Page 1

20MU14

SERVICE MANUAL

COLOR TELEVISION

Chassis No. CD-A

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified should be used.

20MU14

CONTENTS

Page

» ELECTRICAL SPECIFICATIONS......................................................................................................... 1

» IMPORT ANT SERVICE SAFETY PRECAUTION................................................................................. 2

»LOCATION OF USER'S CONTROL.....................................................................................................4

»INSTALLATION AND SERVICE INSTRUCTIONS................................................................................5

»CHASSIS LAYOUT............................................................................................................................10

»BLOCK DIAGRAM.............................................................................................................................11

»SCHEMATIC DIAGRAMS..................................................................................................................12

»PRINTED WIRING BOARD ASSEMBLIES........................................................................................15

»REPLACEMENT PARTS LIST...........................................................................................................18

»PACKING OF THE SET.....................................................................................................................23

ELECTRICAL SPECIFICATIONS

POWER INPUT................................120 V AC 60 Hz

POWER RATING .............................................69 W

PICTURE SIZE.......................1,194cm

CONVERGENCE........................................Magnetic

SWEEP DEFLECTION................................Magnetic

FOCUS...........................Hi-Bi-Potential Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency ................. 45.75 MHz

Sound IF Carrier Frequency .................. 41.25 MHz

Color Sub-Carrier Frequency ................ 42.17 MHz

2 (185sq inch)

(Nominal)

SHARP CORPORATION

AUDIO POWER

OUTPUT RATING...........1.0 W (at 10% distortion)

SPEAKER

SIZE .................................................. 8 cm (Round)

VOICE COIL IMPEDANCE...........8 ohm at 400 Hz

ANTENNA INPUT IMPEDANCE

VHF/UHF................................ 75 ohm Unbalanced

TUNING RANGES

VHF-Channels.......................................... 2 thru 13

UHF-Channels........................................ 14 thru 69

CATV Channels...................................... 1 thru 125

(EIA, Channel Plan U.S.A.)

Specifications are subject to change without

prior notice.

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

1

Page 2

20MU14

IMPORT ANT SER VICE SAFETY PRECAUTION

Ë

Service work should be performed only by qualified service technicians who are thoroughly

familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock

hazards when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material. The nonisolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit. The

isolated ground system is for the low B+ DC voltages

and the secondary circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A

RISK OF FIRE, REPLACE

4A 125V

ONLY WITH SAME TYPE 4A125V FUSE.

SERVICING OF HIGH VOL T AGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the picture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiver employs integral

implosion protection.

2. Replace with tube of the same type number for

continued safety .

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely .

X-RADIA TION AND HIGH VOL TAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation.

The only potential source of X-ray in current solid

state TV receivers is the picture tube. However, the

picture tube does not emit measurable X-Ray

radiation, if the high voltage is as specified in the

"High Voltage Check" instructions.

It is only when high voltage is excessive that Xradiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that servicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated value

-no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem.

Every time a color chassis is serviced, the brightness

should be tested while monitoring the high voltage

with a meter to be certain that the high voltage does

not exceed the specified value and that it is regulating

correctly .

5. Do not use a picture tube other than that specified

or make unrecommended circuit modifications to the

high voltage circuitry .

6. When troubleshooting and taking test measurements

on a receiver with excessive high voltage, avoid being

unnecessarily close to the receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

2

Page 3

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

20MU14

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators and etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

» Plug the AC cord directly into a 120 volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15mF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as electrical conduit or electrical

ground connected to earth ground.

» Use an AC voltmeter having with 5000 ohm per volt,

or higher, sensitivity to measure the AC voltage drop

across the resistor.

» Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon and etc.) and measure the AC voltage

drop across the resistor.

AII checks must be repeated with the AC ine cord

plug connection reversed. (If necessary, a nonpolarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp.

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage and etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by "å"

