Page 1

SERVICE MANUAL

COLOUR TELEVISION

Chassis No. GA-8S

MODEL :

21ES251E

21ES253E

21ES353E

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

FEATURES

Multi 21 System, 100-CH Program Memory

¨

¨

Full Auto Search System

¨

NTSC Colour Comb Filter

¨

CATV (Hyperband) Ready

¨

NTSC Colour Comb Filter Function

High Contrast Picture (Black Strecth Circuit)

¨

White Temperature Select

¨

¨

English Language OSD

¨SPECIFICATIONS .............................................2

¨IMPORTANT SERVICE NOTES ........................ 2

¨ADJUSTMENT PRECAUTIONS ........................ 3

¨TROUBLE SHOOTING TABLE ....................... 16

¨WAVEFORMS.................................................. 18

¨SOLID STATE DEVICE BASE DIAGRAM ....... 19

¨DESCRIPTION OF SCHEMATIC DIAGRAM .. 20

¨ DIAGRAM:

¨DIAGRAM BLOCK CRT ............................. 21

¨DIAGRAM SCHEMATIC CRT ..................... 22

¨

¨

¨

¨

¨

¨

¨

¨

CONTENTS

Page

Blueback Function Noise Mute

OFF Timer & Child Lock

Hotel Mode & AV Mode (Movie/Music/News)

Surround Sound Effect

Rear AV-IN Terminal

Rear AV-OUT Terminal

Save Mode

AV Stereo & Equalizer

Page

¨MAIN BLOCK ........................................... 23

¨MAIN SCHEMATIC ................................... 24

¨REPLACEMENT PARTS LIST

WARNING

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and power

receptacle, when servicing this chassis. To prevent electric shock, do not remove cover. No user - serviceable parts

inside. Refer servicing to qualified service personnel.

SHARP CORPORATION

1

Page 2

IMPORTANT SERVICE NOTES

1.0kV (at

±

A) for the set.

A) in the case of the set. The set has been factory - Adjusted to the above-

m

m

never forget to check for such high voltage after the work.

\\

\\

the high voltage completely.

Maintenance and repair of this receiver should be done by qualified

service personnel only.

SERVICE OF HIGH VOLTAGE SYSTEM AND PIC-

TURE TUBE

When servicing the high voltage system, remove static charge from it by

Connecting a 10K ohm Resistor in series with an insulated wire(such as a

test probe) between picture tube dag and 2nd anode lead. (AC line cord

should be disconnected from AC outlet.)

1. Picture tube in this receiver employs integral implosion protection.

2. Replace with tube of the same type number for continued safety .

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing shatterproof goggles and after discharging

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

Minimum. Since certain malfunctions or servicing may produce potentially

(at beam 0

hazardous radiation with prolonged exposure at close range, the following

precautions should be observed:

1. When repairing the circuit, be sure not to increase the high voltage to more than 26.0kV

\ If there is a possibility that the high voltage fluctuates as a result of the repairs,

beam 1000

mentioned high voltage.

2. To keep the set in a normal operation , be sure to make it function on 23.0kV

cause excess X-ray radiation.

3. Do not substitute a picture tube with unauthorizerd types and/or brands which may

BEFORE RETURNING THE RECEIVER

lodged between the chassis and other metal parts in the receiver .

cabinet backs, adjustment and compartment covers or shields, isolation resistor- ca-

pacity networks, mechanical insulators etc.

Before returning the receiver to the user, perform the following safety Checks.

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not

2. Inspect all protective devices such as non-metallic control knobs, insulating fishpapers,

SPECIFICATIONS

2

88W

at 400 Hz

Elliptic (2pcs)

16 ohms

Electro-Static Focusing

6cm

x

C1(49.75MHz) thru C12(216.25 MHz)

S1(105.25MHz) thru S41(463.25HMz)

PAL I, B/G, D/K & SECAM B/G, D/K, K1,

.

& NTSC M

Width: 597mm

Depth: 341.5 mm

Height: 468.5mm

Weight(approx): 19.5kg

C13(471.25MHz) thru C57(863.25MHz)

2-1 2-2

............................................................................................................. 3.0W(rms)x

........................................................................................................................................

.......................................................................................................................

Convergence ................................................................................................................ Self Convergence System

Focus

Sweep Deflection .........................................................................................................................................Magnetic

6.5MHz ............................................................................................................................................. 32.4MHz

6.0MHz ............................................................................................................................................. 32.9MHz

5.5MHz ............................................................................................................................................. 33.4MHz

Picture IF Carrier ................................................................................................................................. 38.9MHz

Intermediate Frequencies

Colour Sub-Carrier Frequency........................................................................................................... 34.47MHz

Sound IF Carrier Frequency

Power Input ..................................................................................................................... 110 ~ 240V AC 50/60 Hz

Power Consumption

Audio Power Output Rating

.............................................................................................................

.....................................................................................................................................

.................................................................................................................. ....12cm

Size

Voice Coil Impedance

Speaker

VHF/UHF .......................................................................................................................... 75 ohms Unbalanced

Receiving System ...................................................................................

Aerial Input Impedance

UHF-Channels ..................................................................................... E21(471.25MHz) thru E69(855.25MHz)

VHF-Channels ......................................................................................... E2(48.25MHz) thru E12(224.25MHz)

Receiving Channel

Dimensions

Specifications are subject to change without prior notice

Cabinet material ..................................................................................................................................... All Plastics

Page 3

ADJUSTMENT PRECAUTIONS

This model's setting are adjusted in two different ways: through the I2C bus control and in

the conventional analog manner. The adjustments via the I2C bus control include preset-only

items and variable data.

CAUTION : MAKE SURE TV SET IN "NORMAL CONDITION" BEFORE SWITCH TO SERVICE MODE

FOR ADJUSTMENT.

1. Setting the service mode by the microprocessor.

(1) Press SERVICE key on the remote controller to set the TV set to SERVICE mode position,

and the microprocessor is in input mode. (Adjustment through the I2C bus control).

Service Mode also can be reached by by connecting MCU Pin 5 to ground.

(2) Press the MENU key on the remote controller to get ready to select the mode

(Adjustment mode, Setting mode, Check mode, Option mode and NVM Edit mode ) one by one.

(3) Press the CH DOWN / UP key on the remote controller to select the item in Adjustment

mode, Setting mode, Option mode or NVM Edit mode.

(4) Using the VOLUME UP/ DOWN key on the remote controller, the data can be modified.

Please wait approximately 200 msec for data storage in EEPROM before select to

another mode.

(5) In Check mode the data cannot be changed.

(6) Press the SERVICE key again, it will switch to the NORMAL mode position, and the

microprocessor is out of the SERVICE mode.

2. Factory Presetting.

(1) During POWER OFF (AC OFF), switch on service key (by connecting MCU Pin 5 to ground )

after raster appeared on the screen. Initial values are automatically preset, only when

then follow by AC ON. Initial values are automatically preset only when a new EEPROM is used.

(Judge with the first 4 bytes ).

(2) The initial data are preset as listed in page 6~10.

(3) Make sure the data need modification or not (Initial data).

Precaution: If haven't done this initialization, it may possibly generate excessive Beam current.

3.

For reference please check with memory map RH-IXC688WJZZQ (see attachment)

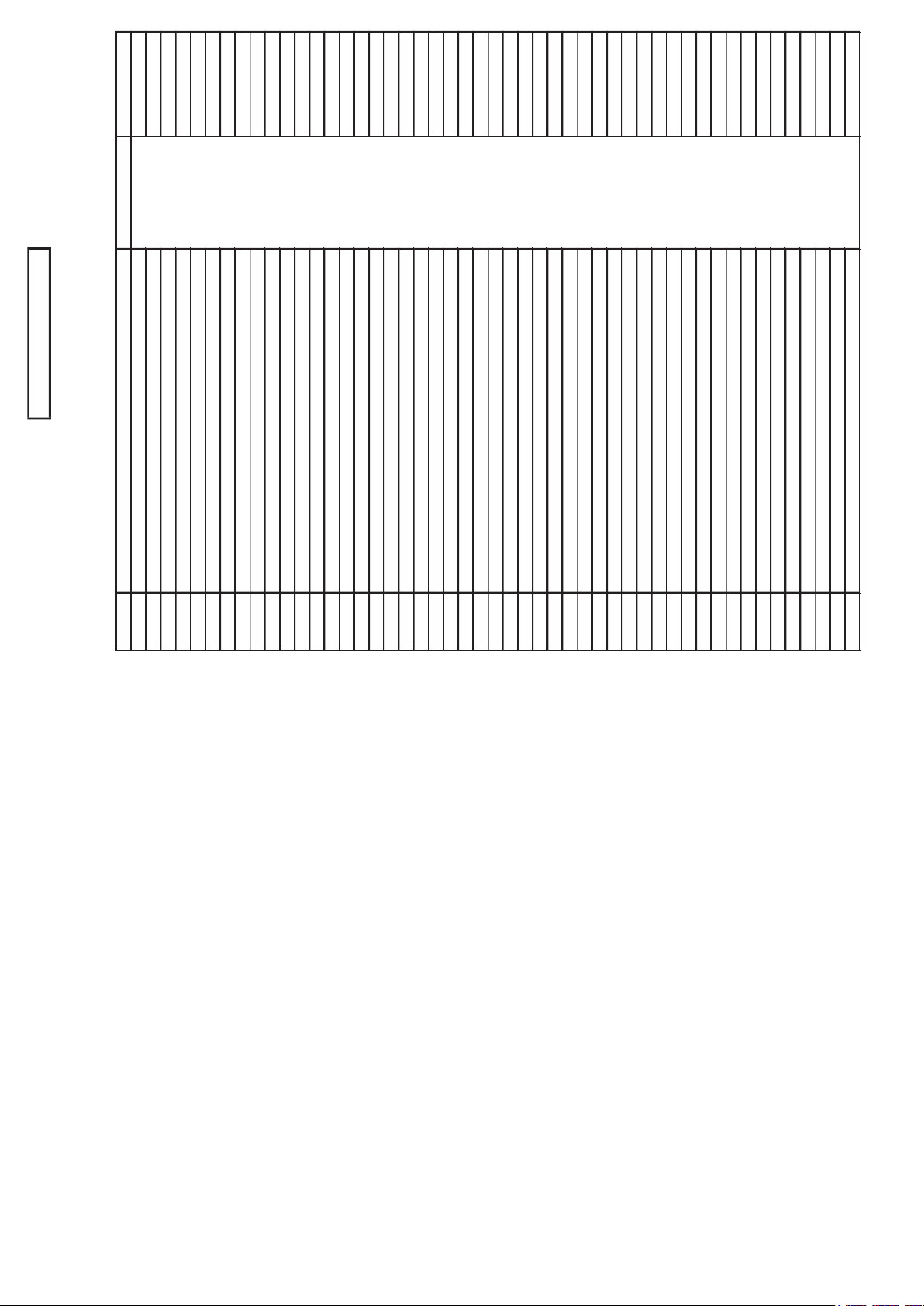

***Below are the adjustment items that should be done, PLS FOLLOW THE PROCEDURE.

Otherwise some adjustment items will not be accurate.

