Page 1

MODEL

AL-1600

AL-1610

DIGITAL COPYING MACHINE

OPERATION MANUAL

Page

• GETTING STARTED

• MAKING COPIES

• STATUS INDICATORS

• GENERAL INFORMATION

2

15

24

32

Page 2

FOR Y OUR PROTECTION...

To aid in reporting this compact copier in case of loss or theft, please record below the

model number and serial number located on the back of the unit. We also suggest you

record all the information listed and retain for future reference.

MODEL NUMBER SERIAL NUMBER

DATE OF PURCHASE

Dealer

Address City

State Zip Telephone

Service Station

Address City

State Zip Telephone

For location of the nearest Sharp Authorized Service, or to

obtain product literature, accessories, or supplies,

please call 1-(630)378-3590 in the USA

or Toll Free 1-877-SHARP-CC in Canada.

For customer assistance, please visit http://www.sharp-

usa.com (for USA) or http://www.sharp.ca (for Canada)

on the World Wide Web or call 1-(630)378-3590 (for USA).

Page 3

CONTENTS Page

INTRODUCTION

This copier has been designed to provide

convenient copying features in a minimum

amount of office space and with maximum

operational ease. To get full use of all copier

features, be sure to familiarize yourself with this

manual and the copier.

For quick reference during copier use, keep this

manual in a handy location.

Conventions used in this

manual

In this manual, the following icons are used to

provide the user with information pertinent to the

use of the copier.

Warns the user that injury to the user or

damage to the copier may result if the

contents of the warning are not properly

followed.

GETTING STARTED

●

CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

●

MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

●

PART NAMES AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . 4

– Overall layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

– Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

●

COPIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . 8

●

CAUTIONS ON HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . 9

●

CHECKING PACKED COMPONENTS

AND ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

●

SET-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

●

LOADING COPY PAPER . . . . . . . . . . . . . . . . . . . . . . 13

MAKING COPIES

●

NORMAL COPYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

●

REDUCTION/ENLARGEMENT/ZOOM . . . . . . . . . . . . . . . 17

●

BYPASS FEED (special paper) . . . . . . . . . . . . . . . . . . . . 18

●

TWO-SIDED COPYING . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

●

INTERRUPTING A COPY RUN . . . . . . . . . . . . . . . . . . . . . 21

●

AUTOMATIC EXPOSURE ADJUSTMENT . . . . . . . . . . . . 22

●

TONER SAVE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

GETTING STARTED

MAKING COPIES

Cautions the user that damage to the copier

or one of its components may result if the

contents of the caution are not properly

followed.

Notes provide information relevant to the

copier regarding specifications, functions,

performance, operation and such, that may

be useful to the user.

Indicates a letter displayed in the copy

quantity display.

STATUS INDICATORS

●

●

●

TD CARTRIDGE REPLACEMENT . . . . . . . . . . . . . . . 24

DRUM CARTRIDGE REPLACEMENT . . . . . . . . . . . . 26

MISFEED REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . 28

GENERAL INFORMATION

●

USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

●

POWER SAVE MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

●

USER MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

●

COPIER TROUBLE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

●

SUPPLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

– Types and sizes of copy paper . . . . . . . . . . . . . . . . . . . . . . . 40

– Supply part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

– Genuine supplies statement . . . . . . . . . . . . . . . . . . . . . . . . . 41

●

MOVING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 42

●

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

●

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

STATUS INDICATORS

GENERAL INFORMATION

1

Page 4

CAUTIONS

GETTING STARTED

Cautions

Follow the cautions below when using this copier.

●

The fusing area is hot. Exercise care in this area when removing misfed paper.

●

Do not look directly at the light source. Doing so may damage your eyes.

●

The socket-outlet shall be installed near the equipment and shall be easily accessible.

●

Place the copier on a firm, level surface.

●

Do not install the copier in a humid or dusty location.

●

When the copier is not used for a long time, for example, during prolonged holidays, turn the

power switch off and remove the power cord from the outlet.

●

When moving the copier , be sure to turn the power switch off and remov e the power cord from the

outlet.

●

Do not cover the copier with a dust cov er , cloth or plastic film while the pow er is on. Doing so may

prevent heat dissipation, damaging the copier.

SAFETY PRECAUTIONS

This Digital Copier is rated Class 1 and complies with 21 CFR 1040.10 and 1040.11 of the CDRH standards. This

means that the copier does not produce hazardous laser radiation. For your safety, observe the precautions below.

●

Do not remove the cabinet, operation panel or any other covers.

●

The copier’s exterior covers contain several safety interlock switches. Do not bypass any safety interlock by

inserting wedges or other items into switch slots.

Use of controls or adjustments or performance of procedures other than those specified herein

may result in hazardous laser radiation exposure.

2

Page 5

MAIN FEATURES

q High-speed laser copying

●

First-copy time is only 7.2 seconds (except in a power save mode or immediately after power on).

●

Copying speed is 16 copies/min., which adapts to business use, allowing improvement of working efficiency.

w High-quality digital image

●

High-quality copying at 600 dpi is performed.

●

In addition to the automatic exposure mode, the manual exposure can be adjusted in five steps.

●

The photo mode copying function allows clear copying of delicate halftone original images such as monochrome

photos and color photos. Photo mode is adjustable in five steps.

e Substantial copying features

●

Zoom copying from 50% to 200% in 1% increments can be performed.

●

Continuous copying of maximum 99 sheets can also be performed.

●

Toner save mode reduces toner consumption by approximately 10%.

r Scan once/ Print many (AL-1610 only)

●

The copier is equipped with a 1-page memory buffer . This memory allows the copier to scan an original 1 time only and

make up to 99 copies. This feature allows for improved workflow , reduced operating noise from the copier and reduced

wear and tear on the scanning mechanism, which provides for a higher reliability.

t Environmentally friendly design

●

Paper output tray is housed in the copier for space saving.

●

Preheat mode and auto power shut-off mode are provided to reduce power consumption and meet the Energy Star

Guidelines.

GETTING STARTED

Main features

As an ENERGY STAR® Partner, SHARP has determined that this product meets the

ENERGY STAR

®

guidelines for energy efficiency.

This copier does not have an internal calendar or clock.

This copier will not be affected by the year 2000.

