Sharp AL-1600,AL-1610 Service Manual

AL-1610

CODE: 00ZAL1610//A1E

DIGITAL COPIER

AL-1600

MODEL AL-1610

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . 4-1

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] ACTUAL WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safty and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

AL-1610

Warning!

This product is a class A product.

If it is operated in households, offices or similar surroundings, it

can produce radio interferences at other appliances, so that the

user has to take adequate countermeasures.

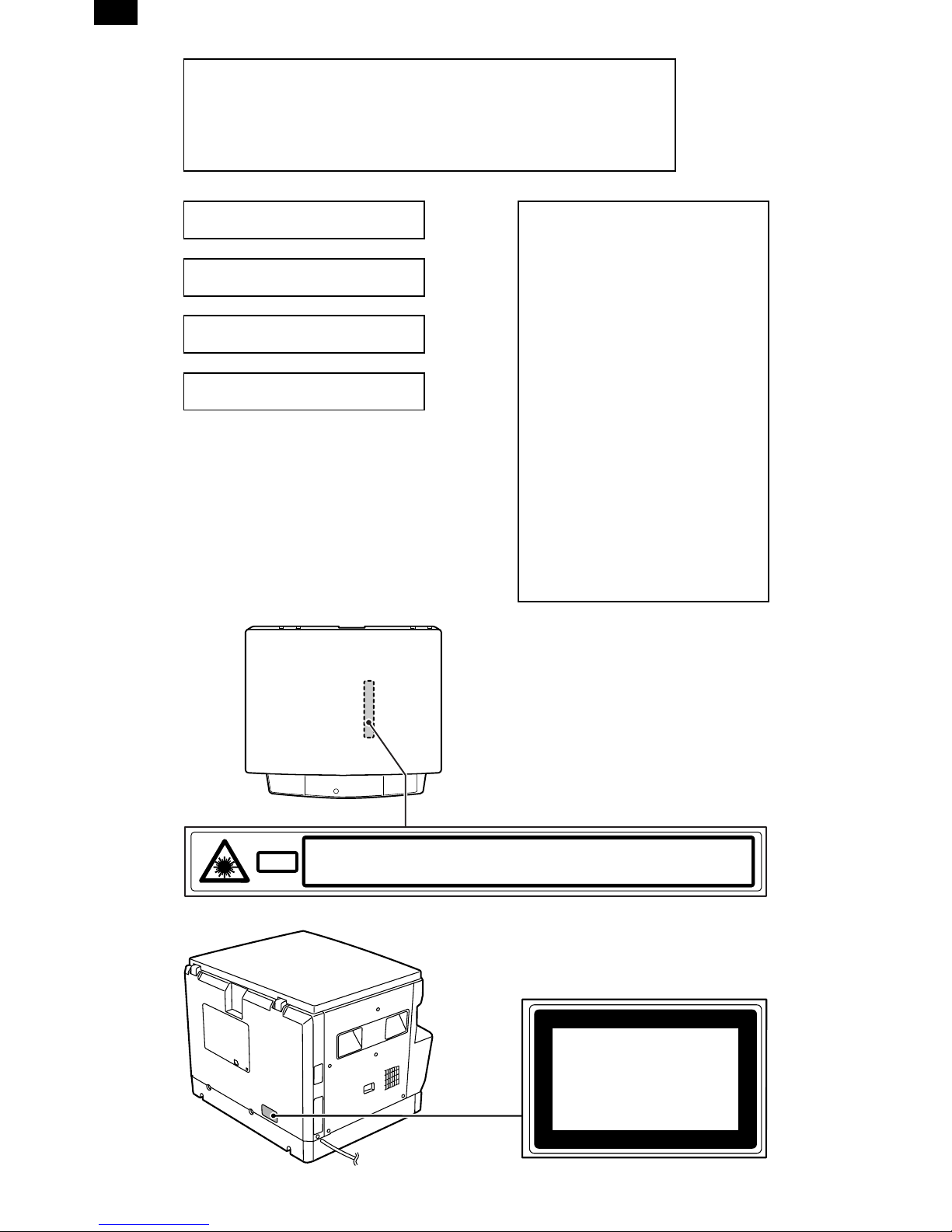

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

VAROITUS!

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

CAUTION

Laserstrahl

VORSICHT

ADVARSEL

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGA UDSAETTELSE FOR STRÅLING.

ADVERSEL

VARNING

VARO!

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

CONTENTS

AL-1610

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Target user copy volum e: M ont hly average . . . 1-1

3. Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

4. Copier installation . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1. Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . 3-1

