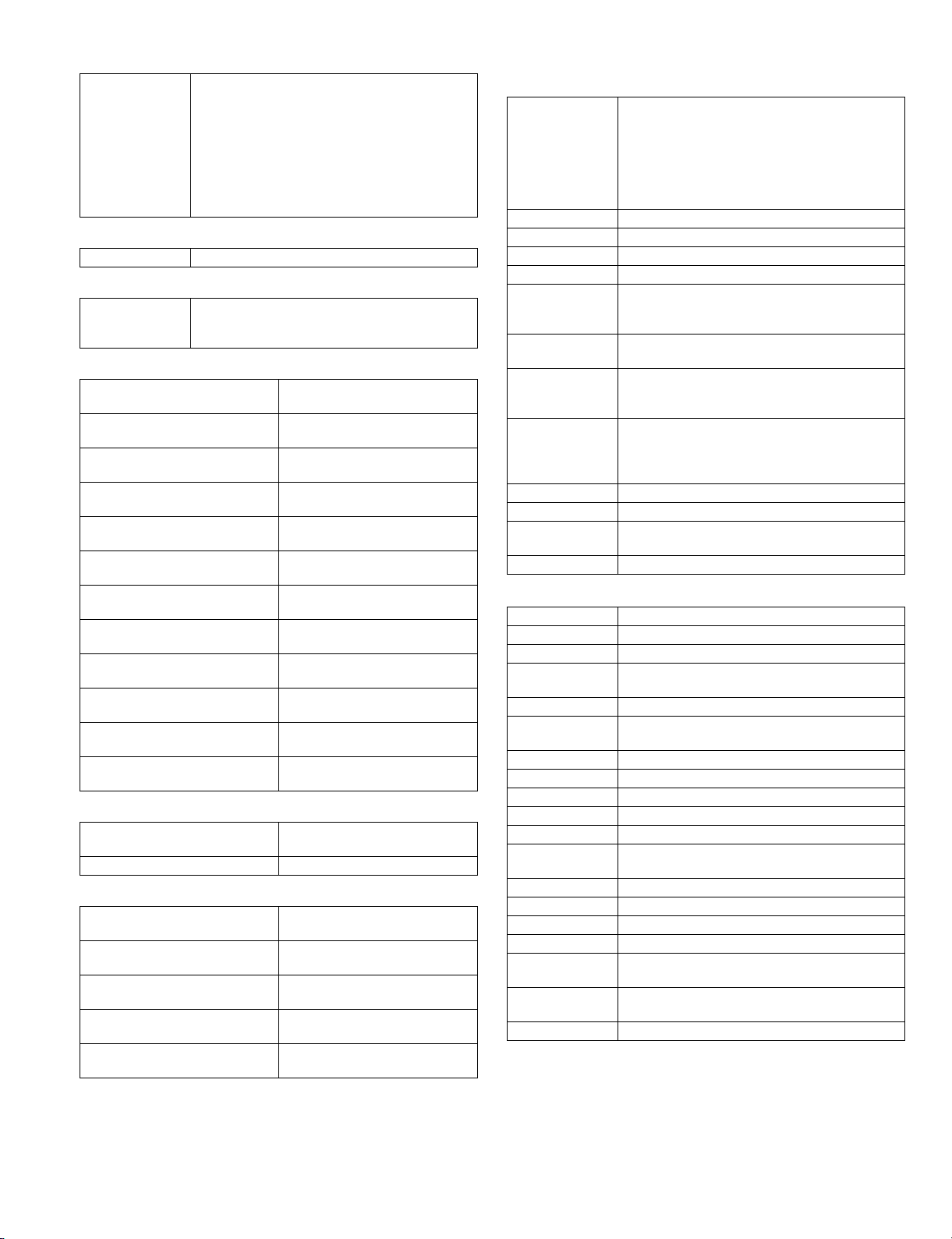

6. Sensor, switch

23

1

22

2

24

3

19

18

20

4

17

16

21

5

6

7

8

15

14

9

10

13

No. Name Code Function operation

1 Mirror home position sensor MHPS Detects the mirror (scanner unit) home position.

2 Side door switch DSWR Side door open detection

3 Paper exit sensor (paper exit side) POD1 Detects paper exit.

4 Shifter home position sensor SFTHP Shifter home position detection

5 Paper exit sensor (DUP side) PDPX Paper transport detection

6 Thermistor RTH Fusing section temperature detection

7 Thermostat Fusing section abnormally high temperature detection

8 Toner density sensor TCS Toner quantity detection

9 2nd tray detection switch 2nd tray detection

10 Manual sensor MPED Manual transport detection

11 2nd tray door open/close sensor DRS2 2nd tray door open/close detection

12 2nd tray door paper pass sensor PPD2 2nd tray paper entry detection

13 2nd tray paper empty sensor CSS2 2 nd tray paper empty detection

14 Paper in sensor PIN Paper transport detection

15 Cassette empty Tray paper entry detection

16 Front cover SW Front cover open detection

17 Power switch MAIN SW Turns ON/OFF the main power source.

18 Tray full sensor TRAY-D Tray full detection

19 Job separator paper presence/empty

sensor

20 Job separator HP sensor LFT UP Job separator HP detection

21 Lower limit switch / JOBS_DLD Job separator tray lower limit position detection

22 OC sensor OCSW Original cover and SPF open/close detection

23 Original size sensor(Main Scaning) DSIN0 Original size detection

24 Original size sensor(Sub Scaning) DSIN1 Original size detection

TRAY-FULL Job separator tray paper presence/empty detection

11

12

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-7