NO *** REVISION

1 BUS SET UP

2 RF-AGC

3 FOCUS ADJ

4 H-VCO ADJ

5 VIF-VCO ADJ

6 S-TRAP ADJ

7 V-SHIFT

8 V-SIZE

9 V-LINEARITY

10 VS CORRECTION

11 H-SHIFT

12 H-SIZE

13 PARABOLA

14 UPPER CORNER

15 LOWER CORNER

16 BOW-ADJ

17 ANGLE ADJ

18 TRAPEZIUM

19 SCREEN

20 WHITE BALANCE

21 SUB-BRIGHTNESS

22 SUB-CONTRAST

23 BEAM CURRENT CHECK

24 SUB-COLOR

25 SUB-TINT

26 SECAM-OFFSET

27 BEAM PROTECTOR CHECK

28 HV PROTECTOR CHECK

29 OTHER PROTECTOR CHECK

30 AV OUT CHECK

31 AV IN CHECK

32 COMPONENT IN CHECK

33 SUB-WOOFER CHECK

34 CONTRAST CONTROL CHECK

35 COLOR CONTROL CHECK

36 BRIGHTNESS CONTROL CHECK

37 TINT CONTROL CHECK

38 SHARPNESS CONTROL CHECK

39 CH DISPLAY COLOR CHECK

40 SURROUND CHECK

41 BALANCE CHECK

42 EQUALIZER CHECK

43 COLOR TEMP CHECK

44 NORMAL DISPLAY CHECK

45 COLOUR SYSTEM CHECK

46 SOUND SYSTEM CHECK

47 NOISE MUTE CHECK

48 OSD LANGUAGE QUANTITY CHECK

49 SHOCK TEST CHECK

ALL MODELS

ADJUSTMENT ITEM

ADJUSTMENT ITEM

EFFECTIVE MODEL

3-2

3-1

Page 4

4-2

USER DATA IN SERVICE MODE

. While SERVICE mode ON, EEPROM DATA will switch to the service data.

Also, once SERVICE mode OFF, EEPROM will switch back to previous USER DATA.

. In the service mode, the user data establish as below,

USER DATA MODELS

CONTRAST MAX 60

COLOUR CENT 0

BRIGHTNESS CENT 0

TINT CENT 0

SHARPNESS CENT 0

WHITE TEMP STANDARD

S-VOLUME MIN

SURROUND OFF

BALANCE CENT 0

AVL *2

BLUE BACK OFF

C SYSTEM AUTO

S SYSTEM *1

EQUALIZER *2

ANTENNA BOOSTER *1

*1: For each CH, data is same as before switch to Service mode.

*2: Data is same as before switch to Serice mode.

The flow of Mode list as following,

* Direct Key-in Mode for Service Items in Service Mode

RC CODE (HEX) R/C KEY NAME

80 POS 1 R-C UP (IN SERVICE MODE V00)

40 POS 2 G-C UP (IN SERVICE MODE V00)

C0 POS 3 B-C UP (IN SERVICE MODE V00)

20 POS 4 R-C DOWN (IN SERVICE MODE V00)

A0 POS 5 G-C DOWN (IN SERVICE MODE V00)

60 POS 6 B-C DOWN (IN SERVICE MODE V00)

E0 POS 7 R-D UP (IN SERVICE MODE V00)

10 POS 8 B-D UP (IN SERVICE MODE V00)

50 POS 0 B-D DOWN (IN SERVICE MODE V00)

E4 FLASHBACK R-D DOWN (IN SERVICE MODE V00)

E4 FLASHBACK Y-MUTE (BESIDES OF SERVICE MODE V00)

75 WHITE TEMP UP RF-AGC (V01)

F5 WHITE TEMP DOWN VIF-VC0 (V02)

C2 TUNE DOWN H-VCO (V03)

8D SHARPNESS DOWN SUB-CON (V04)

D6 BALANCE LEFT SUB-COL (V05)

0D SHARPNESS UP SUB-BRIGHT (V06)

36 BALANCE RIGHT SUB-TINT (V07)

46 TREBLE UP SUB-SHP-PRE (V08)

C6 TREBLE DOWN SUB-COL-YUV (V09)

26 BASS UP SUB-TINT-YUV (V10)

24 COLOUR UP V-SIZE (V11), V-SIZE60 (V16)

54 BRIGHTNESS DOWN V-SHIFT (V12), V-SHIFT60 (V17)

74 TINT DOWN H-SHIFT (V13), H-SHIFT60 (V18)

66 SURROUND UP SCM-BR (V14)

E6 SURROUND DOWN SCM-BB (V15)

C4 CONTRAST DOWN SUB-VOL

4C PICTURE S-TRAP-BG (V19)

CC HOLD S-TRAP-I (V20)

2C TEXT S-TRAP-DK (V21)

AC CANCEL S-TRAP-M (V22)

EC SIZE S-TRAP-574 (V23)

C1 AUTO ADJ FOR V01, V02, V03,V19, V20, V21, V22, V23

CA T-SET

81 SERVICE MODE

SERVICE-ITEM

ALL MODELS

1.) Please set the MCL to

MCL1

as below:

2.) After set the MCL , please set the INITIAL SETTING for each models

.

INITIAL 3 :

All Channel Sound System are set to B/G

CH-No Fv (MHz) Sound Sys

0

1 48.25 B/G

2 62.25 B/G

3 77.25 D/K

4 175.25 B/G

5 182.25 B/G

6 183.25 D/K

7 191.25 D/K

8 196.25 B/G

9 199.25 M

10 210.25 B/G

11 224.25 B/G

12 471.25 B/G

13 487.25 I

14 503.25 B/G

15 575.25 B/G

16 583.25 B/G

17 599.25 B/G

18 621.25 M

19 639.25 D/K

20 703.25 B/G

21 735.25 I

22 767.25 B/G

23 815.25 B/G

24 855.25 I

25 855.25 B/G

26 55.25 M

27 83.25 M

28 183.25 M

29 193.25 M

30 217.25 M

31 471.25 M

32 477.25 M

33 693.25 M

34 885.25 M

35 112.25 B/G

36 168.25 B/G

37

38 294.25 B/G

39 463.25 B/G

40

41 647.25 B/G

42 663.25 B/G

43 679.25 B/G

44 174.95 B/G

45 175.55 B/G464748495051525354555657585960616263646566676869

70

MCL1 (HEX AE)

4-1

Page 5

5-2

SHIPPING SETTING & CHECKING

(1) The following default data has been factory-set for the E2PROM follow by INITIAL DATA selected.

ITEMS DATA SETTING

LAST POWER ON

LAST TV/AV MODE TV MODE

LAST POSITION CH 1

FLASHBACK CHANNEL CH 1

1/2 DIGIT ENTRY 2 DIGIT ENTRY

VOLUME 0 (Min)

BLUE BACK OFF

CHILD LOCK OFF

OFF TIMER --:--

PASSWORD 0000

AFT ALL CH ON

COLOR SYSTEM ALL CH AUTO

SKIP ALL CH OFF

FAVORITE PROGRAM A CH 10

FAVORITE PROGRAM B CH 20

FAVORITE PROGRAM C CH 30

FAVORITE PROGRAM D CH 40

AV MODE MOVIE

CONTRAST 60

COLOR +3

BRIGHTNESS 0

TINT 0(CENTER)

SHARPNESS +3

PICTURE NR OFF

WHITE TEMP 0

SURROUND OFF

AVL ON

BALANCE 0(CENTER)

SAVE MODE

OFF

BOOSTER

ALL CH OFF

INITIAL LANGUAGE SOUND SYSTEM

3 ENGLISH B/G

FACTORY SETTING BY MODEL

(Reference: Geomagnetism Adjustment)

MODEL MAGNETIC FIELD(V, H) nT BACKGROUND LANG. S-SYS LANG QTY

INDONESIA -20,000 40,000 12300°K ENGLISH B/G 1

1: ENGLISH

MODELS

ALL MODELS

**AFTER INITIALIZED THE EEPROM (REFER TO FACTORY PRESETTING), READ DATA FROM

EEPROM ADDRESS 00H ~ 03H,AND COMPARE TO THE LIST BELOW, IF DIFFERENT,

INITIALIZE THE EEPROM.

ADDRESS DATA ADDRESS DATA

00H:

7CH

02H:

78H

01H:

76H

03H:

78H

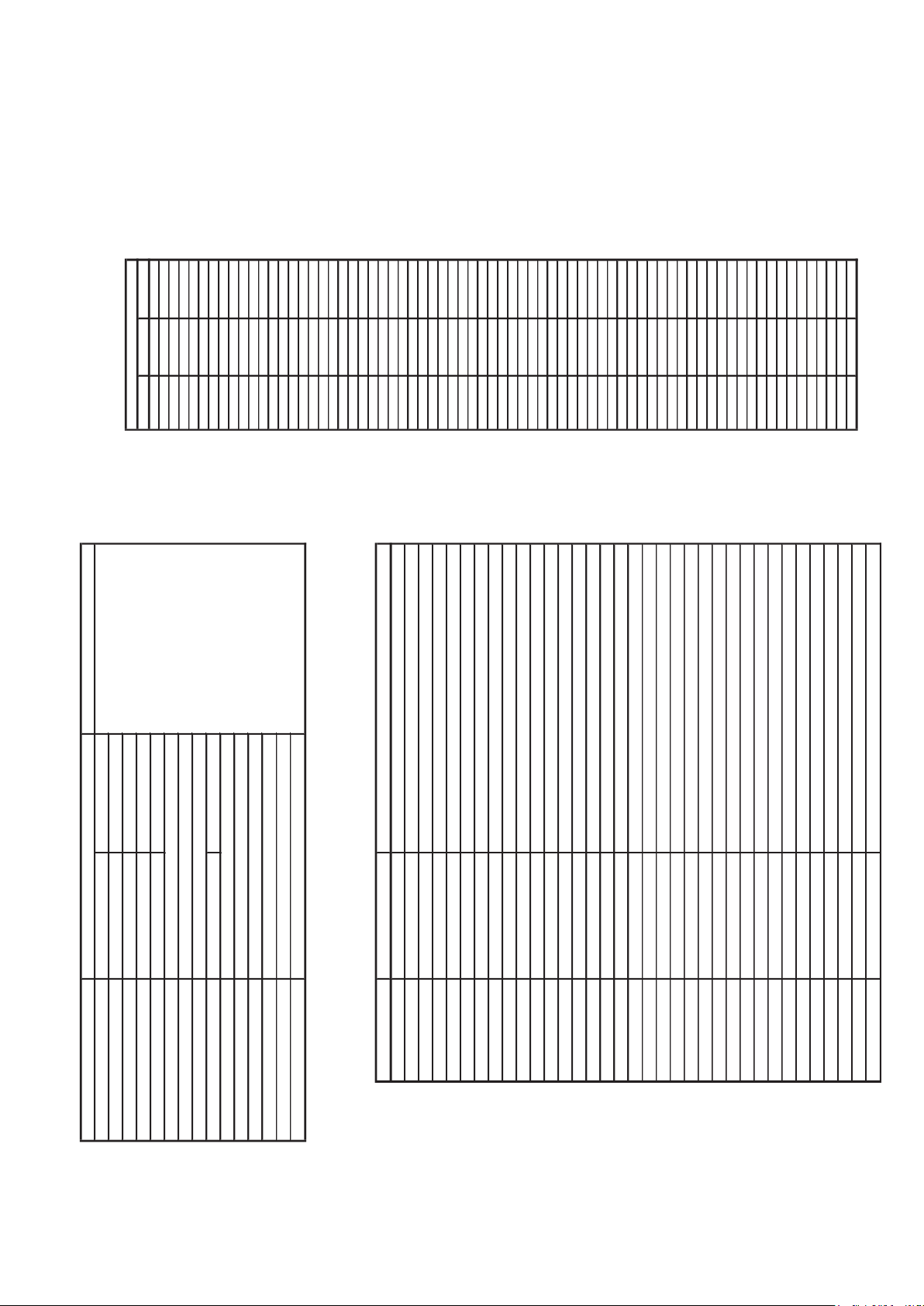

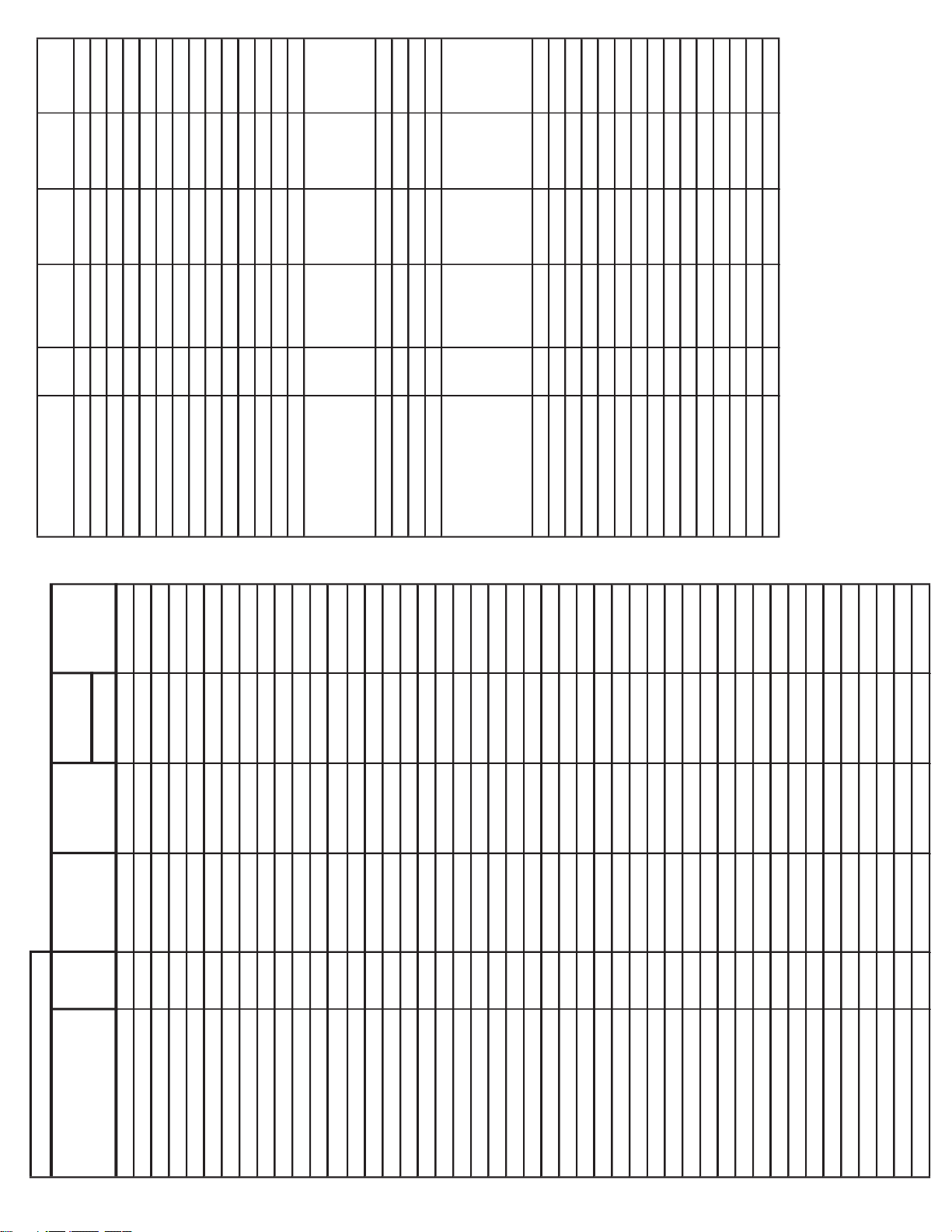

*** There are four stages of service mode data. First stage data from V00~V45 (Adjustment Mode).

To go into second stage of service mode data, press MENU key.Second stage data from F01~F170(Setting Mode).

To go into third stage of service mode data, press MENU key.Third stage data is Check Mode.

To go into fourth stage of service mode data, press MENU key.Fourth stage data from O01~O35 (Option Mode).

SETTING

DATA

21DXS200

V00 0…127 63 63

ADJ

V00 0…127 63 63

ADJ

V00 0…255 127 127

ADJ

V00 0…255 127 127

ADJ

V00 0…255 127 127

ADJ

V01 0…127 50 50

AUTO

V02 0…63 31 31

AUTO

V03 0…7 3 3

AUTO

V04 0…127 100 100

ADJ

V05 0…127 63 63

ADJ

V06 0…255 127 127

ADJ

V07 0…127 63 63

ADJ

V08 0…63 37 28

*FIX

V09 0…127 49 49

FIX

V10 0…127 61 61

FIX

V11 0…63 38 38

ADJ

V12 0…7 3 3

ADJ

V13 0…31 9 9

ADJ

V14 0…63 37 37

ADJ

V15 0…63 22 22

ADJ

V16 -31…0…+31 +6 +6

FIX

V17 -7…0…+7 -2 -2

FIX

V18 -15…0…+15 +2 +2

FIX

V19 0…127 64 64

AUTO

V20 0…127 64 64

AUTO

V21 0…127 64 64

AUTO

V22 0…127 64 64

AUTO

V23 0…127 64 64

AUTO

V24

0…15 0 0

FIX

V25 0…127 25 25

FIX

V26 0…127 95 95

FIX

V27 0…63 38 38

*FIX

ADJUST IF NECESSARY

V28 -13…+13 -9 -9

FIX

V29 0…63 36 36

*FIX

ADJUST IF NECESSARY

V30 -13…+13 +3 +3

FIX

V31 0…63 26 26

FIX

V32 0…63 32 32

ADJ

V33 -13…+13 0 0

FIX

V34 0…63 32 32

ADJ

V35 -13…+13 0 0

FIX

V36 0…63 32 32

ADJ

V37 -13…+13 0 0

FIX

V38 0…63 32 32

ADJ

V39 -13…+13 0 0

FIX

V40 0…63 32 32

ADJ

V41 -13…+13 0 0

FIX

V42 0…63 32 32

ADJ

V43 -13…+13 0 0

FIX

V44 0…63 32 32

ADJ

V45 -13…+13 0 0

FIX

SUB-TINT-YUV

TRAPEZIUM

V LINEARITY60

PARABOLA60

V LINEARITY

SCM-BR

SCM-BB

V-SIZE60

V-SHIFT60

S-TRAP(BG)

VIF-VCO

H-VCO

R-DRI

B-DRI

G-CUT

R-CUT

SUB-CON

RF-AGC

V-SHIFT

H-SHIFT

V-SIZE

SUB-BRIGHT

SUB-TINT

SUB-SHP PRE

SUB-COLOR

SUB-COLOR-YUV

BOW ADJ

BOW ADJ60

ANGLE ADJ

SUB-SHP OV

PARABOLA

LOWER-CORNER

LOWER-CORNER60

UPPER-CORNER60

UPPER-CORNER

TRAPEZIUM60

S-TRAP(DK)

S-TRAP(M)

S-TRAP(574)

TEST PATTERN

ANGLE ADJ60

H-SIZE

H-SIZE60

FIX/ADJ/AUTO

S-TRAP(I)

VS-CORRECT60

S-TRAP ADJ Start

H-SHIFT60

S-TRAP ADJ Stop

VS-CORRECT

REMARK

Adjustment Mode (First Stage)