3

Page 6

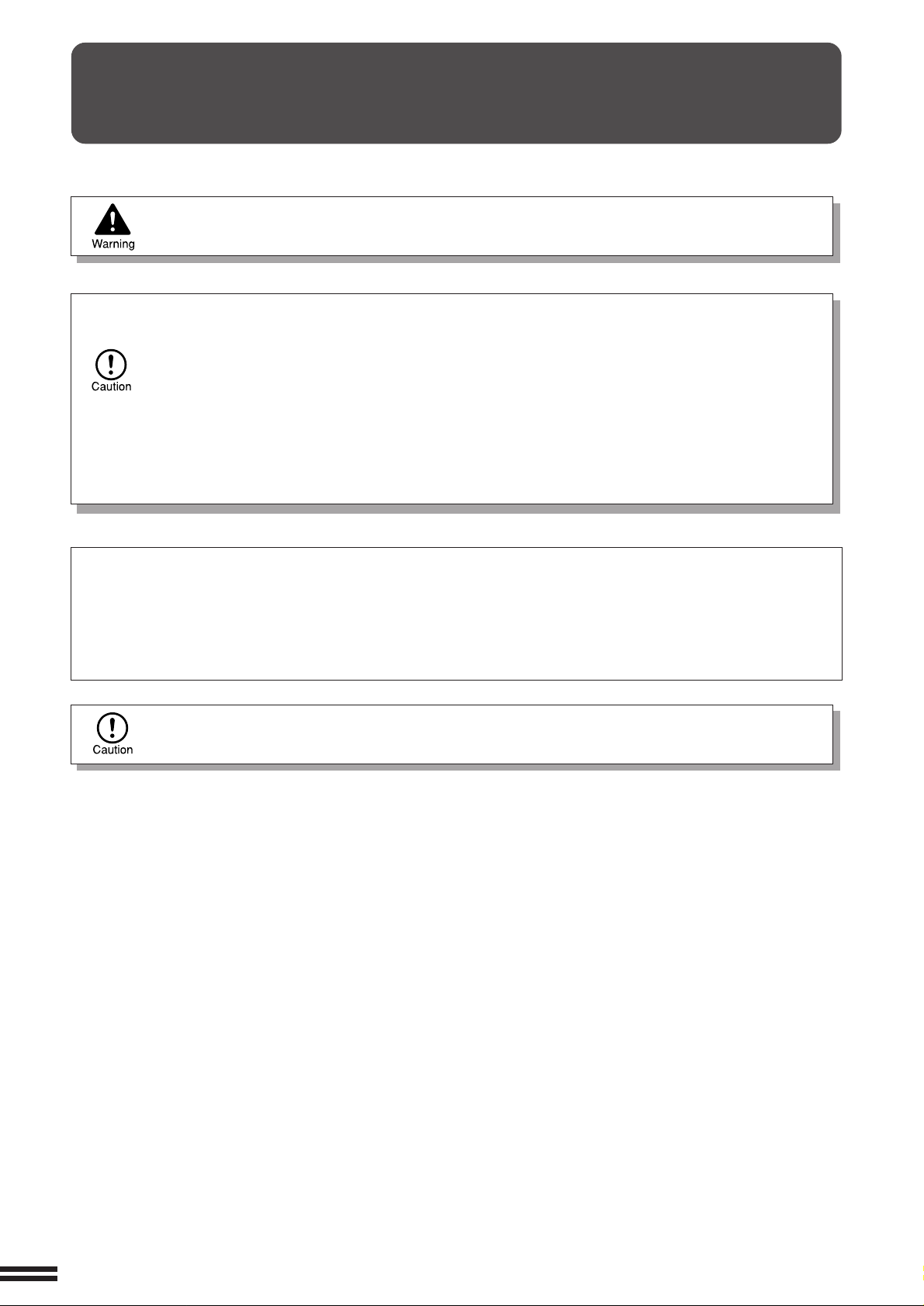

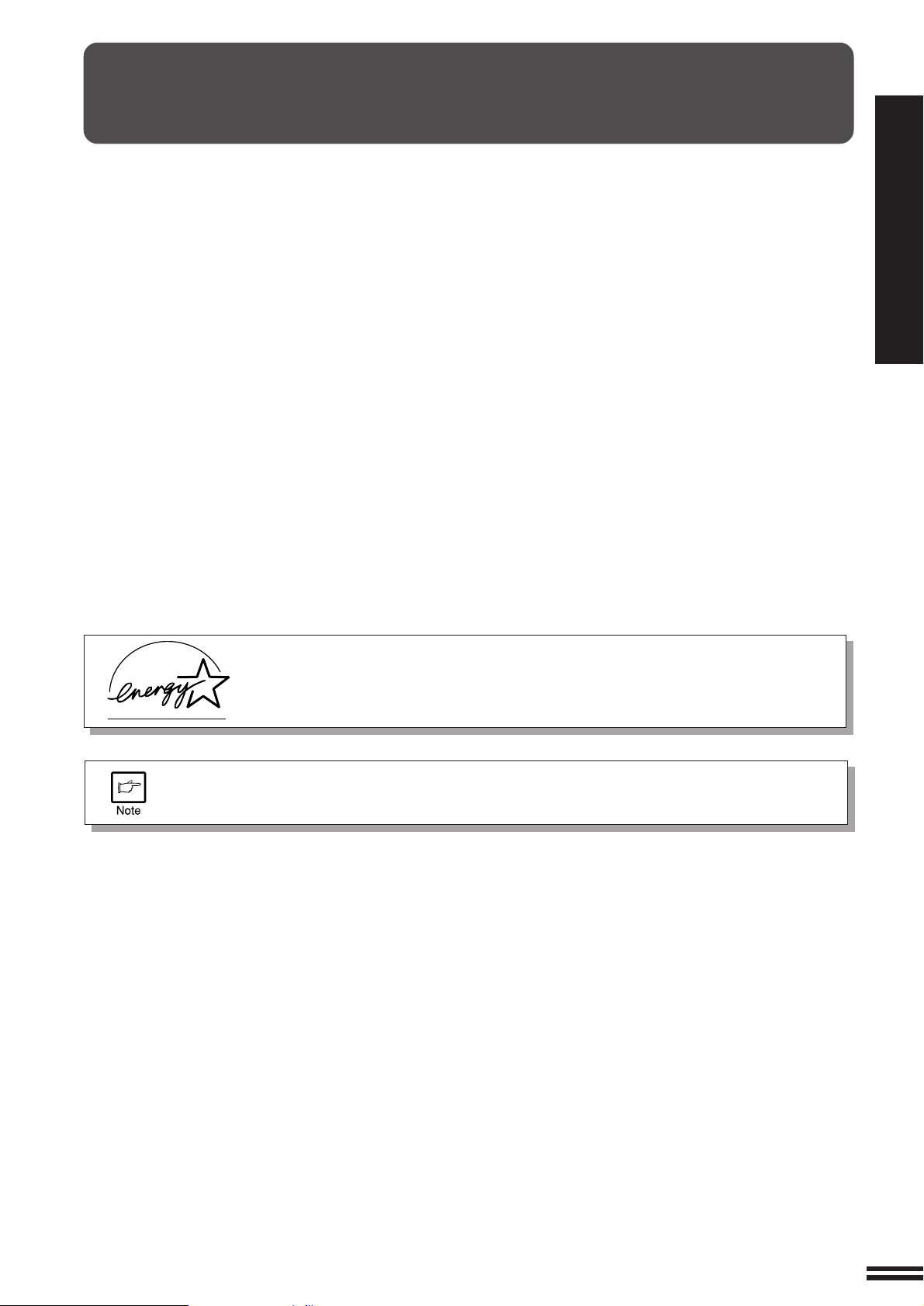

PART NAMES AND FUNCTIONS

q

w

e

r

t

y

u

i

!0

o

e

!2

!1

!3

!4

GETTING STARTED

GETTING STARTED

Overall layout

Part names and functions

q Platen cover

Place the original on the original table and close the

platen cover before copying starts.

w Original table

Place the document to be copied here.

e Handles

Use to move the copier.

r Power switch

Press to turn copier power on and off.

t Operation panel

All copier controls are located here for easy operation.

y Paper output tray

Finished copies are deposited in the paper output tray.

u Front cover

Open to remove misfeeds and for copier servicing.

i Paper tray

Holds 250 sheets of copy paper.

o Side cover

Open to remove misfeeds and to service the copier.

!0 Side cover handle

Lift and pull to open the side cover.

!1 Bypass tray guides

Adjust to the width of the copy paper.

!2 Bypass tray

Special papers (including transparency film) and copy

paper can be fed from the bypass tray.

!3 Bypass tray extension

Pull out when feeding large paper such as 8-1/2" x 14"

and 11" x 17".

!4 Charger cleaner

Use to clean the transfer charger.

4

Page 7

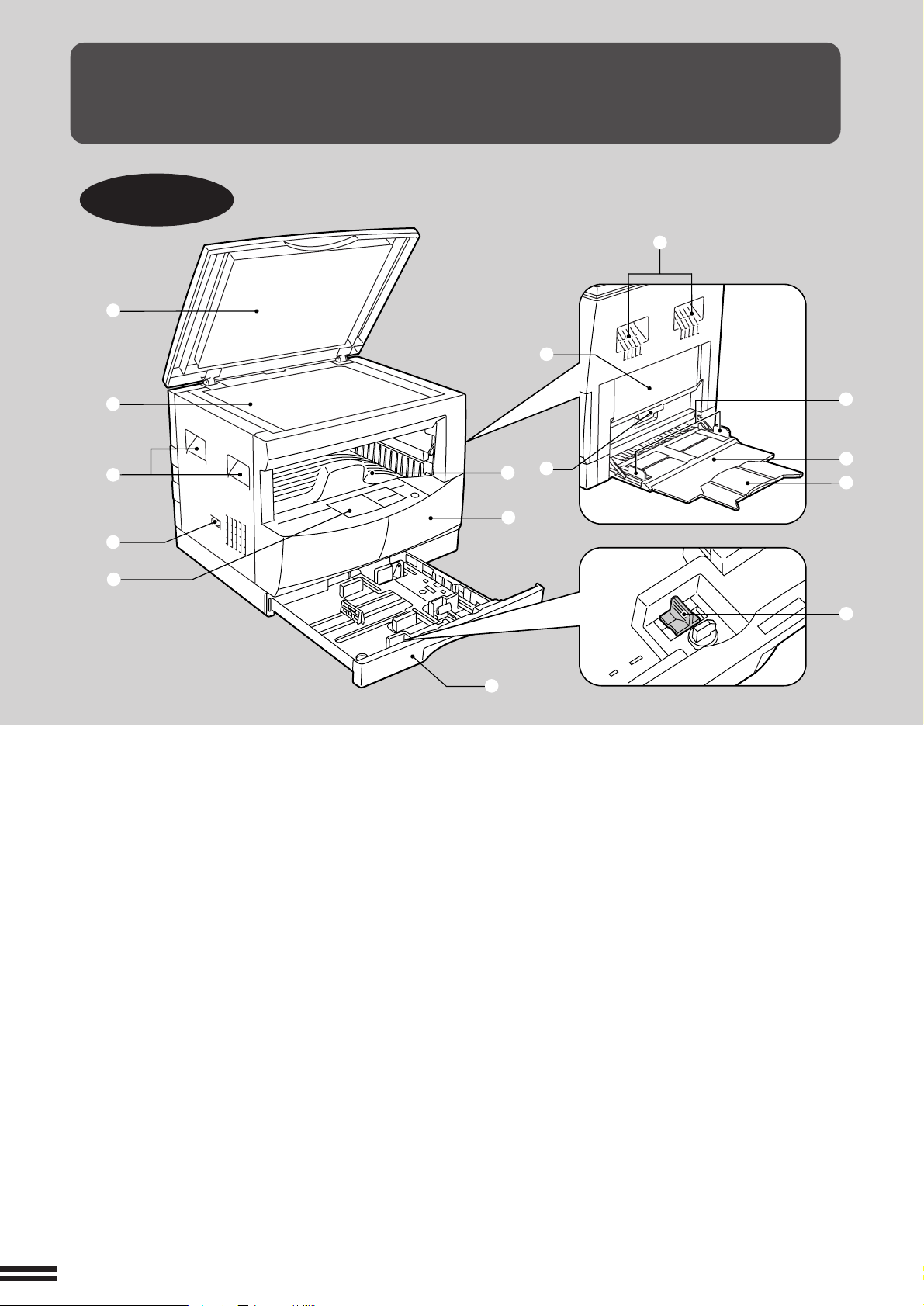

!5

PART NAMES AND FUNCTIONS

GETTING STARTED

GETTING STARTED

Part names and functions

!6

!7

!5 Drum cartridge handle

Hold to pull out the drum cartridge.

!6 Drum cartridge

Copy images are formed on the photoconductive drum.

!8

!9

@2

@0 @1

@1 Fusing unit release levers

Lower to remove misfed paper.

The fusing unit is hot.

Take care in removing paper.

!7 TD cartridge lock release lever

Use to unlock the TD cartridge.

!8 TD cartridge strap

Lift to remove the TD cartridge.

!9 TD cartridge

Contains toner.

@0 Roller rotating knob

Turn to remove misfed paper.

@2 Paper guide

Open to remove misfed paper.

Accessories

Operation manual. . . . . . . . . . . . . . . . . . . . . . . 1

TD cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Charger cleaner . . . . . . . . . . . . . . . . . . . . . . . . 1