Page 23

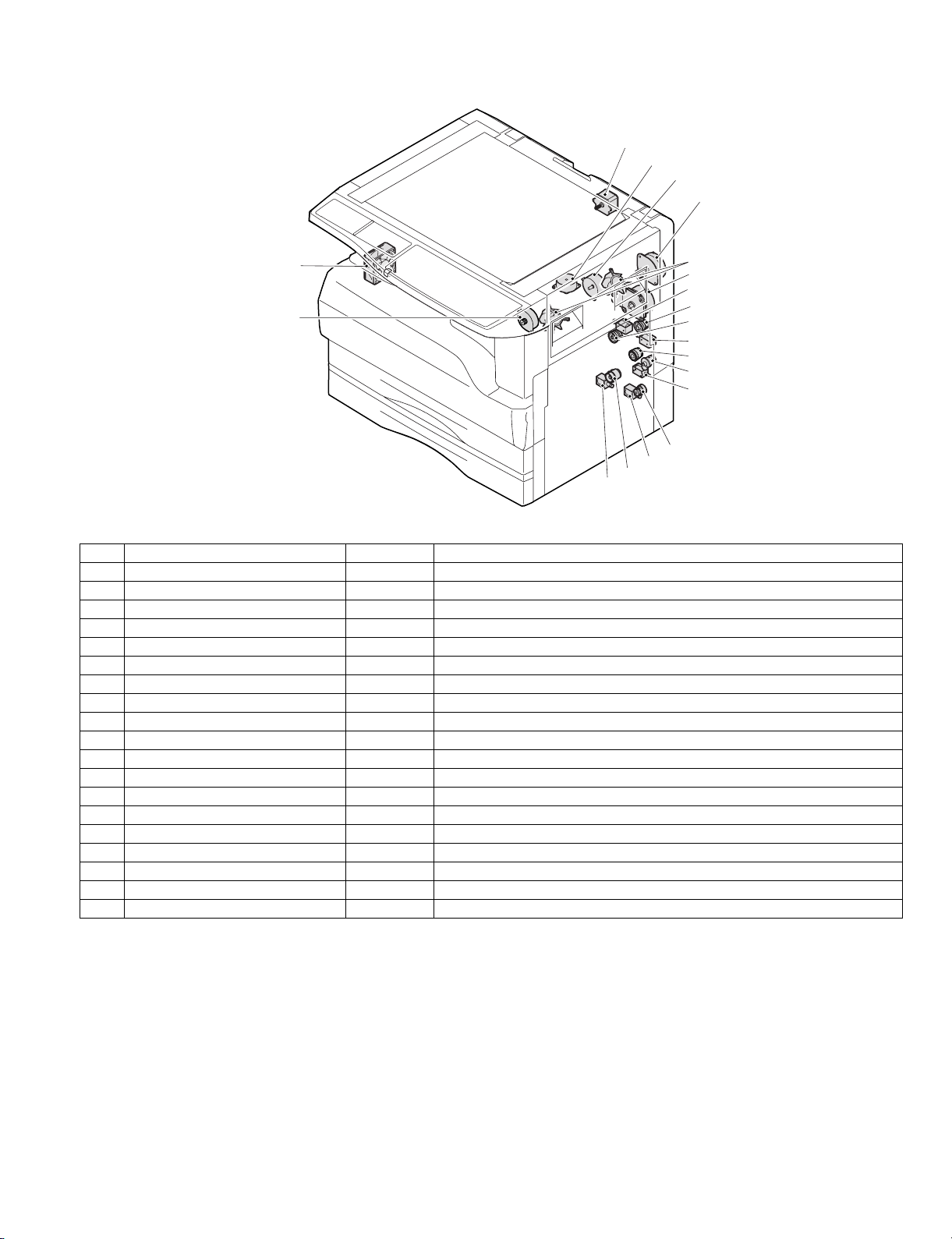

7. PWB unit

2

13

6

3

4

1

12

5

10

11

7

9

8

No. Name Function operation

1 Copy lamp Inverter PWB Copy lamp control

2 I / F PWB USB1.1, IEEE1284 I/F

3 CCD sensor PWB Image scanning

4 Main control PWB Main control PWB

5 Tray PWB Shifter motor control

6 IMC2 PWB Electronic sort, USB2.0 << Option:AR -EB 9>>

7 2nd cassette PWB 2nd cassette control

8 High voltage PWB High voltage control

9 Power PWB AC power input/DC power control

10 Operation main PWB Operation panel input/Display, operation panel section control

11 LCD OPE PWB Display and operation panel control

12 FAX • KEY PWB FAX operation input, key operation input<< Option:AR-FX11>>

13 FAX main PWB F AX control<< Option:AR-FX11>>

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-8

Page 24

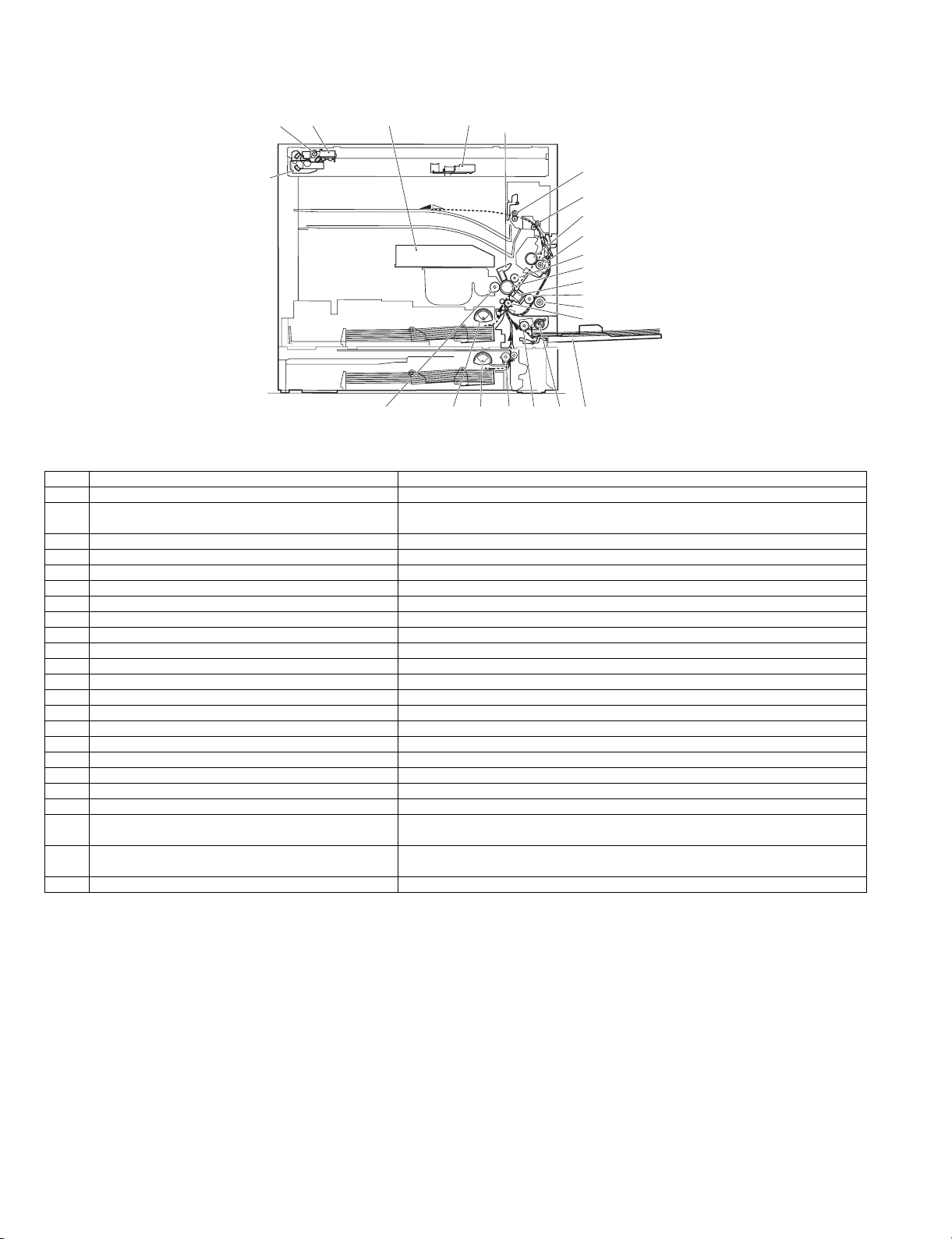

8. Cross sectional view

4

5

6

18

2

1

3

7

8

9

10

11

12

13

14

15

23

No. Name Function/Operation

1 Copy lamp Image radiation lamp

2 Copy lamp unit Operates in synchronization with No. 2/3 mirror unit to radiate documents

3 LSU unit Converts image signals into laser beams to write on the drum.

4 Lens unit Reads images with the lens and the CCD.

5 MC holder unit Supplies negative charges evenly on the drum.

6 Paper exit roller Used to discharge paper.

7 Transport roller Used to transport paper.

8 Upper heat roller Fuses toner on paper (with the Teflon roller).

9 Lower heat roller Fuses toner on paper (with the silicon rubber roller).

10 Waste toner transport roller Transports waste toner to the waste toner box.

11 Drum unit Forms images.

12 Transfer charger unit Transfer images (on the drum) onto paper.

