Page 1

SERVICE MANUAL

COLOR LED PRINTER

MODEL AR-C265P

CONTENTS

CHAPTER 1 CONFIGURATION ......................................... 1-1

CHAPTER 2 EXPLANATION OF OPERATION.................. 2-1

CHAPTER 3 INSTALLATION ............................................. 3-1

CHAPTER 4 REPLACEMENT OF PARTS ......................... 4-1

CHAPTER 5 MAINTENANCE MENUS ............................... 5-1

CHAPTER 6 PERIODICAL MAINTENANCE ...................... 6-1

CHAPTER 7 TROUBLESHOOTING PROCEDURES ........ 7-1

CHAPTER 8 CONNECTION DIAGRAMS........................... 8-1

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Please Reorder: SM-ARC265P

September 2006

Page 2

INTRODUCTION

This manual explains the maintenance methods for the AR-C265P.

The manual has been prepared for use by the maintenance personnel. For operating methods of the

AR-C265P, refer to the corresponding user's manual.

Note!

• The contents of this manual are subject to changes without prior notice.

• Despite that exhaustive efforts were made in preparing the manual to make it accurate, it still may

contain errors. Sharp will not hold itself liable for any damage that results or is claimed to have

resulted from repair, adjustment, or modification of the printer conducted by the user using this

manual.

• The parts employed in the printer are so delicate that they may be damaged if not treated

properly. Sharp strongly recommends that the maintenance of the printer be undertaken by

Sharp's registered maintenance personnel.

• Work after eliminating static electricity.

i

Page 3

CONTENTS

CHAPTER 1 CONFIGURATION

I. SYSTEM CONFIGURATION .............1-1

II. PRINTER CONFIGURATION ............1-2

III. COMPOSITION OF OPTIONAL

ITEMS................................................1-3

IV. SPECIFICATIONS .............................1-4

V. INTERFACE SPECIFICATIONS........1-8

CHAPTER 2 EXPLANATION OF OPERATION

I. ELECTROPHOTOGRAPHIC

PROCESSING MECHANISM ............2-1

CHAPTER 3 INSTALLATION

I. CAUTIONS, AND DO’S AND

DON’TS..............................................3-1

II. UNPACKING METHOD .....................3-2

III. PRINTER INSTALLATION

INSTRUCTIONS ................................3-3

IV. LISTING OF COMPONENT UNITS

AND ACCESSORIES ........................3-4

V. ASSEMBLING METHOD...................3-5

A. Assembly of printer main body .....3-5

A. Parallel interface specifications

(N/A) .............................................1-8

B. USB interface specifications.........1-8

C. Network interface specifications...1-9

II. PRINTING PROCESS .......................2-6

B. Connection of power cable .........3-11

C. Installation of optional items .......3-14

D. Confirmation of recognition

of optional items .........................3-22

VI. MENU MAP PRINT..........................3-23

VII. CONNECTION METHODS..............3-24

VIII. CONFIRMATION OF PAPER

USED BY THE USER ......................3-25

ii

Page 4

CHAPTER 4 REPLACEMENT OF PARTS

I. PRECAUTIONS ON THE

REPLACEMENT OF PARTS............. 4-1

A. Maintenance tools........................ 4-2

II. PART REPLACEMENT

METHODS......................................... 4-3

A. Left side cover.............................. 4-3

B. Right side cover ........................... 4-4

C. Face-up tray................................. 4-5

D. Rear cover.................................... 4-6

E. LED assy /LED assy springs ........ 4-7

F. Control PCB ................................. 4-8

G. Print engine controller PCB.......... 4-9

H. Top cover assembly ................... 4-11

I. Top cover ................................... 4-12

J. Controller panel assy .................4-13

K. Board PRP/Top cover handle.... 4-14

L. Low-voltage power supply/

low-voltage fan/hopping

motor/fuser motor ......................4-15

M. Guide eject assy/color register

assy/board-PRY ........................ 4-16

N. Fan (fuser)/belt motor /high-voltage

power supply board/cover-open

switch ......................................... 4-18

O. MPT assy ................................... 4-19

P. Feeder unit/board-RSF /MPT

hopping roller/frame assy

separator/cover front ................. 4-20

Q. Board-PRZ lift-up motor /

solenoid/paper-end sensor ........ 4-21

R. Feed roller .................................. 4-23

S. Shaft eject assy(FU) /shaft

eject assy(FD)/eject sensor ....... 4-24

T. Fuser Unit................................... 4-25

U. Belt Unit...................................... 4-26

III. LUBRICATING POINTS.................. 4-27

CHAPTER 5 MAINTENANCE MENUS

I. SYSTEM MAINTENANCE MENU

(FOR MAINTENANCE

PERSONNEL) ................................... 5-1

II. MAINTENANCE UTILITY .................. 5-3

III. FUNCTIONS OF USER’S

MAINTENANCE MENU..................... 5-6

A. Maintenance menu (For end

users) ........................................... 5-6

B. Self-diagnostic mode.................... 5-7

IV. SETUP AFTER REPLACEMENT

OF PARTS....................................... 5-40

CHAPTER 6 PERIODICAL MAINTENANCE

I. RECOMMENDED REPLACEMENT

PARTS............................................... 6-1

II. CLEANING ........................................ 6-1

III. CLEANING OF LED LENS

ARRAY .............................................. 6-1

A. Precautions on the replacement

of engine control PCB ................ 5-40

B. Setup of EEPROM after

replacement of SP1/TBH

PCB............................................ 5-42

C. Setup of destination ...................5-44

V. ABOUT THE MANUAL SETUP

OF PRINT DENSITY

ADJUSTMENT ................................ 5-45

IV. CLEANING OF PICKUP

ROLLERS.......................................... 6-3

V. INTERNAL CLEANING OF

PRINTER........................................... 6-4

iii

Page 5

CHAPTER 7 TROUBLESHOOTING PROCEDURES

I. PRECAUTIONS PRIOR TO

REPAIR..............................................7-1

II. ITEMS TO BE CHECKED PRIOR

TO TAKING ACTION ON

ABNORMAL IMAGES........................7-1

III. PRECAUTIONS WHEN TAKING

ACTION ON ABNORMAL

IMAGES.............................................7-1

IV. PREPARATIONS FOR

TROUBLESHOOTING.......................7-1

CHAPTER 8 CONNECTION DIAGRAMS

I. CHECK OF RESISTANCE

VALUES.............................................8-1

V. TROUBLESHOOTING METHOD ......7-1

A. LCD message list .........................7-2

B. Preparing for troubleshooting .....7-18

C. Image problem troubleshooting ..7-57

D. Actions after forced initialization

of HDD/Flash .............................7-65

E. Network Troubleshooting............7-66

VI. CHECK OF FUSES .........................7-67

II. COMPONENT LAYOUT ....................8-5

iv

Page 6

CHAPTER 1

CONFIGURATION

I. SYSTEM CONFIGURATION............. 1-1

II. PRINTER CONFIGURATION............ 1-2

III. COMPOSITION OF OPTIONAL

ITEMS................................................ 1-3

IV. SPECIFICATIONS............................. 1-4

V. INTERFACE SPECIFICATIONS .......1-8

A. Parallel interface specifications

(N/A)............................................. 1-8

B. USB interface specifications ........ 1-8

C. Network interface specifications... 1-9

Page 7

I. SYSTEM CONFIGURATION

CHAPTER 1 CONFIGURATION

DUPLEX PCB 2nd TRAYPCB

IN1 IN2 WR

Front sensor PCB

1st

M

M

Paper feed

P. E

M

BELT

M

IDUP

HOP

ID

solenoid

sensor

Belt unit

PUPCB

FLASH

Color

8Mbit

registration

PCB right

Belt unit

Color

registration

fuse-cut

20MHz

Color drift, density,

thermistor signal

Density

PCB left

Junction PCB

5V,24V, 0VL,0VP

EXIT

sensor

sensor

Fuser fuse-cut,

UP&LOW thermistor/frame

thermistor

Low-voltage PCB

M

Inlet

Unit

Fuser

FUSER

AC-SW

RFID

HDDLAN USB

CPU

CU

CUPCB

FAN

CIF2

ASIC

ROM

Flash

CC1

K LED HEAD

Y LED HEAD

EEP

ROM

RAM

Option

ASIC

C LED HEAD

M LED HEAD

LEISUS

command I/F

DCON I/F LSYNC

Operator panel PCB

ARMORED CPU

EXIT

fuse-cut,

Belt unit

EEPROM

fuse-cut

ID

C toner

M toner

Toner sensor PCB

Y toner

K toner

sensor

sensor

sensor

sensor

Cover-

Belt

Fuser

FAN heater control,

others

High-voltage I/F,

fan control, cover-open

open

sensor

thermi-

stor

fan

Environment

sensor

High-voltage PCB

ID UP/

DOWN

Low-

voltage

Y-ID M-ID C-ID

K-ID

FAN

1-1

Page 8

CHAPTER 1 CONFIGURATION

II. PRINTER CONFIGURATION

The internal part of the AR-C265P printer is composed of the following sections:

• Electrophotographic processing section

• Paper paths

• Control sections (CU sect./PU sect.)

• Operator panel

• Power supply sections (High-voltage sect./low-voltage sect.)

1-2

Air flow

Page 9

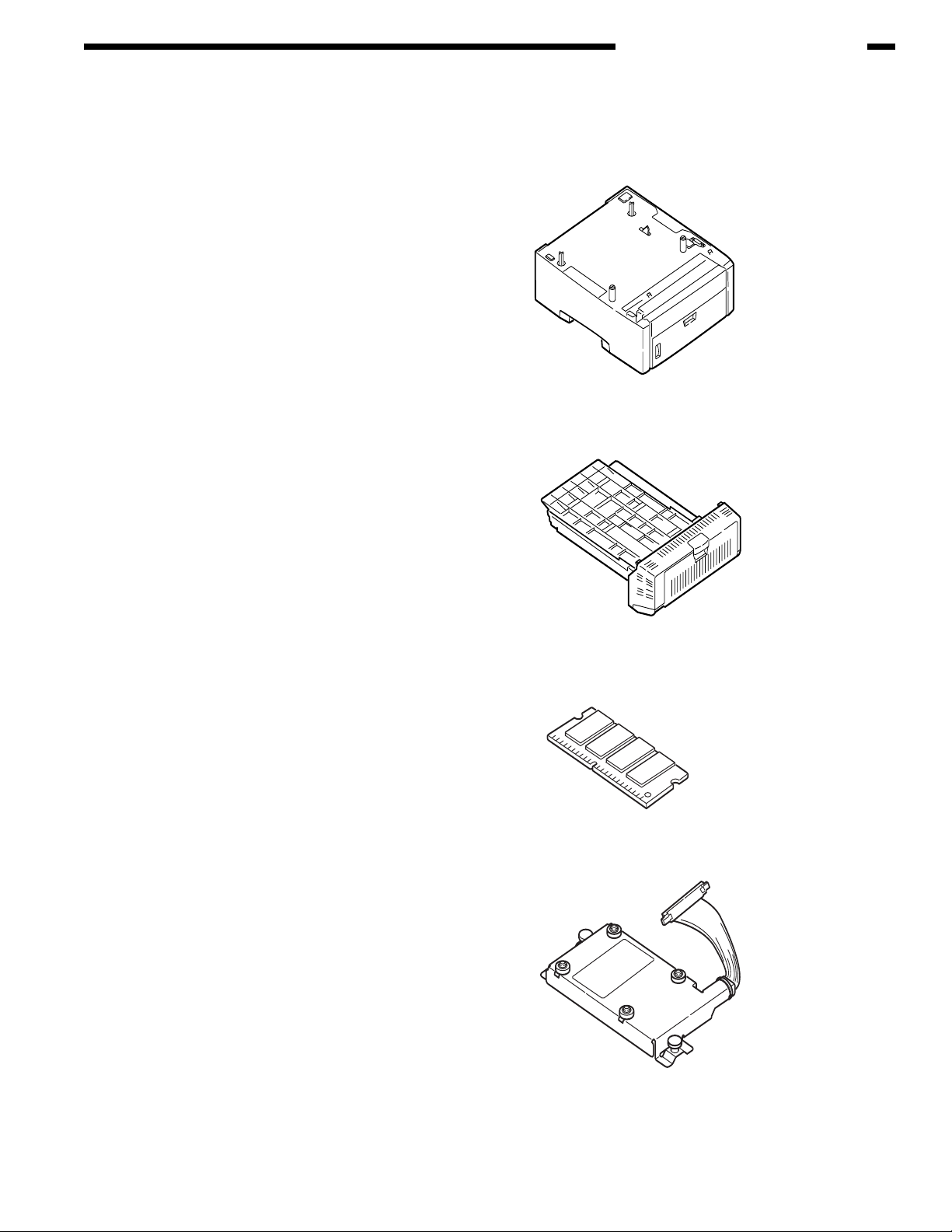

III. COMPOSITION OF OPTIONAL ITEMS

The following optional items are available for the printer:

(1) Second tray

AR-C265PFU

(530 sheet paper tray)

(2) Duplex Unit

AR-C265PADU

CHAPTER 1 CONFIGURATION

(3) Expansion Memory

AR-C265SM1 (256 MB)

AR-C265SM2 (512 MB)

For long printing, it is recommended to

add an expansion memory.

Hard disk

(4)

AR-C265HD (40 GB hard drive)

