Page 1

34N-WF5H

SERVICE MANUAL

S40Z134N-WF5H

COLOR TELEVISION

Chassis No. D00A

MODEL

34N-WF5H

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified should be used.

CONTENTS

Page

» ELECTRICAL SPECIFICATIONS .................................1

» IMPORTANT SERVICE SAFETY PRECAUTION ........2

» LOCATION OF USER'S CONTROL.............................4

» DIMENSIONS...............................................................6

» REMOVING THE MAJOR PARTS ................................7

» DRESSING THE LEADS............................................10

» INSTALLATION AND SERVICE INSTRUCTIONS......11

» ELECTRICAL ADJUSTMENT ....................................12

» CHASSIS LAYOUT .....................................................26

» BLOCK DIAGRAM .....................................................28

» SCHEMATIC DIAGRAMS ..........................................32

» PRINTED WIRING BOARD ASSEMBLIES................65

» REPLACEMENT PARTS LIST....................................76

» PACKING OF THE SET............................................103

Page

ELECTRICAL SPECIFICATIONS

POWER INPUT...................................................... 120V AC 60 Hz

POWER RATING ..................................................................205 W

PICTURE SIZE ..........................................3,160 cm2 (489 sq inch)

CONVERGENCE ............................................................. Magnetic

SWEEP DEFLECTION .................................................... Magnetic

FOCUS ................................................Hi-Bi-Potential Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency ......................................45.75 MHz

Sound IF Carrier Frequency.......................................41.25 MHz

Color Sub-Carrier Frequency .....................................42.17 MHz

(Nominal)

AUDIO POWER

OUTPUT RATING ....24 W (12 W + 12 W)(at 10% distortion and

Dual CH Operate)

SPEAKER

SIZE ................................ 10 cm (BOX)(2 pcs.), Tweeter (2 pcs.)

VOICE COIL IMPEDANCE................................6 ohm at 400 Hz

ANTENNA INPUT IMPEDANCE

VHF/UHF.....................................................75 ohm Unbalanced

TUNING RANGES

VHF-Channels...............................................................2 thru 13

UHF-Channels ............................................................14 thru 69

CATV Channels........................................................... 1 thru 125

(EIA, Channel Plan U.S.A.)

VIDEO INPUT ............. (INPUT 1, 2, 3, 4) Composite

Input Jack :Pin-jack × 1

Input Level:1 Vp-p/75 ohm/Negative Sync

S-VIDEO INPUT .......... (INPUT 1, 2, 3) Y/C

Y :1 Vp-p/75 ohm/Negative Sync

C :0.286 Vp-p/75 ohm

COMPONENT INPUT... (INPUT 4, 5) Component (Y, PB, PR)

Input Jack :Pin-jack × 3 (INPUT 4),

BNC × 3 (INPUT 5)

Input Signal: 480I, 480P, 1080I

Y :1 Vp-p/75 ohm/Negative Sync

PB, PR:0.525 Vp-p/75 ohm

(75% Saturation Level)

HD INPUT ................... (INPUT 3) R, G, B, H.V/R, G, B

Input Jack :D-Sub 15pin × 1

Input Signal: 480P, 1080I

RGB :0.7 Vp-p/75 ohm/No Sync

AUDIO INPUT ............. (INPUT 1, 2, 3, 4, 5)

Input Jack :Pin-jack × 2

0.5 Vrms/22k ohm or over

LINE OUTPUT............. Input Jack :Pin-jack × 2

0.89 Vrms (Max)/2.2k ohm or

less/Veriable

Specifications are subject to change without

prior notice.

SHARP CORPORATION

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

1

Page 2

34N-WF5H

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock hazards

when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material. The nonisolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit. The

isolated ground system is for the low B+ DC v oltages

and the secondary circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A

RISK OF FIRE, REPLACE

5A 125V

ONLY WITH SAME TYPE 5A125V FUSE.

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the picture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiver employs integral

implosion protection.

2. Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely.

X-RADIATION AND HIGH VOLTAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation. The

only potential source of X-ray in current solid state

TV receivers is the picture tube. Howe ver , the picture

tube does not emit measurable X-Ray radiation, if

the high voltage is as specified in the "High Voltage

Check" instructions.

It is only when high voltage is excessive that Xradiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that ser vicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated v alue

−no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem. Every

time a color chassis is serviced, the brightness should

be tested while monitoring the high voltage with a

meter to be certain that the high voltage does not

exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified or

make unrecommended circuit modifications to the

high voltage circuitry.

6. When trouble shooting and taking test measurements

on a receiver with excessiv e high voltage, av oid being

unnecessarily close to the receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

2

Page 3

2

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

34N-WF5H

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators and etc.

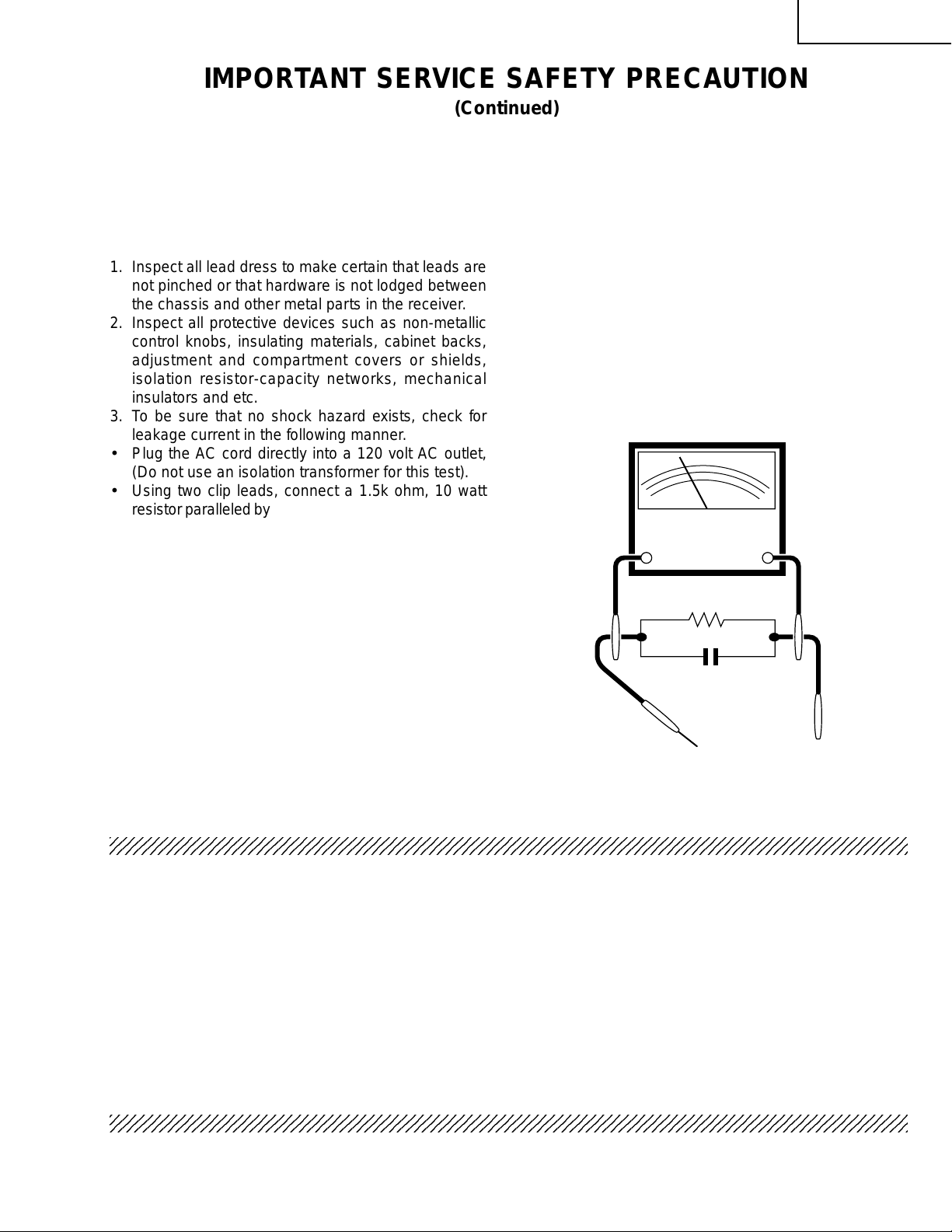

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 120 volt AC outlet,

(Do not use an isolation transformer for this test).

• Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to earth ground.

• Use an AC voltmeter ha ving with 5000 ohm per v olt,

or higher, sensitivity to measure the A C v oltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon and etc.) and measure the AC voltage

drop across the resistor.

AII checks must be repeated with the AC ine cord

plug connection reversed. (If necessary, a nonpolarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp.

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

AC

VOLTMETER

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage and etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by "å"

and shaded areas in the

Replacement Parts Lists

and

Schematic Diagrams.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

For continued protection, replacement parts must be

identical to those used in the original circuit. The use of

substitute replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

3

Page 4

34N-WF5H

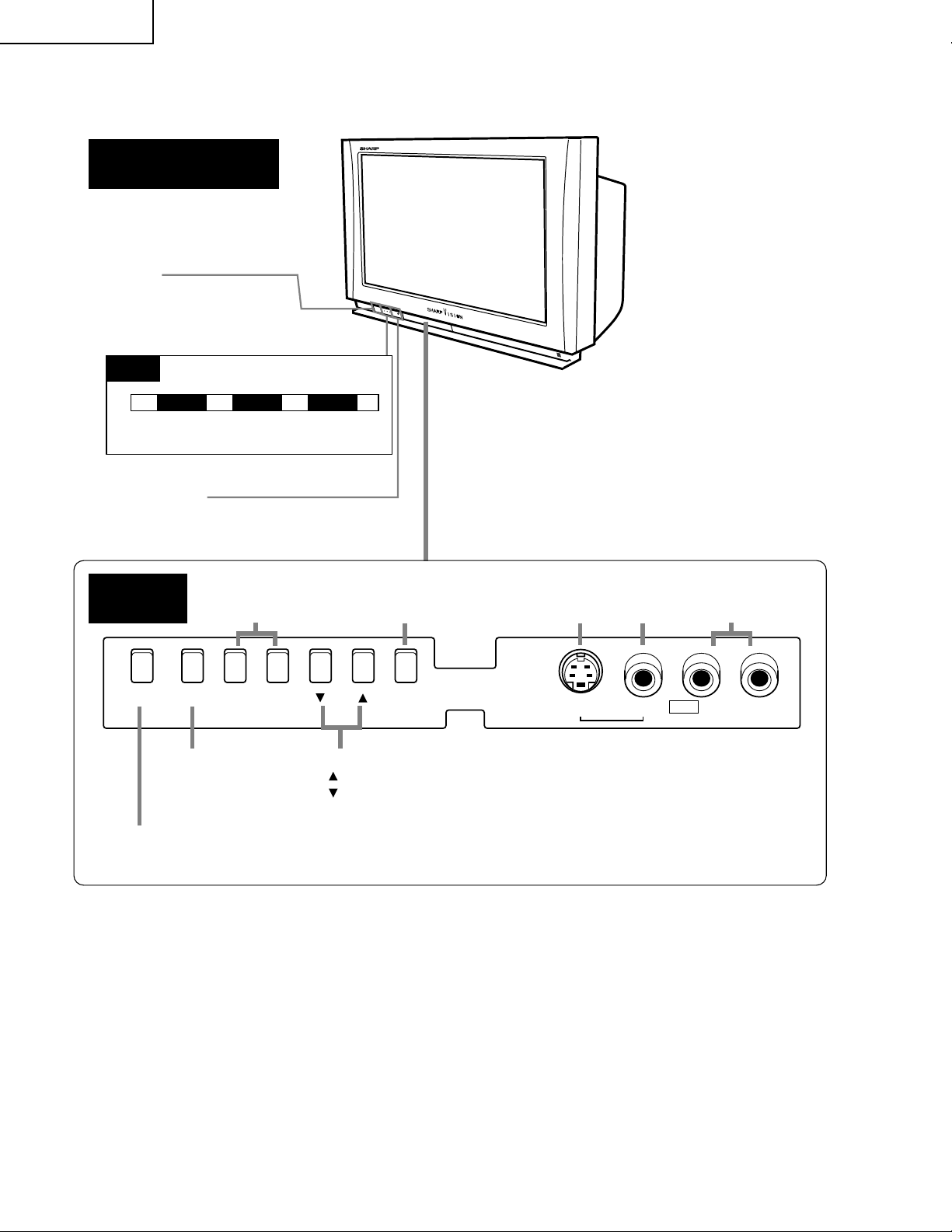

Front control section

POWER

Press →

Press again Off.

LOCATION OF USER'S CONTROL

On.

→

LED

POWER

(Stand-by: RED

ON: GREEN)

SENSOR AREA

FOR REMOTE CONTROL

IN DOOR

DEGAUSS

DEGAUSS button

Press the DEGAUSS button to improve color unevenness of the screen

caused by moving the TV or changing the angle of the screen.

MENU

MENU button

Press MENU button to

access the MAIN MENU

screen

VIEW TIMER

(RED)

VOL(+)/(–) buttons

(+) Increases sound

(–) Decreases sound

–

VOL

+

HD TV

(GREEN)

INPUT button

Selects Input No.

INPUTCH

CH(up)/(down) buttons

( ) Selects next higher channel

( ) Selects next lower channel

AUDIO L/R

S-VIDEO input VIDEO input

input

S-VIDEO VIDEO IN 2 L-AUDIO-R

(These terminals are also provided on the rear)

4

Page 5

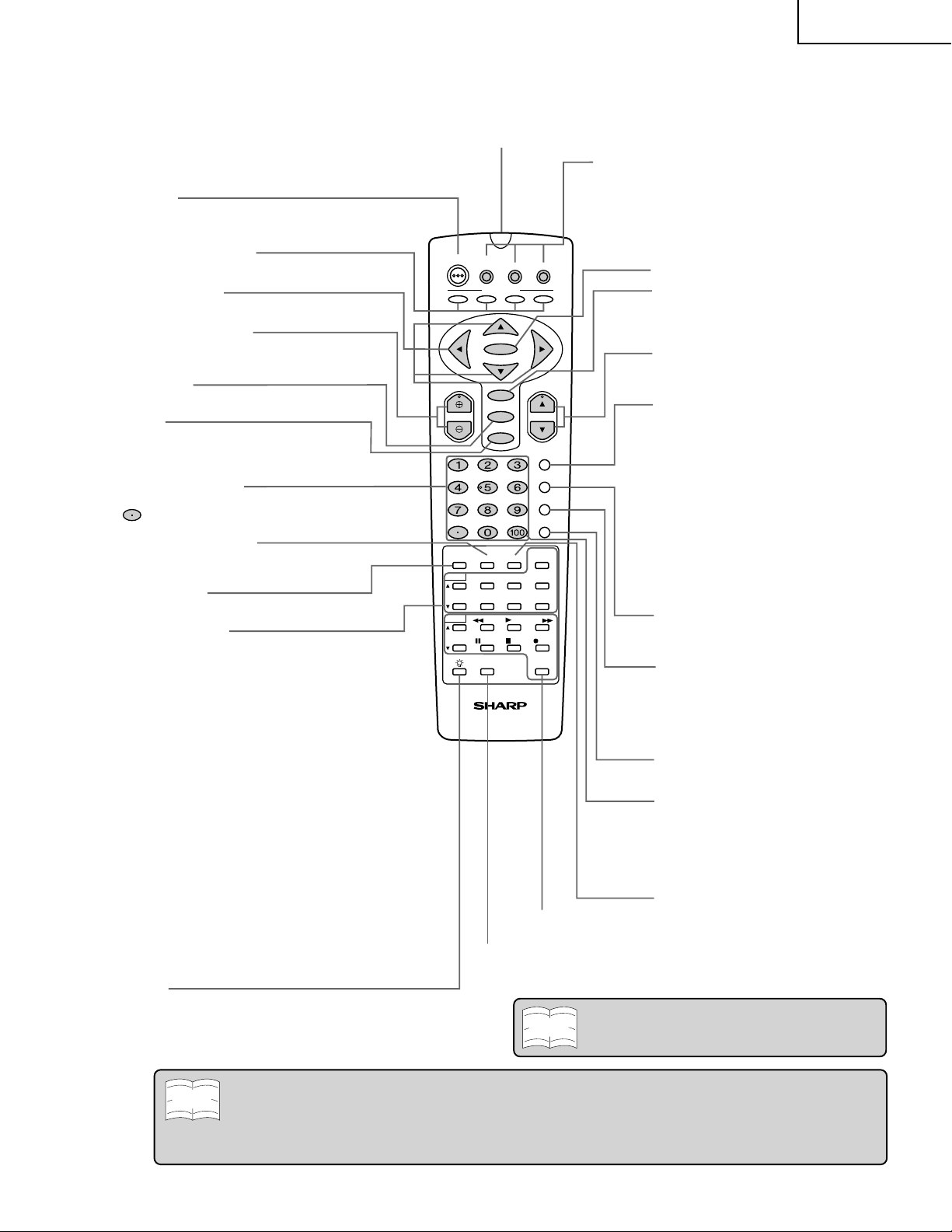

LOCATION OF USER'S CONTROL (Continued)

DTV

STB

POWER

TV

A

ENTER

MENU

VOL CH

AV MODE

MUTE

INPUT

ANT-A/B

DISPLAY

FLASHBACK

ENT.

CC

PLAY FF

POP

REW

PAUSE

STOP

REC

SEARCH

SELECT

DDFC

G1550CE

TWIN CH

VIEW

MODE

TWIN

PICTURE

VCR

POWER

MTS/SAP

L - TWIN ZOOM - R

SWAP FREEZE

BCD

CATV

HD-Ready TV

VCR CH

FAVORITES

VCR

INPUT

Press → Switches to external video

INPUT 1 mode.

