Page 1

AR-161

CODE: 00ZAR161//A1E

DIGITAL COPIER

AR-160

MODEL AR-161

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . 4-1

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

[15] ACTUAL WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safty and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-161AR-161

Warning!

This product is a class A product.

If it is operated in households, offices or similar surroundings, it

can produce radio interferences at other appliances, so that the

user has to take adequate countermeasures.

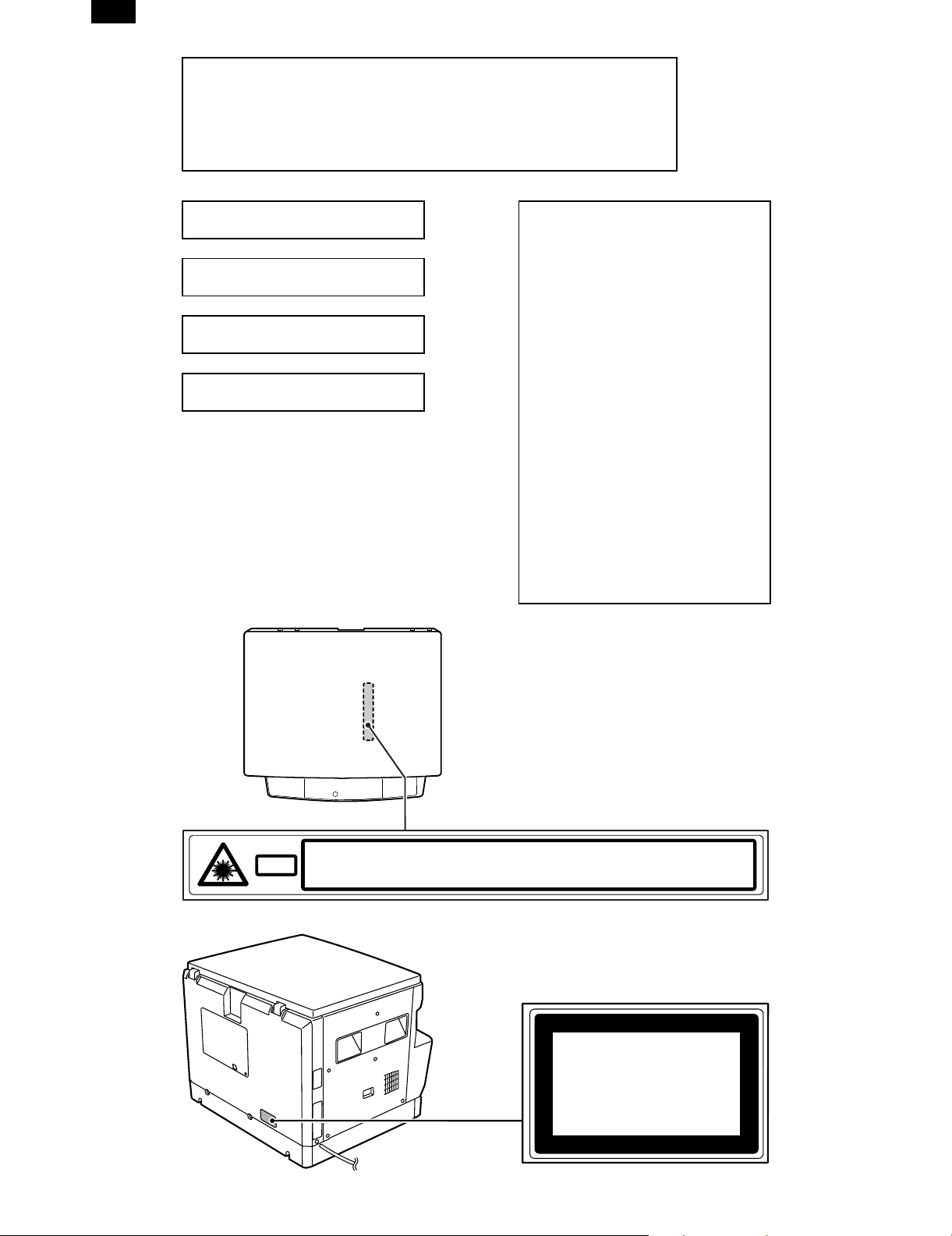

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

VAROITUS!

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

CAUTION

Laserstrahl

VORSICHT

ADVARSEL

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGA UDSAETTELSE FOR STRÅLING.

ADVERSEL

VARNING

VARO!

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Page 3

CONTENTS

AR-161

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Target user copy volum e: M ont hly average . . . 1-1

3. Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

4. System configuration . . . . . . . . . . . . . . . . . . . . . 1-1

5. Copier installation . . . . . . . . . . . . . . . . . . . . . . . 1-1

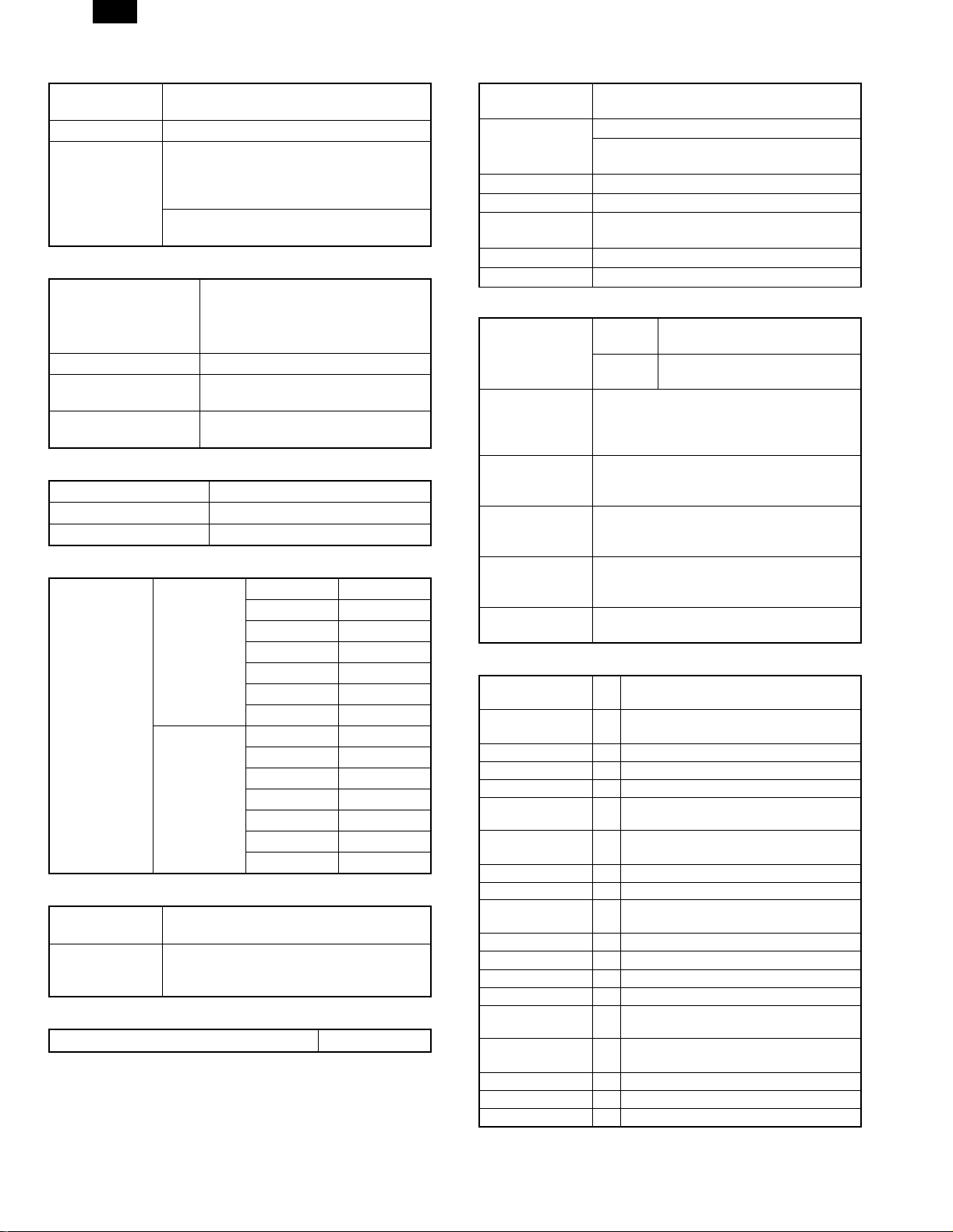

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1. Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . 3-1

1. Supply system table . . . . . . . . . . . . . . . . . . . . . 3-1

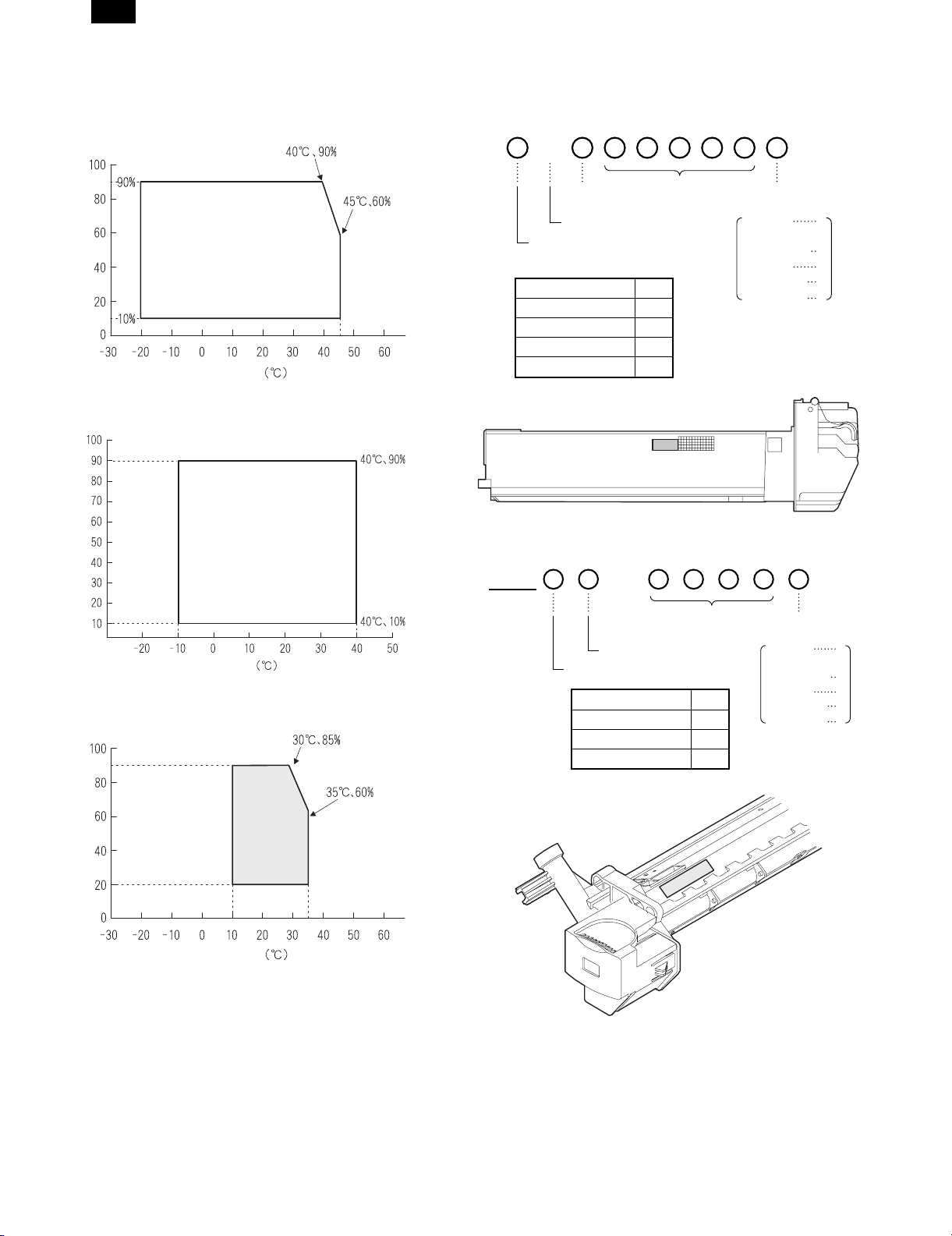

2. Environment conditions . . . . . . . . . . . . . . . . . . . 3-3

3. Production number identification . . . . . . . . . . . . 3-3

4. Consumable parts recycling procedure . . . . . . 3-4

[ 4 ] EXTERNAL VIEWS AND INTERNAL

STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

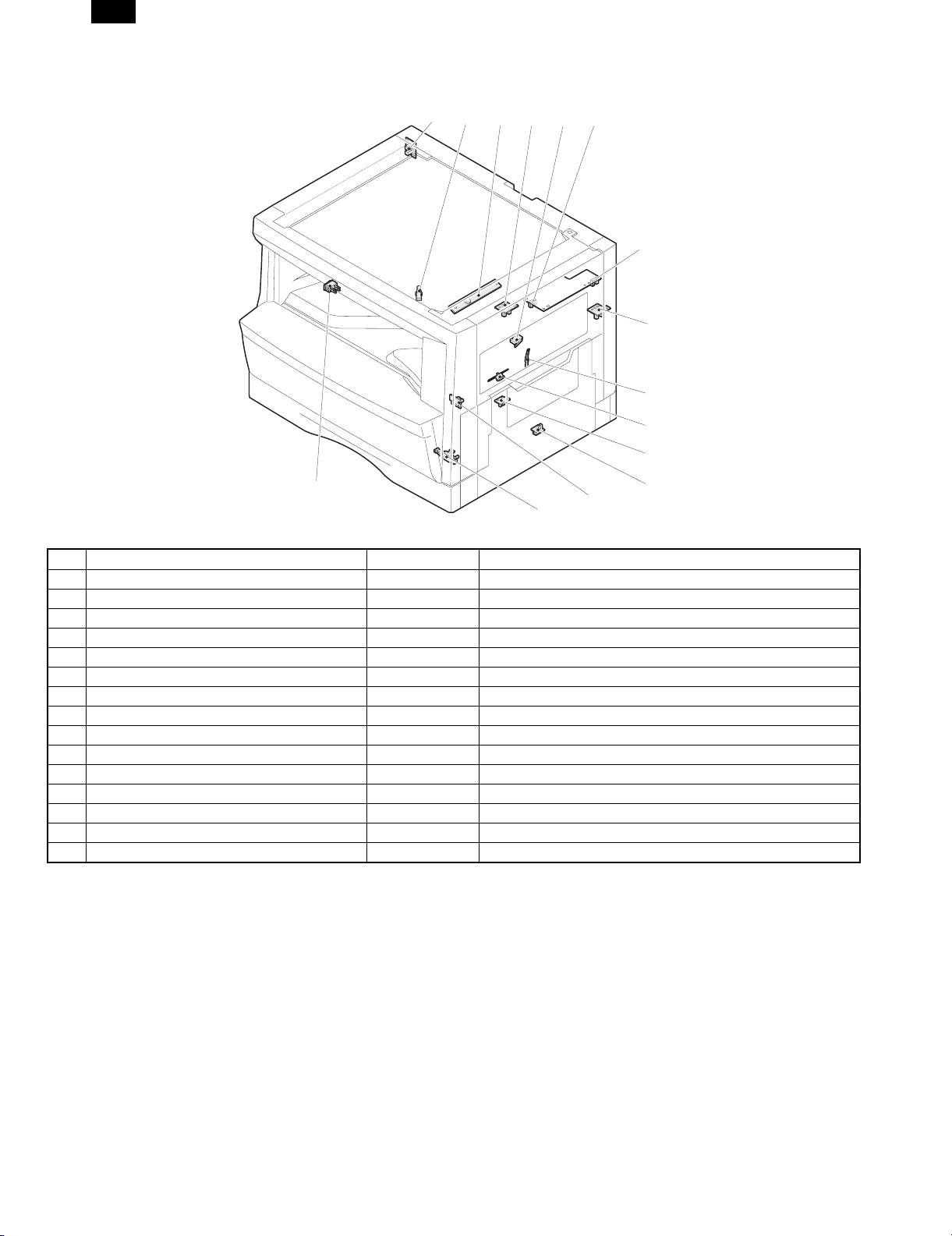

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3. Operation Section . . . . . . . . . . . . . . . . . . . . . . . 4-2

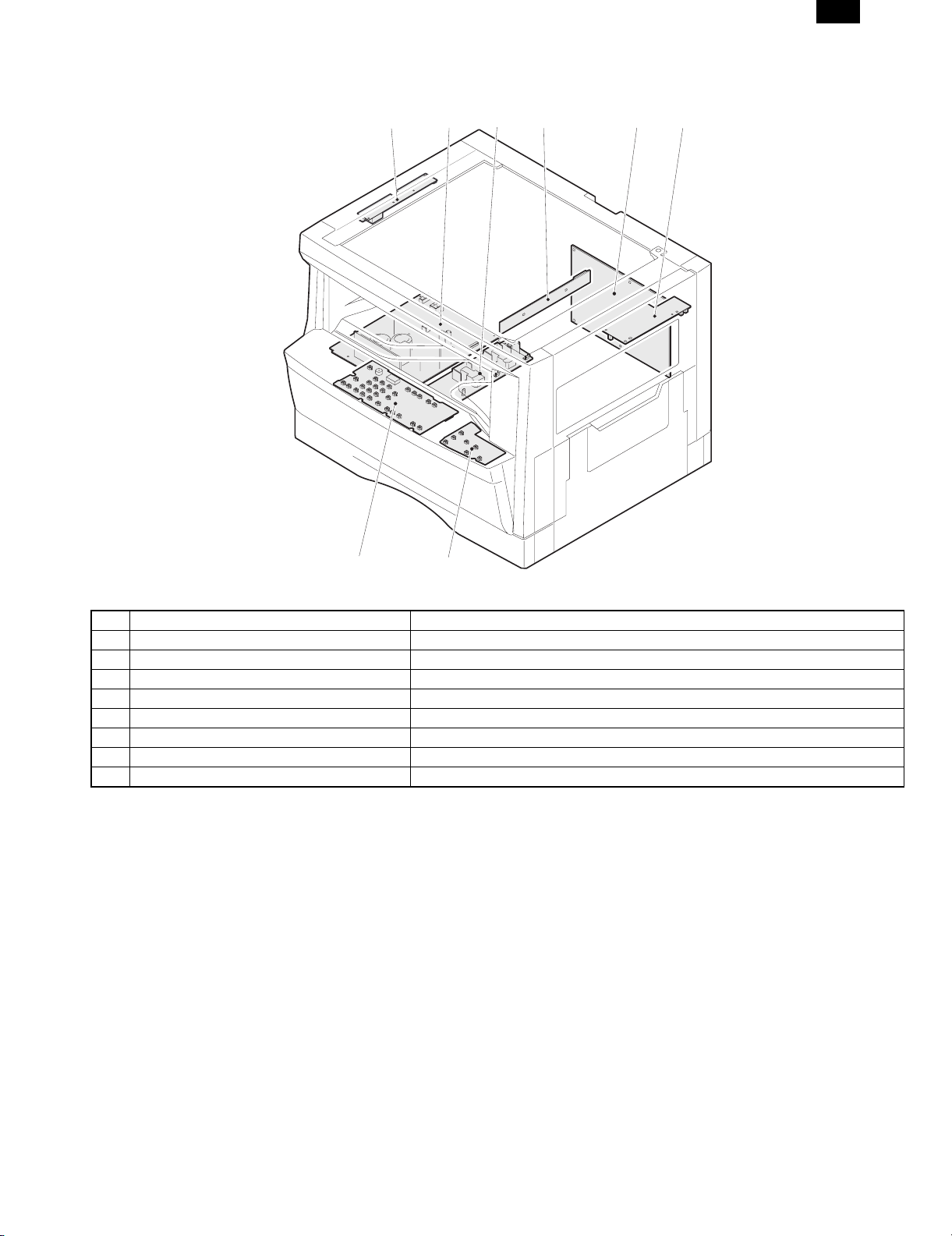

4. Motor, solenoid, clutch . . . . . . . . . . . . . . . . . . . 4-3

5. Sensor, switch . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

7. Cross sect i onal vi ew . . . . . . . . . . . . . . . . . . . . . 4-6

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . 5-1

1. Installat i on of m achine . . . . . . . . . . . . . . . . . . . 5-1

2. Remo val of protective mat erial and fixing scr ew 5-1

3. Installation of developing cartridge . . . . . . . . . . 5-1

4. Removal and storage of fixing screw . . . . . . . . 5-2

5. Changi ng t he copy paper size in the tray . . . . . 5-3

[ 6 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . 6-1

1. Outline of oper ation . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . 6-1

3. Process section . . . . . . . . . . . . . . . . . . . . . . . . 6-2

4. Laser unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

5. Paper feed section . . . . . . . . . . . . . . . . . . . . . . 6-6

6. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Copier adjus tment . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

1. Entering the si m ulat i on m ode . . . . . . . . . . . . . . 8-1

2. Cancelling the simu la tion mode . . . . . . . . . . . . 8-1

3. List of simulation s . . . . . . . . . . . . . . . . . . . . . . . 8-1

4. Contents of simul at i ons . . . . . . . . . . . . . . . . . . . 8-2

[ 9 ] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . 9-1

1. User program f unctions . . . . . . . . . . . . . . . . . . . 9-1

2. Setting change procedure . . . . . . . . . . . . . . . . . 9-2

3. Departmen t counter setting . . . . . . . . . . . . . . . . 9-2

[10] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . 10-1

[11] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

1. Maintena nce tabl e . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] DISASSEMBLY AND ASSEMBLY . . . . . . . . . 12-1

1. High voltage secti on . . . . . . . . . . . . . . . . . . . . 12-1

2. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

3. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . 12-2

4. Paper exit section . . . . . . . . . . . . . . . . . . . . . . 12-4

5. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

6. Optical frame uni t . . . . . . . . . . . . . . . . . . . . . . 12-6

7. LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

8. Tray pa per feed section/

Paper transport section . . . . . . . . . . . . . . . . . . 12-7

9. Manual mu lti paper feed section . . . . . . . . . . 12-8

10. Power section . . . . . . . . . . . . . . . . . . . . . . . 12-10

11. Developing section . . . . . . . . . . . . . . . . . . . . 12-11

12. Process section . . . . . . . . . . . . . . . . . . . . . . 12-12

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . 13-1

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

3. CCD PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

[14] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . 14-1

[15] ACTUAL WIRING DIAGRAM . . . . . . . . . . . . . 15-1

Page 4

AR-161

[1] GENERAL

1. General

This model is a digital personal copier produced with key words of

"Comfort able copy, Clear copy, Easy copy" providing high copy performances and copy productivity.

