Page 1

CODE : 00Z

q

SERVICE MANUAL

CONTENTS

Parts mark ed w ith "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been pub lished to be used

for after sales service only.

The contents are subject to change without notice.

ARD29//A1E

LASER PRINTER OPTIONS

PAPER FEED UNIT

MODEL

AR-D29

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[2] CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[3] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[4] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . 5 - 1

[6] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE . . . . . . . . . 7 - 1

[8] BLOCK DIAGRAM, WIRING DIAGRAM,

CIRCUIT DIAGRAM, PARTS ARRANGEMENT. . . . . . . . . . . . . 8 - 1

PARTS GUIDE

Page 2

AR-D29 PRODUCT OUTLINE

1 – 1

[1] PRODUCT OUTLINE

This unit is installed to one of the following machines to serve as a Paper feed module.

When installing one of the following machines, the stand with multi-purpose tray (AR-D29) must be installed in advance.

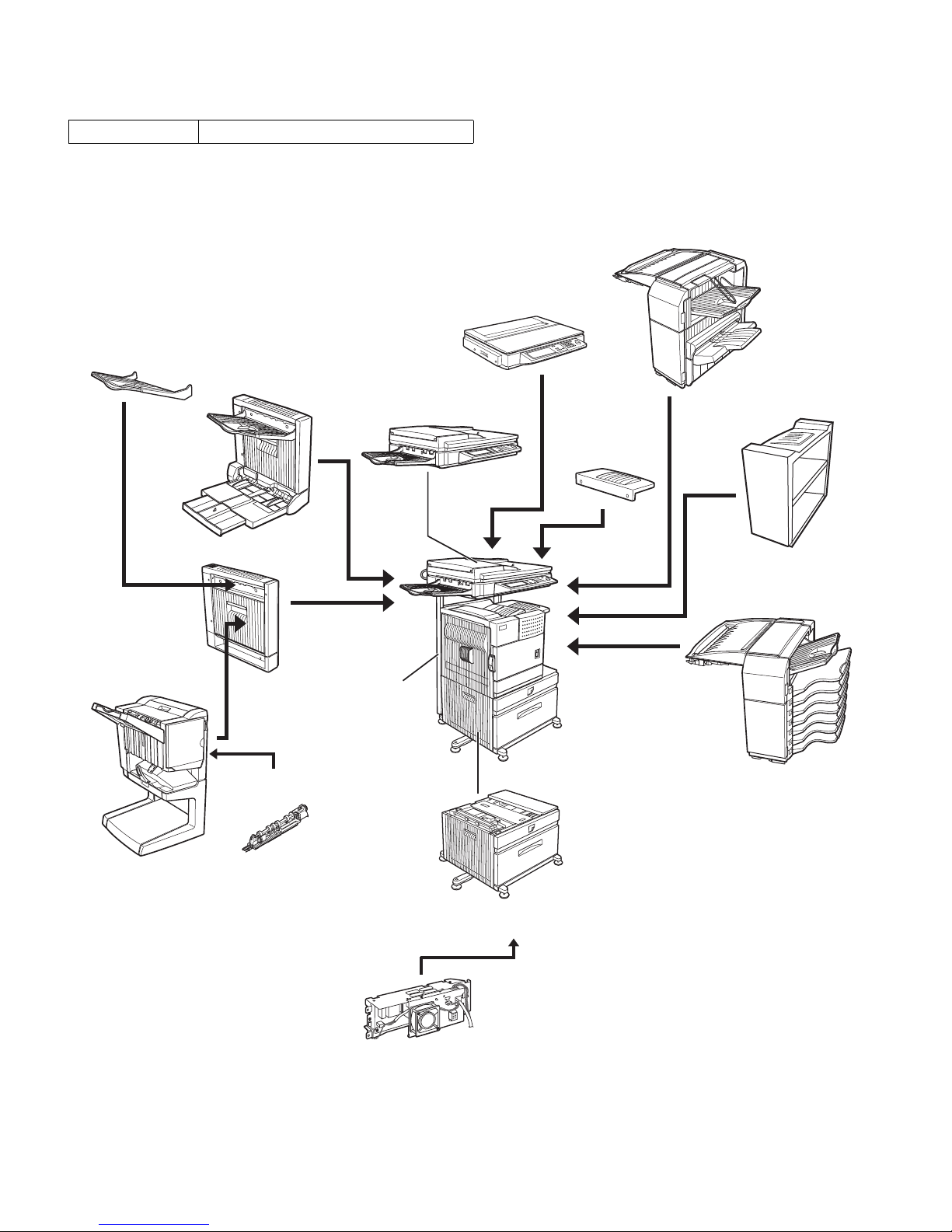

[2] CONFIGURATION

For combinations of options, refer to "C. List of com bination of peripheral devices" described later.

Applicable models AR-M312U/AR-M420U

Upper exit tray

(AR-TE4)

Finisher

(AR-FN6)

Mail-bin stacker

(AR-MS1)

Stand with multipurpose drawer

(AR-D29)

Scanner rack

(AR-RK2)

Saddle stitch

finisher

(AR-FN7)

Duplex module

(AR-DU3)

Duplex module/

bypass tray

(AR-DU4)

Exit tray

(AR-TE3)

Right upper exit tray

(AR-TE5)

Scanner module with DSPF

(AR-EF6)

Scanner module with OC

(AR-EF5)

Punch unit

(AR-PN1A/B/C/D)

Power supply unit

(AR-DC1)

Page 3

AR-D29 SPECIFICATIONS

3 – 1

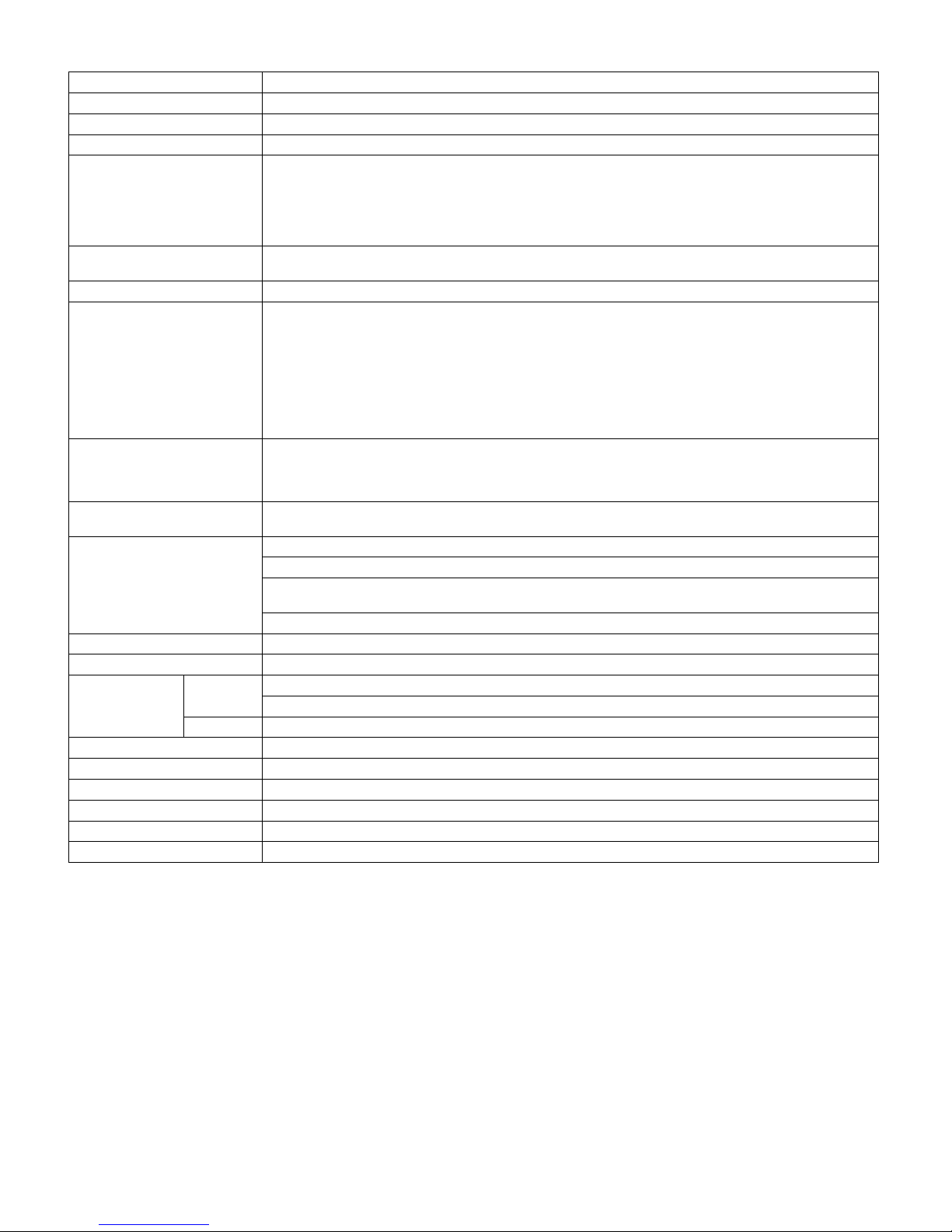

[3] SPECIFICATIONS

Model name AR-D29

Type Stand with multi-purpose drawer

Transport speed To support 31-42 sheet/minute

Transport alignment Center alignment

Paper size A3, B4, A4, A4R, B5, B5R, A5R

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5"R

Executive, Japanese p/c, Monarch ( envelop e)

Com-10 (envelope), DL (envelope),

C5 (envelope), ISO B5 (envelope)

How to change

the paper size

Guide adjustment by user/

Software setting by user

Factory default paper size setting A3

Media available for paper feeding Plain paper : 60-128g/m² / 16-34lbs

Index paper : 176g/m² / 47lbs

Cover paper: 200-205g/m² / 54-55lbs

Envelope : 75-90g/m², 20-24lbs

Transparency film

*

Media heavier than 105g/m² should be A4/8.5 x 11" or smaller. Media heavier than 128g/m² should be fed

from shorter edge.

*

Only single paper feed is enabled for overlay copy or copy on back-side of printed paper.

Paper capacity Standard: 500sheets (80g/m²)

Post card: 40sheets

Envelope: 40sheets

Transparency film: 40sheets

Paper type Plain, recycled, pre-pri nted, pre-pun ched , color, l ett er head, labels, he avy, tr anspa rency, Jap anese p/ c, envel ope

(User can set bi-type for each of the above paper type.)

Sizes to be detected Auto detection-AB: A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R

Auto detection-Inch: 11" x 17", 8.5" x 14", 8.5" x 11", 8.5" x 11"R, 7.25" x 10.5"R, 5.5" x 8.5R

Manual (input detection):

postal card, Monarch (envelope), Com-10 (envelope), DL (envelope), C5 (envelope), ISO B5 (envelope)

Ignore detection selectable:

Paper balance detection Provided (paper empty and 3 steps)

Paper loading system To be loaded from the upper side with front loading system

Tray ascent/

descent time

Ascent Within 7 seconds

At paper empty, required time from tray insert to the empty detection

Descent Own weight descent

Dehumidification heater Not provided

Power consumption 24.5W or lower

Power source Supplied from main unit (DC24V 1A / DC5V 0.1A)

External dimensions 589 x 630 x 404 (mm)

Occupied dimensions 963 x 665 (mm)

