Page 1

AL-1631/AL-1641CS

MODEL

AL-1631

AL-1641CS

DIGITAL LASER COPIER

DIGITAL MULTIFUNCTIONAL

SYSTEM

OPERATION MANUAL

Page

INTRODUCTION

SETTING UP THE UNIT

LOADING PAPER

INSTALLING THE

SOFTWARE

MAKING COPIES

SPECIAL FUNCTIONS

MAINTENANCE

TROUBLESHOOTING

THE UNIT

APPENDIX

(AL-1641CS)

14

19

46

52

57

61

68

4

7

Page 2

FOR YOUR PROTECTION...

To aid in reporting this unit in case of loss or theft, please record below the model number

and serial number located on the back of the unit. We also suggest you record all the

information listed and retain for future reference.

MODEL NUMBER SERIAL NUMBER

DATE OF PURCHASE

Dealer

Address City

State Zip Telephone

Service Station

Address City

State Zip Telephone

To obtain service, or to obtain product literature, accessories, or

supplies,

please call 1-(630)378-3590 in the USA

or 905-568-7140 in Canada.

For customer assistance, please visit http://www.sharpusa.com/

(for USA) or http://www.sharp.ca/ (for Canada) on the World Wide Web

or call 1-(630)378-3590 (for USA).

Do not make copies of anything which is prohibited from copying by law. The

following items are normally prohibited from copying by national law. Other

items may be prohibited by local law.

Money Stamps Bonds Stocks Bank drafts

Checks Passports Driver's licenses

Page 3

CAUTIONS

Caution label on the unit

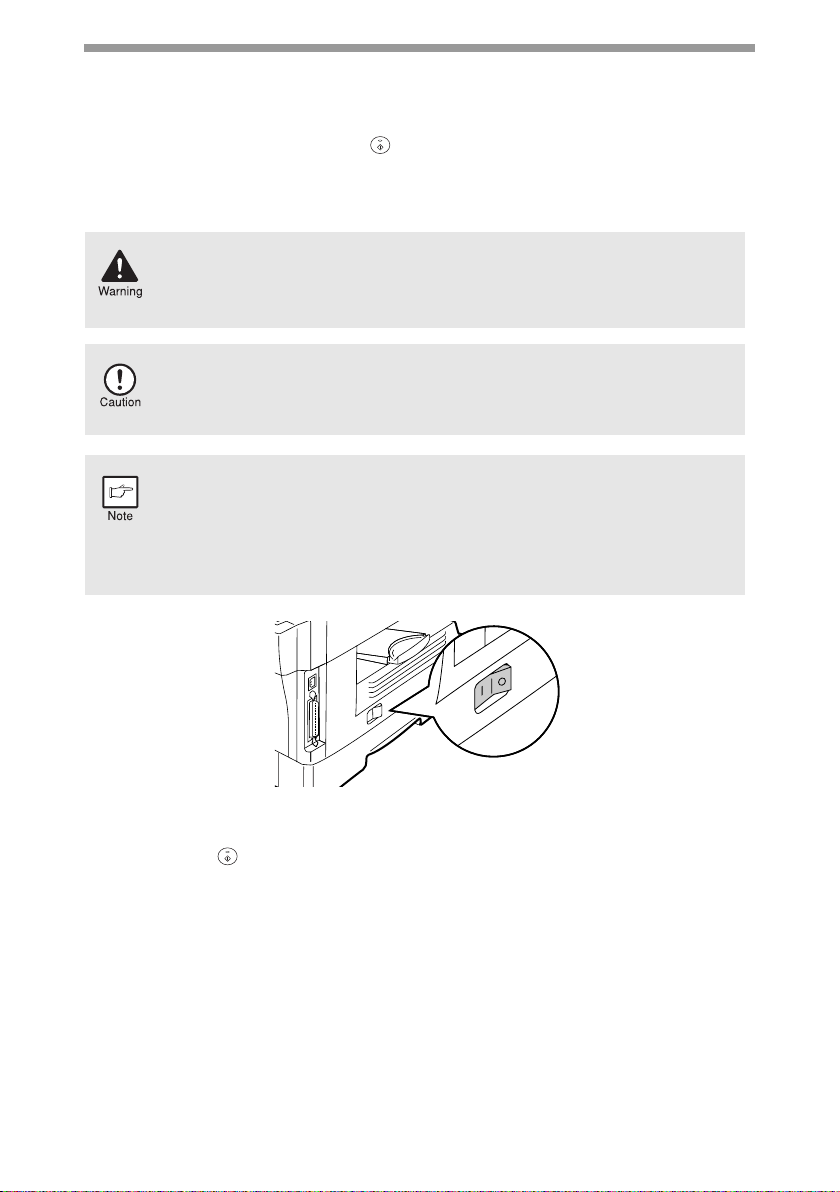

The label ( ) in the fusing area of the unit indicates the following:

: Caution, risk of danger

: Caution, hot surface

Cautions on using

Follow the cautions below when using this unit.

Warning:

• The fusing area is hot. Exercise care in this area when removing misfed paper.

• Do not look directly at the light source. Doing so may damage your eyes.

• Do not switch the unit rapidly on and off. After turning the unit off, wait 10 to 15

seconds before turning it back on.

• Unit power must be turned off before installing any supplies.

Caution:

• Place the unit on a firm, level surface.

• Do not install the unit in a humid or dusty location.

• When the unit is not used for a long time, for example for consecutive holidays,

turn the power switch off and remove the power cord from the outlet.

• When moving the unit, be sure to turn the power switch off and remove the power

cord from the outlet.

• Do not cover the unit with a dust cover, cloth or plastic film while the power is on.

Doing so may prevent heat radiation, damaging the unit.

• Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

• The socket-outlet shall be installed near the unit and shall be easily accessible.

Important points when selecting an installation site

Do not install your unit in areas that are:

• damp, humid, or very dusty

• exposed to direct sunlight

• poorly ventilated

• subject to extreme temperature or humidity changes, e.g., near an air conditioner

or heater.

Be sure to allow the required space around the

machine for servicing and proper ventilation.

4"

(10cm)

8" (20cm)

4"

(10cm)

1

Page 4

Cautions on handling

Be careful in handling the unit as follows to maintain the performance of this unit.

Do not drop the unit, subject it to shock or strike it against any object.

Do not expose the drum cartridge to direct sunlight.

• Doing so will damage the surface (green portion) of the drum cartridge, causing

smudges on copies.

Store spare supplies such as drum cartridges and TD cartridges in a dark

place without removing from the package before use.

• If they are exposed to direct sunlight, smudges on copies may result.

Do not touch the surface (green portion) of the drum cartridge.

• Doing so will damage the surface of the cartridge, causing smudges on copies.

Trademark acknowledgements

•Microsoft® Windows® operating system is a trademark or copyright of Microsoft

Corporation in the U.S.A. and other countries.

• Windows

and Windows® XP are trademarks or copyrights of Microsoft Corporation in the

U.S.A. and other countries.

• IBM and PC/AT are trademarks of International Business Machines Corporation.

• Acrobat

reserved. Adobe, the Adobe logo, Acrobat, and the Acrobat logo are trademarks of

Adobe Systems Incorporated.

• All other trademarks and copyrights are the property of their respective owners.

®

95, Windows® 98, Windows® Me, Windows NT® 4.0, Windows® 2000,

®

Reader Copyright© 1987- 2002 Adobe Systems Incorporated. All rights

For users in the USA

As an ENERGY STAR® Partner, SHARP has determined that

E

this product meets the

efficiency.

NERGY STAR® guidelines for energy

Safety precautions:

This Digital Copier is rated Class 1 and complies with 21 CFR 1040.10 and

1040.11 of the CDRH standards. This means that the unit does not produce

hazardous laser radiation. For your safety, observe the precautions below.

• Do not remove the cabinet, operation panel or any other covers.

• The unit’s exterior covers contain several safety interlock switches. Do not

bypass any safety interlock by inserting wedges or other items into switch slots.

A small amount of ozone is produced within the unit during operation. The

emission level is insufficient to cause any health hazard.

Note:

The present recommended long term exposure limit for ozone is 0.1ppm

(0.2mg/m

However, since the small amount that is emitted may have an objectionable odor,

it is advisable to place the unit in a ventilated area.

For users in Canada

3

) calculated as an 8hr. time-weighted average concentration.

2

The Environmental Choice Program guidelines are applied to

the products only in Canada. The products that meet the

Environmental Choice Program guidelines carry the logo

shown to the left. The products without the logo may not meet

the Environmental Choice Program guidelines.

Page 5

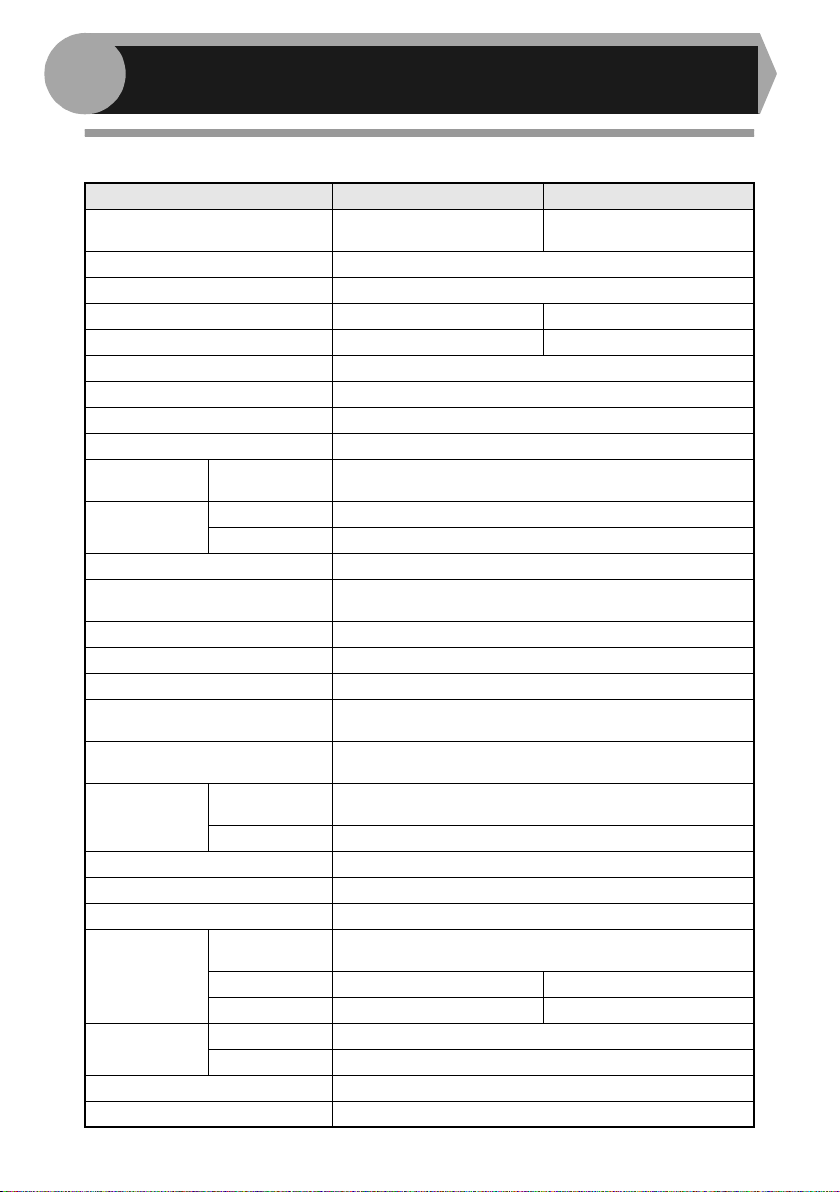

CONTENTS

INTRODUCTION

1

USING THE MANUALS.................4

PART NAMES ............................... 5

OPERATION PANEL.....................6

SETTING UP THE UNIT

2

SETUP PROCEDURE...................7

CHECKING PACKED

COMPONENTS AND

ACCESSORIES............................. 8

PREPARING THE UNIT FOR

INSTALLATION ............................. 8

INSTALLING THE

TD CARTRIDGE.......................... 10

POWER ON................................. 12

LOADING PAPER

3

PAPER.........................................14

LOADING THE PAPER TRAY..... 15

BYPASS FEED

(including special paper)..............17

INSTALLING THE SOFTWARE (AL-1641CS)

4

SOFTWARE FOR THE SHARP

PERSONAL MFP SERIES ..........19

HARDWARE AND SOFTWARE

REQUIREMENTS........................ 20

BEFORE INSTALLATION ........... 20

INSTALLING THE SOFTWARE .. 21

INDICATORS ON THE

OPERATION PANEL...................31

USING THE PRINTER MODE..... 32

USING THE SCANNER MODE... 34

HOW TO USE THE ONLINE

MANUAL...................................... 43

USING OTHER INSTALLED

DRIVERS..................................... 44

CONNECTING THE INTERFACE

CABLE .........................................45

MAKING COPIES

5

COPY FLOW ...............................46

ORIGINAL PLACEMENT............. 47

SET THE COPY QUANTITY .......49

EXPOSURE ADJUSTMENT/

PHOTO COPYING.......................49

REDUCTION/ENLARGEMENT/

ZOOM ..........................................51

SELECTING THE TRAY..............51

SPECIAL FUNCTIONS

6

ABOUT THE SPECIAL

FUNCTIONS OF AL-1641CS ......52

DESCRIPTION OF SPECIAL

FUNCTIONS ................................54

TONER SAVE MODE ..................54

USER PROGRAMS .....................55

DISPLAYING TOTAL NUMBER

OF COPIES .................................56

MAINTENANCE

7

TD CARTRIDGE

REPLACEMENT ..........................57

DRUM CARTRIDGE

REPLACEMENT ..........................58

CLEANING THE UNIT .................59

TROUBLESHOOTING THE UNIT

8

TROUBLESHOOTING.................61

STATUS INDICATORS................62

MISFEED REMOVAL ..................63

APPENDIX

9

SPECIFICATIONS .......................68

ABOUT SUPPLIES AND

OPTIONS.....................................70

MOVING AND STORING

THE UNIT ....................................71

SOFTWARE LICENSE ................72

1

2

3

4

5

6

7

8

MSDS...........................................76

INDEX ..........................................92

9

3

Page 6

1

This chapter provides basic information for using the unit.

Some model may not be available in some countries.

INTRODUCTION

USING THE MANUALS

In addition to this printed manual an online manual is also provided. (The AL-1631 does

not have an online manual.) To get full use of all features and functions of this product,

be sure to familiarize yourself with both manuals. This printed manual provides all

installation and setup instructions as well as instructions in the use of all copier

functions. The online manual contains the following information.

Online manual (AL-1641CS)

Provides you with information on how to specify preferences and troubleshooting. Check

the online manual when you use this unit after all the initial setup is completed.

How to use the online manual

Explains how to use the online manual.

Print

Provides information on how to print a document.

Scan

Explains how to scan using the scanner driver and how to adjust the settings for

the Button Manager.

Troubleshooting

Provides instructions on how to solve driver or software problems.

Conventions used in this manual and online manual

• This operation manual explains the operation of the AL-1631 and AL-1641CS

models. In cases where the operation is the same, the AL-1641CS is used.

• Illustrations of driver screens and other computer screens show the screens that

appear in Windows XP Home Edition. Some of the names that appear in these

illustrations may differ slightly from the screens that appear in other operating systems.

• This operation manual refers to the Single Pass Feeder as the "SPF".

• In this manual, the following icons are used to provide the user with information

pertinent to the use of the unit.

Warns the user that injury may result if the contents of the warning

are not properly followed.

Cautions the user that damage to the unit or one of its components

may result if the contents of the caution are not properly followed.

Notes provide information relevant to the unit regarding

specifications, functions, performance, operation and such, that

may be useful to the user.

Indicates a letter displayed in the display.

4

Page 7

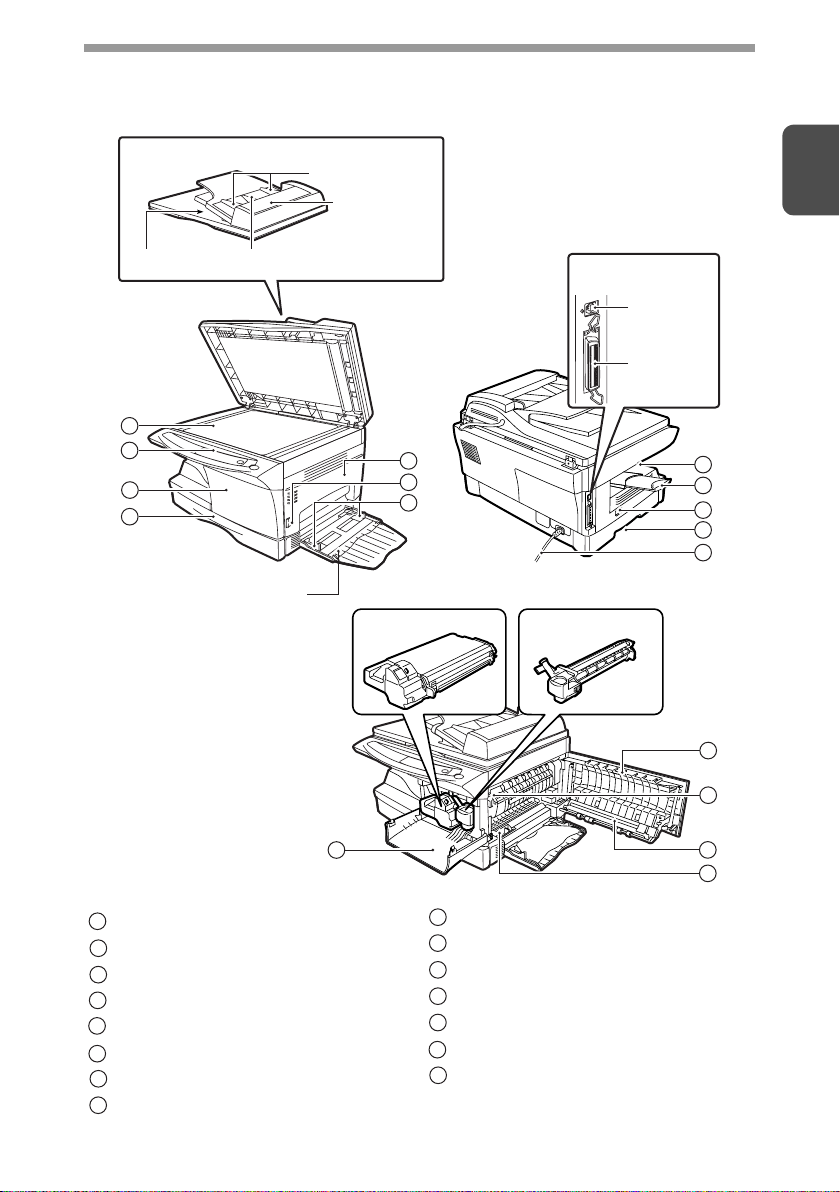

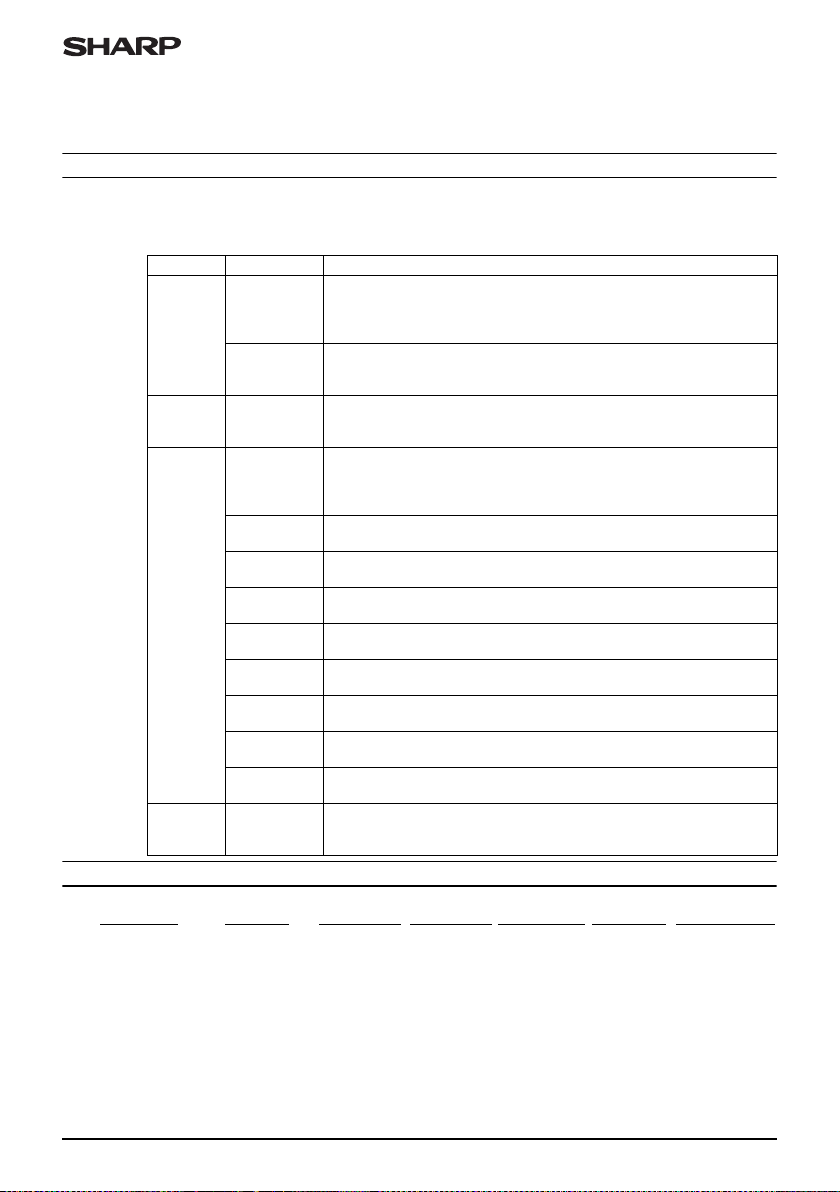

PART NAMES

SPF

Exit area

1

2

3

4

Multi-bypass tray

Original guide

Document

feeder cover

Document feeder tray

TD cartridge Drum cartridge

1

Interface

(AL-1641CS)

