SHARP AR-168N, AR-168L Service Manual

CODE : 00ZAR168N/A1E

DIGITAL MULTIFUNCTIONAL

SYSTEM

(AR-168L)

MODEL

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[ 3 ] CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . . 4 - 1

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

[ 6 ] COPY PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[ 7 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[ 8 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

[ 9 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] TEST COMMAND, TROUBLE CODES. . . . . . . . . . . . . . . . . . . . 10 - 1

AR-168N

AR-168L

[11] MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1

[12] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 1

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 1

[14] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 1

[15] FIRMWARE DOWNLOAD PROCEDURES. . . . . . . . . . . . . . . . . 15 - 1

Parts marked with “ ” are important for maintaining the safety of the machine. Be sure to replace these parts

with the replacement parts specified to maintain the safety and performance of the machine.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

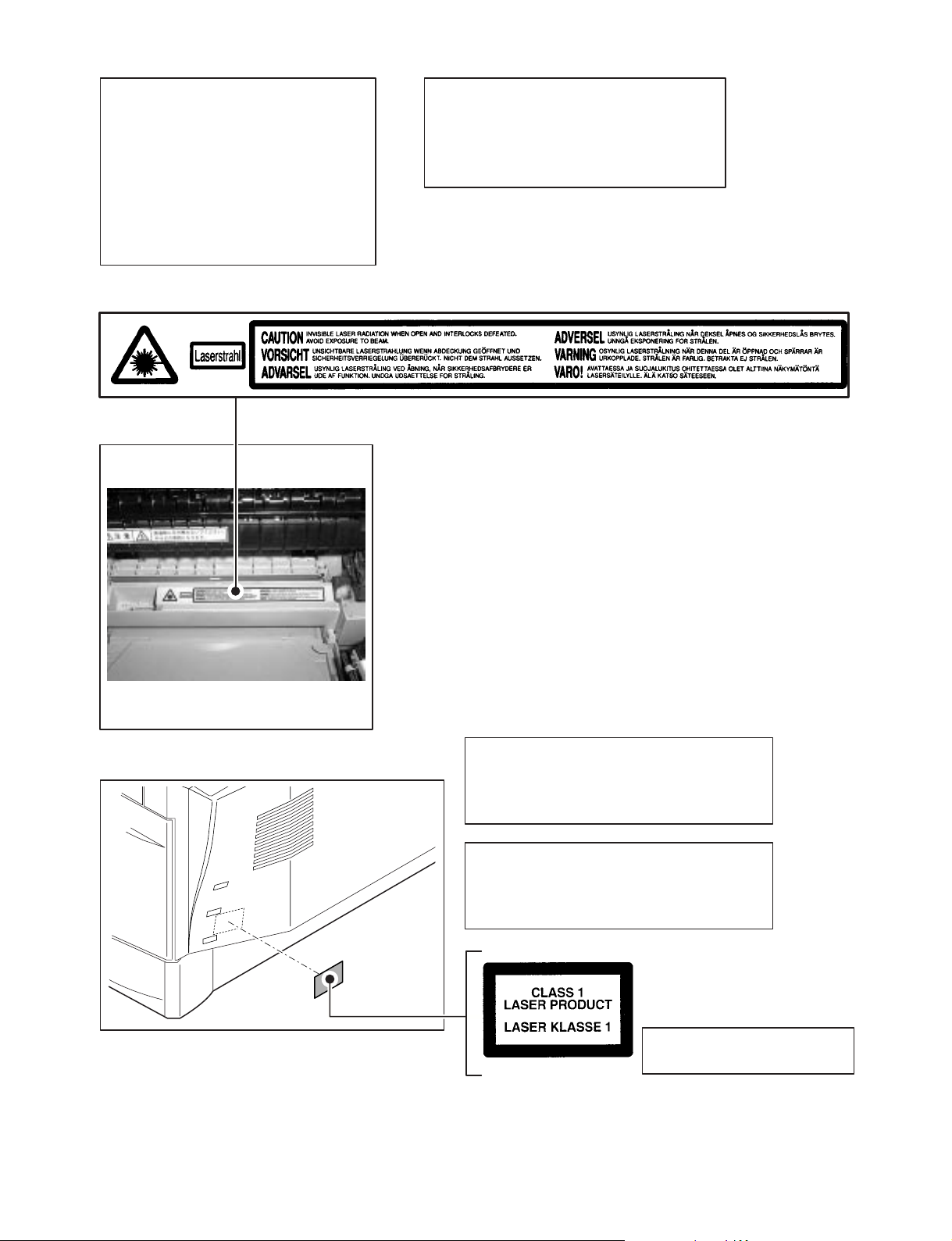

CAUTION

This product is a class 1 laser product that complies with 21CFR 1040 of the CDRH standard and

IEC825. This means that this machine does not produce hazardous laser radiation. The use of controls,

adjustments or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the laser beam is achieved

on the eye’s retina, there is the danger of spot damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of

servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a

unit, not as individual parts.

2) Do not look into the machine with the main switch turned on after removing the developer unit, toner

cartridge, and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected

when removing and installing the optical system.

4) The middle frame contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

LASER WAVE – LENGTH : 770 – 795nm

Pulse times : 10.24µsec

Out put power : 0.15mW

± 0.01mW

CAUTION

INVISIBLE LASER RADIATION,

WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

VORSICHT

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERBRÜCKT.

NICHT DEM STRAHL AUSSETZEN.

VARO !

AVATTAESSA JA SUOJALUKITUS

OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE ÄLÄ

KATSO SÄTEESEEN.

ADVARSEL

USYNLIG LASERSTRÅLNING VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER UDE AF

FUNKTION. UNDGÅ UDSAETTELSE FOR

STRÅLNING.

VARNING !

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL

ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN. – STRÅLEN ÄR

FARLIG.

At the production line, the output power

of the scanner unit is adjusted to 0.57

MILLI-WATT PLUS 20 PCTS and is

maintained constant by the operation of

the Automatic Power Control (APC).

Even if the APC circuit fails in operation

for some reason, the maximum output

power will only be 15 MILLI-WATT 0.1

MICRO-SEC. Giving and accessible

emission level of 42 MICRO-WATT

which is still-less than the limit of

CLASS-1 laser product.

Caution

This product contains a low power laser

device. To ensure continued safety do not

remove any cover or attempt to gain access

to the inside of the product. Refer all

servicing to qualified personnel.

The foregoing is applicable only to the 220V

model, 230V model and 240V model.

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA

KUIN TÄSSÄ KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1 YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT

SÄTT ÄN I DENNA BRUKSANVISNING

SPECIFICERATS, KAN ANVÄNDAREN UTSÄTTAS

FÖR OSYNLIG LASERSTRÅLNING, SOM

ÖVERSKRIDER GRÄNSEN FÖR LASERKLASS 1.

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

[1] GENERAL

1. Major functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Note for servicing and handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS

1. Basic Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Operation specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Copy performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

4. SPLC printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

5. Scan function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

6. RSPF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

[3] CONSUMABLE PARTS

1. Supply list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3. Production control number (lot No.) identification . . . . . . . . . . . . . . . . 3-1

4. TD cartridge replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3. Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4. Motors and solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

5. Sensors and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

[5] UNPACKING AND INSTALLATION

1. Copier installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Cautions on handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Checking packed components and accessories . . . . . . . . . . . . . . . . . 5-1

4. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5. Removing protective packing materials . . . . . . . . . . . . . . . . . . . . . . . 5-2

6. Developer unit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

7. Toner cartridge installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

8. Loading the paper tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

9. Power to copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

10. Software for AR-168N/168L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

A. Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

B. Installing the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

C. Setting up button manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

D. Connecting the machine to your computer . . . . . . . . . . . . . . . . . 5-11

11. Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

A. USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

B. Parallel interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

12. Moving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

[6] COPY PROCESS

1. Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Outline of print process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

3. Actual print process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

[7] OPERATIONAL DESCRIPTIONS

1. Outline of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

A. Scanner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

B. Optical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

C. Drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

3. Laser unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A. Basic structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

B. Laser beam path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

C. Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

4. Fuser section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A. General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

5. Paper feed section and paper transport section . . . . . . . . . . . . . . . . . 7-4

A. Paper transport path and general operations . . . . . . . . . . . . . . . . 7-4

6. RSPF section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

A. Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

B. Document transport path and basic composition . . . . . . . . . . . . . 7-7

C. Operational descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

D. Cases where a document jam is caused . . . . . . . . . . . . . . . . . . . 7-7

E. RSPF open/close detection (book document detection) . . . . . . . . 7-7

7. D-D (Duplex to Duplex) mode paper/document transport

(Duplex model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

A. Initial state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

B. Front copy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

C. Back copy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

8. Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

CONTENTS

[8] DISASSEMBLY AND ASSEMBLY

1. High voltage section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

B. Drum replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

C. Disassembly procedure (Transfer charger unit) . . . . . . . . . . . . . . 8-3

D. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

E. Charger wire cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

F. Charger wire replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

2. Operation panel section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

3. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

4. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

5. Tray paper feed/transport section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

6. Manual paper feed section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

D. Pressure plate holder attachment . . . . . . . . . . . . . . . . . . . . . . . . 8-16

7. Rear frame section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8. Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

9. Duplex motor section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

10. Reverse roller section (RSPF model only) . . . . . . . . . . . . . . . . . . . . 8-18

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

11. RSPF section (RSPF model only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

A. RSPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

B. Intermediate tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

C. Upper cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

D. Pickup unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

E. Upper cover of the pickup unit. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

F. Sensor PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

G. Pickup solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

H. Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

I. Manual paper feed roller, pickup roller . . . . . . . . . . . . . . . . . . . . 8-21

J. Transport unit removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

K. Belt 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

L. Belt 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

M. SPF motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

N. Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

O. Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

P. Paper supply roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Q. Paper entry sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

R. Transport roller 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

S. Paper exit roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

T. Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

[9] ADJUSTMENTS

1. Optical section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

A. Copy magnification ratio adjustment. . . . . . . . . . . . . . . . . . . . . . . 9-1

B. Image position adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2. Copy density adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

A. Copy density adjustment timing . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

B. Note for copy density adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

C. Necessary tool for copy density adjustment . . . . . . . . . . . . . . . . . 9-4

D. Features of copy density adjustment . . . . . . . . . . . . . . . . . . . . . . 9-4

E. Copy density adjustment procedure . . . . . . . . . . . . . . . . . . . . . . . 9-4

3. High voltage adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

A. Main charger (Grid bias) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

B. DV bias check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

4. Duplex adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

A. Adjusting the paper reverse position in memory for

duplex copying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

B. Adjusting trailing edge void in duplex copy mode . . . . . . . . . . . . . 9-6

5. RSPF scan position automatic adjustment . . . . . . . . . . . . . . . . . . . . . 9-7

6. RSPF mode sub scanning direction magnification

ratio adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

7. Automatic black level correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

[10] TEST COMMAND, TROUBLE CODES

1. Entering the test command mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Key rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

3. List of test commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

4. Descriptions of various test commands . . . . . . . . . . . . . . . . . . . . . . 10-3

5. Trouble codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

A. Trouble codes list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

B. Details of trouble codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

[11] MAINTENANCE

1. Maintenance table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. Maintenance display system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

3. Remaining toner indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] USER PROGRAM

1. User programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

A. Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

B. Print mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

2. Selecting a setting for a user program . . . . . . . . . . . . . . . . . . . . . . . 12-3

[13] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

A. Overall block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. Circuit descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