Weight Approx. 25.2kg

Page 4

AR-D29 UNPACKING AND INSTALLATION

4 – 1

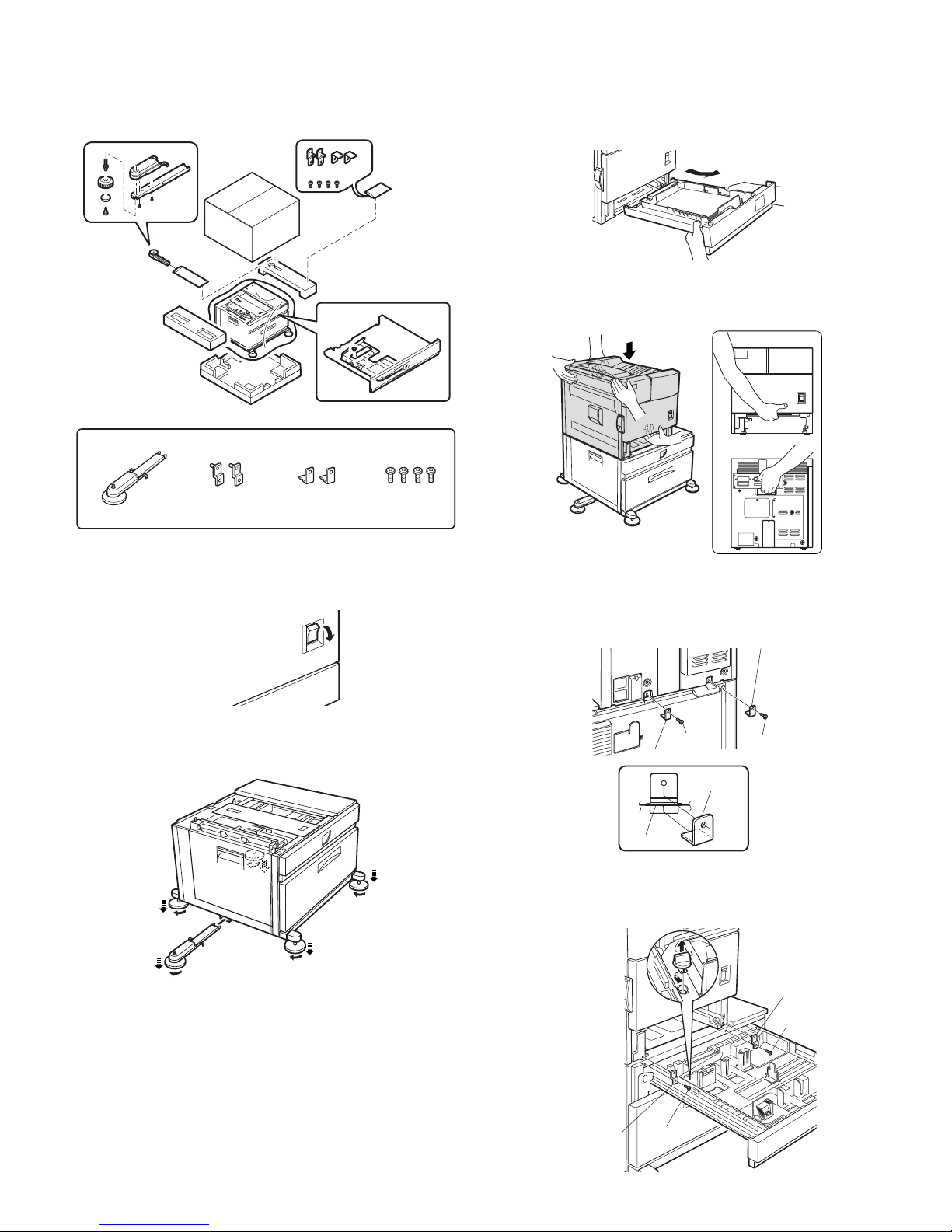

[4] UNPACKING AND INSTALLATION

<BEFORE INSTALLATION>

• Start installation after checking that the DATA and COMMUNICATION indicators on the operation panel are neither lit nor blinking.

1) Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the printer to the

"OFF" position.

Then remove the power plug from the outlet.

2) Attach the adjusters and adjust them.

<1>Insert the left adjusters to the stand/paper drawer.

<2>Turn the each adjusters to lower them until they touch the floor.

*

Be sure to attach the left adjuster to prevent overturning.

Caution: The lower tray cannot be pulled out unless the adjuster is low-

ered to the specified position.

3) Put the main unit of the printer on the stand/paper drawer.

<1>Pull out the paper tray of the main unit until it stops and then

remove it by lifting both ends of the tray.

<2>Hold the main unit of the printer at the positions shown in the illus-

tration and put the main unit on the stand/paper drawer so that the

front side and the left side of the main un it are aligned to those of

the stand/paper drawer.

Caution: For installation of the main unit, it must be held by two persons

and installed without haste.

4) Connect the main unit to the stand/paper drawer.

<1>Attach the rear mounting plates using a supplied screw for each.

Caution: Insert the rear mounting plates under the desk frame.

<2>Pull out the upper paper tray of the stand/paper drawer until it stops

and attach the front mounting pla tes usin g a supp lied scre w for each .

Then, remove the lock of the paper tray and cl ose the tray .

<Parts included>

Left adjuster: 1 pc.

Front mounting

plates: 2 pcs.

Rear mounting

plates: 2 pcs.

Screws (M4x6):

4 pcs.

"OFF"

1

2

2

2

2

Frontside

Rearside

Rear mounting plate

Rear mounting plate

Screw

Screw

Desk frame

Rear

mounting plate

Screw

Screw

Front

mounting plate

Front mounting

plate

Page 5

AR-D29 UNPACKING AND INSTALLATION

4 – 2

<3>Reattach the paper tray of the main unit.

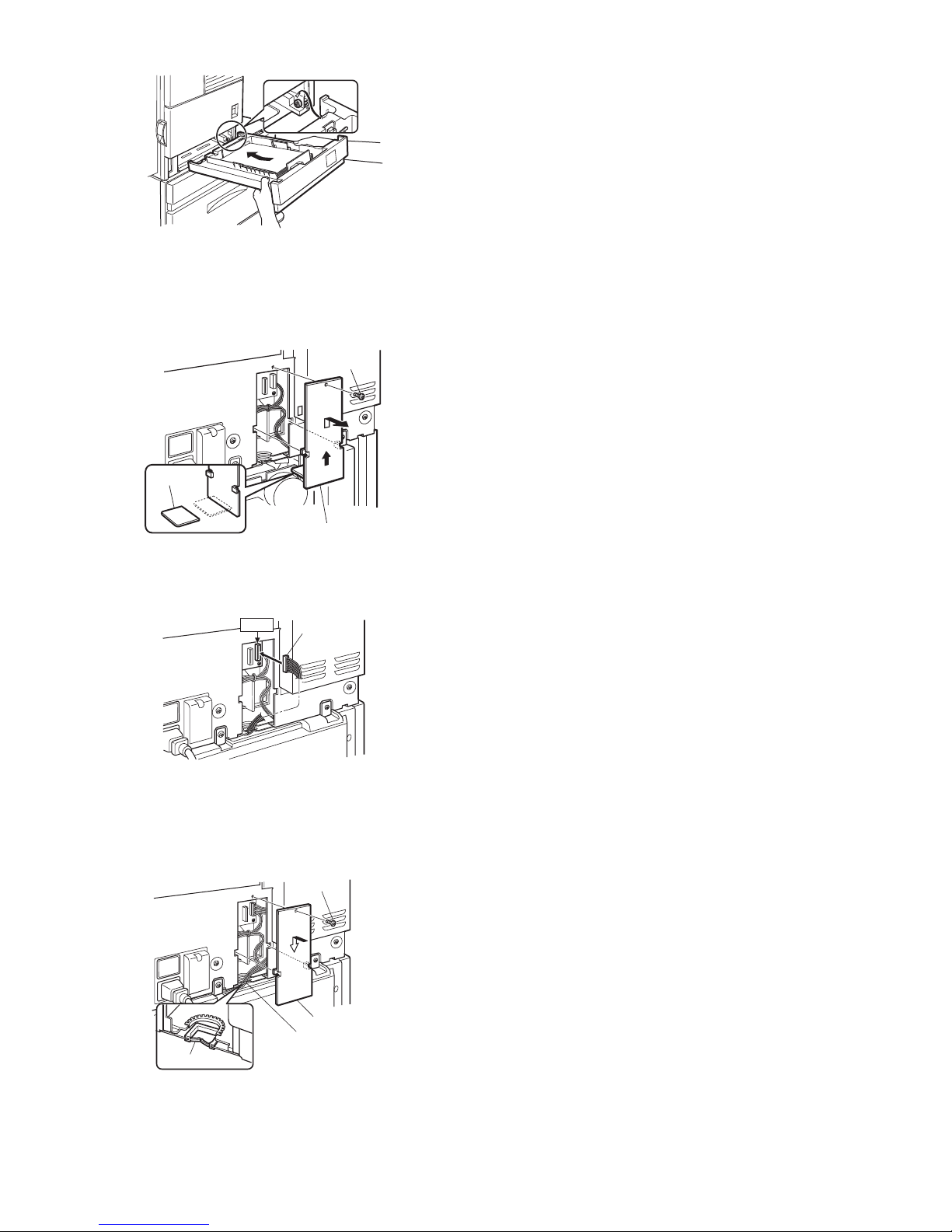

5) Connect the power supply I/F harness to the PCU PWB of the

main unit of the printer.

<1>Remove the screw that fixes the harness co ver of the main unit of

the printer and slide the harness cover up to remove it.

Process the harness cover as shown in the illustration.

<2>Connect the connector of the relay harness of the multi purpose

drawer to the connector of the PCU PWB of the main unit of the printer.

<3>Reattach the power supply I/F harness cover to its original position

and fix it with the removed screw.

At this time, ensure that the power supply I/F harness are arranged

as shown in the illustration.

• Fix the harness securely to the wire saddle.

6) Attach the paper guides to the lower tray (large capacity tray) and

set the size.

Refer to "Setting and adjustment" described later.

*

If another peripheral device must be installed, carry out the following

step at the end of the installation work.

7) Adjust the position of the paper guides of the upper paper tray of

the stand/paper drawer.

Refer to "Setting and adjustment" described later.

8) Carry out the off center adjustment.

Harness cove

r

Cut out.