USB

connector

Parallel

connector

5

6

7

8

9

10

11

12

Document glass

1

Operation panel

2

Front cover

3

Paper tray

4

Side cover

5

Side cover open button

6

Bypass tray paper guides

7

Paper output tray

8

5

13

3

Paper output tray extension

9

Power switch

10

Handle

11

Power cord

12

Fusing unit release lever

13

Transfer charger

14

Charger cleaner

15

14

15

5

Page 8

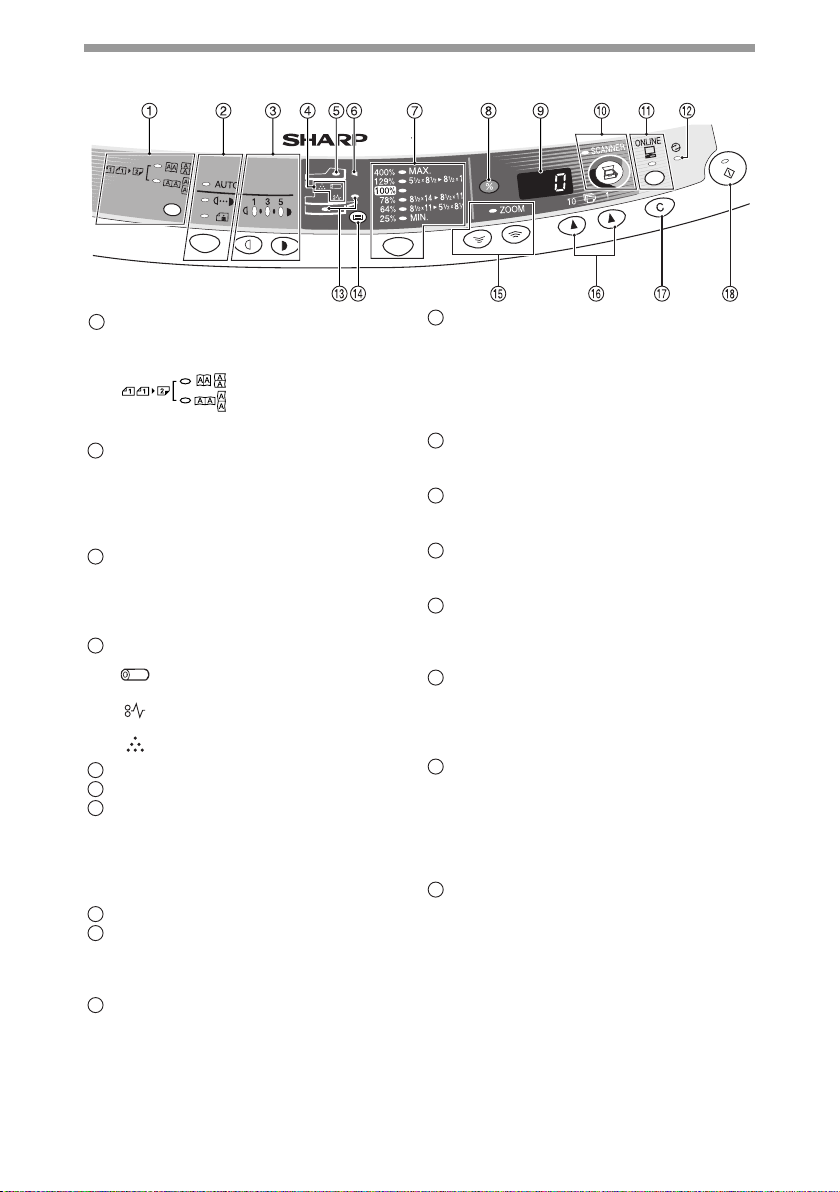

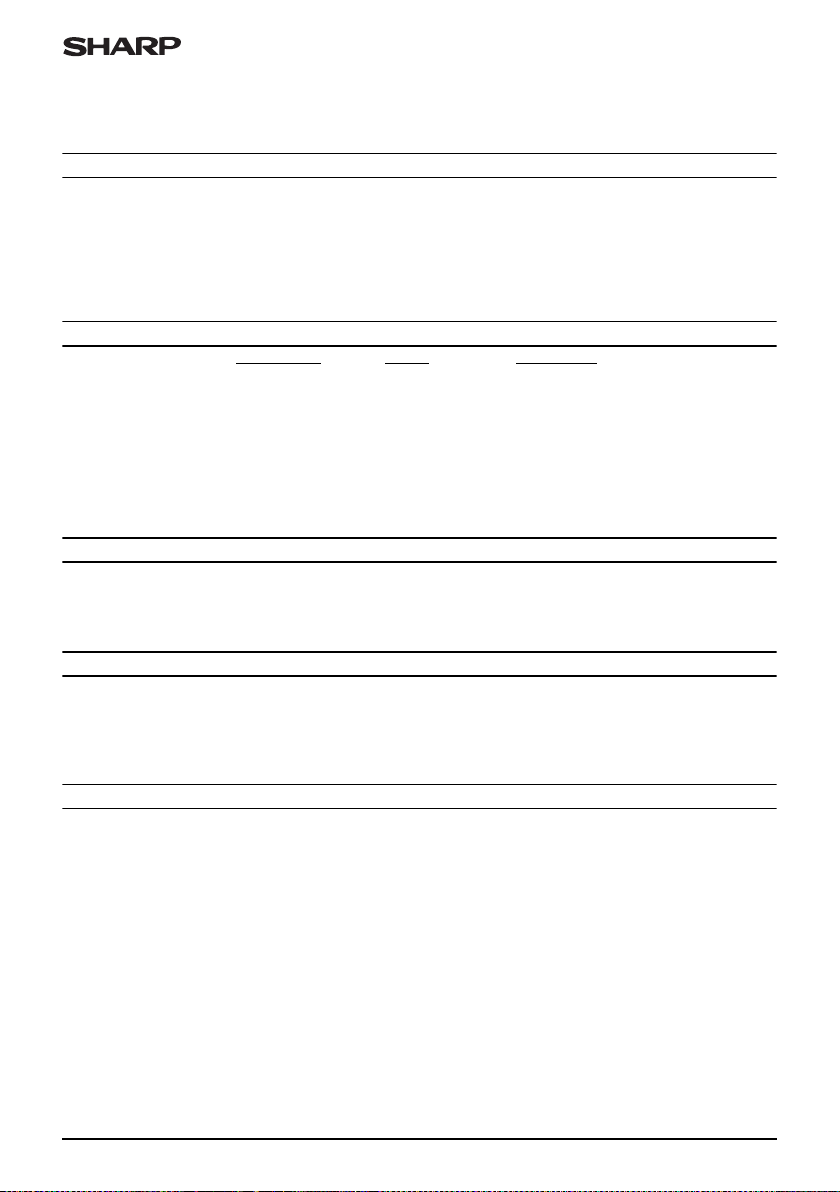

OPERATION PANEL

Original to copy key and indicators

1

(AL-1641CS)

Exposure mode selector key and

2

indicators

Use to sequentially select the exposure

modes: AUTO, MANUAL or PHOTO.

Selected mode is shown by a lit

indicator. (p.49)

Light and dark keys and indicators

3

Use to adjust the MANUAL or PHOTO

exposure level. Selected exposure level is

shown by a lit indicator. (p.49) Use to start

and terminate user program setting. (p.55)

Alarm indicators

4

Drum replacement required

indicator (p.58)

Misfeed indicator (p.63)

TD cartridge replacement

required indicator (p.57)

SPF indicator (p.48)

5

SPF misfeed indicator (p.67)

6

Copy ratio selector key and

7

indicators

Use to sequentially select preset

reduction/enlargement copy ratios.

Selected copy ratio is shown by a lit

indicator. (p.51)

Copy ratio display (%) key (p.51)

8

Display

9

Displays the specified copy quantity,

zoom copy ratio, user program code,

and error code.

SCANNER key and indicator

10

(p.31, p.39)

(AL-1641CS)

Two-sided copies from

one-sided originals.

Turn on Long Edge or

Turn on Short Edge

can be selected.

AL-1641CS

ONLINE key and indicator

11

(AL-1641CS)

Lights up when the unit is used as a

printer and scanner. For description of

the ONLINE indicator, see

"INDICATORS ON THE OPERATION

PANEL" (p.31).

Power save indicator

12

Lights up when the unit is in a power

save mode. (p.54, p.55)

Paper feed location indicators

13

Light up to show the selected paper

feed station.

Tray select key

14

Use to select a paper feed station

(paper tray or multi-bypass tray). (p.51)

ZOOM keys and indicator

15

Use to select any reduction or

enlargement copy ratio from 25% to

400% in 1% increments. (p.51)

Copy quantity keys

16

• Use to select the desired copy

quantity (1 to 99). (p.49)

• Use to make user program entries.

(p.55)

Clear key

17

• Press to clear the display, or press

during a copy run to terminate

copying. (p.49)

• Press and hold down during standby

to display the total number of copies

made to date. (p.56)

Start key and indicator

18

• Copying is possible when the

indicator is on.

• Press to start copying

• Use to set a user program. (p.55)

6

Page 9

2

Follow the installation procedure below to use the unit properly.

If the unit does not function properly during setup or use, or if a function

cannot be used, see "TROUBLESHOOTING THE UNIT" (p.61).

SETTING UP THE UNIT

SETUP PROCEDURE

When using the unit for the first time, setup the unit following the procedure shown

below.

1 Open the package, and make sure that all the accessories are

supplied with the unit. (p.8)

2 Remove the protective materials. (p.9)

3 Install the TD cartridge. (p.10)

4 Load the paper in the paper tray (p.15) or the multi-bypass

tray

. (p.17)

5 Plug the other end of the power cord into the nearest outlet. (p.12)

6 Install the software.* (p.19)

7 Connect the interface cable* (p.45) and turn on the unit. (p.12)

2

8 Now, you can copy (p.46), print (p.33), or scan (p.34) your

document.

* If you are only using the unit for copying, skip this step.

7

Page 10

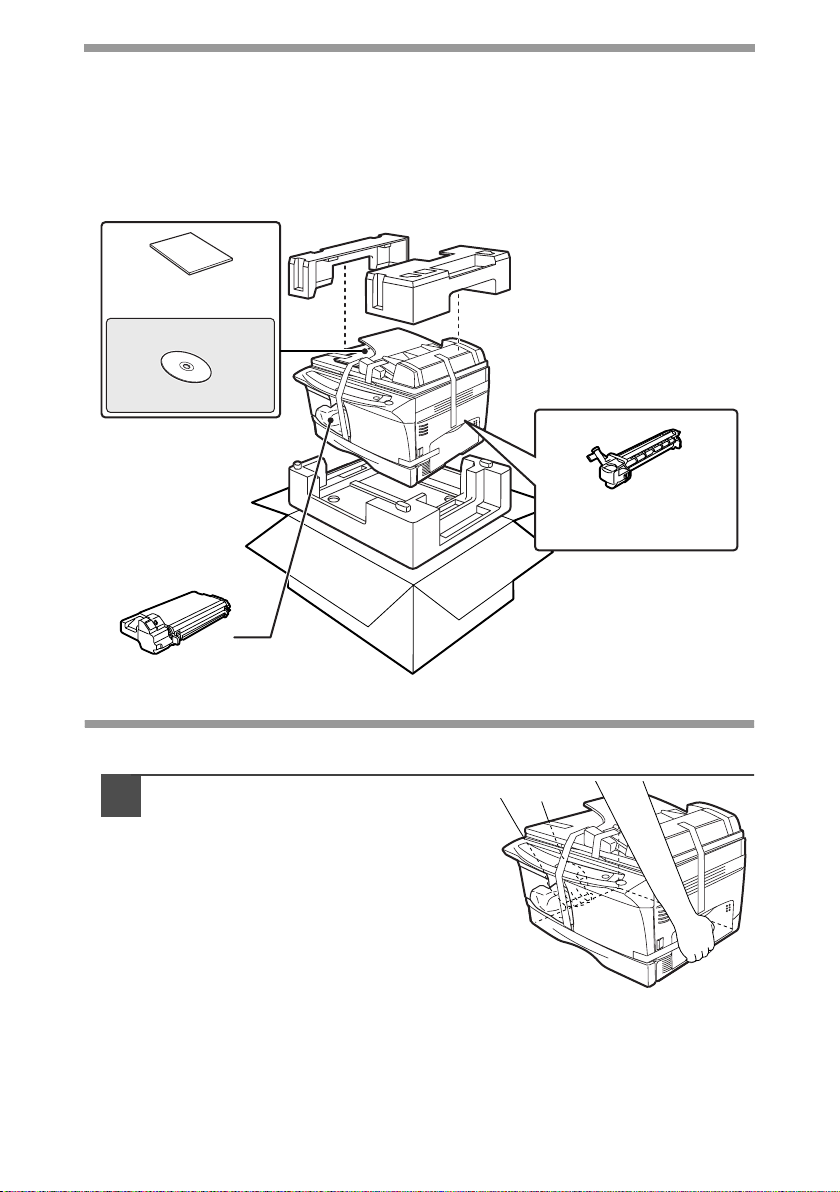

CHECKING PACKED COMPONENTS AND

ACCESSORIES

Open the carton and check if the following components and accessories are

included.

If anything is not included or is damaged, contact our Technical Assistance

Department at 1-(630)378-3590 in the USA or 905-568-7140 in Canada.

Operation manual

AL-1641CS

Software CD-ROM

Drum cartridge

(installed in unit)

TD cartridge

PREPARING THE UNIT FOR INSTALLATION

Be sure to hold the handles on

1

both sides of the unit to unpack

the unit and carry it to the

installation location.

8

Page 11

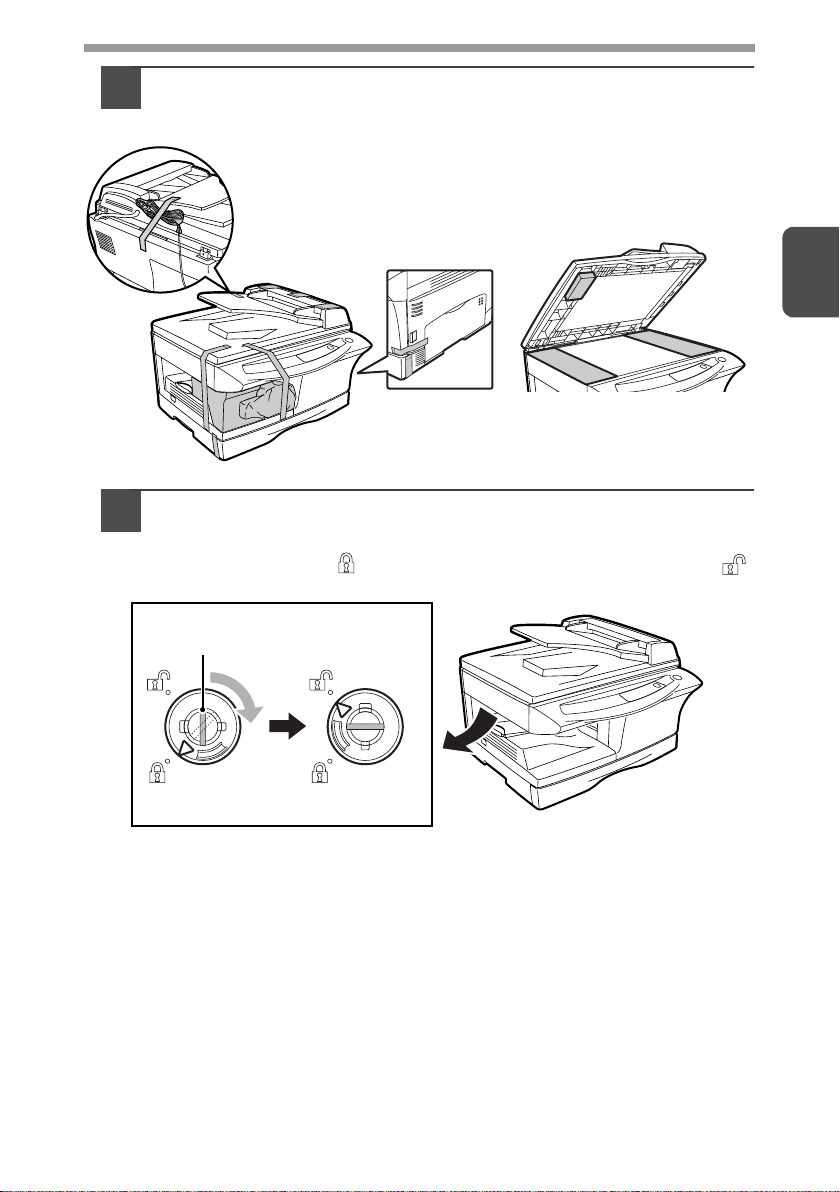

Remove all pieces of tape shown in the illustration below. Then

2

open the SPF and remove protective materials. After that, take

out the bag containing the TD cartridge.

Release the scan head locking switch.

3

The scan head locking switch is under the document glass.

If the switch is locked (), the unit will not operate. Unlock the switch ( )

as shown below.

Grasp here and turn in

the direction of the arrow.

2

Lock Unlock

9

Page 12

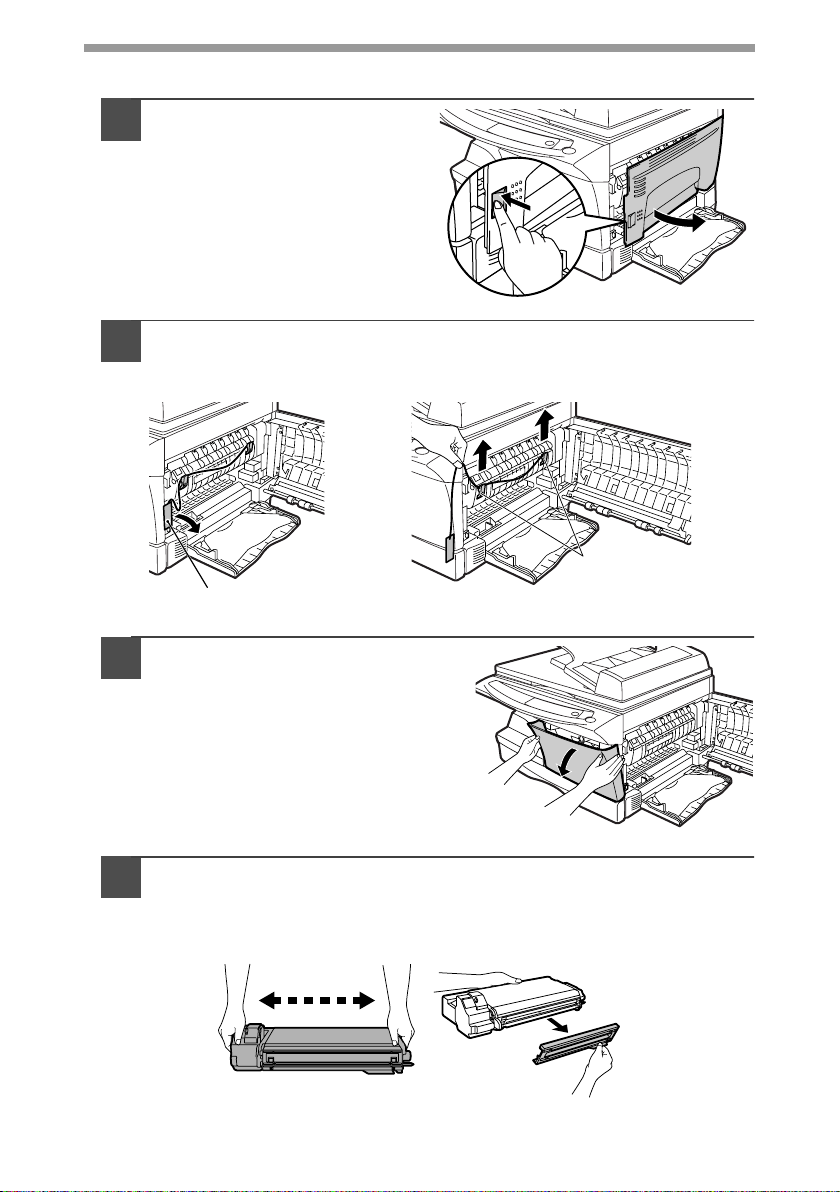

INSTALLING THE TD CARTRIDGE

Open the multi-bypass tray,

1

and then open the side

cover.

