Page 1

29F-PE550 / 29F-PD570

1st Edition

SERVICE MANUAL

COLOUR TELEVISION

Chassis No. GB-7

29F-PE550

29F-PD570 29F-PE550

29F-PD570

In the interests of user safety (Required by safety regulations in some countries) the set should be restored to its original

condition and only parts indentical to those specified should be used.

World Multi 21 System

100-CH Program Memory

AV Mode (Movie/Music/News)

CATV Hyper Band Ready

Blue/White Stretch Circuit

Picture Noise Reduction

White Temp. Select

Gamma Correction

Multi Language OSD (English / Thai)

Hotel Mode

AFT

Off Timer

Rear AV-IN 1, AV Output (Monitor Out),

and Front AV-IN 2 (Auto Select)

Headphone (Front)

Component & Audio Input Terminal

Nicam & A2 Stereo

Child Lock

Surround

Equalizer

AVL

Loundness

CONTENTS

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS.......................................

CHAPTER 2. IMPORTANT SERVICE NOTES

[1] IMPORTANT SERVICE NOTE...................

CHAPTER 3. ADJUSTMENT PRECAUTIONS

[1] ADJUSTMENT PRECAUTIONS .................

[2] ADJUSTMENT ............................................

CHAPTER 4. TROUBLE SHOOTING FLOWCHART

[1] TROUBLE SHOOTING FLOWCHART........

CHAPTER 5. SOLID STATE DEVICE BASE DIAGRAM

[1] SOLID STATE DEVICE BASE DIAGRAM...

CHAPTER 6. CHASSIS LAYOUT

[1] CHASSIS LAYOUT......................................

1-1

2-1

3-1

3-26

4-1

5-1

6-1

WARNING

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and

power receptacle, when servicing this chassis. To prevent electric shock, do not remove cover. No user serviceable parts inside. Refer servicing to qualified service personnel.

CHAPTER 7. BLOCK DIAGRAM

[1] BLOCK DIAGRAM : MAIN UNIT .................

CHAPTER 8. DESCRIPTION OF SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM

CHAPTER 9. WAVEFORM

[1] WAVEFORM...............................................

CHAPTER 10. SCHEMATIC DIAGRAM

[1] SCHEMATIC DIAGRAM : MAIN UNIT.........

[2] SCHEMATIC DIAGRAM : CRT UNIT ..........

CHAPTER 11. PRINTED WIRING BOARD ASSEMBLIES

[1] PWB-A : MAIN UNIT....................................

[2] PWB-B : CRT UNIT .....................................

Parts Guide

...

7-1

8-1

9-1

10-1

10-3

11- 1

11- 3

SHARP MANUFACTURING (THAILAND) CO.,LTD

Page 2

29F-PE550 / 29F-PD570

CHAPTER 1.

[1] SPECIFICA

SPECIFICATIONS

TIONS

SPECIFICATIONS

Convergence ............................................................................... Self Convergence System

Focus..................................................................... Bi-Potential, Uni-Potential Electrostatic

Sweep Deflection ................................................................................................... Magnetic

Intermediate Frequencies

Picture IF Carrier ................................................................................................ 38.9MHz

Sound IF Carrier

6.5MHz ............................................................................................................ 32.4MHz

6.0MHz ............................................................................................................ 32.9MHz

5.74MHz ......................................................................................................... 33.16MHz

5.5MHz ............................................................................................................ 33.4MHz

4.5MHz

Colour Sub-Carrier

PAL................................................................................................................ 34.47MHz

SECAM

NTSC .............................................................................................................. 35.32MHz

Power Input ................................................................................... 110 ~ 240V AC 50/60 Hz

Power Consumption .....................................................................................................

Audio Power Output Rating

Speaker

Size

Aerial Input Impedance

VHF/UHF ......................................................................................... 75

............................................................................................................

.............................................................................................. 34.494/34.65MHz

........................................................................ 7.5 W x 2 (Rated)

.......................................................................... 29F-PE550 : 8 cm x 12 cm (oval) x 2

29F-PD570 : 8 cm Round x 2

ohms

34.4MHz

123W

Unbalanced

Receiving Channels

PAL-B/G, SECAM-B/G

VHF ................................................................................................................ E2 thru E12

UHF .............................................................................................................. E21 thru E69

CATV ......................................................................................... X thru Z + 2, S1 thru S41

PAL-D/K, SECAM-D/K, K1

..........................................................................................

VHF

UHF .......................................................................................... 21 thru 69, C13 thru C57

PAL-I, SECAM-I

VHF .............................................................................................. (IRELAND): B thru J

UHF ............................................................................................ (U.K., H.K.): 21 thru 69

NTSC-M

........................................................................... (U.S.): 2 thru 13, (Japan): 1 thru 12

VHF

UHF ....................................................................... (U.S.): 14 thru 69, (Japan): 13 thru 62

CATV ....................................... (U.S.): A-6 thur A-1, A thru W+29 (Japan): C13 thru C63

Receiving Frequency................................................................ 44.25 MHz thru 863.25 MHz

Dimensions

............................................................................... 29F-PE550 :

29F-PD570 :

R1 thru R12, C1 thru C12

810mm

Width:

Width:

618mm

810mm

618mm

Height:

Depth: 531.5mm

Weight(approx): 42 kg

Height:

Depth: 516.5mm

Weight(approx): 41 kg

Cabinet material .................................................................................................. All Plastics

Specifications are subject to change without prior notice.

1 - 1

Page 3

CHAPTER 2. IMPORTANT SERVICE NOTES

[1] IMPORTANT SERVICE NOTE

IMPORTANT SERVICE NOTES

Maintenance and repairing of this receiver should be done by

qualified service personnel only.

SERVICE OF HIGH VOLTAGE SYSTEM AND

PICTURE TUBE

When servicing the high voltage system, remove static charge from it by

connecting a 10K ohm resistor in series with an insulated wire (such as a test

probe) between picture tube dag and 2nd anode lead. (AC line cord should

be disconnected from AC outlet.)

1. Picture tube in this receiver employs integral implosion protection.

2. Replace with the same type number of picture tube for continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing shatterproof goggles and after discharging

the high voltage completely.

29F-PE550 / 29F-PD570

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

minimum. Since certain malfunctions or servicing may produce potentially

hazardous radiation with prolonged exposure at close range, the following

precautions should be observed:

1. When repairing the circuit, please make sure do not increase the high voltage of the set

to more then 34.0kV (at beam 0 A).

2. To keep the set in a normal operation, please make sure it's function at 30.0kV 1.5kV

(at beam 1700 A). The set has been factory - adjusted to the above-mentioned high voltage.

*If there is a possibility that the high voltage fluctuates as a result of the repaires,

never forget to check for such high voltage after the work.

3. Do not substitute a picture tube with unauthorized types and/or brands which may cause

excessive X-ray radiation.

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the following safety checks.

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metal control knobs, insulating fishpapers,

cabinet backs, adjustment and compartment covers or shields, isolation resistor- capacity networks, mechanical insulators etc.

2 - 1

Page 4

29F-PE550 / 29F-PD570

ADJUSTMENT PRECAUTIONS

This model's setting are adjusted in two different ways: through the I2C bus control and in the

conventional analog manner. The adjustments via the I2C bus control include preset-only items and

variable data.

1. Setting the service mode by the microprocessor.

(1) Press and hold the local key "VOL DOWN" & "CH UP" when power on the main switch,

TV will enter into the SERVICE MODE. (The initial value of EEPROM are automatically

preset when new EEPROM is used)

(2) Press the CH DOWN / UP key on the remote controller to select the setting items

one by one.

(3) Using the VOLUME UP/ DOWN key on the remote controller, the data can be modified.

(4) When press the local key "VOL DOWN" & "CH UP" at the same time,

it will be released from the service mode.

2. Factory Presetting.

(1) Press remote controller key of code "ED" for 4 seconds, the initial values are

automatically preset.

(2) The initial data are preset as listed in page 3-4 and 3-6.

(3) Make sure whether the data need to modify or not (Initial data).

Note: Once the chassis has been assembly together and in ready condition, please make

sure it's go through initialize process (see sect 2 above)

Precaution: If haven't done this initialization, malfunction might be happen.

3-1

Page 5

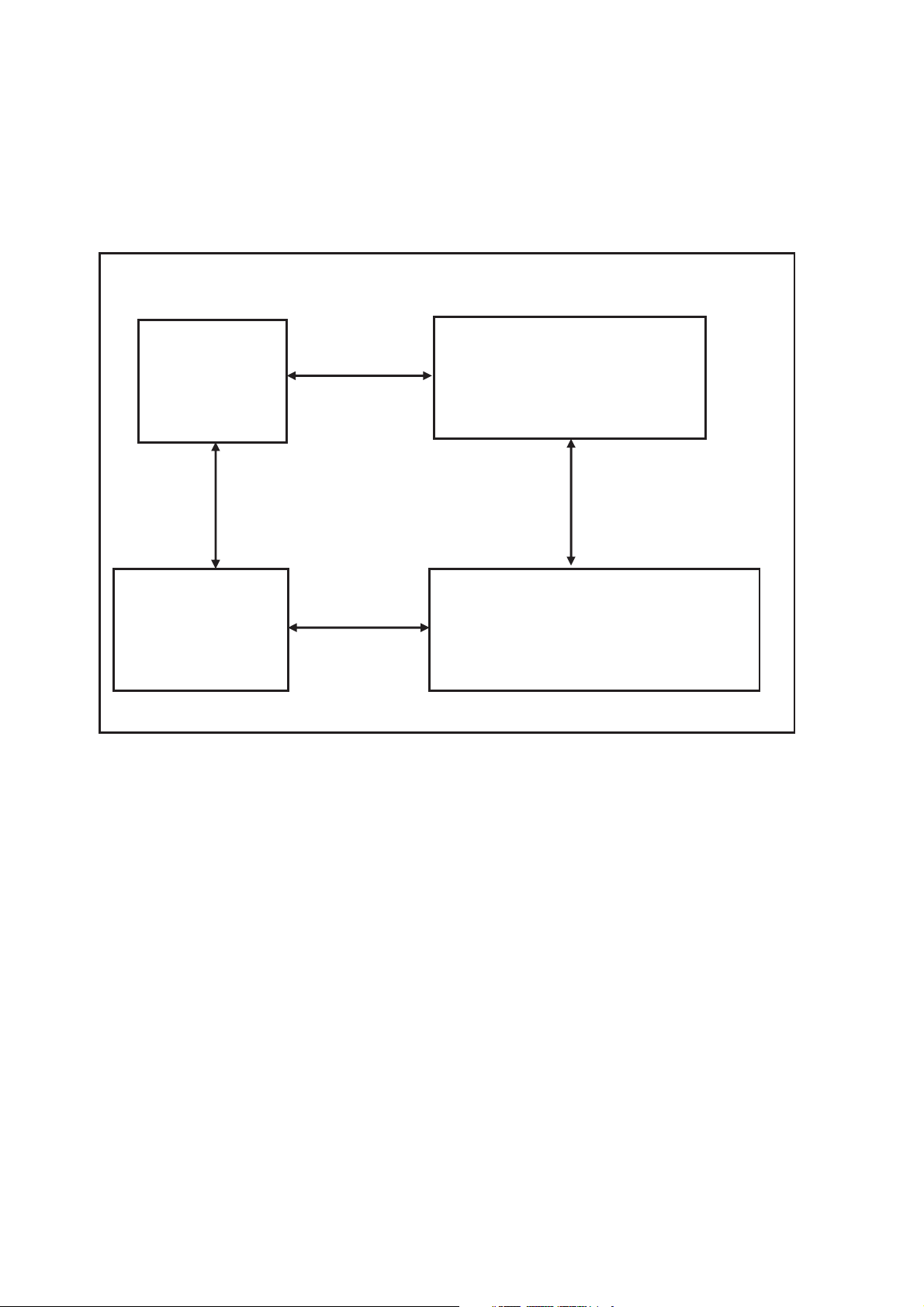

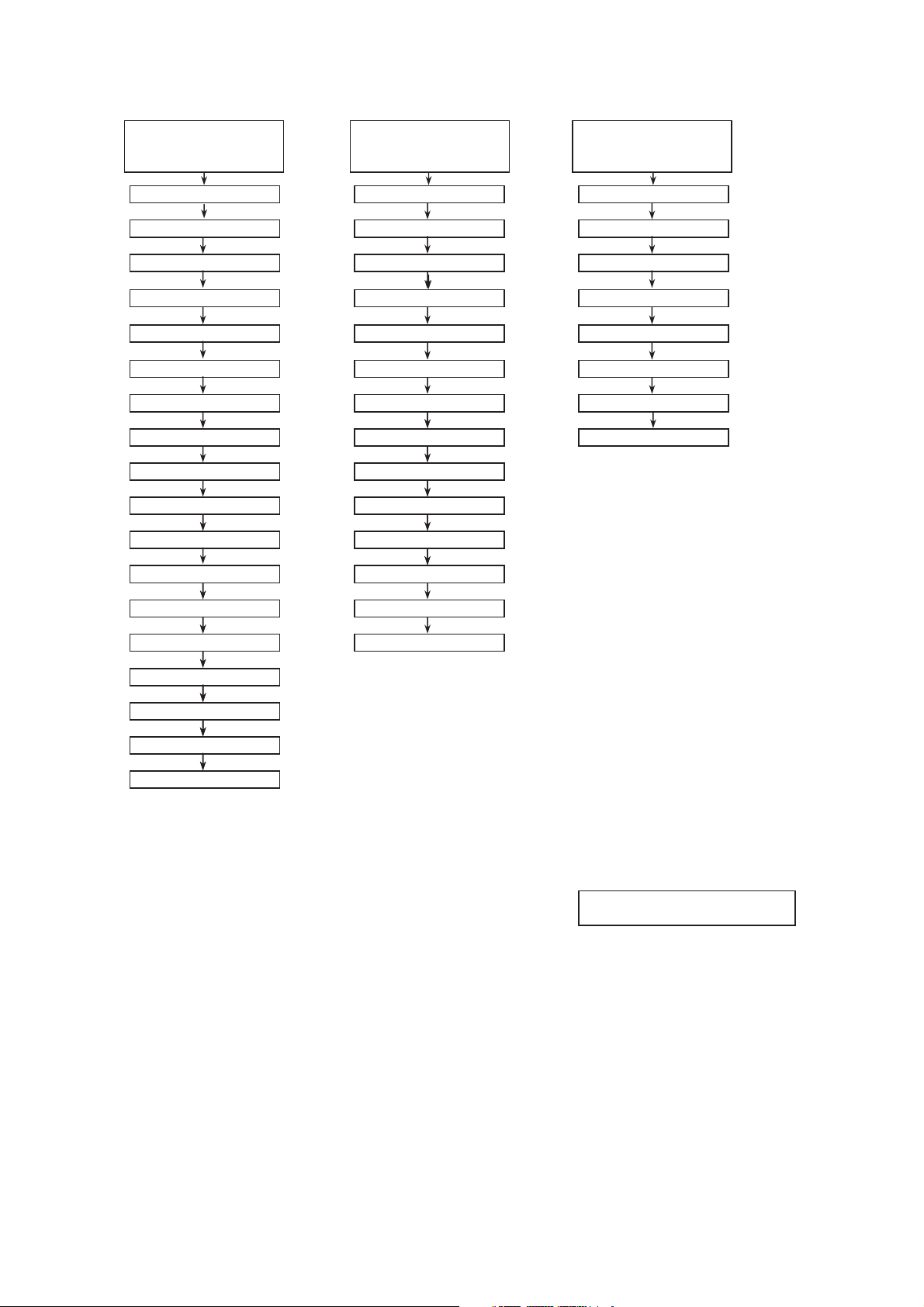

1) In the Service Mode, key is use to select the mode in the following order.