Screw

CN10

Connector

Wire saddle

Harness cove

r

Screw

Wire saddle

Page 6

AR-D29 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 1

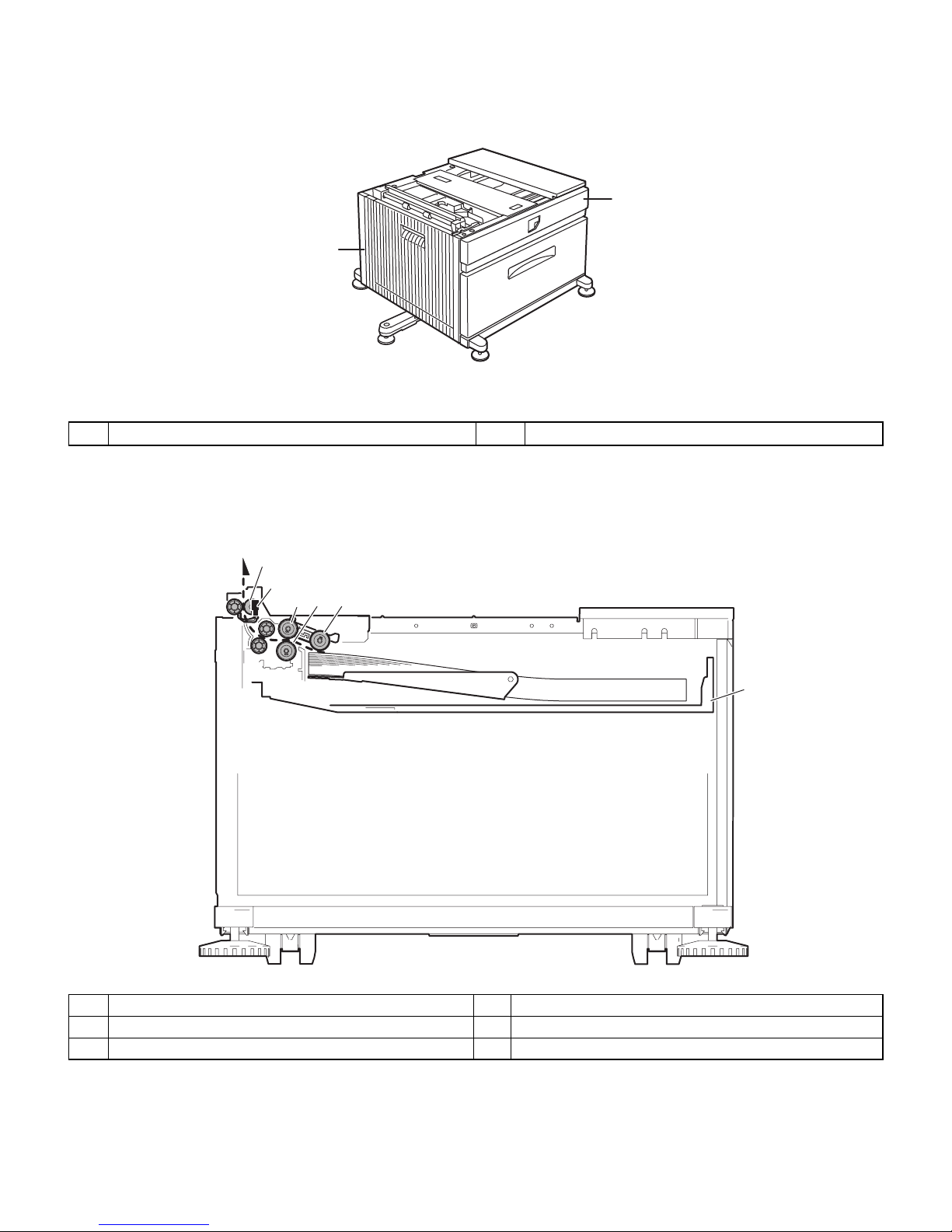

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES

A. EXTERNAL VIEW

B. INTERNAL STRUCTURE

1

2

1 Multi-purpose tray (No. 2 tray) 2 Desk left door

2

1. MCPPD

5

34

6

1 Multi-purpose tray paper transport sensor (MCPPD) 4 Multi-purpose tray separation roller

2 Multi-purpose tray paper transport roller 5 Multi-purpose tray paper take-up roller

3 Multi-purpose tray paper feed roller 6 Multi-purpose tray

Page 7

AR-D29 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 2

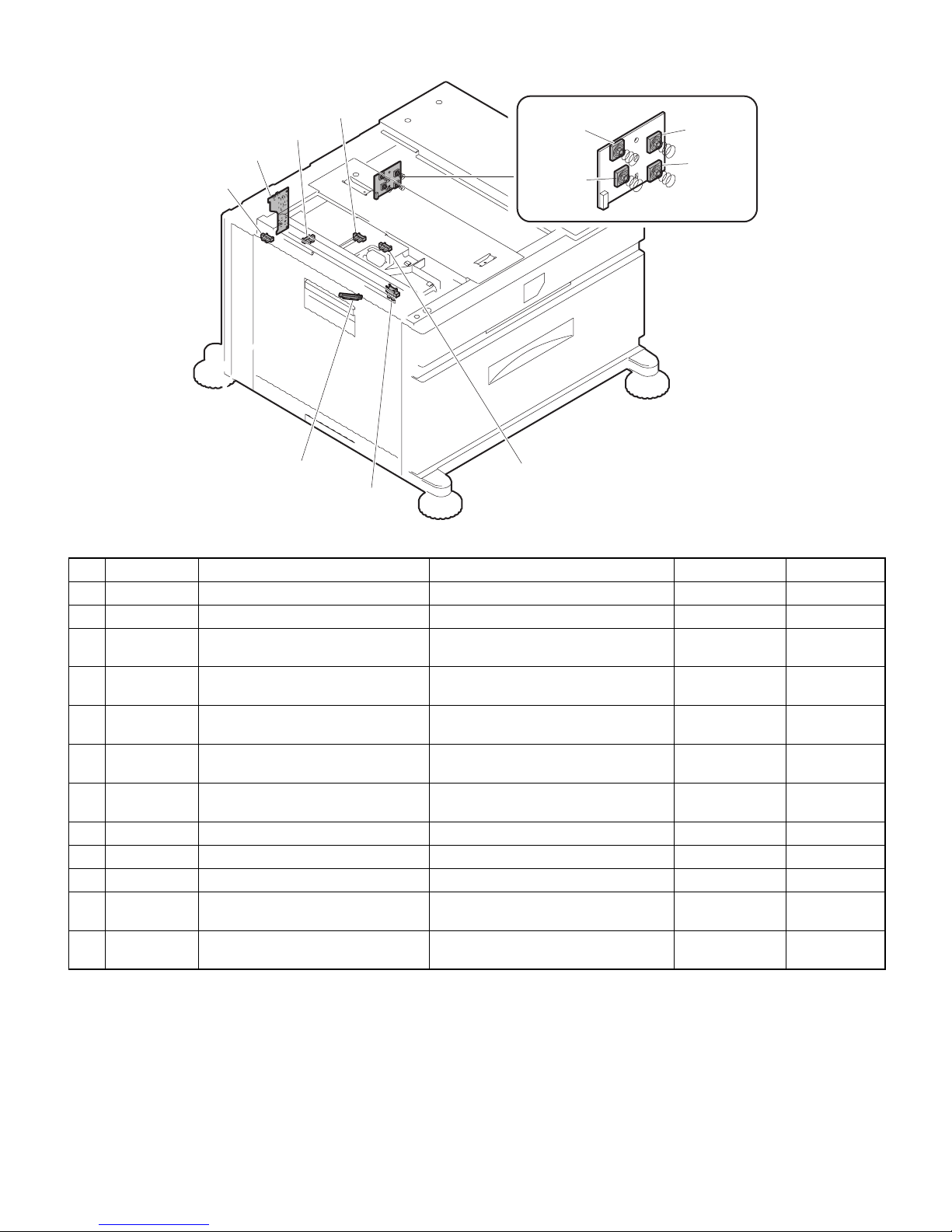

C. PWB, SENSOR

1.MCDRS

10.MCPWS

3.MCLUD

8.MCPED

2.MCSPD

12.MPTPWB

4.MCSS1

11.

5.MCSS2

7.MCSS4

6.MCSS3

9.MCPPD

No. Code Name Function Active condition Remark

1 MCDRS Side door open/close sensor Side door open/close detection H :Door closed

2 MCSPD MP tray remaining paper quantity sensor MP tray remaining paper quantity detection

3 MCLUD MP tray upper limit sensor MP tray upper limit detection H : Upper limit

detected

4 MCSS1 MP tray rear edge sensor 1 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

5 MCSS2 MP tray rear edge sensor 2 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

6 MCSS3 MP tray rear edge sensor 3 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

7 MCSS4 MP tray rear edge sensor 4 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

8 MCPED MP tray paper empty sensor MP tray paper empty detection L : Paper loaded

9 MCPPD MP transport sensor Detection of paper on the path L : Paper detected

10 MCPW S MP tray width sensor MP tray paper width detection Slide volume

11 MP tray rear

edge size PWB

MP tray rear edge size PWB Multi-purpose tray rear edge size detection

12 M PTPWB MPT PWB

Distributed the power supply from the main

unit.

Page 8

AR-D29 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 3

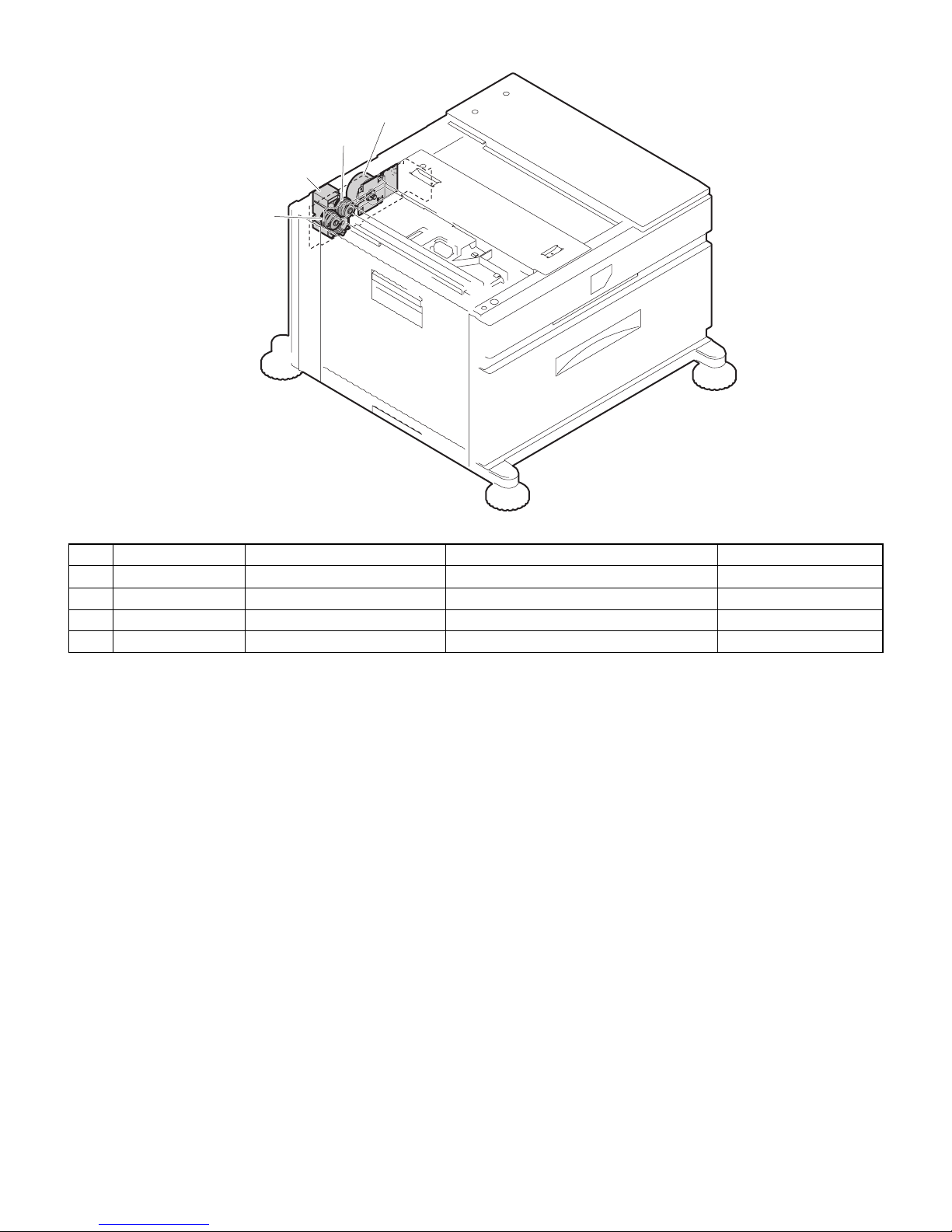

D. MOTOR, CLUTCH

2.MCLUM

3.MCPCL

4.MCM

1.MCFCL

No. Code Name Function Remark

1 MCFCL Multi-purpose transport clutch Clutch for transport from LCC desk

2 MCLUM Multi-purpose tray lift-up motor Multi-purpose tray lift-up

3 MCPCL Mult i-purpose paper feed clutch Clutch for paper feed from Multi-purpose tray

4 MCM Multi-purpose transport motor LCC desk paper transport

Page 9

AR-D29 ADJUSTMENTS

6 – 1

[6] ADJUSTMENTS

1. CHANGING THE PAPER SIZE

[Upper tray]

• A3 to A5R (11 x 7 to 5-1/2 x 8-1/2R) size plain paper can be set.

• Special paper can be set.

• Two maximum height lines are indicated: one for plain paper and one

for special paper.

Use the following procedure to change the size as needed.

1) Pull out paper tray.

If paper remains in the tray, remove it.

2) Adjust the guide plates A and B in the tray to the length and width of

the paper.

The guide plates A and B are slidable. Adjust them to the paper size

to be loaded while squeezing their lock levers.

3) Load paper into the tray.

Do not exceed red line when loading special paper to upper tray.

4) Gently push tray into the machine.

Push the tray firmly all the way into the machine.

5) Set the paper size.

Be sure to set the paper size and paper type referr ing to "2.Setting

the paper type and paper size".

If this is not done, paper misfeeds will occur.

2. SETTING THE PAPER TYPE AND

PAPER SIZE

Follow these steps to change the paper type setting if the paper type is

changed in either paper tray. For the paper types that ca n be used in

each tray.

