Page 1

AM-900U

SERVICE MANUAL

No. 00ZAM900U/SME

DIGITAL MULTIFUNCTIONAL SYSTEM

CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

[1] Specifications ................................................. 1-1

[2] Operation panel.............................................. 1-2

[3] Transmittable documents ............................... 1-3

[4] Installation ...................................................... 1-4

CHAPTER 2. ADJUSTMENTS

[1] Adjustments ................................................... 2-1

[2] Diagnostics and service soft switches............ 2-7

[3] Troubleshooting ........................................... 2-30

[4] Error code table............................................ 2-31

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Mechanical description................................... 3-1

[2] Disassembly and assembly procedures....... 3-18

MODEL

MODEL SELECTION CODE DESTINATION

AM-900 U U.S.A./Canada

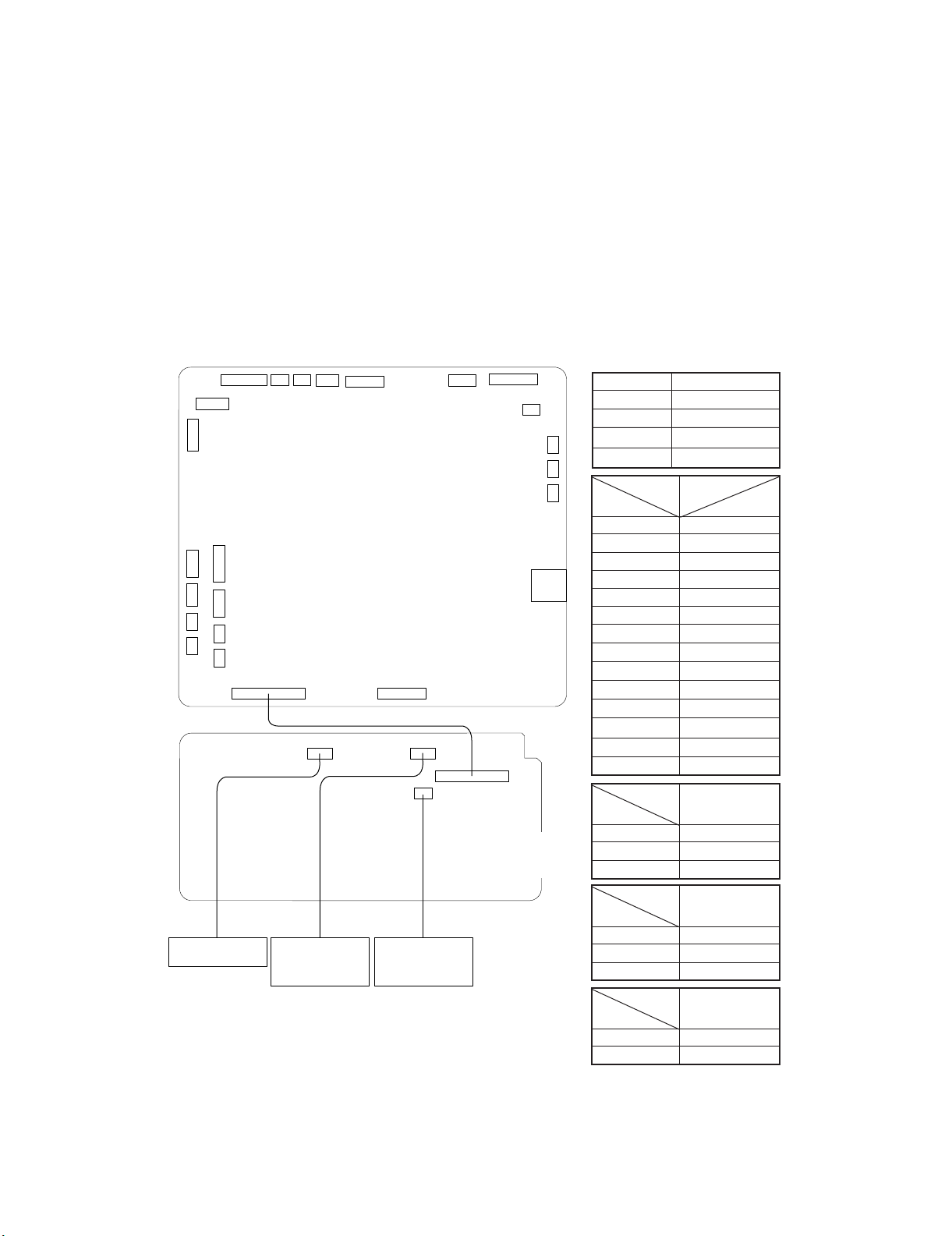

[4] Circuit description of power supply

PWB ............................................................5-21

[5] Circuit description of CIS unit ......................5-22

[6] Circuit description of operation panel

PWB ............................................................5-23

[7] Data flow chart.............................................5-24

[8] Troubleshooting...........................................5-25

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Control PWB circuit .......................................6-1

[2] LIU PWB circuit ...........................................6-14

[3] Power Supply PWB circuit...........................6-17

[4] High Voltage PWB circuit.............................6-19

[5] Operation Panel PWB circuit .......................6-22

AM-900

CHAPTER 4. DIADRAMS

[1] Block diagram ................................................ 4-1

[2] Wiring diagram ............................................... 4-2

[3] Point-to-point diagram.................................... 4-3

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Circuit description........................................... 5-1

[2] Circuit description of control PWB.................. 5-1

[3] Circuit description of LIU PWB..................... 5-19

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

SHARP CORPORATION

CHAPTER 7. OPERATION FLOWCHART

[1] Protocol ......................................................... 7-1

[2] Power on sequence.......................................7-2

CHAPTER 8. OTHER

[1] Service tools ..................................................8-1

[2] Rewriting version up the FLASH ROM ..........8-2

Parts Guide

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AM-900U

CAUTION

This laser facsimile is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the CDRH or IEC60825-1 standard.

This means that this machine does not produce a hazardous laser radiation. The use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

This laser radiation isn't a danger to the skin, but when an exact focusing of the laser beam is achieved on the eyes retina, there is

danger of spot damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of servicing.

1) When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a unit, not an individual part.

2) Do not look into the machine with the main switch turned on after removing the toner/developer unit and drum cartridge.

3) Do not look into the laser beam exposure slit of the laser optical unit with the connector connected when removing and installing

the optical system.

4) The cover of Laser Printer Unit contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot

Laser Wave Length : 780 nm +15/-10 nm

Laser Pulse Times : 12.00 µs/7 mm

Laser Output Power : 0.4 mW ± 0.04 mW

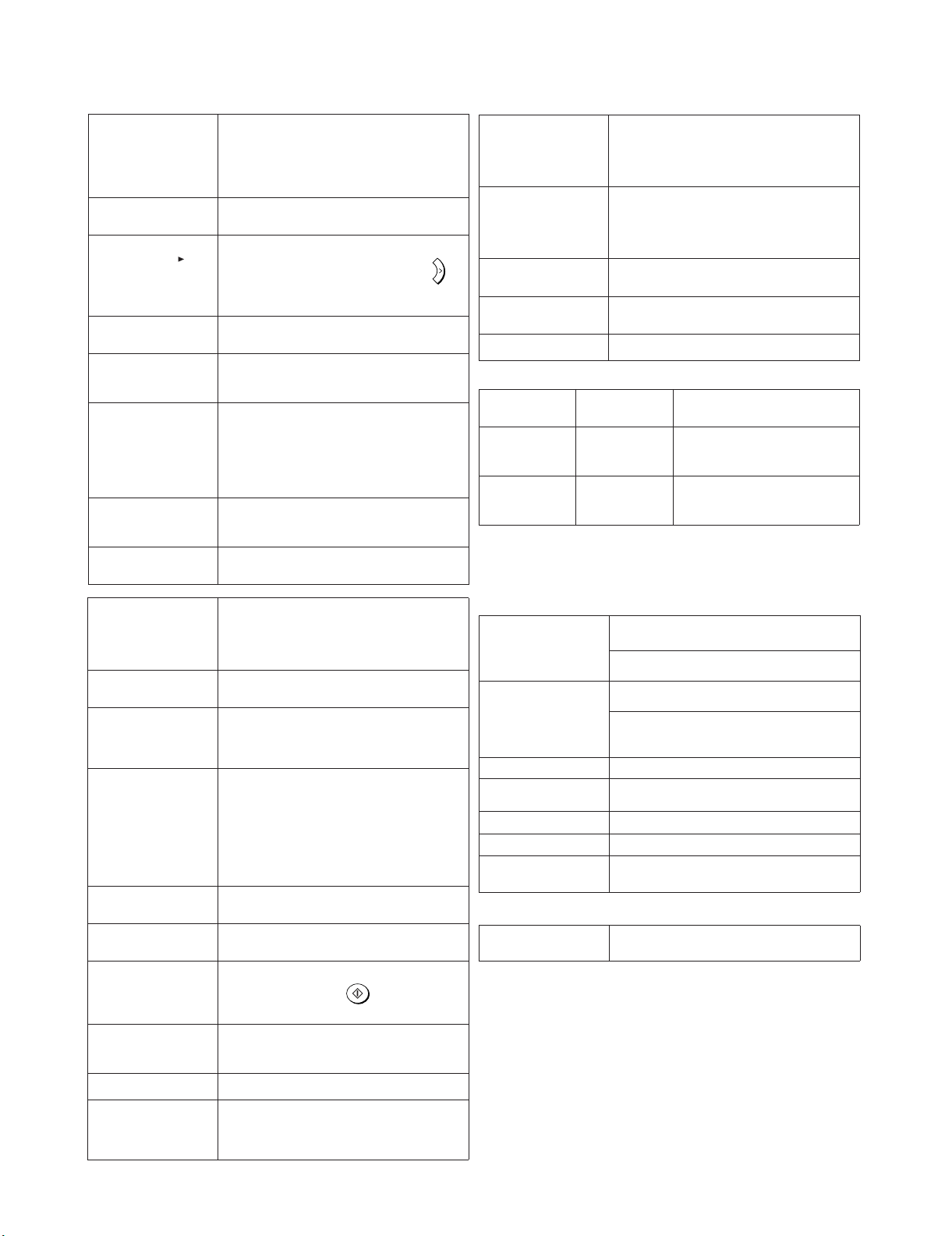

Life of consumable

Section Part Estimated Life Replaced by

Toner cartridge Replacement cartridge

(AM-90ND)

Drum cartridge Replacement cartridge

(AM-90DR)

Paper feed Transfer roller (Refer to the P/G No. 3-19)

(NROLR2525XHZZ)

Fuser Fusing unit (Refer to the P/G No. 5-901)

(DUNTK273DXH01)

Paper transport Feed roller (Refer to the P/G No. 3-29)

(NROLR2333XHZZ)

Unit AM-900 5 years or 50,000 prints of early

3,000 prints

(at Letter/5% chart)

20,000 prints

(at Letter/5% chart)

50,000 prints Service Engineer

50,000 prints Service Engineer

Cleaning as needed ——————

either

.

User

User

——————

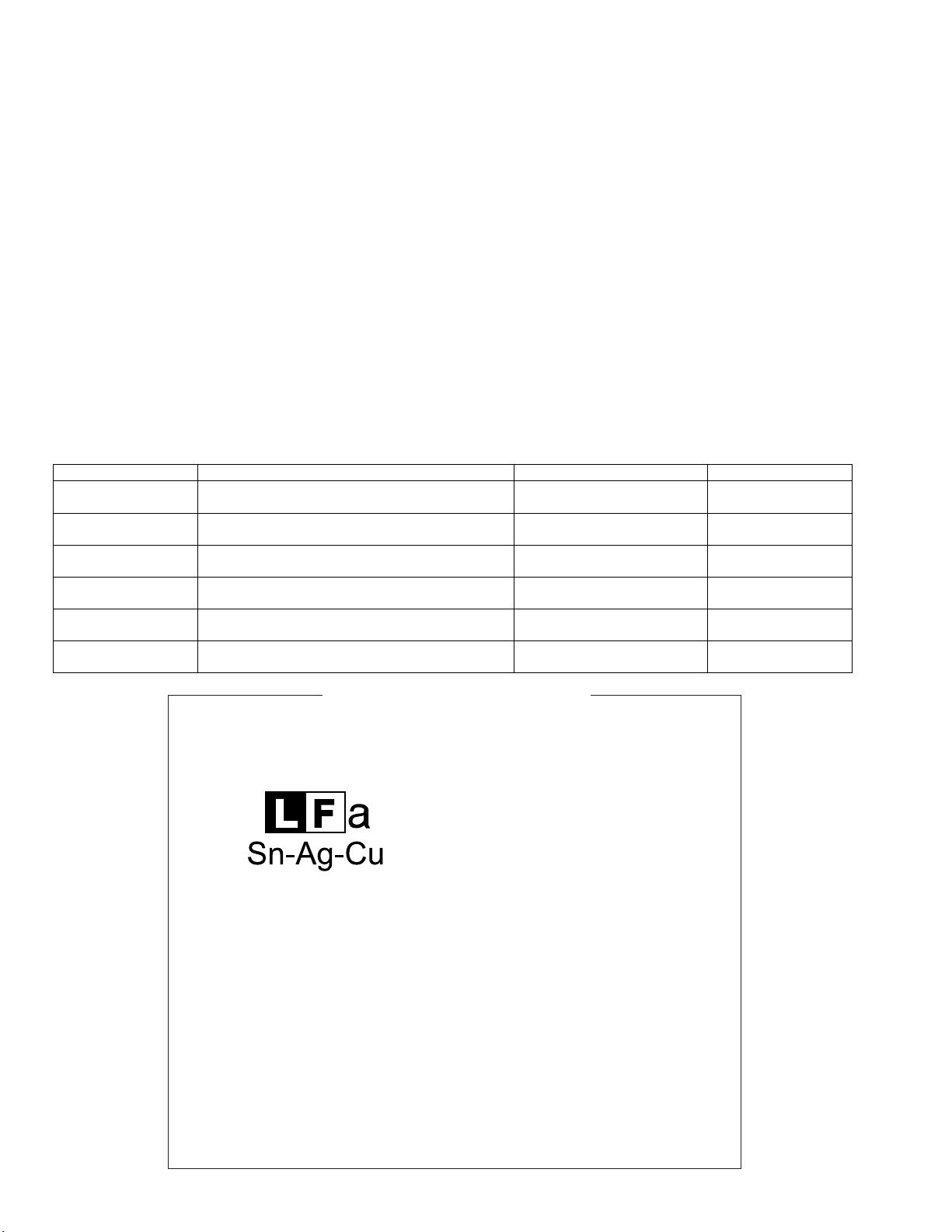

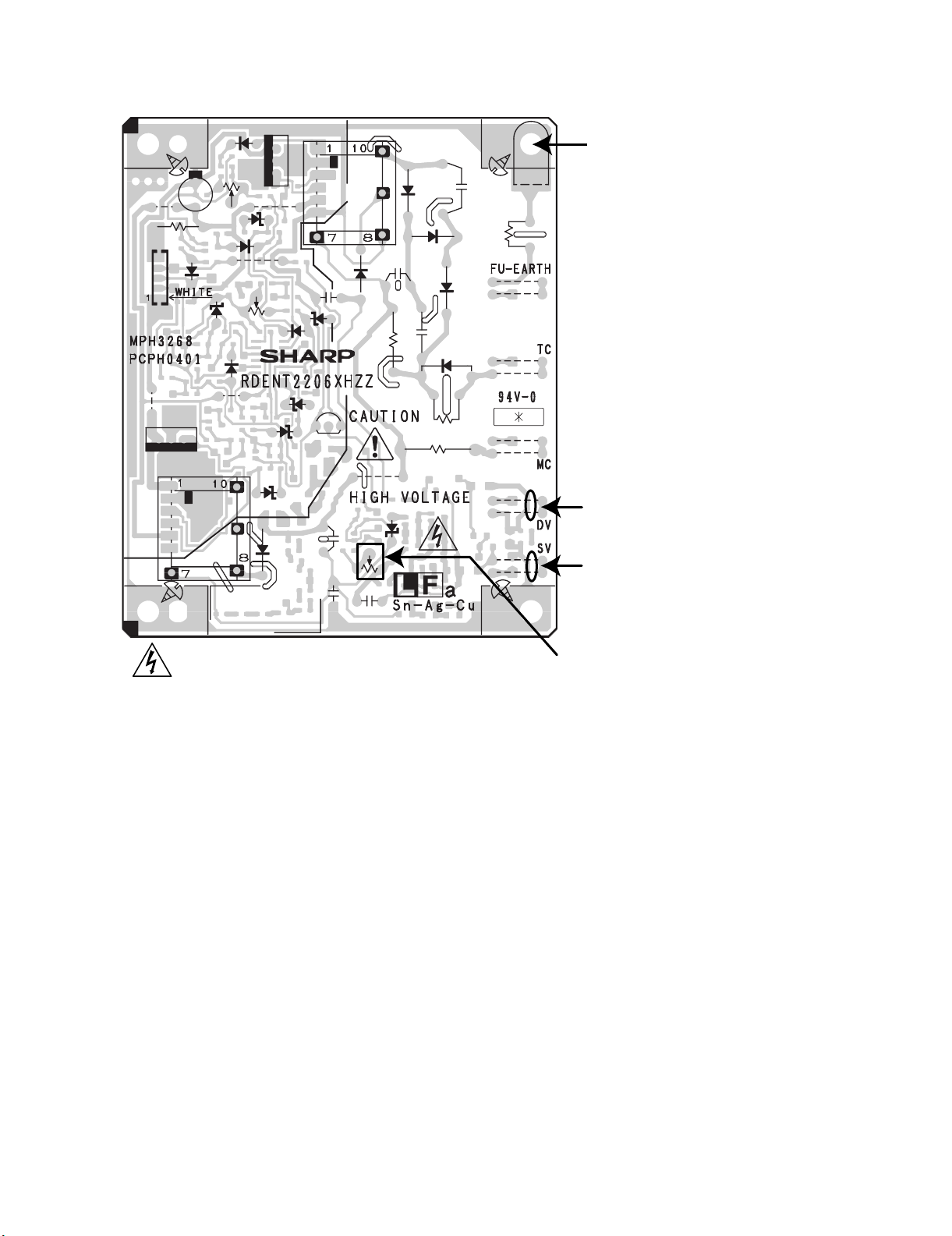

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

This model employs lead-free solder.

This is indicated by the "LF" symbol printed on the PWB and in the service manual.

The suffix letter indicates the alloy type of the solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free solder

When repairing a PWB with the "LF" symbol, only lead-free solder should be used. (Using normal tin/lead alloy solder may

result in cold soldered joints and damage to printed patterns.)

As the melting point of lead-free solder is approximately 40°C higher than tin/lead alloy solder, it is recommended that a

dedicated bit is used, and that the iron temperature is adjusted accordingly.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is higher and has poorer melting point (flow), to prevent damage to the

land of the PWB, extreme care should be taken not to leave the bit in contact with the PWB for an extended period of time.

Remove the bit as soon as a good flow is achieved.

The high content of tin in lead free solder will cause premature corrosion of the bit.

To reduce wear on the bit, reduce the temperature or turn off the iron when it is not required.

Leaving different types of solder on the bit will cause contamination of the different alloys, which will alter their

characteristics, making good soldering more difficult.

It will be necessary to clean and replace bits more often when using lead-free solder. To reduce bit wear, care should be

taken to clean the bit thoroughly after each use.

– i –

Page 3

FAXAM-900UService ManualService ManualMarketE

CHAPTER 1. GENERAL DESCRIPTION

[1] Specifications

AM-900U

1. Print specifications

Printer type:

Toner cartridge yield*:

(continuous printing, 5%

page coverage, letter

paper)

Drum cartridge yield*:

(continuous printing, 5%

page coverage, letter

paper)

PC print speed:

Resolution:

* The yields may vary depending on coverage and operating conditions.

Laser

Initial starter cartridge (included with

machine): Approx. 1500 pages

Replacement cartridge AM-90ND:

Approx. 3000 pages

Initial starter cartridge (included with

machine): 20,000 pages (average)

Replacement cartridge AM-90DR:

20,000 pages (average)

12 ppm (pages per minute)

600 x 600 dpi (dots per inch)

2. Copy specifications

Copy speed:

Copy quality settings:

Copy resolution settings:

Enlargement/Reduction:

Contrast settings:

Halftone (grayscale):

Multiple copies:

Maximum copy size:

12 cpm (copies per minute)

Text, Photo, Text/Photo

300 dpi, 600dpi

25% to 400%

5 levels

256 levels

Max. 99 copies per original

Document glass: Letter (8.5 x 11 in.)

Auto document feeder: Legal (8.5 x 14

in.)

3. Fax specifications

Automatic dialing:

Modem speed:

Transmission time*:

Communication method:

Compression scheme:

Transmission method:

Memory size*:

Resolution:

Halftone (grayscale):

Reception modes:

* Based on Sharp Standard Chart at standard resolution, excluding

time for protocol signals (i.e., ITU-T phase C time only).