A

29F-PE550 / 29F-PD570

SUB : ISSUE OF ADJUSTMENT METHOD

WE ISSUE THE ADJUSTMENT MANUAL AS FOLLOWS.

MODEL: 29F-PE250I (

3WC9E25IL)

ADJUSTMENT MODE

RF AGC

PICTURE/SOUND

SUB ADJ

50Hz / 60Hz

GEOMETRIC ADJ

CUT OFF/

WHITE BALANCE ADJ

3-2

Page 6

ADJUSTMENT MODE ITEMS SEQUENCE

29F-PE550 / 29F-PD570

GEOMETRIC

ADJ MODE

V SLOPE

V-SHI-50

V-AMP-50

V-LIN

S-COR

H-SHI-50

EW-W-50

E/W-PAR-50

UPCOR-PAR

LOCOR-PAR

H-BOW

H-PAR CUT-GS-DVD

WHITE POINT

ADJ MODE

DRI-RS

DRI-GS

DRI-BS

CUT-RS

CUT-GS

CUT-BS

DRI-RC

DRI-RS-DVD

DRI-GS-DVD

DRI-BS-DVD

CUT-RS-DVD

PICTURE SUB ADJ

MODE

SUB-BRI

SUB-BRI-DVD

SUB-COL

SUB-CON

SUB-CON-DVD

SUB-TINT-DVD

SUB-TINT

SUB-SHARP

E/W-TRAP

V-SHI-60

V-AMP-60

H-SHI-60

EW-W-60

E/W-PAR-60

CUT-BS-DVD

DRI-RC-DVD

Notes:

FORWARD : CH UP KEY

REVERSE : CH DOWN KEY

3-3

Page 7

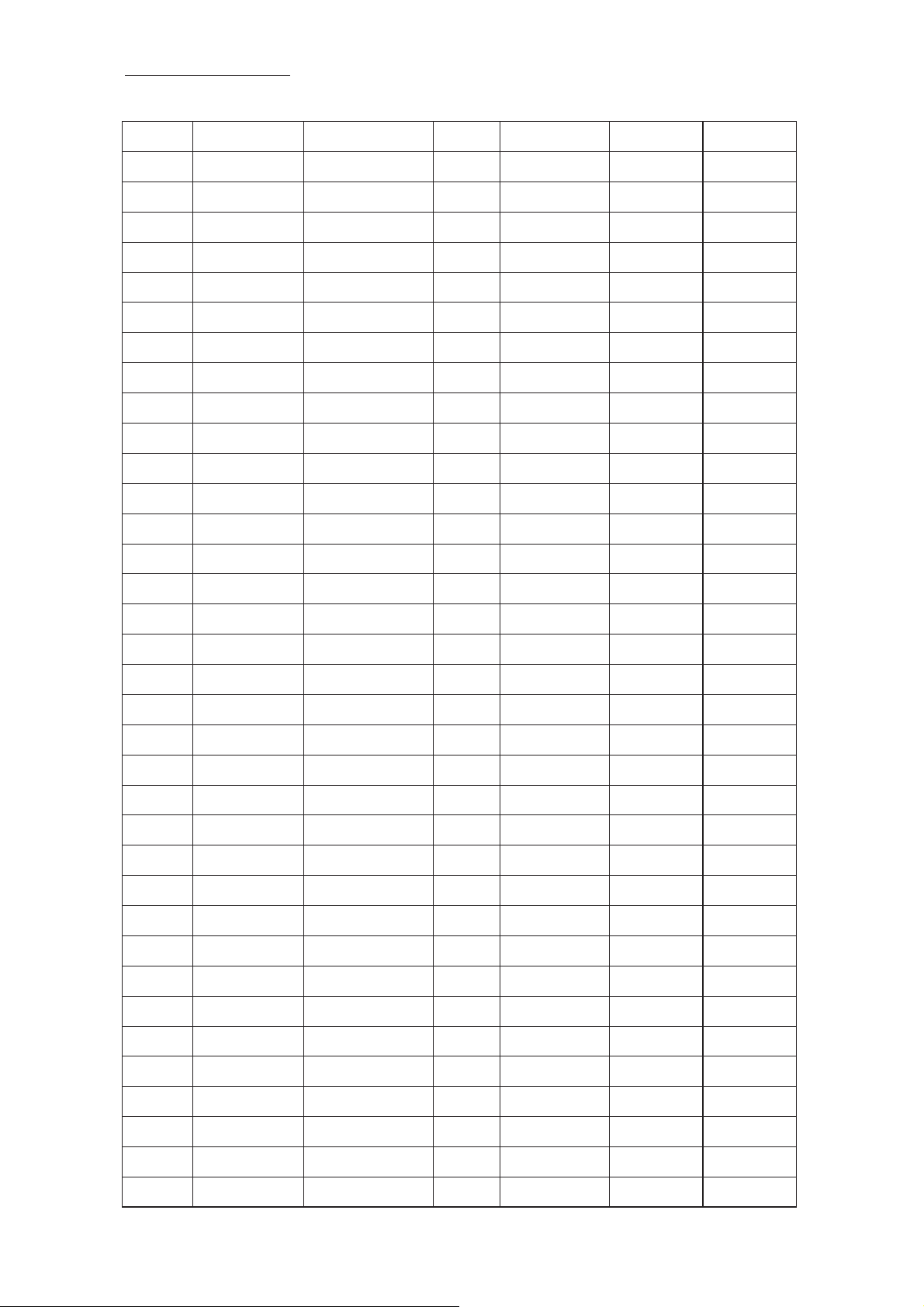

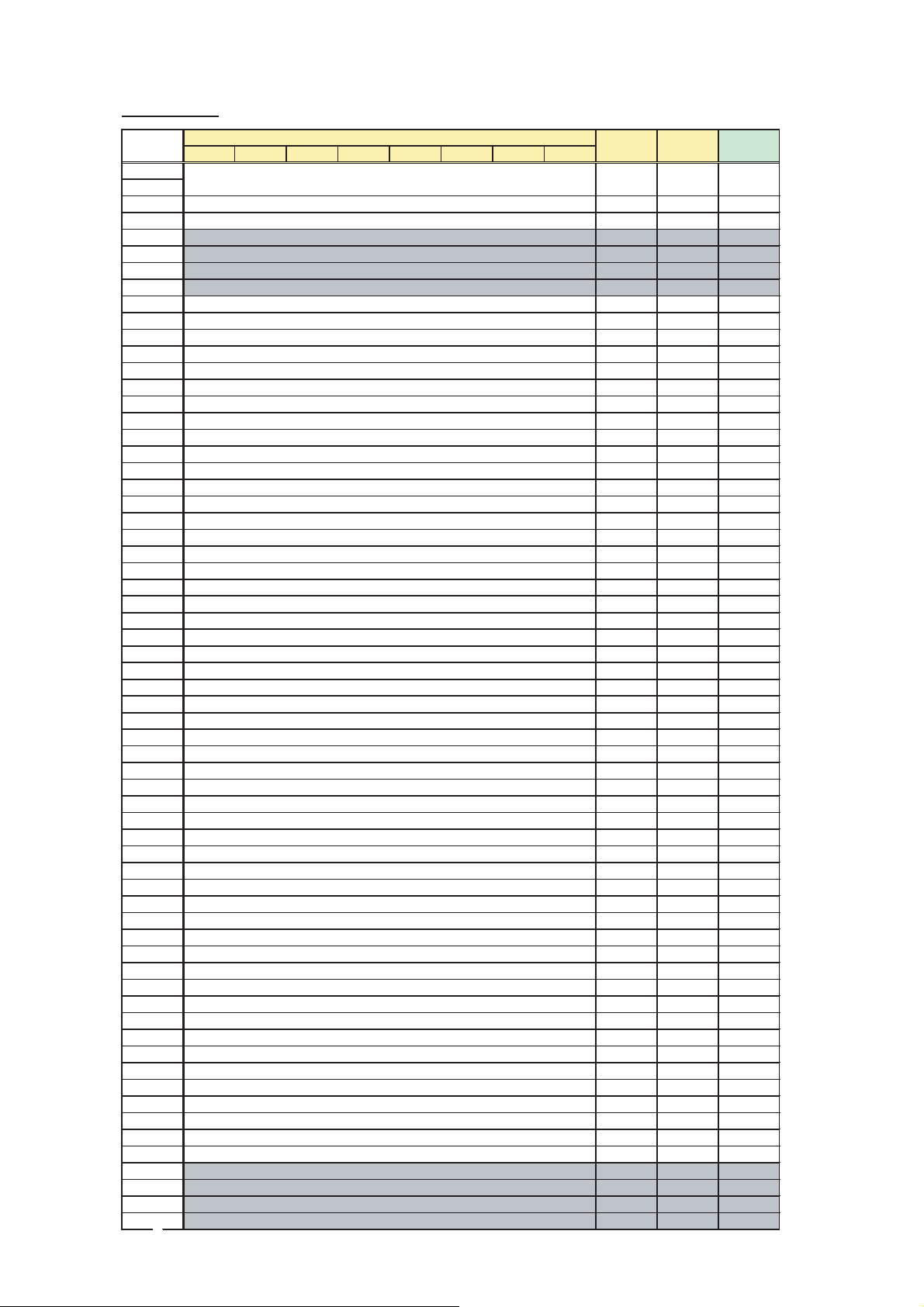

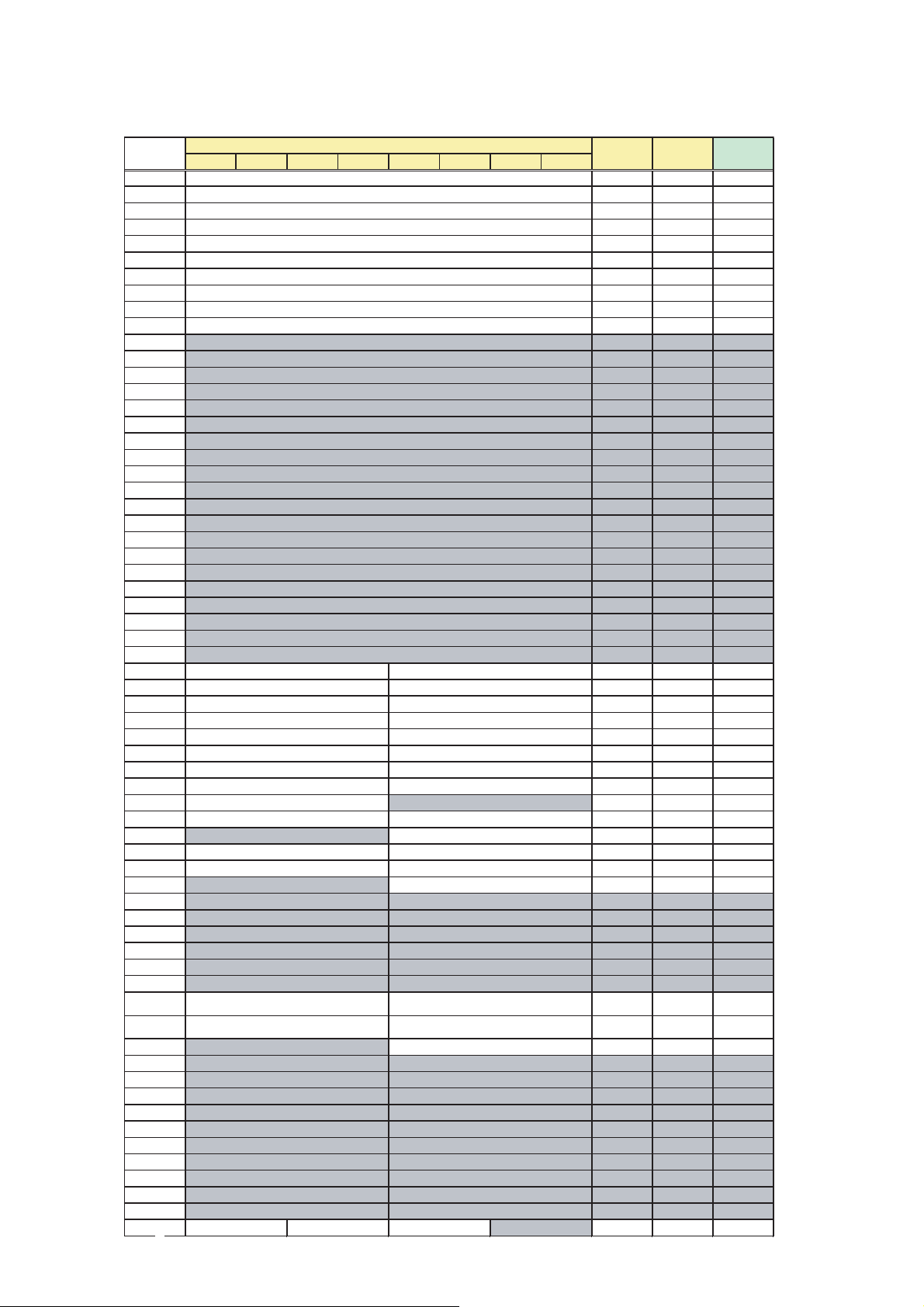

Adjustment Mode Items

㩷

ITEM EEPROM SETTING DATA RANGE

29F-PE550 / 29F-PD570

㪠㪚

OSD INITIAL DATA

SETTING DATA

01 RF-AGC 0…63 UOC-TV

02 V SLOPE 0…63 UOC-TV

03 V-SHI-50 0…63 UOC-TV

04 V-AMP-50 0…63 UOC-TV

05 H-SHI-50 0…63 UOC-TV

06 EW-W-50 0…63 UOC-TV

07 33

08 H-PAR 0…63 UOC-TV

09 H-BOW 0…63 UOC-TV H-BOW 30

10 UPCOR-PAR 0…63 UOC-TV UPCOR-PAR 38

11 LOCOR-PAR 0…63 UOC-TV LOCOR-PAR 38

12 E/W-TRAP 0…63 UOC-TV E/W-TRAP 27

13 V-LIN 0…63 UOC-TV E/W-TRAP 37

14 S-COR 0…63 UOC-TV S-COR 32

15 DRI-RSDRI-RS 0…63 UOC-TV

E/W-PAR-50 0…63 UOC-TV E/W-PAR-50

RF-AGC 23

V SLOPE 32

V-SHI-50 36

V-AMP-50 18

H-SHI-50 35

EW-W-50

H-PAR 30

29

32

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

32

ADJ

16 DRI-GS 0…63 UOC-TV DRI-GS 32

17 DRI-BS 0…63 UOC-TV DRI-BS 32

18 CUT-RS 0…63 UOC-TV CUT-RS 32

19 CUT-GS 0…63 UOC-TV CUT-GS 32

20 CUT-BS 0…63 UOC-TV CUT-BS 32 ADJ

21 SUB-BRI 0…63 UOC-TV SUB-BRI 21

22 SUB-CON 0…63 UOC-TV SUB-CON 58

23 SUB-COL 0…63 UOC-TV SUB-COL 08

24 SUB-TINT 0…63 UOC-TV SUB-TINT 32

25 SUB-SHARP 0…63 UOC-TV SUB-SHARP 32

26 DRI-RW 0…63 UOC-TV DRI-RW 32

27 DRI-GW 0…63 UOC-TV DRI-GW 32

28 DRI-BW 0…63 UOC-TV DRI-BW 32

29 CUT-RW 0…63 UOC-TV CUT-RW 32

30 CUT-GW 0…63 UOC-TV CUT-GW 32

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

32

ADJ

ADJ

ADJ

ADJ

ADJ

31 DRI-RLW 0…63 UOC-TV

32 DRI-GLW 0…63 UOC-TV DRI-GLW 32

33 DRI-BLW 0…63 UOC-TV

34 CUT-RLW 0…63 UOC-TV CUT-RLW 32

DRI-RLW 32

DRI-BLW 32

CUT-GLW 3235 CUT-GLW 0…63 UOC-TV

3-4

ADJ

ADJ

ADJ

ADJ

ADJ

Page 8

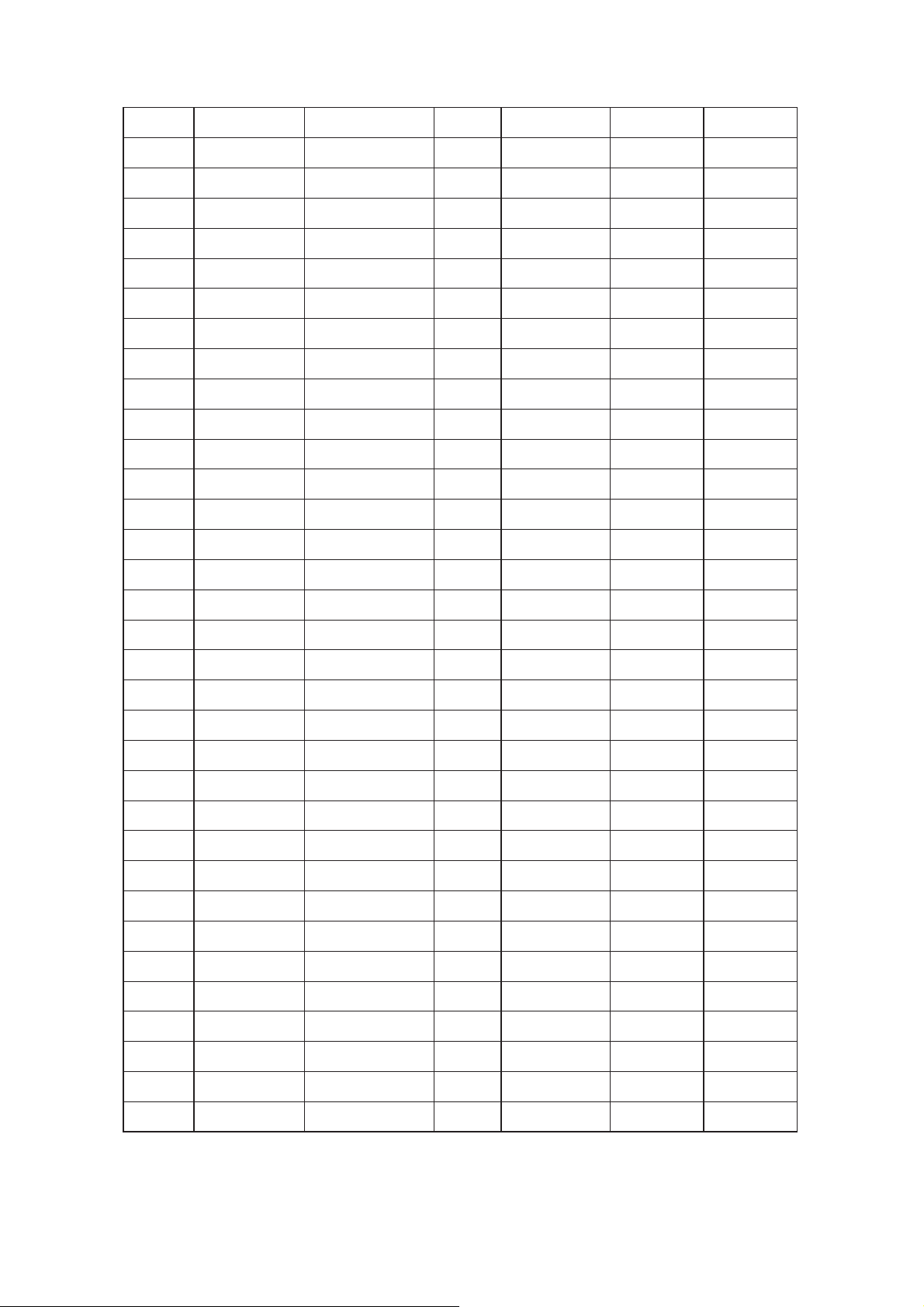

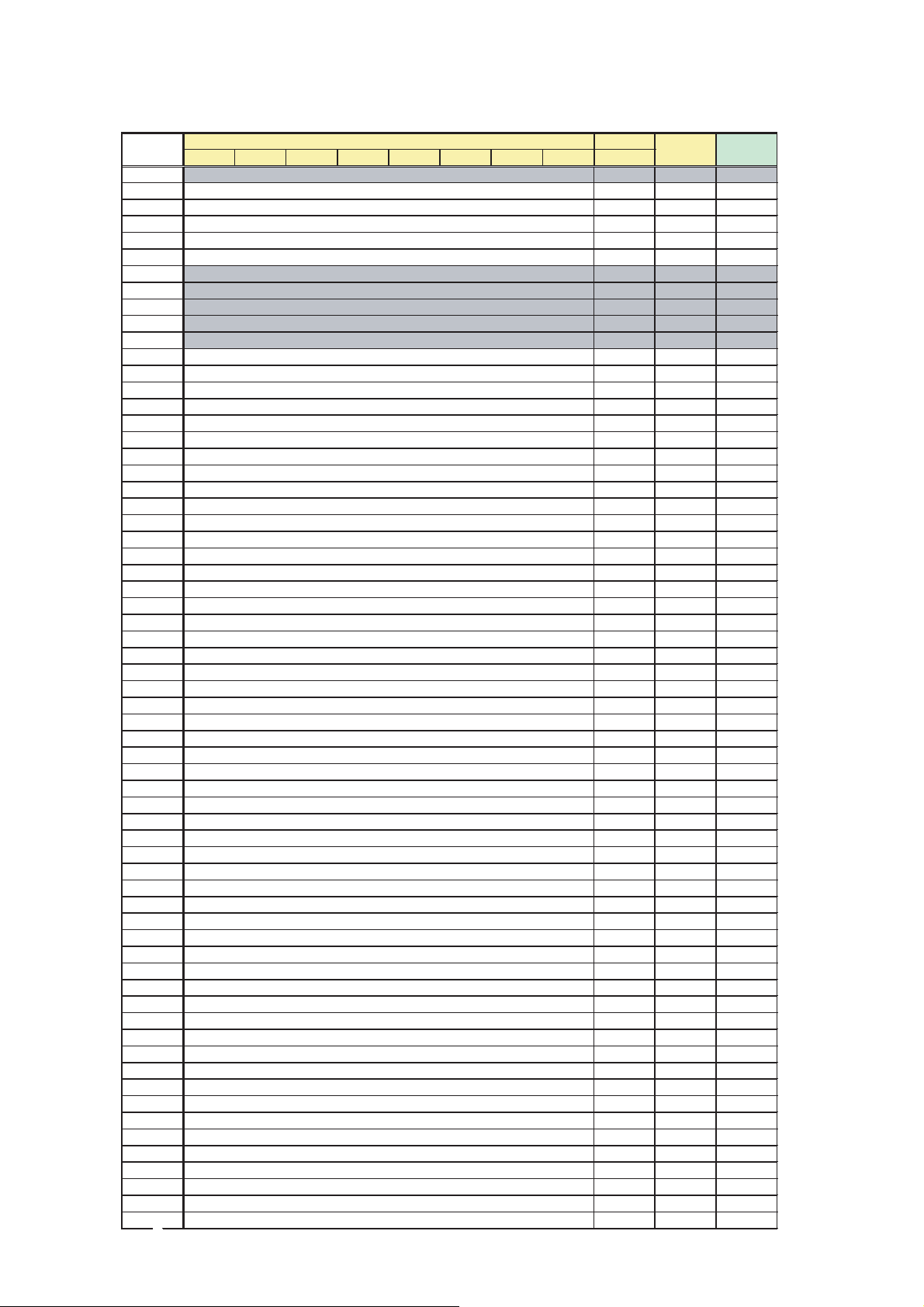

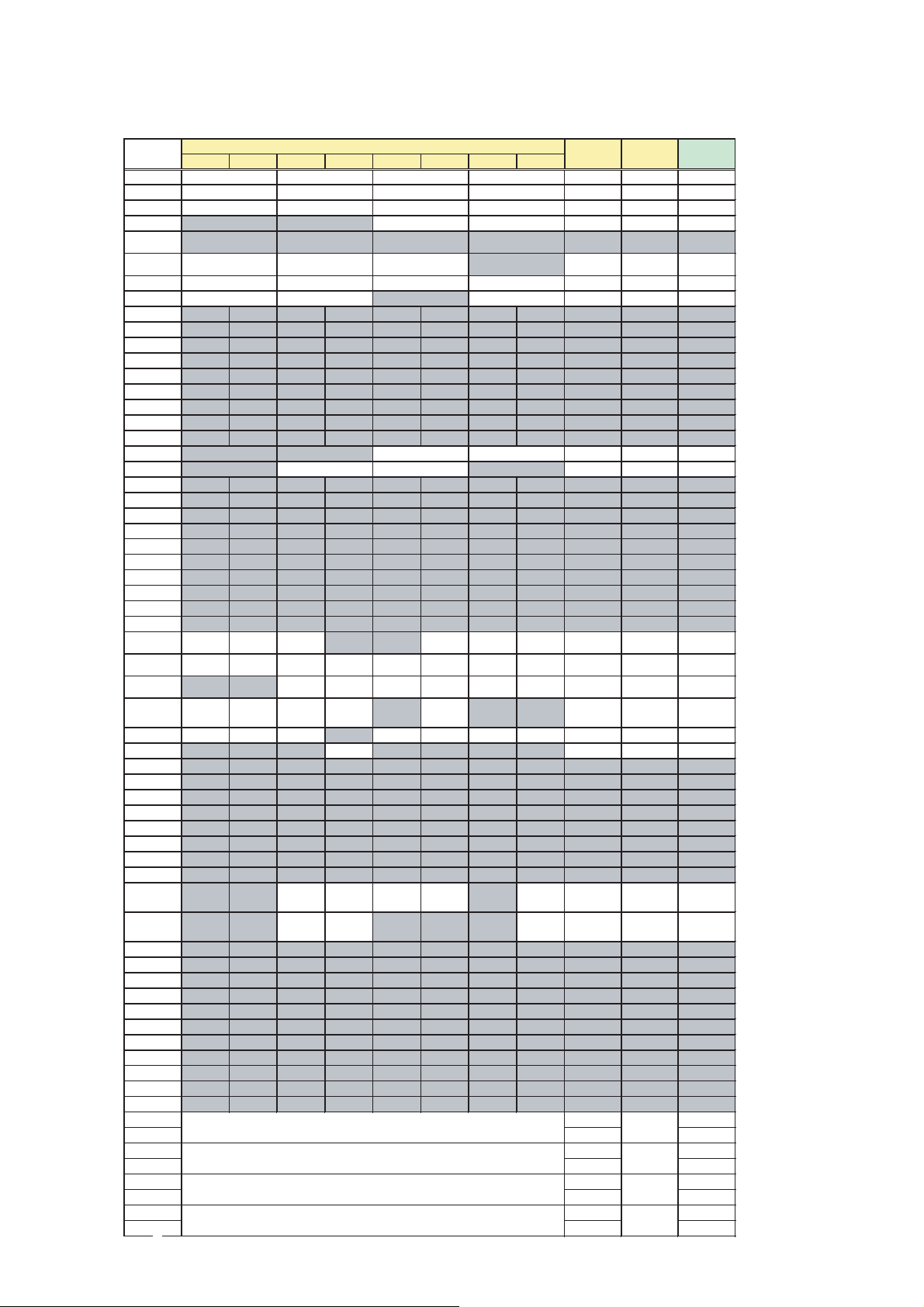

29F-PE550 / 29F-PD570

ITEM EEPROM SETTING DATA RANGE

36 DRI-RC 0…63 UOC-TV DRI-RC 32

37 DRI-GC 0…63 UOC-TV DRI-GC 32

38 DRI-BC 0…63 UOC-TV DRI-BC 32

39 CUT-RC 0…63 UOC-TV CUT-RC 32

40 CUT-GC 0…63 UOC-TV CUT-GC 32

41 DRI-RLC 0…63 UOC-TV DRI-RLC 32

42 DRI-GLC 0…63 UOC-TV

43 DRI-BLC 0…63 UOC-TV DRI-BLC 32

44 CUT-RLC 0…63 UOC-TV

45 CUT-GLC 0…63 UOC-TV CUT-GLC 32

46 DRI-RS-DVD 0…63 UOC-TV DRI-RS-DVD 32

47 DRI-GS-DVD 0…63 UOC-TV

48 DRI-BS-DVD 0…63 UOC-TV DRI-BS-DVD 32

49 CUT-RS-DVD 0…63 UOC-TV CUT-RS-DVD 32

㪠㪚

OSD

DRI-GLC 32

CUT-RLC 32

DRI-GS-DVD 32

INITIAL DATA

SETTING DATA

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

50 CUT-GS-DVD 0…63 UOC-TV CUT-GS-DVD 32

51 CUT-BS-DVD 0…63 UOC-TV CUT-BS-DVD 32 ADJ

52 SUB-BRI-DVD 0…63 UOC-TV SUB-BRI-DVD 19

53 SUB-CON-DVD 0…63 UOC-TV SUB-CON-DVD 56

54 DRI-RW-DVD 0…63 UOC-TV DRI-RW-DVD 32

55 DRI-GW-DVD 0…63 UOC-TV DRI-GW-DVD 32

56 DRI-BW-DVD 0…63 UOC-TV DRI-BW-DVD 32

57 CUT-RW-DVD 0…63 UOC-TV CUT-RW-DVD 32

58 CUT-GW-DVD 0…63 UOC-TV CUT-GW-DVD 32