Remove the CAUTION tape from the front cover and remove the

2

two protective pins from the fusing unit by pulling the strings

upward one at a time.

CAUTION tape

Push gently on both sides of the

3

front cover to open the cover.

Protective pins

10

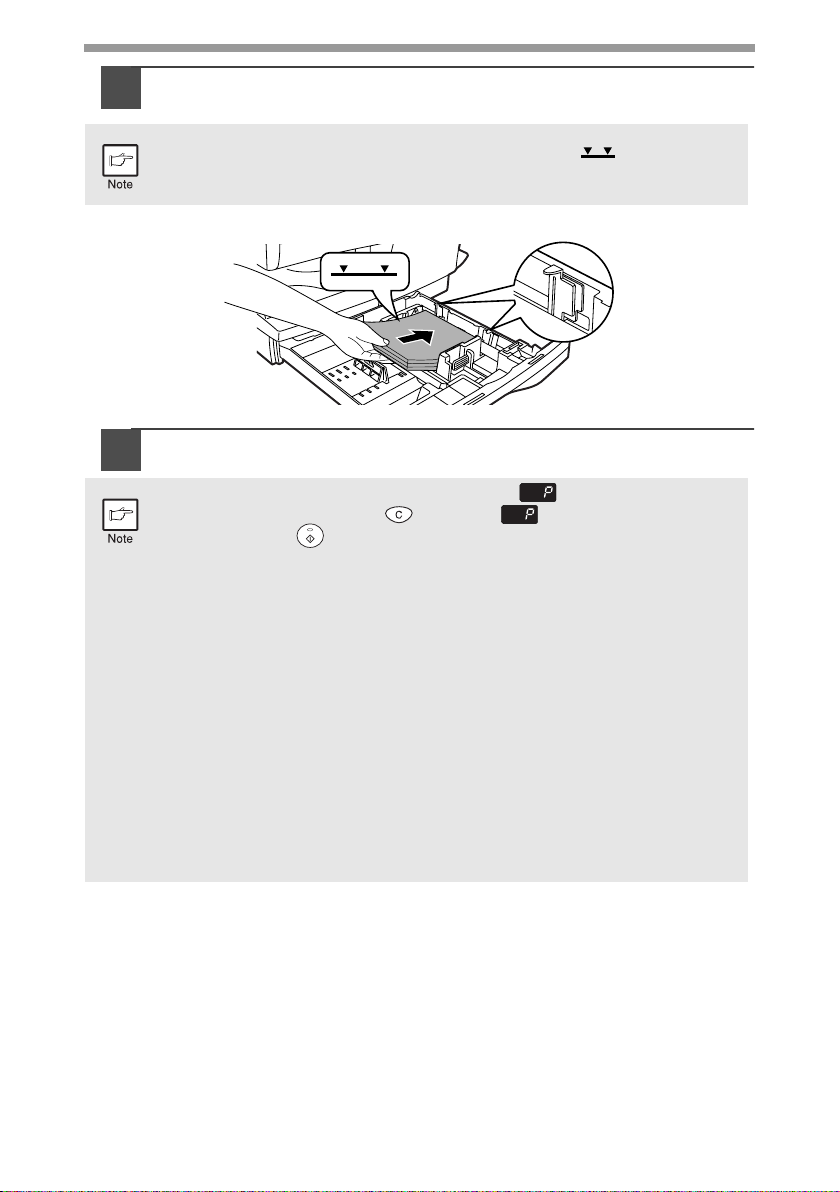

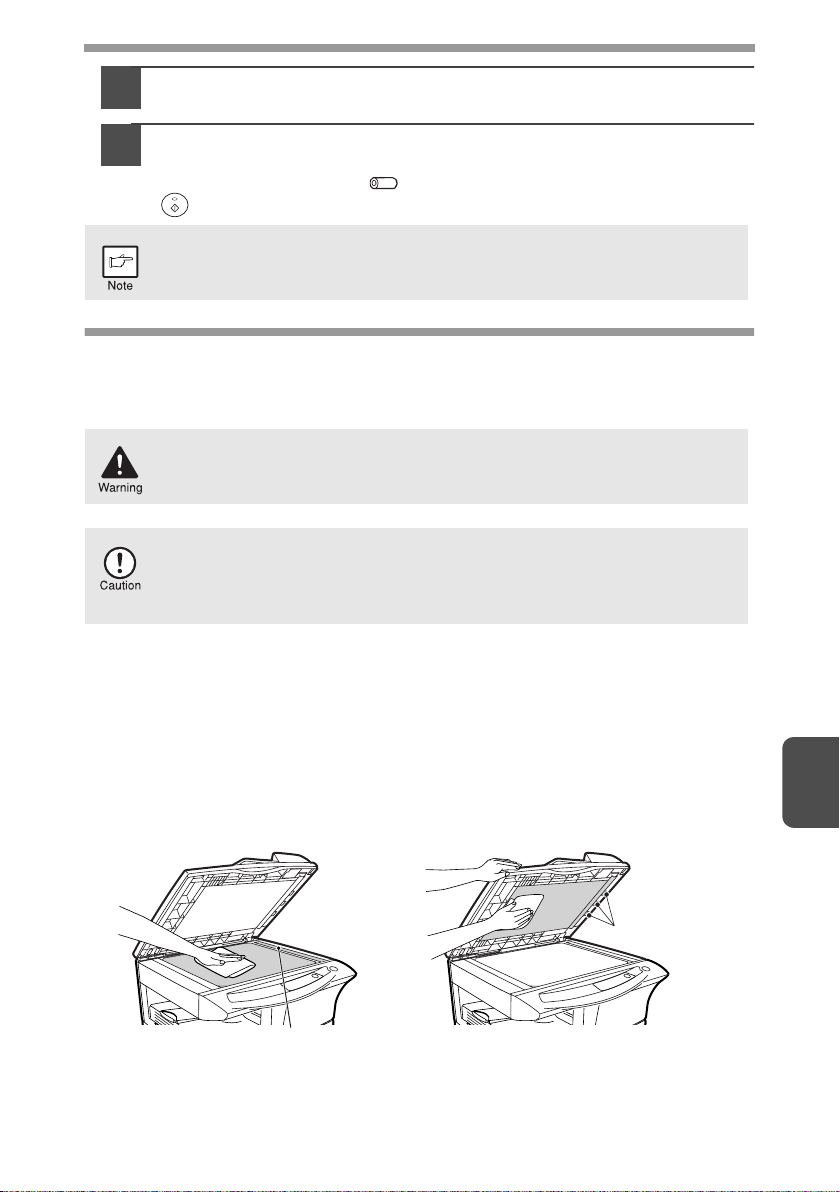

Remove the TD cartridge from the bag. Remove the protective

4

paper. Hold the cartridge on both sides and shake it

horizontally four or five times. Hold the tab of the protective

cover and pull the tab to your side to remove the cover.

4 or 5 times

Page 13

Gently insert the TD cartridge

5

until it locks in place while

pushing the lock release button.

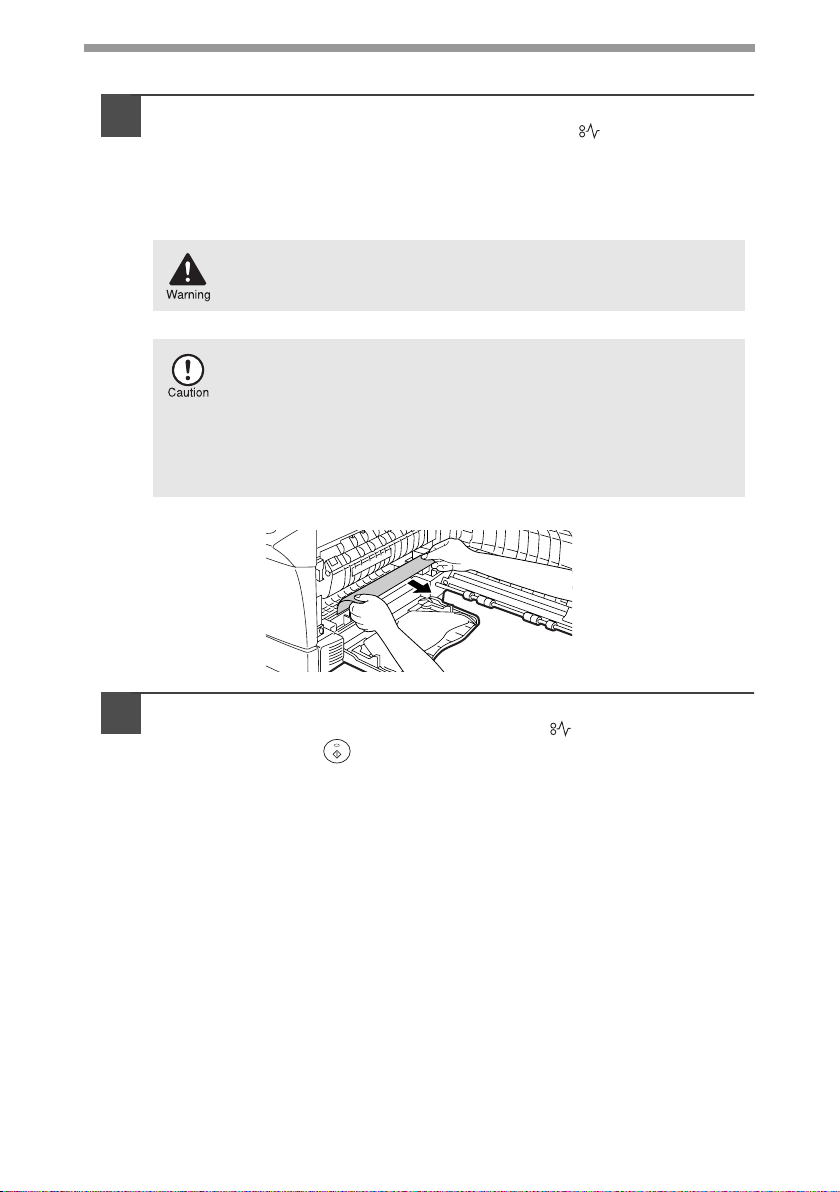

Close the front cover and then

6

the side cover by pressing the

round projections near the

side cover open button.

When closing the covers, be

sure to close the front cover

securely and then close the

side cover. If the covers are

closed in the wrong order, the

covers may be damaged.

2

11

Page 14

POWER ON

Ensure that the power switch of the unit is in the OFF position. Plug the other end of

the power cord into the nearest outlet. Turn the power switch on the left side of the

unit to the "ON" position. The start ( ) indicator will light up and other indicators

which show the initial settings of the operation panel will also light up to indicate the

ready condition. For the initial settings, see the "Initial settings of operation panel"

described on the next page.

If you use the unit in a country other than the country where the unit was

purchased, you will need to make sure that your local power supply is

compatible with your model. If you plug the unit into an incompatible

power supply, irreparable damage to the unit will result.

Only insert the power cord into a properly grounded wall socket.

Do not use extension cords or power strips.

• The unit will enter a power save mode once the set time has elapsed

without any unit operation. The settings of the power save modes can

be modified. See "USER PROGRAMS" (p.55).

• The unit will return to the initial settings a preset amount of time after

the end of copy or scanner job. The preset amount of time (auto clear

time) can be changed. See "USER PROGRAMS" (p.55).

12

About the scan head

The scan head lamp remains on constantly when the unit is in the ready condition

(when the start ( ) indicator is illuminated).

The unit adjusts the scan head lamp periodically to maintain copying quality. At this

time, the scan head moves automatically. This is normal and does not indicate unit

trouble.

Page 15

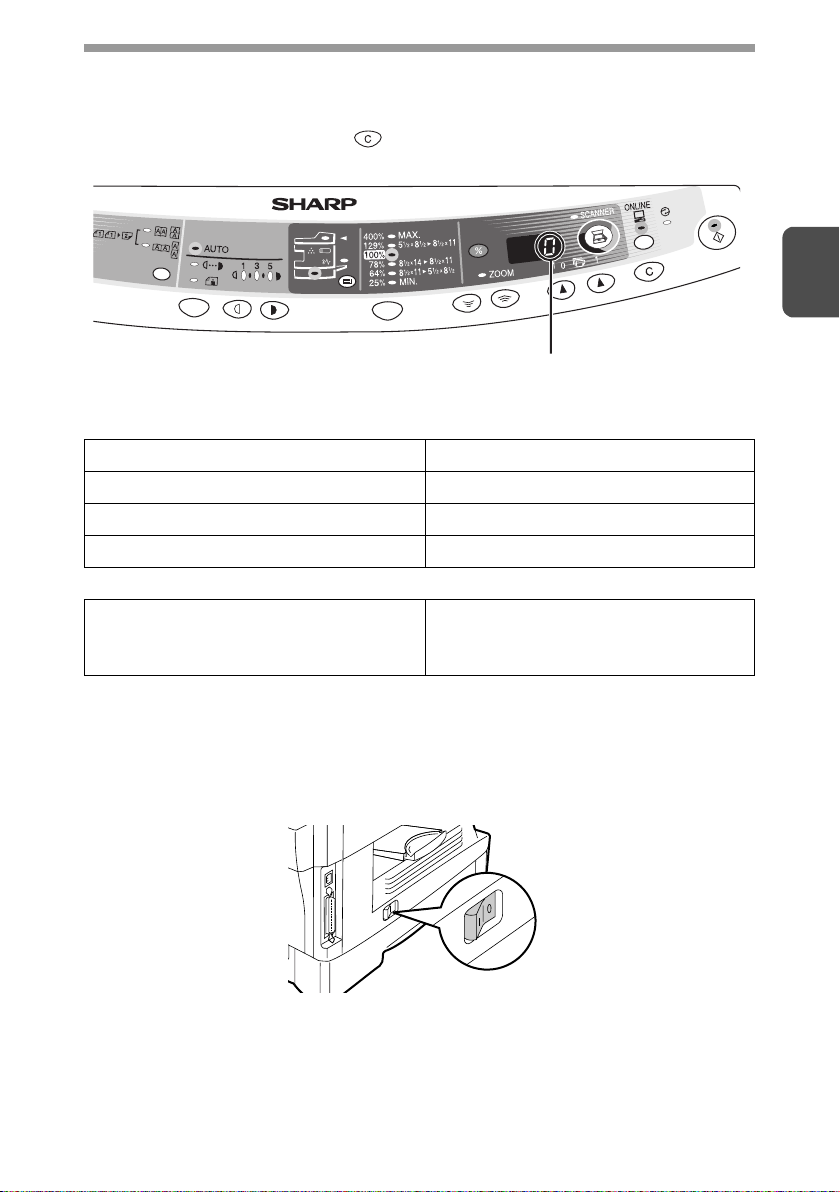

Initial settings of operation panel

When the unit power is on, the operation panel will revert to the initial settings when

the time set with the "Auto clear time" setting (p.55) elapses after a copy or scanner

job is finished, or when the clear ( ) key is pressed twice.

The initial settings of the operation panel are shown below.

AL-1641CS

"0" is displayed in the display.

When copying is begun in this state, the settings in the following table are used.

Copy quantity 1 copy

Exposure adjustment AUTO

Zoom 100%

Tray Paper tray

AL-1641CS only

Original to copy The "Original to copy" indicator does

not illuminate. (One-sided copying

only)

2

Power off methods

If not used for a certain period of time, the unit will automatically enter auto power

shut-off mode (p.54) in order to minimize power consumption. In cases where the

machine will not be used for a long time, turn off the power switch and remove the

power cord from the outlet.

13

Page 16

3

Follow the steps below to load paper into the tray.

LOADING PAPER

PAPER

For best results, use only paper recommended by SHARP.

Type of paper

feeding

Paper tray Standard paper Letter (8-1/2" x 11")

Multi-bypass

tray

* Do not use non-standard envelopes, and envelopes that have metal clasps, plastic

snappers, string closures, windows, linings, self-adhesive, patches or synthetic

materials. Do not use envelopes that are filled with air or envelopes that have

labels or stamps attached. These will cause physical damage to the unit.

** For paper weighing from 28 to 34.5 lbs. (105g/m

maximum size that can be fed through the multi-bypass tray.

• Special papers such as transparency film, labels and envelopes must be fed one

sheet at a time through the multi-bypass tray.

Type of media Size Weight

15 lbs. to 21 lbs.

Standard paper and

thick paper

Special

media

Transparency

film

Envelope* Commercial 10

Legal (8-1/2" x 14")

Invoice (5-1/2" x 8-1/2")

Letter (8-1/2" x 11")

Legal (8-1/2" x 14")

Invoice (5-1/2" x 8-1/2")

Letter (8-1/2" x 11")

(4-1/8" x 9-1/2")

Monarch

(3-7/8" x 7-1/2")

2

to 128g/m2), 8-1/2" x 11" is the

(56g/m2 to

80g/m

14 lbs. to 34.5

lbs.**

(52g/m

128g/m

2

)

2

to

2

)

14

Page 17

LOADING THE PAPER TRAY

Raise the handle of the paper tray

1

and pull the paper tray out until it

stops.

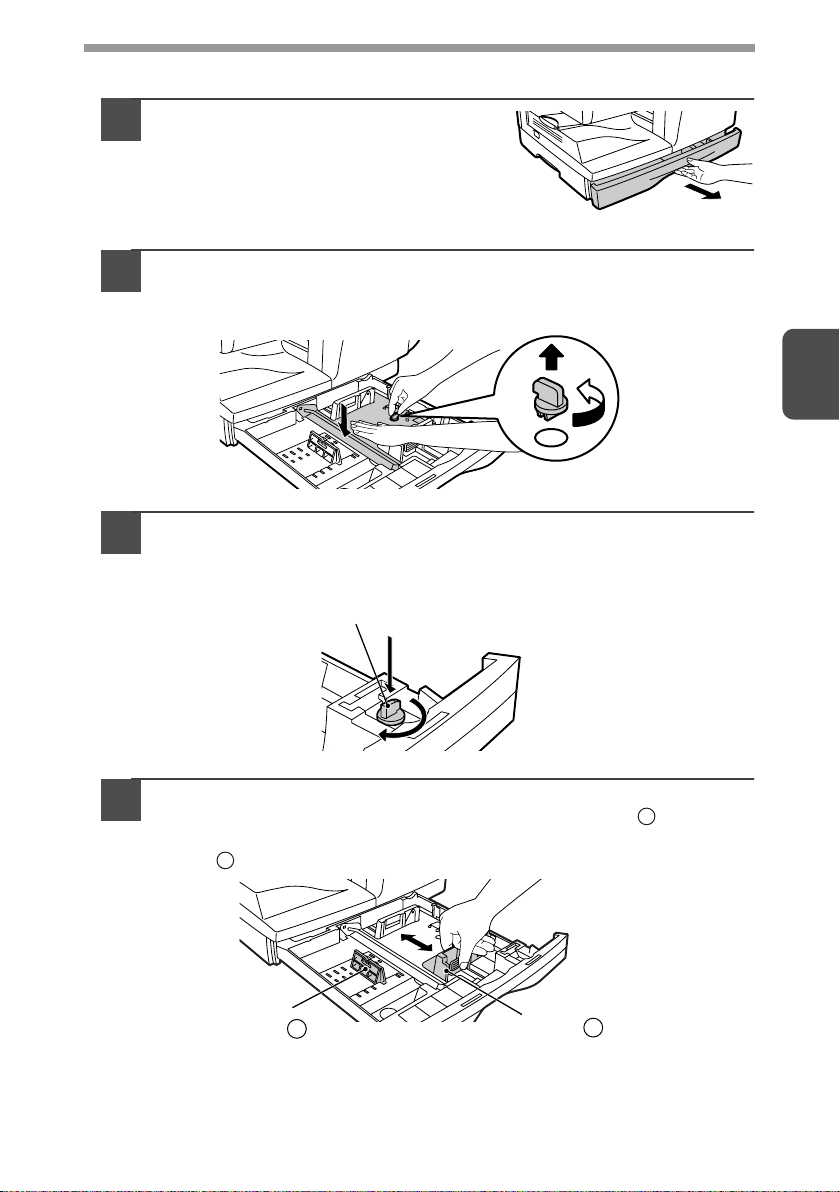

Remove the pressure plate lock. Rotate the pressure plate lock

2

in the direction of the arrow to remove it while pressing down

the pressure plate of the paper tray.