100 Speed Dial numbers

33,600 bps with automatic fallback to

lower speeds (lowest speed 2400 bps)

Approx. 3 seconds

Super G3, G3

MMR, MR, MH

Dither

2 MB (approx. 125 average letter

pages)

Horizontal: 203 lines/inch (8 dots/mm)

Verti cal: Standard: 98 lines/inch

(3.85 lines/mm)

Fine/Halftone: 196 lines/inch

(7.7 lines/mm)

Super fine: 391 lines/inch

(15.4 lines/mm)

256 levels

FAX ONLY, EXT. TEL

4. Scanning specifications

Scanner type:

Resolution:

Scan speed:

Compatibility:

Grayscale:

Color:

CIS (Contact Image Sensor)

300/600 x 300 dpi, 300/600 x 600 dpi

Black and white:

300/600 x 300 dpi: 6 sec/page

300/600 x 600 dpi: 12 sec/page

Color and grayscale:

300/600 x 300 dpi: 18 sec/page

300/600 x 600 dpi: 36 sec/page

TWAIN, WIA

256 levels

24-bit color

5. General specifications

Auto document feeder:

Computer connection:

Effective scanning width:

Effective printing width:

Display:

Paper tray capacity:

(letter-size plain paper)

Power requirements:

Operating temperature:

Humidity:

Power consumption:

Dimensions:

Weight:

Letter size: 20 sheets max. (20 lbs.)

Legal size: 1 sheet max. (20 lbs.)

USB 1.0/1.1 or 2.0 port (USB 1.0/1.1 or

2.0 cable must be purchased separately)

8.2” (208 mm) max.

8.2” (208 mm) max.

16-digit LCD display

250 sheets (20 lbs.)

(At room temperature and normal

humidity)

120 V AC, 60 Hz

50 - 86°F (10 - 30°

20 - 85% RH

Idle: 10 W

Maximum: 690 W

Width: 18.7" (475 mm)

Depth: 16.5" (420 mm)

Height: 14.6" (370 mm)

Approx. 28.0 lbs. (12.7 kg) (including

trays and toner and drum cartridges)

C)

As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for product improvement

without prior notice. The performance specifications figures indicated are nominal values of production units. There may be some deviations from

these values in individual units.

Trademark information

• Microsoft, Windows and Internet Explorer are trademarks of Microsoft Corporation in the

U.S.A. and other countries.

1 – 1

Page 4

AM-900U

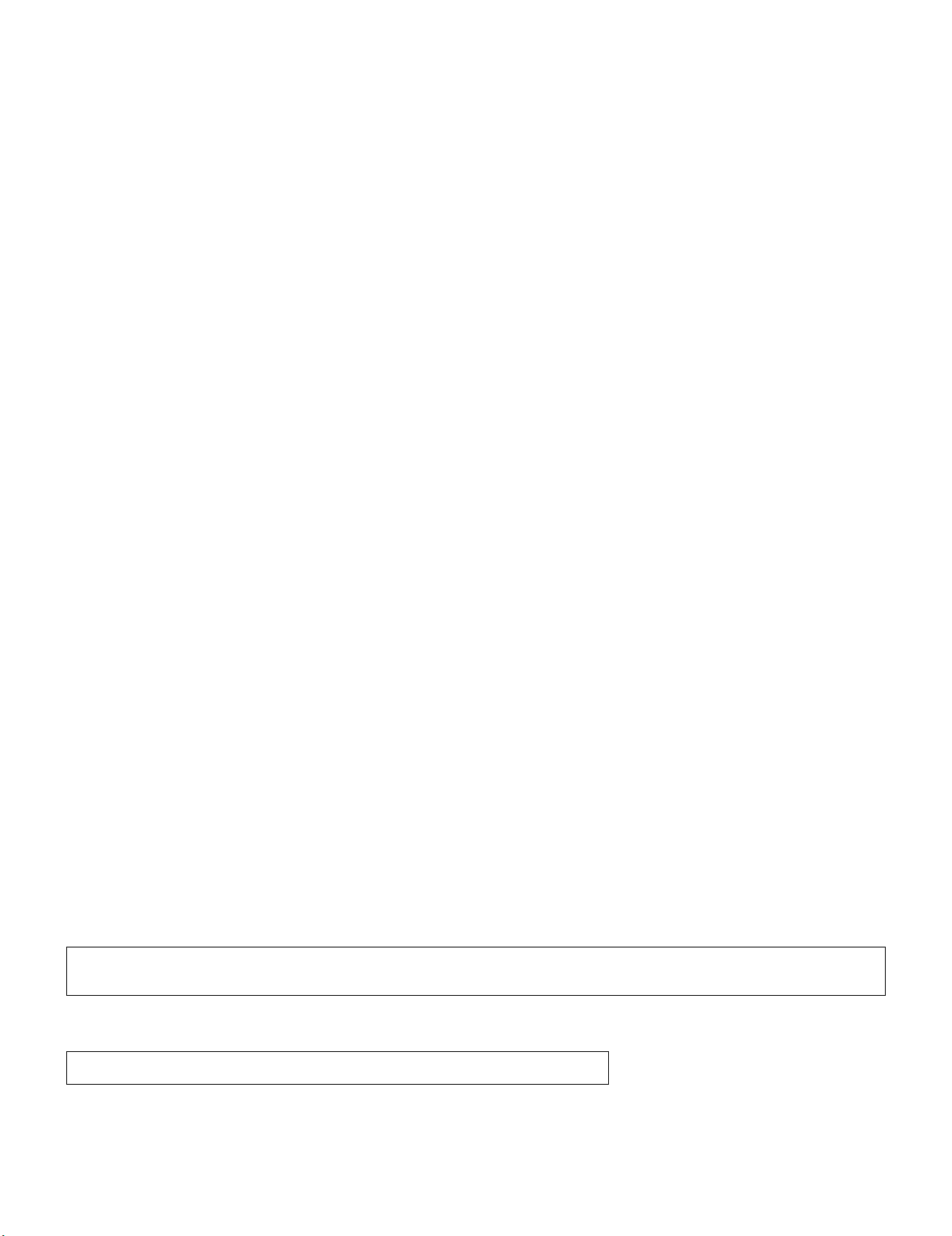

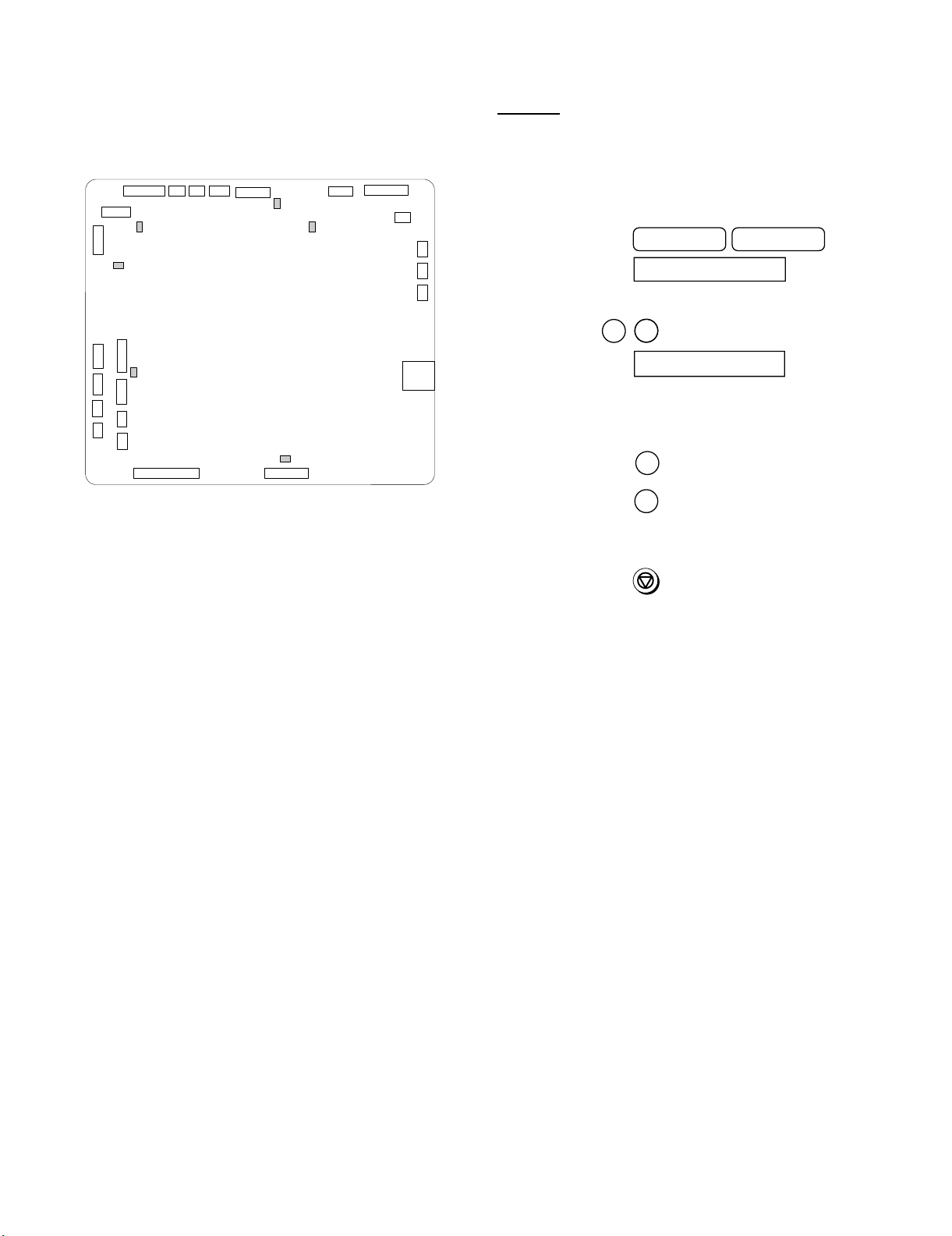

[2] Operation panel

1

2

3

4

6

7

8

9

COPY SCAN FA X

HELP

10511 12

1. Display

This displays messages and prompts to help you operate the

machine.

2. ZOOM key

Press this key to select an enlargement or reduction setting

when making a copy.

3. E-SORT key

Press this key when making multiple copies to have the

copies collated (sorted into sets with the pages ordered 1, 2,

3..., 1, 2, 3..., etc.).

4. QUALITY key

When making a copy, press this key to select the type of

original you are copying (TEXT, PHOTO). When sending a

fax, press this key to select a resolution setting.

5. Right/left arrow keys

When making a copy, press either of these keys after

selecting an enlargement/reduction setting with the ZOOM

key to increase or decrease the setting by 1%. When sending

a fax, press either of these keys to search through your autodial fax numbers.

6. MENU key

Press this key, followed by the left or right arrow key, to

access special functions and settings.

7. CONTRAST key

Press this key to select a contrast setting when making a copy

or sending a fax.

8. REDIAL key

Press this key followed by the Start key to automatically redial

the last number dialed.

9. Stop key

Press this key to cancel operations before they are completed.

10. COPY key

Press this key to select copy mode.

13

!

14

DUPLEX SCAN

15

QUALITY

E-SORT

ZOOM

PRINT STOP

16

CONTRAST

MENU

ZA

ENTER

17 18 19

11. SCAN key

Press this key to select scan mode.

12. HELP (FAX key and SCAN key)

Press the FAX key and SCAN key simultaneously to print the

HELP list, a brief guide to the operation of the machine.

13. FAX key

Press this key to select fax mode. When in fax mode, press

this key to select the Line Monitor function.

14. Alarm indicator

This blinks when the toner cartridge nears empty or the drum

cartridge is near or at the end of its life. This lights steadily

when the toner cartridge is empty, the machine is out of

paper, the print compartment cover is open, or when a paper

jam has occurred (a message will appear to indicate the

problem).

15. DUPLEX SCAN key

Press this key to copy or fax multiple two-sided pages.

16. PRINT STOP key

Press this key to cancel a print job sent to the machine from a

computer.

17. ENTER key

Press this key to enter or select a setting.

18. BROADCAST key

Press this key to send the same fax to multiple destinations.

19. SPEED key

Press this key to dial a fax number using an abbreviated 2digit Speed Dial number.

20. Number keys

Use these keys to enter the number of copies, dial fax

numbers, and enter numbers and letters when storing autodial numbers.

21. Start key

Press this key when you are ready to begin copying, faxing,

or scanning. The key can also be pressed in the date and

time display of fax mode to show the percentage of memory

currently used.

REDIAL

BROADCAST

SPEED

20

21

1 – 2

Page 5

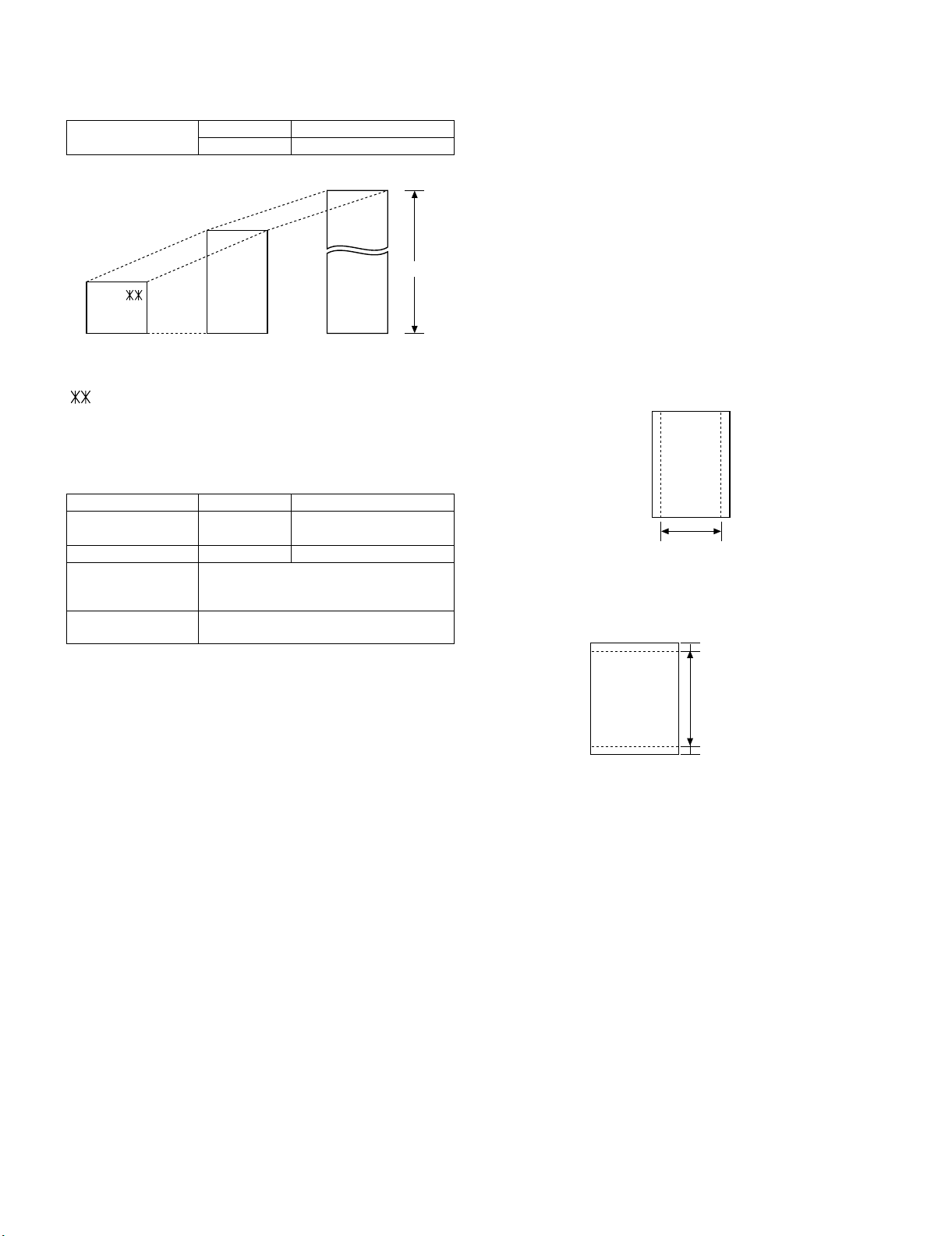

[3] Transmittable documents

m

h

1. Document Sizes

Normal size Width 5.8” - 8.5”(148 - 216 mm)

Length 5.8” - 11”(148 - 279 mm)

(Max.)

AM-900U

5. Automatic Document Feeder Capacity

Number of pages that can be placed into the feeder at anytime is as

follows:

Normal size: max. ADF 20 pages

Special size: single sheet only (manual feed)

NOTE: • When you need to send or copy more pages than the feeder

limit, place additional pages in feeder when last page in feeder

is being scanned.

• Place additional pages carefully and gently in feeder.

If force is used, double-feeding or a document jam may result.

(Max.)

(Min.)

148mm

148mm 216mm

Use document carrier sheet for smaller documents.

• With special sizes, only one sheet can be fed into the machine at a

time. Insert next page into feeder as current page is being scanned.

LETTER

size

[Normal size]

279mm

216mm

[Special size]

600m

2. Paper Thickness & Weight

10 sheets 1 sheet(Manual)

Paper weight 21.5 lbs.

Paper thickness (ref.) 0.1 mm 0.1 mm ~ 0.18mm

Paper size LGL (216 mm x 355.6 mm)

Feeder capacity A4/LTR: 10 sheets max.

2)

(80 g/m

A4 (210 mm x 297 mm)

LTR (216 mm x 279 mm)

LGL : 1 sheet max.

14 lbs. ~ 42 lbs.

2

(52 g/m

~ 157g/m

2)

3. Document Types

• Normal paper

Documents handwritten in pencil (No. 2 lead or softer), fountain

pen, ball-point pen, or felt-tipped pen can be transmitted.

Documents of normal contrast duplicated by a copying machine

can also be transmitted.

• Diazo copy (blue print)

• Diazo copy documents of a normal contrast may be transmitted.

• Carbon copy

A carbon copy may be transmitted if its contrast is normal.

6. Readable Width & Length

The readable width and length of a document are slightly smaller than

the actual document size.

Note that characters or graphics outside the effective document scanning range will not be read.

• Readable width

8.2” (208mm), max

Readable widt

• Readable length

This is the length of the document sent minus 0.16” (4mm) from the

top and bottom edges.

0.16" (4mm)

Readable length

0.16" (4mm)

4. Cautions on Transmitting Documents

• Documents written in yellow, greenish yellow, or light blue ink cannot be transmitted.

• Ink, glue, and correcting fluid on documents must be dry before the

documents can be transmitted.

• All clips, staples and pins must be removed from documents before

transmission.

• Patched (taped) documents should be copied first on a copier and

then the copies used for transmission.

• All documents should be fanned before insertion into the feeder to

prevent possible double feeds.

1 – 3

Page 6

AM-900U

[4] Installation

1. Site selection

Take the following points into consideration when selecting a site for

this model.

ENVIRONMENT

• The machine must be installed on a level surface.

• Keep the machine away from air conditioners, heaters, direct sunlight, and dust.

• Provide easy access to the front, back, and sides of the machine.

In particular, keep the area in front of the machine clear, or the original document may jam as it comes out after scanning.

• The temperature should be between 50 - 86°F (10 - 30°C).

• The humidity should be between 20% and 85% (without condensation).

ELECTRICITY

AC 120V, 60Hz, grounded AC (3-prong) outlet.

Caution!

• Connection to a power source other than that specified will cause

damage to the equipment and is not covered under the warranty.

• If your area experiences a high incidence of lightning or power

surges, we recommend that you install a surge protector for the

power and telephone lines. Surge protectors can be purchased at

most telephone specialty stores.

If the machine is moved from a cold to a warm place...

Condensation may form on the reading glass if machine is moved from

a cold to a warm place, this will prevent proper scanning of documents

for transmission. Turn on the power and wait approximately 2 hours

before using machine.

TELEPHONE JACK

A standard telephone jack must be located near the machine. This is

the telephone jack commonly used in most homes and offices.

• Plugging the fax machine into a jack which is not jack may result in

damage to the machine or your telephone system. If you do not

know what kind of jack you have, or need to have one installed,

contact the telephone company.