1-3

Page 10

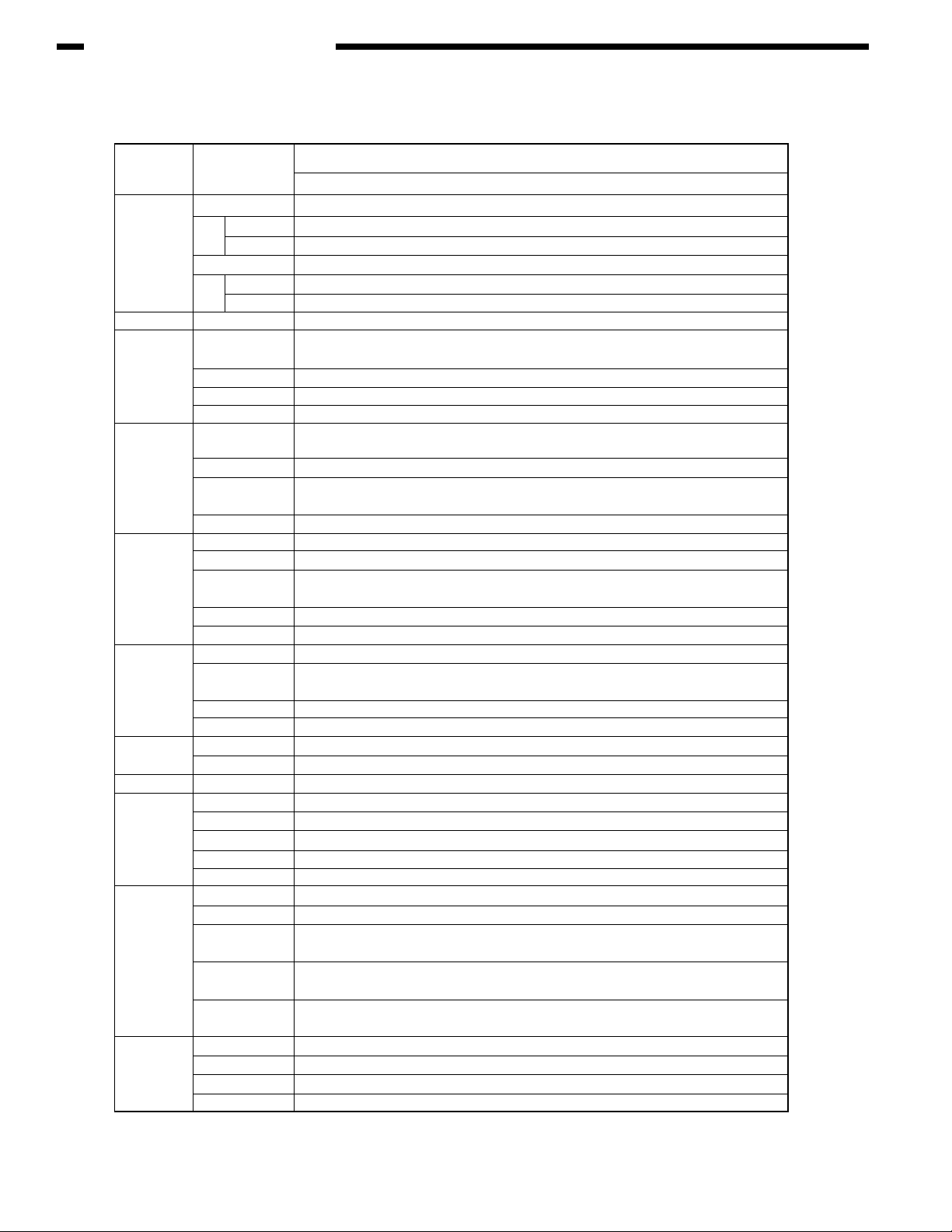

CHAPTER 1 CONFIGURATION

IV. SPECIFICATIONS

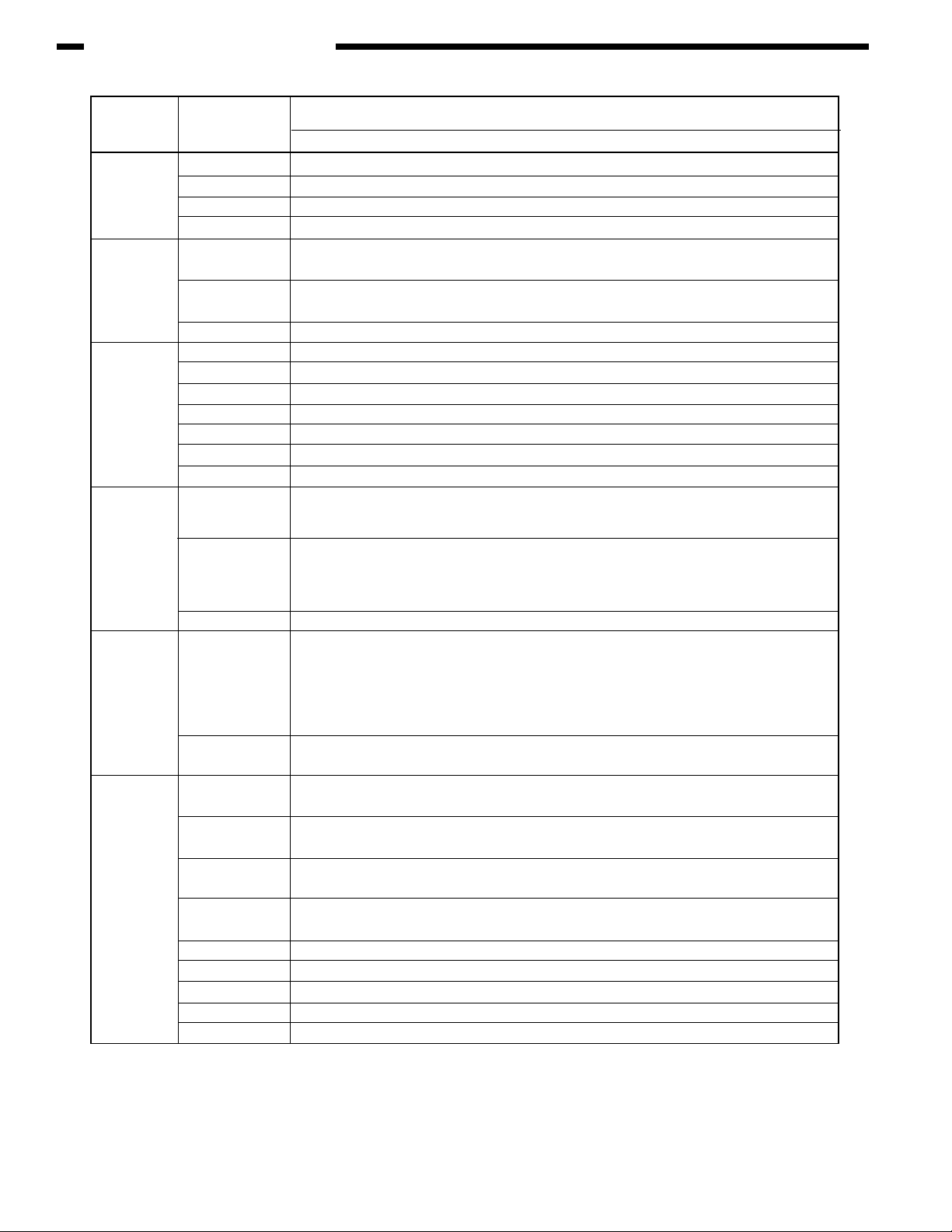

Division

External

dimensions

Print width

Engine speed

(A4)

First print

time(A4)

Resolution

CPU

RAM

ROM

Power

consumption

Operating

environment

(Temperature)

Operating

environment

(Humidity)

Item

Width

Depth With duplex

Without duplex

Height

Mass With duplex

Without duplex

Print width

Monochrome

Color

OHP Color

OHP color/ monochrome

Monochrome

Color

Warm-up time

Low-noise mode

LED head

Max. input resolution

Output resolution

Gradation

Econo-mode

Core

I-cache

D-cache

Clock

Bus width

Resident

Option

Program + font

Power input

Power-save mode

Idle

Normal operation

Peak

When operating

When not operating

When stored

(For max. 1 yr.)

When transported

(For max. 1 mo.)

When transported

(For max. 1 mo.)

When operating

When not operating

When stored

When transported

AR-C265P

32/26ppm

435mm

621mm

563.5,mm

340mm

Approx.29kg

Approx.26kg

A4

32ppm

26ppm

9ppm*1

10ppm

8sec

9sec

45sec

Not applicable

600dpi

600x1200dpi

True 600x1200dpi

True 600x600dpi

600x600x4 level

Toner-saving by reducing lightness

PowerPC750CXR

32KB,

32KB (Internal L2 : 256KB)

500MHz

64bit

256 MB

256/512MB DIMM

Total capacit: 64MB

(120V)110~127VAC , (230V)220~240VAC

15W or less

100W (Average)

490W

1200W

10°C~32°C, 17°C~27°C(Full-color print quality guarantee temperature)

0°C~43°C, Power off

-10°C~43°C, With drum and toner

-29°C~50°C, With drum, but no toner

-29°C~50°C, With drum and toner

20%~80%, 50%~70%(Full-color print quality guarantee humidity)

Max. wet-bulb temp. : 25°C

10%~90%, Max. wet-bulb temp. : 26.8°C, with power off

10%~90%, Max. wet-bulb temp. : 35°C

10%~90%, Max. wet-bulb temp. : 40°C

1-4

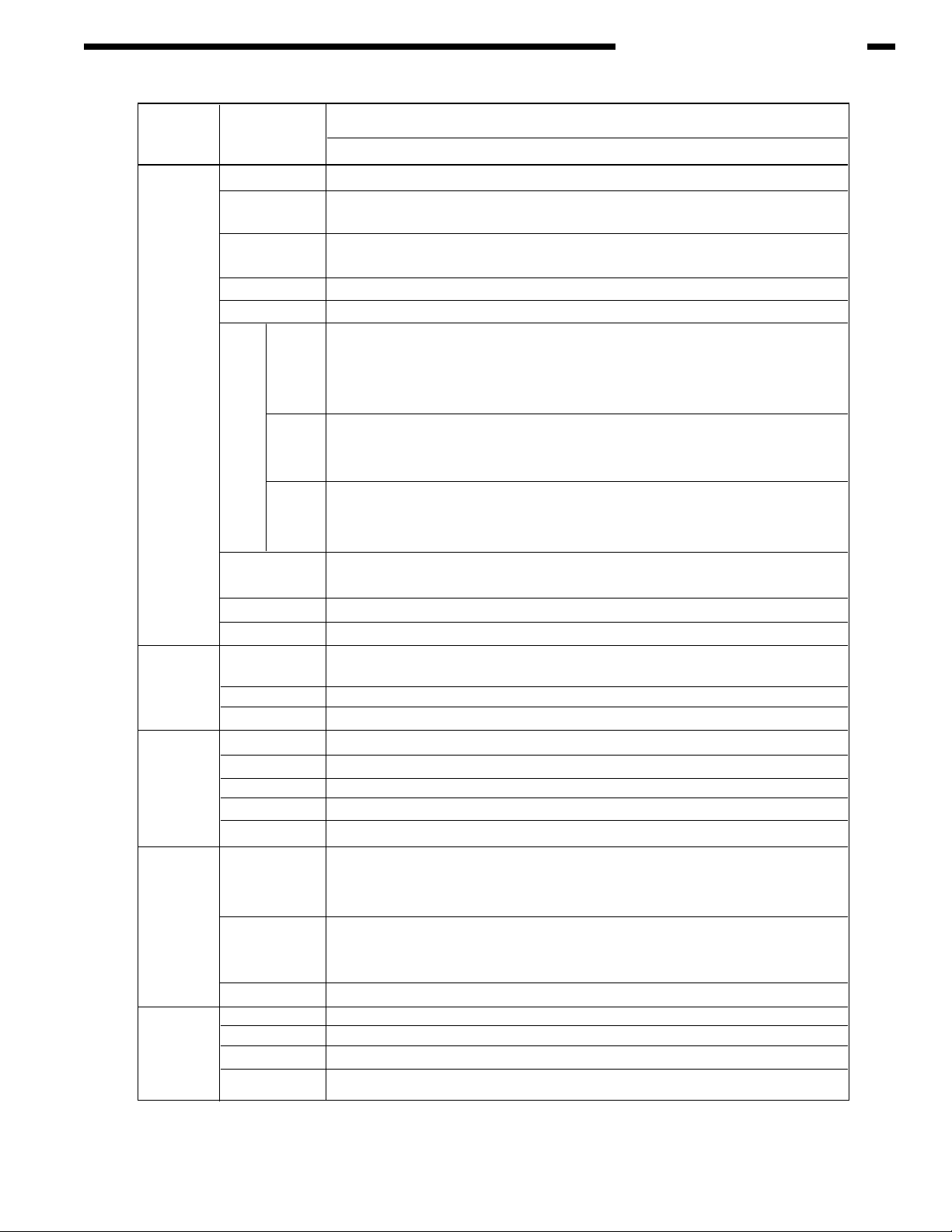

Page 11

CHAPTER 1 CONFIGURATION

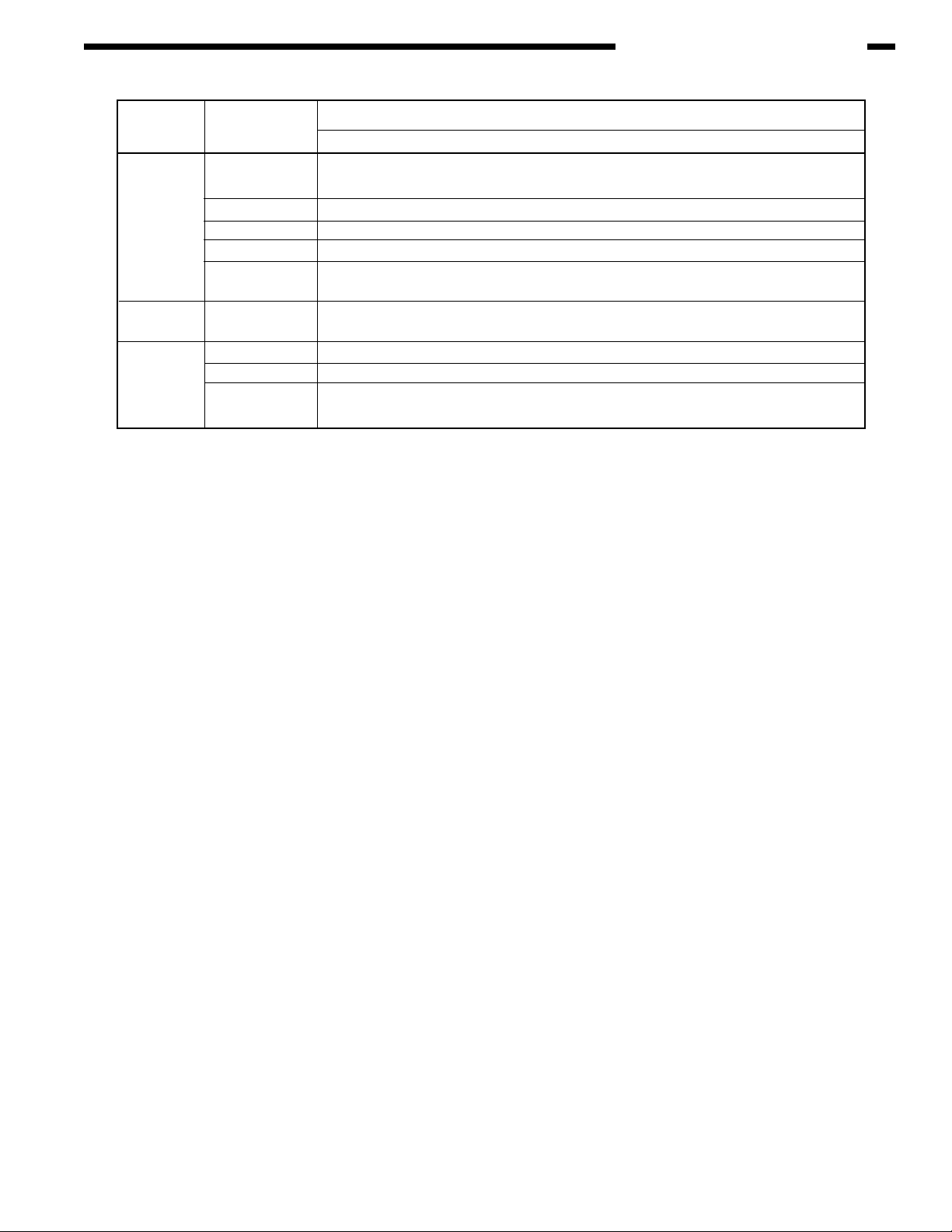

Division

Service life

Operation noise

Paper handling

Paper size

Min. paper size

Item

Printer life

Print duty

(M=L/12, A=L/12/5)

MTBF

(2.3% duty)

MPBF

MTTR

Starter toner

Toner life

(5% duty)

(Attached)

Standard

With 1st

new drum

Image drum life

Transfer belt life

Fuser unit life

In operation

(ISO7779Front)

In one-side print

On standby (ISO7779Front)

Power-save mode

Paper capacity(1st tray)

Paper capacity(2nd tray)

Paper capacity (Manual/auto)

Delivery

Duplex

Legal/universal or

A4-size cassette/universal

cassette

Automatic front feeder

or manual feeder

Two-sided

1st tray

2nd tray

Manual & auto (MPT)

Two-sided

AR-C265P

32/26ppm

420,000 pages, 5 years

Max. 50,000 pages / mo.

Average 4,000 pages / mo.

Not applicable

40,000 pages

20 minutes

Approx. 2,000

pages (Black)

Approx. 2,000

pages (Color)

Approx. 6,000

pages (Black)

Approx. 5,000

pages (Color)

Approx. 5,200

pages (Black)

Approx. 1,200

pages (Color)

Approx.

20,000 pages (With 3 pages / job)

Approx.27

,000 pages (When printed continuously) Drum counter automatically reset

60,000 pages (A4 size, with 3 pages / job), counter automatically reset

60,000 pages (A4 size), counter automatically reset

Legal/universal cassette: 300 sheets (70kg)

Legal/universal cassette (Optional): 530 sheets (70kg)

Standerd multi-purpose tray: 50 OHP sheets or 100 sheets of paper (70kg) or 10 envelopes

250 sheets (70kg) face-down/100 sheets (70kg)face-up in tray

1st cassette: Legal13/13.5/14, letter, executive, A4, A5, B5, A6

2nd

cassette: Legal13/13.5/14, letter, executive, A4, A5, B5

Reply-paid postcard (Max. 176gsm) (Multi-purpose tray)

Legal13/13.5/14, letter, executive

1200mm (When paper length exceeds 356, its width shall be from 210 to 215.9.)

Legal13/13.5/14, letter, executive

, A4, A5, B5, A6, C5, DL, Com-9,Com-10, Monarch, custom size, banners up to

Postcard, reply-paid postcard, Japanese-style envelope

, A4, A5 Custom size (Within permissible size and weight)

105x148mm:A6/(Models for Japan [100x148: Postcard size])

100x148: Postcard size

Approx.

55.6dBA

37dBA

Background level

Standard

148x210mm:A5

148x210mm:A5

12,000 pages (With 1 page / job)

1-5

Page 12

CHAPTER 1 CONFIGURATION

Division

Paper thickness

Operator panel

Status

switch/sensor

Communication

interface

Item

1st tray

2nd tray

Manual & auto (MPT)

Two-sided

LCD

LED (Color)

Switch

Paper out

Paper low

Toner low

Cover open

Fuser unit temp.

Paper size

Stacker full

Standard ( On PCB)

Option for OEM user

AR-C265P

32/26ppm

64~120gsm

64~176gsm

64-203gsm OHP sheets available

64~105gsm

16 characters in 2 line (Roman alphabet/Japanese kana)

No paper size indicated

Two

(Green x1, dark amber x1)

Six

Provided

Not provided

Provided (Y,M,C,K)

Provided

Provided

Not provided

Not provided

• Hi-Speed USB

• Ethernet

• Bidirectional parallel I/F conforming to IEEE std

1284-1994 (OEM)

Emulation

Font

Input/output switch

Standard

Emulation switch

Bit-map type face

Scalable 1 type face

Scalable 2 type face

Scalable 3 type face

Rasterizer

Bar code

OCR

Japanse PCL font

Japanese PS font

Automatic

PCL (PCL5c, HP-GL)

/ PCL XL2.1

SIDM (IBM-PPR,

EPSON-FX)

PostScript3 (Clone)

Automatic

Agfa

1(Line printer)

Agfa micro-type 86

Not available

Agfa micro-type 136

Agfa UFST 4.0 (PCL)

USPS

OCR-A,B

Not available

Not available

1-6

Page 13

CHAPTER 1 CONFIGURATION

Division

Optional Item

(Detachable)

Factory settings

Others

Note!