PLS REFER ADJ ITEM FOR

SCREEN AND WHITE

BALANCE

B-CUT

EEPROM ITEMS

OSD

DATA

LENGTH

INITIAL

DATA

5-1

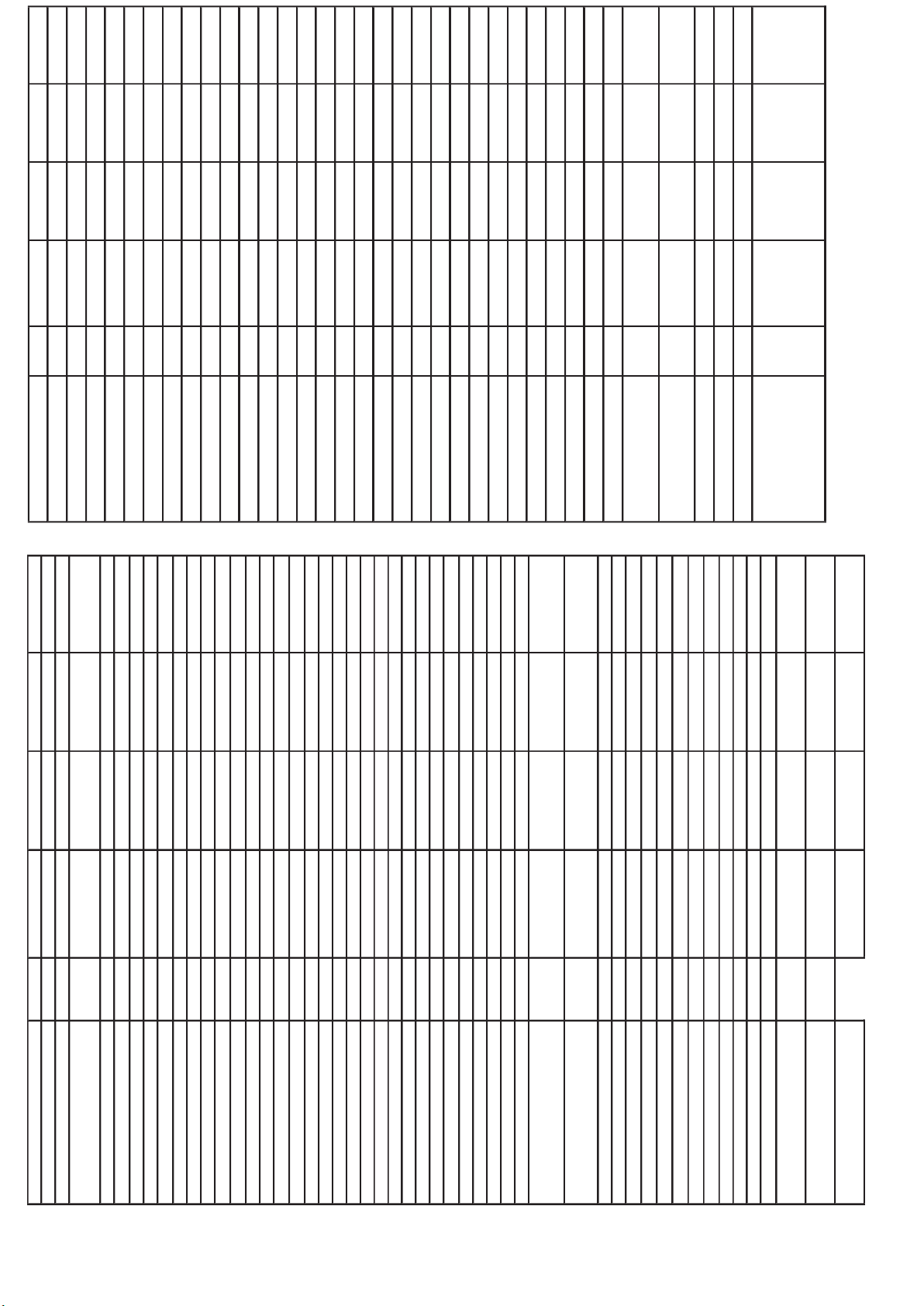

Page 6

SETTING

DATA

21DXS200

F01

0 (Lo)/ 1(Hi)

0 0

FIX

F02

0…7 7 7

FIX

F03

0…7 5 5

FIX

F04

0…7 5 5

FIX

F05

0…7 6 6

FIX

F06

0…7 5 5

FIX

F07

0…7 5 5

FIX

F08

0…7 5 5

FIX

F09

0…7 5 5

FIX

F10

0…7 5 5

FIX

F11

0…7 5 5

FIX

F12

0…7 5 5

FIX

F13

0…7 5 5

FIX

F14

-31…0…+31 -4 -4

FIX

F15

-31…0…+31 +12 +12

FIX

F16

-31…0…+31 +9 +9

FIX

F17

-31…0…+31 +8 +8

FIX

F18

-31…0…+31 +12 +12

FIX

F19

-31…0…+31 +8 +8

FIX

F20

-31…0…+31 +1 +1

FIX

F21

-31…0…+31 +3 +3

FIX

F22

-31…0…+31 +7 +7

FIX

F23

-31…0…+31 +2 +2

FIX

F24

-31…0…+31 +7 +7

FIX

F25

-31…0…+31 +7 +7

FIX

F26

-31…0…+31

-5 -5

FIX

F27

-31…0…+31

+13 +13

FIX

F28

-31…0…+31

+7 +7

FIX

F29

-31…0…+31

+2 +2

FIX

F30

-31…0…+31

+7 +7

FIX

F31

-31…0…+31

+7 +7

FIX

F32

-63…0…+63 -5 -5

FIX

F33

-63…0…+63 +3 +3

FIX

F34

-63…0…+63 +5 +5

FIX

F35

-63…0…+63 -19 -19

FIX

F36

-63…0…+63 -2 -2

FIX

F37

-63…0…+63 +8 +8

FIX

F38

0…3 2 2

FIX

F39

0…3 2 2

FIX

F40

0…3 2 2

FIX

F41

0…3 2 2

FIX

F42

0…3 1 1

FIX

F43

0…3

1 1

FIX

F44

0…3 3 3

FIX

F45

0…15 4 4

FIX

F46

0…2 0 0

FIX

AFC2 GAIN

GAMMA

BS-D/C

BS-GAIN

CTRAP-ADJ-P

CTRAP-ADJ-S

CTRAP-ADJ-N4

CTRAP-ADJ-N3

B-R

R-B

B-B

CTRAP-ADJ

SHP-OV-N3

TINT-AV

TINT-ADJ

R-R

SHP-OV-YUV

SHP-OV-P

SHP-OV-S

SHP-OV-N4

SHP-PRE-S

SHP-PRE-N4

SHP-PRE-N3

SHP-OV-AV

COL-ADJ

SHP-PRE-AV

SHP-PRE-YUV

SHP-PRE-P

YDL-P

YDL-S

YDL-N4

ABCL-Gain

VIF-G

YDL

YDL-N3

YDL-AV

YDL-AV-P

YDL-AV-S

YDL-AV-N4

YDL-AV-N3

YDL-YUV

COL-AV

COL-P

COL-S

COL-N4

COL-N3

FIX/ADJ/AUTO

Setting Mode (Second Stage)

EEPROM ITEMS

OSD

DATA LENGTH

INITIAL DATA

F47

0 (disable)/

1(enable)

0 0

FIX

F48

0…7 1 1

FIX

F49

0…7 2 2

FIX

F50

0…7 3 3

FIX

F51

0…3 3 3

FIX

F52

0…3 3 3

FIX

F53

0…3 3 3

FIX

F54

0…3 0 0

FIX

F55

0…3 0 0

FIX

F56

0…3 1 1

FIX

F57

0…3 0 0

FIX

F58

1…55 42 42

FIX

F59

1…50 35 35

FIX

F60

0…127 15 19

*FIX

F61

0/1 1 1

FIX

F62

0,0 : 600mVrms

0,1 : 450mVrms

1,0 : 375mVrms

1,1 : 300mVrms

1 3

*FIX

F63

0…3 1 1

FIX

F64

0…3 0 0

FIX

F65

0…3 3 3

FIX

F66

0…3 3 3

FIX

F67

0 : 10%

1 : 30%

2 : 50%

3 : 70%

4 : 90%

3 3

FIX

F68

0 (BPF)/ 1(TOF)

1 1

FIX

F69

0 (BPF)/ 1(TOF)

0 0

FIX

F70

0 (103)/ 1(95)

0 0

FIX

F71

0…255

255 255

FIX

F72

0…3 2 2

FIX

F73

0…3 2 2

FIX

F74

0…255 25 25

FIX

F75

0…255 40 40

FIX

F76

0…255 70 70

FIX

F77

0…255 150 150

FIX

F78

0…255 156 156

FIX

F79

0…255 163 163

FIX

F80

0…255 165 165

FIX

F81

0…255 170 170

FIX

F82

0…255 180 180

FIX

S-Demute-Delay

MER

MEL3

MEL4

MEL5

AC-Fail-WO-Bright

Forced-SCM-KIL-TV

Forced-SCM-KIL-AV-YUV

V-Demute-Delay

OSD LEVEL

Take-Off-TV

Take-Off-AV-YUV

C-Angle

AUTO-SCM-KIL-AV-YUV

AFC1-Gain-TV

AFC1-Gain-AV

AFC1-Gain-YUV

OSD-POS-V60

OSD-POS-H

CP

AVL LEVEL

UDL

AUTO-SCM-KIL-TV

SECAM-BGP

OSD-POS-V50

AS/FBP-TV

AS/FBP-AV

AS/FBP-YUV

VDL

OM-DET

SL-TV

SL-AV

SL-YUV

MEL1

MEL2

MEL6

6-2

6-1

Page 7

7-2

F83

0…60 21 21

FIX

F84

0…60 60 60

FIX

F85

0…60 7 7

FIX

F86

0 (disable)/

1(enable)

1 1

FIX

F87

0 … +10 10 10

FIX

F88

0 … +10 10 10

FIX

F89

0 … +10 10 10

FIX

F90

0 … +10 10 10

FIX

F91

0/1 1 1

FIX

F92

0/1

0 0

FIX

F93

0/1

0 0

FIX

F94

0/1

0 0

FIX

F95

-63…0…+63 0 0

FIX

F96

-63…0…+63 0 0

FIX

F97

-63…0…+63 -12 -12

FIX

F98

-63…0…+63 -5 -5

FIX

F99

-63…0…+63 0 0

FIX

F100

-63…0…+63 +2 +2

FIX

F101

-63…0…+63 +4 +4

FIX

F102

-31…0…+31 0 -20

*FIX

F103

0..2

2 2

FIX

F104

-63…0…+63 0 -16

*FIX

F105

-63…0…+63 0 0

FIX

F106

0…15 5 5

FIX

F107

0…15 5 5

FIX

F108

0/1 1 1

FIX

F109

0…3 0 0

FIX

F110

-15…0…+15 -4 -4

FIX

F111

-4…0…+4 0 0

FIX

F112

-4 … +4

0 -1

*FIX

F113

-4 … +4

0 0

FIX

F114

-4 … +4

-2 0

*FIX

F115

-4…0…+4

-1 +1

*FIX

F116

0…3 0 0

FIX

F117

0…7 3 3

FIX

F118

0…7 0 0

FIX

F119

0..60 55 55

FIX

F120

0..60 60 60

FIX

F121

0..60 60 60

FIX

F122

-30..0..+30 0 0

FIX

F123

-30..0..+30 0 0

FIX

F124

-30..0..+30 0 0

FIX

F125

-30..0..+30 0 0

FIX

F126

-30..0..+30 0 0

FIX

F127

-30..0..+30 +3 +3

FIX

F128

-30..0..+30 0 0

FIX

F129

-30..0..+30 0 0

FIX

F130

-30..0..+30 +3 +3

FIX

F131

0(OFF) / 1(ONI) /

2(ONII)

0 0

FIX

F132

0(OFF) / 1(ONI) /

2(ONII)

0 0

FIX

F133

0(OFF) / 1(ONI) /

2(ONII)