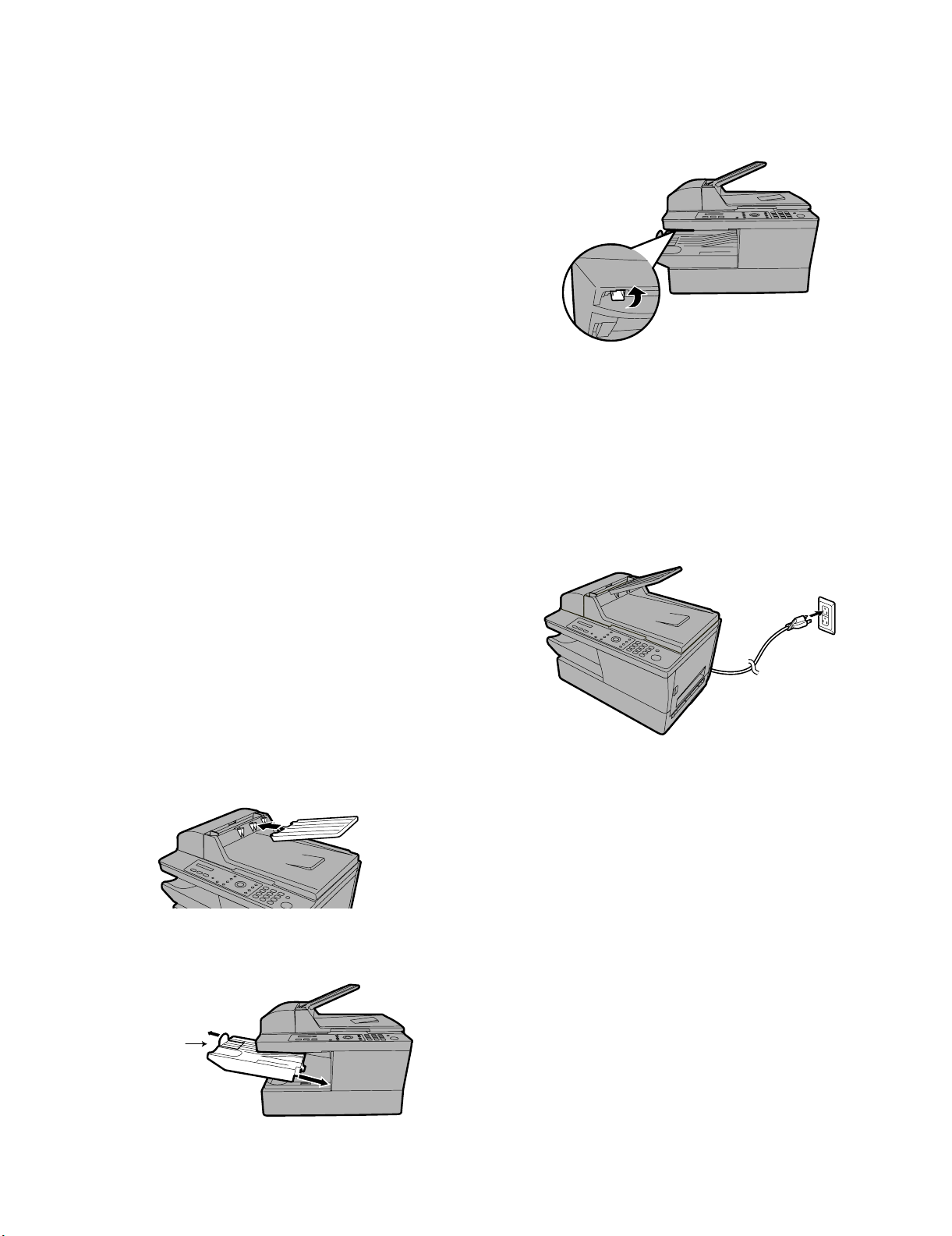

2) Releasing the scanner.

Before plugging in the power cord, pull the scanner release toward

you to release the scanner lock.

• Caution: Plugging in the power cord without releasing the scan-

ner lock may damage the machine.

• In the event that you need to move the machine, push the release

back in to lock the scanner before moving (push the release in after

you have unplugged the power cord).

3) Connecting the power cord.

Plug the power cord into a 120 V, 60 Hz, grounded AC (3-prong)

outlet.

• Caution: Make sure the scanner has been released as explained

on the previous page before plugging in the power cord.

• Do not plug the power cord into any other kind of outlet. This will

damage the machine and is not covered under the warranty.

2. Attaching the trays

1) Attach the document feeder tray.

Slide the output tray into the machine as shown. When it stops, lift

the end slightly and push in so that the tray locks in place.

If you will be

using legal paper,

pull out the tray

extension.

Important: The output tray must be attached correctly or the

machine will not operate.

• The machine does not have a power on/off switch. The power is

turned on and off by simply plugging in or unplugging the power

cord.

• If you area experiences a high incidence of lightning or power

surges, it is recommended that you install surge protectors for the

power and telephone lines. Surge protectors can be purchased

from your dealer or at most telephone specialty stores.

1 – 4

Page 7

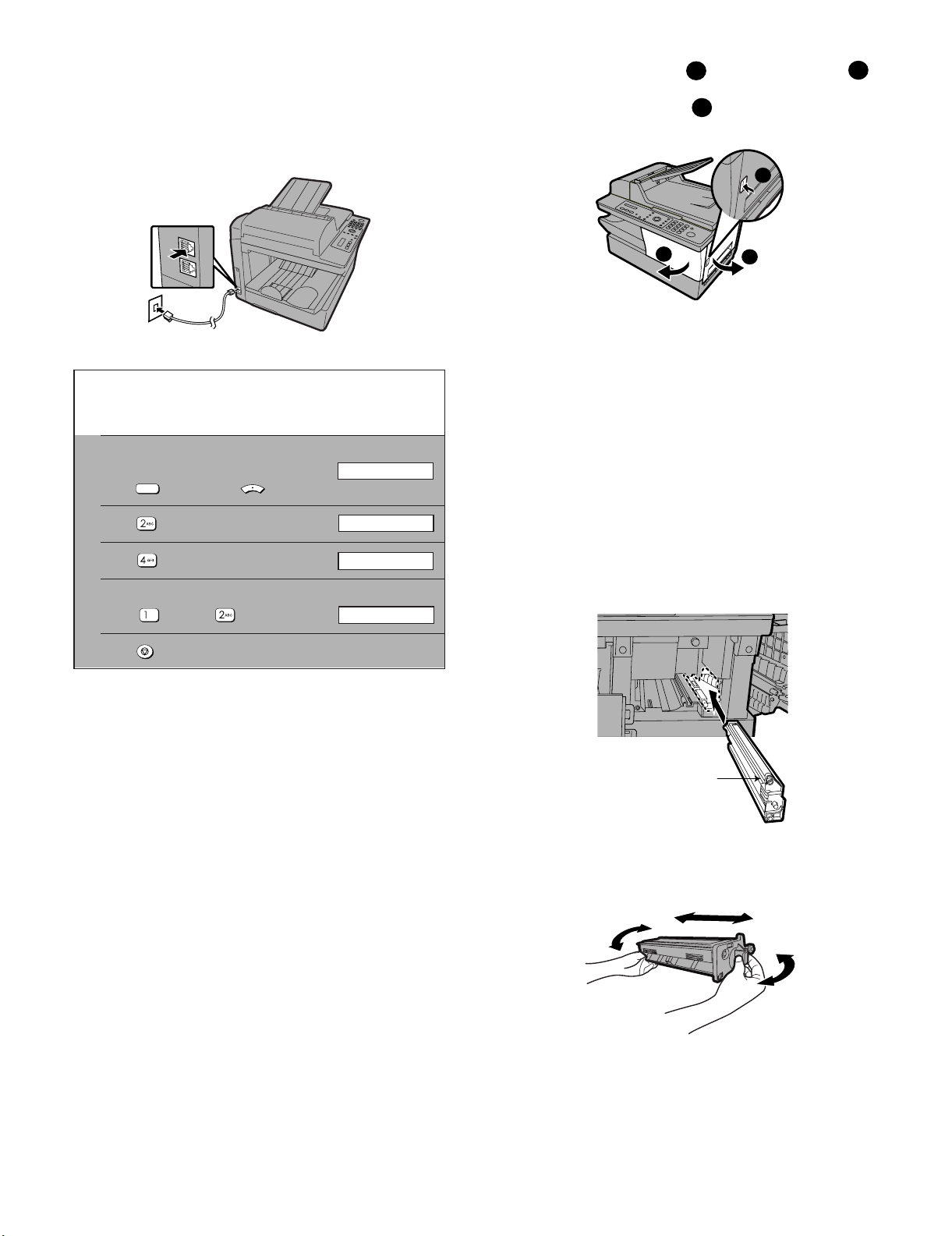

4) Connecting the telephone line cord.

Insert one end of the line cord into the socket on the back of the

machine marked TEL. LINE. Insert the other end into a wall telephone socket.

Make sure that the line cord is inserted into the TEL LINE jack. Do

not insert it into the TEL. SET jack!

TEL.

LINE

TEL.

SET

Setting the dial mode:

The machine is set for tone dialing. If you are on a pulse dial line, you must set

the fax machine for pulse dialing. Press the keys on the operation panel as

follows :

1 Make sure that the date and time

display of fax mode appears (if needed

FAX

press ) and then press

MENU

2 Press .

3 Press .

4 Select the dial mode:

TONE: PULSE:

Display:

FAX SETTING

1: DATE&TIME SET

1:TONE

The display briefly shows

your selection, then:

5: RINGER VOLUME

AM-900U

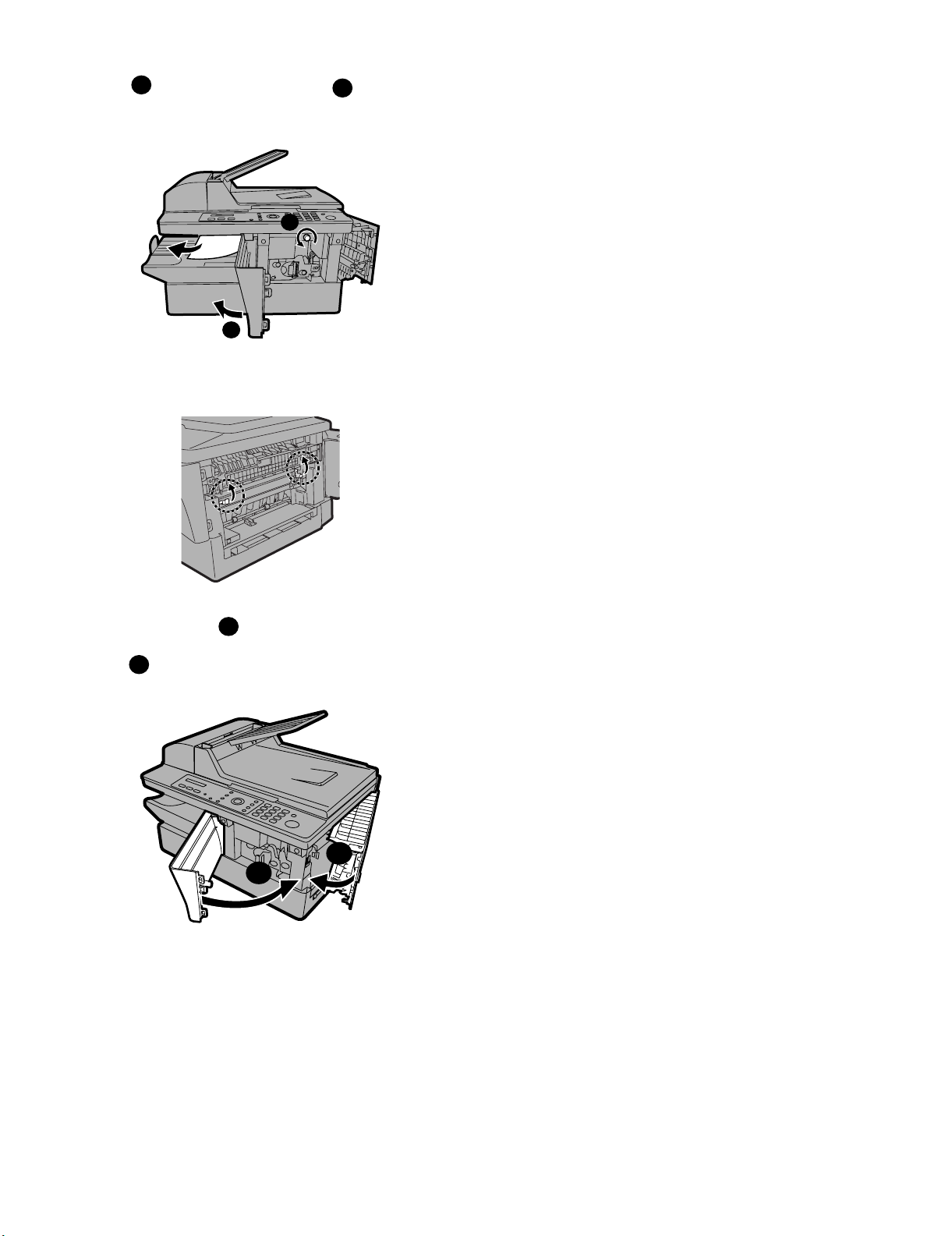

1) Press the side cover release , open the side cover ,

and then open the front cover .

1

3

1

3

2

• Caution! The fusing unit inside the print compartment becomes

very hot during operation. Do not touch the inside of the print compartment after the machine has been in operation.

2) Remove the new drum cartridge from its packaging, and remove

the tape from the top of the cartridge.

3) Insert the drum cartridge into the print compartment, sliding it along

the guides.

• Do not touch or allow other objects to contact the drum (the green

cylinder). This may damage the drum. If fingerprints, dust, or other

contaminants get on the drum, wipe it gently with a clean cloth.

• Exposure to light for more than several minutes will damage the

drum. Be sure to insert the drum cartridge promptly into the

machine.

• If you find it necessary to leave the cartridge out of the machine

for move than several minutes, wrap the cartridge in black paper.

2

5

Press repeatedly to exit.

Important: The facsimile function of this machine is not designed

for use on a line which has call waiting, call forwarding, or certain

other special services offered by your telephone company. If you

attempt to use the facsimile function in conjunction with any of

these services, you may experience errors during transmission and

reception of facsimile messages.

The facsimile function of this machine is not compatible with digital

telephone systems.

3. Installing the toner cartridge and drum cartridge

The laser printer in the machine uses a toner cartridge and drum cartridge.

• The starter toner cartridge included with the machine can print

approximately 1,500 letter-size pages at 5% page coverage.

• When replacing the toner cartridge, use a SHARP AM-90ND toner

cartridge. One cartridge can print about 3,000 letter-size pages at

5% coverage.

• The drum cartridge can print approximately 20,000 letter-size

pages. When replacing the drum cartridge, use a SHARP AM-

90DR drum cartridge.

Follow the steps below to install the toner cartridge and the drum cartridge.

Note: The quality of the toner cartridge is guaranteed for 18 months

after the date of manufacture indicated on the package. The quality of

the drum cartridge is guaranteed for 24 months after the date of manufacture indicated on the package.

Grasp this handle to

push the cartridge in.

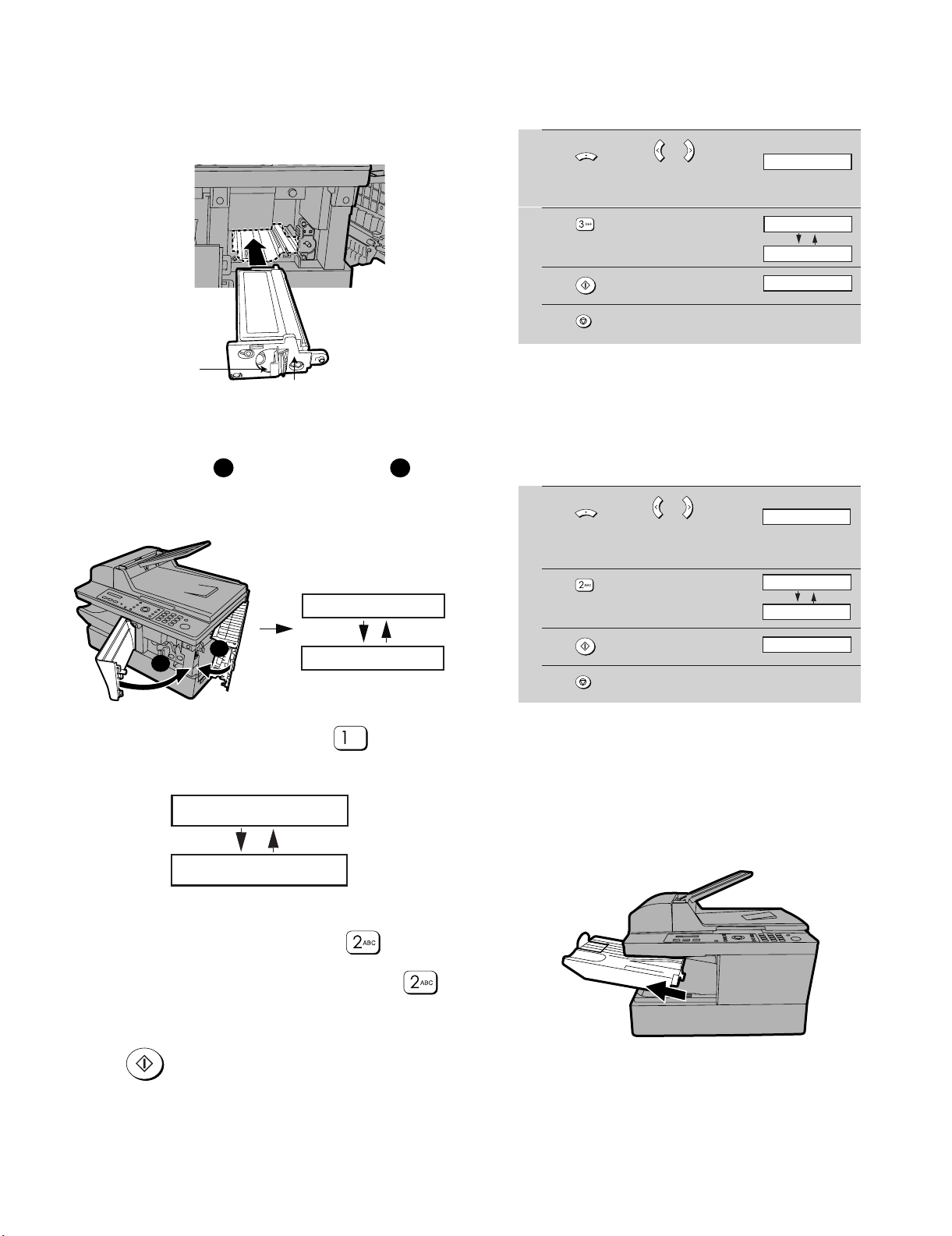

4) Remove the new toner cartridge from its packaging. Shake the cartridge side to side four or five times to distribute the toner evenly

within the cartridge.

1 – 5

Page 8

AM-900U

1 Press and then or

repeatedly until the display at right

appears.

MENU

Z

A

Display:

LIFE

2 Press .

3 Press .

4 Press repeatedly to exit.

CLEAR: START KEY

DRUM COUNTER

1: LIFE COUNTER

1 Press and then or

repeatedly until the display at right

appears.

2 Press .

3 Press .

4 Press repeatedly to exit.

MENU

Z

A

Display:

CLEAR: START KEY

LIFE

TONER COUNTER

3: CLR DRUM COUN T

5) Grasp the cartridge handle and insert the toner cartridge into the

print compartment, sliding it along the guides.

• After inserting the cartridge, press on the arrow mark to mark sure

it “clicks” into place.

• Do not touch the roller in the toner cartridge.

Grasp this

handle to

insert the

cartridge.

6) Close the front cover and then the side cover .

Press on this mark to

make sure the cartridge

"clicks" into place.

1

2

4. Resetting the drum counter

Each time you install a new drum cartridge, follow the steps below to

reset the drum counter to zero.

5. Manually resetting the toner counter

When a new toner cartridge is installed, the toner counter is reset in

Step 7 on the previous page. The procedure below is normally not necessary; however, it can be used in the event that you need to reset the

toner manually.

• Make sure the side cover is completely closed. Otherwise, light

may enter the print compartment and damage the drum.

Display:

TONER EXCHANGED?

1

2

1=YES,2=NO

7) If you installed a new toner cartridge, press to select YES

(this will reset the toner counter to zero).

NEW TONER?

OK: PRESS START

• If you temporarily removed and then replaced an old toner car-

tridge for maintenance or other reason, press to continue

6. Loading printer paper

You can load up to 250 sheets of letter or legal paper (max. 20lbs.) in

the paper tray.

Caution! Do not use the blank side of paper that has already been

printed on.

1) Remove the output tray.

using the previous toner count. (Note: Be sure to press ,

or the machine will not alert you when the toner cartridge is out of

toner.)

8) Press .

9) If you installed a new drum cartridge, reset the drum counter as

explained below.