Press again → Switches to external video

INPUT 2 mode.

Press 3 times → Switches to external video

INPUT 3 mode.

Press 4 times → Switches to external video

INPUT 4 mode.

Press 5 times → Switches to external video

INPUT 5 mode.

Press 6 times → Switches back to the

original TV mode.

POWER

Press → On.

Press again → Off. (Stand-by)

FAVORITES buttons

•

Used to select any of four preset channels.

Cursor buttons

Used to move cursor on menu screen.

ENTER button

CHANNEL UP/DOWN

(+) Selects next higher channel.

(–) Selects next lower channel.

VOLUME UP/DOWN

(+) Increases sound.

(–) Decreases sound.

MENU

Press → Accesses MAIN MENU.

Press again → Exits MAIN MENU.

AV MODE

MUTE

Press → Mutes sound.

Press again → Restores sound.

•

CLOSED CAPTION appears when sound is muted.

DIRECT ACCESS

Accesses any channel by the keypad.

button: Sharp DTV Decoder only

ENT.

Used in some instances where a VCR or

Cable Converter Box requires an “enter”

command after selecting channels, when

using the DIRECT ACCESS button.

DISPLAY

Press → Displays receiving channel for 4

seconds.

Press again → Displays remaining time of

SLEEP TIMER and VIEW

TIMER for 4 seconds.

FLASHBACK

Returns to previously viewed channel.

VIEW MODE

Select view size.

CC (Closed Caption)

Displays captions during

closed-caption broadcasts.

MTS/SAP

MTS/SAP select

VCR CONTROL

DDFC

Used to select High-quality image.

LIGHT

When this button is pressed , some buttons on the

remote control unit will light. The lighting will turn off if no

operations are performed within about six seconds. This

button is used for performing operations in dark places.

ANT-A/B button

Press to switch between ANTENNA-A and

ANTENNA-B when you wish to watch TV.

Remote control mode select buttons

Use to switch the remote control unit modes.

•

This remote control can be used to operate the TV,

a DTV/STB Decoder and a Cable TV converter.

•

By selecting one of the three mode select buttons,

this remote control can be used to adjust common

functions, such as channel selection, for that device.

INFRARED TRANSMITTER WINDOW

POP FUNCTION

With the VIDEO inputs, you can watch two pictures at

the same time.

"-TWIN CH-': Used to switch the channel for the

sub-picture of the TWIN PICTURE

screen.

TWIN PICTURE: Press to turn the TWIN PICTURE

screen function on and off.

SEARCH: Press to select the SEARCH

screen mode.

SELECT: Selects the screen for switching

the channel or input source.

FREEZE: When this button is pressed with

the regular screen, will change to the

TWIN PICTURE screen and the

picture at the time the button was

pressed will become the sub-picture,

displayed as a frozen image.

L-TWIN ZOOM: The left screen is enlarged with the

TWIN PICTURE function.

TWIN ZOOM-R: The right screen is enlarged with the

TWIN PICTURE function.

SWAP: The left and right screens are

interchanged with the TWIN

PICTURE function.

Note

For use of this remote control with an analog TV.

Note

• The above shaded buttons on the Remote Control glow in the dark. To use the glow-in-the-dark display on the

remote control, place it under a fluorescent light or other lighting.

• The phosphorescent material contains no radioactive or toxic material, so it is safe to use.

• The degree of illumination will vary depending on the strength of lighting used.

• The degree of illumination will decrease with time and depending on the temperature.

• The time needed to charge the phosphorescent display will vary depending on the surrounding lighting.

34N-WF5H

5

Page 6

34N-WF5H

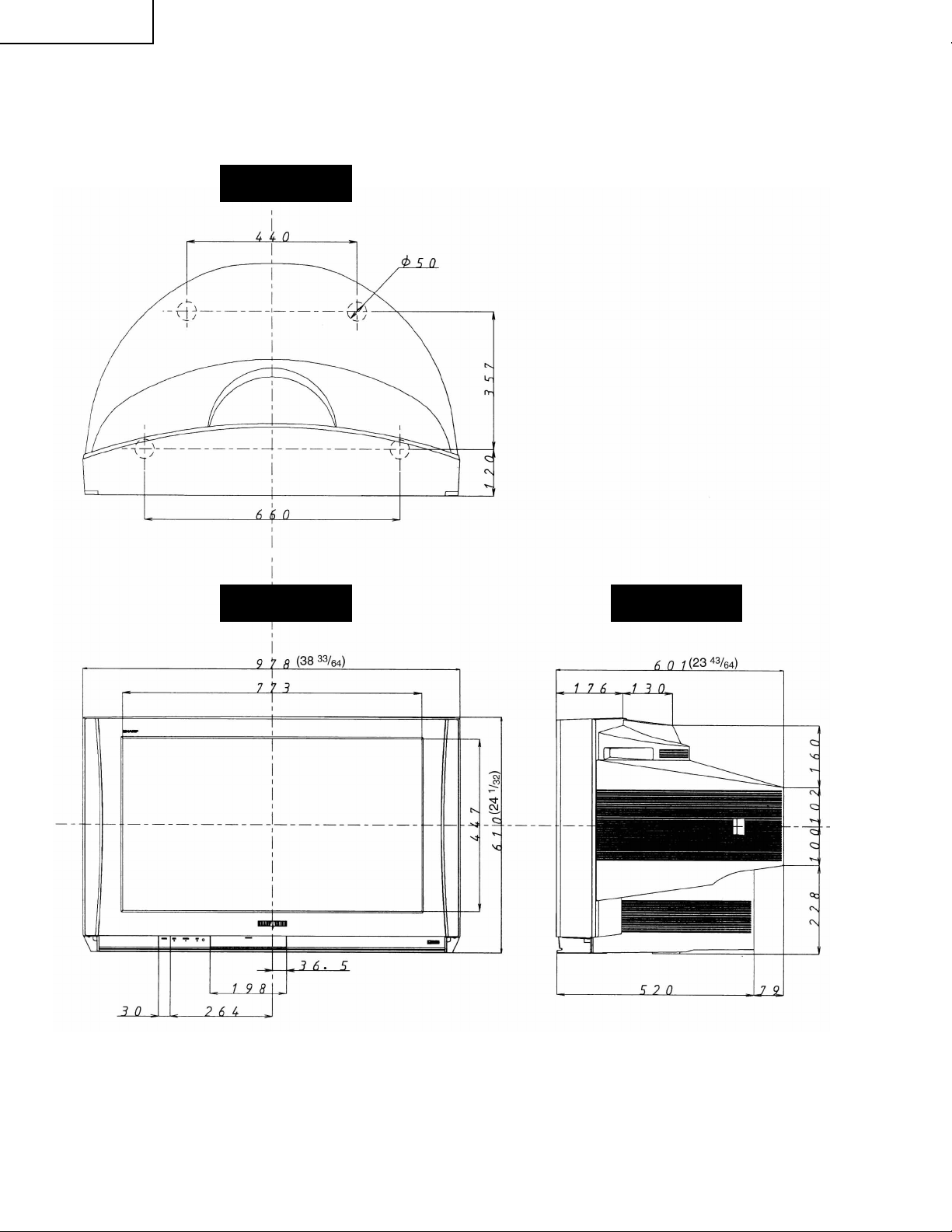

DIMENSIONS

T op View

Front View Side View

[Units: mm (inches)]

6

Page 7

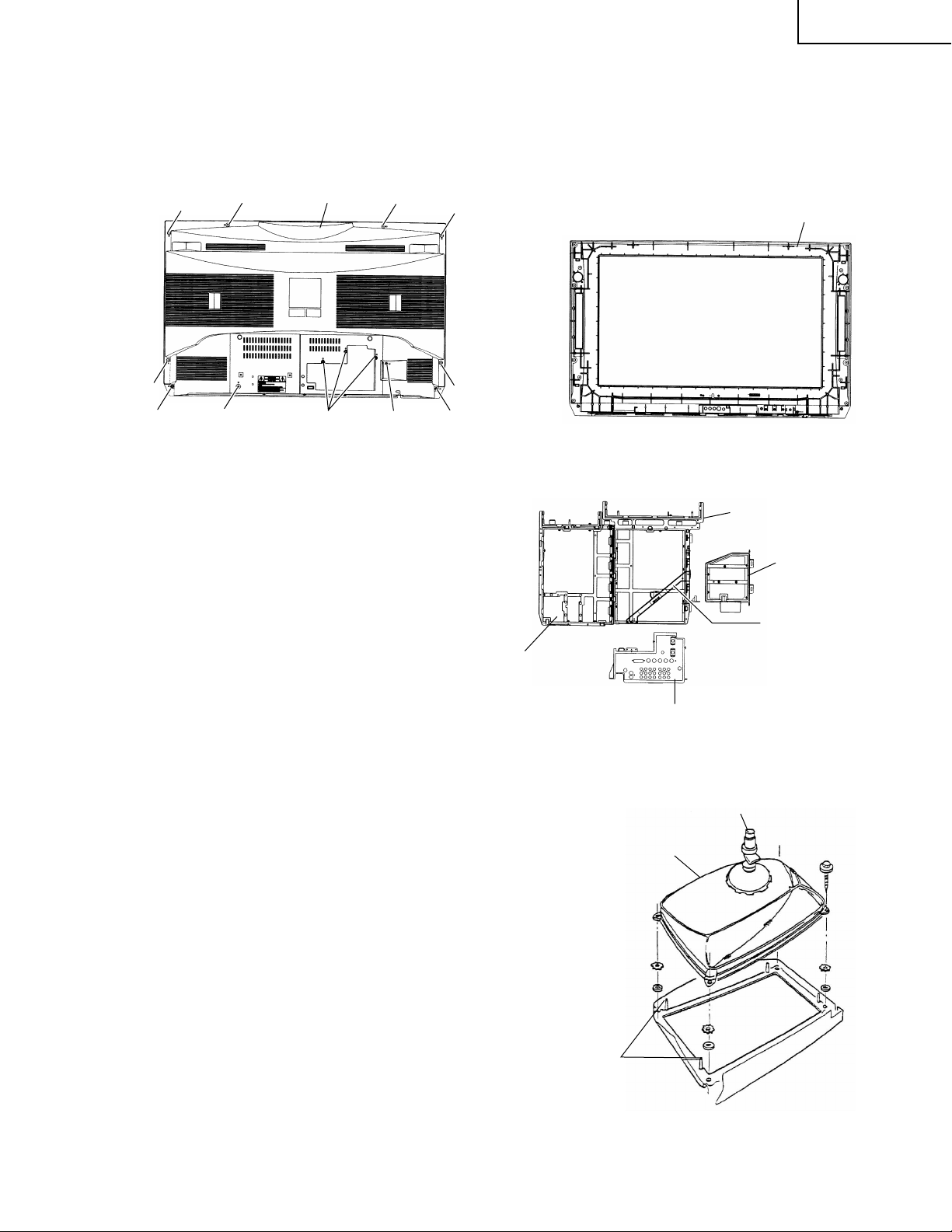

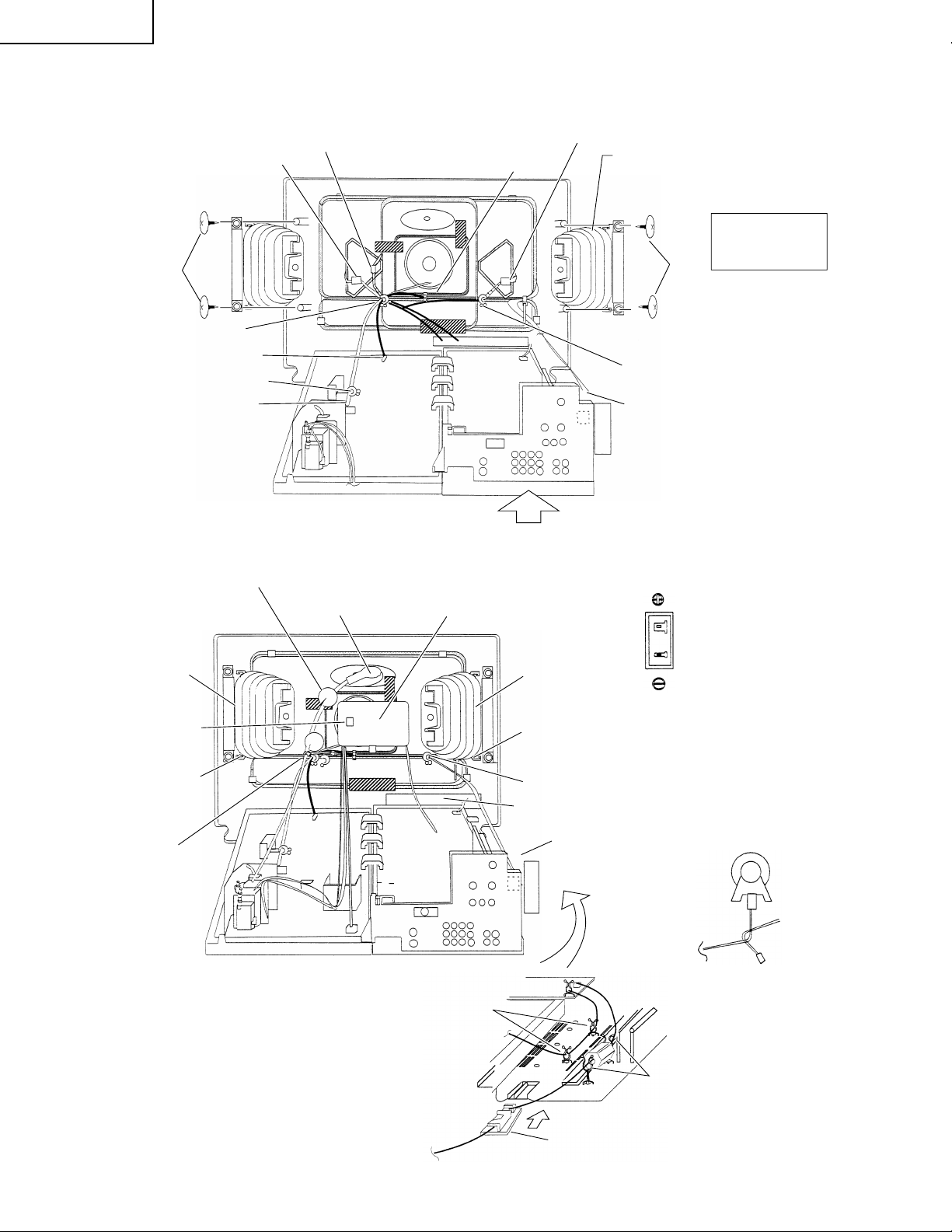

REMOVING THE MAJOR PARTS

1. Remove the 13 lock screws off the rear cover.

2. Holding up the chassis frame, draw out the chassis about 5 cm (1.31/32 inch) first, disconnect the

speaker leads from the signal Unit, and pull out the chassis all the way.

34N-WF5H

~

~

Cabinet B

~

~

~

~

~~

Note: Cabinet B mounting procedure and

precautions

1. Position the cabinet B in parallel with the

cabinet A. Start pushing in the cabinet B.

2. Insert the cabinet B until the clearance

between the cabinets A and B becomes 150

mm or so. Look into the terminal opening in

the back of the cabinet B to make sure the

tuner PWB and shield are out of contact with

the speaker guide boss.

3. Finally insert the coupling ribs of the cabinet

B in this order: left rib, top rib and right rib

when viewed from the back of the product.

~

Cabinet A

~

~

Signal Unit Frame

AC Filter Unit Frame

Frame Holder

Power Unit Frame

Detaching the cathode ray tube

1. Detach the anti-magnetized coil from the four coil holders

that are at the cathode ray tube corners of the cabinet.

2. Remove the four pairs of screws and nuts off the cathode

ray tube, and detach the cathode ray tube. (The tube weighs

about 60 kg (132.2lbs).)

Cathode ray tube handling precautions

Discharging

There may be a build-up of high-tension static electricity at

the high-voltage electrode (covered with the anode cap on

top of the cathode ray tube). Before taking the anode out of

the cathode ray tube, get it discharged.

Carrying

The cathode ray tube weighs 60 kg (132.2lbs) or so and its

shape is awkward to fit your hands. Preferably make a twoperson team to carry and move the tube.

Disposal

The cathode ray tube is under high vacuum inside. Before

disposing of it, get the air vent tip at the tube’s neck socket

cracked in order to turn the tube to the atmospheric pressure

level.

Degaussing Coil

Coil Holders

(4 locations)

Rear Panel

Get the air vent tip cracked.