59 DRI-RLW-DVD 0…63 UOC-TV

60 DRI-GLW-DVD 0…63 UOC-TV DRI-GLW-DVD 32

61 DRI-BLW-DVD 0…63 UOC-TV

62 CUT-RLW-DVD 0…63 UOC-TV CUT-RLW-DVD 32

64 DRI-RC-DVD 0…63 UOC-TV DRI-RC-DVD 32

DRI-RLW-DVD 32

DRI-BLW-DVD 32

CUT-GLW-DVD 3263 CUT-GLW-DVD 0…63 UOC-TV

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

65 DRI-GC-DVD 0…63 UOC-TV DRI-GC-DVD 32

66 DRI-BC-DVD 0…63 UOC-TV DRI-BC-DVD 32

67 CUT-RC-DVD 0…63 UOC-TV CUT-RC-DVD 32

68 CUT-GC-DVD 0…63 UOC-TV CUT-GC-DVD 32

3-5

ADJ

ADJ

ADJ

ADJ

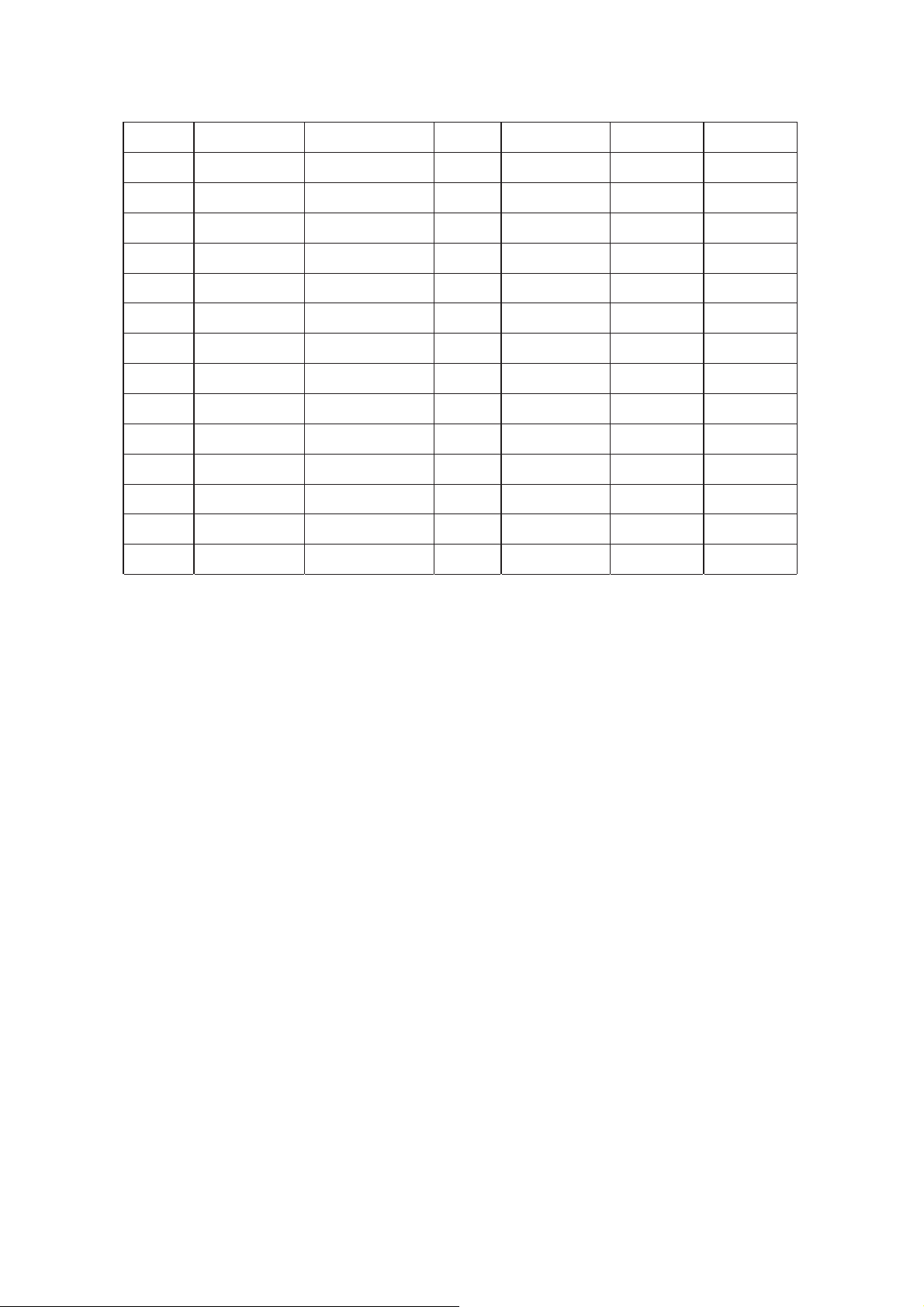

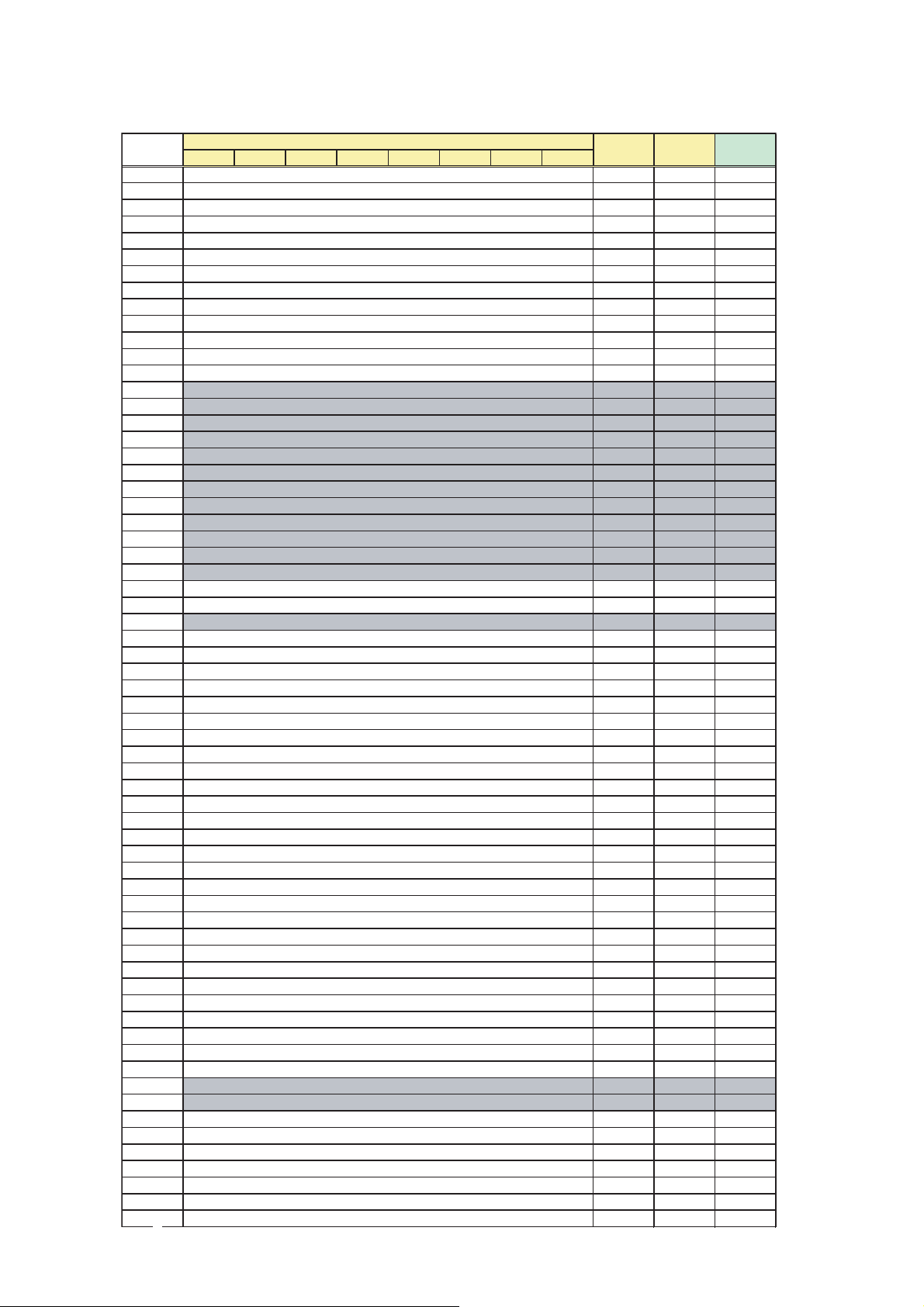

Page 9

29F-PE550 / 29F-PD570

ITEM EEPROM SETTING DATA RANGE

69 DRI-RLC-DVD 0…63 UOC-TV DRI-RLC-DVD 32

70 DRI-GLC-DVD 0…63 UOC-TV

71 DRI-BLC-DVD 0…63 UOC-TV DRI-BLC-DVD 32

72 CUT-RLC-DVD 0…63 UOC-TV

73 CUT-GLC-DVD 0…63 UOC-TV CUT-GLC-DVD 32

74 V-SHI-60 0…63 UOC-TV V-SHI-60 36

75 V-AMP-60 0…63 UOC-TV V-AMP-60 20

76 H-SHI-60 0…63 UOC-TV H-SHI-60 41

77 EW-W-60 0…63 UOC-TV EW-W-60 28

78 E/W-PAR-60 0…63 UOC-TV E/W-PAR-60 31

79 VSD 0/1 UOC-TV VSD 0

80 CUT OFF 0…63 UOC-TV CUT OFF 10

0...255 UOC-TV DCXO 5581 DCXO

82 ISP MODE 0/1 UOC-TV ISP MODE 0

㪠㪚

OSD

DRI-GLC-DVD 32

CUT-RLC-DVD 32

INITIAL DATA

SETTING DATA

ADJ

ADJ

ADJ

ADJ

ADJ

“03”-1

“04”+2

“05”+7

“06”-1

“07”+1

0

24

55

0

3-6

Page 10

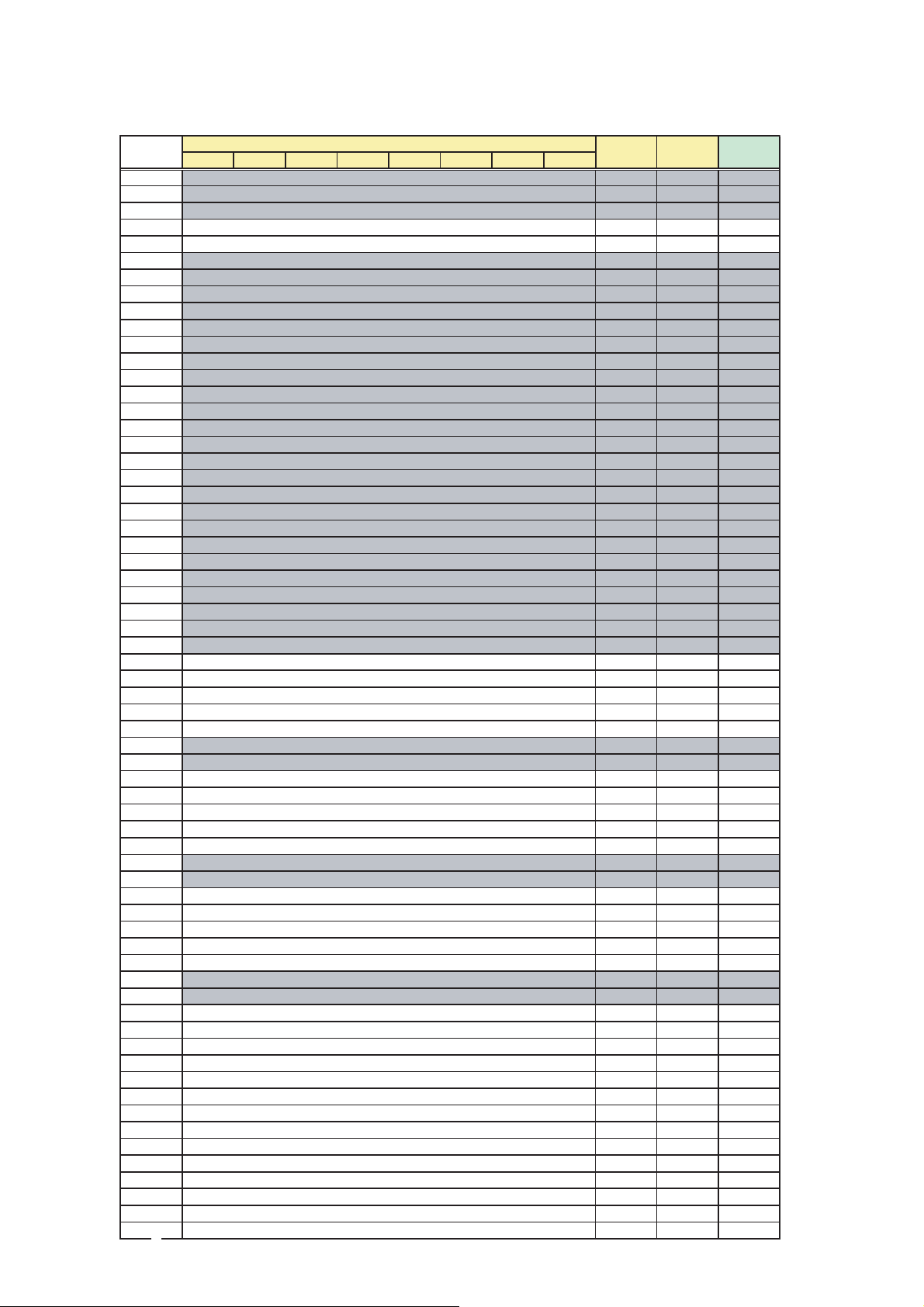

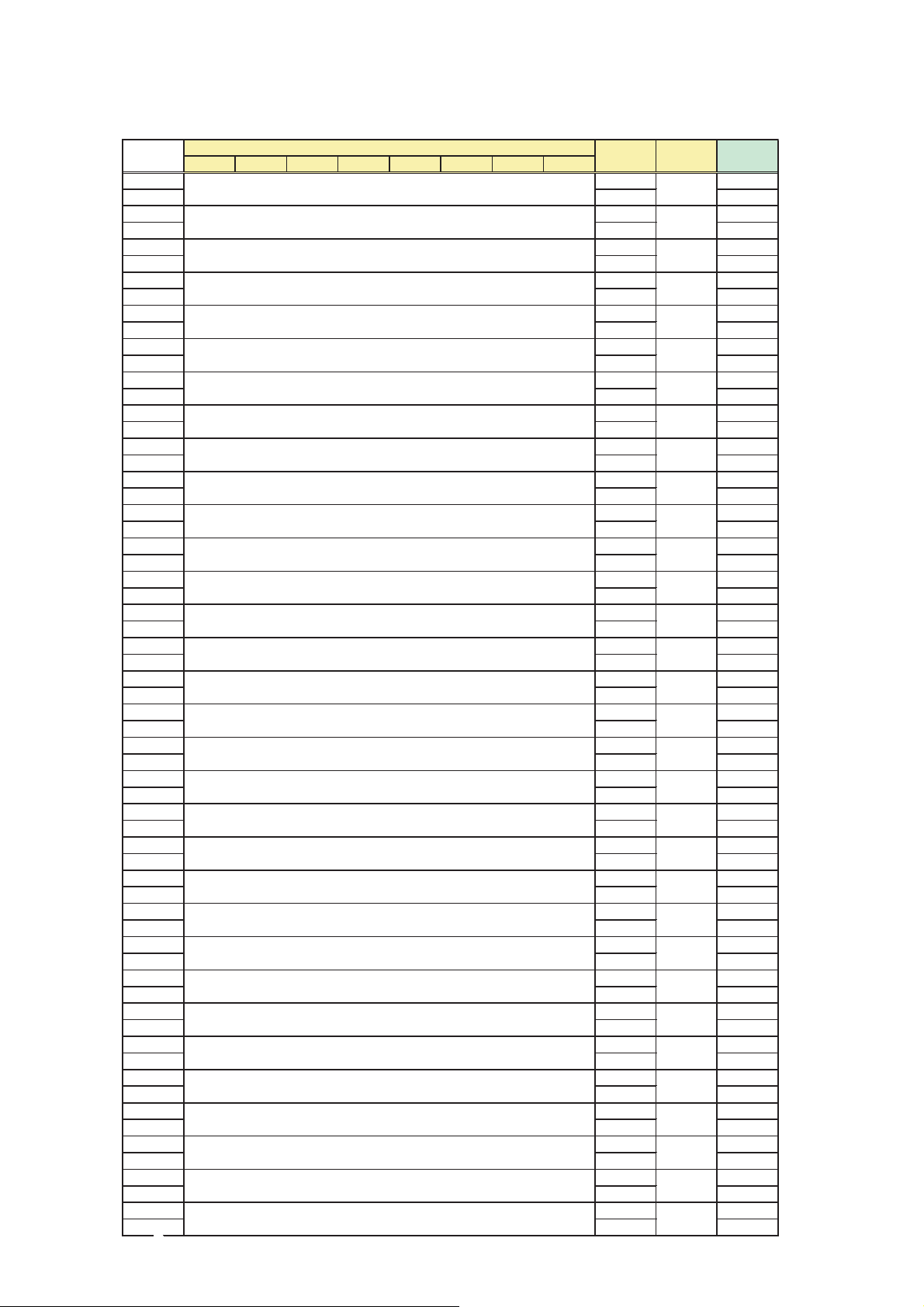

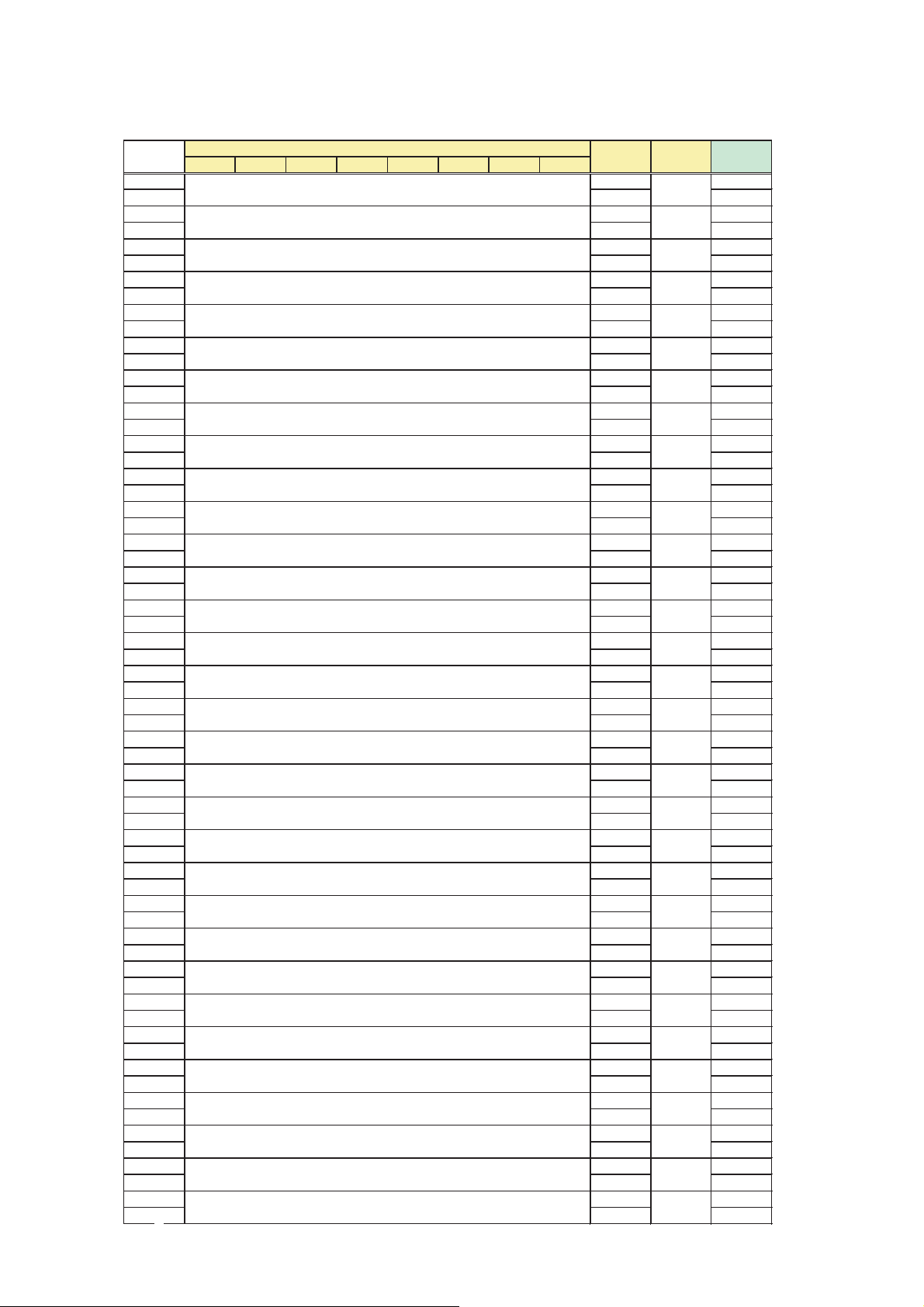

NVM MAP ITEMS

(54)

)

)

)

)

)

)

(57)

(58)

(38)

)

)

)

)

)

)

)

)

)

(36)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

(16)

(04)

)

)

)

)

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0000

0001

0002

0003

0004

0005

0006

0007

0008

0009

000A

000B

000C

000D

000E

000F

0010

0011

0012

0013

0014

0015

0016

0017

0018

0019

001A

001B

001C

001D

001E

001F

0020

0021

0022

0023

0024

0025

0026

0027

0028

0029

002A

002B

002C

002D

002E

002F

0030

0031

0032

0033

0034

0035

0036

0037

0038

0039

003A

003B

003C

003D

003E

003F

DATA

D7 D6 D5 D4 D3 D2 D1 D0

LOCKING PASSWORD

PACKAGE NUMBER (MSB)

PACKAGE NUMBER (LSB)

RF-AGC (01

V-SLOPE (02

V-SHI-50 (03

V-AMP-50

H-SHI-50 (05

EW-W-50 (06

E/W-PAR-50 (07

H-PAR (08

H-BOW (09

UPCOR-PAR (10

LOCOR-PAR (11

E/W-TRAP (12

V-LIN (13

S-COR (14

DRI-RS (15

DRI-GS

DRI-BS (17

CUT-RS (18

CUT-GS (19

SUB-BRI (21

SUB-CON (22

SUB-COL (23

SUB-TINT (24

SUB-SHARP (25

DRI-RS-DVD (46

DRI-GS-DVD (47

DRI-BS-DVD (48

CUT-RS-DVD (49

CUT-GS-DVD (50

SUB-BRI-DVD (52

SUB-CON-DVD (53

SUB-TINT-DVD

DRI-RC

DRI-GC (37

DRI-BC

CUT-RC (39

CUT-GC (40

DRI-RW (26

DRI-GW (27

DRI-BW (28

CUT-RW (29

CUT-GW (30

DRI-RC-DVD (64

DRI-GC-DVD (65

DRI-BC-DVD (66

CUT-RC-DVD (67

CUT-GC-DVD (68

DRI-RW-DVD

DRI-GW-DVD (55

DRI-BW-DVD (56

CUT-RW-DVD

CUT-GW-DVD

VER-SHI-P50

VER-AMP-P50

H0R-SHI-P50

EW-W-P50