1 – 6

Page 9

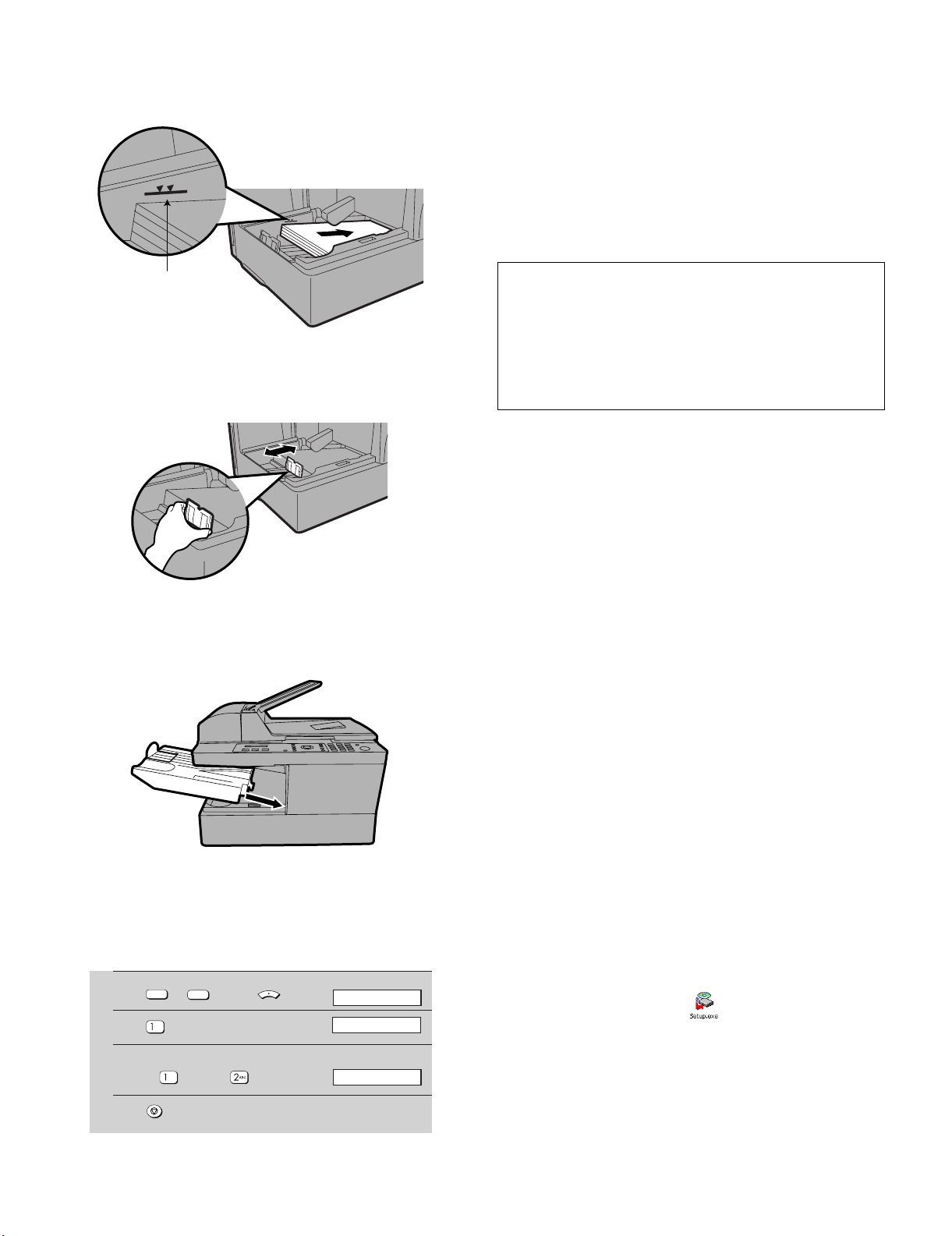

2) Insert a stack of paper into the tray, print side up.

• Important! The stack of paper must not be higher than the paper

height line on the paper tray.

Paper height line

3) Squeeze the sides of the paper guide as shown and slide it to the

slot for the length of the paper you are loading.

4) Replace the output tray.

• If you loaded legal size paper (or you changed the paper size),

change the paper size setting as explained below.

7. Setting the paper size

The machine has been set at the factory to use letter size paper. If you

loaded legal size paper, you must change the paper size setting to

LEGAL.

COPY

1 Press (or ) and then .

SCAN

MENU

2 Press .

3 Select the paper siz e:

LETTER: LEGAL:

4 Press repeatedly to exit.

Display:

COMMON SETTING

1:LETTER

The display briefly shows

your selection, then:

2: AUTO CLE AR

AM-900U

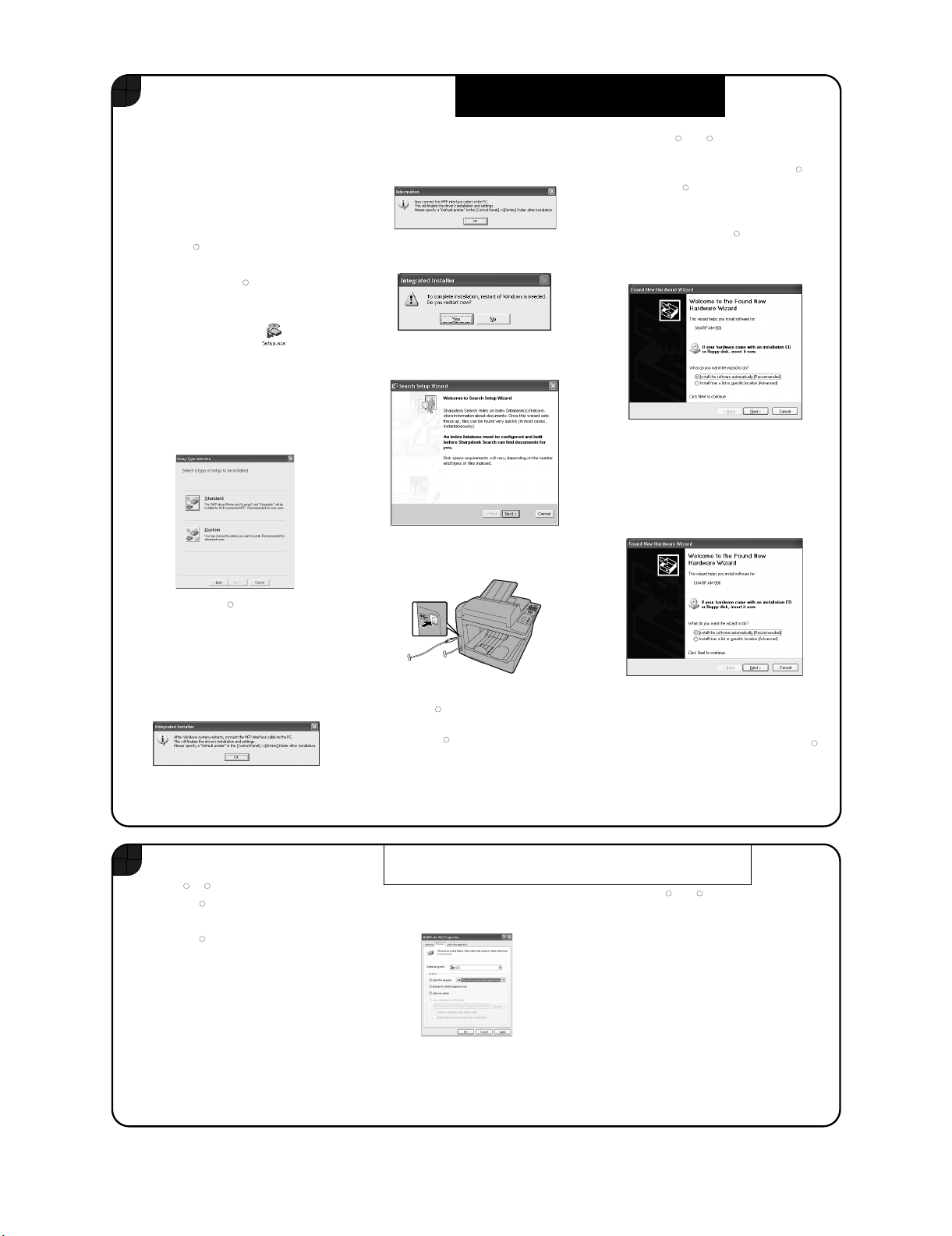

8. Installing the software

To use the machine as a printer and scanner for your computer, you

must install the software and connect a USB cable. The CD-ROM that

comes with the machine contains the following software:

• MFP Drivers: These consist of the printer driver that allows the

machine to be used as a printer, and the scanner driver that allows

you scan using TWAIN and WIA compliant applications.

• Sharpdesk: This is an integrated software environment that makes

it easy to manage image files and launch applications. (Note that

Internet Explorer 5.5 or higher is required to install Sharpdesk; if

this is not installed, you will be prompted during the installation procedure to install Internet Explorer 6.0SP1

Minimum system requirements

Operating system: Windows 98 SE

Port: USB 2.0 or 1.1 port

Display: 800 x 600 (SVGA) with 256 colors or more

Free hard-disk space: 150 MB or more

Other requirements: An environment in which the operating

system can freely operate.

Comments:

• USB 2.0 Hi-Speed is only possible if your computer has a USB 2.0

port and you are using a USB 2.0 cable. In addition, the Microsoft

USB 2.0 driver must be preinstalled in your computer, or the USB

2.0 driver for Windows 2000/XP

Update must be installed. Note that USB 2.0 Hi-Speed is not possible in Windows 98 SE

®

or Me®.

• To scan a legal size document (the maximum size) at 1200 dpi in

full color, at least 600 MB or more of free hard disk space is

required on the drive where your operating system is installed.

Installing the software

• A USB cable is required to connect the machine to your computer.

Please purchase a USB 2.0 or USB 1.0/1.1 cable. (If you wish to

use USB 2.0 Hi-Speed mode and your system meets the requirements for Hi-Speed mode, purchase a USB 2.0 cable.) The USB

cable will be connected during the software installation procedure.

• To install the software on Windows 2000/XP

you must log in with administrator’s rights.

• The windows shown in the following procedure appear in Windows

®

XP

. The windows that appear in other versions of Windows may

be slightly different.

1) Make sure that the USB cable is not connected to your computer.

(The cable will be connected in Step 10.)

• If the USB cable is connected, a Plug and Play window will

appear. Click the Cancel button to close the window and disconnect the cable.

2) Insert the Sharp CD-ROM into your computer’s CD-ROM drive.

3) In Windows XP

®

, click the start button, click My Computer, and

then double-click the CD-ROM icon.

In Windows 98/Me/2000

®

, double-click My Computer on the desk-

top and then double-click the CD-ROM icon.

4) Double-click the setup icon ( ) in the CD-ROM window.

5) Follow the instructions in the windows that appear.

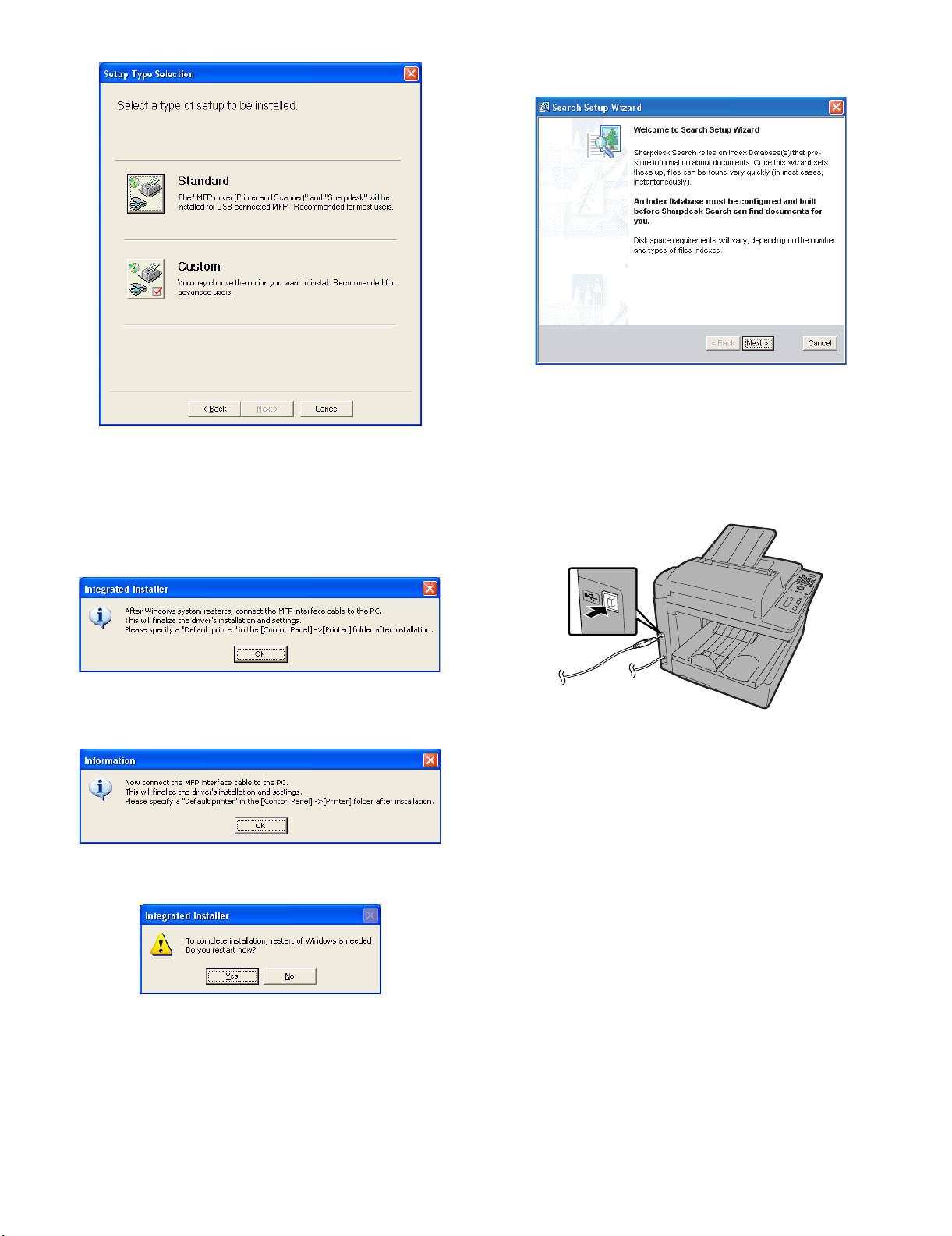

• When the Setup Type Selection window appears, select Standard to install all of the software components (this should normally

be selected). If you only wish to install certain components, select

Custom and then select the components that you wish to install.

Note: If you wish to select the folder where Sharpdesk is installed,

select Custom.

®

from the CD-ROM.)

®

/ Me® / 2000® / XP

®

provided through Windows

®

using the installer,

®

1 – 7

Page 10

AM-900U

• In Windows 2000/XP®, if a warning message appears at any time

regarding the Windows logo test or digital signature, be sure to

click Continue Anyway or Yes.

6) When the Finish window appears to indicate that the selected

packages have been installed, click Close.

7) If the installation was a Standard installation, the following window

will appear. Click OK.

9) The Search Setup Wizard will appear. Follow the on-screen instructions to create an index database for Sharpdesk.

10)Make sure that the power cord of the machine is not plugged in

(the machine is powered off), and then connect the USB cable.

• Insert one end of the USB cable into the USB port on the machine

and the other end into your computer’s USB port.

Note: Do not connect the AM-900 to a hub to which another AM900 is connected. If this is done, the AM-900 will not operate correctly.

• If you installed the MFP drivers using a Custom installation and

did not install Sharpdesk, the following window will appear. Click

OK and go to Step 10.

8) The following window will appear. Click Yes to restart your computer.

11)Plug in the power cord of the machine.

• Windows XP

the software.

• Windows 2000

Note: If a warning message regarding the Windows logo test

appears (the warning may appear twice), click Yes each time the

window appears. This will complete the installation of the software.

• Windows Me

ware.

Completing installation of the software on Windows XP®

(Continued from Steps 10 and 11.)

®

: Go to the procedure for completing installation of

®

: This completes the installation of the software.

®

/98SE®: This completes the installation of the soft-

1 – 8

Page 11

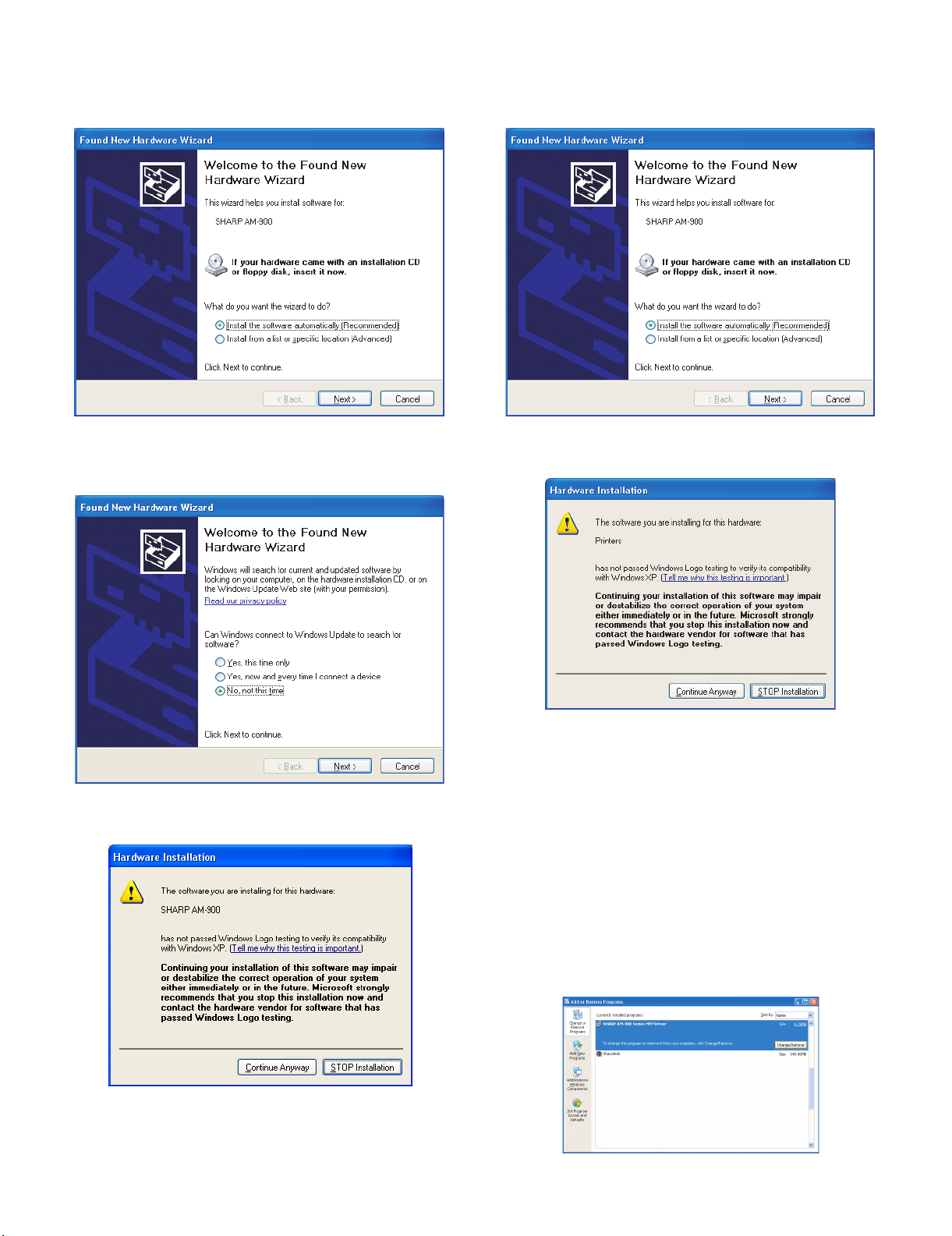

12)In Windows XP®, the Found New Hardware Wizard will appear.

Make sure that Install the software automatically (Recom-

mended) is selected and click Next (this will install software for

using the machine as a scanner).

AM-900U

14)After a brief interval, the Found New Hardware Wizard will appear

again to install software for using the machine as a printer. Make

sure that Install the software automatically (Recommended) is

selected and click Next.

• Note for Windows XP SP2

first. Select No, not this time and click Next. Continue from the

above window.

• If the following warning message appears regarding the Windows

logo test, click Continue Anyway.

®

: The following window will appear

• If the following warning appears regarding the Windows logo test,

click Continue Anyway.

15)When the wizard finishes installing the printer software, click Finish

to close the Wizard. This completes the installation of the software

on Windows XP

Sharpdesk online guide

For information on using Sharpdesk, view the Sharpdesk online

guide on the CD-ROM. To view the online guide, open the Manual

folder and then the EnglishA folder on the CD-ROM, and doubleclick SDUG_Enu.pdf.

Removing the software

In the event that you need to remove the software from your computer, open the Control Panel and select Add or Remove Pro-

grams (or Add/Remove Programs). Select SHARP AM-900

Series MFP Driver (or Sharpdesk) from the list, and click the

Change/Remove button (or the Add/Remove button). When

prompted to confirm the removal, click OK.

®

.

13)When the wizard finishes installing the scanner software, click Finish to close the wizard.