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

For continued protection, replacement parts must be

identical to those used in the original circuit. The use of

substitute replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

3

Page 4

20MU14

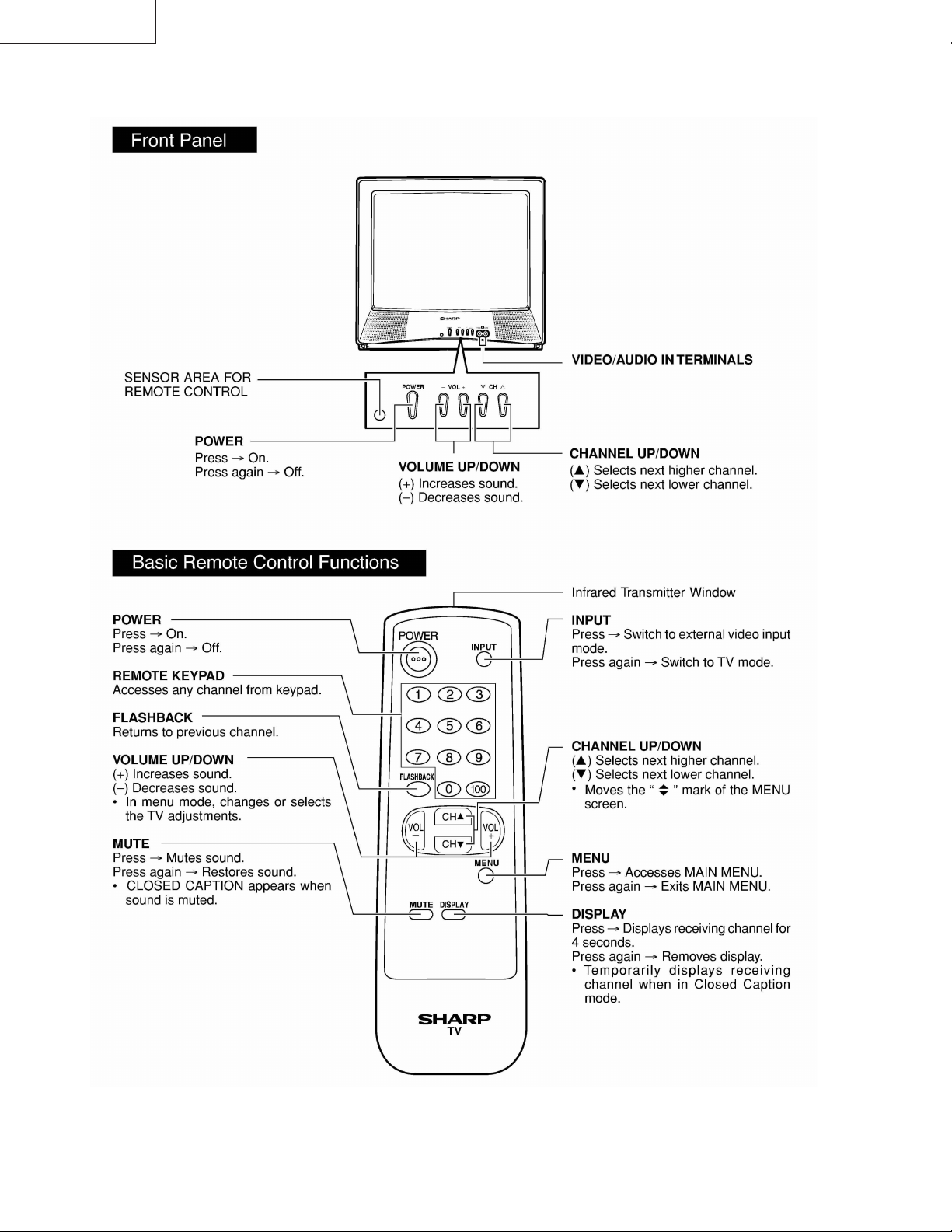

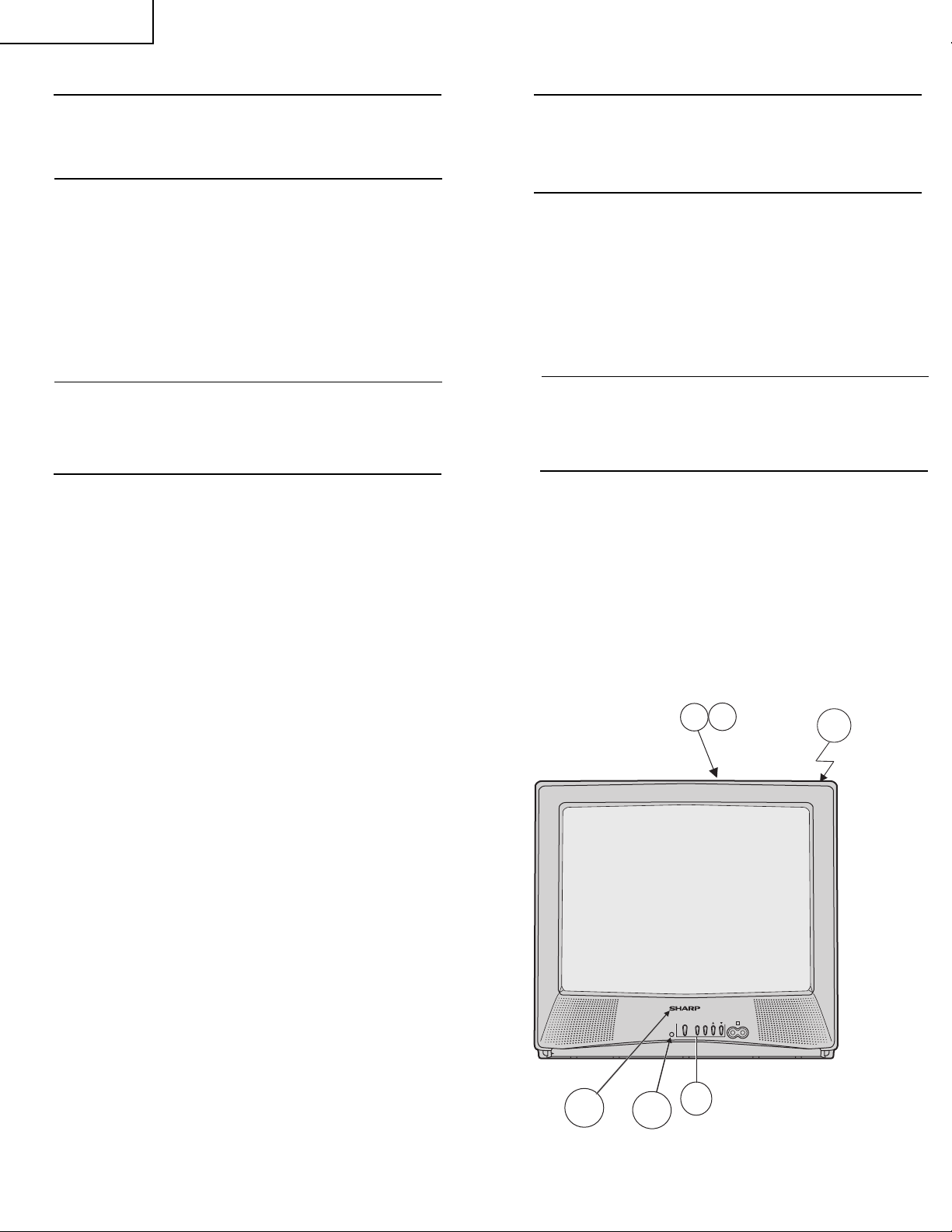

LOCATION OF USER'S CONTROL

4

Page 5

20MU14

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1)When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2)Before performing adjustments, the TV set must be on at least 15 minutes.

CIRCUIT PROTECTION

The receiver is protected by a 4.0A fuse (F701),

mounted on PWB-A, wired into one side of the AC

line input.

X-RADIA TION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high voltage system, +B system,

test the X-Radiation protection circuit to ascertain

proper operation as follows:

1) Apply 120V AC using a variac transformer for

accurate input voltage.

2) Allow for warm up and adjust all customer controls

for normal picture and sound.

3) Receive a good local channel.

4) Connect a digital voltmeter to TP653 and make sure

that the voltmeter reads 21.3 ±1.5 V.

5) Apply external 28.9V DC at TP653 by using an

external DC supply, TV must be shut off.

6) T o reset the protector, unplug the AC cord and make

a short circuit between TP651 and TP652. Now make

sure that normal picture appears on the screen.

7) If the operation of the horizontal oscillator does not

stop in step 5, the circuit must be repaired before

the set is returned to the customer.

HIGH VOL T AGE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 120V AC

line voltage, with a strong air signal or a properly

tuned in test signal.

3. Enter the service mode and select the service

adjustment "S19" and Bus data "01" (Y-mute on).

4. The voltage should be approximately, 26.0kV (at zero

beam).

If a correct reading cannot be obtained, check

circuitry for malfunctioning components. After the

voltage test, make Y-mute off to the normal mode.

5

Page 6

20MU14

For adjustments of this model, the bus data is converted to various analog signals by the D/A converter

circuit.

Note: There are still a few analog adjustments in this series such as focus and master screen voltage.

Follow the steps below whenever the service adjustment is required. See "Table-B" to determine, if service adjustments are required.

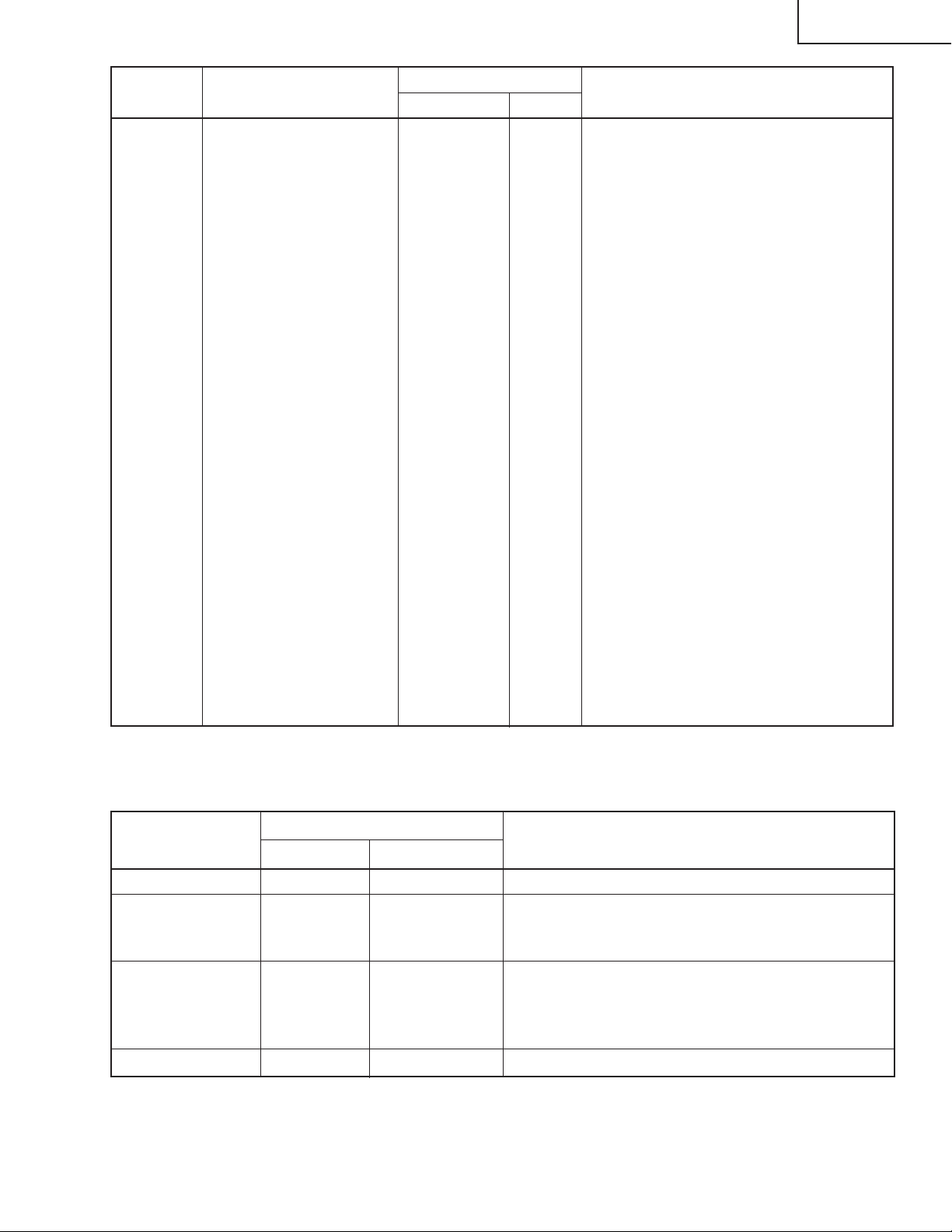

1. Service mode

Before putting unit into the service mode, check that

customer adjustments are in the normal mode. Use

the reset function in the video adjustment menu to

ensure customer controls are in their proper (reset)

position.

2. Service number selection

Once in the service mode, press the Ch-up or Chdown button on the remote controller or at the set.

The service adjustment number will vary in

increments of one, from "S01" to "OP". Select the

item you wish to adjust.

3. Data number selection

Press the Vol-up or down button to adjust the data

number.

DATA NUMBER

SERVICE ADJUSTMENT NUMBER

To enter the service mode and exit service

mode.

While pressing the Vol-up and Ch-up buttons at the

sametime, plug the AC cord into a wall socket.

Now the TV set is switched on and enters the service

mode.

To exit the service mode, turn the television off by

pressing the power button.

CHANNEL

S01

Figure A.

55(085)

02

S01 D:00

6

Page 7

20MU14

SERVICE

NUMBER

S01 PICTURE 55 00-7F

S02 TINT 46 00-7F

S03 COLOR 32 00-7F

S04 BRIGHTNESS 40 00-7F

S05 SHARPNESS 28 00-3F Must be set to "24"

S06 VERTICAL PHASE 00 00-07 Must be set to "00" ~ "03"

S07 HORIZONTAL PHASE 12 00-1F

S08 RF-AGC 23 00-3F

S09 VERTICAL AMP 20 00-3F

S10 VCO 2C 00-7F

S11 R CUT-OFF 00 00-FF

S12 G CUT -OFF 00 00-FF

S13 B CUT-OFF 00 00-FF

S14 G GAIN 7F 00-FF

S15 B GAIN 7F 00-FF

S16 TRAP(3.58MHz) 00 00 or 01 Must be set to "00"

S17 BALANCE 20 00-3F Must be set to "20"

S18 C.C.POSITION 17 00-7F

S19 Y-MUTE 00 00,01,03

S20 ENERGY SA VE OFFSET 20 00-3F Must be set to "23"

S21 D.D.E. OFFSET 03 00-1F Must be set to "03"

S22 OSD SETUP 00 00-03 Must be set to "00"

S23 TUNER SETUP 00 00-01 Must be set to "00"

OP OPTION 30 00-FF Must be set to "02"

ADJUSTMENT ITEM

INITIAL VALUE

DATA

ADJUSTMENT CONTENTS

RANGE

"00" = NORMAL, "01" = No Y, "03" = No VERTICAL

Table - A

Holding down both the CH-up/down buttons on the TV set at service mode for more than 2 seconds will automatically

write the above initial values into IC2101.