2. Target user copy volume: Monthly

average

Stand-alone copier: 2000~3000 sheets

Compound machine: 4000~5000 sheets

3. Main features

A. High-speed laser copying

• First-copy time is only 7.2 seconds (normal mode).

• Copying speed is 16 copies/min., which adapts to business use,

allowing improvement of working efficiency.

B. High-quality digital image

• High-quality copying at 600 dpi is performed.

• In addition to the automatic exposure mode, the manual exposure

can be adjusted in five steps.

• The photo mode copying function allows clear copying of delicate

halftone original images such as monochrome photos and color

photos. Photo mode is adjustable in five steps

C. Substantial copying features

• Zoom copying from 50% to 200% in 1% increments can be per-

formed.

• Continuous copying of maximum 99 sheets can also be per-

formed.

• Useful special features such as the XY zoom, black and white

reverse, and dual page copy are available.

• Toner save mode reduces toner consumption by approximately

10%.

• User programs allow setting/modification of functions for customer

needs. Also the user programs allow the internal auditor to be

controlled.

D. Scan once/ Print many (Only AR-161 for

USA/Canada)

• The copier is equipped with a 1-page memory buffer. This memory

allows the copier to scan an original 1 time only and make up to 99

copies. This feature allows for improved workflow, reduced operating noise from the copier and reduced wear and tear on the scanning mechanism, which provides for a higher reliability.

E. Optional features

• An optional single pass feeder (SPF) allows automatic document

feeding of up to 30 sheets.

• An optional electronic sort board allows many useful copier fea-

tures to be used. Multiple sets of copies can be sorted without the

aid of a sorter and each set can be offset from the previous set.

Also the erase, margin shift, and 4 in 1 and 2 in 1 functions are

available. (To use the 2 in 1 and 4 in 1 and sort/group functions,

an optional SPF is also needed.) (Offset only for AR-161)

• This copier can be used as a laser printer by installing an optional

printer upgrade kit. (Depends on the destination)

• This copier can be used as a facsimile machine by installing an

optional facsimile upgrade kit. (Depends on the destination)

F. Environmentally friendly design

• Paper output tray is housed in the copier for space saving.

• Preheat mode and auto power shut-off mode are provided to

reduce power consumption in standby mode.

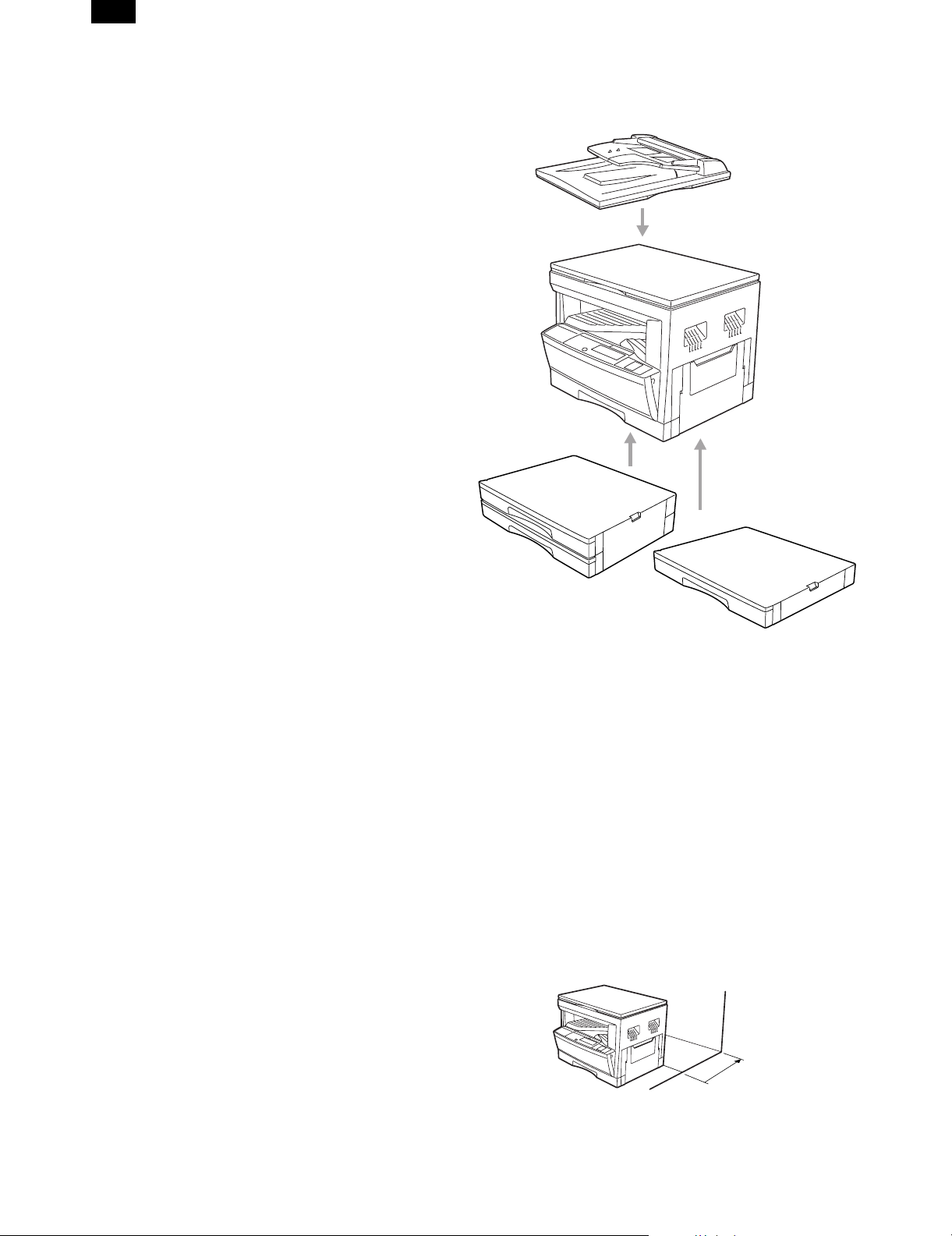

4. System configuration

Single pass feeder

(AR-SP2)

500-sheet paper feed unit

(AR-DE6)

250-sheet paper feed unit

(AR-DE5)

Electronic sorting kit (AR-EB3)

*Facsimile expansion kit (AR-FX2)

*Printer expansion kit (AR-PB8)

*LCD panel kit (AR-PA1)

*Job separator tray (AR-TR2)

*PS2 expansion kit (AR-PS1)

*There may be no setting for AR-FX2, AR-PB8, AR-PA1,

AR-TR2, and AR-151 depending on the destination.)

5. Copier installation

Do not install your copier in areas that are:

• damp, humid, or very dusty

• exposed to direct sunlight

• poorly ventilated

• subject to extreme temperature or humidity changes, e.g., near an

air conditioner or heater.

• Be sure to allow the required space around the machine for servic-

ing and proper ventilation.

4" (10 cm)

1 – 1

Page 5

AR-161

[2] SPECIFICATIONS

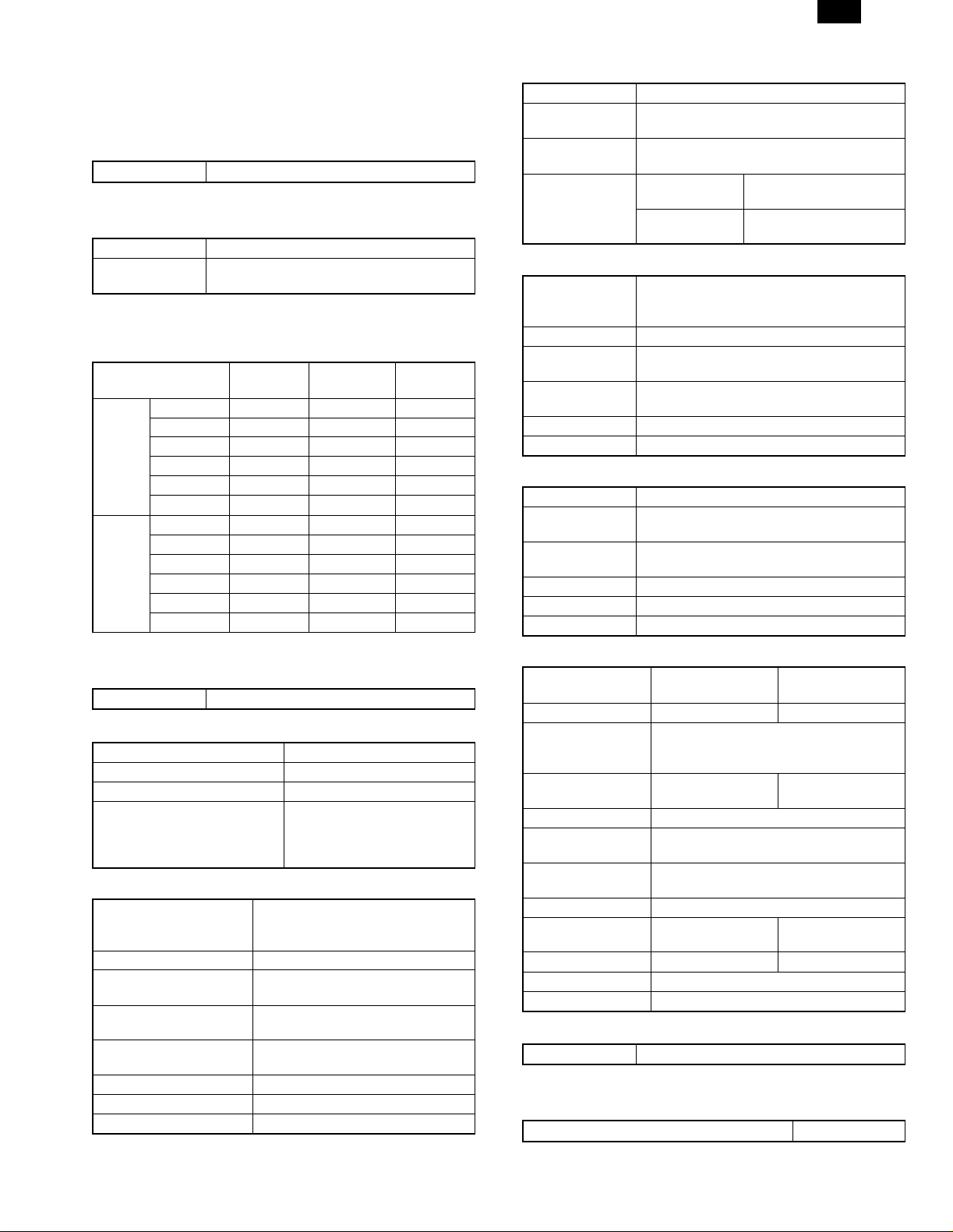

1. Copy mode

A. Type

Type Desk-top

B. Copy speed

(1) Basic speed

1 scan 1 copy 16 sheets/min

1 scan multi copy Not available

(Available for AR-161 for USA/Canada)

Condition: Copy speed in the normal copy from all the paper feed

ports including the manual paper feed port.

(2) Continuous copy speed (Sheets/min)

Paper size Normal

A3 9 9 9

B4 10 10 10

AB

Inch

A4 16 16 14

A4R 12 12 12

B5 16 16 16

B5R 14 14 14

11" × 17" 9 9 9

8.5" × 14" 10 10 10

8.5" × 13" 10 10 10

8.5" × 11" 16 16 14

8.5" × 11"R 12 12 12

8.5" × 5.5" 16 16 16

system

system

Enlargement

(200%)

C. First copy time

(1) Basic speed

First copy time 7.2sec (A4, 8.5" × 11"/1st cassette/with OC)

D. Document

Max. document size A3, 11" × 17"

Document reference position Left side center

Detection (Platen) None

Detection size A3, B4, A4, A4R, B5, B5R

11" × 17", 8.5" × 14",

8.5" × 13", 8.5" × 11",

8.5" × 11"R, 8.5" × 5.5"

(1) SPF/R-SPF

Standard/Option Option

SPF, AR-SP2

RSPF; Not available

Document load capacity 30 sheets (56 ∼ 90g/m2 equivalent)

Document size

(Max. ∼ Min.)

Document replacement

speed

Document set/Paper feed

direction

Document weight 56 ∼ 90g/m2, 15 ∼ 23.9 lbs

Document size detection On the document feed tray

Document mixture Copy mode: Not Available

A3 ∼ A5

11" × 17" ~ 8.5" × 5.5"

16 sheets/min (A4 normal copy)

Face up, Center reference, Paper

feed from the top

Reduction

(50%)

E. Paper feed

Copy size (Max. ∼ Min.) Cassette: (A3 ∼ A6)

Paper feed

system

Paper feed

capacity

Remaining

quantity detection

1 cassette + Multi manual paper feed

250 × 1 (Paper feed tray) + 100 (Multi bypass

feed tray)(56 ∼ 80g/m2 equivalent)

Cassette section Empty detection available,

size detection by key input

Manual tray Only empty detection

available

(1) Paper feed section of the copier

Paper feed size A3, B4, A4, A4R, B5, B5R, A5

Side front Front 1st step

Paper feed

capacity

Detection Paper empty detection available, size

Weight 56 ∼ 80g/m

Special paper Recycled paper

11" × 17", 8.5" × 14", 8.5" × 13", 8.5" × 11",

8.5" × 11"R, 8.5" × 5.5"

250 sheets (56 ∼ 80g/m2 equivalent)

detection (by key input)

2

(2) Manual paper feed section

Paper feed size A3 ∼ A5

Paper feed

capacity

Detection Size detection not available, paper empty

Weight 56 ∼ 128g/m

Special paper Recycled paper, OHP film, labels

Paper feed Single except for recycled paper

100 sheets

detection available

2

(3) Option paper feed unit

1-step paper feed

unit

Model AR-DE5 AR-DE6

Paper feed size A3, B4, A4, A4R, B5, B5R, A5

11" × 17", 8.5" × 14", 8.5" × 13", 8.5" × 11",

Capacity

(56 ∼ 80g/m2)

Paper weight 56 ∼ 80 g/m

Moisture preserving

heater

Detection Paper empty detection, size detection (by

Paper size setting User setting (by key input)

External dimensions

(W × D × H)

Weight About 8.5kg About 14kg

Special paper Recycled paper

Power Supplied from the machine (5V/24V)

About 250 sheets ×

570 × 570 × 103mm 570 × 570 × 208mm

8.5" × 11"R, 8.5" × 5.5"

1 step

Standard provision

2-step paper feed

unit

About 250 sheets ×

2 steps

2

key input)

F. Job speed

S-S (1st step) 100% (document replacement rate)

Condition: With SPF

G. Multi copy

Max. number of multi copy 99 sheets

2 – 1

Page 6

AR-161

H. Warmup time

Warmup time Approx. 35 sec

(Condition: Standard condition)

Pre-heat Available

Jam recovery time Second

(Condition: Left for 60 sec after door open.

Standard condition, polygon motor not

stopped)

Second

(Condition: Polygon motor stopped)

I. Copy magnification ratio

Fixed magnification ratio AB system: 50, 70, 81, 86, 100, 115,

122, 141, 200%

Inch system: 50, 64, 77, 95, 100, 121,

129, 141, 200%

Zooming 50 ∼ 200%

Independent

zooming/vertical

Independent zooming

(horizontal)

Available (50 ∼ 200%)

Available (50 ∼ 200%)

J. Print density

Density mode Auto/Manual/Photo

No. of manual adjustment 5 steps (Manual/Photo)

Toner save mode Set by the user program

K. Print area

Max. print area

AB system

Inch system Max. 428 × 275

Max. 416 × 293

A3 416 × 293

B4 360 × 253

A4 206 × 293

A4R 293 × 206

B5 178 × 253

B5R 253 × 178

11" × 17" 428 × 275

8.5" × 14" 352 × 212

8.5" × 13" 212 × 326

8.5" × 11" 212 × 275

8.5" × 11"R 275 × 212

8.5" × 5.5" 212 × 136

L. Void width

Void area Lead edge 1 ∼ 4mm, rear edge 4mm or less,

both side 4mm or less

Image loss Max. 4mm in total of lead edge and rear

edge, max. 4mm in total of right and left

edges (Normal copy)

M. Auto duplex

Standard/Option Not installable

N. Paper exit/finishing

Paper exit

section capacity

Job separator Job separator, option (AR-TR2)

Full detection Available (Job separator upper step)

Finishing Electronic sort board: Option (AR-EB3)

Electronic sort

capacity

Offset function AR-161: Available

Staple function None

(1) Electronic sort board (Option)

Electronic sort Sorting 60 sheets of A4 standard

Rotation copy If there is paper of same size as the

2 in 1, 4 in 1 Copies of 2 pages or 4 pages are integrated

Edge erase Images surrounding the document are erased

Center erase The image at the center is erased when

Margin shift Binding margin is made at the left edge of the

Face down 250 sheets

Upper: FAX/Printer, Lower: Copier

Upper: 100sheets, Lower 150sheets

A4 standard document 60 sheets

documents

Grouping 60 sheets of A4 standard

documents

document, the image is rotated to copy even

though the paper is set in the different

direction from the document direction.

into one surface. Divided by solid lines,

(Selectable by the user program.)

when copying. (Adjustable in 0 ∼ 20mm by the

user program.)

copying. (Adjustable in 0 ∼ 20mm by the user

program.)

set documents.

O. Additional functions

*

APS

*

AMS

Duplex ✕

Document count ✕

Sorter v When the electronic sort board installed.