1 – 9

Page 12

AM-900U

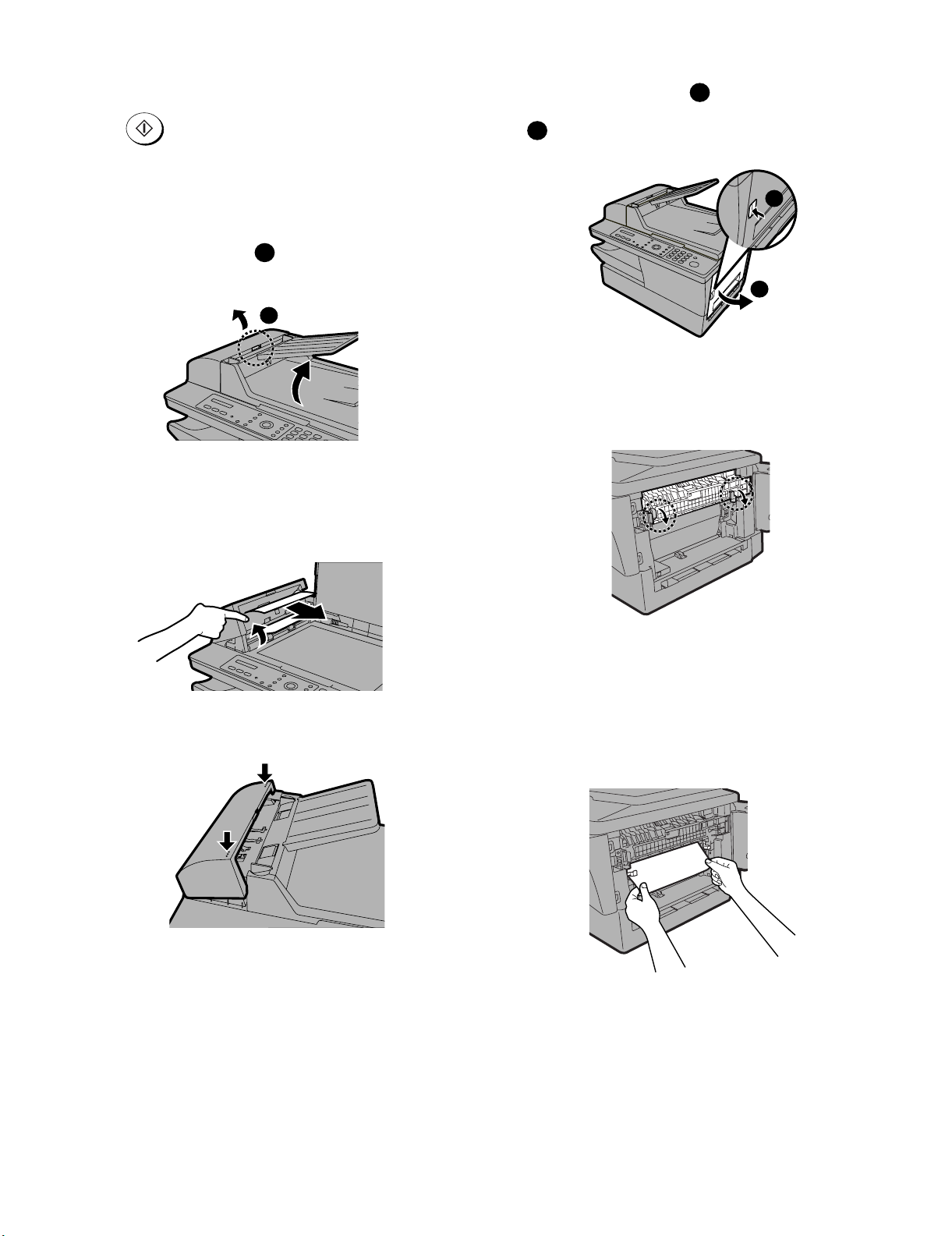

9. Clearing a jammed document

If the original document doesn’t feed properly during transmission or

copying, or DOCUMENT JAMMED appears in the display, first try

10. Clearing jammed printing paper

1) Press the side cover release and then open the side cover

1

pressing . If the document doesn’t feed out, open the auto

document feeder cover and remove it.

Important:

Do not try to remove a jammed without opening the auto document

feeder cover. This may damage the feeder mechanism.

1) Squeeze the cover release and open the auto document

feeder cover. Open the document glass cover.

2) Remove the document.

• The document can be removed from either the top or the bottom

slot, whichever is easiest.

1

1

2

.

1

2

2) Push the two heater roller release levers down to release the

heater roller.

• Caution! The fusing unit (indicated in white at right) becomes

very hot during operation. Do not touch the fusing unit.

3) Close the auto document feeder cover, pressing down on both

sides to make sure it clicks into place.

Press down

on the marks

3) If the jammed page is protruding from the side of the machine, gently pull it out. Take care not to tear the paper or leave any torn

pieces of paper in the print compartment.

• If this clears the jam, go to Step 5.

• If you are unable to clear the jam in this way, go to Step 4.

• Take care not to touch or allow other objects to contact the drum

(the green cylinder). This damage the drum.

1 – 10

Page 13

4) If the jammed page cannot be pulled out directly, open the front

AM-900U

cover and rotate the white knob in the direction

shown to feed the jammed page out into the output tray.

5) After the jammed page has been removed, push the two heater

roller release levers back up.

1

2

1

2

6) Close the front cover (if you opened it) and then the side

cover .

2

1

2

1

1 – 11

Page 14

AM-900U

11. Troubleshooting

1. Display

ADD PAPER Check the printing paper. If the tray is empty, add

BYPASS MISFEED The paper is not inserted correctly in the bypass tray.

BYPASS PAPER! /

IF COPY, PRESS

(alternating messages)

COVER OPEN One or both of the print compartment covers are

DATE/TIME UNSET The date and time need to be set. Note

DOCUMENT JAMMED The original document is jammed. See the following

DOCUMENT READY A document has been inser ted in the auto document

DRUM LIFE OVER This appears when the drum cartridge needs

paper. If there is paper in the tray, make sure it is

inserted correctly (take out the stack, align the edges

evenly, and then reinser t it in the tray). Pr inting will

resume automatically when the output tr ay is

replaced.

Remove the paper and insert it again.

Paper has been inserted in the bypass tray. If the

paper has been inser ted for a copy job, press to

set the paper size. If the paper is for a print job, the

message can be disregarded.

open. Make sure both covers are closed.

that the date and time settings will be lost if the

machine is unplugged or a power failure occurs.

section, Clearing Paper Jams. Document jams will

occurifyouloadmorethan20pagesatonceorload

documents that are too thick.

The document may also jam if the receiving machine

doesn’t respond properly when you attempt to send a

fax.

feeder and the machine is waiting for you to begin

faxing, copying, or scanning.

replacement.

SET BYPASS PAPER /

SIZE: XXXX

(alternating messages; a

paper size appears in

“XXXX”)

SYSTEM ERROR [XX]

(a number appears in

“XX”)

(Refer to Printer error code/

Scanner error code)

A

TONER EMPTY The toner car tridge must be replaced. Printing is not

TONER NEAR EMPTY The toner cartridge is almost out of toner

TOTAL PAGE(S) 01 Number of fax pages transmitted or received.

Paper must be inserted in the bypass tray for a print

job or copy job that requires use of the bypass tray.

Insert the indicated size of paper in the tray.

If this message appears, unplug the power cord, wait

about 10 seconds, and then plug it back in. If the

message still appears, unplug the power cord and call

SHARP’s Customer Assistance Center at at 1-877794-8675 (U.S.A. only).

possible until the toner cartridge is replaced.

(approximately 100 pages can be pr inted).

2. Audible signals

Continuous tone 3 seconds Indicates the end of transmission,

Intermittent tone

(3 beeps)

Rapid intermittent

tone

5 seconds

(1 second on, 1

second off)

35 seconds

(0.7 seconds on,

0.3 seconds off)

reception, or copying.

Indicates incomplete transmission,

reception, or copying.

Indicates that an extension phone

connected to the machine is off hook.

FAX RX IN MEMORY A fax has been received in memory because the

GRP. SPACE FULL This appears if you attempt to store a Group when

LINE ERROR Transmission or reception was not successful. Press

MEMORY IS FULL If faxes have been received to memory because

MEMORY PRINTING The machine is preparing to or printing out a

NO # STORED This appears if you attempt to search for a Speed Dial

OFF HOOK This appears when an extension phone connected to

OUTPUT TRAY OFF The output tray is not attached correctly. Attach it as

PAPER JAMMED The printing paper is jammed.

REMOVE /

BYPASS PAPER

(alternating messages)

toner cartridge needs replacement, you have run out

of printing paper, the paper is jammed, or paper is

inserted in the bypass tray. The fax will pr int out

automatically when the problem is fixed.

both Groups are already programmed.

the STOP key to clear the message and then tr y

again. If the error persists, see Line error.

printing is not possible (an additional message will

indicate the problem), resolve the problem so that

printing can continue (see Substitute Reception to

Memory)

If you are attempting to send a fax, see If the memory

becomes full.

If you are copying, see If MEMORY IS FULL appears.

document from memor y.

number when none have been stored.

the machine is lifted. Only can be pressed in

fax mode when this message appears.

explained. The machine will not operate if the output

tray is not attached correctly.

A fax has been received to memory because paper is

inserted in the bypass tray (faxes cannot be printed

while paper is in the bypass tray). Remove the paper

from the bypass tray to allow the fax to be printed.

3. Printer error code (Troubleshooting Refer to page 5-26 to 5-28)

SYSTEM ERROR [P1] The roller sensor could not detect its home position

SYSTEM ERROR [P2]

SYSTEM ERROR [P3]

SYSTEM ERROR [P4] ROM or RAM error was detected on the printer

SYSTEM ERROR [P5] High temperature error was detected.

SYSTEM ERROR [P6] Low temperature error was detected.

SYSTEM ERROR [P7]

after driving the pick up motor for the specified period.

The roller sensor could not become NOT-Active after

passing the specified period from picking up paper.

The printer controller detected the optical unit (LSU)

error.

The external interrupt signal for optical unit (LSU) or

High-voltage control did not become active after

passing the specified period.

Thermistor error was detected.

control unit.

Communication error between the main controller

and the printer controller was detected.

4. Scanner error code (Troubleshooting Refer to page 5-28)

SYSTEM ERROR [S1] The scanner unit could not detect change point of

home postion. (ON-> OFF or OFF->ON)

1 – 12

Page 15

12. Quick setup guide

AM-900U

For detailed instructions

IMPORTANT!!

Should you require

any assistance

setting up or

operating your

product, please

DO NOT RETURN

YOUR PRODUCT

TO THE STORE.

After referring to the setup

guide and operation

manual, if you still require

assistance please consult

our web page at http://

www.sharpusa.com. From

our web page you will be

able to directly e-mail our

customer support team.

If you would like personal

assistance, please call our

Customer Assistance

Center at 1-877-794-8675

(U.S.A. only).

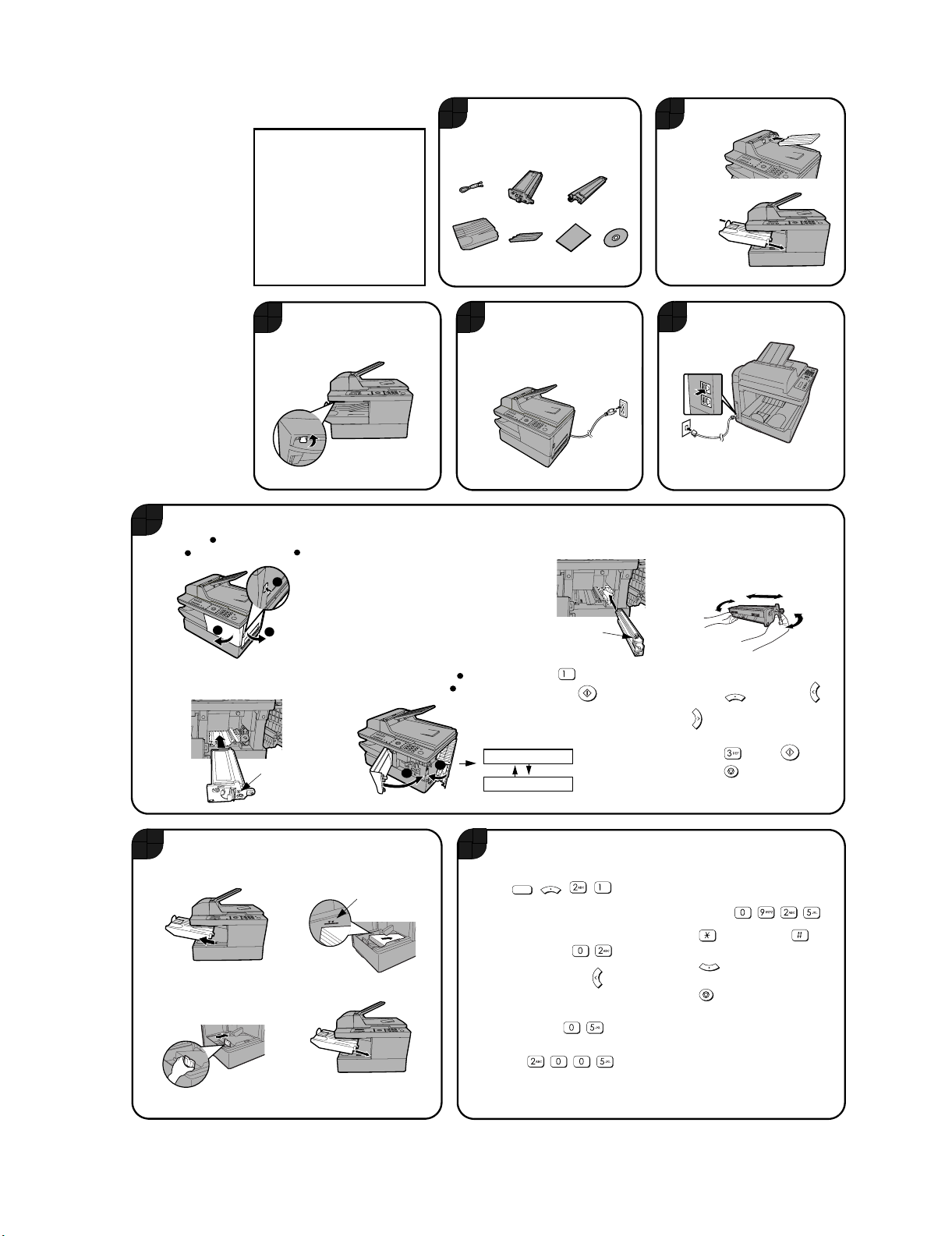

Install the toner cartridge and drum cartridge.

6

1

1. Press . Open the side cover

2

and then the front cover .

3

on setting up and using the AM-900,

see the online guide on the

CD-ROM.

To open the guide, double-click the

Manual folder on the CD-ROM,

double-click EnglishA, and then

double-click Online Manual.pdf.

(Note: Acrobat Reader 5.05 or higher

is required to view the manual.To

install Version 5.05, double-click

Acrobat Reader, English, and then

ar505eng.exe on the CD-ROM.)

3

1

2

Important:

Pull the scanner release toward

you to release the scanner lock.

2. Remove the drum car tridge from its

3

Caution!

Do not touch the fusing unit

under the side cover after the

machine has been in operation,

as it may become ver y hot.

packaging, and remove the tape from

the top of the car tridge.

Make sure you have the following

1

items. If any are missing, contact

your dealer or retailer.

Telephone

line cord

Output tray

Toner

cartridge

Document

feeder tray

Plug the power cord into a 120 V,

4

grounded AC (3-prong) outlet.

Caution: Be sure to release the

scanner lock (Step 3) before

plugging in the power cord.

3. Insert the drum cartridge,

Grasp this handle to

push the cartridge in

Drum

cartridge

Setup

CD-ROM

Guide

sliding it along the guides.

Attach the trays.

2

If you will be

loading legal

paper, pull the

extension out.

When the tray

stops, lift the end

slightly and push in.

Connect the phone line cord

5

to the TEL. LINE jack and a

wall jack.

TEL

.

LIN

E

T

E

L.

S

ET

Note: An extension phone can be

connected to the TEL. SET jack with

removing the seal covering the jack.

4. Remove the toner cartridge from its

packaging. Shake the car tr idge side

to side four or five times to distribute

the toner evenly within the

cartridge.

5. Insert the toner car tridge, sliding it along

the guides

until it clicks into place

Press on the arrow

mark to make sure

the car tridge clicks

into place

Load paper.

7

1. Remove the output tray.

3. Squeeze the sides of the paper

guide and slide it to the slot for

the length of paper loaded.

If you loaded legal paper, see the online guide

to change the paper size setting to LEGAL.

6. Close the front cover and

.

2. Insert a stack of paper

into the tray, print side up.

4. Replace the output tray.

thenthesidecover .

The stack should

not be higher

than this line

1

2

2

1

8

7. Press

then press . (This resets

the toner cartr idge counter.)

Display:

TONER EXCHANGED?

1=YES, 2=NO

Set the date and time that appear

in the fax mode display.

FAX

1. Press , , , .

• The currently set date and time appear

in the display.

2. Enter a 2-digit number for the month.

Example: February

• To clear a mistake press .

3. Enter a two-digit number for the day

("01" to "31").

Example: the 5th

4. Enter the year (four digits)

Example:

to select “YES” and

MENU

Z

8. Reset the drum car tridge counter:

MENU

a.Press

A

display.

b. Press and then .

c. Press repeatedly to exit.

5. Enter a two-digit number for the hour

and a two-digit number for the minute.

Example: 9:25

6. Press to select A.M. or to

select P.M.

7. Press .

ENTER

8. Press repeatedly to exit.

once and then or

until “LIFE” appears in the

Z

1 – 13

Page 16

AM-900U

Install the software on your computer. (The software

9

allows the machine to be used as a printer and scanner.)

1. Make sure that a USB cable is not connected

to the machine and your computer. (The cable

will be connected in Step 10.)

• If a cable is connected and a Plug and Pla y

window appears, close the window and

disconnect the cable.

2. Insert the Sharp CD-ROM into your computer’s

CD-ROM drive.

3. Windows XP

Computer, and double-click the CD-ROM icon.

Windows 98SE/Me/2000

Computer on the desktop and double-click the

CD-ROM icon.

R

: Click the start button, click My

R

: Double click My

4. Double-click the setup icon ( ) in the CD-

ROM window.

5. Follow the on-screen instructions.

• When the Setup Type Selection window

appears, select Standard to install all of the

software components (this should normally be

selected). If you only wish to install certain

components, select Custom and then select the

components that you wish to install.

Note: A USB 2.0 or 1.1 cable is required to connect the

machine to your computer. Please purchase this separately.

• If you installed the MFP drivers using a Custom

installation and did not install Sharpdesk, the

following window will appear. Click OK and go to

Step 10.

8.

The following wind ow will appear. Click Yes to restart

your computer.

9. The Search Setup Wizard will appear. Follow the

on-screen instructions to create an index

database for Sharpdesk.

10. Make sure that the machine’s power cord is not

plugged in, and then connect the USB cable to the

USB port on the machine and on your computer.

R

• Windows Me /98SE : This completes the

installation of the software.

Completing the installation on Windows XP

12. In Windows XP , the Found New Hardware

Wizard will appear. Make sure that Install the

software automatically (Recommended ) is

selected and click Next.

Note for Windows XP SP2

the wizard will ask you if the wizard can connect

to Windows Update. Select No, not this time and

click Next.

• If a warning message appears regarding the

Windows logo test, click Continue Anyway.

13.

When the wizard finishes installing the software, click

Finish to close the wizard.

14. After a brief interval, the Found New Hardware

Wizard will appear again. Make sure that Install

the software automatically (Recommended) is

selected and click Next.

R

R

R

R

: The first window of

• In Windows 2000/XP , if a warning message

appears at any time regarding the Windows logo

test or digital signature, be sure to click Continue

Anyway or Yes .

6. When the Finish window appears to indicate that

the selected packages have been installed, click

Close.

7.

If the installation was a Standard Finstallation, the

following wind ow will appear. Click OK.

Link each scan menu that you wish to use in

10

scan mode to a program on your computer.

Windows XP /Me

1. Windows XP : Click the start button, Control

Panel, Printers and Other Hardware, and

Scanners and Cameras.

Windows Me

Settings, select Control Panel, and double-click

Scanners and Cameras.(IfScanners and

Cameras does not appear, click view all

Control Panel options).

2. Right-click the SHARP AM-900 icon and select

Properties.

3. The SHARP AM-900 Properties appear. Click

on the Events tab.

4. Select SC1 (scan menu SC1) from the Select an

event list.

5. In the Actions field, select Start this program

and then select the program that you wish to link

to scan menu SC1 from the list of programs.

R

R

R

R

R

: Click the Start button, point to

11. Plug in the machine’s power cord.

• Windows XP : Follow Steps 12 through 15 to

complete the installation of the software.

• Windows 2000 : This completes the installation

of the software.

Note: If a warning message regarding the

Windows logo test appears (the warn ing may

appear twice), click Ye s each time the window

appears. This will complete the installation of the

software.

R

R

You can scan directly from the machine by selecting scan mode and then one of scan menus

SC1 to SC6 on the operation panel. When this is done, the program linked to the selected scan

menu will automatically start on your computer and the image will be scanned to the program.

• If a warning message appears regarding the

Windows logo test, click Continue Anyway.

15. When the wizard finishes installing the software,

click Finish to close the wizard. This completes

the installation of the software on Windows XP

Windows 2000 /98SE

• Microsoft Scanner and Camera Wizard is

selected as an example in the window below.