13 DUP follower roller

14 Duplex transport roller Transports paper for duplex .

15 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

16 Manual paper feed tray Manual paper feed tray

17 Manual paper pick up roller Picks up paper in manual paper feed.

18 No. 2/3 mirror unit Reflects the images from the copy lamp unit to the lens unit.

19 Manual transport roller Transports paper from the manual paper feed port.

20 2nd tray paper transport roller Transports paper from the 2nd tray.

21 2nd tray paper pick up roller

(semi-circular roller)

22 1st tray paper feed roller

(semi-circular roller)

23 MG roller Puts toner on the OPC drum.

22

21

20

19

17

sequentially.

Picks up paper from the 2nd tray.

Picks up paper from the 1st tray.

16

AR-M207 M165 M162 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-9

Page 25

[5] UNPACKING AND INSTALLATION

1. Installing conditions

A. Copier installation

Do not install your copier in areas that are:

•damp, humid, or very dusty

•exposed to direct sunlight

•poorly ventilated

•subject to extreme temperature or humidity changes, e.g., near an air

conditioner or heater.

•Be sure to allow the required space around the machine for servicing

and proper ventilation.

B. Power source

•Use an exclusive-use power outlet. If the power plug of this machine is

inserted into a power outlet commonly used with other illumination

units, flickers of the lamp may be result. Use a power outlet which is not

used commonly with any illumination units.

•Avoid complex wiring.

C. Grounding wire connection.

•To avoid danger, be sure to connect a grounding wire. If no grounding

wire is connected and a leakage occurs, a fire or an electric shock may

be result.