A. Main PWB (MCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

B. DC power circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-11

[14] CIRCUIT DIAGRAM

1. MCU PWB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

2. OPERATION PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-26

3. POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-27

4. ACTUAL WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-31

[15] FIRMWARE DOWNLOAD PROCEDURES

1. Initial setting (Serial number setting procedures) . . . . . . . . . . . . . . . 15-1

2. Download procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

3. Version acquisition procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

4. EEPROM data acquisition procedure . . . . . . . . . . . . . . . . . . . . . . . . 15-4

5. Installing procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

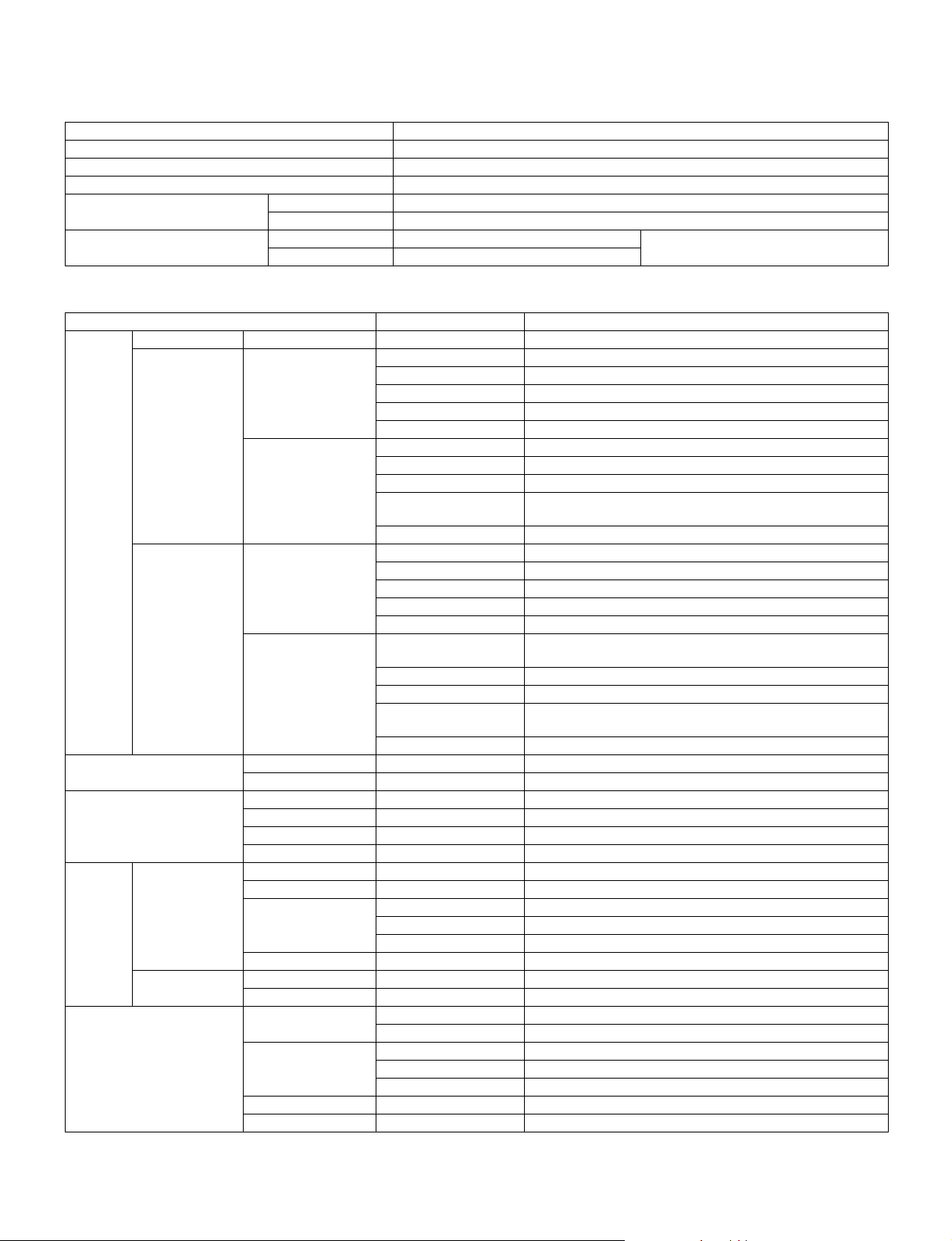

[1] GENERAL

1. Major functions

Configurations

Item CPM /

Model LT A4

AR-168N 16 15 MB Opt ✕✕ ❍ ✕ ❍ ❍ ❍ ❍✕❍❍❍

AR-168L 16 15 MB Opt ✕❍ ❍ ✕ ❍ ❍ ❍ ❍✕❍❍❍

PPM

SB/MB2

Tray

SPF R-SPF

Descriptions of items

CPM: Copy speed (Copies Per Minute)

SB/MB: SB = Manual feed single bypass, MB = Manual feed multi bypass

2 tray: Second cassette unit

SPF: Original feed unit

R-SPF: Duplex original feed unit

Color scanner: Color scanner function

GDI printer: GDI printer function with USB

SPLC: SPLC printer function

E-SORT: Electrical sort

Duplex: Auto duplex copy function

Shifter: Job separator function

FAX: FAX function

Sharpdesk: Scanner utilities

IEEE1284: Interface port (parallel)

USB: Interface port (USB)

RJ45: Interface port (Network)

External NIC: AR-NB2N

Descriptions of table

❍: Standard provision

✕: No function or no option available

Opt: Option

Color

Scanner

(push)

GDI

SPLC E-SORT Duplex Shifter FAX

printer

Sharp

desk

IEEE

1284

USB RJ45

(2.0)

(2.0)

External

NIC

✕❍

✕ Opt

(AR-168L)

2. Note for servicing and handling

When the main unit power is repeatedly turned OFF/ON rapidly (for about 1sec), the IC (OA982) on the MCU PWB may malfunction to cause an error

(E1-00 Communication error), which does not boot the machine. In case of this error, the blank display is kept for several tens seconds and then "E100" is displayed on the panel display.

<Countermeasure>

Turn off the power and keep it for more than 10sec. Then turn on the power.

When the machine is booted.: There is no problem in the MCU PWB.

When the machine is not booted.: The MCU PWB trouble

AR-168N/168L GENERAL 1 - 1

[2] SPECIFICATIONS

1. Basic Specifications

Item

Type Desktop

Copy system Dry, electrostatic

Segment (class) Digital personal copier

Copier dimensions AR-168N 20.4"(W) x 19.8"(D) x 11.7"(H) (518mm(W) x 503mm(D) x 296mm(H))

AR-168L 20.4"(W) x 19.8"(D) x 15.0"(H) (518mm(W) x 503mm(D) x 380mm(H))

Weight (Approximately) AR-168N 37.0lbs.(16.8Kg) TD and drum cartridges included

AR-168L 44.1lbs.(20.0Kg)

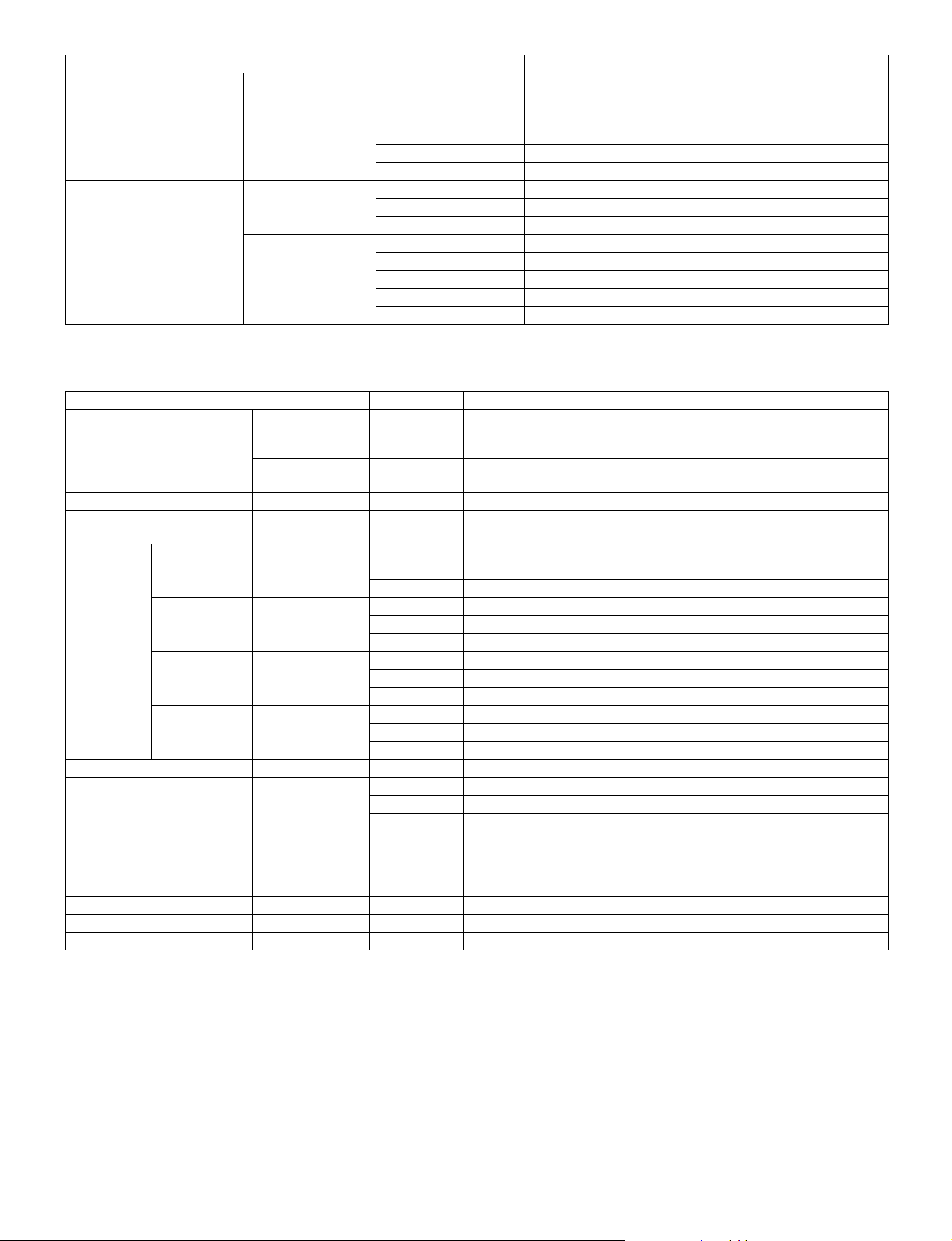

2. Operation specifications

Section, item Details

Paper feed

section

Paper exit section Exit way Face down

Originals Original set Center Registration (left edge)

Optical

section

Image forming Photoconductor type OPC (30ø)

Paper feed system 1 tray (250 sheets) + multi bypass (50 sheets)

AB system Tray paper feed

section

Multi bypass paper

feed section

Inch system Tray paper feed

section

Multi bypass paper

feed section

Capacity of output tray 200 sheets (A4/Letter Standard paper, Normal Condition)

Max. original size A4 (8-1/2" x 14")

Original kinds sheet, book

Original size detection None

Scanning section Scanning system 3 CCDs (RGB) sensor scanning by lighting white lamp

CCD sensor Resolution 600 dpi

Lighting lamp Type CCFL

Output data R, G, B 1 or 8 bits/pixel / A/D 16bit

Writing section Writing system Writing to OPC drum by the semiconductor laser

Laser unit Resolution 600 dpi

Charger Charging system Saw -tooth charging with a grid, / (-) scorotron discharge

Developing Developing system Dry, 2-component magnetic brush development system

Cleaning Cleaning system Counter blade system (Counter to rotation)

Paper size A4, B5, A5, 16K (Landscape)

Paper weight 56 - 80g/m

Paper feed capacity 250 sheets

Kinds Standard paper, specified paper, recycled paper

Remark User adjustment of front paper guide available

Paper size A4, B5, A5, B6, A6 (Post card), 16K (Landscape)

Paper weight 52 - 128g/m

Paper feed capacity 50 sheets

Kinds Standard paper, specified paper, recycled paper, envelope,

OHP, Label (Single copy)

Remark User adjustment of side paper guide available

Paper size 8-1/2" x 14", 8-1/2 x 11", 8-1/2" x 5-1/2" (Landscape)

Paper weight 15 - 21 lbs.

Paper feed capacity 250 sheets

Kinds Standard paper, specified paper, recycled paper

Remark User adjustment of front paper guide available

Paper size 8-1/2" x 14", 8-1/2 x 11", 8-1/2" x 5-1/2", 3-1/2" x 5-1/2"

(Landscape)

Paper weight 14 - 34.5 lbs.

Paper feed capacity 50 sheets

Kinds Standard paper, specified paper, recycled paper, OHP, Label,

Envelop (Single copy)

Remark User adjustment of side paper guide available

Voltage 560Vrms

Power consumption 2.8W

Life 18k

Transfer system (+) DC scorotron system

Separation system (-) DC scorotron system

2

(15 - 21 lbs.)

2

(14 - 34.5 lbs.)

AR-168N/168L SPECIFICATIONS 2 - 1

Section, item Details

Fusing section Fusing system Heat roller system

Upper heat roller type Teflon roller

Lower heat roller type Silicon rubber roller

Heater lamp type Halogen lamp

Voltage 120V

Power consumption 800W

Electrical section Power source Voltage 120V

Frequency 60Hz

Rated current 8A

Power consumption Max. Less than 1000W

Average (during copying) 350 Wh/H *1)

Average (stand-by) 86Wh/H *1)

Pre-heat mode 25Wh/H *1)

Auto power shut-off mode 8.8Wh/H *1)

*1) May fluctuate due to environmental conditions and the input voltage.

3. Copy performance

Section, item Details

Copy magnification Fixed magnification

Manual steps (text, photo) 5 steps

Copy speed First copy time Tray paper feed 9.6 sec. (Pre-heat mode: 25 sec. / Auto power-shut-off mode: 40 sec.)