Item

RAM set

Tray mechanism

Cassette

Duplex print unit

Other

Japan

USB-IF logo

Windows logo

Operation with UPS

Operation with UPS (Uninterruptible power supply) is not guaranteed.

Expansion memories for AR-C265P

AR-C265P

32/26ppm

256,512 MB

2nd tray mechanism

Legal/universal (530 sheets)

Option

2.5" IDE HDD

User- installable (40 GB hard drive)

PCL+PS model

Available

Available

Do not use UPS

! Note

1-7

Page 14

CHAPTER 1 CONFIGURATION

V. INTERFACE SPECIFICATIONS

A. Parallel interface specifications (N/A)

B. USB interface specifications

Outline of USB interface

(1) Basic specifications

USB (Hi-Speed USB supported)

(2) Transmission mode

Full speed (Max. 12Mbps ± 0.25%)

High speed (Max.480Mbps ± 0.05%)

(3) Power control

Self power device

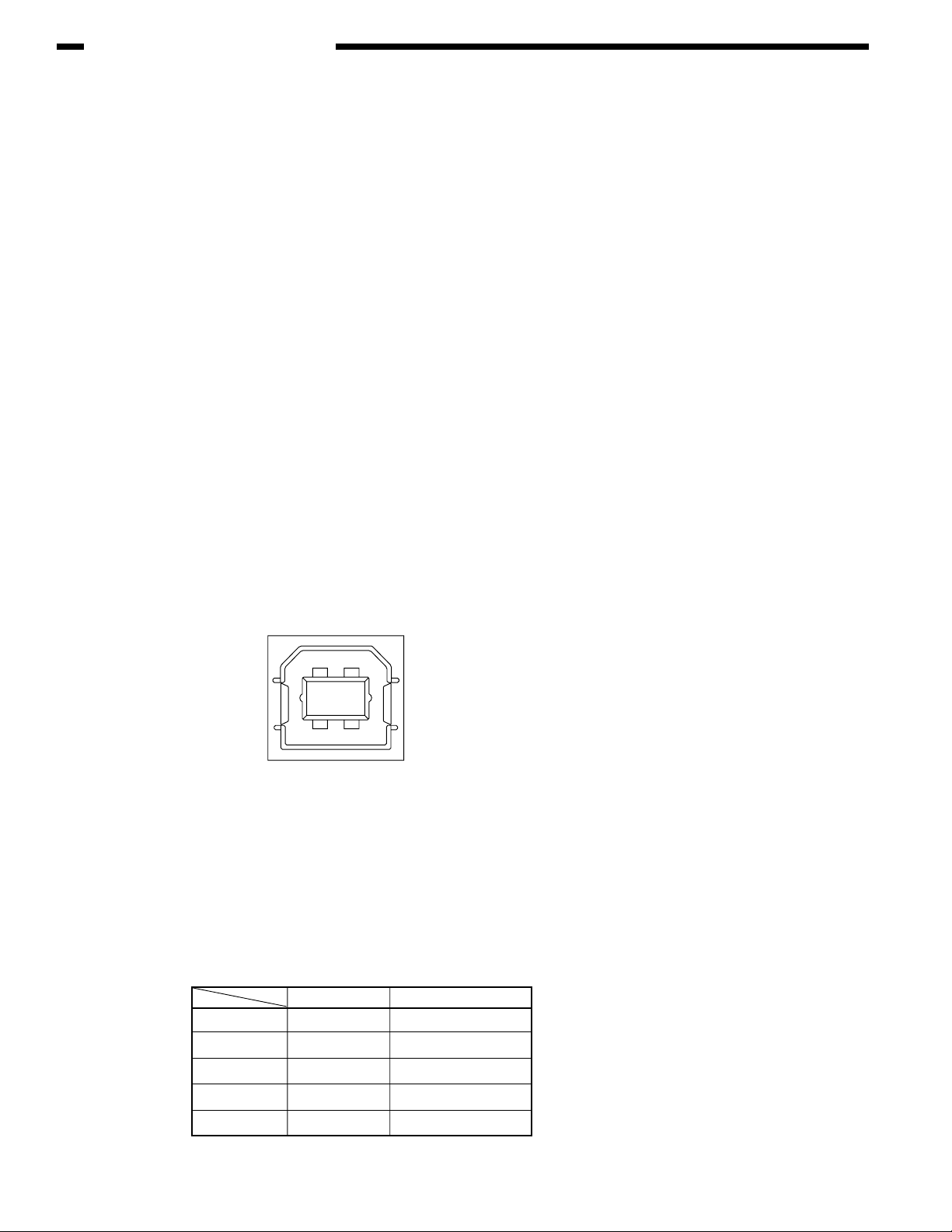

USB interface connectors and cables

(1) Connector

• Printer side: B-receptacle (Female)

Upstream port

Product equivalent to UBR24-4K5C00 (Made by ACON)

Connector pin assignment

• Cable side: B-plug (Male)

(2) Cables

Cable length: Specification: USB2.0 type cables five meters long or shorter. Cables two meters long

or shorter are recommended. (Shielded cable lines shall be used.)

USB interface signals

1

2

3

4

Shell

2

1

34

Signal name

Vbus

D-

D+

GND

Shield

Function

Power supply (+5V)

For data transfer

For data transfer

Signal ground

1-8

Page 15

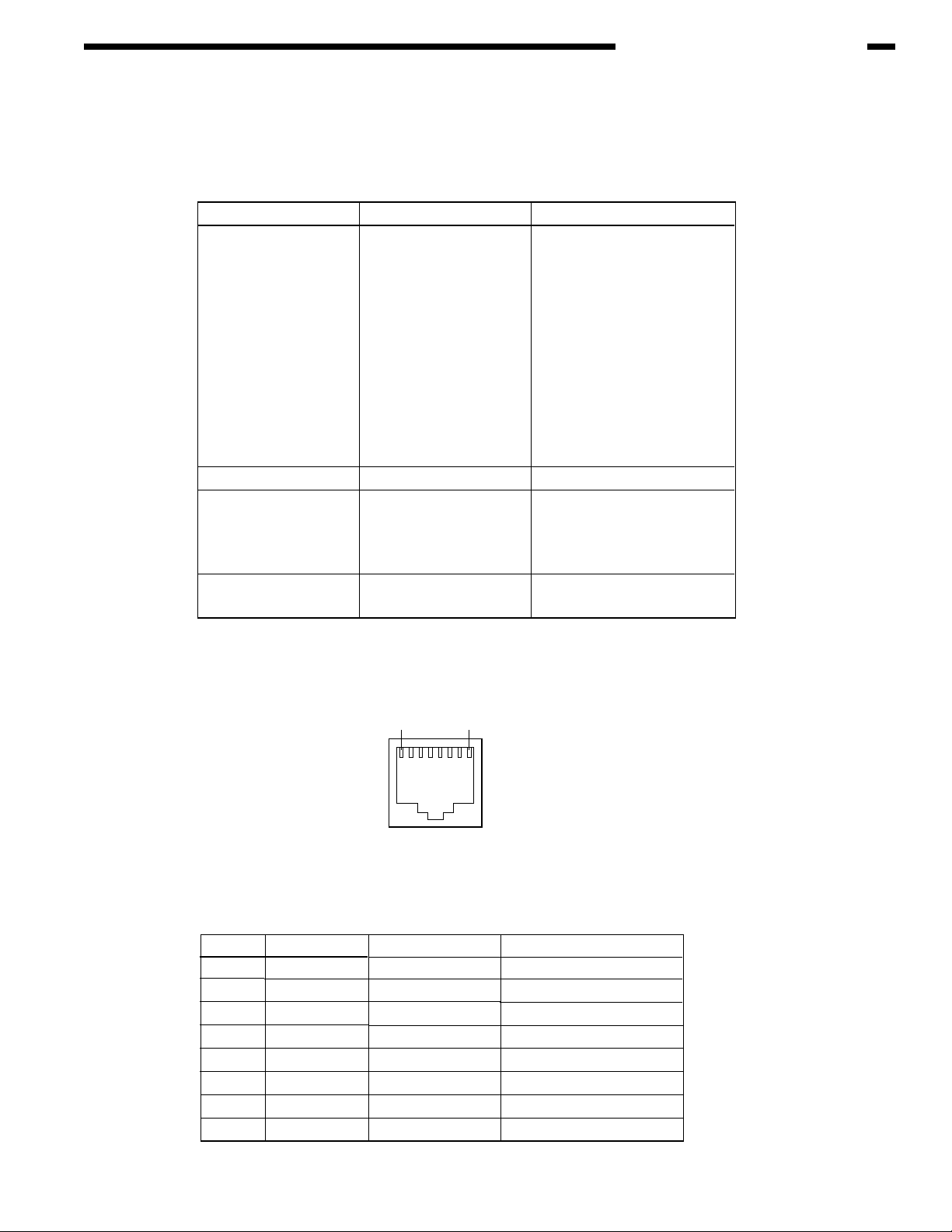

C. Network interface specifications

Outline of network interface

Basic specifications of network interface

CHAPTER 1 CONFIGURATION

Protocol family

TCP/IP

NetBEUI

NetWare

Ether Talk

Network protocol Application

IPv4, IPv6, TCP, UDP,

ICMP, ICMPv6, ARP

NetBIOS

SPX, IPX, SAP, RIP

ELAP, AARP, DDP, AEP,

ZIP, RTMP, ATP, NBP

Network interface connectors and cables

(1) Connectors

100 BASE-TX / 10 BASE-T (Automatically switched, not usable simultaneously)

18

LPR, RAW, IPP, FTP

SMTP/POP3

HTTP

HTTPS

Telenet

SNMPv1/v3

DHCP/BOOTP

DNS

UPnP

Rendezvous

SNTP

WINS, SMB

Q-Server over IPX

Q-Server over IP

R-Printer

N-Printer

PAP

2) Cables

RJ-45 connectorized non-shielded twisted-pair cable (Category 5 recommended)

Network interface signals

Pin No.

1

2

3

4

5

6

7

8

Signal name

TXD+

TXD-

RXD+

-

-

RXD-

-

-

Connector pin assignment

Direction

FROM PRINTER

FROM PRINTER

TO PRINTER

-

-

TO PRINTER

-

-

Function

Transmitting data +

Transmitting data -

Receiving data +

Not in use

Not in use

Receiving data -

Not in use

Not in use

1-9

Page 16

CHAPTER 2

EXPLANATION OF OPERATION

I. ELECTROPHOTOGRAPHIC

PROCESSING MECHANISM............ 2-1

II. PRINTING PROCESS....................... 2-6

Page 17

CHAPTER 2 EXPLANATION OF OPERATION

I. ELECTROPHOTOGRAPHIC PROCESSING MECHANISM

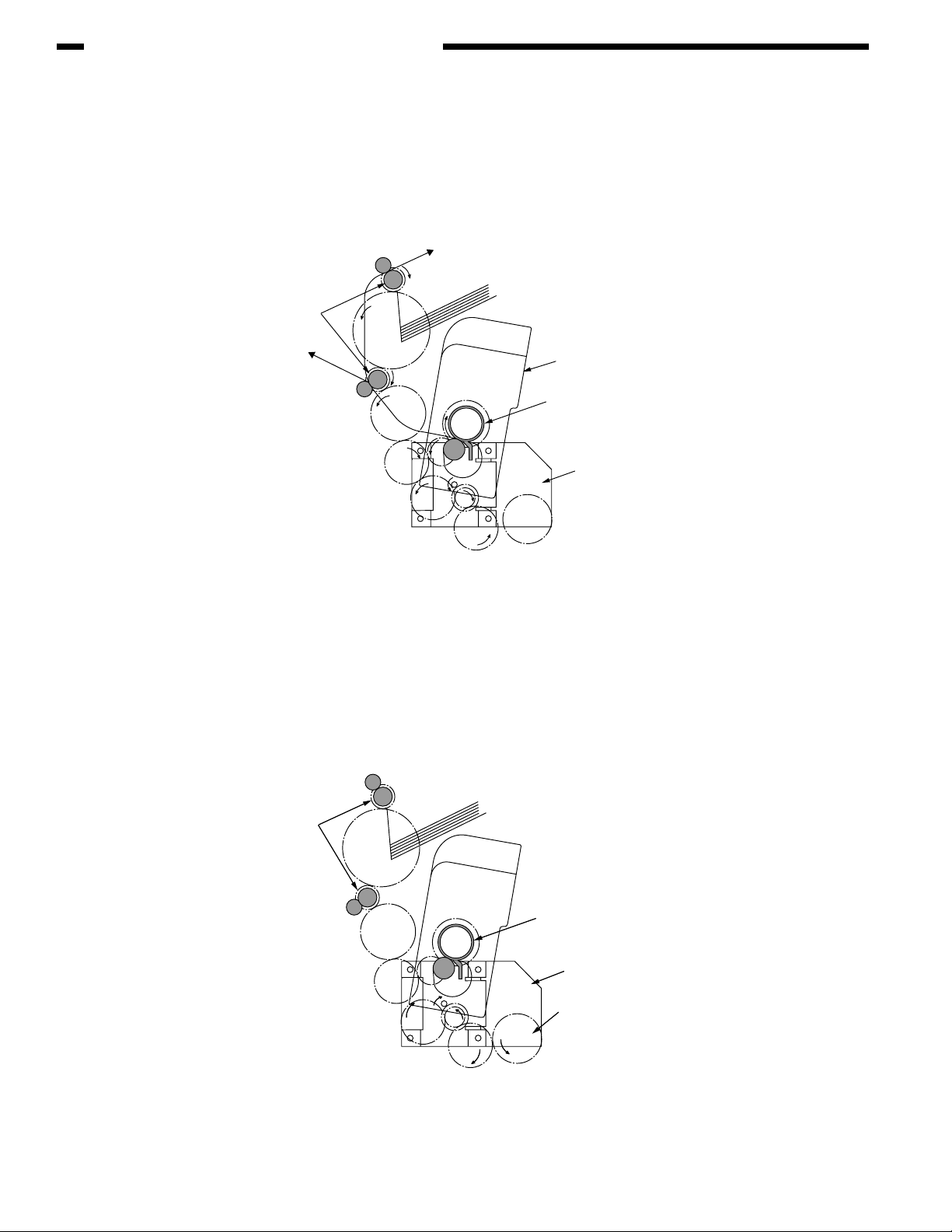

(1) Electrophotographic process

The electrophotographic process is explained briefly below:

1. Charging

A voltage is applied to the CH roller to electrically charge the surface of the OPC drum.

2. Exposure

The LED head radiates light onto the charged OPC drum in accordance with the image

signal. The electric charge of the radiated part of the OPC drum surface attenuates

depending on the intensity of the light, thus forming an electrostatic latent image on the

OPC drum surface.

3. Development

Charged toner adheres to the electrostatic latent image of the OPC drum by electrostatic

power, and forms a visible image on the OPC drum surface.

4. Transfer

Paper is placed over the OPC drum surface and an electric charge is applied to it from

the back side by the transfer roller, so that the toner image is transferred to the paper.

5. Drum cleaning

The drum cleaning blade removes toner remaining on the OPC drum after the transfer.

6. Removal of Electricity

7. Belt cleaning

The belt cleaning blade removes toner remaining on the belt.

8. Fuser

Heat and pressure are applied to the toner image on the paper to promote its fusion.