1. Click the Start button, point to Settings, and

select Control Panel.

2. In the Control Panel, double-click Scanners and

Cameras.

3. Select SHARP AM-900 and click Properties.

4. Click the Events tab in the SHARP AM-900

Properties.

5. Select SC1 (scan menu SC1) from the Scanner

events list.

6. Click the Apply button.

7. Repeat Steps 4 through 6 as needed for any of

the other scan menus (SC2 to SC6) that you

wish to use. When finished, click the OK button.

6. In Send to this application, select the program

(only one) that you wish to link to scan menu SC1.

7. Click the Apply but ton.

8. Repeat Steps 5 through 7 for any of the other

scan menus (SC2 to SC6) that you wish to use.

When finished, click the OK button.

R

.

R

R

1 – 14

Page 17

FAXAM-900UService ManualService ManualMarketE

CHAPTER 2. ADJUSTMENTS

[1] Adjustments

1. General

Since the following adjustments and settings are provided for this

model, make adjustments and/or setup as necessary.

2. Adjustments of output voltage (FACTORY ONLY)

1. Install the power supply unit in the machine.

2. Set the recording paper and document.

3. When the document is loaded, power is supplied to the output

lines. Confirm that outputs are within the limits below.

2.1. Output voltage settings

AM-900U

CNLSR

CNPM

CNHV

CNMM

CNPUM

CNTCT

CNFM

CNROLSNS

CNTCVR

CNBYPE

CNPIN

CNPW

1

FUSING UNIT

CNRTH

CNOUT1

CNOUT2

CONTROL PWB

(TOP SIDE)

14

CNHT

3

1

THERMAL

FUSE-2

CNSCM

CNCIS

CNLIU

CN6

1

1

1

2

CN2

POWER SUPPLY

PWB (TOP SIDE)

INTERLOCK

SWITCH

CNPN

CNFRT

CNORG

CNHPS

CNSP

CNUSB

3

CNPW

14

Output Voltage limits

+24VSUB 23.04V~24.96V

+24VMAIN 23.04V~24.96V

+5VMAIN 4.75V~5.25V

+3.3VMAIN 3.201V~3.399V

Connector CNPW

Pin No.

1

2

3

4

5 +24VMAIN

6 +24VMAIN

7DG

8

9

10

11

12

13

14

Connector

Pin No.

1

2

3

Connector

Pin No.

1

2

3

Connector

Pin No.

1

2

CNPW

MG

+24VSUB

MG

MG

+5VMAIN

DG

+3.3VMAIN

DG

/HEATER ON

/PWRLY

/ZC

CN6

+24VMAIN

N.C.

+24VS

CNHT

N

N.C.

L

CN2

1

2

2 – 1

Page 18

AM-900U

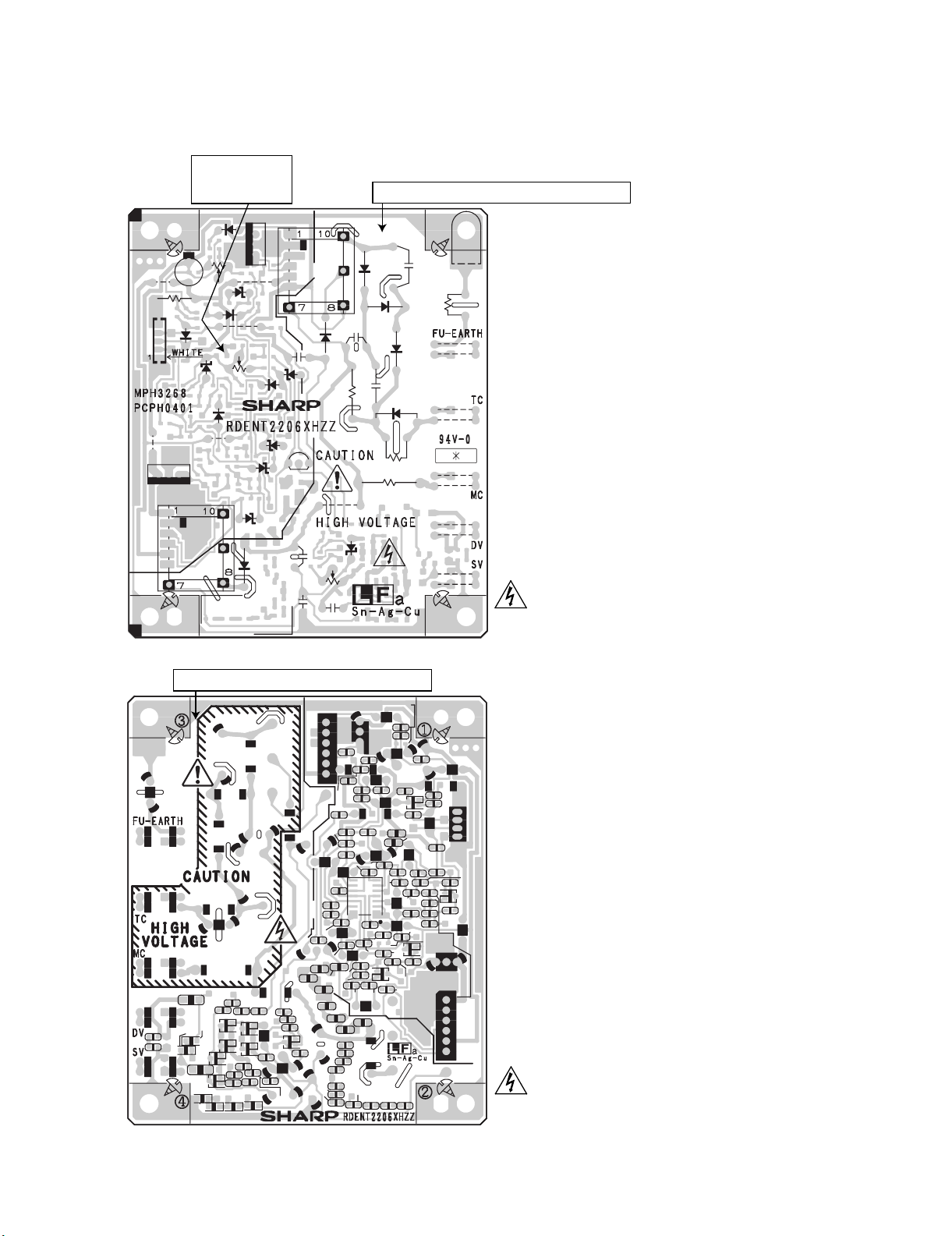

3. High voltage power check

3.1. General

Note: Since the parts of this PWB cannot be supplied, change it as a unit.

CAUTION

DO NOT TOUCH!

CN1

CN3

(VR51)

Q3

D3

D10

J1

QJ005

VR1

D58

J6

D2

D8

J3

VR51

D1

D61

D62

D60

D52

D54

C1

J5

R1

J2

Q52

B51

QJ071

C9

Q38

B1

D9

D53

J4

C56

VR31

C65

C31

CAUTION HIGH VOLTAGE AREA MAX. 4000V

D4

C6

CN4

R93

D5

C5

J52

J51

R15

C7

D7

R16

R67

D31

J12

J11

J22

J21

J42

J41

J32

J31

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by

anyone other than a qualified serviceperson.

There are many high voltage parts inside the unit,

and touching them is dangerous.

CAUTION HIGH VOLTAGE AREA MAX. 4000V

R10

R3

R9

R8

R3

C2

R44

R65

R66

R59

R94

R5

R98

R6

C55

R60

C52

R43

R74

R73

R103

R80

R79

R81

Q34

D42

R42

D41

R102

D59

Q33

Q32

Q31

D57 D56 D55

Q35

R32 R31

R41

R78

Q36

C32

R36

R34

R33 R35

R72

R71

R40

R70

R39

R38

Q37

R37

R86

IC1

C8

R92

R61

C53

R58

R75

R101

R69

R46

R76

R77

R83

R84

R85

R87

R88 R89 R90

C4

R13

R14

R7

R91

C54

R66

R11

R4

R18

R14

R47

Q51

R3

Q1

R19

R63

R53

R100

CN1

C61

R51

Q57

R54

R52

C62

R55

C51

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by

anyone other than a qualified serviceperson.

There are many high voltage parts inside the unit,

and touching them is dangerous.

R2

R17

R57

R56

R99

C66

R48

Q58

R62

R50

R49

R64

2 – 2

Page 19

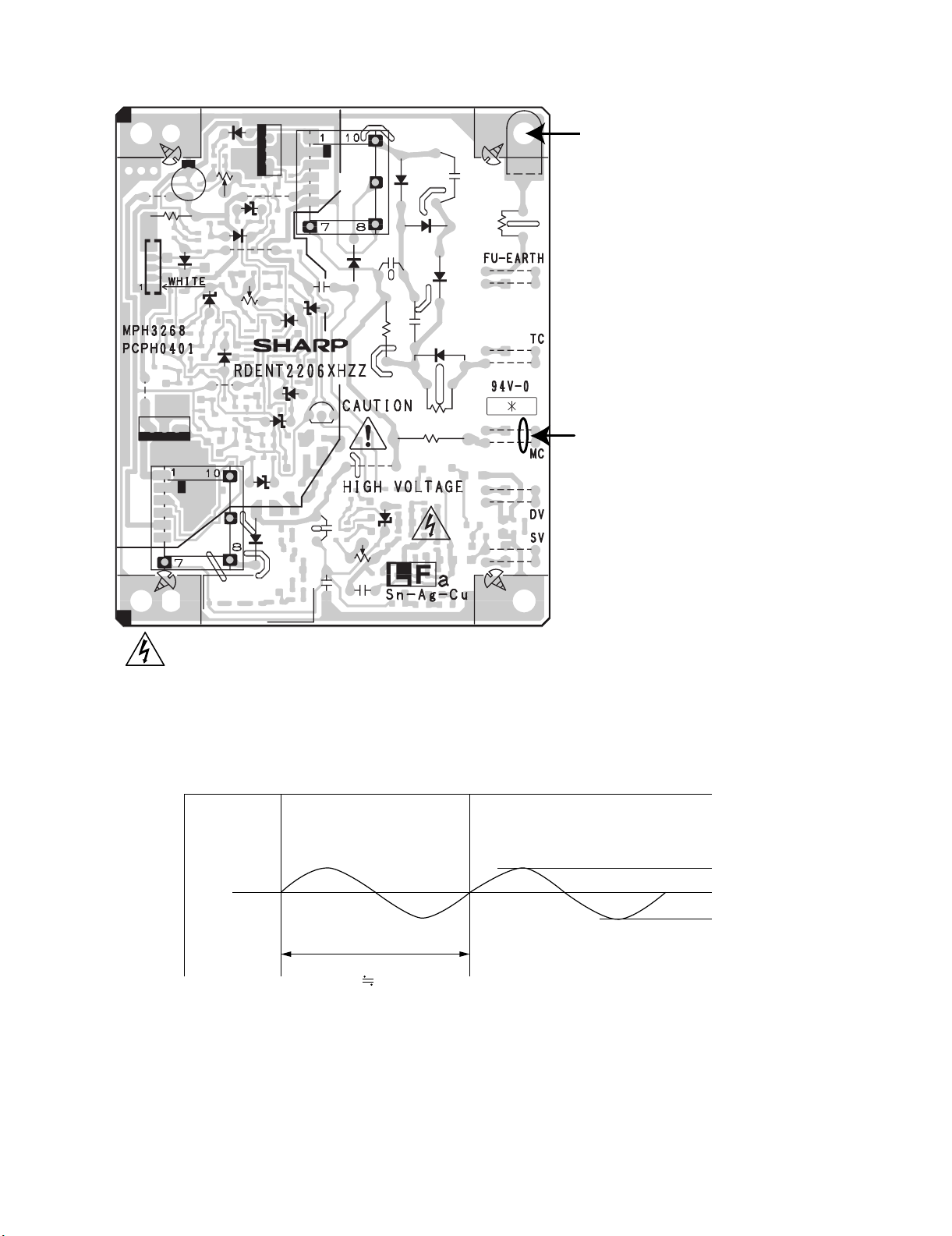

3.2. MC Voltage Check Point

D3

CN3

CN1

C1

J5

R1

J2

Q52

VR1

D8

D10

VR51

D1

D58

J1

QJ005

B51

J3

D60

D52

AM-900U

Q3

J6

D2

D61

D62

D54

QJ071

C9

Q38

C65

D53

B1

GND (-)

D4

C6

D5

VR31

R15

C5

C7

D7

R16

R67

D31

D9

J4

C56

J52

J11

J41

J51

J12

J22

J21

J42

J32

J31

CN4

R93

MC Voltage Check Point (-)

(There is danger of an electric shock!)

Use Measuring instrument:

Input Resistance : more than 100 MΩ

Maximum Voltage : more than 2 kV

VOLTAGE

MC:-950V±20V(PRINTING)

MC:-850V±20V(CLEANING)

C31

1) MC Voltage

Voltage(v)

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by anyone other than

a qualified serviceperson. There are many high voltage parts inside

the unit, and touching them is dangerous.

300Hz

Time(s)

Type

-570V

-950V

-1330V

Tolerance

± 67V

± 20V

± 67V

2 – 3

Page 20

AM-900U

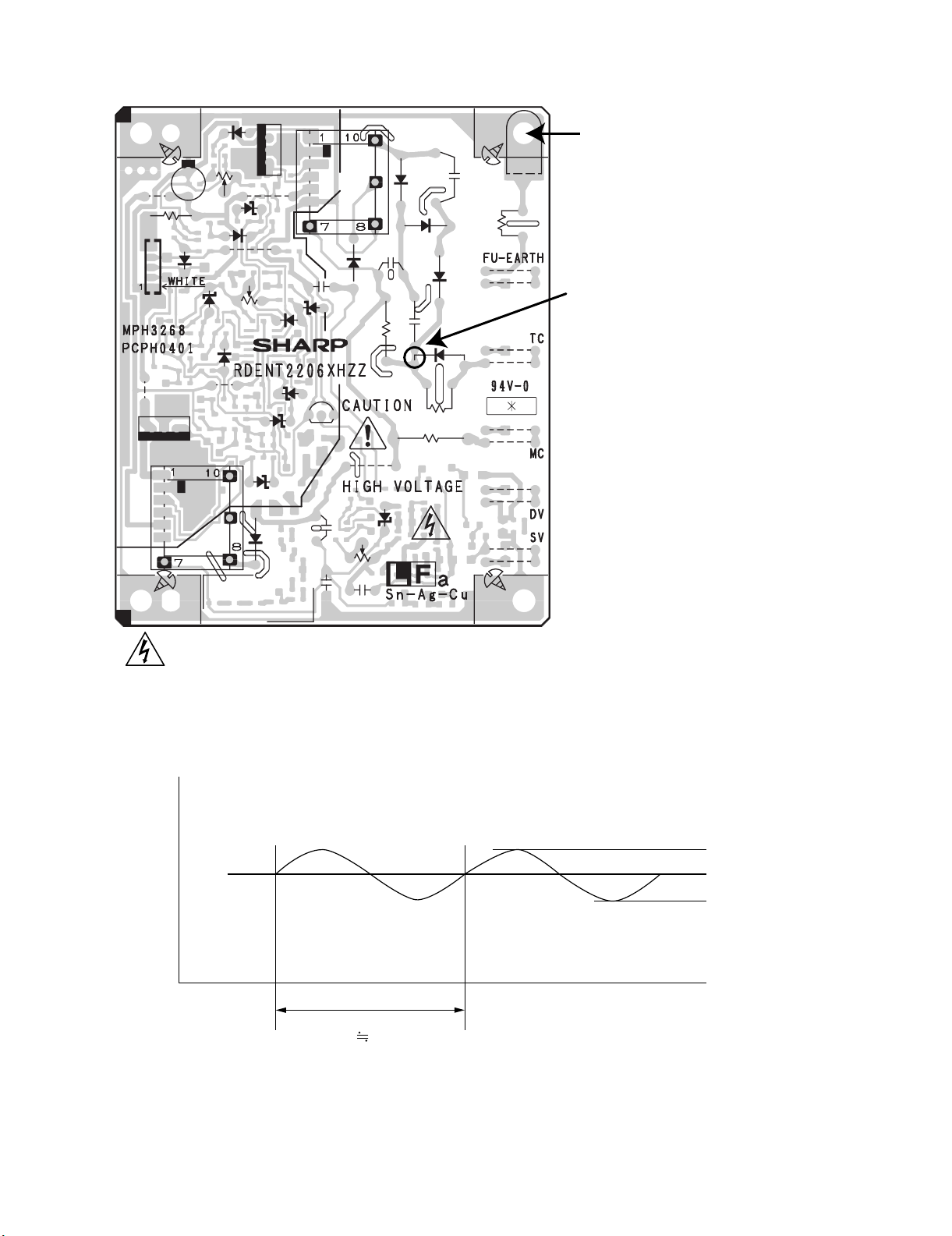

3.3. TC Voltage Check Point

D3

CN3

CN1

C1

J5

R1

J2

Q52

VR1

D8

D10

D1

D58

J1

QJ005

B51

VR51

J3

D60

D52

D2

Q3

J6

D62

D54

D61

QJ071

C9

Q38

D53

D9

C56

B1

GND (-)

D4

R15

C6

D5

C5

C7

D7

J52

J11

J51

J12

CN4

R93

TC Voltage Check Point (+)

(There is danger of an electric shock!)

Use High Voltage Tester:

Requirement of Measuring instrument:

Input Resistance : more than 100 MΩ

Maximum Voltage : more than 5 kV

R16

J22

R67

J4

D31

VR31

J21

J42

J41

J32

J31

VOLTAGE

TC(+):+3600V±72V(PRINTING)

TC(-):-500V±50V(CLEANING)

1) TC Voltage

Voltage(v)

C65

C31

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by anyone other than

a qualified serviceperson. There are many high voltage parts inside

the unit, and touching them is dangerous.

300Hz

Type

-3980V

-3600V

-3220V

Time(s)

Tolerance

± 72V

2 – 4

Page 21

3.4. SV/DV Voltage Check Point and SV (-) Voltage Adjustment Volume

Q3

CN3

CN1

D3

VR1

C1

J5

R1

D10

D1

D58

J1

J2

Q52

J6

D2

D8

J3

VR51

D60

C9

D61

D62

D52

QJ005

B51

D54

CAUTION - HIGH VOLTAGE

The unit's back cover should never be opened by anyone other than

a qualified serviceperson. There are many high voltage parts inside

the unit, and touching them is dangerous.

QJ071

D9

D53

Q38

J4

C56

C65

B1

VR31

C31

R15

D31

D4

C6

R93

D5

C5

J52

J51

C7

D7

R16

R67

J12

J11

J22

J21

J42

J41

J32

J31

AM-900U

GND (-)

CN4

DV Voltage Check Point (+)

VOLTAGE

DV(+):+300V±5V(CLEANING)

DV(-):-220V±5V(PRINTING)

SV Voltage Check Point (+)

VOLTAGE

SV(+):+400V±15V(CLEANING)

SV(-):-320V±15V(PRINTING)

DV (-) Voltage adjustment Volume

VR31

It can be made to change with VR31.

In the range of ± 50V.

DV(-):-220V±50V(PRINTING)

2 – 5

Page 22

AM-900U

4. IC protectors replacement

ICPs (IC Protectors) are installed to protect the CIS unit, LIU PWB

unit, Scanner motor drive circuit, Pickup motor drive circuit, Main

motor drive circuit and IC22 circuit. ICPs protect various ICs and electronic circuits from an overcurrent condition.

The location of ICPs are shown below:

5. Settings

5.1. Dial mode selector

DIAL mode (Soft Switch No. SW5 Data No. 5)

Use this to set the fax machine to the type of telephone line you are

on.

• The factory setting is “TONE”.

CNHV

CNLSR

F5

CNPM

F7

CNRTH

CNOUT2

CNOUT1

CNCIS

F8

CNSCM

F3

CNPN

CNFRT

CNORG

CNHPS

CNSP

CONTROL PWB

CNMM

CNPUM

F6

CNTCT

CNFM

CNROLSNS

CNTCVR

CNBYPE

CNPIN

F6/F8:Top side F3/F4/F5/F7:Bottom side

1) F8 (KAB5002 201) is installed in order to protect IC’s from an

overcurrent generated in the CIS unit. If F8 is open, replace it with a

new one.

2) F4 (KAB5002 251) is installed in order to protect IC’s from an

overcurrent generated in the LIU PWB unit. If F4 is open, replace it

with a new one.

3) F3 (KAB3202 202) is installed in order to protect IC’s from an

overcurrent generated in the scanner motor drive circuit. If F3 is

open, replace it with a new one.

4) F5 (KAB5002 251) is installed in order to protect IC’s from an

overcurrent generated in the IC22 circuit. If F5 is open, replace it

with a new one.

5) F6 (KAB3202 102) is installed in order to protect IC’s from an

overcurrent generated in the pickup motor drive circuit. If F6 is

open, replace it with a new one.