0 0

FIX

SURR MOVIE

SHARP MUSIC

SHARP MOVIE

SURR NEWS

SURR MUSIC

COL NEWS

COL MUSIC

COL MOVIE

SHARP NEWS

CONT MOVIE

BRIGHT NEWS

BRIGHT MUSIC

BRIGHT MOVIE

SIF BPF WIDE HIGH

S-B-TREB

S-BASS

S-TREB

SIF AGC GAIN DOWN

S-St-Point

S-Sp-Point

S-Step

Pow-Storage

S-B-BASS

SIF BPF WIDE LOW

APER-FREQ

CB-PEDESTEL-ADJ

BASS OFFSET

MID1 OFFSET

MID2 OFFSET

CONT NEWS

R MTX UP

SIF-BPF-WIDE

SIF-BPF-WIDE-574

CONT MUSIC

AS-SPEED (DOWN/UP)

MATRIX ADJ

AV2 Brightness OFFSET

WAIT MD TIME

Contrast OFFSET

MID3 OFFSET

Bright OFFSET

CR-PEDESTEL-ADJ

TREBLE OFFSET

R-DRI YUV OFFSET

B-DRI YUV OFFSET

R-CUT YUV OFFSET

G-CUT YUV OFFSET

B-CUT YUV OFFSET

BRT YUV OFFSET

SHP ANT-ONII OFFSET

CON YUV OFFSET

F134

-10..0..+10 -1 0

*FIX

F135

-10..0..+10 +1 +4

*FIX

F136

-10..0..+10 +1 +4

*FIX

F137

-10..0..+10 +1 0

*FIX

F138

-10..0..+10 0 -1

*FIX

F139

-10..0..+10 -1 -2

*FIX

F140

-10..0..+10 0 +2

*FIX

F141

-10..0..+10 -3 -3

FIX

F142

-10..0..+10 -1 -1

FIX

F143

-10..0..+10 +1 +1

FIX

F144

-10..0..+10 0 -2

*FIX

F145

-10..0..+10 +1 -2

*FIX

F146

-10..0..+10 -1 0

*FIX

F147

-10..0..+10 +5 +2

*FIX

F148

-10..0..+10 +3 +1

*FIX

F149

0(OFF) / 1(ON) 0 0

FIX

F150

0(OFF) / 1(ON) 1 1

FIX

F151

0(OFF) / 1(ON) 1 1

FIX

F152

-63…0…+63 +4 +4

FIX

F153

-63…0…+63 -5 -5

FIX

F154

-63…0…+63 -1 -1

FIX

F155

-63…0…+63 +6 +6

FIX

F156

-7 ~ 0 +7 +1 +1

FIX

F157

0…7 1 1

FIX

F158

0…7 3 3

FIX

F159

0/1 1 1

FIX

F160

0(OFF)/1(ON) 1 1

FIX

F161

-15…0 0 0

FIX

F162

0…8 1 1

FIX

F163

0…7 0 0

FIX

F164

0…7 3 3

FIX

F165

0(no Front-det)

1(Front-det)

0 0

FIX

F166

0(1-CHIP)

1(SHAKIT)

0 0

FIX

F167

-31…0…+31 0 0

FIX

F168

-31…0…+31 0 0

FIX

F169

0…63 30 30

FIX

F170

0 : 5ms

1 : 10ms

2 : 15ms

3 : 20ms

1 1

FIX

VD3 / VD2 / VD1-AV-YUV

CORNER UP-LOW ENABLE

VD3 / VD2 / VD1-TV

AUTO SCM-BR OFFSET

GLARE/SAVE MODE OFFSET

FRONT-DET

BOW/ANGLE ENABLE

SHP-NR-OFFSET

RGB MUTE TIME

SURROUND

AUTO SCM-BB OFFSET

H-BLK LEFT

H-BLK RIGHT

B-R-C

R-B-C

B-B-C

TRE OFFSET SUR ONII

S-BOOST NEWS

S-BOOST MUSIC

S-BOOST MOVIE

R-R-C

EQ MID3 MOVIE

EQ TRE NEWS

EQ TRE MUSIC

EQ TRE MOVIE

EQ MID2 MUSIC

EQ MID2 MOVIE

EQ MID3 NEWS

EQ MID3 MUSIC

EQ MID1 NEWS

EQ MID1 MUSIC

EQ MID1 MOVIE

EQ MID2 NEWS

EQ BASS NEWS

EQ BASS MUSIC

EQ BASS MOVIE

H-STOP DELAY

7-1

Page 8

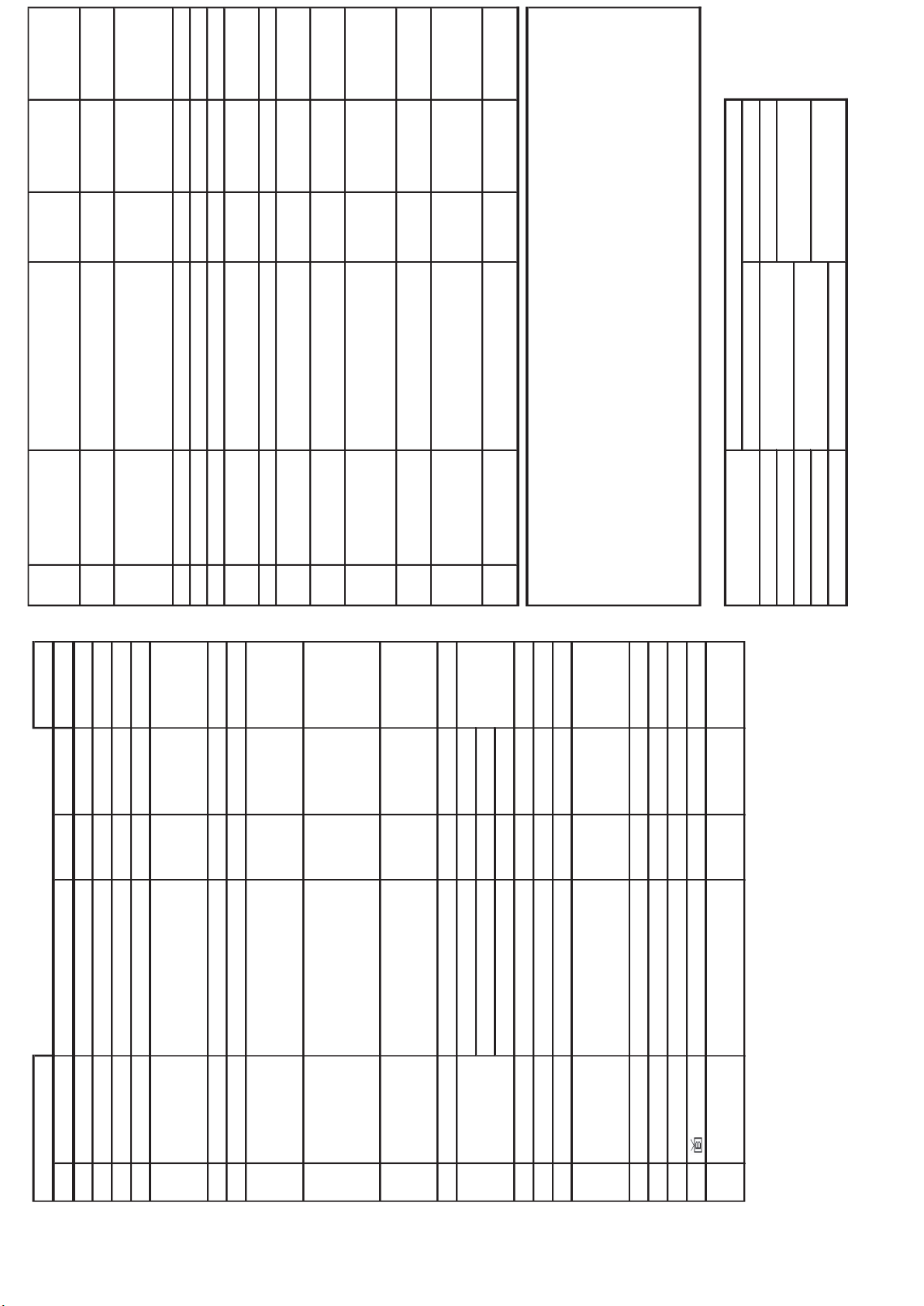

Setting data

Data OPTION FUNCTION Description Range Default Data 21DXS200

O01 ***HTL OFF/ON 0/1 0 0

O02 ***HTL-POS Pos-No,Nil 0…99,-- -- --

O03 ***HTL-VOL Vol-Lvl, Nil 0…60,-- -- --

O04 HTL-MENU KEY Dis/Ena MENU key in HTL mode 0/1 1 1

O05 COL-SYSTEM

0: PAL only

1: 18-system

2: 21-system

0…2 2 2

O06 Force-Col Dis/Ena 0/1 0 0

O07 S-SYS M/DK/I/BG 1…15 15 15

O08 AV

0: No AV

1: AV

2: AV1/AV2

0…2 2 2

O09 YUV

0 : without COMPONENT

1 : COMPONENT (share with AV1)

2 : COMPONENT (individual)

0…2 2 1

O10 S-CTRL

0 : without SOUND-MENU

1 : TONE

2 : EQUALIZER

0…2 2 2

O11 BIL Dis/Ena 0/1 0 0

*/*/A/M/R/F/*/E 1…255 61

*/V/*/M/*/F/C/E 1…255 87

*/*/*/*/*/*/T/E 1…255 3

O13 SERCH-SP 350/450/550/650/750 1…5 3 5

O14 R/C-MENU Ena/Dis 0/1 0 0

O15 LED-CONT One LED/ Two LEDs 0/1 0 0

O16

S-BOOSTER

0: No S-BOOSTER

1: Using DAC IC

2: Using PWM port

0…2 0 0

O17 VOL CURVE Dis/Ena 0/1 0 1

O18

**TUNER BAND Refer to Table 1 0/1 0 0

O19

WHITE BACK Dis/Ena 0/1 1 0

O20 BOOSTER Dis/Ena 0/1 0 1

O21

250 CHANNEL

0 : 100 channels(8k EEPROM)

1 : 250 channels(16k EEPROM)

0/1 0 0

1

Option Mode (Fourth stage)

LANG

O12

O22

AVL

0 : fix to 0

1 : fix to 1

2 : AVL in SOUND MENU

0…2 2 2

O23

LNA TUNER

0 : ALPS

1 : MATSUSHITA

0/1 0 1

O24

NORMAL KEY

Set items to default for

0 : Picture and Sound

1 : Picture only

0/1 0 0

O25

AV MODE Dis/Ena 0/1 1 1

O26

MP-IN Dis/Ena 0/1 1 0

O27

VIRGIN-MODE Dis/Ena 0/1 0 0

O28

WHITE-TEMP

0 : 3 modes

1 : 5 modes

0/1 0 0

O29

LK MENU Dis/Ena 0/1 0 0

O30

ARROW-KEY

0 : CH

△

/

▽

, VOL+/-

1 : /, /º%

0/1 1 1

O31

VOL-TABLE

0 : 7-bit volume table

1 : 8-bit volume table

0/1 0 0

O32

GLARE/SAVE MODE

0: No GLARE/SAVE MODE

1: GLARE MODE

2: SAVE MODE

0…2 1 2

O33

LANGUAGE

PACKAGE

0 : 5-language(E/M/F/R/A)

1 : Vietnam(E/M/F/C/V)

0/1 0 0

O34

CONTRAST TABLE

0 : (-105~0) contrast table

1 : (-60~0) contrast table

2: (-30 ~ 0) contrast table

0…2 0 0

O35

BRIGHTNESS

TABLE

0: (-60 ~ +60) brightness table

1: (-30 ~ +30) brightness table

0/1 0 0

*** HOTEL MODE

OPERATION OF HOTEL MODE:

WHEN CHANGE SERVICE DATA O01 TO 1, HOTEL MODE IS ON

WHEN HOTEL MODE IS ON,

1. Max volume data is determined by option setting HTL-VOL (O03)

2. Channel position after POWER ON is determined by option setting HOTEL-POS (O02) (if option setting

HOTEL-POS is not set, processing is according to last position data).