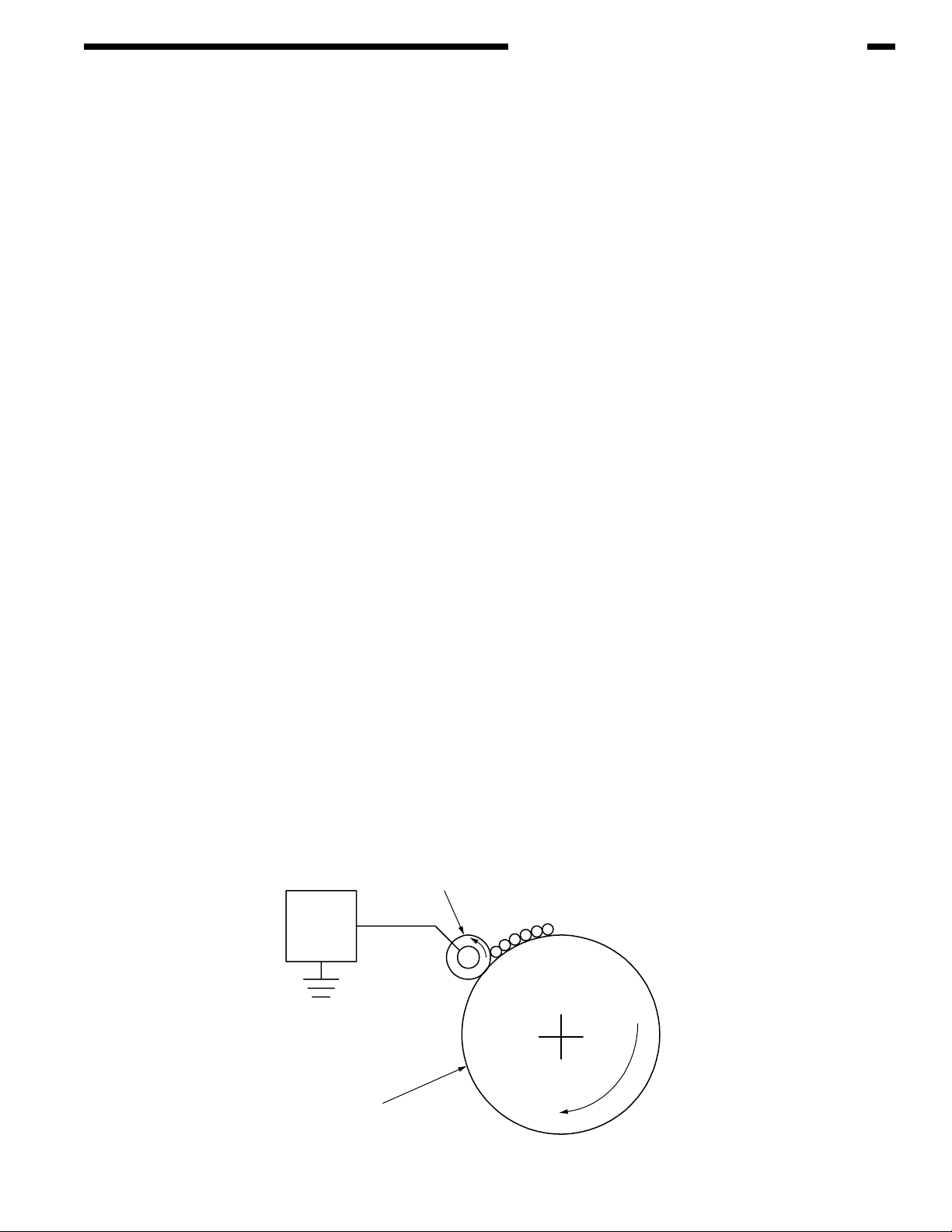

1. Charging

A voltage is applied to the charging roller, which is placed in contact with the OPC drum

surface, to charge the OPC drum surface.

Charging roller

Power

Supply

Unit

-

-

-

-

-

-

OPC drum

2-1

Page 18

CHAPTER 2 EXPLANATION OF OPERATION

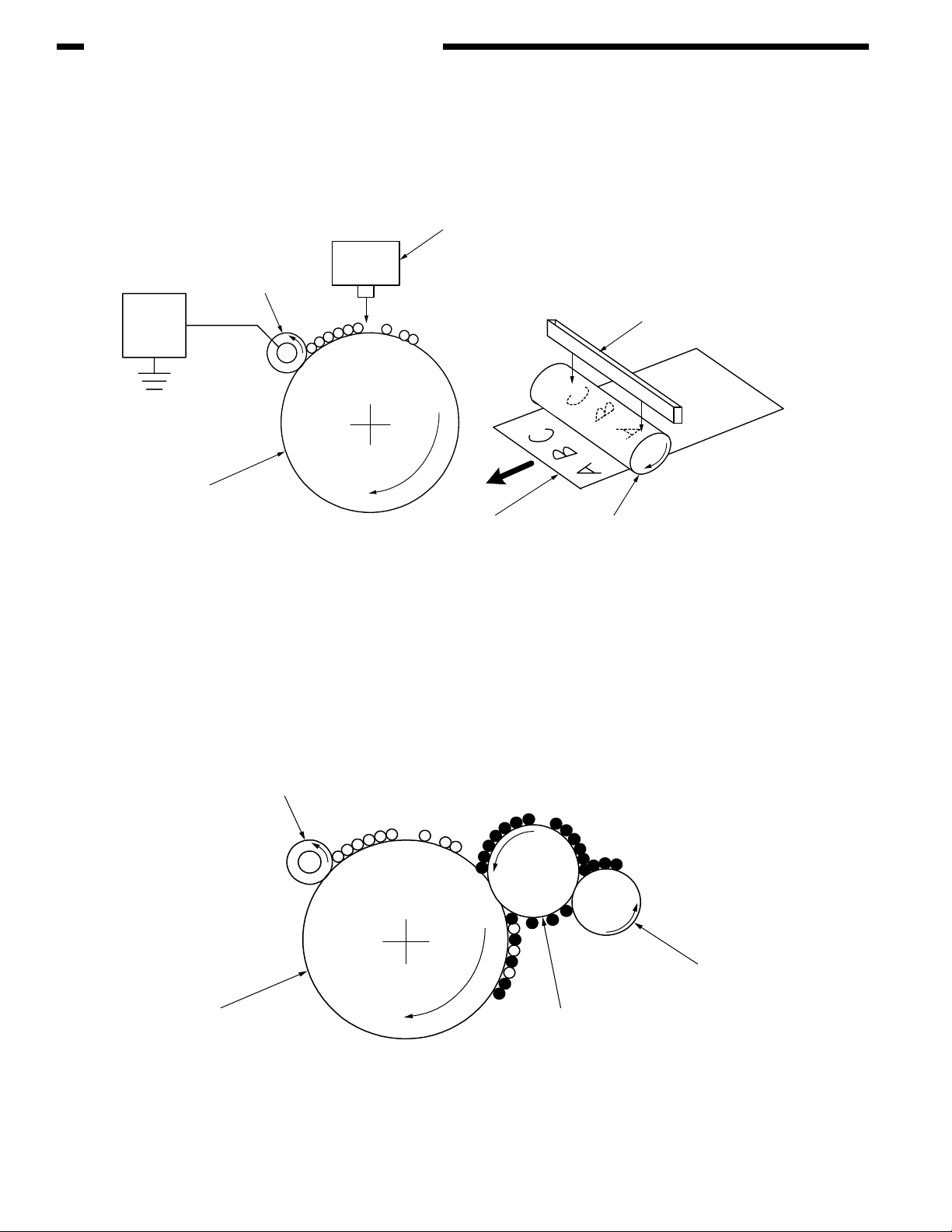

2. Exposure

The light emitted from the LED head is radiated onto the charged surface of the OPC drum.

The charge of the radiated part of the OPC drum attenuates according to the intensity of the

light, forming an electrostatic latent image on the OPC drum surface.

Charging roller

LED head

Power

Supply

Unit

OPC drum

-

-

-

-

-

-

-

-

-

Paper

LED head

OPC drum

3. Development

Toner adheres to the electrostatic latent image on the drum surface, thereby turning the

electrostatic latent image into a toner image.

1. The sponge roller allows the toner to stick to the development roller.

2-2

Charging roller

-

-

-

-

-

-

-

-

-

-

-

Sponge roller

OPC drum

-

Development roller

2. The electrostatic latent image on the OPC drum surface is turned into a visible image

by the toner.

Page 19

CHAPTER 2 EXPLANATION OF OPERATION

4. Transfer

A sheet of paper is placed over the OPC drum surface, and an electric charge is given to the

paper from its back side by the transfer roller.

When a high voltage is applied to the transfer roller from the power source, the charge induced

on the transfer roller moves on to the surface of the paper through the contact part between

the transfer roller and the paper, the toner being attracted to the paper surface from the OPC

drum surface.

-

-

-

OPC drum

-

-

-

-

-

-

-

-

-

-

Paper

-

-+-

-+-

-+-

Transfer roller

+

+

+

-+-+-+-+-+-

+

-

+

-

+

-

+

-

+

-

+

Power

Supply

Transport belt

Unit

5. Drum cleaning

Unfixed toner remaining on the OPC drum is removed by the drum cleaning blade and

collected into the waste toner area of the toner cartridge.

Waste toner

Toner cartridge

Drum cleaning blade

ID unit

-

-

-

-

-

-

-

-

-

-

-

+

+

+

+

+

-

-

+

+

+

+

+

-

+

-

+

2-3

Page 20

CHAPTER 2 EXPLANATION OF OPERATION

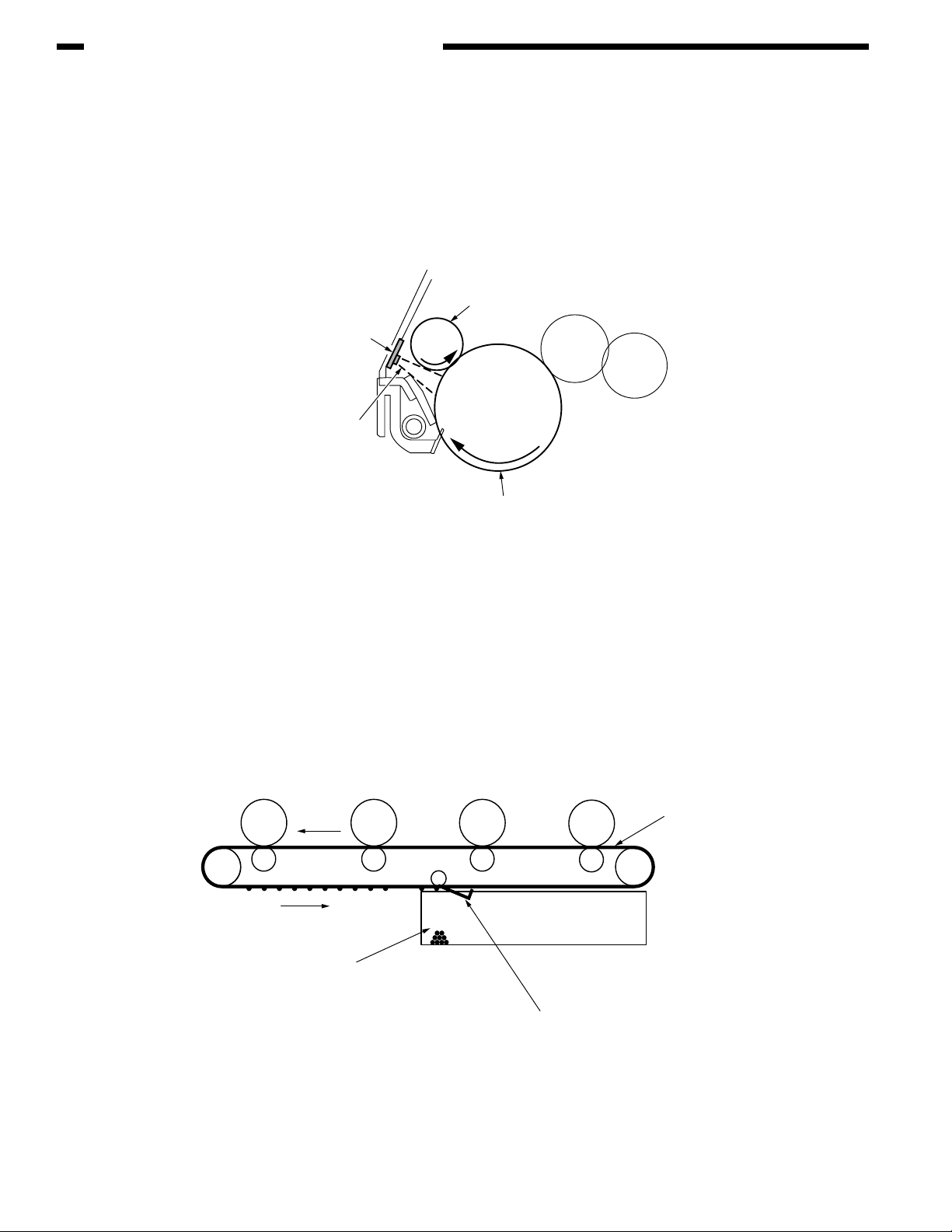

6. Removal of Electricity

Electrically charge on the OPC drum surface decveases by exppsing the OPC drum surface

after transfer to the light.

Board for the light

of the removal of electricity

Light for the

removal of electricity

Charging roller

OPC drum

7. Belt Cleaning

Toner remaining on the transfer belt is scraped off by the belt cleaning blade and collected

into the waste toner box of the transfer belt unit.

Transport belt

2-4

Belt waste toner box

Belt cleaning blade

Page 21

CHAPTER 2 EXPLANATION OF OPERATION

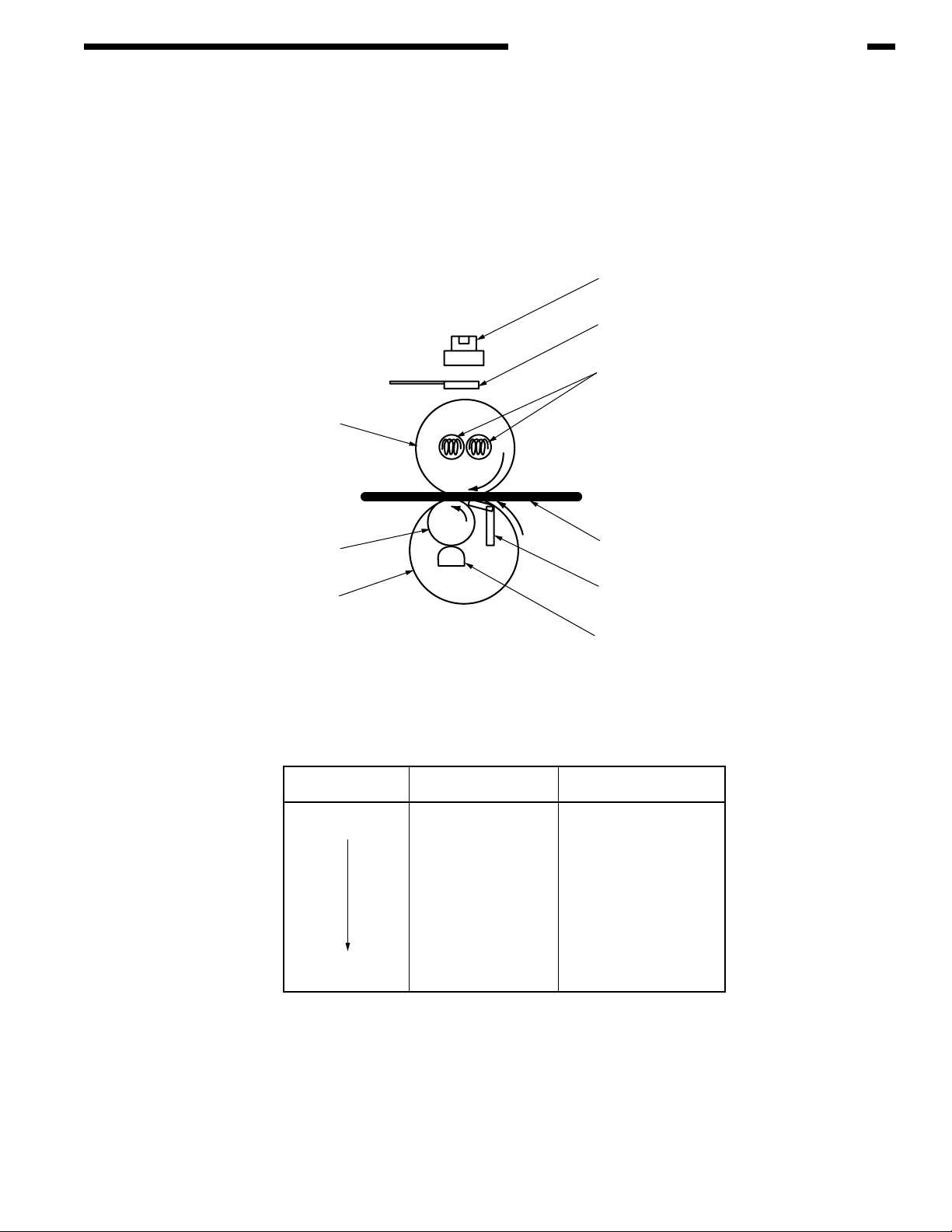

8. Fuser

The toner image which was transferred to the paper is applied heat and pressure as it passes

between the heat roller and the backup roller, and it is therefore fused onto the paper.

For the sake of safety, a thermostat is provided; it comes on to cut off the voltage supplied

to the heater if the heat roller temperature rises above a certain preset temperature.