Independent

zooming

1 set 2 copy F Enlargement inhibited, inhibited during

Binding margin v Shift width 9mm

Edge erase v Width 5mm (Adjustable 0 ∼ 20mm)

Black-white

reversion

2 in 1, 4 in 1 v

Rotation copy v

Memory copy ✕ (AR-161 for USA/Canada: Available)

Pre-heat function F Conditions set by the user program

Auto power shut

off function

Auto tray

switching

Message display v (FAX/Printer extension)

User program F

Total counter F

*

: By the document size set key

v: When an option is installed

F (APS not available by flowing in during

use of SPF)

F (AMS not available by flowing in during

use of SPF)

F Vertical/Horizontal: 50 ∼ 200%

the use of SPF

F Whole surface only

F Conditions set by the user program

F

2 – 2

Page 7

AR-161

P. machine composition

Model

AR-160 Standard model

AR-161 Standard model (with shifter)

(USA/Canada: with memory copy)

(1) Option

Machine Model Power supply

250 sheets paper feed unit AR-DE5 Supplied by the copier.

500 sheets paper feed unit AR-DE6 Supplied by the copier.

SPF AR-SP2 Supplied by the copier

Electronic sorting kit AR-EB3 Supplied by the copier.

Printer expansion kit AR-PB8 Supplied by the copier.

Facsimile extension kit AR-FX2 Supplied by the copier.

LCD panel kit

(20 digits × 2 lines)

Job separator tray AR-TR2

PS2 expantion kit AR-PS1

Extension memory for FAX

(2MB)

Extension memory for FAX

(4MB)

Extension memory for FAX

(8MB)

AR-PA1 Supplied by the copier.

AR-MM5

AR-MM6

AR-MM7

V. Reliability

Target users Stand-alone copier Monthly average

2,000 ∼ 3,000 copies

Compound machine Monthly average

4,000 ∼ 5,000 copies

W. Noise

Noise BA standard

X. Digital performance

Resolution Reading 400 dpi

Writing 600 dpi

Gradation Reading 256 gradations

Writing Binary

Q. Other specifications

Photoconductor type OPC (Organic Photo Conductor)

Photoconductor drum dia. 30mm

Copy lamp Xenon lamp

Developing system Dry 2-component magnetic brush

Charging system Saw teeth charging

Transfer system Non-contact (Corona) electrostatic

Separation system Natural separation

Fusing system Heat roller + Separation pawl

Cleaning system Contact blade

development

transfer

R. Package form

Body Body/Accessaries

S. External view

External dimensions

(W × D × H)

Occupying area (W × D) 590 × 531mm

Weight About 34.1kg

590 × 531 × 467 mm

(When the manual tray is installed.)

T. Power source

Voltage AC120V, 220V, 240V ± 15%

Frequency 50/60Hz common

U. Power consumption

Max. power consumption About 1.3KWh

* EnergyStar standard (The second level conformity)

Pre-heat About 60Wh

Auto power shut off About 4.8Wh

2 – 3

Page 8

AR-161

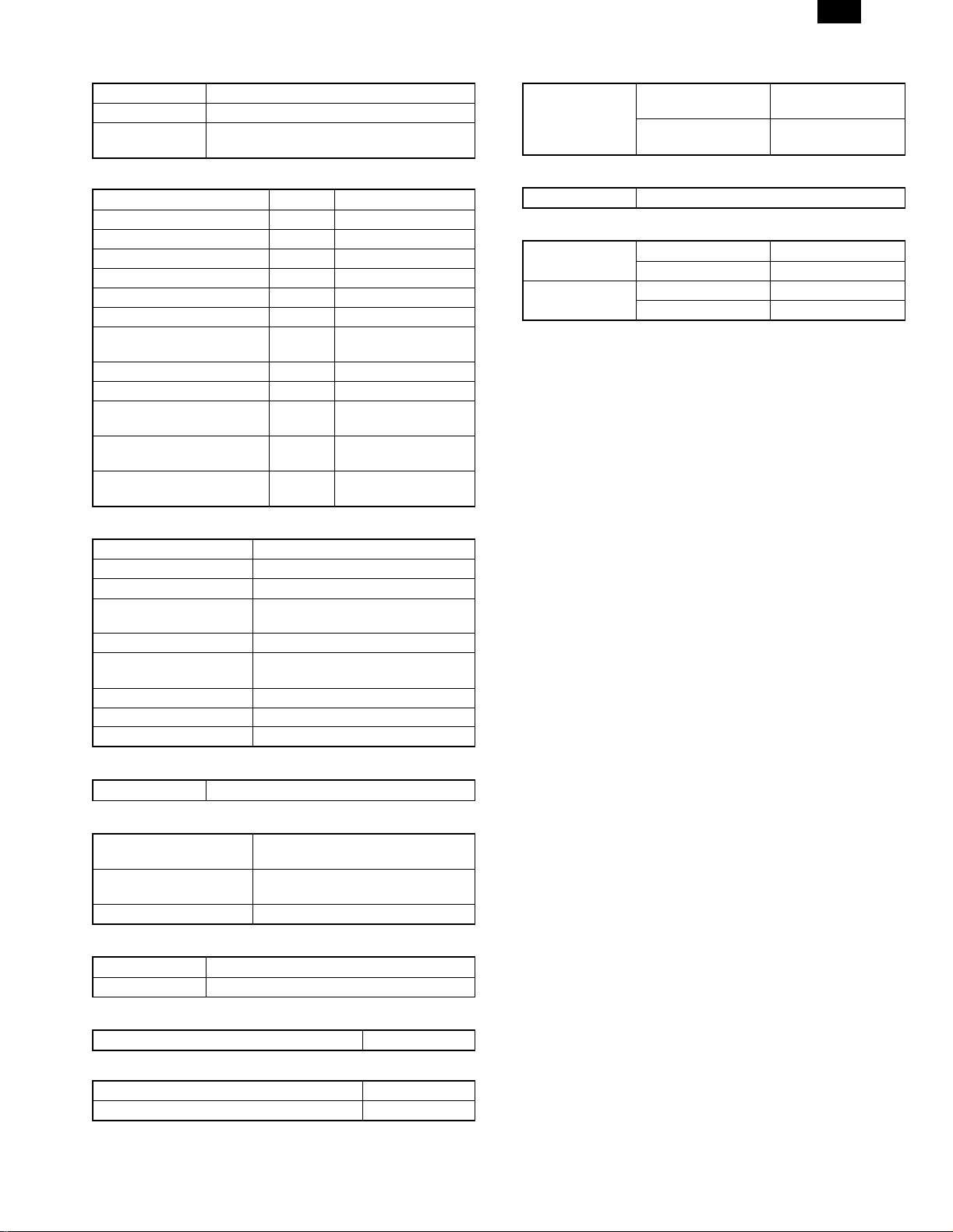

[3] CONSUMABLE PARTS

1. Supply system table

A. USA, CANADA

NO Name Content Life

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DR

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200MT

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 AR-200TB 1

5 Developer kit (Black) Toner bottle (Developer 395g) × 10 150K AR-200MD

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 AR-200MG 1

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 AR-200CB 1

Mocket (F/R) Each × 10

* 1 Production in China for USA

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

× 1 15K AR-200TD

× 1 30K AR-200MR

B. Asia, Southeast Asia

NO Name Content Life

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DR 4

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200CT 1 Life setting by A4 6%

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 AR-200TB 1

5 Developer kit (Black) Toner bottle

(Developer 395g)

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 AR-200MG 1

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 AR-200CB 1

Mocket (F/R) Each × 10

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

× 1 15K AR-200TD 4 Life setting by A4 6%

× 10 150K AR-200CD 1

× 1 30K AR-200CR 10

Product name of

other company

(*1 AR-200TD-J)

(*1 AR-200DR-J)

(*1 AR-200MT-J)

(*1 AR-200MD-J)

(*1 AR-200MR-J)

Product name of

other company

Package Remark

4 Life setting by A4 6%

document

4

1 Life setting by A4 6%

document

1

10

Package Remark

document

document

3 – 1

Page 9

AR-161

C. Europe / Australia / New Zealand / Middle East / Africa / CIS

NO Name Content Life

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DM 4

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200LT 1 Life setting by A4 6%

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 AR-200TB 1

5 Developer kit (Black) Toner bottle (Developer 395g) × 10 150K AR-200LD 1

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 AR-200MG 1

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 AR-200CB 1

Mocket (F/R) Each × 10

× 1 15K AR-200DC 4 Life setting by A4 6%

× 1 30K AR-200LR 10

Product name of

other company

Package Remark

document

document

D. Hong Kong / China

NO Name Content Life

1 Developer cartridge (Black) Toner/developer cartridge

(Toner 610g, Developer 395g)

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AR-200DR-C 4

Vinyl bag × 1

3 Toner kit (Black) Toner bottle (Toner 610g) × 10 150K AR-200CT-C 1 Life setting by A4 6%

Charging hose × 1

Toner cap × 10

4 Waste toner box Waste toner box × 10 AR-200TB-C 1

5 Developer kit (Black) Toner bottle (Developer 395g) × 10 150K AR-200CD-C 1

Developer cap × 10

DV blade × 10

6 Protective cover MG cover × 10 AR-200MG-C

7 Drum kit Drum

Drum fixing plate

8 Blade kit Blade × 10 AR-200CB-C 1

Mocket (F/R) Each × 10

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

× 1 15K AR-200TD-C 4 Life setting by A4 6%

× 1 30K AR-200CR-C 10

Product name of

other company

Package Remark

document

document

3 – 2

Page 10

AR-161

2. Environment conditions

A. Transport condition

(1) Transport conditions

Humidity (%)

Temperature

(2) Storage conditions (packed conditions)

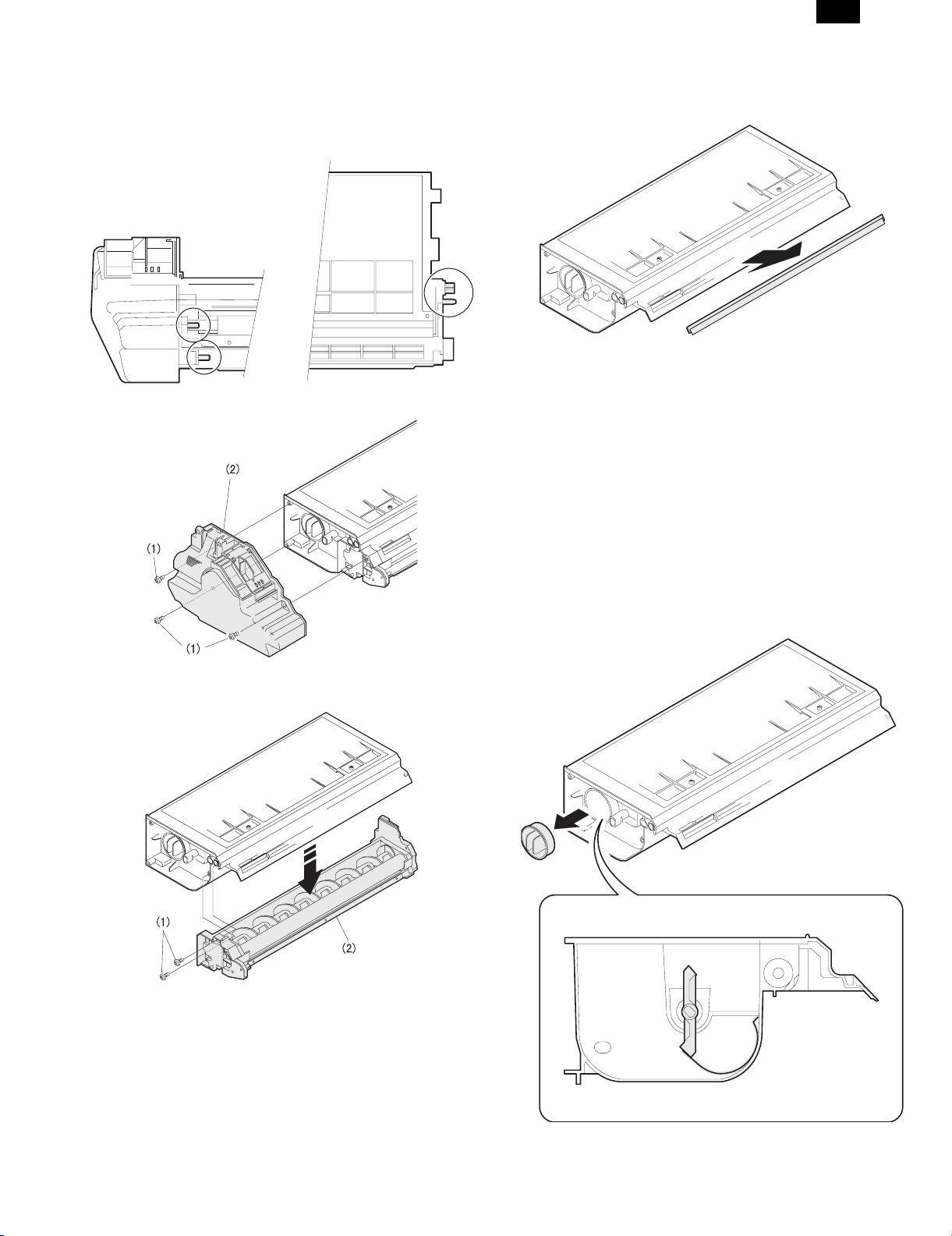

3. Production number identification

<TD cartridge>

The label on the drum cartridge shows the date of production.

B

Destination

(∗)

Indicates production in China.

The end digit of production year

∗: Destination

Division No.

Japan option 1

Ex option 2

Japan, same pack 6

Ex, same pack 7

Serial number

(00001-99999)

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

Humidity (%)

B. Use conditions

Humidity (%)

Temperature

Use environment

conditions

Temperature

<Drum cartridge>

The label on the drum cartridge shows the date of production.

Ver. A

The end digit of production year

1

Serial number (for each

month) (00001-99999)

Factory

Division No.