3. User data updates of EEPROM regarding the video and audio control is not allowed.

4. Preset mode is disable.

5. CH SETTING menu is not available.

* *TUNER BAND

TUNER BAND = 0 (same as GA6)

VHF-L (0001)

VHF-H (0010)

UHF (1000)

TABLE 1

VHF-H (0010)

BAND

P-Freq

122.15MHz ~ 143.10MHz

TUNER BAND = 1

VHF-L (0001)

41.10MHz ~ 122.10MHz

143.15MHz ~ 362.10MHz

362.15MHz ~ 426.10MHz

UHF (1000)

426.15MHz ~ 871.10MHz

8-1 8-2

Page 9

PIF ADJUSTMENT CHECKING

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 RF-AGC (1) Receive "PAL COLOR BAR" signal.

* for Auto ADJ

TAKE OVER POINT

Signal Strength:

refer to *Note 1

1)Receive "PAL COLOR BAR" signal

ADJUSTMENT (2) Connect the oscilloscope to TP201 (Tuner's AGC Terminal) as shown in

signal strength :

refer to *Note 1

(I2C BUS CONTROL) figure 3-1. 1) Go to service mode.

OSCILLOSCOPE 2) Go to service data V01, press R/C to operate

(AUTO & MANUAL ADJ)

auto key (Hex C1) and confirm the 'OK'

display on the screen.

3) If appear NG, increase data some step and

pls repeat step 2.

BIAS BOX 4) Proceed step 4 & 5 in manual mode.

TV SET

Bias Box : about 4.5V

*Note 1

Fig. 3-1

(3) Call "

V01

" mode in service mode. Adjust the "

V01

" bus data to obtain the Tuner

output pin drop

0.1~1.0V

below maximum voltage.

21DXS200

63 ~ 67dBµV

(4) Change the antenna input signal to

*Note 1

, and make sure there

is no noise.

(5)Turn up the input signal to 90 ~ 95 dBµV to be sure that there is no cross

modulation beat.

FOCUS ADJUSTMENT

NO ADJUSTMENT POINT ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR REMARKS

1 FOCUS (1) Receive the "Monoscope Pattern" signal.

(2) Press RESET to set Picture NORMAL condition.

(3) Adjust the focus control to get the best focusing.

ADJUSTMENT PRECAUTION : Make sure TV Set is in "NORMAL CONDITION" before switch to Service Mode for Adjustment.

Model

Signal Strength

Antenna Input Signal

56 ± 1dBµV (75 open)

+ -+

-

TP201

0.1V

Focusing Point

(middle of center and

edge of monoscope

pattern)

9-1 9-2

Page 10

H-VCO, VIF-VCO & S-TRAP fo ADJUSTMENT

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 H-VCO ADJ

(Manual Adj)

(I2C BUS CONTROL) (1) In No signal (RASTER) condition.

(AUTO & MANUAL ADJ)

(2) Go to service mode, choose service data

V03

.

(3) Connect oscilloscope to

IC801 pin13 (H-OUT)

, adj

V03

until freq

become

15.625 ± 0.15 KHz.

(Auto Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode.

(3) Choose service data

V03

, by pressing R/C

Auto (Hex C1)

key, OSD will appear "OK"

at screen.

(4) If appear "NG" pls repeat step 3.

2 VIF-VCO ADJ

(Manual Adj)

*NOTE:

(I2C BUS CONTROL) (1) In No signal (RASTER) condition.

This adjustment must be done after aging

(AUTO & MANUAL ADJ)

(2) Go to service mode, choose service data

V02.

at least 3 minutes.

(3) Connect oscilloscope to

IC801 pin7 (AFT)

, adj

V02

until voltage become

2.5 ± 1 V.

(Auto Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data

V02.

(3) Press the R/C

Auto (Hex C1)

key, OSD will appear "OK" at screen.

(4) If appear "NG" pls repeat step 3.

3 S-TRAP fo ADJ

(

Manual ADJ

)

(I2C BUS CONTROL) (1) In No signal (RASTER) condition.

(AUTO & MANUAL ADJ)

(2) Go to service mode, choose service data

V20.

(3) Connect oscilloscope to

TP 801

, adj

V20

until voltage become

Min

(below 5 V).

(4) After that pls adj service data

V19& V23 same as "V20", V21 to "V20+ 1", V22 to "V20-2".

(

Auto Adj

)

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data

V20 (S-TRAP I).

(3) Press the R/C

Auto (Hex C1)

key, OSD will appear "OK" at screen.

(4) If appear "NG" pls repeat step 3.

HORIZONTAL ,VERTICAL,DEFLECTION LOOP ADJUSTMENT (1)

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 V-SHIFT (1) Receive Monoscope Pattern Signal (PAL 50 Hz). Figure A B

(I2C BUS CONTROL)

(2) Choose the service data

V12

.

(3) Adjust

V12

to align the center of the screen to the geometric center of CRT.

Note: B line (Monoscope middle line) must same or nearest higher position

to the A mark (Tube middle mark),refer to the attach drawing.

OK OK NG

2 V-SIZE (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V11

.

(to be done after V-shift adj)

(3) Adjust

V11

bus data until the overscan become

10 ± 1.5 %.

Caution 1: Pls aging TV more than 10 minutes before adjustment

3 V-LINEARITY (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V29

.

(3 )Already preset. (Adjust this unless the linearity is not achieved.)

4 VS CORRECTION (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V27

.

(3 )Already preset. (Adjust this unless the linearity is not achieved.)

5 H-SHIFT (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V13

.

(3) Adjust the

V13

bus data to have a balance position to spec of

A=B

(as attach drawing).

A B

(4) If cannot make it to

A=B

, adjust from the best point so that A slightly smaller than B.

6 H-SIZE (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V36

(3) Adjust

V36

bus data until the overscan becomes

10 ± 1.5 %.

7 PARABOLA (1) Receive CrossHatch Pattern Signal (PAL 50Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V32

Adjust the 2nd vertical line from the right end of the crosshatch pattern

so that the middle 4 blocks are straight.

(3) Make sure both left / right of 2nd vertical line at optimum point

10

Page 11

HORIZONTAL ,VERTICAL,DEFLECTION LOOP ADJUSTMENT (2)

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

8 UPPER CORNER (1) Receive CrossHatch Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V38

(3) Adjust the 2nd upper vertical line from the right end of the crosshatch pattern

so that the upper line are straight.

(4) Make sure both left / right of 2nd vertical line at optimum point

9 LOWER CORNER (1) Receive CrossHatch Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V40

(3) Adjust the 2nd lower vertical line from the right end of the crosshatch pattern

so that the bottom line are straight.

(4) Make sure both left / right of 2nd vertical line at optimum point

10 BOW-ADJ (1) Receive CrossHatch Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V44 BOW ADJ

(3) Adjust the 2nd vertical line from the end of the crosshatch pattern until line is straight

11 ANGLE ADJ (1) Receive CrossHatch Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V42

(3) Adjust the 2nd vertical line from the end of the crosshatch pattern line is straight

(4) Make sure both left / right of 2nd vertical line at optimum point

12 TRAPEZIUM (1) Receive CrossHatch Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V34

(3) Adjust the 2nd vertical line from the right end of the crosshatch pattern

so that the D1 (center area of the second vertical line - edge of screen)

and D2 (top area of the second vertical line - edge of screen) are same.

(4) Make sure both left / right of 2nd vertical line at optimum point

13 FINAL INSPECTION OF (1) Receive CrossHatch Pattern Signal (PAL 50Hz).

ADJUSTMENT (2) Please make sure picture distortion (overall picture quality) must be balance at

optimum point TOP / BOTTOM at LEFT / RIGHT corner. A1 A2

(3) If NG, please RE-ADJUST follow step 7 to 13 or adjust at NG position to get best A1 B1 B2

picture quality C1 C2

D1 = D2

D2

D1

D2

D1

A1B1C1

A2

D1

B2

D2

C2

~

~

~

~

~

~

OVERALL PICTURE QUALITY MUST

BE BALANCE AT OPTIMUM POINT (

LEFT & RIGHT )

H-BOW

11

Page 12

SCREEN, WHITE BALANCE, SUB-BRIGHTNESS & SUB-CONTRAST ADJUSTMENT (1)

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1

SCREEN

(1) In window pattern signal condition

ADJUSTMENT Note 1:

(I2C BUS CONTROL) (2) Go to service mode, then select V00. R-CUTOFF (R-C) UP

RC key "1" (HEX 80)

R-CUTOFF (R-C) DOWN

RC key "4" (HEX 20)

(3) By pressing R/C key

S-Mute (Hex E8)

,

R-D

auto switch to

63

,

B-D

auto switch to

63

,

G-CUTOFF (G-C) UP

RC key "2" (HEX 40)

R-C

auto switch to

127

,

G-C

auto switch to

127

,

B-C

auto switch to

127

,

G-CUTOFF (G-C) DOWN

RC key "5" (HEX A0)

Sub-brightness V06

auto switch to

127.

B-CUTOFF (B-C) UP

RC key "3" (HEX C0)

Y-mute & Vertical off, screen will be in

vertical cut-off

condition

B-CUTOFF (B-C) DOWN

RC key "6" (HEX 60)

R-DRIVE (R-D) UP

RC key "7" (HEX E0)

(4) Adjust the Screen so that cut-off line appear in low bright, then judge that whether

R-DRIVE (R-D) DOWN

RC key "Flashback" (HEX E4)

the cut-off line appear in Red or Green or Blue color, in this condition between R-C &

B-DRIVE (B-D) UP

RC key "8" (HEX 10)

G-C & B-C, fix the data of the color appear in cut-off line and adj the other two cut-off

B-DRIVE (B-D) DOWN

RC key "0" (HEX 50)

data (Note 1) so that cut-off line color become white.