`

`

`

`

7

Page 8

34N-WF5H

Servicing precautions

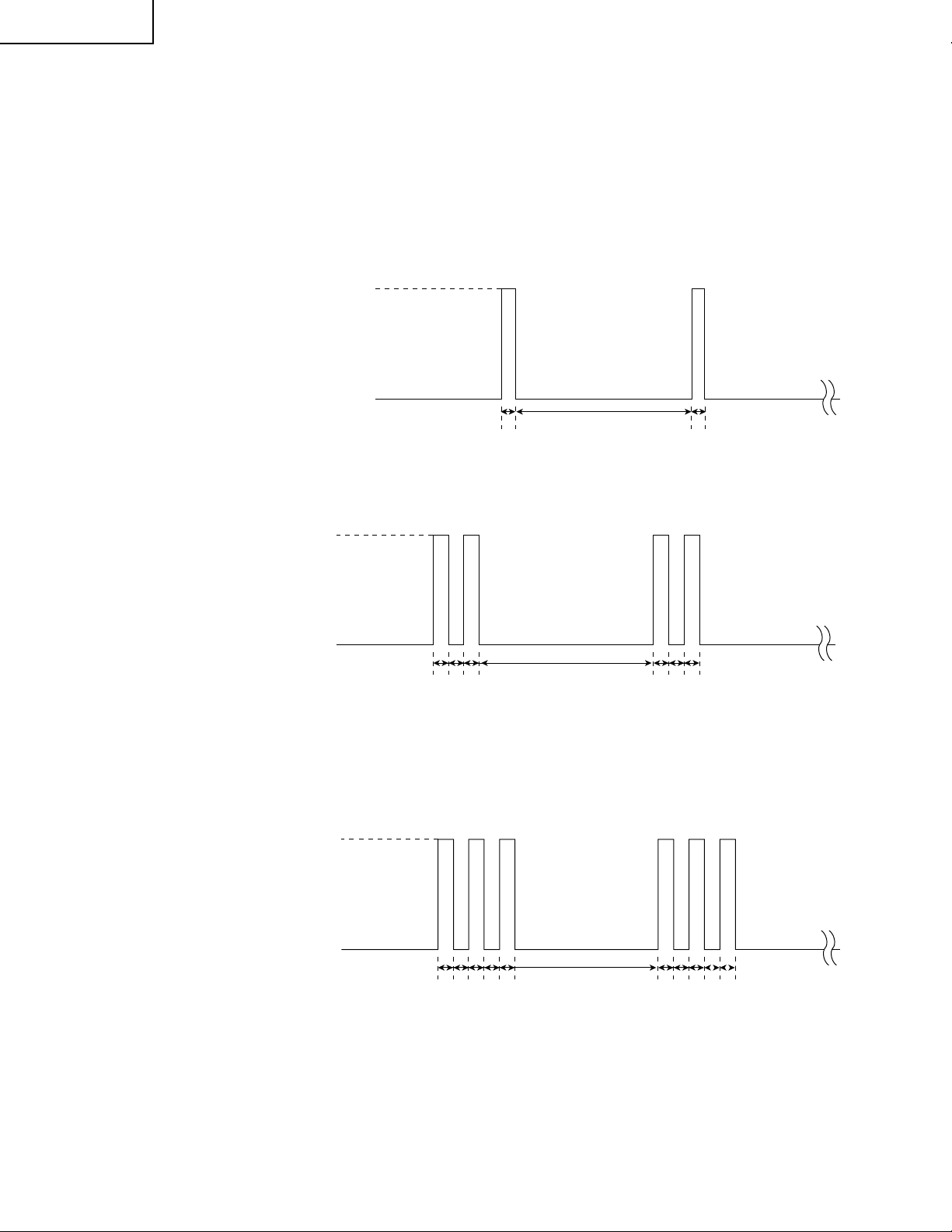

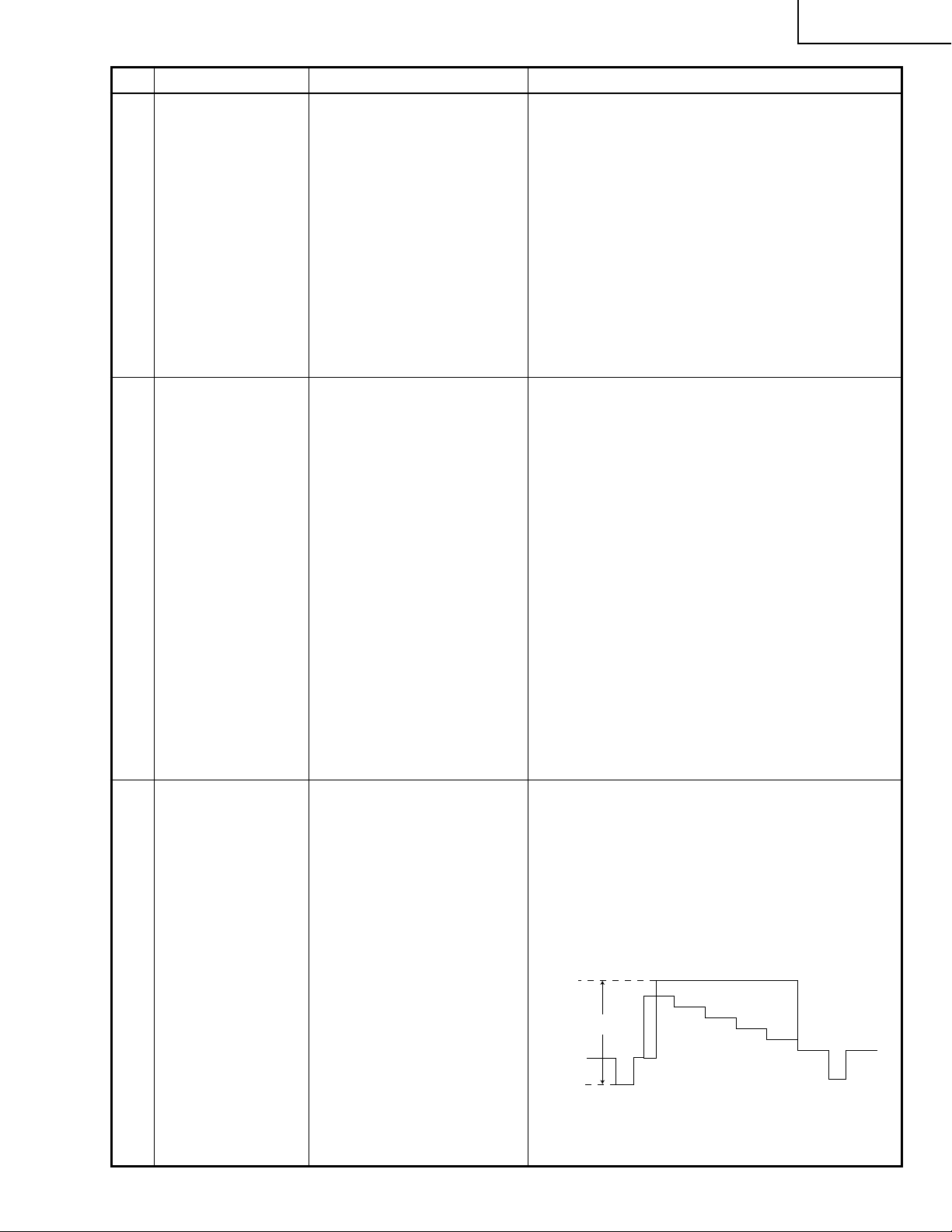

1. Protector Operation

This model is provided with five protector circuits. Below discussed are the behaviors and indications of these circuits.

(Note: In some cases, the LED flashing cycle and possible trouble spot may be inconsistent.)

1 Over-current Protector Circuit:

A rush current into the flyback transformer is detected. The circuit is activ ated if an o ver-current flo ws in.

Indication: The power LED (red) flashes once.

2 X-Radiation Protector Circuit:

This circuit is activated if the rectified heater voltage rises above its specified level.

Indication: The power LED (red) flashes once.

ON

OFF

1.4

0.2

3 Vertical Output Protector Circuit:

The vertical output is detected. The circuit is activated if the vertical output is missing (hor izontal-only

screen or the like).

Indication: The power LED (red) flashes twice

(seconds)

0.2

ON

OFF

4 +B Under-voltage Protector Circuit:

The voltages at the 6V, 10V, 16V, 28V and 30V lines of the switching regulator are detected. The circuit

is activated if any of the voltages drops below its specified level.

5 +B Over-voltage Protector Circuit:

The voltages at the 6V and 10V lines are detected. The circuit is activated if any of the voltages rises

above its specified level.

Indication: The power LED (red) flashes three times.

ON

OFF

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

1.4

1.4

0.2

0.2

0.2

0.2

0.2

0.2

0.2

(seconds)

(seconds)

0.2

2. Stop of Protector Operation

The protector may be kept inactive by opening the detection circuits or grounding C3230 and C3231 (on the Signal

Unit). The ver tical output protector circuit, however, cannot be made inactive.

Note: Be sure to get the protector back to normal after servicing.

8

Page 9

3. Self-diagnostic Function (Protector Circuit Operation)

+130V line

FBT

+10V line

+16V line

1

36

IC501

T630

4

7

10

R620

to FBT

Q750

Q782

Q3255

Q3224

Q781

C3231

C3230

D732 D731

D633

D790

D789

D786

D782

D781

D787

D792

D783

D772

D560

D582

IC3501

(DUNTKA140DE)

(DUNTKA096DE)

(DUNTKA163DE)

85

84

95

1

7

80

Q3208

ACPOW

Q3204

RY3701

(DUNTKA116DE)

Micom UNIT

Horizontal

Protector

Power Protector

Micro-processor

Vertical Protector

Relay Drive

AC Relay

AC Filter UNIT

Signal UNIT

Drive

Drive

IC3210

Inverter IC

+14V line

-14V line

IC770 (Chopper Regulator)

+6V line

+30V line

(VT line)

+28V line

(Audio + B)

Drive Circuit

Power UNIT

Current AMP.

Detection Circuit

A: Detection

B: Possible Trouble Spot

1 Over-Current Protector Circuit

A: +130V line current detected

(Flyback transformer rush current detected)

B: •Flyback transformer defective

•Horizontal deflection circuit transistor or diode

short-circuited

•Flyback transformer secondary-side rectifier circuit

parts short-circuited or load circuit parts short-circuited

2 X-Radiation Protector Circuit

A: Flyback transformer terminal

0 voltage detected

B: •Resonance capacitor open

•Horizontal circuit open

4 Switching Power Secondary-side under-voltage

protector circuit

A: +10V, +16V, +28V, +30V and 6V line voltages detected

B: •+B line rectifier circuit parts (diode, capacitor)

short-circuited

•+B line load short-circuited

5 Switching Power Over-voltage Protector Circuit

A: +10V and +6V line voltage rise detected

B: •Switching power primary-side circuit in trouble

(causing voltage rise)

•Chopper regulator malfunctioning

3 Vertical Output Protector Circuit

A: Vertical output (pulse) monitored and no-pulse

condition detected

B: +14V line circuit in trouble, causing voltage

drop (rectifier circuit parts short-circuited)

or circuit open.

This model is equipped with five protector circuits. Shown below are the detections of the protector circuits and

possible trouble spots (outlined).

34N-WF5H

9

Page 10

34N-WF5H

Bundle K, GS, EW and NS.

Screw

Insert EW ×2

Insert GS.

Bundle K.

Connect K.

DRESSING THE LEADS

Insert GS and dress

Insert NS.

GS

the leads with no

slack. Fold back and

bundle the leads.

SH

Insert EW

Speaker boxe:RSP-Z0109CEZZ x2

Place the speaker boxes in

position and tighten the 4 screws.

Screw:LX-TZ3096CEFD ×4

Tightening torque:

1.17 ±0.19 N-m

(12 ±2 kg-cm)

Screw

Bundle M and EW.

Connect M.

å

Anode clamp: LHLDW1087CEKZ x2

Reposition the anode clamp.

Keep the CRT and other leads

10 mm or more away

from the anode lead.

Couple the speaker

connectors

(for both sides).

Connect

the coating ground lead

(2 points).

Dress the speaker leads

(for both sides).

Catch them at the hooks

indicated.

å

Bundle the K and

anode leads.

Connect the anode

(after connecting the

coating ground lead).

GS

Remove the pin cover

and fit the CRT PWB.

SH

Insert the PWB

(until securely locked).

The wider side is the

positive terminal. Do not

confuse the right and left

speakers. Their polarities

Couple the speaker

connectors

(for both sides).

Dress the speaker leads

(for both sides).

Catch them at the hooks indicated.

Connect Pu.

Insert SH.

Connect M.

(Keep the M leads tight.)

are different from each

other.

Pu/Mg

å

Secure the CA leads

at 2 spots.

10

Earth

å

Secure the AC cord at 2 spots.

Place the core between

the two wire holders.

å

Insert the AC cord holder (LHLDK0014PEZZ)

into the indicated recess.

Page 11

34N-WF5H

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1)When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2)Before performing adjustments, the TV set must be on at least 15 minutes.

CIRCUIT PROTECTION

The receiver is protected by a 5.0A fuse (F701),

mounted on PWB-F, wired into one side of the AC

line input.

X-RADIATION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high voltage system, B+ system,

test the X-Radiation protector circuit to ascertain

proper operation as follows:

1. Apply 120V AC using a variac transformer for

accurate input voltage.

2. Allow for warm up and adjust all customer controls

for normal picture and sound.

3. Receive a good local channel.

4. Connect a digital voltmeter to TP653 and make sure

that the voltmeter reads 10.9 ±0.6V.

5. Apply external 12.0V DC at TP653 by using an

external DC supply, TV must be shut off.

6. To reset the protector, unplug the AC cord and plug

the AC cord power on. Now make sure that normal

picture appears on the screen.

7. If the operation of the horizontal oscillator does not

stop in step 5, the circuit must be repaired before the

set is returned to the customer.

HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 120V AC

line voltage, with a strong air signal or a properly tuned

in test signal.

3. Enter the service mode (JWS mode). Enter the JWS

address "170" and data "1" (Y-Mute and V-Stop).

4. The voltage should be approximately, 35.0kV (at zero

beam).

If a correct reading cannot be obtained, check circuitry

for malfunctioning components. After the voltage test,

make Y-mute off to the normal mode.

11

Page 12

34N-WF5H

ELECTRICAL ADJUSTMENT

The TV set has been factory-adjusted to optimum condition. If by any chance an adjustment point gets out of spec

or readjustment is needed after component part replacement, take the following steps.

» Instruments required for servicing

• STB (Set Top Box)

Use model TU-DTV1000 that is already available on the market.

• HD Signal Generator

Used to generate 1080I monoscope pattern.

• NTSC Signal Generator

Used to generate monoscope, crosshatch and half color bar patterns.

» Calling the service mode (JWS mode)

Holding down the MENU button on the TV set front, turn on the power button on the TV set .

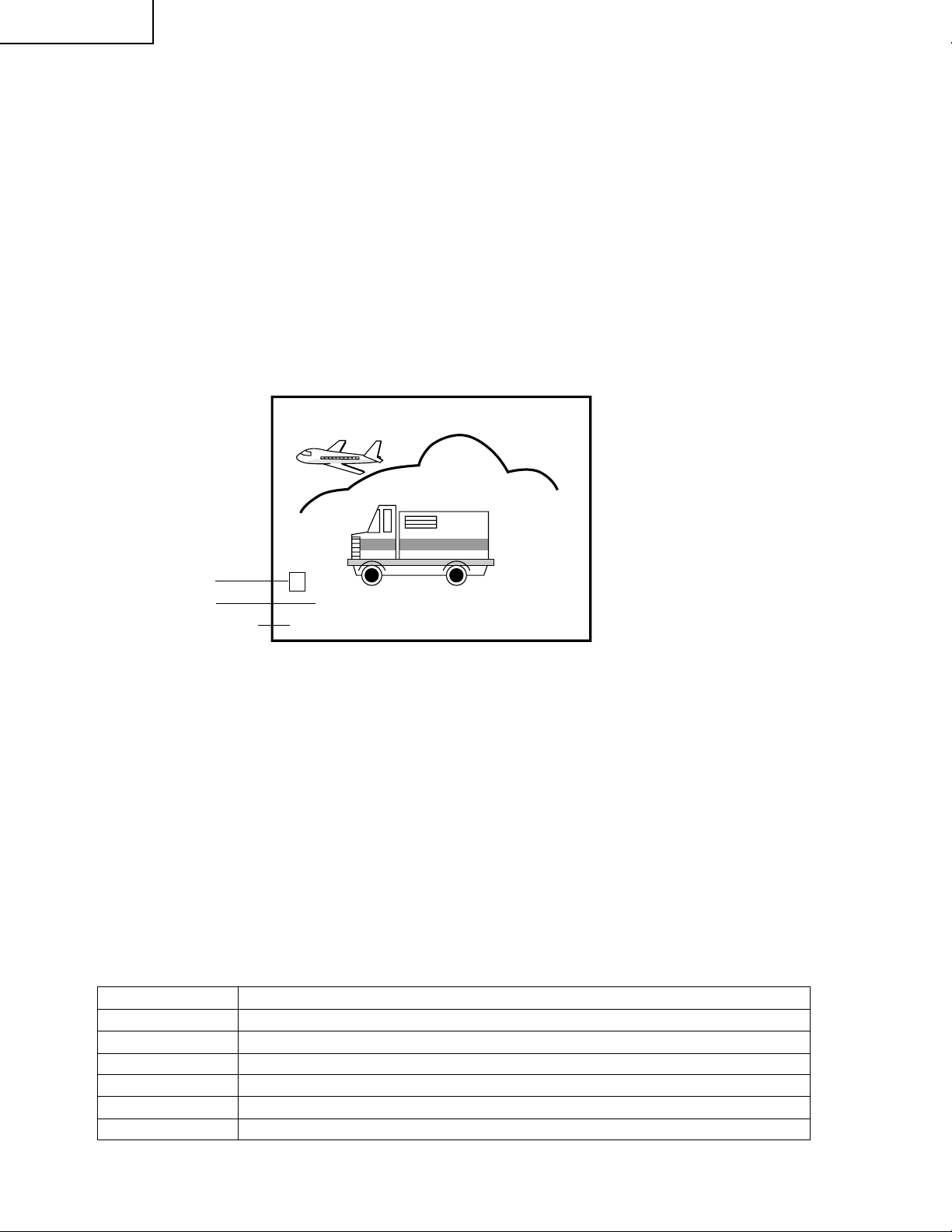

The screen as shown in Figure A. appears and the TV set is now in the service mode (JWS mode).

ADDRESS

DATA

PICTURE MODE

» To Exit the Service Mode (JWS mode)

Turn the television off by pressing the power button.