AB system

A4

(Landscape)

AB system

B5

(Landscape)

Inch system

8-1/2" x 14"

(Landscape)

Inch system

8-1/2" x 11"

(Landscape)

Max. continuous copy quantity 99 (Multi-copy)

Void Void area leading edge 1 - 4mm

Warm-up time 0 sec.

Power save mode reset time 0 sec.

Paper jam recovery time 0 sec.

*1) Under the polygon ready condition.

ratios

Zooming

magnification ratios

Copy speed (CPM) Same size 15

Enlargement 15

Reduction 15

Copy speed (CPM) Same size 15

Enlargement 15

Reduction 15

Copy speed (CPM) Same size 12

Enlargement 12

Reduction 12

Copy speed (CPM) Same size 16

Enlargement 16

Reduction 16

Trailing edge 4mm or less, 6mm or less (Duplex copying/both image)

Side void area 0.5mm or more (per side)

Image loss leading edge Same size: 3.0mm or less (OC) / 4.0mm or less (R-SPF/Duplex)

4 Reduction + 3 Enlargement

(AB system : 25, 50, 70, 86, 100, 141, 200, 400%)

(Inch system : 25, 50, 64, 78, 100, 129, 200, 400%)

OC: 25 - 400% (376 steps in 1% increments), RSPF: 50 - 200% (151 steps

in 1% increments)

A4 or Letter/100%/Auto Exposure *1)

4.5mm or less (total of both sides)

Enlarge: 1.5mm or less (OC) / 3.0mm or less (R-SPF/Duplex)

Reduction (50%): 6.0mm or less (OC) / 8.0mm or less (R-SPF/Duplex)

AR-168N/168L SPECIFICATIONS 2 - 2

4. SPLC printer

Print speed Max. 15ppm (A4 / with ROPM) / 16ppm (Letter / with ROPM)

First print time 9.6 sec. (without data transfer time)

Duplex Yes

ROPM Yes

CPU None

Memory Share the memory with E-SORT function

Interface RJ45 (10 base) / USB 2.0

Network Internal NIC

Emulation SPLC (JBIG GDI)

MIB support No

Resolution 600dpi *1

Supported OS Win 95 / 98 / Me / NT 4.0 / 2000 / XP

WHQL support Yes *2

Application Status window

*1: Engine Resolution

*2: Running change

5. Scan function

Type Flat Bed Color Scanner

Scanning system Document glass / SPF (AR-168N) / RSPF (AR-168L)

Light source 3 CCDs (RGB) sensor scanning by lighting white lamp (2 pcs of CCFL)

Resolution Optical: 600 x 1200dpi

Setting range: 50 - 9600dpi (Preview resolution is fixed at 75dpi)

Originals Sheet type / Book type

Output data R, G, B 1 or 8 bits/pixel / A/D 16bit

Scan range OC / RSPF: 8.5" (297mm) (L) x 14" (431mm) (W)

Original position: Platen: Left center / SPF: Right center

Scan speed OC / SPF: Max. 2.88ms/line (Color/Gray scale), Max. 0.96 ms/line (B & W)

Protocol TWAIN / WIA (Only XP) / STI

Support file format RAW / JPEG

Interface USB2.0

Scanner utility Button Manager / Sharpdesk

Scan key/lamp Yes

Duplex scan No

Supported OS Win 98 / Me / 2000 / XP

Void area No (User settable by PC)

WHQL supported Yes *1

*1: Running change

6. RSPF

Original capacity 30 sheets (52 to 90g/m

Original size A4 to A5 / 8-1/2" x 14" to 5-1/2" x 8-1/2"

Original replacement speed 12CPM (A4/8-1/2" x 11"Landscape)

Job speed (Tray1,Landscape) Single copy S to S 12CPM

S to D 5.6CPM

D to S 5.5CPM

D to D 5.2CPM

Multi copy S to S 16CPM

D to S 16CPM

Original placement Face up

Original weight 52 to 90g/m

Mixed feeding No

Original which cannot Thermal papers, originals with punch holes for files, be used folded paper, transparent originals

such as OHP films, stapled or clip used originals with cover up liquid used, Originals with tape

sealed, originals with high level frictional coefficient such as photos or catalogs.

2

(14 - 23.9lbs.)

AR-168N/168L SPECIFICATIONS 2 - 3

2

) (14 to 23.9 lbs.)

[3] CONSUMABLE PARTS

1. Supply list

A. LAG

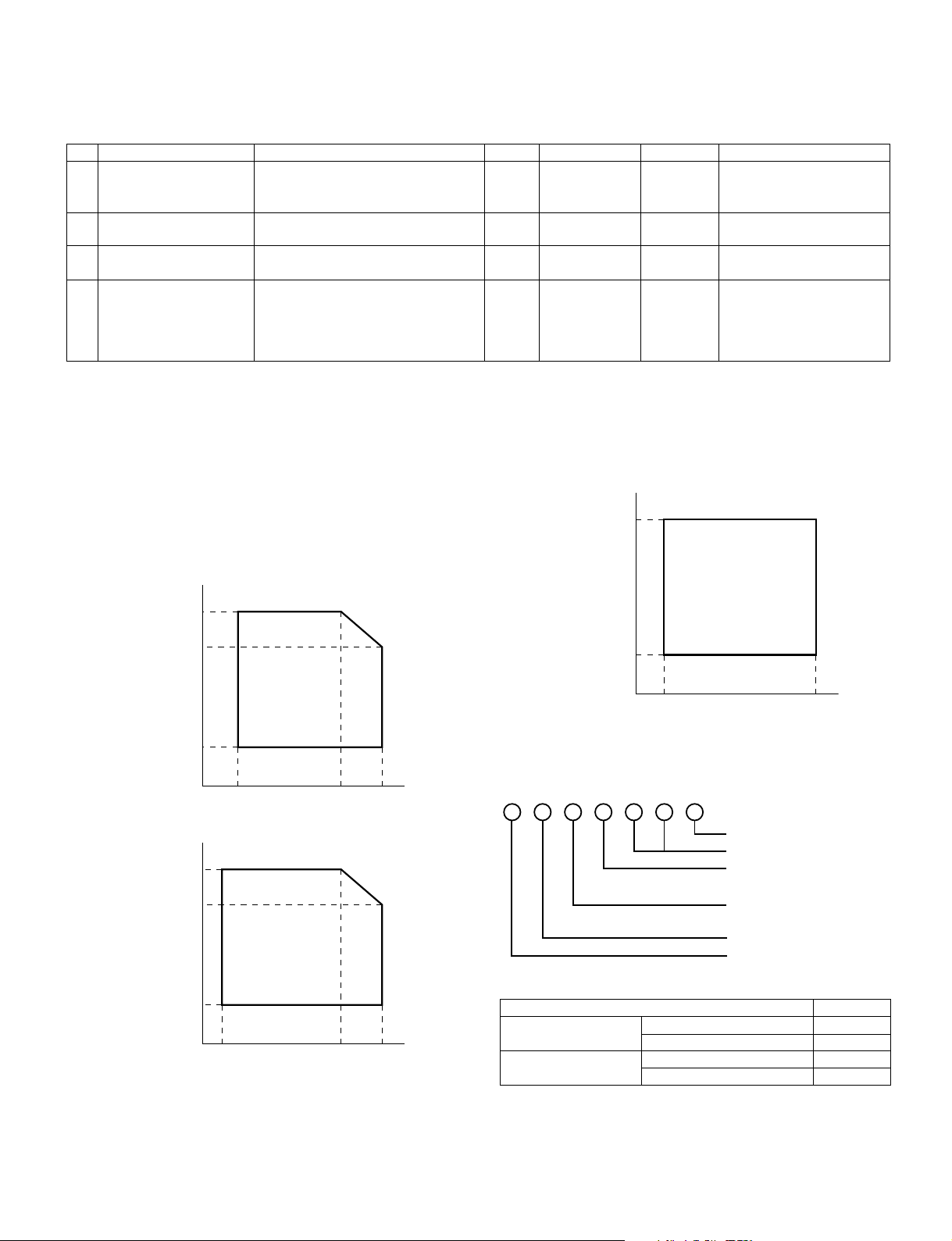

No. Item Content Life Product name Package Remark

1 Toner CA (Black)

(with IC chip)

2 Developer Developer

3 Drum kit Drum × 1 25K AR-152DR 10

4 Toner refill kit Toner (bottled)

Note: Printing of the master/individual cartons for toner cartridge and toner refill kit is made in 5 languages, English/French/Germany/Spanish/

Portuguese.

Printing of the master/individual cartons for developer and drum is made in 2 languages, English/French.

2. Environmental

The environmental conditions for assuring the copy quality and the

machine operations are as follows:

(1) Normal operating condition

Temperature: 20°C to 25

Humidity: 65 ± 5%RH

(2) Acceptable operating condition

Humidity (RH)

85%

Toner

(Toner: Net Weight 243g)

Polyethylene bag × 10

(Developer: Net Weight 170g)

Drum fixing plate × 1

(Toner: Net Weight 243g)

Filling nozzle

Toner cap

IC tip

× 10 80K AR-152LTB 1 ∗ Life setup is based on A4

× 10 250K AR-152MD 1 MD=ND ∗10

× 10 80K AR-152RH 1 ∗ Life setup is based on A4

× 1

× 10

× 10

6%.

MT=NT ∗10

6%.

(4) Supply storage condition

Humidity (RH)

90%

60%

20%

(3) Transportation condition

Humidity (RH)

90%

60%

15%

–25˚C30˚C40˚C

10˚C 30˚C 35˚C

20%

–5˚C45˚C

3. Production control number (lot No.)

identification

<Toner cartridge>

Production month

Production day

Destination code ∗

(Dealer, distributor, OEM, etc.)

Production place

(SOCC: Fixed to B.)

End digit of year

Version No.

∗: Destination code

Classification No.

EX Destination

Option Destination

A packed with machine G

B packed with machine H

AP

BQ

AR-168N/168L CONSUMABLE PARTS 3 - 1

<Drum cartridge>

The label on the drum cartridge shows the date of production.

(SOCC production)

Production month

Production day

Destination code

(Dealer, distributor, OEM, etc.)

Production place

(SOCC: Fixed to B.)

End digit of year

Version No.

(JAPAN production)

X000119Ver.A 1

Production month

(1 - 9 = Jan. - Sep. 0 = Oct. X = Nov. Y = Dec.)

Serial number of month

Fixed to 1.

Pack division

(See table below)

End digit of year

Version No.

Division No.

Option 2

Packed with machine 3

<Developer>

Sub lot

Production day

Production month

End digit of year

Production place

4. TD cartridge replacement

1) Open the front and side cabinets of the copier.

2) Keep holding Toner lover, and

3) Carefully pull out Toner unit from the copier.

2

3

1

Production control

label attachment position

Production control

label attachment position(*1)

4) Put Toner unit in a collection bag immediately after removing it

from the copier

Note: Never carry exposed Toner unit. Be sure to put it in the

collection bag.

∗1 The production control label is not attached to the cartridge of a

China product.