Thermostat

Thermistor

Halogen Lamp

Heat Roller

Backup Roller

Beit

Fusing Temperature Settings

Paper thickness

Thin

Thick

Paper Type Settings

Light

Medium

Heavy

U.Heavy

OHP

Paper

Pad

Thermistor

Temperature Settings

Medium temp

High temp

Medium temp

Low temp

Low temp

2-5

Page 22

CHAPTER 2 EXPLANATION OF OPERATION

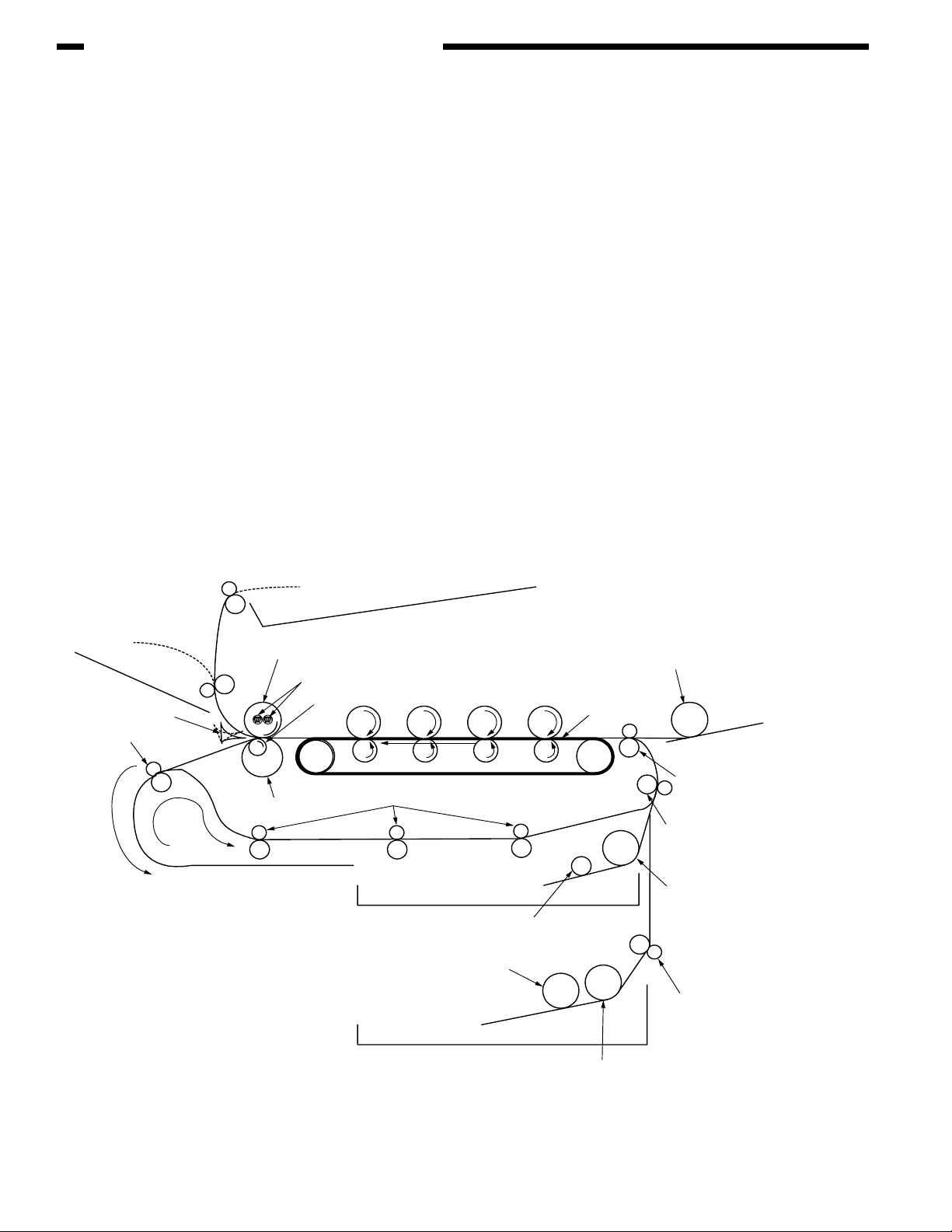

II. PRINTING PROCESS

The paper fed from Tray 1 or Tray 2 is carried by the paper feed roller, register roller L and transport

roller. When the paper is fed from the MPT, it is carried by the MPT paper feed roller and register

roller U. Then, an unfixed toner image is created on the paper transported onto the belt sequentially

through the electrophotographic process of KYMC. Thereafter, the image is fixed under heat and

pressure as the paper goes through the fuser unit. After the image has been fixed, the paper is

unloaded to the stacker either face-up or face-down stacker, according to the outputting method

selected by opening or closing the face-up stacker.

While the above refers to the one-sided print operation of the printer, its operation in two-sided print

will be explained below.

When two-sided print is conducted, the paper that has passed through the fuser unit following first

one-sided print is directed into the Duplex unit by the separator DUP. After entering the paper

reversal transport path, the paper is carried from there to the inside of the Duplex unit by the

inverting operation of the reversal roller. Then, after passed through the Duplex unit by the

transport roller that is located on the transport path inside the Duplex unit, the paper is fed along

the paper feed route of the Duplex unit to eventually merge the same route that comes from the

tray. From here on, the same operation as that of one-sided print of paper fed from the tray takes

place.

Face-up stacker

Separator DUP

Reversal roller

Face-down stacker

Heat roller

Halogen lamp

Backup roller

Belt

Paper reversal transport path

Transport roller

Subroller

Transport belt

Subroller

MPT paper feed roller

MPT

MPT

Register roller

Register roller

Paper feed roller

Transport roller

L

U

2-6

Paper feed roller

Page 23

CHAPTER 2 EXPLANATION OF OPERATION

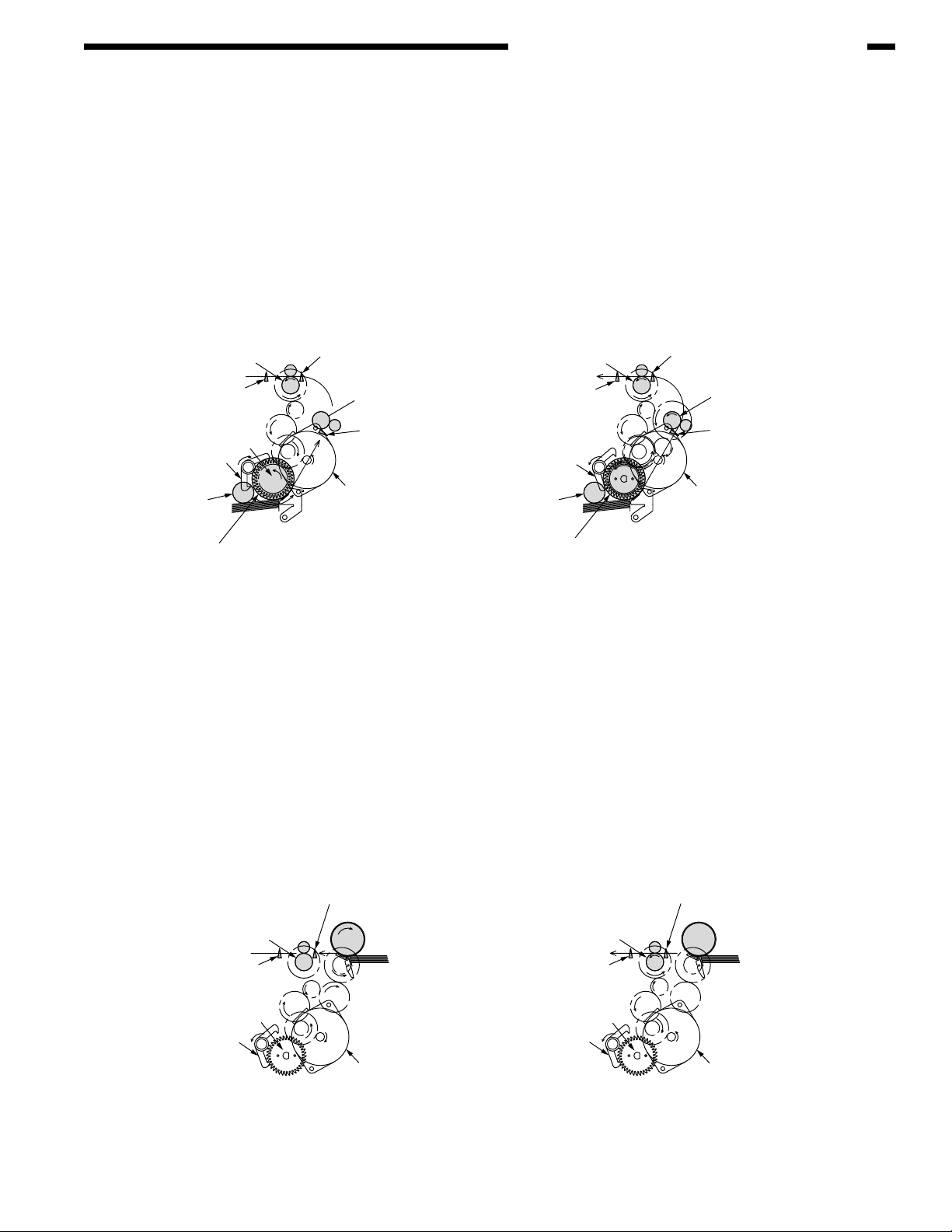

(1) Paper fed from 1st Tray

1. As illustrated in Figure 2-1, when the solenoid is ON, the register motor rotates

(Counterclockwise turn), transporting the paper until the IN1 sensor comes ON. (When the

solenoid is ON, the paper feed roller is driven.)

2. After causing the IN1 sensor to come ON, the paper is further carried over a certain distance

to finally hit register roller L. (This corrects skew of the paper.)

3. As shown in Figure 2-2, the solenoid is turned OFF and the paper is transported by register

roller L. (When the solenoid is OFF, register roller L is driven.)

Register Roller U

(Drive)

WR Sensor

Hopping Gear Assy

Solenoid Lever

(Solenoid ON)

Sub Roller

(Drive)

Hopping Roller

(Drive)

(2) Paper fed from MPT

1. As illustrated in Figure 2-3, when the solenoid is OFF, the register motor rotates (Clockwise

turn), transporting the paper until the IN2 sensor comes ON. (As the register motor rotates

clockwise, the MPT paper feed roller is driven.)

2. After causing the IN2 sensor to come ON, the paper is further carried over a certain distance

to finally hit register roller U. (This corrects skew of the paper.)

IN2 Sensor

Registration Roller L

(Stop)

IN1 Sensor

Solenoid Lever

(Solenoid OFF)

Registration Motor

(CCW)

Paper

Register Roller U

WR Sensor

Sub Roller

(Stop)

(Drive)

Paper

Hopping Roller

(Stop)

Figure 2-1 Figure 2-2

IN2 Sensor

Registration Roller L

(Drive)

IN1 Sensor

Registration Motor

(CCW)

3. As shown in Figure 2-4, the register motor rotates (Counterclockwise turn) to let register

roller U transport the paper. (As the register motor rotates counterclockwise, register roller

U is driven.)

IN2 Sensor

Registration Roller U

(Stop)

WR Sensor WR Sensor

Hopping Gear Assy

Solenoid Lever

(Solenoid OFF)

MPT Hopping Roller

Paper Paper

Hopping Gear Assy

Solenoid Lever

(Solenoid OFF)

Registration Motor

(CW)

Figure 2-3 Figure 2-4

IN2 Sensor

Registration Roller U

(Drive)

Registration Motor

(CCW)

2-7

Page 24

CHAPTER 2 EXPLANATION OF OPERATION

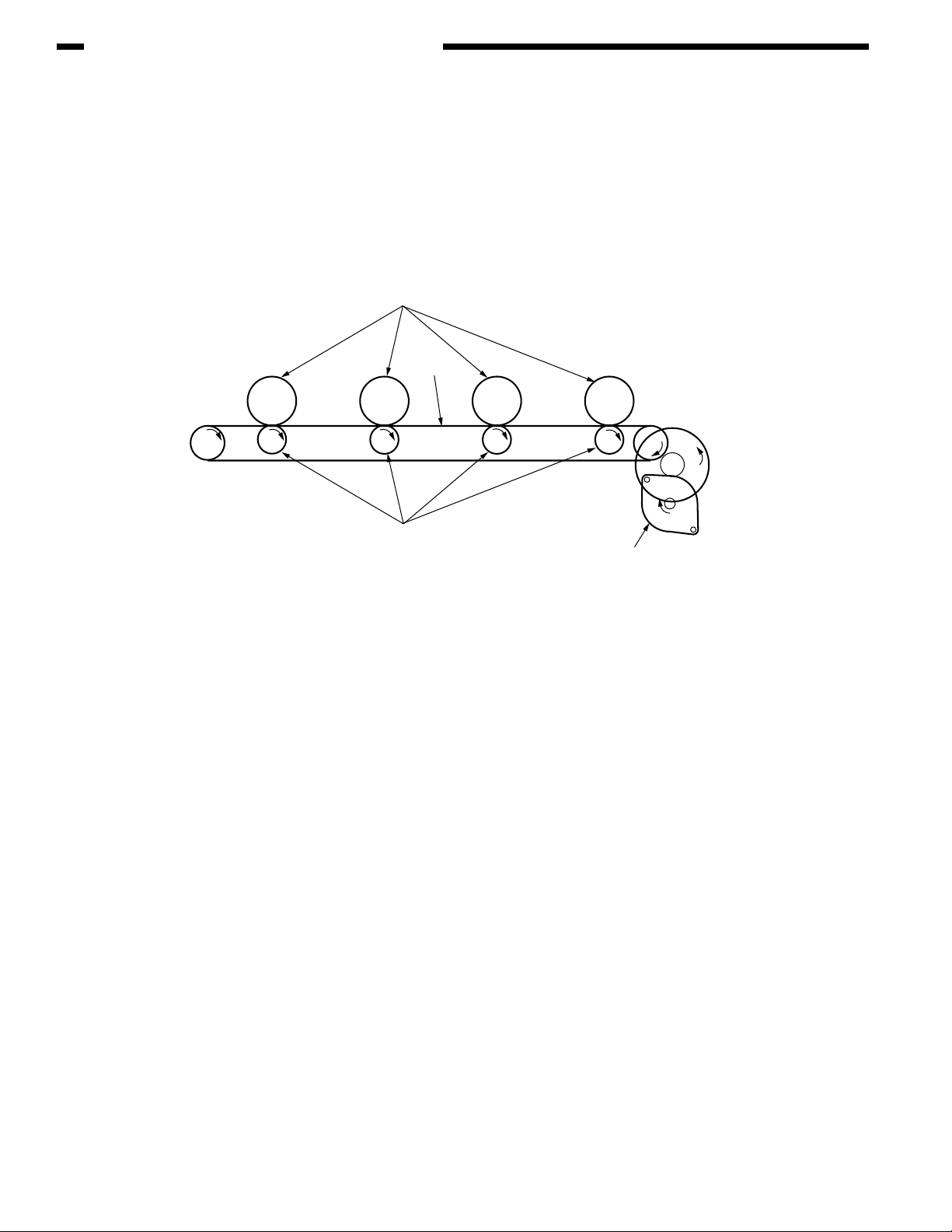

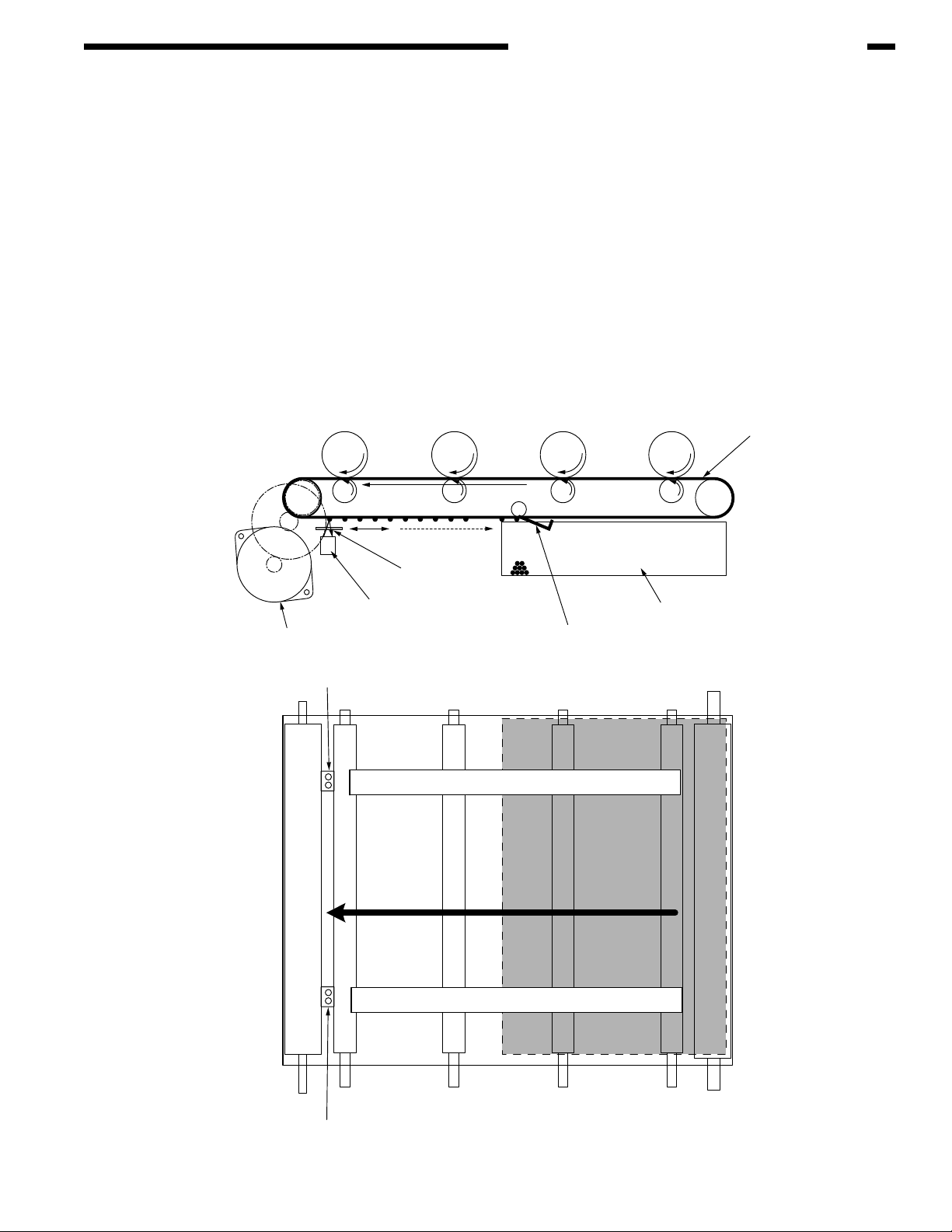

(3) Transport belt

1. As the transport belt motor rotates in the direction of the arrow, the transport belt is driven.

The belt unit consists of one transport roller placed immediately underneath each color

drum, with a transport belt inserted in between them.