» Service Mode (JWS mode) Functions

1) The following adjustments and settings can be handled with the buttons on the R/C unit.

1 Video Adjustments (Picture, Tint, Color, Brightness)

2 Deflection Adjustments (Vertical Linearity, Vertical Size, Vertical Position)

3 Initial Factory Settings (Initial Factory Settings 1 and 2, V-Stop Setting)

4 White Balance Adjustments (Red/Green/Blue Cut-off, Green/Blue Drive)

5 On-Screen Display Positioning (Horizontal Display Position)

2) Applied buttons and their functions

In the service mode (JWS mode), the following buttons on the R/C Unit can be used for special functions.

BUTTON FUNCTION

1~9, 0 Used to enter numerical address settings; corresponding to numbers 0 thru 9.

100 Used as CLEAR button to go back to the initial screen.

INPUT Used as ENTER button to input addresses and data.

VOLUME UP Used to turn up data.

VOLUME DOWN Used to turn down data.

POWER Used to exit the mode.

0 0 0

0

STRETCH

Figure A.

(Horizontal Size, Side Pincushion, Horizontal Position)

12

Page 13

34N-WF5H

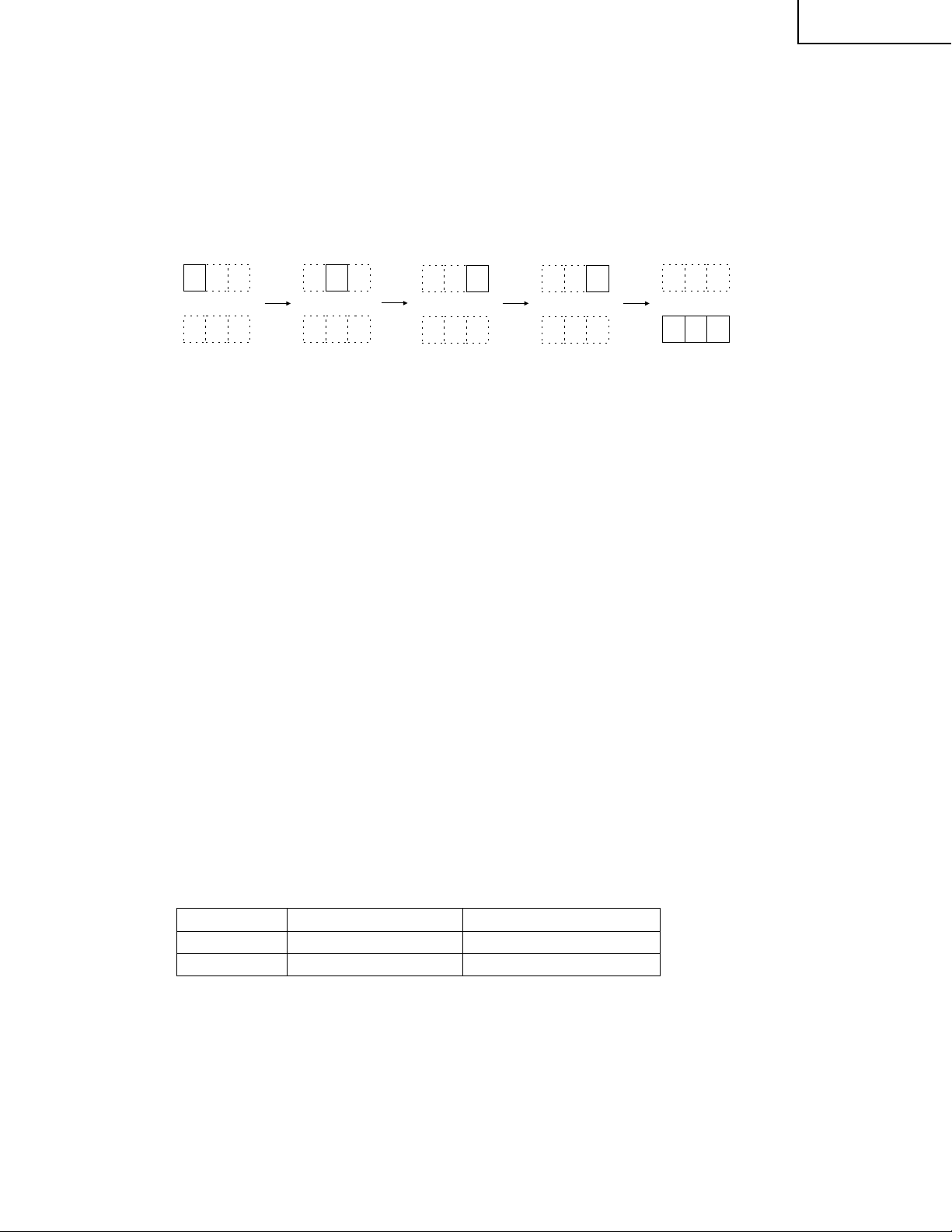

3) Address settings (selecting adjustment and setting items)

1 Using the numeric buttons (0 thru 9), type in an address from the highest digit (left) to the lowest digit

(right) one by one. Each time a digit is buttoned in, the cursor moves to the next entry position.

2 Using the INPUT button, enter the address. The cursor moves to the data display position and the se-

lected address status is displayed there.

3 To adjust the white balance cut-off level, it is necessary to keep the screen cut off. It is therefore impossi-

ble to keep adjusting it with the address being displayed on-screen. (For details, refer to the White Balance Adjustment.)

• Display change example

In selecting the address "100" (vertical linearity):

000 00 00 00

Initial display Button in for "1" Button in for "0" Button in for "0" Button in for "INPUT"

`If the wrong address has been buttoned in, use the “100” key to clear the address display and get it

back to the initial one.

4) Data settings (adjusting and setting items)

1 Use the VOLUME UP/DOWN buttons to modify the data.

2 Use the INPUT button to enter the modified data (setting).

• For a function execute command address (factory-setting function and etc.), the INPUT button is used

to select and call the function. With the adjustment function selected, the button is employed to enter

the data of an item.

` When the data has been modified in the adjustment function, the new data will be immediately

entered regardless of the INPUT button. Keep in mind, therefore, that the original data cannot be

held.

• Data range

Mode Setting Function: 0 or 1

Adjustment Function: As per each adjustment item (separately discussed)

» Initial factory settings

When the following services have been made, it is necessary to make the initial factory settings.

1) When the IC3102 (Memory IC) has been replaced:

This IC stores the video- and deflection-related data in memory. A replacement IC3102 does not have any

data written in (Adjustment 0). It is therefore required to make the initial settings 1 and 2 on it. Take the

following procedure.

1 Initial Factory Settings 1 (Initializing the IC)

2 Initial Factory Settings 2 (Making the software menu setting data to the factory-adjustment level)

3 Various Adjustments

2) When the channel selection IC3501 (Micro-processor) has been replaced:

1 Initial Factory Settings 2

When the micro-processor alone has been replaced, just make this adjustment, not any other ones.

1

1

000

1

0

1

00

19

(Address)

(Data display)

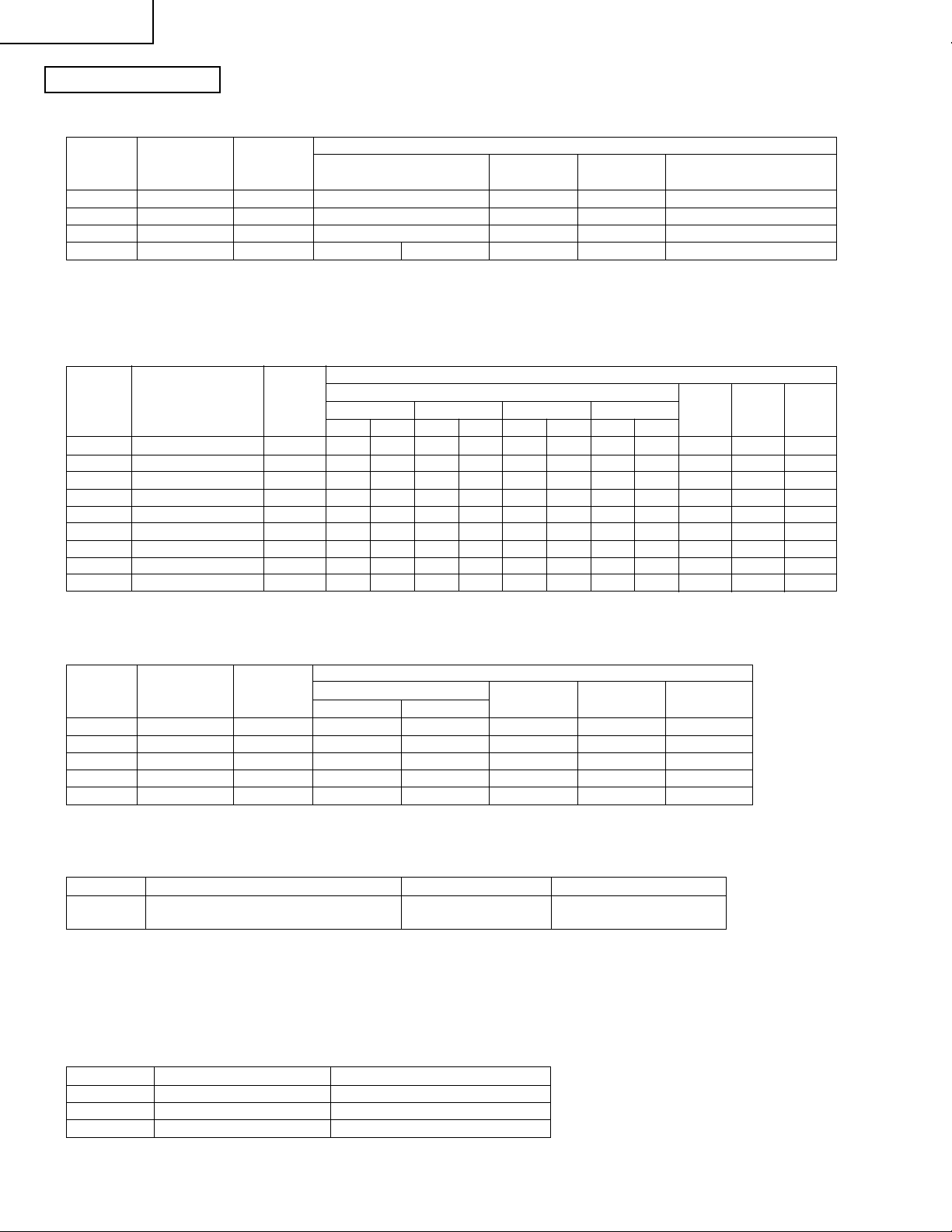

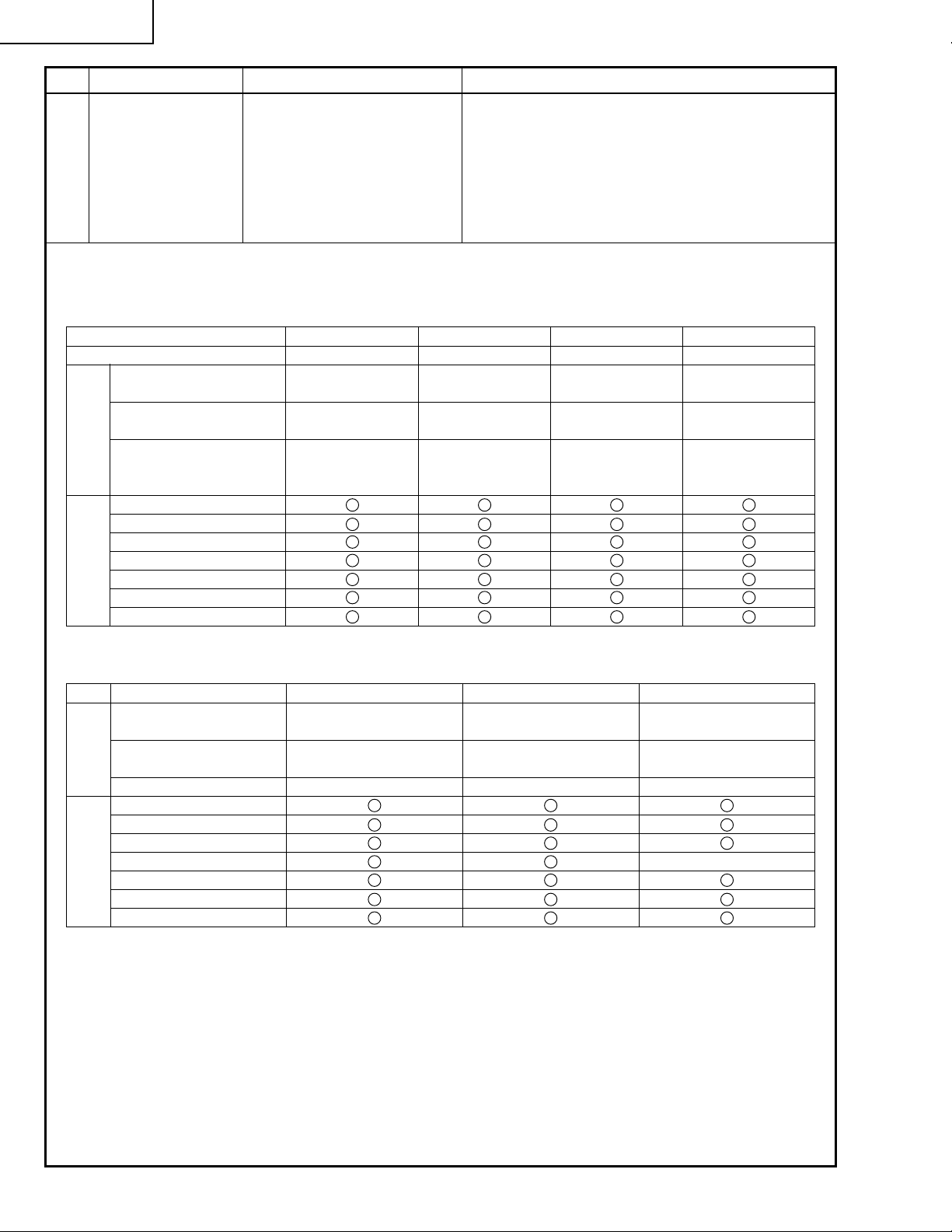

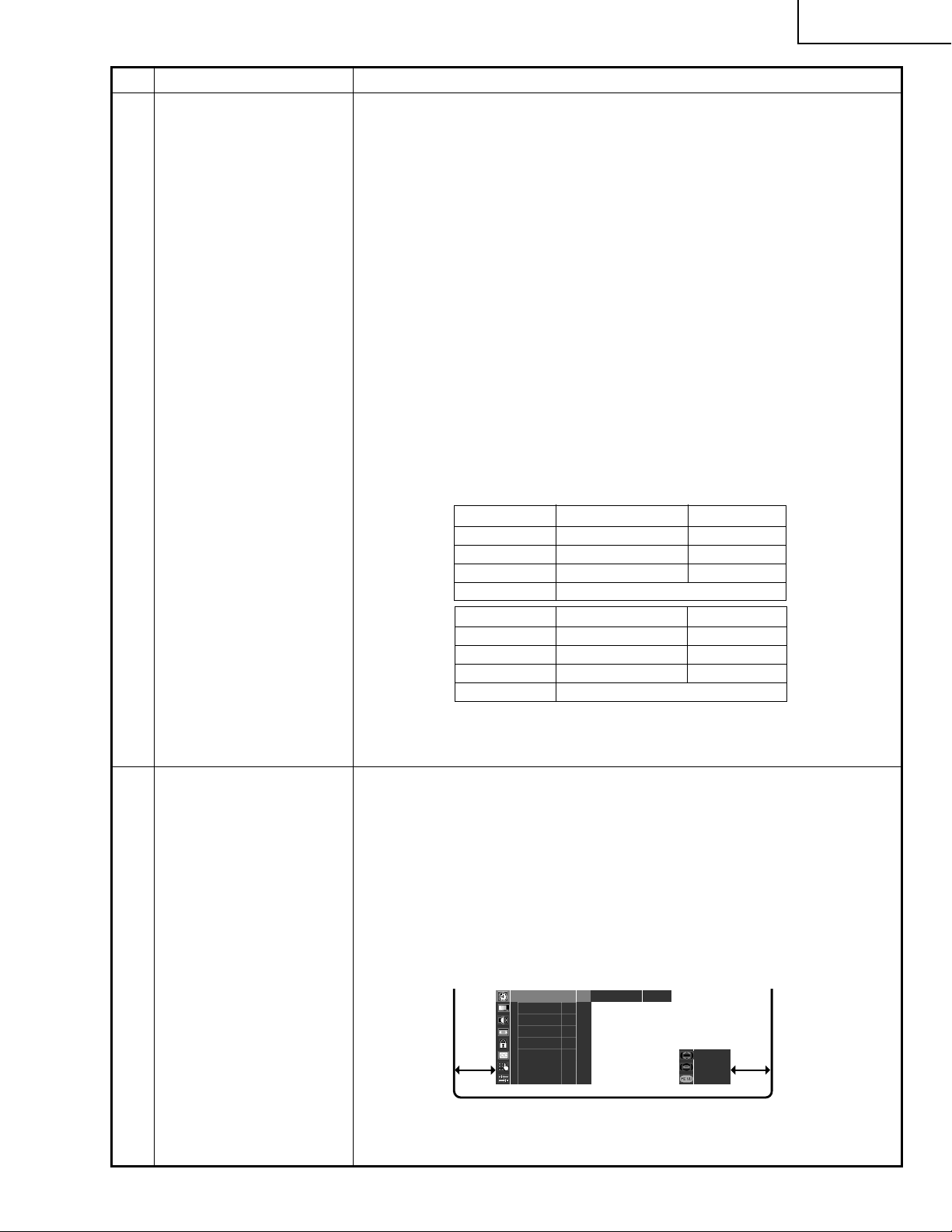

ADDRESS SETTING ITEM DATA VARIABLE RANGE

001 Initial factory settings 1 0/1: Use "1"

002 Initial factory settings 2 0/1: Use "1"

13

Page 14

34N-WF5H

Adjustment items

Video-Related Adjustment

Make the initial factory settings 2 first and then go to this adjustment.