6) F7 (KAB2402 402) is installed in order to protect IC’s from an

overcurrent generated in the main motor drive circuit. If F7 is open,

replace it with a new one.

In addition to the replacement of F3, F4, F5, F6, F7 and F8, the factor causing F3, F4, F5, F6, F7 and F8 to open must also be

repaired. If not, F3, F4, F5, F6, F7 and F8 will open again.

Replacement parts

KAB3202 202 (Sharp code: QFS-L1027YCZZ)

KAB5002 251 (Sharp code: QFS-L2021XHZZ)

KAB3202 102 (Sharp code: QFS-L0004QCZZ)

KAB2402 402 (Sharp code: QFS-L2025XHZZ)

KAB5002 201 (Sharp code: QFS-L2016XHZZ)

(TOP SIDE)

CNPW

CNUSB

F4

CNIU

(step 1) Select "OPTIONAL SETTING".

KEY:

DISPLAY:

(step 2) Select "DIAL MODE".

(step 2) Select "DIAL MODE".

KEY:

KEY: ,

DISPLAY:

DISPLAY:

2

FAX

FAX SETTING

4

1=TONE

MENU

("2=PULSE" is displayed in the

autoscroll mode.)

(step 3) Select, using "1" or "2".

KEY: for TONE

KEY: for PULSE

1

2

(step 4) End, using the "STOP" key.

(Press the "STOP" key three times.)

KEY:

2 – 6

Page 23

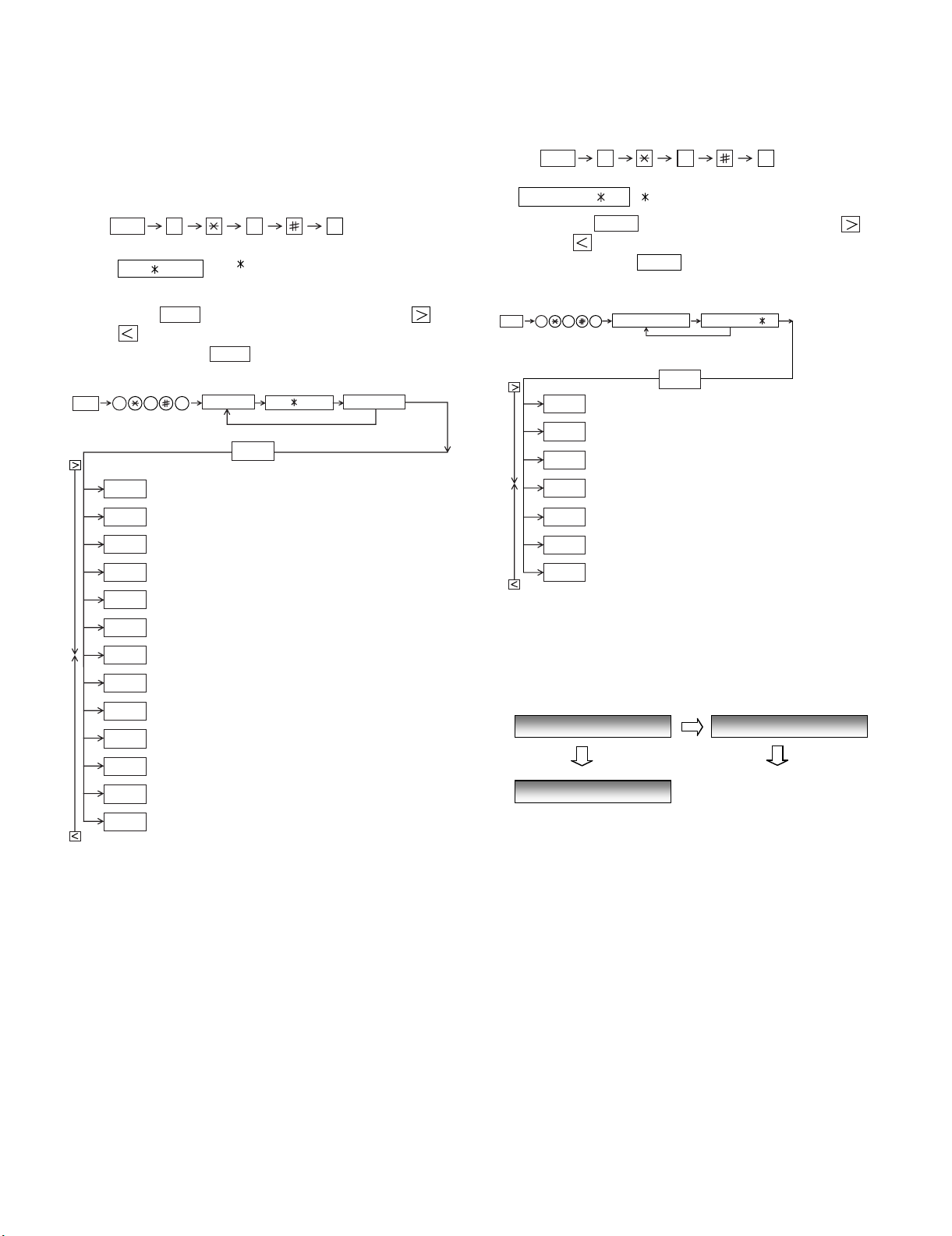

[2] Diagnostics and service soft switches

Press

, and

the

following

display will appear.

MENU

9 8

6

M/C Ver:TE53

(Diag•specifications)

MENU

9 8 6

ENTER SINGLE PRINT

ENTER CONTINUOUS PRINT

ENTER

COPY AGING

ENTER

LIFE MODE

ENTER

TOP VOID ADJUST

ENTER

PRINT ADJUST

ENTER

TEST MODE

START

START

ENTER

Then press the

key. Select the desired item with the

key and the key or select with the rapid key.

Enter the mode with the key.

PRINT DIAG MODE

: PRINTER ROM version

M/C Ver:TE53

(The alternate display of two screens.)

MEMORY CLEAR

1:CLEAR

[1]Key

[2]Key

Stand-by display

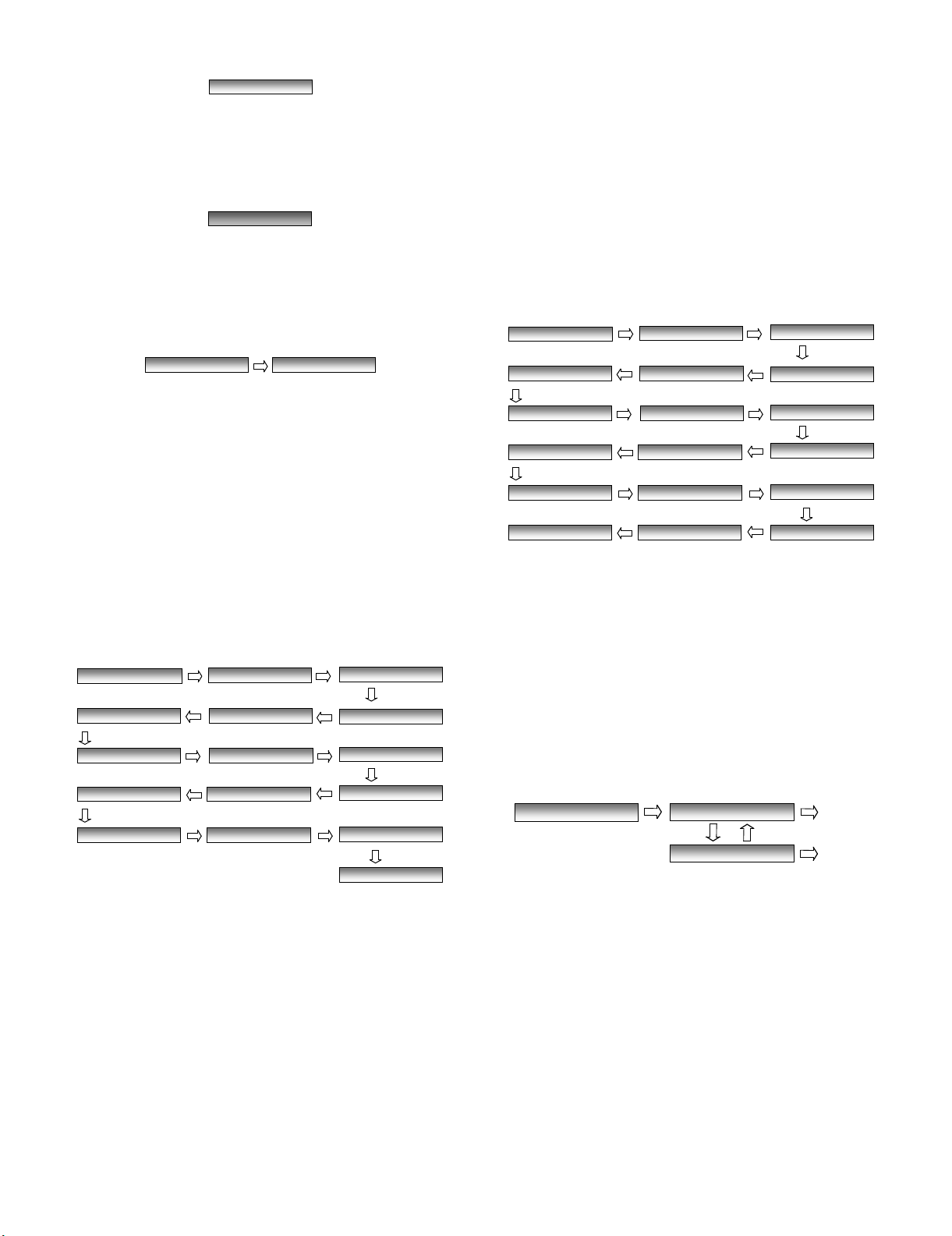

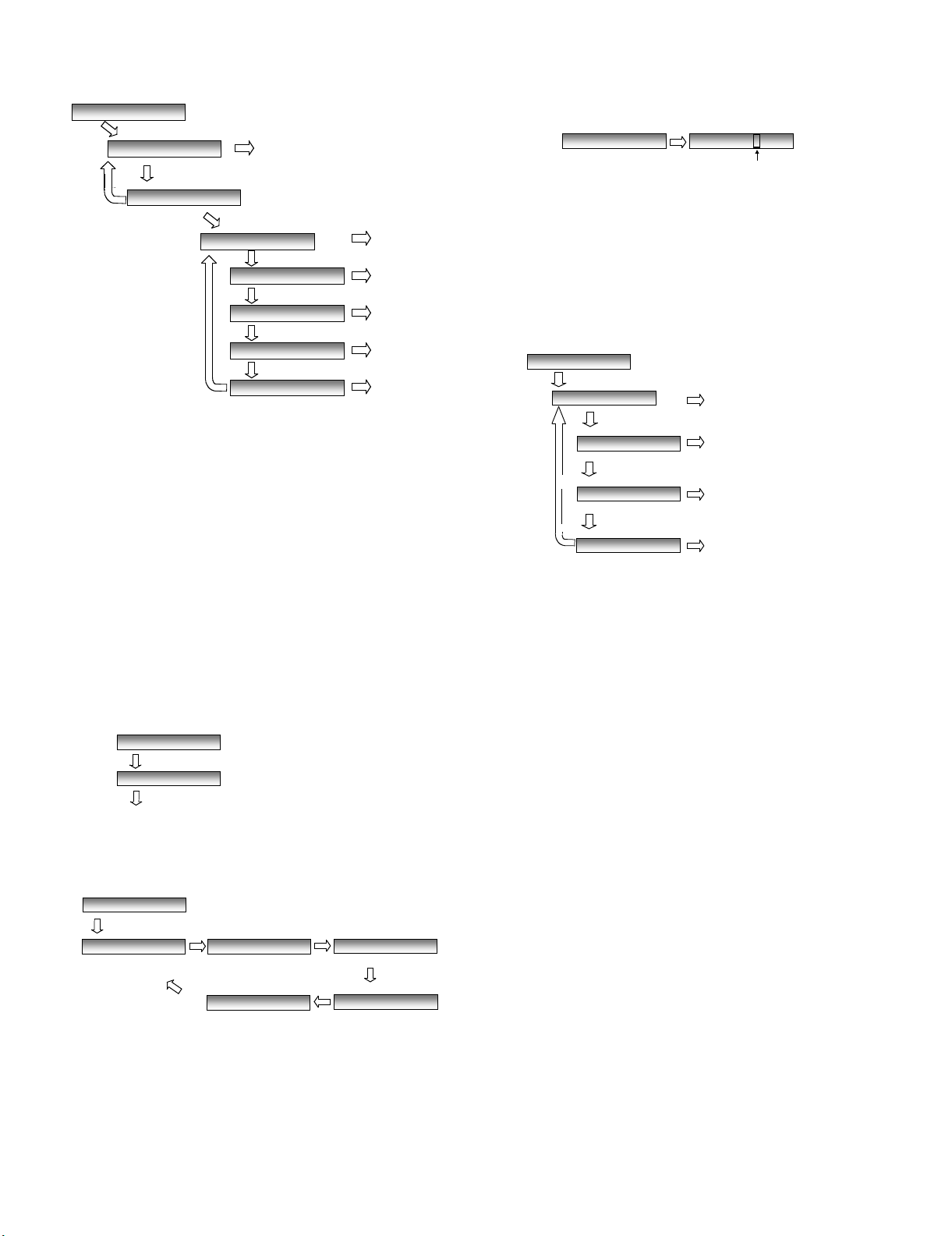

1. Entering the diagnostic mode

1.1. Fax diagnosis

This diagnosis is concerned with the main body of fax which is used

for production and service support.

Entering the diagnostic mode

AM-900U

1.2. Print diagnosis

This diagnosis is concerned with the print which is used for production

and service support.

Entering the diagnostic mode

Press

MENU

9 8

display will appear.

TC84 / x x x x

Then press the

START

: FAX ROM version

x x x x : Check sum

key. Select the desired item with the

and the key or select with the rapid key.

ENTER

Enter the mode with the

(Diag

•

specifications)

9 8 7

MENU

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

SOFT SWITCH MODE

ROM & RAM CHECK

PANEL CHECK MODE

CHECK PATTERN MODE

SIGNAL SEND MODE 1

SIGNAL SEND MODE 2

MEMORY CLEAR

CIS ADJUSTING MODE

DIAL TEST MODE

DIAG MODE U.S.A./Canada

key.

TC84 / x x x x

(The alternate display of three screens.)

START

7

,and

the

following

key

Memory clear when power is turned on

Pressing the START and STOP keys, turn on the main power, and the

following message will be indicated.

ENTER

ENTER

ENTER

ENTER

AUTO FEEDER MODE

FLASH MEMORY TEST

GEAR CHANGE MODE

FLATBED AGING

MEMORY CLEARING

When 1 is selected, the memory will be cleared to be ready to operation.

If 2 is selected, memory will not be cleared and the machine enters

standby mode.

2 – 7

Page 24

AM-900U

ROM & RAM CHECK

ROM = RAM=

Start checking

by pressing [EN TER] key

ROM=OK,RAM=OK

PRINTING

ALL KEY OK !!