5

Page 8

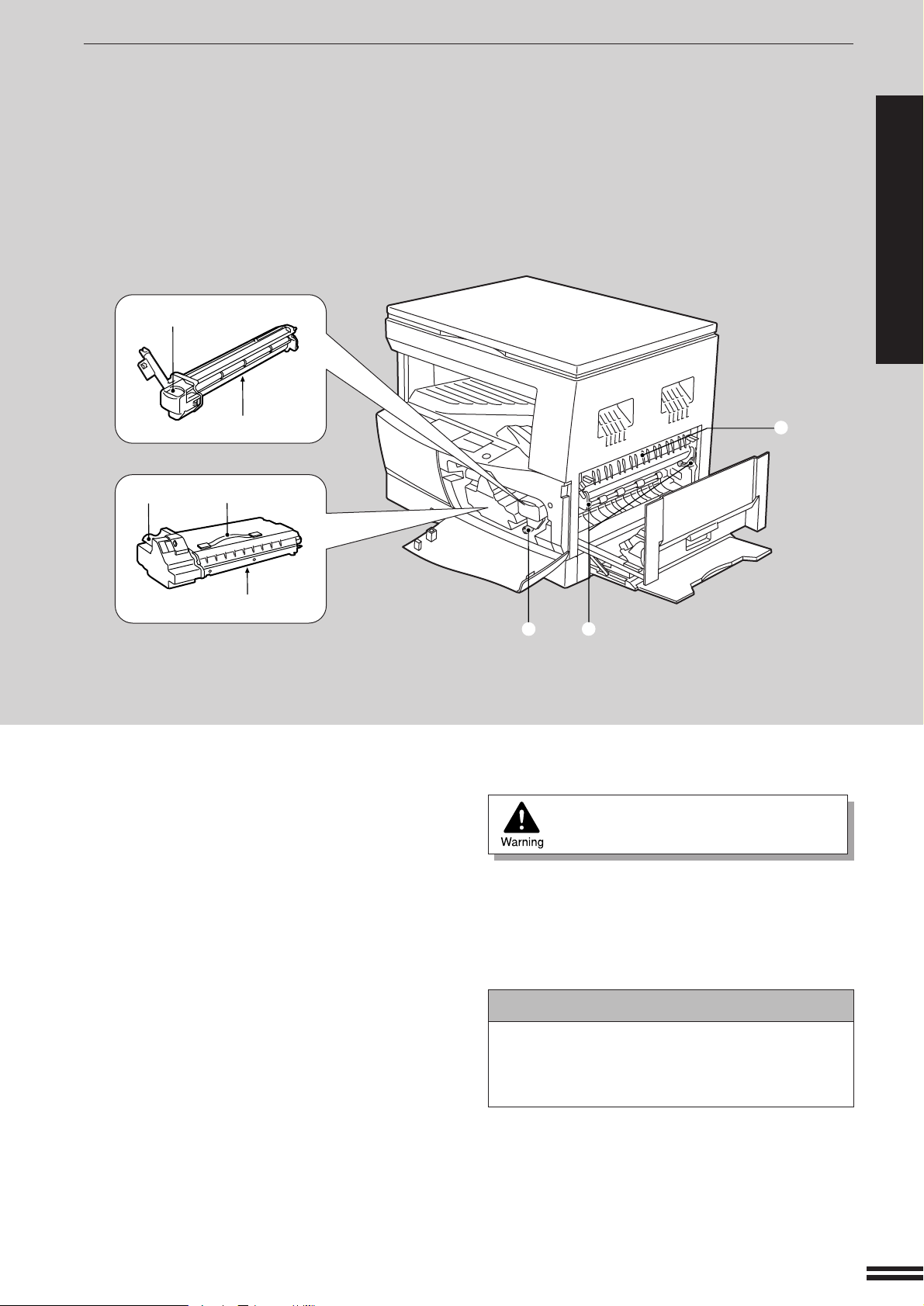

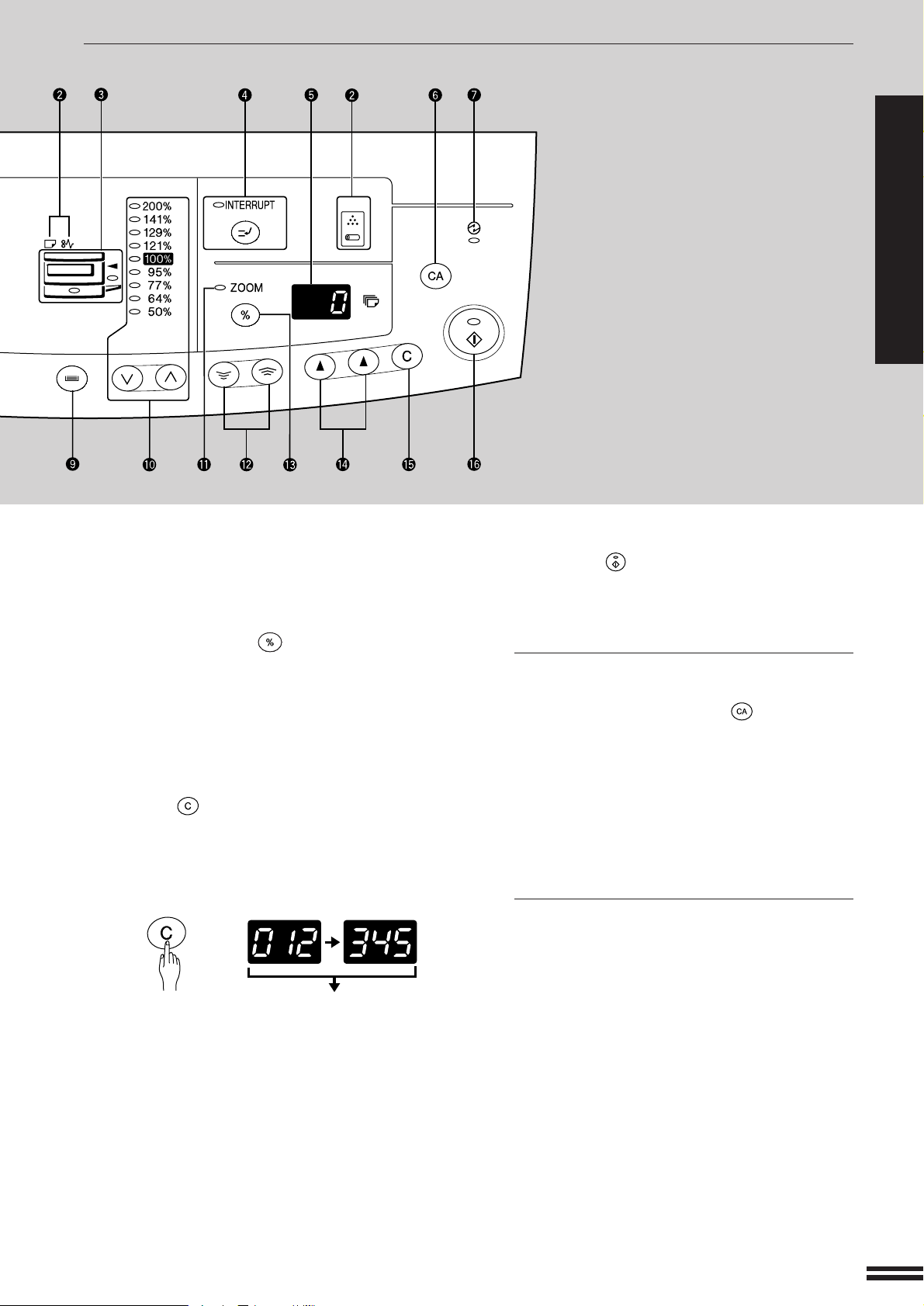

PART NAMES AND FUNCTIONS

Operation

panel

GETTING STARTED

GETTING STARTED

Part names and functions

q AUTO/MANUAL/PHOTO ( / / ) key

and indicators (p. 15)

Use to sequentially select the exposure modes: AUTO,

MANUAL ( ), or PHOTO ( ).

w Alarm indicators

: Paper required indicator (p.13)

: Misfeed indicator (p.28)

: TD cartridge replacement required indicator

(p.24)

: Drum replacement required indicator (p.26)

e Paper feed location/misfeed location indica-

tors (p. 28)

The selected paper feed location is shown by a lit

indicator ( ).

The misfeed location indicator ( ) blinks when a

misfeed has occurred.

r INTERRUPT key and indicator (p. 21)

Interrupts a copy run.

t Copy quantity display

Displays the specified copy quantity during the ready

condition and displays the copy countdown as copies

are made. Also see items !3 and !5.

y CLEAR ALL ( ) key

Clears all selected settings and returns the copier to the

initial settings.

u POWER SAVE ( ) indicator (p. 34)

Lights up when the copier is in the preheat mode.

i Light ( ) and dark ( ) keys and indicators

(p. 15)

Use to adjust the MANUAL ( ) or PHOTO ( )

exposure level.

o TRAY SELECT ( ) key (p. 15)

Use to manually select a paper tray.

!0 PRESET RATIO selector keys and indicators

(p. 17)

Use to sequentially select preset reduction/enlargement

copy ratios: 50%, 64%, 77%, 95%, 100%, 121%, 129%,

141%, 200%.

!1 ZOOM indicator (p.17)

Lights up when a zoom ratio is set.

6

Page 9

PART NAMES AND FUNCTIONS

GETTING STARTED

GETTING STARTED

Part names and functions

!2 Zoom keys (p. 17)

Use to select any reduction or enlargement copy ratio

from 50% to 200% in 1% increments.

!3 Copy ratio display ( ) key (p. 17)

Press and hold down during standby to display the copy

ratio in the copy quantity display.

!4 Copy quantity keys

Use to select the desired copy quantity or to make user

program entries.

!5 CLEAR ( ) key

Clears the copy quantity display or terminates a copy

run.

Press during standby to display the total number of

copies made to date.

1st display

Press and hold down the key. 12,345 sheets output

2nd display

!6 START ( ) key and indicator

Copying is possible when the indicator is on.

Press to start copying.

Initial settings

The copier assumes the initial settings when it is first

turned on, when the CLEAR ALL ( ) key is pressed,

and approximately one minute* after the last copy is

made in any mode.

●

Copy ratio: 100%

●

Exposure: Automatic

●

Copy quantity: 0

●

Paper feed station: Previously selected paper tray

* This time (auto clear time) can be changed. See page

32, USER PROGRAMS.

Note: 11" x 17" size copies are counted as two

copies.

7

Page 10

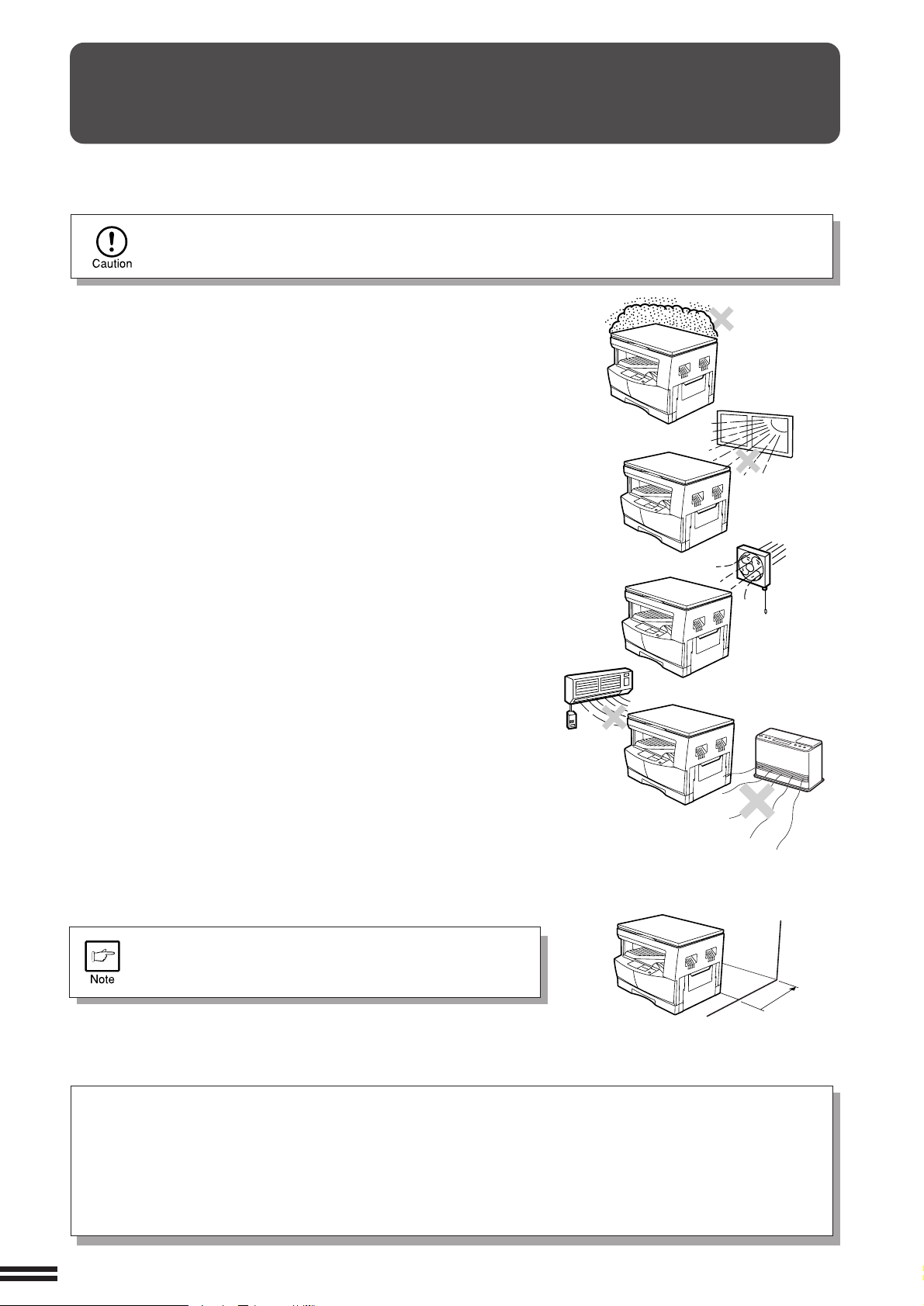

COPIER INSTALLATION

GETTING STARTED

Copier installation

Improper installation may damage the copier. Please note the following

during initial installation and whenever the copier is moved.

Do not install your copier in areas that are:

●

damp, humid, or very dusty

●

exposed to direct sunlight

●

poorly ventilated

If the copier is moved from a cool place to a warm place, condensation may form inside the

copier. Operation in this condition will cause poor copy quality and malfunctions. Leave the

copier at room temperature for at least 2 hours before use.

●

subject to extreme temperature or humidity changes, e.g., near an

air conditioner or heater.

The copier should be installed near an accessible power outlet

for easy connection.

Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Also make certain the outlet is properly grounded.

Connect the copier to a power outlet which is not used

for other electric appliances. If a lighting fixture is

connected to the same outlet, the light may flicker.