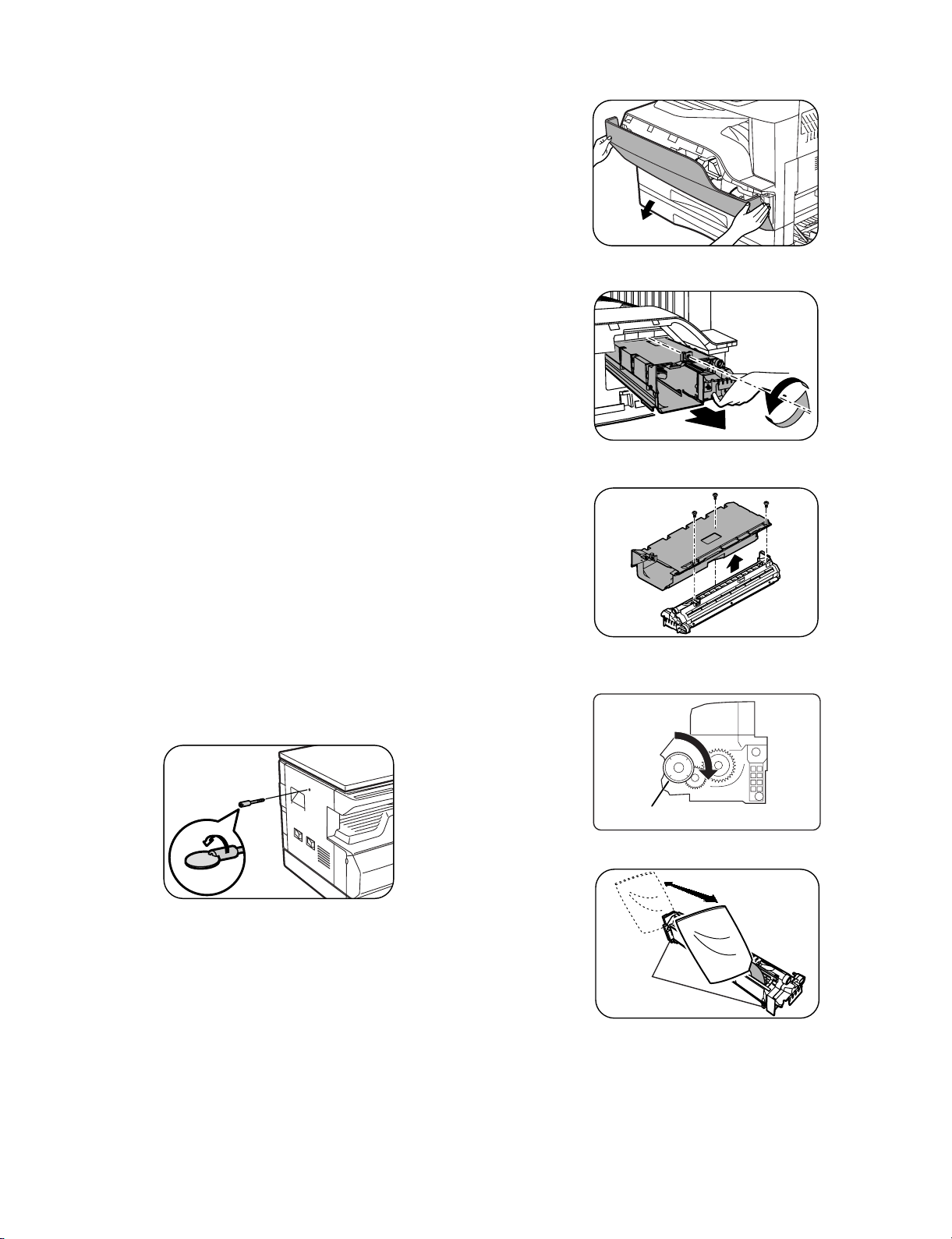

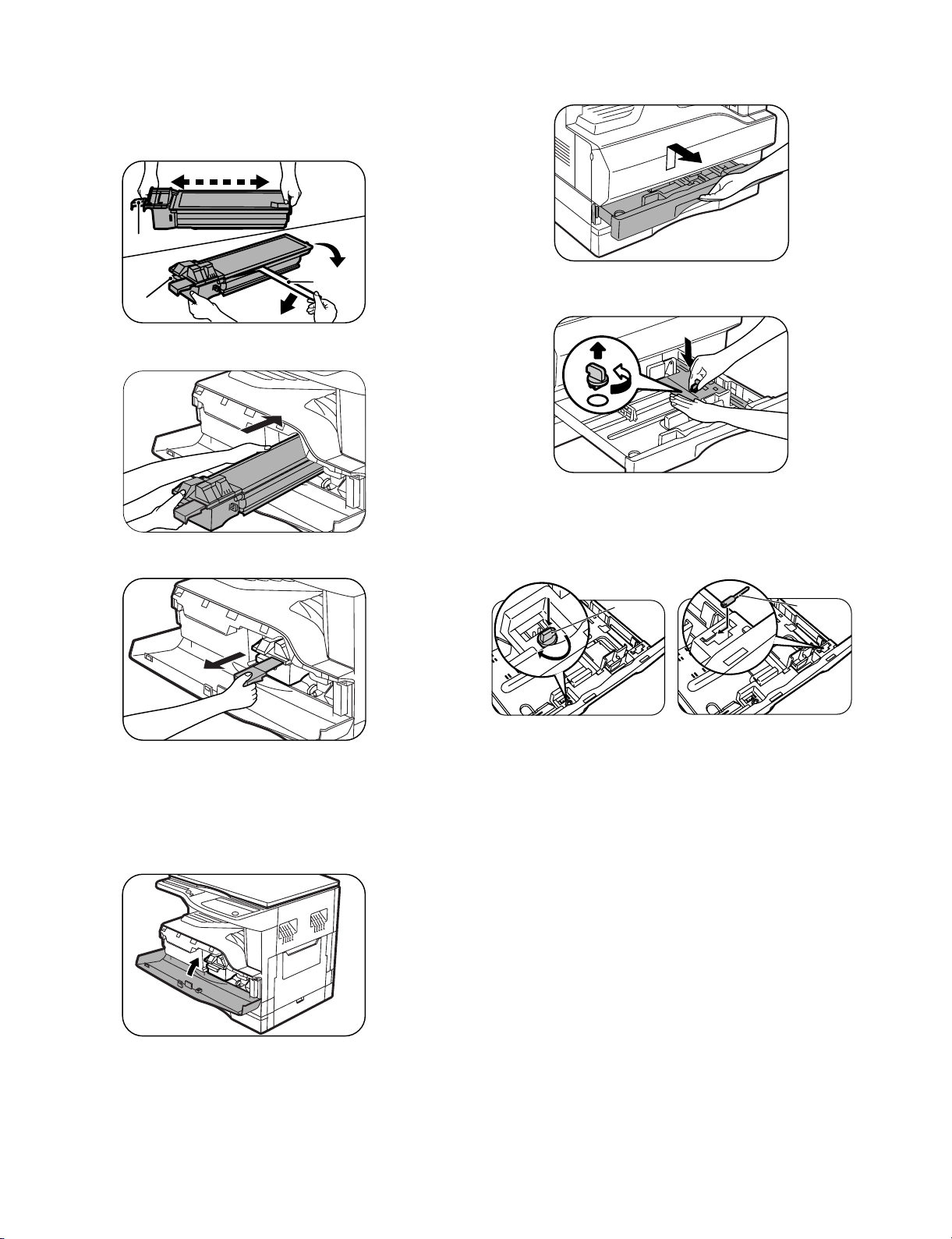

2) Open the front cover.

•Hold the both sides and pull down to open.

3) Loosen the screw and remove the developer cartridge.