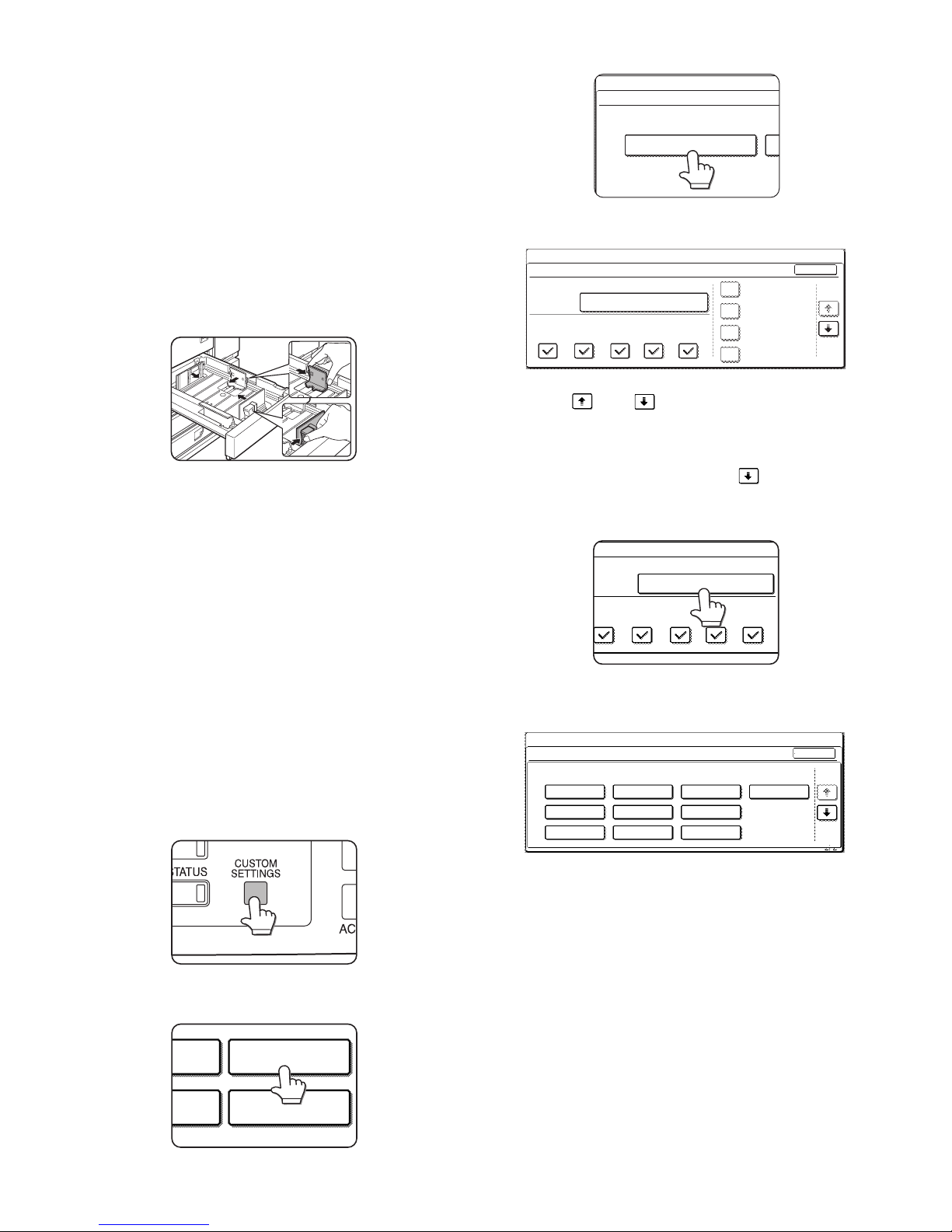

1) Press the [CUSTOM SETT INGS] key.

The custom setting menu screen will appear.

2) Touch the [PAPER TRAY SETTINGS] key.

The paper tray selection screen will appear.

3) Touch the [TRAY SETTINGS] key.

4) Display the setting screen of the desired paper tray.

Touch the key or key to display the setting screen of the

desired paper tray.

Note: To automatically switch to a tray with the same size and type of

paper (if there is one) in the event that the paper tray runs out of

paper, display the last screen with the key and select [AUTO

TRAY SWITCHING].

5) Touch the [TYPE/SIZE] key.

6) Select the type of paper that was loaded in the tray.

Example: The paper type of tray 2 is selected

Touch the desired paper type to select it.

The paper size setting screen will appear.

PAPER TRAY

SETTINGS

TA

PRINTER

CONDITION

TRAY SETTINGS

PAPER TRAY SETTINGS

CUSTOM SETTINGS

1/4

PLAIN / A4

OK

PRINT

PAPER TRAY SETTINGS

TYPE / SIZE

CUSTOM SETTINGS

TRAY 1

FAX

I-FAX

COPY

DOC.

FILING

FIXED PAPER SIDE

DISABLE DUPLEX

DISABLE STAPLE

DISABLE PUNCH

TYPE / SIZE

TRAY 2

PER TRAY SETTINGS

PRINT

COPY

I-FAX

DOC.

FILING

FAX

PLAIN / A4

CANCEL

1/2

PLAIN

RECYCLED

PRE-PRINTED PRE-PUNCHED

LETTER HEAD

COLOUR

HEAVY PAPER

ENVELOPE

LABELS

TRANSPARENCY

TRAY 2 TYPE/SIZE SETTING

SELECT THE PAPER TYPE.

CUSTOM SETTINGS

1/2

Page 10

AR-D29 DISASSEMBLY AND ASSEMBLY, MAINTENANCE

7 – 1

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE

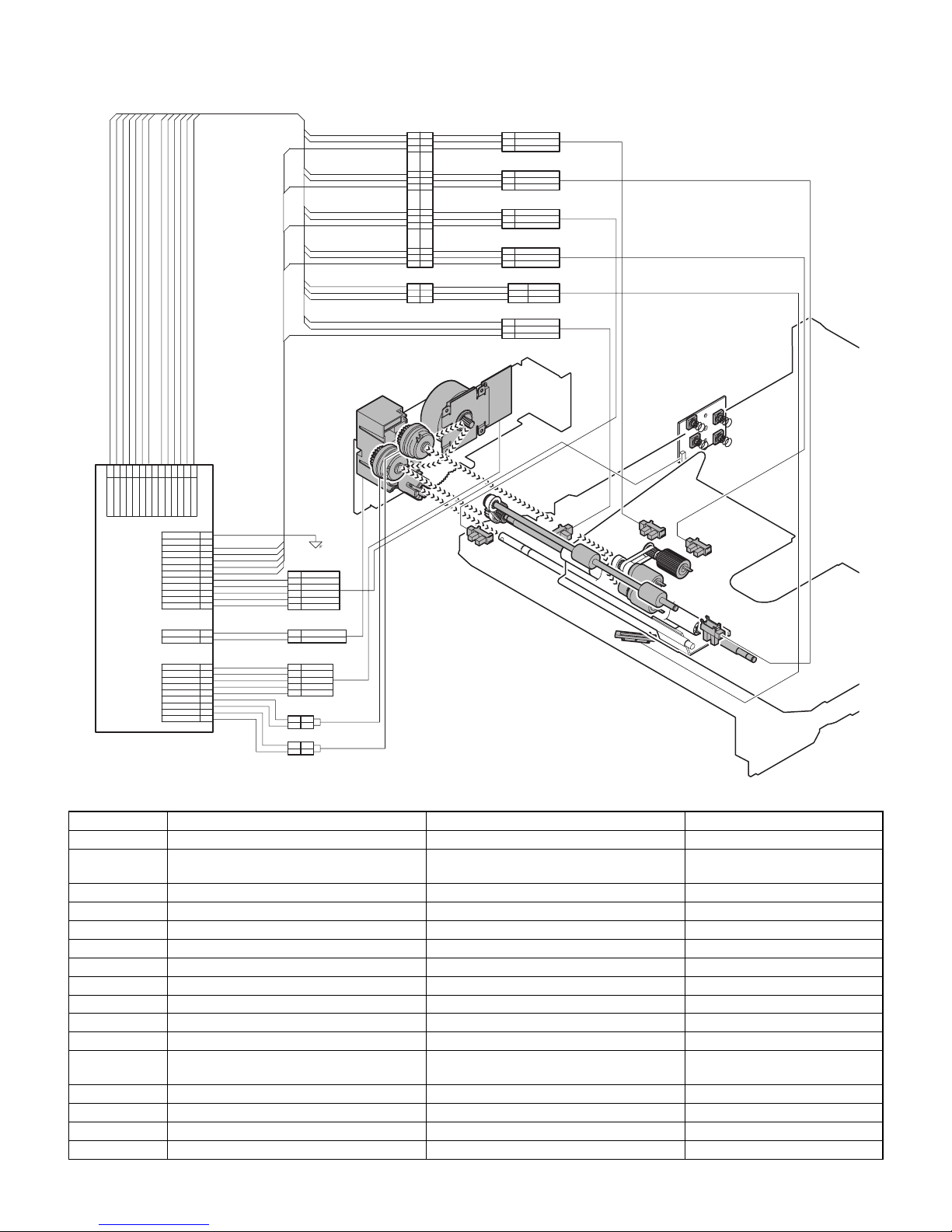

A. MAJOR PARTS AND SIGNAL FUNCTIONS

Code Name Function R e mark

MCDRS MP door open / close sensor MP left door open / close detection

Control PWB Control PWB Communication with the machine,

machine operation control

MCSPD MP tray remaining paper quantity sensor MP tray remaining paper quantity detection

MCLUD MP tray upper limit sensor MP tray upper limit detection

MDSS1 MP tray rear edge sensor 1 MP tray rear edge size detection In MP tray rear edge size PWB

MCSS2 MP tray rear edge sensor 2 MP tray rear edge size detection In MP tray rear edge size PWB

MCSS3 MP tray rear edge sensor 3 MP tray rear edge size detection In MP tray rear edge size PWB

MCSS4 MP tray rear edge sensor 4 MP tray rear edge size detection In MP tray rear edge size PWB

MCPED MP tray paper empty sens or MP tray paper empty detection

MCPPD MP transport sensor Detection of paper on the path

MCPWS MP tray width sensor MP tray paper width detection Slide volume

MP tray rear

edge size PWB

MP tray rear edge size PWB MP tray rear edge size detection

MCFCL Multi-purpose tray transport clutch Multi-purpose tray transport clutch

MCLUM Multi-purpose tray lift-up motor Multi-purpose tray lift-up

MCPCL Multi-purpose paper feed clutch Clutch for paper feed from Multi-purpose tray

MCM Multi-purpose tray transport motor Multi-purpose tray paper transport

MCM

MCM

MCM

MCDRS

MCSPD

MCSPD

MCSPD

MCLUD

MCPED

MCSS2

MCSS4

MCSS1

MCSS3

MCSS3

MCSS3

MCPPD

MCPWS

MCPWS

MCPWS

MCLUM

MCLUM

MCLUM

MCFCL

MCFCL

MCFCL

MCPCL

MCPCL

MCPCL

MPT LD PWB

MPT PWB

12

4

71151036192

8

+5V

MCPWS

+5V

MCPPD

+5V

CN-E

+5V

VAREF

MCPED

N.C.

MCPWS2

MCLUD

14

13

+5V

MCDRS

MCSPD

PHDR-14VS-1

3

1

2

5

MCSS2

8

MCSS1

6

4

7

9

10

GND2

GND2

GND2

CN-F

MCSS3

MCSS41112

GND2

GND2

GND2

GND2

GND2

PHDR-12VS-1

24V

1

MCLUM/

2

PHR-2

MCPCL/

+24V

MCFCL/

+24V

3

1

MCM/

GND1

+24V

MCM-T

2

5

4

MCMCLK/

6

7

8

9

PHR-9

11

22

11

22

SMR-02V-B

SMR-02V-NSMP-02V-NC

SMP-02V-BC

SRA-21T-4

MCLUM/

24V

MCSS2

MCSS3

MCSS4

N.C.