JWS

ADDRESS

160 Picture 0~69 13 13 25(JWS173) 25(JWS173)(0~127)

162 Tint 0~127 32 32 ––

164 Color 0~54 21 21 ––

166 Brightness 16~174 58(480P) 63(1080I) 124 64(JWS174) 64(JWS174)(0~127)

ITEM

DATA

VARIABLE

RANGE

NTSC

Signal Input

T able A.

Deflection-Related Adjustment

Make the initial factory settings 2 first and then go to this adjustment.

In this adjustment, the data are different by the SIDE-BAR, SMART-STRETCH, CINEMA-ZOOM and STRETCH

modes.

JWS

ADDRESS

100 Vertical Linearity 0~31 23 23 23 23 23 22 23 23 23 23 23

102 Vertical Size 0~96 37 44 52 59 70 80 40 47 38 37 40

105 Vertical Position 0~127 65 63 63 63 61 60 65 63 70 70 61

108 Horizontal Size 0~63 18 40 17 39 19 40 17 39 39 41 15

110

112 Horizontal Position 0~127 53 60 53 60 53 60 53 60 59 61 53

114 Trapezoidal Distortion 0~127 67 67 67 67 67 67 67 67 67 67 67

116 Corner Distortion 0~31 22 23 25 26 26 27 22 23 22 22 22

118

Side Pincushion Adjustment

Horizontal Compensation

ITEM

DATA

V ARIABLE

RANGE

0~63 16 19 22 26 31 36 18 22 19 18 17

0~723232323 3 3 2

SIDE BAR

480P 1080I

NTSC Signal Input

SMART STRECH CINEMA ZOOM

480P 1080I 480P 1080I 480P 1080I

REFERENCE DATA

1080I Input

REFERENCE DATA

HD-IN (RGB)

1080I Input

STRECH

HD-IN (RGB)

480P Input

1080I

Input

HD-IN

(RGB)

1080I Input

HD-IN

(RGB)

480P Input

Table B.

White Balance Adjustments

Make the initial factory settings 2 first and then go to this adjustment.

JWS

ADDRESS

150 Red cut-off 64~255 64 64 64 64 64

152 Green cut-off 64~255 64 64 64 64 64

154 Blue cut-off 64~255 64 64 64 64 64

156 Green drive 10~117 64 64 64 64 64

158 Blue drive 10~127 64 64 64 64 64

ITEM

DATA

VARIABLE

RANGE

NTSC Signal Input

480P mode 1080I mode

REFERENCE DATA

1080I Input

HD-IN (RGB)

1080I Input

HD-IN (RGB)

480P Input

Table C.

On-Screen Display Positioning

Make the initial factory settings 3 first and then go to this adjustment.

JWS ADDRESS

020 On-screen Display Horizontal Position

ITEM INITIAL VALUE DATA VARIABLE RANGE

8 (1080I mode)

14 (480P mode)

0~255

Table D.

<Note>

When the initial factory settings 1 have been made, the initial factory settings 2 and the line adjustment data are

all cleared. This would require readjustments for all the modes.

Before replacing an IC, write down the data settings in all the modes. Note, however, that the settings may be

different from unit to unit. Take the above reference data as an adjustment guideline.

JWS ADDRESS

001 Initial Factory Settings 1 Use "1"

002 Initial Factory Settings 2 Use "1"

170 Y-Mute & V-Stop Setting Use "1"

ITEM DATA VARIABLE RANGE

Table E.

14

Page 15

No. AdjustingPoint Adjusting Conditions Adjusting Procedure

34N-WF5H

1 VCO adjustment

(L205 and L255 on

Tuner Unit)

2 RF AGC adjust-

ment (R219 and

R269 on Tuner

Unit)

Signal: Good local channel

Adjusting point:

L205 and L255

Specification:

2.2 ±0.1 Vp-p

Signal: Good local channel

Adjusting point:

R219 and R269

Specification:

No noticeable noise

1. Receive the good local channel.

2. Connect the digital voltmeter to pins (28) and (29)

of JA connector (SC1401).

3. Select the JWS address 033 and set it to "1".

4. Adjust the VCO coils (L205 and L255) to ha v e the

2.2V level. (Main: L205, Sub: L255)

5. Set the JWS address 033 to "0".

6. Clear the JWS address 033 and quit the JWS

mode.

1. Receive the good local channel.

2. Select the JWS address 033 and set it to “1”.

3. Adjust R219 and R269 to achieve optimum screen

without noises and beats. (Main: R219, Sub: R269)

4. Receive other channel signals. Check the screen

as mentioned in the above step 3.

5. Set the JWS address 033 to “0”.

6. Clear the JWS address 033 and quit the JWS

mode.

Note 1:

Before switching to other channels (in Step 4 .

above), take Steps 5. and 6. and quit the JWS

mode.

Note 2:

When the R219 and R269 controls are set to minimum, there will be nothing seen on the screen

(black raster).

3 Detection output

level adjustment

(R233 and R283 on

Tuner Unit)

Signal: NTSC standard half

color bar signal

Adjusting point:

R233 and R283

Specification:

1.0 ±0.05 Vp-p

1. Receive the NTSC standard half color bar signal.

2. Connect the oscilloscope between TP401 (TP402)

on Tuner Unit and GND . (Main: TP401, Sub: TP402)

3. Using the R233 control, adjust the main IF detection output level.

4. Using the R283 control, adjust the sub IF detection output level.

1.0Vp-p

15

Page 16

34N-WF5H

No. Adjusting Point

4 Stereo separation

adjustment

(R329, R331, R301

and R313 on Tuner

Unit)

Adjusting

Conditions

Adjusting point:

R329, R331

Measuring terminal:

(TP301) Pin (7)

of IC301

Specification:

282 ±10 mVp-p

Adjusting point:

R301

Measuring terminal:

(TP303) Pin (22)

of IC301

Specification:

Minimum AC

voltage

Modulator Settings

(Leader LMS237)

1. Internal modulation:

400 Hz

2. Monaural:

100% modulation

1. Internal modulation:

300 Hz

2. Stereo switch at ON,

L-channel output

(130% modulation)

alone (L+R and L-R

not allowed)

3. Stereo mode

Adjusting Procedure

1. Connect the oscilloscope probe

to (TP301) pin (7) of IC301.

2. Adjust the input level to

282mVp-p.

3. Switch the main and sub signals to adjust both R329 and

R331.

1. Connect the oscilloscope probe

to pin (22) (TP303) of IC301.

2. Adjust the separation control

(R301) to get the AC voltage to

minimum.

Adjusting point:

R313

Measuring terminal:

(TP303) Pin (22)

of IC301

Specification:

Minimum AC

voltage

1. Internal modulation:

3 kHz

2. Stereo switch at ON,

L-channel output

(130% modulation)

alone

3. Stereo mode

1. Connect the oscilloscope probe

to pin (22) (TP303) of IC301.

2. Adjust the separation control

(R313) to get the AC voltage to

minimum.

16

Page 17

No. AdjustingPoint Adjusting Conditions Adjusting Procedure

34N-WF5H

5 3D Y/C separation

level adjustment

(R7000: Y/C3D

Unit)

6 Main Y signal level

adjustment

(R/C, JWS address

473)

Signal: NTSC standard half

color bar signal

Adjusting point:

(R7000: Y/C 3D Unit)

Specification:

0.8 ±0.05 Vp-p

Signal: NTSC standard half

color bar signal

Adjusting point:

Remote Control

(JWS address 473)

Specification:

0.7 ±0.05 Vp-p

1. Receive the NTSC standard half color bar signal.

2. Connect the oscilloscope probe between pin (8)

of SC3203 and GND.

3. Adjust R7000 so that the waveform amplitude of

the luminance signal at pin (8) of SC3203 should

be 0.8±0.05 Vp-p.

Note: The amplitude must be measured from the

black level to the white peak.

0.8Vp-p

1. Connect the oscilloscope probe between TP1801

and GND.

2. In the twin-picture mode, receive the NTSC standard half color bar signal for the left-side screen (Main

Screen).

3. Using the VOLUME UP/DOWN keys in the JWS

address 473, adjust the waveform amplitude of the

main luminance signal at TP1801 to 0.7±0.05 Vp-p.

Note: The amplitude must be measured from the

black level to the white peak.

7 Main-screen tint

adjustment

(R/C, JWS address

162)

8 Main-screen color

adjustment

(R/C, JWS address

164)

Signal: Good local channel

Adjusting point:

Remote Control

(JWS address 162)

Specification:

Normal flesh tones

Signal: Good local channel

Adjusting point:

Remote Control

(JWS address 164)

Specification:

Normal color level

1. Set the AV mode to "STD-1".

2. In the twin-picture mode, receive the good local

channel for the left-side screen (Main screen).

3. Enter the JWS address 162. Using the VOLUME

UP/DOWN keys , visually adjust the tint to the best.

4. Switch the channels. Make sure the tint is optimum on other channels.

1. Take the same steps 1. and 2. for the tint adjustment.

2. Enter the JWS address 164. Using the VOLUME

UP/DOWN keys, visually adjust the color to the

best.

3. Switch the channels. Make sure the color is optimum on other channels.

17

Page 18

34N-WF5H

No. AdjustingPoint Adjusting Conditions Adjusting Procedure

9 Brightness adjust-

ment

(R/C, JWS address

166) (480P/1080I)

10 Picture adjustment

(R/C, JWS address

160)

11 Sub-screen Pic-

ture adjustment

(R/C, JWS address

250)

Signal: Good local channel

Adjusting point:

Remote Control

(JWS address 166)

Specification:

Normal brightness

level

Signal: Good local channel

Adjusting point:

Remote Control

(JWS address 160)

Specification:

Normal contrast range

Signal: NTSC standard half

color bar signal

Adjusting point:

Remote Control

(JWS address 250)

Measuring point: TP1801

Specification: 0.7±0.05 Vp-p

1. Make this adjustment after the deflection, white

balance, normal mask, purity, convergence and

focus have all been completely adjusted.

2. Set to the video standard condition.

(Picture at MAX, brightness and sharpness at

CENTER)

3. Set the VIEW MODE to STRETCH.

4. Receive the good local channel.

5. Enter the JWS address 166. Adjust the brightness

to the best point.

6. Switch to the 1080I mode. Make the same adjustment.

1. Make this adjustment after the Y signal level has

been completely adjusted.

2. Take the same steps 1., 2., 3. and 4. f or the brightness adjustment.

3. Enter the R/C address 160. Adjust the picture to

the best point.

1. In the twin-picture mode. Receive the NTSC standard half color bar signal for the right-side screen.

2. Connect the oscilloscope to TP1801. Enter the

JWS address 250. Using the VOLUME UP/DOWN

keys, adjust the amplitude between the black level

and white peak to 0.7±0.05 Vp-p.

12 Sub-screen tint

adjustment (R/C,

JWS address 258)

13 Sub-screen color

adjustment (R/C,

JWS address 259)

14 Deflection distor-

tion, vertical and

horizontal position

adjustments

Signal: Good local channel

Adjusting point:

Remote Control

(JWS address 258)

Specification:

Normal flesh tone

Signal: Good local channel

Adjusting point:

Remote Control

(JWS address 259)

Specification:

Normal color level

1. In the twin-picture mode, receive the good local

channel for the right-side screen (sub-screen).

2. Enter the JWS address 258. Using the VOLUME

UP/DOWN keys , visually adjust the tint on the rightside screen to that on the left-side screen.

3. Switch the channels for the right-side screen. Make

sure the tint is optimum on other channels.

1. In the twin-picture mode, receive the good local

channel for the right-side screen (sub-screen).

2. Enter the JWS address 259. Using the VOLUME

UP/DOWN keys, visually adjust the color on the

right-side screen to that on the left-side screen.

3. Switch the channels for the right-side screen. Make

sure the color is optimum on other channels.

Discussed here are the adjustment procedures for

the STRETCH-mode screen size.

For the other modes, refer to Table B. and go to their

respective procedures.

Make these adjustments for the 480P and 1080I

modes as well.

18

Page 19

No. AdjustingPoint Adjusting Conditions Adjusting Procedure

34N-WF5H

15 STRETCH-mode

vertical linearity

adjustment

(R/C, JWS address

100)

16 STRETCH-mode

vertical position

adjustment

(R/C, JWS address

105)

17 STRETCH-mode

vertical size

adjustment

(R/C, JWS address

102)

18 STRETCH-mode

side pincushion

adjustment (R/C,

JWS address 110)

Signal: Monoscope pattern

signal

Adjusting point:

Remote Control

(JWS address 100)

Specification: Best position

Adjusting point:

Remote Control

(JWS address 105)

Specification:

Center position 0±10 mm

Adjusting point:

Remote Control

(JWS address 102)

Specification:

Overscan at "Table-1"

and "Table-2"

Adjusting point:

Remote Control

(JWS address 110)

Specification:

Straight outermost line

1. Set the AV-mode to "STD-1".

2. Set the screen size to STRETCH-mode.

3. Receive the monoscope pattern signal.

4. Enter the JWS address 100. Using the VOLUME

UP/DOWN keys, adjust the vertical linearity to the

best position.

1. Take the same steps 1., 2. and 3. for the

STERTCH-mode vertical linearity adjustment.

2. Enter the JWS address 105. Using the VOLUME

UP/DOWN keys, adjust the vertical position to

center.

1. Take the same steps 1., 2. and 3. for the

STERTCH-mode vertical linearity adjustment.

2. Enter the JWS address 102. Using the VOLUME

UP/DOWN keys, adjust the overscan at "Table-1"

and "Table-2".

1. Take the same steps 1. and 2. for the STERTCHmode vertical linearity adjustment.

2. Receive the crosshatch pattern signal.

3. Enter the JWS address 110. Using the VOLUME

UP/DOWN keys, adjust the outermost line to be

straight.

4. Make the horizontal position and horizontal size

adjustments and then finely adjust the horizontal

side pincushion.

19 STRETCH-mode

horizontal position

adjustment

(R/C, JWS address

112)

20 STRETCH-mode

horizontal size

adjustment

(R/C, JWS address

108)

21 STRETCH-mode

trapezoidal distortion adjustment

(R/C, JWS address

114)

Adjusting point:

Remote Control

(JWS address 112)

Specification:

Symmetry about

vertical center

Adjusting point:

Remote Control

(JWS address 108)

Specification:

Overscan at "Table-1"

and "Table-2"

Signal: Crosshatch pattern

signal

Adjusting point:

Remote Control

(JWS address 114)

Specification:

Vertical lines parallel

with effective area

1. Take the same steps 1., 2. and 3. for the

STERTCH-mode vertical linearity adjustment.

2. Enter the JWS address 112. Using the VOLUME

UP/DOWN keys, achieve symmetry about the vertical center.

1. Take the same steps 1., 2. and 3. for the

STERTCH-mode vertical linearity adjustment.

2. Enter the JWS address 108. Using the VOLUME

UP/DOWN keys , adjust the setting to "T ab le-1" and

"Table-2".

1. Take the same steps 1. and 2. for the STERTCHmode vertical linearity adjustment.

2. Receive the crosshatch pattern signal.

3. Enter the JWS address 114. Using the VOLUME

UP/DOWN keys, adjust the vertical lines to be

parallel with the effective area.

19

Page 20

34N-WF5H

No. AdjustingPoint Adjusting Conditions Adjusting Procedure

22 STRETCH-mode

corner distortion

adjustment

(R/C, JWS address

116)

Adjusting point:

Remote Control

(JWS address 116)

Specification:

Straight vertical lines

1. Take the same steps 1. and 2. for the STERTCHmode vertical linearity adjustment.

2. Receive the crosshatch pattern signal.

3. Enter the JWS address 116. Using the VOLUME

UP/DOWN keys, adjust the vertical lines to be

straight.