Be sure to allow the required space around the machine for

servicing and proper ventilation.

A small amount of ozone is produced within the copier during operation. The emission le vel is insufficient

to cause any health hazard.

NOTE:

The present recommended long term exposure limit for ozone is 0.1 ppm (0.2 mg/m3) calculated as an

8 hr. time-weighted average concentration.

However, since the small amount that is emitted may have an objectionable odor, it is advisable to

place the copier in a ventilated area.

4" (10 cm)

8

Page 11

CAUTIONS ON HANDLING

Be careful in handling the copier as follows to maintain the performance of

this copier.

Do not drop the copier, subject it to shock or strike it against any

object.

Do not expose the drum cartridge to direct sunlight.

Doing so will damage the surface (green portion) of the drum cartridge,

causing poor copy quality.

Store spare supplies such as drum cartridges and TD cartridges

in a dark place without removing from the package before use.

If they are exposed to direct sunlight, poor copies may result.

GETTING STARTED

Cautions on handling

Do not touch the surface (green portion) of the drum cartridge.

Doing so will damage the surface of the cartridge, causing smudges

on copies.

9

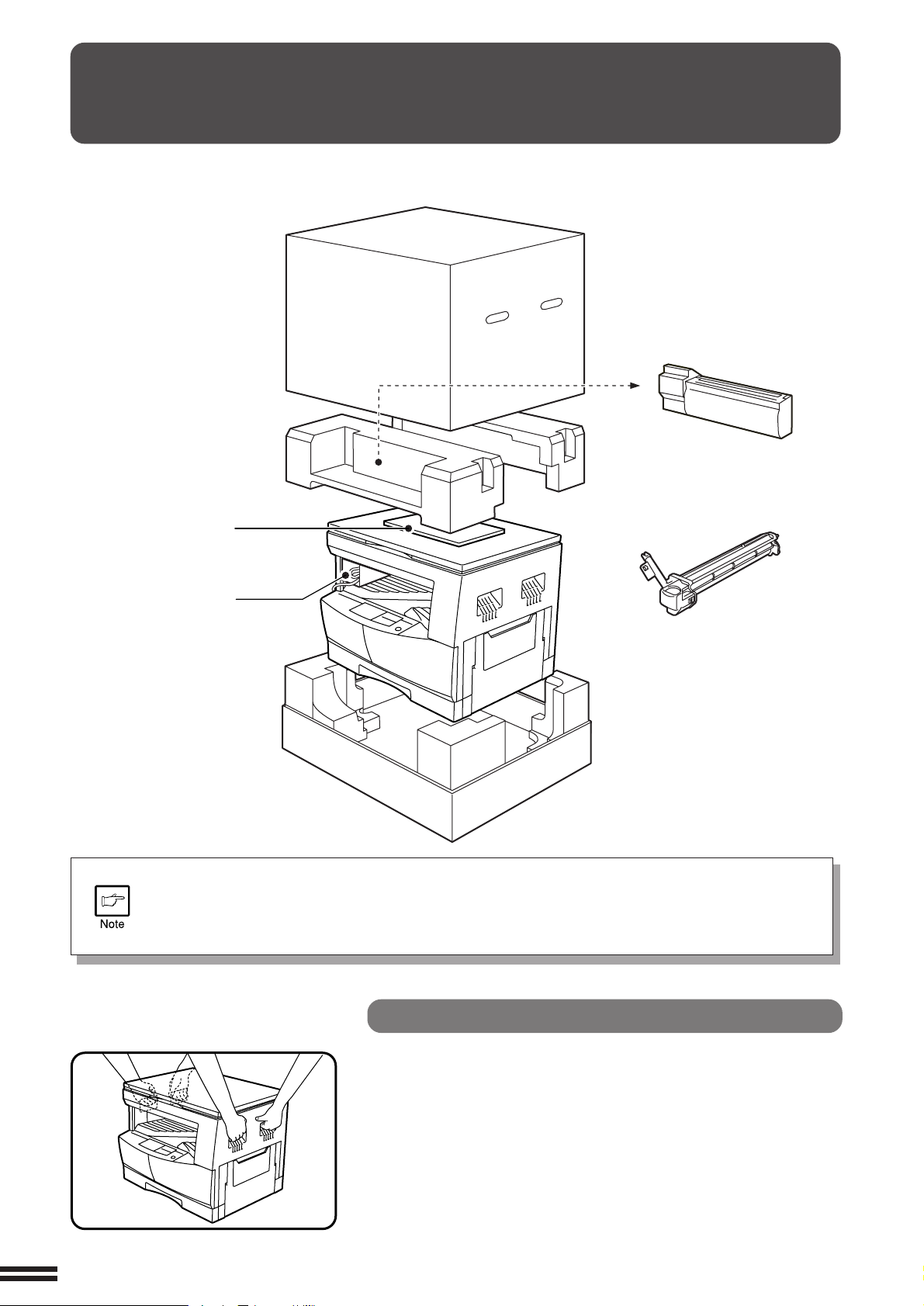

Page 12

CHECKING PACKED COMPONENTS

AND ACCESSORIES

GETTING STARTED

Checking packed components and accessories

Open the carton and check to ensure that the following components and

accessories are included.

Operation manual

Power cord

TD cartridge

Drum cartridge

Copier

●

If anything is not included or is damaged, contact our Technical Assistance Department at 1(630)378-3590 in the USA or Toll Free 1-877-SHARP-CC in Canada.

●

Save the carton and packing materials. These can be re-used f or transporting the machine, should

it be necessary.

(installed in copier)

Unpacking

Be sure to hold the handles on both sides of the copier by two persons to

unpack the copier and carry it to the installation location.