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

0000

03 00-FF 03

11 00-FF 11

17 00-3F 17

20 00-3F 1F

24 00-3F 24

12 00-3F 14

23 00-3F 1E

1D 00-3F 1C

21 00-3F 24

1E 00-3F 1E

1E 00-3F 1E

26 00-3F 2A

26 00-3F 2C

1B 00-3F 1E

25 00-3F 1C

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 20

15 00-3F 15

3A 00-3F 3A

08 00-3F 0A

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 20

13 00-3F 13

38 00-3F 38

20 00-3F 24

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

27 00-3F 27

23 00-3F 23

1F 00-3F 1F

0B 00-3F 0B

0000-

270F

0000

3-7

Page 11

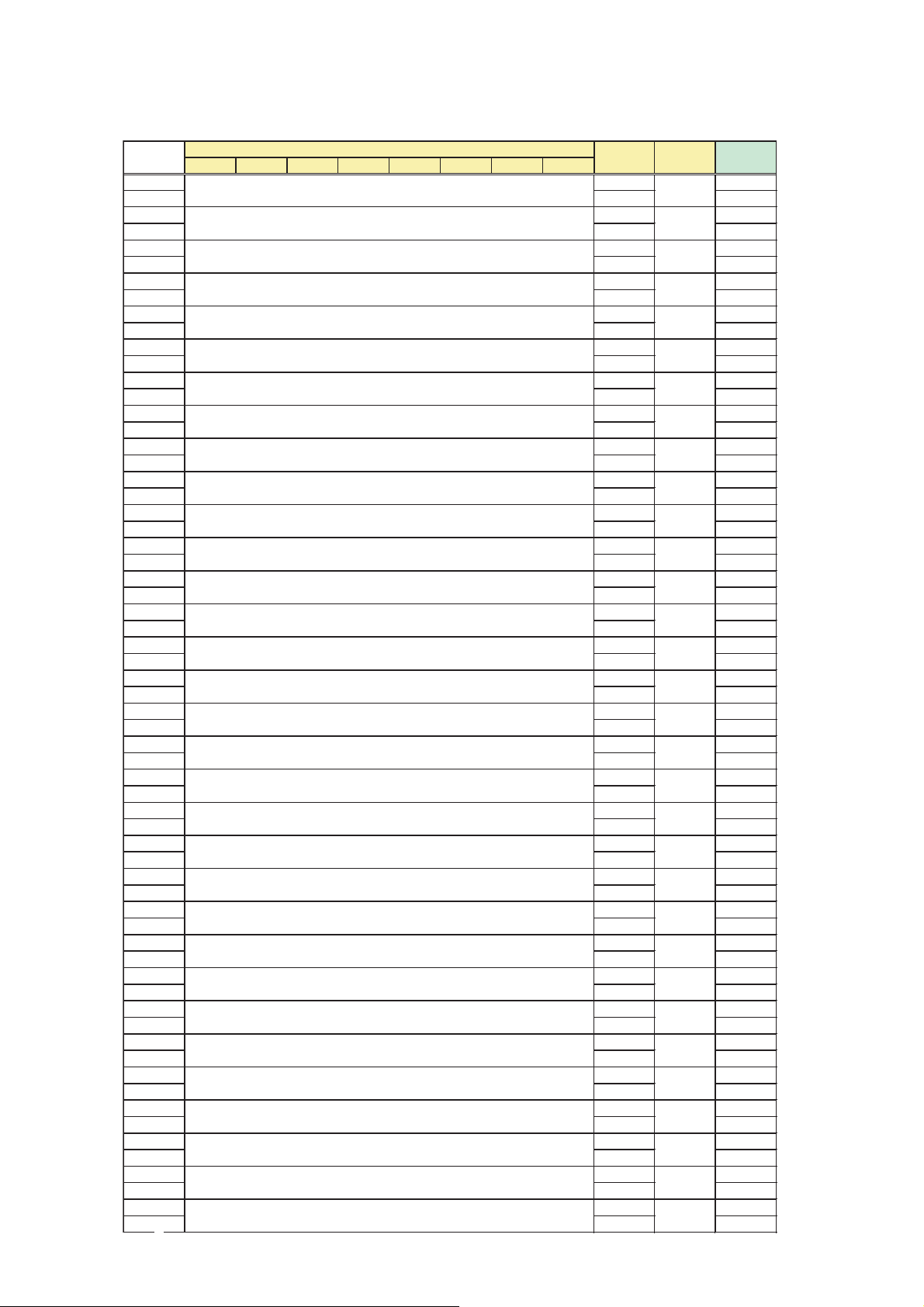

29F-PE550 / 29F-PD570

(76)

)

)

_

_

_

_

_

_OF_

_

(60)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

(74)

)

ADDRESS

(HEX)

0040

0041

0042

0043

0044

0045

0046

0047

0048

0049

004A

004B

004C

004D

004E

004F

0050

0051

0052

0053

0054

0055

0056

0057

0058

0059

005A

005B

005C

005D

005E

005F

0060

0061

0062

0063

0064

0065

0066

0067

0068

0069

006A

006B

006C

006D

006E

006F

0070

0071

0072

0073

0074

0075

0076

0077

0078

0079

007A

007B

007C

007D

007E

007F

DATA

D7 D6 D5 D4 D3 D2 D1 D0

E/W-PAR-P50

V-SHI-60

V-AMP-60 (75

H-SHI-60

EW-W-60 (77

E/W-PAR-60 (78

VER-SHI-P60

VER-AMP-P60

H0R-SHI-P60

EW-W-P60

E/W-PAR-P60

CUT OFF (80

DCXO (81

DRI-RLC (41

DRI-GLC (42

DRI-BLC (43

CUT-RLC (44

CUT-GLC (45

DRI-RLW (31

DRI-GLW (32

DRI-BLW (33

CUT-RLW (34

CUT-GLW (35

DRI-RLC-DVD (69

DRI-GLC-DVD (70

DRI-BLC-DVD (71

CUT-RLC-DVD (72

CUT-GLC-DVD (73

DRI-RLW-DVD (59

DRI-GLW-DVD

DRI-BLW-DVD (61

CUT-RLW-DVD (62

CUT-GLW-DVD (63

OF-COL-TV

OF-COL-AV

OF-COL-DVD

OF-COL-P

OF-COL-S

OF-COL-N4

OF-COL-N3

OF-SHP-TV

OF-SHP-AV

OF-SHP-DVD

OF-SHP-P

OF-SHP-S

OF-SHP-N4

OF-SHP-N3

OF-TINT-TV

OF-TINT-AV

OFFSET

COL_DVD_FIELD_FREQ_60HZ

OF-TINT-ADJ

BB-TINT

U-BASS

U-BASS

U-BASS

U-TREBLE

U-TREBLE

U-TREBLE

U-COL-MUSC

U-COL-NEWS

MUSC

NEWS

MOV

MUSC

NEWS

MOV

U-BRI-MUSC

U-BRI-NEWS

U-BRI-MOV

U-COL-MOV

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

20 00-3F 20

24 00-3F 24

14 00-3F 14

29 00-3F 29

1C 00-3F 1C

1F 00-3F 1F

24 00-3F 24

25 00-3F 25

25 00-3F 25

0A 00-3F 0A

1E 00-3F 1E

0A 00-3F 18

37 00-FF 37

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

20 00-3F 20

20 00-3F 20

20 00-3F 20

20 00-3F 0A

20 00-3F 0A

2D 00-3E 2D

2E 00-3E 2E

30 00-3E 30

28 00-3E 28

1F 00-3E 1F

1F 00-3E 1F

20 00-3E 25

21 00-3E 21

2B 00-3E 2B

2B 00-3E 2B

23 00-3E 23

1F 00-3E 1F

1F 00-3E 1F

28 00-3E 28

1F 00-3E 1A

22 00-3E 22

27 00-3E 21

1F 00-3E 22

20 00-3F 20

18 00-1F 18

18 00-1F 18

17 00-1F 17

11 00-1F 11

11 00-1F 11

10 00-1F 10

1E 00-3E 1E

1E 00-3E 1E

1E 00-3E 1E

1E 00-3E 1E

18 00-3E 18

24 00-3E 24

3-8

Page 12

29F-PE550 / 29F-PD570

_

_

_

_

_

_

_

_OF_

_

_

_

_

_

(61)