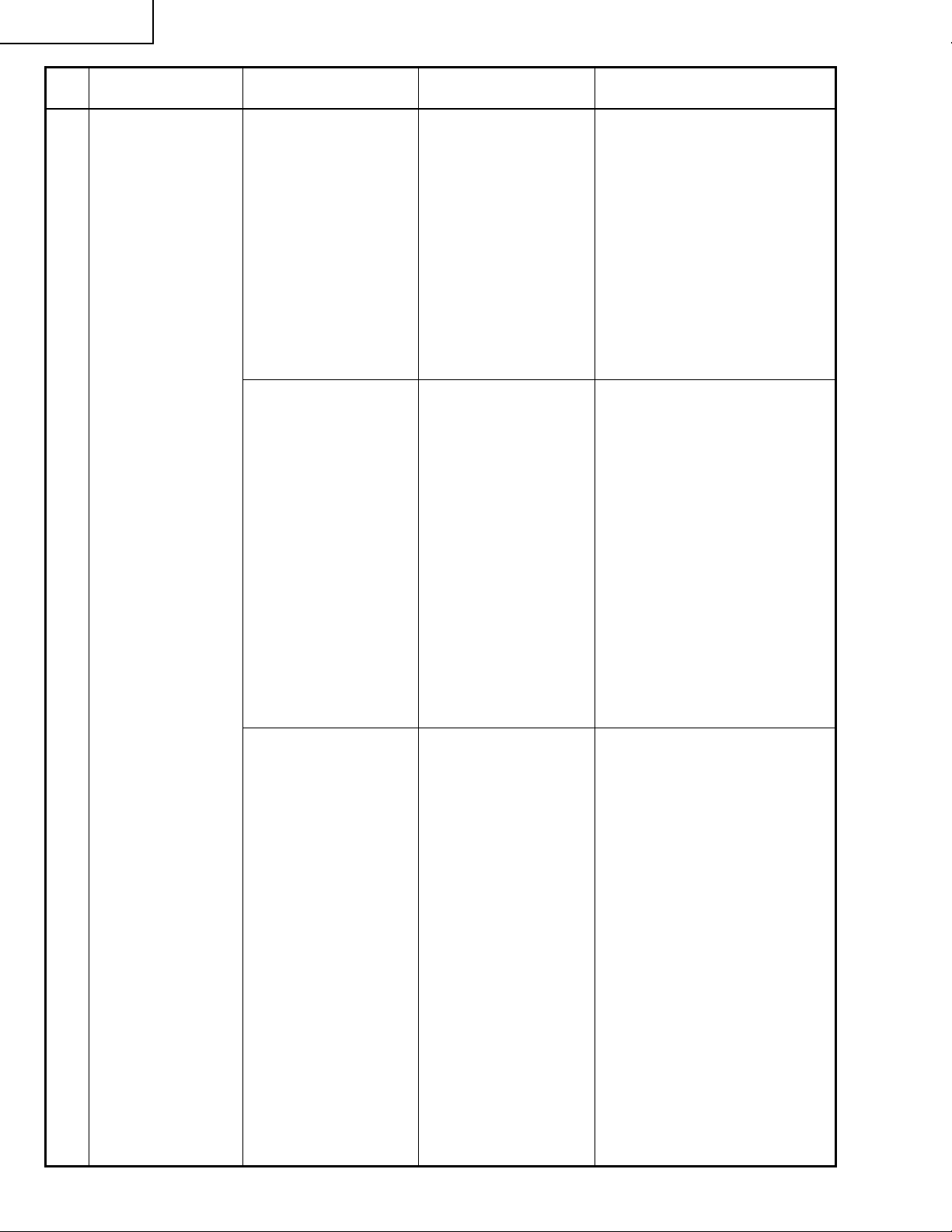

Deflection distortion, vertical and horizontal position adjustments

Make the two-pattern adjustments in the quality-picture modes (480P/1080I).

MODE STRECH SIDE-BAR SMART-STRECH CINEMA-ZOOM

4:3 16:9

Vertical Size (92) (93) (85) (71)

Overscan 8% 7% 15% 29%, 6%

Horizontal Size (92.5) (95) (94) (92)

Overscan 7.5% 5% 6% 8%

Specification

Side Pincushion Adjustment Outermost line

Vertical Size (102)

Vertical Linearity (100)

Vertical Position (105)

Horizontal Size (108)

Side Pincushion (110)

Trapezoidal Distortion (114)

Adjustment items

Horizontal Position (112)

Picture edges

(borders between

mask and picture)

Table-1.

1.5 line from

outermost

Other signal inputs

Vertical Size (92) (92) (92)

Overscan 8% 8% 8%

Horizontal Size (92) (88) (91)

Overscan 8% 12% 9%

Specification

Side Pincushion Adjustment

Vertical Size (102)

Vertical Linearity (100)

Vertical Position (105)

Horizontal Size (108)

Side Pincushion (110)

Trapezoidal Distortion (114)

Adjustment items

Horizontal Position (112)

1080I INPUT HD-IN (RGB) 1080I INPUT HD-IN (RGB) 480P INPUT

Table-2.

20

Page 21

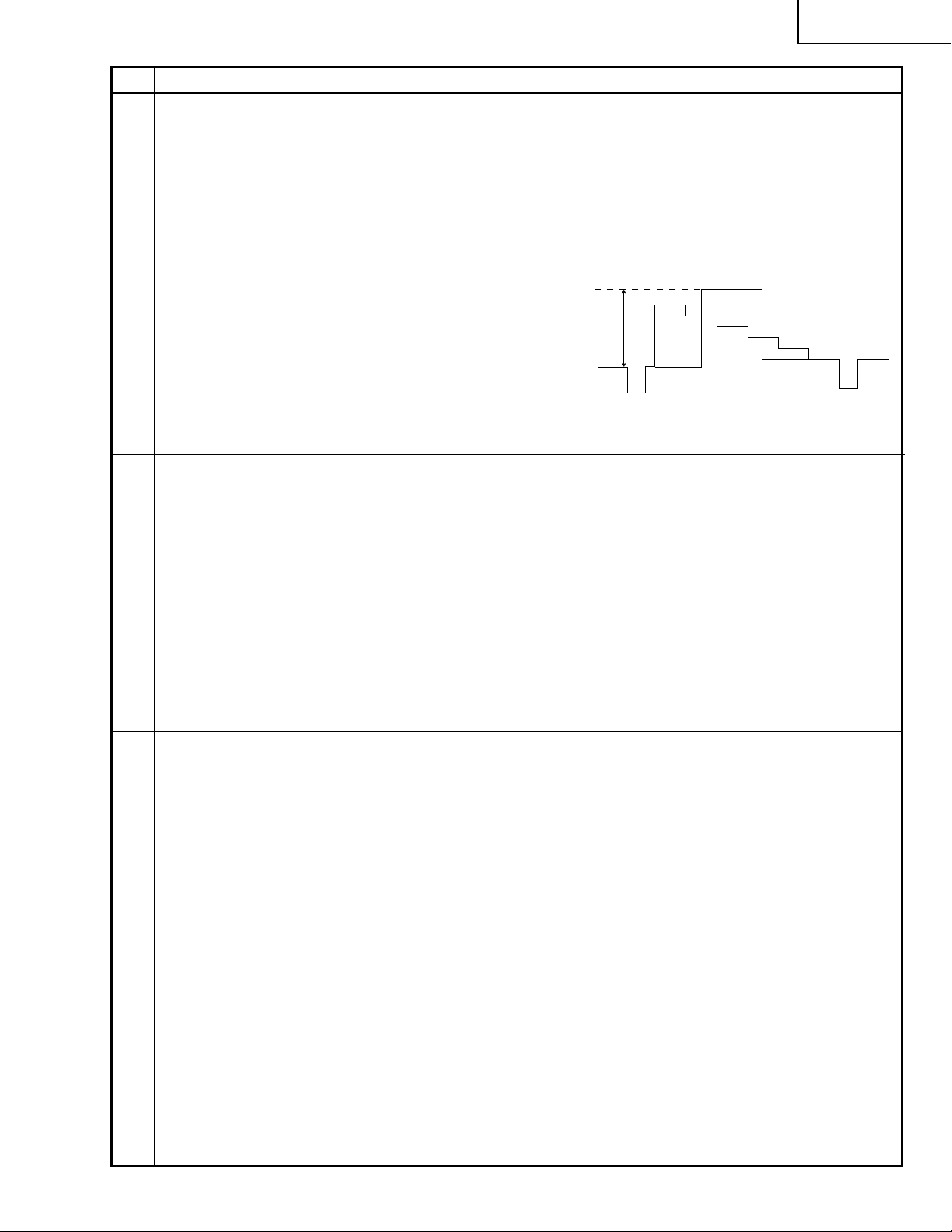

No. AdjustingPoint Adjusting Procedure

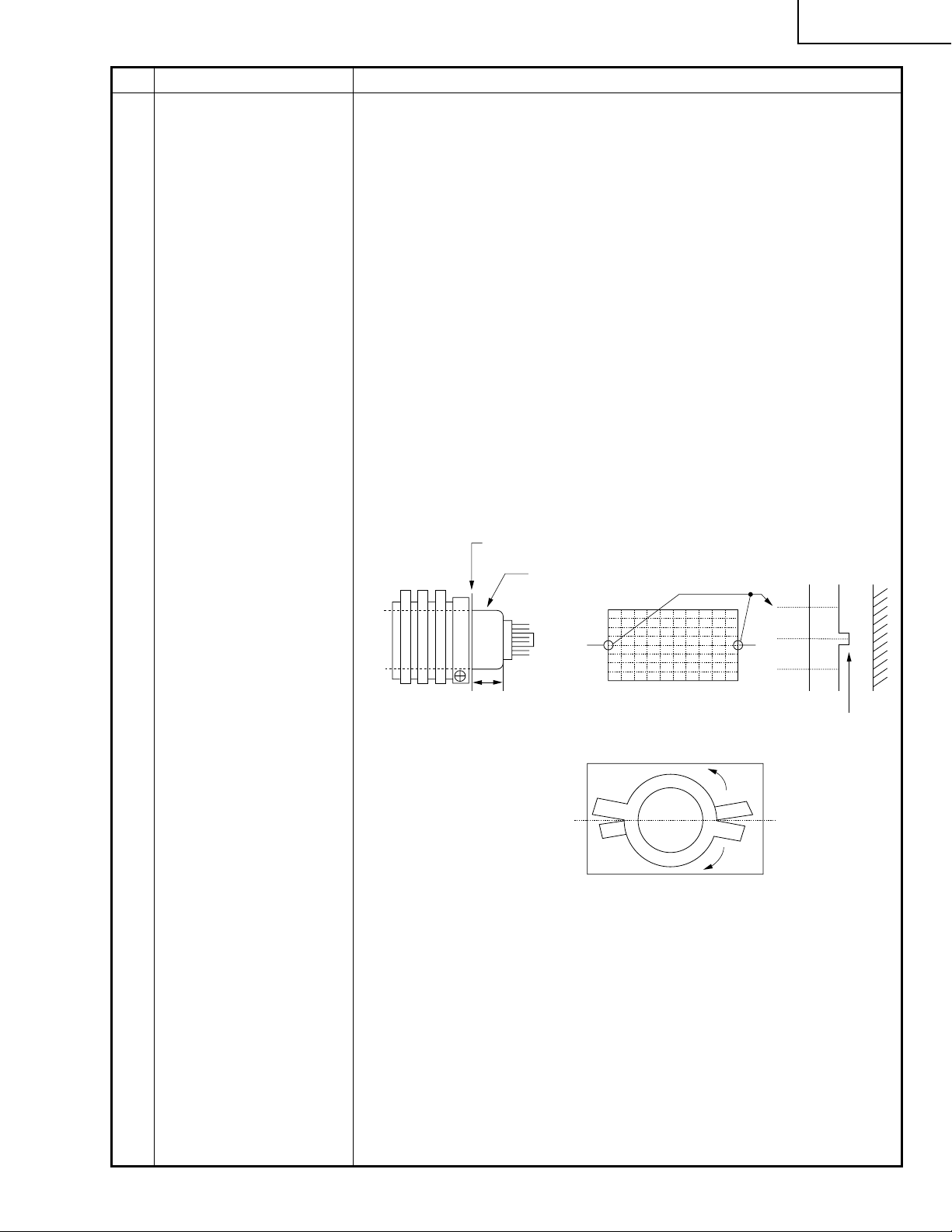

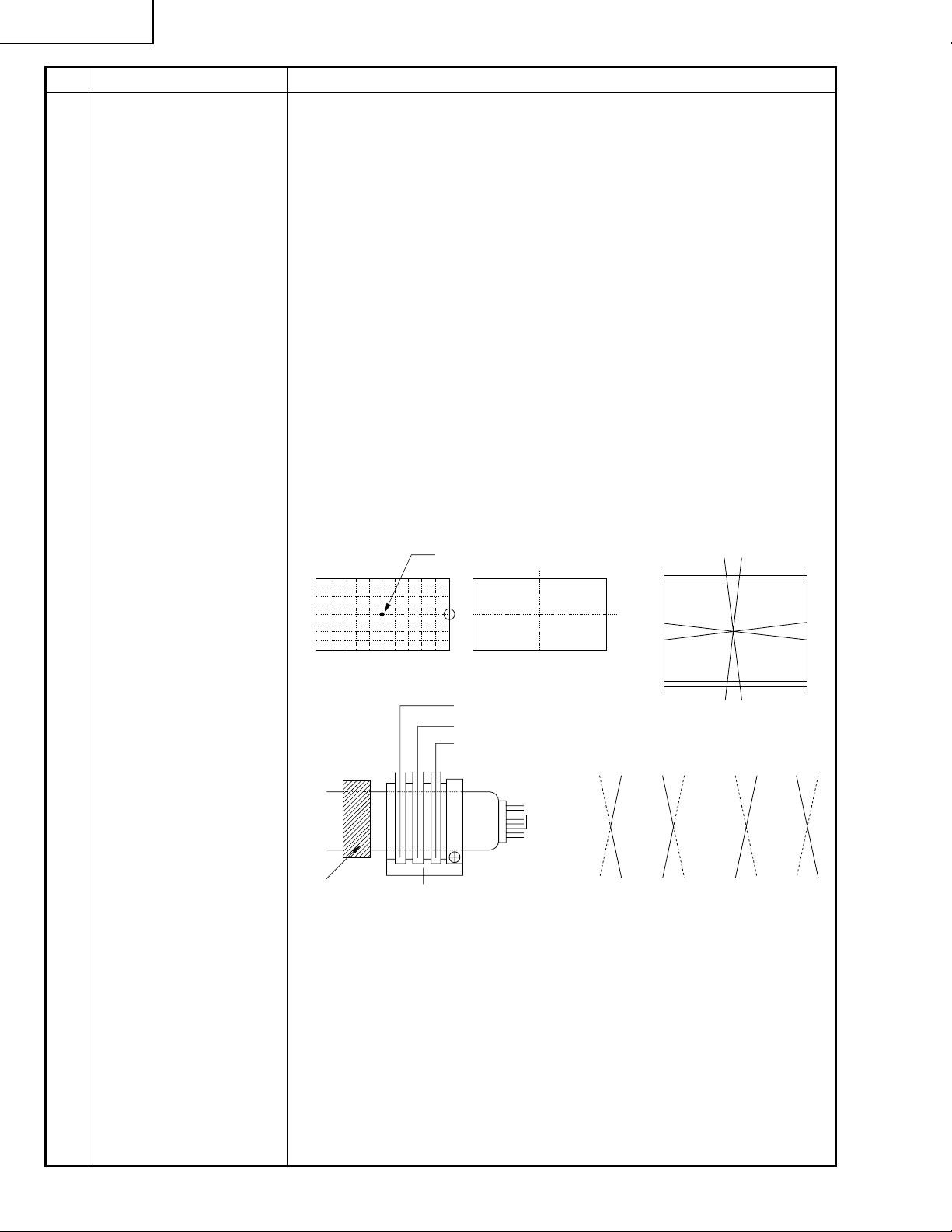

23 Purity adjustment Visual adjustment procedure

(1)Check the purity magnet assembly mounting position.

(2)Receive the crosshatch pattern signal.

(3)Adjust the raster tilt by turning the deflection yoke.

(Align the projections at both ends of CRT’s X axis with the screen’s X

axis.)

(4)Using the 4-pole and 6-pole magnets, adjust the static convergence at

the center of the raster.

(Refer to the convergence adjustment.)

(5)Check the standard mode, and receive the green-only (or white) signal

from the pattern generator.

(6)Keep the deflection yoke’s opening horizontal together with the neck.

Move the deflection yoke to and fro until the screen turns green only (or

white). If the red and blue (or yellow and cyan) colors at both sides are

not symmetrical, get them symmetrical by opening and closing the 2pole magnet in reference to its axis.

(7)Readjust the deflection yoke’s tilt while looking at the crosshatch

pattern. Tighten up the deflection yoke lock screw to secure the yoke in

position.

(8)Finally fix the deflection yoke opening with the wedge.

34N-WF5H

Purity magnet assembly mounting position

Rear end of purity magnet assembly

CRT neck

Mounting dimension

38mm

Crosshatch pattern

2-pole magnet

X axis

Crosshatch

X axis

Cabinet

Projection

21

Page 22

34N-WF5H

No. AdjustingPoint Adjusting Procedure

24 Convergence adjustment (1) Static convergence adjustment

a) Receive the crosshatch pattern signal.

b) Adjust the red and blue colors at the screen center by opening and

closing or moving the 4-pole magnet.

c) Adjust the green and magenta colors at the screen center using the 6-

polemagnet in the same way.

(red, blue)

d) Repeat the above steps b) and c) to finely adjust the green, red and

blue colors at the screen center.

(2) Dynamic convergence adjustment

a) YH

Use the YH-VR control on the DY PWB to produce the specified crosspoint. If the nearby PQH (displaced vertical lines at the corners) is out

of spec, readjust it by using the ferrite sheet and or moving the neck.

(Do not move the neck too much, or vertical distortion may be caused

or the vertical linearity will be adversely affected.)

b) YV

Use the YV-VR control on the DY PWB to adjust the hor izontal lines at

the top and bottom of the screen to optimum.

(3) Look at the entire screen to see if there is no problem. Finally fix the

wedge and purity magnet assembly with glass tape and lacquer.

Crosshatch pattern

Deflection yoke

fastening tape

Screen center

2-pole magnet

4-pole magnet

6-pole magnet

Purity magnet assembly

Y axis

H

Y

X axis

(fig. A) (fig. B) (fig. C) (fig. D)

Red Red Red RedBlue Blue Blue Blue

Adjust with the VR1

control.

Adjust with the VR2

control.

Y

V

X

V

22

Page 23

No. AdjustingPoint Adjusting Procedure

25 White balance adjust-

ment

(1) Receiv e the monoscope pattern signal. Set the A V mode to "STD-1" and the

quality-picture mode to "480P".

(2) Using the R/C unit keys, enter the JWS address170. Set the data "1" (Y-

Mute & V-Stop).

(3) Now turn the screen control until one color (reference color) in the raster

becomes dim.