AR-168N/168L CONSUMABLE PARTS 3 - 2

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

Interface

RSPF

9

10

11

1

2

5

3

4

6

7

13

12

8

1 Document glass 2 Operation panel 3 Front cover

4 Paper tray 5 Side cover 6 Side cover open button

7 Bypass tray paper guides 8 Bypass tray 9 Reversing tray

10 Original guides 11 Document feeder cover 12 Document feeder tray

13 Exit area 14 Paper output tray 15 Paper output tray extension

16 Power switch 17 Handles 18 Power cord

19 USB connector 20 Parallel connector 21 Paper holder arm

19

20

17

21

14

15

16

17

18

2. Internal

Toner cartridge

6

2

3

1

1 Front cover 2 Side cover 3 Fusing unit release lever

4 Transfer charger 5 Charger cleaner 6 Photoconductive drum

4

5

AR-168N/168L EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 - 1

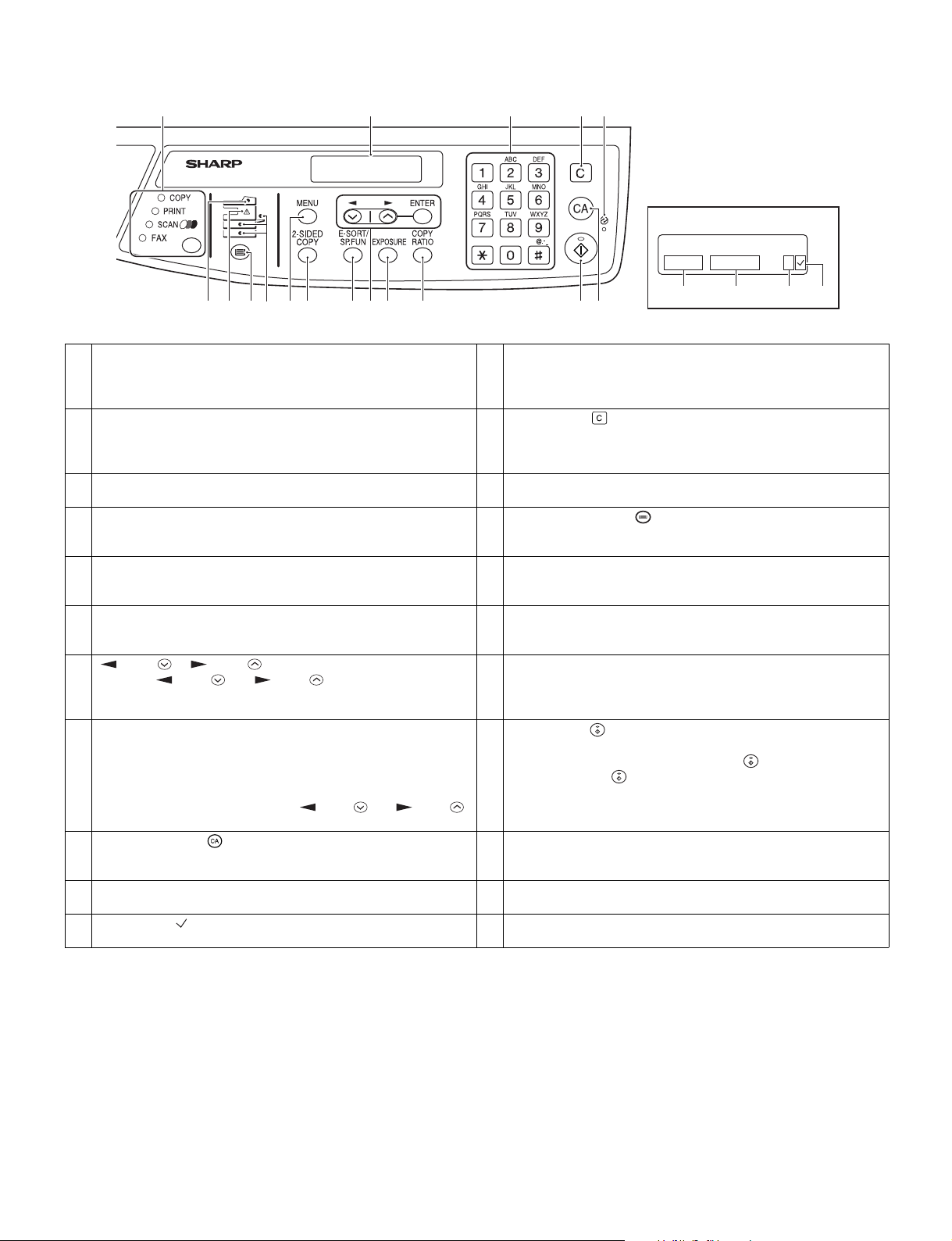

3. Operation panel

12345

AR-168L

6 7 8 9 10 11 12 13 14 15 16 17

Display

READY TO COPY.

100% 8.5x11 0

18 19 20 21

1 [MODE SELECT] key / Mode indicators

Press this key to select the mode. The indicator of the selected mode

lights (copy, printer, scanner, fax mode indicators).

3 Numeric keys

Use these to enter the number of copies and other numerical

settings.

The keys can also be used to select items in function setting menus.

5 Power save indicator

This lights up when the power save function is activated.

7 Error indicator

This lights steadily or blinks when a paper misfeed or other error

occurs.

9 Tray location indicator

Indicates the selected paper tray. The indicator blinks when the tray

is out of paper or is not closed.

11 [2-SIDED COPY] key

Press to select the automatic two-sided copying mode.

13 [ ] key ( ), [ ] key ( ), [ENTER] key

Press the [ ] key ( ) or [ ] key ( ) to select an item in a

function setting menu.

Press the [ENTER] key to enter a selection.

15 [COPY RATIO] key

Press to select an enlargement or reduction ratio.

To select a preset ratio setting, press the [COPY RATIO] key and

select the desired preset ratio. To select a ratio that is not preset,

press the [COPY RATIO] key, select the preset ratio that is closest to

the desired ratio, and then press the [ ] key ( ) or [ ] key ( )

to increase or decrease the ratio in increments of 1%.

17 [CLEAR ALL] key ( )

This returns all functions to the default settings. When pressed in a

setting menu, this returns the settings and display to the initial state.

19 Shows the selected paper size. 20 Shows the number of copies that has been entered with the numeric

21 A checkmark " " appears when the exposure has been changed, or

when two-sided copying, sort, 2 IN 1, or margin shift is selected.

2 Display

This shows messages indicating the machine status and any

problems that occur, as well as user programs and function setting

menus.

4 [CLEAR] key ( )

Use this to clear the set number of copies, as well as cancel a job

that is in progress. When a setting menu appears, use this key to

move back to the previous menu level.

6 RSPF indicator (AR-168L only)

This lights up when an original is placed in the RSPF.

8 [TRAY SELECT] key ( )

Use to select the paper tray that has the desired paper for copying.

10 [MENU] key

Press this key to select the paper size for copying, to configure a

user program or to display the total count.

12 [E-SORT/SP.FUN] key

Press to select the sort function, 2 IN 1 copy function, or margin shift

function.

14 [EXPOSURE] key

Use to switch from auto exposure adjustment to text mode or photo

mode.

16 [START] key ( ) / Ready indicator

The ready indicator lights up when copying or scanning is possible.

To begin copying, press the [START] key ( ).

The [START] key ( ) is also pressed to return to normal operation

from auto power shut-off mode.

18 Shows the current copy ratio.

keys.