PART REPLACED

IC2001

IC201

IC2101 X

CRT X

ADJUSTMENT

NECESSARY

X

UNNECESSARY

X

Data is stored in IC2101.

The adjustment is needed to compensate for characteristics

of parts including IC201.

Holding down both the CH-up/down buttons on the TV set in

the service mode for more than 2 seconds will automatically

write the above initial values into IC2101.

Adjust items related to picture tube only.

NOTES

Table - B

7

Page 8

20MU14

Ë

SERVICE ADJUSTMENT

VCO Adjustment

1. Connect a digital voltmeter between pin (44) of IC201

and ground.

2. Receive a good local channel.

3. Enter the service mode and select the service

adjustment "S10".

4. Adjust the data so that digital voltmeter reads 2.2V.

5. Adjustment is completed, remove the voltmeter,

return to "normal" mode.

RF AGC Adjustment

1. Receive a good local channel.

2. Enter the service mode and select the service

adjustment "S08".

3. Set the data value to point where no noise or beat

appears.

4. Select another channel to confirm that no noise or

beat appears.

Note 1: You will have to come out of the service

mode to select another channel.

Note 2: Setting the data to "00" will produce a black

raster.

White Balance Adjustment

1. Receive a good local channel.

2. Enter the service mode and select the service

adjustment "S03" and set to "00" (minimum

color)(Record original data code under adjustment

"S03" before changing). "S03" does not have to be

adjusted, if you selected a B/W picture or monoscope

pattern.

3. Alternately adjust the service adjustment data of

"S14" and "S15" until a good grey scale with normal

whites is obtained.

4. Select the service adjustment "S03" and adjust data

to obtain normal color level.

Sub-Picture Adjustment

1. Receive a good local channel.

2. Make sure the customer picture control is set to

maximum.

3. Enter the service mode and select the service

adjustment "S01".

4. Adjust the data value to achieve normal contrast

range.

Screen Adjustment

1. Connect a digital voltmeter between TP852 and

TP853 on the CRT Unit.

Note: These test points may not be provided.

Then connect the voltmeter to both ends of

R852 located near Q852 on the foil side.

2. Receive a good local channel.

3. Enter the service mode and select the service

adjustment "S03" and set the data value to "00" to

set the color level to minimum. (Record original data

code under adjustment "S03" before changing) You

may skip this step, if you selected a B/W picture or

monoscope pattern.

4. Select the service adjustment "S19" and adjust the

data value to "01", this turn off the luminance signal

(Y -mute).

5. Select the service adjustment "S04" and adjust data

value to obtain 0.17 volts on the digital voltmeter.

6. Adjust the master screen cotrol until the raster

darkens to the point where raster is barely seen.

7. Adjust the service adjustments "S11" red, "S12"

green and "S13" blue to obtain a good grey scale

with normal whites at low brightness level.

8. Select the service adjustment "S19" and reset data

to "00". Select the service adjustment "S03" and reset

data to obtain normal color level.

9. Remove digital voltmeter, and reset the master

screen control to obtain normal brightness range.

Sub-Tint Adjustment

1. Receive a good local channel.

2. Set customer tint control to center of it's range.

3. Enter the service mode and select the service

adjustment "S02".

4. Adjust "S02" data value to obtain normal flesh tones.

Sub-Color Adjustment

1. Receive a good local channel.

2. Make sure the customer color control is set to center

position .

3. Enter the service mode and select service

adjustment "S03".

4. Adjust "S03" data value to obtain normal color level.

8

Page 9

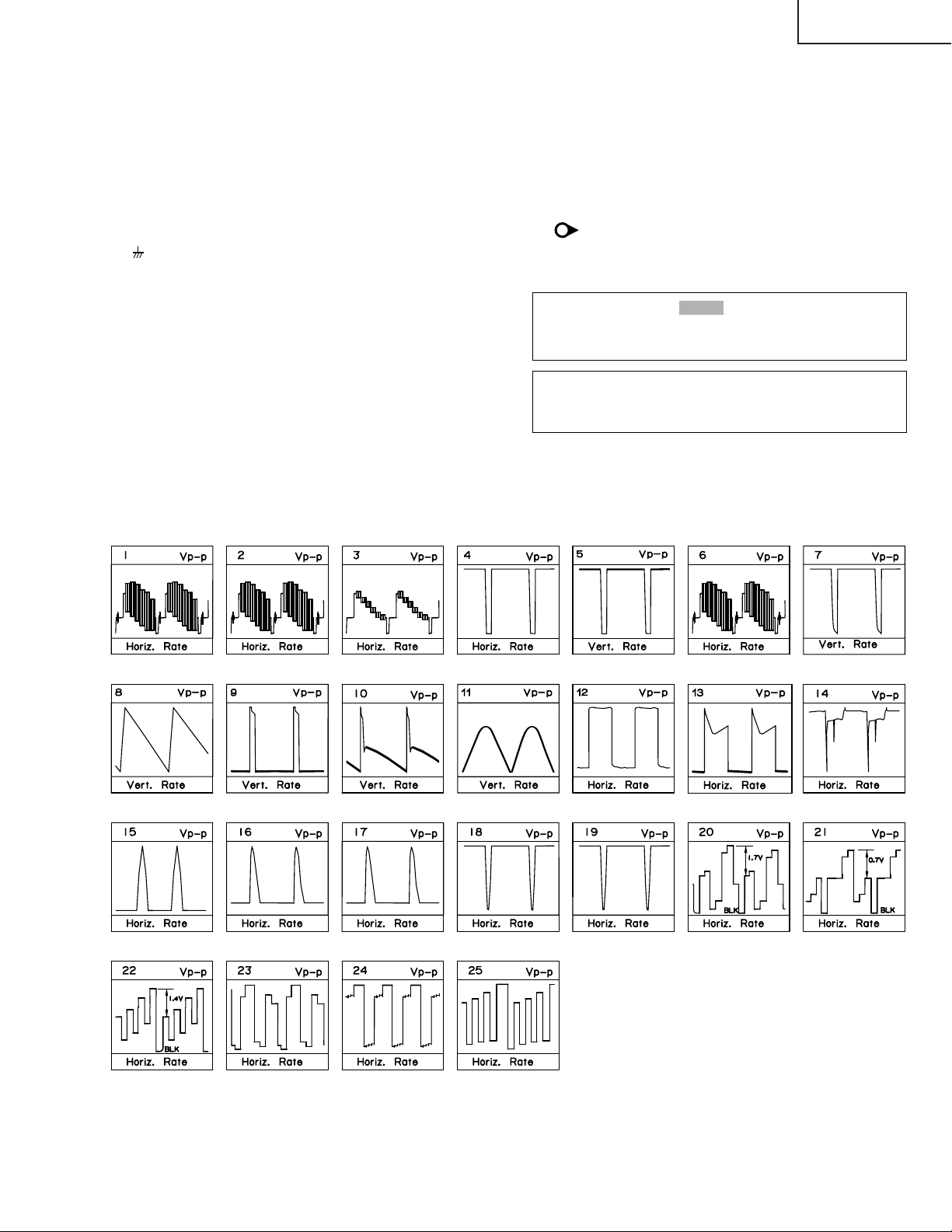

DESCRIPTION OF SCHEMATIC DIAGRAM

20MU14

NOTES:

1. The unit of resistance "ohm" is omitted.

(K=kΩ=1000Ω, M=MΩ)

2. All resistors are 1/10 watt, unless otherwise noted.

3. All capacitors are µF, unless otherwise noted.

(P=pF=µµF)

4. (G) indicates ±2% tolerance may be used.

5. indicates line isolated ground.

VOLTAGE MEASUREMENT CONDITIONS:

1. All DC voltages are measured with DVM connected

between points indicated and chassis ground, line

voltage set at 120V AC and all controls set f or normal

picture unless otherwise indicated.

2. All voltages measured with 1000µV B & W or Color

signal.

WAVEFORMS

1.0

1.0

0.9

WAVEFORM MEASUREMENT CONDITIONS:

1. Photographs taken on a standard gated color bar

signal, the tint setting adjusted for proper color. The

wave shapes at the red, green and blue cathodes of

the picture tube depend on the tint, color level and

picture control.

2.

indicates waveform check points (See chart,

waveforms are measured from point indicated to

chassis ground.)

å

AND SHADED ( ) COMPONENTS

= SAFETY RELATED PARTS.

'

MARK= X-RAY RELATED PARTS.

This circuit diagram is a standard one, printed

circuits may be subject to change for product

improvement without prior notice.