As the specified voltage is applied, the transport belt and the transport rollers send the paper

located on the transport belt to the fuser unit while transferring to it the toner image present

on each color drum.

Drum

Carrier belt

K

KYMC

Carrier (transfer) roller

Figure 2-5

Carrier (transfer) belt motor

2-8

Page 25

CHAPTER 2 EXPLANATION OF OPERATION

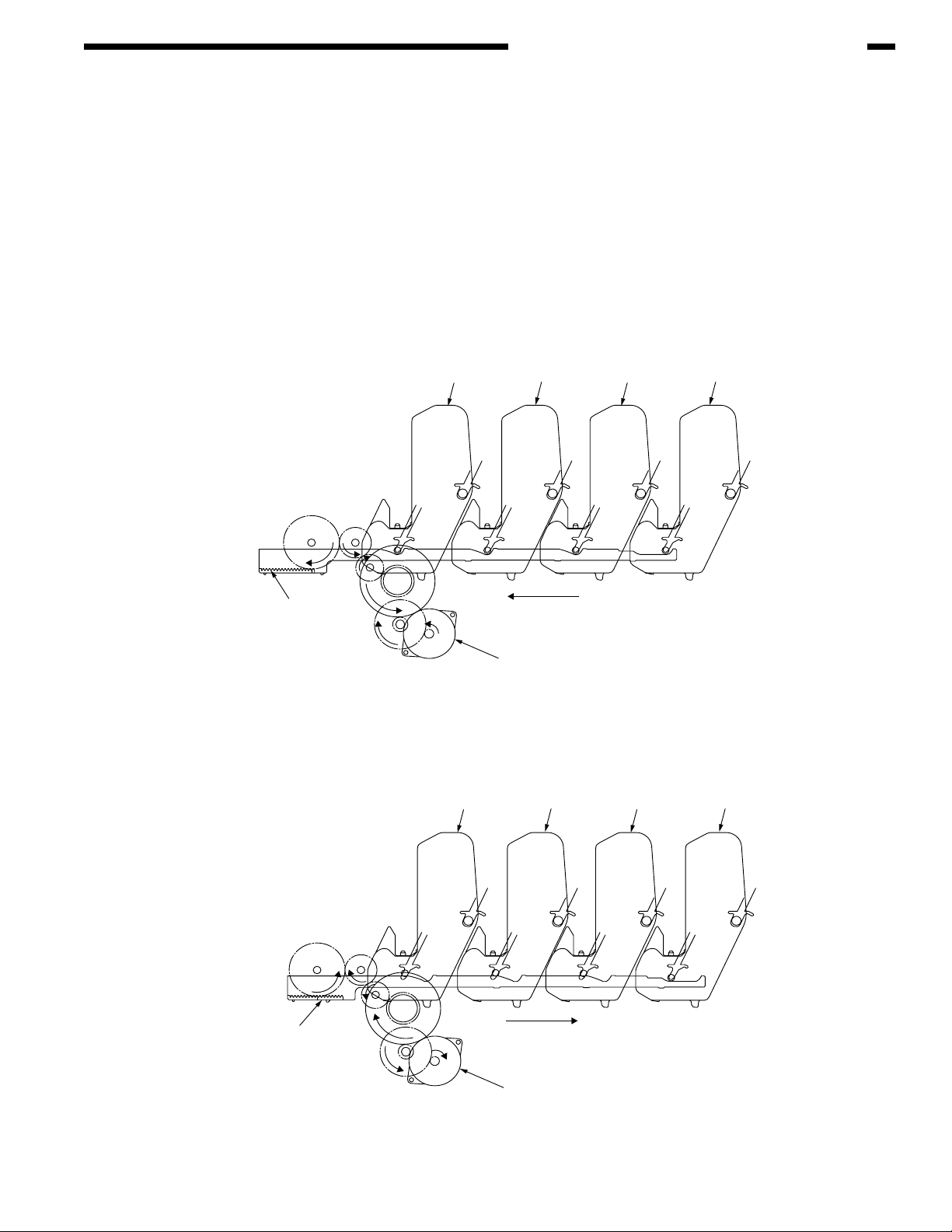

(4) Up/down-motions of ID units

1. The up/down-motions of the ID units take place driven by the lift-up motor.

2. Figure 2-6 shows the motions of the different ID units when the printer is operated for color

print. As the lift-up motor rotates (Clockwise turn), the lift-up link slides to the left, causing

the ID units to come down, as can be seen in Figure 2-6. Namely, the printer is readied for

color print.

3. Figure 2-7 shows the motions of the different ID units when the printer is operated for

monochrome print. As the lift-up motor rotates (Counterclockwise turn), the lift-up link slides

to the right, causing the ID units to go up, except for the K-ID unit, as can be seen in Figure

2-7. Namely, the printer is readied for monochrome print.

ID Unit Operations During Color Printing

C-ID Unit down

C-ID Unit

M-ID Unit down

Y-ID Unit down

K-ID Unit down

M-ID Unit Y-ID Unit K-ID Unit

Lift uplink

Figure 2-6

ID Unit Operations During Monochrome Printing

C-ID Unit

C-ID Unit lift up

M-ID Unit lift up

Y-ID Unit lift up

K-ID Unit down

Lift uplink

C-ID Motor

(CCW)

M-ID Unit Y-ID Unit

K-ID Unit

Figure 2-7

C-ID Motor

(CW)

2-9

Page 26

CHAPTER 2 EXPLANATION OF OPERATION

(5) Fuser unit and paper output

1. As illustrated in Figure 2-8, the fuser unit and delivery roller are driven by the DC motor. As

the fuser motor rotates (Counterclockwise turn), the heat roller is turned. This roller fixes

a toner image by heat and pressure.

2. At the same time, the delivery roller rotates to output the paper.

Eject Roller

(Drive)

Fuser Unit

Heat Roller

(Drive)

Fuser Motor

(CCW)

Figure 2-8

(6) Cover-opening motion of color drift sensor and density sensor

1. As illustrated in Figure 2-9, when the fuser motor rotates (Clockwise turn), the coveropening gear rotates, causing the color drift sensor and density sensor cover to open.

2. As the fuser motor rotates in reverse (Counterclockwise turn), the engagement of the coveropening gear is freed, and the color drift sensor and density sensor cover now closes.

Eject Roller

(Stop)

Heat Roller

(Stop)

Fuser Motor

(CW)

Cover Open Gear

2-10

Figure 2-9

Page 27

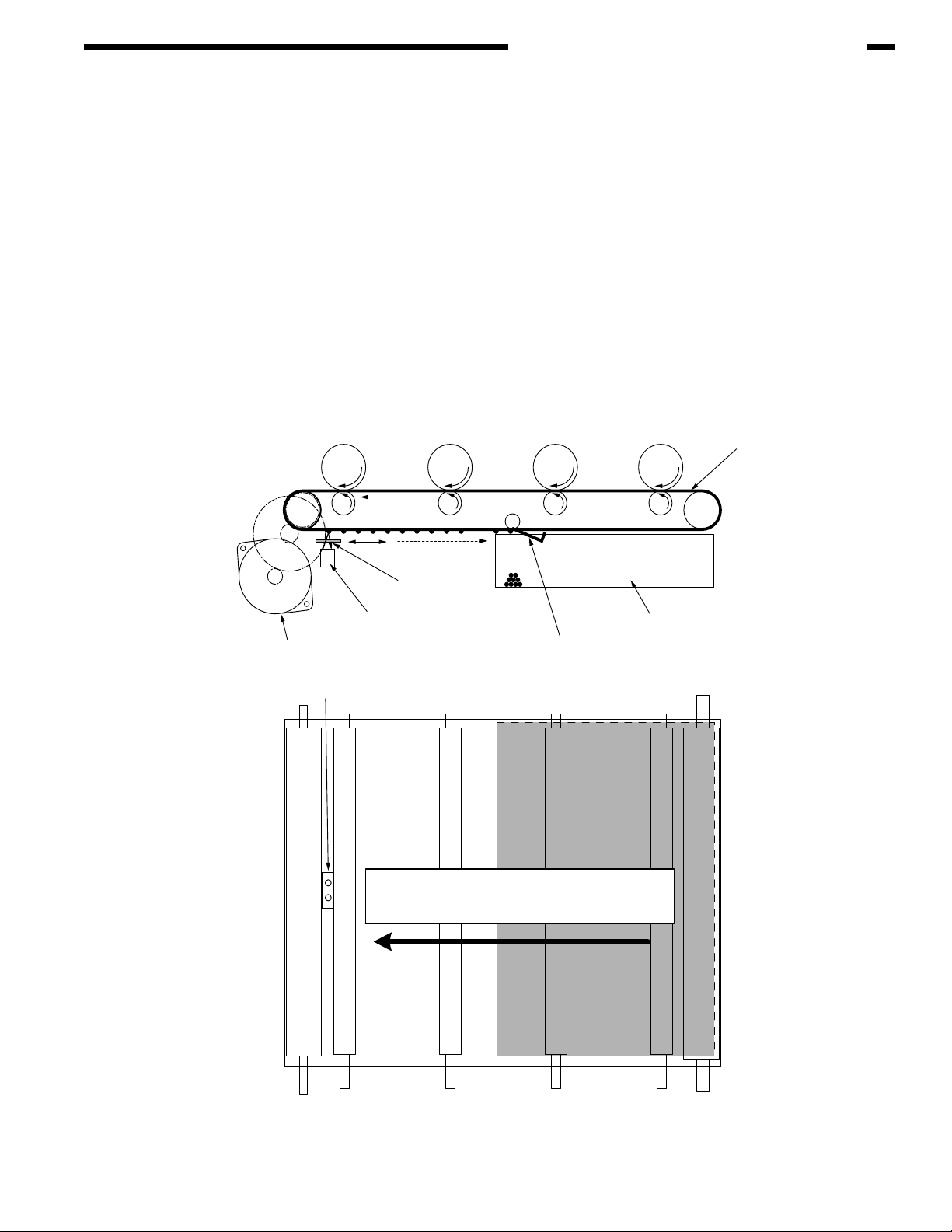

Outline of color drift correction

The color drift correction is implemented reading the correction pattern that is printed on the belt

with the sensor located inside the sensor shutter under the belt unit. This sensor is used to detect

and correct the pattern.

Automatic start timing of color drift correction:

• At power-on

• When the cover is closed after it is opened briefly

• When 400 pages or more have been printed since previous execution

A correction error may be issued due to an inadequate toner amount of the pattern generated,

a sensor stained with toner, deficient opening/closing of the shutter, or for other reasons.

However, even if an error is issued, it is not indicated on the operator panel. Therefore,

forcible color drift correction will have to be performed in the self-diagnostic mode (page 4-21)

to check the error indication.

CHAPTER 2 EXPLANATION OF OPERATION

Transport belt

Belt motor

Color drift sensor

Sensor shutter

Color drift sensor

Right color drift correction pattern

Left color drift correction pattern

Belt waste toner box

Belt cleaning blade

Color drift sensor

2-11

Page 28

CHAPTER 2 EXPLANATION OF OPERATION

Error checking methods and remedial methods

The color drift correction test function among the other self-diagnostic functions is employed to

check errors. (page 4-21)

Remedial methods against different errors

• CALIBRATION (L or R), DYNAMICRANGE (L or R)

Check 1: If the above indication appears, check the connected state of the sensor cable

(FFC).

If the connected state is found abnormal, restore it to the normal state.

Check 2: Check to see whether the sensor surface is stained with toner, paper dust or any

other foreign matter.

If it is found stained, wipe it clean.

Check 3: Check to see whether the sensor shutter opens and closes normally, by the

MOTOR & CLUTCH TEST of the self-diagnostic function. If the shutter operates

imperfectly, replace the shutter unit.

• BELT REFLX ERR

Check 4: If this indication appears, check the cleaned state of the toner remaining on the

belt surface, in addition to making the above checks 1, 2 and 3. Take out the belt

unit, turn the drive gear located on the left rear side, and ensure that the belt

surface has been cleaned thoroughly.

If cleaning is not achieved perfectly and there still remains toner on the belt

surface after the drive gear has been turned, replace the belt unit.

• (Y or M or C) LEFT, (Y or M or C) RIGHT, (Y or M or C) HORIZONTAL

Check 5: If the above indication appears, check to see whether the toner is running short,

based on an NG-issuing color.

Replace the toner cartridge, as needed.

2-12

Page 29

Outline of density correction method

The density correction is implemented reading the correction pattern that is printed on the belt with

the sensor located inside the sensor shutter under the belt unit.

Automatic start timing of density correction:

• If the environment at power-on is greatly different from the one in which previous print was

executed.

• If at least one or more of the four ID count values are close to those of a new product at

power-on.

• When the ID count value exceeds 500 counts since previous execution.

A correction error may be issued due to an inadequate toner amount of the pattern generated, a

sensor stained with toner, deficient opening/closing of the shutter, or for other reasons. However,

even if an error is issued, it is not indicated on the operator panel. Therefore, forcible density

correction will have to be performed in the self-diagnostic mode (page 4-22) to check the error

indication.

CHAPTER 2 EXPLANATION OF OPERATION

Transport belt

Belt motor

Density sensor

Sensor shutter

Density sensor

Density correction pattern

Belt waste toner box

Belt cleaning blade

2-13

Page 30

CHAPTER 2 EXPLANATION OF OPERATION

Error checking methods and remedial methods

The density correction test function among the other self-diagnostic functions is employed to check

errors. (page 4-22)

Remedial methods against different errors

• CALIBRATION ERR, DENS SENSOR ERR

Check 1: If the above indication appears, check the connected state of the sensor cable.

If the connected state is found abnormal, restore it to the normal state.

Check 2: Check to see whether the sensor surface is stained with toner, paper dust or any

other foreign matter.

If it is found stained, wipe it clean.

• DENS SHUTTER ERR

Check 3: Check to see whether the sensor shutter opens and closes normally, by the

MOTOR & CLUTCH TEST of the self-diagnostic function. If the shutter operates

imperfectly, replace the shutter unit.

• DENS ID ERR

Check 4: Take out the ID unit and examine it to see if the drum surface has any abnormal

toner smudge.

Replace the LED head (Blurred focus), or replace the ID unit.

To test-operate a new ID unit, use the Fuse Keep Mode of the maintenance

menu.