(4) For the other two non-luminous colors, enter their JWS address numbers

with the R/C unit keys, ref erring to the table belo w . Adjust the cut-off data so

that the horizontal raster lines become whitish.

(5) Turn down the screen control to cut off the raster.

(6) Using the pow er s witch on the set or the R/C unit, turn the power off and on

again to release the horizontal status.

(7) Using the R/C unit ke ys, enter the JWS address numbers listed below . Adjust

the drive so that the raster becomes whitish.

(8) Lower the brightness and the picture level. Check the white balance on the

dark screen. If out of spec, readjust the cut-off directly.

(9) Repeat the above steps (7) and (8) to have the white balance good on the

bright screen.

(10) Now adjust the brightness as well.

(11) Set the quality-picture mode to "1080I", and take the above steps (7) thru

(10) again.

34N-WF5H

26 OSD (On-screen-display)

position adjustment

(480P, 1080I)

(R/C, JWS address 020)

ADDRESS

150 Red cut-off 64

152 Green cut-off 64

154 Blue cut-off 64

Variable range 64~255

ADDRESS

156 Green drive 64

158 Blue drive 64

Variable range 10~64~117

ADJUSTMENT ITEM INITIAL VALUE

ADJUSTMENT ITEM INITIAL VALUE

Table-3.

(1) Set the AV mode to "STD-1".

(2) Set the screen size to STRETCH.

(3) Receive the monoscope pattern signal.

(4) Enter the JWS address 020.

(5) Using the VOLUME UP/DOWN keys, adjust the right- and left-side pictures

equally spaced.

(6) Get MENU OSD on the screen and check to see if the right- and left-side

areas are equally speced. If not, take the above steps (4) and (5) again.

(7) Switch to the 1080I mode and make similar adjustment.

SLEEP TIME REMA IN

VIDEO

AUDIO

SCREEN

PARENT CTRL

CC

CH SETUP

SETUP

–––

23

SELECT

ENTER

EXIT

Page 24

34N-WF5H

No. AdjustingPoint Adjusting Procedure

27 Deflection distortion,

vertical and horizontal

position adjustments at

various signal inputs

28 White balance adjust-

ment at HD

(1080I component) signal

input

1. HD (component) signal input

1) Set the AV mode to "STD-1".

2) Feed the monoscope pattern (1080I) signal through the INPUT5 BNC

terminal.

3) Referring to Table-2, take the adjustment point step No.15 thru 22.

2. HD-IN (1080I RGB) signal input

1) Set the AV mode to "STD-1".

2) Feed the monoscope pattern (1080I RGB) signal through the INPUT3/

HD INPUT (D-sub 15-pin) terminal.

3) Referring to Table-2, take the adjustment point step No.15 thru 22.

3. HD-IN (480P RGB) signal input

1) Set the AV mode to "STD-1".

2) Feed the monoscope pattern (480P RGB) signal through the INPUT3/

HD INPUT (D-sub 15-pin) terminal.

3) Referring to Table-2, take the adjustment point step No.15 thru 22.

1. Set the AV mode to "STD-1". Feed the monoscope pattern signal (1080I)

through the IN5 BNC terminal (Y). Select and receive the INPUT5 signal.

2. Select the JWS address and make the raster look whitish. (This address is

the same as for the usual white balance adjustment.)

3. Turn down the picture and brightness almost to the cut-off level. Select the

cut-off adjustment address (see T able 3.) and adjust so that the raster turns

gray. (At this time, keep the minimum-level color intact and select the JWS

cut-off address for other colors.)

4. Repeat the above steps 2. and 3. and adjust the white balance on the

bright screen.

5. Make the brightness adjustment as well.

29 Tint adjustment at HD

(1080I component) signal

input

(R/C, JWS address 162)

30 Color adjustment at HD

(1080I component) signal

input

(R/C, JWS address 164)

31 Brightness adjustment at

HD (1080I component)

signal input

(R/C, JWS address 166)

32 Picture adjustment at HD

(1080I component) signal

input

(R/C, JWS address 160)

1. Set the A V mode to “STD-1”. F eed the 1080I component signal through the

IN5 BNC terminal.

2. Select and receive the INPUT5 signal.

3. Enter the JWS address 162. Using the VOLUME UP/DOWN keys, visually

adjust to the normal flesh tones.

1. Take the same steps 1. and 2. for the tint adjustment at HD signal input.

2. Enter the JWS address 164. Using the VOLUME UP/DOWN keys, visually

adjust to the normal color level.

1. Make this adjustment after the white balance adjustment at HD signal input.

2. Take the same steps 1. and 2. for the color tone adjustment at HD signal

input.

3. Enter the JWS address 166. Using the VOLUME UP/DOWN keys, visually

adjust to the normal brightness level.

1. Take the same steps 1. and 2. for the brightness adjustment at HD signal

input.

2. Enter the JWS address 160. Using the VOLUME UP/DOWN keys, visually

adjust to the normal contrast range.

24

Page 25

No. AdjustingPoint Adjusting Procedure

34N-WF5H

33 White balance adjust-

ment at HD-IN

(1080I RGB) signal input

34 Brightness adjustment at

HD-IN (1080I RGB) signal

input

(R/C, JWS address 174)

35 Picture adjustment at

HD-IN (1080I RGB) signal

input

(R/C, JWS address 173)

1. Set the AV mode to "STD-1". Feed the monoscope pattern signal (1080I)

through the INPUT3/HD INPUT (D-sub 15-pin) terminal. Select and receive

the INPUT3 HD-IN signal.

2. Select the JWS address and make the raster look whitish. (This address is

the same as for the usual white balance adjustment.)

3. Turn down the picture and brightness almost to the cut-off level. Select the

cut-off adjustment address (see T able 3.) and adjust so that the raster turns

gray. (At this time, keep the minimum-level color intact and select the JWS

cut-off address for other colors.)

4. Repeat the above steps 2. and 3., and adjust the white balance on the

bright screen.

5. Make the brightness adjustment as well.

1. Make this adjustment after the white balance adjustment at HD-IN signal

input.

2. Take the same steps 1. and 2. for the tint adjustment at HD-IN signal input.

3. Enter the JWS address 174. Using the VOLUME UP/DOWN keys, visually

adjust to the normal brightness level.

1. Take the same steps 1. and 2. f or the brightness adjustment at HD-IN signal

input.

2. Enter the JWS address 173. Using the VOLUME UP/DOWN keys, visually

adjust to the normal contrast range.

36 White balance adjust-

ment at HD-IN

(480P RGB) signal input

37 Brightness adjustment at

HD-IN (480P RGB) signal

input

(R/C, JWS address 174)

38 Picture adjustment at

HD-IN (480P RGB) signal

input

(R/C, JWS address 173)

1. Set the AV mode to "STD-1". Input the monoscope pattern signal (480P)

through the INPUT3/HD INPUT (D-sub 15-pin) terminal. Select and receive

the INPUT3 HD-IN signal.

2. Select the JWS address and make the raster look whitish. (This address is

the same as for the usual white balance adjustment.)

3. Turn down the picture and brightness almost to the cut-off level. Select the

cut-off adjustment address (see T able 3.) and adjust so that the raster turns

gray. (At this time, keep the minimum-level color intact and select the JWS

cut-off address for other colors.)

4. Repeat the above steps 2. and 3. and adjust the white balance on the

bright screen.

5. Make the brightness adjustment as well.

1. Make this adjustment after the white balance adjustment at HD-IN signal

input.

2. Take the same steps 1. and 2. for the tint adjustment at HD-IN signal input.

3. Enter the JWS address 174. Using the VOLUME UP/DOWN keys, visually

adjust to the normal brightness level.

1. Take the same steps 1. and 2. f or the brightness adjustment at HD-IN signal

input.

2. Enter the JWS address 173. Using the VOLUME UP/DOWN keys, visually

adjust to the normal contrast range.

25

Page 26

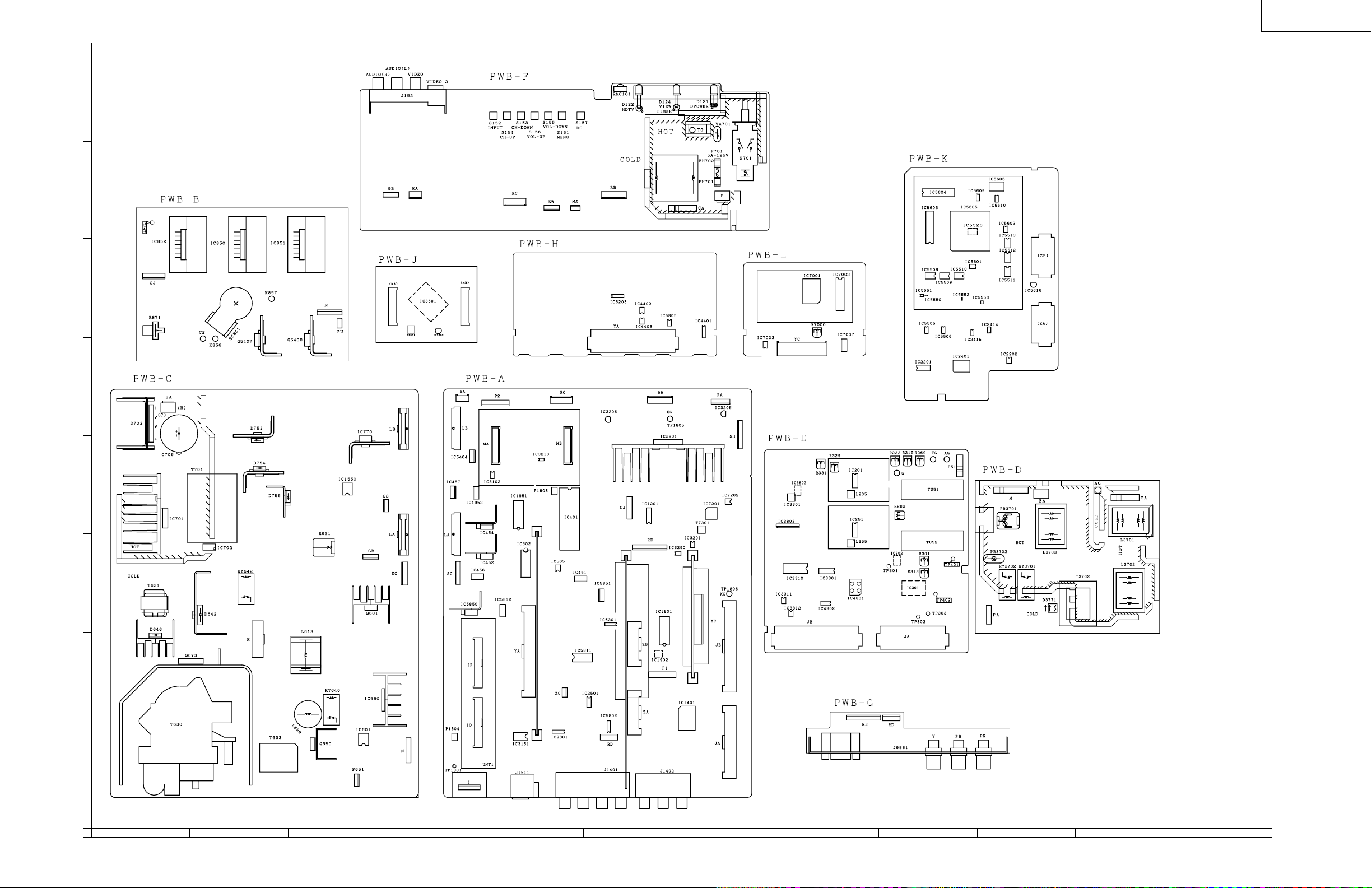

CHASSIS LAYOUT

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

26

27

Page 27

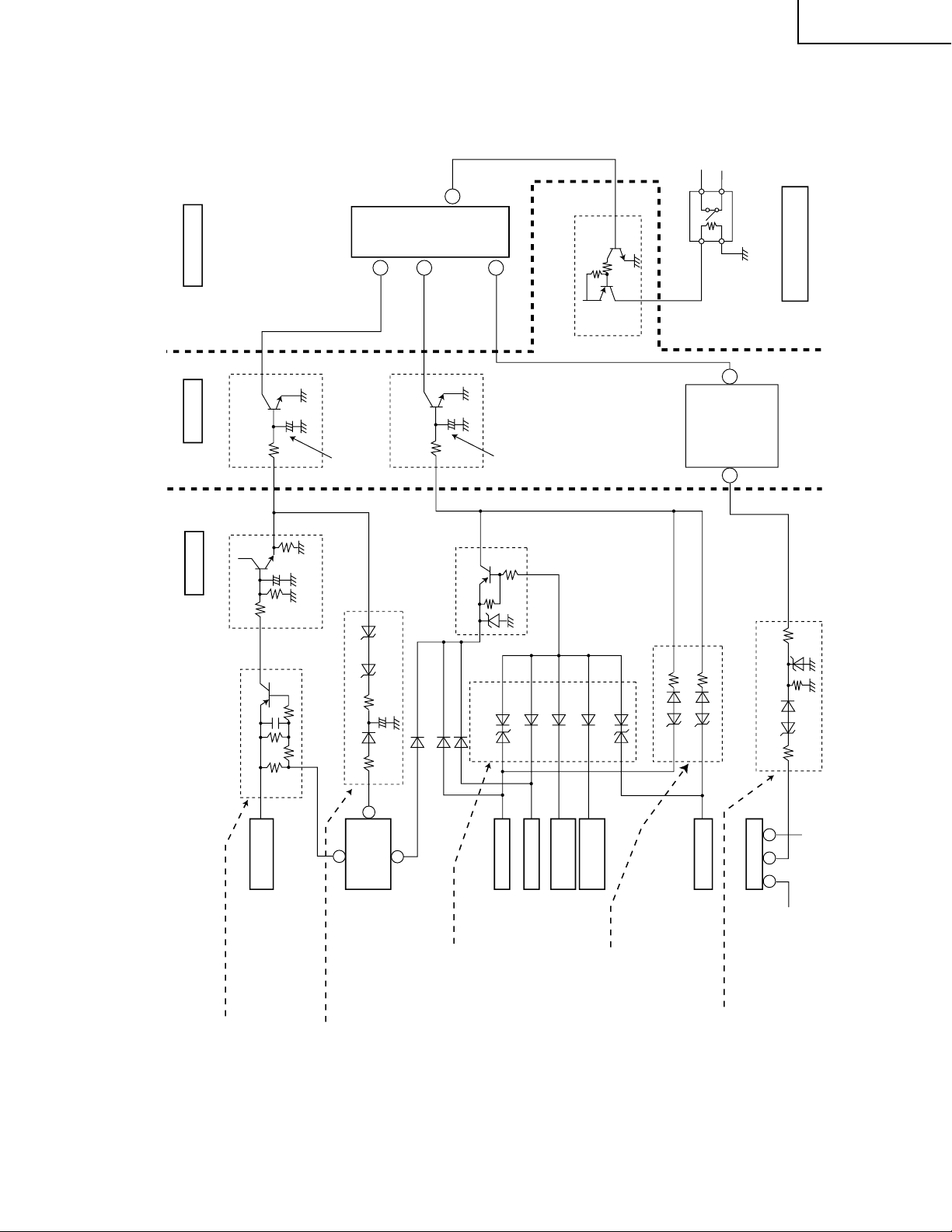

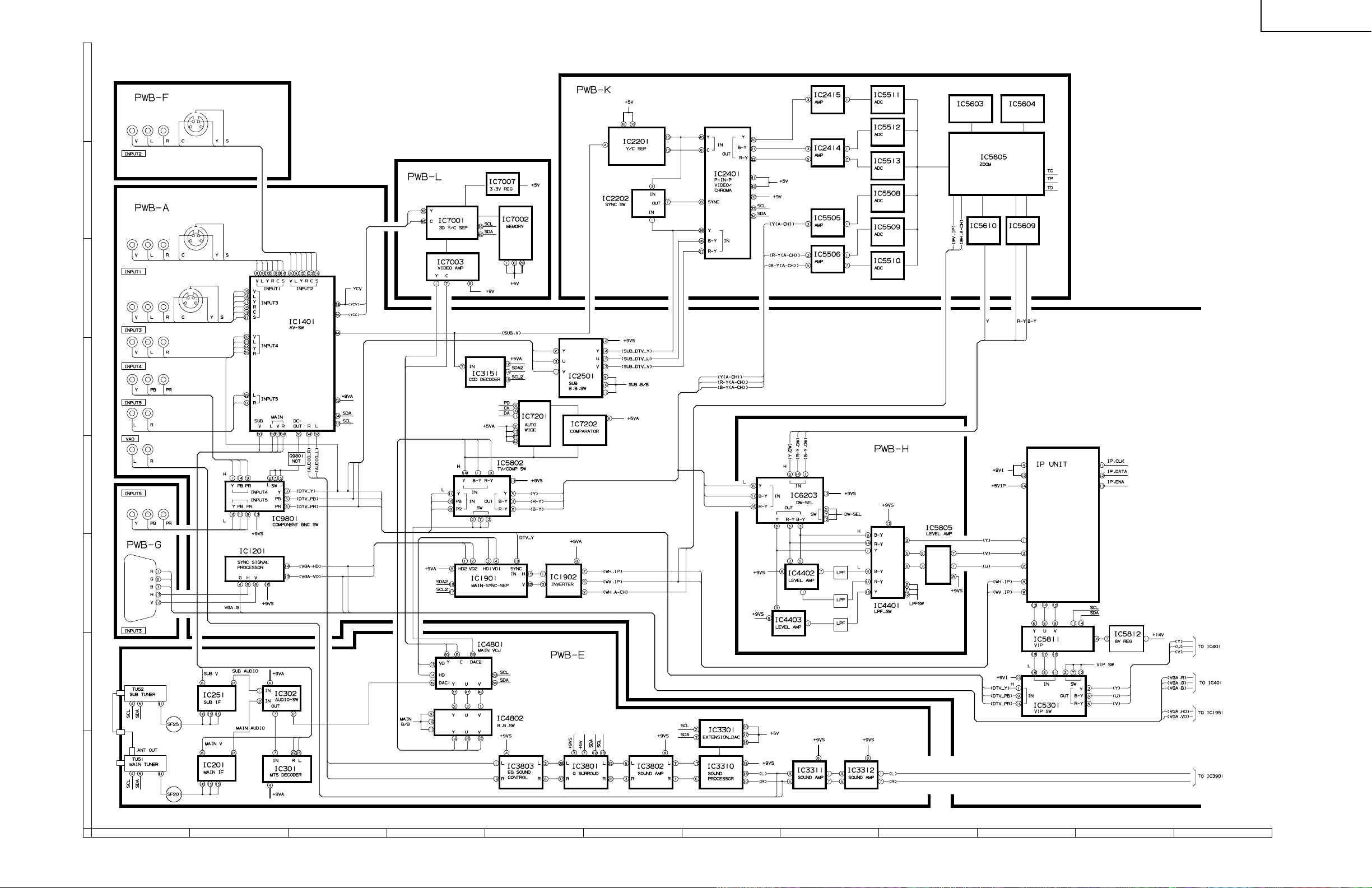

BLOCK DIAGRAM-1/2

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

28

29

Page 28

BLOCK DIAGRAM-2/2

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

30

31

Page 29

34N-WF5H

DESCRIPTION OF SCHEMATIC DIAGRAM

NOTES:

H

1. The unit of resistance "ohm" is omitted.

(K=kΩ=1000Ω, M=MΩ)

2. All resistors are 1/16 watt, unless otherwise noted.

3. All capacitors are µ F, unless otherwise noted.

(P=pF=µµF)

4. (G) indicates ±2% tolerance may be used.