_

_

_

_

_

_

_

_

_

_

_

ADDRESS

(HEX)

0080

0081

0082

0083

0084

0085

0086

0087

0088

0089

008A

008B

008C

008D

008E

008F

0090

0091

0092

0093

0094

0095

0096

0097

0098

0099

009A

009B

009C

009D

009E

009F

00A0

00A1

00A2

00A3

00A4

00A5

00A6

00A7

00A8

00A9

00AA

00AB

00AC

00AD

00AE

00AF

00B0

00B1

00B2

00B3

00B4

00B5

00B6

00B7

00B8

00B9

00BA

00BB

00BC

00BD

00BE

00BF

DATA

D7 D6 D5 D4 D3 D2 D1 D0

U-CON-MUSC

U-CON-NEWS

U-CON-MOV

U-SHP-MUSC

U-SHP-NEWS

U-SHP-MOV

OSD-BRIGHTNESS

V-POS-OSD

H-POS-OSD

AUTO-AGC-MAX

SVM2-0-NTSC

VER-AMP-START

OFFSET

PRESET

PRESET

PRESET

PRESET

PRESET

PRESET

COL_DVD_FIELD_FREQ_50HZ

SMER

SMEL1-GAIN

SMEL1-VOL

SMEL2-GAIN

SMEL2-VOL

SMEL3-GAIN

SMEL3-VOL

SMEL4-GAIN

SMEL4-VOL

SMEL5-GAIN

SMEL5-VOL

SMEL6-GAIN

OPTION

PRESET_EQA_100_MUSC

PRESET

PRESET

PRESET

PRESET

PRESET

PRESET

PRESET

PRESET

PRESET

PRESET

PRESET

LOUDNESS_OFF_BASS_DOWN_MUSC

LOUDNESS_OFF_BASS_DOWN_NEWS

LOUDNESS_OFF_BASS_DOWN_MOV

LOUDNESS_OFF_TREBLE_DOWN_MUSC

LOUDNESS_OFF_TREBLE_DOWN_NEWS

LOUDNESS_OFF_TREBLE_DOWN_MOV

HOTEL_MAX_VOL

OPTION

SUB-VOL

EQA_100_NEWS

EQA_300_NEWS

PRESET

PRESET

PRESET

NLOERLIM

NUPERLIM

DECLEV

MONOLEV

NICLEV

SAPLEV

ADCLEV

DBEADR

DBECOEF

DUBADR

DUBCOEF

BASS-CT

TREB-CT

AVOUT_LEVEL

FSRT

HOTEL_PRG

EQA_300_MUSC

EQA_1K_MUSC

EQA_3K_MUSC

EQA_8K_MUSC

EQA_1K_NEWS

EQA_3K_NEWS

EQA_8K_NEWS

EQA_100_MOV

EQA_300_MOV

EQA_1K_MOV

EQA_3K_MOV

EQA_8K_MOV

IISLEV

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

3C 00-3C 3C

32 00-3C 32

3C 00-3C 3C

1E 00-3E 1E

18 00-3E 18

24 00-3E 24

19 00-1F 0F

30 00-3F 30

01 00-3F 05

0A 00-20 0A

05 00-07 05

19 00-3F 19

27 00-3E 24

50 00-FF 50

96 00-FF 96

31 00-3C 31

9C 00-FF 9C

2A 00-3C 2A

A3 00-FF A3

23 00-3C 23

A5 00-FF A5

1C 00-3C 1C

AA 00-FF AA

15 00-3C 15

B4 00-FF B4

05 003C 05

02 00-63 02

3A 00-3C 3A

14 00-18 14

11 00-18 11

06 00-18 06

0C 00-18 0C

14 00-18 14

0B 00-18 0B

0E 00-18 0E

11 00-18 11

0E 00-18 0E

0B 00-18 0B

15 00-18 15

10 00-18 10

12 00-18 12

0F 00-18 0F

15 00-18 15

64 00-FF 64

C8 00-FF C8

10 00-1F 10

11 00-1F 11

11 00-1F 11

10 00-1F 10

10 00-1F 10

10 00-1F 10

00 00-3F 00

00 00-FF 00

00 00-3F 00

00 00-FF 00

00 00-1F 00

00 00-1F 00

09 00-3C 09

01 00-1E 01

01 00-1E 01

01 00-1E 01

01 00-1E 01

01 00-1E 01

01 00-1E 01

3-9

Page 13

29F-PE550 / 29F-PD570

C

C

C

C

C

C

C

C

C

C

C

C

C

(

)

)

(

)

)

)

)

)

)

(20)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

_

_

_

_

_

_

_

_

_

_

_

ADDRESS

(HEX)

00C0

1

00

2

00

3

00

00C4

00C5

6

00

7

00

8

00

9

00

A

00

B

00

C

00

D

00

E

00

F

00

00D0

00D1

00D2

00D3

00D4

00D5

00D6

00D7

00D8

00D9

00DA

00DB

00DC

00DD

00DE

00DF

00E0

00E1

00E2

00E3

00E4

00E5

00E6

00E7

00E8

00E9

00EA

00EB

00EC

00ED

00EE

00EF

00F0

00F1

00F2

00F3

00F4

00F5

00F6

00F7

00F8

00F9

00FA

00FB

00FC

00FD

00FE

00FF

DATA

D7 D6 D5 D4 D3 D2 D1 D0

CUT-BS

CUT-BS-DVD (51

CONTRAST

COLOUR (MUSIC

BRIGHTNESS (MUSIC

TINT (MUSIC

SHARPNESS (MUSIC

BASS (MUSIC

TREBLE (MUSIC

CONTRAST (NEWS

COLOUR (NEWS

BRIGHTNESS (NEWS

TINT (NEWS

SHARPNESS (NEWS

BASS (NEWS

TREBLE (NEWS

CONTRAST (MOVIE

COLOUR (MOVIE

BRIGHTNESS

TINT (MOVIE

SHARPNESS (MOVIE

BASS (MOVIE

TREBLE (MOVIE

LAST PROGRAM

FAVOURITE_KEY_RED

APRV

APRV

FAVOURITE_KEY_GREEN

APRV

FAVOURITE_KEY_YELLOW

FAVOURITE_KEY_CYAN

APRV

FSND

FSND

FSND

FSND

FSND

FSND

FSND

MUSIC

MOVIE

VOLUME

BALANCE

EQA_100_MUSC

EQA_300_MUSC

EQA_1K_MUSC

EQA_3K_MUSC

EQA_8K_MUSC

EQA_100_NEWS

EQA_300_NEWS

3-10

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

20 00-3F 20

20 00-3F 20

3C 00-3C 3C

1E 00-3C 1E

1E 00-3C 1E

1E 00-3C 1E

1E 00-3C 1E

18 00-14 18

11 00-14 11

32 00-3C 32

18 00-3C 18

1E 00-3C 1E

1E 00-3C 1E

18 00-3C 18

18 00-14 18

11 00-14 11

3C 00-3C 3C

24 00-3C 24

1E 00-3C 1E

1E 00-3C 1E

24 00-3C 24

17 00-14 17

10 00-14 10

00 00-3C 3C

1E 00-3C 1E

01 00-66 0C

0A 00-66 0A

14 00-66 14

1E 00-66 1E

28 00-66 28

14 00-18 14

11 00-18 11

06 00-18 06

0C 00-18 0C

14 00-18 14

0B 00-18 0B

0E 00-18 0E

Page 14

29F-PE550 / 29F-PD570

)

_

_

_

_

_

_

_

_

ADDRESS

(HEX)

0100

0101

0102

0103

0104

0105

0106

0107

0108

0109

010A

010B

010C

010D

010E

010F

0110

0111

0112

0113

0114

0115

0116

0117

0118

0119

011A

011B

011C

011D

011E

011F

0120

0121

0122

0123

0124

0125

0126

0127

0128

0129

012A

012B

012C

012D

012E

012F

0130

0131

0132

0133

0134

0135

0136

0137

0138

0139

013A

013B

013C

013D

013E

013F

DATA

D7 D6 D5 D4 D3 D2 D1 D0

FSND_EQA_1K_NEWS

FSND_EQA_3K_NEWS

FSND_EQA_8K_NEWS

FSND_EQA_100_MOV

FSND_EQA_300_MOV

FSND_EQA_1K_MOV

FSND_EQA_3K_MOV

FSND_EQA_8K_MOV

USER_FE_PROGRAM

APRV

USER_AV_PROGRAM

APRV

YD SECAM YD PAL

YD N443

YD AV-SECAM YD AV-PAL

YD AV-N443 YD AV-N358

CL3-0 YD COMP

PW-TIME SVM2-0-PAL

WBR-50-F-C-P WBF-50-F-C-P

WBR-60-F-C-P WBF-60-F-C-P

BLOC LOUDNESS

INSOEF PWLDAC

FSND

ITEM_AVLLEVEL FSND_ITEM_AVLMODE

ITEM_VDS

FSND

WHITE TEMP (MUSIC) FZOM_ZOOM_MODE

WHITE TEMP (MOVIE) LANGUAGE

PEAKFREQPALN PEAKFREQPALM PEAKFREQPAL443 COR1-0

FSND

YD N358

LDS0-2

ITEM_MAINLONA

FSND

ITEM_CLIPMANAG

ITEM_BAMAFC

FSND

WHITET TEMP (NEWS

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

11 00-18 11

0E 00-18 0E

0B 00-18 0B

15 00-18 15

10 00-18 10

12 00-18 12

0F 00-18 0F

15 00-18 15

01 00-63 01

64 64-66 64

B5 00-FF B5

79 00-FF 79

77 00-FF 77

B5 00-FF 77

97 00-FF 97

35 00-37 35

D6 00-FF D6

D6 00-FF D6

81 00-F0 81

3E 00-5F 3E

65 00-07 05

45 00-F5 45

33 00-54 33

40 00-0F 00

26 46 26

20 41 20

02 04 02

05 00-FC 05

3-11

Page 15

29F-PE550 / 29F-PD570

LCKEY

(

)

(

)

ADDRESS

(HEX)

0140

0141

0142

0143

0144

0145

0146

0147

0148

0149

014A

014B

014C

014D

014E

014F

0150

0151

0152

0153

0154

0155

0156

0157

0158

0159

015A

015B

015C

015D

015E

015F

0160

0161

0162

0163

0164

0165

0166

0167

0168

0169

016A

016B

016C

016D

016E

016F

0170

0171

0172

0173

0174

0175

0176

0177

0178

0179

017A

017B

017C

017D

017E

017F

D7 D6 D5 D4 D3 D2 D1 D0

DATA

PEAKFREQDVD PEAKFREQSECAM

PW-LAST AUDIO-CFG PHI H-POS-FINE

PRESET_WS_NEW S PRESET_COR_NEWS PRESET_W S_MUSC PRESET_COR_MUSC

PRESET_WS_CTM PRESET_CO R_CTM PRESET_WS_MOV PRESET_COR_MOV

PRESET_SURROUND_

NEWS

RPA SOC AAS0_1

FILTBW EIAJ-DEL FILTBW-M RPO

BASSFEATURE_CTL IDMOD-SE BAMAMO OVMT HR

SURROUND (NEWS)

SURROUND (M.P. IN) SURROUND (MONO) SURROUND (STEREO) SURROUND (MOVIE)

PWL VSD (79) VIRGIN BPB2 FMI MUS PHI FORCE

DSK-NOT-

PAL-DVD

AVL_GAIN AVL

ID-PGAIN ID-BYBPF TFR

BAMASUB AVLWGT MAINLOCH NICDEEM NDETPB FMSUB-BW MPX-P-BW

AUTO

SELECT

DSK-PAL-

PRESET_SURROUND_

MUSC

SURROUND (MUSIC) DIGIT ENTRY MODE AV MODE

DSK-PAL-

DVD

M.P. IN BLUE BACK

AV

ISP MODE

(82)

PICTURE

NR (NEWS)