4) Remove the developer tank from the developer cartridge.

2. Removal of protective material and fixing

screw

1) Remove all tapes and protective material.

• Remove all tapes, then open the document cover and remove the

protective material of sheet shape

2) Remove the fixing screw.

•Use a coin to remove the fixing screw.

•The fixing screw is required when transporting the machine. Keep it in

the tray. (Refer to the later description.)

3.Installing procedure

A.Developer cartridge installation

1) Open the manual tray, and open the side cover.

5) Supply developer into the developer tank while rotating the MG roller

in the arrow direction.

MG roller

* Shake the developer bag enough before opening it.

Hook

Note: Check that the DV seal is free from developing agent. If developing

agent is attached to the DV seal, clean it carefully.

Check to insure that the hook is engaged in two positions.

6) Attach the developer tank to the developer cartridge.

* After supplying developer into the developer cartridge, do not tilt or

shake the developer cartridge.

7) Attach the developer cartridge to the copier, and fix it with the screw.

AR-M207 M165 M162 UNPACKING AND INSTALLATION 5-1

Page 26

B. Toner cartridge installation

1) Shake the toner cartr idge several times horizontally, and rem ove the

tape.

* Do not hold the shutter lever when shaking.

* After removing the tape, do not tilt or shake the toner cartridge.

4 or 5 times

Shutter

4. Removal and storage of fixing screw

1) Lift the knob and gently pull out the tray .

Handle

2) Attach the toner cartr idge to the copier.

3) Pull the shutter lever.

Tape

2) Hold the paper pressure plate and turn t he fixing screw in the arrow

direction.

3) Store the fixing pin and the fixing screw in the tray.

•Store the fixing screw which was removed in the abov e procedure 2 and

the fixing screw which was removed in procedure 2 of 2.

•Removal of protective material and fixing screw in the storage place in

the tray.

Pressure

plate

lock

Screw

Close the front cover A, then close the side cover B.

•When closing the front cover, gently press the both sides.

•When closing the side cover, hold the knob.

• When closing the covers, be sure to close the front cover first, then

close the side cover. If closed in a wrong sequence, the covers may be

broken.

AR-M207 M165 M162 UNPACKING AND INSTALLATION 5-2

Page 27

5. Changing the paper size setting of a tray

DUPLEX

SPECIAL FUNCTION

ACC.

DUPLEX SCAN

DUPLEX SCAN

GH

PQR

DUPLEX

SPECIAL FUNCTION

GHI

OK

BACK

If the size of the loaded paper is different from the size shown in the

display, follow the steps below to change the paper size setting of the

tray.

The paper size setting cannot be changed during copying, printing, fax

printing (when the fax option is installed), or interrupt copying, or when a

misfeed has occurred. However, if the machine is out of paper or out of

toner, the paper size setting can be changed during copying, printing,

and fax printing.

The paper size cannot be set for the bypass tray.

4) Press the [ ] or [ ] key to select the paper tray for which the

paper size is being changed.

Example: Tray 2

PAPER SIZE SET

1

2

8 x11 11x17

11x17 8 x14

8 x11

8 x11R

1

2

1

2

1

2

1) Press the [SPECI AL FU NCTION] key.

SPECIAL FUNCTION

SPECIAL MODES

ORIG. SIZE ENTER

PAPER SIZE SET

The special function

screen will appear.

The screen shown above is the copy mode screen.

2) Press the [ ] or [ ] key to select "PAPE R SI ZE SET ".

DISPLAY CONTRAST

SPECIAL FUNCTION

SPECIAL MODES

ORIG. SIZE ENTER

PAPER SIZE SET

DISPLAY CONTRAST

3) Press the [OK] key.

PAPER SIZE SET

1

8 x11R 11x17

2

11x17 8 x14

8 x11

The paper size setting

screen will appear.

8 x11R

5) Press the [ ] key.

PAPER SIZE SET

1

2

8 x11 11x17

11x17 8 x14

8 x11

8 x11R

The cursor moves to the paper size selection position on the right.

6) Press the [ ] or [ ] key to select the paper size.

1

2

1

2

1

2

Example:

Selecting 8-1/2" x 14" size

PAPER SIZE SET

1

2

8 x11 11x17

11x17 8 x14

8 x11

8 x11R

To change the size of another paper tray, press the [ ] key and then

repeat steps 4 to 6.

7) Press the [OK] key.

1

2

1

2

1

2

A message asking you to confirm the new paper size setting will

appear.

8) Press the [OK] key.

The selected paper size will be stored and the display will return to

the base screen.

1

2

1

2

1

2

Note

: Shows tray "1".

: Shows tray "2".

Note

Affix the paper size label for the paper size selected in step 6 to the label

position on the right end of the tray.

AR-M207 M165 M162 UNPACKING AND INSTALLATION 5-3

Page 28

[6] ADJUSTMENTS

1. Adjustment item list

Section Adjustment item Adjustment procedure/SIM No.