1. Supply system table . . . . . . . . . . . . . . . . . . . . . 3-1

2. Environment conditions . . . . . . . . . . . . . . . . . . . 3-2

3. Production number identification . . . . . . . . . . . . 3-2

[ 4 ] EXTERNAL VIEWS AND INTERNAL

STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

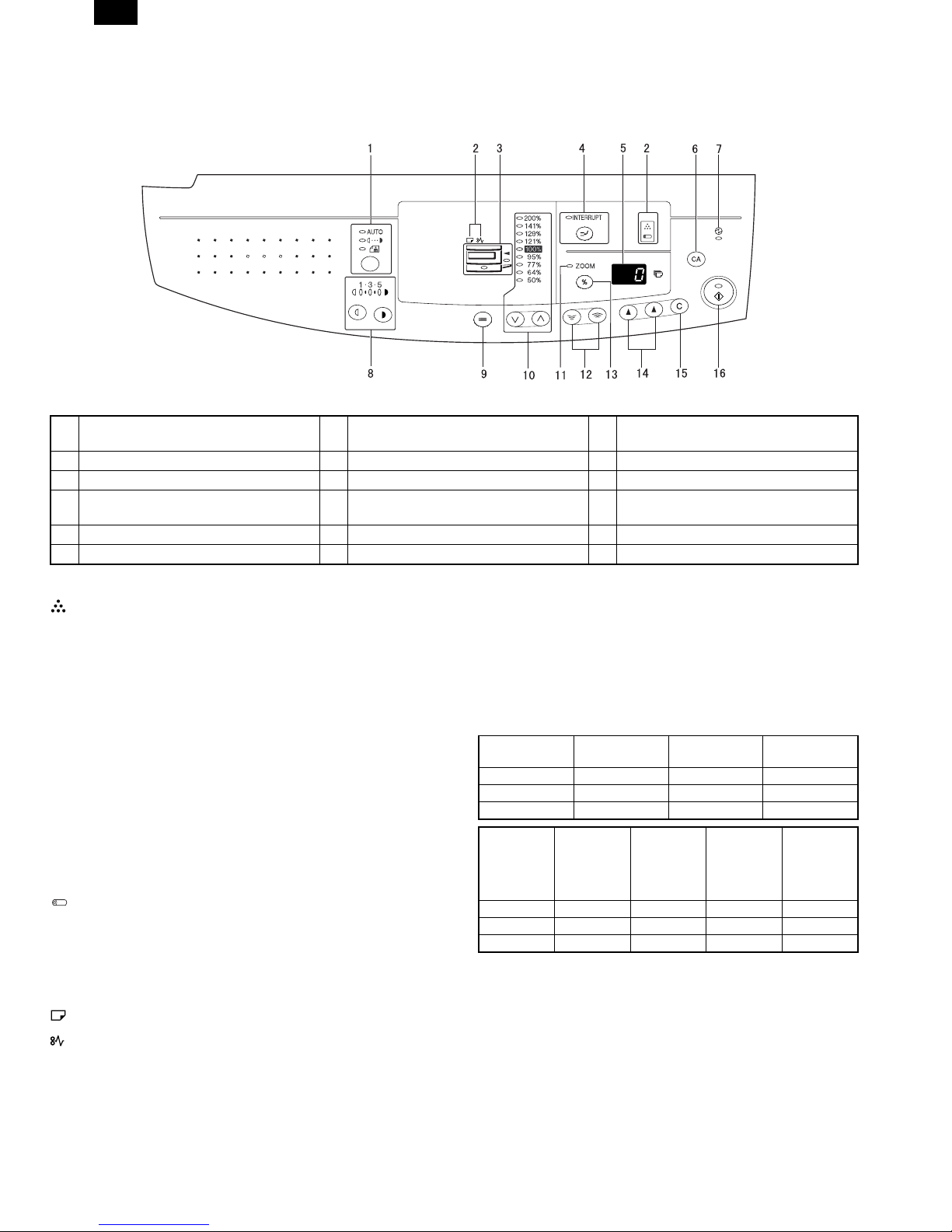

3. Operation Section . . . . . . . . . . . . . . . . . . . . . . . 4-2

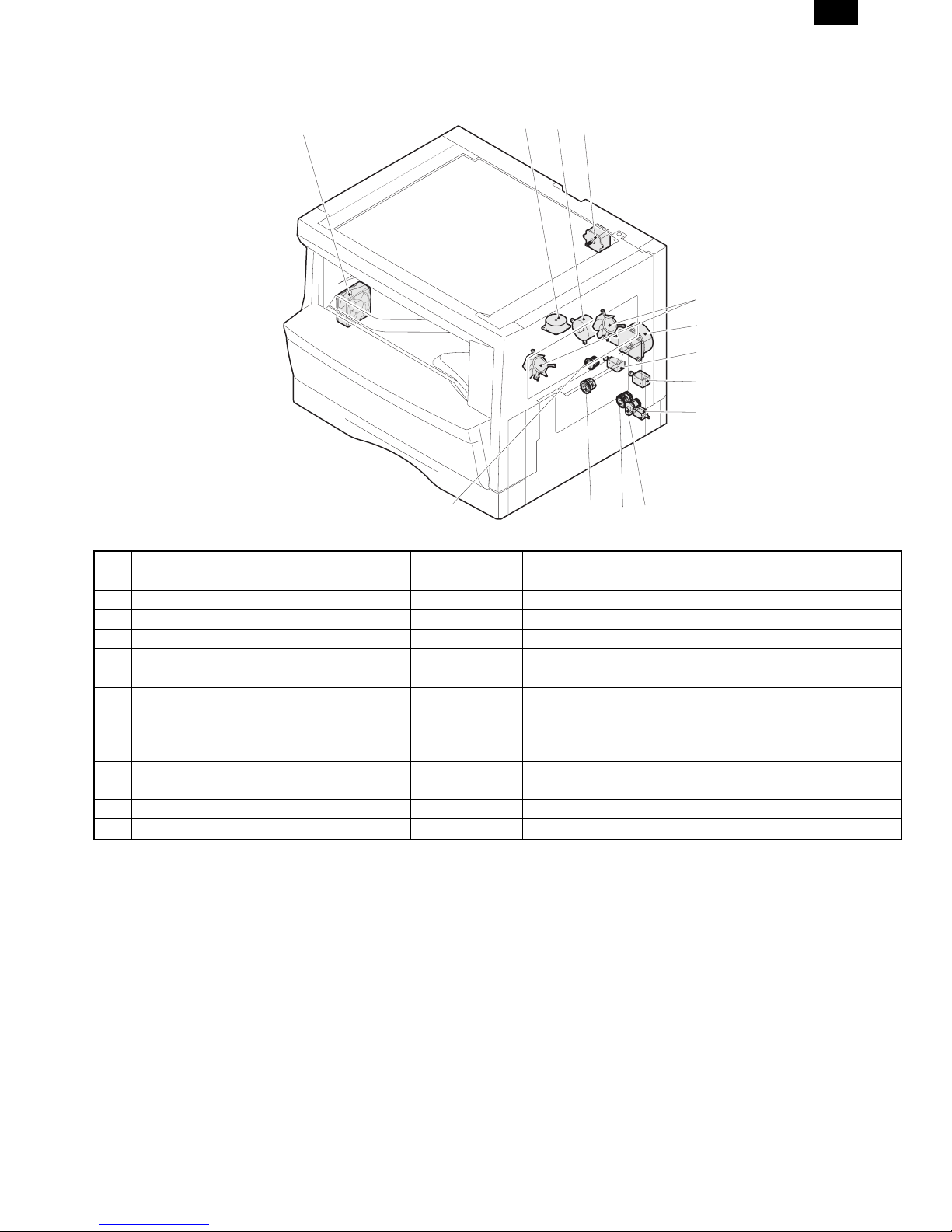

4. Motor, solenoid, clutch . . . . . . . . . . . . . . . . . . . 4-3

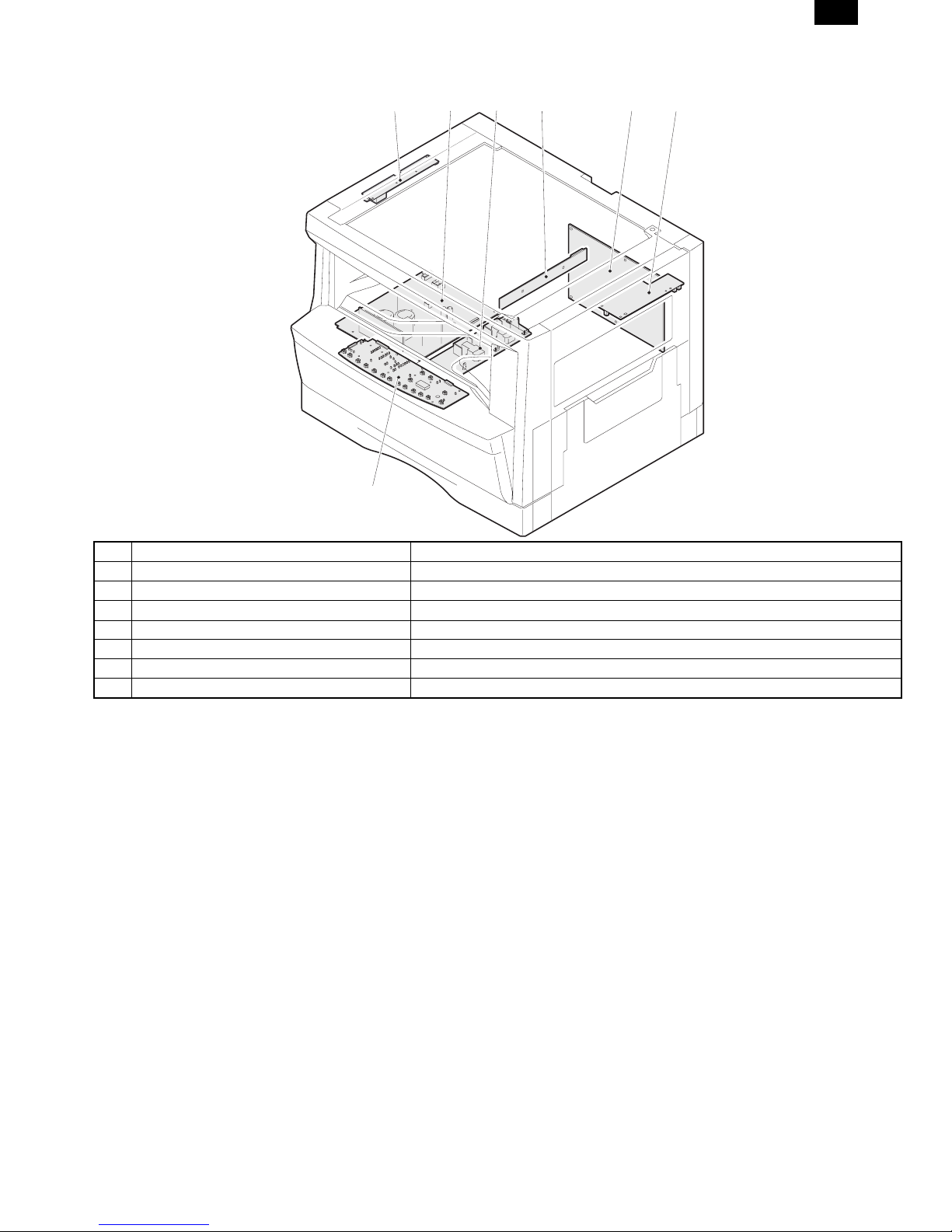