(5)Turn the screen VR of FBT so that cut-off line just

disappea

r and use R/C

by pressing key

S-Mute (Hex E8)

to

disable

the Y-mute & V-cut so that picture

appear in normal mode.

2 WHITE BALANCE ADJ

(1)WHITE (HIGH BEAM)

( In Window Pattern Signal)

(to be done after screen

First use Minolta Color Analyzer CA100, let the gun point at

Dark White

position

adj)

(as drawing attach), Adj

V06

until

LUMINANCE Y

become

4 cd/m2

, then let the gun

(I2C BUS CONTROL)

point at

White

position ( as drawing attach), Adj

V04

until

LUMINANCE Y

become:

150 cd/m2.

White Dark

In service mode V00, adj the

R-D

&

B-D

until the axis of color temperature become White

12300°K X : 0.272 , Y : 0.275

5.5% IRE 9.5% IRE

(2) DARK WHITE (LOW BEAM)

(In Window Pattern Signal)

Let the gun point at

Dark White

position, if the color temperature data shift away from

*Note :

Signal using W/B Pattern Generator

the data adjusted in

step 1

, adjust

R-C, G-C & B-C but between them, first color

SX-1006 (IWATSU) or equivalent.

appears

in

Screen adj item (4) is fixed

, adj the other two so that to obtain the similar Window Pattern Signal output level

axis as above. are as above:

** Repeat step 1 & 2 to get a regulated position

WINDOW PATTERN SIGNAL

50% IRE

SCREEN, WHITE BALANCE, SUB-BRIGHTNESS & SUB-CONTRAST ADJUSTMENT (2)

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

3 SUB-BRIGHTNESS (1) In Window Pattern Signal condition.

(to be done after screen,

(2) Using Minolta Color Analyzer CA-100, let the gun point at

Dark White

position

white balance adj)

(as attach drawing), adjust

V06

Bus data until

LUMINANCE Y = 4 cd/m2

(I2C BUS CONTROL)

Service

Luminance

Mode (cd/m2)

Upper Limit Lower Limit

Enable 4.0 +0.5 -0.5

Disable 4.0 +1.5 -0.5

4 SUB-CONTRAST (1) In Window Pattern Signal condition.

(to be done after screen,

(2) Using Minolta Color Analyzer CA-100, let the gun point at

White

position (as

white balance adj,

attach drawing), adjust

V04

Bus data until

LUMINANCE Y

= 150cd/m2

sub-brightness adj)

(I2C BUS CONTROL)

Service

Luminance

Mode (cd/m2)

Upper Limit Lower Limit

Enable 150.0 +10 -10

Disable 150.0 +10 -10

White

5 BEAM CURRENT (1) Receive the "Monoscope Pattern" signal.

CHECK

(2) Press R/C to set Picture NORMAL condition.

(3) Connect the DC miliammeter between TP 603 ( + ) & TP 602 ( - )

(Full Scale: 3mA Range).

(4) Beam current must be within :

1000 ± 100µA

Tolarance (cd/m2)

Tolarance (cd/m2)

Dark White

WINDOW PATTERN SIGNAL

WINDOW PATTERN SIGNAL

12-1 12-2

Page 13

PAL CHROMA ADJUSTMENT

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 SUB COLOUR (1) Receive the "PAL Color Bar" signal. Cy G B

(I2C BUS CONTROL) (2) Press R/C to set Picture Normal condition.

(to be done after

sub-picture, sub-tint adj)

(3) Connect the oscilloscope to

R-Amp Transistor Base

(JUMPER 401)

Range :

100mV/Div

(AC) (Using 10:1 Probe)

Sweep Time :

10µsec/Div

75% W Y 100% W Mg R

(4) Using the R/C call

V05

in SERVICE mode. Adjust

V05

bus data, so that the 75% White & Red portions of PAL Color Bar be

at the

same level

shown as Fig 1-1. Fig. 1-1

(5) Clear the SERVICE mode.

NTSC CHROMA ADJUSTMENT

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 SUB-TINT (1) Receive the "NTSC 3.58 Color Bar" signal thru AV in.

straight line slope

(I2C BUS CONTROL)

(2) Connect the oscilloscope to B-AMP Transistor Base

(JUMPER 410)

.

Range :

100mV/Div

(AC)

Sweep time :

10µsec/Div

(3) In Service mode, go to

V07, then

press

R/C Y-mute (Hex E4)

or

FLASHBACK

key.

(4) Call the "

V07

" data in service mode. Adjust the "

V07

" bus

data to obtain the waveform shown as Figure 1-1.

(5) Disable

Y-Mute

by pressing key

(Hex E4

) or

FLASHBACK

, then clear the

SERVICE mode. *NOTE : Please make sure waveform is adjusted until getting

good step slope which is can be a straight line slope at the

top of waveform step.

W Y Cy G Mg R B

Fig.1-1

SECAM CHROMA ADJUSTMENT

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 SECAM 1) Receive "SECAM ALL WHITE" signal.

BLACK LEVEL

R-Y / B-Y

2) In the service mode, select service data

V14

.

Fig 2(a)

(I2C BUS CONTROL)

3) Connect oscilloscope to

TP 801

.

Offset

Range:

20mV/Div

(AC) (use 10:1 probe)

Sweep time:

20usec/Div

4) Adjust the

V14

so that the offset of R-Y to minimum, shown in

Fig 2(b)

, it means

adjust the offset of between No signal line and Signal line to minimum

Fig 2(b)

Offset

5) In the service mode, select service data

V15

.

6) Connect oscilloscope to

TP 801

.

Range:

20mV/Div

(AC) (use 10:1 probe)

Sweep time:

20usec/Div

7) Adjust the

V15

so that the offset of B-Y to minimum, shown in

Fig 2(b)

, it means

adjust the offset of between No signal line and Signal line to minimum

become 1 line

13-1 13-2

13

Page 14

PROTECTOR OPERATION CHECKING

NO

ADJUSTMENT POINT

WAVEFORM OR OTHERS

1 BEAM PROTECTOR (1) Receive "Monoscope Pattern" signal.

(2) Set CONTRAST MAX.

Note :

(3) Set BRIGHT MAX.

Select one of Q853/4/5 to do each short.

(4) During the Collector & Emitter of

Q853/4/5

short, make sure the

protector ON and switch to standby mode.

2 H, V PROTECTOR (1) Receive "Monoscope Pattern" signal.

(2) Connect output of Bias Box to

D602

cathode (C602 positive).

(3) Set voltage of Bias Box to

18V

and make sure the protector is not working.

(4) Set voltage of Bias Box to

28.5V

.

and make sure the protector is working.

3 OTHER PROTECTOR (1) Once finish rectified Electrolytic Capacitor short testing in + B line,

check all possible damaged components on +B line.

(Use random selected set for inspection)

A/V INPUT & OUTPUT CHECKING

NO

ADJUSTMENT POINT

WAVEFORM OR OTHERS

1 VIDEO AND AUDIO (1) Receive the "PAL Color Bar" signal (100% White Color Bar,

OUTPUT CHECK Sound 400 Hz 100% Mod).

(2) Terminate the Video output with a 75 ohm impedance.

Make sure the output is as specified

(1.0 Vp-p ± 3 dB).

(3) Terminate the Audio output with a 10K ohm impedance.

Make sure the O/P is as specified

(1.5 Vp-p ± 3 dB)

.

2 VIDEO AND AUDIO (1) Using the TV/VIDEO key on the remote controller, make sure that the modes

Caution:

INPUT CHECK change in order of TV, COMPONENT, AV1,AV2 & TV again and the video & audio output

AV1 share with YUV. Therefore, if YUV signal is connected to

are according to the input terminal for each mode.

Component In terminal, only component will be detected.

(2) Video cross-talk AV to TV checking :

a) When connect AV1 input, check TV also

b) When connect AV2 input, check TV also

3 COMPONENT IN (1) Connect YUV & Audio signal to Component In terminal and Audio terminal.

CHECK (2) Using the INPUT key on the remote controller, press it until the modes change to

COMPONENT confirm output is appear.

(3) Audio source is share with AV1

4 SUB WOOFER (1) Receive "PAL colour bar" signal ( Sound 400Hz, 100 % Mod.)

OUTPUT CHECK (2) Set the sound output to 500mW by volume key.

(3) Terminate the "Sub Woofer" output with a 22 k

W

impedance.

make sure that the output is : 4.0 Vp-p ± 3 dB

ADJUSTMENT CONDITION / PROCEDURE

ADJUSTMENT CONDITION / PROCEDURE

FUNCTION OPERATION CHECKING (VIDEO & AUDIO) (1)

NO

ADJUSTMENT POINT

WAVEFORM OR OTHERS

1 CONTRAST Key (1) Receive "Monoscope Pattern" signal.

(2) Set MENU, then go into PICTURE mode to select CONTRAST.

(3) Press Volume Up/Down key to check whether the CONTRAST effect is OK or not.

2 COLOUR Key (1) Receive "Color Bar" signal.

(2) Set MENU, then go into PICTURE mode to select COLOUR.

(3) Press Volume Up/Down key to check whether the COLOUR effect is OK or not.

3 BRIGHTNESS Key (1) Receive "Monoscope Pattern" signal.

(2) Set MENU, then go into PICTURE mode to select BRIGHTNESS.

(3) Press Volume Up/Down key to check whether the BRIGHTNESS effect is OK

or not.

4 TINT Key (1) Receive the "NTSC Colour Bar" signal thru AV in.

(2) Set MENU, then go into PICTURE mode to select TINT.

(3) Press Volume Up/Down key to check TINT, UP for GREEN direction and

DOWN for PURPLE direction whether is OK or not.

5 SHARPNESS Key (1) Receive "Monoscope Pattern" signal.

(2) Set MENU, then go into PICTURE mode to select SHARPNESS.

(3) Press Volume Up/Down key to check whether the SHARPNESS effect is OK

or not.

6 CH DISPLAY (1) All Ch (1~99) will have an OSD display of the channel number in green colour

COLOUR under AFT ON condition.

7 SURROUND (1) Receive "music" sound signal.

(2) Set MENU, then go into SOUND MENU to select SURROUND.

(3) Press VOLUME UP/DOWN key to check SURROUND I, II and OFF effect.

8 BALANCE (1) Receive mono-tone signal.

(2) Set MENU, then go into SOUND MENU to select BALANCE

(3) Press VOLUME UP/DOWN key to check whether the left to right BALANCE effect

is OK or not

9 EQUALIZER (1) Receive "music" sound signal.

(2) Set MENU, then go into SOUND MENU to select EQUALIZER.

(3) Press VOLUME UP/DOWN key to check EQUALIZER effect is OK or not

10 WHITE TEMP (1) Receive "Monoscope Pattern" signal.

(2) Set MENU, then go into PICTURE mode to select WHITE TEMP.