AR-168N/168L EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 - 2

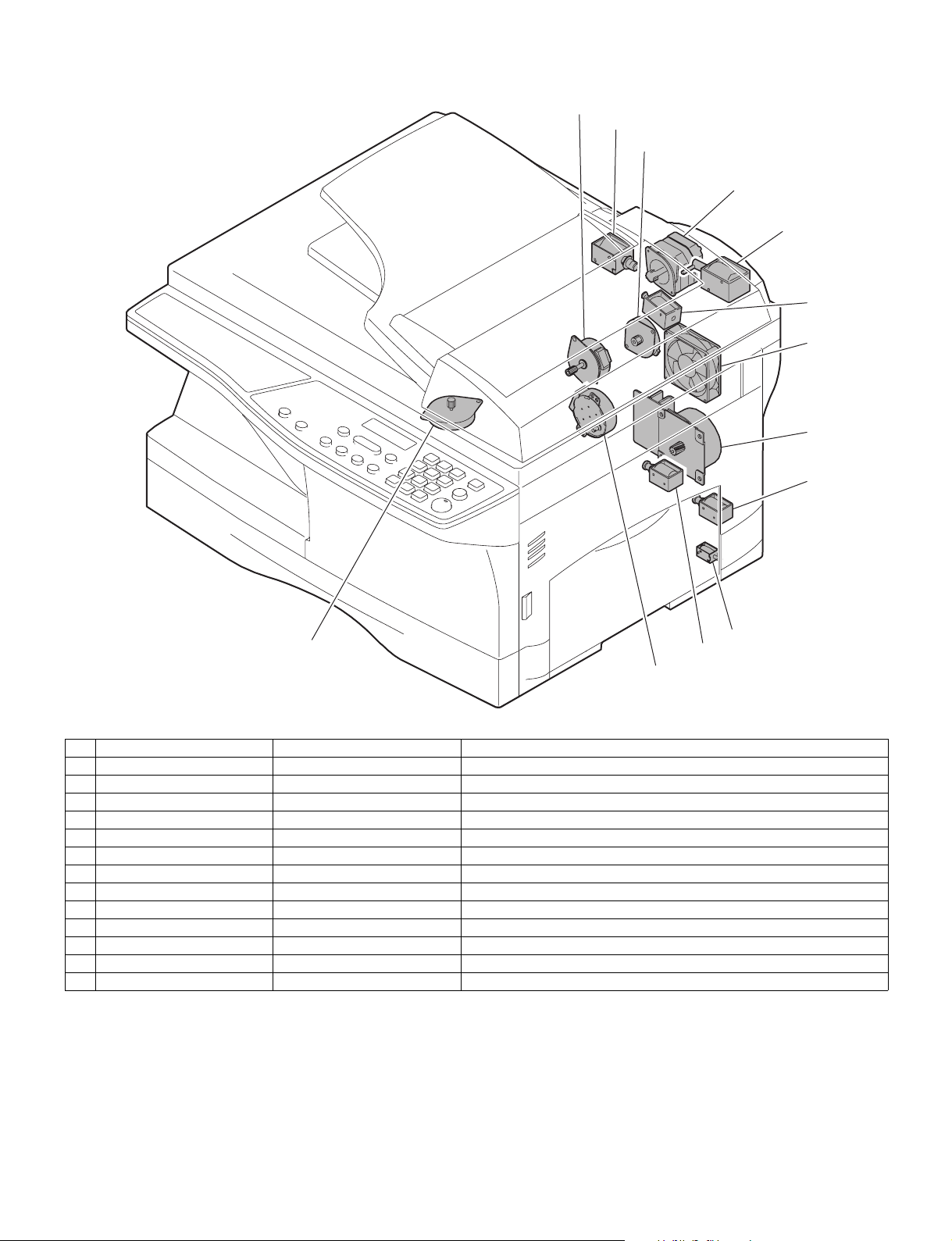

4. Motors and solenoids

9

12

2

8

11

10

4

1

5

13

7

6

3

No. Part name Control signal Function / Operation

1 Main motor MM Drives the copier.

2 Scanner motor MRMT Drives the optical mirror base (scanner unit).

3 Toner motor TM Supplies toner.

4 Cooling fan motor VFM Ventilate the fuser section.

5 Resist roller solenoid RRS Resist roller rotation control solenoid

6 Paper feed solenoid CPFS1 Cassette Paper feed solenoid 1

7 Multi paper feed solenoid MPFS Multi manual pages feed solenoid

8 SPF motor SPFM Drives the single pass feeder (AR-168L only)

9 Duplex motor DMT Devices the duplex paper transport section

10 Original feed solenoid SPUS Original pick up solenoid

11 SPF paper feed solenoid SPFS Original feed solenoid (AR-168L only)

12 SPF gate solenoid SGS Controls the document reverse gate. (AR-168L only)

13 Shifter motor SFTM Drives the shifter.

AR-168N/168L EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 - 3

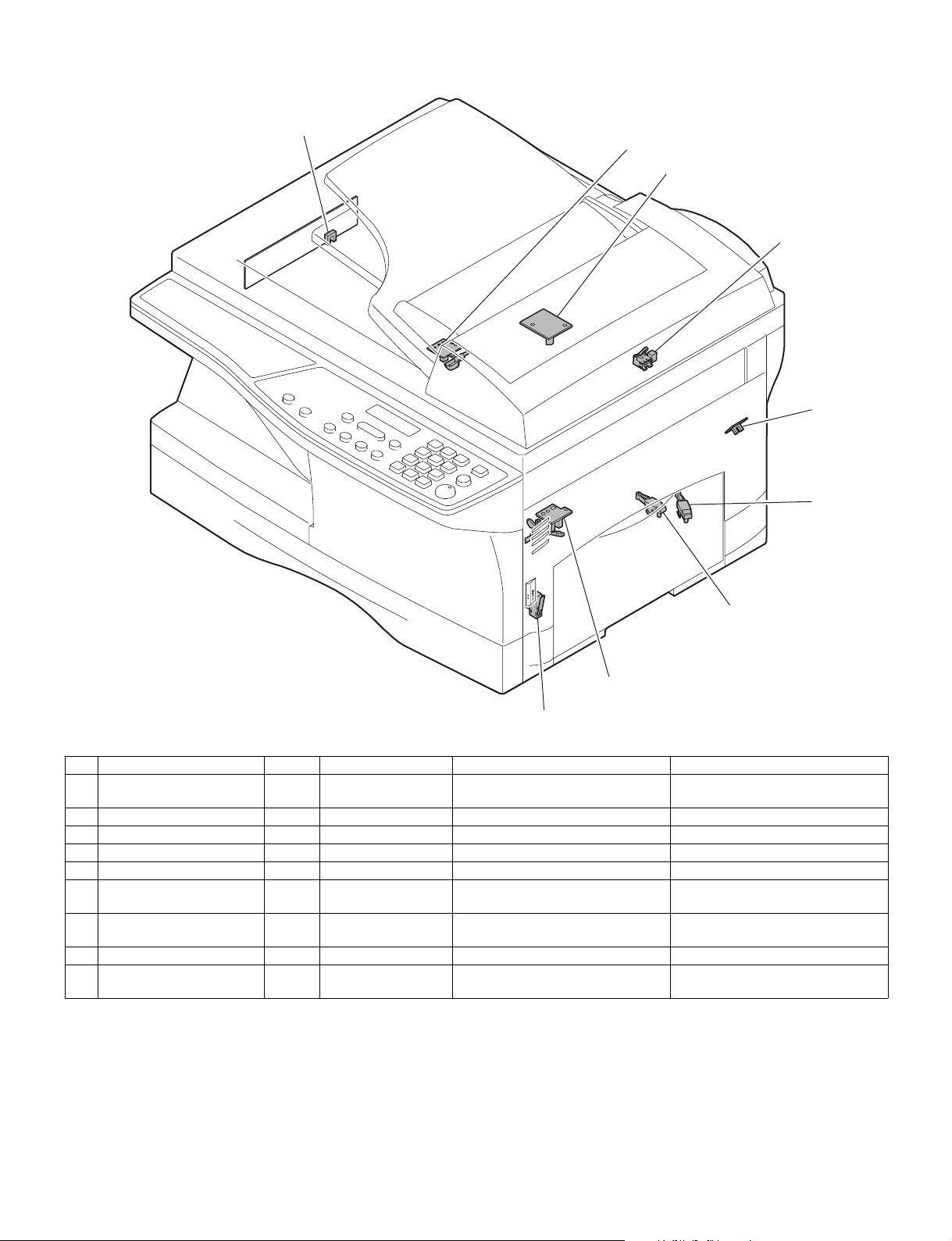

5. Sensors and switches

1

2

7

8

3

4

9

5

6

No. Name Signal Type Function Output

1 Scanner unit home position

sensor

2 POD sensor POD Transmission sensor Paper exit detection "H" at paper pass

3 PPD2 sensor PPD2 Transmission sensor Paper transport detection 2 "L" at paper pass

4 Cassette detection switch CED1 Micro-switch Cassette installation detection "H" at cassette insertion

5 PPD1 sensor PPD1 Transmission sensor Paper transport detection 1 "L" at paper pass

6 Door switch DSW Micro-switch Door open/close detection

7 SPF sensor SPID/

8 SPPD sensor SPPD Transmission sensor Paper transport detection "L" at paper pass

9 PD1 sensor PD1 Micro-switch Paper width detect "H" at A4 size or less

MHPS Transmission sensor Scanner unit home position detection "H" at home position

1 or 0V of 24V at door open

"L" at paper pass

"L" at A4 size or more

SD SW

(safety switch for 24V)

Transmission sensor Paper entry detection

Cover open/close detection

AR-168N/168L EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 - 4

6. PWB unit

5

2

1

8

6

4

3

No. Name Function

1 Exposure lamp inverter PWB Exposure lamp (CCFL) control

2 Main PWB (MCU) Copier control

3 Operation PWB Operation input/display

4 Power PWB AC power input, DC voltage control, High voltage control

5 CCD sensor PWB For image scanning

6 LSU motor PWB For polygon motor drive (In the LSU)

7 TCS PWB For toner sensor control

8 LSU PWB For laser control (In the LSU)

7

AR-168N/168L EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 - 5

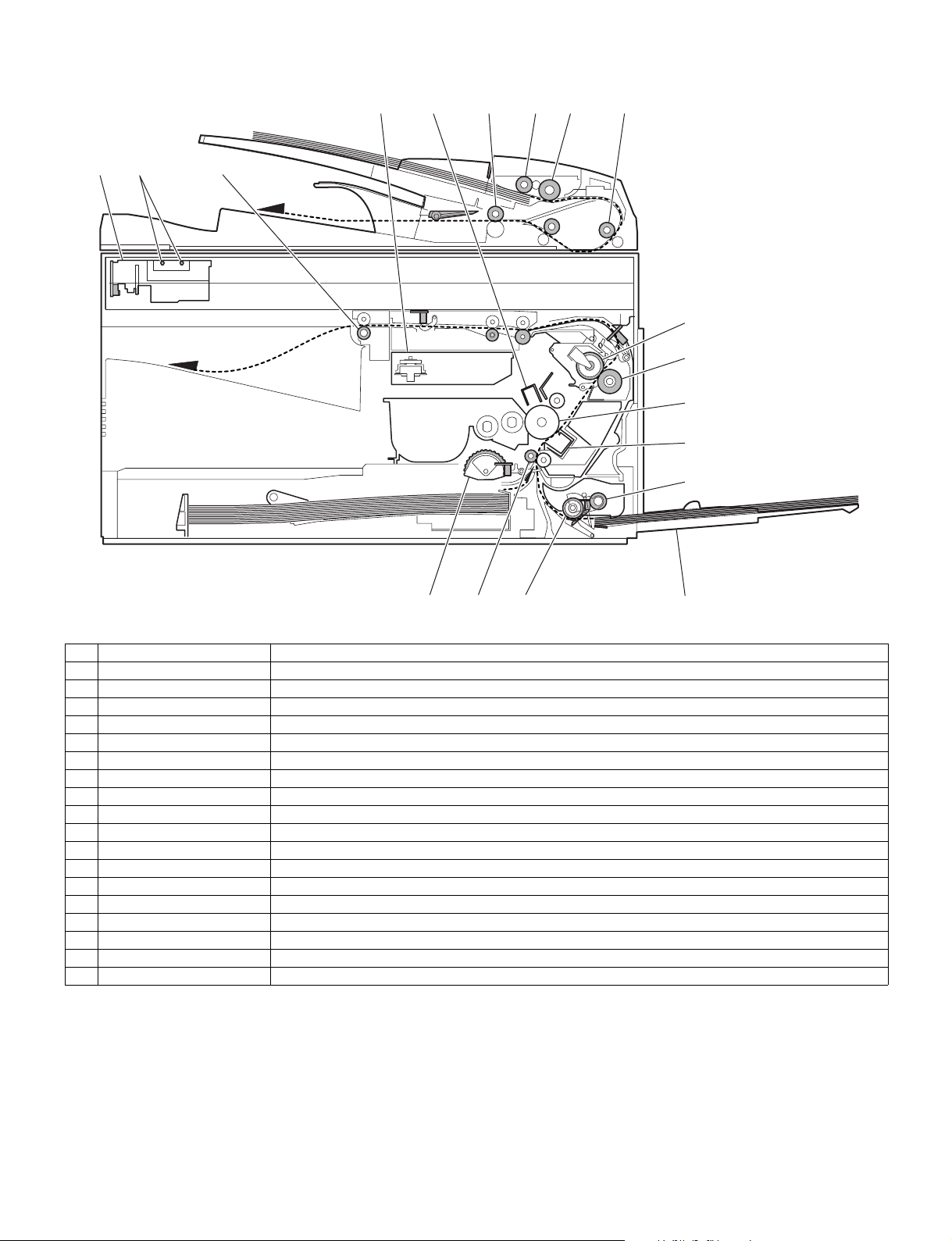

7. Cross sectional view

1 4

2

3 5 18 15

16 17

6

7

8

9

10

111214 13

No. Part name Function and operation

1 Scanner unit Illuminates the original with the copy lamp and passes the reflected light to the lens unit(CCD).

2 Exposure lamp Exposure lamp (CCFL) Illuminates original

3 LSU (Laser unit) Converts the original image signal into laser beams and writes onto the drum.

4 Paper exit roller Roller for paper exit

5 Main charger Provides negative charges evenly to the drum surface.

6 Heat roller Fuses toner on the paper. (Teflon roller)

7 Pressure roller Fuses toner on the paper. (Silicon rubber roller)

8 Drum Forms images.

9 Transfer unit Transfers images onto the drum.

10 Pickup roller Picks up the manual feed paper. (In multi feed only)

11 Manual paper feed tray Tray for manual feed paper

12 Manual paper feed roller Transport the paper from the manual paper feed port.

13 PS roller unit Takes synchronization between the lead edge and the rear edge of the paper.

14 Paper feed roller Picks up a sheet of paper from the cassette.

15 Pickup roller Picks up documents.

16 Separation roller Separates documents to feed properly.

17 PS roller Feeds documents to the scanning section.

18 Paper exit roller Discharges documents.

AR-168N/168L EXTERNAL VIEWS AND INTERNAL STRUCTURES 4 - 6

[5] UNPACKING AND INSTALLATION

1. Copier installation

Improper installation may damage the copier. Please note the following

during initial installation and whenever the copier is moved.

Caution: If the copier is moved from a cool place to a warm place, con-

densation may form inside the copier. Operation in this condition will cause poor copy quality and malfunctions.

Leave the copier at room temperature for at least 2 hours

before use.

Do not install your copier in areas that are:

• damp, humid, or very dusty

• exposed to direct sunlight

2. Cautions on handling

Be careful in handling the copier as follows to maintain the performance of this copier.

Do not drop the copier, subject it to shock or strike it against any

object.

Do not expose the drum cartridge to direct sunlight.

Doing so will damage the surface (green portion) of the drum cartridge,

causing poor print quality.

• poorly ventilated

• subject to extreme temperature or humidity changes, e.g., near an

air conditioner or heater.

The copier should be installed near an accessible power outlet for easy

connection.

Be sure to connect the power cord only to a power outlet that meets

the specified voltage and current requirements.

Also make certain the outlet is properly grounded.

Be sure to allow the required space around the machine for servicing

and proper ventilation.

Store spare supplies such as drum cartridges and TD cartridges in a

dark place without removing from the package before use.

If they are exposed to direct sunlight, poor print quality may result.

Do not touch the surface (green portion) of the drum cartridge.

Doing so will damage the surface of the cartridge, causing poor print

quality.

3. Checking packed components and

accessories

Open the carton and check if the following components and accessories are included.

• Operation manual

Software CD-ROM

4"

(10cm)

8" (20cm)

8"(20cm)

Drum cartridge

(installed in machine)

4"

(10cm)

AR-168N/168L UNPACKING AND INSTALLATION 5 - 1

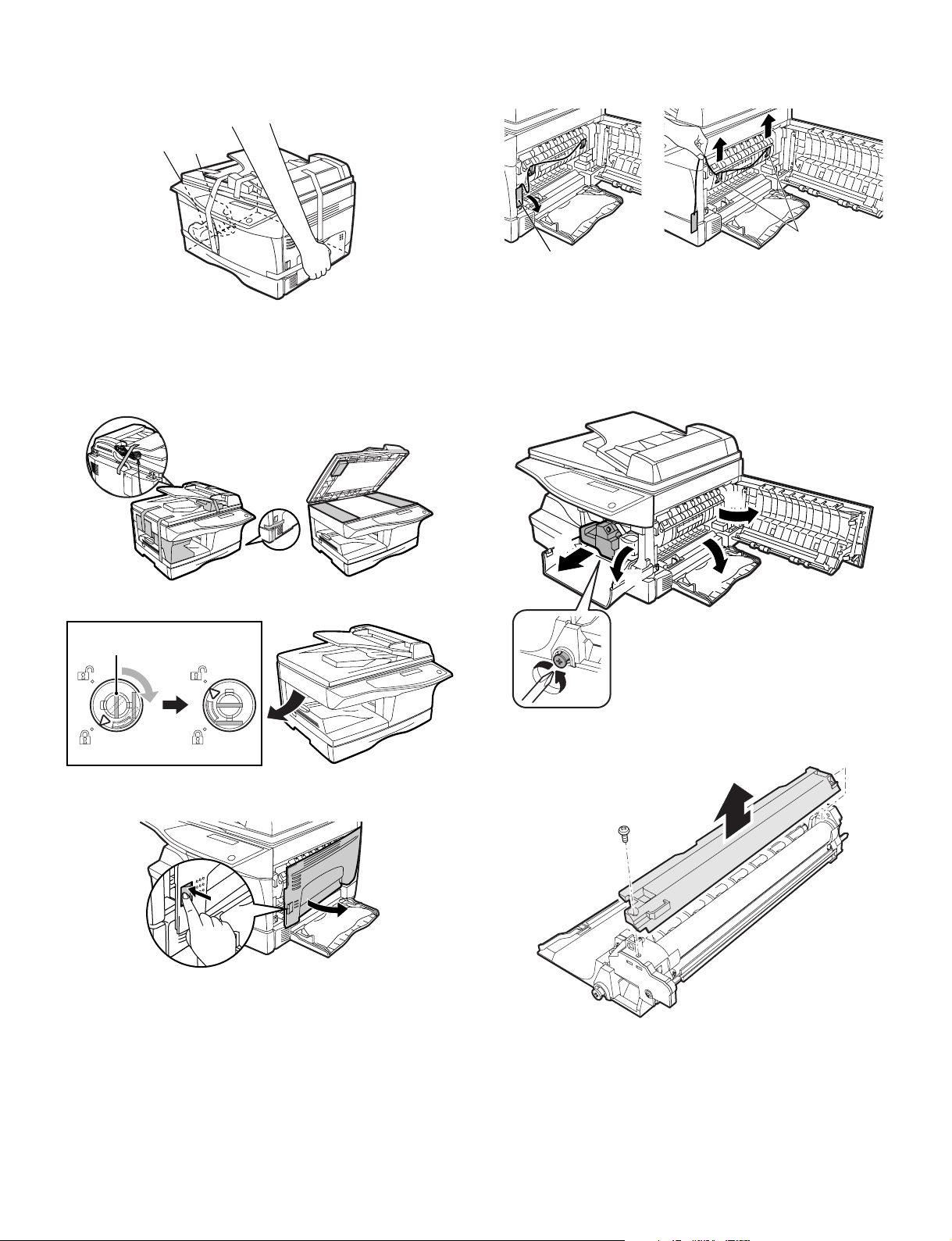

4. Unpacking

Be sure to hold the handles on both sides of the machine to unpack the

machine and carry it to the installation location.