5. Sensor, switch . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

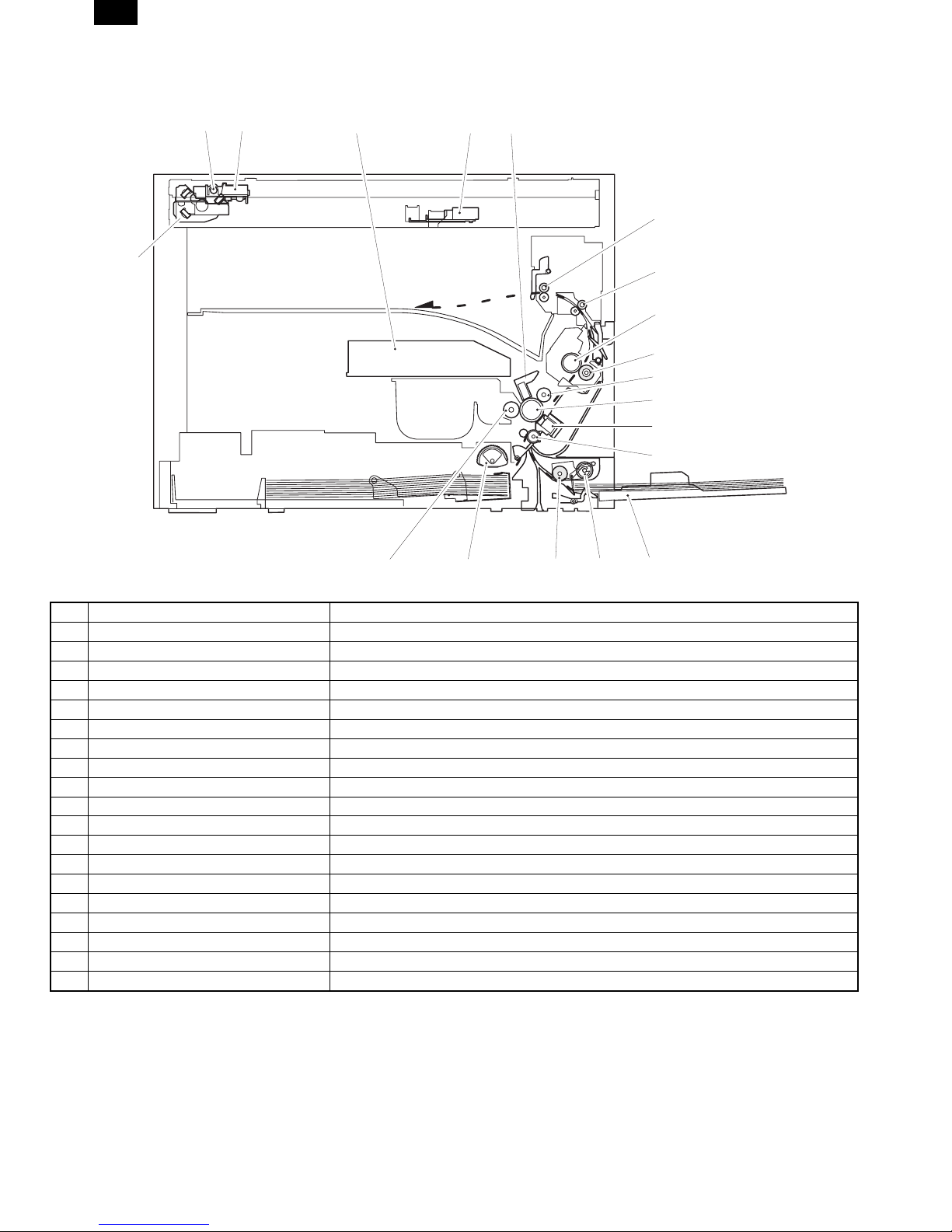

7. Cross sect i onal vi ew . . . . . . . . . . . . . . . . . . . . . 4-6

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . 5-1

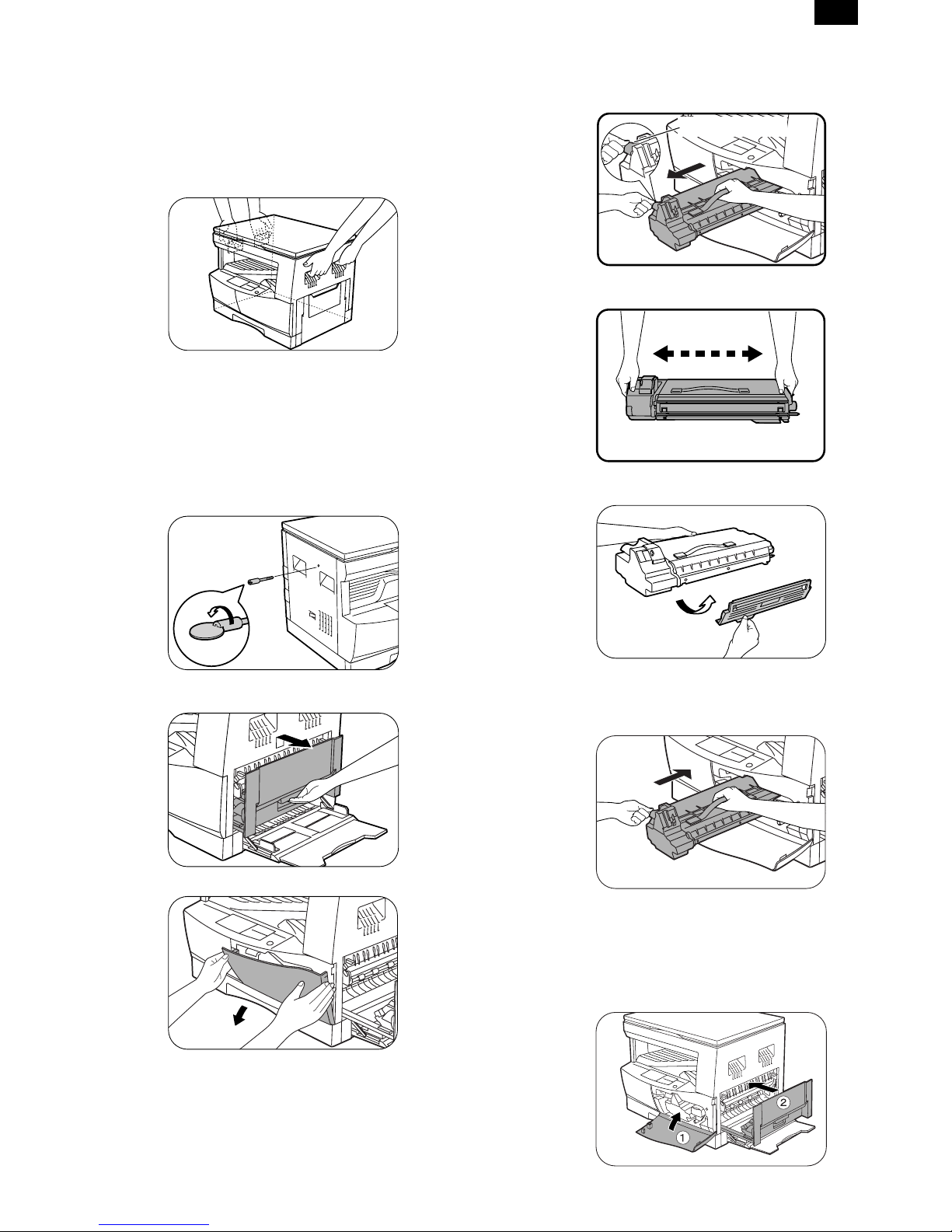

1. Unpaking pr ocedure . . . . . . . . . . . . . . . . . . . . . 5-1

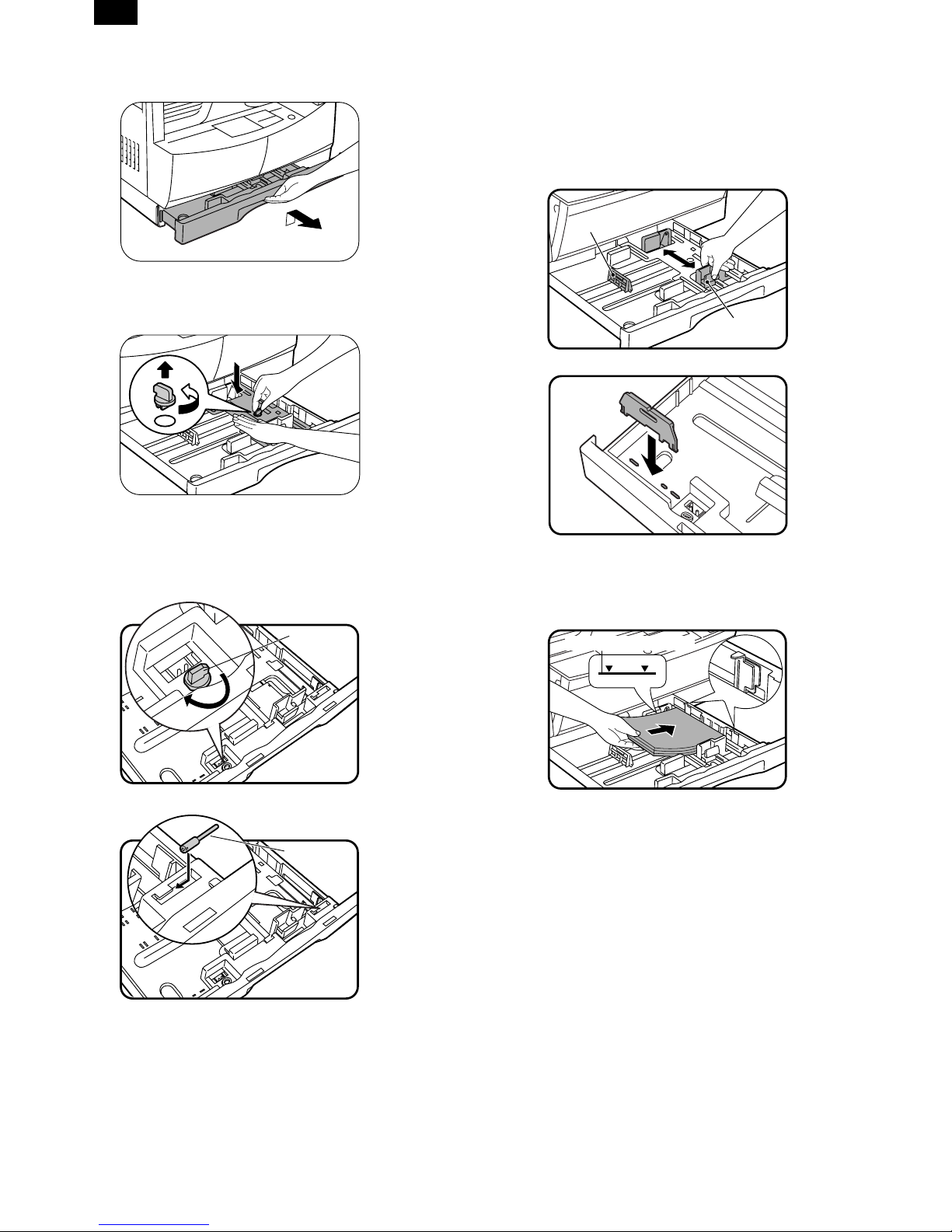

2. Installi ng pr ocedure . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 9 ] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . 9-1