Ex production 1

Option 2

Same pack 3

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

C. Life (packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

3 – 3

Page 11

AR-161

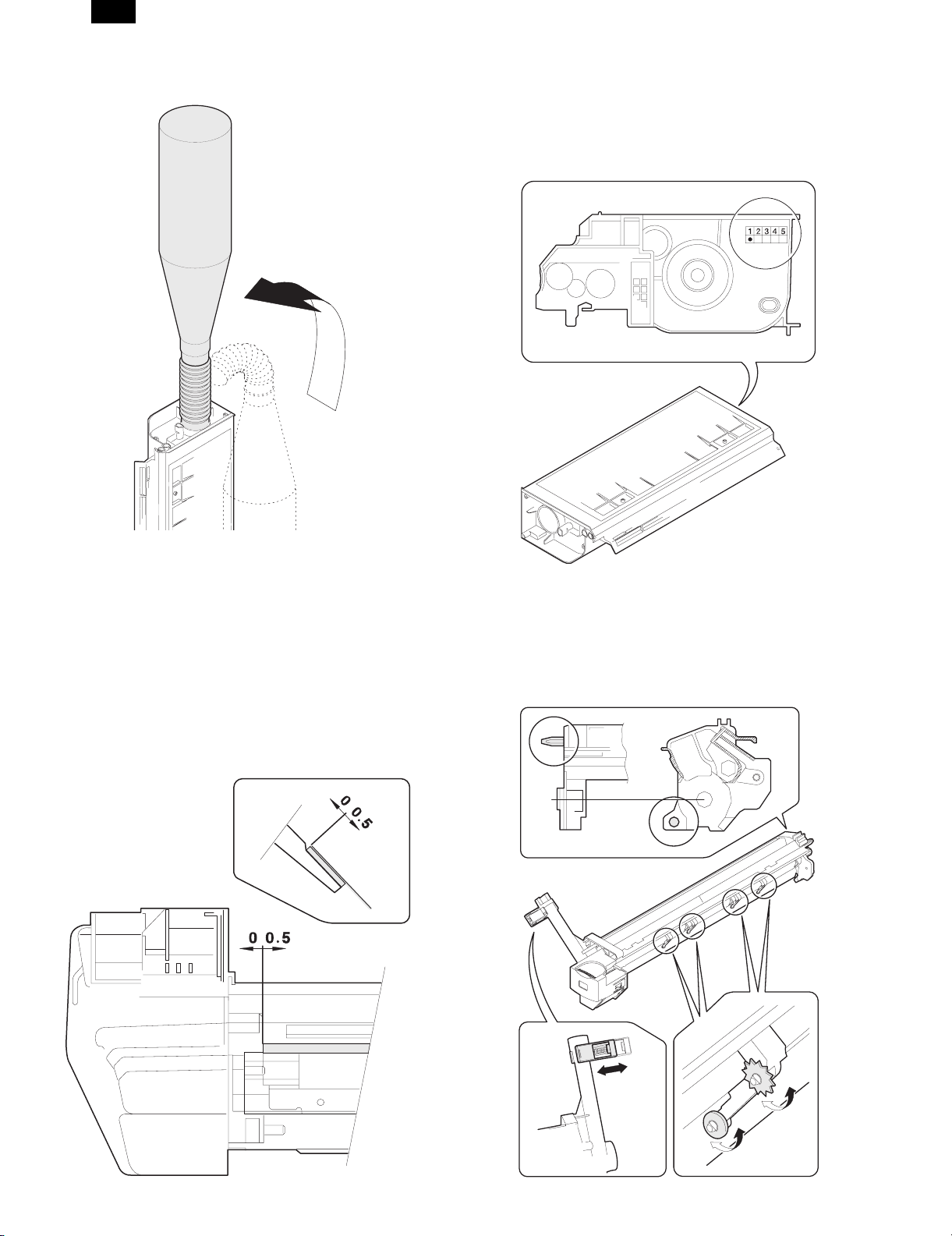

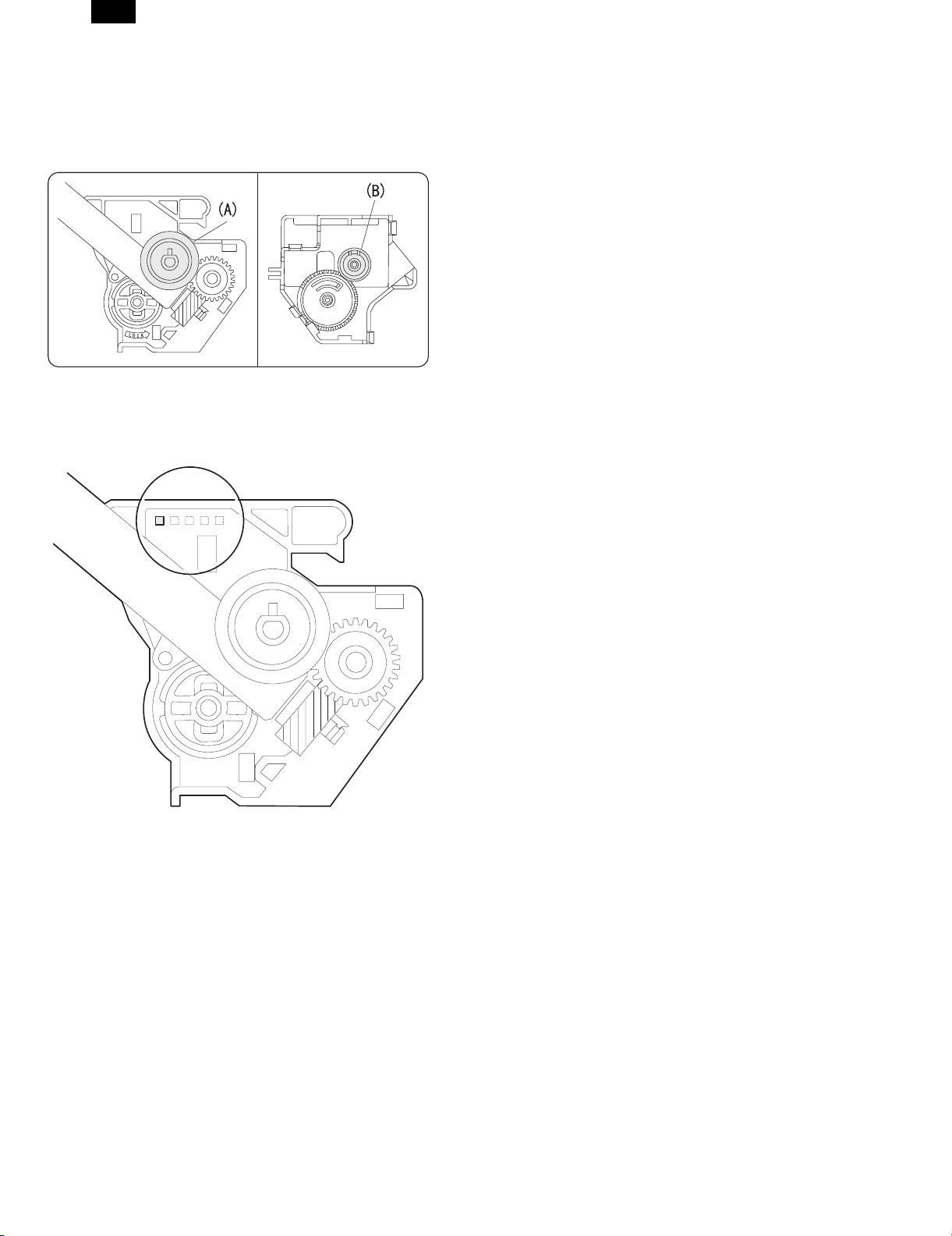

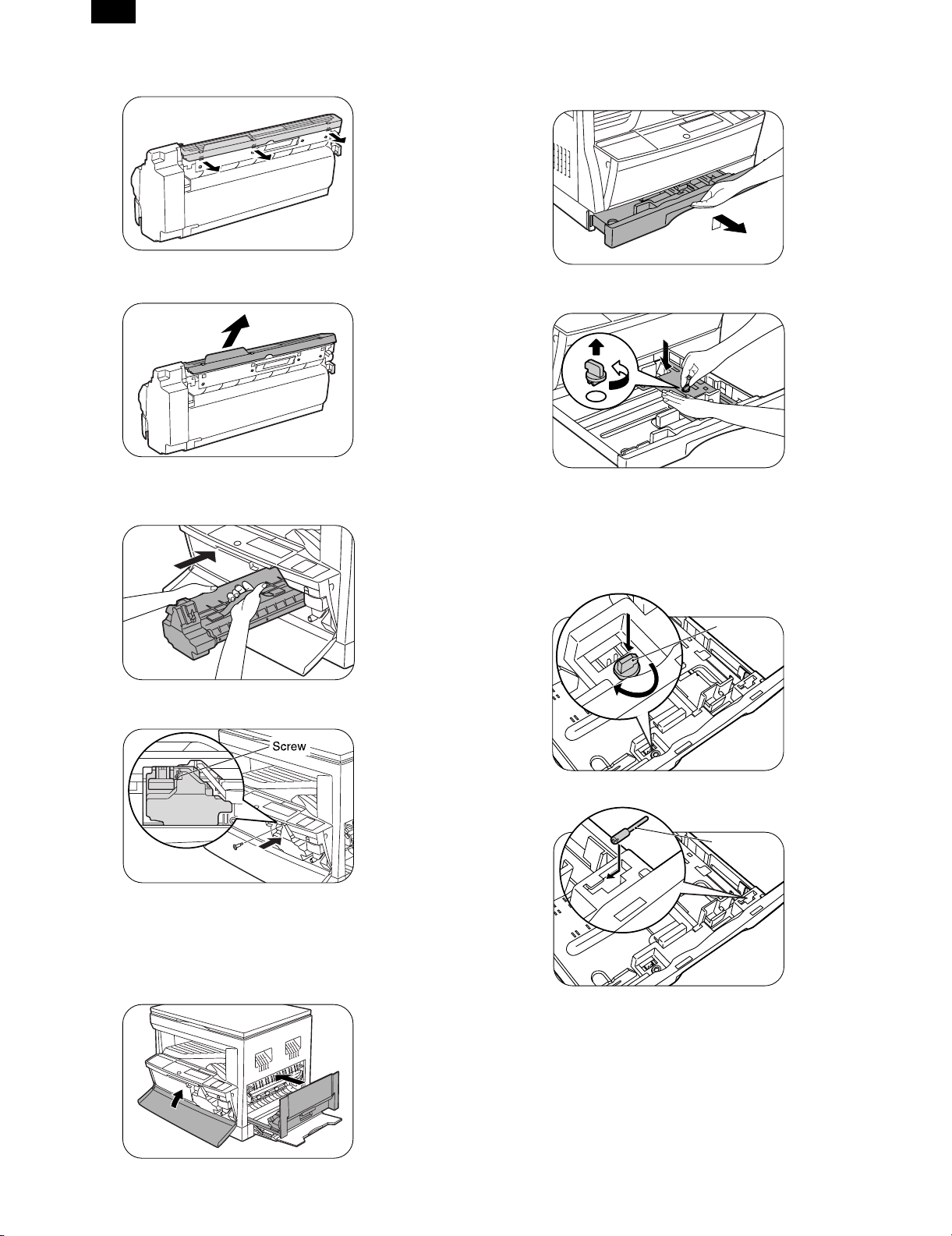

4. Consumable parts recycling procedure

A. TD cartridge

1) Check the external view.

Note: Be careful especially of breakage of the pins and the ATC

sensor connector shown below.

2) Remove the waste toner box unit.

4) Remove the DV blade.

Note: Be sure to remove adhesive completely.

Remove adhesive together with the base PET.

5) Tilt the developing unit, rotate the DV gear clockwise, and

remove developer.

6) Clean and remove developer on the MG roller and toner on the

developing doctor completely with a vacuum cleaner or an air

blower.

7) Shake the developer bottle about 10 times and supply developer

to the developing unit.

Turn the stirring roller to distribute developer evenly.

8) Install the toner box.

9) Shake the toner bottle about 20 times and install the toner supply hose to the toner bottle.

10) Remove the toner cap. While visually inspecting from the toner

supply port, stop the TH shaft at the vertical position. (The TH

mylar is on the lower side.) (Turn the gear on the back of the

toner box counterclockwise to set the TH mylar on the lower

side.)

3) Remove the developing unit.

3 – 4

Page 12

AR-161

11) Face the toner supply port of the toner box upward with the

toner bottle put straight, and insert the supply hose into the toner

supply port.

17) Shake the developing unit 5 times left and right horizontally.

18) Check the distribution state of developer on the MG roller.

Rotate the MG roller and visually check for no improper distribution of developer which may be caused by foreign materials.

19) Mark the number of times of recycling on the back of the toner

box with white paint.

Max. times of recycling: 5 times

12) Lift the toner bottle and supply toner.

13) Remove the supply hose from the toner box with care not to spill

toner, and attach the toner cap.

Note: If the toner cap is not attached properly, toner splash may

occur.

14) Install the waste toner box.

15) Check the operations of the DV lever and the toner box shutter.

16) Wipe and clean the developer unit with alcohol, and attach the

DV blade to it.

(Note) • Dry alcohol completely before attaching the DV blade,

• When attaching the DV blade, be careful not to scratch it

and eliminate slack.

• After attaching, be careful not to scratch and damage the

DV blade.

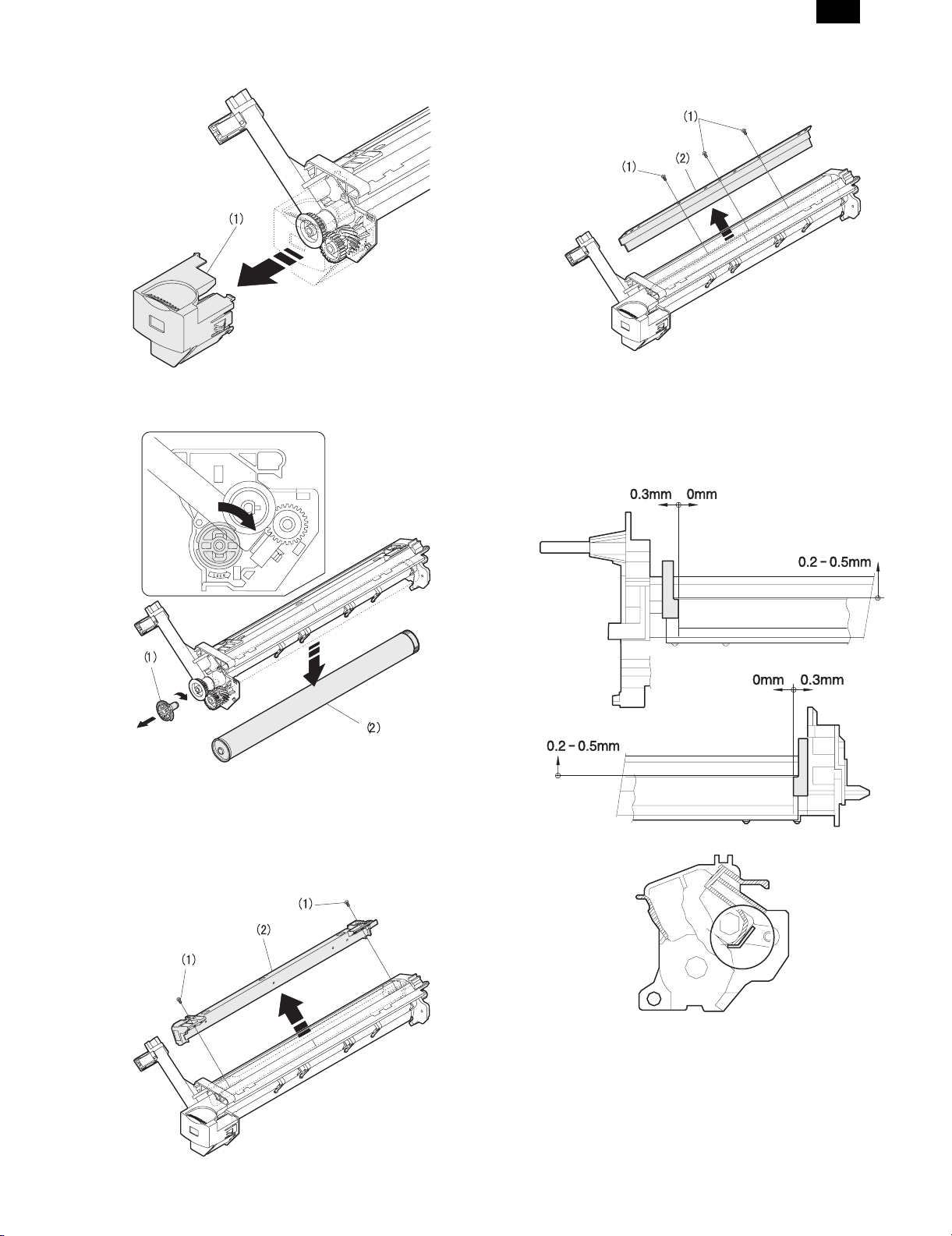

B. Drum unit

1) Check the external view.

• Check for damage or cracks on the boss and the boss hole.

• Check to insure that the waste toner pipe shutter slides

smoothly.

• Check to insure that the start ring and the CRU washer rotate

smoothly.

3 – 5

Page 13

AR-161

2) Remove the drum cover.

3) Remove the drum fixing plate and the photoconductor drum.

(Note) Dispose the drum fixing plate which was removed.

6) Remove the cleaning blade.

Note: Dispose the cleaning blade which was removed.

7) Clean the cleaning section and the waste toner pipe to remove

waste toner completely with a vacuum cleaner.

8) Remove the felt and duplex tape completely.

Note: Be careful not to scratch or bend the sub blade.

9) Attach the cleaning blade.

10) Attach the felt.

4) Check the cleaning blade and the red felt for no damage.

• If there is any damage, execute all procedures from item 5)

and later.

• If there is no damage, execute the procedure of item 12).

5) Remove the main charger.

(Cleaning the screen grid and the sawteeth.)

3 – 6

Page 14

AR-161

11) Attach the main charger.

12) Attach the drum fixing plate and the photoconductor drum.

Apply grease to the inside of the photoconductor drum. (Dia. 2)

13) Attach the detection gear.

Note: • The detection gear is not installed to the drum cartridge

packed with the main body. Add a new one.

14) Attach the drum cover.

Note: After attaching the drum cover, do not make a copy.

15) Mark the number of times of recycling on the side of the cover

with white paint.

Max. times of recycling: 5 times

3 – 7

Page 15

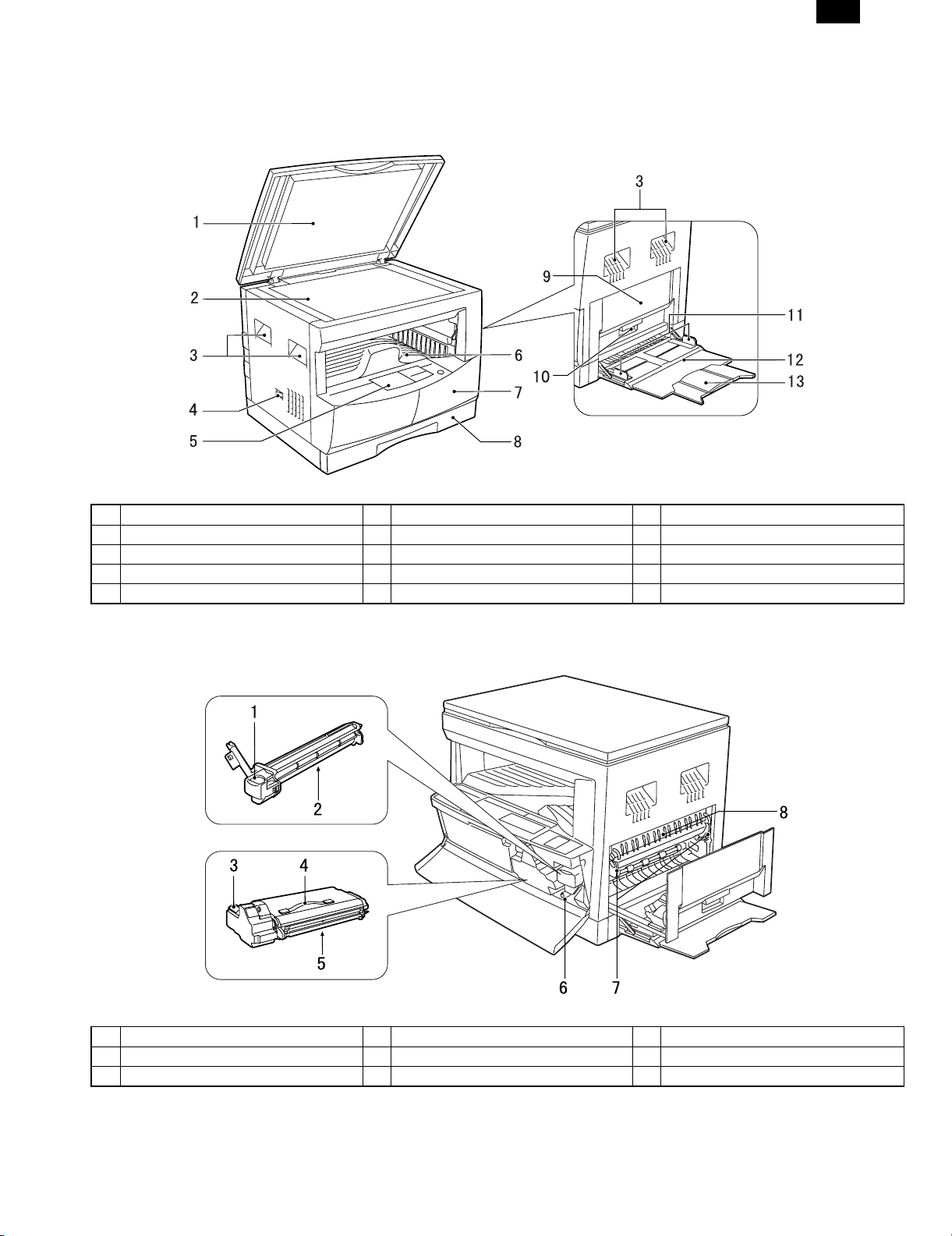

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

AR-161

1 Original cover 2 Original table (OC table) 3 Handles

4 Power switch 5 Operation panel 6 Paper output tray

7 Front cover 8 Paper tray 9 Side cover

10 Side cover handle 11 Bypass tray guides 12 Bypass tray

13 Bypass tray extension

2. Internal

1 Drum cartridge handle 2 Drum cartridge 3 TD cartridge handle

4 TD cartridge strap 5 TD cartridge 6 Roller rotating knob

7 Fusing unit release levers 8 Paper guide

4 – 1

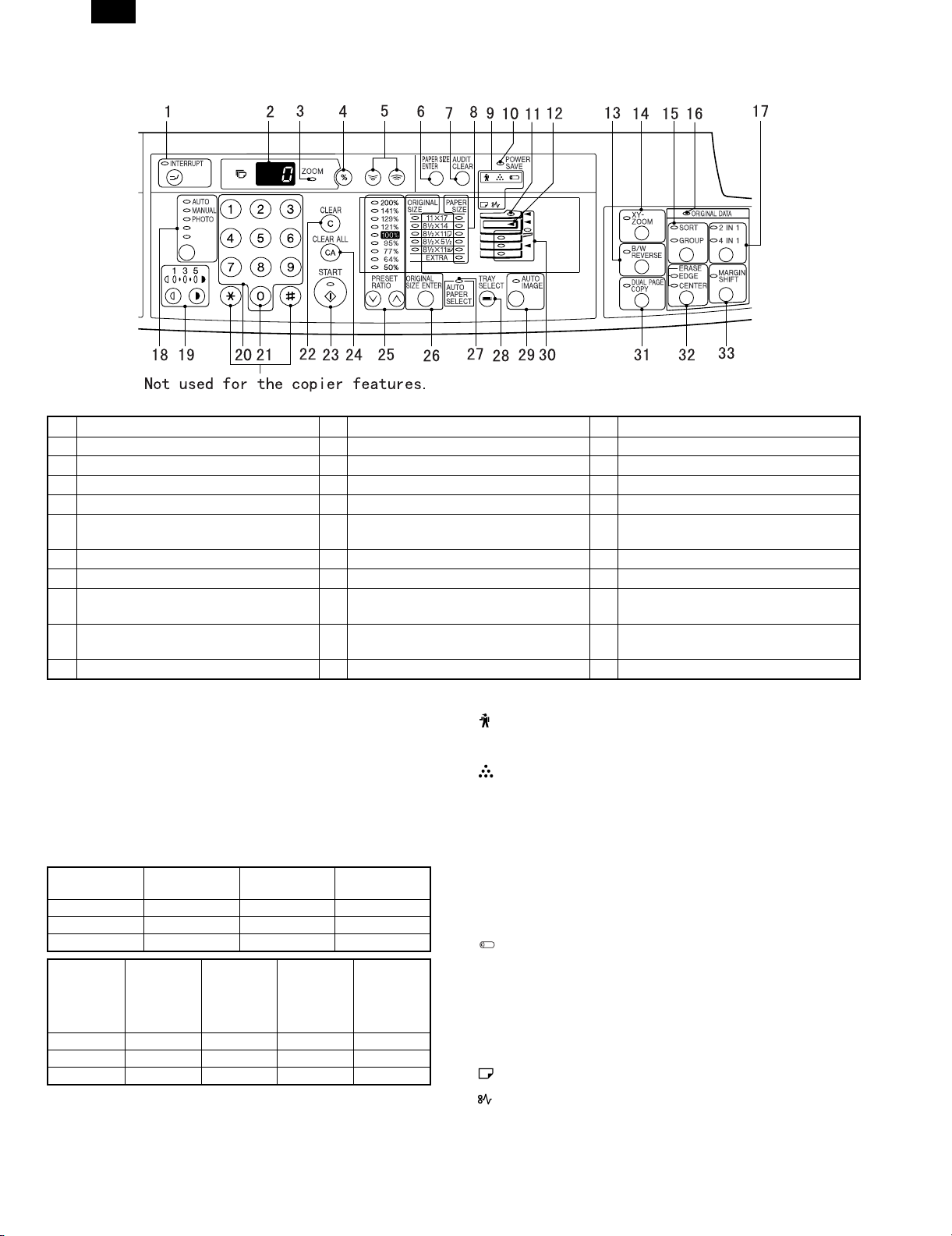

Page 16

AR-161

3. Operation Section

1 Interrupt key and indicator 2 Copy quantity display 3 ZOOM indicator

4 Copy ratio display key 5 Zoom keys 6 PAPER SIZE ENTER key

7 AUDIT CLEAR key 8 PAPER SIZE indicators 9 Alarm indicators

10 POWER SAVE indicator 11 SPF indicator 12 Output tray full indicator

13 B/W REVERSE key and indicator 14 XY-ZOOM key and indicator 15 SORT/GROUP key and indicators

16 ORIGINAL DATA indicator 17 2 IN 1 / 4 IN 1 key and indicators 18 AUTO/MANUAL/PHOTO key and

indicators

19 Light and dark keys and indicators 20 Numeric keys 21 Zero key

22 CLEAR key 23 START key and indicator 24 CLEAR ALL key

25 PRESET RATIO selector keys and

indicators

28 TRAY SELECT key 29 AUTO IMAGE key and indicator 30 Paper feed location/misfeed location

31 DUAL PAGE COPY key and indicator 32 ERASE key and indicators 33 MARGIN SHIFT key and indicator

26 ORIGINAL SIZE ENTER key and

indicators

27 AUTO PAPER SELECT indicator

indicators

* 1

ON: Indicates that the machine is in the energy saving (pre-heat)

mode.