Store the pressure plate lock which has been removed in step

3

2. To store the pressure plate lock, rotate the lock to fix it on the

relevant location.

Pressure plate lock

3

Adjust the paper guides on the paper tray to the copy paper

4

width and length. Squeeze the lever of paper guide and slide

the guide to match with the width of the paper. Move paper

guide to the appropriate slot as marked on the tray.

B

Paper

guide B

Paper

guide A

A

15

Page 18

Fan the paper and insert it into the tray. Make sure the edges go

5

under the corner hooks.

Do not load paper above the maximum height line ( ). Exceeding

the line will cause a paper misfeed.

Gently push the paper tray back into the unit.

6

• After loading paper, to cancel the blinking without restarting

copying, press the clear ( ) key. The in the display will go out

and the start ( ) indicator will light up.

• Be sure that paper is free of rips, dust, wrinkles, and curled or bent

edges.

• Make sure all the paper in the stack is the same size and type.

• When loading paper, ensure there is no space between the paper and

the guide, and check if the guide is not set too narrow causing the

paper to bend. Loading paper in these ways will result in document

skew or a paper jam.

• When not using the unit for an extended period, remove all paper from

the paper tray and store it in a dry place. If paper is left in the unit for

an extended period, the paper will absorb moisture from the air,

resulting in paper jams.

• When adding new paper to the paper tray, remove the old paper

already contained in the tray. Placing new paper on top of the paper

already contained in the tray may result in feeding two sheets at one

time.

16

Page 19

BYPASS FEED (including special paper)

The multi-bypass tray can be used to feed standard paper, transparency film, labels,

envelopes, and other special purpose paper. Paper measuring from 3-1/2" x 5-1/2"

to 8-1/2" x 14" and in the weight range of 14 lbs. to 34.5 lbs. (52g/m2 to 128g/m2) can

be used in this tray. (For paper weighing from 28 lbs. to 34.5 lbs. (105g/m

2

128g/m

), 8-1/2" x 11" is the maximum size.)

• The multi-bypass tray can hold maximum of 50 sheets of paper.

(Capacity will vary depending on the type of paper loaded.)

• The original image must be smaller than the paper or media for

copying. If the original image is bigger than the paper or media, this

may cause smudges on the edges of the copies.

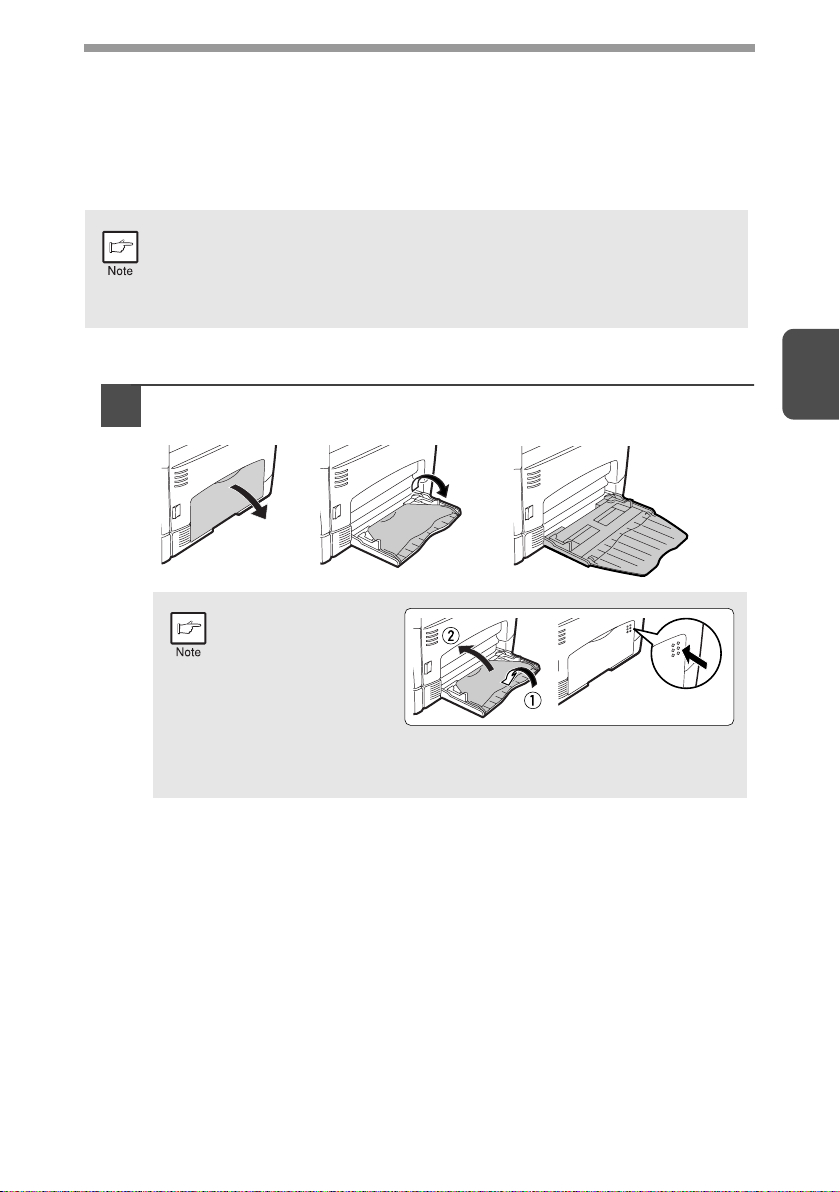

The multi-bypass tray

Open the multi-bypass tray and extend the tray.

1

To close the multibypass tray,

perform step 1

and then step 2 in

the illustration and

push the round

projections at the

right of the tray

until they click.

2

to

3

17

Page 20

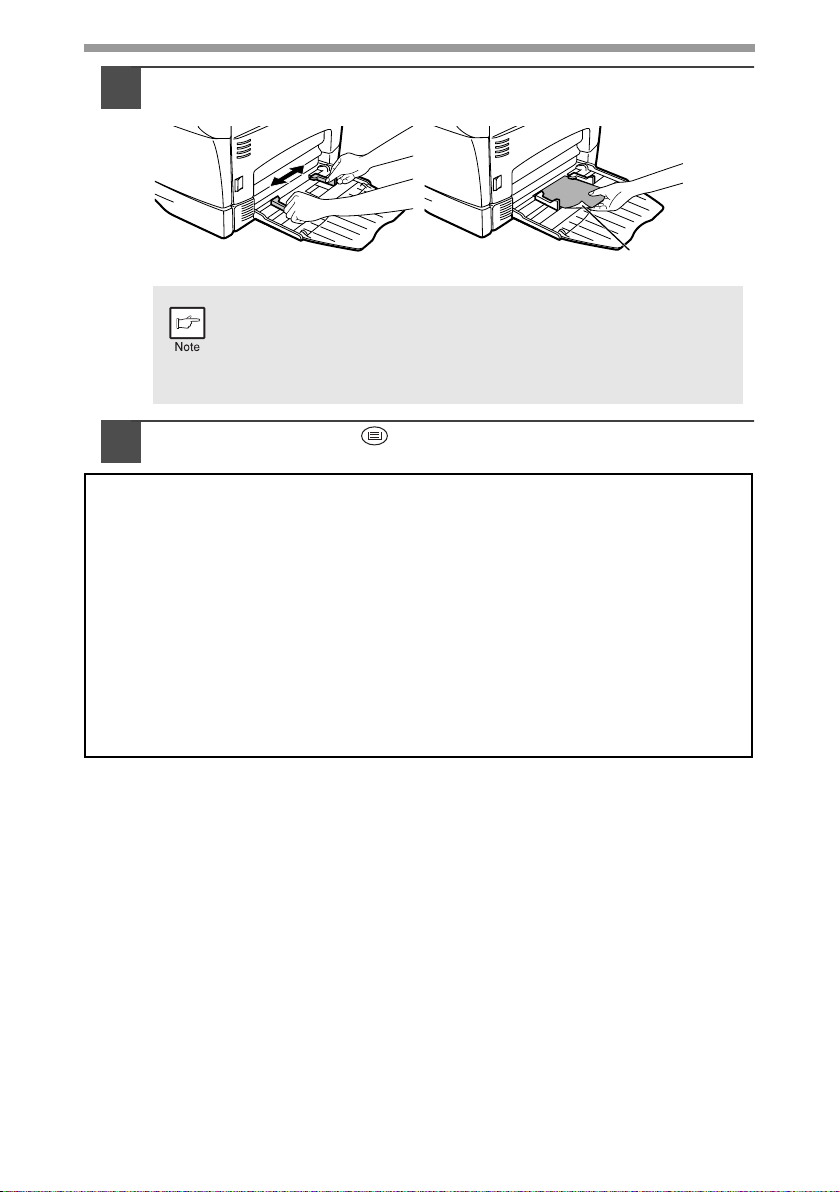

Set the paper guides to the paper width. Insert the paper (print

2

face down) all the way into the multi-bypass tray.

Print face

• Paper must be fed narrow side into the feed slot.

Special papers such as transparency film, labels, and envelopes

•

must be fed one sheet at a time through the multi-bypass tray.

• When copying onto transparency film, remove each copy

promptly. Do not let copies stack up.

Press the tray select ( ) key to select the multi-bypass tray.

3

Note for loading envelopes

• Envelopes must be fed narrow side into the feed slot at a time.

• Do not use non-standard envelopes, and envelopes that have metal clasps, plastic snappers,

string closures, windows, linings, self-adhesive, patches or synthetic materials. Do not use

envelopes that are filled with air or envelopes that have labels or stamps attached.

• Envelopes of which the surface is not flat because of embossing may cause the

copies/prints to become smudged.

• Under high humidity and temperature conditions the glue flaps on some envelopes

may become sticky and be sealed closed when copied/printed.

• Use only envelopes which are flat and crisply folded. Curled or poorly formed

envelopes may be poorly printed or may cause misfeeds.

• Be sure to select either Com10, DL, C5 or Monarch on the paper size setting of the

printer driver. (For detailed information on printer driver, refer to the online manual.)

• It is recommended that you perform a test print before performing the actual copied/

printed job.

18

Page 21

4

INSTALLING THE SOFTWARE (AL-1641CS)

This chapter explains how to install the software that allows the AL-1641CS to be

used as a printer and scanner, and the procedures for using the printer and scanner

functions. The following term is used in this chapter.

CD-ROM

Means the supplied CD-ROM with the SHARP Personal MFP series software.

SOFTWARE FOR THE SHARP PERSONAL MFP

SERIES

The supplied CD-ROM includes software for this unit.

MFP driver

Scanner driver

Permits you to operate scanning function of this unit with TWAIN-compliant and

WIA-compliant application.

Printer driver

Enables you to use the printer function of this unit with your computer.

Print Status Window

The print state and information on current printing are displayed on the status

monitor window.

Sharpdesk

An integrated software environment that makes it easy to manage document and

image files and launch applications.

Button Manager

Button Manager enabling the SCANNER ( ) key located on the unit.

4

The scanning feature is only available with Windows 98/Me/2000/XP

using a USB connection. For users running Windows 95/NT4.0 or using

a parallel connection, only printing is available.

19

Page 22

HARDWARE AND SOFTWARE REQUIREMENTS

Check the following hardware and software requirements in order to install the software.

Computer type IBM PC/AT or compatible computer equipped with a

USB1.1*1 or bi-directional parallel interface (IEEE 1284)

Operating system*2Windows 95, Windows 98, Windows Me, Windows NT

Workstation 4.0 (ServicePack 5 or later)*

Professional*3, Windows XP Professional*3, Windows XP

Home Edition*

3

3

, Windows 2000

Display 800 x 600dots (SVGA) display with 256 colors (or better)

Hard disk free space

Other requirement

for hardware

*1Compatible with Windows 98, Windows Me, Windows 2000 Professional, Windows XP

Professional or Windows XP Home Edition preinstalled model with USB interface

equipped as standard.

2

Printing is unavailable in MS-DOS mode.

*

3

The administrator's authorization is required to install this software using this installer.

*

150MB or more

An environment on which any of the operating systems listed

above can fully operate

BEFORE INSTALLATION

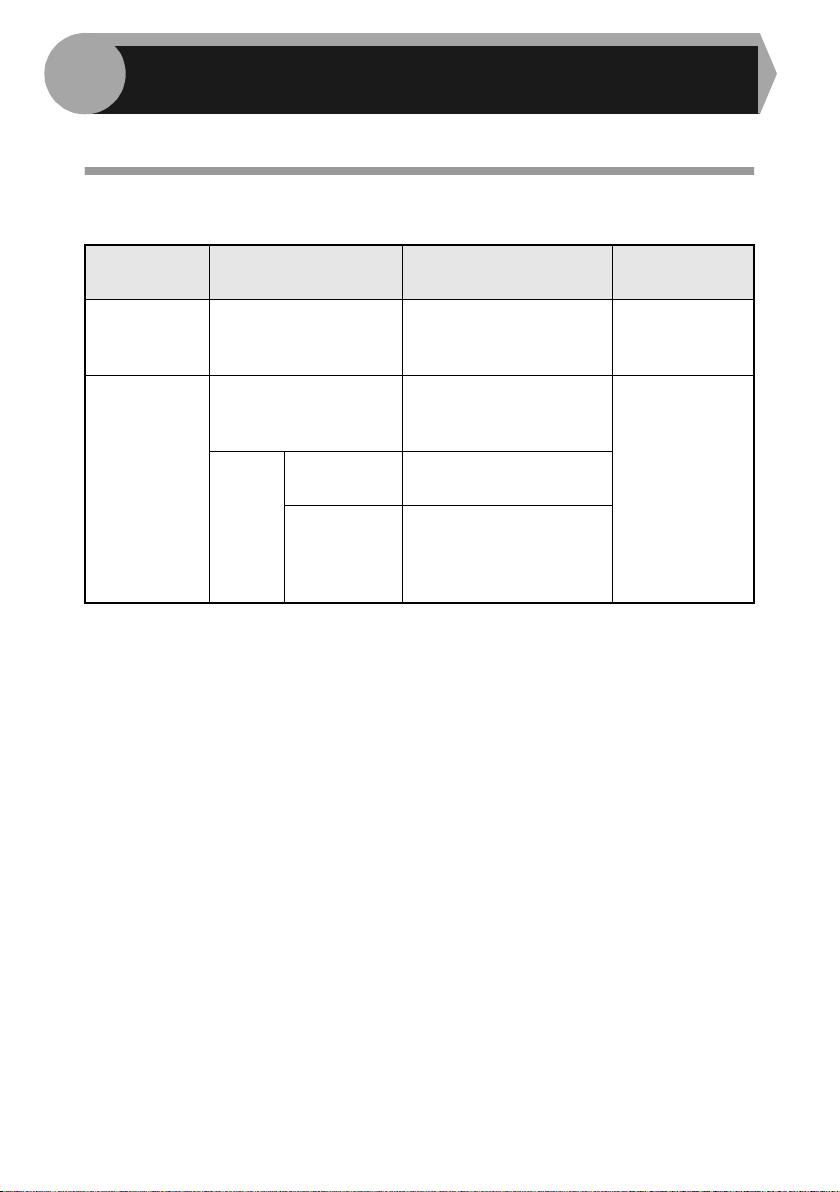

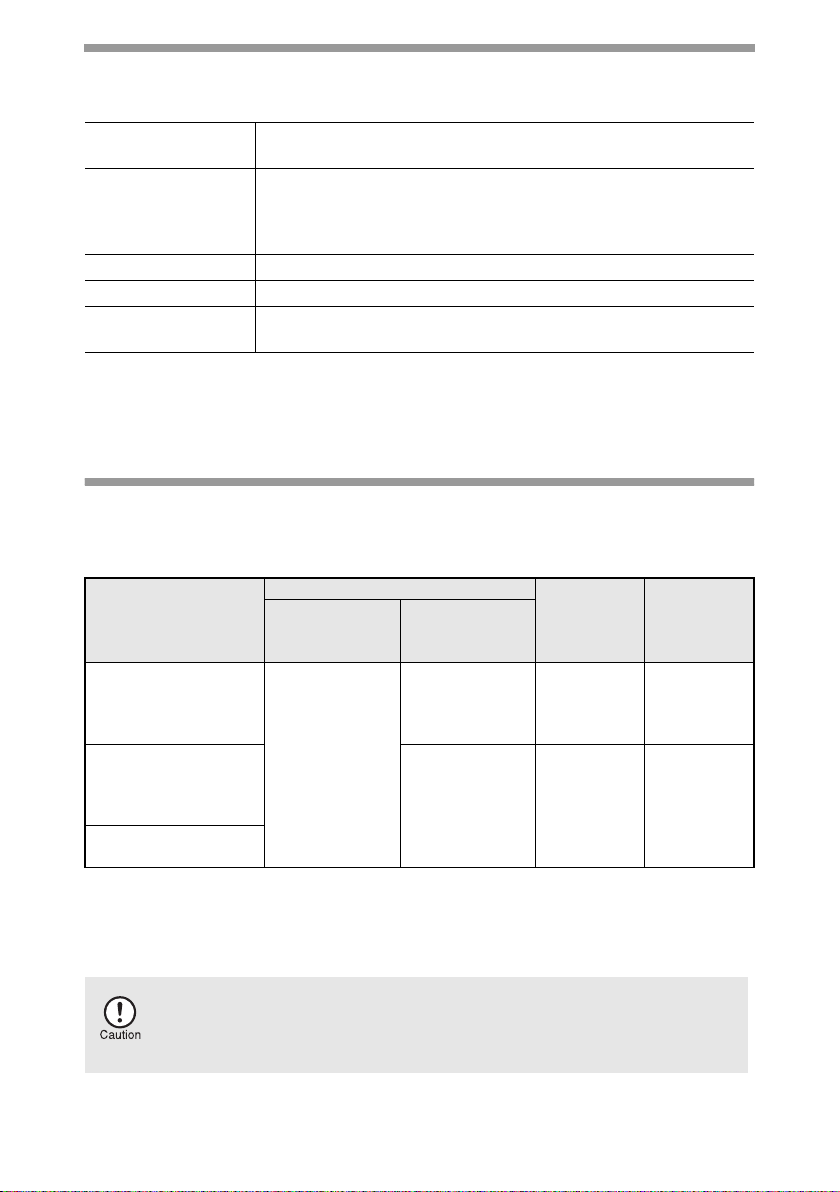

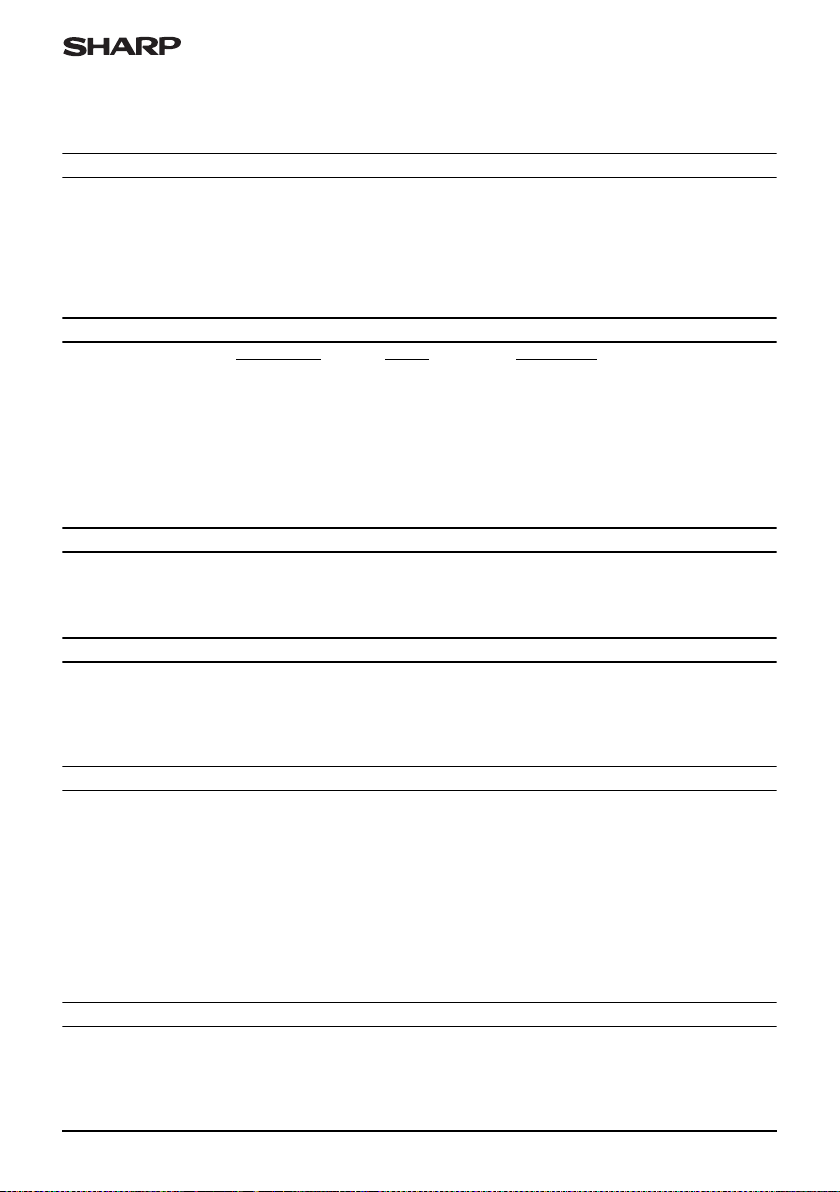

The following table shows the drivers and software that can be installed for each

version of Windows and interface connection method.