AEVS_ITE

M_POR

OPTION_H

LAST

POWER

PICTURE

MOVIE

PEAKFREQNTSCM PEAKFREQNTSC443

TREBLE_FREQ_SELEC

TION

BKS GAM BSD

OTEL

NRR

NR

ERR-

VERTG

LOUDNESS

_HIGH_BO

LOCK TV AVL

ERR-

SUPVOL

OST

DTR AGN DSG

LOUDNESS

BASS_FREQ_SELECTI

ON

PRESET_SURROUND_

MOV

DSK-NOT-

PAL-AV

INCL-AV

SRV-

SAVE

MODE

ERR-1-8-

SUP

PICTURE

NR

MUSIC

ERR-XRAY

TV-FREQUENCY-CH00

TV-FREQUENCY-CH01

TV-FREQUENCY-CH02

TV-FREQUENCY-CH03

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

D1 00-FF D1

6D 00AF 6D

77 00-FF 77

77 00-FF 77

02 00-00 02

31 00-BC 31

02 00-FF 02

01 00-B3 01

04 06 04

55 00-18 55

92 00-E7 92

0B 00-FF 0B

4C 00-3F 0D

0F 00-F4 0F

E0 00-EF E0

07 00-10 00

F4 00-FF F4

01 00-31 01

24

D1

24

D1

24

D1

24

D1

034D-

4399

034D-

4399

034D-

4399

034D-

4399

24

D1

2B

B1

0D

B1

0E

C9

3-12

Page 16

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0180

0181

0182

0183

0184

0185

0186

0187

0188

0189

018A

018B

018C

018D

018E

018F

0190

0191

0192

0193

0194

0195

0196

0197

0198

0199

019A

019B

019C

019D

019E

019F

01A0

01A1

01A2

01A3

01A4

01A5

01A6

01A7

01A8

01A9

01AA

01AB

01AC

01AD

01AE

01AF

01B0

01B1

01B2

01B3

01B4

01B5

01B6

01B7

01B8

01B9

01BA

01BB

01BC

01BD

01BE

01BF

DATA

D7 D6 D5 D4 D3 D2 D1 D0

TV-FREQUENCY-CH04

TV-FREQUENCY-CH05

TV-FREQUENCY-CH06

TV-FREQUENCY-CH07

TV-FREQUENCY-CH08

TV-FREQUENCY-CH09

TV-FREQUENCY-CH10

TV-FREQUENCY-CH11

TV-FREQUENCY-CH12

TV-FREQUENCY-CH13

TV-FREQUENCY-CH14

TV-FREQUENCY-CH15

TV-FREQUENCY-CH16

TV-FREQUENCY-CH17

TV-FREQUENCY-CH18

TV-FREQUENCY-CH19

TV-FREQUENCY-CH20

TV-FREQUENCY-CH21

TV-FREQUENCY-CH22

TV-FREQUENCY-CH23

TV-FREQUENCY-CH24

TV-FREQUENCY-CH25

TV-FREQUENCY-CH26

TV-FREQUENCY-CH27

TV-FREQUENCY-CH28

TV-FREQUENCY-CH29

TV-FREQUENCY-CH30

TV-FREQUENCY-CH31

TV-FREQUENCY-CH32

TV-FREQUENCY-CH33

TV-FREQUENCY-CH34

TV-FREQUENCY-CH35

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

24

D1

24

D1

24

D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24

D1

24

D1

24

D1

24

D1

24

D1

24 24

D1 D1

24

D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24

D1

24

D1

24

D1

24

D1

24

D1

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

0F

E1

10

F9

29

D1

03

C5

04

DD

0F

55

10

6D

11

85

42

D1

11

7F

11

8B

11

7D

11

8D

11

7B

11

8F

07

21

08

11

0D

61

0E

51

0F

19

3-13

Page 17

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

01C0

01C1

01C2

01C3

01C4

01C5

01C6

01C7

01C8

01C9

01CA

01CB

01CC

01CD

01CE

01CF

01D0

01D1

01D2

01D3

01D4

01D5

01D6

01D7

01D8

01D9

01DA

01DB

01DC

01DD

01DE

01DF

01E0

01E1

01E2

01E3

01E4

01E5

01E6

01E7

01E8

01E9

01EA

01EB

01EC

01ED

01EE

01EF

01F0

01F1

01F2

01F3

01F4

01F5

01F6

01F7

01F8

01F9

01FA

01FB

01FC

01FD

01FE

01FF

DATA

D7 D6 D5 D4 D3 D2 D1 D0

TV-FREQUENCY-CH36

TV-FREQUENCY-CH37

TV-FREQUENCY-CH38

TV-FREQUENCY-CH39

TV-FREQUENCY-CH40

TV-FREQUENCY-CH41

TV-FREQUENCY-CH42

TV-FREQUENCY-CH43

TV-FREQUENCY-CH44

TV-FREQUENCY-CH45

TV-FREQUENCY-CH46

TV-FREQUENCY-CH47

TV-FREQUENCY-CH48

TV-FREQUENCY-CH49

TV-FREQUENCY-CH50

TV-FREQUENCY-CH51

TV-FREQUENCY-CH52

TV-FREQUENCY-CH53

TV-FREQUENCY-CH54

TV-FREQUENCY-CH55

TV-FREQUENCY-CH56

TV-FREQUENCY-CH57

TV-FREQUENCY-CH58

TV-FREQUENCY-CH59

TV-FREQUENCY-CH60

TV-FREQUENCY-CH61

TV-FREQUENCY-CH62

TV-FREQUENCY-CH63

TV-FREQUENCY-CH64

TV-FREQUENCY-CH65

TV-FREQUENCY-CH66

TV-FREQUENCY-CH67

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

24

D1

24

D1

24

D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

10

09

10

F9

30

89

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

24

D1

3-14

Page 18

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0200

0201

0202

0203

0204

0205

0206

0207

0208

0209

020A

020B

020C

020D

020E

020F

0210

0211

0212

0213

0214

0215

0216

0217

0218

0219

021A

021B

021C

021D

021E

021F

0220

0221

0222

0223

0224

0225

0226

0227

0228

0229

022A

022B

022C

022D

022E

022F

0230

0231

0232

0233

0234

0235

0236

0237

0238

0239

023A

023B

023C

023D

023E

023F

DATA

D7 D6 D5 D4 D3 D2 D1 D0

TV-FREQUENCY-CH68

TV-FREQUENCY-CH69

TV-FREQUENCY-CH70

TV-FREQUENCY-CH71

TV-FREQUENCY-CH72

TV-FREQUENCY-CH73

TV-FREQUENCY-CH74

TV-FREQUENCY-CH75

TV-FREQUENCY-CH76

TV-FREQUENCY-CH77

TV-FREQUENCY-CH78

TV-FREQUENCY-CH79

TV-FREQUENCY-CH80

TV-FREQUENCY-CH81

TV-FREQUENCY-CH82

TV-FREQUENCY-CH83

TV-FREQUENCY-CH84

TV-FREQUENCY-CH85

TV-FREQUENCY-CH86

TV-FREQUENCY-CH87

TV-FREQUENCY-CH88

TV-FREQUENCY-CH89

TV-FREQUENCY-CH90

TV-FREQUENCY-CH91

TV-FREQUENCY-CH92

TV-FREQUENCY-CH93

TV-FREQUENCY-CH94

TV-FREQUENCY-CH95

TV-FREQUENCY-CH96

TV-FREQUENCY-CH97

TV-FREQUENCY-CH98

TV-FREQUENCY-CH99

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

24 24

D1 D1

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

034D-

4399

3-15

Page 19

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0240

0241

0242

0243

0244

0245

0246

0247

0248

0249

024A

024B

024C

024D

024E

024F

0250

0251

0252

0253

0254

0255

0256

0257

0258

0259

025A

025B

025C

025D

025E

025F

0260

0261

0262

0263

0264

0265

0266

0267

0268

0269

026A

026B

026C

026D

026E

026F

0270

0271

0272

0273

0274

0275

0276

0277

0278

0279

027A

027B

027C

027D

027E

027F

DATA

D7 D6 D5 D4 D3 D2 D1 D0

COLOUR SYSTEM-CH01

COLOUR SYSTEM-CH00

COLOUR SYSTEM-CH03

COLOUR SYSTEM-CH02

COLOUR SYSTEM-CH05

COLOUR SYSTEM-CH04

COLOUR SYSTEM-CH07

COLOUR SYSTEM-CH06

COLOUR SYSTEM-CH09

COLOUR SYSTEM-CH08

COLOUR SYSTEM-CH11

COLOUR SYSTEM-CH10

COLOUR SYSTEM-CH13

COLOUR SYSTEM-CH12

COLOUR SYSTEM-CH15

COLOUR SYSTEM-CH14

COLOUR SYSTEM-CH17

COLOUR SYSTEM-CH16

COLOUR SYSTEM-CH19

COLOUR SYSTEM-CH18

COLOUR SYSTEM-CH21

COLOUR SYSTEM-CH20

COLOUR SYSTEM-CH23

COLOUR SYSTEM-CH22

COLOUR SYSTEM-CH25

COLOUR SYSTEM-CH24

COLOUR SYSTEM-CH27

COLOUR SYSTEM-CH26

COLOUR SYSTEM-CH29

COLOUR SYSTEM-CH28

COLOUR SYSTEM-CH31

COLOUR SYSTEM-CH30

COLOUR SYSTEM-CH33

COLOUR SYSTEM-CH32

COLOUR SYSTEM-CH35

COLOUR SYSTEM-CH34

COLOUR SYSTEM-CH37

COLOUR SYSTEM-CH36

COLOUR SYSTEM-CH39

COLOUR SYSTEM-CH38

COLOUR SYSTEM-CH41

COLOUR SYSTEM-CH40

COLOUR SYSTEM-CH43

COLOUR SYSTEM-CH42

COLOUR SYSTEM-CH45

COLOUR SYSTEM-CH44

COLOUR SYSTEM-CH47

COLOUR SYSTEM-CH46

COLOUR SYSTEM-CH49

COLOUR SYSTEM-CH48

COLOUR SYSTEM-CH51

COLOUR SYSTEM-CH50

COLOUR SYSTEM-CH53

COLOUR SYSTEM-CH52

COLOUR SYSTEM-CH55

COLOUR SYSTEM-CH54

COLOUR SYSTEM-CH57

COLOUR SYSTEM-CH56

COLOUR SYSTEM-CH59

COLOUR SYSTEM-CH58

COLOUR SYSTEM-CH61

COLOUR SYSTEM-CH60

COLOUR SYSTEM-CH63

COLOUR SYSTEM-CH62

3-16

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

Page 20

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0280

0281

0282

0283

0284

0285

0286

0287

0288

0289

028A

028B

028C

028D

028E

028F

0290

0291

0292

0293

0294

0295

0296

0297

0298

0299

029A

029B

029C

029D

029E

029F

02A0

02A1

02A2

02A3

02A4

02A5

02A6

02A7

02A8

02A9

02AA

02AB

02AC

02AD

02AE

02AF

02B0

02B1

02B2

02B3

02B4

02B5

02B6

02B7

02B8

02B9

02BA

02BB

02BC

02BD

02BE

02BF

DATA

D7 D6 D5 D4 D3 D2 D1 D0

COLOUR SYSTEM-CH65

COLOUR SYSTEM-CH64

COLOUR SYSTEM-CH67

COLOUR SYSTEM-CH66

COLOUR SYSTEM-CH69

COLOUR SYSTEM-CH68

COLOUR SYSTEM-CH71

COLOUR SYSTEM-CH70

COLOUR SYSTEM-CH73

COLOUR SYSTEM-CH72

COLOUR SYSTEM-CH75

COLOUR SYSTEM-CH74

COLOUR SYSTEM-CH77

COLOUR SYSTEM-CH76

COLOUR SYSTEM-CH79

COLOUR SYSTEM-CH78

COLOUR SYSTEM-CH81

COLOUR SYSTEM-CH80

COLOUR SYSTEM-CH83

COLOUR SYSTEM-CH82

COLOUR SYSTEM-CH85

COLOUR SYSTEM-CH84

COLOUR SYSTEM-CH87

COLOUR SYSTEM-CH86

COLOUR SYSTEM-CH89

COLOUR SYSTEM-CH88

COLOUR SYSTEM-CH91

COLOUR SYSTEM-CH90

COLOUR SYSTEM-CH93

COLOUR SYSTEM-CH92

COLOUR SYSTEM-CH95

COLOUR SYSTEM-CH94

COLOUR SYSTEM-CH97

COLOUR SYSTEM-CH96

COLOUR SYSTEM-CH99

COLOUR SYSTEM-CH98

SOUND SYSTEM-CH01

SOUND SYSTEM-CH00

SOUND SYSTEM-CH03

SOUND SYSTEM-CH02

SOUND SYSTEM-CH05

SOUND SYSTEM-CH04

SOUND SYSTEM-CH07

SOUND SYSTEM-CH06

SOUND SYSTEM-CH09

SOUND SYSTEM-CH08

SOUND SYSTEM-CH11

SOUND SYSTEM-CH10

SOUND SYSTEM-CH13

SOUND SYSTEM-CH12

SOUND SYSTEM-CH15

SOUND SYSTEM-CH14

SOUND SYSTEM-CH17

SOUND SYSTEM-CH16

SOUND SYSTEM-CH19

SOUND SYSTEM-CH18

SOUND SYSTEM-CH21

SOUND SYSTEM-CH20

SOUND SYSTEM-CH23

SOUND SYSTEM-CH22

SOUND SYSTEM-CH25

SOUND SYSTEM-CH24

SOUND SYSTEM-CH27

SOUND SYSTEM-CH26

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

19 04-19 19

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

3-17

Page 21

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

02C0

02C1

02C2

02C3

02C4

02C5

02C6

02C7

02C8

02C9

02CA

02CB

02CC

02CD

02CE

02CF

02D0

02D1

02D2

02D3

02D4

02D5

02D6

02D7

02D8

02D9

02DA

02DB

02DC

02DD

02DE

02DF

02E0

02E1

02E2

02E3

02E4

02E5

02E6

02E7

02E8

02E9

02EA

02EB

02EC

02ED

02EE

02EF

02F0

02F1

02F2

02F3

02F4

02F5

02F6

02F7

02F8

02F9

02FA

02FB

02FC

02FD

02FE

02FF

DATA

D7 D6 D5 D4 D3 D2 D1 D0

SOUND SYSTEM-CH29

SOUND SYSTEM-CH28

SOUND SYSTEM-CH31

SOUND SYSTEM-CH30

SOUND SYSTEM-CH33

SOUND SYSTEM-CH32

SOUND SYSTEM-CH35

SOUND SYSTEM-CH34

SOUND SYSTEM-CH37

SOUND SYSTEM-CH36

SOUND SYSTEM-CH39

SOUND SYSTEM-CH38

SOUND SYSTEM-CH41

SOUND SYSTEM-CH40

SOUND SYSTEM-CH43

SOUND SYSTEM-CH42

SOUND SYSTEM-CH45

SOUND SYSTEM-CH44

SOUND SYSTEM-CH47

SOUND SYSTEM-CH46

SOUND SYSTEM-CH49

SOUND SYSTEM-CH48

SOUND SYSTEM-CH51

SOUND SYSTEM-CH50

SOUND SYSTEM-CH53

SOUND SYSTEM-CH52

SOUND SYSTEM-CH55

SOUND SYSTEM-CH54

SOUND SYSTEM-CH57

SOUND SYSTEM-CH56

SOUND SYSTEM-CH59

SOUND SYSTEM-CH58

SOUND SYSTEM-CH61

SOUND SYSTEM-CH60

SOUND SYSTEM-CH63

SOUND SYSTEM-CH62

SOUND SYSTEM-CH65

SOUND SYSTEM-CH64

SOUND SYSTEM-CH67

SOUND SYSTEM-CH66

SOUND SYSTEM-CH69

SOUND SYSTEM-CH68

SOUND SYSTEM-CH71

SOUND SYSTEM-CH70

SOUND SYSTEM-CH73

SOUND SYSTEM-CH72

SOUND SYSTEM-CH75

SOUND SYSTEM-CH74

SOUND SYSTEM-CH77

SOUND SYSTEM-CH76

SOUND SYSTEM-CH79

SOUND SYSTEM-CH78

SOUND SYSTEM-CH81

SOUND SYSTEM-CH80

SOUND SYSTEM-CH83

SOUND SYSTEM-CH82

SOUND SYSTEM-CH85

SOUND SYSTEM-CH84

SOUND SYSTEM-CH87

SOUND SYSTEM-CH86

SOUND SYSTEM-CH89

SOUND SYSTEM-CH88

SOUND SYSTEM-CH91

SOUND SYSTEM-CH90

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00

00