10

Page 13

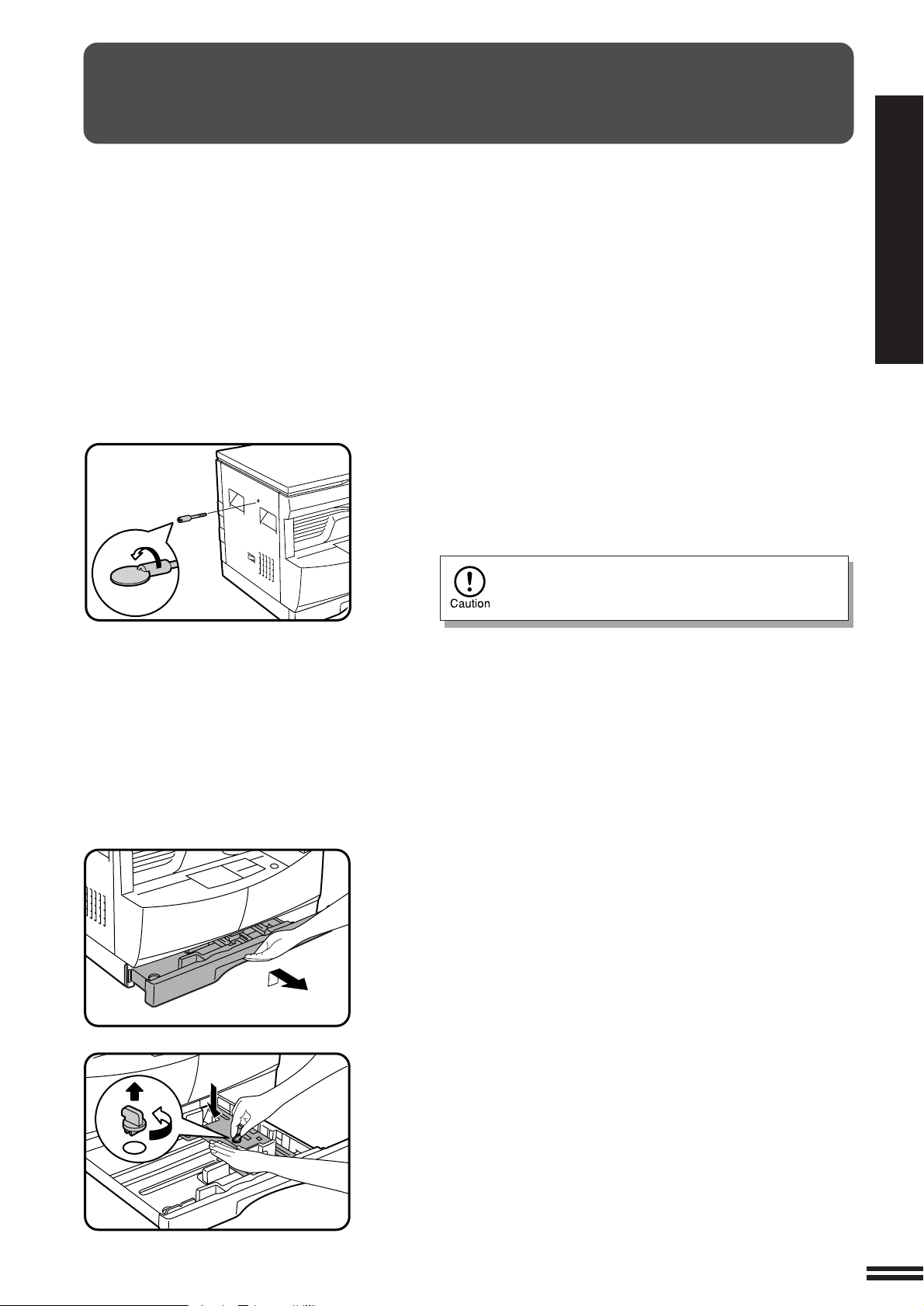

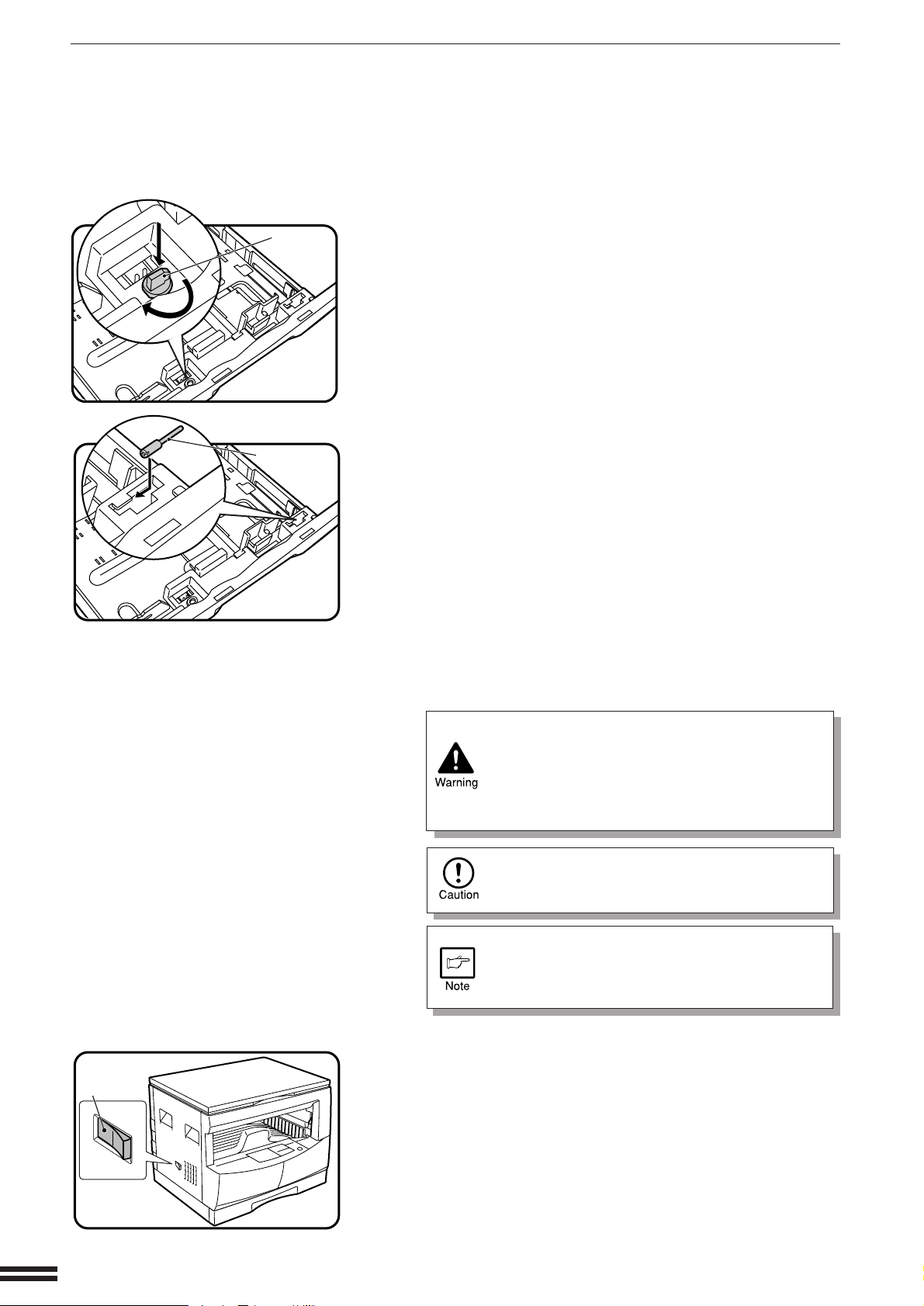

SET-UP

Remove all pieces of tape. Then open the platen

cover and remove the protective material.

1

Use a coin (or suitable object) to remove the screw.

2

GETTING STARTED

Set-up

Store the screw in the paper tray as described in

step 6 because it will be used if the copier has to

be moved. (p. 42)

Install the TD cartridge.

3

●

For installation of the TD cartridge, see steps 1 to 2 and steps 4 to

7 of TD CARTRIDGE REPLACEMENT on pages 24 and 25.

Gently lift and pull out the paper tray until it stops.

4

Remove the pressure plate lock. Rotate the

pressure plate lock in the direction of the arrow to

5

remove it while pressing down the pressure plate of

the paper tray.

11

Page 14

GETTING STARTED

SET-UP

Set-up

Pressure

plate lock

Screw

Store the pressure plate lock which has been

removed in step 5 and the screw which has been

6

removed in step 2 in the front of the paper tray.

●

To store the pressure plate lock, rotate the lock to fix it on the

relevant location.

Ensure that the power switch of the copier is in the

OFF position. Plug the power cord into the nearest

7

outlet.

Power on

If you use the copier in a country other than the

country where the copier was purchased, you will

need to make sure that your local pow er supply is

compatible with your model. If you plug the copier

into an incompatible power supply, irreparable

damage to the copier will result.

Only insert the power cord into a properly

grounded wall socket.

Do not use extension cords or power strips.

Connect the copier to a power outlet which is not

used for other electric appliances. If a lighting

fixture is connected to the same outlet, the light

may flicker.

Turn the power switch on.

8

Load copy paper.

9

●

When loading copy paper for the first time, be sure to turn the

power switch on in advance.

If you use copy paper other than 8-1/2" x 11" (default size), use

user program No. 21 to set the paper size. See page 32.

●

For loading copy paper, see steps 2 to 4 of LOADING COPY

PAPER on page 13.

12

Page 15

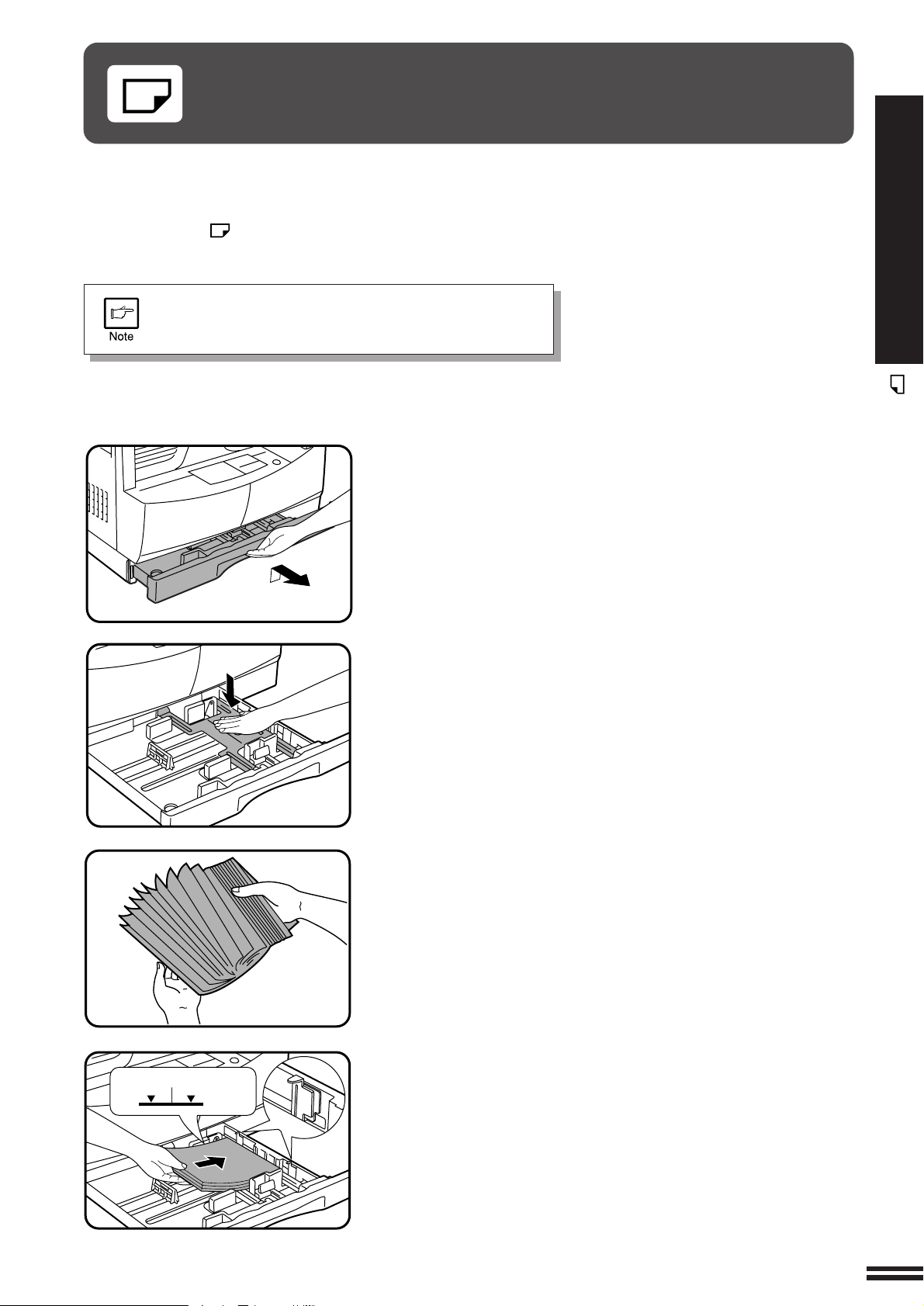

LOADING COPY PAPER

To save space, this copier has been designed with an adjustable front-loading

tray, which is easily opened for paper loading. For best results, use only

SHARP recommended paper. (See page 40.)

The paper required ( ) indicator will light up when there is no copy paper

in the selected paper feed station, or when the paper tray is not installed or is

improperly installed.

If you change the copy paper size in the tray, be sure to

set the paper size using user program No. 21. See page

32.

Gently lift and pull out the paper tray until it stops.

1

GETTING STARTED

Loading copy paper

Maximum height line

Push the pressure plate down until it locks in place.

2

Fan the copy paper and insert it into the tray. Make sure

the edges go under the corner hooks.

3

●

If you change to a different size of copy paper, the tray must be

adjusted. See the next page.

●

Set the paper along the guides.

●

The tray holds up to 250 sheets of 21 lb. bond paper.

Do not load paper above the maximum height line.

Push the paper tray firmly back into the copier.

4

13

Page 16

LOADING COPY PAPER

GETTING STARTED

Loading copy paper

Changing the copy paper size in the tray

Gently lift and pull out the paper tray until it stops.

1

Left guide

Front guide

Push the pressure plate down until it locks in place.

2

Squeeze the lock lever of the front guide and slide the

front guide to match the width of the paper.

3

Move the left guide to the appropriate slot as marked

on the tray.

4

●

When using 11" x 17" copy paper, store the left guide in the slot at the

left front of the paper tray.

14

Load copy paper into the tray.

5

Place the appropriate label to indicate the selected

paper size into the recess on the right front side of the

6

paper tray.

Push the paper tray firmly back into the copier.

7

Use user program No. 21 to set the selected paper size.

See page 32.

8

Page 17

TD CARTRIDGE REPLACEMENT

If the machine detects an insufficient amount of toner being added, copying

will stop and the machine will add toner. During this time the START key

indicator will blink. When sufficient toner has been added the indicator will

remain on steadily indicating that copying can be resumed. However, if

toner addition continues for a maximum of two minutes, the TD cartridge

replacement required ( ) indicator will light up in addition to the START

key being lighted steadily. This indicates that the toner supply is low and a

new cartridge will be needed soon. If copying is continued, the copies will

gradually become lighter until the copier stops and the TD cartridge

replacement required indicator begins to blink, indicating that the cartridge

must be replaced. Replace the TD cartridge by following the procedure

below.

Open the bypass tray. Lift slightly on the side cover and

slide the cover out until it stops.

1

For best copying results, be sure to use only

SHARP Genuine Supplies which are designed,

engineered and tested to maximize the life and

performance of SHARP copiers. Look for the

Genuine Supplies label on the toner package.

GENUINE SUPPLIES

STATUS INDICATORS

TD cartridge replacement

4 or 5 times

TD cartridge lock

release lever

Push gently the right side of the front cover to open the

cover.

2

Lift the TD cartridge lock release lever and pull the

cartridge out until the green strap handle can be grasped

3

by the right hand. Lift the cartridge by the handle while

supporting it with the left hand at the green label position

to remove it.

●

Dispose of the old TD cartridge in accordance with local regulations.

Remove the new TD cartridge from the bag. Hold the

cartridge on both sides and shake it horizontally four or

4

five times.

24

Page 18

TD CARTRIDGE REPLACEMENT

Remove the protective cover from the TD cartridge by

unlatching three cover hooks from the holes on the

5

cartridge and then pulling the cover in the direction

indicated by the arrow in the illustration.

Gently insert the TD cartridge along the guides until it

locks in place.

6

If dirt or dust is adhered to the TD cartridge, remove it

before installing the cartridge.

Close the front cover by pushing both sides with your

hands and then close the side cover by pressing the

7

handle on the cover. The indicator will go out .

STATUS INDICATORS

TD cartridge replacement

When closing the covers, be sure to close the front

cover securely and then close the side cover. If the

covers are closed in the wrong order, the covers may

be damaged.

25

Page 19

DRUM CARTRIDGE REPLACEMENT

The useful life of the drum cartridge is approximately 30,000 copies. When

the internal counter reaches approximately 29,000 copies, the drum

replacement required ( ) indicator will light up indicating that replacement

of the drum cartridge will be needed soon. When the indicator begins to blink,

replace the drum cartridge by following the procedure given below.