MFP Driver

Printer driver/

Print Status

Scanner driver

Window

Users of Windows

98/Me/2000/XP who

will use the USB

Available Available Available

interface connection

Users of Windows

98/Me/2000/XP who

will use the parallel

interface connection

Available*

1

Not Available

Windows 95/NT 4.0

users

*1When the unit is connected through the parallel port, the Print Status Window can only

be used when the parallel port is set to ECP mode. To set the parallel port mode, refer

to your computer manual or ask the manufacturer of your computer.

2

Sharpdesk can be installed when using a parallel interface connection, however, the

*

unit’s scanner function cannot be used.

Is there another GDI printer driver or a Windows Printing System printer

driver already installed? If installed, change the printer port setting. For

the change of the printer port setting, see "USING OTHER INSTALLED

DRIVERS" (p.44).

Button

Manager

Not

Available

Sharpdesk

Available*

2

20

Page 23

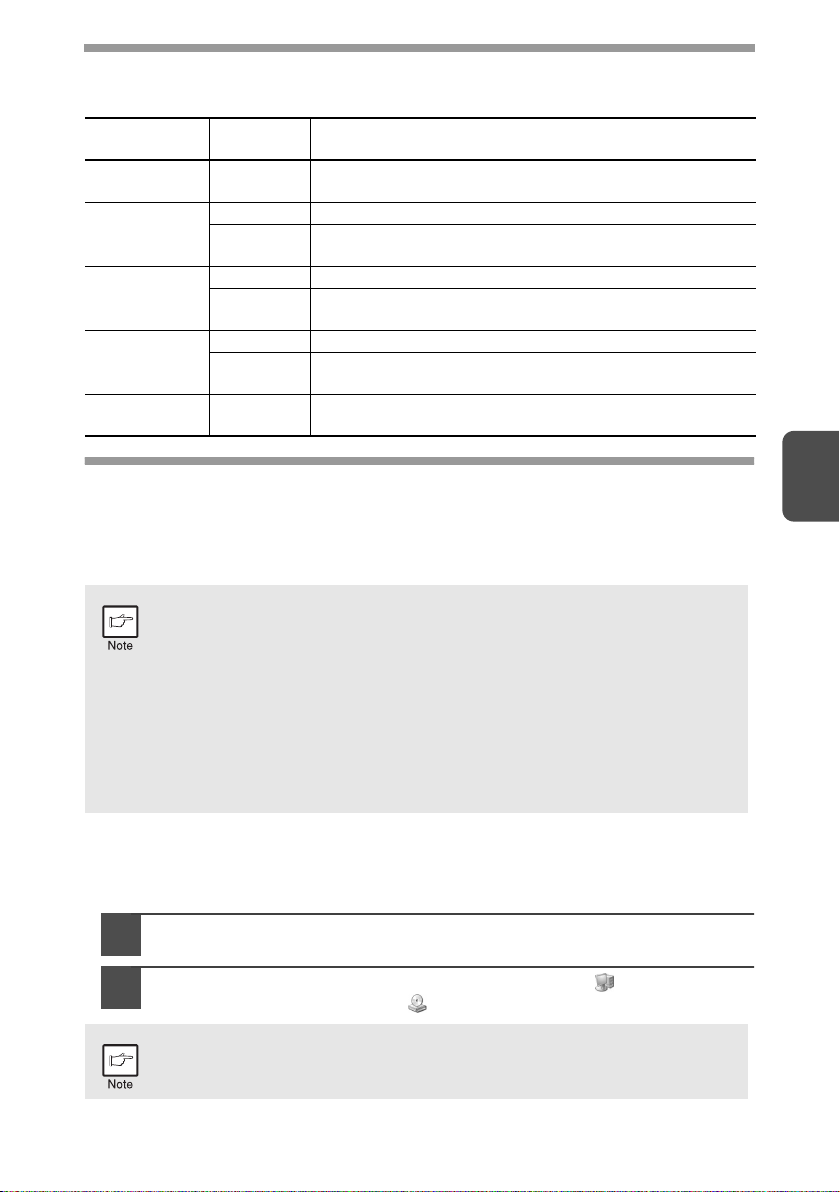

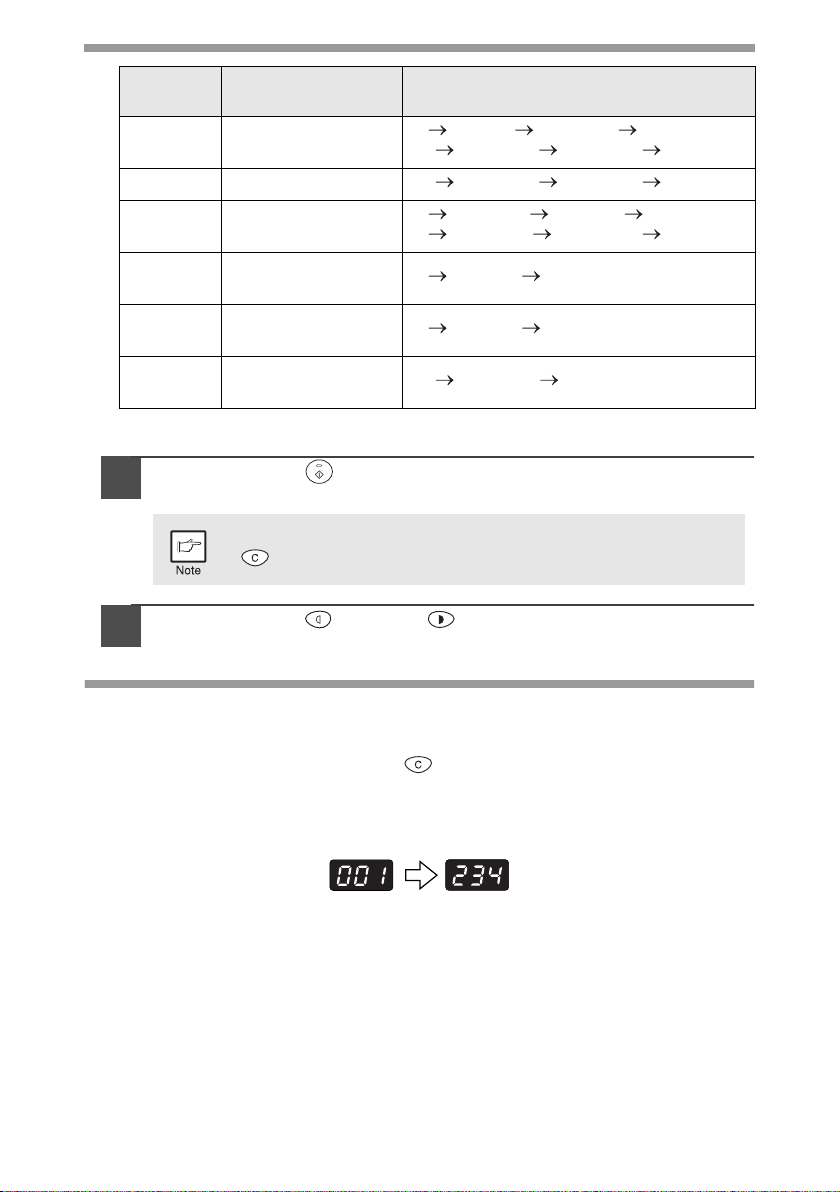

Flow of installation

Refer to the following table and then begin installation.

Operating

system

Windows XP

Windows 98

Windows Me

Windows 2000

Windows 95/

NT 4.0

Interface Reference pages for how to install

USB/

Parallel

USB

Parallel

USB

Parallel

USB

Parallel

Parallel

Installing onto Windows XP (USB/parallel interface)

(p.21)

Installing onto Windows 98/Me/2000 (USB interface) (p.25)

Installing onto Windows 95/98/Me/NT4.0/2000

(Parallel interface) (p.28)

Installing onto Windows 98/Me/2000 (USB interface) (p.25)

Installing onto Windows 95/98/Me/NT4.0/2000

(Parallel interface) (p.28)

Installing onto Windows 98/Me/2000 (USB interface) (p.25)

Installing onto Windows 95/98/Me/NT4.0/2000

(Parallel interface) (p.28)

Installing onto Windows 95/98/Me/NT4.0/2000

(Parallel interface) (p.28)

INSTALLING THE SOFTWARE

The following term is used in this section.

MFP

Means the unit as a printer and scanner.

• For this description, it is assumed that the mouse is configured for

right hand operation.

• To print or scan, the MFP must be in the online state.

• The scanner feature only works when using a USB interface cable.

• If any error message appears, solve the problem following the

instructions on the screen. After your problem is solved, the installing

procedure will be continued. Depending on your problem, you may

have to exit the installer. In this case, click the "Cancel" button to exit

the installer. After solving your problem, reinstall the software from the

beginning.

Installing onto Windows XP (USB/parallel interface)

Before starting the installation, make sure the USB or parallel interface cable is not

connected to the MFP.

Insert the supplied CD-ROM into your CD-ROM drive.

1

Click the "start" button, click "My Computer" ( ), and then

2

double-click the CD-ROM ( ) icon.

When any of "Found New Hardware Wizard" messages appear during

the software installation, be sure to click the "Cancel" button.

4

21

Page 24

Double-click the "setup" ( ) icon.

3

If the language selection screen appears after you double click the

"setup" icon, select the language you wish to use and click the "Next"

button. (Normally, the correct language is selected automatically.)

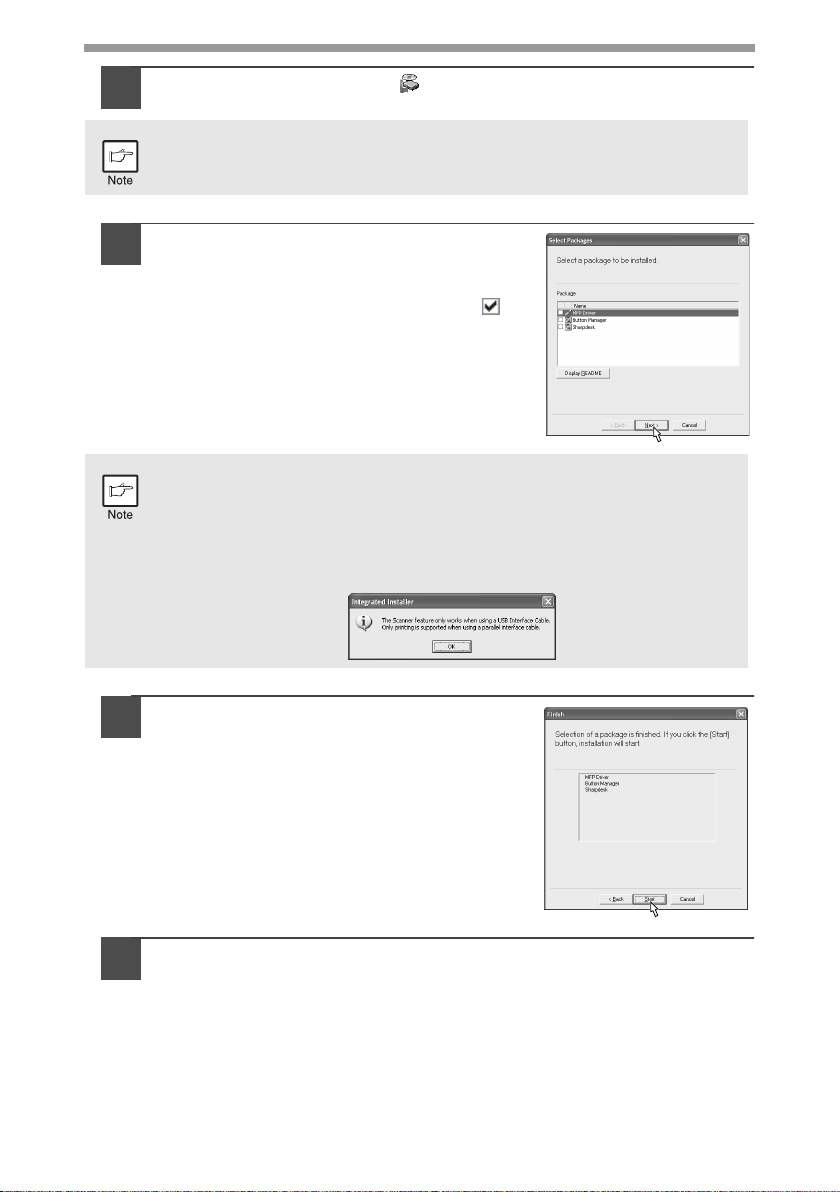

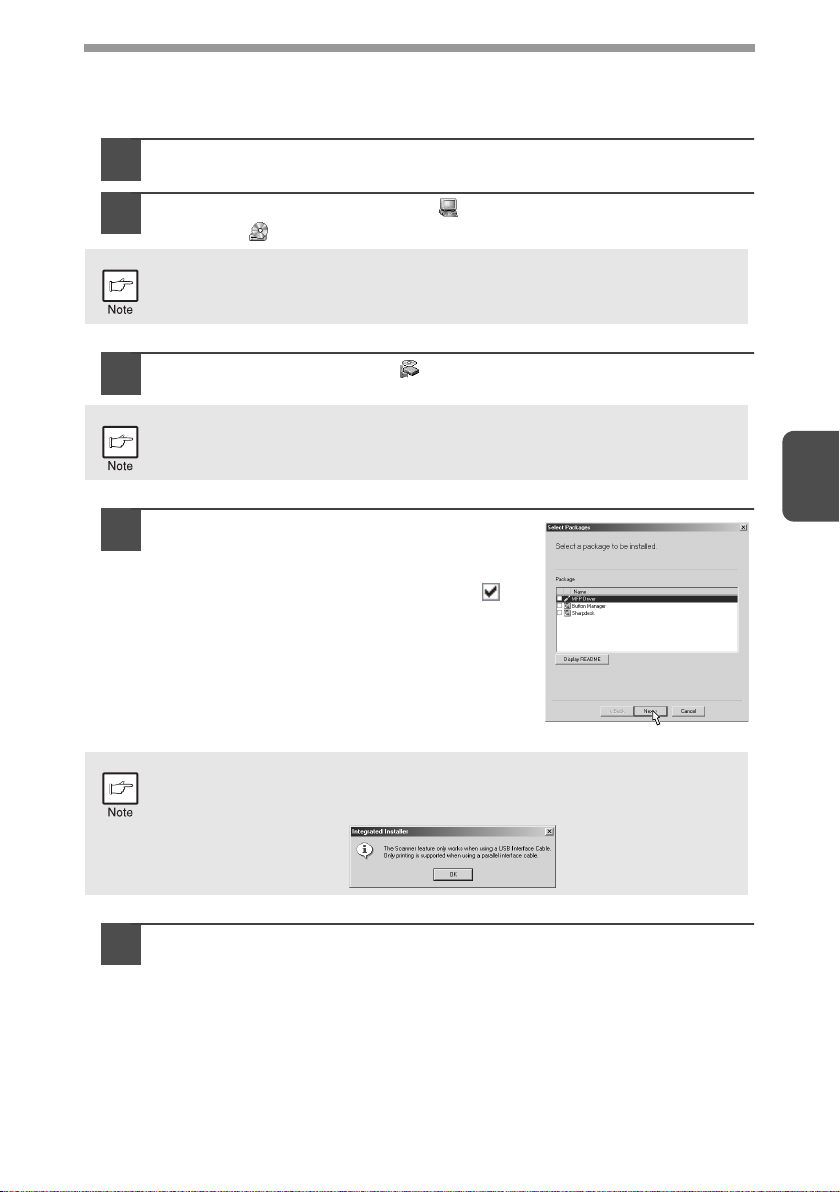

Select the software packages to be

4

installed, and then click the "Next"

button.

The software packages with checkmark ( )

on the list on the screen will be installed.

Click the "Display README" button to show

the information on the selected package.

• If you are using the parallel interface connection, do not select the

Button Manager checkbox because this feature is not supported with

the parallel interface.

• If the following screen appears, click the "OK" button. Review the

contents in "BEFORE INSTALLATION" (p.20), and then select only

appropriate the software packages to be installed.

22

Review the software packages to be

5

installed on the screen, and then click

the "Start" button.

The software packages to be installed will be

displayed on the screen. If inappropriate

packages are displayed, click the "Back" button

to select appropriate packages again.

Copying files for MFP driver installation (This step will start if it

6

was selected in step 4).

After confirming the message in the "Welcome" window, click the

1

"Next" button.

A dialog box appears asking you to verify that the USB or parallel

2

interface cable is not connected to the MFP. Make sure that the

interface cable is not connected and click the "Next" button.

Page 25

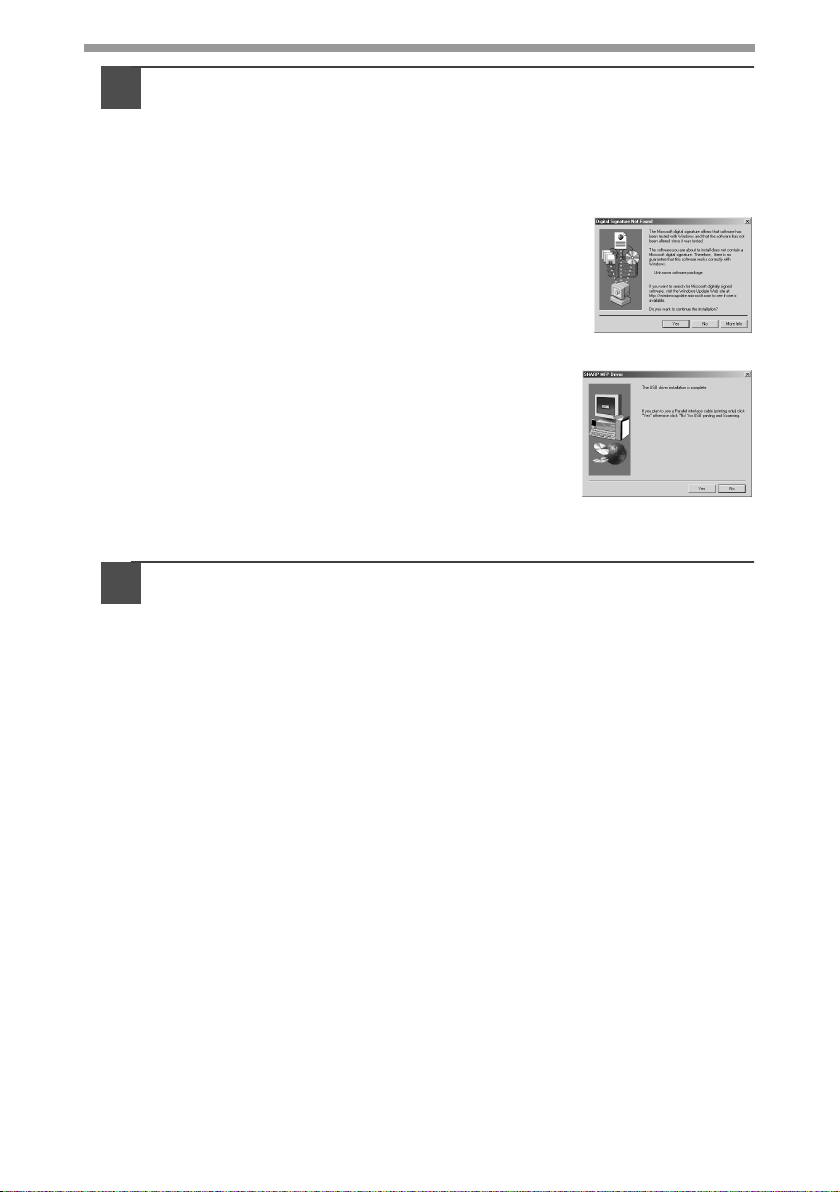

Click the "Next" button in the dialog box to

3

install the MFP driver or Cancel to quit the

installation.