1. User progra m fun ct ions . . . . . . . . . . . . . . . . . . 9-1

2. Setting change procedure . . . . . . . . . . . . . . . . . 9-1

[10] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . 10-1

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . 11-1

1. High voltag e secti on . . . . . . . . . . . . . . . . . . . . 11-1

2. Optical section . . . . . . . . . . . . . . . . . . . . . . . . 11-1

3. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

4. Paper exit section . . . . . . . . . . . . . . . . . . . . . . 11-4

5. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

6. Optical fra m e uni t . . . . . . . . . . . . . . . . . . . . . . 11-6

7. LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

8. Tray paper feed sectio n/

Paper transport section . . . . . . . . . . . . . . . . . . 11-7

9. Manual m ul ti paper feed section . . . . . . . . . . . 11-8

10. Power section . . . . . . . . . . . . . . . . . . . . . . . . 11-10

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . 12-1

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

3. CCD PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

[13] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] ACTUAL WIRING DIAGRAM . . . . . . . . . . . . . 14-1

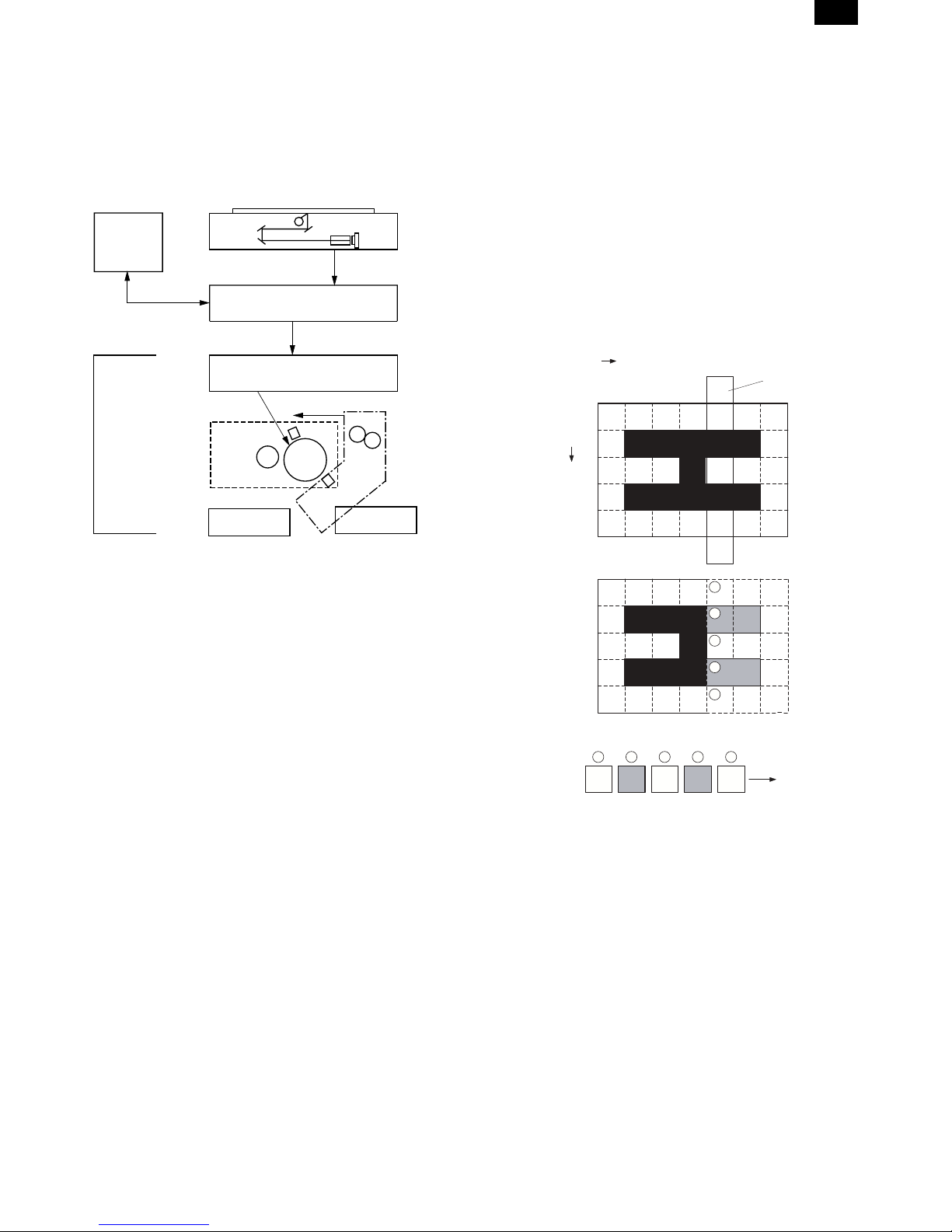

[ 6 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . 6-1

1. Outline of oper ation . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . 6-1

3. Process section . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

4. Laser unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

5. Paper feed section . . . . . . . . . . . . . . . . . . . . . . 6-6

6. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1. Adjustme nt item l ist . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Copier adju st m ent . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

1. Entering t he sim ul at i on m ode . . . . . . . . . . . . . . 8-1

2. Cancellin g the si m ulat io n m ode . . . . . . . . . . . . 8-1

3. List of simulatio ns . . . . . . . . . . . . . . . . . . . . . . . 8-1

4. Contents of simu la tions . . . . . . . . . . . . . . . . . . . 8-2

AL-1610

[1] GENERAL

1. General

This model is a digital personal copier produced with key words of

"Comfort able copy, Clear copy, Easy copy" providing high copy performances and copy productivity.

2. Target User Copy Volume: Monthly

Average

2000~3000 sheets

3. Main features

A. High-speed laser copying

• First-copy time is only 7.4 seconds (normal mode).

• Copying speed is 16 copies/min., which adapts to business use,

allowing improvement of working efficiency.

B. High-quality digital image

• High-quality copying at 600 dpi is performed.

• In addition to the automatic exposure mode, the manual exposure

can be adjusted in five steps.

• The photo mode copying function allows clear copying of delicate

halftone original images such as monochrome photos and color

photos. Photo mode is adjustable in five steps

C. Substantial copying features

• Zoom copying from 50% to 200% in 1% increments can be per-

formed.

• Continuous copying of maximum 99 sheets can also be per-

formed.

• Toner save mode reduces toner consumption by approximately

10%.

• User programs allow setting/modification of functions for customer

needs.

D. Scan once/ Print many (AL-1610 only)

• The copier is equipped with a 1-page memory buffer. This memory

allows the copier to scan an original 1 time only and make up to 99

copies. This feature allows for improved workflow, reduced operating noise from the copier and reduced wear and tear on the scanning mechanism, which provides for a higher reliability.

E. Environmentally friendly design

• Paper output tray is housed in the copier for space saving.

• Preheat mode and auto power shut-off mode are provided to

reduce power consumption in standby mode.

4. Copier installation

Do not install your copier in areas that are:

• damp, humid, or very dusty

• exposed to direct sunlight

• poorly ventilated

• subject to extreme temperature or humidity changes, e.g., near an

air conditioner or heater.

• Be sure to allow the required space around the machine for servic-

ing and proper ventilation.

4" (10 cm)