Do not remove the protective cover on the drum portion

(black paper) of a new drum cartridge before use. The

cover protects the drum against external light.

Open the bypass tray. Lift slightly on the side cover and

slide the cover out until it stops.

1

For best copying results, be sure to use only

SHARP Genuine Supplies which are designed,

engineered and tested to maximize the life and

performance of SHARP copiers. Look for the

Genuine Supplies label on the drum package.

GENUINE SUPPLIES

STATUS INDICATORS

Drum cartridge replacement

TD cartridge lock

release lever

Push gently the right side of the front cover to open the

cover.

2

Lift the TD cartridge lock release lever and pull the

cartridge out until the green strap handle can be grasped

3

by the right hand. Lift the cartridge by the handle while

supporting it with the left hand at the green label position

to remove it.

Grasp the handle of the drum cartridge and gently pull

the cartridge out.

4

●

Dispose of the old drum cartridge in accordance with local regulations.

26

Page 20

DRUM CARTRIDGE REPLACEMENT

Remove the new drum cartridge from the protective bag

and gently insert the lead end of the drum cartridge

5

along the guides.

Do not touch the surface of the drum (green portion) of

the cartridge. Doing so may cause smudges on the

copies.

Remove the protective cover from the drum cartridge

and then push the cartridge all the way into the copier.

6

Gently install the TD cartridge. To install the TD cartridge,

see page 24, TD CARTRIDGE REPLACEMENT.

7

STATUS INDICATORS

Drum cartridge replacement

Close the front cover by pushing both sides with your

hands and then close the side cover by pressing the

8

handle on the cover. The drum replacement required

( ) indicator will go out.

When closing the covers, be sure to close the front

cover securely and then close the side cover. If the

covers are closed in the wrong order, the covers may

be damaged.

27

Page 21

MISFEED REMOVAL

The copier will stop when a misfeed occurs. The misfeed ( ) indicator will

blink.

If paper is accidentally torn during removal, be sure to remove all pieces.

Be careful not to damage the photoconductive drum.

Misfeed in the bypass tray

Gently pull the misfed paper out.

1

STATUS INDICATORS

Misfeed removal

If the misfed paper is seen from this

side, proceed to “C. Misfeed in the

transport area”.

Lift slightly on the side cover and slide the cover out

until it stops. Close the side cover by pressing the

2

handle on the cover.

●

The misfeed ( ) indicator will go out.

Misfeed in the copier

Open the bypass tray. Lift slightly on the side cover and

slide the cover out until it stops.

1

Check the misfeed location. Remove the misfed paper

following the instructions for each location in the

2

illustration below.

If paper is misfed here, proceed to

“B. Misfeed in the fusing area”.

28

If paper is misfed here, proceed to

“A. Misfeed in the paper feed area”.

Page 22

MISFEED REMOVAL

A. Misfeed in the paper feed area

Roller rotating knob

Push gently the right side of the front cover to open the

cover.

1

Carefully remove the misfed paper. Turn the roller

rotating knob in the direction of the arrow to assist in

2

removing it.

The fusing unit is hot. Take care in removing paper.

Do not touch the surface of the drum (green portion) of

the drum cartridge when removing the misfed paper.

Doing so may damage the drum and cause smudges

on copies.

Close the front cover by pushing both sides with your

hands and then close the side cover by pressing the

3

handle on the cover.

●

The misfeed ( ) indicator will go out.

STATUS INDICATORS

Misfeed removal

When closing the covers, be sure to close the front

cover securely and then close the side cover. If the

covers are closed in the wrong order, the covers may

be damaged.

B. Misfeed in the fusing area

Push gently the right side of the front cover to open the

cover.

1

29

Page 23

MISFEED REMOVAL

STATUS INDICATORS

Roller rotating knob

Fusing unit release lever

Turn the roller rotating knob in the direction of the

arrow.

2

Carefully remove the misfed paper. Lower the fusing

unit release levers to allow easier removal. Return the

3

release levers to their operating positions.

The fusing unit is hot. Take care in removing paper.

●

Do not touch the surface of the drum (green portion)

of the drum cartridge when removing the misfed

paper. Doing so may damage the drum and cause

smudges on copies.

●

Be careful about unfixed toner on the misfed paper.

Close the front cover by pushing both sides with your

hands and then close the side cover by pressing the

4

handle on the cover.

●

The misfeed ( ) indicator will go out.

Misfeed removal

When closing the covers, be sure to close the front

cover securely and then close the side cover. If the

covers are closed in the wrong order, the covers may

be damaged.

C. Misfeed in the transport area

Open the paper guide by pressing down the projection

on either side of the guide and remove the misfed paper.

1

The fusing unit is hot. Take care in removing paper.

If the misfed paper cannot be removed by the previous

step but is visible in the paper output area, remove the

2

paper by pulling it into the paper output area.

30

Page 24

MISFEED REMOVAL

Close the side cover by pressing the handle on the

cover.

3

●

The misfeed ( ) indicator will go out.

Misfeed in the paper tray

Before opening the paper tray, be sure to open the bypass tray, lift slightly on

the side cover and slide the cover out until it stops, and then perform steps 1

to 3 described in the “A. Misfeed in the paper feed area” section.

Gently lift and pull out the paper tray and remove the

misfed paper.

1

Close the paper tray.

2

Lift slightly on the side cover and slide the cover out

until it stops. Close the side cover by pressing the

3

handle on the cover.

●

The misfeed ( ) indicator will go out.

STATUS INDICATORS

Misfeed removal

31

Page 25

USER PROGRAMS

The user programs allow the parameters of certain functions to be set,

changed, or canceled as desired.

List of user programs

This copier has the following user programs.

Program No. Program name Description

1 Auto clear time Sets the auto clear time. The copier returns to the initial settings

when the auto clear time elapses after the last copy is made.

2 Preheat mode Sets the time that elapses before the copier enters the preheat

mode after any operation is made. See page 34.

3 Auto power shut-off Sets the time that elapses before the copier enters the auto power

timer shut-off mode after any operation is made. See page 34.

5 Auto power shut-off Enables or disables the auto power shut-off mode. See page 34.

setting

User programs

GENERAL INFORMATION

21 Paper size setting Sets the copy paper size in the tray.

Setting the user programs

Press and hold the light ( ) key for more than 5

seconds until all the alarm indicators ( , , , and

1

) blink and “– –” appears in the copy quantity display.

Enter a program number using the left copy quantity

( ) key.

2

●

The selected program number will blink in the copy quantity display.

●

If a mistake is made in steps 2 to 4, press the CLEAR ( ) key. The

copier will return to step 2.

●

The program numbers are shown in the table above.

For example, to change the setting of the auto power shut-off timer,

enter 3.

32

Press the START ( ) key.

3

●

The entered program number will be steadily lit on the left side of the

copy quantity display and the currently selected parameter number for

the program will blink on the right side.

Page 26

USER PROGRAMS

Select the desired parameter using the right copy quantity

( ) key.

4

●

The entered parameter number will blink on the right side of the copy

quantity display.

●

The parameters are shown in the table below.

For example, to change the setting of the auto power shut-off timer to

60 min., enter 2.

Program name Parameters

Auto clear time 0 e OFF 1 e 30 sec. *2 e 60 sec. 3 e 90 sec. 4 e 120 sec.

5 e 10 sec.

Preheat mode 0 e OFF 1 e 30 sec. 2 e 60 sec. * 3 e 90 sec. 4 e 120 sec.

Auto power shut-off timer * 1 e 30 min. 2 e 60 min. 3 e 90 min. 4 e 120 min. 5 e 240 min.

Auto power shut-off setting 0 e OFF *1 e ON

Paper size setting 1 e 11"x17" 2 e 8-1/2"x14" * 3 e 8-1/2"x11" 4 e 8-1/2"x11"R

5 e 5-1/2"x8-1/2"

Factory default settings are indicated with an asterisk (*).

If you select “0” (OFF) in a program, the corresponding function will be disabled.

Press the START ( ) key.

5

●

The right-hand number in the copy quantity display will be steadily lit

and the entered value will be stored.

To continue with other user programs, press the CLEAR

( ) key and then repeat steps 2 to 5. To exit the user

6

program mode, press the light ( ) key.

●

All the alarm indicators will go out.

User programs

GENERAL INFORMATION

33

Page 27

POWER SAVE MODES

The copier has two power save modes to reduce overall power consumption

thereby reduce the cost of operation. In addition, these modes conserve

natural resources and help reduce environmental pollution. The two power

save modes are preheat mode and auto power shut-off mode.

●

User programs

The preheat activation time and the auto power shut-off time have been

preset at the factory to 90 sec. for preheat mode and 30 min. for auto power

shut-off mode. These times can be changed using user programs. It is

suggested that you set appropriate times according to the actual usage of

the copier. (See page 32.)

Preheat mode

When the copier enters the preheat mode, the POWER SAVE ( ) indicator

will light up and other indicators will remain on or off as before. In this

condition, the fuser in the copier is maintained at a lower heat level, thereby

saving power. The preheat level is, however, high enough to allow the copier

to come to a ready condition or begin copying within 10 seconds after any key

input or copier operation such as paper tray operation is performed.

Power save modes

GENERAL INFORMATION

As an ENERGY STAR® Partner,

SHARP has determined that this

product meets the ENERGY STAR

guidelines for energy efficiency.

Auto power shut-off mode

If the auto power shut-off mode is enabled, the copier will automatically turn

off the power once a programmed length of time has elapsed without any

copier operation after the last copy of a run is made or the power is first turned

on. The power switch will automatically be turned to the “OFF” position.

To turn the power back on, simply turn the power switch to the “ON”

position.

®

34

Page 28

POWER SAVE MODES

Setting the power save modes

The time that elapses before the copier enters a power save mode after any

operation is made can be set manually. This time is set with user program No.

2 for the preheat mode and user program No. 3 for the auto power shut-off

mode. For these settings, see page 32.

●

The copier will enter the preheat mode first and then the auto power shutoff mode after a preset time has elapsed when no copier operation has been

made.

●

If conflicting settings are made with user programs No. 3 and No.5, the last

program set will have priority.

Copying from the preheat mode

Make desired copier selections and press the START

( ) key using the normal copying procedure.

●

When any key input is made or any other copier operation is made, the

POWER SAVE ( ) indicator will start to blink.

●

When the START ( ) key is pressed, the START key ( )

indicator will go out and copying will start within 10 seconds. The

POWER SAVE ( ) indicator will go out when copying starts.

Power save modes

GENERAL INFORMATION

35

Page 29

USER MAINTENANCE

Proper care is essential for clean, sharp copies. Please take a few minutes to

regularly clean your copier.

Original table and platen cover

Stains or dirt on the original table or platen cover will

also be copied. Wipe the original table and platen cover

with a soft, clean cloth.

User maintenance

GENERAL INFORMATION

Paper feed roller

●

If necessary, dampen the cloth with water. Do not use thinner,

benzene, or similar volatile cleaning agents.

Bypass tray paper feed roller

If misfeeds occur frequently when feeding postcards,

envelopes, thick paper, etc. through the bypass tray,

wipe the blue paper feed roller at the feed slot of the

bypass tray with a soft, clean cloth dampened with

alcohol or water.

36

Transfer charger

If copies start becoming streaky or blotchy, the transfer

charger may be dirty. Clean the charger. The cleaning

method is described on the next page.

Page 30

Turn the power switch off.

1

USER MAINTENANCE

Charger

cleaner

Open the bypass tray. Lift slightly on the side cover and

slide the cover out until it stops.

2

Gently lift and pull out the paper tray and take the

charger cleaner out by holding the tab.