5.0

5.0

2.1

1.0

1.2

1160

1.4

25

220

105

47

150

95

4.6

133

105

0.7

220

33

1.7

39.0

0.7

9

Page 10

20MU14

CHASSIS LAYOUT

H

G

F

E

NORMAL

D

PR701

C708

C

B

A

10

654321

Page 11

BLOCK DIAGRAM

H

G

F

20MU14

E

D

C

B

A

654321

11

Page 12

20MU14

SCHEMATIC DIAGRAM: MAIN-1 Unit

H

G

F

E

D

C

B

A

87 109654321

12

Page 13

20MU14

13

1716 1918151413121110

Page 14

20MU14

H

G

F

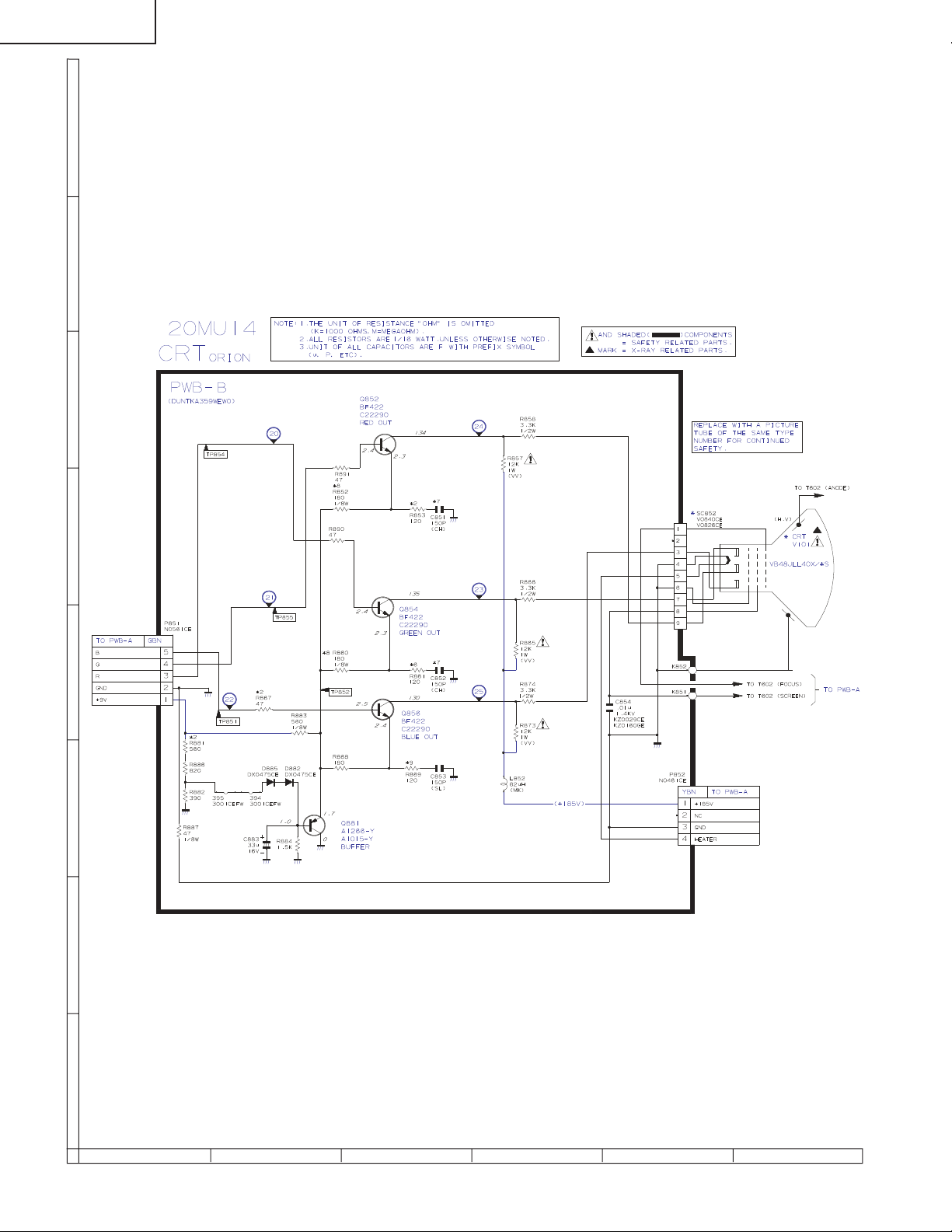

SCHEMATIC DIAGRAM: CRT Unit

E

D

C

B

A

654321

14

Page 15

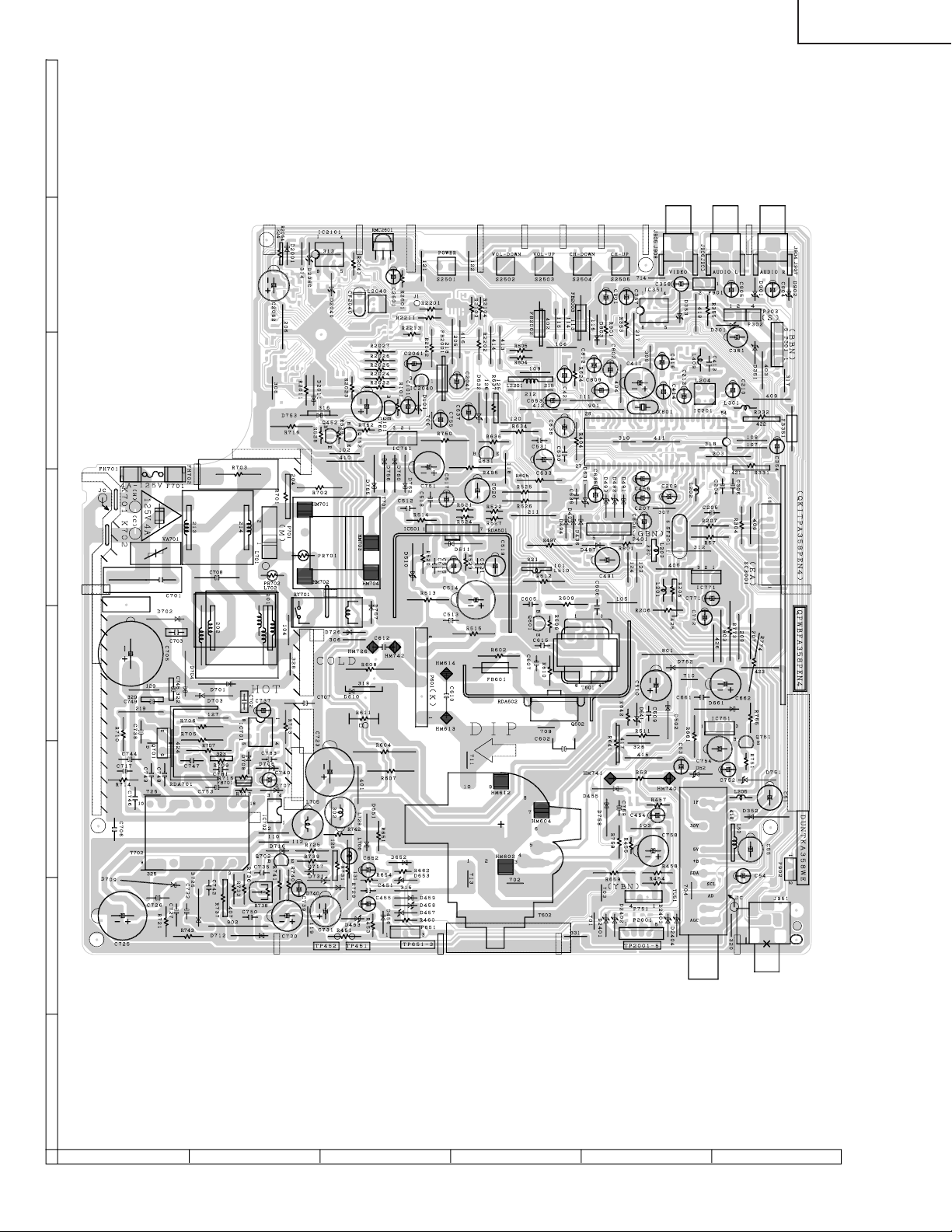

PRINTED WIRING BOARD ASSEMBLIES

H

G

F

20MU14

E

D

C

B

PWB-A: MAIN Unit (Wiring Side)