The setup program will start to copy the files.

If the following screen appears while the files are

being copied (the message may appear more

than once), click "Continue Anyway".

When the "The MFP driver installation is complete." dialog box

4

appears, click the "OK" button.

The Button Manager installer will start.

Begin installation of the Button Manager (This step will start if it

7

was selected in step 4).

After confirming the message in the "Welcome" window, click the

1

"Next" button.

Read the message in the "Please read the following information."

2

window, and then click the "Next" button.

When a message appears that lets you specify the location for the

3

software to be installed, click the "Next" button.

If the program displays "Do you want the Button Manager added to

4

Windows Startup?", check "Yes" and click the "OK" button.

The setup program will start to copy the files.

Click the "Finish" button when the message informs you that

5

setup is successful.

The Sharpdesk installer will start.

Begin installation of the Sharpdesk (This step will start if it was

8

selected in step 4).

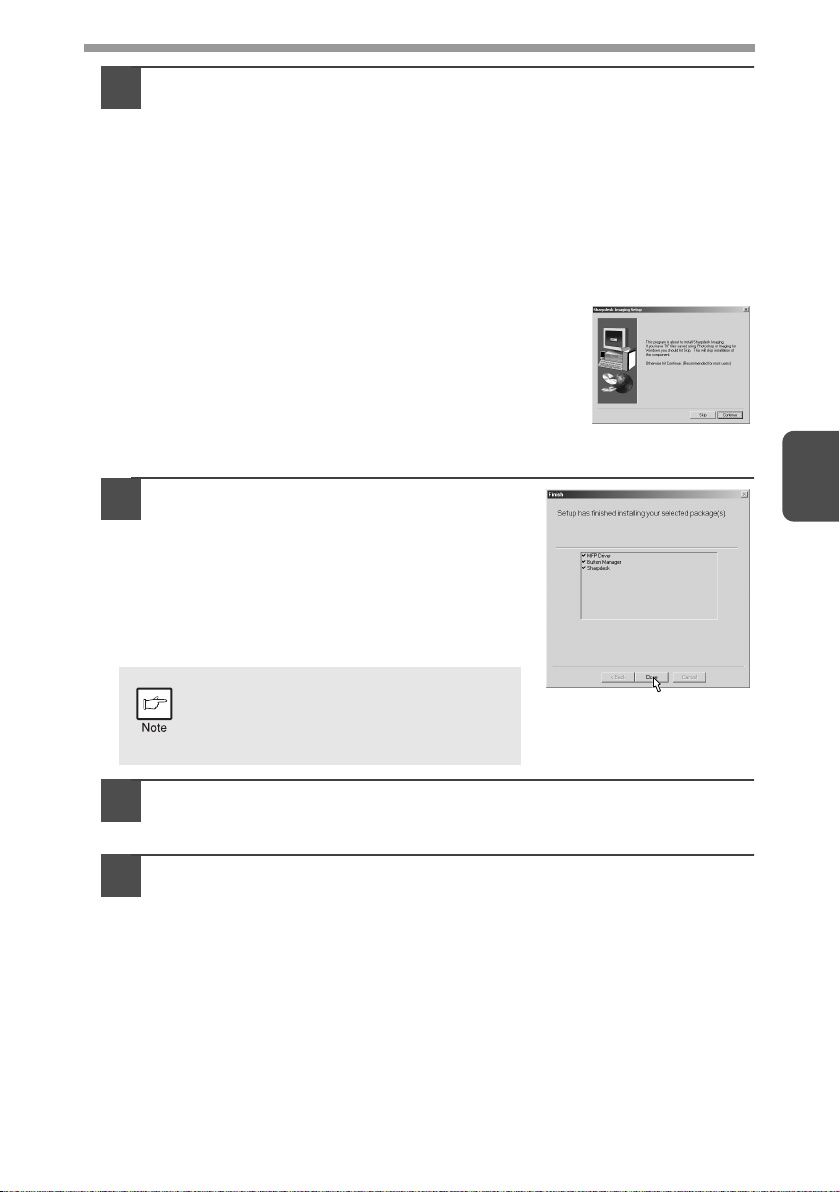

After confirming the message in the "Welcome to Sharpdesk

1

installation" window, click the "Next" button.

Read the message in the "Information" window, and then click the

2

"Next" button.

When the "Choose Destination Location" window appears, click

3

the "Next" button.

When the "Select Program Folder" window appears, click the

4

"Next" button.

The setup program will start to copy the files.

Click the "Finish" button when the message informs you that

5

Setup is complete.

4

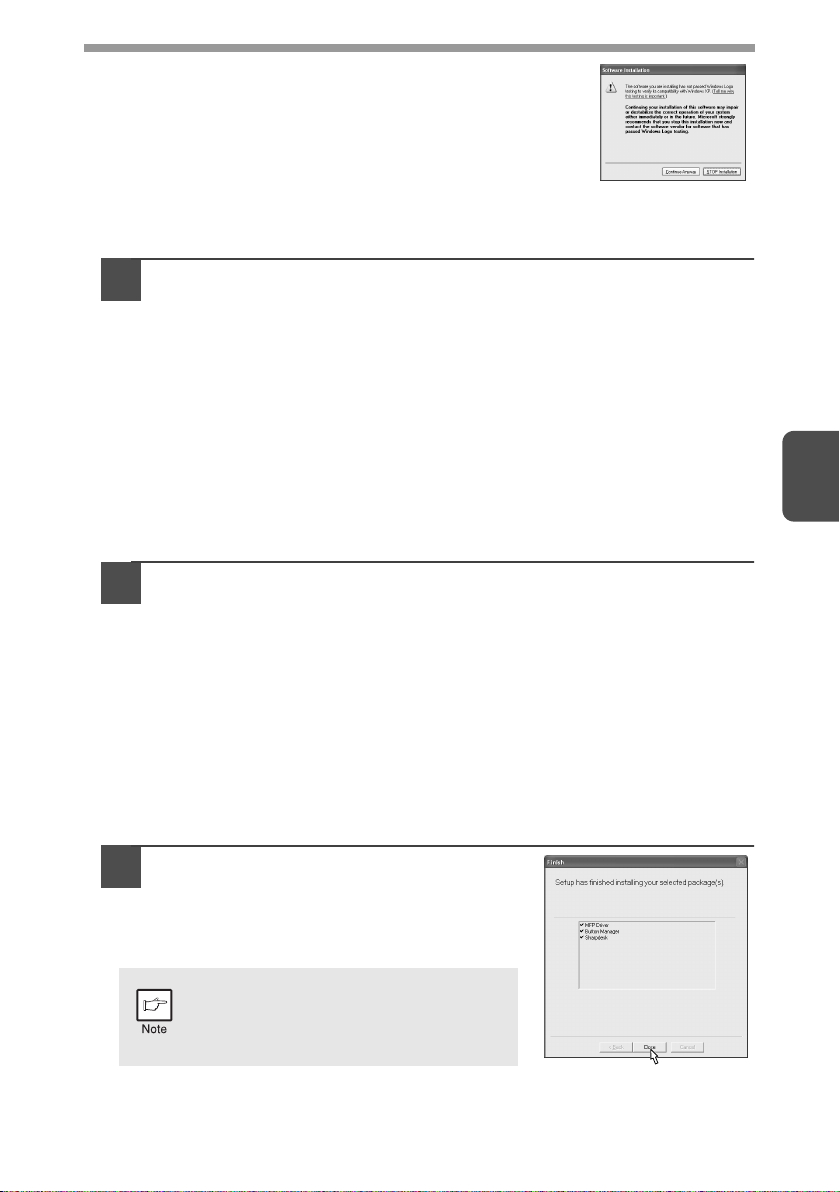

Click the "Close" button when the

9

message informs you that "Setup has

finished". When the "Now connect the

MFP interface cable to the PC" dialog

box appears, click the "OK" button.

After the installation, a message to

restart your computer may be

displayed. In this case, click the "Yes"

button to restart your computer.

23

Page 26

Make sure that the power of the MFP is turned on, and then

10

connect the USB interface cable or parallel interface cable.

(p.45)

Windows will detect the MFP and the Plug and Play screen will appear. If

you are using Windows XP with the parallel interface, go to step 12.

Begin installation of the scanner driver.

11

12

"SHARP AL-1641CS" will appear in the "Found New Hardware

1

Wizard" dialog box. Select "Install the software automatically

(Recommended)" and click the "Next" button.

The "Hardware Installation" dialog box will appear. Click the

2

"Continue Anyway" button.

When installation of the driver is completed, click the "Finish"

3

button to finish the scanner driver installation.

Begin installation of the printer driver.

"SHARP AL-1641CS" will appear in the "Found New Hardware

1

Wizard" dialog box. Select "Install the software automatically

(Recommended)" and click the "Next" button.

The "Hardware Installation" dialog box will appear. Click the

2

"Continue Anyway" button.

When installation of the driver is completed, click the "Finish"

3

button to finish the printer driver installation.

You have completed the installation of all the software.

24

Page 27

Installing onto Windows 98/Me/2000 (USB interface)

Before starting the installation, make sure the USB interface cable is not connected

to the MFP.

Insert the supplied CD-ROM into your CD-ROM drive.

1

Double-click "My Computer" ( ), and then double-click the

2

CD-ROM ( ) icon.

When any of "Hardware Found", or "Found New Hardware Wizard"

messages appear during the software installation, be sure to click the

"Cancel" button.

Double-click the "setup" ( ) icon.

3

If the language selection screen appears after you double click the

"setup" icon, select the language you wish to use and click the "Next"

button. (Normally, the correct language is selected automatically.)

Select the software packages to be

4

installed, and then click the "Next"

button.

The software packages with checkmark ( )

on the list on the screen will be installed. Click

the "Display README" button to show the

information on the selected package.

4

If the following screen appears, click the "OK" button. Review the

contents in "BEFORE INSTALLATION" (p.20), and then select the

appropriate driver software packages to be installed.

Review the software packages to be installed on the screen,

5

and then click the "Start" button.

The software packages to be installed will be displayed on the screen. If

inappropriate packages are displayed, click the "Back" button to select

appropriate packages again.

25

Page 28

Copying files for MFP driver installation.

6

After confirming the message in the "Welcome" window, click the

1

"Next" button.

A dialog box appears asking you to verify that the interface cable

2

is not connected to the MFP. Make sure that the interface cable is

not connected and click the "Next" button.

Click the "Next" button in the dialog box

3

showing the files to be copied for installation

of the MFP driver.

The setup program will start to copy the files.

In Windows 2000, if the following screen appears

while the files are being copied (the message

may appear more than once), click "Yes" in

Windows 2000.

The following screen appears when all of the

4

files for the USB interface connection have

been copied. If you are not using a parallel

interface cable for connection to the MFP,

please click the "No" button.

When the "The MFP driver installation is

5

complete." dialog box appears, click the "OK" button.

The Button Manager installer will start.

Begin installation of the Button Manager (This step will start if it

7

was selected in step 4).

After confirming the message in the "Welcome" window, click the

1

"Next" button.

Read the message in the "Please read the following information."

2

window, and then click the "Next" button.

When a message appears that lets you specify the location for the

3

software to be installed, click the "Next" button.

If the program displays "Do you want the Button Manager added to

4

Windows Startup?", check "Yes" and click the "OK" button.

The setup program will start to copy the files.

Click the "Finish" button when the message to inform you of the

5

completion of the installation appears.

The Sharpdesk installer will start.

26

Page 29

Begin installation of the Sharpdesk (This step will start if it was

8

selected in step 4).

After confirming the message in the "Welcome to Sharpdesk

1

installation" window, click the "Next" button.

Read the message in the "Information" window, and then click the

2

"Next" button.

When the "Choose Destination Location" window appears, click

3

the "Next" button.

When the "Select Program Folder" window appears, click the

4

"Next" button.

The setup program will start to copy the files.

If the dialog box asking "If you have TIF files

saved using Photoshop or Imaging for

Windows you should hit Skip" appears,

answer the question to continue the

Sharpdesk installation.

Click the "Finish" button when the message

5

to inform you of the completion of the installation appears.

Click the "Close" button when the

9

message to inform you of the

completion of the installation appears.

When the "Now connect the MFP

interface cable to the PC." dialog box

or "After Windows system restarts..."

dialog box appears, click the "OK"

button.

4

After the installation, a message to

restart your computer may be

displayed. In this case, click the "Yes"

button to restart your computer.

Make sure that the power of the MFP is turned on, and then

10

connect the USB interface cable. (p.45)

Windows will detect the MFP and the Plug and Play screen will appear.

Follow the instructions in the Plug and Play screen that

11

appears in your version of Windows to begin the installation.

You have completed the installation of the software.

27

Page 30

Installing onto Windows 95/98/Me/NT4.0/2000

(Parallel interface)

Before starting the installation, make sure the USB or parallel interface cable is not

connected to the MFP.

Insert the supplied CD-ROM into your CD-ROM drive.

1

Double-click "My Computer" ( ), and then double-click the

2

CD-ROM ( ) icon.

When any of "Hardware Found", or "Found New Hardware Wizard"

messages appear during the software installation, be sure to click the

"Cancel" button.

Double-click the "setup" ( ) icon.

3

If the language selection screen appears after you double click the

"setup" icon, select the language you wish to use and click the "Next"

button. (Normally, the correct language is selected automatically.)

Select the software packages to be

4

installed, and then click the "Next"

button.

The software packages with checkmark ( )

on the list on the screen will be installed.

Click the "Display README" button to show

the information on the selected package.

In Windows 95/NT 4.0, "Button

Manager" does not appear. In

Windows 98/Me/2000, do not select

the "Button Manager" checkbox.

because this is not supported when

using the parallel interface.

28

The next screen appears. Make sure that the parallel interface

5

cable is not connected, and click "OK".

Windows 95/NT 4.0 Windows 98/Me/2000

Check the contents of the package on the screen, and then

6

click the "Start" button.

The software packages to be installed will be displayed on the screen. If

inappropriate packages are displayed, click the "Back" button to select only

appropriate software packages.

Page 31

Copying files for MFP driver installation and parallel interface

7

setup (This step will start if it was selected in step 4).

After confirming the message in the "Welcome" window, click the

1

"Next" button.

A dialog box appears asking you to verify that the USB or parallel

2

interface cable is not connected to the MFP. Make sure that the

interface cable is not connected and click the "Next" button.

Click the "Next" button in the dialog box to

3

install the MFP driver or Cancel to quit the

installation.

The setup program will start to copy the files.

In Windows 2000, if the following screen appears

while the files are being copied (the message

may appear more than once), click "Yes" in

Windows 2000.

The following screen appears. Click the "Yes" button, and then the

4

Model screen will appear. Select the model number that is the

same as the model name of your MFP and click the "Next" button.

Be sure to select the displayed model number that is the same as the

MFP's model name. If they are not the same, the driver will not be

installed correctly.

Establish the printer settings and click the

5

"Next" button.

Select "LPT1" for the port to be used. If "LPT1"

does not appear, it is likely that another printer or

peripheral device is using "LPT1". Check your

other printers and peripheral devices, and change

the port setting as needed so no device is using

"LPT1". If you wish the MFP to be your default

printer, select "Yes". If not, select "No".

When the "Setup has completed gathering all necessary installation

6

information" dialog box appears, click the "Yes" button.

The parallel interface driver is installed.

When the "The MFP driver installation is complete." dialog box

7

appears, click the "OK" button.

The Sharpdesk installer will start.

4

29

Page 32

Begin installation of the Sharpdesk (This step will start if it was

8

selected in step 4).

After confirming the message in the "Welcome to Sharpdesk

1

installation" window, click the "Next" button.

Read the message in the "Information" window, and then click the

2

"Next" button.

When the "Choose Destination Location" window appears, click

3

the "Next" button.

When the "Select Program Folder" window appears, click the

4

"Next" button.

The setup program will start to copy the files.

If the dialog box asking "If you have TIF files

saved using Photoshop or Imaging for

Windows you should hit Skip" appears,

answer the question to continue the

Sharpdesk installation.

Click the "Finish" button when the message

5

to inform you of the completion of the installation appears.

Click the "Close" button when the

9

message to inform you of the

completion of the installation appears.

When the "Now connect the MFP

interface cable to the PC." dialog box

or "After Windows system restarts..."

dialog box appears, click the "OK"

button.

30

After the installation, a message to

restart your computer may be

displayed. In this case, click the "Yes"

button to restart your computer.

Make sure that the power of the MFP is turned on, and then

10

connect the parallel interface cable. (p.45)

You have completed the installation of all the software.

Page 33

INDICATORS ON THE OPERATION PANEL

The ONLINE indicator and the start ( ) indicator indicate the state of the printer or

scanner.

SCANNER indicator

ONLINE indicator

Start indicator

Power save indicator

Start indicator

On: Indicates the unit is ready for copying or scanning is being performed.

Blinking: The indicator blinks in the following situations:

• When a print job is interrupted.

• When reserving a copy job.

• When toner is being replenished during a copy or print job.

Off: The indicator is off in the following situations:

• During copying or scanning.

• The unit is in the auto power shut-off mode.

• When a misfeed or error has occurred.

ONLINE indicator

The ONLINE key is pressed and on line and off line are changed.

On: Indicates the unit is ready for printing or scanning is being performed.

(On line)

Blinking: Printing or data is being received from a computer.

Off: Copying is being performed. (Off line)

Power save indicator

On: Indicates the unit is in a power save mode.

Blinking: Indicates that the unit is initializing (when the side cover is opened and

closed or the power turned off and on).

SCANNER indicator

On: The SCANNER ( ) key has been pressed and the unit is in scanner

mode.

Blinking: A scan job is being executed from the computer, or scan data is stored

in the unit's memory.

Off: The unit is in the copy mode.

4

31

Page 34

USING THE PRINTER MODE

For problems with the printer function, see the online manual or the help

file for the driver.

Opening the printer driver from the start menu

Open the printer driver setup screen by the method shown below.

Click the "start" button.

1

Click "Control Panel", select "Printers and Other Hardware",

2

and then click "Printers and Faxes".

On Windows 95/98/Me/NT4.0/2000, select "Settings" and click "Printers".

Click the "SHARP AL-1641CS" printer driver icon and from the

3

"File" menu select "Properties".

On windows NT 4.0, select "Document Defaults" to open the

printer driver setup screen.

Click "Printing Preferences" button in the "General" tab.

4

On Windows 95/98/Me, click the "Setup" tab.

The printer driver setup screen will appear.

Refer to the Windows manual or help file for more information

on the "General" tab, "Details" tab, "Color Management" tab and

"Sharing" tab.

32

Page 35

How to print

Make sure that the paper of the desired size and type is loaded

1

in the tray.

The procedure for loading paper is the same as for loading copy paper. See

"LOADING PAPER" (p.14).

Open the document you intend to print, and select "Print" from

2

the application's "File" menu.

Make sure that "SHARP AL-1641CS" is selected as the current

3

printer. If you intend to change any print setting, click the

"Preferences" button to open the setting dialog.

On Windows 95/98/Me/NT 4.0, click the "Properties" button.