(3) Press Volume Up/Down key to check WHITE TEMP function.

The back ground will change to (shift right) bluish and (shift left) reddish.

ADJUSTMENT CONDITION / PROCEDURE

14-2

14-1

Page 15

CHECKING FUNCTION OPERATION (VIDEO & AUDIO) (2)

NO

ADJUSTMENT POINT

WAVEFORM OR OTHERS

11 NORMAL Key (1) Once in PICTURE or SOUND Mode, and the NORMAL key is pressed,

*Note:

all the settings will be preset to normal setting accordingly . In NORMAL Mode, when press NORMAL key,

(Normal setting value for every AV mode : NEWS/MUSIC/MOVIE) will appear NORMAL OSD and all setting

PICTURE MODE

NEWS MUSIC MOVIE

PICTURE, SOUND functions set to NORMAL.

CONTRAST 55 60 60

COLOUR 0 0 +3

BRIGHTNESS 0 0 0

TINT CENTER CENTER CENTER

SHARPNESS 0 0 +3

PICTURE NR OFF OFF OFF

WHITE TEMP Mid Mid Mid

SOUND MODE

SURROUND OFF OFF OFF

BALANCE 0 0 0

AVL ON ON ON

EQUALIZER MENU

* Bar indicator display 0~20

100 10 14 14

300 10 9 8

1K 12 7 9

3K 11 8 8

8K 10 12 11

12 COLOUR SYSTEM (1) Receive the "PAL COLOUR BAR" signal, press MENU, choose CH-SETTING to

select COLOR modes except PAL, check the COLOUR is not working properly.

Then, select the "PAL" mode. Check again its colour so that it is working properly.

(2) Receive "SECAM COLOUR BAR" signal, press MENU, choose CH-SETTING to

select COLOR modes except SECAM, check the COLOUR is not working properly.

Then, select the "SECAM" mode. Check again its colour so that it is working

properly.

(3) Receive "NTSC 4.43" signal, press MENU, choose CH-SETTING to

select COLOR modes except N443, check the COLOUR is not working properly.

Then, select the N443 mode. Check again its colour so that it is working properly.

(4) Receive "NTSC 3.58 COLOUR BAR" signal , press MENU, choose

select COLOR modes except N358, check the COLOUR is not working properly.

Then, select the N358 mode. Check again its colour so that it is working properly

13 SOUND SYSTEM (1) Receive "PAL-D/K" signal, press MENU, choose CH-SETTING then go into SOUND

mode to select B/G, I Check the sound output is not working properly.

Select D/K and check the sound output to make sure it is working properly.

(2) Receive "PAL-I" signal, press MENU, choose CH-SETTING then go into SOUND

mode to select B/G, D/K. Check the sound output is not working properly.

Select I and check the sound output to make sure it is working properly.

(3) Receive "PAL-B/G" signal, press MENU, choose CH-SETTING then go into SOUND

mode to select I, D/K. Check the sound output is not working properly.

Select B/G and check the sound output to make sure it is working properly.

(4) Receive "NTSC3.58 -M" signal, press MENU, choose CH-SETTING then go into

SOUND mode to select I, D/K. Check the sound output is not working properly.

Select M and check the sound output to make sure it is working properly.

ADJUSTMENT CONDITION / PROCEDURE

CHECKING FUNCTION OPERATION (VIDEO & AUDIO) (3)

NO

ADJUSTMENT POINT

WAVEFORM OR OTHERS

14 NOISE MUTE (1) Receive "PAL COLOUR BAR" signal.

CHECKING (2) Turn up the volume control to maximum, make sure the sound is

heard from the speakers. Then put the unit in no signal state.

(3) Check the sound mute is effective.

(4) Finally turn sound level of CTV to minimum.

15 OSD LANGUAGE (1) Check OSD LANGUAGE quantity and type for respect model.

QUANTITY CHECK

MODEL QUANTITY ENGLISH

21DXS200

1

O

SHOCK TEST CHECKING.

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 SHOCK TEST (1) Hit at the top of TV set for two time.

(2) Check TV set not damage and TV operation operate correctly.

ADJUSTMENT CONDITION / PROCEDURE

15-1 15-2

Page 16

Check IC801 and

Check signal appear

from pin (65) & (66) of

IC801 to pin (2) & (4) of

IC301

Check

Speaker

Check IC301 and

peripheral circuit

related circuit.

Check pin (47) of

IC801, Tuner and

related circuit.

Check pin (46) at

IC801 and related

Check the tuner AGC at

JA402.

circuit.

SOUND

NO PICTURE NO SOUND

Does noise or signal appear at pin (30)

of IC801 ?

Check pin (1) of

SF201, Tuner and

Does noise or

signal appear at

pin (48) and (49)

of IC801 ?

Tuner.

PIF.

Automatic Gain Control.

CIRCUITS TO BE CHECKED:

(5V), (32V) Power Source.

Normal

Check Q752 for 8V regulator

circuit and Q752, IC751, Q754

for 5V regulator circuit.

related circuit.

Check Q601,

Q602 and Q604

Normal

Does noise or

signal appear at

pin (8) ,(9),(11) (12)and

of IC301 ?

Does horizontal circuit

Check

NO RASTER

Check T701 pin (8) voltage

(Approx. 310V at 220V AC)

Check Secondary Main+B

(Approx. 125V)

Check CRT connector K-

wire and the signal on it.

Check D751,

IC702 and IC703

IC801

oscillate ?

Check IC801 pin 13

16

Page 17

Is the white balance properly

Check Q202

and peripheral

circuit

adjusted ?

Re-adjust the white balance.

The picture colour is yellow.The picture colour is magenta.The picture colour is cyan.

Check Q853 and its

adjacent circuits.

NO SPECIFIC COLOUR

Is some colour produced in

B/W broadcast reception ?

Check IC801.

Check Q844 and its

adjacent circuits.

Check Q855 and its

adjacent circuits.

NO COLOUR

Check IC1001 and bias

control circuit.

Check X801 (4.43MHz)

C515and

17-1 17-2

Check pins (9), (13),

and (14) of IC801.

Re-adjust vertical size.

(Bus Data)

Vertical linearity and size are

abnormal.

R520.

Check R503, R515, R513

R514.

NEITHER VERTICAL NOR

HORIZONTAL SYNCHRONIZATION

Sync. Separator Circuit.

CIRCUIT TO BE CHECKED:

AND VERTICAL LINEARITY

DEFECTIVE VERTICAL AMP.

VERTICAL SCAN

NO

Check C511

Page 18

(1)1.78 Vp-p

Horiz. Rate

(2)4.80 Vp-p

Horiz. Rate

(3)3.84 Vp-p

Horiz. Rate

(4)4.76 Vp-p

Horiz. Rate

(5)3.16 Vp-p

Horiz. Rate

(6)4.66 Vp-p

(7)5.60 Vp-p

Horiz. Rate

(8)1.57 Vp-p

Vert. Rate

(9)2.60 Vp-p

Horiz. Rate

(10)20.80 Vp-p

Horiz. Rate

(11)1110 Vp-p

Horiz. Rate

(12)63.40 Vp-p

Vert. Rate

(13)7.52 Vp-p

Vert. Rate

(14)147.00 Vp-p

Horiz. Rate

(15)542.00 Vp-p

-

(16)118.00 Vp-p

Horiz. Rate

Vert. Rate

(18)118.80 Vp-p

Horiz. Rate

(17)96.4 Vp-p

Horiz. Rate

WAVE FORM

18

Page 19

21EXS350

8 5

1 4

M24C16

CATHODE CATHODE

8-2

ANODE

EXA520WJ

5-1

EXA535WJ

T R

A1530

CATHODE

27-

ANODEANODE

EXA572WJ

J C

C2735

CATHODE

ANODE

ISS356

80 51

81

IXC844WJ

100

1

IXC844WJ

50

31

30

2SC3198-G

2SC3198-Y

PK0013

2SD468-C

CATHOD

ANODE (RED)

LA42102+

1

LA78041

C6090++1

7

CATHOD

KIA78R05

ANODE

DX0445CE

2SD1913

D3SB 60 74

DX0470CE

STRW6553

SE125N++

2SA1266

GND

COLLECTOR

Vout

19

Page 20

DESCRIPTION OF SCHEMATIC DIAGRAM

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC OUTLET BEFORE

REPLACING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE REGARDED AS

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH " " ( ) ARE IMPORTANT FOR

MAINTAINING THE SAFETY OF THE SET. BE SURE TO REPLACE THESE PARTS WITH SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

SERVICE PRECAUTION:

THE AREA ENCLOSED BY THIS LINE (

CONNECTED WITH AC MAINS VOLTAGE.

WHEN SERVICING THE AREA, CONNECT AN ISOLATING TRANSFORMER BETWEEN TV RECEIVER AND AC LINE TO ELIMINATE

HAZARD OF ELECTRIC SHOCK.

) IS DIRECTLY

NOTES:

1. The unit of resistance "ohm" is omitted.

(K = 1000 ohms, M = Mega ohm).

2. All resistors are 1/16 watt, unless otherwise noted.

3. All capacitors are mF, unless otherwise noted. (P = mmF).

VOLTAGE MEASUREMENT CONDITIONS:

1. Voltages in parenthesis measured with no signal.

2. Voltages without parenthesis measured with 3mV B & W or Colour signal.

3. All the voltages in each point are measured with VTVM.

WAVEFORM MEASUREMENT CONDITIONS:

1. The colour bar generator signal of 1.0V peak applied at pin (24)

of IC201.

2. Approximately 4V AGC bias .

20

Page 21

21ES251E / 21ES253E / 21ES353E

21

Page 22

MGR CHI ENG

MARTINUS DEDI S. DIAN T.

GA-8S CRT (All 21"US)

21EPS258E / 21EMS258E / 21ECS258E /

21ES251E / 21ES353E / 21ES253E

KZ018JCE

Page 23

21ES251E / 21ES253E / 21ES353E

Page 24

(N2)

6800p

4.7k

4.7k

1

1

C383

C384

1

C835

IC801

IXC844WJ

0.01u

6800p

0.1u

50V

0.1u

50V

21ES251E / 21ES253E / 21ES353E

C821

0.01u

C810

0.01u

RA832WJFW

RA759WJFW

EZB526WJ

RA874WJFW

NA890WJ

RA831WJFW

WA303WJ

PA024WJ

NA792WJ

CA054WJ

PA006WJ

VXA210WJ

MAIN GA8S

R1088

1K

RJ8

0

RJ9

0

MARTINUS DEDI S. DIAN T.

MGR CHI ENG

QA040WJN1

Page 25

COPYRIGHT © 20

ALL RIGHTS RESERVED.

Loading...

Loading...