A

654321

15

Page 16

20MU14

H

◗✶✴✴✼

G

F

◗✶✴✺✹

❇✶✴✺✵

◗✶✴✸✼

◗✶✴✺✴◗✶✴✺✵

P✶✴✺✴

◗✶✴✸✻

◗✶✴✺✷

◗✶✴✺✶

❇✶✴✺✴

◗✶✴✺✺

◗✶✴✺✻

◗✶✴✺✼

◗✶✴✻✴

❇✶✴✴✶

◗✶✴✴✽

◗✶✴✴✵

❍❇✶✴✴✵

◗✶✴✴✶

◗✶✴✴✺

◗✶✴✻✶

◗✶✴✵✻

❇✶✴✴✵

◗✶✴✵✼

❇✶✴✵✴

◗✶✴✵✺

◗✶✴✵✸

◗✶✴✵✶

◗I✼

❊❈❇✷

E

❊❈❇✸

❇✶✺✴✶

◗✶✴✸✸

◗✶✵✴✶

◗✶✴✸✹

❇✶✴✹✵◗✶✵✴✵

◗✶✴✸✽

❇✶✶✴✵

◗✶✶✴✷

P✶✶✴✵

◗✶✴✸✴

❇✶✴✶✺

P✶✶✵✵

◗✶✴✷✸

◗✶✴✷✷

◗✶✴✶✼

◗✶✶✵✶

❇✶✶✴✷

❇✶✴✶✹

❇✶✴✶✸

❇✶✴✶✷

❇✶✴✶✶

◗✶✴✶✴

◗✶✴✶✽

❇✶✴✶✵

◗✶✴✵✴

◗I✶✵

❍❇✶✵✴✶

❇✶✶✴✶

◗✶✴✸✵

◗I✶✶

❇✹✵✺

◗✹✵✽◗✹✵✻

◗✶✹✴✻

◗✶✹✴✵

◗✶✹✴✼

◗✶✹✴✽

◗✶✹✴✷

◗✶✹✴✸

◗✶✹✴✹

◗✶✹✴✺

◗I✵✸

◗✸✶✹

◗✶✴✶✶

◗✹✵✼

◗✹✵✺

◗I✶✴

◗✸✶✶

◗✸✶✵

◗✼✴✷

◗✼✴✼◗✼✵✴◗✼✴✽

◗✸✶✸

◗I✶✹

◗✼✴✶

◗✺✶✶

◗✺✶✷

❇✺✶✴

❇✺✷✸

◗✺✷✹

◗✸✽✷

◗✸✽✸

◗✸✽✶

◗✸✽✵

◗✸✽✺

❇✸✽✶

P✸✽✵

◗✷✹✸

◗✷✹✻

◗I✵✷

◗I✵✶◗I✵✵◗I✶✷

❇✼✴✵

◗✺✹✹

❇✼✵✴

❇✼✵✵

◗✼✴✻

◗I✶✸

◗✸✺✵

◗✸✴✵

◗✸✴✶

◗✸✴✷◗I✵✴

❇✶✴✼

❇✼✴✻

◗I✽

◗✸✺✶

◗I✹

◗I✸

◗I✶✽

◗✽✴✶

❇✷✹✺

◗✸✵✶◗✸✵✷

❇✸✵✼

◗✸✵✵

❇✸✵✶

◗✽✺✵

◗✶✵✶

◗✶✵✴◗✽✺✶

◗✶✴✽

◗✶✵✸

◗✶✵✺❇✶✴✷

P✶✴✵

❇✶✴✶

◗✽✶✹

◗I✶✼

❇✷✹✵

◗✸✵✹

P✸✴✶

❇✸✵✻

◗✸✵✺

◗✸✵✸

◗✸✶✷

P✸✴✵

◗✶✵✷

❇✶✶✴

◗✶✵✵

❇✶✵✸

❇✶✵✷

◗✶✴✼

◗✶✴✸

◗✶✴✷

◗✶✴✶

❇✶✴✵

◗✽✴✺

❇✸✴✵

◗✸✵✴

◗I✻

◗✶✶✴

❇✷✴✵

❇✷✴✸

❇✷✴✹

◗✷✴✶

❇✷✴✶

◗✷✴✵

◗✷✴✼

❇✶✴✺❇✶✵✵

❇✷✴✷

◗I✷

◗I✶✻

◗✽✶✸

❊❈❇✺

◗✽✴✹

P✷✴✵

◗✷✴✹

D

◗I✶✺

◗✻✶✴

❇✻✵✴

C

❊❈❇✹

◗✻✶✷

◗✻✴✼

◗✻✶✶

❇✻✴✽

◗✻✵✵

❇✻✼✶

◗✸✹✽

◗✸✹✺

P✸✹✵

◗✻✸✽

◗I✵✼

❇✻✷✷

◗I✵✽

◗✺✹✷

◗✶✸✴✵

◗✶✸✴✶

◗✶✸✴✷

◗✶✸✴✸

◗✶✵✹

◗✶✴✵

◗✹✹

◗✹✸

◗✹✺

◗I✵✺

◗I✶◗I✵

❊❈❇✶

B

PWB-A: MAIN Unit (Chip Parts Side)

A

654321

16

Page 17

20MU14

H

G

F

PWB-B: CRT Unit (Wiring Side)

E

D

\b

\b

\b\\b\\b

C

B

\b\

\b\

\b\

\b

\b

\b

\b

\b

\b\

\b\

\b\b

PWB-B: CRT Unit (Chip Parts Side)

A

654321

17

Page 18

20MU14

PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics

identified in this manual; electrical components having such features

are identified by å and shaded areas in the Replacement Parts Lists

and Schematic Diagrams. The use of a substitute replacement part

which dose no have the same safety characteristic as the factory

recommended replacement parts shown in this service manual may

create shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT P ARTS"

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER 2. REF. NO.

3. PAR T NO. 4. DESCRIPTION

in USA: Contact your nearest SHARP Parts Distributor to order.

For location of SHARP Parts Distributor, Please call TollFree; 1-800-BE-SHARP

★ MARK: SPARE PARTS-DELIVERY SECTION

' MARK: X-RAY RELATED PARTS

Ref. No. Part No. « Description Code

PICTURE TUBE

U V101 VB48JLL40X/*S X CRT 19V (ORION) BR

U L703 RCILG0099PEZZ X DEGAUSSING COIL (19V) AF

U DY601 RCILH0105GJZZ X DY (20V) AQ

QEARC2016PEZZ X EARTH PARTS AC

PMAGF3045CEZZ X PURITY MAGNET AC

PSPAG0012MEZZ X WEDGE AB

PSPAG0001PE00 X CRT SCREW RUB WASHER AE

LHLDW1033PEZZ X WIRE TIE (10.4 CM) AA

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTKA358WEX1 – MAIN Unit —

DUNTKA359WEW0 – CRT Unit —

Ref. No. Part No. « Description Code

PWB-A: DUNTKA358WEX1

MAIN UNIT

TUNER

NOTE:THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDETLY

U TU51 VTUVT1T5UF214 X TUNER AP

INTEGRATED CIRCUITS

IC201 RH-IX3354CEN1 X IX3354CE AM

IC351 VHIAN7511//-1 X AN7511 AC

U IC501 VHILA7840//-1 X LA7840 AE

U IC701 VHITEA1507/-1 X TEA1507 AE

U IC702 RH-FX0034CEZZ X FX0034CE AB

U IC771 VHIKA7805AP-1 X KA7805AP AC

IC2001 RH-IX3492CEZZQ X IX3492CE AN

IC2040 VHIPST994C/-1+ X PST994C AB

IC2102 VHIBR24L16F-1Y X BR24L16F AC

TRANSISTORS

Q101 VS2SC945AQ/-1+ X 2SC945AQ AB

Q201 VS2SC2735//1EY X 2SC2735 AB

Q451 VS2SA1530R/-1Y X 2SA1530R AB

Q452 VS2SA1266-Y-1+ X 2SA1266(Y) AB

Q601 VS2SC2482//-1+ X 2SC2482 AB

U Q602 VS2SD2586//1E X 2SD2586 AF

Q631 VS2SC945AQ/-1+ X 2SC945AQ AB

U Q701 VSSPA04N603-1 X SPA04N603 AF

Q702 VS2SC945AQ/-1+ X 2SC945AQ AB

Q751 VS2SC945AQ/-1+ X 2SC945AQ AB

Q752 VS2SC945AQ/-1+ X 2SC945AQ AB

Q2201 VS2SD601AR/-1Y X 2SD601AR AB

Q2211 VS2SD601AR/-1Y X 2SD601AR AB

DIODES

D52 RH-EX0676GEZZY X Zener Diode 32V AB

D101 RH-EX0617GEZZY X Zener Diode 5.6V AB

D352 VHD1SS119//-1Y X Diode AA

D353 RH-EX0644GEZZY X Zener Diode 13V AB

D453 RH-EX0616GEZZY X Zener Diode 5.6V AB

D455 VHD1SS119//-1Y X Diode AA

D456 RH-DX0475CEZZY X Diode AB

D457 RH-EX0644GEZZY X Zener Diode 13V AB

D458 RH-EX0644GEZZY X Zener Diode 13V AB

D459 VHD1SS119//-1Y X Diode AA

D502 RH-DX0131CEZZY X Diode AB

D511 RH-DX0441CEZZY X Diode AB

D632 RH-EX0630GEZZY X Zener Diode 9.1V AB

D641 RH-EX0630GEZZY X Zener Diode 9.1V AB

D651 VHD1SS244//-1Y X Diode AB

D653 RH-EX0667GEZZY X Zener Diode 27V AB

D661 RH-DX0468CEZZ X Diode AB

D701 RH-DX0490CEZZY X Diode AB

D702 RH-DX0490CEZZY X Diode AB

D703 RH-DX0490CEZZY X Diode AB

D704 RH-DX0490CEZZY X Diode AB

D707 VHD1SS119//-1Y X Diode AA

D708 VHD1SS119//-1Y X Diode AA

D709 RH-DXA006WJZZ X Diode AB

D712 RH-DX0487CEZZY X Diode AB

D717 RH-EX0616GEZZY X Zener Diode 5.6V AB

D725 RH-DX0131CEZZY X Diode AB

D726 VHD1SS119//-1Y X Diode AA

D751 RH-EX0611GEZZY X Zener Diode 5.1V AB

D752 RH-DX0441CEZZY X Diode AB

D753 RH-DX0441CEZZY X Diode AB

D757 VHD1SS119//-1Y X Diode AA

D758 RH-DX0131CEZZY X Diode AB

VA701 RH-VXA009WJZZ X VARISTOR AB

18

PACKAGED CIRCUITS

PR702 RMPTP0092CEZZ X Packaged Circuit AD

X801 RCRSAA010WJZZ X CRYSTAL AC

Page 19

20MU14

Ref. No. Part No. « Description Code

PWB-A: DUNTKA358WEX1

MAIN UNIT (Continued)

CF2040 RFILA0099CEZZ+ X FILTER AB

SF201 RFILC0441CEZZ X SAW Filter AD

L50 VP-DF150K0000Y X Peaking 15mH AB

L201 VP-XF1R2K0000Y X Peaking 1.2mH AB

L202 VP-XF1R2K0000Y X Peaking 1.2mH AB

L203 VP-XF220K0000Y X Peaking 22mH AB

L204 RCILI0632CEZZ X IF Coil AB

L301 VP-XF150K0000Y X Peaking 15mH AB

U L701 RCILF0078PEZZ X Coil Line Filter AC

U L705 RCILP0179CEZZ+ X Coil AB

L706 RCILP0197CEZZ X Coil AB

L2040 RCILB0131CEZZ X Coil (OSC) AB

U T601 RTRNZ0731CEZZ X Transformer AD

U T602 RTRNF0213PEZZ X H-Volt Transformer AP

U T702 RTRNW0003PEZZ X Power Transformer AE

R738 RVR-M4588CEZZ+ X 22k 130V Adj. AB

C51 VCEA0A1AW337M+ X 330 10V EL. AB

C53 VCEA0A1HW105M+ X 1 50V EL. AB

C54 VCEA0A1HW475M+ X 4.7 50V EL. AB

C55 VCEA0A1AW107M+ X 100 10V EL. AB

C101 VCEA0A1CW476M+ X 47 16V EL. AB

C201 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C202 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C203 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C204 VCQYTA1HM223J+ X 0.022 50V Mylar AB