A Process

section

B Mechanism

section

C Image density

adjustment

2. Copier adjustment

A.Process section

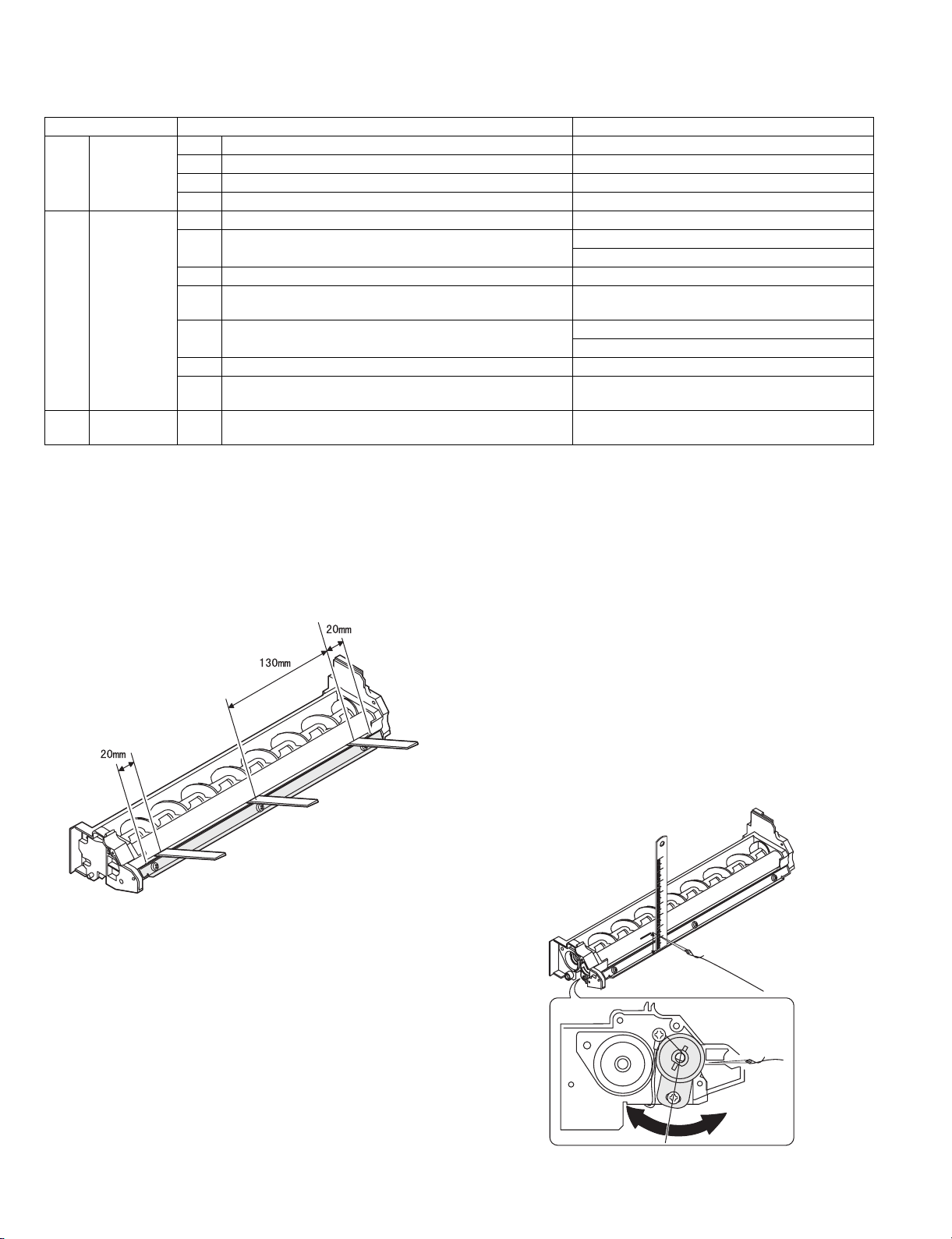

(1) Developing doctor gap adjustment

1) Loosen the developing doctor fixing screw A.

2) Insert a thickness gauge of 1.5mm to the three positions at 20mm

and 130mm from the both ends of the developing doctor as shown.

(1) Developing doctor gap adjustment Developing doctor gap adjustment

(2) MG roller main pole position adjustment MG roller main pole position adjustment

(3) Developing bias v oltage check

(4) Main charger voltage check

(1) Image position adjustment SIM 50

(2) Main scanning direction(FR direction) distortion balance

adjustment

No. 2/3 mirror base unit installing position adjustment

Copy lamp unit installing position adjustment

(3) Main scanning direction (FR direction) distortion adjustment Rail height adjustment

(4) Main scanning direction (FR direction) magnification ratio

SIM 48-1

adjustment

(5) Sub scanning direction (scanning direction) magnification ratio

adjustment

OC mode in copying (SIM 48-1)

SPF mode in copying (SIM 48-5)

(6) Off center adjustment OC mode (SIM 50-12)

(7) SPF white correction pixel position adjustment

SIM 63-7

(required in an SPF model when replacing the lens unit)

(1) Copy mode SIM 46-1

(2) MG roller main pole position adjustment

1) Remove and separate the waste toner box and put the developing

unit on a flat surface.

2) Tie a string to a needle or a pin.

3) Hold the string and bring the needle close to the MG roller

horizontally. (Do not use paper clip, which is too heavy to make a

correct adjustment.) (Put the developing unit horizontally for this

adjustment.)

4) Do not bring the needle into contact with the MG roller, but bring it to

a position 2 or 3mm apar t from the MG roller. Mark the point on the

MG roller which is on the extension line from the needle tip.

5) Measure the distance from the marking position to the top of the

doctor plate of the developing unit to insure that it is 18mm.

If the distance is not within the specified range, loosen the fixing

screw A of the main pole adjustment plate, and move the adjustment

plate in the arrow direction to adjust.

3) Push the developing doctor in the arrow direction, and tighten the

developing doctor fixing screw. (Perform the same procedure for the

front and the rear frames.)

4) Check the clearance of the developing doctor. If it is within the

specified range, then fix the doctor fixing screw with screw lock.

* When inserting a thickness gauge, be careful not to scratch the

developing doctor and the MG roller.

<Adjustment specification>

Developing doctor gap

Both ends (20mm from the both ends) :

C (Center) (150mm from the both ends) :