3

Set the charger cleaner onto the transfer charger and

gently slide the cleaner in the direction indicated by the

4

arrow two or three times.

Slide the charger cleaner from one end to the other end

along the groove of the transfer charger. If the cleaner

is stopped on the way, smudges on copies may occur.

User maintenance

GENERAL INFORMATION

●

If the white sheet metal is smudged with toner, wipe it with a soft, clean

cloth.

Return the charger cleaner to its original position. Close

the paper tray. Close the side cover by pressing the

5

handle on the cover.

Turn the power switch on.

6

37

Page 31

COPIER TROUBLE?

Problem Solution

●

Copier plugged in?

Copier does not operate.

Plug the copier into a grounded outlet.

See page 8.

Copies are too dark or

too light.

Blank copies

Copies smear if rubbed.

Striped copies

Copier trouble?

●

Power switch ON?

●

Copy density properly adjusted?

●

Is the original placed face down?

●

Paper too heavy?

●

Paper damp?

●

Is transfer charger clean?

●

Non-standard paper used?

Turn the power switch ON.

See page 15.

See pages 15 and 22.

Place the original face down on the original

table.

Use copy paper within the specified range.

See page 40.

Replace with dry copy paper.

Be sure to store copy paper in a dry location.

See page 41.

Clean the transfer charger. See page 37.

Use standard paper. If using special paper,

feed the paper through the bypass tray.

See pages 18 and 40.

GENERAL INFORMATION

Paper misfeeds frequently.

Copies are smudged

or dirty.

38

●

Paper properly installed?

●

Pieces of paper inside copier?

●

Paper curled or damp?

●

Original table or platen cover

dirty?

●

Original smudged or blotchy?

Make sure the paper is properly installed. See

pages 13 and 18.

Remove all pieces of misfed paper.

See page 28.

Store copy paper flat in the wrapper in a dry

location. See page 41.

Clean regularly. See page 36.

Use a clean original.

Page 32

Problem Solution

●

Is the POWER SAVE ( )

indicator blinking?

●

Is the indicator on?

Wait until warm-up is complete.

Warm-up time is approximately 35 seconds.

Copy paper is needed. See page 13, LOADING

COPY PAPER.

COPIER TROUBLE?

Power is on but copying

is not possible.

Lighting fixture flickers.

●

Is blinking in the copy

quantity display?

●

Is steadily lit in the copy

quantity display?

●

Is the indicator blinking?

●

Is the indicator blinking?

●

Is the START key ( ) indicator

blinking?

●

Is the same power outlet used for

the lighting fixture and the copier?

The TD cartridge is not installed. Install the

TD cartridge.

Side cover is open.

Close the front and side covers securely.

The TD cartridge must be replaced. See page

24, TD CARTRIDGE REPLACEMENT.

A misfeed has occurred. See page 28,

MISFEED REMOVAL.

Toner replenishment takes up to 2 minutes.

Wait until the START key ( ) indicator

stops blinking.

Copier trouble?

Connect the copier to a power outlet which is

not used for other electric appliances.

Be sure to use only genuine SHARP parts and supplies.

Please contact your SHARP service center immediately if a problem persists

after checking the above.

Self-diagnostic function

An automatic self-diagnostic function is built into the copier. Should the

copier malfunction, the self-diagnostic function will locate the problem and

stop the copier to prevent damage. An alphanumeric code will appear in the

copy quantity display.

Example

Should the copier completely stop and a letter and a number appear alternately,

contact your SHARP service center immediately.

39

GENERAL INFORMATION

Page 33

SUPPLIES

Types and sizes of copy paper

Size Weight Capacity Special paper

(21 lb. bond paper)

Paper tray 5-1/2" x 8-1/2" 15 lbs. to 21 lbs. 250 sheets

to 11" x 17"

Bypass tray Ordinary paper: 15 lbs. to 34 lbs.* 100 sheets Transparency film,

5-1/2" x 8-1/2" (Ordinary paper) labels, envelopes**

to 11" x 17"

Envelopes:

Commercial 10

(4-1/8" x 9-1/2")

International DL

(110 x 220 mm)

International C5

(162 x 229 mm)

* For paper weighing from 28 to 34 lbs., 8-1/2" x 11" is the maximum size

that can be fed through the bypass tray.

** Do not use envelopes that have metal clasps, plastic snappers, string

closures, windows, linings, self-adhesive patches or synthetic materials.

These will cause physical damage to the copier.

●

For best results, use only paper recommended by SHARP.

●

Special papers except envelopes must be fed one sheet at a time through

the bypass tray. Up to 10 envelopes can be set at one time.

Supplies

GENERAL INFORMATION

Supply part numbers

When ordering supplies, please use the correct part numbers as listed below.

Be sure to use only genuine SHARP parts and supplies.

Supply list

Supply Part number Usable life

TD cartridge AL-160TD Approx. 15,000 sheets*

Drum cartridge AL-160DR Approx. 30,000 sheets

*Based on copying onto letter-type paper at 6% toned area

(The life of the TD cartridge which has been included in the copier at the factory is approximately 5,000 sheets.)

40

Page 34

Genuine supplies statement

SUPPLIES

Standard supplies for this copier that are to be replaced by the user are copy

paper, TD cartridge, and drum cartridge.

Proper storage

1. Store the supplies in a location that is:

●

clean and dry,

●

at a stable temperature,

●

not exposed to direct sunlight.

For best copying results, be sure to use only

SHARP Genuine Supplies which are

designed, engineered and tested to maximize

the life and performance of SHARP copiers.

Look for the Genuine Supplies label on the

TD cartridge and drum cartridge.

GENUINE SUPPLIES

2. Store copy paper in the wrapper and lying flat.

●

Paper stored out of the wrapper or in packages standing on end may

curl or get damp, resulting in paper misfeeds.

Supplies

GENERAL INFORMATION

41

Page 35

MOVING INSTRUCTIONS

When moving this copier, follow the procedure below.

When moving this copier, be sure to remove the TD cartridge in advance.

Turn the power switch off and disconnect the power

cord.

1

Open the bypass tray. Lift slightly on the side cover

and slide the cover out until it stops. Push gently the

2

right side of the front cover to open the cover.

Moving instructions

GENERAL INFORMATION

TD cartridge lock

release lever

Lift the TD cartridge lock release lever and pull the

cartridge out until the green strap handle can be grasped

3

by the right hand. Lift the cartridge by the handle while

supporting it with the left hand at the green label position

to remove it.

Close the front cover by pushing both sides with your

hands and then close the side cover by pressing the

4

handle on the cover.

When closing the covers, be sure to close the front

cover securely and then close the side cover. If the

covers are closed in the wrong order, the covers may

be damaged.

Gently lift and pull out the paper tray until it stops.

5

Push the center of the pressure plate down until it locks

in place and lock the plate using the pressure plate lock

6

which has been stored in the front of the paper tray.

Use a coin (or suitable object) to attach to the left side of

the copier the screw that has been stored in the front of

7

the paper tray.

42

8

9

10

When shipping the copier, the screw must be reinstalled

to prevent shipping damage.

Push the paper tray back into the copier.

Close the bypass tray. Attach the packing materials and

tape which were removed during installation of the

copier. See page 11, SET-UP.

Pack the copier into the carton. See page 10, CHECKING

PACKED COMPONENTS AND ACCESSORIES.

Page 36

SPECIFICATIONS

Type Digital copying machine, desktop

Copy system Dry, electrostatic transfer

Originals Sheets, bound documents

Original sizes Max. 11" x 17"

Copy sizes Max. 11" x 17"

Min. 5-1/2" x 8-1/2"

Image loss: Max. 5/32" (4 mm) (leading and trailing edges)

Copying speed 16 copies/min. (8-1/2" x 11")

(at 100% copy ratio) 12 copies/min. (8-1/2" x 11"R)

10 copies/min. (8-1/2" x 14")

9 copies/min. (11" x 17")

Max. 5/32" (4 mm) (along other edges in total)

Continuous copy Max. 99 copies; subtractive counter

First-copy time 7.2 sec. (except in a power save mode)

Warm-up time Approx. 35 sec.

Copy ratio Variable: 50% to 200%, in 1% increments (total 151 steps)

Fixed preset: 50%, 64%, 77%, 95 %, 100%, 121%, 129%, 141%,

200%

Exposure system Moving optical source, slit exposure (stationary platen) with

automatic exposure function

Copy paper feed One paper tray with automatic feed (250 sheets), one bypass tray

with automatic feed (100 sheets)

Fusing system Heat rollers

Developer system Magnetic brush development

Light source Xenon lamp

Resolution Scan: 400 dpi

Output: 600 dpi

Gradation Scan: 256 levels

Output: 2 levels

Specifications

GENERAL INFORMATION

Power supply AC 120V, 60 Hz, 11 amperes

Power consumption Max. 1.5 kW

43

Page 37

SPECIFICATIONS

Overall dimensions 23-15/64" (W) x 20-23/32" (D)

(with bypass tray folded) (590 mm (W) x 526 mm (D))

Weight Approx. 70.6 lbs. (32 kg)

Copier dimensions 23-15/64" (W) x 20-23/32" (D) x 18-33/64" (H)

Operating conditions Temperature: 59°F to 86°F (15°C to 30°C)

TD and drum cartridges included

(590 mm (W) x 526 mm (D) x 470 mm (H))

Humidity: 20% to 85%

Specifications

GENERAL INFORMATION

First-copy time and warm-up time may differ depending on operating conditions, such as powersupply voltage and room temperature.

As a part of our policy of continuous improvement, SHARP reserves the right

to make design and specification changes for product improvement without

prior notice. The performance specification figures indicated are nominal

values of production units. There may be some deviations from these values

in individual units.

44

Page 38

INDEX

A

Auto clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Automatic exposure adjustment . . . . . . . . . . . . . . . . . . 22

Auto power shut-off mode . . . . . . . . . . . . . . . . . . . . . . 34

B

Bypass tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

C

Cautions on handling . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Copier trouble? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Copying

– large original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

– normal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

– reduction/enlargement . . . . . . . . . . . . . . . . . . . . . . . . 17

– through bypass tray . . . . . . . . . . . . . . . . . . . . . . . . . . 18

– two-sided . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Copy paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13, 40

Copy quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Copy ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D

Dark key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Drum cartridge

– indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

– replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

E

Enlargement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Exposure adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 15

F

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fixed copy ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fusing unit release lever . . . . . . . . . . . . . . . . . . . . . . . . 30

I

Initial settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

L

Light key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15, 32

Loading copy paper . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

M

Maintenance

– user maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Manual exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Manual feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Misfeed removal

– bypass tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

– in the copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

– paper tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

N

Names

– operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

– part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

O

Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Original table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

P

Packed components . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Paper

– loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

– special . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

– specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Paper output tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paper size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Paper tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Part names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Photo mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Platen cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10, 12

Power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power save modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preheat mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

R

Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replacement

– drum cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

– TD cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Index

GENERAL INFORMATION

45

Page 39

INDEX

S

Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11, 42

Special paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specifications

– copier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

– paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Supply

– life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

– part number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

– storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

T

TD cartridge replacement . . . . . . . . . . . . . . . . . . . . . . . 24

Toner save mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Total number of copies . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Two-sided copying . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

U

User maintenance

– bypass tray paper feed roller . . . . . . . . . . . . . . . . . . . 36

– original table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

– platen cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

– transfer charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

User programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Z

Zoom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Index

GENERAL INFORMATION

46

Page 40

SHARP

Date Issued:Nov. 1, 1998

MATERIAL SAFETY DATA SHEET

Section 1. Product Identification

Product:

AL-160TD (Black Toner)

Section 2. Supplier’s Name and Address

Sharp Corporation

22-22 Nagaike-cho, Abeno-ku, Osaka, Japan

Local suppliers are listed below. Please contact the nearest supplier for additional information.