4) Remove the CAUTION tape from the front cover and remove the

two protective pins from the fusing machine by pulling the strings

upward one at a time.

Protective pins

CAUTION tape

6. Developer unit installation

5. Removing protective packing materials

1) Remove all pieces of tape shown in the illustration below and then

open the RSPF and remove the protective materials. Take out the

bag containing the toner cartridge.

2) Release the scan head locking switch.

Grasp here and turn in

the direction of the arrow.

Lock Unlock

3) Open the bypass tray, and then open the side cover while pressing

the side cover open button.

1) 2) 3) Open the side and front cabinets of the copier.

4) Remove the locking tape of the developer unit.

5) Remove the screw which is fixing the copier and Developer unit.

6) Remove Developer unit slowly from the copier.

2

5

3

4

7) Remove the screw (1 pc).

8) Remove Upper developer unit.

1

AR-168N/168L UNPACKING AND INSTALLATION 5 - 2

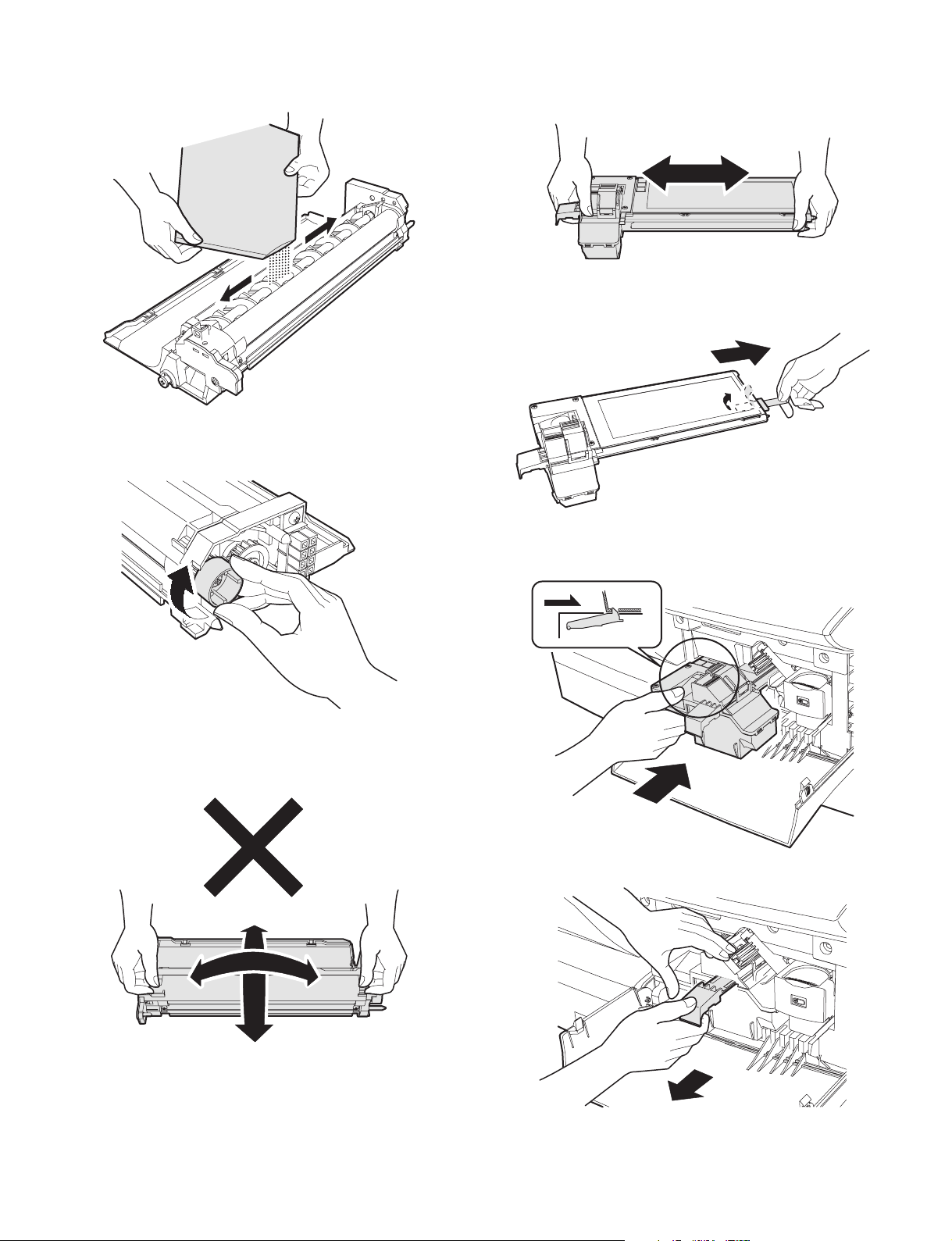

9) Shake the aluminum bag to stir developer

10) Supply developer from the aluminum bag to the top of the MX

roller evenly.

Note: Be careful not to splash developer outside Developer unit.

11) Attach Upper developer unit and fix it with a screw.

12) Rotate the MG roller gear to distribute developer evenly.

7. Toner cartridge installation

1) To prevent against uneven distribution of toner, hold Toner unit with

both hands and shake it several times horizontally.

2) Hold the section of Toner unit shown in the figure below, remove

the packing tape, and remove the cushion.

3) Pull out the cushion in the arrow direction.

Note: Never rotate the gear in the reverse direction.

Note: When carrying Developer unit, do not tilt it extremely as

shown with the arrow in the figure below.

(Prevention of splash of developer)

4) Insert Toner unit carefully into the copier.

5) Insert until the hook is engaged with the copier as shown in the figure below.

6) Pull out the shutter in the arrow direction.

13) Insert Developer unit carefully into the copier.

Note: Quick insertion may result in splash of developer. Be sure

to insert carefully.

14) Confirm that Developer unit is completely inserted to the bottom of

the machine, fix Developer unit and the machine with a screw.

15) Completion of Developer unit installation

AR-168N/168L UNPACKING AND INSTALLATION 5 - 3

Note: Do not hold and carry the shutter. Otherwise the shutter may

drop and Toner unit may drop.

7) Completion of Toner unit installation

Close the front and side cabinets.

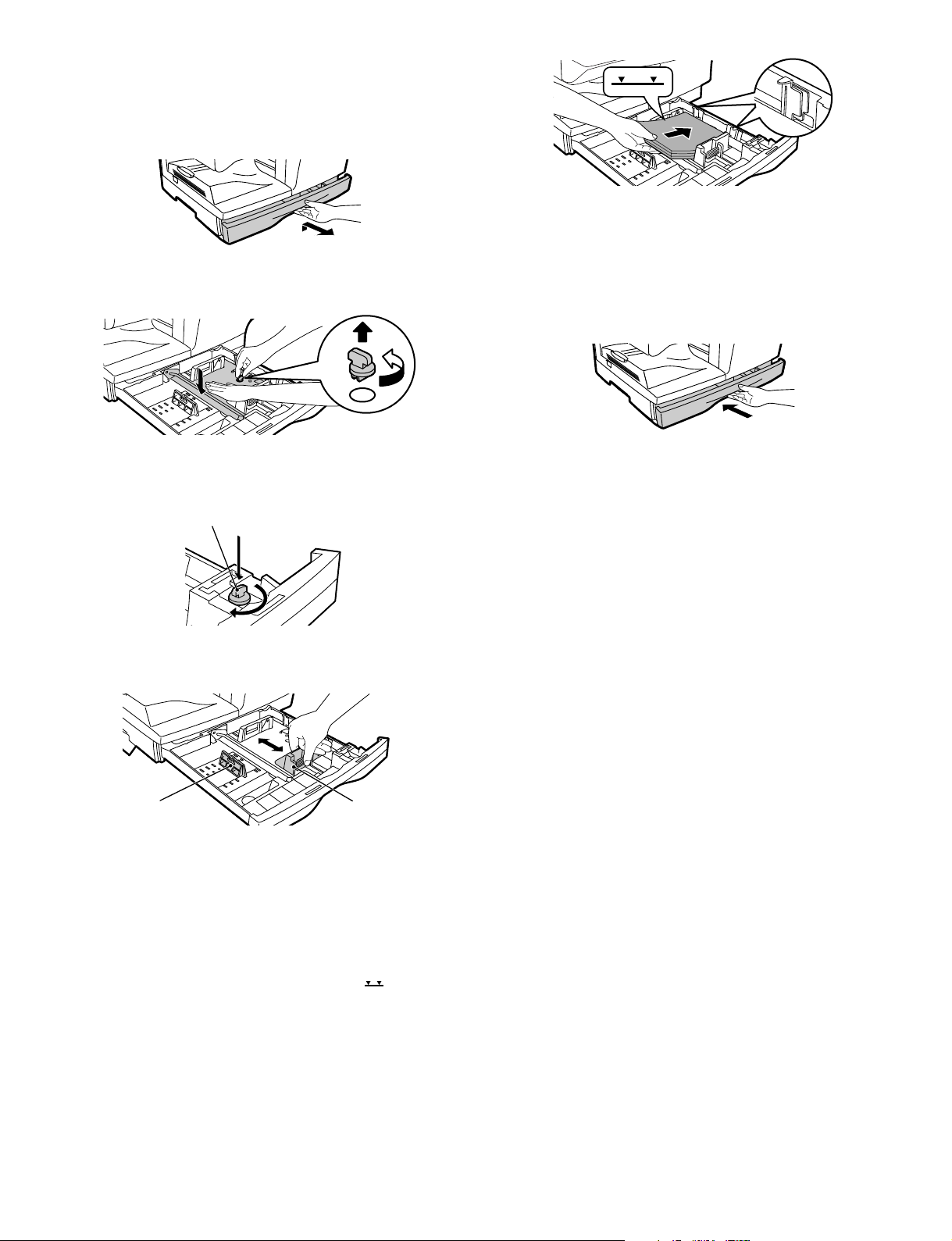

8. Loading the paper tray

Note: Make sure that the paper is not torn, is free of dust, and has no

wrinkles or curled edges.

1) Raise the handle of the paper tray and pull the paper tray out until it

stops.

2) Remove the pressure plate lock. Rotate the pressure plate lock in

the direction of the arrow to remove it while pressing down on the

pressure plate of the paper tray.

6) Gently push the paper tray back into the machine.

Note:

• If you loaded a different size of paper than was loaded previously in

the tray.

• When not using the machine for an extended period, remove all

paper from the paper tray and store it in a dry place. If paper is left in

the machine for an extended period, the paper will absorb moisture

from the air, resulting in paper jams.

3) Store the pressure plate lock which has been removed in step 2. To

store the pressure plate lock, rotate the lock to secure it as shown

below.

Pressure plate lock

4) Squeeze the lock lever of the front guide and slide the front guide to

match the width of the paper, and move the left guide to the appropriate slot as marked on the tray.

Left

guide

• The front guide is a slide-type guide. Grasp the locking knob on

the guide and slide the guide to the indicator line of the paper to

be loaded.

• The left guide is an insert-type guide. Remove it and then insert it

at the indicator line of the paper to be loaded.

5) Fan the paper and insert it into the tray. Make sure that the edges

go under the corner hooks.

Note:

• Do not load paper above the maximum height line ( ).

Exceeding the line will cause a paper misfeed.

• If the paper is not fanned, double-feeds or misfeeds may occur.

• Make sure the stack of paper is straight before loading it. When add-

ing paper, take the remaining paper out and combine it into a single

stack with the new paper.

• Make sure that all the paper in the stack is the same size and type.

• When loading paper, ensure that there is no space between the

paper and the guide, and make sure that the guide is not set too narrow and causes the paper to bend. Incorrect loading will cause the

paper to skew or misfeed.

Front

guide

9. Power to copier

1) Ensure that the power switch of the copier is in the OFF position.

Insert the attached power cord into the power cord socket at the

rear of the copier.

2) Plug the other end of the power cord into the nearest outlet.

10. Software for AR-168N/168L

The CD-ROM that accompanies the machine contains the following

software:

MFP driver

Printer driver

The printer driver enables you to use the printer function of the

machine.

The printer driver includes the Print Status Window*. This is a utility

that monitors the machine and informs you of the printing status, the

name of the document currently being printed, and error messages.