Blink: Indicates that the machine is in the process of resetting from

the energy saving mode or just after supplying the power.

(During warmup)

OFF: Indicates that resetting from the energy saving mode is com-

pleted and that the fusing temperature is in ready state.

The combinations of the above display lamps are as follows:

(F = ON, D = OFF)

Lamp

Pre-heat lamp Blink DD

Ready lamp DFD

Other lamps FFF

Lamp

Pre-heat lamp FFBlink Blink

Ready lamp FDFD

Other lamps FDFF

Immediately after

power ON

Energy

saving mode

(Pre-heating)

Energy

saving mode

(Auto power

shut off)

Ready Copying

Resetting

from energy

saving mode

Copy is

started during

resetting from

energy saving

mode

* 2

Maintenance lamp

When the set count number (set by the simulation) is reached,

the lamp lights up. The machine does not stop.

TD cartridge replacement required indicator

When toner density is lower than a specified level, the TONER

DEVELOPER CARTRIDGE REPLACEMENT indicator lights up

to warn the user.

If toner is not added after approximately 10 sheets are copied,

the indicator starts blinking and machine starts to supply toner.

(Toner Developer cartridge replacement indicator keeps lighting

up)

If toner density is not back to specific level after two minutes, the

READ indicator goes out and Toner Developer indicator starts

blinking, and the copier stops.

Photoconductor cartridge replacement lamp

When the copy count reaches 29,000 after installing a

Photoconductor cartridge, the lamp lights up.

When 1,000 copy is made after that, the lamp blinks instead of

lighting. The machine does not stop.

Press and hold the clear key for 5 sec in the user simulation

mode to display the remaining life of the photoconductor

cartridge in 3 digits x 2 lines on the copy quantity display.

Paper required indicator

Misfeed indicator

4 – 2

Page 17

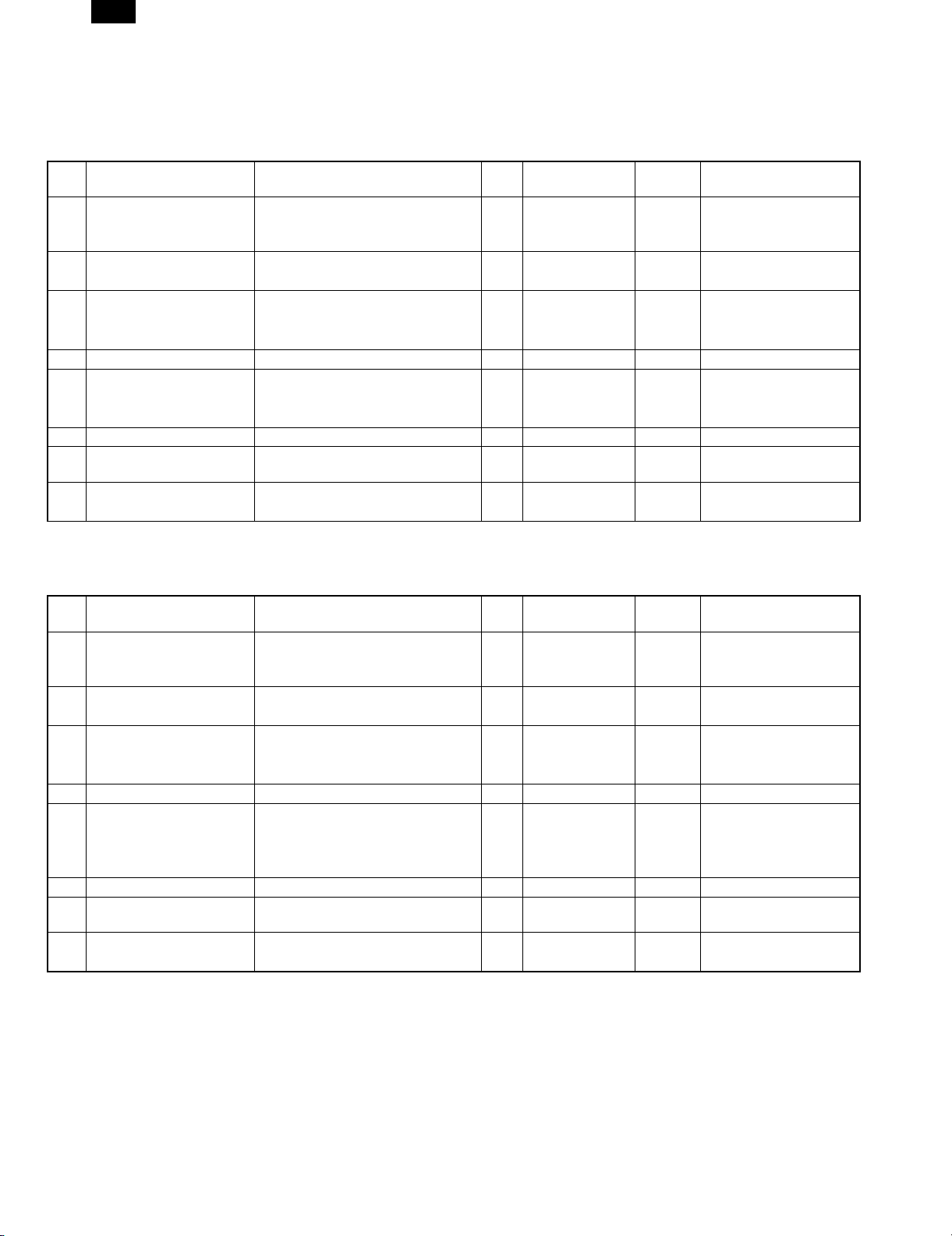

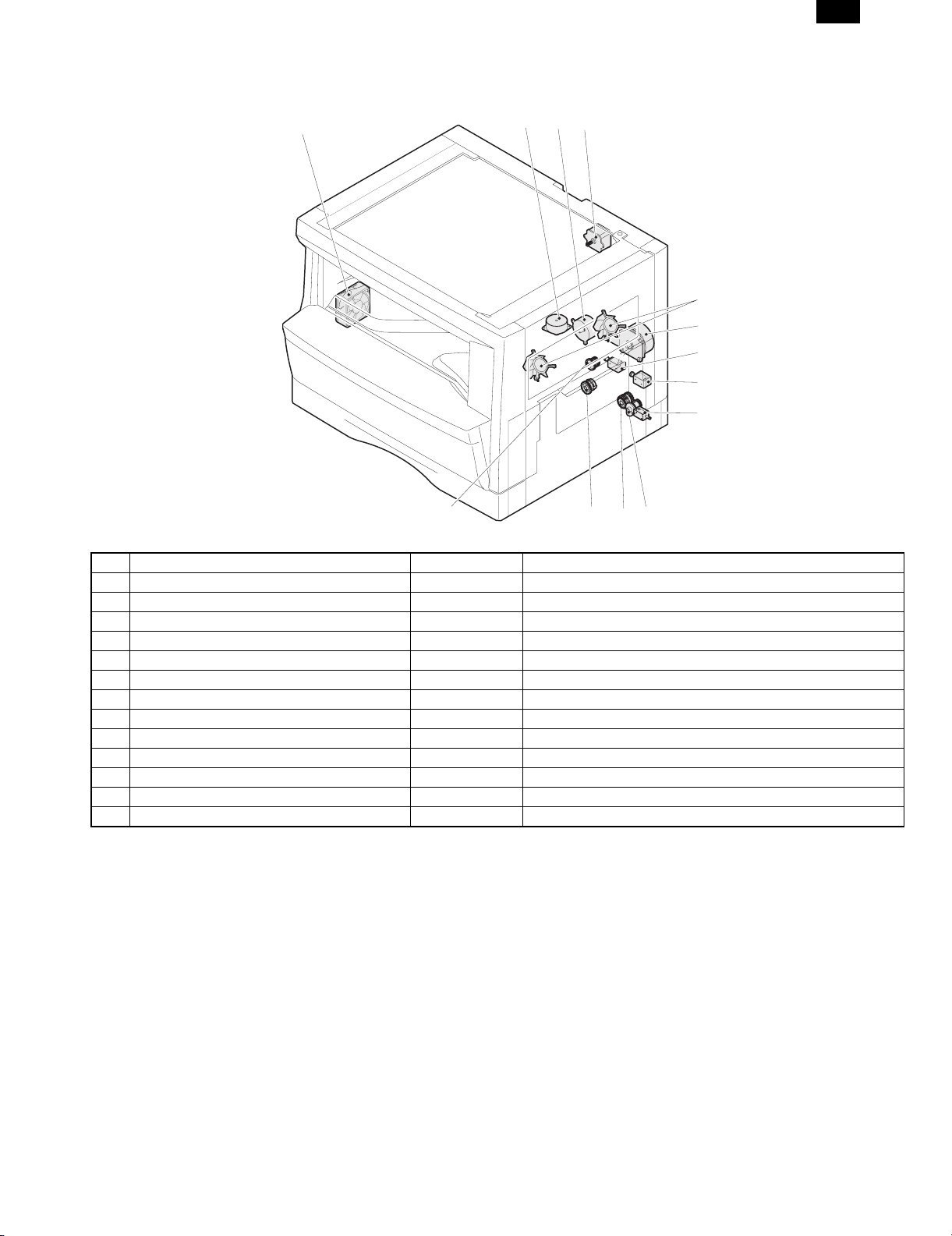

4. Motor, solenoid, clutch

AR-161

1

23

4

5

6

7

8

9

13

No. Name Code Function, operation

1 Exhaust fan motor VFM Cools the inside of the machine.

2 Shifter motor Shifts the paper exit tray. (AR-161)

3 Toner motor TM Toner supply

4 Mirror motor MRM Drives the optical mirror base (scanner unit).

5 Cooling fan motor CFM Cools the inside of the machine.

6 Main motor MM Drives the machine.

7 Paper feed solenoid CPFS1 Solenoid for paper feed from cassette

8 Resist roller solenoid RRS Resist roller rotation control solenoid

9 Manual paper feed solenoid MPFS Manual paper feed solenoid

10 Manual paper transport clutch MPTC Drives the manual paper transport roller.

11 Manual paper feed clutch MPFC Drives the manual paper feed roller.

12 Paper feed clutch CPFC1 Drives the cassette paper feed roller.

13 PS clutch RRC Drives the resist roller

11 1012

4 – 3

Page 18

AR-161

5. Sensor, switch

1234765

8

9

10

11

15

13

12

14

No. Name Code Function, operation

1 Mirror home position sensor MHPS Detects the mirror (scanner unit) home position.

2 Cassette detection switch CSD1 Cassette detection

3 Toner density sensor TCS Toner quantity detection

4 Paper exit sensor (paper exit side) POD1 Detects paper exit.

5 Right door switch DSWR Side door open/close detection

6 Paper full sensor Paper exit tray section full detection <For JOB separator>

7 Lift sensor Paper feed tray lift up detection <For JOB separator>

8 Paper exit sensor (DUP side) POD2 Paper transport detection

9 Thermistor Fusing section temperature detection

10 Thermostat Fusing section abnormally high temperature detection

11 Paper transport sensor PPD Paper transport detection

12 Manual sensor MPED Manual transport detection

13 Cassette paper sensor PED1 Cassette paper empty sensor

14 Drum reset switch DRST New drum detection switch

15 Power switch MAIN SW Turns ON/OFF the main power source.

4 – 4

Page 19

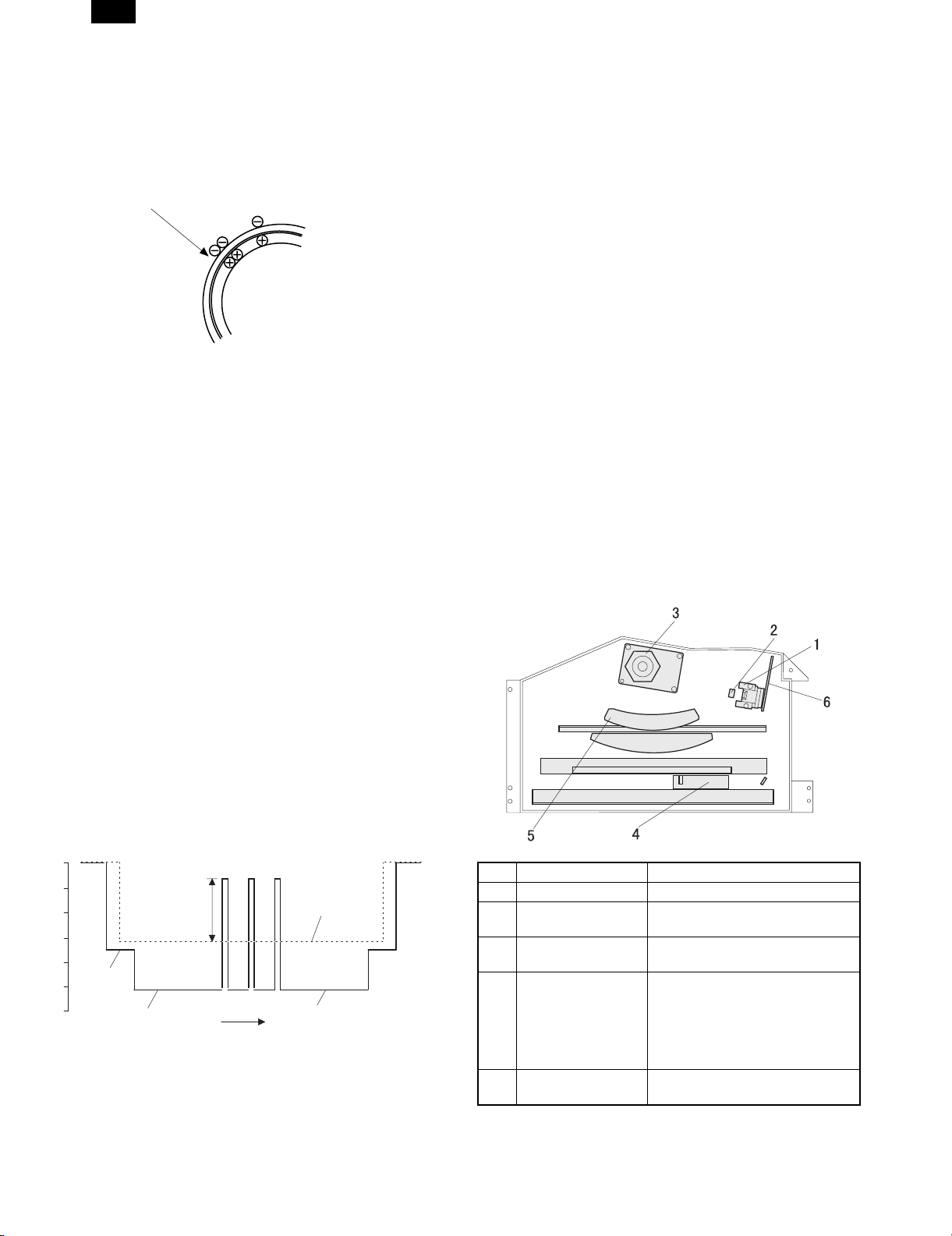

6. PWB unit

AR-161

12

8

3

4

5

6

7

No. Name Function, operation

1 Copy lamp invertor PWB Copy lamp control

2 Power PWB AC power input/DC power control

3 High voltage PWB High voltage control

4 CCD sensor PWB Image scanning

5 Main PWB (MCU) Machine control/Image process

6 Paper exit interface PWB Paepr exit, finishing control

7 Electronic sort function Operation panel input/Display

8 Operation main PWB Operation panel input/Display, operation panel section control

4 – 5

Page 20

AR-161

7. Cross sectional view

12 3 45

6

18

7

8

9

19

10

11

12

17

No. Name Function/Operation

1 Copy lamp Image radiation lamp

2 Copy lamp unit Operates in synchronization with No. 2/3 mirror unit to radiate documents sequentially.

3 LSU unit Converts image signals into laser beams to write on the drum.

4 Lens unit Reads images with the lens and the CCD.

5 MC holder unit Supplies negative charges evenly on the drum.

6 Paper exit roller Used to discharge paper.

7 Transport roller Used to transport paper.

8 Upper heat roller Fuses toner on paper (with the teflon roller).

9 Lower heat roller Fuses toner on paper (with the silicon rubber roller).

10 Drum unit Forms images.

11 Transfer charger unit Transfer images (on the drum) onto paper.

12 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

13 Manual paper feed tray Manual paper feed tray

14 Manual paper feed roller Picks up paper in manual paper feed.

15 Manual transport roller Transports paper from the manual paper feed port.

16 Paper feed roller (semi-circular roller) Picks up paper from the cassette.

17 MG roller Puts toner on the OPC drum.

18 No. 2/3 mirror unit Reflects the images from the copy lamp unit to the lens unit.

19 Waste toner transport roller Transports waste toner to the waste toner box.

13141516

4 – 6

Page 21

AR-161

[5] UNPACKING AND

INSTALLATION

1. Installation of machine

A. Installing conditions

Since the machine performance is largely affected by the installing

place conditions, take enough considerations on the following items

1) Environment

• Avoid installation at a place with direct sunlight. If not, the plastic

parts may be deformed.

• Avoid installation near a heater, a humidifier, or an air conditioner

where humidity and temperature are extremely high or low. If not,

paper may be dampened and dew is formed inside the machine,

causing paper jam or dirty copies.

• Avoid installation at a dusty place. If dust enters the machine, dirty

copy or a trouble may be caused.

• Avoid installation at a place with vibrations. If not, a machine

trouble may be caused.

• Avoid installation at a poorly ventilated place.

• Avoid installation at a place that is filled with ammonium gas. If the

copier is installed near a diazo-copier, dirty copies may be

resulted.

2) Space around the copier

• Allow a space of more than between the copier rear side and the

wall.

3) Power source

• Use an exclusive-use power outlet of 15A and 100V or more. If the

power plug of this machine is inserted into a power outlet commonly used with other illumination units, flickers of the lamp may

be resulted. Use a power outlet which is not used commonly with

any illumination units.

• Avoid complex wiring.

4) Grounding wire connection.

• To avoid danger, be sure to connect a grounding wire. If no groun

ing wire is connected and a leakage occurs, a fire or an electric

shock may be resulted.