On Windows 2000, the "Properties" button does not appear. Set your

preferences by switching the tab in the "Print" dialog box.

Specify the print settings including the number of copies,

4

media type, and print quality, and then click the "Print" button

to start printing.

On Windows 95/98/Me/NT 4.0, click the "OK" button to start printing.

For details on print settings, see the online manual or the help file for the

printer driver.

• If copying is being performed when printing is started, copying will

continue. After copying is complete, printing will be executed when the

clear ( ) key is pressed twice, the ONLINE key is pressed to switch

the unit to the online state or approximately 60 seconds (auto clear

time)* elapse.

* The auto clear time varies with a user program setting. See "USER

PROGRAMS" (p.55).

• Preheat mode and auto power shut-off mode will be canceled when

printing is started.

• If the paper size specified from the software application is larger than

the paper size in the printer, part of the image that is not transferred to

the paper may remain on the surface of the drum. In this case, the

backside of the paper may become dirty. If this occurs, change to the

correct size paper and print two or three pages to clean the image.

• If you start a print job while a scan job is in progress, the print data will

be stored in the unit's memory. When the scan job is completed,

printing will begin.

4

33

Page 36

USING THE SCANNER MODE

The scanner driver for this unit includes an STI (Still image) driver and WIA

(Windows Image Acquisition) driver. You can install software that supports the STI

driver and WIA driver to enable scanning using the operation panel of the unit.

For problems with the scanner function, see the online manual or the

help file for the driver.

Using the Button Manager

Setting up the Button Manager

The Button Manager accessory software supports the STI driver and WIA driver. Setup

that is required in Windows to use the Button Manager is explained in the following.

Windows XP

Click the "start" button, select "Control Panel" and click

1

"Printers and Other Hardware", and then click "Scanners and

Cameras" in the start menu. Right click the "SHARP AL1641CS" icon and click "Properties" in the menu that appears.

In the "Properties" screen, click the

2

"Events" tab.

34

Click the "Select an event" button and

3

select "ScanMenu SC1" from the pull-down

menu. Select "Button Manager (SHARP

Personal MFP series)" in "Start this

program" and click "Apply".

Repeat Step3 to set "ScanMenu SC2" through "ScanMenu SC6".

4

Click the "Select an event" button and select "ScanMenu SC2" from the pulldown menu. Select "Button Manager (SHARP Personal MFP series)" in

"Start this program" and click "Apply". Do the same for each ScanMenu

through "ScanMenu SC6".

When the settings have been completed, click the "OK" button to close the

screen. When the settings have been completed in Windows, start the

Button Manager. Adjust detailed settings and then scan an image from the

unit. For the procedures for starting Button Manager and adjusting settings,

see "Scan Button Destination Setting Dialog Box" (p.36).

Page 37

Windows 98/Me/2000

To scan directly into an application using the Button Manager on Windows 98,

Windows Me and Windows 2000. Set the Event Manager properties to send only to

Button Manager as shown below.

Click the "Start" button, select "Control Panel" from "Settings",

1

and open "Scanners and Cameras" in start menu.

In Windows Me, it occasionally happens that the "Scanners and

Cameras" icon does not appear immediately after installation of the

MFP driver is completed. If the icon does not appear, click "View all

Control Panel options" in the Control Panel and display the "Scanner

and Cameras" icon.

Select "AL-1641CS", and click the "Properties" button.

2

In Windows Me, right click "AL-1641CS" and click "Properties" in the menu

that appears.

In the "Properties" screen, click the

3

"Events" tab.

Click the "Scanner events" button and

4

select "ScanMenu SC1" from the pull-down

menu. Select "Button Manager (SHARP

Personal MFP series)" in "Send to this

application" and click "Apply".

4

If other application are shown,

deselect the checkboxes for the other

applications and leave only the Button

Manager checkbox selected.

Repeat Step4 to set "ScanMenu SC2" through "ScanMenu

5

SC6".

Click the "Scanner events" and select "ScanMenu SC2" from the pull-down

menu. Select "Button Manager (SHARP Personal MFP series)" in "Start this

program" and click "Apply". Do the same for each ScanMenu through

"ScanMenu SC6".

When the settings have been completed, click the "OK" button to close the

screen. When the settings have been completed in Windows, start the

Button Manager. Adjust detailed settings and then scan an image from the

unit. For the procedures for starting Button Manager and adjusting settings,

see "Scan Button Destination Setting Dialog Box" (Next page).

35

Page 38

Scan Button Destination Setting Dialog Box

After you have completed the Button Manager settings in

Windows, configure the scan settings in Button Manager.

To configure the scan settings in Button Manager, right click

the ( ) icon in the Taskbar and select "Setting" from the

menu that appears.

For details on configuring the scan settings in Button

Manager, see the online manual or the help file.

This is the corresponding setting in the Button

Manager to automatically send image(s) in full

color at 75 dpi to Sharpdesk using the

operation panel "SC1" SCANNER ( ) key

selection.

This dialog shows the SC1 event set to go directly to Button Manager.

With the Button Manager set to send the image to Sharpdesk. (factory

default setting) Sharpdesk will open after acquiring the image

automatically.

36

Page 39

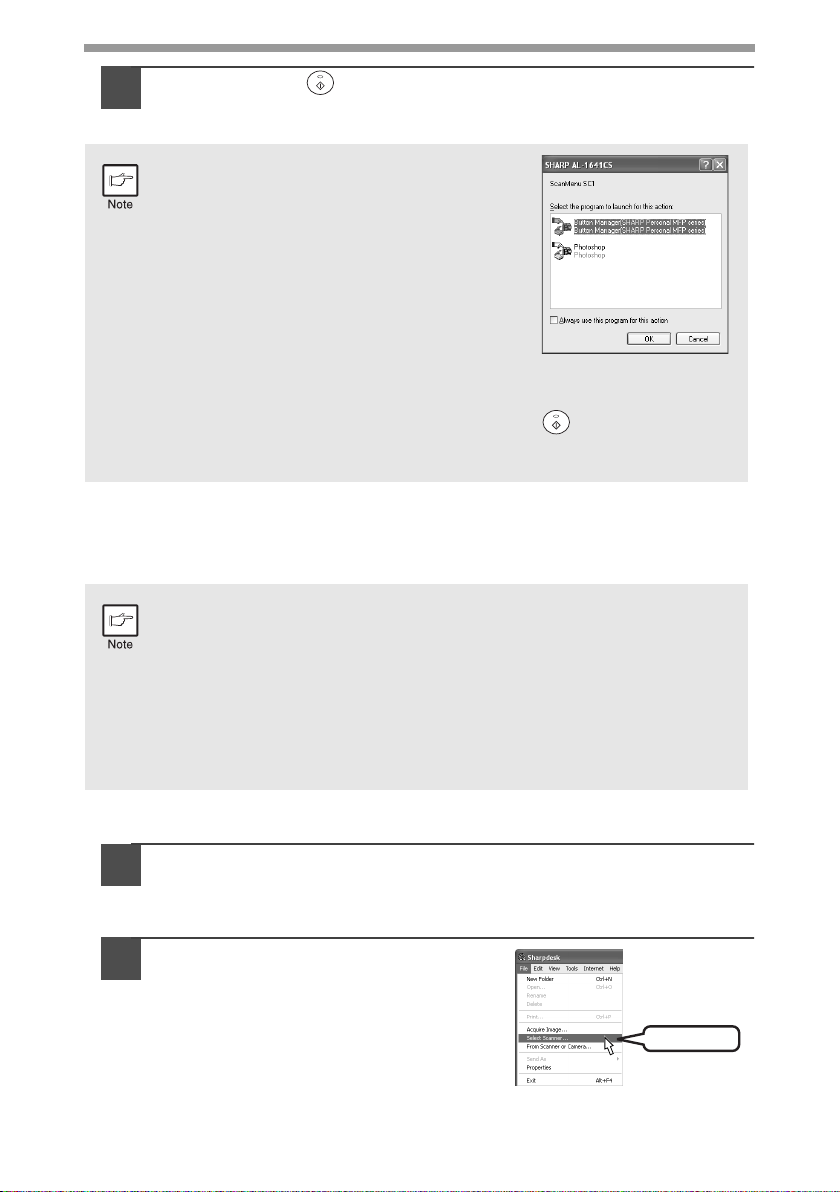

Flow of the Button Manager setting

The Button Manager can directly handle an AL-1641CS device event and start your

selected application according to the scan setting made on the AL-1641CS operation

panel (SC1, SC2, SC3, SC4, SC5, SC6).

This will scan directly into your application from the device.

Scanner AL1641CS

SCANNER

key pressed.

The settings for the Windows Event Manager for

the SHARP AL-1641CS device allow the user to

take advantage of the Sharp Button Manager to

take control of events from Windows and send

scanned images to any application that can be

selected in Button Manager.

This can be done with the Windows OS showing

the Event Manager selection dialog or directly

into a selected application if the Button Manager

is the only allowed handler for device events

from the SHARP AL-1641CS.

This is done by changing the Windows device

settings for the AL-1641CS in the Scanner and

Camera device settings in the Control Panel.

Event

Manager

Windows OS

Button

Manager

No Selection

dialog is

displayed.

User

selected

application

The user

application

opens.

4

This is the Control Panel

Properties dialog for "Scanners and

Cameras".

The AL-1641CS is shown selected.

37

Page 40

All About The Windows Event Manager and scanner events in

Windows 98, Windows Me, Windows 2000 and Windows XP.

Windows Platforms provide a mechanism for software to handle external events for

a scanner device like the SHARP AL-1641CS products. This mechanism is

controlled by the device manager on a device basis. Applications that can handle

events from a scanner/camera device register with the Windows Event Manager and

shown as available in the registered applications. The path an event takes to get to

the user's selected application depends upon the event settings for the device.

Scanner AL1641CS

SCANNER

key pressed.

Event

Manager

Windows OS

Event

Manager

selection

dialog

Displayed on

screen

This is the Windows Event Manager

Selection Dialog.

Shown are two applications registered

to handle the scanner event from the

AL-1641CS device.

User selects

an

application.

The user

application

opens.

38

Page 41

Using the SCANNER key to begin scanning

• Scanning is not possible during a copy job.

•

If the SCANNER ( ) key is pressed during a print job, the scan job will

be stored.

•

When scanning an original that has been placed in the SPF, only one

original can be placed unless you are using Sharpdesk.

Press the SCANNER ( ) key.

1

The unit enters scan mode.

Place the original you wish to scan on the document glass/SPF.

2

For the procedure for placing the original, see "ORIGINAL PLACEMENT"

(p.47).

Press the right copy quantity key to

3

display the number of the application that

you wish to use for scanning.

The application numbers are initially as follows.

4

Application

number

SC1 Sharpdesk (Full color) (if installed)

SC2 Sharpdesk (Monochrome) (if installed)

SC3

SC4 Fax (if a fax program is installed)

SC5 OCR (if an OCR program is installed)

SC6 Microsoft Word (if installed)

To check the settings, see "Scan Button Destination Setting Dialog Box"

(p.36) and then open the settings window of the Button Manager.

E-mail (your standard e-mail program in the

Windows OS you are using)

Application launched

39

Page 42

Press the start ( ) key.

4

Scanning will start and the scanned data will be transferred to the

application.

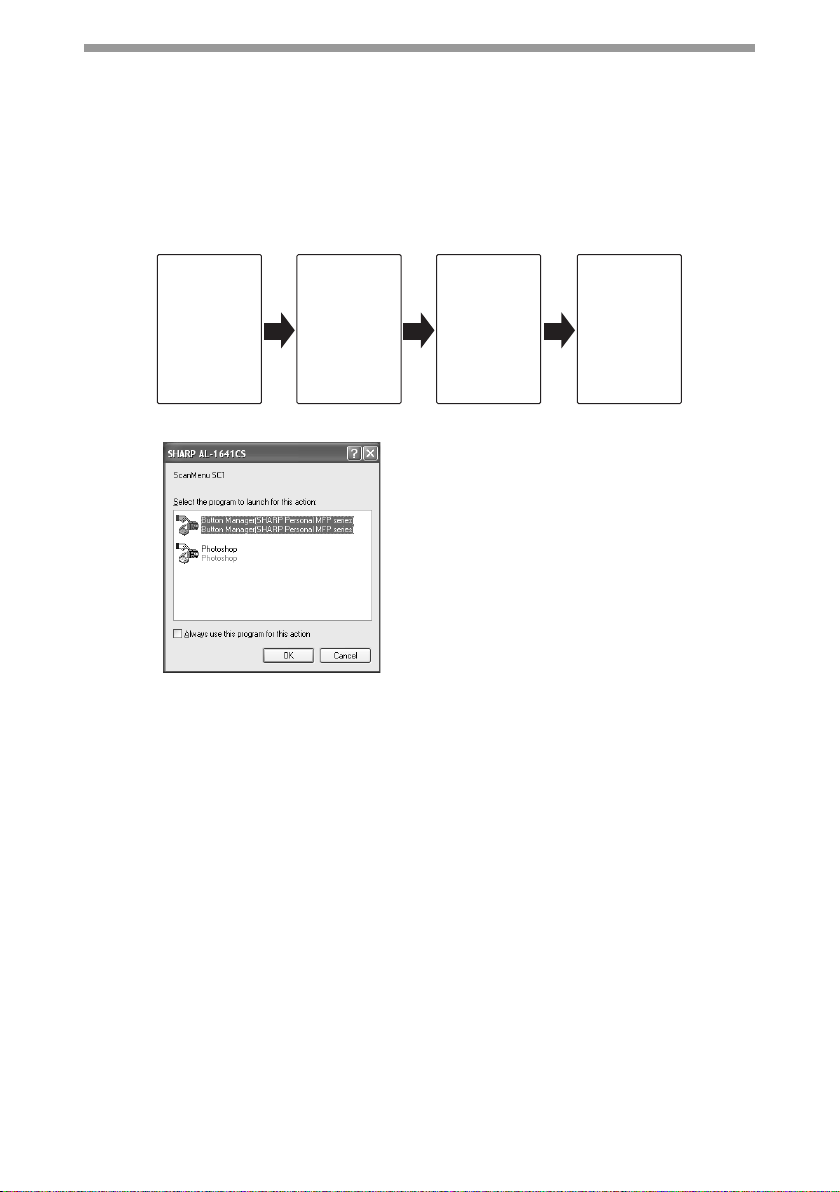

• If the following screen appears, select

Button Manager and click "OK". Button

Manager starts and the application

associated with Button Manager starts. If

you want only Button Manager to start in

this case, set up Button Manager for use in

Windows as explained in "Setting up the

Button Manager" (p.34).

• If step 4 is performed with the "Show

TWAIN setting screen when scanning"

checkbox selected in the Scan Button Destination Setting Dialog Box

(p.36), the TWAIN settings screen (p.41) will automatically appear.

Check the settings, and then press the start ( ) key again or click

the "Scan" button in the TWAIN setting screen to start scanning. The

scanned data will be transferred to the application.

Opening the scanner driver and scanning from your computer

Follow the steps below to open the scanner driver setup screen. As an example, this

instruction is given using Sharpdesk as an image capture application.

• Scanning is not possible during a copy and print job.

• The method for starting the scanner driver differs depending on the

type of application. Refer to the manual or the help file of your

application.

• When using the scanner driver to scan an original that has been

placed in the SPF. If you perform "preview" (see the online manual or

the help file for the scanner driver), the original in the SPF will be

output to the exit area after previewing. To scan the original after

previewing, place the original in the SPF once again.

40

Using the SHARP TWAIN

Place the original(s) you wish to scan on the document glass/

1

SPF.

For the procedure for placing the original, see "ORIGINAL PLACEMENT"

(p.47).

After starting Sharpdesk, click the

2

"File" menu and select "Select

Scanner".

Click here

Page 43

Select "SHARP Personal MFP

3

series", and click the "Select"

button.

If you use more than one scanning device, select the scanner

you want to use through the application. The method for

accessing the "Select Scanner" option, depends upon the

application. For more information, see the online manual or the

help file of your application.

Select "Acquire Image" from

4

the "File" menu, or click the

"Acquire" button ( ) .

Set the configuration for scanning (refer to the online manual

5

and help file), and click the "Scan" button.

Scan is started.

Click here

4

41

Page 44

Scanning with the "Scanner and Camera Wizard" in Windows XP

Windows XP includes as a standard feature an image scanning function. The

procedure for scanning with the "Scanner and Camera Wizard" is explained here.

To cancel scanning, click the "Cancel" button in the screen that is

displayed.

Place the original you wish to scan on the document glass/SPF.

1

For the procedure for placing the original, see "ORIGINAL PLACEMENT"

(p.47).

Click the "start" button, select "Control

2

Panel", and click "Printers and Other

Hardware", and then click "Scanners

and Cameras" in the start menu. Click

the "SHARP AL-1641CS" icon and click

"Get picture" in "Imaging Tasks".

The "Scanner and Camera Wizard"

3

appears. Click "Next" and establish the

basic settings for scanning.

For information on the settings, see the

Windows XP help file. After completing each

setting, click "Next".

42

Select a name, format, and folder for the

4

scanned image.

For information on the image name, file format,

and folder, see the Windows XP help file.

Scanning begins. When scanning ends,

5

select the next task you wish to perform.

For information on each selection, see the

Windows XP help file. To quit the "Scanner and

Camera Wizard", select "Nothing. I’m finished

working with these pictures." and click "Next".

Click "Finish" in the screen that appears.

6

The "Scanner and Camera Wizard" closes and the scanned image is saved.

Page 45

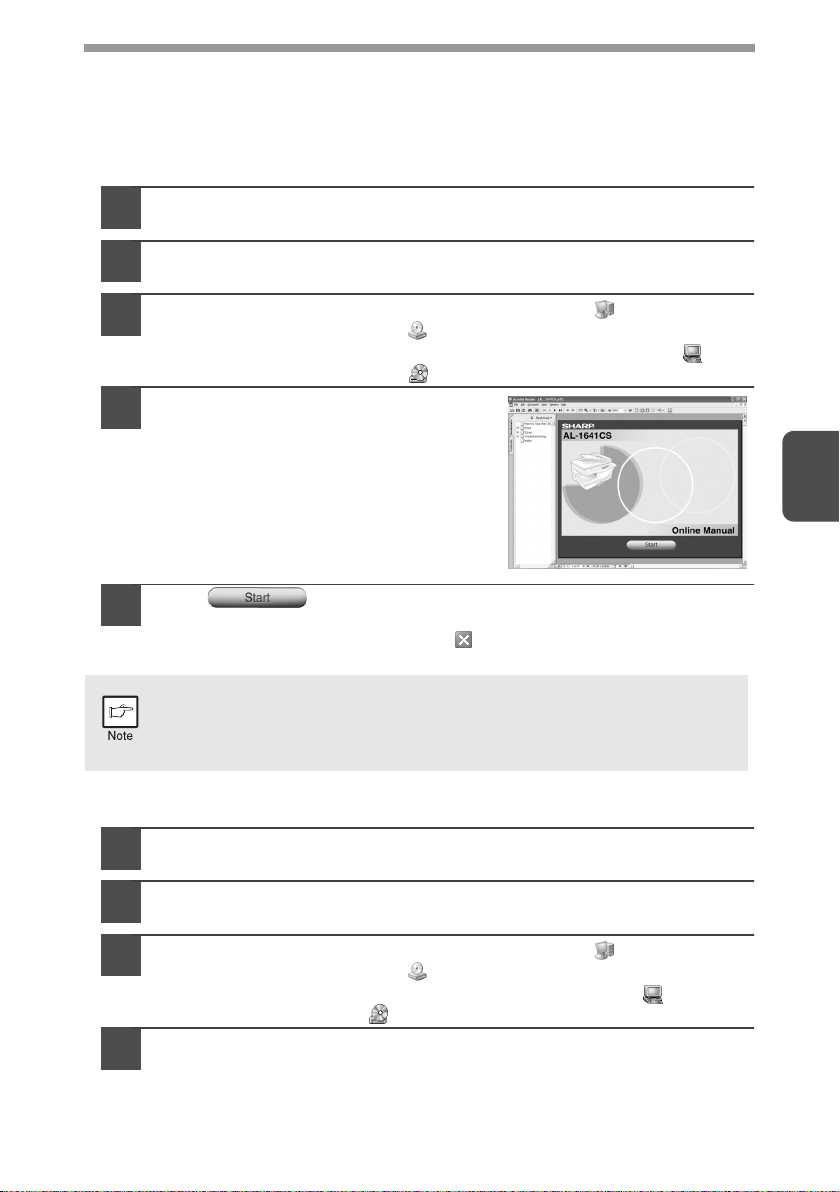

HOW TO USE THE ONLINE MANUAL

The online manual provides detailed instructions for operating the unit as the printer

or scanner and a list of methods for dealing with printing or scanner problems.