MCSS1

GND2

PHR-6

PHR-2

5

2

6

4

3

1

MCMCLK/

MCM/

4

GND1

3

1

MCM-T

5

+24V

2

PHR-5

13

14

17

18

15

16

18

15

13

16

17

14

SMP-03V-BC SMR-03V-B

GND2

1

MCLUD

MCPPD

2

2

+5V

3

+5V

3

GND2

1

1

2

3 GND2

MCSPD

+5V

2

1

CN-D

CN-A

8

4

5

8

696

9

7

5

4

7

SMR-18V-BSMP-18V-BC

3

212

3

1

GND23

GND23

MCPED

+5V

1

MCDRS

1

2

+5V

2

3T

MCPWS2

MCPWS

VAREF

2T

1T

Page 11

AR-D29 DISASSEMBLY AND ASSEMBLY, MAINTENANCE

7 – 2

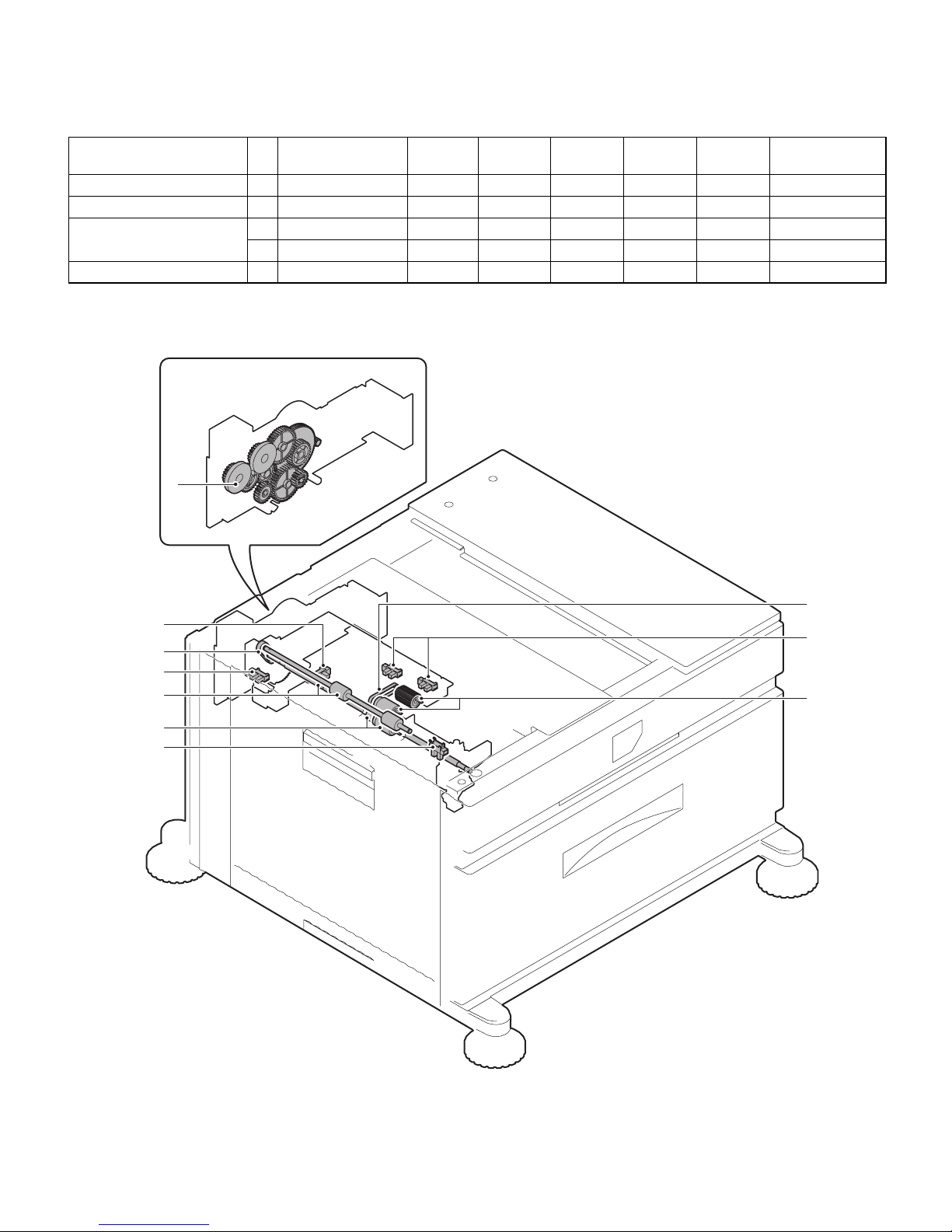

B. MAINTENANCE LIST

(1) MAINTENANCE LIST

*

1:Replacement reference: Use the counter value of each paper feed port as the replacement reference.

Paper feed section pickup roller, paper feed roller: 100K or 1 year

u

Check (Clean, replace, or adjust as necessary.)

F

Clean

b

Replace

v

Adjust , Lubricate

k

Move position

Unit name

No.

Part name

When

calling

100K 200K 300K 400K Remark

Paper feed separation section 1 Paper feed rollers

uuuuu*

1

Transport section 2 Transport rollers

u

FFFF

Drive section 3 Gears

u

,,,,(Specified position)

4Belts

uuuuu

Other 5 Sensors

uuuuu

4

5

5

1

3

5

1

5

2

4

Page 12

AR-D29 DISASSEMBLY AND ASSEMBLY, MAINTENANCE

7 – 3

(2) MAINTENANCE AND PARTS REPLACEMENT

(List of Replacement Parts)

a. Paper feed unit

1) Pull out the multi-purpose tray.

First, pull out the right side of the tray, and then pull out the left side.

2) Remove the left door.

3) Remove the multi-purpose paper feed unit.

a-1. Pick up roller

a-2. Paper feed roller

a-3. Separate roller

a-4. Torque limiter

1) Pull out the multi-purpose tray.

2) Remove the paper guide.

No. Unit Parts

a Paper feed unit 1 Pick up roller

b

2 Paper feed roller

b

3 Separate roller

b

4 Torque limiter

u

5Belts

u

6 Upper limit sensor

u

7 Paper empty sensor

u

8 Paper transport sensor

u

9 Side door open/close sensor

u

10 Transfer rollers

u

b Multi-purpose

drive unit

1 Gears

u

,

c Other 1 Rear edge size PWB

2 Remaining paper quantity sensor

u

a-1

a-8

c-1

a-2

a-7

a-6

a-10

a-9

a-4

a-5

c-2

a

a-10

a-5

a-3

b-1

b

1)

2)

2)

1)

6)

4)

5)

4)

1)

2)

3)

1)

Page 13

AR-D29 DISASSEMBLY AND ASSEMBLY, MAINTENANCE

7 – 4

3) Disengage the roller hook, and remove the roller.

*

When installing the roller, check to ensure that the hook is securely

engaged in the groove.

4) After removing the roller, remove the torque limiter.

*

When installing the torque limiter, check to ensure that the pin is

fully inserted into the torque limiter groove.

a-5. Belts

1) Remove the paper feed unit.

2) Remove the pickup roller and paper feed roller.

a-6. Upper limit sensor

a-7. Paper empty sensor

a-8. Paper transport sensor

a-9. Side door open/close sensor

1) Remove the paper feed unit.

a-10. Transfer rollers

1) Remove the paper feed unit.

a

1)

b

a

a

a

1)

1)

1)

1)

2)

3)

4)

3)

3)

4)

4)

a

a

b

b

a

b

Page 14

AR-D29 DISASSEMBLY AND ASSEMBLY, MAINTENANCE

7 – 5

b. Multi-purpose drive unit

1) Remove the rear cabinet.

2) Remove the multi-purpose tray drive section.

b-1. Gears

1) Remove the multi-purpose tray drive section.

c-1. Rear edge size PWB

c-2. Remaining paper quantity sensor

1) Remove the rear cabinet.

2) Remove the control PWB and the sensors.

2)

1)

1)

3)

2)

2)

1)

2)

1)

1)

a

a

2)

2)

1)

1)

Page 15

AR-D29 BLOCK DIAGRAM, WIRING DIAGRAM,CIRCUIT DIAGRAM, PARTS ARRANGEMENT

8 – 1

[8] BLOCK DIAGRAM, WIRING DIAGRAM,CIRCUIT DIAGRAM, PARTS ARRANGEMENT

A. BLOCK DIAGRAM

A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A

1/1

MCDRS

VD/S-GND

P

R

I

NTER

MAL

TI

CS UNI T

+5V1(VD)

GND2(

P

-GND)

M

C

F

C

L/

M

C

LU

M/

M

C

PCL

/

Multi PWB

+

2

4V2(

V

B

)

VA

R

EF

M

CPP

D

MC

D

R

S

MCPED

MC

L

UD

M

CP

WS

M

CP

WS

MCDR

S

M

CPPD

VD/S-GND

VD/S-GND

M

CLUD

D

C

P

R

/

MCSPD

MCS

E

T

MC

S

S

1

M

C

S

S2

M

CSS3MCSS

4

GND1

(

S-

G

ND

)

MC

M

-T

MCMCL

K

/

M

C

M/

M

CPPD

MCLUD

MCSP

D

VD/S-GND

VD/S-GND

MCP

E

D

M

CSPDMC

PE

D

S-GND

MCSS

1

M

CSS1

S-GND

MCSS2

M

C

S

S2

S-GND

MCS

S

3

MCS

S

3

M

CSS

4

MC

SS

4

S-GND

M

C

PW

S

VAREF

M

C

F

C

L

/

DCPR

/

VB

M

CM

C

L

K

/

MC

FCL/

M

CP

C

L

/

MCM

MCM

-T

VB

M

CLU

M

/

M

CM

/

M

CPCL

/

P-GND

VB/P-GND

MC

L

U

M

/

DH MPF

D

H

PWB

A

C

L

AC N

AC

N

A

C

L

M

CSET

M

C

S

E

T

S-GND

OPTIO

N

AL

Y

VB

DH-SW

Page 16

AR-D29 BLOCK DIAGRAM, WIRING DIAGRAM,CIRCUIT DIAGRAM, PARTS ARRANGEMENT

8 – 2

B. WIRING DIAGRAM

A

B

C

D

87654

3

21

12

3

456

7

8

D

C

B

A

A

B

C

D

87654

3

21

12

3

456

7

8

D

C

B

A

A

B

C

D

87654

3

21

12

3

456

7

8

D

C

B

A

A

B

C

D

87654

3

21

12

3

456

7

8

D

C

B

A

1/1

AC

L1

2N.C

15

12

9

6

3

17

14

11

8

5

2

16

13

10

7

4

1

181920

24

23

22

21

GND1

+5V

GND2

VAREF

MCPPD

MCDRS

MCPED

MCLUD

MCPWS

MCSS4

MCSS1

MCSS2

MCSS3

MCSPD

MCSET

MCPCL/

MCFCL/

MCLUM/

MCM-T

MCMCLK/

MCM/

e/?

DCPR/

12

MCSS4

4

17

MCPCL/

11

MP

T

P

W

B

3

MCMCLK/

GND1

1

5

7

MCPED

MCPCL/

16

11

MCSS3

5

10

MCSET4MCM-T

24

18

12

MCPCL

N.C

MCDRS

+24V

22

20

6

10

MCSS2

3

3

MCSPD

2

14

MCLUM/

VAREF

6

8

MCSS1

MCPPD

1

2

9

MCPWS

MCFCL/

13

DCPR/

2

7

MCFCL/

+5V

1

15

MCFCL

MCM/

GND2

23

19

9

8

MCLUD

+24V

21

2

1

MCLUM

LIFT MOTOR UNIT

3

DCPR/

+24V2

1

N.C

2

1

GND1

MCLUM

+24V

+24V

11221

122

5

MCSS2

8

MCSS1

647

9

10

+5V

MCPWS

+5V

MCPPD

+5V

GND2

MCLUM1GND1

2

MCMCLK/

MCM/

4

GND1

3

1

MCM

MCM-T

5

+24V

2

3

1

MCM/

GND1

+24V

MCM-T

254

MCMCLK/

6

789

+24V

DCPR/

+5V

VAREF

MCPED

N.C.

MCPWS2

GND2

GND2

MCLUD

14

13

+5V

MCDRS

MCSS3

MCSS4

11

12

GND1

GND2

GND2

GND2

GND2

MPT LD PWB

5

2

6

MCSS24MCSS33MCSS4

1

N.C.

MCSS1

GND2

8

4

GND2

13

5

MCDRS

3

8

1

2

GND2

1

14

3

MCLUD

3

MCPPD

17

GND2

MCSPD

2

18

6

MCSPD

MCPED

9

+5V

3T

+5V

1

6

MCPWS2

MCDRS

2

9

MCLUD

1

+5V

15

MCPWS

MCPPD

16

18

VAREF

3

7

5

2T

+5V

15

4

PAPER FEEDING UNIT

2

7

MPT VR UN

MCPED

3

13

1T

+5V

2

GND2

16

1

17

14

321

2

3

1

GND2

PHDR-24VS-1

MCSPD

PHDR-14VS-1

PHDR-12VS-1

PHR-2

SMR-18V-B

SMP-18V-BC

SMP-03V-BC SMR-03V-B

PHR-6

PHR-2

PHR-5

PHR-9

SMR-02V-B

SMR-02V-NSMP-02V-NC

SMP-02V-BC

PHR-3

SRA-21T-4

1

1

2

2

ELR-02VF

AC N 3

2

AC N

AC

L

1

3

N.C

PHR-3

B2P3-VH

B2P3-VH

C

N

-

B

C

N-C

C

N

-

A

N.C

3

D

H

P

W

B

ELP-02

DH

M

P

F

TIG

ER

MAIN UN

ELP-04NV

RES_FIN1

RXD_FIN2/

2

4

TXD_DSK

GND2

2

(N.C)

2

GND

19

14

ELR-02VF

B22B-PADRS

RES_DSK

1

3

GND

13

3

2

RXD_DSK

18

5

GND2

4

PADP-22V-1-R

2

RXD_FIN1/

+24V4

+5V2

TXD_FIN1

TXD_FIN2

15

8

D

C

P

S

RES_FIN2

10

3

TRC_DSK/

11

7

DTR_FIN2/

ELP-02V

1

16

DTR_FIN1/

4

DSR_FIN1/

1

1

2

5

DTR_DSK

17

9

6

1

4

DSR_FIN2/

12

ELR-04V

CN1

1

FGS_FIN/

3

1

GND

21

20

(N.C)

(N.C)

DSR_DSK

22

RXD-DSK/

6

9

RES-DSK

1

GND24DSR-DSK/

7

10

TRC-DSK

P-GND2TXD-DSK

5

8

DTR-DSK/

11

S-GND

3

VD(+5V)

+24V(VB)

C

N

1

0

B24B-PADES PADP-24V-1-E

FUS

E

P

W

B

DH-SW

C

N

-

B

C

N

-

C

C

N

-

F

CN-

E

C

N

-

D

C

N

-

A

POWERSUPPLY I/F UN

OPTION

(OPTION FOR JAPAN)

(OPTION FOR JAPAN)