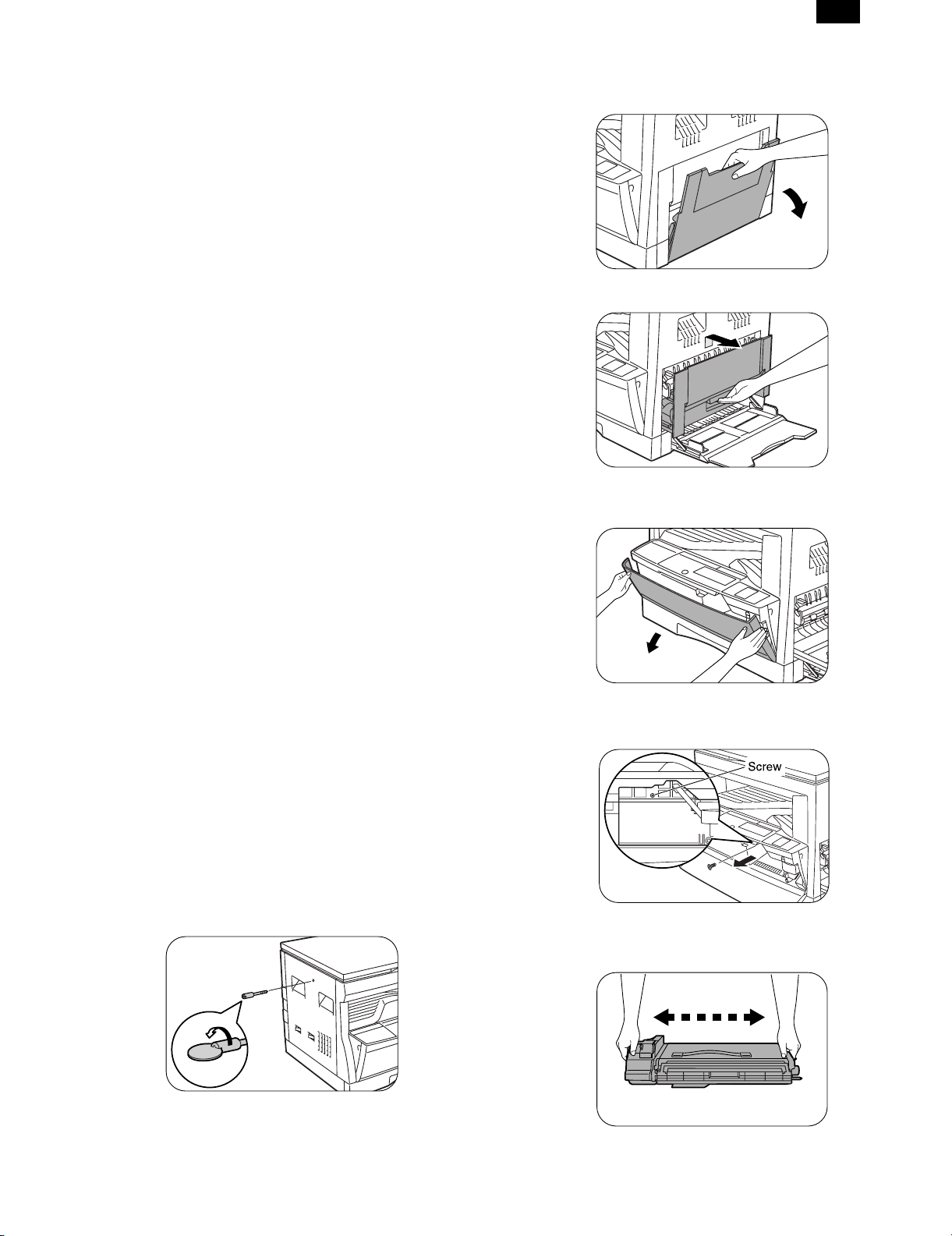

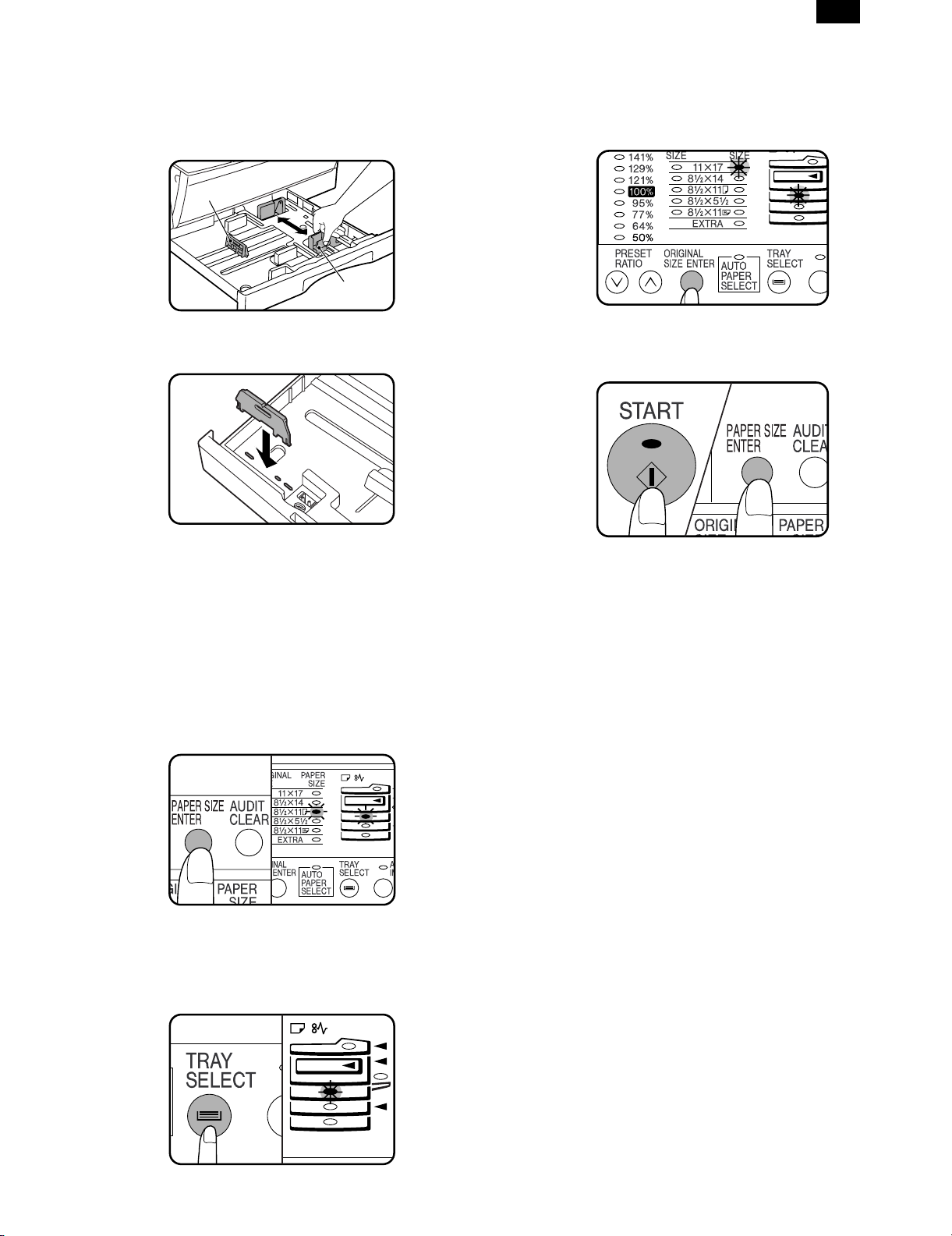

3. Installation of developing cartridge

1) Open the manual paper feed tray.

2) Lift the knob and slide the side cover gently.

3) Open the front cover.

• Hold the both edge gently and open the front cover.

4) Remove the screw from the upper section of the insertion port of

the developer cartridge.

2. Removal of protective material and

fixing screw

1) Remove all tapes and protective material.

• Remove all tapes, then open the document cover and remove

the protective material of sheet shape

2) Remove the fixing screw.

• Use a coin to remove the fixing screw.

• The fixing screw is required when transporting the machine.

Keep it in the tray. (Refer to the later description.)

5) Shake a new developer cartridge a few times as shown.

• Shake it horizontally as shown with the arrow.

5 – 1

Page 22

AR-161

6) Remove the pawls (3 positions) of the protective cover at therear

side.

7) Remove the protective cover.

• Pull the cover in the arrow direction to remove.

8) Insert the developer cartridge.

• Gently insert the developer cartridge along the guide until it

locks.

4. Removal and storage of fixing screw

1) Lift the knob and gently pull out the tray.

2) Hold the paper pressure plate and turn the fixing screw in the

arrow direction.

3) Store the fixing pin and the fixing screw in the tray.

• Store the fixing screw which was removed in the above proce-

dure 2 and the fixing screw which was removed in procedure 2

of 2.

• Removal of protective material and fixing screw in the storage

place in the tray.

9) Fix the developer cartridge with the fixing screw which is packed

together with the machine.

10) Close the front cover A, then close the side cover B.

• When closing the front cover, gently press the both sides.

• When closing the side cover, hold the knob.

• When closing the covers, be sure to close the front cover first,

then close the side cover. If closed in a wrong sequence, the

covers may be broken.

B

Pressure

plate

lock

Screw

A

5 – 2

Page 23

Front guide

Left guide

AR-161

5. Changing the copy paper size in the tray

1) Gently lift and pull out the paper tray until it stops.

2) Push the pressure plate down until it locks in place.

3) Squeeze the lock lever of the front guide and slide the front guide

to match the width of the paper.

4) Move the left guide to the appropriate slot as marked on the tray.

• When using 11" ×17" copy paper, store the left guide in the slot

at the left front of the paper tray.

10) Use the ORIGINAL SIZE ENTER key to select the paper size

which is set.

• Each time the ORIGINAL SIZE ENTER key is pressed, a

paper size will be indicated with a blinking paper size indicator.

11) Press the START key and then the PAPER SIZE ENTER key.

• To change the paper size setting of another tray, repeat steps

9 to 10 after pressing the START key.

5) Load copy paper into the tray.

6) Place the paper size plate in the front of the paper tray.

• The paper size indication which shows through the slot on the

front of the copier should match the selected paper size.

7) Push the paper tray firmly back into the copier.

8) To set the selected paper size, press and hold down the PAPER

SIZE ENTER key. The selected paper feed location indicator and

the corresponding paper size (which has been set) indicator will

blink. All other indicators will go out.

• For paper size setting, ensure that the COPY mode has been

selected. However, if printer or facsimile output is being performed, paper size setting cannot be made even in the COPY

mode.

9) Use the TRAY SELECT key to select the paper tray of which the

paper size has been changed.

• Each time the TRAY SELECT key is pressed, a paper tray is

indicated with a blinking paper feed location indicator. If an

optional paper feed unit is not installed, this operation is not

needed.

5 – 3

Page 24

AR-161

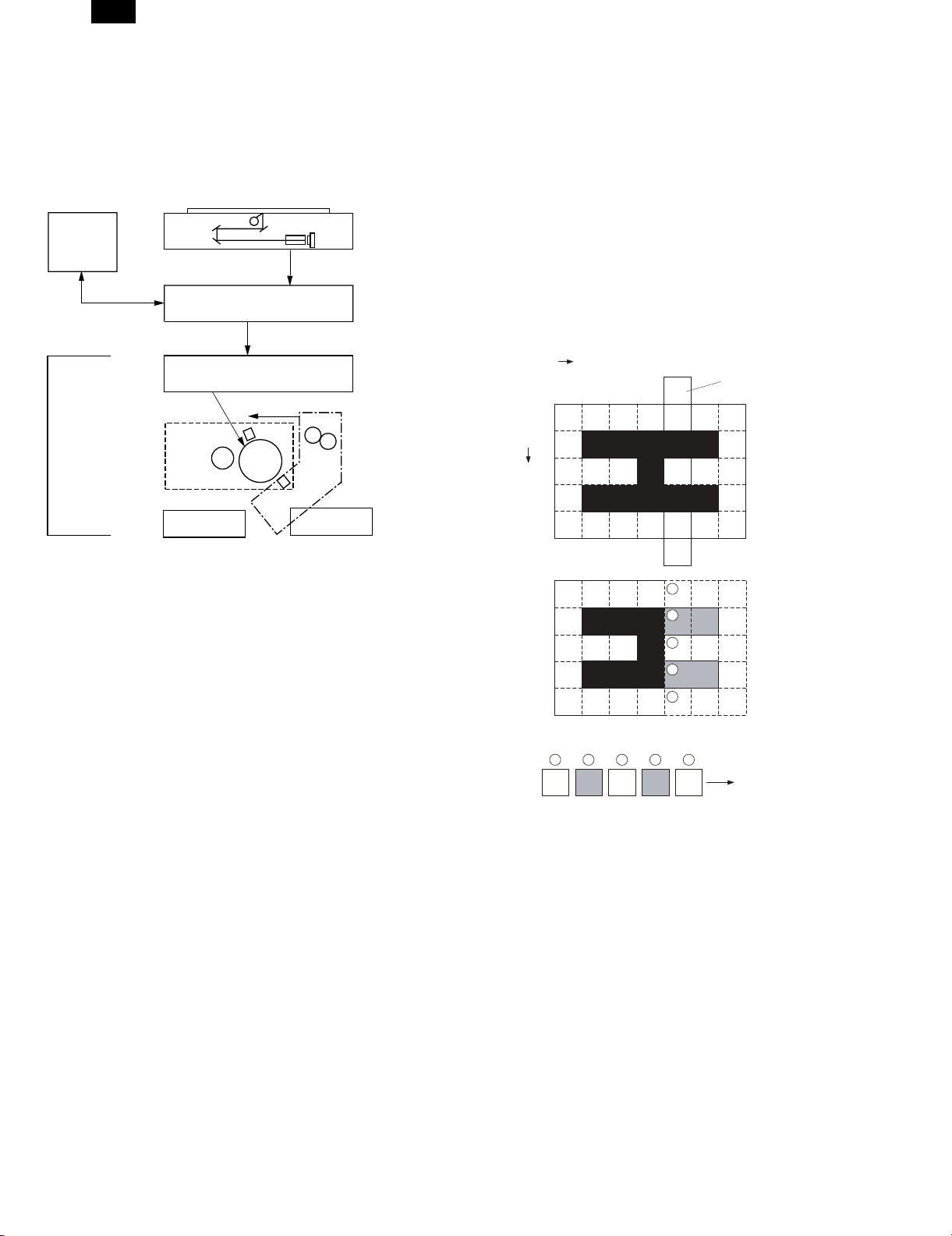

[6] OPERATIONAL DESCRIPTIONS

1. Outline of operation

The outline of operation is described referring to the basic configuration.

(Basic configuration)

Operation

section

Printer section

Scanner section

MCU (Main control/image process section)

LSU (Laser unit)

Laser diode, Polygon mirror lens

Laser beam

Process section

Cassette paper

feed section

Paper exit

CCD

Manual paper

feed section

Fusing section

Paper transport section

G. Fusing: Fusing section

• Heat and a pressure are applied to the toner image on the copy

paper to fuse the image on the paper.

2. Scanner section

A. Scan process

The scanner has sensors that are arranged in a line. These sensors

scan a certain area of a document at a time and deliver outputs

sequentially. When the line is finished, the next line is scanned, and

this procedure is repeated. The figure below shows the case where

an image which is scanned is shown with solid lines.

The direction of this line is called main scanning direction, and the

scanning direction sub scanning direction. In the figure above, one

line is divided into 5 sections. Actually, however, one line is divided

into thousands of sections. For scanning, the light receiving element

called CCD is used.

Sub scanning direction

Sensor scanning area

Main

scanning

direction

Outline of copy operation

A. Setting conditions: Operation panel

• Set copy conditions such as the copy quantity and the copy den-

sity with the operation section, and press the START key. The

information on copy conditions is sent to the MCU.

B. Image scanning: Scanner section

• When the START key is pressed, the scanner section starts scan-

ning of images.The light from the copy lamp is reflected by the

document and passed through the lens to the CCD.

C. Photo signal/Electric signal conversion:

Scanner section

• The image is converted into electrical signals by the CCD circuit

and passed to the MCU.

D. Image process: MCU

• The document image signal sent from the CCD circuit is processed

under the revised conditions and sent to the LSU (laser unit) as

print data.

E. Electric signal/Photo signal (laser beam)

conversion: LSU

• The LSU emits laser beams according to the print data. (Electrical

signals are converted into photo signals.)

• The laser beams are radiated through the polygon mirror and

various lenses to the OPC drum.

F. Printing: Process section

• Electrostatic latent images are formed on the OPC drum according

to the laser beams, and the latent images are developed to be

visible images (toner images).

• Meanwhile the paper is fed to the image transfer section in

synchronization with the image lead edge.

• The toner image is transferred on the paper.

1

2

3

4

5

5 4 3 2

1

To MCU PWB

The basic resolution indicates the scanner capacity. The basic resolution is expressed in dpi (dot/inch) which shows the number of light

emitting elements per inch on the document.

The basic resolution of this machine is 400dpi.

In the sub scanning direction, at the same time, the motor that drives

the optical system is controlled to scan the image at the basic resolution.

6 – 1

Page 25

AR-161

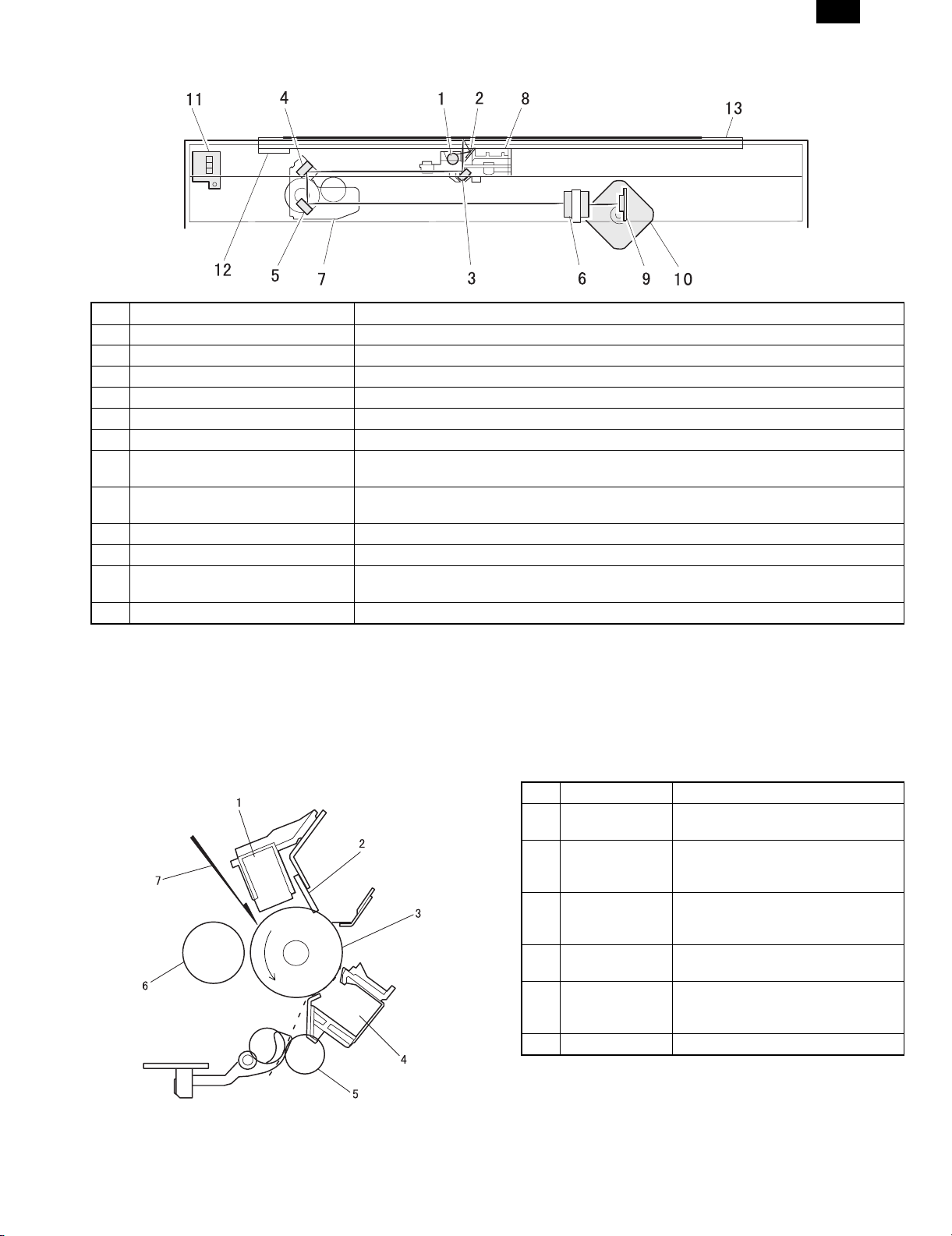

B. Basic structure of scanner section

1 Copy lamp (Xenon lamp) Generate photo energy to scan documents.

2 Reflector (Converging plate) Collects light emitted from the copy lamp and radiate the document.

3 No. 1 mirror Refracts the reflection light from the document to No. 2 mirror.

4 No. 2 mirror Refracts the reflection light from No. 1 mirror.

5 No. 3 mirror Refracts the reflection light from No. 2 mirror.

6 Lens Converges reflected light from the document to form images on the CCD element.

7 No. 2/3 mirror unit Includes No. 2/3 mirror. Driven in synchronization with the copy lamp unit.

8 Copy lamp unit Includes the copy lamp, the reflector, and No. 1 mirror. Driven in synchronization with No. 2/3

mirror unit by the mirror motor.