+0.1

1.5 mm

- 0.15

+0.15

1.55 mm

- 0.2

AR-M207 M165 M162 ADJUSTMENT 6-1

Page 29

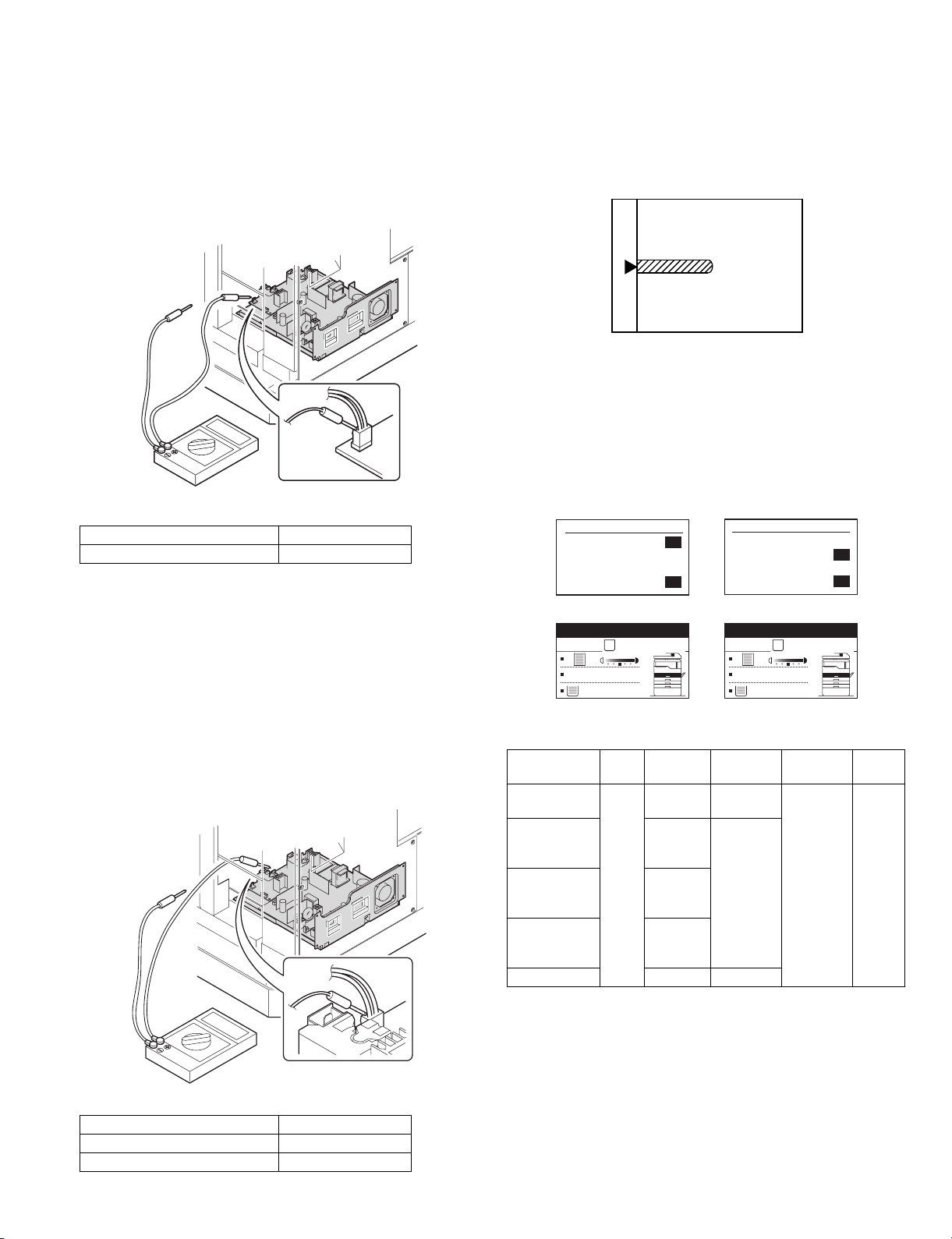

(3)Developing bias voltage check

Note: Use a digital multi-meter with an internal resistance of 10MΩ or

more.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the developing bias

voltage output check pin.

3) Turn on the power, execute SIM25-1.

<Specification>

Mode Specification

Developing bias volt age DC - 400±8V

(4) Grid bias voltage check

Note: Use a digital multi-meter with an internal resistance of 10MΩ or

more.