1 – 1

AL-1610

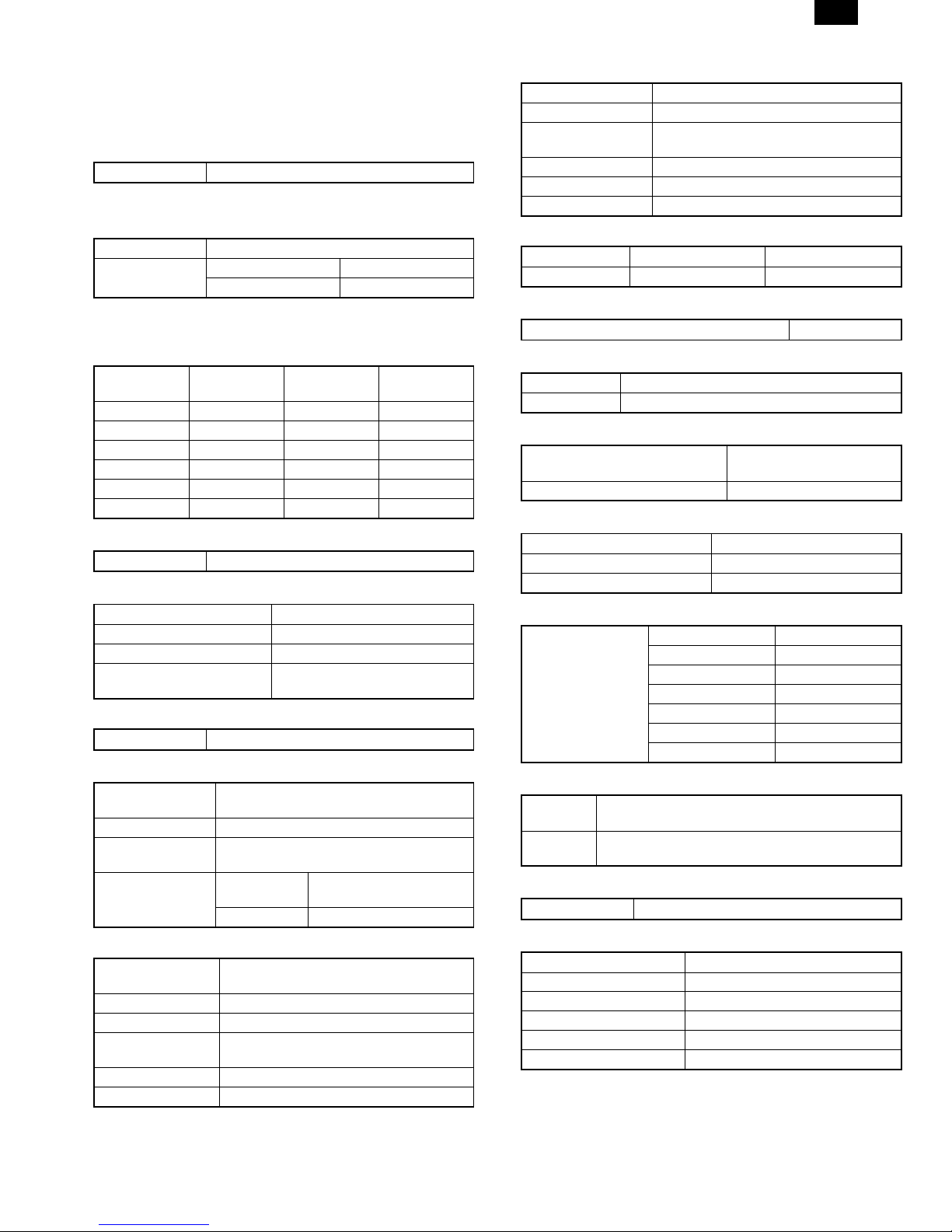

[2] SPECIFICATIONS

1. Copy mode

A. Type

Type Desk-top

B. Copy speed

(1) Basic speed

1 scan 1 copy 16 sheets/min

1 scan multi copy AL-1600 Not available

AL-1610 Available

Condition: Copy speed in the normal copy from all the paper feed

ports including the manual paper feed port.

(2) Continuous copy speed (Sheets/min)

Paper size Normal

11" × 17" 9 9 9

8.5" × 14" 10 10 10

8.5" × 13" 10 10 10

8.5" × 11" 16 16 14

8.5" × 11R" 12 12 12

8.5" × 5.5" 16 16 16

Enlargement

(200%)

C. First copy time

First copy time 7.2sec (11" × 8.5", 1st cassette, with OC)

D. Document

Max. document size 11" × 17"

Document reference position Left side center

Detection (Platen) None

Detection size 11" × 17", 8.5" × 14", 8.5" × 13",

8.5" × 11", 8.5" × 11"R, 8.5" × 5.5"

(1) SPF/R-SPF

Standard/Option Not available

E. Paper feed

Copy size (Max. ∼ Min.) Cassette: (11" × 17" ∼ 8.5" ×

5.5")

Paper feed system 1 cassette + Multi bypass paper feed

Paper feed

capacity

Remaining

quantity detection

(1) Paper feed section of the copier

Paper feed size 11" × 17", 8.5" × 14", 8.5" × 13", 8.5" × 11",

Side front Front 1st step

Paper feed capacity 250 sheets (56 ∼ 80g/m2 equivalent)

Detection Paper empty detection available, size

Weight 56 ∼ 80g/m

Special paper Recycled paper

250 × 1 (Paper feed tray) + 100 (Multi

bypass feed tray)(56 ∼ 80g/m2 equivalent)

Cassette

section

Manual tray Empty detection available

8.5" × 11"R, 8.5" × 5.5"

detection (by key input)

Empty detection available

2

Reduction

(50%)

(2) Manual paper feed section

Paper feed size 11" × 17" ∼ 8.5" × 5.5"

Paper feed capacity 100 sheets

Detection Size detection not available, paper empty

detection available

Weight 56 ∼ 128g/m

Special paper Recycled paper, OHP film, labels

Paper feed Single except for recycled paper

2

(3) Optional paper feed unit

1-step paper feed unit 2-step paper feed unit

Standard/Option Not available Not available

F. Multi copy

Max. number of multi copy 99 sheets

G. Warmup time

Warmup time Approx. 35 sec (Condition: Standard condition)

Pre-heat Available

H. Copy magnification ratio

Fixed magnification ratio 50, 64, 77, 95, 100, 121,

129, 141, 200%

Zooming 50 ∼ 200%

I. Print density

Density mode Auto/Manual/Photo

No. of manual adjustment 5 steps (Manual/Photo)

Toner save mode Set by the user program

J. Print area

Max. print area Max. 428 × 275

11" × 17" 428 × 275

8.5" × 14" 352 × 212

8.5" × 13" 212 × 326

8.5" × 11" 212 × 275

8.5" × 11"R 275 × 212

8.5" × 5.5" 212 × 136

K. Void width

Void area Lead edge 1 ∼ 4mm, rear edge 4mm or less, both

side 4mm or less

Image loss Max. 4mm in total of lead edge and rear edge, max.

4mm in total of right and left edges (Normal copy)

L. Auto duplex

Standard/Option Not installable

M. Paper exit/finishing

Paper exit section capacity Face down 250 sheets

Job separator Job separator not available

Full detection Not available

Finishing Electronic sort board: Not available

Offset function Not available

Staple function Not available

2 – 1

AL-1610

N. Additional functions

APS ✕

AMS ✕

Duplex ✕

Document count ✕

Sorter ✕

Independent zooming ✕

1 set 2 copy ✕

Binding margin ✕

Edge erase ✕

Black-white reversion ✕

2 in 1, 4 in 1 ✕

Rotation copy ✕

Memory copy D AL-1610 only

Pre-heat function F Condition set by the user program

Auto power shut off F Condition set by the user program

Auto tray switching ✕

Message display ✕

User program F

Total counter F

O. Machine composition

Model

AL-1600 16 CPM standard model

AL-1610 16 CPM standard model (With shifter)

(1) Supply parts

Part name

Toner/developer cartridge AL-160-TD-B

Drum cartridge AL-160-DR

T. Power consumption

Max. power consumption About 1.3KWh

* EnergyStar standard (The second level conformity)

Pre-heat About 60Wh

Auto power shut off About 4.8Wh

U. Reliability

Target users Stand-alone copier Monthly average

2,000 ∼ 3,000 copies

V. Noise

Noise BA standard

W. Digital performance

Resolution Reading 400 dpi

Writing 600 dpi

Gradation Reading 256 gradations

Writing Binary

P. Other specifications

Photoconductor type OPC (Organic Photo Conductor)

Photoconductor drum dia. 30mm

Copy lamp Xenon lamp

Developing system Dry 2-component magnetic brush

development

Charging system Saw teeth charging

Transfer system Non-contact (Corona) electrostatic

transfer

Separation system Natural separation

Fusing system Heat roller + Separation pawl

Cleaning system Contact blade

Q. Package form

Body Body/Accessaries

R. External view

External dimensions (W × D × H) 590 × 526 × 467 mm

Occupying area (W × D) 590 × 526mm (When the

manual tray is installed.)