5. indicates line isolated ground.

G

VOLTAGE MEASUREMENT CONDITIONS:

1. All DC voltages are measured with DVM connected

between points indicated and chassis ground, line

voltage set at 120V AC and all controls set f or normal

picture unless otherwise indicated.

2. All voltages measured with 1000µ V B & W or Color

F

signal.

E

WAVEFORMS

WAVEFORM MEASUREMENT CONDITIONS:

1. Photographs taken on a standard gated color bar

signal, the tint setting adjusted for proper color . The

wave shapes at the red, green and blue cathodes of

the picture tube depend on the tint, color level and

picture control.

2.

indicates waveform check points (See chart,

waveforms are measured from point indicated to

chassis ground.)

å

AND SHADED ( ) COMPONENTS

= SAFETY RELATED PARTS.

'

MARK= X-RAY RELATED PARTS.

This circuit diagram is a standard one, printed circuits

may be subject to change for product improvement

without prior notice.

D

C

B

A

32

87109654321

Page 30

SCHEMATIC DIAGRAM: CRT Unit

H

G

F

34N-WF5H

E

D

C

B

A

1716 1918151413121110

654321

33

Page 31

SCHEMATIC DIAGRAM: SIGNAL Unit-1/5

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

34

35

Page 32

SCHEMATIC DIAGRAM: SIGNAL Unit-2/5

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

36

37

Page 33

SCHEMATIC DIAGRAM: SIGNAL Unit-3/5

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

38

39

Page 34

SCHEMATIC DIAGRAM: SIGNAL Unit-4/5

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

40

41

Page 35

SCHEMATIC DIAGRAM: SIGNAL Unit-5/5

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

42

43

Page 36

SCHEMATIC DIAGRAM: POWER Unit

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

44

45

Page 37

SCHEMATIC DIAGRAM: TUNER Unit-1/2

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

46

47

Page 38

SCHEMATIC DIAGRAM: TUNER Unit-2/2

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

48

49

Page 39

SCHEMATIC DIAGRAM: YUV SW Unit

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

50

51

Page 40

SCHEMATIC DIAGRAM: MICOM Unit

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

52

53

Page 41

SCHEMATIC DIAGRAM: ZOOM Unit-1/3

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

54

55

Page 42

SCHEMATIC DIAGRAM: ZOOM Unit-2/3

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

56

57

Page 43

SCHEMATIC DIAGRAM: ZOOM Unit-3/3

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

58

59

Page 44

SCHEMATIC DIAGRAM: Y/D 3D Unit

H

G

F

34N-WF5H

E

D

C

B

A

121110987654321

60

61

Page 45

34N-WF5H

SCHEMATIC DIAGRAM: AC FILTER Unit

AC FILTER

H

G

F

E

D

C

B

A

654321

62

Page 46

SCHEMATIC DIAGRAM: CONTROL Unit

H

(DUNTKA098DE01)

G

F

34N-WF5H

E

D

C

B

A

654321

63

Page 47

34N-WF5H

SCHEMATIC DIAGRAM: TERMINAL Unit

H

G

F

E

D

C

B

A

654321

64

Page 48

PRINTED WIRING BOARD ASSEMBLIES

H

G

F

34N-WF5H

E

D

PWB-B: CRT Unit (Wiring Side)

C

B

PWB-G: TERMINAL Unit (Wiring Side)

A

654321

65

Page 49

34N-WF5H

H

G

F

E

D

C

B

A

PWB-A: SIGNAL Unit (A Side)

654321

66

Page 50

34N-WF5H

H

G

F

E

D

C

B

A

PWB-A: SIGNAL Unit (B Side)

654321

67

Page 51

34N-WF5H

H

G

F

E

PWB-K: ZOOM Unit (A Side)

D

C

B

A

PWB-K: ZOOM Unit (B Side)

654321

68

Page 52

34N-WF5H

H

G

F

E

D

C

B

A

PWB-C: POWER Unit (Wiring Side)

654321

69

Page 53

34N-WF5H

H

G

F

E

D

PWB-E: TUNER Unit (A Side)

C

B

A

PWB-J: MICOM Unit (A Side)

654321

70

Page 54

34N-WF5H

H

G

F

E

D

PWB-E: TUNER Unit (B Side)

C

B

A

PWB-J: MICOM Unit (B Side)

654321

71

Page 55

34N-WF5H

H

G

F

PWB-L: Y/C 3D Unit (A Side)

E

D

C

B

PWB-L: Y/C 3D Unit (B Side)

A

654321

72

Page 56

34N-WF5H

H

G

F

E

D

C

B

PWB-D: AC FILTER Unit (Wiring Side)

A

654321

73

Page 57

34N-WF5H

H

G

F

E

D

C

B

PWB-H: YUV SW Unit (A Side)

PWB-H: YUV SW Unit (B Side)

A

654321

74

Page 58

34N-WF5H

H

G

F

E

D

C

B

A

PWB-F: CONTROL Unit (Wiring Side)

654321

75

Page 59

34N-WF5H

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

Replacement parts which have these special safety characteristics

identified in this manual; electrical components having such features

are identified by å and shaded areas in the Replacement Parts Lists

and Schematic Diagrams. The use of a substitute replacement part

which dose no have the same safety characteristic as the factory

recommended replacement parts shown in this service manual may

create shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

in USA: Contact your nearest SHARP Parts Distributor to order.

Ref. No. Part No. ★ Description Code

çå VB86LQQ350W*J Picture Tube EG

çå RCiLH1915CEZZ J Deflection Y oke AX

L1551 RCiLG0443CEZZ J Rotation Coil AL

L170 RCiLG0431CEZZ J Geomagnetism Coil AM

L171 RCiLG0431CEZZ J Geomagnetism Coil AM

å RCiLG0459CEZZ J Degaussing Coil AZ

å QEARC3608CEZZ J Ground-part AM

PRINTED WIRING BOARD ASSEMBLIES

PWB-ADUNTKA096DE01 – SIGNAL Unit —

PWB-BDUNTKA100DE01 – CRT Unit —

PWB-CDUNTKA140DE01 – POWER Unit —

PWB-DDUNTKA116DE01 – AC FILTER Unit —

PWB-EDUNTKA097DE01 – TUNER Unit —

PWB-F DUNTKA098DE01 – CONTROL Unit —

PWB-GDUNTKA099DE01 – TERMINAL Unit —

PWB-HDUNTKA162DE01 – YUVSW Unit —

PWB-J DUNTKA163DE01 – MICOM Unit —

PWB-KDUNTK9950DE02 – ZOOM Unit —

PWB-L DUNTK9890DE05 – YC3D Unit —

UNT1 RUNTK0655CEZZ J I/P Unit CC

PARTS LIST

PARTS REPLACEMENT

For location of SHARP Parts Distributor, Please call TollFree; 1-800-BE-SHARP

★MARK: SPARE PARTS-DELIVERY SECTION

ç

MARK : X- RAY RELATED PARTS

PICTURE TUBE

PMAGF3091CEZZ J Magnet AR

PMAGG3006CEZZ J Magnet AC

(NOT REPLACEMENT ITEM)

(Unit Replacement Item)

PWB-A: DUNTKA096DE01

SIGNAL UNIT

INTEGRATED CIRCUITS

IC401 RH-iX3323CEZZ J TA1298BN BB

IC451 VHiPQ12RD11-1 J PQ12RD11 AG

IC452 VHiPQ09RD08-1 J PQ09RD08 AF

IC454 VHiPQ09RD08-1 J PQ09RD08 AF

IC456 VHiPQ05RD08-1 J PQ05RD08 AF

IC457 VHiPQ05RD08-1 J PQ05RD08 AF

IC502 VHiTA1241AN-1 J TA1241AN AM

IC505 VHiNJM2904M-1 J NJM2904M AE

IC1201 VHiM52347FP-1 J M52347FP AP

IC1401 VHiCXA2069Q-1 J CXA2069Q AR

IC1901 VHiTA1300AN-1 J TA1300AN AS

IC1902 VHiTC7W04F/-1 J TC7W04F AD

IC1951 VHiTA1300AN-1 J TA1300AN AS

IC1952 VHiPQ09RD08-1 J PQ09RD08 AF

IC2501 VHiTA1287F+-1 J TA1287F (EL) AN

IC3102 VHiBR2416E2-1 J BR24C16F AK

IC3151 VHiZ86130S+-1 J Z8613012SSC AV

IC3205 VHiS81350HG-1 J S-81350HG AF

IC3206 VHiS81350HG-1 J S-81350HG AF

IC3210 VHiTC7W14F/-1 J TC7W14F AD

IC3290 VHiMMHCT32F-1 J MM74HCT32MTCX AD

IC3291 VHiMMHCT00F-1 J MM74HCT00MTCX AD

IC3901 VHiTA8216H/-1 J TA8216H AN

IC5301 VHiM52055FP-1 J M52055FP AH

IC5404 VHiPQ05RD08-1 J PQ05RD08 AF

IC5802 VHiM52055FP-1 J M52055FP AH

IC5811 RH-iX3251CEZZ J TDA9178T/N1 AY

IC5812 VHiTA78M08S-1 J TA78M08S AE

IC5850 VHiPQ09RD08-1 J PQ09RD08 AF

IC5851 VHiPQ05RD08-1 J PQ05RD08 AF

IC7201 RH-iX3289CEZZ J IX3289CE AQ

IC7202 VHiNJM311M/-1 J NJM311M AF

IC9801 VHiM52055FP-1 J M52055FP AH

TRANSISTORS

Q480 VS2SC3928AR-1 J 2SC3928AR AB

Q523 VS2SC3928AR-1 J 2SC3928AR AB

Q524 VS2SC3928AR-1 J 2SC3928AR AB

Q525 VS2SC3928AR-1 J 2SC3928AR AB

Q901 VS2SC3928AR-1 J 2SC3928AR AB

Q902 VS2SC3928AR-1 J 2SC3928AR AB

Q904 VS2SC3928AR-1 J 2SC3928AR AB

Q905 VS2SC3928AR-1 J 2SC3928AR AB

Q906 VS2SC3928AR-1 J 2SC3928AR AB

Q1201 VS2SC3928AR-1 J 2SC3928AR AB

Q1202 VS2SC3928AR-1 J 2SC3928AR AB

Q1203 VS2SC3928AR-1 J 2SC3928AR AB

Q1204 VS2SC3928AR-1 J 2SC3928AR AB

Q1205 VS2SC3928AR-1 J 2SC3928AR AB

Q1360 VS2SC3928AR-1 J 2SC3928AR AB

Q1382 VS2SC3928AR-1 J 2SC3928AR AB

Q1800 VS2SA1530AR-1 J 2SA1530R AB

Q1801 VS2SA1530AR-1 J 2SA1530R AB

Q1802 VS2SA1530AR-1 J 2SA1530R AB

Q1803 VS2SC3928AR-1 J 2SC3928AR AB

Q1804 VS2SK30AG//2E J 2SK30AG AD

Q1805 VS2SC3928AR-1 J 2SC3928AR AB

Q1806 VS2SC3928AR-1 J 2SC3928AR AB

Q1807 VS2SC3928AR-1 J 2SC3928AR AB

Q1808 VS2SC3928AR-1 J 2SC3928AR AB

Q1809 VS2SC3928AR-1 J 2SC3928AR AB

Q1814 VS2SC3928AR-1 J 2SC3928AR AB

Q1815 VS2SA1530AR-1 J 2SA1530AR AB

Q1903 VS2SC3928AR-1 J 2SC3928AR AB

Q1940 VS2SA1530AR-1 J 2SA1530AR AB

Q1954 VS2SC3928AR-1 J 2SC3928AR AB

Q1955 VS2SC3928AR-1 J 2SC3928AR AB

Q1956 VS2SC3928AR-1 J 2SC3928AR AB

Q2501 VS2SC3928AR-1 J 2SC3928AR AB

Q3151 VS2SC3928AR-1 J 2SC3928AR AB

76

Page 60

34N-WF5H

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PWB-A: DUNTKA096DE01

SIGNAL UNIT (Continued)

Q3202 VS2SA1530AR-1 J 2SA1530AR AB

Q3203 VS2SA1530AR-1 J 2SA1530AR AB

Q3204 VS2SC3928AR-1 J 2SC3928AR AB

Q3208 VS2SA950-Y/1E J 2SA950(Y) AD

Q3211 VS2SC3928AR-1 J 2SC3928AR AB

Q3212 VS2SC3928AR-1 J 2SC3928AR AB

Q3219 VS2SA1530AR-1 J 2SA1350AR AB

Q3220 VS2SC3928AR-1 J 2SC3928AR AB

Q3221 VS2SC3928AR-1 J 2SC3928AR AB

Q3222 VS2SC3928AR-1 J 2SC3928AR AB

Q3223 VS2SC3928AR-1 J 2SC3928AR AB

Q3224 VS2SC3928AR-1 J 2SC3928AR AB

çå Q3225 VS2SC3928AR-1 J 2SC3928AR AB

Q3227 VS2SC3928AR-1 J 2SC3928AR AB

Q3228 VS2SC3928AR-1 J 2SC3928AR AB

Q3229 VS2SC3928AR-1 J 2SC3928AR AB

Q3261 VS2SA950-Y/1E J 2SA950(Y) AD

Q3262 VS2SC3928AR-1 J 2SC3928AR AB

Q3930 VSDTC314TK/-1 J DTC314TK AC

Q3931 VSDTC314TK/-1 J DTC314TK AC

Q3933 VS2SC3928AR-1 J 2SC3928AR AB

Q3934 VS2SC3928AR-1 J 2SC3928AR AB

Q5810 VS2SC3928AR-1 J 2SC3928AR AB

Q5811 VS2SC3928AR-1 J 2SC3928AR AB

Q5812 VS2SC3928AR-1 J 2SC3928AR AB

Q5850 VS2SC3928AR-1 J 2SC3928AR AB

Q5851 VS2SC3928AR-1 J 2SC3928AR AB

Q5852 VS2SC3928AR-1 J 2SC3928AR AB

Q5920 VS2SA1530AR-1 J 2SA1530AR AB

Q5960 VS2SC3928AR-1 J 2SC3928AR AB

Q5961 VS2SC3928AR-1 J 2SC3928AR AB

Q5962 VS2SC3928AR-1 J 2SC3928AR AB

Q7205 VS2SC3928AR-1 J 2SC3928AR AB

Q7206 VS2SC3928AR-1 J 2SC3928AR AB

Q7207 VS2SC3928AR-1 J 2SC3928AR AB

Q7281 VS2SC3928AR-1 J 2SC3928AR AB

Q7290 VS2SC3928AR-1 J 2SC3928AR AB

Q9801 VSRT1N441C/-1 J RT1N441C AB

Q9802 VS2SC3928AR-1 J 2SC3928AR AB

Q9803 VS2SC3928AR-1 J 2SC3928AR AB

Q9804 VS2SC3928AR-1 J 2SC3928AR AB

DIODES

D502 RH-EX1250CEZZ J Zener Diode, 6.2V AB

D503 VHDHSU119//-1 J Diode AB

D504 RH-EX1249CEZZ J Zener Diode, 6.2V AB

D505 RH-EX1249CEZZ J Zener Diode, 6.2V AB

D607 VHDHSU119//-1 J Diode AB

D608 VHDHSU119//-1 J Diode AB

D1201 VHDHSU119//-1 J Diode AB

D1202 VHDHSU119//-1 J Diode AB

D1203 VHD1SS226//-1 J Diode AB

D1204 VHD1SS226//-1 J Diode AB

D1205 VHD1SS226//-1 J Diode AB

D1206 RH-EX1249CEZZ J Zener Diode, 6.2V AB

D1207 RH-EX1249CEZZ J Zener Diode, 6.2V AB