To access the online manual, your computer must have Acrobat Reader 5.0 or a

later version. If it is not installed, refer to "Installing Acrobat Reader" (below).

Turn on your computer.

1

Insert the supplied CD-ROM into your CD-ROM drive.

2

Click the "start" button, click "My Computer" ( ), and then

3

double-click the CD-ROM ( ) icon.

On Windows 95/98/Me/NT 4.0/2000, double-click "My Computer" ( ), and

then double-click the CD-ROM ( ) icon.

Double-click the "Manual" folder,

4

double-click the "EnglishA" folder,

and then double-click the

"AL_1641CS.pdf" icon.

The following window will appear.

Click to read the online manual.

5

To close the online manual, click the ( ) button located at the top-right of

the window.

• The online manual can be printed out using Acrobat Reader. SHARP

recommends printing out the sections which you refer to regularly.

• Refer to "Help" of Acrobat Reader for more details on the operation

and function of Acrobat Reader.

4

Installing Acrobat Reader

Turn on your computer.

1

Insert the CD-ROM into the CD-ROM drive.

2

Click the "start" button, click "My Computer" ( ), and then

3

double-click the CD-ROM ( ) icon.

Windows95/98/Me/NT4.0/2000, double-click "My Computer" ( ), and then

double-click the CD-ROM ( ) icon.

Double-click the "Acrobat" folder, and then double-click the

4

"ar500enu.exe" icon.

Follow the on-screen instructions to install Acrobat Reader.

43

Page 46

USING OTHER INSTALLED DRIVERS

If you use another GDI printer or a Windows Printing System printer, interference

between printers may occur and printing may not be performed properly. To use

another GDI printer or a Windows Printing System printer, you must change the port

setting of the printer driver using the following procedure.

If another printer does not operate properly when the SHARP Personal

MFP series printer driver is set to "FILE" as described below, uninstall

the SHARP Personal MFP series printer driver. To uninstall the printer

driver, see the online manual.

Click the "start" button.

1

Click "Control Panel", click "Printer and Other Hardware" and

2

then click "Printer and Faxes".

On Windows 95/98/Me/NT4.0/2000, select "Settings" and then click

"Printers".

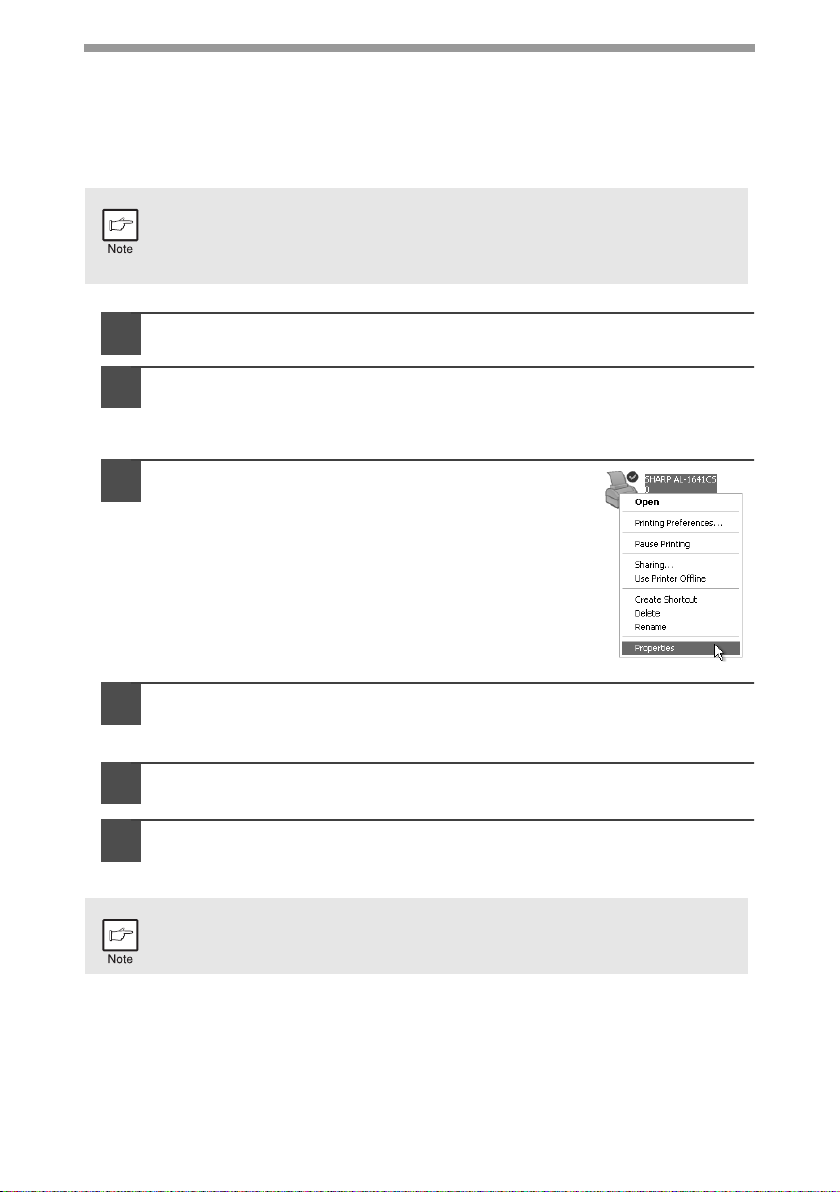

Right-click the "SHARP AL-1641CS" icon in

3

the printer dialog box and then click

"Properties".

44

Click the "Ports" tab ("Details" tab - on Windows 95/98/Me) in

4

the "Properties" dialog box, select "FILE:" in the "Print to the

following port" list box, and click the "OK".

Right-click the icon of the printer to be used and click

5

"Properties".

Click the "Ports" tab ("Details" tab - on Windows 95/98/Me) in

6

the "Properties" window, select "LPT1" (or the currently used

port), and click the "OK" button.

To use the SHARP Personal MFP series again, perform the same

procedure but select the port to be used (for example, LPT1) in step 4.

Page 47

CONNECTING THE INTERFACE CABLE

This unit includes both USB and parallel interface connectors.

Interface cables for connecting the unit to your computer are not included with this

unit. Please purchase the appropriate cable for your computer.

• If you intend to use the unit as a scanner, it must be connected

to your computer with a USB interface cable. The scanner

function cannot be used if the unit is connected with a parallel

cable.

• USB is available with a PC/AT compatible computer that was

originally equipped with USB and had Windows 98, Windows Me,

Windows 2000 Professional, Windows XP Professional or Windows

XP Home Edition preinstalled.

• Do not connect the interface cable before installing the MFP driver.

The interface cable should be connected during installation of the

MFP driver. (p.21)

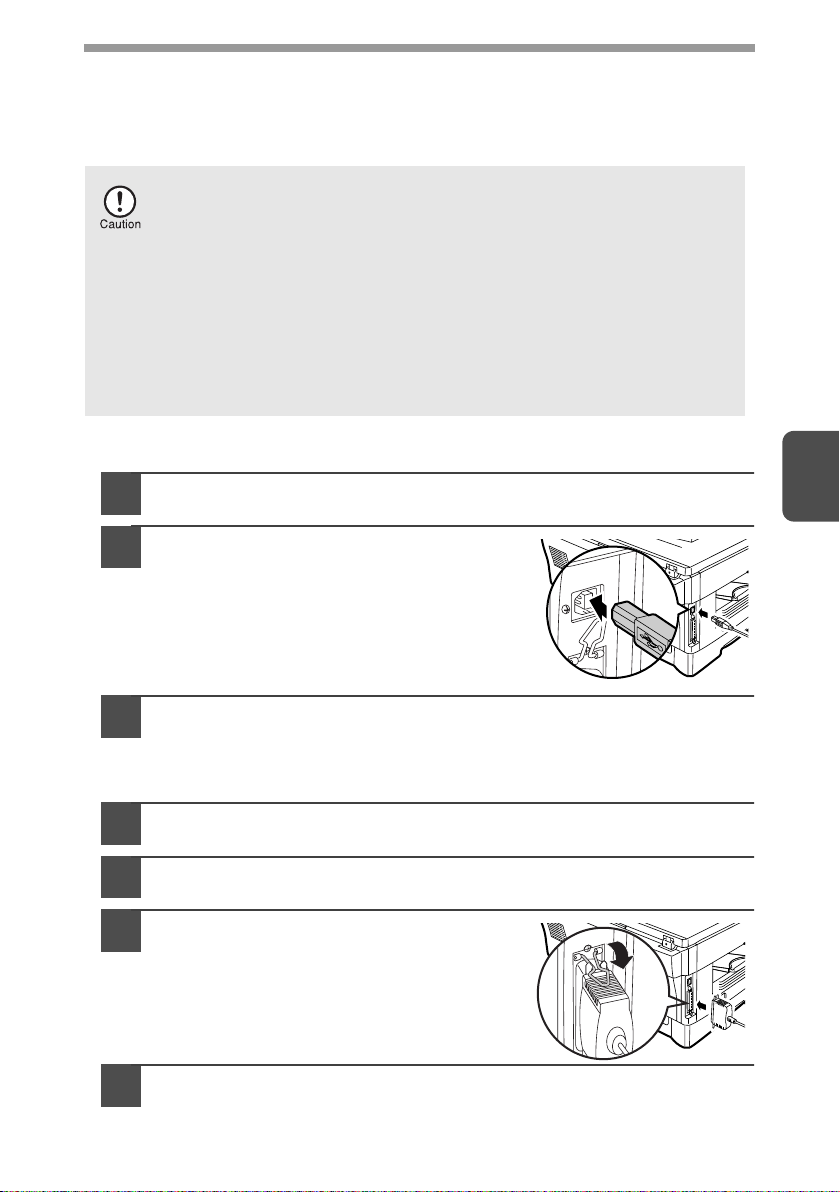

Connecting the USB interface cable

Obtain a shielded USB interface cable.

1

Insert the cable into the USB interface

2

connector located on the rear of the

unit.

Insert the other end of the cable into the interface connector of

3

your computer, or the USB hub connected to your computer.

Connecting the parallel interface cable

Obtain an IEEE1284 shielded parallel interface cable.

1

Ensure that your computer and unit are turned off.

2

Insert the cable into the parallel

3

interface connector located on the

rear of the unit, and fasten with

clasps.

4

Insert the other end of the cable into

4

the interface connector of your computer.

45

Page 48

5

This chapter explains basic and other copying functions.

The unit is equipped with a one-page memory buffer. This memory allows the unit to

scan an original once only and make up to 99 copies. This feature improves

workflow, reduces operation noise from the copier, and provides higher reliability by

reducing wear and tear on the scanning mechanism.

MAKING COPIES

COPY FLOW

1 Make sure that paper has been loaded in the paper tray (p.15)

or multi-bypass tray (p.17), and check the paper size (p.14).

If paper is not loaded, see page 15.

2 Place the original.

If you are using the document glass, see "Using the document glass" (p.47).

If you are using the SPF, see "Using the SPF" (p.48).

When copying onto paper larger than 8-1/2" x 11" size, pull out the paper

output tray extension.

46

3 Select the copy settings.

If you wish to copy using the initial settings (p.13), proceed to the next step.

To set the number of copies, see page 49.

To adjust the resolution and contrast settings, see page 49.

To enlarge or reduce the copy, see page 51.

To change the tray used, see page 51.

AL-1641CS model

To print on both sides of the paper, see page 52.

4 Start copying.

Press the start ( ) key.

Page 49

• If you start a print job while a copy job is in progress, the print job will

begin when the copy job is completed.

• The scanning function cannot be used while a copy job is in progress.

About interrupt copying

If you press the start ( ) key to begin a copy job while a print job using the paper

tray or multi-bypass tray is in progress, the copy job will begin automatically after the

print data in the unit's memory is printed (interrupt copying). When this is done, the

print data remaining in the computer is not sent to the unit. When the copy job ends,

press the clear ( ) key twice, or press the ON LINE key once to change the unit to

the online state (p.31), or wait until the set auto clear time (p.55) elapses. The

remaining print data will be sent to the unit and printing will resume.

ORIGINAL PLACEMENT

Using the document glass

• The document glass can read up to 8-1/2" x 14" original.

• Image loss 5/32" (4mm) can occur at the leading and trailing edges of

the copies. Also image loss 11/64" (4.5mm) in total can occur along

the other edges of the copies.

• When copying a book or an original which has been folded or a

crumpled original, press down the SPF lightly. If the SPF is not

securely closed, the copies may be striped or blurred.

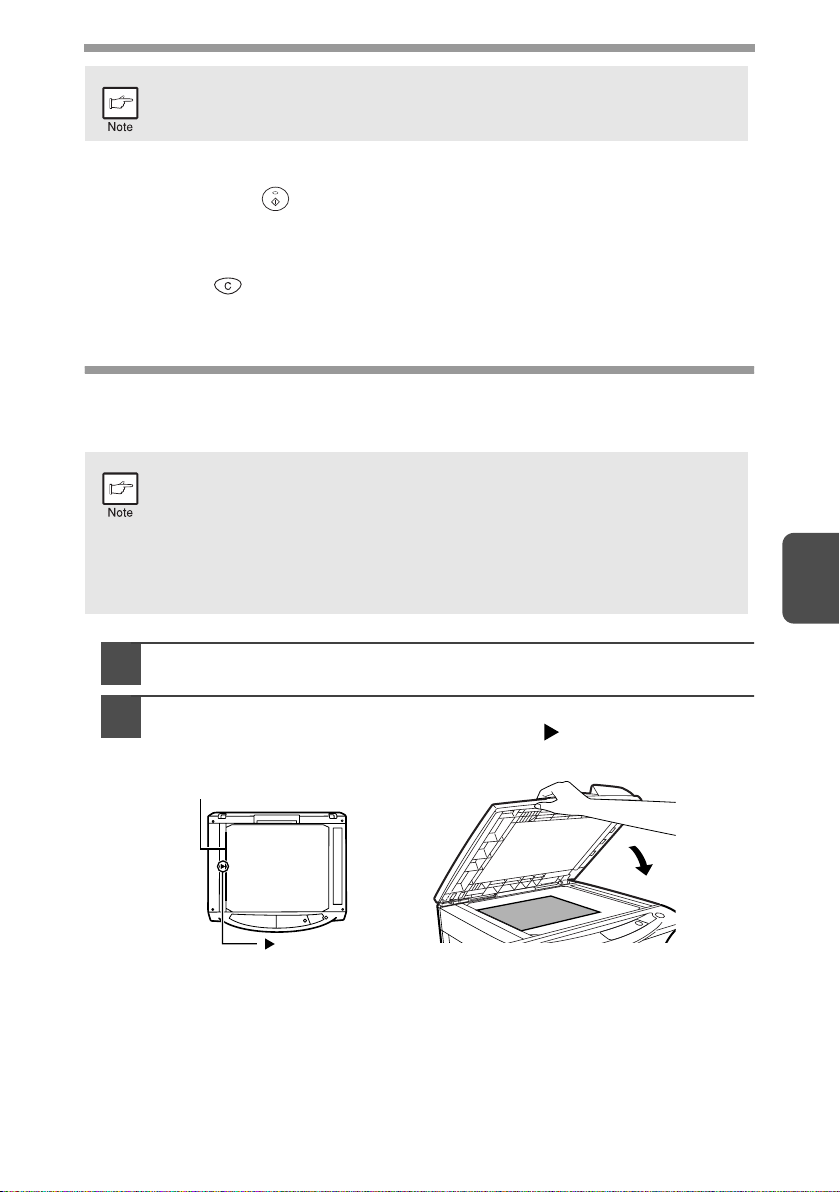

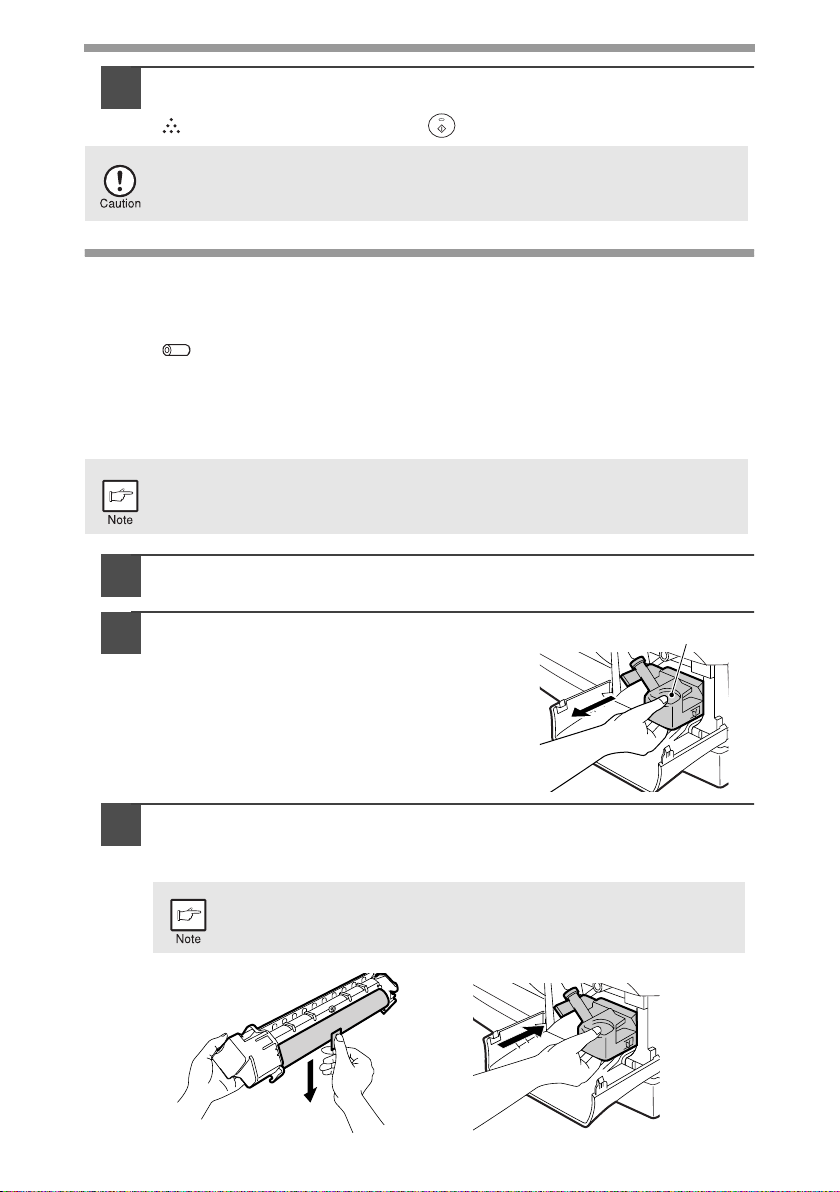

Open the SPF, and place the original.

1

5

Place an original face down on the document glass. Align it

2

with the original scale and the centering ( ) mark. Gently close

the SPF.

Original scale

mark

47

Page 50

Using the SPF

The SPF is designed to hold up to 30 originals measuring from 5-1/2" x 8-1/2" to

8-1/2" x 14" and weighting from 14 lbs. to 23.9 lbs. (52g/m

• Before feeding originals in the document feeder tray, be sure to

remove any staples or paper clips from them.

• Before placing curled or wavy originals into the document feeder tray,

be sure to flatten them. If not, original misfeeds may result.

• The SPF ( ) indicator on the operation panel will light up. If this

indicator does not light up, the originals are not properly set or the

SPF is not properly closed.

• Badly damaged originals may misfeed in the SPF. It is recommended

that such originals be copied from the document glass.

• Special originals such as transparency film should not be fed through

the SPF, but should be placed directly on the document glass.

• Image loss (max. 5/32" (4mm)) can occur at the leading and trailing

edges of the copies. Also image loss (max. 11/64" (4.5mm) in total)

can occur along the other edges of the copies. It can be 15/64" (6mm)

(max.) at the trailing edge of the second copy of two-sided copying.

• To stop continuous copying using the SPF, press the clear ( )

• Copying using one-sided to one-sided mode(AL-1641CS):

Ensure that no indicator is lit among the original to copy indicators.

Make sure that no original is left on the document glass.

1

Adjust the original guides to the size

2

of originals.

2

to 90g/m2).

key.

48

Set the originals face up in the

3

document feeder tray.

Original face up

Stream feeding mode