B. Mechanism section

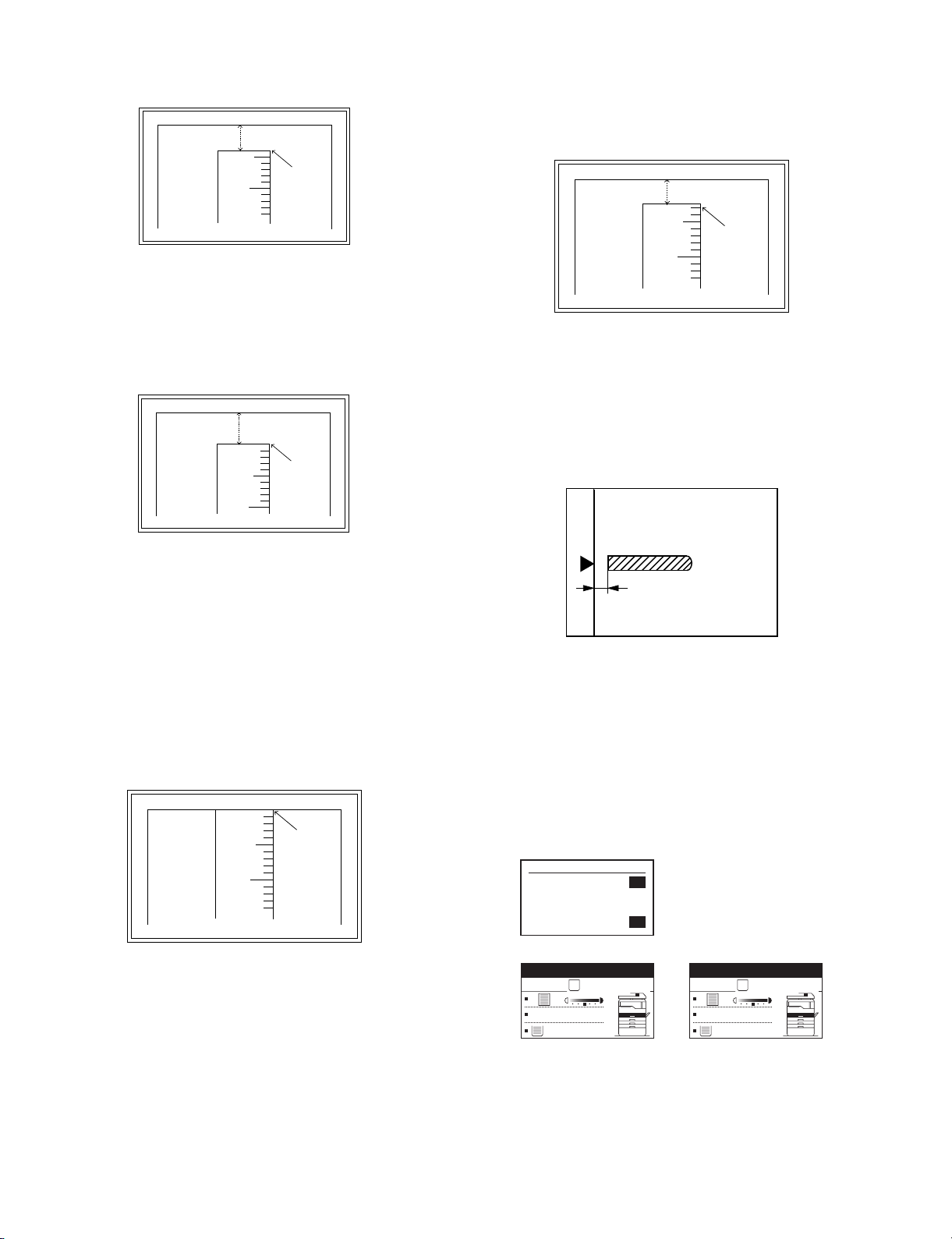

(1) Image position adjustment

a. OC image lead edge position adjustment (SIM 50-1)

Note: In advance to this adjustment, the sub scanning magnification ratio

adjustment must be performed.

1) Set a scale on the OC table as shown below.

2) Make a copy.

3) Check the copy output. If necessary, perform the following

adjustment procedures.

4) Execute SIM 50-01.

Select a desired mode with the arrow keys, enter the adjustment

value with 10-key, and press [OK] key.

When [START] key is pressed, a sheet is printed.

When [RETURN] key is pressed, the process returns to the mode

selection window.

(Mode selection window 1)

Sim50-1 LEAD EDGE

1:TRAY1

2:TRAY2

3:MFT

1/2 [ 1- 99]

(Copy start window)

Ready to copy.

S

50

50

50

50

(Mode selection window 2)

Sim50-1 LEAD EDGE

4:DEN-A

5:RRC-A

6:DEN-B

2/2 [ 1- 99]

(Copy execution window)

Copies in progress.

S

50

1

50

50

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the grid bias voltage

output check pin.

3) Turn on the power.

(The voltage is outputted in the grid bias High output mode during

warming up, and in the grid bias Low output mode when warming up

is completed.)

<Specification>

Mode Specification

Grid bias LOW DC - 380±8V

Grid bias HIGH DC - 525±10V

100%

8 1/2X11

100%

8 1/2X11

<Adjustment specification>

Adjustment

mode

OC image lead

edge position

Main cassette

SIM Display

text array

SIM

RRC-A R/0.1 Lead edge

50-1

TRAY1 H/0.1

Set

value

Spec

value

void:

1 - 4mm

Set

range

1 - 99

print start

position

2nd cassette

print start

TRAY2

Image loss:

3mm or

less

position

Multi bypass

MFT

tray print start

position

Lead edge void DEN-A B/0.05

5) Set the OC lead edge position set value (RRC-A) to [1]

The OC image scanning start position is shifted inside the document

edge.

6) Set the main cassette lead edge void adjustment value (DEN-A)* to [1]

The lead edge void becomes the minimum.

AR-M207 M165 M162 ADJUSTMENT 6-2

Page 30

7) Set the main cassette print st art position value (TRAY1) to [1] and

make a copy.

The print start position is shifted inside the document edge.

5mm

5

4mm

10

10) Set the lead edge void adjustment value (DEN-A)* again.

•1 step of the set value corresponds to about 0.1mm shift.

•Calculate the set value from the formula below.

B/0.05 (mm) = Lead edge void adjustment value

<B: Lead edge void (mm)>

2.5mm

*The dimension varies depending on the model.

8) Measure the image loss R of the copied image. Enter the set value of

the image scanning lead edge position (RRC-A) again.

•1 step of the set value corresponds to about 0.1mm shift.

•Calculate the set value from the formula below.

R/0.1(mm) = Image loss set value

<R: Image loss measurement value (mm)>

5mm

5

10

* The scanning edge is set.

(A line may be printed by scanning the document edge.)

0mm

Example: 4/0.1 = 40 = about 40

Note:If the set value is not obtained from the above formula, perform the

fine adjustment.

9) Measure the distance H between the paper lead edge and the image

print start position. Set the image print start position set value

(TRAY1) again.

•1 step of the set value corresponds to about 0.1mm shift.

•Calculate the set value from the formula below.

H/0.1(mm) = Image print start position set value

<H: Print start position measurement value (mm)>

0mm

5

10

0mm

5

10

2.5mm

Example: When setting the lead edge void to 2.5mm

:2.5 /0.05 = about 50

Note: If the s et value is not obtained from the above formula, perform the

fine adjustment.

b.SPF image lead edge position adjustment (SIM50-6)

1) Set a scale on the OC table as shown below.

Note:Since the printed copy is used as a test chart, put the scale in

parallel with the edge lines.

2) Make a copy, Then us e the copy output as an original to make an

SPF copy again.

3) Check the copy output. If necessary, perform the following

adjustment procedures.

4) Execute SIM 50-6.

5) Set the SPF lead edge p osition set value (SIDE1) so that the same

image is obtained as that obtained in the previous OC image lead

edge position adjustment.

(Mode selection window)

Sim50-6 SPF EDGE

1:SIDE1

2:SIDE2

3:END EDGE

[ 1- 99]

50

50

50

50

*Fit the print edge with the paper edge, and perform the

lead edge adjustment.

Example: 5/0.1 = 50 = about 50

Note:If the set value is not obtained from the above formula, perform the

fine adjustment.

AR-M207 M165 M162 ADJUSTMENT 6-3

(Copy start window)

Ready to copy.

S

100%

8 1/2X11

(Copy execution window)

Copies in progress.

S

100%

8 1/2X1

Page 31

<Adjustment specification>

Adjustment mode SIM Display