9 CCD PWB Reflected light (image) formed on the CCD is converted into electrical signals (analog signals)

10 Mirror motor Drives the copy lamp unit and No. 2/3 mirror unit according to the scanning speed.

11 MHPS (Mirror home position sensor) Detects the home position of No. 2/3 mirror unit.

12 Reference white plate Reference white sheet for scanning documents. The reference line of magnification ratio

13 OC glass Glass table to put a document on it.

The light from the light source (Xenon lamp) is reflected by a document and passed through three mirrors and reduction lenses to the CCD element

(image sensor) where images are formed. This system is known as the reduction image sensor system. Photo energy on the CCD element is

converted into electrical signals (analog signals). (Photo-electric conversion). The output signals (analog signals) are converted into digital signals

(A/D conversion) and passed to the MCU (main control/image process section). The resolution at that time is 400dpi. The mirror unit in the scanner

section is driven by the mirror motor. The MHPS is provided to detect the home position of the copy lamp unit.

then into digital signals and sent to the MCU.

adjustment during SIM is also drawn.

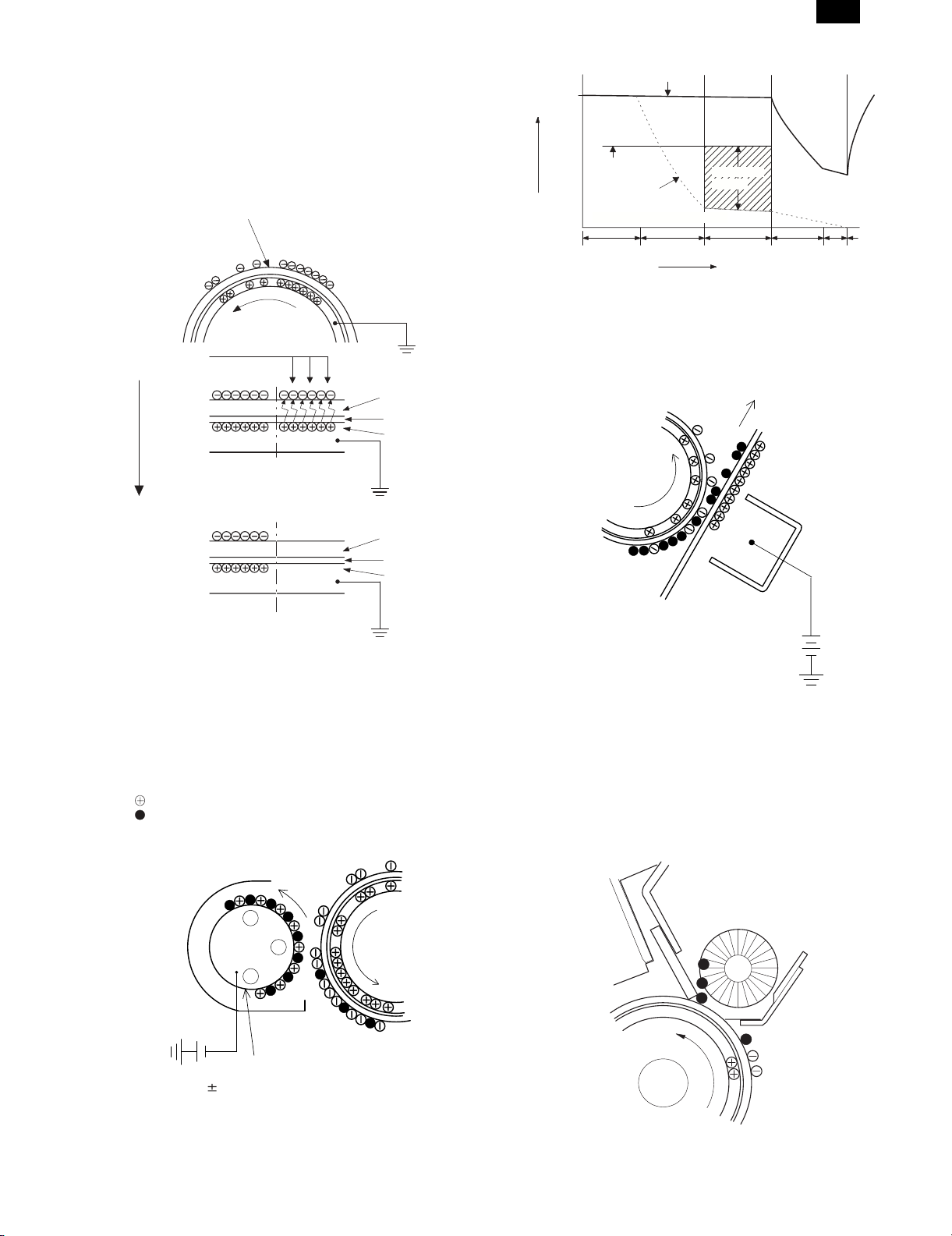

3. Process section

A. Basic structure

1 Main charger unit Charges the OPC drum.

2 Cleaning blade Collects waste toner on the OPC

drum.

3 OPC drum Images are formed by laser beams

electrically, and toner is attached to

the image.

4 Transfer unit Toner on the OPC drum is transferred

to the print paper by the potential

difference.

5 Resist roller Makes synchronization between the

paper and the print image.

6 MG roller Magnetic brush is formed by

developer to put toner on the OPC

drum.

7 (Laser beam) Forms images on the OPC drum.

6 – 2

Page 26

AR-161

Operation cycle

High voltage power

Laser scanning unit

Paper exit roller

Paper exit

Main charger

Waste toner box

Laser beam

Cleaning blade

Charging

Heat roller

Fusing

Exposure

Cleaning

Developing

Developer

Separation

Transfer

Separation charger

Transfer

Synchronization

with drum

Transfer charger

Resist roller

High voltage power

High voltage power

High voltage

power

Developing unit

Toner hopper

B. Outline of print process

The printer section of this machine employs the laser print system

where print images are formed by the laser beams on the OPC drum.

A high voltage (corona) is applied from the main charger to the OPC

drum to charge the OPC drum.

Laser beams are radiated to the charged OPC drum to form electrical

images on the OPC drum. (Exposure)

(At that time, the print image on the OPC drum cannot be seen: latent

electrostatic image)

By the potential difference between the unexposed area and the

latent electrostatic images, toner ia attracted only to the images.(Developing)

(At that time, the print image formed by toner on the OPC drum can

be seen. Visible images)

The toner image on the OPC drum is transferred on the print paper

by the transfer corona (voltage).

After that, the print paper with the toner image on it is subject to heat

and pressure in the fusing section to fuse the image on the paper.

This machine employs the following organic photoconductor (OPC)

drum.

An OPC drum is used for the photoconductor.

(Structure of the OP C dru m layers)

OPC layer

(20microns thick)

Pigment layer (0.2

to 0.3 microns thick)

Alumi nium drum

Toner

Manual paper

feed

Cassette paper

feed

C. Actual print process

(1) Charging

A high voltage is applied to the main charger, and negative charges

are discharged to the OPC drum. A screen grid is provided between

the main charger and the OPC drum, and negative charges are

uniformly charged on the OPC drum surface.

Positive charges are attracted by the negative electrode on the OPC

drum surface and excited in the aluminum layer in the OPC drum.

DC5.5KV

(-525V/-400V)

6 – 3

Page 27

AR-161

(2) Exposure

A Laser beam is generated from the semiconductor laser and controlled by the print pattern signal. The laser writes onto the OPC drum

surface through the polygon mirrors and lens. The resistance of the

OPC layer decreases for an area exposed by the laser beam (corresponding to the print pattern signal). The beam neutralizes the

negative charge. An electrostatic latent image is formed on the drum

surface.

Semiconductor laser

Exposure

(semiconductor laser)

OPC layer

Pigment

layer

Aluminum

layer

Drum surface charge

sfter the exposure

Non-image area Image area

OPC layer

Pigment

layer

Aluminum

layer

Non-image area

-600

Drum surface potential

-400

Developing bias

Image area

Residual potential (-50 to -100V)

0

Charge Exposure Developing Transfer

Toner at tract

potential

Time

Charge

Discharge

Toner is attracted over the shadowed area because of the developing

bias.

(4) Transfer

The visible image on the drum surface is transferred onto the print

paper by applying a positive charge from the transfer corona to the

backside of the print paper.

(3) Developing (DC bias)

A bias potential is applied to the MG roller in the two component

magnetic brush developing method, and the toner is charged negative through friction with the carrier. Non-image area of the drum

surface charged with negative potential repel the toner, whereas the

laser exposed portions where no negative charges exist, attract the

toner. As a result, a visible image appears on the drum surface.

: Carrier (Magnetized particle)

: Toner (Charge negative by friction)

(N) (S) : Pemanent magnet

(provided in three locations)

N

S

N

DC

-400v

MG roller

-8V

(5) Separation

Since the print paper is charged positively by the transfer corona, it is

discharged by the separation corona. The separation corona is connected to ground.

(6) Cleaning

Toner remaining on the drum is removed and collected by the cleaning blade. It is transported to the waste toner collecting section in the

cleaning unit by the waste toner transport roller.

6 – 4

Page 28

AR-161

(7) Optical discharge (Semiconductor laser)

Before the drum rotation is stopped, the semiconductor laser is

radiated onto the drum to reduce the electrical resistance in the OPC

layer and eliminate residual charge, providing a uniform state to the

drum surface for the next page to be printed.

When the electrical resistance is reduced, positive charges on the

aluminum layer are moved and neutralized with negative charges on

the OPC layer.

Semiconductor laser

a. Charge by the Scorotron charger

<1> Function

The Scorotron charger functions to maintain the surface potential of

the drum even at all times which. It is used to control the surface

potential regardless of the charge characteristics of the photoconductor.

<2> Basic function

A screen grid is placed between the saw tooth and the photoconductor. A stable voltage is added to the screen grid to maintain the

corona current on the photoconductor. As the photoconductor is

charged by the saw tooth from the main corona unit, the surface

potential increases. This increases the current flowing through the

screen grid. When the photoconductor potential nears the grid potential, the current turns to flow to the grid so that the photoconductor

potential can be maintained at a stable level.

b. Process controlling

<1> Function

The print pattern signal is converted into an invisible image by the

semiconductor laser using negative to positive (reversible) developing

method. Therefore, if the developing bias is added before the drum is

charged, toner is attracted onto the drum. If the developing bias is not

added when the drum is charged, the carrier is attracted to the drum

because of the strong electrostatic force of the drum.

To avoid this, the process is controlled by adjusting the drum potential and the grid potential of the Scorotron charger.

<2> Basic function

Voltage added to the screen grid can be selected, high and low.

To make it easily understood, the figure below shows voltage transition at the developer unit.

START STOP

0

Toner at tract

potential

2)

3)

1)

Low

4)

High

<3> Start

1) Because the grid potential is at a low level, the drum potential is at

about –400V. (Carrier may not be attracted though the carrier is

pulled towards the drum by the electrostatic force of –400V.)

2) Developing bias (–400V) is applied when the photoconductor

potential is switched from LOW to HIGH.

3) Once developing bias (–400V) is applied and the photo conductor

potential rises to HIGH, toner will not be attracted to the drum.

Print potentioal

Developing bias

Drum potential

Time

<4> Stop

The reverse sequence takes place.

c. Retaining developing bias at an abnormal occurrence

<1> Function

The developing bias will be lost if the power supply was removed

during print process. In this event, the drum potential slightly abates

and the carrier makes deposits on the drum because of strong static

power. To prevent this, the machine incorporates a function to retain

the developing bias for a certain period and decrease the voltage

gradually against possible power loss.

<2> Basic function

Normally, the developing bias voltage is retained for a certain time

before the drum comes to a complete stop if the machine should stop

before completing the normal print cycle. The developing bias can be

added before resuming the operation after an abnormal interruption.

Therefore, carrier will not make a deposit on the drum surface.

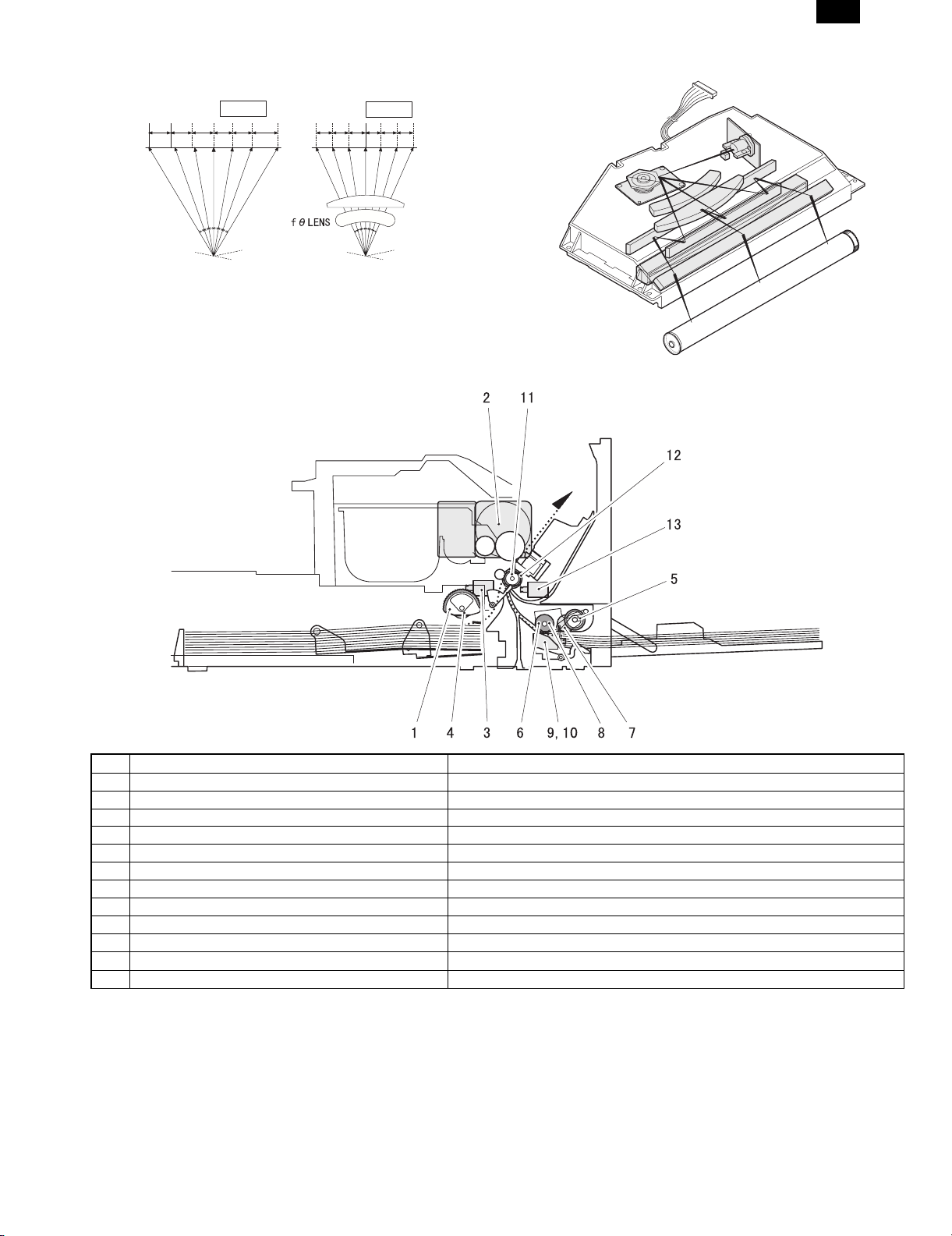

4. Laser unit

The image data sent from the MCU (image process circuit) is sent to

the LSU (laser uni t), where it is converted in to laser beams.

A. Basic structure

The LSU unit is the writing section of the digital optical system.

The semiconductor laser is used as the light source, and images are

formed on the OPC drum by the polygon mirror and fθ lens, etc.

The laser beams are passed through the collimator lens, the cylindrical lens, the polygon mirror, the fθ lens, and the mirror to form images

on the OPC drum in the main scanning direction. The laser emitting

PWB is provided with the APC (auto power control) in order to

eliminate fluctuations in the laser power. The BD PWB works for

measurement of the laser writing start point.

1 Semiconductor laser Generates laser beams

2 Collimator lens Converges laser beams in parallel

3 Polygon

mirror,polygon motor

4 BD (Mirror, lens,

PWB)

5fθ lens Converges laser beams at a spot

6 Laser emitting PWB Emits laser beams according to the

Reflects laser beams at a constant

rpm

Detects start timing of laser

scanning

on the drum.

Makes the laser scanning speeds

at both ends of the drum same as

each other. (Refer to the figure

below.)

image data.

6 – 5

Page 29

AR-161

Makes the laser scanning speeds at both ends of the drum same as

each other.

a ≠ b ≠ c

ab

c

d = e = f

de

f

5. Paper feed section

A. Basic structure

B. Laser beam path

1 No. 1 cassette paper feed roller (Semi-circular roller) Picks up paper from No. 1 cassette.

2 Main motor Drives the process section and the paper transport section.

3 No. 1 cassette paper feed solenoid Rotates and controls No. 1 cassette paper feed roller.

4 No. 1 cassette paper feed roller clutch Drives No. 1 cassette paper feed roller.

5 Manual paper feed roller Picks up paper from the manual paper feed tray.

6 Manual paper transport roller Transport paper which was picked up from the manual paper feed tray.

7 Manual paper feed roller clutch Drives the manual paper feed roller.

8 Manual paper transport roller clutch Drives the manual paper transport roller.

9 Manual paper feed roller solenoid Rotates and controls the manual paper feed roller.

10 Manual paper transport roller solenoid Rotates and controls the manual paper transport roller.

11 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

12 Resist roller clutch Drives the resist roller.

13 Resist roller solenoid Rotates and controls the resist roller.

B. Brief descriptions of operations

This machine allows two ways of paper feed system: cassette paper

feed and manual paper feed.

The cassette of universal type is employed to hold 250 sheets. The

front loading system allows to attach or detach the cassette from the

front of the machine.

Paper size can be selected by the user.

Paper size detection is set by the software. (User setting is allowed.)

By installing the optional 1-step paper feed unit or the multi-step

paper feed unit, the capacity of paper can be increased.

(1) Cassette paper feed operation

Select the cassette and press the START button, and the paper feed

roller solenoid will be turned on and the paper feed clutch will be

released.

The drive power of the main motor is transmitted through the paper

feed roller clutch to the paper feed roller, rotating the paper feed roller

and feeding paper.

6 – 6

Page 30

AR-161

(2) Manual paper feed tray operation

Select the manual paper feed tray and press the START button, and

the manual paper feed roller will be turned on to bring the paper feed

roller in contact with paper and lift the shutter simultaneously.

The drive power of the main motor is transmitted through the manual

paper feed roller clutch to the manual paper feed roller, rotating the

manual paper feed roller and feeding paper.