Weight About 34.1kg

S. Power source

Voltage AC120V ±15%

Frequency 50/60Hz common

2 – 2

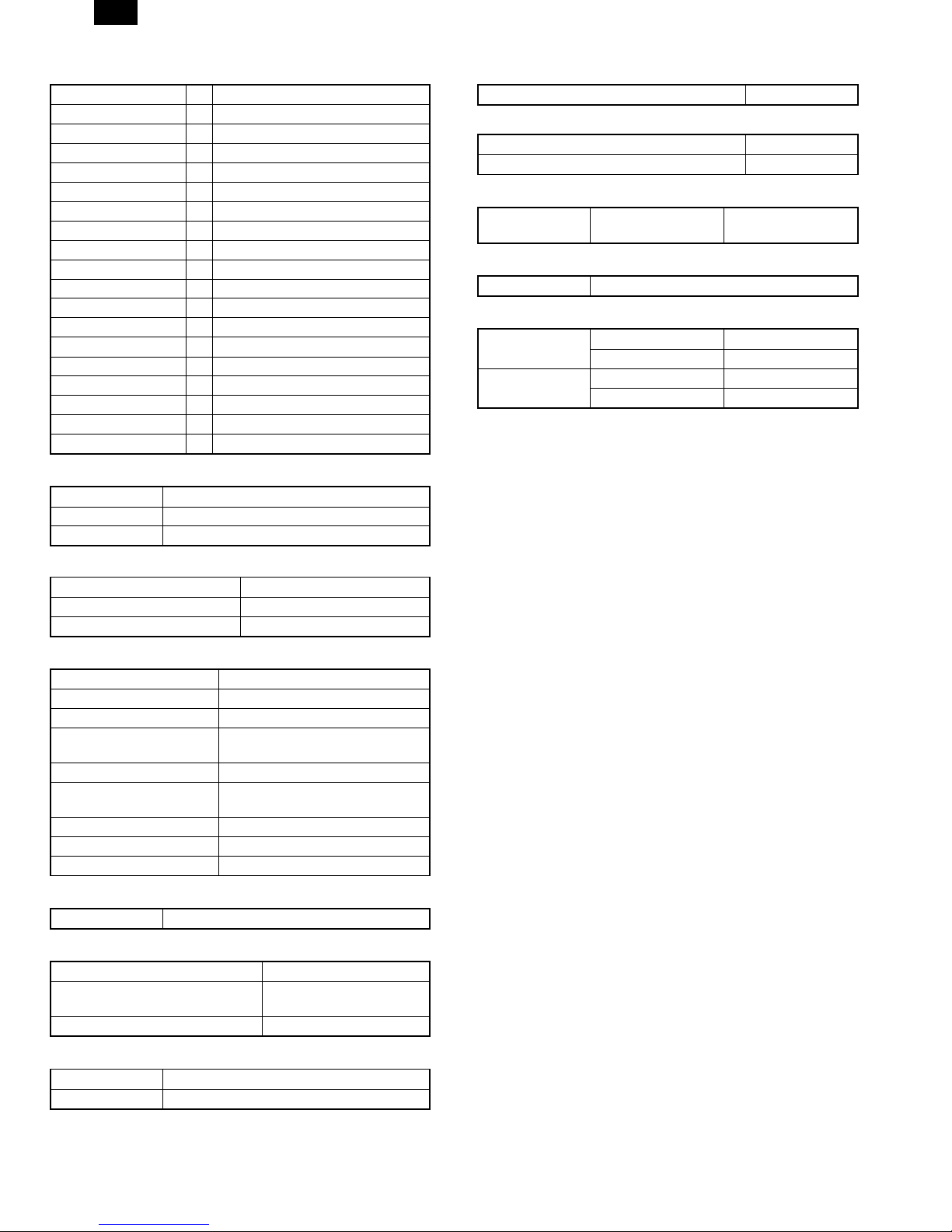

[3] CONSUMABLE PARTS

1. Supply system table

A. USA

No. Name Content Life Product name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner: 600g, Developer: 400g)

Postcard label

(TLABZ0025YSZZ)

Returned Operation Manual × 1

Vinyl bag × 1

Warranty Card × 1

2 Drum cartridge Drum cartridge × 1 30K AL-160DR 4

Warranty Card × 1

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

B. Canada

No. Name Content Life Product name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner: 600g, Developer: 400g)

Postcard label

(TLABZ0025YSZZ)

Returned Operation Manual × 1

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AL-160DR 4

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

C. Europe

No. Name Content Life Product name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner: 600g, Developer: 400g)

Postcard label

(TLABZ0025YSZZ)

Returned Operation Manual × 1

Vinyl bag × 1

2 Drum cartridge Drum cartridge × 1 30K AL-160DR 4

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

D. Australia, New Zealand, Southeast Asia, LAG, Middle East

No. Name Content Life Product name Package Remark

1 Developer cartridge (Black) Toner/developer cartridge

(Toner: 600g, Developer: 400g)

2 Drum cartridge Drum cartridge × 1 30K AL-160DR 4

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

× 1 15K AL-160TD 4 Life setting by A4 6%

documents

× 1

× 1 15K AL-160TD 4 Life setting by A4 6%

documents

× 1

× 1 15K AL-160TD 4 Life setting by A4 6%

documents

× 1

× 1 15K AL-160TD 4 Life setting by A4 6%

documents

AL-1610

3 – 1

AL-1610

2. Environment conditions

A. Transport condition

(1) Transport conditions

Humidity (%)

Temperature

(2) Storage conditions (packed conditions)

Humidity (%)

3. Production number identification

<Developing cartridge>

The label on the drum cartridge shows the date of production.

B

Destination

(∗)

Indicates production in China.

The end digit of production year

∗: Destination

Division No.

Japan option 1

Ex option 2

Japan, same pack 6

Ex, same pack 7

<Drum cartridge>

The label on the drum cartridge shows the date of production.

Ver. A

Serial number

(00001-99999)

1

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

Temperature

B. Use conditions

Use environment

conditions

Humidity (%)

Temperature

C. Life (packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

Serial number (for each

month) (00001-99999)

Factory

The end digit of production year

Division No.