C205 VCKYPA1HB103K+ X 0.01 50V Ceramic AB

C206 VCKYCY1HB102KY X 1000p 50V Ceramic AA

C207 VCEA0A1CW476M+ X 47 16V EL. AB

C208 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C209 VCEA0A1HW105M+ X 1 50V EL. AB

C210 VCEA0A1HW474M+ X 0.47 50V EL. AB

C212 VCEA0A1HW474M+ X 0.47 50V EL. AB

C220 VCKYCY1CB104KY X 0.1 16V Ceramic AA

C301 VCCCCY1HH220JY X 22p 50V Ceramic AA

C302 VCKYCY1HB102KY X 1000p 50V Ceramic AA

C304 VCCCCY1HH220JY X 22p 50V Ceramic AA

C305 VCKYCY1HB103KY X 0.01 50V Ceramic AA

C306 VCQYTA1HM103J+ X 0.01 50V Mylar AB

C354 VCEA0A1HW225M+ X 2.2 50V EL. AB

C356 VCKYCY1HB332KY X 3300p 50V Ceramic AA

C357 VCEA0A1HW106M+ X 10 50V EL. AB

C358 VCEA0A1HW106M+ X 10 50V EL. AB

C361 VCEA0A1CW227M+ X 220 16V EL. AB

C401 VCCCCY1HH470JY X 47p 50V Ceramic AA

C411 VCEA0A1AW108M+ X 1000 10V EL. AB

C412 VCKYCY1HB103KY X 0.01 50V Ceramic AA

C414 VCEA0A1HW225M+ X 2.2 50V EL. AB

C416 VCEA0A1HW105M+ X 1 50V EL. AB

C418 VCKYCY1HB103KY X 0.01 50V Ceramic AA

C421 VCEA0A1HW106M+ X 10 50V EL. AB

C451 VCQYTA1HM563J+ X 0.056 50V Mylar AB

C454 VCEA0A1HW475M+ X 4.7 50V EL. AB

C455 VCEA0A1CW226M+ X 22 16V EL. AB

C456 VCEA0A1HW475M+ X 4.7 50V EL. AB

C509 VCKYPA2HB102K+ X 1000p 500V Ceramic AB

C510 VCEA0A1VW477M+ X 470 35V EL. AB

C512 VCFYSA1JB224J+ X 0.22 63V Mylar AB

C513 VCFYSA1JB473J+ X 0.047 63V Mylar AB

C514 VCEA0A1EW477M+ X 470 25V EL. AB

C515 VCEA0A1HW475M+ X 4.7 50V EL. AB

PACKAGED CIRCUITS

FILTERS AND COILS

TRANSFORMERS

CONTROL

[EL.··· Electrolytic, M-Poly.··· Metalized Polypro Film]

CAPACITORS

Ref. No. Part No. « Description Code

CAPACITORS

C516 VCKYCY1HB222KY X 2200p 50V Ceramic AA

C517 VCEA0A1CW226M+ X 22 16V EL. AB

C520 VCEA0A1HW107M+ X 100 50V EL. AB

C530 VCFYFA1HA334J+ X 0.33 50V Mylar AB

C531 VCFYFA1HA564J+ X 0.56 50V Mylar AB

C606 VCKYPA2HB561K+ X 560p 500V Ceramic AB

C607 VCKYPA1HB472K+ X 4700p 50V Ceramic AB

C610 VCFPVC3ZA772H X 7700p 1.5kV M-Poly. AB

C612 VCFPVC2DB474J X 0.47 200V M-Poly. AB

C633 VCEA0A1AW337M+ X 330 10V EL. AB

C634 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C635 VCEA0A1HW105M+ X 1.0 50V EL. AB

C636 VCQYTA1HM153J+ X 0.015 50V Mylar AB

C637 VCEA0A1CW476M+ X 47 16V EL. AB

C652 VCEA0A1HW475M+ X 4.7 50V EL. AB

C653 VCEA0A1HW105M+ X 1.0 50V EL. AB

C661 VCKYPA2HB152K+ X 1500p 500V Ceramic AB

C662 VCEA0A1CW477M+ X 470 16V EL. AB

C701 RC-FZ036SCEZZ X

C702 RC-KZ0029CEZZ+ X 0.01 250V Ceramic AB

C703 RC-KZ0029CEZZ+ X 0.01 250V Ceramic AB

C705 RC-EZ0718CEZZ X 470 200V EL. AE

C706 RC-KZ0092GEZZA X 3300p AC125V Ceramic AB

C717 VCKYPA2HB472K+ X 4700p 500V Ceramic AB

C723 RC-EZ0638CEZZ X 33 160V EL. AC

C725 RC-EZ0724CEZZ X

C726 VCKYPH3DB561K X 560p 2kV Ceramic AB

C727 VCKYPA2HB472K+ X 4700p 500V Ceramic AB

C730 VCEA0A1CW108M+ X

C731 VCEA0A1EW107M+ X

C732 VCKYPA1HF103Z+ X 0.01 50V Ceramic AA

C735 VCCCPA1HH680J+ X 68p 50V Ceramic AA

C737 VCEA0A1EW226M+ X 22 25V EL. AB

C738 RC-KZ0040CEZZ X 820p 2kV Ceramic AB

C739 VCEA0A1HW104M+ X 0.1 50V EL. AB

C740 VCEA0A1EW476M+ X 47 25V EL. AB

C743 VCKYPH3DB561K X 560p 2kV Ceramic AB

C750 VCKYPA1HF103Z+ X 0.01 50V Ceramic AA

C752 VCEA0A1CW476M+ X 47 16V EL. AB

C754 VCEA0A1CW476M+ X 47 16V EL. AB

C758 VCEA0A2EW106M+ X 10 250V EL. AB

C759 VCKYPA2HB102K+ X 1000p 500V Ceramic AB

C760 VCEA0A1CW108M+ X 1000 16V EL. AB

C771 VCEA0A1CW476M+ X 47 16V EL. AB

C772 VCEA0A1CW476M+ X 47 16V EL. AB

C783 VCQYTA1HM103J+ X 0.01 50V Mylar AB

C801 VCCCCY1HH180JY X 18p 50V Ceramic AA

C802 VCEA0A1CW106M+ X 10 16V EL. AB

C807 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C808 VCEA0A1CW106M+ X 10 16V EL. AB

C809 VCEA0A1HW105M+ X 1.0 50V EL. AB

C811 VCKYCY1CB473KY X 0.047 16V Ceramic AA

C812 VCEA0A1HW474M+ X 0.47 50V EL. AB

C901 VCEA0A1HW105M+ X 1.0 50V EL. AB

C905 VCEA0A1HW106M+ X 10 50V EL. AB

C2001 VCCCCY1HH101JY X 100p 50V Ceramic AA

C2002 VCKYCY1HF103ZY X 0.01 50V Ceramic AA

C2040 VCEA0A1AW107M+ X 100 10V EL. AB

C2041 VCEA0A1HW105M+ X 1.0 50V EL. AB

C2060 VCKYCY1CB104KY X 0.1 16V Ceramic AA

C2061 VCKYCY1HB222KY X 2200p 50V Ceramic AA

C2062 VCEA0A1AW107M+ X 100 10V EL. AB

C2201 VCKYCY1HB682KY X 6800p 50V Ceramic AA

C2202 VCCCCY1HH560JY X 56p 50V Ceramic AA

C2601 VCEA0A0JW107M+ X 100 6.3V EL. AB

C2602 VCCCCY1HH101JY X 100p 50V Ceramic AA

RESISTORS

[M-Ox.··· Metal Oxide, M-Film ··· Metal Film]

RJ2 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ7 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ8 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

0.1mF

100mF

1000mF

220mF

AC125V Plastic AB

160V EL. AC

16V EL. AB

25V EL. AB

19

Page 20

20MU14

Ref. No. Part No. « Description Code

PWB-A: DUNTKA358WEX1

MAIN UNIT (Continued)

RESISTORS

[M-Ox.··· Metal Oxide, M-Film ··· Metal Film]

RJ9 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ10 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ12 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ18 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ19 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ20 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ21 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ16 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ18 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ19 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ20 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

RJ21 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R53 VRS-RG3LB223J+ X 22k 3W M-Ox. AB

R54 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R55 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R56 VRS-CY1JF823JY X 82k 1/16W M-Ox. AA

R57 VRD-RA2BE563JY X 56k 1/8W Carbon AA

R101 VRD-RA2BE152JY X 1.5k 1/8W Carbon AA

R201 VRS-CY1JF221JY X 220 1/16W M-Ox. AA

R202 VRS-CY1JF122JY X 1.2k 1/16W M-Ox. AA

R203 VRS-CY1JF682JY X 6.8k 1/16W M-Ox. AA

R204 VRS-CY1JF270JY X 27 1/16W M-Ox. AA

R205 VRD-RA2BE680JY X 68 1/8W Carbon AA

R206 VRD-RA2EE151JY X 150 1/4W Carbon AA

R207 VRD-RA2BE223JY X 22k 1/8W Carbon AA

R208 VRS-CY1JF332JY X 3.3k 1/16W M-Ox. AA

R209 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R210 VRS-CY1JF104JY X 100k 1/16W M-Ox. AA