2-14

Page 31

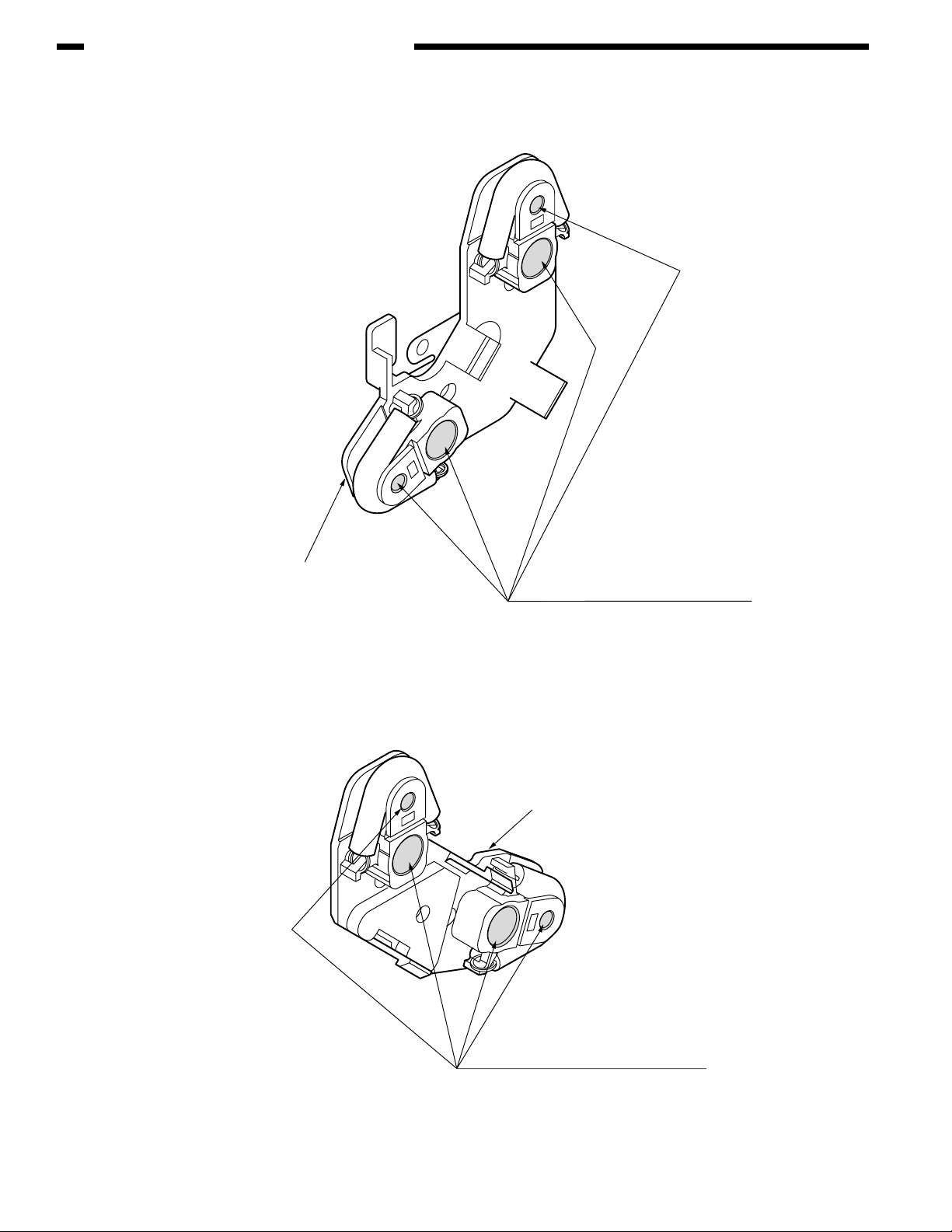

Principle of toner sensor detection

Toner LOW is detected by the toner sensor (Reflection sensor) installed inside the printer. The

shielding plate is mounted inside the ID and rotates in synchronization with toner agitation.

Moreover, the ID has a shutter fitted. The shutter is synchronized with the operation lever of the

toner cartridge, and the toner sensor can detect that the toner cartridge has been loaded properly.

Detection may not take place normally, and a toner sensor error may be issued, if the shield plate

or toner sensor is stained with toner, or if the ID unit and toner sensor do not remain exactly opposite

to each other in their positions.

CHAPTER 2 EXPLANATION OF OPERATION

Shutter

Toner Sensor

Principle of toner counter

After image data is developed to binary data which the printer can print, it is counted by an LSI as

a number of print dots. The amount of toner consumed is calculated from that count value, and the

remaining amount of toner is thus indicated. As opposed to this, the toner LOW detection by the

toner sensor is implemented when the toner amount remaining inside the ID unit physically

decreases to below a certain level.

Principles of ID, belt and Fuser counters

ID counter: One count represents the value that results from dividing the amount of rotation

of the drum by three when three A4-size sheets are printed continuously.

Belt counter: One count represents the value that results from dividing the amount of rotation

of the belt by three when three A4-size sheets are printed continuously.

Fuser counter: One count is registered when paper is shorter than the length of Legal 13-inch

paper. When paper is longer than that, the count number is determined by the

number of times the Legal 13-inch paper length is exceeded. (Decimal fractions

rounded up)

Shield

plate

2-15

Page 32

CHAPTER 3

INSTALLATION

I. CAUTIONS, AND DO’S AND

DON’TS ............................................. 3-1

II. UNPACKING METHOD..................... 3-2

III. PRINTER INSTALLATION

INSTRUCTIONS................................ 3-3

IV. LISTING OF COMPONENT UNITS

AND ACCESSORIES ........................ 3-4

V. ASSEMBLING METHOD................... 3-5

A. Assembly of printer main body ..... 3-5

B. Connection of power cable......... 3-11

C. Installation of optional items....... 3-14

D. Confirmation of recognition

of optional items ......................... 3-22

VI. MENU MAP PRINT .........................3-23

VII. CONNECTION METHODS .............3-24

VIII. CONFIRMATION OF PAPER

USED BY THE USER...................... 3-25

Page 33

I. CAUTIONS, AND DO’S AND DON’TS

• Do not install the printer at high temperature or near fire.

• Do not install the printer in a location where chemical reaction can take place (laboratory, etc.).

• Do not install the printer in the proximities of inflammable solvents, such as alcohol, paint thinner,

etc.

• Do not install the printer within reach of small children.

• Do not install the printer in an unstable location (e.g., on a rickety bench or grade).

• Do not install the printer in a location laden with moisture or heavy dust, or in direct sun.

• Do not install the printer in an environment with sea wind or corrosive gas.

• Do not install the printer in a location with heavy vibration.

• In the event that the printer is inadvertently dropped or its cover is damaged, remove the power

plug from the power outlet and contact Customer Center.

Such mishap could lead to an electric shock, fire or injury.

• Do not connect the power cord, printer cable or grounding wire in any other manner than the way

specified in the manual. Failure to observe the above could result in fire.

• Do not stick in an object into the vent hole.

Such action could lead to an electric shock, fire or injury.

• Do not place a glass filled with water or the like on the printer.

Such action could lead to an electric shock or fire.

• When the printer cover has been opened, do not touch the fuser unit.

Burns could be suffered.

• Do not throw the toner cartridge or the image drum cartridge into fire.

Dust explosion could cause burns.

• Do not use a highly combustible spray near the printer.

Fire could be caused, since the printer contains a part that gets extremely hot inside.

• In the event that the cover becomes unusually hot, emits smoke, ill odor, or abnormal noise,

remove the power plug from the power outlet and contact Customer Center.

Fire could break out.

• If water or any other liquid enters the inside of the printer, remove the power plug from the power

outlet and contact Customer Center.

Fire could break out.

• If a pao not operate or disassemble the printer in any other manner than the way specified in the

manual.

Failure to observe this warning could result in an electric shock, fire or injury.

CHAPTER 3 INSTALLATION

3-1

Page 34

CHAPTER 3 INSTALLATION

• Do not install the printer in a location where its vent hole is blocked.

• Do not install the printer directly on a shaggy carpet or rug.

• Do not install the printer in a sealed room or other location with poor ventilation or permeability.

• Install the printer away from a heavy magnetic field or noise source.

• Install the printer away from a video monitor or TV.

• To move the printer, hold it by both sides of it.

• This printer, which weighs Approx. 29kg (with Duplex)/Approx. 26kg (w/o Duplex), should be lifted

up by two or more persons.

• When the printer has the power switched on or is printing, do not come close to the paper delivery

section.Such action could lead to injury.

When the precautionary notes concerning the installation and operation are explained, the user

should be referred to the precautionary notes given in the User's Manual. Especially, give thorough

explanation on the power cord and grounding wire.

1+

II. UNPACKING METHOD

Personal injuries may occur.

Make sure to lift up this printer by two or more persons, since it weighs Approx. 29kg (with Duplex)/

Approx. 26kg (w/o Duplex)

• Remove the four handles from the sides of the box and lift up the corrugated fiberboard

box.

3-2

Page 35

CHAPTER 3 INSTALLATION

III. PRINTER INSTALLATION INSTRUCTIONS

• Install the printer in a location where the following temperature and humidity are met:

Ambient temperature: 10 - 32˚C

Ambient humidity: 20 - 80 %RH(Relative humidity)

Max. wet-bulb temperature: 25˚C

• Use caution to avoid dew condensation.

• If the printer is installed in a location with ambient relative humidity below 30%, use a

humidifier or antistatic mat.

Installation space

• Place the printer on a flat desk large enough to accommodate its footings.

• Provide ample spaces around the printer.

Plan view

60cm

Side View

20cm

20cm

100cm

60cm

20cm

100cm

20cm

70cm70cm

3-3

Page 36

CHAPTER 3 INSTALLATION

IV. LISTING OF COMPONENT UNITS AND ACCESSORIES

• Check to make sure that the component units are free from damage, dirt or other irregularities

in the appearance.

• Ensure that none of the accessories to the units is missing and that they are free from

breakage or other flaw.

• If any irregularity is discovered, contact User Management Section for instructions.

Personal injuries may occur.

Make sure to lift up this printer by two or more persons, since it

weighs Approx. 29kg (with Duplex)/Approx. 26kg (w/o Duplex)

Printer (Main body)

AR-C265P

Image drum cartridges (4 sets) fitted with starter toner cartridges (Installed in the printer)

Inform the user that the toner cartridges and image drum cartridges can be separated one from

the other.

Printer software CD-ROM

LED lens cleaner

Power cord

Warranty Card and User Registration Card

User's Manual (Setup)

User's Manual (CD-ROM)

Quick Guide

Dedicated bag for Quick Guide

3-4

Note!

No printer cable is supplied with the printer.

Page 37

V. ASSEMBLING METHOD

A. Assembly of printer main body

Removing the protective materials

1) Peel off the protective tapes (5) and the slip of paper from the front part of the printer,

and also peel off the protective tapes (2) from the back of the printer.

Slip of paper

CHAPTER 3 INSTALLATION

Protective Tape

2) Draw out the paper cassette.

3) Pull out the retainer forward.

4) Open the top cover by pressing the OPEN button.

Retainer

Paper cassette

OPEN button

5) Detach the stopper release (Orange) while pressing down the lever (Blue) of the fuser unit

in the direction of arrow 1.

Note!

Instruct the user of the printer to be sure to keep the stopper release, which is used for

transporting the printer, at hand.

Lever (Blue) of fuser unit

Protective Tape

1

212

Stopper release (Orange)

3-5

Page 38

CHAPTER 3 INSTALLATION

Installing the image drum cartridges

1) Take out the image drum cartridges (4) gently along with the toner cartridges attached.

Note!

• The image drum (Green tubular section) is extremely vulnerable. Exert good caution in

handling it.

• Do not expose the image drum cartridges to direct sun or intense light (1500 lux or

more). Do not expose them to the room lighting for over five minutes.

• In the above operation, be careful not to actuate the blue lever of the toner cartridge.

Toner cartridge

Image drum cartridge

2) Place the image drum cartridge on a flat-top desk or the like, peel off the tape fastening

protective sheet 1, and pull out the sheet in the direction of the arrow.

Note!

Do not work with the image drum floating in the air.

Protective sheet 1

Tape

Protective sheet 1

Protective sheet 2

3) Pull out protective sheet 2 from the image drum cartridge in the direction of the arrow.

3/ Protective sheet

Protective sheet 2

3-6

Page 39

CHAPTER 3 INSTALLATION

4) Match the label colors of the image drum cartridges to those on the printer.

5) Gently put the image drum cartridges (4) back in their respective positions.

Label

Image drum cartridge

Labels

6) Turn the blue levers (4) of the toner cartridges fully into the direction of the arrow.

Note!

• The starter toners (Toner cartridges supplied with the product) can print approximately

1500 A4-size sheets with 5% print density.

• If the error message [CHECK TONER CARTREGE] nstays permanently on the

operator panel,check to make sure that the levers of the toner cartridges have fully

been moved in the direction of the arrow.

• If normal starter toner cartridges have been used, the starter toners can no longer be

used. First use the starter toners, and use normal toners after the starter toners are

exhausted.

• Make sure to change the starter toners only after [REPLACE TONER] is indicated.

If the starter toners are replaced before the above message appears, the correct toner

remaining level will not be able to be indicated.

Blue

Lever

3-7

Page 40

CHAPTER 3 INSTALLATION

1) Pull out the paper cassette.

Note!

Do not peel off the rubber attached to the plate.

2) Set the paper stopper securely, according to the paper size.

Paper stopper

3) Loosen the paper well and line up its vertical and lateral edges.

Paper guide

Plate

4) Load the paper with the print face down.

Note!

• Place the paper aligned to the forward end of the paper cassette.

• Load the paper by avoiding to exceed the (

70kg ream weight paper).

5) Fasten the paper with the paper guides.

6) Put the paper cassette back into the printer.

mark

) mark of the paper guide. (300 sheets of

Print face down

3-8

Paper guide

Indication of remaining

amount of paper

Page 41

Loading paper in the multi-purpose tray

1) Open the multi-purpose tray and also the paper supporter.

2) Set the manual feed guide to the paper size.

3) Line up the vertical and lateral edges of the paper.

CHAPTER 3 INSTALLATION

Multi-purpose tray

Manual feed guide

Multi-purpose tray

Paper supporter

Manual feed guide

4) Insert the paper, print-face up, along the manual feed guide straight as far as it will go.

mark

5) Press the set button.

Set button

3-9

Page 42

CHAPTER 3 INSTALLATION

Storing the Quick Guide

Paste the dedicated Quick Guide bag to the printer, and put the Quick Guide in it.

Turning back the dedicated Quick Guide bag and peeling off the adhesive double coated tapes (2).

Adhesive double coated tapes

Pasting the dedicated bag to the printer.

Vent hole

Dedicated Quick Guide bag

Note!

When pasting the bag, avoid blocking the vent hole of the printer.

Quick Guide

3-10

Page 43

B. Connection of power cable

Power requirements

• Observe the following conditions:

AC: 115 V ± 10%

Power frequency: 60Hz ± 2Hz Approx.

• If the available power is unstable, have it inspected and corrected by a qualified electrician.

• The maximum power consumption of this printer is 1200W. Ensure that the power source offers

an ample margin in the power capacity.

It may expose you to electric shocks or cause a fire.

• Always before connecting or disconnecting the power cord and grounding wire, first turn off the

power switch.

• The grounding wire should be connected to a grounding terminal. Do Not in any event tie it to a

water service piping, gas piping, ground of telephone lines, lightning arrester or the like.

• When plugging in or unplugging the power cord, be sure to hold the power plug.

• Insert the power plug securely into the power outlet as far as it will go.

• Do not insert or remove the power plug with a wet hand.

• Lay the power cord in a location where it is not likely stepped on, and avoid placing anything on

the power cord.

• Do not bundle or tie the power cord.

• Do not use a damaged power cord.

• Avoid a starburst connection of cables.

• Do not connect the printer to the same power outlet shared by other electric appliances.

Especially, if the printer is connected to the same power outlet in conjunction with an airconditioner, copy machine or shredder, electric noise may cause false operation of the printer. If

it is inevitable to connect them to the same power outlet, use a commercial noise filter or noisecut transformer.

• Operate the printer with the supplied power cord only.

• Do not use an extension cord. If it is inevitable to use an extension cord, use one with rating of 15A

or more.

• Use of an extension cord may hinder the printer from operating normally because of voltage drop.

• Do not turn off the power or pull out the power plug while the printer is printing.

• If the printer is going to be placed out of use for an extended period of time due to a long spell of

CHAPTER 3 INSTALLATION

About the connections of the power cord and grounding wire, the user should be given thorough

explanation on the basis of the User's Manual.

3-11

Page 44

CHAPTER 3 INSTALLATION

During holidays or a trip out of town, unplug the power cord.

Connecting the power cord

Note!

Ensure that the power switch is in OFF (O).

1) Insert the power cord into the printer.

2) After connecting the grounding wire to the ground terminal of the power outlet, insert the

power plug into the power outlet.

OI

Ground terminal

Grounding wire

Pressing ON (|) of the power switch

The following indication will be produced on the operator panel, and [Online] will appear when the

printer has started up completely.

OI

RAM checking

* * * * * * * * * * * * * * * *

Initializing

3-12

PLEASE WAIT

[Online] and [Inspect] lights

and backlight flash.

Online

Tray 1

Page 45

Turning off the power

On the AR-C265P which is not equipped with the built-in type hard disk (optional) the power

can be turned off as is.

CHAPTER 3 INSTALLATION

OI

Note!

On the AR-C265P equipped with the built-in type hard disk (optional), do not outright

turn off the power, but follow the procedure described below.

Note!

Do not turn off the power while the printer is printing.

• Abrupt disconnection of the power could damage the built-in hard type disk, disabling

it.

• [SHUTDOWN MENU] is displayed only when the printer is equipped with the optional

built-in type hard disk.

(1) Press the "Back" switch for four seconds or longer to cause

[SHUTTING DOWN] to appear.

(2) Press the "Set" switch.

[SHUTDWN] is displayed, and the shutdown processing begins

(3) When [PLEASE POW OFF/SHUTDOWN COMP] shows up, press OFF (O) of the power

switch.

OI

3-13

Page 46

CHAPTER 3 INSTALLATION

C. Installation of optional items

(1) Installation of expansion memory set

AR-C265P expansion memory

Model name

Memory volume

(Total memory volume)

None (Standard)

AR-C265SM1

AR-C265SM2

Note!