* When the machine is connected through the parallel port, the Print

Status Window can only be used when the parallel port is set to ECP

mode. To set the parallel port mode, refer to your computer manual

or ask the manufacturer of your computer.

Scanner driver (USB only)

The scanner driver allows you to use the scanning function of the

machine with TWAIN-compliant and WIA-compliant applications.

Sharpdesk

Sharpdesk is an integrated software environment that makes it easy to

manage documents and image files, and launch applications.

Button Manager

Button Manager allows you to use the scanner menus on the machine

to scan a document.

Note: The scanning feature can only be used with computers that are

running Windows 98/Me/2000/XP and are connected to the

machine by a USB cable. If you are running Windows 95/NT 4.0

or are connected to the machine by a parallel connection, only

the printer function can be used.

AR-168N/168L UNPACKING AND INSTALLATION 5 - 4

A. Before Installation

(1) Hardware and software requirements

Check the following hardware and software requirements in order to

install the software.

Computer type IBM PC/AT or compatible computer equipped with

a USB2.0*

(IEEE1284)

Operating

3

system*

*

Windows 95, Windows 98, Windows Me, Windows

4

NT Workstation 4.0 (ServicePack 5 or later)*

Windows 2000 Professional*

Professional*

Display 800 x 600 dots (SVGA) display with 256 colors (or

better)

Hard disk free

150MB or more

space

Other hardware

requirements

1

The machine's USB connector will transfer data at the speed speci-

*

An environment on which any of the operating

systems listed above can fully operate

fied by the USB 2.0 (Hi-Speed) only if the Microsoft USB 2.0 driver is

preinstalled in the computer, or if the USB 2.0 driver for Windows

2000 Professional/XP that Microsoft provides through its "Windows

Update" is installed.

2

Compatible with Windows 98, Windows Me, Windows 2000 Profes-

*

sional, Windows XP Professional or Windows XP Home Edition preinstalled model standardly equipped with a USB port.

3

Printing is not available in MS-DOS mode.

*

4

The machine does not support printing from a Macintosh environ-

*

ment.

5

Administrator's rights are required to install the software using the

*

installer.

(2) Installation environment and usable software

The following table shows the drivers and software that can be

installed for each version of Windows and interface connection

method.

Cable

USB*

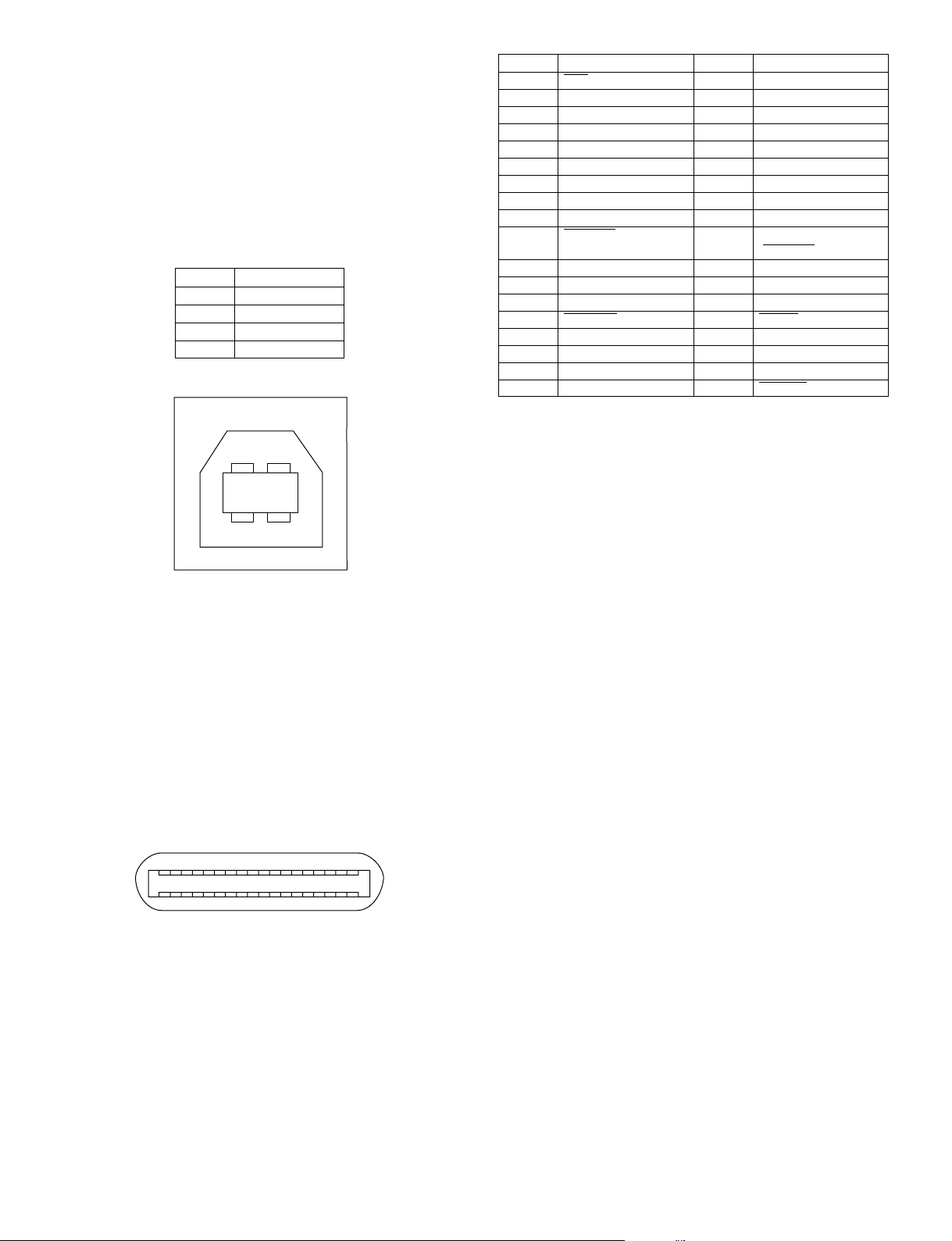

Parallel Windows 95/

1

Windows 98/Me does not support USB 2.0. A USB 2.0 connection

*

can be used in Windows 98/Me, however, the performance will be

the same as USB 1.1. The print speed based on USB 2.0 specifications can only be attained if your computer is running Windows

2000/XP, you are using a cable that supports USB 2.0 (USB 1.1 or

USB 2.0 certified), and the cable is connected to a USB 2.0 port on

your computer. If the connection is made through a hub, the hub

must support USB 2.0.

2

The printer driver that is installed will vary depending on the type of

*

connection between the machine and your computer.

3

Although it is possible to install Button Manager and Sharpdesk on

*

Windows 98/Me/2000/XP, neither Button Manager nor the scanner

function of Sharpdesk can actually be used.

Operating

system

1

Windows 98/

Me/2000/XP

98/Me/NT 4.0/

2000/XP

1

/1.1*2 or bi-directional parallel interface

5

5

, Windows XP Home Edition*

MFP Driver

Printer

driver

Scanner

driver

, Windows XP

Button

Manager

Available

Available

2

*

Not Available*

5

,

5

Sharpdesk

3

B. Installing the software

Note:

• If you need to use a different connection method after installing the

software based on a USB or parallel connection, you must first uninstall the software and then install it using the new connection

method.

• In the following explanations it is assumed that the mouse is config-

ured for right hand operation.

• The scanner feature only works when using a USB cable.

• If an error message appears, follow the instructions on the screen to

solve the problem. After the problem is solved, the installation procedure will continue. Depending on the problem, you may have to click

the "Cancel" button to exit the installer. In this case, reinstall the software from the beginning after solving the problem.

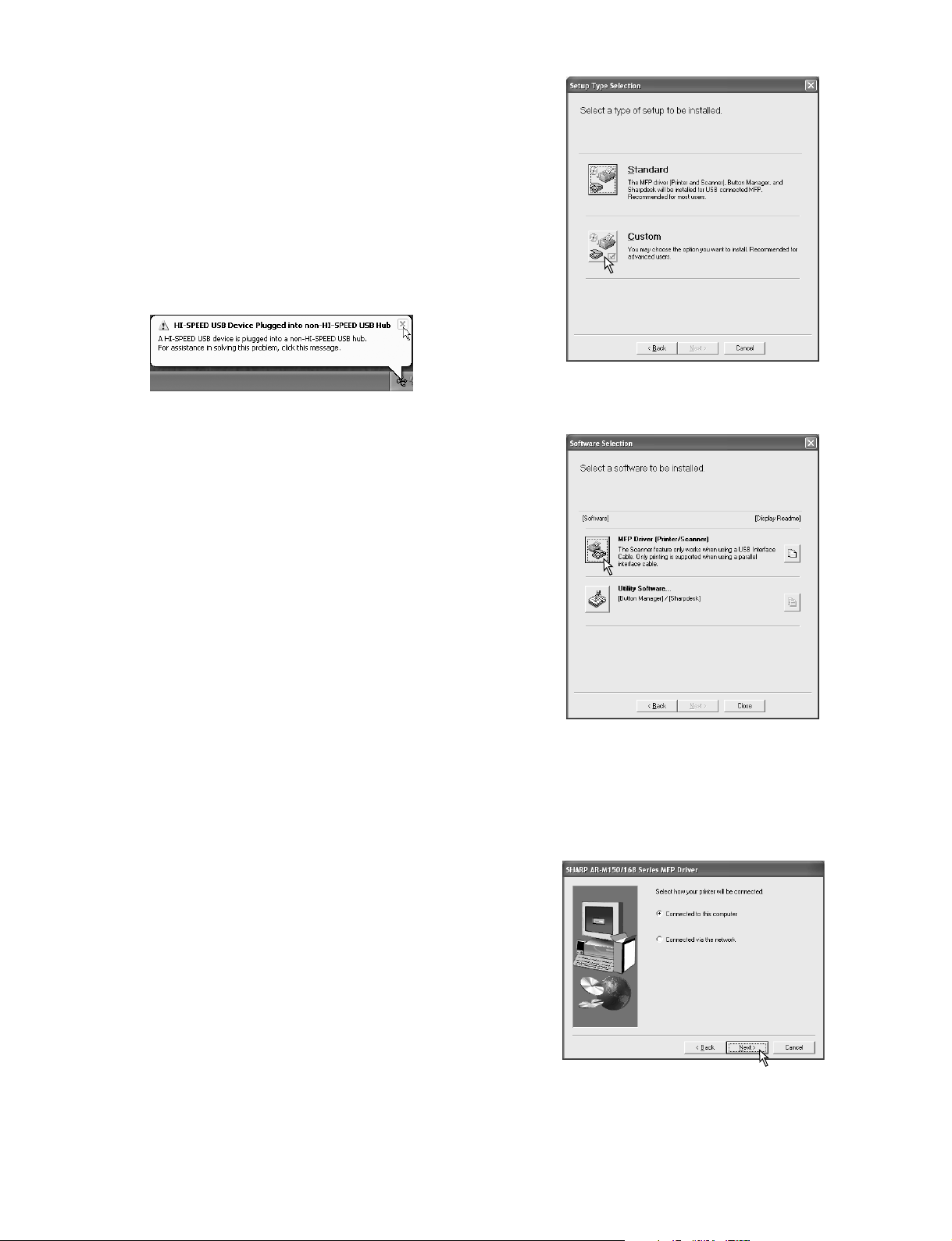

[Standard installation (USB only)]

The procedure for a standard installation of the software is explained

below. If the machine is connected by a USB cable, it is recommended

that you use the standard installation.

Note: The standard installation can only be used when the machine is

connected by a USB cable. If the machine is connected by a

parallel cable, use the custom installation procedure.

1) The USB cable must not be connected to the machine. Make sure

that the cable is not connected before proceeding.

If the cable is connected, a Plug and Play window will appear. If this

happens, click the "Cancel" button to close the window and disconnect the cable.

Note: The cable will be connected in step 9).

2) Insert the CD-ROM into your computer's CD-ROM drive.

3) Click the "start" button, click "My Computer", and then double-click

the CD-ROM icon.

In Windows 98/Me/2000, double-click "My Computer", and then

double-click the CD-ROM icon.

4) Double-click the "setup" icon.

Note: If the language selection screen appears after you double click

the "setup" icon, select the language that you wish to use and

click the "Next" button. (Normally the correct language is

selected automatically.)

5) The "SOFTWARE LICENSE" window will appear. Make sure that

you understand the contents of the software license, and then click

the "Yes" button.

6) Read the "Readme First" in the "Welcome" window and then click

the "Next" button.

7) Click the "Standard" button.

"Integrated Installer is preparing..." will appear and then installation

of the MFP driver, Button Manager, and Sharpdesk will begin automatically.

Follow the on-screen instructions.

AR-168N/168L UNPACKING AND INSTALLATION 5 - 5

8) When the "Finish" screen appears, click the "Close" button.