Page 17

AR-D29 BLOCK DIAGRAM, WIRING DIAGRAM,CIRCUIT DIAGRAM, PARTS ARRANGEMENT

8 – 3

C. CIRCUIT DIAGRAM

A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A

1/1

MPT PWB

M

CND-2

VD

VB

VB

CNC-1

+5V1

CNC-2

VAREF

CNC-3

+24V2

CNC-4

GND1

CNC-5

GND2

CNC-6

MCPPD

CNC-7

MCDRS

CNC-8

MCPED

CNC-9

MCLUD

CNC-10

MCPWS

CNC-12

MCSS2

CNC-13

MCSS3

CNC-14

MCSS4

CNC-24

DCPR/

CNC-15

MCSPD

CNC-16

MCS

E

T

CNC-17

MCPCL/

CNC-18

MCFCL/

CNC-19

MCLUM/

CNC-20

MCM-T

CNC-21

MCMCLK/

CNC-22

MCM/

CNC-11

MCSS1

CND-9

MCPCL/

CND-7

MCFCL/

CNE-9

MCPWS

CNE-6

VAREF

CNE-13

MCLUD

CNE-12

MCPED

CNE-10

MCPPD

CNA-2

GND1

CND-3

MCM/

CND-4

MCM-T

CNF-1,3,4,5,6,7,8

GND2

CNE-14

MCSPD

CNB-2

DCPR/

CNF-12

MCSS4

CNF-11

MCSS3

CNF-10

MCSS2

CND-5

MCMCLK/

CNE-11

MCDRS

CNF-9

MCSS1

C004

223Z/50V

C003

47u/35V

+

C002

223Z/50V

C001

47u/35V

+

C005

47u/35V

+

C006

223Z/50V

CNE-1,2,3,4,5

+5V1

CND-1,6,8

CNB-1

+24V

2

JP001

GND

CNC-23

N.C

CNE-8

MCPWS2

CND-2

R002

2.4kJ1/2W

TR001

2SB1240

2.4kJ1/4W

R001

2.4kJ1/2W

R004

TR002

2SB1240

2.4kJ1/4W

R003

D001

DSM1D

CNF-2

D003

1SS133

D002

1SS133

ICP001

ICP-N20

JP002

(MCLUM)

CNA-1

MCLUM

Parts View

CN-A

CN-B

CN-D

CN-C

CN-E

CN-F

CN-A

CN-C

CN-D

CN-E

CN-F

CN-B

(JST:B2B-PH-K-S)

(JST:B3B-PH-K-S)

231

1

DCPR/

+24V2

N.C

MCLUM2GND1

(JST:B24B-PHDSS-B)

1

2

468

10

12

1416182022

24

3

579111315171921

23

+5V1

+24V2

GND2

MCDRS

MCLUD

MCSS1

MCSS3

MCSPD

MCPCL/

MCLUM/

MCMCLK/

N.C

VAREF

GND1

MCPPD

MCPED

MCPWS

MCSS2

MCSS4

MCSET

MCFCL/

MCM-T

MCM/

DCPR/

(JST:B9B-PH-K-S)

1

2

3

4

5

6

7

8

9

+24V2

GND1

MCM/

MCM-T

MCMCLK/

+24V2

MCFCL/

+24V2

MCPCL/

(JST:B14B-PHDSS-B)

1

3

579

11

13

2468101214

+5V1

+5V1

+5V1

+5V1

+5V1

VAREF

MCPWS2

MCPPD

MCPED

MCSPD

N.C

MCPWS

MCDRS

MCLUD

(JST:B12B-PHDSS-B)

13579

11

2

468

10

12

GND2

GND2

GND2

GND2 GND2

GND2

GND2

GND2

MCSS1

MCSS3

MCSS2

MCSS4

Page 18

AR-D29 BLOCK DIAGRAM, WIRING DIAGRAM,CIRCUIT DIAGRAM, PARTS ARRANGEMENT

8 – 4

D. PARTS ARRANGEMENT

■ CONTROL PWB

Page 19

q

PARTS GUIDE

CONTENTS

1

Exteriors

2

Left door

3

Frame 1

4

Frame 2

5

Tandem cassette

6

Multi paper feed

7

Multi drive

8

500 cassette[Multi purpose]

MODEL

AR-D29

9

Packing Material & Accessories

■

Index

Page 20

DEFINITION

The definition of each Rank is as follows and also noted in the list

Rank A : Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts

Rank B : Performance/function parts (sensors, clutches, and other electrical parts), consumable parts

Rank E : Unit parts including PWB

Rank D : Preparation parts (External fitting, packing, parts packed together)

Rank C : Parts other than the above (excluding sub components of PWB)