• Be sure to use genuine Sharp parts. If any other parts are used, the printer will not

256MB (256MB)

+256MB (512MB)

+512MB (768MB)

function.

• Adding 64-MB memory is recommended for (600 x 600dpi x 2bit) banner-sheet printing.

Added 64-MB memory may reduce the time for (600 x 1200dpi or 600 x 600 x 2bit)

duplex printing.

• To conduct long print on the AR-C265P, it is recommended to add a 256MB

expansion memory.

• There is only one memory slot.

Turning OFF the printer power and disconnecting the power cord

Note!

If an expansion memory is installed with the power switched ON, the printer may be

broken.

OI

Opening the top cover and front cover

3-14

OPEN button

Handle

Top cover

Front cover

Front cover

Page 47

Remove Side Cover

1) Loosen the screw (1).

2) Remove the side cover.

To remove the side cover, slide it while holding up its upper part.

Front cover

Top cover

CHAPTER 3 INSTALLATION

Screw

1

Side cover

Installing the memory

1) Before taking the memory out of the bag, place the bag in contact with a metal part to

fuser eliminate its static electricity.

2) Insert the memory into the idle slot.

3) Ensure that it is securely fastened by the right and left lock levers.

Note!

• Do not touch the electronic parts and connector pins.

• Pay attention to the orientation of the memory. The terminal part of the memory has a

notch, which is designed to engage with the connector of the slot.

2

3-15

Page 48

CHAPTER 3 INSTALLATION

Attaching the side cover

1) Mount the side cover.

2) Fasten it with the screw (1).

3) Close the top cover and front cover.

Front cover

3

Top cover

3

2

Screw

Side cover

1

(2) Installation of second tray unit

This tray is intended to increase the amount of paper that can be loaded in the printer. It holds

530 sheets of 70kg ream weight paper, allowing to print 930 sheets continuously when

combined with the standard paper cassette and multi-purpose tray.

Type: AR-C265PFU

Turning OFF the printer power and disconnecting the power cord

3-16

Note!

If an expansion memory is installed with the power switched ON, the printer may be

broken.

OI

Page 49

Placing the printer on the second tray unit.

CHAPTER 3 INSTALLATION

Note!

The printer weighs Approx. 29kg (with Duplex)/Approx. 26kg (w/o Duplex). It should be

lifted up by two or more persons.

1) Align the holes in the bottom of the printer to the protrusions of the second tray unit.

2) Place the printer gently on the second tray unit.

To detach the second tray unit, follow the same procedure inversely.

Holes in the printer bottom

Protrusions

(3) Installation of duplex unit

This unit is used for printing on two sides of paper.

Note!

For two-sided printing, it is recommended to add an expansion memory. For details,

see "Expansion memories."

Type: AR-C265PADU

Turning OFF the printer power and disconnecting the power cord

Note!

If an expansion memory is installed with the power switched ON, the printer may be

broken.

OI

3-17

Page 50

CHAPTER 3 INSTALLATION

Peeling the protective tapes off the duplex unit

Install Duplex Unit

1) Insert the duplex unit into the lower part on the back of the printer as far as it will

2) Ensure that the claw on either side of the duplex unit is securely accommodated

in the hole of the printer.

Protective tapes (2)

go.

Holes

Claws

Two-sided print unit

(4) Installation of built-in type hard disk

This is a built-in type hard disk to be added to the printer. It is used to conduct confirmation print,

authentication print, to store print jobs, or to make buffer print, and also when the [ COLLATE

FAIL] is indicated in a section-by-section print. Fonts cannot be downloaded to it.

Note!

When the printer has a built-in type hard disk installed, make certain to switch off the

printer after executing the shutdown menu. If the power is turned off outright, the hard

disk may be damaged and broken.

Type: AR-C265HD

3-18

Memo

The hard disk is segmented into the three partitions of "PCL," "Common" and "PSE."

When the printer is shipped out of the factory or the hard disk is initialized, the following

sizes are assigned to the partitions:

Page 51

CHAPTER 3 INSTALLATION

Turning OFF the printer power and disconnecting the power cord and printer cable

Note!

If an expansion memory is installed with the power switched on, the printer may be

broken.

Opening the top cover and front cover

1) Open the top cover by pressing the OPEN button.

OI

Top cover

Front cover

OPEN button

Handle

2) Push up the handle located in the center of the front cover and pull the front cover forward.

Front cover

Note!

The way the front cover is opened is different from that of the multi-purpose tray. (See

figure below.)

Multi-purpose tray

3-19

Page 52

CHAPTER 3 INSTALLATION

Detaching the side cover

1) Loosen the screw (1).

2) Remove the side cover.

To remove the side cover, slide it while holding up its upper part.

Front cover

Top cover

2

1

Screw

Side cover

Memo

If you have difficult detaching the side cover, check to see if the front cover is open.

Installing the built-in type hard disk

1) Insert part "a" of the built-in type hard disk into hole "b" of the printer main body, and align

the positions of the screw holes.

2) Install the two screws.

3) Push in the connector, until it snags in there with a click.

Front cover

b

Multi-purpose tray

3-20

a

Connector

Hard disk

Page 53

Attaching the side cover

1) Mount the side cover.

2) Fasten it with the screw (1).

3) Close the top cover and front cover.

Front cover

3

Top cover

3

1

CHAPTER 3 INSTALLATION

Screw

2

Side cover

Connecting the power cord and printer cable to the printer, and turning on the

power

Executing the Menu Map print, and ensuring that the built-in type hard disk has

been installed properly.

1) Execute the Menu Map print.

Conduct the Menu Map print by referring to "VI. Menu Map print."

2) Ensure that the capacity of the built-in type hard disk is indicated in "HDD."

Memo

Note!

The capacity of the hard disk may be different from the example shown above.

If no HDD capacity is indicated, redo the installation of the built-in type hard disk.

Then, setting needs to be made with the printer driver to have the built-in type hard disk

recognized.

If there is no printer driver set up, see Sections 3 to 9 of the Setup Part of the User's Manual,

and set up the printer driver. Then, make the setting.

3-21

Page 54

CHAPTER 3 INSTALLATION

D. Confirmation of recognition of optional items

To check to see whether or not the optional items have been installed properly, execute the Menu

Map print by referring to "VI. Menu Map print".

(1) Confirmation of recognition of expansion memory

Checking the contents of the Menu Map.

Check the total memory volume indicated in "Total Memory Size" of the header.

(2) Confirmation of recognition of second tray

<Confirmation of recognition of second tray>

Check the contents of the Menu Map.

Ensure that "Tray 2" is displayed in "Media Menu."

(3) Confirmation of recognition of duplex unit

<Confirmation of recognition of duplex unit>

Check the contents of the Menu Map.

Ensure that [Ryomen insatus: installed] is displayed in the header section.

3-22

Page 55

VI. MENU MAP PRINT

This print is intended to ensure that the printer operates normally.

1) Load Letter paper in the tray.

2) Press the "Menu +" switch several times to cause [Information Menu] to be displayed.

3) Press the "Set" switch to cause [PRINT MENU MAP/EXECUTE] to appear.

4) Press the "Set" switch.

The Menu Map print will get under way. (Two pages)

When [Network] is displayed and the "Set" switch is pressed in (3) above, network

information will be printed.

Or, press and hold down for two seconds or longer the push switch above the network

connector on the back of the printer main unit.

(Sample)

CHAPTER 3 INSTALLATION

AR-C265P

3-23

Page 56

CHAPTER 3 INSTALLATION

VII. CONNECTION METHODS

<USB connection>

Preparing a USB cable

Note!

• No printer cable is supplied with the printer. Provide one separately.

• Prepare a USB type cable separately.

• When connection is to be made in "Hi-Speed" mode of USB2.0, use a USB cable

conforming to the Hi-Speed specification.

Switching OFF the printer and computer

Memo

The USB cable can be plugged in or unplugged with the computer and printer switched

ON. However, to be able to conduct the subsequent installation of the printer driver and

USB driver securely, the power to the printer should be turned OFF.

Interconnecting the computer and the printer

1) Plug the USB cable into the USB interface connector of the printer.

2) Plug the USB cable into the USB interface connector of the computer.

3-24

Note!

USB interface connector

Be careful not to plug the USB cable into the network interface connector. Such wrong

connection could cause malfunction.

Page 57

<LAN cable connection>

Preparing a LAN cable

Switching off the printer and computer

1) Plug the Ethernet cable into the Network interface connector of the printer.

2) Insert the Ethernet cable into the hub.

Network interface connector

CHAPTER 3 INSTALLATION

VIII. CONFIRMATION OF PAPER USED BY THE USER

Load the media used by the user in the printer, make Media Type/Weight settings, execute the

Menu Map/Demo print, and check to make sure that the printouts are free from toner flaking.

2

for

Light

Medium

Heavy

Ultra heavy

-

-

film

Regular

3

paper*

Postcard*

Envelope*

Label paper

Transparency

5

*

4

4

film

WeightTypes

2

55-64kg (64-74g/m

65-89kg (75-104g/m

90-103kg (105-120g/m

104-172kg (121-200g/m

Less than 0.1-0.17mm

0.17-0.2mm

)

2

)

-

-

-

Setting values of the operation

panel

Media weight

Light

Medium

2

)

2

)

Heavy

Ultra heavy

-

-

Thicker paper

Thickest paper

-

Media type *

Light

-

-

Label paper

Transparency

film

Setting *

[Media weight] of the

1

printer driver

Label paper 1

Label paper 2

Transparency

*1: The printer comes with Media Type set to [Light] at the factory.

*2: The thickness and type of paper can be set on the operator panel and also via the printer

driver. If those parametersare set via the printer driver, the settings of the printer driver will

have priority. If [Auto selectio] is selected in [Feed Trey] of the printer driver, or [Printer

setting] is selected in [Media weight] , the print will take place with the settings made on

the operator panel.

*3: The paper thickness with which two-sided print can be conducted is from 65 to 90kg (75

2

to 105g/m

) of ream weight.

*4: For postcards and envelopes, there is no setting of Media Weight or Media Type.

*5: For OHP sheets, Media Type only is set. There is no need to make setting in Media Weight.

Memo

If [Heavy] or [Ultra heavy] is selected in Media Weight, or [Label paper] or [OHP] in

Media Type, the print speed will be affected.

3-25

Page 58

CHAPTER 4

REPLACEMENT OF PARTS

I. PRECAUTIONS ON THE

REPLACEMENT OF PARTS............. 4-1

A. Maintenance tools........................ 4-2

II. PART REPLACEMENT

METHODS......................................... 4-3

A. Left side cover.............................. 4-3

B. Right side cover ........................... 4-4

C. Face-up tray................................. 4-5

D. Rear cover.................................... 4-6

E. LED assy /LED assy springs ........ 4-7

F. Control PCB ................................. 4-8

G. Print engine controller PCB.......... 4-9

H. Top cover assembly ................... 4-11

I. Top cover ................................... 4-12

J. Controller panel assy .................4-13

K. Board PRP/Top cover handle.... 4-14

L. Low-voltage power supply/

low-voltage fan/hopping

motor/fuser motor ......................4-15

M. Guide eject assy/color register

assy/board-PRY ........................ 4-16

N. Fan (fuser)/belt motor /high-voltage

power supply board/cover-open

switch ......................................... 4-18

O. MPT assy ................................... 4-19

P. Feeder unit/board-RSF /MPT

hopping roller/frame assy

separator/cover front ................. 4-20

Q. Board-PRZ lift-up motor /

solenoid/paper-end sensor ........ 4-21

R. Feed roller .................................. 4-23

S. Shaft eject assy(FU) /shaft

eject assy(FD)/eject sensor ....... 4-24

T. Fuser Unit................................... 4-25

U. Belt Unit...................................... 4-26

III. LUBRICATING POINTS.................. 4-27

Page 59

CHAPTER 4 REPLACEMENT OF PARTS

This section explains the field replacement procedures for parts, assemblies and component units.

While those replacement procedures refer to the disassembling of parts, follow the same

procedures inversely for reassembling them.

The part numbers (1, 2, etc.) employed in this manual are different from those assigned in the

corresponding documentation.

I. PRECAUTIONS ON THE REPLACEMENT OF PARTS

(1) Prior to replacing a part, be sure to disconnect the AC cord and interface cable.

(a) To disconnect the AC cord, always follow the procedure described below:

1 Turn off ("O") the power switch of the printer.

2 Pull out the AC plug of the AC cord from the AC power outlet.

3 Unplug the AC cord and interface cable from the printer.

(b) To reconnect the printer, always follow the procedure described below:

1 Plug the AC cord and interface cable into the printer.

2 Insert the AC plug into the AC power outlet.

3 Turn on ("|") the power switch of the printer.

Disconnect

(2) Do not disassemble the printer as long as it is operating normally.

(3) Limit disassembly to a necessary minimum. Do not remove other parts than those specified

(4) Use the designated maintenance tools.

(5) Conduct disassembly by following the specified sequential order. Failure to observe this order

(6) Screws, collars and other small parts should be attached provisionally to their original

(7) When handling a microprocessor, ROM, RAM and other ICs and circuit boards, do not wear

Connect

in the part replacement procedure.

could damage the parts.

positions, since they are liable to be lost.

gloves that tend to generate static electricity.

(8) Printed-circuit boards should not be placed directly on an equipment or floor.

4-1

Page 60

CHAPTER 4 REPLACEMENT OF PARTS

A. Maintenance tools

Tools necessary to replace printed-circuit boards and component units.

No. Q' ty Place of use RemarksService Tools

1

2

3

4

5

6

7

8

No. 2-200 Philips

screwdriver, Magnetized

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

Handy cleaner

LED Head cleaner

E-ring pliers

Tools necessary for using maintenance utilities.

1

3~5 mm screws

1

1

1

1

1

1

Cleans LED head

1

No. Q' ty Place of use RemarksService Tools

Laptop computer

1

2 USB cable 1

Must have maintenance

utilities installed

1

4-2

Page 61

CHAPTER 4 REPLACEMENT OF PARTS

II. PART REPLACEMENT METHODS

This subsection explains the replacement methods for the parts and assemblies illustrated in the

disassembly system diagram below.

A. Left side cover

(1) Open the top cover.

(2) Open the feeder unit.

(3) Remove screw (silver) 1, and detach left side cover 2. (Tool No.1)

Top cover

1

Feeder unit

2

Left side cover

4-3

Page 62

CHAPTER 4 REPLACEMENT OF PARTS

B. Right side cover

(1) Open the top cover.

(2) Open the feeder unit.

(3) Loosen screw 1, and detach right side cover 2. (Tool No.1)

Top cover

1

(Loosen)

2

4-4

Feeder unit

Right side cover

Page 63

C. Face-up tray

(1) Open face-up tray 1 into the direction of the arrow, free the engagement on either side of it

while deflecting the tray, and remove the tray.

CHAPTER 4 REPLACEMENT OF PARTS

Face-Up Tray

1

4-5

Page 64

CHAPTER 4 REPLACEMENT OF PARTS

D. Rear cover

(1) Open the face-up tray.

(2) Remove two screws (silver) 1. (Tool No. 1)

(3) Insert the flat-tipped screwdriver (Tool No. 3) into hole A, as illustrated in Figure (2), and

release two claws A.

(4) Now, release two claws B, and pull the upper part of rear cover 2 in the direction of arrow

A.

(5) Push the lower part of rear cover 2 in the direction of arrow B, as shown in Figure (3), and

detach rear cover 2 by freeing three claws C.

2

Figure (1)

ClawB

ClawA

1

A

B

Figure (2)

2

A

ClawC

ClawB

1

HoleA

ClawA

HoleA

4-6

ClawC

Figure (3)

Rear Cover

Page 65

E. LED assy/LED assy springs

(1) Open the top cover.

(2) After disconnecting the cable, first free hook part A by applying force in the direction of the

arrow, as illustrated in Figure (2), and then, free hook part B, to finally remove LED Assy 1.

(In this operation, two springs2will come out together with LED Assy 1.)

CHAPTER 4 REPLACEMENT OF PARTS

Hook part A

Top cover

2

Figure (1)

Hook part A

1

Figure (2)

Hook part B

LED Assy / LED Assy-Springs

4-7

Page 66

CHAPTER 4 REPLACEMENT OF PARTS

F. Control PCB

(1) Open the top cover.

(2) Detach the right side cover. (See Section "B. Right side cover".)

(3) Remove eight screws (silver) 1, and detach plate shield assembly (PCL) 2 by releasing

connector claws A. (Tool No. 1)

(4) Remove screw 3, and disconnect head cable 4. (Tool No. 1)

(5) Remove seven screws (silver) 5, disconnect all the cables, and disassemble control PCB

6 (TBH-1 PCB). (Tool No. 1)

Top cover

5

3

×7

6

M

C

Claws A

K

Y

4

4

2

1

4-8

Controller PCB

1

×

Connector

8

Page 67

G. Print engine controller PCB

(1) Remove the plate shield Assy(PCL/GDI). (See Section "F. Control PCB" (1) through (3).)

(2) Remove all the connectors and two screws (silver) 1, and disassemble the print engine

controller PCB 2. (Tool No. 1)