(3) Resist roller

In order to make synchronization between the paper lead edge fed

from the paper feed port and the image lead edge, the roller is kept

stationary for a certain time after the paper reaches at the roller to

warp the paper a little.

When the paper is warped to a certain level, the resist roller solenoid

is turned on to release the resist roller clutch.

The drive power of the main motor is transmitted through the resist

roller clutch to the resist roller, rotating the resist roller and feeding

paper.

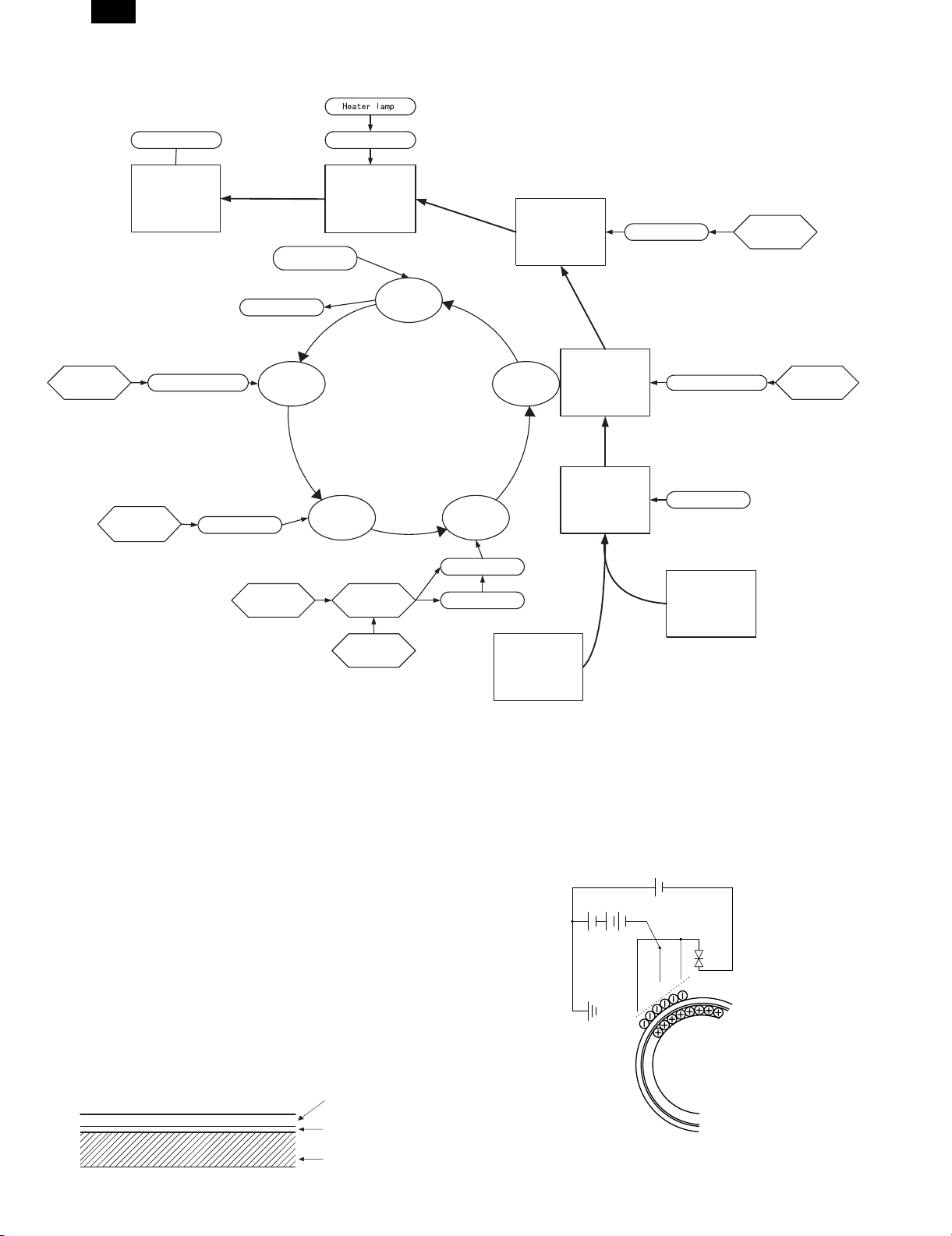

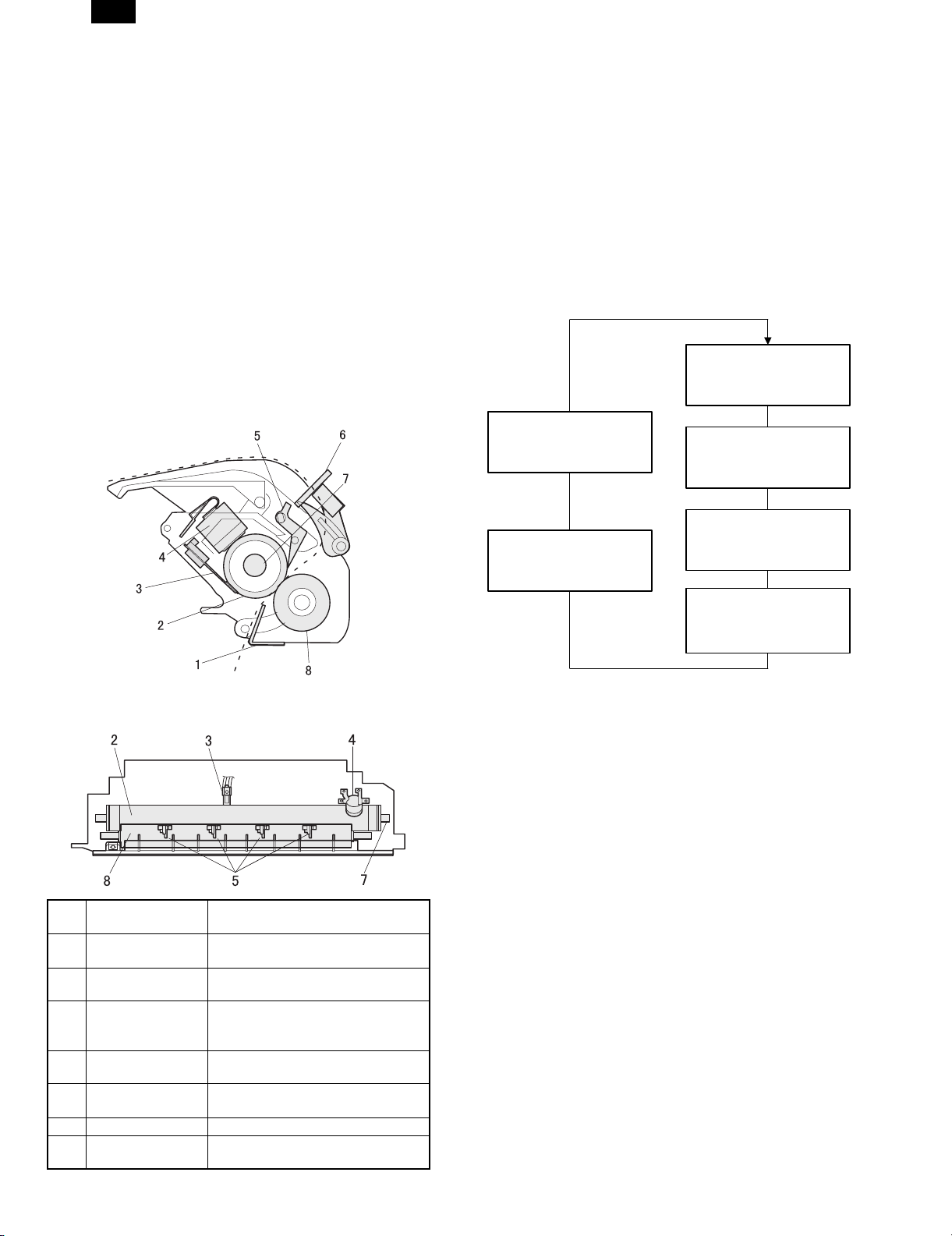

6. Fusing section

A. Basic composition

B. Heat roller

A pressure roller is used for the heat roller and a silicone rubber roller

is used for the lower heat roller for better toner fusing performance

and paper separation.

C. Separator pawl

Four separator pawls are used on the upper heat roller. The

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

D. Thermal control

1) The heater lamp, thermistor, main PWB, DC power supply PWB,

and triac within the power supply unit are used to control the

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety purposes.

Heated by the

heater lamp.

(950W )

Safety device

(thermal breaker, thermal

fuse)

The surface temperature

of the upper heat roller

is sensed by the thermistor.

(Top view)

1 Before-fusing

paper guide

2 Upper heat roller Applies heat and pressure to the

3 Thermistor Detects the surface temperature of

4 Thermostat Stops power supply to the heat roller

5 Separation pawl Separates the print paper from the

6 POD1 Detects that the paper has been

7 Heater lamp Heats the heat roller.

8 Lower heat roller Applies a pressure to the paper

Guides the paper transported from

the process section to the fusing unit.

paper to fuse.

the upper heat roller.

in case of an abnormally high

temperature of the heat roller.

upper heat roller.

transported from the fusing section.

together with the upper heat roller.

Level of the thermistor is

Triac (in the

power supply unit)

2) The surface temperature of the upper heat roller is set to 180˚C ~

195˚C. The surface temperature during the power save mode is

set to 100˚C.

3) The self-check function comes active when one of the following

malfunctions occurs, and an "H" is displayed on the copy quantity

display.

Fusing temperature error value

H4 (Low temperature error)

controlled by the main PWB.

With the signal from the

main PWB, the triac is

controlled on and off.

(power supply PWB )

• During machine operation

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

• During printing

When the fusing temperature (thermistor output value) falls

below 145˚C.

H3 (High temperature error)

Fusing temperature (thermistor output value) of about 220 to

240˚C (varies depending on the resistance.)

E. Fusing resistor

(1) Fusing resistor

Since the upper heat roller is conductive when copy paper is highly

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

6 – 7

Page 31

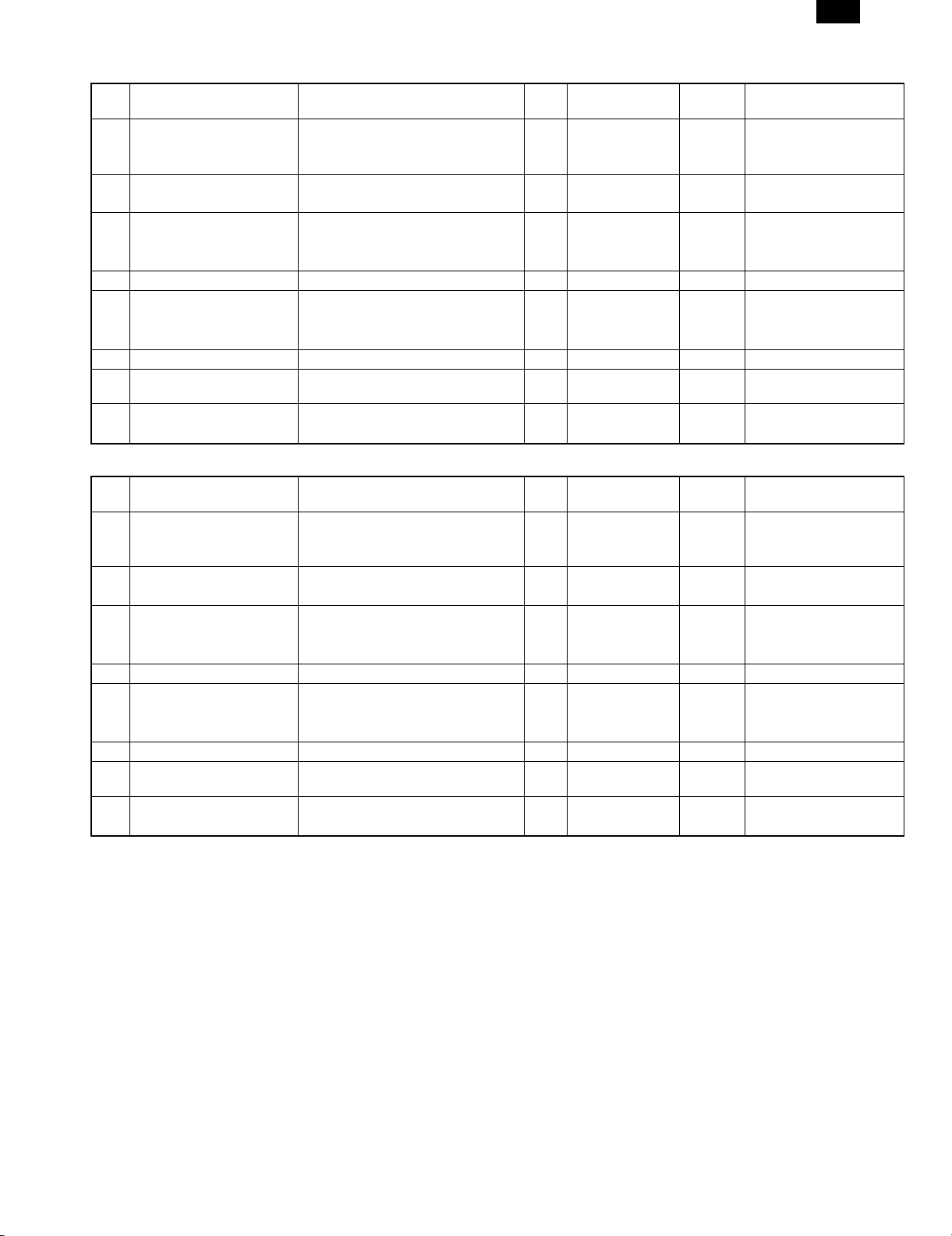

[7] ADJUSTMENTS

1. Adjustment item list

Section Adjustment item Adjustment procedure/SIM No.

A Process section (1) Developing doctor gap adjustment Developing doctor gap adjustment

(2) MG roller main pole position adjustment MG roller main pole position adjustment

(3) Developing bias voltage output adjustment SIM 8-1

(4) Main charger voltage output adjustment SIM 8-2/SIM 8-3

(5) Transfer charger current adjustment SIM 8-6

B Mechanism section (1) Image position adjustment SIM 50-1/SIM 50-10

(2) Main scanning direction (FR direction)

distortion balance adjustment

(3) Main scanning direction (FR direction)

distortion adjustment

(4) Sub scanning direction (scanning direction)

distortion adjustment

(5) Main scanning direction (FR direction)

magnification ratio adjustment

(6) Sub scanning direction (scanning direction)

magnification ratio adjustment

(7) Off center adjustment a OC mode (SIM 50-13)

(8) Document size detection sensor SIM 41-2

C Image density adjustment (1) Copy mode SIM 46-1

No. 2/3 mirror base unit installing position

adjustment

Copy lamp unit installing position adjustment

F rail height adjustment

Winding pulley position adjustment

SIM 48-1

a OC mode in copying (SIM 48-2)

b SPF mode in copying (SIM 48-5)

c OC mode in FAX (SIM 48-6)

d SPF mode in FAX (SIM 48-7)

b SPF mode (SIM 50-16)

AR-161

2. Copier adjustment

A. Process section

(1) Developing doctor gap adjustment

1) Loosen the developing doctor fixing screw A.

2) Insert a thickness gauge of 1.5mm to the three positions at 20mm

and 130mm from the both ends of the developing doctor as

shown.

3) Push the developing doctor in the arrow direction, and tighten the

developing doctor fixing screw. (Perform the same procedure for

the front and the rear frames.)

4) Check the clearance of the developing doctor. If it is within the

specified range, then fix the doctor fixing screw with screw lock.

* When inserting a thickness gauge, be careful not to scratch the

developing doctor and the MG roller.

<Adjustment specification>

Developing doctor gap

Both ends (20mm from the both ends): 1.5±0.1mm

C (Center)(150mm from the both ends): 1.5±0.1mm

(2) MG roller main pole position adjustment

1) Remove and separate the waste toner box and put the developing

unit on a flat surface.

2) Tie a string to a needle or a pin.

3) Hold the string and bring the needle close to the MG roller

horizontally. (Do not use paper clip, which is too heavy to make a

correct adjustment.) (Put the developing unit horizontally for this

adjustment.)

4) Do not bring the needle into contact with the MG roller, but bring it

to a position 2 or 3mm apart from the MG roller. Mark the point on

the MG roller which is on the extension line from the needle tip.

7 – 1

Page 32

AR-161

5) Measure the distance from the marking position to the top of the

doctor plate of the developing unit to insure that it is 18mm.

If the distance is not within the specified range, loosen the fixing

screw A of the main pole adjustment plate, and move the adjustment plate in the arrow direction to adjust.

<Adjustment specification>

Mode Specification SIM

Developing bias voltage DC-400±8V SIM 8-1 VR31

(4) Grid bias voltage adjustment (SIM 8-2, SIM 8-3)

Note: • Use a digital multi-meter with an internal resistance of

10MΩ or more.

• First adjust the grid LOW output, then adjust the grid HIGH

voltage.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the grid bias voltage

output check pin.

3) Execute SIM 8-3. (The grid bias voltage is outputted in the grid

bias LOW output mode for 30 sec.)

4) Adjust the adjustment volume VR52 so that the output voltage is

within the specified range shown below.

5) Execute SIM 8-2. (The grid bias voltage is outputted in the grid

bias HIGH output mode for 30 sec.)

6) Adjust the adjustment volume VR51 so that the output voltage is

within the specified range shown below.

(3) Developing bias voltage adjustment (SIM 8-1)

Note: • Use a digital multi-meter with an internal resistance of

10MΩ or more.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the developing bias

voltage output check pin.

3) Execute SIM 8-1. (The developing bias voltage is outputted for 30

sec.)

4) Adjust the adjustment volume VR31 so that the output voltage is

within the specified range shown below.

<Adjustment specification>

Mode Specification SIM

Grid bias LOW DC-400±20V SIM 8-3 VR52

Grid bias HIGH DC-525±10V SIM 8-2 VR51

B. Mechanism section

(1) Image position adjustment (SIM 50-1/SIM 50-10)

a. Image lead edge position adjustment

1) Set a scale on the document table as shown below.

2) Make a copy.

3) Check the copy. If, necessary, perform the following adjustment

procedure.

4) Execute SIM 50-1. Set AE (Laser radiation timing)/Lead edge void

7 – 2

Page 33

AR-161

value to 0. Make a copy (100%) again.

5) Set the laser radiation timing (image loss amount). Measure R in

the figure below.

Laser radiation timing = R (mm) × 10

6) Set the lead edge void.

Measure H in the figure below.

Lead edge void = H(mm) × 10

7) Enter the set value and press the start key.

The correction value is stored and a copy is made.

(Example)

Lead edge void H

Image loss R

5mm

10mm

<Adjustment specification>

Mode Specification SIM Set value Set range

Laser radiation

timing

1 ~ 4mm SIM

45-1

1 step:

0.1mm shift

1 ~ 99

Lead edge void

adjustment

b. Rear edge void adjustment

1) Set a scale as shown in the figure below.

A4(8.5" x 11")

Paper rear edge

2) Set the document size to A4, and make two copies at 100%.

3) Check the second copy. If necessary, perform the following adjustment procedure.

* The first copy does not show the void. Be sure to check the

second copy.

Void amount (Standard value: 0

4mm)

4) Execute SIM 50-1 and set the density mode to AE + TEXT +

PHOTO (Rear edge void).

The currently set adjustment value is displayed.

5) Enter the set value and press the start key.

The correction value is stored and a copy is made.

<Adjustment specification>

Mode Specification SIM Set value Set range

Rear edge void 4mm or less SIM

50-1

1 step:

0.1mm shift

1-99

c. Paper off center adjustment

1) Execute SIM 50-1 and set the density mode of Manual (TEXT)

(Left edge void) to 0.

2) Set a test chart (UKOG-0089SCZZ) on the document table.

3) Select a paper feed port and make a copy.

Compare the copy and the test chart. If necessary, perform the

following adjustment procedure.

4) Execute SIM 50-10.

After completion of warmup, shading is performed and the cur-

rently set off center adjustment value of each paper feed port is

displayed.

5) Enter the set value and press the start key.

The correction value is stored and a copy is made.

<Adjustment specification>