Ex production 1

Option 2

Same pack 3

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

3 – 2

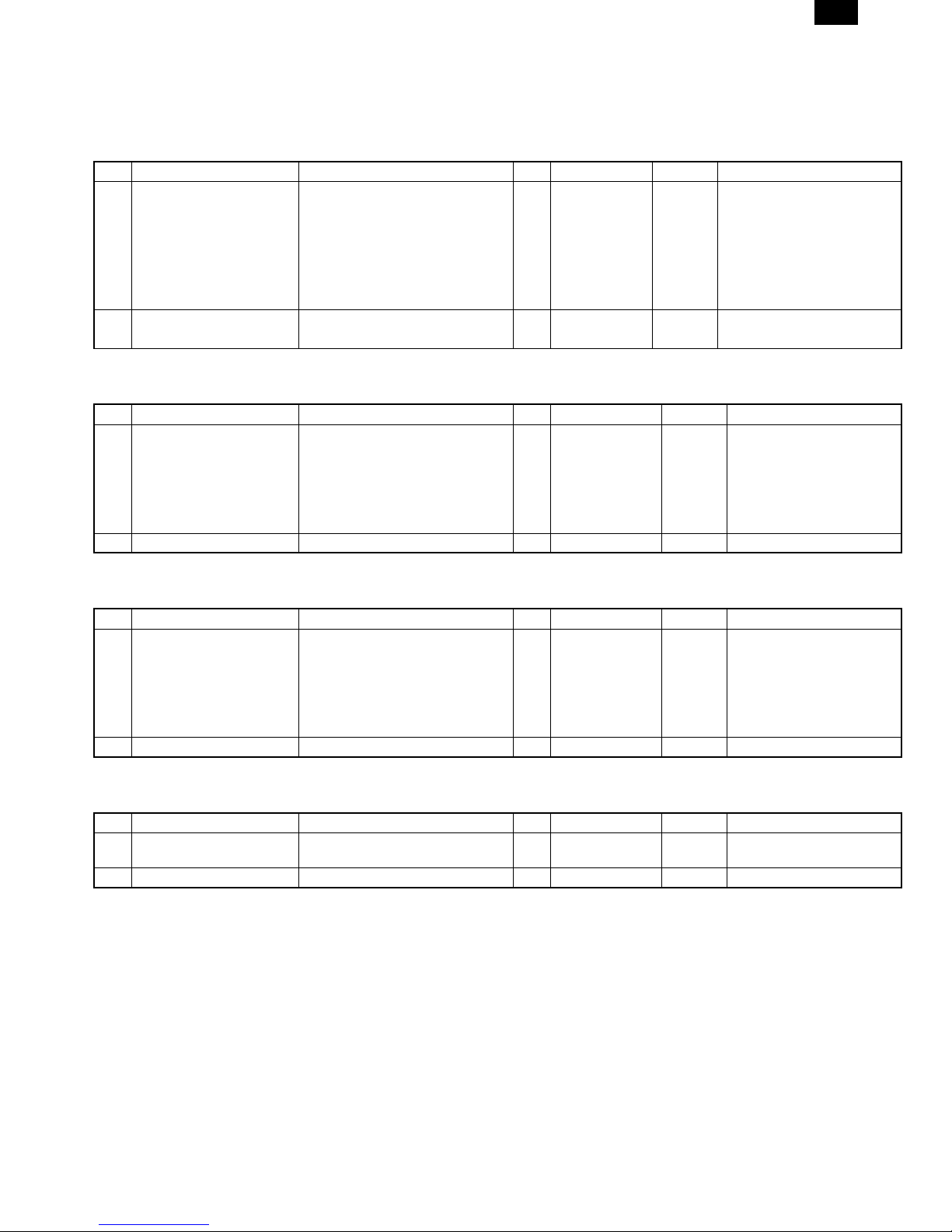

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

AL-1610

1 Original cover 2 Original table (OC table) 3 Handles

4 Power switch 5 Operation panel 6 Paper output tray

7 Original size detector 8 Front cover 9 Paper tray

10 Side cover 11 Side cover handle 12 Bypass tray guides

13 Bypass tray

2. Internal

1 Bypass tray extension 2 Drum cartridge handle 3 Drum cartridge

4 TD cartridge handle 5 TD cartridge strap 6 TD cartridge

7 Roller rotating knob 8 Fusing unit release levers 9 Paper guide

4 – 1

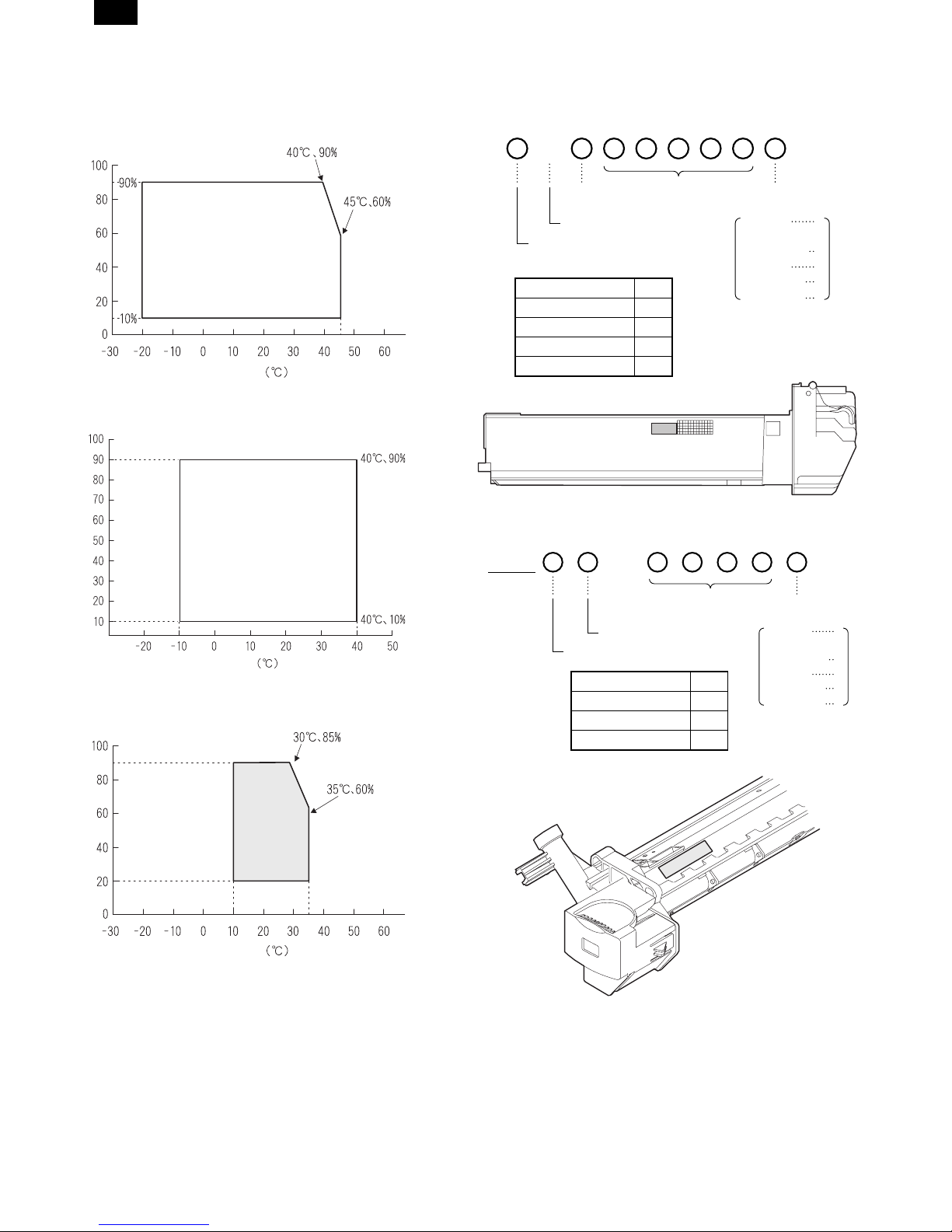

AL-1610

3. Operation Section

1 AUTO/MANUAL/PHOTO key and

indicators

2 Alarm indicators 3 Paper feed location/misfeed location

indicators

4 Interrupt key and indicator 5 Copy quantity display 6 CLEAR ALL key

7 POWER SAVE indicator 8 Light and dark keys and indicators 9 TRAY SELECT key

10 PRESET RATIO selector keys and

11 ZOOM indicator 12 Zoom keys

indicators

13 Copy ratio display key 14 Copy quantity keys 15 CLEAR key

16 START key and indicator

* 1

TD cartridge replacement required indicator

The TD cartridge replacement required indicator will light up

when toner is needed. If copying is continued while the indicator

is lit, copies will gradually become lighter until the copier stops

and the indicator begins blinking. Replace the old TD cartridge

by following the procedure given below.

After the copier stops, it may be possible to make a few more

copies by taking the TD cartridge out of the copier, shaking it

horizontally, then reinstalling it. If copying is not possible after

this operation, replace the TD cartridge. During long copy run of

a dark original, the START key indicator may blink, the indicator

light up, and the copier stop, even though toner is left. The

copier will feed toner for up to 2 minutes and then the START

key indicator will light up. Press the START key to restart copying.

For best copying results, be sure to use only SHARP Genuine

Supplies which are designed, engineered and tested to maximize the life and performance of SHARP copiers. Look for the

Genuine Supplies label on the toner package.

Drum replacement required indicator

The useful life of the drum cartridge is approximately 30,000

copies. When the internal counter reaches approximately 29,000

copies, the drum replacement required indicator will light up in-

* 2

ON: Indicates that the machine is in the energy saving (pre-heat)

mode.

Blink: Indicates that the machine is in the process of resetting from

the energy saving mode or just after supplying the power.

OFF: Indicates that resetting from the energy saving mode is com-

pleted and that the fusing temperature is in ready state.

The combinations of the above display lamps are as follows:

(F = ON. D = OFF)

Lamp

Pre-heat lamp Blink DD

Ready lamp DFD

Other lamps DFF

Lamp

Pre-heat lamp FFBlink Blink

Ready lamp FDFD

Other lamps FDFF

Immediately after

power ON

Energy

saving mode

(Pre-heating)

Energy

saving mode

(Auto power

shut off)

dicating that replacement of the drum cartridge will be needed

soon. When the indicator begins to blink, replace the drum

cartridge by following the procedure given below.