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

Exteriors

1

PRICE

NEW

NO. PARTS CODE

1 GCAB-0953FCN2 BM D Top side cabinet

2 XHBS740P10000 AA C Screw(4×10)

4 XHBS740P06000 AA C Screw(4×6)

5 GCAB-0955FCN2 BR D Desk right cabinet

6 PCOVP1796FCNZ AQ D Adjuster cover N

7 GCAB-0975FCN3 BD D Desk front lower cabinet

8 GCAB-0954FCN1 AY D Tandem left front cabinet

9 GCAB-0958FCN2 BA D Desk left lower cabinet

10 GCAB-0957FCN1 BA D Desk left rear cabinet

11 GCAB-0974FCN1 AY D Desk side rear cabinet

12 GCAB-0956FCN5 BU D Desk rear cabinet

13 PCOVP1586FCNZ AR D AC inlet cover

14 XEBS730P10000 AC C Screw(3×10)

RANK

MARK

PART

RANK

DESCRIPTION

Left door

2

PRICE

NEW

NO. PARTS CODE

1 GDOR-0033FCNZ BP D Desk left door

3 NSFTZ2635FCZZ AX C Desk left door lock shaft

4 PTME-0284FCZZ AE C Desk left door lock pawl

5 LX-BZ3006SC0M AA C Screw(3×6)

6 MLEVP0818FCN3 AN C Desk left door cancellation lever

10 XEBS740P12000 AA C Screw(4×12)

11 XWHSD40-08120 AA C Washer

12 MSPRC2916FCZZ AC C Desk left door lock spring

13 PGIDM1944FCZ1 BH D Desk left door PG

RANK

MARK

PART

RANK

DESCRIPTION

– 1 –

Page 21

1

Exteriors

2

14

12

2

11

2

2

10

2

2

2

9

13

2

11

2

2

8

2

2

7

1

4

2

5

2

2

6

2

2

Left door

1

2

10

13

6

10

12

2

2

10

11

5

4

3

5

6

5

FCP08831

10

10

10

11

10

4

10

FCP08832

– 2 –

Page 22

Frame 1

3

PRICE

NEW

NO. PARTS CODE

1 LPLTM5958FCZZ AD C U turn PG fulcrum plate 1

2 XHBS740P08000 AA C Screw(4×8)

4 JHNDM0179FCZZ AZ D Handle base plate

5 LRALM0190FCZ1 BG C Cassette rail R

6 PCLR-0441FCZZ AK C Roller(φ16)

7 LX-BZ0926FCZ1 AD C Screw

10 LSTYM0270FCZZ BG C Top side stay

11 XHBS740P06000 AA C Screw(4×6)

15 LRALM0191FCZ1 BL C Slide rail

18 LHLDZ1466FCZ1 AG C Desk left door fulcrum

19 XHBS740P08000 AA C Screw(4×8)

23 NSFTZ2852FCZ1 AH C Adjuster D

24 PAJS-0017FCZZ AG C Adjuster wheel(φ50)

25 LX-BZ0769FCZZ AC C Step screw H

26 GLEGG0075FCZZ AE C Rubber foot

27 GLEGP0076FCZ1 AS D Caster

28 LBRC-0065FCZZ AN C Left adjuster fixing bracket

29 PCOVP1588FCN1 AX D Left adjuster cover

30 CSTYM0287FC01 BN C Left adjuster stay Assy

31 XEBS740P12000 AA C Screw(4×12)

32 LRALM0189FCZ2 BG C Cassette rail L

33 MSPRT2893FCZZ AD C Width detect spring

34 LDAIU0631FCZZ AX D Width detect fixing base

35 PCASZ0293FCZ2 AZ D Width detect case bottom

37 MARMP0267FCZ1 AF C Width detect arm

38 XEBS720P06000 AC C Screw(2×6)

39 DHAI-3267FCPZ AG C MPT width detect slide resistance harness

46 LSTYM0271FCZZ AD C Paper feed support plate F

47 LX-BZ0930FCZZ AC C Screw(4×6)

48 PCOVP1819FCNZ AM C Handle cover

49 LX-BZ0728FCZ1 AC C Screw(3×8)

50 LX-BZ0957FCZZ AC C Screw(4×18)

51 XWHSD40-08100 AA C Washer

52 XBBS740P08000 AA C Screw(4×8)

53 LPLTM6474FCZZ AV C Handle support plate

54 PCOVP1890FCZZ BT N C Left tarnster cover

55 LSTPP0355FCZZ AD C Desk left door stopper

56 LPLTM5830FCZZ AP C Vertical transfer fixing plate R

RANK

MARK

PART

RANK

DESCRIPTION

– 3 –

Page 23

3

Frame 1

46

2

49

15

49

51

50

50

7

51

5

2

6

48

2

4

49

2

2

10

11

2

48

4

2

2

53

11

2

2

2

2

2

2

18

47

39

38

35

32

37

56

2

1919

2

2

7

6

2

34

2

19

56

33

15

19

2

2

52

2

11

2

1

2

18

19

54

2

19

55

23

24

29

23

24

26

25

30

31

26

25

49

24

2

2

25

2

27

47

2

27

2

47

23

24

26

25

27

2

2

23

24

26

2

25

FCP08833

23

26

2

4

49

49

2

48

2

2

28

27

2

2

– 4 –

Page 24

Frame 2

4

PRICE

NEW

NO. PARTS CODE

1 XHBS740P08000 AA C Screw(4×8)

2 CFRM-1041FC33 BF E Multi desk drive unit

3 CPWBF1592FCE1 AN E MPT vertical detect PWB

4 QSW-M0131FCZZ AC B Push switch

5 MSPRC2894FCZZ AC C Vertical detect switch spring

6 QCNCM0542FCZZ AC C Connector(S6B-PH-K-S)

7 LHLDZ1464FCZZ AG C Vertical detect spring holder

8 LHLDZ1463FCZZ AX C Vertical detect holder

9 XHBS740P10000 AA C Screw(4×10)

10 LPLTP5808FCZZ AF C Multi cassette lock plate

11 MSPRD2987FCZZ AD C T cassette earth spring

12 PCOVP1577FCZ1 AV D Multi remainder detect cover

13 VHPGP1A73A+-1 AG B Photo sensor(GP1A73A)

14 DHAI-3271FCPZ BA C MPT paper feed interface harness N

15 LX-BZ0927FCZZ AG C Body position decide step screw

16 LBSHC0350FCZZ AF C Edge holder(EH-18)

17 PCOVP1576FCZZ AP D Multi paper feed drive cover

18 XRESP50-06000 AA C E type ring(E5)

19 NROLP0896FCZZ AC C Transfer follower roller

20 NSFTZ2631FCZZ AE C T cassette lock shaft

Frame 2

4

RANK

MARK

PART

RANK

1

2

DESCRIPTION

14

3

4

1

6

20

19

18

17

15

16

1

13

1

15

5

7

4

7

8

9

10

9

11

1

FCP08834

10

1

9

12

– 5 –

Page 25

Tandem cassette

5

PRICE

NEW

NO. PARTS CODE

1 XHBS740P08000 AA C Screw(4×8)

2 CPLTM6666FC01 CE N C Cassette case

3 XHBS740P10000 AA C Screw(4×10)

4 XWHSD40-08120 AA C Washer

5 XEBS740P12000 AA C Screw(4×12)

6 PCOVP1609FCZ1 AP D Tandem knob cover

7 GCAB-0959FCN2 BS D Tandem front cabinet

8 XRESP50-06000 AA C E type ring(E5)

9 MSPRD2909FCZZ AG C T cassette lock arm spring

10 MARMP0270FCZZ AK C T cassette lock arm

11 NSFTZ2631FCZZ AE C T cassette lock shaft

Tandem cassette

5

RANK

MARK

PART

RANK

DESCRIPTION

11

2

10

9

8

3

5

1

4

3

1

4

1

3

3

4

5

3

4

4

4

3

1

5

6

5

7

FCP08835

– 6 –

Page 26

Multi paper feed

6

PRICE

NEW

NO. PARTS CODE

1 LPLTM5825FCZZ AQ C Paper feed PG upper support plate

2 XEBS740P12000 AA C Screw(4×12)

3 XHBS740P10000 AA C Screw(4×10)

4 NROLR1336FCZZ AU B Transfer roller 2

5 NBRGM0096FCZ1 AC C Bearing(φ6 WD)

6 XRESP50-06000 AA C E type ring(E5)

7 XEBS730P08000 AC C Screw(3×8)

8 LPLTP5827FCZZ AF C Multi sensor fixing plate

9 VHPGP1A73A+-1 AG B Photo sensor(GP1A73A)

10 DHAI-3250FCPZ AW C MPT paper feed harness

11 MSPRC2965FCZZ AB C Pick up roller earth spring

12 MLEVP0813FCZ2 AH C Multi PE actuator

13 PGIDM1912FCZ1 AW C Paper feed paper guide F

14 XHBS740P10000 AA C Screw(4×10)

15 MLEVP0812FCZ1 AG C Multi transfer actuator

16 MSPRD2900FCZZ AC C Multi transfer actuator spring

17 PGIDM1911FCZ2 BF D Multi paper feed paper guide upper

18 MLEVP0814FCZ1 AK C Pick up move lever

19 MSPRD2903FCZZ AC C Pick up move lever spring

20 LPLTM5824FCZZ AH C Paper feed roller fixing plate

21 LPINS0165FCZZ AB C Pin(2×8)

22 NBLTH0337FCZZ AK B Belt(S2M102)

23 LPINS0133FCZZ AA C Pin(2×10)

24 NGERH1406FCZZ AG C Gear(18/22P)

25 NGERH0863FCZZ AB C Pick up roller gear(18T)

26 PCLR-0470FCZZ AE C Drive joint collar

28 XRESP70-08000 AA C E type ring(E7)

29 NROLP1364FCZZ AC C Transfer roller M

30 NROLR1335FCZ1 AQ B Transfer roller 1

31 MSPRT2902FCZ1 AC C Multi pick pressure spring

32 NSFTZ2620FCZZ AP C Pick up roller shaft

33 NPLYZ0365FCZZ AC C Pick up roller pulley

34 NBLTH0338FCZZ AH B Belt(B55MXL)

35 NROLR1509FCZZ AX A Pick up roller

36 NROLR1508FCZZ AX B Paper feed separate roller

37 NCPL-0049FCZZ AH C Oneway coupling

38 NSFTZ2621FCZZ AN C Multi transfer follower shaft 2

39 NSFTZ2619FCZ1 AX C Multi paper feed roller shaft

40 PGIDM1914FCZ1 BA D Multi paper feed lower PG

41 NSFTZ2623FCZZ AT C Transfer follower shaft

42 PCLC-0305FCZZ AV B Torque limiter multi

43 LPINS0089FCZZ AA C SP pin(2×8)

44 LX-WZ2011SCZZ AA C Washer

45 MSPRC2905FCZ1 AC C Transfer follower spring 1

46 MLEVP0834FCZ1 AF C Multi separate lever

47 MSPRC2904FCZ2 AC C Multi pressure spring

48 MARMP0269FCZZ AE C Multi separate roller arm

49 PGIDM1915FCZ1 AZ D Multi U turn paper guide

50 LPLTM5826FCZZ AM C Paper feed under PG support plate

55 NCPL-0049FCBZ AT C Multi separate coupling(with oneway)

56 NSFTZ2622FCZ2 AX C Multi separation roller shaft

57 NROLP0896FCZZ AC C Transfer follower roller

58 PGIDM1913FCZ1 AV C Multi paper exit paper guide

59 XRESP40-06000 AA C E type ring(E4)

60 MSPRT2901FCZ1 AC C Multi transfer follower spring 2

61 LHLDZ1465FCZ2 AP C Pick up roller holder

62 NPLYZ0378FCZZ AF C Pulley(22P S2M)

63 MSPRT2973FCZZ AD C Multi separate pressure spring

64 NPLYZ0373FCZZ AH C Paper feed roller pulley

66 LPLTM5958FCZZ AD C U turn PG fulcrum plate 1

67 XHBS740P08000 AA C Screw(4×8)

RANK

MARK

PART

RANK

DESCRIPTION

– 7 –

Page 27

Multi paper feed

6

3

2

1

2

2

21

60

26

44

23

5

6

5

10

9

5

59

2

28

2

20

A

B

14

29

30

58

57

18

17

59

A

5

19

10

16

29

28

6

5

4

7

9

6

8

11

31

14

61

5

12

15

10

5

6

7

8

9

8

7

9

10

5

6

32

64

33

34

2

13

35

6

25

24

21

6

22

62

FCP08836

41

57

60

49

67

B

66

2

– 8 –

40

6

55

6

48

47

46

2

3

63

2

45

57

39

38

50

37

36

56

44

6

43

42

36

2

2

Page 28

Multi drive

7

PRICE

NEW

NO. PARTS CODE

1 DHAI-3218FCPZ AZ C MPT body interface harness

2 CFRM-1041FC01 AU C Multi drive frame 1 Assy

3 RMOTP0868FCZZ BP B Transfer motor C

4 DHAI-3269FCPZ AR N C MPT drive harness

5 XHBS740P06000 AA C Screw(4×6)

6 NGERH1404FCZ1 AN C Gear(28/84T)

7 XRESP70-08000 AA C E type ring(E7)

8 CFRM-1042FC02 BC C Multi drive frame 2 Assy

9 LX-BZ4008SC0S AA C Screw(4×8)

10 LBNDJ0013FCZ1 AE C Snap band

11 NGERH0863FCZZ AB C Pick up roller gear(18T)

12 LPINS0134FCZZ AB C Pin(2×12)

13 XRESP50-06000 AA C E type ring(E5)

14 NGERH1471FCZZ AF C M transfer gear(22T)

15 NBRGC0504FCZZ AC C Bearing

17 0EUHLD0218C// AE C Mini clamp(UAMS-05S-2)

19 PCLR-0470FCZZ AE C Drive joint collar

20 PCLC-0310FCPZ BB N B 5K clutch(W)

21 NGERH1405FCZ1 AG C Gear(43T)

22 NSFTZ2624FCZZ AT C Paper feed clutch shaft

23 NGERH1238FCZZ AD C Waste toner gear(24T)

24 NGERH1245FCZZ AF C Transfer gear(28T)

25 XRESP60-08000 AA C E type ring(E6)

26 PCLC-0311FCPZ BB N B 5K clutch(B)

27 NSFTZ2625FCZ1 AY C Transfer clutch shaft

28 DHAI-3216FCPZ AF C MPT lift up harness

29 CPWBN1476FC34 AZ N E MPT PWB

30 LSUPP0083FCZZ AB C Board support(LCBS-3)

31 NCPL-0052FCZZ AH C Lift coupling

32 MSPRC2907FCZ1 AC C Lift up spring

33 CCOVP1607FC31 BB B Lift motor A

34 XHBSD30P35000 AA C Screw(3×35)

RANK

MARK

PART

RANK

DESCRIPTION

Multi drive

7

34

28

33

32

29

31

30

1

4

5

10

3

7

15

21

15

7

23

22

2

7

13

15

5

6

7

17

7

10

8

20

27

25

24

17

13

9

19

11

FCP08837

26

– 9 –

13

15

13

12

14

9

12

19

13

Page 29

500 cassette[Multi purpose]

8

PRICE

NEW

NO. PARTS CODE

1 LPLTP5812FCZZ AW C Regulation plate R

3 CPLTM5814FC01 AD C Regulation plate

5 LPLTP5813FCZ1 AX C Regulation plate F

6 MSPRC2896FCZZ AC C Side plate lever spring

7 MLEVP0755FCZ1 AE C Side plate lever

9 LPLTM5819FCZZ AF C Regulation bottom plate F

10 LX-BZ0531FCZZ AA C Screw(4×8)

11 LPLTP5815FCZ2 AQ C Rear edge plate

12 XEBS740P12000 AA C Screw(4×12)

13 PCOVP1579FCPZ AM D Cassette knob cover

14 LHLDZ1462FCZZ AG C Rear edge plate holder

15 MARMP0268FCZZ AW C Multi size detect arm

16 XWHSD40-08120 AA C Washer

17 GCASP0176FCZ3 BU D 500 sheets Cassette

18 CPLTM5828FC01 AU C Lift plate Assy

19 XEBS740P12000 AA C Screw(4×12)

20 XRESP70-08000 AA C E type ring(E7)

21 XPSSJ40-25000 AA C SP pin(4×25)

22 NBRGP0626FCZZ AC C CG resin bearing

23 PSHEZ4865FCZZ AD C Multi seperate front sheet

24 LPLTM5811FCZZ AU C Turn plate

25 PSHEZ3130FCZZ AB C Turn plate sheet

26 MSPRT2898FCZZ AC C Remainder detect spring

27 MLEVP0811FCZ1 AH C Remainder actuator

28 MSPRC2897FCZZ AD C Cassette earth spring

29 LDAIU0632FCZZ AG D Wrong insert prevention block

30 XEBS730P10000 AC C Screw(3×10)

31 LPLTP5817FCZZ AR C Multi size detect plate

32 XEBS730P10000 AC C Screw(3×10)

33 LPLTP5816FCZZ AG C OC adjust plate

34 NGERH1449FCZZ AF C Gear(18T)

35 LHLDW1226FCZZ AB C Turn fastener

36 TLABZ4452FCZZ AC D Label

37 TLABZ4453FCZZ AF D Label

RANK

MARK

PART

RANK

DESCRIPTION

500 cassette[Multi purpose]

8

26

35

22

21

25

24

27

28

20

29

30

18

23

31

33

34

16

32

10

19

1

37

5

3

3

11

36

17

12

6

7

9

10

12

14

10

13

15

FCP08838

– 10 –

Page 30

Packing Material & Accessories

9

PRICE

NEW

NO. PARTS CODE

1 SPAKA6519FCZZ BD D Desk top cushion

2 PCOVP1588FCN1 AX D Left adjuster cover

3 CSTYM0287FC01 BN C Left adjuster stay Assy

4 XEBS740P12000 AA C Screw(4×12)

5 PAJS-0017FCZZ AG C Adjuster wheel(φ50)

6 LHLDW1226FCZZ AB C Turn fastener

11 SSAKZ0020FCZZ AF D Vinyl bag

17 0EUSAK0617P// AB D Vinyl bag(90×170)

18 XHBS740P06000 AA C Screw(4×6)

19 CPLTM5823FC01 AG C OP fixing plate F Assy

20 LPLTM5807FCZZ AD C OP fixing plate R

22 NSFTZ2852FCZ1 AH C Adjuster D

24 0EUSAK0601J// AG D Vinyl bag(1250×700)

31 LX-BZ0769FCZZ AC C Step screw H

34 GLEGG0075FCZZ AE C Rubber foot

35 SPAKC6738DSZZ BF N D Packing case

36 CPAKA6187FC01 BG D Bottom case

37 SPAKA6788FCZZ AF N D Spacer R

38 SPAKA6787FCZZ AE N D Spacer L

Packing Material & Accessories

9

RANK

MARK

PART

RANK

DESCRIPTION

34

22

31

19

20

2

5

18

17

3

4

35

6

1

11

37

24

1

38

FCP08839

36

– 11 –

Page 31

■

Index

PARTS CODE NO.