(Country) (Name and Telephone Number)

U.S.A. Sharp Electronics Corporation

Telephone number for information: 1-800-237-4277

Emergency telephone number: 1-800-255-3924

Canada Sharp Electronics of Canada Ltd.

Telephone number for information: 905-890-2100

Emergency telephone number: 1-800-255-3924

United Kingdom Sharp Electronics (U.K.) Ltd.

Telephone number for information: 01923-474013

MSDS No. F-00841

Section 3. Ingredients

Ingredients CAS No. Proportion OSHA PEL ACGIH TLV Other Limits

Styrene-Acrylate copolymer 29497-14-1 > 88 % Not listed Not listed None

Carbon black 1333-86-4 < 6.0% 3.5mg/m

Iron oxide 1309-38-2 < 4.5% Not listed Not listed None

Metal Complex dye 109125-51-1 < 1.5% 0.5mg/m

109125-50-0

84179-66-8

3

3

3.5mg/m

0.5mg/m

3

3

None

None

Section 4. Hazardous Identification (Emergency Overview)

T oner is a fine , black powder possessing no immediate hazard. There are no anticipated carcinogenic effects from

exposure based on animal tests performed using toner . When used as intended according to instructions, studies

do not indicate any symptoms of fibrosis will occur.

Section 5. Health Hazard Data

Route(s) of Entry: Inhalation? Skin? Ingestion?

Yes No Possible but very unusual.

Health Hazards: Acute oral toxicity-------- LDL0 of this toner is over 2,000mg/kg.

Mutagenicity --------------The result of Ames test is negative.

Carcinogenicity: In 1996 the IARC reevaluated carbon black as a Group 2B carcinogen (possible human

carcinogen). This classification is given to chemicals for which there is inadequate human

evidence, but sufficient animal evidence on which to base an opinion of carcinogenicity. The

classification is based upon the development of lung tumors in r ats receiving chronic inhalation

exposures to free carbon black at levels that induce particle overload of the lung. Studies

performed in animal models other than rats did not show any association between carbon

black and lung tumors. Moreo ver , a two-year cancer bioassay using a typical toner prepar ation

containing carbon black demonstrated no association between toner exposure and tumor

development in rats.

Chronic Effect:: In a study in rats of chronic inhalation exposure to a typical toner, a mild to moderate degree

of lung fibrosis was observed in 92% of the rats in the high concentration (16mg/m3) exposure

group, and a minimal to mild degree of fibrosis w as noted in 22% of the animals in the middle

(4mg/m3) exposure group, but no pulmonary change was reported in the lowest (1mg/m3)

exposure group, the most relevant level to potential human exposures.

Signs and Symptoms of Exposure: Minimal irritation to respiratory tract may occur as with exposure to any

non-toxic dust.

Medical Conditions Generally Aggravated by Exposure: None

Emergency and First Aid Procedures:

Inhalation; Remove to fresh air. If effects occur, consult medical personnel.

Eye; In case of contact, immediately flush eyes with water for 15 minutes.

47

Page 41

Section 6. Physical Chemical Characteristics

Boiling / Melting Point: Not applicable Specific Gravity: 1.1

Vapor Pressure: Not applicable Solubility in Water: Negligible

Vapor Density: Not applicable PH: Not applicable

Evaporation Rate: Not applicable Viscosity: Not applicable

Appearance: Fine powder Color: Black

Odor: Odorless

Section 7. Fire and Explosion Data

Flash Point (Method Used): Not applicable

Ignition Temperature: >350°C

Flammable Limits: (LEL); Not applicable (UEL); Not applicable

Extinguishing Media: CO2, dry chemical, foam or water

Special Fire Fighting Procedure: None

Unusual Fire and Explosion Hazard: This material has no unusual fire or explosion hazards.

Sensitivity to Mechanical Impact: None

Sensitivity to Static Charge: None

Section 8. Reactivity Data

Stability: Stable

Incompatibility (Material to Avoid): None

Hazardous Decomposition: CO and NOx

Hazardous Polymerization: Will not occur.

Section 9. Precautions for Safe Handling and Use

Personal Protection Information (Respiratory, Eye Protection and Protective Glove):

Use of a dust mask is recommended when handling a large quantity of toner or during long

term exposure, as with any non-toxic dust.

Engineering Control / Ventilation: Not required.

Work / Hygienic Practice: Inhalation should be minimized as with any non-toxic dust.

Steps to be taken in case of Spill or Leak: Sweep up or clean up with vacuum cleaner.

Waste Disposal Method: Waste material may be dumped or incinerated under conditions

which meet all federal, state and local environmental regulations .

Section 10. Regulatory Information

NFPA Rating (U.S.A.): Health = 1 Flammability = 1 Reactivity = 0

WHMIS Legislation (Canada): This product is not a controlled product.

Transport Information: This product is not a hazardous material.

UN No.: None allocated.

Section 11. Other Information

References: IARC (1996) IARC Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Humans,

Vol. 65, Printing Process and Printing inks, Carbon Black and Some Nitro Compounds, Ly on, pp149-261

H. Muhle, B. Bellmann, O. Creutzenberg, C. Dasenbrock, H. Er nst, R. Kilpper, J. C. MacKenzie,

P. Morrow, U. Mohr, S. Takenaka, and R. Mermelstein (1991) Pulmonary Response to Toner upon

Chronic Inhalation Exposure in Rats. Fundamental and Applied Toxicology 17, pp. 280-299

48

Page 42

SHARP

Date Issued :Nov. 1, 1998

MATERIAL SAFETY DATA SHEET

Section 1. Product Identification

Product

AL-160TD(Black Developer)

Section 2. Supplier’s Name and Address

Sharp Corporation

22-22 Nagaike-cho, Abeno-ku, Osaka, Japan

Local suppliers are listed below. Please contact the nearest supplier for additional information.

(Country) (Name and Telephone Number)

U.S.A. Sharp Electronics Corporation

Telephone number for information: 1-800-237-4277

Emergency telephone number: 1-800-255-3924

Canada Sharp Electronics of Canada Ltd.

Telephone number for information: 905-890-2100

Emergency telephone number: 1-800-255-3924

United Kingdom Sharp Electronics (U.K.) Ltd.

Telephone number for information: 01923-474013

MSDS No. F-30841

Section 3. Ingredients

Ingredients CAS No. Proportion OSHA PEL ACGIH TLV Other Limits

Iron powder 7439-89-6 > 92.5% Not listed Not listed None

Styrene-Acrylate copolymer 29497-14-1 < 7.0% Not listed Not listed None

Carbon black 1333-86-4 < 0.5% 3.5mg/m

3

3.5mg/m

3

None

Section 4. Hazardous Identification (Emergency Overview)

Developer is a black powder containing small amounts of toner, and possessing no immediate hazard.

There are no anticipated carcinogenic effects from exposure based on animal tests performed using toner.

Section 5. Health Hazard Data

Route(s) of Entry: Inhalation? Skin? Ingestion?

No No Possible but very unusual.

Health Hazards: Acute oral toxicity------------ LDL0 of this toner which is included in this developer is over

2,000mg/kg.

Mutagenicity ------------------ The toner, which is included in this developer , has been tested on

Ames test. The result is negative.

Carcinogenicity: In 1996 the IARC reevaluated carbon black as a Group 2B carcinogen (possible human

carcinogen). This classification is given to chemicals for which there is inadequate human

evidence, but sufficient animal evidence on which to base an opinion of carcinogenicity. The

classification is based upon the development of lung tumors in r ats receiving chronic inhalation

exposures to free carbon black at levels that induce particle overload of the lung. Studies

performed in animal models other than rats did not show any association between carbon

black and lung tumors.

While there have been no studies to date using developer, a two-year cancer bioassay using

a typical toner preparation containing carbon black (a small amount of toner is included in the

developer mixture) demonstrated no association between toner exposure and tumor

development in rats.

Signs and Symptoms of Exposure: Minimal irritation to respiratory tract may occur as with exposure to any

non-toxic dust.

Medical Conditions Generally Aggravated by Exposure: None

Emergency and First Aid Procedures:

Inhalation; Remove to fresh air. If effects occur, consult medical personnel.

Eye; In case of contact, immediately flush eyes with water for 15 minutes.

49

Page 43

Section 6. Physical Chemical Characteristics

Boiling / Melting Point: Not applicable Specific Gravity: about 7.3

Vapor Pressure: Not applicable Solubility in Water: Negligible

Vapor Density: Not applicable PH: Not applicable

Evaporation Rate: Not applicable Viscosity: Not applicable

Appearance: Fine powder Color: Black

Odor: Odorless

Section 7. Fire and Explosion Data

Flash Point (Method Used): Not applicable

Ignition Temperature: >350°C

Flammable Limits: (LEL); Not applicable (UEL); Not applicable

Extinguishing Media: CO2, dry chemical, foam or water

Special Fire Fighting Procedure: None

Unusual Fire and Explosion Hazard: This material has no unusual fire or explosion hazards.

Sensitivity to Mechanical Impact: None

Sensitivity to Static Charge: None

Section 8. Reactivity Data

Stability: Stable

Incompatibility (Material to Avoid): None

Hazardous Decomposition: CO and NOx

Hazardous Polymerization: Will not occur.

Section 9. Precautions for Safe Handling and Use

Personal Protection Information (Respiratory, Eye Protection and Protective Glove):

None required under normal use.

Engineering Control / Ventilation: Not required.

Work / Hygienic Practice: Not required.

Steps to be taken in case of Spill or Leak: Sweep up or clean up with vacuum cleaner.

Waste Disposal Method: Waste material may be dumped or incinerated under conditions

which meet all federal, state and local environmental regulations .

Section 10. Regulatory Information

NFPA Rating (U.S.A.): Health = 1 Flammability = 1 Reactivity = 0

WHMIS Legislation (Canada): This product is not a controlled product.

Transport Information: This product is not a hazardous material.

UN No.: None allocated.

Section 11. Other Information

References: IARC (1996) IARC Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Humans,

Vol. 65, Printing Process and Printing inks, Carbon Black and Some Nitro Compounds, Ly on, pp149-261

H. Muhle, B. Bellmann, O. Creutzenberg, C. Dasenbrock, H. Er nst, R. Kilpper, J. C. MacKenzie,

P. Morrow, U. Mohr, S. Takenaka, and R. Mermelstein (1991) Pulmonary Response to Toner upon

Chronic Inhalation Exposure in Rats. Fundamental and Applied Toxicology 17, pp. 280-299

50

Page 44

MEMO

51

Page 45

MEMO

Page 46

♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠

♠

♠

♠

For users in the USA

WARNING:

FCC Regulations state that any unauthorized changes or modifications

to this equipment not expressly approved by the manufacturer could void

the user’s authority to operate this equipment.

Note:

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

operation manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user wil be

required to correct the interference at his own expense.

♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠

♠

♠

♠

♠

♠

♠

♠

♠

♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠

♠

♠

♠

♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠♠

Page 47

AL-1600/AL-1610

SHARP ELECTRONICS CORPORATION

Sharp Plaza, Mahwah, New Jersey 07430-2135.

SHARP ELECTRONICS OF CANADA LTD.

335 Britannia Road East, Mississauga, Ontario, L4Z 1W9

SHARP CORPORATION

PRINTED IN JAPAN

99A KS➀

TINSE0109QSZZ

Loading...

Loading...