Paper required indicator

Misfeed indicator

Ready Copying

Resetting

from energy

saving mode

Copy is

started during

resetting from

energy

saving mode

4 – 2

4. Motor, solenoid, clutch

AL-1610

1

23

4

5

6

7

8

9

13

No. Name Code Function, operation

1 Exhaust fan motor VFM Cools the inside of the machine.

2 Shifter motor Shifts the paper exit tray. (AL-1610)

3 Toner motor TM Toner supply

4 Mirror motor MRM Drives the optical mirror base (scanner unit).

5 Cooling fan motor CFM Cools the inside of the machine.

6 Main motor MM Drives the machine.

7 Paper feed solenoid CPFS1 Solenoid for paper feed from cassette

8 Resist roller solenoid RRS Resist roller rotation

Resist roller rotation control solenoid

9 Manual paper feed solenoid MPFS Manual paper feed solenoid

10 Manual paper transport clutch MPTC Drives the manual paper transport roller.

11 Manual paper feed clutch MPFC Drives the manual paper feed roller.

12 Paper feed clutch CPFC1 Drives the cassette paper feed roller.

13 Clutch RRC Drives the resist roller

11 1012

4 – 3

AL-1610

5. Sensor, switch

1234765

8

9

10

11

15

13

12

14

No. Name Code Function, operation

1 Mirror home position sensor MHPS Detects the mirror (scanner unit) home position.

2 Cassette detection switch CSD1 Cassette detection

3 Toner density sensor TCS Toner quantity detection

4 Paper exit sensor (paper exit side) POD1 Detects paper exit.

5 Right door switch DSWR Side door open/close detection

6 Paper full sensor Paper exit tray section full detection <For JOB separator>

7 Lift sensor Paper feed tray lift up detection <For JOB separator>

8 Paper exit sensor (DUP side) POD2 Paper transport detection

9 Thermistor Fusing section temperature detection

10 Thermostat Fusing section abnormally high temperature detection

11 Paper transport sensor PPD Paper transport detection

12 Manual sensor MPED Manual transport detection

13 Cassette paper sensor PED1 Cassette paper empty sensor

14 Drum reset switch DRST New drum detection switch

15 Power switch Turns ON/OFF the main power source.

4 – 4

6. PWB unit

AL-1610

1234

6

5

7

No. Name Function, operation

1 Copy lamp invertor PWB Copy lamp control

2 Power PWB AC power input/DC power control

3 High voltage PWB High voltage control

4 CCD sensor PWB Image scanning

5 Main PWB (MCU) Machine control/Image process

6 Paper exit interface PWB Paepr exit, finishing control

7 Operation main PWB Operation panel input/Display, operation panel section control

4 – 5

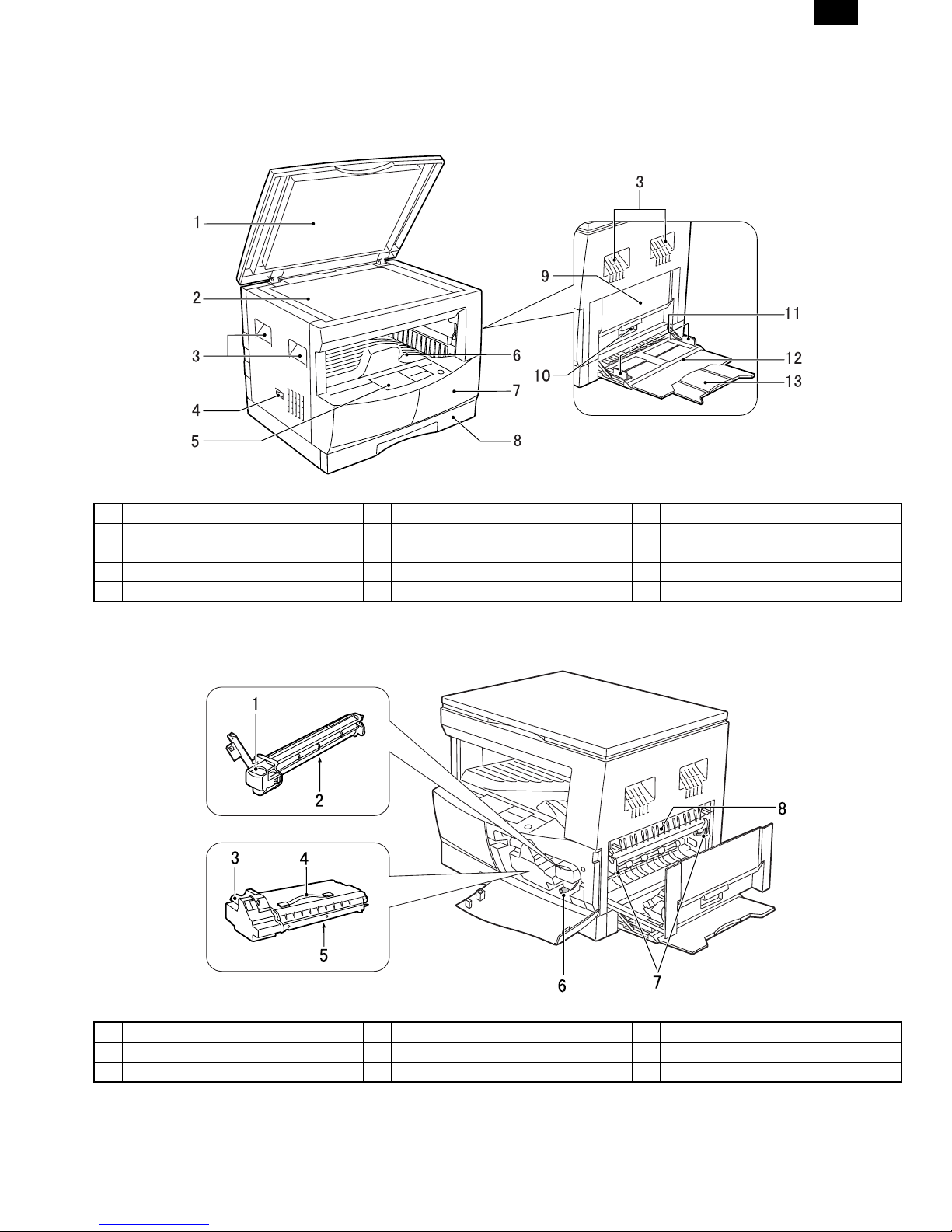

AL-1610

7. Cross sectional view

12 3 45

6

18

7

8

9

19

10

11

12

17

No. Name Function/Operation

1 Copy lamp Image radiation lamp

2 Copy lamp unit Operates in synchronization with No. 2/3 mirror unit to radiate documents sequentially.

3 LSU unit Converts image signals into laser beams to write on the drum.

4 Lens unit Reads images with the lens and the CCD.

5 MC holder unit Supplies negative charges evenly on the drum.

6 Paper exit roller Used to discharge paper.

7 Transport roller Used to transport paper.

8 Upper heat roller Fuses toner on paper (with the teflon roller).

9 Lower heat roller Fuses toner on paper (with the silicon rubber roller).

10 Drum unit Forms images.

11 Transfer charger unit Transfer images (on the drum) onto paper.

12 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

13 Manual paper feed tray Manual paper feed tray

14 Manual paper feed roller Picks up paper in manual paper feed.

15 Manual transport roller Transports paper from the manual paper feed port.

16 Paper feed roller (semi-circular roller) Picks up paper from the cassette.

17 MG roller Puts toner on the OPC drum.

18 No. 2/3 mirror unit Reflects the images from the copy lamp unit to the lens unit.

19 Waste toner transport roller Transports waste toner to the waste toner box.

13141516

4 – 6

AL-1610

[5] UNPACKING AND

INSTALLATION

1. Unpaking procedure

Be sure to hold the handles on both sides of the copier by two

persons to unpack the copier and carry it to the installation location.

2. Installing procedure

1) Remove all pieces of tape. Then open the original cover and

remove the protective material.

2) Use a coin (or suitable object) to remove the screw.

• Store the screw in the paper tray because it will be used if the

copier has to be moved. (Refer to the description in the following.)

5) Gently pull the TD cartridge out while holding the handle.

6) Hold the strap on the cartridge and remove the TD cartridge upward.

TD cartridge handle

7) Remove the new TD cartridge from the bag. Hold the cartridge on

both sides and shake it horizontally four or five times.

4 or 5 times

8) Hold the tab of the protective cover and pull the tab towards you

to remove the cover.

3) Ensure that the bypass tray is open. Raise the side coverrelease

handle and pull out the side cover until it stops.

4) Push gently on both sides of the front cover to open the cover.

9) Gently insert the TD cartridge along the guides until it locks in

place.

• If dirt or dust is adhered to the TD cartridge, remove it before

installing the cartridge.

10) Close the front cover by holding both sides with your hands and

then close the side cover. The TD cartridge replacement required indicator will go out and the START key indicator will light

up.

• When closing the covers, be sure to close the front cover

securely and then close the side cover. If the covers are

closed in the wrong order, the covers may be damaged.

5 – 1

Front guide

Left guide

Maximum height line

AL-1610

11) Raise the handle of the paper tray and pull the paper tray out

until it stops.

12) Remove the pressure plate lock. Rotate the pressure plate lock

in the direction of the arrow to remove it while pressing down the

pressure plate of the paper tray.

13) Store the pressure plate lock which has been removed in step 5

and the screw which has been removed in step 2 in the front of

the paper tray.

• To store the pressure plate lock, rotate the lock to fix it on the

relevant location.

Pressure

plate

lock

14) Push the pressure plate down until it locks in place.

15) Squeeze the lock lever of the front guide and slide the front

guide to match the width of the paper.

16) Move the left guide to the appropriate slot as marked on the

tray.

• When using 11" × 17" copy paper, store the left guide in the

slot at the left front of the paper tray.

17) Load copy paper into the tray.

• Set the paper along the guides.

• The tray holds up to 250 sheets of about 9kg bond paper.

Do not load paper above the maximum height line.

Screw

18) Push the paper tray firmly back into the copier.

19) Ensure that the power switch of the copier is in the OFF position.

Insert the supplied power cord into the power cord socket at the

rear of the copier.

• If you use the copier in a country other than the country

where the copier was purchased, you will need to make sure

that your local power supply is compatible with your model. If

you plug the copier into an incompatible power supply, irreparable damage to the copier will result.

20) Plug the other end of the power cord into the nearest outlet.

• Only insert the power cord into a properly grounded wall

socket.

Do not use extension cords or power strips.

5 – 2

AL-1610

[6] OPERATIONAL DESCRIPTIONS

1. Outline of operation

The outline of operation is described referring to the basic configuration.

(Basic configuration)

Operation

section

Printer section

Scanner section

MCU (Main control/image process section)

LSU (Laser unit)

Laser diode, Polygon mirror lens

Laser beam

Process section

Cassette paper

feed section

Paper exit

CCD

Manual paper

feed section

Fusing section

Paper transport section

G. Fusing: Fusing section

• Heat and a pressure are applied to the toner image on the copy

paper to fuse the image on the paper.

2. Scanner section

A. Scan process

The scanner has sensors that are arranged in a line. These sensors

scan a certain area of a document at a time and deliver outputs

sequentially. When the line is finished, the next line is scanned, and

this procedure is repeated. The figure below shows the case where

an image which is scanned is shown with solid lines.

The direction of this line is called main scanning direction, and the

scanning direction sub scanning direction. In the figure above, one

line is divided into 5 sections. Actually, however, one line is divided

into thousands of sections. For scanning, the light receiving element

called CCD is used.

Sub scanning direction

Sensor scanning area

Main

scanning

direction

Outline of copy operation

A. Setting conditions: Operation panel

• Set copy conditions such as the copy quantity and the copy den-

sity with the operation section, and press the START key. The

information on copy conditions is sent to the MCU.

B. Image scanning: Scanner section

• When the START key is pressed, the scanner section starts scan-

ning of images.The light from the copy lamp is reflected by the

document and passed through the lens to the CCD.

C. Photo signal/Electric signal conversion:

Scanner section

• The image is converted into electrical signals by the CCD circuit

and passed to the MCU.

D. Image process: MCU

• The document image signal sent from the CCD circuit is processed

under the revised conditions and sent to the LSU (laser unit) as

print data.

E. Electric signal/Photo signal (laser beam)

conversion: LSU

• The LSU emits laser beams according to the print data. (Electrical

signals are converted into photo signals.)

• The laser beams are radiated through the polygon mirror and

various lenses to the OPC drum.

F. Printing: Process section

• Electrostatic latent images are formed on the OPC drum according

to the laser beams, and the latent images are developed to be

visible images (toner images).

• Meanwhile the paper is fed to the image transfer section in

synchronization with the image lead edge.

• The toner image is transferred on the paper.

1

2

3

4

5

5 4 3 2

1

To MCU PWB

The basic resolution indicates the scanner capacity. The basic resolution is expressed in dpi (dot/inch) which shows the number of light

emitting elements per inch on the document.

The basic resolution of this machine is 400dpi.

In the sub scanning direction, at the same time, the motor that drives

the optical system is controlled to scan the image at the basic resolution.

6 – 1

Loading...

Loading...