R211 VRS-CY1JF104JY X 100k 1/16W M-Ox. AA

R212 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R215 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R220 VRS-CY1JF331JY X 330 1/16W M-Ox. AA

R301 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R302 VRS-CY1JF152JY X 1.5k 1/16W M-Ox. AA

R353 VRD-RA2BE683JY X 68k 1/8W Carbon AA

R354 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R355 VRD-RA2BE223JY X 22k 1/8W Carbon AA

R357 VRS-CY1JF822JY X 8.2k 1/16W M-Ox. AA

R401 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R402 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R403 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R404 VRD-RA2BE102JY X 1.0k 1/8W Carbon AA

R411 VRS-CY1JF684JY X 680k 1/16W M-Ox. AA

R412 VRS-CY1JF391JY X 390 1/16W M-Ox. AA

R413 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R414 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R421 VRS-CY1JF223JY X 22k 1/16W M-Ox. AA

U R451 VRS-RG2HC103J+ X 10k 1/2W M-Ox. AB

R453 VRD-RA2BE152JY X 1.5k 1/8W Carbon AA

R454 VRD-RA2EE334JY X 330k 1/4W Carbon AA

R455 VRD-RA2BE392JY X 3.9k 1/8W Carbon AA

R456 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R457 VRD-RA2BE102JY X 1.0k 1/8W Carbon AA

R458 VRD-RA2EE334JY X 330k 1/4W Carbon AA

R460 VRD-RA2BE152JY X 1.5k 1/8W Carbon AA

R461 VRS-CY1JF184JY X 180k 1/16W M-Ox. AA

R462 VRS-CY1JF273JY X 27k 1/16W M-Ox. AA

R495 VRS-RG3DB820J+ X 180k 1/16W M-Ox. AB

R512 VRD-RM2HD102JY X 1.0k 1/2W Carbon AA

R513 VRD-RM2HD102JY X 1.0k 1/2W Carbon AA

R514 VRD-RM2HD1R0JY X 1.0 1/2W Carbon AA

R515 VRS-RG3AB391J+ X 390 1W M-Ox. AB

R516 VRS-CY1JF153JY X 15k 1/16W M-Ox. AA

R517 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R518 VRS-CY1JF333JY X 33k 1/16W M-Ox. AA

R519 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R520 VRD-RM2HD1R5JY X 1.5 1/2W Carbon AA

R522 VRD-RA2BE102JY X 1.0k 1/2W Carbon AA

R523 VRD-RA2BE562JY X 5.6k 1/8W Carbon AA

R525 VRD-RA2BE272JY X 2.7k 1/8W Carbon AA

Ref. No. Part No. « Description Code

R527 VRD-RA2BE223JY X 22k 1/8W Carbon AA

R528 VRD-RA2BE272JY X 2.7k 1/8W Carbon AA

R529 VRD-RA2BE472JY X 4.7k 1/8W Carbon AA

U R604 VRS-RG3DB682J+ X 6.8k 2W M-Ox. AB

R605 VRD-RA2BE121JY X 120 1/8W Carbon AA

R606 VRD-RA2BE102JY X 1.0k 1/8W Carbon AA

R607 VRS-RG3DB682J+ X 6.8k 2W M-Ox. AB

U R608 VRS-RG3DB391J+ X 390 2W M-Ox. AB

U R609 VRS-RG3AB562J+ X 5.6k 1W M-Ox. AB

R610 VRD-RM2HD220JY X 22 1/2W Carbon AA

U R611 VRS-KA3HG3R3K X 3.3 5W M-Ox. AB

R622 VRS-CY1JF222JY X 2.2k 1/16W M-Ox. AA

R623 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R624 VRN-RA2BK472FY X 4.7k 1/8W M-Film AB

R634 VRD-RM2HD121JY X 120 1/2W Carbon AA

R635 VRS-CY1JF332JY X 3.3k 1/16W M-Ox. AA

R636 VRD-RA2EE221JY X 220 1/4W Carbon AA

U R641 VRS-RG3AB682J+ X 6.8k 1W M-Ox. AB

R651 VRD-RM2HD270JY X 27 1/2W Carbon AA

R653 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R654 VRD-RA2BE154JY X 150k 1/8W Carbon AA

R655 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R659 VRN-RL3AB3R3J+ X 3.3 1W M-Ox. AB

R661 VRN-RL3ABR47J+ X 0.47 1W M-Film AB

R662 VRD-RA2BE102GY X 1.0k 1/8W Carbon AA

U R702 RR-DZ0049CEZZY X 3.9M 1/2W Carbon AB

U R703 VRW-KP3HC1R8K X 1.8 5W Cement AB

U R705 VRN-RL3ABR39J+ X 0.39 1W M-Ox. AB

U R706 VRN-RL3ABR39J+ X 0.39 1W M-Ox. AB

U R707 VRD-RM2HD270JY X 27 1/2W Carbon AA

U R708 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

U R710 VRS-RG2HC102J+ X 1k 1/2W M-Ox. AB

U R711 VRS-CY1JF334JY X 330k 1/16W M-Ox. AA

R712 VRD-RA2BE100JY X 10 1/8W Carbon AA

R713 VRS-RG2HC122J+ X 1.2k 1/2W M-Ox. AB

R715 VRD-RA2BE150JY X 15 1/8W Carbon AA

R716 VRS-RG3AB121J+ X 120 1W M-Ox. AB

R721 VRD-RM2HD124JY X 120k 1/2W Carbon AA

R723 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R725 VRS-RG2HC821J+ X 820 1/2W M-Ox. AB

R733 VRD-RA2EE394JY X 390k 1/4W Carbon AA

R736 VRD-RM2HD184JY X 180k 1/2W Carbon AA

R739 VRD-RM2HD332JY X 3.3k 1/2W Carbon AA

R740 VRD-RM2HD470JY X 47 1/2W Carbon AA

R741 VRN-RA2BK682FY X 6.8k 1/8W M-Film AB

R751 VRD-RA2BE821JY X 820 1/8W Carbon AA

R752 VRD-RA2BE392JY X 3.9k 1/8W Carbon AA

U R755 VRD-RM2HD151JY X 150 1/2W Carbon AA

U R758 VRS-RG2HC100J+ X 10 1/2W M-Ox. AB

R759 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

U R773 VRS-VV3LB270J X 27 3.0W M-Ox. AB

R774 VRS-VV3LB680J X 68 3.0W M-Ox. AB

R801 VRD-RM2HD470JY X 47 1/2W Carbon AA

R807 VRS-CY1JF272JY X 2.7k 1/16W M-Ox. AA

R808 VRS-CY1JF222JY X 2.2k 1/16W M-Ox. AA

R809 VRS-CY1JF223JY X 22k 1/16W M-Ox. AA

R810 VRS-CY1JF223JY X 22k 1/16W M-Ox. AA

R901 VRD-RA2BE101JY X 100 1/8W M-Ox. AA

R902 VRS-CY1JF750JY X 75 1/16W M-Ox. AA

R906 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R925 VRS-CY1JF104JY X 100k 1/16W M-Ox. AA

R961 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R962 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R2001 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R2002 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2006 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2008 VRS-CY1JF472JY X 4.7k 1/16W M-Ox. AA

R2009 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R2010 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R2012 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2016 VRS-CY1JF223JY X 22k 1/16W M-Ox. AA

R2018 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2020 VRS-CY1JF223JY X 22k 1/16W M-Ox. AA

R2022 VRS-CY1JF333JY X 33k 1/8W Carbon AA

R2023 VRD-RA2BE223JY X 22k 1/8W Carbon AA

R2024 VRD-RA2BE682JY X 6.8k 1/8W Carbon AA

R2025 VRD-RA2BE682JY X 6.8k 1/8W Carbon AA

R2026 VRD-RA2BE682JY X 6.8k 1/8W Carbon AA

R2027 VRD-RA2BE682JY X 6.8k 1/8W Carbon AA

R2028 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

20

Page 21

20MU14

Ref. No. Part No. « Description Code

PWB-A: DUNTKA358WEX1

MAIN UNIT (Continued)

RESISTORS

R2029 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2032 VRD-RA2BE471JY X 470 1/8W Carbon AA

R2033 VRS-CY1JF684JY X 680k 1/16W M-Ox. AA

R2034 VRS-CY1JF684JY X 680k 1/16W M-Ox. AA

R2040 VRS-CY1JF102JY X 1.0k 1/16W M-Ox. AA

R2041 VRS-CY1JF333JY X 33k 1/16W M-Ox. AA

R2042 VRD-RA2BE101JY X 100 1/8W M-Ox. AA

R2043 VRD-RA2BE101JY X 100 1/8W M-Ox. AA

R2044 VRS-CY1JF683JY X 68k 1/16W M-Ox. AA

R2045 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R2047 VRS-CY1JF221JY X 220 1/16W M-Ox. AA

R2048 VRS-CY1JF562JY X 5.6k 1/16W M-Ox. AA

R2049 VRS-CY1JF333JY X 33k 1/16W M-Ox. AA

R2060 VRS-CY1JF221JY X 220 1/16W M-Ox. AA

R2061 VRS-CY1JF562JY X 5.6k 1/16W M-Ox. AA

R2062 VRS-CY1JF183JY X 18k 1/16W M-Ox. AA

R2063 VRS-CY1JF222JY X 2.2k 1/16W M-Ox. AA

R2065 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R2066 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2067 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2068 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2070 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2072 VRS-CY1JF103JY X 10k 1/16W M-Ox. AA