A message will appear instructing you to connect the machine to

your computer. Click the "OK" button.

Caution: If you are running Windows 2000/XP and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Continue Anyway" or "Yes".

Note: After the installation, a message prompting you to restart your

computer may appear. In this case, click the "Yes" button to

restart your computer.

9) Make sure that the power of the machine is turned on, and then

connect the USB cable.

Windows will detect the machine and a Plug and Play screen will

appear.

Caution: If the following message appears on your computer screen,

close it.

A window regarding "HI-SPEED USB Device" will then

appear. Close the window.

This message appears when the machine's USB 2.0 mode is

not set to "HI-SPEED". For information on switching the USB

2.0 mode.

10) Follow the instructions in the plug and play window to install the

MFP driver.

Follow the on-screen instructions.

Caution: If you are running Windows 2000/XP and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Continue Anyway" or "Yes".

Note: A "USB 2.0 Composite Device" installation window may appear

prior to this procedure. In this case, follow the instructions in the

window to install the USB 2.0 Composite Device.

This completes the installation of the MFP driver.

• If you installed Button Manager, set up Button Manager as explained

in "C. SETTING UP BUTTON MANAGER".

[Custom installation]

The procedure for a custom installation of the software is explained

below. Use the custom installation procedure when the machine is

connected by a parallel cable, when the machine is used as a shared

printer on a network, or when you wish to install the MFP driver, Button

Manager, or Sharpdesk separately.

(1) Windows XP (USB/Parallel)

1) The USB/parallel cable must not be connected to the machine.

Make sure that the cable is not connected before proceeding.

If the cable is connected, a Plug and Play window will appear. If this

happens, click the "Cancel" button to close the window and disconnect the cable.

Note: The cable will be connected in step 14).

2) Insert the CD-ROM into your computer's CD-ROM drive.

3) Click the "start" button, click "My Computer", and then double-click

the CD-ROM icon.

In Windows 98/Me/2000, double-click "My Computer", and then

double-click the CD-ROM icon.

4) Double-click the "setup" icon.

Note: If the language selection screen appears after you double click

the "setup" icon, select the language that you wish to use and

click the "Next" button. (Normally the correct language is

selected automatically.)

5) The "SOFTWARE LICENSE" window will appear. Make sure that

you understand the contents of the software license, and then click

the "Yes" button.

6) Read the "Readme First" in the "Welcome" window and then click

the "Next" button.

7) Click the "Custom" button.

8) Click the "MFP Driver" button.

To view detailed information on the software, click the "Display

Readme" button.

9) The "Welcome" window will appear. Click the "Next" button.

10) When you are asked how the printer is connected, select "Connected to this computer" and click the "Next" button.

If you are using the machine as a shared printer on a network,

select "Connected via the network". For more information on this

setting, see "Using the machine as a shared printer".

Follow the on-screen instructions.

Caution: If you are running Windows XP and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Continue Anyway".

AR-168N/168L UNPACKING AND INSTALLATION 5 - 6

11) You will return to the window of step 8). If you wish to install Button Manager or Sharpdesk, click the "Utility Software" button.

If you do not wish to install the Utility Software, click the "Close"

button and go to step 14).

Note: After the installation, a message prompting you to restart your

computer may appear. In this case, click the "Yes" button to

restart your computer.

Installing the Utility Software

12) Click the "Button Manager" button.

To view detailed information on the software, click the "Display

Readme" button.

Follow the on-screen instructions.

If you wish to install Sharpdesk, click the "Sharpdesk" button in

this window and follow the on-screen instructions.

Caution:

• Button Manager can only be used when the machine is connected

by a USB cable.

• The scanner function of Sharpdesk can only be used when the

machine is connected by a USB cable.

Caution: If the following screen appears during installation of Sharp-

desk, click the "Skip" button or the "Continue" button as

appropriate to continue the Sharpdesk installation.

14) Make sure that the power of the machine is turned on, and then

connect the USB/parallel cable.

Windows will detect the machine and a Plug and Play screen will

appear.

Caution: If the following message appears on your computer screen,

close it.

A window regarding "HI-SPEED USB Device" will then

appear. Close the window.

This message appears when the machine's USB 2.0 mode is

not set to "HI-SPEED". For information on switching the USB

2.0 mode.

15) Follow the instructions in the plug and play window to install the

MFP driver.

Follow the on-screen instructions.

Caution: If you are running Windows XP and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Continue Anyway".

Note: A "USB 2.0 Composite Device" installation window may appear

prior to this procedure. In this case, follow the instructions in the

window to install the USB 2.0 Composite Device.

This completes the installation of the MFP driver.

• If you installed Button Manager, set up Button Manager as explained

in "C. Setting up button manager".

(2) Windows 98/Me/2000 (USB)

1) The USB cable must not be connected to the machine. Make sure

that the cable is not connected before proceeding.

If the cable is connected, a Plug and Play window will appear. If this

happens, click the "Cancel" button to close the window and disconnect the cable.

Note: The cable will be connected in step 8).

2) Perform steps 2) through 7) in "Custom installation".

3) Click the "MFP Driver" button.

To view detailed information on the software, click the "Display

Readme" button.

If "Skip" is selected, the Sharpdesk installation will continue

without installing Sharpdesk imaging.

If "Continue" is selected, Sharpdesk Imaging will be installed.

If Imaging for Windows is installed on your computer, Sharpdesk Imaging will overwrite Imaging for Windows.

13) When installation of Button Manager is finished, you will return to

the window of step 12). Click the "Close" button.

A message will appear instructing you to connect the machine to

your computer. Click the "OK" button.

Note: After the installation, a message prompting you to restart your

computer may appear. In this case, click the "Yes" button to

restart your computer.

AR-168N/168L UNPACKING AND INSTALLATION 5 - 7

4) The "Welcome" window will appear. Click the "Next" button.

5) When you are asked how the printer is connected, select "Con-

nected to this computer" and click the "Next" button.

6) When the interface selection screen appears, select "USB" and

click the "Next" button.

If you are using the machine as a shared printer on a network,

select "Connected via the network". For more information on this

setting, see "Using the machine as a shared printer".

Follow the on-screen instructions.

(3) Windows 95/98/Me/NT 4.0/2000 (Parallel)

1) The parallel cable must not be connected to the machine. Make

sure that the cable is not connected before proceeding.

If the cable is connected, a Plug and Play window will appear. If this

happens, click the "Cancel" button to close the window and disconnect the cable.

Note: The cable will be connected in step 10).

2) Perform steps 2) through 7) in "Custom installation".

3) Click the "MFP Driver" button.

To view detailed information on the software, click the "Display

Readme" button.

Note: In Windows 95/NT4.0, the "Utility Software" button does not

appear and only the printer driver can be installed.

Caution: If you are running Windows 2000 and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Yes".

7) You will return to the window of step 3). If you wish to install Button

Manager or Sharpdesk, click the "Utility Software" button.

To install the Utility Software, see "Installing the Utility Software"

(steps 12) and 13) on page 7).

If you do not wish to install the Utility Software, click the "Close"

button.

A message will appear instructing you to connect the machine to

your computer. Click the "OK" button.

Note: After the installation, a message prompting you to restart your

computer may appear. In this case, click the "Yes" button to

restart your computer.

8) Make sure that the power of the machine is turned on, and then

connect the USB cable.

Windows will detect the machine and a Plug and Play screen will

appear.

9) Follow the instructions in the plug and play window to install the

MFP driver.

Follow the on-screen instructions.

Caution: If you are running Windows 2000 and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Yes".

Note: A "USB 2.0 Composite Device" installation window may appear

prior to this procedure. In this case, follow the instructions in the

window to install the USB 2.0 Composite Device.

This completes the installation of the MFP driver.

• If you installed Button Manager, set up Button Manager as explained

in "C. Setting up button manager".

4) The "Welcome" window will appear. Click the "Next" button.

5) When you are asked how the printer is connected, select "Connected to this computer" and click the "Next" button.

If you are using the machine as a shared printer on a network,

select "Connected via the network". For more information on this

setting, see "Using the machine as a shared printer".

6) When the interface selection screen appears, select "Parallel" and

click the "Next" button.

AR-168N/168L UNPACKING AND INSTALLATION 5 - 8

7) Select the printer port and whether the machine is to be used as the

default printer, make the selections and click the "Next" button.

Select "LPT1" for the printer port.

Note:

• If "LPT1" does not appear, another printer or peripheral device is

using LPT1. In this case continue the installation, and after the

installation is finished, change the port setting so that the machine

can use LPT1.

• The "Add Network port" button is used when the machine is used as

a shared printer. Do not click this button here.

8) When the model selection window appears, select model name of

your machine and click the "Next" button.

Follow the on-screen instructions.

Caution: If you are running Windows 2000 and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Yes".

9) You will return to the window of step 3). If you wish to install Sharpdesk, click the "Utility Software" button.

To install the Utility Software, see "Installing the Utility Software"

(steps 12) and 13) on page 7).

If you do not wish to install the Utility Software, click the "Close"

button.

A message will appear instructing you to connect the machine to

your computer. Click the "OK" button.

10) Make sure that the power of the machine is turned on, and then

connect the parallel cable.

This completes the installation of the MFP driver.

(4) Using the machine as a shared printer

If the machine will be used as a shared printer on a network, follow

these steps to install the MFP driver in the client computer.

Note:

• To configure the appropriate settings in the print server, see the

operation manual or help file of your operating system.

"Print server" as explained here is a computer that is directly connected to the machine, and a "Client" is any other computer that is

connected to the same network.

• When the machine is used via a network connection, only the printer

function can be used; the scanner function cannot be used.

1) Perform steps 2) through 7) in "Custom installation".

2) Click the "MFP Driver" button.

To view detailed information on the software, click the "Display

Readme" button.

3) The "Welcome" window will appear. Click the "Next" button.

4) When you are asked how the printer is connected, select "Connected via the network" and click the "Next" button.

5) When you are asked to select the printer port to be used, click the

"Add Network Port" button.

AR-168N/168L UNPACKING AND INSTALLATION 5 - 9

6) Select the network printer that is shared and click the "OK" button.

Ask your network administrator for the server name and printer

name of the machine on the network.

4) Select "SC1:" from the "Select an event" pull-down menu.

7) In the printer port selection window, verify the network printer that is

shared and whether the machine is to be used as the default

printer, make the selections and click the "Next" button.

8) When you are asked to select the model name, select the model

that you are using and click the "Next" button.

Follow the on-screen instructions.

Caution: If you are running Windows 2000/XP and a warning message

appears regarding the Windows logo test or digital signature,

be sure to click "Continue Anyway" or "Yes".

9) You will return to the window of step 2). Click the "Close" button.

Note: After the installation, a message prompting you to restart your

computer may appear. In this case, click the "Yes" button to

restart your computer.

This completes the installation of the MFP driver.

C. Setting up button manager

Button Manager is a software program that works with the scanner

driver to enable scanning from the machine.

To scan using the machine, Button Manager must be linked with the

scan menu on the machine. Follow the steps below to link Button Manager to scanner events.

(1) Windows XP

1) Click the "start" button, click "Control Panel", click "Printers and

Other Hardware", and then click "Scanners and Cameras".

2) Click the "SHARP AR-XXXX" icon and select "Properties" from the

"File" menu.

3) In the "Properties" screen, click the "Events" tab.

5) Select "Start this program" and then select "Sharp Button Manager

E" from the pull-down menu.

6) Click the "Apply" button.

7) Repeat Steps 4) through 6) to link Button Manager to "SC2:"

through "SC6:".

Select "SC2:" from the "Select an event" pull-down menu. Select

"Start this program", select "Sharp Button Manager E" from the pulldown menu, and then click the "Apply" button. Do the same for

each ScanMenu through "SC6:".

When the settings have been completed, click the "OK" button to

close the screen.

Button Manager is now linked to the scan menu (1 through 6).

The scan settings for each of scan menu 1 through 6 can be changed

with the setting window of Button Manager.

For the factory default settings of the scan menu and the procedures

for configuring Button Manager settings.

(2) Windows 98/Me/2000

1) Click the "Start" button, select "Settings", and then click "Control

Panel".

2) Double-click the "Scanners and Cameras" icon.

Note: If the "Scanners and Cameras" icon does not appear in

Windows Me, click "view all Control Panel options".

3) Select "SHARP AR-XXXX" and click the "Properties" button.

In Windows Me, right click "SHARP AR-XXXX" and click "Properties" in the pop-up menu.

4) In the "Properties" screen, click the "Events" tab.

AR-168N/168L UNPACKING AND INSTALLATION 5 - 10

5) Select "SC1:" from the "Scanner events" pull-down menu.

6) Select "Sharp Button Manager E" in "Send to this application".

D. Connecting the machine to your computer

(1) Connecting a USB cable

Follow the procedure below to connect the machine to your computer.