2. Diagnostic items description

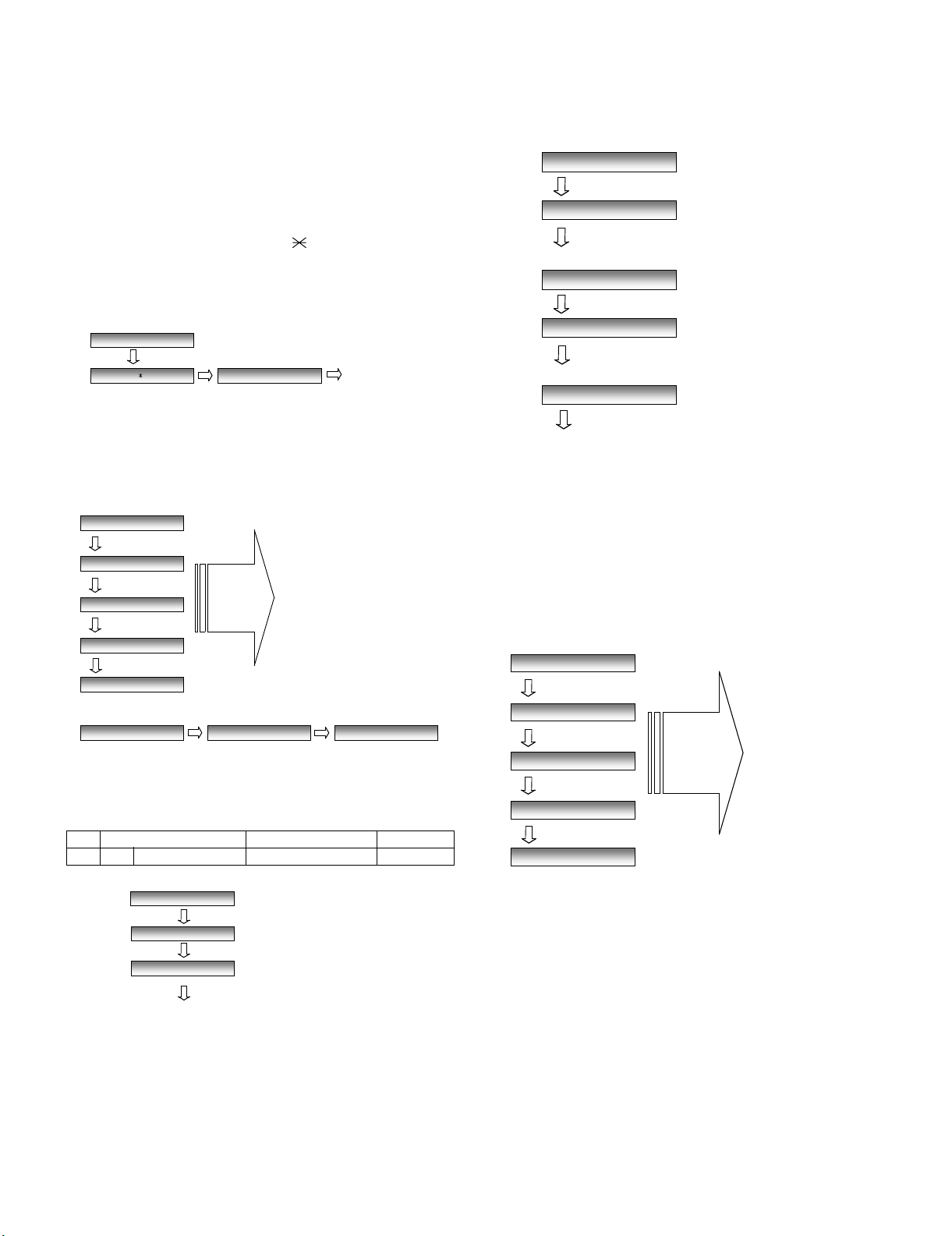

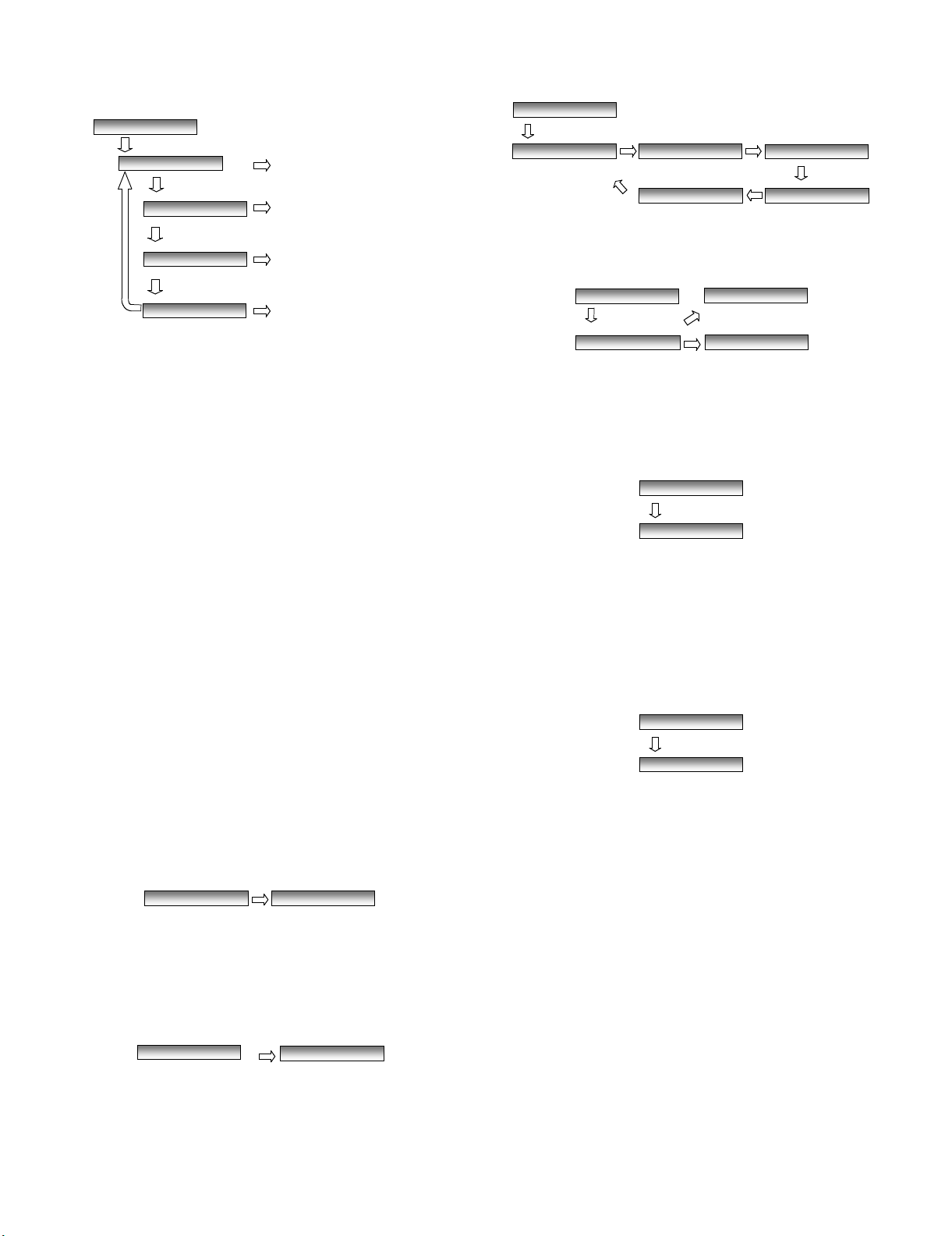

2.1. Fax diagnosis

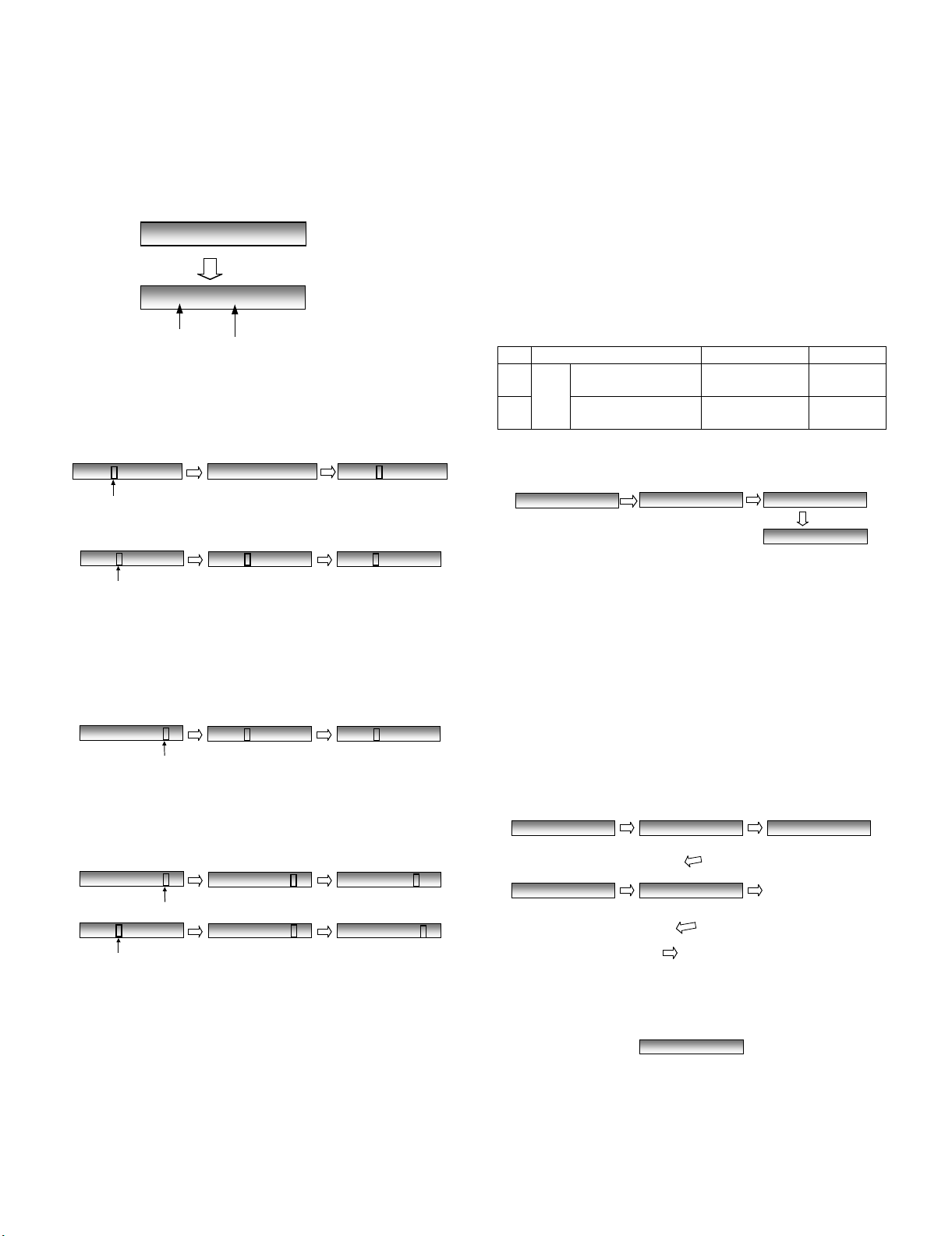

2.1.1 Soft switch mode

In this mode, the soft switches are set and the soft switch list is printed.

1. Operation

Soft switch mode screen

SOFTSWITCH MODE

[ENTER] Key

SW01=01010010

Switch No.

2. Switch number selection and data setting

1) Enter two digits of a soft switch number to set the switch num-

ber. Of a switch number of non-existing soft switch is entered,

key error buzzer sounds to reject the input.

SW01=01010010

cursor position

2) Press [ENTER] key for setting of the next soft switch.

12345678:DataNo.

SW01 =

[1]key

SW16=01010010

[ 6 ] key

5. Storage of data

In the following cases, the data if the soft switches set will be

stored.

• It is shifted to set the next soft switch by pressing [ENTER] key.

• It is shifted to set the next soft switch with the [>] key.

• It is shifted to the last soft switch with the [<] key.

• It is shifted to set another soft switch by inputting two digits as

the switch number.

• Output of the soft switch list starts.

6. Protocol monitor

If the SW No. 8 Data No. 5 is set to 1, the protocol monitor result is

printed after fax communication.

2.1.2 ROM & RAM check

To check the sum value of Firmware or RAM.

No. Device Alarm Buzzer Remarks

1

2 D-RAM1(*1) 2 times <Short

*1 WORK MEMORY (SDRAM 16M).

1. Display

ROM

(PROGRAM FLASH)

Main

1 time <Short

sound>

sounds>

SW01=01010010

cursor position

[ENTER]Key

SW02=01001100

SW03=01001100

[ENTER]Key

3) Data number selection

(a) Pressing [>] key moves the cursor to the right.

If the cursor is on data number 8, pressing [>] key shifts the cursor to data number 1 of the next switch number. If the switch

number is the final, pressing [>] key will exit the soft switch

mode.

SW01=01010010

cursor position

SW02=01001100

[>]Key

SW03=01001100

with the cursor on bit8

[>]Key

(b) Pressing [<] key moves the cursor to the left.

If the cursor is on data number 1, pressing [<] key shifts the cursor to data number 1 of the former switch number. If the switch

number is 1, pressing [<] key do not move the cursor.

SW03 = 01010010

cursor p ositio n

SW03 = 0 1001100

cursor p ositio n

SW03=01001100

[<]Key

SW02=01001100

[<]Key

SW03=01001100

[<]Key

SW01=01001100

with the cursor on bit 1

[<]Key

3. Data setting

Press the [MENU] key, and the data to the position of the cursor will

be reversed to 1 when it is 0, or to 0 when it is 1.

4. Outputting method of soft switch list

In the soft switch mode, press [QUALITY] key, and the soft switch

list will be printed. If the recording paper runs out or is clogged, the

key error buzzer will sound with the process not received.

2. Result printing

After checking, the results print starts.

2.1.3 Panel key test

This is used to check whether each key is normally operated or not.

When the test is started, a LED will blink (1000ms cycle) for the LED

test. During the test. After the test, the test result will be printed.

* When any numeric key is pressed during the panel test, the DTMF

signal correspond to the key number is sent to the line. If another key

is pressed the DTMF signal will stop. This function becomes valid by

changing the value of soft switch. (Default: Disable)

1) Flow

Press any key except [STOP] key. At this time, the name of each

key will be displayed every push of the key.

PANEL CHECK MODE

1

To finish this mode, press [STOP] k ey

PRESS EACH KEY

[ENTER] key

START

[START ]Key

Go to (a or b).

a) When all keys can be inputted, the following message will be displayed.

Then the screen will be all displayed in blank (Refer to (2)) and the

test result will be printed.

1

[1]Key

..... (other key)

2 – 8

Page 25

b) If any key skipped, the following message will be displayed.

SIGNAL SEND2

CML ON

[ENTER]Key

V.34 33600bps

V.34 26400bps V.34 28800bps

[ENTER]Key

V.34 31200bps

V.34 24000bps V.34 21600bps

[ENTER]Key

V.34 19200bps

V.34 12000bps V.34 14400bps

[ENTER]Key

V.34 16800bps

V.34 9600bps

V.34 7200bps

[ENTER]Key

V.34 4800bps

V.34 2400bps

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

ANSam V.21 0 - 300bps

[ENTER]Key

[ENTER]Key

CIS ADJUST

[ENTER]Key

The motor will move to the specified position and the reading lamp is lit on.

1: COLOR

1 key

2: MONO

2 key

KEY ERROR !!

A key name that is not pressed yet is displayed so that this test can

be continued.

At that time, pressing the [STOP] key will exit this mode. And the

result will be printed.

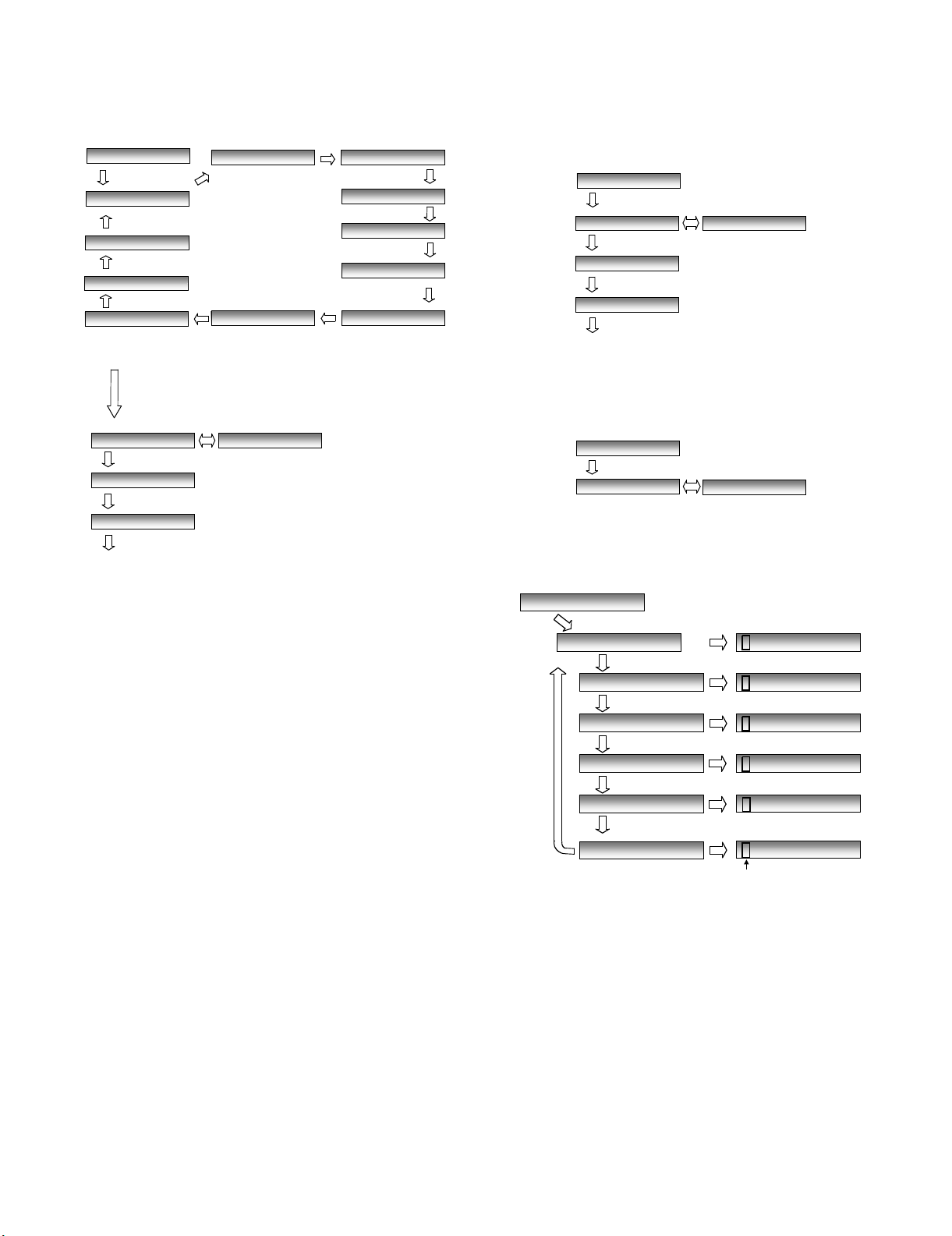

2) Black screen

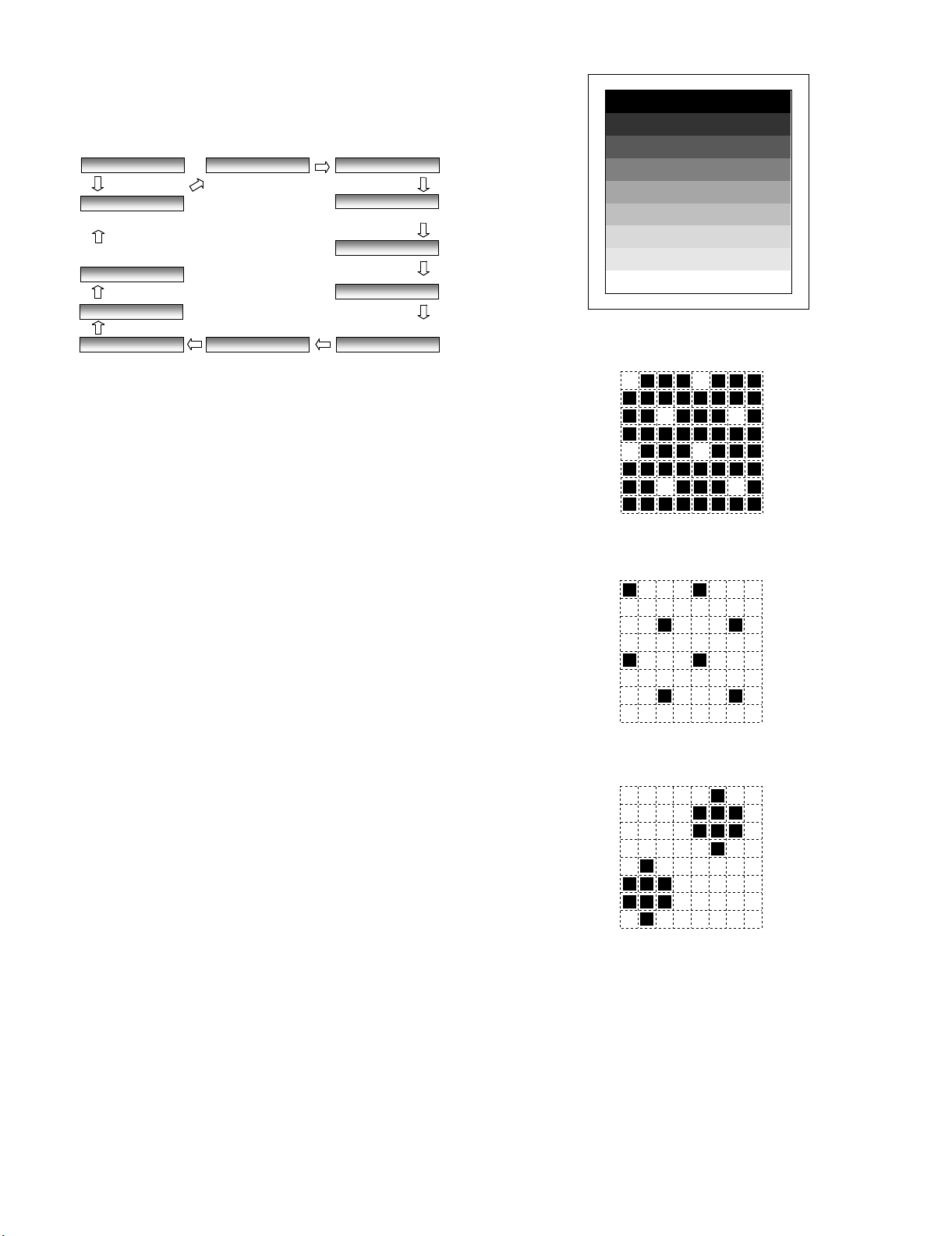

2.1.4 Check pattern mode

The effective printing area frame is printed in the specified sheet size

of the standard tray (Letter/Legal/A4).

1. Printing the pattern

Printing size depends on Paper Size setting in Common Setting.

AM-900U

2.1.6 Signal send mode 2

The specified signals about V.34 and V.8 mode transmitted in the following sequence to check the modem.

1. Press the [ENTER] key, and no signals with the loop state starts.

[ 1] No signals (making the loop) [ 9] 16800bps (V.34)

[ 2] 33600bps (V.34bis) [10] 14400bps (V.34)

[ 3] 31200bps (V.34bis) [11] 12000bps (V.34)

[ 4] 28800bps (V.34) [12] 9600bps (V.34)

[ 5] 26400bps (V.34) [13] 7200bps (V.34)

[ 6] 24000bps (V.34) [14] 4800bps (V.34)

[ 7] 21600bps (V.34) [15] 2400bps (V.34)

[ 8] 19200bps (V.34) [16] 0-300bps (V. 21)

[17] ANSam

CHECKP ATTERN

[ENTER]Key

NOW AGING

2.1.5 Signal send mode 1

The specified signals are transmitted in the following sequence to

check the modem.

1. Press the [ENTER] key, and no signals with the loop state starts.

[ 1] No signals (making the loop) [ 9] 9600bps (V.29)

[ 2] 4800bps (V.27ter) [10] 7200bps (V.29)

[ 3] 14400bps (V.33) [11] 4800bps (V.27ter)

[ 4] 12000bps (V.33) [12] 2400bps (V.27ter)

[ 5] 14400bps (V.17) [13] 300Hz (FLAG)

[ 6] 12000bps (V.17) [14] 2100Hz (CED)

[ 7] 9600bps (V.17) [15] 1100Hz (CNG)

[ 8] 7200bps (V.17)

SIGNAL SEND1

V.17 14400bps V.33 12000bps

[ENTER]Key

V.17 12000bps V.17 9600bps

V.27ter 4800bps V.29 7200bps

[ENTER]Key

V.27ter 2400bps

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

CML ON

FLAG (300bps)

2. Pressing the [ENTER] key during transmitting CNG signal, or

pressing the [STOP] key will stop the output of signal and exit the

mode.

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

[ENTER]Key

V.27ter 4800bps

[ENTER]Key

V.33 14400bps

V.17 7200bps

[ENTER]Key

V.29 9600bps

2100 Hz (CED TONE)

[ENTER]Key

1100 Hz (CNG)

2. Pressing the [ENTER] key during transmitting ANSam signal, or

pressing the [STOP] key will stop the output of signal and exit the

mode.

2.1.7 Memory clear

Clear the backup memory including the soft switches, registration

data. After executing this mode, the memory clear report is printed.

Note: The following data is not cleared. Values for Printer life including

the adjusted value of printing void.

2.1.8 CIS adjusting mode

When the "color scan" or "monochrome scan" is selected in this mode,

the scanner motor moves from its home position to the specified value.

Then, the document reading lamp is turned on.

1. Press the [STOP] key to exit the mode.

2 – 9

Page 26

AM-900U

GEAR CHARGE MODE

ADF : COUNT = 00001

FBED : COUNT = 00001

ADF : COUNT = 00002

FBED : COUNT = 00002

[ENTER]Key

Drive the gear as Flatbed mode.

Move from Home Position to the reading direction. After

pause, move to the reading position from ADF.

Drive the gear as ADF mode.

Pause and drive reversely.

Move from Home Position to the reading direction.

After pause, move to the reading position from ADF.

Pause and drive reversely.

This sequence w ill be terminated by pressing STOP key.

Drive the gear as ADF mode.

Drive the gear as Flatbed

Press STOP key to terminate this aging.

MOTOR AGING MODE

300 MONO

600 MONO

300 COLOR

600 COLOR

[ENTER]Key

[>] Key

[>] Key

[>] Key

Aging will start

by pressing ENTER key.

2.1.9 Dial test mode