R2103 VRD-RA2BE101JY X 100 1/8W M-Ox. AA

R2104 VRD-RA2BE101JY X 100 1/8W M-Ox. AA

R2201 VRD-RA2BE103JY X 10k 1/8W M-Ox. AA

R2202 VRD-RA2BE473JY X 47k 1/8W Carbon AA

R2203 VRS-CY1JF332JY X 3.3k 1/16W M-Ox. AA

R2211 VRD-RA2BE222JY X 2.2k 1/8W Carbon AA

R2212 VRS-CY1JF682JY X 6.8k 1/16W M-Ox. AA

R2213 VRD-RA2BE223JY X 22k 1/8W Carbon AA

R2401 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R2402 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R2403 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R2404 VRS-CY1JF101JY X 100 1/16W M-Ox. AA

R2501 VRS-CY1JF123JY X 12k 1/16W M-Ox. AA

R2503 VRS-CY1JF273JY X 27k 1/16W M-Ox. AA

R2504 VRS-CY1JF123JY X 12k 1/16W M-Ox. AA

R2505 VRS-CY1JF563JY X 56k 1/16W M-Ox. AA

R2506 VRS-CY1JF563JY X 56k 1/16W M-Ox. AA

R2507 VRS-CY1JF823JY X 82k 1/16W M-Ox. AA

R2508 VRS-CY1JF153JY X 15k 1/16W M-Ox. AA

R2509 VRS-CY1JF272JY X 2.7k 1/16W M-Ox. AA

R2601 VRD-RA2BE100JY X 10 1/8W Carbon AA

R2603 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R2605 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

R2607 VRS-CY1JF000JY X 00 1/16W M-Ox. AA

SWITCHES

S2501 QSW-K0202PEZZ+ X SWITCH Power AB

S2502 QSW-K0202PEZZ+ X SWITCH Vol-Down AB

S2503 QSW-K0202PEZZ+ X SWITCH Vol-Up AB

S2504 QSW-K0202PEZZ+ X SWITCH CH-Down AB

S2505 QSW-K0202PEZZ+ X SWITCH CH-Up AB

MISCELLANEOUS PARTS

U RY701 RRLYJ0081CEZZ X RELAY AD

U F701 QFS-B4023CEZZ X FUSE - 4A 125V AB

FB351 RBLN-0047CEZZY X FERRITE BEAD AB

FB601 RBLN-0047CEZZY X FERRITE BEAD AB

FB2002 RBLN-0037CEZZY X FERRITE BEAD AB

FH701 QFSHD1013CEZZ+ X FUSE CLIP AB

FH702 QFSHD1014CEZZ+ X FUSE CLIP AB

(Continued)

Ref. No. Part No. « Description Code

P651 QPLGN0361CEZZA X PLUG (3 PINS) RHU AB

P701 QPLGN0260CEZZ X PLUG (2 PINS) AB

P751 QPLGN0461CEZZA X PLUG (4 PINS) RHU AB

P2001 QPLGN0561CEZZA X PLUG (5 PINS) RHU AB

RMC2601 RRMCU0222CEZZ X R/C RECEIVER AD

JA409 RBLN-0047CEZZ* X FERRITE BEAD AB

RDA501 PRDAR0106GJFW X HEATSINK (STEEL) AB

RDA602 PRDAR0216PEFW X HEATSINK (STEEL) AB

RDA701 PRDAR0026PEFW X HEATSINK (STEEL) AB

MISCELLANEOUS PARTS

LX-BZ3100CEFD X SCREW AA

LX-TZ3004CEFD X SCREW AA

DUNTKA359WEW0

PWB-B CRT Unit

TRANSISTORS

Q852 VSBF422////-1+ X BF422 AB

Q854 VSBF422////-1+ X BF422 AB

Q856 VSBF422////-1+ X BF422 AB

Q881 VS2SA1266-Y-1+ X 2SA1266(Y) AB

DIODES

D882 RH-DX0475CEZZY X Diode AB

D885 RH-DX0475CEZZY X Diode AB

COILS

L852 VP-MK820K0000+ X Peaking

CAPACITORS

C851 VCCCCY1HH151JY X 150p 50V Ceramic AA

C852 VCCCCY1HH151JY X 150p 50V Ceramic AA

C853 VCCSPA1HL151J+ X 150p 50V Ceramic AA

C854 RC-KZ0029CEZZ+ X 0.01 250V Ceramic AB

C883 VCEA0A1CW336M+ X 33 16V EL. AB

RESISTORS

R852 VRD-RA2BE181JY X 180

R853 VRS-CY1JF121J

U R857 VRS-VV3AB123J X 12K 1W M-Ox. AB

R858 VRD-RM2HD332JY X 3.3k 1/2W Carbon AA

R860 VRD-RA2BE181JY X 180

R861 VRS-CY1JF121JY X 120 1/16W M-Ox. AA

U R865 VRS-VV3AB123J X 12K 1W M-Ox. AB

R866 VRD-RM2HD332JY X 3.3k 1/2W Carbon AA

R867 VRS-CY1JF470J

R868 VRS-CY1JF181J

R869 VRS-CY1JF121JY X 120 1/16W M-Ox. AA

U R873 VRS-VV3AB123J X 12K 1W M-Ox. AB

R874 VRD-RM2HD332JY X 3.3k 1/2W Carbon AA

R881 VRS-CY1JF561J

R882 VRS-CY1JF391JY X 390 1/16W M-Ox. AA

R883 VRD-RA2BE561J

R884 VRS-CY1JF152JY X 1.5k 1/16W M-Ox. AA

R886 VRS-CY1JF821J

R887 VRD-RA2BE470J

R890 VRS-CY1JF470JY X 47 1/16W M-Ox. AA

R891 VRS-CY1JF470JY X 47 1/16W M-Ox. AA

Y X

Y X 47 1/16W M-Ox. AA

Y X 180 1/16W M-Ox. AA

Y X 560

Y X 560 1/8W Carbon AA

Y X 820 1/16W M-Ox. AA

Y X 47 1/8W Carbon AA

120

MISCELLANEOUS PARTS

P851 QPLGN0561CEZZ X PLUG (5 PINS) AB

P852 QPLGN0461CEZZ X PLUG (4 PINS) AB

SC852 QSOCV0840CEZZ X SOCKET (CRT) AC

82 mH

1/8W Carbon AA

1/16W M-Ox. AA

1/8W Carbon AA

1/16W

M-Ox. AA

AB

JACK (A/V)

J9

03

J905 QJAKE0211CE04 X JACK (VIDEO IN) AC

QJAKE0211CE09 X JACK (AUDIO IN)

AC

PLUG

P302 QPLGN0261CEZZ X PLUG (2 PINS) AB

P401 QPLGN0561CEZZA X PLUG (5 PINS) RHU AB

P601 QPLGN0660CEZZ X PLUG (6 PINS) AB

21

Page 22

20MU14

Ref. No. Part No. « Description Code

MISCELLANEOUS PARTS

U ACC701 QACCDA015WJPZ X AC-CORD AE

SP1 VSP0080PBK98A X SPEAKER AD

QCNW-2111PEZZ X WIRE (YBN) AB

QCNW-2111PEZZ X SPEAKER WIRE AC

QCNW-2160PEZZ X WIRE (GBN) AC

LHLDK0014PEZZ X AC CORD HOLDER AB

LHLDZ0063PEZZ X HOLDER (INSULATOR RING) AB

TLABM0003GJZZ X MODEL LABEL (NOM-120V) AB

TLABN0101GJZZ X REMARK LABEL(CHASSIS ID) AB

LX-TZ0104GJFD X SCREW (CRT) AB

LX-WZ0102GJFD X CRT WASHER AB

XTASD40P20000 X SCREW (CAB) AA

SUPPLIED ACCESORRIES

RRMCG1339CESB X R/C GUN AH

TINS-B157WJZZ

TCAUS3000GJZZ X CAUTION LABEL AA

X OPERATION MANUAL AC

Ref. No. Part No. « Description Code

PACKING PARTS

(NOT REPLACEMENT ITEM)

SPAKCB228WJZZ X PACKING CASE AP

SPAKP0102GJZZ X LAMIFOAM (457MM X 1800MM) AC

SPAKX0003GJZZ

SSAKA0101GJZZ X PLASTIC BAG AB

X PACKING FOAM AG

CABINET PARTS

1 CCABA0108WEJ1 X CAB-A ASSY AY

1-1 Not Available — FRONT CABINET

1-2

GCOVA0003GJSA

1-3

HBDGB1001GJSA

1-4 JBTN-0003GJSG X BUTTON Button(Power, AD

X R/C COVER

X BADGE AB

Vol-up/down,CH-up/down)

2

GCABB0109GJKA

X REAR CABINET AS

1-1

1

POWER VIDEO IN AUDIO

C

H

–

L

V

+

O

2

22

1-3

1-4

1

-

2

Page 23

★ Wrapping Paper

20MU14

PACKING OF THE SET

★ Polyethylene Bag

Operation Manual

Infrared R/C Unit

★ Batteries

★ Buffer Material

FRONT

★ MARK : Not replacement items.

★ Packing Case

Use tape to

fix the top side of

packing case.

REAR

Use 10 staples to

fix the bottom side

of packing case.

23

Page 24

20MU14

COPYRIGHT © 2003 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

QRC0003-L

Dec. 2003

Modify : SEMEX

Design and Production Information

Design base : JAPAN

Production : SEMEX

J B

SHARP ELECTRONICA MEXICO S. A. DE C. V.

Quality & Reliability Control Center

Blvd. SHARP No. 3510 Parque Industrial Rosarito

Playas de Rosarito, México B. C. 22710

Loading...

Loading...