03

00

03

03

03

03

03

03

00

03

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

3-18

Page 22

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0300

0301

0302

0303

0304

0305

0306

0307

0308

0309

030A

030B

030C

030D

030E

030F

0310

0311

0312

0313

0314

0315

0316

0317

0318

0319

031A

031B

031C

031D

031E

031F

0320

0321

0322

0323

0324

0325

0326

0327

0328

0329

032A

032B

032C

032D

032E

032F

0330

0331

0332

0333

0334

0335

0336

0337

0338

0339

033A

033B

033C

033D

033E

033F

DATA

D7 D6 D5 D4 D3 D2 D1 D0

SOUND SYSTEM-CH93

SOUND SYSTEM-CH92

SOUND SYSTEM-CH95

SOUND SYSTEM-CH94

SOUND SYSTEM-CH97

SOUND SYSTEM-CH96

SOUND SYSTEM-CH99

SOUND SYSTEM-CH98

MPX-CH01

MPX-CH00

MPX-CH03

MPX-CH02

MPX-CH05

MPX-CH04

MPX-CH07

MPX-CH06

MPX-CH09

MPX-CH08

MPX-CH11

MPX-CH10

MPX-CH13

MPX-CH12

MPX-CH15

MPX-CH14

MPX-CH17

MPX-CH16

MPX-CH19

MPX-CH18

MPX-CH21

MPX-CH20

MPX-CH23

MPX-CH22

MPX-CH25

MPX-CH24

MPX-CH27

MPX-CH26

MPX-CH29

MPX-CH28

MPX-CH31

MPX-CH30

MPX-CH33

MPX-CH32

MPX-CH35

MPX-CH34

MPX-CH37

MPX-CH36

MPX-CH39

MPX-CH38

MPX-CH41

MPX-CH40

MPX-CH43

MPX-CH42

MPX-CH45

MPX-CH44

MPX-CH47

MPX-CH46

MPX-CH49

MPX-CH48

MPX-CH51

MPX-CH50

MPX-CH53

MPX-CH52

MPX-CH55

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00-03

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00MPX-CH54

3-19

Page 23

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0340

0341

0342

0343

0344

0345

0346

0347

0348

0349

034A

034B

034C

034D

034E

034F

0350

0351

0352

0353

0354

0355

0356

0357

0358

0359

035A

035B

035C

035D

035E

035F

0360

0361

0362

0363

0364

0365

0366

0367

0368

0369

036A

036B

036C

036D

036E

036F

0370

0371

0372

0373

0374

0375

0376

0377

0378

0379

037A

037B

037C

037D

037E

037F

DATA

D7 D6 D5 D4 D3 D2 D1 D0

MPX-CH57

MPX-CH56

MPX-CH59

MPX-CH58

MPX-CH61

MPX-CH60

MPX-CH63

MPX-CH62

MPX-CH65

MPX-CH64

MPX-CH67

MPX-CH66

MPX-CH69

MPX-CH68

MPX-CH71

MPX-CH70

MPX-CH73

MPX-CH72

MPX-CH75

MPX-CH74

MPX-CH77

MPX-CH76

MPX-CH79

MPX-CH78

MPX-CH81

MPX-CH80

MPX-CH83

MPX-CH82

MPX-CH85

MPX-CH84

MPX-CH87

MPX-CH86

MPX-CH89

MPX-CH88

MPX-CH91

MPX-CH90

MPX-CH93

MPX-CH92

MPX-CH95

MPX-CH94

MPX-CH97

MPX-CH96

MPX-CH99

MPX-CH98

FAVORITPAGES-CH01

FAVORITPAGES-CH00

FAVORITPAGES-CH03

FAVORITPAGES-CH02

FAVORITPAGES-CH05

FAVORITPAGES-CH04

FAVORITPAGES-CH07

FAVORITPAGES-CH06

FAVORITPAGES-CH09

FAVORITPAGES-CH08

FAVORITPAGES-CH11

FAVORITPAGES-CH10

FAVORITPAGES-CH13

FAVORITPAGES-CH12

FAVORITPAGES-CH15

FAVORITPAGES-CH14

FAVORITPAGES-CH17

FAVORITPAGES-CH16

FAVORITPAGES-CH19

FAVORITPAGES-CH18

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

3-20

Page 24

29F-PE550 / 29F-PD570

ADDRESS

(HEX)

0388

0389

038A

038B

038C

038D

03B8

03B9

03BA

03BB

03BC

03BD

03BE

03BF

03D8

03D9

03DA

03DB

03DC

03DD

03DE

03DF

DATA

D7 D6 D5 D4 D3 D2 D1 D0

FAVORITPAGES-CH29

FAVORITPAGES-CH28

FAVORITPAGES-CH31

FAVORITPAGES-CH30

FAVORITPAGES-CH33

FAVORITPAGES-CH32

:

:

:

FAVORITPAGES-CH77

FAVORITPAGES-CH76

FAVORITPAGES-CH79

FAVORITPAGES-CH78

FAVORITPAGES-CH81

FAVORITPAGES-CH80

FAVORITPAGES-CH83

FAVORITPAGES-CH82

:

:

:

FAVORITPAGES-CH09

FAVORITPAGES-CH08

FAVORITPAGES-CH11

FAVORITPAGES-CH10

FAVORITPAGES-CH13

FAVORITPAGES-CH12

FAVORITPAGES-CH15

FAVORITPAGES-CH14

:

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00

00

00

00

00

00

00

00

03F6

03F7

03F8

03F9

03FA

03FB

03FC

03FD

03FE

03FF

0402

0403

0404

0405

0406

0407

042E

042F

0430

0431

0432

0433

0434

0435

0436

0437

0438

0439

FAVORITPAGES-CH39

FAVORITPAGES-CH38

FAVORITPAGES-CH41

FAVORITPAGES-CH40

FAVORITPAGES-CH43

FAVORITPAGES-CH42

FAVORITPAGES-CH45

FAVORITPAGES-CH44

FAVORITPAGES-CH47

FAVORITPAGES-CH46

:

:

:

FAVORITPAGES-CH51

FAVORITPAGES-CH50

FAVORITPAGES-CH53

FAVORITPAGES-CH52

FAVORITPAGES-CH55

FAVORITPAGES-CH54

:

:

FAVORITPAGES-CH95

FAVORITPAGES-CH94

FAVORITPAGES-CH97

FAVORITPAGES-CH96

FAVORITPAGES-CH99

FAVORITPAGES-CH98

FAVORITPAGES-CH01

FAVORITPAGES-CH00

FAVORITPAGES-CH03

FAVORITPAGES-CH02

FAVORITPAGES-CH05

FAVORITPAGES-CH04

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

3-21

Page 25

29F-PE550 / 29F-PD570

C

ADDRESS

(HEX)

0446

0447

0448

0449

044A

044B

044C

044D

05

0

05C1

05C2

05C3

05C4

05C5

05C6

05C7

05C8

05C9

05CA

05CB

05CC

05CD

05CE

05CF

05D0

05D1

05D2

05D3

05D4

05D5

05D6

05D7

DATA

D7 D6 D5 D4 D3 D2 D1 D0

FAVORITPAGES-CH19

FAVORITPAGES-CH18

FAVORITPAGES-CH21

FAVORITPAGES-CH20

FAVORITPAGES-CH23

FAVORITPAGES-CH22

FAVORITPAGES-CH25

FAVORITPAGES-CH24

FAVORITPAGES-CH97

FAVORITPAGES-CH96

FAVORITPAGES-CH99

FAVORITPAGES-CH98

FAVORITPAGES-EXT-SRC

FAVORITPAGES-EXT-SRC

FAVORITPAGES-EXT-SRC

FAVORITPAGES-EXT-SRC

FAVORITPAGES-EXT-SRC

FAVORITPAGES-EXT-SRC

SKIP-CH15 SKIP-CH14 SKIP-CH13 SKIP-CH12 SKIP-CH11 SKIP-CH10 SKIP-CH09 SKIP-CH08

SKIP-CH07 SKIP-CH06 SKIP-CH05 SKIP-CH04 SKIP-CH03 SKIP-CH02 SKIP-CH01 SKIP-CH00

SKIP-CH31 SKIP-CH30 SKIP-CH29 SKIP-CH28 SKIP-CH27 SKIP-CH26 SKIP-CH25 SKIP-CH24

SKIP-CH23 SKIP-CH22 SKIP-CH21 SKIP-CH20 SKIP-CH19 SKIP-CH18 SKIP-CH17 SKIP-CH16

SKIP-CH47 SKIP-CH46 SKIP-CH45 SKIP-CH44 SKIP-CH43 SKIP-CH42 SKIP-CH41 SKIP-CH40

SKIP-CH39 SKIP-CH38 SKIP-CH37 SKIP-CH36 SKIP-CH35 SKIP-CH34 SKIP-CH33 SKIP-CH32

SKIP-CH63 SKIP-CH62 SKIP-CH61 SKIP-CH60 SKIP-CH59 SKIP-CH58 SKIP-CH57 SKIP-CH56

SKIP-CH55 SKIP-CH54 SKIP-CH53 SKIP-CH52 SKIP-CH51 SKIP-CH50 SKIP-CH49 SKIP-CH48

SKIP-CH79 SKIP-CH78 SKIP-CH77 SKIP-CH76 SKIP-CH75 SKIP-CH74 SKIP-CH73 SKIP-CH72

SKIP-CH71 SKIP-CH70 SKIP-CH69 SKIP-CH68 SKIP-CH67 SKIP-CH66 SKIP-CH65 SKIP-CH64

SKIP-CH95 SKIP-CH94 SKIP-CH93 SKIP-CH92 SKIP-CH91 SKIP-CH90 SKIP-CH89 SKIP-CH88

SKIP-CH87 SKIP-CH86 SKIP-CH85 SKIP-CH84 SKIP-CH83 SKIP-CH82 SKIP-CH81 SKIP-CH80

SKIP-CH99 SKIP-CH98 SKIP-CH97 SKIP-CH96

MICON EEPROM EEPROM

DEFAULT䌛hex

䌝

RANGE䌛hex䌝WRITE(CPU)

00

00

00

00

00

00

00

00

43

43

43

43

00

00

00

00

43

21

00

00

00

00

00

00

00

00

00

00

00

00

00

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-0F

43

43

43

43

00

00

00

00

43

21

00

00

00

00

00

00

00

00

00

00

00

00

00

05E2

AFC-CH07 AFC-CH06 AF C-CH05 AFC-CH04 AFC-CH03 AFC-CH02 AFC-CH01 AFC-CH00

FF

00-FF

FF

05E3

05E4

05E5

05E6

05E7

05E8

05E9

05EA

05EB

05EC

05ED

05EE

05EF

06FE

06FF

AFC-CH23 AFC-CH22 AF C-CH21 AFC-CH20 AFC-CH19 AFC-CH18 AFC-CH17 AFC-CH16

AFC-CH15 AFC-CH14 AF C-CH13 AFC-CH12 AFC-CH11 AFC-CH10 AFC-CH09 AFC-CH08

AFC-CH39 AFC-CH38 AF C-CH37 AFC-CH36 AFC-CH35 AFC-CH34 AFC-CH33 AFC-CH32

AFC-CH31 AFC-CH30 AF C-CH29 AFC-CH28 AFC-CH27 AFC-CH26 AFC-CH25 AFC-CH24

AFC-CH55 AFC-CH54 AF C-CH53 AFC-CH52 AFC-CH51 AFC-CH50 AFC-CH49 AFC-CH48

AFC-CH47 AFC-CH46 AF C-CH45 AFC-CH44 AFC-CH43 AFC-CH42 AFC-CH41 AFC-CH40

AFC-CH71 AFC-CH70 AF C-CH69 AFC-CH68 AFC-CH67 AFC-CH66 AFC-CH65 AFC-CH64

AFC-CH63 AFC-CH62 AF C-CH61 AFC-CH60 AFC-CH59 AFC-CH58 AFC-CH57 AFC-CH56

AFC-CH87 AFC-CH86 AF C-CH85 AFC-CH84 AFC-CH83 AFC-CH82 AFC-CH81 AFC-CH80

AFC-CH79 AFC-CH78 AF C-CH77 AFC-CH76 AFC-CH75 AFC-CH74 AFC-CH73 AFC-CH72

AFC-CH99 AFC-CH98 AF C-CH97 AFC-CH96

AFC-CH95 AFC-CH94 AF C-CH93 AFC-CH92 AFC-CH91 AFC-CH90 AFC-CH89 AFC-CH88

FACTORY SHIPOUT SOUND SYSTEM

FACTORY SHIPOUT LANGUAGE

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

0F

FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-FF

00-0F

00-FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

0F

FF

00

01

3-22

Page 26

INITIAL SETTING

(1) Execute MCL key to set the following data in EEPROM.

SMTL

R/C CODE

MCL (170 : AAh)

TV-CH. CH-No. Fv (MHz) S-SYSTEM

0

1 Thai Local CH-3 559.25 PAL B / G

2 Thai Local CH-5 175.25 PAL B / G

3

Thai Local CH-7 189.25 PAL B / G

4 Thai Local CH-9 203.25 PAL B / G

5

Thai Local CH-11 217.25 PAL B / G

6 Thai Local CH-29 535.25 PAL B / G

7

8

9

10

11 SMTL Factory CH-E2 48.25 PAL B / G

12 SMTL Factory CH-E4 62.25 PAL B / G

13 SMTL Factory CH-E8 196.25 PAL B / G

14 SMTL Factory CH-E10 210.25 SECAM B / G

15 SMTL Factory CH-E12 224.25 PAL B / G

16 SMTL Factory CH-E21 471.25 PAL B / G

17 SMTL Factory CH-E69 855.25 PAL B / G

18

19

20

21 SMTL Factory CH-E12 -0.3MHz. 223.95 PAL B / G

22 SMTL Factory CH-E12 +0.3MHz. 224.55 PAL B / G

23 SMTL Factory CH-E12 -0.4MHz. 223.85 PAL B / G

24 SMTL Factory CH-E12 +0.4MHz. 224.65 PAL B / G

25 SMTL Factory CH-E12 -0.5MHz. 223.75 PAL B / G

26 SMTL Factory CH-E12 +0.5MHz. 224.75 PAL B / G

27

28

29

30

31 SMTL Factory CH-J1 91.25 NTSC M

32 SMTL Factory CH-J3 103.25 NTSC M

33 SMTL Factory CH-J4 171.25 NTSC M

34 SMTL Factory CH-J6 183.25 NTSC M

35 SMTL Factory CH-J8 193.25 NTSC M

36 SMTL Factory CH-J10 205.25 NTSC M

37 SMTL Factory CH-J12 217.25 NTSC M

38 SMTL Factory CH-J38 621.25 NTSC M

39

40

41

29F-PE550 / 29F-PD570

3-23

Page 27

E

SHIPPING SETTING & CHECKING

(1) The following default data has been factory-setting for the EEPROM.

GB7 PACKAGE 5 MODEL SET

Model set: Only one key used for all model, software change if different setting for different model.

29F-PE550 / 29F-PD570

MODEL-SET KEY OSD LANGUAG

3 THAILAND B/G NICAM

Default settings:

Items Default Settings

GENERAL

Last power ON

Last TV/AV mode TV mode

Last position-TV Program 1

Flashback Program-TV Program 1

Favorite Program A Program 10

Favorite Program B Program 20

Favorite Program C Program 30

Favorite Program D Program 40

1/2 digit entry 2 digit

Volume 0

AFT All programs ON

PICTURE menu

AV MODE MOVIE MUSIC NEWS

Contrast 60 60 50

Colour +6 0 -6

Brightness 0 0 0

Tint 0 0 0

Sharpness +6 0 -6

Picture NR OFF OFF OFF

White temp 0 0 0

EQUALIZER menu

100 (0~24)

300 (0~24)

1K (0~24)

3K (0~24)

8K (0~24)

SOUND menu

Surround

Balance

AVL

Loundness

FEATURE menu

AV MODE MOVIE

Off timer --:-Lock TV OFF

Password 0000

Blue back OFF

CH-SETTING menu

COLOUR SYSTEM AUTO

SOUND SYSTEM B/G NICAM

SKIP

All programs OFF

21

16

18

15

21

OFF

0

ON

ON

except CH 0

SOUND SYSTEM

20

17

6

12

20

11

14

17

14

11

Refer to next page for setting of each destination.

3-24

Page 28

(1) Refer to below table (2.1) for setting of each destination.

29F-PE550 / 29F-PD570

MODEL LANGUAGE S-SYS

THAI

HONG KONG 20,000 40,000 CHINESE B/G

SINGAPORE

MALAYSIA

MIDDLE EAST

SAUDI

KUWAIT

AUSTRALIA -50,000 20,000 ENGLISH