[C]

CCOVP1607FC31

CFRM-1041FC01

CFRM-1041FC33

CFRM-1042FC02

CPAKA6187FC01

CPLTM5814FC01

CPLTM5823FC01

CPLTM5828FC01

CPLTM6666FC01

CPWBF1592FCE1

CPWBN1476FC34

CSTYM0287FC01

DHAI-3216FCPZ

DHAI-3218FCPZ

DHAI-3250FCPZ

DHAI-3267FCPZ

DHAI-3269FCPZ

DHAI-3271FCPZ

GCAB-0953FCN2

GCAB-0954FCN1

GCAB-0955FCN2

GCAB-0956FCN5

GCAB-0957FCN1

GCAB-0958FCN2

GCAB-0959FCN2

GCAB-0974FCN1

GCAB-0975FCN3

GCASP0176FCZ3

GDOR-0033FCNZ

GLEGG0075FCZZ

GLEGP0076FCZ1

JHNDM0179FCZZ

LBNDJ0013FCZ1

LBRC-0065FCZZ

LBSHC0350FCZZ

LDAIU0631FCZZ

LDAIU0632FCZZ

LHLDW1226FCZZ

LHLDZ1462FCZZ

LHLDZ1463FCZZ

LHLDZ1464FCZZ

LHLDZ1465FCZ2

LHLDZ1466FCZ1

LPINS0089FCZZ

LPINS0133FCZZ

LPINS0134FCZZ

LPINS0165FCZZ

LPLTM5807FCZZ

LPLTM5811FCZZ

LPLTM5819FCZZ

LPLTM5824FCZZ

LPLTM5825FCZZ

LPLTM5826FCZZ

LPLTM5830FCZZ

LPLTM5958FCZZ

LPLTM6474FCZZ

LPLTP5808FCZZ

LPLTP5812FCZZ

LPLTP5813FCZ1

LPLTP5815FCZ2

LPLTP5816FCZZ

LPLTP5817FCZZ

LPLTP5827FCZZ

LRALM0189FCZ2

LRALM0190FCZ1

LRALM0191FCZ1

LSTPP0355FCZZ

LSTYM0270FCZZ

LSTYM0271FCZZ

LSUPP0083FCZZ

"

[D]

[G]

"

[J]

[L]

"

"

PRICE

NEW

MARK

PART

RANK

RANK

7- 33 BB B

7- 2 AU C

4- 2 BF E

7- 8 BC C

9- 36 BG D

8- 3 AD C

9- 19 AG C

8- 18 AU C

5- 2 CE N C

4- 3 AN E

7- 29 AZ N E

3- 30 BN C

9- 3 BN C

7- 28 AF C

7- 1 AZ C

6- 10 AW C

3- 39 AG C

7- 4 AR N C

4- 14 BA C

1- 1 BM D

1- 8 AY D

1- 5 BR D

1- 12 BU D

1- 10 BA D

1- 9 BA D

5- 7 BS D

1- 11 AY D

1- 7 BD D

8- 17 BU D

2- 1 BP D

3- 26 AE C

9- 34 AE C

3- 27 AS D

3- 4 AZ D

7- 10 AE C

3- 28 AN C

4- 16 AF C

3- 34 AX D

8- 29 AG D

8- 35 AB C

9- 6 AB C

8- 14 AG C

4- 8 AX C

4- 7 AG C

6- 61 AP C

3- 18 AG C

6- 43 AA C

6- 23 AA C

7- 12 AB C

6- 21 AB C

9- 20 AD C

8- 24 AU C

8- 9 AF C

6- 20 AH C

6- 1 AQ C

6- 50 AM C

3- 56 AP C

3- 1 AD C

6- 66 AD C

3- 53 AV C

4- 10 AF C

8- 1 AW C

8- 5 AX C

8- 11 AQ C

8- 33 AG C

8- 31 AR C

6- 8 AF C

3- 32 BG C

3- 5 BG C

3- 15 BL C

3- 55 AD C

3- 10 BG C

3- 46 AD C

7- 30 AB C

PARTS CODE NO.

LX-BZ0531FCZZ

LX-BZ0728FCZ1

LX-BZ0769FCZZ

"

LX-BZ0926FCZ1

LX-BZ0927FCZZ

LX-BZ0930FCZZ

LX-BZ0957FCZZ

LX-BZ3006SC0M

LX-BZ4008SC0S

LX-WZ2011SCZZ

[M]

MARMP0267FCZ1

MARMP0268FCZZ

MARMP0269FCZZ

MARMP0270FCZZ

MLEVP0755FCZ1

MLEVP0811FCZ1

MLEVP0812FCZ1

MLEVP0813FCZ2

MLEVP0814FCZ1

MLEVP0818FCN3

MLEVP0834FCZ1

MSPRC2894FCZZ

MSPRC2896FCZZ

MSPRC2897FCZZ

MSPRC2904FCZ2

MSPRC2905FCZ1

MSPRC2907FCZ1

MSPRC2916FCZZ

MSPRC2965FCZZ

MSPRD2900FCZZ

MSPRD2903FCZZ

MSPRD2909FCZZ

MSPRD2987FCZZ

MSPRT2893FCZZ

MSPRT2898FCZZ

MSPRT2901FCZ1

MSPRT2902FCZ1

MSPRT2973FCZZ

[N]

NBLTH0337FCZZ

NBLTH0338FCZZ

NBRGC0504FCZZ

NBRGM0096FCZ1

NBRGP0626FCZZ

NCPL-0049FCBZ

NCPL-0049FCZZ

NCPL-0052FCZZ

NGERH0863FCZZ

"

NGERH1238FCZZ

NGERH1245FCZZ

NGERH1404FCZ1

NGERH1405FCZ1

NGERH1406FCZZ

NGERH1449FCZZ

NGERH1471FCZZ

NPLYZ0365FCZZ

NPLYZ0373FCZZ

NPLYZ0378FCZZ

NROLP0896FCZZ

"

NROLP1364FCZZ

NROLR1335FCZ1

NROLR1336FCZZ

NROLR1508FCZZ

NROLR1509FCZZ

NSFTZ2619FCZ1

NSFTZ2620FCZZ

NSFTZ2621FCZZ

NSFTZ2622FCZ2

NSFTZ2623FCZZ

NSFTZ2624FCZZ

NSFTZ2625FCZ1

NSFTZ2631FCZZ

"

NSFTZ2635FCZZ

NSFTZ2852FCZ1

"

PRICE

NEW

MARK

PART

RANK

RANK

8- 10 AA C

3- 49 AC C

3- 25 AC C

9- 31 AC C

3- 7 AD C

4- 15 AG C

3- 47 AC C

3- 50 AC C

2- 5 AA C

7- 9 AA C

6- 44 AA C

3- 37 AF C

8- 15 AW C

6- 48 AE C

5- 10 AK C

8- 7 AE C

8- 27 AH C

6- 15 AG C

6- 12 AH C

6- 18 AK C

2- 6 AN C

6- 46 AF C

4- 5 AC C

8- 6 AC C

8- 28 AD C

6- 47 AC C

6- 45 AC C

7- 32 AC C

2- 12 AC C

6- 11 AB C

6- 16 AC C

6- 19 AC C

5- 9 AG C

4- 11 AD C

3- 33 AD C

8- 26 AC C

6- 60 AC C

6- 31 AC C

6- 63 AD C

6- 22 AK B

6- 34 AH B

7- 15 AC C

6- 5 AC C

8- 22 AC C

6- 55 AT C

6- 37 AH C

7- 31 AH C

6- 25 AB C

7- 11 AB C

7- 23 AD C

7- 24 AF C

7- 6 AN C

7- 21 AG C

6- 24 AG C

8- 34 AF C

7- 14 AF C

6- 33 AC C

6- 64 AH C

6- 62 AF C

4- 19 AC C

6- 57 AC C

6- 29 AC C

6- 30 AQ B

6- 4 AU B

6- 36 AX B

6- 35 AX A

6- 39 AX C

6- 32 AP C

6- 38 AN C

6- 56 AX C

6- 41 AT C

7- 22 AT C

7- 27 AY C

4- 20 AE C

5- 11 AE C

2- 3 AX C

3- 23 AH C

9- 22 AH C

– 12 –

Page 32

PARTS CODE NO.

[P]

PAJS-0017FCZZ

"

PCASZ0293FCZ2

PCLC-0305FCZZ

PCLC-0310FCPZ

PCLC-0311FCPZ

PCLR-0441FCZZ

PCLR-0470FCZZ

"

PCOVP1576FCZZ

PCOVP1577FCZ1

PCOVP1579FCPZ

PCOVP1586FCNZ

PCOVP1588FCN1

"

PCOVP1609FCZ1

PCOVP1796FCNZ

PCOVP1819FCNZ

PCOVP1890FCZZ

PGIDM1911FCZ2

PGIDM1912FCZ1

PGIDM1913FCZ1

PGIDM1914FCZ1

PGIDM1915FCZ1

PGIDM1944FCZ1

PSHEZ3130FCZZ

PSHEZ4865FCZZ

PTME-0284FCZZ

[Q]

QCNCM0542FCZZ

QSW-M0131FCZZ

[R]

RMOTP0868FCZZ

[S]

SPAKA6519FCZZ

SPAKA6787FCZZ

SPAKA6788FCZZ

SPAKC6738DSZZ

SSAKZ0020FCZZ

[T]

TLABZ4452FCZZ

TLABZ4453FCZZ

[V]

VHPGP1A73A+-1

"

[X]

XBBS740P08000

XEBS720P06000

XEBS730P08000

XEBS730P10000

"

"

XEBS740P12000

"

"

"

"

"

"

XHBS740P06000

"

"

"

XHBS740P08000

"

"

"

"

XHBS740P10000

"

"

"

"

XHBSD30P35000

XPSSJ40-25000

XRESP40-06000

XRESP50-06000

"

"

"

PRICE

NEW

MARK

PART

RANK

RANK

3- 24 AG C

9- 5 AG C

3- 35 AZ D

6- 42 AV B

7- 20 BB N B

7- 26 BB N B

3- 6 AK C

6- 26 AE C

7- 19 AE C

4- 17 AP D

4- 12 AV D

8- 13 AM D

1- 13 AR D

3- 29 AX D

9- 2 AX D

5- 6 AP D

1- 6 AQ D

3- 48 AM C

3- 54 BT N C

6- 17 BF D

6- 13 AW C

6- 58 AV C

6- 40 BA D

6- 49 AZ D

2- 13 BH D

8- 25 AB C

8- 23 AD C

2- 4 AE C

4- 6 AC C

4- 4 AC B

7- 3 BP B

9- 1 BD D

9- 38 AE N D

9- 37 AF N D

9- 35 BF N D

9- 11 AF D

8- 36 AC D

8- 37 AF D

4- 13 AG B

6- 9 AG B

3- 52 AA C

3- 38 AC C

6- 7 AC C

1- 14 AC C

8- 30 AC C

8- 32 AC C

2- 10 AA C

3- 31 AA C

5- 5 AA C

6- 2 AA C

8- 12 AA C

8- 19 AA C

9- 4 AA C

1- 4 AA C

3- 11 AA C

7- 5 AA C

9- 18 AA C

3- 19 AA C

3- 2 AA C

4- 1 AA C

5- 1 AA C

6- 67 AA C

1- 2 AA C

4- 9 AA C

5- 3 AA C

6- 14 AA C

6- 3 AA C

7- 34 AA C

8- 21 AA C

6- 59 AA C

4- 18 AA C

5- 8 AA C

6- 6 AA C

7- 13 AA C

PARTS CODE NO.

XRESP60-08000

XRESP70-08000

"

"

XWHSD40-08100

XWHSD40-08120

"

"

[0]

0EUHLD0218C//

0EUSAK0601J//

0EUSAK0617P//

PRICE

NEW

MARK

PART

RANK

RANK

7- 25 AA C

6- 28 AA C

7- 7 AA C

8- 20 AA C

3- 51 AA C

2- 11 AA C

5- 4 AA C

8- 16 AA C

7- 17 AE C

9- 24 AG D

9- 17 AB D

– 13 –

Page 33

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Dispose of used batteries according to manufacturer's instructions.

(Finnish) VAROITUS

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

ll y a danger d'explosion s'il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

Mettre au rébut les batteries usagées conformément aux

Udskiftning må kun ske med batteri

Levér det brugte batteri tilbage til leverandoren.

Danger of explosion if battery is incorrectly replaced.

Paristo voi räjähtää,jos se on virheellisesti asennettu.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

même type on d'un type équivalent recommandé par

af samme fabrikat og type.

Replace only with the same or equivalent type

recommended by the manufacturer.

mukaisesti.

le constructeur.

instructions du fabricant.

(Swedish) VARNING

(German) Achtung

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

(For USA,CANADA)

(MANGANESS DIOXIDE) MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. REMOVE THE

BATTERY FROM THE PRODUCT AND CONTACT YOUR

LOCAL ENVIRONMENTAL AGENCIES FOR INFORMATION

CE PRODUIT CONTIENT UNE PILE DE SAUVEGARDE DE

MÉMOIRE LITHIUM PRIMAIRE (DIOXYDE DE MANGANESE)

QUI DOIT ÊTRE TRAITÉE CORRECTEMENT. ENLEVEZ LA

PILE DU PRODUIT ET PRENEZ CONTACT AVEC VOTRE

AGENCE ENVIRONNEMENTALE LOCALE POUR DES

INFORMATIONS SUR LES MÉTHODES DE RECYCLAGE ET

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekornmenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

Explosionsgefahr bei Verwendung inkorrekter Batterien.

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anwerisugen.

CAUTION FOR BATTERY DISPOSAL

THIS PRODUCT CONTAINS A LITHIUM PRIMARY

ON RECYCLING AND DISPOSAL OPTIONS.

"TRAITEMENT DES PILES USAGÉES"

Instruktion.

"BATTERY DISPOSAL"

DE TRAITEMENT.

Page 34

q

SHARP CORPORATION

Digital Document Systems Group

QUALITY ENHANCEMENT CENTER

Yamatokoriyama, Nara 639-1186, Japan

2005 June Printed in Japan

t

COPYRIGHT2005 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

Loading...

Loading...